IBC

IBC Technologies Inc.

Vancouver, Canada

VFC Series Fixed Firing Gas Boiler

Model VFC 160

INSTALLATION AND OPERATING INSTRUCTIONS

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

Should overheating occur or the gas supply fail to shut off, do not turn off or

disconnect the electrical supply to the pump. Instead shut off the gas supply at a

location external to the appliance

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

VFCF160-v1.0

TABLE OF CONTENTS

1. INSTALLATION ...................... 3

1.1 GENERAL..........................................3

1.2 CODE REQUIREMENTS ................3

1.3 Location ..............................................4

1.4 Venting ................................................5

1.4.1 Applications................................5

1.4.2 Category IV Venting ................10

1.4.3 Closet Installations ...................10

1.5 Water Piping.....................................10

1.6 Gas Piping.........................................12

1.7 Electrical Connections .....................13

1.7.1 Mains Hook-up.........................13

1.7.2 Thermostat wiring.....................13

1.7.3 Thermostat Heat Anticipator ....14

2. STARTUP.............................. 15

2.1 PRIOR TO START-UP ...................16

2.1.1 Test Ignition System Safety

Shutoff Device.............................................16

2.4 CHECK BOILER INPUT .............. 17

2.5 SET OPERATOR LIMIT .............. 17

3. MAINTENANCE AND

TROUBLESHOOTING..................18

3.1 BOILER OPERATION .................. 18

3.1.1 Normal Operation .................... 18

3.1.2 Post-Purge Cycle ..................... 18

3.1.3 Boiler Safety System ............... 18

3.2 BOILER MAINTENANCE............ 19

3.2.1 General Care ............................ 19

3.2.2 Inspection................................. 19

3.3 COMPONENT DESCRIPTION.... 20

3.3.1 Pressure Switch........................ 20

3.3.2 Flow Switch............................. 20

3.3.3 Operator ................................... 20

3.3.4 Hi-Limit ................................... 20

3.3.5 Transformer ............................. 21

3.3.6 Gas Valve ................................ 21

3.3.7 Blower ..................................... 21

3.3.8 Ignition Control Module(ICM) 21

3.3.9 Igniter Probe/Flame Sensor ..... 21

3.3.10 DC Power /Enunciator Panel... 21

3.3.11 Detailed System Checks .......... 22

2.2 GAS VALVE ADJUSTMENT........16

2.3 BLOWER ADJUSTMENT .............17

IBC Technologies Inc. - 2 - VFC 160

1. INSTALLATION

1.1 GENERAL

The VFC 160 boiler is a low pressure,

fully condensing unit having a fixed

firing rate input of 160 MBH (160,000

Btu/hr). The boiler is approved for

either Direct Vent (sealed combustion)

or Category IV (indoor air) applications,

providing a great degree of installation

flexibility.

The installer must clearly indicate the

vent category for the installation on

the rating plate using an indelible

marker. See section 1.4 - Venting.

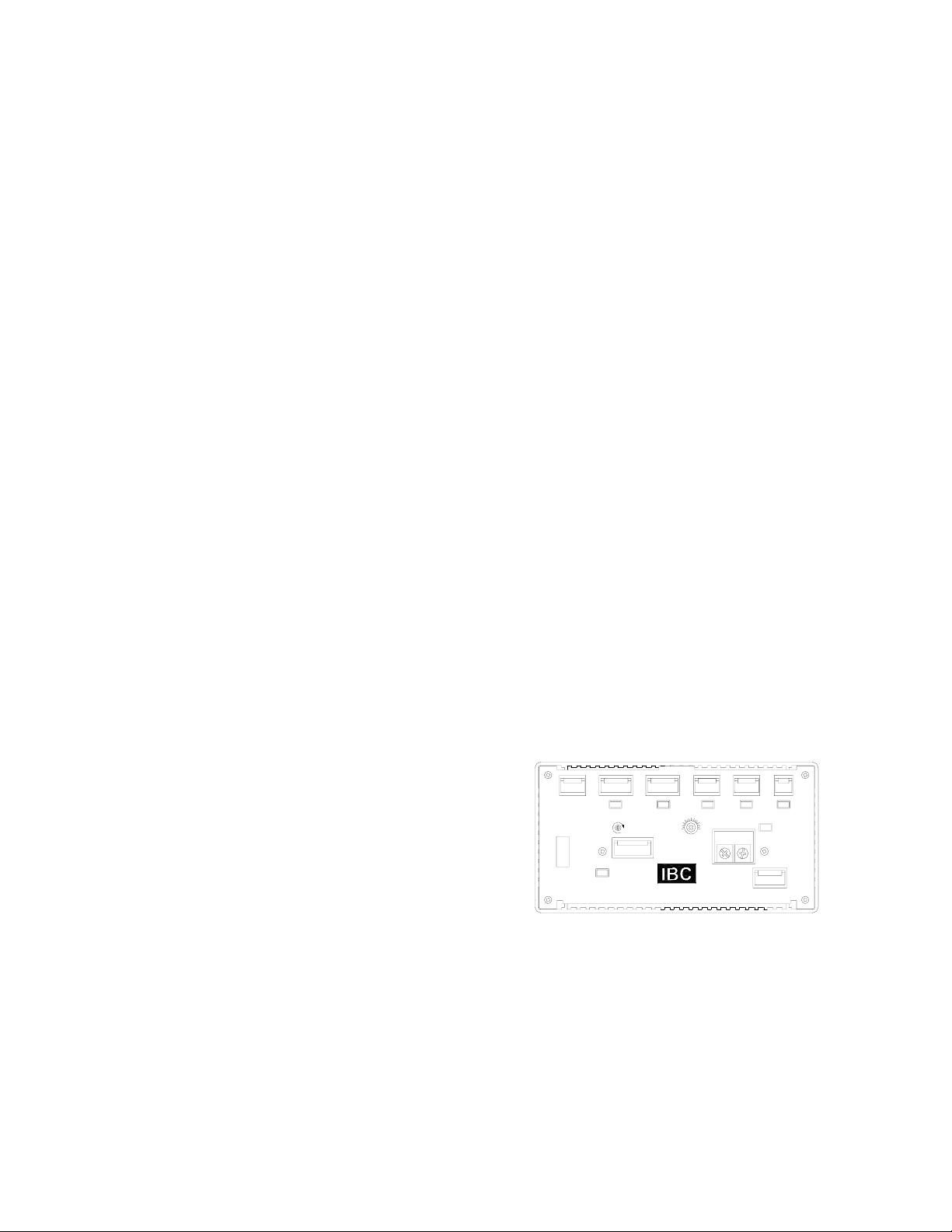

Figure 1. shows outer case dimensions

and piping and electrical holes. Use this

diagram to find a suitable location for

the boiler. (see also Section 1.3 Location.)

22.5" [572mm]

12" [305mm]

Table 1 - Connections

Description Size

A water outlet 1” NPT

B water inlet 1” NPT

C gas ½” NPT

D electrical power 3/4”

E thermostat 3/4”

F pump 3/4”

G combustion air 4.0"

H exhaust vent 4.0"

1.2 CODE REQUIREMENTS

Gas manifold and controls met safe

lighting and other performance criteria

when boiler underwent tests specified in

ANSI Z21.13-2000.

Installation must conform to local codes,

A

or in the absence of these, with the latest

editions of the National Fuel Gas Code

ANSI Z223.1 and the National

Electrical Code ANSI/NFPA 70.

34" [864mm]

Where required by jurisdiction,

installation must conform to the

Standard for Controls and Safety

Instructions to put the boiler in operation

are located on the inside surface of this

cover panel.

FOR YOUR SAFETY

Do not store or use gasoline of other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1. If there is any

22.5" [572mm]

conflict in the above requirements, then

the more stringent requirement will

apply.

12" [305mm]

G

H

In Canada, installations must conform to

the current CAN/CGA B149 and the

Canadian Electrical Code Part 1 CSA

Figure 1. Dimensions/Connections

C22.2 No. 1.

IBC Technologies Inc. - 3 - VFC 160

1.3 Location

Keep boiler area free and

clear of combustible

materials, gasoline, and other

flammable vapours and

liquids.

The VFC-series boilers are designed and

approved for wall or floor installation

(on combustible flooring), with

significant flexibility of location

provided with the available venting

options. The boiler can be placed in an

alcove, basement, closet or utility room.

Care must be taken not install the boiler

in areas where the combustion air source

is subject to chemical fouling.

Experience has shown that exposure to

corrosive chemical fumes such as

chlorinated and/or fluorinated

hydrocarbons can reduce the life of a

boiler. Cleaners, bleaches, air fresheners,

refrigerants, aerosol propellants, drycleaning fluids, de-greasers and paintremovers all contain vapours which can

form corrosive acid compounds when

burned in a gas flame. Airborne chorides

such as those released with the use of

laundry detergents are also to be

avoided. For this reason, the Category

IV (indoor air) venting option using air

surrounding the boiler should not be

used in a laundry room installation.

It is recommended that the boiler be

located in an area where water leakage

will not result in damage to the area. If a

location such as this cannot be found, a

suitable drain pan, should be installed

under the appliance. The boiler is not to

be installed above carpeting.

In addition to the foregoing, other

factors determining potential mounting

sites:

• ensure minimum clearance

requirements for combustible

materials(see Table 2) are satisfied

• 36” clearance at the front is

recommended for adequate servicing

• gas ignition system components

should be protected from water

(dripping, spraying, rain, etc.)

• boiler should not be exposed to

water leaks from piping or

components located overhead

• in a new construction installation,

particular action must be taken to

protect the boiler from dust;

combustion air should be drawn

from a CLEAN source (e.g.

outdoors) and the boiler must be

isolated from interior dust sources.

Do not seal boiler case openings

directly - allow for air circulation

and ventilation in the immediate

area.

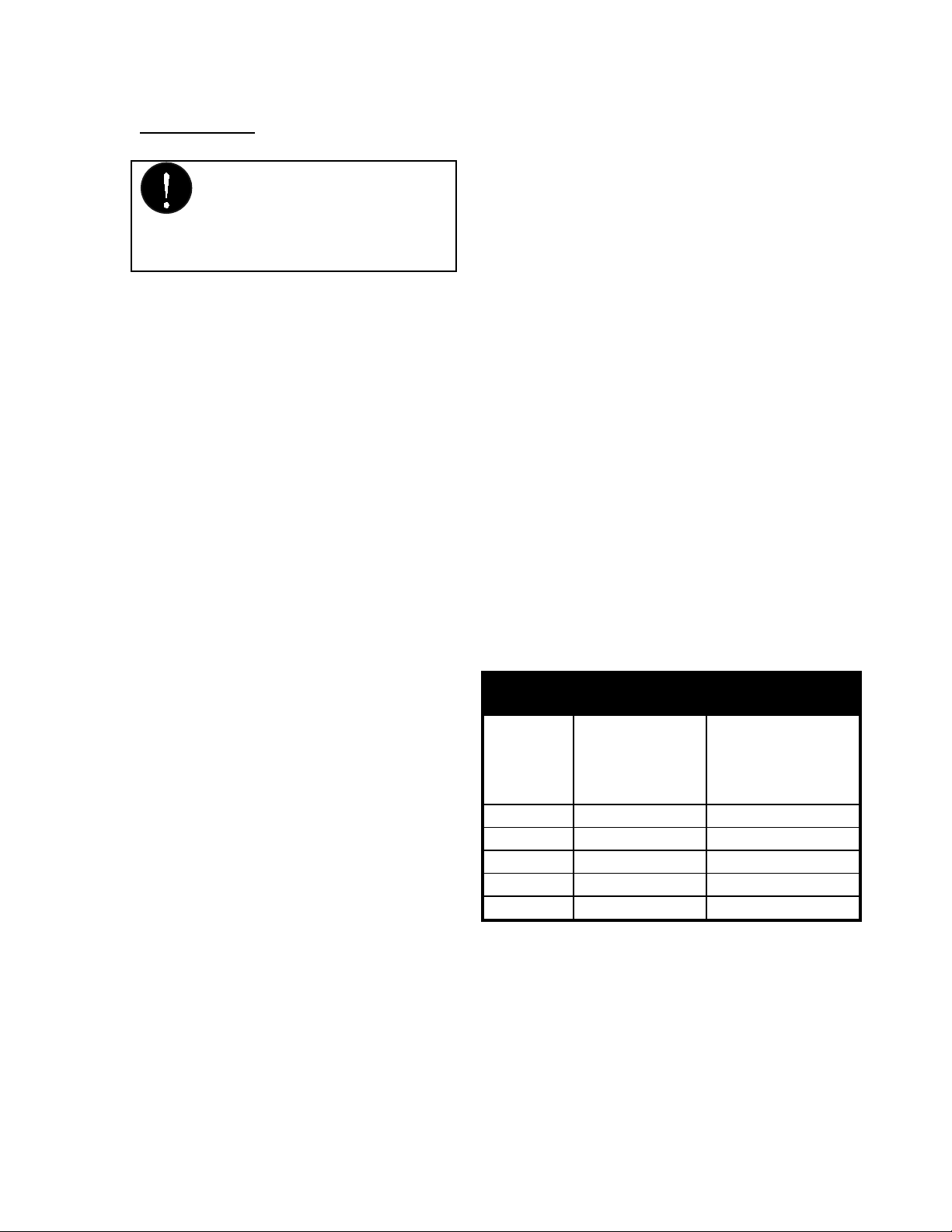

Table 2 - Clearance from Boiler Cabinet

Surface Distance

from

Combustible

Surfaces

Front 2” 24”

Rear 0” 0”

L. Side 0” 12”

R. Side 2” 18”

Top 10” 10”

Below the boiler, 12” is required to

rovide clearance for the inlet and

exhaust venting together with the

required condensation trap. Legs are

available as an accessory for floormounting of the boiler; the 14” legs

provide the necessary clearance.

Recommended

Distance for

Service

IBC Technologies Inc. - 4 - VFC 160

1.4 Venting

All venting must be installed in

accordance with the requirements of the

jurisdiction having authority: in the USA

Part 7, Venting of Equipment of the

National Fuel Gas Code, ANSI 223.1,

latest edition, and any other local

building codes are to be followed. In

Canada, Part 7 - Venting Systems of the

B149 Code prevails. Where there is a

discrepancy between the installation

instructions below, and the code

requirements, the more stringent shall

apply.

IMPORTANT

When an existing boiler is removed from

a common venting system, the common

venting system is likely to be too large

for proper venting of the appliances

remaining connected to it.

At the time of removal of an existing

boiler the following steps shall be

followed with each appliance remaining

connected to the common venting

system placed in operation, while the

other appliances remaining connected to

the common venting system are not in

operation.

a) seal any unused opening in the

common venting system.

b) Visually inspect the venting system

for proper size and horizontal pitch

and determine there is no blockage

or restriction, leakage, corrosion and

other deficiencies which could cause

an unsafe condition.

any appliance not connected to the

common venting system. Turn on

any exhaust fans, such as range

hoods and bathroom exhausts, so

they will operate at maximum speed.

Do not operate a summer exhaust

fan. Close fireplace dampers.

d) Place in operation the appliance

being inspected. Follow the lighting

instructions. Adjust thermostat so

appliance will operate continuously.

e) After it has been determined that

each appliance remaining connected

to the common venting system

properly vents when tested as

outlined above, return doors,

windows, exhaust fans, fireplace

dampers and any other gas-burning

appliance to their previous

conditions of use.

f) Any improper operation of the

common venting system should be

corrected so the installation

conforms with the National Fuel Gas

Code, ANSI Z223.1 - latest edition.

In Canada, all installations must

conform with the current CAN/CGA

- B149 Installation Code and/or local

codes.

When resizing any portion of the

common venting system, the common

venting system should be resized to

approach the minimum size as

determined using the appropriate tables

in the National Fuel Gas Code, ANSI

Z223.1 - latest edition. In Canada, use

the CAN/CGA - B149 Installation Code.

c) Insofar as is practical, close all

building doors and windows and all

doors between the space in which the

appliances remaining connected to

the common venting system are

located and other spaces of the

building. Turn on clothes dryers and

IBC Technologies Inc. - 5 - VFC 160

1.4.1 Applications

The VFC 160 boiler is approved with

alternative venting options: either Direct

Vent or Category IV venting can be used

offering flexibility to meet the specific

requirements of the installation. With the

Direct Vent case, combustion air is

piped directly to the boiler’s air intake

from outdoors. Using the Category IV

alternative, air for combustion is drawn

from the indoor air surrounding the

boiler or drawn from ventilated attic or

crawl spaces.

The VFC 160 is shipped with a high

water temperature limit switch set for

200°F.

Provided the maximum overall vent

length limit is not exceeded, the installer

may choose to vent the boiler through

the wall, directly through the roof or

upward using an existing - but otherwise

unused - chimney as a vent raceway (see

below).

All boilers are shipped with connectors

permitting attachment of 2” intake

piping.

It is a code requirement that the

rating plate reflect the nature of the

boiler vent configuration as installed.

To facilitate such venting installation

flexibility, VFC boilers are shipped

with the rating plate unmarked. The

installer shall indelibly mark the

appropriate box on the rating plate to

recognize the venting alternative

chosen.

Exhaust venting is to be connected

directly to the 2” NPT male threaded

stainless steel fitting on the bottom of

the pressure vessel using a 2” CPVC

NPT x Socket fitting (female threaded

adaptor or 90° elbow). A condensate

trap of CPVC and PVC shall be spliced

into the CPVC exhaust pipe at or near

the base of the boiler (see Figure 2).

Combustion air piping is connected at

the base of the boiler using a standard 2"

PVC coupler or elbow. Screen material

shall be placed at the inlet termination as

appropriate for the environment (e.g.

insects, dust).

1.4.1.2 Vent Travel

With the specified 2 1/2" or 3” piping

(after 10' of 2" CPVC on the exhaust

side), the boiler can be sited up to 90

equivalent feet from the vent

termination. The actual vent travel is

reduced for fittings in accordance with

Table 3. - for example, using 5 x 90º

long-sweep* ABS elbows, the maximum

lineal measure is 65 feet.

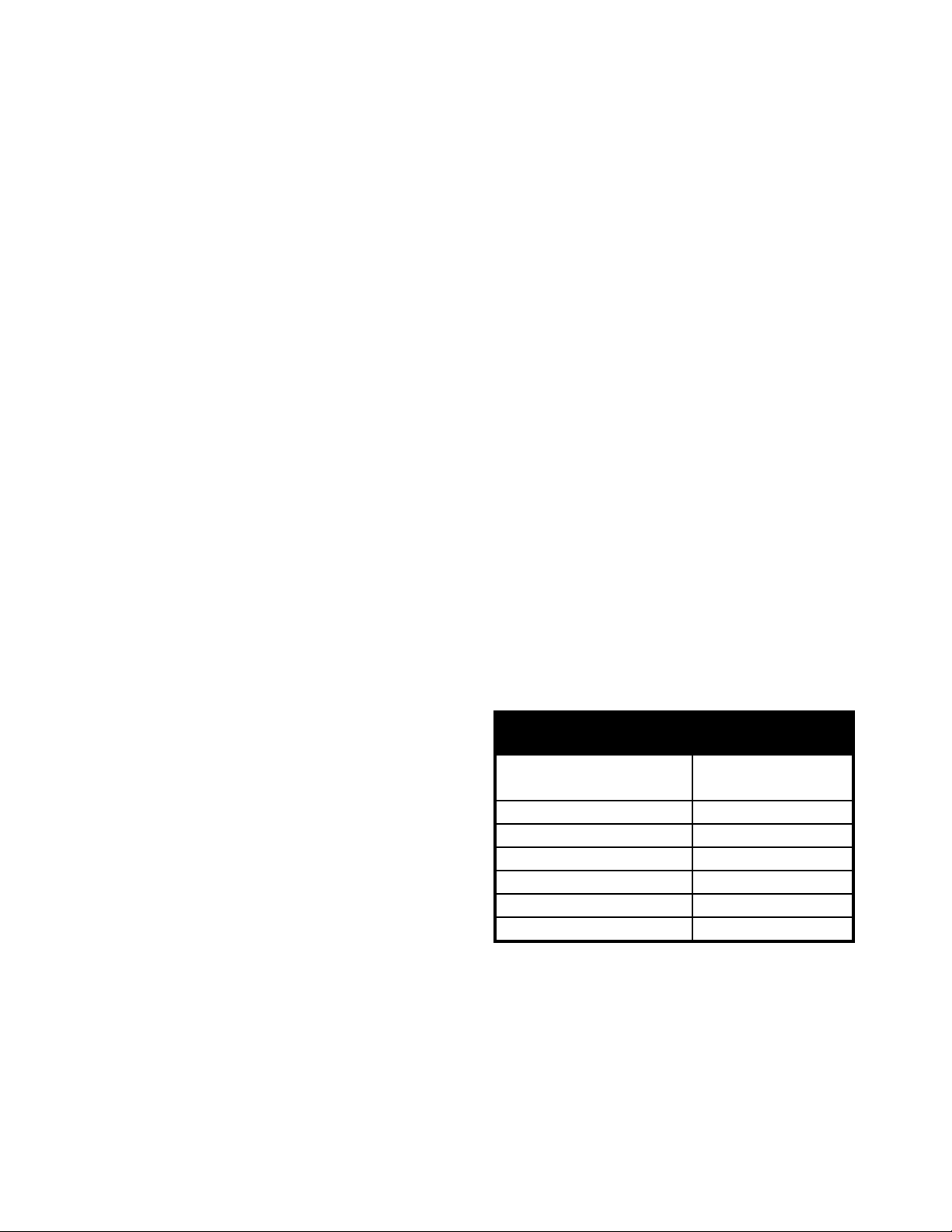

Table 3 - Max. Venting Length

Pipe Size

( * = long sweep)

Max.

Equiv.Length

1.4.1.1 Intake/Exhaust Vent Material

The approved materials of construction:

For the exhaust vent-

• 2" CPVC Sch. 40 or 80 pipe (per

ASTM F441) and Sch. 40 or 80 fittings

for the initial 10 lineal feet of travel

• 2 1/2" or 3" Sch 40 CPVC or PVC, or

3" ABS (Sch. 40/ASTM D2661 or F628)

and fittings thereafter;

For the inlet air - ABS and PVC (ASTM

D1785 or D2665) are permitted.

See Vent Travel- below.

IBC Technologies Inc. - 6 - VFC 160

3” (after 10' of 2") 90’ (incl 1st 10')

90° elbow(CPVC/PVC) Allow 8’ equiv.

45° elbow(CPVC/PVC) Allow 4’ equiv.

90° elbow*(ABS) Allow 5’ equiv.

45° elbow*(ABS) Allow 2.5’ equiv.

A 3” x 2” (or 2.5" x 2" as appropriate)

bushing is to be used in the inlet piping

within 3 feet of the combustion air line

clearance hole at the base of the boiler.

The 3’ interval (which is part of the 90’

max. travel distance) is allowed to

provide space for splicing in an optional

2” compatible air filter unit.

The junction between the initial 2" vent

section (e.g. 10' of CPVC ), the vent line

diameter is increased through use of a

3”- 2” (or 2.5" x 2") reducer. It shall be

placed in a vertical section of the flue

gas vent to avoid pooling of condensate.

Exhaust venting must slope back to the

trap/drain with a pitch of at least ¼” per

foot so condensate runs towards the trap.

Support should be provided every 2 to 3

feet for each of the intake and vent

piping. Insulate exhaust piping where it

passes through unheated space with

appropriate pipe insulation to prevent

freezing of condensates.

Ensure all venting components are clean

of burrs/debris prior to assembly.

Particular care is to be taken to avoid

ingestion into the fan of CPVC/ABS

debris left in the combustion air piping.

straight 2" tee or a 2” x ½” x 2” reducing

tee). The trap itself is formed using ½”

CPVC pipe for the drop leg, with ½”

PVC pipe, elbows and threaded union

fittings. The trap must be installed as

follows:

• Have 5” minimum neck depth

• Piped to within 3” of a drain or be

connected to a condensate pump

• Drainage line must slope down to the

drain at a pitch of ¼” per foot so

condensate runs towards the trap

• IMPORTANT! Fill trap with

water before boiler is first fired to

prevent exhaust fumes from

entering room. Never operate the

boiler unless the trap is filled with

water.

• Trap should be checked every 6

months. Clean and refill as

necessary.

All joints must be secured using CPVC,

ABS or ABS/PVC solvent cement to

bond the respective pipe material. Use

solvent cement on the connector located

at the CPVC/ABS junction (e.g. 10’

along the exhaust piping). Follow the

cement manufacturer’s instructions

closely when joining various

components.

All vent connections must be liquid and

pressure tight. Test exhaust venting

connections, under fan pressure with

vent blocked, using a soap/water

solution prior to firing.

1.4.1.3 Condensate Trap

A condensate trap must be installed at

the base of the boiler (or within 12” of

the first 90° exhaust line elbow), as

shown in Figures 2. (e.g. spliced into

the 2” CPVC exhaust vent using a

¼" vertical per

horizontal foot

fill wit h wat er

(CP VC D rop leg)

to drain or condensate trap

5" min.

Figure 2 -Condensation Trap Alternatives

IBC Technologies Inc. - 7 - VFC 160

1.4.1.4 Venting Passage Through

Ceiling and Floor

12" min.

24" min.

The following instructions apply to 2”,

2.5" and 3” piping:

• pipe clearances - no specific

requirements - follow local codes

• piping must be supported in the

flooring

• all piping must be liquid and

pressure tight.

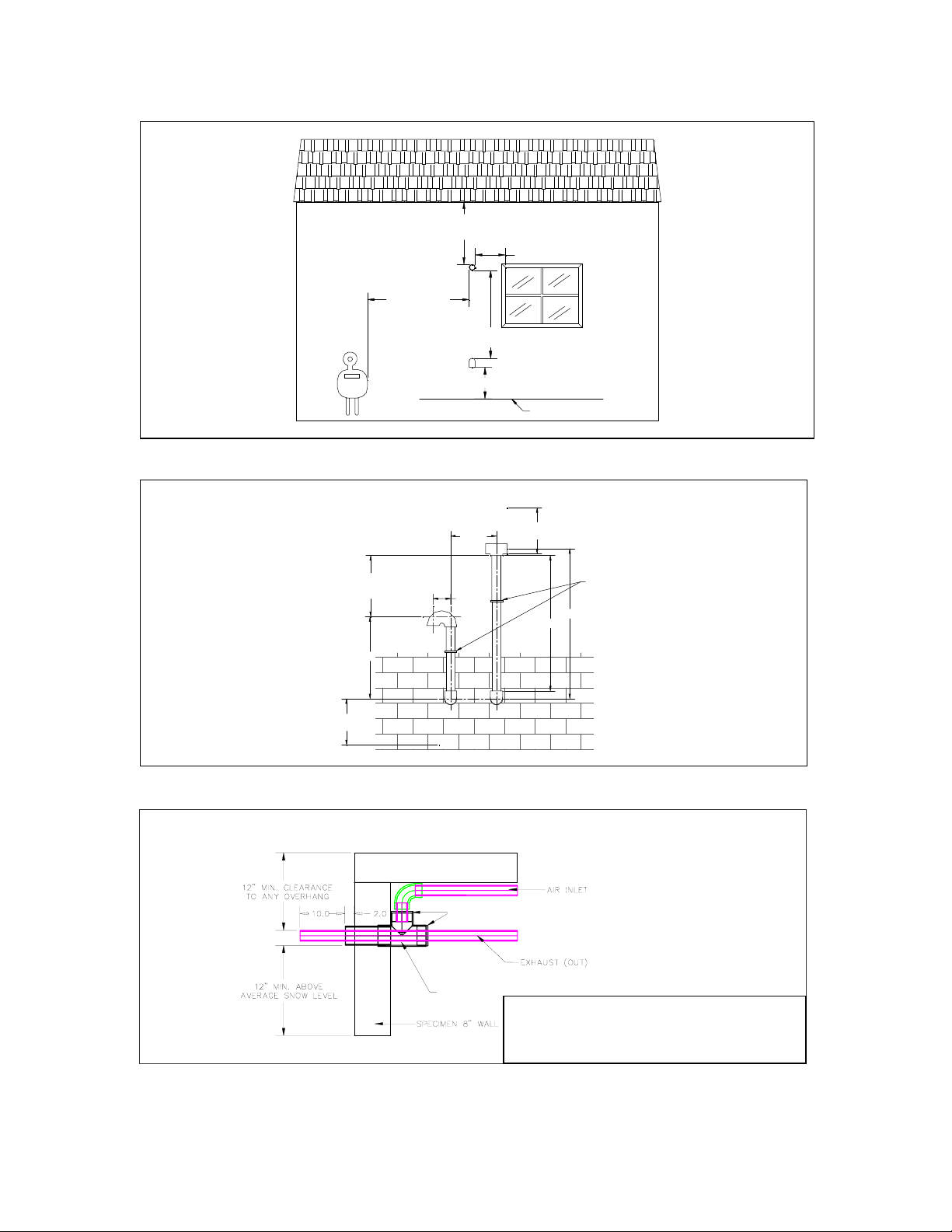

1.4.1.5 Rooftop Vent Termination

Vents must terminate as follows:

• 12” above grade and normal snow

line to vent terminal bottom

• DO NOT exhaust vent into a

common venting system

(See Figures 3 & 4 for rooftop vent

terminations)

exhaust vent with s creen

air intake 1 80° elbow

with screen face down

12"min.

12" min.

snow line

2" min.

10 ft. or less

2 ft. min.

2" min.

Figure 3. Vent Terminations through

a Pitched Roof

1.4.1.6 Sidewall Vent Termination

Vents must terminate as follows:

• minimum 12” from any building

opening

36" min.

snow line

12" min.

2" min.

other than as listed, vents terminate in the sam

e manner as in figure 3. above.

Figure 4. Vent Terminations Through

a Flat Roof

• minimum 3’ above any forced air

intake located within 10’

• minimum 4’ horizontally from (and

in no case above or below unless 4’

horizontal distance is maintained),

from electric or gas meters,

regulators and relief equipment

• not to be located over public

walkway, in a confined space, or

under any overhang or deck

• vents must be installed such that flue

gas does not discharge towards

neighbor’s windows, or where

personal injury or property damage

can occur.

• For Direct Vent installations

employing sidewall vent

terminations, both the inlet and

exhaust terminations shall be located

on the same plane (side) of the

building, with the exhaust outlet

placed above the inlet to avoid reingestion (later point not applicable

to concentric vent termination).

(See Figures 5, 6 & 7 for side wall vent

terminations)

IBC Technologies Inc. - 8 - VFC 160

Figure 5. Side Wall Venting

vent tee sh ould be parallel to side wall.

intake should be swung to parallel

with side wall.

min. 12 " between

bottom of intake

and bottom of vent

MIN. 24" TO

ANY OVERHANG

MIN. 4’

HORIZONTAL

DISTANCE

FROM ANY

GAS OR

ELECTRICAL

METER

MIN 36" TO

INTAKE

MIN. 12"

installation below average snow level

4−3/8"

minimum

5−1/2"

12"

MIN. 12" TO ANY OPENING

SNOW LINE

12" m in. clearance

to any overhang

FIELD SUPPLIED PLASTIC

STRAPPING MUST BE USED

TO SECURE THE VENT TO

THE STRUCTURE

24−1/2"

18−1/2"

12" min. above

average snow leve l

Figure 6. Side Wall Vent Terminations (Configuration 1)

2.5" or 3" PVC or 3" ABS

"−

"

"

2.5"/3" PVC or 3" ABS or CPVC

4"x4"x4" ABS/PVCTee(alt: 4x4x3 Tee with approp.bushing)

If 3" venting is used, the exhaust line must be reduced

to 2½" immediately prior to entering the 4" termination

tee to allow adequate intake clearance. Use a 3 x 2½"

Figure 7. Side Wall Vent Terminations (Configuration 2)

IBC Technologies Inc. - 9 - VFC 160

1.4.2 Category IV Venting

A category IV venting system is one in

which air for combustion is take from

the ambient air around the boiler. Vent

piping is run horizontally or vertically to

the outdoors.

1.4.2.1 Ventilation and Air Supply

To support combustion, an ample air

supply is required. This may require

direct openings in the boiler room to the

outside. If the boiler is not in a room

adjacent to an outside wall, air may be

ducted from outside wall openings.

Provisions for combustion and

ventilation air must be made as follows:

in the USA, in accordance with Section

5.3 Air for Combustion and Ventilation

of the National Fuel Gas Code, ANSI

Z223.1 (latest edition), or applicable

provisions of the local building codes; in

Canada, in compliance with CAN 1.4.3.

The following lists are recommendations

for buildings of energy-saving

construction, fully caulked and weatherstripped:

• an opening to the outside, within 18”

of the floor, but no less than 6” off

the floor, should be provided in the

room. Each opening should be

covered in a grill, and have an area

of 1” per 1,000 BTUh for ALL

APPLIANCES in the area.

• Openings must not be closed or

reduced. Doors and windows used

for air supply must be locked open.

• Mechanical draft exhaust or supply

fans are not to be used in or near the

boiler area

• Boiler combustion and ventilation

airflow must not be obstructed

Category IV venting is installed in the

same manner as for the exhaust side of

Direct Vent installations.

1.4.3 Closet Installations

For installations in a confined space

(such as a closet), ventilation openings

must be provided through a door or wall

to prevent excessive heat from building

up inside the space.

Minimum requirements:

• one opening within 12” of the ceiling

(100 sq. in. opening)

• one opening within 12” of the floor

(100 sq. in. opening)

1.5 Water Piping

Follow applicable Codes and good

piping practice. Any uninsulated hot

water pipes must be installed with a

minimum 1” clearance from combustible

materials.

System piping is connected to the boiler

using the 1” NPT female threaded

fittings provided at the locations shown

on page 10. Typical piping systems are

shown in Figures 8,9, &10.

A 30 psi pressure relief valve (¾” NPT)

is supplied for field installation in the

flow supply line, in the manner shown in

Figures 8,9, & 10. Relief valve

discharge piping must terminate 6”

above a drain using plain un-threaded

end, or per local Code.

To avoid exposure to water damage,

system piping and components are not to

be located overhead the boiler.

Indoor combustion air must not expose

the boiler to contamination - see Section

1.3 - Location, above. In other respects,

IBC Technologies Inc. - 10 - VFC 160

(s)

stop & waste

(

)

backflow

or ball valve

boiler feedwater

preventer

Figure 8. Sample Piping Schematic (1)

cold supply

flow

check

system

supply

hydronic flow check(s) o

zone valves to prevent

thermal circulation

contractor

supplied

system

circulator

air purger

diaphragm

expansion tank

auto fill valve

12 psi min.

drain

air vent

12−18"

pressure

relief

valve

system supply piping

tee & boiler drain

for system purging

ball

valve

system return piping

system return piping

#30

#15

Figure 910. Sample Piping Schematic (2)

note: wire aquastat or control contacts in series wit

parallel wired zone control end switches or pump relay

air

eliminator

diaphragm

expansion

tank

pressure

relief

valve

pressure

relief

valve

contacts.

buffer/tempering

tank

flow

check

additional zones

zones

aquastat

indirect

T&P

domestic

relief

water

heater

wire to zone

valve end switches

or relay contacts

hot

cold

Figure 10. Sample Piping Schematic (3)

IBC Technologies Inc. - 11 - VFC 160

The VFC boiler is designed for supply

water temperatures within the range

80°F to 180°F, with a 20°F rise. Water

flow rates and pressure drop (head in ft.

w.c.) associated with a 20°F maximum

rise (∆°T) for the respective VFC

models are as follows:

Table 4 - Flow Rate

Model Flow

(Usgpm)

VFC 160 16.0 12

Water flow rates must not be allowed to

fall below 8 gpm in any possible

operating condition (eg. Single zone in

use).

To achieve system flow rates and

temperatures within such limits, care

must be taken to select the appropriate

pump. Evaluate pressure drop across the

system, including the above head values

for the boiler itself. Ensure pump is

rated for the design circulating water

temperatures; some pumps have a

minimum water temperature rating

above the low temperature potential of

the boiler. Following installation,

confirm actual performance by

measuring ∆°T (under high and low flow

conditions) after establishing the correct

firing rate (see Section 2.2 – Check

Boiler Input).

VFC-series boilers are supplied with a

integral low-water flow switch, which

allows installation of the boiler above

radiation level. The flow switch is

calibrated to close with at 4.5 US gpm

and open at 4.0 US gpm.

When installed in a low mass heating

system such as an in-floor radiant

application, the VFC-series boilers may

benefit through use of a buffer tank to

Approx.

Head (ft. wc)

ensure a controlled supply temperature,

and to prevent short cycling. It is highly

recommended that a buffer tank be

included in any heating system in which

any single zone has radiative loading

lower than 1/3rd of the minimum input of

the boiler (i.e. at 160 000 BTU/hr, the

boiler should be buffered if any single

zone attached is below 55 000 Btu/hr).

Propylene glycol solution is commonly

used in a water heating loop where

freeze protection is required. Its density

is lower than that of water, resulting in

lower thermal performance at a given

flow and pressure. As a rule of thumb, a

50%:50% solution of propylene glycol

and water will require an increased

system circulation rate (gpm up 10%),

and system head (up 20%) to provide

performance equivalent to straight water.

Whether required by local Codes or

otherwise, it is recommended that piping

systems include a suitable check valve,

gate valve and feedwater regulator set at

12 psig. In the make-up water link with

the city main. Use of unions and gate or

ball valves at the boilers supply and

return water connections is

recommended to simplify servicing.

1.6 Gas Piping

The boiler requires an inlet gas pressure

of at least 3.5” w.c. and no greater than

14.0” w.c. Confirm this pressure range

is available with your local gas utility.

The inlet gas connection of the boiler’s

gas valve is 1/2” NPT (female).

Adequate gas supply piping shall be

provided with no smaller than 1/2” Iron

Pipe Size (IPS), in accordance with the

following chart:

IBC Technologies Inc. - 12 - VFC 160

Table 5 - Max. Pipe Length (ft)

Model 1/2” IPS 3/4” IPS 1” IPS

VFC 160

8 35 120

Gas piping must have a sediment trap

ahead of the boiler’s gas valve (see

Figure 11.). A manual shutoff valve

must be located outside the boiler, in

accordance with local codes/standards.

All threaded joints in gas piping should

be made with a piping compound

resistant to the action of natural gas - do

not use Teflon tape. Use proper hangers

to support gas supply piping.

union

gas valve inside

install manual

main shutoff

valve 5 ft.

above floor

when required

by local code

full size

sediment

trap

Figure 11. Typical Gas Piping

The boiler must be disconnected or

otherwise isolated from the gas supply

during any pressure testing of the system

at test pressures in excess of 1/2 psig.

Dissipate test pressure prior to

reconnecting.

The boiler and its gas piping shall be

leak tested before being placed into

operation.

The gas valve is provided with pressure

taps to measure gas pressure upstream

(supply pressure) and downstream

(manifold pressure) of the gas valve.

1.7 Electrical Connections

All Electrical wiring to the boiler

(including grounding) must conform to

local electrical codes and/or National

Electrical Code, ANS/NFPA No. 70 –

latest edition, or The Canadian Electrical

Code, C22.1 - Part 1.

1.7.1 Mains Hook-up

Line-voltage wiring is done within the

field-wiring box. Referring to Wiring

Diagram on page 26, connect the boiler

to the mains power using a separate,

fused circuit and a disconnect means

within sight of the boiler. Use 14-gauge

conductors in BX cable or conduit

appropriately anchored to the boiler case

for both mains supply and pump circuits.

The transformer primary (black wire) is

connected to the neutral and line (hot)

wires. The red conductors for the pump

contacts should be wired into the

ungrounded leg of the pump circuit.

Note: The combined current of all

pumps connected through the on-board

pump relay (red conductors) should not

exceed 10 amps.

1.7.2 Thermostat wiring

The Thermostat terminal block is located

on the control module. The thermostat

terminals should NOT be connected to

any other power source and should only

be connected to a room thermostat,

isolated, zone valve end switches or

circulator end switches. When using 3wire zone valves (non-isolated) the zone

valve end contacts must be isolated from

the thermostat terminals using an

appropriate relay.

IBC Technologies Inc. - 13 - VFC 160

1.7.3 Thermostat Heat Anticipator

When installed in a non-zoned system,

the heat anticipator setting is dependant

on the gas valve installed in the boiler:

Gas Valve Anticipator

Current

Setting

White-Rodgers 36E22 0.5 A

White-Rodgers 36E36 0.5 A

White-Rodgers 36F22 0.5 A

White-Rodgers 36G22 0.3 A

Honeywell VR8205A 0.7 A

For zoned systems, each room

thermostat’s heat anticipator should be

adjusted to the current draw of its

associated zone valve.

IBC Technologies Inc. - 14 - VFC 160

2. STARTUP

WARNING: If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal injury or loss of life.

FOR YOUR SAFETY READ BEFORE OPERATING

A. This appliance does not have a pilot. It is equipped

with an ignition device which automatically lights the

burner. Do not try to light the burner by hand.

B. BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas suppliers

instructions.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this

label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance by

selecting main power switch to Off.

4. This appliance is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

Gas Inlet

• If you cannot reach your gas supplier, call the

fire department.

C. Use only your hand to turn the gas control knob.

Never use tools. If the knob will not turn by hand,

don’t try to repair it, call a qualified service

technician. Force or attempted repair may result in

a fire or explosion.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

6. Turn gas control knob clockwise ¬ to Off.

7. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you smell

gas, STOP! Follow B in the safety information

above on this label. If you don’t smell gas, go to the

next step.

8. Turn gas control knob counterclockwise « to On.

9. Replace front cover on appliance.

10. Turn on electric power to appliance by selecting

main power switch to On.

Gas valve

shown in ON

position

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the

instructions “To Turn Off Gas To Appliance” and call

your service technician or gas supplier.

5. Remove front cover from appliance.

TO TURN OFF GAS APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn of all electric power to the appliance by selecting main power switch to Off.

3. Remove front cover from appliance.

4. Turn gas control knob clockwise ¬ to Off.

5. Replace front cover on appliance

Also ensure items under the following caption 2.1 Prior to Start-up have been addressed.

IBC Technologies Inc. - 15 - VFC 160

2.1 PRIOR TO START-UP

Ensure venting system is complete and

seal tested. Confirm any common venting

system at the installation site is isolated

and independent of the VFC boiler and

that any holes left from removal of a

previous boiler have been sealed. Fill

condensation trap to full 5” (min.) neck

height. Check water piping system is fully

charged, and that all air has been

discharged through loosened bleed caps.

Use a minimum operating water pressure

of 12 psig. Perform a final check of

electrical wiring.

2.1.1 Test Ignition System Safety

Shutoff Device

With the boiler in operation, test the

ignition system safety shutoff device by

shutting the manual gas valve immediately

outside the boiler case. Ensure boiler has

shut off and error and gas valve lights are

flashing. To restart boiler, reset power.

setting (using manual Fan Speed

screw as shown in Figure 13) until

pressure switch indicator illuminates

5. Open gas supply and start boiler

6. Raise thermostat to trigger call-for-

heat. Within 40s, gas valve will open

and boiler will attempt to ignite

7. Once stable combustion has been

achieved, remove set screw on top of

gas valve. Turn calibration screw on

gas valve until pressure gauge reads

3.0” w.c. Ensure set screw has been

returned to its original position.

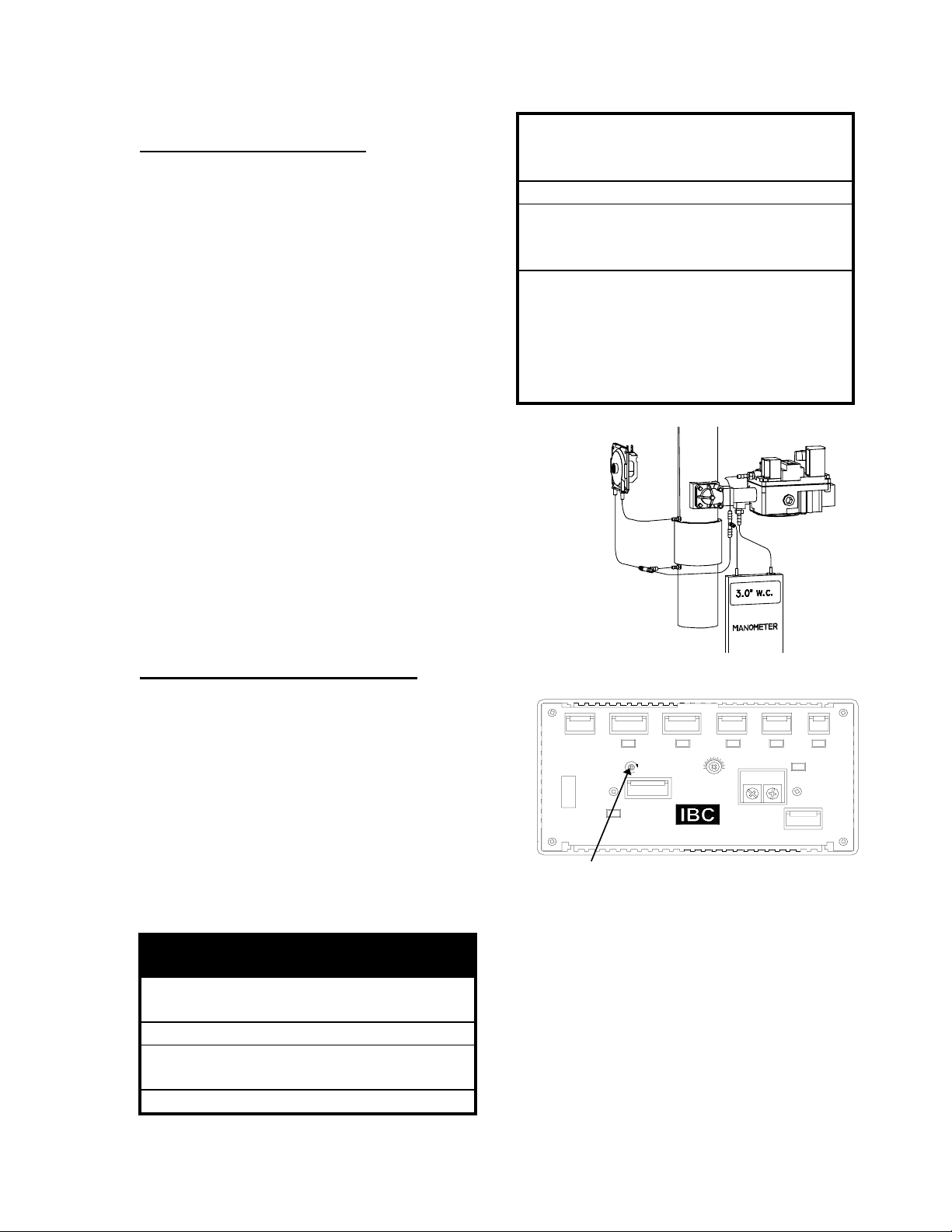

2.2 GAS VALVE ADJUSTMENT

The gas valve is factory pre-set for proper

gas/air mixing at mean sea-level pressure,

however some adjustment may be

required, e.g. for altitude.

To ensure gas input is set to the desired

boiler output, set the gas valve using the

method described in this section. A

pressure measurement gauge (with

0.1”w.c. divisions) should be used as

shown in Figure 13.

Table 6 - Gas Valve Adjustment

1. Ensure that vents are not obstructed

(see Troubleshooting Guide)

2. Set pressure measurement gauge to 0

3. Connect pressure measurement gauge

as shown in Figure 12

4. Increase blower speed from lowest

Figure 12. Gas Valve Adjustment

Ignition Module

Pump

Fan adjust

Pressure Switch

Power

H

Fan Speed

L

Fan

Operator

Flow Switch Vent Hi-Lim it W ater Hi-Lim it

180°F

80°F

Set Point

FXFR

Therm ostat

Figure 13. Fan Adjustment Screw

24 V

Call for Heat

AC

IBC Technologies Inc. - 16 - VFC 160

2.3 BLOWER ADJUSTMENT

To ensure a proper gas/air ratio, adjust the

blower using the manometer as shown in

Figure 14.

Ignition Module

Pump

Fan adjust

Pressure Switch

Power

H

Fan Speed

L

Operator

Flow Switch Vent Hi-Limit Wa ter Hi-Limit

180°F

80°F

Set Point

Fan

FXFR

Therm osta t

24 V

Call for Heat

AC

Figure 15. Fan Adjustment

2.4 CHECK BOILER INPUT

To ensure that the boiler input is correct,

check the boiler input rate using the

following procedure:

Figure 14. Blower Adjustment

Connections

Table 7 - Blower Adjustment

1. Once again, ensure that vents are not

obstructed (see Troubleshooting Guide)

2. Connect manometer in the

configuration shown in Fig.14

3. Increase blower speed (using manual

Fan Speed screw as shown in Figure 15)

until 1.20”wc differential is achieved

4. Open gas supply and start boiler

5. Raise thermostat to trigger call-for-heat.

Within 40s, gas valve will open and

boiler will attempt to ignite

6. Once stable combustion has been

achieved, take CO2 sample at vent

termination

7. Turn Fan adjust screw on enunciator

panel to vary fan speed (and airflow)

until combustion analyzer reading of

9.2% CO2 is achieved

2.5 SET OPERATOR LIMIT

Adjust operator limit as temperature

demands require.

Table 8 - Check Boiler Input

1. Start boiler

2. Ensure other gas appliances are not

using the supply gas

3. Observe the number of cubic feet used

by the boiler in 1 minute

4. Consult gas supplier for gas heating

value(typically 1000 BTU/cu. ft.)

5. Verify output by using the formula at

the end of this section

6. If fuel flow is too high or low, check

the orifice plate size. Adjust gas valve

(per Section 2.2) as required to

achieve Rating gas plate input;

recheck flue gas composition at 9.2%

CO2 if adjustment is made.

Boiler Input Formula

3600

INPUTHV

=×

time

time = seconds for 1 cu. ft. of

natural gas through meter

HV = heating value of gas as

provided by gas supplier

INPUT = gas input(in BTU/hr)

Table 9 - Operator Setting

Dial Colour "A" to "E" Temp. Range

Red 130°F - 170°F

Black 100°F - 140°F

IBC Technologies Inc. - 17 - VFC 160

3. MAINTENANCE AND TROUBLESHOOTING

commanded to an ultra-lowflow mode for

3.1 BOILER OPERATION

3.1.1 Normal Operation

1. On power-up, the boiler exercises the

fan and pump by entering into a postpurge routine - see below.

up to 90 minutes to act as a vent-damper.

The pump maintains normal circulation

throughout the phase. This low intensity

mode is a simple way of ensuring moisture

does not migrate and re-condense around

and above the burner area (e.g. fouling the

igniter) during the off-cycle.

2. On a call for heat, the blower and

pump switch on.

3. After 20-40 seconds, the gas valve

opens and the igniter probe sparks.

The ignition module will issue a spark

to the burner for approximately 10

seconds. If no flame is present, the gas

valve closes, and locks out until there

is a new call for heat.

4. On successful ignition, the spark is

discontinued and the gas valve remains

open.

5. If water or vent temperature conditions

exceed safe operating limits, or vent

pressure falls below the calibrated

value, the gas valve closes and the

burner remains off until a safe

condition exists. A post-purge cycle

follows.

6. If the call for heat ends, the gas valve

closes and the boiler will enter a postpurge cycle.

The post-purge is immediately interrupted

by a new call for heat, or return to safe

condition of a tripped limit switch (in the

case of a shutdown caused by an open hilimit). In such case the mode ends and the

boiler enters an ignition cycle. The

interrupt is deferred however, to allow a 2

minute low-flow interval prior to return to

the ignition routine in the event of an

opening of the control circuit at the air

pressure switch; this is to allow for

clearance of any excess buildup of

condensates in the vent.

3.1.3 Boiler Safety System

There are 5 safety devices that can cause

the boiler to shut down:

1. Outlet Water Limit: closes gas-valve

when outlet water exceeds 200°F.

2. Vent Hi-Limit: closes gas-valve when

vent temperature exceeds 230°F.

3. Pressure Switch: closes gas-valve

when air pressure drops below 0.9”wc.

3.1.2 Post-Purge Cycle

The post-purge cycle employs the variable

speed fan to clear exhaust gases from the

boiler and its venting, and the pump to

utilize residual heat from the boiler vessel

during cool-down. The fan and pump

provide normal flow rates for an initial 10

second period; subsequently the fan is

IBC Technologies Inc. - 18 - VFC 160

4. Flow Switch: Shuts boiler off if water

flow drops below US 4 gpm

5. Flame Presence: the ignition module

will lockout if no flame is detected

during its 21 second trial period.

Causes for this can be found in Section

4 - Troubleshooting Guide under

Lockout.

3.2 BOILER MAINTENANCE

blockage exists, trap must be cleared and

refilled.

The installer is responsible to ensure the

owner aware of the importance of regular

maintenance, and that improper

maintenance may result in a hazardous

condition.

Unless otherwise specified, boiler must be

inspected at the beginning of each heating

season by a qualified technician.

CAUTION: Label all wires prior to

disconnection when servicing controls.

Wiring errors can cause improper and

dangerous operation.

3.2.1 General Care

Keep combustible materials and

flammable liquids and vapours away from

the boiler.

Keep vent terminals clear of obstructions

(snow, dirt, etc.).

3.2.2 Inspection

Burner

Visually inspect burner through sight

glass. Ensure flame is stable and without

excessive fluttering. Normal flame pattern

is evenly distributed over the burner

surface.

Annual inspection of the burner is not

necessary. If operating improperly,

remove burner and clean or replace.

Use a CO2 analyzer to determine proper

combustion. CO2 level should be 9.2%.

Pump

Check that the pump is on in normal

operation.

Heat Exchanger

In the unlikely event of boiler flue passage

blockage, service to remedy situation must

be performed only by an authorized IBC

representative.

Annual inspection of the boiler to be

performed by a qualified technician.

Venting

Check vent terminals and vent piping for

and remove any obstructions.

Check for holes or leaks in venting.

Examine for any signs of moisture caused

by sweating intake air pipes; insulate as

required.

If any of these conditions exists, contact a

qualified technician.

Air Filter

Replace or clean air filter annually.

Condensate Traps

Check condensate traps every 6 months

for water seal and blockages. If a

Gas Piping

Check for damage or leaks and repair as

needed.

Ignition Module/Igniter Probe

Check that boiler ignites 40s after a call

for heat. Ensure that fan and pump are on

when a call for heat occurs.

There should be no unusual crackling

noise when igniting the boiler. If there is,

consult Section 4 - Troubleshooting.

Enunciator

Check that the blower is on in normal

operation, and pump remains on and

blower operates at normal speed for 10

seconds then ultra-low speed (for 90 min.

max.) after boiler shuts off.

Water

IBC Technologies Inc. - 19 - VFC 160

Check water pressure and temperature.

There should be no noticeable change if

boiler is functioning normally. Check for

any noise in the system.

Check water piping for damage or leaks

and repair as needed.

volume must not exceed 50% of the total

volume of water in the system.

WARNING: Do not use Ethylene

Glycol, automotive-type

antifreeze, or undiluted

antifreeze. This may result in

severe boiler damage.

Freeze Protection

Use only antifreeze made specifically for

hydronic systems. Inhibited propylene

glycol is recommended. Antifreeze

3.3 COMPONENT DESCRIPTION

A diagram of components and their

placement can be found at the end of this

manual.

For a list of supplier for all components,

contact IBC Technologies or visit our

website at www.ibcboiler.com.

The following list provides a summary

description of major components:

3.3.1 Pressure Switch

Part#/Type: #VFCF-P011-NO4 /

Honeywell C6065D Differential Pressure

Switch, calibrated to 0.88” (Alt: Micro

Pneumatics 9300-0.88)

Function: used to confirm adequate flow

of combustion air; shuts boiler off when

intake air pressure differential drops below

0.9” at measurement point -

Verify proper operation after servicing.

Installation: Ensure that arrow points

towards the pressure vessel; shift bar to

“NO” position.

3.3.3 Operator

Part#/Type: #VFCF-P010-150 or -120 /

High range (red face): calibrated for 150°F

centerpoint, 20°F differential; low range

(black face): 120°F centerpoint, 20°F diff.

Function: Switch closes/opens to

enable/prevent boiler operation to provide

desired water temperature range.

Installation: Mount with Honeywell

Tradeline #107408 Heat Conductive

Compound between the base of the

operator and the surface of the tee. Set to

desired operating temperature - see

Section 3.5 - Set Operator Limit above.

Installation: see diagram at the end of

the manual for correct installation.

3.3.2 Flow Switch

Part#/Type: #VFCX-P002 / ½" NPT

paddle type brass/spst reed switch

Function: for confirmation of adequate

circulating water flow; shuts boiler off

when flowrate drops below US 4.0 gpm

IBC Technologies Inc. - 20 - VFC 160

3.3.4 Hi-Limit

Part#/Type: #VFCX-HL200 / Therm-ODisc 37T_21, calibrated for 200°F, 15°F

differential.

Function: Shuts boiler off when water

temperature exceeds safety limit. Two hilimits are available depending on the

desired maximum.

Installation: Mount with Honeywell

Tradeline #107408 Heat Conductive

Compound between the base of the

operator and the mounting surface.

3.3.5 Transformer

Part#/Type: #VFCX-P006 /Hammond

DG2G control transformer; Alternate: Rex

CS100AW/X Primary- 120VAC; Sec.- 24

VAC; 100VA

Function: Provides 24 VAC for (1) the

control circuit and (2) AC to DC power

converter, to drive the brushless DC fan

Installation: see wiring & ladder

diagrams.

3.3.6 Gas Valve

Type: White-Rodgers 36E22 (alts:

36E36; 36F22 or 36G22) Fast-Opening

Valve. Alternative: Honeywell VR8205A

Function: regulates and supplies gas for

gas:air mixing; opens/closes on signal

from the ignition control module.

Installation: see Section 2.2 Gas Valve

Adjustment.

3.3.7 Blower

1. 30 second (approx.) prepurge on a call

for heat

2. opens gas valve

3. provides ignition spark (30,000 V open

circuit, which provides approx 8,000 V

on a formed-arc basis) for a single

trial-for-ignition period of 20 second.

Checks for flame presence; locks out if

no flame by end of ignition trial. See 4

- Troubleshooting, under Lockout.

4. discontinues spark if flame present

5. on loss of flame, a timed trial-for-

ignition is repeated (locks out if trialfor-ignition period ends before flame

is re-established)

Installation: see wiring diagram.

3.3.9 Igniter Probe/Flame Sensor

Part#/Type: #VFCX-P004 / single probe

of Kanthal A1 and Alumina ceramic.

Function: Transmits spark from ICM

to burner for ignition, and sends electrical

signal back to ICM for flame proving.

Installation: Set gap between burner and

probe end must be between 3/16 - 1/4”.

Part#/Type: #VFCX-P005 / RG130/0800

24V DC blower

Function: Moves combustion air and flue

gas products through the boiler and

venting.

Installation: see Section 2.3 Blower

Adjustment.

3.3.8 Ignition Control Module(ICM)

Type: #VFCF-M003 / Honeywell S87J1034 Direct Spark Ignition Control

Module.

Function: Boiler ignition, flame proving

and gas valve control.

On a call for heat, the S87J-1034 performs

the following functions:

3.3.10 DC Power /Enunciator Panel

Ignition Module

Pump

Pressure Switch

Power

H

Fan Speed

L

Fan

Operator

Flow Switch Vent Hi-Limit Water Hi-Limit

180°F

80°F

Set Point

FXFR

Thermostat

24 V

Call for Heat

AC

Figure 16. DC Power & Enunciator

Part#/Type: #VFCF-M002 / combination

dc power supply and wiring bus

Function: Provides DC power supply for

fan operation and a PWM electronic signal

for fan speed variation. Also acts as a

IBC Technologies Inc. - 21 - VFC 160

connector bus for control circuit wiring.

The integrity of the series control circuit is

preserved in the FXFR module’s internal

circuitry. Finally, the module comprises

the circuitry supporting the optional

Electronic Operator.

The Enunciator panel carries seven

indicator lamps (LEDs) pertaining to the

various control circuit components wired

to the module. The LEDs provide a visual

aid for locating open switches within the

control circuit. on the boiler showing the

states of the boiler:

1. power

2. airflow

3. water temperature operating range

(Operator)

4. water flow

5. vent temperature limit

6. water temperature limit

7. thermostat

The remaining indicators light up in series

from right to left, beginning with the

thermostat. If an indicator is off, all

indicators to the left of it will be off. The

first unlit indicator shows an open circuit

at that point. If the boiler is heating, all

indicators will be on.

Output of the fan may be adjusted during

installation using the fan speed adjustment

screw. This allows optimization of fan

speed to minimize electrical consumption

and noise for each installation. Fan

adjustment should only be done by a

qualified technician with appropriate

equipment (incl. combustion analyzer)

during installation or servicing.

The DC Power / Enunciator module

circuitry also manages the Post-Purge

cycle - see 3.1.2 Post-Purge Cycle above.

The power indicator light always remains

on except when there is no power to the

boiler.

3.3.11 Detailed System Checks

Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the

electrical supply to the pump. Instead shut off the gas supply at a location external to the

appliance.

Do not use this boiler if any part has been under water. Immediately call a qualified service

technician to inspect the boiler and to replace any part of the control system and any gas

control which has been under water.

IBC Technologies Inc. - 22 - VFC 160

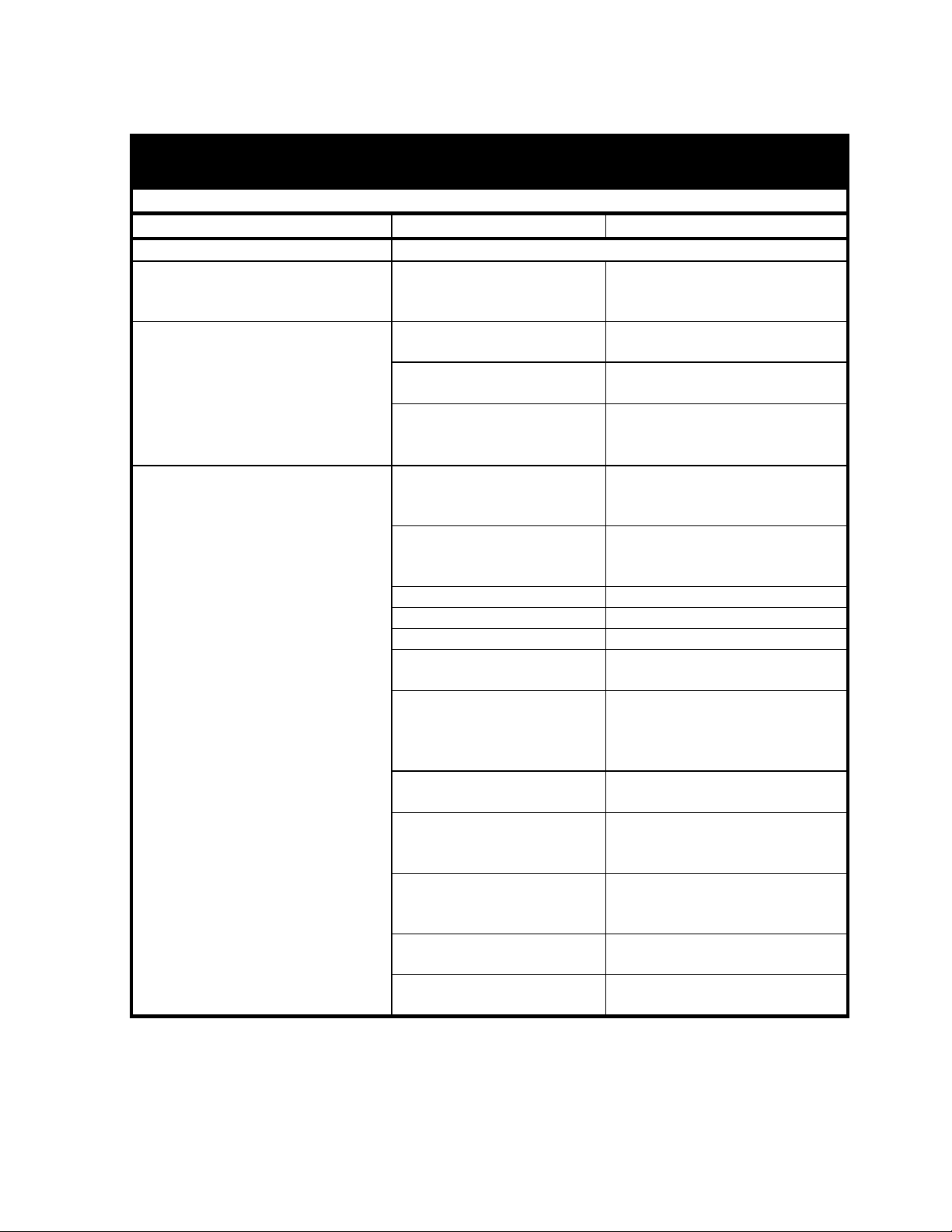

4. Detailed Systems Troubleshooting

Cycling Problems

Symptom Diagnosis Remedy

Rapid Cycling

i) Gas valve clicks on and

off repeatedly when

igniting.

ii) Water noise in exhaust

venting

no other symptoms

Obstruction in Intake/

Exhaust venting.

Excess Condensate in

venting.

•

Obstruction in

condensate trap.

•

Improper vent length.

•

Improper slope to vent.

Incorrect anticipator setting

or defective thermostat.

Air in system (check for

flashing flowswitch lamp),

of marginal water flow.

Slow combustion air blower. Check that CO2 level is 9.2%.

Dirty burner/heat exchanger. Check pressure drop.

Insufficient water flow.

•

Improper piping.

•

Undersized pump.

•

Restriction in water

pipe.

Insufficient radiation. Check actual amount of

Unit overfired. Clock gas meter/check gas

Unit Oversized. Refer to Load Calculation vs.

Improperly set or defective

operating/safety controls

Inspect vent terminals and

tubing. Clear any obstructions.

Check venting angles

Inspect and clean condensate

trap.

Check venting. Compare vent

length and diameter to

Maximum Venting

Check operation. Refer to

manufacturer’s instructions.

Check setting with ammeter.

Bleed/purge system as required.

Confirm adequate pump size

and temp rise in HX

Refer to recommended piping in

ection 1.5

S

Check manufacturer’s rating

charts/check temperature

differential across heat

exchanger.

Check temperature differential

across zone/heat exchanger.

radiation per zone and refer to

manufacturer’s rating tables.

pressure with manometer/ check

level.

CO

2

Boiler Output

Check operation with

Ohmmeter/Voltmeter

.

Table 3-

.

IBC Technologies Inc. - 23 - VFC 160

Ignition Problems

Symptom Diagnosis Remedy

Noisy spark when igniting. Ignition lead is not firmly

connected.

Contaminants/moisture

on igniter probe/flame

sensor.

Boiler rumbles when igniting. Poor gas/air mixture. Check CO2 in exhaust. Check

Fluctuating gas pressure/

gas pressure too high/too

low.

Boiler will not attempt to ignite.

i) Fan and pump are

operating normally.

ii) Fan and pump are off

No lights on display

iii) Fan off and pump on

Boiler ignites but shuts off

within seconds

No power to ignition

control module.

Igniter probe/flame

sensor disconnected.

Blown fuse in ignition

module.

Defective Control

Module.

No power to boiler Check line voltage

Defective transformer. Check transformer.

Bad electrical grounding

of vessel defeats flame

rectification

Loose or bad igniter

cable

Reconnect ignition lead

Ensure probe is dry by rerunning post-purge;

otherwise, clean or replace

igniter probe.

mass airflow sensor.

Check pressure with

manometer during ignition.

Check mass airflow sensor.

Check system wiring.

Check airswitch & air tubing.

Reconnect probe.

Check fuse.

If blown, replace.

Check ignition output from

control module.

Reconnect or replace as

needed.

Confirm continuity between

pressure vessel and ground

terminal on Control Module.

Check and replace as required

Miscellaneous

Symptom Diagnosis Remedy

Fumes and High Humidity Improperly installed

condensate trap

Leak in CPVC/ABS/PVC

vent piping

Flue gas leak in heat

exchanger

IBC Technologies Inc. - 24 - VFC 160

Refer to installation/operation

instructions

Visually inspect using soap

solution

Visually inspect all

mechanical connections

Temperature Problems

Symptom Diagnosis Remedy

Insufficient heat. Operating temp. too low

Unit undersized Refer to Load Calculation vs.

Air trapped within system Bleed system as required.

Improper system piping Refer to recommended piping

System pump undersized Check pump manufacturer’s

Poor gas/air mixing Check CO2 level.

Defective thermostat. Refer to manufacturer’s

Incorrect gas/air orifices. Refer to orifice sizing table

Obstruction in condensate

drain.

Unit cycling on operating/

safety controls.

System radiation

undersized

Temperature exceeds thermostat

setting

One or more zones do not heat

properly.

One or more zones do not heat

properly.

Incorrect anticipator

setting

Thermostat not level. Check level.

Air trapped within

zone(s)

piping

Insufficient radiation/

excessive heat loss.

Insufficient flow rate to

zone(s).

Defective zone valve/

zone circulator.

Defective zone

thermostat.

Improper control wiring. Check wiring per

Improper/obstructed

baseboard radiation.

Operating limit set

improperly.

Boost setpoint per Section

2.3.1 above

Boiler Output

in Section 1.5.

data/check temp differential

across heat exchanger.

instructions.

Inspect and clean condensate

drain.

Check operation with

Ohmmeter/Voltmeter.

Check manufacturer’s rating

tables for capacity per foot.

Check with Ammeter.

Vent system/zone as required.

Check actual length of pipe

using radiation / heat loss

calculation.

Check temperature drop

across zone.

Check operation per

manufacturer’s instructions.

Check operation per

manufacturer’s instructions.

manufacturer’s instructions.

Check baseboard

manufacturer’s instructions/

check at zone.

Check limit setting/operation.

IBC Technologies Inc. - 25 - VFC 160

IBC Technologies Inc. - 26 - VFC 160

pressure

switch

w

b

o

operator

+25V

(GND)

b

valve

valve

+25V

gnd

(burner)

b

b

r

r

b

b

b

G

flow

switch

vent

limit

r

w

b

b

water

limit

b

b

Ignition Module

r

r

Pump

pump

Pressure Switch

Power

Fan Speed

Operator

Flow Switch Vent Hi-Limit Water Hi-Limit

°

°

Set Point

Thermostat

FXFR

Call for Heat

G

b

b

r

r

rwbry

thermostat

pwm−V tac +v

blower

jb1

(control)

n

n

l

115V AC

G

24V AC

l

Wiring Diagram for IBC VFC 160 Boiler

IBC Technologies Inc. - 27 - VFC 160

Component Layout Diagram

1. Igniter Probe/Flame Sensor

2. Blower

3. Tridicator

4. Water Hi-Limit

5. Operator

6. Gas Valve

7. Pressure Switch

8. Ignition Control Module (ICM)

9. Enunciator

10. Transformer

11. Flow Switch

12. Vent Hi-Limit

IBC Technologies Inc. - 28 - VFC 160

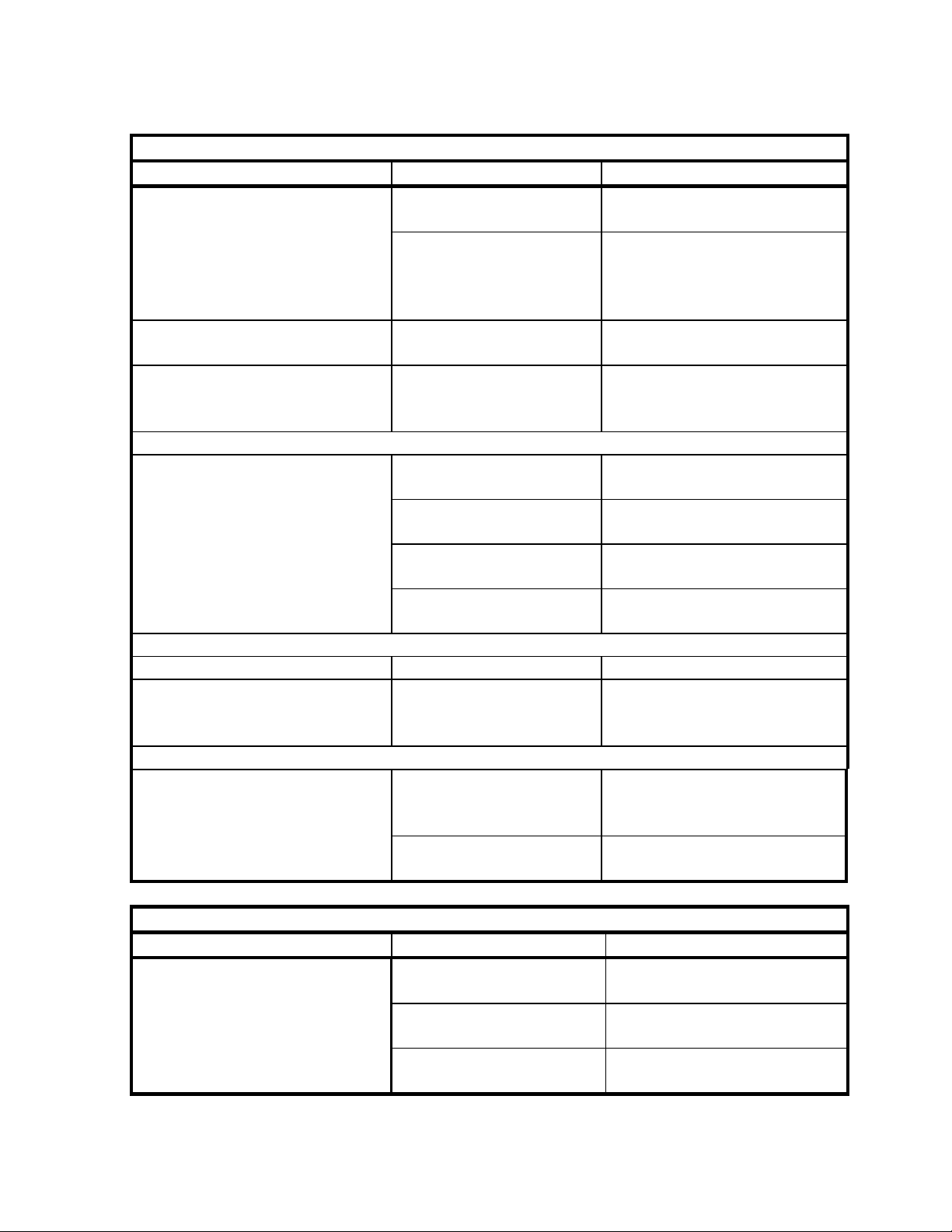

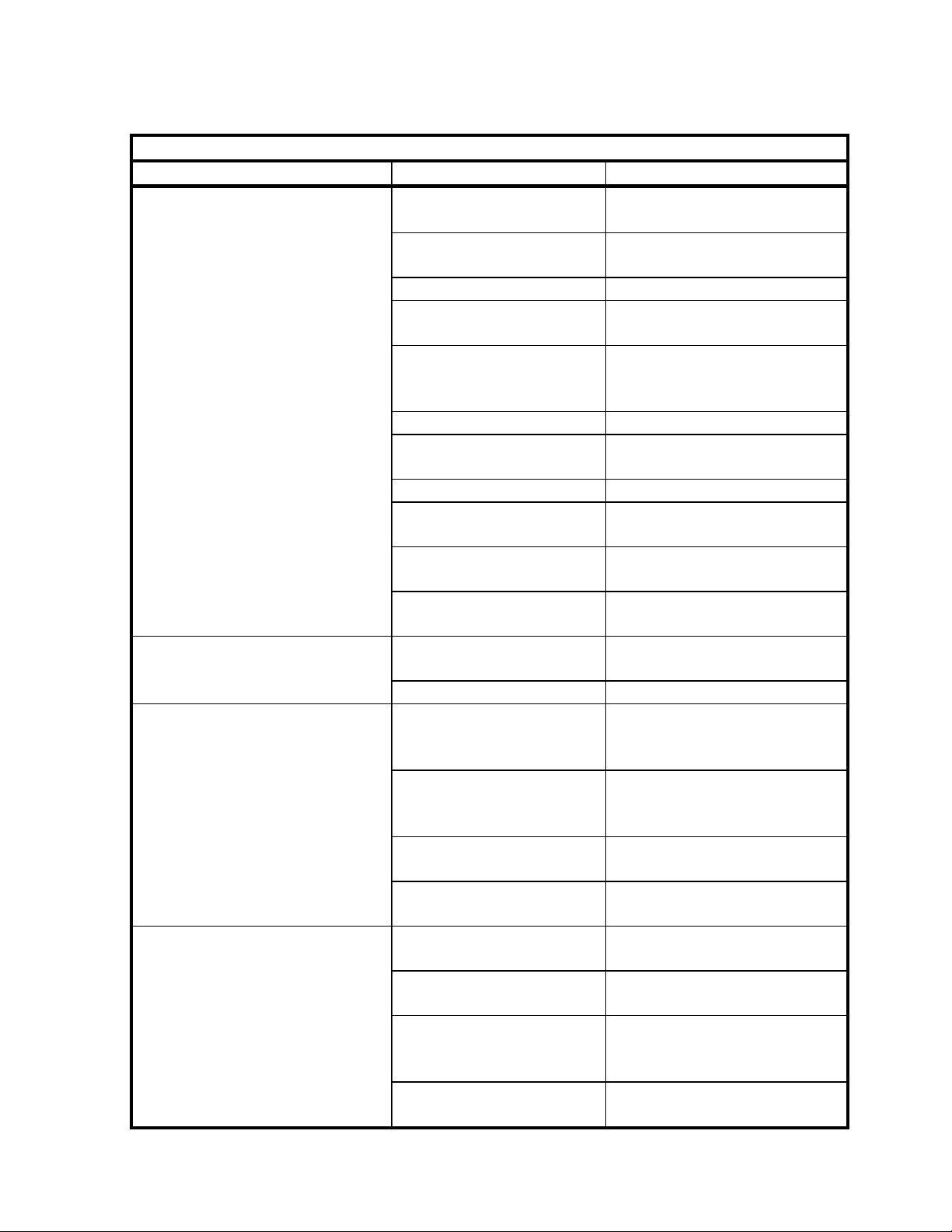

Installation Checklist

Model#: Water Tank #:

Dealer Name: Serial#: Installation Date:

Heat Loss: BTUhr ft. of Radiation: # of Zones:

BTU/ft.: Total Radiation Output: BTUhr

Electrical Information

Thermostat: Anticipator Setting: Amps

Supply Voltage: Volts Combusti on Air Blower Amp Draw: Amps

Boiler Information

Type of Gas: Operating Gas Inlet Pressure: in. w.c.

CO

reading: % Air Intake Orifice Size:

2

Air Pressure Differential Across Air Intake Orifice Plate: in. w.c.

Exhaust Vent Piping: in. ft.

Air Intake Piping: in. ft.

Temperature Rise Through Boiler

Space Heating: °F

Domestic Hot Water: °F Flue Gas Temp.: °F Operating Temp.: °F

Water Manifold Pipe Size

Supply: DHW Tank Aquastat Setting: °F Two-Way:

Return: Differential Setting: °F Three-W ay:

System Pump Model #: Additonal Pump Model #:

Expansion Tank Model #: Expansion Tank Size:

Type of Air Elimination

Spirovent Honeywell

Manual Air Bleed Manual

Pipe Size

perator Setting(A-E): Operating Pressure: psig

Pipe Size to DHW Tank: Valve Type to DHW Tank

Vent/Intake Piping

Water Pressure/Temperature

Water Piping

Actual Length # of 90 and 45 Elbows

Tridicator Gauge

System Bypass Type

None

Notes:

IBC Technologies Inc. - 29 - VFC 160

Air Switch Reference Line Connections

IBC Technologies Inc. - 30 - VFC 160

Loading...

Loading...