Page 1

Touch Panel Teaching

CON-PT, CON-PD, CON-PG

Operating Manual

sixth Edition

IAI America, Inc.

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Operation Manual explains the handling methods, structure and maintenance of this product, among

others, providing the information you need to know to use the product safely.

Before using the product, be sure to read this manual and fully understand the contents explained herein

to ensure safe use of the product.

The CD/DVD that comes with the product contains operation manuals for IAI products.

When using the product, refer to the necessary portions of the applicable operation manual by printing

them out or displaying them on a PC.

After reading the Operation Manual, keep it in a convenient place so that whoever is handling this product

can reference it quickly when necessary.

[Important]

x

This Operation Manual is original.

x The product cannot be operated in any way unless expressly specified in this Operation Manual. IAI

shall assume no responsibility for the outcome of any operation not specified herein.

x Information contained in this Operation Manual is subject to change without notice for the purpose of

product improvement.

x If you have any question or comment regarding the content of this manual, please contact the IAI

sales office near you.

x Using or copying all or part of this Operation Manual without permission is prohibited.

x The company names, names of products and trademarks of each company shown in the sentences

are registered trademarks.

Page 4

Page 5

Table of Contents

Safety Guide (Read This Section Before Use).............................................................................. 1

Handling Precautions .................................................................................................................... 8

Product Check............................................................................................................................... 9

Supported Models .......................................................................................................................

10

1. Basic Specification ............................................................................................................... 11

2. Explanation of Each Part...................................................................................................... 13

3. Connection and Disconnection to/from Controller................................................................ 15

4. Connection of CON-PG and Controller ................................................................................ 16

5. Operation of CON Controllers .............................................................................................. 17

5.1 Displayed Language Change....................................................................................................17

Transition of Operating States................................................................................................... 18

5.2

5.3 Initial Screen.............................................................................................................................. 22

5.4 Changing Operating Axis........................................................................................................... 23

5.5 Menu Selection.......................................................................................................................... 24

5.6 Monitor....................................................................................................................................... 25

5.7 Position Editing.......................................................................................................................... 35

5.7.1 Position Data...................................................................................................................... 34

5.7.2 Entering New Data............................................................................................................. 43

5.7.3 Changing Position Data ..................................................................................................... 63

5.7.4 Clearing Position Data, Clearing All Position Data ............................................................ 64

5.8 Parameter Editing...................................................................................................................... 68

5.9 Trial Operation........................................................................................................................... 70

5.9.1 Jog/Inching Operation........................................................................................................ 72

5.9.2 Position Movement Operation ........................................................................................... 74

5.9.3

5.9.4 I/O Test...............................................................................................................................76

5.10 TP Operation Mode ................................................................................................................... 77

5.11 Alarm List................................................................................................................................... 78

5.12 Controller Restart ...................................................................................................................... 80

5.13 User Adjustment ........................................................................................................................ 81

5.14 Parameter Initialization .............................................................................................................. 82

5.15 Axis Number Setting.................................................................................................................. 84

5.16 Information Display.................................................................................................................... 85

5.17 Environment Setting .................................................................................................................. 86

5.18 Data Backup .............................................................................................................................. 90

Direct Movement Operation............................................................................................... 75

6. Operation of SEP Controllers ............................................................................................... 91

6.1 Displayed Language Change ....................................................................................................91

Transition of Operating States................................................................................................... 92

6.2

6.3 Initial Screen.............................................................................................................................. 95

6.4 Initial Setting .............................................................................................................................. 96

6.5 Changing Operating Axis........................................................................................................... 97

6.6 Menu Selection.......................................................................................................................... 98

6.7 Monitor....................................................................................................................................... 99

Page 6

6.8 Information...............................................................................................................................

6.9 Alarm List.................................................................................................................................

Position Setting (Setting of Position-related Data, Jog/Inching Operation).............................

6.10

6.11 I/O Setting (Setting of Operation Parameters, Etc.) ................................................................

6.12 Parameters (Parameter Editing, Axis Number Setting, Parameter Initialization to Factory

Default Settings, System Password) ....................................................................................... 139

6.13 Test (I/O Tests, Operation Tests for Axis Movement)............................................................. 147

6.14 Environment set (Sound, Language, Auto Monitor, Display (Screen Adjustment)) ................ 152

6.15 Data Backup ............................................................................................................................ 155

101

103

104

128

7. Operation of MEC Controllers ............................................................................................ 156

7.1 Displayed Language Change ..................................................................................................

7.2 157

Transition of Operating States.................................................................................................

7.3 Initial Screen............................................................................................................................ 161

7.4 Initial Setting ............................................................................................................................ 162

7.5 MEC Menu Selection............................................................................................................... 163

7.6 Initial Setting ............................................................................................................................ 164

7.7 Position Setting (Position Data Setting and Manual Axis Operation (Jogging, Inching))........ 169

7.8 Trial Operation......................................................................................................................... 189

7.9 Information............................................................................................................................... 191

7.10 Maintenance – Parameters .....................................................................................................193

7.11 Maintenance – I/O Tests ......................................................................................................... 201

7.12 Maintenance – Alarm List........................................................................................................ 202

7.13 Maintenance – Data Backup ...................................................................................................204

7.14 Maintenance – Environment Setting ....................................................................................... 205

7.15 Monitor..................................................................................................................................... 208

156

8. Error Display....................................................................................................................... 212

8.1 Occurrence of Alarm................................................................................................................ 212

8.1.1 Alarms Detected by Controller......................................................................................... 212

8.1.2 Alarms Detected by Touch-panel Teaching Pendant....................................................... 212

8.2 Error Messages on Touch Panel............................................................................................. 214

9. Warranty..............................................................................................................................215

9.1 Warranty Period................................................................................................................ 215

9.2 Scope of the Warranty............................................................................................................. 215

9.3 Honoring the Warranty 215............................................................................................................

9.4 Limited Liability 215

9.5 Conditions of Conformance with Applicable Standards/Regulations, Etc., and Applications 216

9.6 Other Items Excluded from Warranty 216

.......................................................................................................................

......................................................................................

.......

..

10. Change History................................................................................................................... 217

Page 7

Safety Guide

³6DIHW\*XLGH´KDVEHHQZULWWHQWRXVHWKHPDFKLQHVDIHO\DQGVRSUHYHQWSHUVRQDOLQMXU\RUSURSHUW\

GDPDJHEHIRUHKDQG0DNHVXUHWRUHDGLWEHIRUHWKHRSHUDWLRQRIWKLVSURGXFW

Safety Precautions for Our Products

7KHFRPPRQVDIHW\SUHFDXWLRQVIRUWKHXVHRIDQ\RIRXUURERWVLQHDFKRSHUDWLRQ

1R

0RGHO

2SHUDWLRQ

'HVFULSWLRQ

6HOHFWLRQ

'HVFULSWLRQ

Ɣ7KLVSURGXFWKDVQRWEHHQSODQQHGDQGGHVLJQHGIRUWKHDSSOLFDWLRQZKHUH

KLJKOHYHORIVDIHW\LVUHTXLUHGVRWKHJXDUDQWHHRIWKHSURWHFWLRQRI

KXPDQOLIHLVLPSRVVLEOH$FFRUGLQJO\GRQRWXVHLWLQDQ\RIWKHIROORZLQJ

DSSOLFDWLRQV

0HGLFDOHTXLSPHQWXVHGWRPDLQWDLQFRQWURORURWKHUZLVHDIIHFWKXPDQ

OLIHRUSK\VLFDOKHDOWK

0HFKDQLVPVDQGPDFKLQHU\GHVLJQHGIRUWKHSXUSRVHRIPRYLQJRU

WUDQVSRUWLQJSHRSOH)RUYHKLFOHUDLOZD\IDFLOLW\RUDLUQDYLJDWLRQIDFLOLW\

,PSRUWDQWVDIHW\SDUWVRIPDFKLQHU\6DIHW\GHYLFHHWF

Ɣ 'RQRWXVHWKHSURGXFWRXWVLGHWKHVSHFLILFDWLRQV)DLOXUHWRGRVRPD\

FRQVLGHUDEO\VKRUWHQWKHOLIHRIWKHSURGXFW

Ɣ'RQRWXVHLWLQDQ\RIWKHIROORZLQJHQYLURQPHQWV

/RFDWLRQZKHUHWKHUHLVDQ\LQIODPPDEOHJDVLQIODPPDEOHREMHFWRU

H[SORVLYH

3ODFHZLWKSRWHQWLDOH[SRVXUHWRUDGLDWLRQ

/RFDWLRQZLWKWKHDPELHQWWHPSHUDWXUHRUUHODWLYHKXPLGLW\H[FHHGLQJ

WKHVSHFLILFDWLRQUDQJH

/RFDWLRQZKHUHUDGLDQWKHDWLVDGGHGIURPGLUHFWVXQOLJKWRURWKHUODUJH

KHDWVRXUFH

/RFDWLRQZKHUHFRQGHQVDWLRQRFFXUVGXHWRDEUXSWWHPSHUDWXUH

FKDQJHV

/RFDWLRQZKHUHWKHUHLVDQ\FRUURVLYHJDVVXOIXULFDFLGRUK\GURFKORULF

DFLG

/RFDWLRQH[SRVHGWRVLJQLILFDQWDPRXQWRIGXVWVDOWRULURQSRZGHU

/RFDWLRQVXEMHFWWRGLUHFWYLEUDWLRQRULPSDFW

Ɣ)RUDQDFWXDWRUXVHGLQYHUWLFDORULHQWDWLRQVHOHFWDPRGHOZKLFKLV

HTXLSSHGZLWKDEUDNH,IVHOHFWLQJDPRGHOZLWKQREUDNHWKHPRYLQJSDUW

PD\GURSZKHQWKHSRZHULVWXUQHG2))DQGPD\FDXVHDQDFFLGHQWVXFK

DVDQLQMXU\RUGDPDJHRQWKHZRUNSLHFH

1

Page 8

No.

Operation

Description

Description

2 Transportation Ɣ When carrying a heavy object, do the work with two or more persons or

utilize equipment such as crane.

Ɣ When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

Ɣ When in transportation, consider well about the positions to hold, weight

and weight balance and pay special attention to the carried object so it

would not get hit or dropped.

Ɣ Transport it using an appropriate transportation measure.

The actuators available for transportation with a crane have eyebolts

attached or there are tapped holes to attach bolts. Follow the instructions

in the operation manual for each model.

Ɣ Do not step or sit on the package.

Ɣ Do not put any heavy thing that can deform the package, on it.

Ɣ When using a crane capable of 1t or more of weight, have an operator

who has qualifications for crane operation and sling work.

Ɣ When using a crane or equivalent equipments, make sure not to hang a

ORDGWKDWZHLJKVPRUHWKDQWKHHTXLSPHQW¶VFDSDELOLW\OLPLW

Ɣ Use a hook that is suitable for the load. Consider the safety factor of the

hook in such factors as shear strength.

Ɣ Do not get on the load that is hung on a crane.

Ɣ Do not leave a load hung up with a crane.

Ɣ Do not stand under the load that is hung up with a crane.

3 Storage and

Preservation

Ɣ The storage and preservation environment conforms to the installation

environment. However, especially give consideration to the prevention of

condensation.

Ɣ Store the products with a consideration not to fall them over or drop due to

an act of God such as earthquake.

4 Installation

and Start

(1) Installation of Robot Main Body and Controller, etc.

Ɣ Make sure to securely hold and fix the product (including the work part). A

fall, drop or abnormal motion of the product may cause a damage or injury.

Also, be equipped for a fall-over or drop due to an act of God such as

earthquake.

Ɣ Do not get on or put anything on the product. Failure to do so may cause

an accidental fall, injury or damage to the product due to a drop of

anything, malfunction of the product, performance degradation, or

shortening of its life.

Ɣ When using the product in any of the places specified below, provide a

sufficient shield.

1) Location where electric noise is generated

2) Location where high electrical or magnetic field is present

3) Location with the mains or power lines passing nearby

4) Location where the product may come in contact with water, oil or

chemical droplets

2

Page 9

No.

Operation

Description

4 Installation

and Start

Description

(2) Cable Wiring

Ɣ8VHRXUFRPSDQ\¶VJHQXLQHFDEOHVfor connecting between the actuator

and controller, and for the teaching tool.

Ɣ Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not

coil it around. Do not insert it. Do not put any heavy thing on it. Failure to

do so may cause a fire, electric shock or malfunction due to leakage or

continuity error.

Ɣ Perform the wiring for the product, after turning OFF the power to the unit,

so that there is no wiring error.

Ɣ When the direct current power (+24V) is connected, take the great care of

the directions of positive and negative poles. If the connection direction is

not correct, it might cause a fire, product breakdown or malfunction.

Ɣ Connect the cable connector securely so that there is no disconnection or

looseness. Failure to do so may cause a fire, electric shock or malfunction

of the product.

Ɣ Never cut and/or reconnect the cables supplied with the product for the

purpose of extending or shortening the cable length. Failure to do so may

cause the product to malfunction or cause fire.

(3) Grounding

Ɣ The grounding operation should be performed to prevent an electric shock

or electrostatic charge, enhance the noise-resistance ability and control

the unnecessary electromagnetic radiation.

Ɣ For the ground terminal on the AC power cable of the controller and the

grounding plate in the control panel, make sure to use a twisted pair cable

with wire thickness 0.5mm

2

(AWG20 or equivalent) or more for grounding

work. For security grounding, it is necessary to select an appropriate wire

thickness suitable for the load. Perform wiring that satisfies the

specifications (electrical equipment technical standards).

Ɣ Perform Class D Grounding (former Class 3 Grounding with ground

resistance 100: or below).

3

Page 10

No.

4 Installation

Operation

Description

and Start

Description

(4) Safety Measures

Ɣ When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

Ɣ When the product is under operation or in the ready mode, take the safety

measures (such as the installation of safety and protection fence) so that

nobody can enter the area within tKHURERW¶VPRYDEOHUDQJH:KHQWKH

robot under operation is touched, it may result in death or serious injury.

Ɣ 0DNHVXUHWRLQVWDOOWKHHPHUJHQF\VWRSFLUFXLWVRWKDWWKHXQLWFDQEH

VWRSSHGLPPHGLDWHO\LQDQHPHUJHQF\GXULQJWKHXQLWRSHUDWLRQ

Ɣ 7DNHWKHVDIHW\PHDVXUHQRWWRVWDUWXSWKHXQLWRQO\ZLWKWKHSRZHUWXUQLQJ

ON. Failure to do so may start up the machine suddenly and cause an

LQMXU\RUGDPDJHWRWKHSURGXFW

Ɣ Take the safety measure not to start up the machine only with the

HPHUJHQF\VWRSFDQFHOODWLRQRUUHFRYHU\DIWHUWKHSRZHUIDLOXUH)DLOXUHWR

do so may result in an electric shock or injury due to unexpected power

input.

Ɣ:KHQWKHLQVWDOODWLRQRUDGMXVWPHQWRSHUDWLRQLVWREHSHUIRUPHGJLYH

FOHDUZDUQLQJVVXFKDV³8QGHU2SHUDWLRQ'RQRWWXUQ21WKHSRZHU´HWF

Sudden power input may cause an electric shock or injury.

Ɣ Take the measure so that the work part is not dropped in power failure or

HPHUJHQF\VWRS

Ɣ:HDUSURWHFWLRQJORYHVJRJJOHRUVDIHW\VKRHVDVQHFHVVDU\WRVHFXUH

safety.

Ɣ 'RQRWLQVHUWDILQJHURUREMHFWLQWKHRSHQLQJVLQWKHSURGXFW)DLOXUHWRGR

VRPD\FDXVHDQLQMXU\HOHFWULFVKRFNGDPDJHWRWKHSURGXFWRUILUH

Ɣ:KHQUHOHDVLQJWKHEUDNHRQDYHUWLFally oriented actuator, exercise

SUHFDXWLRQQRWWRSLQFK\RXUKDQGRUGDPDJHWKHZRUNSDUWVZLWKWKH

DFWXDWRUGURSSHGE\JUDYLW\

7HDFKLQJ Ɣ When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

Ɣ3HUIRUPWKHWHDFKLQJRSHUDWLRQIURPRXWside the safety protection fence, if

possible. In the case that the operaWLRQLVWREHSHUIRUPHGXQDYRLGDEO\

inside the safety protection fence,SUHSDUHWKH³6WLSXODWLRQVIRUWKH

2SHUDWLRQ´DQGPDNHVXUHWKDWDOOWKHZRUNHUVDFNQRZOHGJHDQG

understand them well.

Ɣ When the operation is to be performed inside the safety protection fence,

WKHZRUNHUVKRXOGKDYHDQHPHUJHQF\VWop switch at hand with him so that

WKHXQLWFDQEHVWRSSHGDQ\WLPHLQDQHPHUJHQF\

Ɣ When the operation is to be performed inside the safety protection fence,

LQDGGLWLRQWRWKHZRUNHUVDUUDQJHa watchman so that the machine can

EHVWRSSHGDQ\WLPHLQDQHPHUJHQF\$OVRNHHSZDWFKRQWKHRSHUDWLRQ

so that any third person can not operate the switches carelessly.

Ɣ3ODFHDVLJQ³8QGHU2SHUDWLRQ´DWWKHSRVLWLRQHDV\WRVHH

Ɣ:KHQUHOHDVLQJWKHEUDNHRQDYHUWLFally oriented actuator, exercise

SUHFDXWLRQQRWWRSLQFK\RXUKDQGRUGDPDJHWKHZRUNSDUWVZLWKWKH

DFWXDWRUGURSSHGE\JUDYLW\

* Safety protection Fence : In the case that there is no safety protection

IHQFHWKHPRYDEOHUDQJHVKRXOGEHLQGLFDWHG

4

Page 11

No.

Operation

Description

Description

6 Trial Operation Ɣ When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

Ɣ After the teaching or programming operation, perform the check operation

one step by one step and then shift to the automatic operation.

Ɣ When the check operation is to be performed inside the safety protection

fence, perform the check operation using the previously specified work

procedure like the teaching operation.

Ɣ Make sure to perform the programmed operation check at the safety

speed. Failure to do so may result in an accident due to unexpected

motion caused by a program error, etc.

Ɣ Do not touch the terminal block or any of the various setting switches in

the power ON mode. Failure to do so may result in an electric shock or

malfunction.

7 Automatic

Operation

Ɣ Check before starting the automatic operation or rebooting after operation

stop that there is nobody in the safety protection fence.

Ɣ Before starting automatic operation, make sure that all peripheral

equipment is in an automatic-operation-ready state and there is no alarm

indication.

Ɣ Make sure to operate automatic operation start from outside of the safety

protection fence.

Ɣ In the case that there is any abnormal heating, smoke, offensive smell, or

abnormal noise in the product, immediately stop the machine and turn

OFF the power switch. Failure to do so may result in a fire or damage to

the product.

Ɣ When a power failure occurs, turn OFF the power switch. Failure to do so

may cause an injury or damage to the product, due to a sudden motion of

the product in the recovery operation from the power failure.

5

Page 12

No.

8 Maintenance

Operation

Description

and Inspection

Description

Ɣ When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

Ɣ Perform the work out of the safety protection fence, if possible. In the case

that the operation is to be performed unavoidably inside the safety

SURWHFWLRQIHQFHSUHSDUHWKH³6WLSXODWLRQVIRUWKH2SHUDWLRQ´DQGPDNH

sure that all the workers acknowledge and understand them well.

Ɣ When the work is to be performed inside the safety protection fence,

basically turn OFF the power switch.

Ɣ When the operation is to be performed inside the safety protection fence,

the worker should have an emergency stop switch at hand with him so that

the unit can be stopped any time in an emergency.

Ɣ When the operation is to be performed inside the safety protection fence,

in addition to the workers, arrange a watchman so that the machine can

be stopped any time in an emergency. Also, keep watch on the operation

so that any third person can not operate the switches carelessly.

Ɣ3ODFHDVLJQ³8QGHU2SHUDWLRQ´DWWKHSRVLWLRQHDV\WRVHH

Ɣ For the grease for the guide or ball screw, use appropriate grease

according to the Operation Manual for each model.

Ɣ Do not perform the dielectric strength test. Failure to do so may result in a

damage to the product.

Ɣ When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

Ɣ The slider or rod may get misaligned OFF the stop position if the servo is

turned OFF. Be careful not to get injured or damaged due to an

unnecessary operation.

Ɣ Pay attention not to lose the cover or untightened screws, and make sure

to put the product back to the original condition after maintenance and

inspection works.

8VHLQLQFRPSOHWHFRQGLWLRQPD\FDXVHGDPDJHWRWKHSURGXFWRUDQLQMXU\

6DIHW\SURWHFWLRQ)HQFH,QWKHFDVH that there is no safety protection

fence, the movable range should be indicated.

9 Modification

and Dismantle

Ɣ Do not modify, disassemble, assemble or use of maintenance parts not

specified based at your own discretion.

10 Disposal Ɣ When the product becomes no longer usable or necessary, dispose of it

properly as an industrial waste.

Ɣ When removing the actuator for disposal, pay attention to drop of

components when detaching screws.

Ɣ Do not put the product in a fire when disposing of it.

The product may burst or generate toxic gases.

11 Other Ɣ Do not come close to the product or the harnesses if you are a person

who requires a support of medical devices such as a pacemaker. Doing so

may affect the performance of your medical device.

Ɣ6HH2YHUVHDV6SHFLILFDWLRQV&RPSliance Manual to check whether

complies if necessary.

Ɣ For the handling of actuators and controllers, follow the dedicated

operation manual of each unit to ensure the safety.

6

Page 13

Alert Indication

7KHVDIHW\SUHFDXWLRQVDUHGLYLGHGLQWR³'DQJHU´³:DUQLQJ´³&DXWLRQ´DQG³1RWLFH´DFFRUGLQJWRWKH

ZDUQLQJOHYHODVIROORZVDQGGHVFULEHGLQWKH2SHUDWLRQ0DQXDOIRUHDFKPRGHO

/HYHO 'HJUHHRI'DQJHUDQG'DPDJH 6\PERO

'DQJHU

:DUQLQJ

&DXWLRQ

1RWLFH

7KLVLQGLFDWHVDQLPPLQHQWO\KD]DUGRXVVLWXDWLRQZKLFKLIWKH

SURGXFWLVQRWKDQGOHGFRUUHFWO\ZLOOUHVXOWLQGHDWKRUVHULRXVLQMXU\

7KLVLQGLFDWHVDSRWHQWLDOO\KD]DUGRXVVLWXDWLRQZKLFKLIWKHSURGXFW

LVQRWKDQGOHGFRUUHFWO\FRXOGUHVXOWLQGHDWKRUVHULRXVLQMXU\

7KLVLQGLFDWHVDSRWHQWLDOO\KD]DUGRXVVLWXDWLRQZKLFKLIWKHSURGXFW

LVQRWKDQGOHGFRUUHFWO\PD\UHVXOWLQPLQRULQMXU\RUSURSHUW\

GDPDJH

7KLVLQGLFDWHVORZHUSRVVLELOLW\IRUWKHLQMXU\EXWVKRXOGEHNHSWWR

XVHWKLVSURGXFWSURSHUO\

'DQJHU

:DUQLQJ

&DXWLRQ

1RWLFH

7

Page 14

Handling Precautions

For CON related controllers, do not touch [ ] key or [ ] key too fast to switch the windows in the table to

edit the position data.

‘0’ is occasionally shown to the data values that are already registered.

The data is not lost even though ‘0’ is displayed. Touch [ ] key and [ ] key to switch the window and come

back, and you will find the data showing the right values.

↑

Position Data Table

↓

↑

↓

Caution

This touch-panel teaching pendant CON-PT/CON-PD/CON-PG is exclusively designed for use with IAI

controllers. Never connect it to other equipment.

Failure may occur.

8

Page 15

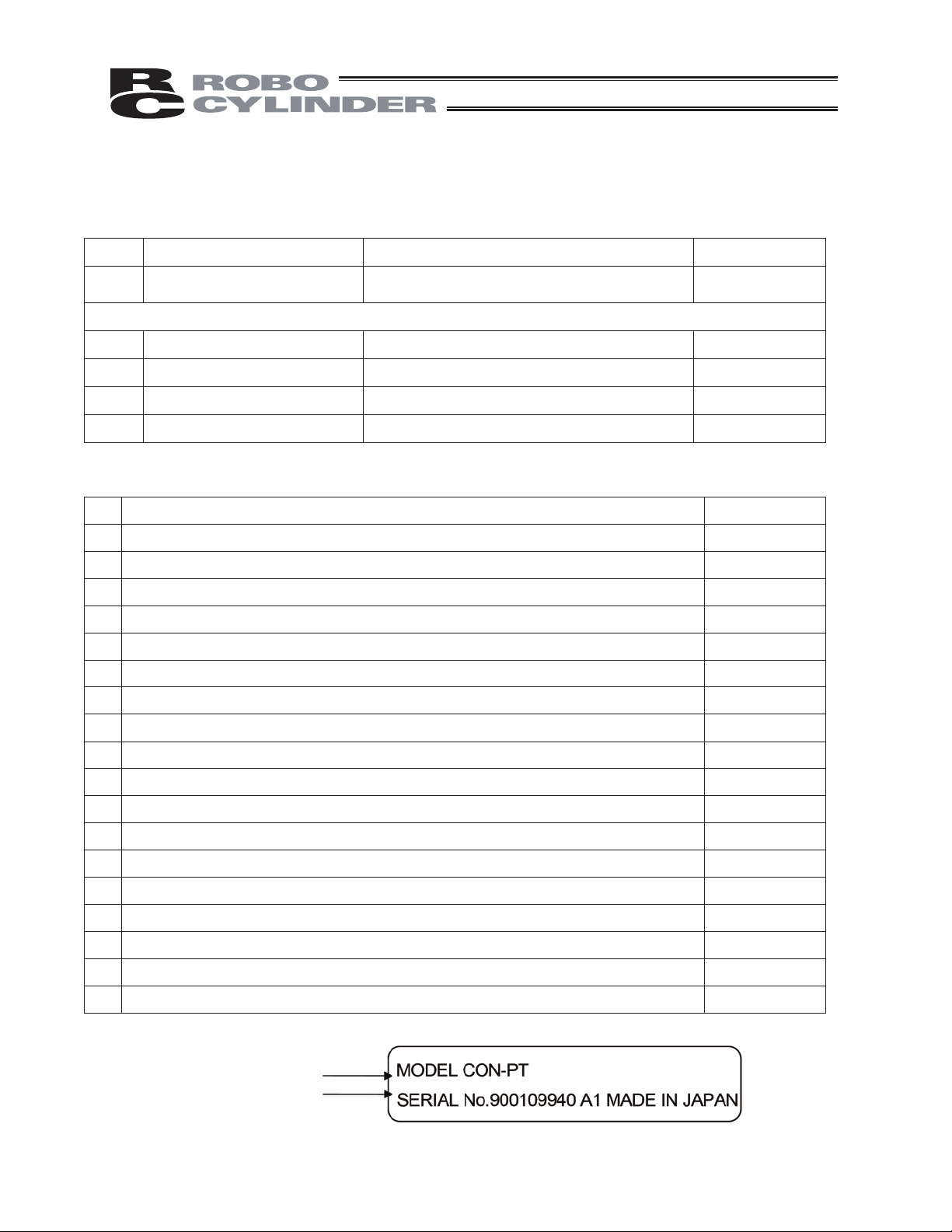

Product Check

This product, if adopting a standard configuration, consists of the parts listed below.

1. Component (excluding options)

No. Product name Model number Remarks

1 Teaching pendant

Accessories

2 Touch pen Built into teaching pendant

3 First step guide

4 Operation manual (CD/DVD)

5 Safety guide

2. Operation manual related to this product, stored in the CD/DVD

1 Operation manual for touch-panel teaching pendant CON-PT/CON-PD/CON-PG ME0227

2 Operation manual for actuator integrated with ERC2 controller (PIO type) ME0158

3 Operation manual for actuator integrated with ERC2 controller (SIO type) ME0159

Refer to "How to Read Model Nameplate" and

"How to Read Model Number."

rebmunlortnoCemaN.oN

4 Operation manual for actuator integrated with ERC3 controller ME0297

5 ME0289

Operation manual for PCON-CA controller

6 Operation manual for PCON-C/CG/CF controller ME0170

7 Operation manual for PCON-CY controller

8 Operation manual for PCON-SE controller ME0163

9 Operation manual for PCON-PL/PO controller ME0164

10 Operation manual for ACON-C/CG controller ME0176

11 Operation manual for ACON-CY controller ME0167

12 Operation manual for ACON-SE controller ME0171

13 Operation manual for ACON-PL/PO controller ME0166

14 Operation manual for SCON controller ME0161

15 Operation manual for SCON-CA ME0243

16 Operation manual for ROBONET ME0208

17 Operation manual for ASEP/PSEP/DSEP controller ME0216

18 Operation manual for PMEC/AMEC controller

3. How to Read Model Nameplate

ME0156

ME0245

Model numbe

Serial number

r

9

Page 16

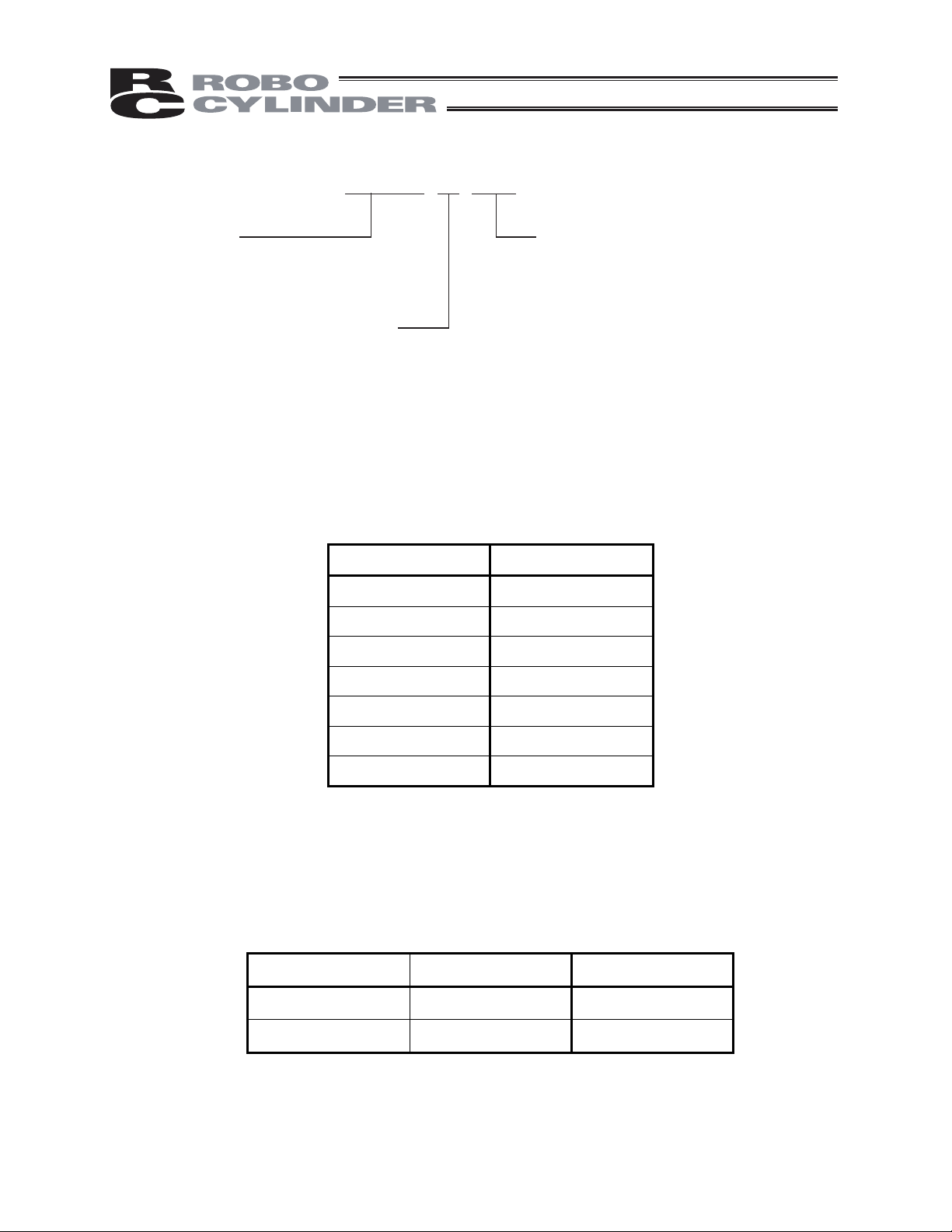

4. How to Read Model Number

CON - PT - M - ENG

<Model number>

CON-PT: Standard type

CON-PD: With deadman switch

CON-PG: With safety category 4 switch

<Display color>

M: Monochrome LCD (3 backlight colors)

Supported Models

The table below lists supported models.

Controller model

List of Supported Models

ERC2*

ERC3*

1

3

ACON

PCON

PCON-CA*

SCON*

3

2

<Option>

Not specified: Screens are displayed in Japanese.

(Display can be changed to English)

ENG: Screens are displayed in English.

(Display can be changed to Japanese)

JCH: Screens are displayed in Japanese.

(Display can be changed to Chinese)

CHJ: Screens are displayed in Chinese.

(Display can be changed to Japanese)

ECH: Screens are displayed in English.

(Display can be changed to Chinese)

CHE: Screens are displayed in Chinese.

(Display can be changed to English)

Controller model

RPCON

ASEP

PSEP

AMEC

PMEC

DSEP*

3

RACON

*1 Whether or not ERC2 is supported can be checked on the sticker attached to the left side face of the cover

(as viewed from the rear).

Information on sticker

I/O type Not supported Supported

NP NP U5 M NP T1 4904

PN PN U3 M PN T1 4904

Note that touch-panel teaching pendants can be connected to ERC2 controllers of SIO type via a SIO converter

regardless of their version.

*2 SCON-CA is supported from version 1.20.

*3 ERC3, PCON-CA and DSEP are supported from version V1.50.

10

Page 17

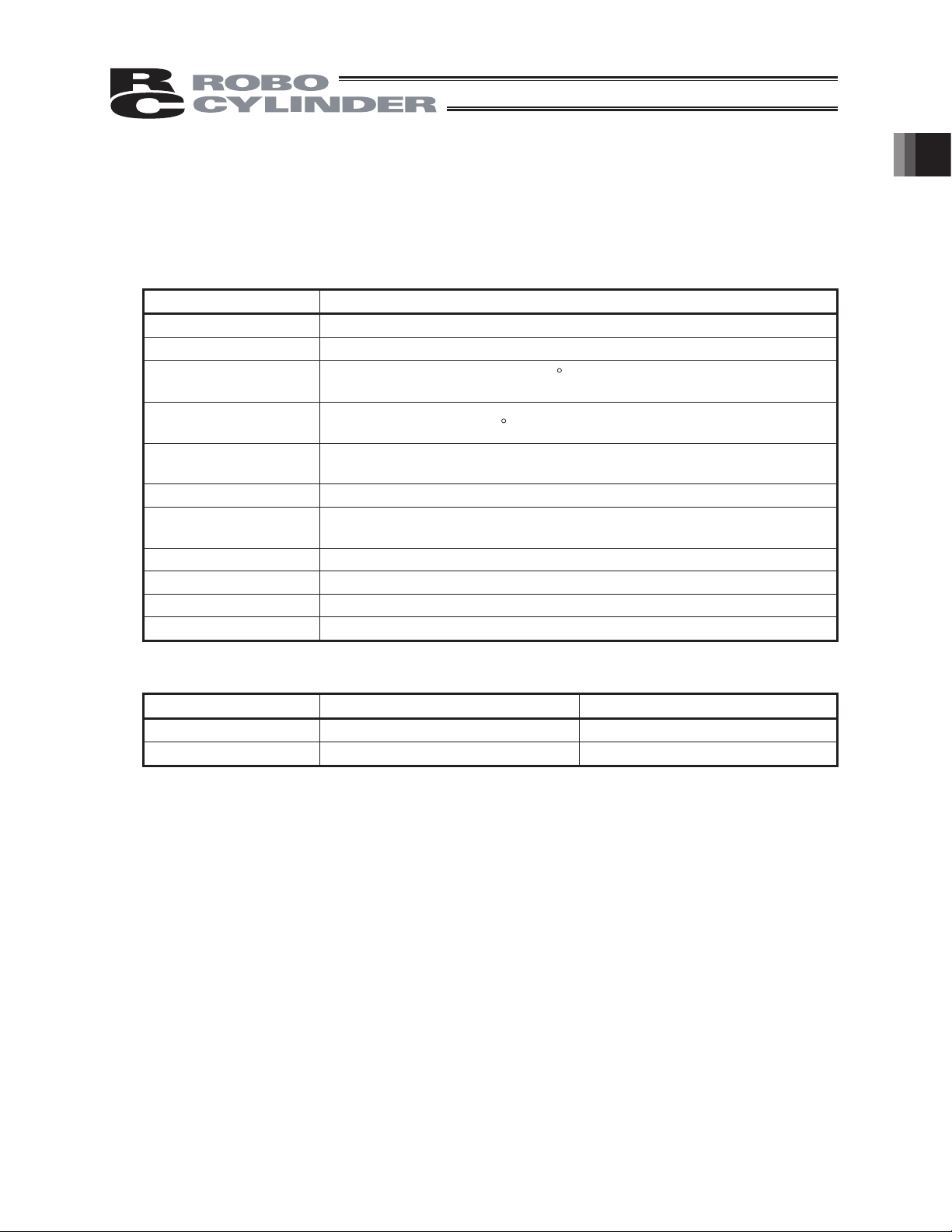

1. Basic Specification

This touch-panel teaching pendant is a display operation unit you can use to display or edit data

saved in the controller as a result of communication with the controller (parameter data, position data,

etc.). This unit is used for checking teaching alarms or performing other tasks in an offline state when

no host PLC, etc., is connected.

snoitacificepSmetI

emorhconoM LCD type

Power consumption 2.4 W or less (100 mA or less)

Surrounding air

temperature, humidity

Ambient storage

temperature, humidity

Vibration resistance

Impact resistance 98 m/s2 or more, applied 4 times each in X, Y and Z directions

Environmental

resistance

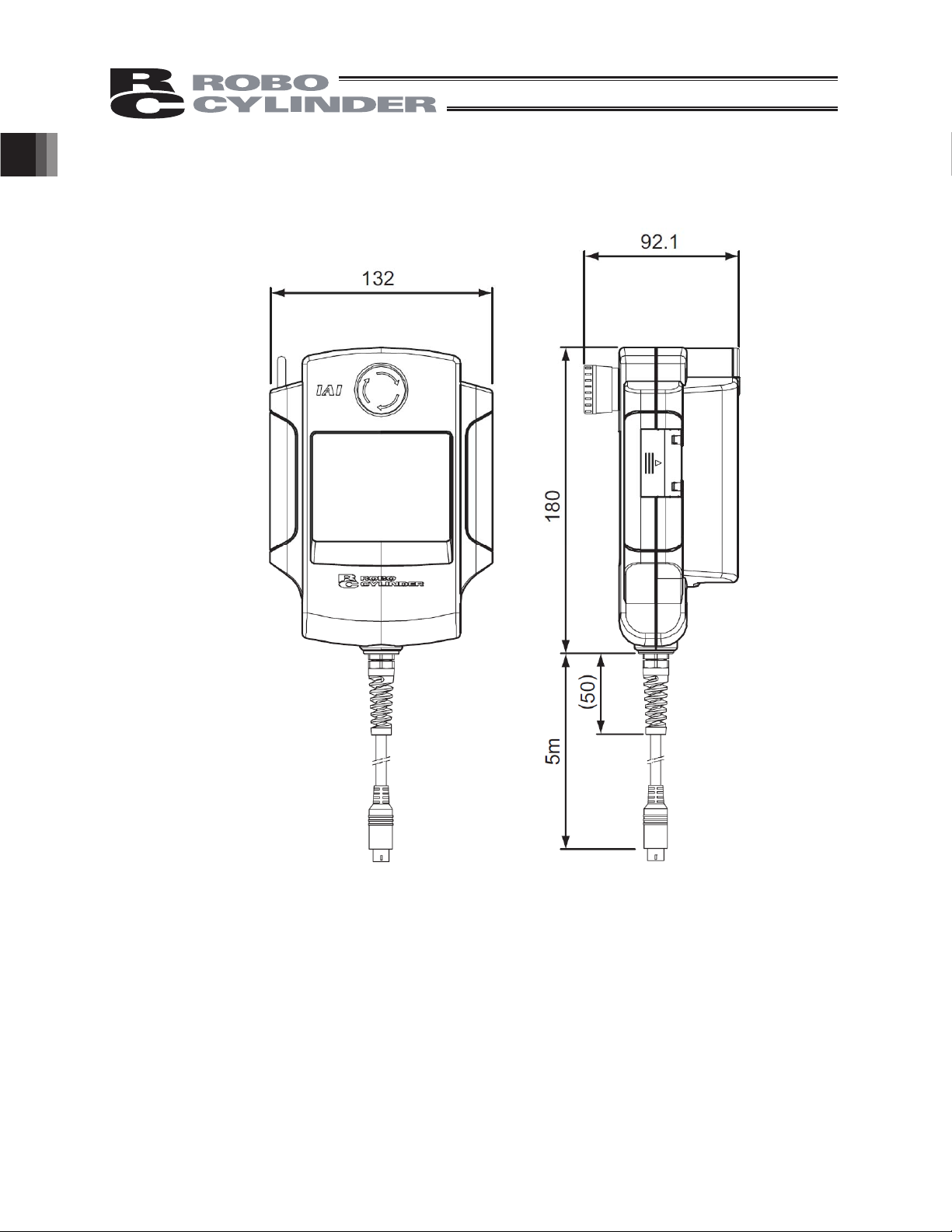

Dimension 180 mm (H) x 132 mm (W) x 92.1 mm (D)

Mass Approx. 780 g (including 5 m of cable)

Cable length 5 m (standard)

Temperature -20 to 60

10 to 55 Hz (1-minute period) based on reversed amplitude of

Temperature 0 to 50

C, humidity 10 to 85% RH (non-condensing)

0.75 mm in X, Y and Z directions for 10 minutes

IP 40 or equivalent

C, humidity 20 to 85% RH

(non-condensing)

hcuoTseirosseccA pen

%DVLF6SHFL¿FDWLRQ

Language Change

Displayed Language (in Delivery)Model

EnglishCON-PT-M-ENG

CON-PT-M-ECH English

Available Language

Japanese

Chinese

11

Page 18

External Dimensions

%DVLF6SHFL¿FDWLRQ

12

Page 19

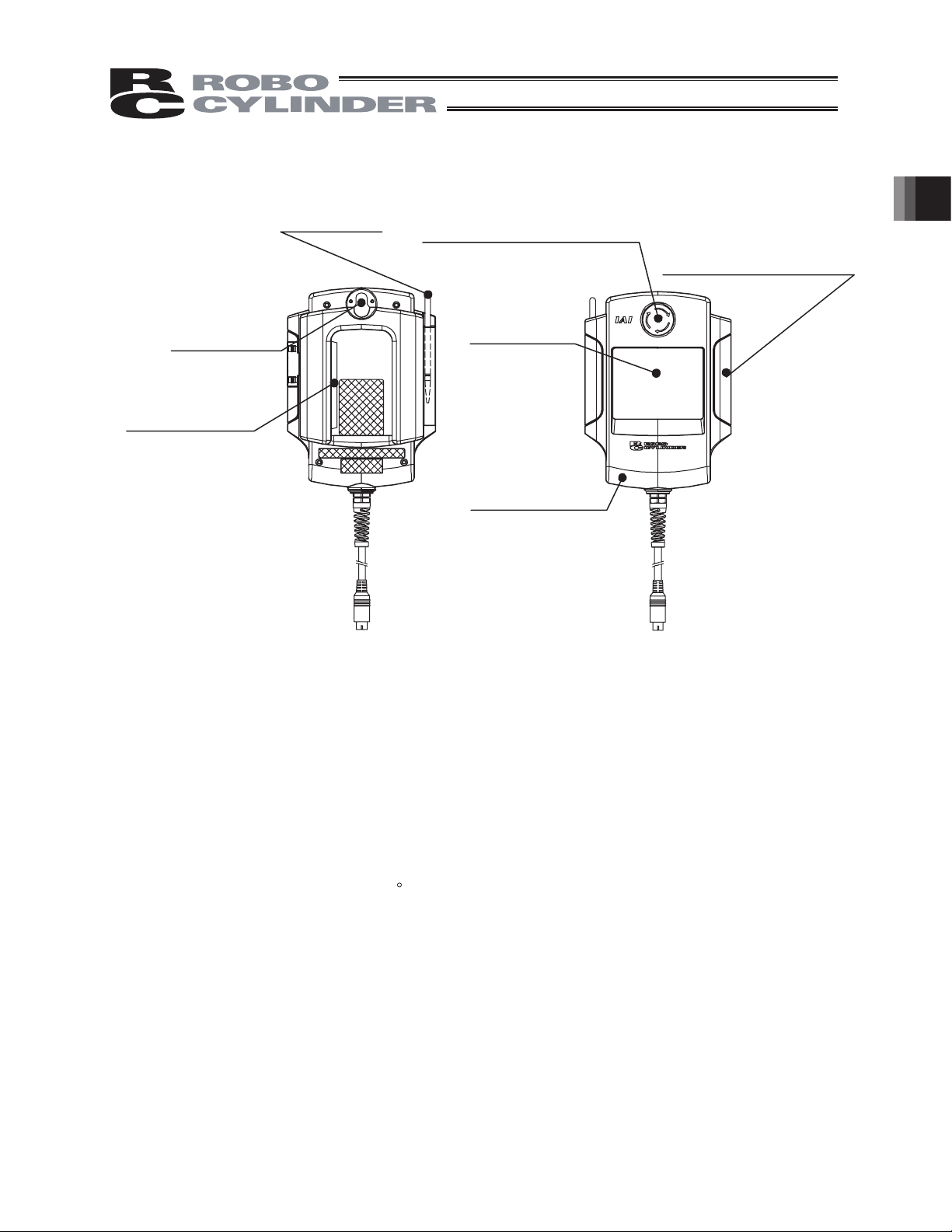

2. Explanation of Each Part

[3] Touch pen

[4] Wall-mounting

hook

[6] Dead-man Switch

(CON-PD, PG)

[1] Touch-panel operation display screen

The screen consists of a STN monochrome LCD and a touch panel.

Various settings that have been edited or taught are displayed.

To operate the screen, use a finger or the touch pen to touch

panel.

[2] EMERGENCY STOP (pushbutton

switch for emergency stop)

[1] Touch panel

operation

display screen

[5] Strap securing part

(Note 1)

desired parts of the touch

(Note) Do not open this lid.

2. Explanation of Each Part

(for future expansion)

(Note 1) This touch panel is of analog resistance membrane type, so do not touch two or more

locations on the screen at the same time.

If two or more locations are touched at the same time, the centers of all touched

locations may respond and trigger multiple operations.

(Note 2) When operating the touch panel, do not apply a force exceeding 0.5 N.

If any greater force is applied, the touch panel may be damaged.

(Note 3) The life of touch panel is approx. 1 million touches at the same location. (Assuming a

use environment of 25

C)

[2] EMERGENCY STOP (Pushbutton switch for emergency stop)

This switch actuates an emergency stop.

[3] Touch pen

This touch pen is used to touch the touch-panel operation display screen.

[4] Wall-mounting hook

This hook is used to mount the touch panel on a wall.

[5] Strap securing part

This part is used to attach a strap (optional).

13

Page 20

[6] Dead-man Switch (CON-PD, PG)

There are three stages for the dead-man switch. The ON/OFF in each stage are described as

follows.

1st Stage

2nd Stage

3rd Stage

The servo-motor can be turned ON under the switch ON condition.

When the switch is turned OFF, the driving power source is disconnected and the servo-motor is

turned OFF.

Even when the switch is turned OFF, the operations in the modes where turning ON the

2. Explanation of Each Part

servo-motor is not required are available. (such as edit mode)

Switch OFF

Switch ON

Switch OFF

The condition where finger is released from the switch, or the

force of pressing the switch is very weak.

Condition where the switch is pressed with appropriate force.

Condition where the switch is pressed strongly.

14

Page 21

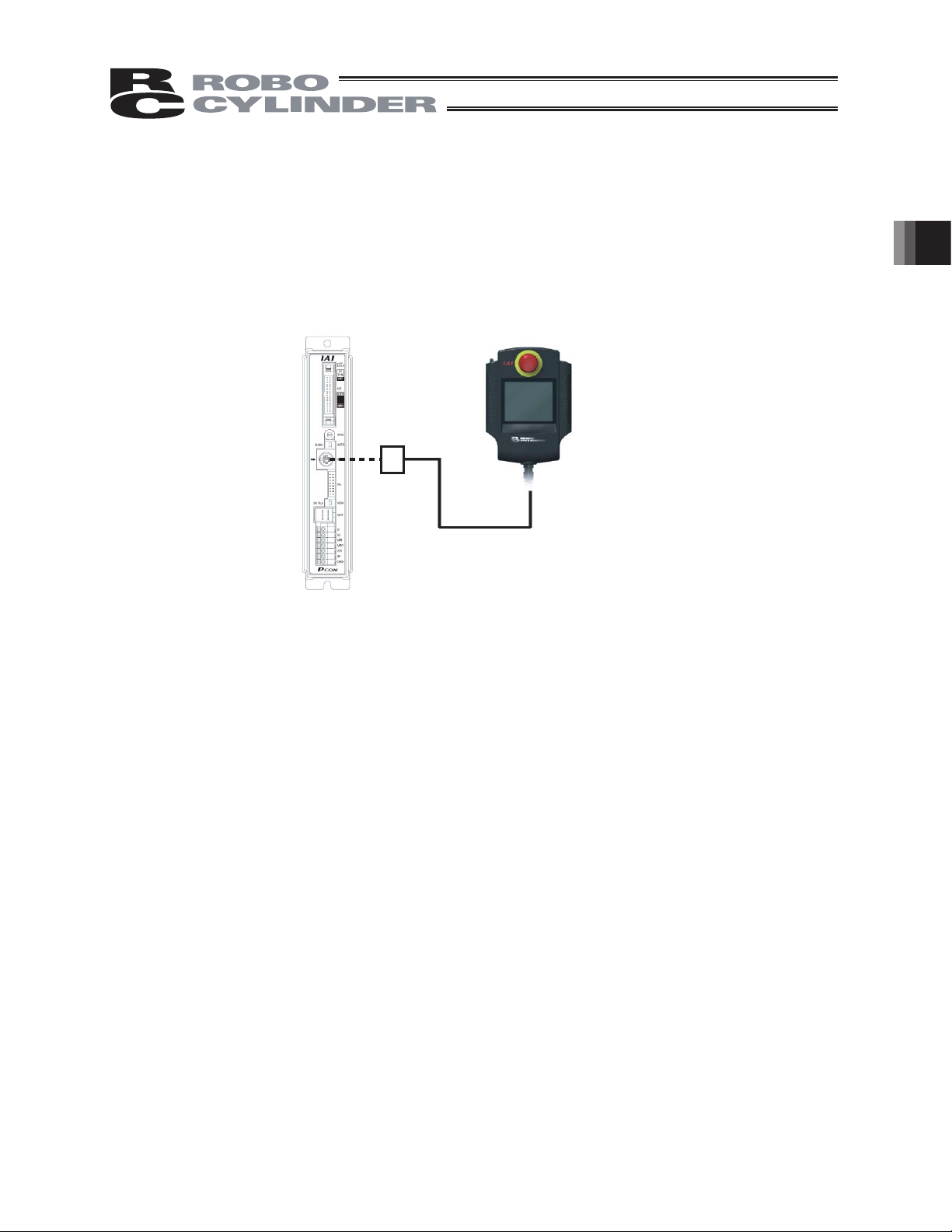

3. Connection and Disconnection to/from Controller

The touch-panel teaching pendant CON-PT can be connected or disconnected without turning off the

controller power first.

If an alarm occurs, the CON-PT can be connected while the controller power is still supplied, to check

the details of the alarm.

3. Connection and Disconnection to/from Controller

Controller

CON-PT, PD

15

Page 22

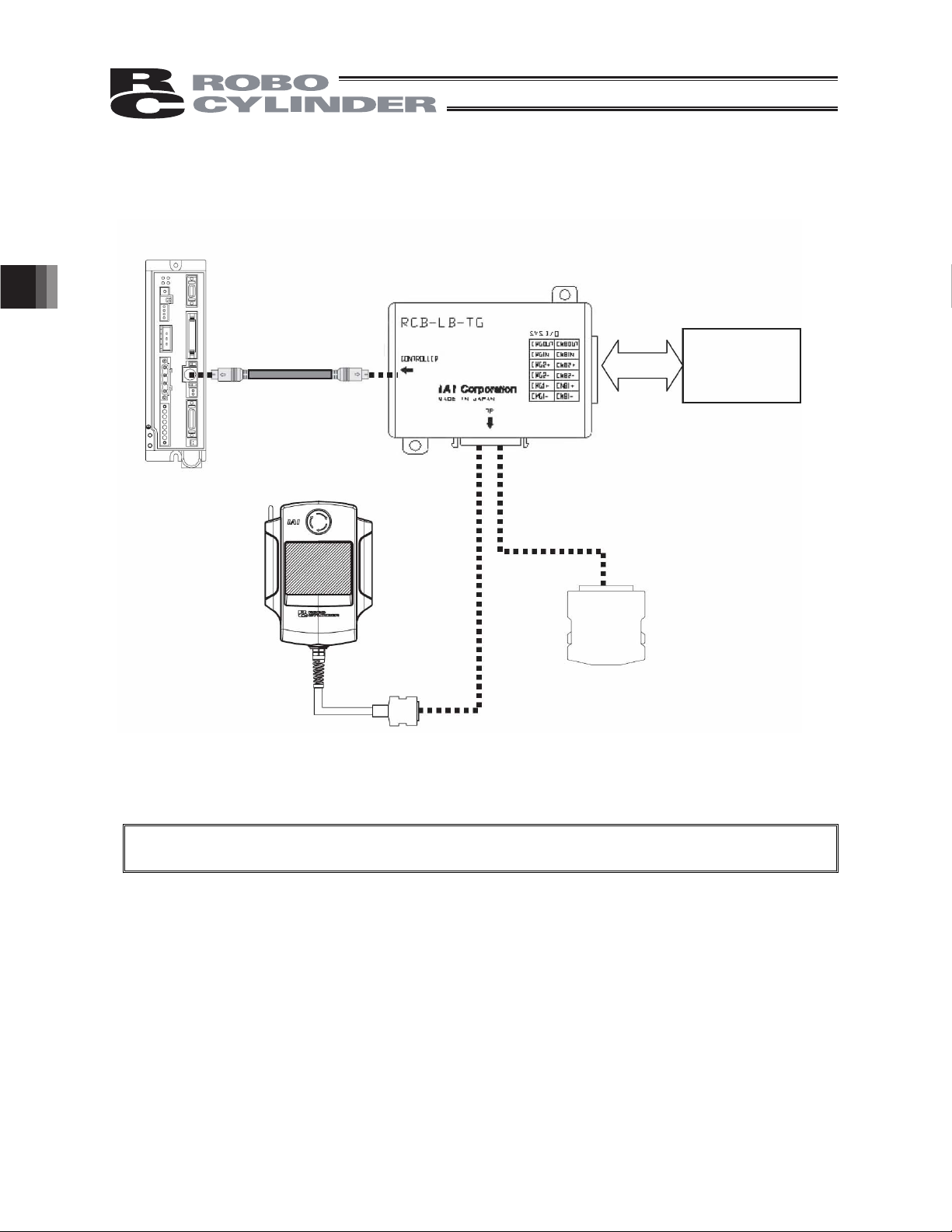

4. Connection of CON-PG and Controller

Controller

Controller-adapter

connection cable

Model: CB-CON-LB

Teaching pendant

CON-PG

4. Connection of CON-PG and Controller

Teaching pendant adapter

RCB-LB-TG

Safety circuit

(relay, safety

relay)

Dummy plug

DP-4

Caution: While the teaching pendant CON-PG is not connected, be sure to connect the dummy plug

DP-4 to the teaching pendant adapter.

16

Page 23

5. Operation of CON Controllers

CON controllers: ERC2, ERC3 (CON Mode), ACON, PCON, SCON-C, SCON-CA, RACON, RPCON

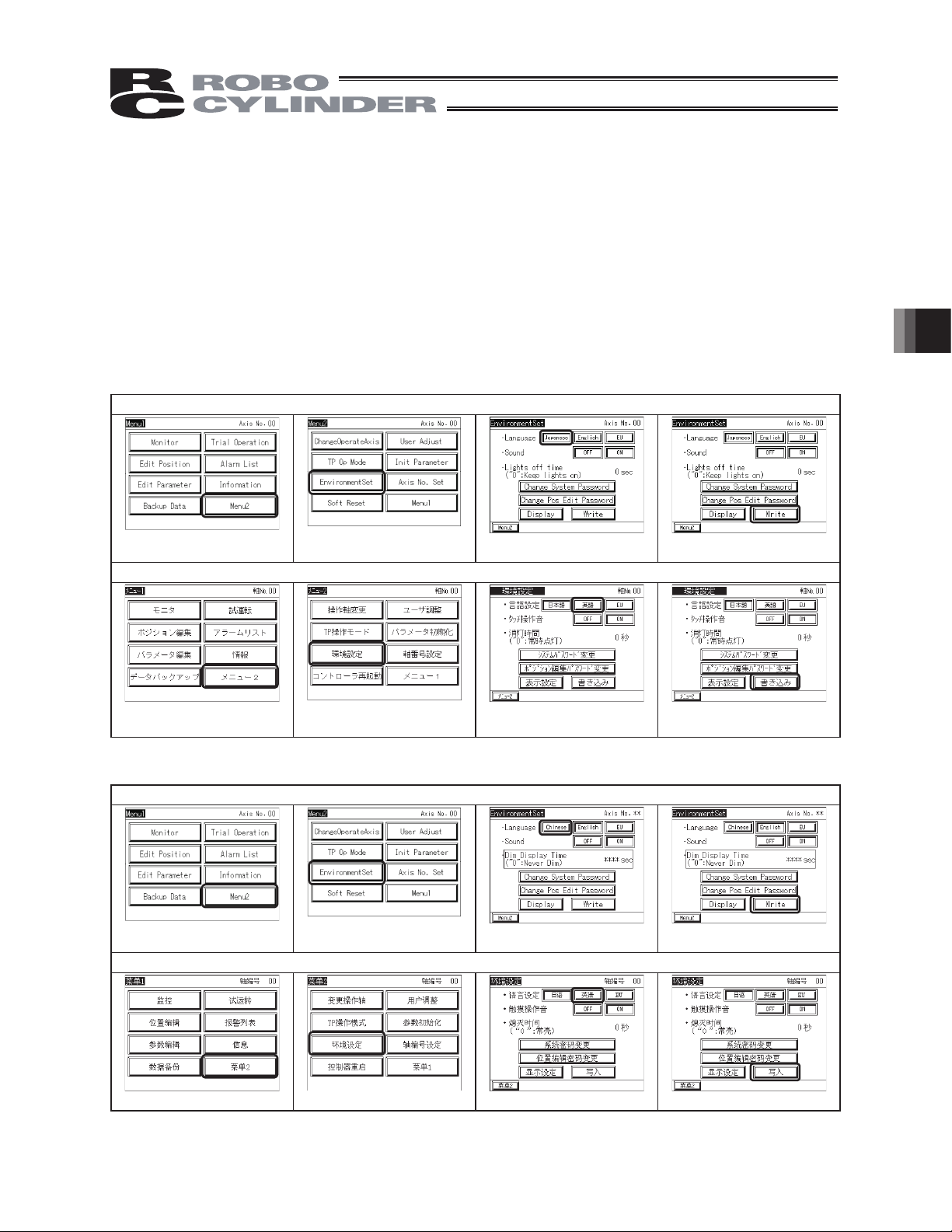

5.1 Displayed Language Change

The language can be changed by following the steps below.

For the operations after the language change, please refer to the instruction manual written in each

language.

Model: CON-PT-M-ENG CON-PT-M-JCH

Display change from English to Japanese

5. Operation of CON Controllers

Touch [Menu2] in Menu1.

Touch [EnvironmentSet] in

Menu2.

Display change from Japanese to English

Touch [

࠾ࡘ

ࡔ࠾ࡘ

1.

2] in

ࡔ

Touch [

࠾ࡘ

ⅣႺ⸳ቯ

2.

Model: CON-PT-M-ECH CON-PT-M-CHE

Display change from English to Chinese

Touch [Menu2] in Menu1.

Touch [EnvironmentSet] in

Menu2.

Display change from Chinese to English

]in

ࡔ

Touch [Japanese]. Touch [Write]

Touch [

Touch [Chinese]

⧷⺆]

Touch [

Touch [Write]

ᦠ߈ㄟߺ]

Touch [

㦰

2] in

㦰

Touch [

1.

⦃๗䆒ᅮ

]in

㦰

2.

Touch [

]. Touch [

㣅䇁

ݭܹ]

17

Page 24

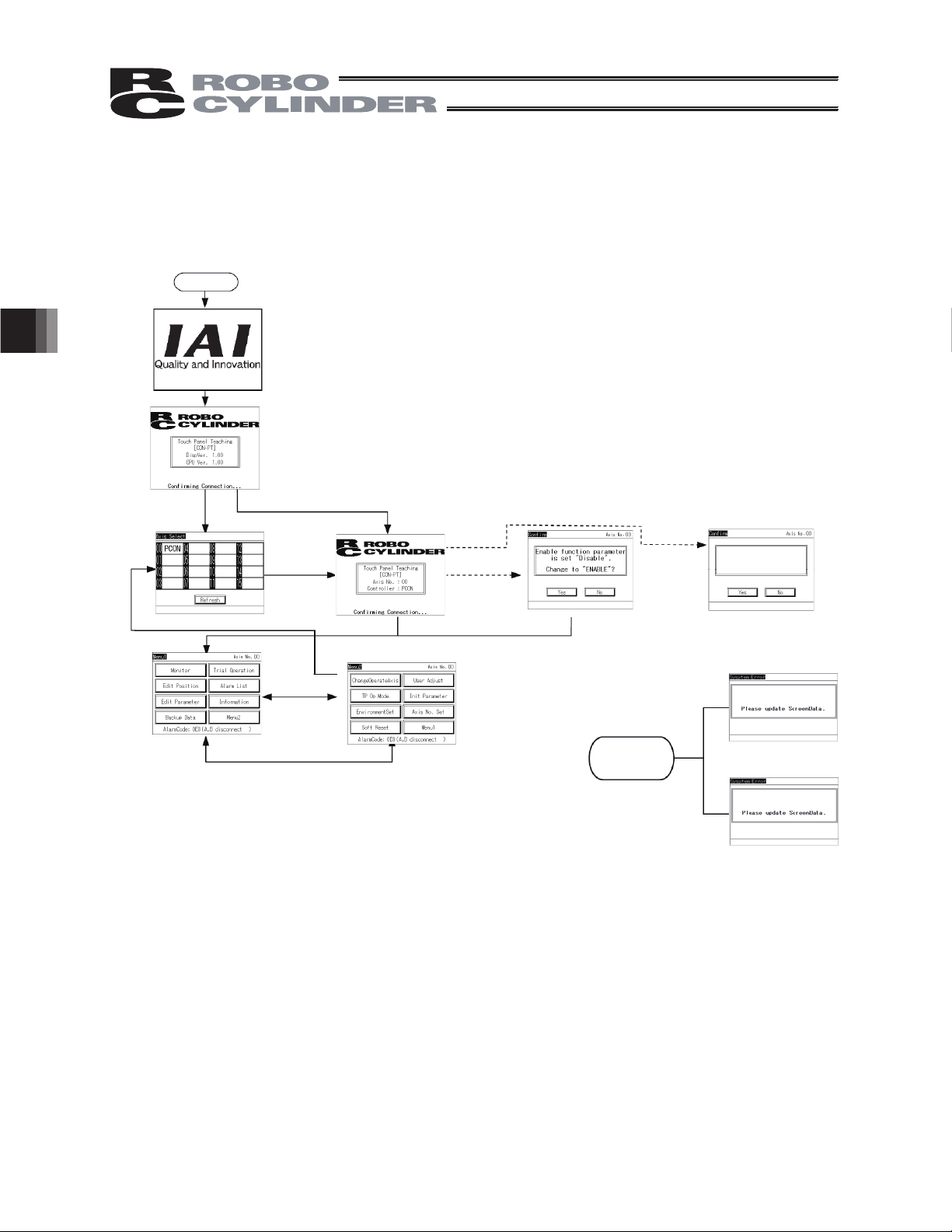

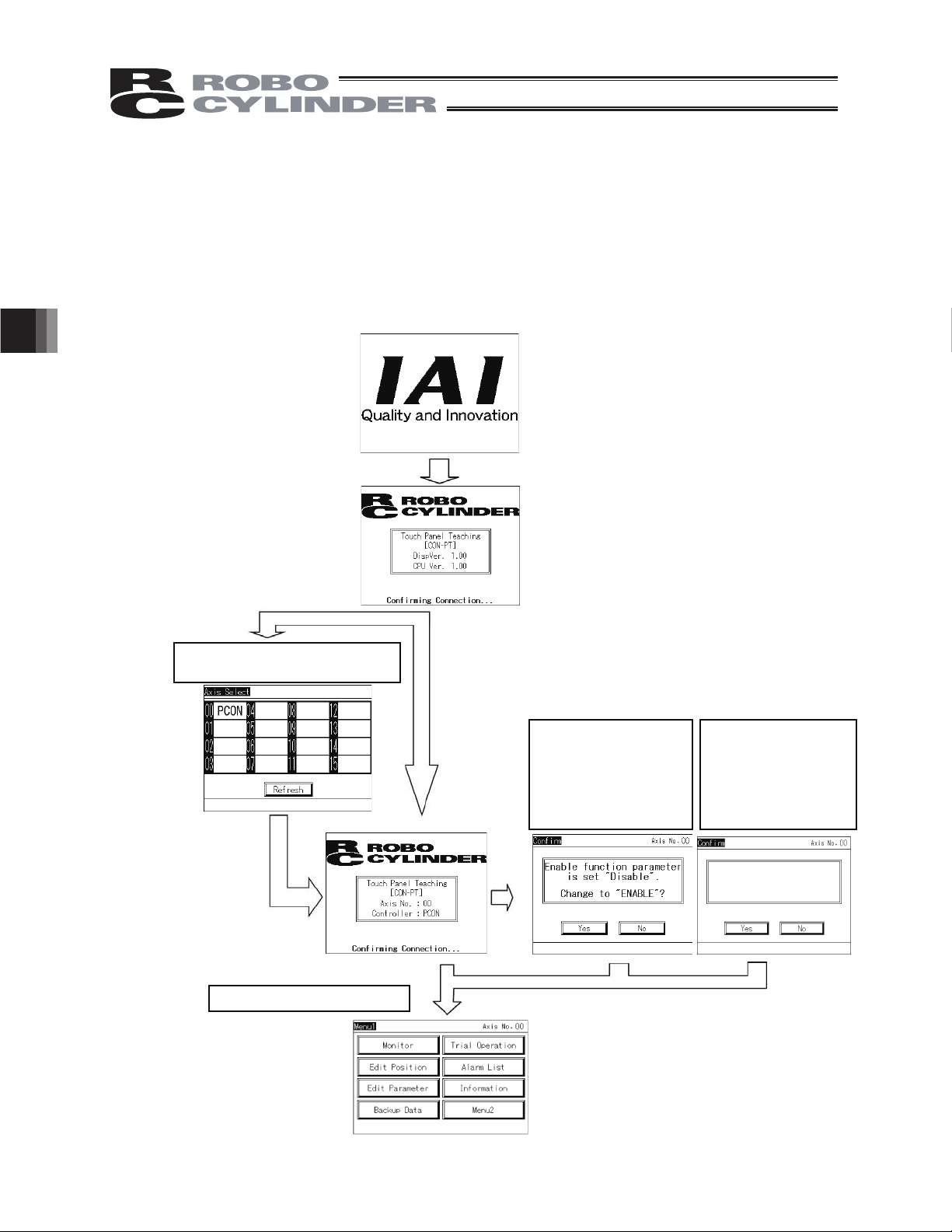

5.2 Transition of Operating States

y

Transition of operating states when the touch-panel teaching pendant CON-PT is connected to a

CON controller is shown.

Power ON

Title display

* Displayed for 1

second.

Version displa

If multiple axes are

connected

5. Operation of CON Controllers

Axis selection

Menu-1

Menu-2

This screen appears

when the enable

function is disabled on

a controller CON-PT,

PD or PG.

This screen

appears when the

enable function is

enabled on a

controller CON-PT.

If the versions do

not match

Enable function parameter

is set “Enable” .

Change to “Disable” ?

Screen version does not match

sub CPU board version.

Sub CPU board version does

not match screen version.

18

Page 25

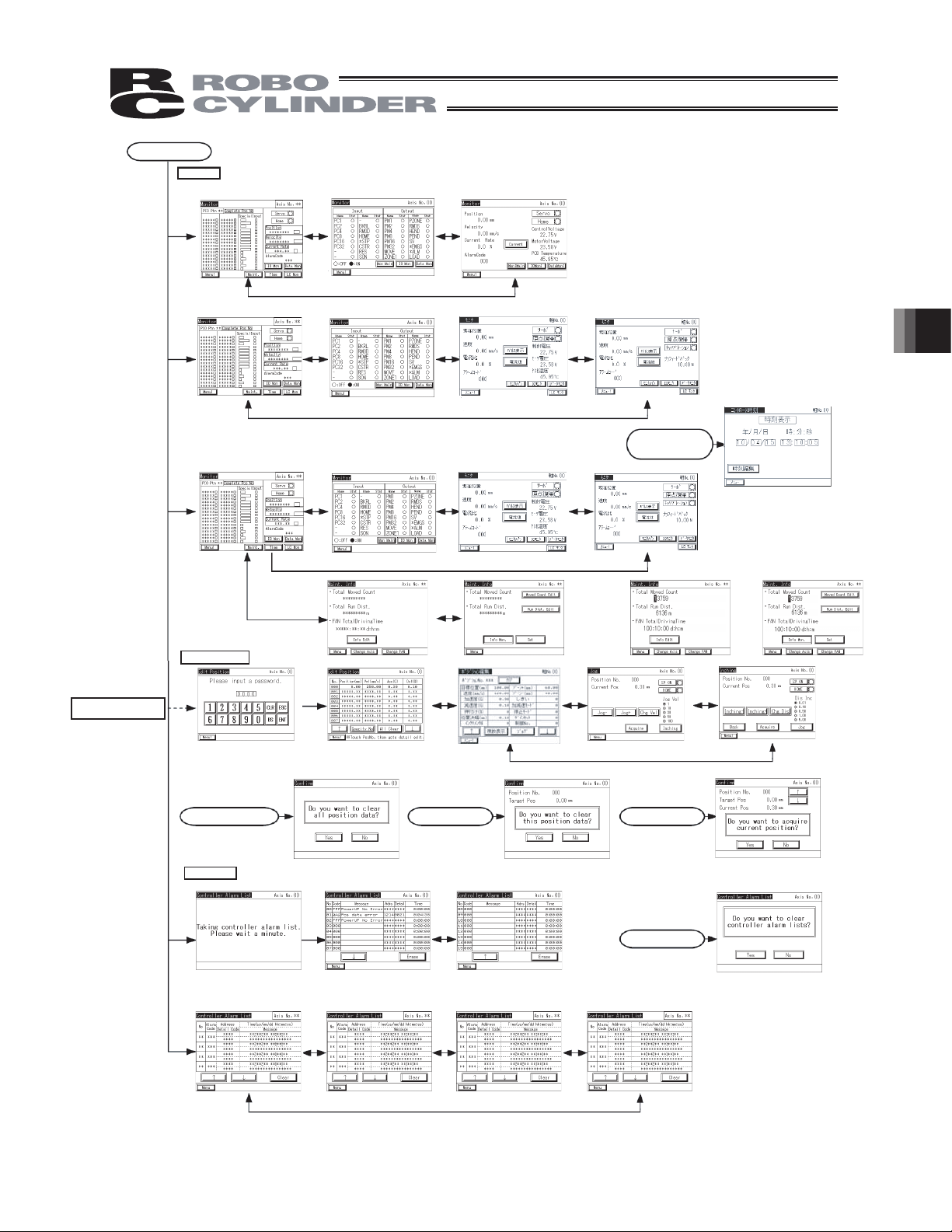

r

Menu-1

Monito

Models other than SCON-CA

When an editing

password is entered

Main monitor

SCON-CA (CON-PT version 1.20 or later)

Main monitor

SCON-CA (CON-PT Version 1.30 or Later), ERC3, PCON-CA (Version 1.50 or Later)

Main monitor

Position editing

IO monitor

IO monitor

IO monitor

Maintenance information screen

Data monitor

Data monitor

Data monitor

Maintenance information screen in edit mode Maintenance information screen in edit modeMaintenance information screen

LC monitor

LC monitor

When the [Time]

switch is pressed on

the monitor screen

[Display shown only for SCON-CA]

PCON-CFA

5. Operation of CON Controllers

Password entry

[All Clear]

Alarm List

Models other than SCON-CA

SCON-CA

Position editing

– Multiple position view

Alarm List

Position editing

– Individual position view

[Clear]

Alarm List

Position editing

– Jog operation

[Import]

[Erase]

Position editing

– Inching operation

19

Page 26

If the system password

function is enabled

Menu-1

Edit Parameter

Password entry

[Menu-1]

Trial operation

(Note)

5. Operation of CON Controllers

If a change is made

I/O test is available

in V1.20 or later

Parameter editing

Jog operation

Position movement

Parameter editing

Inching operation

Direct movement

If a controller alarm

generates

If a TP alarm or

message generates

[Inquiry]

Parameter editing

Please turn on the power again.

20

V1.20 or laterI/O test

Information

Backup Data

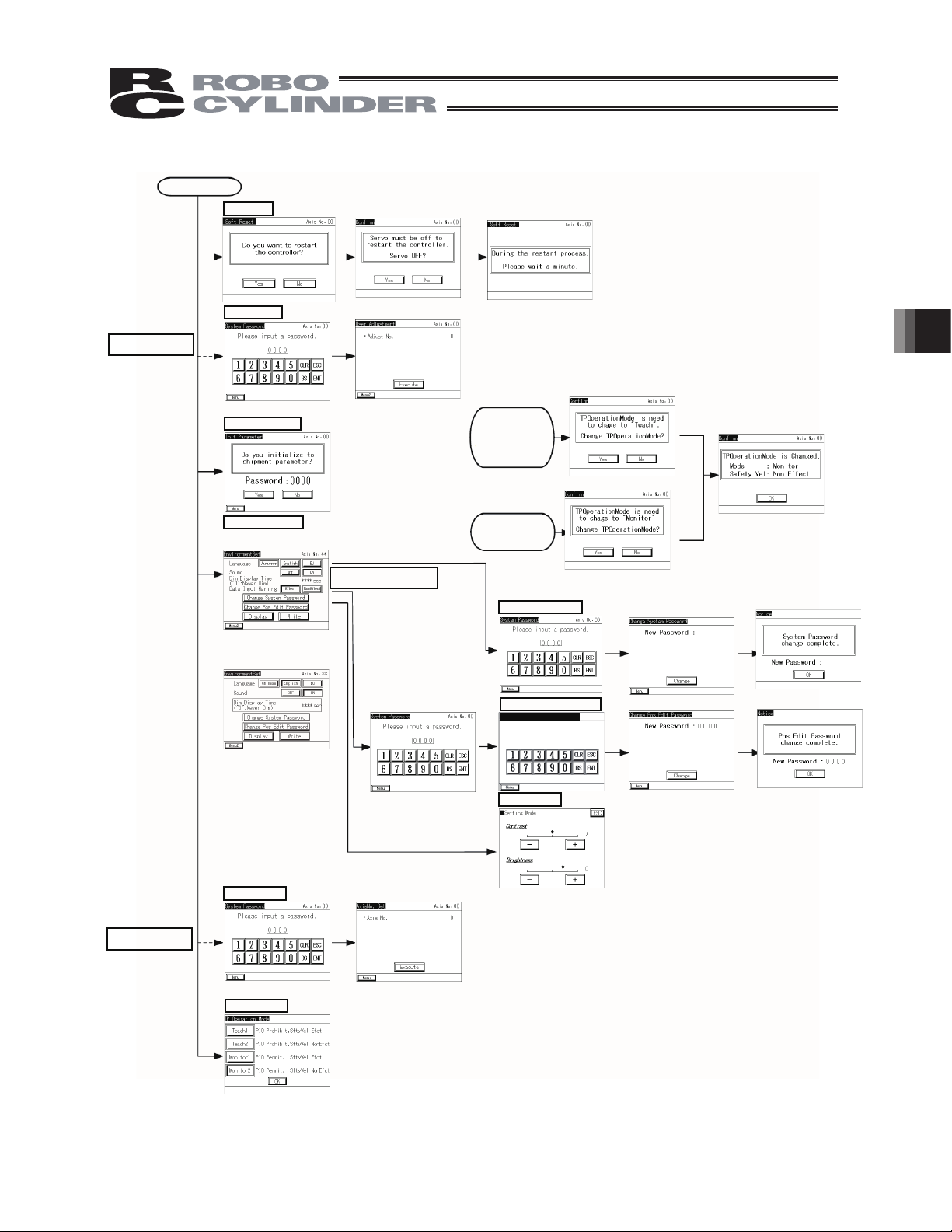

Page 27

If the system password

function is enabled

Menu-2

Soft Reset

User Adjust

5. Operation of CON Controllers

Password entry

Int. Parameter

Environment Set

Display for Japanese/English/EU languages setting change

(Option model code : ENG)

Display for Chinese/English/EU

languages setting change

(Option model code : ECH)

Version V1.30 or later

User adjustment

If the system password

function is enabled

If an attempt is

made to change to

the “position data,”

“movement” or “user

parameter” screen

when the TP

operation mode is

Monitor

If an attempt is made to

change to the “monitor”

screen when the TP

operation mode is

Teaching

System Password

Change Pos Edit Password

Change Pos Edit

New Password: 0000

Display

5119

5119

If the system password

function is enabled

Axis No. Set

Password entry

TP Op Mode

Axis number setting

21

Page 28

5.2 Initial Screen

5.3

Upon connection to the controller, power is supplied to the touch-panel teaching pendant and

processing starts.

When the power is turned on, the IAI logo is displayed for approx. 1 second on the operation display

screen (hereinafter referred to as "operation screen") of the touch-panel teaching pendant, after

which version information is displayed.

5. Operation of CON Controllers

If multiple units are connected, the

axis selection screen appears.

PCON

Select the axis you want

to connect.

[Refer to 5.3, "Changing

Operating Axis."]

The Menu 1 screen appears.

On CON-PD/PG

pendants, this screen is

displayed when the

enable function

parameter of the

controller is set to

“Disable.”

Select [Yes] (Enable) or

[No] (Disable) for the

enable function

On CON-PT pendants,

this screen is displayed

when the enable

function parameter of

the controller is set to

“Enable.”

Enable function parameter is

set “Enable” .

Change to “Disable” ?

Select [Yes] (Disable) or

[No] (Enable) for the

enable function

22

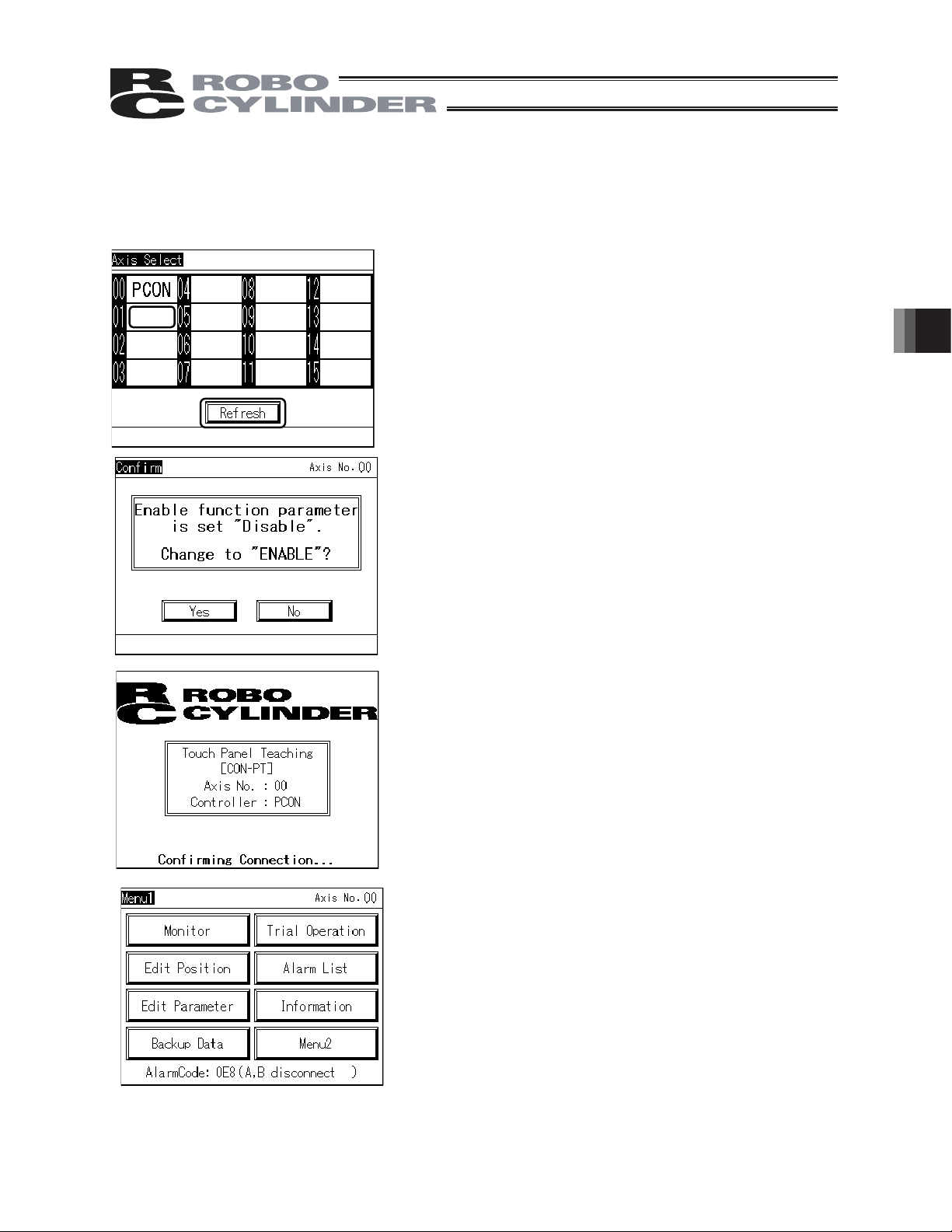

Page 29

5.4

5.3 Changing Operating Axis

If multiple controllers are connected to the communication line, the axis selection screen appears.

This screen also appears when [Change Operate Axis] is touched on the Menu 2 screen.

If only one controller is connected, you need not select an axis.

Select and touch the axis you want to connect the touchpanel teaching pendant to.

PCON

ACON

This screen appears when the enable function parameter of

the controller, other than CON-PT, is set to [Disable].

Select and touch [Yes] (Enable) or [No] (Disable) for the

enable function.

5. Operation of CON Controllers

Connection with the selected controller axis starts.

When connection with the controller is established, the Menu

1 screen appears.

23

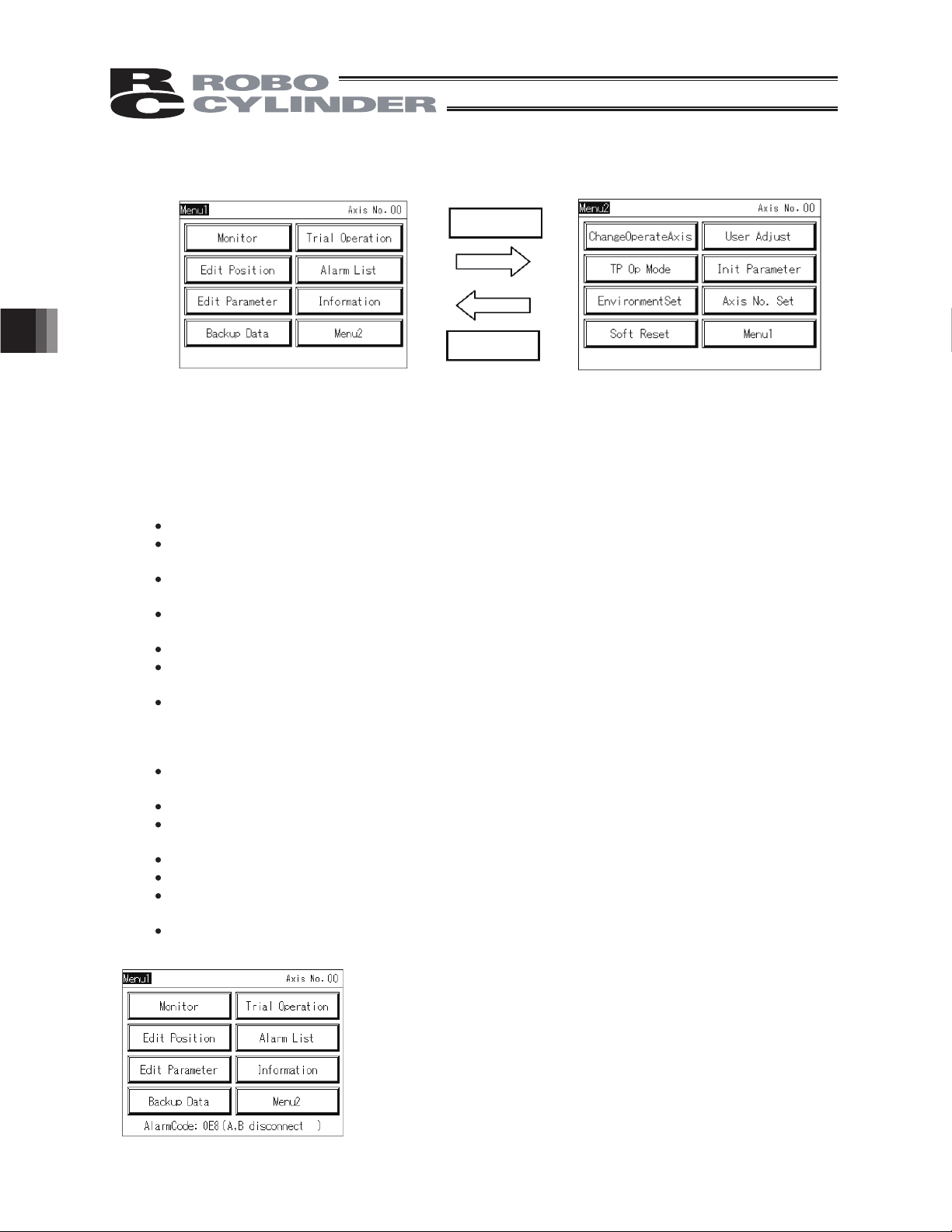

Page 30

5.4 Menu Selection

5.55.5

Two menu selection screens, Menu 1 and Menu 2, are available.

Touching [Menu2] on the Menu 1 screen changes the display to the Menu 2 screen.

Touching [Menu1] on the Menu 2 screen changes the display to the Menu 1 screen.

The Menu 1 screen and Menu 2 screen provide seven menu items, respectively. Select and touch

one of these items.

The screen changes to the one corresponding to the menu item you have touched.

Menu 1 list

Monitor Display the controller status. [Refer to 5.6, "Monitor."]

Edit Position Display and edit the position data table. [Refer to 5.7, "Position

Edit Parameter Display and edit zone boundary+ and other parameters. [Refer to

5. Operation of CON Controllers

5. Operation of CON Controllers

Trial Operation Perform operation test for jogging, inching and axis movement.

Alarm List Display alarm details. [Refer to 5.11, "Alarm List."]

Information Display controller information such as the version. [Refer to 5.16,

Backup Data Transfer data between the memory of the touch-panel teaching

2uneM1uneM

Menu 2

Menu 1

Editing."]

5.8, "Parameter Editing."]

[Refer to 5.9, "Trial Operation."]

"Information."]

pendant and the controller. [Refer to 5.18, "Data Backup."]

24

Menu 2 list

Change Operating Axis Select the controller axis to connect the touch-panel teaching

pendant to. [Refer to 5.4, "Changing Operating Axis."]

Soft Reset Restart the controller. [Refer to 5.12, "Restarting Controller."]

TP Op Mode Select a desired TP operation mode. [Refer to 510, "TP Operation

Mode."]

User Adjust Execute home return, etc. [Refer to 5.13, "User Adjustment."]

Init Parameter Initialize parameters. [Refer to 5.14, "Parameter Initialization."]

Axis No. Set Set the axis number of the controller. [Refer to 5.15, "Axis Number

Setting."]

Environment Set Set the language and touch tone, change the system password, etc.

[Refer to 5.17, "Environment Setting."]

When an alarm generates, the corresponding alarm code and

message will appear at the bottom of the screen and the

backlight color will change to pink. If an emergency stop is

detected, the backlight color will change to red.

Page 31

5.6

5.6 Monitor

The I/O statuses, current position and other information of the controller connected to the serial

communication line are displayed.

Touch [Monitor] on the Menu 1 screen.

If the TP operation mode is not Monitor Mode 1 or 2, the following message screen appears.

Touch [Yes] to change to Monitor Mode 1 or 2.

If not, touch [No].

(Note) The safety speed does not change.

If the current mode is Teaching Mode 1, it changes to

Monitor Mode 1.

If the current mode is Teaching Mode 2, it changes to

Monitor Mode 2.

Touch [OK].

5. Operation of CON Controllers

Models other than SCON-CA, PCON-CA, ERC3

SCON-CA (CON-PT version 1.20 or later, but before 1.30)

PCON-CA, ERC3

The main monitor screen appears.

SCON-CA (CON-PT version 1.30 or later)

Maintenance information can be displayed.

25

Page 32

The main monitor screen appears.

Models other than SCON-CA, PCON-CA, ERC3

PCON-CA, ERC3 (CON-PT version 1.5 later)

5. Operation of CON Controllers

Touching [IOMoni] changes the display to one

showing only I/Os.

Touching [DataMon] changes the display to one

showing only the current position, etc.

Touching Axis No. switches to the axis selection

screen.

Touching [IO Mon] changes the display to show only

IOs.

Touching [Maintenance] changes the display to show

maintenance information.

Touching [Data Mon] changes the display to show

data such as the current position and control voltage.

Touching [Time] shows the window for time edit adjustment.

Touching [Axis No.] switches the screen to one

where you can select an axis.

SCON-CA (CON-PT version 1.20 or later, but before 1.30)

Touching [IO Mon] changes the display to show only

IOs.

Touching [Data Mon] changes the display to show

data such as the current position and control voltage.

Touching [LC Mon] changes the display to show data

such as the current position and force feedback.

Touching [Time] shows the window for time edit adjustment.

Touching [Axis No.] switches the screen to one

where you can select an axis.

26

Page 33

SCON-CA (CON-PT version 1.30 or later)

Touching [IO Mon] changes the display to show only

IOs.

Touching [Maintenance] changes the display to show

maintenance information.

Touching [Data Mon] changes the display to show

data such as the current position and control voltage.

Touching [LC Mon] changes the display to show data

such as the current position and force feedback.

Touching [Time] shows the window for time edi

adjustment.

.

Touching [Axis No.] switches the screen to one

where you can select an axis

[Displayed Items]

x IO Pattern The PIO pattern number set to the controller is shown.

x Complete Pos No The position number achieved upon completion of positioning is shown.

x IN The status of each input port is shown. ON is lit. OFF is unlit.

x OUT The status of each output port is shown. ON is lit. OFF is unlit.

x Special Input The statuses of the enable switch, etc., are shown. ON is lit. OFF is unlit.

(The displayed items vary depending on the model.)

x Servo The servo ON status is shown. ON is lit. OFF is unlit.

x Home The home return status is shown. Lit, if home return has completed.

x Position The current position is shown.

x Velocity The speed is shown.

x Current Rate The command value of electrical current is shown as a percentage of the rated

current.

x Alarm Code The applicable alarm code is shown.

5. Operation of CON Controllers

27

Page 34

Models other than SCON-CA, PCON-CA, ERC3

IO monitor screen

Touching [MoniMain] switches to the main monitor

display.

Touching [DataMoni] changes the display to one

showing only the current position, etc.

Touching Axis No. switches to the axis selection

screen.

x Input The status of each input port is shown. ON is lit. OFF is unlit.

x Output The status of each output port is shown. ON is lit. OFF is unlit.

Models other than SCON-CA, PCON-CA, ERC3

Data monitor screen

5. Operation of CON Controllers

Position The current position is shown.

Position The current position is shown.

x

Velocity The speed is shown.

Velocity The speed is shown.

x

Pulse count The pulse count is shown. Touching [Pulse Count] displays the pulse count. (It’ll

Pulse count The pulse count is shown. Touching [Pulse Count] displays the pulse count. (The pulse

x

Current Rate The command value of electrical current is shown as a percentage of the rated

Current Rate The command value of electrical current is shown as a percentage of the rated current.

x

Current The command value of electrical current is shown. Touch [Current Rate] to display the

x

Current The command value of electrical current is shown. Touch [Current] to display the

AlarmCode The applicable alarm code is shown.

x

Alarm Code The applicable alarm code is shown.

Servo The servo ON status is shown. ON is lit. OFF is unlit.

x

Servo The servo ON status is shown. ON is lit. OFF is unlit.

Home The home return status is shown. Lit, if home return has completed.

x

Home The home return status is shown. Lit, if home return has completed.

ControlVoltage The voltage of the control power supply is shown.

x

Control Voltage The voltage of the control power supply is shown.

MotorVoltage The voltage of the motor power supply is shown.

x

Motor Voltage The voltage of the motor power supply is shown.

PCB Temperature The PCB temperature is shown.

x

PCB Temperature The PCB temperature is shown.

Touching [MoniMain] switches to the main monitor

display

Touching [IOMoni] changes the display to one

showing only I/Os.

Touching Axis No. switches to the axis selection

screen.

Touch [Current] to display [Current Rate].

Touch [Current Rate] to display [Current]

be shown in the pulse-train control controller mode such as PCON-PL/PC.)

count is shown in the pulse-train control mode.)

current.

command value.

command value.

28

Page 35

PCON-CA and ERC3

IO monitor screen

Input The status of each input port is shown. ON is lit. OFF is unlit.

Output The status of each output port is shown. ON is lit. OFF is unlit.

PCON-CA and ERC3

Data monitor screen

Touching [Mon Main] switches to the main monitor

display

Touching [Data Mon] changes the display to show

data such as the current position and control voltage.

Touching [Axis No.] switches the screen to one

where you can select an axis.

5. Operation of CON Controllers

Touching [Mon Main] switches to the main monitor

display

Touching [IO Mon] changes the display to one

showing only I/Os.

Touching [Axis No.] switches the screen to one

where you can select an axis.

Touch [Current] to display [Current Rate].

Touch [Current Rate] to display [Current].

Position The current position is shown.

Velocity The speed is shown.

Pulse count The pulse count is shown. Touching [Pulse Count] displays the pulse count.

(The pulse count is shown in the pulse-train control mode.)

Current Rate The command value of electrical current is shown as a percentage of the rated

current.

Current The command value of electrical current is shown. Touch [Current Rate] to

display the command value.

Alarm Code The applicable alarm code is shown.

Servo The servo ON status is shown. ON is lit. OFF is unlit.

Home The home return status is shown. Lit, if home return has completed.

MotorVoltage The voltage of the motor power supply is shown.

PCB Temperature The PCB temperature is shown.

29

Page 36

SCON-CA

IO monitor screen

x Input The status of each input port is shown. ON is lit. OFF is unlit.

x Output The status of each output port is shown. ON is lit. OFF is unlit.

SCON-CA

Data monitor screen

5. Operation of CON Controllers

Touching [MoniMain] switches to the main monitor

display

Touching [Data Mon] changes the display to show

data such as the current position and control voltage.

Touching [LC Mon] changes the display to show data

such as the current position and force feedback.

Touching [Axis No.] switches the screen to one

where you can select an axis.

Touching [MoniMain] switches to the main monitor

display

Touching [IOMoni] changes the display to one

showing only I/Os.

Touching [LC Mon] changes the display to show data

such as the current position and force feedback.

Touching [Axis No.] switches the screen to one

where you can select an axis.

Touch [Current] to display [Current Rate].

Touch [Current Rate] to display [Current]

x Position The current position is shown.

Position The current position is shown.

x

x Velocity The speed is shown.

Velocity The speed is shown.

x

x Pulse count The pulse count is shown. Touching [Pulse Count] displays the pulse count.

Pulse count The pulse count is shown. Touching [Pulse Count] displays the pulse count. (The pulse

x

x Current Rate The command value of electrical current is shown as a percentage of the rated

Current Rate The command value of electrical current is shown as a percentage of the rated current.

x

Current The command value of electrical current is shown. Touch [Current Rate] to display the

x

x Current The command value of electrical current is shown. Touch [Current] to display the

AlarmCode The applicable alarm code is shown.

x

x Alarm Code The applicable alarm code is shown.

Servo The servo ON status is shown. ON is lit. OFF is unlit.

x

x Servo The servo ON status is shown. ON is lit. OFF is unlit.

Home The home return status is shown. Lit, if home return has completed.

x

x Home The home return status is shown. Lit, if home return has completed.

MotorVoltage The voltage of the motor power supply is shown.

x

x Control Voltage The voltage of the control power supply is shown.

PCB Temperature The PCB temperature is shown.

x

x Motor Voltage The voltage of the motor power supply is shown.

(The pulse count is shown in the pulse-train control mode.)

count is shown in the pulse-train control mode.)

current.

command value.

command value.

x PCB Temperature The PCB temperature is shown.

30

Page 37

SCON-CA

LC monitor screen

Touching [MoniMain] switches to the main monitor

display

Touching [IOMoni] changes the display to one

showing only I/Os.

Touching [Data Mon] changes the display to show

data such as the current position and control voltage.

Force feedback

10.00 N

x Position The current position is shown.

Position The current position is shown.

x

x Velocity The speed is shown.

Velocity The speed is shown.

x

x Pulse count The pulse count is shown. Touching [Pulse Count] displays the pulse count.

Pulse count The pulse count is shown. Touching [Pulse Count] displays the pulse count. (The pulse

x

x Current Rate The command value of electrical current is shown as a percentage of the rated

Current Rate The command value of electrical current is shown as a percentage of the rated current.

x

Current The command value of electrical current is shown. Touch [Current Rate] to display the

x

x Current The command value of electrical current is shown. Touch [Current] to display the

AlarmCode The applicable alarm code is shown.

x

x Alarm Code The applicable alarm code is shown.

Servo The servo ON status is shown. ON is lit. OFF is unlit.

x

x Servo The servo ON status is shown. ON is lit. OFF is unlit.

Home The home return status is shown. Lit, if home return has completed.

x

x Home The home return status is shown. Lit, if home return has completed.

Calibration The calibration status of the load cell is shown. Lit, if calibration of the load cell has been

x

x Calibration The calibration status of the load cell is shown. Lit, if calibration of the load cell

completed.

Force feedback The force feed back from the load cell is shown.

x

x Force feedback The force feed back from th

(The pulse count is shown in the pulse-train control mode.)

count is shown in the pulse-train control mode.)

current.

command value.

command value.

has been completed.

Touch [Current] to display [Current Rate].

Touch [Current Rate] to display [Current]

e load cell is shown.

5. Operation of CON Controllers

31

Page 38

SCON-CA (CON-PT version 1.30 or later), PCON-C, ERC3 (CON-PT version 1.50 or later)

Maintenance information screen

PCON-CFA

5. Operation of CON Controllers

Touching [Info Edit] switches the screen to one

where you can edit maintenance information.

• Total number of movements The cumulative total number of actuator movements is shown.

••Total travelled distance The cumulative total distance travelled by the actuator is shown.

Total fan driving time Shows the total driving time of the fan on the controller

The above values can be changed on the maintenance information editing screen.

[Thresholds for Total Number of Movements and Total Travelled Distance]

You can set thresholds for total number of movements and total travelled distance in the parameters specified

below, to cause an alarm to generate when each threshold is exceeded.

emaN.oNretemaraP

147 Threshold for total number of movements

148 Threshold for total travelled distance

Message-level alarms

Alarm code

4E

Movements threshold

exceeded

This alarm generates when the total

number of movements exceeds the

noitpircseDemaN

threshold set in parameter No. 147.

This alarm generates when the total

travelled distance exceeds the threshold

set in parameter No. 148.

4F

Travelled distance

threshold exceeded

32

Page 39

(1) Editing maintenance information

SCON-CA, PCON-CA, ERC3

PCON-CFA

Touching [Moved Count Edit] or [Run Dist. Edit]

displays the keyboard screen.

Enter a desired value and press [ENT], and the

current setting will change to the value you have

entered.

Touching [Set] display returns you to the previous

maintenance information screen.

5. Operation of CON Controllers

Touching [Display Information] without touching [Set]

first returns you to the maintenance information

screen showing the original value. The setting will not

change to the value you have entered.

33

Page 40

With SCON-CA, PCON-CA, ERC3 PIO converter controllers, you can set the controller time.

[How to Set Time]

5. Operation of CON Controllers

Touching [Time] displays the time setting screen.

Touch [Edit Time].

Touch the value of year, month, day, hours, minutes or seconds you

want to change.

34

The numeric key pad appears. Enter a desired value, and then press

[ENT].

Touch [Set].

The current time on the SCON-CA, PCON-CA, ERC3 PIO converter

controller is changed.

Page 41

5.7

5.6 Position Editing

Set/edit the target position, speed, acceleration, deceleration and other data related to positions. You

can move the axis by jogging or inching.

Touch [Edit Position] on the Menu 1 screen.

If a position password is set, the password setting screen appears.

Enter the position password.

The default password is "0000."

A position data table appears.

5. Operation of CON Controllers

Position No.

Data of the selected position number appears.

Version V1.20 and Earlier

Touching [Multi Pos] returns the screen to the position data

table display.

Version V1.20 or later

100.00

120.00

0.30

0.10

0

0.10

0

60.00

40.00

0

0

0

0

0

Touch Specify No. to set the position number

you want to set, and a table showing the

position number you have just set appears.

To set data other than the target position,

speed, acceleration and deceleration shown in

the table, touch other position number such as

"000."

35

Page 42

5.7.1

S-motion

Vibration

Control

×

×

×

×

{

×

{

×

×

×

{

×

×

×

×

×

{

×

{

×

{

×

{

×

{

{

5.6.1 Position Data

5.7.1

Position data table screen

Data display screen showing the selected position number

Version V1.20 and Earlier

Version V1.20 or later

5. Operation of CON Controllers

The items set in the position data table include target position, speed, acceleration, deceleration,

push, positioning band, incremental, zone+, zone-, threshold, acceleration/deceleration mode, stop

mode and command mode.

The settings of zone+, zone-, threshold, acceleration/deceleration mode and stop mode are enabled

or disabled depending on the controller type, as shown in the table.

Position table Zone +/-

ERC2

ERC2-SE

ERC3

ERC3PIO Converter

PCON-C/CG/CF

PCON-CA

-CY

-SE

ACON-C/CG

-CY

-SE

SCON-C positioner

mode

SCON-CA positioner

mode

36

100.00

120.00

0.30

0.10

0.10

60.00

40.00

0

0

0

{

{

{

{

{

{

{

{

{

{

{

{

{

PIOpattern:0,1,2,4,5,6,7

0

0

0

0

PIO pattern: 3

-

PIO pattern: 2

PIO pattern:0,1,2,4,5

PIO pattern:0,1,2,4,5

PIO pattern:0,1,2,4,5

PIO pattern: 1

-

PIO pattern:0,1,2,4,5

PIO pattern: 1

-

PIO pattern:0,1,2,4,5

Trapezoid

{

{

{

{

{

{

{

{

{

{

{

{

{

AccDcl Mode Stop mode

Primary

delay

×

×

{

{

×

{

×

×

Servo

Autom atic

Full

servo

OFF

{{

{

{{

{{

{{

{{

{{

{

{{

{{

{

{{

{{{

Gain set

×

××

×

×

×

×

×

××

×

×

××

×

Page 43

(1) No.

The position data number is shown.

Warning: Be sure to specify absolute coordinates on PCON-C/CG, ACON-C/CG, SCON-C,

PCON-CA, ROBONET and ERC3 PIO converter controllers of solenoid valve mode 2,

or PCON-CY and ACON-CY controllers of solenoid valve mode 1.

If incremental coordinates are specified on these controllers, a position data error

occurs.

Also note that completion of push motion cannot be determined when the push is

specified if incremental coordinates are specified.

(2) Target position [mm]

Enter the target position to move the actuator to.

Absolute coordinate specification: Enter the target position you want to move the actuator to, based

on the distance from the home. A negative value cannot be

entered.

••Incremental coordinate specification: Enter the target position you want to move the actuator to, based

on the distance from the current position. A negative value can

also be entered.

(Negative direction on displayed coordinate system)

(3) Speed [mm/sec]

Enter the speed at which to move the actuator.

The default value varies depending on the actuator type.

(Note) For SCON-CA, PCON-CA and ERC3, an alarm will be displayed if the set value is lower than the

minimum velocity.

(4) Acceleration/deceleration [G]

Enter the acceleration/deceleration at which to move the actuator.

Basically you should set acceleration/deceleration not exceeding the rated value shown in the catalog.

The input range permits entry of values larger than the rated value shown in the catalog, but this is because

"shorter tact time when the transferring mass is significantly lighter than the rated value" is assumed.

If the load vibrates during acceleration/deceleration to present problems, decrease the value set here.

(Reference) Acceleration is explained. The same concept applies to deceleration.

1 G = 9800 mm/s

per second.

0.3 G: Acceleration at which the actuator can increase its speed up to 2940 mm/s (9800 mm/s

x 0.3) per second.

2

: Acceleration at which the actuator can increase its speed up to 9800 mm/s

Speed

5. Operation of CON Controllers

Time

(Note) For SCON-CA, PCON-CA and ERC3, an alarm will be displayed if the set value exceeds

the rated acceleration/deceleration.

Caution

Acceleration/deceleration setting

(1) Set accelerations/decelerations not exceeding the rated acceleration/deceleration specified in the catalog or

this operation manual. If any acceleration/deceleration is set that exceeds the rated

acceleration/deceleration, the life of the actuator may be significantly reduced.

(2) If the actuator or work part receives impact or generates vibration, lower the acceleration/deceleration. If the

system is used continuously with the actuator or work part receiving impact or generating vibration, the life

of the actuator may be significantly reduced.

(3) If the load transferred by the actuator is significantly lighter than the rated payload capacity, you may be

able to set accelerations/decelerations exceeding the rating. If this is the case, the tact time can be

reduced, so contact IAI. When contacting IAI, tell us the weight, shape and installation method of your work

part and installation condition (horizontal/vertical) of your actuator.

37

Page 44

(5) Push

Select "Positioning operation" or "Push-motion operation."

The factory setting is 0.

0: Normal positioning operation

Other than 0: A current limiting value is indicated, meaning that this is a push-motion operation.

Caution: With PCON, ACON, SCON-C, SCON-CA, ERC2,ERC3 and ROBONET controllers,

the value entered in the "Push" field may be rounded to a multiple of the controller's

minimum resolution. (When data is acquired from the controller)

(6) Positioning band

What this setting means is different between "Positioning operation" and "Push-motion operation."

"Positioning operation":

Define how far before the target position you want to turn the completion signal ON.

The factory setting is 0.1 mm.

Standard type

Increasing the value of positioning band quickens the start of

the next sequence operation, so the tact time can be

reduced. Set an optimal value by considering the balance of

the entire system.

5. Operation of CON Controllers

Note that on PCON-C/CG, ACON-C/CG, SCON-C, SCON-CA, ROBONET and ERC3 PIO converter controllers

of 3-point type or PCON-CY and ACON-CY controllers of proximity switch type, set the band after which

the completion signal turns ON.

PCON-C/CG, ACON-C/CG and SCON-C, SCON-CA, ROBONET and ERC3 PIO converter in solenoid

valve mode 2, PCON-CY, or ACON-CY in solenoid valve mode 1

"Push-motion operation":

Define the maximum push distance from the target position in push-motion operation.

Set an appropriate positioning band by considering the mechanical variation of the load, by making sure

positioning will not complete before the actuator contacts the load.

Completion signal

Timing at which the

completion signal turns ON

Positioning band

Positioning band

Target

position

Target

position

38

Position at which the load is contacted and completion of

push-motion operation is deemed complete and therefore

the completion signal turns ON

Load

Positioning band ON

Target position

(Maximum push distance)

Page 45

(7) Incremental

Specify absolute coordinates or incremental coordinates.

The factory setting is 0.

0: Absolute coordinate specification

1: Incremental coordinate specification

Warning: Be sure to specify absolute coordinates on PCON-C/CG, ACON-C/CG and SCON-C

SCON-CA, ROBONET and ERC3 PIO converter controllers of solenoid valve mode 2,

or PCON-CY and ACON-CY controllers of solenoid valve mode 1.

If incremental coordinates are specified on these controllers, a position data error

occurs.

(8) Zone +/-

Define, for the standard type, the zone in which the zone output signal turns ON.

For added flexibility, these parameters can be set differently for each target position.

[Setting example]

No. Position [mm] Zone + [mm] Zone - [mm] Remarks

0 5.00 100.00 0.00 Backward end

1 380.00 400.00 300.00 Forward end

2 200.00 250.00 150.00

Intermediate

position

Movement command to backward end

5. Operation of CON Controllers

Backward

Home

end

Zone output signal

Movement command to forward end

Forward

end

Zone output signal

Movement command to intermediate position

Midway

point

Zone output signal

(9) Threshold

With PCON-CF controllers, a load output signal (PIO) is output if the command torque exceeds the

value (%) set in "Threshold" inside the verification range.

The verification range is set by "Zone+/Zone-."

It is used to determine if press-fitting action was performed successfully.

* For details, refer to the operation manual for your PCON-CF controller.

39

Page 46

(10) Acceleration/deceleration mode

Define the acceleration/deceleration pattern.

The factory setting is 0.

0: Trapezoid pattern

1: S-motion

2: Primary delay filter

Trapezoid pattern

* Set the acceleration and deceleration in the "Acc" and "Dcl" fields of the position table.

S-motion

The acceleration curve rises gradually at first and then suddenly shoots up in the middle.

Use this mode if you want to set high acceleration/deceleration to meet the required tact time, but

want to move the actuator gradually at the start of movement and immediately before stopping.

5. Operation of CON Controllers

* The S-motion level is set by parameter No. 56 [S-motion ratio setting]. The setting unit is %, while the

setting range is 0 to 100.

(The graph above assumes that the parameter is set to 100%.)

If 0 is set, the S-motion control is disabled.

Note that the setting made here is not reflected in jogging or inching feed performed from a PC or

teaching pendant.

(Note) This setting is not available on ERC2 and PCON controllers. On these controllers, parameter No.

56 is reserved.

Speed

Acceleration

Speed

Deceleration

Time

Time

Primary delay filter

The acceleration/deceleration curve becomes more gradual than linear acceleration/deceleration

(trapezoid pattern).

Use this mode if you don't want to apply fine vibration to the load during acceleration/deceleration.

Speed

Time

* The primary delay level is set by parameter No. 55 [Primary filter time constant for position commands].

The setting unit is 0.1 msec, while the setting range is 0.0 to 100.0.

If 0 is set, the primary delay filter is disabled.

Note that the setting made here is not reflected in jogging or inching feed performed from a PC or

teaching pendant.

(Note) This setting is not available on ERC2 and PCON controllers. On these controllers, parameter No.

55 is reserved.

40

Page 47

(11) Stop mode

Define the power-saving mode to be used while the actuator is standing by after completion of

positioning to the target position set in the "Position" field of the applicable position number.

0: Disable power-saving mode * The factory setting is 0 (Disable).

1: Auto servo OFF mode, with the delay time defined by parameter No. 36

2: Auto servo OFF mode, with the delay time defined by parameter No. 37

3: Auto servo OFF mode, with the delay time defined by parameter No. 38

4: Full servo control mode

Auto servo OFF mode

The servo is turned OFF automatically upon elapse of a specified time after completion of positioning.

(Since holding current does not flow, power consumption is reduced.)

When the PLC issues the next movement command, the servo is turned ON and then the actuator

starts moving.

Movement command

Servo OFF in auto mode

Servo status

(A green LED blinks.)

Servo ON status

Actuator movement

Target position

T: Delay time (in seconds) after the

positioning is completed until the servo

turns OFF. T is set by a parameter.

Full servo control mode

The holding current can be decreased by servo-controlling the pulse motor.

Although the rate of decrease in holding current varies depending on the actuator model, loading