Page 1

ERC3

Actuator with Integrated Controller

Instruction Manual

Eighth Edition

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Instruction Manual describes all necessary information items to operate this product safely

such as the operation procedure, structure and maintenance procedure.

Before the operation, read this manual carefully and fully understand it to operate this product

safely.

The enclosed CD or DVD in this product package includes the Instruction Manual for this product.

For the operation of this product, print out the necessary sections in the Instruction Manual or

display them using the personal computer.

After reading through this manual, keep this Instruction Manual at hand so that the operator of this

product can read it whenever necessary.

[Important]

x This Instruction Manual is original.

x The product cannot be operated in any way unless expressly specified in this Instruction

Manual. IAI shall assume no responsibility for the outcome of any operation not specified

herein.

x Information contained in this Instruction Manual is subject to change without notice for the

purpose of product improvement.

x If you have any question or comment regarding the content of this manual, please contact

the IAI sales office near you.

x Using or copying all or part of this Instruction Manual without permission is prohibited.

x The company names, names of products and trademarks of each company shown in the

sentences are registered trademarks.

Page 4

Page 5

Table of Contents

Safety Guide ···················································································································1

Guideline for Control Method····························································································8

Precautions in Operation ·································································································· 9

International Standards Compliances············································································· 13

Names of the Parts ········································································································· 14

Actuator Coordinate········································································································ 23

Starting Procedures ········································································································ 24

Chapter 1 Specifications Check ··············································································· 31

1.1 Product Check ················································································································ 31

1.1.1 Parts················································································································· 31

1.1.2 Teaching Tool ···································································································32

1.1.3 Instruction manuals related to this product, which are contained

in the DVD.······································································································· 32

1.1.4 How to read the model plate············································································33

1.1.5 How to read the model·····················································································34

1.2 Specifications·················································································································· 36

1.2.1 Actuator············································································································ 36

[1] High Output Setting·················································································36

[2] Maximum speed ······················································································38

[3] MAX. Acceleration, Payload Capacity····················································· 40

[4] Driving System • Position Detector ·························································52

[5] Positioning Precision··············································································· 53

[6] Current Limit Value and Pressing Force ················································· 54

[7] Option······································································································ 58

1.2.2 Built-in Controller ····························································································· 59

[1] Basic Specifications················································································· 59

[2] I/O Specifications····················································································· 60

1.2.3 Control Option··································································································62

[1] PIO Converter (Model: RCB-ƑƑƑ)··························································· 62

[2] Quick Teach (Model: RCM-PST-Ƒ)·························································· 66

Chapter 2 Installation ·······························································································69

2.1 Transportation·················································································································69

[1] Handling of Actuator, PIO Converter and Quick Teach ···························69

[2] Handling of Multi-Axes Type···································································· 70

[3] Handling of Robot Mounted on Mechanical Equipment (System) ··········70

2.2 Installation and Storage Environment············································································· 71

[1] Installation Environment··········································································71

[2] Storage • Preservation Environment ······················································· 72

2.3 How to Install ·················································································································· 73

2.3.1 Posture of Actuator Attachment ······································································· 73

2.3.2 Installation of Slider Type ················································································· 74

[1] Attachment of Actuator Body··································································· 74

[2] Load Attachment ·····················································································77

2.3.3 Installation of Rod Type····················································································79

[1] Installation of Actuator Type Unit····························································· 79

[2] Load Attachment ·····················································································84

2.3.4 Noise Prevention and How to Attach Electrical Devices·································· 86

[1] Noise Elimination Grounding (Frame Ground)········································ 86

[2] Precautions regarding wiring method······················································90

[3] Noise Sources and Elimination ······························································· 90

[4] Cooling Factors and Installation······························································90

Page 6

Chapter 3 Wiring ······································································································ 93

3.1 Positioner Mode 1 (Standard Type)················································································93

3.1.1 Wiring Diagram (Connection of construction devices)····································· 93

3.1.2 PIO Pattern Select and PIO Signal·································································· 94

[1] PIO Pattern (Control Pattern) Selection·················································· 94

[2] PIO Patterns and Signal Assignment······················································95

[3] List of PIO Signals··················································································· 96

3.1.3 Circuit Diagram ································································································ 97

[1] Power Line and Emergency Stop Circuit················································· 97

[2] PIO Circuit ·······························································································98

3.2 Pulse Train Control Mode ·····························································································101

3.2.1 Wiring Diagram (Connection of construction devices)··································· 101

3.2.2 PIO Pattern Selection and PIO Signal··························································· 102

[1] PIO Pattern (Control Pattern) Selection················································ 102

[2] PIO pattern and Signal Allocation·························································· 102

[3] List of PIO Signals················································································· 103

3.2.3 Circuit Diagram ······························································································ 104

[1] Power Line and Emergency Stop Circuit··············································· 104

[2] Command Pulse Train Circuit································································ 105

[3] PIO Circuit ·····························································································106

3.3 Positioner Mode 2 (Extension Type by PIO Converter)················································108

3.3.1 Wiring Diagram (Connection of construction devices)··································· 108

3.3.2 PIO Pattern Selection and PIO Signal··························································· 109

[1] PIO Pattern (Control Pattern) Selection················································ 109

[2] PIO Patterns and Signal Assignment···················································· 110

[3] List of PIO Signals················································································· 112

3.3.3 Circuit Diagram ······························································································ 114

[1] Power Line and Emergency Stop Circuit··············································· 114

[2] PIO Converter to ERC3········································································· 116

[3] PIO Circuit ····························································································· 117

3.4 MEC Mode 1 (Operation with PLC)··············································································123

3.4.1 Wiring Diagram (Connection of construction devices)··································· 123

3.4.2 PIO Pattern Selection and PIO Signal··························································· 124

[1] Operation pattern ·················································································· 124

[2] Operation Patterns and Signal Assignments········································· 125

[3] List of PIO Signals················································································· 126

3.4.3 Circuit Diagram ······························································································ 127

[1] Power Line and Emergency Stop Circuit··············································· 127

[2] PIO Circuit ·····························································································128

3.5 MEC Mode 2 (Operation Using PIO Converter)··························································· 130

3.5.1 Wiring Diagram (Connection of construction devices)··································· 130

3.5.2 PIO Pattern Selection and PIO Signal··························································· 131

[1] Operation pattern ·················································································· 131

[2] Operation Patterns and Signal Assignments········································· 132

[3] List of PIO Signals················································································· 133

3.5.3 Circuit Diagram ······························································································ 134

[1] Power Line and Emergency Stop Circuit··············································· 134

[2] PIO Converter to ERC3·········································································136

[3] PIO Circuit ·····························································································137

3.6 MEC Mode 3 (Solo Operation with Quick Teach)························································· 139

3.6.1 Wiring Diagram (Connection of construction devices)··································· 139

[1] RCM-PST-0 (24V DC power supply type)·············································139

[2] RCM-PST-1 ··························································································· 140

[3] RCM-PST-2/RCM-PST-EU····································································141

Page 7

3.7 Wiring Method···············································································································142

3.7.1 Wiring of Actuator··························································································· 142

[1] PIO type power and I/O cable (Model : CB-ERC3P-PWBIOƑƑƑ)········· 142

[2] SIO type power and I/O cable (Model : CB-ERC3S-PWBIOƑƑƑ)········· 143

3.7.2 Wiring between PIO Converter and Quick Teach ··········································144

3.7.3 Wiring between PIO Converter and Host Controller (e.g. PLC) ···················· 145

3.7.4 Wiring of PIO Converter Power Line Connector············································ 149

3.7.5 Pulse Converter: AK-04 (Optional accessory) ··············································· 150

3.7.6 Teaching Port Connector Connection of ERC3 Main Unit ·····························151

3.7.7 Connection of SIO Connector of PIO Converter············································ 152

Chapter 4 Operation·······························································································153

4.1 Basic Operation ············································································································153

4.1.1 Basic Operation Methods··············································································· 153

[1] Positioner Mode 1 (PIO Operation of ERC3) ········································ 153

[2] Pulse Train Control Mode (Pulse Train Operation of ERC3)·················154

[3] Positioner Mode 2 (Extended Operation of ERC3)······························· 155

[4] MEC Mode 1 ························································································· 156

[5] MEC Mode 2 ························································································· 157

[6] MEC Mode 3 ························································································· 157

4.1.2 Parameter Settings ························································································158

4.2 Operation in Positioner Mode ·······················································································159

4.2.1 Set of Position Table ······················································································ 159

4.2.2 Operation in Positioner Mode 1 ····································································· 164

[1] PIO Pattern Selection and Main Functions ···········································164

[2] Overview of major Functions································································· 165

[3] Power Supply and Emergency Stop Release (CP, MP, EMG, PEND) ·· 166

[4] Brake release BK ·················································································· 167

[5] Time Constant for Control Signal Input ················································· 167

[6] Operation Ready and Auxiliary Signals·················································168

[7] Operation with the Position No. Input =

Operations of PIO Patterns 0 and 2······················································172

[8] Direct Position Specification (3-point <Solenoid valve> type) =

PIO Pattern 1························································································· 185

4.2.3 Operation in Positioner Mode 2 (Operation Using PIO Converter)················ 197

[1] PIO Pattern Selection and Main Functions ···········································197

[2] Overview of major Functions································································· 198

[3] Power Supply and Emergency Stop Release

(CP24, MPI, MPO, EMG(-))··································································· 199

[4] Time Constant for Control Signal Input ················································· 199

[5] Operation Ready and Auxiliary Signals·················································200

[6] Operation with the Position No. Input =

Operations of PIO Patterns 0 to 3 ·························································209

[7] Direct Position Specification (Solenoid Valve Mode 1) =

Operation of PIO Pattern 4···································································· 226

[8] Direct Position Specification (Solenoid Valve Mode 2)

= Operations of PIO Pattern 5 in PIO Converter···································238

4.3 Operation in Pulse Train Control Mode (How to Operate Pulse Train Control Type) ··· 245

[1] Guideline for PIO Pattern Selection and Supportive Functions ············ 245

[2] Guideline for Supportive Functions······················································· 245

[3] Power Supply and Emergency Stop Release (CP, MP, EMG) ·············· 246

[4] Brake Release BK·················································································246

[5] Time Constant for Control Signal Input ················································· 247

[6] Operation Ready and Auxiliary Signals·················································247

[7] Pulse Train Input Operation··································································· 251

[8] Settings of Basic Parameters Required for Operation·························· 254

[9] Parameter Settings Required for Advanced Operations······················· 257

Page 8

4.4 Operation in MEC Mode 1 and 2 (Operation with PLC) ···············································259

[1] Outline for Operation Patterns and Functions·······································259

[2] Table for Operational Conditions (Position Table) and

Positioning Complete Signal ································································· 260

[3] Power Supply and Emergency Stop Release ······································· 264

[4] Brake release BK ·················································································· 266

[5] Time Constant for Control Signal Input ················································· 266

[6] Operation when Operation Pattern is “2-Point Stop (2-Point

Positioning)”··························································································· 267

[7] Operation when Operation Pattern is “3-Point Stop (3-Point

Positioning)”··························································································· 268

4.5 Operation in MEC Mode 3 (Test Run with Quick Teach.) ·············································271

4.5.1 Operation Panel Functions ············································································ 271

4.5.2 Operations······································································································ 272

[1] Switches Used for Mode Selection (Auto Њ Manual) ························· 272

[2] Switch Used for Servo ON/OFF Operation ··········································· 272

[3] Switch Used for Home-Return Operation··············································272

[4] Switches Used for Manual Operation····················································272

[5] Switch Used for Brake Release ···························································· 273

[6] Switches Used to Change Positioning Point Number··························· 273

[7] Switches Used for Position Teaching ···················································· 274

[8] Switches and Rotary Knobs Used in Acceleration/Deceleration and

Speed Settings ······················································································277

[9] Switches Used in Test Run···································································· 277

[10] Switches Used in Alarm Reset······························································ 277

4.5.3 Test Run with Operation Panel ······································································ 278

Chapter 5 Power-saving Function

(Automatic Servo-off and Full Servo Functions) ···································· 287

5.1 Positioner Mode 1 and 2······························································································· 287

5.2 Pulse Train Control Mode ·····························································································290

5.3 MEC Mode 1, 2 and 3··································································································· 291

5.3.1 Automatic Servo-off Function········································································· 291

5.3.2 Full Servo Function ························································································293

Chapter 6 Adjustment of Operation ········································································295

6.1 Absolute Reset and Absolute Battery···········································································295

6.1.1 Absolute Reset·······························································································295

[1] Absolute reset procedure from teaching tool ········································295

[2] Absolute reset using PIO······································································· 296

[3] Absolute Battery····················································································298

6.2 High Output Setting and Gain Scheduling Function····················································· 301

6.2.1 High Output Setting························································································ 301

6.2.2 Gain Scheduling Function··············································································301

6.2.3 Setting in Positioner Mode 1 & 2 and Pulse Train Control Mode··················· 301

6.2.4 Setting in MEC Mode 1 to 3···········································································302

6.3 I/O Parameter ··············································································································· 303

6.3.1 Positioner Mode 1, Positioner Mode 2 and Pulse Train Control Mode·········· 304

[1] I/O Parameter List ·················································································304

[2] Detail Explanation of Parameters··························································308

[3] Servo Adjustment ··················································································335

6.3.2 MEC Mode 1, MEC Mode 2 and MEC Mode 3·············································· 338

[1] I/O Parameter List ·················································································338

[2] Detail Explanation of Parameters··························································340

[3] Servo Adjustment ··················································································348

Page 9

Chapter 7 Troubleshooting·····················································································351

7.1 Action to Be Taken upon Occurrence of Problem·························································351

7.2 Fault Diagnosis ············································································································· 353

7.2.1 Impossible operation of controller··································································353

7.2.2 Positioning and speed of poor precision (incorrect operation) ······················ 358

7.2.3 Generation of noise and/or vibration······························································360

7.3 Alarm Level ··················································································································· 361

7.4 Alarm List······················································································································362

Chapter 8 Actuator Maintenance Check ································································375

8.1 Inspection Items and Schedule ···················································································· 375

8.2 External Visual Inspection ···························································································· 375

8.3 Cleaning························································································································375

8.4 Internal Inspections for Slider Type ··············································································376

8.5 Internal Cleaning for Slider Type ··················································································376

8.6 Grease Supply ··············································································································377

8.6.1 Grease Supply for Slider Type·······································································377

8.6.2 How to Supply Grease on Slider Type ···························································378

8.6.3 Grease Supply for Rod Type·········································································· 380

8.6.4 How to Supply Grease on Rod Type······························································381

8.7 Motor Replacement Process ························································································383

Chapter 9 External Dimensions··············································································385

9.1 ERC3-SA5C··················································································································385

9.2 ERC3-SA7C··················································································································386

9.3 ERC3-RA4C ·················································································································387

9.4 ERC3-RA6C ·················································································································388

Chapter 10 Appendix································································································389

10.1 Input and Output Response Performance When PIO Converter is Used ···················· 389

10.2 Way to Set Multiple Controllers with 1 Teaching Tool ··················································· 390

10.2.1 Connecting Example······················································································ 391

10.2.2 Detailed Connection Diagram of Communication Lines································ 392

10.2.3 Axis No. Setting······························································································ 392

10.2.4 Handling of e-CON connector (how to connect)············································ 393

10.2.5 SIO Converter ································································································394

10.2.6 Communications Cable·················································································· 396

10.3 Conformity to Safety Category ····················································································· 397

[1] System Configuration············································································397

[2] Wiring and setting of safety circuit ························································398

[3] Examples of safety circuits···································································· 400

[4] TP adapter and accessories·································································· 406

10.4 When Connecting Power Supply with + Grounding ····················································· 408

Page 10

10.5 Example of Basic Positioning Sequence (PIO Patterns 0 to 3 in PIO Converter)········ 409

10.5.1 I/O Assignment······························································································· 409

10.5.2 Ladder Sequence··························································································· 410

[1] Servo ON (Emergency Stop) Circuit ····················································· 410

[2] Operation and Stop Circuit ····································································410

[3] Pause Circuit ························································································· 411

[4] Reset Circuit·························································································· 412

[5] Home Return Circuit·············································································· 413

[6] Decode Circuit of Positioning Complete Position No.··························· 414

[7] Actuator Start Circuit ·············································································414

[8] Position 1 Operation Circuit··································································· 415

[9] Position 2 Operation Circuit··································································· 416

[10] Position 3 Operation Circuit···································································417

[11] Commanded Position No. Output Ready Circuit··································· 418

[12] Commanded Position No. Output Circuit ··············································419

[13] Start Signal Output Circuit····································································· 419

[14] Other Display Circuits (Zone 1, Position Zone, and Manual Mode)······ 420

10.6 Life ································································································································ 421

10.6.1 Product Life of Slider Type············································································· 421

10.6.2 Product Life of Rod Type ··············································································· 421

Chapter 11 Warranty ································································································423

11.1 Warranty Period············································································································ 423

11.2 Scope of the Warranty··································································································423

11.3 Honoring the Warranty·································································································· 423

11.4 Limited Liability ············································································································· 423

11.5 Conditions of Conformance with Applicable Standards/Regulations, Etc.,

and Applications············································································································424

11.6 Other Items Excluded from Warranty ··········································································· 424

Change History ············································································································· 425

Page 11

1

Safety Guide

“Safety Guide” has been written to use the machine safely and so prevent personal injury or

property damage beforehand. Make sure to read it before the operation of this product.

Safety Precautions for Our Products

The common safety precautions for the use of any of our robots in each operation.

No.

Operation

Description

Description

1 Model

Selection

Ɣ This product has not been planned and designed for the application

where high level of safety is required, so the guarantee of the protection

of human life is impossible. Accordingly, do not use it in any of the

following applications.

1) Medical equipment used to maintain, control or otherwise affect

human life or physical health.

2) Mechanisms and machinery designed for the purpose of moving or

transporting people (For vehicle, railway facility or air navigation

facility)

3) Important safety parts of machinery (Safety device, etc.)

Ɣ Do not use the product outside the specifications. Failure to do so may

considerably shorten the life of the product.

Ɣ Do not use it in any of the following environments.

1) Location where there is any inflammable gas, inflammable object or

explosive

2) Place with potential exposure to radiation

3) Location with the ambient temperature or relative humidity exceeding

the specification range

4) Location where radiant heat is added from direct sunlight or other

large heat source

5) Location where condensation occurs due to abrupt temperature

changes

6) Location where there is any corrosive gas (sulfuric acid or

hydrochloric acid)

7) Location exposed to significant amount of dust, salt or iron powder

8) Location subject to direct vibration or impact

Ɣ For an actuator used in vertical orientation, select a model which is

equipped with a brake. If selecting a model with no brake, the moving

part may drop when the power is turned OFF and may cause an

accident such as an injury or damage on the work piece.

Page 12

2

No.

Operation

Description

Description

2 Transportation Ɣ When carrying a heavy object, do the work with two or more persons or

utilize equipment such as crane.

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ When in transportation, consider well about the positions to hold, weight

and weight balance and pay special attention to the carried object so it

would not get hit or dropped.

Ɣ Transport it using an appropriate transportation measure.

The actuators available for transportation with a crane have eyebolts

attached or there are tapped holes to attach bolts. Follow the

instructions in the instruction manual for each model.

Ɣ Do not step or sit on the package.

Ɣ Do not put any heavy thing that can deform the package, on it.

Ɣ When using a crane capable of 1t or more of weight, have an operator

who has qualifications for crane operation and sling work.

Ɣ When using a crane or equivalent equipments, make sure not to hang a

load that weighs more than the equipment’s capability limit.

Ɣ Use a hook that is suitable for the load. Consider the safety factor of the

hook in such factors as shear strength.

Ɣ Do not get on the load that is hung on a crane.

Ɣ Do not leave a load hung up with a crane.

Ɣ Do not stand under the load that is hung up with a crane.

3 Storage and

Preservation

Ɣ The storage and preservation environment conforms to the installation

environment. However, especially give consideration to the prevention

of condensation.

Ɣ Store the products with a consideration not to fall them over or drop due

to an act of God such as earthquake.

4 Installation

and Start

(1) Installation of Robot Main Body and Controller, etc.

Ɣ Make sure to securely hold and fix the product (including the work part).

A fall, drop or abnormal motion of the product may cause a damage or

injury.

Also, be equipped for a fall-over or drop due to an act of God such as

earthquake.

Ɣ Do not get on or put anything on the product. Failure to do so may cause

an accidental fall, injury or damage to the product due to a drop of

anything, malfunction of the product, performance degradation, or

shortening of its life.

Ɣ When using the product in any of the places specified below, provide a

sufficient shield.

1) Location where electric noise is generated

2) Location where high electrical or magnetic field is present

3) Location with the mains or power lines passing nearby

4) Location where the product may come in contact with water, oil or

chemical droplets

Page 13

3

No.

Operation

Description

Description

(2) Cable Wiring

Ɣ Use our company’s genuine cables for connecting between the actuator

and controller, and for the teaching tool.

Ɣ Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not

coil it around. Do not insert it. Do not put any heavy thing on it. Failure to

do so may cause a fire, electric shock or malfunction due to leakage or

continuity error.

Ɣ Perform the wiring for the product, after turning OFF the power to the

unit, so that there is no wiring error.

Ɣ When the direct current power (+24V) is connected, take the great care

of the directions of positive and negative poles. If the connection

direction is not correct, it might cause a fire, product breakdown or

malfunction.

Ɣ Connect the cable connector securely so that there is no disconnection

or looseness. Failure to do so may cause a fire, electric shock or

malfunction of the product.

Ɣ Never cut and/or reconnect the cables supplied with the product for the

purpose of extending or shortening the cable length. Failure to do so

may cause the product to malfunction or cause fire.

4 Installation

and Start

(3) Grounding

Ɣ The grounding operation should be performed to prevent an electric

shock or electrostatic charge, enhance the noise-resistance ability and

control the unnecessary electromagnetic radiation.

Ɣ For the ground terminal on the AC power cable of the controller and the

grounding plate in the control panel, make sure to use a twisted pair

cable with wire thickness 0.5mm

2

(AWG20 or equivalent) or more for

grounding work. For security grounding, it is necessary to select an

appropriate wire thickness suitable for the load. Perform wiring that

satisfies the specifications (electrical equipment technical standards).

Ɣ Perform Class D Grounding (former Class 3 Grounding with ground

resistance 100: or below).

Page 14

4

No.

Operation

Description

Description

4 Installation

and Start

(4) Safety Measures

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ When the product is under operation or in the ready mode, take the

safety measures (such as the installation of safety and protection fence)

so that nobody can enter the area within the robot’s movable range.

When the robot under operation is touched, it may result in death or

serious injury.

Ɣ Make sure to install the emergency stop circuit so that the unit can be

stopped immediately in an emergency during the unit operation.

Ɣ Take the safety measure not to start up the unit only with the power

turning ON. Failure to do so may start up the machine suddenly and

cause an injury or damage to the product.

Ɣ Take the safety measure not to start up the machine only with the

emergency stop cancellation or recovery after the power failure. Failure

to do so may result in an electric shock or injury due to unexpected

power input.

Ɣ When the installation or adjustment operation is to be performed, give

clear warnings such as “Under Operation; Do not turn ON the power!”

etc. Sudden power input may cause an electric shock or injury.

Ɣ Take the measure so that the work part is not dropped in power failure or

emergency stop.

Ɣ Wear protection gloves, goggle or safety shoes, as necessary, to secure

safety.

Ɣ Do not insert a finger or object in the openings in the product. Failure to

do so may cause an injury, electric shock, damage to the product or fire.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

5 Teaching Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ Perform the teaching operation from outside the safety protection fence,

if possible. In the case that the operation is to be performed unavoidably

inside the safety protection fence, prepare the “Stipulations for the

Operation” and make sure that all the workers acknowledge and

understand them well.

Ɣ When the operation is to be performed inside the safety protection

fence, the worker should have an emergency stop switch at hand with

him so that the unit can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch on

the operation so that any third person can not operate the switches

carelessly.

Ɣ Place a sign “Under Operation” at the position easy to see.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

Page 15

5

No.

Operation

Description

Description

6 Trial

Operation

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ After the teaching or programming operation, perform the check

operation one step by one step and then shift to the automatic

operation.

Ɣ When the check operation is to be performed inside the safety

protection fence, perform the check operation using the previously

specified work procedure like the teaching operation.

Ɣ Make sure to perform the programmed operation check at the safety

speed. Failure to do so may result in an accident due to unexpected

motion caused by a program error, etc.

Ɣ Do not touch the terminal block or any of the various setting switches in

the power ON mode. Failure to do so may result in an electric shock or

malfunction.

7 Automatic

Operation

Ɣ Check before starting the automatic operation or rebooting after

operation stop that there is nobody in the safety protection fence.

Ɣ Before starting automatic operation, make sure that all peripheral

equipment is in an automatic-operation-ready state and there is no

alarm indication.

Ɣ Make sure to operate automatic operation start from outside of the

safety protection fence.

Ɣ In the case that there is any abnormal heating, smoke, offensive smell,

or abnormal noise in the product, immediately stop the machine and

turn OFF the power switch. Failure to do so may result in a fire or

damage to the product.

Ɣ When a power failure occurs, turn OFF the power switch. Failure to do

so may cause an injury or damage to the product, due to a sudden

motion of the product in the recovery operation from the power failure.

Page 16

6

No.

Operation

Description

Description

8 Maintenance

and

Inspection

Ɣ When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

Ɣ Perform the work out of the safety protection fence, if possible. In the

case that the operation is to be performed unavoidably inside the safety

protection fence, prepare the “Stipulations for the Operation” and make

sure that all the workers acknowledge and understand them well.

Ɣ When the work is to be performed inside the safety protection fence,

basically turn OFF the power switch.

Ɣ When the operation is to be performed inside the safety protection

fence, the worker should have an emergency stop switch at hand with

him so that the unit can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch on

the operation so that any third person can not operate the switches

carelessly.

Ɣ Place a sign “Under Operation” at the position easy to see.

Ɣ For the grease for the guide or ball screw, use appropriate grease

according to the Instruction Manual for each model.

Ɣ Do not perform the dielectric strength test. Failure to do so may result in

a damage to the product.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

Ɣ The slider or rod may get misaligned OFF the stop position if the servo

is turned OFF. Be careful not to get injured or damaged due to an

unnecessary operation.

Ɣ Pay attention not to lose the cover or untightened screws, and make

sure to put the product back to the original condition after maintenance

and inspection works.

Use in incomplete condition may cause damage to the product or an

injury.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

9 Modification

and Dismantle

Ɣ Do not modify, disassemble, assemble or use of maintenance parts not

specified based at your own discretion.

10 Disposal Ɣ When the product becomes no longer usable or necessary, dispose of it

properly as an industrial waste.

Ɣ When removing the actuator for disposal, pay attention to drop of

components when detaching screws.

Ɣ Do not put the product in a fire when disposing of it.

The product may burst or generate toxic gases.

11 Other Ɣ Do not come close to the product or the harnesses if you are a person

who requires a support of medical devices such as a pacemaker. Doing

so may affect the performance of your medical device.

Ɣ See Overseas Specifications Compliance Manual to check whether

complies if necessary.

Ɣ For the handling of actuators and controllers, follow the dedicated

instruction manual of each unit to ensure the safety.

Page 17

7

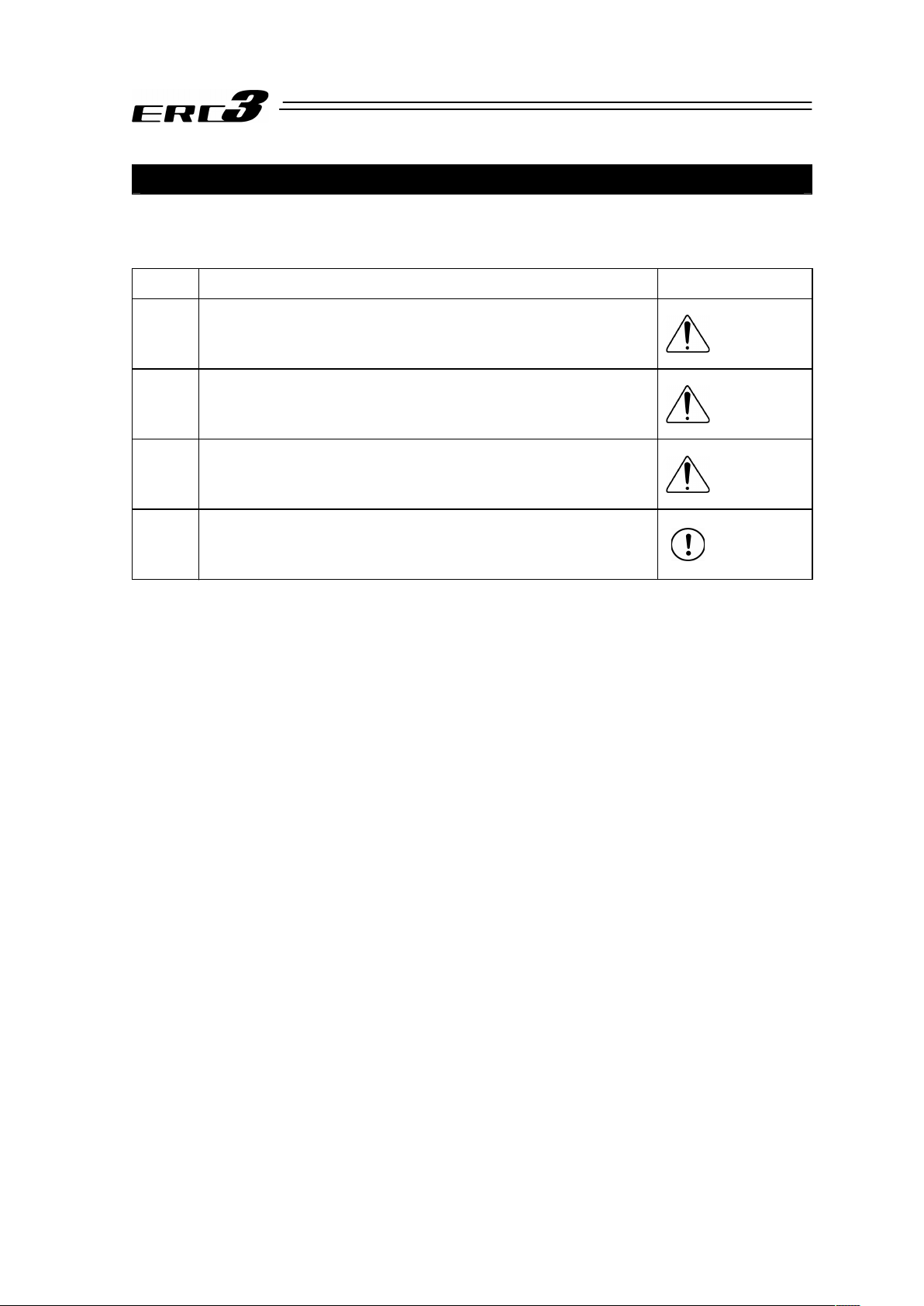

Alert Indication

The safety precautions are divided into “Danger”, “Warning”, “Caution” and “Notice” according to the

warning level, as follows, and described in the Instruction Manual for each model.

Level Degree of Danger and Damage Symbol

Danger

This indicates an imminently hazardous situation which, if the

product is not handled correctly, will result in death or serious

injury.

Danger

Warning

This indicates a potentially hazardous situation which, if the

product is not handled correctly, could result in death or serious

injury.

Warning

Caution

This indicates a potentially hazardous situation which, if the

product is not handled correctly, may result in minor injury or

property damage.

Caution

Notice

This indicates lower possibility for the injury, but should be kept to

use this product properly.

Notice

Page 18

8

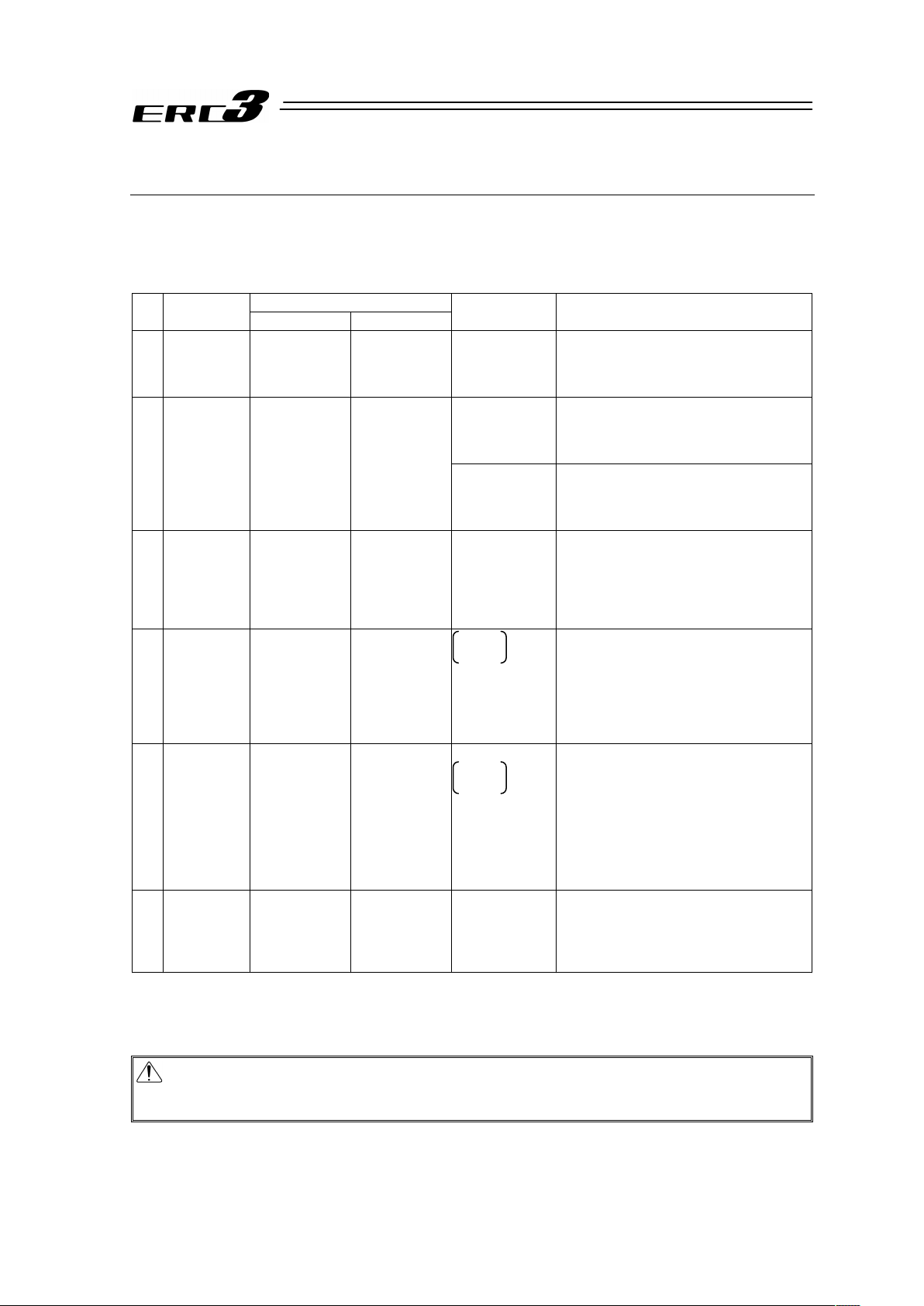

Guideline for Control Method

ERC3 has numerous operation patterns and options to meet many criteria for different applications.

Check Chapter 4 Operation for more details.

When Quick Teach is used with Con mode only Jog Operation is available.

Codes in brackets are model codes

Controller

No.

Type of

Operation

I/O Type Controller Type

Compulsory

Option

Overview

1 Positioner

Mode 1

(Standard

Type)

PIO Type

(NP/PN)

CON Mode

(CN)

– • Select from 3 types of PIO patterns for

the operation method

• Number of maximum positioning points:

16 points

– • An operation by pulse train input is

available.

• There are 2 types of operation methods

(Positioning/Pressing)

2 Pulse Train

Control

Mode

Pulse Train

Control Type

(PLN/PLP)

(Note 1)

CON Mode

(CN)

Pulse Converter

AK-04

• Applicable for open collector pulse train

output

• There are 2 types of operation methods

(Positioning/Pressing)

3 Positioner

Mode 2

(Expansion

Type)

SIO Type

(SE)

CON Mode

(CN)

PIO Converter • Select from 6 types of PIO patterns for

the operation method

• Number of maximum positioning points:

512 points

• Capable for Simple Absolute Type

application

4 MEC Mode 1 PIO Type

(NP/PN)

MEC Mode

(MC)

Quick

(Note 2)

Teach

• The same control as air cylinder is

available

• Simple operation is available with Quick

Teach (teaching pendant)

• There are 2 types of operation patterns

(2-Point Positioning/3-Point

Positioning)

5 MEC Mode 2 SIO Type

(SE)

MEC Mode

(MC)

PIO Converter

Quick

(Note 2)

Teach

• The same control as air cylinder is

available

• Simple operation is available with Quick

Teach (teaching pendant)

• There are 2 types of operation patterns

(2-Point Positioning/3-Point

Positioning)

• Capable for Simple Absolute Type

application

6 MEC Mode 3 SIO Type

(SE)

MEC Mode

(MC)

Quick Teach • Individual operation is available by

Quick Teach

• There are 2 types of operation patterns

(2-Point Positioning/3-Point

Positioning)

Note 1 The pulse train input is the differential input (Line Driver) type. For PLN, PIO is NPN type

and PLP is PNP type.

Note 2 It is also available to use any teaching tool other than Quick Teach.

Caution : The selection of the controller type is determined by the selection of the model code.

The type of built-in controller differs for each type. Since the hardware is different, it

is not possible to select the type with parameters after the product is delivered out.

Page 19

9

Precautions in Operation

1. It is set to “high output” when the machine is delivered from the factory.

There is a limit in the duty for the high output setting. Even though the transportable weight and

maximum speed decrease, an operation with the duty 100% becomes available if the high

output setting is set invalid in the parameters.

See 1.2.1 Settings for Valid/Invalid of High Output Setting for more details.

2. Set the operation patterns.

There are some operation (PIO) patterns prepared for each model classified by the built-in

controller.

Set the operation pattern and parameters suitable for the operation method of each model.

See Chapter 4 Operation for more details.

Caution : Please note it is very risky when the control sequence and PIO pattern setting do not

match to each other. It may not only cause the normal operation disabled, but also

may cause an unexpected operation.

3. Do not set speeds and accelerations/decelerations equal to or greater than the

respective ratings.

If the actuator is operated at a speed or acceleration/deceleration exceeding the allowable

value, abnormal noise or vibration, failure, or shorter life may result.

4. The allowable load moment for the slider type should be within the allowable

range.

If the actuator is operated under a load equal to or greater than the allowable load moment,

abnormal noise or vibration, failure, or shorter life may result. In an extreme case, flaking may

occur.

5. The overhung for the slider type should be within the allowable range.

Attaching a load beyond the allowable overhang length may generate vibration or abnormal

noise.

6. Do not attempt to apply a rotary torque the rod type.

Doing so may damage the internal component such as the rod stopper, and may result in an

operation failure.

7. Back and forth operation in short distance may wear out the oil film of the

grease.

If the actuator is moved back and forth continuously over a short distance of 30 mm or less,

grease film may run out. As a guide, move the actuator back and forth repeatedly for around 5

cycles over a distance of 50 mm or more after every 5,000 to 10,000 cycles. Keep using the

actuator with the grease worn out may cause malfunction. If it is extreme, flaking may occur on

the guide.

Page 20

10

8. Do not attempt to hit the slider or rod against an obstacle with high speed.

It may destroy the coupling.

9. Make sure to attach the actuator properly by following this instruction manual.

Using the product with the actuator not being certainly retained or affixed may cause abnormal

noise, vibration, malfunction or shorten the product life.

10. Make sure to follow the usage condition, environment and specification range

of the product.

Operation out of the guarantee could cause a drop in performance or malfunction of the

product.

11. Use the dedicated teaching tool.

Check 1.1.2 Teaching Tool for the PC software and teaching pendant available for this

controller.

12. Do not connect Quick Teach while a tool (teaching) is being connected to the

8-pin mini DIN connector on the ERC3 main unit.

Communication between ERC3 and the tool (teaching or PC) becomes unable.

13. Do not connect Quick Teach while a tool is being connected to TP connector

(8-pin mini DIN) on ERC3 side.

Since the communication with Quick Teach cannot be established, ERC3 cannot receive the

high-output invalid command and runs with the high-output setting condition, resulting in a

generation of the voltage drop error due to the capacity drop of the power supply unit inside

Quick Teach.

14. Backup the data to secure for breakdown.

A non-volatile memory is used as the backup memory for this controller. All the registered

position data and parameters are written into this memory and backed-up at the same time.

Therefore, you will not usually lose the data even if the power is shut down. However, make

sure to save the latest data so a quick recovery action can be taken in case when the controller

is broken and needs to be replaced with another one.

How to Save Data

(1) Save the data to CD-R or hard disk with using the PC software

(2) Hard-copy the information of position tables and parameters on paper

15. Clock Setting in Calendar Function

When power is supplied to the PIO converter for the first time, “Error Code 069 Real Time Clock

Vibration Stop Detected” May get generated. In the case this happens, set the current time with

a teaching tool.

If the battery is fully charged, the clock data is retained for approximately 10 days after the

power is turned OFF. Even though the time setting is conducted before the product is shipped

out, the battery is not fully charged. Therefore, there may be a case that the clock data is lost

even with fewer days than described above passed since the product is shipped out.

16. Pulse Train Control Type cannot be operated with the serial communication.

It is able, however, to monitor the current position or the conditions of the status.

Page 21

11

17. When using Pulse Train Control type, pay close attention to the pulse

frequency; so the frequency will no exceed the actuator specification.

In the pulse train control, the acceleration/deceleration speed is also controlled by the change

of the command pulse frequency from the host controller. Be careful not to exceed the

maximum acceleration/deceleration speed of the actuator. The use of the actuator with

excessive acceleration/deceleration rate may cause a malfunction.

18. For CON Mode Type, an operation cannot be made unless the servo-on signal

and pause signal are input.

(1) Servo ON Signal SON

Servo-on signal SON is selectable from either “Enable” or “Disable” by the parameter.

This setting can be performed in Parameter No.21 “Servo ON input disable selection”.

[Refer to Chapter 7 Parameters.]

If it is set to “Enable”, the actuator would not operate unless turning this signal ON.

If parameter No.21 is set to “1”, SON is made disable. If it is set to “Disable”, the servo

becomes ON and the actuator operation becomes enabled as soon as the power supply to

the controller is turned ON and the emergency stop signal is cancelled.

The factory setting is “0” (Enable). Have the setting that suits the desired control logic.

(2) Pause Signal *STP

The input signal of the pause signal *STP is always ON considering the safety. Therefore,

in general, the actuator would not operate if this signal is not ON.

It is available to make this signal to “Disable”, if this signal is undesirable.

It is settable by parameter No.15 “Pause input disable”.

[Refer to Chapter 7 Parameters.]

If parameter No.15 is set to “1” (Disable), the actuator can operate even if this signal is not

ON.

This parameter is set to “0” (Enable) at delivery.

Page 22

12

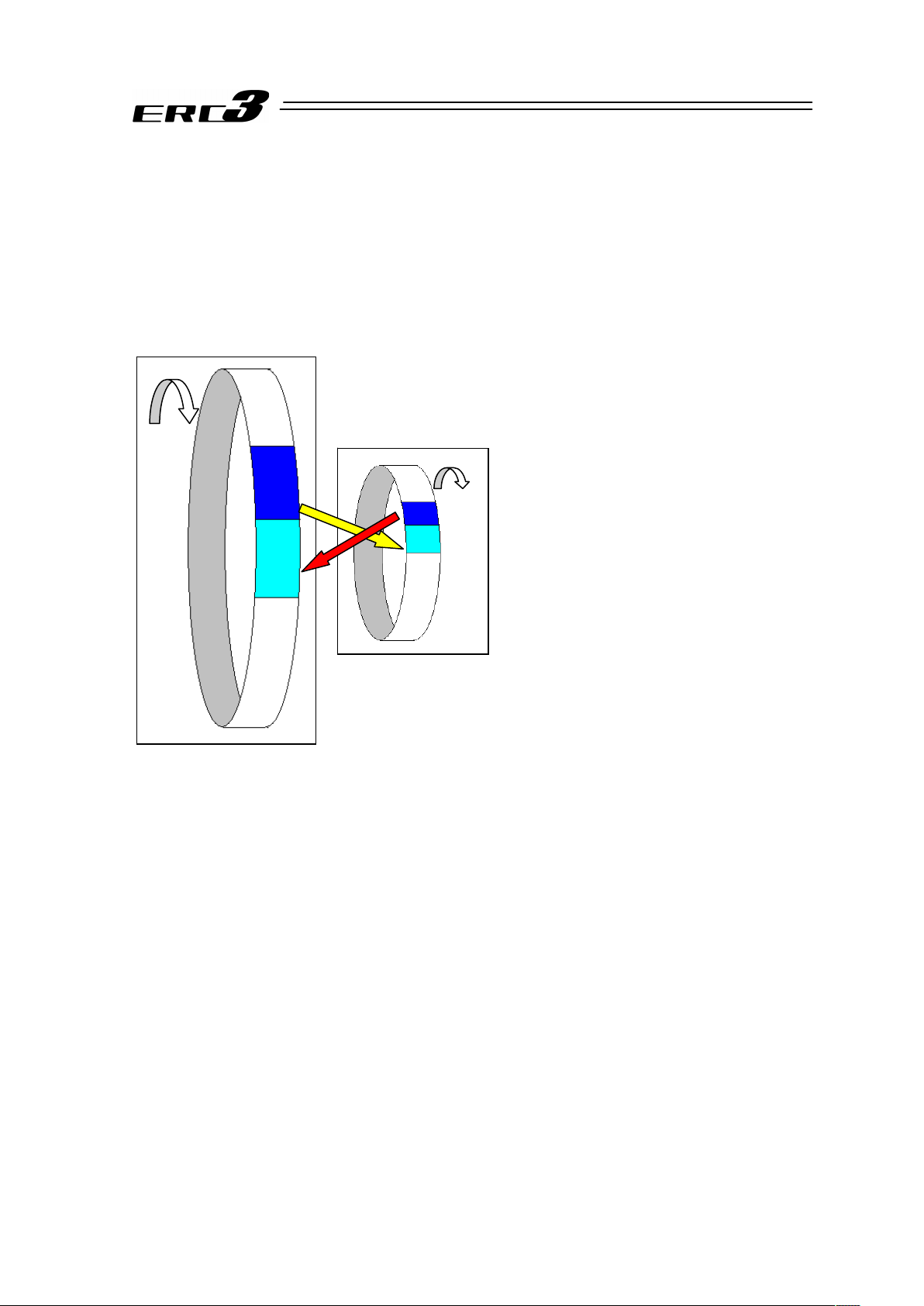

19. Transference of PIO Signal between Controllers

Please note the following when conducting transference of PIO signal between controllers.

To certainly transfer the signal between controllers with different scan time, it is necessary to

have longer scan time than the one longer than the other controller. To ensure to end the

process safely, it is recommended to have the timer setting more than twice as long as the

longer scan time at least.

䎃

Ɣ Operation Image

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

Also, if one tries to read the signal that is being re-written by the other, the signal may be read wrongly.

Make sure to read the signal after the rewriting is complete. (It is recommended to have more than 2 scan

periods to wait.) Make sure not to have the output side to change the output until the other side completes

the reading. Also, a setting is made on the input area not to receive the signal less than a certain time to

prevent a wrong reading of noise. This duration also needs to be considered.

20. PLC Timer Setting

Do not have the PLC timer setting to be done with the minimum setting.

Setting to “1” for 100msec timer turns ON at the timing from 0 to 100msec while 10msec timer

from 0 to 10msec for some PLC.

Therefore, the same process as when the timer is not set is held and may cause a failure such

as the actuator cannot get positioned to the indicated position number in Positioner Mode.

Set “2” as the minimum value for the setting of 10msec timer and when setting to 100msec, use

10msec timer and set to “10”.

This controller

(scan time 1msec)

PLC

(e.g. scan time is 20msec)

Output

Process

Input

Process

As shown in the diagram, the input and output

timings of two devices that have different scan

time do not match, of course, when transferring

a signal.

There is no guarantee that PLC would read the

signal as soon as this controller signal turns on.

In such a case, make the setting to read the

signal after a certain time that is longer than the

longer scan time to ensure the reading process

to succeed on the PLC side.

It is the same in the case this controller side

reads the signal.

In such a case, it is recommended to ensure 2

to 4 times of the scan time for the timer setting

margin.

It is risky to have the setting below the scan

time since the timer is also processed in the

scan process.

In the diagram, PLC can only read the input

once in 20msec even though this controller

output once in 1msec.

Because PLC only conducts output process

once in 20msec, this controller identifies the

same output status for that while.

Page 23

13

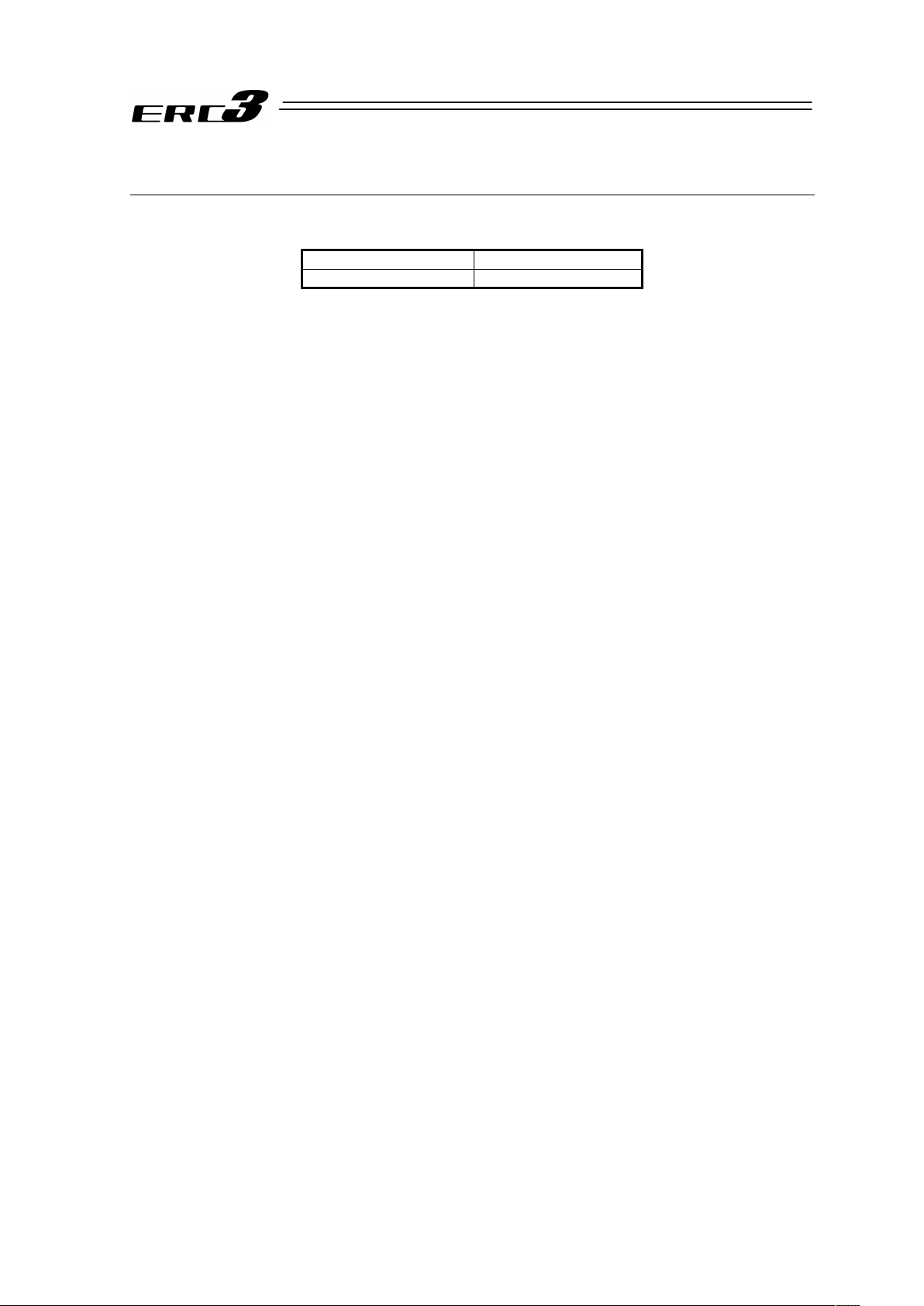

International Standards Compliances

This product complies with the following overseas standard.

RoHS Directive CE Marking

{

To be scheduled

Page 24

14

Names of the Parts

1. Main Body

In this instruction manual, the right and left sides of the actuator is expressed in the way it is placed

horizontally and is looked from the motor side as shown in the figure below.

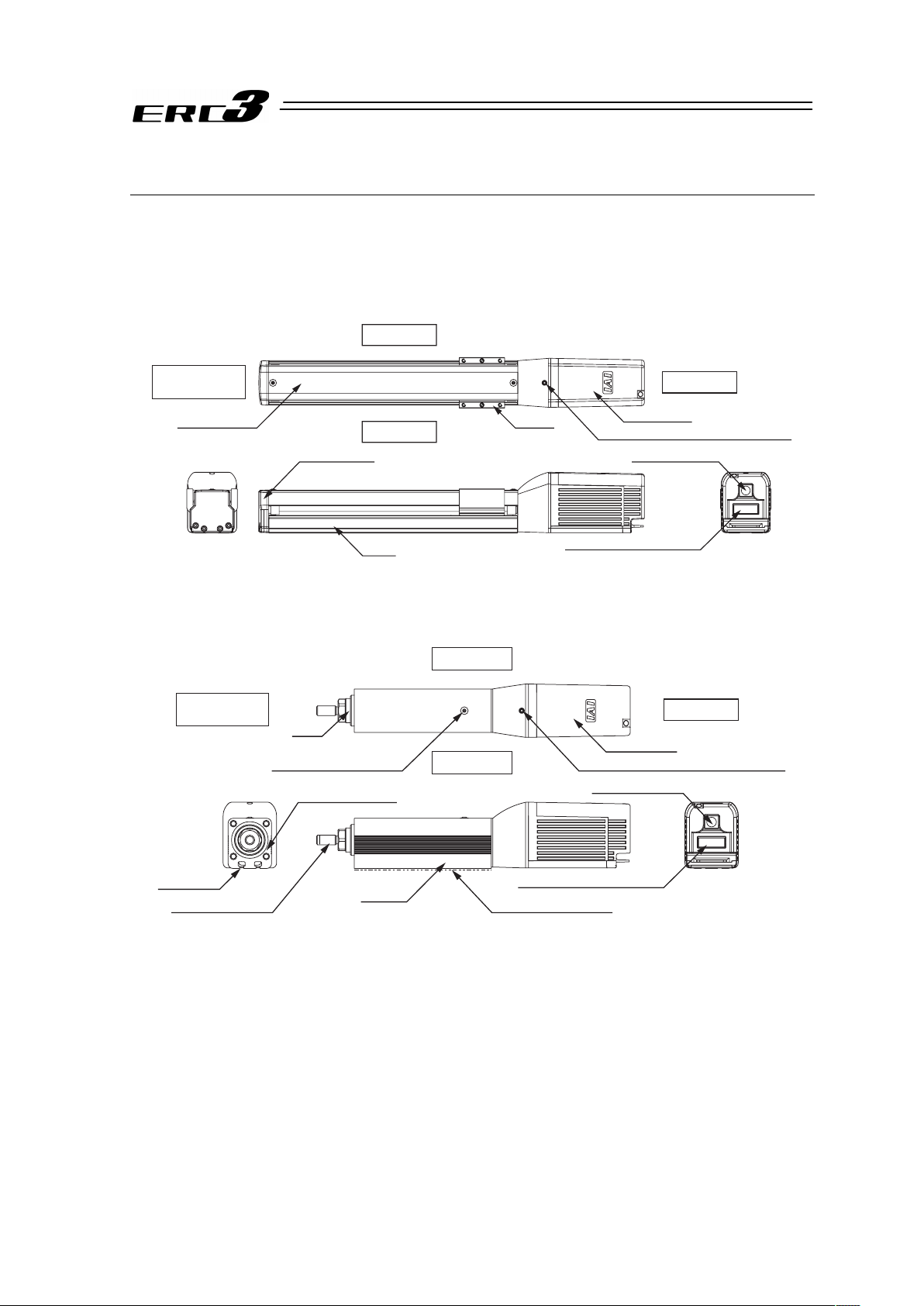

(1) Slider Type

Right Side

Left Side

Screw Cover Slider

Motor Unit

Screw for motor unit attachment

Front Cover

Base

External I/F Connector

Teaching Port

Opposite Side

of the Motor

Motor Side

(2) Rod Type

Rod

Motor Unit

Screw for motor unit attachment

Rod End Fitting Range of T-groove

External I/F Connector

Teaching Port

Frame

Grease Supply Gate

(Thin-Head Screw)

Right Side

Left Side

Opposite Side

of the Motor

Motor Side

T-groove

Flange Surface

Page 25

15

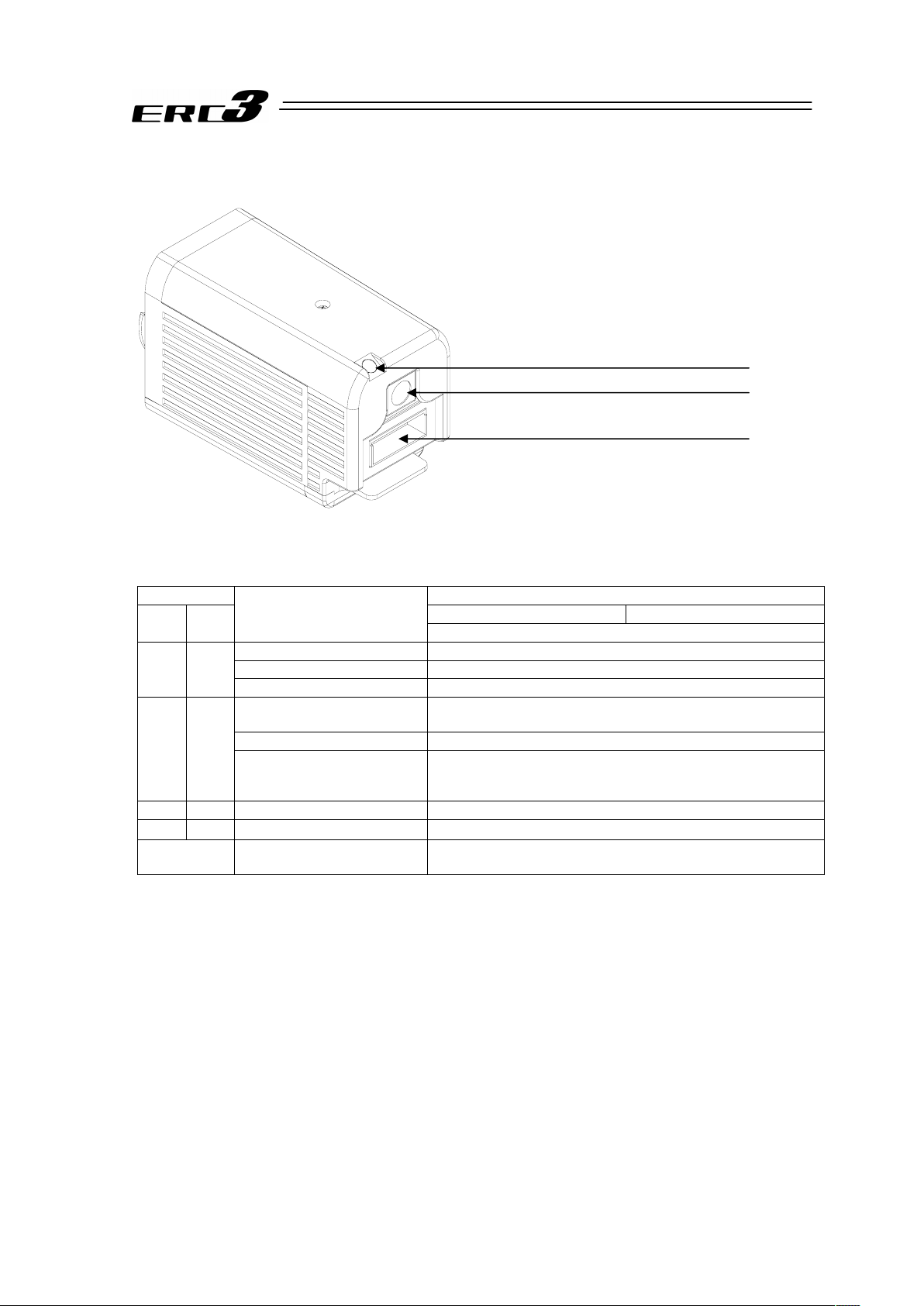

2. Motor Unit

1) Status Indicator LED

Following show the controller operation status:

{ : Illuminating × : OFF ڏ : Flashing

LED Status of PIO Output Signal

CON Mode Type MEC Mode Type

SV

(GN)

ALM

(RD)

Operation status

*ALM Output

(Note 1)

Control Power Supply ON ON

Control Power Supply OFF OFF

× ×

Servo OFF OFF

Motor driving power supply

OFF

OFF

Emergency Stop OFF

×

{

Alarm

(Operation cancellation level

or more)

OFF

{

× Servo ON ON

ڏ × During automatic servo-off ON

{ (OR)

In initializing process at

power being ON

OFF

Note 1 The output signals with * mark are the active low signals that turn ON in normal condition and turn

OFF while in abnormal condition.

2) Teaching Port

It is the connector dedicated for the connection of a teaching tool such as PC software.

3) External I/F Connector

It is I/F connector for controls with PIO and SIO.

1) Status Indicator LED (SV/ALM)

2) Teaching Port

3) External I/F Connector

Page 26

16

3. Option

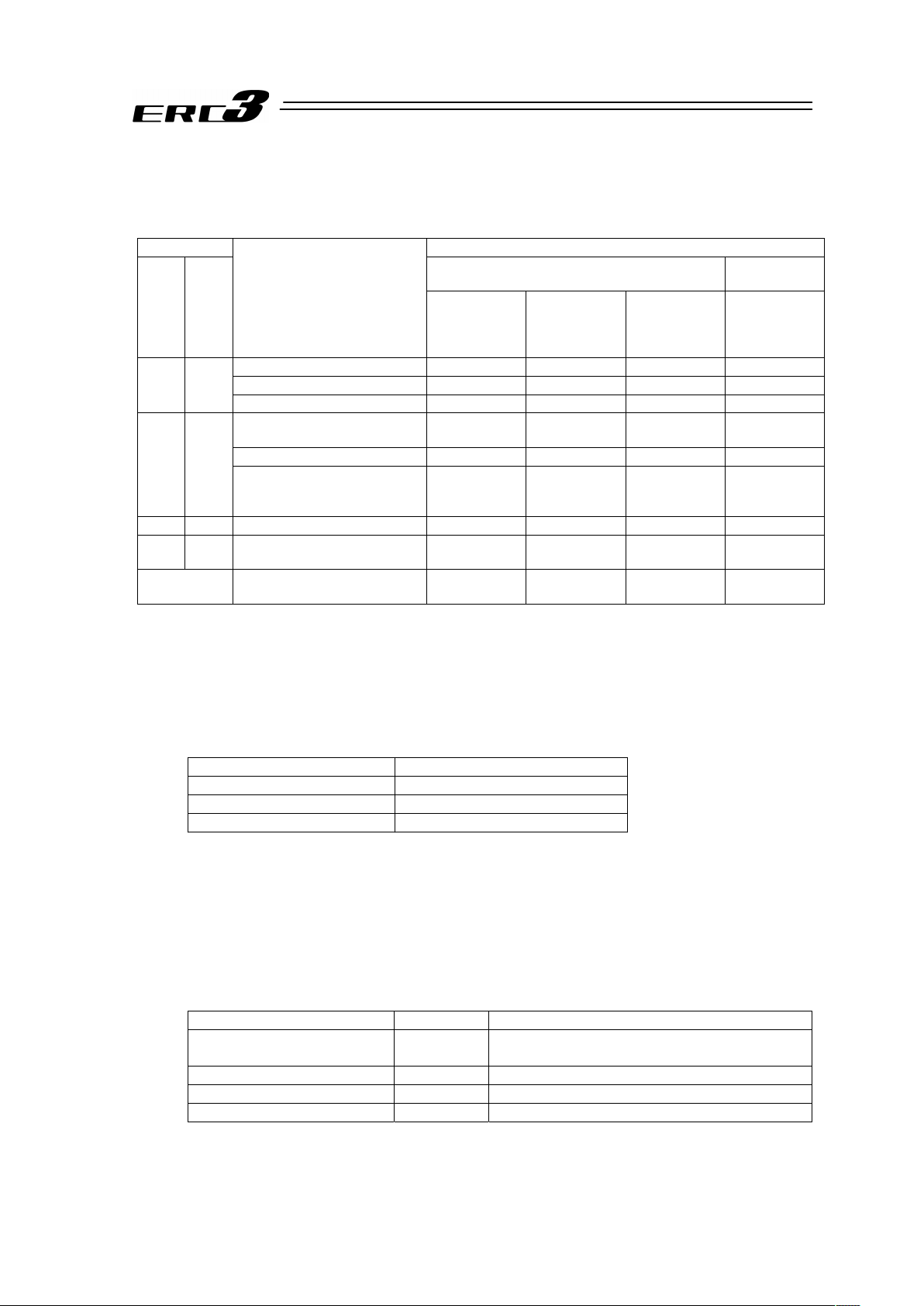

(1) PIO Converter (Model: RCB-CV/CVG-**)

The functions of CON mode type in ERC3 can be extended. See 4.2.3 Operation in Positioner

Mode 2 for details.

Also, if ERC3 is Simple Absolute Type, the absolute battery is to be attached to this PIO

Converter, thus it is mandatory.

6) Status Indicator LED

5) Absolute Battery LED

(For Simple Absolute Type)

4) Brake Release Switch

3) SIO Connector

1) PIO Connector

11) FG Terminal Block

7) Absolute Reset LED

(For Simple Absolute Type)

8) Mode Changeover Switch

for Status LEDs

(with monitor LED)

9) Status Display Mode LED

(with monitor LED)

10) Status LED

(with monitor LED)

䎽䎃

2) Absolute Battery

(For Simple Absolute Type)

12) Power Supply

Connector

14) Absolute Battery Connector

(For Simple Absolute Type)

Z View

2) Absolute Battery

(For Simple Absolute Type)

13) ERC3

Connector

Page 27

17

1) PIO Connector (I/O) [Refer to 3.2.2 [2]]

The PIO connector is used for control I/O signals.

2) Absolute Battery [Refer to Chapter 6]

This is the battery to retain the encoder information for Simple Absolute Type. Affix it with

fabric hook-and-loop fastener on the side of PIO Converter.

If ERC3 is Simple Absolute Type, it is necessary that PIO Converter is a type that is

applicable for Simple Absolute Type.

3) SIO Connector (SIO) [Refer to 3.7.6]

This is the connector for the communication cable connection with a teaching tool such as

the PC software.

4) Brake Release Switch (RLS/NOM)

For the actuator equipped with a brake, the switch is used to release the brake forcibly.

RLS ···········Brake release

NOM··········Normal Operation (brake is activated)

Warning : Always set the switch to “NOM” in normal operation.

(Keep the chance to set the switch to RLS side as less as possible, and make

sure to set it on NOM side in ordinary use.)

The brake would not work even with the servo OFF condition if the switch is

on the RLS side. In the vertical oriented mount, the work may drop and cause

an injury or the work to be damaged.

5) Absolute Battery LED (BAT)

It shows the absolute reset status, complete or incomplete.

It is equipped if applicable for Simple Absolute Type.

LED Operation Status

OFF Control Power Supply OFF

Green Light is turned ON. Battery Fully Charged

Orange Light is turned ON. Battery Charging Operation

Red Light is turned ON. Battery Disconnected

Page 28

18

6) Status Indicator LED (SYS)

Following show the controller operation status:

{ : Illuminating × : OFF ڏ : Flashing

LED Status of PIO Output Signal

CON Mode Type

MEC Mode

Type

SV

(GN)

ALM

(RD)

Operation status

SV Output

(Servo ON)

*ALM Output

(Note 1)

(Alarm)

*EMGS Output

(Note 1)(Note2)

(Emergency

Stop Status)

*ALM Output

(Note 1)

Control Power Supply ON OFF ON ON ON

Control Power Supply OFF OFF OFF OFF OFF

× ×

Servo OFF OFF OFF – OFF

Motor driving power supply

OFF

OFF OFF – OFF

Emergency Stop OFF OFF OFF OFF

×

{

Alarm

(Operation cancellation level

or more)

OFF OFF – OFF

{

× Servo ON ON ON ON ON

ڏ

×

During automatic servo-off

(Note 3)

OFF ON – ON

{ (OR)

In initializing process at power

being ON

OFF OFF – OFF

Note 1 The output signals with * mark are the active low signals that turn ON in normal condition and turn

OFF while in abnormal condition.

Note 2 *EMGS output is not prepared for Pulse Train Control Type.

Note 3 Servo-motor Auto OFF [Refer to Chapter 5 Power-saving Function]

7) Absolute Reset LED (ABS)

It shows the absolute reset status, complete or incomplete.

It is to be mounted to Simple Absolute Type.

LED Operation Status

OFF Control Power Supply OFF

Green Light is turned ON. Absolute Reset Complete

Red Light is turned ON. Absolute Reset Incomplete

8) Mode Changeover Switch for Status LEDs (SCT)

The display modes (0 to 3) of LED 0 to 15 switch over every time the switch is pressed and

the contents of display can be changed. The selection of the mode can be checked with the

color of Status Display Mode LED.

9) Status Display Mode LED (SYS)

The mode selected with Status LED Mode Changeover Switch is expressed with the display

colors.

LED Mode Contents of LED 0 to 15 Displays

OFF Mode 0

Command Current Ratio Level/

Control Power Supply OFF

Green Light is turned ON. Mode 1 Alarm Code

Yellow Light is turned ON. Mode 2 Monitoring of PIO input signal

Red Light is turned ON. Mode 3 Monitoring of PIO output signal

Page 29

19

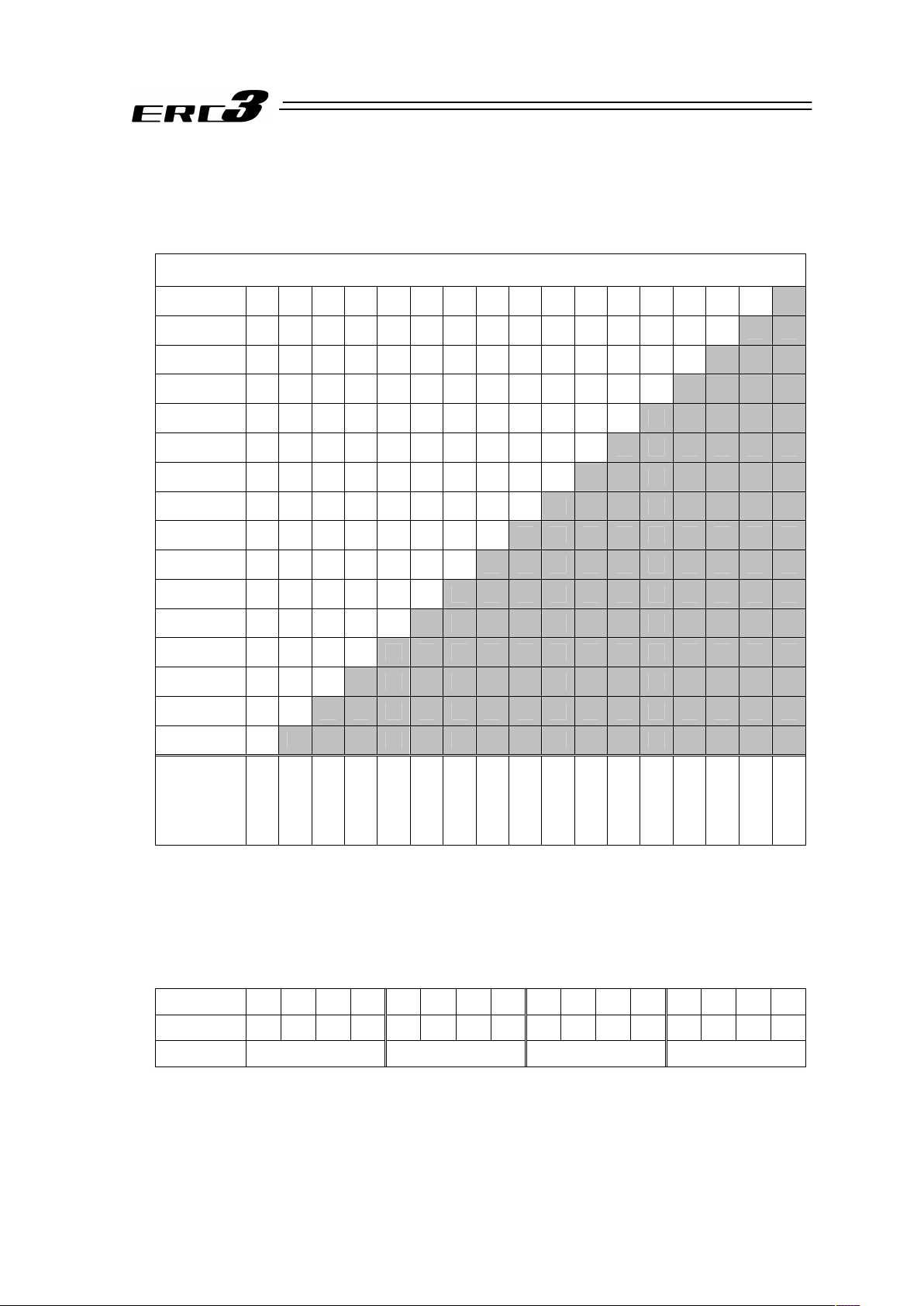

10) Status LED (0 to 15)

• Display while Mode 0 (Command Current Ratio Level) being selected

The command current ratio level of the motor rated current as 100% is displayed in a bar

graph with green lights.

{: LED Illuminating, × : LED OFF

Status of LEDs

15 × × × × × × × × × × × × × × × ×

{

14 × × × × × × × × × × × × × × ×

{ {

13 × × × × × × × × × × × × × ×

{ { {

12 × × × × × × × × × × × × ×

{ { { {

11 × × × × × × × × × × × ×

{ { { { {

10 × × × × × × × × × × ×

{ { { { { {

9 × × × × × × × × × ×

{ { { { { { {

8 × × × × × × × × ×

{ { { { { { { {

7 × × × × × × × ×

{ { { { { { { { {

6 × × × × × × ×

{ { { { { { { { { {

5 × × × × × ×

{ { { { { { { { { { {

4 × × × × ×

{ { { { { { { { { { { {

3 × × × ×

{ { { { { { { { { { { { {

2 × × ×

{ { { { { { { { { { { { { {

1 × ×

{ { { { { { { { { { { { { { {

0 ×

{ { { { { { { { { { { { { { { {

Command

Current

Ratio [%]

0

to 6.24

to 12.24

to 18.74

to 24.99

to 31.24

to 37.49

to 43.74

to 49.99

to 56.24

to 62.49

to 68.74

to 74.99

to 81.24

to 87.49

to 93.74

to 100.00

• Display while Mode 1 (Alarm Code) being selected [refer to Chapter 7 for Alarm Codes]

The alarm code issued in ERC3 is displayed in the hexadecimal system with the LED 0 to

15 used as 1 word of bit 0 to 15.

(Example) If Alarm Code “083” (absolute position movement command at home-return

incomplete) is generated, the display is as shown below:

{: LED Illuminating, × : LED OFF

LED 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Alarm Display × × × × × × × ×

{

× × × × ×

{ {

Alarm Code 0 0 8 3

Page 30

20

• Display while Mode 2 (PIO Input Signal Monitor) being selected

It displays the status of PIO control input (PLC ĺ PIO Converter) whether it is ON or OFF.

[Refer to 2.1 [2]]

LED turned ON in green : input signal ON

LED being OFF : input signal OFF

• Display while Mode 2 (PIO Output Signal Monitor) being selected

It displays the status of PIO control input (PIO Converter ĺ PLC) whether it is ON or OFF.

[Refer to 2.1 [2]]

LED turned ON in green : output signal ON

LED being OFF : output signal OFF

11) FG Terminal Block [Refer to 2.3.4 [1] (2)]

This is the grounding terminal for protection from electric shock and noise. Make sure to

conduct the Class D grounding (formerly Class 3 grounding: grounding resistance at 100 or

less).

12) Power Supply Connector [Refer to 3.3.3 [1], 3.5.3 [1]]

This is the connector for the connections of power supply, emergency stop input, driving

cutoff and the emergency stop switch signal output for the teaching pendant.

13) ERC3 Connector [Refer to 3.3.3 [2], 3.5.3 [2]]

This is the connector for the relay cable to connect ERC3 and PIO Converter.

14) Absolute Battery Connector [Refer to Chapter 6]

It is the connector to plug in the enclosed battery if applicable for Simple Absolute Type.

Page 31

21

(2) Quick Teach (Model: RCM-PST-**)

You can operate ERC3 easily. Not only JOG operation and home-return operation, but also the

settings and changes of stop positions (2 or 3 points), acceleration/deceleration, speed and try

run (forward / backward / continuous operations) are available.

Check Chapter 4 Operation for the functions of each LED and operation switch.

1) Emergency Stop Connector

2) External 24V Connector

3) ERC3 Connector

4) Brake Release Switch

5) 24V DC Power Supply Unit

With 24V DC Power Supply Unit

Model: RCM-PST-1

RCM-PST-2

RCM-PST-EU

24V Power Supply Type

Model: RCM-PST-0

Page 32

22

1) Emergency Stop Connector [Refer to Chapter 2]

This is the input connector for the external emergency stop signals. There is a plug equipped

with a jumper cable attached on at the delivery. Remove the jumper when a wiring for the

external emergency stop is required. Connect a signal that turns ON in normal condition and

OFF when in abnormal for the external emergency stop signal.

2) External 24V Connector

Use this connector to supply power when it is not equipped with

24V DC power supply unit or is to be used without the power

supply unit being attached.

Power Supply 24V DC ±10% 2.5A or more

When the excitation detection is operating after the

power is turned ON (normally for 100ms) MAX. 2.5A

3) ERC3 Connector

When operating ERC3 directly with Quick Teach, plug the SIO type power supply and I/O

cable.

When Quick Teach is used as the teaching pendant, plug the SIO communication cable.

Power for SIO Type • I/O Cable : Model CB-ERC3S-PWBIOƑƑƑ

(ƑƑƑ shows the cable length, Example 020 = 2m,

MAX. 10m)

SIO Communication Cable : Model CB-PST-SIO050 (Standard 5m)

4) Brake Release Switch

This is a switch to compulsorily release the brake of the actuator equipped with a brake.

Release ····· Brake release

Normal·······Normal Operation (brake is activated)

Warning : Always set the switch to “Normal” in normal operation.

(Keep the chance to set the switch to release side as less as possible, and

make sure to set it on normal side in ordinary use.)

The brake would not work even with the servo OFF condition if the switch is

on the release side. In the vertical oriented mount, the work may drop and

cause an injury or the work to be damaged.

5) 24V DC Power Supply Unit

This is a 24V DC power supply unit to provide power to Quick Teach from AC power source.

This can be used with being detached. It is necessary to provide power from external 24V

connector when it is detached.

Quick Teach Model Power Voltage

Rated

Current

Peak

Current

Remarks

RCM-PST-1 (100V Type)

Single-phase 100 to 115V AC

±10%

2.5A 3.2A

Cable 2m

Equipped with 3-pin

power socket plug

RCM-PST-2 (200V Type)

Single-phase 100 to 230V AC

±10%

2.1A

RCM-PST-EU

(200V type for Europe)

Single-phase 100 to 230V AC

±10%

2.1A

Cable 2m

Equipped with

I4.3-hole

solderless ring

tongue terminals

+

–

Page 33

23

Actuator Coordinate

The coordinate system of ERC3 is as shown below.

0 defines the home position, and items in ( ) are for the home-reversed type (option).

For MEC Mode, the home position is the origin point and positive side is the end point.

(1) Rod Type

(2) Slider Type

+

(0)

0

(+)

+

(0)

0

(+)

Page 34

24

Starting Procedures

1. Positioner Mode 1

When using this product for the first time, make sure to avoid mistakes and incorrect wiring by

referring to the procedure below. “PC” stated in this section means “RC PC software”.

Caution

Please perform this process with the actuator away from the mechanical end or

interfering subjects as much as possible. Put the actuator away if it interferes with

surroundings. It may generate an alarm if the actuator hit the mechanical end or

interfering subjects when the servo is turned ON.

The slider may get slightly dropped by self-weight if servo ON and OFF is repeatedly

performed at the same position. Be careful not to pinch the hand or damage the work.

Ļ Yes

ĺ

No ĺ

Ļ

ĺ

No ĺ

Contact us or our distributor.

Ļ Yes

No ĺ

ĺ

Check Item

Is the red light [ALM] on the

LED status display OFF?

Connect the teaching tool

such as PC to confirm the

content of alarm and have

an appropriate treatment.

Servo ON

Turn the servo ON with the operation on the teaching tool such as PC.

Check Item

Does the status

LED [SV] on the

panel?

Safety Circuit Check