Hytork MAC050515 Maintenance Manual

Installation, Operation and Maintenance Manual

Hytork XL Pneumatic Actuator

MAC050515 EN Rev. E

July 2019

Table of Contents

July 2019

Installation, Operation and Maintenance Manual

MAC050515 EN Rev. E

Contents

1 Important Safety Procedures ........... 1

2 ATEX instructions for use in (potential)

explosive areas ....................................2

2.1 Intended use ...............................................2

2.2 Safety Instructions ......................................2

2.3 Temperature range for (potential) explosive

areas ...........................................................2

3 Operating Media, Pressures and

Temperatures .................................. 3

3.1 Operating media ........................................3

3.2 Operating Temperature range ...................3

4 Actuator to Valve Installation ........... 3

4.1 Bi-directional Travel Stops ..........................3

4.2 Travel Stop Adjustments .............................3

5 Piping Instructions ........................... 3

6 Solenoid Valves on Spring Return

Actuators ............................................. 4

10 Assembly Instructions ...................... 6

10.1 End Cap and Springs Disassembly on Spring

Return Actuators ........................................6

10.2 Pinion Assembly .........................................6

10.3 Alignment of pinion for correct piston

assembly ................................................ 6

10.4 Piston Assembly .........................................6

10.4.1 Clockwise rotation ........................................6

10.4.2 Counter-Clockwise rotation ..........................7

10.5 Travel stop assembly ...................................7

10.6 End cap assembly on double acting

actuators ....................................................7

10.7 Spring Return Actuators .............................7

10.7.1 Spring set adjustments ..................................7

10.7.2 Installing the Springs .....................................7

11 Testing the Hytork Actuator ............. 8

12 Retractor Rods ................................. 8

7 Position Feedback ............................ 4

8 Spares Recommendations ................ 4

9 Disassembly Procedure .................... 4

9.1 End cap and springs disassembly on Spring

Return actuators .........................................4

9.2 Changing spring sets on XL26 to XL681 .....5

9.3 End cap disassembly on Double Acting

actuators ....................................................5

9.4 Piston disassembly .....................................5

9.5 Pinion disassembly .....................................5

9.6 Inspection ...................................................5

12.1 Spring Removal System Board ....................8

13 Service ............................................. 8

14 Parts and Materials .......................... 9

I Table of Contents

Installation, Operation and Maintenance Manual

MAC050515 EN Rev. E

1 Important Safety Procedures

Hytork XL

July 2019

Table 1. Applicable Models

XL 26 XL 281 XL 2586

XL 71 XL 426 XL 4581

XL 131 XL 681

XL 186 XL 1127

XL 221 XL 1372

Hytork XL actuators are only intended for use in

large-scale xed installations excluded from the

scope of Directive 2011/65/EU on the restriction of

the use of certain hazardous substances in electrical

and electronic equipment (RoHS 2).

Installation, adjustment, putting into service, use,

assembly, disassembly and maintenance of the

Actuator is strictly reserved to qualied personnel.

Before installation, operation and maintenance, read

the relevant sections of:

- This manual

- Quick Reference Guide: DOC.QRG.XL

!

CAUTION - BEFORE YOU START

• Always disconnect the Air and Electrical

supplies before carrying out any form of

maintenance on an Actuator.

• When removing any ball valve or plug valve

assemblies from a pipe system, isolate the

piping system on which the Actuator is

installed and relieve any media pressure

that may be trapped in the valve cavities

before removing the Actuator for

maintenance.

• Always contain the Spring tension with

Hytork Retractor Rods as explained in

Section 9 (Disassembly procedure).

Follow instructions for using the Retractor

Rod carefully. Only Hytork manufactured

or approved Retractor Rods are to be used

for Spring removal. As with any threaded

tool that is frequently used Retractor Rods

should be checked to ensure that the

threads are not worn or damaged in any

way and greased regularly. Any damaged

or worn Rods must not be used and must

be destroyed.

• Never attempt to ‘BLOW OUT’ the Pistons

or the End caps from the Actuator Body by

using air pressure.

• Never turn the stop screws completely out

when the actuator is under pressure.

Numbers in brackets (#) refer to parts on the exploded

view drawing (Chapter 15). All Hytork XL Spares Kits

are supplied with SAFEKEY assemblies (13/14) cut to an

exact length which will t the circumference of the End

Cap (21) when fully assembled into the Actuator.

Any shortened SAFEKEY must not be used.

If in doubt contact Emerson or your local Hytork

Stocking Distributor. Read the relevant sections

carefully before continuing.

IMPORTANT - STORAGE

• Failure to follow proper storage guidelines

will void warranty.

• Warehouse storage: Hytork Actuators

should be stored in a clean, dry warehouse,

free from excessive vibration and rapid

temperature changes. Actuators should not

be stored on any oor surface.

• On site storage: Hytork actuators should be

stored in a clean, dry warehouse, free from

excessive vibration and rapid temperature

changes. Prevent moisture or dirt entering

the actuator. Plug or seal both air connection

ports.

!

WARNING - LIFTING INSTRUCTIONS

• Use lifting equipement as required by

national or local legislation.

• Use lifting straps to lift the assembly of

actuator and valve.

• Do not attach lifting straps to only the

actuator, to lift the assembly of actuator and

valve.

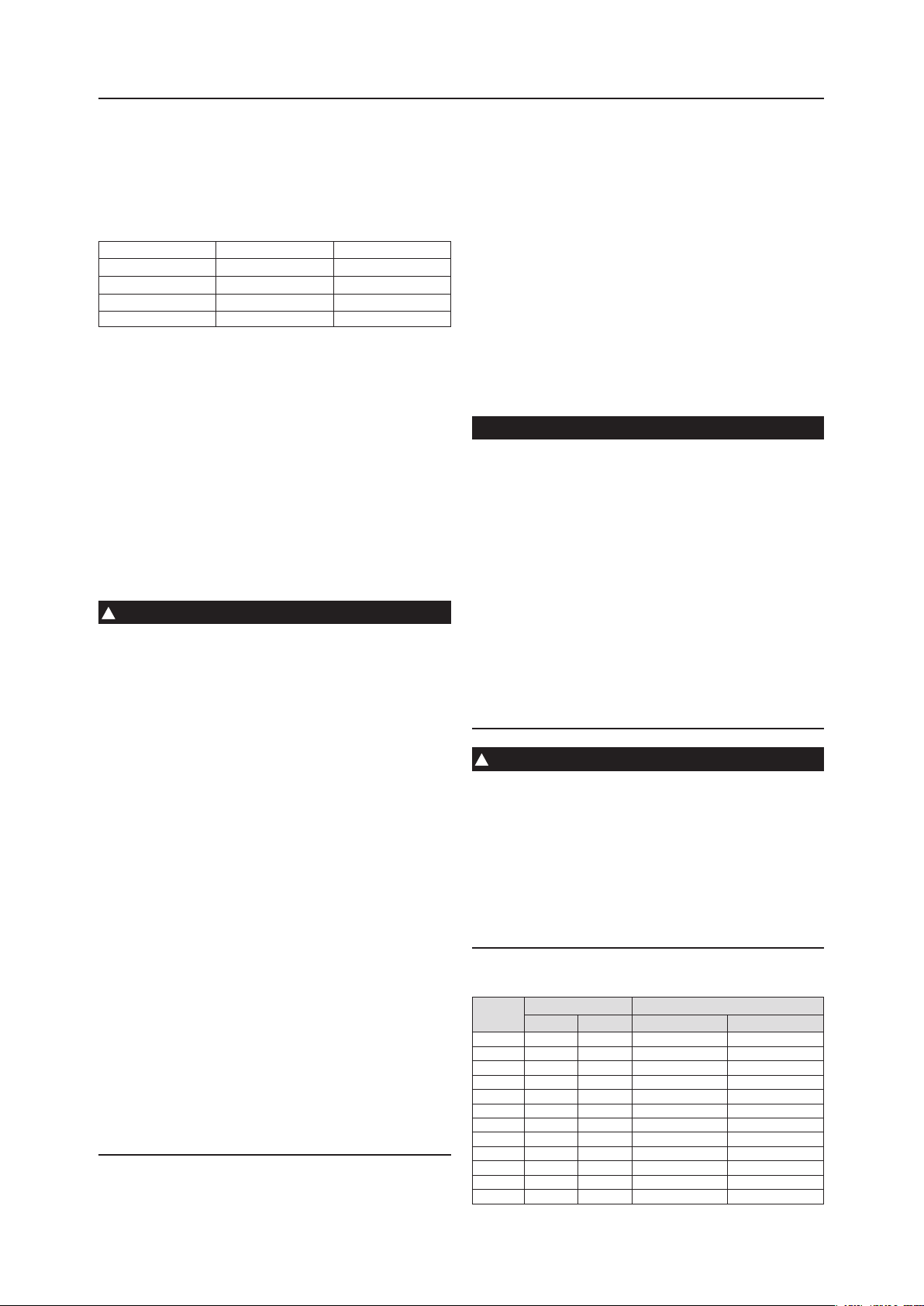

Table 2. Weight of Actuators

Model

XL26 1.39 3.06 1.53 3.37

XL71 2.39 5.27 2.78 6.13

XL131 3.90 8.60 4.76 10.49

XL186 4.77 10.52 5.45 12.02

XL221 6.19 13.65 7.76 17.11

XL281 7.02 15.47 9.90 21.83

XL426 7.30 16.10 12.50 27.56

XL681 8.80 19.40 22.50 49.60

XL1127 22.00 48.50 36.00 79.37

XL1372 27.00 59.52 46.60 102.73

XL2586 46.00 101.41 79.00 174.16

XL4581 83.00 182.98 142.00 313.05

Double Acting Spring Return with S80 Springs

Kg Lbs Kg Lbs

1

Hytork XL

July 2019

Installation, Operation and Maintenance Manual

MAC050515 EN Rev. E

2 ATEX instructions for use in (potential) explosive areas

2.1 Intended use

The Hytork XL series pneumatic actuators are a Group II category 2 equipment and intended for use in areas

in which explosive atmospheres caused by mixtures of air and gases, vapours, mists or by air/dusts are likely to

occur. Therefore it may be used in (ATEX) classied Zones 1, 2 (Gasses) and/or 21, 22 (Dust).

2.2 Safety Instructions

a. Assembly, disassembly and maintenance, is only allowed at the actuator, when, at the time of the

activity, there is not an explosive mixture.

b. Prevent entry of explosive mixtures into the actuator. We suggest utilizing a solenoid with a

“breather” function on spring return actuators when used in potentially explosive atmospheres.

c. The plastic position indicator caps are approved for ATEX gas group IIB areas.

- In areas where ATEX gas group IIC requirements apply, the plastic indicator for actuator sizes

XL26 to 281 is approved for use.

- In areas where ATEX gas group IIC requirements apply, do not use the plastic position

indicator cap of sizes XL426 up to XL4581, to avoid build up of static electricity.

d. In order to avoid increasing dust explosion risk, periodically clean dust deposits from all equipment.

e. When equipment is installed in a hazardous area location (potentially explosive atmosphere), prevent

sparks by proper tool selection and avoiding other types of impact energy.

f. Proper care must be taken to avoid generation of static electricity on the non-conductive external

surfaces of the equipment (e.g. rubbing of surfaces, etc.).

g. Hytork XL actuators do not have an inherent ignition source due to electro-static discharge, but

explosion hazard may be present due to the discharge of static electricity from other valve assembly

components.

- To avoid personal injury or property damage, make sure that the valve is grounded to the

pipeline before placing the valve assembly into service.

- Use and maintain alternate shaft-to-valve body bonding, such as a shaft-to-body bonding

strap assembly.

h. The paint protection must not exceed 200 μm if the actuator is used in a group IIC atmosphere.

For group IIA or IIB atmospheres the paint protection must not exceed a thickness of 2 mm (0.08”).

!

WARNING - SURFACE TEMPERATURE

• The actuator’s surface temperature is dependent upon process operating conditions. Personal injury

or property damage, caused by fire or explosion, can result if the actuator’s surface temperature

exceeds the acceptable temperature for the hazardous area classification. To avoid an increase of

instrumentation and/or accessory surface temperature due to process operating conditions, ensure

adequate ventilation, shielding, or insulation of these actuator components installed in a potentially

hazardous or explosive atmosphere.

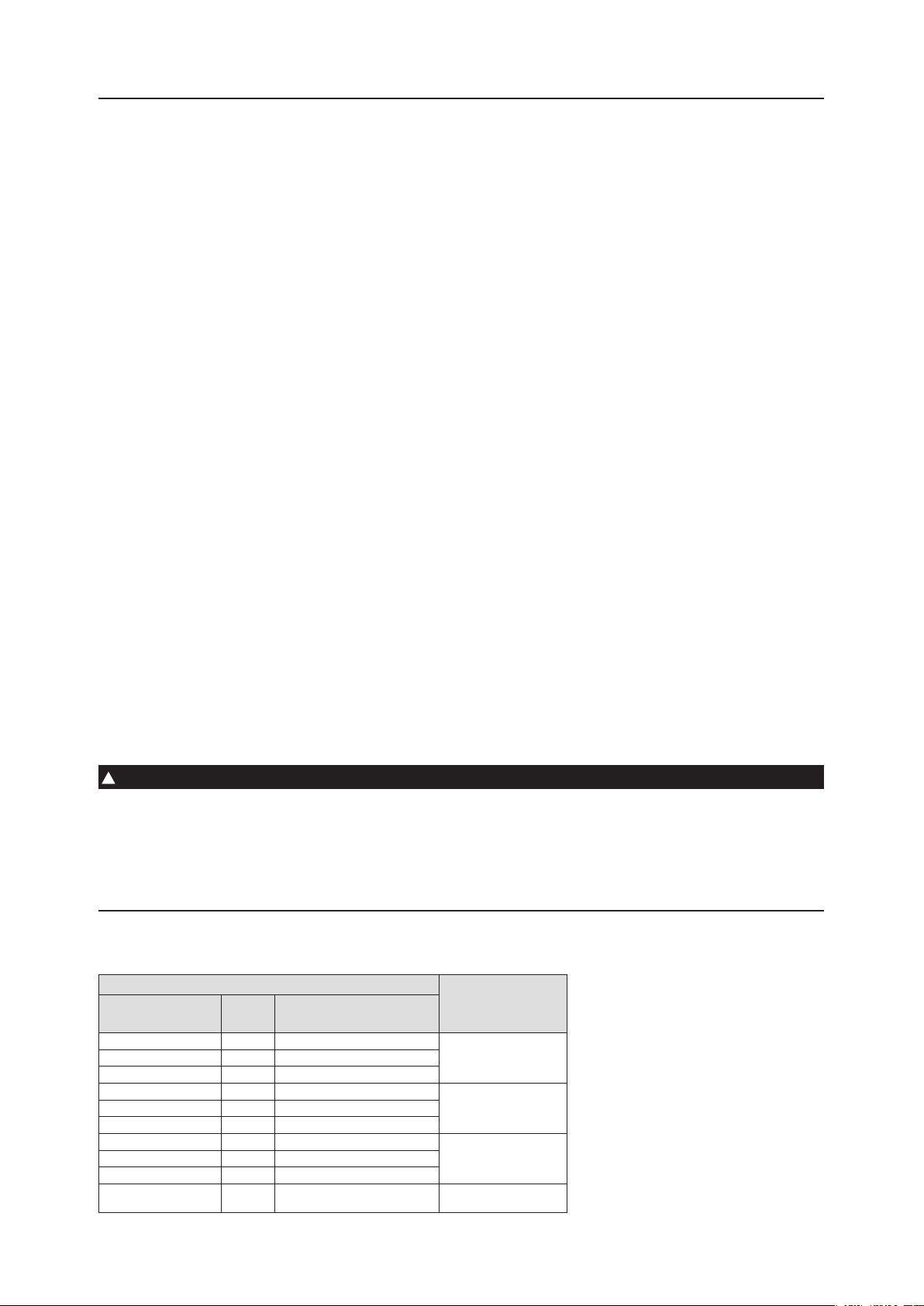

2.3 Temperature range for (potential) explosive areas

Table 3.

Temperature

Ambient range

-20..75°C T6 T85°C (185°F)

-20..80°C T5 T90°C (194°F)

-20..80°C T1...T4 T90°C (194°F)

-20..75°C T6 T85°C (185°F)

-20..90°C T5 T100°C (212°F)

-20..120°C T1...T4 T130°C (266°F)

-40..75°C T6 T85°C (185°F)

-40..80°C T5 T90°C (194°F)

-40..80°C T1...T4 T90°C (194°F)

-20..250°C for

2 hours

ATEX

class

(ATEX surface temperature)

T2 T260°C 500°F)

TX

Valid for

actuator model

Standard Temperature

models

High Temperature

models

Low Temperature

models

Tunnel application

models

NOTE:

a. The specied values are

valid with the following

conditions:

- Maximum working

frequency of the actuator is

1Hz at a maximum of 50

cycles per hour and at

maximum load.

2

Loading...

Loading...