IBC Intergas DC 15-95, DC 15-96, DC 20-125, DC 33-160 User Manual

DC Series Boilers / Water Heaters

DC 15-95, DC 15-96, DC 20-125, DC 33-160

(Natural Gas or Propane)

WARNING: If the information in this manual is not followed exactly, a re or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other ammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

Installation and service must be performed by a qualied installer, service

agency or the gas supplier.

This Manual is also available in French - contact IBC or visit our web site www.ibcboiler.com

INSTALLATION AND OPERATING INSTRUCTIONS

www.ibcboiler.com

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

WARNING

If the information in this

manual is not followed

exactly, a re or explosion

may result causing property

damage, personal injury, or

loss of life.

SAFETY CONSIDERATIONS

Installation, start-up and servicing of IBC boilers / water heaters must

be done with due care and attention, and should only be performed by

competent, qualied, licensed and trained heating technicians. Failure to

read and comply with all instructions and applicable National and local

codes may result in hazardous conditions that could result in property

damage and injury to occupants which in extreme cases might result in

death.

HAZARDS & PRECAUTIONS

DANGER

Points out an immediately

hazardous situation which

must be avoided in order to

prevent serious injury or

death.

WARNING

Points out a potentially

hazardous situation which

must be avoided to prevent

serious injury or death.

CAUTION

Points out a potentially

hazardous situation which

must be avoided to prevent

possible moderate injury and/

or property damage

NOTE

Points out installation,

maintenance and operation

details that will result in

enhanced eciency, longevity

and proper operation of your

boiler / water heater.

BEST PRACTICES

Points out recommendations

for better installation.

Supplied with the boiler / water heater - The IBC boiler / water heater is

shipped with an accessory parts kit consisting of the following items:

• 1 x Wall Mounting Bracket, IBC Part # 250-647

• 1 x Condensate Assembly

• 1 x Pressure Relief valve, 3/4NPT, 30psi

• 1 x Outdoor Temperature Sensor

• Air Vent and Relief Valve ttings

• 1 x Automatic Air Vent

• 4 x Lag Screws, Hex Head, Zn-Pl, 1/4 x 2-1/2 and Washers

• 1 x DC Installation & Operating Instructions

• 1 x DC/HC User Manual

• 1 x DC/HC Controller Manual

2

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

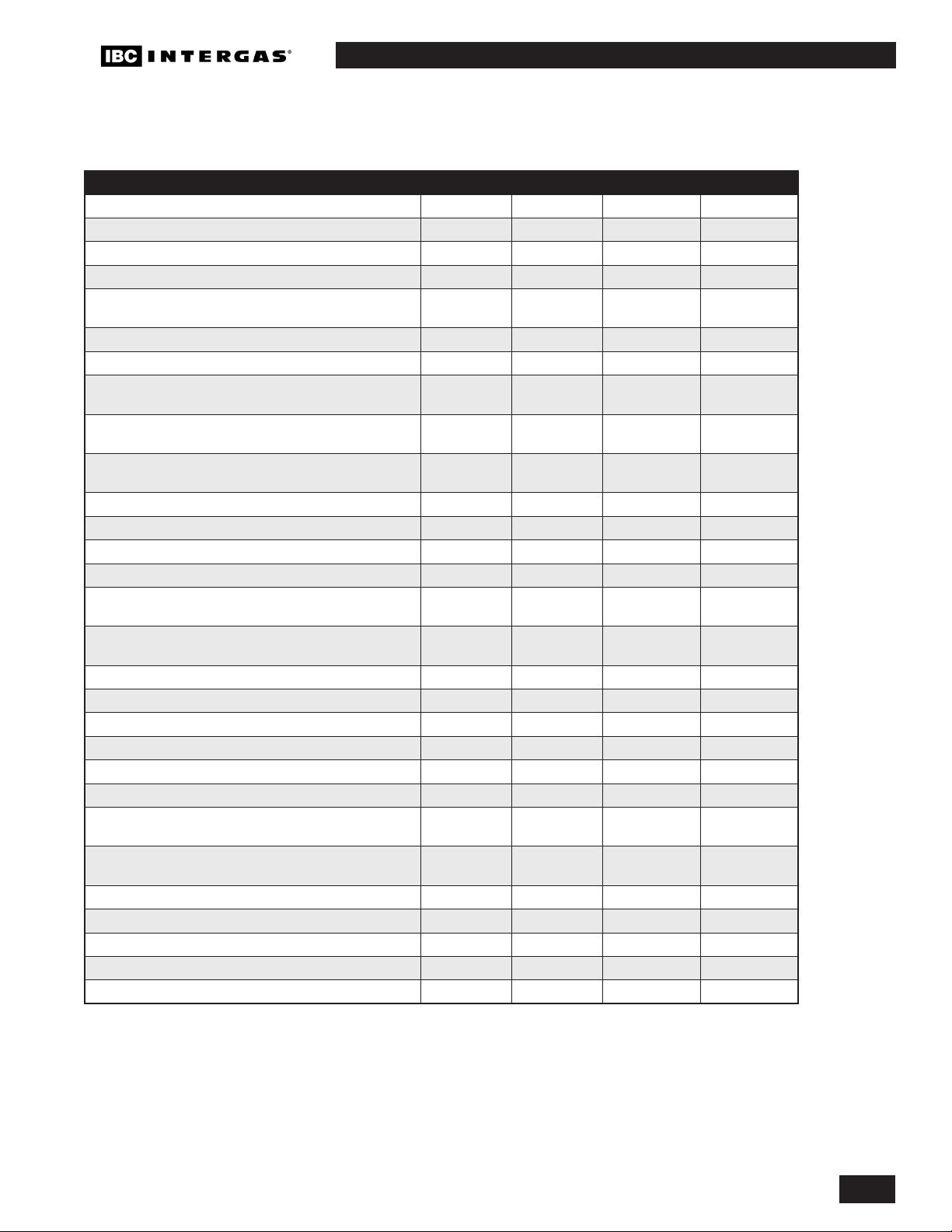

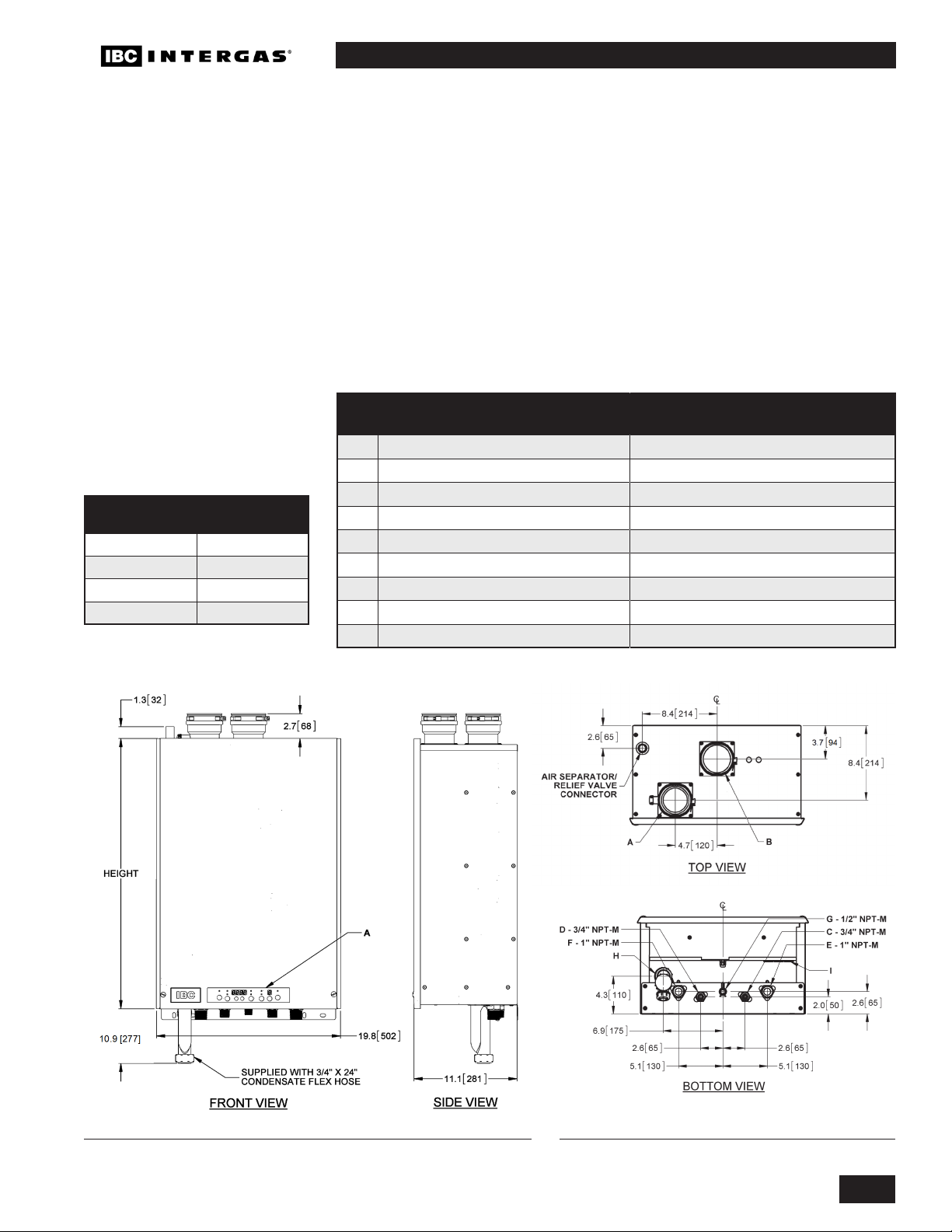

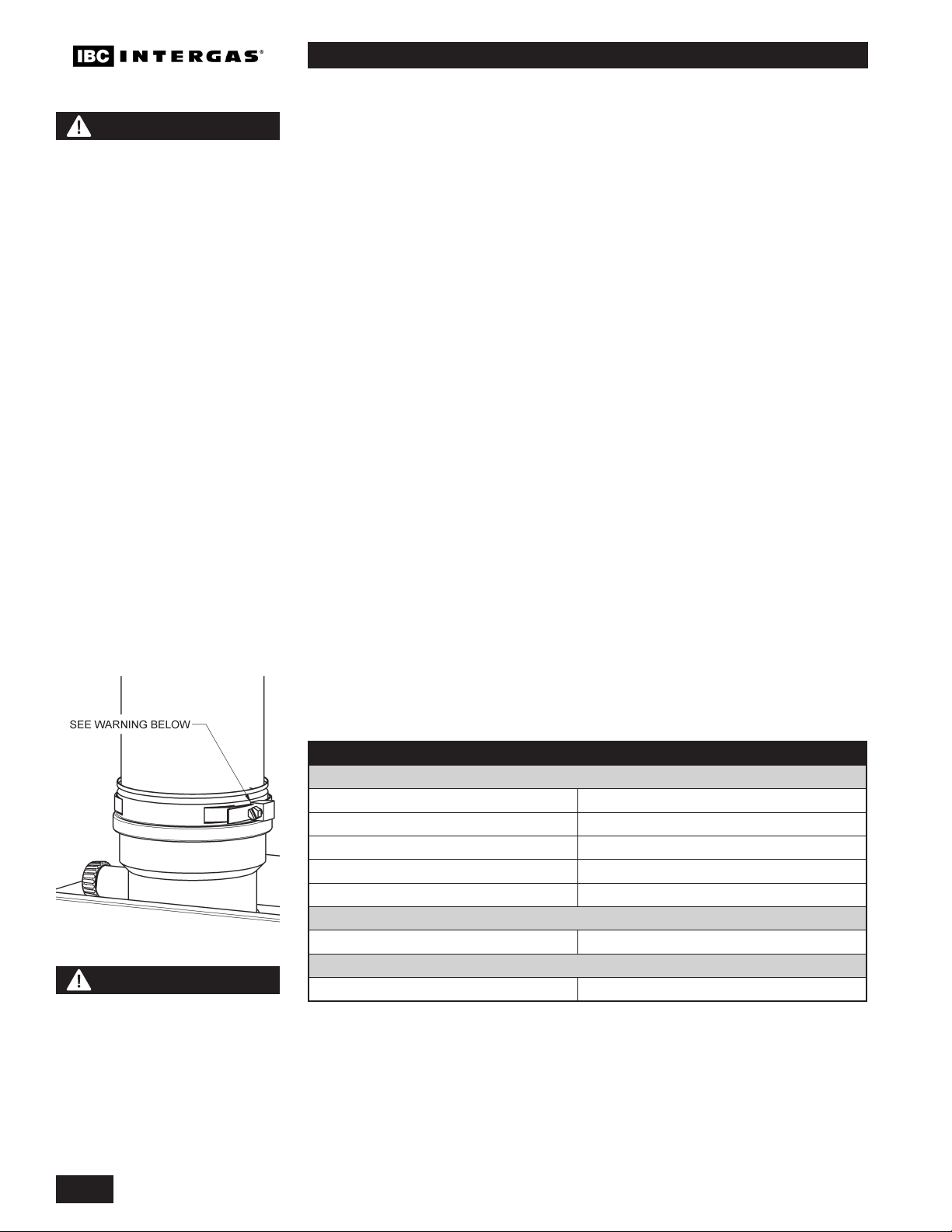

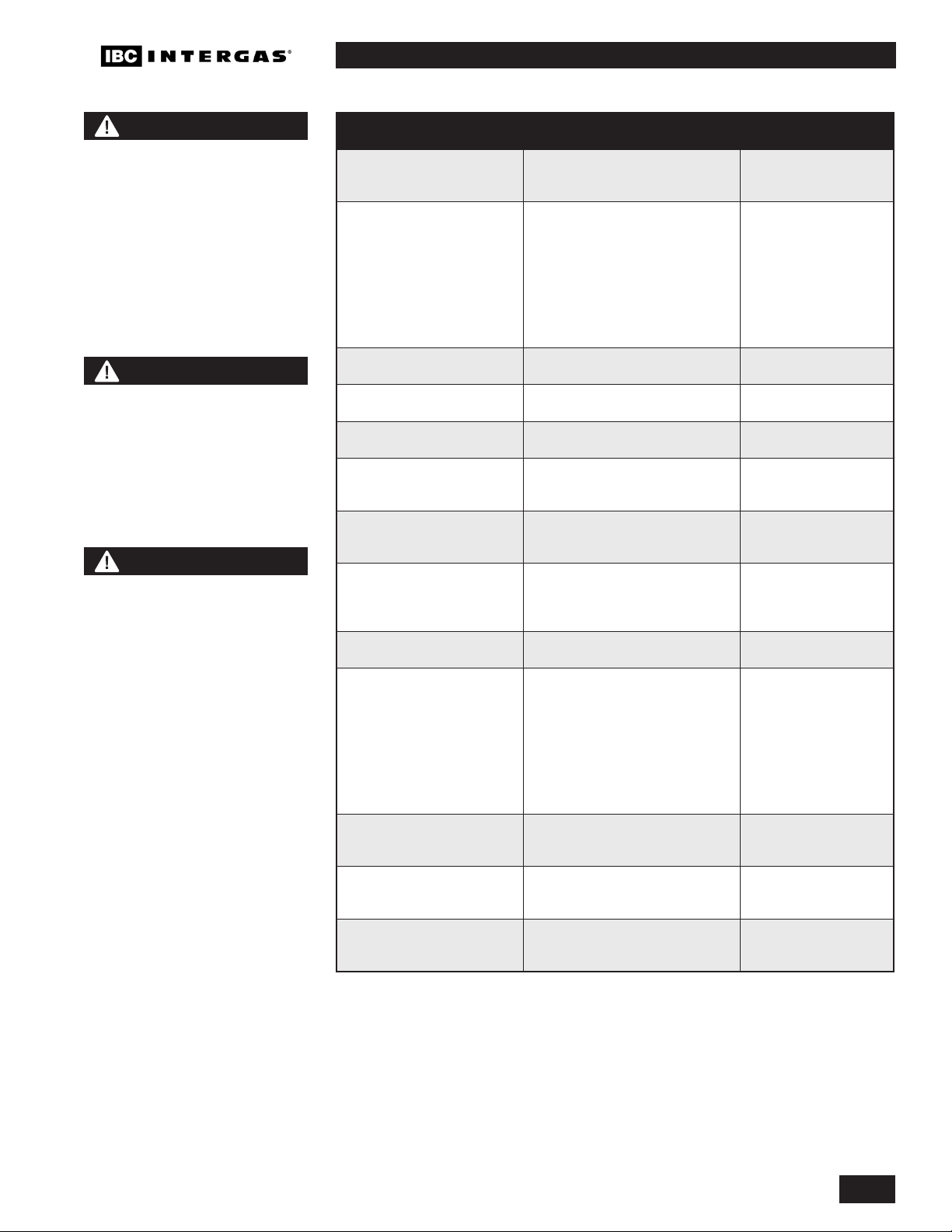

SPECIFICATIONS

SPECIFICATION DC 15-95 DC 15-96 DC 20-125 DC 33-160

CSA Input (Natural Gas or Propane) – MBH 15 - 95 15 - 96 20 - 125 33 - 160

CSA Input (Natural Gas or Propane) – KW 4.4 - 27.8 4.4 - 28.1 5.6 - 36.6 9.7 - 46.9

CSA Output – MBH 14.4 - 85.5 14.5 - 85.9 18.6 - 110.8 30.4 - 140.0

CSA Output - KW 4.2 - 25.0 4.3 - 25.2 5.4 - 32.5 8.9 - 41.0

DHW - CSA Input (Natural Gas or Propane) MBH

DHW - CSA Input (Natural Gas or Propane) - KW 4.4 - 27.8 4.4 - 28.1 5.6 - 36.6 9.7 - 36.3

A.F.U.E 95% 96% 95% 94%

Min Gas Pressure (Nat. Gas or Propane) – inch

w.c.

Max Gas Pressure (Nat. Gas or Propane) – inch

w.c.

Power (120Vac/60Hz) - Watts @ full re with

internal pump

Weight (empty) – lbs/Kg 97 / 44 105 / 48 105 / 48 105 / 48

Pressure Vessel water content – USG/Liters 0.37 / 1.4 0.5 / 1.9 0.5 / 1.9 0.5 / 1.9

Max boiler ow rate - USgpm 10 10 11 11

Min boiler ow rate - USgpm 2 2 3 3

Max Operating Pressure – Space Heating Coil -

psig

Max Operating Pressure – Domestic Hot Water

Coil - psig

Approved installation altitude - ASL 10,000 ft 10,000 ft 10,000 ft 10,000 ft

Ambient Temperature – Low (°F/°C) 32 / 0 32 / 0 32 / 0 32 / 0

Ambient Temperature – High (°F/°C) 122 / 50 122 / 50 122 / 50 122 / 50

Max relative humidity (non-condensing) 90% 90% 90% 90%

Min water Temperature - Space Heating (°F/°C) 50 / 10 50 / 10 50 / 10 50 / 10

Max water Temperature – Space Heating (°F/°C) 194 / 90 194 / 90 194 / 90 194 / 90

Min water Temperature – Domestic Hot Water

(°F/°C)

Max water Temperature – Domestic Hot Water

(°F/°C)

Min ow rate to activate DHW heating - USgpm 0.5 0.5 0.5 0.5

Max ow rate DHW heating - USgpm 3.0 3.0 4.0 4.0

DHW delivery: @70°F/ 39°C temp. rise gpm 2.5 2.5 3.2 3.2

Max equivalent vent length 3" (each side) 120' 120' 120' 120'

Max equivalent vent length 2" (each side) 35' 35' 35' 35'

* Natural Gas boilers / water heaters require a Propane conversion kit (see page #3-2, Table 10) to be ordered separately if converting a Natural Gas boiler / water

heater to Propane. Propane (LP) boilers / water heaters require a Natural Gas conversion kit (see page #3-2, Table 10) to be ordered separately if converting a

Propane boiler / water heater to Natural Gas.

† boilers / water heaters are shipped with 30 psig pressure relief valve

15 - 95 15 - 96 20 - 125 33 - 124

5 5 5 5

14 14 14 14

128 128 130 164

43.5 43.5 43.5 43.5

150 150 150 150

104 / 40 104 / 40 104 / 40 104 / 40

149 / 65 149 / 65 149 / 65 149 / 65

INSTALLATION AND OPERATING INSTRUCTIONS

3

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

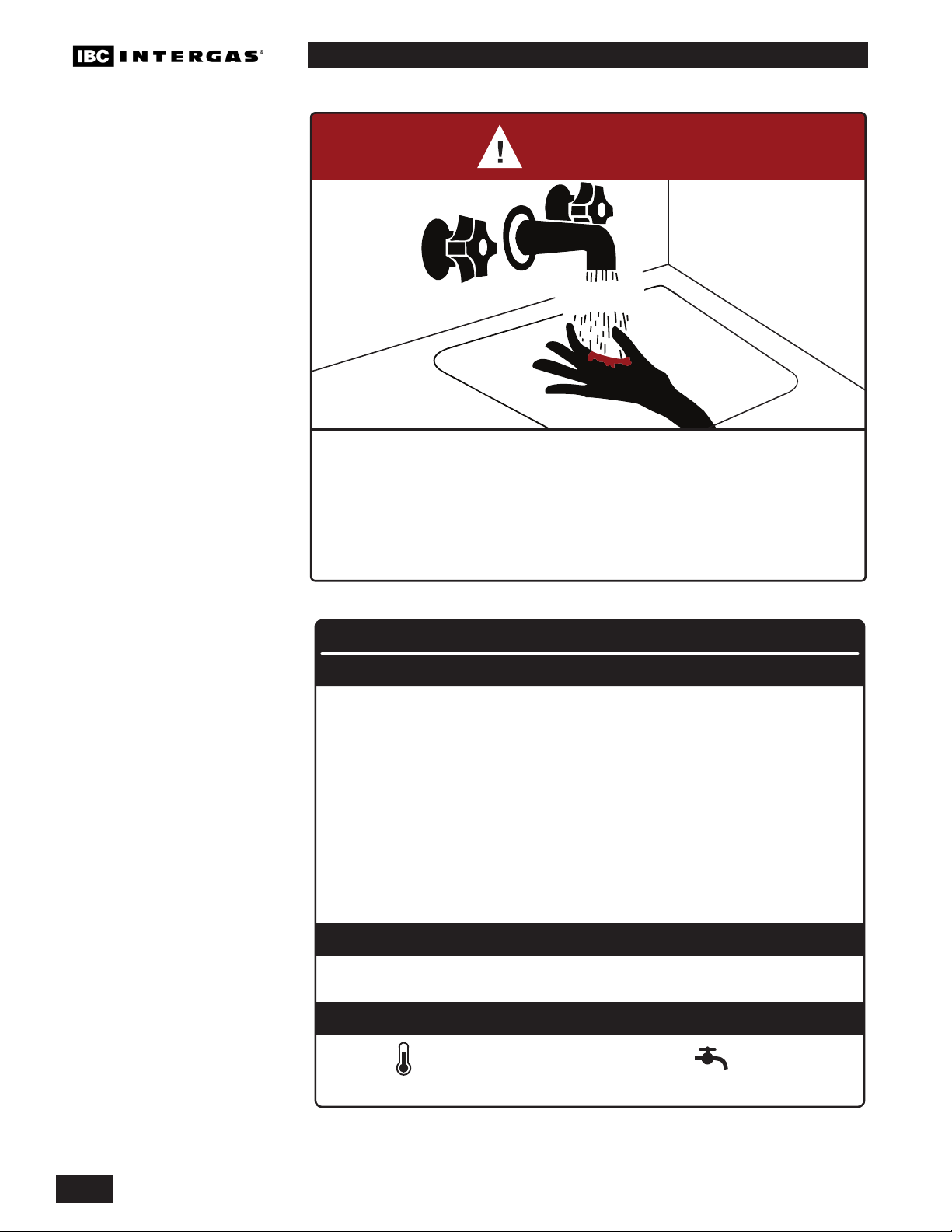

DANGER

HOT

BURN

Water temperture over 125°F (52°C) can cause severe burns instantly

°

or death from scalds.

Children, disabled, and elderly are at highest risk of being scalded.

°

See instruction manual before setting temperature at boiler.

°

Feel water before bathing or showering.

°

Temperature limiting valves are available, see manual.

°

WATER HEATER INSTALLATION GUIDELINES

WARNING

This boiler must be installed in accordance with local codes, if any; if not follow the National

°

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code,

CAN/CSA B149.1, as applicable.

Failure to correctly install and operate this appliance can result in severe personal injury

°

or death.

The water heater, if utilized, shall have a pressure relief valve installed within 6” [152mm] of the

°

DHW HOT outlet connection.

Refer to the Boiler User’s Manual before operating relief valve.

The water heater, if utilized, requires a pressure relief valve identified with the ASME V or HV

°

symbol and set to relieve at or below 150psi of domestic water pressure and a minimum

relieving capacity of 125,000 Btu/hr with 3/4” NPT threads. For safe operation of the water

heater, the relief valve must not be removed from its designated point of installation or plugged.

For complete information refer to installation manual.

°

Read and follow warnings and instructions.

°

CAUTION

Hotter water increases the risk of scald injury. Before changing the temperature setting, see

°

instruction manual.

ADJUSTABLE TEMPERATURE SETTING

Press the and hold for 2 seconds, then press again. When the LED is lit, the

°

Domestic Hot Water temperature can be set.

4

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

CONTENTS

1.0 INSTALLATION....................................................1-1

1.1 GENERAL ...................................................1-1

1.2 CODE REQUIREMENTS........................................1-2

1.3 LOCATION ...................................................1-2

1.4 EXHAUST VENTING AND AIR INTAKE.............................1-3

1.5 CONDENSATE REMOVAL......................................1-16

1.6 WATER PIPING - SPACE HEATING ..............................1-20

1.7 DOMESTIC HOT WATER SYSTEM...............................1-28

1.8 GAS PIPING.................................................1-32

1.9 ELECTRICAL CONNECTIONS ..................................1-33

2.0 BOILER / WATER HEATER SYSTEMS AND OPERATION..................2-1

2.1 GENERAL ...................................................2-1

2.2 CONTROL ...................................................2-2

2.3 INSTALLER INTERFACE ........................................2-2

2.4 TANKLESS DOMESTIC HOT WATER MODES.......................2-4

2.5 ADDING DOMESTIC HOT WATER STORAGE.......................2-4

2.6 SPACE HEATING..............................................2-5

2.7 SEQUENCE OF OPERATION ....................................2-6

3.0 STARTUP AND COMMISSIONING ....................................3-1

3.1 LIGHTING AND SHUTTING DOWN THE BOILER ....................3-1

3.2 PRIOR TO START-UP ..........................................3-2

3.3 COMMISSIONING .............................................3-2

3.4 FUEL CONVERSION ...........................................3-4

4.0 MAINTENANCE ...................................................4-1

4.1 BOILER / WATER HEATER MAINTENANCE ........................4-1

5.0 TROUBLESHOOTING ..............................................5-1

5.1 PRELIMINARY CHECKS ........................................5-1

5.2 ELECTRONIC COMPONENTS ...................................5-2

6.0 DIAGRAMS.......................................................6-1

6.1 PARTS DIAGRAMS ............................................6-2

6.2 WIRING DIAGRAMS ...........................................6-6

INSTALLATION AND OPERATING INSTRUCTIONS

5

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

The Installer must carefully read this manual to ensure that all installation

details can be adhered to. Special attention is to be paid to clearances and

access, vent travel and termination, gas supply, condensate removal and

combustion air supply.

DANGER

Should overheating occur

or the gas supply fails to

shut o, do not turn o or

disconnect the electrical

supply to the pump. Instead

shut o the gas supply at

a location external to the

appliance.

WARNING

Do not use this boiler / water

heater if any part has been

under water. Immediately call

a qualied service technician

to inspect the boiler / water

heater and to replace any part

of the control system and

any gas control that has been

under water.

CAUTION

Care must be taken to

properly size the boiler /

water heater for its intended

use. Prolonged full re run

time, over-sizing or undersizing, and incorrect ow

rates through the boiler /

water heater can lead to

increased maintenance

costs, equipment stress and

premature failure.

The Installer should do a pre-installation check the to ensure that the

following precautions can be observed:

• The boiler / water heater should be installed in areas where the combustion

air source is not subject to chemical fouling or agricultural vapours.

Exposure to corrosive chemical fumes such as chlorinated and/or uorinated

hydrocarbons can reduce the life of a boiler. Cleaners, bleaches, air

fresheners, refrigerants, aerosol propellants, dry-cleaning uids, de-greasers

and paint-removers all contain vapours which can form corrosive acid

compounds when burned in a gas ame. Airborne chlorides such as those

released with the use of laundry detergents are also to be avoided.

• The boiler / water heater should be located where water leakage will not result

in damage to the area. If a location such as this cannot be found, a suitable

drain pan should be installed under the appliance. The boiler / water heater is

not to be installed above carpeting.

• At a new construction site, or during renovations, action must be taken to

protect the boiler / water heater from drywall dust or other construction related

contaminants; combustion air should be drawn from a CLEAN source (e.g.

outdoors) and the boiler / water heater should be isolated from interior dust

sources.

• When the boiler / water heater is in operation, the impact of the steam plume

normally experienced at the exhaust terminal of a condensing boiler / water

heater should be assessed. Generally, intake and exhaust pipes should

terminate at a rooftop or sterile wall location. Boiler / water heater condensate

is corrosive. Protective measures must be taken to prevent corrosion

damage to metal roofs or other metal building components in contact with

the condensate. Keep exhaust plumes well away from all building air intakes

including those of neighbouring properties.

• The exhaust outlet should be placed so as to reach 12" minimum above the

down-turned intake - to avoid exhaust re-ingestion.

• For sidewall venting options: Both the inlet and exhaust terminations should

normally be located on the same plane (side) of the building. The elevation of

both pipes can be raised in “periscope style” after passing through the wall to

gain required clearance above grade and snow level.

• Examine the condensate outlet to ensure proper disposal of condensate will

occur during operation. If condensates are to be discharged into building drain

piping materials that are subject to corrosion, a neutralization package must

be used.

• Ensure that the pressure relief valve will be installed with no valves or other

means of isolation between its inlet and the boiler / water heater. Make sure

the relief valve outlet will be piped with unobstructed piping (minimum 3/4"

diameter) to a safe discharge location.

• In locations where power supply quality varies or is unstable, installation of

surge protection and power conditioners up to and including battery back-up

uninterrupted power supply devices should be considered.

• Ensure the domestic hot water demands are considered before purchasing

the DC Series boiler / water heater. The addition of a storage tank or an IBC

Indirect Water Heater may be required in some cases.

6

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

INSTALLATION1.0

MODEL

NUMBER

DC 15-95 29.0" [736]

DC 15-96 31.3" [796]

DC 20-125 31.3" [796]

DC 33-160 31.3" [796]

HEIGHT

1.1

GENERAL

DC Series gas-red modulating boilers / water heaters are low pressure, fully

condensing units having variable input ranges (see specication chart - page 3).

The boilers / water heaters are approved as “Category IV” vented appliances

using Direct Vent (sealed combustion).

Figure 1 shows outer case dimensions and piping and electrical holes. Use this

diagram to nd a suitable location for the boiler / water heater. See also Section

1.3 Location.

DESCRIPTION

A Exhaust Outlet 3" Schedule 40

B Combustion Air 3" Schedule 40

C

Cold Domestic Water Connection

D Hot Domestic Water Connection 3/4" Male NPT

E Heating Water Inlet (Return) 1" Male NPT

F Heating Water Outlet (Supply) 1" Male NPT

G Gas Inlet 1/2" Male NPT

H Condensate Outlet 3/4" Hose

I Knock-out (3) 1/2"

DC SERIES BOILERS / WATER

HEATERS

3/4" Male NPT

Table 1: Connections

Figure 1a: Dimensions / Connections for DC Series Figure 1b: Dimensions / Connections for DC Series

INSTALLATION

1-1

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

1.2

1.3

WARNING

Keep boiler / water heater area

free and clear of combustible

materials, gasoline, and

other ammable vapours and

liquids.

WARNING

Combustion air must not be

drawn from areas containing

corrosive air from swimming

pools or spas, including air

directly next to outdoor pools

and spas.

WARNING

The boiler / water heater

shall not be exposed to

water leaks from piping or

components located overhead.

This includes condensation

dropping from un-insulated

cold water lines overhead.

WARNING

Ensure the gas ignition

system components are

protected from water (dripping,

spraying, rain, etc.) during

appliance operation and when

servicing (pump replacement,

condensate trap servicing,

control replacement, etc.)

CODE REQUIREMENTS

The DC 15-95, DC 15-96, DC 20-125, DC 33-160 models were tested to and

certied under CSA 4.9 / ANSI Z21.13 and Water Heater CSA 4.3 / ANSI

Z21.10.3.

The installation must conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, and/or Natural Gas and Propane Installation Code,

CAN/CSA B149.1. The installation must also conform to the Canadian Electrical

Code Part 1 CSA C22.2 No.1 and/or the National Electrical Code ANSI/NFPA

70. Where required by jurisdiction, installation must conform to the Standard for

Controls and Safety Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

If there is any conict, then the more stringent will apply.

LOCATION

The DC series boilers / water heaters are designed and approved for indoor

installation (wall), with signicant exibility of location provided with the available

venting options. The boiler / water heater can be placed in an alcove, basement,

closet or utility room. Surrounding ambient conditions shall be 0°C to 50°C and less

than 90% relative humidity.

Install the boiler / water heater in areas where the combustion air source is

not subject to chemical fouling or agricultural vapours. Exposure to corrosive

chemical fumes such as chlorinated and/or uorinated hydrocarbons can

reduce the life of a boiler / water heater. Cleaners, bleaches, air fresheners,

refrigerants, aerosol propellants, dry-cleaning uids, de-greasers and paint-

removers all contain vapours which can form corrosive acid compounds when

burned in a gas ame. Airborne chlorides such as those released with the use of

laundry detergents are also to be avoided. Similarly, ensure any direct vent air

source is not adjacent to a clothes dryer exhaust terminal. Avoid agricultural

applications where the boiler / water heater and/or the intake air source are

aected by ammonia and/or dust.

Locate the boiler / water heater where water leakage will not result in damage to

the area. If a location such as this cannot be found, a suitable drain pan should

be installed under the appliance. The boiler / water heater is not to be installed

above carpeting.

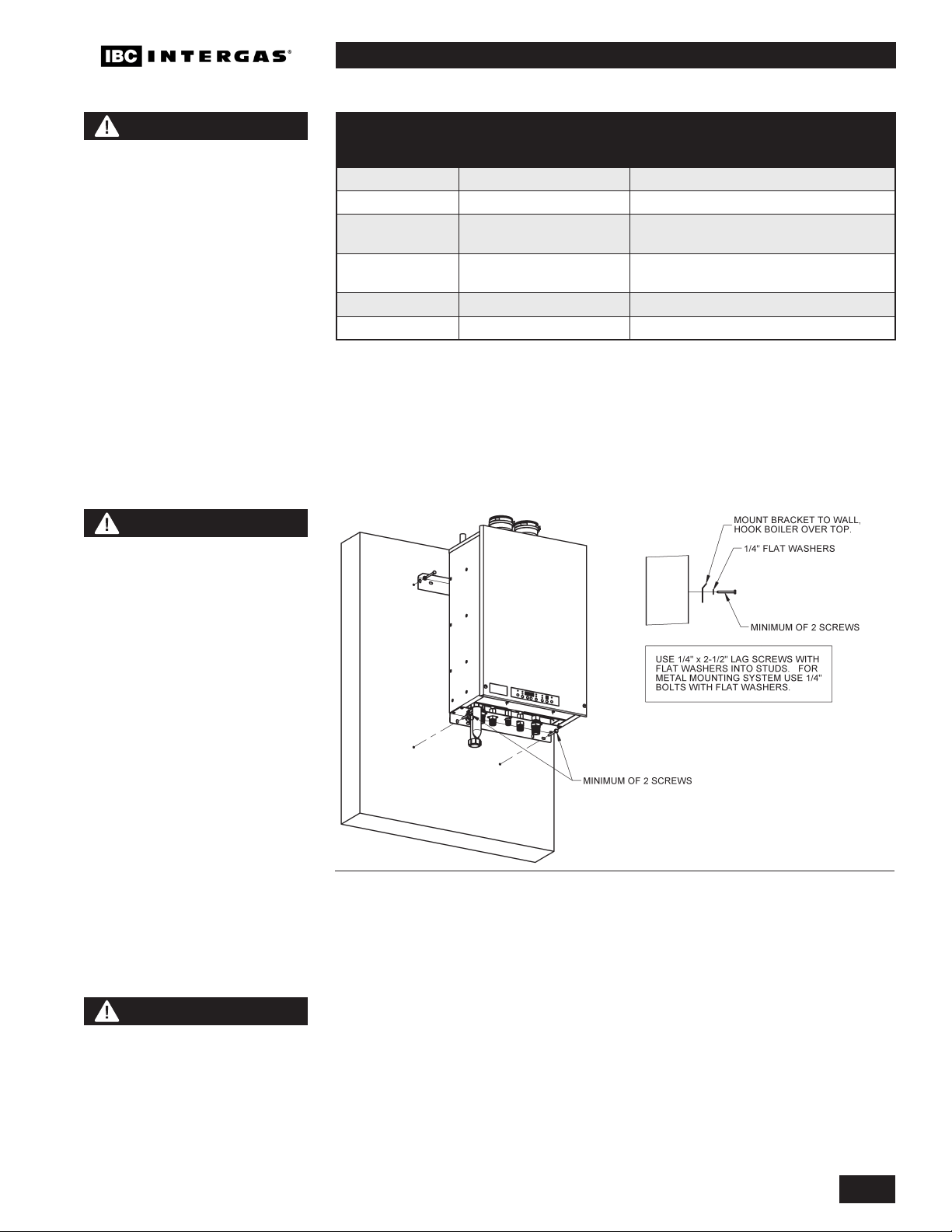

Boiler / Water Heater Weight – approximately 105 lb / 44 kg. For support fasteners,

use the supplied 4 x 1/4" x 2-1/2" long lag screws. Installer to supply 1/4" bolts if

metal mounting systems are used. Fasteners are to be attached to solid material

capable of supporting the combined weight of the boiler / water heater and piping

assembly components.

Other factors aecting potential mounting sites:

• Ensure minimum clearance requirements for combustible materials (see

Table 2) are satised.

• Minimum 24" clearance at the front and 10" above is recommended for

adequate servicing. Check local codes for additional access and service

clearance requirements.

•

At a new construction site, or during renovations, action must be taken to

protect the boiler / water heater from drywall dust or other construction

related contaminants; combustion air should be drawn from a CLEAN

source (e.g. outdoors) and the boiler / water heater should be isolated

from interior dust sources.

1-2

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

WARNING

Exposed water piping and

associated components

(relief valves, circulators, etc.)

should not be in contact with

combustible materials. Check

local codes for required

clearances and/or provide

adequate insulation.

WARNING

DO NOT MOUNT THIS

BOILER / WATER HEATER

TO HOLLOW WALL

STRUCTURES - The

combined weight of the

boiler, its water contents

and associated piping

components can exceed 150

pounds. Fasteners must be

rated for this strain, and must

be rmly anchored into solid

material that will support this

weight.

DISTANCE FROM

SURFACE

Front 2" 24"

Rear 0" 0"

Left Side 1.5"

Right Side 4"

Top 2" 24"

Bottom 8" 24"

Table 2: Clearance from boiler / water heater cabinet

A minimum distance below the boiler / water heater of 11" is required to

provide clearance for the supplied condensation trap assembly. More

clearance will typically be required to accommodate associated water and

gas piping.

COMBUSTIBLE

SURFACES

RECOMMENDED DISTANCE

FOR INSTALLATION AND

SERVICE

6" (labels may be dicult to read with

reduced clearance)

6" (labels may be dicult to read with

reduced clearance)

Installers are to take all

necessary precautions

to avoid injury during the

installation of this boiler /

water heater.

1.4

DANGER

Do not common vent the DC

modulating series boilers /

water heaters with any other

existing or new appliance.

INSTALLATION

Figure 2: Wall mounting of boiler

EXHAUST VENTING AND AIR INTAKE

It is important to carefully plan the installation to ensure the appropriate

vent materials, travel and termination decisions are incorporated. Specic

attention is warranted to manage the impact of the steam plume normally

experienced at the exhaust terminal of a condensing boiler. Generally,

intake and exhaust pipes should terminate at a rooftop or sterile wall

location, to maximize customer satisfaction. Keep exhaust plumes

well away from all building air intakes including those of neighbouring

properties.

1-3

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

WARNING

Venting, condensate drainage,

and combustion air systems

for all IBC boilers / water

heaters must be installed in

compliance with all applicable

codes and the instructions of

their respective Installation

Manuals.

Inspect nished vent and air

piping thoroughly to ensure

all are airtight and comply

with the instructions provided

and with all requirements of

applicable codes.

Failure to comply will result

in severe personal injury or

death.

All venting must be installed in accordance with the requirements of the

jurisdiction having authority: in Canada, Part 8, Venting Systems of the B149.110 Code and any other local building codes are to be followed. In the USA

the National Fuel Gas Code, ANSI 223.1, latest edition, prevails. Where there

is a discrepancy between the installation instructions below, and the code

requirements, the more stringent shall apply.

Provisions for combustion and ventilation air in accordance with the section “Air

for Combustion and Ventilation,” of the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, or Clause 8.2, 8.3 or 8.4 of Natural Gas and Propane Installation Code,

CAN/CSA B149.1, or applicable provisions of the local building codes.

NOTE

The minimum wall thickness

for venting is 1” and the

maximum wall thickness for

venting is 14”.

NOTE

A water heater shall not be

connected to a chimney ue

serving a separate appliance,

designed to burn solid fuel.

Figure 3: Basic exhaust vent assembly

IMPORTANT

When an existing boiler / water heater is removed from a common venting

system, the common venting system is likely to be too large for proper venting of

the appliances remaining connected to it.

When re-sizing any portion of the common venting system, the common venting

system should be re-sized to approach the minimum size as determined using

the appropriate tables in the National Fuel Gas Code, ANSI Z223.1 - latest

edition. In Canada, use the B149.1 Installation Code - latest edition.

At the time of removal of an existing boiler the following steps shall be followed

with each appliance remaining connected to the common venting system placed

in operation, while the other appliances remaining connected to the common

venting system are not in operation.

• Seal any unused opening in the common venting system.

• Visually inspect the venting system for proper size and horizontal pitch and

determine there is no blockage or restriction, leakage, corrosion and other

deciencies which could cause an unsafe condition.

• Insofar as is practical, close all building doors and windows and all doors

between the space in which the appliances remaining connected to the

common venting system are located and other spaces of the building. Turn

on clothes dryers and any appliance not connected to the common venting

system. Turn on any exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do not operate a summer

exhaust fan. Close replace dampers.

1-4

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

• Place in operation the appliance being inspected. Follow the lighting

instructions. Adjust thermostat so appliance will operate continuously.

• After it has been determined that each appliance remaining connected to the

common venting system properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers and any other gas-burning

appliance to their previous conditions of use.

• Any improper operation of the common venting system should be corrected

so the installation conforms with the National Fuel Gas Code, ANSI Z223.1 latest edition. In Canada, all installations must conform with the current CAN/

CGA - B149.1 Installation Code and/or local codes.

1.4.1 Applications

All DC Series boilers / water heaters must be installed as a Direct Vent venting

system. The combustion air must be piped in from the outdoors and connected

directly to the boilers / water heaters combustion air connection. See section

1.4.7 for air intake piping requirements.

1.4.2 Exhaust Vent Material

WARNING

Covering non-metallic vent

pipe and ttings with thermal

insulation shall be prohibited.

EXHAUST VENT MATERIAL – CANADA

Only PVC, CPVC, Polypropylene (PPs) or stainless steel* vent component

systems approved under ULC-S636 Standard for Type BH Gas Venting Systems

are to be used. Ensure compliance with exhaust temperature limitations for

the respective materials. The vent temperature is limited with the use of a ue

temperature sensor and software to ensure the maximum temperature of the

PVC venting material is not exceeded.

• ULC-S636 PVC

• ULC-S636 CPVC

• ULC-S636 PPs

EXHAUST VENT MATERIAL – USA

PVC, CPVC, PPs venting materials are approved for use with this boiler /

water heater in the USA. The vent temperature is limited with the use of a ue

temperature sensor and software to ensure the maximum temperature of the

PVC venting material is not exceeded. PVC venting material shall be certied to

Sch. 40 ASTM D1785 or D2665. CPVC venting material shall be certied to Sch.

40 ASTM F441.

INSTALLATION

1-5

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

WARNING

Do not mix venting materials

from dierent Manufacturers.

These venting materials are

designed to be installed as

part of a complete system.

Failure to comply may result

in severe personal injury or

death.

Do not use ABS or any cellular core pipe for exhaust venting.

Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel®

(polyphenolsulfone) in venting systems shall be prohibited.

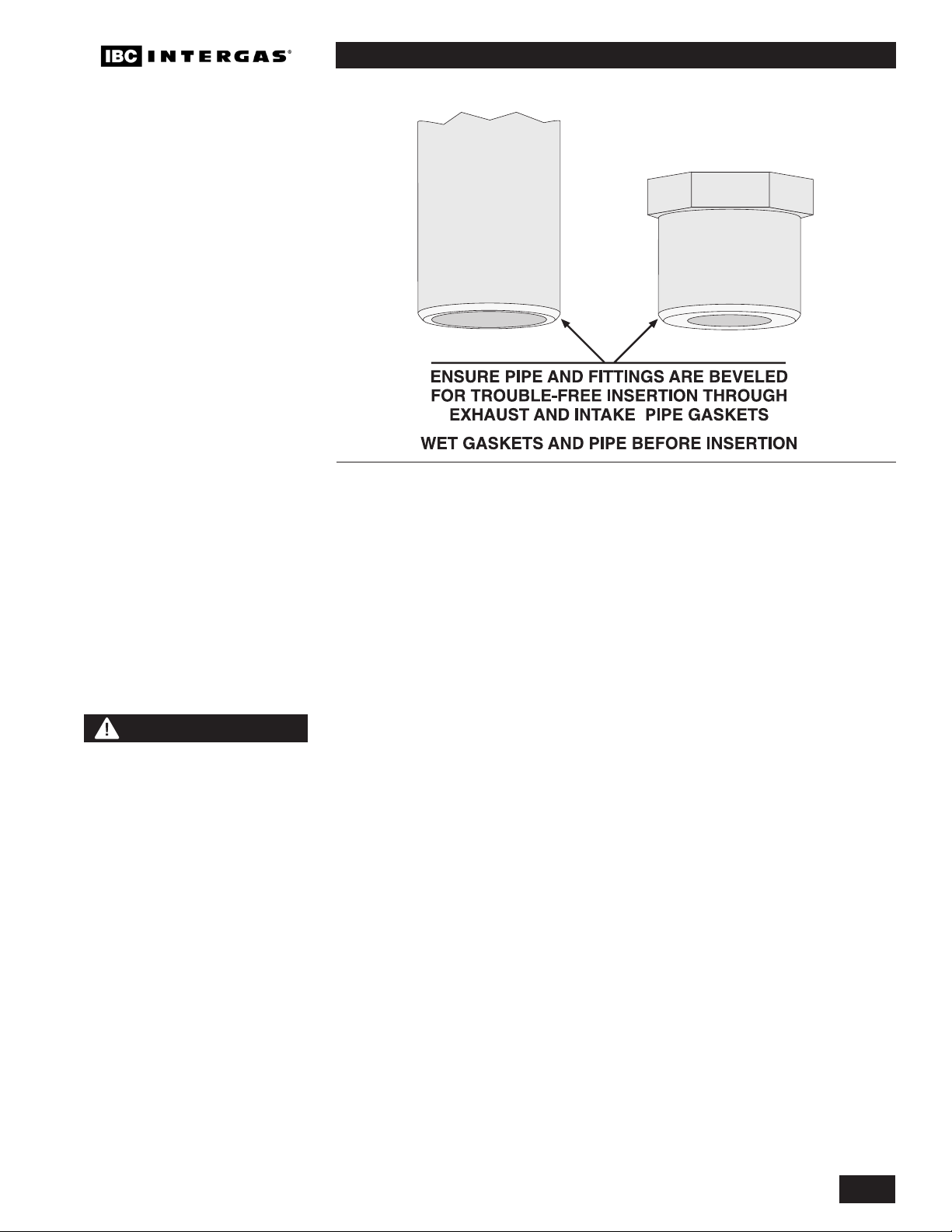

The boiler / water heater oers 3" venting connections. Fittings are to be used

to adapt to the appropriate diameter (see Vent Travel below). CPVC or PVC

Exhaust Venting is to be inserted directly into the 3" female stainless steel tting

on left side of the boiler’s top panel. The clamp must be tightened to secure the

pipe into the tting. If PPs materials are being used, ensure the proper adapter is

used to transition from the Schedule 40 diameter to the PPs size diameter.

For PPs material, use the 3" transition/ adaptor tting (Sch 40 to PPs) oered

by the respective PPs manufacturers Centrotherm / InnoueTM (their part #

ISAA0303) or M&G Dura Vent /PolyPro (#3PPS-AD). For PPs material exposed to

outdoor weather, follow the venting suppliers’ recommendations on UV protection.

Combustion air piping is inserted directly into the 3" female stainless steel tting

on the right (see Section 1.4.7).

Venting shall be supported in accordance with applicable code.

1.4.3 Vent Travel

CPVC or PPs (Rigid Single Wall) piping is the standard venting option; with

this, the DC Series boilers / water heaters, for example, can be vented up to

120 equivalent feet from the vent termination using 3". The actual vent travel

allowance is reduced for ttings in accordance with Table 3. – e.g. for the models

listed above using 6 x 90º CPVC long sweep elbows, the maximum lineal

measure of pipe allowed using 3" pipe is 90 feet (120' – (6 x 5' = 30) = 90').

WARNING

Fully insert the approved

venting material into the

boilers / water heaters

exhaust outlet and tighten

clamp to ensure the venting

connection is locked in place.

For 3" Flexible PPs, up to 35 actual lineal feet are allowed in a nominally vertical

orientation (>45°). The equivalent length of 3" Flexible PPs shall be computed

using a multiple of 1.4:1, e.g. 35' x 1.4 = 49' equivalent. The balance of the

venting allowance is still available for use with rigid PPs piping material. 2"

Flexible PPs is not allowed.

EXHAUST PIPE SIZE/FITTINGS MAXIMUM EQUIVALENT LENGTH

Schedule 40 PVC, CPVC or PPs – Allowances are for each side separately.

2" 35'

3" 120'

2" or 3" 90' Long Sweep Vent Elbow Allow 5 equivalent feet

2" or 3" 90' Short Sweep Vent Elbow Allow 8 equivalent feet

2" or 3" 45' Vent Elbow Allow 3 equivalent feet

PPS

PPs 87-90' Elbow Allow 8 equivalent feet

Flex PPS

3" PPs Flex (Max. 35) actual feet times 1.4

Table 3: Maximum Exhaust Venting Length

Exhaust venting must slope down towards the boiler / water heater with a pitch

of at least 1/4" per foot (PPs vent: follow PPs manufacturer requirements) so

condensate runs back towards the trap. Support should be provided for intake

and vent piping, particularly so for horizontal runs (follow local code).

1-6

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

Figure 4

Exhaust piping is inserted directly into the 3" female stainless steel tting on the

top, left side of the boiler / water heater and run horizontally or vertically to the

outdoors. Bird screen of 1/4" stainless steel or plastic mesh (eg. IPEX System

636 drain grate for CPVC systems) is useful to guard against foreign objects.

BEST PRACTICES

To reduce the possibility of

expansion noise, allow a 1/4"

gap around the exhaust and

air intake piping.

Follow all installation instructions supplied by the pipe and tting

manufacturer.

Ensure all venting components are clean of burrs/debris prior to assembly.

Care is to be taken to avoid ingestion into the fan of PVC/ABS debris left in the

combustion air piping.

All joints must be secured using appropriate solvent cement to bond the

respective pipe material (Canada: CPVC cement approved under ULC-S636,

in accordance with its manufacturer instructions; USA: PVC (ASTM D2564),

or PVC/ABS (D2235) - Use transition glue anywhere that PVC and CPVC are

joined. Follow the cement manufacturer’s instructions closely when joining

various components. For PPs, connections shall be secured using approved

retainer clips supplied by the respective PPs manufacturer.

All vent connections must be liquid and pressure tight. Prior to ring the boiler,

and before any of the venting run is concealed by the building construction, the

installer must test the exhaust joints under fan pressure with the vent blocked,

using a soap/water solution. Installer must ll condensate trap prior to test.

1.4.4 Venting Passage Through Ceiling and Floor

• Conrm material meets local codes including re stopping requirements.

• Some local jurisdictions require a minimum initial length of pipe be exposed or

accessible for inspection.

• Pipe clearances - no IBC requirements, but best practice allows a minimum

1/4" gap around the pipe to prevent binding and expansion noise; follow local

codes.

• All piping must be liquid and pressure tight.

INSTALLATION

1-7

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

CAUTION

Vent termination clearances

in this section are

code minimum, or IBC

recommended minimum

requirements, and may

be inadequate for your

installation. Building envelope

details must be examined

carefully, and ingress of

moisture into building

structures is to be avoided.

Serious structural damage

may occur if adequate

precautions and clearances

are not allowed for.

These precautions are to be

observed for neighbouring

structures as well as for the

structure the boiler(s) are

installed in.

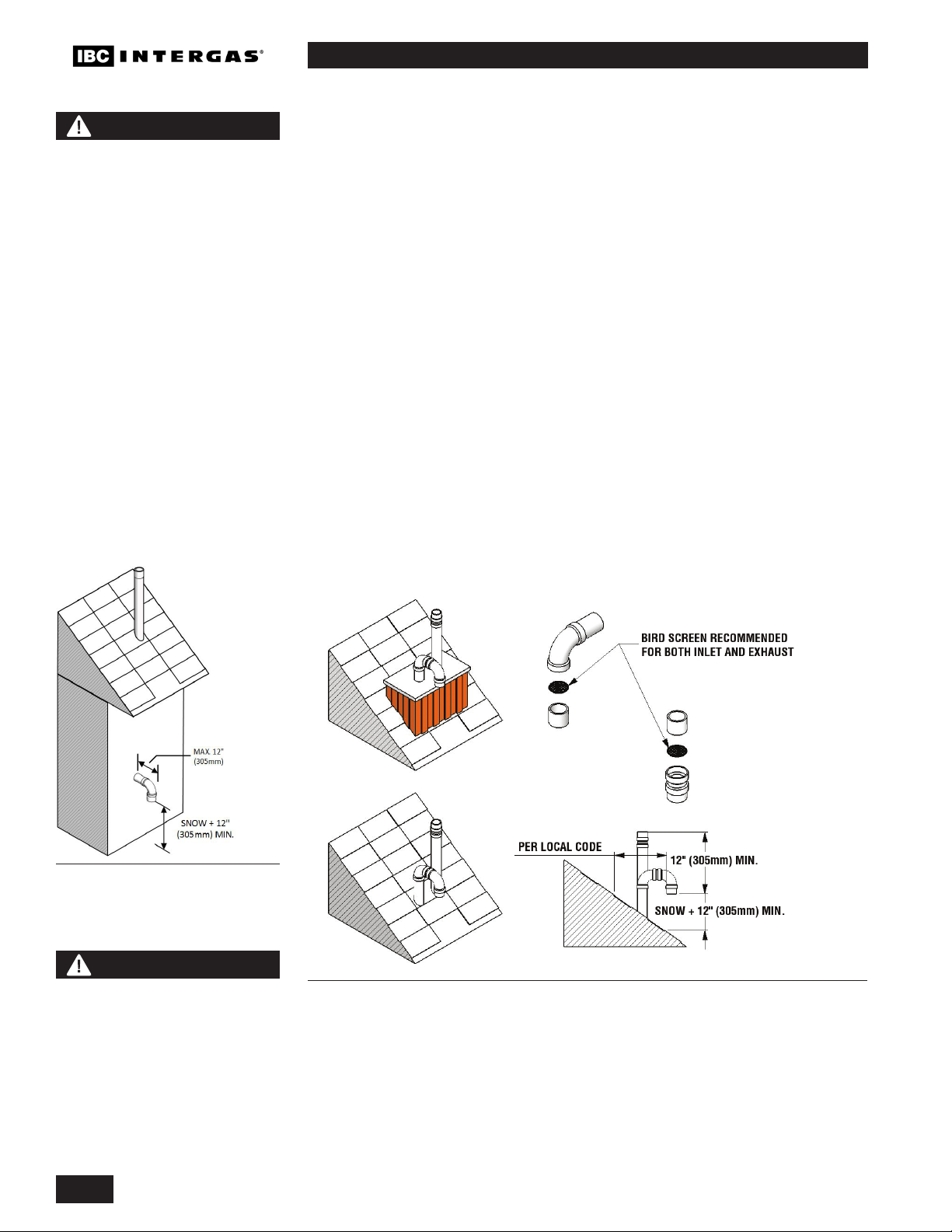

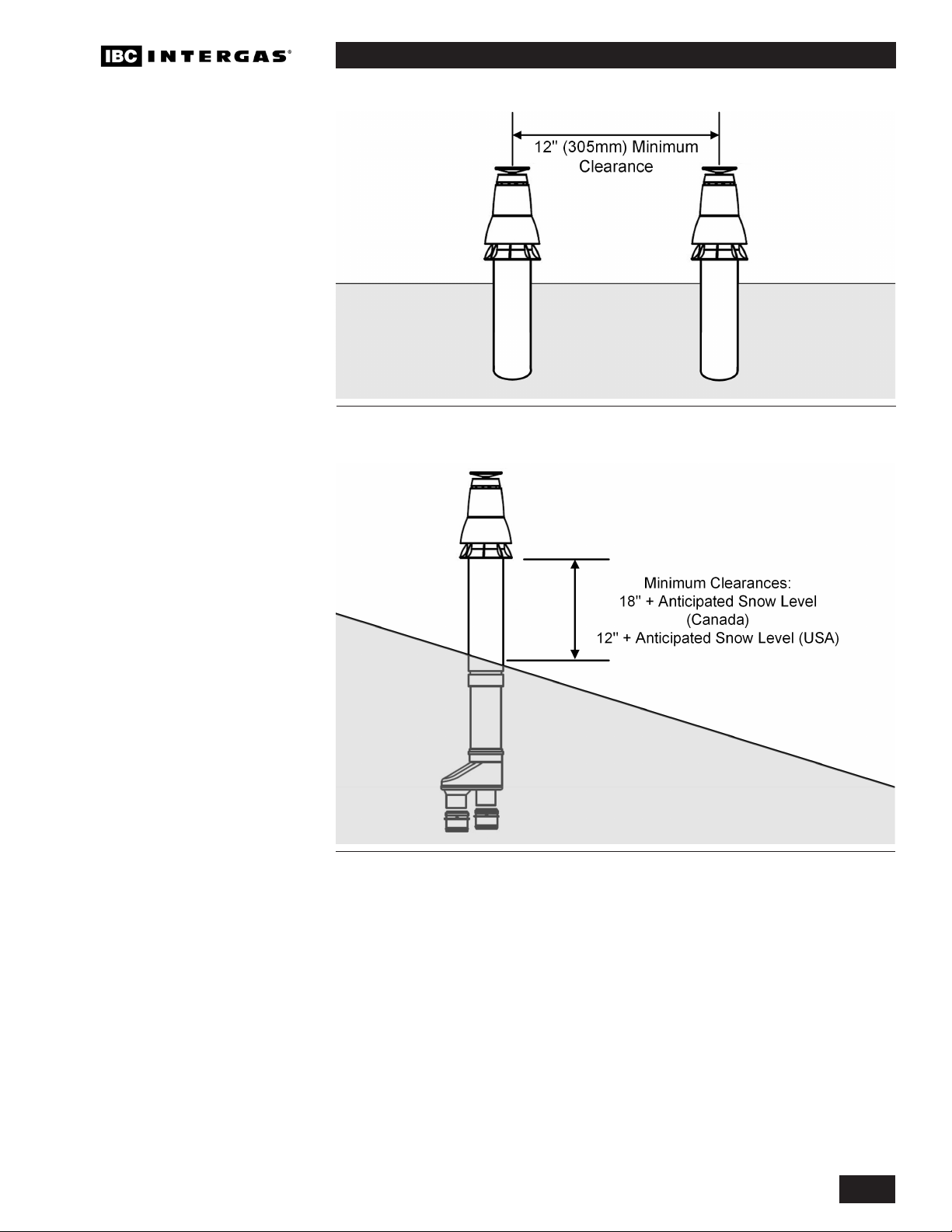

1.4.5 Rooftop Vent Termination

DIRECT VENT - TWO PIPE

Rooftop vents must terminate as follows:

•

The exhaust pipe can terminate in an open vertical orientation without concern

about rain inltration; rain will drain away through the condensate trap.

•

The intake air pipe is not typically drained, so it must be terminated with a downturned elbow (see Figure 5). The intake pipe does not need to penetrate the roof

at the same elevation as the exhaust; lower down the roof is OK.

• The air intake pipe may terminate on the side wall of the building as long as

the air intake terminal is turned down and the side wall of the building is not

exposed to large wind loads i.e.: prevailing winds.

• Optional bird screen may be placed in a termination tting. Leave unglued,

and hold in place with a short nipple. This permits easy access for cleaning.

• For roof top venting of multiple boiler / water heater sets, group all intake

terminals together for a common penetration through a custom cap.

Alternatively, place in the closest proximity achievable using commonly

available pipe ashing. Similarly group the exhaust pipes and place the 2

separate groups of pipes at least 3' apart (the closest intake and exhaust

pipes shall be 36" - or more - apart). Use the same 12" (minimum) vertical

separation for 2 pipe option. For alternate group terminations, contact the IBC

Factory for written guidance.

• DO NOT exhaust vent into a common venting system.

Figure 5a: Rooftop exhaust venting

with sidewall combustion air.

WARNING

Condensate can cause

corrosion of metal roong

components and other

roong materials. Check

with the builder or roong

contractor to ensure that

materials will be resistant to

acidic condensate. pH levels

can be as low as 3.0

1-8

Figure 5b: Rooftop vent terminal congurations

DIRECT VENT CONCENTRIC ROOF TOP TERMINATION

Roof Top Concentric Termination Kits are approved for use with this boiler / water

heater model. The installation of the vertical roof top concentric termination must

follow the installation instructions supplied with the venting material manufacturer.

Care must be taken to install the termination kit a minimum horizontal distance of

10' (305cm) away from any portion of the building and a minimum of 18" (46cm)

above the roof line plus the anticipated snow line. See Figure 6 and 7 on page 1-9.

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

Figure 6: Vertical Concentric Termination - Two Kits

INSTALLATION

Figure 7: Vertical Concentric Termination - Single Kit

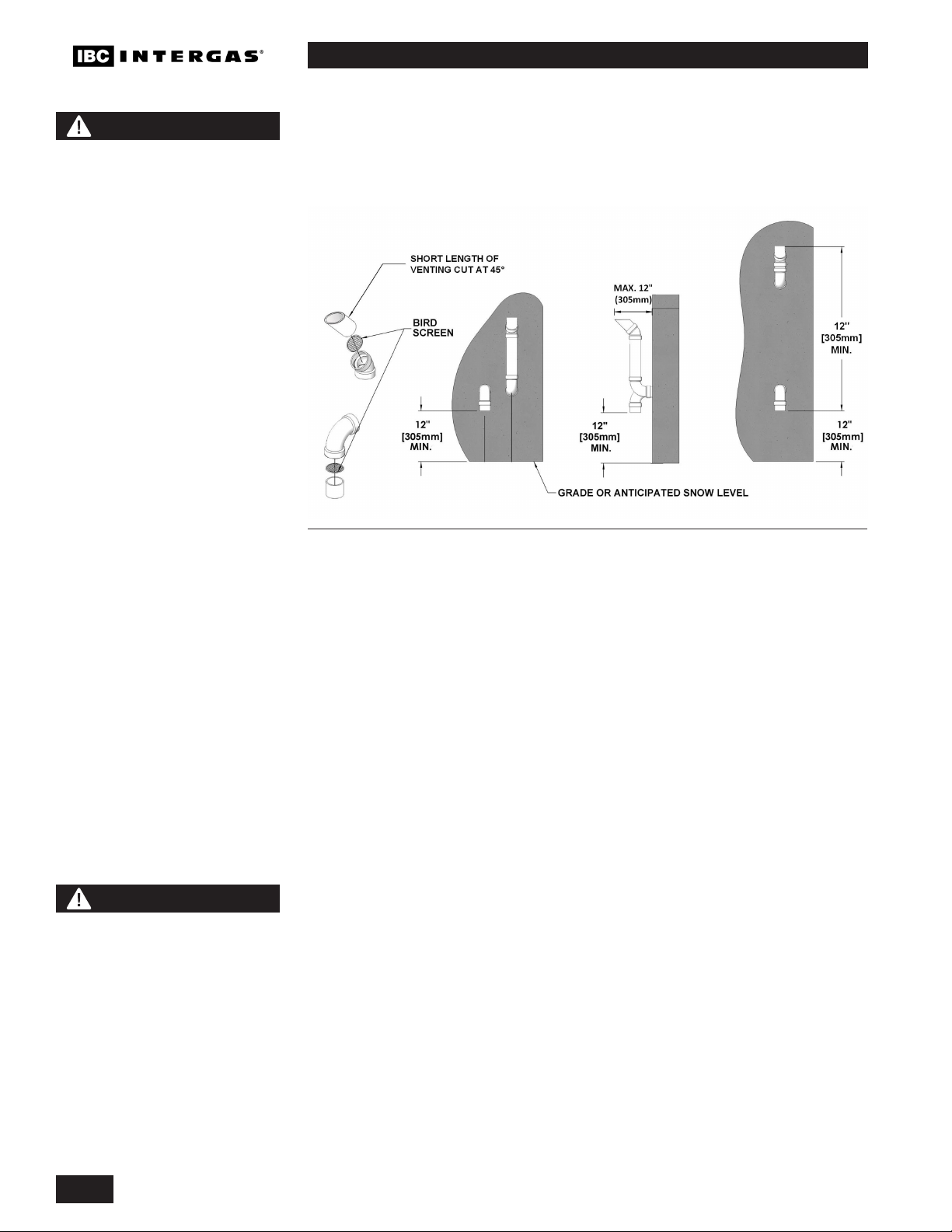

1.4.6 Sidewall Vent Termination

DIRECT VENT - TWO PIPE

Sidewall direct vent applications shall be vented as follows:

• Both the inlet and exhaust terminations should normally be located on the

same plane (side) of the building.

• The exhaust outlet is to be placed so as to reach 12" minimum above the

down-turned intake - to avoid intake re-ingestion of exhaust gases.

• The elevation of both pipes can be raised in “periscope style” after passing

through the wall, then congured as in Figure 8, to gain required clearance.

1-9

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

WARNING

It is extremely important to

maintain at least the minimum

separation of exhaust vent

termination from boiler /

water heater intake air as

illustrated in gures 5, 8 and

13. Failure to do so can result

in a dangerous situation

where exhaust gasses are

re-ingested with combustion

air. Damage to the boiler

/ water heater can result

from a failure to maintain

these separations. Improper

installation will void the

warranty.

• Use a 45° elbow on the exhaust termination to launch the plume up and o

the sidewall, for protection of wall.

• Bird screen of 1/4" stainless steel or plastic mesh eg. (IPEX System 636 drain

grate for CPVC systems) is useful to guard against foreign objects.

Figure 8: Sidewall vent termination - piping conguration

WARNING

In areas of high snowfall,

Users must be advised to

check side wall vent and

air intake terminations on

a regular basis to ensure

blockage does not occur.

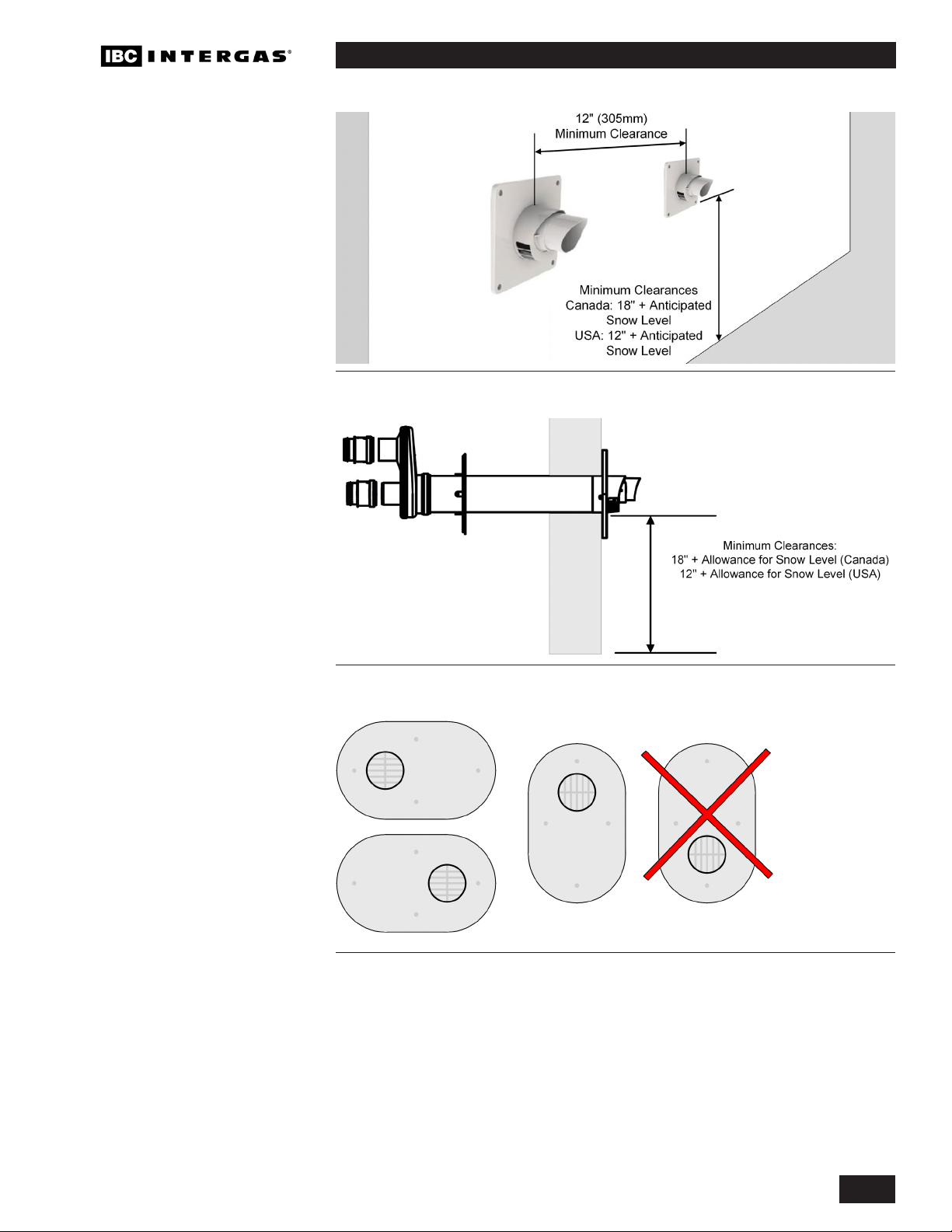

DIRECT VENT SIDE WALL TERMINATION KITS

The following Side Wall Termination Kits are approved for use with the DC series

boilers / water heaters and are subject to the following restrictions. NOTE: Some

jurisdictions may not allow this type of side wall termination due to close proximity

to the neighboring properties. See Figures 9a, 9b and 10 on page 1-11.

The installation instructions, clearances and wall thickness requirements of the

approved vent termination manufactures must be followed.

Approved Side Wall Termination Kits are listed as follows: (Alternate vent

termination kits must be submitted to IBC for approval prior to installation.)

• Ipex - #196984 – 2" PVC low prole termination kit (see Figure 10).

• Ipex - #196985 – 3" PVC low prole termination kit (see Figure 10).

1-10

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

Figure 9a: Horizontal Concentric Termination - Two Kits

INSTALLATION

Figure 9b: Horizontal Concentric Termination - Single Kit

Figure 10: Ipex #196984 2" PVC and #196985 3" PVC

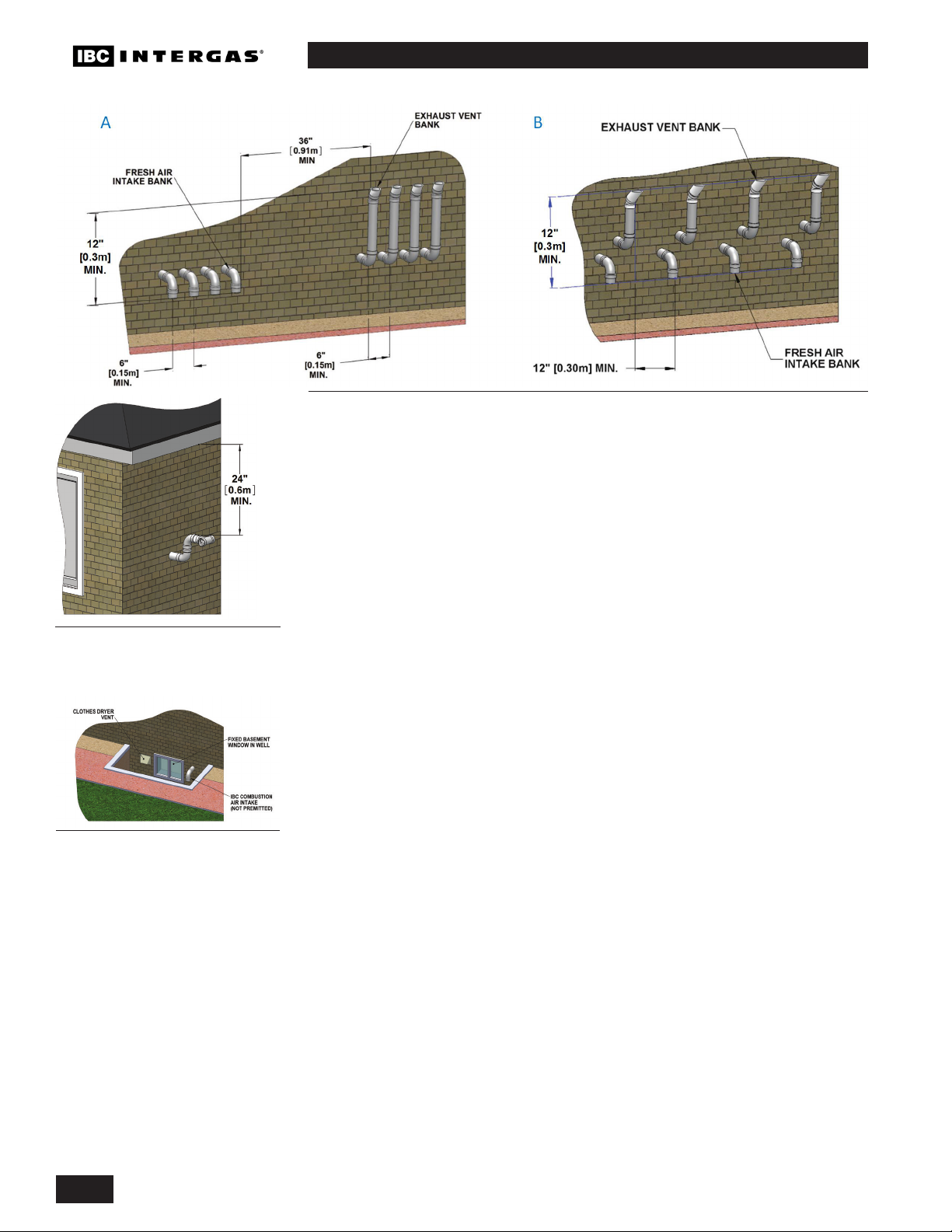

For side venting of multiple boiler / water heater sets, group all intake terminals

together with 6" (minimum) lateral spacing, and similarly group the exhaust

pipes. Place the 2 groups on the same plane of the building (e.g. north facing

wall). Place the 2 groups of pipes at least 3' apart (the closest intake and exhaust

pipes shall be 36" - or more – apart. Use same 12" (minimum) vertical separation

(See (A) in Figure 13). Alternately, as long as the boilers / water heaters are

identical models - intake and exhaust terminals can maintain a minimum of 12" of

separation horizontally from any exhaust or inlet termination of an adjacent boiler

(See (B) in Figure 13). For alternate group terminations, contact the IBC Factory

for written guidance.

1-11

Figure 11: IBC recommended

minimum vent terminal clearance

under ventilated sot

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

Figure 13: Sidewall vent termination - multiple vent piping conguration

CONCENTRIC SIDE WALL TERMINATION KITS:

Must be installed on the same horizontal line (not stacked)

Must be installed with a min separation of 12” center to center

Use caution when installing Concentric Side Wall Termination Kits when the outdoor

design temperature is below 5°F / -15°C. Possible blockage of the combustion air

intake increases when the outdoor temperature drops below this temperature.

The clearances recommended by the vent termination manufacture must be followed.

Approved Concentric Side Wall Termination Kits are listed as follows: (Alternate

vent termination kits must be submitted to IBC for approval prior to installation.)

• Centrotherm – Innoue #ICWT242 (2” termination) + ICTC0224 (2” concentric

transition to 2 pipe)

• Centrotherm – Innoue #ICWT352 (3” termination) + ICTC0335 (3” concentric

transition to 2 pipe)

• Duravent – Polypro #3PPS-HK – Horizontal Termination Kit – Concentric

• Ipex - # 197009 – 3” CPVC concentric termination kit

• Ipex - # 196006 – 3” PVC concentric termination kit

Figure 12: Prohibited installation

1-12

VENT TERMINAL CLEARANCE MINIMUMS ARE AS FOLLOWS:

The vent for this appliance shall not terminate:

1. Over public walkways; or

2. Near sot vents or crawl space vents or other areas where condensate or

vapor could create a nuisance or hazard or cause property damage; or

3. Where condensate vapor could cause damage or could be detrimental to the

operation of regulators, relief valves, or other equipment.

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

WARNING

In addition to preventing

ingestion of chemical

contaminants, care must

be taken to ensure air

intake terminals are not

installed in locations where

contamination might occur

due to ingestion of particulate

foreign material (dust, dirt

and debris).

WARNING

Intake air openings must be

congured such that rain

or other forms of moisture

cannot enter the air intake

piping system. Otherwise

serious damage to the boiler /

water heater may result.

NOTE

Care must be taken when

installing air intake piping to

ensure that a “trap” is not

formed in the piping so as to

allow a build-up of water, and

blockage of intake air.

Such blockage will result in

a boiler / water heater safety

shut-down.

CANADIAN

INSTALLATIONS1

A= Clearance above grade,

veranda, porch, deck, or

balcony

B= Clearance to window or

door that may be opened

C= Clearance to window or

door that may be opened

D= Clearance to

permanently closed window

E= Clearance to

unventilated sot

F= Clearance to outside

corner

G= Clearance to inside

corner

H= Clearance to each side

of center line extended

above meter/regulator

assembly

I= Clearance to service

regulator vent outlet

J= Clearance to

nonmechanical air supply

inlet to building or the

combustion air inlet to any

other appliance

K= Clearance to a

mechanical air supply inlet

L= Clearance above paved

sidewalk or paved driveway

located on public property

M= Clearance under

veranda, porch deck, or

balcony

1 In accordance with the current CSA B149.1 Natural Gas and Propane Installation Code

2 In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code

† A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family

dwellings and serves both dwellings.

‡ Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the oor.

* Clearance in accordance with local installation codes and the requirements of the gas supplier.

12 in (30 cm) 12 in (30 cm)

6 in (15 cm) for appliances ≤

10,000 Btuh (3 kW), 12 in (30

cm) for appliances > 10,000 Btuh

(3 kW) and ≤ 100,000 Btuh (30

kW), 36 in (91 cm) for appliances

≤100,000 Btuh (30 kW)

* *

* *

* *

* 4 ft (1.22m) or local code,

whichever is stricter

* 4 ft (1.22m) or local code,

whichever is stricter

3 ft (91 cm) within a height 15

ft above the meter/regulator

assembly

3 ft (91 cm) *

6 in (15 cm) for appliances ≤

10,000 Btuh (3 kW), 12 in (30

cm) for appliances > 10,000 Btuh

(3 kW) and ≤ 100,000 Btuh (30

kW), 36 in (91 cm) for appliances

≤100,000 Btuh (30 kW)

6 feet (1.83 m) 3 ft (91 cm) above

7 ft (2.13 m) † *

12 in (30 cm) ‡ *

US

INSTALLATIONS

6 in (15 cm) for

appliances ≤ 10,000

Btuh (3 kW), 9 in (23

cm) for appliances >

10,000 Btuh (3 kW)

and ≤ 50,000 Btuh (15

kW), 12 in (30 cm) for

appliances > 50,000

Btuh (15 kW)

* 4 ft (1.22m) or local

code, whichever is

stricter

* 4 ft (1.22m) or local

code, whichever is

stricter

*

6 in (15 cm) for

appliances ≤ 10,000

Btuh (3 kW), 9 in (23

cm) for appliances >

10,000 Btuh (3 kW)

and ≤ 50,000 Btuh (15

kW), 12 in (30 cm) for

appliances > 50,000

Btuh (15 kW)

if within 10 ft (3 m)

horizontally

2

INSTALLATION

1-13

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

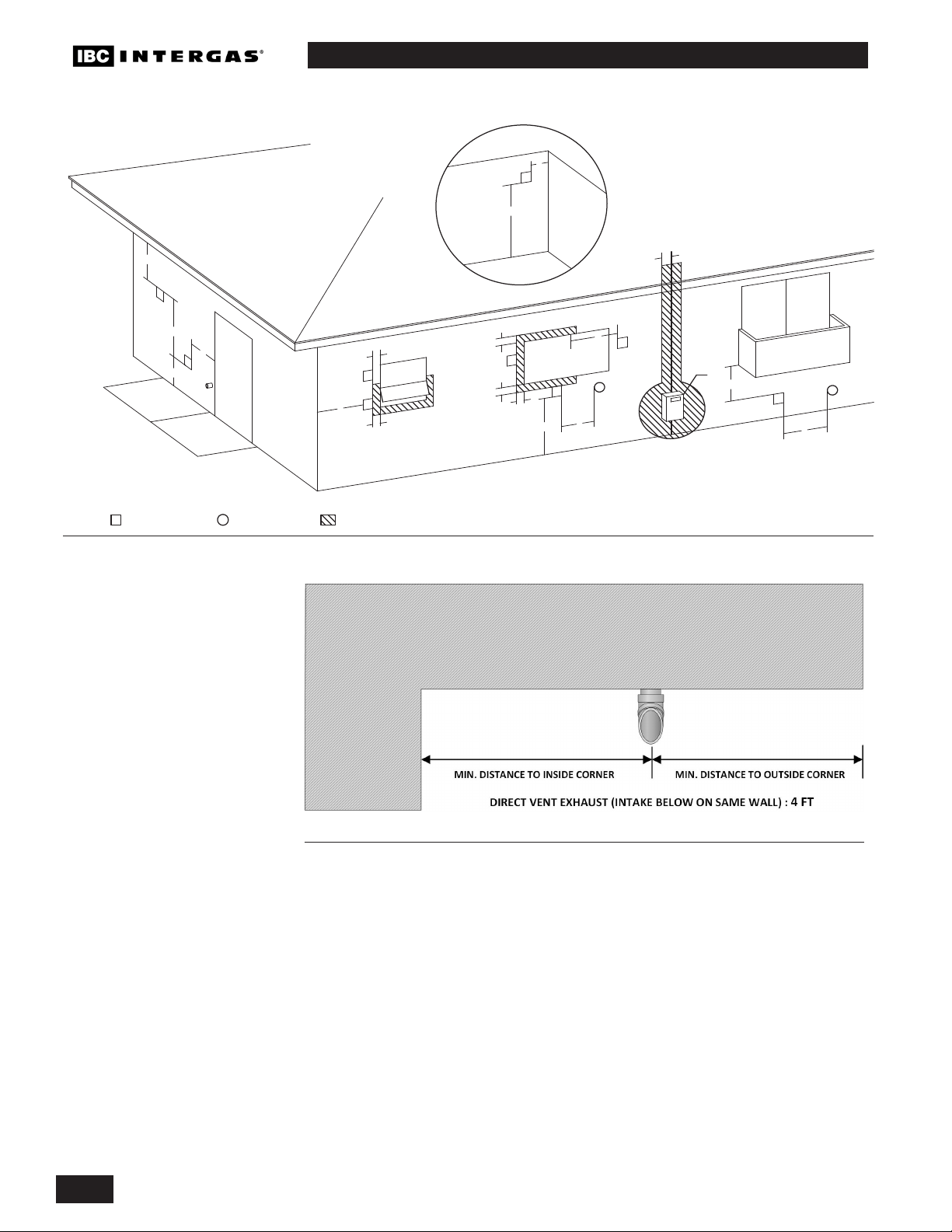

INSIDE

CORNER DETAIL

G

V

A

D

V

E

B

V

L

V VENT TERMINAL X AIR SUPPLY INLET AREA WHERE TERMINAL IS NOT PERMITTED

Figure 14A: Vent Terminal Clearance

H

B

C

FIXED

V

CLOSED

OPERABLE

V

F

B

B

V

B

OPERABLE

A

B

V

FIXED

CLOSED

I

X

V

J

M

V

X

K

1-14

Figure 14B: Distance Inside / outside minimums

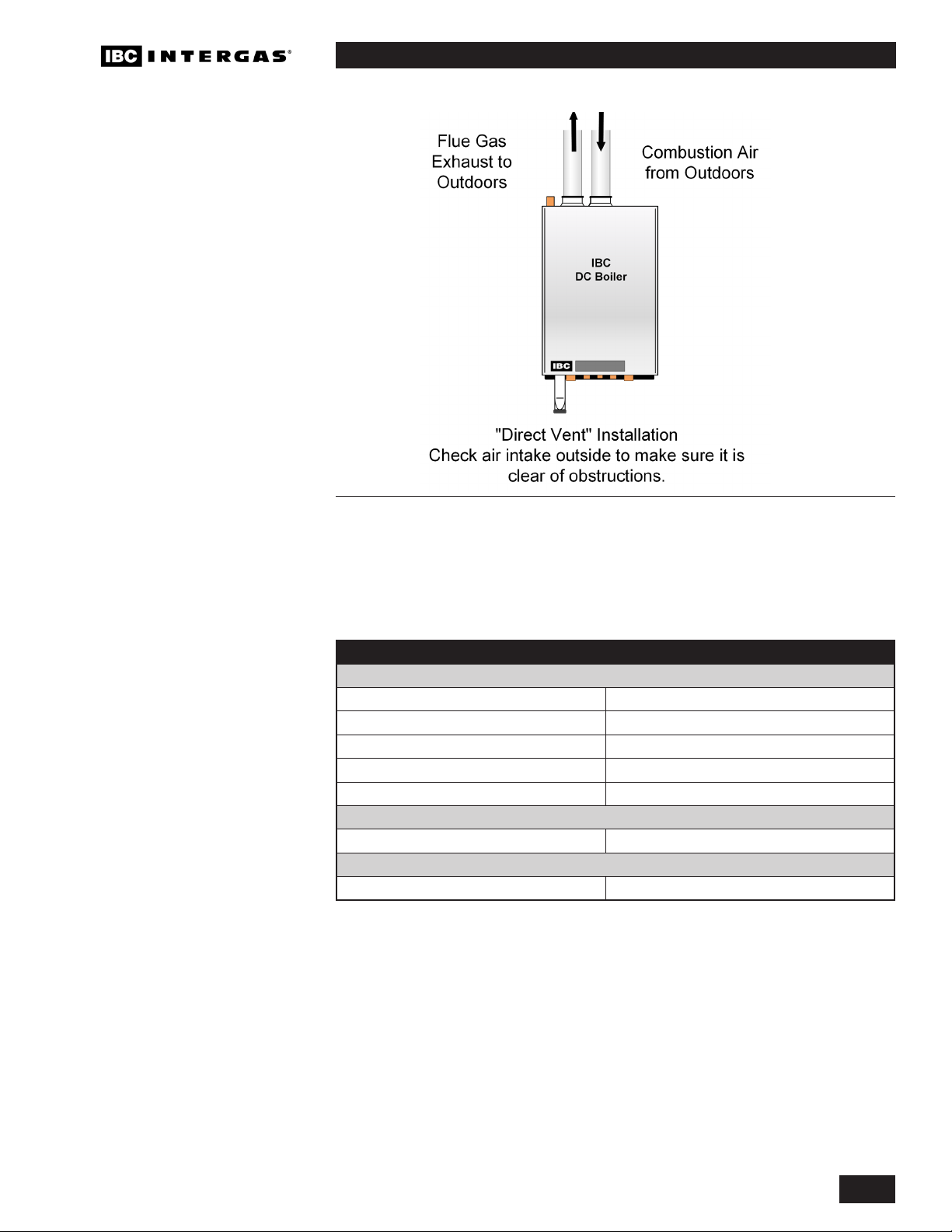

1.4.7 “Direct Vent” Combustion Air Intake Piping

The boiler / water heater must always be installed as a Direct Vent venting

system with the combustion air piped directly from the outdoors to the boilers

/ water heaters combustion air connection. Provisions for combustion and

ventilation air in accordance with the section “Air for Combustion and Ventilation,”

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Clause 8.2, 8.3 or 8.4

of Natural Gas and Propane Installation Code, CAN/CSA B149.1, or applicable

provisions of the local building codes.

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

Figure 15: Direct vent combustion air intake

For 3" Flexible PPs, up to 35 actual lineal feet are allowed in a nominally vertical

orientation (>45°). The equivalent length of 3" Flexible PPs shall be computed

using a multiple of 1.4:1, e.g. 35' x 1.4 = 49' equivalent. The balance of the

venting allowance is still available for use with rigid PPs piping material. 2"

Flexible PPs is not allowed.

INTAKE PIPE SIZE/FITTINGS MAXIMUM EQUIVALENT LENGTH

Schedule 40 ABS PVC, CPVC or PPs – Allowances are for each side separately.

2" 35'

3" 120'

2" or 3" 90' Long Sweep Vent Elbow Allow 5 equivalent feet

2" or 3" 90' Short Sweep Vent Elbow Allow 8 equivalent feet

2" or 3" 45' Vent Elbow Allow 3 equivalent feet

PPS

PPs 87-90' Elbow Allow 8 equivalent feet

Flex PPS

3" PPs Flex (Max. 35) actual feet times 1.4

Table 4: Maximum intake piping length.

For the inlet air – Schedule 40 PVC, CPVC, ABS or PPs piping of any type is

permitted. Use same diameter as Vent pipe.

INSTALLATION

Combustion air piping is inserted directly into the 3" female stainless steel tting

on the top, right side of the boiler / water heater and run horizontally or vertically

to the outdoors. Bird screen of 1/4" stainless steel or plastic mesh (eg. IPEX

System 636 drain grate for CPVC systems) is useful to guard against foreign

objects.

Care must be taken to ensure adequate separation is maintained between the

air intake inlet and the vent terminal. Refer to the vent terminal conguration

drawings in the Vent Termination section above.

1-15

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

Support should be provided for intake piping, particularly so for horizontal runs

(follow local code).

WARNING

Fill trap with water before

boiler / water heater is rst

red to prevent exhaust

fumes from entering room.

Never operate the boiler /

water heater unless the trap is

lled with water.

Failure to comply will result

in severe personal injury or

death.

1.5

1.4.8 “Indoor Air” Combustion Air Intake

Using Indoor Combustion Air is not approved for use with the DC series boilers /

water heaters.

1.4.9 Closet Installations

For installations in a conned space (such as a closet), ventilation openings may

be needed through a door or wall to prevent excessive heat from building up

inside the space.

The boiler / water heater shall not be exposed to ambient conditions above 122°F

(50°C) or below 32°F (0°C).

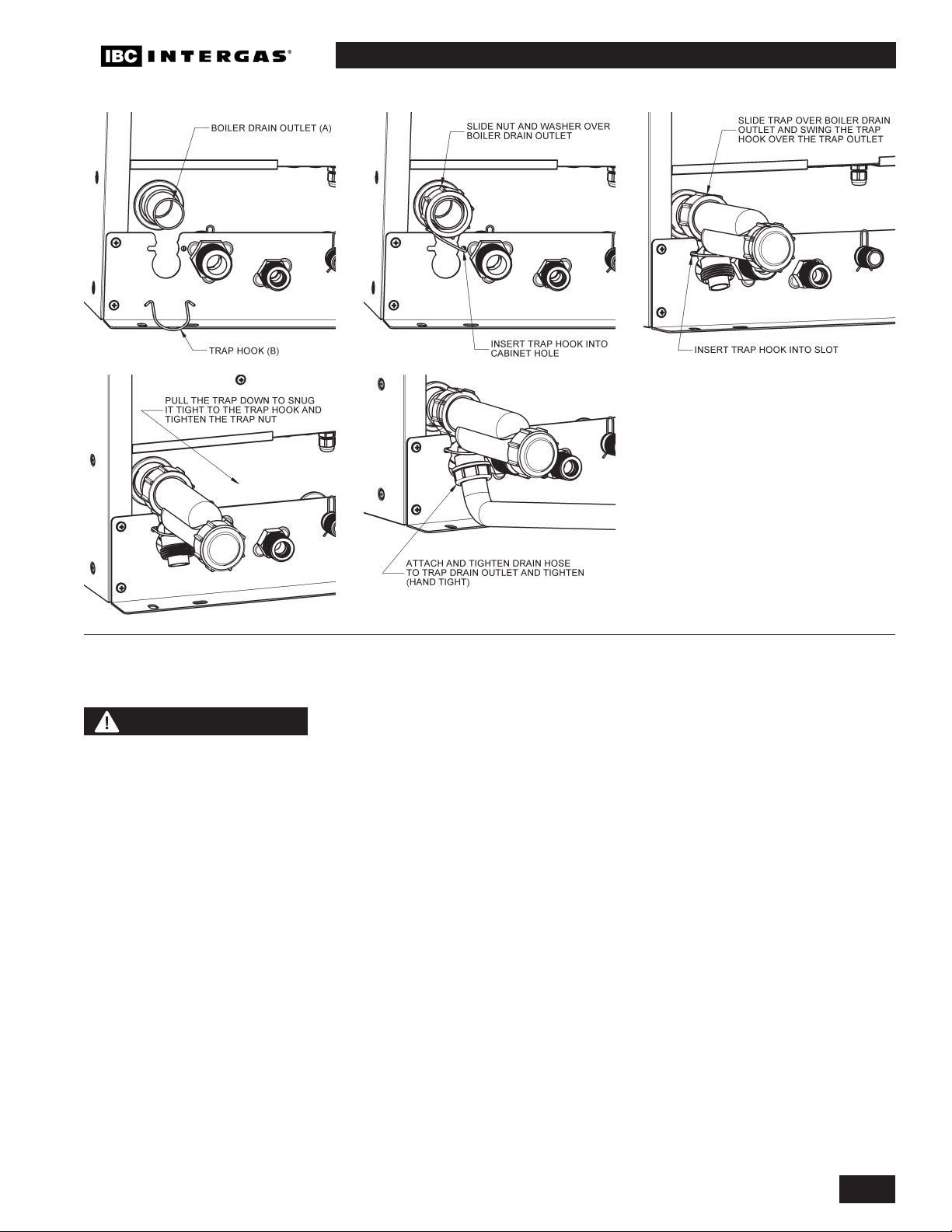

CONDENSATE REMOVAL

IBC’s specied vent conguration promotes the safe drainage of moisture from

the boiler / water heater and exhaust venting without owing liquids back through

the heat exchanger.

Reliable system operation requires (1) proper design and installation of exhaust

venting to allow condensate to run back to the drain/trap; (2) acid neutralization

as appropriate. To achieve these:

WARNING

The Trap Hook must be

installed as instructed and all

trap ttings must be tightened

as instructed to prevent

leakage of ue gasses.

Failure to comply may result

in severe personal injury or

death.

1-16

Figure 17: Condensate Trap, disassembled

1. Allow for a 1/4" per foot slope back to the vent connection, with appropriate

hangers to maintain that gradient.

2. Ensure the supplied trap is correctly installed and lled with water.

3. When required, add (and maintain in good condition) a neutralization tank.

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

Figure 18: Condensate trap installation

NOTE

It is the responsibility of

the installing and/or service

Contractor to advise and

instruct the end User in how

to perform the Trap cleaning

procedure, and to advise

that the Trap be checked at

least every two months and

cleaned as required.

1.5.1 Condensate Trap

A condensate trap must be installed on the drain connection at the base of the

boiler / water heater as shown in Figure 18.

1.5.2 Condensate Trap Assembly - Installation

1. Undo Drain Spout Compression Nut, remove Drain Hose from Trap Drain

Outlet. Remove Upper Compression Nut and Washer and slide over Boiler

/ Water Heater Drain Outlet (A). Insert one Trap Hook barb into the back

mounting hole.

2. Fill Trap with water, and slide Trap Body over Boiler / Water Heater Drain

Outlet (A). Swing Trap Hook (B) around the Drain Outlet connection threads.

Insert remaining Trap Hook barb into the front hole. Pull the trap slightly

downward to seat it against the hook and tighten Upper Compression nut.

3. Attach Drain Hose and tighten Drain Spout Compression Nut.

INSTALLATION

1-17

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

1.5.3 Condensate Trap Assembly - cleaning procedure

1. Turn o the power to the boiler / water heater and allow it to cool down.

2. Remove the trap from the boiler / water heater (reverse the installation

procedure above).

3. Remove the Trap Cleanout Assembly, from the Trap Body and clean and

ush the debris out.

4. Re-assemble trap components, re-ll trap, and replace on boiler / water

heater as described in the installation instructions above.

1.5.4 Further installation details

• Condensate drain must be piped to within 1" of a drain or be connected to a

condensate pump.

• Drainage line must slope down to the drain at a pitch of 1/4" per foot so

condensate runs towards the drain.

• Condensate traps should be checked every 2 months, and cleaned and

relled as necessary.

1-18

INSTALLATION AND OPERATION INSTRUCTIONS

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

Figure 19: Condensate trap

disassembly for cleaning

WARNING

If condensates are to be

discharged into building drain

piping materials that are subject

to corrosion, a neutralization

package must be used.

DANGER

The water in the condensate

neutralizer can cause severe

burns to the skin. Use extreme

caution when servicing the

condensate neutralizer. Wear

protective gloves and eyewear.

Figure 20: Condensate trap drainage

CAUTION

When a condensate

neutralization package

is installed, the pH of the

condensate discharge must

be measured on a regular

schedule to ensure the

neutralizing agent is active

and eective.

INSTALLATION

Figure 21: Condensate neutralization tank

1-19

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

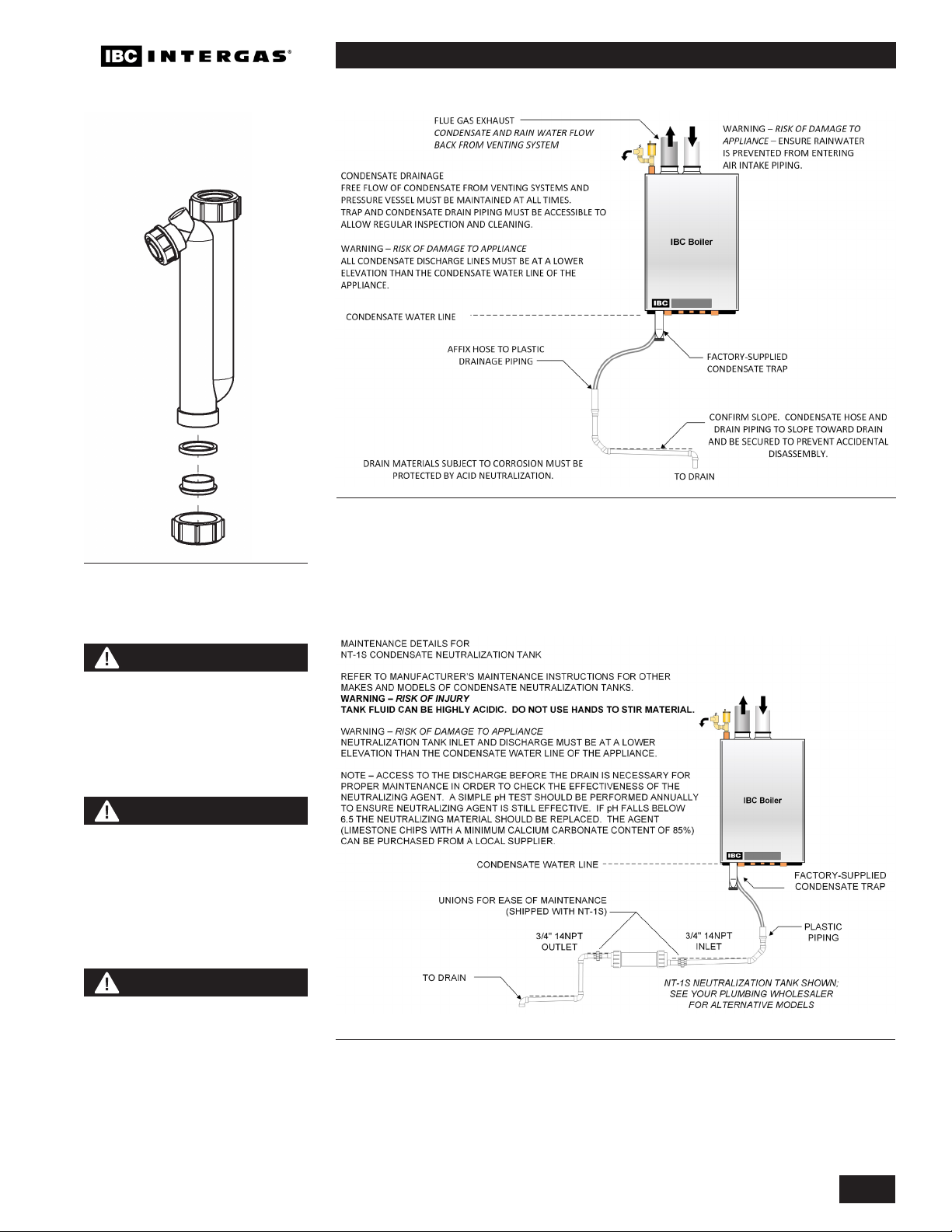

1.6

WATER PIPING - SPACE HEATING

1.6.1 General Piping Considerations

The DC series boilers / water heaters include a factory installed, integral

Grundfos UP 15/58 heating pump. The pump is designed to provide adequate

ow through the boiler / water heater and near boiler / water heater piping. The

pump is pre wired.

Figure 22: Overview of piping options

Primary/secondary piping or the use of a buer tank / hydraulic separator is

recommended for maximum exibility in multi zone/load applications. Piping

loads in parallel is only acceptable in systems where the minimum ow rate is

guaranteed to be higher than the minimum for the boiler / water heater and the

boilers / water heaters pump is adequate to provide the required ow rate and

pump head for the system.

There are some important details to consider however, and this section of the

Installation and Operating Manual will walk you through them so you can enjoy a

trouble-free installation.

1-20

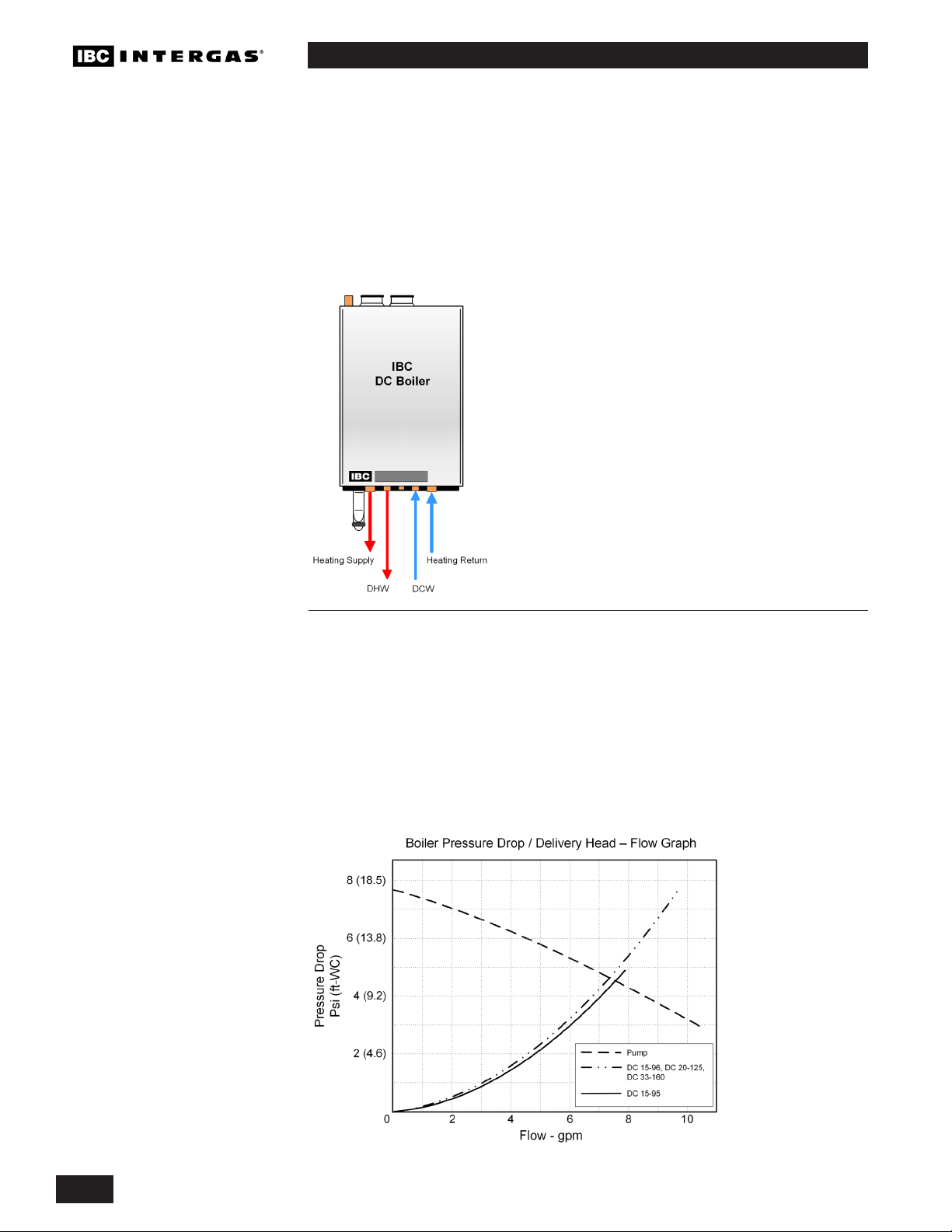

Table 5: Boiler side pump curve

INSTALLATION AND OPERATION INSTRUCTIONS

Loading...

Loading...