Page 1

MSEP Controller

Instruction Manual Fourth Edition

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Instruction Manual describes all necessary information items to operate this product safely

such as the operation procedure, structure and maintenance procedure.

To ensure the safe operation of this product, please read and fully understand this manual.

The enclosed DVD in this product package includes the Instruction Manual for this product.

For the operation of this product, print out the necessary sections in the Instruction Manual or

display them using the personal computer.

After reading through this manual, keep this Instruction Manual at hand so that the operator of this

product can read it whenever necessary.

[Important]

x This Instruction Manual is original.

x The product cannot be operated in any way unless expressly specified in this Instruction

Manual. IAI shall assume no responsibility for the outcome of any operation not specified

herein.

x Information contained in this Instruction Manual is subject to change without notice for the

purpose of product improvement.

x If you have any question or comment regarding the content of this manual, please contact

the IAI sales office near you.

x Using or copying all or part of this Instruction Manual without permission is prohibited.

x The company names, names of products and trademarks of each company shown in the

sentences are registered trademarks.

x DeviceNet is a registered mark of ODVA.

x CC-Link is a registered mark of Mitsubishi Electric Corporation.

x PROFIBUS is a registered mark of Siemens.

x CompoNet is the registered trademark of OMRON Corporation.

x MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

x EtherCAT® is a registered mark of Beckoff Automation GmbH.

x EtherNet/IP is a trademark used under the license of ODVA.

Page 4

Page 5

Table of Contents

Safety Guide ·····················································································································1

Precautions in Operation ··································································································8

International Standards Compliances············································································· 11

Name for Each Parts and Their Functions······································································12

Actuator Axes··················································································································16

Starting Procedures ········································································································18

Chapter 1 Specifications Check ···················································································19

1.1 Product Check ············································································································19

1.1.1 Parts ····················································································································19

1.1.2 Teaching Tool······································································································· 19

1.1.3 Instruction manuals related to this product, which are contained in the

instruction manual (DVD). ··················································································· 20

1.1.4 How to read the model plate················································································20

1.1.5 How to read the model························································································· 21

1.2 List of Basic Specifications ························································································· 22

1.3 Calculation for Power Capacity··················································································· 23

1.4 Specifications for each Fieldbus ················································································· 24

1.4.1 Specifications of DeviceNet Interface··································································24

1.4.2 Specifications of CC-Link Interface······································································24

1.4.3 Specifications of PROFIBUS-DP Interface·························································· 25

1.4.4 Specifications of CompoNet Interface ·································································25

1.4.5 Specifications of MECHATROLINK-I/II Interface················································· 25

1.4.6 Specifications of EtherNet/IP Interface ································································26

1.4.7 Specifications of EtherCAT Interface ··································································· 26

1.4.8 PIO Input and Output Interface············································································27

1.5 External Dimensions··································································································· 28

1.5.1 Controller Main Unit·····························································································28

1.5.2 Absolute Battery Box ···························································································29

1.6 Option ························································································································· 30

1.6.1 Absolute Battery Box ···························································································30

1.6.2 Regenerative Resistor Unit··················································································31

1.7 Installation and Storage Environment········································································· 32

1.8 Noise Elimination and Mounting Method ···································································· 33

Chapter 2 Wiring ·········································································································· 35

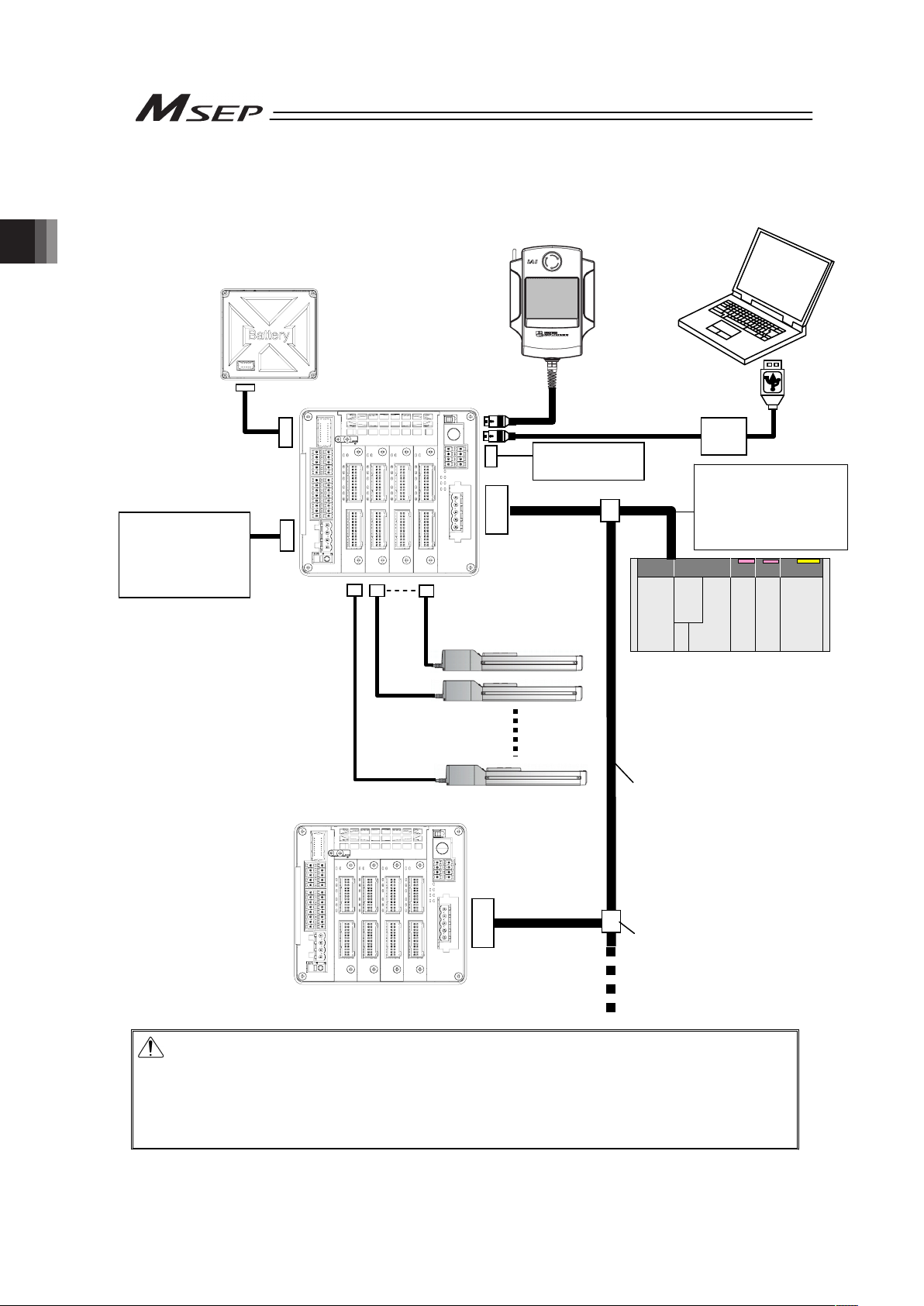

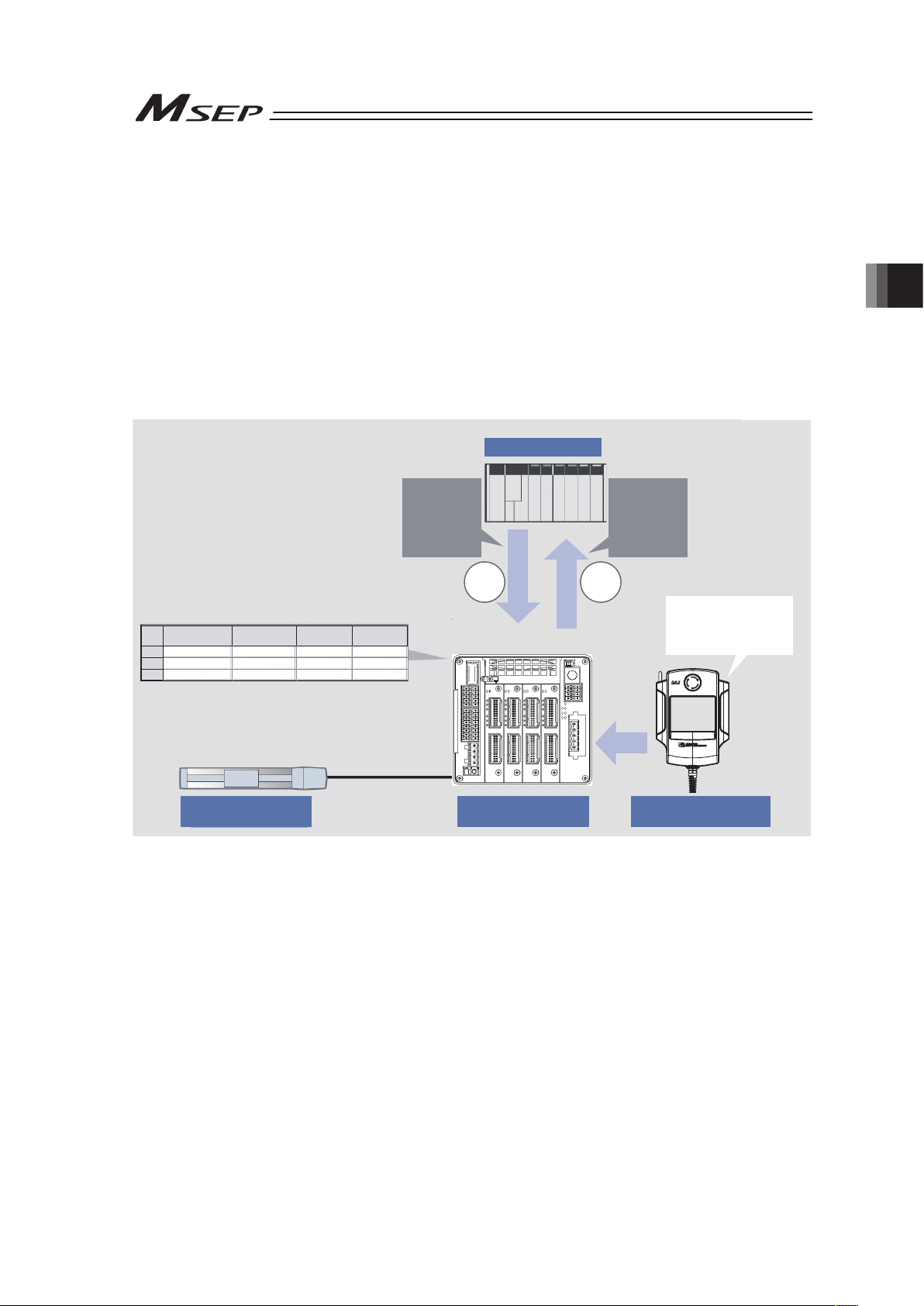

2.1 Wiring Diagram (Connection of construction devices)················································ 35

2.1.1 For PIO Control····································································································35

2.1.2 When Controlled by Fieldbus ·············································································· 36

2.1.3 For RC Gateway Control ·····················································································37

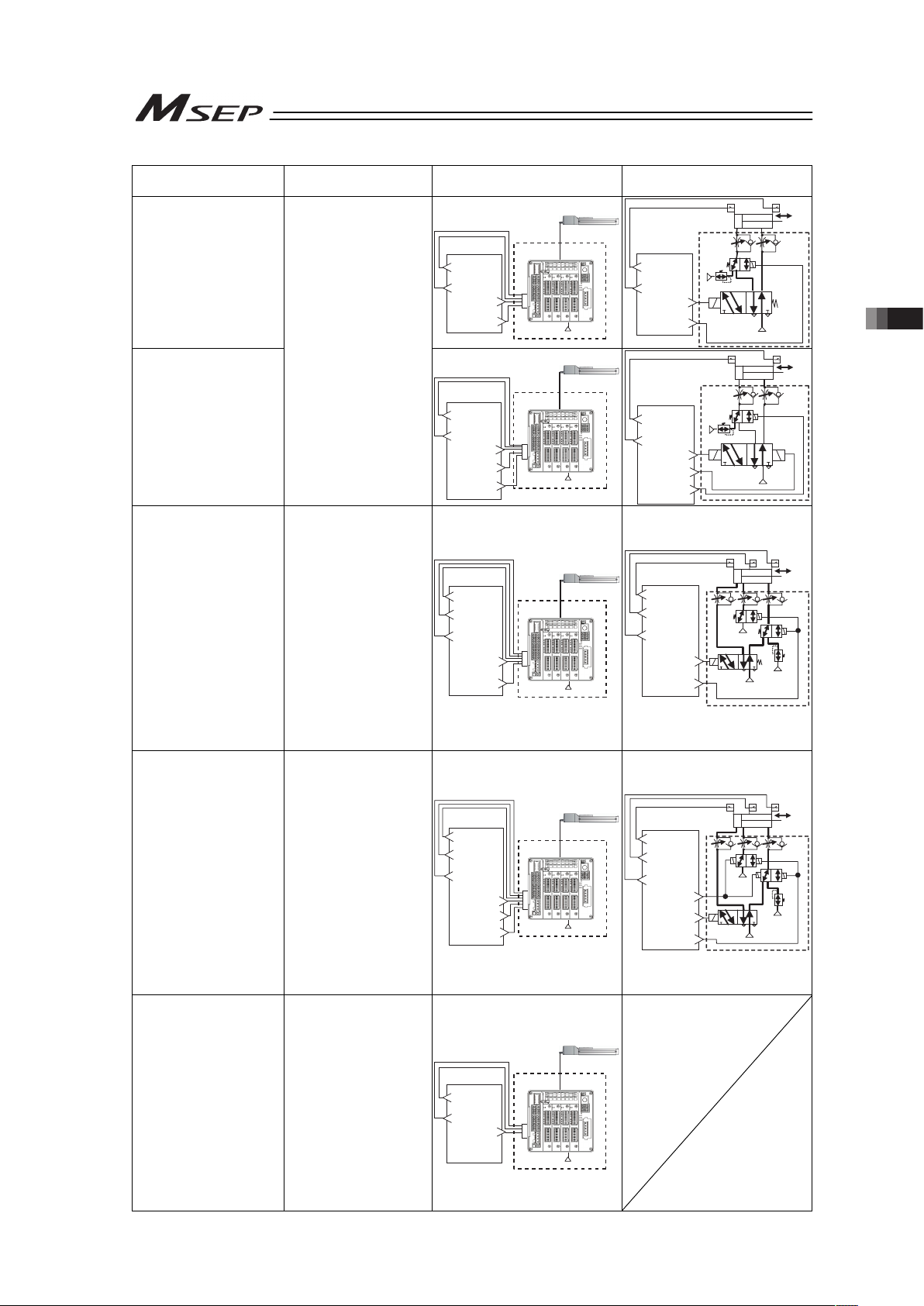

2.2 Operation Pattern Selected ························································································ 38

2.2.1 Outline for Operation Patterns············································································· 38

2.2.2 PIO Pattern Selection and PIO Signal································································· 39

2.3 Circuit Diagram ··········································································································· 42

2.4 Wiring Method············································································································· 56

2.4.1 Connection to Power Input Connector································································· 56

2.4.2 Wiring Layout of System I/O Connector ······························································ 57

2.4.3 Connection of Drive Cutoff/Emergency Stop Input Connector ···························· 58

2.4.4 Connecting with Actuator ·····················································································59

2.4.5 Connection of Absolute Battery Connector·························································· 60

2.4.6 Connection of External Brake Connector ···························································· 61

2.4.7 Connection of SIO Connector··············································································62

2.4.8 Connection of PIO (for PIO Type)········································································63

2.4.9 Wiring Layout of Fieldbus Connector ··································································64

Page 6

Chapter 3 Operation·····································································································69

3.1 Basic Operation ··········································································································69

3.1.1 Basic Operation Methods ···················································································· 69

3.1.2 Parameter Settings······························································································75

3.2 Initial Setting ···············································································································76

3.3 Setting of Position Data ······························································································ 85

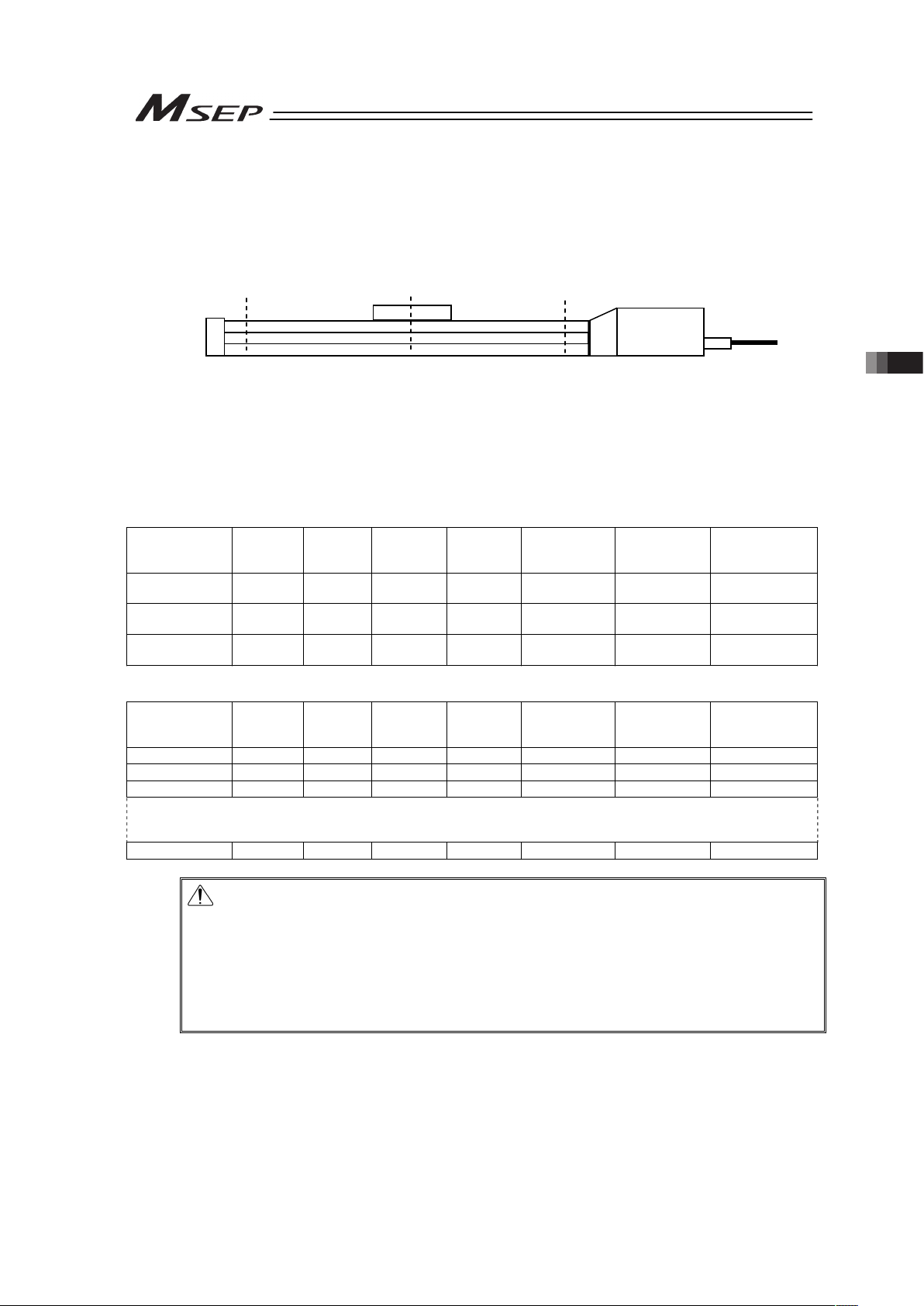

3.4 Fieldbus Type Address Map························································································90

3.4.1 PLC Address Construction by each Operation Mode·········································· 90

3.4.2 Example for each Fieldbus Address Map····························································92

3.4.3 Gateway Control Signals (in common for all operation modes) ························ 104

3.4.4 Control Signals for Positioner 1/Simple Direct Mo ············································ 107

3.4.5 Control Signals for Direct Indication Mode ························································ 112

3.4.6 Control Signals for Positioner 2 Mode······························································· 119

3.4.7 Control Signals for Positioner 3 Mode·······························································123

3.4.8 Control Signals for SEP I/O Mode ·····································································126

3.4.9 About Commands (Position Data Read/Write and Alarm Axis Read) ··············· 128

3.5 Control Signals for PIO Operation ············································································143

3.6 Control of Input Signal ······························································································ 146

3.6.1 PIO Input Signal Process··················································································· 146

3.6.2 Input and Output Signal Process for Fieldbus Type ··········································147

3.7 Power Supply············································································································149

3.8 I/O Signal Controls and Function··············································································150

3.8.1 Input and Output Signal for Fieldbus Type (except for SEP I/O Mode)············· 150

3.8.2 SEP I/O Mode and PIO Operation for Fieldbus Type········································163

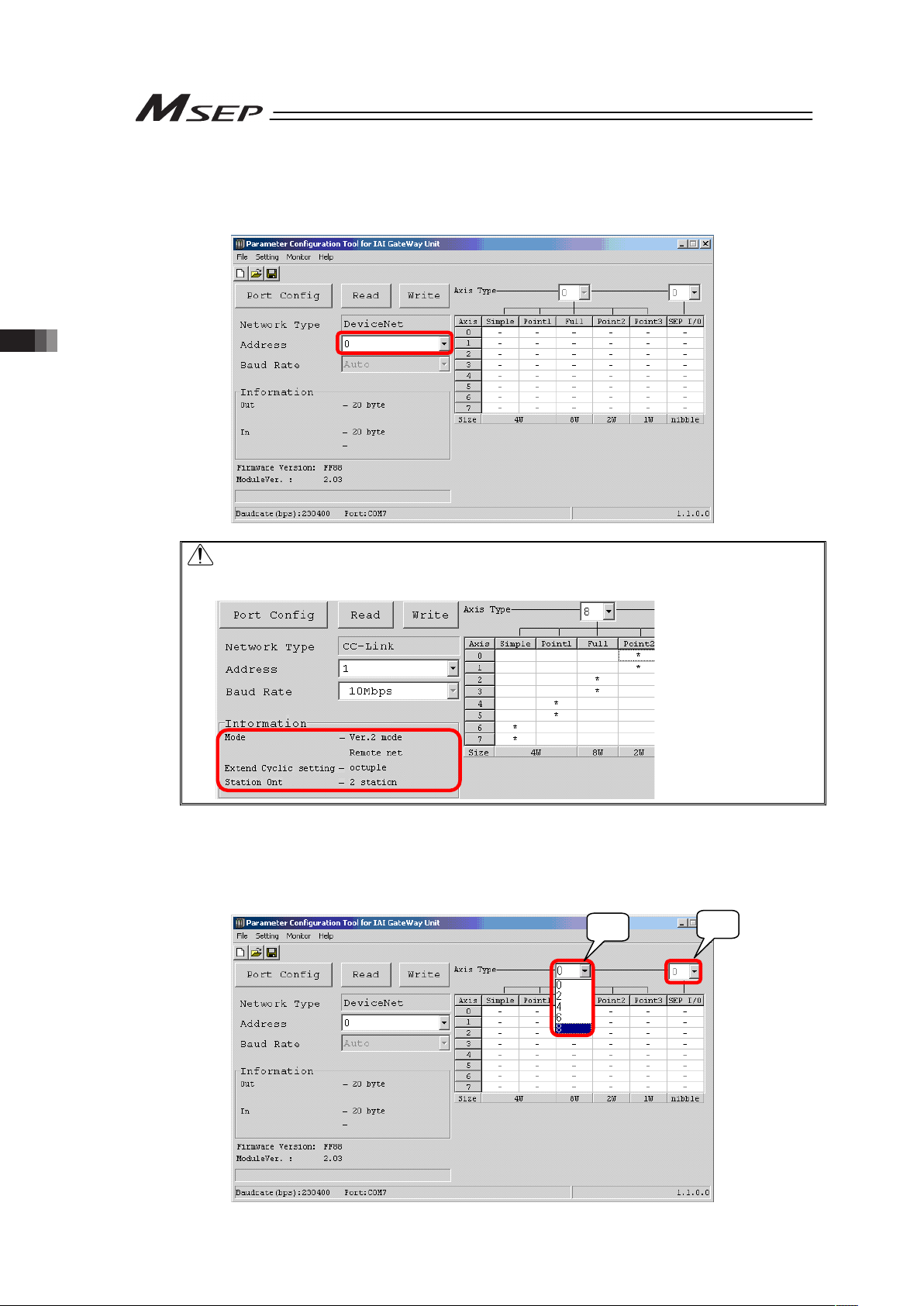

3.9 About Gateway Parameter Setting Tool····································································175

3.9.1 Startup of Tool ···································································································· 175

3.9.2 Explanation of each Menu················································································· 176

3.9.3 Description of Functions ····················································································178

3.9.4 Operation Mode Setting·····················································································185

3.10 Status LED ················································································································185

Chapter 4 Absolute Reset and Absolute Battery························································ 195

4.1 Absolute Reset··········································································································195

4.2 Absolute Battery········································································································ 198

4.2.1 Absolute encoder backup specifications ···························································199

4.2.2 Absolute Battery Charge···················································································· 199

4.2.3 Absolute Battery Voltage Drop Detection ·························································· 200

Chapter 5 I/O Parameter ···························································································· 201

5.1 I/O Parameter List····································································································· 202

5.2 Detail Explanation of Parameters ·············································································204

5.3 Servo Adjustment······································································································ 215

Chapter 6 Troubleshooting·························································································217

6.1 Action to Be Taken upon Occurrence of Problem·····················································217

6.2 Fault Diagnosis ·········································································································218

6.2.1 Impossible operation of controller······································································218

6.2.2 Positioning and speed of poor precision (incorrect operation)·························· 219

6.2.3 Generation of noise and/or vibration ·································································220

6.2.4 Impossible Communication ··············································································· 220

6.3 Alarm Level ···············································································································221

6.4 Alarm List ·················································································································· 222

6.4.1 Gateway Alarm Codes ·······················································································222

6.4.2 Simple Alarm Code···························································································· 225

6.4.3 Alarm Codes for Driver Board (Each Axis) ························································227

Page 7

Chapter 7 Appendix····································································································237

7.1 Fan Replacement······································································································ 237

7.2 List of Specifications of Connectable Actuators························································ 238

7.2.1 Specifications for Servo Motor Type Actuator···················································· 238

7.2.2 Specifications for Pulse Motor Type Actuator ····················································250

Chapter 8 Warranty ···································································································· 283

8.1 Warranty Period········································································································283

8.2 Scope of the Warranty ······························································································ 283

8.3 Honoring the Warranty······························································································ 283

8.4 Limited Liability ·········································································································283

8.5 Conditions of Conformance with Applicable Standards/Regulations,

Etc., and Applications································································································ 284

8.6 Other Items Excluded from Warranty········································································ 284

Change History ············································································································· 285

Page 8

Page 9

1

Safety Guide

“Safety Guide” has been written to use the machine safely and so prevent personal injury or

property damage beforehand. Make sure to read it before the operation of this product.

Safety Precautions for Our Products

The common safety precautions for the use of any of our robots in each operation.

No.

Operation

Description

Description

1 Model

Selection

Ɣ This product has not been planned and designed for the application

where high level of safety is required, so the guarantee of the protection

of human life is impossible. Accordingly, do not use it in any of the

following applications.

1) Medical equipment used to maintain, control or otherwise affect

human life or physical health.

2) Mechanisms and machinery designed for the purpose of moving or

transporting people (For vehicle, railway facility or air navigation

facility)

3) Important safety parts of machinery (Safety device, etc.)

Ɣ Do not use the product outside the specifications. Failure to do so may

considerably shorten the life of the product.

Ɣ Do not use it in any of the following environments.

1) Location where there is any inflammable gas, inflammable object or

explosive

2) Place with potential exposure to radiation

3) Location with the ambient temperature or relative humidity exceeding

the specification range

4) Location where radiant heat is added from direct sunlight or other

large heat source

5) Location where condensation occurs due to abrupt temperature

changes

6) Location where there is any corrosive gas (sulfuric acid or

hydrochloric acid)

7) Location exposed to significant amount of dust, salt or iron powder

8) Location subject to direct vibration or impact

Ɣ For an actuator used in vertical orientation, select a model which is

equipped with a brake. If selecting a model with no brake, the moving

part may drop when the power is turned OFF and may cause an

accident such as an injury or damage on the work piece.

Page 10

2

No.

Operation

Description

Description

2 Transportation Ɣ When carrying a heavy object, do the work with two or more persons or

utilize equipment such as crane.

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ When in transportation, consider well about the positions to hold, weight

and weight balance and pay special attention to the carried object so it

would not get hit or dropped.

Ɣ Transport it using an appropriate transportation measure.

The actuators available for transportation with a crane have eyebolts

attached or there are tapped holes to attach bolts. Follow the

instructions in the instruction manual for each model.

Ɣ Do not step or sit on the package.

Ɣ Do not put any heavy thing that can deform the package, on it.

Ɣ When using a crane capable of 1t or more of weight, have an operator

who has qualifications for crane operation and sling work.

Ɣ When using a crane or equivalent equipments, make sure not to hang a

load that weighs more than the equipment’s capability limit.

Ɣ Use a hook that is suitable for the load. Consider the safety factor of the

hook in such factors as shear strength.

Ɣ Do not get on the load that is hung on a crane.

Ɣ Do not leave a load hung up with a crane.

Ɣ Do not stand under the load that is hung up with a crane.

3 Storage and

Preservation

Ɣ The storage and preservation environment conforms to the installation

environment. However, especially give consideration to the prevention

of condensation.

Ɣ Store the products with a consideration not to fall them over or drop due

to an act of God such as earthquake.

4 Installation

and Start

(1) Installation of Robot Main Body and Controller, etc.

Ɣ Make sure to securely hold and fix the product (including the work part).

A fall, drop or abnormal motion of the product may cause a damage or

injury.

Also, be equipped for a fall-over or drop due to an act of God such as

earthquake.

Ɣ Do not get on or put anything on the product. Failure to do so may cause

an accidental fall, injury or damage to the product due to a drop of

anything, malfunction of the product, performance degradation, or

shortening of its life.

Ɣ When using the product in any of the places specified below, provide a

sufficient shield.

1) Location where electric noise is generated

2) Location where high electrical or magnetic field is present

3) Location with the mains or power lines passing nearby

4) Location where the product may come in contact with water, oil or

chemical droplets

Page 11

3

No.

Operation

Description

Description

(2) Cable Wiring

Ɣ Use our company’s genuine cables for connecting between the actuator

and controller, and for the teaching tool.

Ɣ Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not

coil it around. Do not insert it. Do not put any heavy thing on it. Failure to

do so may cause a fire, electric shock or malfunction due to leakage or

continuity error.

Ɣ Perform the wiring for the product, after turning OFF the power to the

unit, so that there is no wiring error.

Ɣ When the direct current power (+24V) is connected, take the great care

of the directions of positive and negative poles. If the connection

direction is not correct, it might cause a fire, product breakdown or

malfunction.

Ɣ Connect the cable connector securely so that there is no disconnection

or looseness. Failure to do so may cause a fire, electric shock or

malfunction of the product.

Ɣ Never cut and/or reconnect the cables supplied with the product for the

purpose of extending or shortening the cable length. Failure to do so

may cause the product to malfunction or cause fire.

4 Installation

and Start

(3) Grounding

Ɣ The grounding operation should be performed to prevent an electric

shock or electrostatic charge, enhance the noise-resistance ability and

control the unnecessary electromagnetic radiation.

Ɣ For the ground terminal on the AC power cable of the controller and the

grounding plate in the control panel, make sure to use a twisted pair

cable with wire thickness 0.5mm

2

(AWG20 or equivalent) or more for

grounding work. For security grounding, it is necessary to select an

appropriate wire thickness suitable for the load. Perform wiring that

satisfies the specifications (electrical equipment technical standards).

Ɣ Perform Class D Grounding (former Class 3 Grounding with ground

resistance 100: or below).

Page 12

4

No.

Operation

Description

Description

4 Installation

and Start

(4) Safety Measures

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ When the product is under operation or in the ready mode, take the

safety measures (such as the installation of safety and protection fence)

so that nobody can enter the area within the robot’s movable range.

When the robot under operation is touched, it may result in death or

serious injury.

Ɣ Make sure to install the emergency stop circuit so that the unit can be

stopped immediately in an emergency during the unit operation.

Ɣ Take the safety measure not to start up the unit only with the power

turning ON. Failure to do so may start up the machine suddenly and

cause an injury or damage to the product.

Ɣ Take the safety measure not to start up the machine only with the

emergency stop cancellation or recovery after the power failure. Failure

to do so may result in an electric shock or injury due to unexpected

power input.

Ɣ When the installation or adjustment operation is to be performed, give

clear warnings such as “Under Operation; Do not turn ON the power!”

etc. Sudden power input may cause an electric shock or injury.

Ɣ Take the measure so that the work part is not dropped in power failure or

emergency stop.

Ɣ Wear protection gloves, goggle or safety shoes, as necessary, to secure

safety.

Ɣ Do not insert a finger or object in the openings in the product. Failure to

do so may cause an injury, electric shock, damage to the product or fire.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

5 Teaching Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ Perform the teaching operation from outside the safety protection fence,

if possible. In the case that the operation is to be performed unavoidably

inside the safety protection fence, prepare the “Stipulations for the

Operation” and make sure that all the workers acknowledge and

understand them well.

Ɣ When the operation is to be performed inside the safety protection

fence, the worker should have an emergency stop switch at hand with

him so that the unit can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch on

the operation so that any third person can not operate the switches

carelessly.

Ɣ Place a sign “Under Operation” at the position easy to see.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

Page 13

5

No.

Operation

Description

Description

6 Trial

Operation

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ After the teaching or programming operation, perform the check

operation one step by one step and then shift to the automatic

operation.

Ɣ When the check operation is to be performed inside the safety

protection fence, perform the check operation using the previously

specified work procedure like the teaching operation.

Ɣ Make sure to perform the programmed operation check at the safety

speed. Failure to do so may result in an accident due to unexpected

motion caused by a program error, etc.

Ɣ Do not touch the terminal block or any of the various setting switches in

the power ON mode. Failure to do so may result in an electric shock or

malfunction.

7 Automatic

Operation

Ɣ Check before starting the automatic operation or rebooting after

operation stop that there is nobody in the safety protection fence.

Ɣ Before starting automatic operation, make sure that all peripheral

equipment is in an automatic-operation-ready state and there is no

alarm indication.

Ɣ Make sure to operate automatic operation start from outside of the

safety protection fence.

Ɣ In the case that there is any abnormal heating, smoke, offensive smell,

or abnormal noise in the product, immediately stop the machine and

turn OFF the power switch. Failure to do so may result in a fire or

damage to the product.

Ɣ When a power failure occurs, turn OFF the power switch. Failure to do

so may cause an injury or damage to the product, due to a sudden

motion of the product in the recovery operation from the power failure.

Page 14

6

No.

Operation

Description

Description

8 Maintenance

and

Inspection

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ Perform the work out of the safety protection fence, if possible. In the

case that the operation is to be performed unavoidably inside the safety

protection fence, prepare the “Stipulations for the Operation” and make

sure that all the workers acknowledge and understand them well.

Ɣ When the work is to be performed inside the safety protection fence,

basically turn OFF the power switch.

Ɣ When the operation is to be performed inside the safety protection

fence, the worker should have an emergency stop switch at hand with

him so that the unit can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch on

the operation so that any third person can not operate the switches

carelessly.

Ɣ Place a sign “Under Operation” at the position easy to see.

Ɣ For the grease for the guide or ball screw, use appropriate grease

according to the Instruction Manual for each model.

Ɣ Do not perform the dielectric strength test. Failure to do so may result in

a damage to the product.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

Ɣ The slider or rod may get misaligned OFF the stop position if the servo

is turned OFF. Be careful not to get injured or damaged due to an

unnecessary operation.

Ɣ Pay attention not to lose the cover or untightened screws, and make

sure to put the product back to the original condition after maintenance

and inspection works.

Use in incomplete condition may cause damage to the product or an

injury.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

9 Modification

and Dismantle

Ɣ Do not modify, disassemble, assemble or use of maintenance parts not

specified based at your own discretion.

10 Disposal Ɣ When the product becomes no longer usable or necessary, dispose of it

properly as an industrial waste.

Ɣ When removing the actuator for disposal, pay attention to drop of

components when detaching screws.

Ɣ Do not put the product in a fire when disposing of it.

The product may burst or generate toxic gases.

11 Other Ɣ Do not come close to the product or the harnesses if you are a person

who requires a support of medical devices such as a pacemaker. Doing

so may affect the performance of your medical device.

Ɣ See Overseas Specifications Compliance Manual to check whether

complies if necessary.

Ɣ For the handling of actuators and controllers, follow the dedicated

instruction manual of each unit to ensure the safety.

Page 15

7

Alert Indication

The safety precautions are divided into “Danger”, “Warning”, “Caution” and “Notice” according to the

warning level, as follows, and described in the Instruction Manual for each model.

Level Degree of Danger and Damage Symbol

Danger

This indicates an imminently hazardous situation which, if the

product is not handled correctly, will result in death or serious

injury.

Danger

Warning

This indicates a potentially hazardous situation which, if the

product is not handled correctly, could result in death or serious

injury.

Warning

Caution

This indicates a potentially hazardous situation which, if the

product is not handled correctly, may result in minor injury or

property damage.

Caution

Notice

This indicates lower possibility for the injury, but should be kept to

use this product properly.

Notice

Page 16

8

Precautions in Operation

1. Make sure to follow the usage condition, environment and specification range

of the product.

Not doing so may cause a drop of performance or malfunction of the product.

2. Use an appropriate teaching tool.

Use the PC Software for RoboCylinder or an appropriate teaching pendant to interface with this

controller.

[Refer to 1.1.2 Teaching Tool]

3. Create a secure data backup for use in case of a breakdown.

A non-volatile memory is used as the backup memory for this controller. All the registered

position data and parameters are written into this memory and backed-up at the same time.

Therefore, you will not usually lose the data even if the power is shut down. However, make

sure to save the latest data so a quick recovery action can be taken in case the controller is

broken and needs to be replaced with another one.

How to Save Data

(1) Save the data to CD-R or hard disk using the PC software

(2) Hard-copy the information of position tables and parameters on paper

4. Set the operation patterns.

This product can be applied an various ways according to application requirements. It can be

controlled via PIO or a fieldbus, with multiple patterns of operation available in either mode.

The setup can be performed in the initial setting. [Refer to Chapter 3 Operation and Chapter 5

Parameter]

The PIO pattern is set to “0” (Standard Type) when the unit is delivered. Set the operation

pattern setting to the logic that suits your use after the power is turned ON.

Warning : Please note it is very risky when the control sequence and PIO pattern setting do

not match each other. The normal operation might not occur. There may be no

movement, or there may be unexpected movement.

Page 17

9

5. Actuator would not operate without servo-on and pause signals.

(1) Servo ON Signal (SON)

The servo-on signal (SON) is available to select whether to enable or disable in the initial

setting process “Servo Control”.

If it is set to “Enable”, the actuator would not operate unless turning this signal ON.

If parameter No.21 is set to “Not to use”, SON is made disable. If it is set to “Disable”, the

servo becomes on and the actuator operation becomes enabled as soon as the power

supply to the controller is turned ON and the emergency stop signal is cancelled.

Have the setting that suits to the desirable control logic.

(2) Pause Signal (STP, *STP)

If Single Solenoid is selected and the stop signal is set to “Use” in the initial setting, unless

this signal is enabled, the actuator would not operate.

If this signal is not to be used, set the stop signal to “Not to use” in the initial setting

process.

If not in use, the operation of the actuator is available even with this signal not being

enabled.

6. Clock Setting in Calendar Function

There may be a case in the first time to supply the power after delivery that Gateway Error

Code 4A “Real Time Clock Vibration Stop Detected” is generated. In the case this happens, set

the current time with a teaching tool.

If the battery is fully charged, the clock data is retained for approximately 10 days after the

power is turned OFF.

Even though the time setting is conducted before the product is shipped, the battery is not fully

charged. Therefore, there may be a case that the clock data is lost even if the days described

above have not passed.

7. Rotary actuator cannot be set to Multi-Rotation Specification.

Rotary actuator cannot be set to Multi-Rotation Specification since the index mode setting

cannot be performed.

8. The controller is not applicable for the high output function.

This controller does not respond to the high output even if it is connected to an actuator that is

applicable for the high output function. It provides the operation in normal output.

Page 18

10

9. According to Sequence Program Creation

Please note the following things when creating a sequence program.

When data transfer is necessary between two devices that have a different scan time from

each other, duration more than the longer scan time is required to certainly read the signal. (It is

recommended to have a timer setting of at least twice as long as the scan time in order for the

PLC to adequately perform the reading process.)

䎃

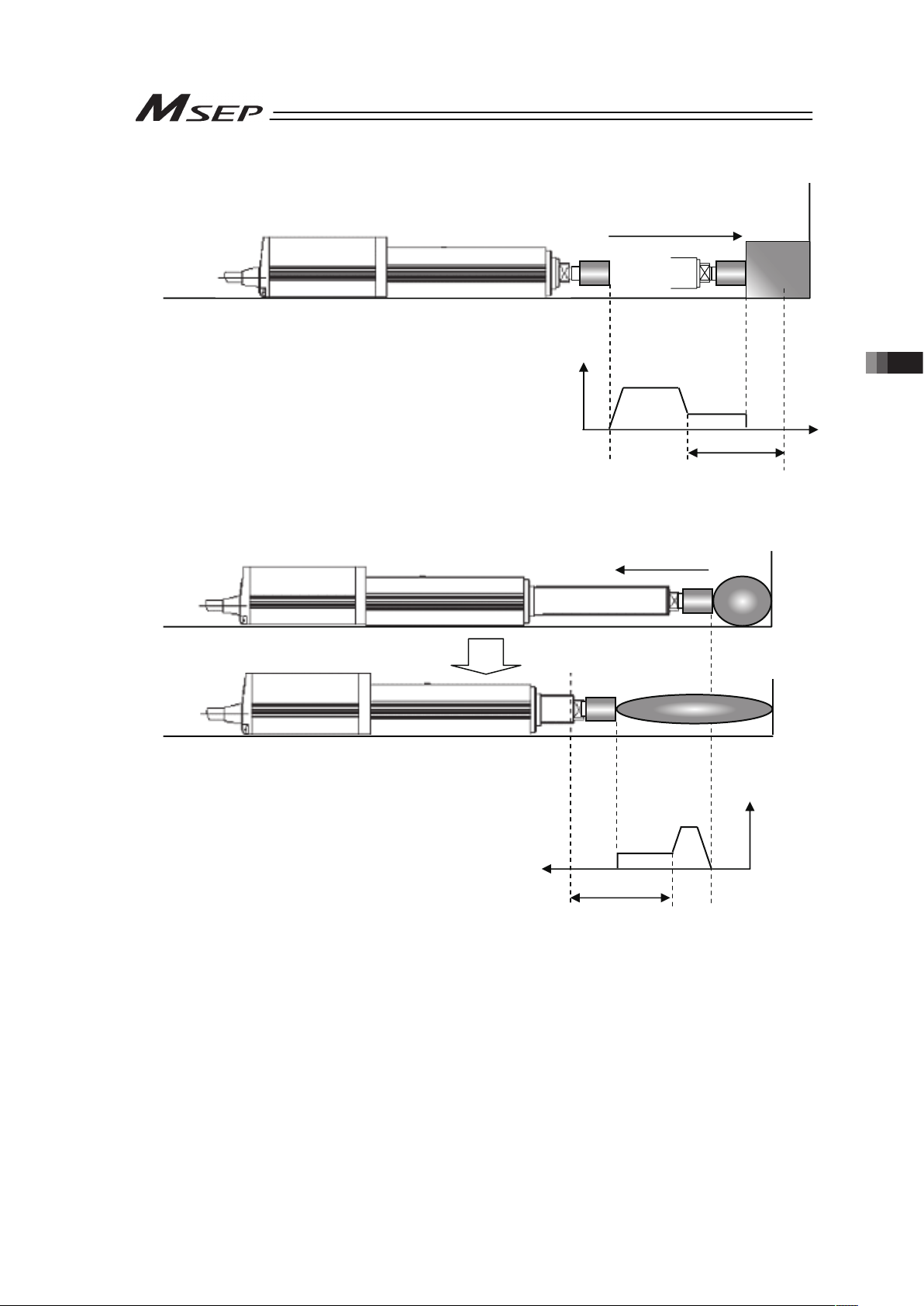

Ɣ Operation Image

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

Also, if one tries to read the signal that is being re-written by the other, the signal may be read wrong.

Make sure to read the signal after the rewriting is complete. (It is recommended to have more than 2 scan

periods to wait.) Make sure not to have the output side to change the output until the other side completes

the reading. Also, a setting is made on the input area not to receive the signal less than a certain time to

prevent a wrong reading of noise. This duration also needs to be considered.

10. PLC Timer Setting

Do not have the PLC timer setting to be done with the minimum setting.

Setting to “1” for 100msec timer turns ON at the timing from 0 to 100msec while 10msec timer

from 0 to 10msec for some PLC.

Therefore, the same process as when the timer is not set is held and may cause a failure such

as the actuator cannot get positioned to the indicated position number in Positioner Mode.

Set “2” as the minimum value for the setting of 10msec timer and when setting to 100msec, use

10msec timer and set to “10”.

This controller

(scan time 1msec)

PLC

(e.g. scan time is 20msec)

Output

Process

Input

Process

As shown in the diagram, the input and output

timings of two devices that have different scan

time do not match, when transferring a signal.

There is no guarantee that PLC would read the

signal as soon as this controller signal turns ON.

In such a case, make the setting to read the

signal after a certain time that is longer than the

longer scan time to ensure the reading process

succeeds on the PLC side.

It is the same in the case this controller side

reads the signal.

In such a case, it is recommended to ensure 2 to

4 times of the scan time for the timer setting

margin.

It is risky to have the setting below the scan time

since the timer is also processed in the scan

process.

In the diagram, PLC can only read the input once

in 20msec even though this controller output

once in 1msec.

Because PLC only conducts output process once

in 20msec, this controller identifies the same

output status for that entire time period.

Page 19

11

International Standards Compliances

MSEP with the following overseas standard.

Refer to Overseas Standard Compliance Manual (ME0287) for more detailed information.

RoHS Directive CE Marking UL

{

To be scheduled To be scheduled

Page 20

12

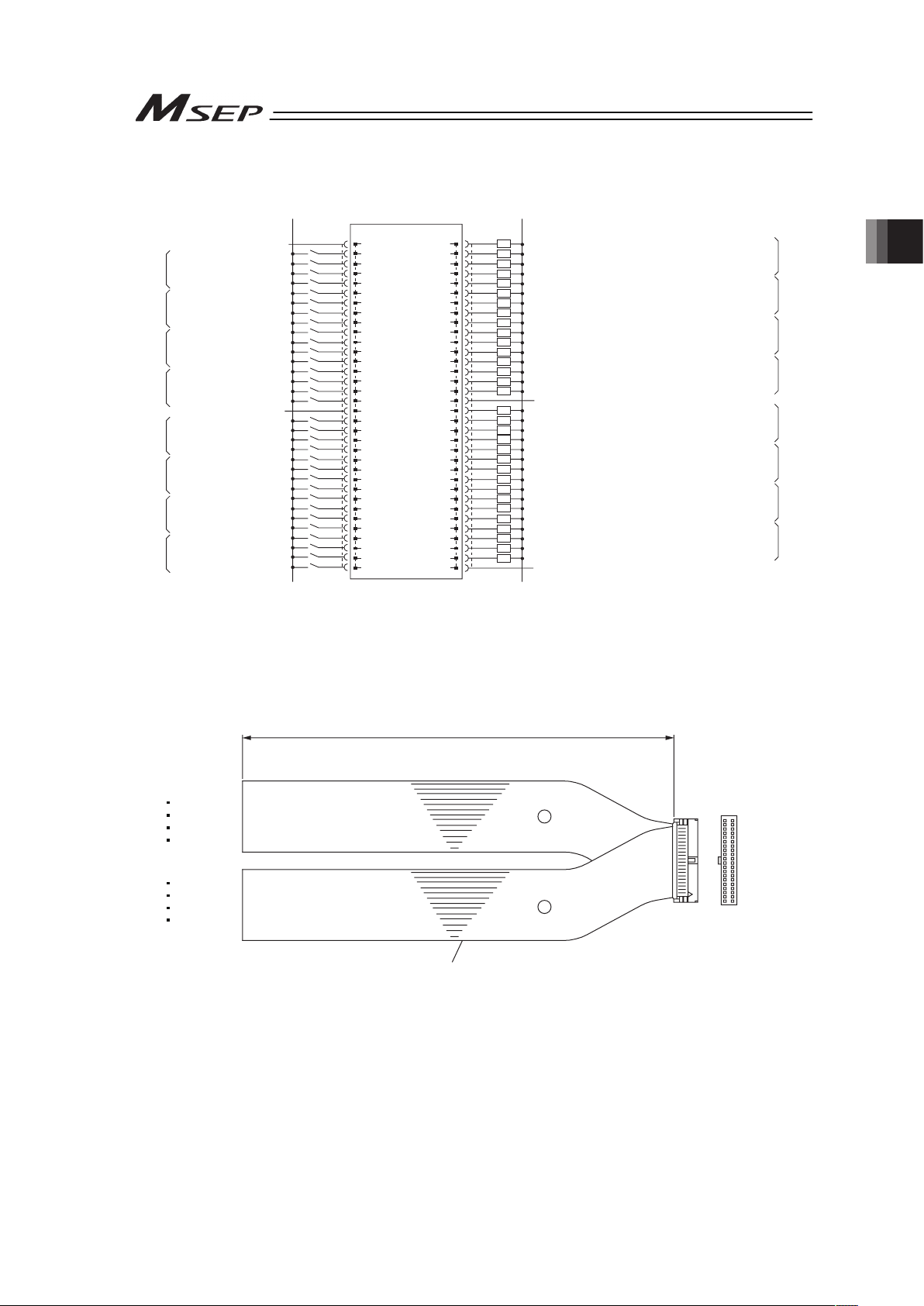

Name for Each Parts and Their Functions

9) Operation Mode

Setting Switch

10) SIO Connector

17) Slot 0

Actuator Connector

Upper side (1st axis) : Axis No.0 (AX0)

Lower side (2nd axis) : Axis No.1 (AX1)

7) Status LEDs for Driver

6) Absolute Battery Connector

5) External Brake Input

Connector

4) Drive Cutoff/Emergency

Stop Input Connector

2) Power Line Input Connector

1) FG Terminal Block

3) Model Code Record Card

11) System I/O

Connector

12) Status LED

13) Fieldbus

/PIO Connector

8) Fan Unit

16) Slot 1

Actuator Connector

Upper side (3rd axis) : Axis No.2 (AX2)

Lower side (4th axis) : Axis No.3 (AX3)

15) Slot 2

Actuator Connector

Upper side (5th axis) : Axis No.4 (AX4)

Lower side (6th axis) : Axis No.5 (AX5)

14) Slot 3

Actuator Connector

Upper side (7th axis) : Axis No.6 (AX6)

Lower side (8th axis) : Axis No.7 (AX7)

Page 21

13

1) FG Terminal Block

This is the terminal block for frame grounding. Since this controller is made of plastic, it is

necessary to ground from this terminal block. Ground Type should be Class D (formally

Class 3 grounding = ground resistance 100ȍ or less).

2) Power Line Input Connector

This is the connector to supply 24V DC power supply to the controller. The control power

supply and the motor power supply are to be input separately. This enables external drive

cutoff that cuts only the motor power supply.

3) Model Code Record Card

This is a card with information of the connected axes recorded on for eight axes at the

maximum. It is available to pull out from the controller and check the information.

4) Drive Cutoff/Emergency Stop Input Connector

External drive cutoff and emergency stop can be performed individually for each slot (2

axes).

5) Compulsory Brake Release Signal Input Connector

An external compulsory brake release can be performed on each axis. The brake is

ordinarily released with the servo ON and activated with the servo OFF. In the tuning at the

startup or in the maintenance work, have a brake release switch for each axis connected to

this connector to make a compulsory brake release available, and the actuator can be

moved manually while the servo is OFF.

6) Absolute Battery Connector

This connector is mounted on the absolute type. An external absolute battery box for eight

axes can be connected with one cable. This is not mounted on the incremental type.

7) Status LEDs for Driver

These lamps indicate the status of the driver and that for absolute type for each slot (in 2

axes unit). There is no absolute status display for the incremental type.

Part Name Description

SYS I System status of driver for axis connected to

upper connector

(Servo ON: GN,

Servo OFF: OFF,

Alarm generated: RD)

SYS II System status of driver for axis connected to

lower connector

(Servo ON: GN,

Servo OFF: OFF,

Alarm generated: RD)

I–0 Absolute status of driver for axis connected

to upper connector 0

I–1 Absolute status of driver for axis connected

to upper connector 1

I–2 Absolute status of driver for axis connected

to upper connector 2

II–0 Absolute status of driver for axis connected

to lower connector 0

II–1 Absolute status of driver for axis connected

to lower connector 1

II–2 Absolute status of driver for axis connected

to lower connector 2

SYS

I II

0

1

2

0

1

2

I

II

Page 22

14

8) Fan Unit

This is the fan unit to cool down the controller. This unit can be detached from the controller

for maintenance by removing the screw on the hook in the front of the controller.

9) Operation Mode Setting Switch

This is a switch to change the operation mode between Automatic Operation (AUTO) and

Manual Operation (MANU). The operation modes are provided to avoid the duplication of

the SIO (Serial) communication operation using PC software or a teaching pendant

(described as teaching tool from now on) and the operation with Fieldbus or PIO (Parallel

I/O)

For the details of the mode selection, refer to 11) System I/O Connector.

10) SIO Connector

This is a connector dedicated for the teaching tool connection.

11) System I/O Connector

This is a connector for additional devices for the input of all-axes external emergency stop,

AUTO/MANU switchover and external regenerative resistor.

It is connected in a series with the operation mode setting switch (AUTO/MANU) on the front

panel. The controller can be in the following modes by the mode selection on each switch

and teaching tool.

Condition

MSEP status

Switch on Front Panel Teaching Tool

Note 1

Operation Mode

Switchover Input

Note 2

AUTO Prohibit PIO Startup OFF (Input 0V)

AUTO Accept PIO Startup OFF (Input 0V)

AUTO Accept PIO Startup ON (Release)

MANU Accept PIO Startup ON (Release)

AUTO

MANU Accept PIO Startup OFF (Input 0V)

AUTO Prohibit PIO Startup ON (Release)

MANU Prohibit PIO Startup ON (Release)

MANU

MANU Prohibit PIO Startup OFF (Input 0V)

Note 1 : “Accept PIO Startup” and “Prohibit PIO Startup” are the functions to select the

operation mode of when the teaching tool is connected.

Note 2 : Refer to 2.3 [4] for the details.

Caution : (1) If “Accept PIO Startup” is selected on the teaching tool, the AUTO operation

becomes available no matter the condition of the front panel or external

switchover signal input, thus attention may have to be paid. In such a

condition, the actuator may get activated by following the signal from the host.

(2) The information of “Accept PIO Startup” or “Prohibit PIO Startup” is remained

when the teaching tool is removed from the controller. Do not fail to select

“Prohibit PIO Startup” when removing the teaching tool after finishing the

teaching operation or debugging.

Page 23

15

12) Status LED

They are the LED lamps to show the status of the controller and PIO or Fieldbus.

The layout and the content of LED display differ depending on PIO or each Fieldbus.

Refer to the operation of each mode for the details.

[Refer to 3.10 Status LEDs.]

13) Fieldbus/PIO Connector

A connector for Fieldbus connection is mounted for the Fieldbus. Type while PIO connector

is equipped for PIO Type.

14) to 17) Slot 0 to 3 Actuator Connector

Insert one driver board to one slot each. (Four driver boards are available to insert at the

maximum.)

Each driver board can control two axes.

Caution : (1) There are two types of driver board, one is for the pulse motor and the other

for the 24V servo motor, and each board is available for the connection of

different actuators.

(2) Do not attempt to insert the driver board to a slot other than the one that the

board was originally inserted to.

The parameter dedicated for the indicated actuator is already written to the

driver board at the purchase order. Inserting the driver board to another slot

may lead to a wrong wiring.

(3) On the slot without a driver board inserted, there is a face plate attached.

Caution : Cutoff/boot of driving source is to be done on each driver board (2 axes) (control

by one axis to another cannot be performed). Therefore, when Cold Start Level

(Drive Cutoff) Alarm is generated on one axis out of two, the other axis with the

alarm not being generated will also stop. Consider this when constructing the

system.

Driver Board

For pulse motor or 24V servo motor

(to be indicated at the purchase order considering

the connected actuator type)

Page 24

16

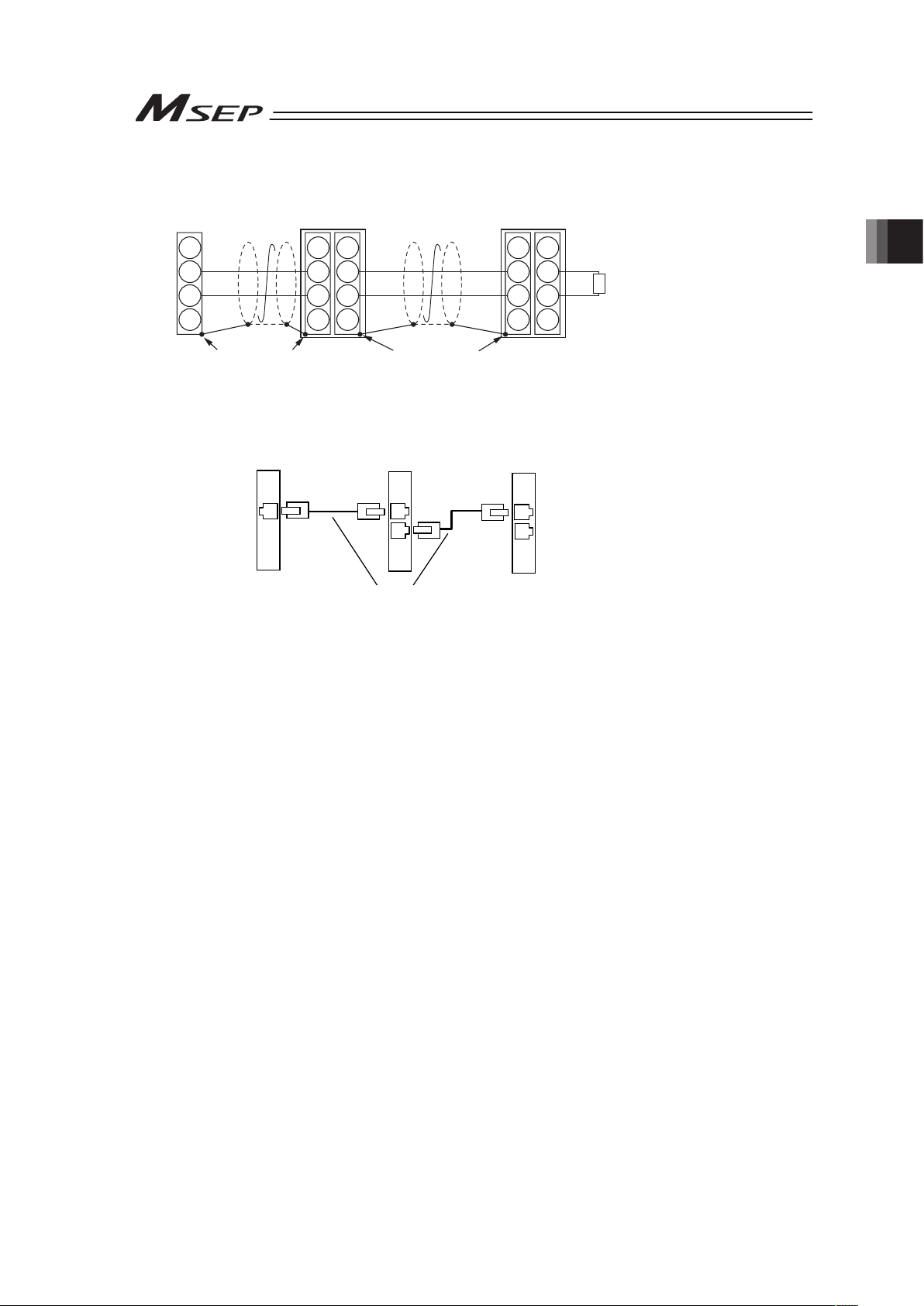

Actuator Axes

Refer to the pictures below for the actuator axes that can be controlled by MSEP.

0 defines the home position, and items in ( ) are for the home-reversed type (option).

(1) Rod Type

(2) Slider Type

(3) Table Type

(4) Arm Type

Caution: There are some actuators that are not applicable to the origin reversed type.

Check further on the catalog or the Instruction Manual of the actuator.

+

(0)

0

(+)

0

(+)

+

(0)

+

(0)

0

(+)

+

(0)

0

(+)

Page 25

17

(5) Gripper Type

(3-Finger Gripper)

Note Finger attachment is not included in the actuator package. Please prepare separately.

(6) Rotary Type

(330q Rotation Type) (360q Rotation Type)

For 360q Rotation Type with the origin reversed type, the directions of + and – are the other way

around.

0

330°

㧙

+

+

+

+

Finger Attachment

(Note)

Page 26

18

Starting Procedures

When using this product for the first time, make sure to avoid mistakes and incorrect wiring by

referring to the procedure below. “PC” stated in this section means “PC software”.

Ļ

ĺ

No ĺ

ω

ĺ

No ĺ

Contact your local IAI distributor.

ĻYes

No ĺ

ĺ

Check Item

Is SYS in Status LEDs turned

ON in green?

Connect the teaching tool,

such as the PC software,

confirm the alarm code,

and remedy the indicated

situation.

Check Item

Is SYS* on the status LED display for the driver

on the axis number indicated for the servo-on

turned ON in green?

Safety Circuit Check

Does the emergency stop circuit (drive

cutoff circuit) work properly and turn the

servo OFF?

Target Position Setting [Except for simple direct mode and direct

numerical specification mode: Chapter 3]

Set the target position in “Position” Box in each position table.

ĸ

ĻYes

Test Run Adjustment 1

Cancel the emergency stop, remove the

work piece, set to low speed and check

the operation in the command of the host

controller (PLC, XSEL, etc.).

After doing so, set the speed back to the

indicated, put back the work piece and

check the operation.

Check if there is any problem with the

installation of the actuator and the condition of

the actuator use exceeds the ranges of the rated

values.

Adjust the servo if necessary.

Connect the teaching tool, such as the PC

software, confirm the alarm code, and

remedy the indicated situation.

ĻYes

ĸYes

Test Run Adjustment 2

1) Put the operation mode setting switch to AUTO side.

2) Output the operation command from PLC to the controller and check the system operation.

Check Item

Any vibration or

abnormal noise?

No ĺ

ĻYes

Check of Packed Items

Have all the items been delivered?

Installation and Wiring [Refer to Chapter 1,

Section 2 1 and 2.3]

Perform the installation of and wiring for the actuator

and controlle

r

.

Point Check Item

• Is frame ground (FG) connected?

• Has the noise countermeasure been taken?

Power Supply and Alarm Check

Connect a teaching tool such as the PC software, set

the operation mode setting switch to “MANU” side and

turn the power ON.

Select “Teach Mode 1 Safety Speed Effective/Prohibit

PIO Startup” on a teaching tool such as the PC

software.

Initial setting and operation mode select [Refer to Section 3.2]

Conduct the initial setting using the PC software, and make the operation mode select and

other necessary selections.

Register the operation mode selected in the initial setting to MSEP Gateway using

Gateway Parameter Setting Tool.

Servo ON

Turn the servo ON for all the connected axes by operating a teaching tool such as PC.

Check the emergency stop circuit.

Caution

Please perform this process with the actuator away from the mechanical end or

interfering objects as much as possible.

Move the actuator away from interfering surroundings. It may generate an alarm if the

actuator hit the mechanical end or interfering objects when the servo is turned ON.

The slider may get slightly dropped by self-weight if servo ON and OFF is repeatedly

performed at the same position. Be careful not to pinch the hand or damage the work.

No ĺ

ĻYes

Ļ

Page 27

Chapter 1 Specications Check

19

Chapter 1 Specifications Check

1.1 Product Check

1.1.1 Parts

The standard configuration of this product is comprised of the following parts.

If you find any faulty or missing parts, contact your local IAI distributor.

No. Part Name Model Remarks

1 Controller Main Body

Refer to “How to read the model plate”,

“How to read the model”.

Accessories

2 Power Connector

FKC2.5HC/4-ST-5.08

(Supplier : PHOENIX CONTACT)

3

External Brake Input

Connector

FMCD1.5/5-ST-3.5

(Supplier : PHOENIX CONTACT)

4

Drive Cutoff/Emergency

Stop Input Connector

FMCD1.5/8-ST-3.5

(Supplier : PHOENIX CONTACT)

5 System I/O Connector

FMCD1.5/4-ST-3.5

(Supplier : PHOENIX CONTACT)

6

I/O Flat Cable

(For PIO Type)

CB-MSEP-PIO***

***shows the cable length

(Example) *** : 020 = 2 [m]

7

CC-Link Connector

(For CC-Link Type)

MSTB2.5/5-ST-5.08 ABGY AU

(Supplier : PHOENIX CONTACT)

8

DeviceNet Connector

(For DeviceNet Type)

MSTB2.5/5-ST-5.08 ABGY AU

(Supplier : PHOENIX CONTACT)

9

Absolute Battery Box

(Option)

MSEP-ABU (Battery AB-7) For Simple Absolute Type

10 First Step Guide

11 Instruction Manual (DVD)

12 Safety Guide

1.1.2 Teaching Tool

A teaching tool such as PC software is necessary when performing the setup for position

setting, parameter setting, etc. that can only be done on the teaching tool.

Please prepare either of the following teaching tools.

No. Part Name Model

1

PC Software

(Includes RS232C Exchange Adapter + Peripheral Communication

Cable)

RCM-101-MW

2

PC Software

(Includes USB Exchange Adapter + USB Cable + Peripheral

Communication Cable)

RCM-101-USB

3 Teaching Pendant (Touch Panel Teaching) CON-PTA

4

Teaching Pendant

(Touch Panel Teaching with deadman switch)

CON-PDA

5

Teaching Pendant

(Touch Panel Teaching with deadman switch + TP Adapter

(RCB-LB-TG))

CON-PGA

Page 28

Chapter 1 Specications Check

20

1.1.3 Instruction manuals related to this product, which are contained in the

instruction manual (DVD).

No. Name Manual No.

1 MSEP Controller Instruction Manual ME0299

2

PC Software

RCM-101-MW/RCM-101-USB Instruction Manual

ME0155

3 Touch Panel Teaching CON-PTA/PDA/PGA Instruction Manual ME0295

4 X-SEL Controller RC Gateway Function Instruction Manual ME0188

1.1.4 How to read the model plate

Model ĺ

MODEL MSEP-C-5-20PI–N-42PI–PI-10I-20ILA-DV-2-0-ABB

Sereial No.ĺ

SERIAL No. 200307221

Manufactured date ĺ

PRODUCT DATE 2012/02/01

Manual No. ĺ

MANUAL No. MJ0299

CP INPUT DC24V 2.0A

Input power supply ĺ

MP INPUT DC24V 7.6A

AXIS No. /OUTPUT

0 0-24Vac 3ph 0-333Hz 1.0A

1

2 0-24Vac 3ph 0-333Hz 2.0A

3 0-24Vac 3ph 0-333Hz 2.0A

4 0-24Vac 3ph 0-333Hz 1.3A

5 0-24Vac 3ph 0-333Hz 1.3A

6

Information of the

connected axes ĺ

(Axis No.0 to 7)

7

CAUTION: Connect the wiring correctly and properly.

Use IAI Corporation specified cables.

Made In Japan

Page 29

Chapter 1 Specications Check

21

1.1.5 How to read the model

(Example) Consists of 5 axes: Axes No.0, 2, 3 : Pulse motor type

Axes No.4, 5 : Servo motor type

Axis No.1 : Not connected

Axis No.3 : Inactive Axis

MSEP – C – 5 – 20PI–N–42PI–PI–10I–20ILA – DV – 2 – 0 – ABB – **

<Type>

C : Standard Type

<Connected Axes>

1 to 8 : Number of driver axes

<Detail of Connected Axis>

[Motor Type]

20P : Applicable for 20Ƒ pulse motor

28SP: Applicable for 20Ƒ pulse motor

28P : Applicable for 28Ƒ pulse motor

28SP : Applicable for 28Ƒ pulse motor

35P : Applicable for 35Ƒ pulse motor

42P : Applicable for 42Ƒ pulse motor

56P : Applicable for 56Ƒ pulse motor

2 : Applicable for 2W servo motor

5 : Applicable for 5W servo motor

5S : Applicable for 5W servo motor

10 : Applicable for 10W servo motor

20 : Applicable for 20W servo motor

20S : Applicable for 20W servo motor

30 : Applicable for 30W servo motor

A : Ineffective axis (equipped with pulse motor driver)

P : Ineffective axis (equipped with servo motor driver)

N : Not connected (not equipped with motor driver)

[Encoder Type]

I : Incremental

[Option (if servo motor is selected)]

HA : High Acceleration/Deceleration Type

LA : Low Power Consumption Type

<Identification for IAI use only>

* There is no identification in some

cases

<Applicable for Simple Absolute Type>

ABB : Simple Absolute Type

(with absolute battery)

ABBN : Simple Absolute Type

(with no absolute battery)

No description : Incremental Type

<Power Voltage>

0: 24V DC

<I/O Cable Length>

0 : No cable 2 : 2m (Standard)

3 : 3m 5 : 5m

<I/O Type>

NP : NPN PIO Type (Sink type)

PN : PNP PIO Type (Source type)

DV : DeviceNet Type

CC : CC-Link Type

PR : PROFIBUS-DP Type

CN : CompoNet Type

ML : MECHATROLINK Type

EC : EtherCAT Type

EP : EtherNet/IP Type

C

Page 30

Chapter 1 Specications Check

22

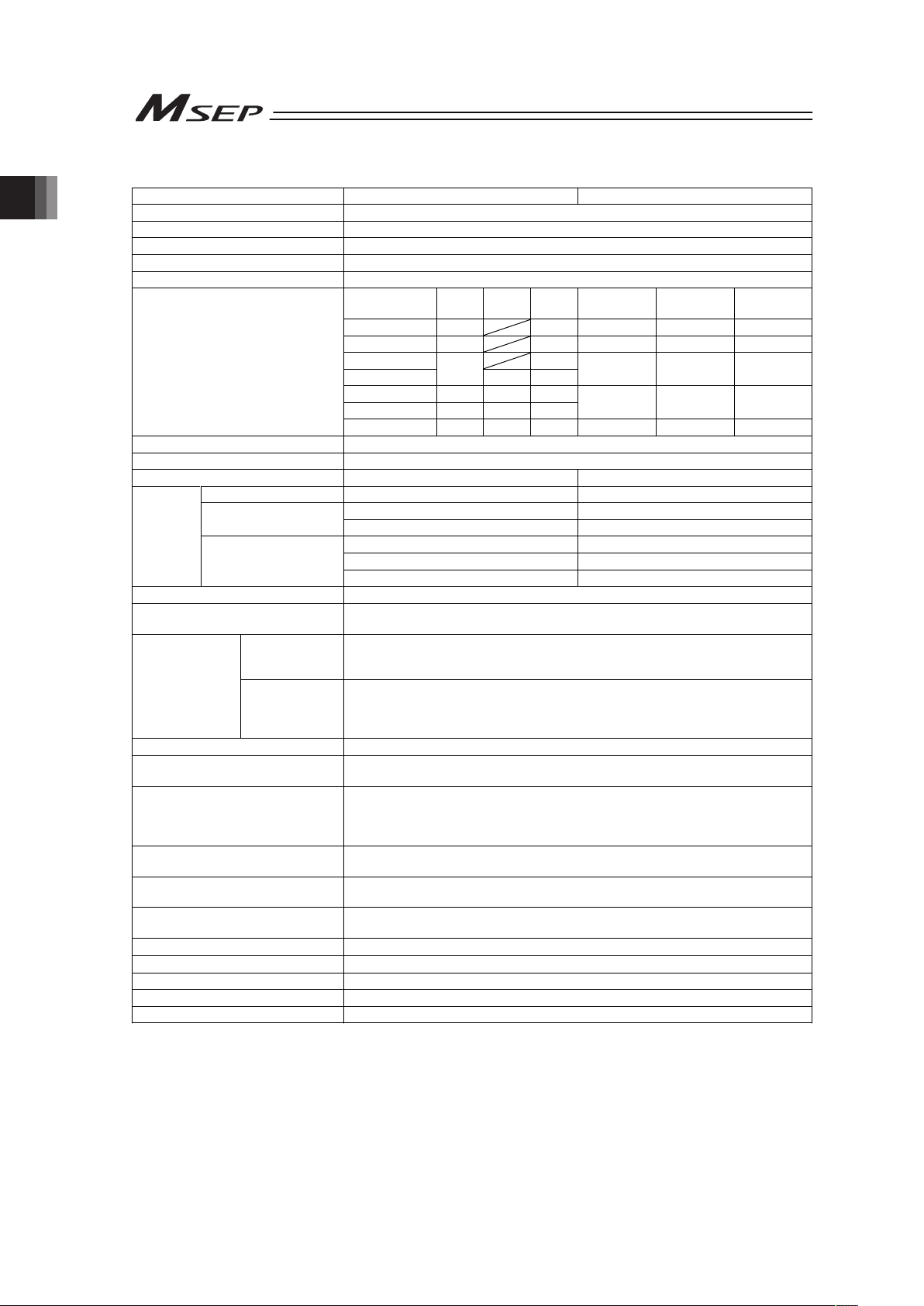

1.2 List of Basic Specifications

Specification Item Driver for Servo Motor Driver for Pulse Motor

Number of Controlled Axes MAX. 8 axis

Control/Motor Power Supply Voltage 24V DC ±10%

Brake Power Supply 0.15A × Number of axes

Control Power Current Consumption 0.8A

Control Power In-Rush Current MAX. 5A 30ms or less

Motor type Rated

Low

power

MAX.

(Note 1)

Motor flange

size

Rated MAX.

(Note 2)

2W 0.8A 4.6A 20P 1.0A 2.0A

5W 1.0A 6.4A 28P 1.0A 2.0A

10W (RCL) 6.4A

10W (RCA/RCA2)

1.3A

2.5A 4.4A

35P 2.0A 2.0A

20W 1.3A 2.5A 4.4A

20W (20S type) 1.7A 3.4A 5.1A

42P 2.0A 2.0A

Motor Current Consumption

30W 1.3A 2.2A 4.4A 56P 2.0A 2.0A

Motor Power In-Rush Current Number of slots × MAX. 10A 5ms or less

Controller Heat Generation 26W

Control System Vector control Weak field-magnet vector control

RCA, RCP2, RCP3, RCP4

All types 800Pulse/rev

RCA2-ƑƑƑN 1048Pulse/rev RCA2

Other than RCA2-ƑƑƑN 800Pulse/rev

RA1L • SA1L • SA4L • SM4L 715Pulse/rev

RA2L • SA2L • SA5L • SM5L 855Pulse/rev

Encoder

Resolution

RCL

RA3L • SA3L • SA6L • SM6L 1145Pulse/rev

Actuator Cable Length MAX. 20m (Note) 10m maximum for Simple Absolute type

Serial Communication

(SIO Port: Only for teaching)

RS485 1CH (complying with Modbus Protocol) Speed 9.6 to 230.4kbps

PIO Type

PIO Type: Signal I/O dedicated for 24V DC (to be selected when purchased NPN/PNP)

Number of max. input: 4 points per axis, Number of max. output: 4 points per axis

Cable length MAX. 10m

External Interface

Fieldbus Type

DeviceNet

(Note)

, CC-Link, PROFIBUS-DP, CompoNet, MECHATROLINK, EtherNet/IP

and EtherCAT [Refer to Section 1.4 Specifications for each Fieldbus.]

An operation by RC Gateway Function is available. Refer to the other instruction

manual for more details.

Data Setting and Input PC software, Touch panel teaching, Gateway parameter setting tool

Data Retention Memory

Position data and parameters are saved in the nonvolatile memory. (There is no

limitation in number of writing)

Positioning Points

PIO Type: 2 or 3 points

Fieldbus Type: 256 points (There is no limit for simple direct and direct indication modes)

(Note) The number of positioning points differs depending on the operation mode

select by the parameter setting.

LED Display (mounted on Front

Panel)

8 LED lamps for driver status display (for each driver board)

Status LED 4 points (PIO type), 7 points (Fieldbus type)

Forcibly Releasing of Electromagnetic

Brake

Can be released with the forcibly releasing signal input (24V DC input) to each axis

Protective Functions

(Note 3)

Overcurrent Protection (Equipped with a built-in cutoff circuit using a semiconductor

for each slot)

Protection Function against Electric Shock

Class I basic insulation

Insulation Resistance

500V DC 10M:

Weight

620g, For simple absolute type, 690g plus 1950g for absolute battery box (for 8-axis type)

Cooling Method Forced air-cooling

External Dimensions 123W × 115H × 95D

Page 31

Chapter 1 Specications Check

23

Specification Item Driver for Servo Motor Driver for Pulse Motor

Ambient Temperature

0 to 40qC

Ambient Humidity 85%RH or less (non-condensing)

Ambient Environment [Refer to Installation Environment]

Ambient Storage

Temperature

-20 to 70qC (0 to 40qC for absolute battery)

Ambient Storage Humidity

85%RH or less (non-condensing)

Usable Altitude 1000m or lower above sea level

Vibration Durability

Frequency 10 to 57Hz / Swing width: 0.075mm

Frequency 57 to 150Hz / Acceleration: 9.8m/s

2

XYZ Each direction Sweep time: 10 min. Number of sweep: 10 times

Shock Resistance 150mm/s2 11ms Semi-sine wave pulse three times to each of the directions X, Y and Z

Environment

Protection Class IP20

Note 1 Maximum current draw is realized during the excitation phase following the initial servo power ON. (Normal: Approx.

1 to 2 sec, MAX: 10 sec).

Note 2 The current is maximized at the excitation phase detection conducted in the first servo-on process after the power is

supplied (ordinary 100ms). However, approximately 6A current flows at the recovery (when the drive power is

supplied) from an emergency stop (approx. 1 to 2ms).

Note 3 For servo motor, the over-current protection is triggered at 1.4 times the maximum load current.

Note 4 It is not applicable for the high output setting even if RCP4 is connected.

1.3 Calculation for Power Capacity

For the calculation of 24V DC power capacity, figure out the numbers for (1) to (6) below, and

then follow Step (7).

(1) Control Power Current Consumption : 0.8A ·······································································1)

(2) Motor Power Current Consumption :

Add the total motor current consumption of all connected actuators.·································2)

(3) Current Consumption at Excitation Phase Detection :

Add the inrush current for all connected axes. ···································································3)

(4) Add the Control Power Inrush Current : Number of slots × 5A each.·································4)

(5) Add the Motor Power Inrush Current : Number of slots × 10A each. ·································5)

(6) Current consumption of brake power supply : Number of actuators with brake × 0.15A····6)

(7) Selection of Power Supply :

Usually, the rated current is to be approximately 1.3 times higher than the total of Control

Power (1) and Motor Power (2) and brake power (6) above considering approximately 30%

of margin to the load current. However, considering the inrush currents [excitation (3),

control (4) and motor power (5)], even though it is a short time, select a power supply with

“sufficient peak load capacity. High cumulative inrush currents can be avoided by taking

precautions to phase the initial servo ON condition and e-stop recovery so that they occur

at different times. If a power supply with insufficient peak capacity is utilized, voltage

drooping may occur. This may present issues with power supplies providing remote sensing

functionality.

(Note) Ensure motor and control power supplies reference the same potential when using

multiple power supplies.

(Reference) Selection of Power Supply Protection Circuit Breaker

It is recommended that the power supply protection is conducted on the primary side (AC

power side) of the 24V DC power supply unit.

When selecting the protection breaker, consider the rated cutoff current of the circuit breaker so

a cutoff is surely performed even in the case of inrush current of 24V DC power supply unit or a

short-circuit of the power supply.

• Rated Breaking Current > Short-circuit Current = Primary Power Supply Capacity/Power

Voltage

• (Reference) In-rush Current of IAI Power Supply Unit PS241 = 50 to 60A, 3msec

Page 32

Chapter 1 Specications Check

24

1.4 Specifications for each Fieldbus

1.4.1 Specifications of DeviceNet Interface

Item Specification

DeviceNet2.0

Group 2 Dedicated Server

Communication Protocol

Network-Powered Insulation Node

Baud Rate Automatically follows the master

Communication System Master-Slave System (Polling)

Number of Occupied Channels Refer to 3.4.1 PLC Address Construction by each Operation Mode

Number of Occupied Nodes 1 Node

Baud Rate

Max. Network

Length

Total Branch Line

Length

Max. Branch Line

Length

500kbps 100m 39m

250kbps 250m 78m

Communication Cable Length

(Note 2)

125kbps 500m 156m

6m

Communications Cable Use the dedicated cable.

Connector

(Note 1)

MSTBA2.5/5-G-5.08-ABGY AU (Manufactured by PHOENIX CONTACT or equivalent)

Consumption Current of

Communication Power Supply

60mA

Communication Power Supply 24V DC (Supplied from DeviceNet)

Note 1 The cable-side connector is a standard accessory. (PHOENIX CONTACT MSTB2.5/5-ST-5.08ABGY AU)

Note 2 For T branch communication, refer to the Instruction Manuals for the master unit and programmable controller (PLC)

to be mounted.

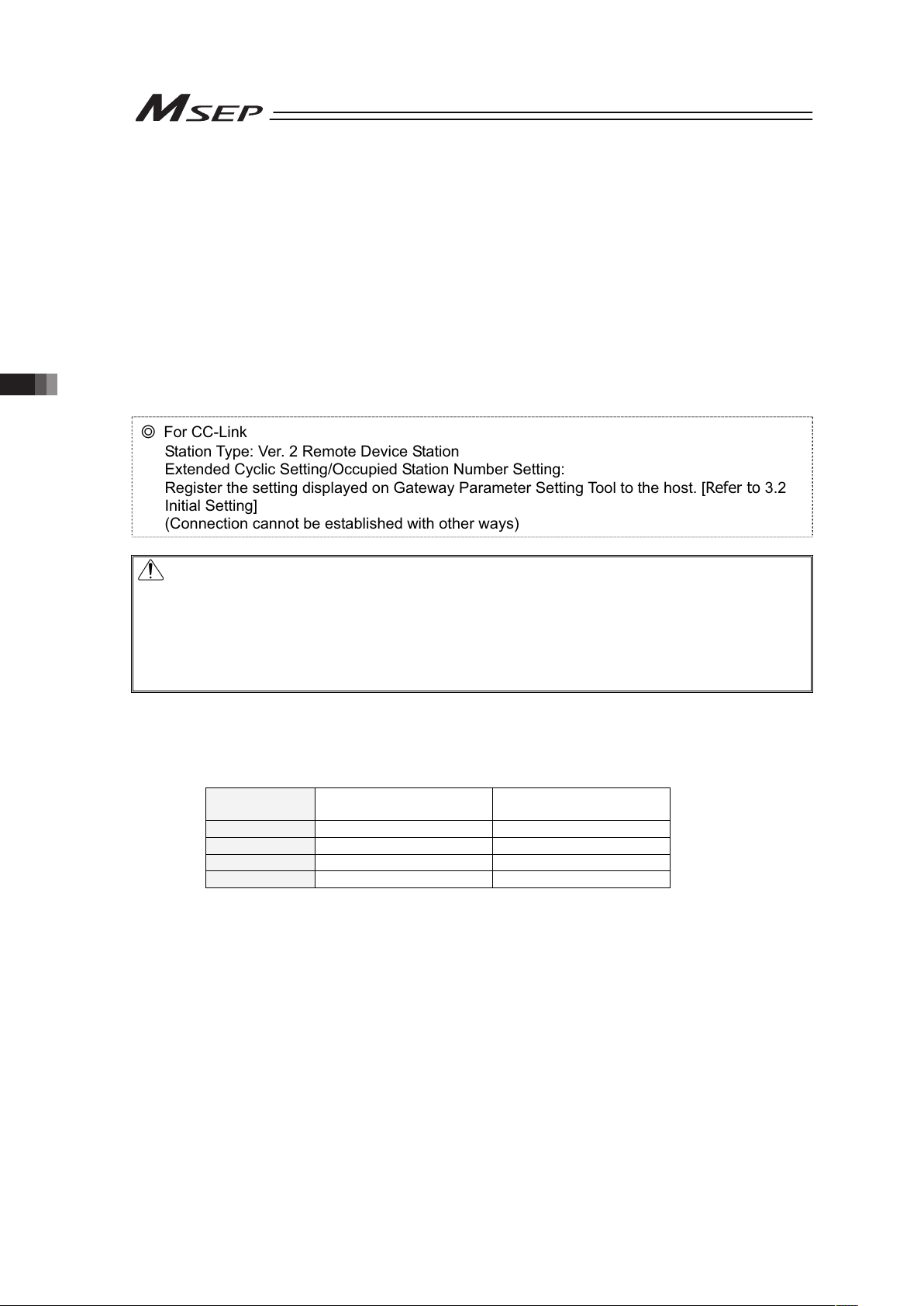

1.4.2 Specifications of CC-Link Interface

Item Specification

Communication Protocol CC-Link ver1.1 or ver2

Station Type Remote Device Station (MAX. four stations occupied)

Baud Rate 10M/5M/2.5M/625k/156kbps

Communication System Broadcast Polling System

Number of occupied stations Refer to 3.4.1 PLC Address Construction by each Operation Mode

Baud Rate (bps) 10M 5M 2.5M 625k 156k Communication Cable Length

(Note 2)

Total Cable Length (m) 100 160 400 900 1200

Communications Cable Apply the dedicated cable

Connector

(Note 1)

MSTBA2.5/5-G-5.08-ABGY AU (Manufactured by PHOENIX CONTACT or equivalent)

Note 1 The cable-side connector is a standard accessory. (PHOENIX CONTACT MSTBA2.5/5-ST-5.08-ABGY AU)

Note 2 For T branch communication, refer to the Instruction Manuals for the master unit and PLC to be mounted.

Page 33

Chapter 1 Specications Check

25

1.4.3 Specifications of PROFIBUS-DP Interface

Item Specification

Communication Protocol PROFIBUS-DP

Baud Rate Automatically follows the master

Communication System Hybrid System (Master-Slave System or Token Passing System)

Number of occupied stations Refer to 3.4.1 PLC Address Construction by each Operation Mode

MAX. Total Network Baud Rate Cable Type

100m 12,000/6,000/3,000kbps

200m 1,500kbps

400m 500kbps

1000m 187.5kbps

Communication Cable Length

1200m 9.6/19.2/93.75kbps

Type A Cable

Communications Cable STP cable AWG18

Connector

(Note 1)

9-pin female D-sub Connector

Transmission Path Format Bus/Tree/Star

Note 1 Please prepare a 9-pin male D-sub connector for the cable-end connector.

1.4.4 Specifications of CompoNet Interface

Item Specification

Communication System CompoNet dedicated protocol

Communication Type Remote I/O communication

Baud Rate Automatically follows the master

Communication Cable Length Follows CompoNet specifications

Slave Type Word-Mixed Slave

Available Node Addresses for Setting 0 to 63 (Setting conducted on controller parameter)

Number of occupied channels Refer to 3.4.1 PLC Address Construction by each Operation Mode

Communications Cable

(Note 1)

Round Cable (JIS C3306, VCTF2-core)

Flat cable I (with no sheathed)

Flat cable II (sheathed)

Connector (Controller Side) XW7D-PB4-R (Manufactured by OMRON or equivalent)

Note 1 Prepare the communication cable separately.

1.4.5 Specifications of MECHATROLINK-II Interface

Item Specification

Slave Type Intelligent I/O

Baud Rate MECHATROLINK II 10Mbps

Max. Transmittable Distance 50m

Min. Distance between Stations 0.5m

Number of occupied bytes Refer to 3.4.1 PLC Address Construction by each Operation Mode

Transmission Frequency 1 to 8ms

Data Length MECHATROLINK II 32 bytes

Settable Node Address Range 61 to 7F [hex.]

Communications Cable

(Note 1)

STP cable with a Shield (characteristic impedance 130:)

Connector Controller Side DUSB-ARB82-T11A-FA (Manufactured by DDK or equivalent)

Note 1 Prepare the communication cable separately.

Page 34

Chapter 1 Specications Check

26

1.4.6 Specifications of EtherNet/IP Interface

Item Specification

Communication Protocol IEC61158 (IEEE802.3)

Baud Rate 10BASE-T/100BASE-T (Autonegotiation setting is recommended)

Communication Cable Length

Follows EtherNet/IP specifications (Distance between hub and each node: 100m

max.)

Number of Connection Master Unit

Available Node Addresses for Setting 0.0.0.0 to 255.255.255.255

Communications Cable

(Note 1)

Category 5e or more

(Double shielded cable braided with aluminum foil recommended)

Connector RJ45 Connector × 1pc

Note 1 Prepare separately for the communication cable.

1.4.7 Specifications of EtherCAT Interface

Item Specification

Communication Protocol IEC61158 type 12

Physical Layer 100Base-TX (IEEE802.3)

Baud Rate Automatically follows the master

Communication Cable Length Follows EtherCAT® specifications (Distance between each node: 100m max.)

Slave Type I/O slave

Available Node Addresses for Setting

0 to 127 (17 to 80: When connected to the master (CJ1W-NC*82) manufactured by

OMRON)

Communications Cable

(Note 1)

Category 5e or more

(Double shielded cable braided with aluminum foil recommended)

Connector RJ45 Connector × 2pcs (Input × 1, Output × 1)

Connect Daisy chain only

Note 1 Prepare separately for the communication cable.

Page 35

Chapter 1 Specications Check

27

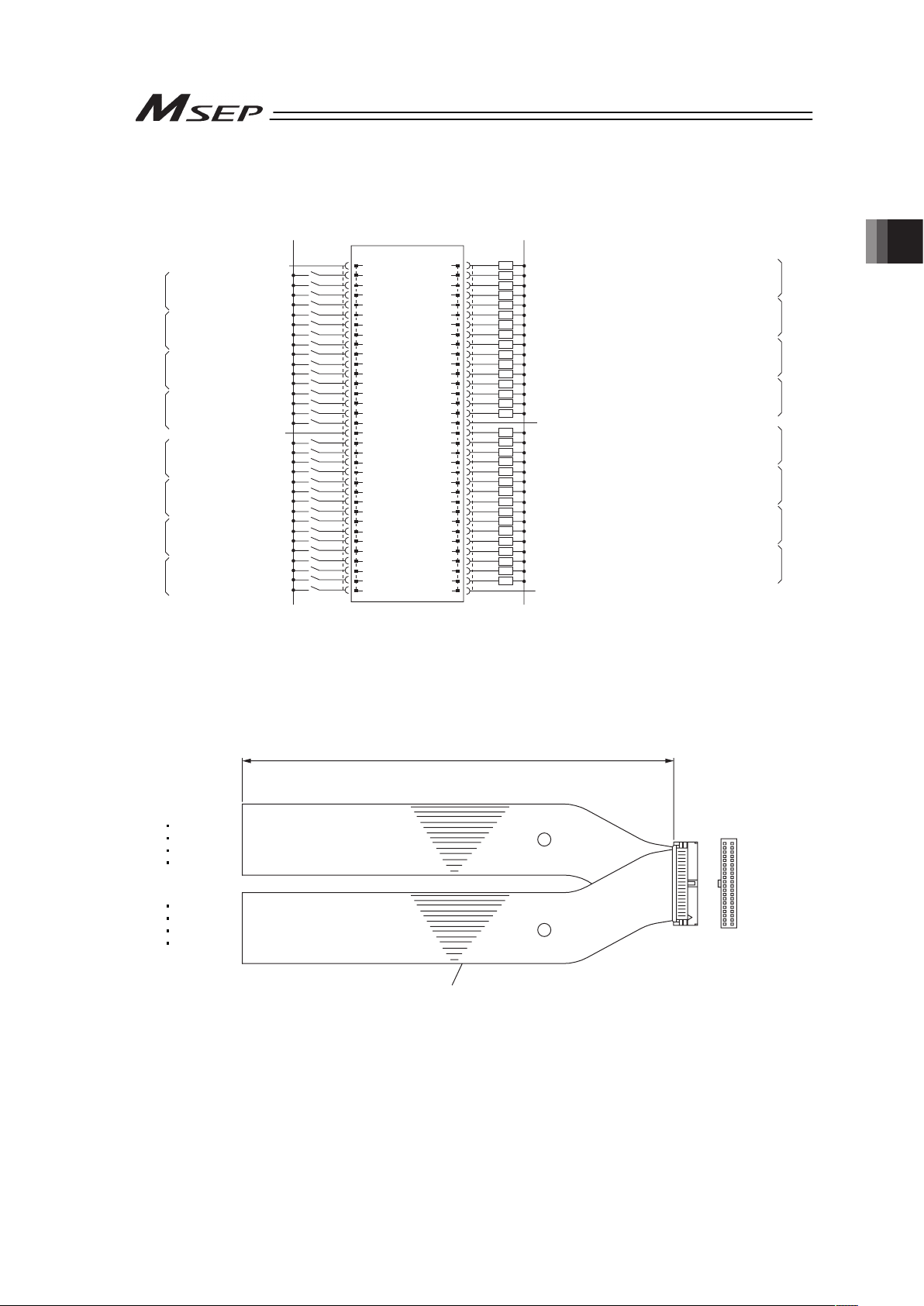

1.4.8 PIO Input and Output Interface

Input section Output section

Input Voltage

24V DC r10%

Load Voltage

24V DC r10%

Input Current 5mA 1 circuit

Peak Load

Electric Current

50mA 1 circuit

ON/OFF

voltage

ON voltage MIN. 18V DC

OFF voltage MAX. 6V DC

Leak Current MAX 2mA/1 point

Specification

External circuit insulation with Photocoupler

NPN

Internal

Power Source

680

5.6K

P24

MSEP

Input

Terminal

External

Power Source

24V DC

15

P24

N

MSEP

Internal

Power Source

External

Power Source

24V DC

Output

Terminal

Load

PNP

680

5.6K

N

MSEP

Internal

Power Source

Input

Terminal

External

Power Source

24V DC

15

P24

N

MSEP

Internal

Power Source

External

Power Source

24V DC

Output

Terminal

Load

I/O Cable Refer to 2.4.7 Connection of PIO

24V NPN Type 0V 24V PNP Type 0V

Pin No.

A1

A2

A3

A16

A17

A18

A19

A32

A33

A34

B1

B2

B3

B16

B17

B18

B19

B32

B33

B34

Pin No.

A1

A2

A3

A16

A17

A18

A19

A32

A33

A34

B1

B2

B3

B16

B17

B18

B19

B32

B33

B34

Load

Load

Load

Load

Page 36

Chapter 1 Specications Check

28

1.5 External Dimensions

1.5.1 Controller Main Unit

123

115

95

111

108

7.5

59 from DIN rail center

10.5

φ5

φ

5

5

5

(4)

4

10.5

Front View

Rear View

Side View

Page 37

Chapter 1 Specications Check

29

1.5.2 Absolute Battery Box

111

108

59 from DIN rail center

10.5

φ

5

φ

5

5

5

(4)

4

123

115

98

Front View

Rear View

Side View

Page 38

Chapter 1 Specications Check

30

1.6 Option

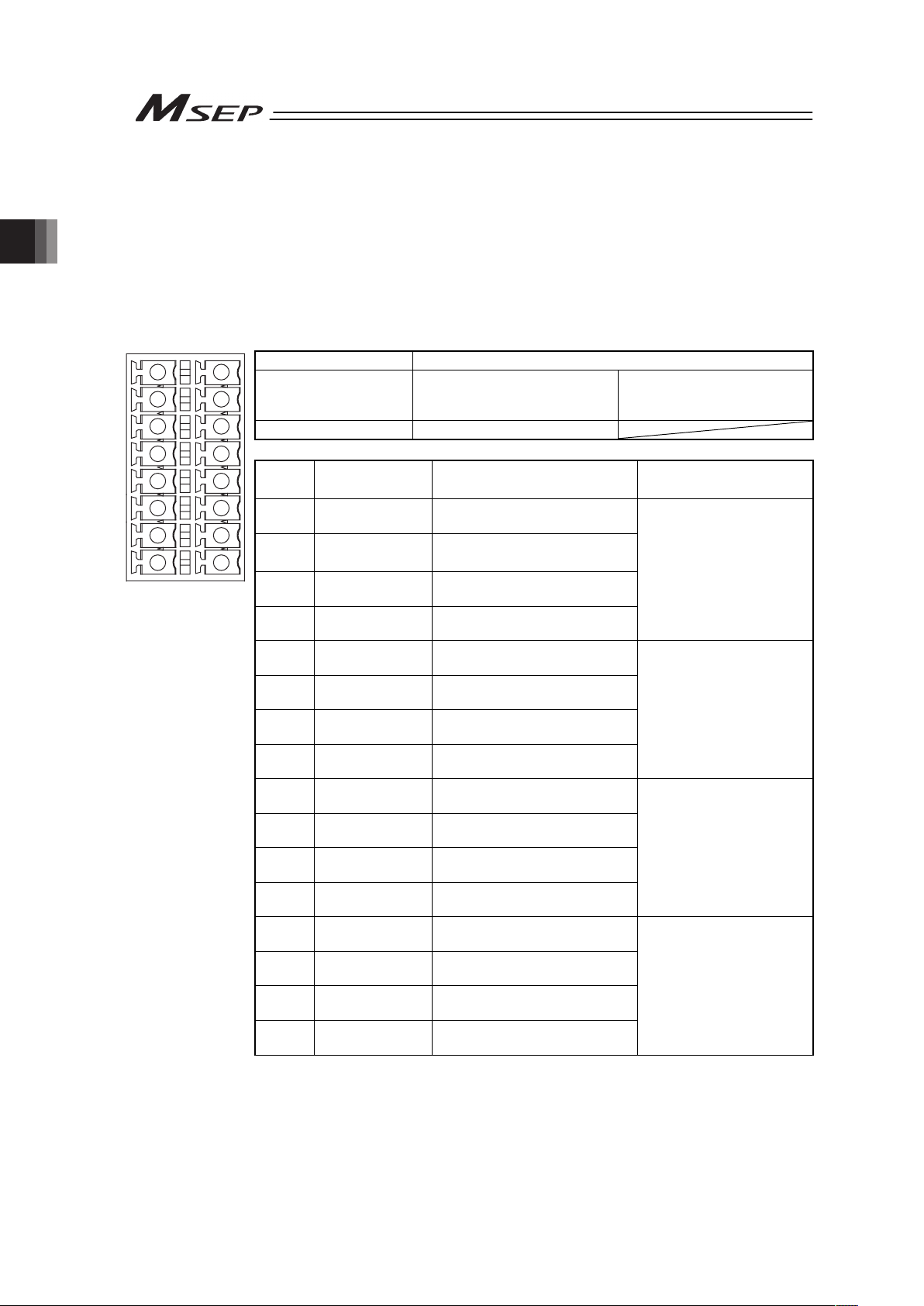

1.6.1 Absolute Battery Box

For Simple Absolute type, an absolute battery box capable for the batteries for 8 axes is used.

The battery is to be attached only to the axes for Simple Absolute Type.

The connection to MSEP controller is to be made with the dedicated cable

(CB-MSEP-AB005).

(Note) Cable length: 0.5m

Front View when Cover ON

#:

#:

#:

#:#:#:#:

#:#: #:#:

#:

#:

#:

#:

#:

5th Axis Battery

(Axis No.4)

7th Axis Battery

(Axis No.6)

1st Axis Battery

(Axis No.0)

3rd Axis Battery

(Axis No.2)

6th Axis Battery

(Axis No.5)

8th Axis Battery

(Axis No.7)

2nd Axis Battery

(Axis No.1)

4th Axis Battery

(Axis No.3)

Front View when Cover OFF

Connector to connect with

MSEP

(Note) Do not apply force

not being

perpendicular to

the connector when

insert or detach the

cable.

Page 39

Chapter 1 Specications Check

31

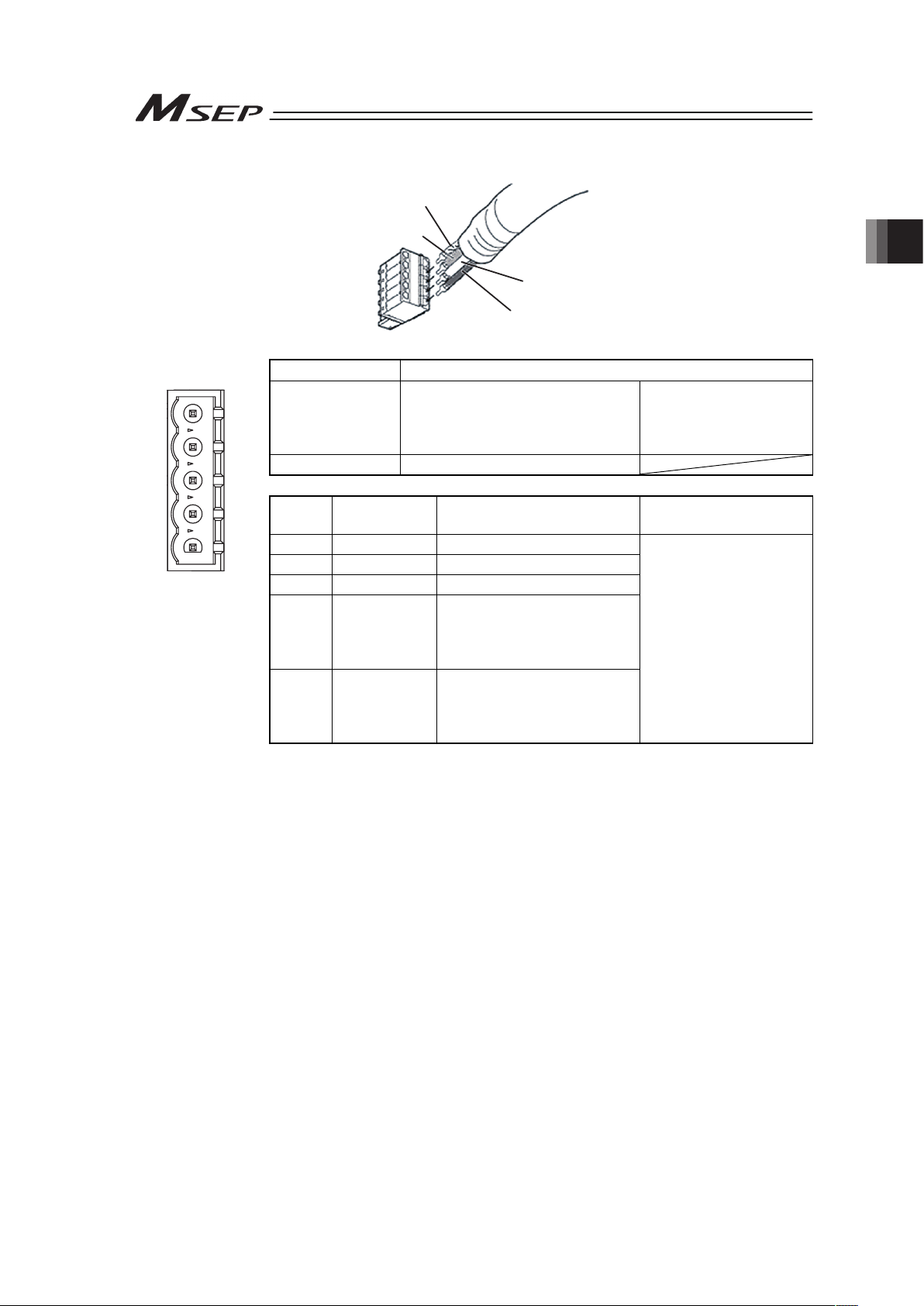

1.6.2 Regenerative Resistor Unit

This unit is necessary to be connected in the case that the regenerative energy cannot be

consumed by the regenerative resistor built into the MSEP controller.

It is necessary to connect the unit in the following case:

φ

4.2

8

12

3

6

9.5

9.5

14

0.6

48

(25) (20)

500

(20) (30)

0.3SQ SPMCU-2(K) (Kaneko Cord)

Cable Diameter φ4.6

2.8

Rectangular Wire-wound Resistor:

BGR10THA12RJ (KOA)

Condition to Require Regenerative Units

Number of Connected Actuator 3 to 8 units of high acceleration/deceleration type

actuators

Number of Regenerative Unit 1

Caution: The regenerative resistor consumes regenerative current and converts it to heat.

Therefore, the temperature may get high in some operational conditions.

Attach on the metal part of the device with a screw to radiate the heat.

Page 40

Chapter 1 Specications Check

32

1.7 Installation and Storage Environment

This product is capable for use in the environment of pollution degree 2*1 or equivalent.

*1 Pollution Degree 2 : Environment that may cause non-conductive pollution or transient

conductive pollution by frost (IEC60664-1)

[1] Installation Environment

Do not use this product in the following environment.

x Location where the surrounding air temperature exceeds the range of 0 to 40qC

x Location where condensation occurs due to abrupt temperature changes

x Location where relative humidity exceeds 85%RH

x Location exposed to corrosive gases or combustible gases

x Location exposed to significant amount of dust, salt or iron powder

x Location subject to direct vibration or impact

x Location exposed to direct sunlight

x Location where the product may come in contact with water, oil or chemical droplets

x Environment that blocks the air vent [Refer to 1.8 Noise Elimination and Mounting Method]

When using the product in any of the locations specified below, provide a sufficient shield.

x Location subject to electrostatic noise

x Location where high electrical or magnetic field is present

x Location with the mains or power lines passing nearby