Page 1

A

A

A

A

CatalogNo.ME0193-2A

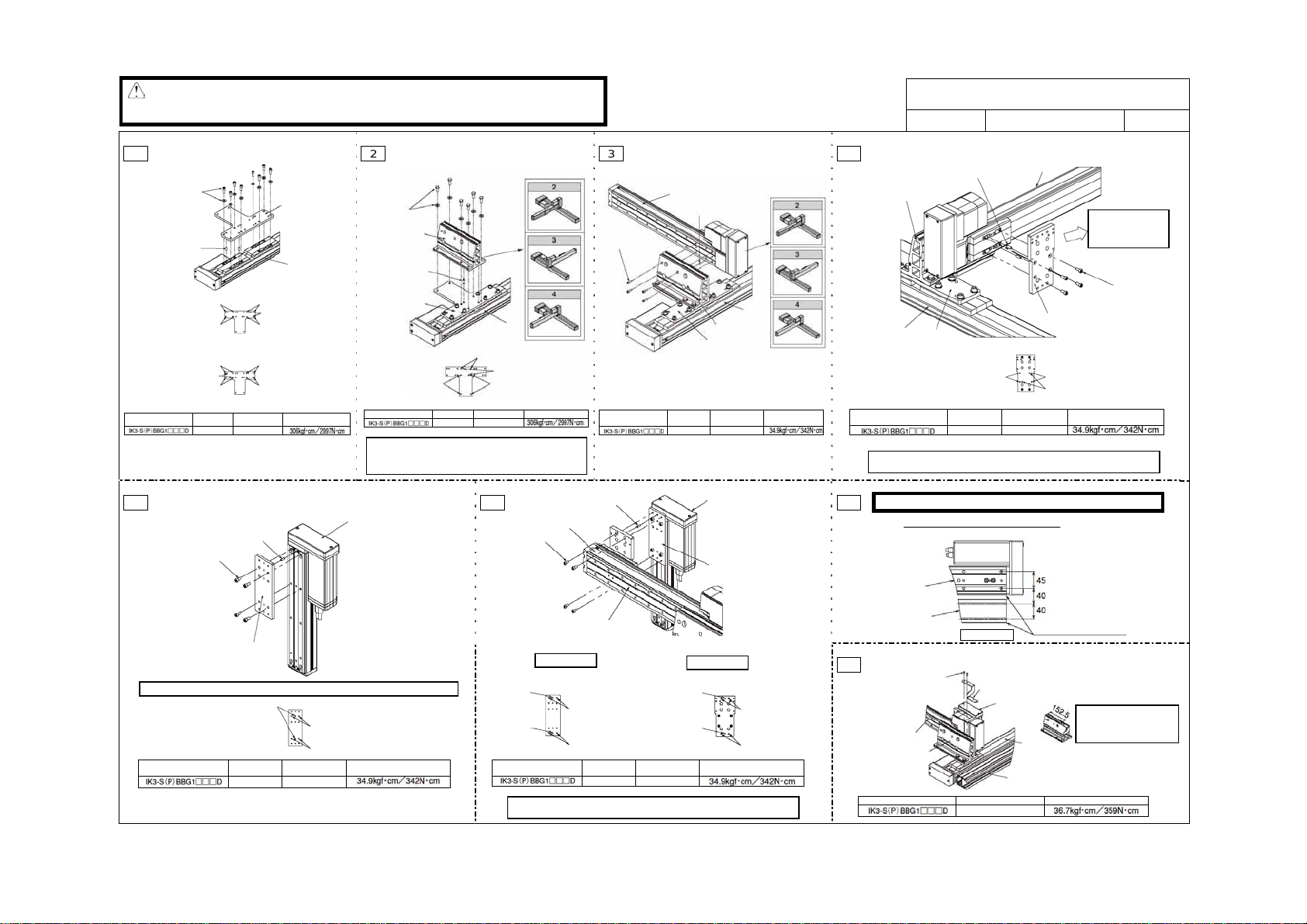

IA Kit IK Series Assembly Procedures Edition 2

Thank you for purchasing an IAI product.

Use this Assembly Procedures as reference to assemble

your product correctly.

ROBO Cylinder Combinations

XY base fixed type

[Model]

xis configuration RCS2

xis configuration RCP2

[1] Configuration type

[2] Combination direction

Symbol X-axis (axis 1) Y-axis (axis 2)

A1 SS8R (150W) SS8R (100W)

A2 SS8C (150W) SS8C (100W)

B1 SS8R (150W) SA7R

B2 SS8C (150W) SA7R

C1 SS7R SA6R

C2 SS7C SA6R

D1 SS7R SA5R

D2 SS7C SA5R

* If the X-axis is reversed, only 1 and 2 are applicable.

Symbol

Shape

[4] Slider type

[3] Speed type

[2] Combination direction

[1] Configuration type

[3] Speed type [4] Slider type

Symbol Type

HH High speed High speed

HM High speed Medium speed

HL High speed Low speed

MM Medium speed Medium speed

Symbol Type

S Single

D Double

No. Type DWG No.

1

2

3

4

5

6

7

8

[IA kit components]

* Single slider type

For A1, A2, B1

and B2

[5] Cable bearer 1

For RCP2 actuators

C1, C2, D1 and D2

[1] XY bracket

[6] Bearer

mounting bracket 1

* Double slider type

For A1, A2, B1

and B2

[5] Cable bearer 1

[Assembly procedure]

* Single slider type

* Double slider type

For RCP2 actuators

C1, C2, D1 and D2

[1] XY bracket

[6] Bearer

mounting bracket 1

DWG No.: GMM07-053E

DWG No.: GMM07-054E

List of Drawings Referenced in Assembly Procedures

XY base fixed type Single slider type GMM07-053E

XY base fixed type

Upright type Single slider type GMM07-055E

Upright type

Crossed-type base fixed Single slider type GMM07-057E

XYB + Z base fixed type Single slider type GMM07-058E

XYB + Z base fixed type

Cable affixing method

For RCS 2

actuators C1, C2,

D1 and D2

[7] Guide rail Y

For RCS 2

actuators C1, C2,

D1 and D2

[7] Guide rail Y

Double slider type

Double slider type

Double slider type

[2] Plate X

[8] Cable bearer 2

[2] Plate X

[8] Cable bearer 2

GMM07-054E

GMM07-056E

GMM07-059E

GMM07-060E

[3] Guide rail X [4] Fra me co ve r X

[3] Guide rail X [4] Frame co ve r X

Upright type

[Model]

[1] Configuration type

Symbol X-axis (axis 1)Y-axis (axis 2)

B1 SS8R (150W) SA7R

[2] Combination direction

Symbol

Shape

[3] Speed type [4] Slider type

Symbol Type

HH High speed High speed

HM High speed Medium speed

HL High speed Low speed

MM Medium speed Medium speed

[IA kit components]

* Single slider type

[1] XZ bracket

* Double slider type

[1] XZ bracket

[Assembly procedure]

* Single slider type

DWG No.: GMM07-055E

* Double slider type

DWG No.: GMM07-056E

xis configuration RCS2

xis configuration RCP2

[4] Slider type

[3] Speed type

[2] Combination direction

[1] Configuration type

Symbol Type

S Single

D Double

[2] Cable bearer

[2] Cable bearer

[3] Bearer

mounting bracket

[3] Bearer

mounting bracket

Page 2

A

A

g

A

A

Crossed-type base fixed

[Model]

xis configuration RCS2

xis configuration RCP2

[4] Slider type

[3] Speed type

[2] Combination direction

[1] Configuration type

[1] Configuration type

[2] Combination direction

Symbol

Shape

Symbol X-axis (axis 1) Y-axis (axis 2)

B1 SS8R (150W) SA7R

[3] Speed type [4] Slider type

Symbol Type

HH High speed High speed

HM High speed Medium speed

HL High speed Low speed

MM Medium speed Medium speed

[IA kit components]

* Single slider type

[1] Plate YZ

[2] Guide rail Y [3] Frame cover Y

[4] Cable bearer 1

[7] Bearer mounting

bracket 2

[Assembly procedure]

* Single slider type

DWG No.: GMM07-057E

Symbol Type

S Single

[5] Bearer

mountin

bracket 1

[6] Cable bearer 2

XYB + Z base fixed type

[IA kit componen ts]

* Single slider type

[Model]

xis configuration RCS2

xis configuration RCP2

[4] Slider type

[3] Speed type

[2] Combination direction

[1] Configuration type

[1] Configuration type G1

Y-axis

Symbol X-axis (axis 1)

G1 SS8R (100W) SA7R SA6R

[2] Combination direction

* If the X-axis is reversed, only 1 and 2 are applicable.

Symbol

Shape

(axis 2)

Z-axis

(axis 3)

[3] Speed type [4] Slider type

Symbol Type

HHH High speed High speed High speed

HHM High speed

HHL High speed

High speed

High speed

Medium speed

Low speed

[7] Cable bearer 1

[7] Cable bearer 1

Symbol Type

S Single

D Double

[1] XY bracket

[2] Plate X [3] Plate YZ1 [6] Frame cover X [4] Plate YZ2 [5] Guide rail X

[8] Bearer

mounting bracket 1

* Double slider type

[1] XY bracket

[2] Plate X [3] Plate YZ1 [6] Frame cover X [4] Plate YZ2 [5] Guide rail X

[8] Bearer

mounting bracket 1

[Assembly procedure]

* Single slider type

DWG No.: GMM07-058E

* Double slider type

DWG No.: GMM07-059E

[9] Guide rail Y

[9] Guide rail Y

[10] Cable bearer 2

[10] Cable bearer 2

[11] Bearer mounting

bracket 2

[11] Bearer

mounting bracket 2

Page 3

j

j

(P)

A

A

g

Note: z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exercise due caution durin

[Tools] Allen wrench, spanner wrench, ruler

1

Parallel pin (1 pc or 2 pcs)

Screw lock holes

Model Parallel pin Hex head bolt Tightening torque

Note: To ensure squareness of the X-axis and Y-axis, place one parallel pin.

After ad

usting the squareness of the X-axis and Y-axis, affix the hex head bolt.

Parallel pin holes

∅8h7 x 25

∅5h7 x 25

4

Hex socket-head bolt (2 pcs)

Hex nut (2 pcs)

Y-axis

[1] XY bracket

Set the dimension from the side face

of the XY bracket to the tip of bearer

mounting bracket 1 [6] to 152.5 mm.

* This assembly procedure applies to combination direction 1. With other combination directions such as 2 and 3 , the actua tor and bracket directions are dif ferent. If y ou are using co mbination direction 2 or 3, assemble the p art s by

referring to this drawing.

Model

Hex socket-head bolt

assembly to prevent pinching of your hands and fingers.

2

Hex head bolt + plain washer (4 pcs)

[1] XY bracket

[2] Plate X

Hex socket-head bolt (4 pcs)

X-axis

Screw lock holes

Insert a washer

in the case of

S

M8 x 30 mm

M5 x 25 mm

Note: To ensure squareness of the X-axis and Y-axis, place one parallel pin.

5

[6] Bearer mounting bracket 1

X-axis

[3] Guide rail X

[6] Bearer

mounting

bracket 1

Set the dimension from the side face

of the XY bracket to the tip of bearer

mounting bracket 1 [6] to 172.5 mm.

M4 x 8 mm

Tightening torque

Y-axis

Parallel pin (1 pc or 2 pcs)

SXBA.

Model Parallel pin

After ad

Hex socket-head countersunk (4 pcs)

Y-axis

X-axis

Model

∅5h7 x 12

∅4h7 x 10

∅4h7 x 10

∅4h7 x 10

usting the squareness of the X-axis and Y-axis, affix the hex head bolt.

[1] XY bracket

Hex socket-head bolt

M8 x 18 mm

M5 x 15 mm

M5 x 12 mm

M5 x 12 mm

[5] Cable bearer 1

[3] Guide rail X

Hex socket-head

countersunk

M3 x 6 mm

[2] Plate X

Hex socket-head countersunk (4 pcs)

With combination directions 2

through 4, the actuator and

bracket directions are different.

X-axis

Tightening torque

Hex nut (4 pcs)

Align the end face of cable

bearer 1 [5] with the end

face of guide rail X [3].

Tightening torque

3

6

XY base fixed type: Single slider type

IK2-S(P)XBS

DWG. No. GMM07-053E 1/2

The following procedures apply to configurations with a cable bearer.

Install the X-axis and guide rail X.

X-axis

[3] Guide rail X

X-axis

[3] Guide rail X

Y-axis

Model

Bottom view

Bottom view

T-slot in XY bracket [1]

[7] Guide rail Y

Hex socket-head bolt

M4 x 8 mm

lign the end face of

the base with the end

face of guide r ail X.

lign the end face of

the base with the end

face of guide rail X.

Align the end face position of

guide rail Y [7] with the end face

position of the XY bra c k et [1] .

Hex socket-head bolt (3 pcs)

Hex nut (3 pcs)

X-axis

Tightening torque

Page 4

(

(Note) One side of cable bearer 2 [8] is free. The customer should

7

install cable bearer 2 when installing a handle, etc.

Y-axis

[7] Guide rail Y

Hex socket-head countersunk (4 pcs)

Hex nut (4 pcs)

Model

[7] Guide rail Y

Installation position of IK2-S(P) SXBA (SXBB) S

Y-axis str o k e

50 mm 81.5

100 mm 106.5

150 mm 131.5

200 mm 156.5

250 mm 181.5

300 mm 206.5

350 mm 231.5

400 mm 256.5

Installation position of IK2-S(P) SXBC (SXBD) S

Y-axis str o k e

50 mm 80.0

100 mm 105.0

150 mm 130.0

200 mm 155.0

250 mm 180.0

300 mm 205.0

350 mm 230.0

400 mm 255.0

[8] Cable bearer 2

Hex socket-head

countersunk

M3 x 6 mm

Installation position of cable bearer 2 [8]

Y-axis

See the table below.

Length from end face of guide rail Y

(front side) to fixed end of bearer

Length from end face of guide rail Y

(front side) to fixed end of bearer

Tightening torque

[8] Cable bearer 2

XY base fixed type: Single slider type

IK2-S(P)XBS

DWG. No. GMM07-053E 2/2

Arrange the wires so that each axis will not contact the cables and

8

connectors when the axis is moved over its entire stroke.

(Note) If you want to move the actuator with brake by hand, connect the

controller and supply the power and then set the brake release switch to

RLS) side.

the release

Y-axis

Cables from hand, etc.

[8] Cable bearer 2

Connect the motor

cable/encoder

cable connectors.

Guide rail

* Refer to “Cable affixing method: GMM07-060” for affixing of cables.

X-axis

Frame cover

[5] Cable bearer 1

Page 5

g

j

p

∅

A

A

j

(P)

Note: z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exercise due caution durin

[Tools] Allen wrench, spanner wrench, ruler

1

Hex socket-head bolt +

lain washer (8 pcs)

Parallel pin (2 pcs)

Screw lock holes

Screw lock holes

Combination directions 1, 3

Model Parallel pin Hex s ocket-head bolt Tightening torque

Screw lock holes

Parallel

pin holes

Screw lock

holes

∅8h7 x 18

∅5h7 x 14

4

The following procedures apply to configurations with a cable bearer.

Install the X-axis and guide rail X.

X-axis

[3] Guide rail X

Bottom view

assembly to prevent pinching of your hands and fingers.

2

Hex head bolt +

high-tension washer (6 pcs)

[2] Plate X

Parallel pin (1 pc or 2 pcs)

X-axis

Screw lock holes

Parallel

pin holes

Screw lock

holes

Combination directions 2, 4

Screw lock holes

Screw lock holes

M8 x 20 mm

M5 x 20 mm

Note: To ensure squareness of the X-axis and Y-axis, place one parallel pin.

5

Hex socket-head bolt (2 pcs)

Hex nut (2 pcs)

lign the end face of

the base with the end

face of guide rail X.

[1] XY bracket

X-axis

[3] Guide rail X

Bottom view

lign the end face of

the base with the end

face of guide rail X.

Set the dimension from the side face

of the XY bracket to the tip of bearer

mounting bracket 1 [6] to 152.5 mm.

With combination direct ions 2 and 3,

the bracket direction is diff er ent.

[1] XY bracket

[2] Plate X

Screw lock holes: ∅9

Screw lock holes:

Model Parallel pin Hex head bolt Tightening torque

After ad

usting the squareness of the X-axis and Y-axis, affix the hex head bolt.

Y-axis

Model Hex socket-head bolt Tightening torque

9

∅8h7 x 18

∅5h7 x 14

M8 x 20 mm

M5 x 18 mm

M4 x 8 mm

X-axis

Parallel pin hol es : ∅8

Screw lock holes: ∅9

[6] Bearer mounting bracket 1

Set the dimension from the side face

of the XY bracket to the tip of bearer

mounting bracket 1 [6] to 172.5 mm.

X-axis

[3] Guide rail X

3

Hex socket-head bolt (4 pcs)

Insert a washer

in the case of

SXBA.

S

Note: To ensure squareness of the X-axis and Y-axis, place one parallel pin.

6

Hex socket-head countersunk (4 pcs)

[6] Bearer

mounting

bracket 1

X-axis

XY base fixed type: Double slider type

IK2-S(P)XBD

DWG. No. GMM07-054E 1/2

With combination directions 2 through 4,

Y-axis

Parallel pin ( 1 pc or 2 pcs)

Model Parallel pin Hex soc ket-head bolt Tightening torque

usting the squareness of the X-axis and Y-axis, affix the hex head bolt.

After ad

Y-axis

Model

∅5h7 x 12

∅4h7 x 10

∅4h7 x 10

∅4h7 x 10

Hex socket-head

countersunk

the actuator direction is different.

X-axis

[1] XY bracket

[2] Plate X

M8 x 18 mm

M5 x 15 mm

M5 x 12 mm

M4 x 12 mm

Hex socket-head countersunk (4 pcs)

[5] Cable bearer 1

[3] Guide rail X

M3 x 6 mm

Hex nut (4 pcs)

Align the end face of cable

bearer 1 [5] with the end

face of guide rail X [3].

Tightening torque

* This assembly procedure applies to combination direction 1. With other combination directions such as 2 and 3 , the actua tor and bracket directions are dif ferent. If y ou are using co mbination direction 2 or 3, assemble the p art s by

referring to this drawing.

Page 6

(

XY base fixed type: Double slider type

IK2-S(P)XBD

DWG. No. GMM07-054E 2/2

7

T-slot in XY bracket [1]

Align the end face position of

guide rail Y [7] with the end face

position of the XY bracket [1].

Y-axis

[7] Guide rail Y

Hex socket-head bolt (3 pcs)

X-axis

Hex nut (3 pcs)

Model Hex socket-head bolt Tightening torque

M4 x 8 mm

8

(Note) One side of cable bearer 2 [8] is free. The customer should

install cable bearer 2 when installing a handle, etc.

Y-axis

[8] Cable bearer 2

[7] Guide rail Y

Hex socket-head countersunk (4 pcs)

Hex nut (4 pcs)

Model

Installation position of cable bearer 2 [8]

Y-axis

Hex socket-head

countersunk

M3 x 6 mm

Tightening torque

[8] Cable bearer 2

[7] Guide rail Y

See the table below.

Installation position of IK2-S(P) SXBA (SXBB) D

Y-axis str o k e

100 mm 106.5

150 mm 131.5

200 mm 156.5

250 mm 181.5

300 mm 206.5

350 mm 231.5

400 mm 256.5

Installation position of IK2-S(P) SXBC (SXBD) D

Y-axis str o k e

100 mm 105.0

150 mm 130.0

200 mm 155.0

250 mm 180.0

300 mm 205.0

350 mm 230.0

400 mm 255.0

Length from end face of guide rail Y

50 mm 81.5

50 mm 80.0

(front side) to fixed end of bearer

Length from end face of guide rail Y

(front side) to fixed end of bearer

Arrange the wires so that each axis will not contact the cables and

9

connectors when the axis is moved over its entire stroke.

(Note) If you want to move the actuator with brake by hand, connect the

controller and supply the power and then set the brake release switch to

RLS) side.

the release

Y-axis

Cables from hand, etc.

X-axis

[8] Cable bearer 2

Connect the motor

cable/encoder

cable connectors.

[5] Cable bearer 1

Guide rail

Frame cov er

* Refer to “Cable affixing method: GMM07-060” for affixing of cables.

Page 7

(

g

Note: z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exercise due caution durin

[Tools] Allen wrench, spanner wrench, ruler

1

Parallel pin

( 2 pcs)

Model Parallel pin Hex head bolt Tightening torque

(Note) One side of the cable bearer is free. The customer should install the cable

4

∅8h7 x 18

bearer as necessary.

[1] XZ bracket

[Installation of cable bearer [2] on bearer mounting bracket [3]]

Model

* This assembly procedure applies to combination direction 1. With other combination directions such as 2 and 3 , the actua tor and bracket directions are dif ferent. If y ou are using co mbination direction 2 or 3, assemble the p art s by

referring to this drawing.

Hex socket-head

countersunk

M3 x 6 mm

assembly to prevent pinching of your hands and fingers.

With combination direct ions 2 through

4, the bracket direction is different.

Hex head bolt + plain washer

(4 pcs)

[1] XZ bracket

X-axis

M8 x 20 mm

Z-axis

Hex socket-head countersunk (4 pcs)

[2] Cable bearer

X-axis

Tightening torque

2

With combination directions 2 through

4, the actuator direction is different.

Parallel pin ( 2 pcs)

Hex socket-head bolt (4 pcs)

Model Parallel pin

5

Arrange the wires so that each axis will not contact the cables and

connectors when the axis is moved over its entire stroke.

(Note) If you want to move the actuator with brake by hand, connect the

* Refer to “Cable affixin g me th od : GM M0 7- 060 ” f or affix i ng of ca bl es .

∅4h7 x 10

controller and supply the power and then set the brake release switch to

the release

RLS) side.

Z-axis

[1] XZ brac ket

Hex socket-head

bolt

M5 x 12 mm

X-axis

Tightening torque

3

Hex socket-head bolt (2 pcs)

Upright type: Single slider type

IK2-S(P)XZS

DWG. No. GMM07-055E 1/1

The following procedures apply to configurations with a cable bearer.

[1] XZ bracket

[3] Bearer mounting bracket

[Installation of bearer mounting bracket [3] on XZ bracket [1]]

Model Hex socket-head bolt Tightening torque

With combination directions 2 through 4, the installation direction of

the bearer mounting bracket [3] is differ ent.

[3] Bearer

mounting

bracket

[3] Bearer

mounting

bracket

M6 x 10 mm

Z-axis

[3] Bearer

mounting

bracket

X-axis

Page 8

(

r

Note: z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exe

[Tools] Allen wrench, spanner wrench, ruler

1

Parallel pin(2 pcs)

4

* This assembly procedure applies to combination direction 1. With other combination directions such as 2 and 3 , the actua tor and bracket directions are dif ferent. If y ou are using co mbination direction 2 or 3, assemble the p art s by

referring to this drawing.

cise due caution during assembly to prevent pinching of your hands and fingers.

With combination directions 2 through

4, the bracket direction is different.

Hex head bolt + plain

washer (4 pcs)

[1] XZ bracket

X-axis

Model Parallel pin Hex head bolt Tightening torque

∅8h7 x 18

M8 x 20 mm

(Note) One side of the cable bearer is free. The customer should install the cable

bearer as necessary.

Z-axis

Hex socket-head countersunk (4 pcs)

[2] Cable bearer

[1] XZ bracket

X-axis

[Installation of cable bearer [2] on bearer mounting bracket [3]]

Model

Hex socket-head

countersunk

M3 x 6 mm

Tightening torque

2

With combination directions 2 through

4, the actuator direction is different.

Parallel pin (2 pcs)

Hex socket-head bolt (4 pcs)

Model Parallel pin

5

Arrange the wires so that each axis will not contact the cables and

connectors when the axis is moved over its entire stroke.

(Note) If you want to move the actuator with brake by hand, connect the

* Refer to “Cable affixing method: GMM07-060” for affixing of cables.

∅4h7 x 10

controller and supply the power and then set the brake release switch to

the release

RLS) side.

Z-axis

[1] XZ bracket

Hex socket-head

bolt

M5 x 12 mm

X-axis

Tightening torque

3

Hex socket-head bolt (2 pcs)

Upright type: Double slider type

IK2-S(P)XZD

DWG. No. GMM07-056E 1/1

The following procedures apply to configurations with a cable bearer.

[1] XZ bracket

[3] Bearer moun ting bracket

[Installation of be arer mounti ng bracket [ 3 ] on XZ bracket [1]]

Model Hex socket-head bolt Tightening torque

With combination directions 2 through 4, the installation direction of

the bearer mounting bracket [3] is different.

[3] Bearer

mounting

bracket

[3] Bearer

mounting

bracket

M6 x 10 mm

Z-axis

[3] Bearer

mounting

bracket

X-axis

Page 9

p

A

g

Note: z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exercise due caution durin

1

[Tools] Allen wrench, spanner wrench, ruler

Hex socket-head bolt +

lain washer (4 pcs)

[1] Plate YZ

Model Parallel pin

∅8h7 x 18

assembly to prevent pinching of your hands and fingers.

2

Y-axis

Parallel pin ( 2 pcs)

Hex socket-head

bolt

M8 x 15 mm

Tightening torque

Model Parallel pin

With combination direction 2, the actuator direction is different.

Z-axis

Parallel pin (1 pc)

[1] Plate YZ

Y-axis

Hex socket-head bolt (4 pcs)

∅4h7 x 10

Hex socket-head

bolt

M5 x 18 mm

Tightening torque

3

Crossed-type base fixed: Single slider type

IK2-S(P)YBS

DWG. No. GMM07-057E 1/2

The following procedures apply to configurations with a cable bearer.

Install the Y-axis and guide rail Y.

lign the end face of

the base with the end

[2] Guide rail Y

Y-axis

face of the guide rail.

4

Z-axis

[1] Plate YZ

[5] Bearer mounting bracket 1

[2] Guide rail Y

Y-axis

Hex socket-head bolt (2 pcs)

Model Hex socket-head bolt Tightening torque

* This assembly procedure applies to combination direction 1. With other combination directions such as 2, the actuator and bracket directions are different. If you are using combination direction 2 or 3, assemble the parts by

referring to this drawing.

M5 x 18 mm

5

Hex socket-head countersunk

(4 pcs)

Hex nut (4 pcs)

Align the end face of cable

bearer 1 [4] with the end

face of guide rail Y [2].

[4] Cable bearer 1

[5] Bearer mounting bracket 1

[Installation of cable bearer 1 [4] on bearer mounting bracket 1 [5]]

Model

Model

Hex socket-head

countersunk (4 pcs)

[1] Plate YZ

[2] Guide rail Y

[Installation of cable bearer 1 [4] on gui de rai l 2 [2] ]

Y-axis

Hex socket-head

countersunk

M3 x 6 mm

Hex socket-head

countersunk

M3 x 6 mm

Tightening torque

Tightening torque

Z-axis

(Note) One side of cable bearer 2 is free. The customer should install cable

6

Hex socket-head

countersunk (4 pcs)

[6] Cable bearer 2

[4] Cable bearer 1

bearer 2 as necessary.

[1] Plate YZ

[Installation of bearer mounting bracket 2 [7] on pl ate YZ [1]]

Model Hex socket-head bolt Tightening torque

[Installation of cable bearer 2 [6] on bearer mounting bracket 2 [7]]

Model

M5 x 15 mm

Hex socket-head

countersunk

M3 x 6 mm

Z-axis

[7] Bearer mounting bracket 2

Hex socket-head bolt (2 pcs)

Y-axis

[2] Guide rail Y

Tightening torque

Page 10

(

(

Crossed-type base fixed: Single slider type

IK2-S(P)YBS

DWG. No. GMM07-057E 2/2

Arrange the wires so that each axis will not contact the cables and

7

connectors when the axis is moved over its entire stroke.

(Note) If you want to move the actuator with brake by hand, connect the

controller and supply the power and then set the brake release switch to

RLS) side.

the release

Y-axis (axis 1): With cable bearer / Z-axis (axis 2): Without cable bearer

* Refer to “Cable affixing method: GMM07-060” for affixing of cables.

Arrange the wires so that each axis will not contact the cables and

connectors when the axis is moved over its entire stroke.

(Note) If you want to move the actuator with brake by hand, connect the

controller and supply the power and then set the brake release switch to

the release

RLS) side.

Y-axis (axis 1): With cable bearer / Z-axis (axis 2): With cable bearer

* Refer to “Cable affixing method: GMM07-060” for affixing of cables.

Page 11

j

∅

∅

j

j

∅

∅

g

∅

A

j

[

Note: z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exercise due caution durin

[Tools] Allen wrench, spanner wrench, ruler

1

Parallel pin (1 pc or 2 pcs)

Screw lock holes:

Model Parallel pin Hex head bolt Tightening torque

Note: To ensure squareness of the X-axis and Y-axis, place one parallel pin.

After ad

9

Parallel pin holes: ∅8

∅8h7 x 25

usting the squareness of the X-axis and Y-axis, affix the hex head bolt.

4

Parallel pin (1 pc or 2 pcs)

Hex socket-head bolt (4 pcs)

[4] Plate YZ2

Note: On some models, only one parallel pin may be accommodated depending on the axis.

Parallel pin holes:

4

Model Parallel pin

∅4h7 x 10

* This assembly procedure applies to combination direction 1. With other combination directions such as 2 through 4, the actuator and bracket directions are different. If you are using combination direction 2 through 4, assemble

the parts by referring to this drawing.

assembly to prevent pinching of your hands and fingers.

2

Hex head bolt + plain washer (4 pcs)

[2] Plate X

Hex socket-head bolt (4 pcs)

X-axis

Screw lock holes:

9

M8 x 30 mm

5

Z-axis

Hex socket-head

bolt (4 pcs)

Parallel pin

holes: ∅4

Screw lock holes: ∅5.5

Screw lock holes: ∅5.5

Hex

socket-head bolt

M5 x 12 mm

Tightening torque

Parallel pin

holes: ∅4

With combination directions 2

through 4, the actuator and

Y-axis

Parallel pin (1 pc or 2 pcs)

[1] XY bracket

[2] Plate X

Y-axis

Hex socket-head

M5 x 15 mm

Parallel pin

holes: ∅4

Parallel pin

holes: ∅4

Hex

socket-head bolt

M5 x 10 mm

Model Parallel pin

Note: To ensure squareness of the X-axis and Y-axis, place one parallel pin.

After ad

Parallel pin (1 pc or 2 pcs)

[3] Plate YZ1

[4] Plate YZ2

∅4h7 x 10

usting the squareness of the X-axis and Y-axis, affix the hex head bolt.

Screw lock holes: ∅5.5

Screw lock holes: ∅5.5

Model Parallel pin

Note: To ensure squareness of the Y-axis and Z-axis, place one parallel pin.

After ad

∅4h7 x 10

usting the squareness of the Y-axis and Z-axis, affix the hex head bolt.

bracket direct ions are different.

X-axis

bolt

Z-axis

[4] Plate YZ2

[3] Plate YZ1

Tightening torque

Screw lock holes: ∅5.5

Screw lock holes: ∅5.5

Tightening torque

3

6

7

XYB + base fixed type: Single slider type

IK3-S(P)BBS

DWG. No. GMM07-058E 1/2

Parallel pin (1 pc or 2 pcs)

[1] XY bracket

[2] Plate X

X-axis

Screw lock holes:

Model Parallel pin

Note: To ensure squareness of the X-axis and Y-axis, place one parallel pin.

The following procedures apply to configurations with a cable bearer.

usting the squareness of the X-axis and Y-axis, affix the hex head bolt.

After ad

5.5

∅5h7 x 14

Install the X-axis and guide rail X.

X-axis

[5] Guide rail X

Bottom view

Hex socket-head bolt (2 pcs)

Hex nut (2 pcs)

Y-axis

[1] XY bracket

Model Hex socket-head bolt Tightening torque

[8] Bearer mounting bracket 1

Z-axis

M4 x 8 mm

Y-axis

Screw lock holes: ∅5.5

Parallel pin holes:

Hex socket-head

bolt

M5 x 12 mm

the base with the end

face of guide r ail X.

X-axis

[5] Guide rail X

After installing plate

YZ1, move the Y-axis

slider toward the

counter-motor end.

Hex socket-head bolt

[3] Plate YZ1

Tightening torque

lign the end face of

Set the dimension from the

side face of the XY bracket to

the tip of bearer mounting

bracket 1

(4 pcs)

5

8] to 152.5 mm.

Page 12

(

8

Hex socket-head countersunk (4 pcs)

Z-axis

Y-axis

[8] Bearer mounting

bracket 1

[Installation of ca ble bearer 1 [7] on bearer mounting br a cket 1 [8]]

Model

[Installation of cable bearer 1 [7] on guide rail X [5]]

Model

11

Y-axis

[3] Guide rail Y

Hex socket-head countersunk (4 pcs)

Hex nut (4 pcs)

[11] Bearer mounting

bracket 2

[Installation of cable b earer 2 [10] on guide rail Y [9]]

Model

[Installation of cable bearer 2 [10] on bearer mounting bracket 2 [11]]

Model

Hex socket-head

countersunk

Hex socket-head

countersunk

Hex socket-head

countersunk

Hex socket-head

countersunk

Hex head bolt countersunk (4 pcs)

[7] Cable bearer 1

[5] Guide rail X

Tightening torque

M3 x 6 mm

Tightening torque

M3 x 6 mm

[10] Cable bearer 2

Hex socket-head countersunk (4 pcs)

Tightening torq ue

M3 x 6 mm

Tightening torq ue

M3 x 6 mm

Hex nut (4 pcs)

X-axis

Align the end face of cable

bearer 1 [7] with the end

face of guide r ail X [5].

Z-axis

9

[1] T-slot in XY bracket

Z-axis

Y-axis

[9] Guide rail Y

Model Hex socket-head bolt Tightening torque

Installation position of cable bearer 2 [10]

[9] Guide rail Y

Y-axis st r ok e

50 mm 81.5

100 mm 106.5

150 mm 131.5

200 mm 156.5

250 mm 181.5

300 mm 206.5

350 mm 231.5

400 mm 256.5

M4 x 8 mm

Y-axis

See the table below.

Length from end face of guide rail Y

(front side) to fixed end of bearer

Align the end face of guide

rail Y [9] with the end face

of the XY bracket [1].

X-axis

Hex socket-head bolt (3 pcs)

Hex nut (3 pcs)

[10] Cable bearer 2

XYB + base fixed type: Single slider type

IK3-S(P)BBS

DWG. No. GMM07-058E 2/2

10

Y-axis

[9] Guide rail Y

Screw lock holes: ∅5.5

Model Hex s o c ket-head bolt Tightening torque

12

Arrange the wires so that each axis will not contact the cables and

connectors when the axis is moved over its entire stroke.

(Note) If you want to move the actuator with brake by hand, connect the

controller and supply the power and then set the brake release switch to

the release

* Refer to “Cable affixing method: GMM07-060” for affixing of cables.

[3] Plate YZ1

Z-axis

Hex socket-head bolt (2 pcs)

X-axis

[11] Bearer mounting bracket 2

M5 x 10 mm

RLS) side.

Page 13

g

a

ead bolt

∅

∅

j

∅

∅

∅

∅

j

A

[

Note: z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exercise due caution durin

[Tools] Allen wrench, spanner wrench, ruler

1

Hex socket head

bolt + plain washer

(8 pcs)

Parallel pin (2 pcs)

Screw lock holes

Screw lock holes

Combination directions 1, 3

Screw lock holes

Parallel pin holes

Screw lock holes

Combination directions 2, 4

Model

Parallel pin

∅8h7 x 18

Screw lock holes

Parallel pin holes

Screw lock holes

Screw lock holes

Screw lock holes

Hex

socket-head bolt

M8 x 20 mm

5

Parallel pin (1 pc or 2 pcs)

Hex socket-head bolt (4 pcs)

[4] Plate YZ2

Note: On some models, only one parallel pin may be accommodated depending on the axis.

Parallel pin holes:

4

Model Parallel pin

∅4h7 x 10

assembly to prevent pinching of your hands and fingers.

With combination directions

2 through 4, the bracket

directi o n i s different .

[2] Plate X

X-axis

2

Hex head bolt +

high-tension

washer (6 pcs)

[1] XY bracket

Parallel pin

(1 pc or 2 pcs)

[2] Plate X

Tightening torque

Screw lock holes: ∅9

Model

Note: To ensure squareness of the X-axis and Y-axis, place one

parallel pin.

After adjusting the squareness of the X-axis and Y-axis,

ffix the hex h

Screw lock holes: ∅9

Screw lock holes:

Parallel pin

Hex head bolt Tightening torque

M8 x 20 mm

∅8h7 x 18

.

6

Z-axis

Hex socket-head

bolt (4 pcs)

Parallel pin

holes: ∅4

Screw lock holes: ∅5.5

Screw lock holes: ∅5.5

Hex

socket-head bolt

M5 x 12 mm

Tightening torque

Parallel pin

holes: ∅4

X-axis

Parallel pin holes:

Note: To ensure squareness of the Y-axis and Z-axis, place one parallel pin.

3

Hex socket-head

bolt (4 pcs)

With combination directions 2 through

4, the actuator direction is different.

Y-axis

Parallel pin (1 pc or 2 pcs)

8

9

Model

Parallel pin (1 pc or 2 pcs)

[3] Plate YZ1

Y-axis

[4] Plate YZ2

Screw lock holes: ∅5.5

Screw lock holes: ∅5.5

Model Parallel pin

After ad

∅4h7 x 10

usting the squareness of the Y-axis and Z-axis, affix the hex head bolt.

Parallel pin

∅4h7 x 10

Parallel pin

holes: ∅4

Parallel pin

holes: ∅4

Hex

socket-head bolt

M5 x 10 mm

[3] Plate YZ1

[1] XY bracket

[2] Plate X

Hex

socket-head bolt

M5 x 15 mm

Z-axis

[4] Plate YZ2

Screw lock holes: ∅5.5

Screw lock holes: ∅5.5

Tightening torque

X-axis

Tightening

torque

XYB + base fixed type: Double slider type

IK3-S(P)BBD

DWG. No. GMM07-059E 1/2

4

[1] XY bracket

Parallel pin (1 pc or 2 pcs)

[2] Plate X

X-axis

Screw lock holes:

Model Parallel pin

Note: To ensure squareness of the X-axi s and Y-axis, place one paralle l pin.

After ad

∅5h7 x 14

usting the squareness of the X-axis and Y-axis, affix the hex head bolt.

The following procedures apply to configurations with a cable bearer.

7

Install the X-axis and guide rail X.

X-axis

[5] Guide rail X

Bottom view

8

Hex socket-head bolt (2 pcs)

Hex nut (2 pcs)

[8] Bearer mounting bracket 1

Y-axis

[1] XY bracket

Model Hex socket-head bolt Tightening torque

5.5

Hex socket-head

Z-axis

M4 x 8 mm

Y-axis

[3] Plate YZ1

Screw lock holes:

Parallel pin holes:

bolt

M5 x 12 mm

X-axis

[5] Guide rail X

lign the end face of

the base with the end

face of guide rail X.

After installing plate

YZ1, move the Y-axis

slider toward the

counter-motor end.

Hex socket-head bolt

(4 pcs)

5.5

5

Tightening torque

Set the dimension from the

side face of the XY bracket to

the tip of bear e r mounting

bracket 1

8] to 152.5 mm.

* This assembly procedure applies to combination direction 1. With other combination directions such as 2 through 4, the actuator and bracket directions are different. If you are using combination direction 2 through 4, assemble

the parts by referring to this drawing.

Page 14

(

9

Hex socket-head bolt (4 pcs)

Z-axis

Y-axis

[8] Bearer mounting

bracket 1

[Installation of cable bearer 1 [7] on bearer mounting bracket 1 [8]]

Model

[Installation of cabl e bearer 1 [7] on guide rail X [5]]

Model

12

Y-axis

[3] Guide rail Y

Hex socket-head countersunk (4 pcs)

Hex nut (4 pcs)

[11] Bearer mounting

bracket 2

[Installation of cable bearer 2 [10] on guide rail Y [9]]

Model

[Installation of cable bearer 2 [10] on bearer mounting bracket 2 [11]]

Model

Hex socket-head

countersunk

M3 x 6 mm

Hex socket-head

countersunk

M3 x 6 mm

Hex socket-head

countersunk

Hex socket-head

countersunk

[7] Cable bearer 1

[5] Guide rail X

[10] Cable bearer 2

Hex socket-head bolt (4 pcs)

M3 x 6 mm

M3 x 6 mm

Hex head bolt countersunk (4 pcs)

Hex nut (4 pcs)

X-axis

Align the end face of cable

bearer 1 [7] with the end

face of guide rail X [5].

Tightening torque

Tightening torque

Tightening torque

Tightening torque

Z-axis

10

[1] T-slot in XY bracket

Z-axis

Y-axis

[9] Guide rail Y

Model Hex socket-head bolt Tightening torque

Installation position of cable bearer 2 [10]

[9] Guide rail Y

Y-axis str o k e

50 mm 81.5

100 mm 106.5

150 mm 131.5

200 mm 156.5

250 mm 181.5

300 mm 206.5

350 mm 231.5

400 mm 256.5

M4 x 8 mm

Y-axis

See the table below.

Length from end face of guide rail Y

(front side) to fixed end of bear er

Align the end face of guide

rail Y [9] with the end face

of the XY bracket [1].

Hex socket-head bolt (3 pcs)

Hex nut (3 pcs)

X-axis

[10] Cable bearer 2

XYB + base fixed type: Double slider type

IK3-S(P)BBD

DWG. No. GMM07-059E 2/2

11

Y-axis

[9] Guide rail Y

Model Hex socket-head bolt Tightening torque

13

Arrange the wires so that each axis will not contact the cables and

connectors when the axis is moved over its entire stroke.

(Note) If you want to move the actuator with brake by hand, connect the

controller and supply the power and then set the brake release switch to

the release

* Refer to “Cable affixing method: GMM07-060” for affixing of cables.

[3] Plate YZ1

[11] Bearer mounting bracket 2

M5 x 10 mm

RLS) side.

Z-axis

Hex socket-head bolt (2 pcs)

X-axis

Page 15

g

A

g

g

Note: z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exercise due caution durin

assembly to prevent pinching of your hands and fingers.

XY base fixed type

ffixing to XY bracket [1] Affixing to cable bearer 1 [5]

Y-axis

[5] Cable

bearer 1

Use the T-slot to

affix the cables.

Tie-mount KR5G5 (HellermannTyton)

Hex socket-head countersunk M4-8

Hex nut

Affix the cables

usin

an Insulock.

[1] XY bracket

Upright type

Z-axis

Affixing to XY bracket [1]

Use the cable affixing

holes to affix t he cables.

Tie-mount KR5G5

(HellermannTyton)

Hex socket-head

countersunk M4-8

Affix the cables

usin

an Insulock.

Y-axis

[5] Cable bearer 1

Use an Insulock to affix each cable

directly to cable bearer 1 [5].

[1] XZ bracket

Use this part

to affix the

cables.

Cable affixing holes

(Affix from the back

side.)

Cable affixing method

DWG. No. GMM07-060E 1/2

Crossed type

Affixing to Z-axis

[4] Cable bearer 1

Secure the cables

together to the

motor cover.

Z-axis

Tie-mount MB-1

(HellermannTyton)

Hex socket-head countersunk M3-8

Hex nut

First, remove the thin

head bolts (2 locations).

Next, affix the cables

using an Insulock.

Note: Since the hex socket on the thin head bolt is small, the hex socket may

be stripped (damaged) depending on how the bolt is loosened. Exercise

due caution when loosening the thin head bolts.

[4] Cable bearer 1

Z-axis

XZ bracket

* The cable affixing method shown above assumes a Z-axis stroke of 50 mm.

If the Z-axis stroke is more than 50 mm, lay the cables straight when affixing, instead of bending them as shown in the figure.

Note: Arrange the wires so that each axis will not contact the cables and connectors when the axis is moved over its entire stroke. If you want to move the actuator with brake by hand, connect the controller and supply the power and then set the brake release

switch to the release (RLS) side.

Cable bearer

Bound the cables using

an Insulock.

Page 16

A

g

y

g

A

A

XY base fixed type

Between Z-axis and cable bearer 2

1

Tie-mount installation direction

Between Y-axis and cable bearer 1

2

Y-axis

Cable bearer 1

Z-axis cable

connector

Z-axis

Affixing to plate YZ1 [1]

Y-axis cable connector

Cable affixing method

ffixing to plate YZ1 [3] Affixing to cable bearer

Use this part to

Tie-mount installation direction

Tie-mount KR5G5 (HellermannTyton)

Hex socket-head countersunk M4-8

Install a tie-mount on plate YZ1 [3] and

affix the cable s usin

Use plate YZ1 to

affix the cables.

Use the T-slot to

affix the cables.

Hex socket countersunk bolt M4-8

Tie-mount KR5G5

(HellermannTyton)

Brass spacer

Plain washer

Hex nut

Affix the cables using

an Insulock.

Cable affixing holes

an Insulock.

3

[3] Plate YZ1

Between cable bearer 1 and cable bearer 2

ffixing to cable bearer 1 [10]

Use this part to

affix the cables.

Y-axis

Y-axis cable

Z-axis cable

Use an Insulock to affix

each cable dire ct ly t o c able

bearer 1 [5].

affix the cables.

Cable bearer 2

Use an Insulock to affix each cable

directl

to cable bearer 2 [10].

Y-axis

Affix the cable s us ing

an Insulock.

Z-axis

Affix the cables directly

to cable bearer 2 [10]

an Insulock.

usin

Use the T-slot to

affix the cables.

Tie-mount MB-1 (HellermannTyton)

Hex socket-head countersunk M-8

Affix the cables using

an Insulock.

4

Between cable bearer 1 and cable bearer 2

X-axis

DWG. No. GMM07-060E 2/2

Cable bearer 2

Z-axis

ffixing to cable bearer 1 [10]

Cable bearer 1

Use this part to

affix the cables.

Use an Insulock to affix

each cable directly to cable

bearer 1 [5].

Note: Arrange the wires so that each axis will not contact the cables and connectors when the axis is moved over its entire stroke. If you want to move the actuator with brake by hand, connect the controller and supply the power and then set the brake release

switch to the release (RLS) side.

Loading...

Loading...