Installation and

EX 700

EX 850

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapors and liquids or other combustible

materials in the vicinity of this or any other appliance.

If you smell gas:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a nearby phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the fire department. Installation and service must

be performed by a qualified installer, service agency or the gas supplier.

Operating Manual

EX SERIES

Commercial Boilers

Water quality

Warning

Water quality has a significant impact on the lifetime and performance of a boiler's heat exchanger.

Improperly prepared water in a heating circuit may cause damage to the heat exchanger through

fouling or corrosion. Repeated or uncontrolled water fills will increase the potential for damage.

High levels of dissolved solids or minerals may precipitate out of the fluid onto the hottest part of the

heat exchanger, impairing heat transfer and resulting in overheating and premature failure. The

amount of solids that may form on the heat exchanger will depend on the degree of hardness and

the total water volume in the system. A high water volume system with a low hardness count may

cause as much damage as a system with less volume and higher hardness, so it is recommended

to treat water so as to remove all dissolved solids. Other water chemistry allowable limits are as

follows:

Acidity pH is to be between 6.6 and 8.5

Chloride is to be less than 125 mg/l

Iron is to be less than 0.3 mg/l

Cu less than 0.1 mg/l

Conductivity is to be less than 400μS/cm (at 77°F [25°C])

Hardness is to be 7 grains per gallon or less / 120 ppm or less

Important: Ensure that these limits are acceptable for the other water-side components in the

system.

Shipped with the boiler:

4 x anchor brackets (installed on pallet)

Condensate trap IBC # P-1221

Tridicator IBC # P-1234

Relief valve IBC # P-1205

2 x Inlet gas pressure test fittings, IBC part # 190-206

2 x spare air filters, IBC # P-381

Outdoor sensor, IBC part 240-025

1

Contents

Safety information 5

Manual safety markings 5

Important safety instructions 5

Known contaminants 6

Specifications 7

Connection specifications 8

Cabinet dimensions 9

1.0 Introduction 11

1.1 Standard features and benefits 12

1.2 Warranty 12

2.0 Before installation 13

3.0 Installation 15

3.1 Code requirements 15

3.2 Determining location of the unit 15

3.2.1 Factors to consider for best installation conditions 16

3.3 Unpacking a boiler 17

3.4 Installation clearances 18

3.5 Exhaust venting and air intake venting 18

3.5.1 Code 19

3.5.2 Applications 21

3.5.3 Exhaust vent material 21

3.5.4 Vent travel 22

3.5.5 Venting passage through ceiling and floor 24

3.5.6 Rooftop vent termination 25

3.5.7 Sidewall vent termination 27

3.5.8 Direct vent combustion air intake piping 32

3.5.9 Indoor air combustion air intake 35

3.5.10 Combustion air filtration system 36

3.6 Installing a condensate trap 37

3.7 Installing a condensate neutralizer 39

3.8 Water Piping 41

3.8.1 General piping best practices 43

3.8.2 System piping 44

3.9 Gas piping 54

3.9.1 Gas pressure 54

3.10 Electrical connections 55

3.10.1 Power quality and electrical protection 55

3.10.2 120VAC line-voltage hook-up 56

3.10.3 Other wiring 59

3.10.4 Thermostat / sensor wiring 59

3.10.5 Thermostat heat anticipator 60

4.0 About the boiler controller 61

4.1 Controller 61

4.2 Control interface 62

5.0 Before operating the boiler 63

5.1 Important pre-ignition checks 63

5.1.1 Checklist for electrical conditions, ducting and water connections 63

6.0 Service and maintenance 65

6.1 Maintenance checklists for manager of unit 65

6.2 Maintenance checklists for heating contractor 65

6.2.1 Venting 66

6.2.2 Condensate trap 66

6.2.3 Burner 66

6.2.4 Heat exchanger 67

6.2.5 Pump 67

6.2.6 Gas piping 67

6.2.7 Touchscreen boiler controller 67

6.2.8 Water 68

6.2.9 Freeze protection 69

2

Section: Contents

6.2.10 Boiler treatment 69

6.2.11 Relief valve - maintenance and testing 69

6.3 Replacing the fan, gas valve, and burner 70

6.3.1 Replacing the fan 71

6.3.2 Replacing the gas valve 72

6.3.3 Replacing the burner 74

6.4 Replacing the air filter 76

6.5 Cleaning a condensate trap 77

7.0 Troubleshooting 79

7.1 Preliminary checks 79

7.2 Electronic components 80

7.2.1 Temperature sensors 80

7.2.2 Fan 81

7.2.3 Air pressure sensor 81

7.2.4 Water pressure sensor 81

7.2.5 Gas pressure switches 82

7.2.6 Safety and Ignition Module (SIM) 82

7.3 Troubleshooting error messages 85

7.3.1 Touchscreen error messages 85

7.3.2 Maximum ignition trials error 86

7.3.3 Hi/Low gas pressure switch error 87

7.3.4 Hi Limit cut-off temperature error 87

7.3.5 Low Water Cut-off error 87

7.3.6 Aux. Interlock 1 or 2 88

7.4 Miscellaneous touchscreen controller errors 88

7.4.1 Ignition issues 89

7.4.2 Temperature issues 90

7.4.3 Miscellaneous issues 91

7.4.4 Cycling issues 92

Appendices 93

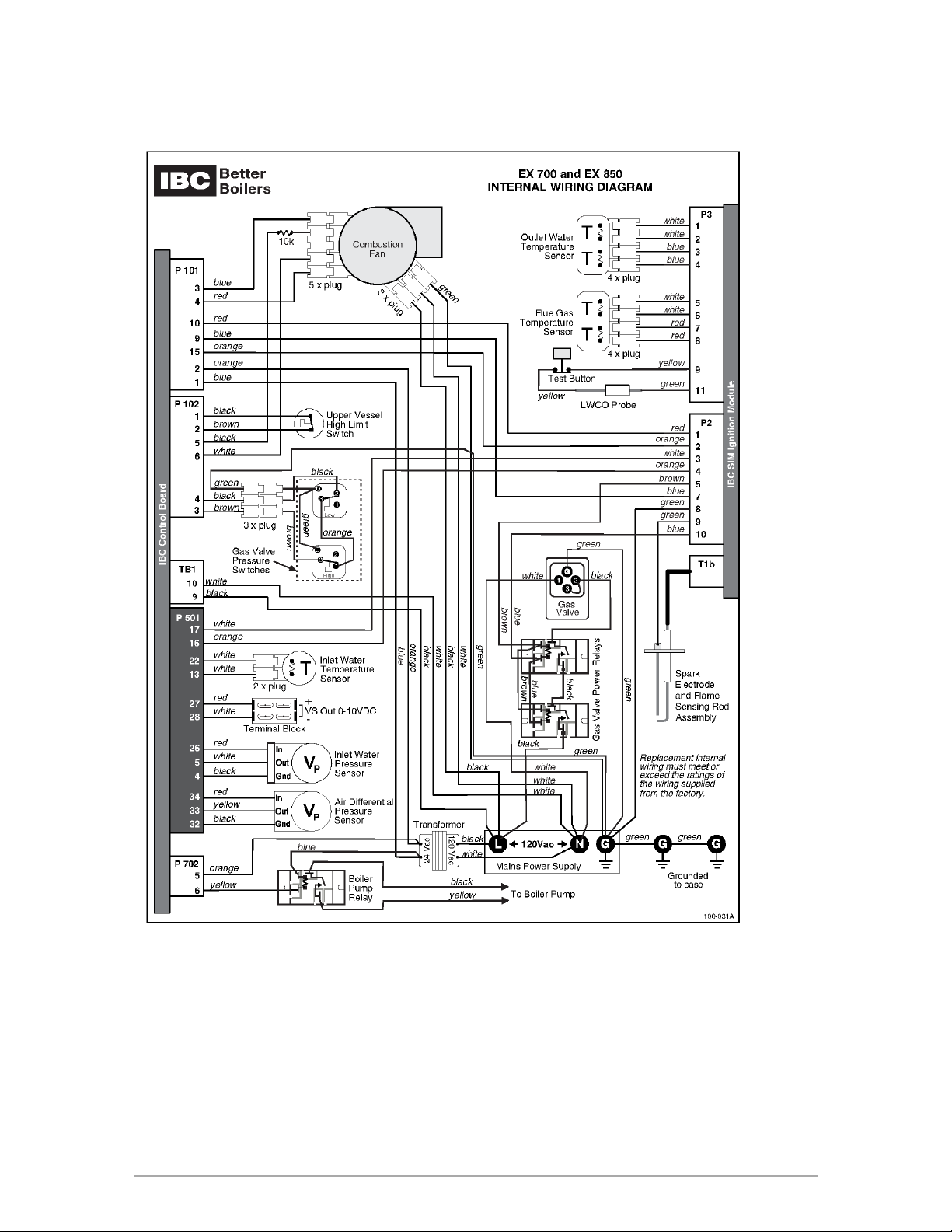

Wiring diagrams 93

3

Installation & Commissioning Report 96

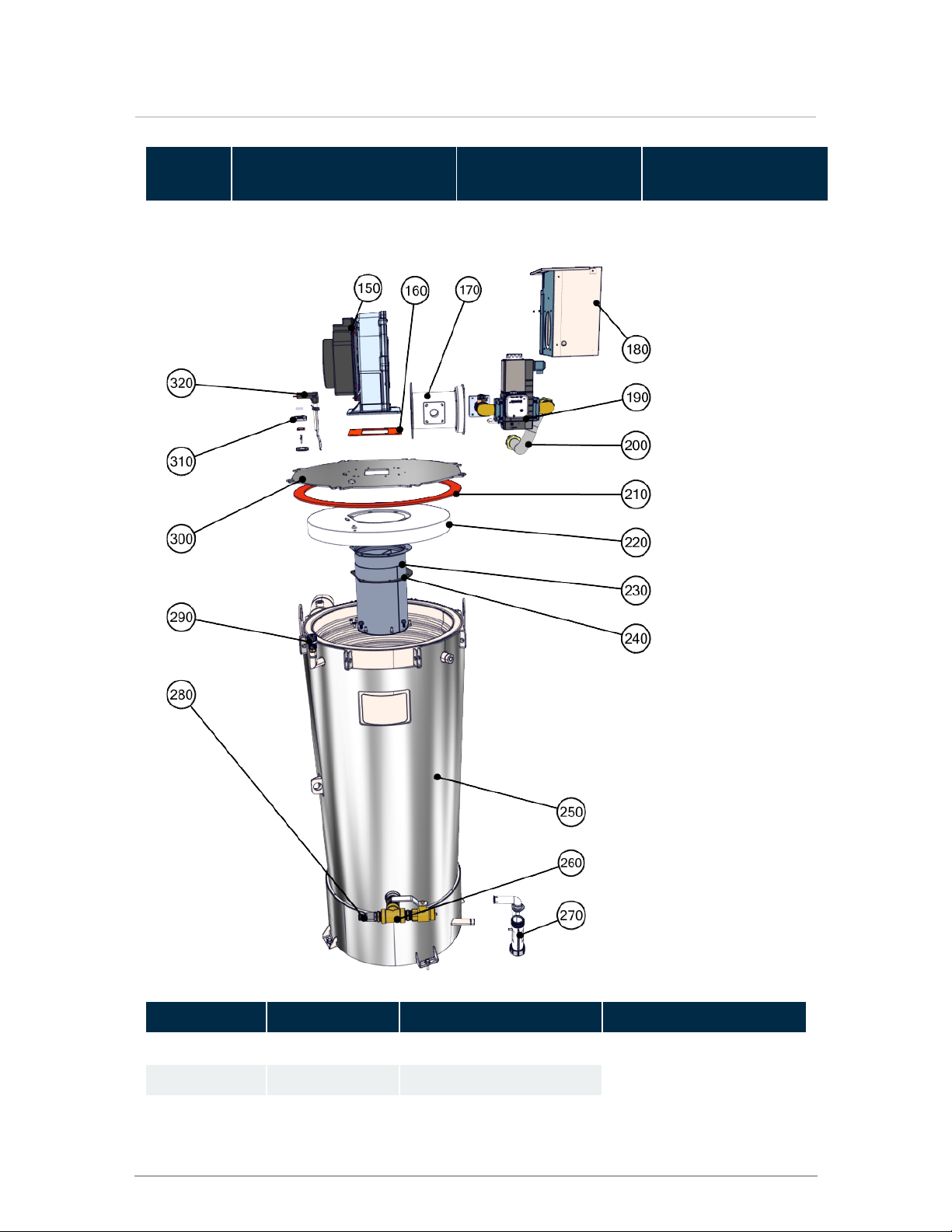

Boiler parts diagram 97

Revision history 101

4

Section: Contents

5

Safety information

Danger

Points out an immediate hazardous

situation that must be avoided to

prevent serious injury or death.

Warning

Points out a potential hazardous situation

that must be avoided to prevent serious

injury or death.

Caution

Points out a potential hazardous

situation that must be avoided to

prevent possible moderate injury

and/or property damage.

Note

Points out installation, maintenance and

operational notes to enhance efficiency,

longevity and proper operation of the

boiler.

Danger

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other

appliance. If you smell gas vapors, do not try to operate any appliance - do not touch any

electrical switch or use any phone in the building. Immediately, call the gas supplier from a phone

located remotely. Follow the gas supplier’s instructions, or if the supplier is unavailable, contact

the fire department.

Warning

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

personal injury, or loss of life. Read and understand the entire manual before attempting

installation, start-up, operation, or service. Installation and service must be performed only by an

experienced, skilled installer or service agency.

Failure to follow all instructions in the proper order can cause personal injury or death. Read all

instructions, including all those contained in component manufacturers’ manuals before installing,

starting up, operating, maintaining, or servicing the unit.

Manual safety markings

Important safety instructions

Installation, start-up and servicing of IBC boilers must be performed by competent, qualified, licensed and

trained heating technicians.

Failure to read and comply with all instructions and applicable national and local codes may result in

hazardous conditions that could result in property damage and injury to occupants, and in extreme cases to

death. Keep instructions near the air handling unit for future reference.

Warning

Disconnect power supply before any wiring/service is performed. Failure to do so could result

in damage to unit and/or electric shock.

Caution

The boiler must be installed so that electrical components are not exposed to water during

operation.

Known contaminants

Known Corrosive Contaminants to Avoid

Cements and glues

Paint or varnish removers

Adhesives used to fasten building products and other similar products

Chlorinated waxes or cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for snow and ice clearing

Sodium chloride or potassium chloride used for water softening

Refrigerant leaks from cracks in coils

Hydrochloric acid or muriatic acid used in household cleaning and stain removal

Chemicals in perming solutions

Chlorofluorocarbon chemicals found in spray cans

Chlorine-type bleaches, detergents, and cleaning solvents found in household laundry rooms

Antistatic dryer sheets in clothes dryers

6

Section: Safety information

7

Specifications

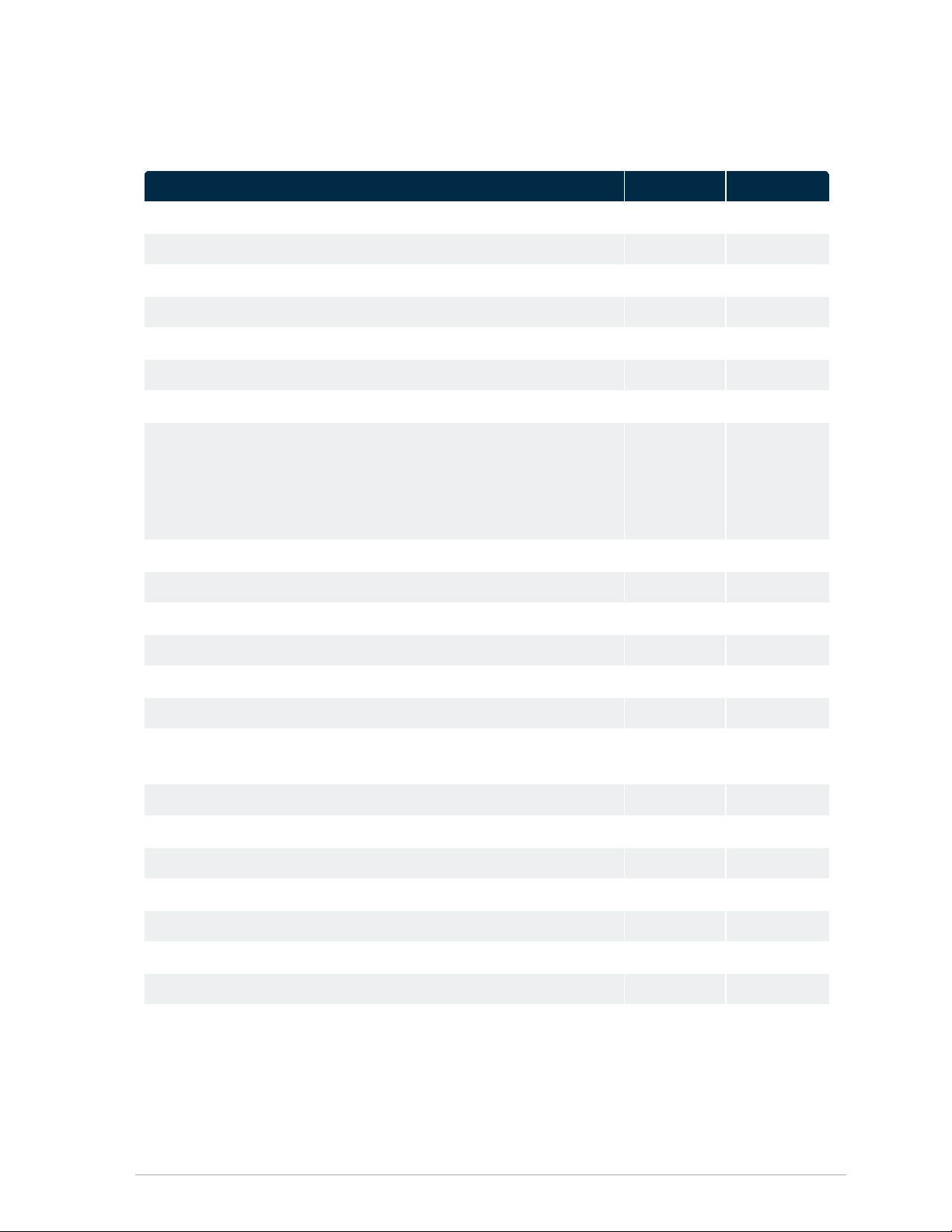

EX 700 EX 850

CSA Input (Natural Gas or Propane) - MBH 70 - 700 85 - 850

CSA Input (Natural Gas or Propane) - kW 20.5 - 205 24.9 - 249

CSA Output - MBH 679 824.5

CSA Output - kW 199 241.6

Thermal Efficiency 97% 97%

Minimum gas supply pressure (Natural Gas or Propane) - inch w.c. 4 4

Maximum gas supply pressure (Natural Gas or Propane) - inch w.c. 14 14

Ambient temperature:

Low °F / °C

High °F / °C

32 / 0

122 / 50

32 / 0

122 / 50

Max. relative humidity (non-condensing) 90% 90%

Minimum water temp. °F / °C 34 / 1 34 / 1

Maximum water temp. (electronic hi-limit) °F / °C 190 / 88 190 / 88

Max. ΔT - supply/return (electronic fence) °F / °C 80 / 44 80 / 44

Max. Water Temperature Lockout Limit °F / °C 201 / 94 201 / 94

Power use (120Vac/60Hz) @ full fire - Watts (less pumps) 195 228

Weight (empty) - lbs/Kg Approx. 440 /

200

Approx. 520 /

236

Heating Surface Area - ft2/ m

2

84.6 / 7.86 99.88 / 9.28

Pressure vessel water content - USG/Liters 17.5 / 66.2 17.5 / 66.2

Maximum boiler flow rate - USgpm 100 100

Minimum boiler flow rate - USgpm 18 21

Maximum operating water pressure* - psig 160 160

Minimum water pressure - psig 8 8

Relief valve pressure (supplied) - psig* 50 50

Approved installation altitude - ASL 0 - 12,000' 0-12,000'

EX 700 EX 850

Maximum equivalent vent length Each side (Vent & Air Intake)) (Natural

Gas or Propane)

Air intake options: either direct vent or indoor supply

120' 120'

*These alternative relief valves can be purchased: 30, 100, 125 and 150.

Flue Outlet 6" Schedule 40

Combustion Air Inlet 4" Schedule 40

Water Outlet 2½" NPT-M

Water Inlet 2½" NPT-M

Knock-outs (8) ½"

Gas Inlet 1" NPT-F

Condensate Outlet ¾" Hose

8

Section: Specifications

Table 1 Specifications

Connection specifications

The following table displays the required connection specifications for each model.

Table 2 Connections

Cabinet dimensions

Figure 1 Frontal view Figure 2 Top view

Figure 3 Back view

9

Cabinet dimensions

10

Section: Specifications

11

1.0 Introduction

IBC's range of large commercial boilers is the solution for large-scale projects such as apartment buildings,

office buildings, big schools, hospitals, and hotels.

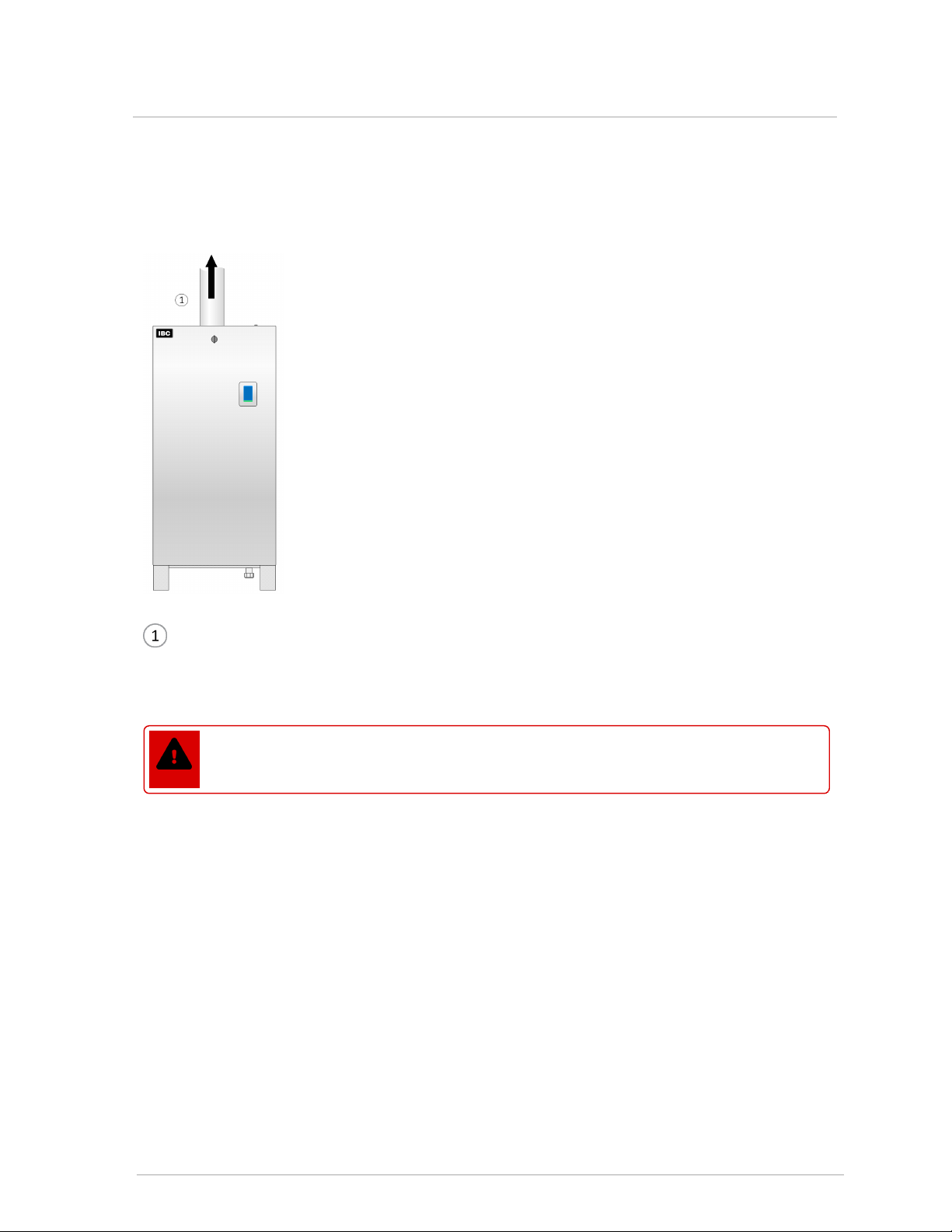

Figure 4 Front internal view

Figure 5 Back view of boiler

1.1 Standard features and benefits

12

Section: Introduction

High thermal efficiency

Built-in BACnet option

Turn-down ratio 10 to 1

Built-in 4-zone pump control

Multiple boilers: Up to 24 boilers can be connected without external controls

Maximum allowable ∆T=80 °F (44 °C)

50 psi relief valve (345 kPa)

Boiler pump control up to ¾ H.P. 120V or 208/240V

1.2 Warranty

IBC offers a 10-year warranty on the EX series heat exchanger and a 1-year warranty on all parts against

defects in materials or workmanship and failures due to thermal shock.

For more information and to obtain the EX series warranty form, go to ibcboiler.com.

13

2.0 Before installation

Precautions Check

Care must be taken to properly size the boiler for its intended use.

Prolonged full fire run time, over-sizing or under-sizing, and incorrect flow rates through the boiler

can lead to increased maintenance costs, equipment stress and premature failure.

□

Ensure you install the boiler where the combustion air source is not subject to chemical fouling or

agricultural vapors.

Exposure to corrosive chemical fumes such as chlorinated and/or fluorinated hydrocarbons can

reduce the life of a boiler. Cleaners, bleaches, air fresheners, refrigerants, aerosol propellants, drycleaning fluids, de-greasers and paint-removers all contain vapors that can form corrosive acid

compounds when burned in a gas flame. Airborne chlorides such as those released with the use of

laundry detergents are also to be avoided.

□

Locate the boiler where water leakage will not result in damage to the area.

If there is no suitable location, install a suitable drain pan under the boiler. Do not install above

carpeting.

□

At a new construction site, or during renovations, protect the boiler from drywall dust or other

construction related contaminants.

Draw combustion air from a clean source (e.g., outdoors) and isolate the boiler from interior dust

sources. Do not seal boiler case openings directly when firing - allow for air circulation and

ventilation in the immediate area.

□

Place the exhaust outlet 12" minimum above the down-turned intake to avoid exhaust re-ingestion.

□

For sidewall venting options, place the inlet and exhaust terminations on the same side of the

building.

The elevation of both pipes can be raised in “periscope style” after passing through the wall to gain

required clearance above grade and snow level.

□

If using the indoor combustion air option, ensure combustion air openings to the boiler room

remain unblocked and free of obstructions.

□

Examine the condensate outlet to ensure proper disposal of condensate will occur during

operation. If condensates are to be discharged into building drain piping materials that are subject

to corrosion, a neutralization package must be used.

□

Ensure that the pressure relief valve is installed with no valves or other means of isolation between

its inlet and the boiler.

Make sure the relief valve outlet is piped with unobstructed piping (minimum 1" diameter) to a safe

□

Before installing the unit, it is important to review and observe the following checklist of precautions:

Precautions Check

discharge location.

If the boiler is likely to be exposed to fluid temperatures below 34° F (1° C), a method of protection

to prevent freezing of condensate should be employed. Contact the factory for further information.

□

When the boiler is in operation, assess the impact of the steam plume normally at the exhaust

terminal of a condensing boiler.

Generally, intake and exhaust pipes should terminate at a rooftop or sterile wall location. Boiler

condensate is corrosive. Protective measures must be taken to prevent corrosion damage to metal

roofs or other metal building components in contact with the condensate. Keep exhaust plumes

well away from all building air intakes including those of neighboring properties.

□

Caution

Care must be taken to properly size the boiler for its intended use. Prolonged full fire run time,

over-sizing or under-sizing, and incorrect flow rates through the boiler can lead to increased

maintenance costs, equipment stress and premature failure.

14

Section: Before installation

15

3.0 Installation

The gas-fired modulating boilers are low pressure, fully condensing units having a variable input range.

Approved as “Category IV” vented appliances, the boilers use either Direct Vent (sealed combustion) or

indoor combustion air, providing a great degree of installation flexibility.

3.1 Code requirements

The boilers are tested and certified under CSA 4.9-2017 / ANSI Z21.13-2017. Below are the code

requirements for every installation.

Canada US

Conform to local codes, or in the absence of these,

with the latest editions of CAN/CGA B149.1 and the

Canadian Electrical Code Part 1 CSA C22.2 No. 1.

Where required by jurisdiction, installation must

conform to the Standard for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME

CSD-1.

If there is any conflict, follow the more stringent

regulations.

Table 3 Code requirements by country

Conform to the current National Fuel Gas Code ANSI

Z223.1 and the National Electrical Code ANSI/NFPA

70.

Where required by jurisdiction, installation must

conform to the Standard for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME

CSD-1.

If there is any conflict, follow the more stringent

regulations.

3.2 Determining location of the unit

The boilers are designed and approved for indoor installation in areas such as an alcove, basement, or utility

room. These areas should have a surrounding temperature of 32 °F (0°C) to 122 °F (50 °C) and less than

90% relative humidity.

Even though EX models are approved from installation on combustible floors, do not install them on carpet.

Warnings

Keep the area around a boiler clear of combustible materials, gasoline, and other

flammable vapors and liquids.

Ensure combustion air is not drawn from areas containing corrosive air such as

swimming pools or spas, including air directly next to outdoor pools and spas.

Ensure that a boiler is not exposed to water leaks from piping or components located

overhead, including condensation from uninsulated cold water lines overhead.

Protect the gas ignition system components from water (dripping, spraying, rain, etc.)

during appliance operation and when servicing (pump replacement, condensate trap

servicing, control replacement, etc.).

Ensure that combustible materials do not make contact with exposed water piping

and associated components (relief valves, circulators, etc.). Check local codes for

required clearances and/or provide adequate insulation.

3.2.1 Factors to consider for best installation conditions

16

Section: Installation

Install the boiler in areas where the combustion air source is not subject to chemical fouling or

agricultural vapors. Exposure to corrosive chemical fumes such as chlorinated and/or

fluorinated hydrocarbons can reduce the life of a boiler. See list of Known contaminants on page

6. For this reason, do not use the indoor air venting option (using air surrounding the boiler) in a

laundry room. Similarly, ensure any direct vent air source is not near a clothes dryer exhaust

terminal. Avoid agricultural applications where the boiler and/or the intake air source are

affected by ammonia and/or dust.

Avoid installing a boiler where water leakage will cause damage; for example, above carpeting.

If unavoidable, install a suitable drain pan under the appliance.

Other factors to consider:

The minimum clearance requirements for combustible materials (see Table 4 ).

For adequate servicing, we recommend a minimum 30" clearance at the front and 12" above the

boiler. Check local codes for additional access and service clearance requirements.

At a new construction site, or during renovations:

Take action to protect the boiler from drywall dust or other construction related

contaminants

Ensure combustion air is drawn from a clean source (e.g., outdoors)

Isolate the boiler from interior dust sources. Do not seal boiler case openings directly when

firing - allow for air circulation and ventilation in the immediate area.

3.2.1.1 Anchoring the boiler

17

3.3 Unpacking a boiler

Boiler weight – without water and any effect of system piping and components – is approximately 500 lbs /

225 kg.

Use the brackets provided to secure the boiler to the floor.

3.3 Unpacking a boiler

The boiler is shipped bolted to a pallet with four (4) anchor brackets and 3/8" Hex head bolts. Once the

anchor brackets are removed they can be used to secure the boiler to the floor.

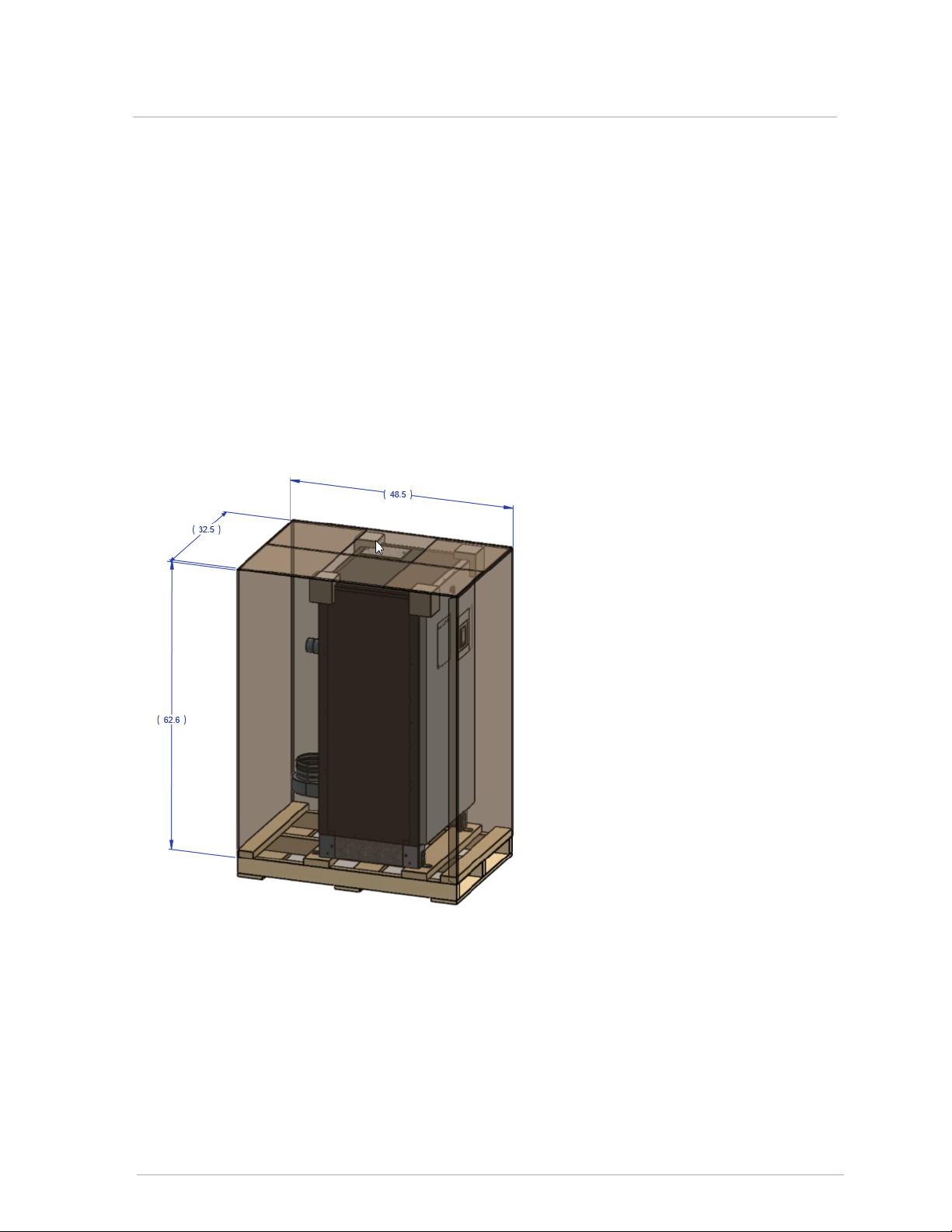

Figure 6 Boiler packaging dimensions (inches)

3.4 Installation clearances

Warning

Exposed water piping and associated components (relief valves, circulators, etc., should not

be in contact with combustible materials. Check local codes for required clearances and / or

provide adequate insulation.

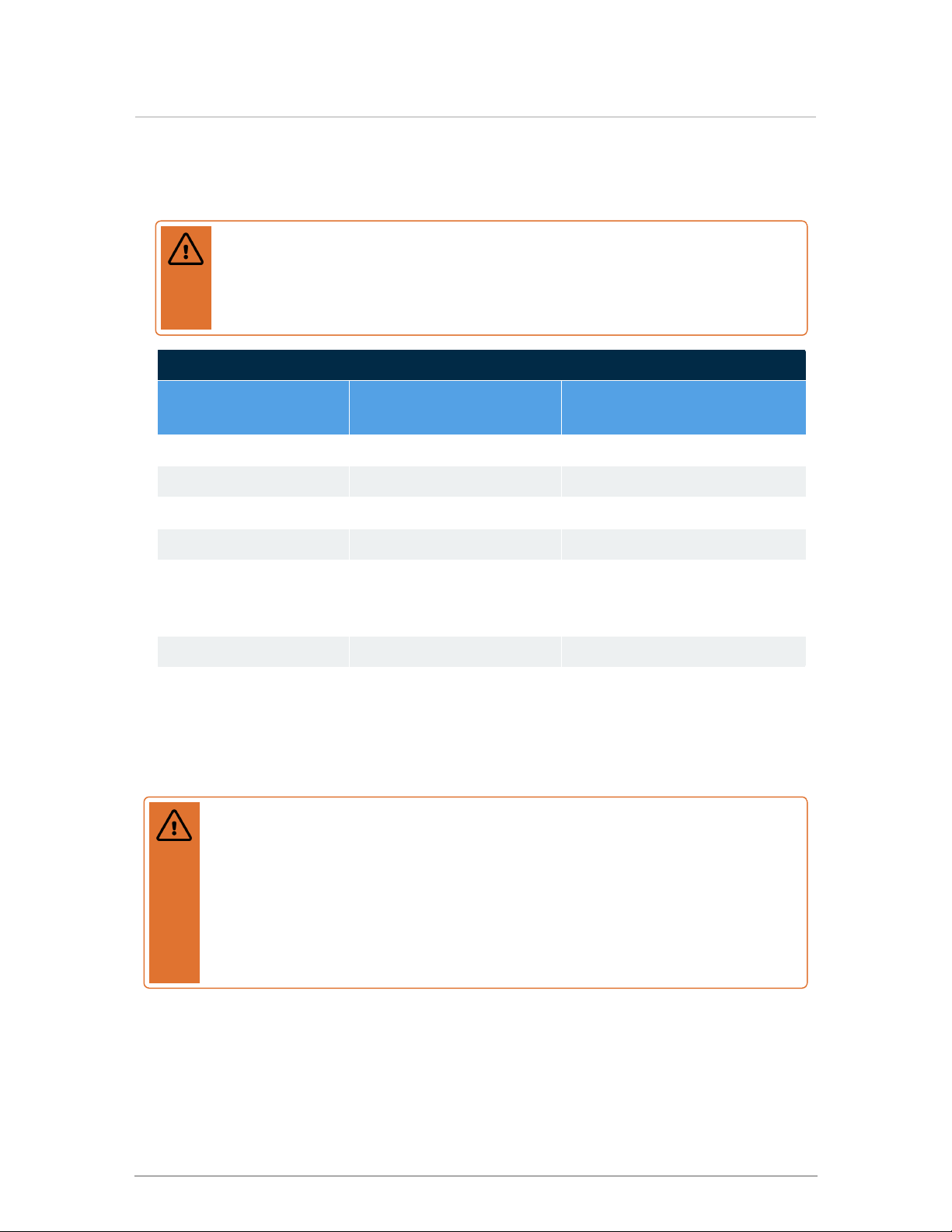

EX 700, 850

Surface

Minimum distance from

combustible surfaces

Recommended clearance for

installation and service

Front 2" 30"

Rear flue connection 2" 24"

Left side 1" 2"

Right side 1" 4"

Top 6"

12"

(required for filter replacement)

Bottom 0 0

Warning

Venting, condensate drainage, and combustion air systems for all IBC boilers must be

installed in compliance with all applicable codes and with instructions provided in the

respective installation manuals.

Inspect finished vent and air piping thoroughly to ensure all are airtight, and comply with the

instructions provided as well as with the requirements of applicable codes. Failure to comply

will result in severe personal injury or death.

18

Section: Installation

Table 4 Clearance distances for boiler mounting sites

3.5 Exhaust venting and air intake venting

When planning a boiler's installation, consider the appropriate vent materials, travel and termination.

An important consideration is managing the impact of the steam plume normally at the exhaust terminal of a

Danger

Do not common vent EX series modulating boilers with any other existing or new appliance.

19

3.5.1 Code

condensing boiler. Generally, intake and exhaust pipes should terminate at a rooftop or sterile wall location

to maximize customer satisfaction. Keep exhaust plumes well away from all building air intakes including

those of neighboring properties.

Flue gas exhaust to outdoors

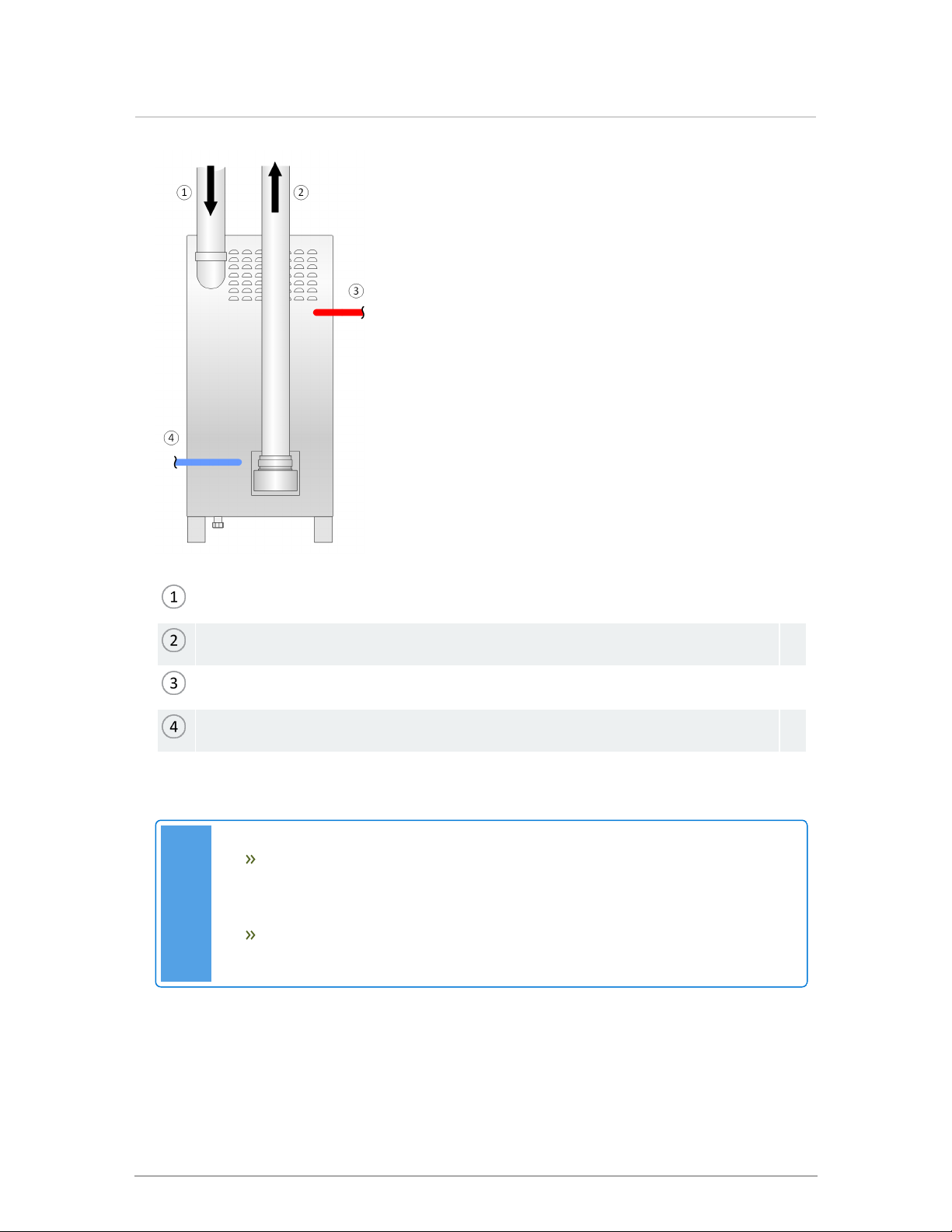

Figure 7 Flue gas venting

3.5.1 Code

All venting must be installed in accordance with the requirements of the jurisdiction having authority: in

Canada, Part 8, Venting Systems of the B149.1-10 Code and any other local building codes are to be

followed. In the USA, the National Fuel Gas Code, ANSI 223.1, latest edition, prevails. Where there is a

discrepancy between the installation instructions provided, and the code requirements, apply the more

stringent.

Provisions for the combustion and air ventilation must be in accordance with the section “Air for

Combustion and Ventilation” of the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Clause 8.2, 8.3 or

8.4 of the Natural Gas and Propane Installation Code, CAN/CSA B149.1, or applicable provisions of the

local building codes.

3.5.1.1 Important considerations when removing an existing boiler:

Warning

Covering non-metallic vent pipe and fittings with thermal insulation is prohibited.

20

Section: Installation

When an existing boiler is removed from a common venting system, the common venting system is

likely to be too large for proper venting of the appliances that remain connected to it. When resizing any

portion of the common venting system, use the minimum size according to the appropriate tables in the

National Fuel Gas Code, ANSI Z223.1 - latest edition. In Canada, use the B149.1 Installation Code.

At the time of removal of an existing boiler the following steps shall be followed with each appliance

remaining connected to the common venting system placed in operation, while the other appliances

remaining connected to the common venting system are not in operation:

Seal any unused opening in the common venting system.

Visually inspect the venting system for proper size and horizontal pitch. Determine that there is

no blockage or restriction, leakage, corrosion and other deficiencies that could cause an unsafe

condition.

(Where practical) Close all building doors and windows such as doors adjacent to appliances

remaining connected to the common venting system and other spaces of the building.

Turn on clothes dryers and any appliance not connected to the common venting system.

Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

Place in operation the appliance being inspected.

Follow the lighting instructions.

Adjust the thermostat so that the appliance operates continuously.

After determining that each appliance remaining connected to the common venting system

properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace

dampers and any other gas-burning appliance to their previous condition.

Any improper operation of the common venting system should be corrected, so the installation

conforms with the National Fuel Gas Code, ANSI Z223.1 - latest edition. In Canada, all

installations must conform with the current CAN/CGA - B149.1-10 Installation Code and/or local

codes.

3.5.2 Applications

Warning

Condensate can cause corrosion of metal roofing components and other roofing materials.

Check with the builder or roofing contractor to ensure that materials are resistant to acidic

condensate. pH levels can be as low as 3.0.

21

3.5.2 Applications

All EX series boilers are approved with alternative venting options: either 2-pipe Direct Vent or Vent pipe

with Indoor Air. With the Direct Vent case, combustion air is piped directly to the boiler’s air intake from

outdoors (see Vent termination clearance on page 30) for air intake piping requirements. Using the indoor

air alternative, air for combustion is drawn from the indoor air surrounding the boiler.

Provided the maximum overall vent length limit is not exceeded, the boiler may be vented through the wall,

directly through the roof, or upward using an existing -- but otherwise unused - chimney as a vent raceway.

3.5.3 Exhaust vent material

Exhaust vent material – CANADA

Use PVC, CPVC, Polypropylene (PPs), or Stainless Steel (SS) vent component systems approved under

ULC-S636 Standard for Type BH Gas Venting Systems, or stainless steel Type BH venting systems*. The

vent temperature is limited by the boiler controller with the use of a flue temperature sensor to ensure the

maximum temperature of the PVC venting material is not exceeded.

Exhaust vent material – USA

PVC, CPVC, PPs, or SS venting materials are approved for use with these boilers in most of the USA.

Check local codes to determine if any materials are prohibited. The vent temperature is limited with the use

of the flue temperature sensor and software to ensure that the maximum temperature of the PVC venting

material is not exceeded. PVC venting material shall be certified to Sch. 40 ASTM D1785 or D2665. CPVC

material shall be certified to Sch. 40/ASTM F441.

Exhaust vent material

Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel® (polyphenolsulfone) in venting

systems is prohibited.

Do not use ABS or any cellular core pipe for exhaust venting.

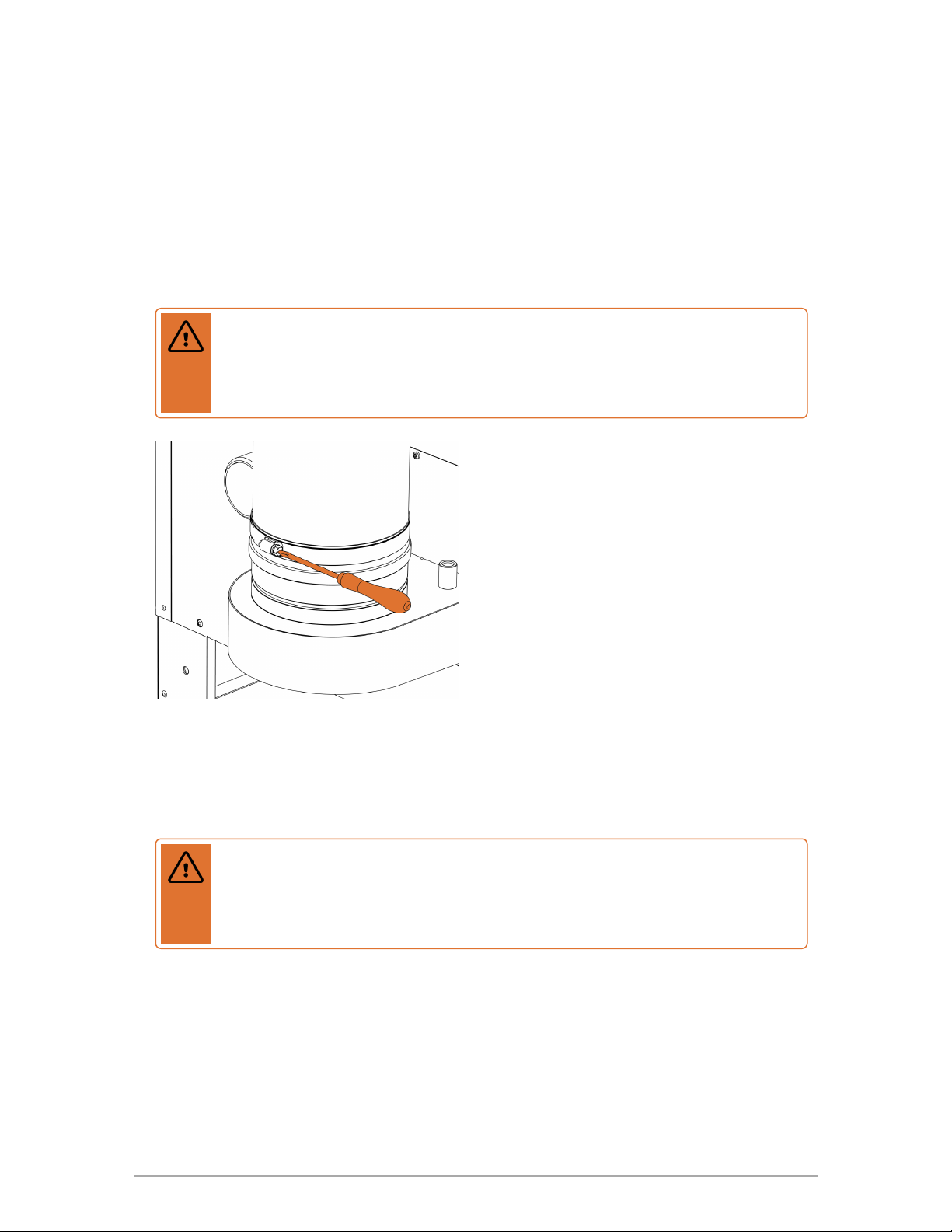

The exhaust fitting has a 6" PVC (schedule 40) connection. Use fittings to adapt to either PPs or SS venting

material. Insert exhaust venting directly into the 6" female stainless steel fitting, and secure with the built-in

clamp (see Figure 8 ).

For PPs material, use the 6" transition / adaptor fitting (Sch 40 to PPs) offered by the respective PPs

Warning

Ensure that you lubricate the gasket with silicone grease before inserting the venting

material. Fully insert the approved venting material into the boiler's exhaust outlet, and

tighten clamp to ensure the venting connection is locked in place (as shown below).

Warning

Do not mix PPs venting materials from different manufacturers. These venting materials are

designed to be installed as part of a complete system. Failure to comply may result in severe

personal injury or death.

22

Section: Installation

manufacturers Centrotherm / InnoflueTM (their part # ISAAL0606) or M&G Dura Vent / PolyProTM (#

6PPS-06PVCM-6PPF [10004281]), (# 4PPs-AD). For PPs material exposed to outdoor weather, follow

the venting supplier’s recommendations on UV protection.

For SS material, use the 6" transition / adaptor fitting offered by the SS manufacturers M&G Dura Vent (#

FSA-6PVCM-6FNSF [300538]) or Heat Fab (Saf-T-Vent) 9601PVC.

Figure 8 Securing the vent connection

Venting must be supported in accordance with the applicable code and instructions supplied by the

manufacturers.

3.5.4 Vent travel

PVC/CPVC (Schedule 40), PPs (Rigid Single Wall), or SS approved piping are the standard venting

options that can be sited up to 120 equivalent feet from the vent termination.

Warning

Follow all installation instructions supplied by the pipe and fitting manufacturer.

The actual vent travel allowance is reduced for fittings as shown in the following tables:

EX 700, EX 850

Exhaust Pipe Size Maximum Equivalent Length

Sched.40; Rigid PPs

6" PVC/CPVC / Rigid PPs/SS 120' (each side)

90° vent elbow allow 5' equivalent

45° elbow allow 3' equivalent

PPs 87-90° elbows use 5' equivalent

For example, for an EX 850 using 6 x 90º CPVC vent elbows, the maximum lineal measure of pipe

allowed is 90 feet (120' – (6 x 5' = 30) = 90').

Note

Unused intake travel cannot be added to the exhaust. Unequal intake and exhaust piping is

allowed.

23

3.5.4 Vent travel

Table 5 Maximum Exhaust Venting Length for EX 700, 850

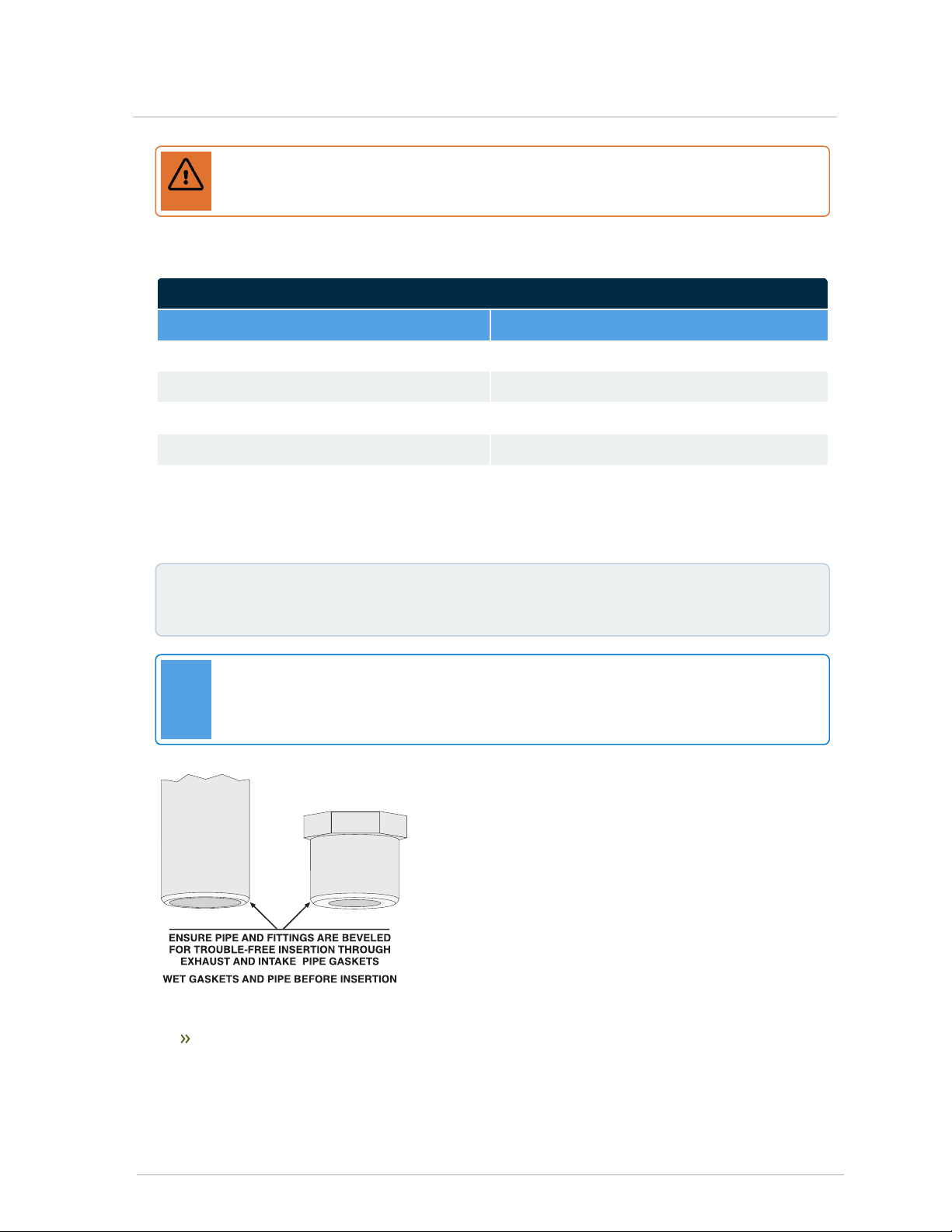

Exhaust venting must slope down towards the boiler with a pitch

of at least 1/4" per foot (PP vent: follow PP manufacturer

requirements for slope), so condensate runs back towards the

trap. Support should be provided for intake and vent piping,

particularly for horizontal runs (follow local code).

Figure 9 Pipe and fitting beveling

Check that material meets local codes including fire stopping requirements. Some local jurisdictions

require a minimum initial length of pipe be exposed or accessible for inspection. Pipe clearances -

no IBC requirements; follow local codes. All piping must be liquid and pressure tight.

Ensure all venting components are clear of burrs/debris prior to assembly. Clear plastic debris

24

Section: Installation

left in the combustion air piping to avoid intake into the fan.

Secure joints using appropriate solvent cement to bond the respective pipe material (Canada:

CPVC cement approved under ULC-S636, in accordance with its manufacturer instructions;

USA: PVC (ASTM D2564), or PVC/ABS (D2235) - Use transition glue anywhere that PVC and

CPVC are joined. Follow the cement manufacturer’s instructions closely when joining various

components. For PPs, connections shall be secured using approved retainer clips supplied by

the respective PPs manufacturer.

Check that vent connections are liquid and pressure tight. Prior to firing the boiler, and before

any of the venting run is concealed by the building construction, the installer must test the

exhaust joints under fan pressure with the vent blocked, using a soap and water solution .the

installer must fill the condensate trap prior to testing.

To drive the fan into manual high speed operation for vent leak testing, from the touchscreen controller

Main Menu go to Diagnostics>Test Operation>Set Vent Test to On. Paint all joints with an approved

leak test solution just as you would joints in a gas line, and make sure there are no leaks. We suggest

attaching a tag on the vent line near the condensate drain tee with the type of test, the date and the

installer’s name.

3.5.5 Venting passage through ceiling and floor

Confirm material meets local codes including fire stopping requirements.

Check the local jurisdiction on the minimum initial length of pipe that should be exposed or

accessible for inspection.

Follow the local codes for pipe clearances - no IBC requirements.

Ensure that piping is liquid and pressure tight.

3.5.6 Rooftop vent termination

Warning

Condensate can cause corrosion of metal roofing components and other roofing materials.

Check with the builder or roofing contractor to ensure that materials are resistant to acidic

condensate. pH levels can be as low as 3.0.

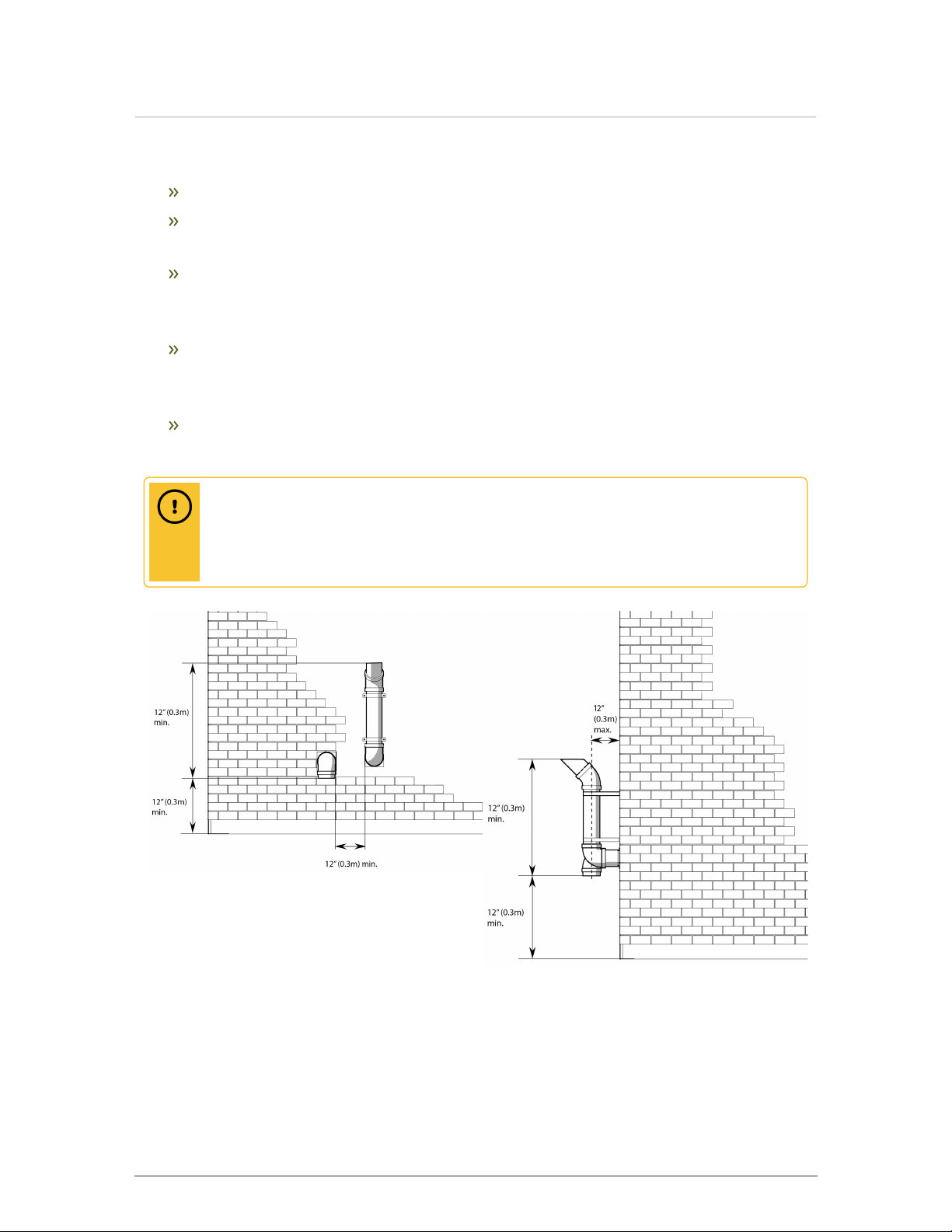

Figure 10 Rooftop vent terminal

configurations

Figure 11 Rooftop vent termination with

sidewall combustion air

25

3.5.6 Rooftop vent termination

a. Rooftop vents must terminate as follows:

The exhaust pipe can terminate in an open vertical orientation without concern about rain

infiltration; rain will drain away through the condensate trap.

Optional bird screen may be placed in a termination fitting. Leave unglued, and hold in

place with a short nipple. This permits easy access for cleaning.

Do not exhaust vent into a common venting system.

b. For rooftop direct vent systems:

Rooftop, two pipe, direct vent configurations, including typical clearance requirements are

shown below in the following images.

Vent screen retainer

Exhaust

Vent screen

Inlet

Flashing

Figure 12 Rooftop vent terminal vent screen and retainer

Best Practice: To reduce the possibility of expansion noise, allow a ¼" gap

around the exhaust and air intake piping.

26

Section: Installation

The intake air pipe is not typically drained, so it must be terminated with a down-turned

elbow as shown.

The intake pipe does not need to penetrate the roof at the same elevation as the exhaust

(as shown); lower down on the roof is acceptable.

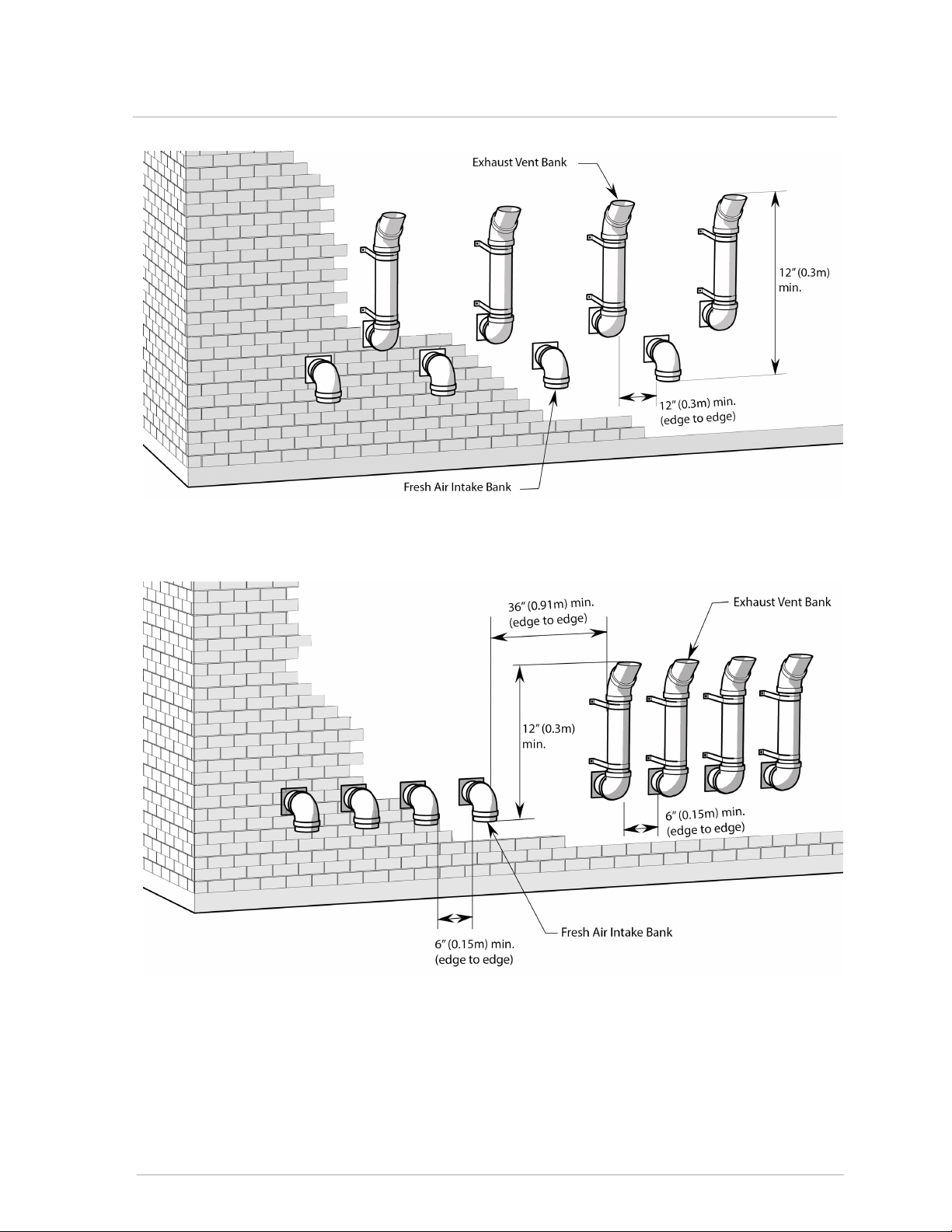

For roof top venting of multiple boiler sets, group all intake terminals together for a common

Caution

Vent termination clearances in this section are code minimum, or IBC recommended minimum

requirements, and may be inadequate for your installation. Building envelope details must be

examined carefully. Take action to avoid moisture entering building structures. Serious structural

damage may occur if adequate precautions and clearances are not allowed for. These

precautions apply to neighboring structures as well as to the structure the boiler(s) are installed

in.

27

3.5.7 Sidewall vent termination

penetration through a custom cap. Alternatively, place close together using commonly

available pipe flashing. Similarly, group the exhaust pipes and place the two separate

groups of pipes at least 3' apart (the closest intake and exhaust pipes shall be 36", or more,

apart). Use the same 12" (minimum) vertical separation for all termination options. For

alternate group terminations, contact the IBC Factory for written guidance.

Roof top termination kits are approved for use with the boiler model. Installation of the

vertical roof top termination must follow the installation instructions supplied with the venting

material manufacturer. Care must be taken to install the termination kit a minimum horizontal

distance of 10' (305 cm) away from any portion of the building and a minimum of 2' (61 cm)

above the roof line plus the anticipated snow line.

3.5.7 Sidewall vent termination

Figure 13 Minimum clearances from vent/air inlet terminations (see legend on adjacent page)

Description US Installations

1

1

Canadian

Installations

2

2

A Clearance above grade, veranda, porch, deck, or

balcony

1' (30 cm) 1' (30 cm)

B Clearance to window or door that may be opened 4' (1.2 m) below or to

side of opening

3' (91 cm)

C Clearance to permanently closed window

*

*

28

Section: Installation

1

In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Code.

2

In accordance with the current CAN/ CSA-B149 Inst allation C odes.

*

Clearances in acc ordance wit h local installation codes and the requirements of the gas supplier.

Description US Installations

1

1

Canadian

Installations

2

2

D Vertical clearance to ventilated soffit located above

the terminal within a horizontal distance of 2' (61 cm)

from the center line of the terminal

5' (1.5 m) *

E Clearance to unventilated soffit * *

F Clearance to outside corner 6' (1.83 m)* 6' (1.83 m)*

G Clearance to inside corner 6' (1.83 m) 6' (1.83 m)*

H Clearance to each side of center line extended above

meter/regulator assembly

* 3' (91 cm) within a

height 15' above the

meter/ regulator

assembly

I Clearance to service regulator vent outlet * 6' (1.83 m)

J Clearance to non-mechanical air supply inlet to

building or the combustion air inlet to any other

appliance

4' (1.2 m) below or to

side of opening; 1'

(30 cm) above

opening

3' (91 cm)

K Clearance to mechanical air supply inlet * 6' (1.83 m)

L Do not terminate above paved sidewalk or paved

driveway

Slip hazard due to

frozen condensate

Slip hazard due to

frozen condensate

M Clearance under veranda, porch, deck or balcony * 12" (30 cm)

3

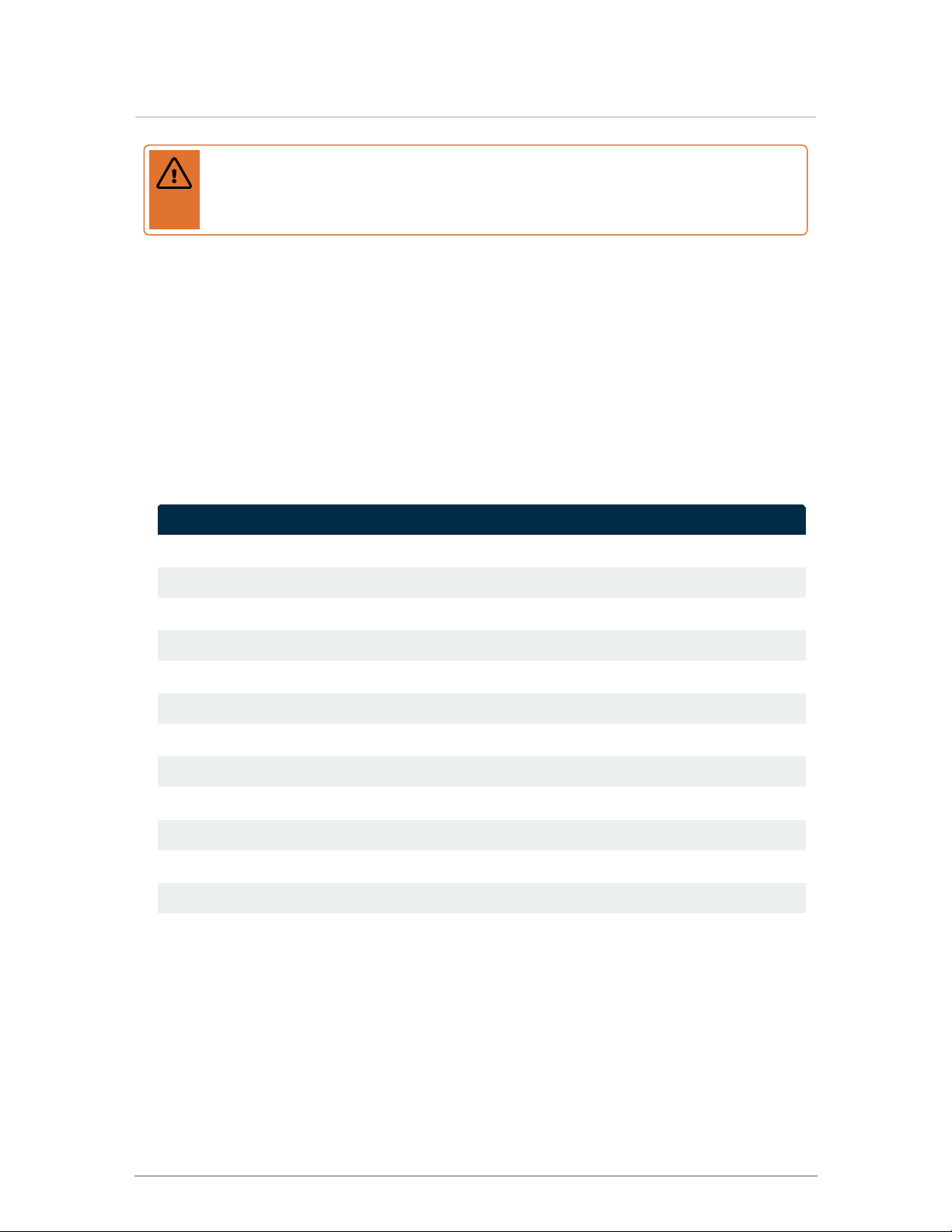

Warning

Important!: Maintain at least the minimum separation of exhaust vent termination from boiler

intake air as illustrated in Figure 14 , Figure 15 , Figure 16 and Figure 17 . Failure to do so can

result in a dangerous situation where exhaust gasses are re-ingested with combustion air.

Damage to the boiler can result from a failure to maintain these separations. Third party vent

termination kits and concentric wall penetration kits that do not maintain these minimum

separations shall not be used. Improper installation will void the warranty. Do not use proprietary

InnoFlue or PolyPro PPs terminals without specific approval from IBC.

29

3.5.7 Sidewall vent termination

Table 6 Vent/air inlet termination clearances

1

In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Code.

2

In accordance with the current CAN/ CSA-B149 Inst allation C odes.

3

Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor and t op of terminal, and underside of

veranda, porch, deck or balcony is greater than 1' (30 cm).

Sidewall direct vent with separate vent and air pipes shall be terminated as follows:

Caution

When the outdoor temperature drops below 5°F/-15°C, take care installing Concentric Side

Wall Termination kits. Possible blockage of the combustion air intake can occur when the

outdoor temperature drops below this temperature.

Figure 14 Vent termination clearance Figure 15 Vent termination clearances

30

Section: Installation

Locate the intake air and exhaust vent terminations on the same plane (side) of the building.

Place the exhaust vent termination, so that it reaches 12" minimum above the down-turned intake

to avoid exhaust re-ingestion.

(Optionally) Raise the elevation of both terminations in “periscope style” after passing through the

wall, then to gain the required clearance configure as shown in Figure 14 , Figure 15 , and Figure

16 .

Use a 45° elbow on the exhaust termination to launch the plume up and off the sidewall (for

protection of wall). A short piece of venting cut at 45° gives a horizontal termination protected from

wind loads (see Figure 14 , Figure 15 , and Figure 16 ).

Suggest use of a bird screen of ¼" stainless steel or plastic mesh (IPEX System 636 drain grate) to

guard against foreign objects.

Figure 16 Sidewall vent termination configuration option 1

31

3.5.7 Sidewall vent termination

Figure 17 Sidewall vent termination configuration option 2

Warning

In areas of high snowfall, users must be advised to check side wall vent and air intake

terminations on a regular basis to ensure blockage does not occur.

3.5.8 Direct vent combustion air intake piping

Known Corrosive Contaminants to Avoid

Cements and glues

Paint or varnish removers

Adhesives used to fasten building products and other similar products

Chlorinated waxes or cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for snow and ice clearing

Sodium chloride or potassium chloride used for water softening

Refrigerant leaks from cracks in coils

Hydrochloric acid or muriatic acid used in household cleaning and stain removal

Chemicals in perming solutions

Chlorofluorocarbon chemicals found in spray cans

Chlorine-type bleaches, detergents, and cleaning solvents found in household laundry rooms

Antistatic dryer sheets in clothes dryers

32

Section: Installation

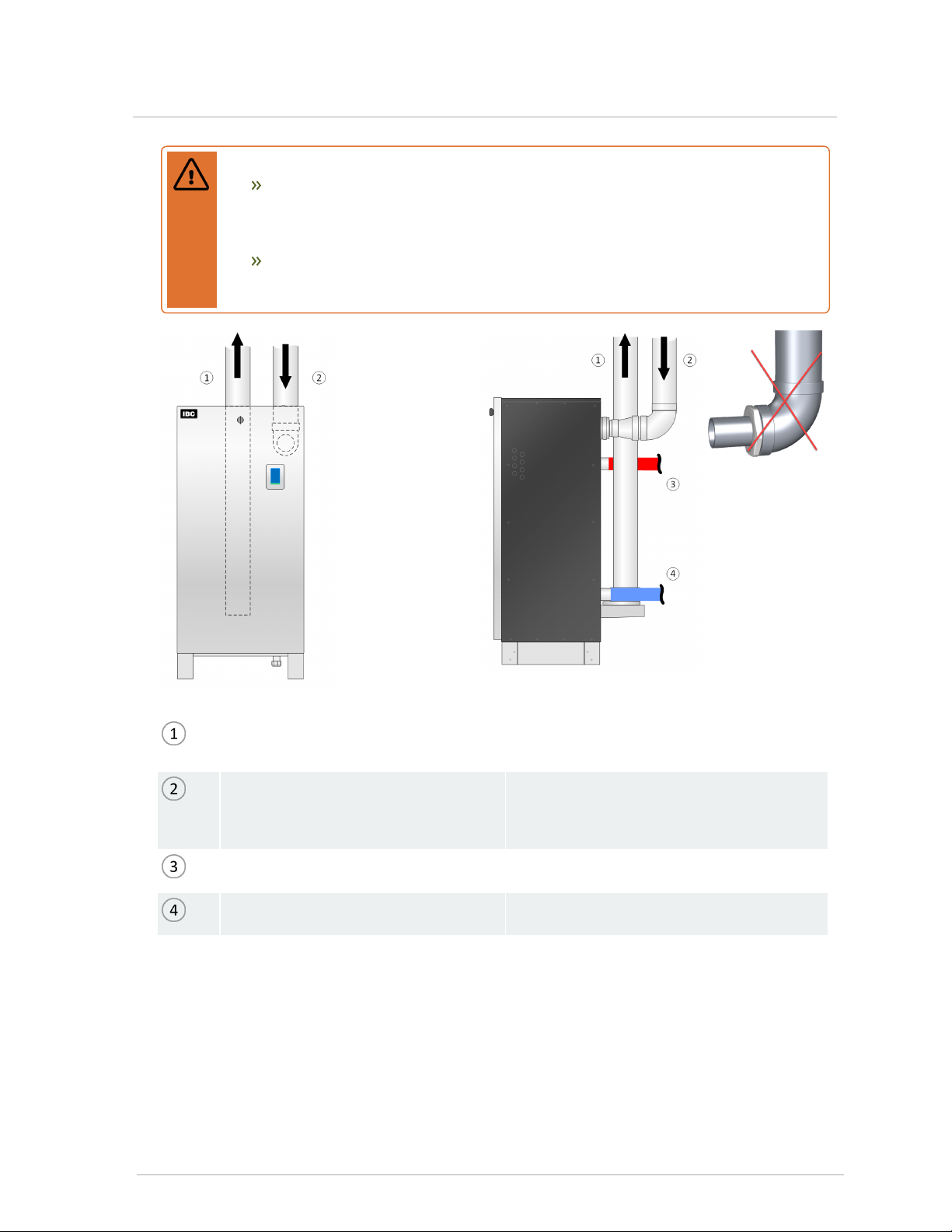

The direct vent option uses piping from the outside to supply combustion air directly to the boiler’s

combustion air connection. Combustion air piping - if used - is inserted directly into the 4" PVC-sized

fitting, and increased immediately to 6".

At a new construction site, or during renovations, action must be taken to protect the boiler from drywall

dust or other construction related contaminants; combustion air should be drawn from a clean source

(e.g. outdoors) and the boiler should be isolated from interior dust sources. Do not seal boiler case

openings directly when firing - allow for air circulation and ventilation in the immediate area.

Warnings

In addition to preventing ingestion of chemical contaminants, ensure air intake

terminals are not installed in locations where contamination might occur due to

ingestion of particulate foreign material (dust, dirt and debris).

Configure intake air openings, so that rain or other forms of moisture cannot enter the

air intake piping system. Otherwise serious damage to the boiler may result.

Do not use

bushing

Flue gas exhaust to outdoors (connection at

rear of boiler)

Flue gas exhaust to outdoors

Combustion air from outdoors. "Direct Vent"

installation: check air intake outside is clear

of obstructions.

Combustion air from outdoors. Use reducing

coupling to transition from 4" connection to 6"

venting before first elbow.

Boiler supply

Boiler return

Figure 18 Direct vent combustion air intake Figure 19 Combustion air intake - side view

33

3.5.8 Direct vent combustion air intake piping

Combustion air from outdoors

Flue gas exhaust to outdoors

Boiler supply connection at rear of boiler

Boiler return connection at rear of boiler

Figure 20 Rear view - combustion air intake

Notes

When installing air intake piping, ensure that a “trap” is not formed in the piping

causing a build-up of water and blockage of intake air. Such blockages will cause a

boiler safety shut-down.

Filters require checking and cleaning or replacing on a regular schedule based on

the severity of the problem.

34

Section: Installation

EX 700, EX 850

Note

Unused intake travel cannot be added to the exhaust. Unequal intake and exhaust piping is

allowed.

Warning

When using indoor air options, supply adequate combustion air to the boiler room according to

the requirements of all applicable codes.

35

3.5.9 Indoor air combustion air intake

Intake Pipe Size Maximum Equivalent Length

Sched.40; Rigid PPs

6" PVC/CPVC / Rigid PPs/SS 120' each side

90° vent elbow allow 5' equivalent

45° elbow allow 3' equivalent

PPs 87-90° elbows use 5' equivalent

Table 7 Maximum intake pipe venting length for EX 700, 850

For the inlet air – 6" Schedule 40 PVC, CPVC, ABS, PPs or SS piping of any type is permitted.

Ensure that adequate separation is maintained between the air intake inlet and the vent terminal. Refer to

the vent terminal configuration drawings in the Vent Termination section above.

Use support for intake piping, particularly for horizontal runs (follow local codes).

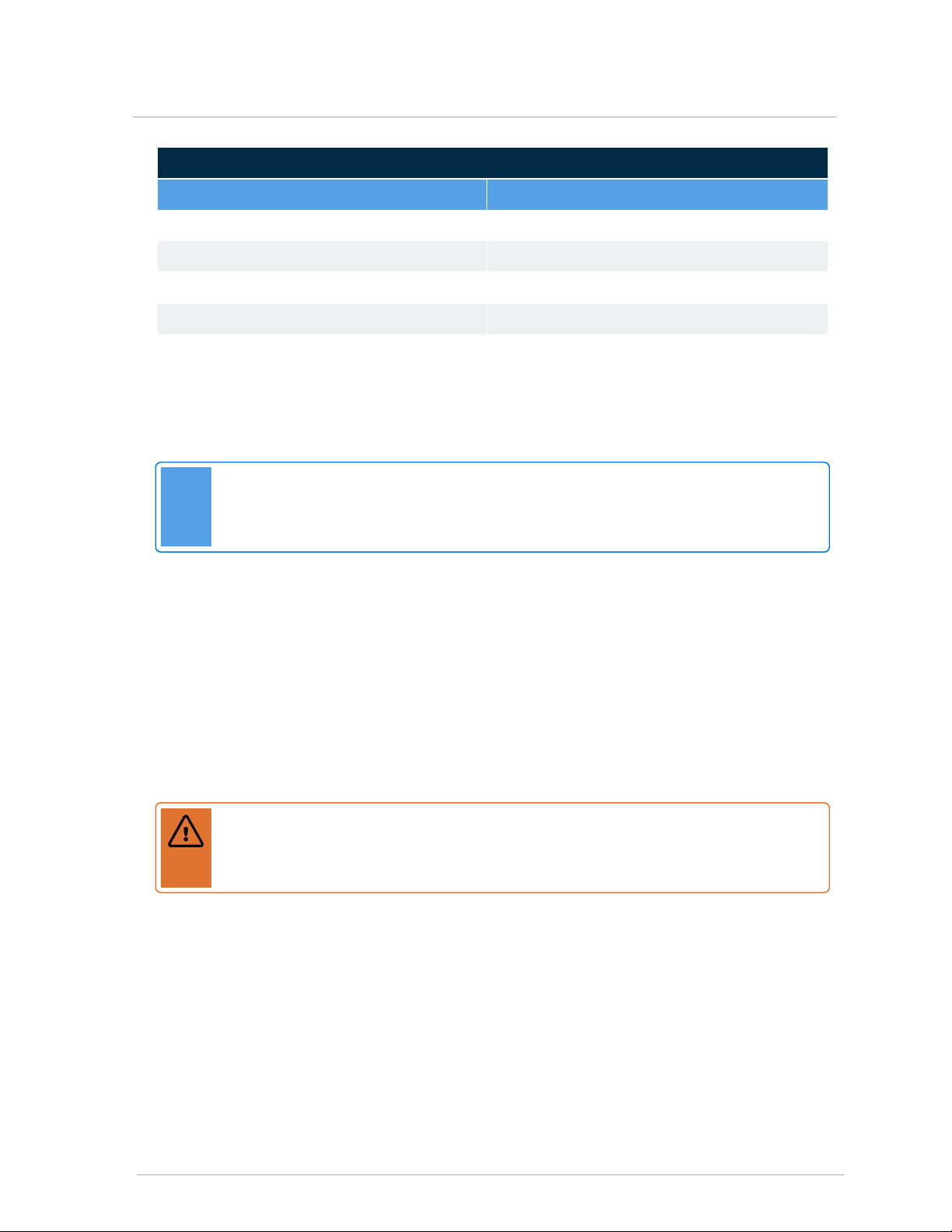

3.5.9 Indoor air combustion air intake

An “Indoor Combustion Air installation” can be described as air for combustion that is taken from the air

surrounding the boiler.

Flue gas exhaust to outdoors

Combustion air from boiler room. For indoor air installation, check air intake and boiler room

combustion air opening(s) to ensure they are clear of obstructions.

Figure 21 Indoor combustion air intake

36

Section: Installation

To support combustion, an ample air supply is required. This may require direct openings in the boiler

room to the outside. If the boiler is not in a room adjacent to an outside wall, air may be ducted from

outside wall openings.

Provisions for combustion and ventilation air must be made as follows:

in the USA, in accordance with the National Fuel Gas Code, ANSI Z223.1 (latest edition), or

applicable provisions of the local building codes

in Canada, in compliance with B149.1 (latest edition).

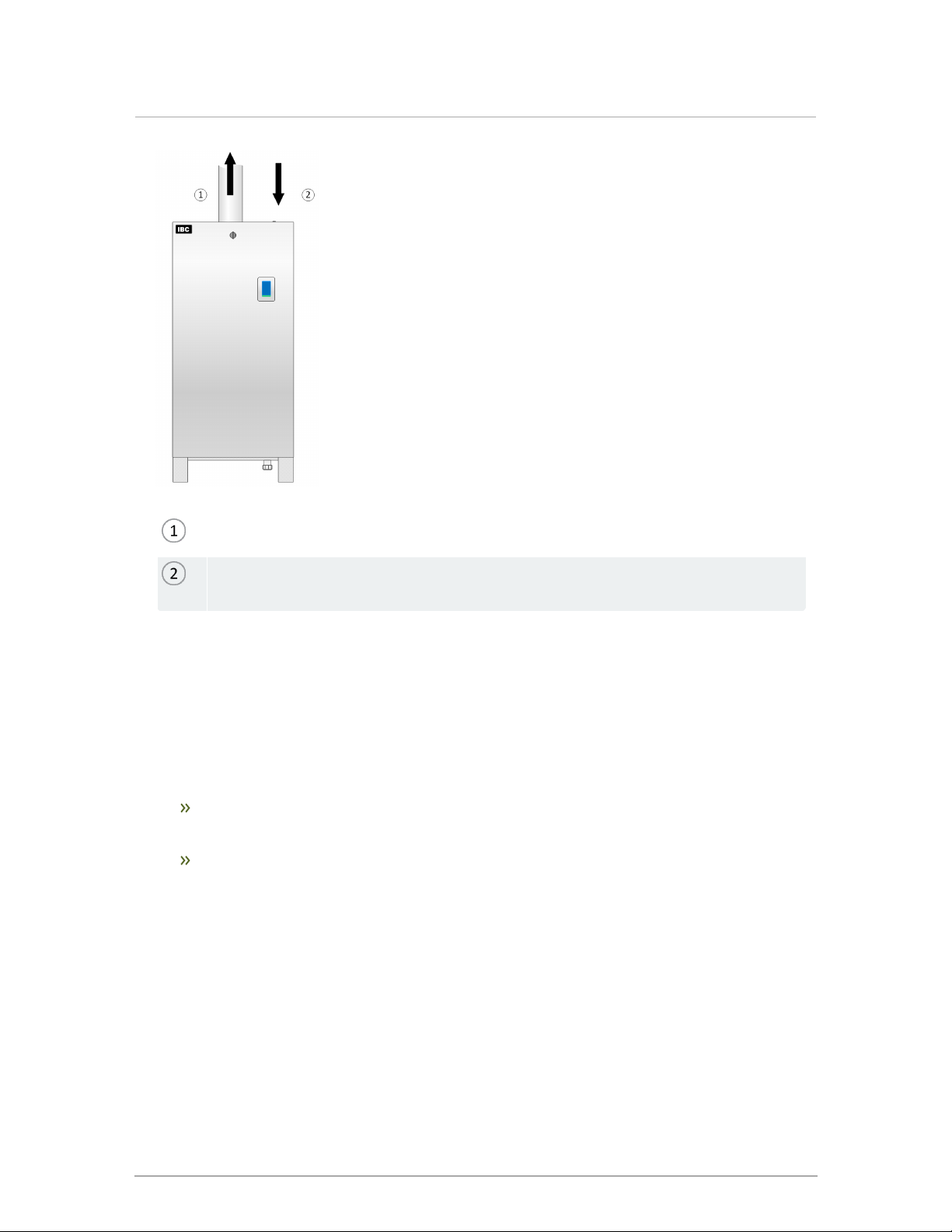

3.5.10 Combustion air filtration system

A built-in combustion air filter system is supplied with the boiler, and is located at the top of the unit. The

boilers use a 10" x 10" x 1" (MERV 8) filter.

End users will need to be instructed on how to maintain the filter in the boiler.

37

3.6 Installing a condensate trap

For instructions on how to replace the filter, see Replacing the air filter on

page 76.

Figure 22 Filter door - top view of boiler

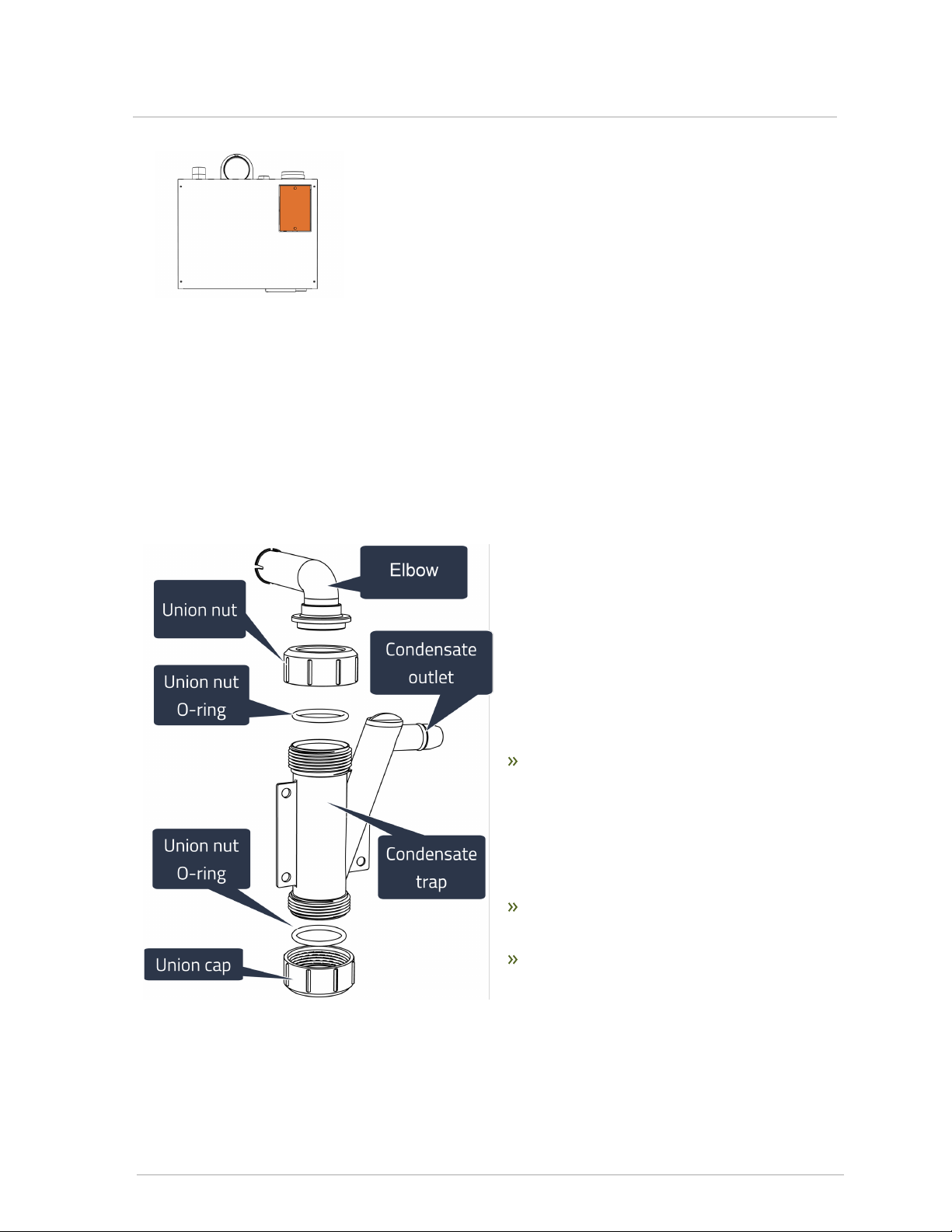

3.6 Installing a condensate trap

IBC’s specified vent configuration promotes the safe drainage of moisture from the boiler and exhaust

venting without flowing liquids back through the heat exchanger (as done by some other condensing

boilers).

Reliable system operation requires:

1. Proper design and installation of exhaust

venting to allow condensate to run back to the

drain/trap.

Installing a condensate neutralizer on page 39.

2. Acid neutralization as appropriate.

To achieve these:

Allow a minimum ¼" per foot slope back to the

vent connection, with appropriate hangers to

maintain that gradient. For PPs venting, follow

the manufacturer's requirements. This will

ensure proper drainage and prevent

condensate from clogging.

Ensure the supplied trap is correctly installed

and filled with water.

When required, add (and maintain in good

condition) a neutralization tank. For information

on installing a condensate neutralizer, see

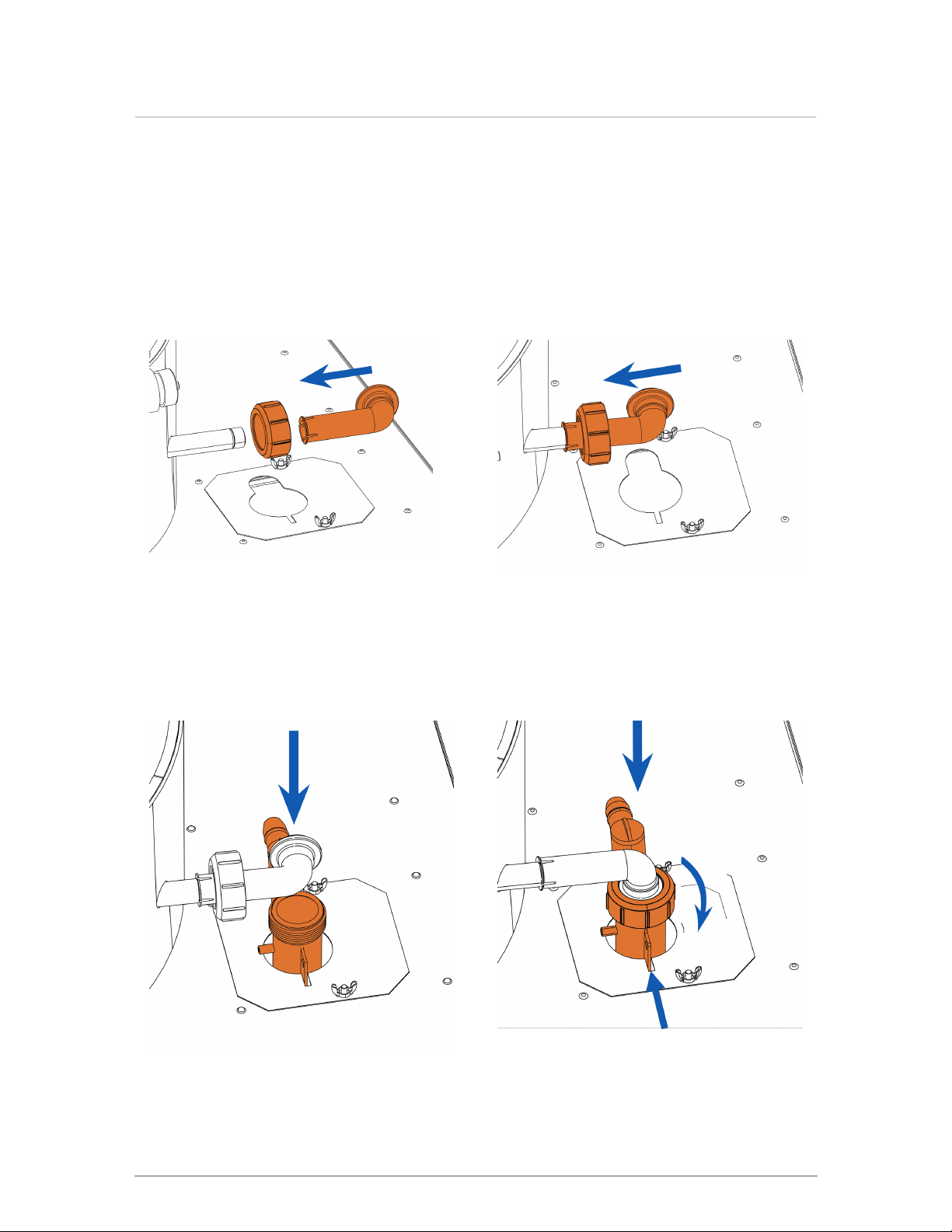

The condensate trap must be installed on the drain connection at the base of the boiler. The condensate

1.

Slide the union nut onto the elbow. The union

nut must include an embedded O-ring. Ensure

that the O-ring seal is in place on the heat

exchanger's stainless steel outlet tube.

2.

Attach the elbow and union nut firmly

to the boiler's outlet tube, making

sure that you rotate the elbow

sideways.

3.

Fill the condensate trap with water and insert

the trap into the hole of the metal plate.

4.

Rotate the elbow, and tighten the union

nut, so that the elbow and condensate

trap are secured. Ensure the union nut

O-ring is included. Check for leaks.

38

Section: Installation

drain must be piped to within 1" of a drain or connected to a condensate pump. The drainage line must

slope down to the drain at a pitch of ¼" per foot so condensate runs towards the drain.

Warning

Fill the trap with water before initially firing the boiler to prevent exhaust fumes from entering the

room. Never operate the boiler unless the trap is filled with water. Failure to comply will result in

severe personal injury or death.

3.7 Installing a condensate neutralizer

Warning

After installing a condensate neutralization package, the pH of the condensate discharge must be

measured on a regular schedule to ensure the neutralizing agent is active and effective.

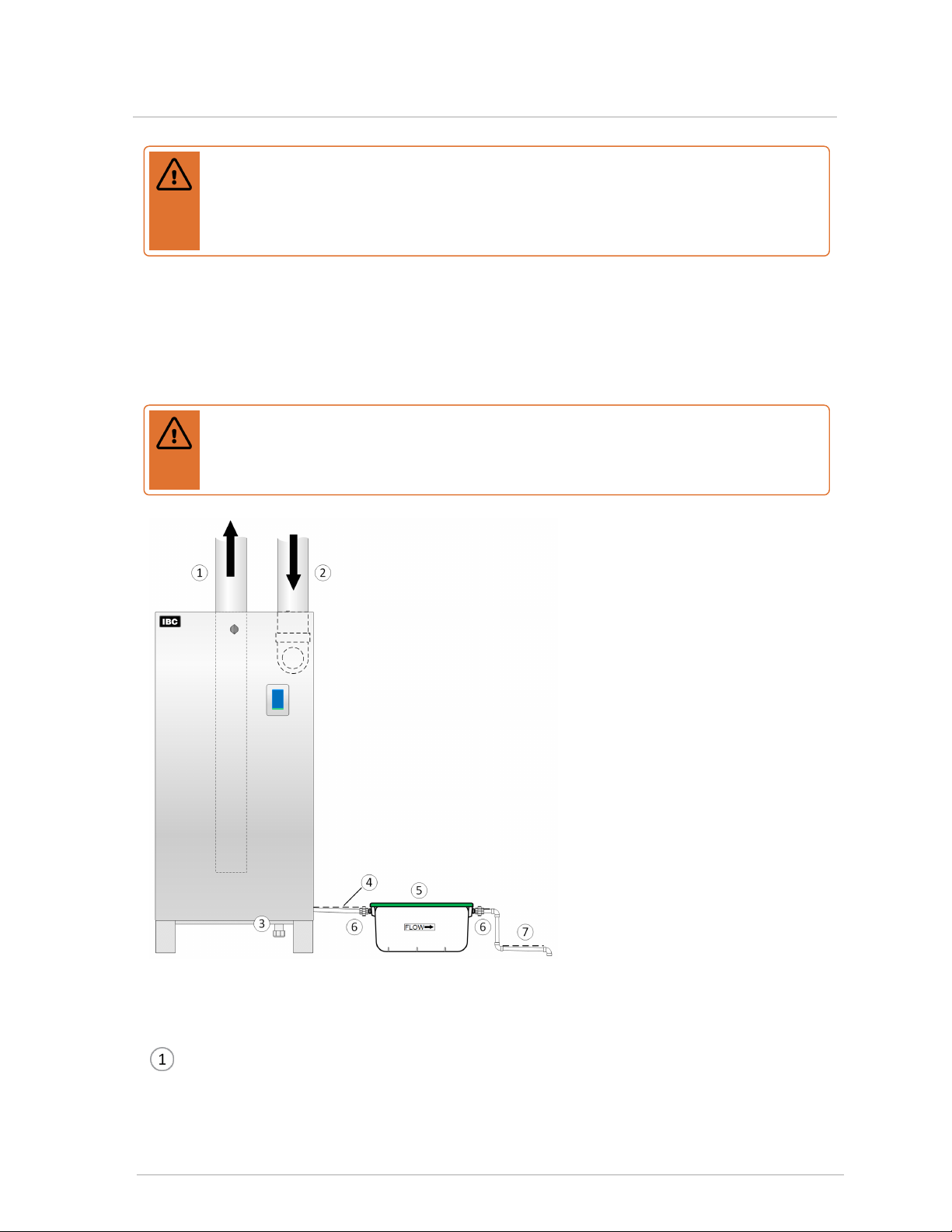

Flue gas exhaust (connection at rear of boiler): condensate, and potentially rain water, flow back from

the venting system.

39

3.7 Installing a condensate neutralizer

If discharging condensate into building drain piping materials that are subject to corrosion, use a

neutralization package.

Figure 23 Condensate neutralization tank

Air intake piping: Warning - Risk of damage to appliance. Ensure rain water is prevented from

entering.

Free flow of condensate from venting systems and the pressure vessel must be maintained at all

times. Trap and condensate drain piping must be accessible to allow regular inspection and cleaning.

Condensate water line: Warning - Risk of damage to appliance. All condensate discharge lines,

including neutralization tank inlet, must be at a lower elevation than the condensate water line of the

appliance.

Condensate neutralizer: Drain materials subject to corrosion must be protected by acid neutralization.

Warning - Risk of injury. Tank fluid can be highly acidic. Do not use hands to stir material. Refer to the

neutralization instructions of the manufacturer. Access to the discharge, before the drain, is necessary

for proper maintenance in order to check the effectiveness of the neutralizing agent. A simple pH test

should be performed annually to ensure neutralizing agent is still effective. If the pH falls below 6.5

the neutralizing material should be replaced. The agent (limestone chips with a minimum calcium

carbonate content of 85%) can be purchased from a local supplier.

1" FPT inlet and outlet. Unions for ease of maintenance (ships with shown model NT-25, IBC part 180-

048).

To drain. Confirm slope. Slope the condensate hose and drain piping toward the drain and secure to

prevent accidental dis-assembly.

Danger

The water in the condensate neutralizer can cause severe burns to the skin. Wear protective

gloves and eye wear when servicing the condensate neutralizer.

40

Section: Installation

3.8 Water Piping

Warning

Water quality has a significant impact on the lifetime and performance of a boiler's heat

exchanger.

Improperly prepared water in a heating circuit may cause damage to the heat exchanger through

fouling or corrosion. Repeated or uncontrolled water fills will increase the potential for damage.

High levels of dissolved solids or minerals may precipitate out of the fluid onto the hottest part of

the heat exchanger, impairing heat transfer and resulting in overheating and premature failure.

The amount of solids that may form on the heat exchanger will depend on the degree of hardness

and the total water volume in the system. A high water volume system with a low hardness count

may cause as much damage as a system with less volume and higher hardness, so it is

recommended to treat water so as to remove all dissolved solids. Other water chemistry allowable

limits are as follows:

Acidity pH is to be between 6.6 and 8.5

Chloride is to be less than 125 mg/l

Iron is to be less than 0.3 mg/l

Cu less than 0.1 mg/l

Conductivity is to be less than 400μS/cm (at 77°F [25°C])

Hardness is to be 7 grains per gallon or less / 120 ppm or less

Important: Ensure that these limits are acceptable for the other water-side components in the

system.

Boiler Head Loss - EX 700, 850

Flow rate (gpm) 20 30 40 50 60 70 80 90 100

Head @ flow (ft) 2.6 2.9 3.2 3.7 4.2 4.8 5.5 6.4 7.2

41

3.8 Water Piping

Table 8 Boiler Head Loss - EX 700, 850

Ensure that the pump is rated for the design circulating water temperatures; some pumps have a minimum

water temperature rating above the low temperature potential of the boiler. Following installation, confirm the

actual performance by measuring Δ°T (under high and low flow conditions) after establishing the correct

firing rate.

To use legacy heat, we recommend water flow after burner shutdown. This is significant due to the mass

Warning

Do not use automotive-type ethylene or other types of automotive glycol antifreeze, or

undiluted antifreeze of any kind. This may result in severe boiler damage. Installers must

ensure that glycol solutions are formulated to inhibit corrosion in hydronic heating systems of

mixed materials. Improper mixtures and chemical additives may cause damage to ferrous and

non-ferrous components as well as non-metallic, wetted components, normally found in

hydronic systems. Ethylene glycol is toxic, and may be prohibited for use by codes applicable

to your installation location. For environmental and toxicity reasons, IBC recommends only

using non-toxic propylene glycol.

42

Section: Installation

of the heat exchanger plus its internal water volume. Default load settings will run the boiler’s primary

pump for up to 5 minutes (300 seconds) after burner shutdown. Secondary pumps can be set to run up to

15 minutes after burner shutdown (for the last calling load). As shipped, the default settings will run the

Load pump for 5 minutes to place the legacy heat where it is useful. Any secondary pump can be set to

run for 0 – 900 seconds in the heat purge mode. Guard against deadheading pumps when all zone

valves are closed by setting the load Pump Post Purge (sec) to '0'.

The primary pump must be under the control of the boiler to allow pump purge after burner shut-down.

Installers must conform to the piping design configurations provided to simplify the control application,

promote good loads and flow management.

Propylene glycol usage

Propylene glycol solution is commonly used in a closed loop where freeze protection is required. Its

density is lower than that of water, resulting in lower thermal performance at a given flow and pressure.

Generally, a 50%:50% solution of propylene glycol and water requires an increased system circulation

rate (gpm up 10%), and system head (up 20%) to provide performance equivalent to straight water.

These boilers are designed for use within a closed loop, forced circulation, low pressure system. A 50 psi

pressure relief valve (¾" NPT inlet, 1" NPT outlet) is supplied for field installation in the relief valve fitting

on top of the boiler. An optional relief valve, with a rating of up to 150 psi, can be used where required on

closed loop systems. Relief valve discharge piping must terminate between 6" (15 cm) and 12" (30 cm)

above the floor or per local code.

Warning

During operation, the relief valve may discharge large amounts of steam and/or hot water. To

reduce the potential for bodily injury and property damage, install a discharge line that:

Is connected from the valve outlet with no intervening valve and directed downward to a

safe point of discharge.

Allows complete drainage of both the valve and the discharge line.

Is independently supported and securely anchored, so as to avoid applied stress on the

valve.

Is as short and straight as possible.

Terminates freely to atmosphere where any discharge will be clearly visible and is at no

risk of freezing. terminates with a plain end which is not threaded.

Is constructed of a material suitable for exposure to temperatures of 375° F or greater.

Is, over its entire length, of a pipe size equal to or greater than that of the valve outlet (1"

NPT).

Do not cap, plug or obstruct the discharge pipe outlet.

3.8.1 General piping best practices

Caution

Contact local water purveyors about the suitability of the supply for use in hydronic heating

systems.

If unsure about water quality, request testing and assessment (and treatment, if required) from a

local water treatment expert.

Alternatively, water or hydronic fluid of known quality can be brought to the site.

43

3.8.1 General piping best practices

Primary/secondary piping, or the use of a hydraulic separator (such as the Caleffi 549 SEP4™ 4-in-1

Magnetic Hydraulic Separators) is recommended for maximum flexibility in multi-load applications. Piping

loads in parallel is also encouraged in systems that only have two loads, or when loads are operating

simultaneously. The extremely low pressure drop through the heat exchanger of the EX series affords more

flexible options unavailable in other designs.

3.8.2 System piping

Warning

Close the fill valve after any addition of water to the system, to reduce risk of water

escapement.

Example: In these EX models, the minimum flow rate required through the heat exchanger is 18

or 21 gpm (depending on model) and a maximum of 100 gpm is allowed. Primary/Secondary

piping ensures adequate flow and de-couples Δ°T issues (boiler vs. distribution). Aim for a 20°

to 30° F Δ°T across the heat exchanger at high fire (there is a boiler protection throttle fence

limiting the Δ°T to 80°F).

44

Section: Installation

System piping is connected to the boiler using 2½" NPT-Male threaded fittings. To simplify servicing, we

recommend using unions or flanged fittings, gate or ball valves at the boilers supply and return water

connections. You must install un-insulated hot water pipes with a minimum ¼" clearance from

combustible materials.

Fluid fill is most often accomplished by using a boiler regulator & fill valve set at 12 psig or more, with

the appropriate backflow prevention device as required by local code. This is acceptable in areas

where municipal water or well water has been treated and filtered to remove excessive minerals and

sediment, and water chemistry is known to be suitable for closed loop hydronic systems. In areas where

water quality is in question, or when chemical treatment or glycol is required, other options should be

considered. Follow the applicable codes and good piping practice.

There are a number of boiler feed and pressurization devices on the market today that may be a better

choice than a raw water fill from the mains. When regular maintenance requires relief valve blow-off, the

discharge may be directed back into the pressurization unit for recycling of boiler fluid and chemicals

back into the system. In buildings that may be unoccupied for long periods of time, pressurization units

are useful to prevent flood damage should leakage occur from any component in the system. An

additional benefit is that backflow prevention devices are not required when using these devices.

Do not place any water connections above the boiler; leaks can damage the fan and controls. If

needed, create a shield over the top of the cover, but allow clearance for airflow and service access.

For best results, use a Primary/Secondary piping system, with a pumped boiler loop using 2½" piping.

Refer to Table 8 for boiler head loss information.

Check valves or thermal traps should be used to isolate both the supply and return piping for each load

- to avoid thermal siphoning and reverse flow.

To ensure adequate water flow through the boiler under high-head / single zone space heating

conditions, a pressure activated bypass or other means of bypass must be used on any load where the

flow rate might drop below minimum requirements (18 or 21 gpm - depending on model).

For further information and details, consult our Concept Drawings – which provide detail on specific single

Note

The piping drawings in this manual are simple schematic guides to a successful installation.

There are many necessary components not shown, and details such as thermal traps are left

out so the drawings have greater clarity. We require that our boilers be installed by licensed

and experienced trades people who are familiar with the applicable local and national codes.

System design is to be completed by an experienced hydronic designer or Engineer. It is

necessary to carefully read and follow these installation instructions along with the application

drawing that fits your system.

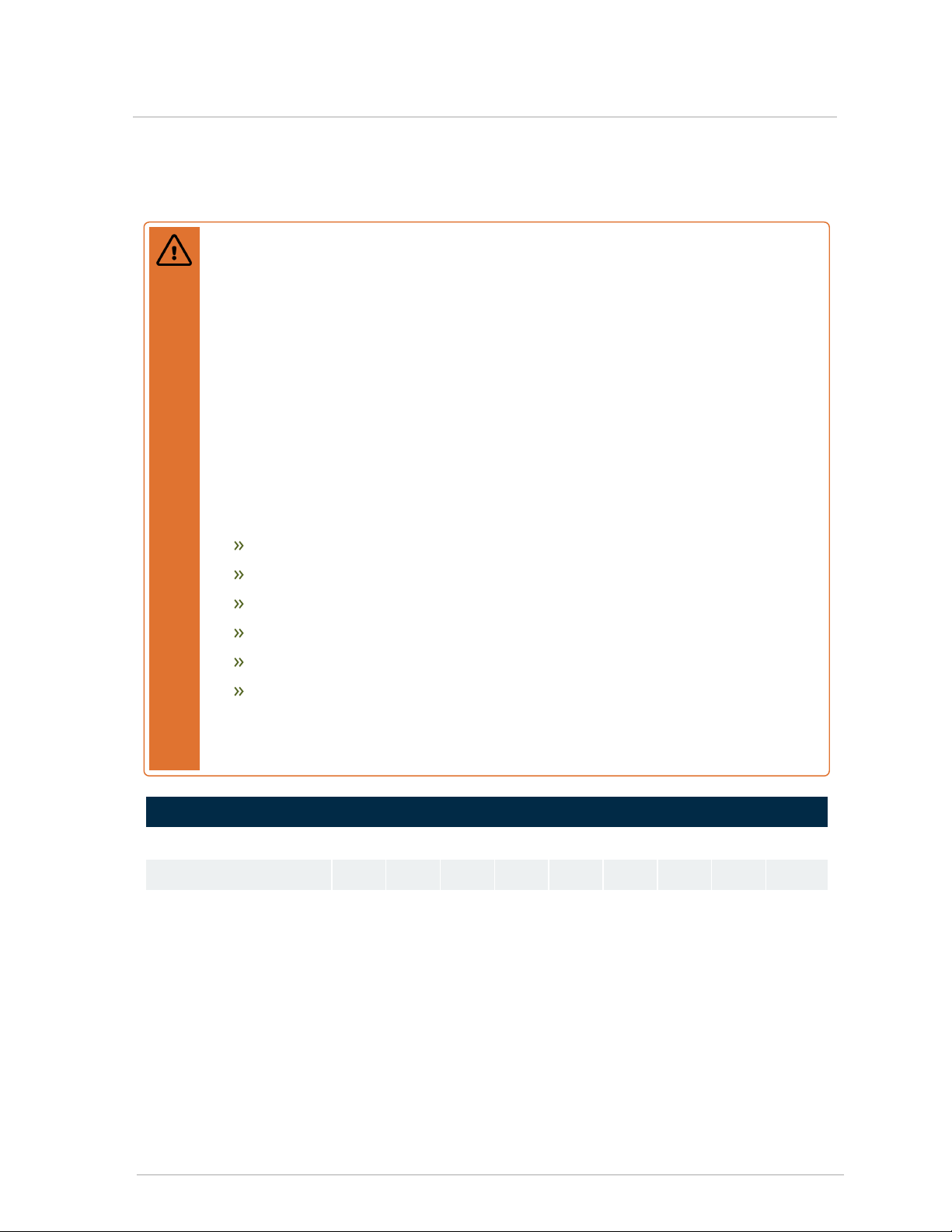

Low water cut-off (LWCO): the IBC EX series comes factory-equipped with an internally mounted

Certified Low Water Cut-Off. Sometimes an external device is required by local jurisdiction. These

devices have specific installation requirements not illustrated here. Consult the IBC factory or the

LWCO manufacturer for proper application of these devices.

Pressure relief valve (ships with boiler): no isolation valve permitted between boiler and relief valve.

Tridicator / external pressure and temperature gauge (ships with boiler).

45

3.8.2 System piping

and multiple boiler applications “Piping”, “Wiring” and “Settings”. (available at www.ibcboiler.com or from

your IBC Representative).

Optional external water high limit (manual reset). The IBC EX series comes factory-equipped with

an internally mounted manual reset mechanical water temperature high limit. It can be fitted with an

external manual reset mechanical water temperature high limit if required by local jurisdiction.

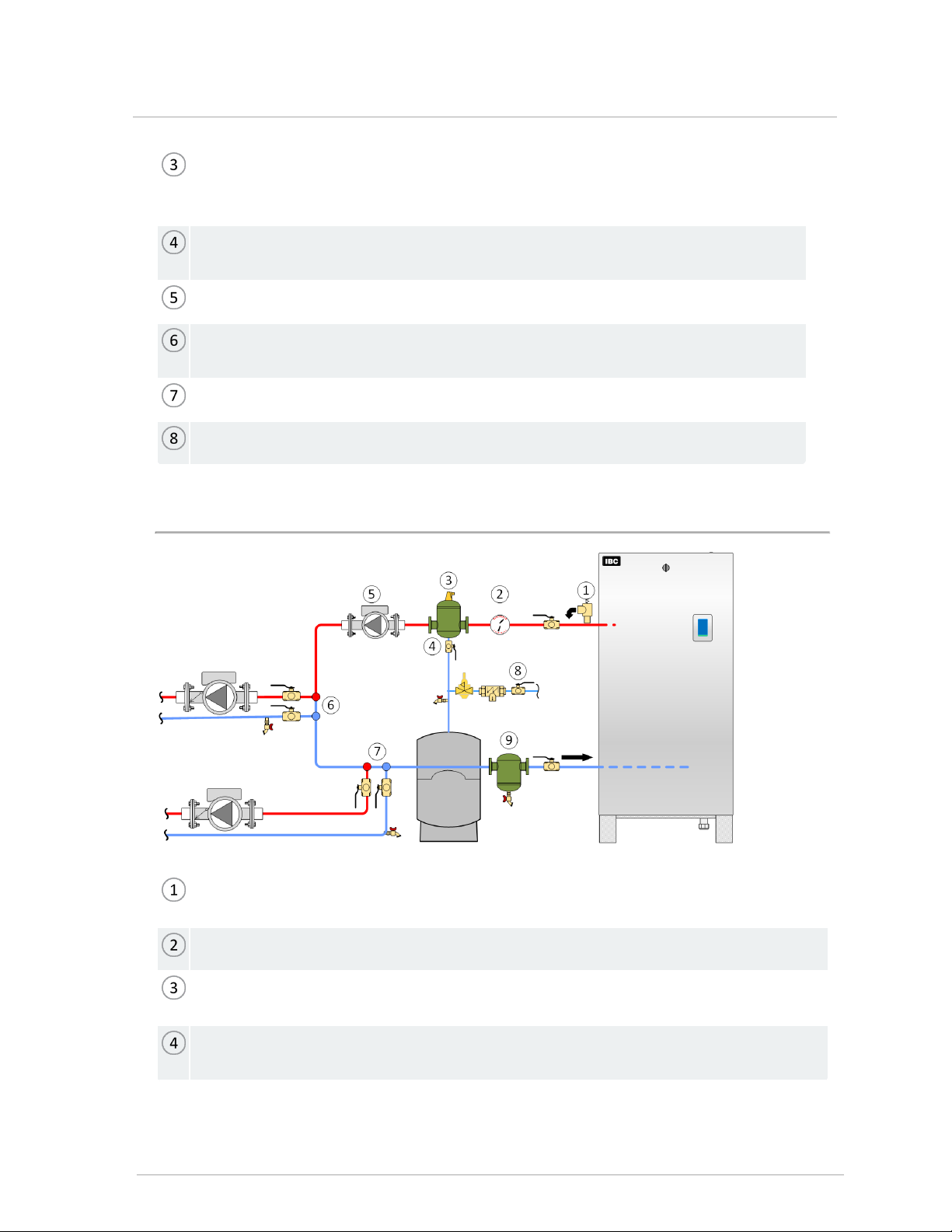

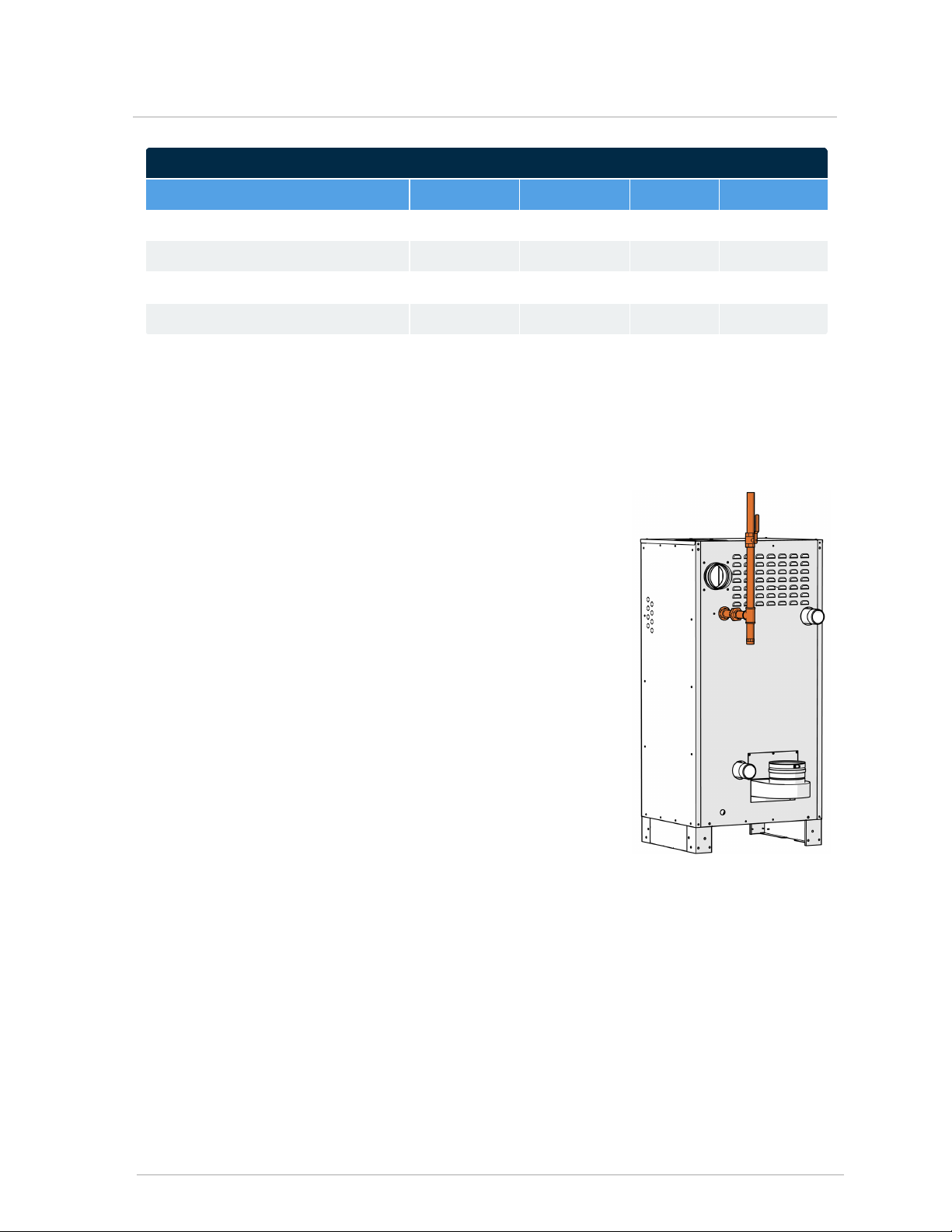

To supply manifold

From return manifold

Optional flow switch: follow manufacturer’s instructions. Typical requirements include installing on a

horizontal run, with at least five (5) pipe diameters of straight piping both upstream and downstream

of flow switch, and ensuring proper paddle engagement for the piping size.

Integrated boiler drain

Figure 24 Trim for multiple boiler installations

Pressure relief valve (shipped with boiler): no isolation valve is permitted between the boiler and

relief valve.

Tridicator or external pressure and temperature gauge (shipped with boiler).

46

Section: Installation

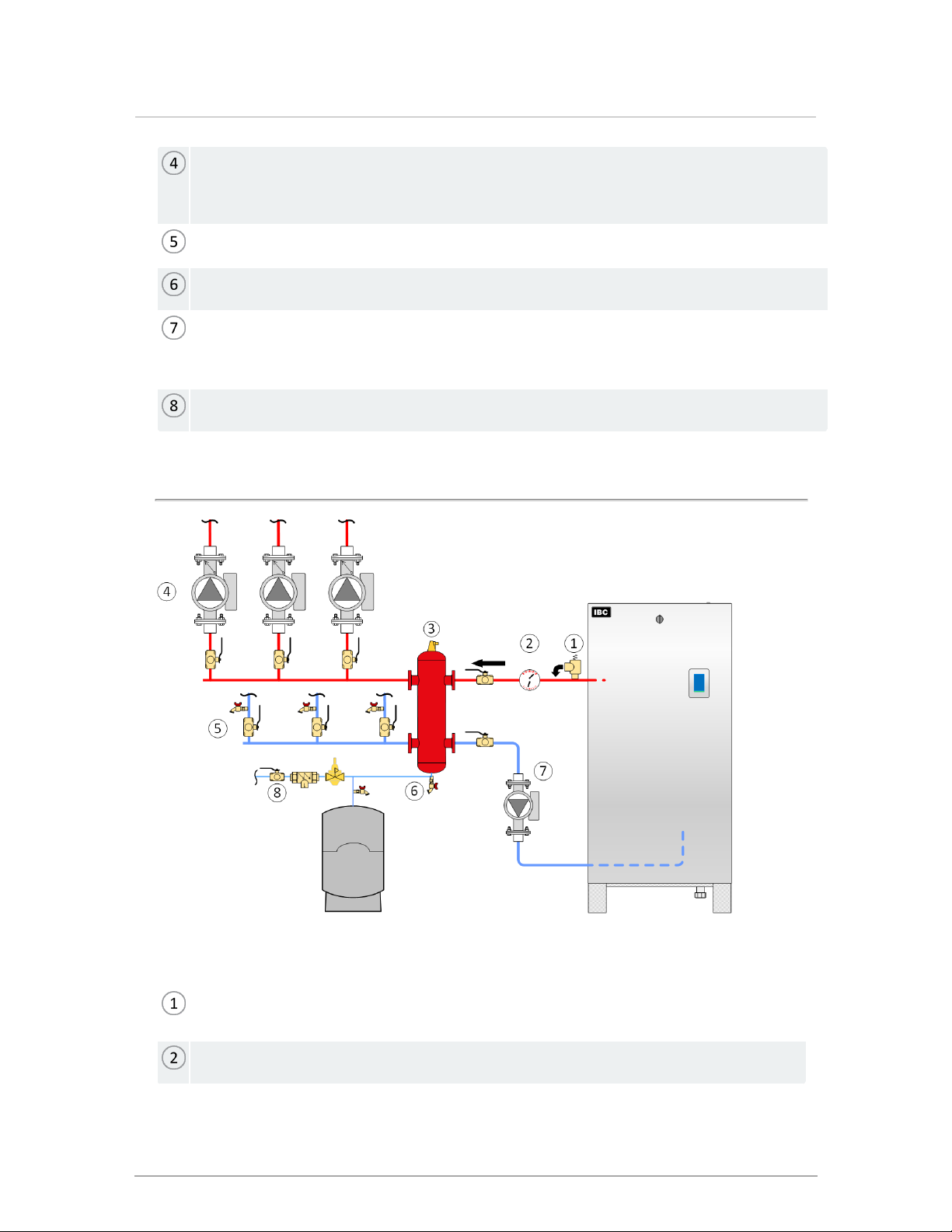

Hydraulic separator (low-loss header) provides primary/secondary hydraulic separation, a

microbubble air eliminator and a dirt separator. Air eliminator is installed at the most effective

point, where the fluid is at the highest temperature and lowest pressure.

Secondary pumps to multiple loads or zones. All receive identical temperatures. Note integrated

check valves.

Return lines from loads.

Expansion tank connection (point of no pressure change)should be on the suction side of the

circulator.

Primary pump or boiler circulator into connection at rear of boiler.

Fill station with isolation valve closed, or fill tank.

Figure 25 Primary/Secondary piping concept with hydraulic separator

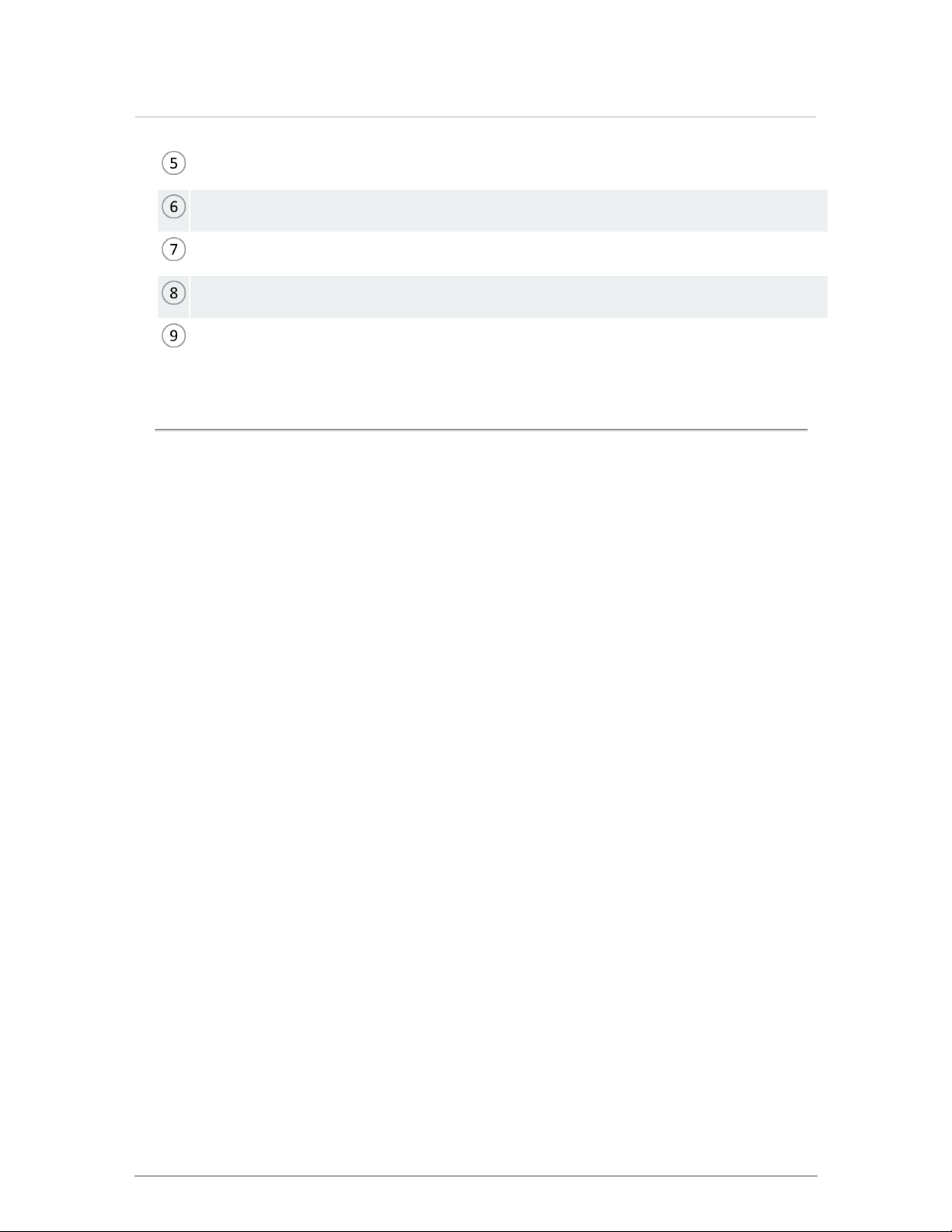

Pressure relief valve (field-supplied): no isolation valve is permitted between the boiler and relief

valve.

Tridicator or external pressure and temperature gauge (field-supplied).

Microbubble air eliminators are best installed where the fluid is at the highest temperature and

lowest pressure.

Expansion tank connection (point of no pressure change) should be on the suction side of the

circulator.

47

3.8.2 System piping

Primary pump or boiler circulator.

Closely-spaced tees to or from load 1.

Closely-spaced tees to or from load 2.

Fill station with isolation valve closed, or fill tank.

Dirt separator recommended.

Figure 26 Boiler trim options - single boiler

48

Section: Installation

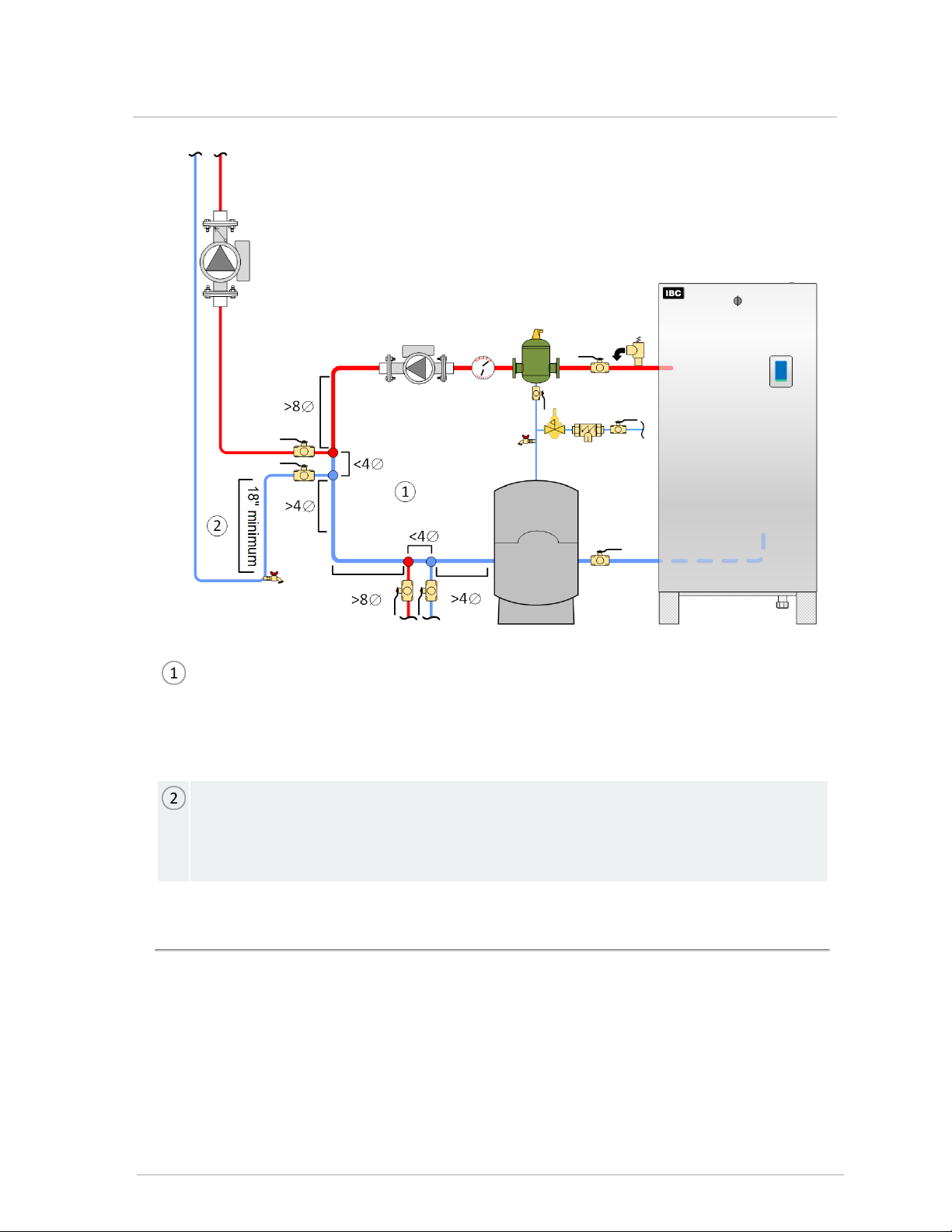

Closely-spaced tees: To avoid induced flow, install each set of tees with straight piping a minimum

of 8 pipe diameters upstream and 4 pipe diameters downstream. Avoid using elbow or other

component that may create turbulent flow. Position tees as close together as possible (maximum 4

pipe diameters apart) and ensure that there are no restrictions between the fittings that would result

in a pressure drop.

Heat migration: On secondary loops that extend vertically to a load that is above the primary loop,

steps must be taken such as fabricating a thermal trap in the return piping - minimum 18" (46 cm)

drop - to prevent thermal siphoning and heat migration to the load when there is no demand for heat

to that loop. Alternatively, use check valves on both supply and return of secondary piping.

Figure 27 Important Primary/Secondary piping details with closely-spaced tees

49

3.8.2 System piping

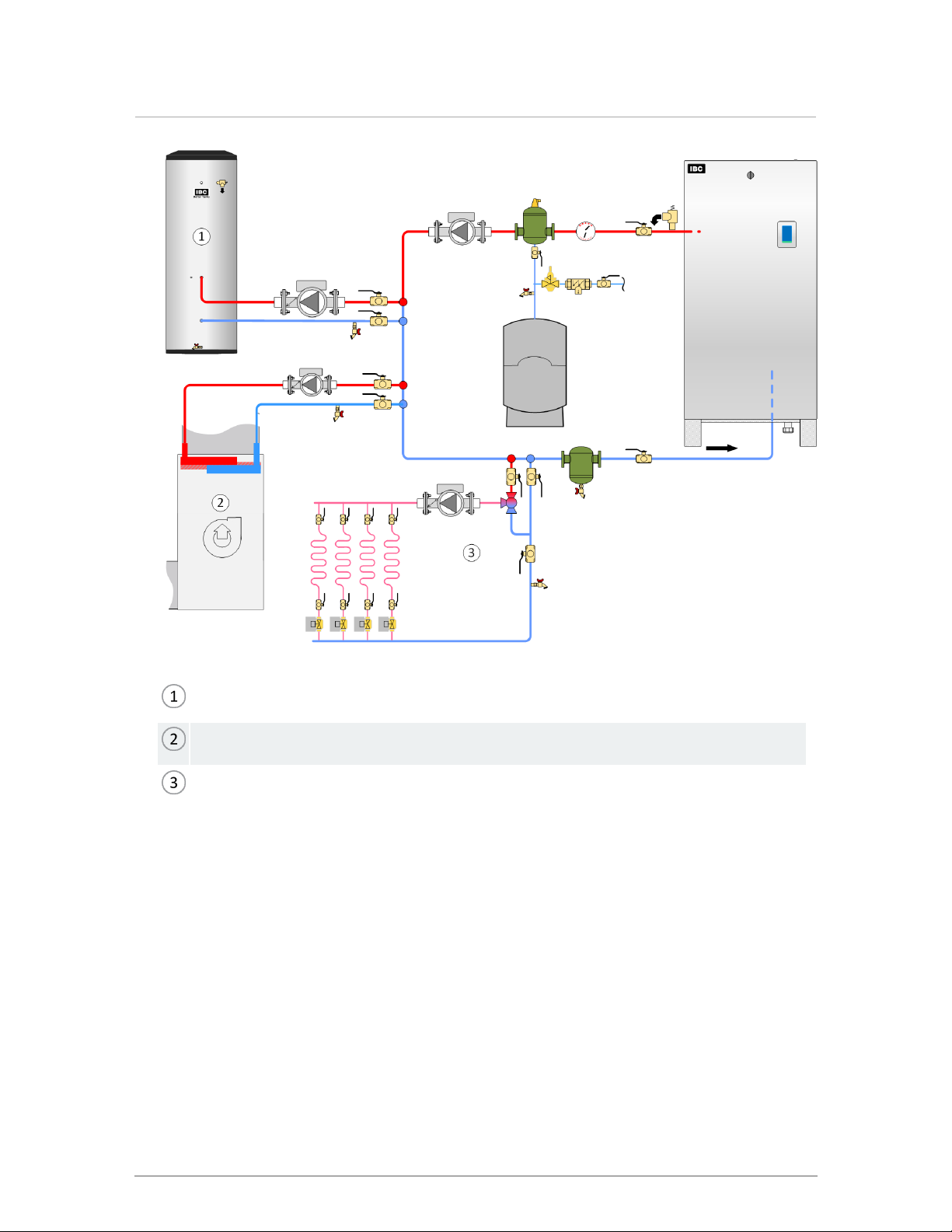

DHW indirect tank

Air handler

Low temperature radiant protected by a mixing valve for simultaneous heating during higher

temperature air handler operation. Boiler can return to lower supply temperature when radiant

alone is operating.

Figure 28 Primary/Secondary piping concept with simultaneous heating calls

50

Section: Installation

DHW indirect tank

Air handler

Check valves (may be integral to pumps - not shown)

51

3.8.2 System piping

Figure 29 Two pump, two load - parallel piping concept

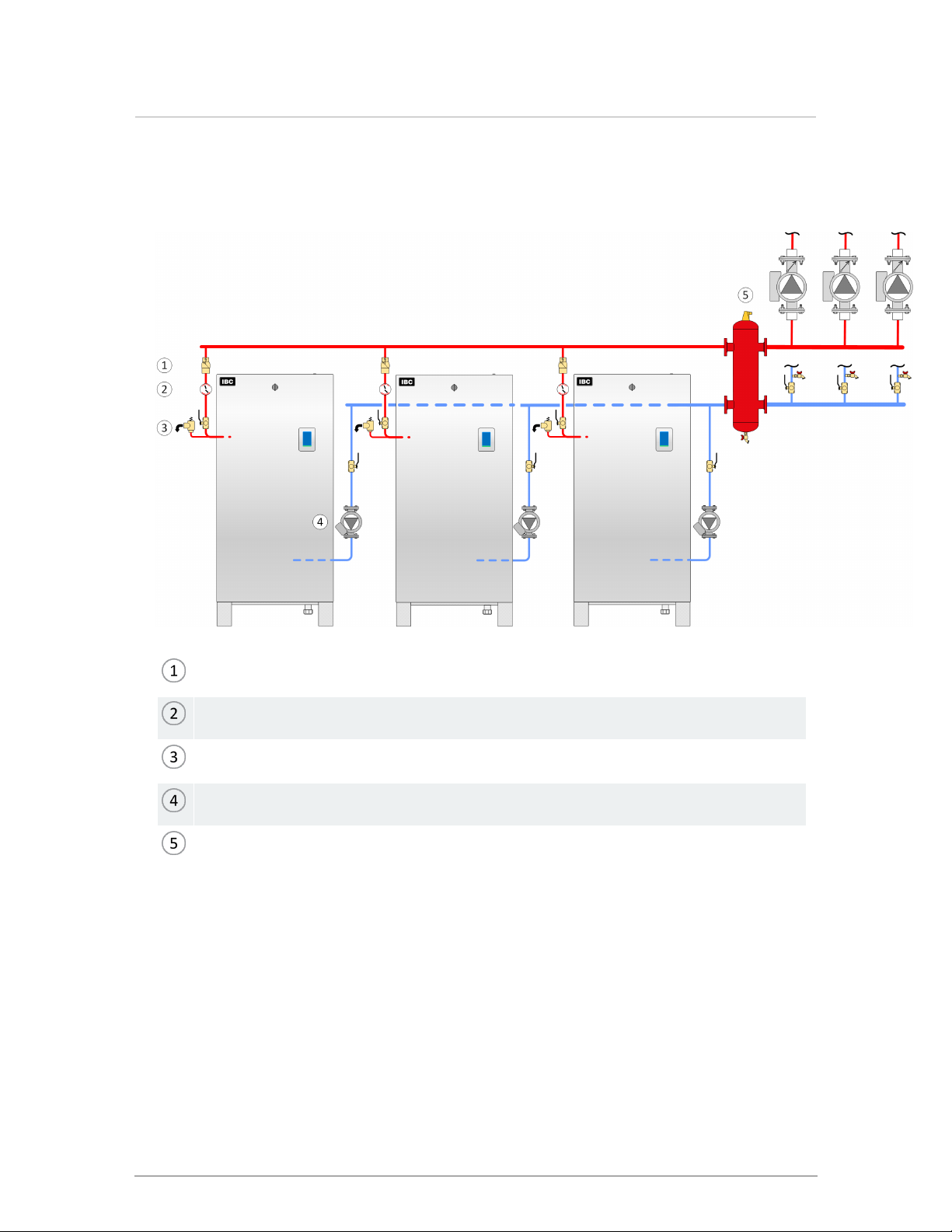

The boilers can supply multiple heating loads with compatible supply temperature requirements.

Check valve (typical of each boiler - may be integral to pump).

Tridicator (shipped with boiler) typical of each boiler.

Pressure relief valve (shipped with boiler) typical of each boiler.

Boiler pump into rear connection (typical of each boiler).

Low-loss header / hydraulic separator (shown) or closely-spaced tees 'bridge' to load piping.

52

Section: Installation

Always ensure that loads sensitive to high temperatures are protected using means such as mixing

valves.

Figure 30 Multiple boiler piping

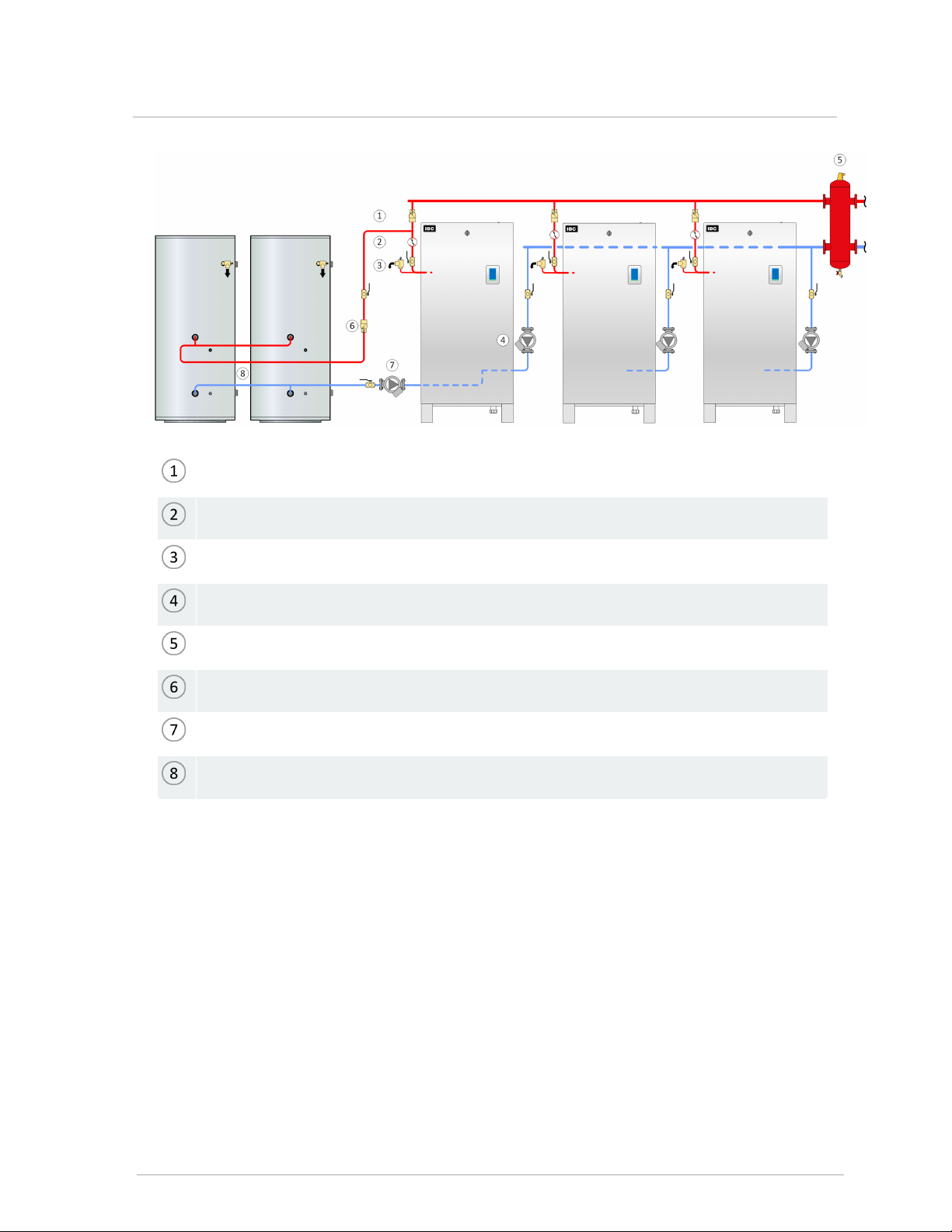

Pressure relief valve (shipped with boiler) typical of each boiler.

Tridicator (shipped with boiler) typical of each boiler.

Check valve (typical of each boiler)

Boiler pump into rear connection (typical of each boiler)

Low-loss header / hydraulic separator (shown) or closely-spaced tees 'bridge' to load piping

Check valve for opt-out circuit.

Opt-out pump into rear side (opt-out boiler(s) only)

Opt-out load piping in reverse-return for balanced flows

Figure 31 Multiple boiler opt-out piping

53

3.8.2 System piping

3.9 Gas piping

Note

Due to the precision of modern modulating boilers it is important to pay special attention to

gas pressure regulation.

Important: Check gas supply pressure to each boiler with a manometer or other high-quality

precision measuring device. Pressure should be monitored before firing the boiler, during

operation throughout the boiler's full modulation range, and after the call when the regulator is

in a "lock-up" condition.

Pay special attention to retrofit situations where existing regulators may have an over-sized

orifice and/or worn seats, causing pressure “creep” and high lock-up pressures.

A high quality regulator will maintain constant pressure above the boiler’s minimum

specification at all firing rates, and will not exceed the boiler’s maximum pressure rating when

locked-up with no load.

54

Section: Installation

3.9.1 Gas pressure

The boilers require a minimum inlet gas supply pressure of 4.0" w.c. for natural gas or propane during

high fire operation. For either fuel, the inlet pressure shall be no greater than 14.0" w.c. Confirm this

pressure range is available with your local gas supplier.

The inlet gas connection to the boiler is 1" NPT (female).

The high gas pressure switch setpoint is set at 14" wc and the low gas pressure setpoint is set at 3.5" wc.

To locate the switches on the boiler, see EX 700, 850 - gas valve and fan components.

Adequate gas supply piping must be installed with no smaller than 1¼" Schedule 40 (e.g. Iron Pipe Size

(IPS) and using a 1" w.c. pressure drop, in accordance with the following chart.

Maximum Gas Pipe Length (ft)

Model 1¼" IPS 1½" IPS 2" IPS 2½" IPS

EX 700 (Natural Gas) 50' 100' 350' 800'

EX 700 (Propane) 150' 300' 900' 2000'

EX 850 (Natural Gas) 40' 80' 250' 600'

EX 850 (Propane) 100' 200' 700' 1600'

Table 9 Maximum Gas Pipe Length (ft)

55

3.10 Electrical connections

Gas piping must have a sediment trap ahead of the boiler’s gas valve. A manual shutoff valve must be

located outside the boiler, in accordance with local codes or standards. All threaded joints in gas piping

should be made with an approved piping compound resistant to the action of natural gas or propane. Use

proper hangers to support gas supply piping as per applicable codes.

The boiler must be disconnected or otherwise isolated from the gas supply

during any pressure testing of the system at test pressures in excess of ½

psig. Dissipate test pressure prior to reconnecting. The boiler and its gas

piping shall be leak tested before being placed into operation.

The gas valve is provided with pressure taps to measure gas pressure

upstream (supply pressure) and downstream (manifold pressure) of the gas

valve (see Figure 2 on page 1). Note that manifold pressure varies slightly in

accordance with firing rates with the modulating series boilers, but will always

be close to 0" wc. An adapter fitting is supplied with the boiler.

Figure 32 Typical gas piping

3.10 Electrical connections

All electrical wiring to the boiler (including grounding) must conform to local

electrical codes and/or to the National Electrical Code, ANS/NFPA No. 70 –

latest edition, or to the Canadian Electrical Code, C22.1 - Part 1.

3.10.1 Power quality and electrical protection

In areas of unreliable power, appropriate surge protectors and or power conditioning equipment should be

installed in power supply wiring circuits.

Note

The IBC boiler (like any modern appliance that contains electronic equipment) must have a

“clean” power supply, and is susceptible to power surges and spikes, lightning strikes and

other forms of severe electrical “noise”. Power conditioning equipment (surge protectors,

APC or UPS devices) may be required in areas where power quality is suspect.

3.10.2 120VAC line-voltage hook-up

Caution

The on-board controller load pump relays are protected with 5 Amp fuses. The maximum

recommended load on each fuse is 4 Amps (80% of rating). The maximum combined pump

load is 10 Amps. Isolation relays or contactors must be used if the loads exceed these

maximums.

56

Section: Installation

Line-voltage wiring is done within the field-wiring box (see Wiring diagrams on page 93). Connect the

boiler to the grid power using a separate, fused circuit and on/off switch within sight of the boiler. Use 14gauge wire in BX cable or conduit properly anchored to the boiler case for mains supply and pump

circuits.

Figure 33 Line voltage load pump terminals

Connect a 120VAC / 15 amp supply to the “AC IN” tagged leads in the wiring box.

3.10.2.1 Load pumps

The 120VAC power supply to the load pumps (P/V1, P/V2, P/V3, and P/V4) is factory installed and

connected to P/V-L and P/V-N for your convenience. If you use the P/V relay connections for zone valves,

you need to remove and cap off the 120VAC connections at P/V-L and P/V-N. The 24VAC can then be

applied using an external transformer to supply power to zone valves. The upper 4 pairs of contacts on

the connector strip are then powered to manage up to 4 load pumps – the top pair for Load 1, the second

pair for #2 etc. Once the controller is programmed for the respective loads, the boiler manages all the

loads without need of further relays (for loads up to ⅓ HP; for more – use a protective relay).

3.10.2.2 Boiler pump

Power in - black wire.

To boiler - yellow wire.

57

3.10.2 120VAC line-voltage hook-up

The boiler (primary) pump is powered by the yellow wire from the pair labeled "Boiler Pump". Wire the

pump's neutral to the white wire labeled "AC In". Do not attempt to connect the boiler pump to the pump/zone

valve terminal block along the controller’s right edge as this is reserved for the secondary pumps and/or zone

valves only.

Figure 34 Electrical box with boiler pump relay - black and yellow wires

If the total boiler amperage drawn is less than 12 amps and the boiler pump is 120V, you can connect the

black wire from the relay to the line voltage mains supplied to the boiler. For 120 volt boiler pumps, the black

wire can be connected to the line voltage mains and the yellow wire connected to boiler pump. For 208/240

volt boiler pumps, the black wire can be one leg of the 208/240 voltage mains and the yellow wire connected

to the boiler pump. The boiler pump relay may require connection to a second electrical circuit (amperage

greater than 4 amps). The boiler pump relay is rated for a maximum amperage load of ¾ horsepower. A

disconnect switch should be installed to isolate the boiler pump and the boiler pump relay power supply.

Pumps can be switched on/off using the touchscreen controller, so there is no need for temporary pump

58

Section: Installation

wiring during system filling / air purging. If pumps are hard-wired to the panel during the system fill/purge

phase, re-wire the boiler pump to the primary pump leads inside the wiring box so the primary pump

purge function is active.

In a new construction application, use a construction thermostat, or jumper with an in-line on/off switch –

for on/off management of the boiler. Do not just turn off power from the unit, or its moisture management

routine will be interrupted (fan turns at ultra low rpm for 90 minutes after burner shutdown). Treat it like a

computer, where you do not just pull the plug when done. If a "low airflow / check vent" error signal

shows, check for (and remove) any water in the clear vinyl air reference tubes. This has been seen

occasionally at construction sites where the boiler has been repeatedly de-powered wet.

The combined current of all load pumps connected through the on-board pump relays should not exceed

10 amps. The control circuit board is protected using on-board field replaceable fuses. Each pump is

fused with a separate 5 Amp fuse. The Alarm contact is fused with a 5 Amp fuse and the 24VAC boiler

control circuit is protected with a 2 Amp fuse.

3.10.2.3 Variable speed boiler pumps

Variable speed boiler pumps are for connecting and managing speed in pumps that accept 0-10VDC on

4-20 mA input signal.

Figure 35 Electrical box with new variable speed connection

3.10.3 Other wiring

Danger

Do not connect sensors to “Therm” terminals. Overheating components can result in serious

personal injury and/or property damage.

Note

Sensors connected to any sensor input contacts must be of the NTC Thermister type with a

resistance of 10,000 ohms at 77°F (25°C) and β = 3892. We do not recommend using 3rd party

supplied sensors. Compatible water temperature sensors and outdoor sensors can be

supplied by your IBC distributor.

59

3.10.3 Other wiring

Other optional low voltage connections to the control board include:

Two auxiliary Interlocks - for external safety devices as may be required by some jurisdictions, such

as an external low-water cutoff.

Contacts for indoor and outdoor temperatures sensors associated with reset heating. A 10K ohm

thermister (resistor dependent on temperature) for outdoor reset sensing is supplied with the boiler

for improved comfort and combustion efficiency.

One pair for a DHW tank sensor. Connect to "DHW S" (not the respective Therm. 1,2,3,4 location)

and the boiler automatically detects and calls a smart DHW routine.

One pair of contacts for remote secondary loop temperature control.

One pair (marked BoilerNet) for network connection – this is used for connecting multiple IBC

modulating units for autonomous staging.