Page 1

DSEP Controller

ASEP Controller

PSEP Controller

Instruction Manual Tenth Edition

/

Page 2

Page 3

/

[Important]

This Instruction Manual is original.

The product cannot be operated in any way unless expressly specifi ed in this Instruction Manual.

IAI shall assume no responsibility for the outcome of any operation not specifi ed herein.

Information contained in this Instruction Manual is subject to change without notice for the purpose

of product improvement.

If you have any question or comment regarding the content of this manual, please contact the IAI

sales offi ce near you.

Using or copying all or part of this Instruction Manual without permission is prohibited.

The company names, names of products and trademarks of each company shown in the

sentences are registered trademarks.

Please Read Before Use

Thank you for purchasing our product.

This Instruction Manual describes all necessary information items to operate this product safely such as

the operation procedure, structure and maintenance procedure.

Before the operation, read this manual carefully and fully understand it to operate this product safely. The

enclosed CD/DVD in this product package includes the Instruction Manual for this product.

For the operation of this product, print out the necessary sections in the Instruction Manual or display

them using the personal computer.

After reading through this manual, keep this Instruction Manual at hand so that the operator of this

product can read it whenever necessary.

Page 4

/

Page 5

/

Table of Contents

Safety Guide .............................................................................................................................1

International Standards Compliances .....................................................................................8

CE Marking ...............................................................................................................................9

Precautions in Operation .......................................................................................................10

Name for Each Parts and Their Functions ............................................................................14

Actuator Axes .........................................................................................................................16

Starting Procedures ...............................................................................................................18

1. Specifi cations Check ......................................................................................................19

1.1 Product Check ..................................................................................................................................19

1.1.1 Parts …………………………………………………………………………………………… 19

1.1.2 Teaching Tool (to be purchased separately) ………………………………………………… 19

1.1.3 Instruction manuals related to this product, which are contained in the

instruction manual (CD/DVD). ……………………………………………………………… 20

1.1.4 How to read the model plate ………………………………………………………………… 20

1.1.5 How to read the model of the controller ……………………………………………………… 20

1.2 Basic Specifi cations .........................................................................................................................22

1.3 External Dimensions ........................................................................................................................24

1.4 I/O Specifi cations .............................................................................................................................25

1.4.1 PIO Input and Output Interface ……………………………………………………………… 25

1.5 Installation Environment...................................................................................................................26

1.6 Installation and Noise Elimination ...................................................................................................27

2. Wiring ..............................................................................................................................29

2.1 Wiring Diagram (Connection of construction devices) ...................................................................29

2.2 PIO Pattern Selection and PIO Signal ............................................................................................30

2.3 Circuit Diagram (Example) ..............................................................................................................35

2.4 Wiring Method ..................................................................................................................................41

2.4.1 Wiring Layout of Power Supply Connector ………………………………………………… 41

2.4.2 Wiring Layout of FG Terminal Block ………………………………………………………… 42

2.4.3 Connection to Actuator ……………………………………………………………………… 43

2.4.4 Connection of PIO …………………………………………………………………………… 44

2.4.5 SIO Connector Connection …………………………………………………………………… 45

2.4.6 Battery Connector Connection (For Simple Absolute Type) ……………………………… 46

Page 6

/

3. Operation .........................................................................................................................48

3.1 Setting ...............................................................................................................................................48

3.1.1 Initial Setting …………………………………………………………………………………… 48

3.1.2 Position Data Setting ………………………………………………………………………… 50

3.1.3 Absolute Reset

(This function is effective only when the controller and actuator are the absolute type). … 54

3.2 Power-up and PIO Control ..............................................................................................................55

3.2.1 Control of Input Signal ………………………………………………………………………… 55

3.2.2 Power Input …………………………………………………………………………………… 56

3.2.3 Home-return …………………………………………………………………………………… 57

3.3 Timing Chart .....................................................................................................................................58

3.4 User Parameters ..............................................................................................................................63

3.5 Servo Adjustment .............................................................................................................................65

3.5.1 Adjustment for ASEP and PSEP …………………………………………………………… 65

3.5.2 Adjustment for DSEP ………………………………………………………………………… 66

3.5.3 Servo Parameter ……………………………………………………………………………… 68

3.6 Alarm.................................................................................................................................................69

3.6.1 Alarm Level …………………………………………………………………………………… 69

3.6.2 Alarm Codes and Trouble Shooting ………………………………………………………… 70

4. Appendix .........................................................................................................................75

4.1 List of Specifi cations of Connectable Actuators ..............................................................................75

4.2 Pressing Force and Current Limit Value .........................................................................................99

5. Warranty ........................................................................................................................106

5.1 Warranty Period .............................................................................................................................106

5.2 Scope of Warranty .........................................................................................................................106

5.3 Honoring the Warranty ...................................................................................................................106

5.4 Limited Liability ...............................................................................................................................106

5.5 Conditions of Conformance with Applicable Standards/Regulations, Etc., and Applications .....107

5.6 Other Items Excluded from Warranty ............................................................................................107

Change History .....................................................................................................................108

Page 7

1

/

Safety Precautions for Our Products

The common safety precautions for the use of any of our robots in each operation.

No.

Operation

Description

Description

1 Model Selection ● This product has not been planned and designed for the application

where high level of safety is required, so the guarantee of the protection of

human life is impossible. Accordingly, do not use it in any of the following

applications.

1) Medical equipment used to maintain, control or otherwise affect human

life or physical health.

2) Mechanisms and machinery designed for the purpose of moving or

transporting people (For vehicle, railway facility or air navigation facility)

3) Important safety parts of machinery (Safety device, etc.)

● Do not use the product outside the specifi cations. Failure to do so may

considerably shorten the life of the product.

● Do not use it in any of the following environments.

1) Location where there is any infl ammable gas, infl ammable object or

explosive

2) Place with potential exposure to radiation

3) Location with the ambient temperature or relative humidity exceeding

the specifi cation range

4) Location where radiant heat is added from direct sunlight or other large

heat source

5) Location where condensation occurs due to abrupt temperature

changes

6) Location where there is any corrosive gas (sulfuric acid or hydrochloric

acid)

7) Location exposed to signifi cant amount of dust, salt or iron powder

8) Location subject to direct vibration or impact

● For an actuator used in vertical orientation, select a model which is

equipped with a brake. If selecting a model with no brake, the moving part

may drop when the power is turned OFF and may cause an accident such

as an injury or damage on the work piece.

Safety Guide

“Safety Guide” has been written to use the machine safely and so prevent personal injury or property

damage beforehand. Make sure to read it before the operation of this product.

Page 8

2

/

No.

Operation

Description

Description

2 Transportation ● When carrying a heavy object, do the work with two or more persons or

utilize equipment such as crane.

● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● When in transportation, consider well about the positions to hold, weight

and weight balance and pay special attention to the carried object so it

would not get hit or dropped.

● Transport it using an appropriate transportation measure.

The actuators available for transportation with a crane have eyebolts

attached or there are tapped holes to attach bolts. Follow the instructions

in the instruction manual for each model.

● Do not step or sit on the package.

● Do not put any heavy thing that can deform the package, on it.

● When using a crane capable of 1t or more of weight, have an operator

who has qualifi cations for crane operation and sling work.

● When using a crane or equivalent equipments, make sure not to hang a

load that weighs more than the equipment’s capability limit.

● Use a hook that is suitable for the load. Consider the safety factor of the

hook in such factors as shear strength.

● Do not get on the load that is hung on a crane.

● Do not leave a load hung up with a crane.

● Do not stand under the load that is hung up with a crane.

3 Storage and

Preservation

● The storage and preservation environment conforms to the installation

environment. However, especially give consideration to the prevention of

condensation.

● Store the products with a consideration not to fall them over or drop due to

an act of God such as earthquake.

4 Installation and

Start

(1) Installation of Robot Main Body and Controller, etc.

● Make sure to securely hold and fi x the product (including the work part). A

fall, drop or abnormal motion of the product may cause a damage or injury.

Also, be equipped for a fall-over or drop due to an act of God such as

earthquake.

● Do not get on or put anything on the product. Failure to do so may

cause an accidental fall, injury or damage to the product due to a drop

of anything, malfunction of the product, performance degradation, or

shortening of its life.

● When using the product in any of the places specifi ed below, provide a

suffi cient shield.

1) Location where electric noise is generated

2) Location where high electrical or magnetic fi eld is present

3) Location with the mains or power lines passing nearby

4) Location where the product may come in contact with water, oil or

chemical droplets

Page 9

3

/

No.

Operation

Description

Description

4 Installation and

Start

(2) Cable Wiring

● Use our company’s genuine cables for connecting between the actuator

and controller, and for the teaching tool.

● Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not

coil it around. Do not insert it. Do not put any heavy thing on it. Failure to

do so may cause a fi re, electric shock or malfunction due to leakage or

continuity error.

● Perform the wiring for the product, after turning OFF the power to the unit,

so that there is no wiring error.

● When the direct current power (+24V) is connected, take the great care of

the directions of positive and negative poles. If the connection direction is

not correct, it might cause a fi re, product breakdown or malfunction.

● Connect the cable connector securely so that there is no disconnection or

looseness. Failure to do so may cause a fi re, electric shock or malfunction

of the product.

● Never cut and/or reconnect the cables supplied with the product for the

purpose of extending or shortening the cable length. Failure to do so may

cause the product to malfunction or cause fi re.

(3) Grounding

● The grounding operation should be performed to prevent an electric shock

or electrostatic charge, enhance the noise-resistance ability and control

the unnecessary electromagnetic radiation.

● For the ground terminal on the AC power cable of the controller and the

grounding plate in the control panel, make sure to use a twisted pair cable

with wire thickness 0.5mm

2

(AWG20 or equivalent) or more for grounding

work. For security grounding, it is necessary to select an appropriate

wire thickness suitable for the load. Perform wiring that satisfi es the

specifi cations (electrical equipment technical standards).

● Perform Class D Grounding (former Class 3 Grounding with ground

resistance 100Ω or below).

Page 10

4

/

No.

Operation

Description

Description

4 Installation and

Start

(4) Safety Measures

● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● When the product is under operation or in the ready mode, take the safety

measures (such as the installation of safety and protection fence) so that

nobody can enter the area within the robot’s movable range. When the

robot under operation is touched, it may result in death or serious injury.

● Make sure to install the emergency stop circuit so that the unit can be

stopped immediately in an emergency during the unit operation.

● Take the safety measure not to start up the unit only with the power turning

ON. Failure to do so may start up the machine suddenly and cause an

injury or damage to the product.

● Take the safety measure not to start up the machine only with the

emergency stop cancellation or recovery after the power failure. Failure

to do so may result in an electric shock or injury due to unexpected power

input.

● When the installation or adjustment operation is to be performed, give

clear warnings such as “Under Operation; Do not turn ON the power!” etc.

Sudden power input may cause an electric shock or injury.

● Take the measure so that the work part is not dropped in power failure or

emergency stop.

● Wear protection gloves, goggle or safety shoes, as necessary, to secure

safety.

● Do not insert a fi nger or object in the openings in the product. Failure to do

so may cause an injury, electric shock, damage to the product or fi re.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

5 Teaching ● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● Perform the teaching operation from outside the safety protection

fence, if possible. In the case that the operation is to be performed

unavoidably inside the safety protection fence, prepare the “Stipulations

for the Operation” and make sure that all the workers acknowledge and

understand them well.

● When the operation is to be performed inside the safety protection fence,

the worker should have an emergency stop switch at hand with him so that

the unit can be stopped any time in an emergency.

● When the operation is to be performed inside the safety protection fence,

in addition to the workers, arrange a watchman so that the machine can

be stopped any time in an emergency. Also, keep watch on the operation

so that any third person can not operate the switches carelessly.

● Place a sign “Under Operation” at the position easy to see.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

Page 11

5

/

No.

Operation

Description

Description

6 Trial Operation ● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● After the teaching or programming operation, perform the check operation

one step by one step and then shift to the automatic operation.

● When the check operation is to be performed inside the safety protection

fence, perform the check operation using the previously specifi ed work

procedure like the teaching operation.

● Make sure to perform the programmed operation check at the safety

speed. Failure to do so may result in an accident due to unexpected

motion caused by a program error, etc.

● Do not touch the terminal block or any of the various setting switches in

the power ON mode. Failure to do so may result in an electric shock or

malfunction.

7 Automatic

Operation

● Check before starting the automatic operation or rebooting after operation

stop that there is nobody in the safety protection fence.

● Before starting automatic operation, make sure that all peripheral

equipment is in an automatic-operation-ready state and there is no alarm

indication.

● Make sure to operate automatic operation start from outside of the safety

protection fence.

● In the case that there is any abnormal heating, smoke, offensive smell,

or abnormal noise in the product, immediately stop the machine and turn

OFF the power switch. Failure to do so may result in a fi re or damage to

the product.

● When a power failure occurs, turn OFF the power switch. Failure to do so

may cause an injury or damage to the product, due to a sudden motion of

the product in the recovery operation from the power failure.

Page 12

6

/

No.

Operation

Description

Description

8 Maintenance

and Inspection

● When the work is carried out with 2 or more persons, make it clear who is

to be the leader and who to be the follower(s) and communicate well with

each other to ensure the safety of the workers.

● Perform the work out of the safety protection fence, if possible. In the

case that the operation is to be performed unavoidably inside the safety

protection fence, prepare the “Stipulations for the Operation” and make

sure that all the workers acknowledge and understand them well.

● When the work is to be performed inside the safety protection fence,

basically turn OFF the power switch.

● When the operation is to be performed inside the safety protection fence,

the worker should have an emergency stop switch at hand with him so that

the unit can be stopped any time in an emergency.

● When the operation is to be performed inside the safety protection fence,

in addition to the workers, arrange a watchman so that the machine can

be stopped any time in an emergency. Also, keep watch on the operation

so that any third person can not operate the switches carelessly.

● Place a sign “Under Operation” at the position easy to see.

● For the grease for the guide or ball screw, use appropriate grease

according to the Instruction Manual for each model.

● Do not perform the dielectric strength test. Failure to do so may result in a

damage to the product.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

● The slider or rod may get misaligned OFF the stop position if the servo

is turned OFF. Be careful not to get injured or damaged due to an

unnecessary operation.

● Pay attention not to lose the cover or untightened screws, and make sure

to put the product back to the original condition after maintenance and

inspection works.

Use in incomplete condition may cause damage to the product or an injury.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

9 Modifi cation and

Dismantle

● Do not modify, disassemble, assemble or use of maintenance parts not

specifi ed based at your own discretion.

10 Disposal ● When the product becomes no longer usable or necessary, dispose of it

properly as an industrial waste.

● When removing the actuator for disposal, pay attention to drop of

components when detaching screws.

● Do not put the product in a fi re when disposing of it.

The product may burst or generate toxic gases.

11 Other ● Do not come close to the product or the harnesses if you are a person who

requires a support of medical devices such as a pacemaker. Doing so may

affect the performance of your medical device.

● See Overseas Specifi cations Compliance Manual to check whether

complies if necessary.

● For the handling of actuators and controllers, follow the dedicated

instruction manual of each unit to ensure the safety.

Page 13

7

/

Alert Indication

The safety precautions are divided into “Danger”, “Warning”, “Caution” and “Notice” according to the

warning level, as follows, and described in the Instruction Manual for each model.

Level Degree of Danger and Damage Symbol

Danger

This indicates an imminently hazardous situation which, if the

product is not handled correctly, will result in death or serious

injury.

Danger

Warning

This indicates a potentially hazardous situation which, if the

product is not handled correctly, could result in death or serious

injury.

Warning

Caution

This indicates a potentially hazardous situation which, if the

product is not handled correctly, may result in minor injury or

property damage.

Caution

Notice

This indicates lower possibility for the injury, but should be kept to

use this product properly.

Notice

Page 14

8

/

ASEP/PSEP and DSEP comply with the following international standards:

RoHS Directive CE Marking UL

(Note)

○○○

(Note) The DSEP is not applicable to UL.

International Standards Compliances

Page 15

9

/

CE Marking

If a compliance with the CE Marking is required, please follow Overseas Standards Compliance

Manual (ME0287) that is provided separately.

Page 16

10

/

Precautions in Operation

1. Use the following teaching tools.

Use the teaching tool such as the PC software stated in the next clause as the applicable for this

controller.

● Teaching Tools that is applicable for this controller

[Refer to 1.2.2]

2. Backup the data to secure for breakdown.

A non-volatile memory is used as the backup memory for this controller. All the registered

position data and parameters are written into this memory and backed-up at the same time.

Therefore, you will not usually lose the data even if the power is shut down. However, make sure

to save the latest data so a quick recovery action can be taken in case when the controller is

broken and needs to be replaced with another one.

How to Save Data

(1) Save the data to CD-R or hard disk with using the PC software

(2) Hard-copy the information of position tables and parameters on paper

3. Set the operation patterns.

This controller possesses 6 types of control logics to meet various ways of usage, and changes

the role of each PIO signal following the selected control logic.

The setup can be performed in the initial setting.

[Refer to 2.1]

The PIO pattern is set to “0” (Standard Point-to-Point Movement) when the unit is delivered. Set

the operation pattern setting to the logic that suits to your use after the power is turned on.

Warning:

Please note it is very risky when the control sequence and PIO pattern setting do not match to each

other. It may not only cause the normal operation disabled, but also may cause an unexpected

movement.

Page 17

11

/

4. Operation cannot be performed unless there is an input of Servo-on

Signal and Pause Signal.

(1) Servo-on Signal (SON)

Servo-on signal (SON) is selectable from either “Enable” or “Disable” by the setting.

It is settable in the initial setting.

[Refer to 2.1 Setting]

If it is set to “Enable”, the actuator would not operate unless turning this signal on.

If it is set to “Disable”, the servo becomes on and the actuator operation becomes enabled

as soon as the power supply to the controller is turned on and the emergency stop signal is

cancelled.

[Refer to 2.1 Setting]

It is set to “Disable” when the unit is delivered. Have the setting that suits to the desirable control

logic.

(2) Pause Signal (*STP)

The input signal of the pause signal (*STP) is always on considering the safety. Therefore, in

general, the actuator would not operate if this signal is not on.

It is available to make this signal to “Not to use”, if this signal is undesirable.

It is settable in the initial setting.

[Refer to 2.1 Setting]

If it is set to “Not to use”, the actuator operation is available even without this signal being on.

It is set to “Not to use” when the unit is delivered.

5. Rotary actuator cannot be set to Multi-Rotation Specifi cation.

Rotary actuator cannot be set to Multi-Rotation Specifi cation since the index mode setting cannot

be performed.

Page 18

12

/

Output

Process

Input

Process

6. Transference of PIO Signal between Controllers

Please note the following when conducting transference of PIO signal between controllers.

To certainly transfer the signal between controllers with different scan time, it is necessary to

have longer scan time than the one longer than the other controller. To ensure to end the process

safely, it is recommended to have the timer setting more than twice as long as the longer scan

time at least.

● Operation Image

PLC

(e.g. scan time is 20msec)

Also, if one tries to read the signal that is being re-written by the other, the signal may be read wrongly.

Make sure to read the signal after the rewriting is complete. (It is recommended to have more than 2

scan periods to wait.) Make sure not to have the output side to change the output until the other side

completes the reading. Also, a setting is made on the input area not to receive the signal less than a

certain time to prevent a wrong reading of noise. This duration also needs to be considered.

This controller

(scan time 1msec)

As shown in the diagram, the input and output

timings of two devices that have different scan

time do not match, of course, when transferring

a signal.

There is no guarantee that PLC would read the

signal as soon as this controller signal turns on.

In such a case, make the setting to read the

signal after a certain time that is longer than the

longer scan time to ensure the reading process

to succeed on the PLC side.

It is the same in the case this controller side

reads the signal.

In such a case, it is recommended to ensure 2

to 4 times of the scan time for the timer setting

margin.

It is risky to have the setting below the scan

time since the timer is also processed in the

scan process.

In the diagram, PLC can only read the input

once in 20msec even though this controller

output once in 1msec.

Because PLC only conducts output process

once in 20msec, this controller identifi es the

same output status for that while.

Page 19

13

/

7. PLC Timer Setting

Do not have the PLC timer setting to be done with the minimum setting.

Setting to “1” for 100msec timer turns on at the timing from 0 to 100msec while 10msec timer

from 0 to 10msec for some PLC.

Therefore, the same process as when the timer is not set is held and may cause a failure such

as the actuator cannot get positioned to the indicated position number in Positioner Mode.

Set “2” as the minimum value for the setting of 10msec timer and when setting to 100msec, use

10msec timer and set to “10”.

8. Cautions when turning Servo on (for ASEP/PSEP)

The magnetic pole phase detection may not be performed normally if the servo is turned on near

the mechanical end, and may cause such problems like an abnormal operation, magnetic pole

not being defi ned or electromagnetic detection error.

Put it away from the mechanical end when turning the servo on.

9. Make sure to follow the usage condition, environment and

specifi cations of the product.

Not doing so may cause a drop of performance or malfunction of the product.

Page 20

14

/

1) Battery Connector (It is not equipped for Incremental Type and DSEP)

If Absolute Type actuator, it is the battery connector for absolute data retention.

2) LED for ABS (It is not equipped for Incremental Type and DSEP)

Following shows the absolute data retention battery status:

Signal Indication Status Description

2

Green Light is turned ON. System Normal

Red Light is turned ON. System abnormality

1

Green Light is turned ON Absolute Unit Reset Complete (ST2 lighting ON in Green)

Red Light is turned ON.

• Absolute Unit Reset Incomplete (ST2 lighting ON in Green)

• Hardware Error (ST2 lighting ON in Red)

0

Green Light is turned ON Battery Fully Charged

Orange Light is turned ON. In Battery Charging Operation

Red Light is turned ON. Battery Disconnected

Name for Each Parts and Their Functions

Pictures show ASEP, It should be the same for PSEP and DSEP.

1) Battery Connector

(It is not equipped

for Incremental Type and DSEP)

2) LED for ABS

(It is not equipped

for Incremental Type and DSEP)

3) StatusLED

(for SV, ALM and EMG)

4) SIO Connector

5) PIO Connector

6) Motor · Encoder

Connector

7) Power Supply

Connector

8) FG Terminal Block

Page 21

15

/

Pin No. Signal Description

5BK

For Brake Forced Release Power Supply (ASEP/PSEP)

Keep DSEP disconnected.

4 MP Motor Driving Power Supply

3 24V Positive side of the 24V power supply

2 0V Negative side of the 24V power supply

1 EMG EMG’s Confi rmation Signal

8) FG Terminal Block

It is the connector to connect the protection ground. Make sure to conduct the Class D grounding

(formerly Class 3 grounding: grounding resistance at 100 or less)

BK

MP

24V

0V

EMG

3) StatusLED (For SV, ALM and EMG)

Following show the controller operation status:

Indication Status Description

SYS

Green Light is turned ON. Servo ON Status

Light is turned OFF Servo OFF Status

Flashing in green (1Hz) Servo ON Status

Red Light is turned ON. In the alarm issue or emergency stop

4) SIO Connector

It is the connector for the connection of the communication cables for the teaching pendant and

PC software.

5) PIO Connector

It is the connector for 24V DC I/O signal connection.

6) Motor · Encoder Connector

It is the connector to connect the actuator motor · encoder cable.

7) Power Supply Connector

It is the connector to supply the power to the controller and to the control board.

Page 22

16

/

Actuator Axes

Refer to the pictures below for the actuator axes that can be controlled by ASEP/PSEP and DSEP.

(There are some types that cannot be controlled depending on the controller. Check the catalog for

the details.)

0 defi nes the home position, and items in ( ) are for the home-reversed type (option).

(1) Rod Type

(2) Slider Type

(3) Table Type

(4) Arm Type

Page 23

17

/

(5) Gripper Type

0

0

0

+

+

+

Finger Attachment

(Note)

00

++

Finger Attachment

(Note)

Note: Finger attachment is not included in the actuator package. Please prepare separately.

(6) Rotary Type

0

+−

330

°

(330° Rotation Specification)

(Multi-Rotation Specification)

Page 24

18

/

When using this product for the fi rst time, make sure to avoid mistakes and incorrect wiring by referring to

the procedure below.

Installation and Wiring

Perform the installation of and wiring for the controller and

actuator according to the instructions in the Instruction

Manual for the actuator and this Instruction Manual.

Contact our distributor or us.

↓Yes

←

Check Item

Does the STATUS indicator LED light ON in red?

Check of Safety Circuit

Check that the emergency stop circuit (or motor drivepower

cutoff circuit) operates normally to turn off the servo.

Check the emergency stop circuit.

Set-up for operation is completed,

Perform the system operation adjustment.

Servo ON

Turn ON the servo-motor on the PC Software unit or touch panel teaching unit

and confirm that the STATUS indicator LED lights ON in green (SVON).

(Note) If the servo-on control is disabled in the initial setting, the controller

automatically turns the servo on.

Check of Packed Items

Are there all the delivered items?

↓

No→

↓

Target Position Setting

Set the parameters for those such as “Backward Position”, “Forward Position”, “Intermediate Position” and “Speed” (which differ

for each PIO pattern) in the position table on the PC software or the position setting on the touch panel teaching.

↓Yes

↓No

→

→

→

→

No→

Point Check Item

• Have you performed the installation and the connection

of the frame ground and protective ground?

• Has the noise countermeasure been taken?

Power Supply and Alarm Check

Connect the PC Software unit or touch panel

teaching unit and turn ON the power to the unit.

Confirm that the emergency stop switch has been

cancelled. When the switch has been cancelled,

confirm the alarm description using the PC Software

unit or touch panel teaching unit and settle it.

Yes

←No

No

←

Yes

Confirm the alarm description using

the PC Software unit or touch panel

teaching unit and settle it.

No→

Yes

Trial Run Adjustment

Perform the performance check on the Position Table

in the PC software or on the “Performance Check” window

(Sequence: “Touch panel teaching” → “Initial Setting” ).

↓

Is there any vibration

or abnormal noise?

→→

Confirm that there is no problem

in the actuator installation or the

actuator operation condition

demands more than the rated

voltage.

Yes

Perform the initial setting according

to the instructions on the window. [Refer to Section

2.1 Setting

]

[Refer to the Instruction Manual for the PC software or touch panel teaching]

Have you completed the initial settings?

Warning : Turning the servo on near the mechanical end may disturb the

magnetic pole phase detection work properly, and may cause

such problems as an abnormal operation, the magnetic pole

unconfirmed error or the excitation detection error.

Put away from the mechanical end when turning the servo on.

Caution : In the case the actuator is installed in vertical orientation,the

actuator may get slightly dropped by self-weight if servo on and off

is repeatedly performed. Be careful not to pinch the hand or

damage the work.

Starting Procedures

Page 25

19

/

1. Specifi cations Check

1. Specifi cations Check

1.1 Product Check

This product is comprised of the following parts if it is of standard confi guration.

If you fi nd any fault in the contained model or any missing parts, contacts us or our distributer.

1.1.1 Parts

No. Part Name Model

1 Controller [Refer to “1.1.4 How to read the model plate”]

Accessories

2 I/O Flat Cable

Standard type CB-APSEP-PIO*** (***shows the cable length)

Dust-proof type

(Equivalent to IP53)

CB-APSEPW-PIO*** (***shows the cable length)

3 Power Connector MC1.5/5-ST-3.5 (PHOENIX CONTACT)

4 Spacer PFP-S (OMRON)

5

Absolute Battery Unit

(For Simple Absolute Type Only)

SEP-ABUM (Standard type)

SEP-ABUM-W (Dust-proof type)

6 Instruction Manual (This Manual)

7 Instruction Manual (CD/DVD)

8 Safety Guide

1.1.2 Teaching Tool (to be purchased separately)

For the setups such as position setting and parameter setting using the teaching operation, the teaching tool

is required. Please prepare either of the following teaching tools.

No. Part Name Model

1

PC Software (Includes RS232C Exchange Adapter External Machine

Communication Cable)

RCM-101-MW

2

PC Software (Includes USB Exchange Adapter USB Cable External

Machine Communication Cable)

RCM-101-USB

3

Teaching Pendant (Touch Panel Teaching)

CON-PTA

4

Teaching Pendant (Touch panel teaching equipped with a dead man’s

switch)

CON-PDA

5

Teaching Pendant (Touch panel teaching equipped with a dead man’s

switch TP adapter (RCB-LB-TG))

CON-PGA

6

Teaching Pendant dedicated for SEP Controller (Touch Panel Teaching)

SEP-PT

7

Teaching Pendant (Touch Panel Teaching)

CON-PT

(Note 1)

8

Teaching Pendant (Touch panel teaching equipped with a dead man’s

switch)

CON-PD

(Note 1)

9

Teaching Pendant (Touch panel teaching equipped with a dead man’s

switch TP adapter (RCB-LB-TG))

CON-PG

(Note 1)

Note 1) It is not applied for DSEP.

Page 26

20

/

1. Specifi cations Check

1.1.3 Instruction manuals related to this product, which are contained in the

instruction manual (CD/DVD).

No Name Manual No.

1 ASEP/PSEP/DSEP Instruction Manual ME0267

2 PC Software RCM-101-MW/RCM-101-USB Instruction Manual ME0155

3 Touch Panel Teaching CON-PTA/PDA/PGA Instruction Manual ME0294

4

Teaching Pendant dedicated for SEP Controller (Touch Panel Teaching)

Instruction Manual

ME0217

1.1.4 How to read the model plate

Model

Serial number

1.1.5 How to read the model of the controller

<Detail of Connected Axis>

[Motor Type]

<Identification for IAI use only>

* There is no identification in some cases.

<Applicable to Simplified Absolute Unit>

ABU

ABUN

No description

(Note) ABU and ABUN are the already existing

models, which do not comply with UL.

<Power-supply Voltage>

0 : 24V DC

<I/O Cable Length>

0 : No Cable 3 : 3m

2:2m 5 :5m

<I/O Signal Pattern>

NP : NPN Specification

(Sync. Type) (Standard)

PN : PNP Specification

(Source Type)

:

Simple Absolute Type

(with the Absolute Battery Unit)

:

Simple Absolute Type

(with no Absolute Battery Unit)

:

Incremental Type

2W

5W

10W

20W

:

:

:

:

20W

(For RCA-R□3, SRA4, RCA2-SA4/TA5)

30W::

20S

30

[Encoder Type]

I : Incremental

[Option]

LA : Power Consumption Type

HA : High Acceleration/Deceleration Type

2

5

10

20

[ASEP]

<Series>

<Type>

C : Standard type

CW : Dust-proof type

(Equivalent to IP53)

ASEP – C – 20ILA – NP – 0 – 0 – ABU – **

Page 27

21

/

1. Specifi cations Check

<Detail of Connected Axis>

[Motor Type]

[Encoder Type]

I : Incremental

* It is not the absolute type.

<Identification for IAI use only>

* There is no identification in some cases.

<Power-supply Voltage>

0 : 24V DC

<I/O Cable Length>

0 : No Cable 3 : 3m

2 : 2m 5 : 5m

<I/O Signal Pattern>

NP : NPN Specification

(Sync. Type) (Standard)

PN : PNP Specification

(Source Type)

3W:3

[DSEP]

<Series>

<Type>

C : Standard type

CW : Dust-proof type

DSEP – C – 3I – NP – 0 – 0 – **

<Identification for IAI use only>

* There is no identification in some cases.

<Option>

H

No description

<Applicable to Simplified Absolute Unit>

ABU

ABUN

No description

(Note) ABU and ABUN are the already existing

models, which do not comply with UL.

<Power-supply Voltage>

0 : 24V DC

<I/O Cable Length>

0 : No Cable 3 : 3m

2:2m 5 :5m

: High Acceleration

Transportable Type

: Standard

:

Simple Absolute Type

(with the Absolute Battery Unit)

:

Simple Absolute Type

(with no Absolute Battery Unit)

:

Incremental Type

<Detail of Connected Axis>

[Motor Type]

<Series>

<Type>

C : Standard Type

CW : Dust-proof type

(Equivalent to IP53)

20 □Size

28 □Size

28 □Size

(For RA3C)

:

:

:

35 □Size

42 □Size

56 □Size

:

:

:

35P

42P

56P

[Encoder Type]

I : Incremental

20P

28P

28SP

[PSEP]

<I/O Signal Pattern>

NP : NPN Specification

(Sync. Type) (Standard)

PN : PNP Specification

(Source Type)

PSEP – C – 20PI – NP – 0 – 0 – ABU – H – **

Page 28

22

/

1. Specifications Check

23

/

1.2 Basic Specifications

Specifications

Item ASEP PSEP DSEP

Number of controlled axes 1-axis

Power-supply voltage 24V DC ±10%

Control power capacity 0.5A (For Simple Absolute Type,0.8A)

Load

current

Motor type

Rated

Low Power

Consumption

MAX.

(Note 1)

Rated

MAX.

(Note 2)

Rated MAX.

2W 0.8A 4.6A

5W 1.0A 6.4A

10W

(RCL series)

1.3A 6.4A

10W

(RCA/RCA2 series)

1.3A 2.5A 4.4A

20W 1.3A 2.5A 4.4A

20W

(Model code display

20S)

1.7A 3.4A 5.1A

30W 1.3A 2.2A 4.4A

20P 0.17A 2.0A

28P 0.17A 2.0A

35P 0.9A 2.0A

42P 0.9A 2.0A

56P 0.9A 2.0A

3W 0.7A 1.5A

Heat generation 8.4W 9.6W 4W

Rush current MAX. 10A

Motor control system Sinusoidal wave (AC) driving Weak field-magnet

vector control

Square wave (DC)

drive

Applicable

encoder

resolution

RCA series 800pulse/rev

RCA2

series

RCA2-***N 1048pulse/rev

Except for

RCA2-***N

800pulse/rev

RCL

series

RA1L, SA1L,

SA4L, SM4L

715pulse/rev

RA2L, SA2L,

SA5L, SM5L

855pulse/rev

RA3L, SA3L,

SA6L, SM6L

1145pulse/rev

RCP2, RCP3, RCP4

800pulse/rev

RCD

400pulse(RA1D/GRSN),

480pulse(RA1DA/GRSNA)

Actuator cable length MAX. 20m

Serial communication interface

(SIO port)

RS485 : 1CH (based on Modbus Protocol RTU/ASCII)

External interface Signal I/O dedicated for 24V DC (selected from NPN/PNP) … Input 4 points

max., output 4 points max. Cable length MAX. 10m

Data setting and input PC softwar, touch panel teaching, teaching pendant

Data retention memory Position data and parameters are saved in the nonvolatile memory. (About

100,000 times of reloading

(Note 3)

)

Operation mode/No. of positions Positioner mode Positioning points : 2 to 3 points

LED display (mounted on front

panel)

1 point (for controller status display)

Page 29

23

/

1. Specifi cations Check

Item ASEP PSEP DSEP

Forcibly releasing of

electromagnetic brake switch

None

Supply 24V DC 150mA to BK on power connector when

a compulsory release of the brake is required.

None

Brake cannot

be compulsorily

released.

Dielectric withstanding voltage/

resistance

500V DC 10M

W

Protection Function against

Electric Shock

Class I basic insulation

Cooling method Natural air-cooling

Environment

Use environment Pollution degree 2

Surrounding air

temperature

0 to 40°C

Surrounding humidity 85% RH or less (non-condensing)

Surrounding

environment

[Refer to 1.5 Installation Environment.]

Surrounding storage

temperature

-25 to 65°C (Battery to be stored at 40°C or lower)

Usage altitude 1000m or lower above sea level

Protection code IP20: Equivalent to IP53 (Option) with the installation of the dust-proof cover

Vibration durability Frequency 10 to 57Hz / Swing width : 0.075mm

Frequency 57 to 150Hz / Acceleration : 9.8m/ S

2

XYZ Each direction Sweep time : 10 minutes Number of sweep : 10 times

Weight

130g or less, 160g or less (INC-Dust-proof type)

External dimensions 30W × 100H × 66.2D (mm)

Note 3: Position data and parameters are written to EEPROM. The limitation for the reload is

about 100,000 times. Take the greatest care.

Do not turn the power off during the rewriting process.

As a 24V DC power supply, select the power

supply of the “peak load support” specifi cation

or one with suffi cient capacity.

In the case that the capacity margin is not

suffi cient, voltage might be dropped in

a moment. Especially, the power supply

equipped with remote sensing reacts to the

transient voltage drop and raises the voltage

for adjustment, which may result in overvoltage

error.

(Note 1) The current reaches its maximum level when the servo-motor

exciting phase is detected which is to be performed in the fi rst

servo-motor turning ON processing after the power injection.

(Normal: Approx. 1 to 2sec, Max.: 10sec)

(Note 2) The excitation detection operation is performed after the power

is input. In such a case, the current becomes maximum.

(normally 100msec)

However, a current of approx. 6.0A fl ows if the motor driving

power is turned on again after its shutdown. (for approx. 1 to

2msec)

Page 30

24

/

1. Specifi cations Check

1.3 External Dimensions

110mm

30mm 72.2mm

Front View Side View

Bottom View

[ASEP/PSEP/DSEP-C]

105mm

30mm 72.2mm

Front View

Side View

Bottom View

[Absolute Battery Unit SEP-ABUM (only applies to ASEP/PSEP)]

107mm

34mm

105.7mm

Front View Side View

Bottom View

[Dust-Proof Cover : ASEP/PSEP/DSEP-CW]

Page 31

25

/

1. Specifi cations Check

1.4 I/O Specifi cations

1.4.1 PIO Input and Output Interface

Input Section Output Section

Specifi -

cation

Input Voltage 24V DC10% Load Voltage 24V DC

Input Current 4mA 1circuit

Peak Load Electric

Current

50mA/1circuit

ON/OFF Voltage

ON Voltage MIN.18V DC

OFF Voltage MAX.6V DC

Leakage Current MAX.0.1mA/1point

NPN

680

5.6K

P24

External

Power Supply

24V DC

Controller

Internal

Power Supply

Input

Terminal

Controller

22

P24

0

Load

External

Power Supply

24V DC

Internal

Power Supply

Output

Terminal

PNP

Controller

680

5.6K

0

External

Power Supply

24V DC

Internal

Power Supply

Input

Terminal

Controller

Load

22

P24

0

External

Power Supply

24V DC

Internal

Power Supply

Output

Terminal

I/O

Cable

Refer to 2.1.3 Circuit Diagram

0V 24V

NPN Type

Pin No.

1

2

3

4

5

6

7

8

9

10

Load

24V 0V

PNP Type

Pin No.

1

2

3

4

5

6

7

8

9

10

Load

Page 32

26

/

1. Specifi cations Check

1.5 Installation Environment

This product is capable for use in the environment of pollution degree 2*1 or equivalent.

*1 Pollution Degree 2: Environment that may cause non-conductive pollution or transient

conductive pollution by frost (IEC60664-1)

Do not use this product in the following environment.

Location where the surrounding air temperature exceeds the range of 0 to 40C

Location where condensation occurs due to abrupt temperature changes

Relative humidity less than 10%RH or greater than 85%RH

Location exposed to corrosive gases or combustible gases

Location exposed to signifi cant amount of dust, salt or iron powder

Location subject to direct vibration or impact

Location exposed to direct sunlight

Location where the product may come in contact with water, oil or chemical droplets

When using the product in any of the locations specifi ed below, provide a suffi cient shield.

Location subject to electrostatic noise

Location where high electrical or magnetic fi eld is present

Location with the mains or power lines passing nearby

For Dust-proof type (Equivalent to IP53)

The protection structure level is enhanced to IP53 with the installation of the dust-proof cover (option).

“5” in IP53 stands

for the structure

Where the amount of dust which can affect the normal operation and

safety, can not enter the unit.

“3” in IP53 stands

for the structure

Where normal operation and safety is not affected even with the

precipitation from above.

Page 33

27

/

1. Specifi cations Check

1.6 Installation and Noise Elimination

(1) Noise Elimination Grounding (Frame Ground)

Connect it using an earth cable

made of soft copper with the diameter

of AWG16 (1.25mm

2

).

Class D grounding

(Formerly Class-III grounding: Grounding resistance at 100Ω or less)

Controller

Controller

Other

equipment

Other

equipment

Other

equipment

Do not share the ground wire with or connect

to other equipment. Ground each controller.

(2) Precautions regarding wiring method

1) Twist the wires for the 24V DC power unit.

2) Separate signal lines and encoder cables from

high-power lines such as the power wire.

(3) Noise Sources and Elimination

Carry out noise elimination measures for power devices on

the same power path and in the same equipment.

The following are examples of measures to eliminate noise

sources.

1) AC solenoid valves, magnet switches and relays

[Measure] Attach the surge killer in parallel with the

coil.

2) DC solenoid valves, magnet switches and relays

[Measure] Attach the diode in parallel with the coil.

For the DC relay, use the built-in diode type.

Noise Killer

+24V

+24V

0V

0V

Relay

coil

Relay coil

R

C

+ -

Page 34

28

/

1. Specifi cations Check

(4) Heat Radiation and Installation

Conduct design and manufacture in consideration of the control box size, controller layout and

cooling in such a way that the temperature around the controller will be 40C or less.

DIN Rail

DIN Rail

Min.

5mm

Spacer :

PFP-S (OMRON) 1 Unit

Min. 20mm

Min. 20mm

Min. 50mm

Ensure

enough space

for wiring.

Note Install the Absolute Battery Unit securely under the controller.

Page 35

29

/

2. Wiring

2. Wiring

2.1 Wiring Diagram (Connection of construction devices)

SIO Connector

Touch Panel Teaching

(to be purchased separately)

PC software

Flat Cable

Accessories

PIO Connector

MPG Connector

Power Connector

FG Connector

Actuator

Class D grounding

(Formerly Class-III grounding : Grounding resistance at 100Ω or less)

FG Cable : AWG16

(1.25mm2)

Absolute Battery Unit

(Note 2)

SEP-ABUM

Connection Cable

between Controller and

Absolute Battery

(Note 1)

Host System (PLC)

(Note 1) Connection Cable between Controller and Absolute Battery

CB-APSEP-ABM005• • • Applicable Controller : ASEP-C-□-□-□-0-ABUM□

PSEP-C-□-□-□-0-ABUM□

CB-APSEP-AB005• • • Applicable Controller : ASEP-C-□-□-□-0-ABU□

(Existing models: Not complied with UL) PSEP-C-□-□-□-0-ABU□

(Note 2) It is not compatible with DSEP.

Note Turn the power to the controller off before connecting and disconnecting SIO connector

plugged in the controller from the PC software or touch panel teaching.

Inserting or removing the connector while the power is turned ON causes a controller

failure.

Page 36

30

/

2. Wiring

2.2 PIO Pattern Selection and PIO Signal

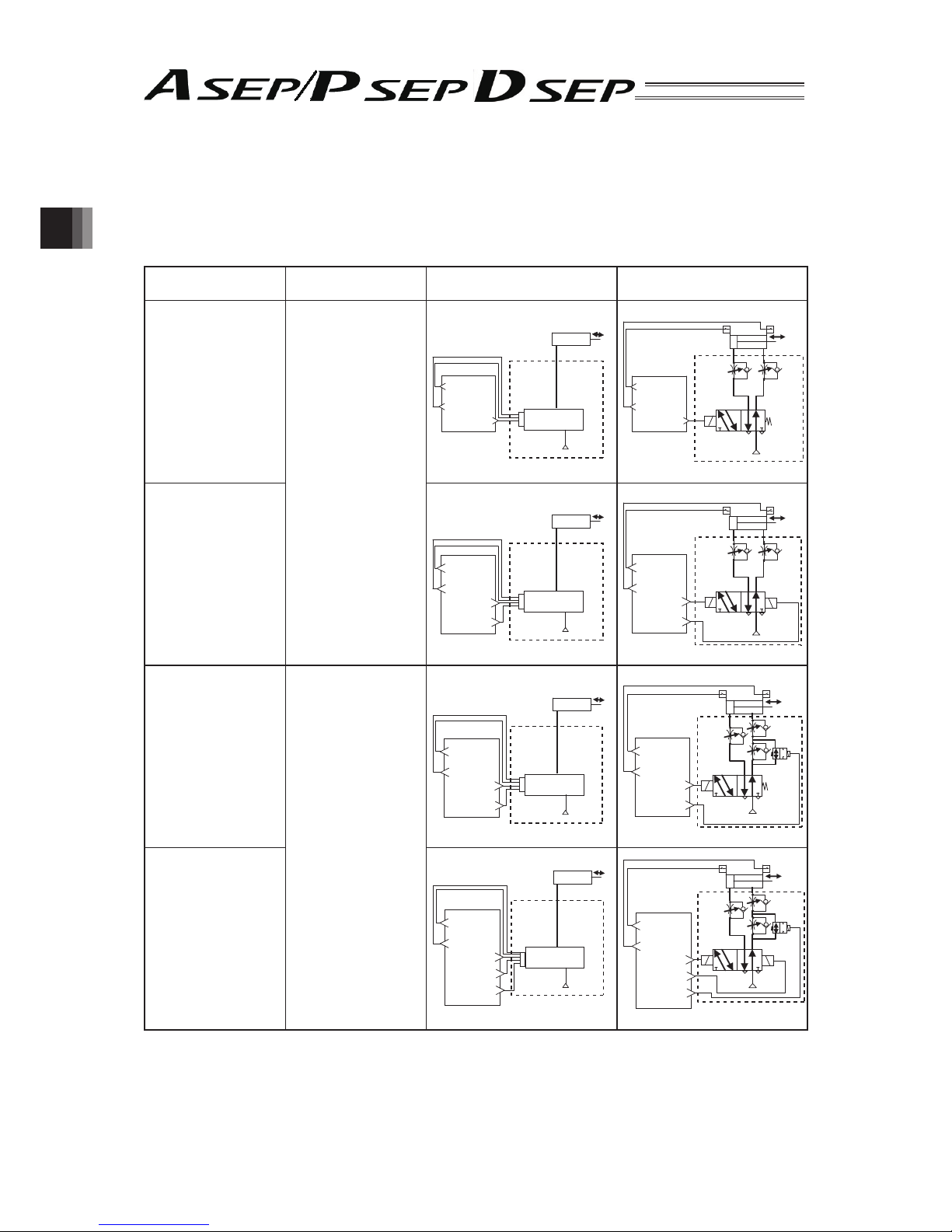

(1) Operation Pattern

The 6 operation patterns (For PIO Pattern). Each of these 6 patterns is described as in the table. Also,

the corresponding air cylinder circuit is described for reference.

Operation Pattern Contents

Example for Electric Cylinder

Connection

Example for Air Cylinder

Connection (Reference)

PIO Pattern 0

Single Solenoid System

(Standard Point-to-Point

Movement)

The actuator pointto-point movement is

available using the same

control function as for

the air cylinder.

The target position

setting (forward position

and backward position)

is available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation

is available.

PLC

+24V

ASEP,

PSEP,

DSEP

Electric Cylinder

Dedicated

Cable

Movement Signal

(ST0)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

R2 R1

B A

Spring

Solenoid

Air Cylinder

PLC

Movement Signal

(ST0)

P(Air)

Forward

Position Detection

(LS1)

Backward

Position Detection

(LS0)

PIO Pattern 0

Double Solenoid System

(Standard Point-to-Point

Movement)

+24V

ASEP,

PSEP,

DSEP

Electric Cylinder

Dedicated

Cable

PLC

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

R2 R1

B A

Solenoid

Solenoid

Air Cylinder

PLC

P(Air)

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

PIO Pattern 1

Single Solenoid System

(

Point-to-Point Movement

)

(

Movement Speed Setting

)

The actuator pointto-point movement is

available using the same

control function as for

the air cylinder.

The speed change in the

movement operation is

available.

The target position

setting (forward position

and backward position)

is available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation

is available.

+24V

ASEP,

PSEP,

DSEP

Electric Cylinder

Dedicated

Cable

PLC

Movement Signal

(ST0)

Movement Speed

Change Signal

(SPDC)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Spring

R2

R1

B A

Solenoid

Air Cylinder

PLC

P(Air)

Movement Signal

(ST0)

Movement Speed

Change Signal

(SPDC)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

PIO Pattern 1

Double Solenoid System

(

Point-to-Point Movement

)

(

Movement Speed Setting

)

+24V

ASEP,

PSEP,

DSEP

Electric Cylinder

Dedicated

Cable

PLC

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1)

Movement Speed

Change Signal

(SPDC)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

R2

R1

B A

Solenoid

Solenoid

Air Cylinder

PLC

P(Air)

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1)

Movement Speed

Change Signal

(SPDC)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Page 37

31

/

2. Wiring

Operation Pattern Contents

Example for Electric Cylinder

Connection

Example for Air Cylinder

Connection (Reference)

Single Solenoid System

(

Point-to-Point Movement

)

(Target Position Setting

(Position Data) Change)

The actuator pointto-point movement is

available using the same

control function as for

the air cylinder.

The change-over

between the positioning

and pressing operations

during the operation is

available.

The target position

setting (forward position

and backward position)

is available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation

is available.

+24V

ASEP,

PSEP,

DSEP

Electric Cylinder

Dedicated

Cable

PLC

Movement Signal

(ST0)

Target Position

Change Signal

(CN1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

R2

R1

B A

Air Cylinder

PL C

P(Air)

P(Air)

Movement Signal

(ST0)

Target Position

Change Signal

(CN1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

PIO Pattern 2

Double Solenoid System

(

Point-to-Point Movement

)

(Target Position Setting

(Position Data) Change)

+24V

ASEP,

PSEP,

DSEP

Electric Cylinder

Dedicated

Cable

PLC

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1 )

Target Position

Change Signal

(CN1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

R2

R1

B

A

Air Cylinder

PLC

P(Air)

P(Air)

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1 )

Target Position

Change Signal

(CN1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

PIO Pattern 3

(2-Input, 3-Point

Movement)

The actuator 3-Point

Movement is available

using the same control

function as for the air

cylinder.

The target position

setting (forward position,

backward position and

intermediate position) is

available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation at

the positions except for

the intermediate position

is abailable.

+24V

ASEP,

PSEP,

DSEP

Electric Cylinder

Dedicated

Cable

PLC

Movement

Signal 1

(ST0)

Movement

Signal 2

(ST1 )

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Intermediate

Position Detection

(LS2)

Air Cylinder

PLC

P(Air)

P(Air)

P(Air)

Movement

Signal 1

(ST0)

Movement

Signal 2

(ST1 )

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Intermediate

Position Detection

(LS2)

PIO Pattern 4

(3-Input, 3-Point

Movement)

The actuator 3-Point

Movement is available

using the same control

function as for the air

cylinder.

The target position

setting (forward position,

backward position and

intermediate position) is

available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation

at the positions except

for the intermediate

position is abailable.

+24V

ASEP,

PSEP,

DSEP

Dedicated

Cable

PLC

Electric Cylinder

Intermediate Position

Movement Signal

(ST2)

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Intermediate

Position Detection

(LS2)

Air Cylinder

PLC

P(Air)

P(Air)

P(Air)

Intermediate Position

Movement Signal

(ST2)

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Intermediate

Position Detection

(LS2)

Page 38

32

/

2. Wiring

Operation Pattern Contents

Example for Electric Cylinder

Connection

Example for Air Cylinder

Connection (Reference)

PIO Pattern 5

(Continuous

Reciprocating

Operation)

The actuator’s pointto-point reciprocating

operation is performed

between the forward

position and backward

position.

The target position

setting (forward position

and backward position)

is available.

Speed and acceleration

settings in the actuator

movement are available.

The pressing operation

is available.

Note: The air cylinder circuit is described with the symbols for the signals corresponding to those in

ASEP/PSEP/DSEP.

[Refer to the next page for the details of each signal.]

Page 39

33

/

2. Wiring

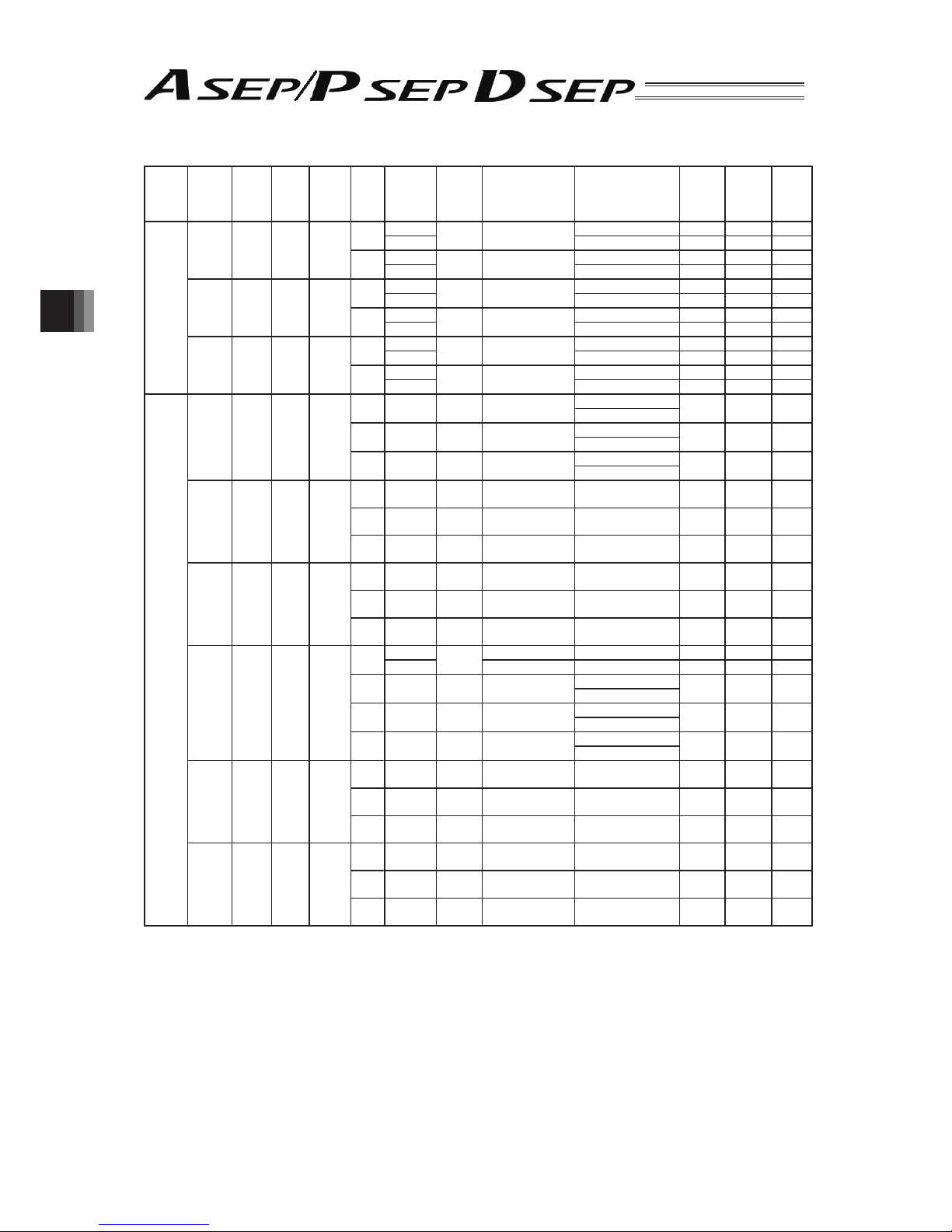

(2) PIO Pattern and Signal Assignment

Pattern 0 1 2 3 4 5

Point-to-Point

Movement

(Standard)

Point-to-Point

Movement

(Movement

Speed Setting)

Point-to-Point

Movement

(Target Position

Setting Change)

3-Point

Movement

(2-Input)

3-Point

Movement

(3-Input)

Point-to-Point

Reciprocating

Movement

(Continuous

Reciprocating

Operation)

Pin

No.

Cable

Color

Input/

Output

Single

Double

Single

Double

Single

Double

-

Double

-

1 BR COM 24V 24V 24V 24V 24V 24V

2 RD COM 0V 0V 0V 0V 0V 0V

3OR

I

N

0 ST0 ST0 ST0 ST0 ST0 ST0 ST0 ST0 ASTR

4YW 1

*

STP

ST1

(Note 1)

*

STP

ST1

(Note 1)

*

STP

ST1

(Note 1)

ST1

(Note 1)

ST1

(Note 1)

*

STP

5 GN 2 RES SPDC (RES)

(Note 2)

CN1 (RES)

(Note 2)

RES ST2(RES)

(Note 2)

RES

6BL 3 /SON

/SON

/SON

/SON

/SON

/SON

7PL

O

U

T

0 LS0/PE0 LS0/PE0 LS0/PE0 LS0/PE0 LS0/PE0 LS0/PE0

8 GY 1 LS1/PE1 LS1/PE1 LS1/PE1 LS1/PE1 LS1/PE1 LS1/PE1

9 WT 2 HEND/SV HEND/SV HEND/SV LS2/PE2 LS2/PE2 HEND/SV

10 BK 3

*

ALM/SV

*

ALM/SV

*

ALM/SV

*

ALM/SV

*

ALM/SV

*

ALM/SV

(Note 1) : It is invalid before home-return operation.

(Note 2) : The description in the brackets shows the condition before the home return operation.

(Note 3) : *STP and *ALM are the signals that are negative logic.

(Reference) Signal of Active Low

Signal with “*” expresses the signal of active low. A signal of active low is a signal that the input signal

is processed when it is turned off, output signal is ordinary on while the power is on, and turns off when

the signal is output.

Page 40

34

/

2. Wiring

(3) List of PIO Signal Functions

Signal

Type

Symbol Signal Name Function

Power

Input

24V I/O Power Supply

It is the common power source for I/O circuit. The positive () side of 24V

DC is connected.

0V I/O Power Supply

It is the common power source for I/O circuit. The positive () side of 24V

DC is connected.

Input

ST0

• Movement Signal

[Single Solenoid System]

• Backward Position

Movement Signal

[Double Solenoid System]

• Movement Signal 1

[PIO Pattern 3]

The positioning to the corresponding target position is performed, when the

signal leading edge created in the mode change from OFF to ON, or ON

level is detected.

ST1

• Forward Position

Movement Signal

• Movement Signal 2

[PIO Pattern 3]

ST2

Intermediate Position

Movement Signal

*STP Pause Signal

When this signal is turned OFF the deceleration is stopped. When the signal

is turned ON again, the movement is re-started.

RES Reset Signal

When the signal leading edge created in the mode change from OFF to ON,

is detected, the currently issued alarm is reset.

* Depending on the alarm level, alarm reset might not be available.

Refer to the Trouble Shooting for the details.

SON Servo ON Signal

During the time when this signal is turned ON, the servo-motor is in the ON mode.

SPDC

Movement Speed Change

Signal

When the movement speed is changed during the movement, do it with this

signal turned ON.

* This signal is effective when the PIO pattern 1 has been set.

CN1

Target Position Change

Signal

When the conditions for the positioning operation or pressing operation, etc.,

are changed to operate the system, turn ON this signal.

When this signal is turned ON or OFF during the operation, the position data

is changed.

* This signal is effective when the PIO pattern 2 has been set.

ASTR

Continuous Reciprocating

Operation Signal

During the time when this signal is turned ON, the actuator’s continuous

reciprocating operation is performed between the forward position and the

backward position. When this signal is turned OFF during the movement

operation, after the actuator is positioned to the current target, it is stopped.

* This signal is effective when the PIO pattern 5 has been set.

Output

LS0

Backward Position

Detection

The same operation as of the limit switch of the air cylinder is performed.

It is turned ON when the current position is within the positioning width for

each position detection output.

LS1 Forward Position Detection

LS2

Intermediate Position

Detection

PE0

Backward Positioning

Completion

This signal is turned ON when the current position goes within the positioning width, and the positioning to the target position is complete.

It is turned OFF in the Servo-Motor OFF mode or the Emergency Stop

Mode.

PE1

Forward Positioning

Completion

PE2

Intermediate Positioning

Completion

HEND Home Return Completion This signal is turned ON when the home return operation is completed.

SV Servo ON Signal

This signal is turned ON when the servo-motor is turned ON and driving is enabled.

*ALM Alarm Output Signal

This signal is turned ON when the controller is in the normal condition and

turned OFF when the controller is in the alarm condition. In such case,

monitor this signal in the PLC and take an appropriate measure.

Note For the PLC Input signal, keep it ON for at least 7ms or more.

Page 41

35

/

2. Wiring

2.3 Circuit Diagram (Example)

[1] Power/Emergency Stop Circuit

CR

CR

CR

Brake Power Sopply

Motor Power Sopply

ASEP/PSEP/DSEP

Emergency

Stop Release

Switch

24V 0V

EMG (Emergency Stop Input)

BK

(BK connection not required for DSEP)

MP

24V 0V

Emergency

Stop Switch

for Device

(System)

Power Supply Connector

Turn ON to

Release Brake

[2] Pattern 0 : Point-to-Point Movement (Standard)

1) Single Solenoid System

ASEP/PSEP/DSEP

PIO Connector

Movement Signal

Pause Signal

(Reset Signal)

Servo ON Signal

0V (NPN Type)

24V DC (PNP Type)

BR

OR

YW

GN

BL

1

3

4

5

6

RD

PL

GY

WT

BK

2

7

8

9

10

P24

ST0

*STP

RES

–/SON

0V

LS0/PE0

LS1/PE1

HEND/SV

*ALM/SV

24V DC (NPN Type)

0V (PNP Type)

Backward Position Detection/

Backward Positioning Completion

Forward Position Detection/

Forward Positioning Completion

Home Return Completion/

Servo ON Signal

Alarm Output Signal/

Servo ON Signal

Load

24V DC

Supply

0V Supply

2) Double Solenoid System

ASEP/PSEP/DSEP

PIO Connector

Backward Position

Movement Signal

Forward Position

Movement Signal

(Reset Signal)

Servo ON Signal

0V (NPN Type)

24V DC (PNP Type)

BR

OR

YW

GN

BL

1

3

4

5

6

RD

PL

GY

WT

BK

2

7

8

9

10

P24

ST0

*STP

RES

–/SON

0V

LS0/PE0

LS1/PE1

HEND/SV

*ALM/SV

24V DC (NPN Type)

0V (PNP Type)

Backward Position Detection/

Backward Positioning Completion

Forward Position Detection/

Forward Positioning Completion

Home Return Completion/

Servo ON Signal

Alarm Output Signal/

Servo ON Signal

Load

24V DC

Supply

0V Supply

Page 42

36

/

2. Wiring

[3] Pattern 1 : Point-to-Point Movement (Movement Speed Change)

1) Single Solenoid System

ASEP/PSEP/DSEP

PIO Connector

Movement Signal

Pause Signal

Movement Speed Change Signal

(Reset Signal)

Servo ON Signal

0V (NPN Type)

24V DC (PNP Type)

BR

OR

YW

GN

BL

1

3

4

5

6

RD

PL

GY

WT

BK

2

7

8

9

10

P24

ST0

*STP

SPDC (RES)

–/SON

0V

LS0/PE0

LS1/PE1

HEND/SV

*ALM/SV

24V DC (NPN Type)

0V (PNP Type)

Backward Position Detection/

Backward Positioning Completion

Forward Position Detection/

Forward Positioning Completion

Home Return Completion/

Servo ON Signal

Alarm Output Signal/

Servo ON Signal

Load

24V DC

Supply

0V Supply

2) Double Solenoid System

ASEP/PSEP/DSEP

PIO Connector

Backward Position

Movement Signal

Forward Position

Movement Signal

Movement Speed Change Signal

(Reset Signal)

Servo ON Signal

0V (NPN Type)

24V DC (PNP Type)

BR

OR

YW

GN

BL

1

3

4

5

6

RD

PL

GY

WT

BK

2

7

8

9

10

P24

ST0

ST1 (–)

SPDC (RES)

–/SON

0V

LS0/PE0

LS1/PE1

HEND/SV

*ALM/SV

24V DC (NPN Type)

0V (PNP Type)

Backward Position Detection/

Backward Positioning Completion

Forward Position Detection/

Forward Positioning Completion

Home Return Completion/

Servo ON Signal

Alarm Output Signal/

Servo ON Signal

Load

24V DC

Supply

0V Supply

Page 43

37

/

2. Wiring

[4] Pattern 2 : Point-to-Point Movement (Target Position Change)

1) Single Solenoid System

ASEP/PSEP/DSEP

PIO Connector

Movement Signal

Pause Signal