Page 1

FWA8208 Series

Networking Appliance

Users Manual

Version: 1.1

0

Page 2

Table of Contents

Chapter 1 Introduction 3

Chapter 2 System Specification ............................................................................................................ 4

Chapter 3 Hardware Configuration ....................................................................................................... 6

Chapter 4 Console Mode Information ................................................................................................. 14

Chapter 5 Open the Chassis ............................................................................................................... 16

Chapter 6 Installing DDR3 Memory .................................................................................................... 16

Chapter 7 Installing CompactFlash Card ............................................................................................ 17

Chapter 8 Removing and Installing the Battery ................................................................................... 17

Chapter 9 Installing 2.5” HDD (FWA8208 & FWA8208-RPSU) ........................................................... 18

Chapter 10 Installing Optional Dual 2.5” HDD Kit ................................................................................ 19

Chapter 11 Installing Add-on Card ...................................................................................................... 20

Chapter 12 Installing Mini PCI-e Card ................................................................................................. 20

Chapter 13 BIOS Information .............................................................................................................. 21

Chapter 14 Watchdog Timer Configuration ......................................................................................... 33

Chapter 15 Digital I/O Sample Configuration ...................................................................................... 37

Chapter 16 Drivers Installation ............................................................................................................ 42

Appendix-A I/O Port Address Map ....................................................................................................... 53

Appendix-B Interrupt Request Lines (IRQ) ........................................................................................... 53

Appendix-C FWA8208 Series Configurations ..................................................................................... 54

1

Page 3

Foreword

To prevent damage to the system board, please handle it with care and follow the measures below,

which are generally sufficient to protect your equipment from static electricity discharge:

When handling the board, use a grounded wrist strap designed for static discharge elimination grounded

to a metal object before removing the board from the antistatic bag. Handle the board by its edges only;

do not touch its components, peripheral chips, memory modules or gold contacts.

When handling processor chips or memory modules, avoid touching their pins or gold edge fingers.

Return the Network Appliance system board and peripherals back into the antistatic bag when not in use

or not installed in the chassis.

Some circuitry on the system board can continue to operate even though the power is switched off.

Under no circumstances should the Lithium battery cell used to power the real-time clock be allowed to

be shorted. The battery cell may heat up under these conditions and present a burn hazard.

WARNING!

1. "CAUTION: DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED.

REPLACE ONLY WITH SAME OR EQUIVALENT TYPE RECOMMENDED BY THE

MANUFACTURER. DISCARD USED BATTERIES ACCORDING TO THE

MANUFACTURER’S INSTRUCTIONS"

2. This guide is for technically qualified personnel who have experience installing and configuring

system boards. Disconnect the system board power supply from its power source before you

connect/disconnect cables or install/remove any system board components. Failure to do this can

result in personnel injury or equipment damage.

3. Avoid short-circuiting the lithium battery; this can cause it to superheat and cause burns if touched.

4. Do not operate the processor without a thermal solution. Damage to the processor can occur in

seconds.

5. Do not block air vents at least minimum 1/2-inch clearance required.

2

Page 4

Chapter 1 Introduction

FWA8208 series was specifically designed for the network security & management market.

Network Security Applications:

• Firewall

• Unified Threat Management (UTM)

• Virtual Private Network (VPN)

• Proxy Server

• Caching Server

Network Management Applications:

• Load balancing

• Quality of Service

• Remote Access Service

The FWA networking appliance product line covers the spectrum from offering platforms

designed for:

• SOHO

• SMB

• Enterprise

Each product is designed to address the distinctive requirements of its respective market

segment from cost effective entry-level solutions to high throughput and performance-bound

systems for the Enterprise level.

3

Page 5

Chapter 2 System Specification

Product Name

FWA8208

Form Factor

19” 1U Mainstream Networking Product

Motherboard

MB967

CPU

Intel® LGA1155 Series Processors

Chipset

Intel® Panther Point C216 PCH

Supported CPUs

Intel® Xeon E3-1275 v2

Intel® Xeon E3-1225 v2

Intel® Core i7-3770

Intel® Core i5-3550S

Intel® Core i3-3220

Intel® Celeron G540

Intel® Celeron G440

Intel® Celeron G1620

Intel® Celeron G2120

Intel® Pentium G850

Network

Seven onboard GLAN + one Management (ATM 8.0)

Two segments hardware Bypass

Expansion Slot

Two PCI-e x8 Golden Finger

CF Card Socket

Mini PCI-e Socket (m-SATA compatible)

CFast card socket x1

Storage

One internal 2.5” HDD (FWA8208 & FWA8208-RPSU)

One internal 3.5” HDD (FWA8208-2SLOT)

Front Panel

Two RJ-45 1x4 connectors for Eth1~4 & 5~6

USB 3.0 x2

RJ-45 (for console, COM1)

Three LEDs for Power, Bypass & Status

Factory Mode Restore Reset Switch

Rear Panel

PSU inlet

1x or 2x Slot (Depend on product SKU)

USB Port

Two USB 3.0 ports at front panel

USB 3.0 box header on board

Four USB 2.0 pin header on board

ATM

ATM 8.0

TPM

nuvoTon WPCT210 TPM1.2

VGA

Pin header on board

LCM

2x16 characters LCM

Watchdog Timer

256 segments, 0, 1, 2…255 sec/min

Power Supply

300W Single PSU (FWA8208 & FWA8208-2SLOT)

275W 1+1 redundant PSU (FWA8208-RPSU)

Dimensions

44 (H) x 440 (W) x 406.5 (D) mm

Operation Temperature

0 ~ 45 ˚ C

Storage Temperature

-20 ~ 70 ˚ C

4

Page 6

Operation Humidity

5% ~ 95%

Certifications

CE, FCC

Compatible Front

Expansion Cards

IBP161: 4-port RJ-45 10/100/1000 Copper LAN Module Card

IBP162: 2-port 10 GbE SFP+ LAN Module Card

IBP163: 2+2 ports GbE Copper or SFP LAN Module Card

IBP164: Crypto Acceleration Card

5

Page 7

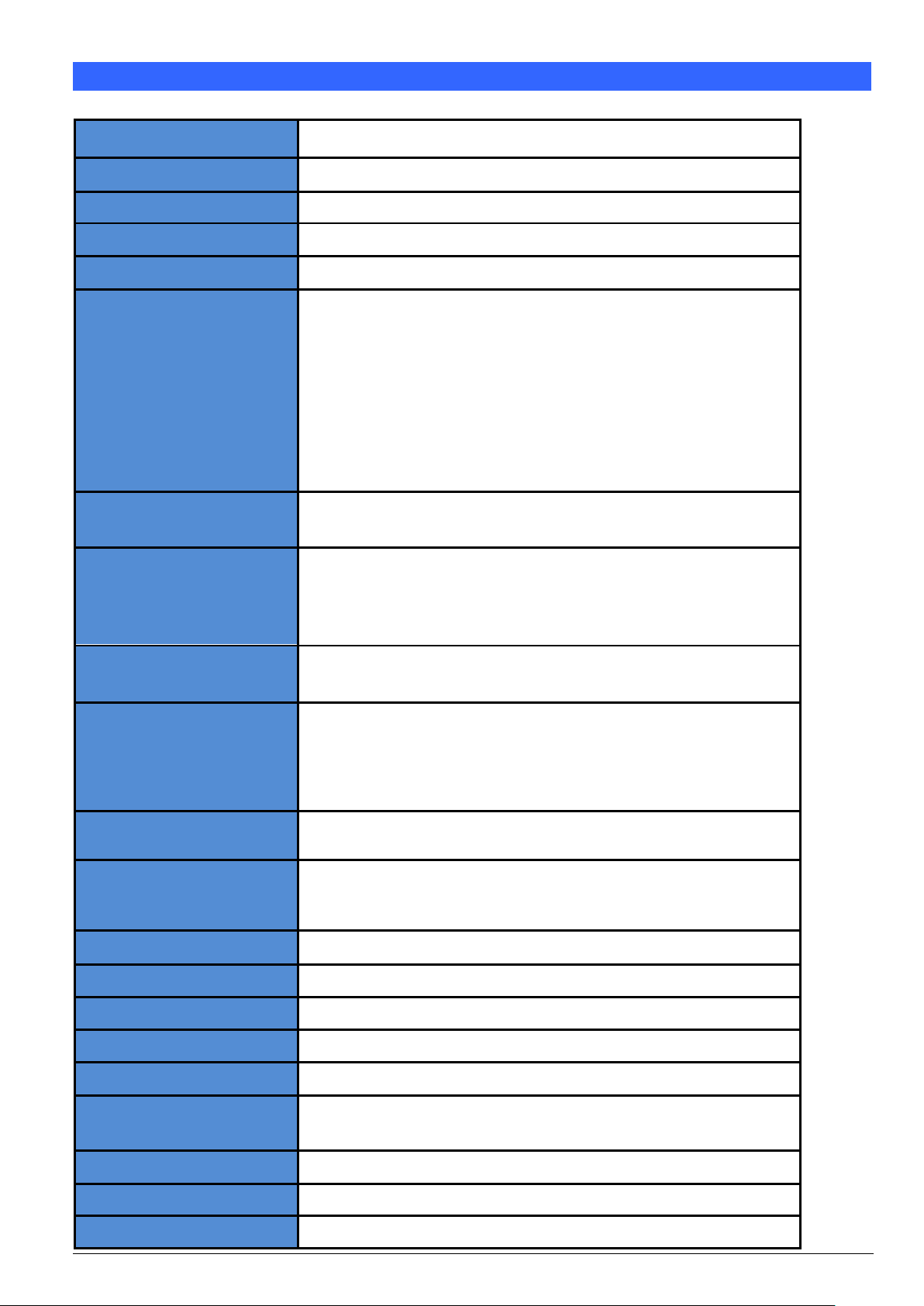

Chapter 3 Hardware Configuration

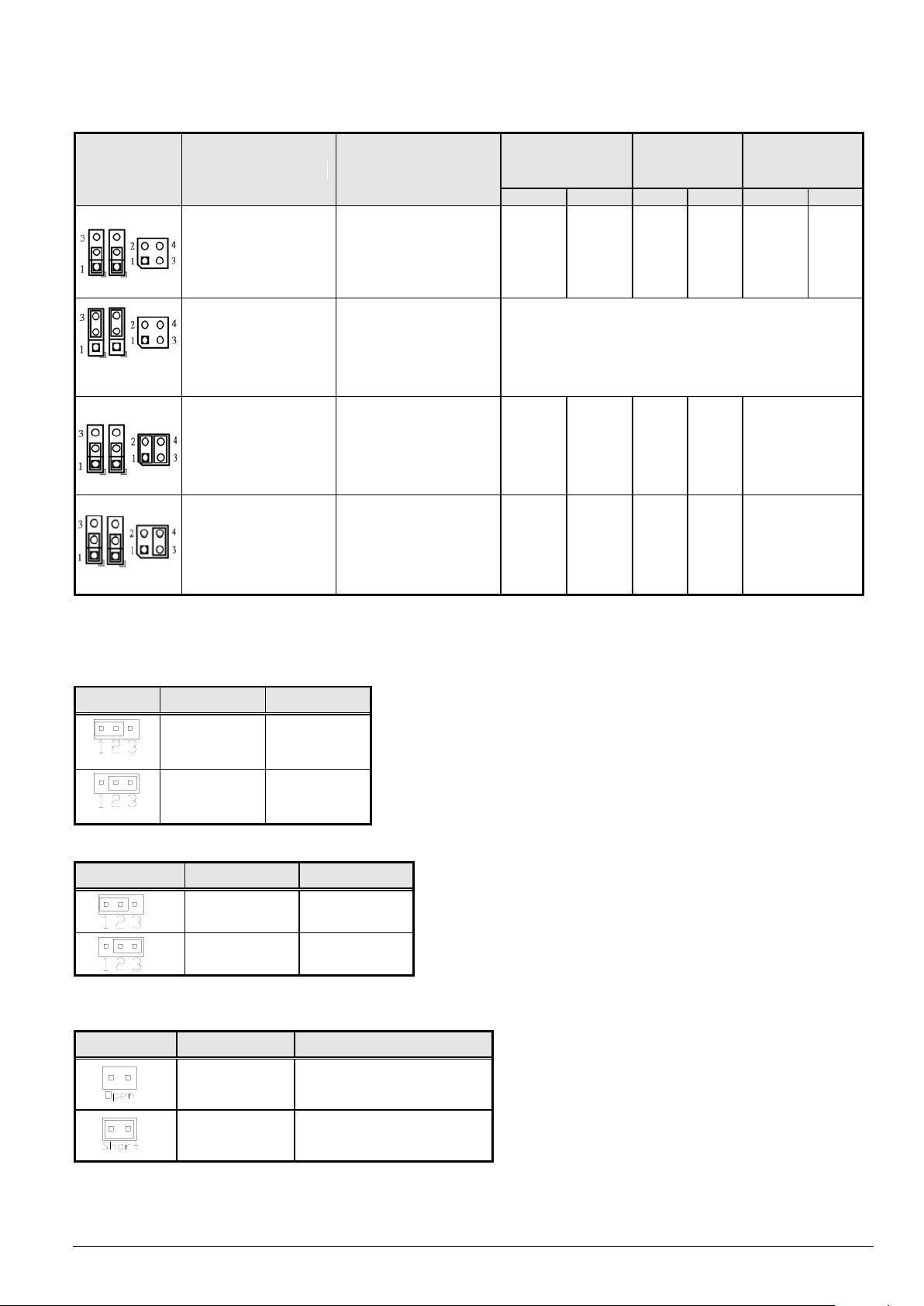

Jumper Locations on MB967

6

Page 8

JP3

Setting

Function

Pin 1-2

Short/Close

d

Normal

Pin 2-3

Short/Close

d

Clear CMOS

JP3

Setting

Function

Pin 1-2

Short/Closed

Normal

Pin 2-3

Short/Closed

Clear ME RTC

JP7

Setting

Function

Open

Disable

(Default)

Short/Closed

Enable to update BIOS

JP6,JP5

JP4

Setting

Function

Power OFF

Power ON

Power ON,

OS run

software

Normal

Bypass

Normal

Bypass

Normal

Bypass

JP4 Pin 1-2 & 3-4

Open

JP5,JP6 Pin 1-2

Closed

System will bypass

LANs upon the time

out of watchdog

timer.

JP4 Pin 1-2 & 3-4

Open

JP5,JP6 Pin 2-3

Closed

System LANs bypass

function controlled by

SIO GPIO43&44 or

BIOS Select.

By BIOS Setting

JP4 Pin 1-2 & 3-4

Closed

JP5,JP6 Pin 1-2

Closed

System will reboot

upon the time out of

watchdog timer.

LAN Bypass &

System reboot

JP4 Pin 3-4 Closed

& 1-2 Open

JP5,JP6 Pin 1-2

Closed

System will bypass

LANs & reboot upon

the time out of

watchdog timer.

LAN Normal &

System reboot

Default

Setting

Jumper Settings on MB967

JP6, JP5, JP4: Bypass LANs & Reboot Setting

JP2: Clear CMOS Contents

Use JP2 to clear the CMOS contents. Note that the ATX-power connector should be disconnected from the board before

clearing CMOS.

JP3: Clear ME RTC Contents

JP7: Flash Descriptor Security Override

(ME BIOS Update Jumper)

7

Page 9

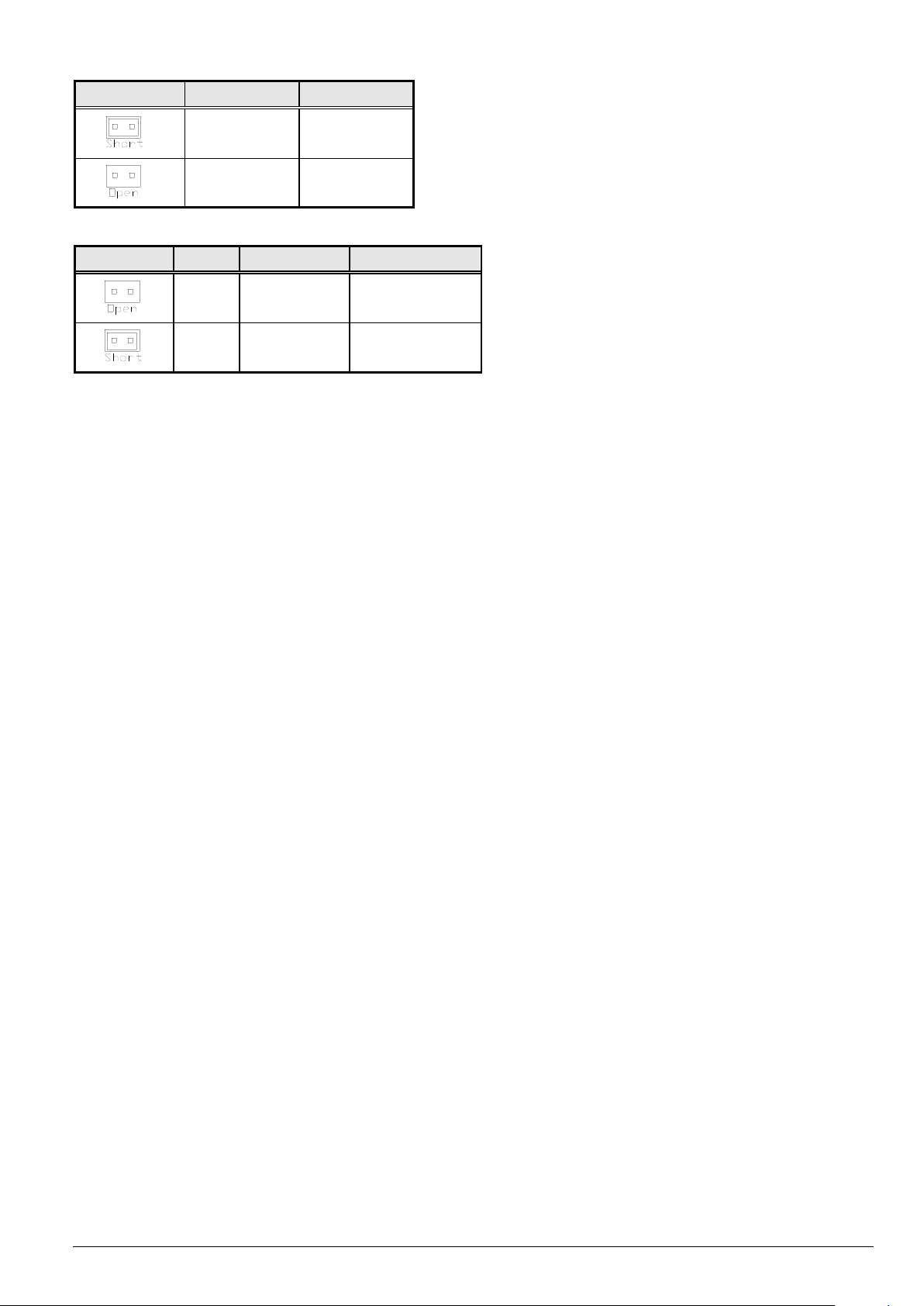

JP9: ATX & AT Mode Select

JP9

Setting

Function

Short/Closed

AT Mode

(Default)

Open

ATX Mode

J17

Setting

Function

Remarks

Open

Combine to

1x16

For CPU with

1x16 support

Short /

Closed

Separate

to2x8

Default for CPU

with 2x8 support

J17: PCIE1 & PCIE2 Golden Finger PCI-e Configuration

8

Page 10

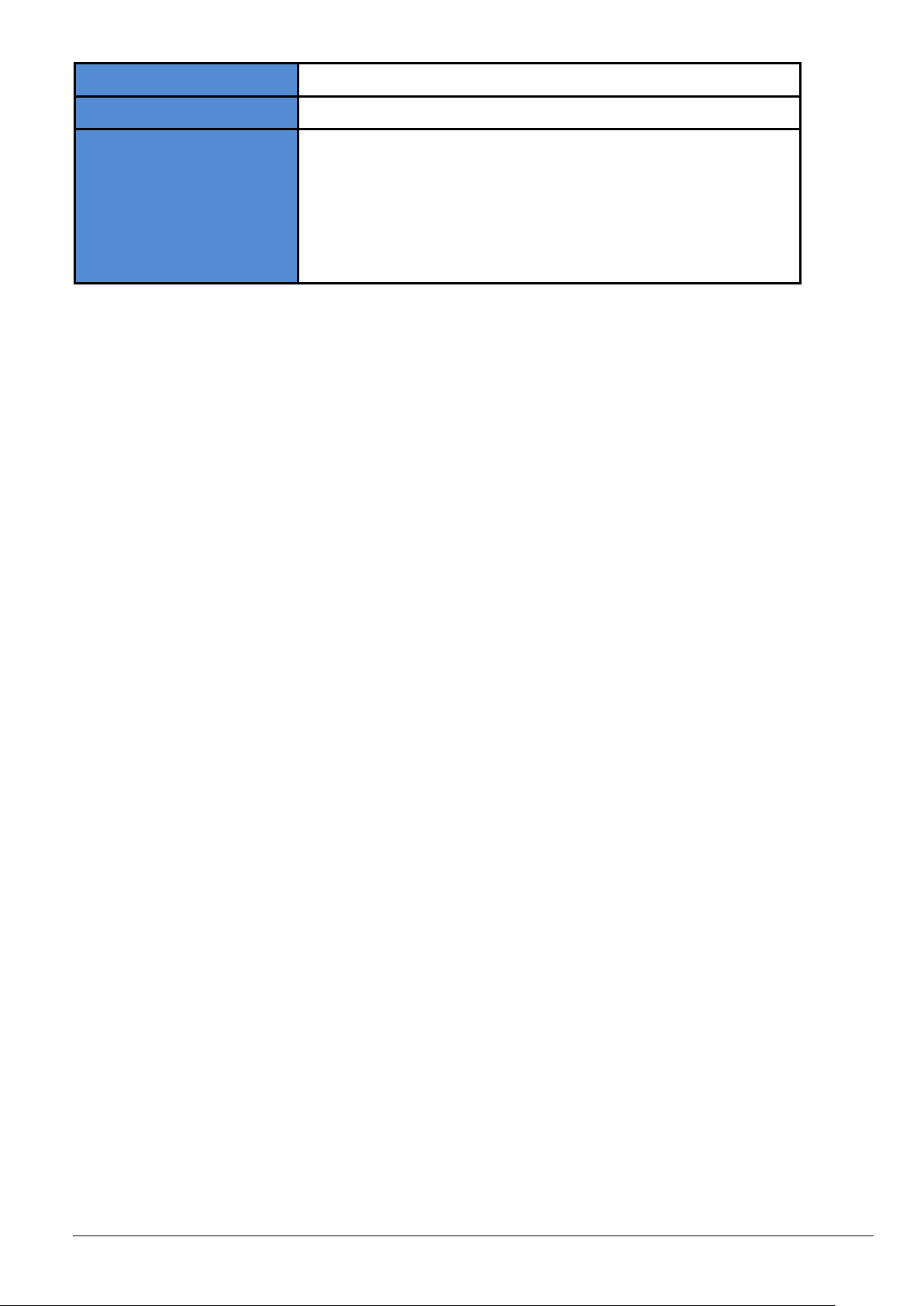

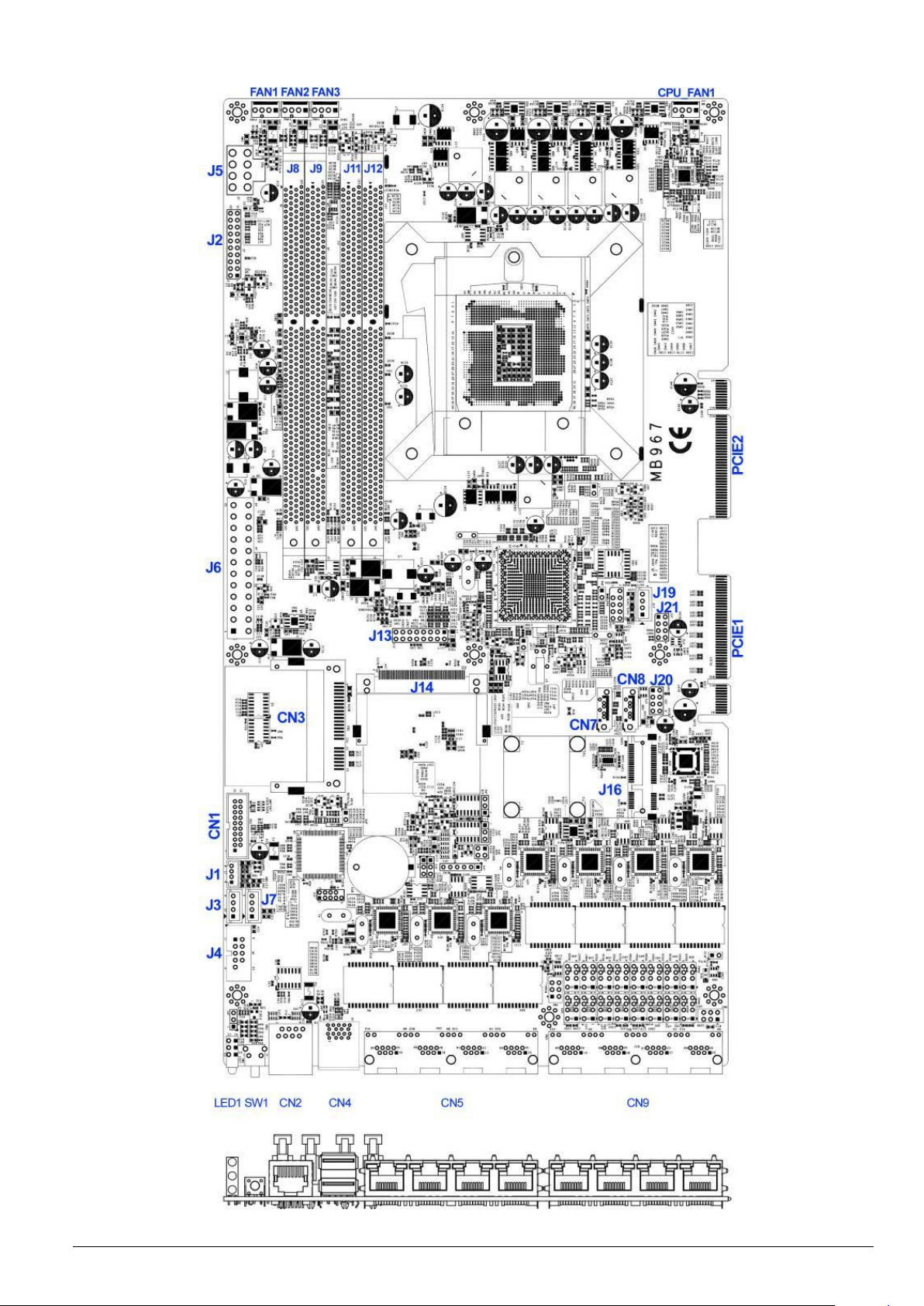

Connector Locations on MB967

9

Page 11

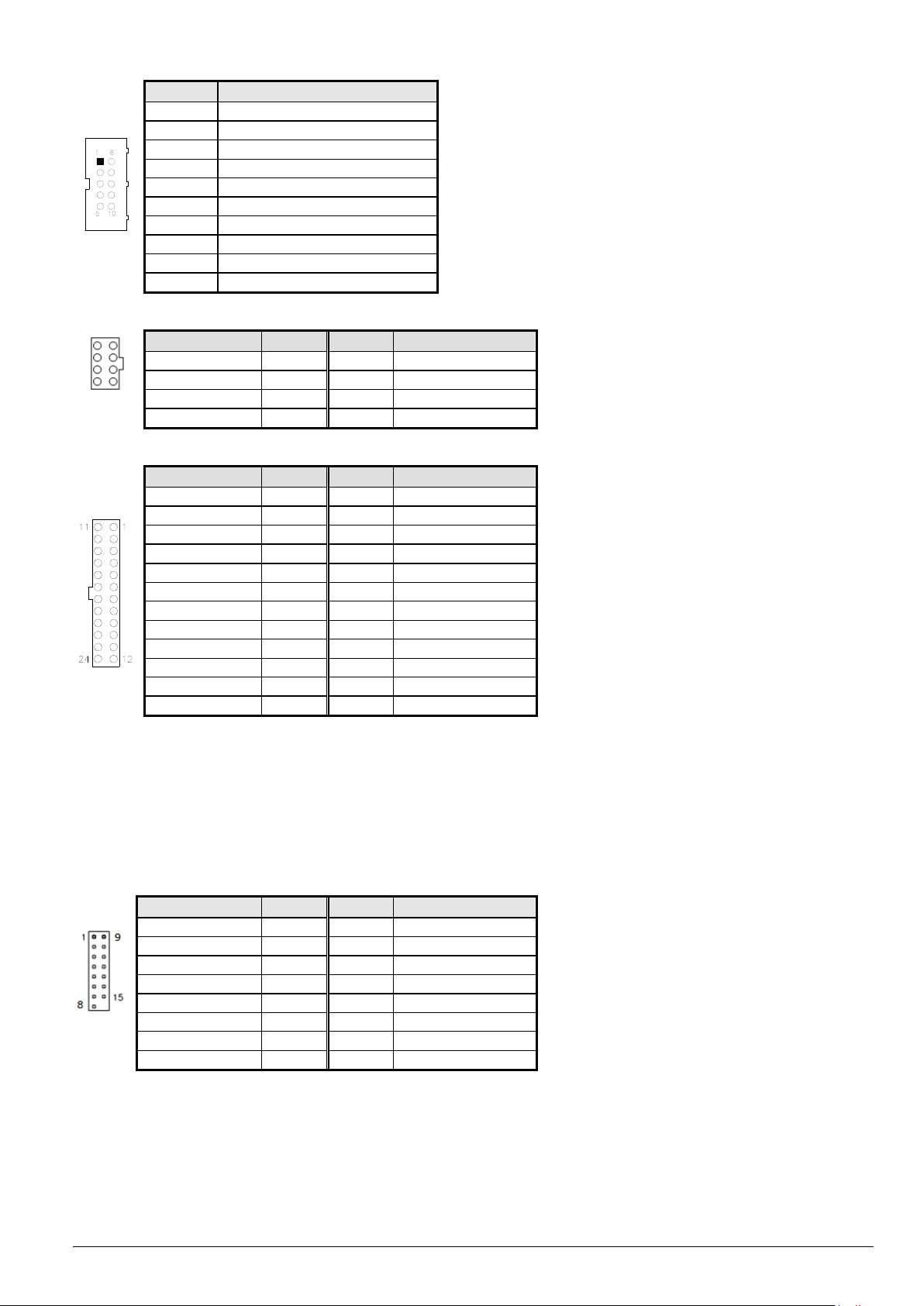

CN1: USB 3.0 Box Header

Pin #

Signal Name (RS-232)

1

RTS, Request to send

2

DTR, Data terminal ready

3

TXD, Transmit data

4

Ground

5

Ground

6

RXD, Receive data

7

DSR, Data set ready

8

CTS, Clear to send

Pin #

Signal Name

1

Ground

2

TX+

3

TX-

4

Ground

5

RX-

6

RX+

7

Ground

Pin #

Signal Name

1

+5V

2

GND

3

GND

4

+12V

Signal Name

Pin #

Pin #

Signal Name

PWR LED +

1 2 SPK +

NC

3 4 NC

PWR LED- (GND)

5 6 SPK – (GND)

NC

7 8 +5V

GND

9

10

NC

GND

11

12

NC

PWR_SW

13

14

PWR_SW

SLED+

15

16

SLED-

GND

17

18

RST

HDD LED +

19

20

HDD LED -

14

CN2: COM1 RJ45 Connector

CN3: CFast Connector

CN4: USB Connector

CN5, CN9: LAN Connectors

CN7, CN8: SATA HDD Connector

J1, J3, J7, J19: Power Output Connector

J2: Front Panel Function Connector

10

Page 12

J4: COM2 Serial Port

Pin #

Signal Name (RS-232)

1

DCD, Data carrier detect

2

RXD, Receive data

3

TXD, Transmit data

4

DTR, Data terminal ready

5

Ground

6

DSR, Data set ready

7

RTS, Request to send

8

CTS, Clear to send

9

RI, Ring indicator

10

No Connect.

Signal Name

Pin #

Pin #

Signal Name

+12V

5

1

Ground

+12V

6 2 Ground

+12V

7 3 Ground

+12V

8 4 Ground

Signal Name

Pin #

Pin #

Signal Name

3.3V

13 1 3.3V

-12V

14 2 3.3V

Ground

15 3 Ground

PS-ON

16 4 +5V

Ground

17 5 Ground

Ground

18 6 +5V

Ground

19 7 Ground

-5V

20 8 Power good

+5V

21 9 5VSB

+5V

22

10

+12V

+5V

23

11

+12V

Ground

24

12

+3.3V

Signal Name

Pin #

Pin #

Signal Name

R

1 9 +5V

G

2

10

GND

B

3

11

NC

NC

4

12

SPD1

GND

5

13

Hsync

GND

6

14

Vsync

GND

7

15

SPCLK

GND

8

J5: ATX 12V Power Connector

J6: 24-pin ATX Power Connector

J8, J9: Channel B DDR3 Socket

J8, J9 are the second-channel DDR3 sockets.

J10: LPC Debug Port (Reserved for factory use only)

J11, J12: Channel A DDR3 Socket

J11, J12 are the first-channel DDR3 sockets.

J13: VGA Box Header

J14: Slim Type II Compact Flash Connector

J16: Mini PCI-e Card & m-SATA Connector

J18: SPI Debug Port (Reserved for factory use only)

11

Page 13

J20, J21: USB 2.0 Pin Header

Pin #

Signal Name

1

Ground

2

+12V

3

Rotation detection

4

Control

Pin #

Signal Name

1

Ground

2

+12V

3

Rotation detection

4

Control

Signal Name

Pin #

Pin #

Signal Name

GND

1

2

PCH

GPIO7

Signal Name

Pin #

Pin #

Signal Name

SIO GPIO32

C1

A1

SIO GPIO33

Bypass LED-

C2

A2

Bypass LED+

POWER LED-

C3

A3

POWER LED+

STATUS LED

GPIO33

GPIO32

YELLOW

H L RED

L

H

C1

C2

C3

A1

A2

A3

FAN1, 2, 3: System Fan Power Connector

FAN1/2/3 are 4-pin headers for System fan power.

CPU_FAN1: CPU Fan Power Connector

SW1: Software reset button

PCIE1: PCI-e x8 Golden Finger 1

PCIE2: PCI-e x8 Golden Finger 2

LED1: Power, Bypass & Status LED

IO Base:

Read IO 0x500 and set bit 7 to “1” (Enabled GPIO function)

Read IO 0x504 and set bit 7 to “1” (GPIO act as GPI )

Read IO 0x50C and check the bit 7 (Control Pin)

Note: SW3 is controlled by GPIO only.

Index port: 4E

Data port: 4F

Device: 06

30h bit1 = 1

C0h set bit2, bit3 = 1 for GPO

C3h set bit2, bit3 = 1 for Push Pull

C1h bit2, bit3 (Control pin) for GPO32, 33

12

Page 14

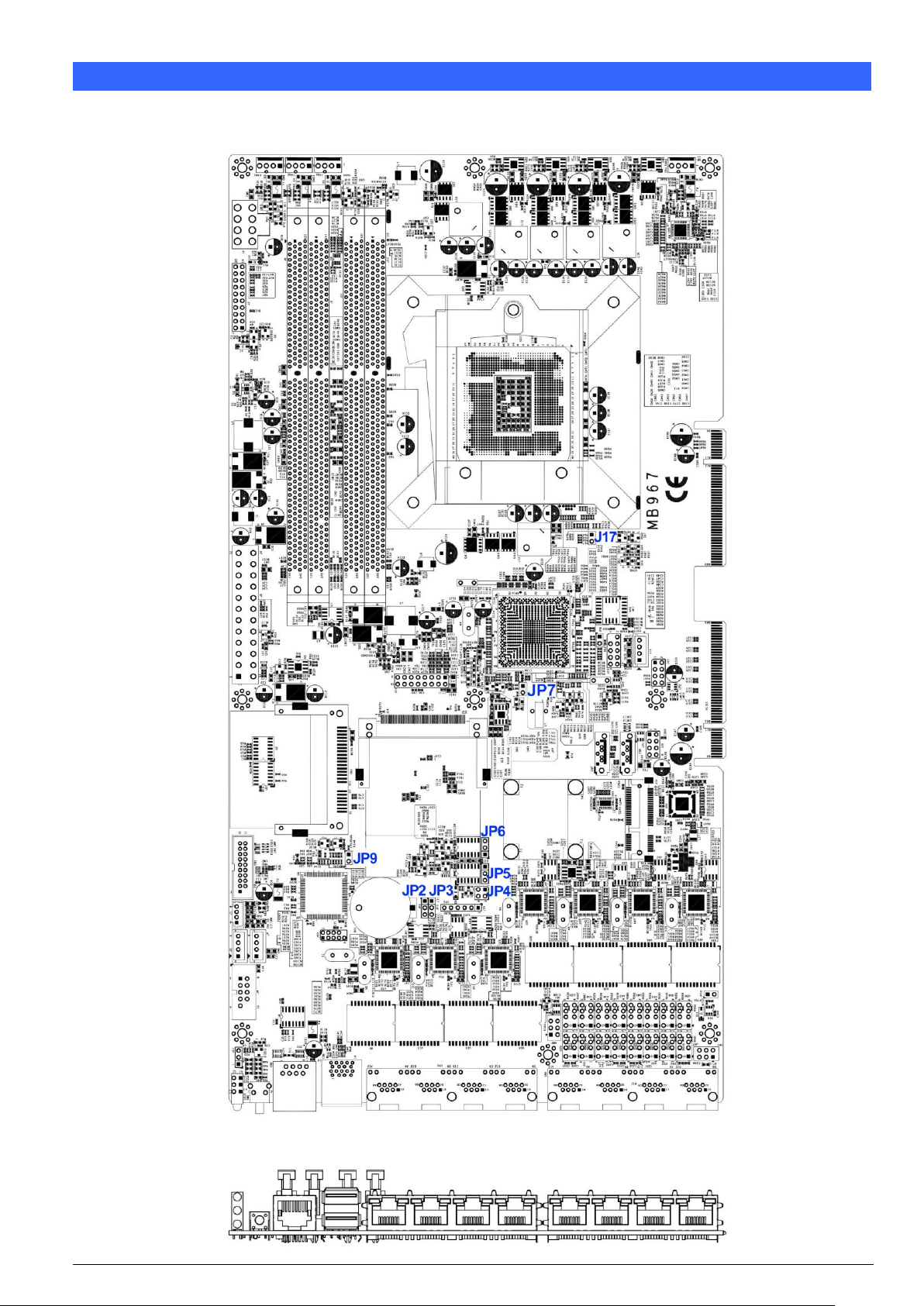

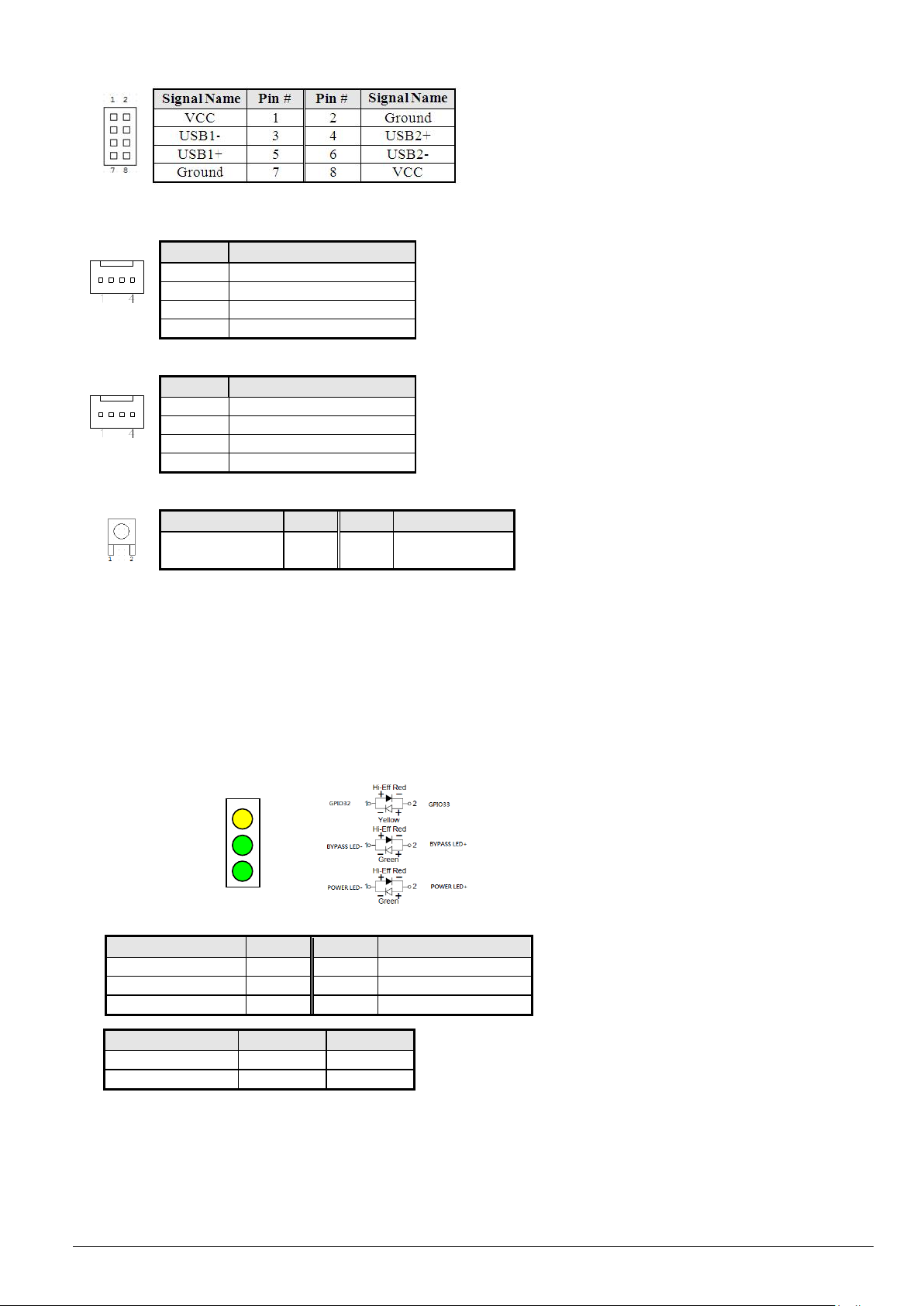

Front Panel Features

3x Smart Fans

One or two

Add-on Card Expansion

Slot Opening

300W Power Supply

LCM

Console

LEDs

Management Port

Eth1 2 3 4 5 6 7 8

Optional

Front Expansion Card

275W 1+1 Redundant Power Supply

One Add-on Card

Expansion Slot Opening

Rear Panel Features

FWA8208 & FWA8208-2SLOT

FWA8208-RPSU

13

Page 15

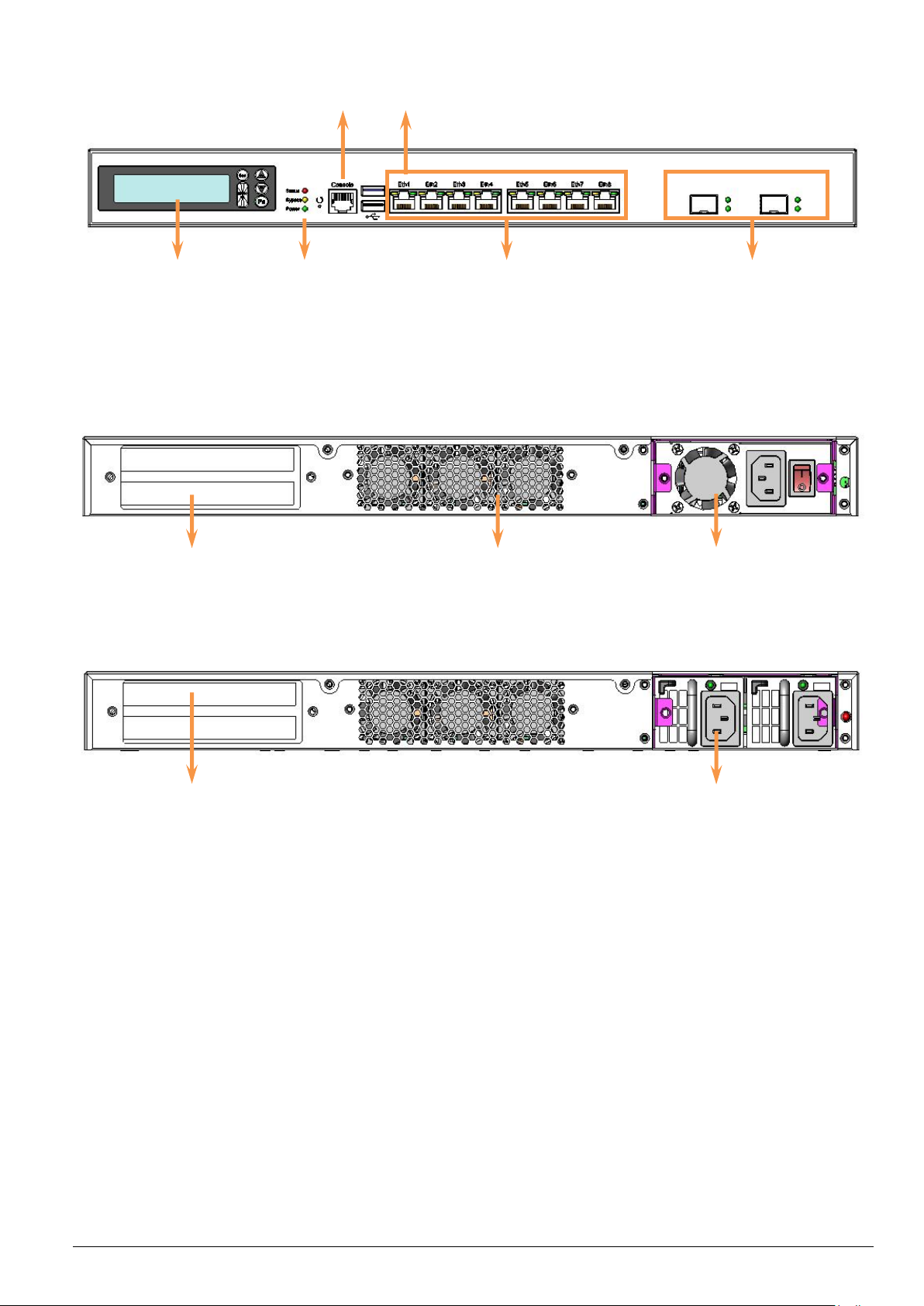

Chapter 4 Console Mode Information

FWA8208 supports output information via Console in BIOS level.

Prepare a computer as client loaded with an existing OS such as Windows XP and Windows 7.

Connect client computer and FWA8208 with NULL Modem cable.

Follow the steps below to configure the Windows Hyper Terminal application setting:

1. Execute Hyper Terminal. Issue command “hypertrm”.

2. Customize your name for the new connection.

3. Choose COM port on the client computer for the connection.

14

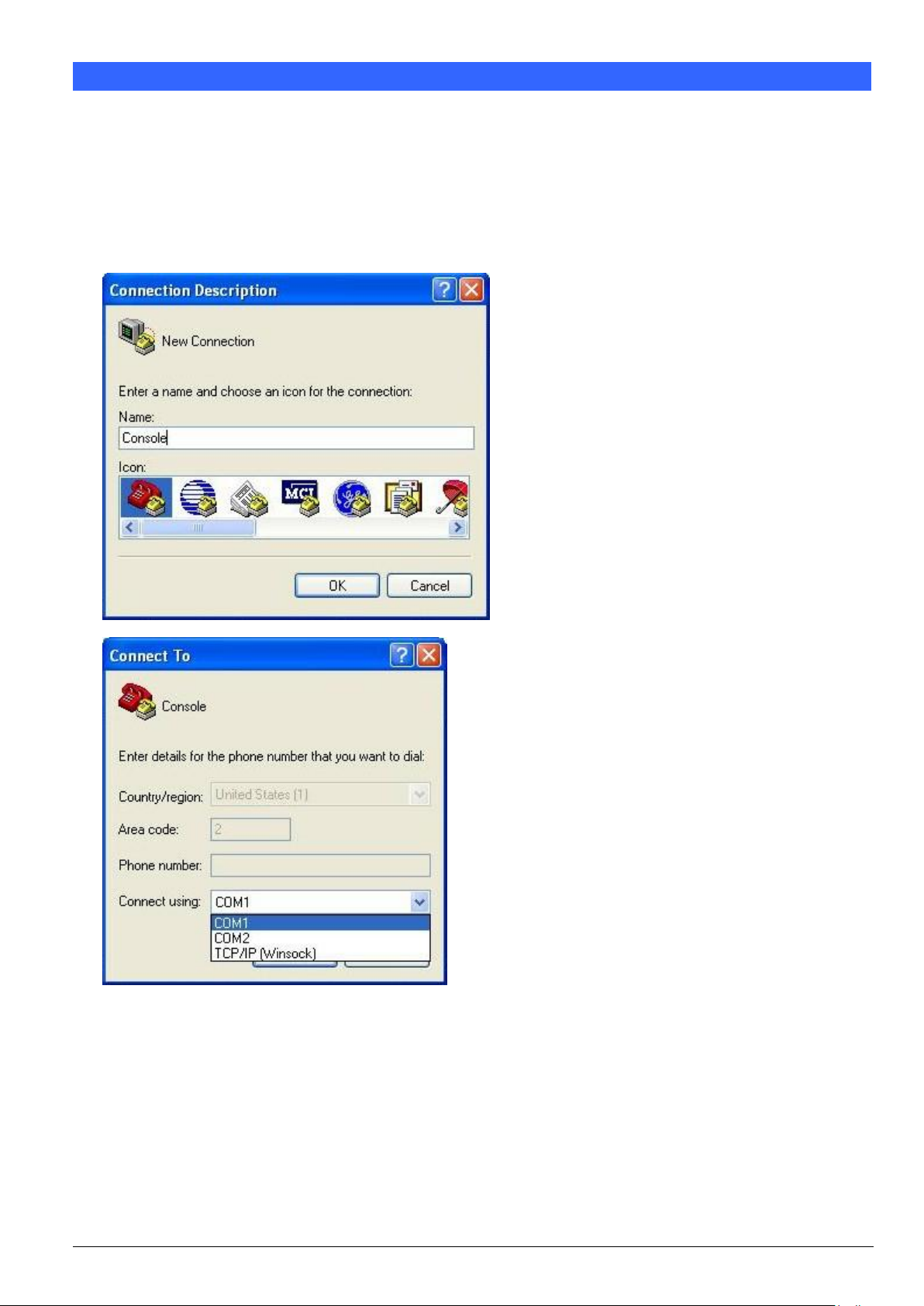

Page 16

4. Please make the port settings to Baud rate 19200, Parity None, Data bits 8, Stop bits 1

5. Power on FWA8208.

Press <Tab> key to enter BIOS setup screen in Console mode.

Press <Del> key to enter BIOS setup screen in VGA mode.

15

Page 17

Chapter 5 Open the Chassis

Fig. 5-2 Take off six screws and open the top lead

Fig. 5-3 The base stand

Fig. 6-1 Open both arms on DIMM socket

Fig. 6-2 Install DIMM

Chapter 6 Installing DDR3 Memory

Install system memory by pulling the socket’s arm and pressing it into the slot gently.

Notice:

1. MB967 supports two groups of dual channels memory.

One group is on the black DIMM sockets, and the other one is blue DIMM sockets.

2. The recommended height of memory module doesn’t exceed 30 mm.

16

Page 18

Chapter 7 Installing CompactFlash Card

Fig. 7-1 Insert CompactFlash Card into the

CF interface

Fig. 7-2 Completion of CompactFlash Card

connection

Fig. 8-1 Eject the battery and replace with new one

Insert CompactFlash card into the socket.

Chapter 8 Removing and Installing the Battery

1. Press the metal clip back to eject the button battery.

2. Replace it with a new one by pressing the battery with fingertip to restore the battery

17

Page 19

Chapter 9 Installing 2.5” HDD (FWA8208 & FWA8208-RPSU)

Fig. 9- Take off two screws on bottom to

remove 2.5” HDD bracket.

Fig. 9-2 Fasten the four screws to lock HDD and

bracket together.

Fig. 9-3 Push HDD into connector

Fig. 9-4 Completion of HDD connection

Fig. 9-5 Fix HDD bracket with two

screws

Front

Front

18

Page 20

Chapter 10 Installing Optional Dual 2.5” HDD Kit

Fig. 10-1 Push eight shock-absorbent pads to

fasten HDD bracket.

Fig. 10-2 Fasten the screws to lock 2.5” HDD

bracket and bracket together.

Fig. 10-3 Fix HDD bracket on chassis with four

screws

The following is for optional Dual 2.5” HDD kit:

19

Page 21

Chapter 11 Installing Add-on Card

Fig. 11-1 Loosen screw on slot bracket.

Fig. 11-2 Slide in PCI-e add-on card.

Fig. 11-3 Fix the add-on card

Fig. 12-1 Insert Mini PCI-e card.

Fig. 12-2 Push down Mini PCI-e card.

Chapter 12 Installing Mini PCI-e Card

20

Page 22

Chapter 13 BIOS Information

Main Advanced Chipset Boot Security Save & Exit

BIOS Information

Choose the system default

language

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

System Language

[English]

System Date

[Tue 06/19/2012]

Access Level

Administrator

Main Advanced Chipset Boot Security Save & Exit

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

► PCI Subsystem Settings

► ACPI Settings

► Wake up event setting

► Trusted Computing

► CPU Configuration

► SATA Configuration

► Shutdown Temperature Configuration

► AMT Configuration

► Acoustic Management Configuration

► USB Configuration

► F81866 Super IO Configuration

► F81866 H/W Monitor

► Serial Port Console Redirection

► CPU PPM Configuration

Main Advanced Chipset Boot Security Save & Exit

PCI Bus Driver Version V 2.05.02

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

PCI 64bit Resources Handling

Above 4G Decoding

[Disabled]

PCI Common Settings

PCI Latency Timer

[32 PCI Bus Clocks]

VGA Palette Snoop

[Disabled]

PERR# Generation

[Disabled]

SERR# Generation

[Disabled]

► PCI Express Settings

This setup allows you to view processor configuration used in your computer system and set the system time and

date.

Main Settings

System Language

Choose the system default language.

System Date

Set the Date. Use Tab to switch between Data elements.

System Time

Set the Time. Use Tab to switch between Data elements.

Advanced Settings

This section allows you to configure and improve your system and allows you to set up some system features according to your

preference.

Aptio Setup Utility – Copyright © 2011 American Megatrends, Inc.

Aptio Setup Utility

PCI Subsystem Settings

Aptio Setup Utility

21

Page 23

Above 4G Decoding

Main Advanced Chipset Boot Security Save & Exit

PCI Express Device Register Settings

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Relaxed Ordering

[Disabled]

Extended Tag

[Disabled]

No Snoop

[Enabled]

Maximum Payload

[Auto]

Maximum Read Request

[Auto]

PCI Express Link Register Settings

ASPM Support

[Disabled]

WARNING: Enabling ASPM may cause

some

PCI-E devices to fail

Extended Synch

[Disabled]

Link Training Retry

[5]

Link Training Timeout

100 Unpopulated Links

[Keep Link ON]

Enables or Disables 64bit capable devices to be decoded in above 4G address space (only if system supports 64 bit PCI

decoding).

PCI Latency Timer

Value to be programmed into PCI Latency Timer Register.

VGA Palette Snoop

Enables or disables VGA Palette Registers Snooping.

PERR# Generation

Enables or disables PCI device to generate PERR#.

SERR# Generation

Enables or disables PCI device to generate SERR#.

PCI Express Settings

Change PCI Express devices settings.

PCI Express Settings

Aptio Setup Utility

Relaxed Ordering

Enables or disables PCI Express Device Relaxed Ordering.

Extended Tag

If ENABLED allows device to use 8-bit Tag field as a requester.

No Snoop

Enables or disables PCI Express Device No Snoop option.

Maximum Payload

Set Maximum Payload of PCI Express Device or allow System BIOS to select the value.

Maximum Read Request

Set Maximum Read Request Size of PCI Express Device or allow System BIOS to select the value.

ASPM Support

Set the ASPM Level: Force L0s – Force all links to L0s State:

AUTO – BIOS auto configure : DISABLE – Disables ASPM.

Extended Synch

If ENABLED allows generation of Extended Synchronization patterns.

Link Training Retry

Defines number of Retry Attempts software will take to retrain the link if previous training attempt was unsuccessful.

Link Training Timeout

Defines number of Microseconds software will wait before polling ‘Link Training’ bit in Link Status register. Value range

from 10 to 1000 uS.

22

Page 24

Unpopulated Links

Main Advanced Chipset Boot Security Save & Exit

ACPI Settings

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Enable Hibernation

[Enabled]

ACPI Sleep State

[S1 only (CPU Stop C…]

Lock Legacy Resources

S3 Video Repost

[Disabled]

[Disabled]

Main Advanced Chipset Boot Security Save & Exit

Wake system with Fixed Time [Disabled]

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Wake on Ring

[Disabled]

Wake on PCIE Wake Event

[Disabled]

Main Advanced Chipset Boot Security Save & Exit

Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Security Device Sup

[Disabled]

Current TPM Status Information

SUPPORT TUREND OFF

In order to save power, software will disable unpopulated PCI Express links, if this option set to ‘Disable Link’.

ACPI Settings

Aptio Setup Utility

Enable Hibernation

Enables or Disables System ability to Hibernate (OS/S4 Sleep State). This option may be not effective with some OS.

ACPI Sleep State

Select ACPI sleep state the system will enter, when the SUSPEND button is pressed.

Lock Legacy Resources

Enabled or Disabled Lock of Legacy Resources.

S3 Video Repost

Enable or disable S3 Video Repost.

Wake up event settings

Aptio Setup Utility

Wake system with Fixed Time

Enables or Disables System wake on alarm event. When enabled, System will wake on the hr::min:: sec specified.

Wake on PCIE PME Wake Event

The options are Disabled and Enabled.

Trusted Computing

Security Device Support

Enables or disables BIOS support for security device. O.S. will not show Security Device. TCG EFI protocol and INT1A

interface will not be available.

Aptio Setup Utility

23

Page 25

CPU Configuration

Main Advanced Chipset Boot Security Save & Exit

CPU Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Intel(R) Xeon(R) CPU E3-1225 V2 @ 3.20GHz

CPU Signature

306a8

Microcode Patch

c

CPU Speed

3200 MHz

Processor Cores

4

Intel HT Technology

Not Supported

Intel VT-x Technology

Supported

Intel SMX Technology

Supported

64-bit

Supported

Active Processor Cores

[All]

Limit CPUID Maximum

[Disabled]

Execute Disable Bit

[Enabled]

Intel Virtualization

[Disabled]

Hardware Prefetcher

[Disabled]

Adjacent Cache Line Prefetch

[Enabled]

Main Advanced Chipset Boot Security Save & Exit

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

SATA Controller(s)

[Enabled]

SATA Mode Selection

[IDE]

SATA Port0

Empty

Software Preserve

Unknown

SATA Port1

Empty

Software Preserve

Unknown

SATA Port2

Empty

Software Preserve

Unknown

SATA Port3

Empty

Software Preserve

Unknown

SATA Port4

WDC WD5000BPKT (5

Software Preserve

SUPPORTED

SATA Port5

Empty

Software Preserve

Unknown

This section shows the CPU configuration parameters.

Aptio Setup Utility

Active Processor Cores

Number of cores to enable in each processor package.

Limit CPUID Maximum

Disabled for Windows XP.

Execute Disable Bit

XD can prevent certain classes of malicious buffer overflow attacks when combined with a supporting OS (Windows

Server 2003 SP1, Windows XP SP2, SuSE Linux 9.2, Re33dHat Enterprise 3 Update 3.)

Intel Virtualization Technology

When enabled, a VMM can utilize the additional hardware capabilities provided by Vanderpool Technology.

Hardware Prefetcher

To turn on/off the Mid level Cache (L2) streamer Prefetcher.

Adjacent Cache Line Prefetch

To turn on/off prefetching of adjacent cache lines.

SATA Configuration

SATA Devices Configuration.

Aptio Setup Utility

SATA Controller(s)

Enable / Disable Serial ATA Controller.

24

Page 26

SATA Mode Selection

Main Advanced Chipset Boot Security Save & Exit

APCI Shutdown Temperature

[Disabled]

Main Advanced Chipset Boot Security Save & Exit

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Intel AMT

[Enabled]

BIOS Hotkey Pressed

[Disabled]

MEBx Selection Screen

[Disabled]

Hide Un-Configure ME Confirmation

[Disabled]

Un-Configure ME

[Disabled]

Amt Wait Timer

0

Activate Remote Assistance Process

USB Configure

PET Progress

[Disabled]

[Enabled]

[Enabled]

AMT CIRA Timeout

0

Watchdog

[Disabled]

OS Timer

0

BIOS Timer

0

(1) IDE Mode.

(2) AHCI Mode.

(3) RAID Mode.

Shutdown Temperature Configuration

ACPI Shutdown Temperature

Set function Disabled or 70/75/80/85/90/95 ℃

AMT Configuration

Aptio Setup Utility

Aptio Setup Utility

AMT Configuration

Options are Enabled and Disabled.

Note: iAMT H/W is always enabled. This option just controls the BIOS extension execution. If enabled, this requires

additional firmware in the SPI device.

Unconfigure ME

Perform AMT/ME unconfigure without password operation.

Amt Wait Timer

Set timer to wait before sending ASF_GET_BOOT_OPTIONS.

Activate Remote Assistance Process

Trigger CIRA boot.

PET Progress

User can Enable/Disable PET Events progress to receive PET events or not.

Watchdog Timer

Enable/Disable Watchdog Timer.

25

Page 27

Acoustic Management Configuration

Main Advanced Chipset Boot Security Save & Exit

Acoustic Management Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Automatic Acoustic Management

[Disabled]

Main Advanced Chipset Boot Security Save & Exit

USB Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

USB Devices:

1 Keyboard, 2 Hubs

Legacy USB Support

[Enabled]

USB3.0 Support

[Enabled]

XHCI Hand-off

[Enabled]

EHCI Hand-off

[Enabled]

Port 60/64 Emulation

[Enabled]

USB hardware delays and time-outs:

USB Transfer time-out

[20 sec]

Device reset tine-out

[20 sec]

Device power-up delay

[Auto]

USB Configuration

Aptio Setup Utility

Aptio Setup Utility

Legacy USB Support

Enables Legacy USB support.

AUTO option disables legacy support if no USB devices are connected.

DISABLE option will keep USB devices available only for EFI applications.

USB3.0 Support

Enable/Disable USB3.0 (XHCI) Controller support.

XHCI Hand-off

This is a workaround for OSes without XHCI hand-off support. The XHCI ownership change should be claimed by XHCI

driver.

EHCI Hand-off

Enabled/Disabled. This is a workaround for OSes without EHCI hand-off support. The EHCI ownership change should be

claimed by EHCI driver.

Port 64/60 Emulation

Enables I/O port 60h/64h emulation support. This should be enabled for the complete USB keyboard legacy support for

non-USB aware OSes.

USB Transfer time-out

The time-out value for Control, Bulk, and Interrupt transfers.

Device reset tine-out

USB mass Storage device start Unit command time-out.

Device power-up delay

Maximum time the device will take before it properly reports itself to the Host Controller. ‘Auto’ uses default value: for a

Root port it is 100ms, for a Hub port the delay is taken from Hub descriptor.

26

Page 28

F81866 Super IO Configuration

Main Advanced Chipset Boot Security Save & Exit

Super IO Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

F81866 Super IO Chip

F81866

► Serial Port 0 Configuration

► Serial Port 1 Configuration

Power Failure

KB/MS Power On

[Always off]

[None]

LAN5,6 Bypass Function

LAN7,8 Bypass Function

[Normal]

[Normal]

Main Advanced Chipset Boot Security Save & Exit

PC Health Status

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

CPU smart fan control

[60 C]

Fan1 smart fan control

[60 C]

Fan2 smart fan control

[60 C]

CPU temperature

+41 C

SYS temperature

+35 C

CPU Fan Speed

7315 RPM

FAN1 Speed

7308 RPM

FAN2 Speed

7313 RPM

Vcore

+0.928 V

+5V

+5.213 V

+12V

+12.144 V

1.5V

+1.544 V

+3.3V

+3.360 V

Main Advanced Chipset Boot Security Save & Exit

COM0

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Console Redirection

[Enabled]

► Console Redirection Settings

COM1 (Pci Bus0, Dev0, Func0)

Console Redirection Port Is Disabled

[Enabled]

(Disabled)

Aptio Setup Utility

Serial Port Configuration

Set Parameters of Serial Ports. User can Enable/Disable the serial port and Select an optimal settings for the Super IO

Device.

LAN5, 6 Bypass Function

LAN5, 6 Bypass Function Setting [Bypass] or [Normal]

LAN7, 8 Bypass Function

LAN7, 8 Bypass Function Setting [Bypass] or [Normal]

F81866 H/W Monitor

Aptio Setup Utility

Temperatures/Voltages

These fields are the parameters of the hardware monitoring function feature of the motherboard. The values are read-only

values as monitored by the system and show the PC health status.

CPU/Fan1/Fan2 Smart Fan Control

This field enables or disables the smart fan feature. At a certain temperature, the fan starts turning. Once the temperature

drops to a certain level, it stops turning again.

Serial Port Console Redirection

Aptio Setup Utility

27

Page 29

Console Redirection Settings

Main Advanced Chipset Boot Security Save & Exit

COM0

Emulation: ANSI:

Extended ASCII char

Set. VT100: ASCII char

Set. VT100+: Extends

VT100 to support color,

Function keys, etc.

VT-UTF8: Uses UTF8

Encoding to map Unicode

Chars onto 1 or more

-------------------------------------------

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Console Redirection Settings

Terminal Type

[VT100+]

Bits per second

Data Bits

Parity

Stop Bits

Flow Control

VT-UTF8 Combo Key Sup

Recorder Mode

Resolution 100x31

Legacy OS Redirection

Putty KeyPad

[115200]

[8]

[None]

[1]

[None]

[Enabled]

[Disabled]

[Disabled]

[80x24]

[VT100]

Main Advanced Chipset Boot Security Save & Exit

PCH Parameters

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

► PCH-IO Configuration

► System Agent (SA) Configuration

Main Advanced Chipset Boot Security Save & Exit

Intel PCH RC Version 1.1.0.0

PCI Express

Configuration settings

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Intel PCH SKU Name

C216

Intel PCH Rev ID

O4/C1

► PCI Express Configuration

► USB Configuration

PCH LAN Controller

[Enabled]

Wake on LAN

[Disabled]

High Precision Event Timer Configuration

High Precision Timer

[Enabled]

SLP_S4 Assertion Width

[4-5 Seconds]

Aptio Setup Utility

Chipset Settings

This section allows you to configure and improve your system and allows you to set up some system features according to your

preference.

Aptio Setup Utility

PCH-IO Configuration

This section allows you to configure the North Bridge Chipset.

PCH LAN Controller

Enable or disable onboard NIC.

Aptio Setup Utility

28

Page 30

Main Advanced Chipset Boot Security Save & Exit

PCI Express Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

PCI Express Clock Gating

[Enabled]

DMI Link ASPM Control

[Enabled]

DMI Link Extended Synch Control

[Disabled]

PCIe-USB Glitch W/A

[Disabled]

Subtractive Decode

[Disabled]

PCIE Port 1 is assign

► PCI Express Root Port 2

► PCI Express Root Port 3

► PCI Express Root Port 4

► PCI Express Root Port 5

► PCI Express Root Port 6

► PCI Express Root Port 7

► PCI Express Root Port 8

Main Advanced Chipset Boot Security Save & Exit

USB Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

XHCI Pre-Boot Driver

[Disabled]

xHCI Mode

[Auto]

HS Port #1 Switchable

[Enabled]

HS Port #2 Switchable

[Enabled]

HS Port #3 Switchable

[Enabled]

HS Port #4 Switchable

[Enabled]

xHCI Streams

[Enabled]

EHCI1

[Enabled]

EHCI2

[Enabled]

USB Ports Per-Port Disable Control

[Disabled]

Wake on LAN

Enable or disable integrated LAN to wake the system. (The Wake On LAN cannot be disabled if ME is on at Sx state.)

SLP_S4 Assertion Width

Select a minimum assertion width of the SLP_S4# signal.

PCI Express Configuration

PCI Express Clock Gating

Enable or disable PCI Express Clock Gating for each root port.

DMI Link ASPM Control

The control of Active State Power Management on both NB side and SB side of the DMI link.

PCIe-USB Glitch W/A

PCIe-USB Glitch W/A for bad USB device(s) connected behind PCIE/PEG port.

USB Configuration

HS Port #1/2/3/4 Switchable

Allows for HS port switching between xHCI and EHCI. If disabled, port is routed to EHCI. If HS port is routed to xHCI,

the corresponding SS port is enabled.

xHCI Streams

Enable or disable xHCI Maximum Primary Stream Array Size.

EHCI1/2

Control the USAB EHCI (USB 2.0) functions. One EHCI controller must always be enabled.

USB Ports Per-Port Disable Control

Control each of the USB ports (0~13) disabling.

29

Page 31

System Agent (SA) Configuration

Main Advanced Chipset Boot Security Save & Exit

System Agent Bridge Name IvyBridge

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

System Agent RC Version

1.1.0.0

VT-d Capability

Supported

VT-d

[Enabled]

CHAP Device (B0:D7:F0)

[Disabled]

Thermal Device (B0:D4:F0)

[Disabled]

Enable NB CRID

[Disabled]

BDAT ACPI Table Support

C-State Pre-Wake

[Disabled]

[Enabled]

► Graphics Configuration

► Memory Configuration

Main Advanced Chipset Boot Security Save & Exit

Graphics Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

IGFX VBIOS Version

2132

IGfx Frequency

350 MHz

Primary Display

Primary PEG

[Auto]

[Auto]

Internal Graphics

[Auto]

GTT Size

[2MB]

Aperture Size

[256MB]

DVMT Pre-Allocated

[64M]

DVMT Total Gfx Mode

Gfx Low Power Mode

[256M]

[Disabled]

Main Advanced Chipset Boot Security Save & Exit

Memory Information

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Memory Frequency

1333 MHz

Total Memory

32768 MB (DDR3)

DIMM#0

8192 MB (DDR3)

DIMM#1

8192 MB (DDR3)

DIMM#2

8192 MB (DDR3)

DIMM#3

8192 MB (DDR3)

CAS Latency (tCL)

9

Minimum delay time

CAS to RAS (tRCDmin)

9

Row Precharge (tRPmin)

9

Active to Precharge (tRASmin)

24

VT-d

Check to enable VT-d function on MCH.

Graphics Configuration

Aptio Setup Utility

Aptio Setup Utility

Primary Display

Select which of IGFX/PEG/PCI graphics device should be primary display or select SG for switchable Gfx.

Internal Graphics

Keep IGD enabled based on the setup options.

DVMT Pre-Allocated

Select DVMT 5.0 Pre-Allocated (Fixed) graphics memory size used by the internal graphics device.

DVMT Total Gfx Mem

Select DVMT 5.0 total graphics memory size used by the internal graphics device.

Gfx Low Power Mode

This option is applicable for SFF only.

Memory Configuration

Aptio Setup Utility

30

Page 32

Boot Settings

Main Advanced Chipset Boot Security Save & Exit

Boot Configuration

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Setup Prompt Timeout

1

Bootup NumLock State

[On]

Quiet Boot

[Disabled]

Fast Boot

[Disabled]

CSM16 Module Version

07.68

GateA20 Active

[Upon Request]

Option ROM Messages

[Force BIOS]

INT19 Trap Response

[Immediate]

Boot Option Priorities

Boot Option #1

[SATA PM: WDC W

Hard Drive BBS Priorities

► CSM parameters

Main Advanced Chipset Boot Security Save & Exit

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Launch CSM

[Always]

Boot option filter

[UEFI and Legacy]

Launch PXE OpROM policy

[Do not launch]

Launch Storage OpROM policy

[Legacy only]

Launch Video OpROM policy

[Legacy only]

Other PCI device ROM priority

[UEFI OpROM]

Aptio Setup Utility

Setup Prompt Timeout

Number of seconds to wait for setup activation key.

65535(0xFFFF) means indefinite waiting.

Bootup NumLock State

Select the keyboard NumLock state.

Quiet Boot

Enables/Disables Quiet Boot option.

Fast Boot

Enables/Disables boot with initialization of a minimal set of devices required to launch active boot option. Has no effect

for BBS boot options.

GateA20 Active

UPON REQUEST – GA20 can be disabled using BIOS services.

ALWAYS – do not allow disabling GA20; this option is useful when any RT code is executed above 1MB.

Option ROM Messages

Set display mode for Option ROM. Options are Force BIOS and Keep Current.

INT19 Trap Response

Enable: Allows Option ROMs to trap Int 19.

Boot Option Priorities

Sets the system boot order.

CSM parameters

This section allows you to configure the boot settings.

Aptio Setup Utility

Boot option filter

This option controls what devices system can boot to.

31

Page 33

Launch PXE OpROM policy

Main Advanced Chipset Boot Security Save & Exit

Password Description

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

If ONLY the Administrator’s password is set, then

this only limit access to Setup and is only asked

for when entering Setup.

If ONLY the User’s password is set, then this is a

power on password and must be entered to boot

or enter Setup. In Setup the User will have

Administrator rights

The password length must be

in the following range:

Minimum length

3

Maximum length

20

Administrator Password

User Password

Main Advanced Chipset Boot Security Save & Exit

Save Changes and Exit

→ ← Select Screen

↑↓ Select Item

Enter: Select

+- Change Field

F1: General Help

F2: Previous Values

F3: Optimized Default

F4: Save ESC: Exit

Discard Changes and Exit

Save Changes and Reset

Discard Changes and Reset

Save Options

Save Changes

Discard Changes

Restore Defaults

Save as User Defaults

Restore User Defaults

SATA PM: WDC WD5000BPKT-0

Controls the execution of UEFI and Legacy PXE OpROM.

Launch Storatge OpROM policy

Controls the execution of UEFI and Legacy Storage OpROM.

Launch Video OpROM policy

Controls the execution of UEFI and Legacy Video OpROM.

Other PCI device ROM priority

For PCI devices other than Network, Mass storage or Video defines which OpROM to launch.

Security Settings

This section allows you to configure and improve your system and allows you to set up some system features according to your

preference.

Aptio Setup Utility

Administrator Password

Set Setup Administrator Password.

User Password

Set User Password.

Save & Exit Settings

Save Changes and Exit

Exit system setup after saving the changes.

Discard Changes and Exit

Exit system setup without saving any changes.

Save Changes and Reset

Reset the system after saving the changes.

Discard Changes and Reset

Reset system setup without saving any changes.

Aptio Setup Utility

32

Page 34

Save Changes

Save Changes done so far to any of the setup options.

Discard Changes

Discard Changes done so far to any of the setup options.

Restore Defaults

Restore/Load Defaults values for all the setup options.

Save as User Defaults

Save the changes done so far as User Defaults.

Restore User Defaults

Restore the User Defaults to all the setup options.

Chapter 14 Watchdog Timer Configuration

The WDT is used to generate a variety of output signals after a user programmable count. The WDT is suitable for

use in the prevention of system lock-up, such as when software becomes trapped in a deadlock. Under these sorts

of circumstances, the timer will count to zero and the selected outputs will be driven. Under normal circumstance,

the user will restart the WDT at regular intervals before the timer counts to zero.

SAMPLE CODE:

This code and information is provided "as is" without warranty of any kind, either expressed or implied, including but

not limited to the implied warranties of merchantability and/or fitness for a particular purpose.

//--------------------------------------------------------------------------//

// THIS CODE AND INFORMATION IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY

// KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

// IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR

// PURPOSE.

//

//--------------------------------------------------------------------------#include <dos.h>

#include <conio.h>

#include <stdio.h>

#include <stdlib.h>

#include "F81866.H"

//--------------------------------------------------------------------------int main (int argc, char *argv[]);

void EnableWDT(int);

void DisableWDT(void);

//--------------------------------------------------------------------------int main (int argc, char *argv[])

{

unsigned char bBuf;

unsigned char bTime;

char **endptr;

char SIO;

printf("Fintek 81866 watch dog program\n");

SIO = Init_F81866();

if (SIO == 0)

{

printf("Can not detect Fintek 81866, program abort.\n");

return(1);

}//if (SIO == 0)

if (argc != 2)

33

Page 35

{

printf(" Parameter incorrect!!\n");

return (1);

}

bTime = strtol (argv[1], endptr, 10);

printf("System will reset after %d seconds\n", bTime);

if (bTime)

{ EnableWDT(bTime); }

else

{ DisableWDT(); }

return 0;

}

//--------------------------------------------------------------------------void EnableWDT(int interval)

{

unsigned char bBuf;

bBuf = Get_F81866_Reg(0x2B);

bBuf &= (~0x20);

Set_F81866_Reg(0x2B, bBuf); //Enable WDTO

Set_F81866_LD(0x07); //switch to logic device 7

Set_F81866_Reg(0x30, 0x01); //enable timer

bBuf = Get_F81866_Reg(0xF5);

bBuf &= (~0x0F);

bBuf |= 0x52;

Set_F81866_Reg(0xF5, bBuf); //count mode is second

Set_F81866_Reg(0xF6, interval); //set timer

bBuf = Get_F81866_Reg(0xFA);

bBuf |= 0x01;

Set_F81866_Reg(0xFA, bBuf); //enable WDTO output

bBuf = Get_F81866_Reg(0xF5);

bBuf |= 0x20;

Set_F81866_Reg(0xF5, bBuf); //start counting

}

//--------------------------------------------------------------------------void DisableWDT(void)

{

unsigned char bBuf;

Set_F81866_LD(0x07); //switch to logic device 7

bBuf = Get_F81866_Reg(0xFA);

bBuf &= ~0x01;

Set_F81866_Reg(0xFA, bBuf); //disable WDTO output

bBuf = Get_F81866_Reg(0xF5);

bBuf &= ~0x20;

bBuf |= 0x40;

Set_F81866_Reg(0xF5, bBuf); //disable WDT

}

//--------------------------------------------------------------------------//--------------------------------------------------------------------------//

// THIS CODE AND INFORMATION IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY

// KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

// IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR

// PURPOSE.

//

34

Page 36

//--------------------------------------------------------------------------#include "F81866.H"

#include <dos.h>

//--------------------------------------------------------------------------unsigned int F81866_BASE;

void Unlock_F81866 (void);

void Lock_F81866 (void);

//--------------------------------------------------------------------------unsigned int Init_F81866(void)

{

unsigned int result;

unsigned char ucDid;

F81866_BASE = 0x4E;

result = F81866_BASE;

ucDid = Get_F81866_Reg(0x20);

if (ucDid == 0x07) //Fintek 81866

{ goto Init_Finish; }

F81866_BASE = 0x2E;

result = F81866_BASE;

ucDid = Get_F81866_Reg(0x20);

if (ucDid == 0x07) //Fintek 81866

{ goto Init_Finish; }

F81866_BASE = 0x00;

result = F81866_BASE;

Init_Finish:

return (result);

}

//--------------------------------------------------------------------------void Unlock_F81866 (void)

{

outportb(F81866_INDEX_PORT, F81866_UNLOCK);

outportb(F81866_INDEX_PORT, F81866_UNLOCK);

}

//--------------------------------------------------------------------------void Lock_F81866 (void)

{

outportb(F81866_INDEX_PORT, F81866_LOCK);

}

//--------------------------------------------------------------------------void Set_F81866_LD( unsigned char LD)

{

Unlock_F81866();

outportb(F81866_INDEX_PORT, F81866_REG_LD);

outportb(F81866_DATA_PORT, LD);

Lock_F81866();

}

//--------------------------------------------------------------------------void Set_F81866_Reg( unsigned char REG, unsigned char DATA)

{

Unlock_F81866();

outportb(F81866_INDEX_PORT, REG);

outportb(F81866_DATA_PORT, DATA);

Lock_F81866();

}

//--------------------------------------------------------------------------unsigned char Get_F81866_Reg(unsigned char REG)

{

unsigned char Result;

Unlock_F81866();

outportb(F81866_INDEX_PORT, REG);

Result = inportb(F81866_DATA_PORT);

Lock_F81866();

35

Page 37

return Result;

}

//--------------------------------------------------------------------------//--------------------------------------------------------------------------//

// THIS CODE AND INFORMATION IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY

// KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

// IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR

// PURPOSE.

//

//--------------------------------------------------------------------------#ifndef __F81866_H

#define __F81866_H 1

//--------------------------------------------------------------------------#define F81866_INDEX_PORT (F81866_BASE)

#define F81866_DATA_PORT (F81866_BASE+1)

//--------------------------------------------------------------------------#define F81866_REG_LD 0x07

//--------------------------------------------------------------------------#define F81866_UNLOCK 0x87

#define F81866_LOCK 0xAA

//--------------------------------------------------------------------------unsigned int Init_F81866(void);

void Set_F81866_LD( unsigned char);

void Set_F81866_Reg( unsigned char, unsigned char);

unsigned char Get_F81866_Reg( unsigned char);

//--------------------------------------------------------------------------#endif //__F81866_H

36

Page 38

Chapter 15 Digital I/O Sample Configuration

Filename:Main.cpp

//---------------------------------------------------------------------------

//

// THIS CODE AND INFORMATION IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY

// KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

// IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR

// PURPOSE.

//

//--------------------------------------------------------------------------#include <dos.h>

#include <conio.h>

#include <stdio.h>

#include <stdlib.h>

#include "F81865.H"

#define BIT0 0x01

#define BIT1 0x02

#define BIT2 0x04

#define BIT3 0x08

#define BIT4 0x10

#define BIT5 0x20

#define BIT6 0x40

#define BIT7 0x80

//--------------------------------------------------------------------------int main (void);

void Dio5Initial(void);

void Dio5SetOutput(unsigned char);

unsigned char Dio5GetInput(void);

void Dio5SetDirection(unsigned char);

unsigned char Dio5GetDirection(void);

//--------------------------------------------------------------------------int main (void)

{

char SIO;

unsigned char DIO;

printf("Fintek 81865/81866 digital I/O test program\n");

SIO = Init_F81865();

if (SIO == 0)

{

printf("Can not detect Fintek 81865/81866, program abort.\n");

return(1);

}//if (SIO == 0)

Dio5Initial();

/*

//for GPIO50..57

Dio5SetDirection(0xF0); //GP50..53 = input, GP54..57=output

printf("Current DIO direction = 0x%X\n", Dio5GetDirection());

printf("Current DIO status = 0x%X\n", Dio5GetInput());

printf("Set DIO output to high\n");

Dio5SetOutput(0x0F);

printf("Set DIO output to low\n");

Dio5SetOutput(0x00);

*/

//for GPIO50..57

Dio5SetDirection(0xF0); //GP50..53 = input, GP54..57=output

37

Page 39

Dio5SetOutput(0x00); //clear

// DIO = Dio5GetInput() & 0x0F;

Dio5SetOutput(0x00); //clear

DIO = Dio5GetInput() & 0x0F;

if (DIO != 0x0A)

{

printf("The Fintek 81865 digital IO abnormal, abort.\n");

return(1);

}//if (DIO != 0x0A)

Dio5SetOutput(0xA0); //clr# is high

Dio5SetOutput(0xF0); //clk and clr# is high

Dio5SetOutput(0xA0); //clr# is high

DIO = Dio5GetInput() & 0x0F;

if (DIO != 0x05)

{

printf("The Fintek 81865 digital IO abnormal, abort.\n");

return(1);

}

printf("!!! Pass !!!\n");

return 0;

}

//--------------------------------------------------------------------------void Dio5Initial(void)

{

unsigned char ucBuf;

//switch GPIO multi-function pin for gpio 50~57

//gpio53~57 UR5_FULL_EN(bit1), clear UR6_FULL_EN(bit3)

//set UR5_FULL_EN,should set UR_GP_PROG_EN = 1 (reg26,bit0) first

ucBuf = Get_F81865_Reg(0x26);

ucBuf |= BIT0;

Set_F81865_Reg(0x26, ucBuf);

//set UR5_FULL_EN(bit1), clear UR6_FULL_EN(bit3)

ucBuf = Get_F81865_Reg(0x2A);

ucBuf &= ~BIT3;//clear bit 3,

ucBuf |= BIT1;//set bit 1,

Set_F81865_Reg(0x2a, ucBuf);

//GPIO51 ~ GPIO52

//clear UR6_ALT_EN(bit5), IR_ALT_EN(bit4),set FDC_GP_EN(bit3)

//GPIO50

//set FDC_GP_EN(bit3), clear RTS6_ALT_EN(RTS6_2_ALT_EN)(bit6)

ucBuf = Get_F81865_Reg(0x2A);

ucBuf &= ~(BIT4+BIT5+BIT6); //clear UR6_ALT_EN(bit5), IR_ALT_EN(bit4),

RTS6_ALT_EN(RTS6_2_ALT_EN)(bit6)

Set_F81865_Reg(0x2a, ucBuf);

//set FDC_GP_EN(bit3), should clear UR_GP_PROG_EN (reg26,bit0) first

ucBuf = Get_F81865_Reg(0x26);

ucBuf &= ~BIT0;

Set_F81865_Reg(0x26, ucBuf);//clear UR_GP_PROG_EN = 0 (reg26,bit0)

ucBuf = Get_F81865_Reg(0x2A);

ucBuf |= BIT3; //set FDC_GP_EN(bit3),

Set_F81865_Reg(0x2a, ucBuf);

Set_F81865_LD(0x06); //switch to logic device 6

//enable the GP5 group

38

Page 40

ucBuf = Get_F81865_Reg(0x30);

ucBuf |= 0x01;

Set_F81865_Reg(0x30, ucBuf);

Set_F81865_Reg(0xA0, 0x00); //define as input mode

Set_F81865_Reg(0xA3, 0xFF); //push pull mode

}

//--------------------------------------------------------------------------void Dio5SetOutput(unsigned char NewData)

{

Set_F81865_LD(0x06); //switch to logic device 6

Set_F81865_Reg(0xA1, NewData);

}

//--------------------------------------------------------------------------unsigned char Dio5GetInput(void)

{

unsigned char result;

Set_F81865_LD(0x06); //switch to logic device 6

result = Get_F81865_Reg(0xA2);

return (result);

}

//--------------------------------------------------------------------------void Dio5SetDirection(unsigned char NewData)

{

//NewData : 1 for input, 0 for output

Set_F81865_LD(0x06); //switch to logic device 6

Set_F81865_Reg(0xA0, NewData);

}

//--------------------------------------------------------------------------unsigned char Dio5GetDirection(void)

{

unsigned char result;

Set_F81865_LD(0x06); //switch to logic device 6

result = Get_F81865_Reg(0xA0);

return (result);

}

//---------------------------------------------------------------------------

Filename:81865.cpp

//---------------------------------------------------------------------------

//

// THIS CODE AND INFORMATION IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY

// KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

// IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR

// PURPOSE.

//

//--------------------------------------------------------------------------#include "F81865.H"

#include <dos.h>

//--------------------------------------------------------------------------unsigned int F81865_BASE;

void Unlock_F81865 (void);

void Lock_F81865 (void);

//--------------------------------------------------------------------------unsigned int Init_F81865(void)

{

unsigned int result;

unsigned char ucDid;

F81865_BASE = 0x4E;

result = F81865_BASE;

39

Page 41

ucDid = Get_F81865_Reg(0x20);

if (ucDid == 0x07||ucDid == 0x10) //Fintek 81865/66

{ goto Init_Finish; }

F81865_BASE = 0x2E;

result = F81865_BASE;

ucDid = Get_F81865_Reg(0x20);

if (ucDid == 0x07||ucDid == 0x10) //Fintek 81865/66

{ goto Init_Finish; }

F81865_BASE = 0x00;

result = F81865_BASE;

Init_Finish:

return (result);

}

//--------------------------------------------------------------------------void Unlock_F81865 (void)

{

outportb(F81865_INDEX_PORT, F81865_UNLOCK);

outportb(F81865_INDEX_PORT, F81865_UNLOCK);

}

//--------------------------------------------------------------------------void Lock_F81865 (void)

{

outportb(F81865_INDEX_PORT, F81865_LOCK);

}

//--------------------------------------------------------------------------void Set_F81865_LD( unsigned char LD)

{

Unlock_F81865();

outportb(F81865_INDEX_PORT, F81865_REG_LD);

outportb(F81865_DATA_PORT, LD);

Lock_F81865();

}

//--------------------------------------------------------------------------void Set_F81865_Reg( unsigned char REG, unsigned char DATA)

{

Unlock_F81865();

outportb(F81865_INDEX_PORT, REG);

outportb(F81865_DATA_PORT, DATA);

Lock_F81865();

}

//--------------------------------------------------------------------------unsigned char Get_F81865_Reg(unsigned char REG)

{

unsigned char Result;

Unlock_F81865();

outportb(F81865_INDEX_PORT, REG);

Result = inportb(F81865_DATA_PORT);

Lock_F81865();

return Result;

}

//---------------------------------------------------------------------------

Filename:81865.h

//---------------------------------------------------------------------------

//

// THIS CODE AND INFORMATION IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY

// KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

// IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR

// PURPOSE.

//

//---------------------------------------------------------------------------

40

Page 42

#ifndef __F81865_H

#define __F81865_H 1

//--------------------------------------------------------------------------#define F81865_INDEX_PORT (F81865_BASE)

#define F81865_DATA_PORT (F81865_BASE+1)

//--------------------------------------------------------------------------#define F81865_REG_LD 0x07

//--------------------------------------------------------------------------#define F81865_UNLOCK 0x87

#define F81865_LOCK 0xAA

//--------------------------------------------------------------------------unsigned int Init_F81865(void);

void Set_F81865_LD( unsigned char);

void Set_F81865_Reg( unsigned char, unsigned char);

unsigned char Get_F81865_Reg( unsigned char);

//--------------------------------------------------------------------------#endif //__F81865_H

41

Page 43

Chapter 16 Drivers Installation

This section describes the installation procedures for software and drivers under the Windows. The software and

drivers are included with the board. If you find the items missing, please contact the vendor where you made the

purchase. The contents of this section include the following:

Intel® Chipset Software Installation Utility

Intel® Graphics Driver Installation

LAN Drivers Installation

Intel® Management Engine Interface

IMPORTANT NOTE:

After installing your Windows operating system, you must install first the Intel® Chipset Software Installation Utility

before proceeding with the drivers installation.

Intel® Chipset Software Installation Utility

The Intel Chipset Drivers should be installed first before the software drivers to enable Plug &

Play INF support for Intel chipset components. Follow the instructions below to complete the

installation.

1. Insert the CD that comes with the board. Click Intel and then Intel(R) 7 Series Chipset Drivers.

2. Click Intel(R) Chipset Software Installation Utility.

[

42

Page 44

3. When the Welcome screen to the Intel® Chipset Device Software appears, click Next to continue.

4. Click Yes to accept the software license agreement and proceed with the installation process.

5. On the Readme File Information screen, click Next to continue the installation.

43

Page 45

6. The Setup process is now complete. Click Finish to restart the computer and for changes to take effect.

VGA Drivers Installation

NOTE: Before installing the Intel(R) C216 Chipset Family Graphics Driver, the Microsoft .NET Framework 3.5 SPI

should be first installed.

To install the VGA drivers, follow the steps below.

1. Insert the CD that comes with the board. Click Intel and then Intel(R) Q7 Series Chipset

Drivers.

2. Click Intel(R) C216 Chipset Family Graphics Driver.

[

44

Page 46

3. When the Welcome screen appears, click Next to continue.

4. Click Yes to to agree with the license agreement and continue the installation.

5. On the Readme File Information screen, click Next to continue the installation of the Intel® Graphics Media

Accelerator Driver.

45

Page 47

6. On Setup Progress screen, click Next to continue.

7. Setup complete. Click Finish to restart the computer and for changes to take effect.

LAN Drivers Installation

1. Insert the CD that comes with the board. Click Intel and then Intel(R) Q7 Series Chipset

Drivers.

2. Click Intel(R) PRO LAN Network Driver.

46

Page 48

3. Click Install Drivers and Software.

4. When the Welcome screen appears, click Next.

5. Click Next to to agree with the license agreement.

47

Page 49

6. Click the checkbox for Drivers in the Setup Options screen to select it and click Next to continue.

7. The wizard is ready to begin installation. Click Install to begin the installation.

8. When InstallShield Wizard is complete, click Finish.

48

Page 50

Intel® Management Engine Interface

Follow the steps below to install the Intel Management Engine.

1. Insert the CD that comes with the board. Click Intel and then Intel(R) AMT 8.0 Drivers.

2. When the Welcome screen to the InstallShield Wizard for Intel® Management Engine Components, click the

checkbox for Install Intel® Control Center & click Next.

49

Page 51

3. Click Yes to to agree with the license agreement.

4. When the Setup Progress screen appears, click Next. Then, click Finish when the setup progress has been

successfully installed.

[

50

Page 52

Intel® USB 3.0 Drivers

1. Insert the CD that comes with the board. Click Intel and then Intel(R) C216 Series Chipset Drivers.

2. Click Intel(R) USB 3.0 Drivers.

3. When the Welcome screen to the InstallShield Wizard for Intel® USB 3.0 eXtensible Host Controller Driver, click

Next.

51

Page 53

4. Click Yes to to agree with the license agreement and continue the installation.

5. On the Readme File Information screen, click Next to continue the installation of the Intel® USB 3.0 eXtensible

Host Controller Driver.

6. Setup complete. Click Finish to restart the computer and for changes to take effect.

52

Page 54

Appendix-A I/O Port Address Map

Address

Device Description

000h - 01Fh

DMA Controller #1

020h - 03Fh

Interrupt Controller #1

040h - 05Fh

Timer

060h - 06Fh

Keyboard Controller

070h - 07Fh

Real Time Clock, NMI

080h - 09Fh

DMA Page Register

0A0h - 0BFh

Interrupt Controller #2

0C0h - 0DFh

DMA Controller #2

0F0h

Clear Math Coprocessor Busy Signal

0F1h

Reset Math Coprocessor

1F0h - 1F7h

IDE Interface

2F8h - 2FFh

Serial Port #2(COM2)

2B0h- 2DFh

Graphics adapter Controller

360h - 36Fh

Network Ports

3F8h - 3FFh

Serial Port #1(COM1)

Level

Function

IRQ0

System Timer Output

IRQ1

Keyboard

IRQ3

Serial Port #2

IRQ4

Serial Port #1

IRQ8

Real Time Clock

IRQ14

Primary IDE

IRQ15

Secondary IDE

Each peripheral device in the system is assigned a set of I/O port addresses which also becomes the identity of the

device. The following table lists the I/O port addresses used.

Appendix-B Interrupt Request Lines (IRQ)

Peripheral devices use interrupt request lines to notify CPU for the service required. The following table shows the

IRQ used by the devices on board.

53

Page 55

Appendix-C FWA8208 Series Configurations

The following lists the available SKUs of FWA8208 for different system requirement.

FWA8208 2.5” HDD x1, PCI-e add-on card rear expansion x1, front panel expansion

card x1, 300W PSU

MB967 x1

IP331 x1: 1-to-1 Riser Card

IP332 x1: PCI-e Adapter

Single 2.5” HDD Bracket x1

4-pin Smart Fan x3

300W Single Power Supply

FWA8208 Optional Items

IBP161, IBP162: Expansion LAN Card

Dual 2.5” HDD Bracket Kit SC2FWA8208-0A1100P

VGA cable: C501VGA0415272000P

Console Cable: C501PK15108A12000P

Rear Rackmount Kit: 600 or 800mm

FWA8208-2SLOT 3.5” HDD x1, PCI-e add-on card rear expansion x2, 300W PSU

MB967 x1

IP333 x1: 2-to-2 Riser Card

Single 3.5” HDD Bracket x1

4-pin Smart Fan x3

300W Single Power Supply

FWA8208-2SLOT Optional Items

Dual 2.5” HDD Bracket Kit SC2FWA8208-0A1100P

VGA cable: C501VGA0415272000P

Console Cable: C501PK15108A12000P

Rear Rackmount Kit: 600 or 800mm

FWA8208-RPSU 2.5” HDD x1, PCI-e add-on card rear expansion x1, front panel

expansion card x1, 275W 1+1 Redundant PSU

MB967 x1

IP331 x1: 1-to-1 Riser Card

IP332 x1: PCI-e Adapter

Single 2.5” HDD Bracket x1

4-pin Smart Fan x3

275W 1+1 Redundant Power Supply

FWA8208-RPSU Optional Items

IBP161, IBP162: Expansion LAN Card

VGA cable: C501VGA0415272000P

Console Cable: C501PK15108A12000P

Rear Rackmount Kit: 600 or 800mm

54

Loading...

Loading...