IBC V-10 User Manual

®

V-10 TOUCHSCREEN

BOILER CONTROLLER

OPERATING AND USER INSTRUCTIONS

Ce manuel est également disponible en français auprès d’IBC et sur notre site Web, au www.ibcboiler.com

www.ibcboiler.com

Contents

CHAPTER 1 Concepts & Features................................1

Handling the Touchscreen ...............................................1

Getting to Know the Controller’s Interface..................................2

Screen Types ........................................................3

Menu Screen .......................................................3

Settings Screen .....................................................3

Status Display Screen ................................................4

Home Screen..........................................................5

Main Menu ............................................................5

Express Setup........................................................7

Load Status .........................................................7

User Settings.........................................................7

Date and Time Settings ...............................................7

Temperature Overrides for a Load .......................................7

The Screen Backlight.................................................7

Installer Settings ......................................................8

Diagnostics ..........................................................8

Error Logs .........................................................8

Error Conditions.....................................................8

Sensors Status Screen ...............................................9

Safety and Ignition Module (SIM) .....................................10

Safety and Ignition Module Plus (SIM+) .................................10

SIM’s Status Indicators .............................................11

Fan Operation .....................................................11

Network Information.................................................11

Boiler Information...................................................12

Clean the Screen...................................................12

Advanced Diagnostics Screen.........................................12

System Settings .....................................................13

Other Operating Features ..............................................14

Prioritizing Loads.....................................................14

Reset Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Temperature Dierential Settings ........................................17

Daily Temperature Overrides............................................17

Unoccupied Mode ....................................................17

Summer Shutdown ...................................................18

External Control......................................................18

Multiple Boiler Networking: Boiler “Opt-out” to Serve Call for DHW ..............19

What to Consider for DHW Opt-out Boilers ...............................19

Alarm Contacts ......................................................20

Controller’s Operational States/Cycles ...................................20

V-10 TOUCH SCREEN BOILER CONTROLLER

CHAPTER 2 Usage...........................................21

Powering Up a Boiler ..................................................21

Programming a New Touchscreen Controller ..............................21

Setting Loads ........................................................22

Setting Loads Using the Express Setup ...................................22

Setting up Loads on a New Boiler ......................................22

Changing Settings in a Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Resetting a Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Setting Loads Using the Installer Settings..................................24

Setting Up Loads ...................................................24

Changing a Load Type for a Load ......................................25

Changing Settings in a Load Type .....................................25

Removing an Assigned Load Type from a Load ...........................25

Managing Errors ......................................................25

Clearing System Errors ................................................25

Viewing Errors.......................................................26

Clearing Entries in the Error Log.........................................26

Networking Multiple Boilers.............................................26

Conguring a Boiler as the Master Boiler ..................................28

Conguring a Subordinate Boiler ........................................30

Combining Loads .....................................................30

Basic (simple) mode ..................................................30

Full mode...........................................................30

What to Consider for Combining Loads ...................................32

Load Priority.......................................................32

Target Temperature .................................................32

Combining Two Loads.................................................32

Restricting Access to Areas in the Controller ..............................33

Turning On Password Control...........................................33

Turning O Password Control ...........................................33

Setting the Venting Material.............................................34

Setting Overrides .....................................................34

Switching a Boiler to Unoccupied “Away” Mode ...........................35

Turning On Unoccupied Mode ..........................................35

Removing a Boiler’s Unoccupied Mode ...................................35

Low Water Cuto: Resetting and Testing ..................................35

Resetting the Boiler after a LWCO Lockout.................................35

Testing the LWCO Function.............................................36

Hi-Limit Temperature: Resetting and Testing ..............................36

Resetting the Boiler after a Hi-Limit Lockout................................36

Testing the Hi-Limit Cuto Temperature Function ............................36

Testing Fan Operation .................................................37

Testing Fan Heat Output ..............................................37

Checking the Heat Output Values........................................37

Setting the Date and Time ..............................................37

Setting the Date and Time in a Boiler Connected to the Internet ................38

Setting the Date and Time in a Boiler Not Connected to the Internet .............38

INSTALLATION AND OPERATING INSTRUCTIONS

CHAPTER 3 Setup for Internet Access ...........................39

Connecting a Boiler’s Controller to an IP Network ..........................39

Setup to Access the IBC Portal ..........................................40

Registering a Boiler with IBC............................................40

Registering a Boiler from the Touchscreen Controller .......................40

Registering a Boiler on the IBC Portal...................................41

Accessing the IBC Portal...............................................44

BACnet Support ......................................................44

CHAPTER 4 Updating the Software Version .......................45

Updating Software in a Boiler Connected to the Internet .....................45

Updating Software in a Boiler Without Internet Access ......................45

Saving the Latest Software to a USB Using Windows ........................45

Saving the Latest Software to a USB Using a Mac Computer ..................47

Viewing a Controller’s Software Version ..................................47

CHAPTER 5 Troubleshooting ..................................49

CHAPTER 6 Diagrams .......................................51

Electrical Wiring Diagram ..............................................51

Thermostat Connections ..............................................52

Controller Board Layout................................................53

Sequence of Operation Diagram .........................................54

Denition of Terms .....................................55

Notes ..............................................60

Revision History.............................................61

V-10 TOUCH SCREEN BOILER CONTROLLER

CHAPTER 1 Concepts &

Features

This chapter describes features and concepts relating to the V-10 Touchscreen Boiler

Controller.

All VFC and SL series condensing boilers have an IBC V-10 boiler touchscreen controller.

The touchscreen controller is engineered to be backward compatible with previous IBC

5-button boiler controllers.

The controller provides:

• Control of up to 5 pumps – 1 boiler

pump + 4 separate load pumps

• Outdoor Reset control

• Set Point temperature regulation

• Domestic Hot Water (DHW)

• External control via 0-10VDC or

4-20mA signaling

• Alarm dry contacts

• Zoning of up to 4 loads

• Load Combining – simultaneous

operation of 2 loads with similar or

dierent water temperature

• The ability to manage and/or operate

in a network of up to 24 IBC VFC or

SL boilers

Advanced features:

• Express Setup menu for simple,

quick programming

• Software that can be updated in the

eld with an SD card, USB stick, or

via the Internet

• Set up conguration back-up and

cloning using an SD card, USB stick,

or via the Internet

• Advanced error messages with

visual display on the Home Screen

• Internet/LAN connectivity

• BACnet (with activation)

• Portal

OPERATING INSTRUCTIONS

Handling the Touchscreen

The touchscreen responds to a light nger touch on the screen.

If the touchscreen is:

• Left unattended, the screens will step back one screen at a time in 10-minute

intervals. The pop-up windows will also step back automatically in 2-minute intervals.

• Not activated for a user-dened period (10 minutes by default), the Home screen dims

to save power.

Caution

1

V-10 TOUCH SCREEN BOILER CONTROLLER

Getting to Know the Controller’s

Interface

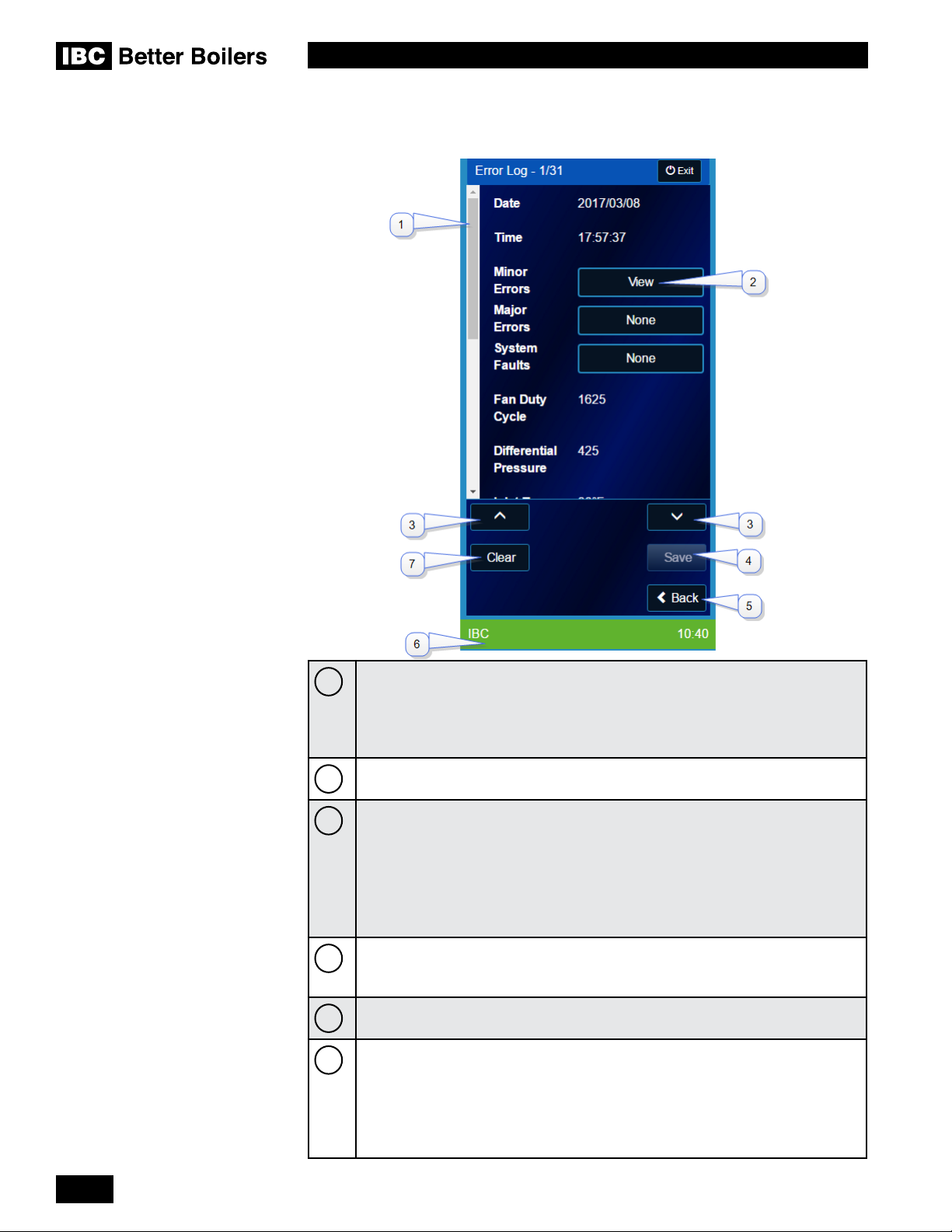

The slide bar (left side) allows the viewing of a list that is longer than the active

1

display area. For example, while editing a load in the installer menu, the list of

items is longer than the screen size. Simply touch and hold the slide bar until it

turns blue, and slowly drag it down to scroll down the list of items. You can also

tap the arrows at either end of the slide bar to move the bar up or down.

View button is available only in the Error Log to display minor errors, major

2

errors, or system faults associated with the logged error event.

The Up and Down arrows are available in the Error Log menu and enable you

3

to scroll through the list of event records, one at a time.

Left and Right arrows are available in the Load Proles screen to scroll

through the four separate loads plus the remote load if the boiler is operating as

part of a multi boiler network.

Typically the Save button saves the displayed settings and returns you to the

4

previous screen. However, in the Error Log screen, it gives you the ability to

save the error logs (e.g., to a USB).

Returns you to the previous screen without saving any changes. This button is

5

found at the bottom right on all Setting Screens and all menu screens.

Boiler Status Bar - Indicates if the boiler is in a normal, warning or alarm state.

6

When no warning or alarm state is present, the bar is green and the time is

displayed inside the green area. The bar can also display as yellow or red,

corresponding to a warning or to an alarm state. Text inside the bar indicates

the specic warning or alarm present. If more than one alarm is present, the text

display slowly rotates though the various alarm states.

2

OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

Screen Types

There are three screen types: menu screens, settings screens, and status display

screens.

Menu Screen

Menu screens provide a list of choices that lead to other screens. At the bottom of an

active screen, there is a Back button to return to the previous page.

Settings Screen

Accepts the settings displayed in a pop-up window and closes the window.

1

Ignores the settings displayed in a pop-up window and close the window.

2

OPERATING INSTRUCTIONS

3

V-10 TOUCH SCREEN BOILER CONTROLLER

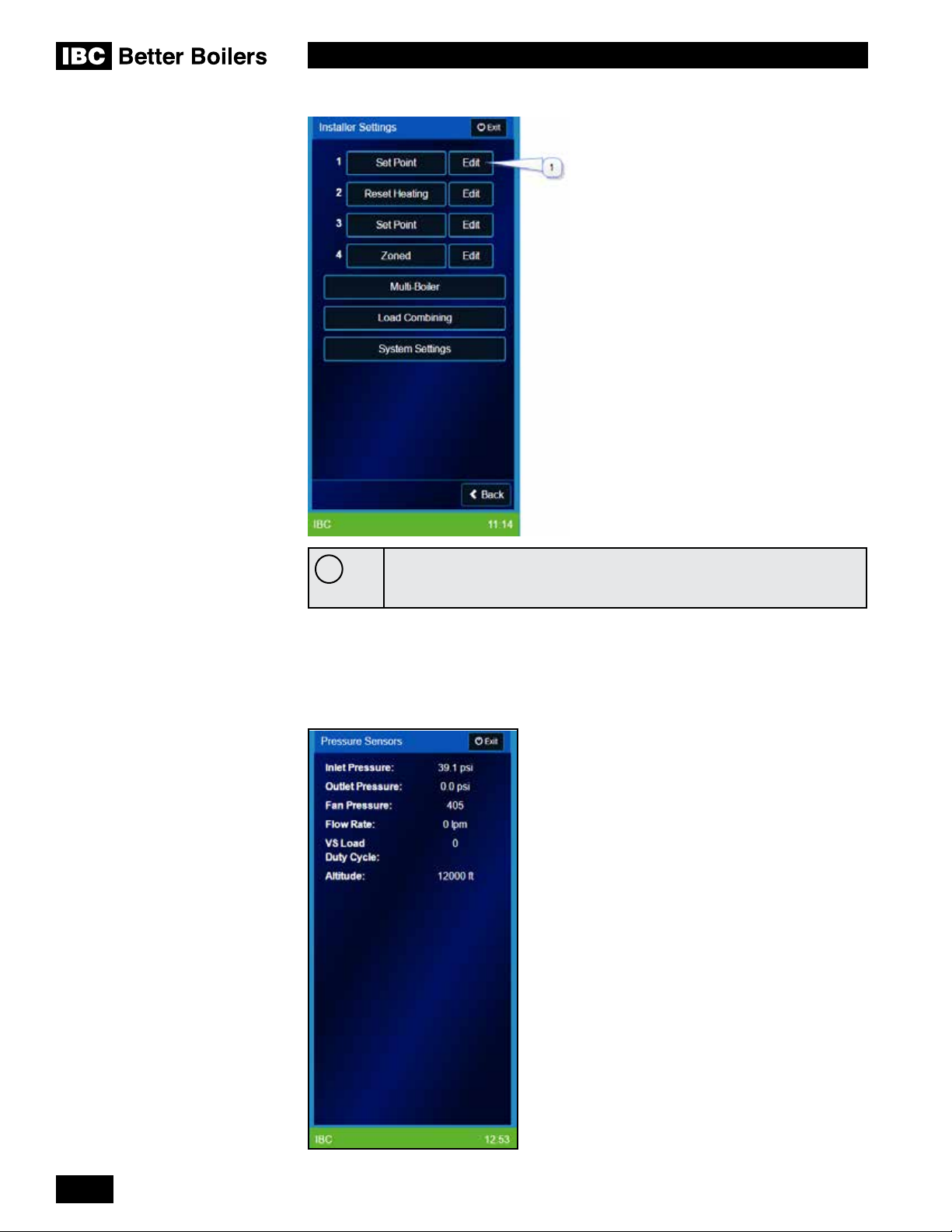

1

Is only available in the Installer Settings menu and active only on loads

that have been dened. Pressing Edit enters the Settings screen for the

corresponding load or setting.

Status Display Screen

Text describing various parameters is listed along with the current value for each.

Information cannot be entered or values changed on these screens. If there are no buttons

on the screen, touching the screen anywhere in the active area exits the screen.

4

OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

Home Screen

The Home screen includes basic boiler status information such as:

• The Title bar showing the boiler model number and boiler ID number.

• The current operating state (just below the title bar).

• The Load currently being serviced, if any.

• A list of up to eight of the current operating values.

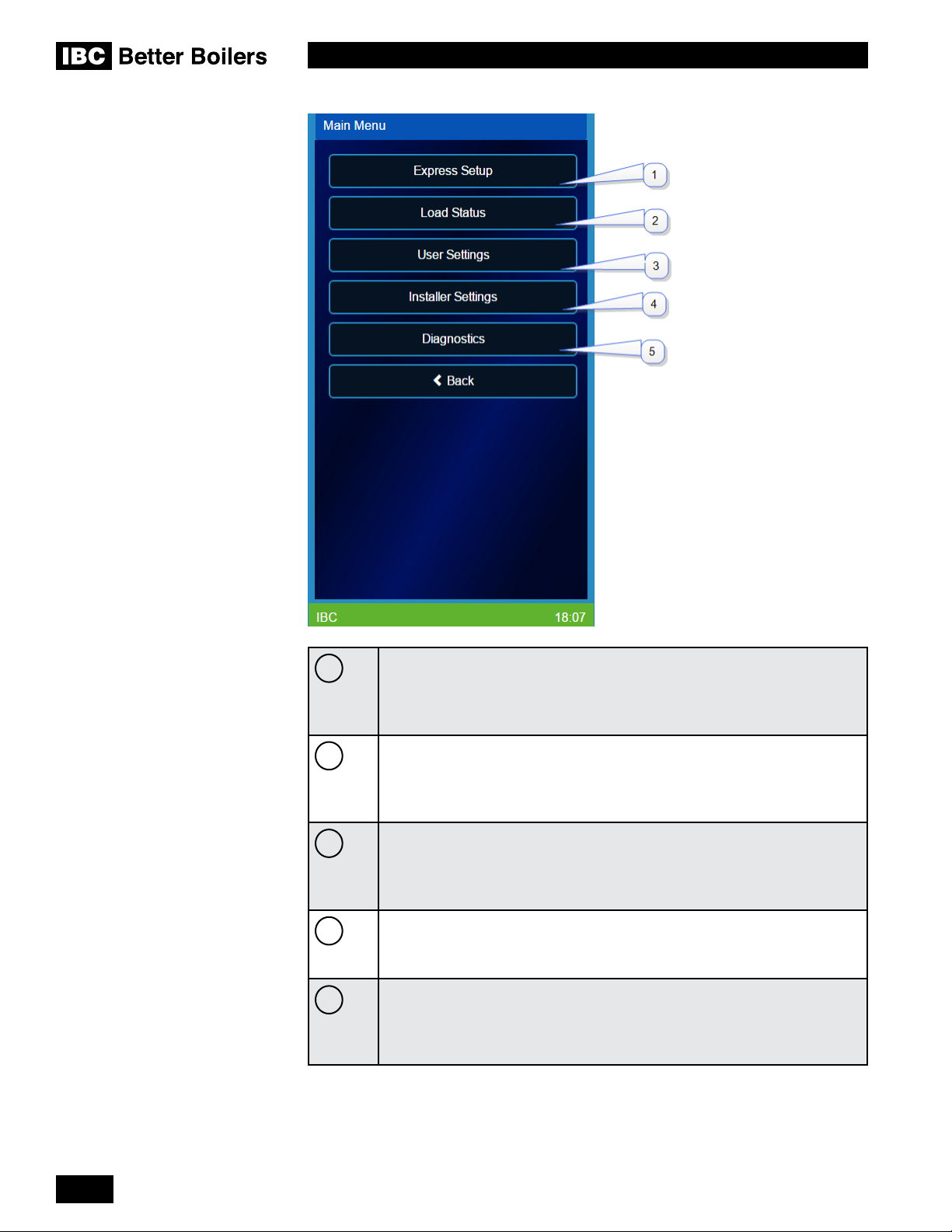

Main Menu

The Main Menu provides ve options that access operational and diagnostic information,

and allow the adjustment of control settings. To enter the Main Menu screen, tap

anywhere on the Home screen. If the display is dimmed, tap the screen twice.

OPERATING INSTRUCTIONS

5

V-10 TOUCH SCREEN BOILER CONTROLLER

1

Express Setup walks you through a basic setup of the controller. You can

select default values that will work for the selected load type. If you wish, you

can change these default settings later.

2

Load Status displays a menu screen with six possible selections to display

the current status details for the four individual loads, operating load

statistics, and operational load proles (graphs) for each load.

3

User Settings enables the user (installer or homeowner) to set or adjust the

time and date, overrides, screen brightness, hot water tank temperature,

occupied status as well as choose Imperial or Metric units.

4

5

Installer Settings provides access to the full functionality of the system for

the appropriately trained heating professional.

Diagnostics displays mostly information screens; for example, displays error

logs.

6

OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

Express Setup

Express Setup enables you to congure a boiler’s parameters using default values

including all the appropriate values to operate each load type under most operating

conditions.

Load Status

Load Status provides informational screens. For example, if you select:

• One of the Load 1 to 4 buttons:

• The status display screen lists specic operational information about that load in

real time.

• If a sensor is not connected to the controller (for example, a DHW sensor or the

Outdoor sensor), the screen shows n/c (Not Connected).

• Cycles/Day shows a running tally of the number of calls for heat that a load

has received in the last 24 hours. In general, fewer cycles per day equal better

eciency and usually better comfort.

• The Load Statistics button, a status screen lists the run time statistics for the boiler

including specics for each load.

• The Load Proles button, a screen displays each load, showing a bar graph prole

of the time the boiler is ring at various throttle levels.

User Settings

The User Settings screen is a combination menu and settings screen. Date & Time,

Overrides and Backlight are the three available menu buttons. The water Tank

Temperature is changed by touching the entry box.

Date and Time Settings

On the Time and Date settings screen, you can choose NTP Server or Internal. The

controller must be connected to the Internet for the NTP Server selection to work properly.

For instructions, see “Setting the Date and Time” on page 37.

Temperature Overrides for a Load

In the Overrides screen, you can enable the override program set for each load. When

you select the Edit button you can set the override temperatures with corresponding start

and end times for each load by day of the week. There are two override programs for each

day of the week.

For instructions on conguring overrides, see “Setting Overrides” on page 34.

The Screen Backlight

OPERATING INSTRUCTIONS

The Backlight setting is a power saving feature. The Backlight Settings screen provides a

slide bar to set the screen backlight level (brightness). Also, the Dim Time setting controls

the length of time there is no interaction with the touchscreen before the screen is dimmed.

7

V-10 TOUCH SCREEN BOILER CONTROLLER

Installer Settings

The advanced installer can access:

• Settings for assigning load types to four Loads.

• Multi-Boiler to set parameters in a boiler to operate as part of a group of boilers at

a site. For instructions on how to set up multiple boilers, see “Networking Multiple

Boilers” on page 26.

• Load Combining to set parameters to enable the boiler’s Load Combining

(previously known as Load Pairing) feature. For instructions on how to combine loads,

see “Combining Loads” on page 30.

• System Settings to perform security- and backup-related tasks such as:

• Restricting access to areas in the controller with password protection.

• Changing the default venting material.

Diagnostics

The Diagnostics menu is a valuable tool for the installer and service provider. It provides

mostly information such as error logs to help identify problems.

Error Logs

Errors are logged and stored in the controller memory. An error record includes the date,

time, classication, type(s) and the state of key boiler operating parameters at the time

the error event occurred. The controller can store a practically unlimited number of error

records.

The Error Log screen title bar shows “Error Log: (record no) (total no. of error records)”.

If there are no error records logged the title bar shows “Error Log: 1/0” and the Date

shows as End of Log. An Error record includes all the errors present at the time of the

error event.

Error Conditions

If the sensors indicate that the boiler is operating outside its limits, an error condition

occurs. The controller records any or all errors dating back to the original power-up,

including the date and time of the error.

There are three types of error conditions:

• Minor Errors

Minor errors result when an abnormal condition exists that does not present an

immediate safety hazard. The boiler shuts o the fuel and enters an extended purge,

followed by the error cycle of 5 minutes for all conditions other than maximum ignition

trials (a modied Major error which locks out for 1 hour after 3 unsuccessful ignition

attempts). Following the purge, the fan and pump are stopped until the end of the error

cycle. Normal operation then resumes.

8

OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

• Major Errors

Major errors result when a condition exists that may be a safety hazard. The boiler

enters an extended purge then the fan and pump are stopped. The boiler is in a

lockout, and must be checked and restarted by a service technician.

Exception: The Ign. Trials Exceeded error will time-out for one hour before the system

attempts re-ignition.

• System Errors typically relate to the touchscreen controller.

OPERATING INSTRUCTIONS

Users can:

• Display the error(s) present at the time of the error event.

• Clear (delete) all error log entries.

• Save an error log to an SD card or USB ash memory, inserted into the controller.

For a list of errors and their xes, see “CHAPTER 5 Troubleshooting” on page 49.

Sensors Status Screen

The Sensors status screen displays the current active value for each of the temperature

and pressure (e.g., water Flow Rate, VS Load Duty Cycle and the Altitude) sensors.

If a:

• Temperature sensor is not connected to the controller the text ‘n/c’ is displayed.

• Pressure sensor is not connected to the controller ‘0’ is displayed.

9

V-10 TOUCH SCREEN BOILER CONTROLLER

Safety and Ignition Module (SIM)

The SIM is a safety control used in certain models (SL 26-260 G3 and SL 40-399 G3). It

is certied to conform to the UL 60730-5-5 and ANSI Z21.20-2014 • CAN/CSA-C22.2 No.

60730-2-5-14 standards.

The SIM is available only in the 3rd-generation models. The module controls the boiler’s

gas valve, including:

• Direct spark automatic ignition

• Flame detection and current measurement

• Supply water temperature sensing

• Flue gas temperature sensing

• Supply water maximum temperature shutdown

• Flue gas maximum temperature shutdown

• Low water cut-o.

Users can perform:

• A LWCO test and reset.

• A hi-limit temperature test and reset.

For instructions on using the LWCO feature, see “Low Water Cuto: Resetting and

Testing” on page 35.

For instructions on using the hi-limit feature, see “Hi-Limit Temperature: Resetting and

Testing” on page 36.

Safety and Ignition Module Plus (SIM+)

The SIM+ is a safety control used in certain models (SL 14-115 G3 and SL 20-160 G3). It

is certied to conform to the UL 60730-5-5 and ANSI Z21.20-2014 • CAN/CSA-C22.2 No.

60730-2-5-14 standards.

The SIM

• Direct spark automatic ignition

• Flame detection and current measurement

• Supply water temperature sensing

• Flue gas temperature sensing

• Supply water maximum temperature shutdown

• Flue gas maximum temperature shutdown

• Low water cut-o

• VDC gas valve operation

+

controls the boiler’s gas valve and provides:

10

• Combustion fan operation.

Users can perform:

• A LWCO test and reset.

• A hi-limit temperature test and reset.

OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

For instructions on using the LWCO feature, see “Low Water Cuto: Resetting and

Testing” on page 35.

For instructions on using the hi-limit feature, see “Hi-Limit Temperature: Resetting and

Testing” on page 36.

Users can also test fan operation performance and check vents for blocks or leaks. For

instructions on fan testing, see “Testing Fan Operation” on page 37.

The SIM+ continuously communicates with the boiler’s main controller reporting sensor

readings and status. The sensor readings and error status (if any) are displayed on the

boiler’s touchscreen controller.

SIM’s Status Indicators

The SIM’s two status LEDs indicate the operating status as shown in the table below.

LED 1 LED 2 STATE

Rapid Flash Rapid Flash Power up or Resetting Startup checks and initialization

O O Standby

O On Pre-Purge or Inter-Purge

On On Heating

Rapid Flash On Igniting

O Flashing Lockout

Flash Alternately

with LED 2

Flash Alternately with LED 1 Fail-Safe A critical internal fault was detected.

DESCRIPTION, LED STATUS

INDICATION

LED1 O = No Flame or Sparking

LED 2 = Burner-On Call state

LED1 O = No Flame or Sparking

LED 2 = Burner-On Call state

LED 1 On = Flame detected

LED 2 = Burner-On Call state

LED 1 ashing = Electrode Sparking,

LED 2 = Burner-On Call state

An operating limit was exceeded or a

sequence failed or an external sensor

fault was detected.

Fan Operation

The Fan Operation screen displays specic information related to the current fan

operation.

OPERATING INSTRUCTIONS

The Fan Test Heat Out entry box allows the fan to be activated independently and set

to speeds corresponding to the entered Heat Out value. For example, for all models

(excluding the G3 models) the fan heat output MBtu should be close to the heat output.

You can use the Fan Test Heat Out feature when a boiler is not heating. If the boiler is

heating, you can check that the heat output values correspond. For instructions, see

“Testing Fan Operation” on page 37.

Network Information

The Network Information screen displays information related to the web interface and

BACnet settings of the boiler. Also available here is the Multi Boiler network information.

To set up an internet connection to register the boiler and to control and monitor the boiler

through the IBC Portal, see “Connecting a Boiler’s Controller to an IP Network” on page

39.

11

V-10 TOUCH SCREEN BOILER CONTROLLER

Boiler Information

Boiler Information lists basic information such as the controller software version and the

boiler model.

Clean the Screen

Clean the Screen enables the touchscreen to be de-activated (will not respond to touch)

for 60 seconds while the screen is being cleaned.

Note

Advanced Diagnostics Screen

The Advanced Diagnostics menu screen includes the following advanced level

selections for the experienced installer.

• The Display Parameters screen lists key operational parameters and their current

readings.

• The ATD Channels screen lists the raw, unltered input values from the analog

inputs.

Note

Users can:

• Clear Errors. This function clears any currently latched error states and forces the

controller to reassess the boiler’s error status and determine if any error state is still

present. We recommend using this method to clear errors because it is faster than a

power cycle.

• Perform an update to the controller’s software via an SD memory card, a USB

memory stick, or the Internet. For instructions on updating software, see “CHAPTER 4

Updating the Software Version” on page 45.

• Initiate a full boiler controller restart. A restart takes approximately two minutes to

complete.

• Reset factory defaults. This function returns all boiler operating parameters to their

factory default settings except for the Network and Date & Time settings. The error log

and operating history are not cleared. Reset Factory Defaults will take approximately

two minutes to complete.

12

• Calibrate the touchscreen.

resulting in the touch locations being out of line with the displayed touch points such as

buttons or entry boxes. Touchpad calibration resolves these alignment issues.

Over time the touch pad calibration can drift slightly

OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

System Settings

System Settings contains:

• Site Settings. Use to access boiler operating parameters that are not specic to any

load. Included are the load control type, primary pump purge time, manual pump

purge, venting material, and the variable speed output control settings.

• Network Settings. Use to assign the boiler its ID, address and network conguration

to support multi-boiler operation and to connect to internet data networks.

For instructions on connecting a boiler to the internet, see “CHAPTER 3 Setup for

Internet Access” on page 39.

• A security control setting that allows the Security mode to be set On or O. When

On is selected the User Password and Installer Password are displayed until OK or

Back are pressed.

For instructions on using security control, see “Restricting Access to Areas in the

Controller” on page 33.

• Licensing. Use to activate special add-on software packages such as BACnet.

• Advanced Settings. This setting is available only for IBC’s technical support sta

for troubleshooting.

• Backup & Restore. Use to back up or restore the boiler’s complete controller

conguration and settings to/from a USB memory stick or SD-Card inserted into the

controller.

The Backup/Restore Type can be This Boiler or Boiler Model:

* “This Boiler” creates or loads a copy of the conguration for the specic single

boiler.

* “Boiler Model” creates or loads a copy/clone of the conguration. This feature

facilitates the creation of a standard boiler conguration that can quickly be

loaded into another boiler of the same model.

OPERATING INSTRUCTIONS

13

V-10 TOUCH SCREEN BOILER CONTROLLER

Other Operating Features

Prioritizing Loads

When more than one load is dened, you can prioritize a scheduling routine to manage the

boiler’s operation. Typically, loads declared as DHW receive signicant - but not absolute

- priority. Multiple heating loads - with varying temperature targets - are run sequentially as

opposed to simultaneously (with a mixing valve).

The objective is to serve each load at the minimum possible temperature, as opposed to

running hot then mixing down (with hardware), saving the related hardware and fuel cost.

The approach optimizes the low temperature combustion benets of direct cool running of

a radiant oor. The large throttle turndown range coupled with outdoor reset means that

several loads can receive heat in turn, with less on/ o duty cycling than would occur with

other heat sources.

Default Values for Dened Loads

The boiler is shipped with default values for each type of declarable load (e.g., DHW,

radiant oor). The preset variables for DHW (a value of 85-87 on a 20-90 scale) give it

substantial priority, which declines over time if another load is calling. Spacing heating

loads (with Outdoor Reset) are given default values starting at a low of 28, while other

Set Point loads start with 62. Over time, such points are transferred between the loads in

accordance with the system rules.

The boiler automatically shifts between loads once the points totals reach an upset value.

Upon a load transfer, the burner modulates down to its base level and will then throttle up

as required for the new load. If competing loads have not been satised at the load switch

stage, the controller registers the ring rate and returns rapidly to the rate on the next

rotation.

Heat-apportioning can be changed in the Installer Settings input section.

Example: If baseboards (set up with Outdoor Reset as Load 3) are not providing the

desired heat, the on-time of the baseboards can be increased by increasing the Priority

value relative to the other declared channels (e.g., moving the Load 3 preset value from

43 to 50 or reducing another load’s value). Temperature targets for the under-served load

can also be raised in this example.

The basic function is that the dierence between settings equals the run time (in minutes,

for the initial cycle) of the higher load setting before switch-over to the simultaneously

calling load, e.g., DHW with priority set to 80 will run for about 35 minutes before switching

to a clashing load set with priority 45. Following the initial cycle, the competing loads will

switch back and forth after a further 10-minute interval pending satisfaction of one or both

loads.

To cause repeated unequal run times (for example, constant 35 vs 5 minute runs) you

need to integrate an external load removing relay or timer on one of the heat calls (contact

the Factory for details). Do not set each load to the top value, and in general, avoid equal

ratings.

14

Note

OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

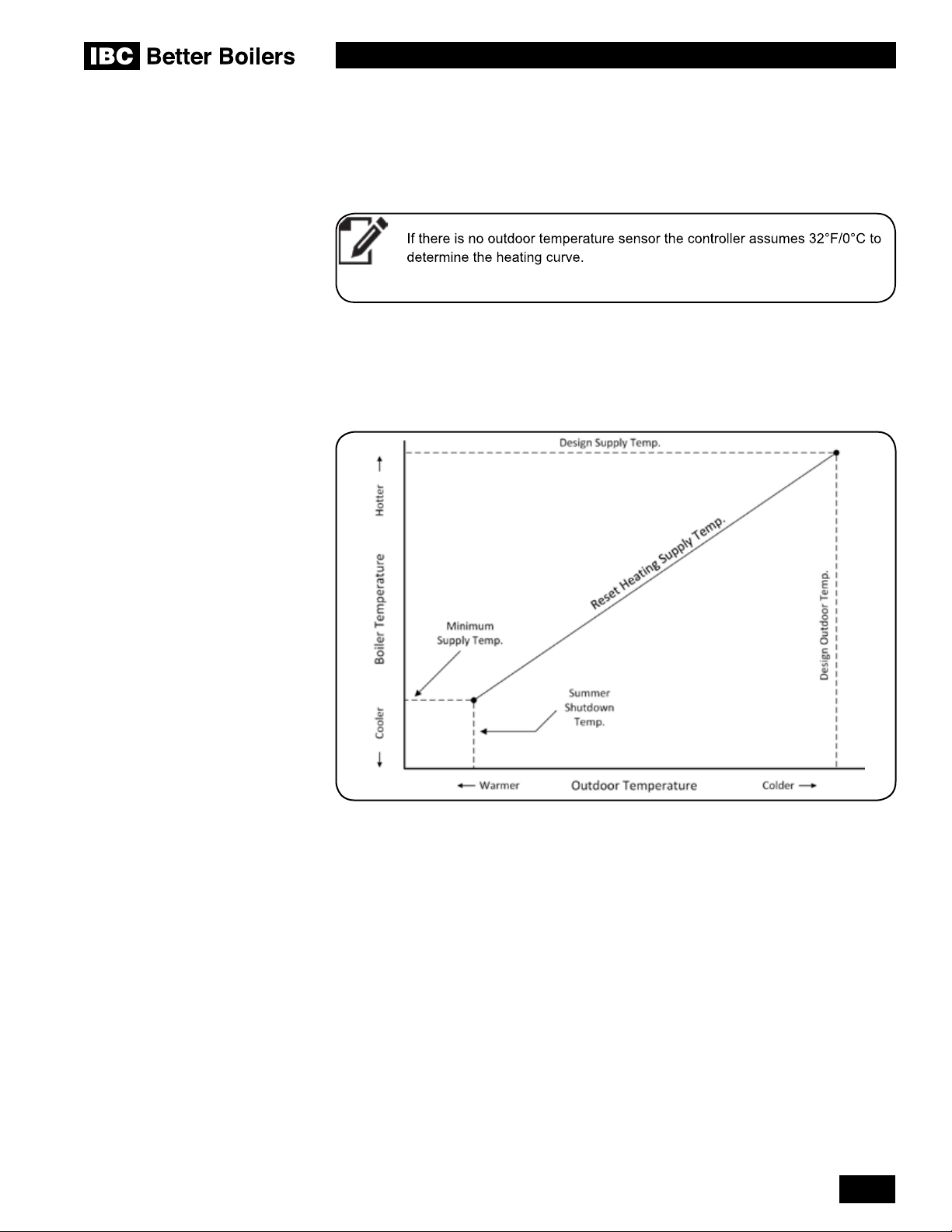

Reset Heating

The boiler oers reset heating or outdoor reset control as standard equipment. Reset

heating coordinates the control of boiler supply/outlet water temperature for space heating

with the outdoor temperature.

Note

Reset Heating uses variable supply water temperatures to compensate for the diering

rates of heat loss that a building experiences as the outdoor temperature changes. For

any outdoor temperature above the coldest day expected, reset heating automatically

uses lower heating temperatures than would otherwise be used. This saves energy

without sacricing comfort.

OPERATING INSTRUCTIONS

When applied within a condensing boiler, outdoor reset control oers direct and signicant

combustion eciency benets by allowing generally lower circulating water temperature.

This provides cooler return water to the boiler, promoting more condensation (= energy

capture).

Contacts are provided for connection of an outdoor sensor (shipped with each boiler) to be

placed in an appropriate outdoor position (typically on the north face of the building away

from any heat source). The temperature management algorithm exes the boiler supply

temperature according to heating curves that are automatically called up through the load

declaration process.

15

V-10 TOUCH SCREEN BOILER CONTROLLER

Open Loop Reset System

In an “open loop” reset system, a room or zone thermostat is used to send a call for

heat over a 24VAC lead. This opens the respective zone valve, and signals the boiler to

re using onward leads to the boiler’s dry contacts (use one of the connections marked

“Therm 1, 2, 3 or 4” on the TB2 terminal strip). Gang such leads in parallel from multiple

zone valves for single connection to the boiler. Note that typical room thermostats simply

provide a call for heat. They do not control the circulating water temperature from the

boiler in an open loop reset system. Adjustment of a room thermostat from 72°F/22°C to

86° F/30°C will make no further dierence to the delivered temperature if the oor slab has

stabilized at the boiler temperature determined by the reset curve.

Outdoor Reset

Where outdoor reset is applied without the indoor sensor feedback option, some manual

adjustment may be required to achieve the desired comfort level.

Note

Fine adjustment can be made by editing the Indoor Setpoint ° variable, on the Reset

Heating settings screen. To increase heat (e.g., from 72°F/22°C to 74°/23°C) move the

Indoor Setpoint ° value upward (warmer) from the level otherwise chosen. This shifts the

position of the reset curve, and adjusts the boiler water temperature by a similar amount.

Do not adjust the Design Indoor ° value. Moving the Design Indoor ° value upwards with

the Indoor Setpoint ° adjustment will be ineective.

Optional Indoor Temperature Sensor

An optional indoor temperature feedback routine can be activated with the installation of

an indoor sensor, connected to the designated TB2 contacts to automate adjustment of

the outdoor reset routine.

Note

The key inputs on initial setup are:

1. Design Outdoor °

– the coldest expected outdoor temperature typically experienced

at the installation site.

2. Design Supply °

3. Design Indoor °

Setpoint °

– the desired boiler outlet temperature to occur on the coldest day.

- the temperature value that anchors the reset curve. The

Indoor

setting is the primary means for the user to “bias” the outdoor reset routine

to add or reduce heat.

16

4. Summer Shutdown - this value is essential for the reset curve to calculate the

correct water temperature.

If Reset Heating is selected and there is no signal received from the Outdoor Sensor, the

controller assigns a provisional 32°F/0°C value and adopts the appropriate temperature

target from the relevant reset curve.

OPERATING INSTRUCTIONS

Loading...

Loading...