Page 1

Slider Type

First Edition ME3769-1A

RCS4- SA4C/SA6C/SA7C/SA8C

SA4R/SA6R/SA7R/SA8R

RCS4CR- SA4C/SA6C/SA7C/SA8C

Specifications

Installation

Maintenance and

Inspection

External Dimensions

Life

Warranty

Appendix

ROBO Cylinder

®

ch.

1

ch.

2

ch.

3

ch.

4

ch.

5

ch.

6

ch.

7

ch.

8

Instruction Manual

Connecting with

the Controller

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This instruction manual explains the handling methods, structure and maintenance of this product,

providing the information you need in order to use the product safely.

Before using the product, be sure to read this manual and fully understand the contents explained

herein to ensure safe use of the product.

The DVD enclosed with the product contains instruction manuals for IAI products.

When using the product, refer to the necessary sections of the applicable instruction manual by

printing them out or displaying them on a PC.

After reading the instruction manual, keep it in a convenient place so that whoever is handling the

product can refer to it quickly when necessary.

[Important]

● This instruction manual is an original document dedicated for this product.

● This product cannot be used in ways not shown in this instruction manual. IAI shall not be

liable for any result whatsoever arising from the use of the product in any other way than what

is noted in the manual.

● The information contained in this instruction manual is subject to change without notice for the

purpose of product improvement.

● If any issues arise regarding the information contained in this instruction manual, contact our

customer center or the nearest sales office.

● Use or reproduction of this instruction manual in full or in part without permission is prohibited.

● The company names, names of products and trademarks of each company shown in the text

are registered trademarks.

Page 4

RCS4 Slider Type Instruction Manual Configuration

Product name Instruction manual name

Control

number

RCS4 First Step Guide ME3775

RCS4 Slider Type

Instruction Manual

(this document)

ME3769

SCON-CB/CFB Controller

SCON-CB/CFB Controller

Instruction Manual

ME0340

SCON-CAL/CGAL Controller

SCON-CAL/CGAL Controller

Instruction Manual

ME0243

MSCON-C Controller

MSCON-C Controller

Instruction Manual

ME0306

SSEL-CS Controller

SSEL-CS Controller

Instruction Manual

ME0157

XSEL-P/Q Controller

XSEL-P/Q Controller

Instruction Manual

ME0148

XSEL-R/S Controller

XSEL-R/S Controller

Instruction Manual

ME0313

XSEL-RA/SA Controller

XSEL-RA/SA Controller

Instruction Manual

ME0359

PC Compatible Software for RC/EC

RCM-101-MW/RCM-101-USB

Instruction Manual

ME0155

PC Compatible Software for XSEL

IA-101-X-MW/IA-101-X-USBMW

Instruction Manual

ME0154

Touch Panel Teaching Pendant

TB-01/01D/01DR

Applicable for Position Controller

Instruction Manual

ME0324

Touch Panel Teaching Pendant

TB-02/02D

Applicable for Position Controller

Instruction Manual

ME0355

Data Setter

TB-03

Applicable for Position Controller

ME0376

Touch Panel Teaching Pendant

TB-01/01D/01DR

Applicable for Program Controller

Instruction Manual

ME0325

Touch Panel Teaching Pendant

TB-02/02D

Applicable for Program Controller

Instruction Manual

ME0356

Data Setter

TB-03

Applicable for Program Controller

ME0377

Page 5

Contents

Safety Guide ···················································································· Intro-1

Precautions for Handling ···································································· Intro-9

International Standard Compliance ······················································· Intro-10

Names of the Parts ··········································································· Intro-11

Chapter 1 Specifications

1.1 Checking the product ································································ 1-1

Parts ··············································································································· 1-1

How to Read the Model Nameplate ········································································· 1-2

How to Read the Model Number ············································································ 1-2

Product list ········································································································ 1-3

1.2 Specifications ·········································································· 1-4

Specifications ····································································································· 1-4

Double Slider (Option) ·························································································· 1-28

Duty ratio ·········································································································· 1-29

1.3 Options ·················································································· 1-31

With brake (Model Code: B) ··················································································· 1-31

Cable Exit Direction Changed

(Model Code: CJT, CJR, CJL, CJB and CJO) ·················································· 1-31

High Precision Specifications (Model Code: HPR) ······················································ 1-31

Motor Reversed Direction (Model Code: ML, MR) ······················································· 1-31

Reversed-home Specification (Model Code: NM) ······················································· 1-31

Slider Roller Specification (Model Code: SR) ····························································· 1-32

Vacuum Joint Attachment Opposite Type (Model Code: VR)········································· 1-32

Double Slider Specification (Model Code: W) ···························································· 1-32

Rear Attachment Plate (Model Code: RP) ································································· 1-32

Slider spacer (Model Code: SS) ············································································· 1-33

1.4 Accessories ············································································ 1-35

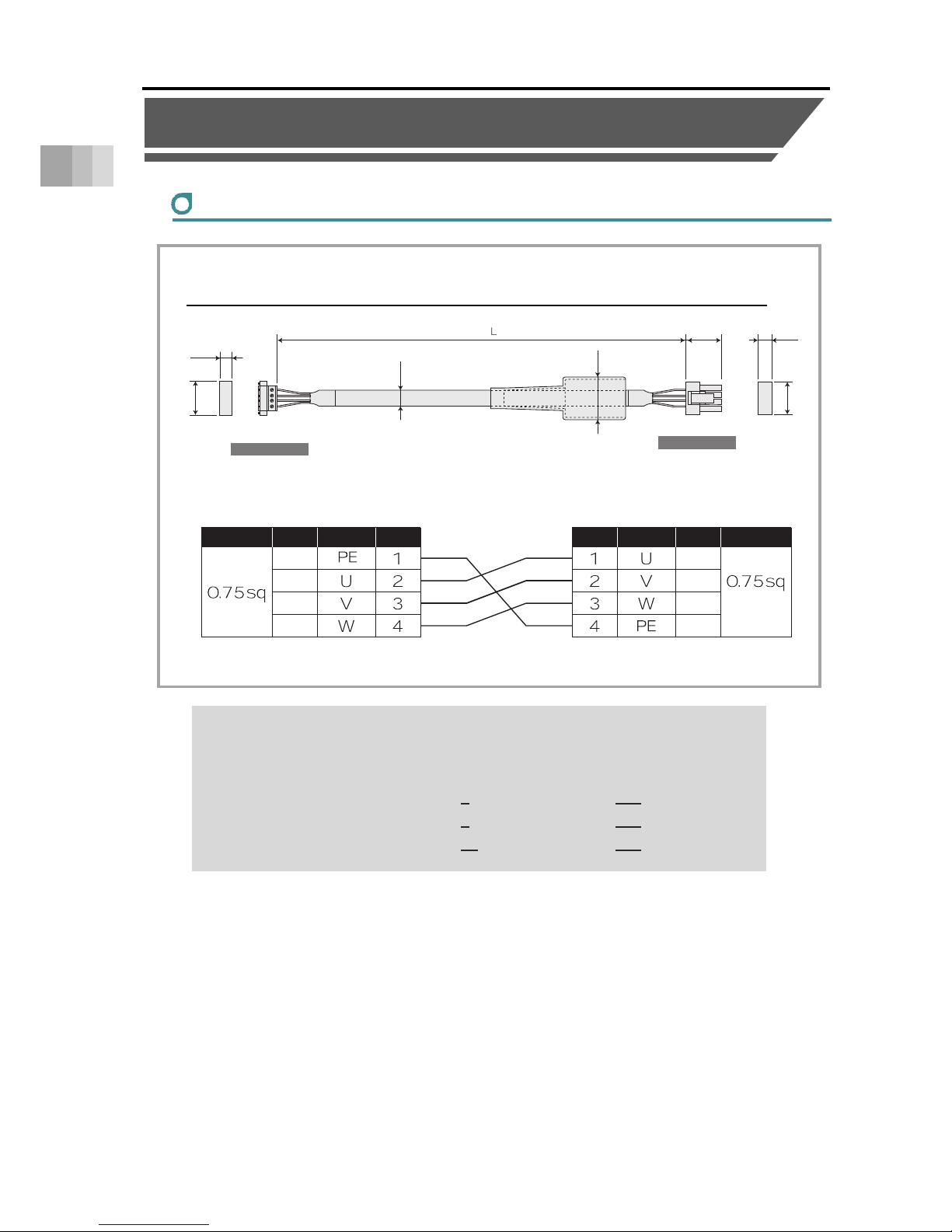

Motor Cable ······································································································· 1-35

Encoder Cable ···································································································· 1-36

Chapter 2 Installation

2.1 Precautions for transportation ····················································· 2-1

2.2 Installation and storage/preservation environment ··························· 2-3

Installation Environment ······················································································· 2-3

Storage/preservation environment ·········································································· 2-4

2.3 How to Install ·········································································· 2-5

Installation Orientation ························································································· 2-5

Precautions regarding stainless steel sheet ······························································ 2-6

Installation surface ······························································································ 2-7

Installation of the Main Unit ··················································································· 2-8

Mounting transported objects ················································································· 2-16

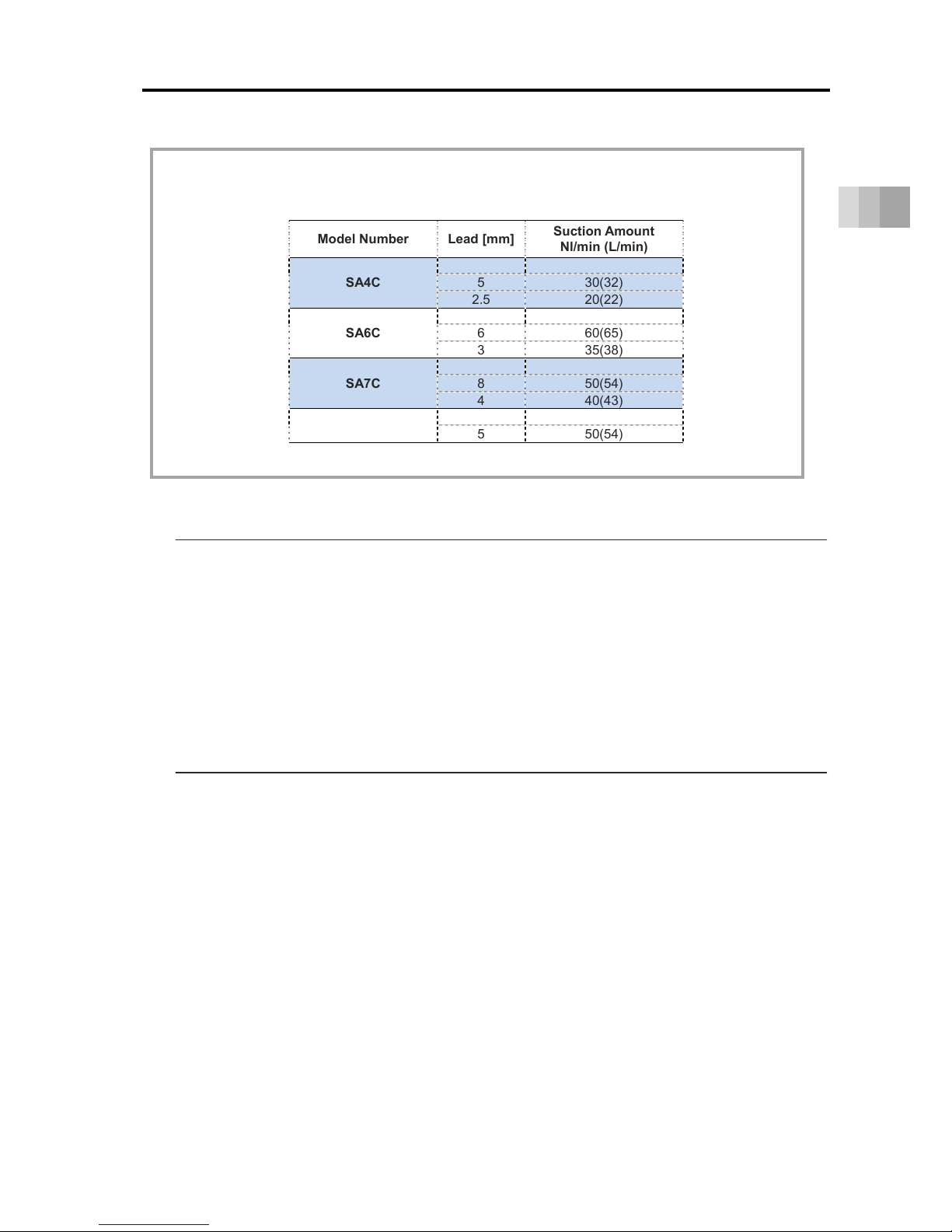

About Suction of the Cleanroom Type ····································································· 2-19

Chapter 3 Connecting with the Controller

3.1 Connecting with the Controller ···················································· 3-1

Page 6

Chapter 4 Maintenance and Inspection

4.1 Precautions for maintenance and inspection work ··························· 4-1

4.2 Inspection Items and Schedule ··················································· 4-3

Slider type ········································································································· 4-3

Grease supply timing (Guideline) ············································································ 4-3

4.3 Visual inspection items ······························································ 4-4

External visual inspection ······················································································ 4-4

Internal visual inspection ······················································································· 4-5

4.4 Cleaning ················································································ 4-7

External cleaning ································································································ 4-7

Internal Cleaning ································································································· 4-7

4.5 Greasing method ····································································· 4-8

Grease used ······································································································ 4-8

Greasing method ································································································ 4-10

4.6 How to replace components ······················································· 4-13

Stainless steel sheet replacement/adjustment ··························································· 4-13

Belt replacement/adjustment ·················································································· 4-19

Motor Replacement ····························································································· 4-24

Chapter 5 External Dimensions

5.1 External Dimensions ································································· 5-1

RCS4-SA4C ······································································································· 5-1

RCS4-SA6C ······································································································· 5-2

RCS4-SA7C ······································································································· 5-3

RCS4-SA8C ······································································································· 5-4

RCS4-SA4R ······································································································· 5-5

RCS4-SA6R ······································································································· 5-7

RCS4-SA7R ······································································································· 5-8

RCS4-SA8R ······································································································· 5-10

RCS4CR-SA4C ·································································································· 5-12

RCS4CR-SA6C ·································································································· 5-13

RCS4CR-SA7C ·································································································· 5-14

RCS4CR-SA8C ·································································································· 5-15

Chapter 6 Life

6.1 Concept of life for slider type ······················································ 6-1

How to calculate operation life ················································································ 6-1

Relation between operation life and moment ····························································· 6-3

Chapter 7 Warranty

7.1 Warranty period ······································································· 7-1

7.2 Scope of the warranty ······························································· 7-1

7.3 Honoring the warranty ······························································· 7-1

7.4 Limited liability ········································································· 7-2

7.5 Conformance with applicable standards/regulations,etc.,

and application conditions ·························································· 7-2

7.6 Other Items excluded from warranty ············································· 7-2

Chapter 8 Appendix

8.1 Index ····················································································· 8-1

8.2 Revision history ······································································· 8-3

Page 7

Safety Guide

Intro-1

Safety Guide

The Safety Guide is intended to permit safe use of the product and thus to prevent risks and property

damage. Be sure to read it before handling the product.

Page 8

Safety Guide

Intro-2

Safety Precautions for Our Products

Common safety precautions for the use of robots in various operations are indicated here.

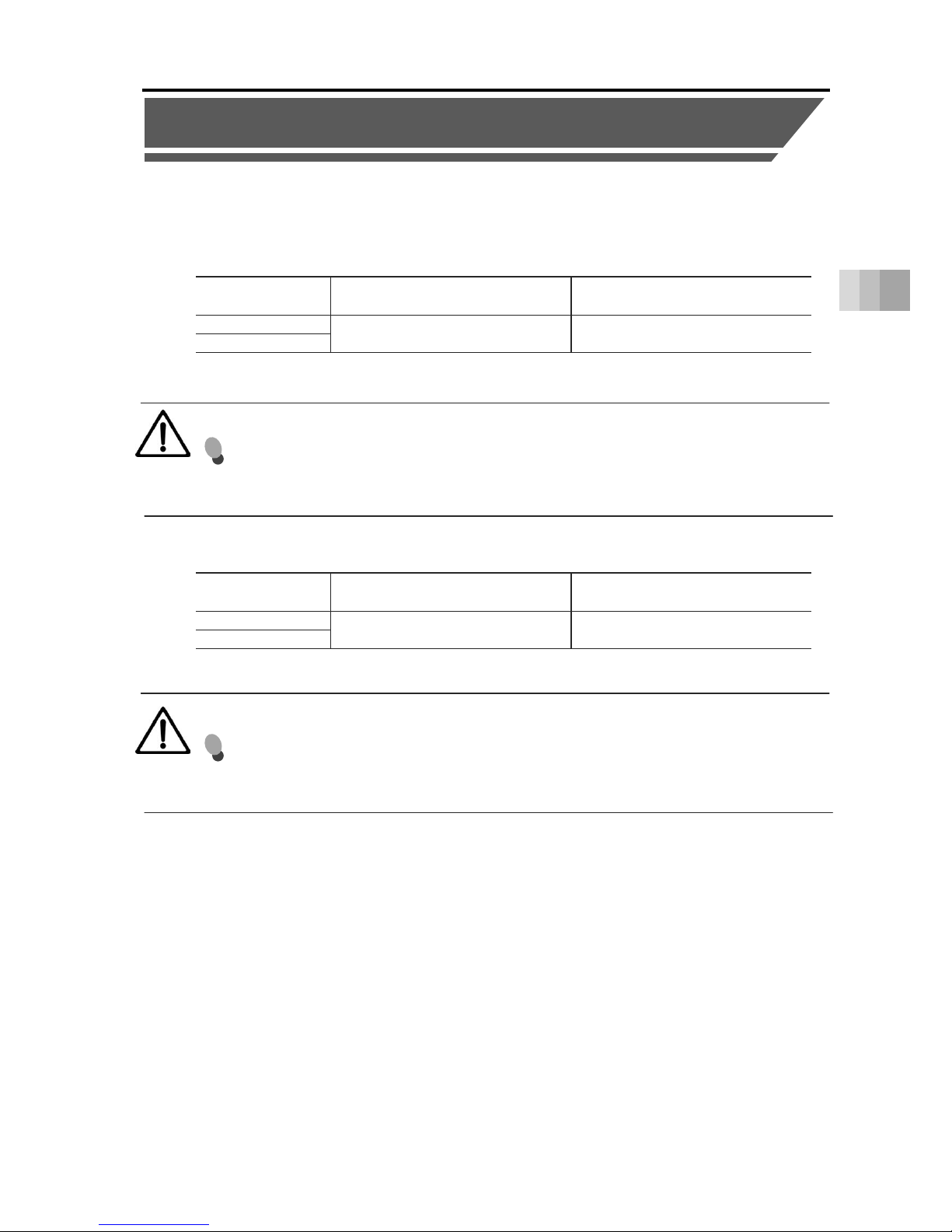

No. Operation Precautions

1 Model

Selection

● This product is not intended or designed for applications where high levels of

safety are required, and so cannot guarantee that human lives will be

protected. Accordingly, do not use it in any of the following applications.

(1) Medical equipment used to maintain, control or otherwise affect human life

or physical health

(2) Mechanisms or machinery designed for the purpose of moving or

transporting people (vehicles, railway facilities, aviation facilities etc.)

(3) Machinery components essential for safety (safety devices etc.)

● Do not use the product outside the range of the specifications. Otherwise,

the product life may be drastically shortened, and product damage or facilities

stoppage may occur.

● Do not use it in any of the following environments.

(1) Locations with flammable gases, ignitable objects or explosives

(2) Locations with potential exposure to radiation

(3) Locations with ambient temperature or relative humidity exceeding the

specifications range

(4) Locations where radiant heat is applied by direct sunlight or other large

heat source

(5) Locations where condensation occurs due to abrupt temperature changes

(6) Locations with corrosive gases (sulfuric acid, hydrochloric acid, etc.)

(7) Locations exposed to significant amounts of dust, salt or iron powder

(8) Locations subject to direct vibration or impact

● For an actuator used in vertical orientation, select a model which is equipped

with a brake. If a model without brake is selected, the moving parts may fall

when the power is turned OFF, causing accidents such as injury or workpiece

damage.

Page 9

Safety Guide

Intro-3

No. Operation Precautions

2 Transportation ● When transporting heavy objects, do the work with two or more persons or

utilize equipment such as a crane.

● When working with two or more persons, make it clear who is to be in charge

and communicate well with each other to ensure safety.

● During transportation, carefully consider the carrying positions, weight, and

weight balance, and be careful to avoid collisions or dropping.

● Use appropriate transportation measures for transport.

The actuators available for transportation with a crane have eyebolts attached

or tapped holes to attach bolts. Follow the instructions in the instruction manual

for each model.

● Do not climb onto the package.

● Do not put anything heavy that could deform the package on it.

● When using a crane with capacity of 1t or more, have an operator qualified for

crane operation and sling work.

● When using a crane or equivalent equipment, make sure not to suspend loads

exceeding the equipment's rated load.

● Use a hook that is suitable for the load. Consider the safety factor of the hook in

such factors as shear strength. Also, check to make sure that the hook is free of

damage.

● Do not climb on loads suspended from cranes.

● Do not leave loads suspended from cranes for long periods.

● Do not stand under loads suspended from cranes.

3 Storage

and

Preservation

● For the storage and preservation environment, see the installation

environment. However, give especial consideration to the prevention of

condensation.

● Store the products so as to prevent them from falling over or down in the case

of natural disasters such as earthquakes.

Page 10

Safety Guide

Intro-4

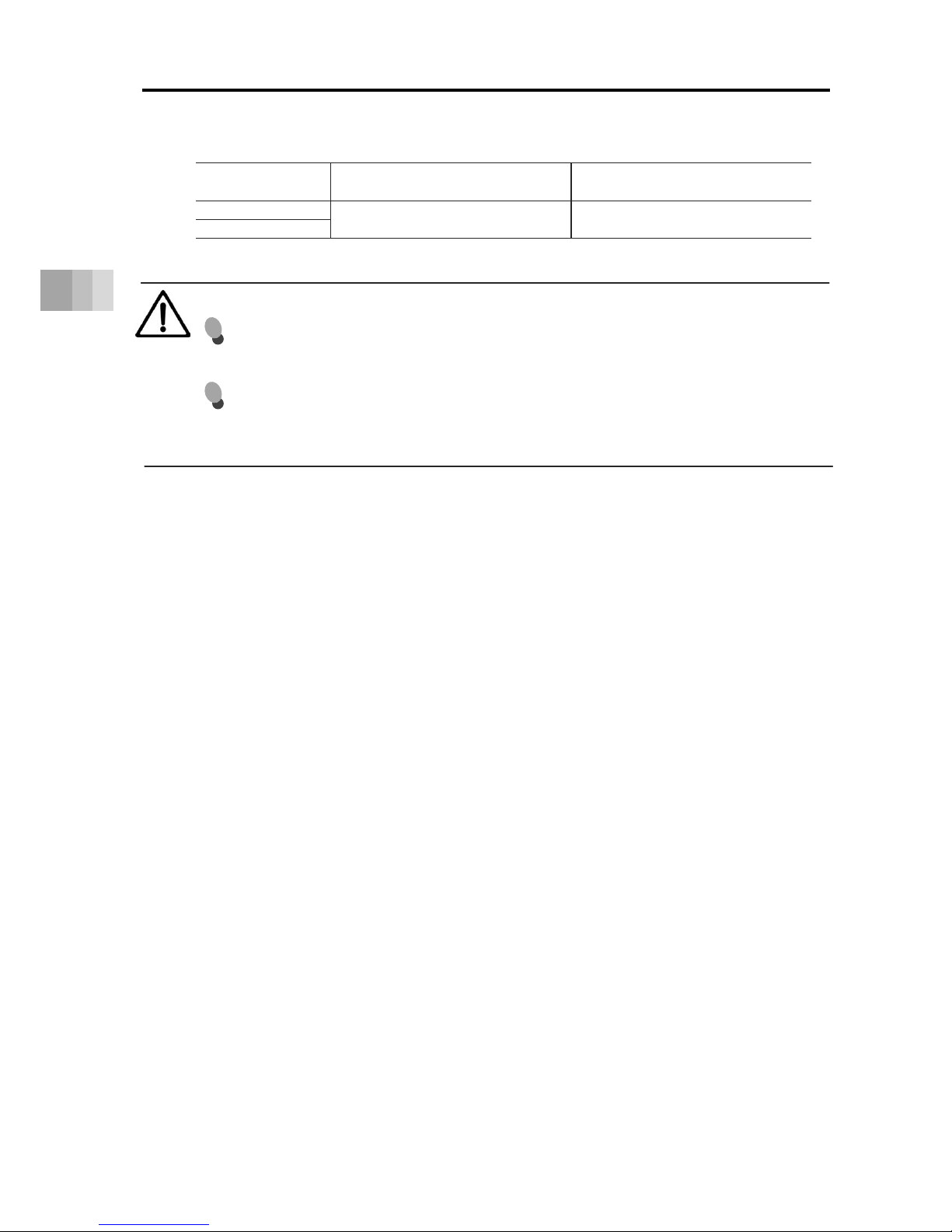

No. Operation Precautions

4 Installation

and

Startup

(1) Installation of robot body and controller, etc.

● Be sure to securely hold and fix the product (including the workpiece).

If the product falls over, is dropped, or operates abnormally, it may lead to

damage and injury.

Also, be equipped for falls over or down due to natural disasters such as

earthquakes.

● Do not climb on or put anything on the product. Otherwise, this may lead to

accidental falling, injury or damage to the product due to falling objects, product

loss of function or performance degradation, or shortening of product life.

● When using the product in any of the places specified below, provide sufficient

shielding.

(1) Locations where electrical noise is generated

(2) Locations with strong electrical or magnetic fields

(3) Locations with mains or power lines passing nearby

(4) Locations where the product may come in contact with water, oil or

chemical spray

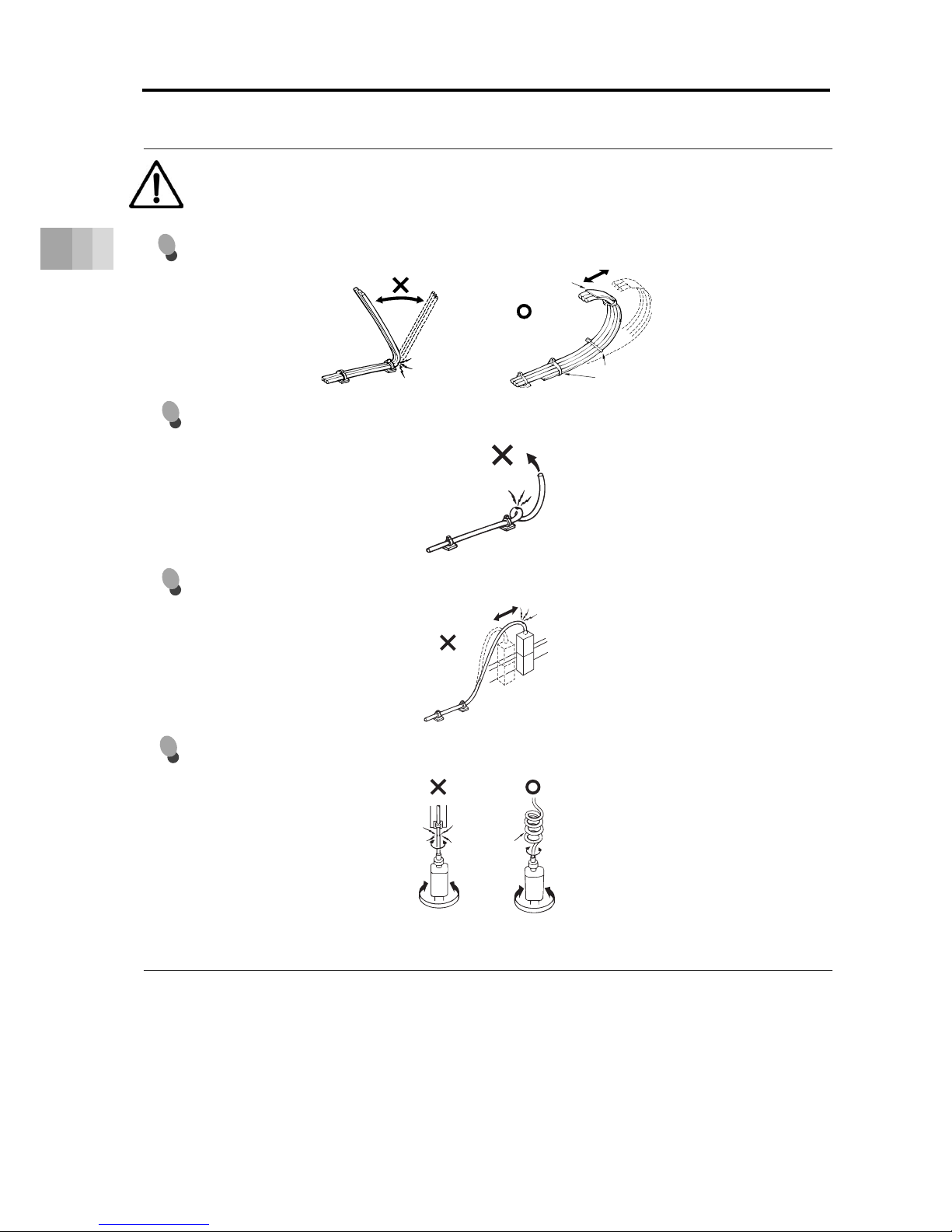

(2) Cable wiring

● Use IAI genuine cables for connecting the actuator and controller, and for the

teaching tools.

● Do not scratch cables, bend them forcibly, pull them, coil them, snag them,

or place heavy objects on them. Otherwise, this may lead to fire, electric shock,

or abnormal operation due to leakage or conduction malfunction.

● Perform the wiring for the product after turning OFF the power to the unit, and

avoid miswiring.

● When wiring DC power (+24V), be careful with the positive/negative polarity.

Incorrect connections may lead to fire, product breakdown or abnormal

operation.

● Connect the cable connector securely so that there is no disconnection or

looseness. Otherwise, this may lead to fire, electric shock, or abnormal

operation of the product.

● Never cut or reconnect the cables supplied with the product for the purpose of

extending or shortening the cable length. Otherwise, this may lead to fire or

abnormal operation of the product.

(3) Grounding

● Grounding must be performed, in order to prevent electric shocks or

electrostatic charge, enhance noise-resistant performance and control

unnecessary electromagnetic radiation.

● For the ground terminal on the AC power cable of the controller and the

grounding plate in the control panel, be sure to use a twisted pair cable with

wire thickness 0.5mm

2

(AWG20 or equivalent) or more for grounding work.

For safeguard grounding, it is necessary to select an appropriate wire diameter

for the load. Perform wiring that satisfies the specifications (electrical

equipment technical standards).

● Perform Class D grounding (former Class 3 grounding, with ground resistance

100Ω or below).

Page 11

Safety Guide

Intro-5

No. Operation Precautions

4 Installation

and

Startup

(4) Safety measures

● When working with two or more persons, make it clear who is to be in charge

and communicate well with each other to ensure safety.

● When the product is operating or in the ready mode, take safety measures

(such as the installation of safety/protection fences) so that nobody can enter

the area within the robot's movable range. Contact with an operating robot may

lead to death or serious injury.

● Be sure to install an emergency stop circuit so that the unit can be stopped

immediately in an emergency during operation.

● Take safety measures such that turning the power ON alone will not start up the

unit. Otherwise, this may cause the product to start unexpectedly, leading to

injury or product damage.

● Take safety measures such that emergency stop cancel or recovery after

power failure alone will not start up the unit. Otherwise, this may lead to injury

or equipment damage.

● When installation or adjustment operation is to be performed, display signs

such as "Operating: No Power ON!" etc. Sudden power input may cause

electric shock or injury.

● Take measures to prevent workpieces, etc. from falling during power failures or

emergency stop.

● Wear protection gloves, goggles and safety shoes, as necessary, to secure

safety.

● Do not insert fingers or objects into the openings in the product. Otherwise,

this may lead to injury, electric shock, product damage, or fire.

● When releasing the brake on a vertically oriented actuator, be careful that it

does not fall under its own weight, catching the operator's hand or damaging

workpieces.

5 Teaching ● When working with two or more persons, make it clear who is to be in charge

and communicate well with each other to ensure safety.

● Perform teaching operation from outside the safety/protection fence,

if possible. If operation must be performed within the safety/protection fence,

prepare "Work Regulations" and make sure that all the workers acknowledge

and understand them well.

● When operation is to be performed inside the safety/protection fence,

operators should have emergency stop switches available at hand so that the

unit can be stopped at any time if abnormalities occur.

● When operation is to be performed inside the safety/protection fence,

have a monitor standing by in addition to the operator(s) so that the unit can be

stopped at any time if abnormalities occur. Also, keep watch on the operation

so that a third party cannot operate the switches carelessly.

● Place a sign indicating "Operating" where it can be seen easily.

● When releasing the brake on a vertically oriented actuator, be careful that it

does not fall under its own weight, catching the operator's hand or damaging

workpieces.

* Safety/protection fence: If there is no safety/protection fence, the movable

range should be indicated.

Page 12

Safety Guide

Intro-6

No. Operation Precautions

6 Trial

Operation

● When working with two or more persons, make it clear who is to be in charge

and communicate well with each other to ensure safety.

● After teaching or programming, carry out trial operation step by step before

switching to automatic operation.

● When trial operation is to be performed inside the safety/protection fence,

use the same work procedure, determined in advance, as teaching operation.

● Be sure to confirm program operation at safe speeds. Otherwise, this may lead

to accidents due to unexpected motion caused by program error, etc.

● Do not touch the terminal block or any of the various setting switches while the

equipment is live. Otherwise, this may lead to electric shock or abnormal

operation.

7 Automatic

Operation

● Check before starting automatic operation or restarting after operation stop that

there is nobody within the safety/protection fence.

● Before starting automatic operation, make sure that all peripheral equipment is

ready for automatic operation and that there is no alarm indication.

● Be sure to start automatic operation from outside the safety/protection fence.

● If the product produces abnormal heat, smoke, odor, or noise, immediately stop

it and turn OFF the power switch. Otherwise, this may lead to fire or damage to

the product.

● When a power failure occurs, turn OFF the power switch. Otherwise, this may

lead to injury or product damage due to unexpected product motion during

recovery from the power failure.

8 Maintenance

and

Inspection

● When working with two or more persons, make it clear who is to be in charge

and communicate well with each other to ensure safety.

● Perform the work outside the safety/protection fence, if possible.

If operation must be performed within the safety/protection fence, prepare

"Work Regulations" and make sure that all the workers acknowledge and

understand them well.

● When work is to be performed inside the safety/protection fence, turn OFF the

power switch as a rule.

● When operation is to be performed inside the safety/protection fence,

operators should have emergency stop switches available at hand so that the

unit can be stopped at any time if abnormalities occur.

● When operation is to be performed inside the safety/protection fence,

have a monitor standing by in addition to the operator(s) so that the unit can be

stopped at any time if abnormalities occur. Also, keep watch on the operation

so that a third party cannot operate the switches carelessly.

● Place a sign indicating "Operating" where it can be seen easily.

● For the grease for the guide or ball screw, use appropriate grease according to

the Instruction Manual for each model.

● Do not perform dielectric strength testing. Otherwise, this may lead to damage

to the product.

Page 13

Safety Guide

Intro-7

No. Operation Precautions

8 Maintenance

and

Inspection

● When releasing the brake on a vertically oriented actuator, be careful that it

does not fall under its own weight, catching the operator's hand or damaging

workpieces.

● The slider or rod may be misaligned from the stop position if the servo is turned

OFF. Avoid injury or damage due to unnecessary operation.

● Be careful not to lose the cover or any removed screws, and be sure to return

the product to the original condition after maintenance and inspection work.

Otherwise, this may lead to product damage or injury due to incomplete

mounting.

* Safety/protection fence: If there is no safety/protection fence, the movable

range should be indicated.

9 Modification

and

Disassembly

● Do not modify, disassemble/assemble, or use maintenance parts not specified

on your own discretion.

10 Disposal ● When the product exceeds its useful life or is no longer needed, dispose of it

properly as industrial waste.

● When removing the actuator for disposal, avoid dropping components when

detaching screws.

● Do not put the product in a fire when disposing of it. The product may rupture or

generate toxic gases.

11 Other ● If you are equipped with a medical device such as a pacemaker, do not

approach the product or its wiring, as the device may be affected.

● See the Overseas Specifications Compliance Manual to check compliance with

overseas standards if necessary.

● For the handling of actuators and controllers, follow the dedicated instruction

manual of each unit to ensure safety.

Page 14

Safety Guide

Intro-8

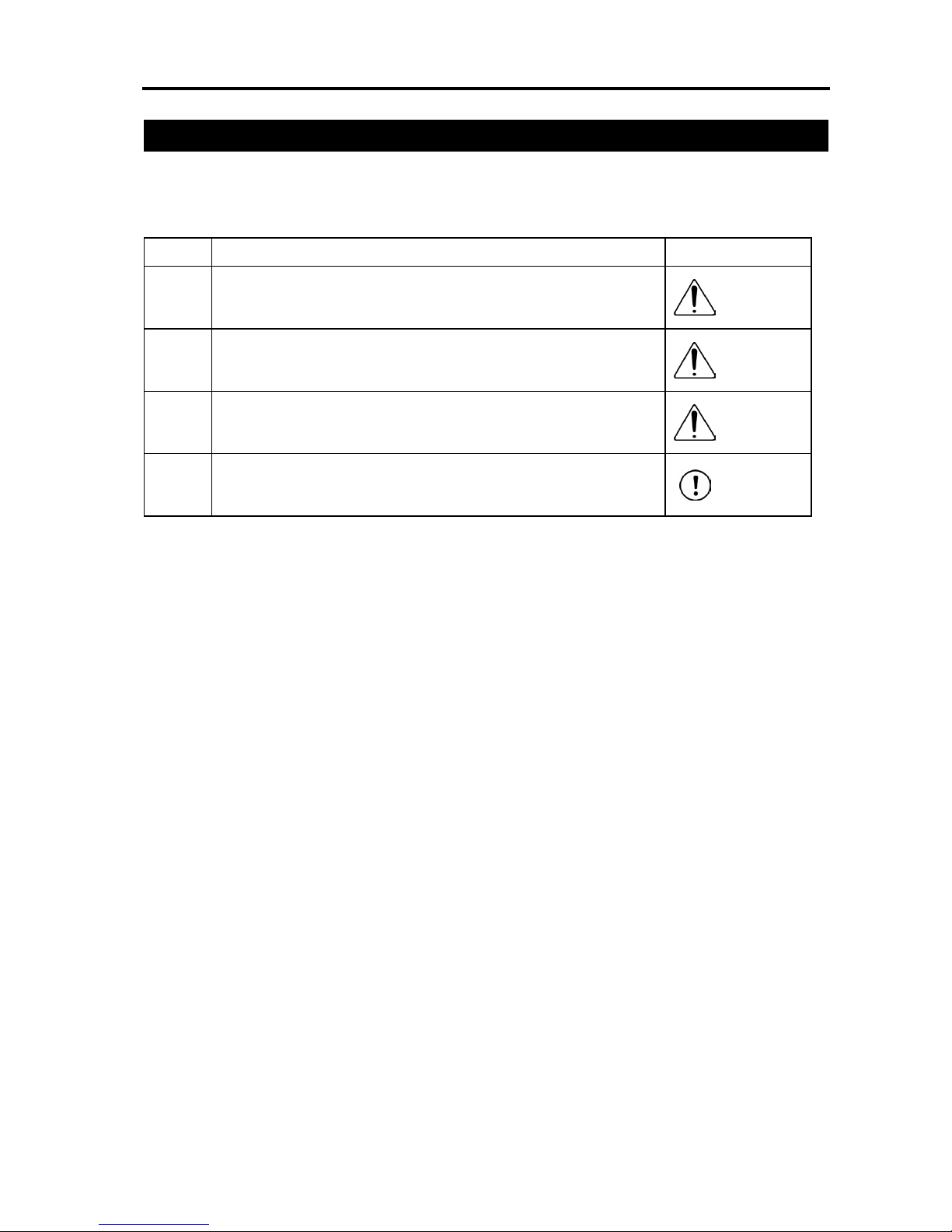

Precaution Indications

The safety precautions are divided into "Danger", "Warning", "Caution" and "Notice" according to

the warning level, as follows, and described in the Instruction Manual for each model.

Level Degree of risk to persons and property Symbol

Danger

This indicates an imminently hazardous situation which, if the product

is not handled correctly, will result in death or serious injury.

Danger

Warning

This indicates a potentially hazardous situation which, if the product

is not handled correctly, could result in death or serious injury.

Warning

Caution

This indicates a potentially hazardous situation which, if the product

is not handled correctly, may result in minor injury or property

damage.

Caution

Notice

This indicates a situation in which, while injury is not a likely result,

the precautions should be observed in order to use the product

appropriately.

Notice

Page 15

Precautions for Handling

Intro-9

Precautions for Handling

1. The Safety Guide attached with the product is intended to permit safe use of

the product and thus to prevent risks and property damage. Be sure to read it

before handling the product.

2. Do not attempt any handling or operation that is not indicated in this instruction

manual.

3. Make sure to secure the actuator properly in accordance with this instruction

manual.

If the actuator is not securely fixed, this may lead to abnormal noise, vibration, breakdown or

shortened product life.

4. Make sure to observe the usage conditions and environment of the product.

Operation outside the warranty could cause decreased performance or product breakdown.

Use within the allowable range for each item.

Item

Cautions

for use

Problems or breakdowns which may

occur if the allowable

range is exceeded

Speed and

acceleration/deceleration

Use within the

allowable

range

May lead to abnormal noise, vibration,

breakdown, or shortened product life.

Allowable load moment

Use within the

allowable

range

May lead to abnormal noise, vibration,

breakdown, or shortened product life.

In extreme cases, flaking may occur on the

guide or ball screw.

Overhang load length

Mounting a load with an overhang length

greater than the allowable values may lead

to vibration or abnormal noise.

Page 16

Precautions for Handling

International Standard Compliance

Intro-10

5. If return operations are continued over a short distance, they may rapidly

degrade the film of grease.

Continuous return operation within a distance less than 30mm may cause the grease film to

degrade rapidly.

As a guideline, in every 5,000 to 10,000 cycles, have approximately 5 cycles of return operation

over a 50mm distance or more to regenerate the oil film. Continued use of the actuator in that

state may lead to breakdown.

In extreme cases, flaking may occur on the guide or ball screw.

6. Do not attempt to have sliders collide with an obstacle at high speed.

This may damage the coupling or other mechanical parts.

7. For Double Slider Specification (Option Code: W) in Reversed-home

Specification (Option Code: NM), make sure to have the home-return

operation conducted after joining the driver slider and free slider.

8. In some conditions of environment of use, postures of installation and

conditions of operation, the base oil separated from the grease may come out

of ROBO Cylinder.

It is recommended to have a protection in case the peripheral devices could

get influence of the base oil.

International Standard Compliance

The ROBO Cylinder complies with the following overseas standards.

Refer to the Overseas Standard Compliance Manual (ME0287) for more detailed information.

CE Marking RoHS Directive

{ {

Page 17

Names of the Parts

Intro-11

Names of the Parts

In this manual, the actuator left/right sides and motor/opposite sides are shown as in the figure

below.

Standard Type Motor Straight Type

Standard Type Motor Reversing Type

Rea

r

Bracke

t

Reverse Bracket

Opposite Side

of the Motor

Left Side

Motor Side

Sheet Retaine

r

Stainless Steel Shee

t

Moto

r

Cove

r

A

ctuato

r

Cable Assy

Tapped hole fo

r

Ground Line Attachment

Sheet Retainer

End Cove

r

Slider Cove

r

Slide

r

Coupling Cove

r

Motor Bracket

Pulley Cove

r

Front Bracket

Side Cover

Base

MotorUnit

Right Side

Page 18

Names of the Parts

Intro-12

Cleanroom Type Motor Straight Type

Page 19

Specifications

1.1 Checking the product ··············································· 1-1

Parts ······················································································ 1-1

How to Read the Model Nameplate ·············································· 1-2

How to Read the Model Number ·················································· 1-2

Product list ·············································································· 1-3

1.2 Specifications ························································· 1-4

Specifications ·········································································· 1-4

Double Slider (Option) ······························································· 1-28

Duty ratio ················································································ 1-29

1.3 Options ································································· 1-31

With brake (Model Code: B) ························································ 1-31

Cable Exit Direction Changed

(Model Code: CJT, CJR, CJL, CJB and CJO) ······························· 1-31

High Precision Specifications (Model Code: HPR) ··························· 1-31

Motor Reversed Direction (Model Code: ML, MR) ··························· 1-31

Reversed-home Specification (Model Code: NM) ···························· 1-31

Slider Roller Specification (Model Code: SR) ·································· 1-32

Vacuum Joint Attachment Opposite Type (Model Code: VR) ············· 1-32

Double Slider Specification (Model Code: W) ································· 1-32

Rear Attachment Plate (Model Code: RP) ······································ 1-32

Slider spacer (Model Code: SS) ··················································· 1-33

1.4 Accessories ··························································· 1-35

Motor Cable ············································································· 1-35

Encoder Cable ········································································· 1-36

ROBO Cylinder

Chapter

Page 20

1.1 Checking the Product

1-1

1. Specifications

1.1 Checking the Product

Parts

The following table shows the product configuration for the standard specification.

See the component list for the details of the enclosed components. If you find any fault or missing

parts, contact your local IAI distributor.

Body Accessories

Actuator Quantity 1 Motor Cable Quantity 1

Encoder Cable Quantity 1

Accessories

In-house Made Seals

Quantity 1

Cross Recessed Pan Head

Screw with Captive Washer M3×6

Quantity 2

For affixing ground cable

Cable Band Quantity 2

For clamping connector cover

* Refer to International

Application Manual (ME0287)

for how to use it.

Accessories (Documents/DVD)

First Step Guide

Quantity 1

Safety Guide Quantity 1

Instruction Manual (DVD)

Quantity 1

Page 21

1.1 Checking the Product

1-2

1. Specifications

How to Read the Model Nameplate

How to Read the Model Number

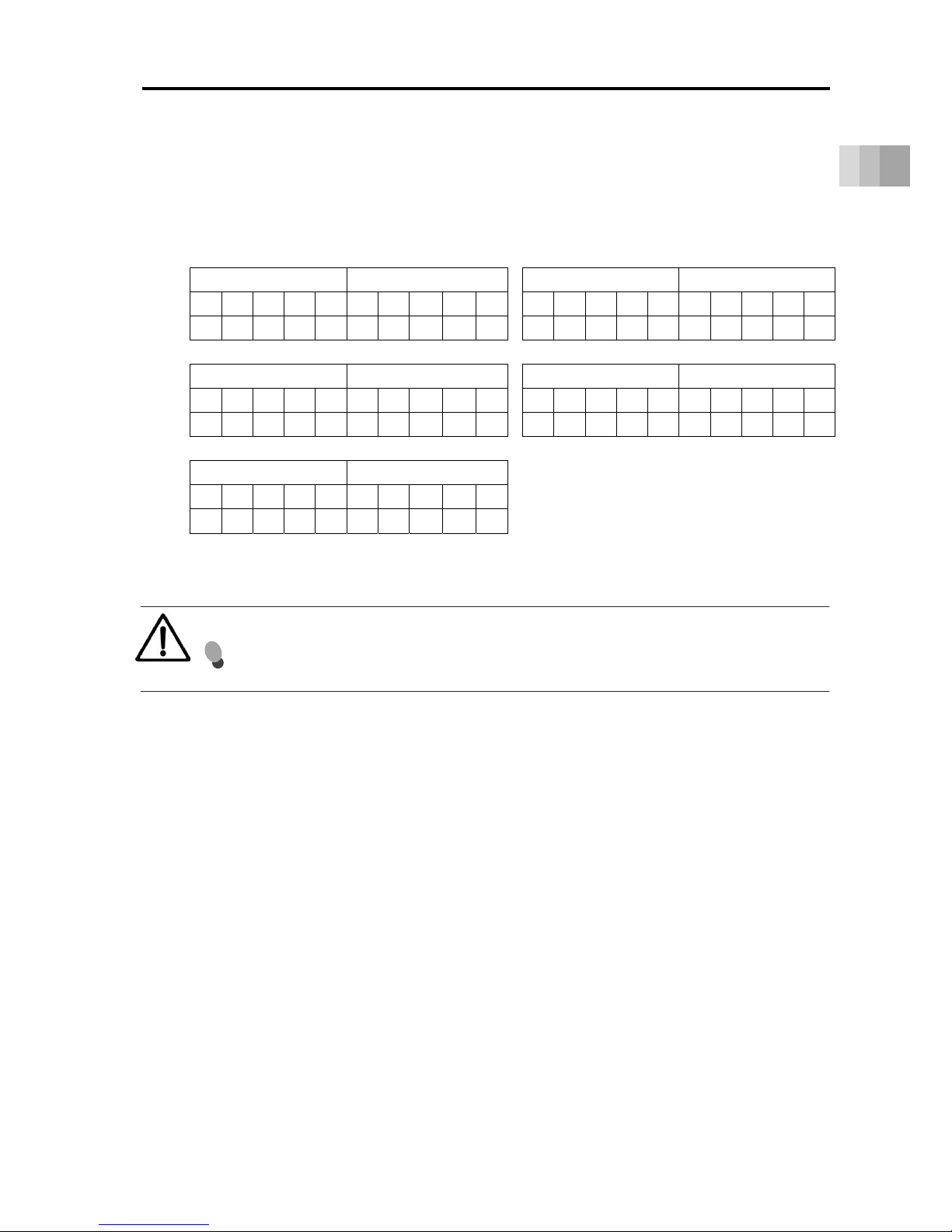

Model→

Serial number→

[Nameplate Position]

N

P

S

M

X□□

R□□

None

1m

3m

5m

Length Specification

Robot Cable

(Setting available in

every 50mm for pitch)

WA Battery-less Absolute

Applicable

Controller

Ball Screw

Lead

Encoder

Type

Motor

Wattage

Type Series

Stroke

WA

RCS4

SA4C

SA6C

SA7C

SA8C

SA4R

SA6R

SA7R

SA8R

Body Width 40mm

Coupling Type

B

CJT

CJR

CJL

CJO

CJB

HPR

ML

MR

NM

RP

SS

SR

W

With brake

Cable Exit Direction Changed (Top)

Cable Exit Direction Changed (Right)

Cable Exit Direction Changed (Left)

Cable Exit Direction Changed (Outward)

Cable Exit Direction Changed (Bottom)

High Precision Specifications

Motor Left Reversed Direction

Motor Right Reversed Direction

Reversed-home Specification

Rear Attachment Plate

Slider spacer

Slider Roller Specification

Double Slider Specification

60

100

200

400

60W

100W

200W

400W

* Please note that the available range of ball screw lead, stroke and options will differ depending on the actuator type.

T2

SCON

MSCON

SSEL

XSEL-P/Q

XSEL-RA/SA

Options

Cable Length

2.5

3

4

5

6

8

10

12

16

20

24

30

36

48

Lead 2.5mm

Lead 3mm

Lead 4mm

Lead 5mm

Lead 6mm

Lead 8mm

Lead 10mm

Lead 12mm

Lead 16mm

Lead 20mm

Lead 24mm

Lead 30mm

Lead 36mm

Lead 48mm

50

1100

50mm

1100mm

to

to

Body Width 60mm

Coupling Type

Body Width 70mm

Coupling Type

Body Width 90mm

Coupling Type

Body Width 40mm

Motor-Reversed Type

Body Width 60mm

Motor-Reversed Type

Body Width 70mm

Motor-Reversed Type

Body Width 90mm

Motor-Reversed Type

N

P

S

M

2.5

3

4

5

6

8

10

12

16

20

24

50

1100

WA

WARCS4CR

SA4C

SA6C

SA7C

SA8C

B

CJT

CJR

CJL

CJB

HPR

NM

VR

W

Vacuum Joint Attachment Opposite Type

60

100

200

400

T2

Applicable

Controller

Ball Screw

Lead

Encoder

Type

Motor

Wattage

Type Series

Stroke

Options

Cable Length

Body Width 40mm

Coupling Type

Body Width 60mm

Coupling Type

Body Width 70mm

Coupling Type

Body Width 90mm

Coupling Type

Battery-less Absolute

(Setting available in

every 50mm for pitch)

to

to

None

Length Specification

Robot Cable

With brake

Cable Exit Direction Changed (Top)

Cable Exit Direction Changed (Right)

Cable Exit Direction Changed (Left)

Cable Exit Direction Changed (Bottom)

High Precision Specifications

Reversed-home Specification

Double Slider Specification

Lead 2.5mm

Lead 3mm

Lead 4mm

Lead 5mm

Lead 6mm

Lead 8mm

Lead 10mm

Lead 12mm

Lead 16mm

Lead 20mm

Lead 24mm

SCON

MSCON

SSEL

XSEL-P/Q

XSEL-RA/SA

50mm

1100mm

* Please note that the available range of ball screw lead, stroke and options will differ depending on the actuator type.

60W

100W

200W

400W

1m

3m

5m

X□□

R□□

Page 22

1.1 Checking the Product

1-3

1. Specifications

Product list

Cleanroom Type

Max. Speed

(mm/s)

Category Type Appearance

Body Width

(mm)

Lead

(mm)

Motor Wattage

(W)

Positioning Repeatability

(mm)

Stroke

(mm)

Horizontal

Max. Payload (kg)

Vertical

16

10

5

2.5

30

20

12

6

3

36

24

16

8

4

48

30

20

10

5

16

10

5

2.5

30

20

12

6

3

36

24

16

8

4

48

30

20

10

5

960

600

300

150

1600

1200

720

360

180

1800

1500

1000

500

240

2200

1800

1200

600

300

960

600

300

150

1600

1200

720

360

180

1800

1500

1000

500

240

2100

1800

1200

600

300

53

85

170

340

57

85

142

283

566

95

142

214

427

855

141

226

339

678

1357

53

85

170

340

57

85

142

283

566

95

142

214

427

855

141

226

339

678

1357

10

14

17

20

11

18

30

45

45

7

30

40

45

50

8

30

60

80

90

10

14

17

20

11

18

30

45

45

7

30

38

45

50

8

30

60

80

90

3

5

8

12

3.5

6

11

15

15

4

7

12

20

25

-

12

20

35

45

2.5

4.5

8

12

3

5

9

15

15

4

6

12

18

25

-

12

20

35

45

±0.01

[±0.005]

±0.01

±0.01

±0.01

±0.01

±0.01

±0.01

±0.01

±0.01

±0.01

±0.01

60

100

200

400

60

100

200

400

50 to 500

(Every 50 st)

50 to 800

50 to 800

50 to 1100

50 to 500

50 to 800

50 to 800

50 to 1100

Values in brackets [ ] show specifications for high-precision type

40mm

60mm

70mm

90mm

40mm

60mm

70mm

90mm

Motor

Straight

Type

Motor

Reversing

Type

SA4C

SA6C

SA7C

SA8C

SA4R

SA6R

SA7R

SA8R

Rated Thrust

(N)

(Every 50 st)

(Every 50 st)

(Every 50 st)

(Every 50 st)

(Every 50 st)

(Every 50 st)

(Every 50 st)

[±0.005]

[±0.005]

[±0.005]

Values in brackets [ ] show specifications for high-precision type

16

10

5

2.5

20

12

6

3

24

16

8

4

20

10

5

1200

600

300

339

678

1357

60

80

90

20

35

45

3

5

8

12

18

30

45

45

30

40

45

50

6

11

15

15

7

12

20

25

10

14

17

20

1200

720

360

180

1500

1000

500

240

85

142

283

566

142

214

427

855

960

600

300

150

53

85

170

340

±0.01

60

100

200

400

50 to 500

50 to 800

50 to 800

50

to

1100

±0.01

±0.01

±0.01

±0.01

40mm

60mm

70mm

90mm

SA4C

SA6C

SA7C

SA8C

Cleanliness

Class 10

(Fed.Std.209D

Standards)

Class 2.5 Equivalent

(ISO14644-1

Standards)

Max. Speed

(mm/s)

Category Type Appearance

Body Width

(mm)

Lead

(mm)

Motor Wattage

(W)

Positioning Repeatability

(mm)

Stroke

(mm)

Horizontal

Max. Payload (kg)

Vertical

Rated

Thrust

(N)

[±0.005]

Motor

Straight

Type

[±0.005]

[±0.005]

[±0.005]

(Every 50 st)

(Every 50 st)

(Every 50 st)

(Every 50 st)

Page 23

1.2 Specifications

1-4

1. Specifications

1.2 Specifications

Specifications

[1] RCS4(CR)-SA4C

[Lead and Payload]

Lead

(mm)

Max. Payload

Rated Thrust

(N)

Horizontal(kg) Vertical(kg)

16 10 3 53

10 14 5 85

5 17 8 170

2.5 20 12 340

[Stroke and Max Speed]

Unit: mm/s

Lead

(mm)

50 to 450

(Every 50mm)

500

(mm)

16 960 875

10 600 555

5 300 275

2.5 150 135

Caution

The maximum speed may not be achieved when the stroke or movement distance is

short or when acceleration/deceleration is set low.

Setting at or below the minimum speed may lead to abnormal noise or unstable speeds.

Do not attempt to set below the minimum speed.

The minimum speed can be calculated with the equation below.

Minimum speed [mm/s] = ball screw lead [mm/r] ÷ 16384 [p/r] x 1000 [1/s]

(mm/r: movement per 1 motor revolution, p/r: pulse per 1 motor revolution)

Page 24

1.2 Specifications

1-5

1. Specifications

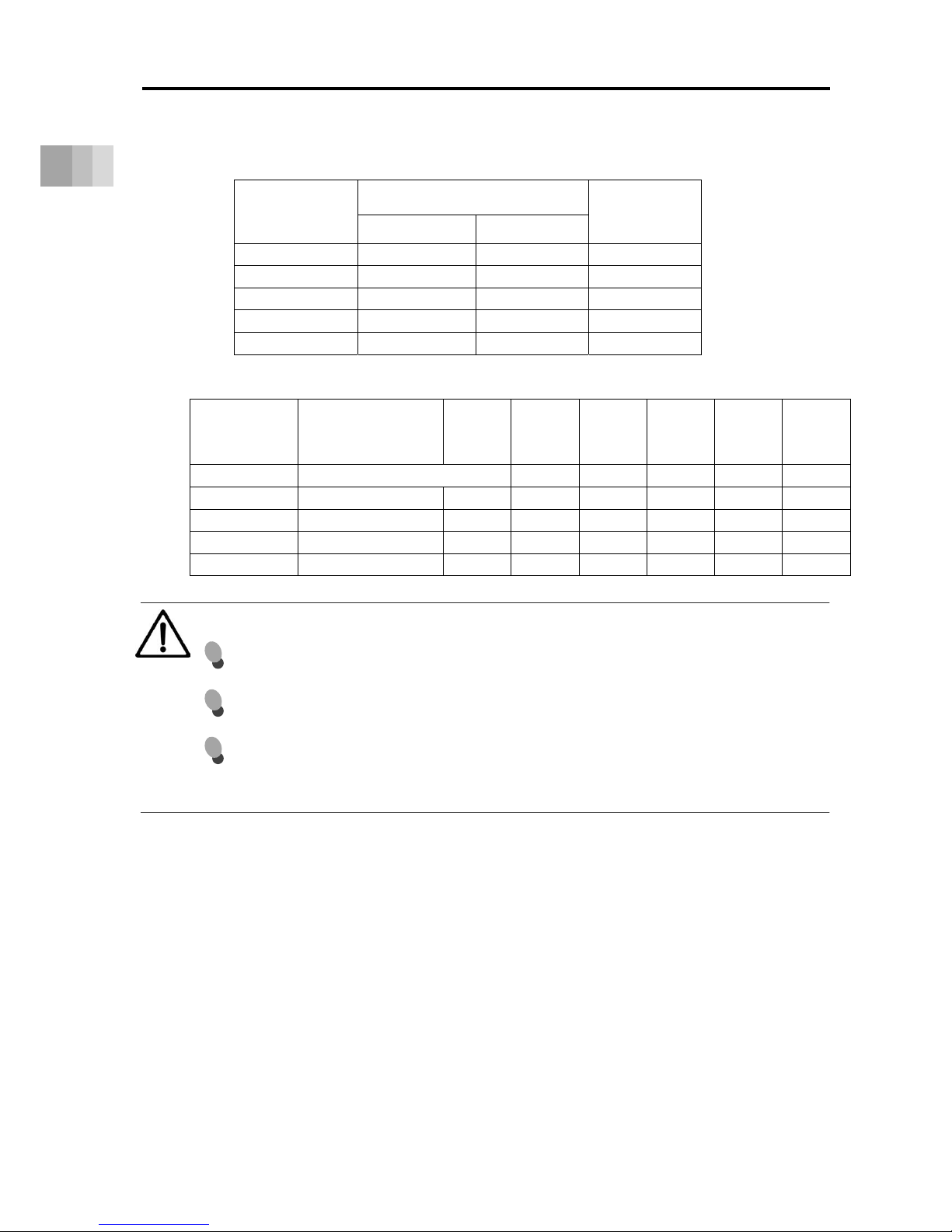

[Payload by Acceleration]

At low load capacity, the acceleration/deceleration can be increased.

Lead 16 Lead 10

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

10 8 6 6 4 3 3 1.5 1.5 1 14 14 12 10 6 5 5 3 3 2

Lead 5 Lead 2.5

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

17 17 15 15 ‒ 8 8 6 6 ‒ 20 20 20 ‒ ‒ 12 12 10 ‒ ‒

Caution

Do not attempt to configure settings for acceleration/deceleration above the specifications.

This may lead to vibration, breakdown, or shortened product life.

Page 25

1.2 Specifications

1-6

1. Specifications

[Actuator Specifications]

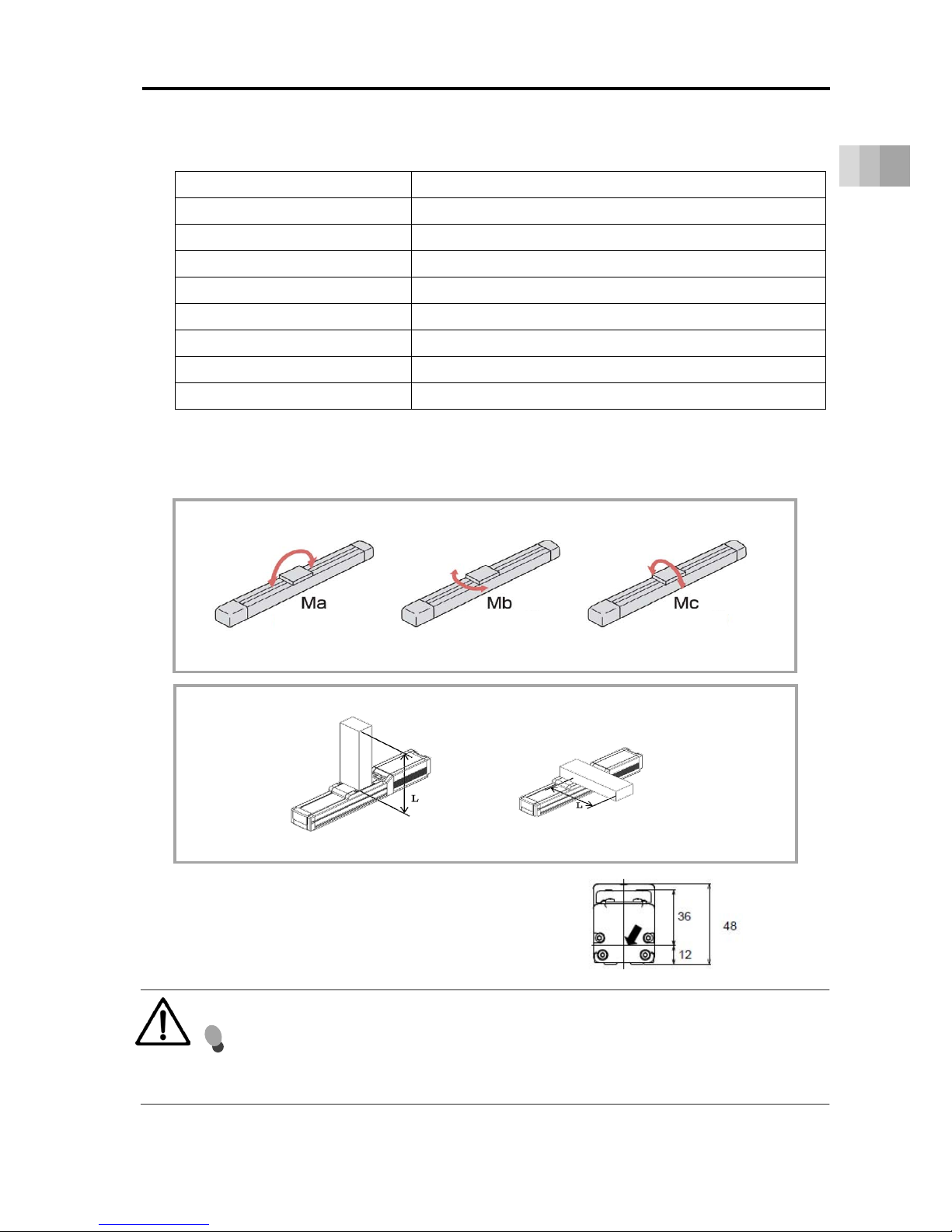

Item Content

Drive System Ball Screw φ8mm, Rolled C10

Positioning Repeatability (*1) ±0.01mm [±0.005mm]

Lost Motion 0.1mm or less

Base Material: Aluminum, White Anodized

Allowable static moment Ma direction: 13.0 N•m, Mb direction: 18.6 N•m, Mc direction: 25.3 N•m

Allowable dynamic moment (*2) Ma direction: 5.0 N•m, Mb direction: 7.1 N•m, Mc direction: 9.7 N•m

No. of Encoder Pulses 16384

Ambient operating temperature/humidity 0 to 40°C, 85%RH or less (Non-condensing)

• Overhang load length guideline: 150mm or less

(*1) Number in brackets [ ] show the specification for high precision type.

(*2) For reference rated life of 5000km. The running life differs according to operation conditions and mounting

status.

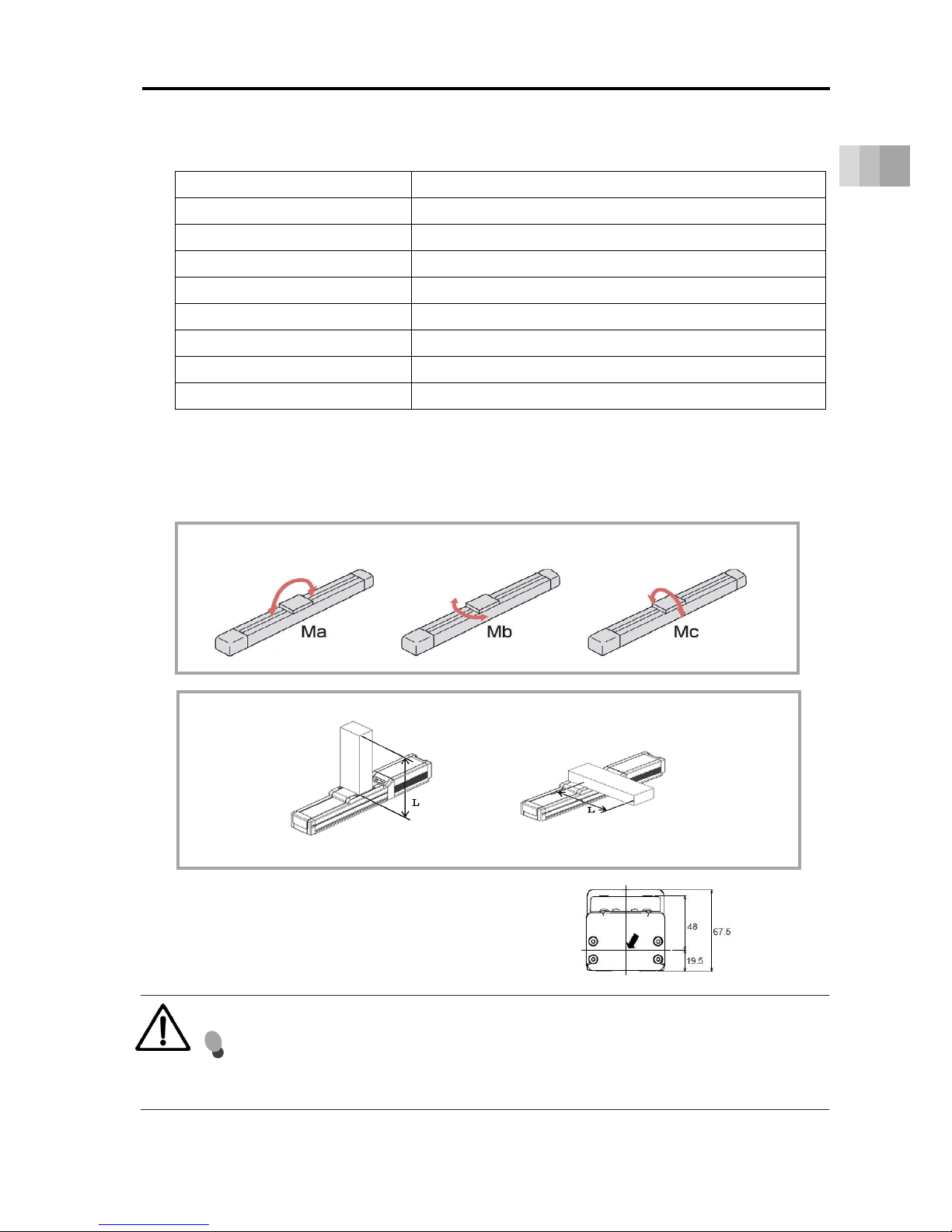

Slider type moment direction

Slider type overhang load length (L = 150mm or less)

Ma direction Mb•Mc direction

* For calculation of Ma and Mc moments,

take the position pointed with an arrow as the datum.

Caution

If the actuator is used with excessive allowable moment and overhang load, it may not

only lead to abnormal noise and vibration but also significantly reduce the life of the

actuator.

(Pitching)

(Yawing) (Rolling)

Page 26

1.2 Specifications

1-7

1. Specifications

[2] RCS4(CR)-SA6C

* There is no Lead 30 prepared for Cleanroom Type RCS4CR-SA6C.

[Lead and Payload]

Lead

(mm)

Max. Payload

Rated Thrust

(N)

Horizontal(kg) Vertical(kg)

30 11 3.5 57

20 18 6 85

12 30 11 142

6 45 15 283

3 45 15 566

[Stroke and Max Speed] Unit: mm/s

Lead

(mm)

50 to 500

(Every 50mm)

550

(mm)

600

(mm)

650

(mm)

700

(mm)

750

(mm)

800

(mm)

30 1600 1450 1260 1100 970 860

20 1200 1130 970 840 735 650 575

12 720 620 535 460 405 355 315

6 360 305 265 230 200 175 155

3 180 150 130 115 100 85 75

Caution

The maximum speed may not be achieved when the stroke or movement

distance is short or when acceleration/deceleration is set low.

Setting at or below the minimum speed may lead to abnormal noise or unstable

speeds.

Do not attempt to set below the minimum speed.

The minimum speed can be calculated with the equation below.

Minimum speed [mm/s] = ball screw lead [mm/r] ÷ 16384 [p/r] x 1000 [1/s]

(mm/r: movement per 1 motor revolution, p/r: pulse per 1 motor revolution)

Page 27

1.2 Specifications

1-8

1. Specifications

[Payload by Acceleration]

At low load capacity, the acceleration/deceleration can be increased.

Lead30 Lead20

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

11 6 6 4 3 3.5 2 2 1.51.5 18 15 10 8 6 6 5 4 4 2

Lead12 Lead6

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

30 24 20 15 15 11 10 10 8 8 45 30 20 20 ‒ 15 15 15 15 ‒

Lead3

Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

45 30 20 ‒ ‒ 15 14 10 ‒ ‒

Caution

Do not attempt to configure settings for acceleration/deceleration above the specifications.

This may lead to vibration, breakdown, or shortened product life.

Page 28

1.2 Specifications

1-9

1. Specifications

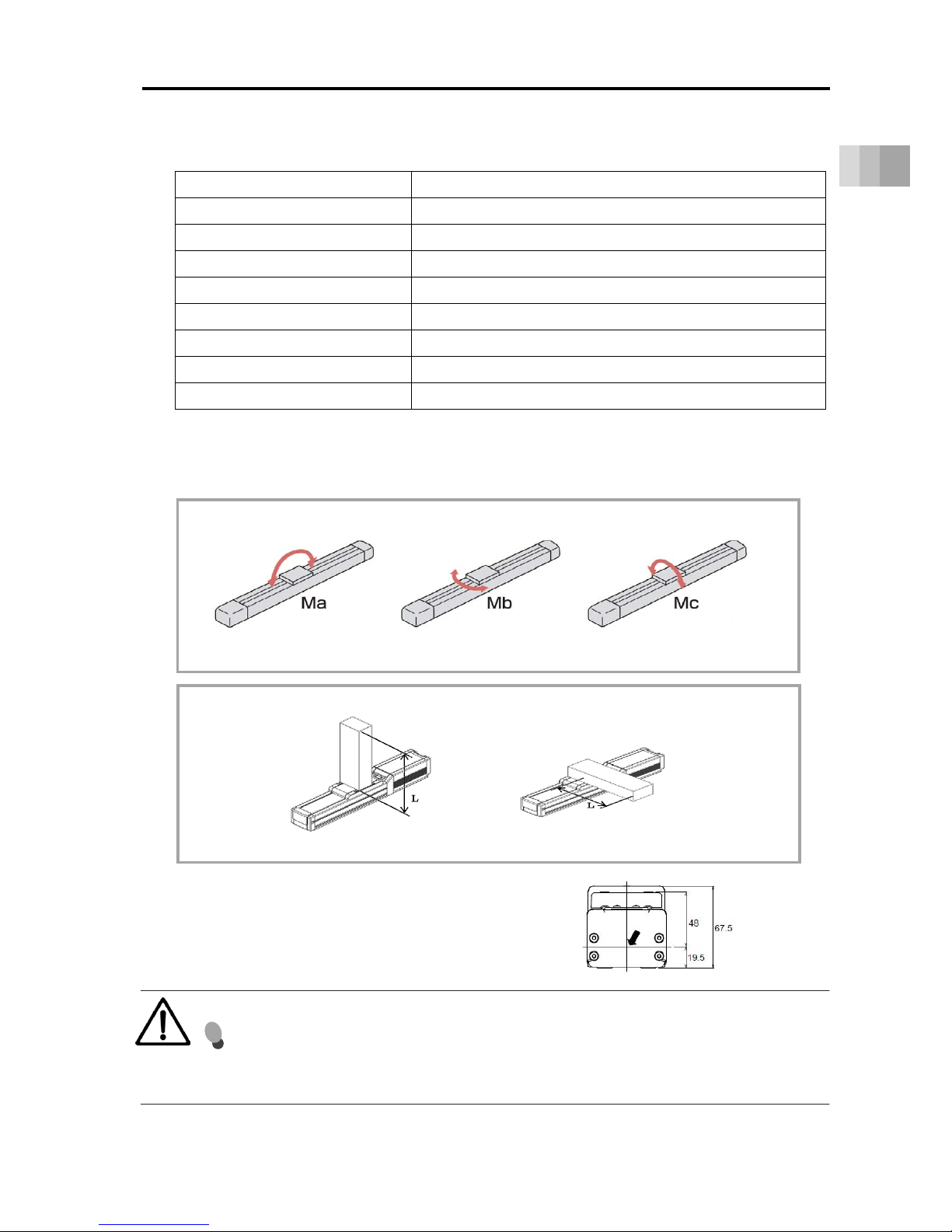

[Actuator Specifications]

Item Content

Drive System Ball Screw φ 10mm, Rolled C10

Positioning Repeatability (*1) ±0.01mm [±0.005mm]

Lost Motion 0.1mm or less

Base Material: Aluminum White Anodized

Allowable static moment Ma direction: 48.5 N•m, Mb direction: 69.3 N•m, Mc direction: 103 N•m

Allowable dynamic moment (*2) Ma direction: 11.6 N•m, Mb direction: 16.6 N•m, Mc direction: 24.6 N•m

No. of Encoder Pulses 16384

Ambient operating temperature/humidity 0 to 40°C, 85%RH or less (Non-condensing)

• Overhang load length guideline: 220mm or less

(*1) Number in brackets [ ] show the specification for high precision type.

(*2) For reference rated life of 5000km. The running life differs according to operation conditions and mounting

status.

Slider type moment direction

Slider type overhang load length (L = 220mm or less)

Ma direction Mb•Mc direction

* For calculation of Ma and Mc moments,

take the position pointed with an arrow as the datum.

Caution

If the actuator is used with excessive allowable moment and overhang load, it

may not only lead to abnormal noise and vibration but also significantly reduce

the life of the actuator.

(Pitching) (Yawing) (Rolling)

Page 29

1.2 Specifications

1-10

1. Specifications

[3] RCS4(CR)-SA7C

* There is no Lead 36 prepared for Cleanroom Type RCS4CR-SA7C.

[Lead and Payload]

Lead

(mm)

Max. Payload

Rated Thrust

(N)

Horizontal(kg) Vertical(kg)

36 7 4 95

24 30 7 142

16 40 12 214

8 45 20 427

4 50 25 855

[Stroke and Max Speed]

Unit: mm/s

Lead

(mm)

50 to 500

(Every 50mm)

550

(mm)

600

(mm)

650

(mm)

700

(mm)

750

(mm)

800

(mm)

36 1800 1620 1420 1260 1120

24 1500 1440 1240 1095 965 850 760

16 1000 965 830 720 635 560 500

8 500 475 410 355 315 275 245

4 240 235 205 175 155 135 120

Caution

The maximum speed may not be achieved when the stroke or movement

distance is short or when acceleration/deceleration is set low.

Setting at or below the minimum speed may lead to abnormal noise or unstable speeds.

Do not attempt to set below the minimum speed.

The minimum speed can be calculated with the equation below.

Minimum speed [mm/s] = ball screw lead [mm/r] ÷ 16384 [p/r] x 1000 [1/s]

(mm/r: movement per 1 motor revolution, p/r: pulse per 1 motor revolution)

Page 30

1.2 Specifications

1-11

1. Specifications

[Payload by Acceleration]

At low load capacity, the acceleration/deceleration can be increased.

Lead 36 Lead 24

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

7 7 6 4 3 4 4 3 2 2 30 12 10 6 5 7 7 6 5 4

Lead 16 Lead 8

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

40 30 15 15 12 12 12 10 8 8 45 40 40 35 ‒ 20 20 20 18 ‒

Lead 4

Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

50 50 40 ‒ ‒ 25 25 20 ‒ ‒

Caution

Do not attempt to configure settings for acceleration/deceleration above the specifications.

This may lead to vibration, breakdown, or shortened product life.

Page 31

1.2 Specifications

1-12

1. Specifications

[Actuator Specifications]

Item Content

Drive System Ball Screw φ12mm, Rolled C10

Positioning Repeatability (*1) ±0.01mm[±0.005mm]

Lost Motion 0.1 mm or less

Base Material: Aluminum, White Anodized

Allowable static moment Ma direction:115 N•m,Mb direction:115 N•m,Mc direction:229 N•m

Allowable dynamic moment (*2) Ma direction:44.7 N•m,Mb direction:44.7 N•m,Mc direction:89.1 N•m

No. of Encoder Pulses 16384

Ambient operating temperature/humidity 0 to 40°C, 85%RH or less (Non-condensing)

• Overhang load length guideline:300mm or less

(*1) Number in brackets [ ] show the specification for high precision type.

(*2) For reference rated life of 5000km. The running life differs according to operation conditions and mounting

status.

Slider type moment direction

Slider type overhang load length (L = 300mm or less)

Ma direction Mb•Mc direction

* For calculation of Ma and Mc moments,

take the position pointed with an arrow as the datum.

Caution

If the actuator is used with excessive allowable moment and overhang load, it may not

only lead to abnormal noise and vibration but also significantly reduce the life of the

actuator.

(Pitching) (Yawing) (Rolling)

Page 32

1.2 Specifications

1-13

1. Specifications

[4] RCS4(CR)-SA8C

* There is no Lead 30 and Lead 48 prepared for Cleanroom Type RCS4CR-SA8C.

[Lead and Payload]

Lead

(mm)

Max. Payload

Rated Thrust

(N)

Horizontal(kg) Vertical(kg)

48 8 ‒ 141

30 30 12 226

20 60 20 339

10 80 35 678

5 90 45 1357

[Stroke and Max Speed]

Unit: mm/s

Lead

(mm)

50 to 600

(Every

50mm)

650

(mm)

700

(mm)

750

(mm)

800

(mm)

850

(mm)

900

(mm)

950

(mm)

1000

(mm)

1050

(mm)

1100

(mm)

48 2200 2180 1950 1760 1590 1450 1320 1210 1110

30 1800 1640 1440 1280 1155 1040 940 855 780 715 660

20 1200 1090 960 860 770 695 630 570 520 480 440

10 600 540 480 430 385 345 310 285 260 235 220

5 300 270 240 215 190 175 155 140 130 120 110

Caution

The maximum speed may not be achieved when the stroke or movement

distance is short or when acceleration/deceleration is set low.

Setting at or below the minimum speed may lead to abnormal noise or unstable speeds.

Do not attempt to set below the minimum speed.

The minimum speed can be calculated with the equation below.

Minimum speed [mm/s] = ball screw lead [mm/r] ÷ 16384 [p/r] x 1000 [1/s]

(mm/r: movement per 1 motor revolution, p/r: pulse per 1 motor revolution)

Page 33

1.2 Specifications

1-14

1. Specifications

[Payload by Acceleration]

At low load capacity, the acceleration/deceleration can be increased.

Lead 48 Lead 30

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

8 8 8 5 4 ‒ ‒ ‒ ‒ ‒ 30 25 20 15 10 12 12 10 8 6

Lead 20 Lead 10

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

60 40 30 20 15 20 20 18 15 12 80 80 70 60 ‒ 35 35 35 30 ‒

Lead 5

Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

90 90 70 ‒ ‒ 45 45 35 ‒ ‒

Caution

Do not attempt to configure settings for acceleration/deceleration above the specifications.

This may lead to vibration, breakdown, or shortened product life.

Page 34

1.2 Specifications

1-15

1. Specifications

[Actuator Specifications]

Item Content

Drive System Ball Screw φ16mm, Rolled C10

Positioning Repeatability (*1) ±0.01mm[±0.005mm]

Lost Motion 0.1mm or less

Base Material: Aluminum, White Anodized

Allowable static moment Ma direction:219 N•m, Mb direction:219 N•m, Mc direction:414 N•m

Allowable dynamic moment (*2) Ma direction:77.0 N•m, Mb direction:77.0 N•m, Mc direction:146 N•m

No. of Encoder Pulses 16384

Ambient operating temperature/humidity 0 to 40°C, 85%RH or less (Non-condensing)

• Overhang load length guideline:400mm or less

(*1) Number in brackets [ ] show the specification for high precision type.

(*2) For reference rated life of 5000km. The running life differs according to operation conditions and mounting

status.

Slider type moment direction

Slider type overhang load length (L = 400mm or less)

Ma direction Mb•Mc direction

*For calculation of Ma and Mc moments,

take the position pointed with an arrow as the datum.

Caution

If the actuator is used with excessive allowable moment and overhang load, it may not

only lead to abnormal noise and vibration but also significantly reduce the life of the

actuator.

(Pitching)

(Yawing) (Rolling)

Page 35

1.2 Specifications

1-16

1. Specifications

[5] RCS4-SA4R

[Lead and Payload]

Lead

(mm)

Max. Payload

Rated Thrust

(N)

Horizontal(kg) Vertical(kg)

16 10 2.5 53

10 14 4.5 85

5 17 8 170

2.5 20 12 340

[Stroke and Max Speed]

Unit: mm/s

Lead

(mm)

50 to 450

(Every 50mm)

500

(mm)

16 960 875

10 600 555

5 300 275

2.5 150 135

Caution

The maximum speed may not be achieved when the stroke or movement distance is

short or when acceleration/deceleration is set low.

Setting at or below the minimum speed may lead to abnormal noise or unstable speeds.

Do not attempt to set below the minimum speed.

The minimum speed can be calculated with the equation below.

Minimum speed [mm/s] = ball screw lead [mm/r] ÷ 16384 [p/r] x 1000 [1/s]

(mm/r: movement per 1 motor revolution, p/r: pulse per 1 motor revolution)

Page 36

1.2 Specifications

1-17

1. Specifications

[Payload by Acceleration]

At low load capacity, the acceleration/deceleration can be increased.

Lead 16 Lead 10

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

10 8 6 6 ‒ 2.5 2.5 1.5 1.5 ‒ 14 14 12 10 ‒ 4.5 4.5 3 3 ‒

Lead 5 Lead 2.5

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

17 17 15 13 ‒ 8 8 6 6 ‒ 20 20 20 ‒ ‒ 12 12 10 ‒ ‒

Caution

Do not attempt to configure settings for acceleration/deceleration above the specifications.

This may lead to vibration, breakdown, or shortened product life.

Page 37

1.2 Specifications

1-18

1. Specifications

[Actuator Specifications]

Item Content

Drive System Ball Screw φ8mm, Rolled C10

Positioning Repeatability (*1) ±0.01mm[±0.005mm]

Lost Motion 0.1mm or less

Base Material: Aluminum, White Anodized

Allowable static moment Ma direction: 13.0 N•m, Mb direction: 18.6 N•m, Mc direction: 25.3 N•m

Allowable dynamic moment (*2) Ma direction: 5.0 N•m, Mb direction: 7.1 N•m, Mc direction: 9.7 N•m

No. of Encoder Pulses 16384

Ambient operating temperature/humidity 0 to 40°C, 85%RH or less (Non-condensing)

• Overhang load length guideline:150mm or less

(*1) Number in brackets [ ] show the specification for high precision type.

(*2) For reference rated life of 5000km. The running life differs according to operation conditions and mounting

status.

Slider type moment direction

Slider type overhang load length (L = 150mm or less)

Ma direction Mb•Mc direction

* For calculation of Ma and Mc moments,

take the position pointed with an arrow as the datum.

Caution

If the actuator is used with excessive allowable moment and overhang load, it may not

only lead to abnormal noise and vibration but also significantly reduce the life of the

actuator.

(Pitching)

(Yawing) (Rolling)

Page 38

1.2 Specifications

1-19

1. Specifications

[6] RCS4-SA6R

[Lead and Payload]

Lead

(mm)

Max. Payload

Rated Thrust

(N)

Horizontal(kg) Vertical(kg)

30 11 3 57

20 18 5 85

12 30 9 142

6 45 15 283

3 45 15 566

[Stroke and Max Speed]

Unit: mm/s

Lead

(mm)

50 to 500

(Every 50mm)

550

(mm)

600

(mm)

650

(mm)

700

(mm)

750

(mm)

800

(mm)

30 1600 1450 1260 1100 970 860

20 1200 1130 970 840 735 650 575

12 720 620 535 460 405 355 315

6 360 305 265 230 200 175 155

3 180 150 130 115 100 85 75

Caution

The maximum speed may not be achieved when the stroke or movement distance is

short or when acceleration/deceleration is set low.

Setting at or below the minimum speed may lead to abnormal noise or unstable speeds.

Do not attempt to set below the minimum speed.

The minimum speed can be calculated with the equation below.

Minimum speed [mm/s] = ball screw lead [mm/r] ÷ 16384 [p/r] x 1000 [1/s]

(mm/r: movement per 1 motor revolution, p/r: pulse per 1 motor revolution)

Page 39

1.2 Specifications

1-20

1. Specifications

[Payload by Acceleration]

At low load capacity, the acceleration/deceleration can be increased.

Lead 30 Lead 20

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

11 6 6 4 ‒ 3 2 2 1.5‒ 18 15 10 8 ‒ 5 5 4 4 ‒

Lead 12 Lead 6

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

30 24 20 15 ‒ 9 9 9 8 ‒ 45 30 20 20 ‒ 15 15 15 15 ‒

Lead 3

Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

45 30 20 ‒ ‒ 15 14 10 ‒ ‒

Caution

Do not attempt to configure settings for acceleration/deceleration above the specifications.

This may lead to vibration, breakdown, or shortened product life.

Page 40

1.2 Specifications

1-21

1. Specifications

[Actuator Specifications]

Item Content

Drive System Ball Screw φ10mm, Rolled C10

Positioning Repeatability (*1) ±0.01mm[±0.005mm]

Lost Motion 0.1 mm or less

Base Material: Aluminum, White Anodized

Allowable static moment Ma direction: 48.5 N•m, Mb direction: 69.3 N•m, Mc direction: 103 N•m

Allowable dynamic moment (*2) Ma direction: 11.6 N•m, Mb direction: 16.6 N•m, Mc direction: 24.6 N•m

No. of Encoder Pulses 16384

Ambient operating temperature/humidity 0 to 40°C, 85%RH or less (Non-condensing)

• Overhang load length guideline:220mm or less

(*1) Number in brackets [ ] show the specification for high precision type.

(*2) For reference rated life of 5000km. The running life differs according to operation conditions and mounting

status.

Slider type moment direction

Slider type overhang load length (L = 220mm or less)

Ma direction Mb•Mc direction

* For calculation of Ma and Mc moments,

take the position pointed with an arrow as the datum.

Caution

If the actuator is used with excessive allowable moment and overhang load, it may not

only lead to abnormal noise and vibration but also significantly reduce the life of the

actuator.

(Pitching)

(Yawing) (Rolling)

Page 41

1.2 Specifications

1-22

1. Specifications

[7] RCS4-SA7R

[Lead and Payload]

Lead

(mm)

Max. Payload

Rated Thrust

(N)

Horizontal(kg) Vertical(kg)

36 7 4 95

24 30 6 142

16 38 12 214

8 45 18 427

4 50 25 855

[Stroke and Max Speed] Unit: mm/s

Lead

(mm)

50 to 500

(Every 50mm)

550

(mm)

600

(mm)

650

(mm)

700

(mm)

750

(mm)

800

(mm)

36 1800 1620 1420 1260 1120

24 1500 1440 1240 1095 965 850 760

16 1000 965 830 720 635 560 500

8 500 475 410 355 315 275 245

4 240 235 205 175 155 135 120

Caution

The maximum speed may not be achieved when the stroke or movement distance is

short or when acceleration/deceleration is set low.

Setting at or below the minimum speed may lead to abnormal noise or unstable speeds.

Do not attempt to set below the minimum speed.

The minimum speed can be calculated with the equation below.

Minimum speed [mm/s] = ball screw lead [mm/r] ÷ 16384 [p/r] x 1000 [1/s]

(mm/r: movement per 1 motor revolution, p/r: pulse per 1 motor revolution)

Page 42

1.2 Specifications

1-23

1. Specifications

[Payload by Acceleration]

At low load capacity, the acceleration/deceleration can be increased.

Lead 36 Lead 24

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

7 7 6 4 ‒ 4 4 3 2 ‒ 30 12 10 6 ‒ 6 6 5 5 ‒

Lead 16 Lead 8

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

38 30 15 15 ‒ 12 12 10 8 ‒ 45 40 40 35 ‒ 18 18 18 16 ‒

Lead 4

Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

50 50 40 ‒ ‒ 25 25 20 ‒ ‒

Caution

Do not attempt to configure settings for acceleration/deceleration above the specifications.

This may lead to vibration, breakdown, or shortened product life.

Page 43

1.2 Specifications

1-24

1. Specifications

[Actuator Specifications]

Item Content

Drive System Ball Screw φ12mm, Rolled C10

Positioning Repeatability (*1) ±0.01mm[±0.005mm]

Lost Motion 0.1mm or less

Base Material: Aluminum, White Anodized

Allowable static moment Ma direction:115 N•m, Mb direction:115 N•m, Mc direction:229 N•m

Allowable dynamic moment (*2) Ma direction:44.7 N•m, Mb direction:44.7 N•m, Mc direction:89.1 N•m

No. of Encoder Pulses 16384

Ambient operating temperature/humidity 0 to 40°C 85%RH or less (Non-condensing)

• Overhang load length guideline:300mm or less

(*1) Number in brackets [ ] show the specification for high precision type.

(*2) For reference rated life of 5000km. The running life differs according to operation conditions and mounting

status.

Slider type moment direction

Slider type overhang load length (L = 300mm or less)

Ma direction Mb•Mc direction

* For calculation of Ma and Mc moments,

take the position pointed with an arrow as the datum.

Caution

If the actuator is used with excessive allowable moment and overhang load, it may not

only lead to abnormal noise and vibration but also significantly reduce the life of the

actuator.

(Pitching)

(Yawing) (Rolling)

Page 44

1.2 Specifications

1-25

1. Specifications

[8] RCS4-SA8R

[Lead and Payload]

Lead

(mm)

Max. Payload

Rated Thrust

(N)

Horizontal(kg) Horizontal(kg)

48 8 - 141

30 30 12 226

20 60 20 339

10 80 35 678

5 90 45 1357

[Stroke and Max Speed]

Unit: mm/s

Lead

(mm)

50 to 600

(Every

50mm)

650

(mm)

700

(mm)

750

(mm)

800

(mm)

850

(mm)

900

(mm)

950

(mm)

1000

(mm)

1050

(mm)

1100

(mm)

48 2100 1950 1760 1590 1450 1320 1210 1110

30 1800 1640 1440 1280 1155 1040 940 855 780 715 660

20 1200 1090 960 860 770 695 630 570 520 480 440

10 600 540 480 430 385 345 310 285 260 235 220

5 300 270 240 215 190 175 155 140 130 120 110

Caution

The maximum speed may not be achieved when the stroke or movement distance is

short or when acceleration/deceleration is set low.

Setting at or below the minimum speed may lead to abnormal noise or unstable speeds.

Do not attempt to set below the minimum speed.

The minimum speed can be calculated with the equation below.

Minimum speed [mm/s] = ball screw lead [mm/r] ÷ 16384 [p/r] x 1000 [1/s]

(mm/r: movement per 1 motor revolution, p/r: pulse per 1 motor revolution)

Page 45

1.2 Specifications

1-26

1. Specifications

[Payload by Acceleration]

At low load capacity, the acceleration/deceleration can be increased.

Lead 48 Lead 30

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

8 8 8 5 ‒ ‒ ‒ ‒ ‒ ‒ 30 25 20 15 ‒ 12 12 10 8 ‒

Lead 20 Lead 10

Horizontal Vertical Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

60 40 30 20 ‒ 20 20 18 15 ‒ 80 80 70 60 ‒ 35 35 35 30 ‒

Lead 5

Horizontal Vertical

0.3 0.5 0.7 1.0 1.2 0.3 0.5 0.7 1.0 1.2

90 90 70 ‒ ‒ 45 45 35 ‒ ‒

Caution

Do not attempt to configure settings for acceleration/deceleration above the specifications.

This may lead to vibration, breakdown, or shortened product life.

Page 46

1.2 Specifications

1-27

1. Specifications

[Actuator Specifications]

Item Content

Drive System

Ball Screw

φ

16mm, Rolled C10

Positioning Repeatability (*1) ±0.01mm[±0.005mm]

Lost Motion 0.1mm or less

Base Material: Aluminum, White Anodized

Allowable static moment Ma direction: 219 N•m, Mb direction: 219 N•m, Mc direction: 414 N•m

Allowable dynamic moment (*2) Ma direction: 77.0 N•m, Mb direction: 77.0 N•m, Mc direction: 146 N•m

No. of Encoder Pulses 16384

Ambient operating temperature/humidity 0 to 40°C, 85%RH or less (Non-condensing)

• Overhang load length guideline:400mm or less

(*1) Number in brackets [ ] show the specification for high precision type.

(*2) For reference rated life of 5000km. The running life differs according to operation conditions and mounting

status.

Slider type moment direction

Slider type overhang load length (L = 400mm or less)

Ma direction Mb•Mc direction

* For calculation of Ma and Mc moments,

take the position pointed with an arrow as the datum.

Caution

If the actuator is used with excessive allowable moment and overhang load, it may not

only lead to abnormal noise and vibration but also significantly reduce the life of the

actuator.

(Pitching)

(Yawing) (Rolling)

Page 47

1.2 Specifications

1-28

1. Specifications

Double Slider (Option)

[Table for Double Slider Type]

Name

of Type

Allowable dynamic moment Allowable static moment

Overhang

load

length

(mm)

Slider

Mass

(kg)

Slider

length

(mm)

Min.

Effective

Stroke

for

Double

Slider

(mm)

Standard

rated life

(km)

Slider Span (mm)

Ma

direction

(N•m)

Mb

direction

(N•m)

Mc

direction

(N•m)

Ma

direction

(N•m)

Mb

direction

(N•m)

Mc

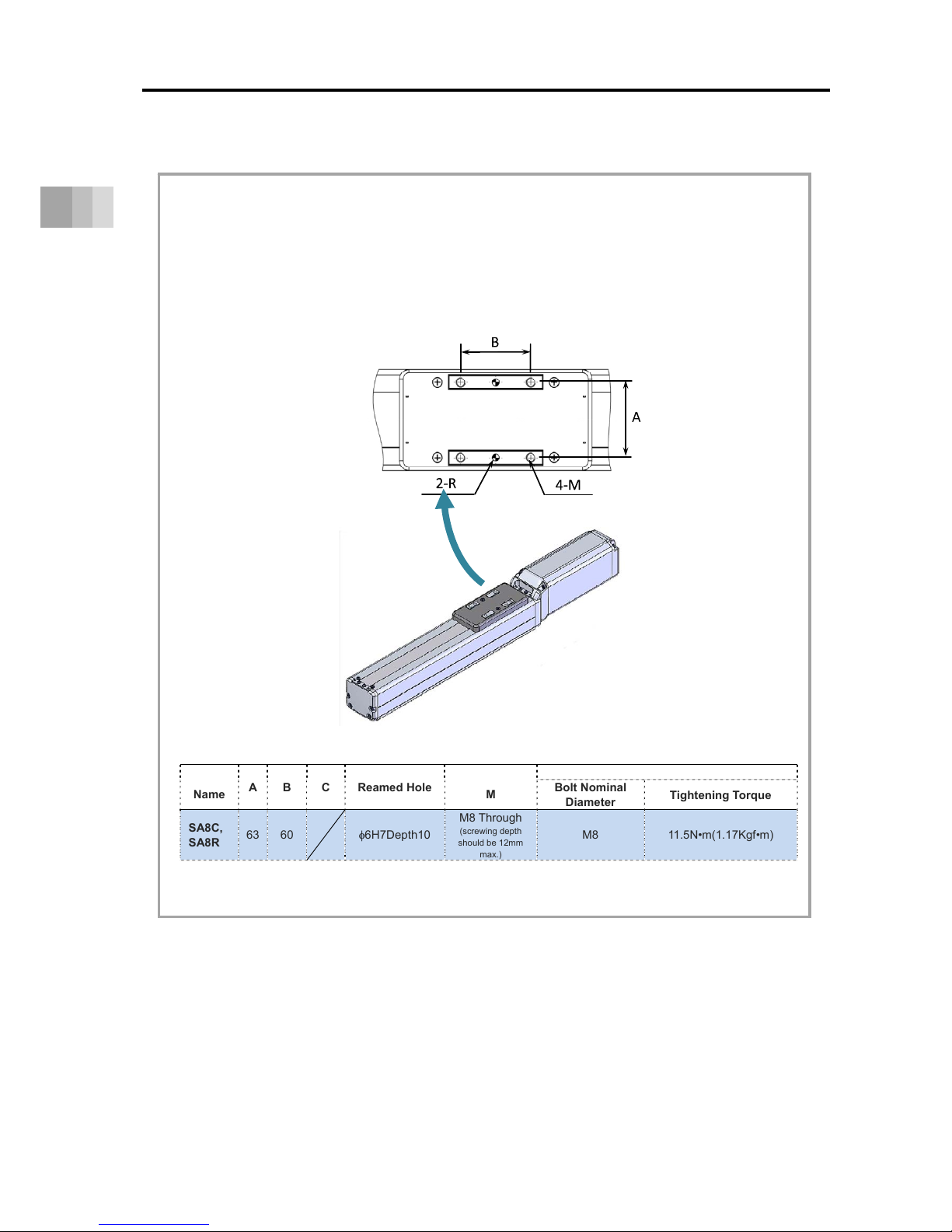

direction

(N•m)

Ma

direction

Mb•Mc

direction

Actual

Slider

Span

Slider

Cover

Span

SA4 5000 60 24 44.6 63.6 15.7 143 204 50.5 420 1 76 50

SA6 5000 90 40 106 152 40 546 779 205 630 2 110 50

SA7 5000 70 20 285 285 145 900 900 458 810 2 130 50

SA8 5000 120 35 565 565 237 1980 1980 828 1200 2.5 165 50

【Figure of Double Slider】

Caution

If double slider (option) is ordered, consider the available stroke should be the value that

the length of slider and slider cover span are subtracted from the stroke shown in the

model code. Therefore, add the following number to the necessary stroke when indicate

the stroke at order. Also, make sure that the “necessary stroke” should be the minimum

effective stroke of the double slider type or above.

Stroke Length to Order (Nominal Stroke)

“Necessary Stroke” + “Slider Cover Span” + “Slider Length” or more

The payload of the double slider should consider the weight of the slider itself subtracted

from the performance in the specification for the maximum.

When you consider the maximum velocity, consider the stroke length to order (nominal

stroke) as the value of stroke in [Stroke and Max Speed].

Slider length

Slider Cover Span

Actual Slider Span

Page 48

1.2 Specifications

1-29

1. Specifications

Duty ratio

The duty ratio is the operating rate,

shown in %, of the actuator operating

time within one cycle.

As the reference for duty available to use may differ depending on the operation conditions

(payload, acceleration / deceleration, etc.), it is necessary to figure out the load factor LF and

acceleration / deceleration time ratio t

od

using the calculation formulae below and find it out from

the graph.

1) Figure out the load factor LF using the calculation formulae below.

Maximum payload at the acceleration 0.3G is described in 1.2 Specifications.

2) Figure out the acceleration / deceleration time ratio tod using the calculation formulae

below.

Acceleration / Deceleration Time Ratio tod =

Acceleration Time during Operation + Deceleration Time during Operation

Duration of Operation

[%]

Acceleration Time =

Velocity during Operation [mm/s]

Acceleration during Operation [mm/s

2

] [sec]

Acceleration [mm/s

2

] = Acceleration [G] × 9,800mm/s2

Deceleration Time =

Velocity during Operation [mm/s]

Deceleration during Operation [mm/s

2

] [sec]

Deceleration [mm/s

2

] = Deceleration [G] × 9,800mm/s

2

[When indicated acceleration / deceleration is at

acceleration / deceleration 0.3G or below]

Load Factor: LF =

M×α

M

r

×0.3

[%]

Max. Payload at Acceleration 0.3G

: Mr [kg]

Acceleration / Deceleration 0.3G : 0.3 [G]

Payload during Operation : M [kg]

Acceleration during Operation : α [G]

[When indicated acceleration / deceleration is at

acceleration / deceleration 0.3G or above]

Load Factor: LF =

M×α

M

d

×α

=

M

M

d

[%]

Payload at Indicated Acceleration : M

d

[kg]

Payload during Operation : M [kg]

Acceleration during Operation : α [G]

Page 49

1.2 Specifications

1-30

1. Specifications

3) Read a reference for duty with the figured out “Load Factor” and “Acceleration /

Deceleration Time Ratio”.

e.g.) The reference for duty when the load factor LF is 80% and the acceleration / deceleration time

ratio t

od

is 80% should be approximately 75%.

0

20

40

60

80

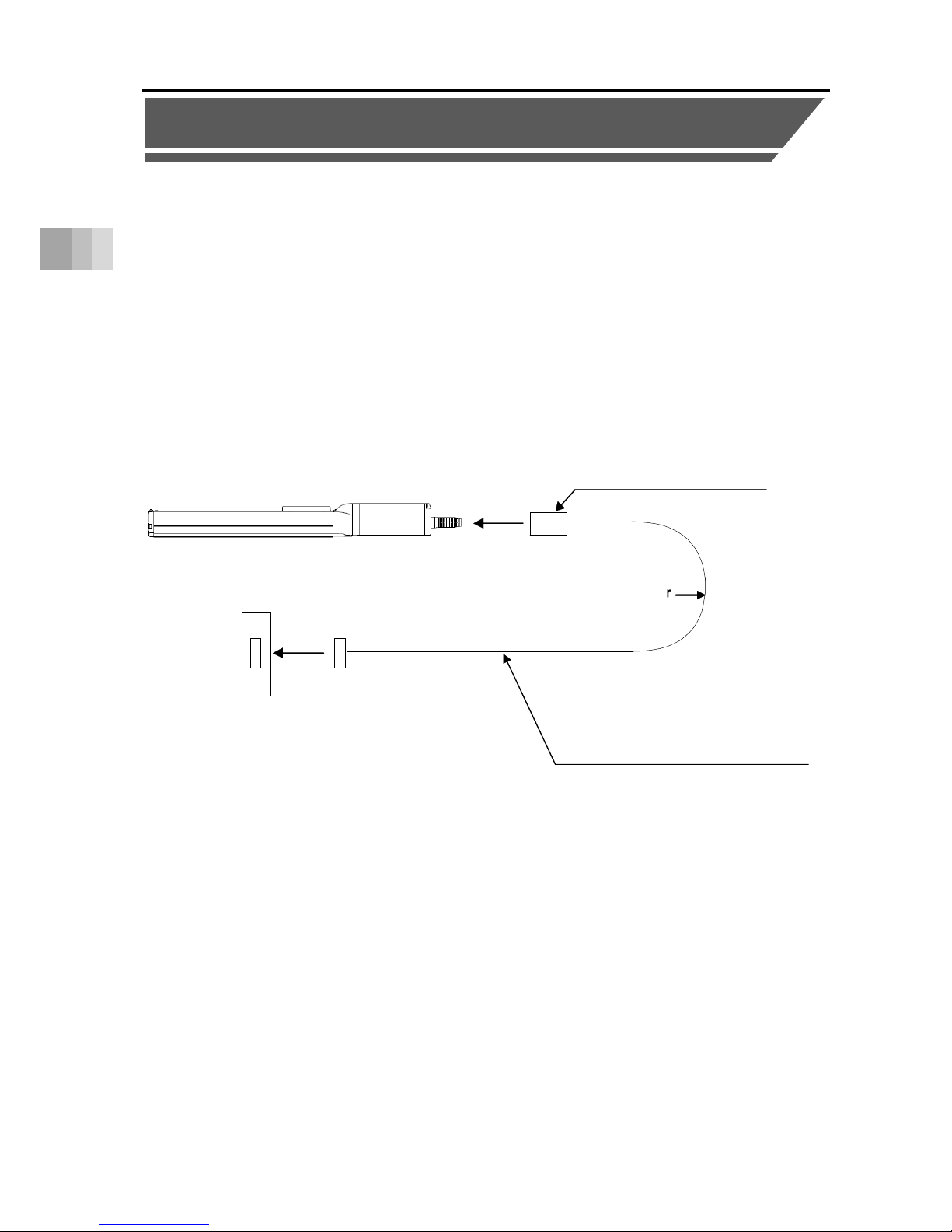

100