Page 1

Teaching Pendant

(Super SEL DS Controller Type)

Operating Manual

Intelligent Actuator, Inc.

Page 2

This publication was written to assist you in better understanding this part of your IA system. If you require further assistance, please contact

IA Technical Support. For Central and East Coast Time Zones, please call our Itasca, IL office at 1-800-944-0333 or FAX 630-467-9912.

For Mountain and Pacific Time Zones, please call our Torrance, CA office at 1-800-736-1712 or FAX 310-891-0815; Monday thru Friday from

8:00 AM to 5:00PM.

Intelligent Actuator

Intelligent Actuator, Inc.

U.S. Headquarters

2690 West 237th Street

Torrance, CA 90505

310-891-6015 / 310-891-0815 FAX

Intelligent Actuator, Inc.

Midwest Regional Office

1261 Hamilton Parkway

Itasca, IL 60143

630-467-9900/ 630-467-9912 FAX

© September 1998 Intelligent Actuator, Inc. All rights reserved.

No portion of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechnical, recording, or otherwise, without the prior written permission of Intelligent Actuator, Inc.

Disclaimer

The information and technical data contained herein are subject to change without notice. Intelligent Actuator, Inc. assumes no responsibility for

any errors or omissions regarding the accuracy of the information contained in this publication.

Page 3

1. Foreword

Thank you very much for purchasing the T eaching Pendant for the IA Super SEL • DS Controller type. Without knowing

beforehand how to correctly use or operate the controller, not only will the user be unable to take full advantage of all the

functions built into this product but he might inadvertently cause damage to the controller or shorten its life. Please read this

manual carefully to acquire an understanding of the proper method of handling and operating the controller. Keep the manual

handy so that you can refer to the appropriate sections as the need arises.

*All precautions have been taken to ensure the accuracy of the contents of this manual. However, if you become aware of any

inaccuracies or discrepancies, please contact your IAI sales representative or technical service department.

Page 1

Page 4

Table of Contents

1. Foreword.............................................................................................................................................................. 1

2. Before You Begin ............................................................................................................................................... 4

3. Safety Precautions ............................................................................................................................................. 5

4. Warranty Period and Scope .............................................................................................................................. 6

5. Teaching Pendant Function and Specification .............................................................................................7~9

5.1 Main Operation Keys and Function ................................................................................................................7

5.2 Specification ....................................................................................................................................................8

5.3 RS232C Connector (D-sub 25 DTE Special*) E · G Type............................................................................ 8

5.4 RS232C Connector (D-sub 25 DTE Special*) DS Type...............................................................................9

6. Function Keys Above the LCD Display (Outline) ....................................................................................... 10

7. Programming ........................................................................................................................................... 12

7.1 Position Program ......................................................................................................................................... 12

7.2 Commands .................................................................................................................................................. 13

7.2-1 SEL Language Structure ................................................................................................................. 13

7.2-2 Expansion Conditions ..................................................................................................................... 14

8. Examples of Simple Operational Procedure............................................................................................16~31

8.1 Creating Position Data ................................................................................................................................. 16

8.2 Creating Application Program...................................................................................................................... 23

8.2-1 Creating Application Program which moves the location of the position data composed in 8.1 . 23

8.2-2 How to continue inputting other programs .................................................................................... 31

9. Methods of Operation ................................................................................................................................32~48

9.1 Program Operation ....................................................................................................................................... 32

9.2 Changing Application Program .................................................................................................................... 34

9.2-1 How to set a repeated movement using Program ........................................................................... 34

9.2-2 How to stop during operation or by other methods excluding EXIT............................................. 39

9.2-3 Expansion Condition Input Procedure............................................................................................ 40

9.3 Positioning Ooperation (DS Type only) ...................................................................................................... 44

9.3-1 Step Operation ................................................................................................................................ 44

9.3-2 Consecutive Operation ................................................................................................................... 46

9.3-3 Consecutive Operation Sequence ................................................................................................... 48

Page 2

Page 5

Table of Contents

10. Explanation of Each Function Screen ......................................................................................................49~71

10.1 Program Mode ........................................................................................................................................... 49

10.1-1 Position Edit Screen .................................................................................................................... 49

10.1-2 Program Edit Screen .................................................................................................................... 56

10.2 Play Mode .................................................................................................................................................. 57

10.2-1 Play Program Input Mode ............................................................................................................ 57

10.2-2 Play Position Input Mode (DS type only) ................................................................................... 62

10.3 Parameter Mode......................................................................................................................................... 63

10.3-1 Axis Parameters ........................................................................................................................... 63

10.3-2 System Parameters....................................................................................................................... 68

10.4 Test Mode ................................................................................................................................................... 71

11. Supplement ......................................................................................................................................77~81

11.1 Recovery From Emergency Stop ............................................................................................................... 77

11.2 Error Codes ................................................................................................................................................ 79

11.3 How to Investigate an Axis Error Using the Teaching Pendant ................................................................. 80

Page 3

Page 6

2. Before Y ou begin

! A W ord of Caution

Q Please read this manual carefully to operate the controller properly.

R You are not allowed to use or reproduce this manual or any portion thereof without permission.

S We cannot accept any responsibility for possible damage resulting from the use of this manual.

T We reserve the right to change the information contained in this manual without prior notice.

! Emergency Procedures

If hazardous conditions arise while using the controller, immediately turn OFF all power switches for the controller and any

devices connected to it, or pull all the power plugs from the electric outlet. ("Hazardous condition" refers to excessive

heat,smoke or flames coming from the controller or any conditions which might lead to fire or cause damage to the

controller.)

Page 4

Page 7

3. Safety Precautions

Safety Precautions

Please follow the following safety precautions when operating your IA system:

(1) Any operation not specifically addressed in this manual should not be attempted. If you have any questions, please

contact your IA sales representative or contact IA technical support at: 1-800-736-1712.

(2) Use only IA cables when connecting IA actuators and controllers. IA cables are matched for use with IA actuators and

are specially designed to withstand repeated bending.

(3) Stand clear of your IA system when operating or preparing to operate. Surround your IA system with safety partitions

if there is any possibility that someone may become injured by an operating IA system.

(4 ) Before assembling, adjusting, or performing maintenance on your IA system, please make sure that people around you

are aware that the system is not to be powered up or turned on. You may want to disconnect the power cable completely, keep the power cable close to the operator, or use a safety plug to ensure that the power cable will not be

plugged in inadvertently .

(5 ) When more than one person is working on your IA system, use signs to inform everyone of the operating status of the

equipment. Make sure that everyone stands clear prior to operation. Operate your system only after you are sure that

everyone knows that you are initiating system start-up and that everyone is clear of the system.

(6 ) In situations where the cables must be lengthened, be sure to double check all connections before powering up your IA

system.

Page 5

Page 8

4. Warranty Period and Scope

Warranty Period and Scope

The Super SEL controller undergoes stringent testing before it is shipped from our factory. IAI provides the following warranty.

1. Warranty Period

The warranty period is 12 months from the date the unit is shipped to the customer.

2. Scope of Warranty

If within the period specified above, a breakdown occurs while operating the controller under normal conditions and is

clearly the responsibility of the manufacturer, IAI will repair the unit at no cost. However, the following items are not

covered by this warranty .

• Faded paint or other changes that occur naturally over time.

• Consumable components that wear out with use (battery, etc.).

• Unit seems to be noisy or similar impressions that do not affect machinery performance.

• Damage resulting from improper handling or use.

• Damage resulting from user error or failure to perform proper maintenance.

• Any alterations not authorized by IAI or its representatives.

• Damage caused by fire and other natural disasters or accidents.

The warranty pertains to the purchased product itself and does not cover any loss that might arise from a breakdown of the

product. Any repairs will be done at our factory.

3. Service

The purchase price of the product does not include programming or expenses for sending technicians to the customer's site.

Even if the product is still under the warranty period, separate charges will be assessed for the following services.

• Assistance with unit installation or trial operation.

• Inspection and maintenance.

• Technical instruction and training for controller operation and wiring.

• Writing programs or technical instruction and training for programming.

• Any other services or work for which IAI normally assesses separate charges.

Page 6

Page 9

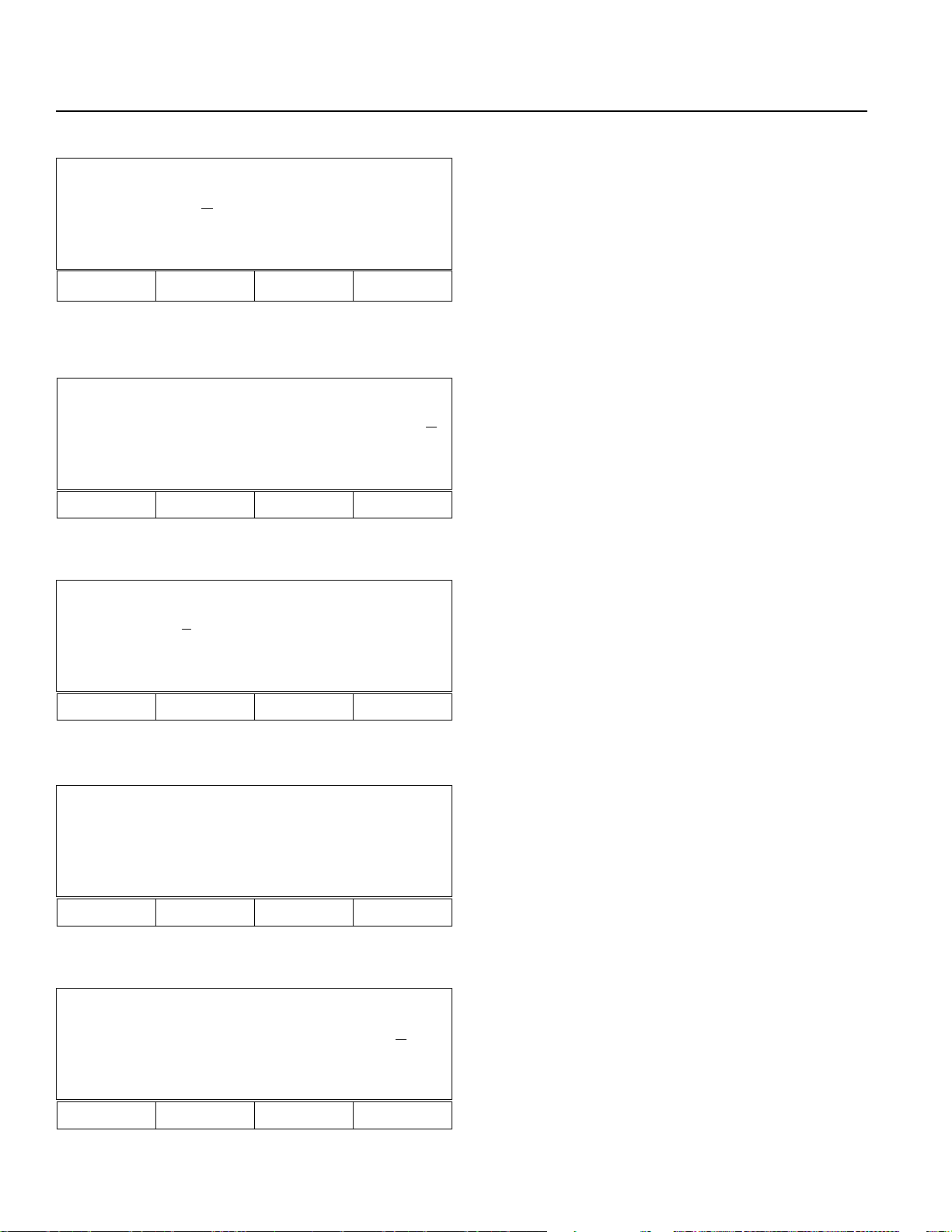

5. T eaching Pendant Function and Specification

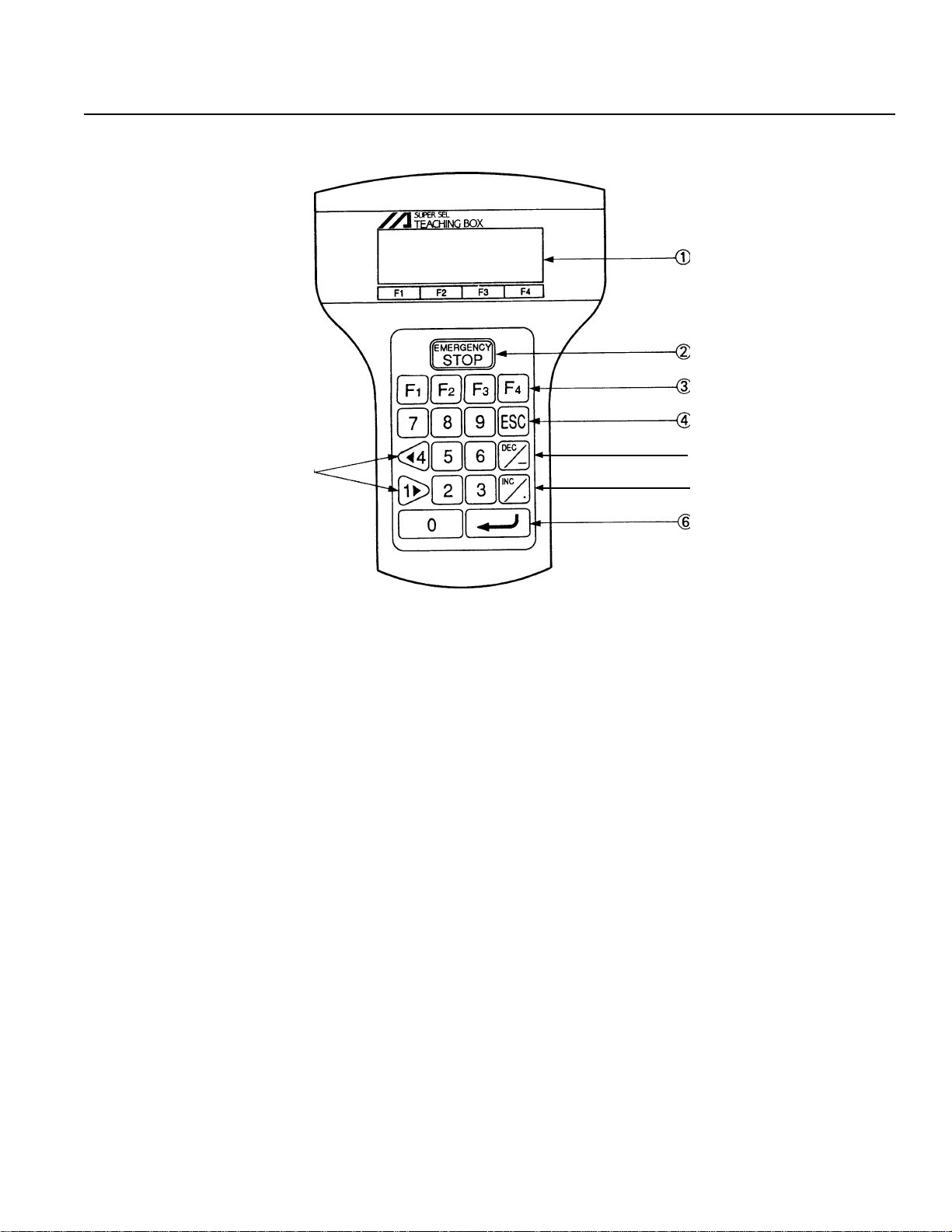

5.1 Main Operational Keys and Functions

➀

➁

➂

➃

➇

➀ LCD Display

4 lines with a 20 character per line capacity display. Shows program and motion status.

➁ EMERGENCY STOP

Whenthe emergency stop button is pressed, servos will disengage and all programmable outputs will

be turned OFF. To release the emergency stop, press Restart (F1) on the LCD Display. When an emergency stop is

pressed from a peripheral device while using the teaching pendant, you must also press the emergency stop from the

teaching pendant. Otherwise, normal operation can not be executed (See Page 77 for reference).

➂ F1, F2, F3, F4 (Multi-function Key)

Multi-function keys that correspond with the LCD Display.

➃ ESC (Escape)

The Escape Key allows the operator to go backwards in one-step increments to previous displays

to make corrections or to switch to different modes.

➄

➅

➆

➄ DEC / - (Decrement / Minus Key)

Dual function keys for use in data input and axis Jog functions.

➅ Inc / . (Increment / Point Number Key)

This key increases the Step Number or Point Number.

➆

↵ ↵

↵ (Return Key)

↵ ↵

Return Key is used to change operations and to move the cursor position.

▲

➇ 1 , 4 (Data Key, Jog Key)

Dual function key for use in data input and axis Jog functions.

▲

Page 7

Page 10

5. T eaching Pendant Function and Specification

5.2 Specification

metImetI

metImetI noitpircseDnoitpircseD

metI

ytidimuH&erutarepmeTtneibmA sselroHR%58:ytidimuHC°04~0:erutarepmeT

tnemnorivnEgnitarepOtsudevissecxeon,sagevisorrocfoeerF

thgieWtinUG005

htgneLelbaCm2

yalpsiD4X02htiwyalpsiDDCL

5.3 RS232C Connector (D-Sub 25 DTE Special*) For the E • G Type

.oNniP.oNniP

.oNniP.oNniP emaNlangiSemaNlangiS

.oNniP.oNniP

.oNniP.oNniP emaNlangiSemaNlangiS

.oNniP

1GF

2DXT

3DXR

4)STR(

5)STC(

6RSD

7GS

8CN

9CN

01CN

11CN

21CN

31CN

emaNlangiSemaNlangiS

emaNlangiS

*

*

*

* Pin numbers 18, 23, and 25 are for use with the teaching pendant signal.

Do not connect these pins.

.oNniP

41CN

51CN

61CN

71CN

81tuptuOV2.6+

91CN

02RTD

12CN

22CN

32WSpotSycnegremEWS.GME

42CN

52)2.6+(VO

noitpircseDnoitpircseD

noitpircseD

emaNlangiSemaNlangiS

emaNlangiS

■ RS232C Cable

Please use RS232 cable pin configuration (between controller and computer serial port).

SPMC-8DG

NEC PC

(25 Pin )

Drain

Shield

FG

1

Yellow

TXD

2

Orange

RXD

3

Gray

RTS

4

Red

CTS

5

Brown

DSR

6

Green

DTR

20

Blue

GND 7

Warning Please only use cables as specified in the charts above. Connection using other types of cables may cause breakdown in the PC interface area.

Black

Drain

Shield

Orange

Yellow

Red

Gray

Green

Blue

Black

Controller

(25 P)

1

2

3

4

5

6

20

7

FG

TXD

RXD

RTS

CTS

DSR

DTR

GND

IBM PC

(9S)

RXD

TXD

CTS

RTS

DTR

DSR

GND

(The Shield line is connected to the shell clamp area)

Page 8

2

3

8

7

4

6

5

SPMC-8DG

Shield

Orange

Yellow

Red

Gray

Green

Brown

Blue

Black

Controller

(25 P)

Orange

Yellow

Red

Gray

Green

Brown

Blue

Black

1

2

3

4

5

6

20

7

FG

TXD

RXD

RTS

CTS

DSR

DTR

GND

Page 11

5. T eaching Pendant Function and Specification

5.4 RS232C Connector (D-Sub 25 DTE Special*) for the DS Type

.oNniP.oNniP

.oNniP.oNniP emaNlangiSemaNlangiS

.oNniP

1GF

2DXT

3DXR

4)STR(

5)STC(

6RSD

7GS

8CN

9CN

01CN

11CN

212SGME

*

)

311SGME

*

• Pin numbers 12, 13, 18, 19, 23, 25 are for use with the teaching pendant signal. Do not connect these pins for RS232C.

• Pin numbers 4 and 5 are short-circuited.

• Pin numbers 12 and 13 are connected for emergency stop (B contact).

• Pin numbers 18 and 19 are ENABLE SW connecting terminal.

emaNlangiSemaNlangiS

emaNlangiS

.oNniP.oNniP

.oNniP.oNniP emaNlangiSemaNlangiS

.oNniP

41CN

51CN

61CN

71CN

81tuptuOV2.6+

*

*

91ELBANE

02RTD

12CN

22CN

32WSpotSycnegremEWS.GME

*

42CN

52)2.6+(VO

*

emaNlangiSemaNlangiS

emaNlangiS

FG

TXD

RXD

RTS

CTS

DSR

DTR

GND

Soldering

within

the shell

■ RS232C Cable

Please use RS232 cable pin configuration (between controller and computer serial port).

PC Side

(25 Pin)

1

2

3

4

5

6

20

7

SPMC-8DG

Shield

Yellow

Orange

Brown

Green

Blue Blue

Black

Red

Gray

Black

White

Drain

Orange

ShieldDrain

Orange

Yellow

Green

Brown

Black

Red

Gray

Controller Side

(25 Pin)

1

FG

2

TXD

3

RXD

4

RTS

5

CTS

6

DSR

20

DTR

7

GND

19

ENABLE

18

6V

13

EMG S1

12

EMG S2

RXD

TXD

CTS

RTS

DTR

DSR

GND

Soldering

within

the shell

PC Side

(9S)

2

3

8

7

4

6

5

SPMC-8DG

Orange Orange

Yellow

Green

Brown

Blue

Black

Red

Gray

Black

Controller Side

(25 Pin)

Shield

Yellow

Green

Brown

Blue

Black

Red

Gray

1

2

3

4

5

6

20

7

19

18

13

12

FG

TXD

RXD

RTS

CTS

DSR

DTR

GND

ENABLE

6V

EMG S1

EMG S2

EMG S1

EMG S2

EMG SW Side

Warning Please only use cables as specified in the charts above. Connection using other types of cables may cause breakdown in the PC interface area.

White

1

2

Black

EMG S1

EMG S2

EMG SW Side

White

1

Black

2

(The shield line is connected to the

shell clamp area)

Page 9

Page 12

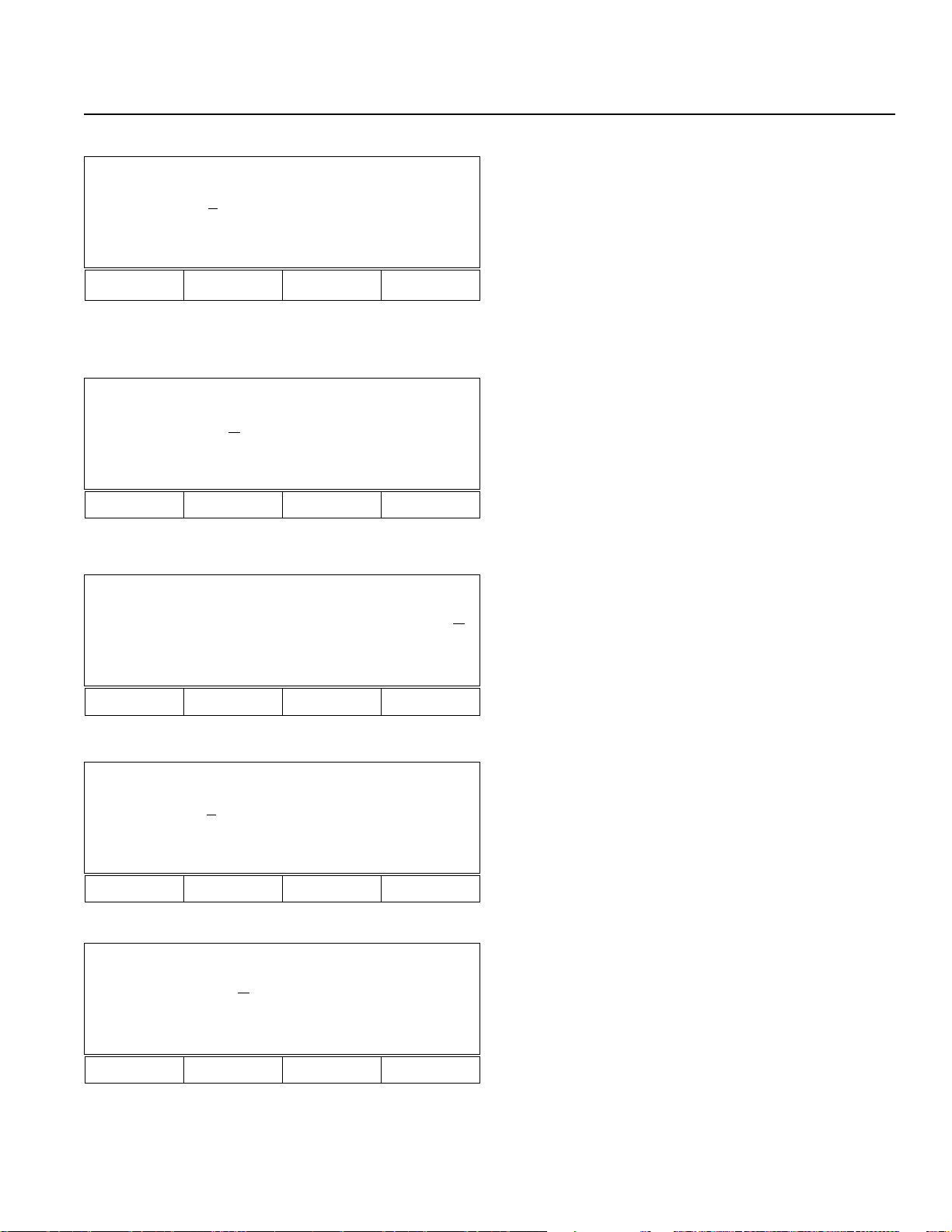

6. Main Function Keys Above the LCD Display

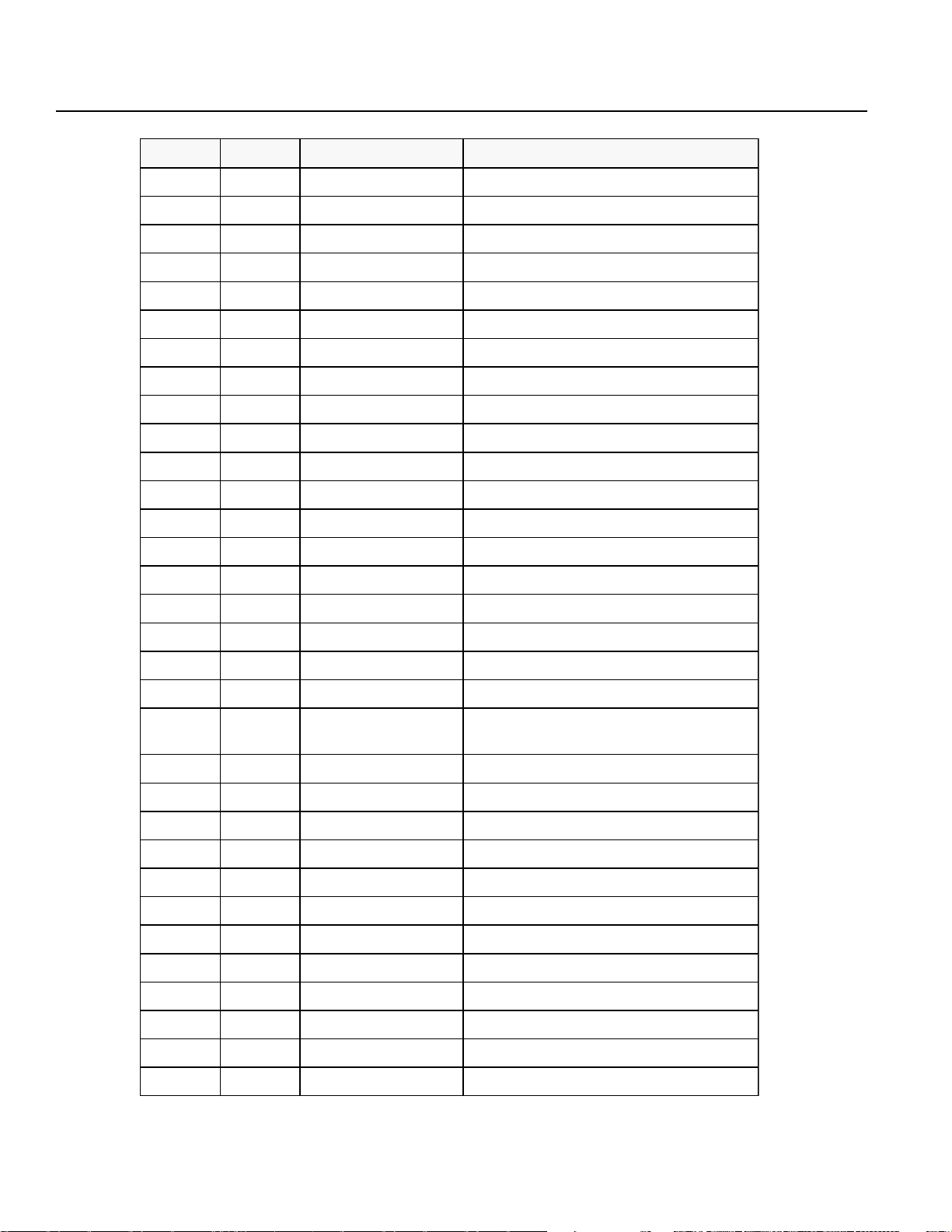

rebmuNrebmuN

rebmuNrebmuN yeKyeK

rebmuN

1ccAnoitareleccAnoitareleccA

2llAllAllA

3dnAdnA)tcudorplacigoL(dnA

4grpAmargorPnoitacilppAneercstidemargorP

5sixAsixAneercsedomretemarapsixA

6+sixAsulPsixA.oNsixamorf1ddA

7-sixAsuniMsixA.oNsixamorf1tcartbuS

8SBecapSkcaBsdrawkcabrosrucehtevomdnatupniraelC

9naClecnaClecnaC

01riCelcriCneercsedomretamarapcrametsyS

11rlCraelCraelC

21?KORLC?yakOraelC?atadehtraelcotyakotisI

31ypoCypoCypoC

yeKyeK emaNdnammoCemaNdnammoC

yeK

emaNdnammoCemaNdnammoC tnetnocdnammoCtnetnocdnammoC

emaNdnammoC

tnetnocdnammoCtnetnocdnammoC

tnetnocdnammoC

*Alphabetical order

41ceDtnemerceD.oNmorf1tcartbuS

51leDeteleDeteleD

61tidEtidEneercsedomtidE

71ctEctEnoitcelesunemrehtO

81galFgalFnoitcelesyalpsidnoitairavgalF

91oGoGnoitucexeetangiseD

02emoHemoH

12TLHtlaHpotS

22cnItnemercnI.oNddA

32snItresnItresnI

42goJgoJneercsedomgoJ

52leVJyticoleVgoJneercsyticolevgoJ

62niaMniaMnoisrevMORniamedisrellortnoC

72idMtupnIataDlaunaMtupnitceridatadnoitisoP

82rtoMrotoMneercsedomretemaraprotomsixA

92emaNemaNneercsretemarapemansixA

sixaelbacilppa/edomretemarapnigirosixA

neercsedomtessixaelbacilppa-noN

03+emaNsulPemaN1(emansixAot1ddA →9, A→ )Z

13-emaNsuniMemaNZ(emansixAmorf1tcartbuS →A, 9→ )1

23toNtoN)yneD(toN

Page 10

Page 13

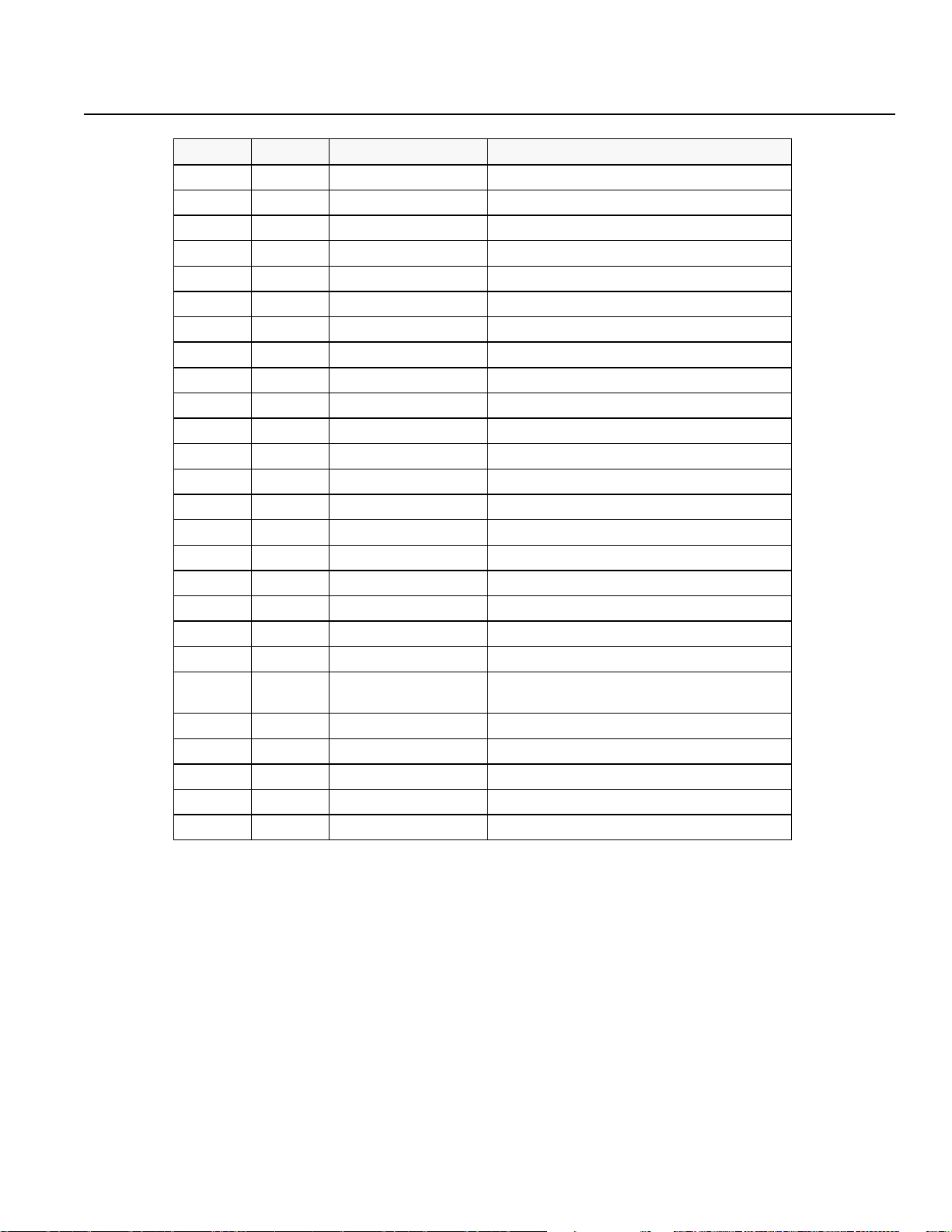

6. Main Function Keys Above the LCD Display

rebmuNrebmuN

rebmuNrebmuN yeKyeK

rebmuN

33rOrO)noitareporO(rO

43araPretemaraPraelcretemarapmetsyS

53mraPretemaraPedomretemaraP

63yalPyalPedomnoitucexE

73soPnoitisoPraelcaeraatadnoitisop,edomretemaraptnioP

83isoPnoitisoPneercstideatadnoitisoP

93gorPmargorPraelcaeramargorp,neercsedommargorP

04LCmaRraelCmaRneercsedomraelcyromeM

14nuRnuRdetucexegniebmargorP

24tfihStfihSedoM

34wohSwohSrotinometangiseD

44oiSC232SRO/IlaireSneercsedomretemaraPO/IlaireS

54tatSsutatSnoitidnocnoitucexemargorpetangiseD

64petSpetSpetsatadnoitisoP

74potSpotSpotS

841ptS1potSrosrucehtybdetacidnimargorpehtpotS

94LAptSllApotSsmargorpgnitucexellapotS

05ovrSovreSneercsretemarapovreS

15fovSffOovreStnadnepgnihcaettcerid•launaM

25sySmetsySneercsedomretmarapmetsyS

35caeT

45tseTtseTedomtseT

55leVyticoleVyticoleVgnittesnoitarelecca•

65reVnoisreVneeercsyalpsidnoisrevtnerruC

75trWetirWnietirW

851/01ro01ro0otyalpsidehtegnahC

yeKyeK emaNdnammoCemaNdnammoC

yeK

emaNdnammoCemaNdnammoC tnetnocdnammoCtnetnocdnammoC

emaNdnammoC

,gnihcaeTataDnoitisoP

tnadnePgnihcaeT

tnetnocdnammoCtnetnocdnammoC

tnetnocdnammoC

yalpsidnoisrevtnadnepgnihcaet,gnihcaeT

Note: Depending on the operation, there are other function keys not listed in the chart above.

Page 11

Page 14

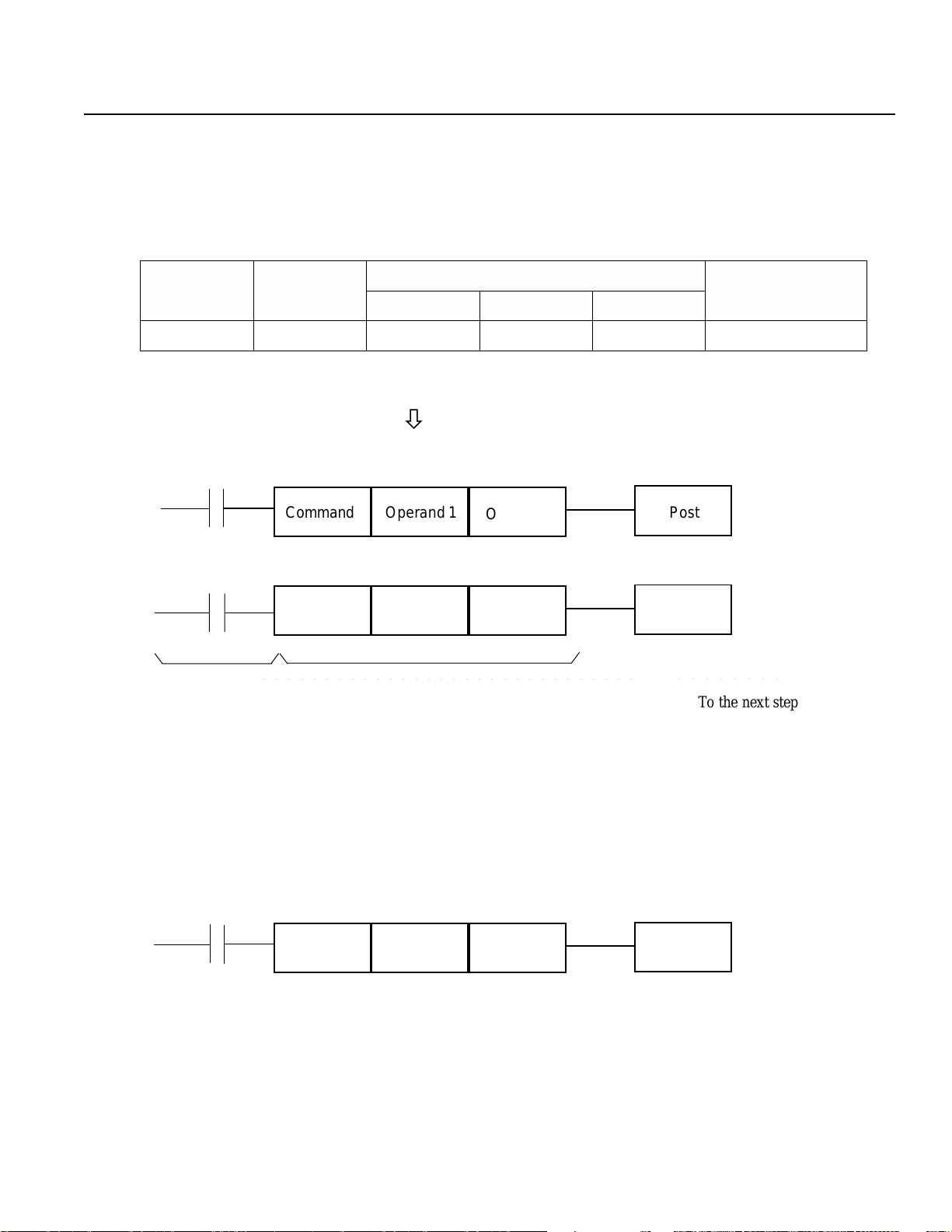

7. Programming

SEL Language Structure

The SEL programming consists of a position and application program (command) section.

7.1 Position Program

In the position section, we have coordinates, velocity and acceleration.

*1, 2

1~1500 mm/sec

1

2

3

4

* 1 Varies according to the actuator model.

* 2 When velocity and acceleration are set in the position data, this has priority over the data set in the

*2

Standard

0.3G

noitisoP

.oN

yticoleVnoitareleccA1sixA2sixA3sixA4sixA5sixA6sixA7sixA8sixA

±9999.999mm

7991

8991

9991

0002

application program. To validate the application data, set x.xxx or 0 in the position data.

Note: The DS type is a single axis only. Also position numbers go up to 500.

Page 12

Page 15

7. Programming

7.2 Commands

The outstanding feature of the SEL language is the simplicity of its command structure which eliminates the need for a

compiler and allows high speed operation with just an interpreter.

7. 2- 1 SEL Language Structure

One step of the command has the following structure.

Putting this in a ladder

diagram,

(1) The conditions before the commands are equivalent to "if ~ then" statements in BASIC language.

IF ~ THEN ELSE

noisnapxE

)RO·DNA(

noitidnoCtupnI

)galF·O/I(

dnammoC 1dnarepO 2dnarepO

ò

Command PostOperand 1

Command

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Operand 1

Operand 2

Operand 2

dnammoC

tsoP

)galF·troptuptuO(

Post

○○○○○○○○

To the next step

ò

Carry out a command when an input condition is established, and turn the output port ON, if output is

designated. When not established, go on to the next step regardless of the next command (ex. WTON,

WTOF). The designated output port remains the same , however it needs to be monitored carefully.

If there is no conditioning set up, carry out command unconditionally.

If condition is used as "negative condition", then place an "N" (NOT).

Input/output port & flag can be used for condition.

(2 ) Output is set based on the result of the command execution.

Operand 1

Operand 2Command Post

Actuators motion control commands: becomes OFF immediately after the command starts to be executed,

and becomes ON when the command is completed.

Computation commands: when the result becomes a certain value, it turns ON, and it stays OFF otherwise.

Output port and flag can be used for output section.

Page 13

Page 16

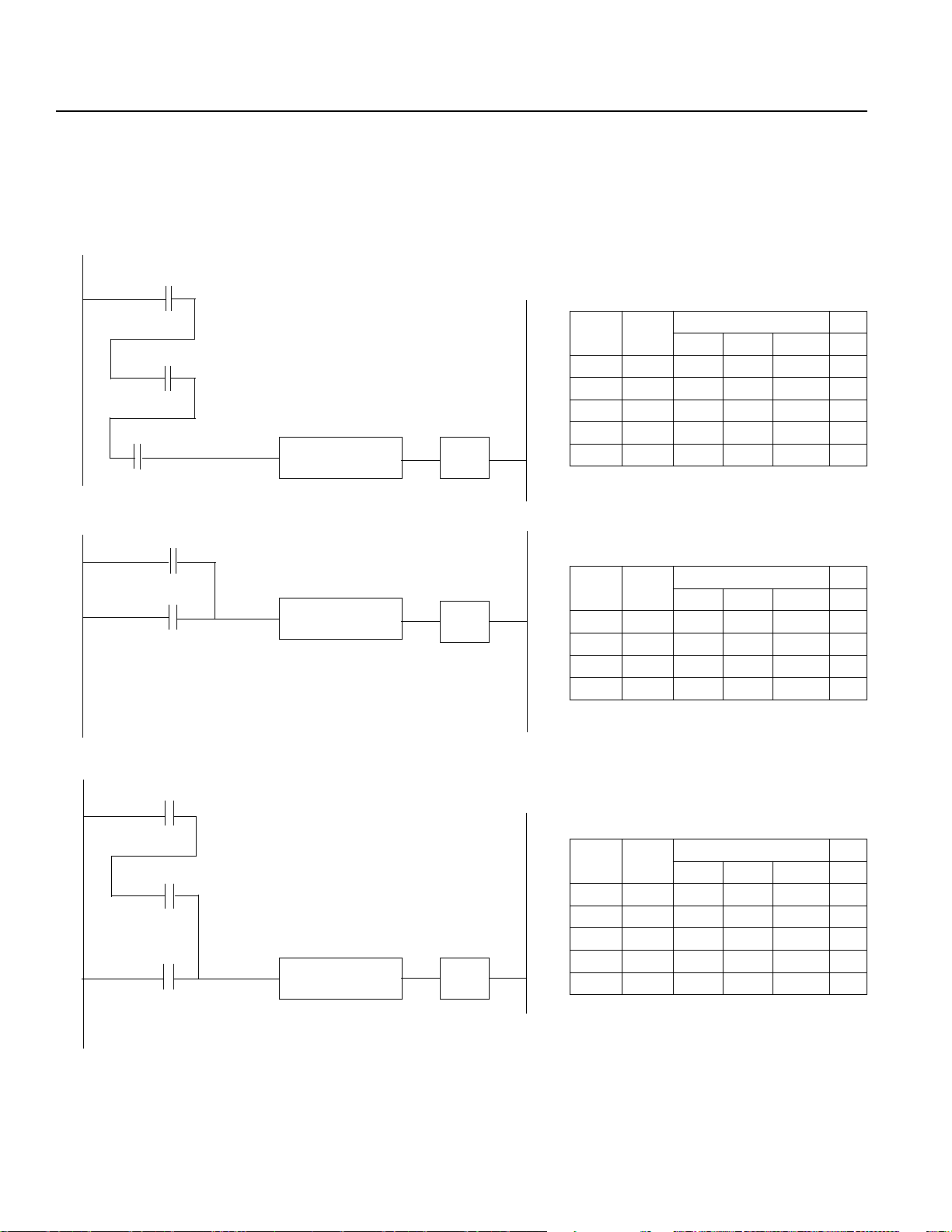

7. Programming

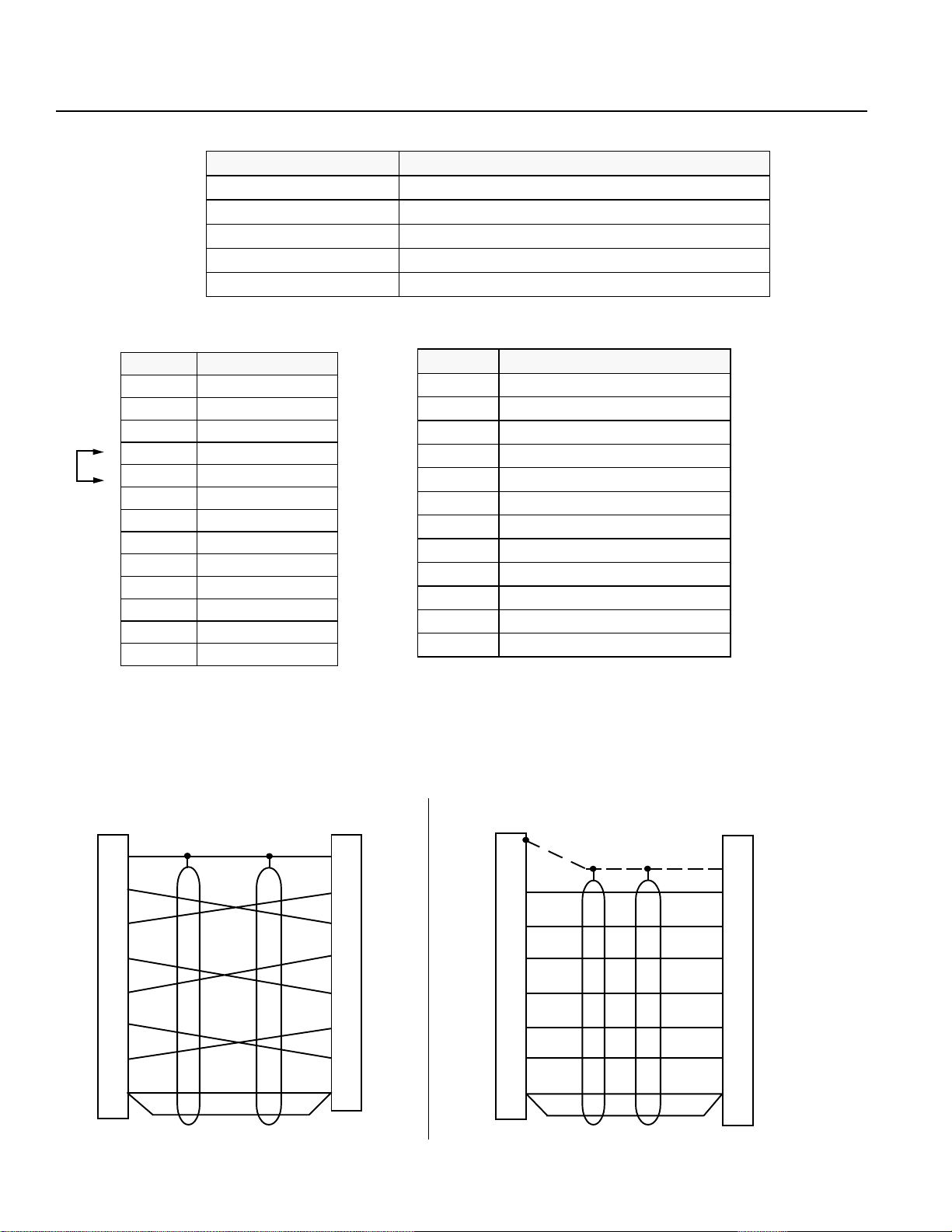

7.2-2 Expansion Condition

It is possible to combine conditions to make more complicated conditions as follows:

AND Expansion (Ladder Diagram display) (SEL Language)

Cond 1

Cond 2

Cond 3

OR Expansion

Cond 1

Cond 2

AND

AND

OR

noitanalpxEtupnI

DNA2noitidnoC

DNA3noitidnoCdnammoC1dnarepO2dnarepO

noitanalpxEtupnI

RO2noitidnoCdnammoC1dnarepO2dnarepO

dnammoC1dnarepO2dnarepO

1noitidnoC

dnammoC1dnarepO2dnarepO

1noitidnoC

sdnammoCtuptuO

sdnammoCtuptuO

AND/OR Expansion

Cond 1

Cond 2

Cond 3

AND

OR

noitanalpxEtupnI

DNA2noitidnoC

RO3noitidnoCdnammoC1dnarepO2dnarepO

dnammoC1dnarepO2dnarepO

1noitidnoC

sdnammoCtuptuO

Note: By convention, all “AND” operations are performed before the “OR” operations when they are used in

conjunction.

Page 14

Page 17

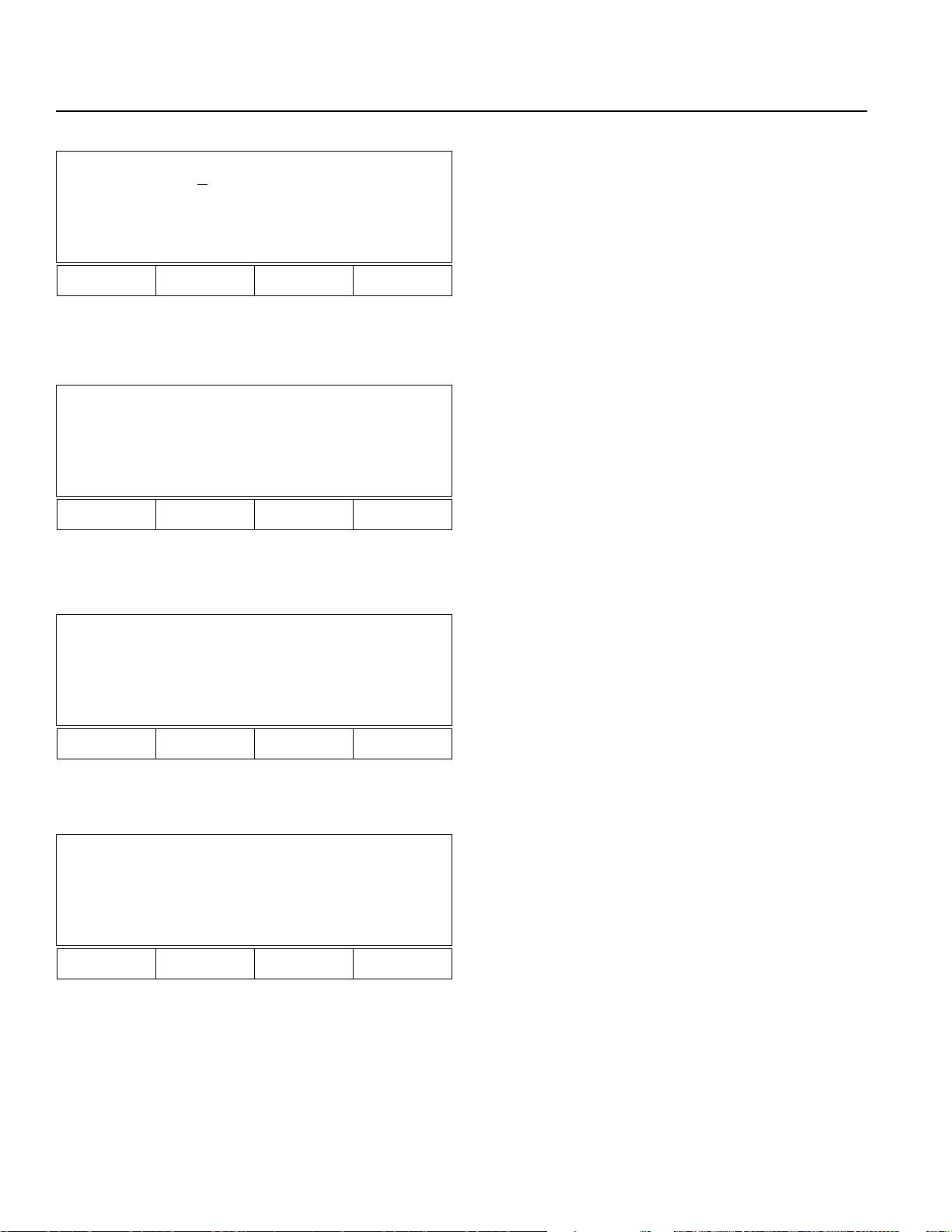

8. Examples of Simple Operation Procedure

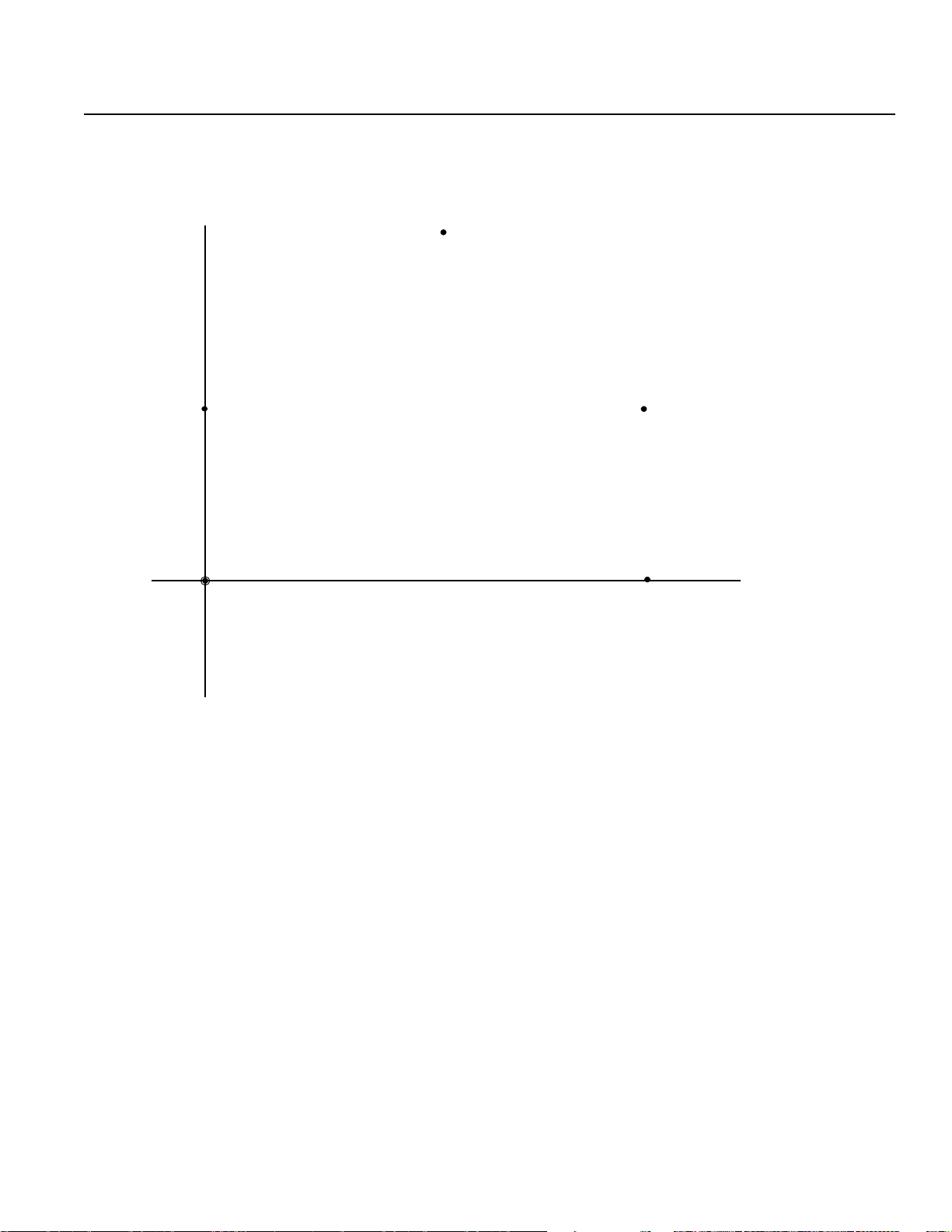

In this chapter, we will design a program which draws a 5 sided shape. It will pass through 6 points

(➀ and ➅ share the same position), taught by a 2-axes (X,Y) actuator.

Y

100

50

➀ /

➅

➁

➂

➄

0

Origin

Position data

50

➅➀ ~

➃

100

X

* Please finish reading the rest of the operational procedure before moving ➀~ ➅.

Page 15

Page 18

8. Examples of Simple Operation Procedure

8.1 Creating a Position Data

First, we will input data for 6 points to draw a 5 sided shape, similar to the position data list shown below:

Position Data • list*

No. Acc Vel Axis (1) Axis (2)

1 x.xx xxxx 0 50

2 x.xx xxxx 50 100

3 x.xx xxxx 100 50

4 x.xx xxxx 100 0

5 x.xx xxxx 0 0

6 x.xx xxxx 0 50

SEL Teaching

Teach V2.00 09/01/97

Start (Blinking)

F1 F2 F3 F4

SEL Teaching

T each V2.00 09/01/97

Main V2.50 07/14/95

Start (Blinking)

*This is a printout of the controller

position data which we will

create in this section.

LCD Display:

Once the characters appears on the LCD display, you may

advance to the next step by pressing the appropriate function

Key located on the lower part of the screen.

First, press the F1 Key (Start).

Controller ROM Version Display:

Press the F1 Key (Start).

F1 F2 F3 F4

Mode Selection Display:

Mode Select

This is the basic screen for all operation.

Prog Play Parm Test

F1 F2 F3 F4

*Note* In case of a selection or input error, press the ESC key to return to the previous screen and then resume operation.

For any operation, if you continue pressing the ESC Key, you will eventually return to the above basic screen.

Press F1 Key (Prog).

Page 16

Page 19

8. Examples of Simple Operation Procedure

Program Mode Screen:

Prog

Press the F1 Key (Posi).

Posi Aprg

F1 F2 F3 F4

Posi

Mdi Teac Step Etc

F1 F2 F3 F4

Position data Axis 1

Mdi - 1 No 1 [1] - 2

XXXXX.XXX XXXXX.XXX

Inc Dec Clr Del

F1 F2 F3 F4

Screen explanation:

Mdi - 1 No 1 [1] - 2

Position # Axis Name

Axis # No. of axes connected

Position (Position Data) Edit Screen:

Press the F1 Key (Mdi - manual data input).

Axis 2

Position Number Input Mode:

The cursor is on the position number location.

XXXXX.XXX will display if there is no data.

Press the Return Key and match the cursor to

the position data for Axis 1.

Note 1: For existing data, keep pressing the F1

Key until reaching the screen which displays

the XXXXX.XX. Then, execute data input, or

do a substitution so that the previous data will

dissappear.

Page 17

Note 2: This screen can only display up to a maximum

of four axes. When the number of axes are

over five, please refer to Page 50 for

reference.

Page 20

8. Examples of Simple Operation Procedure

Q Data input for point 1

Mdi - 1 No 1 [1] - 2

XXXXX.XX

X XXXXX.XXX

Wrt Can Clr Etc

F1 F2 F3 F4

* It is possible to input position data up to for integer 4 digits before the decimal point and 3 digits after. The range depends on

the type of the machine. Therefore, please verify the range according to the appropriate product catalog.

Input the number 0 and press the Return Key.

0.000 will display, and the axis number and name

will change to 2. Then, the cursor position will move

to the position data for the axis 2.

Mdi - 1 No 2 [2] - 2

0.000 XXXXX.XX

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 1 No 2 [1] - 2

0.00

0 50.000

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 2 No 1 [1] - 2

XXXXX.XX

X XXXX.XXX

Input 50 into the position data for axis 2, then,

press the Return Key.

X

*Since the cursor position moves every time the

Return Key is pressed, input in sequence, first axis 1,

then, axis 2. For input error, move the cursor to that

location and do a substitution.

Using the F1 Key (Wrt) to establish, the Position No.

will advance by 1, turning into 2.

② Data input for point 2

Input 50 into the position data for axis 1, then press the

Return Key.

Wrt Can Clr Etc

F1 F2 F3 F4

Page 18

Page 21

8. Examples of Simple Operation Procedure

Mdi - 2 No 2 [2] - 2

50.000 XXXXX.XX

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 2 No 1 [1] - 2

50.00

0 100. 000

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 3 No 2 [2] - 2

XXXXX.XX

X XXXXX.XXX

Wrt Can Clr Etc

Since the cursor position moves to the position

data for the axis 2, input 100 and press the Return Key.

X

Using the F1 Key (Wrt) to establish, then, advance the

Position No. to 3.

③ Data input for point 3

Input 100 into the position data for axis 1, then press

the Return Key.

F1 F2 F3 F4

Mdi - 3 No 1 [1] - 2

100.00

0 XXXXX.XXX

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 3 No 1 [1] - 2

100.00

0 50.000

Wrt Can Clr Etc

F1 F2 F3 F4

Input 50 into position data for axis 2, then press the

Return Key.

Press the F1 Key (Wrt), then, advance Position No.

to 4.

Page 19

Page 22

8. Examples of Simple Operation Procedure

Mdi - 4 No 1 [1] - 2

XXXXX.XX

X XXXXX.XXX

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 4 No 2 [2] - 2

100.000 XXXXX.XX

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 4 No 1 [1] - 2

100.00

0 0.000

④ Data input for point 4

Input 100 into the position data for axis 1, then press the

Return Key.

Input 0 into the position data for the axis 2, then

press the Return Key.

X

Press the F1Key (Wrt), and advance the Position No. to 5.

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 5 No 1 [2] - 2

XXXXX.XXX XXXXX.XXX

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 5 No 2 [2] - 2

0. 000 XXXXX.XX

X

Wrt Can lir Etc

F1 F2 F3 F4

⑤ Data input for point 5.

Input 0 into the position data for axis 1, then push the Return

Key.

Input 0 into the position data for axis 2, then press the

Return Key.

Page 20

Page 23

8. Examples of Simple Operation Procedure

Mdi - 5 No 1 [1] - 2

0.00

0 0.000

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 6 No 1 [1] - 2

XXXXX.XX

X XXXXX.XXX

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 6 No 2 [2] - 2

0.000 XXXXX.XX

Press the F1 Key (Wrt), and advance the Position No. to 6.

➅Data input for point 6

Input 0 into the position data for axis 2, and then

press the Return Key.

Input 50 into the position data for axis 2, and then press the

Return Key.

X

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 6 No 1 [1] - 2

0.00

0 50.000

Wrt Can Clr Etc

F1 F2 F3 F4

Mdi - 7 No 1 [1] - 2

XXXXX.XX

X XXXXX.XXX

Wrt Can Clr Etc

F1 F2 F3 F4

Press the F1Key (Wrt) to establish, and then the Position No.

screen will turn into 7.

Page 21

Page 24

8. Examples of Simple Operation Procedure

Push the ESC key to return to the Position Edit Screen.

Mdi - 7 No 1 [1] - 2

XXXXX.XXX XXXXX.XXX

Wrt Can Clr Etc

F1 F2 F3 F4

Push the ESC key again to dsiplay the Program Mode Screen.

Posi

Mdi Teac Step Etc

F1 F2 F3 F4

Prog

Posi Aprg

F1 F2 F3 F4

Mode Select

Prog Play Parm T est

F1 F2 F3 F4

Push the ESC key again to return to the Mode Selection

Screen.

* Pressing the ESC key further will not change the screen.

This concludes the basic position data input.

Page 22

Page 25

8. Examples of Simple Operation Procedure

8.2 Creating an application program

8.2-1 In this section, we will create an application program which will move the position data location that was

created in the previous section.

Application program • list *

Line A/O N (1) OP-CODE OPERAND1 OPERAND2 POST COMMENT

1 HOME 11

2 V EL 100

3 MOVL 1

4 MOVL 2

5 MOVL 3

6 MOVL 4

7 MOVL 5

8 MOVL 6

9 EXIT

* This is a printout of the application program which we will create (input) in this section.

The order of the application program input in the teaching pendant differs from the application program coding sheet (see

diagram below). The order in the teaching pendant is as follows: command (OP-CODE), operand 1, 2 (OPRND 1, 2), output

requirement (POST), expansion requirement (A/O) and continuous requirement (N).

OP-CODE

[Example]

[Example]

In the coding sheet:

petSpetS

petSpetSO/AO/A

petS

11111DNADNA

O/AO/ANNNNNEDOC-POEDOC-PO

O/A

DNADNA02N02N

02N02NEMOHEMOH

DNA

02N

EDOC-POEDOC-PO1DNRPO1DNRPO

EDOC-PO

EMOHEMOH1111111111009009

EMOH

➨

In the LCD screen:

Program No.

Edit 1 - 1 [ 50]

HOME 11

STEP No.

900 A N 20

1DNRPO1DNRPO2DNRPO2DNRPO

1DNRPO

2DNRPO2DNRPOTSOPTSOP

2DNRPO

TSOPTSOPTNEMMOCTNEMMOC

TSOP

009009

009

Step number

POST

TNEMMOCTNEMMOC

TNEMMOC

N

Inc Dec Clr Del

F1 F2 F3 F4

OPRND1 A/O

Page 23

Page 26

8. Examples of Simple Operation Procedure

Mode Select

Prog Play Parm T est

F1 F2 F3 F4

Prog

Posi Aprg

F1 F2 F3 F4

Aprg

Select the F1 Key (PROG) from the Mode Selection Screen.

Select the F2 Key (Aprg) from the Program Mode Screen.

Select the F1 Key (Edit) from the Application Program Edit

Screen.

Edit Copy

F1 F2 F3 F4

Edit 1- 1 [ 0]

ABPG ACC ADD AND

F1 F2 F3 F4

Edit

1- 1 [ 0]

ABPG ACC ADD AND

F1 F2 F3 F4

After the screen changes to program No. Input Mode Screen,

move the cursor location using the Return Key. Then, press

the Return Key twice.

*For existing program data input, substitution will clear the

previous data.

Edit command input mode:

Retrieve the HOME command (Homing). Pressing the DEC /

- Key will place the alphabet of the command in a

descending order. Pressing the INC /. Key will place the

alphabet of the command in an ascending order.

Page 24

Page 27

8. Examples of Simple Operation Procedure

Retrieval is performed either by the DEC / - Key or INC

Edit 1 - 1 [ 0]

_

HOME IN INB JBWF

F1 F2 F3 F4

/. Key. Continue pressing either of the Keys until the target

command displays. Since HOME is displayed in the display

window, in this example, select the F1 (HOME) Key. HOME

is displayed on the command input location.

[Note: In some cases, the displayed function key location

(F1 ~F4) of Home will differ.

Edit 1 - 1 [ 0]

Home

HOME IN INB JBWF

F1 F2 F3 F4

Edit 1 - 1 [ 0]

Home 11_

* BS Clr

F1 F2 F3 F4

Since the cursor moves to the operand 1 input position when

pressing the Return Key, input 11 so that both X and Y axes

homes at the same time. Why 11?

0 • • Not used

?1 1

1 • • Used.

Therefore, homing will be executed

Y-Axis

Press the Return Key.

X-Axis

to both axes in this example

(See Page 65 for Homing reference*1).

Edit 1 - 1 [ 0]

Home 11

_

BS Clr

F1 F2 F3 F4

Edit 1- 1 [ 0]

Home 11

And Or Clr Not

F1 F2 F3 F4

Press the Return Key.

Press the Return Key.

Page 25

Page 28

8. Examples of Simple Operation Procedure

Select the F4 Key (Wrt), and advance to Step No.2.

Edit 1- 1 [ 0]

HOME 11

Clr Wrt

F1 F2 F3 F4

Edit 1- 2 [ 1]

_

HOME IN INB JBWF

F1 F2 F3 F4

Edit 1- 2 [ 1]

_

TIMW VEL WTOF WTON

F1 F2 F3 F4

Edit 1- 2 [ 1]

VEL

Continuously press either the DEC / - Key or INC / . Key,

and retrieve VEL.

In this example, select the F2 Key (VEL).

[Note: In some cases, the displayed function key location

(F1~F4) of VEL may differ.]

Press the Return Key.

TIMW VEL WTOF WTON

F1 F2 F3 F4

Edit 1- 2 [ 1]

VEL _

* BS Clr

F1 F2 F3 F4

Here, we will input velocity as 100, then, press the Return

Key.

[Note: To verify maximum velocity, please refer to the

appropriate product catalog.]

Page 26

Page 29

8. Examples of Simple Operation Procedure

Press the Return Key.

Edit 1- 2 [ 1]

VEL 100

And Or Clr Not

F1 F2 F3 F4

Edit 1- 2 [ 1]

VEL 100

Clr Not

F1 F2 F3 F4

Edit 1- 3 [ 2]

_

TIMW VEL WTOF WTON

F1 F2 F3 F4

Edit 1 - 3 [ 2]

_

MOD MOVL MOVP MULT

Press the F4 Key, and advance to Step No.3.

Continuously press the DEC / - Key until MOVL is

displayed.

In this example, select the F2 Key (MOVL).

[Note: In some cases, the displayed function key location

(F1~F4) of MOVL may differ.]

F1 F2 F3 F4

? The difference between MOVL and MOVP:

MOVP moves the actuator to the designated position number from point to point without interpolation.

MOVL moves the actuator to the designated point while using interpolation (not point to point).

Edit 1 - 3 [ 2]

MOVL

MOD MOVL MOVP MULT

F1 F2 F3 F4

Press the Return Key. Then, input 1 for Position No. into

operand 1.

Page 27

Page 30

8. Examples of Simple Operation Procedure

Press the Return Key 3 times.

Edit 1- 3 [ 2]

MOVL 1_

* BS Clr

F1 F2 F3 F4

Select the F4 Key (Wrt). The screen will advanced to Step

Edit 1- 3 [ 2]

MOVL 1

Clr Wrt

F1 F2 F3 F4

No. 4.

Edit 1- 4 [ 3]

_

MOD MOVL MOVP MULT

F1 F2 F3 F4

Edit 1- 4 [ 1]

MOVL 2_

* BS Clr

F1 F2 F3 F4

Edit 1- 5 [ 4]

_

MOD MOVL MOVP MULT

In this example, select the F2 Key (MOVL), and then press

the Return Key. Input 2 for Position No. into operand 1.

[Note: In some cases, the displayed function key location

(F1 ~F4) of MOVL may differ.]

Press the Return Key 3 times, and select the F4 Key (Wrt).

The screen will advance to Step No.5.

In this example, select the F2 Key (MOVL), and then press

the Return Key. Input 3 for position No. into operand 1.

[Note: In some cases, the displayed function key location

(F1 ~F4) of MOVL may differ.]

F1 F2 F3 F4

Page 28

Page 31

8. Examples of Simple Operation Procedure

Press the Return Key 3 times, and select the F4 Key (Wrt).

Edit 1- 5 [ 4]

MOVL 3 _

* BS Clr

F1 F2 F3 F4

Edit 1- 6 [ 5]

_

MOD MOVL MOVP MULT

F1 F2 F3 F4

The screen will advance to Step No. 6.

In this example, select the F2 Key (MOVL), and select the

Return Key. Input 4 for position No. into operand 1.

[Note: In some cases, the displayed function key location

(F1 ~F4) of the MOVL may differ.]

Edit 1- 6 [ 5]

MOVL 4_

* BS Clr

F1 F2 F3 F4

Edit 1- 7 [ 6]

MOVL 5_

* BS Clr

F1 F2 F3 F4

Press the Return Key 3 times, and select the F4 Key (Wrt).

The screen will advance to Step No. 7. In this example,

select the F2 Key (MOVL), and press the Return Key.

Input 5 for position No. into operand 1.

[Note: In some cases, the displayed function key location

(F1 ~F4) of MOVL may differ.]

Press the Return Key 3 times, and select the F4 Key (Wrt).

The screen will advance to Step No. 8. In this example,

select the F2 Key (MOVL), and press the Return Key.

Input 6 for position No. into operand 1.

[Note: In some cases, the displayed function key location

(F1 ~F4) of MOVL may differ.]

Page 29

Page 32

8. Examples of Simple Operation Procedure

Press the Return Key 3 times, and select the F4 Key (Wrt).

Edit 1- 8 [ 7]

MOVL 6_

The screen will advance to Step No. 9. Continuously press the

DEC/ - Key until EXIT displays. In this example, select the

F3 Key (EXIT) and then, press the Return Key.

* BS Clr

F1 F2 F3 F4

?

EXIT ends a program. In order to stop without inputing EXIT above a program, please refer to Page 39, section

9.2-2, entitled, “How to stop operation during or methods other than EXIT.”

Edit 1- 9 [ 8]

EXIT

EDSR EOR EXIT EXPG

F1 F2 F3 F4

[Note: In some cases, the displayed function key location

(F1

~F4) of the EXIT may differ.]

Press the Return Key twice, and establish with the F4 Key

(Wrt).

Edit 1- 10 [ 9]

EXIT

EDSR EOR EXIT EXPG

F1 F2 F3 F4

Mode Select

Prog Play Parm Test

F1 F2 F3 F4

* For this example, programming ends. To continue

inputting another program, refer to Page 31.

After pressing the ESC Key several times, return the screen

to the Mode Selection Screen.

Page 30

Page 33

8. Examples of Simple Operation Procedure

8. 2-2 How to input another program as a continuation

[Continuation from P.30]

Edit 1-10 [ 9]

_

EDSR EOR EXIT EXPG

F1 F2 F3 F4

Edit 1-1

0 [ 9]

In c Dec Clr Etc

F1 F2 F3 F4

Press the ESC Key to execute Step No. Input Mode.

(To verify each step, either do a direct number input into

Step No. during this screen. Or use the F1 Key (Inc) and

F2 Key (DEC) to observe the Step No. you wish to verify.

By pressing the ESC Key once more will change the

screen into Program No. Input Mode Screen. Therefore,

either do a direct number, or by pressing the F1 Key (Inc),

the Program No.will turn into 2, allowing you to create

another program.

Edit 2-1 [ 0]

The Mode Selection Screen will return by continuously

pressing the ESC key.

Inc Dec Clr Etc

F1 F2 F3 F4

Mode Select

Prog Play Parm Test

F1 F2 F3 F4

* To turn Mode Selection Screen into Program No. Input Mode Screen, please refer to Page 23 and on. Use the program No.

Input Mode Screen to verify that the cursor is at the Program No. location. Then, either press the F1 Key or do an direct

number input. Make sure that other programs can be input into the screen so that new programs can be created.

Page 31

Page 34

9. Operation

9.1 Program Operation

In this section, we will operate the program which was created in the previous chapter.

Select the F2 Key (Play) from the Mode Selection Screen.

Mode Select

Prog Play Parm Test

F1 F2 F3 F4

Select the F1 Key (Prog).

Play

Prog Posi

F1 F2 F3 F4

Play 1- 1 [ 9]

HOME 11

In c Dec Clr

F1 F2 F3 F4

Play

1- 1 [ 9]

HOME 11

Show Go Stat HL T

(Note: The left screen will only be displayed for the

DS type. For the Super SEL type, the screen will

shift directly to the screen below.)

After confirming that the Play Program Input Mode

Program No. is 1, press the Return Key.

* If the Program No. 1 is not the program you input, then

continue pressing the F1 Key, and match your program

with the Program No.

When F2 Key (Go) is selected, homing begins. When

homing is completed, the program will move according

to the created Position Data Program.

F1 F2 F3 F4

Page 32

Page 35

9. Operation

Play 1 [ProgStatus]

ERR_STEP [NONE] [STOP]

Posi Play Stat Etc

F1 F2 F3 F4

Play 1- 1 [ 9]

HOME 1 1

Inc Dec Clr

F1 F2 F3 F4

Mode Select

When the operation is done by EXIT, this screen will be

displayed. Press the ESC Key.

By continuously pressing the ESC Key, the screen will

display the Mode Selection Screen.

Prog Play Parm Test

F1 F2 F3 F4

Page 33

Page 36

9. Operation

9.2 Application Program Changes

9.2-1 Setting a continuous movement in a program (Ins: insert, Del: delete)

In this section, we will set a continuous movement in a program using commands TAG and GOTO.

? GOTO refers to jump. By setting TAG before jump, you can repeat and skip a program.

Mode Select

Prog Play Parm Test

F1 F2 F3 F4

Prog

Posi Aprg

F1 F2 F3 F4

Aprg

Select the F1 Key (Prog) from the Mode Selection Screen.

Select the F2 Key (Aprg) from the Program Mode Screen.

Select the F1 Key (Edit) from the Application Program Edit

Screen.

Edit Copy

F1 F2 F3 F4

Page 34

Page 37

9. Operation

Edit 1- 1 [ 9]

HOME 11

Inc Dec Clr Etc

F1 F2 F3 F4

Edit 1-

HOME 11

Inc Dec Clr Etc

F1 F2 F3 F4

1 [ 9]

Since the screen changes to the Program Edit Mode Screen,

press the Return Key once, and match the cursor location to

the Step No. location.

Input TAG between Step No. 2 of command VEL and Step No.

3 of command MOVL, by either directly inputting the number

3 or pressing the F1 Key (Inc) twice until the number 3 is

displayed.

Edit 1-

3 [ 9]

MOVL 1

Inc Dec Clr Etc

F1 F2 F3 F4

Edit 1- 3 [ 9]

MOVL 1

Ins Del Etc

F1 F2 F3 F4

Edit 1- 3 I [ 9]

_

Select the F4 (Etc) Key.

Select the F1 Key (Ins). 1 of Insert will be displayed behind

Step No.3.

Continusouly press either the DEC/- Key or the INC /.

Key. In this example, select the F2 Key (TAG), and press the

Return Key.

EDSR EOR EXIT EXPG

F1 F2 F3 F4

[Note: In some cases, the displayed function key location

(F1~F4) of TAG may differ.]

Page 35

Page 38

9. Operation

Input number 1 into operand 1.

Edit 1- 3 I [ 9]

Tag _

BS Clr

F1 F2 F3 F4

* When inputting a number into TAG operand 1, the number should be a convenient number that is under 64. However, please

select a number that correspond to the number which will enter GOTO operand 1.

Edit 1 - 3 I [ 9]

TAG 1_

BS Clr

F1 F2 F3 F4

Edit 1 - 4 I [ 10]

_

SVON TAG TAN TIMC

F1 F2 F3 F4

Edit 1 - 4 [ 10]

MOVL 1

Press the Return Key, and select the F4 Key (Wrt).

Press the ESC Key, and display the Step No. 4 Screen.

Either input the number 3 or select the F2 (Dec) Key, and

press the Return Key. Verify that Step 3 step number is

changed from 9 to 10 in the TAG Command Screen.

Inc Dec Clr Etc

F1 F2 F3 F4

Page 36

Page 39

9. Operation

Edit 1- 3 [ 10]

TAG 1

SVON TAG TAN TIMC

F1 F2 F3 F4

Edit 1-

TAG 1

Inc Dec Clr Etc

F1 F2 F3 F4

3 [ 10]

Press the ESC Key, and match the cursor to the Step No.

location.

Next, delete EXIT and insert GOTO, by either leaving the

cursor location where it is and directly inputting the number

10, or pressing the F1 Key (Inc) 7 times until the number 10

is displayed.

Edit 1 - 10_ [ 10]

Exit

Inc Dec Clr Etc

F1 F2 F3 F4

Edit 1-10 [ 9]

Ins Del Etc

F1 F2 F3 F4

Edit 1-10 [ 10]

EXIT

Select the F4 (Etc) Key.

Select the F2 (Del) Key.

Since Del is blinking, select the F2 Key (Del) once again.

Del (Blinking)

F1 F2 F3 F4

Page 37

Page 40

9. Operation

Edit 1 - 10 [ 9]

Ins Del Et c

F1 F2 F3 F4

Press the Return Key.

Edit 1 - 1

0 [ 9]

_

SVON TAG TAN TIMC

F1 F2 F3 F4

Edit 1 - 10 [ 9]

GOTO

EXSR GOTO GRP HOLD

F1 F2 F3 F4

Edit 1- 10 [ 9]

GOTO 1_

Continuosly press either the DEC/ - Key, or INC / . Key until

GOTO is displayed. In this example, select the F2 Key

(GOTO).

[Note: In some cases, the displayed function key location

(F1∼F4) of GOTO may differ.]

Press the Return Key, and input the same number which was

input in operand 1 of TAG operand 1. Here, 1 is input.

Press the Return Key twice and establish with the F4 Key

(Wrt). Return to the Mode Selection Screen, and repeat the

movement one more time (see Page 32 and on).

* BS Clr

F1 F2 F3 F4

Page 38

Page 41

9. Operation

9. 2-2 How to stop operation during or by other methods excluding EXIT

Select the STOP Key when executing a program, when the EXIT command is not input, or when

you wish to force end a program.

Edit 1- 0 [ 9]

MOVL 6

Posi Play Stat Etc-

F1 F2 F3 F4

While in execution, press the F4 Key (Etc) twice until STOP

is displayed.

Play [ Run 1- 1 ]

1-6

Stop Etc-

F1 F2 F3 F4

PlayStop [ Run 1- 1 ]

1-6

StpAL Stp1

F1 F2 F3 F4

PlayStop [ Run 0- 0 ]

Press the F1 Key (Stop). When several programs are being

operated using the multi-task, the StpAL will stop all of the

programs, while the Stp 1 will select and stop a Program No.

Here, you may select either the F3 Key or the F4 Key to

stop.

Use the ESC Key to return to the Mode Selection Screen.

Although the 01 will continue to be displayed on the

controller code display, this is not a problem.

Please press any key

F1 F2 F3 F4

* You may also use EMERGENCY STOP to force a stop (for reference, see Page 77).

(For the DS type, P01 will be displayed).

Page 39

Page 42

9. Operation

9.2 -3 Expansion Condition Input Procedure

In this section, we will learn the expansion condition input procedure using the Application Program List example

below:

Program No 2

Line A/O N (1) OP-CODE OPERAND 1 OPERAND 2 POST COOMMENT

l N22

2 AND N2 0 HOME 11 900

Mode Select

Application Program • List

Select the F1 Key from the Mode Selection Screen.

Prog Play Parm Test

F1 F2 F3 F4

Prog

Posi Aprg

F1 F2 F3 F4

Aprg

Edit Copy

Select the F2 Key (Aprg) from the Program Mode Screen.

Select the F1 Key from the Application Program Edit Screen.

F1 F2 F3 F4

Page 40

Page 43

9. Operation

Edit 1 - 1 [ 10]

HOME 11

Inc Dec Clr Del

F1 F2 F3 F4

The screen will change into the Program No. Input Mode

Screen, while the screen condition will change into the

Program No. 1 which was created in the Application

Program. Either press the F1 Key (Inc), or input the number

2 to turn the Program No. into 2.

Edit 2 - 1 [ 0]

Inc Dec Clr Del

F1 F2 F3 F4

Edit 2 -

1 [ 0]

Inc Dec Clr Del

F1 F2 F3 F4

Edit 2 - 1 [ 0]

_

EXSR GOTO GRP HOLD

Press the Return Key, and move the cursor to the Step No.

position.

Press the Return Key once again, and move the cursor to the

command input position.

Here, we will not input a command. Instead, since this is only

for a requirement input, press the Return Key once to change

the screen into the Continuous Requirement Input Mode

Screen.

F1 F2 F3 F4

Edit 2 - 1 [ 0]

And Or Clr Not

F1 F2 F3 F4

Select the F4 Key (Not).

Page 41

Page 44

9. Operation

Edit 2- 1 [ 0]

N_

And Or Clr Not

F1 F2 F3 F4

Edit 2- 1 [ 0]

N22_

And Or Clr Not

F1 F2 F3 F4

Edit 2- 2 [ 1]

_

EXSR GOTO GRP HOLD

The screen will display N of NOT (A is for AND, and O

is for OR). Here, we will input the number 22.

Press the Return Key, and establish with the F4 Key (Wrt).

Then, advance to No.2.

In this example, press the INC /. Key once and display

HOME. Then, select the F1 Key (HOME).

[Note: In some cases, the displayed function key location

(F1 ~F4) of the HOME may differ.]

F1 F2 F3 F4

Edit 2- 2 [ 1]

HOME

HOME IN INB JBWF

F1 F2 F3 F4

Edit 2- 2 [ 1]

HOME 1 1

_

BS Clr

F1 F2 F3 F4

Press the Return Key once, and input the number 11 into

operand 1. Then, once again press the Return Key.

Since the screen will display the Result Input Mode Screen,

input 900 of result output. Then, press the Return Key.

Page 42

Page 45

9. Operation

Edit 2- 2 [ 1]

HOME 11

900 _

And Or Clr Not

F1 F2 F3 F4

Edit 2- 2 [ 1]

HOME 11

900 A_

And Or Clr Not

F1 F2 F3 F4

Edit 2- 2 [ 1]

HOME 11

900 A N20_

Here, the screen will change into the Continuous Input Mode

Screen. Select the F1 Key (And).

The screen will display A of AND. Select the F4 Key (Not)

and input the number 20.

Press the Return Key.

And Or Clr Not

F1 F2 F3 F4

Edit 2- 2 [ 1]

HOME 11

900 A N20_

Clr Wrt

F1 F2 F3 F4

Edit 2- 3 [ 2]

_

HOME IN INB JBWF

Select the F4 Key (Wrt).

Use the ESC Key to return to the Program Mode Screen.

This concludes the Expansion Condition Input Procedure.

F1 F2 F3 F4

Page 43

Page 46

9. Operation

9.3 Position Operation (DS type only)

There are two methods in Position Operation: One is “Moving One Step at a Time” Method, and the second is the

“Consecutive Movement” Method.

9.3 -1 Step Operation

Mode Select

Prog Play Parm Test

F1 F2 F3 F4

Play

Prog Posi

F1 F2 F3 F4

Select the F2 Key (Play) from the Mode Selection Screen.

Selec the F2 Key (Posi).

Play

HOME

F1 F2 F3 F4

Play

Moving now to Home

F1 F2 F3 F4

Select the F1 Key (HOME) to execute homing.

This is the screen during homing.

Page 44

Page 47

9. Operation

Play - 2 No 1 [1] -1

200.000

Inc Dec

F1 F2 F3 F4

Play - 2 No 1 [1] -1

200.000

Step Cont

F1 F2 F3 F4

Press either the F1 Key (Inc) or F2 Key (Dec), and select the

first Position No. you wish to move. then, determine with the

Return Key ( ↵).

(Here, select the Position No. 2)

* F1 Key (Inc) will increase the No. while the F2 Key

(DEC) will decrease the No.

Press the F1 Key (Step), and select the Step Operation.

Play S - 2 No 1 [1] -1

200.000

Go+ Go-

F1 F2 F3 F4

When F1 Key (Go+) is selected:

Press the F1 Key (Go+) to move to Position No. 2.

When the move is completed, Position No.3 is displayed.

When the F2 Key (Go-) is selected:

Press the F2 Key (Go-) to move to Position No. 2.

When the move is completed, Position No.1 is displayed.

Page 45

Page 48

9. Operation

9.3- 2 Consecutive Operation

Mode Select

Prog Play Parm Test

F1 F2 F3 F4

Select the F2 Key (Play) from the Mode Selection Screen.

Play

Prog Posi

F1 F2 F3 F4

Play

HOME

F1 F2 F3 F4

Play

Selec the F2 Key (Posi).

Select the F1 Key (HOME) to execute homing.

This is the screen during homing.

Moving now to Home

F1 F2 F3 F4

Page 46

Page 49

9. Operation

Play - 2 No 1 [1] - 1

200.000

Inc Dec

F1 F2 F3 F4

Play - 2 No 1 [1] - 1

200.000

Step Cont

F1 F2 F3 F4

Play C- 2 No 1 [1] - 1

200.000

Press either the F1 Key (Inc) or F2 Key (Dec), and select the

first Position No. you wish to move. Then, determine with the

Return Key (↵).

(Here, select position No. 2)

* F1 Key (Inc) will increase the No. while the F2 Key

(DEC) will decrease the No.

Press the F2 Key (Cont), and select Step Operation.

When F1 Key (Go) is pressed, the moving position will

execute Consecutive Operation while displaying in sequence.

To stop, press the F2 Key (Stop).

Go Stop

F1 F2 F3 F4

Page 47

Page 50

9. Operation

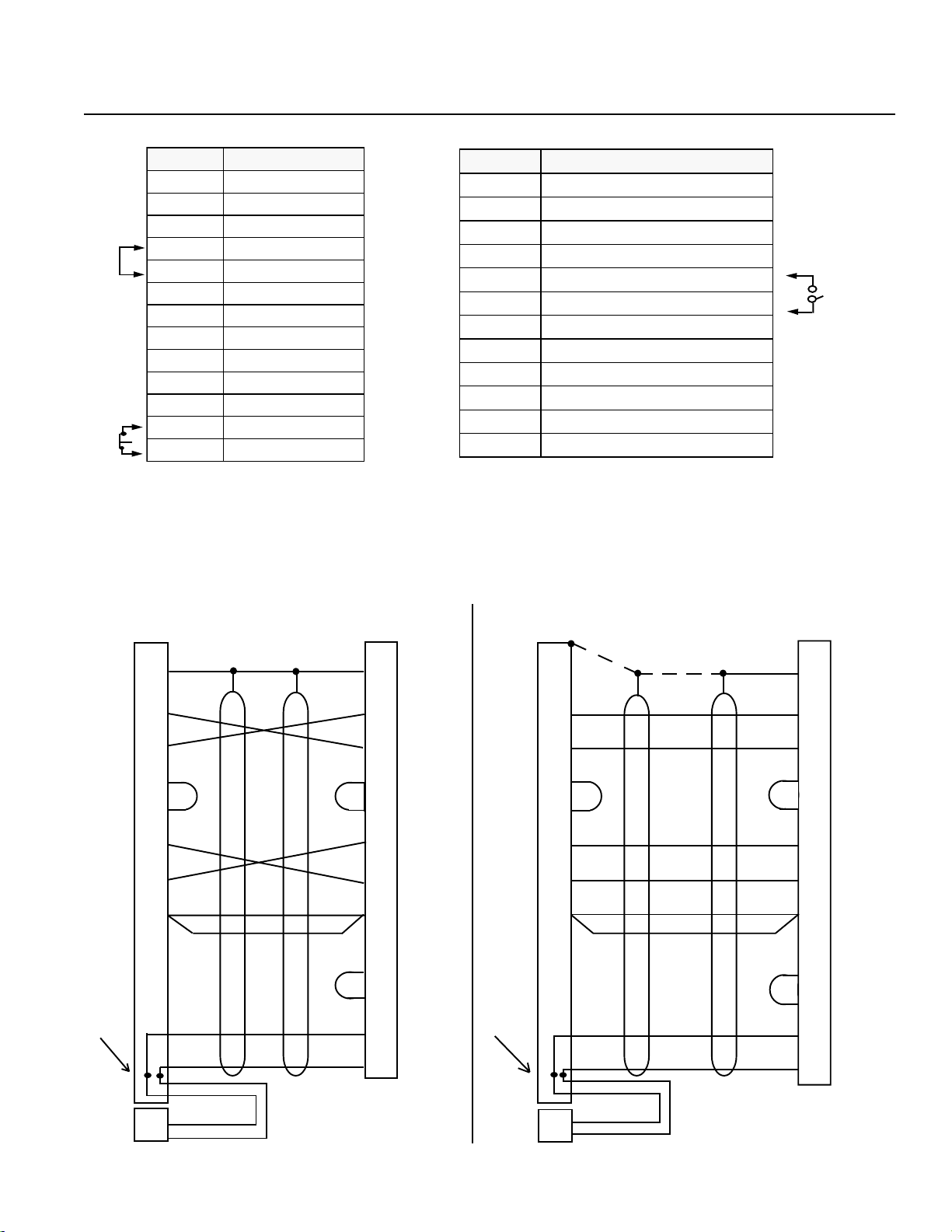

9.3 -3 Consecutive Operation Sequence)

During a Consecutive Operation Movement, execute the set Position No. to the next Position No. in sequence. For an

unregistered position, return to the next position No. in front of the previous unregistered Position No. Then, execute the set

Position No. to the next Position No. in sequence.

.oNnoitisoPnoitareleccAyticoleVnoitisoP

13.0057000.05

23.0057000.002

33.0005000.051

43.0005000.002

• • • • Unregistered position

➃

↓

➄

↓

➀

↓

➁

↓

➂

• • • • Unregistered position

Set Position No.

5x.xxxxxxx.xxx

6 3.0 057 000.001

7 3.0 006 000.002

8 3.0 002 000.003

9 3.0 057 000.052

01 3.0 057 000.051

11x.xxxxxxx.xxx

21x.xxxxxxx.xxx

313.0005000.001

Page 48

Page 51

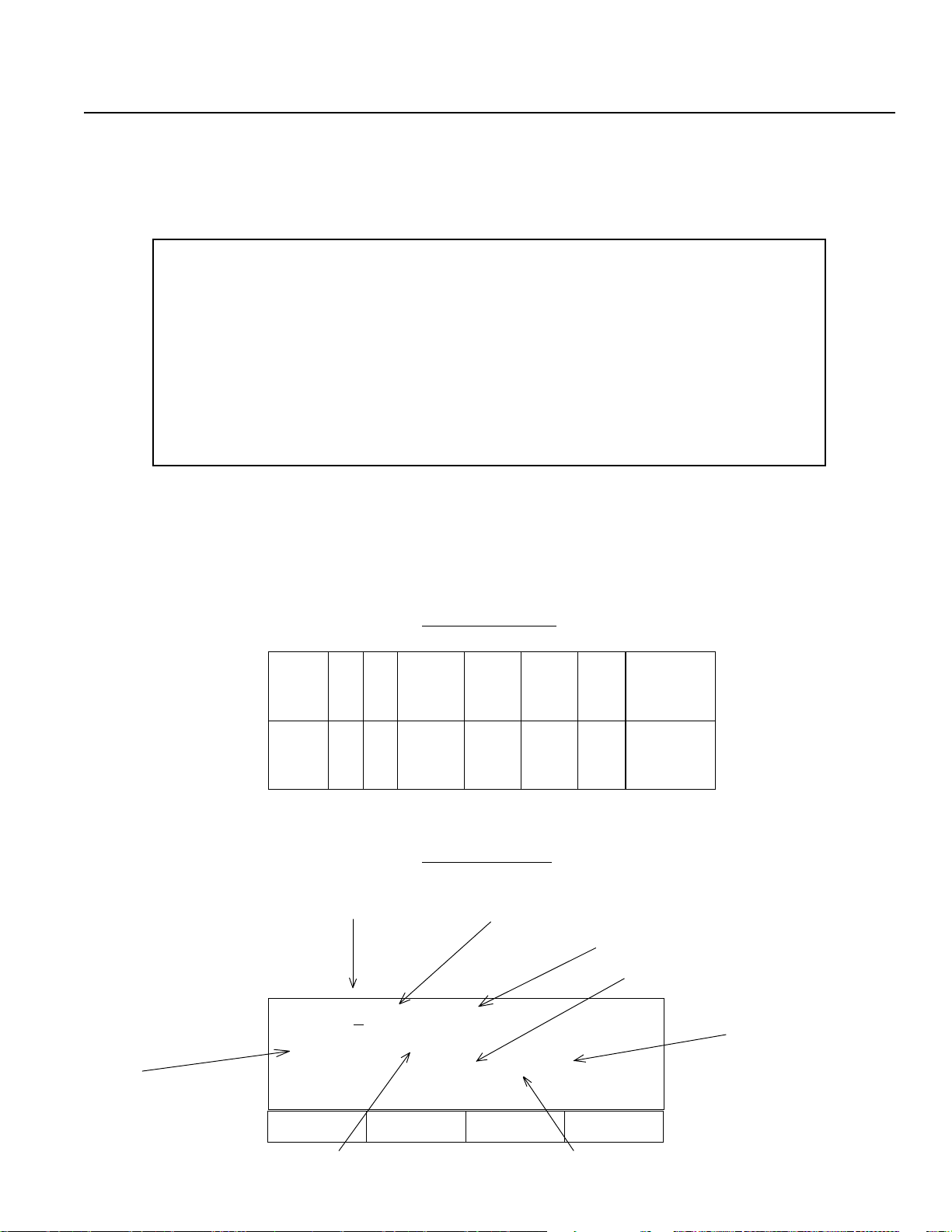

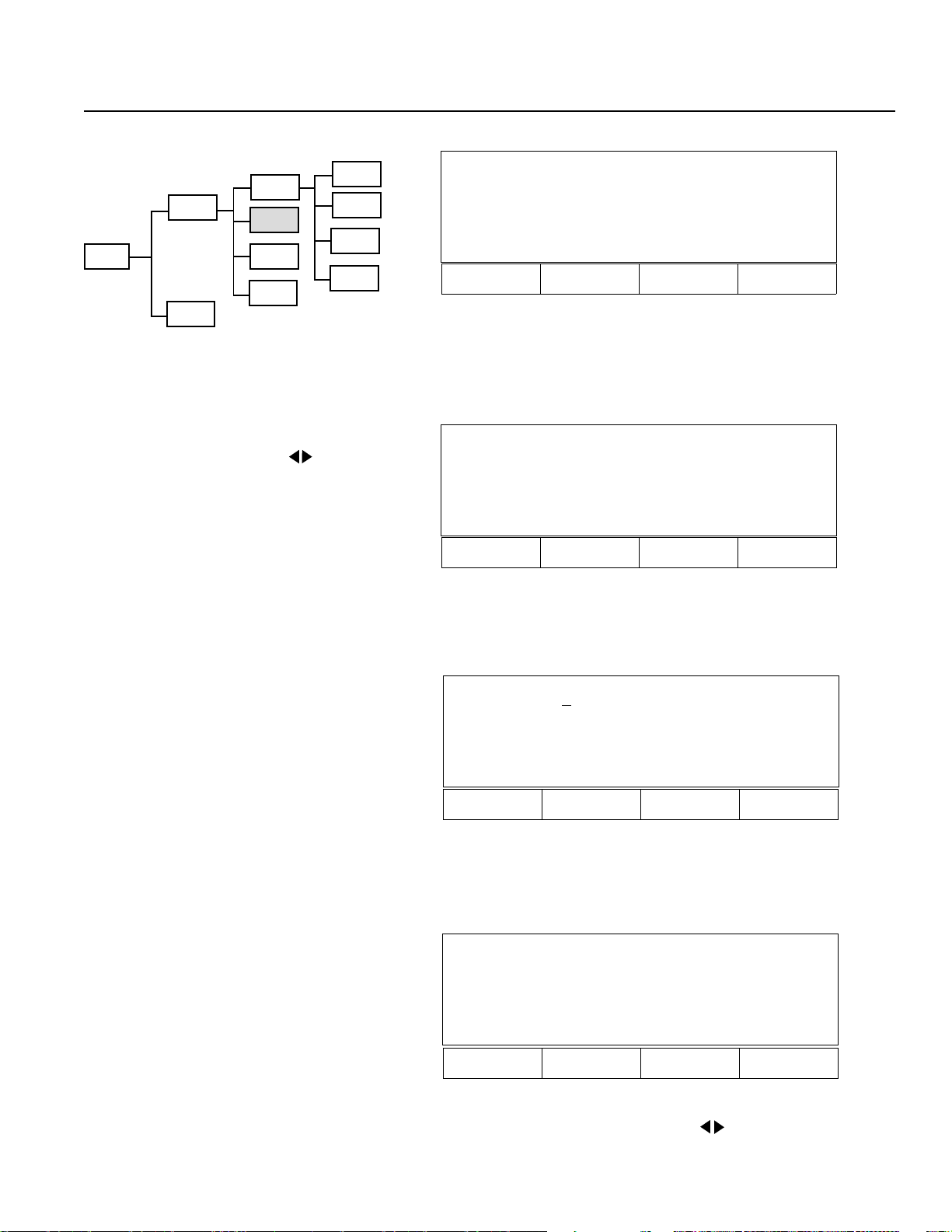

10. Explanation of Each Function Screen

Mode Selection Screen

Prog

Mode

Select

Play

Parm

Test

10.1 Prgra m Mode

Program Mode Screen

Prog

Mode

Select

10.1-1 Position Edit Screen

Play

Parm

Test

Posi

Aprg

Mode Select

Prog Play Parm Test

F1 F2 F3 F4

This the basic screen for all operation.

Use the “ESC” Key to return to this screen.

Prog

Posi Aprg

F1 F2 F3 F4

Select the F1 Key (Posi) to view the Position Edit Screen.

Mode

Select

Prog

Play

Parm

Test

Posi

Aprg

Mdi

Teac

Step

Etc

Posi

Mdi Teac Step Etc

F1 F2 F3 F4

Select the F1 Key (Mdi) to input position data number.

Page 49

Page 52

10. Explanation on Each Function Screen

Position Input Mode

Mdi

Posi

Prog

Aprg

You may numerically input a position.

Position Input Mode Screen

Teac

Step

Etc

↵

Mdi

Teac

Posi

Step

Etc

Inc

Dec

Clr

Etc

Inc

Dec

Clr

Del

Wrt

Can

Clr

Etc

Mdi - 1 No 1 [1] - 2

xxxx.xxx xxxxx.xxx

200. 000

Inc Dec Clr Del

F1 F2 F3 F4

You may move Position No.1 through 2000, or input a number

directly.

(For the DS type, you may move position No. 1 through 500.)

Please refer to Page 16, section 8.1, entitled, “Creating

Position Data” for input procedure.

The screen has the following two methods:

Axis 1

Mdi - 1 No 1 [1] - 8

100.00

0 100. 000

100.000 100. 000

Axis 3

Wrt Can Clr Etc

F1 F2 F3 F4

Axis 2

Axis 4

When the number of actuator axes is over 5 axes,

the next screen will appear.

Continuously press the Return Key 4 times

↵

Mdi - 1 No 1 [1] - 8

Axis 5

Axis 7

100.00

100.000 100. 000

Axis+ Axis- V e l Etc

Use either the Axis+ or Axis- to move the cursor until it has

reached Axis 5. Then, once again, select Etc.

Mdi - 1 No 5 [5] - 8

100.00

100.000 100. 000

Mdi Teac Step Etc

F1 F2 F3 F4

The screen will change into the position input mode for Axis

5 though Axis 8.

Page 50

0 100. 000

F1 F2 F3 F4

0 100. 000

When Etc is selected

Axis 6

Axis 8

Page 53

10. Explanation on Each Function Screen

Teaching Mode

Prog

Mdi

Posi

Aprg

There are two methods in Position

Teaching: One is the Direct Manual

Actuator Move Method, and the other is

the Teaching Using the Key Method.

Teac

Step

Etc

Inc

Dec

Clr

Del

Teac

Display (Blinking)

HOME Teac Step Etc

F1 F2 F3 F4

Upon installing power and in teaching mode, the screen will

change to the Homing Screen.

Press the F1 Key (HOME).

➨

Teac

Moving now to Home

F1 F2 F3 F4

This screen appears during homing. Unless the power is turned OFF

thereafter, this screen will be skipped, and the screen below will first

appear.

Upon homing

➨

Teac -

1 No 1 [1] - 2

0.000 50.000

Inc Dec Clr Del

F1 F2 F3 F4

➨

↵ (Return Key)

➨

Mdi - 1 No 1 [1] - 2

0.000 50.000

Jvel Jog Svof Etc

F1 F2 F3 F4

Select either the F2 Key (Jog) or the F3 Key (Svof).

Jog • • • Allows you to move a position using key during Servo ON.

Svof • • • Allows you to manually position the actuator during Servo OFF

.

Page 51

Page 54

10. Explanation on Each Function Screen

Jog Speed Set Mode

Jvel

Teac

* The maximum value varies according to

machine type. Therefore, please refer to

the appropriate product catalog.

Jog Mode

T eac

↵

↵

Jog

Svof

Etc

Jvel

Jog

Svof

Etc

Axis

Clr

Wrt

Jvel

Svof

Etc

Teac - 1 No 1 [1] - 2

0.000 50.000

Jvel [ 03

0 ] JAcc [0.30]

Axis Clr

F1 F2 F3 F4

Initial set value using a parameter

(for reference, see Page 61).

Jog - 1 No 2 [2] - 2

0.00

0 0.000

Wrt Jvel Svof Etc

F1 F2 F3 F4

Use the Key to move the actuator. The current position

data displays on the screen.

- +

Continue pressing the Key. The data will stop changing once you

release the Key.

➨

Velocity Set • Axis Change Mode

Jog - 1 No 1 [1] - 2

18.62

5 0.000

Wrt Jvel Svof Etc

F1 F2 F3 F4

To move the cursor to Axis 2, either press the Return Key or by

selecting the F4 Key, the Axis No. and Axis Name will change.

By selecting the F4 Key (Etc),

➨

Jog - 1 No 1 [1] - 2

18.625

0.00

0

Wrt Jvel Svof Etc

F1 F2 F3 F4

+

Once the cursor position moves to Axis 2, use the Key to execute

axis move.

Page 52

Page 55

10. Explanation on Each Function Screen

Teaching Velocity Set Mode

Wrt

Jvel

Prog

* The maximum value varies according to machine

type. Therefore, please refer to the appropriate

product catalog.

T eac

Svof

Etc

Servo OFF Mode

↵

Axis+

Axis-

Vel

Etc

Jvel

Jog

Svof

Etc

Wrt

Axis

Clr

Wrt

Jvel

Jog

Etc

Jog - 1 No 2 [2 ] - 2

18.625 7. 510

Vel [

0 ] ACC [0.00 ]

Wrt Axis Clr

F1 F2 F3 F4

Set the velocity • acceleration, and press the Return Key.

F1 Key (Wrt): Writes to memory.

F2 Key (Axis): To Axis Change Mode Screen

F3 Key (Cir): Clears the input number, and inputs the number once

again.

Svof - 1 No 1 [1] - 2

59.729 99.625

Wrt Jvel Jog Etc

F1 F2 F3 F4

Manually operate the actuator to move the axis position,

and then, write in using the F1 Key (wrt). Each time the F1

Key is pressed, the Position No. advances.

Wrt

Jvel

Svof

Prog

* The maximum value varies according to machine

type. Therefore, please refer to the appropriate

product catalog.

Jog

Etc

Wrt

Jvel

Jog

Etc

Axis+

Axis-

Vel

Etc

Axis+

AxisVel

Etc

Wrt

Axis

Clr

Svof - 1 No 1 [1] - 2

48.593 99.625

Wrt Jvel Jog Etc

F1 F2 F3 F4

You may select the velocity set • axis No.

Svof - 2 No 1 [1] - 2

48.593 99.625

Vel [

0 ] Acc [ 0.00]

Wrt Axis Clr

F1 F2 F3 F4

Set the velocity • acceleration, and press the Return Key.

F1 Key (Wrt): Writes to memory.

F2 Key (Axis): To Axis Change Mode Screen

F3 Key (Clr): Clears the input number, and inputs the number once

again.

Page 53

Page 56

10. Explanation on Each Function Screen

Prog

Prog

Position Step Mode

Posi

Aprg

Position Data Edit Screen 2

Posi

Aprg

• • • Verify position

Mdi

Teac

Step

Etc

Mdi

T eac

Step

Etc

Inc

Dec

Go

Jvel

Shift

Copy

Step - 1 No 1 [1] - 2

48.59

3 99. 625

Inc Dec Go Jvel

F1 F2 F3 F4

Input the Position No. you wish to move.

F1 Key: +1 to Position No.

F2 Key: -1 to Positon No.

F3 Key: Move to the assigned Position No. (Data).

F4 Key: Assign move velocity.

Posi

Shift Copy Clr Etc

F1 F2 F3 F4

Clr

Etc

Position Shift (Move) Mode

Mdi

Teac

Posi

Step

Etc

Moves the consecutive Position No. (data).

Shift

Copy

Clr

Etc

Clr

F1 Key: To Position Data Move Mode

F2 Key: To Position Data Copy Mode

F3 Key: To Position Data Clear Mode

F4 Key: To Positon Edit Screen

Posi Shift

From St.

1 Ed.

T o St. Ed.

Clr

F1 F2 F3 F4

Input (From) start of previous move Position No. to the

end. Next, input (To) start of move ahead Position No. to

the end.

➨

Posi Shift

From St. 1 Ed. 3

T o St. 4 Ed. 6

Shift

F1 F2 F3 F4

Press the F1 Key (Shift) to complete move.

Page 54

Page 57

10. Explanation on Each Function Screen

Position Copy Mode

Mdi

T eac

Posi

Step

Etc

Copies the consecutive Position No. (data).

Position Clear Mode

Mdi

Teac

Posi

Step

Etc

Shift

Copy

Clr

Etc

Shift

Copy

Clr

Clr

Clr

Posi Copy

From St. 1 Ed.

To St. Ed.

Clr

F1 F2 F3 F4

Operand is input in the same method as the Position Shift (move).

Clear All Position

Clr

Etc

F1 F2 F3 F4

Use the F1 key to clear all positions.

Page 55

Page 58

10. Explanation on Each Function Screen

10.1-2 Program Edit Mode

Edit 1- 1 [13]

Prog

Posi

Aprg

Copy Mode

Edit

Copy

Inc

Dec

Clr

Del

Home 1 1

Inc Dec Clr Del

F1 F2 F3 F4

For operation method, please refer to the section 8.2, entitled,

“Creating an Application Program.”

350 N350

Mdi

Posi

T eac

Copy and Overwrite Select Mode

Edit

Copy

Prog Copy

From 1 [ 10]

To 1

F1 F2 F3 F4

Input (From) the Program No. you wish to copy, and then, input

(To) the transfer ahead Porgram No. Use the Return Key to

select Copy and Overwrite Selection Mode.

0 [ 20]

Clr

➨

Return Key

↵

➨

Prog Copy

From 1

To 10

Copy OWrt

F1 F2 F3 F4

F1 Key (Copy) - Adds onto the end of the transfer ahead

program

F2 Key (OWrt) - Overwrites to the transfer ahead program.

Page 56

Page 59

10. Explanation on Each Function Screen

10.2 Play Mode

10.2-1 Play Program Input Mode

(Super SEL T ype)

Prog

Prog

Play

Parm

Inc

Dec

Play

Home 11

1 - 1 [10]

Test

(DS T ype)

Prog

Mode

Select

Execute, Stop, Select Screen

Execute Assign, Stop Condition Select Screen

Play

Play

Parm

T est

↵

Clr

Prog

Posi

Show

Go

Stat

HLT

Inc

Dec

Clr

Posi

Play

Stat

Etc

Inc Dec Clr

F1 F2 F3 F4

➨

Return Key

↵↵

↵

↵↵

➨

Play 1 - 1 [ 10]

Home 11

Show Go Stat HLT

F1 F2 F3 F4

Play 1 - 0 [ 10]

MOVL 2

Posi Play Stat Etc

F1 F2 F3 F4

Start Axis

Play Axis Condition Display Mode

Axis+

Axis-

Stat

Go

Posi

Play

Stat

Etc

Play 1 - No 1 [1] - 2

99.256 51.328

Axis+ Axis- Stat

F1 F2 F3 F4

Select the axes not displayed (5 axes or greater).

Page 57

Page 60

10. Explanation on Each Function Screen

Status Display Mode

Axis+

Play 1 - No 1 [1] - 2

Home [ON] Servo [ON]

Move [OFF] 59.237

Posi

AxisStat

Axis+

Axis-

Axis+ Axis- Pos

Pos

Rerun, Stop Assign Mode

Go

Posi

Play

Stat

Inc

Dec

Clr

Play 1 - 1 [ 10]

HOME 11

Inc Dec Clr

HLT

* Multi-task • • • You may simultaneously execute 16 programs

(For the DS type: 8 programs).

Execute Program Status Mode

F1 F2 F3 F4

EMOHNO/FFO

OVRESNO/FFO

EVOMNO/FFO

F1 F2 F3 F4

Go

Posi

Play

Stat

Etc

↔

Prog

Play 1 - 1 [Run -1]

1-4

Prog

F1 F2 F3 F4

Execute Program No.

➨

Play

ERR - STEP [NONE] [RUN]

F1 F2 F3 F4

1 [Prog Status]

Stat

1: Execution condition

2: Execution allowable

condition

4: Wait condition

8: Forced wait condition

Page 58

Page 61

10. Explanation on Each Function Screen

Input • Output Port, Flag Condition Selection Mode

Posi

Play 1 - 0 [ 10]

MOVL 5

In Out Flag Etc

F1 F2 F3 F4

F1 Key: Input port changes display selection

F2 Key: Output port changes display selection

F3 Key: Flag changes display selection

F4 Key: Execute Assign, Status Selection Screen

Play 0123456789 (In)

000

010

__

> 0010000000 <

__

> 0000000000 <

Inc Dec

F1 F2 F3 F4

Go

Play

Stat

Etc

Play Input Port Display Mode

In

Out

Etc

Flag

Etc

In

Out

Flag

Etc

Inc

Dec

__

__

009

019

Play Output Port Display Mode

In

Inc

Play

Out

Dec

Flag

Etc

Play Flag Display Mode

In

Etc

Out

Inc

Flag

Dec

Etc

Displays the condition when IN 002 is ON.

(Peripheral device operation)

0 0 1 0 0 0 0 0 0 0

→

000 001 002

→

→

… … … … … … … … … … …… … …

→

009 Port No.

F1 Key: +10 to input port

F2 Key: -10 to input port

Play 0123456789 (Out)

300

310

__

> 0100000000 <

__

> 0000000000 <

__

__

309

319

Inc Dec

F1 F2 F3 F4

F1 Key: +10 to output port

F2 Key: -10 to output port

Play 0123456789 (Flg)

600

610

__

> 0000000000 <

__

> 0000000000 <

__

__

609

619

Inc Dec

F1 F2 F3 F4

F1 Key: +10 to flag

F2 Key: -10 to flag

Page 59

Page 62

10. Explanation on Each Function Screen

Progam Executing Display

Posi

Play [ Run 1- 1]

1- 4

Stop Etc

F1 F2 F3 F4

Please refer to Page 39, section 9.2.2, entitled, “How to

stop operation during, or by other methods excluding

Go

How to stop using

Play

Stat

HLT

In

Out

Flag

Etc

HLT

Stop

Etc

EXIT .”

Inc

Play

Show Mode • • • Monitors program movement

Play

Dec

Clr

Inc

Dec

Clr

→

→

↵

Show

Go

Stat

HLT

Posi

Show

↵

Go

Stat

HLT

Play

Stat

Etc

Press the F1 Key

→ to return to the Play Mode Screen.

Play 2 [ Prog Status]

ERR_ STEP [NONE] [STOP]

Posi Play Stat Etc

F1 F2 F3 F4

Movment is same as during Stop.

Play 1- 0 [ 10]

MOVL 3

Posi Play Stat Etc

F1 F2 F3 F4

Page 60

Page 63

10. Explanation on Each Function Screen

When program in not moving

Show

Posi

(P57)

Play

(P58)

Stat

(P58)

Etc

(P59)

↔

Axis+

Axis-

Stat

Inc

Dec

Clr

Prog

In

Out

Flag

Etc

↔

Posi

Stop

Etc

Play 1 [Prog Status]

ERR_STEP [NONE] [STOP]

Posi Play Stat Etc

F1 F2 F3 F4

* For details on each screen, please refer to Page 57 ~ 59.

Page 61

Page 64

10. Explanation on Each Function Screen

10.2-2 Play Program Input Mode (DS type only)

Prog

Mode

Select

Operation Method Selection Screen

Step Operation Mode

Posi

Play

Parm

T est

↵

Prog

Posi

Step

Cont

Go

Inc

Dec

Go+

Go-

Play - 2 No 1 [1] - 1

200.000

Inc Dec