Page 1

RCP5/RCP5CR/RCP5W Actuator

Slider Type/Rod Type

First Step Guide Seventh Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the product in addition to this

First Step Guide to ensure correct use.

This Instruction Manual is original.

• Using or copying all or part of this Instruction Manual without permission is prohibited.

• The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

Product Check

This product is comprised of the following parts if it is of standard configuration.

If you find any fault in the contained model or any missing parts, contact us or our distributor.

1. Parts (The option is excluded.)

No. Part Name Model Quantity Remarks

1 Actuator Main Body

Refer to How to read the

model No.

1

Accessories

2

Motor • Encoder Cable

(Note 1)

1

3

Home Position Marking

Stick er

Packaged in slider type.

4 Nut

Packaged in rod type.

Refer to list below.

5

Caution and Warning Labels

Seal

1 set

Packaged in

Dustproof/Splash Proof

Type RCP5W-RA8C and

RA10C.

6 First Step Guide 1

7 Instruction Manual (DVD) 1

8 Safety Guide 1

Note 1 Please refer to the wiring layout for the enclosed motor・encoder cables.

(List of Included Nut Type)

Nut (M10×1.25) Nut (M14×1.5) Nut (M20×1.5) Nut (M22×1.5)

RA4C, RA4R

RA6C, RA6R

1

RA7C, RA7R 1

RA8C, RA8R 1

RA10C, RA10R 1

[Refer to of the instruction manual 6. External Dimensions for the dimensions of nuts.]

The square nut will be enclosed for RCP5W-RA6C and RA7C.

Square Nut (7×7 M4) Square Nut (8×8 M5)

RCP5W-RA6C 4

RCP5W-RA7C 4

2. How to Read the Model Plate

3. How to Read the Model No.

3.1 Slider Type

RCP5

–SA4C –WA –35P –5 –50 –P3 –P –B –**

Note 1 Identification for IAI use only : It may be displayed for IAI use. It is not a code to show the model type.

3.2 Rod Type

RCP5

–RA4C –WA –35P –5 –60 –P3 –P –B –**

Precautions in Handling

1. Handling of the Packed Product

Take the greatest care in transporting the product, not to bump or drop it.

• An operator should never attempt to carry a heavy package on his own.

• When setting down the package temporarily, keep it horizontal.

• Do not step on the package.

• Do not place on the package a heavy object that may cause the box deformation or apply

stress on it.

2. Handling of the Unpacked Product

Do not transport the actuator by holding the cable or move it by pulling the cable.

• When the actuator is taken out from the package and handled, hold the base section.

• When the stainless sheet is attached, never hold the stainless sheet section.

• When transporting the actuator, be careful not to hit it against other objects. In particular,

pay attention to the side cover.

• Do not give any unnatural force to any of the sections in the actuator. In particular, pay

attention not to apply any force on the stainless steel sheet if the actuator is equipped with

the stainless steel sheet.

Environments for Installation, Storage and Preservation

1. Installation Environment

Please attempt to avoid installing the product to such places as listed below.

It is generally the environment where a worker can work without any protection gear.

Also, make sure to keep enough space necessary for maintenance work.

• Place where exposed to radiant heat from a huge heat source such as heat treatment

• Place where the ambient temperature goes out of the applicable range from 0 to 40°C

• Place where condensation would occur due to sudden temperature change

• Place where the relative humidity exceeds 85% RH

• Dustproof/splash proof type RCP5W possesses the protection structure against dust and

water equivalent to IP65.

• Place where exposed to the direct sunlight

• Place where corrosive gas or flammable gas exist

• Place where it contains a lot of dust, salt or iron (Outside of an ordinary assembly plant)

(Dustproof/splash proof type RCP5W-RA6C and RA7C possesses the protection

structure against dust equivalent to IP67.)

(Dustproof/splash proof type RCP5W-RA8C and RA10C possesses the protection

structure against dust equivalent to IP65.)

• Place where water, oil (includes oil mist and cutting fluid) or chemical is splashed

(Dustproof/splash proof type RCP5W-RA6C and RA7C possesses the protection

structure against water equivalent to IP67.)

(Dustproof/splash proof type RCP5W-RA8C and RA10C possesses the protection

structure against water equivalent to IP65.)

• Place where the product main body receives vibration or hit impact

• Place with an altitude of 2,000m or more

Make sure to have a treatment for blocking when using in the following conditions:

• Place where noise is generated by such facts as static electricity

• Place where exposed to the influence of strong electric or magnetic field

• Place where exposed to the influence of ultraviolet or radiant rays

2. Storage a nd Preservation Environment

• The storage and preservation environment should comply with the same standards as

those for the installation environment. In particular, when the machine is to be stored for a

long time, pay close attention to environmental conditions so that no dew condensation

forms.

• Unless specially specified, moisture absorbency protection is not included in the package

when the machine is delivered. In the case that the machine is to be stored and preserved

in an environment where dew condensation is anticipated, take the condensation

preventive measures from outside of the entire package, or directly after opening the

package.

• For storage and preservation temperature, the machine withstands temperatures up to

60°C for a short time, but in the case of the storage and preservation period of 1 month or

more, control the temperature to 50°C or less.

• The product should be settled in the horizontal orientation while in storage and

reservation. In the case it is stored in the packaged condition, follow the posture

instruction if any displayed on the package.

<Series name>

Standard type

RCP5

Dustproof/Splash proof type

RCP5W

<Type>

Motor straight type

RA4C, RA6C

RA7C, RA8C

RA10C

Motor reversing type

RA4R, RA6R, RA7R,

RA8R, RA10R

<Encoder type>

WA : Battery-less absolute

<Motor type>

35P : 35□ size 42P : 42□ size

42SP:

42□ size 56P : 56□ size

56SP:

56□ size 60P : 60□ size

86P : 86□ size

<Lead>

RA4C, RA4R

2.5/5/10/16

RA6C, RA6R

(Note1)

3/6/12/20

RA7C, RA7R

(Note1)

4/8/16/24

RA8C, RC8R

5/10/20

RA10C, RC10R

2.5/5/10

<Stroke>

[Refer to 1.2 Specifications of the Instruction Manual]

<Series name>

Standard type

RCP5

Cleanroom type

RCP5CR

<Type>

Motor straight type

SA4C

SA6C

SA7C

Motor reversing type

SA4R

SA6R

SA7R

<Encoder type>

WA : Battery-less absolute

<Motor type>

35P : 35□ size

42P : 42□ size

56P : 56□ size

<Lead>

SA4C, SA4R

2.5/5/10/16

SA6C, SA6R

3/6/12/20

SA7C, SA7R

4/8/16/24

<Stroke>

[Refer to 1.2 Specifications of the Instruction Manual]

Warning : Operation of this equipment requires detailed installation and operation instructions which are

provided on the DVD Manual included in the box this device was packaged in. It should be retained

with this device at all times.

A hard copy of Manual can be requested by contacting your nearest IAI Sales Office listed at

the back cover of the Instruction Manual or on the First Step Guide.

MODEL RCP5-SA4C-WA-35P-5-50-P3-P-B

SERIAL No.100090266

MADE IN JAPAN

Model

Serial numbe

r

Identification for IAI use only

(Note 1)

<Options>

B : Brake

NM : Reversed-home specification

CJT : Cable exit direction changed

(Top)

CJR : Cable exit direction changed

(Right)

CJL : Cable exit direction changed

(Left)

CJB : Cable exit direction changed

(Bottom)

CJO : Cable eject direction changed

(Outward)

ML : Motor left reversed(Standard)

MR : Motor right reversed

SS : Slider spacer(SA7R)

SR : Slider part roller type

VR : Air vacuum joint on other side

<Cable length>

N : None

P : 1m

S : 3m

M : 5m

X□□ : Length specification

R□□ : Robot cable

<Controller>

P3 : PCON-CA

MSEP

MSEL

Identification for IAI use only

(Note 1

)

<Options>

B : Brake

NM : Reversed-home specification

FL : Flange br acket

FT : Foot bracket

FFA : Tip adapter (Flange)

NFA : Tip adapter (Internal thread)

KFA : Tip adapter (Keyway)

ML : Motor left reversed (Standard)

MR : Motor right reversed

CJT : Cable exit direction changed

(Top)

CJR : Cable exit direction changed

(Right)

CJL : Cable exit direction changed

(Left)

CJO : Cable exit direction changed

(Outward)

CJB : Cable exit direction changed

(Bottom)

AT : Cable exit direction (Top)

A3 : Cable exit direction (Right)

A1 : Cable exit direction (Left)

<Cable length>

N : None

P : 1m

S : 3m

M : 5m

X□□ : Length specification

R□□ : Robot cable

<Controller>

P3 : PCON- CA

MSEP

MSEL

P4 : PCON-CFA

*1 Identification for IAI use only : It may be displayed for IAI use. It is not a code to show the model type.

Note 1 There is no RCP5W-RA6C Lead 20 and RCP5W-RA7C Lead 24.

(Note)

The motor types RCP5W-RA6C 42SP and RCP5W-RA7C 56SP are equipped with a brake in standard.

There is no option without brake.

Page 2

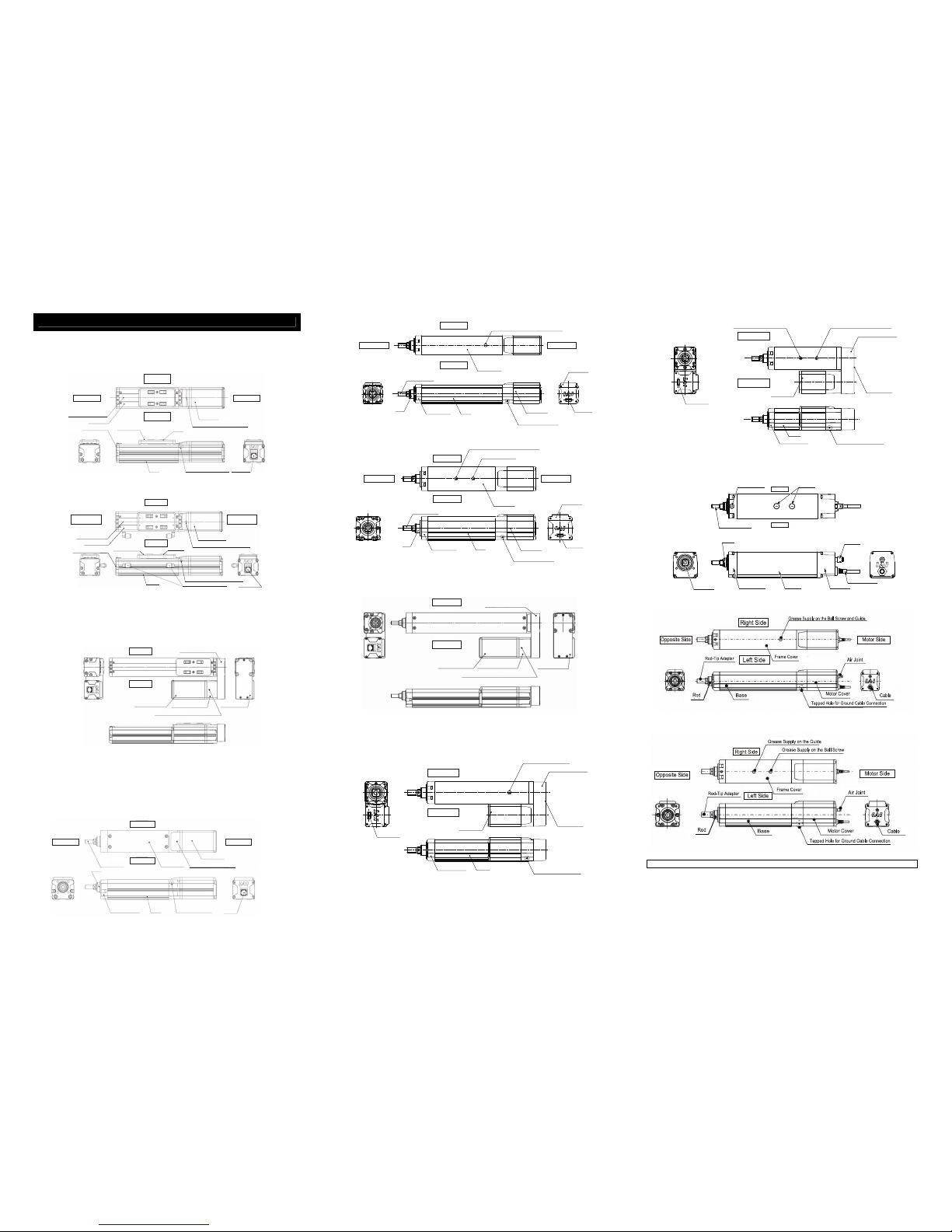

Air Vacuum Joint Type

Air Tube Outer Diameter

•

SA4/6 : φ6

•

SA7 : φ8

Stainless steel sheet

Side cover

Front bracket

Slider cover

Opposite Side

Right Side

Left Side

Slider

Base

Motor unit

Screw for motor unit attachment

Tapped hole for ground cable connection

Connector

Motor Side

Motor Unit

Screw for Motor Unit Attachment

Rod-Tip Adapter

Front

bracket

Rod

Base

Tapped Hole for Ground

Cable Connection

Connector

Frame Cover

Right Side

Left Side

Opposite Side Motor Side

Names of the Parts

1. Slider Type

1.1 Motor Straight Type

1.1.1 SA4C, 6C and 7C

[1] Standard Type Motor Straight Type RCP5

Motor unit

Screw for motor unit attachment

Stainless steel sheet

Side cover

Front bracket

Slider cover

Slider

Base

Tapped hole for

ground cable connection Connector

Left Side

Right Side

Opposite Side Motor Side

[2] Cleanroom Type Motor Straight Type RCP5CR

1.2 Motor Reversing Type

1.2.1 SA4R, 6R and 7R

[1] Standard Type Motor Reversing Type RCP5

The direction of the motor is either left reversed: ML (shown in figure above), right reversed:

MR.There is no top reversed type.

Note) Reversing types are not applicable to CR specifications.

2. Rod Type

2.1 Standard Type Motor Straight Type RCP5

2.1.1 RA4C, 6C and 7C

2.1.2 RA8C

Grease Supply on the Ball Screw and Guide

Rod-Tip Adapter

Rod

Rear Cover

Right Side

Left Side

Opposite Side Motor Side

Frame Cover

Base

Connector

Motor Cover

Tapped Hole for Ground

Cable Connection

Front Bracket

2.1.3 RA10C

2.2 Standard Type Motor Reversing Type RCP5

2.2.1 RA4R, 6R and 7R

The direction of the motor is either left reversed: ML (shown in figure above, standard) or right

reversed: MR (option).

2.2.2 RA8R

Right Side

Left Side

Motor Unit

Connector

Base

Tapped Hole for Ground

Cable Connection

Grease Supply on the

Ball Screw and Guide

Reversing Bracket

Pulley Cover

Front Bracket

2.2.3 RA10R

Right Side

Left Side

Grease Supply on the Ball Screw

Grease Supply on the Guide

Pulley Cover

Tapped Hole for Ground

Cable Connection

Reversing Bracket

Motor Unit

Base

Connector

Front Bracket

2.3 Dustproof/Splash Proof Type Motor Straight Type RCP5W

2.3.1 RA6C and RA7C

Cap

Grease Nipple

Rod

Rod-Tip Adapter

Flame

Rear Cover

Actuator Cable

Air joint

Scraper

Front Bracket

Right Side

Left Side

2.3.2 RA8C

2.3.3 RA10C

For the details of dimensions and outlines, refer to the catalog or Instruction Manual (DVD).

Right Side

Left Side

Opposite Side Motor Side

Rod-Tip Adapter

Rod

Base

Rear Cover

Frame Cover

Connector

Motor Cover

Tapped Hole for Ground

Cable Connection

Grease Supply on the Ball Screw and Guide

Reversing Bracket

Front Bracket

Reversing bracket

Pulley bracket

Pulley cover

Left Side

Right Side

Motor unit

Screw for motor unit attachment

Screw for Motor Unit Attachment

Reversing Bracket

Motor Unit

Pulley Cover

Pulley Bracket

Right Side

Left Side

Page 3

Attachment

Refer to the Instruction Manual (DVD) for the attachments of the actuator and loads.

[Precautions for Attachments]

No. Item Precautions

1 Installation

• Installing the slider type in the horizontally oriented wall mount or ceiling

mount may cause the stainless steel sheet to be loosened or be off the

right position. Continued use of the actuator with this condition may

result in the breakage of the stainless steel sheet. Adjust the sheet

tension accordingly in the regular inspection.

(Refer to the maintenance section on the Instruction Manual for the

procedure of stainless steel sheet tension adjustment.)

• Avoid using the actuator with no brake in the vertical orientation.

2 Attachment Surface

• The base has to have a structure with sufficient rigidity to prevent

oscillation.

• The side and the bottom surfaces of the base of the actuator are the

datum for the slider drive. If accuracy for its run is required, use these

surfaces as a datum of the installation.

Datum Surface

Datum Surface

• The actuator mounting surface and other surfaces that are used as a

datum should be flat enough with an accuracy of machining or

equivalent treatment, and the flatness of the mounting surface needs to

be 0.05mm/m or less.

• Secure the space where maintenance work can be performed.

3

Bolt to be used

• For the bolts to be used, a high-tensile bolt complying with ISO-10.9 or

more is recommended.

• Use stainless steel screws for Dustproof/splash proof type RCP5W.

• If using the tapped holes, use screws with the thread length dimension

being less than the effective depth of the holes.

• In case the tapped hole is a through hole, be careful so the screw tip

does not exceed the surface of the tapped hole.

• For the actuator mounting, use a bolt with the dimension of its effective

mating length to the tapped hole is as stated below.

If tapped hole on steel → thread length same as nominal diameter

If tapped hole on aluminum → thread length 1.8 times longer than

nominal diameter

However, when utilizing the tapped hole actuator attach on,

RCP5-RA4C/4R is 6mm or less,

RCP5-RA8C/8R is 12mm or less,

RCP5-RA10C/10R is 15mm or less,

RCP5W-RA6C is 6mm or less,

RCP5W-RA7C is 7.5mm or less.

RCP5W-RA8C is 8.5mm or less,

RCP5W-RA10C is 10mm or less.

4

Tightening Torque

• Please follow the specification values stated in the Instruction Manual

(DVD) for the tightening torque.

Failure to do so may cause an operation problem.

5

Load Moment and

Overhung length

• Please follow t he specification values stated in the In struction Manual

(DVD) for the load moment and the overhung length of the slider type.

Failure to do so may cause abnormal vibration or noise, and also may

remarkably shorten the product life.

6

Rod Tip Allowable

Static Load, Load

Offset Distance

• Follow the specific values described in the instruction manual (DVD) for

the rod tip dynamic allowable load and the load offset distance for the

rod type. Failure to do so may cause abnormal vibration or noise, and

also may remarkably shorten the product life.

7

Stainless steel sheet

• Please do not hold the stainless steel sheet directly with hands. Please,

also, be careful not to make a dent on the stainless steel sheet.

Stainless sheet is easy to get dented because it is thin. Using it with a

dent on may cause a breakage.

• If there is dust or metal contamination attached on the stainless steel

sheet, please wipe it off the sheet surface. Operation with the stainless

sheet that has foreign matters on its surface may cause problems such

as sheet damage, waviness, etc. inside the slider.

• Please do not operate the unit in the ambient with dust or metal

contamination.

For the controller, only the dedicated controller manufactured by our company can be used.

For the connection between the actuator and controller, use the attached dedicated connection

cable.

[Prohibited Items in the Cable Processing]

• Do not pull or bend forcibly the cable so as not to give any extra load or tension to the

cable.

• Do not process the cable for extension or shortening by means of cutting out,

combination or connecting with another cable.

• Do not bend the cable in the area from the connector tip to 150mm on the both ends.

Standard cable : CB-CAN-MPA

□□□, CB-CFA3-MPA□□□

Robot cable : CB-CAN-MPA

□□□-RB, CB-CFA3-MPA□□□-RB

150mm 150mm

• Do not let the cable flex at a single

point.

• Do not let the cable bend, kink or twist.

• Do not pull the cable with a strong

force.

• Do not let the cable receive a turning force

at a single point.

• Do not pinch, drop a heavy object

onto or cut the cable.

• When fixing the cable, provide a moderate

slack and do not tension it too tight.

• Separate the I/O line,

communication line and power line

from each other.

Do not store in the same duct.

Follow the instructions below when using a

cable track.

• If there is an indication to the cable for the

space factor in a cable track, refer to the

wiring instruction given by the supplier

when storing the cable in the cable track.

• Avoid the cables to get twined or twisted

in the cable track, and also to have the

cables move freely and do not tie them

up. (Avoid tension being applied when the

cables are bent.)

Do not pile up cables. It may cause faster

abrasion of the sheaths or cable

breakage..

Note:

• When the cable is connected or disconnected, make sure to turn off the power to the

controller. When the cable is connected or disconnected with the controller power turned

ON, it might cause a malfunction of the actuator and result in a serious injury or damage

to the machinery.

• When the connector connection is not correct, it would be dangerous because of a

malfunction of the actuator. Make sure to confirm that the connector is connected

correctly.

Head Office: 577-1 Obane Shimizu-KU Shizuoka City Shizuoka 424-0103, Japan

TEL +81-54-364-5105 FAX +81-54-364-2589

website: www.iai-robot.co.jp/

Ober der Röth 4, D-65824 Schwalbach am Taunus, Germany

TEL 06196-88950 FAX 06196-889524

SHANGHAI JIAHUA BUSINESS CENTER A8-303, 808, Hongqiao Rd. Shanghai 200030, China

TEL 021-6448-4753 FAX 021-6448-3992

website: www.iai-robot.com

Technical Support available in USA, Europe and China

Head Office: 2690 W. 237th Street, Torrance, CA 90505

TEL (310) 891-6015 FAX (310) 891-0815

Chicago Office: 110 East State Parkway, Schaumburg, IL 60173

TEL(847) 908-1400 FAX (847) 908-1399

TEL (678) 354-9470 FAX (678) 354-9471

website: www.intelligentactuator.com

Atlanta Office: 1220 Kennestone Circle, Suite 108, Marietta, GA 30066

825 PhairojKijja Tower 12th Floor, Bangna-Trad RD., Bangna, Bangna, Bangkok 10260, Thailand

TEL +66-2-361-4458 FAX +66-2-361-4456

Steel Strap

(Piano Wire)

Tie them up softly.

Do not use spiral tube in any

position where cables are bent

frequently.

Power Line

Duct

I/O Line

(Flat Cable, etc.)

Manual No.: ME3736-7B

Wiring

Loading...

Loading...