Hytork Dossier XL 45, XL 70, XL 130, XL 425, XL 280 Installation, Operating And Maintenance Instructions

...

Hytork

Dossier

XL

Series

Actuators

Contents

Important Safety Procedures

Mounting and

Operating Instructions

Piping Instructions

Solenoid Valves on

Spring Return Actuators

Spares Recommendations

Complete Disassembly-

Double Acting Actuator

Complete Disassembly-

Spring Return Actuator

Assembly Instructions-

Double Acting Actuator

Assembly Instructions-

Spring Return Actuators

Spring Adjustments

Testing and Cycling of

Infrequently Used or

Stored Actuators

Spares Kits

Retractor Rods

Service

1 Important Safety

Procedures

Qualified maintenance personnel

should read and follow these

straightforward instructions.

ALWAYS disconnect the Air and Electrical

Supplies before carrying out any form

of maintenance on an Actuator.

Always contain the Spring tension with

HYTORK Retractor Rods as explained in

Section 7.2. Follow instructions for using

the Retractor Rods carefully.

Never attempt to remove the Pistons

from the Actuator body by using air

pressure when the End Caps have

been removed.

Do not shorten or distort the SAFEKEYS;

correct length SAFEKEYS are supplied

with the Maintenance Kit.

When replacing items use only those

supplied by HYTORK or its Stocking

Distributors.

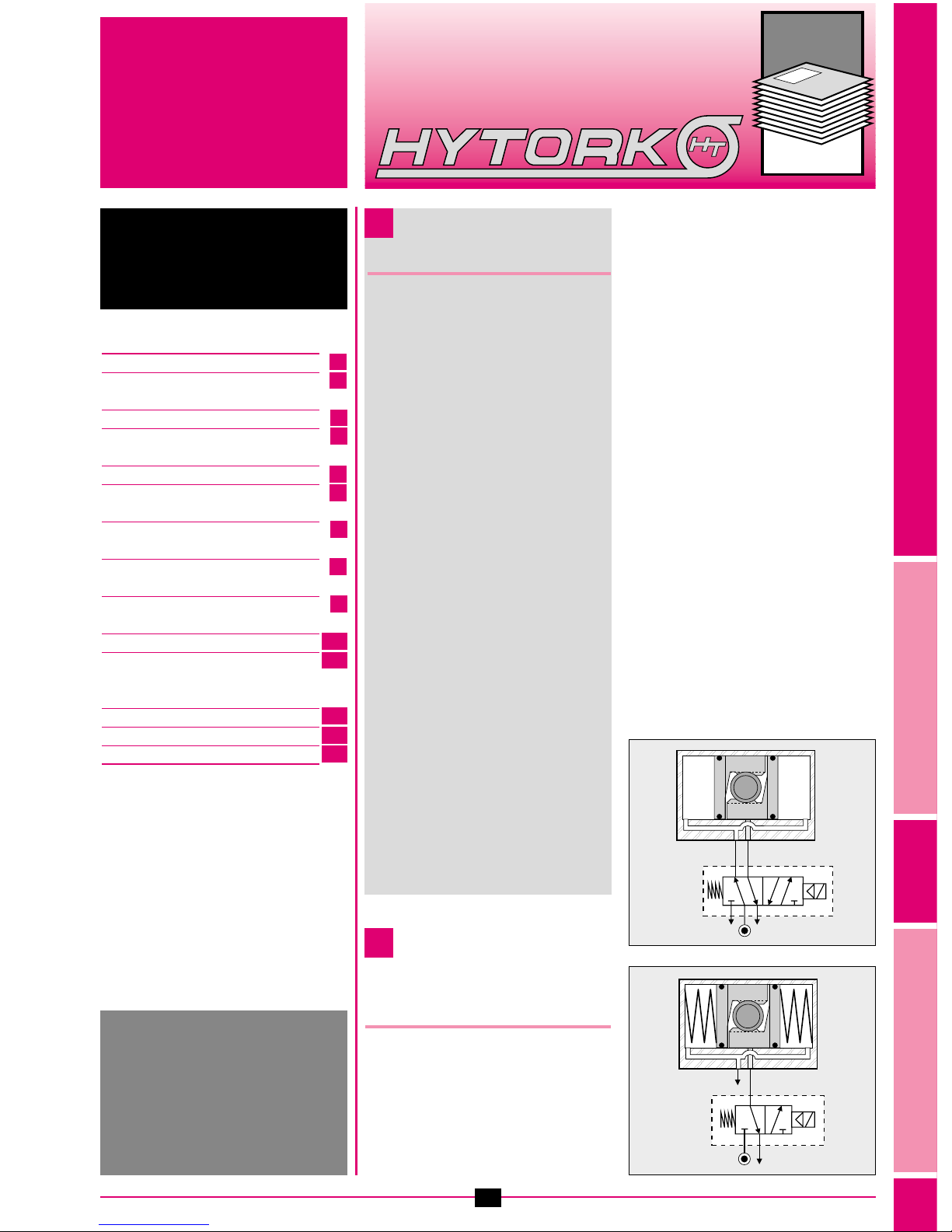

Numbers in brackets (#) refer to parts

on the exploded XL diagram (Fig. 1).

Read the relevant sections

carefully before continuing.

2 Mounting and

Operating

Instructions (Refer to Fig. 1)

2.1 Actuator to Valve Installation.

The mounting hole sizes and bolt hole

circle are to ISO 5211. These holes are

ISO METRIC COARSE on metric models

(UNC COARSE on imperial models for the

USA) as standard. When mounting the

Actuator to a Valve using a Mounting Kit,

the Pinion drive, coupling device and Valve

Stem should be centred and concentric to

prevent any side loading to the bottom

Pinion Radial Bearing and Valve Stem

Seal area.

Ensure that the square coupling shaft

to be operated is a close, but free

sliding fit into the female drive in the

Actuator shaft (4).

2.2 Maximum Operating Pressure.

XL models 45 to 2585

Do not exceed 8.2 bar (120 psi).

XL model 4580

Do not exceed 7 bar (100 psi).

2.3 Operating media.

Use clean, dry or lubricated air. Other

medias may be used, but consult your

local HYTORK VALVE AUTOMATION

CENTER for confirmation as to suitability.

Installation,

Operating and

Maintenance

Instructions

Installation, Operating and Maintenance Instructions XL Series Actuators

MAC099811

1

MAC099811

Fig. 2a

Fig. 2b

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Quality

Assured

registered

management

systems

to ISO 9001

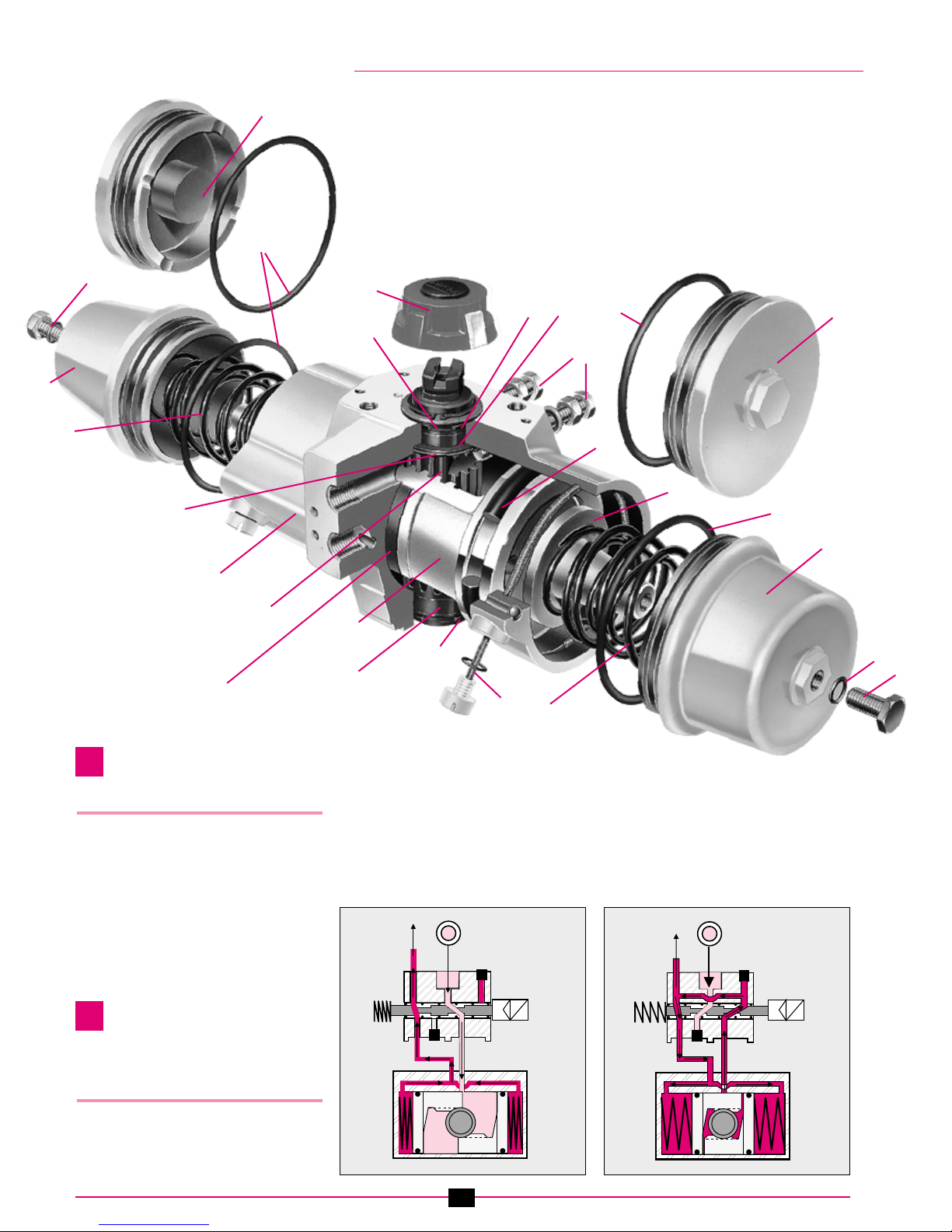

3 Piping

Instructions (Fig. 2a & 2b)

All Actuators can be either piped with solid

or flexible tubing with the Solenoid Valve

mounted remotely from the Actuator or

by mounting a NAMUR designed Solenoid

Valve DIRECTLY onto the NAMUR

Mounting Pad on the side of the Actuator.

(ALL Solenoids made to the NAMUR

standard can be mounted in this way.)

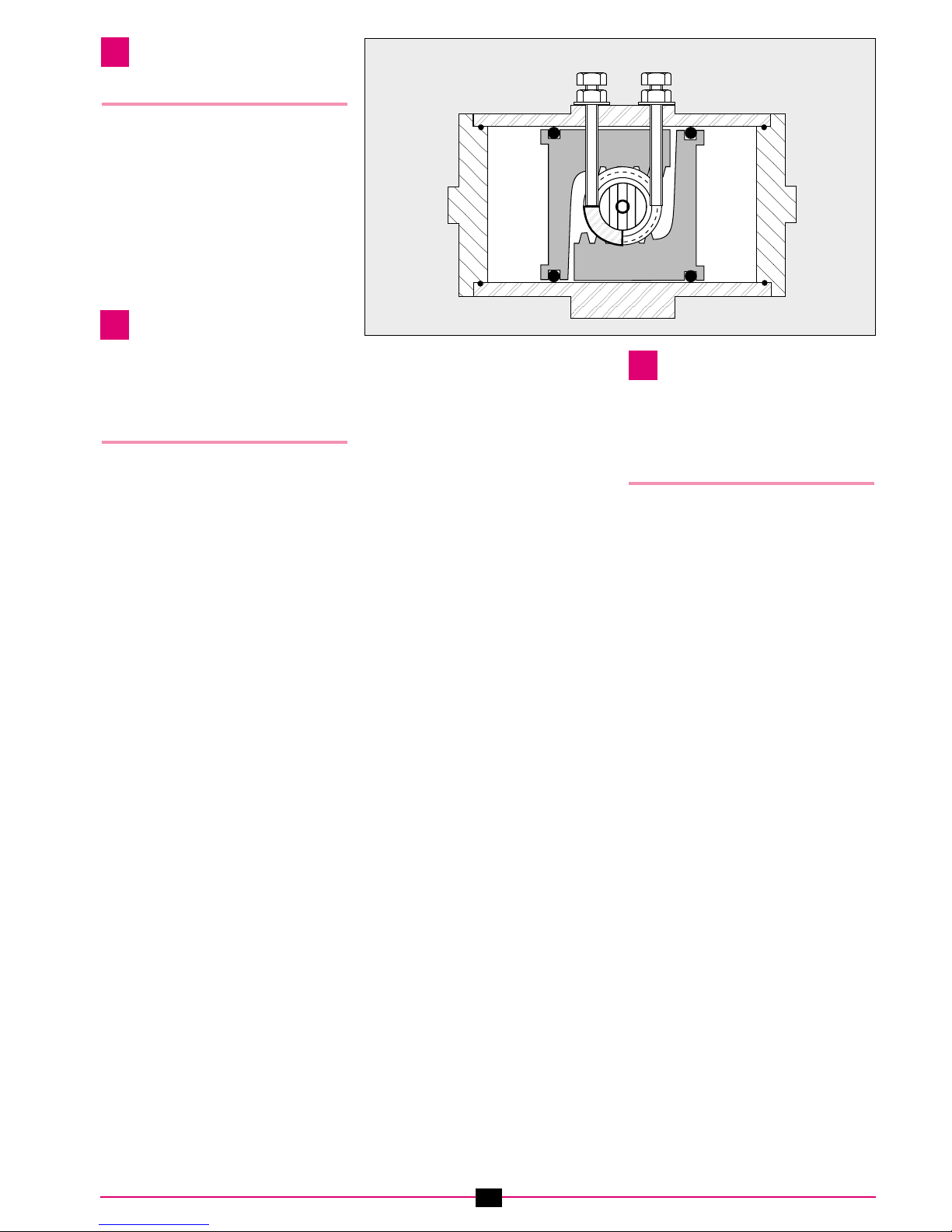

4 Solenoid Valves

on Spring Return

Actuators (Fig. 3a & 3b)

It is recommended that on Spring Return

Actuators, the HYTORK “CATS” Solenoid

Valves are used. These Valves are

specially designed to prevent

contamination of the internals of the

Actuator by dirt from the atmosphere.

This increases the working life of the

Actuator which reduces down time and

maintenance periods.

(See Dossier DSLxxxxx1)

2

Part

No. Component Quantity

1 Travel Stops & Seals 2

2 End Caps 2

3 Pistons 2

4 Pinion 1

5 Body 1

6 SAFEKEYS & ‘O’ Rings 2

7 Springs* 2, 3 or 4

8 Retractor Caps* 2

9 DURASTRIP Pinion Radial Bearings 2

bk DURASTRIP Piston Bearing Strips 2

Part

No. Component Quantity

bl Piston ‘O’ Rings 2

bm End Cap ‘O’ Rings 2

bn Pinion ‘O’ Rings 2

bo DURASTRIP Thrust Bearings 2

bp Steel Thrust Washers 2

bq Snap Ring (Circlip) 1

br Position Indicator 1

bs Sealing ‘O’ Rings* 2

bt Sealing Bolts* 2

*Spring Return Models only

1

2

bm

bm

bm

bobpbq

bobp

br

bs

bt

bt

9

9

7

8

7

6

3

4

2

2

2

bn

bn

bs

Fig. 1

spot pantone process yellow CV

spot pantone magenta

Fig. 3a

spot pantone process yellow CV

spot pantone magenta

Fig. 3b

Double

Acting

Spring

Return

5

bl

bk

3

5 Spares

Recommendations

When disassembling and carrying out

maintenance work on the XL Actuator, a

HYTORK XL Spares Kit must be used to

replace all ‘O’ Rings, DURASTRIP Bearing

Strips, Washers etc. This Kit is available

from HYTORK or its Stocking Distributors.

Important: Read Safety Instructions

before starting (see Section 1).

6 Complete

Disassembly -

Double Acting

Actuator

6.1 Removal of Travel Stops.

(Fig. 4)

Release the lock nut and remove both

Travel Stops and Seals (1) (cast Identity

numbers 1 & 2), which are located at the

top of the Actuator body (5) on the side

opposite the Actuator air connections.

6.2 Removal of End Caps.

Unscrew the two slotted SAFEKEY screws

(6) (cast Identity letters C & D) located in

the body next to each End Cap (2), and

gently pull them from the body, removing

each SAFEKEY. If the SAFEKEY screw

tends to spring, then rotate the End Cap

slightly to assist release. For larger

models (1125 to 4585) use a wrench

(spanner) on the End Cap to turn it to

assist the release of the SAFEKEY

(ensuring the End Cap is always flush to

the body). When both SAFEKEYS have

been removed, detach the Position

Indicator (17) from the top of the Pinion

and use a wrench (spanner) to rotate the

Pinion (4), driving the Pistons (3) apart

until they partially push the End Caps from

the body. Remove the End Caps by pulling

them free from the body, keeping them

square to the end face of the body.

6.3 Removal of Pistons.

Rotate the Pinion using a wrench (spanner)

to drive the Pistons apart until the Pinion

rotates freely. Rotate the Pistons in the

Actuator approximately 10 degrees.

Rotate the Pinion carefully with a little

force and the Pistons will push free of the

Actuator body. On later models of XL

Actuators, the Pistons are provided with

cast extraction holes in the face of the

Piston. By screwing the Travel Stop Bolt

into this hole it can be used to pull the

Pistons from the Actuator body using

pliers or vice grips.

6.4 Removal of Pinion.

On XL models 680, 1125 & 1370 with

Location Rings to ISO 5211 (metric

versions only), the Location Ring is a loose

item and must be removed before the

removal of the Pinion. Remove the Snap

Ring (Circlip) (16), Steel Thrust Washer

(15) and Thrust Bearing (14) from the top

of the Pinion and CAREFULLY remove the

Pinion from the cylinder body through the

bottom. (If the Actuator is a 680, 1125 or

1370 gently tap the top of the Pinion with

a rubber hammer to remove the Location

Ring first.) Care MUST be taken to ensure

that the Pinion Radial Bearing Strips (9) on

the top and bottom of the Pinion do not

become trapped in the bores during this

operation. Take care that the Pinion does

not damage the Pinion bores on removal.

If necessary, remove any burrs, etc. from

the top of the Pinion before removing it.

6.5 Inspection.

Clean and examine all parts for

damage and wear. Check SAFEKEYS for

damage and length (Fig. 10). HYTORK

recommends that ALL ‘O’ Rings, Bearing

Strips, Washers etc. are replaced using a

HYTORK XL Spares Kit.

7 Complete

Disassembly -

Spring Return

Actuator

7.1 Removal of Travel Stops.

(Fig. 4)

Release the lock nut and unscrew both

Travel Stops and Seals (1) (cast Identity

numbers 1 & 2), which are located at the

top of the Actuator body (5) on the side

opposite the Actuator air connections.

7.2 Removal of Spring Pack Modules.

(Fig. 5)

Remove Sealing Bolts (19) and ‘O’ Rings

(18) from each End Cap (2). Place the

HYTORK Retractor Rod (see Section

13.10) through the hole in the End Caps

and screw the Rod into the Spring

Retractor Caps (8) until travel is stopped,

the nut and washer being free of the End

Cap face. Screw the nut and washer

clockwise down the Retractor Rod until

they come up against the face of the End

Cap. Using a wrench (spanner), continue

to screw the nut clockwise down the Rod

exactly two turns, to draw the Spring

Retractor Cap away from the Piston

head (3). This compression of the Springs

releases the Spring force and unlocks the

SAFEKEY for removal. Repeat for the

other End Cap. Rotate the Caps to ensure

that the Springs are retracted; if the Cap

will not turn easily, screw the nut further.

Once the Retractor Rods have

compressed the Spring and the Caps can

be rotated freely, unscrew the two

SAFEKEY slotted screws (6) located in the

body (5) next to each End Cap to which

the SAFEKEYS (cast Identity letters C & D)

Travel Stop (1)

12

Viewed

from above

Pinion Slot

Body (5)

SAFEKEY C (6) SAFEKEY D (6)

End

Caps (2)

Double Acting

Fig. 4

Loading...

Loading...