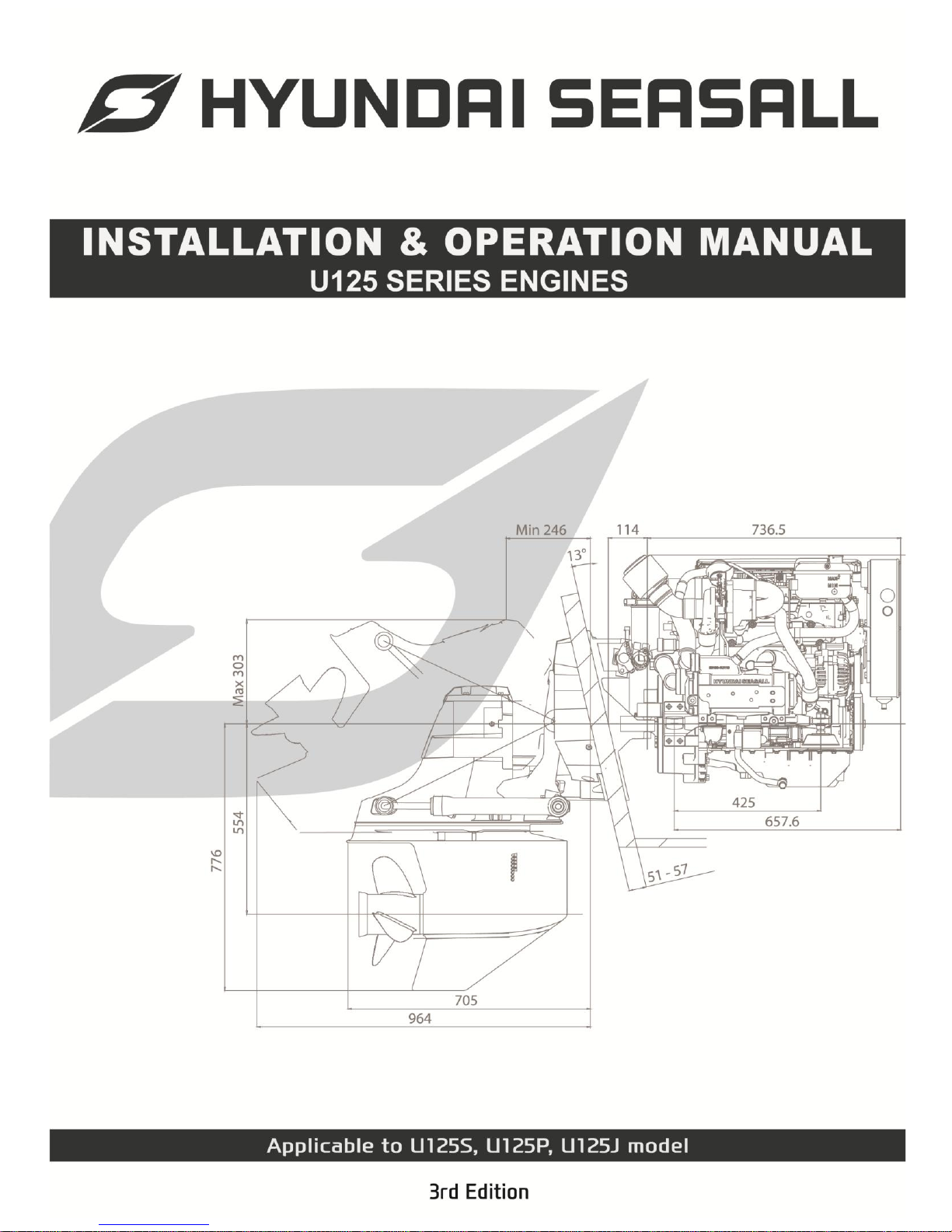

Hyundai U125S, U125J, U125P Installation & Operation Manual

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-1-

TABLE OF CONTENTS

ABOUT THIS MANUAL …………………………………………………….…………………

SAFETY PRECAUTIONS……………………………………………………………………

APPROXIMATE CONVERSIONS FROM STANDARD……………………………………..

CHAPTER 1 ENGINE OVERVIEW ………………………………………………………..

1. ENGINE COMPONENTS …………………………………………………

2. ENGINE HANGER……………..……………………………………………

3. ENGINE IDENTIFICATION ………………………………………….…..

4. SCHEMATIC DIAGRAM OF COMMON RAIL DIESEL ENGINE ……

5. TECHNICAL DATA ……………………………………………...…..……

6. PERFORMANCE CURVE ……………………………………………..…

7. BELT LAYOUT & ENGINE DIMENSIONS……….……………………

CHAPTER 2 ENGINE MOUNT SYSTEM .……………………………………………….

1. PREPARING THE ENGINE INSTALLATION….……………....….…..

1.1 CHECK THE MOUNT HOLE………………………………….

2. BELLHOUSING FIXING………………………………………………….

3. ASSEMBLING ENGINE MOUNTS……………………..………….……

CHAPTER 3 COOLING & EXHAUST SYSTEM …………………………………….……

1. SCHEMATIC DIAGRAM OF ENGINE COOLING CIRCUIT ……….…

2. SEAWATER FLOW………………………………………….……….……

2.1 WATER PICKUP …………………………………..……….……

2.2 SEAWATER STRAINER ………………………..……….…….

2.3 SEAWATER PUMP ……………………………..………………

2.4 CHECKING SEA WATER PUMP & IMPELLER …….……..

2.5 SEA WATER DRAIN …………………………..………………..

3. ENGINE COOLANT FLOW………..…………………………….………

3.1 ENGINE COOLANT……………………..…………………..…

3.2 REMOVING AIR BUBBLE ………..….….……………….…...

3.3 CABIN HEATER CONNECTION.…..…….……………..……

4. EXHAUST SYSTEM ………………………………………………………

CHAPTER 4 FUEL SYSTEM ………………………………………………………….……

1. FUEL FLOW………. ……………………………….……..………………

2. LOW PRESSURE FUEL LINE …………………....…………….…………

3. ACCELERATION SENSOR AND CONTROL LEVER …………………

4. RECOMMENDED FUEL QUALITY ………………....…………….………

5. DRAINING WATER FROM FUEL FILTER ………………………………

CHAPTER 5 AIR INTAKE SYSTEM …………………………………………………………

1. ENGINE AIR CONSUMPTION….………………………….……………

2. ENGINE ROOM VENTILATION……………………………….…..………

3. AIR FILTER MAINTENANCE………………………………………………

CHAPTER 6 LUBRICATION SYSTEM ………………………………………………….…

1. ENGINE OIL LEVEL CHECKS ………………………………….………

2. RECOMMENDED OIL QUALITY ………………………….…….....……

3. ENGINE OIL EXTACTION PUMP ………………………..………..……

4. OIL FILTER REPLACEMENT …………………………………….………

3

4

5

6

6

7

8

9

10

11

13

16

16

16

17

17

18

18

19

19

19

20

21

22

23

23

25

25

26

27

28

28

29

30

30

31

31

31

32

33

33

33

34

34

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-2-

TABLE OF CONTENTS

CHAPTER 7 ELECTRICAL SYSTEM ……………………………………………………

1. BATTERY CABLE CONNECTIONS …………………………….......…

2. BATTERY CHECKS ………………………………………………….…

3. FUSE AND RELAY ………………………………………………….……

CHAPTER 8 INSTRUMENT SYSTEM ……………………...…………………..…………

1. INSTRUMENTS CONNECTION …………..……………….….……...…

2. CUT-OUT FOR GAUGE…………………………………………………

3. CUT-OUT FOR EOI SYSTEM …………………..………….……….……

4. SEASLINK PRODUCT COMPONENTS………………….……..………

5. INSTALLATION OF SEASLINK DONGLE……………….……………..

CHAPTER 9 EOI SYSTEM …………………………………………..…………………..

1. OVERVIEW OF EOI SYSTEM ……………………..…………………..…

1.1 INFORMATION LCD ITEM ……………………...……………...…

1.2 SWITCHES ………………………………………......…………..….

1.3 ALARM LAMPS ………………………………………..………...…

2. EOI CONNECTIONS ………………………………………......……..…

3. EOI PIN ASSIGNMENT …………..………………………………........

4. NEUTRAL SWITCH AND DUAL EOI CONNECTION …………….…

5. TRI

M WIRING CONNECTION DIAGRAM ………………………...…

6. G-SCAN……………………………………………………………..…….

7. ALARM AND DTC(DIAGNOSIS TROUBLE CODE) ………………….

7.1 ALARM AND DTC(DIAGNOSIS TROUBLE CODE) …………….

7.2 DTC(DIAGNOSIS TROUBLE CODE) LIST………….……………

CHAPTER 10 ANTI CORROSION SYSTEM …………………………………………….

CHAPTER 11 ENGINE OPERATION …………………………………………………..….

1. ENGINE ON/OFF ……………………………………………………….…

2. ENGINE BRAKE IN………………………………………………………

3. EMERGENCY STOP …………………..…………………………….……

CHAPTER 12 ENGINE STORAGE …………………………………………………..……

WINTER STORAGE…………………………………….………………….

CHAPTER 13 MAINTENANCE …………………………………………………………..…

1. THE INITIAL RUNNING CHECK..……………………………….………

2. MAINTENANCE SCHEDULE …………………………………..………

3. STERNDRIVE & TRANSMISSION MAINTENANCE SCHEDULE ….

4. MAINTENANCE LOG……………………………………………………

CHAPTER 14 TROUBLESHOOTING GUIDE ……………………………………………

CHAPTER 15 WARRANTY …………………………………………………………………

WARRANTY REGISTRATION CARD ……………………………..………

35

35

36

37

39

39

42

42

43

44

45

45

45

46

46

47

48

50

51

52

53

53

56

61

62

62

63

64

65

66

67

67

68

69

70

71

73

78

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-3-

ABOUT THIS MANUAL

This engine installation and operation manual is provided as guidance for the installation of

Hyundai SeasAll engine in a boat, and to describe engine operation. Its purpose is to provide

technical information to aid in performing an effective engine installation so as to achieve both

maximum performance and service life. For information on installation, operation and maintenance

of the ZF Marine Transmissions and Sterndrive Bravo Models, please see the separate booklets

included in the original packaging of your Hyundai SeasAll purchase.

Hyundai SeasAll is committed to making clear and accurate information available for those who

maintain, own and repair the U125 Series engines. Hyundai SeasAll values your input regarding

revisions and additional information for our manuals.

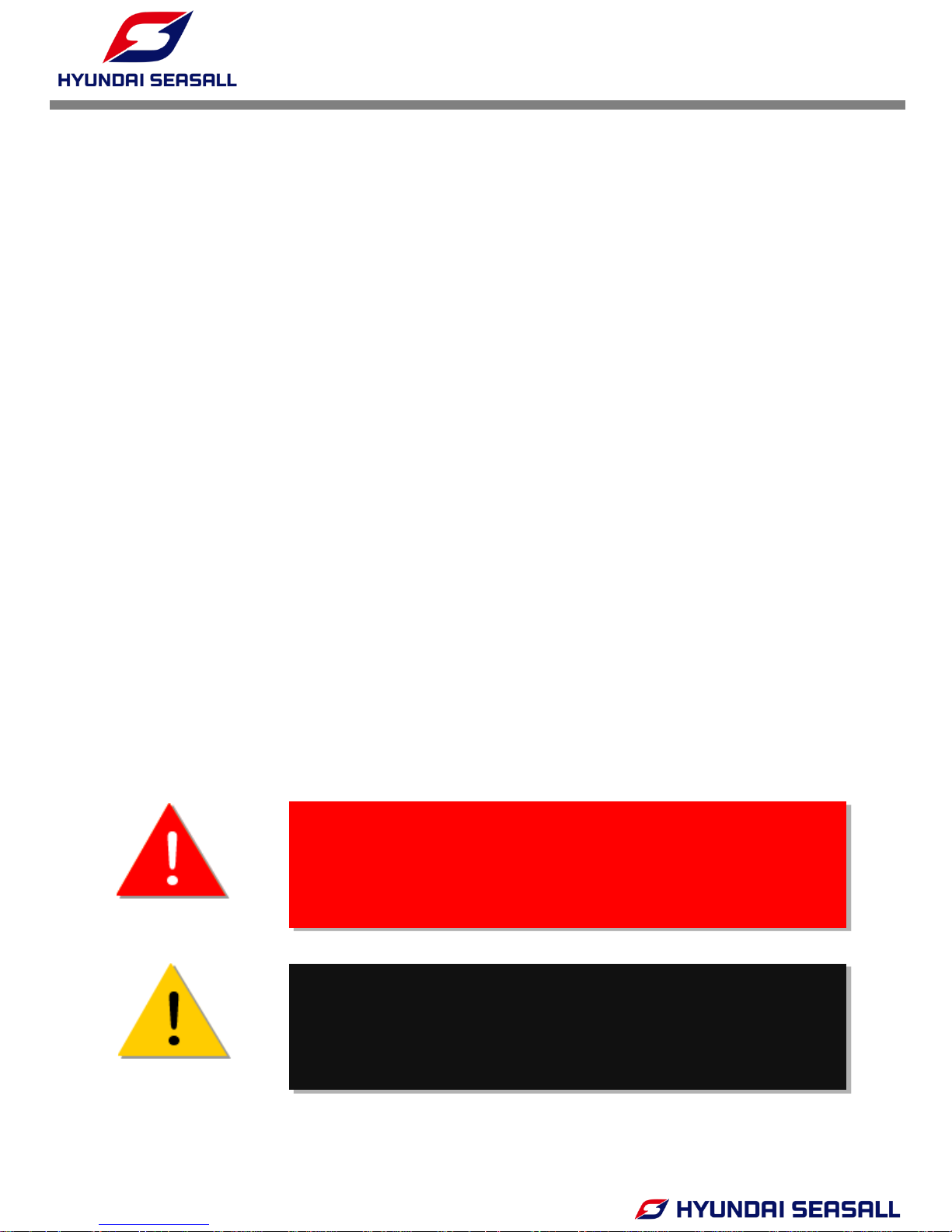

WARNING

DEVIATION FROM INSTALLATION INSTRUCTIONS AND OPERATION

GUIDELINES MAY LEAD TO PERSONAL INJURY OR DEATH TO

OPERATORS AND NEARBY PERSONNEL.

CAUTION

DEVIATION FROM INSTALLATION INSTRUCTIONS AND OPERATION

GUIDELINES MAY LEAD TO IMPROPER OPERATION, DAM AGE OR

DESTRUCTION OF THE ENGINE.

The manufacturer is not liable for any damages or losses caused by faulty installation, wrong

handling of the equipment and/or deficient maintenance.

The operator is responsible for the correct and safe operation of the engine and safety of its

occupants and general public.

It is strongly recommended that each operator read and understand this manual before

installing and operating the engine.

This manual as well as safety labels posted on the engine use the following safety alerts to

draw your attention to special safety instructions that should be followed.

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-4-

SAFETY PRECAUTIONS

HOT SURFACES AND FLUIDS

• There is always a risk of burns when working

with a hot engine. Be aware of hot parts like

the turbocharger system, the exhaust system,

hot coolant hoses, etc. Wait until the engine

is fully cool to do inspection and maintenance.

REFUELING

• Refuel only after the engine completely stops.

• Use only the recommended fuel. The wrong

grade of fuel can cause operating problems,

can cause the engine to stop and can cause

engine damage.

• Pay special attention to safe practices when

refueling.

PAINT DAMAGE

• Damage of the engine or parts paint during

maintenance and inspection can cause

corrosion. Any damage must be repainted

after inspection and maintenance.

WELDING ON ENGINE

• Welding directly on the engine block can

cause damage to the engine control systems.

The ECU and related electronic devices must

be disconnected and removed if unavoidable

welding is needed.

.

• Read and understand this operator’s manual

as well as other information supplied by

Hyundai SeasAll for safe use of these

products. Be sure to check your engine

regularly.

• Do not use the engine for a purpose other

than what is intended by Hyundai SeasAll.

Do not modify the performance of the

supplied engine without the express

permission of Hyundai SeasAll. This can be

dangerous, can shorten the life of your

engine and can invalidate your warranty.

• Original and genuine parts supplied from

Hyundai SeasAll must be used for

inspections and maintenance. Hyundai

SeasAll does not guarantee any damage

caused by the use of imitation parts.

• Engine inspection and maintenance should

be carried out by properly trained and factory

approved service engineers.

• The engine should be inspected if the

electronic engine control unit shuts down the

engine.

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-5-

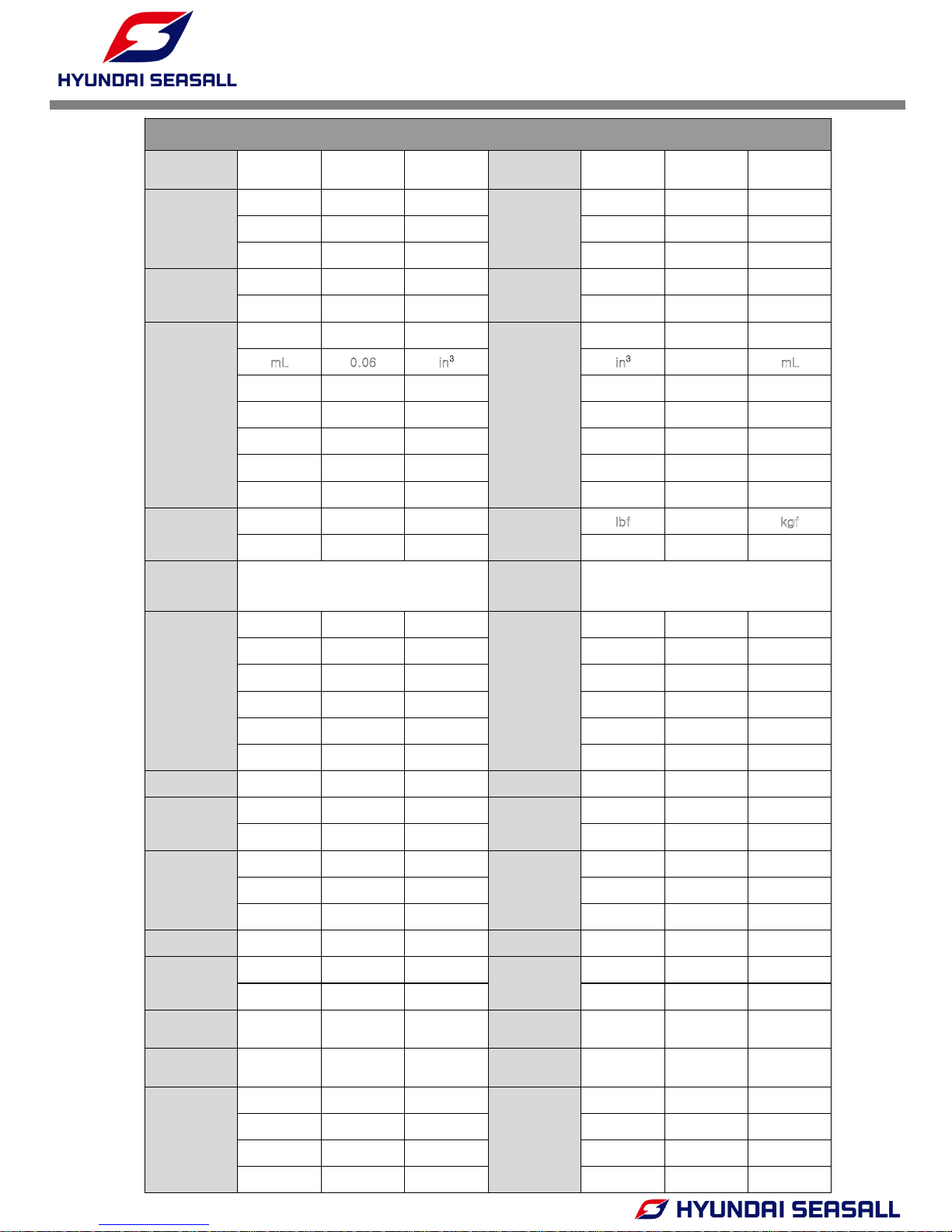

APPROXIMATE CONVERSIONS FROM STANDARD

SYMBOL

MULTIPLY

BY

SYMBOL

SYMBOL

MULTIPLY

BY

SYMBOL

LENGTH

mm 0.039 inch

LENGTH

inch 25.4 mm

cm 0.4 inch inch 2.54 cm

m 3.28 ft ft 0.3048 m

AREA

mm

2

0.0016 in2

AREA

in2 645.2 mm2

m

2

10.764 ft2 ft2 0.093 m2

VOLUME

cm

3

0.061 in³

VOLUME

in³ 16.388 cm3

mL

0.06 in3 in3

16

mL

Ldm

3

61.023 in³ in³ 0.016 Ldm3

Ldm

3

0.22 imp.gallon imp.gallon 4.545 Ldm3

Ldm

3

0.264 U.S.gallon U.S.gallon 3.785 Ldm3

m

3

0.76 yd3 yd3 1.3 m3

m

3

35.315 ft³ ft³ 0.028 m3

FORCE

kgf 2.204 lbf

FORCE

lbf

0.453

kgf

N 0.224 lbf lbf 4.448 N

TEMP.

o

F=9/5x℃+32 TEMP.

o

C=5/9x(℉-32)

PRESSURE

Bar 14.5 psi

PRESSURE

psi 0.068 Bar

MPa 145 psi psi 0.0068 MPa

Pa 0.102 mmWc mmWc 9.807 Pa

Pa 0.004 inWc inWc 249.098 Pa

KPa 4 inWc inWc 0.249 KPa

mWg 39.37 inWc inWc 0.025 mWg

TORQUE Nm 0.738 lbf ft TORQUE lbf ft 1.356 Nm

WEIGHT

kg 2.205 lb

WEIGHT

lb 0.454 kg

kg 35.273 oz oz 0.028 kg

WORK

kJ/kWh 0.43 BTU/lb

WORK

BTU/lb 2.326 kJ/kWh

MJ/kg 430 BTU/lb BTU/lb 0.0023 MJ/kg

kJ/kg 0.24 Kcal/kg Kcal/kg 4.184 kJ/kg

ENERGY kJ/kg 0.697 BTU/hph ENERGY BTU/hph 1.435 kJ/kg

FUEL

CONSUMP.

g/kWh 0.736 g/hph

FUEL

CONSUMP.

g/hph 1.36 g/kWh

g/kWh 0.0016 lb/hph lb/hph 616.78 g/kWh

FLOW RATE

(GAS)

m

3

/h 0.588 ft³/min

FLOW RATE

(GAS)

ft³/min 1.699 m3/h

FLOW RATE

(LIQUID)

m

3

/h 4.403 US gal/min

FLOW RATE

(LIQUID)

US gal/min 0.2271 m3/h

SPEED

m/s 3.281 ft/s

SPEED

ft/s 0.3048 m/s

kph 0.539 knots knots 1.852 kph

mph 0.869 knots knots 1.1508 mph

kph 0.62 mph mph 1.61 kph

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-6-

CHAPTER 1

ENGINE OVERVIEW

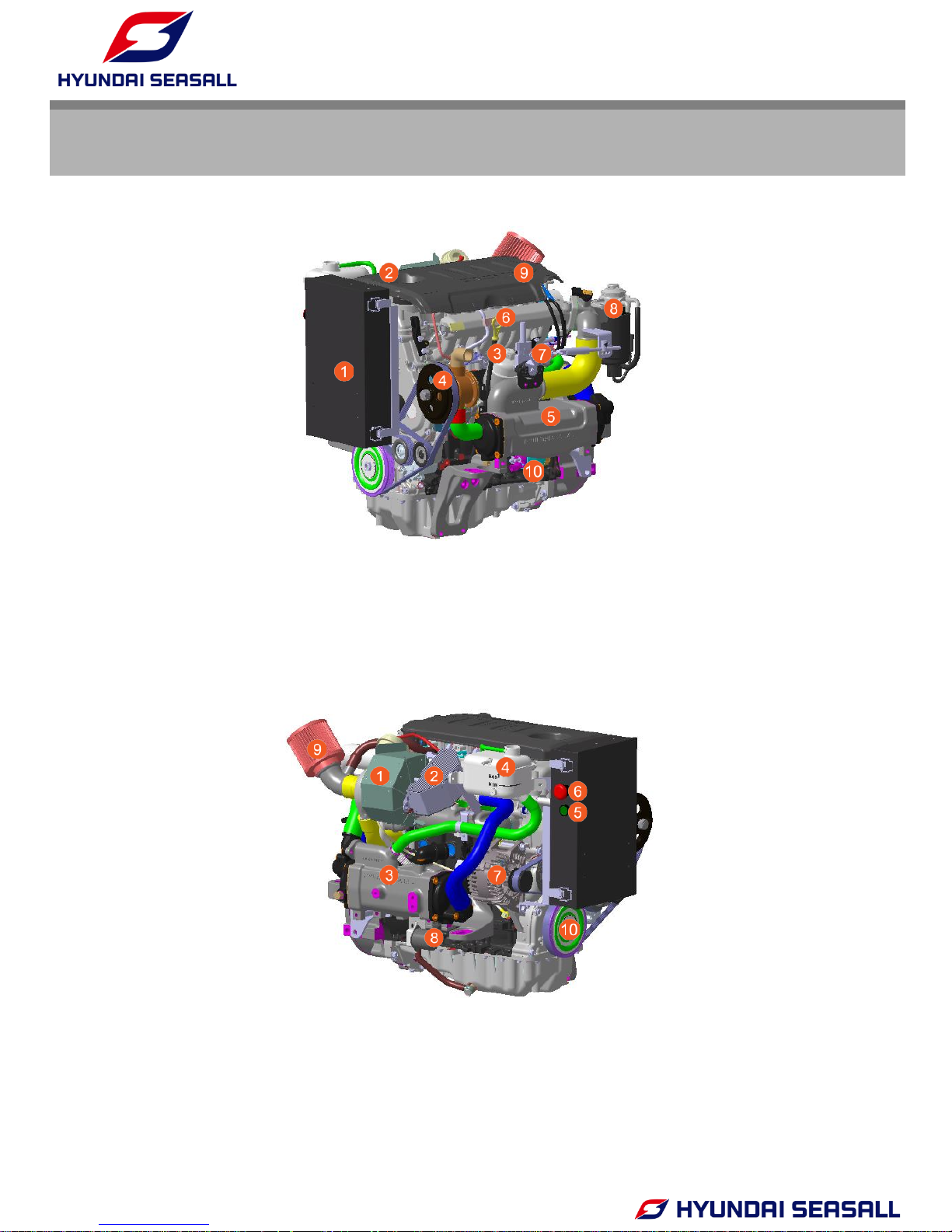

1. ECU Box

2. Engine Oil Cap

3. Engine Oil Filter

4. Seawater Pump

5. Intercooler

6. Engine Oil Gauge

7. Acceleration Lever Sensor

8. Fuel Filter

9. Eng. Cover

10.Starter

1. Turbo Heat Protector

2. Exhaust Elbow Heat protector

3. Heat Exchanger

4. Expansion Tank

5. Engine Oil Extraction Button

6. Engine Emergency Stop Button

7. Alternator

8. Oil Extraction Pump

9. Air filter

10. Crank Pulley

1.ENGINE COMPONENTS

INSTALLATION & OPERATION MANUAL

U125 Series Engines

- 7 -

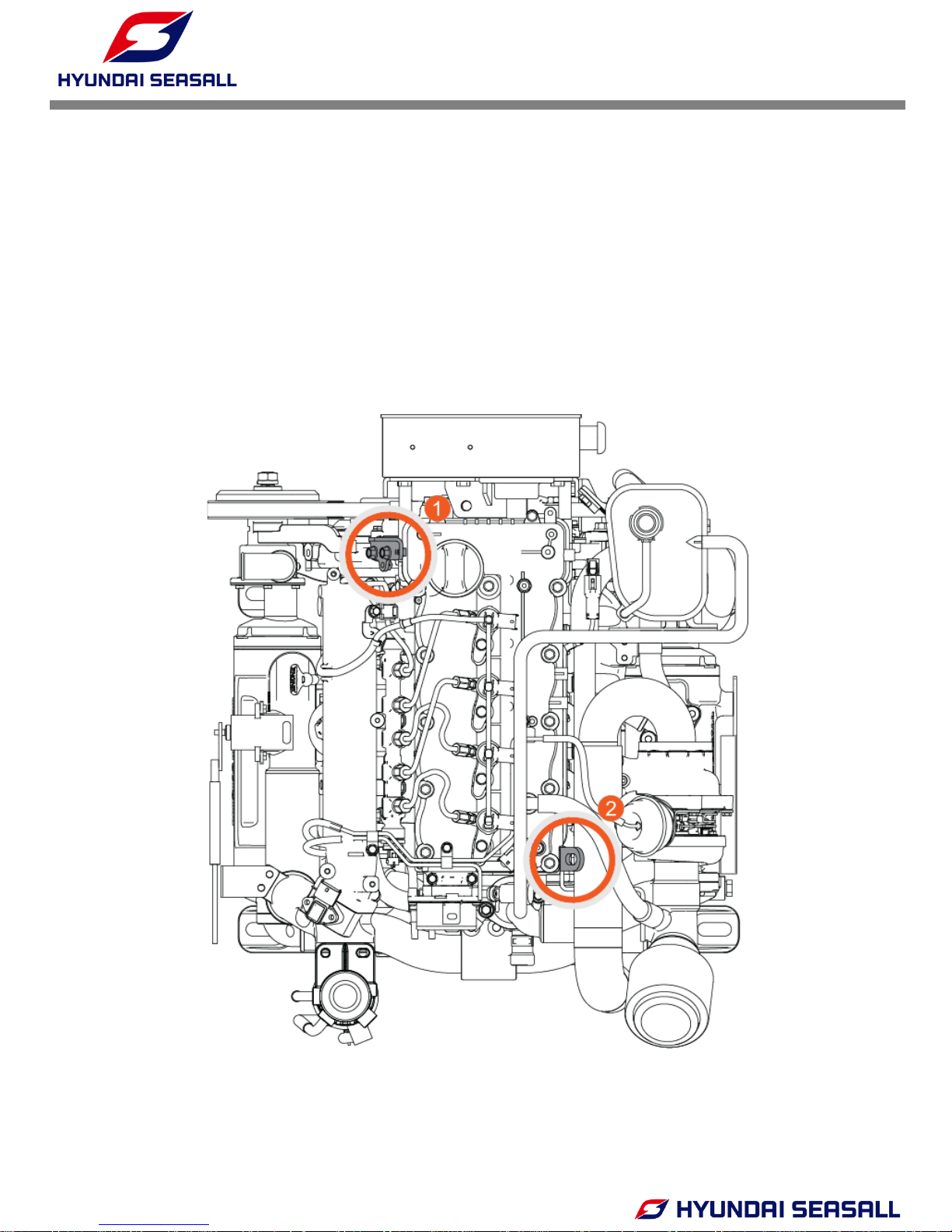

• To lift the engine, first remove the engine cover. You will find two engine hanger (see

figure)

• To avoid engine damage, take care that engine lift chains or belts do not hit or touch

surrounding parts during engine lifting.

2. ENGINE HANGER

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-8-

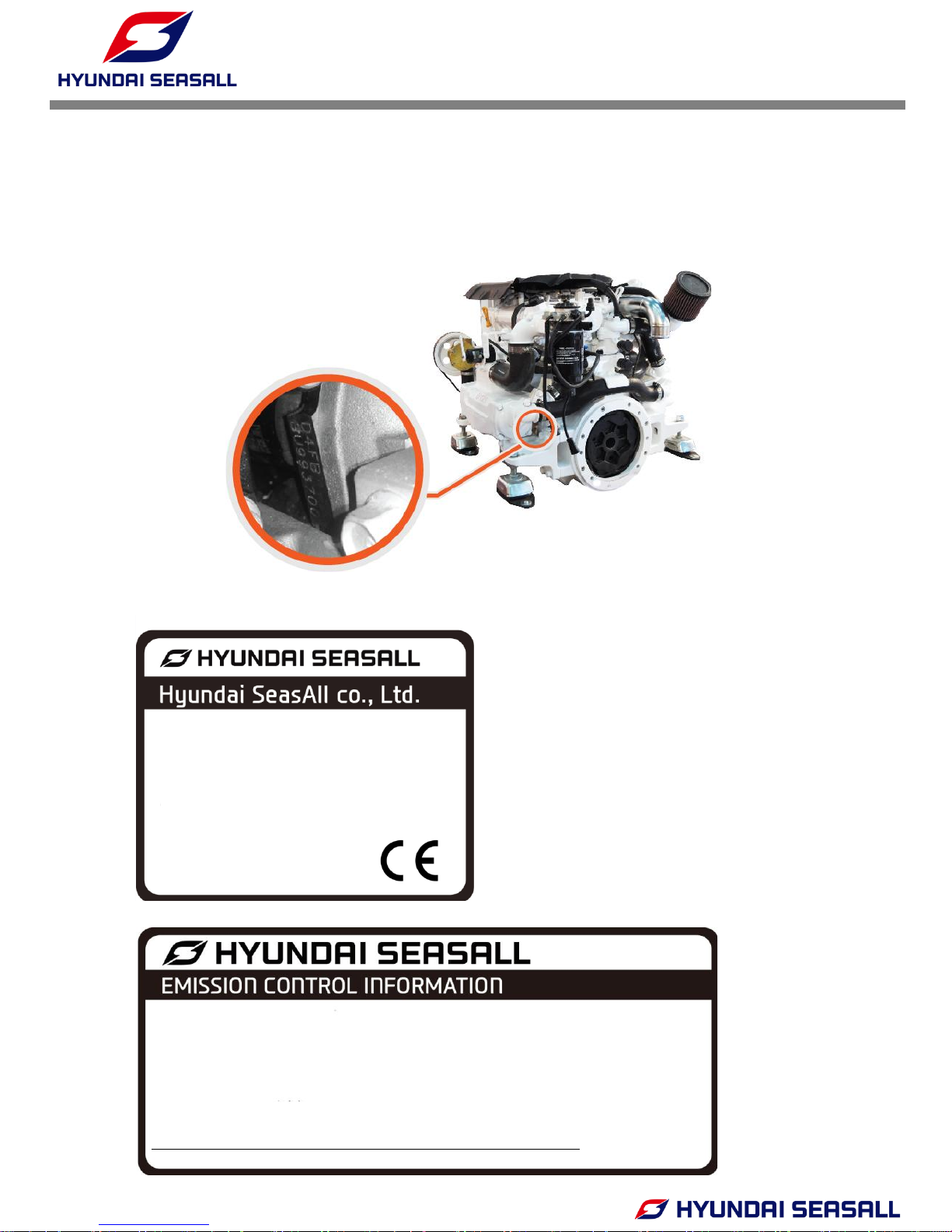

SERIAL NUMBER ON THE ENGINE BLOCK

Engine identification is affixed to the engine block and the ECU box (see figure).

3. ENGINE IDENTIFICATION

• ENGINE NAME PLATE

Engine Family

Engine Type

Engine Serial No.

Rated Power @Speed

No. Of Cylinder

Bore x Stroke

D4FB

U125X

XXXXXXXX

125PS @ 4000rpm

4

77.2mm x 84.5mm

EPA Engine Family FHYSN2.94HYS IMO Engine Family FHYSN2.94HYS

Max Power 93 (kW) Power Density 58.8 (kW/L)

Displacement / Cylinder 0.4 (L/cyl) Date of Manufacture MM/YYYY

Application Recreational Useful Life 1,000 hours or 10 years

Emission Standard THC+NOx : 5.8 (g/kWh) PM : 0.15 (g/kWh) CO : 5.0 (g/kWh)

EMISSION CONTROL SYSTEM

THIS ENGINE IS EQUIPPED WITH ELECTRONIC DIRECT FUEL INJECTION SYSTEM. THIS

ENGINE IS CERTIFIED TO OPERATE ON DIESEL

THIS MARINE ENGINE COMPLIES WITH U.S. EPA REGULATION FOR 2015

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-9-

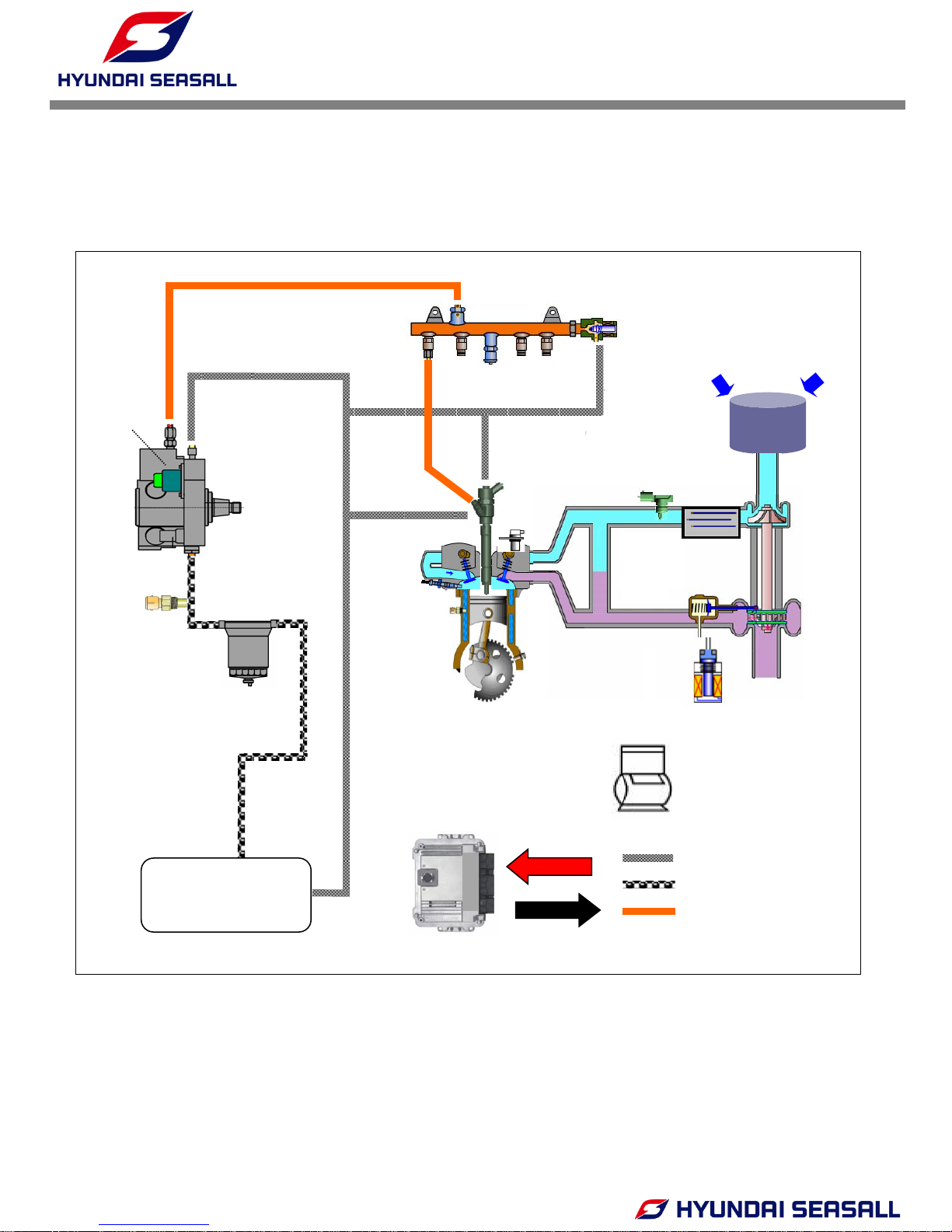

4. SCHEMATIC DIAGRAM OF COMMON RAIL DIESEL ENGINE

ECU

Fuel feed (low pressure)

Fuel feed (High pressure)

Fuel return

Fuel temperature

sensor

Glow

Plug

Crankshaft Position

sensor

VGT

actuator

Water sensor

in fuel

Injector

Intercooler

High pressure

pump

Main fuel filter

Air filter

Pump pressure

regulator valve

Acc. Position

sensor

Boost pressure

sensor &

Air Temp.

sensor

Sensor

Actuator

Fuel Tank

Feed

Return

Return

Return

VGT

Rail pressure

regulator valve

Return

Coolant

Temp.

Sensor

Vacuum

modulator

Common rail

Rail pressure

Sensor

Cam Position

sensor

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-10-

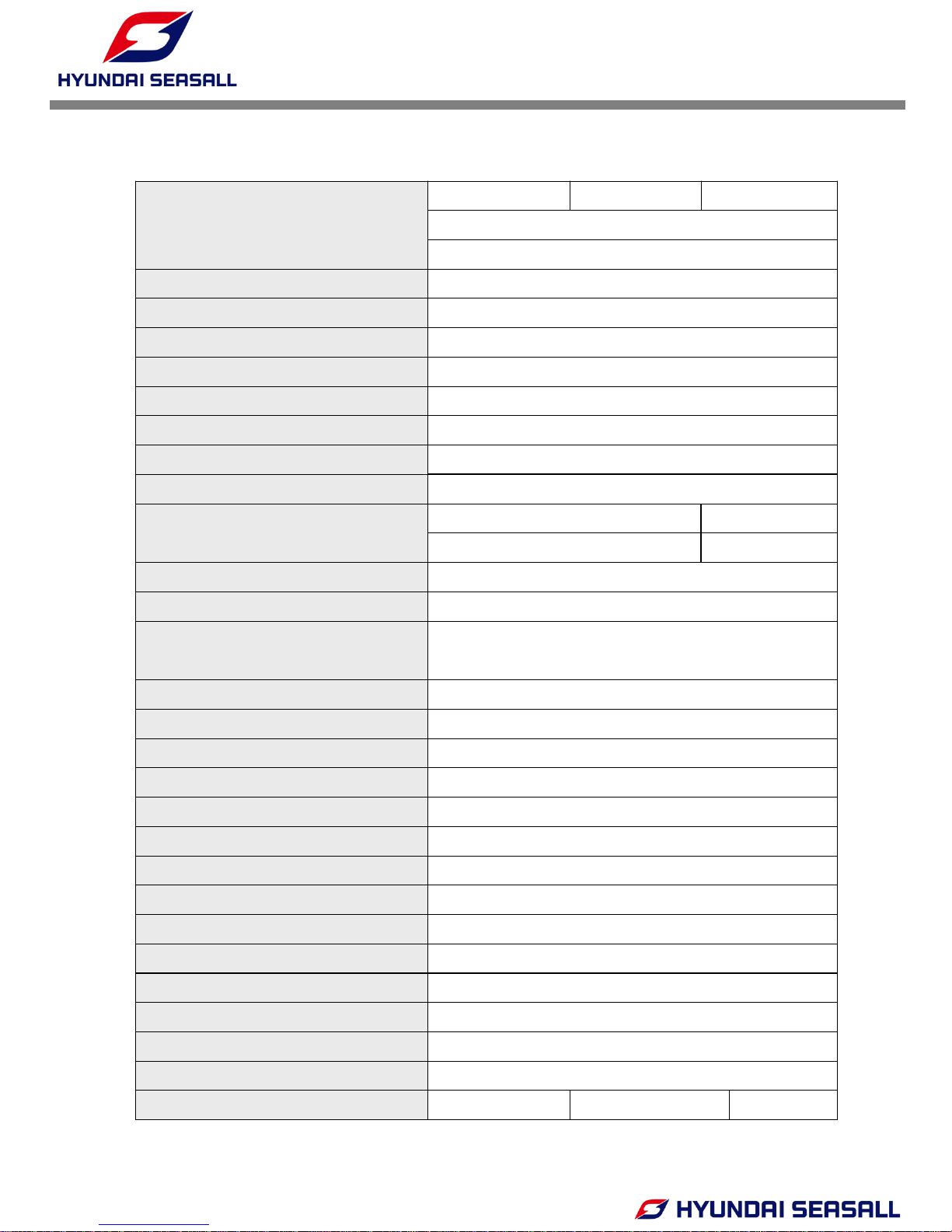

5. TECHNICAL DATA

Engine type

U125S U125P U125J

4-stroke, 16-valve

After-cooled, direct-injection, water cooling

Output ps (kW) 125ps (93)

rpm at full load 4000

Cylinders In-line 4

Ignition sequence 1-3-4-2

Displacement [cm

3

] 1,582

Bore [mm] 77.2

Stroke [mm] 84.5

Compression ratio 17.3 : 1

Max. torque [kgm]

@ speed [rpm]

26.3 23.5

2000 3700

Injection system Common rail direct injection

Diesel fuel at least CN 51 as per DIN EN 590

Intake air pressure (abs. bar)

@ speed [rpm]

2.5 bar @ 4000 rpm

Coolant quantity (liter) 5.5

Coolant cap opening pressure (bar) 1.1

Engine oil (liter) 5.7

Engine oil pressure (bar)

2~3 at 1800rpm, 100 ℃(oil temp.)

Exhaust gas pressure (kPa) Max. 45

Alternator [A] 130

Engine diagnosis Yes

Weight (kg) 220

Battery capacity (AH) 12V, 150AH recommended

Thermostat opening temp. (℃)

85 (starting to open), 95 (fully open)

Idle rpm warmed up (rev/min) 730

Permissible eng. oil temp (℃)

135

Permissible eng. coolant temp (℃)

105

Fuel Consumption (Rated) (l/hr) @ 27.3 @ 4000 rpm

Propulsion system Sterndrive Shaftdrive Waterjet

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-11-

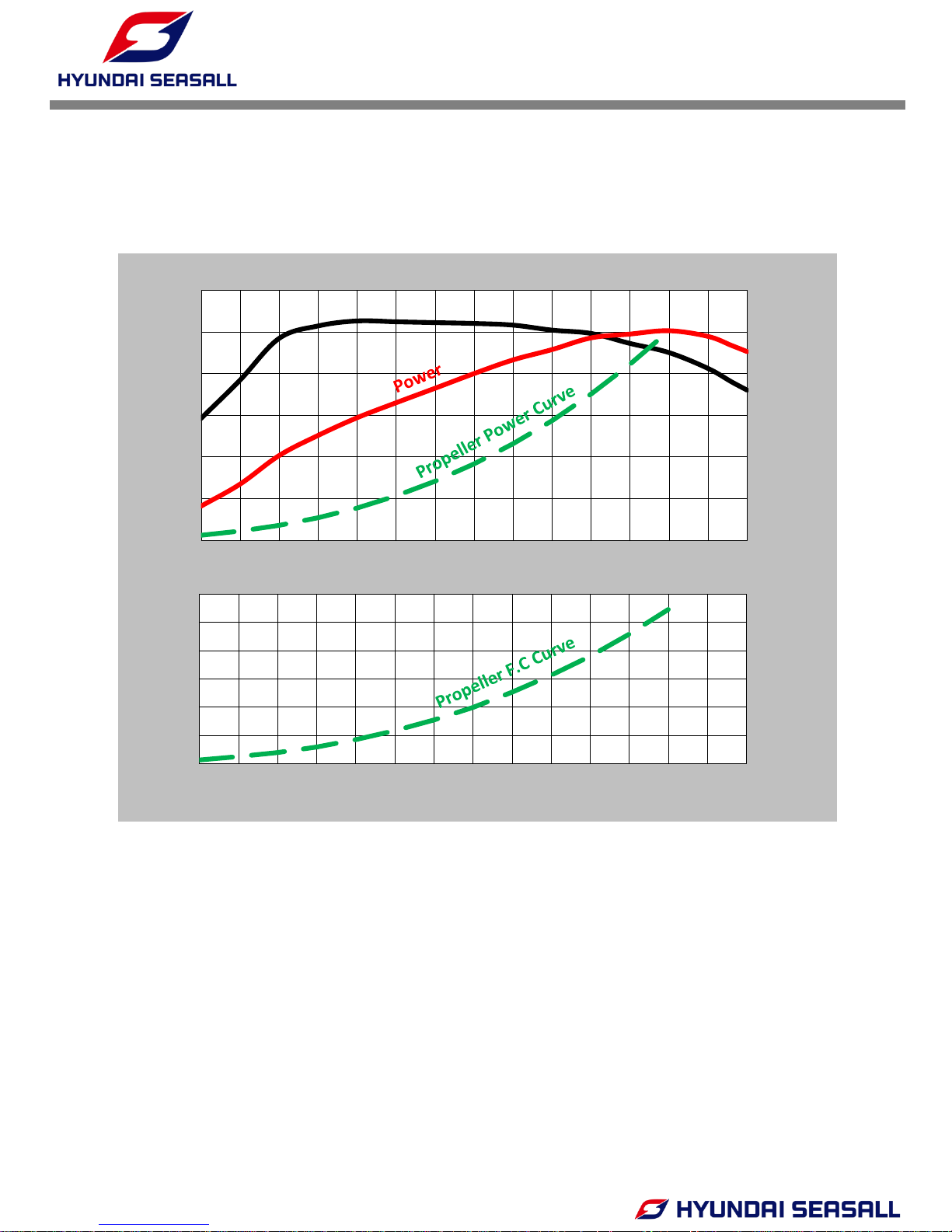

6. PERFORMANCE CURVE

U125S & U125P MODEL

*F.C : Fuel Consumption

0

25

50

75

100

125

150

0

5

10

15

20

25

30

1000 1500 2000 2500 3000 3500 4000 4500

Power (ps)

Torque (kgm)

Torque

0

5

10

15

20

25

30

1000 1500 2000 2500 3000 3500 4000 4500

F.C (L/h)

Engine Speed (rpm)

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-12-

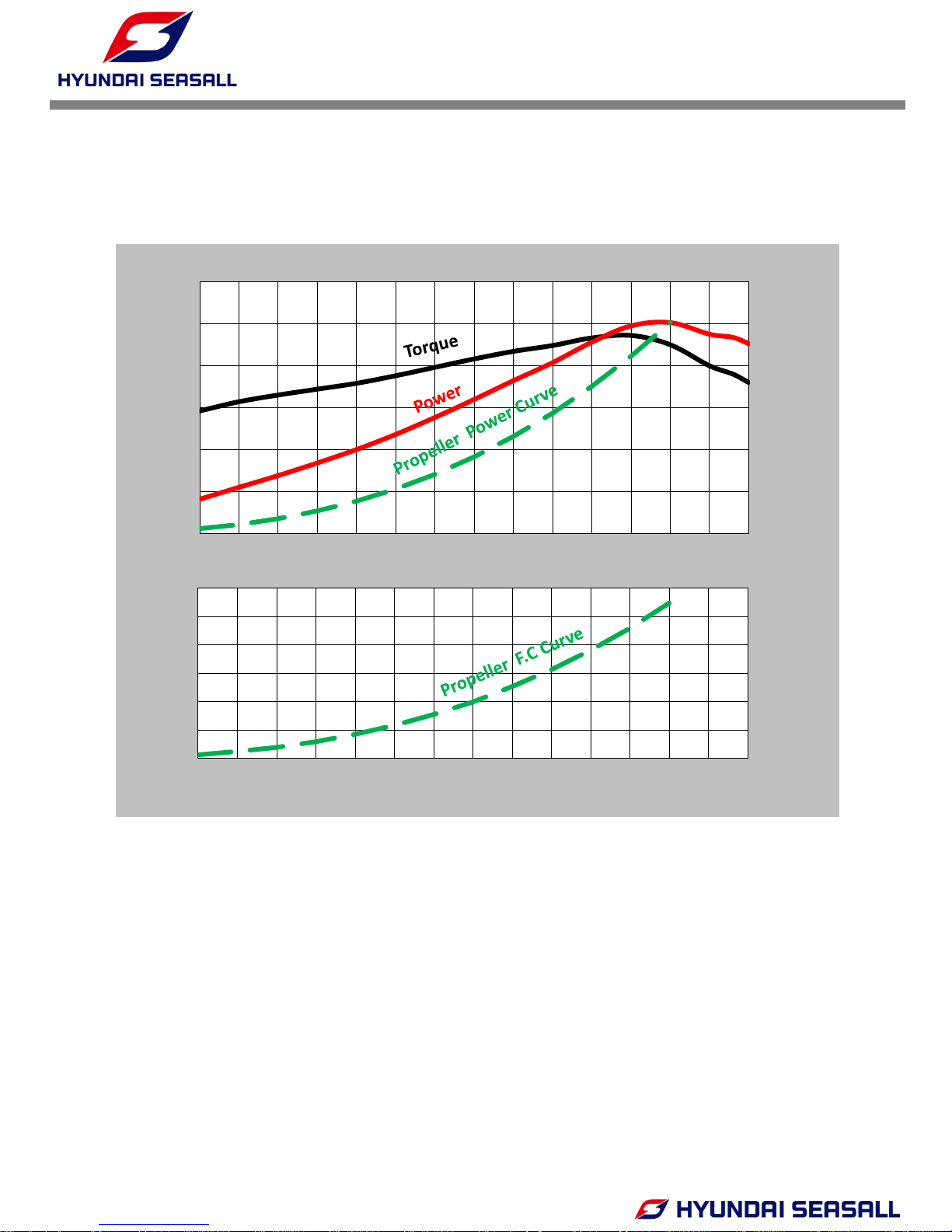

U125J MODEL

*F.C : Fuel Consumption

0

25

50

75

100

125

150

0

5

10

15

20

25

30

1000 1500 2000 2500 3000 3500 4000 4500

Power(ps)

Torque (kgm)

0

5

10

15

20

25

30

1000 1500 2000 2500 3000 3500 4000 4500

F.C (L/h)

Engine Speed (rpm)

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-13-

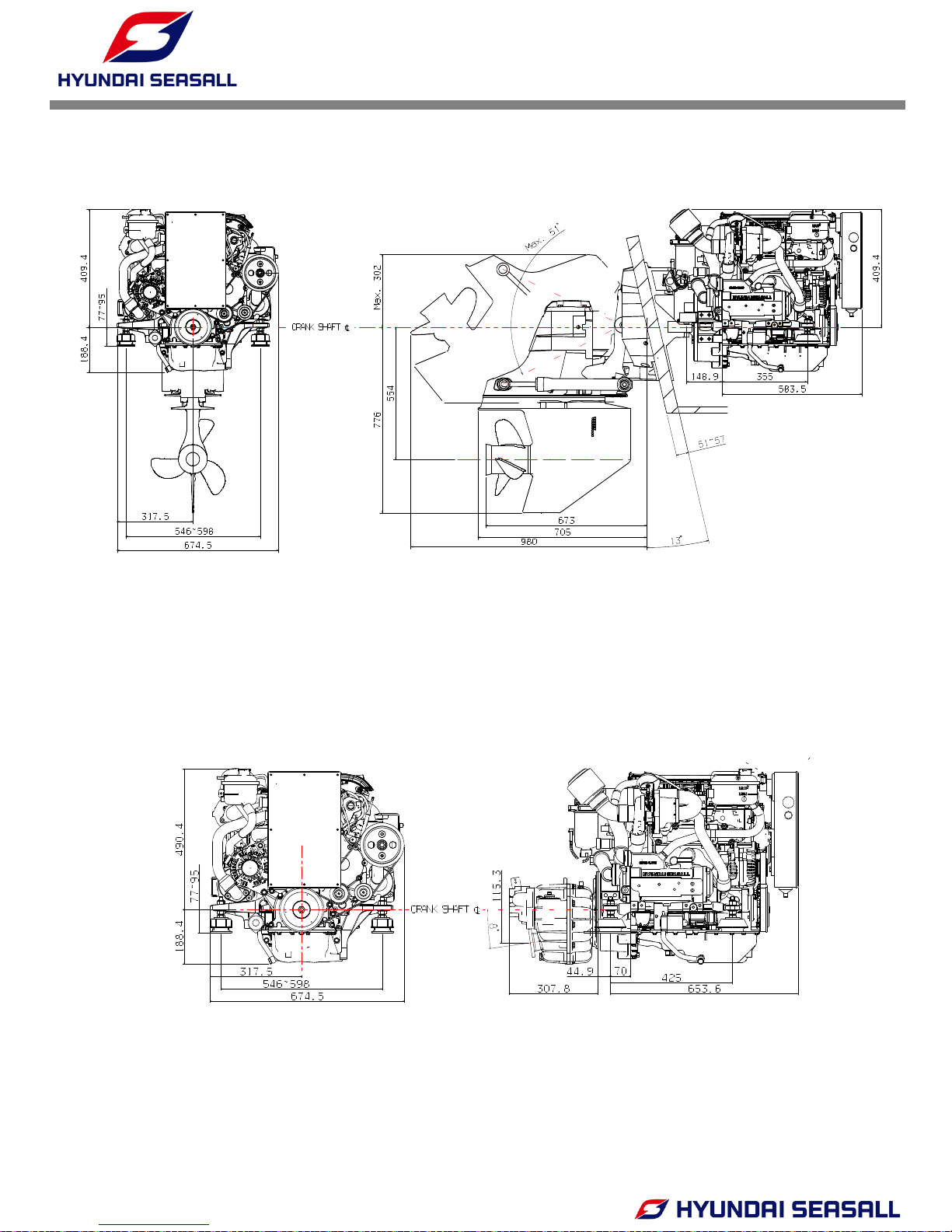

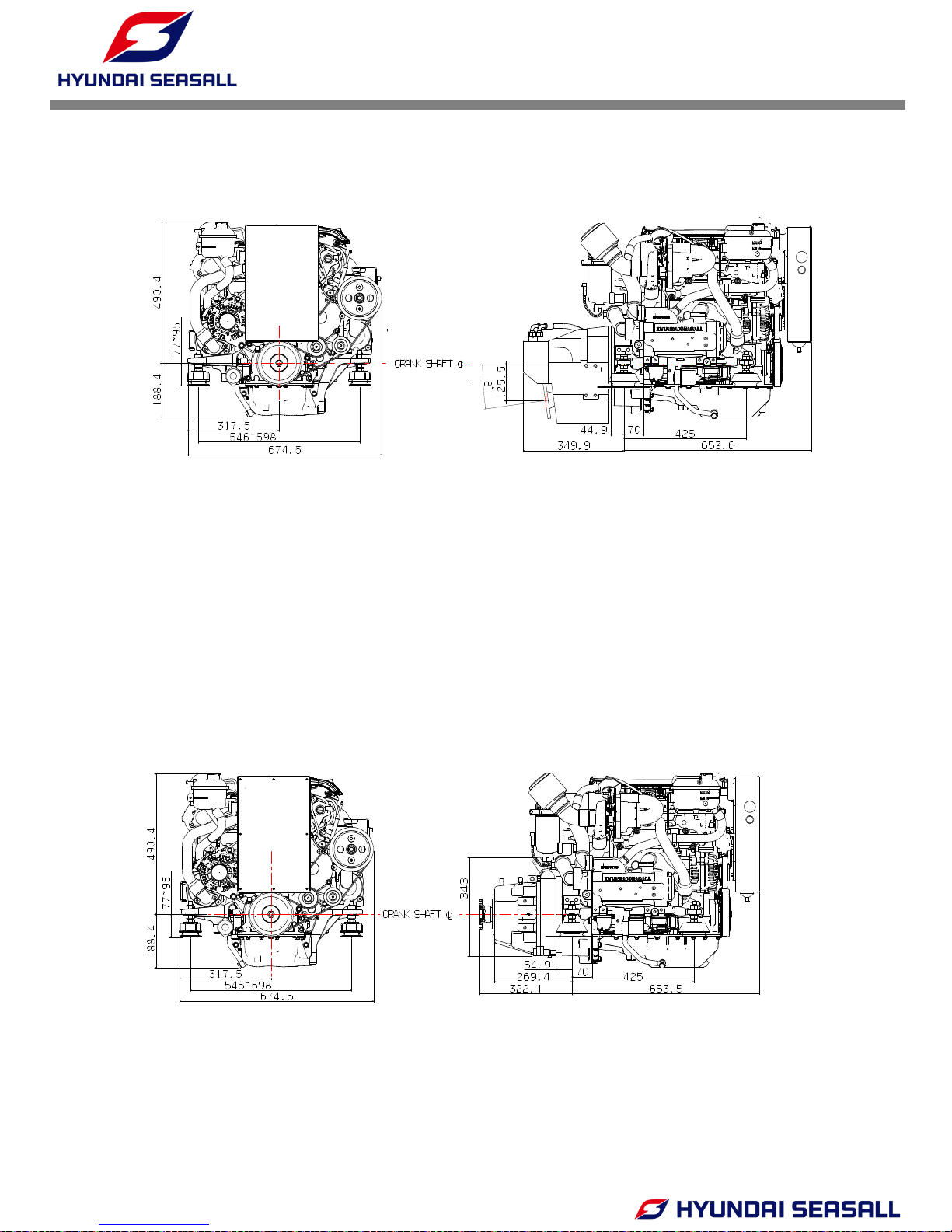

7. BELT LAYOUT & ENGINE DIMENSIONS

Bobtail

Side view [for sterndrive]

Side view [for shaftdrive] Side view [for waterjet with bearing housing]

V-RIBBED BELT LAYOUT

Front view

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-14-

Side view

ZF 25 A

Front view

Side view

MerCruiser Bravo One X Diesel

Front view

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-15-

ZF 45 A

Front view

Side view

ZF 45 C

Front view

Side view

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-16-

CHAPTER 2

ENGINE MOUNT SYSTEM

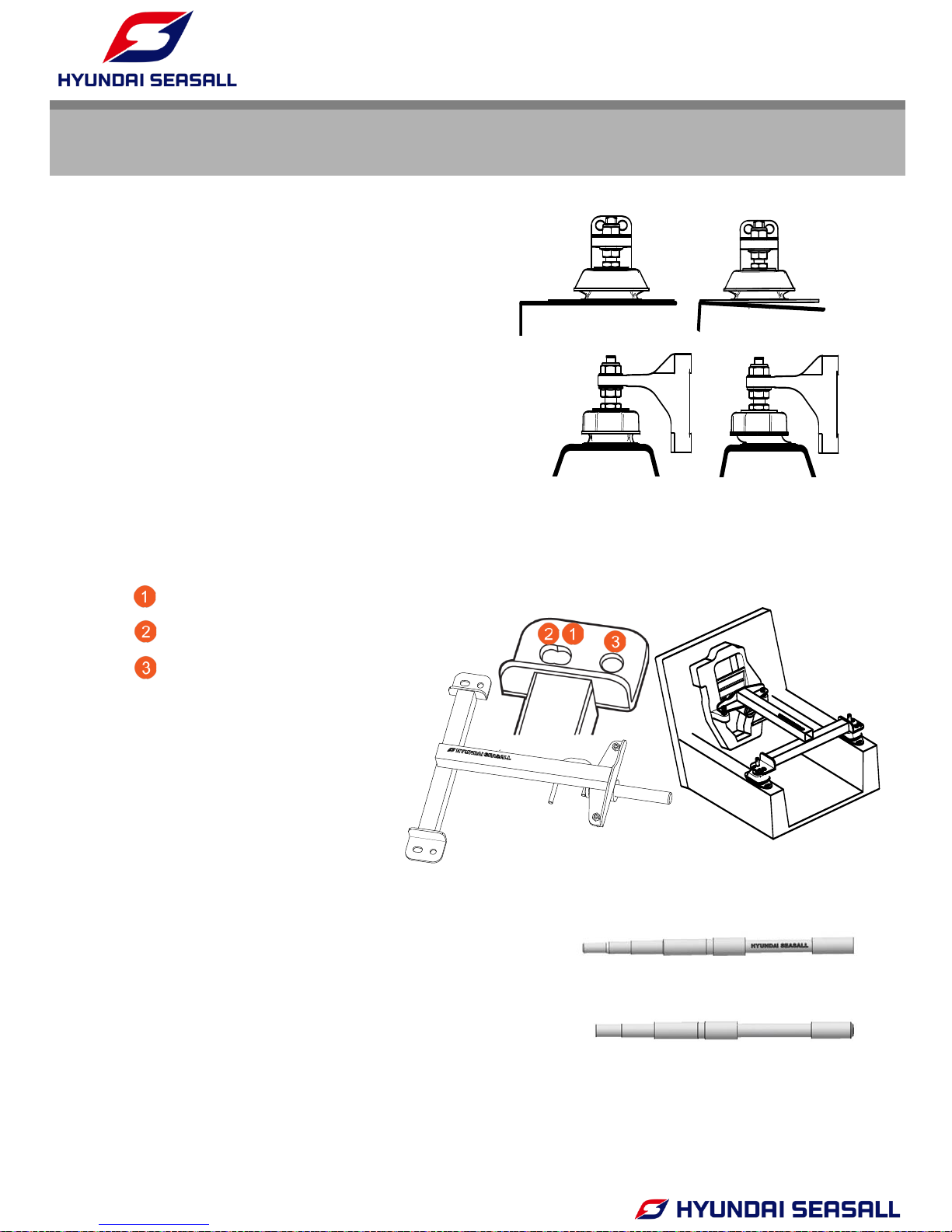

1.1 CHECK THE MOUNT HOLE

Mount hole for U125 model

Mount hole for D170 and D150 model

Mount hole for S250 and S270 model

-. It is essential that the engine bed is perfectly flat

before using the engine mount tool.

-. Make sure that the rubber engine mounts are

installed so that no pre-load or side forces occur

when the engine has been installed and aligned

with the stern drive

<Check the position of

the Engine Mounts >

1. PREPARING THE ENGINE INSTALLATION

<Engine mount tool>

(X) (O)

(X)

(O)

Hyundai-SeasAll alignment tool(5 Step)

MerCruiser alignment tool(4 Step)

(O)

(X)

-. Engine installation must be done by a qualified

technician. Hyundai SeasAll engines must be aligned

using the genuine Hyundai SeasAll alignment tool

Otherwise the drive coupler will be damaged.

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-17-

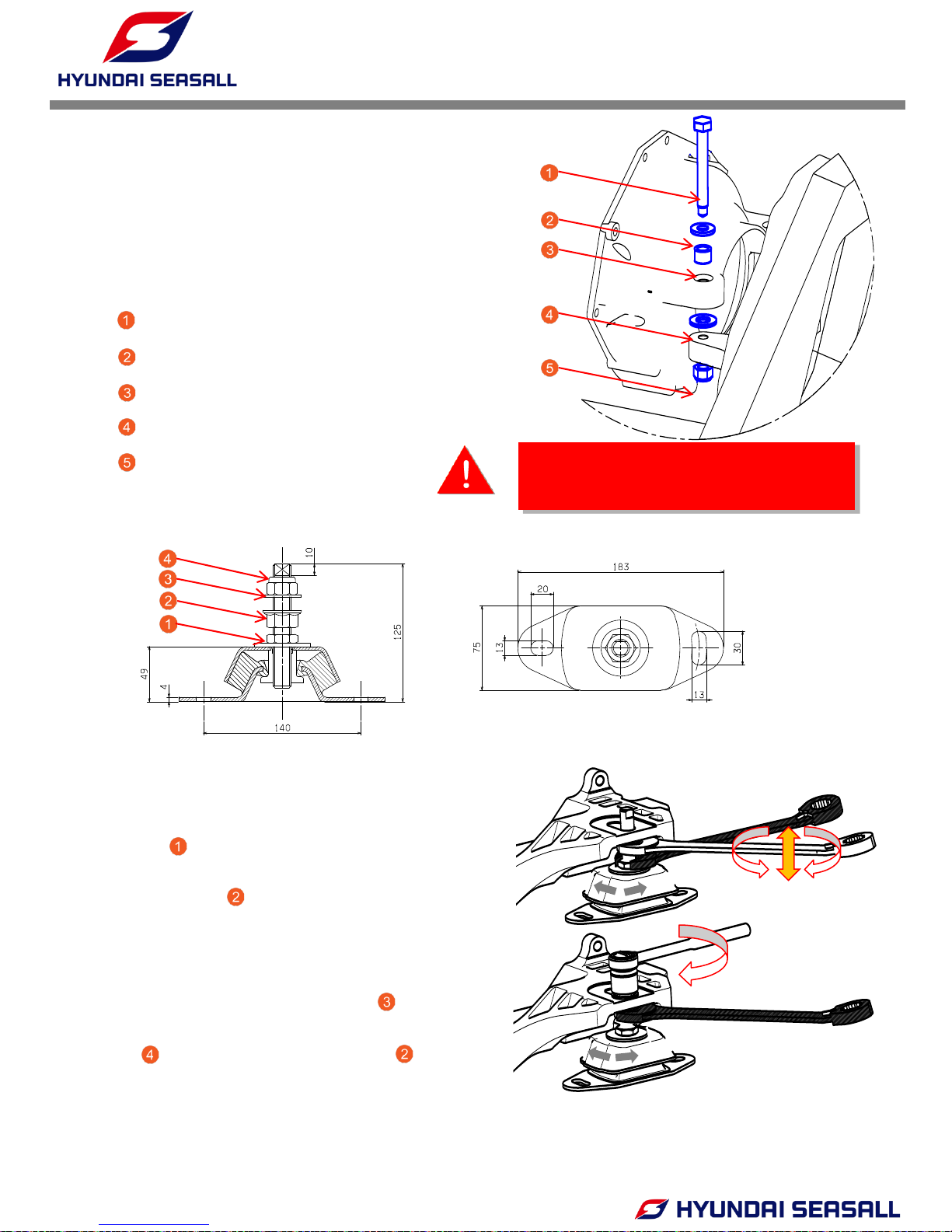

1) To prevent twisting the engine mount during

engine alignment, use a spanner on the lower

nut ( ) to keep the bolt from turning while

adjusting the engine height by turning the

middle nut ( ). Adjust the engine height until

the Hyundai SeasAll alignment tool can be

properly inserted.

2) After alignment, place washer ( ) on top of

engine support bracket and tighten lock nut

( )while keeping the middle nut ( ) from

turning with a spanner.

-. Assemble exhaust pipe after tightening the

mounting bolts between bell housing and

transom plate. Use the following parts:

Mounting Bolt

Washer

Spacer

Fiber Washer

Nut

3. ASSEMBLING ENGINE MOUNTS

2. BELLHOUSING FIXING

WARNING

DON’T USE THE SPRING WASHER.

IF YOU USE SPRING WASHER, THE PROBLEM OF

ENGINE ALIGNMENT CAN BE OCCURRED.

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-18-

CHAPTER 3

COOLING & EXHAUST SYSTEM

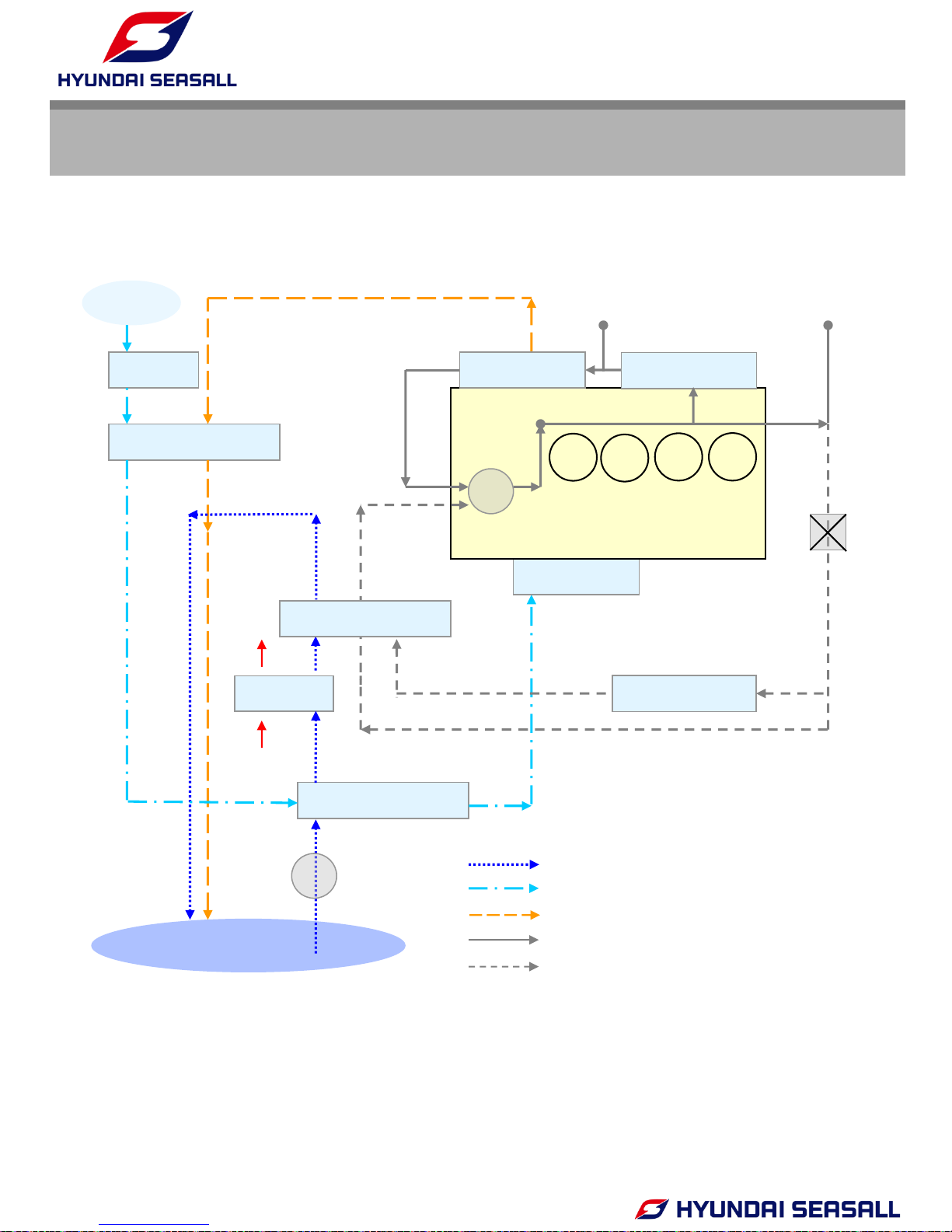

1. SCHEMATIC DIAGRAM OF ENGINE COOLING CIRCUIT

IN-MANIFOLD

Pc

COOLANT

PUMP

INTERCOOLER

OIL COOLER

TURBO CHARGER

AIR FILTER

SEA WATER

PUMP

THERMOSTAT

OIL

SEAWATER

INTAKE AIR

EXHAUST AIR

COOLANT ( THERMOSTAT CLOSED & OPENED )

COOLANT (THERMOSTAT OPENED )

SEAWATER

EXPANSION TANK

AIR

ENG.OIL COOLER

HEAT EXCHANGER

EX-MANIFOLD

Ps

CABIN HEATER

CONNECTOR

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-19-

Water strainer ← Water valve ← Water pickup

↓

① Seawater pump

↓

② Intercooler

↓

③ Transmission oil cooler

↓

④ Heat exchanger

↓

⑤ Exhaust elbow

↓

Sea water

2. SEAWATER FLOW – OPEN COOLING CIRCUIT

2.1 WATER PICKUP

• Water pickup should be installed in an area where it won’t pick up air bubbles and will

access clean water during all phases of the engine operation.

• For use in sterndrive models, please see the section “Installing Sterndrive Seawater Pickup”

of the BRAVO MODELS INSTALLATION MANUAL, included in the original packaging.

• For further safety, you can use an additional transom or bottom mounted clamshell-type

water pickup.

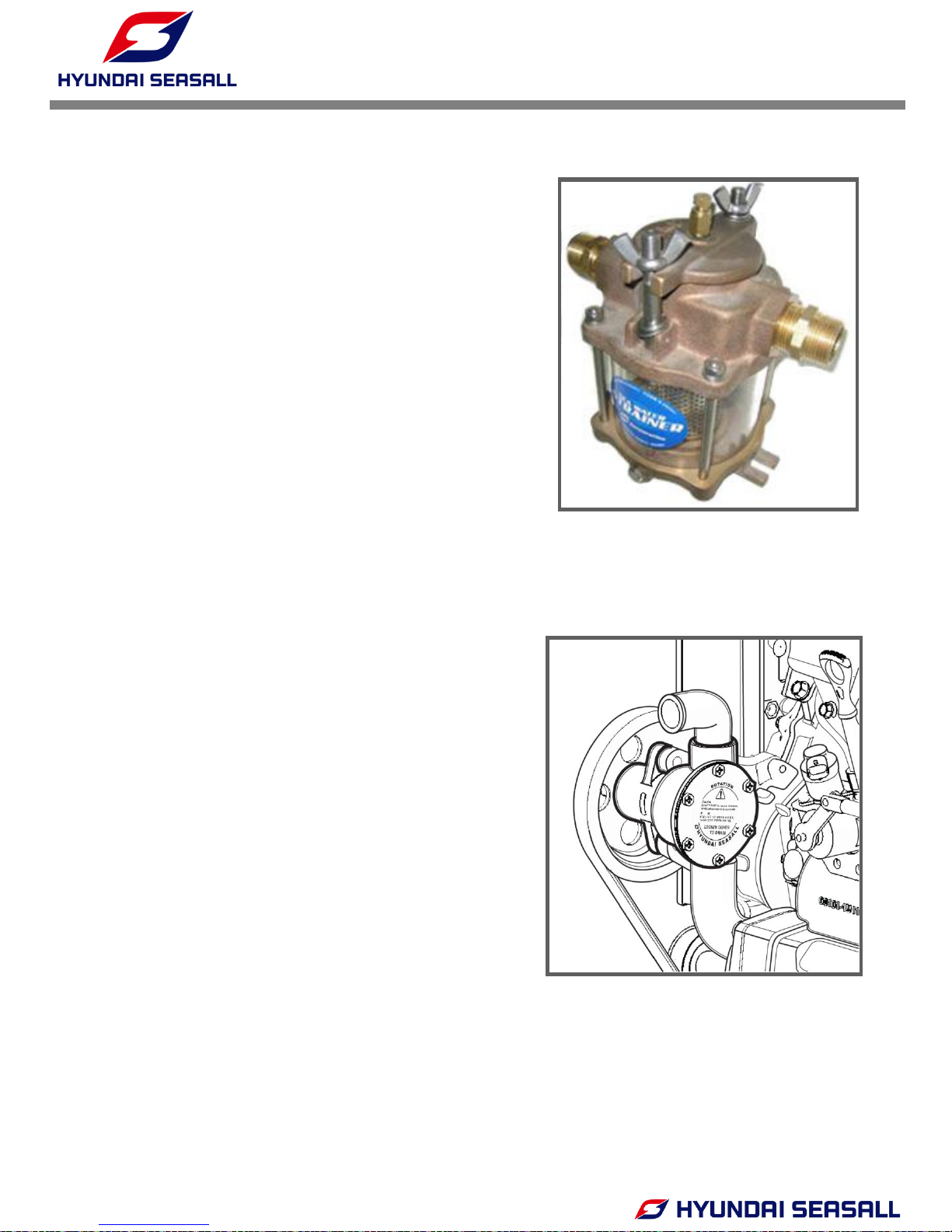

2.2 WATER STRAINER

• Strainer should be located in an area where it will

be easily accessible for periodic seawater flow

inspection and cleaning.

• The size of strainer must be of sufficient capacity

to pass the seawater (a flow rate over 150 liters

per minute flow rate).

• Strainer filter size should be Ø

2

• Strainer must be installed after water inlet valve in

order to allow user to shut off seawater when

cleaning strainer filter.

CAUTION

IF THE SEAWATER STRAINER IS NOT PROPERLY ASSEMBLED, AIR

CAN BE SUCKED INTO THE COOLING CIRCUIT, DISTURBING THE

VACUUM PROCESS. THIS CAN CAUSE THE ENGINE TO OVERHEAT.

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-20-

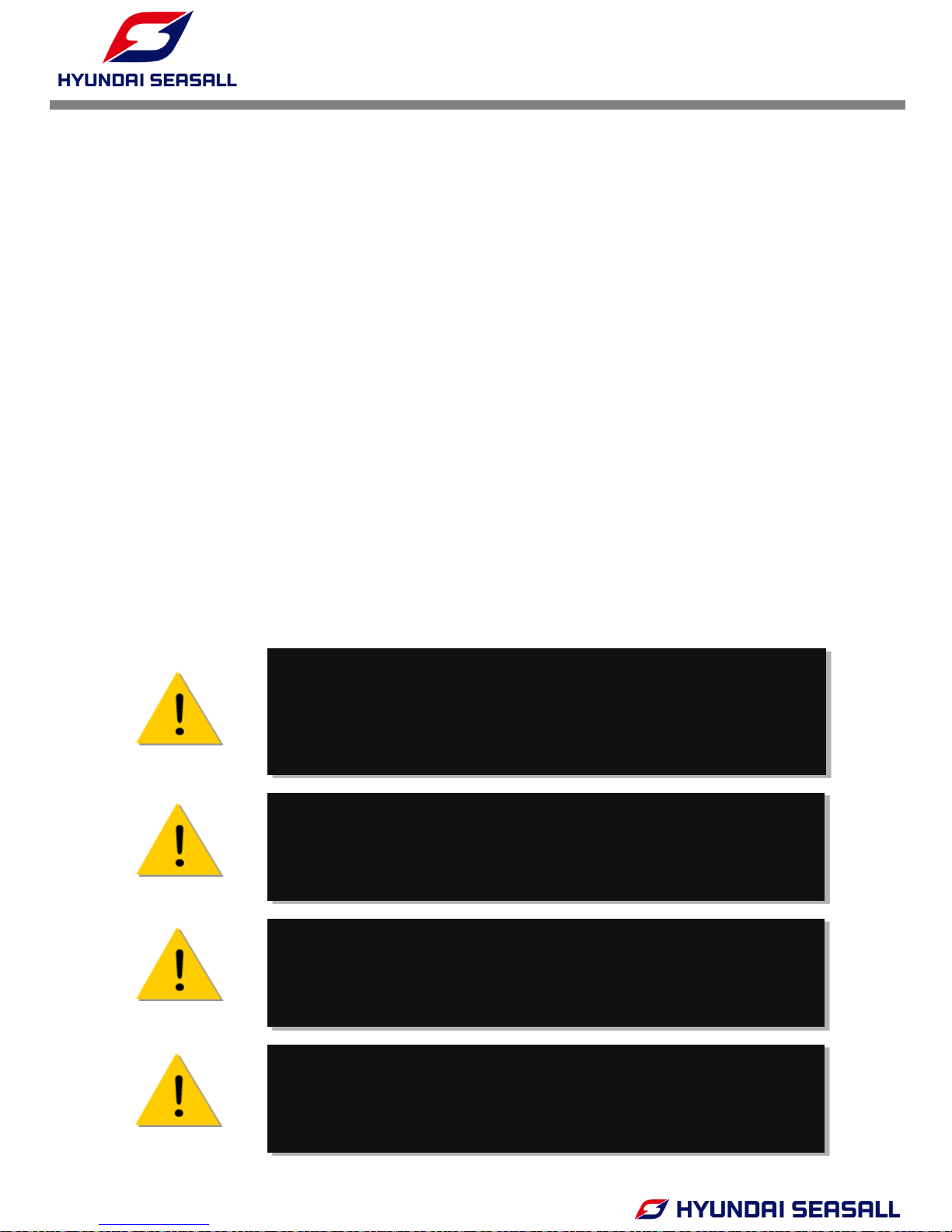

2.3 SEAWATER PUMP

• Stop the engine and close the water valve.

• Remove the filter cap.

• Remove the filter element, flush it thoroughly

with clean water or compressed air.

• Insert the cleaned filter element and screw on

the filter cap.

• Check the cap and the gasket for correct

seating and sealing.

• Open the water valve.

• Start the engine and check if there is water

leakage.

CLEAN STRAINER FILTER

• The internal diameter of hose connected to

seawater pump inlet should be Ø32.

• The cross section of the hose may shrink due to

inlet pressure drop. Therefore, the hose from

water pickup in the boat’s hull to the seawater

pump inlet should be as short as possible and

must be made of steel wire reinforced material.

• The seawater pump impeller must be checked

periodically and replaced if necessary.

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-21-

CAUTION

DO NOT RUN THE ENGINE WITHOUT SEAWATER. THE SEAWATER

PUMP IMPELLER WILL BE DAM AGED. BEFORE STARTING THE

ENGINE, BE SURE TO SUPPLY SEAWATER TO THE PASSAGES.

CAUTION

IMPELLER DAMAGE MAY OCCUR IF APPROPRIATE TOOLS ARE NOT

USED WHEN REMOVING THE IMPELLER. MAKE SURE TO CHECK ORING CONDITION AFTER SEAWATER PUMP REASSEMBLY.

CAUTION

DO NOT INSTALL ADDITIONAL DEVICES WHICH COULD OBSTRUCT

THE FLOW OF SEAWATER. THIS CAN CAUSE THE ENGINE TO

OVERHEAT.

• Stop the engine and close the water valve.

• Remove the impeller housing cover.

• Remove the impeller from inside the seawater pump.

• Check the condition of impeller and bushing.

• Apply soapy water to impeller when assembling, and reassemble towards rotation direction.

• Replace of the O-ring on the impeller housing cover.

• Open the water valve.

• Start the engine and check if there is water leakage.

2.4 CHECKING SEA WATER PUMP & IMPELLER

CAUTION

IF ASSEMBLY IS NOT CONDUCTED PROPERLY, AIR CAN BE SUCKED

IN, DISTURBING THE VACUUM PROCESS. THIS CAN CAUSE THE

ENGINE TO OVERHEAT.

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-22-

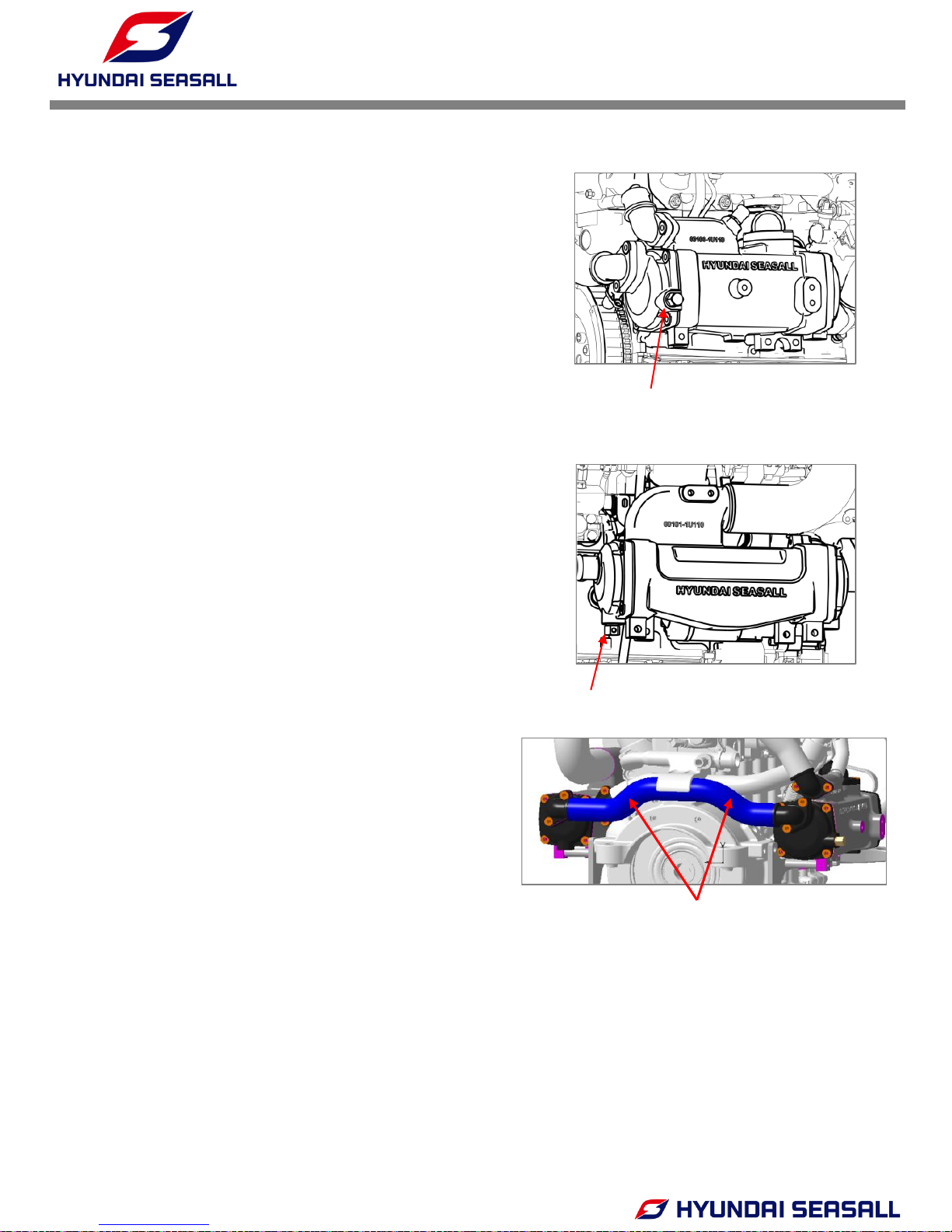

2.5 SEA WATER DRAIN

• Remove anode, then please let the sea water drain.

• Removing and Inspection procedure

1. Remove the anode plugs on the heat exchanger

(A) and the intercooler (B).

2. Squeeze the hose (C) connecting the heat

exchanger to the intercooler several time to

ensure that seawater does not remain in the

hose and bundle.

3. While anodes are removed, inspect for usability

(See Chapter 11 – Anti-Corrosion System).

4. Replace anode plugs before running engine.

(A) Anode plug (water)

HEAT EXCHANGER

INTERCOOLER

(B) Anode plug (water)

(C)

INSTALLATION & OPERATION MANUAL

U125 Series Engines

-23-

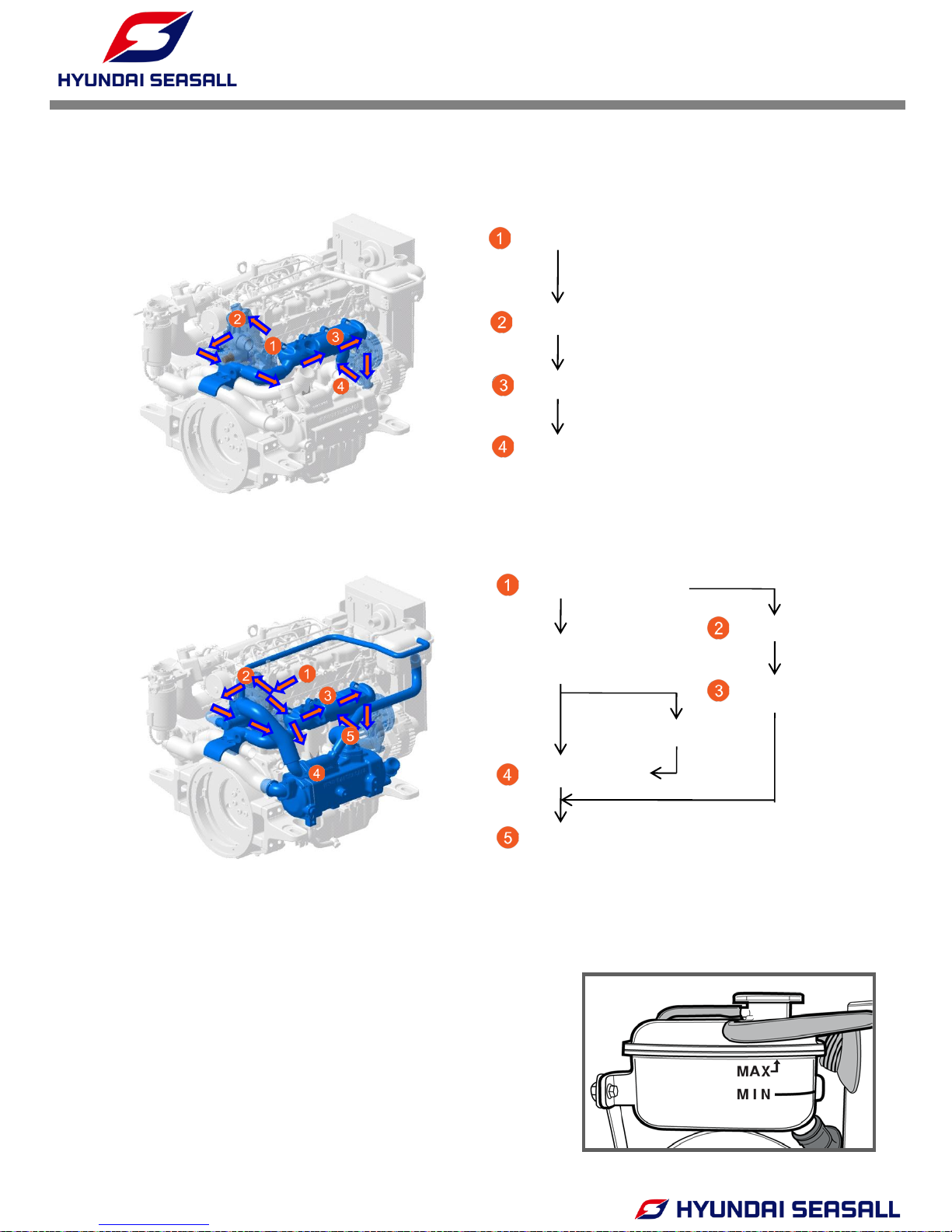

THERMOSTAT OPENED

THERMOSTAT CLOSED

• The high-pressure cooling system has a reservoir

filled with year-round antifreeze coolant. The reservoir

is filled at the factory.

• The coolant level should be between MAX and MIN

marks on the side of the coolant reservoir when the

engine is cool.

3.1 ENGINE COOLANT

① Engine coolant outlet

② Engine oil cooler

③ Exhaust manifold

④ Engine coolant inlet

① Engine coolant outlet

② Engine oil cooler

Thermostat opened

(opening temp 85℃)

③ Exhaust manifold

Expansion tank

④ Heat exchanger

⑤ Engine coolant inlet

3. ENGINE COOLANT FLOW

Loading...

Loading...