Page 1

MSEL Controller

Instruction Manual Fifth Edition

Page 2

Page 3

Please Read Before Use

Thank you for purchasing our product.

This Instruction Manual describes all necessary information items to operate this product safely

such as the operation procedure, structure and maintenance procedure.

To ensure the safe operation of this product, please read and fully understand this manual.

The enclosed DVD in this product package includes the Instruction Manual for this product.

For the operation of this product, print out the necessary sections in the Instruction Manual or

display them using the personal computer.

After reading through this manual, keep this Instruction Manual at hand so that the operator of this

product can read it whenever necessary.

[Important]

This Instruction Manual is original.

The product cannot be operated in any way unless expressly specified in this Instruction

Manual. IAI shall assume no responsibility for the outcome of any operation not specified

herein.

Information contained in this Instruction Manual is subject to change without notice for the

purpose of product improvement.

If you have any question or comment regarding the content of this manual, please contact

the IAI sales office near you.

Using or copying all or part of this Instruction Manual without permission is prohibited.

The company names, names of products and trademarks of each company shown in the

sentences are registered trademarks.

Page 4

Page 5

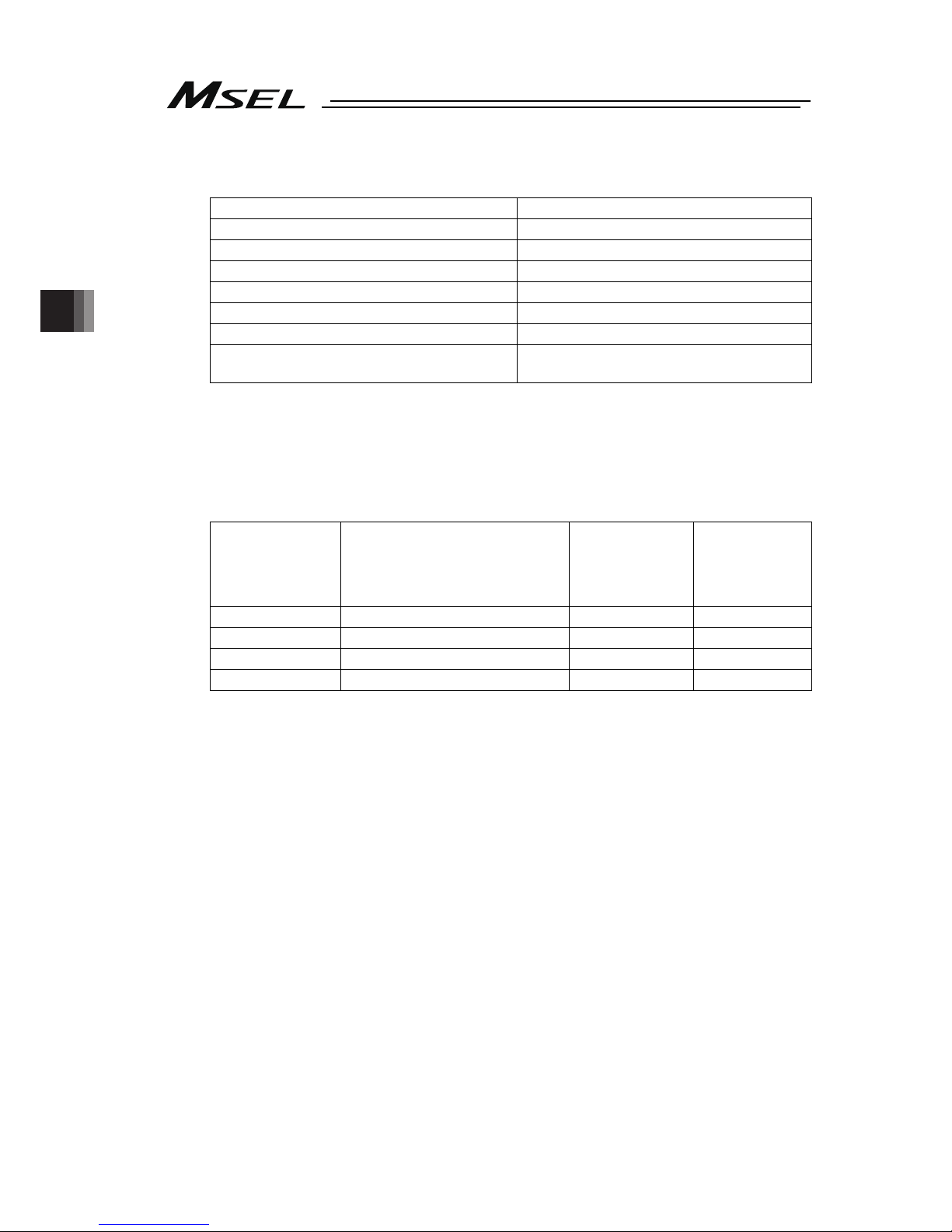

Table of Contents

Safety Guide ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ1

Controller Model Codes and Applicable Actuators ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ8

Precautions in Operation ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ9

International Standards Compliances ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ12

Name for Each Parts and Their Functions ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 13

Actuator Axesꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ17

Chapter 1

Specifications Checkꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 23

1.1 Product Checkꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 23

1.1.1 Parts (Excluding Options) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 23

1.1.2 Teaching Tool (Optional)ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 23

1.1.3 Instruction Manuals Related to this Product, which are Contained in the

Instruction Manual (DVD). ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 24

1.1.4 How to Read the Model Plateꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 24

1.1.5 How to Read the Model ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 24

1.2 Basic Specificationsꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 27

1.2.1 Selection of the Circuit Breakerꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 28

1.2.2 Selection of the Leakage Breakerꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 28

1.3 External Dimensions ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 29

1.4 Interfaces ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 30

1.4.1 Standard I/O ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 30

1.4.2 Extension I/Oꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 31

1.5 Absolute Battery Box (to be Connected for Simple Absolute Type) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 32

1.6 Installation and Storage Environmentꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 33

1.7 Noise Prevention and the Installationꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 34

Chapter 2 Wiring ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 37

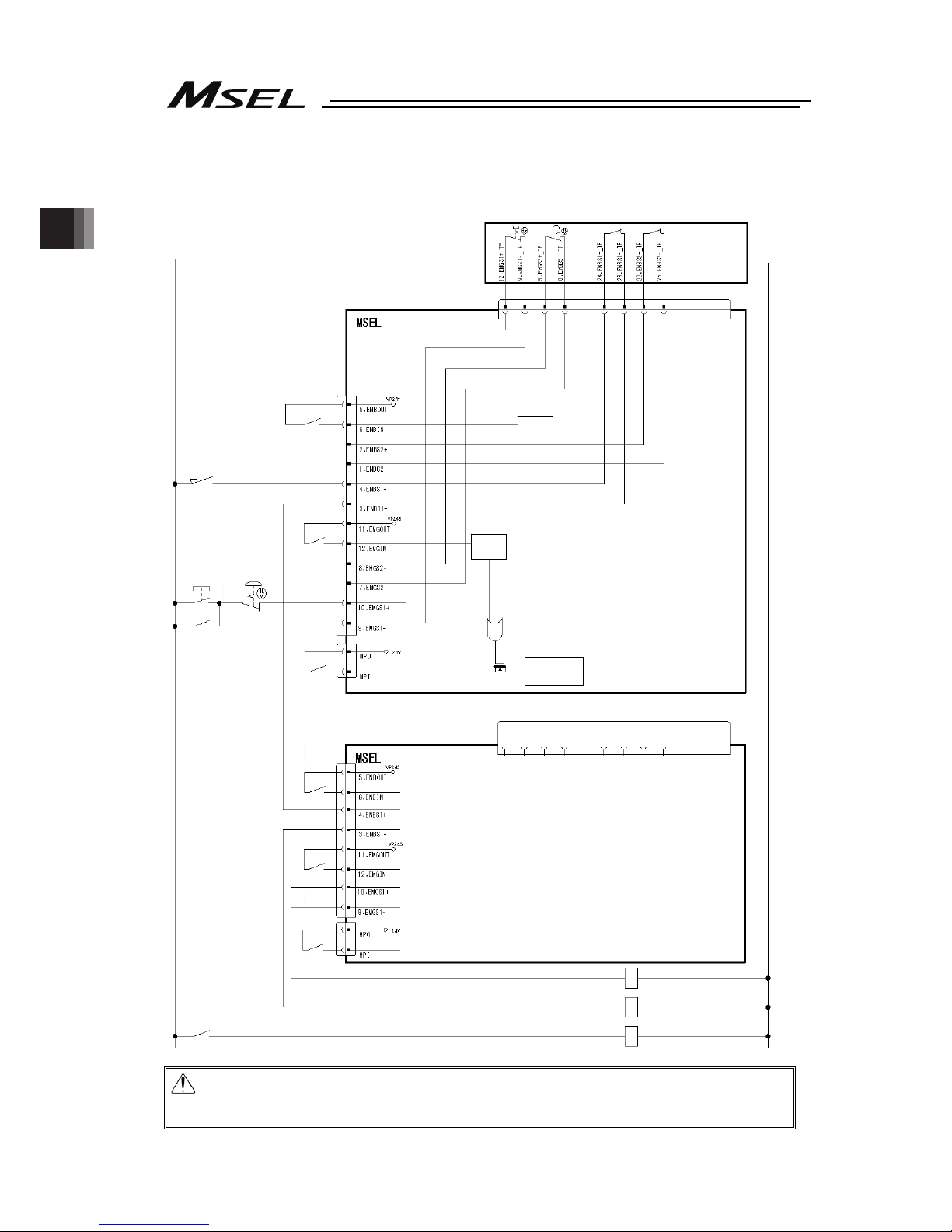

2.1 Wiring (Example connection of devices) Diagram ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 37

2.2 Circuit Diagram (Example) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 39

2.2.1 Power Supply Circuit ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 39

2.2.2 Emergency Stop and Enable Circuit (PC/PCF/PCX Type)ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 40

2.2.3 Emergency Stop and Enable Circuit (PG/PGF/PGX Type) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 42

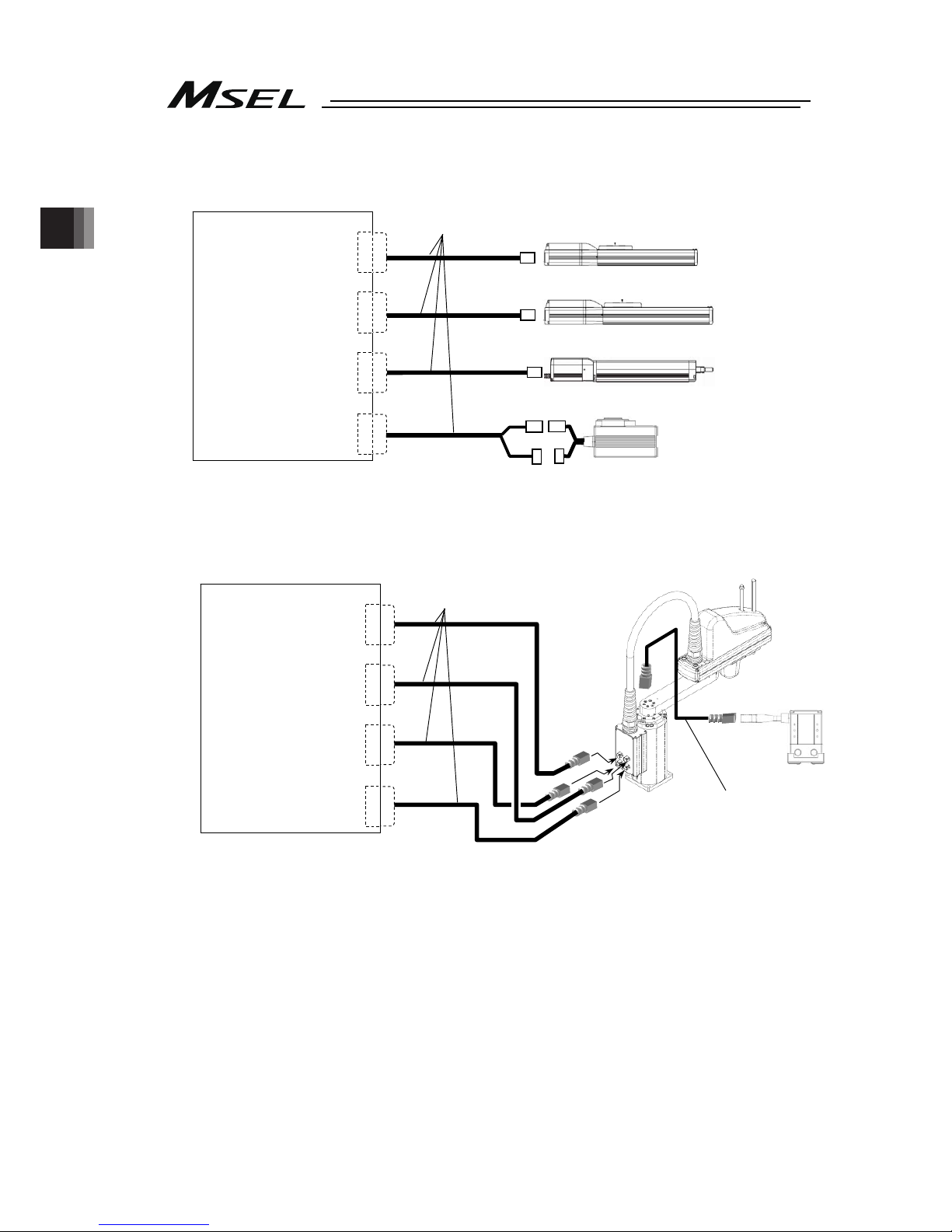

2.2.4 Motor Encoder Circuitꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 44

2.2.5 PIO Circuit ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 46

2.2.6 Connection to Absolute Battery Box (only for PC/PG/PCF/PGF Type Simple

Absolute) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 53

2.3 Wiring Method ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 54

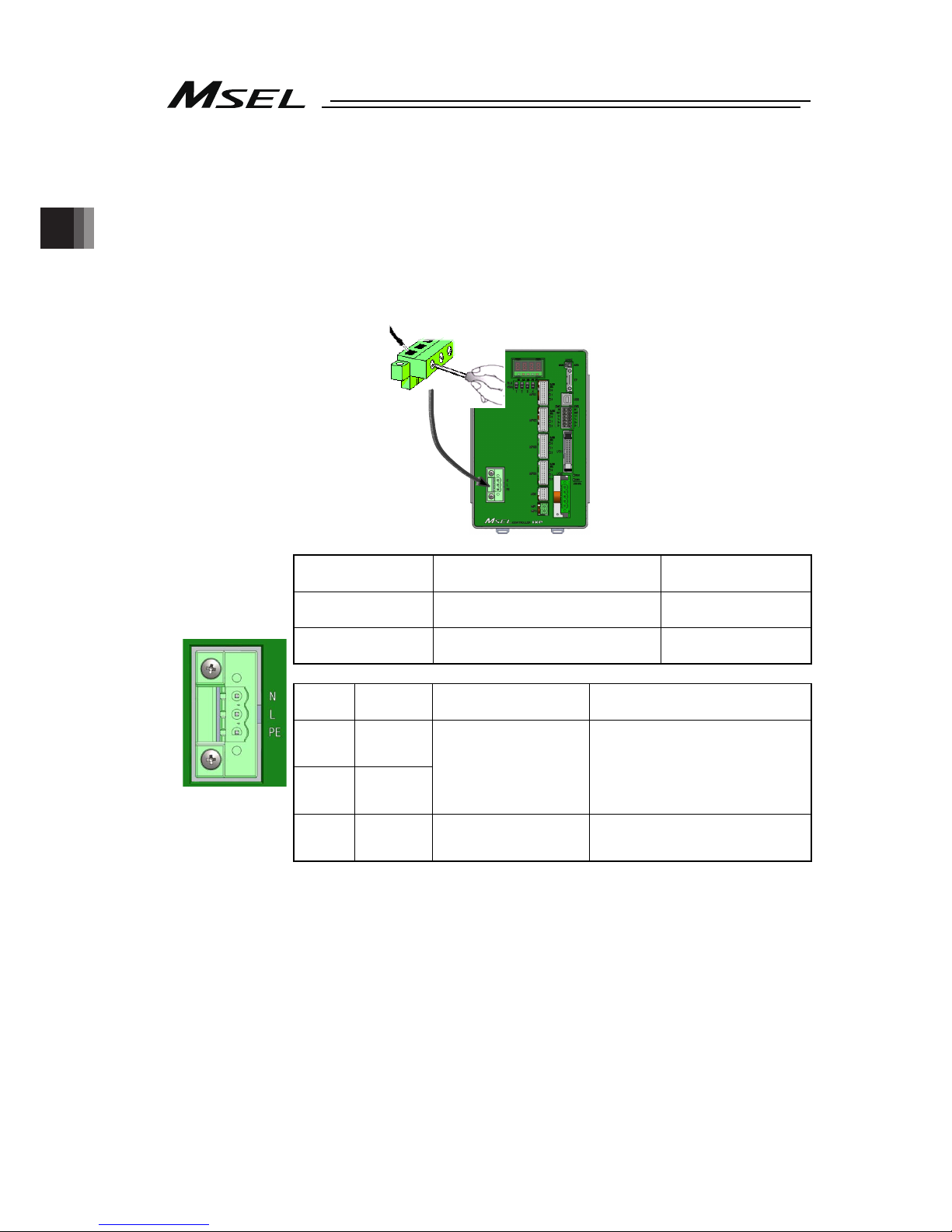

2.3.1 Connection to AC Power Input Connector ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 54

2.3.2 Wiring the Emergency Stop Circuit (System I/O)ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 55

2.3.3 Wiring for Actuator ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 56

2.3.4 Wiring for Motor Driving Power Line Connector ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 57

2.3.5 Wiring to Single Absolute Battery Unit ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 57

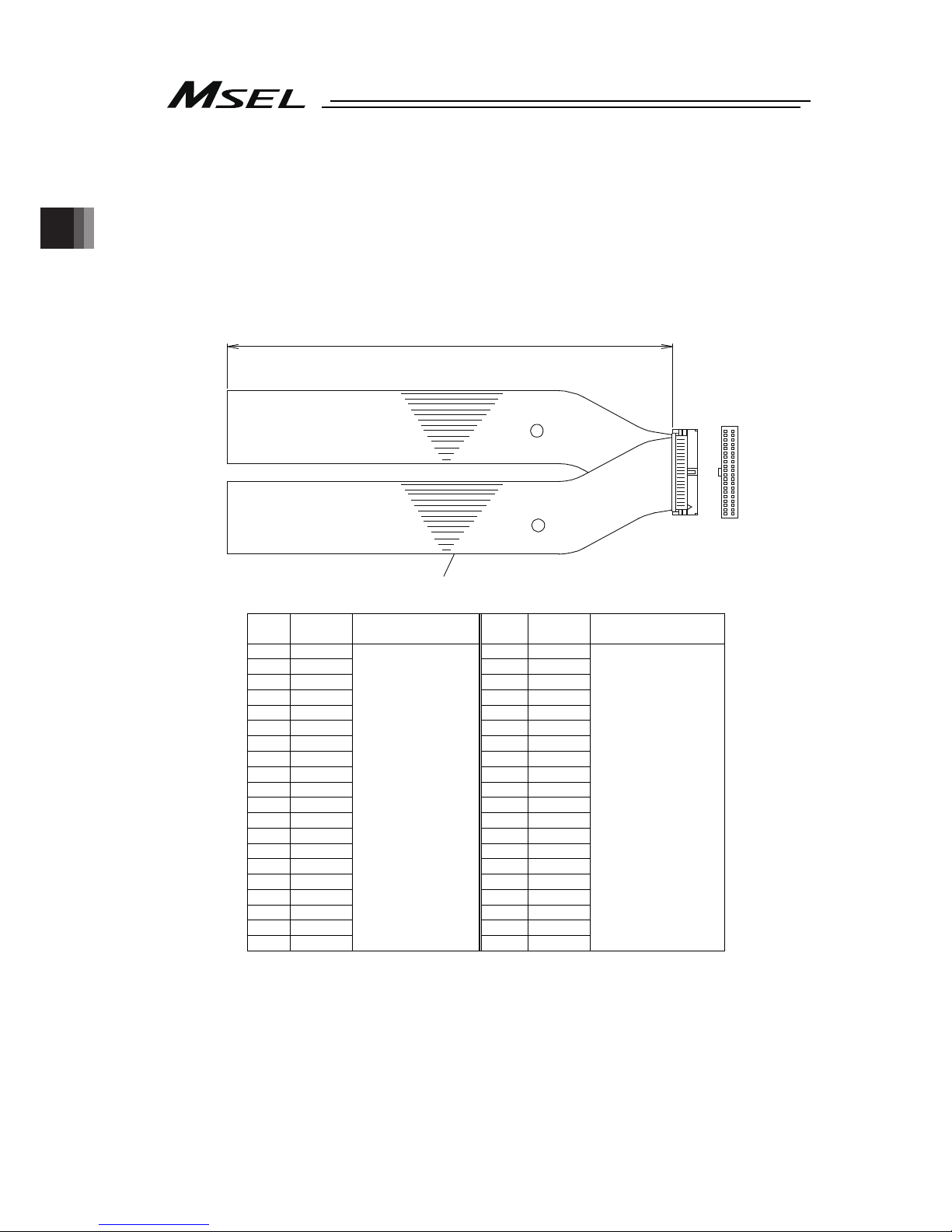

2.3.6 Wiring for PIOꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 58

2.3.7 Wiring for the Teaching Tool (SIO Connector, USB Connector) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 59

Chapter 3 Operationꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 61

3.1 Types of Operationsꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 61

3.2 Receiving and Forwarding of I/O Signals Necessary for Operation ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 62

3.3 Starting the Controllerꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 65

3.3.1 Turning on the Power and Cutoffꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 65

3.3.2 Panel Window Display ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 66

3.3.3 Status LEDꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 68

3.3.4 Position Table and Program Creation and Writing ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 70

Page 6

3.4 Program Operation ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 71

3.4.1 Auto Start upon Power Onꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 71

3.4.2 Starting a Program by Specifying its Program Numberꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 73

3.4.3 7-Segment Display SEL Programꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 74

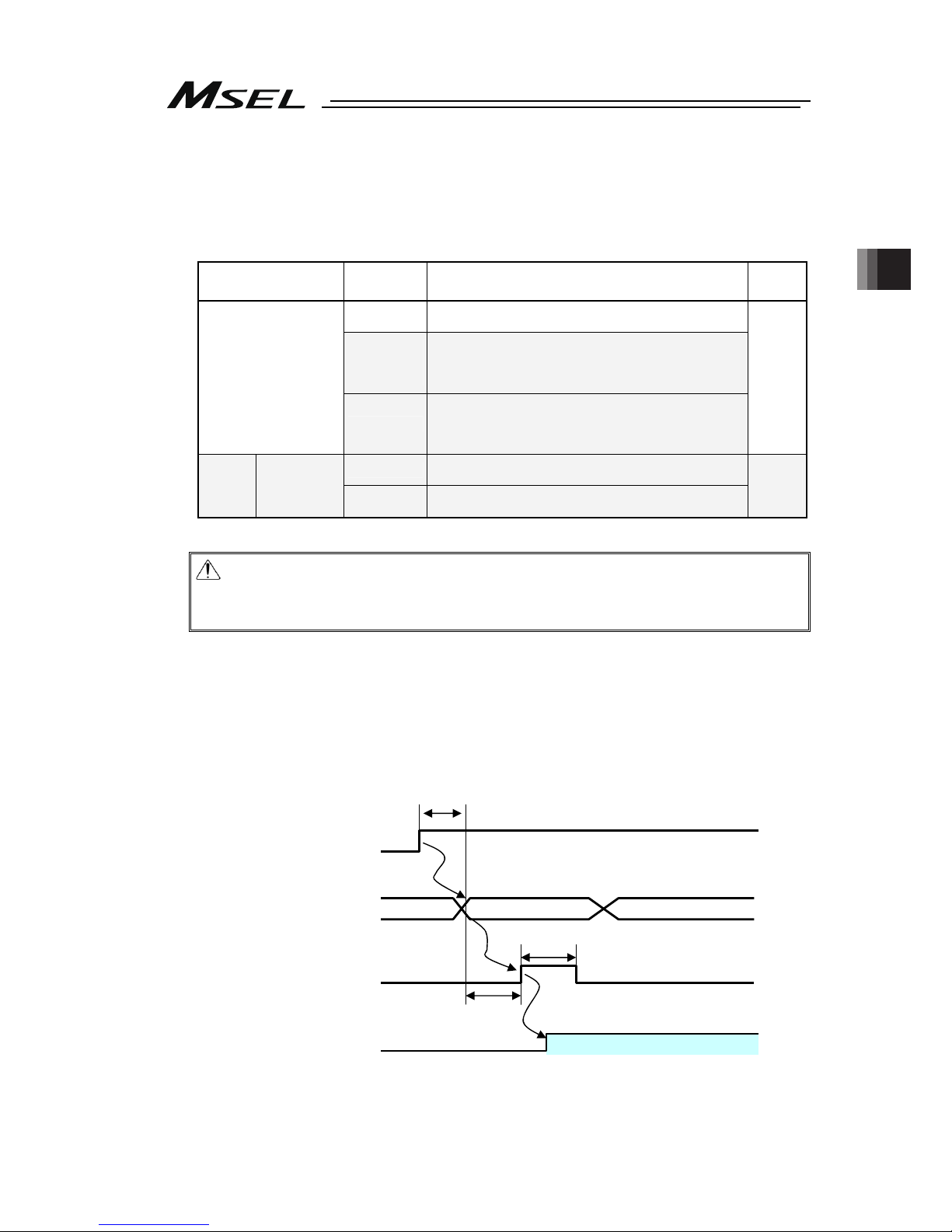

Chapter 4 Home-Return / Absolute Reset ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 77

4.1 Home-Return Preparation (Incremental Type)ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 77

4.2 Absolute Reset Preparation (for Battery-less Absolute Type except for

SCARA Robot) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 78

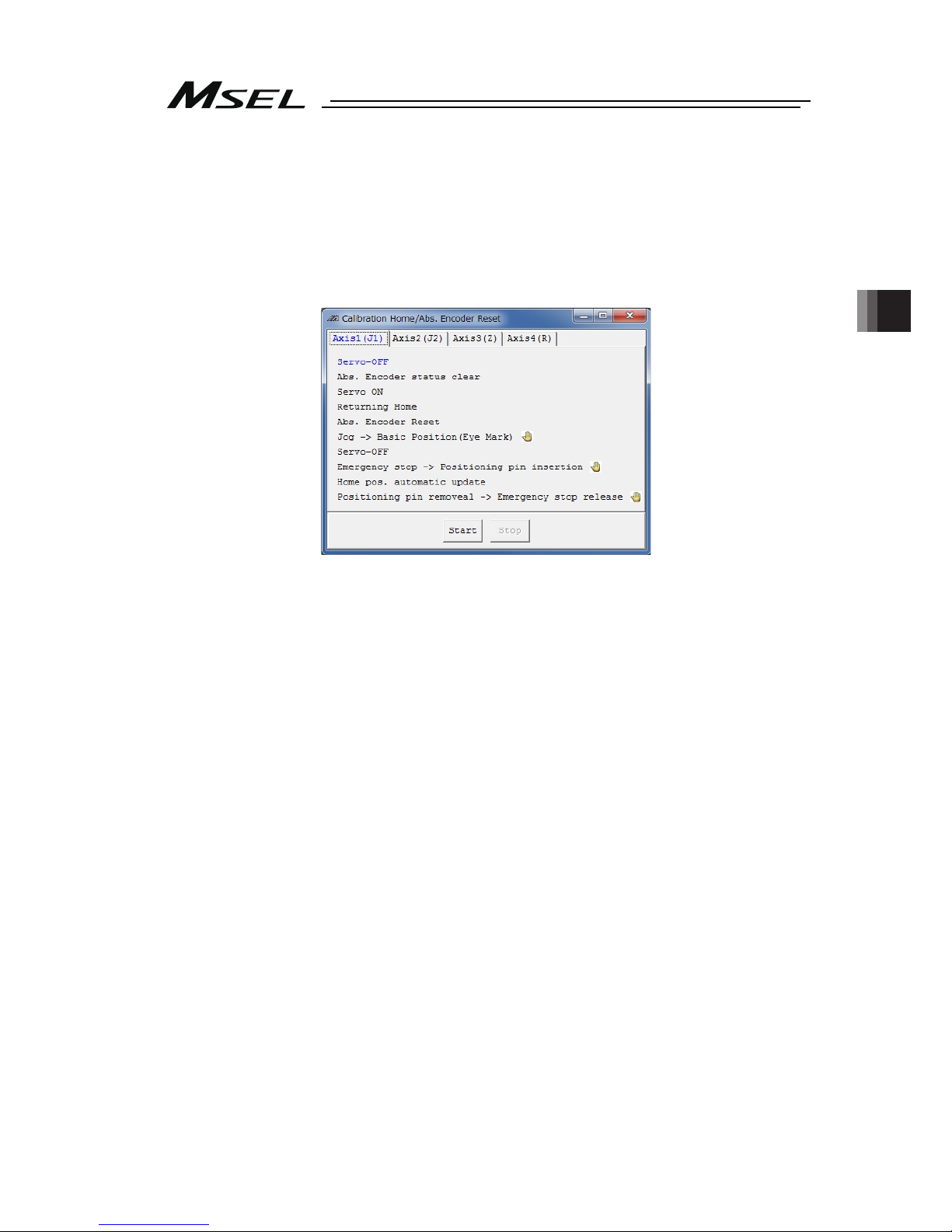

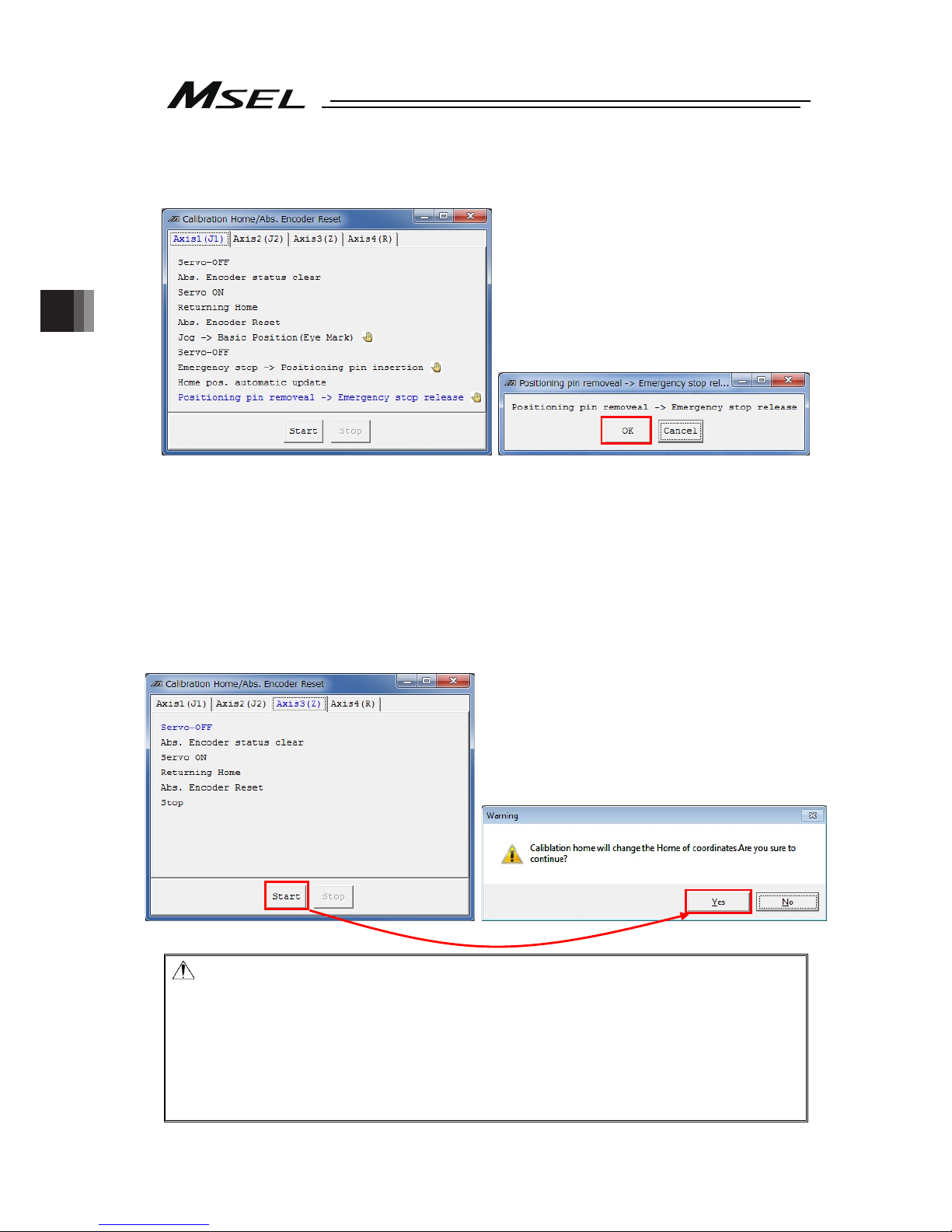

4.3 Absolute Reset for SCARA Robot (Battery-less Absolute Type) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 81

4.3.1 Absolute Reset Preparation ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 82

4.4 Simple Absolute Type (PC/PG/PCF/PGF Type Dedicated)ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 90

4.4.1 Status LEDꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 90

4.4.2 Absolute Reset Preparation ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 90

4.4.3 Simple Absolute Typeꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 91

4.4.4 Absolute Encoder Backup Type ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 92

4.4.5 Charging Absolute Battery ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 92

4.4.6 Detection of Absolute Battery Voltage Drop ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 93

Chapter 5 I/O Parameter ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 95

5.1 I/O Parameters ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 97

5.2 All Axes Common Parametersꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 113

5.3 Axis-Specific Parameters ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 119

5.4 Driver Card Parameters ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 127

5.5 Encoder Parameters ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ130

5.6 I/O-Slot Card Parametersꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ131

5.7 Other Parametersꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ135

5.8 Parameters for Linear / Rotation Controls ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ139

5.9 Permission of SIO/PIO Program Startup with Password ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 142

5.10 Parameter Setting (Applied)ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 143

5.10.1 Want to Operate the System Tentatively Without Using I/Osꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 144

5.10.2 Want to Output an Auto Operation Determination Signal from the Controller ꞏꞏꞏ 144

5.10.3 Want to Retain Current Output Statuses Even during Emergency Stop ꞏꞏꞏꞏꞏꞏꞏ 144

5.10.4 Want to Start an Emergency Program ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ145

5.10.5 Want to Enable Auto Recovery (Restart) upon Cancellation of

Emergency Stopꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ145

5.10.6 Want to Enable Auto Recovery (Error Reset) upon Cancellation of

Emergency Stopꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ146

5.10.7 Want to Return to the Condition Immediately before Emergency Stop ꞏꞏꞏꞏꞏꞏꞏꞏ146

5.10.8 Want to Restart the Controller Externally ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ146

5.10.9 Want to Turn ON the Servo Externallyꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ146

5.10.10 Want to Make a Home-Return on Actuators Externally ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 147

5.10.11 Want to Execute the Controller Program Externally ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ147

5.10.12 Want to Execute a Program Externally by Making an Indication of

a Program Number in Binaryꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ147

5.10.13 Want to Pause Controller Externally during Automatic Operation ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ147

5.10.14 Want to Reset Errors Externally ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 148

5.10.15 Want to Change Input Port Assignmentsꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ148

5.10.16 Want to Change Output Port Assignments ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 149

5.10.17 Want to Output that Home-Return (Home Position) Operation is Complete

on All Actuators ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 149

5.10.18 Want to Output the Error Level ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ150

5.10.19 Want to Output the Emergency Stop Status ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ150

5.10.20 Want to Know the Current Operation Mode ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ150

Page 7

Chapter 6 Troubleshooting ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 151

6.1 Action to Be Taken upon Occurrence of Problemꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 151

6.2 Error Level Control ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 152

6.3 Error List (MAIN Application)ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 154

Chapter 7 Appendix ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 197

7.1 Example of Safety Circuit for PG/PGF/PGX Type

(Conforming to Safety Category) ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 197

7.2 Stopping method and Recoveryꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 201

7.2.1 Stopping method ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ201

7.2.2 Recovery ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 202

7.3 Extension SIO ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 203

7.3.1 Specificationꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 203

7.3.2 Functionsꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 203

7.3.3 Wiring ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ203

7.3.4 Status Displayꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ204

7.3.5 Parameter Settings ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 204

7.4 Cartesian Axis Coordinate Systemsꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 207

7.4.1 Coordinates for Coordinate System Definition Unitꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 207

7.4.2 Base Coordinate Systemꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 208

7.4.3 Work Coordinate Systemꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ209

7.4.4 Tool Coordinate System ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 213

7.4.5 Setting of Parametersꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ217

7.4.6 Caution Note ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ219

Chapter 8 Warrantyꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 221

8.1 Warranty Periodꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ221

8.2 Scope of the Warrantyꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ221

8.3 Honoring the Warranty ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 221

8.4 Limited Liability ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 221

8.5 Conditions of Conformance with Applicable Standards/Regulations, Etc., and

Applications ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ222

8.6 Other Items Excluded from Warranty ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 222

Change Historyꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 223

Page 8

Starting Procedures

When using this product for the first time, make sure to check the safety guide in the next section,

and then start working with care to avoid mistakes and incorrect wiring by referring to the procedure

below.

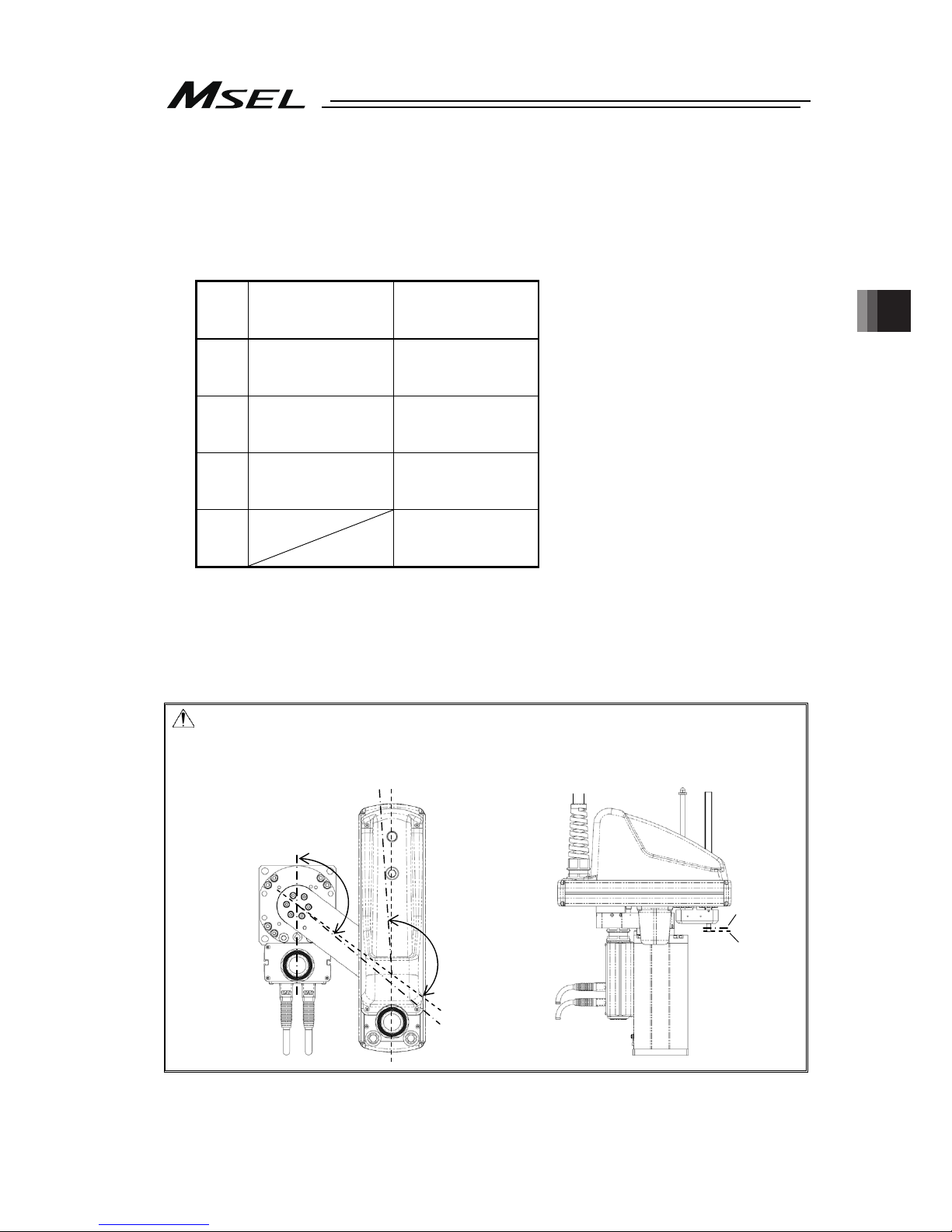

Warning

:

Make sure to put the brake release switch on the bottom side (NOM) before

turning ON the power. If on the top side (RLS : Compulsory Release), the

actuator may drop with its weight and pinch yourself or damage the work piece.

Make sure to connect the robot with the manufacturing number indicated on the

controller.

Connecting other than not indicated may cause a wrong operation.

No →

↓

↓

No →

Contact us or our distributor.

↓ Yes

No →

↓

Check Item

Is the panel window showing “ ”?

Connect the teaching tool such as PC to confirm the

content of alarm and have an appropriate treatment.

It is necessary to supply I/O power for PIO type.

When I/O is not to be used, set I/O Parameter No.

10 = 0

Connect to the upper master for fieldbus type

(Set I/O parameter No. 18 = 0 when not connecting

to master)

Check Item

Confirm that “Servo-ON: SV” is turned on in a teaching tool such

as PC.

Safety Circuit Check

Does the emergency stop circuit (drive cutoff circuit) work properly and turn the servo OFF?

Check the emergency

stop circuit.

No →

↓ Yes

Operation check on actuator

Check by JOG operation that operation of the full stroke can be performed with no abnormality.

If an alarm is generated, connect the PC or

teaching pendant and check the content of the

alarm to have the right treatment.

↓ Yes

↓

↓ Yes

Check of Packed Items

Are there all the delivered items?

Caution To ensure safety, it is recommended that safety speed be enabled during initial movements.

When putting the brake release switch to “RLS” side on a robot installed vertically, pay

attention not to pinch fingers or damage a hand by the actuator dropped by its own weight.

Installation and Wiring [Refer to Chapter 1 and 2.1]

Perform the installation of and wiring for the actuator and controller.

Point Check Item

• Is frame ground (FG) and

protection earthing (PE) connected? • Has the noise countermeasure been taken?

Power Supply and Alarm Check

Connect a teaching tool such as PC, turn the operation mode setting switch to “MANU” side and turn the power ON for unit.

Servo ON

Turn the servo ON with the operation on the teaching tool such as PC.

Now, preparation for operation is complete.

[Refer to Section 3 for how to operate]

Caution

Please perform this process with the actuator away from the mechanical end or interfering subjects as much as possible.

Put the actuator away if it interferes with surroundings. It may generate an alarm if the actuator hit the mechanical end or

interfering subjects when the servo is turned ON.

The slider may get slightly dropped by self-weight if servo ON and OFF is repeatedly performed at the same position. Be

careful not to pinch the hand or damage the work.

Page 9

1

Safety Guide

“Safety Guide” has been written to use the machine safely and so prevent personal injury or

property damage beforehand. Make sure to read it before the operation of this product.

Safety Precautions for Our Products

The common safety precautions for the use of any of our robots in each operation.

No.

Operation

Description

Description

1 Model

Selection

● This product has not been planned and designed for the application

where high level of safety is required, so the guarantee of the protection

of human life is impossible. Accordingly, do not use it in any of the

following applications.

1) Medical equipment used to maintain, control or otherwise affect

human life or physical health.

2) Mechanisms and machinery designed for the purpose of moving or

transporting people (For vehicle, railway facility or air navigation

facility)

3) Important safety parts of machinery (Safety device, etc.)

● Do not use the product outside the specifications. Failure to do so may

considerably shorten the life of the product.

● Do not use it in any of the following environments.

1) Location where there is any inflammable gas, inflammable object or

explosive

2) Place with potential exposure to radiation

3) Location with the ambient temperature or relative humidity exceeding

the specification range

4) Location where radiant heat is added from direct sunlight or other

large heat source

5) Location where condensation occurs due to abrupt temperature

changes

6) Location where there is any corrosive gas (sulfuric acid or

hydrochloric acid)

7) Location exposed to significant amount of dust, salt or iron powder

8) Location subject to direct vibration or impact

● For an actuator used in vertical orientation, select a model which is

equipped with a brake. If selecting a model with no brake, the moving

part may drop when the power is turned OFF and may cause an

accident such as an injury or damage on the work piece.

Page 10

2

No.

Operation

Description

Description

2 Transportation ● When carrying a heavy object, do the work with two or more persons or

utilize equipment such as crane.

● When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

● When in transportation, consider well about the positions to hold,

weight and weight balance and pay special attention to the carried

object so it would not get hit or dropped.

● Transport it using an appropriate transportation measure.

The actuators available for transportation with a crane have eyebolts

attached or there are tapped holes to attach bolts. Follow the

instructions in the instruction manual for each model.

● Do not step or sit on the package.

● Do not put any heavy thing that can deform the package, on it.

● When using a crane capable of 1t or more of weight, have an operator

who has qualifications for crane operation and sling work.

● When using a crane or equivalent equipments, make sure not to hang a

load that weighs more than the equipment’s capability limit.

● Use a hook that is suitable for the load. Consider the safety factor of the

hook in such factors as shear strength.

● Do not get on the load that is hung on a crane.

● Do not leave a load hung up with a crane.

● Do not stand under the load that is hung up with a crane.

3 Storage and

Preservation

● The storage and preservation environment conforms to the installation

environment. However, especially give consideration to the prevention

of condensation.

● Store the products with a consideration not to fall them over or drop due

to an act of God such as earthquake.

4 Installation

and Start

(1) Installation of Robot Main Body and Controller, etc.

● Make sure to securely hold and fix the product (including the work part).

A fall, drop or abnormal motion of the product may cause a damage or

injury.

Also, be equipped for a fall-over or drop due to an act of God such as

earthquake.

● Do not get on or put anything on the product. Failure to do so may

cause an accidental fall, injury or damage to the product due to a drop

of anything, malfunction of the product, performance degradation, or

shortening of its life.

● When using the product in any of the places specified below, provide a

sufficient shield.

1) Location where electric noise is generated

2) Location where high electrical or magnetic field is present

3) Location with the mains or power lines passing nearby

4) Location where the product may come in contact with water, oil or

chemical droplets

Page 11

3

No.

Operation

Description

Description

(2) Cable Wiring

● Use our company’s genuine cables for connecting between the actuator

and controller, and for the teaching tool.

● Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do

not coil it around. Do not insert it. Do not put any heavy thing on it.

Failure to do so may cause a fire, electric shock or malfunction due to

leakage or continuity error.

● Perform the wiring for the product, after turning OFF the power to the

unit, so that there is no wiring error.

● When the direct current power (+24V) is connected, take the great care

of the directions of positive and negative poles. If the connection

direction is not correct, it might cause a fire, product breakdown or

malfunction.

● Connect the cable connector securely so that there is no disconnection

or looseness. Failure to do so may cause a fire, electric shock or

malfunction of the product.

● Never cut and/or reconnect the cables supplied with the product for the

purpose of extending or shortening the cable length. Failure to do so

may cause the product to malfunction or cause fire.

4 Installation

and Start

(3) Grounding

● The grounding operation should be performed to prevent an electric

shock or electrostatic charge, enhance the noise-resistance ability and

control the unnecessary electromagnetic radiation.

● For the ground terminal on the AC power cable of the controller and the

grounding plate in the control panel, make sure to use a twisted pair

cable with wire thickness 0.5mm

2

(AWG20 or equivalent) or more for

grounding work. For security grounding, it is necessary to select an

appropriate wire thickness suitable for the load. Perform wiring that

satisfies the specifications (electrical equipment technical standards).

● Perform Class D Grounding (former Class 3 Grounding with ground

resistance 100 or below).

Page 12

4

No.

Operation

Description

Description

4 Installation

and Start

(4) Safety Measures

● When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

● When the product is under operation or in the ready mode, take the

safety measures (such as the installation of safety and protection

fence) so that nobody can enter the area within the robot’s movable

range. When the robot under operation is touched, it may result in

death or serious injury.

● Make sure to install the emergency stop circuit so that the unit can be

stopped immediately in an emergency during the unit operation.

● Take the safety measure not to start up the unit only with the power

turning ON. Failure to do so may start up the machine suddenly and

cause an injury or damage to the product.

● Take the safety measure not to start up the machine only with the

emergency stop cancellation or recovery after the power failure. Failure

to do so may result in an electric shock or injury due to unexpected

power input.

● When the installation or adjustment operation is to be performed, give

clear warnings such as “Under Operation; Do not turn ON the power!”

etc. Sudden power input may cause an electric shock or injury.

● Take the measure so that the work part is not dropped in power failure

or emergency stop.

● Wear protection gloves, goggle or safety shoes, as necessary, to

secure safety.

● Do not insert a finger or object in the openings in the product. Failure to

do so may cause an injury, electric shock, damage to the product or

fire.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

5 Teaching ● When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

● Perform the teaching operation from outside the safety protection

fence, if possible. In the case that the operation is to be performed

unavoidably inside the safety protection fence, prepare the “Stipulations

for the Operation” and make sure that all the workers acknowledge and

understand them well.

● When the operation is to be performed inside the safety protection

fence, the worker should have an emergency stop switch at hand with

him so that the unit can be stopped any time in an emergency.

● When the operation is to be performed inside the safety protection

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch

on the operation so that any third person can not operate the switches

carelessly.

● Place a sign “Under Operation” at the position easy to see.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

Page 13

5

No.

Operation

Description

Description

6 Trial

Operation

● When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

● After the teaching or programming operation, perform the check

operation one step by one step and then shift to the automatic

operation.

● When the check operation is to be performed inside the safety

protection fence, perform the check operation using the previously

specified work procedure like the teaching operation.

● Make sure to perform the programmed operation check at the safety

speed. Failure to do so may result in an accident due to unexpected

motion caused by a program error, etc.

● Do not touch the terminal block or any of the various setting switches in

the power ON mode. Failure to do so may result in an electric shock or

malfunction.

7 Automatic

Operation

● Check before starting the automatic operation or rebooting after

operation stop that there is nobody in the safety protection fence.

● Before starting automatic operation, make sure that all peripheral

equipment is in an automatic-operation-ready state and there is no

alarm indication.

● Make sure to operate automatic operation start from outside of the

safety protection fence.

● In the case that there is any abnormal heating, smoke, offensive smell,

or abnormal noise in the product, immediately stop the machine and

turn OFF the power switch. Failure to do so may result in a fire or

damage to the product.

● When a power failure occurs, turn OFF the power switch. Failure to do

so may cause an injury or damage to the product, due to a sudden

motion of the product in the recovery operation from the power failure.

Page 14

6

No.

Operation

Description

Description

8 Maintenance

and

Inspection

● When the work is carried out with 2 or more persons, make it clear who

is to be the leader and who to be the follower(s) and communicate well

with each other to ensure the safety of the workers.

● Perform the work out of the safety protection fence, if possible. In the

case that the operation is to be performed unavoidably inside the safety

protection fence, prepare the “Stipulations for the Operation” and make

sure that all the workers acknowledge and understand them well.

● When the work is to be performed inside the safety protection fence,

basically turn OFF the power switch.

● When the operation is to be performed inside the safety protection

fence, the worker should have an emergency stop switch at hand with

him so that the unit can be stopped any time in an emergency.

● When the operation is to be performed inside the safety protection

fence, in addition to the workers, arrange a watchman so that the

machine can be stopped any time in an emergency. Also, keep watch

on the operation so that any third person can not operate the switches

carelessly.

● Place a sign “Under Operation” at the position easy to see.

● For the grease for the guide or ball screw, use appropriate grease

according to the Instruction Manual for each model.

● Do not perform the dielectric strength test. Failure to do so may result in

a damage to the product.

● When releasing the brake on a vertically oriented actuator, exercise

precaution not to pinch your hand or damage the work parts with the

actuator dropped by gravity.

● The slider or rod may get misaligned OFF the stop position if the servo

is turned OFF. Be careful not to get injured or damaged due to an

unnecessary operation.

● Pay attention not to lose the cover or untightened screws, and make

sure to put the product back to the original condition after maintenance

and inspection works.

Use in incomplete condition may cause damage to the product or an

injury.

* Safety protection Fence : In the case that there is no safety protection

fence, the movable range should be indicated.

9 Modification

and Dismantle

● Do not modify, disassemble, assemble or use of maintenance parts not

specified based at your own discretion.

10 Disposal ● When the product becomes no longer usable or necessary, dispose of it

properly as an industrial waste.

● When removing the actuator for disposal, pay attention to drop of

components when detaching screws.

● Do not put the product in a fire when disposing of it.

The product may burst or generate toxic gases.

11 Other ● Do not come close to the product or the harnesses if you are a person

who requires a support of medical devices such as a pacemaker. Doing

so may affect the performance of your medical device.

● See Overseas Specifications Compliance Manual to check whether

complies if necessary.

● For the handling of actuators and controllers, follow the dedicated

instruction manual of each unit to ensure the safety.

Page 15

7

Alert Indication

The safety precautions are divided into “Danger”, “Warning”, “Caution” and “Notice” according to

the warning level, as follows, and described in the Instruction Manual for each model.

Level Degree of Danger and Damage Symbol

Danger

This indicates an imminently hazardous situation which, if the

product is not handled correctly, will result in death or serious

injury.

Danger

Warning

This indicates a potentially hazardous situation which, if the

product is not handled correctly, could result in death or serious

injury.

Warning

Caution

This indicates a potentially hazardous situation which, if the

product is not handled correctly, may result in minor injury or

property damage.

Caution

Notice

This indicates lower possibility for the injury, but should be kept to

use this product properly.

Notice

Page 16

8

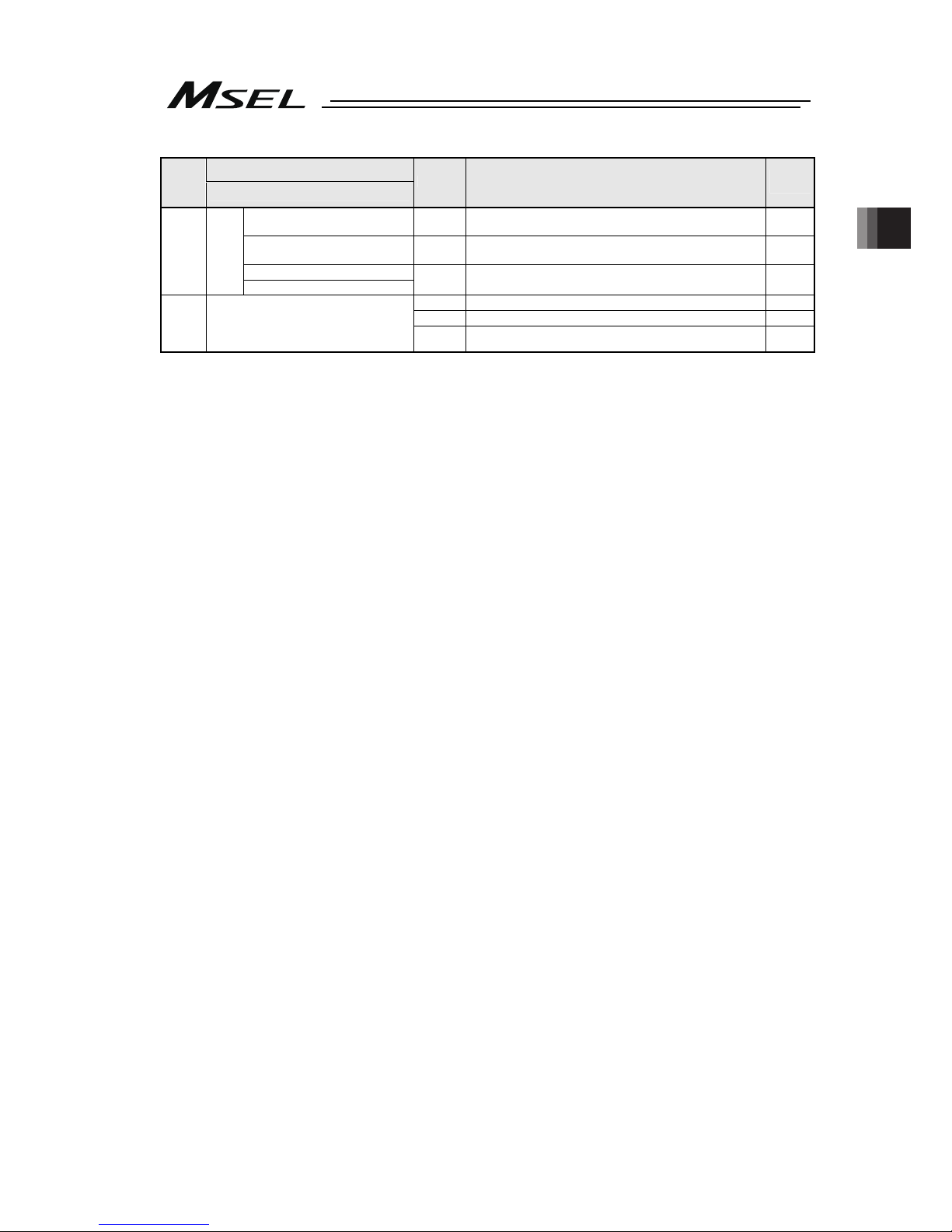

Controller Model Codes and Applicable Actuators

The controllable actuator differs depending on the model code for this controller.

No. Model Type Controllable Actuator

1 MSEL-PCX3 Standard specification

2 MSEL-PGX3 Safety category compliant specification

*2

Power-con SCARA robot

3 MSEL-PCX4 Standard specification

4 MSEL-PGX4 Safety category compliant specification

*2

Power-con SCARA robot

+ additional axis within 1 axis

5 MSEL-PC Standard specification

6 MSEL-PG Safety category compliant specification

*2

Multi-Axis 4 axes or less*1 (With

no connection of high-thrust

axis)

7 MSEL-PCF High-thrust specification

8 MSEL-PGF

High-thrust safety category compliant

specification

*2

Multi-Axis 4 axes or less

*1

(With high-thrust axis connected

to 1

st

axis or 1st and 2nd axes)

*1 Robo cylinder RCP2/RCP3/RCP4/RCP5/RCP6

*2 Category B to 3

Page 17

9

Precautions in Operation

1. Make sure to follow the usage condition, environment and specification range

of the product.

In case it is not secured, it may cause a drop in performance or malfunction of the product.

2. Wait for 5 seconds or more before rebooting the power.

For the reason of controller circuit structure, startup may not be conducted in normal condition

if the time to turn the power ON after turning it OFF (rebooting) is too short.

3. Use a dedicated teaching tool.

Check in 1.1.2 Teaching Tool for the PC software and the teaching pendant applicable for this

controller.

4. Backup the data to secure for breakdown.

Such data as the position data, programs, parameters and so on registered to this controller is

maintained by being written to the non-volatile memory. Therefore, you will not usually lose the

data even if the power is shut down. However, make sure to save the latest data so a quick

recovery action can be taken in case when the controller is broken and needs to be replaced

with another one.

How to Save Data

(1) Save the data to external memory or hard disk with using the PC software

(2) Hard-copy the information of position tables and parameters on paper

5. Clock Setting in Calendar Function

There may be a case that “Error Code 228 Calendar Data Lost Error (RTC Vibration

Generated Stop Detected)” occurs at the first startup after delivery. In the case this happens,

set the current time with a teaching tool. [Refer to Teaching Tool Instruction Manual described

in 1.1.2 Teaching Tool (Option)]

If the battery is fully charged, the clock data is retained for approximately 10 days after the

power is turned off. Even though the time setting is conducted before the product is shipped

out, the battery is not fully charged. Therefore, there may be a case that the clock data is lost

even with fewer days than described above passed since the product is shipped out.

Page 18

10

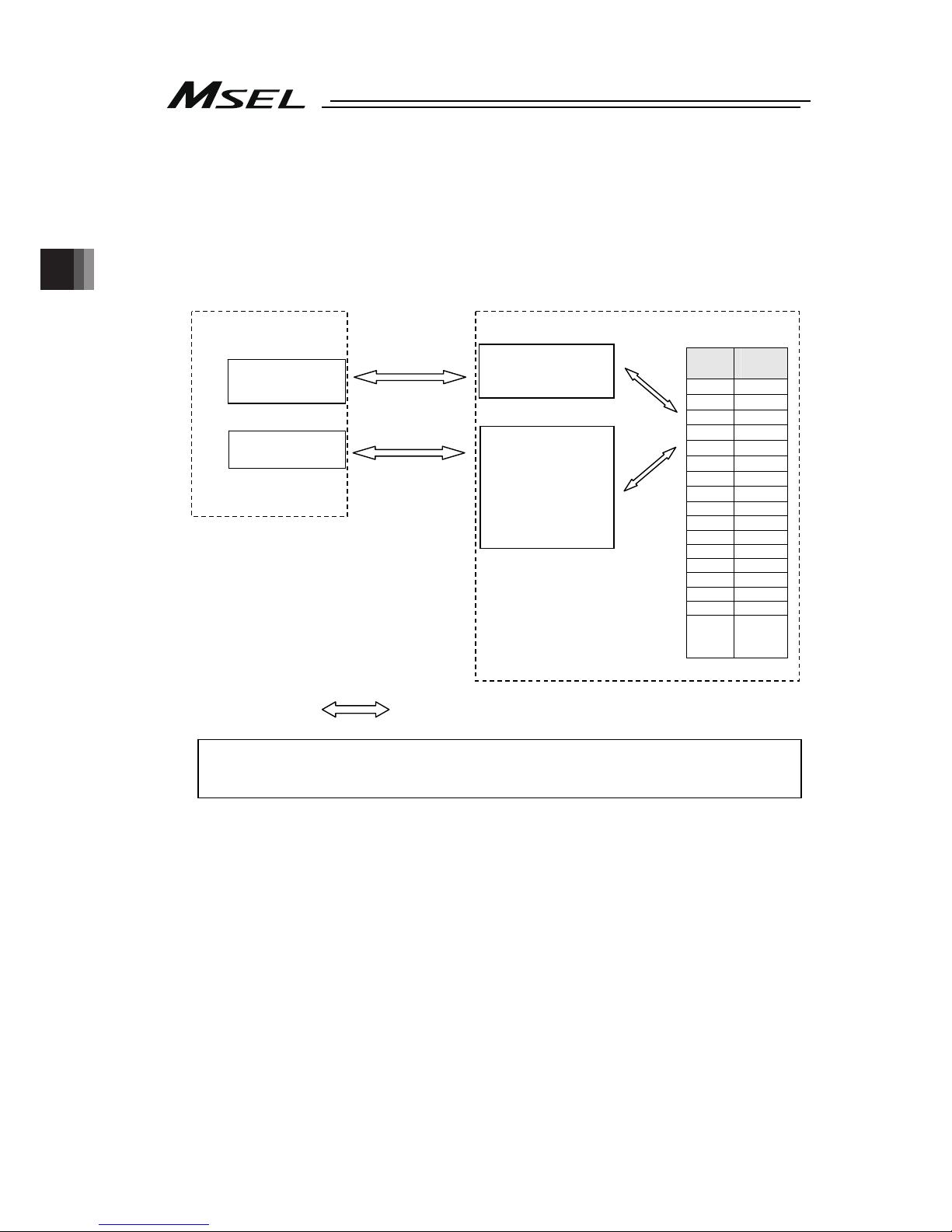

6. Transference of PIO Signal between Controllers

Please note the following when conducting transference of PIO signal between controllers.

To certainly transfer the signal between controllers with different scan time, it is necessary to

have longer scan time than the one longer than the other controller. To ensure to end the

process safely, it is recommended to have the timer setting more than twice as long as the

longer scan time at least.

● Operation Image

Also, if one tries to read the signal that is being re-written by the other, the signal may be read

wrongly.

Make sure to read the signal after the rewriting is complete. (It is recommended to have more

than 2 scan periods to wait.) Make sure not to have the output side to change the output until

the other side completes the reading. Also, a setting is made on the input area not to receive

the signal less than a certain time to prevent a wrong reading of noise. This duration also

needs to be considered.

Note 1 Because this controller performs two or more processing works including program

execution and error processing, in addition to I/O processing, the scan time in not

fixed.

7. PLC Timer Setting (Reference)

Do not have the PLC timer setting to be done with the minimum setting.

Setting to “1” for 100msec timer turns ON at the timing from 0 to 100msec while 10msec timer

from 0 to 10msec for some PLC.

Therefore, the same process as when the timer is not set is held and may cause a failure.

Set “2” as the minimum value for the setting of 10msec timer and when setting to 100msec,

use 10msec timer and set to “10”.

As shown in the diagram, the input and

output timings of two devices that have

different scan time do not match, of

course, when transferring a signal.

There is no guarantee that PLC would

read the signal as soon as this controller

signal turns on.

In such a case, make the setting to read

the signal after a certain time that is

longer than the longer scan time to

ensure the reading process to succeed on

the PLC side.

It is the same in the case this controller

side reads the signal.

In such a case, it is recommended to

ensure 2 to 4 times of the scan time for

the timer setting margin.

It is risky to have the setting below the

scan time since the timer is also

processed in the scan process.

In the diagram, PLC can only read the

input once in 20msec even though this

controller output once in some msec.

Because PLC only conducts output

process once in 20msec, this controller

identifies the same output status for that

while.

This controller

(scan time some msec)

(Note 1)

PLC

(e.g. scan time is 20msec)

Output

Process

Input

Process

Page 19

11

8. Regarding Battery-less Absolute Type Actuator at the Excluding of the SCARA

Axis

The battery-less absolute type actuator can have the setting switched over between the

absolute type and incremental type with the parameters.

Parameter No.38 Encoder ABS/INC Type

Set to 0 = Incremental Type

Set to 2 = Absolute Type

9. Regarding Battery-less Absolute Type Actuator

1) For the first time to turn the servo on after turning on the power, it will have slight position

adjustment due to the characteristics of the stepping motor.

At that time, the current position displayed on the teaching tool before turning the servo on

is the coordinates before adjustment operation. Shown below is the maximum amount of

movement.

Linear Drive Axis

: Actuator Lead Length × 0.025 [mm]

SCARA Axis : J1, J2 Axis 4.9[mm] ꞏ ꞏ Arm Length 350mm Type

4.3[mm] ꞏ ꞏ

Arm Length 450mm Type

Vertical Axis 0.2[mm]

Rotary Axis 2.7deg

2)

After the first time the servo is tuned on after the power has been supplied, the home-return

complete signal and the limit switch output signal (LS) are output.

3)

When the first servo-on is conducted out of the soft limit range, an error would not be

output.

Soft limit monitoring starts after it is moved into the range.

Page 20

12

International Standards Compliances

MSEL comply with the following international standards:

Refer to Overseas Standard Compliance Manual (ME0287) for more detailed information.

RoHS Directive CE Marking UL

(except for PCX) To be scheduled

Page 21

13

Name for Each Parts and Their Functions

[1] PC/PG/PCF/PGF Type (Cartesian, Single-Axis Robot Control Type)

1) AC Power input connector

2) Absolute battery connector

(when simple absolute type is used)

6) Simple absolute status

LED lamps for each axis

10) System I/O connector

5) Panel window

9) USB connector

7) Operation mode setting switch

12) Status LED for extension

I/O

13) Extension I/O connector

14) Motor drive power supply

line connector

8) SIO connector

4) Brake release switch

11) Standard I/O connector

3) Actuator connection connector

y MPG1:1st axis

y MPG2:2nd axis

y MPG3:3rd axis

y MPG4:4th axis

Page 22

14

[2] PCX/PGX Type (IXP Series SCARA Robot Control Type)

1) AC power input connector

Supply the main power source, single-phase 100V to 230V AC.

Warning :

Do not attempt to touch this connector or wires while the power is on as it

may cause electric shock.

Make sure to ground the protection earthing “PE” terminal to prevent

electric shock.

2) Absolute battery connector (PC/PG/PCF/PGF type dedicated)

It is mounted for Simple Absolute Type. A battery box placed separately is to be connected

with one cable for four axes. It is not to be mounted for Incremental Type and Battery-less

Absolute Type.

3) Actuator connection connector [MPG1 to MPG4]

Connect the motor encoder cable of the actuator.

Connect the 1

st

axis (J1) to “MPG1”, and connection made up to “MPG4” = 4th axis (J4) in

order.

3) Actuator connection connector

(SCARA Robot)

y MPG1:J1 axis

y MPG2:J2 axis

y MPG3:J3 axis

y MPG4:J4 axis

1) AC Power input connector

2) Extension connectors

(Not equipped / Not to use)

6) Extension LED

(Not to use)

10) System I/O connector

5) Panel window

9) USB connector

7) Operation mode setting switch

12) Status LED for extension I/O

13) Extension I/O connector

14) Motor drive power supply

line connector

8) SIO connector

4) Brake release switch

(This may not be equipped.)

11) Standard I/O connector

Page 23

15

4) Brake release switch (each axis of 1 to 4)

It is the switch to release the brake compulsorily (excitation release) for the actuator

equipped with a brake. When it is desired to move an actuator manually in such cases as

to set up the equipment, in teaching and in an error, the brake can be compulsorily

released by putting the switch to RLS side after turning the power on.

Keep the switch set on NOM side unless necessary.

Switch position Function

RLS (Brake release) Top side Brake is released compulsorily.

NOM (Automatic

mode)

Bottom

side

Brake gets controlled automatically by

controller.

Servo ON : Brake release

Servo OFF : Brake effective

Warning : After conducting the brake compulsory release, make sure to set the

switch back to NOM (automatic mode) so the controller can perform the

automatic control on the brake. In RLS (brake release), it is very

dangerous as the brake would not work when emergency stop is occurred

or servo is turned OFF. For vertically mounted actuators, the slider or rod

can drop and it may cause a critical accident.

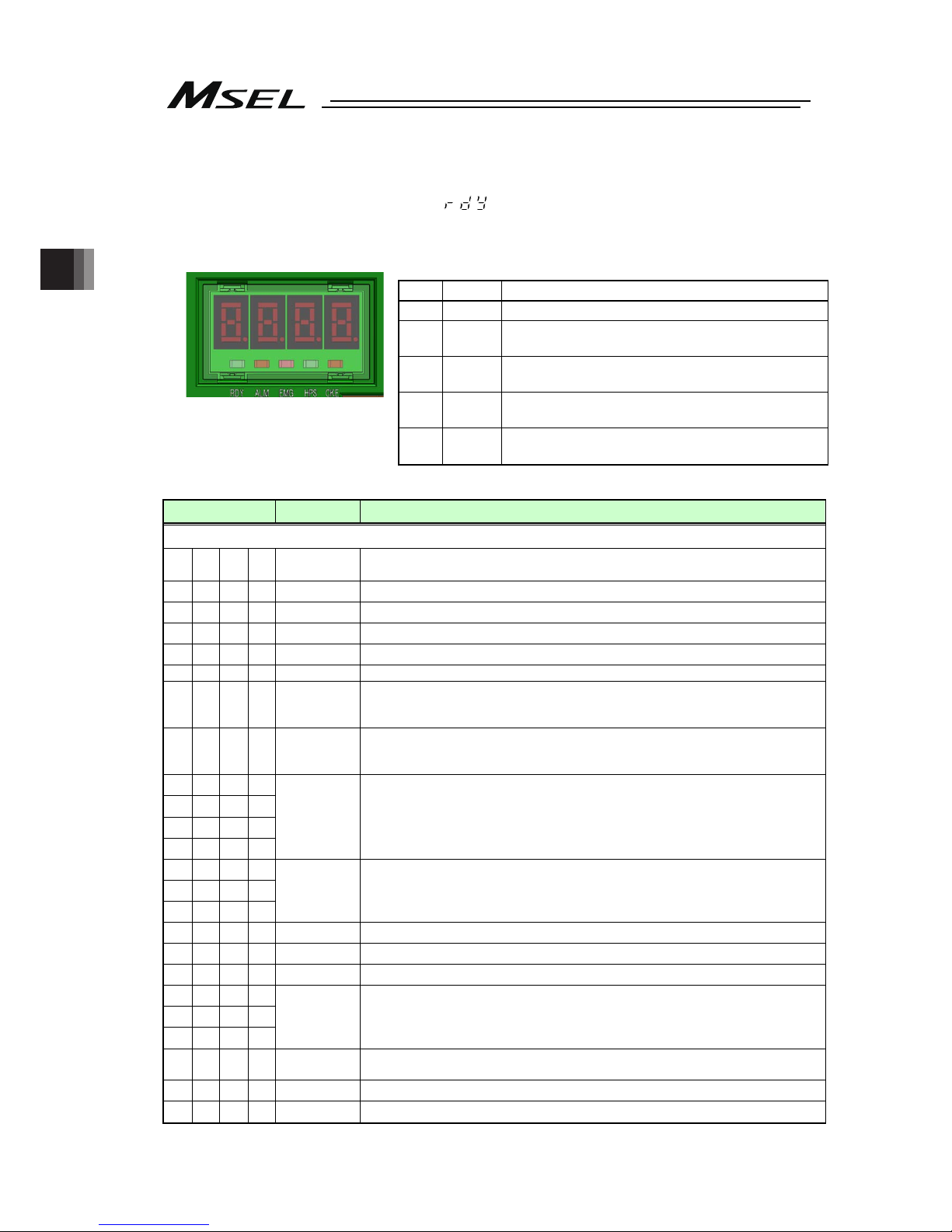

5) Panel window

It shows the controller status with the 4-digit 7-segment display and 5 LED lamps.

6) Simple Absolute Status LED Lamps for Each Axis (PC/PG type dedicated)

This displays the status of simple absolute. This status display is not equipped for

Incremental Type and Battery-less Absolute Type. [Refer to 3.3.3 Status LED]

7) Operation mode setting switch

It is a switch to indicate the operation mode of the controller.

Switch position Function

MANU

(Operation mode)

Left side Teaching tool is activated.

AUTO

(Automatic mode)

Right side

Teaching tool is inactivated.

(Note) Apply the enclosed dummy plug (DP-4S)

to SIO connector for PG / PGX types.

Emergency stop cannot be cancelled if it

is not plugged.

8) SIO connector

It is the connector dedicated for the connection of a teaching tool.

9) USB connector

It is a connector to plug in a USB. It is used to connect a teaching tool by USB connection.

Caution :

y

USB connector and SIO connector cannot be used at the same time.

USB connection is prioritized.

y

When using the USB ports, connect the controllers to use one by one,

and install the USB driver stored in the XSEL PC software CD-ROM.

See the instruction manual of XSEL PC software for how to install.

y

Apply the enclosed dummy plug (DP-4S) to SIO connector when using

the USB ports.

Page 24

16

10) System I/O connector

It is the input and output connectors to manage the safety control on the controller.

For PG / PGX types (safety category complied), it is available to comply with up to

category 3 by connecting an external safety circuit to this controller.

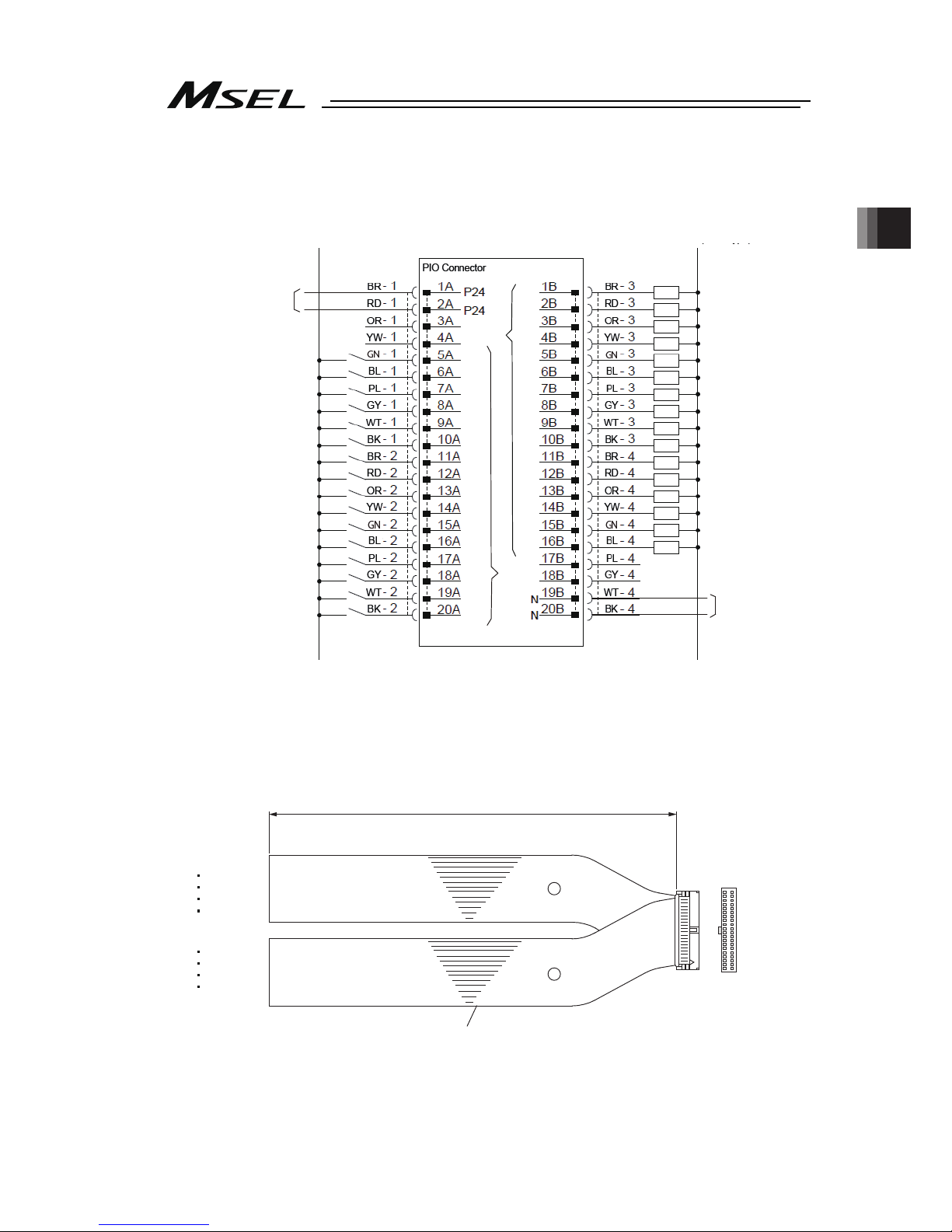

11) Standard I/O connector

It is the connector to apply PIO signals of 16 points each of general-purposed input and

output.

12) Status LED for extension I/O

It shows the status of PIO or fieldbus plugged to the extension I/O connector.

[Refer to Status LED in Section 3.3.3]

13) Extension I/O connector

It is equipped when PIO or fieldbus is selected as the extension I/O. It is a connector for

the general-purposed I/O signal for PIO type and for connection of each fieldbus for

fieldbus type.

14) Motor drive power supply line connector

It is generally used by short-circuiting MPI and MPO. When supply / cut off the motor

driving power externally to construct the safety circuit, connect a contact point between

MPI and MPO.

Page 25

17

Actuator Axes

Refer to the pictures below for the actuator axes that can be controlled

0 defines the home position, and items in ( ) are for the home-reversed type (option).

(1) Rod Type

(2) Slider Type

(3) Table Type

(4) Rotary Type

(330° rotation specification) (Multi rotation specification)

For multiple rotation type with the origin reversed type, the directions of + and - are the other

way around.

Caution: There are some actuators that are not applicable to the origin reversed type.

Check further on the catalog or the Instruction Manual of the actuator.

-

+

0°

330°

+

(0)

0

(+)

0

(+)

+

(0)

+

(0)

0

(+)

Page 26

18

(5) Gripper Type

(3-finger gripper)

Note Finger attachment is not included in the actuator package. Please prepare separately.

(6) Cartesian Robot (dedicated for combination with indicated controller P1 in IK2/IK3 Series)

There are three types of coordinate systems, base coordinate system, work coordinate

system and tool coordinate system.

[Refer to 7.4 Cartesian Axis Coordinate Systems for detail]

+

+

+

Finger attachment (Note)

3

r

d

axis (Z-axis)

(AXIS3)

2

n

d

axis (Y-axis)

(AXIS2)

1

s

t

axis (X-axis)

(AXIS1)

1

s

t

axis (X-axis)

(AXIS1)

3

r

d

axis (Z-axis)

(AXIS3)

2

n

d

axis (Y-axis)

(AXIS2)

-

+

0 (Home)

-

+

-

+

Page 27

19

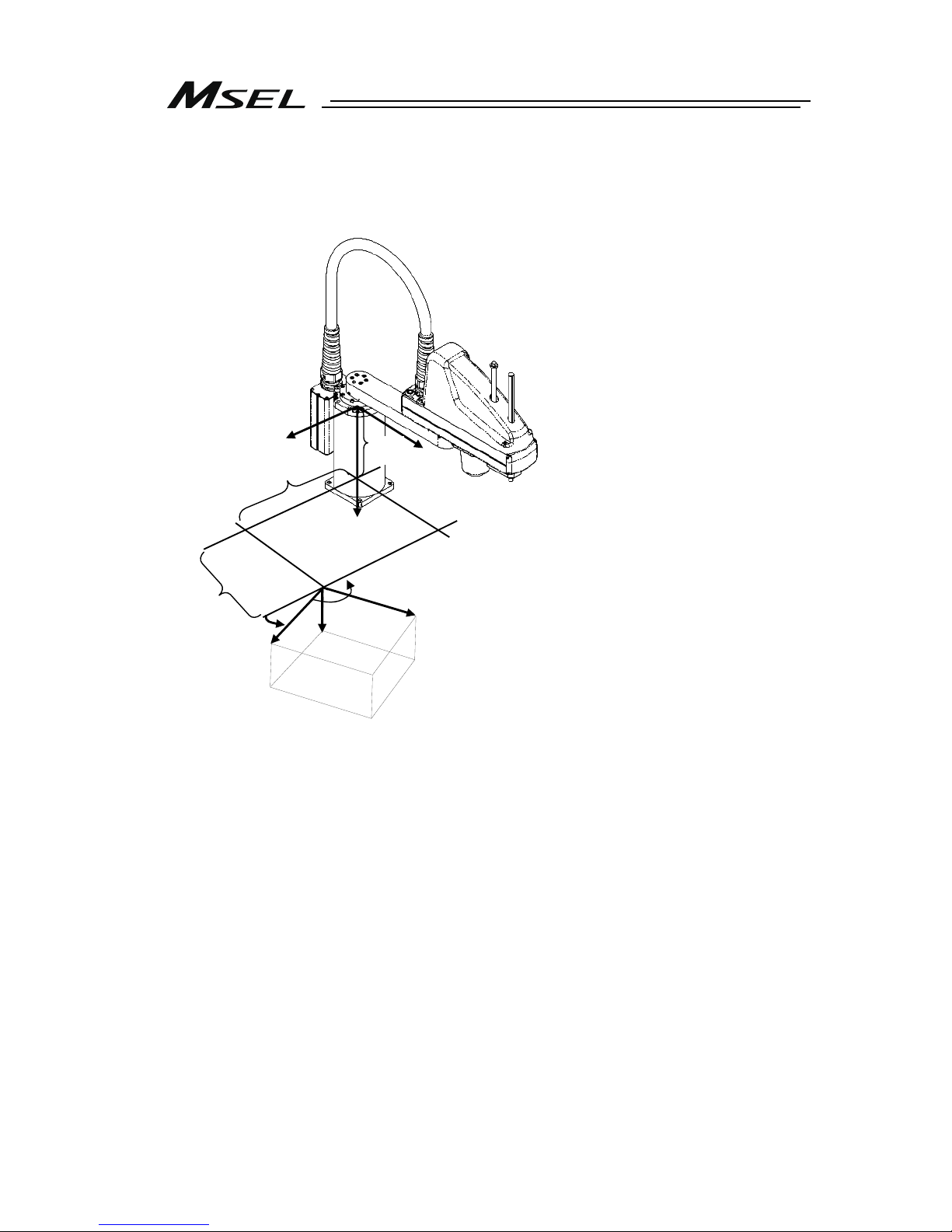

(7) Horizontal Articulated (SCARA) Robot ⋅ ⋅ IXP Type Dedicated

There are three types of coordinate systems, base coordinate system, work coordinate system

and tool coordinate system.

[Base Coordinate System (= Work Coordinate System No. 0)]

It is the 3-dimensional orthogonal coordinates + rotation axis coordinate (dedicated for 4-axis

type) defined in the robot at delivery.

Work coordinate system No. 0 (work coordinate system offset 0) = Base coordinate system.

The origin of X and Y axes is the center of the base (rotation center of the 1

st

arm).

The origin of Z axis is the upper end of the effective stroke on the Z axis.

The origin of R axis is the position that the D-cut surface faces –Xb direction.

X axis of base coordinate system is described as Xb, Y axis as Yb, Z axis as Zb and R axis as

Rb.

Top view of J2 axis

Rb

(For 4

-axis specification)

Xb

Zb

Yb

+Zb

Stroke

Z-axis position

Zb=0

-Zb

-Xb

+Rb

-Rb

Center of tool

attachment face

D-cut surface on

r

otational axis

Page 28

20

[Work Coordinate System]

It is 32 types of the 3-dimensional orthogonal coordinates + rotation axis coordinate defined by

the offset to base coordinate system. Work coordinate system No. 0 is reserved as base

coordinates (= work coordinate system offset = 0) by the system.

Xb

Zb

Yb

Zofwn

Xwn

Zwn

Ywn

Yofwn

Rofwn

Rwn

Xofwn

Xofwn : X Work coordinate system offset

Yofwn : Y Work coordinate system offset

Zofwn : Z Work coordinate system offset

Rofwn : R Work coordinate system offset

Xwn : Work coordinate system X axis

Ywn : Work coordinate system Y axis

Zwn : Work coordinate system Z axis

Rwn : Work coordinate system R axis

(n is the work coordinate system number)

Page 29

21

[Tool Coordinate System]

It is 128 types of the 3-dimensional orthogonal coordinates + rotation axis coordinate defined

by the tool (such as hand) dimension (offset) attached to the tool attachment surface. Work

coordinate system No. 0 is reserved as offset 0 of tool coordinates by the system.

If the defined tool coordinate system number is selected, the tool tip is used as the reach point

at the positioning, not the center of the tool attachment surface.

Select the defined tool coordinate system and operate the R axis with JOG operation, and

such movement as shown in the figure below can be performed.

Xoftn : X Tool coordinate system offset

Yoftn : Y Tool coordinate system offset

Zoftn : Z Tool coordinate system offset

Roftn : R Tool coordinate system offset

Xtn : Tool coordinate system X axis

Ytn : Tool coordinate system Y axis

Ztn : Tool coordinate system Z axis

Rtn : Tool coordinate system R axis

(n is the toof coordinate system number)

Tool

R-axis

Tool ti

p

Page 30

22

Page 31

Chapter 1 Specications Check

23

Chapter 1 Specifications Check

1.1 Product Check

The standard configuration of this product is comprised of the following parts.

If you find any faulty or missing parts, contact your local IAI distributor.

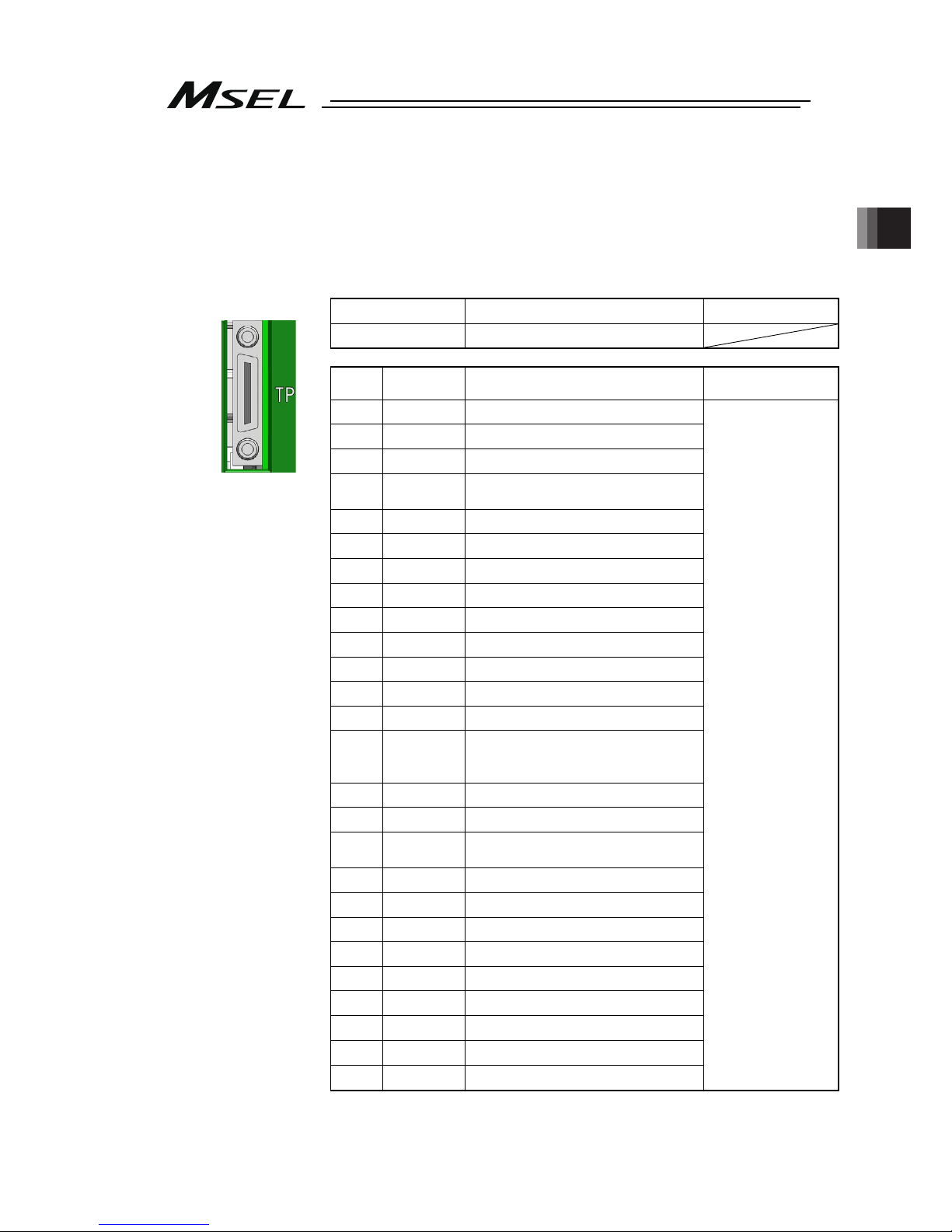

1.1.1 Parts (Excluding Options)

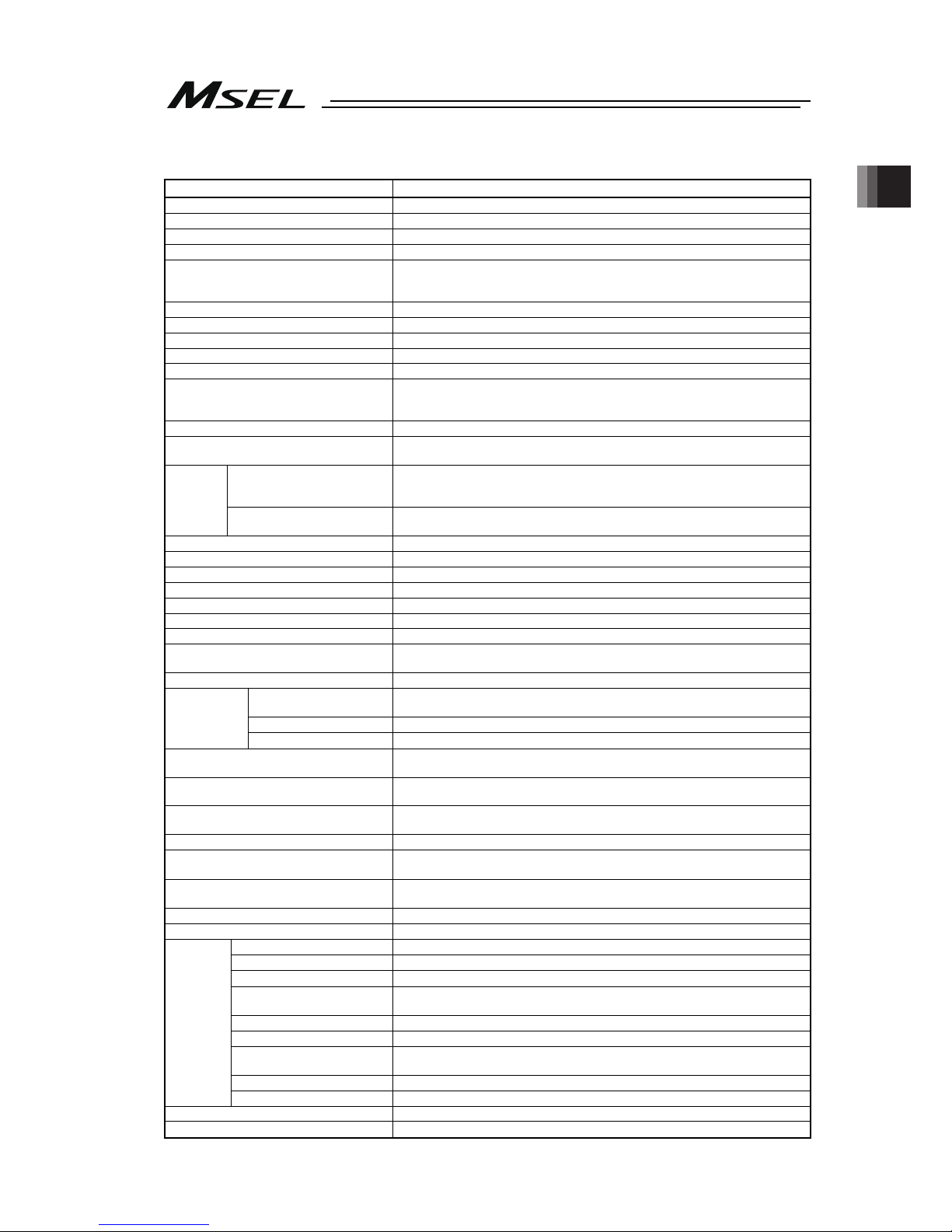

No. Part Name Model

Quantity

1 Controller Main Body

Refer to “How to read the model plate”, “How to read the

model”. [Refer to 1.1.4 or 1.1.5.]

1

Accessories

2 System I/O Plug DFMC1.5/6-ST-3.5 (Supplier: PHOENIX CONTACT) 1

3 AC Power Plug

MSTB2.5/3-STF-5.08 (SK: N-PE)

(Supplier: PHOENIX CONTACT)

1

4

Motor Drive Power

Line Connector

FKIC2.5HC/2-ST-5.08 (Supplier: PHOENIX CONTACT) 1

5 Dummy Plug DP-4S (Enclosed in PG, PGF or PGX) 1

6 I/O Flat Cable

CB-PAC-PIO□□□ □□□ shows the cable length

(Example) □□□ : 020 = 2m

(In common for both standard I/O and extension I/O (PIO

type))

1 or 2

(for number of

mounted PIO)

Model CC: MSTB2.5/5-STF-5.08AU

(Supplier: PHOENIX CONTACT)

7 CC-Link Connector

Model CC2: TMSTBP2.5/5-STF-5.08 AUBD-FG

(Supplier: PHOENIX CONTACT)

1

Model DV: MSTB2.5/5-STF-5.08AUM

(Supplier: PHOENIX CONTACT)

8 DeviceNet Connector

Model DV2: TMSTBP2.5/5-STF-5.08 AUM

(Supplier: PHOENIX CONTACT)

1

9 First Step Guide 1

10

Instruction Manual

(DVD)

1

11 Safety Guide 1

1.1.2 Teaching Tool (Optional)

A teaching tool such as PC software is necessary when performing the setup for creating a

program, position setting and parameter setting, etc. that can only be done on the teaching tool.

Please prepare either of the following teaching tools.

No. Part Name Model

1

PC Software (with RS232C Cable + Connector Conversion Cable ・ with Emergency

Stop Box)

IA-101-X-MW-JS

2 PC Software (with USB Cable (CB-SEL-USB030) + Dummy Plug (DP-4S)) IA-101-X-USBS

3 Teaching Pendant TB-02

4 Teaching Pendant TB-01

Page 32

Chapter 1 Specications Check

24

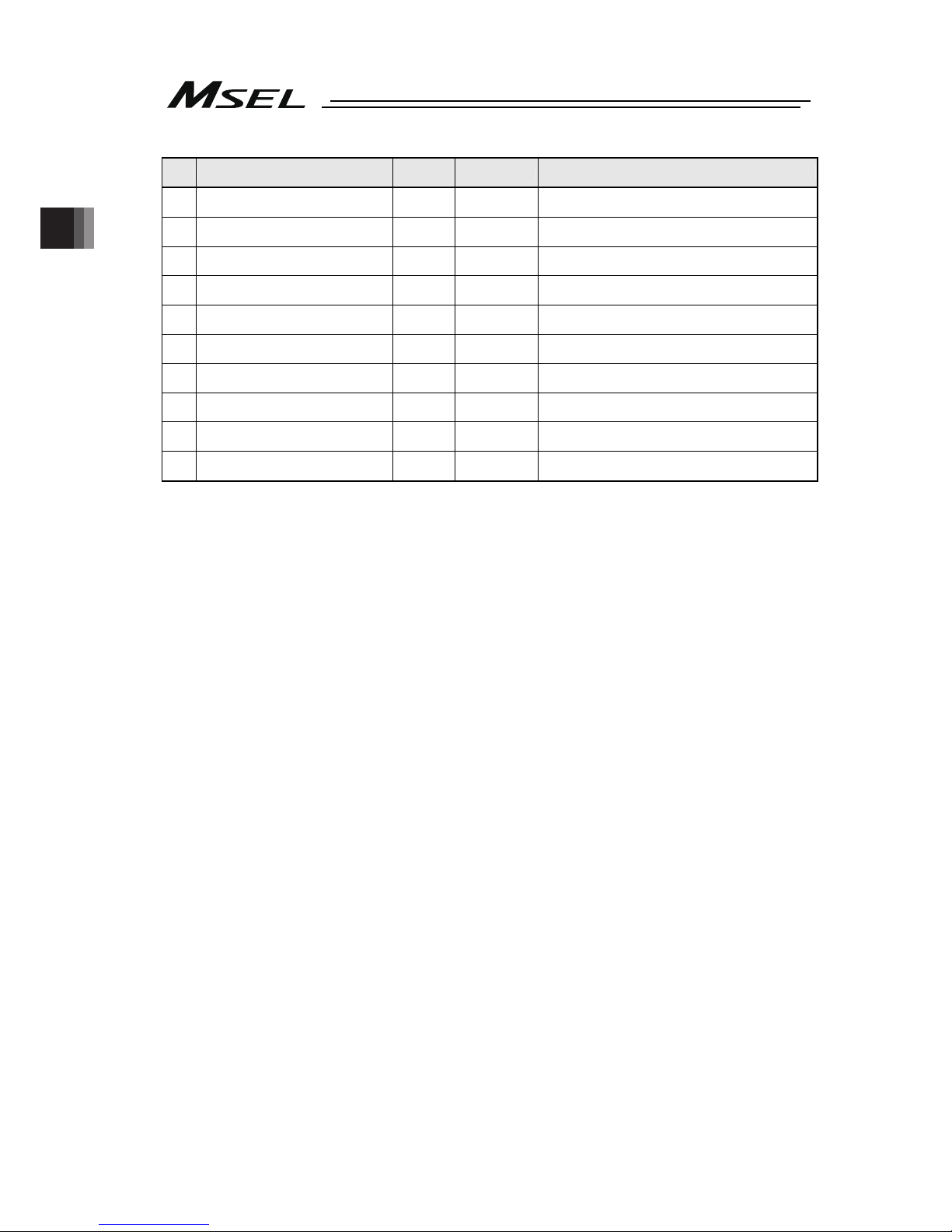

1.1.3 Instruction Manuals Related to this Product, which are Contained in the

Instruction Manual (DVD).

No. Name Manual No.

1 SEL Language Programming Manual ME0224

2

PC Software

IA-101-X-MW-JS/IA-101-X-USBS Instruction Manual

ME0154

3 Touch Panel Teaching TB-01/TB-01D Instruction Manual ME0325

4 Touch Panel Teaching TB-02 Instruction Manual ME0356

5 DeviceNet Instruction Manual ME0124

6 CC-Link Instruction Manual ME0123

7 PROFIBUS-DP Instruction Manual ME0153

8 Ethernet Instruction Manual ME0140

9 EtherNet/IP Instruction Manual ME0308

10 EtherCAT Instruction Manual ME0309

11 PROFINET IO Instruction Manual ME0361

1.1.4 How to Read the Model Plate

1.1.5 How to Read the Model

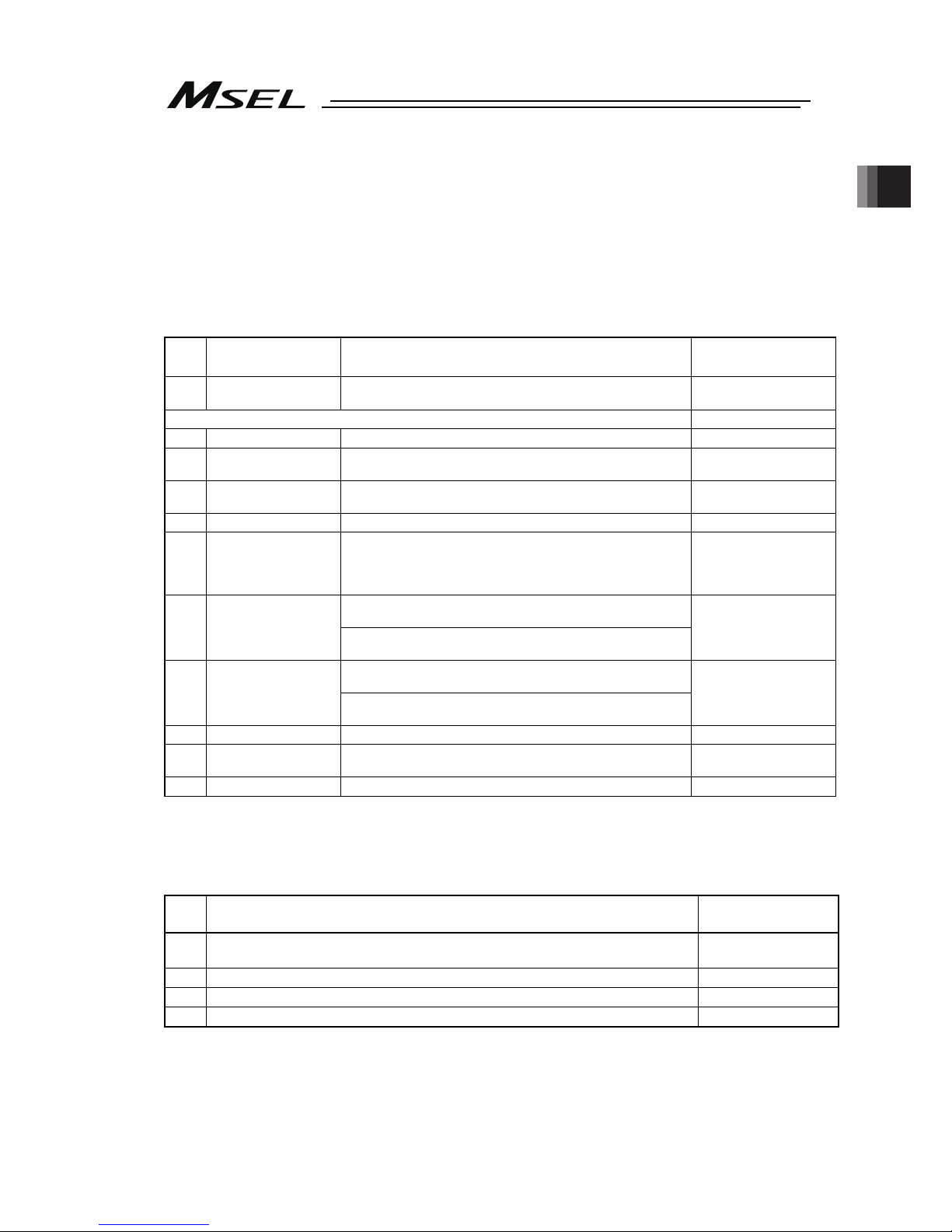

[1-1] Single-Axis and Cartesian Type Controllers

Connected Axis Content

Series

Controller

type

Axis

No.

Pulse motor

type

Encoder

type

(Note 3)

Optional

Standard

I/O content

Extension I/O content

I/O

cable length

Power

supply

voltage

Absolute

Battery

(Note 2)

Mount

specification

WAI

(Note 3)

(battery-

less

absolute/

incremental)

Not

specified

HS

(Note 1)

(homeposition

check

sensor)

B

(brake)

Not specified

(battery-

less absolute/

incremental)

20P

(20 frame)

20SP

(20 frame)

28P

(28 frame)

28SP

(28 frame)

35P

(35 frame)

42P

(42 frame)

42SP

(42 frame)

56P

(56 frame)

SA

(Note 2, Note 3)

(simple

absolute)

B

(brake)

MSEL

PC

(standard

type)

PG

*1

(safety

category

compliant

type)

1

(

1 axis

)

2

(2 axes

)

3

(

3 axes

)

4

(

4 axes

)

WUS

(Note 4)

WUM

NP

(NPN PIO

connect)

PN

(PNP PIO

connect)

E : Not for use

DV : (DeviceNet

connect)

CC : (

CC-Link connect

)

PR : (PROFIBUS-DP

connect)

EP : (EtherNet/IP

connect)

NP : (

NPN PIO connect

)

EC : (EtherCAT

connect)

PRT : (PROFINET IO

connect)

DV2 : (DeviceNet

connect

Connector for

multidrop

enclosed)

CC2 : (CC-Link connect

Connector for

multidrop

enclosed)

SE1 : (RS232C

connect)

SE2 : (RS485 connect)

IA : (IA net connect)

0

(no cable)

2

(2m:

standard)

3

(3m)

5

(5m)

4

(100 AC

to 230V

input)

ABB

(Note 2)

Simple

absolute

(with battery

box)

ABBN

(Note2)

Simple

absolute

(without

battery box)

Not specified

(screw

mounting)

DN

(DIN

rail mounting)

*1 Safety Category Complied Type: This is a type that enables to construct a safety protection circuit

Note 1 It is available to select when the actuator is “Incremental Type”.

Note 2 When “Simple Absolute Type” has been selected, select “ABB” or “ABBN”.

Note 3 “Battery-less Absolute / Incremental Type” and “Simple Absolute Type” cannot be used together.

Note 4 WUS and WUM occupy two axes. It is not necessary to describe an encoder type or option.

Model

Serial numbe

r

MODEL MSEL-PCX4-3N4515WAI-56PWAI-NP-CC-2-4-DN-**

SERIAL No.200198765 MADE IN JAPAN

Page 33

Chapter 1 Specications Check

25

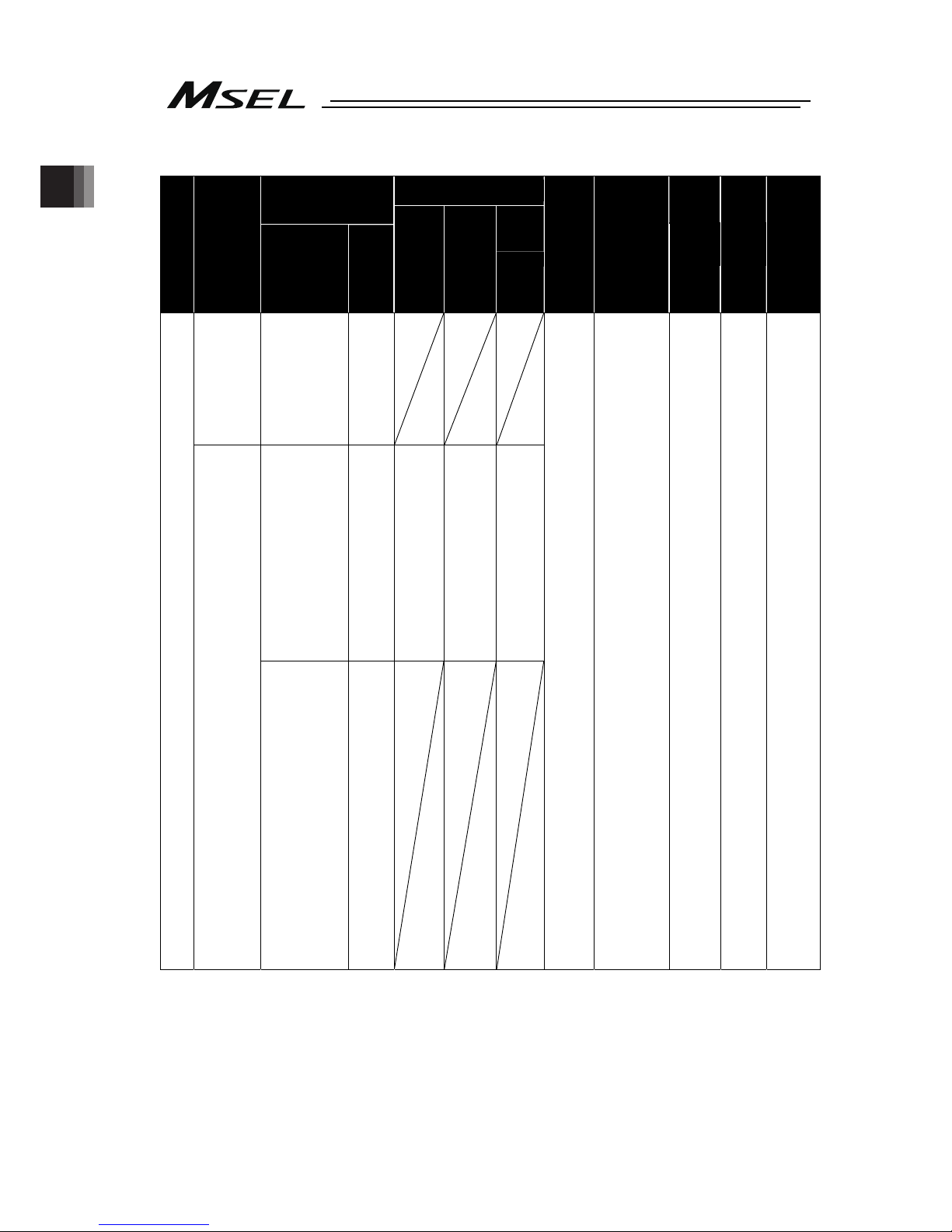

[1-2] Single-Axis and Cartesian Type Controllers (High-Thrust Specification)

Connected Axis Content

Series

Controller

type

Axis

No.

Pulse motor

type

Encoder

type

(Note 3)

Optional

Standard

I/O content

Extension I/O content

I/O

cable length

Power

supply

voltage

Absolute

Battery

(Note 2)

Mount

specification

WAI

(Note 4)

(battery-less

absolute/

incremental)

Not

specified

HS

(Note1)

(

home-

position

check

sensor

)

B

(

brake

)

Not specified

(battery-less

absolute/

incremental)

MSEL

PCF

(high-thrust

type)

PGF

*1

(high-thrust

safety

category

compliant

type)

1

(1 axis)

2

(2 axis)

3

(3 axis)

4

(4 axis)

1

st

and 2nd

axes

56SP

(56 frame)

60P

(60 frame)

86P

(86 frame)

2

nd

to 4th

axes

20P

(20 frame)

20SP

(20 frame)

28P

(28 frame)

28SP

(28 frame)

35P

(35 frame)

42P

(42 frame)

42SP

(42 frame)

56P

(56 frame)

(Note 3, Note 5)

SA

(Note2 to Note 4)

(simple

absolute)

B

(

brake

)

NP

(NPN PIO

connect)

PN

(PNP PIO

connect)

E : Not for use

DV : (DeviceNet

connect)

CC : (CC-Link

connect)

PR : (PROFIBUS-DP

connect)

EP : (EtherNet/IP

connect)

NP : (NPN PIO

connect)

EC : (EtherCAT

connect)

PRT : (PROFINET-IO

connect)

DV2 : (DeviceNet

connect

Connector for

multidrop

enclosed)

CC2 : (CC-Link connect

Connector for

multidrop

enclosed)

SE1 : (RS232C

connect)

SE2 : (RS485 connect)

IA : (IA net connect)

0

(no cable)

2

(2m:

standard)

3

(3m)

5

(5m)

4

(AC100

to 230V

input)

ABB

(Note 2)

Simple

absolute

(with battery

box)

ABBN

(Note 2)

Simple

absolute

(without

battery box)

Not specified

(screw

mounting)

DN

(DIN rail

mounting)

*1 Safety Category Complied Type: This is a type that enables to construct a safety protection circuit

Note 1 It is available to select when the actuator is “Incremental Type”.

Note 2 When “Simple Absolute Type” has been selected, select “ABB” or “ABBN”.

Note 3 Simple Absolute cannot be selected in the high-thrust type (56SP, 60P and 86P motors).

Note 4 “Battery-less Absolute/Incremental Type” and “Simple Absolute Type” cannot be used together on

the 3

rd

and 4th axes. 2nd, 3rd and 4th axes can be existed together.

Note 5 For the 2

nd

axis, the type can be selected at the order from the standard type (20P to 56P motor)

and the high-thrust type (56SP, 60P or 86P motor).

(Driver board is different.)

Page 34

Chapter 1 Specications Check

26

[2] SCARA Robot Controller

Added axis content

Power-con SCARA model

Series

Controller

type

Following type

symbols come in □

N : Standard

C : Cleanroom

W : Dust Proof/Splash

Proof

Optional

Pulse

motor type

Encoder

type

Optional

Standard

I/O content

Extension I/O

content

I/O

cable

length

Power

supply

voltage

Mount

specification

PCX3

(3 axes

standard

type)

PGX3

*1

(3 axes safety

category

compliant

type)

(3 axes type)

3N1808WAI

3N2508WAI

3�3515WAI

3�4515WAI

3�5520WAI

3�6520WAI

B

(Note2)

(Brake)

(3 axes type)

3N1808WAI

3N2508WAI

3�3515WAI

3�4515WAI

3�5520WAI

3�6520WAI

B

(Note2)

(Brake)

20P

(20 frame)

20SP

(20 frame)

28P

(28 frame)

28SP

(28 frame)

35P

(35 frame)

42P

(42 frame)

42SP

(42 frame)

56P

(56 frame)

WAI

(Battery-

less

absolute/

Incremental)

Not

specified

HS

(Note 1)

(home-

position

check

sensor)

B

(brake)

MSEL

PCX4

(4 axes

standard

type)

PGX4

*1

(4 axes safety

category

compliant

type)

(4 axes type)

4N1808WAI

4N2508WAI

4�3515WAI

4�4515WAI

4�5520WAI

4�6520WAI

(3 axes type+

Gripper mounted)

3N1808GMWAI

3N2508GMWAI

3N3515GMWAI

3N4515GMWAI

3N3510GLWAI

3N4510GLWAI

3N5515GLWAI

3N6515GLWAI

3N5515GWWAI

3N6515GWWAI

B

(Note2)

(Brake)

NP

(NPN PIO

connect)

PN

(PNP PIO

connect)

E : (not for

use)

DV : (DeviceNet

connect)

CC : (

CC-Link

connect

)

PR :

(PROFIBUS-DP

connect)

EP :

(EtherNet/IP

connect)

NP : (

NPN PIO

connect

)

EC : (EtherCAT

connect)

PRT : (PROFINET

IO connect)

DV2 : (DeviceNet

connect

Connector

for

multidrop

enclosed)

CC2 : (CC-Link

connect

Connector

for

multidrop

enclosed)

SE1 : (RS232C

connect)

SE2 : (RS485

connect)

IA : (IA net

connect)

0

(No

cable)

2

(2m:

standard)

3

(3m)

5

(5m)

4

(100 AC

to 230V

input)

Not

specified

(Screw

mounting)

DN

(DIN

Rail mounting)

*1 Safety Category Complied Type: This is a type that enables to construct a safety protection circuit

Note 1 It is available to select when the actuator is “Incremental Type”.

Note 2

When SCARA Robot is with the arm length 550mm or 650mm, it can be selected for Z-axis.

Page 35

Chapter 1 Specications Check

27

1.2 Basic Specifications

Specification Item

Number of Controlled Axes 1 axis to 4 axes (Total of RC axis or SCARA axis + RC axis is four axes max.)

Power Supply Voltage Single-phase 100V AC to 230V±10%

Power Current (typ value) 2.9A (100V AC), 1.4A (200V AC), 1.2A (230V)

Power Supply Frequency 50Hz/60Hz±5%

Rush Current (typ value)

(Note 1)

15A(100V AC), 30A(200V AC)

(Ambient Temp. 25degC, Measurement in one time of turn-ON: when no

repeating of ON/OFF)

Leakage Current

(Note 2)

0.75mA or less

Transient Power Cutoff Durability 20ms or more

Heat Generation 40W (100V AC), 35.2W (200V AC), 30.4W (230V AC)

PIO Power Supply

(Note 3)

DC24V±10% (Supplied from external equipment)

Motor Control System Weak field-magnet vector control

Applicable Encoder

(The resolution differs depending on the

actuator type)

Battery-less absolute encoder or Incremental encoder

resolution 800pulse/rev or 8192pulse/rev

Actuator Cable Length MAX. 20m (when simple absolute type is used Max.10m)

Serial Communication Interface (SIO port

or USB port)

Teaching tool dedicated connector (SIO ports and USB ports excluded)

(XSEL serial communication protocol (Format B))

(Standard / extension) PIO

24V DC general-purposed signal I/O (NPN / PNP selection)

Input 32 points max., output 32 points max. (Total of standard and extension)

Cable length MAX.10m

External

Interface

(Extension dedicated) Fieldbus

DeviceNet, CC-Link, PROFIBUS-DP, EtherNet/IP

(Note 4)

, EtherCAT,

PROFINET IO, RS232C, RS485

Data Setting and Input PC software or teaching pendant

Program Specification SEL Language

Max. Number of Program Steps 9999 steps

Max. Number of Positions 30000 position

Max. Number of Programs 255 program

Max. Number of Multitask Programs 16 program

Data Retention Memory Flash ROM and FeRAM

Clock Function

Retaining time after power turned OFF: approximately 10 days

Time for battery charge after the clock data is lost: approximately 100 hours

System I/O Emergency stop input, safety gate input

Drive-source cutoff method

Contact point for semiconductor (connect externally such as driving source cutoff

relay when required to comply with safety categories for PG/PGF/PGX types)

Emergency-stop input

b contact (normally closed) Input (internal power supply)

Safety Circuit

Configuration

Enable input

b contact (normally closed) Input (internal power supply)

Protective Functions

Motor over current, overload, encoder open circuit detection, soft limit over,

system abnormality, battery abnormality

Absolute Battery (when simple absolute

type is used)

AB-7

Protection Function Against Electric

Shock

Class I In case grounding conducted on ground terminal in addition to basic

insulation for electric shock proof.

Overvoltage Category Category II Voltage durability 2500V at less than 300V AC for input rating

Insulation Resistance

10MΩ or more (between power terminal and I/O terminal and also all external

terminals and case at the power supply of DC500V)

Insulation Strength

1500V AC for 1 min (between primary and PE)

3000V AC for 1 min (between primary and secondary)

Protection Conduction 10A 1.0V or less (for 10sec)

Cooling Method Forced air-cooling

Surrounding air temperature 0 to +40°C

Surrounding humidity

85% RH or less (non-condensing)

Surrounding environment

(Refer to the Item for the 1.6 Installation Environment).

Surrounding storage

temperature

-20 to 70C (Note) 0 to 40C for absolute battery

Surrounding storage humidity

85% RH or less (non-condensing)

Maximum operation height 1000m

Vibration resistance

10 to 57 Hz in XYZ directions Swing width: 0.075mm

57 to 150Hz Acceleration: 9.8m/s

2

Protection class IP20

Environment

Pollution degree Pollution degree 2

External Dimensions [Refer to the 1.3 External Dimensions]

Mass

Approx. 1.4kg

Page 36

Chapter 1 Specications Check

28

Note 1 Rush current at the power connection continues for 5 msec. Note that the value of in-rush current

differs depending on the impedance of the power supply line.

Note 2 Leak current varies depending on the capacity of connected motor, cable length and the surrounding

environment. Measure the leak current at the point where a ground fault circuit interrupter is to be

installed when leakage protection is conducted.

Regarding the leakage breaker, it is necessary to have a clear purpose for selection such as a fire

protection or protection of human body.

Note 3 Power supply is not necessary if PIO is not to be used.

Note 4 EtherNet/IP can also communicate (teletype procedure communication) with EtherNet.

1.2.1 Selection of the Circuit Breaker

For the selection of the circuit breaker, perform it according to the following items.

Select the breaker that does not trip with the rush current. (Refer to the Operation

Characteristic Curve described in the catalogue of each manufacturer.)

For the rated breaking current, select the current value which can break the current even

when a short circuit occurs.

Rated Interrupting Current > Short Circuit Current = Power Source Current [Refer to 1.2

Basic Specifications]

Consider margin for the rated current on the circuit breaker.

Circuit Breaker Rated Current > Power Source Current [A] × Safety Margin (Reference 1.2 to 1.4)

1.2.2 Selection of the Leakage Breaker

Regarding the leakage breaker, it is necessary to have a clear purpose for selection such

as a fire protection or protection of human body.

Leak current varies depending on the capacity of connected motor, cable length and the

surrounding environment. Measure the leak current at the point where a ground fault

circuit interrupter is to be installed when leakage protection is conducted.

Page 37

Chapter 1 Specications Check

29

116

185

4-4.5

130

19

5

(10.9)

5

.

9

125

(75mm from DIN Rail center)

3

3

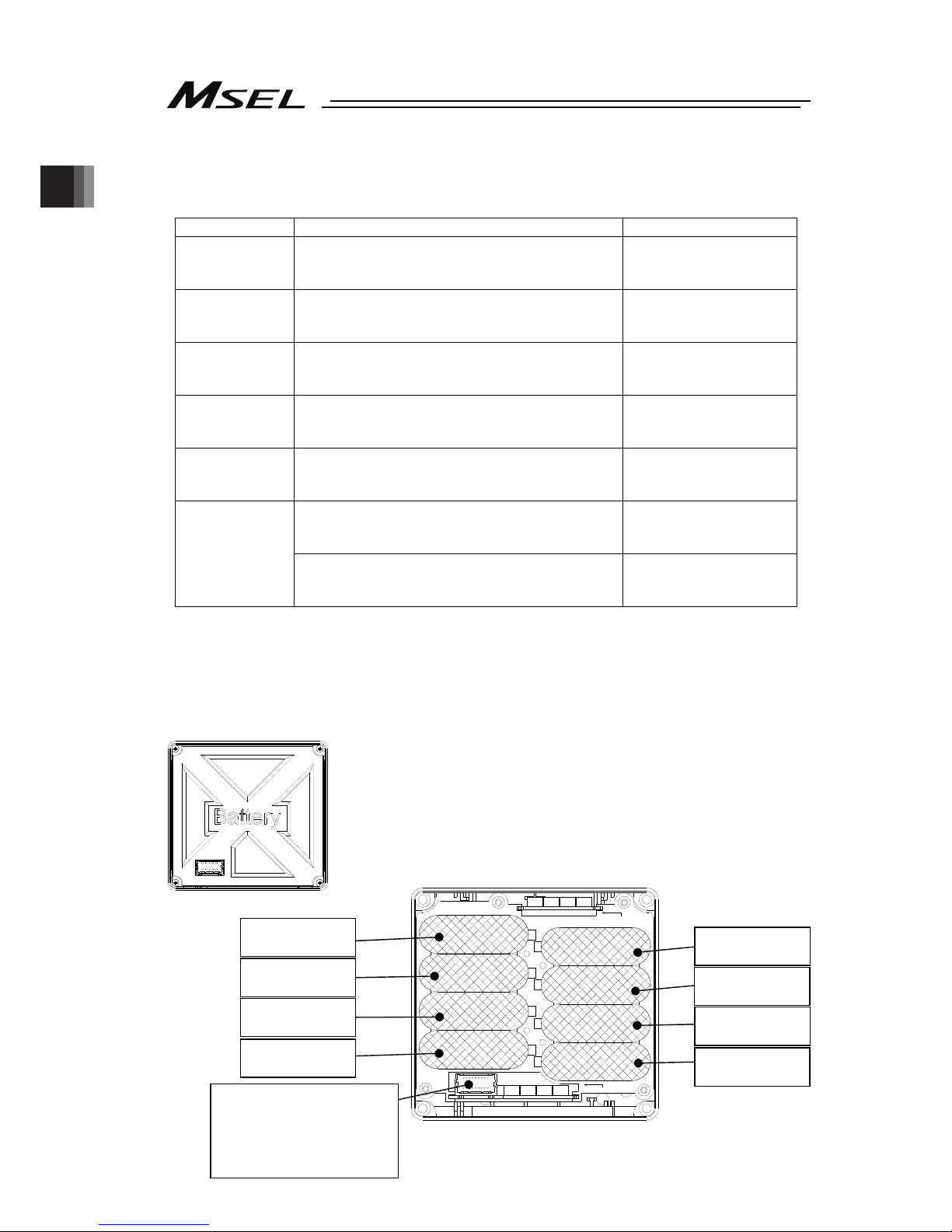

1.3 External Dimensions

1) Main Body

2) Absolute Battery Box (Simple Absolute Type)

(59mm from DIN Rail center)

5

111

123

98

10.5

5

5

108

115

(4)

4

5

Page 38

Chapter 1 Specications Check

30

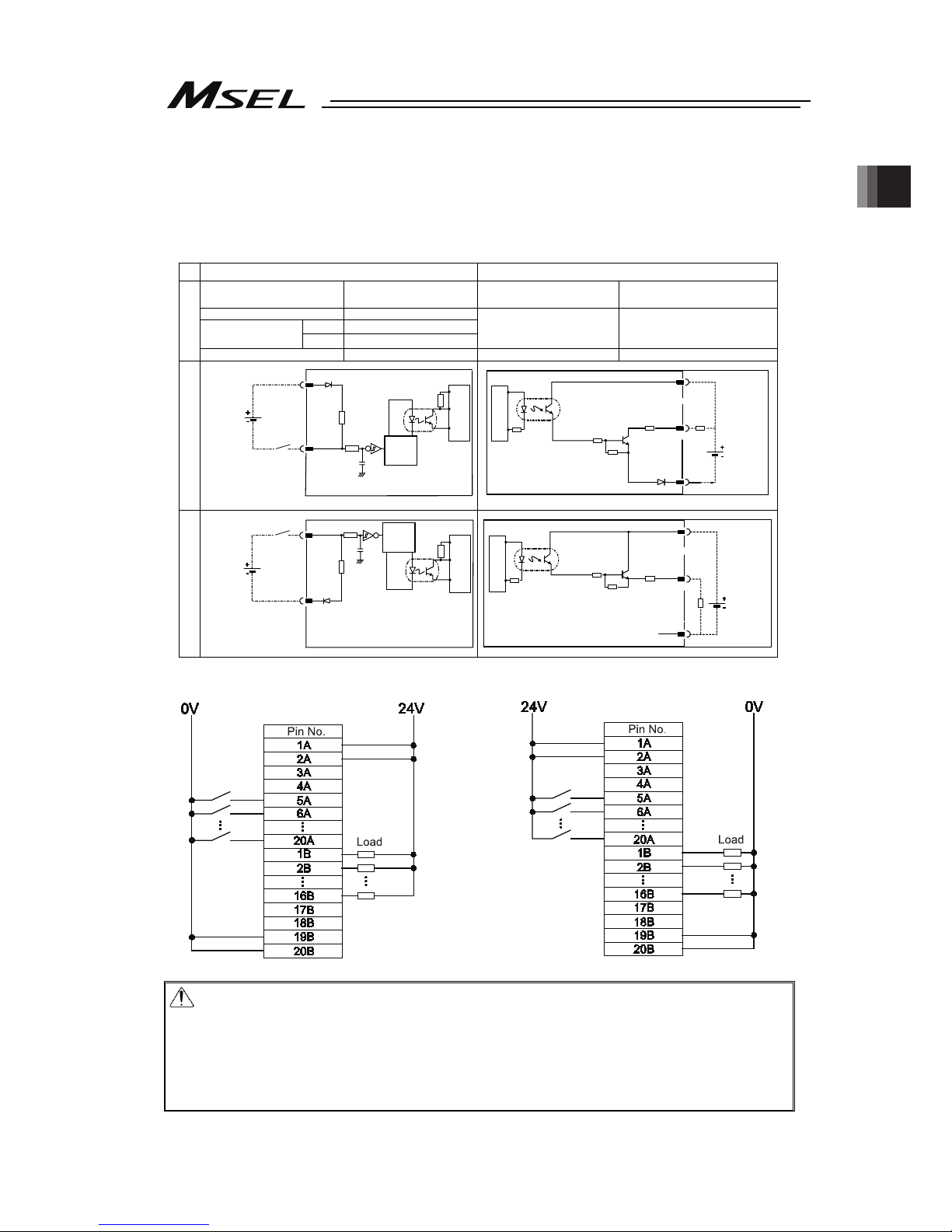

1.4 Interfaces

Standard I/O can be equipped with PIO (NPN or PNP).

1.4.1 Standard I/O

Input Output

Input Voltage 24V DC ±10%

Load Voltage

24V DC ±10%

Input Current 7mA / 1 Circuit

ON

Min. 16V DC

ON/OFF

Voltage

OFF

Max. 5V DC

Load Current 100mA / 1 Circuit, 400mA / 8 Port

*1

Specification

Insulation Type

Photocoupler Insulation

Insulation Type

Photocoupler Insulation

NPN PNP

Note 1 The total of lead current reaches max. 400mA every 8 ports from output port No. 300.

NPN specification PNP specification

Caution:

If a non-contact circuit is connected externally, malfunction may result from

leakage current. Use a circuit in which leakage current in a OFF state does not

exceed 1mA.

At the default settings, the system recognizes the ON/OFF durations of input

signals if they are continuous approx. 4 msec or longer. The ON/OFF duration

settings can also be changed using I/O parameter No. 20 (input filtering

frequency).

MSEL

560Ω

3.3kΩ

Input Terminal

Input

Terminal

560Ω

Output

Terminal

10Ω

Load

Output

Terminal

10Ω

Load

MSEL

3.3kΩ

External

Power

Source

24V DC

±10%

External

Power

Source

24V DC

±10%

External

Power

Source

24V DC

±10%

External

Power

Source

24V DC

±10%

MSEL

MSEL

Internal circuit

Internal circuit

Internal circuit

Internal circuit

Page 39

Chapter 1 Specications Check

31

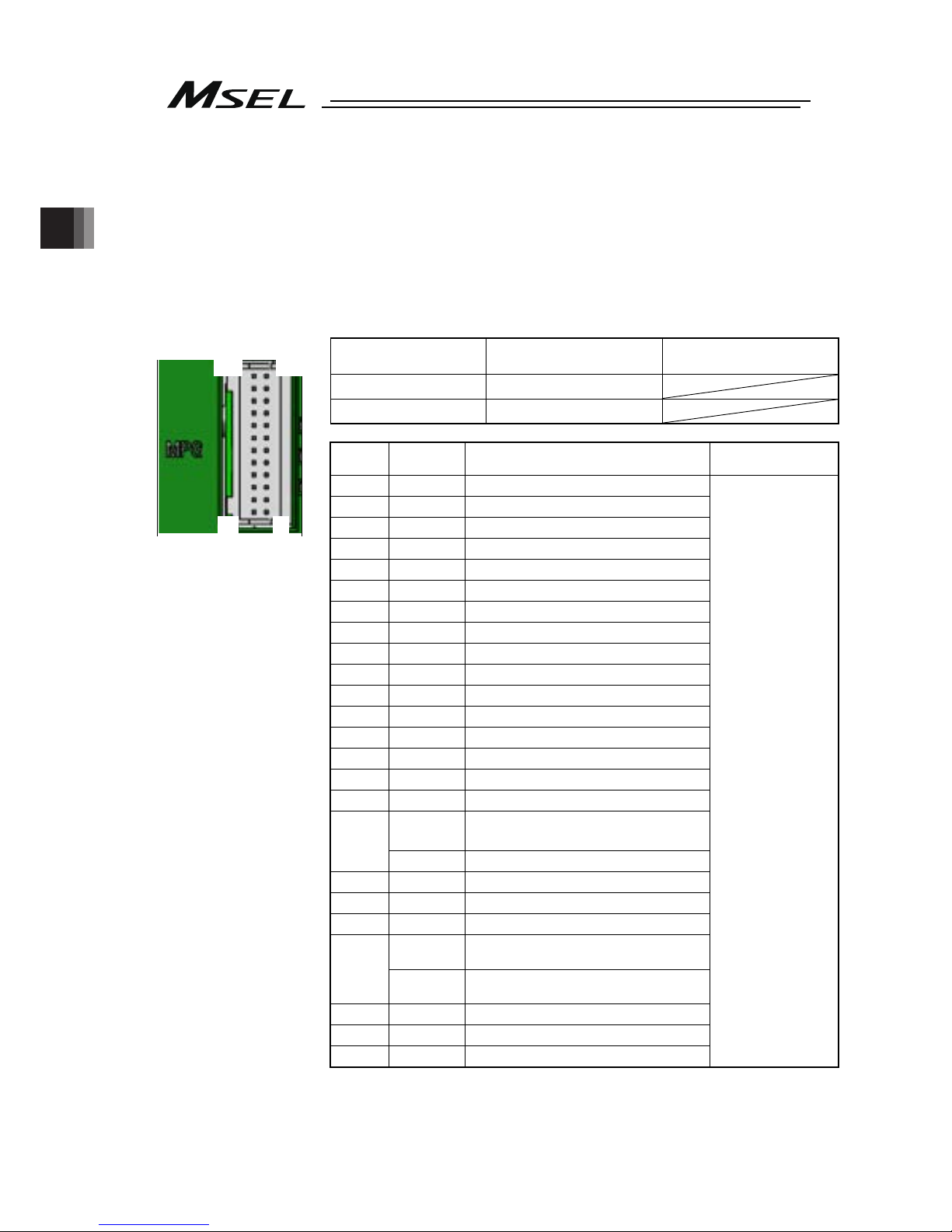

1.4.2 Extension I/O

For extension I/O, selection can be made from PIO (NPN or PNP) and six types of fieldbus

(CC-Link, DeviceNet, FROFIBUS-DP, EtherNet/IP, EtherCAT or PROFINET-IO) to be equipped

with.

[1] PIO Interfaces

Input Output

Input Voltage 24V DC ±10%

Load Voltage

24V DC ±10%

Input Current 4mA / 1 Circuit

ON

Min. 18V DC

ON/OFF

Voltage

OFF

Max. 6V DC

Load Current 50mA / 1 Circuit

Specificatio

Insulation Type

Photocoupler Insulation

Insulation Type

Photocoupler Insulation

NPN PNP

NPN type PNP type

Caution:

If a non-contact circuit is connected externally, malfunction may result from

leakage current. Use a circuit in which leakage current in a OFF state does not

exceed 1mA.

At the default settings, the system recognizes the ON/OFF durations of input

signals if they are continuous approx. 4 msec or longer. The ON/OFF duration

settings can also be changed using I/O parameter No. 20 (input filtering

frequency).

MSEL

5.6kΩ

Input Terminal

logic

circuit

Input

Terminal

5.6kΩ

logic

circuit

Output

Terminal

15Ω

Load

Output

Terminal

15Ω

Load

MSEL

External

Power

Source

24V DC

±10%

External

Power

Source

24V DC

±10%

External

Power

Source

24V DC

±10%

External

Power

Source

24V DC

±10%

MSEL

MSEL

Internal circuit

Internal circuit

Internal circuit

Internal circuit

Page 40

Chapter 1 Specications Check

32

[2] Fieldbus

Following fieldbus can be selected. For details, refer to each instruction manual provided

separately.

Type Overview Details

DeviceNet DeviceNet Field Network Board

This board communicates the I/O data as the

remote I/O terminal.

Refer to the separate.

(ME0124)

CC-Link CC-Link Field Network Board

This board communicates the I/O data as the

Ver1.10 remote device station.

Refer to the separate.

(ME0123)

PROFIBUS-DP PROFIBUS-DP Field Network Board

This board communicates the I/O data as the

slave station.

Refer to the separate.

(ME0153)

PROFINET-IO PROFINET-IO Field Network Board

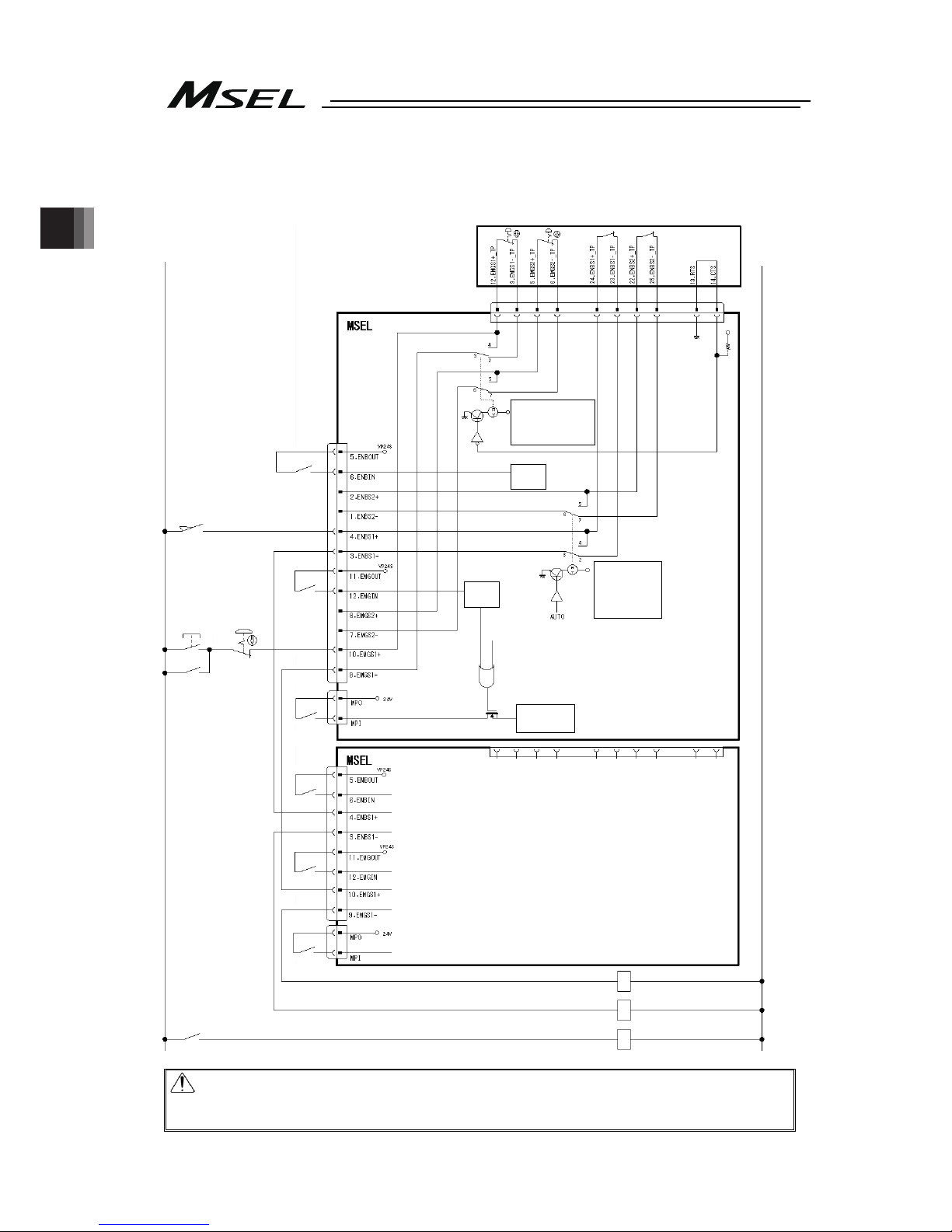

This board communicates the I/O data as the