Hyundai Dynamic auto 350M Operation Manual

Visit our website at

www.HDWELD.co.kr

VER 2. 0

2007. 7

DYNAMIC AUTO

350M/500M

OPERATION MANUAL

HEAD OFFICE: ILSONG BLDG. 16th fl.157-37,

SAMSUNG-DONG, KANGNAM-KU, SEOUL, KOREA

TEL : (+82-2)6230-6062~5 FAX: (+82-2)522-2030

FACTORY : 9-2, SAEUM-DONG, ICHEON-SI, GYEONGGI-DO, KOREA

TEL : (+82-31)636-3100 FAX: (+82-31)636-3957

www.hyundaiwelding.com

- 1 -

TABLE OF CONTE NTS

SECTION 1 - SAFETY PR E CAUTIONS - RE AD BE FOR E U SING -----------------

2

1-1. Symbol Usage ------------------------------------------------------------- 2

1-2. Arc Welding Hazards -------------------------------------------------------- 2

1-2-1. Hazard in Welding Power While in Use ------------------------------------ 3

1-2-2. Hazard Around Working Area While in Use --------------------------------- 5

1-3. Additional Symbols For Installation, Operation, And Maintenance ----------------- 8

SECTION 2 - DEFINITIONS -------------------------------------------------

9

2-1. Manufacturer's Warning Label Definitions --------------------------------------- 9

2-2. Manufacturer's Rating Label -------------------------------------------------- 10

SECTION 3 - INSTALLATION ------------------------------------------------

11

3-1. Specifications --------------------------------------------------------------- 11

3-2. Duty Cycle And Overheating ------------------------------------------------- 11

3-3. Selecting A Location -------------------------------------------------------- 12

3 -3-1. Dimension and Weight --------------------------------------------------- 12

3 -3-2. Site Selection ---------------------------------------------------------- 12

3 -3-3. Transporting Methods ---------------------------------------------------- 14

3-4. Weld Output Receptacles And Selecting Cable Sizes ---------------------------- 14

3 -4-1. Weld Output Connections ------------------------------------------------ 15

3-5. Receptacle Information ------------------------------------------------------- 17

3 -5-1. DYNAMIC AUTO 350M -------------------------------------------------- 17

3 -5-2. DYNAMIC AUTO 500M -------------------------------------------------- 17

3-6. Electrical Service Guide ------------------------------------------------------ 18

3-7. Connecting Input Power ----------------------------------------------------- 18

3 -7-1. Electrical Input Requirements --------------------------------------------- 19

SECTION 4 - OPER ATION --------------------------------------------------

20

4-1. Front Panel Controls -------------------------------------------------------- 2 0

4 -1-1. DYNAMIC AUTO 350M --------------------------------------------------- 20

4 -1-2. DYNAMIC AUTO 500M--------------------------------------------------- 21

SECTION 5 - SEQUE NCE OF OPE R ATION -----------------------------------

22

5-1. Dynamic Auto 350M -------------------------------------------------------- 22

5-2. Dynamic Auto 500M -------------------------------------------------------- 24

SECTION 6 - PCB SETTING ------------------------------------------------

25

6-1. DYNAMIC AUTO 350M ------------------------------------------------------ 25

6-2. DYNAMIC AUTO 500M ------------------------------------------------------ 27

SECTION 7 - FUNCTION DIAGRAM ------------------------------------------

28

7-1. DYNAMIC AUTO 350M ------------------------------------------------------ 28

7-2. DYNAMIC AUTO 500M ------------------------------------------------------ 29

SECTION 8 - MAINTE NANCE & T R OUBLE SH OOTING --------------------------

30

8-1. Routine Maintenance -------------------------------------------------------- 30

8-2. Troubleshooting(Dynamic Auto 350M) ------------------------------------------ 30

8-3. Troubleshooting(Dynamic Auto 500M) ------------------------------------------ 34

SECTION 9 - ELE CTR ICAL DIAGR AM -----------------------------------------

36

9-1. DYNAMIC AUTO 350M ------------------------------------------------------ 36

9-2. DYNAMIC AUTO 500M ------------------------------------------------------ 37

SECTION 10 - PARTS LIST - ------------------------------------------------

38

10-1. Main Assembly-Dy namic Auto 350M ------------------------------------------ 38

10-2. Main Assembly-Dynam ic Auto 500M ------------------------------------------ 40

VER 2. 0

- 2 -

SE CTION 1 - SAFE TY PR E CAUTIONS

- R E AD BE FOR E USING

1-1. Sy m b o l Us a g e

The sy m b o l s sh o w n be l o w ar e u se d t h r o u g h o u t th i s ma n u a l to ca l l at t e n t i o n to an d id e n t i f y

po s s i b l e ha z a r d s . Wh e n yo u se e th e sy m b o l , wa t c h ou t , an d fo l l o w th e re l a t e d in s t r u c t i o n s to

av o i d t h e h a z a rd .

This safety alert symbol is used with the signal words DANGER and WARNING to

call attention to the safety statements.

DANGER statements identify procedures or practices which must be followed to avoid

serious personal injury or loss of life.

WARNING statements identify procedures or practices which must be followed to avoid

minor personal injury or damage to this equipment.

statements identify special instructions necessary for the most efficient

operation of this equipment.

1-2. Ar c W e l d i n g H a z ard s

Means Danger! Warning! Watch Out! There are possible hazards with this procedures!

The possible hazards are shown in the adjoining symbols.

This group of symbols means Danger! W arning! Watch Out! possible ELECTRIC

SHOCK and HOT PARTS hazards. Consult symbols and related instructions below for

necessary actions to avoid the hazards.

VER 2. 0

- 3 -

1-2-1. H a z a r d s i n W e l d i n g Po w e r S o u r ce Wh i l e i n Us e

DANGE R

ELE CTR IC SHOCK c a n k i l l .

Touching live electrical parts can cause fatal shocks or severe burns. The electrode

and work circuit is electrically live whenever the output is on.

The input power circuit and machine internal circuits are also live when power is on.

In semiautomatic or automatic wire welding, the wire, wire reel, drive roll housing, and

all metal parts touching the welding wire are electrically live. Incorrectly installed or

improperly grounded equipment is a hazard.

•Do not touch live electrical parts.

•Wear dry, hole-free insulating gloves and body protection.

•Insulate yourself from work and ground using dry insulating mats or covers big enough to prevent

any physical contact with the work or ground.

•Do not use AC output in damp areas, if movement is confined, or if there is a danger of falling.

•Use AC output ONLY if required for the welding process.

•If AC output is required, use remote output control i f present on unit.

•Disconnect input power or stop engine before installing or servicing this equipment.

•Properly install and ground this equipment according to its Owner's Manual and national, state, and

local codes.

•Always verify the supply ground-check and be sure that input power cord ground wire is properly

connected to ground terminal in disconnect box or that cord plug is connected to a properly

grounded receptacle outlet.

•When making input connections, attach proper grounding conductor first-double-check connections.

•Frequently inspect input power cord for damage or bare wiring-replace cord immediately if damaged-

bare wiring can kill.

•Turn off all equipment when not in use.

•Do not use worn, damaged, undersized, or poorly spliced cables.

•Do not drape c ables over your body.

•If earth grounding of the workpiece is required, ground it directly with a separate cable-do not use

work clamp or work cable.

•Do not touch electrode if you are in contact with the work, ground, or another electrode from a

different machine.

•Use only well-maintained equipment. Repair or replace damaged parts at once. Maintain unit

according to this manual.

•Wear a safety harness if working above floor level.

•Keep all panels and covers securely in place.

•Clamp work cable with good metal-to-metal contact to workpiece or workcable as near the weld as

practical.

•Insulate work clamp when not connected to workpiece to prevent contact with any metal object.

•Do not connect more than one electrode or work cable to any single weld output terminal.

VER 2. 0

- 4 -

DANGE R

HOT PARTS c a n c a u s e s e v e r e bu r n s .

•Do not touch hot parts bare handed.

•Allow cooling period before working on gun or torch.

DANGE R

MAGNE TIC FIELDS c a n a f f e c t p a c e m a k e r s .

•Pacemaker wearers keep away.

•Wearers should consult their doctor before going near arc welding, gouging, or spot

welding operations.

Abo u t Pa c e m a k er s

Pacemaker wearers consult your doctor first. If cleared by your doctor, then following

the above procedures is recommended.

DANGE R

•Electromagnetic energy can interfere with sensitive electronic equipment such as

computers and computer-driven equipment such as robots.

•Be sure all equipment in the welding area is electromagnetically compatible

•To reduce possible interference, keep weld cables as short as possible, close

together, and down low, such as on the floor.

•Be sure this welding machine is installed and grounded according to this manual.

•If interference still occurs, the user must take extra measures such as moving the

welding machine, using shielded cables, using line filters, or shielding the work a rea.

VER 2. 0

- 5 -

1-2-2 . H a z a r d s Ar o u n d W o r k i n g Ar e a W h i l e in Us e

W ARN ING

NOISE ca n d a m a g e h e a r i n g .

Noise from some processes or equipment can damage hearing.

•Wear approved ear protection if noise level is high.

DANGE R

BUILDUP OF GAS c a n i n j u r e o r ki l l .

•Shut off shielding gas supply when not in use.

•Always ventilate confined spaces or use approved air-supplied respirator.

DANGE R

FUME S AND GASES c a n b e ha z a r d o u s .

Welding produces fumes and gases. Breathing these fumes and gases can be

hazardous to your health.

•Keep your head out of the fumes. Do not breathe the fumes.

•If inside, ventilate the area and/or use exhaust at the arc to remove welding fumes and gases.

•If ventilation is poor, use an approved air-supplied respirator.

•Work i n a confined space only if it is well ventilated, or while wearing an air-supplied respirator.

Always have a trained watch person nearby. Welding fumes and gases can displace air a nd lower

the oxygen level causing injury or death. Be sure the breathing air is safe.

•Do not weld in locations near degreasing, cleaning, or spraying operations. The heat and rays of the

arc can react with vapors to form highly toxic and irritating gases.

•Do not weld on coated metals, su ch as galvanized, lead, or cadmium plated steel, unless the coating

is removed from the weld area, the area is well ventilated, and if necessary, while wearing an

air-supplied respirator. The coatings and any metals containing these elements can give off toxic

fumes if welded.

VER 2. 0

- 6 -

DANGE R

CYLINDER S ca n e x p l o d e i f d a m a g e d .

Shielding gas cylinders contain gas under high pressure. If damaged, a cylinder can

explode. Since gas cylinders are normally part of the welding process, be sure to

treat them carefully.

•Protect compressed gas cylinders from excessive heat, mechanical shocks, slag, open flames,

sparks, and arcs.

•Install cylinders in an upright position by securing to a stationary support or cylinder rack to prevent

falling or tipping.

•Keep cylinders away from any welding or other electrical circui ts.

•Never drape a welding torch over a gas cylinder.

•Never allow a welding electrode to touch any cylinder.

•Never weld on a pressurized cylinder-explosion will result.

•Use only correct shielding gas cylinders, regulators, hoses, and fittings designed for the specific

application; maintain them and associated parts i n good condition.

•Turn face away from valve outlet when opening cylinder valve.

•Keep protective cap in place over valve except when cylinder is in use or connected for use.

•Read and follow instructions on compressed gas cylinders, associated equipment.

W AR NING

ARC R AYS ca n b u r n e y e s an d s k i n .

Arc rays from the welding process produce intense visible and invisible (ultraviolet

and infrared) rays that can burn eyes and skin. Sparks fly off from the weld.

•Wear a welding helmet fitted with a proper shade of filter to protect your face and

eyes when welding or watching.

•Safety gloves must be worn.

•Face protection must be worn.

•Use protective screens or barriers to protect others from flash and glare; warn

others not to watch the arc.

•Wear protective clothing made from durable, flame-resistant material (leather and

wool) and foot protection.

VER 2. 0

- 7 -

WA RNI NG

FLYING ME T AL c a n i n j u r e f a c e .

•Welding, chipping, wire brushing, and grinding cause sparks and flying metal. As

welds cool, they can throw off slag.

•Wear approved safety glasses with side shields even under your welding helmet.

DANGE R

WE LDING can ca u s e f i r e o r e x p l o s i o n .

Welding on closed containers, such as tanks, drums, or pipes, can cause them to

blow up. Sparks can fly off from the welding arc. The flying sparks, hot workpiece,

and hot equipment can cause fires and burns. Ac cidental contact of electrode to

metal objects can cause sparks, explosion, overheating, or fire. Check and be sure

the area is safe before doing a ny welding.

•Welding on closed containers, such as tanks, drums, or pipes, can cause them to blow up. Sparks

can fly off from the welding arc. The flying sparks, hot workpiece, and hot equipment can cause

fires and burns. Accidental contact of electrode to metal objects can cause sparks, explosion,

overheating, or fire. Check a nd be sure the area is safe before doing any welding.

•Protect yourself and others from flying sparks and hot metal.

•Do not weld where flying sparks can strike flammable material.

•Remove all flammables within 10.7 m of the welding arc. If this is not possible, tightly cover them

with approved covers.

•Be alert that welding sparks and hot materials from welding can easily go through small cracks and

openings to adjacent areas.

•Watch for fire, and keep a fire extinguisher nearby.

•Be aware that welding on a ceiling, floor, bulkhead, or partition can cause fire on the hidden side.

•Do not weld on closed containers such as tanks, drums, or pipes.

•Connect work cable to the work as close to the welding area as practical to prevent welding current

from traveling long, possibly unknown paths and causing electric shock and fire hazards.

•Do not use welder to thaw frozen pipes.

•Remove stick electrode from holder or cut off welding wire at contact tip when not in use.

•Wear oil-free protective garments such as leather gloves, heavy shirt, cuffless trousers, high shoes,

and a cap.

•Remove any combustibles, such as a butane lighter or m atches, from your person before doing any

welding.

VER 2. 0

- 8 -

1-3. Ad d i t i o n a l S ymbo l s Fo r In s t a l l a t i o n , Op e r a t i on, An d M a i n t e n a n c e

DANGE R

FIRE OR E XPLOSION h a z a r d .

•Do not install or place unit on, over, or near combustible surfaces.

•Do not install unit near flammables.

•Do not overload building wiring - be sure power supply system is properly sized,

rated, and protected to handle this unit.

• Manufactures will not take responsibility on machine and related accident if

user change the design & function

☞ It must be kept original condition as supplier's design.

☞ Do not operate the machine without all the protective guards in the

closed position.

☞ Never attempting to repair, adjusting, clean, or lubricate and moving parts

while machine in motion.

VER 2. 0

- 9 -

SE CTION 2 - DE FINITIONS

2-1. M a n u f a c t u r e r ' s W a r n i n g La b e l D e f i n i t i o n s

1

2

1. Electricity, Electrical Hazard

•Disconnect power supplies before opening control box or servicing electrical unit.

☞ Electric power must be checked before connection.

☞ Place must be enough space to handle the working job for safety purpose.

2. HOT PARTS can cause severe burns.

•Do not touch hot parts bare handed.

•Allow cooling period before working on gun or torch.

Do n o t r e m o v e or p a i n t o v e r t h e la be l .

VER 2. 0

- 10 -

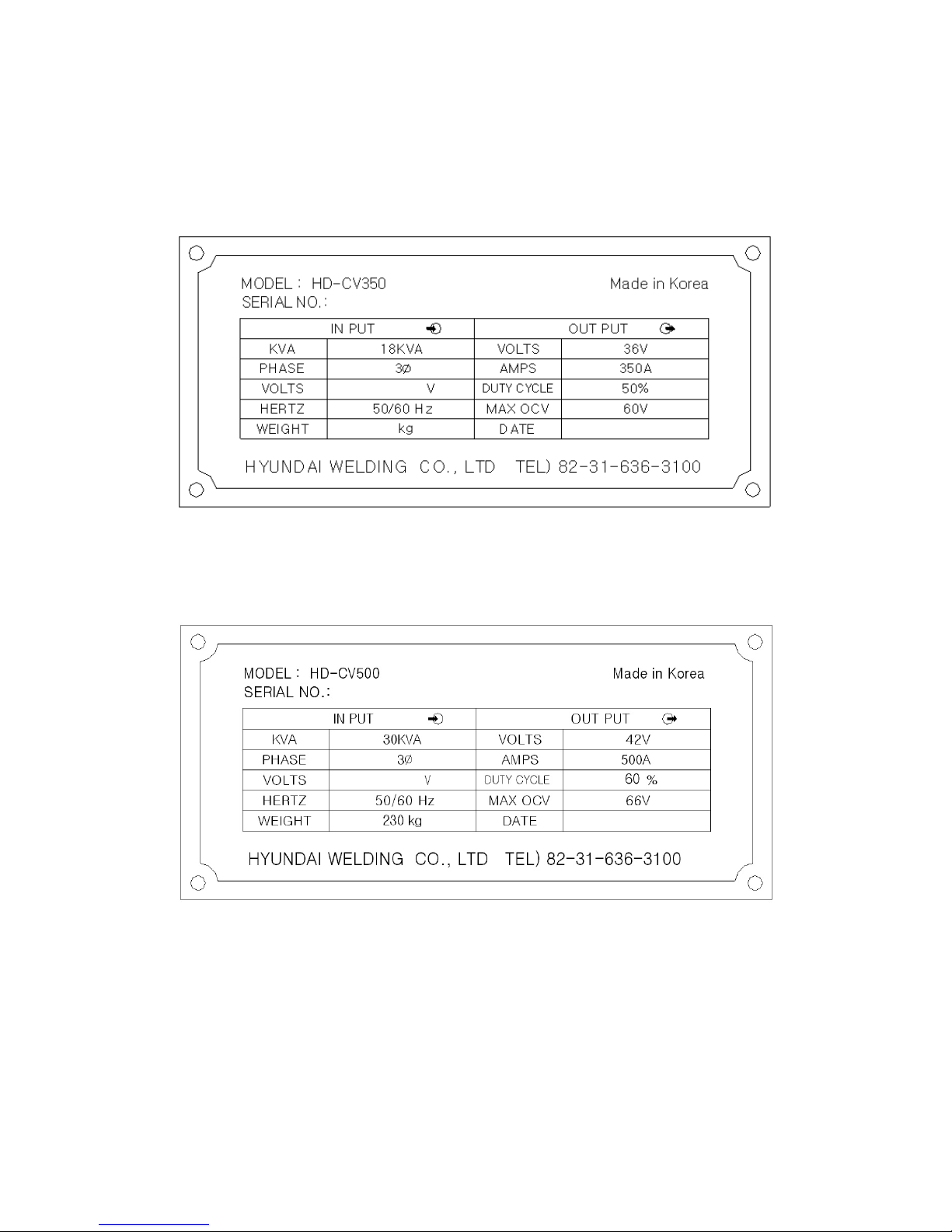

2-2 . M a n u f a c t u r e r ' s R a t i ng La b e l

VER 2. 0

- 11 -

SE CTION 3 - INSTALLATION

3-1. Sp e c i f ica t i o n s

Model Dynamic Auto 350M Dynamic Auto 500M

TYPE HD-CV350 HD-CV500

Rated Input Power 18KVA,16KW 30KVA,25.5KW

Input Voltage 3

Φ 220/380/440 ± 10%

Frequency 50/60Hz 50/60Hz

Rated Welding Current 350A 500A

Rated Welding Voltage 36V 42V

Output Current Range 40A-350A 50A-500A

Output Voltage Range 14V-36 V 15V-42V

Max. Open-Circuit Voltage DC 60V 66V

Duty Cycle 50% 60%

Temperature 160℃ 160℃

Weight 130Kg 180Kg

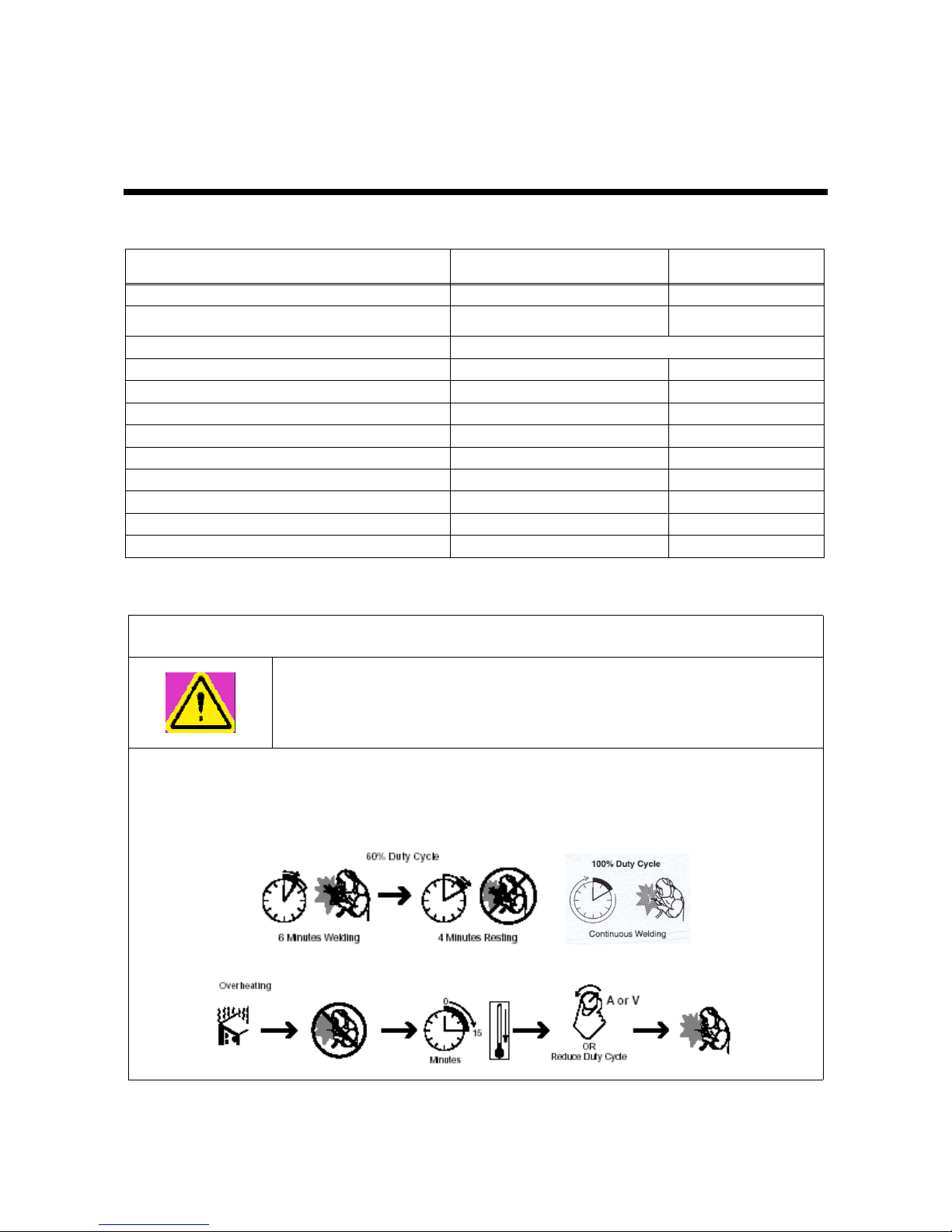

3-2 . Du t y Cy c l e a n d Over h e a t i n g

CAUTION

Ex c e e d i n g Du t y Cyc l e R a t i n g s w i l l c a u s e t h e r m a l o v e r l o a d p r o t e c t i o n

ci r c u i t t o b e c o m e en e r g i z e d a n d s h u t d o w n o u t p u t un t i l u n i t h a s c o o l e d t o

op e r a t i n g t e m p e r a t u r e .

The duty cycle is the percentage of a ten minute period that a welding power source can be operated

at a given output without causing overheating and damaging the unit.

This unit is rated at 60 %, 100% duty cycle for 350, 500, 600 amperes; therefore, this unit can be

operated continuously without causing damage to the unit.

VER 2. 0

- 12 -

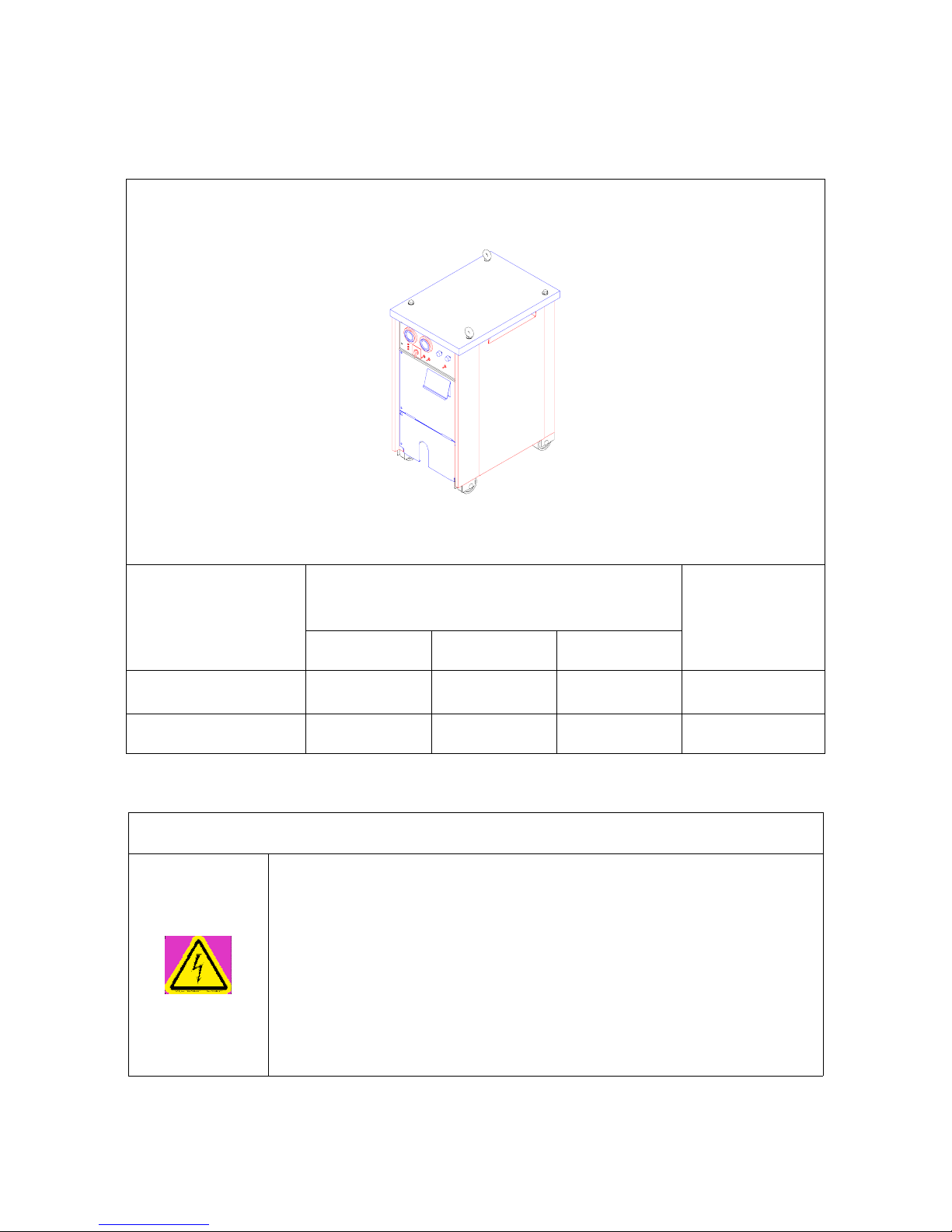

3-3 . Se l e c t i ng a Lo c a t i o n

3-3 -1. Dim e n s i o n s an d W e ig h t

MODEL

Dimension(mm)

Weight(Kg)

DWH

Dynamic Auto 350M 650 445 800 130

Dynamic Auto 500M 675 495 970 180

3-3 -2 . Sit e Sel e c t i o n

CAUTION /

Select an installation site which p rovides the following:

1. Correct input power supply (see unit nameplate)

2. Shielding gas supply (if applicable)

3. Water supply (if applicable)

4. Adequate ventilation and fresh air supply

5. No flammables

6. A clean and dry area

7. Proper temperature that avoids extremes of heat or cold

8. Proper airflow around unit

Loading...

Loading...