Page 1

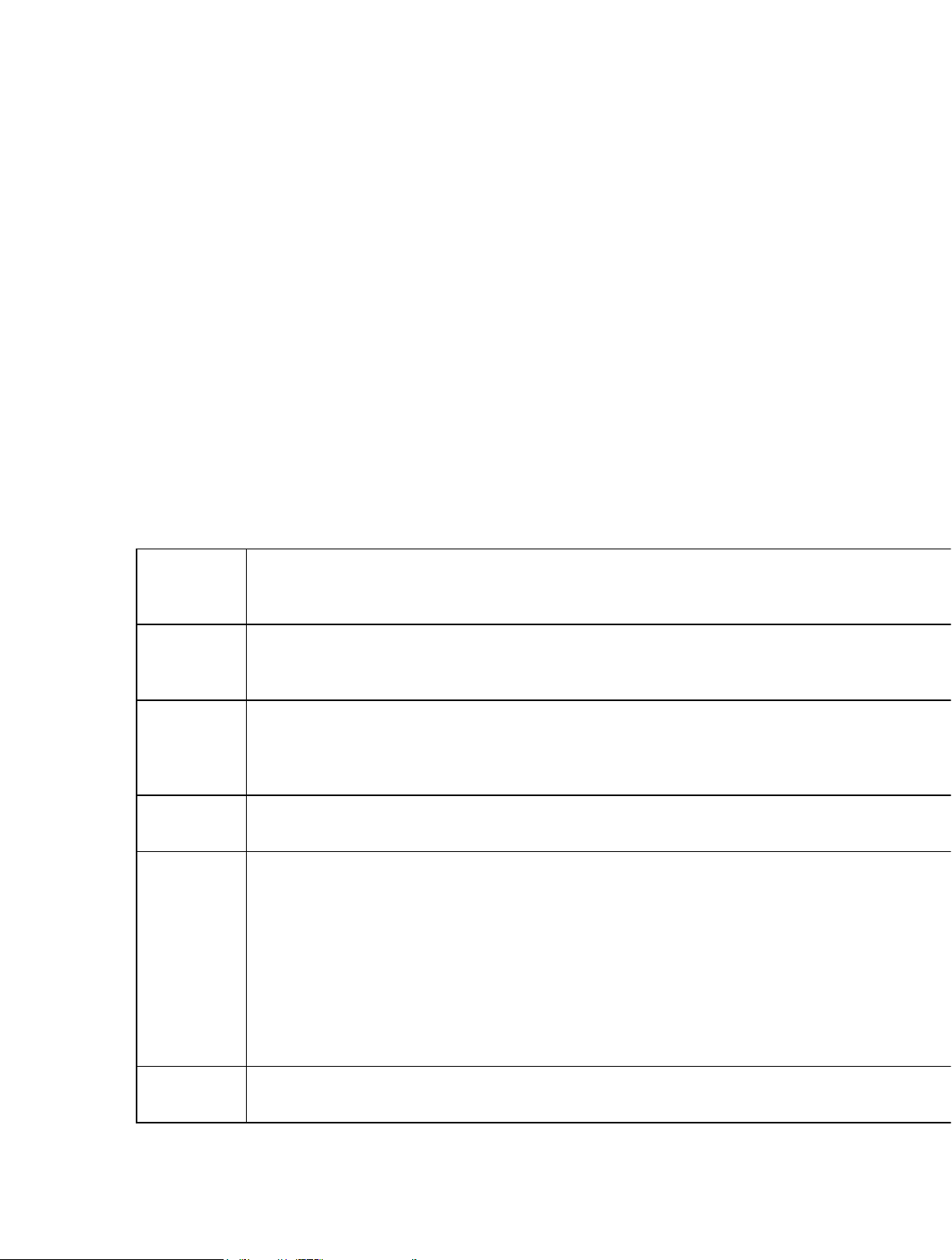

In five-digit Hyundai error codes, the first character means:

P - malfunctions of the engine, transmission unit and electronics;

B - breakdowns in the work of body systems;

C - malfunctions of the chassis and electronics;

U - malfunctions in the operation of electronic systems or sensors, as well as the control unit.

Second character:

0 - general OBD2 code;

1 - code of the vehicle manufacturer.

Third character of the code:

1 - malfunctions in the functioning of fuel systems or air supply;

2 - also problems associated with the air supply or the car's power system;

3 - ignition;

4 - systems and mechanisms of auxiliary control;

5 – idling of the engine;

6 - ECU module and its electrical circuits ;

7 - car gearbox;

8 - errors associated with the transmission unit.

The fourth and fifth characters indicate the sequence number of the fault.

Table with errors

U3FFF

Message that appears when using unlicensed OBD 2 diagnostic software. It is not necessary to

purchase a license to check, you can use other software.

P3C00

On Hyundai NF and other models, this code cannot be deciphered and appears when using a

scanner that cannot read all combinations of errors

P250F

The on-board computer detected a too low level of engine fluid in the engine. It is necessary to

check the volume of the consumable and, if necessary, test the operation of the sensor designed

to fix its level.

486B

Unknown code associated with the use of inappropriate diagnostic equipment

9406

General error on airbags.

Items to check:

SRS security system control unit;

airbag sensors;

pretensioning elements of the system;

wires running from the security system control unit to its constituent components.

P0000

Absence of malfunctions in the operation of vehicle components and systems

Page 2

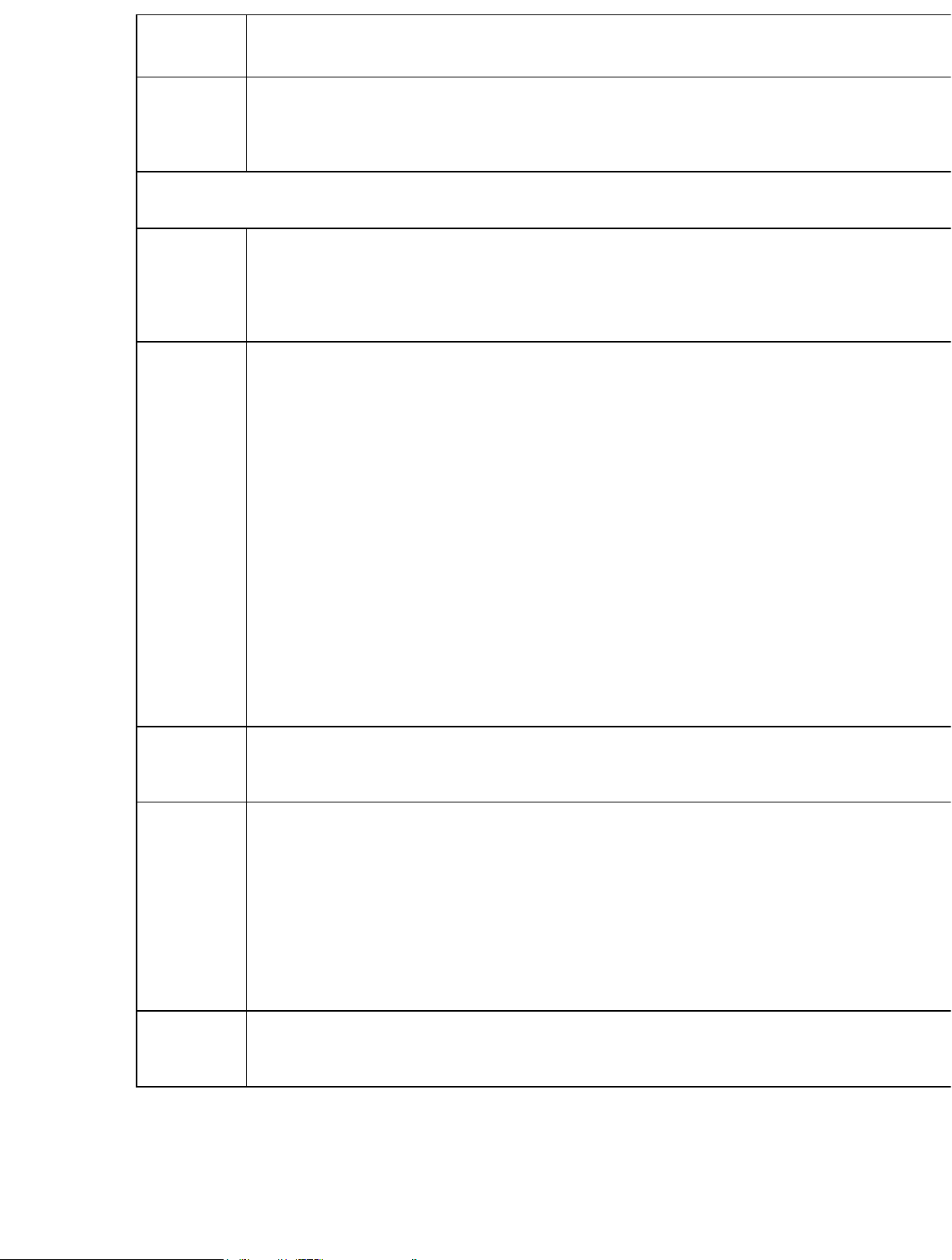

P0441

The verbatim interpretation of error P0441 is “poor-quality purge of the fuel vapor recovery

system”. When code 0441 or 441 appears, you should diagnose the sensors of the system, and

also make sure that all pipes are intact.

P0401

The combination P0401 (0401) appears with low efficiency or its absence in the operation of the

exhaust gas recirculation system. When such a problem occurs, the user needs to diagnose all

sensors, as well as make sure the integrity of the pipes and lines. Damaged channels must be

replaced.

P0444

The P0444 combination appears when the purge valve of the evaporative emission system is

stuck open. With error 0444, you should check the operation of the device and replace it in case

of a breakdown. It is possible that the valve lies as a result of the lack of lubrication on the

moving mechanism.

P0446

Code P0446 indicates a malfunction in the air valve control mechanism of the vapor recovery

system. With error P0 446, it is necessary to check the functionality of the drive and test the

operation of all controllers.

P0455

The on-board computer recorded a serious leak in the fuel vapor recovery system. With error

P0455, a detailed check of all system components for leaks is required, damaged hoses and

pipes are replaced with new ones.

P0741

Incorrect clutch adjustment. The appearance of error P0741 may be due to a malfunction of the

mechanism itself, as well as one of the sensors in the system. In some cases, the reason is due to

incorrect operation of the microprocessor module.

P1127

The on-board computer indicates problems related to exhaust gases. The user should start

looking for the cause by testing the oxygen controllers, since they did not self-diagnose after

starting the engine.

P1372

Literally, this code stands for "incorrect receipt of the segment time." Most likely, the reason is

a malfunction of the engine control unit or malfunctions in its operation.

P1770

Code P1770 appears when the control module of the EMC system malfunctions

P1782

Code P1782 indicates a malfunction in the intake manifold control system. The control unit

informs the car owner that the first bank of the engine is stuck in the open position. A detailed

diagnosis of the power unit is required.

P1847

Code P1847 on Hyundai AX35 and other models is common and indicates a malfunction in the

traction control system.

Possible causes of the malfunction:

malfunction of one of the sensors of the ABS system;

wiring malfunction, damage to electrical circuits , oxidation of contacts, bending of wires;

malfunctions of the engine control module;

Page 3

malfunctions in the functioning of the ABS control unit.

B1650

The power steering pressure switch is out of self-test range. The most likely cause of the

problem is a damaged wiring or incorrect resistance detected by the on-board computer on the

power line of the switch.

Code

Fuel system malfunctions

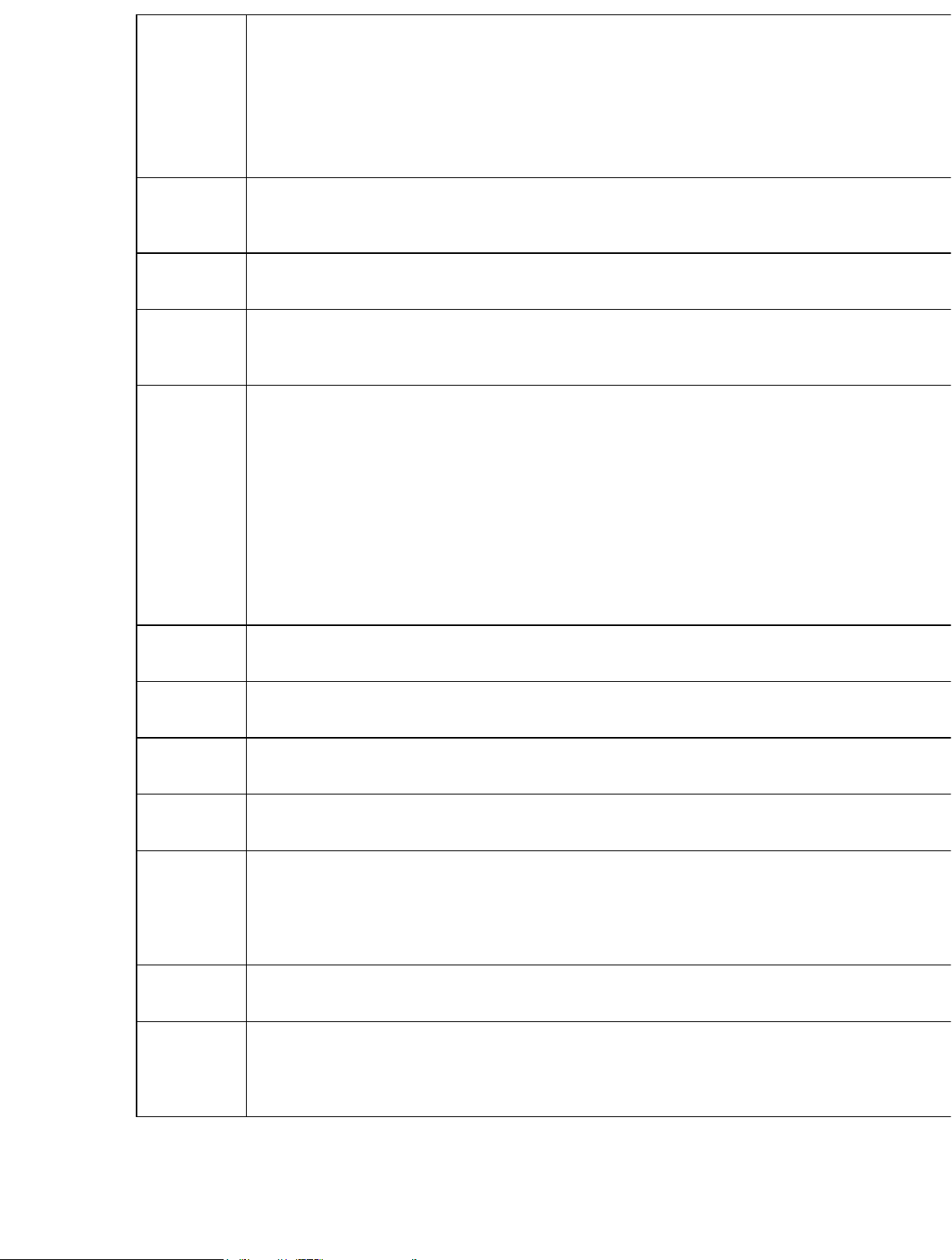

P0087

Error P0087 appears when the pressure in the fuel line decreases, which can be caused by the

following problems:

breakdown of the fuel pressure sensor;

malfunction of the fuel pumping device located in the tank;

malfunctions of the fuel pressure control valve;

failure or clogging of the fuel injector;

wear of the pusher device located in the high pressure fuel pump.

Symptoms associated with this problem:

increased fuel consumption;

swimming speed when starting the power unit, which leads to an arbitrary stop of the motor;

difficulty starting the engine on a cold;

the transition of the engine into emergency operation and the impossibility of increasing the

speed above 3 thousand per minute.

P0088

Code P0088 appears with increased pressure in the fuel rail. Error 0088 may be due to a

malfunction of the system sensor itself.

P0456

The control unit has detected a small leak in the evaporative exhaust gas emission control

system.

Possible causes of the problem:

the user did not close the fuel filler cap or it was lost;

leakage in one or more nozzles or fuel filler hose;

leak in the adsorber or gas tank.

P1188

Code P1188 indicates a fuel system leak. The cause of the problem may be damage to the lines

of the system or incorrect operation of the sensors.

Page 4

Code

Engine malfunctions

P0011

The P0011 code can literally be decoded as "camshaft position error A. Synchronization or

system performance."

Possible reasons for the appearance of code 0011:

use of contaminated or low-quality motor fluid;

failure of the valve for changing the valve timing;

damage to the power supply wiring of the VTC valve or short circuit of the contact elements;

mechanical malfunctions in the operation of the power unit;

damage to the contacts on the electrical block of the VTC sensor;

failure, damage or incorrect operation of the ECM control module.

When this code appears, the engine may run less smoothly at idle, and engine power may also

be reduced.

P0012

Literally, error P0012 stands for "camshaft position A - too long ignition lag."

Possible causes of the malfunction:

poor contact of the controller with the car's electrical network;

contamination of the engine fluid or clogging of the oil channel with contaminants;

oil regulator failure.

P0014

The code indicates an incorrect position in the camshaft . The cause of the problem may lie in

the sensors, as well as incorrect adjustment of the marks when replacing the timing belt.

P0016

Code 0016 appears when there is a violation of the relationship between the crankshaft and

camshafts. The appearance of error P0016 may be due to a mismatch in pulses from the

controllers. It is necessary to check the operation of the sensors and their wiring. If the problem

appeared after replacing the timing belt, then you need to make sure that the marks on the

pulleys match.

P0017

With error P0017, the on-board computer reports a desynchronization of the signals from the

crankshaft and camshaft sensors

P0170

Error P0170 is associated with a violation of the ratio in the formation of the air-fuel mixture,

possible causes of the problem:

clogged air filter;

malfunction of the air flow meter or oxygen controller installed before the catalyst device;

Page 5

failure of spark plugs or the appearance of soot and deposits on them;

air leakage in the intake tract, pipes under the throttle assembly, intake manifold and behind the

sensors are subject to diagnostics;

malfunction of the injectors as a result of the appearance of soot on them;

damage to the exhaust ventilation pipe.

P0171

Error 0171 is associated with a lean air-fuel mixture due to air leakage. You need to look for a

leak by checking all system components for integrity.

P0172

Code P0172 indicates a rich mixture in one or more engine cylinders

P0299

Error P0299 appears when the pressure recorded in the turbine or blower is too low. A possible

cause could be the boost pressure controller.

P0300

Error P0300 is general and indicates single or multiple misfires in one of the engine cylinders.

Possible reasons for the appearance of code 0300:

incorrect composition of the air-fuel mixture associated with malfunctions in the operation of

the injectors;

malfunction of high-voltage candles, wires or other components of the ignition system;

reduction in compression in the cylinders of the power unit, associated with the destruction or

sticking of the piston rings.

P0301

Code P0301 is associated with misfires in the first cylinder of the engine.

P0302

The control unit has registered misfires in cylinder No. 2 of the power unit

P0303

Error P0303 (0303) reports a misfire in the third cylinder of the engine

P0304

The on-board computer recorded misfires in the fourth cylinder of the engine

P0420

Code P0420 appears as a result of low catalyst throughput. If the device itself is intact, then

combination 0420 may be due to the use of low-quality fuel or the failure of the second oxygen

regulator. To fix the problem, the user needs to make sure that there is no coolant in the engine,

and also check the ignition timing.

P0421

Literally, the code P0421 stands for "too low heating efficiency of the catalyst device B1"

P0422

The combination of P0 422 or 0422 is associated with the low efficiency of the main catalyst

B1. The operating parameter of the device is below the acceptable threshold. The user needs to

check the catalyst assembly, as well as make sure that all lines of the system are intact.

Page 6

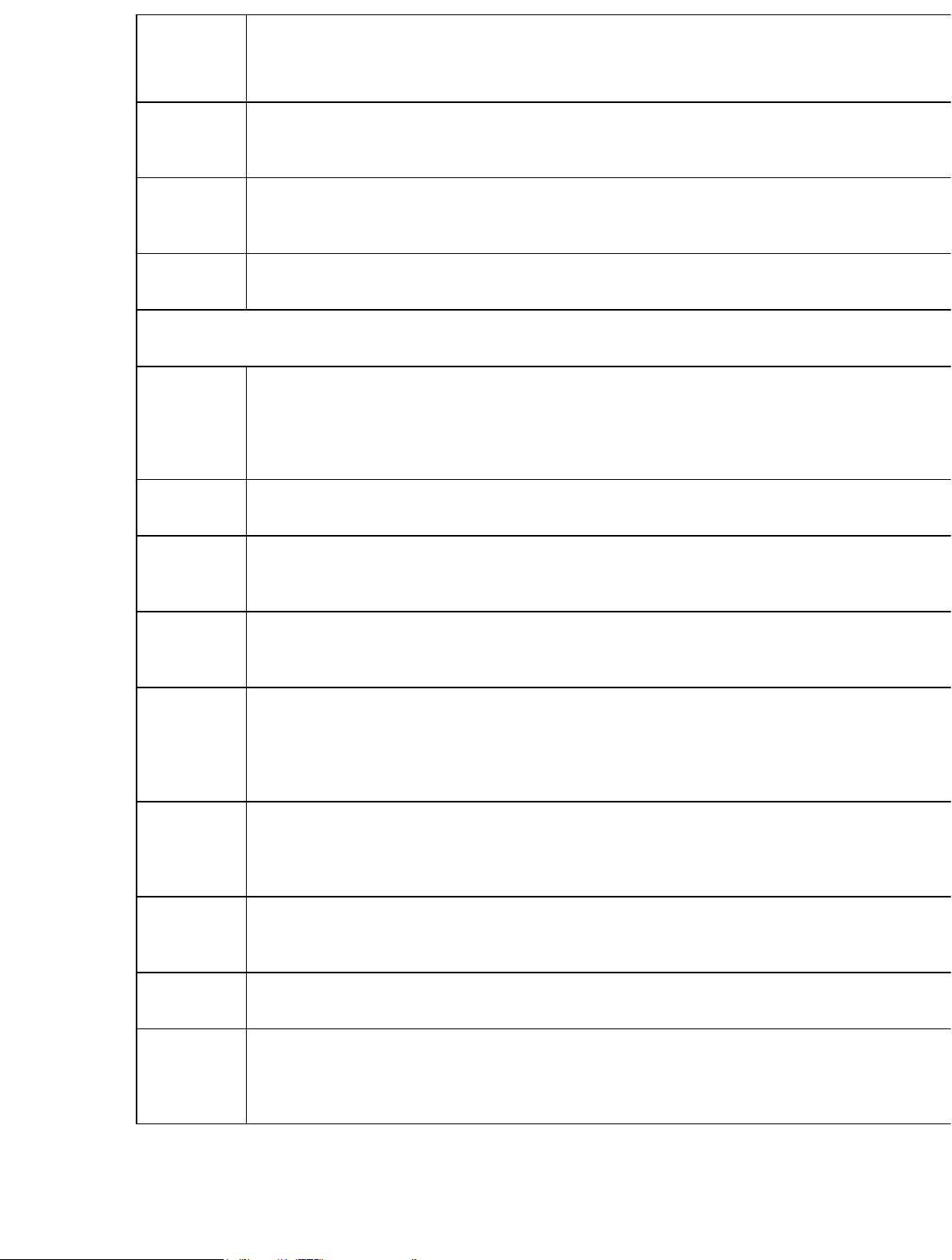

P0430

Code P0430 appears when the efficiency of the catalyst system B2 is reduced

P0670

Malfunctions or incorrect functioning of the glow plug control module. Motor failures are

possible. To fix the problem, you should check the quality of the connection of all wires to the

candle control module.

P1119

The control unit reports malfunctions in the operation of the fuel control solenoid valve

P1123

P1123 or 1123 combinations appear as a result of the re-enrichment of the air-fuel mixture in

one of the engine cylinders

R1183

Fuel pressure regulator stuck open. The error may be due to injector malfunctions.

P1190

Failure or incorrect operation of the intake throttle drive mechanism. The cause of the problem

may be in the electric motor of the device.

P1193

The control unit recorded a reduced engine speed that does not correspond to the normalized

parameters. The user is advised to first check the operation of the idle speed sensor.

P1335

Throttle actuator control system malfunction. With error 1335, the damper position is out of

range.

P1402

Error P1402 is associated with a malfunction in the catalysis system.

P1403

Code 1403 is associated with a malfunction in the valve of the leak diagnostic module

P1505

Vehicle idle control system works in adaptive mode

P1513

The on-board computer reported a malfunction in the IMRC intake manifold control. The

problem lies in the second bank of the engine - the node is stuck in the closed position.

P1553

Code 1553 appears when the idle system valve is permanently closed. The cause of the problem

may lie both in the sensor itself and in its wiring.

P1890

Malfunction in the operation of the clutch that determines the engine torque. The lower limit of

the operating parameter does not correspond to the normalized indicators. It is recommended to

check the quality of the contact, as well as the mechanism itself. The cause of the problem may

be in the 4WD control module.

P2002

The error appears only on cars with a diesel power system and reports a failure of the particulate

filter. A detailed diagnosis of the cleaning device is required and its replacement if necessary.

Page 7

P2096

Code P2096 or 2096 appears when the air-fuel mixture in the cylinders of the power unit is lean.

Information is sent to the control unit from oxygen controllers that detect an excess of oxygen

and a shortage of fuel in the exhaust gases.

Possible causes of the problem:

the appearance of cracks in the exhaust manifold;

damage to gaskets or sealing rings;

contamination of fuel injectors;

failure or incorrect operation of the fuel pump;

clogged fuel or air filter;

failure or malfunction of the fuel pressure sensor.

P2106

The error is related to the forced voltage limitation in the throttle device drive system. The code

appears when the motor torque, measured as a result of wiring damage, exceeds the allowable

values for a particular crankshaft speed and gas pedal position. The cause of the problem may be

poor contact or an open and short circuit in the power line of the electric motor.

P2113

Code 2113 reports a malfunction in the operation of the throttle assembly, the user needs to

check the operation of the damper

P2119

Error P2119 indicates a malfunction in the throttle assembly. The cause of the problem may be

an incorrect signal coming from the device, as well as damage to the throttle body. It is

necessary to make sure that the integrity of the electric motor, high-quality contact, and also that

the adaptation of the assembly was performed correctly.

P2187

When code P2187 appears, the engine control unit reports a lean air-fuel mixture in the engine

cylinders when driving at idle. The combination is fixed with a working MAP sensor, as well as

working temperature controllers for antifreeze and afterburning fuel vapors.

Possible reasons for the appearance of code 2187:

air leakage as a result of damage to one of the highways;

fuel pressure does not correspond to normalized indicators;

stuck PCV valve;

coking of injectors.

P2188

The P2188 combination appears when the air-fuel mixture in the cylinders of the power unit is

re-enriched .

Reasons for the appearance of error 2188 on cars 2004, 2005, 2009 and other years of

production:

1. Clogged air filter located in the engine compartment. The device must be cleaned or replaced.

2. Clogged fuel pump or its incorrect operation. Perhaps the cause of the problem is a breakdown

of the fuel pressure sensor in the fuel line.

3. Malfunction of nozzles, due to which the adjustment of the composition of the combustible

mixture is violated. Devices are subject to detailed diagnostics using a stand.

Page 8

4. Malfunction of air pressure controllers or flow meter. Sensors should be replaced or cleaned if

appropriate.

P2189

Lean air-fuel mixture when the engine is idling. The problem should be sought in the second

bank of the power unit.

P2191

Code P2191 (2191) is associated with a lean air-fuel mixture when the engine is running at high

loads

P2192

The P2192 combination appears when the air-fuel mixture is enriched at high engine loads

Code

Sensor malfunctions

134

Complete failure or problems in the functioning of the oxygen controller

P0036

Error P0036 appears when the oxygen controller does not work correctly. The user needs to run

diagnostics on all sensors, since the regulator number is not indicated.

P0105

Error P0105 is associated with a breakdown of the air pressure regulator. It is necessary to test

the operation of all connectors and wires connected to the controller.

P0130

The combination P0130 (0130) appears in the event of a malfunction of the first oxygen sensor

installed in bank 1 of the engine. If the error is not related to a breakdown of the lambda probe,

then the cause should be sought in the wiring or poor-quality contact of the regulator with the

wiring.

P0133

Code P0 133 indicates a slow response of the oxygen regulator 1 installed in the first bank of the

engine. As a result of the appearance of error 0133, problems with the formation of the air-fuel

mixture are possible.

P0135

Code P0135 reports a malfunction associated with the heating element of the first lambda probe

installed in bank 1

P0136

Malfunction of the second oxygen regulator installed in the first bank of the engine

P0141

Combination P0141 is associated with a malfunction of the heating mechanism of the second

oxygen controller installed in the first bank. Sometimes the cause of error 0141 is the sensor

itself or its poor contact with the car's on-board network.

Page 9

P0156

On Santa Fe 24l Diesel and other versions of Hyundai, this code appears when the second

lambda probe fails or malfunctions. This refers to the controller located in the second bank.

P0335

Code P0335 is fixed by the control unit in the event of a failure of the crankshaft position sensor

A. To fix this problem, you need to test the operation of the controller and diagnose its wiring.

Clogged sensor connectors must be cleaned or replaced. Error code 0335 may be due to worn

insulation on the device's power wire.

P0336

Malfunction in the operation of the engine crankshaft position sensor A. The on-board computer

clarifies that the reason is related to the omission of one tooth on the shaft. The user should

check the crankshaft and camshafts, and then test the controller itself.

P0340

camshaft controller malfunctions . To fix the problem, remove the sensor and clean its contacts,

since it is located in such a way that dirt can remain on the connector in rainy weather.

P0507

The on-board computer recorded malfunctions in the idle speed sensor - the engine speed is too

high. With error P0507, it is necessary to check the controller and its connection, damaged

contacts and wires are replaced with new ones.

P0660

Malfunction in the operation of the adjusting valve for changing the length of the intake

manifold

P0707

Reduced pulse coming from the transmission unit controller. For errors P0707 or 0707, it is

necessary to check the operation of the gearbox sensor, as well as the control module of the

device.

P0711

The combination 0711 appears when the readings from the gearbox oil temperature controller

are incorrect. The cause of the problem may be that the device is out of adjustment.

P0717

Error P0717 is associated with a malfunction of the turbine speed controller. From this device,

no signal is sent to the control unit, which may also indicate damage to the wire or poor

connection of the regulator.

P0750

Failure or incorrect operation of the switching device A of the solenoid

P1128

Code P1128 or 1128 appears when there is a breakdown or malfunction of the top-level

controllers with heated oxygen

P1131

The on-board computer, with error P1131, cannot determine the presence of a heated oxygen

controller switch. The data coming from the regulator indicates the depletion of the air mixture

in the first bank of the engine.

Page 10

P1166

Code P1166 appears when the oxygen controller installed in the first bank of the engine

malfunctions.

Possible reasons for the appearance of code 1166:

the appearance of air leakage in one of the highways;

poor connection of vacuum pipes or their damage;

mechanical failure of one of the elements of the exhaust system to the catalyst device;

malfunction or clogging of the throttle, cleaning may be required to fix the problem;

clogged air filter.

P1167

Combination 1167 appears when the oxygen regulator breaks down

P1180

Malfunctions in the fuel pressure regulator

P1181

Code 1181 appears when the fuel pressure sensor fails

P1186

Error P1186 appears as a result of a breakdown or incorrect operation of the fuel pressure

sensor. With code 1186, the cause of the problem may be a broken wiring or damaged contacts

on the regulator.

P1187

Code P1187 indicates a malfunction of the fuel pressure regulator. With such an error, the valve

of the device will be stuck in the open or closed positions.

R1189

The on-board computer detected a malfunction in the fuel pressure sensor. The readings sent by

the controller deviate from the normalized parameters at a high speed of the power unit.

P1307

Rough Road Sensor Malfunction

R1309

Failure or malfunction of the acceleration controller

R1507

Literally, this code stands for "too low signal in the idle speed sensor drive circuit in the second

winding."

Possible reasons for this error:

breakage of the idle speed controller fuse, if the car is equipped with it;

damage to the cable or its breakage in the area from the sensor to the control module;

failure or clogging of the fuel filter device, which led to a decrease in pressure in the system;

mechanical damage to the idle speed sensor housing;

damage to the contact elements of the controller;

sticking of the controller in one of the positions, which led to the fact that the power unit could

not gain momentum;

damaged cable for powering the device from the battery;

too high resistance of the touch device on the controller;

Page 11

malfunction of the control module of the power unit;

failure of the idle speed sensor servo.

P1605

Malfunction of the knock control sensor, this problem is accompanied by the following

"symptoms":

difficulty starting the power unit;

“ triple ” of the motor, the appearance of a metallic knock of “fingers” from under the hood at

high loads;

reduction in engine power.

P1624

The on-board computer detected malfunctions in the operation of the engine cooling fan at the

first speed.

Possible reasons for the appearance of this code:

relay malfunction;

failure of the fan itself, in particular, its electric motor;

malfunction of the engine control unit.

P2122

Malfunction of the controller for turning off the position of the gas pedal or throttle valve. It is

recommended to diagnose both sensors, as well as check their wiring and the quality of the

connection to the mains. The cause of the problem may be dirt sticking to the pad contacts.

P2159

Error P2159 reports a malfunction or malfunction of the sensor speed controller installed on the

wheel. On cars made in 2011 and other years of production, this problem can usually be solved

by cleaning the contact elements on the device connection block.

B1214

Malfunctions in the operation of the rear left sensor. It is necessary to check the operation of the

ABS controller installed in the wheel. A possible cause may be a damaged power cable of the

device or poor contact with the network. Also, the problem may be clogging of the contact

elements on the connection block.

B1329

Malfunction of the front impact controller located on the driver's side. The cause of the problem

may be a communication failure.

C1200

Malfunctions in the speed controller of the front left wheel. The cause of the problem may be a

broken wiring or damage to the pad, so you should check the integrity of the electrical circuit

and connector.

C1201

Error C1201 Indicates a malfunction in the front left wheel rotation controller.

C1202

Breakage or incorrect operation of the front left wheel speed controller. Diagnostics of all

contacts on the sensor connector is required, as well as checking the quality of its connection.

The cause of the problem may be clogging of the contact elements.

Page 12

C1203

Malfunction of the speed controller installed on the front right wheel

C1204

Another error code that reports a malfunction in the anti-lock braking system sensor installed on

the front right wheel

C1205

Malfunction of the controller of frequency of rotation of the right forward wheel

C1206

Error C1206 indicates problems with the rear left wheel speed controller. The cause of the

malfunction may be a broken or damaged wiring, as well as a short circuit in the power supply

circuit of the device.

C1208

Malfunction of the sensor of frequency of rotation of a back left wheel

C1209

Failure or malfunction of the speed controller mounted on the rear right wheel

C1210

Failure or incorrect operation of the speed controller located on the rear right wheel

C1211

Another error regarding the rear right wheel speed controller

C1213

Failure or incorrect operation of the traction control controller .

Possible reasons for the error:

failure of the sensor itself;

incorrect installation of the controller or its incorrect connection;

failure of the rotor mechanism and wheel bearing.

C1245

Malfunction of the left traction control controller

C1274

ABS sensor failure

C1283

Vehicle yaw controller malfunction. The cause of the problem should be sought in the sensor

itself, its wiring and block.

C1290

Damaged or incorrect operation of the steering angle sensor

C1292

The on-board computer indicates a malfunction in the functioning of the torque controller. The

cause of the problem is the failure of the main or auxiliary signals, or both pulses at once.

C1513

Malfunction of the switch installed on the brake pedal. The cause of the problem may be due to

clogged pins on the sensor connection block, so first you should check the connector.

Page 13

C2380

Error in the operation of the traction control valve . The device is subject to detailed diagnostics

and replacement in case of breakdown.

U0126

Steering angle communication failure. The user needs to test the operation of the 4WD module,

since he does not see a pulse from the sensor.

U1111

Damage to the battery sensor (battery). With such a malfunction, the battery icon on the

dashboard may light up, even if the device is charged.

Code

Electrical and electronic faults

P250C

Reduced voltage recorded on the power line of the engine fluid level controller. It is necessary

to check all the connectors and the integrity of the wires, and then diagnose the sensor itself.

P0030

Faulty oxygen sensor heating element power cable. The number of the lambda probe is not

indicated, so the user needs to look for the controller on their own.

P0031

The error is related to damage or breakage of the wiring that feeds the heating element of the

oxygen regulator installed in the first bank. The cause of the problem may be the low voltage

fixed on the power line of the device. If the wiring is intact, then the oxygen controller must be

replaced.

P0032

The on-board computer recorded an increased voltage on the control line of the heating device

of the oxygen regulator 1 installed in the first bank.

Possible reasons for the appearance of the code P0032:

cable breakage of the heating element of the oxygen regulator or short circuit in the line;

malfunction of the heating device;

poor-quality contact or disconnection of the controller power wire;

failure or incorrect operation of the ECM or PCM modules.

P0037

On Hyundai Elantra 4 2010 and other years of production, this code reports a low voltage

registered on the control line of the heater device of the second lambda probe. It is necessary to

test in detail the sensor located in the first bank.

P0038

Increased voltage recorded by the on-board computer on the power line of the lambda probe

heating device. With error P0038, the Check Engine indicator is always on on the instrument

cluster .

Page 14

P0047

Malfunction or incorrect signal fixed on the power line of the turbocharger pressure control

solenoid valve

P0056

On the Hyundai Sonata 5, Elanta J3 and other car models, this code indicates a failure in the

heating circuit of the second oxygen controller. This refers to the lambda probe located in the

second row of cylinders.

P0077

Damage to the line of the solenoid valve at the inlet

P0079

Breakage or damage to the cable supplying the electromagnetic exhaust valve installed in the

first row of cylinders

P0102

Error P0102 appears with a reduced pulse coming from the flow meter. It is recommended to

clean the mass air flow sensor before replacing it, a special carburetor cleaner can be used to

complete the task.

P0101

The malfunction is related to the out-of-range range of the signal coming from the mass air flow

sensor

P0106

Error P0106 or 0106 appears as a result of the air pressure controller pulse going out of the

normalized range

P0108

On the 2001 Sonata EF and other models, code 0108 reports an increased signal from the

airflow pressure controller. It is necessary to diagnose the flow meter and its contacts. The cause

of the problem may be a clogged sensor, a carburetor cleaner can be used to remove

contaminants.

P0113

The car's on-board computer detected a too high signal on the power line of the intake air

temperature controller

P0116

The on-board computer has registered a signal from the antifreeze temperature controller in the

cooling system that goes beyond the normalized values. It is necessary to check the operation of

the sensor and the resistance on the electrical circuit of its power supply. Perhaps the cause of

the problem is not in the device, but in the use of low-quality refrigerant.

P0117

Reduced pulse coming from antifreeze temperature controller

P0118

The engine control unit detects an increased signal coming from the antifreeze temperature

regulator

P0121

Code P0121 is associated with a malfunction in the wiring that feeds the throttle position

controller A. The pulse supplied from the sensor is out of range.

Page 15

P0123

Increased voltage on the power line of the throttle position regulator A. With such an error, the

cause of the problem may be the resistance of the wire and the oxidation of the contacts, or

damage to the insulating layer.

P0132

Increased signal level coming from the first lambda probe located in bank 1 of the engine

P0134

Error P0134 indicates that the output pulse of the first lambda probe is not active. If there is no

signal, the cause must be sought in the wiring or contacts of the device.

P0138

Code P0138 indicates an increased level of the output pulse coming from the second oxygen

controller installed in the first bank of the engine

P0139

Malfunctions associated with the electrical circuit or the oxygen sensor 2 itself, installed in the

first bank. The device is giving an incorrect signal with too slow a response to a rich or lean airfuel mixture.

P0140

Code P0140 is associated with the lack of activity of the output pulse of the second oxygen

controller installed in the first bank of the engine

P0183

Increased pulse level recorded in the electrical circuit of the temperature controller A

P0193

Increased pulse coming from the fuel pressure controller in the fuel rail. It is necessary to check

all the contacts of the sensor and make sure the integrity of its wires.

P0230

Error P0230 appears as a result of damage to the power cable of the primary control circuit of

the fuel pump. A possible cause may be the fuel pump relay control circuit.

P0320

Code P0 320 appears when the power line of the ignition switchgear is damaged. It is necessary

to check all contacts of the distributor and clean or replace them if necessary. First of all, with

error 0320, it is necessary to diagnose high-voltage wires.

P0325

Code 0325 appears when there is a malfunction in the electrical circuit of the first knock

controller

P0326

Combinations P0326 or 0326 appear as a result of an incorrect pulse supplied from the first

detonation regulator. Sensor 1 must be checked for integrity and its operating parameters of

voltage and resistance should be compared with the normalized ones (the latter are indicated in

the service manual).

If the sensor is really faulty, this may be accompanied by the following symptoms:

tripping of the engine when driving at idle;

reduction in the power of the power unit;

spontaneous engine stop in traffic jams, at traffic lights;

increase or decrease in idle speed.

Page 16

P0339

The P0339 combination appears when the signal from the crankshaft position controller A is

incorrect

P0341

Error P0 341 indicates that the pulse supplied to the control device from the camshaft controller

is out of performance range

P0342

Errors P0342 or 0342 indicate a low signal coming from the camshaft controller

P0343

The P0343 combination indicates a too high pulse level coming from the engine camshaft

controller

P0350

Damage or short circuit on the primary or secondary line of the ignition coil

P0404

The pulse from the EGR controller is out of performance range. With error P0404, a detailed

check of the sensor and the wiring going from it to the control unit is performed.

P0405

Low voltage on the line of the EGR controller. The cause of the problem may lie in the drive

device of the system, as well as the position line of the electric motor.

P0449

Violation of the integrity or operation of the power line of the canister purge solenoid valve

circuit. If, with error P0449, the cable is intact, it is necessary to test the operation of the valve

itself.

P0489

Low voltage on the EGR sensor circuit

P0500

The on-board computer determined the absence of a pulse from the vehicle speed controller to

the motor control unit

P0501

Code P0 501 appears as a result of an incorrect signal from the speed controller. The pulse from

the sensor is outside the operating range.

P0504

Code P0504 appears when there is a mismatch between the signals of the sensors installed on

the brake pedal

P0560

Code P0560 indicates a too low supply voltage that does not correspond to the normalized

indicators

P0562

Code 0562 is associated with a low system supply voltage.

Possible causes of the problem:

discharge of the battery or its mechanical damage, which led to the leakage of electrolyte;

Page 17

malfunction of the generator device (voltage regulator relay, clutch or other structural

components of the unit).

P0605

Microprocessor module internal memory error

P0611

Malfunction of the injector control module. The cause of the problem may lie in the unit itself or

a short circuit in the power circuit of the devices.

P0620

Damage to the wiring through which the generator unit is connected. With such a problem,

power surges in the car's electrical network are possible. The user needs to check the battery, as

well as the generator device, diagnose all the wires connected to the node.

P0650

Error P0650 is associated with damage or malfunction of the power line of the malfunction

indicator light. The user needs to check the operation of the MIL device, make sure that it is in

good contact with the wiring.

P0703

The on-board computer detected problems with the integrity of the power line of the controller

In reducing the torque during braking

P0704

Code P0704 appears as a result of a malfunction or damage to the wiring that feeds the clutch

controller.

Possible causes of the problem:

the sensor itself is faulty;

damage to the cable or wear of the insulating layer;

ingress of moisture, dirt or dust on the contact elements of the sensor connector;

damage to the pins on the block of the device;

incorrect operation or failure of the microprocessor module.

P0705

Damage to the power line of the transmission sensor. The causes of the problem may be the

same as in the case of the clutch controller.

P0708

Transmission controller sends signal too high

P0715

Error P0715 appears when the power line of the turbine speed controller is damaged or broken

P0720

Damage or breakage of the cable supplying the speed sensor of one of the shafts. With error P0

720 (0720), a detailed check of the conductor for integrity is required.

P0721

Error P0 721 means an incorrect pulse recorded on the power line of the speed controller

P0722

Combination 0722 appears when there is no signal from the shaft speed controller

Page 18

P1116

The control unit registered an opening in the heating circuit of one of the oxygen controllers.

The regulator number is not specified, so the user will have to look for a damaged cable on their

own.

P1120

Code P1120 appears when the signal from the throttle position sensor is incorrect

P1134

Malfunction of the oxygen sensor activation timer. If the lambda probe turns on at the wrong

time, this will affect the formation of the air-fuel mixture and the ratio of air and fuel in it.

Accordingly, such a problem can lead to a decrease in engine power.

P1135

The on-board computer reports a malfunction in the power line of the air or fuel controller

heating system. The user needs to check both sensors, as well as the quality of their connection

to the car's electrical network.

P1324

The P1324 combination reports a malfunction of the temperature switch

P1500

Code P1500 is the result of damage or a break in the power line of the fuel pump relay. In some

cases, the reason is a malfunction of the relay or fuse responsible for the operation of this node.

P1502

This OBD2 code indicates a short to +12 volts in the fuel pump relay. The first thing to do in

such cases is to check the operation of the safety elements, relays and contacts in the sockets.

R1503

Immobilizer malfunction , possible causes of malfunctions in the operation of the engine

blocker:

software failure;

breakage or mechanical damage to the microcircuit;

malfunction of the engine control unit;

mechanical damage to the key, antenna failure or battery discharge;

damage or breakage of the switching buses responsible for the exchange of information between

the engine blocking elements.

P1520

Code P1520 reports a malfunction in the intake manifold control power line

P1593

Literally, this code translates as "unreliable automatic recognition of 2WD / 4WD systems." The

cause of the malfunction may lie in the wire of the recognition system itself, as well as in

damage to the electrical circuit of the communication line via the digital interface. Also, the

problem may be a malfunction of the ECM.

P1609

Lack of communication or loss of signal between the engine control unit and the immobilizer

P1610

The OBD 2 error P1610 (1610) appears as a result of a communication failure between the

microprocessor engine control module and the engine blocker. The cause of the problem in

practice is usually interruptions or increased voltage.

Page 19

P1616

The microprocessor module reports malfunctions in the coding memory in the engine control

unit

P1623

Breakage or damage to the power line of the fault indication lamp " Check Engine ". When error

P1623 (1623) occurs, the user needs to test the power line of the indicator light installed on the

dashboard.

P1630

Short circuit in the power circuit of the fan relay. The cause of the problem may be a broken

wiring, so the line should be diagnosed for integrity.

R1672

The control light for low engine fluid pressure is out of order or does not function correctly. A

detailed check of the wire and light bulb connected to the instrument cluster is required.

R1675

Evaporative Emission System Solenoid Control Circuit Faulty, Wiring Diagnosis Required

P1676

Immobilizer malfunction , diagnostics of all components of the engine blocking system is

required. With error P1676, it may be difficult to start the power unit.

P1678

Literally, the code P1678 translates as " immobilizer , no signal or request from the EMS

module." The most likely cause of the problem is a damaged communication line, so the user

needs to diagnose the pads for disconnection, poor contact and bends. If there are signs of

corrosion on the contacts, the block must be replaced.

R1689

Malfunction in the error memory module

P1690

Faulty diagnostic indicator light. If error P1690 appears, you should check the bulb's

performance, and also make sure that the wiring and contacts on the connection block are intact.

P1692

Engine lock indicator light malfunction

P1693

Code P1693 (1693) reports incorrect operation of the MIL bus or controller. The cause of the

problem is due to an overestimated signal coming from the device. The user needs to check all

the wires and contacts on the connection block, and also make sure that the cables are intact.

P1695

Combination P1695 (1695) reports an internal malfunction of the immobilizer EMS memory

P1696

With errors P1696 or 1696, the vehicle's on-board computer reports that the engine lock key is

not recognized by the control module. It is necessary to look for the cause of the problem in the

immobilizer control unit and its contacts.

P1709

The P1709 combination appears when the parking radar switch malfunctions. The device does

not work or does not show the neutral position during self-diagnosis.

P1726

The on-board computer reports the absence of a signal at the input of the TPS module

Page 20

P1752

General error indicating an unreliable signal in the power supply system

P1765

Error P 1765 appears when the wiring for reducing engine torque is damaged, there may be

problems in the operation of the power unit

P1771

The P1771 combination appears when the EMC module is arbitrarily turned off

P1801

When registering error P1801, the engine control module reports malfunctions in the

immobilizer . Code 1801 is usually associated with the use of an immo bypass block .

P1805

Codes 1801 and 1805 are associated with incorrect immobilizer operation . If, with error P1805,

the engine does not start, you need to check the operation of the blocker. Perhaps the cause of

the problem is the discharge of the battery installed in the key.

P1820

The on-board computer recorded too high a current level on the electric motor of the pumping

device for the 4WD system. The cause of the problem may be a lack of contact, a broken or

shorted wiring. If the cable is intact, then the fault should be sought in the internal fault of the

coupling.

P1830

4WD Module Clutch Malfunction

P1822

Open load of pump electric motor wiring for 4WD system. The user needs to check the contact

elements, the integrity of the wiring, and also diagnose the coupling for internal faults.

P1843

Invalid pulse from powertrain coolant temperature controller

P2015

Wiring fault or incorrect signal detected on the controller circuit or switch of the intake

manifold length change system

P2017

The on-board computer registered an increased voltage level on the supply line of the intake

manifold length sensor. It is required to check the working element of the adjustable swirl valve

position controller.

R2095

If the on-board computer issues code 2095, this indicates damage to the camshaft position

actuator control circuit

P2118

An out-of-spec signal has been detected on the throttle control circuit. The performance of the

node control motor is reduced.

P1221

The microprocessor module reports a lack of communication with the throttle valve

P2271

On Hyundai NF and other models with a gasoline or diesel engine, this code indicates the

absence or incorrect signal coming from the oxygen controller 1 installed in the first bank of the

engine. A detailed diagnosis of wiring and connection quality is required.

Page 21

P2454

The error indicates a fault in line A of the differential pressure controller installed on the CPF

filter unit. The on-board computer notes that too high a signal is detected on this circuit, which

may be associated with cable damage or disconnected contacts. The reason may be the wear of

the insulation on the electrical circuit , as a result of which the resistance changes on the line.

B1102

Vehicle battery voltage is too low. It is necessary to check the battery, as well as the operation

of the generator set.

B1112

Low voltage in the electrical circuit of the ignition system

B1238

Break in the wiring supplying the outdoor temperature controller

B1346

Code B1346 is associated with an increased resistance level in the driver's airbag circuit . The

module itself is located in the center of the steering wheel under the plastic upholstery. High

resistance may be due to damage to the insulating layer of the cable that feeds the pillow, as

well as clogged contacts.

B1367

Increased resistance value recorded on the power line of the seat belt pretensioner on the front

passenger side.

Possible causes of the problem:

poor connection of the device or its arbitrary disconnection as a result of vibrations during

movement;

lack of contact between the shunt jumper and the release rod of the device;

malfunctions in the operation of the RVRT control module;

malfunction of the SRSCM device.

B1406

Malfunction in the operation of the sensor of the security system designed to detect the front

passenger. It is necessary to diagnose the contacts and the power circuit of the device.

B1462

On Hyundai Sonata EF 2006 and other years of release, this code appears when the power line

of the passenger presence controller is interrupted

B1511

Short circuit in the power line to the battery of the seat belt switch, installed on the driver's side

B1620

Internal malfunction of the SRS system. If the airbag sensors and pretensioners are intact, the

node control module needs to be diagnosed.

B1701

Increased voltage level on the power line of the tensioner element of the strap bracket on the

driver's side. It is necessary to test the wiring supplying the pretensioner for breaks and short

circuits.

B1706

Increased resistance in the front passenger's seat belt buckle tensioner line

Page 22

B2406

Malfunctions in the electric motor of the air mixing damper of the air conditioning system.

Possible causes of the problem:

poor-quality contact in the wiring harness for connecting the electric motor;

open or short circuit in the electric motor power supply circuit ;

malfunction of the air mixing drive device on the driver's side;

malfunction or breakdown of the air conditioning control unit.

B2500

Code 2500 indicates a malfunction in the operation of the air bag control indicator. The user

should diagnose the wiring that feeds the light bulb, and also check the operation of the control

unit if the electrical circuit is intact.

B2503

Malfunction or absence of a signal from the warning indicator SRS - security systems

B2505

Failure of the airbag deactivation indicator light

C1103

General voltage error in the ignition system. The cause of the problem may lie both in the

battery with the generator set, and in the lock itself. You should check all the contacts of the

switch and its power contacts.

C1616

Error C 1616 is the result of a disconnection or inoperability of the CAN interface. It is

necessary to check all the connectors on the wires connected to the microprocessor module.

C1259

Malfunction or damage to the power supply circuit of the steering wheel position regulator.

The following components need to be checked:

a harness with power wires for a short circuit or open circuit;

harness with "ground" cables for possible damage or short circuit;

steering angle controller;

EPS system control unit.

C1260

Damage to the power supply line of the steering wheel controller. If, with error C 1260, the

sensor itself is working, it is necessary to calibrate it.

C1274

Open or short circuit in the electric circuit of the longitudinal acceleration controller

C1503

Malfunction of the switching device of the ESP module. The cause of the problem may be the

switch itself, as well as an open or short circuit in the power line.

C1555

Code C1555 appears as a result of welding of the contact elements of the relay of the electric

motor or the electric motor of the power steering mechanism. The relay is located in the

microprocessor module and must be replaced in case of failure.

Page 23

C1604

EPS unit hardware failure. To begin with, you should check the quality of the connection of the

device, but, most likely, the module of the electric power steering system will have to be

changed. In some cases, flashing the device can fix the problem .

C1611

Literally, the code C1611 stands for "timeout of the signal from the electronic control unit

(ECU) of the engine on the CAN bus." This means that the microprocessor-based electric power

steering control module does not receive information from the motor ECU. It is necessary to

check all wiring and connectors and change the amplifier control unit if necessary.

C1627

Code C1627 appears as a result of a lack of communication via the CAN interface with the

4WD control module. To fix the problem, the user needs to diagnose all the wires and contact

elements on the block connector.

C1652

The on-board computer reports a CAN interface signal error

C1702

Error C1702 can literally be translated as "failures in the coding of the variant." The fault is

network and usually consists in damage to the contacts on the CAN interface of the transmission

unit control module.

C2112

Faulty electronic valve relay. The user needs to look for an open or short in the IGN+ power

circuit .

C2402

Error C2402 reports a break in the winding of the traction control motor . A possible cause may

be damage to the case of the device and water getting inside. To eliminate the malfunction, it is

necessary to dismantle and disassemble the module, followed by cleaning the brushes.

U0001

Disabling the high speed CAN interface

U0003

Lack of communication with digital CAN interface. The user needs to check all the wires and

connectors connected to the control module.

U0004

Too high speed detected on the data bus line of the digital CAN interface

U0008

Malfunction in the high speed CAN bus - the on-board computer detected an increased voltage

on the line

U0009

Diagnostics of the CAN digital interface is also required, since the signal passing on the line

does not correspond to the normalized parameters. With error 0009, the connector of the engine

control unit is checked first.

U0010

The average speed of the CAN interface does not correspond to the normalized indicators. It is

recommended to check the diagnostic connector and clean it to remove contaminants from the

contacts.

Page 24

U0019

This fault indicates a reduced data rate on the CAN switching bus. The cause of the problem

may be damaged or clogged contacts on the connectors, as well as a short circuit.

U0101

Disruption or lack of communication between the engine control modules and the gearbox via

the CAN bus. Possible causes may be malfunctions of the speed controllers of the primary or

secondary shafts, as well as the drive mechanism.

U1112

Loss of communication with the LIN interface. To fix the problem, the user needs to diagnose

each module connected to the LIN interface, as well as the battery sensor.

U1451

The control unit does not receive a signal from the control module of the passive anti-theft

system PATS. The on-board computer clarifies that the device's electric motor is turned off.

U0D00

General digital CAN interface error

Code

Transmission malfunction

P0218

Overheating of the transmission unit.

Possible causes of the problem:

use of low-quality or expired transmission fluid;

failure of one of the gearbox sensors;

incorrect operation or malfunctions in the operation of the transmission unit control unit;

malfunction or breakdown of the torque converter.

P0700

The P0700 combination indicates problems with the transmission control system. With error

0700, it is recommended to check the control module with the transmission unit, as well as to

diagnose all the contacts of the block. A possible cause may be damaged wires.

P0701

The control system of the transmission unit is out of the range of permissible characteristics, an

incorrect signal is given from the control module device

P0702

Malfunction of the electric transmission control system

P0705

Damaged wiring or malfunction of the box sensor

P0706

The transmission controller is not working properly or the device is out of adjustment

Page 25

P0707

Reduced value coming from the transmission sensor

P0713

The error indicates overheating of the transmission oil or incorrect readings from the lubricant

temperature sensor.

Possible causes of code P0713:

breakdown of the oil temperature controller in the gearbox;

poor sensor connection, damage to contacts, broken wiring;

wear of the oil filter in the transmission unit;

use of low-quality or expired transmission fluid.

First of all, it is recommended to check the quality of the consumables. If traces of deposits and

sediment are visible in the oil, then the fluid must be replaced.

P0730

Generic code indicating lack of vehicle gearbox adjustment

P0731

The combination indicates incorrect first gear adjustment. It is necessary to diagnose the control

module as well as the drive unit and the transmission selector.

P0732

Code P0732 is associated with incorrect adjustment of the second gear. With error 0732, the

user is advised to check the transmission control unit.

P0733

Code P0733 appears when the third transmission speed is incorrectly adjusted

P0734

The combination P0734 (0734) appears as a result of incorrect adjustment of the fourth gear.

The troubleshooting steps are similar.

P0753

Shift Control Solenoid A Malfunction

P0885

Transmission control error. The cause of the malfunction should be sought in the power relay of

the gearbox control module.

P1529

Code P1529 reports damage to the automatic transmission control module. Fault 1529 may be

due to poor or broken communication between the engine ECU and the transmission.

R1586

Combination 1586 appears as a result of an automatic or manual transmission signal coding

failure. In some cases, the cause of the problem is a component failure in the powertrain control

module. Sometimes an error appears when the connection to the “ground” of the output or the

electrical circuit for automatic recognition of the electronic engine control unit is poor.

P1728

Literally, the code P1728 stands for "transmission slip error". It is recommended to check the

operation of the transmission unit drive, as well as the device control unit.

Page 26

P1766

This code appears if the engine does not receive information and requests from the transmission

to reduce torque at the time of gear shifting. Because of this problem, shocks and jerks are

possible when turning on the speed. It is required to check all the connectors connected to the

transmission control unit.

Loading...

Loading...