Page 1

Teaching Pendant

Operating Manual First edition

IAI America Inc.

Page 2

Page 3

CAUTION

Disconnection of the Teaching Pendant from the

PCON/ACON/SCON/ERC2 Controller

* After disconnecting the Teaching Pendant from the PCON/ACON/SCON controller with the AUTO/MANU

switch, always turn the AUTO/MANU switch to AUTO.

* For the PCON/ACON/ERC2 controller without AUTO/MANU switch, always set the TP Operation Mode to

“Monitor 2” before disconnecting the Teaching Pendant from the controller.

(Refer to “8.10 TP Operation Mode.”)

(Note) When the controller is set by connecting the Teaching Pendant to ERC2, the conditions shown

below occur.

When the controller is set by connecting the Teaching Pendant to the gateway unit/SIO converter,

the conditions shown below occur.

● If the Teaching Pendant is disconnected while the setting of “Teach 1” or “Teach 2”

remains, I/O will become invalid and control from PLC will become impossible.

● If the Teaching Pendant is disconnected while the setting of “Monitor 1” remains, the

maximum speed will become the safety speed set for the parameter regardless of a command

from PLC.

Page 4

Page 5

Support Models

The following are the versions to which we have started support:

Table 1 List of Support Models

Model Name Support Started Version

RCP *1 V1.00

RCS *1 V1.31

E-Con *1 V1.44

RCP2 *1 V1.61

ERC *1 V1.61

ERC2 V2.00

PCON V2.00

ACON V2.00

SCON V2.00

*1: This Teaching Pendant also supports the RCP, RCS,

E-Con, RCP2, and ERC controllers.

* Check the model to connect and the version of the Teaching Pendant. If any unsupported model is

connected, unexpected movement may occur.

* The software reset function is effective for models corresponding to 1.61 or later of the support started

version.

* ERC2, PCON, ACON, or SCON cannot be used by linking to any model of those shown in *1.

Page 6

MEMO

Page 7

Table of Contents

1. Foreword.................................................................................................................................................... 1

2. Before You Begin....................................................................................................................................... 1

3. Safety Precautions ................................................................................................................................... 2

4. Warranty and Scope of Warranty ............................................................................................................... 3

5. Application Environment ............................................................................................................................ 4

6. Functions and Specifications of Teaching Pendant ................................................................................... 5

6-1 Specifications ................................................................................................................................ 5

6-2 External View ................................................................................................................................ 6

6-3 Description of Each Part................................................................................................................ 7

7. Connection With the Controller ................................................................................................................ 11

7-1 Connection with the Teaching Pendant....................................................................................... 11

7-2 How to Disengage the Teaching Pendant ................................................................................... 11

8. Operation: Mode Flow Chart .................................................................................................................... 12

8-1 Initial Screen and TP Operation Mode Screen During Power – UP............................................. 14

8-2 Controller Selection (when using multiple units).......................................................................... 16

8-3 Operation Mode Selection ........................................................................................................... 17

8-3-1 Positioner (PCON-PL/PO, ACON-PL/PO, or SCON: Mode Other than Pulse Train Mode)......... 17

8-3-2 Pulse Train (PCON-PL/PO, ACON-PL/PO, or SCON: Pulse Train Mode) .................................. 18

8-4 Edit/Teaching .............................................................................................................................. 19

8-4-1 PCON, ACON, SCON, or ERC2.................................................................................................. 19

8-4-2 RCP, RCS, E-Con, RCP2, or ERC .............................................................................................. 21

8-5 Position Data Table Contents...................................................................................................... 23

8-5-1 Position Data Table Contents for PCON, ACON, SCON, and ERC2 .......................................... 23

8-5-2 Position Data Table Contents for RCP, RCS, E-Con, RCP2,and ERC ....................................... 29

8-5-3 Data New Input............................................................................................................................ 31

8-5-4 Data Modification......................................................................................................................... 56

8-5-5 Clear • All Clear ........................................................................................................................... 56

8-5-6 Move ........................................................................................................................................... 61

8-5-7 Servo ON/OFF ............................................................................................................................ 68

8-5-8 Pulse Train (PCON-PL/PO, ACON-PL/PO, SCON: Pulse Train Mode) Based Jogging .............. 70

8-6 Monitor ........................................................................................................................

8-7 Error List...................................................................................................................................... 75

................ 72

Page 8

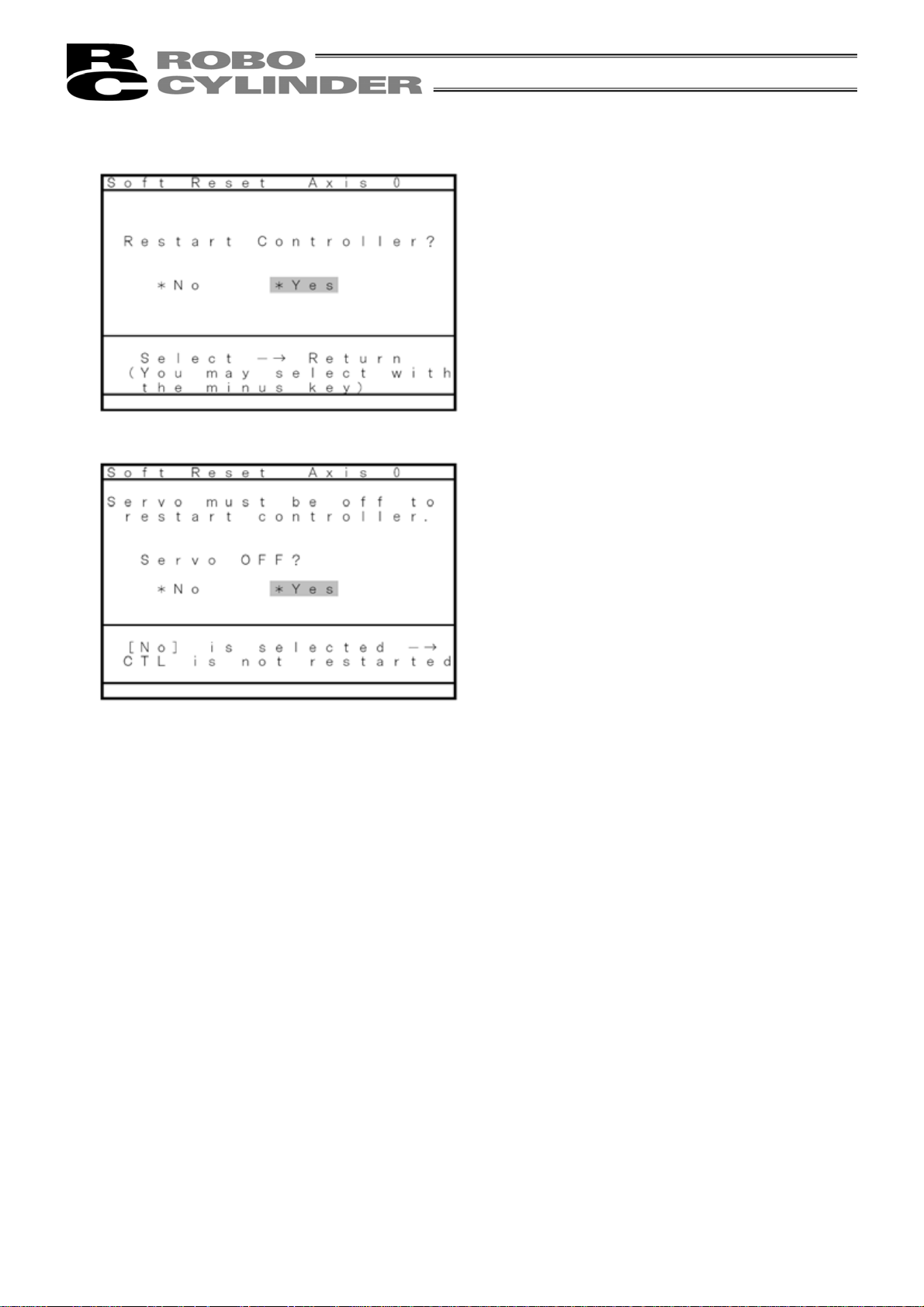

8-8 User Parameters ......................................................................................................................... 77

8-9 User Adjustment.......................................................................................................................... 81

8-9-1 Pause, servo ON input enable and disable setting, homing operation, axis number setting...... 81

8-9-2 Software Reset ............................................................................................................................ 83

8-9-3 Error List Clear ............................................................................................................................ 85

8-10 TP Operation Mode ..................................................................................................................... 87

8-11 End.............................................................................................................................................. 89

9. Message Area.......................................................................................................................................... 90

9-1 Warning Label Error (Code No. 000h – 07Fh)............................................................................. 90

9-2 Teaching Pendant Message Level Error ..................................................................................... 91

9-3 Controller Error............................................................................................................................ 91

* Appendix....................................................................................................................................................... 92

Parameter (Shipment) Initialization Method .................................................................................................... 92

Teaching Pendant error table.......................................................................................................................... 95

Page 9

1. Foreword

Thank you very much for purchasing our Teaching Pendant for the Robo Cylinder. Improper usage or

mishandling may result in a product not only being unable to deliver full functions but also produce unexpected

troubles or shorten the product’s life. Please read this Manual carefully, and operate the product properly by

paying attention to its handling. When operating the Teaching Pendant, always keep this Manual on hand and

read the relevant items as required.

For the actuator and controller to be used, be sure to refer to the Instruction Manuals attached to the

products.

Caution: Do not edit position data while the actuator is operating by PLC, etc.

Also, do not edit any position number not actually operated.

2. Before You Begin

(1) Be sure to read this Instruction Manual for proper use of this product.

(2) Part or all of this Instruction Manual may not be used or reproduced without permission.

(3) For any handling and operating methods other than those described in this Instruction Manual,

interpret them as “don’t

(4) Please take note that we shall not be liable for any effects resulting from using this Instruction Manual.

(5) Descriptions in this Instruction Manual are subject to change due to product improvements etc.,

without prior notice in the future.

” or “can’t.”

1

Page 10

3. Safety Precautions

(1) Use a genuine product specified by us for wiring between the actuator and the Controller.

(2) Keep out of the operating range of a machine such as an actuator while it is operating or in a ready

state (condition in which the controller’s power is ON). When using it in places where persons may

approach, fence it off.

(3) Before carrying out assembly and adjustment work or maintenance and inspection work of the

machine, be sure to disconnect the power cord. While working, display the plate specified as such at

an easy-to-read location. In addition, give special consideration to prevent third parties from turning on

the power carelessly by hauling in the power cord to the operator. Alternatively, lock the power plug or

receptacle and direct the operator to keep the key or prepare a safety plug.

(4) When more than one operator works, advance work by determining the signal method and checking

each other’s safety. Especially, for work associated with axial movement regardless of power ON/OFF

or motor-driven/manual operation, be sure to confirm safety by calling out to other(s) in advance.

(5) When the user (customer) extends wiring, malfunction may occur due to faulty wiring. In this case,

inspect wiring thoroughly and check it for properness before turning on the power.

2

Page 11

4. Warranty and Scope of Warranty

The Teaching Pendant you purchased has been delivered upon completion of our strict shipping tests.

We shall warrantee this product as follows:

1. Warranty term

The warranty term shall be either of the following terms, whichever is reached first.

▪ 18 months after our shipment

▪ 12 months after delivery to the place designated by you

2. Warranty coverage

Where a defective condition occurs during proper use conditions and obviously under the responsibility of

the manufacturer, within the term above, we shall repair the product without charge. However, any items that

apply to the following are excluded from the warranty coverage:

▪ Defects resulting from changes over time such as natural color fading of paint

▪ Defects resulting from use wear of consumable parts (such as a cable)

▪ Defects resulting from sensory phenomena such as generated noise that have no functional effects

▪ Defects resulting from mishandling or improper use

▪ Defects resulting from an inadequacy or error in maintenance and inspection

▪ Defects resulting from the use of any part other than our genuine parts

▪ Defects resulting from a modification not approved by us or our dealers

▪ Defects resulting from Acts of God, accident, fire, etc.

Only a delivered product shall be singly warranted, and no damage induced by the defect of the delivery

product can be warranted. For repair, transport the product to our factory.

3. Service coverage

The cost of a delivered product does not include expenses for program creation and engineer dispatching.

Therefore, the following are charged separately even within the warranty term:

▪ Maintenance and inspection

▪ Technical guidance and technical training in operating instructions

▪ Technical guidance and technical training on program-related matters such as program creation

3

Page 12

5. Application Environment

- In order to avoid breakdown, please do not apply any type of machinery impact to the Teaching

Pendant.

- Always hold onto the entire Teaching Pendant Body so that the Teaching Pendant Cable does not get

pulled by unwanted cables.

Caution: This Teaching Pendant is designed exclusively for IAI RC Controllers (PCON, ACON,

SCON, ERC2, RCP, RCS, E-Con, RCP2, and ERC,) and should not be used to connect

with other devices.

: Turn the controller front side PORT switch OFF before connecting to controller equipped

with a PORT switch.

4

Page 13

6. Functions and Specifications of Teaching Pendant

This Teaching Pendant was created exclusively for the PCON, ACON, SCON ERC2, RCP, RCS, E-Con,

RCP2, and ERC, Controllers.

Through the communication between the controllers, the RC Controller is designed to function as the

Display Operation Unit to edit or display the data (parameter data, position data, etc.,) that is stored inside

the controller, as well as to execute teaching without using the PC Interface Software.

Utilizing a large liquid crystal display kit, the display will show each description simultaneously for easy

operation.

In addition, for quick reference, a manual card is stored inside the Teaching Pendant body.

Large type LCD

Manual card storage

6-1 Specifications

・・・・・・・・・

・・・・

Horizontal 21 characters Vertical 16 columns

Up to 3 cards

Item Specification

Ambient Temperature & Humidity

Operating Environment Free of corrosive gas, especially, no excessive dust

Weight 500g

Cable Length 5m

Temperature: 0°~40°C Humidity: 85% RH or less

* RH relative humidity

5

Page 14

6-2 External View

External Dimensions

When drawing out

the manual card.

6

Page 15

6-3 Description of Each Part

y

y

(1) Large LCD Display

(2) Manual Card

(4) Arrow key

(7)

(5)

(8)

(10) DEADMAN SWITCH

(Minus) key

key

key

(3) EMERGENCY STOP

(6)

(9)

(Return) ke

ke

(1) Large LCD Display

This is a liquid crystal display with a range of 62.69 × 62.69mmm with a maximum of horizontal: 21

characters per column, and vertical: 16 columns per row.

7

Page 16

(2) Manual Card

This is a simplified operational instruction printed on 3 pages. You may observe the instruction by pulling

out the Manual Card from the right side of the Teaching Pendant during operation. When not in use, the

Manual Card may be stored inside the Teaching Pendant Body.

(3) EMERGENCY STOP (Emergency Stop Push Button Switch)

This switch connects serially with the controller emergency stop signal line. Once pushed down, this

switch will be in an emergency stop status and the power supply to the motor will be cut off (normally,

closed: b contact).

(* For information on the Emergency Stop Line and its status, please refer to the RC Robo Cylinder

Operating Manual.)

Caution: If multiple controllers are connected using link cables, the EMERGENCY STOP switch is

enabled only for the axis of the controller which is connected to the Teaching Pendant.

Caution: For the RCP2-CG (cutout relay external type) and ERC/ERC2 series, the EMERGENCY STOP

switch is enabled only when the emergency stop circuit is externally installed. Always read the

operating manual of the controller carefully.

(4) Arrow key:

Every time you press the cursor key of the Selection Display Column Selection and the cursor Move key

of the Position Display Table Main Display Area, the cursor will move to the first item. When pressed for

more than one second the cursor will move continuously. When the content display is composed of more

than two screens (position table and monitor display), these keys scroll to the next screen.

In the farthest right row, push down right arrow key: Next page

In the farthest left row, push down left arrow key: Previous page

In the bottom row, push down arrow key: Next page

In the top row, push down top arrow key: Previous page

8

Page 17

(5)

- By pressing this key for more than 2.5 seconds, the screen changes to the “BEGIN/END” screen and

you can reconnect the axis and execute Teaching Pendant configuration.

- If entering data via key pad, you may cancel midway using this key.

- You may clear error warning.

- When an error occurs, a message for this error will appear at the very bottom of the display screen.

Use this key to clear the error and to clear this message.

- Stop key during continuous movement:

Although the continuous movement functions as a test run for several continuous positions, during this

movement, this key will cause a Stop Command. Once the position move command completes, it will

stop.

key

(6)

(7) (Minus) key

(8)

key

- Although Teaching Pendant operation is composed of several screens, using this key will return the

user to the previous screen.

Note: When you don’t understand the operation, undo the operation by pressing the

- Switches between Relative Coordinates and Absolute Coordinates. Move the cursor to the position

table "No" and press the Minus key. “=” will be displayed between "No" and position to indicate it is

Relative Coordinates. By pressing the Minus key one more time, "=” disappears to indicate it is in

Absolute Coordinates mode.

- Position Table Column: When you push this in an area such as positioning width which allows minus

input, the key functions as the “-“ (minus) and the rest as ".” (point). When you input either

in the beginning of the number, in the proper area, the key will automatically recognize it as O. This

key is used during cursor move within the Mode Select Screen and Sub-Display Screen (e.g,

continuous, step, etc.).

key

key.

or

- This key is used for numeric input.

(9)

9

(Return) key

- This is used for data input and operation confirm.

Page 18

(10) DEADMAN SWITCH (Servo Enable Switch) * Option Setting

The switch mounted on both sides of the Teaching Pendant is connected serially with the Emergency

Stop Switch, and causes e-stop when not pressed (normally, this switch is a "open: a-contact").

Caution: If multiple controllers are connected using link cables, the Deadman SW is enabled only for the axis

of the controller which is connected to the Teaching Pendant.

For the RCP2-CG (cutout relay external type) and ERC/ERC2 series, the Deadman SW is enabled

only when the emergency stop circuit is externally installed. Always read the operating manual of

the controller carefully.

10

Page 19

7. Connection With the Controller

7-1 Connection with the Teaching Pendant

(1) Connect the Teaching Pendant Cable to the “PORT IN” connector which is located on the front of the

controller.

Always turn the PORT switch OFF first before connecting a controller having this switch.

For the locations of the main communication “Port IN” connector and PORT switch, refer to the

operating manual for the controller you use.

(2) After connecting, turn the PORT switch of the controller having this switch ON.

(If the Deadman SW is attached as an option, execute while the Deadman SW button on both sides

are pressed.)

7-2 How to Disengage the Teaching Pendant

Hold down the BEGlN/END key which is located in the upper left corner of the key pad. Select "*

Complete" to finish.

Then, turn the PORT switch OFF for the controller having this switch.

Operation:

1. Hold down the

2. Use the Arrow key to select “* Complete” Screen, and then press the Return key.

3. Turn the PORT switch OFF for the controller having this switch.

4. Remove the Teaching Pendant connector.

key for more than 2.5 seconds.

Caution: In the case of PCON, ACON, SCON, or ERC2, an instantaneous stop will be made when

the Teaching Pendant is disconnected. However, this is not an error.

Caution: In the case of the PCON, ACON, or ERC2 controller not having the AUTO/MANU switch,

set the TP Operation Mode to “Monitor 2” before disconnecting the Teaching Pendant from

the controller. (Refer to “8.10 TP Operation Mode.”)

In the case of ERC2 or when controller setting is made by connecting the Teaching Pendant

to the gateway unit or SIO converter:

● If the Teaching Pendant is disconnected while the setting of “Teach 1” or “Teach 2”

remains, I/O will become invalid and control from PLC will become impossible.

● If the Teaching Pendant is disconnected while the setting of “Monitor 1” remains, the

maximum speed will become the safety speed set for the parameter regardless of a

command from PLC.

11

Page 20

8. Operation: Mode Flow Chart

r

r

(1) Positioner (PCON-PL/PO, ACON-PL/PO, SCON: Mode other than the Pulse Train Mode)

The total picture of operations performed with the Teaching Pendant has the tree structure as shown

below. To return to the previous screen, press the ESC key.

Power-ON

Set-up Communication

TP Operation Mode

Select Axis

* Displayed only when

2 or more axes are

connected

Press & hold the

[BEGIN/END] key

Operation

Start/End

Return to “Set-up

Communication” when

Reconnection is selected

Return

Press & hold the

[BEGIN/END] key

End

* Displayed only for PCON, ACON, SCON, and ERC2.

Return Return Return

Mode Select

* When the

servo is OFF

Servo OFF

Check

* When the

servo is ON

Soft

Reset

* Before changing the parameter

or leaving the mode, check

Edit/Teach

(Position)

whether to reset software.

Monitor

Error List

User Parameter

* Selectable only

* Selectable only

CTR ErrList

Homing

Select with

Clr/All

when the cursor

is located at

“No.”

Select with

Teach/Play

when the cursor

is located at

“Position (mm)”

key

Clea

All Clea

key

Return

Direct teach

Jog

Increment

Homing

Move

Continuous

Srv ON/OFF

User Adjustment

TP operation mode

* Available only for

PCON, ACON,

SCON, and ERC2

Suspend Enable/Disable Setting

Srv ON Enable/Disable Setting

Axis No. Setting

Soft Reset

ErrList Clear

Sip Para

12

Page 21

g

(2) Pulse Train (PCON-PL/PO, ACON-PL/PO, SCON: Pulse Train Mode)

The total picture of operations performed with the Teaching Pendant has the tree structure as shown

below.

To return to the previous screen, press the ESC key.

Power-ON

Set-up Communication

TP Operation Mode

Select Axis

* Displayed only when

2 or more axes are

connected

Press & hold the

[BEGIN/END] key

Operation

Start/End

Return to “Set-up

Communication” when

Reconnection is selected

Press & hold the

[BEGIN/END] key

End

* Displayed only for PCON, ACON, SCON, and ERC2.

Return

Mode Select

* When the

Servo OFF

Check

* When the

Return

Jo

Soft

Reset

* Before changing the parameter or leaving the

mode, check whether to reset software.

Monitor

Error List

User Parameter

User Adjustment

TP operation mode

Suspend Enable/Disable Setting

CTR ErrList

Homing

Axis No. Setting

Srv ON Enable/Disable Setting

Soft Reset

ErrList Clear

Sip Para

13

Page 22

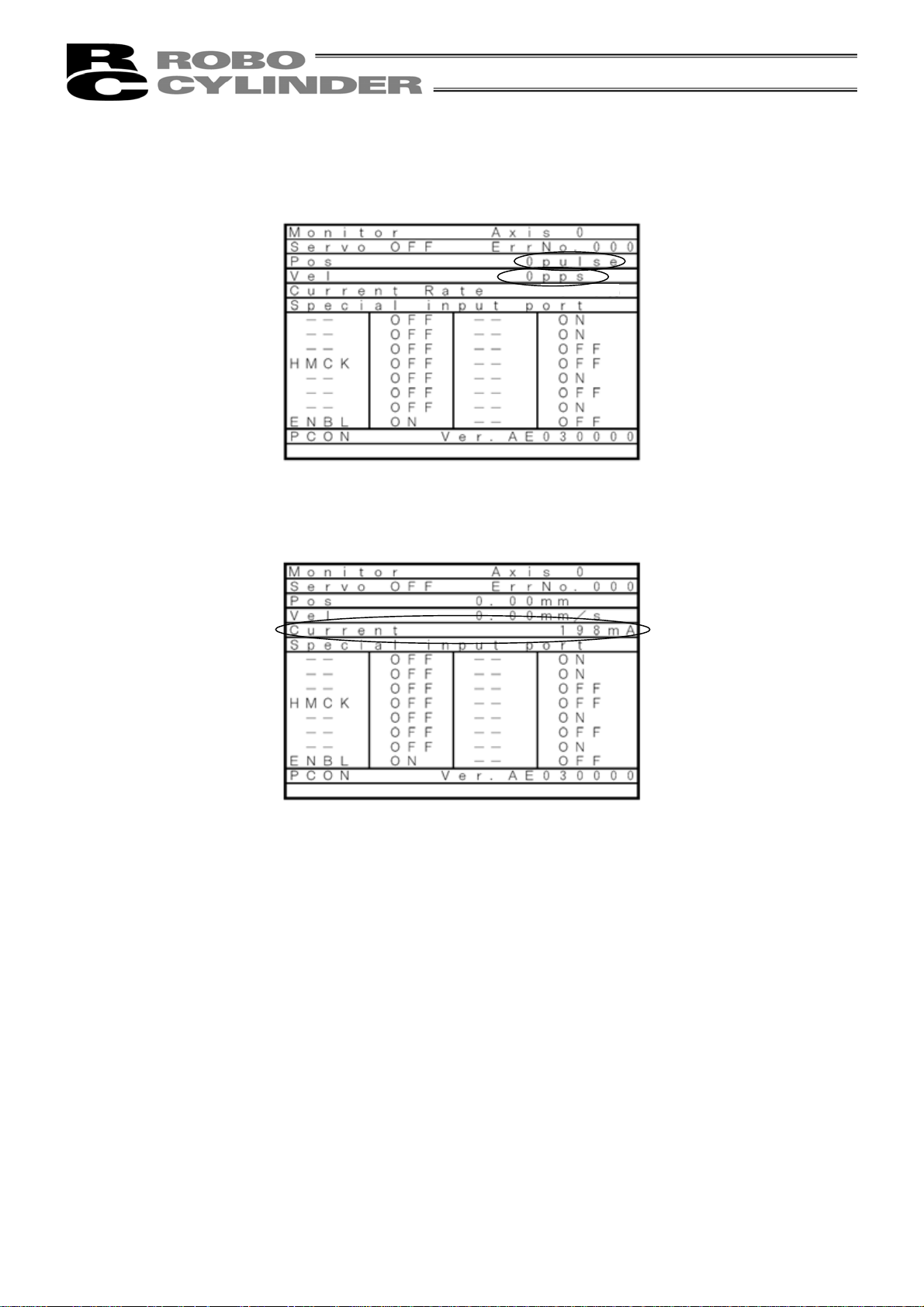

8-1 Initial Screen and TP Operation Mode Screen During Power – UP

When Teaching Pendant is connected to the controller, power is supplied to the Teaching Pendant

and operation starts.

In the case of a controller with a PORT switch, power will be supplied to the Teaching Pendant and

operation will start once power is supplied to the Teaching Pendant.

Upon power-on, the LCD display screen (hereinafter called the “screen”) displays the Teaching

Pendant software version as follows:

Fig. 8.1 Initial Screen During Power – UP

14

Page 23

In the case of the PCON, ACON, SCON, or ERC2 controller, the screen will automatically move to

the TP Operation Mode selection screen once checking of the connection is completed.

In the case of the RCP, RCS, E-Con, RCP2, or ERC controller, the screen will automatically move to

the Select Axis screen if multiple units are connected.

Select a menu item using the arrow keys

(

) or minus key and press the

Return key. The screen will move to the

Select Axis screen.

Fig. 8.2 TP Operation Mode Selection Screen

Select an operation mode from the following 4 menu items:

- Teach 1 (PIO Prh・SftyVel Efct)

PIO Prh: Enables writing of position data, parameters, etc., in the controller and

commands of the actuator movement system.

SftyVel Efct: Keeps the maximum speed at the safety speed set for the parameter regardless

of position data.

- Teach 2 (PIO Prh・SftyVel Non)

PIO Prh: Enables writing of position data, parameters, etc., in the controller and

commands of the actuator movement system.

SftyVel Non: Enables movement at the speed described in position data.

- Monitor 1 (PIO Prm・SftyVel Efct)

PIO Prm: Enables monitoring only. Writing of position data, parameters, etc., in the

controller and commands of the actuator movement system are disabled.

SftyVel Eft: Keeps the maximum speed at the safety speed set for the parameter regardless

of a command from PLC.

- Monitor 2 (PIO Prm・SftyVel Non)

PIO Prm: Enables monitoring only. Writing of position data, parameters, etc., in the

controller and commands of the actuator movement system are disabled.

SftyVel Non: Enables movement at the speed according to a command from PLC.

15

Page 24

8-2 Controller Selection (when using multiple units)

In the case of multiple units connected serially via the communication line, the axis selection screen

will be displayed. For a single unit, since there is no need to select the axis, the first screen below will

not appear (refer to Section 8.3 entitled Operational Mode Selection of this manual).

When a screen has a reversed character background such as

now on, referred to as the "cursor location"). By pressing either arrow key switches Iocated

on the key sheet or the

The controller can connect up to 16 units. However, the PCON, ACON, SCON, or ERC2 controller

cannot be used by linking to the RCP, RCS, E-Con, RCP2, or ERC controller. All the controller axis

numbers (0-15) will be displayed. In the case of PCON, ACON, SCON, or ERC2, a connected model

will be displayed for the connected controller.

In the case of RCP, RCS, E-Con, RCP2, or ERC, “Connected” will be displayed.

By placing the cursor on the desired controller, and pressing the Return key, selection will occur.

The screen will then change to the "Mode Select" screen.

key, the cursor will move.

(3) (1) (2)

, this field is selected (from

Fig. 8.3 Axis Selection Screen

(1) Protocol type display M: Modbus, T: proprietary protocol

(2) Board type display 1: Flash ROM 128KB board, 2: Flash ROM 1MB board

(3) Connection axis display: In the case of PCON, ACON, SCON, or ERC2, the model name of the

connection axis such as PCON will be displayed.

In the case of RCP, RCS, E-Con, RCP2, or ERC, “Connected” will be

displayed.

The above screen shows the following three controllers are connected to the communication line:

Controller axis number: No. 00, No. 04, and No. 13

(Only the powered controller(s) will be detected when power is present for the Teaching Pendant.)

Caution: In the case of controllers with the PORT switch, only the powered controller(s) will be

detected when the PORT switch is ON and power is present for the Teaching Pendant.

The content explained hereinafter will be based on operation in response to the selected axis (controller).

16

Page 25

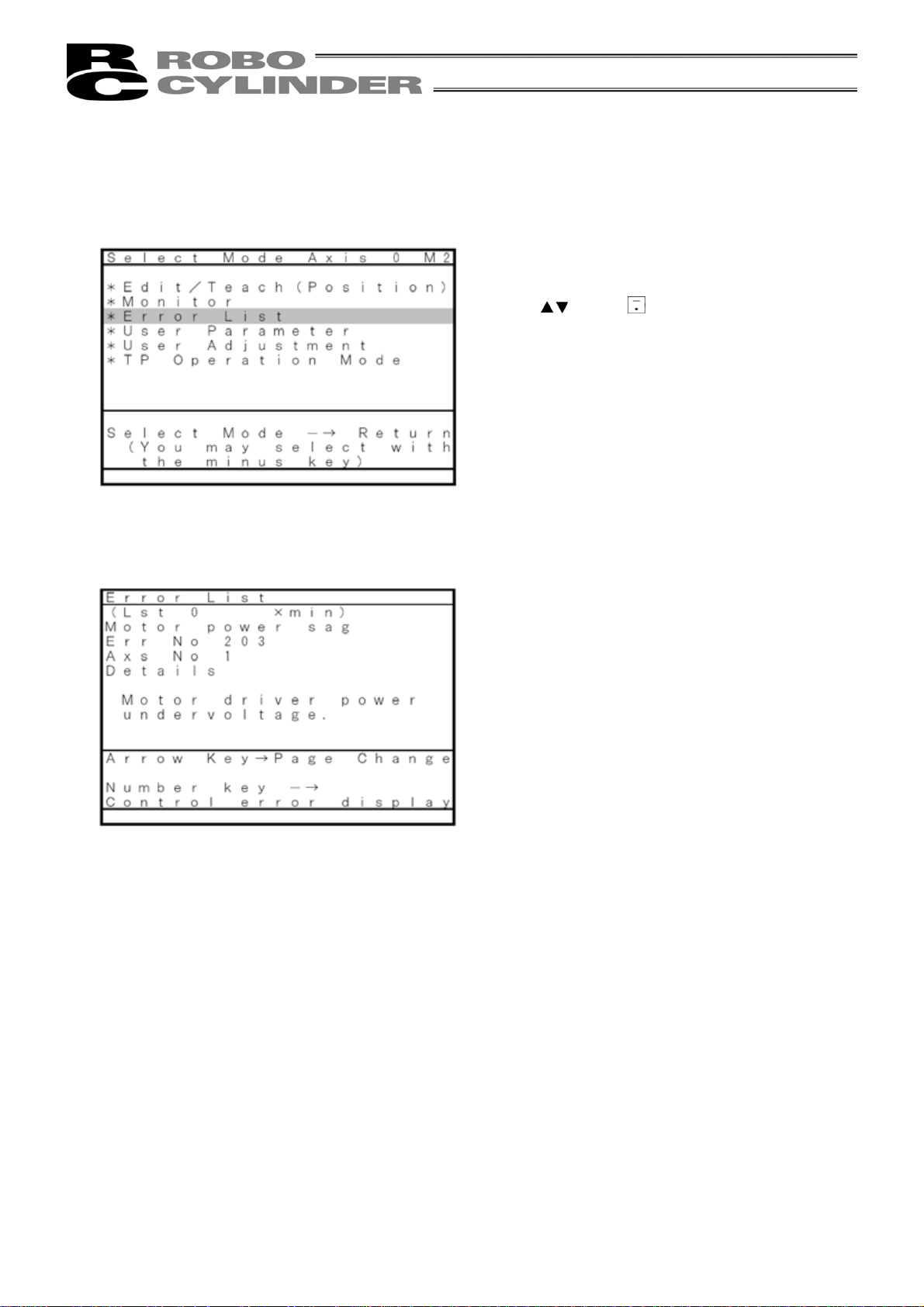

8-3 Operation Mode Selection

r

8-3-1 Positioner (PCON-PL/PO, ACON-PL/PO, or SCON: M ode Other than P ulse

Train Mode)

In the case of the positioner controller of PCON-PL/PO, ACON-PL/PO, or SCON (mode other

than the Pulse Train Mode), the Select Mode screen will be displayed in Fig. 8.4.

Screen Display Name

Listing of modes

Selected controller

axis numbe

Protocol type display

Board type display

Fig. 8.4 Mode Selection Screen

For the modes, select one of the 6 options as it appears on the above screen.

To select it, move the cursor to the mode desired and with an arrow key switch or

and confirm it with the Return key.

Caution: The “* TP Operation Mode” will be displayed only for PCON, ACON, SCON, or ERC2.

Category of Modes

1. * Edit/Teach (Position) Teach and Edit function for position table

(Refer to 8.4 and 8.5)

2. * Monitor Controller status display (Refer to 8.6)

3. * Error list Alarm content detailed display (Refer to 8.7)

4. * User Parameter Setting of axis zone signal output range and axis attributes (Refer to 8.8)

5. * User Adjustment Executing homing and axis number setting of controller series. (Refer to 8.9)

6. * TP Operation Mode Setting of operation mode (Refer to 8.10). Displayed only for PCON, ACON,

SCON, or ERC2.

key switch

17

Page 26

8-3-2 Pulse Train (PCON-PL/PO, ACON-PL/PO, or SCON: Pulse Train Mode)

r

In the case of the PCON-PL/PO, ACON-PL/PO, or SCON controller (pulse train mode), the Select

Mode screen shown in Fig. 8.5 will be displayed.

Screen Display Name

Listing of modes

Fig. 8.5 Mode Selection Screen

For the modes, select one of the 6 options as it appears on the above screen.

To select it, move the cursor to the mode desired and with an arrow key switch or key switch

and confirm it with the Return key.

Category of Modes

1. * Jog Servo ON, homing, jogging, increment movement (Refer to 8.5.8)

2. * Monitor Controller status display (Refer to 8.6)

3. * Error list Alarm content detailed display (Refer to 8.7)

4. * User Parameter Setting of axis zone signal output range and axis attributes (Refer to 8.8)

5. * User Adjustment Executing homing and axis number setting of actuator-integrated controller.

(Refer to 8.9)

6. * TP Operation Mode Setting of operation mode (Refer to 8.10).

Selected controller

axis numbe

Protocol type display

Board type display

18

Page 27

8-4 Edit/Teaching

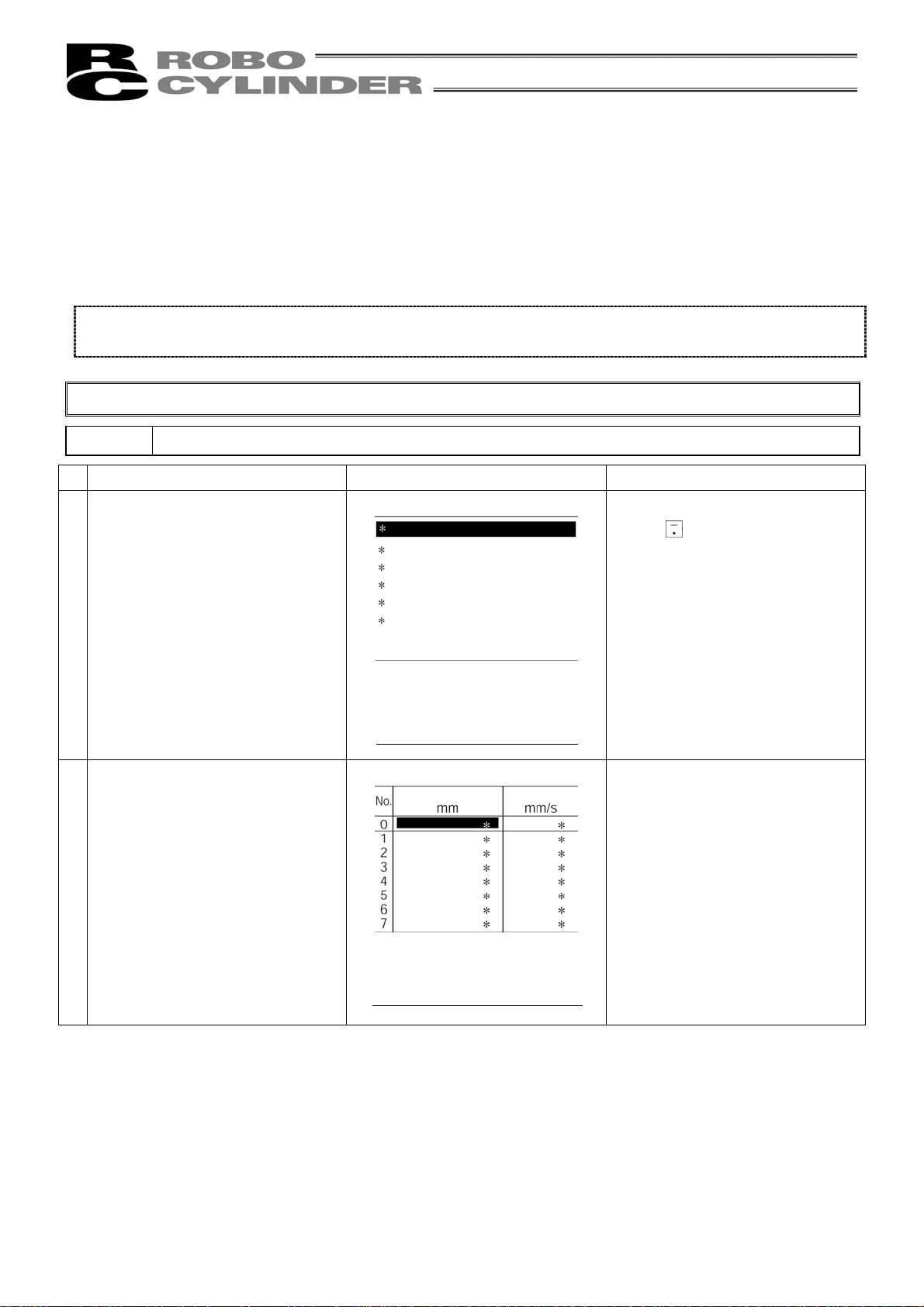

8-4-1 PCON, ACON, SCON, or ERC2

When “* Edit/Teach (Position)” mode is selected, the contents of the position table saved in the

controller will be displayed.

* In the case of PCON-PL/PO, ACON-PL/PO, or SCON (Pulse Train mode), they will not be

displayed.

Title Display Area

Main Display Area

Sub Display Area

Editing axis number

Status Display Area

Error Display Area

Caution: Use the arrow keys (

When the cursor is located inside the sub display area, use the

cursor.

Screen Display Descriptions:

The screen display is divided into the following 5 areas for use:

Title Display Area: Displays the current mode and the selected controller axis number

Main Display Area: Displays the movement position data saved in the controller

Sub Display Area: Used for sub command assignment such as position add and delete

Status Display Area: Display servo status and current location

Error Display Area: Displays messages during editing

Fig. 8.6 Position Data Table Display Screen

) to move the cursor within the main display area.

key to move the

19

Page 28

Stop

Mode

Mode

Cmnd

Mode

AccDcl

Zone- Zone+ Range LoTh Push Dcl Acc Vel Position

The position data main display area is divided and displayed as below.

You can change the screens by continuing to press the arrow keys ( ).

key for 2 sec. or more, the screen will change to the “BEGIN/END” screen.

key and key simultaneously.

the

(If you continue pressing the

Note) When the cursors on the position data table main display area are flashing, you can change the right-and-left areas by pressing

Note) The position number changes according to the model and PIO pattern.

20

Page 29

8-4-2 RCP, RCS, E-Con, RCP2, or ERC

When “* Edit/Teach (Position)” mode is selected, the contents of the position table saved in the

controller will be displayed.

Title Display Area

Main Display Area

Sub Display Area

Status Display Area

Error Display Area

Fig. 8.7 Position Data Table Display Screen

Editing axis number

Caution: Use the arrow keys (

When the cursor is located inside the sub display area, use the key to move the

cursor.

Screen Display Descriptions:

The screen display is divided into the following 5 areas for use:

Title Display Area: Displays the current mode and the selected controller axis number

Main Display Area: Displays the movement position data saved in the controller

Sub Display Area: Used for sub command assignment such as position add and delete

Status Display Area: Display servo status and current location

Error Display Area: Displays messages during editing

) to move the cursor within the main display area.

21

Page 30

The position data main display area is divided and displayed as below.

You can change the screens by continuing to press the arrow keys (

Position Vel Acc Push Range Acc

).

Note)

When the cursors on the position data table main display area are flashing, you can change the right-and-left

areas by pressing the key and key simultaneously.

(If you continue pressing the key for 2 sec. or more, the screen will change to the

“BEGIN/END” screen.

Note) The position number is 0 to 63 for E-Con (RCP2 according to the parameter setting).

22

Page 31

8-5 Position Data Table Contents

8-5-1 Position Data Table Contents for PCON, ACON, SCON, and ERC2

The setting items of the position data table are No., Position, Vel, Acc/Dcl, Push, LoTh, Range,

Zone+, Zone-, AccDcl Mode, Cmnd Mode, and Stop Mode. They are displayed in 10 screens.

The items of Zone+, Zone-, AccDcl Mode, and Stop Mode are enabled (ON) or disabled (OFF)

according to the controller type.

List of ON/OFF of Position Table According to Model

AccDcl Mode Stop Mode

Position Table Zone +/-

ERC2 ○ PIO pattern: 3 ○ × × ○ ○

ERC2-SE ○ - ○ × × ○ ×

PCON-C/CG/CF ○ PIO pattern: 0, 1, 2, 4, 5 ○ × × ○ ○

-CY ○ PIO pattern: 1 ○ × × ○ ○

-SE ○ - ○ × × ○ ×

ACON-C/CG ○ PIO pattern: 0, 1, 2, 4, 5 ○ ○ ○ ○

-CY ○ PIO pattern: 1 ○ ○ ○ ○

-SE ○ - ○ ○ ○ ×

SCON positioner

○ PIO pattern: 0, 1, 2, 4, 5 ○ ○ ○ ○

(1) No. Indicates the position data number.

To specify relative coordinates, move the cursor here and press the minus key. The “=”

sign will appear between No. and Position.

By pressing the minus key again, “=” disappears and the screen returns to absolute

coordinates.

Trapezoid S-shape

First-order

Delay

Full Servo

Auto

Servo

OFF

Warning: Always specify absolute coordinates for the 3-point type of PCON-C/CG,

ACON-C/CG, and SCON-C and the proximity switch type of PCON-CY and

ACON-CY.

If you specify relative coordinates, a position data error will occur.

(2) Position: Input the target position to move the actuator to, in [mm].

- Absolute Coordinates: Input the target location by determining the distance

between the original point and target position. No negative

value can be input.

- Relative Coordinates: Input the target location by determining the distance

between the current position and target position. Any

negative value can be input (if coordinates are in the

negative direction).

Caution: In the case of PCON, ACON, SCON, or ERC2, there are cases where the input value to

“Push” may be rounded off to a multiple of the minimum resolution of the controller

(during data acquisition from the controller).

23

Page 32

(3) Vel: Input the speed at which the actuator will be moved, in [mm/sec].

p

p

The initial value will depend on the actuator type.

(4) Acc/Dcc: Input the acceleration/deceleration at which the actuator will be moved, in [G].

Basically, use acceleration/deceleration within the catalog rated value range.

The input range allows larger value input than the catalog rated values, on the

assumption that the tact time will be reduced if the transfer mass is significantly smaller

than the rated value.

Make the numeric value smaller if transfer work vibrates and causes trouble during

acceleration/deceleration.

Speed

Acceleration

Deceleration

Start

osition

Target

The acceleration will become sudden if the numeric value is made larger,

and it will become gradual if the numeric value is made smaller.

Caution: Enter appropriate values for Vel and Acc/Dec in such a way as to prevent excessive

impact or vibration from being applied to the actuator in consideration of the installation

conditions and the shape of transferred work by referring to the “List of Actuator

Specifications” in the Appendix.

Increasing such values largely relates to the transfer mass and the actuator

characteristics vary depending on the model, consult IAI regarding the input-limiting

values.

(5) Push: - Select the positioning operation or push operation.

The default value is “0.”

0: Normal positioning operation

Other than 0: Indicates the current-limiting value and indicates the push operation.

osition

Time

24

Page 33

(6) LoTh: - This field is invalid.

The default value is 0.

(7) Range: - The “positioning operation” and “push operation” have different meanings.

Positioning operation:

It defines the distance to the target position from a position at which the position

complete signal turns ON.

The default value is 0.1 mm.

Timing of position

complete signal turning ON

Since increasing the positioning width value

hastens the next sequence operation, it

becomes a factor for tact time reduction.

Set the optimum value by considering the

balance of the entire equipment.

Positioning width

Target

position

However, it defines the width of the position complete signal for the 3-point type of

PCON-C/CG, ACON-C/CG, and SCON and the proximity switch type of PCON-CY and

ACON-CY.

3-point type and proximity switch type

Position complete signal

ON

Positioning width

Target

position

Push operation:

It defines the maximum push amount from the target position in the push

operation.

Set the positioning width in such a way as to prevent positioning completion

before the actuator contacts work by considering mechanical variations of

work.

Position at which the position complete

signal turns ON when the actuator contacts

Work

Positioning width

Target

position

(maximum push amount)

25

Page 34

(8) Zone +/-: - It defines the zone where the zone output signal of the standard type turns

ON.

Individual setting is available for each target position to give flexibility.

[Setting example]

No.

Position

[mm]

0 5.00 100.00 0.00

1 380.00 400.00 300.00

Zone+

[mm]

Zone-

[mm]

Comment

Backward

end

Forward

end

2 200.00 250.00 150.00 Midpoint

Movement command to backward end

Zone output signal

Home

Backward

end

Movement command to forward end

Zone output signal

Forward

end

+ side limit

Movement command to midpoint

Zone output signal

Midpoint

(9) Acc/Dcl Mode: - It defines the acceleration/deceleration characteristics.

The default value is 0.

0: Trapezoid pattern

1: S-shaped motion

2: First-order delay filter

Trapezoid pattern

Speed

Acceleration

Deceleration

Time

* Set the acceleration and deceleration in the “Acc” and “Dcl” fields of the position

table.

26

Page 35

S-shaped motion

A curve, which is gradual at the beginning of acceleration but rises sharply

halfway, is drawn.

Use it in the applications for which you want to set the

acceleration/deceleration high due to tact time requirement but desire a

gradual curve at the beginning of movement or immediately before stop.

Speed

Time

* Set the degree of the S-shaped motion with the parameter No. 56 [S-shaped

motion ratio setting]. The setting unit is % and the setting range is between 0 and

100.

(The above is the image graph when 100% setting is made.)

If “0” is set, the S-shaped motion becomes invalid.

However, it will not be reflected in jogging/increment movement by PC or

Teaching Pendant operation.

(Note) It cannot be set for the ERC2 or PCON controller. The parameter No. 56 is

reserved.

First-order delay filter

More gradual acceleration/deceleration curves are drawn than the linear

acceleration/deceleration (trapezoid pattern).

Use this in the applications by giving micro vibrations to work during

acceleration/deceleration not desired.

Speed

Time

* Set the degree of the first-order lag with the parameter No. 55 (constant for the

position command first-order filtering). The setting unit is 0.1 msec and the

setting range is between 0.0 and 100.0.

If “0” is set, the first-lag filter will become invalid.

However, it will not be reflected in jogging/increment movement by PC or

Teaching Pendant operation.

(Note) It cannot be set for the ERC2 or PCON controller. The parameter No. 55 is

reserved.

(10) Cmnd Mode: - This field is invalid.

The factory setting is 0.

27

Page 36

A

(11) Stop Mode: - It defines the power saving method on standby after completion of

positioning to the target position set in the “Position” field of the position

number.

0: Invalid power saving method * The default setting is 0 (invalid).

1: Auto servo OFF method. Delay time defined with the parameter No. 36

2: Auto servo OFF method. Delay time defined with the parameter No. 37

3: Auto servo OFF method. Delay time defined with the parameter No. 38

4: Full servo control method

Full servo control method

The holding current can be reduced by servo-controlling the pulse motor.

The degree of reduction varies depending on the actuator model, load condition, etc., but the

holding current decreases approximately by a factor of 2 to 4.

No displacement occurs since this method maintains the servo ON status.

The actual holding current can be checked on the monitoring screen of PC-compatible

software.

Auto servo OFF method

When a given length of time has elapsed after completion of positioning, the servo OFF status

is automatically entered.

(Since the holding current does not flow, the power consumption can be saved by the same

amount.)

When a movement command is subsequently given from PLC, the status returns to the servo

ON and the actuator starts to move.

Movement

command

28

Auto servo OFF

Servo status

Servo ON status

ctuator

movement

Target position

(Green LED flashing)

T: Delay time (sec) until the servo

OFF status is entered after

completion of positioning

It is set with the parameter.

Page 37

8-5-2 Position Data Table Contents for RCP, RCS, E-Con, RCP2,and ERC

The setting items of the position data table are No., Position, Vel, Acc/Dcl, Push, Range, and Acc

only MAX. They are displayed in 4 screens.

(1) No. Indicates the position data number.

To specify relative coordinates, move the cursor here and press the minus key. The “=”

sign will appear between No. and Position.

By pressing the minus key again, “=” disappears and the screen returns to absolute

coordinates.

(2) Position: Input the target position to move the actuator to, in [mm].

- Absolute Coordinates: Input the target location by determining the distance

between the original point and target position. No negative

value can be input.

- Relative Coordinates: Input the target location by determining the distance

between the current position and target position. Any

negative value can be input (if coordinates are in the

negative direction).

Caution: In the case of PCON, ACON, SCON, or ERC2, there are cases where the input value to

“Push” may be rounded off to the multiple of the minimum resolution of the controller

(during data acquisition from the controller).

(3) Vel: Input the speed at which the actuator will be moved, in [mm/sec].

The initial value will depend on the actuator type.

(4) Acc/Dcc: Input the acceleration/deceleration at which the actuator will be moved, in [G].

The initial value will depend on the actuator type.

(5) Push: - Select the positioning operation or push operation.

The default value is “0.”

0: Normal positioning operation

Other than 0: Indicates the current-limiting value and indicates the push operation.

- In the case of push mode, data number is the servo motor current control value during

push. Uses a value that matches the actuator with a maximum value of 100%.

Time

29

Page 38

(6) Range: - Enter the positioning completion detection width in mm (distance to the target

position) in the positioning mode.

- The distance to the target position indicates that the value input here is the upstream

distance prior to reaching the target position, and the position complete signal is

output when the actuator enters that upstream range.

The default value will depend on the actuator type. (see diagram A)

- Enter the maximum push amount (distance from the target position) in the push

mode. [mm] (see diagram B)

- When the push direction is a minus direction from the displayed coordinate, a “minus”

sign should be placed in the range column.

Speed Speed

(5) When push = 0

(2) Distance up to the position

(5) When push = other than 0

(2) Distance up to the position

Diagram A Diagram B

Transfer distance Transfer distance

(6) Positioning

width

(7) Acc only MAX: - Selects either the assigned acceleration or the maximum acceleration. Inputs

are either 1 or 0. The default value is set as 0.

0: Assigned acceleration

The value placed in (4) will be used as the actual acceleration value and

deceleration value.

1: Maximum acceleration

This will automatically utilize the maximum acceleration matched to the

load.

Deceleration remains as the assigned value in (4).

Speed

(7) When Acc only MAX = 0

(4) The value set in

Acc/Decl

Speed

Transfer

distance

(7) When Acc only MAX = 1

The maximum acceleration

matches the load

(6) Positioning

width

(4) The value set in

Acc/Decl

Transfer

distance

30

Page 39

8-5-3 Data New Input

The following 4 ways to input new position data exist:

(1) Manual Input Manually enter the position data directly from the Teaching Pendant key pad.

(For the input example, see page 34.)

(2) Direct Teach Turn the servo controller OFF, manually move the slider to match the desired

location, and read and command that location into the position table. (For the

input example, see page 43.)

(3) Jog Use the arrow key to jog move and match the desired location, and read that

location (current position) into the position table. (For the input example, see

page 46.)

If you continue pressing the arrow key, the actuator will move at a specified

speed (1, 10, 30, 50, 100 mm/sec). However, only the maximum speed will be

gained if the maximum speed is slower than the specified speed.

(4) Increment Use the arrow key to incrementally move and match the desired location, and

read that location (current position) into the position table. (For the input

example, see page 49.)

If you press the arrow key once, the actuator will move by a specified pitch

(0.03, 0.10, 0.50 [mm]). If you continue pressing the arrow key, the actuator

will move by jogging at 1 mm/sec. in 2 sec. The speed will then increase every

one second. Finer movement than jogging is possible.

Examples of each operation will be explained as follows.

Caution: When input position data is performed first after power-on or method of (2), (3), or (4),

it is required to perform home return operation in advance. (Increment specification)

: Jog and Increment movement prior to homing incomplete status is possible up to the

slider end. Visually, perform the interference check.

31

Page 40

1) Homing

Perform temporary stop reset and servo ON input in advance.

Alternatively, disable servo ON input and temporary stop reset with User Adjustment.

(There is no servo ON input for RCP.)

Caution: Operating instructions are described on the screens of PCON, ACON, SCON, and ERC2.

Operation Screen Reference

1. Select the “* Edit/Teach” and

press the Return key.

Select Mode Axis 1

Edit/Teach (Position)

The cursor will move by the arrow

key or

key.

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may select with

the minus key)

2. Match the cursor to the position.

The number can be anywhere.

Edit/Teach Axis 1

Position Vel

Data unregistered position data

will display “*” sign.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

3. Press the Return key. Edit/Teach Axis 1

Position Vel

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

For numeric values, press just the

Return key.

32

Page 41

Operation Screen Reference

4. Use the key for the cursor and

move to “* Home.”

Edit/Teach Axis 1

Position Vel

Use the key to move the

cursor in the sub display area.

* Direct Teach (Servo OFF)

* Jog *Increment *Home

* Move *Continuous

[Srv ON Pos 0.00]

5. Press the Return key. Edit/Teach Axis 1

Position Vel

* Direct Teach (Servo OFF)

* Jog *Increment *Home

* Move *Continuous

[Srv ON Pos 0.00]

6. Press the key will turn the

mode into Ten key Card Mode.

Edit/Teach Axis 1

Position Vel

Automatically executes home.

* Direct Teach (Servo OFF)

* Jog *Increment *Home

* Move *Continuous

[Srv ON Pos 0.00]

33

Page 42

2) Numeric Input

Caution: Operating instructions are described on the screens of PCON, ACON, SCON, and ERC2.

Example 1: 2 point continuous loop move 30mm <-> 250mm, Speed 300mm/sec

Operation Screen Reference

1. Select * Edit/Teach and press the

Return key.

Select Mode Axis 1

Edit/Teach (Position)

The cursor will move by the arrow

key or

key.

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may also select the

minus key)

2. Match the cursor to the position of

the position number column you

wish to input.

The mode will automatically turn

into the ten key input mode.

Edit/Teach Axis 1

Position Vel

The cursor will move with the

arrow key. Any remaining data

will be written over.

Data unregistered position data

will display “*” sign.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

3. Input here, and press the

Return key again.

Edit/Teach Axis 1

Position Vel

In order to stop during numeric

input, press the

key

to cancel the input.

Example)

With the left operation, by

pressing

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

immediately after inputting after

inputting

, the status will

return to the “*” display.

34

Page 43

Operation Screen Reference

4. Edit/Teach Axis 1

Position Vel

During new position data

registration, the initial values set

with the user parameters for

velocity, acceleration,

deceleration, etc., will be input

automatically.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

In the left screen, the initial value

is set as 100mm/sec.

5. Input here, and press

the Return key again (the cursor

Edit/Teach Axis 1

Position Vel

automatically moves, If change is

not needed, press the Return key

again.)

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

6. Edit/Teach Axis 1

Position Vel

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

35

Page 44

Operation Screen Reference

7. Input here, and press

the Return key again.

Edit/Teach Axis 1

Position Vel

In order to stop during numeric

input, press the

key

to cancel the input.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

8. Edit/Teach Axis 1

Position Vel

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

9. Input here, and press

the Return key.

Edit/Teach Axis 1

Position Vel

The cursor will automatically

move to speed.

36

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

Page 45

Example 2:

2 point continuous loop move Push operation 10mm position <-> 80mm position

(Push range 5mm)

Operation Screen Reference

1. Select * Edit/Teach and press the

Return key..

Select Mode Axis 1

Edit/Teach (Position)

The cursor will move by the arrow

key or

key.

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may also select the

minus key)

2. Match the cursor to the position of

the position number column you

wish to input. The mode will

automatically turn into the ten key

input mode.

Edit/Teach Axis 1

Position Vel

The cursor will move with the

arrow key. Any remaining data

will be written over.

Data unregistered position data

will display “*” sign.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

3. Input here, and press the

Return key again.

Edit/Teach Axis 1

Position Vel

In order to stop during numeric

input, press the

key

to cancel the input.

Example)

With the left operation, by

pressing

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

immediately after inputting after

inputting

, the status will

return to the “*” display.

37

Page 46

Operation Screen Reference

4. Edit/Teach Axis 1

Position Vel

During new position data

registration, the initial values set

with the user parameters for

velocity, acceleration,

deceleration, etc., will be input

automatically.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

In the left screen, the initial value

is set as 100mm/sec.

5. Press the Return key. Edit/Teach Axis 1

Position Vel

At the left, the user parameter is

used as it is.

The cursor will move to the

position of No. 1 by the left

operation.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

6. Input here, and press the

Return key.

Edit/Teach Axis 1

Position Vel

38

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

Page 47

Operation Screen Reference

7. Edit/Teach Axis 1

Position Vel

The cursor will automatically

move to “Vel.”

8. Press the key when the cursor

is located at “Vel.”

9. Press the key when the cursor

is located at “Acc.” The cursor

position will move to “Dcl.”

Press the

key again.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

Edit/Teach Axis 1

Acc Dcl

Acc and Dcl can be

individually set.

[Srv ON Pos 0.00]

Edit/Teach Axis 1

Push LoTh Range

The screen will switch.

The screen will switch.

Push = 0: PTP else: Push

Push, Range > 0: Forward

< 0: Backward

[Srv ON Pos 0.00]

39

Page 48

Operation Screen Reference

10. Input the current value during

push.

Edit/Teach Axis 1

Push LoTh Range

* For push control, refer to the

Controller Operating Manual.

In this example, input 30%.

Input

, and then press the

Return key.

11. Input the maximum push range

during push into the Range.

In this example, input 5 mm.

Input

and press the Return

key.

Push = 0: PTP else: Push

Push, Range > 0: Forward

< 0: Backward

[Srv ON Pos 0.00]

Edit/Teach Axis 1

Push LoTh Range

Push = 0: PTP else: Push

Push, Range > 0: Forward

< 0: Backward

[Srv ON Pos 0.00]

40

Page 49

Example 3: Relative Coordinates pitch movement 30 mm → 40 mm → 50 mm….

Operation Screen Reference

1. Select * Edit/Teach and press the

Return key.

Select Mode Axis 1

Edit/Teach (Position)

The cursor will move by the arrow

key or

key.

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may also select the

minus key)

2. Match the cursor to the position of

the position number column you

wish to input. The mode will

automatically turn into the ten key

input mode.

Edit/Teach Axis 1

Position Vel

The cursor will move with the

arrow key. Any remaining data

will be written over.

Data unregistered position data

will display “*” sign.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

3. Input here, and press the

Return key again.

Edit/Teach Axis 1

Position Vel

In order to stop during numeric

input, press the

key

to cancel the input.

Example)

With the left operation, by

pressing

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

immediately after inputting ,

the status will return to the “*”

display.

41

Page 50

Operation Screen Reference

4. The cursor will move

automatically to the Vel. If there

are no changes, press the Return

key.

Edit/Teach Axis 1

Position Vel

During new position data

registration, the initial values set

with the user parameters for

velocity, acceleration,

deceleration, etc., will be input

automatically.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

In the left screen, the initial value

is set as 100mm/sec.

5. The cursor moves to the next

(No.1) position automatically.

Press the

key to move the

Edit/Teach Axis 1

Position Vel

cursor to No.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

6. Press the key here. Edit/Teach Axis 1

Position Vel

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

Relative coordinate mode

42

Page 51

Operation Screen Reference

7. Press the key to move the

cursor to the Position.

Edit/Teach Axis 1

Position Vel

The “=” sign will be displayed

between No. and position to

indicate that it is the relative

coordinate mode.

By pressing the

key, “=”

disappears and returns the mode

to the absolute coordinate mode.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

8. Input here, and press the

Return key.

Edit/Teach Axis 1

Position Vel

The relative repositioning rate

plus 10 mm are input.

To input the relative repositioning

rate in the negative direction,

press the

key prior to numeric

input.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

9. Edit/Teach Axis 1

Position Vel

The cursor will move

automatically to the Vel.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

43

Page 52

3) Direct Teach

(Method: Manually moving the actuator, matching to the desired position, and teaching that position into the

position table)

When direct teach operation is performed first after power-on, it is required to perform home return operation

in advance. (Refer to page 32.) (Increment specification)

Caution: Operating instructions are described on the screens of PCON, ACON, SCON, and ERC2.

Example: 2 point continuous loop Point A --> Point B, speed 300mm/sec

Operation Screen Reference

1. Select * Edit/Teach and press the

Return key..

Select Mode Axis 1

Edit/Teach (Position)

The cursor will move by the arrow

key or

key.

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may also select the

minus key)

2. Match the cursor to the position of

the position number column you

wish to input.

The mode will automatically turn

into the ten key input mode.

Edit/Teach Axis 1

Position Vel

The cursor will move with the

arrow key. Any remaining data

will be written over.

Data unregistered position data

will display “*” sign.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

3. Press the Return key again. Edit/Teach Axis 1

Position Vel

The numeric value will input the

Return key only.

44

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

Page 53

Operation Screen Reference

4. Use key to move the cursor,

and then select *Direct Teach and

press the Return key (upon

Edit/Teach Axis 1

Position Vel

Use the key to move the

cursor inside the sub display

area.

pressing the Return key, status

will be in servo off. The diagram

on the right shows display before

pressing.)

* Direct Teach (Servo OFF)

* Jog * Increment * Home

* Move * Continuous

[Srv ON Pos 0.00]

5. Manually move the slider and

match to the desired position.

Press the Return key.

Edit/Teach Axis 1

Position Vel

The controller status will be

displayed on the bottom row of

the screen.

Servo Control: OFF

Position: 100.00

Direct Teach (Servo OFF)

Return -> Acquire

[Srv OFF Pos 100.00]

Use the

cursor of the main screen and

change the inputting position

number.

key to move the

45

Page 54

Operation Screen Reference

6. Use the key to move the

cursor to * YES.

Press the Return key again.

Edit/Teach Axis 1

Position Vel

Pressing the Return key will read

the position.

7. Manually move the slider and

match to the next desired

position.

Press the Return key.

Acquire position No. 0?

* NO * Yes

[Srv OFF Pos 0.00]

Edit/Teach Axis 1

Position Vel

Direct Teach (Servo OFF)

Return -> Acquire

[Srv OFF Pos 100.00]

The position data number will

automatically select the next

number (auto increment). As for

the speed and Acc/Dec value, the

initial value set in the user

parameter will automatically

input.

In the example at the left, the

initial value is 300mm/sec.

(Only during new position data

input).

46

Page 55

Operation Screen Reference

8. Use the key to move the

cursor to * YES.

Press the Return key again.

Edit/Teach Axis 1

Position Vel

Pressing the Return key will read

the position.

Acquire position No. 1?

* NO * Yes

[Srv OFF Pos 30.00]

9. Press the key twice. Edit/Teach Axis 1

Position Vel

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

10. Press the key gain.

Select Mode Axis 1

Edit/Teach (Position)

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may also select the

minus key)

The screen will return to the

Edit/Teach main screen.

At this time, the servo control will

turn ON.

The screen will return to the

mode select screen.

47

Page 56

4) Jog Teach

(Method: Tagging the actuator, matching to the desired position, and teaching that position into the position

table)

If you continue pressing the arrow key, the actuator will move at a specified speed (1, 10, 30, 50, 100

[mm/sec]).

However, only the maximum speed will be gained if the maximum speed is slower than the specified speed.

When jog operation is performed first after power-on, it is required to perform home return operation in

advance. (Refer to page 32.) (Increment specification)

Caution: Operating instructions are described on the screens of PCON, ACON, SCON, and ERC2.

Example: 2 point continuous loop Point A --> Point B, speed 300mm/sec

Operation Screen Reference

1. Select * Edit/Teach and press the

Return key..

Select Mode Axis 1

Edit/Teach (Position)

The cursor will move by the arrow

key or

key.

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may also select the

minus key)

2. Match the cursor to the position of

the position number column you

wish to input. The mode will

automatically turn into the ten key

input mode.

Edit/Teach Axis 1

Position Vel

The cursor will move with the

arrow key. Any remaining data

will be written over.

Data unregistered position data

will display “*” sign.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

48

Page 57

Operation Screen Reference

3. Press the Return key again. Edit/Teach Axis 1

Position Vel

The numeric value will input the

Return key only.

4. Use key to move the cursor,

and then select * Jog and press

the Return key.

5. Select speed with the key.

Move the slider with the key

and match it to the desired

position.

: Plus direction of display

coordinates

: Minus direction of display

coordinates

Press the Return key.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

Edit/Teach Axis 1

Position Vel

* Direct Teach (Servo OFF)

* Jog * Increment * Home

* Move * Continuous

[Srv ON Pos 0.00]

Edit/Teach Axis 1

Position Vel

Jog (<- · -> key)

Speed 1 2 3 4 5 -> Fast

Return --> Acquire

[Srv ON Pos 500.00]

Use the key to move the

cursor inside the sub display

area.

: Speed select

Using the

key, move the

main screen cursor to change the

inputting position number.

Vel 1: 1 mm/sec

Vel 2: 10 mm/sec

Vel 3: 30 mm/sec

Vel 4: 50 mm/sec

Vel 5: 100 mm/sec

However, only the maximum

speed will be gained if the

maximum speed is slower than

the specified speed.

49

Page 58

Operation Screen Reference

6. Use the key to move the

cursor to * YES.

Press the Return key again.

Edit/Teach Axis 1

Position Vel

Pressing the Return key will read

the position.

7. Match to the next desired

position.

Press the Return key.

Acquire position No. 0?

* NO * Yes

[Srv ON Pos 500.00]

Edit/Teach Axis 1

Position Vel

Jog (<- · -> key)

Speed 1 2 3 4 5 -> Fast

Return --> Acquire

[Srv ON Pos 100.00]

The position data number will

automatically select the next

number (auto increment). As for

the speed and Acc/Dec value, the

initial value set in the user

parameter will automatically

input.

In the example at the left, the

initial value is 300mm/sec.

50

Page 59

Operation Screen Reference

8. Use the key to move the

cursor to * YES.

Press the Return key again.

Edit/Teach Axis 1

Position Vel

Pressing the Return key will read

the position.

9. Press the key.

Then press the

key gain.

10. Press the key.

Acquire position No. 1?

* NO * Yes

[Srv OFF Pos 100.00]

Edit/Teach Axis 1

Position Vel

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 100.00]

Select Mode Axis 1

Edit/Teach (Position)

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may also select the

minus key)

The screen will return to the

Edit/Teach main screen.

The screen will return to the

mode select screen.

51

Page 60

5) Increment

(Method: Incremental movement using arrow key, matching to the desired position, and teaching that

position into the position table)

If you press the arrow key once, the actuator will move by a specified pitch (0.03, 0.10, 0.50 [mm]).

If you continue pressing the arrow key, the actuator will move by jogging at 1 mm/sec. The speed will

increase every one second. Finer movement than jogging is possible.

When increment movement is performed first after power-on, it is required to perform home return operation

in advance. (Refer to page 32.) (Increment specification)

Caution: Operating instructions are described on the screens of PCON, ACON, SCON, and ERC2.

Example: 2 point continuous loop Point A --> Point B, speed 300mm/sec

Operation Screen Reference

1. Select * Edit/Teach and press the

Return key..

Select Mode Axis 1

Edit/Teach (Position)

The cursor will move by the arrow

key or

key.

Monitor

Error list

User Parameter

User Adjustment

TP Operation Mode

Select Mode -- > Return

(You may also select the

minus key)

2. Match the cursor to the position of

the position number column you

wish to input. The mode will

automatically turn into the ten key

input mode.

Edit/Teach Axis 1

Position Vel

The cursor will move with the

arrow key. Any remaining data

will be written over.

Data unregistered position data

will display “*” sign.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

52

Page 61

Operation Screen Reference

3. Press the Return key again. Edit/Teach Axis 1

Position Vel

The numeric value will input the

Return key only.

4. Use key to move the cursor,

and then select * Increment and

press the Return key.

5. Select speed with the key.

Move the slider with the key

and match it to the desired

position.

: Plus direction of display

coordinates

: Minus direction of display

coordinates

Press the Return key.

Clr/All: No -- > Return

Teach/Play: (Ten key Match)

Position -- > Return

[Srv ON Pos 0.00]

Edit/Teach Axis 1

Position Vel

* Direct Teach (Servo OFF)

* Jog * Increment * Home

* Move * Continuous

[Srv ON Pos 0.00]

Edit/Teach Axis 1

Position Vel

* Increment -> Jog (<- · -> key)

Distance 0.03 0.10 0.05

Return --> Acquire

[Srv ON Pos 0.00]

Use the key to move the

cursor inside the sub display

area.

: Increment distance select

When ( is pressed for more

than 2 seconds, jog movement is

possible. (Upon that, the speed

will increase to 1, 10, 30, 50, and

100 mm/sec every one second.

However, only the maximum

speed will be gained if the

maximum speed is slower than

the specified speed.)

When the desired position is far,

move close to this function, and

release the arrow key once, and

return to the increment for detail

adjustment.

53

Page 62

Operation Screen Reference

6. Use the key to move the

cursor to * YES.

Press the Return key again.

Edit/Teach Axis 1

Position Vel

Pressing the Return key will read

the position.

7. Match to the next desired