Page 1

ROBO Cylinder

Slider Type

RCP2 Actuators

Motor Straight Type: SA5C, SA6C, SA7C, SS7C, SS8C, HS8C

Motor Reversing Type: SA5R, SA6R, SA7R, SS7R, SS8R, HS8R

RCP2CR Actuators, Cleanroom Specification

SA5C, SA6C, SA7C, SS8C, HS8C

Operating Manual

First Edition

IAI America Inc.

Page 2

Page 3

Note

Greasing Actuators of Cleanroom Specification

For ROBO Cylinder actuators of cleanroom specification, use grease of low-dust-raising

type for cleanroom applications.

The grease specified in the maintenance/inspection sections of the Operating Manual is for

actuators of standard specification.

Using the grease for the standard actuators on the cleanroom actuators may generate dust.

Recommended grease:

C Grease by Kuroda Precision Industries Ltd.

C Grease by Kuroda Precision Industries is applied to the cleanroom actuators before

shipment from IAI.

Page 4

Safety Precautions (Please read before using the product.)

Before installing, operating, maintaining or inspecting this product, please peruse this operating manual as well

as the operating manuals and other related documentations for all equipment and peripheral devices

connected to this product in order to ensure the correct use of this product and connected equipment/devices.

Those performing installation, operation, maintenance and inspection of the product must have sufficient

knowledge of the relevant equipment and their safety. The precautions provided below are designed to help

you use the product safely and avoid bodily injury and/or property damage.

In this operating manual, safety precautions are classified as “Danger,” “Warning,” “Caution” and

“Note,” according to the degree of risk.

Danger

Failure to observe the instruction will result in an imminent danger leading to death or

serious injury.

Warning

Failure to observe the instruction may result in death or serious injury.

Caution

Failure to observe the instruction may result in injury or property damage.

Note

The user should take heed of this information to ensure the proper use of the product,

although failure to do so will not result in injury.

It should be noted that the instructions under the

Caution

and

Note

headings may also

lead to serious consequences, if unheeded, depending on the situation.

All instructions contained herein provide vital information for ensuring safety. Please read the contents

carefully and handle the product with due caution.

Please keep this operating manual in a convenient place for quick reference whenever needed, and also make

sure that the manual will get to the end-user.

● Do not use this product for the following applications:

1. Medical equipment used to maintain, control or otherwise affect human life or physical health

2. Mechanisms and machinery designed for the purpose of moving or transporting people

3. Important safety parts of machinery

This product has not been planned or designed for applications requiring high levels of safety. Use of this

product in such applications may jeopardize the safety of human life. The warranty covers only the product

as it is delivered.

● Do not use this product in a place exposed to ignitable, inflammable or explosive substances. The product

may ignite, burn or explode.

Danger

General

Installation

Page 5

2

● When installing the product, make sure to securely support and affix it (including the work). Failure to do

so may cause the product to tip over, drop or malfunction, resulting in injury.

● Avoid using the product in a place where the main unit or controller may come in contact with water or oil

droplets.

● Never cut and/or reconnect the cables supplied with the product for the purpose of extending or

shortening the cable length. Doing so may result in fire.

● Do not enter the machine’s range of operation while the product is operating or standing by. The actuator

may move suddenly, causing injury.

● Do not pour water onto the product. Spraying water over the product, washing it with water or using it in

water may cause the product to malfunction, resulting in injury, electric shock, fire, etc.

● Never modify the product. Unauthorized modification may cause the product to malfunction, resulting in

injury, electric shock, fire, etc.

● Do not disassemble and reassemble the components relating to the basic structure of the product or its

performance and function. Doing so may result in injury, electric shock, fire, etc.

● Do not use the product outside the specifications. Using the product outside the specifications may cause

it to fail, stop functioning or sustain damage. It may also significantly reduce the service life of the product.

In particular, observe the maximum loading capacity and speed.

● If the machine will stop in the case of system problem such as emergency stop or power failure, design a

safety circuit or other device that will prevent equipment damage or injury.

● Make sure to provide Class D grounding for the controller and actuator (formerly Class 3 grounding:

Grounding resistance at 100 Ω or less). Leakage current may cause electric shock or malfunction.

● Before supplying power to and operating the product, always check the operation area of the equipment to

ensure safety. Supplying power to the product carelessly may cause electric shock or injury due to contact

with the moving parts.

● Wire the product correctly by referring to the operation manual. Securely connect the cables and

connectors so that they will not be disconnected or come loose. Failure to do so may cause the product to

malfunction or cause fire.

● Before operating the moving parts of the product by hand (for the purpose of manual positioning, etc.),

confirm that the servo is turned off (using the teaching pendant). Failure to observe this instruction may

result in injury.

● Do not scratch the cables. Scratching, forcibly bending, pulling, winding, crushing with heavy object or

Operation

Warning

General

Installation

Operation

Maintenance, Inspection, Repair

Page 6

pinching a cable may cause it to leak current or lose continuity, resulting in fire, electric shock, malfunction,

etc.

● Turn off the power to the product in the event of power failure. Failure to do so may cause the product to

suddenly start moving when the power is restored, thus resulting in injury or product damage.

● If the product is generating heat, smoke or a strange smell, turn off the power i mmediately. Continuing to

use the product may result in product damage or fire.

● If noise or abnormally high vibration is detected, stop the operation immediately. Continuing to use the

product may result in product damage, malfunction due to damage, runaway machine, etc.

● If any of the product’s protective functions (alarms) has actuated, turn off the power immediately.

Continuing to use the product may result in injury due to product malfunction, or cause product breakdown

or damage. After the power has been cut off, identify and remove the cause of the problem, and then

reconnect the power.

● Do not step on the product, use it as a footstool or place any object on it. You may slip and fall or the

product may tip over or drop, resulting in injury. Malfunction, runaway product, etc., may also result due to

product breakdown or damage.

● Before commencing maintenance/inspection, servicing, replacement or any other work on the product,

make sure to completely cut off the power supply to the product. Also take heed of the following

precautions:

1. Put up a sign bearing “WORK IN PROGRESS. DO NOT TURN ON POWER” or other warning

statement to that effect, to prevent a bystander from accidentally turning on the power.

2. If multiple operators work together to perform maintenance/inspection work, the operators should

always give verbal cues to one another to ensure safety before turning on/off the power or moving

any axis.

● Do not throw the product into flames. The product may explode or toxic gases may generate.

● Do not use the product in a place exposed to direct sunlight (ultraviolet ray), dusty place or place where air

contains salt or iron powder, humid place, or in any ambience where the product may come in contact with

organic solvent, hydraulic oil containing phosphate ester, etc. If used in theses places/ambiences, the

product may lose its function over a short period of time or suffer rapid performance deterioration, or the

service life of the product may be reduced.

● Do not use the product in an ambience area where it may come in contact with corrosive gases (sulfuric

acid, hydrochloric acid, etc.). The product may lose its strength due to rust.

● Provide sufficient shielding measures if the product is used in any of the following places. If proper

measures are not taken, the product may malfunction:

1. Place where large current or strong magnetic field generates

2. Place where arc discharge occurs due to welding work, etc.

Maintenance, Inspection, Repair

Disposal

Caution

Installation

Page 7

4

3. Place where noise generates due to electrostatic, etc.

4. Place where the product may come in contact with radiation

● Do not install the product in a place subject to vibration or shock.

● Provide an emergency stop device in an easily accessible position so the device can be immediately

actuated should danger occur during operation. Failure to do so may result in injury.

● Provide sufficient maintenance space when installing the product. If sufficient space is not available, daily

inspection, maintenance and other necessary work cannot be carried out, resulting in system shutdown or

product damage.

● When transporting or installing the product, support the product using a lift or suspension equipment or

carry it with multiple operators working together, and exercise due caution to ensure safety.

● When installing the product, do not hold the moving parts or cables of the product. Doing so may result in

injury.

● Use IAI’s genuine cables to connect the actuator and controller. Also use IAI’s genuine components for

the actuator, controller, teaching pendant, etc.

● The brake mechanism is designed to prevent the slider from dropping upon turning off the power when the

actuator is installed vertically. Do not use the brake mechanism as a safety brake.

● When installing, adjusting or carrying out any other work on the actuator, put up a sign bearing “WORK IN

PROGRESS. DO NOT TURN ON POWER” or other warning statement to that effect, to prevent the

product from being powered on accidentally. If the power is turned on accidentally, injury may result due to

electric shock or sudden movement of the actuator.

● Turn on th e power to individual equip ment one by one, starting from the equ ipment at the highest level in

the system hierarchy. Failure to do so may cause the product to start suddenly, resulting in injury or

product damage.

● Do not insert a finger or object in the openings in the product. It may cause fire, electric shock or injury.

● Do not step on the product, use it as a footstool or place any object on it. It may cause scoring, dents or

deformation of the driving part, resulting in product damage, unintended stopping due to damage, or

performance drop.

● Wear protective goggles when applying grease to the actuator. Failure to do so may result in eye

inflammation due to spattered grease.

● If the product is used in a vertical setup, make sure to use the vertical specification (with brake).

● Protection covers or other guards must be provid ed for the moving parts of the equipment to avoid direct

contact with the operators.

● Do not configure a control circuit that will cause the work to drop in case of power failure. Configure a

control circuit that will prevent the tabl

e or work from dropping when the power to the machine is cut off or

an emergency stop is actuated.

Maintenance, Inspection, Repair

Operation

Note

Installation

Page 8

● The following conditions must be met in order to improve the straightness of the table movement and

ensure the smooth movement of the ball screw and linear guides:

1. Flatness of the mounting surface must be within 0.05mm.

2. The mounting surface area must be large enough to ensure the rigidity of the actuator.

● When handling the product, wear protective gloves, protective goggles, safety shoes or other necessary

gear to ensure safety.

● When performing maintenance, apply the specified grease to the guides and ball screw. Pay special

attention not to let fluoride grease mix with lithium grease. The machine may be damaged due to poor

lubrication, increased resistance, etc.

● When the product becomes no longer usable or necessary, dispose of it properly as an industrial waste.

■ IAI shall not be liable whatsoever for any loss or damage arising from a failure to observe the items

specified in “Safety Precautions.”

Installation, Operation, Maintenance

Maintenance, Inspection, Repair

Disposal

Others

Page 9

6

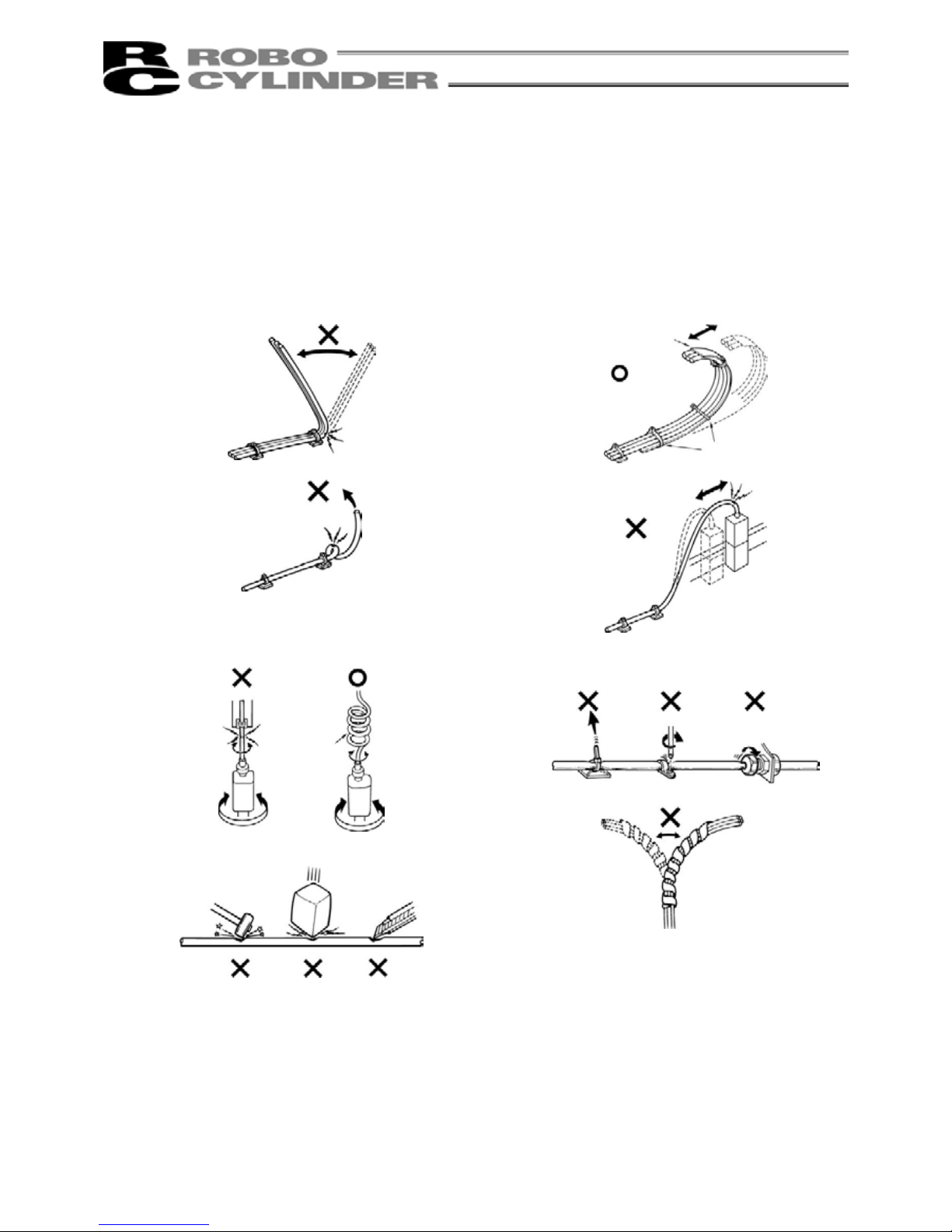

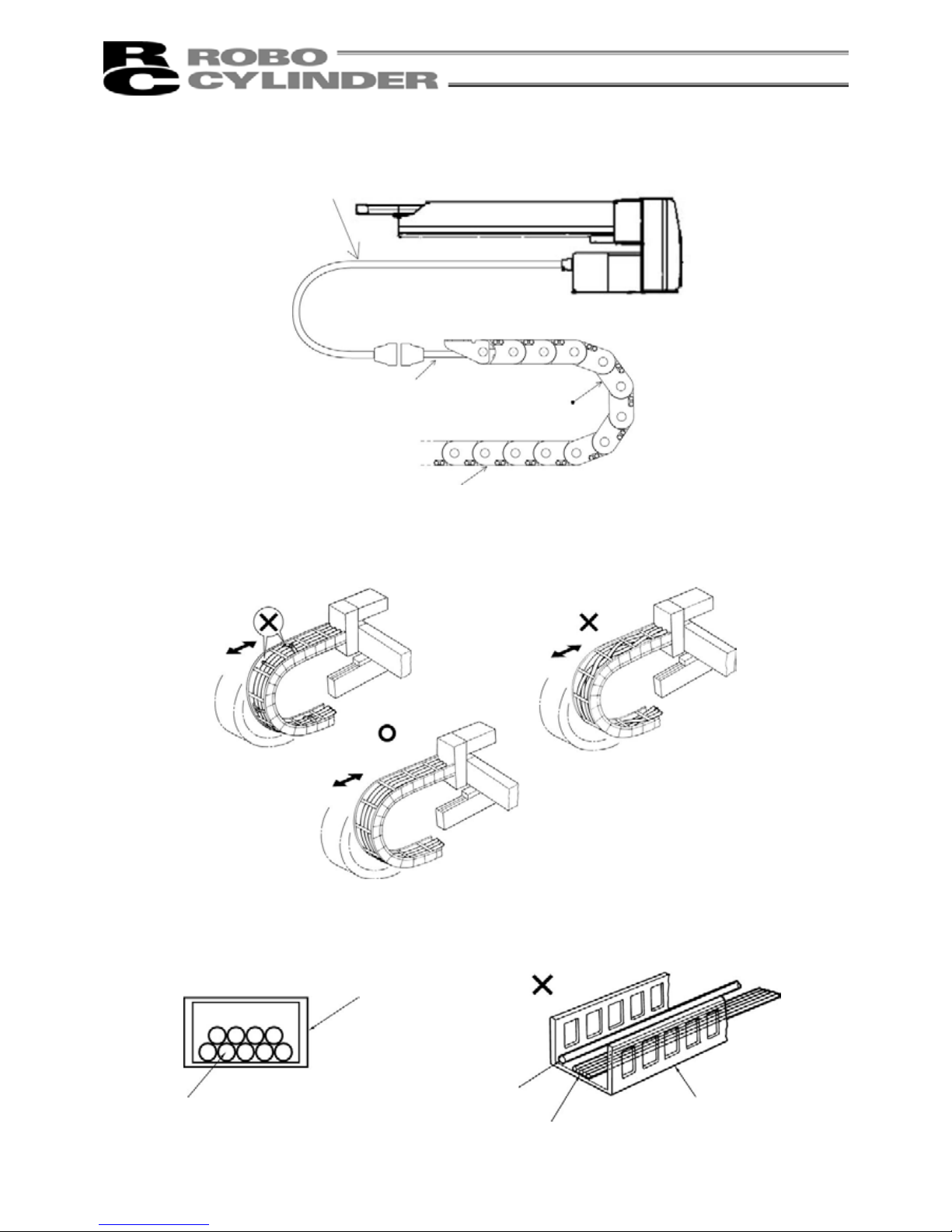

Prohibited Handling of Cables

When designing an application system using IAI’s actuators and controllers, incorrect wiring or connection of

each cable may cause unexpected problems such as a disconnected cable or poor contact, or even a runaway

system. This section explains prohibited handling of cables. Read the information carefully to connect the

cables properly.

1.

Do not let the cable flex at a single point.

2.

Do not let the cable bend, kink or twist.

3.

Do not pull the cable with a strong force.

4.

Do not let the cable receive a turning force at a

single point.

5.

6.

Do not pinch, drop a heavy object onto or cut the

cable.

When fixing the cable, provide a moderate

slack and do not tension it too tight.

Steel band

(piano wire)

Bundle loosely.

Use a curly cable.

Do not use a spiral

tube where the cable

flexes frequently.

Page 10

7.

Notes on using cable bearers

● The supplied cables are not robot cables.

Accordingly, never store the cables in a cable bearer.

● Always use a robot cable for

each relay cable.

● Use a cable bearer with a bending radius (r)

of 50mm or greater.

● Do not let the cable get tangled or kinked in a cable bearer or flexible tube. When bundling the cable, keep

a certain degree of flexibility (so that the cable will not become too taut when bent).

● Do not cause the cables to occupy more than

60% of the space in the cable bearer.

● Do not lay signal lines together with circuit

lines that create a strong electric field.

Bending radius (r)

Cable beare

r

Cable

Power line

Signal lines (flat cable)

Duct

Page 11

Table of Contents

1. Foreword.................................................................................................................................................... 1

2. Safety Precautions..................................................................................................................................... 1

2.1 Basic Operating Instructions............................................................................................................... 1

2.2 Maintenance and Inspection............................................................................................................... 1

3. Warranty .................................................................................................................................................... 2

3.1 Warranty Period.................................................................................................................................. 2

3.2 Scope of Warranty.............................................................................................................................. 2

4. Names of Parts .......................................................................................................................................... 3

4.1 Motor Straight Type (Standard) RCP2................................................................................................ 3

4.2 Motor Straight Type (Cleanroom Specification) RCP2CR................................................................... 4

4.3 Motor Reversing Type......................................................................................................................... 6

5. Transporting and Handling......................................................................................................................... 8

5.1 Handling the Actuator ......................................................................................................................... 8

5.1.1 Handling the Packed Unit.............................................................................................................. 8

5.1.2 Handling the Actuator after It is Unpacked.................................................................................... 8

5.2 Handling the Actuator Assembly......................................................................................................... 9

5.2.1 Condition of Shipment from IAI (Assembled)................................................................................. 9

5.2.2 Handling after Assembly with Peripheral Equipment..................................................................... 9

6. Operating and Storage Environment........................................................................................................ 10

6.1 Operating Environment..................................................................................................................... 10

6.2 Storage Environment ........................................................................................................................ 10

7. Installation................................................................................................................................................ 11

7.1 Installing the Main Body.................................................................................................................... 12

7.1.1 Using the Tapped Holes at Back of the Base (All Types)............................................................ 12

7.1.2 Using the Mounting Holes on Top of the Base (SA5C, SA6C, SA7C)......................................... 13

7.2 Mounting Surface ...........................................................................................................

................... 14

7.3 Clamp Screws

................................................................................................................................... 15

7.4 Installing the Load to the Slider

......................................................................................................... 16

8. Wiring Cable ............................................................................................................................................ 17

9. Load on the Act uator................................................................................................................................ 18

Page 12

10. Cleanroom Specification.......................................................................................................................... 20

10.1 Recommended Suction Rate............................................................................................................ 20

10.2 Suction Joint ..................................................................................................................................... 20

11. Maintenance ............................................................................................................................................ 21

11.1 Maintenance Schedule ..................................................................................................................... 21

11.2 Visual Inspection of the Machine Exterior......................................................................................... 21

11.3 Cleaning............................................................................................................................................ 21

11.4 Interior Inspection ............................................................................................................................. 22

11.5 Internal Cleaning............................................................................................................................... 23

11.6 Lubricating the Guides and Ball Screw............................................................................................. 23

11.6.1 Other than Cleanroom Specification.......................................................................................... 23

11.6.2 Cleanroom Specification............................................................................................................ 24

11.6.3 How to Apply Grease................................................................................................................. 25

11.7 Replacing/Adjusting the Stainless Sheet .......................................................................................... 26

11.8 Reduction Belt [Motor Reversing Type]:........................................................................................... 31

11.8.1 Inspecting the Belt......................................................................................................................... 31

11.8.2 Applicable Belt .............................................................................................................................. 31

11.8.3 Adjusting the Belt Tension ............................................................................................................ 31

●SA5R, SA6R ............................................................................................................................... 31

●SA7R........................................................................................................................................... 32

●SS7R, SS8R, HS8R.................................................................................................................... 32

11.8.4 Replacing the Belt......................................................................................................................... 33

●SA5R, SA6R ............................................................................................................................... 33

●SA7R........................................................................................................................................... 36

●SS7R, SS8R, HS8R.................................................................................................................... 39

11.9 Replacing the Motor.......................................................................................................................... 41

11.9.1 Motor Straight Type....................................................................................................................... 41

●SA5C, SA6C .....................................................................................................................

.......... 41

●SA5C, SA6C ............................................................................................................................... 45

●SS7C

........................................................................................................................................... 50

●SS8C, HS8C............................................................................................................................... 55

11.9.2 Motor Reversing Type................................................................................................................... 59

●SA5R, SA6R ............................................................................................................................... 59

●SA7R........................................................................................................................................... 63

●SS7R, SS8R, HS8R.................................................................................................................... 65

Appendix · How to use the home mark ........................................................................................................... 67

Page 13

1

1. Foreword

Thank you for purchasing the Robo Cylinder Actuator. This manual explains the structure, correct operation

and maintenance of the Robo Cylinder Actuator. Please read this manual carefully before using the actuator.

For more complete information on operating the actuator, please refer to the controller operating manual.

2. Safety Precautions

2.1 Basic Operating Instructions

• Please do not attempt to use or operate the actuator in any manner not indicated in this manual or the

controller manual.

• Please make sure to use only the cable provided by IAI to connect the actuator and controller.

• Please do not allow people within the moving range of the unit when it is in operation or when the power is

ON since this is dangerous.

2.2 Maintenance and Inspection

• When doing maintenance and inspection work, alw ays shut down the controller power first.

• When doing inspection, make sure that no one can inadvertently turn the power ON.

• Make sure that a sign indicating work in progress is clearly visible.

• If several persons are working, make sure to watch out for each other's safety. In particular, check before

turning power ON or OFF and let others know if you are doing work involving axis movement.

(Note)

• The content of this manual is subject to change without notice for the purpose of improvement.

• This manual was created with utmost attention to accuracy. Should you find any error, howe ver, or if you

have any question, please contact IAI’s Sales Engineering or Technical Service Section.

Page 14

2

3. Warranty

3.1 Warranty Period

Warranty period shall be either of the following periods whichever ends first:

• 18 months after shipment from our factory

• 12 months after delivery to a specified location

• 2500 hours of operation time

3.2 Scope of Warranty

If a breakdown occurs within the period specified above and is due to the manufacturer's error, we will repair

the unit at no cost. However, the following items are not covered by this warranty.

• Faded paint or other changes that occur naturally over time.

• Consumable components that wear out with use (stainless sheet, etc.).

• Unit seems to be noisy or similar impressions that do not affect machinery performance.

• Damage resulting from improper handling by the user or lack of proper maintenance.

• Any alterations made by other than IAI or its representatives.

• Breakdowns caused by using controllers made by other manufacturers.

• Any damages caused by fire and other natural disasters or accidents.

The warranty pertains to the purchased product itself and does not cover any damages that might arise from

a breakdown of the supplied product.

Any repairs will be done at our factory. Even if the product is still covered under the warranty period, we will

assess a separate charge for sending technicians to the customer's site.

Page 15

3

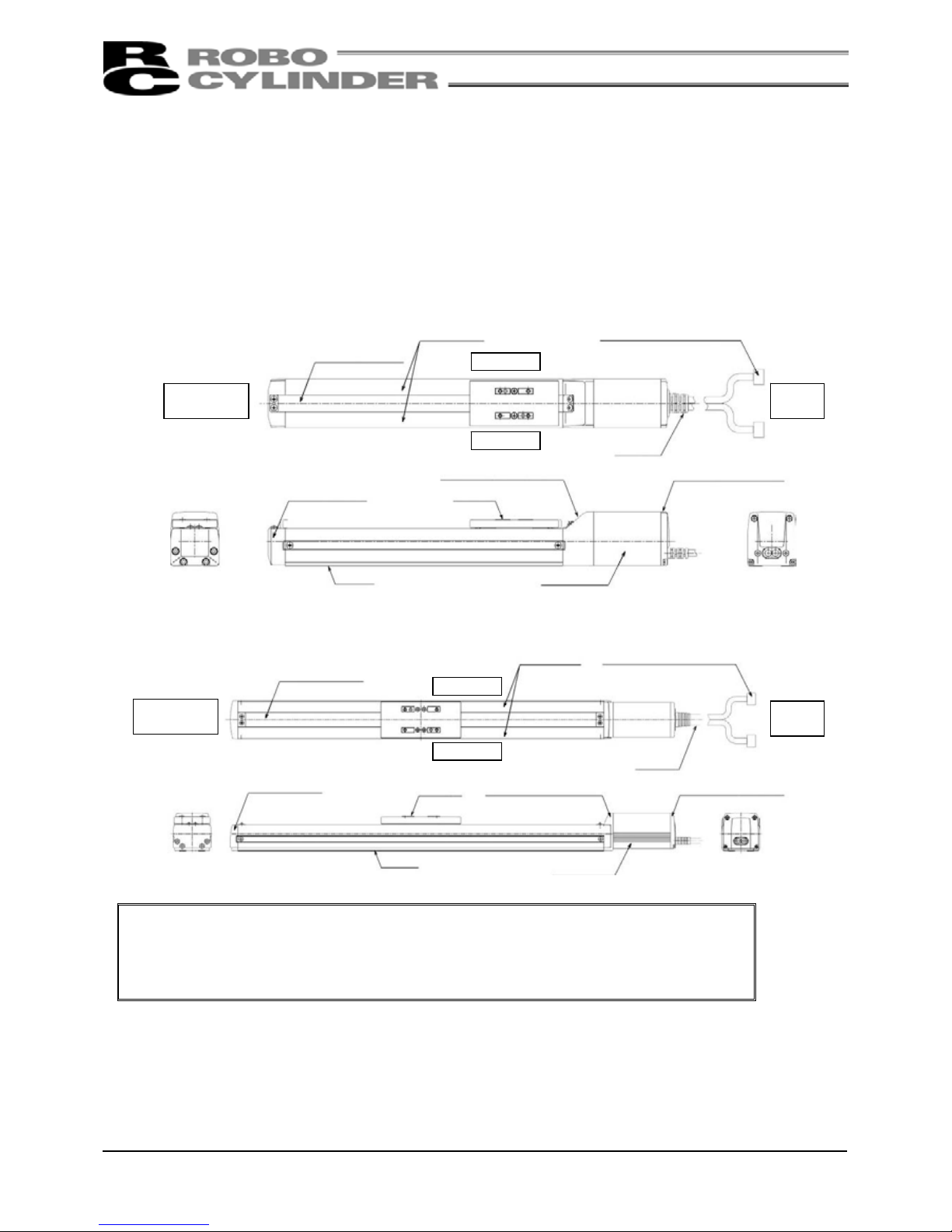

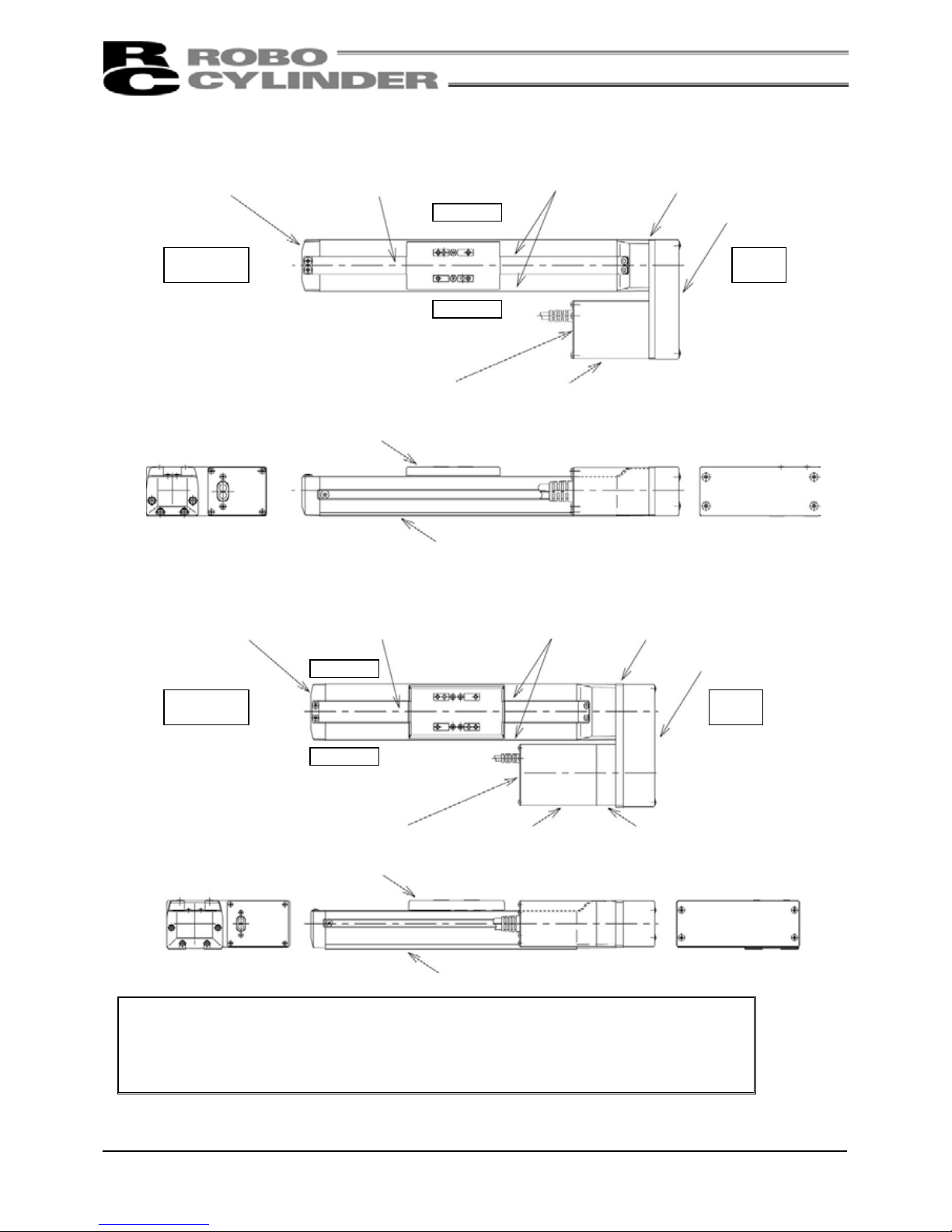

4. Names of Parts

The names of the actuator parts are indicated below.

The left and right sides are indicated by looking at the actuator from the motor end with the actuator set

down horizontally. Front end means the side opposite the motor end.

4.1 Motor Straight Type (Standard) RCP2

●SA5C, SA6C, SA7C

●SS7C, SS8C, HS8C

Caution: The cable directly connected to the actuator is not a robot cable even when

ordered with a robot cable option. When designing, please make sure not to give

repeated bending loads to this cable.

The robot cable is applicable only to the connecting cables.

Stainless Sheet

Opposite

Motor End

Side Cove

r

Right Side

Left Side

Cable Joint Connector

Cable

Motor

End

Front Cove

r

Base

Bearing Housing

Slider

Motor End Cap

Motor Cove

r

Opposite

Motor End

Motor

End

Stainless Sheet

Side Cove

r

Cable Joint Connector

Cable

Right Side

Left Side

Front Cove

r

Slide

r

Bearing Housing

Motor End Cap

Motor Cove

r

Base

Page 16

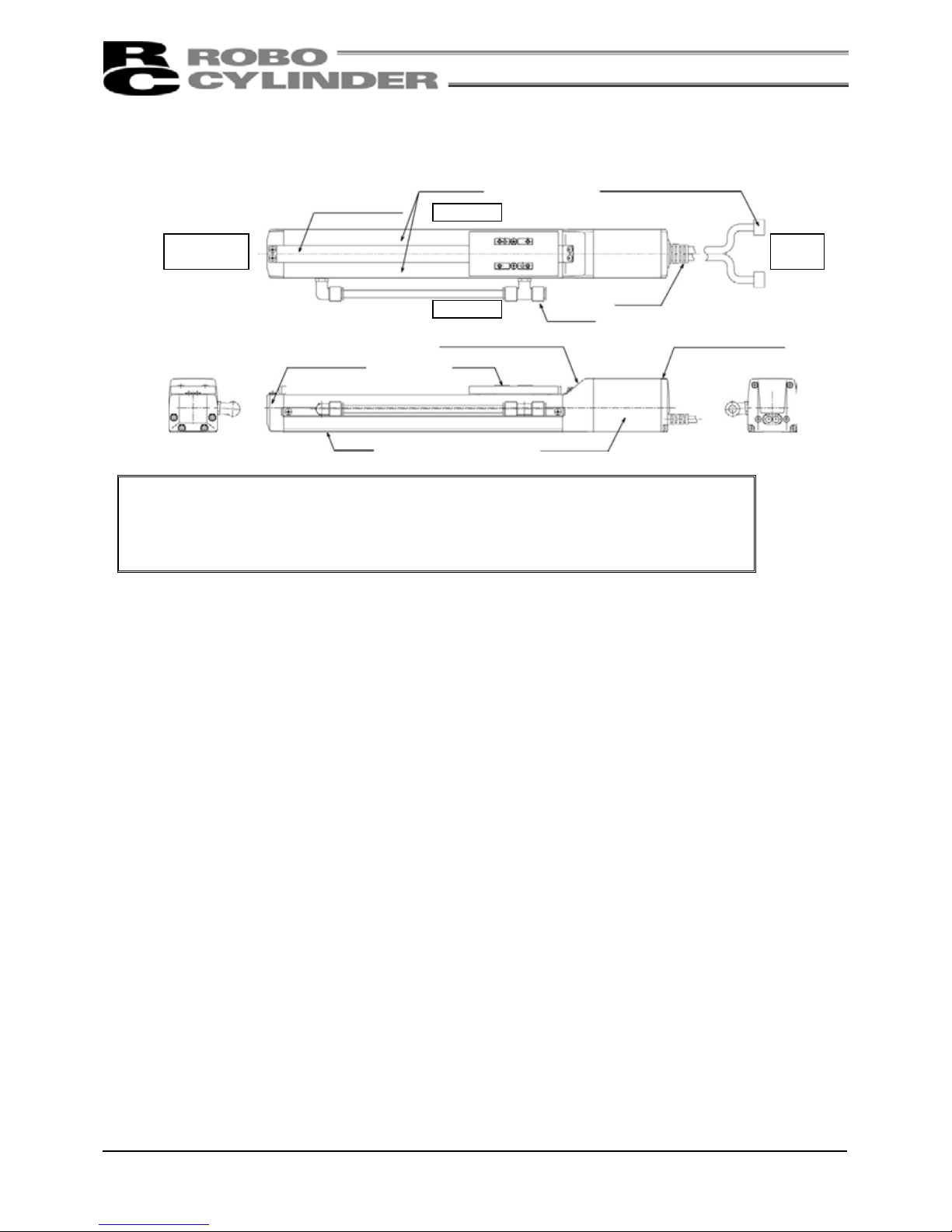

4

4.2 Motor Straight Type (Cleanroom Specification) RCP2CR

●SA5C, SA6C, SA7C

Caution: The cable directly connected to the actuator is not a robot cable even when

ordered with a robot cable option. When designing, please make sure not to give

repeated bending loads to this cable.

The robot cable is applicable only to the connecting cables.

Stainless Sheet

Opposite

Motor End

Side Cove

r

Right Side

Left Side

Cable Joint Connector

Cable

Motor

End

Front Cove

r

Base

Bearing Housing

Slider

Motor End Cap

Motor Cove

r

Suction

Joint

Page 17

5

●SS7C, SS8C, HS8C

Caution: The cable directly connected to the actuator is not a robot cable even when

ordered with a robot cable option. When designing, please make sure not to give

repeated bending loads to this cable.

The robot cable is applicable only to the connecting cables.

Stainless Sheet

Opposite

Motor End

Side Cove

r

Right Side

Left Side

Cable Joint Connector

Cable

Motor

End

Front Cove

r

Base

Bearing Housing

Slider

Motor End Cap

Motor Cove

r

Suction Joint

Page 18

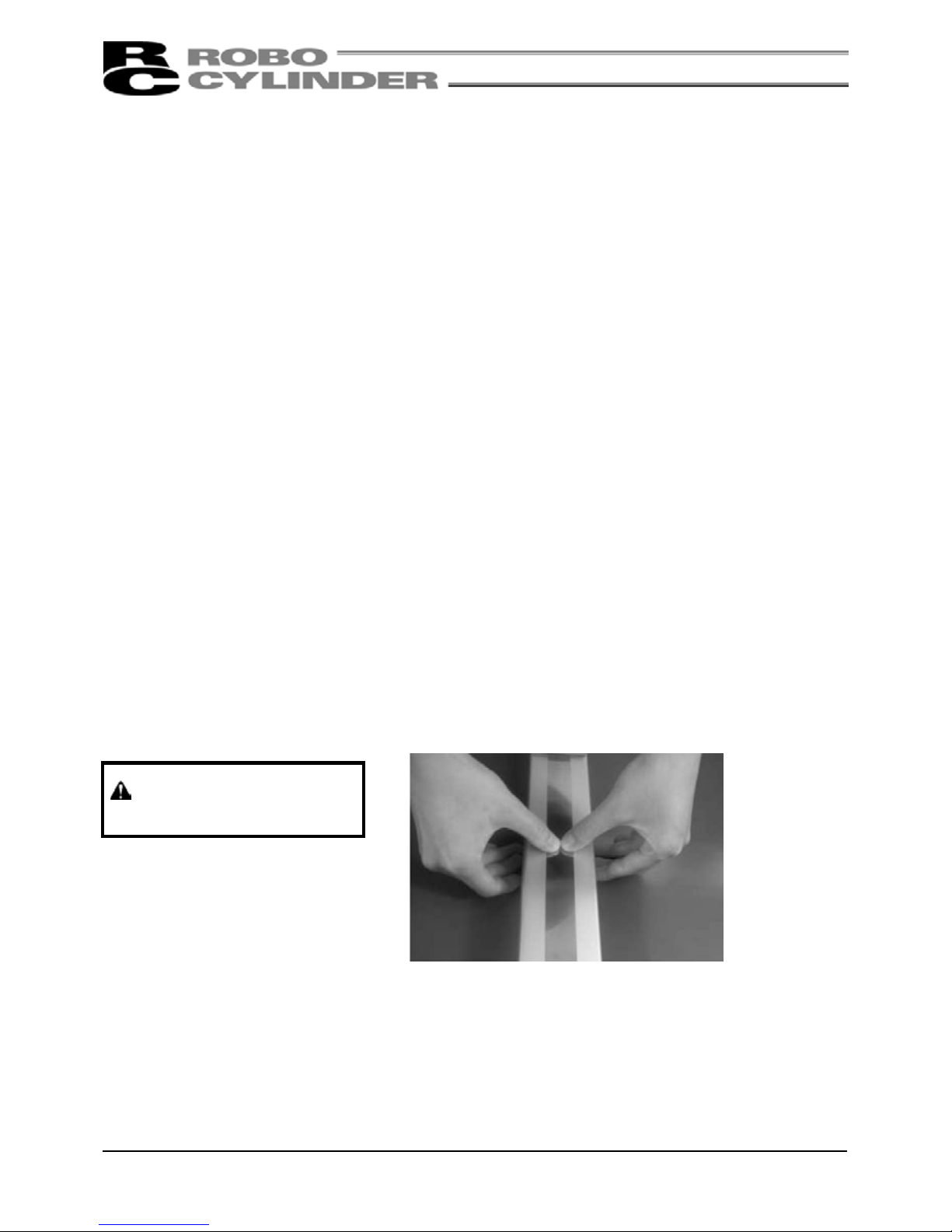

6

4.3 Motor Reversing Type

●SA5R, SA6R

●SA7R

Caution: The cable directly connected to the actuator is not a robot cable even when

ordered with a robot cable option. When designing, please make sure not to give

repeated bending loads to this cable.

The robot cable is applicable only to the connecting cables.

Stainless Sheet

Opposite

Motor End

Side Cove

r

Right Side

Left Side

Cable

Motor

End

Front Cove

r

Base

Mounting Flange

Pulley Cover

Motor End Cap Motor Cove

r

Slider

Stainless Sheet

Opposite

Motor End

Side Cove

r

Right Side

Left Side

Cable

Motor

End

Front Cove

r

Base

Mounting Flange

Pulley Cover

Motor End Cap

Motor Cove

r

Slider

Motor Bracket

Page 19

7

●SS7R, SS8R, HS8R

Caution: The cable directly connected to the actuator is not a robot cable even when

ordered with a robot cable option. When designing, please make sure not to give

repeated bending loads to this cable.

The robot cable is applicable only to the connecting cables.

Stainless Sheet

Opposite

Motor End

Side Cove

r

Right Side

Left Side

Mounting Flange

Motor Bracket

Motor

End

Front Cove

r

Base

Slider

Motor End Cap Motor Cove

r

Pulley Cove

r

Page 20

8

5. Transporting and Handling

5.1 Handling the Actuator

5.1.1 Handling the Packed Unit

Unless otherwise specified, each actuator (axis) is shipped individually. Please make sure that the shipping

box is not dropped or subjected to strong impact during transport.

• Operators should not carry heavy shipping boxes by themselves.

• If the shipping box is left standing, it should be in a horizontal position.

• Do not climb on top of the shipping box.

• Do not place heavy objects which may deform the shipping box or objects with concentrated loads on top of

the box.

5.1.2 Handling the Actuator after It is Unpacked

Lift the actuator up by the base to remove it from the packing.

• When carrying the actuator, make sure not to bump it. Take particular care with the front cover and motor

cover.

• Do not exert excessive force on any part of the actuator.

• Be careful not to cause the cables to receive a tensile force.

• Be careful when handling the stainless sheet

The stainless sheet is designed very thin (thickness: 0.1mm) in order to ensure flexibility. Therefore, the

stainless sheet is easily dented or scratched. Once dented or scratched, the stainless sheet may break during

use.

Warning: Do not press the sheet

directly with hands.

*Please refer to Section 4 above for the names of the actuator parts.

Page 21

9

5.2 Handling the Actuator Assembly

Make sure to the following instructions when transporting an assembly of actuator axes.

5.2.1 Condition of Shipment from IAI (Assembled)

The actuators you have ordered are assembled at IAI, after which the assembly receives a shipping inspection

and is shipped in an outer frame with skids.

The assembly is packed with sliders securely affixed so that they will not move unexpectedly during

transportation. In the case of a combined unit, the actuator ends are secured to prevent swinging due to

external vibration.

• The package is not designed with special considerations for protection against impact due to dropping or

collision, so please handle the package with care. Also, do not place any heavy object on the outer frame, as

it is not strong enough to withstand loads.

• When suspending the package using ropes, etc., pass the ropes from underneath the reinforcement frames

at the bottom of the skids. When lifting with a forklift, also place the forks underneath the skids.

• Set down the package carefully so as not to apply impact to the assembly or cause it to bounce.

After unpacking, handle the actuator assembly correctly by observing the instructions given below.

5.2.2 Handling after Assembly with Peripheral Equipment

When transporting the actuators that have been assembled with peripheral equipment either at IAI or at your

site, observe the instructions given below.

• Secure each slider to prevent unexpected movement during transportation.

• If any actuator end is protruding, secure it to prevent swinging due to external vibration.

• If the actuator ends are not secured, do not apply any impact force exceeding 0.3G during transportation.

• When suspending the actuator-assem bled peripheral equipment using ropes, etc., make sure that the ropes

do not contact the actuators directly.

• Pass the ropes over appr opriate cushion materials, and make sure the loads from the ropes will be received

directly by the base of each actuator.

• Secure the end of the Y-axis using a separate rope to maintain the axis in a stable horizontal position. At this

time, be careful not to apply loads on the screw cover.

• Be careful not to allow the brackets, covers and connector box of each actuator to receive loads. Also protect

the cables from pinching or excessive deformation.

Page 22

10

6. Operating and Storage Environment

6.1 Operating Environment

The actuator should be set up in an environment, which meets the following criteria:

• Avoid direct sunlight.

• Avoid radiant heat from strong heat sources such as a furnace.

• Ambient temperature should be 0 - 40°C.

• The humidity should be less than 85% and there should be no condensation.

• Avoid exposure to corrosive or combustible gases.

• The area should have very little dust and be suitable for normal assembly operation.

• Avoid exposure to oil mist or fluids used in cutting.

• The unit should not be subject to impact or vibrations.

• Avoid extreme electromagnetic waves, ultraviolet rays and radiation.

• This product is not intended to be used in a chemical environment.

In general, the environment should be one in which an operator can work without protective equipment or

protective clothing.

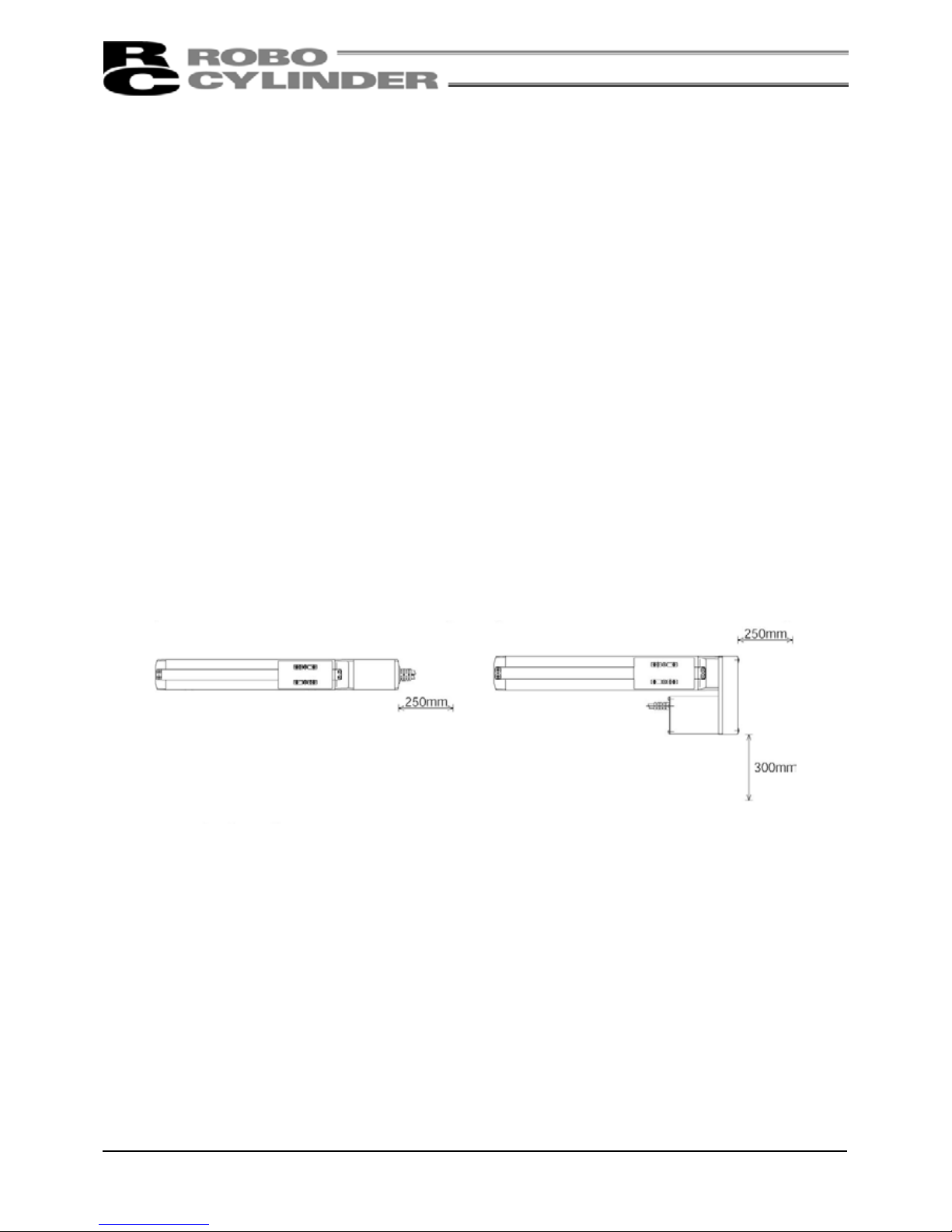

Work space needed for maintenance/inspection

6.2 Storage Environment

The storage environment should be similar to the operating environment. In addition, you must take

precautions against condensation if the unit is to be stored for a long period of time. Unless there are special

instructions, we do not include moisture absorption agents when shipping the unit. If you are storing the unit

where condensation might occur, then you must treat the entire package from outside of the package or treat

the unit itself after it is unpacked to prevent condensation. The unit can withstand up to 60°C during a short

storage interval but only up to 50°C if the storage period is longer than one month.

[

Motor Straight T

y

pe]

[

Motor Reversing Type

]

Page 23

11

7. Installation

Notes on Installation

The stainless sheet is designed very thin (thickness: 0.1mm) in order to ensure flexibility. Therefore, the

stainless sheet is easily dented or scratched. Once dented or scratched, the stainless sheet may break during

use.

When installing the stainless sheet, make sure to the following points:

1. Do not press the sheet directly with

hands.

2. Protect the sheet from dents by making

sure not to drop tools and workpieces

onto the sheet.

3. Do not allow powder dust or iron powd er to generate around the stainless sheet.

If it generates, wipe the stainless sheet fully after operation to remove all particles attached to the

sheet.

If the actuator is operated with the stainless sheet carrying foreign particles, those particles may

enter the slider and damage the sheet or cause the sheet to deform, lift or present other problems.

For SS and HS, the stainless sheet is held in place by means of a magnet on the side covers. Since

metal particles, iron powder or other magnetic substances in ambient air are likely to attach to the

magnets, make sure to the surrounding environment.

Dent

Page 24

12

7.1 Installing the Main Body

Mount the actuator to a machined surface or one of the flat surfaces of comparable precision.

The side faces and lower surface of the base run parallel with the guides. When traveling precision is required,

use these as the reference planes for mounting.

7.1.1 Using the Tapped Holes at Back of the Base (All Types)

Tapped holes are provided on the back of the base for

mounting the actuator. Install the actuator using these

tapped holes. The effective depths of base mounting screws

are listed below. Be careful not to let the ends of bolts

project from the holes. If necessary, use the additional

reamed holes that are provided for positioning purposes.

Type Tap Size Screw Effective Depth Reamed Hole

SA5C M4 4mm or more and 7mm or less φ4H7, depth 5mm or less

SA6C M5 5mm or more and 9mm or less φ4H7, depth 5mm or less

SA7C M5 5mm or more and 9mm or less φ4H7, depth 5mm or less

SS7C M5 5mm or more and 8mm or less φ4H7, depth 5mm or less

SS8C M8 8mm or more and 10mm or less Φ5H7, depth 5mm or less

HS8C M8 8mm or more and 10mm or less Φ5H7, depth 5mm or less

Page 25

13

7.1.2 Using the Mounting Holes on Top of the Base (SA5C, SA6C, SA7C)

Through holes are provided in the base for installing the

actuator on its top face.

When installing the actuator, remove the side covers.

(Remove the two thin-head screws [M3 x 6mm] for mounting

the cover using an Allen wrench of 1. 5mm across flats.)

When securing with bolts, protect the stainless sheet from

dents or damage by making sure not to drop bolts or tools

onto the stainless sheet or contact them with it.

As for mounting bolts, use hexagon socket-head bolts conforming to the applicable specification in the table

below in accordance with the machine frame material.

Type

When the mating material

is steel

When the mating material

is aluminum

Mounting Hole (Reference)

SA5C M4 × 10 M4 × 15 φ4.5 drill, φ8 counterbore depth 4.5

SA6C M4 × 10 M4 × 15 φ4.5 drill, φ8 counterbore depth 4.5

SA7C M5 × 10 M4 × 15 φ6 drill, φ9.5 counterbore depth 5.5

(Note) When reinstalling the side covers, do not let them contact the end faces of the stainless sheet. This

may damage or bend the stainless sheet, causing the sheet to deteriorate or wear quickly.

Therefore, install the side covers and check for bending according to the procedure below.

(1) To prevent the side covers from contacting

the end faces of the sheet, insert a shim

(approx. 0.1 to 0.2mm) between the sheet

and each cover to provide a slight allowance,

and gently push in the cover.

(2) Remove the slider covers and check to see

that the right and left clearances between the

slider and sheet are nearly equal and no

bending is created.

(3) Finally, move the slider back and forth several times along the entire stroke to check that the slider does not

contact the sheet.

Slider

Shee

t

Right and left clearances

are nearly equal

Page 26

14

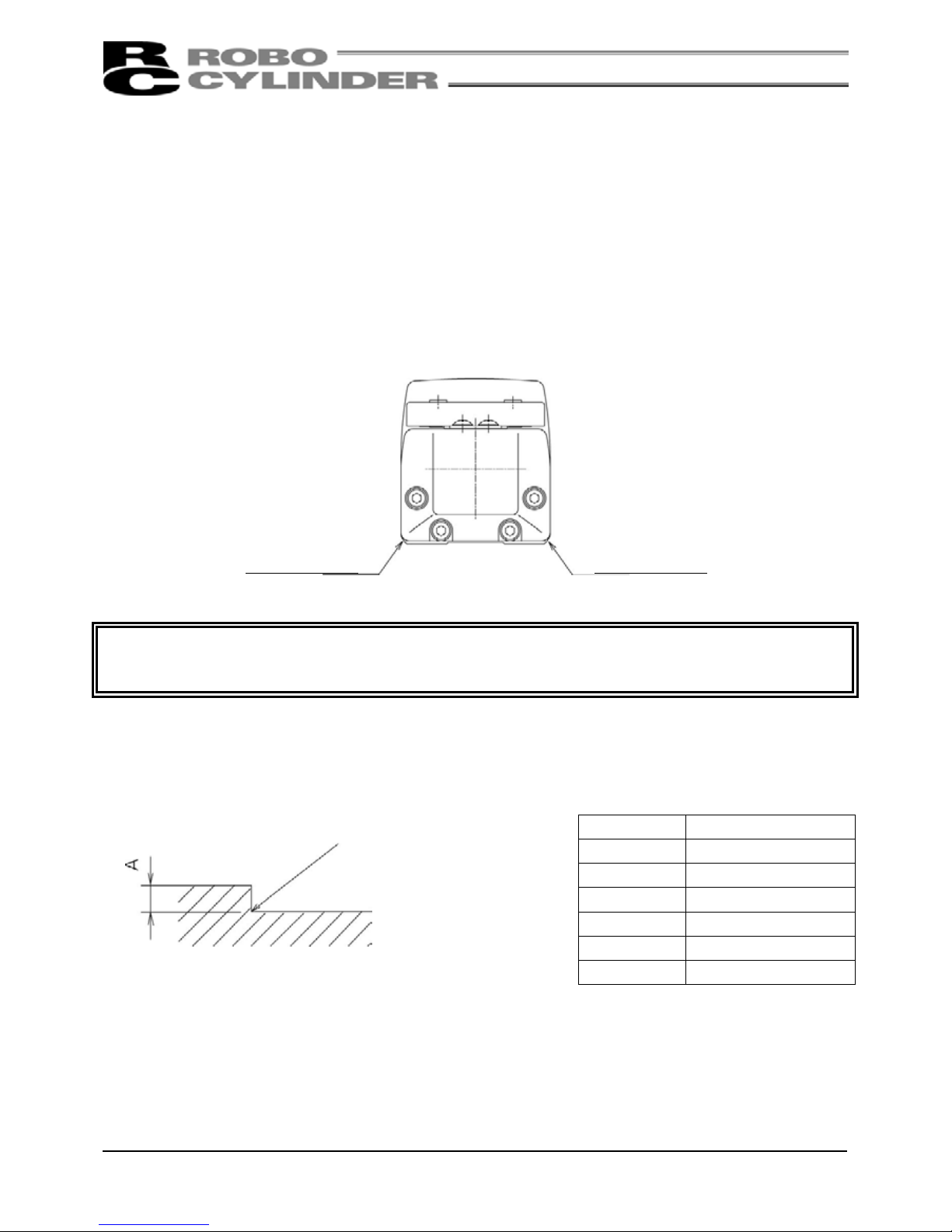

7.2 Mounting Surface

• The mounting table should have sufficient rigidity to avoid generating vibration.

• The surface where the actuator will be mounted should be machined or be equally level and the flatness

tolerance between the actuator and the table should be within 0.05mm.

• Provide sufficient space around the actuator to permit maintenance work to be performed.

• The side and bottom faces of the actuator base provide the reference planes for slider travel.

• When traveling precision is required, use these surfaces as the reference planes for mounting.

Caution: As shown above, the side faces of the base provide the reference planes for slider travel. When

precision is required, use these surfaces as the reference planes for mounting.

When using the base as the reference planes for mounting the actuator to the machine frame, follow the

machining dimensions shown below.

Type Dimension A (mm)

SA5C 2 to 3.5

SA6C 2 to 3.5

SA7C 2 to 5

SA7C 2 to 5

SS8C 2 to 5

HS8C 2 to 5

Reference plane

(

Side face of the base

)

R0.3 or less

Reference plane

(

Side face of the base

)

Page 27

15

7.3 Clamp Screws

• The male screws for mounting the base should be M4 for SA5C, M5 for SS7C/SA6C/SA7C, and M8 for

SS8C/HS8C. (Use hexagon socket-head bolts.)

• For the bolts, we recommend high strength bolts of ISO-10.9 or higher.

• When using a foot base to attach to a mounting table, use the special washer made for high strength bolts

that comes with the actuator if the bolt is M8 or larger. This is unnecessary for M6 or smaller bolts. Do not use

a common spring washer.

• The recommended screw torque is given below.

Screw Torque

Screw Nominal

Diameter

When the bolt seating surface is steel When the bolt seating surface is aluminum

M4 3.6N·m (0.38kgf·m) 1.8N·m (0.18kgf·m)

M5 7.3N·m (0.74kgf·m) 3.4N·m (0.35kgf·m)

M6 30.0N·m (3.1kgf·m) 11.5N·m (1.17kgf·m)

Page 28

16

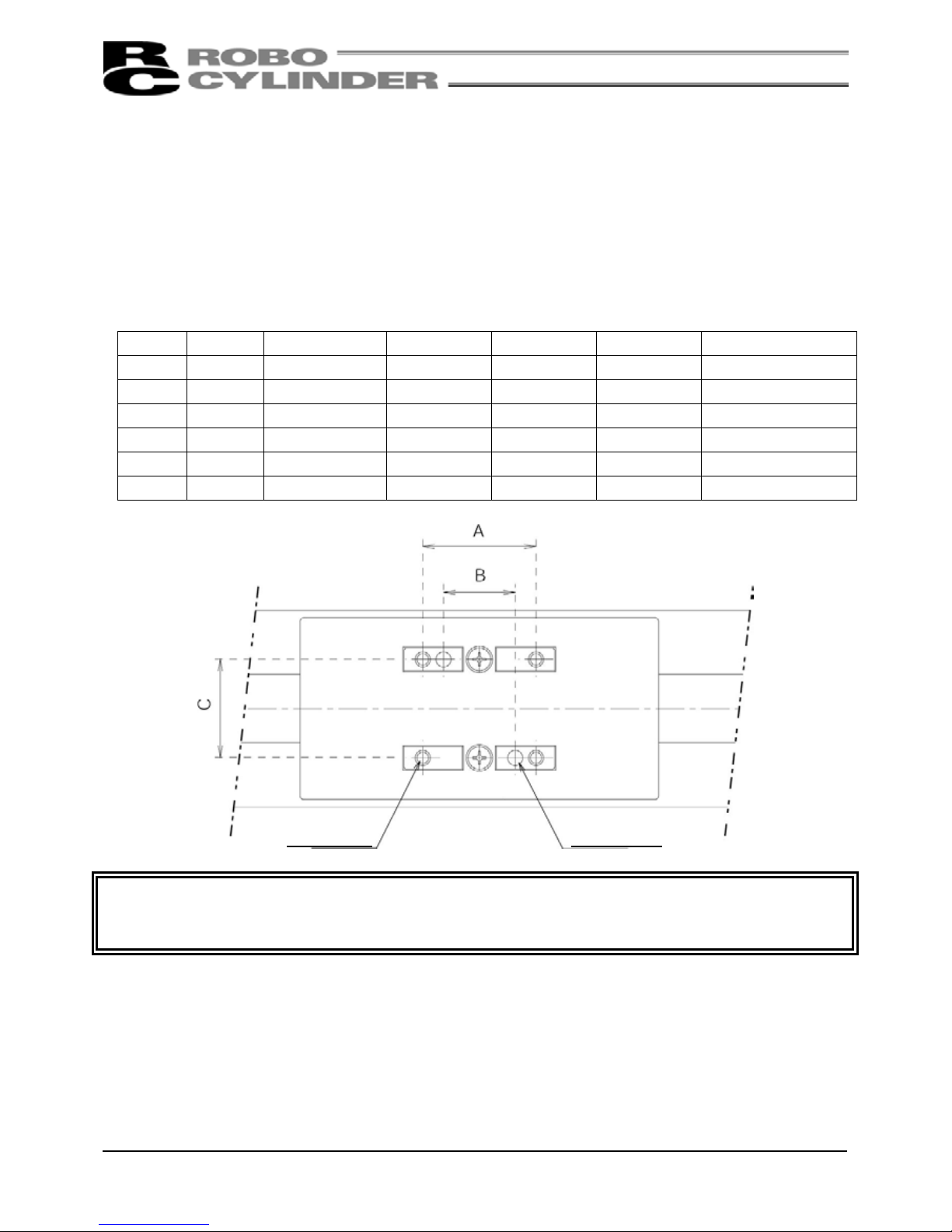

7.4 Installing the Load to the Slider

• Tapped holes are provided on the slider for installing the load. The method of clamping varies according to

how to mount the main body.

• In case of moving the main body with the slider secured, use the same tapped holes on the slider.

• Please use two reamed holes on the slider when repeatability of mounting and dismounting is required. When

fine adjustment of the squareness is necessary, use only one reamed hole to allow adjustment.

Sizes and depths of tapped holes and reamed holes on slider

Model Tap size Depth of thread A B C Reamed hole size

SA5C M4 9mm 30mm 19mm 26mm φ4H7, depth 6mm

SA6C M5 9mm 50mm 32mm 31mm φ5H7, depth 6mm

SA7C M5 10mm 50mm 32mm 39mm φ5H7, depth 10mm

SS7C M5 10mm 50mm 32mm 32mm φ5H7, depth 10mm

SS8C M8 10mm 75mm 45mm 45mm φ8H7, depth 10mm

HS8C M8 10mm 75mm 45mm 45mm φ8H7, depth 10mm

*Caution: When installing the load, do not allow adhesives, paints or other viscous substances to attach to the

stainless sheet. Also, avoid applying a concentrated force that will dent the sheet. It may cause the

slider to malfunction or damage the sheet.

Tapped hole

Reamed hole

Page 29

17

8. Wiring Cable

• In an application where the cable cannot be anchored, try to place the cable so that it sags only under its own

weight or use a self-standing type cable as a large radial wire duct to limit the load on the cable.

• Never cut and/or reconnect the cables supplied with the product for the purpose of extending or shortening

the cable length.

• The cables supplied with an actuator offer excellent flexibility, but they are not robot cables. If the cables are

to be stored in a movable cable duct (cable bearer, etc.), use robot cables.

For cable modification, please contact your IAI sales representatives.

Page 30

18

9. Load on the Actuator

Do not exceed the load shown in the load specification column. Please note the slider moment, allowable

overhang length and the load weight.

Allowable load moments

Type Ma Mb Mc

SA5C 4.9N·m (0.5kgf·m) 6.8N·m (0.7kgf·m)

Stroke: 50 to 300mm - 11.7N·m (1.2kgf·m)

Stroke: 350 to 500mm - 7.8N·m (0.8kgf·m)

SA6C 8.9N·m (0.9kgf·m) 12.7N·m (1.3kgf·m) 18.6N·m (1.9kgf·m)

SA7C 13.9N·m (1.4kgf·m) 19.9N·m (2.0kgf·m) 38.3N·m (3.9kgf·m)

SS7C 14.7N·m (1.5kgf·m) 14.7N·m (1.5kgf·m) 33.3N·m (3.4kgf·m)

SS8C 36.3N·m (3.7kgf·m) 36.3N·m (3.7kgf·m) 77.4N·m (7.9kgf·m)

HS8C 36.3N·m (3.7kgf·m) 36.3N·m (3.7kgf·m) 77.4N·m (7.9kgf·m)

Allowable overhang lengths

Model Ma direction Mb direction Mc direction

SA5C 150mm or less 150mm or less 150mm or less

SA6C 220mm or less 220mm or less 220mm or less

SA7C 230mm or less 230mm or less 230mm or less

SS7C 300mm or less 300mm or less 300mm or less

SS8C 450mm or less 450mm or less 450mm or less

HS8C 450mm or less 450mm or less 450mm or less

• The allowable overhang lengths are based on a configuration where the center of gravity of the load mounted

on the actuator corresponds to the center of the overhang length.

Mb, Mc

directions

Ma

direction

Directions of moment forces

Directions of allowable overhangs

Page 31

19

The body of the base warps easily when the actuator is used as the Y-axis in an X-Y overhang setup. In this

case, use the actuator so that the Ma and Mc moments are kept to one-half the allowable moment or less (see

the figure below).

Caution: Allowing the slider to receive an excessive load moment will shorten the service life of the guides. If

the allowable overhang length is exceeded, vibration may generate or the service life of the guides

may be reduced.

Y-axis

X-axis

The Ma and Mc moments applied

on this slider should be kept to

one-half the allowable moment.

Page 32

20

10. Cleanroom Specification

This actuator can deliver performance which ensures its operation in conformance with the requirements of

cleanliness class 10 (0.1μm) by suctioning air into the suction joint. The recommended suction rate of each

model at the maximum speed is specified below.

10.1 Recommended Suction Rate

Model Maximum speed Suction rate (NI/min)

SA5C, lead 12mm 600mm/s 50

SA5C, lead 6mm 300mm/s 30

SA5C, lead 3mm 150mm/s 15

SA6C, lead 12mm 600mm/s 50

SA6C, lead 6mm 300mm/s 30

SA6C, lead 3mm 150mm/s 15

SA7C, lead 16mm 533mm/s 70

SA7C, lead 8mm 266mm/s 40

SA7C, lead 4mm 133mm/s 30

SS7C, lead 12mm 600mm/s 50

SS7C, lead 6mm 300mm/s 30

SS7C, lead 3mm 150mm/s 15

SS8C, lead 20mm 666mm/s 80

SS8C, lead 10mm 333mm/s 40

SS8C, lead 5mm 165mm/s 20

HS8C 1200mm/s 180

• If there is suction equipment, check its capacity. If there is no suction equipment, select suction equipment

such as a vacuum pump and blower by referring to the values above.

10.2 Suction Joint

• As for the suction joint, a one-touch type is employed and its structure allows the joint to be easily connected

with a commercial air tube.

Model Joint type Tube outer diameter

SA5C

SA6C

SA7C

SS7C

KAT08-U01 (SMC) φ8

SS8C

HS8C

KAT12-U03 (SMC) φ12

A

ir tube connecting port

Page 33

21

11. Maintenance

11.1 Maintenance Schedule

Perform maintenance work according to the schedule below.

The schedule is set assuming eight hours of operation a day. When the operation time is long such as a

24-hour operation, shorten the maintenance intervals as needed.

Visual inspection Check interior Grease supply

Start of operation ○

After 1 month of operation ○

After 6 months of operation ○ ○

After 1 year of operation ○ ○ ○

Every 6 months thereafter ○

Every 1 year ○ ○ ○

11.2 Visual Inspection of the Machine Exterior

Check the following items when carrying out visual inspection.

Body Loose mounting bolts?

Cables Damage to cables or connection to connector box?

Stainless sheet Damage or foreign deposit?

General Unusual noise or vibrations?

11.3 Cleaning

• Clean the exterior as needed.

• Wipe off dirt with a soft cloth.

• Do not use strong compressed air on the actuator as this may force dust into the crevices.

• Do not use petroleum-based solvents on plastic parts or painted surfaces since such solvents damage them.

• If the unit is badly soiled, apply a neutral detergent or alcohol to a soft cloth, and wipe gently.

Page 34

22

11.4 Interior Inspection

Turn off the power, remove the side covers, and then visually inspect the interior.

Check the following items during interior inspection.

Body Loose mounting bolts?

Guides Lubrication appropriate? Soiling?

Ball screw Lubrication appropriate? Soiling?

How to inspect the interior:

1) Remove both side covers.

Use an Allen wrench of 1.5mm across flats for SA5C/SA6C/SA7C/SS7C or an Allen wrench of 2.00mm

across flats for SS8C/HS8C.

Make a visual check of the interior to see if there is any dust

or foreign matter in the unit and check the lubrication. Even

if the grease you see around the parts is brown, the

lubrication is fine as long as the traveling surface appears

shiny.

2) If the grease becomes dirty and dull or if the grease has worn away due to extended operating time,

lubricate the parts after cleaning them.

3) When the inspection/maintenance work is complete, install the side covers.

Tightening torque: SA5C/SA6C/SA7C/SS7C: Thin-head screw M3 × 6 - 87.2N·cm (8.90kgf·cm)

SS8C/HS8C: Thin-head screw M4 × 6 - 204N·cm (20.8kgf·cm)

When installing the side covers, do not let them contact the

end faces of the stainless sheet. This may damage or bend

the stainless sheet, causing the sheet to deteriorate or wear

quickly. To prevent this problem, insert a shim (approx. 0.1

to 0.2mm) between the sheet and each cover between the

sheet and each cover to provide a slight allowance, and

gently push in the cover.

Caution: When checking the interior, be careful not to bend or scratch the stainless sheet. Wear protective

gloves when handling the stainless sheet, because it has sharp edges that may cause accidental

cuts.

The front cover is supporting the ball screw; so do not disassemble the front cover.

If the front cover is misaligned, the shaft centers may become offset, thus increasing the traveling

resistance, reducing the service life of each part, or generating noise.

Page 35

23

11.5 Internal Cleaning

• Wipe off dirt with a soft cloth.

• Do not use strong compressed air on the actuator as this may force dust into the crevices.

• Do not use petroleum-based solvent, neutral detergent or alcohol.

Caution: Do not use flushing oil, molybdenum grease or anti-rust lubricant.

When grease is soiled with a large amount of foreign substances, wipe off the dirty grease and then

apply new grease.

11.6 Lubricating the Guides and Ball Screw

11.6.1 Other than Cleanroom Specification

(1) What Grease to Use on the Guides

The following grease is used when we ship the unit.

Idemitsu Kosan Daphne Eponex Grease No. 2

Other companies also sell a grease similar to this. If ordering from another maker, give the name of this

product and request something comparable. Comparable products include the following:

Showa Shell Oil Albania Grease No. 2

Mobil Oil Mobilux 2

(2) What Grease to Use on the Ball Screw

The following grease is used when we ship the unit.

This grease offers excellent properties such as low heat generation, and is suitable for lubricating ball screws.

Kyodo Yushi Multemp LRL3

Warning: Never use any fluorine-based grease. It will cause a chemical reaction when mixed with a

lithium-based grease and may cause damage to the actuator.

Page 36

24

11.6.2 Cleanroom Specification

(1) What Grease to Use on the Guide and Ball Screw

For guides and ball screw, a urea-based grease of low-dust-raising type which has stable torque

characteristics and superior lubrication performance as well as the anti-rust effect equivalent to that of a

lithium-based grease is used. The following grease is used when we ship the unit:

Kuroda Precision Industries C Grease

Caution: Never use grease for the standard specification. It may allow dust to generate.

Warning: Never use any fluorine-based or lithium-based grease. It will cause the grease to lose its

lubrication performance and may damage the actuator or reduce cleanliness performance

when mixed with an urea-based grease.

Page 37

25

11.6.3 How to Apply Grease

1) When greasing the guide, use a spatula or grease applicator to squeeze or inject grease into the space

between the slider and base, and then move the slider back and forth several times to let grease spread

evenly.

Apply grease on the guides on both sides.

Remove excess grease.

2) When greasing the ball screw, clean the ball screw, apply grease using a finger, and then move the slider

back and forth several times to let the grease spread evenly.

At this time, be careful not to deform the stainless sheet by accidentally touching the sheet.

Remove excess grease.

3) Install the side covers.

Tightening torque: SA5C/SA6C/SA7C/SS7C: Thin-head screw M3 × 6 87.2N·cm (8.90kgf·cm)

SS8C/HS8C: Thin-head screw M4 × 6 204N.cm (20.8kgf.cm)

Refer to 3) in 11.4, “Interior Inspection,” for notes on installing the side covers.

Page 38

26

11.7 Replacing/Adjusting the Stainless Sheet

[Items Required for Replacement]

• Replacement stainless sheet

• Clearance-checking tool (a regular slider cover with holes)

(This tool is available from IAI’s Sales Engineering Section. If you are replacing the stainless sheet, please

contact us to make a rental arrangement or purchase the tool.)

• Allen wrench set • Phillips screwdriver • Scale

[Note on Stainless Sheet Tension]

Deterioration and wear of the stainless sheet is affected by its tension.

If the stainless sheet is too tight, excessive clearances will be created between the sheet and slider covers and

the sheet may undergo a fatigue failure.

If the stainless sheet is too loose, the sheet will contact the back of the slider covers and generate shaving.

Therefore, use a dedicated adjustment tool to properly adjust the tension of the stainless sheet so that the

clearances between the stainless sheet and slider covers conform to the specified dimension.

[Names of Each Part]

Stainless-sheet

retainer plate

Slider-cover affixing screw

(flat countersunk-head

screw)

Stainless-sheet

retainer screw

Stainless sheet Slider cover

Stainless-sheet

retainer screw

Page 39

27

[Procedure]

1) Remove the slider-cover affixing screws and remove the covers.

After the slider covers have been removed

Caution: Remove the slider covers slowly and gently. If the actuator is installed on the ceiling or oriented

vertically or horizontally on its side, place a plastic bag, etc., underneath the slider covers so as not

to lose the coil springs and spacers in case they drop off.

[1] Standard specification (slider structure)

•

SA5C/SA6C

•

SA7C/SS7C/SS8C/HS8C

[2] Cleanroom specification (roller structure)

•

SA5C/SA6C

•

SA7C/SS7C/SS8C/HS8C

Sheet slider

Sheet slider

Sheet slider

Sheet slider

Plate spring

Coil spring

Coil spring

Coil spring

Coil spring

Coil spring

Coil spring

Coil spring

Coil spring

Coil spring

Coil spring

Coil spring

Coil spring

Spacer

Spacer

Roller

Roller

Roller

Roller

Page 40

28

2) Remove the stainless-sheet retainer screws on both sides and pull out the stainless sheet.

3) Guide a new stainless sheet into the slider.

4) Hold the stainless sheet in place, and affix the retainer plates and screws.

At this time, securely tighten the screws only on the motor side, and leave the screws on the counter-motor

side loose.

●How to prevent the stainless sheet from lifting (SA5C/SA6C/SA7C)

Slightly bend the stainless sheet downward near the center of the mounting holes so that the sheet can be

held securely.

5) Install the clearance-checking tool.

Sheet slider

Stainless-sheet retainer plates and screws

Securely tighten the screws only on the motor side,

and leave the screws on the counter-motor side

loose.

Stainless sheet

Near the center of the mounting holes

Slightly bend the sheet

downward.

Peripheral

openings

Center

openings

Install the clearance-checking

tool instead of the slider covers.

Page 41

29

6) Adjust the tension of the stainless sheet.

[1] While looking through the center ope ning in the clearance-checking tool, move the stainless sheet on the

loose end in the directions of arrows until the clearance between the top face of the stainless sheet and the

back of the clearance-checking tool falls within the specified range.

[2] When the stainless sheet has been properly positioned, tighten the screws on the loose end to a level that

the stainless sheet no longer moves.

Move the stainless sheet in the directions of arrows to

adjust the tension.

While looking through the center opening, check the clearance between the top face

of the stainless sheet and the back of the clearance-checking tool. (If the clearance is

within the specified tolerance range, the tension is appropriate even when the

clearance varies along the entire stroke or between right and left.)

(Standard)

(Cleanroom specification)

Page 42

30

[3] Move the slider and check the tension of the stainless sheet along the entire stroke.

If the conditions in Checkpoints 1 and 2 are not satisfied, loosen the screws and readjust the position

and tension of the stainless sheet again from [1].

Note) If the condition in Checkpoint 2 cannot be met after the readjustment, try installing the stainless sheet

in the reverse direction or placing it upside down. If the stainless sheet is still not adjusted properly,

replace it with a new sheet.

[4] When proper clearances are obtained between the slider body and stainless sheet and an absence of

contact between the two is confirmed, tighten the two screws on the loose end alternately, and then finally

tighten all screws to a uniform torque to securely affix the stainless sheet. If the screws are not tightened

uniformly, the sheet may meander or lift.

[5] Remove the clearance-checking tool and install the slider covers.

Note) Again, make sure not to lose the coil springs and spacers.

Checkpoint 1:

Check if the clearance between the top face of the stainless sheet and the back of the

clearance-checking tool falls within the specified range along the entire stroke.

Checkpoint 2:

Look through the peripheral openings and confirm that the stainless

sheet edges do not contact the slider body.

Move the slider back and forth at least three times over the entire stroke

to ensure the edges do not contact the slider.

The sheet may move during the slider strokes, but slight movement is

acceptable as long as the offset does not increase and the sheet does

not contact the slider.

If the stainless sheet contacts the slider, repeat the adjustment from [1].

The stainless sheet is not perfectly straight, but it bends to the right and

left slightly.

It is impossible to adjust the right and left clearances perfectly uniform.

Slight variation in clearance in the stroke direction or between the right

and left is acceptable, as long as the stainless sheet edges do not

contact the slider body over the entire stroke.

Clearances between stainless sheet edges and

slider body

Slider body

Stainless sheet

Apply additional torque to the screws on both ends until the stainless sheet no longer moves.

Tightening torque: SA5C/SA6C/SA7C/SS7C: 87.2N·cm (8.90kgf·cm) (Standard)

45.5N·cm (4.64kgf·cm) (Cleanroom specification) [Reference value]

SS8C/HS8C: 204N·cm (20.8kgf·cm) (Standard)

106N·cm (10.8kgf·cm) (Cleanroom specification) [Reference value]

Page 43

31

11.8 Reduction Belt [Motor Reversing Type]:

11.8.1 Inspecting the Belt

Remove the pulley cover and visually inspect the belt.

Durability of the reduction belt is affected significantly by the operating condition, and there is no standard

guideline as to when the belt should be replaced.

Generally, the belt is designed to withstand several millions of flexing loads.

As a practical guideline, replace the reduction belt when any of the conditions listed below are observed:

• The teeth and end faces of the belt have worn significantly.

• The belt has swollen due to deposits of oil, etc.

• Cracks and other damages are found on the teeth or back of the belt.

• The belt has broken.

11.8.2 Applicable Belt

Manufacturer: Bando Chemical Industries

Model: 60S2M184R: 6mm wide, Rubber STS cleanroom type specification (SA5R/SA6R)

150S3M255U: 15mm wide, Polyurethane rubber specification (SA7R)

100S3M219U: 10mm wide, Polyurethane rubber specification (SS7R)

150S3M252U: 15mm wide, Polyurethane rubber specification (SS8R/HS8R)

11.8.3 Adjusting the Belt Tension

Remove the pulley cover and loosen the four tension adjusting bolts. Apply a tensile load to the belt by moving

the motor to the left and tighten the tension adjusting bolts.

●SA5R, SA6R

SA5R, SA6R, SA7R,

SS7R, SS8R, HS8R

Move the motor cover.

Motor

Tensile load:

Tension adjusting bolts (4 pcs.)

Tension adjusting bolt tightening torque:

Use an Allen wrench of 2.5mm

across flats.

Motor-cover affixing bolts (2 pcs.)

Page 44

32

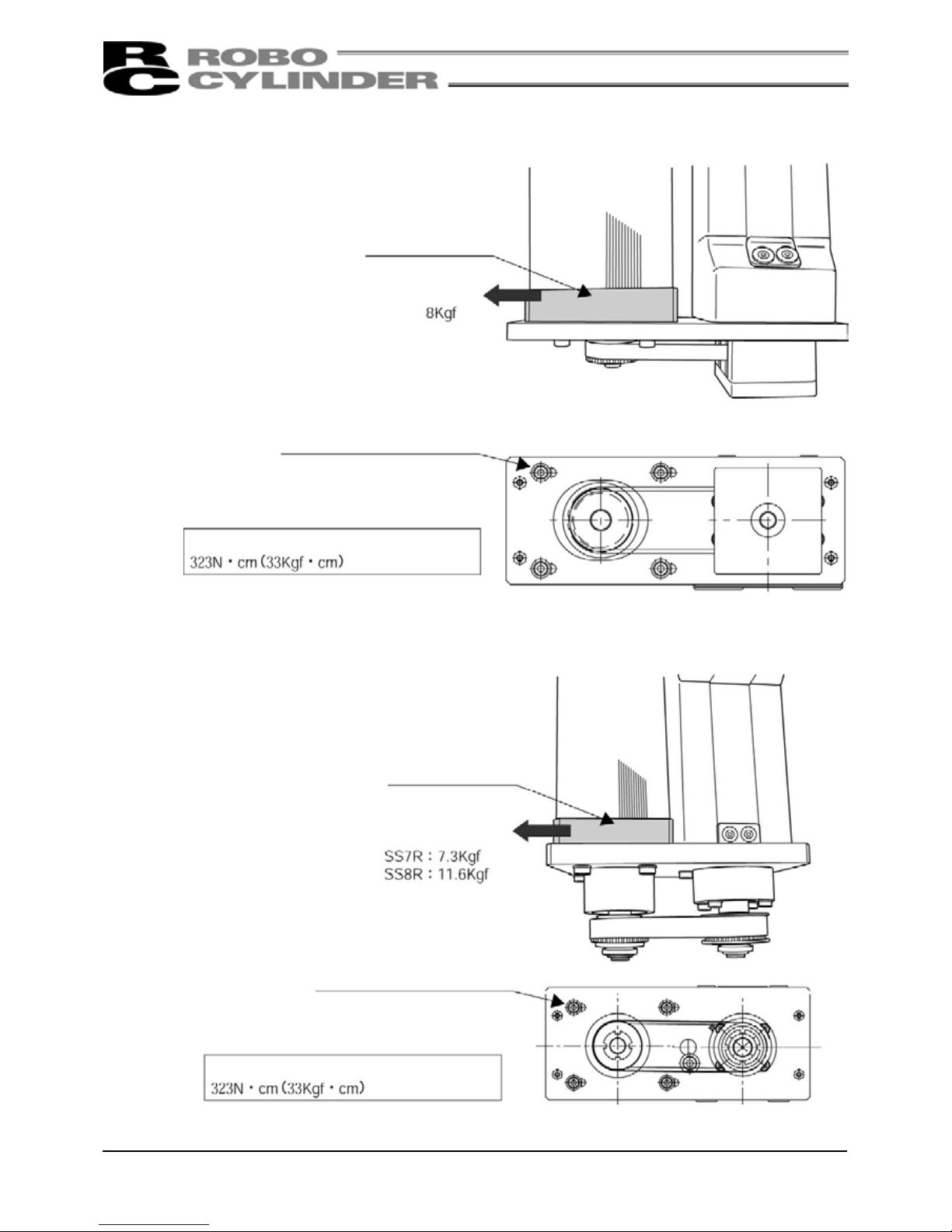

●SA7R

●SS7R, SS8R, HS8R

Motor bracket

Tensile load:

Tension adjusting bolts (4 pcs.)

Tension adjusting bolt tightening torque:

Use an Allen wrench of 3mm

across flats.

Motor bracket

Tensile load:

Tension adjusting bolts (4 pcs.)

Tension adjusting bolt tightening torque:

Use an Allen wrench of 3mm

across flats.

Page 45

33

11.8.4 Replacing the Belt

●SA5R, SA6R

[Items Required for Replacement]

• Replacement reduction belt • Allen wrench set

• Tension gauge (Capable of tensioning to 3kgf or greater)

• Strong string, looped (or long tie-band)

[Procedure]

1) Remove the pulley cover.

Remove the four affixing thin-head screws using an Allen wrench of 1.5mm across flats.

: SA5R, SA6R, SA7R, SS7R, SS8R, HS8R

2) Pull out the two motor-cover affixing bolts and move the motor cover approx. 20mm.

(Use an Allen wrench of 2.5mm across flats.)

3) Loosen the four tension adjusting bolts to loosen the belt.

(Use an Allen wrench of 2.5mm across flats.)

4) Remove the belt from the pulleys.

Page 46

34

8) Attach the pulley cap.

Tighten the hexagon socket-head bolts (M3 x 8mm, 2 pcs.) using an Allen wrench of 2.5mm across flats.

Tightening torque: 83N·cm (8.47kgf·cm)

5) Remove the pulley assembly.

•

Remove the four affixing bolts using an Allen

wrench of 2.5mm across flats.

•

Pull out the assembl

y

by hand.

6) Remove the pulley cap.

•

Remove the two affixing bolts using an Allen

wrench of 2.5mm across flats.

7) Pull out the belt and insert a new belt.

Pulley cap

Insert the belt into

this clearance.

Page 47

35

Tightening torque: 83N·cm (8.47kgf·cm) Tightening torque: 87.2N·cm (8.90kgf·cm)

9) Install the pulley assembly.

•

Align the angles of projections and depressions

on the couplings.

• Tighten the hexagon socket-head

screws (M3 × 22, 4 pcs.) using an Allen

wrench of 2.5mm across flats.

Align the angles of projections and depressions.

10) Loop the belt over the pulleys.

11) Pass a looped strong string (or long tie-band) aro und the motor-end flange and pull it with a tension

gauge to the specified tension. In this condition, uniformly tighten the adjusting bolts (hexagon

socket-head bolts: M3 × 10, 4 pcs.).

(Use an Allen wrench of 2.5mm across flats.)

Tightening torque: 83N·cm (8.47kgf·cm)

Tension: 2.5kgf

Adjusting bolt tightening torque:

162N·cm (16.5kgf·cm)

12) Install the motor cover.

Tighten the hexagon socket-head screws

(M3 × 12, 2 pcs.) using an Allen wrench o

f

2.5mm across flats.

13) Install the pulley cover.

Tighten the thin-head screws (M3 × 6, 4

pcs.) using an Allen wrench of 1.5mm

across flats.

Page 48

36

●SA7R

[Items Required for Replacement]

• Replacement reduction belt • Allen wrench set

• Tension gauge (Capable of tensioning to 8kgf or greater)

• Strong string, looped (or long tie-band)

[Procedure]

1) Remove the pulley cover.

Remove the four affixing thin-head screws using an Allen wrench of 1.5mm across flats.

2) Loosen the four tension adjusting bolts to

loosen the belt.

(Use an Allen wrench of 3mm across flats.)

4) Remove the pulley assembly.

•

Remove the four affixing bolts using an

Allen wrench of 2.5mm across flats.

•

Pull out the assembly by hand.

3) Remove the belt from the pulleys.

Page 49

37

7) Install the pulley cap.

Tighten the hexagon socket-head bolts (M3 × 10, 4 pcs.) using an Allen wrench of 2.5mm across flats.

Tightening torque: 83N·cm (8.47kgf·cm)

5) Remove the pulley assembly.

• Remove the four affixing bolts using an Allen

wrench of 2.5mm across flats.

6) Pull out the belt and insert a new belt.

Pulley cap

Insert the belt into

this clearance.

Page 50

38

8) Install the pulley assembly.

•

Align the angles of projections and depressions

on the couplings.

• Tighten the hexagon socket-head

screws (M3 × 40, 4 pcs.) using an Allen

wrench of 2.5mm across flats.

Align the angles of projections and depressions.

9) Loop the belt over the pulleys.

10) Pass a looped strong string (or long tie-band) aro und the motor bracket and pull it with a tension gauge

to the specified tension. In this condition, uniformly tighten the adjusting bolts (hexagon socket-head

bolts: M4 × 20, 4 pcs.).

(Use an Allen wrench of 3mm across flats.)

Tightening torque: 83N·cm (8.47kgf·cm)

Tension: 8kgf

Adjusting bolt tightening torque:

323N·cm (33kgf·cm)

11) Install the pulley cover.

Tighten the thin-head screws (M3 × 6, 4

pcs.) using an Allen wrench of 1.5mm

across flats.

Tightening torque: 87.2N·cm (8.90kgf·cm)

Page 51

39

●SS7R, SS8R, HS8R

[Items Required for Replacement]

• Replacement reduction belt • Allen wrench set

• Tension gauge (Capable of tensioning to 12kgf or greater)

• Strong string, looped (or long tie-band)

[Procedure]

1) Remove the pulley cover.

Remove the four affixing thin-head screws using an Allen wrench of 2mm across flats.

2) Loosen the four tension adjusting bolts to

loosen the belt.

(Use an Allen wrench of 3mm across flats.)

4) Loop a new belt over both pulleys.

5) Pass a looped strong string (or long tie-band) around the motor bracket and pull it with a tension gauge

to the specified tension. In this condition, uniformly tighten the adjusting bolts (hexagon socket-head

bolts: M4 × 20, 4 pcs.).

3) Remove the belt from the pulleys.

Tension: SS7R: 7.3kgf

SS8R/HS8R: 11.6kgf

Adjusting bolt tightening torque:

323N·cm (33kgf·cm)

Page 52

40

6) Install the pulley cover.

Tighten the thin-head screws (M4 × 6, 4 pcs.) using an Allen wrench of 2mm across flats.

Tightening torque: 204N·cm (20.8kgf·cm)

Page 53

41

11.9 Replacing the Motor

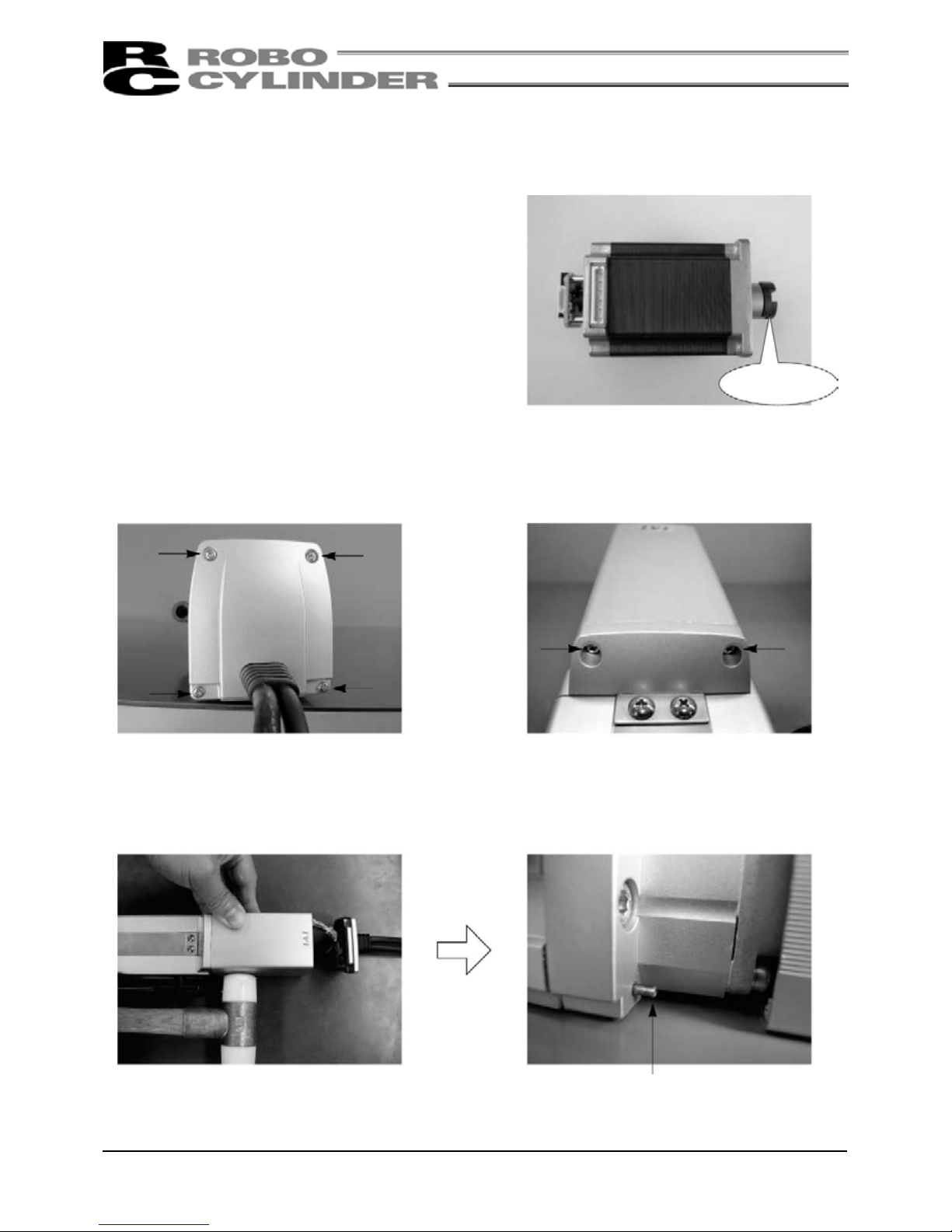

11.9.1 Motor Straight Type

●SA5C, SA6C

[Items Required for Replacement]

• Replacement motor NRC42* (with a coupling on the

motor shaft: see the photograph at the right)

• Allen wrench set

• Phillips screwdriver

• Grease (Kyodo Yushi’s Multemp LRL3 or equivalent)

[Procedure]

1) After removing the flat countersunk-head screws (M3 × 8, 2 pcs.) affixing the cable ends on the motor-end

cap, remove the pan-head screws affixing the motor-end cap.

2) Push in the cable-end molding to create a slack along the inner cable.

Push in the molding as far as possible.

• Pan-head screws (M3 × 80, 4 pcs.)

• Flat countersunk-head screws (M3 × 8, 2 pcs.)

3) Pull out the motor connector.

4) Pull out the encoder connector.

Caution: Do not apply a force to the

encoder by touching it directly.

Coupling

Page 54

42

Pilot alignment metal

If this metal is attached on the

decoupled motor, put it back to

the pilot on the actuator side.

Kyodo Yushi’s Multemp LRL3 has been

applied before shipment.

5) Remove the motor.

•

Remove the affixing bolts (M3 × 50, 2 pcs.) using

an Allen wrench of 2.5mm across flats.

• Pull out the motor by hand.

• Decoupled motor

6) Apply grease to the coupling on the actuator side.

Note: Never use any fluorine-based grease.

It will chemically react with

lithium-based

g

rease and damage the

Page 55

43

7) Install a new motor.

• After confirming that the angles of projections and depressions on the couplings are aligned, tighten the

affixing bolts (M3 × 50, 2 pcs.).

(Use an Allen wrench of 2.5mm across flats.)

Tightening torque: 59N·cm (6kgf·cm)

8) Connect the encoder connector.

9) Connect the motor connector.

Caution: Do not apply a force to the

encoder by touching it directly.

10) Replace the cable-end molding in the original position, and affi

x

it with the flat countersunk-head screws (M3 × 8, 2 pcs.).

Page 56

44

11) Affix the motor end cap with the pan-h ead screws (M3 × 80, 4 pcs.).

At this time, make sure not to pinch the cables.

Tightening torque: 61.5N·cm (6.3kgf·cm)

Page 57

45

●SA7C

[Items Required for Replacement]

• Replacement motor NRC56-* (with a coupling on the motor shaft; see the photograph below.)

• Allen wrench set • Phillips screwdriver

• Grease (Kyodo Yushi’s Multemp LRL3 or equivalent)

[Procedure]

1) After removing the flat countersunk-head screws (M3 × 8, 2 pcs.) affixing the cable ends on the motor end

cap, remove the pan-head screws (M3 × 105, 4 pcs.) affixing the motor end cap.

• Pan-head screws (M3 × 105, 4 pcs.)

• Flat countersunk-head screws (M3 × 8, 2 pcs.)

Coupling

Page 58

46

2) Push in the cable-end molding to create a slack along the inner cable.

Push in the molding as far as possible.

3) Pull out the motor connector.

4) Pull out the encoder connector.

Caution: Do not apply a force to the

encoder by touching it directly.

Page 59

47

Pilot alignment metal

If this metal is attached on the decoupled

motor, put it back to the pilot on the

actuator side.

Kyodo Yushi’s Multemp LRL3 has been

applied before shipment.

5) Remove the motor.

•

Remove the affixing bolts (M4 × 15, 4 pcs.) using an Allen wrench of 3mm across flats.

• Decoupled motor

6) Apply grease to the coupling on the actuator side.

Note: Never use any fluorine-based grease. It

will chemically react with lithium-based

g

rease and damage the actuator.

• Pull out the motor by hand.

Page 60

48

7) Install a new motor.

• After confirming that the angles of projections and depressions on the couplings are aligned, tighten the

affixing bolts (M4 × 15, 4 pcs.).

(Use an Allen wrench of 3mm across flats.)

Tightening torque: 176N·cm (18kgf·cm)

8) Connect the encoder connector.

9) Connect the motor connector.

Caution: Do not apply a force to the

encoder by touching it directly.

10) Replace the cable-end molding in the original position, and affi

x

it with the flat countersunk-head screws (M3 × 8, 2 pcs.).

Page 61

49

11) Affix the motor end cap with the pan-h ead screws (M3 × 105, 4 pcs.).

At this time, make sure not to pinch the cables.

Tightening torque: 61.5N·cm (6.3kgf·cm)

Page 62

50

●SS7C

[Items Required for Replacement]

• Replacement motor SSM42-* (with a coupling on the motor shaft; see the photograph below.)

• Allen wrench set • Phillips screwdriver

• Plastic hammer

[Procedure]

1) Remove the pan-head screws affixing the motor-end cap.

2) Remove the motor cover.

The motor cover is engaged with a positioning pin. If the cover does not come off easily, use a plastic

hammer to gently tap the motor cover from the side, and pull out the cover.

• Pan-head screws (M2 × 10, 2 pcs.)

• Pan-head screws (M3 × 95, 2 pcs.)

Coupling

Positioning pin

Page 63

51

3) Push in the motor-end cap into the motor cover.

4) Pull out the motor connector.

5) Pull out the encoder connector.

Caution: Do not apply a force to the

encoder by touching it directly.

Page 64

52

Motor flange

6) Remove the motor.

•

Remove the affixing bolts (M3 × 15, 2 pcs./M3 × 18, 2 pcs.) using an Allen wrench of 2.5mm

across flats.

• Decoupled motor

• Pull out the motor by hand.

• Remove the motor flange.

Remove the affixing bolts (M3 × 8, 4 pcs.) using an

Allen wrench of 2.5mm across flats.

Page 65

53

7) Install a new motor.

8) Connect the encoder connector.

9) Connect the motor connector.

Caution: Do not apply a force to the

encoder by touching it directly.