Page 1

ROBO Cylinder

Rod Type

RCA Actuators

RCAW Actuators, Dustproof/Splash-proof Type

Operating Manual

Eighth Edition

䎰䏒䏗䏒䏕䎃䎶䏗䏕䏄䏌䏊䏋䏗䎃䎷䏜䏓䏈䎃䎋䎦䏒䏘䏓䏏䏌䏑䏊䎃䎷䏜䏓䏈䎌䎃

䎵䎤䎖䎦䎏䎵䎪䎶䎖䎦䎏䎵䎪䎧䎖䎦䎏䎵䎤䎗䎦䎏䎵䎪䎶䎗䎦䎏䎵䎪䎧䎗䎦䎃

䎰䏒䏗䏒䏕䎃䎶䏗䏕䏄䏌䏊䏋䏗䎃䎷䏜䏓䏈䎃䎋䎥䏘䏌䏏䏗䎐䏌䏑䎃䎷䏜䏓䏈䎌䎃

䎵䎤䎖䎧䎏䎵䎪䎶䎖䎧䎏䎵䎪䎧䎖䎧䎏䎵䎤䎗䎧䎏䎵䎪䎶䎗䎧䎏䎵䎪䎧䎗䎧䎃

䎰䏒䏗䏒䏕䎃䎵䏈䏙䏈䏕䏖䏌䏑䏊䎃䎷䏜䏓䏈䎃

䎵䎤䎖䎵䎏䎵䎪䎧䎖䎵䎏䎵䎤䎗䎵䎏䎵䎪䎧䎗䎵䎃

䎃

䎰䏒䏗䏒䏕䎃䎶䏗䏕䏄䏌䏊䏋䏗䎃䎷䏜䏓䏈䎃䎋䎦䏒䏘䏓䏏䏌䏑䏊䎃䎷䏜䏓䏈䎌䎃

䎵䎤䎖䎦䎏䎵䎤䎗䎦䎃

䎰䏒䏗䏒䏕䎃䎶䏗䏕䏄䏌䏊䏋䏗䎃䎷䏜䏓䏈䎃䎋䎥䏘䏌䏏䏗䎐䏌䏑䎃䎷䏜䏓䏈䎌䎃

䎵䎤䎖䎧䎏䎵䎤䎗䎧䎃

䎰䏒䏗䏒䏕䎃䎵䏈䏙䏈䏕䏖䏌䏑䏊䎃䎷䏜䏓䏈䎃

䎵䎤䎖䎵䎏䎵䎤䎗䎵䎃

IAI America, Inc.

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Operation Manual explains the handling methods, structure and maintenance of this product,

among others, providing the information you need to know to use the product safely.

Before using the product, be sure to read this manual and fully understand the contents explained herein

to ensure safe use of the product.

The CD or DVD that comes with the product contains Operation Manuals for IAI products.

When using the product, refer to the necessary portions of the applicable Operation manual by printing

them out or displaying them on a PC.

After reading the Operation Manual, keep it in a convenient place so that whoever is handling this

product can reference it quickly when necessary.

[Important]

x This Operation Manual is original.

x The product cannot be operated in any way unless expressly specified in this Operation Manual. IAI

shall assume no responsibility for the outcome of any operation not specified herein.

x Information contained in this Operation Manual is subject to change without notice for the purpose

of product improvement.

x If you have any question or comment regarding the content of this manual, please contact the IAI

sales office near you.

x Using or copying all or part of this Operation Manual without permission is prohibited.

x The company names, names of products and trademarks of each company shown in the sentences

are registered trademarks.

Page 4

Page 5

Table of Contents

Safety Guide ························································································································1

Precautions·························································································································· 8

International Standards Compliances ·················································································· 9

Names of the Parts ············································································································10

1. Specifications Check··································································································· 13

1.1 Checking the Product ·····································································································13

1.1.1 Parts ··································································································································13

1.1.2 Instruction Manuals related to this product, which are contained in the CD/DVD.···········14

1.1.3 How to Read the Model Nameplate··················································································14

1.1.4 How to Read the Model Number·······················································································15

1.2 Specification····················································································································16

1.2.1 Speed································································································································16

1.2.2 Maximum Acceleration and Transportable Weight ···························································17

1.2.3 Driving System • Position Detector ···················································································19

1.2.4 Positioning Precision·········································································································20

1.2.5 Rod Non-Rotation Accuracy······························································································20

1.2.6 Allowable Running Torque ································································································22

1.2.7 Relation of Allowable Tip Load and Running Life ·····························································22

1.2.8 Radial load and Tip Flexure ······························································································23

1.2.9 Duty Ratio in Continuous Operation ·················································································24

1.2.10 Protection class·················································································································25

1.3 Options ···························································································································26

1.3.1 Brake Type························································································································26

1.3.2 High Acceleration/Deceleration Type················································································26

1.3.3 Home-Position Check Sensor···························································································26

1.3.4 Power Saving Type ···········································································································26

1.3.5 Motor Left Reversed, Motor Right Reversed (Model No. : ML, MR)·································26

1.3.6 Guide Attachment Directions (Only for Single guide type) ···············································26

1.3.7 Front Flange (Model No. : FL)···························································································27

1.3.8 Rear Flange (Model No. : FLR)·························································································28

1.3.9 Foot (Model No. : FT)········································································································30

1.3.10 Foot (Attached on the Right Side/Left Side) ·····································································32

1.3.11 Knuckle Joint (Model No. : NJ) ·························································································33

1.3.12 Clevis (Model No. : QR)····································································································34

1.3.13 Rear Attachment Plate (Model No. : RP) ··········································································35

1.3.14 Front Trunnion (Model No. : TRF)·····················································································36

1.3.15 Rear Trunnion (Model No. : TRR)·····················································································37

1.4 Motor • Encoder Cables··································································································38

1.4.1 Motor cable ·······················································································································38

1.4.2 Encoder cable/robot encoder cable

CB-ACS-PAƑƑƑ/CB-ACS-PA-ƑƑƑ-RB··············································································38

1.4.3 Motor/Encoder Integrated Cable for AMEC/ASEP····························································39

2. Installation···················································································································40

2.1 Transportation·················································································································40

2.2 Installation and Storage • Preservation Environment······················································42

2.3 How to Installation···········································································································43

2.3.1 General Rules on Installation····························································································43

2.3.2 Installation ·························································································································44

2.3.3 Connecting the Air Tube of the RCAW Dustproof/Splash-proof Type·······························54

Page 6

3. Connecting with Controller ··························································································55

4. Maintenance ··············································································································· 59

4.1 Maintenance Schedule ···································································································59

4.2 Visual Inspection of the Machine ····················································································59

4.3 Cleaning··························································································································59

4.4 Applying Grease to the Sliding Surface of the Rod ························································60

4.5 Reduction Belt [Motor Reversing Type] ··········································································61

4.5.1 Inspecting the Belt ············································································································61

4.5.2 Applicable Belt ··················································································································61

4.5.3 Adjusting the Belt Tension·································································································62

4.5.4 Replacing the Belt of the Motor Reversing Type: RA3R/RA4R Types ·····························63

4.6 Replacing the Motor········································································································68

4.6.1 Replacing the Motor of the Motor Straight Type (Coupling Type):

RA3C/RA4C Types ···········································································································68

4.6.2 Replacing the Motor of the Motor Reversing Type: RA3R/RA4R Types ··························75

4.7 Replacing the Bellows of the RCAW Dustproof/Splash-proof Type ································81

5. Appendix ·····················································································································84

5.1 RCA-RA3C ·····················································································································84

5.2 RCA-RA4C ·····················································································································85

5.3 RCA-RA3D ·····················································································································86

5.4 RCA-RA4D ·····················································································································87

5.5 RCA-RA3R ·····················································································································88

5.6 RCA-RA4R ·····················································································································89

5.7 RCA-RGS3C···················································································································90

5.8 RCA-RGS4C···················································································································91

5.9 RCA-RGS3D···················································································································92

5.10 RCA-RGS4D ·················································································································93

5.11 RCA-RGD3C··················································································································94

5.12 RCA-RGD4C ·················································································································95

5.13 RCA-RGD3D ·················································································································96

5.14 RCA-RGD4D ·················································································································97

5.15 RCA-RGD3R ·················································································································98

5.16 RCA-RGD4R ·················································································································99

5.17 RCAW-RA3C/RA3D/RA3R··························································································100

5.18 RCAW-RA4C/RA4D/RA4R··························································································101

6. Life ····························································································································102

7. Warranty ··················································································································· 103

7.1 Warranty Period············································································································103

7.2 Scope of the Warranty ··································································································103

7.3 Honoring the Warranty··································································································103

7.4 Limited Liability ·············································································································104

7.5 Conditions of Conformance with Applicable Standards/Regulations, Etc.,

and Applications············································································································104

7.6 Other Items Excluded from Warranty············································································104

Change History ················································································································105

Page 7

1

Safety Guide

“Safety Guide” has been written to use the machine safely and so prevent personal injury or property damage

beforehand. Make sure to read it before the operation of this product.

Safety Precautions for Our Products

The common safety precautions for the use of any of our robots in each operation.

No.

Operation

Description

Description

1 Model Selection Ɣ This product has not been planned and designed for the application where high

level of safety is required, so the guarantee of the protection of human life is

impossible. Accordingly, do not use it in any of the following applications.

1) Medical equipment used to maintain, control or otherwise affect human life

or physical health.

2) Mechanisms and machinery designed for the purpose of moving or

transporting people (For vehicle, railway facility or air navigation facility)

3) Important safety parts of machinery (Safety device, etc.)

Ɣ Do not use the product outside the specifications. Failure to do so may

considerably shorten the life of the product.

Ɣ Do not use it in any of the following environments.

1) Location where there is any inflammable gas, inflammable object or

explosive

2) Place with potential exposure to radiation

3) Location with the ambient temperature or relative humidity exceeding the

specification range

4) Location where radiant heat is added from direct sunlight or other large heat

source

5) Location where condensation occurs due to abrupt temperature changes

6) Location where there is any corrosive gas (sulfuric acid or hydrochloric acid)

7) Location exposed to significant amount of dust, salt or iron powder

8) Location subject to direct vibration or impact

Ɣ For an actuator used in vertical orientation, select a model which is equipped

with a brake. If selecting a model with no brake, the moving part may drop

when the power is turned OFF and may cause an accident such as an injury or

damage on the work piece.

Page 8

2

No.

Operation

Description

Description

2 Transportation Ɣ When carrying a heavy object, do the work with two or more persons or utilize

equipment such as crane.

Ɣ When the work is carried out with 2 or more persons, make it clear who is to be

the leader and who to be the follower(s) and communicate well with each other

to ensure the safety of the workers.

Ɣ When in transportation, consider well about the positions to hold, weight and

weight balance and pay special attention to the carried object so it would not

get hit or dropped.

Ɣ Transport it using an appropriate transportation measure.

The actuators available for transportation with a crane have eyebolts attached

or there are tapped holes to attach bolts. Follow the instructions in the

Operating manual for each model.

Ɣ Do not step or sit on the package.

Ɣ Do not put any heavy thing that can deform the package, on it.

Ɣ When using a crane capable of 1t or more of weight, have an operator who has

qualifications for crane operation and sling work.

Ɣ When using a crane or equivalent equipments, make sure not to hang a load

that weighs more than the equipment’s capability limit.

Ɣ Use a hook that is suitable for the load. Consider the safety factor of the hook

in such factors as shear strength.

Ɣ Do not get on the load that is hung on a crane.

Ɣ Do not leave a load hung up with a crane.

Ɣ Do not stand under the load that is hung up with a crane.

3 Storage and

Preservation

Ɣ The storage and preservation environment conforms to the installation

environment. However, especially give consideration to the prevention of

condensation.

Ɣ Store the products with a consideration not to fall them over or drop due to an

act of God such as earthquake.

4 Installation and

Start

(1) Installation of Robot Main Body and Controller, etc.

Ɣ Make sure to securely hold and fix the product (including the work part). A fall,

drop or abnormal motion of the product may cause a damage or injury.

Also, be equipped for a fall-over or drop due to an act of God such as

earthquake.

Ɣ Do not get on or put anything on the product. Failure to do so may cause an

accidental fall, injury or damage to the product due to a drop of anything,

malfunction of the product, performance degradation, or shortening of its life.

Ɣ When using the product in any of the places specified below, provide a

sufficient shield.

1) Location where electric noise is generated

2) Location where high electrical or magnetic field is present

3) Location with the mains or power lines passing nearby

4) Location where the product may come in contact with water, oil or chemical

droplets

Page 9

3

No.

Operation

Description

Description

(2) Cable Wiring

Ɣ Use our company’s genuine cables for connecting between the actuator and

controller, and for the teaching tool.

Ɣ Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not coil it

around. Do not insert it. Do not put any heavy thing on it. Failure to do so may

cause a fire, electric shock or malfunction due to leakage or continuity error.

Ɣ Perform the wiring for the product, after turning OFF the power to the unit, so

that there is no wiring error.

Ɣ When the direct current power (+24V) is connected, take the great care of the

directions of positive and negative poles. If the connection direction is not

correct, it might cause a fire, product breakdown or malfunction.

Ɣ Connect the cable connector securely so that there is no disconnection or

looseness. Failure to do so may cause a fire, electric shock or malfunction of

the product.

Ɣ Never cut and/or reconnect the cables supplied with the product for the

purpose of extending or shortening the cable length. Failure to do so may

cause the product to malfunction or cause fire.

4 Installation and

Start

(3) Grounding

Ɣ The grounding operation should be performed to prevent an electric shock or

electrostatic charge, enhance the noise-resistance ability and control the

unnecessary electromagnetic radiation.

Ɣ For the ground terminal on the AC power cable of the controller and the

grounding plate in the control panel, make sure to use a twisted pair cable with

wire thickness 0.5mm

2

(AWG20 or equivalent) or more for grounding work. For

security grounding, it is necessary to select an appropriate wire thickness

suitable for the load. Perform wiring that satisfies the specifications (electrical

equipment technical standards).

Ɣ Perform Class D Grounding (former Class 3 Grounding with ground resistance

100: or below).

Page 10

4

No.

Operation

Description

Description

4 Installation and

Start

(4) Safety Measures

Ɣ When the work is carried out with 2 or more persons, make it clear who is to be

the leader and who to be the follower(s) and communicate well with each other

to ensure the safety of the workers.

Ɣ When the product is under operation or in the ready mode, take the safety

measures (such as the installation of safety and protection fence) so that

nobody can enter the area within the robot’s movable range. When the robot

under operation is touched, it may result in death or serious injury.

Ɣ Make sure to install the emergency stop circuit so that the unit can be stopped

immediately in an emergency during the unit operation.

Ɣ Take the safety measure not to start up the unit only with the power turning ON.

Failure to do so may start up the machine suddenly and cause an injury or

damage to the product.

Ɣ Take the safety measure not to start up the machine only with the emergency

stop cancellation or recovery after the power failure. Failure to do so may result

in an electric shock or injury due to unexpected power input.

Ɣ When the installation or adjustment operation is to be performed, give clear

warnings such as “Under Operation; Do not turn ON the power!” etc. Sudden

power input may cause an electric shock or injury.

Ɣ Take the measure so that the work part is not dropped in power failure or

emergency stop.

Ɣ Wear protection gloves, goggle or safety shoes, as necessary, to secure safety.

Ɣ Do not insert a finger or object in the openings in the product. Failure to do so

may cause an injury, electric shock, damage to the product or fire.

Ɣ When releasing the brake on a vertically oriented actuator, exercise precaution

not to pinch your hand or damage the work parts with the actuator dropped by

gravity.

5 Teaching Ɣ When the work is carried out with 2 or more persons, make it clear who is to be

the leader and who to be the follower(s) and communicate well with each other

to ensure the safety of the workers.

Ɣ Perform the teaching operation from outside the safety protection fence, if

possible. In the case that the operation is to be performed unavoidably inside

the safety protection fence, prepare the “Stipulations for the Operation” and

make sure that all the workers acknowledge and understand them well.

Ɣ When the operation is to be performed inside the safety protection fence, the

worker should have an emergency stop switch at hand with him so that the unit

can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection fence, in

addition to the workers, arrange a watchman so that the machine can be

stopped any time in an emergency. Also, keep watch on the operation so that

any third person can not operate the switches carelessly.

Ɣ Place a sign “Under Operation” at the position easy to see.

Ɣ When releasing the brake on a vertically oriented actuator, exercise precaution

not to pinch your hand or damage the work parts with the actuator dropped by

gravity.

* Safety protection Fence : In the case that there is no safety protection fence,

the movable range should be indicated.

Page 11

5

No.

Operation

Description

Description

6 Trial Operation Ɣ When the work is carried out with 2 or more persons, make it clear who is to be

the leader and who to be the follower(s) and communicate well with each other

to ensure the safety of the workers.

Ɣ After the teaching or programming operation, perform the check operation one

step by one step and then shift to the automatic operation.

Ɣ When the check operation is to be performed inside the safety protection

fence, perform the check operation using the previously specified work

procedure like the teaching operation.

Ɣ Make sure to perform the programmed operation check at the safety speed.

Failure to do so may result in an accident due to unexpected motion caused by

a program error, etc.

Ɣ Do not touch the terminal block or any of the various setting switches in the

power ON mode. Failure to do so may result in an electric shock or

malfunction.

7 Automatic

Operation

Ɣ Check before starting the automatic operation or rebooting after operation stop

that there is nobody in the safety protection fence.

Ɣ Before starting automatic operation, make sure that all peripheral equipment is

in an automatic-operation-ready state and there is no alarm indication.

Ɣ Make sure to operate automatic operation start from outside of the safety

protection fence.

Ɣ In the case that there is any abnormal heating, smoke, offensive smell, or

abnormal noise in the product, immediately stop the machine and turn OFF the

power switch. Failure to do so may result in a fire or damage to the product.

Ɣ When a power failure occurs, turn OFF the power switch. Failure to do so may

cause an injury or damage to the product, due to a sudden motion of the

product in the recovery operation from the power failure.

Page 12

6

No.

Operation

Description

Description

8 Maintenance

and Inspection

Ɣ When the work is carried out with 2 or more persons, make it clear who is to be

the leader and who to be the follower(s) and communicate well with each other

to ensure the safety of the workers.

Ɣ Perform the work out of the safety protection fence, if possible. In the case that

the operation is to be performed unavoidably inside the safety protection fence,

prepare the “Stipulations for the Operation” and make sure that all the workers

acknowledge and understand them well.

Ɣ When the work is to be performed inside the safety protection fence, basically

turn OFF the power switch.

Ɣ When the operation is to be performed inside the safety protection fence, the

worker should have an emergency stop switch at hand with him so that the unit

can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection fence, in

addition to the workers, arrange a watchman so that the machine can be

stopped any time in an emergency. Also, keep watch on the operation so that

any third person can not operate the switches carelessly.

Ɣ Place a sign “Under Operation” at the position easy to see.

Ɣ For the grease for the guide or ball screw, use appropriate grease according to

the Operating manual for each model.

Ɣ Do not perform the dielectric strength test. Failure to do so may result in a

damage to the product.

Ɣ When releasing the brake on a vertically oriented actuator, exercise precaution

not to pinch your hand or damage the work parts with the actuator dropped by

gravity.

Ɣ The slider or rod may get misaligned OFF the stop position if the servo is

turned OFF. Be careful not to get injured or damaged due to an unnecessary

operation.

Ɣ Pay attention not to lose the cover or untightened screws, and make sure to

put the product back to the original condition after maintenance and inspection

works.

Use in incomplete condition may cause damage to the product or an injury.

* Safety protection Fence : In the case that there is no safety protection fence,

the movable range should be indicated.

9 Modification and

Dismantle

Ɣ Do not modify, disassemble, assemble or use of maintenance parts not

specified based at your own discretion.

10 Disposal Ɣ When the product becomes no longer usable or necessary, dispose of it

properly as an industrial waste.

Ɣ When removing the actuator for disposal, pay attention to drop of components

when detaching screws.

Ɣ Do not put the product in a fire when disposing of it.

The product may burst or generate toxic gases.

11 Other Ɣ Do not come close to the product or the harnesses if you are a person who

requires a support of medical devices such as a pacemaker. Doing so may

affect the performance of your medical device.

Ɣ See Overseas Specifications Compliance Manual to check whether complies if

necessary.

Ɣ For the handling of actuators and controllers, follow the dedicated Operating

manual of each unit to ensure the safety.

Page 13

7

Alert Indication

The safety precautions are divided into “Danger”, “Warning”, “Caution” and “Notice” according to the warning

level, as follows, and described in the Operating manual for each model.

Level Degree of Danger and Damage Symbol

Danger

This indicates an imminently hazardous situation which, if the product is

not handled correctly, will result in death or serious injury.

Danger

Warning

This indicates a potentially hazardous situation which, if the product is

not handled correctly, could result in death or serious injury.

Warning

Caution

This indicates a potentially hazardous situation which, if the product is

not handled correctly, may result in minor injury or property damage.

Caution

Notice

This indicates lower possibility for the injury, but should be kept to use

this product properly.

Notice

Page 14

8

Precautions

1. Ensure use of the product in the specified conditions, environments and ranges.

Operation out of the specified conditions could cause a drop in performance or malfunction of the product.

2. Set the allowable load of the move on rod tip within the allowable range.

An operation with the load beyond the allowable load of the move on rod tip may cause an abnormal noise,

vibration, malfunction or shortened life. If it is extreme, flaking may occur on the guide.

3. If back and forth operations are performed repeatedly in short distance, it may wear out

the film of grease.

Continuous back and forth operation within a distance less than 30mm may cause wear of grease.

As a reference, have approximately 5 cycles of back and forth operation in a distance more than 50mm in

every 5,000 to 10,000 cycles to regenerate the oil film. Keep using the actuator with the grease worn out

may cause malfunction. If it is extreme, flaking may occur on the guide.

4. Do not apply any rotation torque on the rod.

Doing so may damage the internal component such as the rod stopper, and may result in an operation

failure.

Page 15

9

International Standards Compliances

This actuator complies with the following overseas standard.

Refer to Overseas Standard Compliance Manual (ME0287) for more detailed information.

RoHS CE Marking

{ {

Page 16

10

Names of the Parts

In this Operation Manual, the left and right sides are indicated by looking at the actuator from the motor end,

with the actuator placed horizontally, as shown in the figure below.

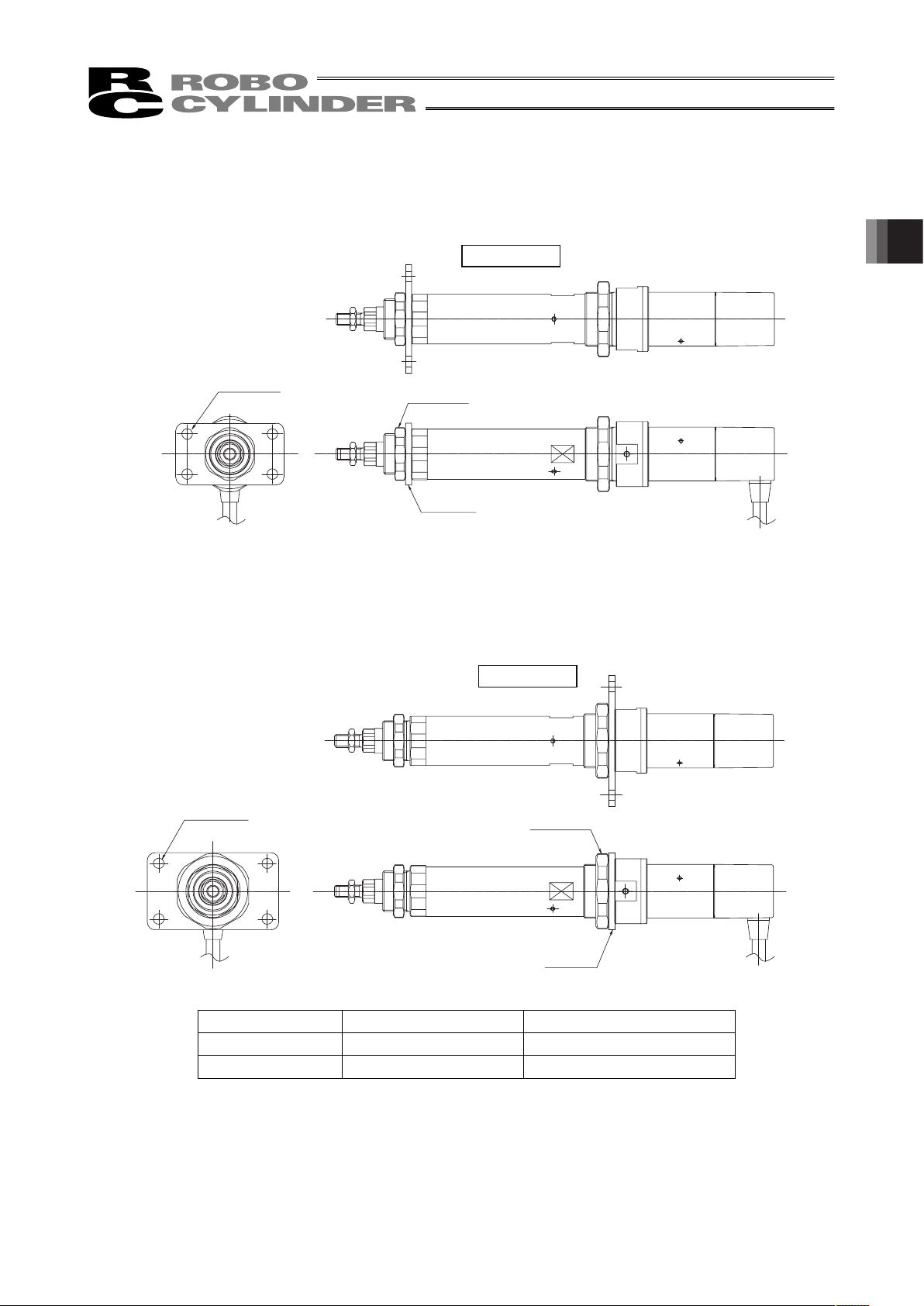

[RA3C, RA4C]

[RA3D, RA4D]

[RA3R, RA4R]

Rod Cover

Motor Unit

Head Cover

Cylinder Tube

Right

Left

Motor SideRod Side

Rod

Rod-Tip Adapter

Cable

Brake Unit

Head Cover

Cylinder Tube

Right

Left

Motor Side

Rod Side

Rod Cover

Motor Unit

Cable

Rod-Tip Adapter

Rod

Right

Left

Motor SideRod Side

Brake Unit

Cable

Pulley Case

Head Cover

Cylinder Tube

Rod Cover

Rod

Rod-Tip Adapter

Brake Unit

Page 17

11

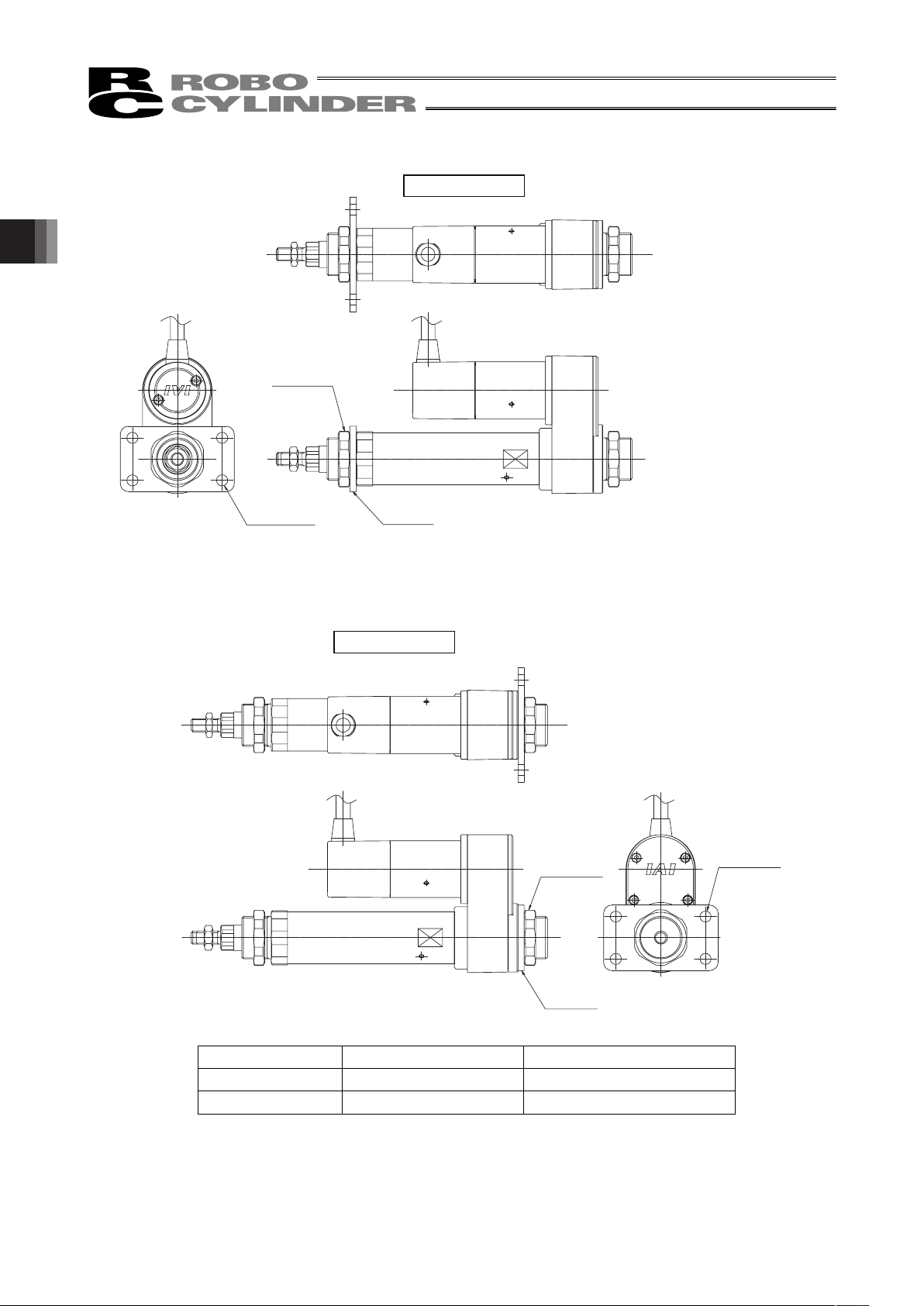

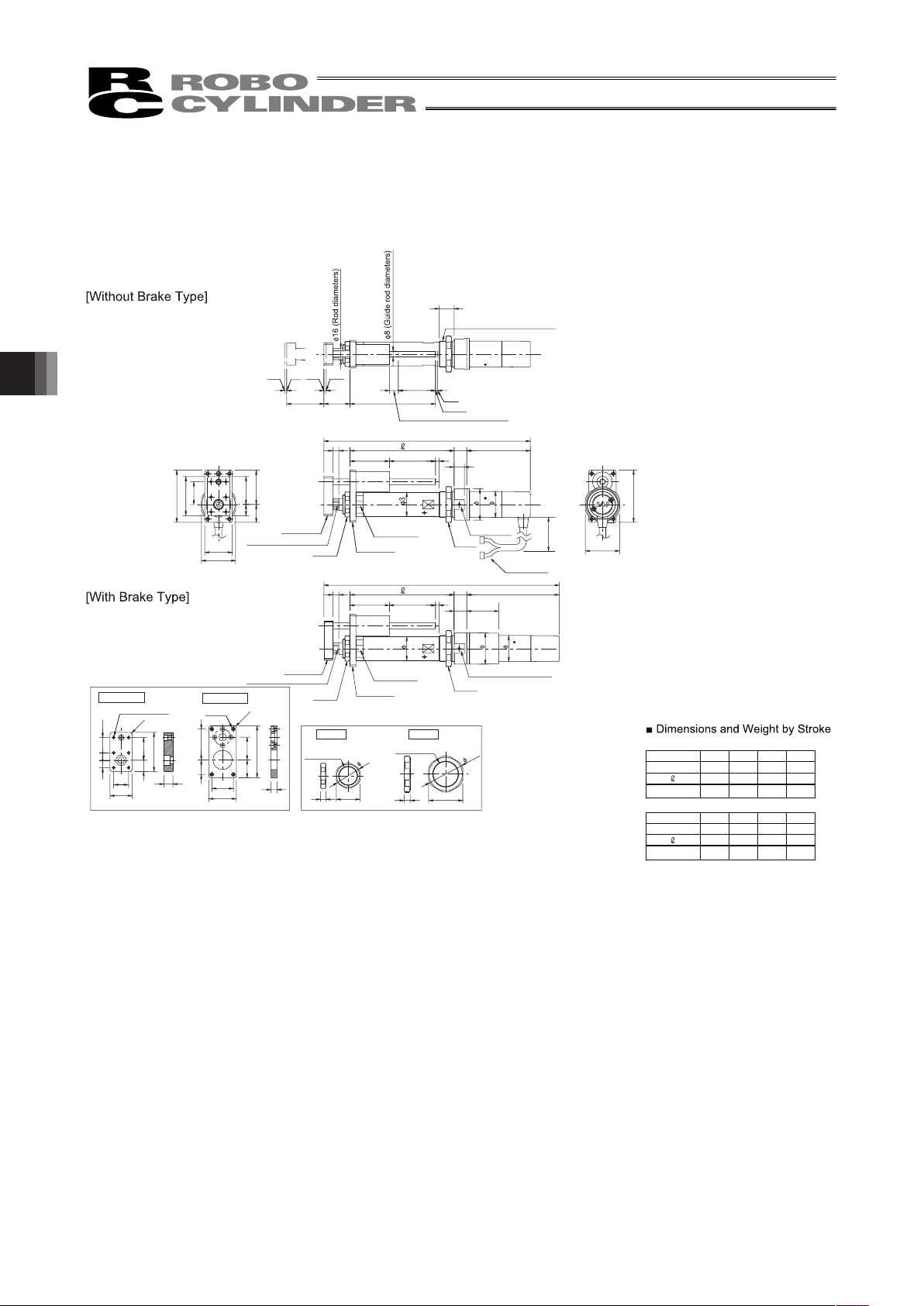

[RGS3C, RGS3D, RGS4C, RGS4D]

RGS3D and RGS4C are non-brake-equipped types.

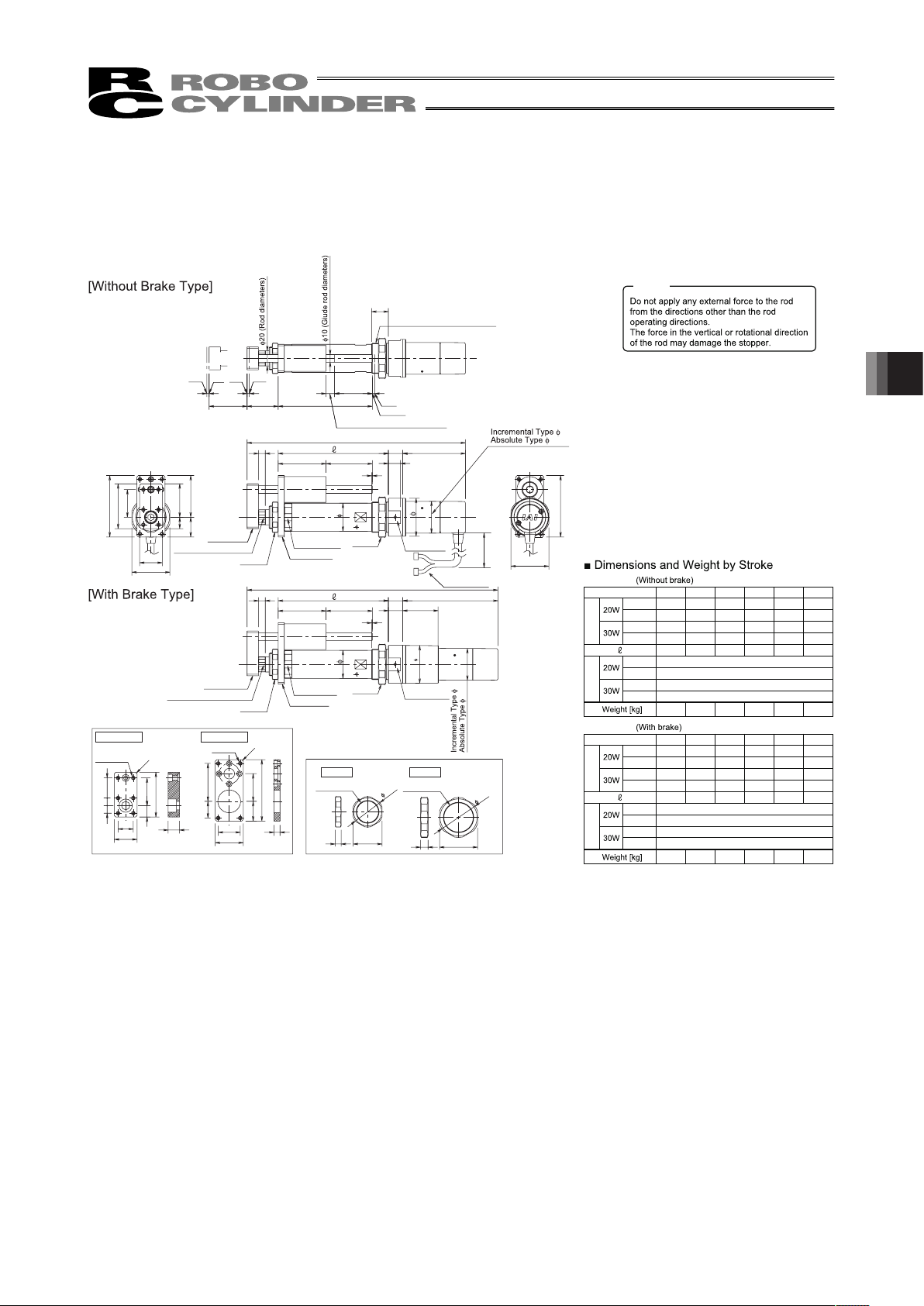

[RGD3C, RGD3D, RGD4C, RGD4D]

RGD3D and RGD4C are non-brake-equipped types.

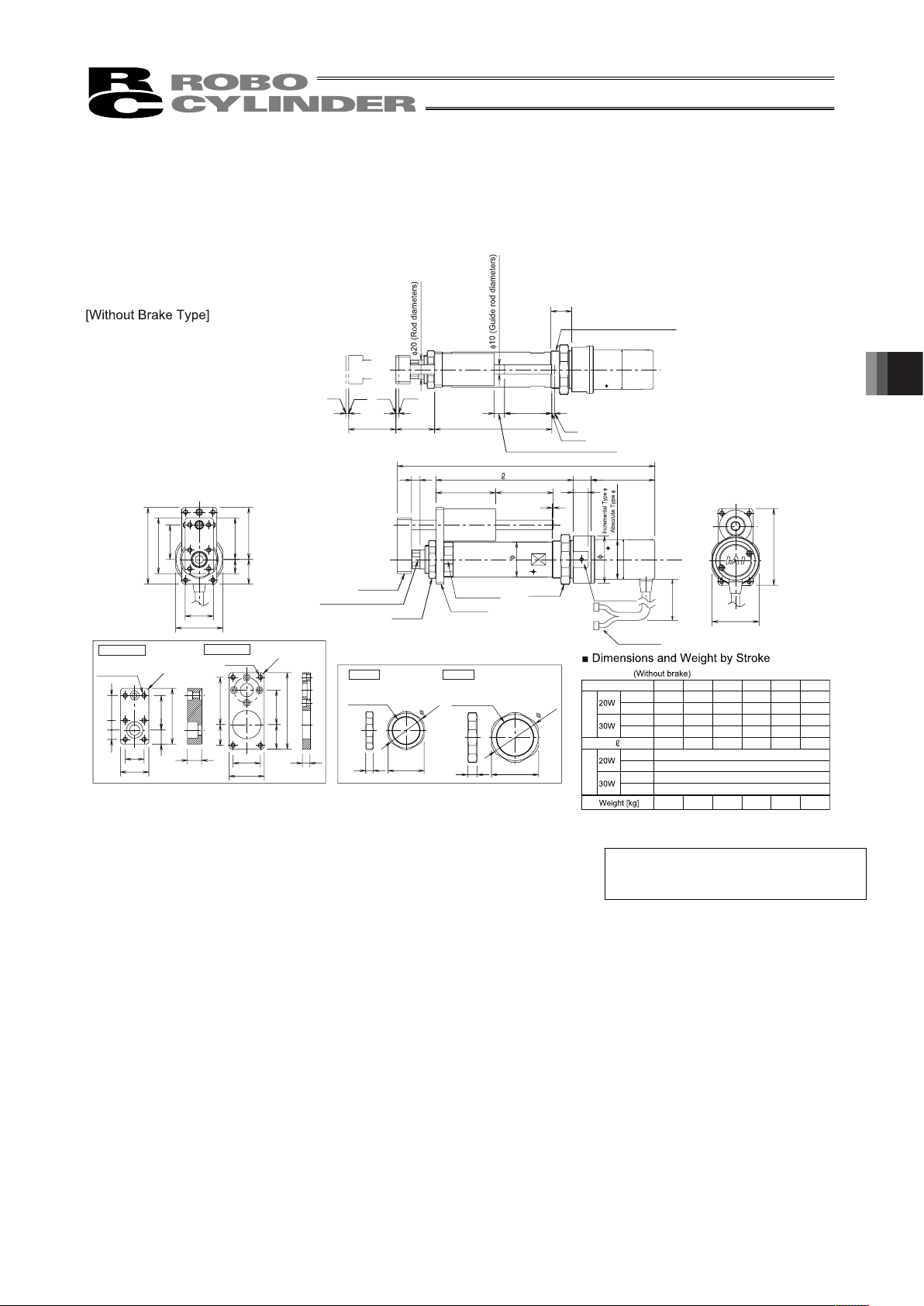

[RGD3R, RGD4R]

Right

Left

Motor SideRod Side

Guide Bearing

Guide Rod

Head Cover

Motor Unit

Cable

Cylinder Tube

Rod Cover

Rod

Guide Bracket

Brake Unit

Right

Left

Guide Bracket

Guide Bearing

Guide Rod

Head Cover

Motor Unit

Motor Side

Rod Side

Rod

Rod Cover

Cylinder Tube

Cable

Brake Unit

Right

Left

Guide Bearing

Guide Bracket

Guide Rod

Head Cover

Motor Unit

Rod Cover

Rod

Cable

Motor Side

Rod Side

Brake Unit

Page 18

12

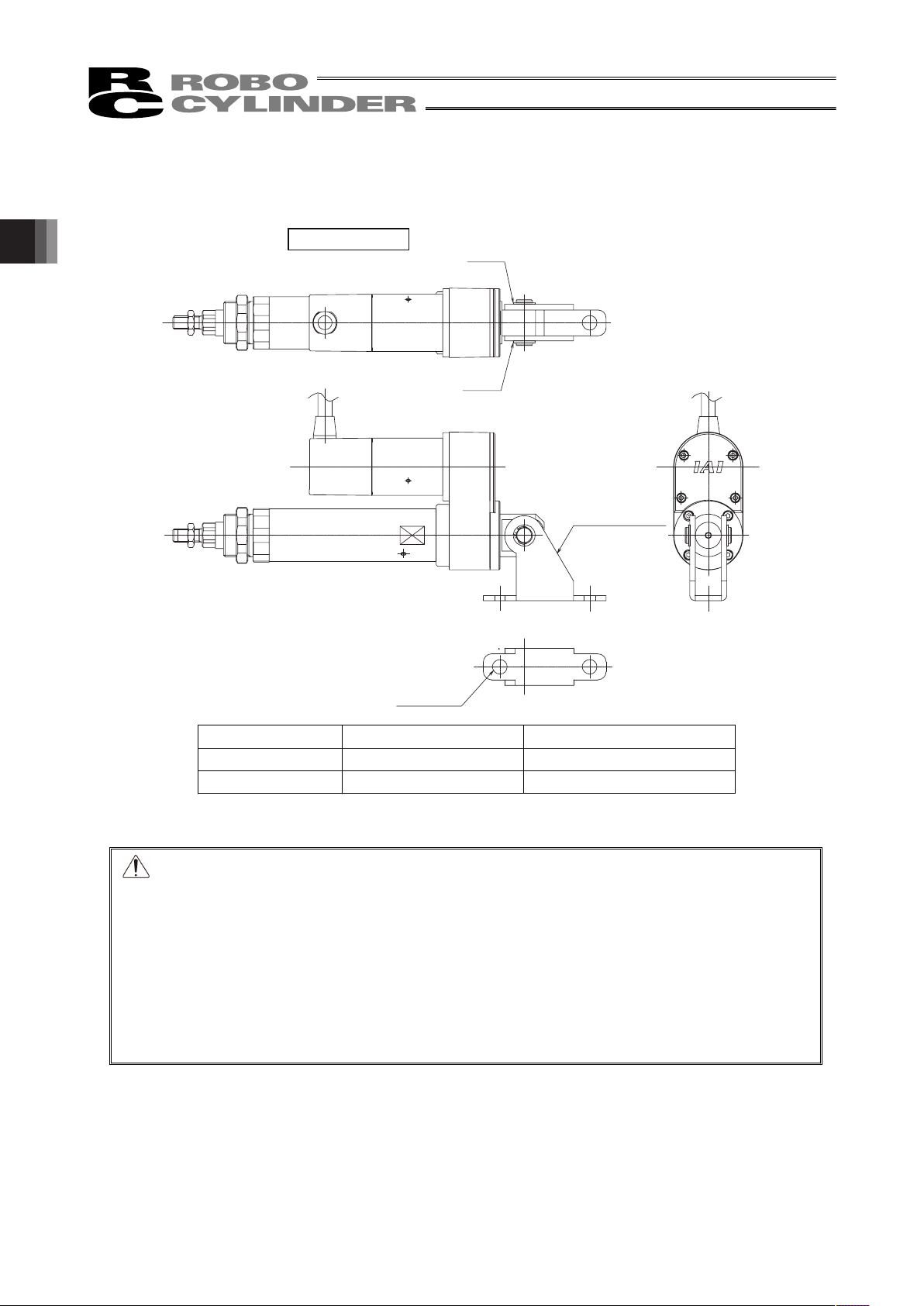

Dust and Splash-Proof Type

[RA3C, RA3D, RA4C, RA4D]

RA3D and RA4D are non-brake-equipped types.

[RA3R, RA4R]

Bellows

Right

Left

Motor SideRod Side

Suction/Exhaust Port

Cylinder Tube

Head Cover

Motor Unit

Cable

Rod Cover

Rod

Rod-Tip Adapter

Brake Unit

Bellows

Right

Left

Suction/Exhaust Port

Cable

Motor Unit

Rod

Rod-Tip Adapter

Cylinder Tube

Rod Cover

Pulley Case

Head Cover

Motor Side

Rod Side

Brake Unit

Page 19

13

1. Specifications Check

1.1 Checking the Product

The standard configuration of this product is comprised of the following parts.

Caution: Check for the enclosed components referring to the component list. If you find any fault or

missing part, contact your local IAI distributor or our company.

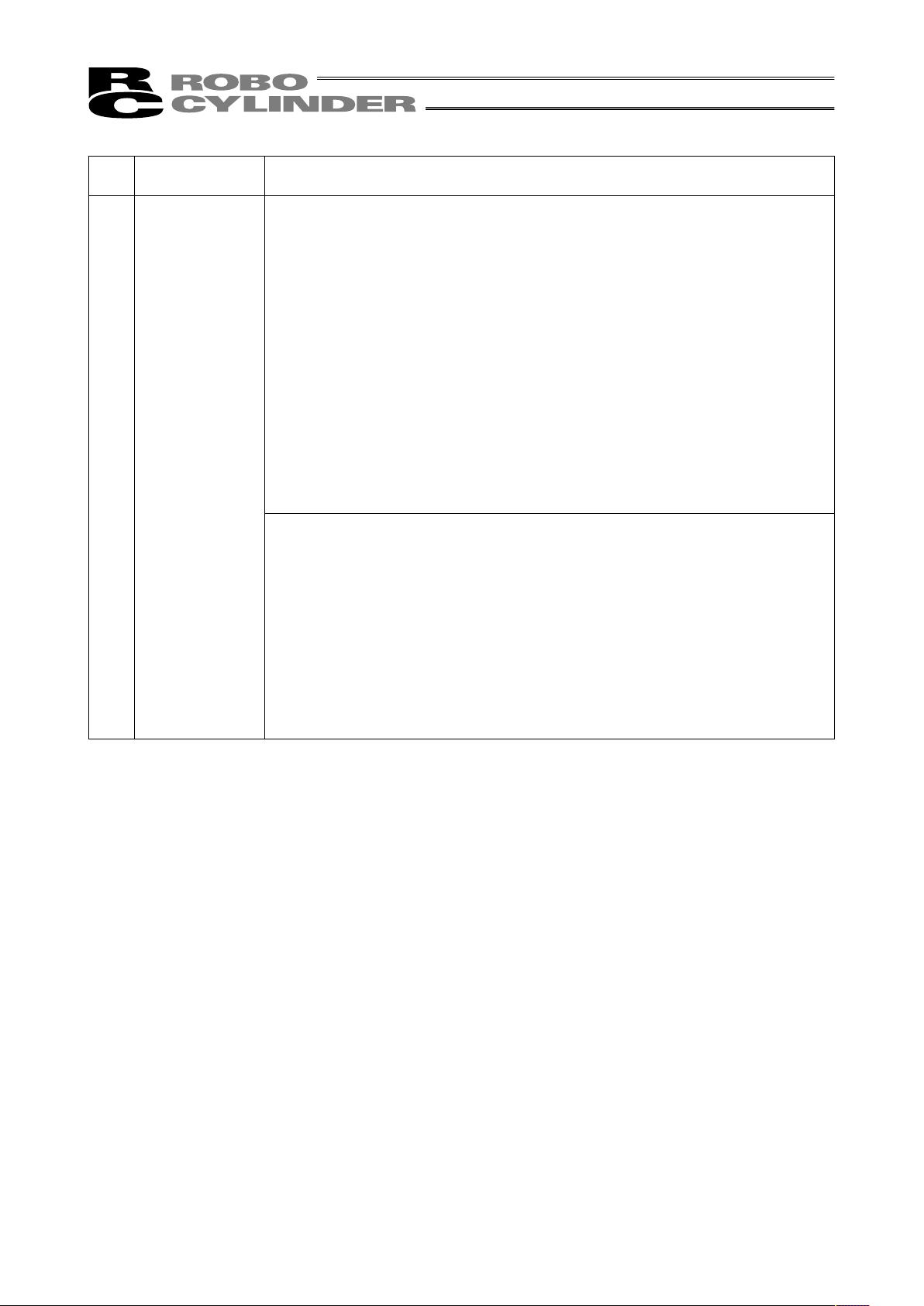

1.1.1 Parts

No. Part Name Model Quantity Remarks

1 Actuator Main Body

Refer to “1.1.3 How to Read the

Model Nameplate”, “1.1.4 How to

Read the Model Number”

1

Accessories

2

Motor • Encoder Cable

Note1

1

3 Nut Refer to list below

4 First Step Guide 1

5 Instruction Manual (CD/DVD) 1

6 Safety Guide 1

Model No.

Nut A

M26•1.5

Nut B

M35•1.5

Nut C

M8•1.5

Nut A

M30•1.5

Nut B

M40•1.5

Nut C

M10•1.5

RCA-RA3C 1 1 1

RCA-RA4C 1 1 1

RCA-RA3D 1 1 1

RCA-RA4D 1 1 1

RCA-RA3R 2 1

RCA-RA4R 2 1

RCA-RGS3C 1 1

RCA-RGS4C 1 1

RCA-RGS3D 1 1

RCA-RGS4D 1 1

RCA-RGD3C 1 1

RCA-RGD4C 1 1

RCA-RGD3D 1 1

RCA-RGD4D 1 1

RCA-RGD3R 2

RCA-RGD4R 2

Note1 The motor • encoder cables supplied vary depending on the controller used.

[Refer to 1.4, “Motor • Encoder Cables.”]

1. Specications Check

Page 20

1. Specications Check

14

1.1.2 Instruction Manuals related to this product, which are contained in the

CD/DVD.

Shown below is a list of the instruction manuals for the controllers related to this product which is

recorded in Instruction Manual (CD/DVD).

No. Name Control No.

1 ASEL Controller Operation Manual ME0165

2 ACON-C/CG Controller Operation Manual ME0176

3 ACON-CY Controller Operation Manual ME0167

4 ACON-SE Controller Operation Manual ME0171

5 ACON-PL/OP Controller Operation Manual ME0166

6 AMEC Controller Operation Manual ME0245

7 ASEP/PSEP Controller Operation Manual ME0216

8 MSEP Controller Operation Manual ME0299

9 PC software IA-101-X-MX/ IA-101-X-USBMW Operation Manual ME0154

10 PC software RCM-101MW/RCM-101-USB Operation Manual ME0155

11 MEC PC Software Operation Manual ME0248

12 Teaching pendant SEL-T/TD Operation Manual ME0183

13 Teaching pendant CON-T/TD Operation Manual ME0178

14 Touch Panel Teaching CON-PT/PD/PG Operation Manual ME0227

15 Touch Panel Teaching CON-PTA/PDA/PGA Operation Manual ME0295

16 Touch Panel Teaching SEP-PT Operation Manual ME0217

17 Simplified Teaching pendant RCM-E Operation Manual ME0174

18 Data setter RCM-P Operation Manual ME0175

19 Data setter RCM-PM-01 Operation Manual ME0182

1.1.3 How to Read the Model Nameplate

Model

Serial numbe

r

MODEL RCA-RA3C-I-20-10-50-A1-P-B-**

SERIAL No.600090266 MADE IN JAPAN

Page 21

15

1.1.4 How to Read the Model Number

Note 1 Identification for IAI use only : It may be displayed for IAI use. It is not a code to show the model

type.

<Series Name>

Standard Type

RCA

Dust and Splash-Proof Type

RCAW

<Type>

Standard Type

Coupling Type

RA3C, RA4C

Built-in Type

RA3D, RA4D

Motor-Reversing Type

RA3R, RA4R

Single-Guide Type

Coupling Type

RGS3C, RGS4C

Built-in Type

RGS3D, RGS4D

Double-Guide Type

Coupling Type

RGD3C, RGD4C

Built-in Type

RGD3D, RGD4D

Motor-Reversing Type

RGD3R, RGD4R

Short Length Type

SRA4R

Short Length Type

With Single Guide

SRGS4R

Short Length Type

With Double Guide

SRGD4R

R C A - R A 3 C - I - 2 0 - 1 0 - 5 0 - A 1 - P - B - * *

Identification for IAI use onl

y

*1

<Option>

B : Brake

FT : Foot Bracket

FT2 : Foot Bracket (right attached)

FT4 : Foot Bracket (left attached)

GS2 : Single Guide, right attached

FL : Flange Bracket (front)

FLR : Flange Bracket (rear)

HA : High Accel/Decel Type

HS : Home-Check Sensor

LA : Power Saving Type

NJ : Knuckle Joint

NM : Reversed-Home Type

TRF : Trunnion Bracket (front)

TRR : Trunnion Bracket (rear)

QR : Clevis Bracket

RP : Rear Attachment Plate

<Cable Length>

N : None

P : 1m

S : 3m

M : 5m

XƑƑ : Specified Length

RƑƑ : Robot Cable

<Controller>

A1: ASEL

ACON-C/CG

ACON-CY

ACON-SE

ACON-PL/PO

A3: AMEC

ASEP

<Encoder Type>

I : Incremental

A : Absolute

<Motor Type>

20 :20W

30 :30W

<Lead>

2.5 :2.5mm

3 : 3mm

5 : 5mm

6 : 6mm

10 :10mm

12 :12mm

<Stroke>

1. Specications Check

Page 22

1. Specications Check

16

1.2 Specification

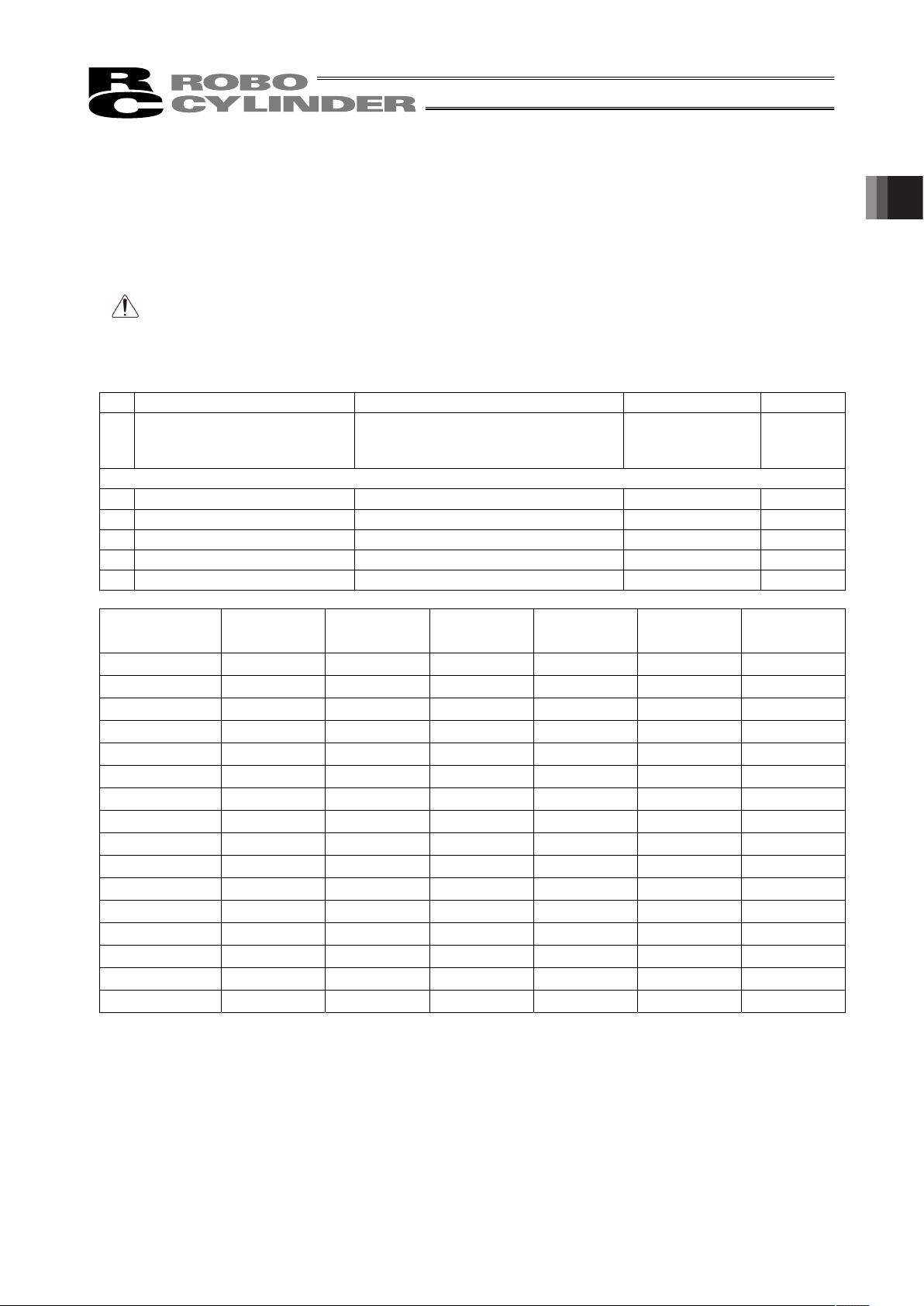

1.2.1 Speed

Speed limits (Unit: mm/s)

Stroke [mm]

Size

Motor

Type

Lead

[mm]

50 100 150 200 250 300

2.5 125

5 250

RA3C

RA3D

RA3R

RGD3C

RGD3D

RGD3R

RGS3C

RGS3D

20W

10 500

3 150

6 300

RA4C

RA4D

RA4R

RGD4C

RGD4D

RGD4R

RGS4C

RGS4D

20W

12 600

3 150

6 300

RA4C

RA4D

RA4R

RGD4C

RGD4D

RGD4R

RGS4C

RGS4D

30W

12 600

(Note) The speed may not reach the maximum in some ways of the acceleration/deceleration settings.

Page 23

17

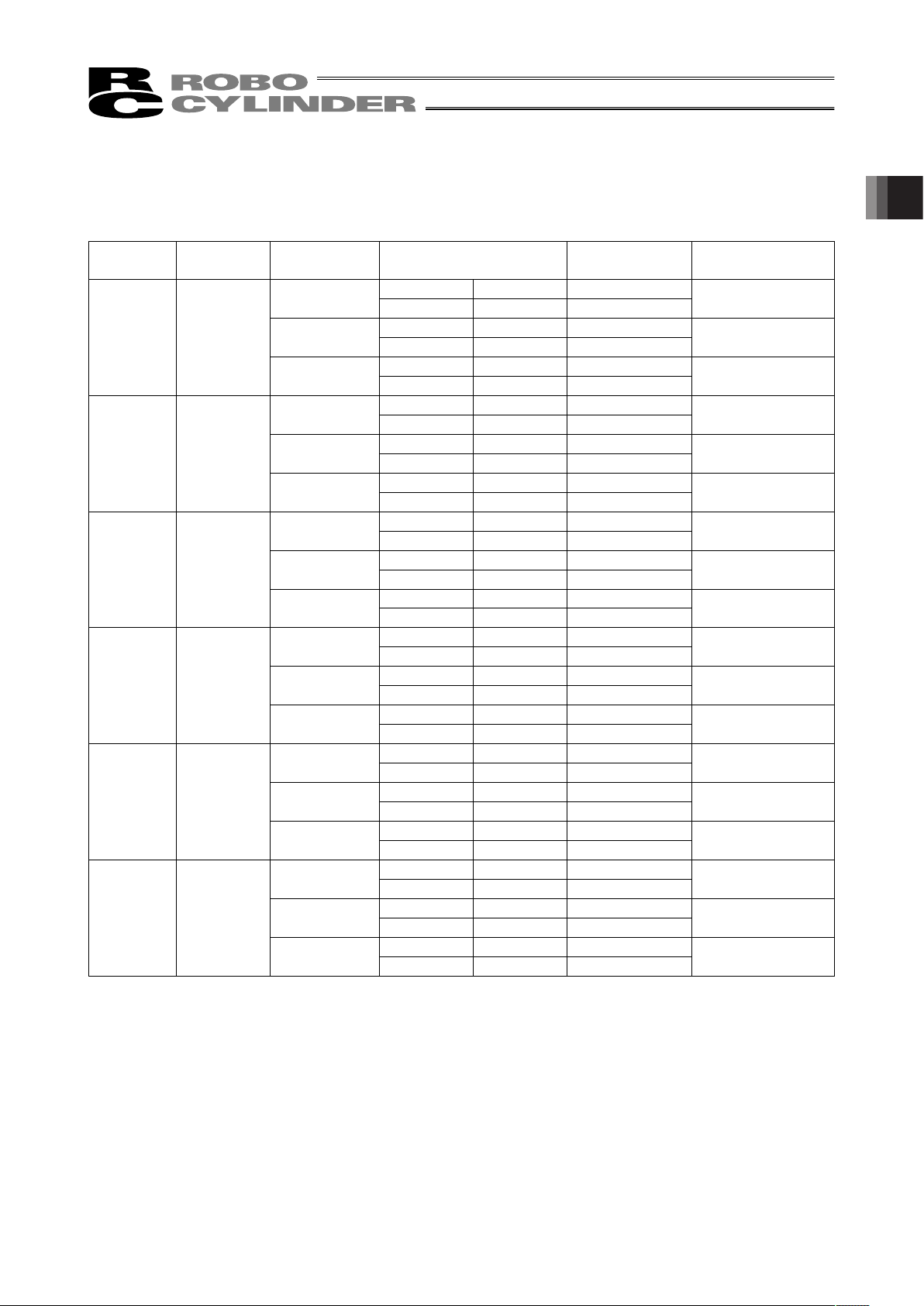

1.2.2 Maximum Acceleration and Transportable Weight

If the transportable weight is smaller than as specified, the acceleration/deceleration can be raised

beyond the applicable level.

Type Motor Type Lead [mm] Rated Acceleration [G]

Transportable

Weight [kg]

Rated Thrust [N]

Horizontal 0.2 18

2.5

Vertical 0.2 6.5

144.8

Horizontal 1 9

5

Vertical 1 3

72.4

Horizontal 1 4

RA3C 20W

10

Vertical 1 1.5

36.2

Horizontal 0.2 18

2.5

Vertical 0.2 6.5

144.8

Horizontal 0.3 9

5

Vertical 0.3 3

72.4

Horizontal 0.3 4

RA3D

RA3R

20W

10

Vertical 0.3 1.5

36.2

Horizontal 0.2 18

2.5

Vertical 0.2 6.2

144.8

Horizontal 1 9

5

Vertical 1 2.7

72.4

Horizontal 1 4

RGD3C

RGS3C

20W

10

Vertical 1 1.2

36.2

Horizontal 0.2 18

2.5

Vertical 0.2 6.2

144.8

Horizontal 0.3 9

5

Vertical 0.3 2.7

72.4

Horizontal 0.3 4

RGD3D

RGD3R

RGS3D

20W

10

Vertical 0.3 1.2

36.2

Horizontal 0.2 12

3

Vertical 0.2 4

75.4

Horizontal 0.3 6

6

Vertical 0.3 2

37.7

Horizontal 0.3 3

RA4C

RA4D

RA4R

20W

12

Vertical 0.3 1

18.9

Horizontal 0.2 12

3

Vertical 0.2 3.5

75.4

Horizontal 0.3 6

6

Vertical 0.3 1.5

37.7

Horizontal 0.3 3

RGD4C

RGD4D

RGD4R

RGS4C

RGS4D

20W

12

Vertical 0.3 0.5

18.9

1. Specications Check

Page 24

1. Specications Check

18

Type Motor Type Lead [mm] Rated Acceleration [G]

Transportable

Weight [kg]

Rated Thrust䈀N䈁

Horizontal 0.2 18

3

Vertical 0.2 6.5

113.1

Horizontal 1 9

6

Vertical 1 3

56.6

Horizontal 1 4

RA4C 30W

12

Vertical 1 1.5

28.3

Horizontal 0.2 18

3

Vertical 0.2 6.5

113.1

Horizontal 0.3 9

6

Vertical 0.3 3

56.6

Horizontal 0.3 4

RA4D

RA4R

30W

12

Vertical 0.3 1.5

28.3

Horizontal 0.2 18

3

Vertical 0.2 6

113.1

Horizontal 1 9

6

Vertical 1 2.5

56.6

Horizontal 1 4

RGD4C

RGS4C

30W

12

Vertical 1 1

28.3

Horizontal 0.2 18

3

Vertical 0.2 6

113.1

Horizontal 0.3 9

6

Vertical 0.3 2.5

56.6

Horizontal 0.3 4

RGD4D

RGD4R

RGS4D

30W

12

Vertical 0.3 1

28.3

Caution: Do not set accelerations/decelerations equal to or greater than the respective ratings. Doing

so may result in vibration, failure or shorter life.

Page 25

19

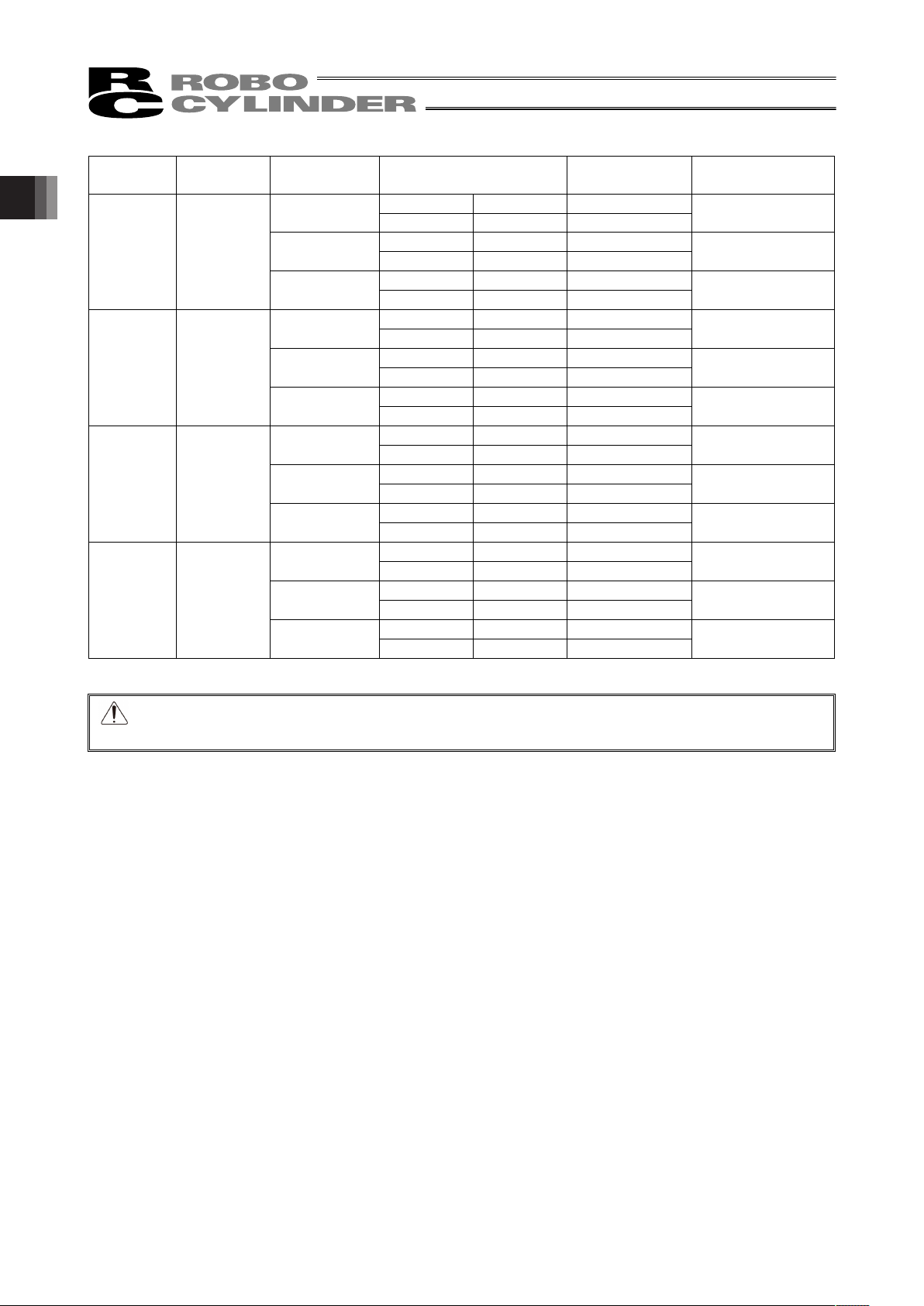

1.2.3 Driving System • Position Detector

Type Motor Type Lead [mm]

No. of Encoder

Pulses [P/R]

Drive System

2.5 200

5 200

RA3C

RA3D

RA3R

RGD3C

RGD3D

RGD3R

RGS3C

RGS3D

20W

10 200

Ball Screw

I8

Rolled C10

3 200

6 200

20W

12 200

3 200

6 200

RA4C

RA4D

RA4R

RGD4C

RGD4D

RGD4R

RGS4C

RGS4D

30W

12 200

Ball Screw

I10

Rolled C10

1. Specications Check

Page 26

1. Specications Check

20

1.2.4 Positioning Precision

Item Tolerance

Positioning repeatability ±0.02mm

Backlash 0.1mm or less

Base Material : Aluminum Anodizing treatment

This is an option already attached when it is shipped out from the factory.

It does not include the consideration of time-dependent change as it is used.

1.2.5 Rod Non-Rotation Accuracy

z Standard

Model Name Motor Type Lead [mm] Rod Diameter

Rod Non-Rotation

Accuracy

2.5

5

RA3C 20W

10

I8mm ±1.0°

2.5

5

RA3D 20W

10

I8mm ±1.0°

3

6

RA4C

RA4D

20W

12

I10mm ±1.0°

3

6

RA4C 30W

12

I10mm ±1.0°

3

6

RA4D 30W

12

I10mm ±1.0°

z Motor Reversing

Model Name Motor Type Lead [mm] Rod Diameter

Rod Non-Rotation

Accuracy

2.5

5

RA3R 20W

10

I8mm ±1.0°

3

6

RA4R 20W

12

I10mm ±1.0°

3

6

RA4R 30W

12

I10mm ±1.0°

Page 27

21

z With single guide

Model Name Motor Type Lead [mm] Rod Diameter

Rod Non-Rotation

Accuracy

2.5

5

RGS3C 20W

10

I8mm ±0.05°

2.5

5

RGS3D 20W

10

I8mm ±0.05°

3

6

RGS4C

RGS4D

20W

12

I10mm ±0.05°

3

6

RGS4C 30W

12

I10mm ±0.05°

3

6

RGS4D 30W

12

I10mm ±0.05°

z With double guide

Model Name Motor Type Lead [mm] Rod Diameter

Rod Non-Rotation

Accuracy

2.5

5

RGD3C 20W

10

I8mm ±0.05°

2.5

5

RGD3D

RGD3R

20W

10

I8mm ±0.05°

3

6

RGD4C

RGD4D

RGD4R

20W

12

I10mm ±0.05°

3

6

RGD4C 30W

12

I10mm ±0.05°

3

6

RGD4D

RGD4R

30W

12

I10mm ±0.05°

1. Specications Check

Page 28

1. Specications Check

22

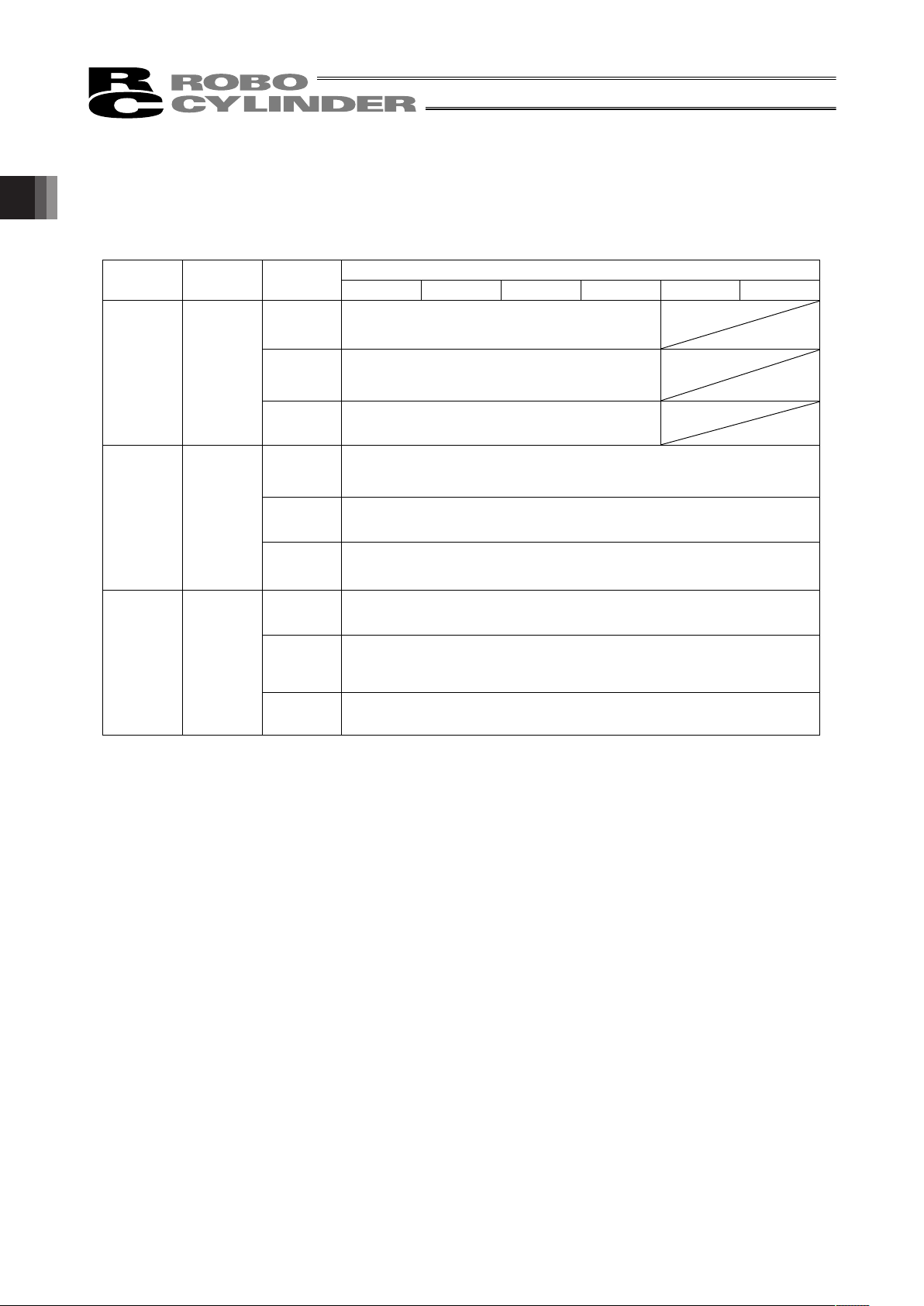

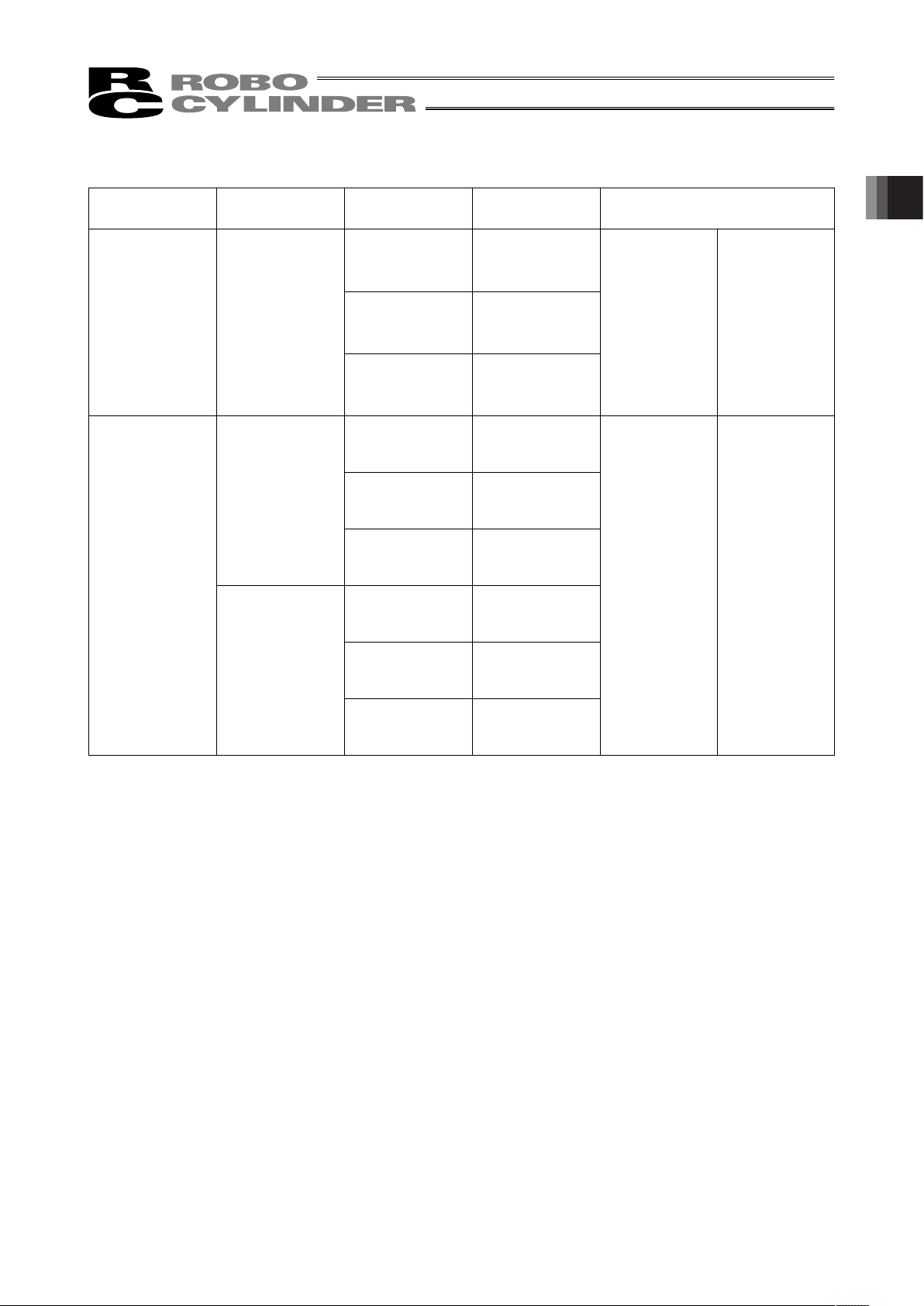

1.2.6 Allowable Running Torque

The allowable torque for each model is as shown below.

Make sure to use the product within the range specified below when applying running torque to the

product.

Also, please note that the single guide type is not capable to receive any running torque.

(1) Double guide

1.2.7 Relation of Allowable Tip Load and Running Life

The bigger the load on the tip of the guide gets, the shorter the life becomes.

(1) Single guide

* Single guide type is not capable

for any load except for those

from the top and bottom.

(2) Double guide

Allowable Rotary Torque (N䍃m)

Stroke (mm)

<Vertical>

<Horizontal>

Radial Load (N)

Operating Life (km)

Radial Load (N)

Operating Life (km)

Page 29

23

1.2.8 Radial load and Tip Flexure

Shown below is the correlation graph of the load applied to the guide tip and the flexure at that time.

(1) Single guide

* Single guide type is not capable

for any load except for those

from the top and bottom.

(2) Double guide

Double guide <Vertical> type Double guide <Horizontal> type

<Horizontal>

Flexure (mm)

Load (N)

Flexure (mm)

Load (N)

Flexure (mm)

Load (N)

<Vertical>

1. Specications Check

Page 30

1. Specications Check

24

1.2.9 Duty Ratio in Continuous Operation

Perform an operation with the duty ratio below the allowable range.

Duty ratio is the rate of operation expressed in % that presents the time of the actuator being operated in

1 cycle of operation.

Caution: If the overload error occurs, try either to reduce the duty by extending the stop time or to

reduce the acceleration/deceleration speed.

[How to Calculation Duty]

Figure out the load ratio and acceleration/deceleration time ratio, and read the duty ratio from the graph.

If the load ratio if less than 50%, operation with 100% of the duty ratio (continuous operation) is

available.

1) Duty ratio LF

The maximum transportable weight at the rated acceleration and the rated acceleration/deceleration

speed are described in 1.2 Specifications.

Duty ratio:LF䋽 [%]

Max. Transportable Weight at Rated Acceleration : Mr [kg]

Rated Acceleration/Deceleration Speed : Dr [G]

Transported Weight during Operation : M [kg]

Acceleration/Deceleration Speed during Operation : D [G]

2) Acceleration/Deceleration Time Ratio t

od

Acceleration/Deceleration Time Ratio t

od

=

Acceleration Time during Operation + Deceleration Time during

Operation

Deceleration time

[%]

Acceleration time =

Speed during Operation[mm/s]

Acceleration during Operation[mm/s

2

]

䌛Sec䌝

Deceleration time =

Speed during Operation [mm/s]

Deceleration during Operation [mm/s

2

]

䌛Sec䌝

Acceleration [mm/s

2

] = Acceleration [G] u 9,800mm/s

2

Deceleration [mm/s

2

] = Deceleration [G] u 9,800mm/s

2

M×D

Mr×D

Page 31

25

3) From the load ratio LF and the acceleration/deceleration time ratio tod that were used to figure out the

duty ratio, read the duty ratio.

e.g.) When the load ratio LF = 80% and the acceleration/deceleration time ratio t

od

= 80%, the

reference for the duty is approximately 75%.

1.2.10 Protection class

RCAW-RA3C/RA3D/RA3R/RA4C/RA4D/RA4R 㧩 IP54

Reference for Operation Duty

Acceleration/Deceleration Time Ratio t

od

About

72 %

Less than 50 %

High Accel/Decel Type

High Accel/Decel Type

High Accel/Decel Type

High Accel/Decel Type

1. Specications Check

Page 32

1. Specications Check

26

1.3 Options

1.3.1 Brake Type (Model No.: B)

The brake is a mechanism designed to prevent the rod from dropping on a vertically installed actuator

when the power or servo is turned OFF.

Use the brake to prevent the installed load, etc., from being damaged due to the falling rod.

The model code should be expressed with B.

1.3.2 High Acceleration/Deceleration Type (Model No.: HA)

This is an option to upgrade the rated acceleration (0.3G) of the standard type to 1G.

This enables the operation with the transported weight same as at 0.3G even with 1G of the

acceleration.

Since the setting of the controller is different from that for the standard type, it is necessary also to have

the controller made applicable for the high acceleration/deceleration type when operating with high

acceleration/deceleration.

The model code should be expressed with HA.

1.3.3 Home-Position Check Sensor (Model No.: HS)

This is a sensor to monitor the rod to see if it is certainly moved to the home position when a

home-return is executed.

* This cannot be used for the home reversed type.

The model code should be expressed with HS.

1.3.4 Power Saving Type (Model No.: LA)

This is an option to reduce the power domain in the controller.

For standard type / high acceleration/deceleration type, if the power saving type is selected, the power

consumption can be dropped down to 3.4A at maximum, which the maximum is 5.1A in normal use.

(The maximum value may differ depending on the model. Refer to the power capacity of ACON/ASEL

Controller for the detail.)

The model code should be expressed with LA.

1.3.5 Motor Left Reversed, Motor Right Reversed (Model No.: NM)

From the view of the motor side, the type with the motor reversed to the left is ML, and the motor

reversed to the right is MR.

The model code should be expressed with NM.

1.3.6 Guide Attachment Directions (Only for Single guide type)

(Model No. : Attached on the right (GS2), attached on the bottom (GS3) and

attached on the left (GS4).)

The rod attachment position for the Single Guide type, can be selected from “Attachment on the Right”,

“Attachment on the Bottom” and “Attachment on the Left”.

Page 33

27

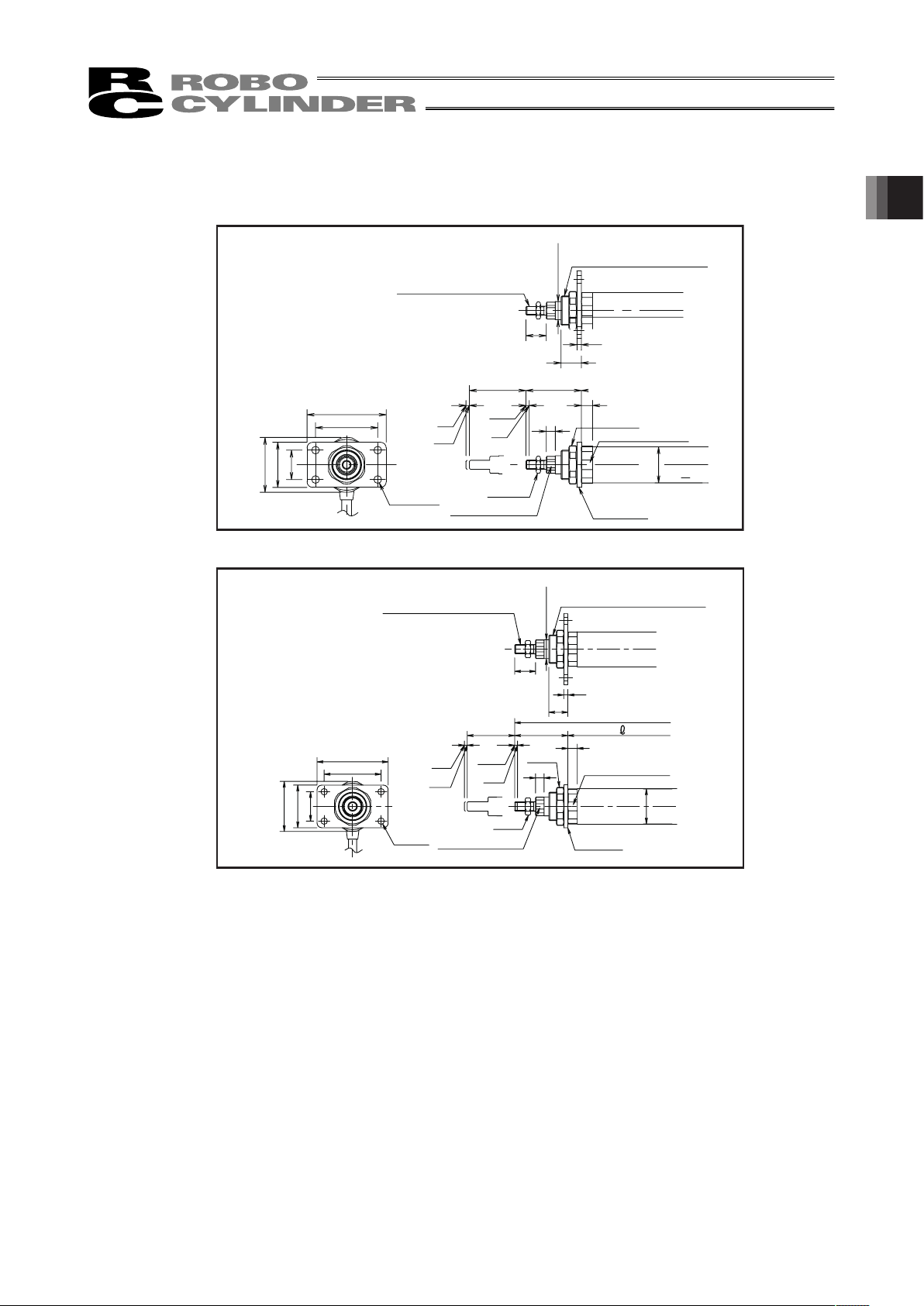

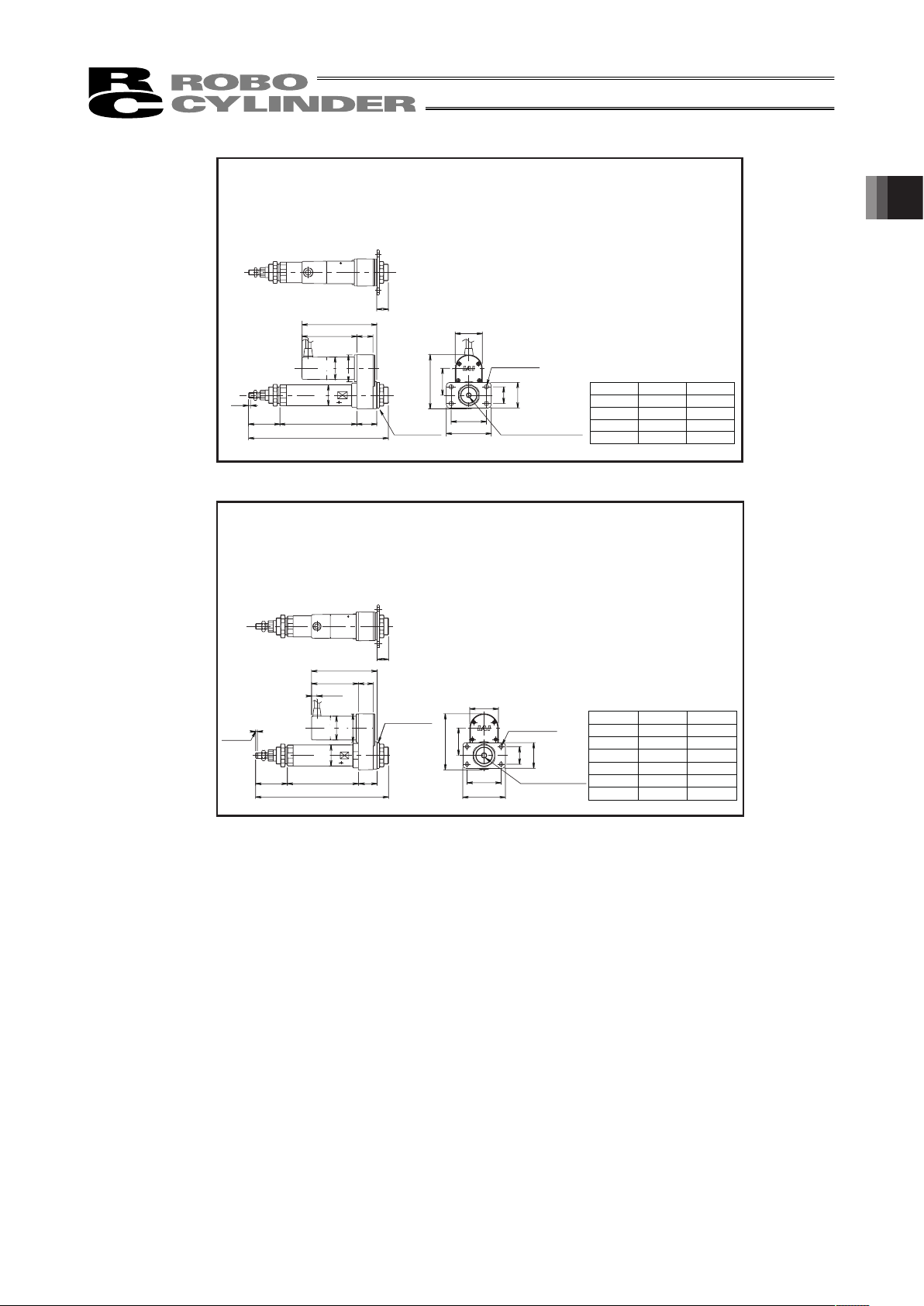

1.3.7 Front Flange (Model No. : FL)

This metal part is used for fixing the actuator from the actuator body side using the bolts.

33

SE

18

4

49st

8

55

70

26

40

48.6

10

18

RCA / RCAW-RA3 □

RCA -FL-RA 3

Model code of single product

(Effective screw range = 16)

(Effective screw range = 15.5)

φ

32

(ROD O/D)

4 - φ6.8

Nut A

φ

16

Nut C

Home

Flange

14 (Width across Flats)

32 (Width across Flats)

M8×1.25

M26×1.5

ME

ME

20

4

L

56

10

9

22

3

st

SE

75

52.8

45

31

60

RCA /

RA 4 □

RCAW /

RA 4 □

RCA -FL-RA 4

Model code of single product

(Effective screw range = 20)

(Effective screw range = 17.5)

(ROD O/D)

4 - φ6.8

Nut

φ

20

Nut

Home

Flange

19 (Width across Flats)

36(Width across Flats)

M10×1.25

M30×1.5

ME

ME

φ

37

3

1. Specications Check

Page 34

1. Specications Check

28

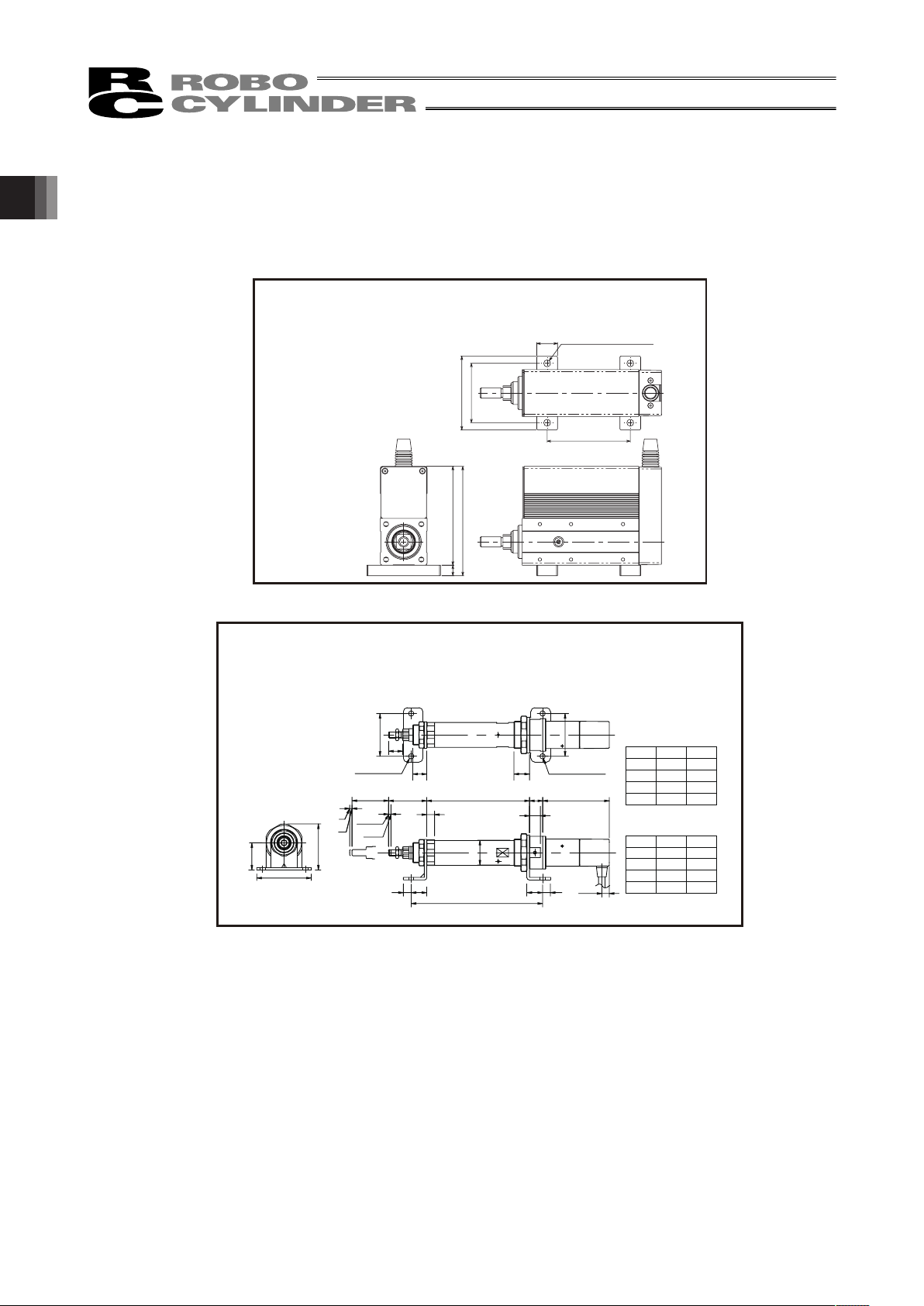

1.3.8 Rear Flange (Model No. : FLR)

This metal fitting is used for fixing the actuator from the actuator rear side.

0.25

44.5

34

5.25

75

60

10

RCA-SRA 4 R

-FL-S RA4

4-φ6.6, through

Model code of single product RCA

85

70

85.5

17

14

L149

36

50

st L1

RCA -FL R-RA3

Model code of single product

Home

Flange

40(Width

across Flats)

φ

35

φ

42

φ

32

4 - φ6.8

50

100

150

200

132

182

232

282

RCA / RCAW-RA3C, RA3D

st

50

100

150

200

250

300

L1

137

187

237

287

337

487

m

RCA

20w

67.5

80.5

80.5

30w

82.5

95.5

95.5

RCS2

55

41

90

75

16

9

m56 19L1

φ

37

φ

42

φ

50

RCA -FL R-RA4

Model code of single product

φ

37

φ

42

φ

50

Flange

Home

Nut B

4 - φ6.8

m Dimensions

Incremental

Absolute

Incremental•

Absolute

47(Width

across Flats)

RCA / RCAW-RA4C, RA4D

Page 35

29

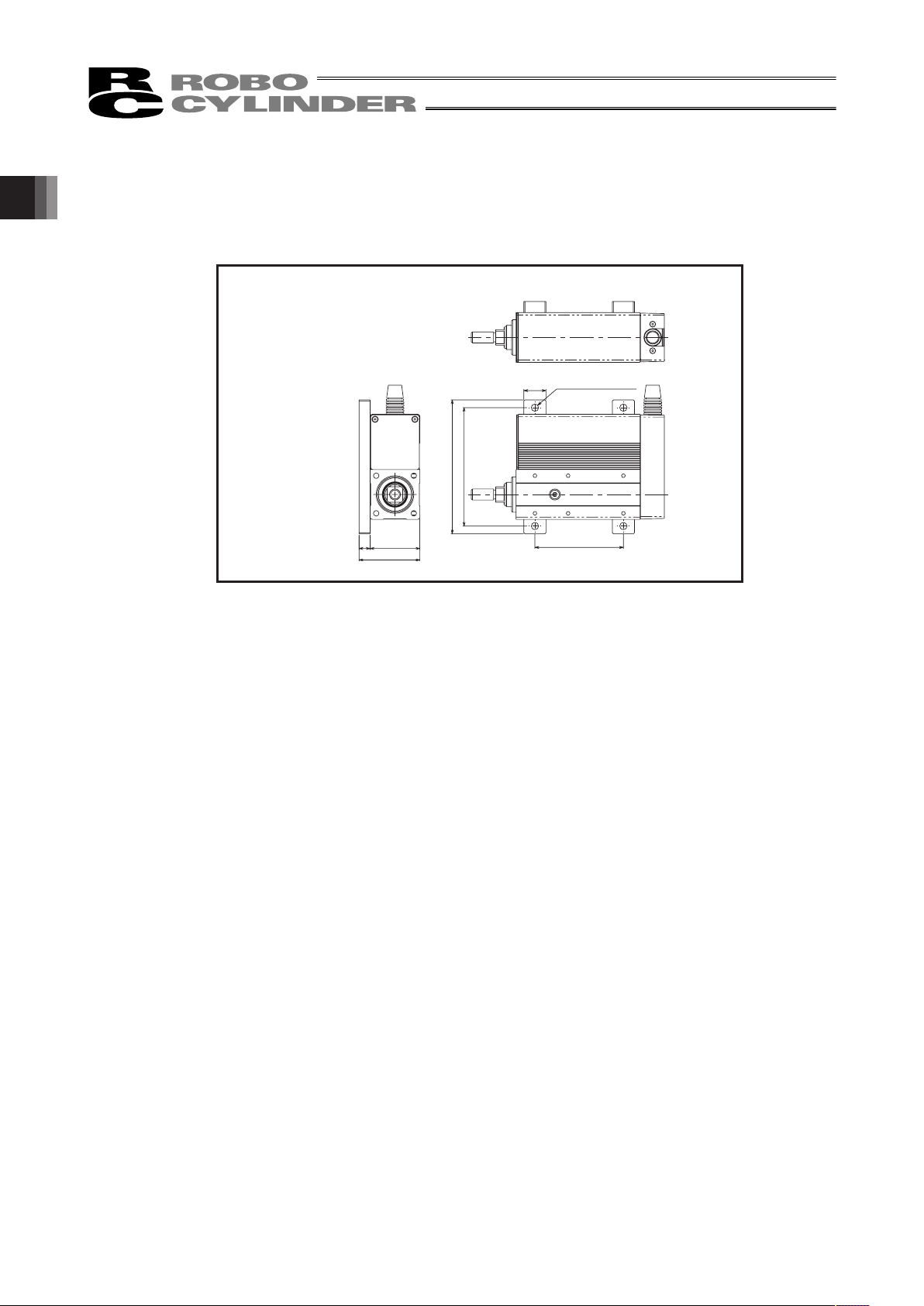

st L1 L2

120 218

170 268

220 318

270 368

42

40

70

26

55

18

84.4

42.4

31L1

L2

49

3

116.5

25

85.5

φ

35

φ 42

φ 32

RCA -FL-RA 3

50

100

150

200

Model code of single product

*The front flange and the rear

flange can be used in common

for the motor reversing type.

φ

35

φ

42

φ

32

Flange

4 - φ6.8

M8, Depth 15

RCA / RCAW-RA3R

st L1 L2

50 125 234

100 175 284

150 225 334

200 275 384

250 325 434

300 375 484

48

82.5

115.5

45

31

75

60

50.5

98.5

L2

33L156

26

9.5

20

φ 42

φ 50

φ 37

RCA -FL-RA 4

Model code of single product

*The front flange and the rear

flange can be used in common

for the motor reversing type.

φ

37

φ

42

φ

50

Flange

Home

4 - φ6.8

M10, Depth 18

RCA / RCAW-RA4R

1. Specications Check

Page 36

1. Specications Check

30

1.3.9 Foot (Model No. : FT)

This metal part is used for fixing the actuator from the top side using the bolts.

* Refer to the attachment pitch size in the drawing for each actuator, for the attachment pitch between

the foot metal parts.

st+10

71

57

20

105

95

10

RCA -SRA 4 R

Model code of single product RCA-FT-SRA4

4-φ6.6, through

50

100

150

200

140

190

240

290

176.8

226.8

276.8

326.8

L1st L2

9.5

70

59.3

35

3

3

SE

ME

18

18

20

L1

17

85.5

st

14

49

10

L2

10 20

02 01

55

55

50

100

150

200

132

182

232

282

168.8

218.8

268.8

318.8

ts 1L L2

<RGS3C/RGD3C>

<RA3C>

RCA -RA3 C / RG S 3 C / RGD 3 C

Model code of single product RCA-FT-RA3

2 - φ6.8 2 - φ6.8

ME

Home

φ

32

Page 37

31

SE

ME

20

22

22

L1

19

56

3

st

3

9.5

m

75

40

66.4

60

60

10

16

L2

10 20

02 01

<RGS4C/RGD4C>

<RA4C>

m

RCA

20w

67.5

80.5

80.5

30w

82.5

95.5

95.5

RCS2

50

100

150

200

250

300

145

195

245

295

345

495

181.8

231.8

281.8

331.8

381.8

431.8

ts 1L L2

50

100

150

200

250

300

137

187

237

287

337

487

173.8

223.8

273.8

323.8

373.8

423.8

ts 1L L2

RCA -RA 4 C / RGS 4 C / RG D4 C

Model code of single product RCA-FT-RA4

ME

Home

2 - φ6.8

2 - φ6.8

φ

37

m Dimensions

Incremental

Absolute

Incremental•

Absolute

128

178

228

278

L1

50

100

150

200

st

199

249

299

349

L2

SE

ME

9.5

85.5

25

116.5

L1

20

31

18

18

18

49st

3 3

8

10

L2 1010

34

70

35

98.2

55

55

42.4

20

<RGS3R/RGD3R>

120

170

220

270

L1

50

100

150

200

st

191

241

291

341

L2

<RA3R>

RCA / RA 3 R / RGS 3 R / RG D 3 R

Model code of single product RCA-FT-RA3R

ME

Home

2 - φ6.8

2 - φ6.8

φ

32

Model code of single product RCA-FT-RA4R

ME

Home

2 - φ6.8

50

100

150

200

250

300

133

183

233

283

333

383

206

256

306

356

406

456

L1st L2

ME

SE

st

22

9.5

26

L1

3

3

82.5

115.5

20

20

33

φ

37

56

10

9

L2

10

10

39

75

40

113.2

60

50.5

20 20

<RGS4R/RGD4R>

50

100

150

200

250

300

125

175

225

275

325

375

198

248

298

348

398

448

ts 1L L2

<RA4R>

RCA -RA 4 R / RGS 4 R / RG D4 R

Nut A

2 - φ6.8

1. Specications Check

Page 38

1. Specications Check

32

1.3.10 Foot (Attached on the Right Side/Left Side)

(Model No.: FT2 (Attached on the Right Side), FT4 (Attached on the Left Side)

This metal part is used for fixing the actuator from the top side using the bolts. For RCA-SRA4R, the

actuator can be attached also to the side.

st+10

121

107

20

55

45

10

RCA-S RA 4 R

4 - φ6.6, through

Model code of single product

RCA-FTS-SRA4

Page 39

33

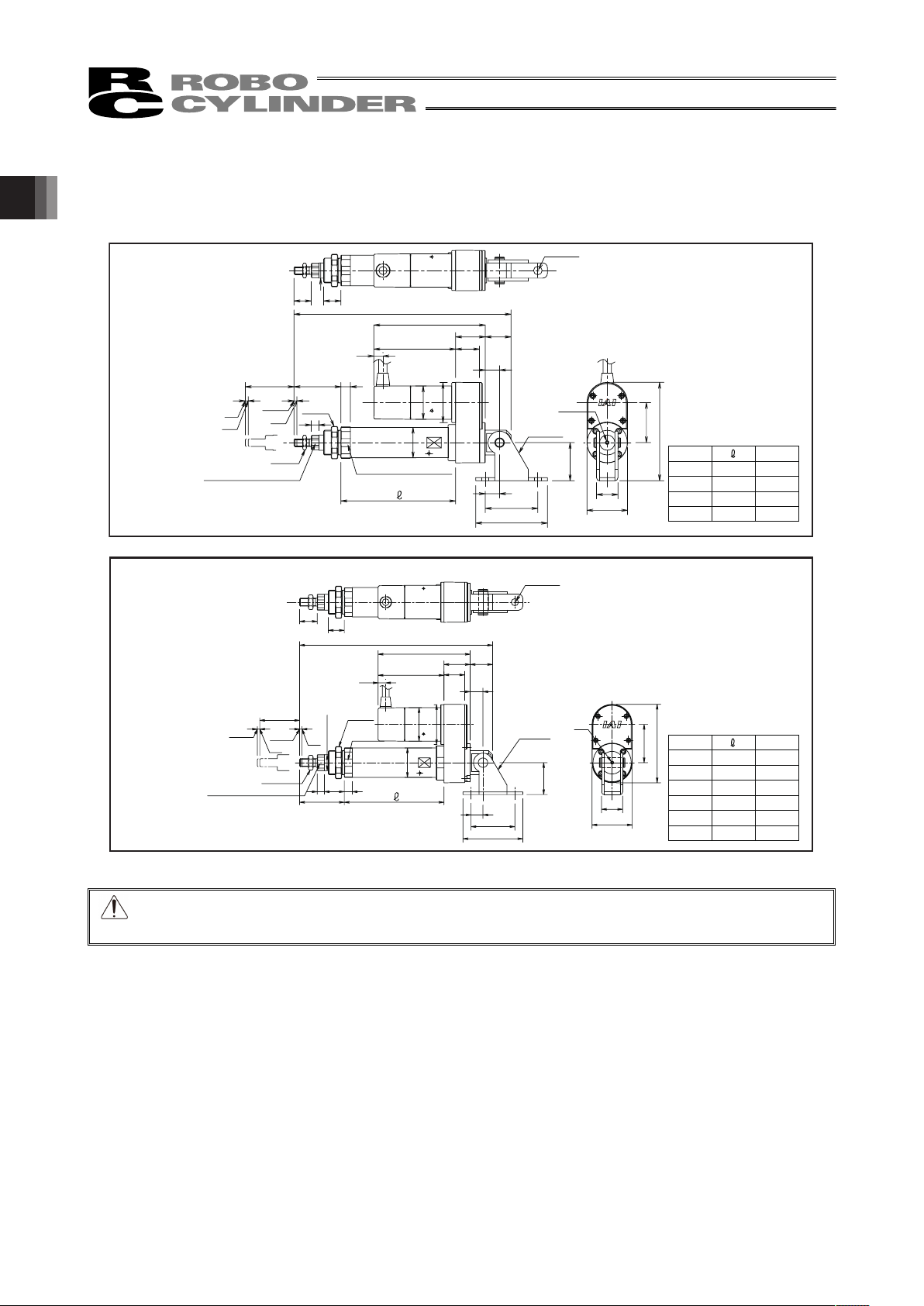

1.3.11 Knuckle Joint (Model No. : NJ)

This metal part is used to give some degree of freedom (rotation) in the movement at the rod end of the

actuator when Clevis or trunnion part is used.

16

25 25 10

16

Joint Pin

Joint S

Joint W

Nut

M8×1.25 Depth 11

For RCA-RA3□

Model code of single product RCA-NJ-RA3

20

30 30 11

20

Joint Pin

Joint S

Joint W

Nut

M10×1.25 Depth 13

For RCA-RA4□

Model code of single product

RCA-NJ-RA4

1. Specications Check

Page 40

1. Specications Check

34

1.3.12 Clevis (Model No. : QR)

This bracket is used to make the cylinder follow up when the movement of an object attached on the tip

of the rod is different from the direction of rod movement. Attach on the rod.

φ

32

3 3

8

49

10

9.5

85.5

L

18 18

116.5

25

15

27

31

ME

ME

15

M4

42.4

22.4

55

40

42

103.2

75

st

SE

50

100

150

200

120

170

220

270

227

277

327

377

st

L

RCA-RA3 R

Model code of single product

RCA-QR-RA3

2 - φ6.8

Nut A

Nut B

Home

32 (Width across Flats)

14 (Width across Flats)

φ

42

φ

35

Clevis

22

20

L

15

55

75

115.5

9.5

3

3

9 10

56

82.5

33

26

28

16

M4

50.5

26.4

48

98.5

ME

ME

st

SE

40

50

100

150

200

250

300

125

175

225

275

325

375

242

292

342

392

442

492

st

L

RCA -R A 4 R

Model code of single product

RCA-QR-RA4

2 - φ9

Nut A

Nut B

Home

φ

37

32 (Width

across Flats)

14 (Width across Flats)

φ42φ

50

Clevis

φ

20

(ROD O/D)

Caution: Attach the external guide so that any load is not given to the rod other than in the forward

direction, when the Clevis bracket is attached and rod is moved.

Page 41

35

1.3.13 Rear Attachment Plate (Model No. : RP)

This plate is used to fix the rear side of the motor reversing rod type (RA3R/RA4R) onto the system.

φ

32

φ

42

φ

35

3 3

49

8 10

9.5

85.5 25

116.5

L

31 2.5

42.4

4-M4

st

0

42

84.4

SE

ME

ME

φ

34

Model code of single product

RCA-RP-RA3

Home

φ

26h9 (-0.052)

φ

16(ROD O/D)

14(Width across Flats)

32(Width across Flats)

Nut A

Nut B

For RCA-RA3R

9.5

82.5

115.5

26

3

9

10

56

st

0

SE

ME

ME

33 2.5 50.5

L

4-M4

48

98.5

Model code of single product

RCA-RP-RA4

Home

φ

37

φ

50

φ

42

φ

39

φ

30h9 (-0.052)

φ

20(ROD O/D)

14(Width across Flats)

32(Width

across Flats)

Nut A

Nut B

For RCA-RA4R

1. Specications Check

Page 42

1. Specications Check

36

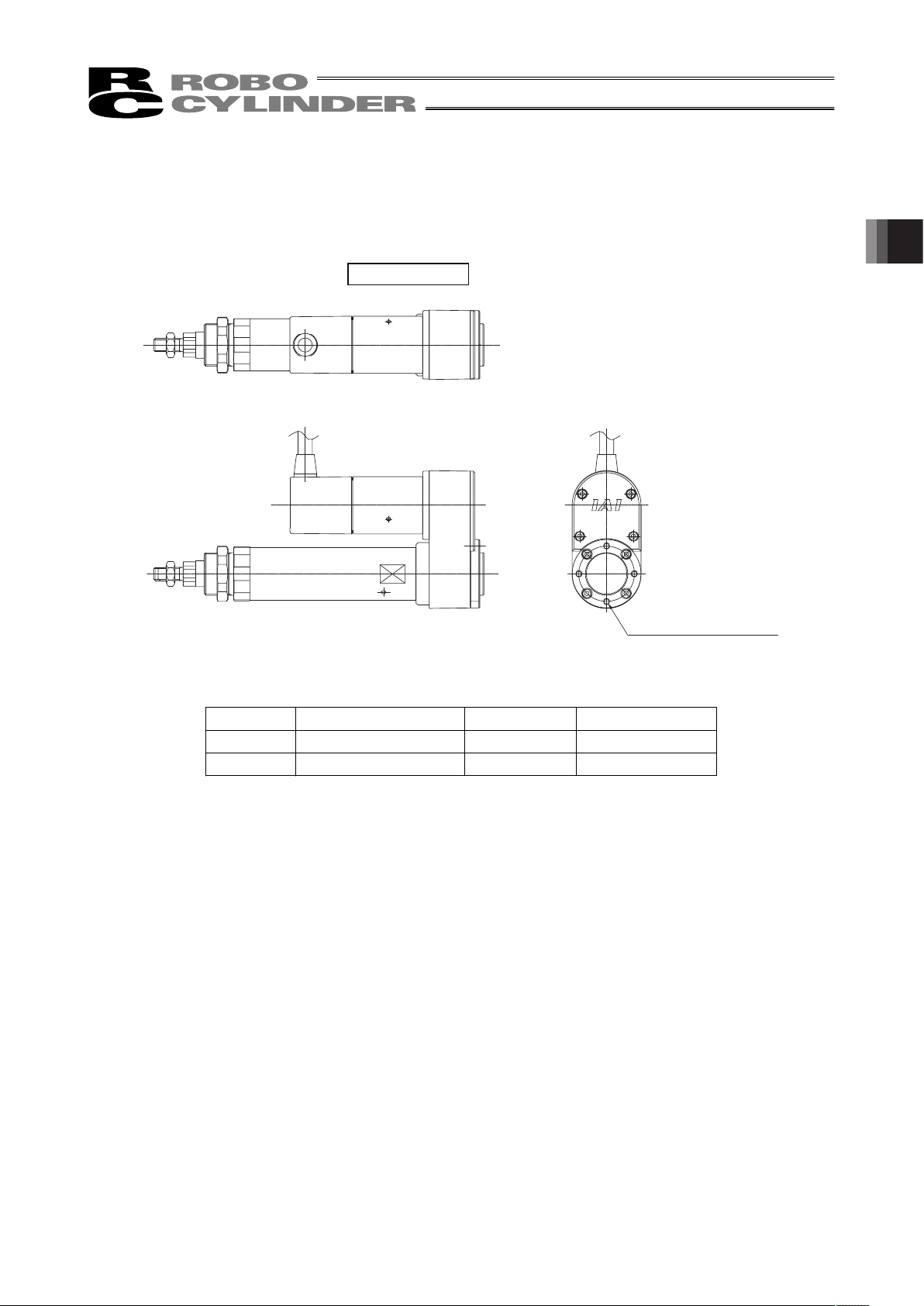

1.3.14 Front Trunnion (Model No. : TRF)

This bracket is used to make the cylinder follow up when the movement of an object attached on the tip

of the rod is different from the direction of rod movement. Attach on the rod.

φ

32

φ

42

φ

35

Model code of single product

RCA-TRF-RA3

14(Width

across Flats)

32(Width across Flats)

Nut A

For RCA-RA3□

9.5

33

SE

ME

18

20

49

10

st

90

64.3

40

40

70

8

60

5

10

55

M8×1.25 (Effective screw range = 16)

M35×1.5

(Effective screw range = 17.5)

φ

16 (ROD O/D)

2-φ6.8

40(Width across Flats)

Home

Nut C

Bracket A

Ring

Bracket B

ME

φ

20 (ROD O/D)

22

3

9

55610

55

3

10

st

ME

ME

SE

94

64

40

22

74

9.5

66.4

40

M10×1.25 (Effective screw range = 20)

M40×1.25

(Effective screw range = 19.5)

φ

37

19(Width

across Flats)

36(Width across Flats)

47(Width across Flats)

Home

Nut C

Bracket A

Ring

Bracket B

Model code of single product

RCA-TRF-RA4

For RCA-RA4□

Caution: Use the guide equipped type or attach the external guide so that any load is given to the rod

other than in the forward direction, when the trunnion is attached and the rod is moved.

Page 43

37

1.3.15 Rear Trunnion (Model No. : TRR)

This bracket is used to make the cylinder follow up when the movement of an object attached on the tip

of the rod is different from the direction of rod movement. Attach on the rod.

9.5

33

SE

49st

8

40

83

10

73

103

40

64.3

10

55

18

φ

32

φ

42

φ

35

Model code of single product

RCA-TRR-RA3

For RCA-RA3□

Bracket A

Bracket B

2-φ6.8

M26×1.5

(Effective screw range = 15.5)

M8×1.25 (Effective screw range = 16)

φ

16 (ROD O/D)

14(Width

across Flats)

32(Width across Flats)

Nut A

40(Width across Flats)

Home

Nut C

ME

ME

3

ME

ME

9

56

st

SE

9.5

107

77

40

20

22

10

10

40

87

66.5

φ

37

Model code of single product

RCA-TRR-RA4

For RCA-RA4□

φ

20 (ROD O/D)

M10×1.25 (Effective screw range = 20)

M40×1.25

(Effective screw range = 17.5)

36(Width across Flats)

47(Width across Flats)

Nut A

19(Width across Flats)

Home

Nut C

Caution: Use the guide equipped type or attach the external guide so that any load is given to the rod

other than in the forward direction, when the trunnion is attached and the rod is moved.

1. Specications Check

Page 44

1. Specications Check

38

1.4 Motor • Encoder Cables

1.4.1 Motor cable

CB-ACS-MA ƑƑƑ

1.4.2 Encoder cable/robot encoder cable

CB-ACS-PA ƑƑƑ/CB-ACS-PA ƑƑƑ-RB

Controller end

Actuator end

Width

Cable

Color

Signal

Name

Pin

No.

Red U 1 1 U Red

White V 2 2 V White

AWG22

(crimped)

Black W 3 3 W Black

AWG22

(crimped)

1

3

Width

Cable

Color

Signal

Name

Pin

No.

Controller end

Actuator end

AWG26

(

crimped

)

White/purple

White

/

purple

White/gray

White/gray

Yellow

Yellow

Blue

Blue

White/blue

White/blue

White/yellow

White/yellow

White/red

White/red

White/black

White/black

Orange

Orange

Green

Green

Purple

Purple

Gray

Red

Black

Drain

Black

Gray

Red

-

-

-

-

-

-

LS +

LS -

BK +

BK -

A +

A -

B +

B -

SD/Z +

SD/Z -

BAT +

BAT -

VCC

GND

-

-

-

FG

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

A +

A -

B +

B -

-

-

-

-

-

-

-

-

LS + LS +

-

-

FG FG

Z +

Z -

-

/PS

BAT +

BAT -

SD +

SD -

VCC

GND

VCC

GND

LS -

BK +

BK -

LS -

BK +

BK -

AWG26

(crimped)

18 17

2 1

9 18

1 10

Width

Cable

Color

Signal

Name

Pin

No.

Pin

No.

Width

Cable

Color

Signal Name

For ABZ For Serial

Drain

Page 45

39

1.4.3 Motor/Encoder Integrated Cable for AMEC/ASEP

CB-ASEP-MPA ƑƑƑ

Controller end

Actuator end

Width

Cable Color

Signal

Name

Pin

No.

1

2

3

18

17

7

16

1

2

3

4

10

11

14

13

15

6

5

8

12

9

Identification Tape

U

V

NC

NC

W

NC

BK+

BK-

LS+

LS-

A+

A-

B+

B-

Z+

Z-

VCC

VPS

GND

Spare

NC

NC

NC

FG

AWG22

(crimped)

AWG26

(crimped)

Red

Yellow

Black

Orange

Gray

Black

Brown

White

Yellow

Red

Green

Black

Brown

White

Yellow

Red

Green

Width

Cable Color

Signal

Name

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

U

V

NC

NC

W

NC

BK+

BK-

LS+

LS-

A+

A-

B+

B-

Z+

Z-

VCC

VPS

GND

Spare

NC

NC

NC

FG

AWG22

(crimped)

AWG26

(crimped)

Red

Yellow

Black

Orange

Gray

Black

Brown

White

Yellow

Red

Green

Black

Brown

White

Yellow

Red

Green

Identification Tape

1. Specications Check

Page 46

2. Installation

40

2. Installation

2.1 Transportation

[1] Handling of Robot

Unless otherwise specified, the actuators are packaged individually.

(1) Handling the Packed Unit

y Do not damage or drop. The package is not applied with any special treatment that enables it to resist

an impact caused by a drop or crash.

y Transport a heavy package with at least more than two operators. Consider an appropriate method for

transportation.

y Keep the unit in horizontal orientation when placing it on the ground or transporting. Follow the

instruction if there is any for the packaging condition.

y Do not step or sit on the package.

y Do not put any load that may cause a deformation or breakage of the package.

(2) Handling the Actuator After Unpacking

y Do not attempt to carry the actuator with holding a cable or move it by pulling a cable.

y Hold either the base part or the bracket part when transporting the actuator main body.

y Do not hit or drop the actuator during transportation.

y Do not carry an actuator by motor unit and a cable or attempt to move it by pulling the cable.

Page 47

41

[2] Handling in Assembled Condition

This is the case when the product is delivered from our factory under a condition that it is assembled

with other actuators. The combined axes are delivered in a package that the frame is nailed on the

lumber base. The rods are fixed so they would not accidently move. The actuators are also fixed so the

tip of it would not shake due to the external vibration.

(1) How to Handle in Package

y Do not hit or drop the package. No special treatment is conducted on this package to endure a drop or

impact on it.

y Do not attempt to carry a heavy package with only one worker. Also, have an appropriate method for

transportation.

y When hanging up with ropes, support on the reinforcement frame on the bottom of the lumber base.

When bringing up the package with a forklift, also support on the bottom of the lumber base.

y Handle with care when putting the package down to avoid impact or bounce.

y Do not step on the package.

y Do not put anything on the package that could deform or damage it.

(2) How to Handle after Unpackaged

y Fix the rod so they would not accidently move during transportation.

y If the tip of an actuator is overhanging, have an appropriate way to fix it to avoid shake due to the

external vibration. In the transportation without the tip being fixed, do not apply any impact with 0.3G or

more.

y When hanging up with ropes, have appropriate cushioning to avoid any deformation of the actuator

body. Also keep it in stable horizontal orientation. Make a fixture utilizing the attachment holes and the

tapped holes on the actuator body if necessary.

y Do not attempt to apply load on the actuators or the connector box. Also pay attention not to pinch

cables and bend or deform them forcefully.

[3] Handling in Condition of being assembled in Machinery Equipment (System)

This is some caution notes for when transporting the actuator being assembled in the machinery

equipment (system).

y Fix the cables so they would not move during transportation.

y If the tip of an actuator is overhanging, have an appropriate way to fix it to avoid shake due to the

external vibration. In the transportation without the tip being fixed, do not apply any impact with 0.3G or

more.

y When hanging up the machinery equipment (system) with ropes, do not attempt to apply load on the

actuators or the connector box. Also pay attention not to pinch cables and bend or deform them

forcefully.

2. Installation

Page 48

2. Installation

42

2.2 Installation and Storage • Preservation Environment

[1] Installation Environment

The actuator should be installed in a location other than those specified below.

In general, the installation environment should be one in which an operator can work without protective

gear.

Also provide sufficient work space required for maintenance inspection.

y Where the actuator receives radiant heat from strong heat sources such as heat treatment furnaces

y Where the ambient temperature exceeds the range of 0 to 40qC

y Where the temperature changes rapidly and condensation occurs

y Where the relative humidity exceeds 85% RH

y The product will possess water-proof performance of the protection structure of IP65 if air purge is

conducted.

y Where the actuator receives direct sunlight

y Where the actuator is exposed to corrosive or combustible gases

y Where the ambient air contains a large amount of powder dust, salt or iron (at level exceeding what

is normally expected in an assembly plant)

y Where the actuator is subject to splashed water, oil (including oil mist or cutting fluid) or chemical

solutions

y Where the actuator receives impact or vibration

If the actuator is used in any of the following locations, provide sufficient shielding measures:

y Where noise generates due to static electricity, etc.

y Where the actuator is subject to a strong electric or magnetic field

y Where the actuator is subject to ultraviolet ray or radiation

[2] Storage • Preservation Environment

y The storage and preservation environment should comply with the same standards as those for the

installation environment. In particular, when the machine is to be stored for a long time, pay close

attention to environmental conditions so that no dew condensation forms.

y Unless specially specified, moisture absorbency protection is not included in the package when the

machine is delivered. In the case that the machine is to be stored and preserved in an environment

where dew condensation is anticipated, take the condensation preventive measures from outside of

the entire package, or directly after opening the package.

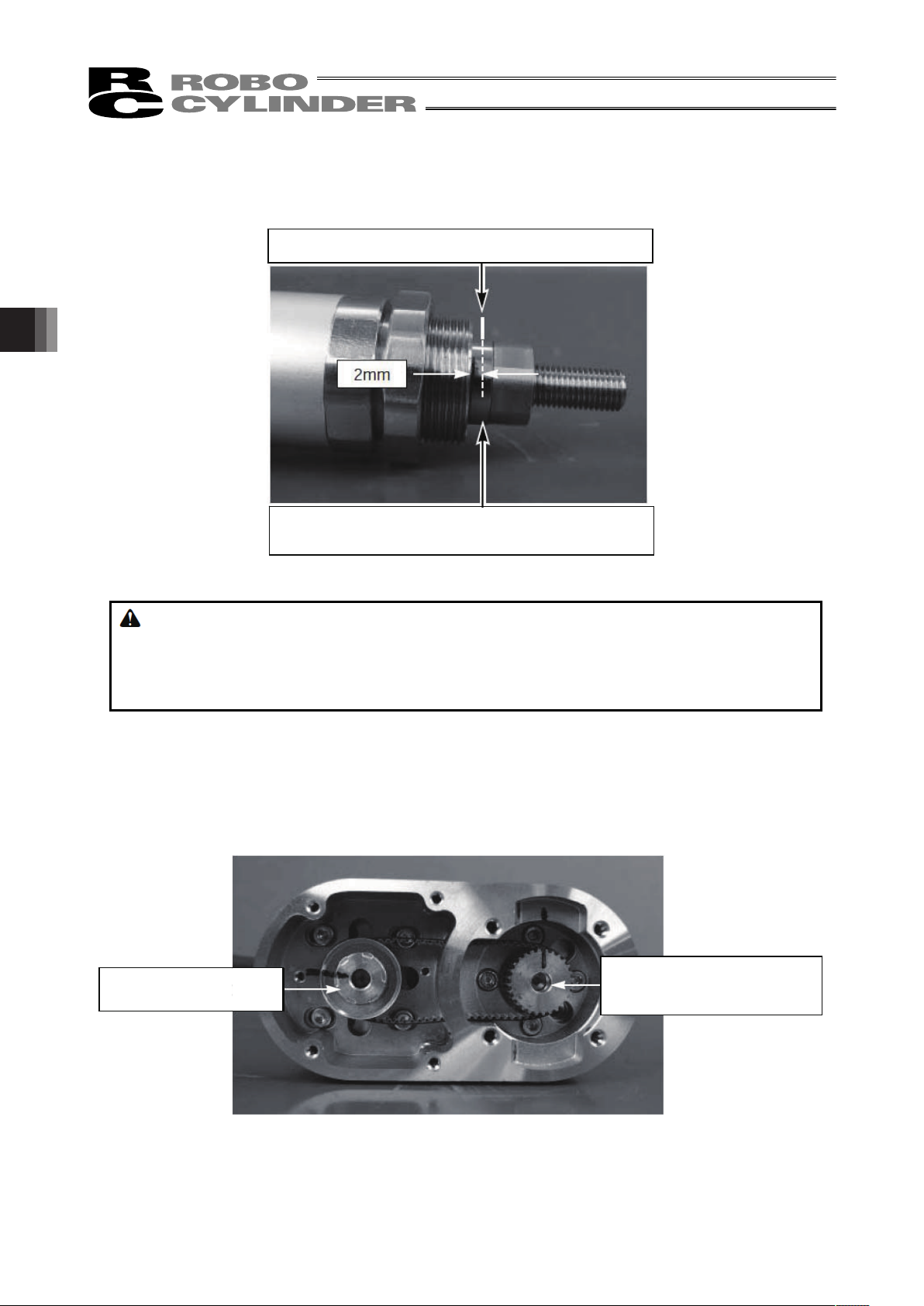

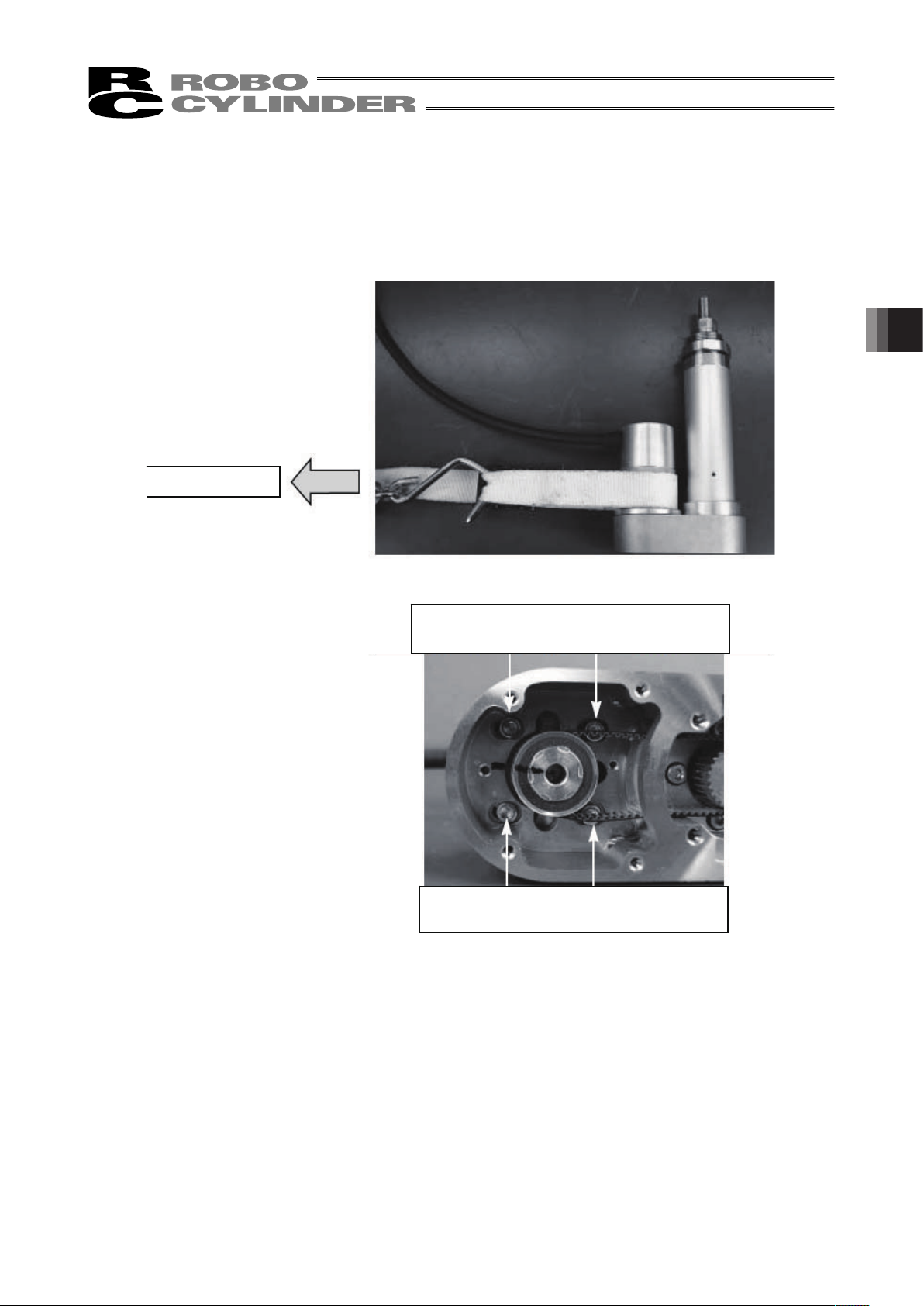

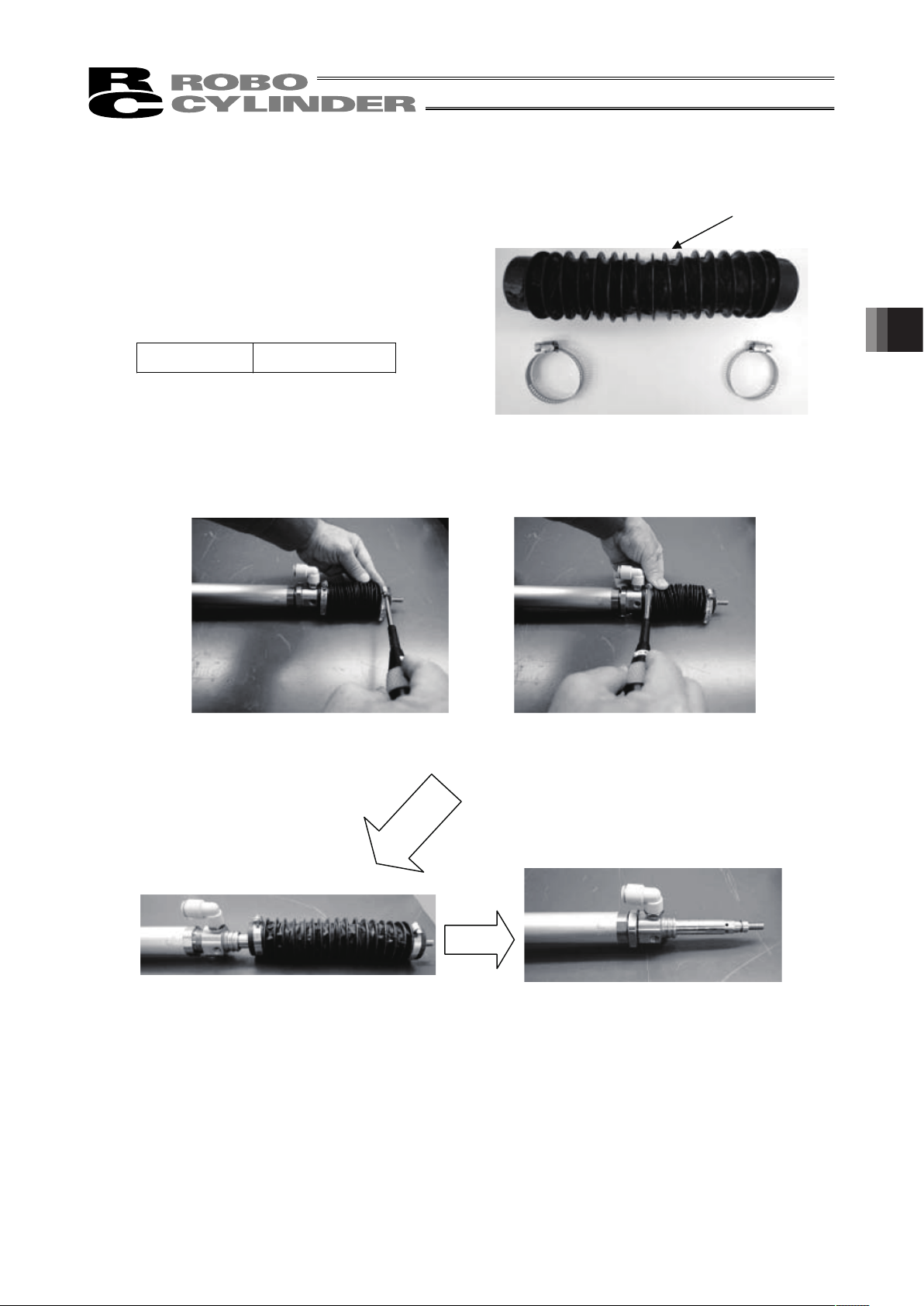

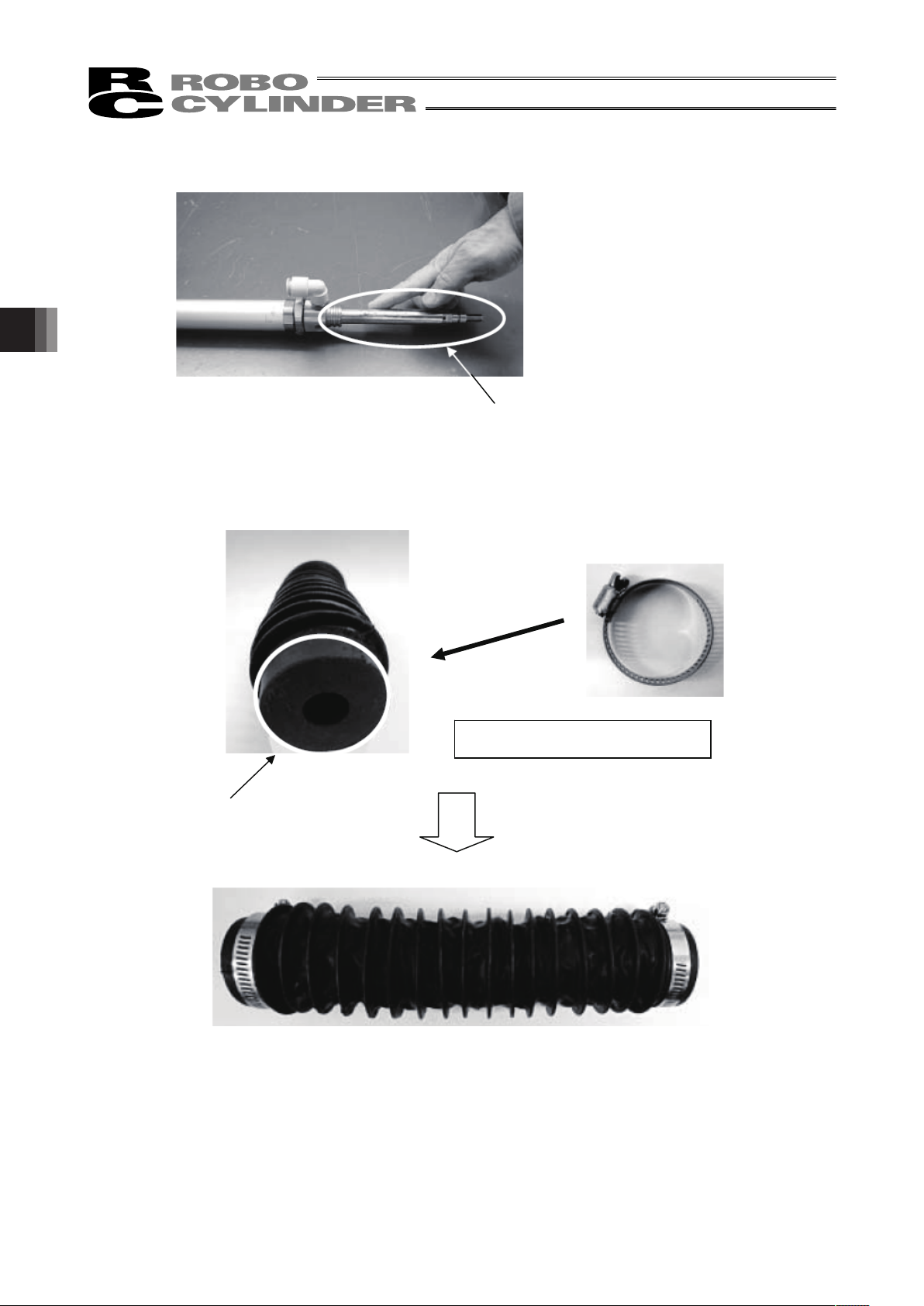

y For storage and preservation temperature, the machine withstands temperatures up to 60qC for a