Page 1

X-axis Linear Servo Type Cartesian Robot

Assembly Procedures

Thank you for purchasing an IAI product.

Assemble your product correctly by referring to these Assembly Procedures.

First Edition

LSA (Large Size Linear Servo Actuator) + ISA confi guration unit

Number of

No.

confi gured axes

1 2 axes ICSPA2-B1L

2 3 axes Z-axis base mount ICSPA3-B1L

3 3 axes Z-axis slider mount ICSPA3-B1L

4 4 axes ICSPA4-B2L1H GMM07-070

5 6 axes Z-axis base mount ICSPA6-B2L1HB3H (M) GMM07-071

6 6 axes Z-axis slider mount ICSPA6-B2L1HS3M GMM07-072

Z-axis installation method

Model Drawing No.

□

H GMM07-067

□

HB3H (M) GMM07-068

□

HS3M GMM07-069

X-axis Linear Servo Type Cartesian Robot – High-precision 2-axis Specification

[Model]

ICSPA2-B1L H

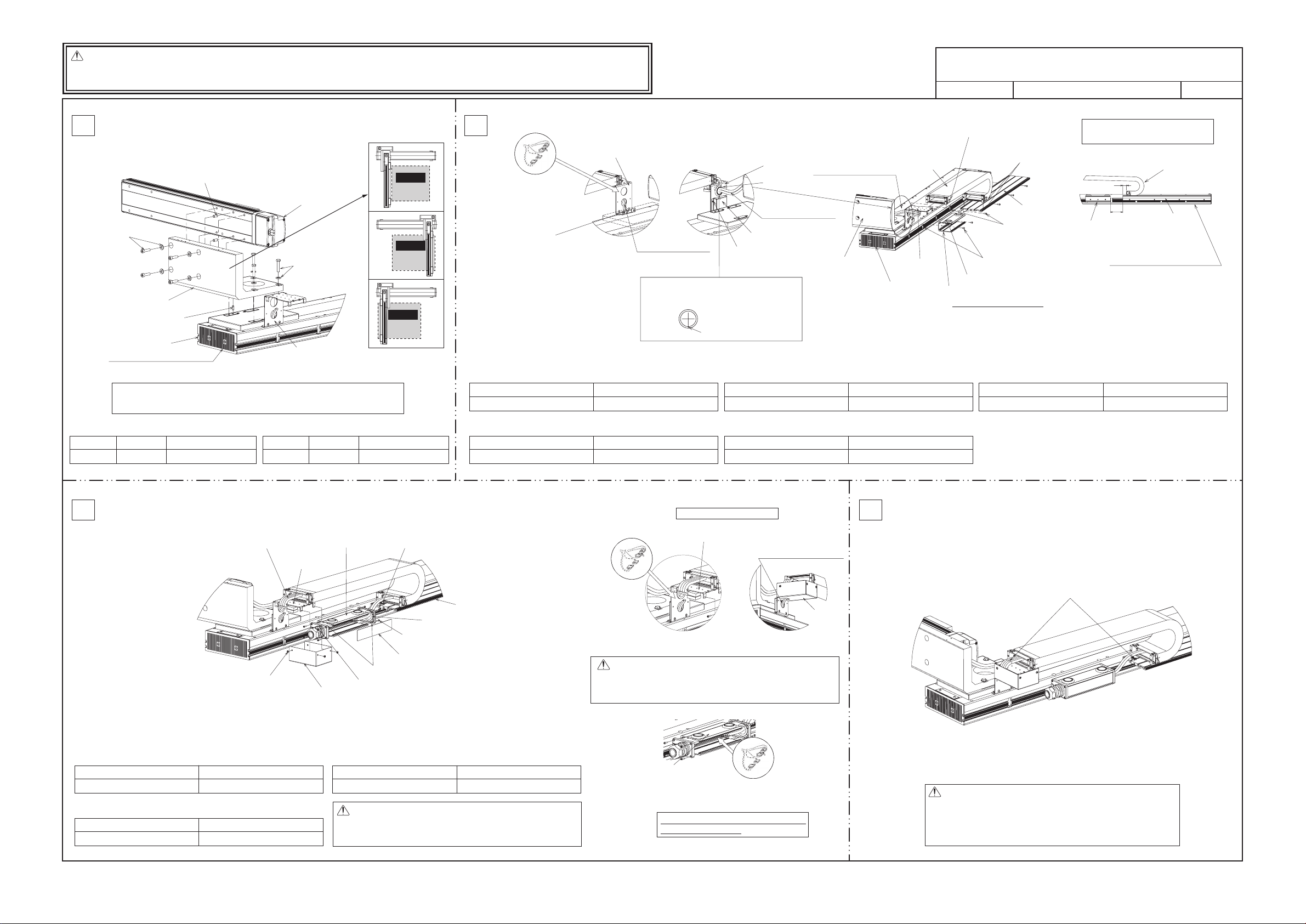

[1] XY configuration direction

[1] XY configuration directions

Configuration

direction: 1

(Range of operation)

Configuration

direction: 3

(Y-axis installed

on opposite side)

(Range of operation)

Configuration

direction: 2

(Reverse of 1)

(Range of operation)

Configuration

direction: 4

(Reverse of 3)

(Range of operation)

[Assembled parts]

[1] XY bracket [2] Guide rail [3] Cable track

[4] Connector box [5] Connector cover

[7] Joint cover

[8] Grommet with film

[Constituent axes]

Constituent axis

X-axis

LSA-W21SS-I-400- (stroke) -T2-L-

Y-axis

ISPA-MYM-I-200-20- (stroke) -T2-AQ

*

Either of NT1 (for configurations 1 and 3) or

NT2 (for configurations 2 and 4)

comes to in the model code above.

Model

[10] Metal cover

[Assembly Procedure] Drawing No.: GMM07-067

[6] Box cover

[9]

Controller-actuator

cable with cable fix cap

X-axis Linear Servo Type Cartesian Robot – High-precision 3-axis Specification,

X-axis Linear Servo Type Cartesian Robot – High-precision 3-axis Specification,

Z-axis Base Mount

[Model] [Model]

ICSPA3-B1L HB3H (M)

H: Z-axis high-speed type

M: Z-axis medium-speed type

[1] XY configuration direction

[1] XY configuration directions

Configuration

direction: 1

(Range of operation)

Configuration

direction: 3

(Y-axis installed

on opposite side)

(Range of operation)

Configuration

direction: 2

(Reverse of 1)

(Range of operation)

Configuration

direction: 4

(Reverse of 3)

(Range of operation)

[Constituent axes]

Constituent axis

X-axis

LSA-W21SS-I-400- (stroke) -T2-L-

Y-axis

ISPA-MYM-I-200-20- (stroke) -T2-AQ

Z-axis

*

ISPA-MXM-I-200-20<10>- (stroke) -T2-AQ-B

Either of NT1 (for configurations 1 and 3) or

NT2 (for configurations 2 and 4)

comes to in the model code above.

Model

[Assembled parts]

[11] YZ

[1] XY

bracket

[4]

Connector

box 1

[7] Joint

cover 1

[10] Metal

cover

[2] Guide

rail

[5]

Connector

cover

[8] Grommet

with film

[3] Cable

track 1

[6] Box

cover 1

[9] Controller-actuator

cable

with cable

fix cap

mounting bracket 2

plate

[14] Track

[17] Box

cover 2

[12] Track

mounting plate

[15] Cable

track 2

[18] Joint

cover 2

support bracket

[16] Connector

[Assembly Procedure] Drawing No.: GMM07-068

[13] Track

box 2

ICSPA3-B1L HS3M

[1] XY configuration directions

[Constituent axes]

Constituent axis

X-axis

Y-axis

Z-axis

*

Either of NT1 (for configurations 1 and 3) or

NT2 (for configurations 2 and 4)

comes to in the model code above.

Z-axis Slider Mount

M: Z-axis medium-speed type

[1] XY configuration direction

Configuration

direction: 1

(Range of operation)

Configuration

direction: 3

(Y-axis installed

on opposite side)

(Range of operation)

Model

LSA-W21SS-I-400- (stroke) -T2-L-

ISPA-MYM-I-200-20- (stroke) -T2-AQ

ISPA-MZM-I-200-10- (stroke) -T2-AQ-B-NM

Configuration

direction: 2

(Reverse of 1)

(Range of operation)

Configuration

direction: 4

(Reverse of 3)

(Range of operation)

[Assembled parts]

[11] YZ

[1] XY

bracket

[4]

Connector

box 1

[7] Joint

cover 1

[10] Metal

cover

[2] Guide

rail

[5]

Connector

cover

[8] Grommet

with film

[3] Cable

track 1

[6] Box

cover 1

[9] Controller-actuator

cable

with cable

fix cap

mounting bracket 2

[17] Connector

bracket

[14] Track

box 2

[12] Track

mounting plate

[15] Track

mounting bracket 3

[18] Box

cover 2

support bracket

[Assembly Procedure] Drawing No.: GMM07-069

[13] Track

[16] Cable

track 2

[19] Joint

cover 2

X-axis Linear Servo Type Cartesian Robot – High-precision 4-axis Specification

[Model]

ICSPA4-B2L 1 H

[1] XY configuration direction

[Assembled parts]

[1] XY bracket [3] Guide rail[2] XY bracket

[1] XY configuration directions

[4] Cable track [5] Connector cover

Configuration direction: 1

(Range of operation)

[7] Wiring box cover

[8] Grommet with film

[Constituent axes]

Constituent axis

X-axis

Y1-axis

Y2-axis

LSA-W21SM-I-400- (stroke) -T2-L-NT1

ISPA-MYM-I-200-20- (stroke) -T2-AQ

ISPA-MYM-I-200-20- (stroke) -T2-AQ

Model

[10] Metal cover

[Assembly Procedure] Drawing No.: GMM07-070

[6] Wiring box bracket

Controller-actuator

[9]

cable with cable fix cap

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z-axis Base Mount

[Model]

ICSPA6-B2L 1 HB3H (M)

H: Z-axis high-speed type

M: Z-axis medium-speed type

[1] XY configuration direction

[Assembled parts]

[1] XY

bracket

[2] XY

bracket

[3] Guide

rail

[11] YZ

plate

[12] Track

mounting plate

[1] XY configuration directions

[14] Track

[Constituent axes]

Constituent axis

LSA-W21SM-I-400- (stroke) -T2-L-NT1

X-axis

ISPA-MYM-I-200-20- (stroke) -T2-AQ

Y1-axis

ISPA-MYM-I-200-20- (stroke) -T2-AQ

Y2-axis

ISPA-MXM-I-200-20<10>- (stroke) -T2-AQ-B

Z1-axis

ISPA-MXM-I-200-20<10>- (stroke) -T2-AQ-B

Z2-axis

Model

Configuration direction: 1

(Range of operation)

[4] Cable

track 1

[7] Wiring

box cover

[10] Metal

cover

[5] Connector

[8] Grommet

cover

with film

[6] Wiring

box bracket

[9] Controller-actuator

cable

with cable

fix cap

mounting bracket 2

[Assembly Procedure] Drawing No.: GMM07-071

[17] Box

cover

[15] Cable

track 2

[18] Joint

cover

[13] Track

support bracket

[16] Connector

box

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z-axis Slider Mount

[Model]

ICSPA6-B2L 1 HS3M

M: Z-axis medium-speed type

[1] XY configuration direction

[Assembled parts]

[1] XY

bracket

[2] XY

bracket

[3] Guide

rail

[11] YZ

bracket

[12] Track

mounting plate

[1] XY configuration directions

[4] Cable

[Constituent axes]

Constituent axis

LSA-W21SM-I-400- (stroke) -T2-L-NT1

X-axis

Y1-axis

ISPA-MYM-I-200-20- (stroke) -T2-AQ

Y2-axis

ISPA-MYM-I-200-20- (stroke) -T2-AQ

Z1-axis

ISPA-MZM-I-200-10- (stroke) -T2-AQ-B-NM

Z2-axis

ISPA-MZM-I-200-10- (stroke) -T2-AQ-B-NM

Model

Configuration direction: 1

(Range of operation)

track 1

[7] Wiring

box cover

[10] Metal

cover

[5] Connector

[8] Grommet

with film

cover

[6] Wiring

box bracket

[9] Controller-actuator

cable

with cable

fix cap

[Assembly Procedure] Drawing No.: GMM07-072

[14] Track

mounting bracket 2

[17] Connector

box

[15] Track

mounting bracket 3

[18] Box

cover

[13] Track

support bracket

[16] Cable

track 2

[19] Joint

cover

Manual No.: ME0197-1A

Page 2

Caution: l Although each part has been chamfered to remove sharp edges, exercise due caution during

Hexagonal bolt M8s40

+ high-tension washer

(4 sets)

Parallel pin (1 pc or 2 pcs)

Hexagonal socket head bolt

M8s30

+ high-tension washer

(4 sets)

Parallel pin (2 pcs)

Y-axis: ISPA

[1] XY bracket

X-axis: LSA

X-axis base, reamed-hole side

Track mounting bracket

(Already attached to LSA)

In the case of configuration direction types 2 to 4,

the actuator and bracket directions are different.

(Reverse of 1)

Configuration

direction: 2

(Range of

operation)

Hexagonal socket head bolt M4s10

Hexagonal socket head bolt M4

s

10

+ hexagonal nut (2 sets)

Flange socket

(hexagonal socket head type) M4

s

10

+ hexagonal nut (4 sets)

Hexagonal socket head bolt M4

s

6

+ hexagonal nut (2 sets)

Hexagonal socket head bolt

M3

s

3 (4 pcs)

Cable Tie Mount MB1

(Manufacturer: HellermannTyton)

+ M3 hex socket flat head cap screw

s

5 pcs (1 set)

Guide the Y-axis actuator

cables through the hole.

[3] Cable track

[2] Guide rail

[3] Cable track

[4] Connector box

[2] Guide rail

30

100

[4] Connector box

[8] Grommet with film

Track mounting

bracket

X-axis: LSA

[1] XY bracket

Track mounting bracket

[8] Grommet with film

X-axis motor and encoder

cables.

Guide the cables to the

other side through the hole

* Affix cables using Insulok.

[5] Connector cover

Y-axis actuator cable

Track mounting bracket

Affixing positions of guide rail [2],

cable track [3] and connector box [4]

Make a cut in the film on the grommet to put

through the cables, and then attach it to

the track mounting bracket.

X axis: Joint of the motor

and encoder cables on

LSA side and the cable

connectors coming out of

the X-axis cable track

(on the back side)

Make a cross cut.

Align the guide rail [2] surface

with the end face of the base.

Put the X-axis motor and

encoder cables into the

box through the opening.

X-axis Linear Servo Type Cartesian Robot – High-precision 2-axis Specification

ICSPA2-BIL□H

[Tools] Allen wrench, spanner wrench

[Installation of X-axis: LSA on XY bracket [1]] [Installation of Y-axis: ISPA on XY bracket [1]] [Installation of X-axis: LSA side of guide rail [2] in the upper T-slot]

[Installation of cable track [3] on track mounting bracket]

[Installation of guide rail [2] for cable track [3] in T-slot]

[Installation of X-axis: LSA side of connector box [4] in the upper T-slot][Cable Tie Mount Attachment to Track Mounting Bracket]

[[5] Connector cover Attachment to Track Mounting Bracket]

Note: To ensure squareness between the X-axis and Y-axis, insert one parallel pin.

Adjust the angle between the X-axis and Y-axis to the right angle, and then

mount the hexagonal bolts.

1

3

2

4

GMM07-067 1/1

Drawing No.

Parallel pin

Hexagonal bolt

Tightening torque

F6h7s15 M8s40mm 306kgfvcm/2997Nvcm

Parallel pin

Hexagonal socket

head bolt

Tightening torque

F8h7s18 M8s30mm 306kgfvcm/2997Nvcm

(Y-axis installed

on opposite side)

Configuration

direction: 3

(Range of

operation)

(Reverse of 3)

Configuration

direction: 4

(Range of

operation)

Tightening torque

M3s5mm 15.8kgfvcm/154Nvcm

Hexagonal socket head bolt

Tightening torque

M3s3mm 15.8kgfvcm/154Nvcm

Hexagonal socket head bolt

Tightening torque

M4s6mm 18.0kgfvcm/176Nvcm

Hexagonal socket head bolt Tightening torque

M4s10mm 36.7kgfvcm/359Nvcm

Hexagonal socket head bolt

Tightening torque

M4s10mm 18.0kgfvcm/176Nvcm

Flange socket

(hexagonal socket head type)

[6] Box cover

[8] Grommet with film

[7] Joint cover

[9] Controller-actuator cable with cable fix cap

[10] Metal cover

Track mounting

bracket

[4] Connector box

[2] Guide rail

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt

+ hexagonal nut (1 set)

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt (1 set)

Thin-head bolt M3

s

12 (4 pcs)

Hexagonal socket head bolt M3

s

12 (8 pcs)

[Installation of box cover 1 [6] on connector box [4]]

Tightening torque

M3s12mm 5.51kgfvcm/54Nvcm

Hexagonal socket head bolt

[Installation of tie-mount on track mounting bracket]

[Cable Tie Mount Attachment to T-Slot of [2] Guide Rail]

Tightening torque

M4s6mm 11.7kgfvcm/114Nvcm

Hexagonal socket head button bolt

[Installation of metal cover [10] on track mounting bracket]

Tightening torque

M3s4mm 7.12kgfvcm/69.8Nvcm

Thin-head bolt

Track mounting bracket

[10] Metal

cover

Connector joint

for Y-axis: ISPA

M cable and

PG cable

(LS cable)

Cable connector connection

[4] Connector box

Connector jo in t fo r ca ble inside tr ac k

and contro ll er -a ct ua to r cable

Make sure the numbers on the connectors

to be connected match.

Caution: The cables for X-axis (axis 1) and Y-axis (axis 2) are

placed in tracks. Install each cable correctly.

[Cable markings]

v X-axis (axis 1): 1 v Y-axis (axis 2): 2

Secure the cables using wraps.

Caution: Secure the wires to prevent the cables and connectors

from contacting each axis when the axis is moved over its

entire stroke.

When manually moving the actuator with brake, connect

the controller, supply the power, and then release the brake

release switch (by turning the switch to the RLS side).

Attach to the upper T-slot.

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

the assembly to prevent injury. If necessary, wear gloves or other protective gears.

Exercise due caution during the assembly to prevent pinching of hands and ngers.

l

* This assembly procedure applies to conguration direction 1. If other conguration direction such as 2, 3 or 4 is used, the actuator and bracket directions vary. However, you can still use this assembly drawing as a reference.

Page 3

Caution: z Although each part has been chamfered to remove sharp edges, exercise due caution during

the assembly to prevent injury. If necessary, wear gloves or other protective gears.

Exercise due caution during the assembly to prevent pinching of hands and fi ngers.

z

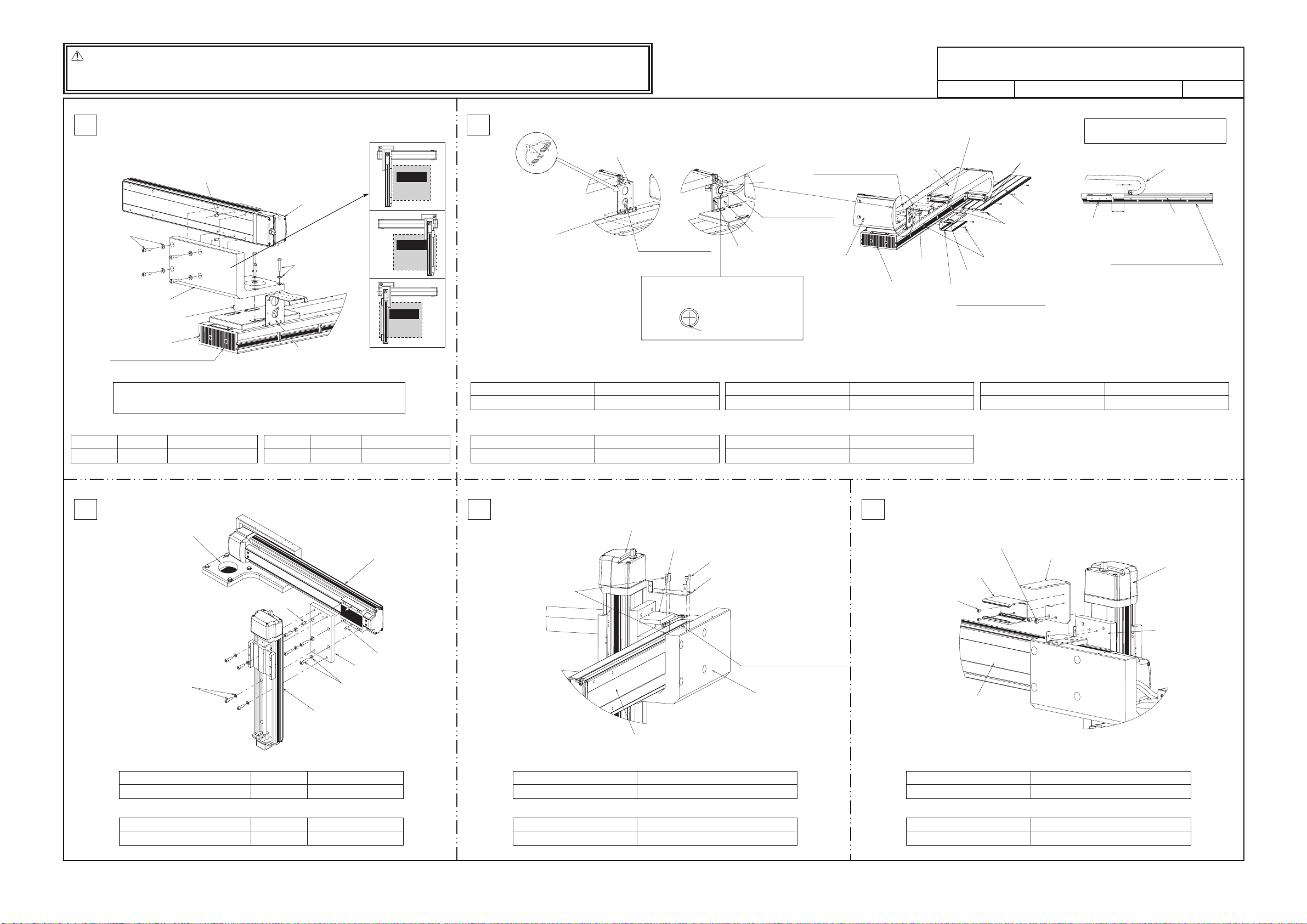

X-axis Linear Servo Type Cartesian Robot – High-precision 3-axis Specification,

Z Base Mount

ICSPA3-B1L□HB3H (M)

Drawing No.

GMM07-068 1/2

[Tools] Allen wrench, spanner wrench

1

In the case of configuration direction types 2 to 4,

the actuator and bracket directions are different.

Parallel pin (2 pcs)

Y-axis: ISPA

Hexagonal socket head bolt

M8s30

+ high-tension washer

(4 sets)

[1] XY bracket

Parallel pin (1 pc or 2 pcs)

X-axis: LSA

X-axis base, reamed-hole side

Note: To ensure squareness between the X-axis and Y-axis, insert one parallel pin.

Adjust the angle between the X-axis and Y-axis to the right angle, and then

mount the hexagonal bolts.

[Installation of X-axis: LSA on XY bracket [1]] [Installation of Y-axis: ISPA on XY bracket [1]]

Parallel pin

F6h7s15 M8s40mm 306kgfvcm/2997Nvcm

Hexagonal bolt

Tightening torque

Hexagonal bolt M8s40

+ high-tension washer

(4 sets)

Track mounting bracket

(Already attached to LSA)

Parallel pin

F8h7s18 M8s30mm 306kgfvcm/2997Nvcm

Hexagonal socket

head bolt

Tightening torque

Configuration

direction: 2

(Reverse of 1)

(Range of

operation)

Configuration

direction: 3

(Y-axis installed

on opposite side)

(Range of

operation)

Configuration

direction: 4

(Reverse of 3)

(Range of

operation)

2

Track mounting bracket

X axis: Joint of the motor

and encoder cables on

LSA side and the cable

connectors coming out of

the X-axis cable track

(on the back side)

Cable Tie Mount MB1

(Manufacturer: HellermannTyton)

+ M3 hex socket flat head cap screw

s

5 pcs (1 set)

* Affix cables using Insulok.

Hexagonal socket head bolt

M3s5mm 15.8kgfvcm/154Nvcm

[[5] Connector cover Attachment to Track Mounting Bracket]

Hexagonal socket head bolt

M3s3mm 15.8kgfvcm/154Nvcm

X-axis motor and encoder

cables.

Guide the cables to the

other side through the hole

Make a cut in the film on the grommet to put

through the cables, and then attach it to

the track mounting bracket.

Tightening torque

Tightening torque

Track mounting bracket

[5] Connector cover

Hexagonal socket head bolt

s

3 (4 pcs)

M3

Make a cross cut.

[Installation of X-axis: LSA side of connector box 1 [4] in the upper T-slot][Cable Tie Mount Attachment to Track Mounting Bracket]

Hexagonal socket head bolt Tightening torque

[Installation of X-axis: LSA side of guide rail [2] in the upper T-slot]

(hexagonal socket head type)

Hexagonal socket head bolt M4s10

Guide the Y-axis actuator

cables through the hole.

[8] Grommet with film

Y-axis actuator cable

[1] XY bracket

M4s6mm 18.0kgfvcm/176Nvcm

Flange socket

M4s10mm 18.0kgfvcm/176Nvcm

[3] Cable track 1

Track mounting

bracket

X-axis: LSA

Tightening torque

Tightening torque

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

[2] Guide rail

Flange socket

(hexagonal socket head type) M4

+ hexagonal nut (4 sets)

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

[8] Grommet with film

[4] Connector box 1

Attach to the upper T-slot.

[Installation of cable track 1 [3] on track mounting bracket]

[Installation of guide rail [2] for cable track 1 [3] in T-slot]

Hexagonal socket head bolt

Affixing positions of guide rail [2],

cable track 1 [3] and connector box 1 [4]

s

10

[3] Cable track 1

30

100

[4] Connector box 1

s

10

Align the guide rail [2] surface

s

6

with the end face of the base.

M4s10mm 36.7kgfvcm/359Nvcm

[2] Guide rail

3

[1] XY bracket

Hexagonal socket head bolt M8s25

+ M8 dedicated washer (4 sets)

Parallel pin

F8h7s18 M8s30mm 306kgfvcm/2997Nvcm

Parallel pin

F8h7s25 M8s25mm 306kgfvcm/2997Nvcm

Parallel pin (1 pc)

Z-axis: ISPA

[Installation of YZ plate [11] on Y-axis: ISPA]

[Installation of Z-axis: ISPA on YZ plate [11]]

Hexagonal socket

head bolt

Hexagonal socket

head bolt

Tightening torque

Tightening torque

Y-axis: ISPA

Parallel pin (2 pcs)

[11] YZ plate

Hexagonal socket head bolt M8s30

+ flat washer (4 sets)

4

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

[Installation of track support metal [13] on track mounting plate [12]]

Hexagonal socket head bolt Tightening torque

M4s16mm 36.7kgfvcm/359Nvcm

Z-axis: ISPA

[12] Track mounting plate

Hexagonal socket head bolt M4s8 (2 pcs)

s

16

Y-axis: ISPA

[Installation of track support bracket [13] on XY bracket [1]]

[13] Track support bracket

Place the M4 hexagonal nut in

the T slot beforehand to secure

the tie-mount in position.

[1] XY bracket

5

Hexagonal socket head bolt M6s15 (2 pcs)

[16] Connector box 2

Hexagonal socket head bolt

M4

s

5 (2 pcs)

Hexagonal socket head bolt Tightening torque

[Installation of connector box 2 [16] on track mounting bracket 2 [14]]

Hexagonal socket head bolt Tightening torque

[14] Track mounting bracket 2

Z-axis: ISPA

[11] YZ plate

Y-axis: ISPA

[Installation of track mounting bracket 2 [14] on YZ plate [11]]

M6s15mm 126kgfvcm/1234Nvcm

M4s5mm 18.0kgfvcm/176Nvcm

* This assembly procedure applies to confi guration direction 1. If other confi guration direction such as 2, 3 or 4 is used, the actuator and bracket directions vary. However, you can still use this assembly drawing as a reference.

Page 4

X-axis Linear Servo Type Cartesian Robot – High-precision 3-axis Specification,

Z Base Mount

ICSPA3-B1L□HB3H (M)

Drawing No.

GMM07-068 2/2

6

[15] Cable track 2

Hexagonal

socket head

bolt M4

s

12

Hexagonal socket head bolt

M4

s

12

+ hexagonal nut (2 sets)

[13] Track support bracket

Hexagonal socket head bolt M4s8 (2 pcs)

[14] Track mounting bracket 2

Z-axis: ISA, etc.

[16] Connector box 2

[17] Box cover 2

[8] Grommet with film

Hexagonal socket head bolt

s

12 (8 pcs)

M3

[1] XY bracket

[Installation of cable track 2 [15] on track support bracket [13]]

Hexagonal socket head bolt

M4s12mm 36.7kgfvcm/359Nvcm

[Installation of cable track 2 [15] on XY bracket [1]]

Hexagonal socket head bolt

M4s12mm 36.7kgfvcm/359Nvcm

[Installation of cable track 2 [15] on track mounting bracket 2 [14]]

Hexagonal socket head bolt

M4s8mm 36.7kgfvcm/359Nvcm

[Installation of box cover 2 [17] on connector box 2 [16]]

Hexagonal socket head bolt

M3s12mm 5.51kgfvcm/54Nvcm

[18] Joint cover 2

Tightening torque

Tightening torque

Tightening torque

Tightening torque

Cable connector connection

[16]

Connector

box 2

Connector joint for

ISPA M cable and

PG cable (LS cable)

7

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt (1 set)

Thin-head bolt M3

[Installation of box cover 1 [6] on connector box 1 [4]]

Hexagonal socket head bolt

M3s12mm 5.51kgfvcm/54Nvcm

[Installation of tie-mount on track mounting bracket]

[Cable Tie Mount Attachment to T-Slot of [2] Guide Rail]

Hexagonal socket head button bolt

M4s6mm 11.7kgfvcm/114Nvcm

s

12 (4 pcs)

Tightening torque

Tightening torque

[4] Connector box 1

Track mounting

bracket

[10] Metal cover

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt

+ hexagonal nut (1 set)

[2] Guide rail

[8] Grommet with film

s

Hexagonal socket head bolt M3

[7] Joint cover 1

[6] Box cover 1

[9] Controller-actuator cable with cable fix cap

[Installation of metal cover [10] on track mounting bracket]

Thin-head bolt

M3s4mm 7.12kgfvcm/69.8Nvcm

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

12 (8 pcs)

Tightening torque

Cable connector connection

Track mounting bracket

Connector joint

for Y-axis: ISPA

M cable and

PG cable

(LS cable)

Caution: The cables for X-axis (axis 1), Y-axis (axis 2) and Z-axis

(axis 3) are placed in tracks. Install each cable correctly.

[Cable markings]

v X-axis (axis 1): 1 v Y-axis (axis 2): 2 v Z-axis (axis 3): 3

[4] Connector box 1

Connector joint for cable inside track

and controller-actuator cable

Make sure the numbers on the connectors

to be connected match.

Put the X-axis motor and

encoder cables into the

box through the opening.

[10] Metal

cover

8

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt

M4

Y-axis: ISPA

[13] Track support bracket

s

6 (2 sets)

[1] XY bracket

[Installation of tie-mount in track mounting bracket 2 [14]]

[Installation of tie-mount on track support bracket [13]]

[Installation of tie-mount in T slot of Y-axis: ISPA

[Installation of tie-mount on track mounting bracket]

Hexagonal socket head button bolt

M4s6mm 11.7kgfvcm/114Nvcm

[14] Track mounting bracket 2

Tie-mount KR5G5

(by HellermannTyton)

+ hexagonal socket head button bolt M4

+ hexagonal nut (1 set)

Install in the T slot of the Y-axis.

Track mounting bracket

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4

Tightening torque

s

6 (1 set)

9

Z-axis cables X-axis, Y-axis cables

s

6

Secure the cables using wraps.

Secure the cables using wraps.

Secure the cables using wraps.

Caution: Secure the wires to prevent the cables and connectors

Secure the cables using wraps.

from contacting each axis when the axis is moved over its

entire stroke.

When manually moving the actuator with brake, connect

the controller, supply the power, and then release the brake

release switch (by turning the switch to the RLS side).

Page 5

Caution: z Although each part has been chamfered to remove sharp edges, exercise due caution during

the assembly to prevent injury. If necessary, wear gloves or other protective gears.

Exercise due caution during the assembly to prevent pinching of hands and fi ngers.

z

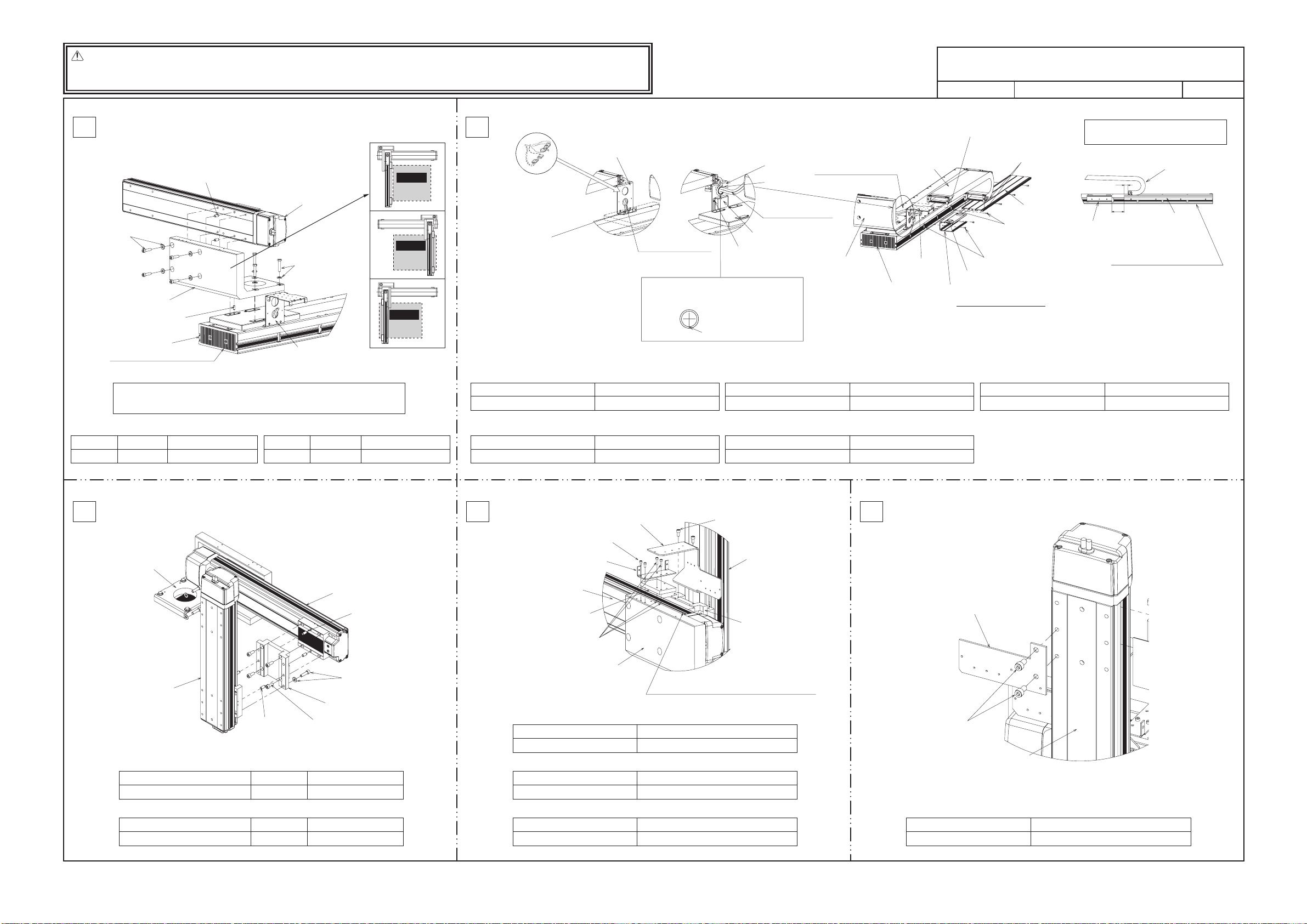

X-axis Linear Servo Type Cartesian Robot – High-precision 3-axis Specification,

Z Slider Mount

ICSPA3-B1L□HS3M

Drawing No.

GMM07-069 1/2

[Tools] Allen wrench, spanner wrench

1

In the case of configuration direction types 2 to 4,

the actuator and bracket directions are different.

Parallel pin (2 pcs)

Y-axis: ISPA

Hexagonal socket head bolt

M8s30

+ high-tension washer

(4 sets)

[1] XY bracket

Parallel pin (1 pc or 2 pcs)

X-axis: LSA

X-axis base, reamed-hole side

Note: To ensure squareness between the X-axis and Y-axis, insert one parallel pin.

Adjust the angle between the X-axis and Y-axis to the right angle, and then

mount the hexagonal bolts.

[Installation of X-axis: LSA on XY bracket [1]] [Installation of Y-axis: ISPA on XY bracket [1]]

Parallel pin

F6h7s15 M8s40mm 306kgfvcm/2997Nvcm

Hexagonal bolt

Tightening torque

Hexagonal bolt M8s40

+ high-tension washer

(4 sets)

Track mounting bracket

(Already attached to LSA)

Parallel pin

F8h7s18 M8s30mm 306kgfvcm/2997Nvcm

Hexagonal socket

head bolt

Tightening torque

Configuration

direction: 2

(Reverse of 1)

(Range of

operation)

Configuration

direction: 3

(Y-axis installed

on opposite side)

(Range of

operation)

Configuration

direction: 4

(Reverse of 3)

(Range of

operation)

2

Track mounting bracket

X axis: Joint of the motor

and encoder cables on

LSA side and the cable

connectors coming out of

the X-axis cable track

(on the back side)

Cable Tie Mount MB1

(Manufacturer: HellermannTyton)

+ M3 hex socket flat head cap screw

s

5 pcs (1 set)

* Affix cables using Insulok.

Hexagonal socket head bolt

M3s5mm 15.8kgfvcm/154Nvcm

[[5] Connector cover Attachment to Track Mounting Bracket]

Hexagonal socket head bolt

M3s3mm 15.8kgfvcm/154Nvcm

X-axis motor and encoder

cables.

Guide the cables to the

other side through the hole

Tightening torque

Tightening torque

Track mounting bracket

[8] Grommet with film

Y-axis actuator cable

[5] Connector cover

Hexagonal socket head bolt

s

3 (4 pcs)

M3

Make a cut in the film on the grommet to put

through the cables, and then attach it to

the track mounting bracket.

Make a cross cut.

[Installation of X-axis: LSA side of connector box 1 [4] in the upper T-slot][Cable Tie Mount Attachment to Track Mounting Bracket]

Hexagonal socket head bolt Tightening torque

M4s6mm 18.0kgfvcm/176Nvcm

[Installation of X-axis: LSA side of guide rail [2] in the upper T-slot]

Flange socket

(hexagonal socket head type)

M4s10mm 18.0kgfvcm/176Nvcm

Guide the Y-axis actuator

cables through the hole.

[1] XY bracket

X-axis: LSA

Tightening torque

Tightening torque

Hexagonal socket head bolt M4s10

[3] Cable track 1

Track mounting

bracket

+ hexagonal nut (2 sets)

[8] Grommet with film

[4] Connector box 1

Attach to the upper T-slot.

Affixing positions of guide rail [2],

cable track 1 [3] and connector box 1 [4]

Hexagonal socket head bolt M4

[2] Guide rail

Flange socket

(hexagonal socket head type) M4

+ hexagonal nut (4 sets)

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

[Installation of cable track 1 [3] on track mounting bracket]

[Installation of guide rail [2] for cable track 1 [3] in T-slot]

Hexagonal socket head bolt

M4s10mm 36.7kgfvcm/359Nvcm

s

10

30

100

[4] Connector box 1

s

10

Align the guide rail [2] surface

s

6

with the end face of the base.

[3] Cable track 1

[2] Guide rail

3

[1] XY bracket

Z-axis: ISPA

Parallel pin Tightening torque

Parallel pin

Y-axis: ISPA

Parallel pin (2 pcs)

Hexagonal bolt M8

+ flat washer (4 sets)

[11] YZ bracket

Parallel pin (2 pcs)

[Installation of YZ bracket [11] on Y-axis: ISPA]

Hexagonal bolt

F8h7s18 M8s35mm 117kgfvcm/1148Nvcm

[Installation of Z-axis: ISPA on YZ bracket [11]]

F8h7s18 M8s40mm 306kgfvcm/2997Nvcm

Hexagonal socket

head bolt

Hexagonal socket head bolt M8

(4 pcs)

Tightening torque

4

Hexagonal socket head bolt

M4

[13] Track support bracket

[12] Track mounting plate

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

s

35

s

40

[Installation of track support bracket [13] and track mounting plate [12] on Y-axis: ISPA]

[14] Track mounting bracket 2

s

8 (2 pcs)

Y-axis: ISPA

s

16

[1] XY bracket

Hexagonal socket head bolt Tightening torque

M4s16mm 36.7kgfvcm/359Nvcm

[Installation of track support bracket [13] on XY bracket [1]]

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

[Installation of track mounting bracket 2 [14] on YZ bracket [11]]

Hexagonal socket head bolt Tightening torque

M6s12mm 126kgfvcm/1234Nvcm

Place the M4 hexagonal nut (1 pc) in the T slot

beforehand to secure the tie-mount in position.

Hexagonal socket head bolt

M6

s

12 (2 pcs)

Z-axis: ISPA

[11] YZ bracket

5

[15] Track mounting bracket 3

Hexagonal socket head bolt

M8

s

15 (2 pcs)

Z-axis: ISPA

[Installation of track mounting bracket 3 [15] on Z-axis: ISPA]

Hexagonal socket head bolt Tightening torque

M8s15mm 306kgfvcm/2997Nvcm

* This assembly procedure applies to confi guration direction 1. If other confi guration direction such as 2, 3 or 4 is used, the actuator and bracket directions vary. However, you can still use this assembly drawing as a reference.

Page 6

[3] Cable track 1

Hexagonal socket head bolt M4s8

(2 pcs)

Hexagonal socket head bolt M4

s

12

+ hexagonal nut (2 sets)

Hexagonal socket head bolt M4

s

12

(2 pcs)

Hexagonal socket head bolt M4s8 (2 pcs)

Hexagonal socket head bolt M4

s

8 (2 pcs)

Z-axis: ISPA

Y-axis: ISPA

[1] XY bracket

[13] Track support bracket

[14] Track mounting bracket 2

[15] Track mounting bracket 3

[16] Cable track 2

ICSPA3-B1L□HS3M

[Installation of cable track 2 [16] on track mounting bracket 2 [14]]

[Installation of cable track 2 [16] on track mounting bracket 3 [15]]

[Installation of cable track 1 [3] on track mounting bracket 2 [14]]

[Installation of cable track 1 [3] on XY bracket [1]]

[Installation of cable track 1 [3] on track support bracket [13]]

Z-axis cables X-axis, Y-axis cables

Put the X-axis motor and

encoder cables into the

box through the opening.

6

8

7

GMM07-069 2/2

Drawing No.

9

[6] Box cover 1

[8] Grommet with film

[7] Joint cover 1

[9] Controller-actuator cable with cable fix cap

[10] Metal cover

Track mounting

bracket

[4] Connector box 1

[2] Guide rail

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt

+ hexagonal nut (1 set)

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt (1 set)

Thin-head bolt M3

s

12 (4 pcs)

Hexagonal socket head bolt M3

s

12 (8 pcs)

[Installation of metal cover [10] on track mounting bracket]

[Installation of tie-mount on track mounting bracket]

[Cable Tie Mount Attachment to T-Slot of [2] Guide Rail]

[Installation of box cover 1 [6] on connector box 1 [4]]

Tightening torque

M3s4mm 7.12kgfvcm/69.8Nvcm

Thin-head bolt

Tightening torque

M3s12mm 5.51kgfvcm/54Nvcm

Hexagonal socket head bolt

Tightening torque

M4s6mm 11.7kgfvcm/114Nvcm

Hexagonal socket head button bolt

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

Track mounting bracket

[10] Metal

cover

Connector joint

for Y-axis: ISPA

M cable and

PG cable

(LS cable)

[4] Connector box 1

Connector jo in t fo r ca ble inside tr ac k

and contro ll er -a ct ua to r cable

Make sure the numbers on the connectors

to be connected match.

Cable connector connection

Caution: The cables for X-axis (axis 1), Y-axis (axis 2) and Z-axis

(axis 3) are placed in tracks. Install each cable correctly.

[Cable markings]

v X-axis (axis 1): 1 v Y-axis (axis 2): 2 v Z-axis (axis 3): 3

[15] Track mounting bracket 3

KR5G5 tie-mount (by HellermannTyton)

+ hexagonal socket head button bolt M4

s

4 (2 sets)

Z-axis: ISPA

[Installation of tie-mount on track mounting bracket 3 [15]]

Tightening torqueHexagonal socket head button bolt

M4s4mm 11.7kgfvcm/114Nvcm

[14] Track mounting bracket 2

[13] Track support bracket

[1] XY bracket

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4s4 (1 set)

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt

M4s6 (1 set)

KR5G5 tie-mount

(by HellermannTyton)

+ hexagonal socket head

button bolt M4s4 (2 sets)

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4s6 (1 set)

Y-axis: ISPA

Install in the T slot of the Y-axis.

Install on the back side.

[Installation of tie-mount on track mounting bracket 2 [14]]

Tightening torqueHexagonal socket head button bolt

M4s4mm 11.7kgfvcm/114Nvcm

[18] Box cover 2

[17] Connector box 2

[8] Grommet with film

[19] Joint cover 2

Hexagonal socket head bolt M4s6

+ hexagonal nut (2 sets)

Hexagonal socket head bolt

M3

s

12 (8 pcs)

Connector joint for

ISPA M cable and

PG cable (LS cable)

[Installation of connector box 2 [17] on Z-axis: ISPA]

[Installation of box cover 2 [18] on connector box 2 [17]]

Tightening torqueHexagonal socket head bolt

M3s12mm 5.51kgfvcm/54Nvcm

Tightening torqueHexagonal socket head bolt

M4s6mm 18.0kgfvcm/176Nvcm

[Installation of tie-mount on track support bracket [13]]

[Installation of tie-mount in T slot of Y-axis: ISPA]

Tightening torqueHexagonal socket head button bolt

M4s6mm 11.7kgfvcm/114Nvcm

Z-axis: ISPA

[15] Track mounting bracket 3

Secure the cables using wraps.

Secure the cables using wraps.

Wire the cable in a manner

preventing contact with the Z-axis.

Secure the cables using wraps.

Y-axis: ISPA

[1] XY bracket

Secure the cables using wraps.

Secure the cables using wraps.

[14] Track mounting bracket 2

[13] Track support bracket

Secure the cables using wraps.

Caution: Secure the wires to prevent the cables and connectors

from contacting each axis when the axis is moved over its

entire stroke.

When manually moving the actuator with brake, connect

the controller, supply the power, and then release the brake

release switch (by turning the switch to the RLS side).

Hexagonal socket head bolt Tightening torque

M4s12mm 36.7kgfvcm/359Nvcm

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

Hexagonal socket head bolt Tightening torque

M4s12mm 36.7kgfvcm/359Nvcm

X-axis Linear Servo Type Cartesian Robot – High-precision 3-axis Specification,

Z Slider Mount

Page 7

Caution: z Although each part has been chamfered to remove sharp edges, exercise due caution during

the assembly to prevent injury. If necessary, wear gloves or other protective gears.

[Tools] Allen wrench, spanner wrench

Exercise due caution during the assembly to prevent pinching of hands and fi ngers.

z

1

Parallel pin (2 pcs)

Hexagonal socket head bolt

M8x30

+ high-tension washer

(4 sets)

[1] XY bracket

Parallel pin (1 pc or 2 pcs)

X-axis: LSA

X-axis base, reamed-hole side

Note: To ensure squareness between the X-axis and Y-axis, insert one parallel pin.

Adjust the angle between the X-axis and Y-axis to the right angle, and then

mount the hexagonal bolts.

[Installation of X-axis: LSA on XY bracket [1]] [Installation of Y1-axis: ISPA on XY bracket [1]]

Parallel pin Hexagonal bolt Tightening torque

F6h7s15 M8s40mm 306kgfvcm/2997Nvcm

Parallel pin

Assembly of Y1-axis side

Y1-axis: ISPA

Hexagonal bolt M8x40

+ high-tension washer

(4 sets)

Track mounting bracket

(Already attached to LSA)

Hexagonal socket

head bolt

F8h7s18 M8s30mm 306kgfvcm/2997Nvcm

Tightening torque

[1] XY bracket

X1-axis slider side

(base, reamed-hole side)

Track mounting bracket

(Already attached before delivery)

Y1-axis: ISPA

X-axis: LSA

Y2-axis: ISPA

[2] XY bracket

X2-axis slider side

(base, slotted-hole side)

(different direction)

* The direction is different on the Y2-axis side.

Assemble the parts by referring to

the Y1-axis side.

X-axis Linear Servo Type Cartesian Robot – High-precision 4-axis Specification

ICSPA4-B2L1H

Drawing No.

2

Flange socket

(hexagonal socket head type)

M4

s

10

+ hexagonal nut (3 sets)

[3] Guide rail

[9] Controller-actuator cable with

cable fix cap (for axis 1 or 2)

Hexagonal socket head bolt M4s6

+ hexagonal nut (2 sets)

[6] Wiring box bracket

[9] Controller-actuator cable with

cable fix cap (for axis 3 or 4)

Caution: The cables for Y1-axis side (axes 1 and 2) and Y2-axis side

GMM07-070 1/2

Y1-axis: ISPA

X-axis: LSA

[8] Grommet with film

Y2-axis: ISPA

[3] Guide rail

Attach to the upper T-slot.

Flange socket (hexagonal socket head type) M4s10

+ hexagonal nut (3 sets)

(axes 3 and 4) are placed in tracks. Install each cable correctly.

[Cable markings]

v Y1-axis side (axes 1 and 2): 1-M, PG, (LS), 2-M, PG, (LS)

v Y2-axis side (axes 3 and 4): 3-M, PG, (LS), 4-M, PG, (LS)

3

Hexagonal socket head bolt M4s10 (2 pcs)

Track mounting bracket

[3] Guide rail

[4] Cable track

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

Y1-axis: ISPA

s

Hexagonal socket head bolt M4

X-axis: LSA

s

10

[4] Cable track

s

10

[Installation of cable track [4] on track mounting bracket]

[Installation of guide rail [3] for cable track [4] in T-slot]

Hexagonal socket head bolt

[3] Guide rail

M4s10mm 36.7kgfvcm/359Nvcm

10 (2 pcs)

Y2-axis: ISPA

Track mounting bracket

Tightening torque

Wiring box

In this assembly procedure, the controller-actuator cable is

taken out from the wiring box in the direction shown above.

The cable can also be taken out in the directions shown below.

Affix the wiring box bracket [6] using the holes

on the inner side, and use the upper T-slot.

Affixing positions of guide rail [3], cable track 1 [4] and wiring box bracket [6]

[6] Wiring box bracket

[4] Cable track

30 30

[3] Guide rail

[Installation of wiring box bracket [6] in the upper T slot on X-axis: LSA side]

Hexagonal socket head bolt

M4s6mm 18.0kgfvcm/176Nvcm

[Installation of guide rail [3] in the upper T slot on X-axis: LSA side]

Flange socket (hexagonal socket head type)

M4s10mm 18.0kgfvcm/176Nvcm

[4] Cable track

4343

[3] Guide rail

Align the guide rail [3] surface with the end

face of the base. (Same on the other side)

Hexagonal socket head bolt

Hexagonal socket head bolt

Page 8

X-axis Linear Servo Type Cartesian Robot – High-precision 4-axis Specification

ICSPA4-B2L1H

Drawing No.

GMM07-070 2/2

4

[4] Cable track

Controller-actuator cable

Cable wiring diagram

Y1-axis: ISPA

Cable inside track

X-axis: LSA

Installation of metal cover [10]

Detail view of A

Track mounting bracket

[10] Metal cover

[Installation of metal cover [10] on track mounting bracket]

Thin-head bolt

M3s4mm 7.12kgfvcm/69.8Nvcm

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

Tightening torque

Caution:

The cables for X-axis slider on

Y1-axis side (axis 1), Y1-axis (axis 2),

X-axis slider on Y2-axis side (axis 3)

and Y2-axis (axis 4) are placed in

tracks.

Install each cable correctly.

[Cable markings]

v X-axis on Y1-axis side (axis 1): 1

v Y1-axis (axis 2)

v X-axis on Y2-axis side (axis 3): 3

v Y2-axis (axis 4)

X axis: Joint of the motor

and encoder cables on

LSA side and the cable

connectors coming out of

the X-axis cable track

(on the back side)

: 2

: 4

Cable Tie Mount MB1

(Manufacturer: HellermannTyton)

+ M3 hex socket flat head cap screw

s

5 pcs (1 set)

* Affix cables using Insulok.

[Installation of tie-mount on track mounting bracket] [Installation of connector cover [5] on track mounting bracket]

Hexagonal socket head bolt

M3s5mm 15.8kgfvcm/154Nvcm

Y1-axis:

Connector joint for

ISPA M cable and

PG cable (LS cable)

Detail view of A

Connector connection of ISPA, NS cable and cable inside track

Hexagonal socket head bolt

M3

s

Track mounting bracket

X-axis motor and encoder

cables.

Guide the cables to the

other side through the hole

Tightening torque

Cable Connector Joints

Track mounting bracket

3 (4 pcs)

Put the X-axis motor and encoder cables

into the box through the opening.

Track mounting bracket

[8] Grommet with film

[5] Connector

cover

Hexagonal socket head bolt

M3s3mm 15.8kgfvcm/154Nvcm

[10] Metal cover

Y-axis actuator cable

Make a cut in the film on the grommet to put

through the cables, and then attach it to

the track mounting bracket.

Make a cross cut.

Tightening torque

Assemble the Y2-axis side by referring

*

to the Y1-axis side.

Connector connection of cable inside cable track and controller-actuator cable

Installation of wiring box cover [7]

[7] Wiring box cover

[6] Wiring box bracket

[Installation of wiring box cover [7] on wiring box bracket [6]]

Thin-head bolt

M3s4mm 7.12kgfvcm/69.8Nvcm

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

*

[8] Grommet with film

Cable inside track

Thin-head bolt M3s4 (6 pcs)

Connector joint for cable inside track

and controller-actuator cable

Make sure the numbers on the

connectors to be connected match.

Tightening torque

Assemble the Y2-axis side by referring

to the Y1-axis side.

5

Tie-mount KR5G5

(by HellermannTyton)

+ hexagonal socket head bolt

M4

s

6 (1 set)

Track mounting bracket

Hexagonal socket head button bolt

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head bolt M4

+ hexagonal nut (1 set)

[3] Guide rail

[Installation of tie-mount on track mounting bracket]

[Installation of tie-mount in T slot of guide rail [3]]

Tightening torque

M4s6mm 11.7kgfvcm/114Nvcm

Assemble the Y2-axis side by referring

*

to the Y1-axis side.

X-axis: LSA

6

Secure the cables using wraps.

s

6

Secure the cables using wraps.

X-axis: LSA

Assemble the Y2-axis side by referring

*

to the Y1-axis side.

Caution: Secure the wires to prevent the cables and connectors

from contacting each axis when the axis is moved over its

entire stroke.

When manually moving the actuator with brake, connect

the controller, supply the power, and then release the brake

release switch (by turning the switch to the RLS side).

Page 9

Caution: z Although each part has been chamfered to remove sharp edges, exercise due caution during

the assembly to prevent injury. If necessary, wear gloves or other protective gears.

[Tools] Allen wrench, spanner wrench

Exercise due caution during the assembly to prevent pinching of hands and fi ngers.

z

1

Parallel pin (2 pcs)

Hexagonal socket head bolt M8s30

+ high-tension washer (4 sets)

[1] XY bracket

Parallel pin (1 pc or 2 pcs)

X-axis: LSA

X-axis base, reamed-hole side

Note: To ensure squareness between the X-axis and Y-axis, insert one parallel pin.

Adjust the angle between the X-axis and Y-axis to the right angle, and then

mount the hexagonal bolts.

[Installation of X-axis: LSA on XY bracket [1]] [Installation of Y1-axis: ISPA on XY bracket [1]]

Parallel pin Hexagonal bolt Tightening torque

F6h7s15 M8s40mm 306kgfvcm/2997Nvcm

Assembly of Y1-axis side

Y1-axis: ISPA

Hexagonal bolt M8s40

+ high-tension washer

(4 sets)

Track mounting bracket

(Already attached to LSA)

Parallel pin

F8h7s18 M8s30mm 306kgfvcm/2997Nvcm

Hexagonal socket

head bolt

Tightening torque

[1] XY bracket

X1-axis slider side

(base, reamed-hole side)

Track mounting bracket

(Already attached before delivery)

3

Y1-axis: ISPA

X-axis: LSA

Y2-axis: ISPA

[2] XY bracket

X2-axis slider side

(base, slotted-hole side)

(different direction)

* The direction is different on the Y2-axis side.

Assemble the parts by referring to

the Y1-axis side.

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z Base Mount

ICSPA6-B2L1HB3H (M)

Drawing No.

2

Flange socket

(hexagonal socket head type)

M4

s

10

+ hexagonal nut (3 sets)

[3] Guide rail

[9] Controller-actuator cable with

cable fix cap (for axis 1, 2 or 3)

Hexagonal socket head bolt M4s6

+ hexagonal nut (2 sets)

[6] Wiring box bracket

[9] Controller-actuator cable with

cable fix cap (for axis 4, 5 or 6)

Caution: The cables for Y1-axis side (axes 1, 2 and 3) and Y2-axis side

GMM07-071 1/4

Y1-axis: ISPA

X-axis: LSA

[8] Grommet with film

[3] Guide rail

Attach to the upper T-slot.

Flange socket (hexagonal socket head type) M4

+ hexagonal nut (3 sets)

(axes 4, 5 and 6) are placed in tracks. Install each cable correctly.

[Cable markings]

v Y1-axis side (axes 1, 2 and 3):

v Y2-axis side (axes 4, 5 and 6):

1-M, PG, (LS), 2-M, PG, (LS),

3-M, PG, (LS)

4-M, PG, (LS), 5-M, PG, (LS),

6-M, PG, (LS)

Y2-axis: ISPA

s

10

Hexagonal socket head bolt M4s10 (2 pcs)

Track mounting bracket

[3] Guide rail

[4] Cable track 1

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

Y1-axis: ISPA

Hexagonal socket head bolt M4

s

10

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

s

10 (2 pcs)

X-axis: LSA

[4] Cable track 1

s

10

[Installation of cable track 1 [4] on track mounting bracket]

[3] Guide rail

[Installation of guide rail for cable track 1 [4] in T-slot]

M4s10mm 36.7kgfvcm/359Nvcm

Track mounting bracket

Tightening torqueHexagonal socket head bolt

Y2-axis: ISPA

Wiring box

In this assembly procedure, the controller-actuator cable is

taken out from the wiring box in the direction shown above.

The cable can also be taken out in the directions shown below.

Affixing positions of guide rail [3], cable track 1 [4] and wiring box bracket [6]

[6] Wiring box bracket

[4] Cable track 1

30 30

[3] Guide rail

Affix the wiring box bracket [6] using the holes

on the inner side, and use the upper T-slot.

[Installation of wiring box bracket [6] in the upper T slot on X-axis: LSA side]

Hexagonal socket head bolt

M4s6mm 18.0kgfvcm/176Nvcm

[Installation of guide rail [3] in the upper T slot on X-axis: LSA side]

Flange socket (hexagonal socket head type)

M4s10mm 18.0kgfvcm/176Nvcm

[4] Cable track 1

4343

[3] Guide rail

Align the guide rail [3] surface with the end

face of the base. (Same on the other side)

Hexagonal socket head bolt

Hexagonal socket head bolt

Page 10

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z Base Mount

ICSPA6-B2L1HB3H (M)

Drawing No.

GMM07-071 2/4

4

Hexagonal socket head bolt M8s25

+ M8 dedicated washer (4 sets)

[1] XY bracket

Parallel pin

F8h7s18 M8s30mm 306kgfvcm/2997Nvcm

Parallel pin

F8h7s25 M8s25mm 306kgfvcm/2997Nvcm

Parallel pin (1 pc)

+ flat washer (4 sets)

Z1-axis: ISPA

[Installation of YZ plate [11] on Y1-axis: ISPA]

[Installation of Z1-axis: ISPA on YZ plate [11]]

Hexagonal socket

head bolt

Hexagonal socket

head bolt

Tightening torque

Tightening torque

Y1-axis: ISPA

Parallel pin (2 pcs)

[11] YZ plate

Hexagonal socket head bolt M8s30

Z1-axis: ISPA

5 6

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

Hexagonal socket head bolt Tightening torque

Hexagonal socket head bolt Tightening torque

s

16

[Installation of track support bracket [13] on XY bracket [1]]

M4s8mm 36.7kgfvcm/359Nvcm

[Installation of track support metal [13] on track mounting plate [12]]

M4s16mm 36.7kgfvcm/359Nvcm

[12] Track mounting plate

Hexagonal socket head bolt M4s8 (2 pcs)

[13] Track support bracket

Place the M4 hexagonal nut in

the T slot beforehand to secure

the tie-mount in position.

[1] XY bracket

Y1-axis: ISPA

Hexagonal socket head bolt M6s15 (2 pcs)

[16] Connector box

Hexagonal socket head bolt

M4

s

5 (2 pcs)

Y1-axis: ISPA

[Installation of track mounting bracket 2 [14] on YZ plate [11]]

Hexagonal socket head bolt Tightening torque

M6s15mm 126kgfvcm/1234Nvcm

[Installation of connector box [16] on track mounting bracket 2 [14]]

Hexagonal socket head bolt Tightening torque

M4s5mm 18.0kgfvcm/176Nvcm

[14] Track mounting bracket 2

Z1-axis: ISPA

[11] YZ plate

[15] Cable track 2

7

Hexagonal

socket head

s

12

bolt M4

Hexagonal socket head bolt

M4

s

12

+ hexagonal nut (2 sets)

[13] Track support bracket

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

Hexagonal socket head bolt M4s8 (2 pcs)

[Installation of cable track 2 [15] on track support bracket [13]]

Hexagonal socket head bolt Tightening torque

Hexagonal socket head bolt Tightening torque

[Installation of cable track 2 [15] on track mounting bracket 2 [14]]

Hexagonal socket head bolt Tightening torque

Hexagonal socket head bolt Tightening torque

[14] Track mounting bracket 2

Z1-axis: ISA, etc.

[16] Connector box

[17] Box cover

[8] Grommet with film

Hexagonal socket head bolt

s

12 (8 pcs)

M3

[1] XY bracket

M4s12mm 36.7kgfvcm/359Nvcm

[Installation of cable track 2 [15] on XY bracket [1]]

M4s12mm 36.7kgfvcm/359Nvcm

M4s8mm 36.7kgfvcm/359Nvcm

[Installation of box cover [17] on connector box [16]]

M3s12mm 5.51kgfvcm/54Nvcm

[18] Joint cover

Cable connector connection

[16]

Connector box

Connector joint for

ISPA M cable and

PG cable (LS cable)

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

Page 11

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z Base Mount

ICSPA6-B2L1HB3H (M)

Drawing No.

GMM07-071 3/4

8

[4] Cable track

Controller-actuator cable

Cable wiring diagram

Y1-axis: ISPA

Cable inside track

X-axis: LSA

Installation of metal cover [10]

Detail view of A

Track mounting bracket

[10] Metal cover

[Installation of metal cover [10] on track mounting bracket]

Thin-head bolt

M3s4mm 7.12kgfvcm/69.8Nvcm

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

Tightening torque

Caution:

The cables for X-axis slider on Y1-axis side

(axis 1), Y1-axis (axis 2), Z1-axis (axis 3),

X-axis slider on Y2-axis side (axis 4),

Y2-axis (axis 5) and Z2-axis (axis 6)

are placed in tracks.

Install each cable correctly.

[Cable markings]

v X-axis slider on Y1-axis side (axis 1): 1

v Y1-axis (axis 2)

v Z1-axis (axis 3)

v X-axis slider on Y2-axis side (axis 4): 4

v Y2-axis (axis 5)

v Z2-axis (axis 6)

X axis: Joint of the motor

and encoder cables on

LSA side and the cable

connectors coming out of

the X-axis cable track

(on the back side)

Cable Tie Mount MB1

(Manufacturer: HellermannTyton)

: 2

+ M3 hex socket flat head cap screw

: 3

s

5 pcs (1 set)

* Affix cables using Insulok.

: 5

: 6

[Installation of tie-mount on track mounting bracket] [Installation of connector cover [5] on track mounting bracket]

Hexagonal socket head bolt

M3s5mm 15.8kgfvcm/154Nvcm

Y1-axis:

Connector joint for

ISPA M cable and

PG cable (LS cable)

Detail view of A

Connector connection of ISPA, NS cable and cable inside track

Hexagonal socket head bolt

M3

s

Track mounting bracket

X-axis motor and encoder

cables.

Guide the cables to the

other side through the hole

Tightening torque

Cable Connector Joints

Track mounting bracket

3 (4 pcs)

Put the X-axis motor and encoder cables

into the box through the opening.

Track mounting bracket

[8] Grommet with film

[5] Connector

cover

Hexagonal socket head bolt

M3s3mm 15.8kgfvcm/154Nvcm

[10] Metal cover

Y-axis actuator cable

Make a cut in the film on the grommet to put

through the cables, and then attach it to

the track mounting bracket.

Make a cross cut.

Tightening torque

*

Assemble the Y2-axis side by referring

to the Y1-axis side.

Connector connection of cable inside cable track and controller-actuator cable

Installation of wiring box cover [7]

[7] Wiring box cover

[6] Wiring box bracket

[Installation of wiring box cover [7] on wiring box bracket [6]]

Thin-head bolt

M3s4mm 7.12kgfvcm/69.8Nvcm

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

[8] Grommet with film

Cable inside track

Thin-head bolt M3s4 (6 pcs)

Connector joint for cable inside track

and controller-actuator cable

Make sure the numbers on the

connectors to be connected match.

Tightening torque

Assemble the Y2-axis side by referring

*

to the Y1-axis side.

Page 12

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z Base Mount

ICSPA6-B2L1HB3H (M)

Drawing No.

GMM07-071 4/4

9

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4

[13] Track support bracket

[1] XY bracket

[Installation of tie-mount in track mounting bracket 2 [14]]

[Installation of tie-mount on track support bracket [13]]

[Installation of tie-mount in T slot of Y1-axis: ISPA]

Hexagonal socket head button bolt

M4s6mm 11.7kgfvcm/114Nvcm

Z1-axis cables

[14] Track mounting bracket 2

s

6 (2 sets)

Tie-mount KR5G5

(by HellermannTyton)

+ hexagonal socket head button bolt

M4

s

6 (1 set)

Install in the T slot of the Y-axis.

Tightening torque

Tie-mount KR5G5

(by HellermannTyton)

+ hexagonal socket head bolt

M4

s

6 (1 set)

Track mounting bracket

[3] Guide rail

[Installation of tie-mount on track mounting bracket]

[Installation of tie-mount in T slot of guide rail [3]]

Hexagonal socket head button bolt

X-axis, Y1-axis cables

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head bolt M4

+ hexagonal nut (1 set)

Tightening torque

M4s6mm 11.7kgfvcm/114Nvcm

X-axis: LSA

s

6

10

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

Z1-axis cables X-axis, Y1-axis, Z1-axis cables

Secure the cables using wraps.

Secure the cables using wraps.

Secure the cables using wraps.

*

Assemble the Y2-axis side by referring

to the Y1-axis side.

Assemble the Y2-axis side by referring

*

to the Y1-axis side.

Secure the cables using wraps.

X-axis: LSA

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

Caution: Secure the wires to prevent the cables and connectors

from contacting each axis when the axis is moved over its

entire stroke.

When manually moving the actuator with brake, connect

the controller, supply the power, and then release the brake

release switch (by turning the switch to the RLS side).

Page 13

Caution: z Although each part has been chamfered to remove sharp edges, exercise due caution during

the assembly to prevent injury. If necessary, wear gloves or other protective gears.

[Tools] Allen wrench, spanner wrench

Exercise due caution during the assembly to prevent pinching of hands and fi ngers.

z

1

Parallel pin (2 pcs)

Hexagonal socket head bolt M8s30

+ high-tension washer (4 sets)

[1] XY bracket

Parallel pin (1 pc or 2 pcs)

X-axis: LSA

X-axis base, reamed-hole side

Note: To ensure squareness between the X-axis and Y-axis, insert one parallel pin.

Adjust the angle between the X-axis and Y-axis to the right angle, and then

mount the hexagonal bolts.

[Installation of X-axis: LSA on XY bracket [1]] [Installation of Y1-axis: ISPA on XY bracket [1]]

Parallel pin Hexagonal bolt Tightening torque

F6h7s15 M8s40mm 306kgfvcm/2997Nvcm

Parallel pin

Assembly of Y1-axis side

Y1-axis: ISPA

Hexagonal bolt M8s40

+ high-tension washer

(4 sets)

Track mounting bracket

(Already attached to LSA)

Hexagonal socket

head bolt

F8h7s18 M8s30mm 306kgfvcm/2997Nvcm

Tightening torque

[1] XY bracket

X1-axis slider side

(base, reamed-hole side)

Track mounting bracket

(Already attached before delivery)

Y1-axis: ISPA

X-axis: LSA

Y2-axis: ISPA

[2] XY bracket

X2-axis slider side

(base, slotted-hole side)

(different direction)

* The direction is different on the Y2-axis side.

Assemble the parts by referring to

the Y1-axis side.

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z Slider Mount

ICSPA6-B2L1HS3M

Drawing No.

2

Flange socket

(hexagonal socket head type)

M4

s

10

+ hexagonal nut (3 sets)

[3] Guide rail

[9] Controller-actuator cable with

cable fix cap (for axis 1, 2 or 3)

Hexagonal socket head bolt M4s6

+ hexagonal nut (2 sets)

[6] Wiring box bracket

[9] Controller-actuator cable with

cable fix cap (for axis 4, 5 or 6)

Caution: The cables for Y1-axis side (axes 1, 2 and 3) and Y2-axis side

GMM07-072 1/4

Y1-axis: ISPA

X-axis: LSA

[8] Grommet with film

[3] Guide rail

Attach to the upper T-slot.

Flange socket (hexagonal socket head type) M4

+ hexagonal nut (3 sets)

(axes 4, 5 and 6) are placed in tracks. Install each cable correctly.

[Cable markings]

v Y1-axis side (axes 1, 2 and 3):

v Y2-axis side (axes 4, 5 and 6):

1-M, PG, (LS), 2-M, PG, (LS),

3-M, PG, (LS)

4-M, PG, (LS), 5-M, PG, (LS),

6-M, PG, (LS)

Y2-axis: ISPA

s

10

3

Hexagonal socket head bolt M4s10 (2 pcs)

Track mounting bracket

[3] Guide rail

[4] Cable track 1

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

Y1-axis: ISPA

s

10

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

Hexagonal socket head bolt M4

X-axis: LSA

[4] Cable track 1

s

10

[Installation of cable track 1 [4] on track mounting bracket]

[3] Guide rail

[Installation of guide rail for cable track 1 [4] in T-slot]

M4s10mm 36.7kgfvcm/359Nvcm

s

10 (2 pcs)

Track mounting bracket

Tightening torqueHexagonal socket head bolt

Y2-axis: ISPA

Wiring box

In this assembly procedure, the controller-actuator cable is

taken out from the wiring box in the direction shown above.

The cable can also be taken out in the directions shown below.

Affixing positions of guide rail [3], cable track 1 [4] and wiring box bracket [6]

[6] Wiring box bracket

[4] Cable track 1

30 30

[3] Guide rail

Affix the wiring box bracket [6] using the holes

on the inner side, and use the upper T-slot.

[Installation of wiring box bracket [6] in the upper T slot on X-axis: LSA side]

Hexagonal socket head bolt

M4s6mm 18.0kgfvcm/176Nvcm

[Installation of guide rail [3] in the upper T slot on X-axis: LSA side]

Flange socket (hexagonal socket head type)

M4s10mm 18.0kgfvcm/176Nvcm

[4] Cable track 1

4343

[3] Guide rail

Align the guide rail [3] surface with the end

face of the base. (Same on the other side)

Hexagonal socket head bolt

Hexagonal socket head bolt

Page 14

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z Slider Mount

ICSPA6-B2L1HS3M

Drawing No.

GMM07-072 2/4

4

[1] XY bracket

Z1-axis: ISPA

Parallel pin Tightening torque

Parallel pin

Y1-axis: ISPA

Parallel pin (2 pcs)

Hexagonal bolt M8

+ flat washer (4 sets)

[11] YZ bracket

Parallel pin (2 pcs)

[Installation of YZ bracket [11] on Y1-axis: ISPA]

Hexagonal bolt

F8h7s18 M8s35mm 117kgfvcm/1148Nvcm

[Installation of Z1-axis: ISPA on YZ bracket [11]]

F8h7s18 M8s40mm 306kgfvcm/2997Nvcm

Hexagonal socket

head bolt

Hexagonal socket head bolt M8

(4 pcs)

Tightening torque

[14] Track mounting bracket 2

5 6

s

35

s

40

Hexagonal socket head bolt

M4

s

8 (2 pcs)

[13] Track support bracket

Y1-axis: ISPA

[12] Track mounting plate

s

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

[Installation of track support bracket [13] and track mounting plate [12] on Y1-axis: ISPA]

Hexagonal socket head bolt Tightening torque

M4s16mm 36.7kgfvcm/359Nvcm

[Installation of track support bracket [13] on XY bracket [1]]

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

[Installation of track mounting bracket 2 [14] on YZ bracket [11]] [Installation of track mounting bracket 3 [15] on Z1-axis: ISPA]

Hexagonal socket head bolt Tightening torque

M6s12mm 126kgfvcm/1234Nvcm

16

[1] XY bracket

Place the M4 hexagonal nut (1 pc) in the T slot

beforehand to secure the tie-mount in position.

Hexagonal socket head bolt

s

12 (2 pcs)

M6

Z1-axis: ISPA

[11] YZ bracket

[15] Track mounting bracket 3

Hexagonal socket head bolt

M8

s

15 (2 pcs)

Z1-axis: ISPA

Hexagonal socket head bolt Tightening torque

M8s15mm 306kgfvcm/2997Nvcm

7

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

Hexagonal socket head bolt M4s8 (2 pcs)

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

Hexagonal socket head bolt M4

[Installation of cable track 1 [4] on track support bracket [13]]

Hexagonal socket head bolt Tightening torque

M4s12mm 36.7kgfvcm/359Nvcm

s

12

s

12 (2 pcs)

Y1-axis: ISPA

[1] XY bracket

[4] Cable track 1

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

Z1-axis: ISPA

[16] Cable track 2

s

Hexagonal socket head bolt M4

[15] Track mounting bracket 3

Hexagonal socket head bolt M4

[14] Track mounting bracket 2

[13] Track support bracket

[Installation of cable track 2 [16] on track mounting bracket 3 [15]]

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

8 (2 pcs)

s

8 (2 pcs)

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

[Installation of cable track 1 [4] on XY bracket [1]]

Hexagonal socket head bolt Tightening torque

M4s12mm 36.7kgfvcm/359Nvcm

[Installation of cable track 1 [4] on track mounting bracket 2 [14]]

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

[Installation of cable track 2 [16] on track mounting bracket 2 [14]]

Hexagonal socket head bolt Tightening torque

M4s8mm 36.7kgfvcm/359Nvcm

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

Page 15

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z Slider Mount

ICSPA6-B2L1HS3M

Drawing No.

GMM07-072 3/4

8

[4] Cable track

Controller-actuator cable

Cable wiring diagram

Y1-axis: ISPA

Cable inside track

X-axis: LSA

Installation of metal cover [10]

Detail view of A

Track mounting bracket

[10] Metal cover

[Installation of metal cover [10] on track mounting bracket]

Thin-head bolt

M3s4mm 7.12kgfvcm/69.8Nvcm

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

Tightening torque

Caution:

The cables for X-axis slider on Y1-axis side

(axis 1), Y1-axis (axis 2), Z1-axis (axis 3),

X-axis slider on Y2-axis side (axis 4),

Y2-axis (axis 5) and Z2-axis (axis 6)

are placed in tracks.

Install each cable correctly.

[Cable markings]

v X-axis slider on Y1-axis side (axis 1): 1

v Y1-axis (axis 2)

v Z1-axis (axis 3)

v X-axis slider on Y2-axis side (axis 4): 4

v Y2-axis (axis 5)

v Z2-axis (axis 6)

X axis: Joint of the motor

and encoder cables on

LSA side and the cable

connectors coming out of

the X-axis cable track

(on the back side)

Cable Tie Mount MB1

(Manufacturer: HellermannTyton)

+ M3 hex socket flat head cap screw

: 2

s

5 pcs (1 set)

: 3

* Affix cables using Insulok.

: 5

: 6

[Installation of tie-mount on track mounting bracket] [Installation of connector cover [5] on track mounting bracket]

Hexagonal socket head bolt

M3s5mm 15.8kgfvcm/154Nvcm

Y1-axis:

Connector joint for

ISPA M cable and

PG cable (LS cable)

Detail view of A

Connector connection of ISPA, NS cable and cable inside track

Hexagonal socket head bolt

M3

s

Track mounting bracket

X-axis motor and encoder

cables.

Guide the cables to the

other side through the hole

Tightening torque

Cable Connector Joints

Track mounting bracket

3 (4 pcs)

Put the X-axis motor and encoder cables

into the box through the opening.

Track mounting bracket

[8] Grommet with film

[5] Connector

cover

Hexagonal socket head bolt

M3s3mm 15.8kgfvcm/154Nvcm

[10] Metal cover

Y-axis actuator cable

Make a cut in the film on the grommet to put

through the cables, and then attach it to

the track mounting bracket.

Make a cross cut.

Tightening torque

Assemble the Y2-axis side by referring

*

to the Y1-axis side.

Connector connection of cable inside cable track and controller-actuator cable

[7] Wiring box cover

[6] Wiring box bracket

Installation of wiring box cover [7]

[8] Grommet with film

Cable inside track

Thin-head bolt M3s4 (6 pcs)

Connector joint for cable inside track

and controller-actuator cable

Make sure the numbers on the

connectors to be connected match.

[Installation of wiring box cover [7] on wiring box bracket [6]]

Thin-head bolt

M3s4mm 7.12kgfvcm/69.8Nvcm

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

Tightening torque

Assemble the Y2-axis side by referring

*

to the Y1-axis side.

Page 16

X-axis Linear Servo Type Cartesian Robot – High-precision 6-axis Specification,

Z Slider Mount

ICSPA6-B2L1HS3M

Drawing No.

GMM07-072 4/4

9

Z1-axis cables

KR5G5 tie-mount (by HellermannTyton)

+ hexagonal socket head button bolt M4

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4s4 (1 set)

[14] Track mounting bracket 2

[13] Track support bracket

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4s6 (1 set)

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4s6 (1 set)

Install in the T slot of the Y-axis.

[Installation of tie-mount on track mounting bracket 2 [14]]

M4s4mm 11.7kgfvcm/114Nvcm

[15] Track mounting bracket 3

s

4 (2 sets)

[Installation of tie-mount on track mounting bracket 3 [15]]

Tightening torqueHexagonal socket head button bolt

M4s4mm 11.7kgfvcm/114Nvcm

KR5G5 tie-mount

(by HellermannTyton)

+ hexagonal socket head

button bolt M4s4 (2 sets)

Install on the back side.

Y1-axis: ISPA

[1] XY bracket

[Installation of tie-mount on track support bracket [13]]

[Installation of tie-mount in T slot of Y1-axis: ISPA]

Tightening torqueHexagonal socket head button bolt

M4s6mm 11.7kgfvcm/114Nvcm

Z1-axis: ISPA

(by HellermannTyton)

Tightening torqueHexagonal socket head button bolt

Hexagonal socket head bolt M4

+ hexagonal nut (2 sets)

[18] Box cover

Hexagonal socket head bolt

s

12 (8 pcs)

M3

[17] Connector box

[8] Grommet with film

[19] Joint cover

[Installation of connector box [17] on Z1-axis: ISPA]

M4s6mm 18.0kgfvcm/176Nvcm

[Installation of box cover [18] on connector box [17]]

M3s12mm 5.51kgfvcm/54Nvcm

* The direction is different on the Z2-axis side.

Assemble the parts by referring to the Z1-axis side.

Connector joint for

ISPA M cable and

PG cable (LS cable)

Tightening torqueHexagonal socket head bolt

Tightening torqueHexagonal socket head bolt

s

6

Tie-mount KR5G5

(by HellermannTyton)

+ hexagonal socket head bolt

M4

s