Hytorc BTM-0250-DOC, BTM-0750-DOC, BTM-2000-DOC, BTM-1000-DOC, BTM-3000-DOC Operation Manual

LITHIUM SERIES® Electric Torque Tool

(BTM-DOC Models)

Operations Manual

Mahwah, NJ 07430

USA

CATLITHIUM_SERIESMAN

800-FOR-HYTORC

(800-367-4986)

201-512-9500

hytorc.com333 Route 17 N.

TECHNICAL CERTIFICATIONS

Models

BTM-0250-DOC

BTM-0750-DOC

BTM-1000-DOC

BTM-2000-DOC

BTM-3000-DOC

Notice. The information contained in this document is subject to change without notice. HY TORC makes no warranty of any kind

with regard to this material, including but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

HYTORC shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this material. It is further recommended that the end-user or repair technician insure they have obtained and

are familiar with the latest revision of the manual for the equipment outlined in this document.

Restricted Rights Legend. Use and duplication of the information contained within this manual is limited to the purchaser, end user,

or licensed HYTORC representative. It is recommended that proper training for the equipment outlined in this manual be conducted

by a HYTORC-authorized training representative for any person who is operating or repairing the equipment outlined in this document. Modification of, or disclosure by any other agency or representative is strictly forbidden.

Product Modifications. HYTORC DOES NOT ALLOW any of the products listed in this manual to be modified by any end user without

exception. Should an application require a modification to the tool, or any of the standard accessories please consult with your local

HYTORC representative and they will be able to obtain the assistance for any modification that may be required.

Technical Certifications

Conforms to UL STDS 60745-1 & 60745-2-2

Certified to CSA STD C22.2 Nos. 60745-1 & 60745-2-2

For Hand-Held Motor-Operated Electric Tools.

EN ISO 12100-1:2011

EN ISO 12100-2:2011

EN ISO 14121-1:2007

EN ISO 11148-6:2012

5002282

LITHIUM SERIES® is a registered trademark of HYTORC.

Copyright © 2018 HYTORC All Rights Reserved. Reproduction, adaptation, or translation without prior written permission is prohib-

ited, except as allowed under the copyright laws.

Warranty. The LITHIUM SERIES Tool has a one-year limited warranty. Every tool is tested before leaving the factory and is warranted

to be free from defects in workmanship and materials. HYTORC will repair or replace, without charge, any tool which, upon examination, proves to be defective in workmanship or materials for one (1) year after the date of purchase. This warranty does not cover damage resulting from repairs made or attempted by unauthorized repair facilities. The repair and replacement remedies described herein

are exclusive. In no event shall HYTORC be liable for any incidental, special, or consequential damages, including loss of profits. This

warranty is exclusive and in lieu of all other warranties or conditions, written or oral, expressed or implied for merchantability or fitness

for particular use or purpose. This warranty gives you specific legal rights. You may also have other rights that vary from state to state

and province to province. In those states that do not allow the exclusion of implied warranties or limitation of incidental or consequential damages, the above limitations or exclusions may not apply to you. If you have questions about the warranty, contact our customer

service center at 201-828-5270.

Printed in the USA. April 2018

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

TABLE OF CONTENTS

1. IMPORTANT SAFETY INFORMATION

2. TOOL DESCRIPTION

3. SERVICE

FREE SERVICES

REPAIRS

TOOL RENTALS

HELP 11

FOLLOW US ONLINE 11

4. CARE AND HANDLING

INSPECT TOOLS & CALIBRATION

ENVIRONMENTAL CONSIDERATIONS

5. CHARGE, TEST & INSTALL BATTERY

CHARGE THE BATTERY

CHARGING INDICATOR

TEST THE BATTERY

INSTALL THE BATTERY

BATTERY RECYCLING

6. OPERATING THE CONTROL PANEL

PRIMARY CONTROL FEATURES

TOGGLE TORQUE, ANGLE & RELEASE

SET TORQUE

SET ANGLE

SET RELEASE 17

7. NAVIGATING THE MENUS

MAIN MENU AND SUBMENUS

OPERATION MENU

JOB DATA MENU

CONNECT USB CABLE

SAMPLE E XCEL FILE

SYSTEM MENU

ADMIN MENU

8. DUAL SPEED OPERATION

TWOSPEED OPERATION 27

DUALSPEED JOG

9. BOLTING WITH CONVENTIONAL REACTION ARM

INSTALL REACTION ARM

INSTALL SOCKET 29

CONVENTIONAL TORQUE SETUP

CONVENTIONAL TORQUE TIGHTENING

CONVENTIONAL TORQUE LOOSENING

10. BOLTING WITH THE HYTORC WASHER

INSTALL HY TORC WASHER DRIVER

TIGHTENING WITH THE HYTORC WASHER DRIVER

LOOSENING WITH THE HYTORC WASHER

11. BOLTING WITH THE HYTORC NUT

INSTALL HY TORC NUT DRIVER

TIGHTENING THE HYTORC NUT 36

LOOSENING THE HY TORC NUT

12. ADDENDUM IMPORTANT

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

5

. IMPORTANT SAFETY INFORMATION

Read and understand this material before operating or servicing the LITHIUM SERIES® Electronic Torque Tool. Failure to

understand how to safely operate this tool could result in an accident causing serious injury or death.

• Inspect all Tool components as they are removed from the shipping container. If damage is found to any component,

contact the shipper immediately. Do not use the tool.

• Failure to follow correct tool usage could result in personal injury, co-worker injury, and/or damaged tools and

equipment.

• Ensure your working area is clean and unobstructed before beginning work.

• Tool maintenance and repair must be performed by a qualified technician.

• Modifying a tool or tool accessory is dangerous and invalidates the warranty.

• Inspect the tool before each use. Have any obviously worn or damaged parts replaced.

• When not in use, store the tool and tool accessories in the plastic storage case supplied with the tool. Do not expose the

gun to high humidity or large temperature variations.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

PERSONAL PROTECTIVE EQUIPMENT TOOL SAFETY WARNINGS

Always wear the appropriate personal protective equipment

when operating a tool including gloves, safety goggles,

hearing protection, hard hat, and safety shoes.

• Keep work area clean and well lit. Cluttered or dark areas invite accidents. Do not operate the tool in explosive

atmospheres, such as in the presence of flammable liquids, gases or dusts. The tool can create sparks which may

ignite the dusts or fumes.

• Keep children and bystanders away while operating the tool. Distractions can cause you to lose control.

6

Read all safety warnings and all instruction. Failure to follow

the warnings and instructions may result in electric shock,

fire, and/or serious injury.

WORK SAFETY AREA

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating the tool. Do not use

the tool while you are tired or under the influence of

drugs, alcohol, or medication. A moment of inattention

while operating the tool may result in serious personal

injury.

• Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

• Prevent unintentional starting. Ensure the switch is

in the o-position before connecting to power source

and or battery pack, picking up or carrying the tool.

Carrying the tool with your finger on the switch or

energizing power tools that have the switch on invites

accidents.

LITHIUM TOOL USE AND CARE

• Do not force the tool. Use the correct tool for your

application. The correct tool will do the job better and

safe rat the rate for which it is designed.

• Do not use the tool if the switch does not turn it on

and o. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/

or the battery pack from the tool before making

any adjustments, changing accessories, or storing

tool. Such preventive safety measures reduce the risk of

starting the tool accidentally.

• Store idle tools out of the reach of children and do

not allow persons unfamiliar with the tool or these

instructions to operate the tool. Tools are dangerous in

the hands of untrained users.

• Maintain tools. Check the misalignment or binding

of moving parts, breakage of parts and any other

condition that may aect the power of tool’s

operation. If damaged, have the tool repaired before

use. Many accidents are caused by poorly maintained

tool.

• Remove any adjusting key or wrench before turning

the tool on. A wrench or a key left attached to a rotating

part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the tool in

unexpected situations.

• Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from the

moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

• Use the tool, accessories in accordance with these

instructions, taking into account the working

conditions and the work to be performed.

• Using the tool for the operations dierent from those

intended could result in a hazardous situation

• Rechargeable only with the charger specified by

manufacturer. A charger that is suitable for one type of

battery pack may create as risk of fire when used with

another battery pack.

• Use the tool only with specifically designated battery

packs. Use of any other battery pack my risk injury and

fire.

• When the battery pack is not in use, keep it away

from other metal objects, like paper clips, coins, keys,

nails, screws and other small metal objects that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause burns

or a fire.

• Under abusive conditions, liquid may be ejected from

the battery; avoid contact. if contact accidentally

occurs, flush it with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from the

battery may cause irritation or burns.

• Have your tool serviced by a qualified repair person using identical replacement parts. This will ensure that the

safety of the tool is maintained.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

SERVICE

7

IMPORTANT BATTERY PACK INSTRUCTIONS

• Do not splash or immerse in water or other liquids.

• Do not incinerate the battery pack even if it is

severely damaged or is completely worn out. The

battery pack can explode in a fire. Toxic fumes and

materials are created when lithium ion battery packs are

burned.

• Do not charge or use the battery in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Inserting or removing the battery

from the charger may ignite dust or fumes.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water.

WARNING!

Burn hazard. Battery liquid may be flammable if exposed to spark or flame.

WARNING!

• If battery liquid gets into the eyes, rinse over the

open eye for 15 minutes or until irritation ceases. If

medical attention is needed, the battery electrolyte is

composed of a mixture of liquid organic carbonates and

lithium salts.

• Contents of opened battery cells may cause

respiratory irritation. Provide fresh air. If symptoms

persist, seek medical attention.

• Charge the battery packs only in battery chargers

supplied for charging this product.

• Do not pack with conductive items.

Fire hazard. Do not store or carry battery so that metal objects can contact exposed battery terminals.

For example, do not place battery in aprons, pockets, tool boxes, product kit boxes, drawers with

loose nails, screws, keys etc. Transporting batteries can possibly cause fires if the battery terminals

inadvertently come in contact with conductive materials such as keys, coins, hand tools and the like.

WARNING!

Never attempt to open the battery pack for any reason. If battery pack case is cracked or damaged,

do not insert into charger or tool. Do not crush, drop, or damage battery pack. Do not use a battery

pack or charger that has received a sharp blow, has been dropped or has been run over or damaged

in any way (i.e. pierced with a nail, hit with a hammer, stepped on). Damaged battery packs should be

returned to an authorized HYTORC service center for recycling.

US Department of Transportation Hazardous Materials Regulations

The US Department of Transportation Hazardous Materials Regulations (HMR) actually prohibit

transporting batteries in commerce or on airplanes, (i.e. packed in suitcases and carry-on luggage).

When transporting individual batteries, make sure that the battery terminals are protected and well

insulated from materials that could contact them and cause a short circuit. For any other concerns in

regarding the transportation of LI-ION batteries, consult your Transportation Carrier.

8

IMPORTANT BATTERY CHARGER SAFETY INSTRUCTIONS

• Before using charger, read all instructions and

cautionary markings on charger, battery pack and

product using battery pack.

• Do not attempt to charge the battery pack with any

chargers other than the one in this manual. The

charger and battery pack are specifically designed to

work together.

• These chargers are not intended for any uses other

than batteries supplied with LITHIUM SERIES Tools

as described in this manual. Any other uses may result

in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• To disconnect charger, firmly grasp plug and remove.

Do not disconnect the charger by pull-ing on the cord.

• Make sure the cord is located so that it will not be

stepped on, tripped over, or otherwise subjected to

damage or stress.

• Do not use an extension cord unless it is absolutely

necessary.

• An extension cord must have adequate wire size

(AWG) for safety. In general the larger the wire size the

greater the capacity of the cable.

• Do not block any ventilation slots on charger power

supply.

• DO NOT attempt to charge the battery pack with

any chargers other than the one in this manual. The

charger and battery pack are specifically designed to

work together.

• These chargers are not intended for any uses other

than batteries supplied with LITHIUM SERIES Tools

as described in this manual. Any other uses may result

in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• To disconnect charger, firmly grasp plug and remove.

Do not disconnect the charger by pull-ing on the cord.

• Make sure the cord is located so that it will not be

stepped on, tripped over, or otherwise subjected to

damage or stress.

• Do not use an extension cord unless it is absolutely

necessary.

• An extension cord must have adequate wire size

(AWG) for safety. In general the larger the wire size the

greater the capacity of the cable.

• Do not block any ventilation slots on charger power

supply.

WARNING!

Burn hazard. Battery liquid may be flammable if exposed to spark or flame.

WARNING!

Burn hazard. To reduce the risk of injury, charge only tool batteries. Other types of batteries may burst

causing personal injury and damage.

CAUTION!

Under certain conditions, with the charger plugged into the power supply, the charger can be

shorted by foreign material. Foreign materials of a conductive nature such as, but not limited to, steel

wool, aluminum foil, or any buildup of metallic particles should be kept away from charger cavities.

Always unplug the charger from the power supply when there is no battery pack in the cavity. Unplug

charger before attempting to clean.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

9

. TOOL DESCRIPTION

Square Drive Compatible

with Standard Sockets

Reaction Spline

Planetary Gear Box

Dual Speed Switch

Trigger

Pistol Grip Handle

Battery Lock Button

Batter Test Button and

Charge Indicator

36V Rechargeable and

Interchangeable Battery

Cooling Vents

Brushed DC Motor and

Cooling Fans

USB Micro Port

Eyelet

PUSH-BUTTON CONTROL PANEL

The LITHIUM SERIES® Electric Torque Tool provides the following.

• High-strength planetary gear drive powered by brushed DC electric motor

• Two Speeds: Fast run-down, high powered torque.

• Electronic control and setup via push-button menu.

• Heads-Up LCD display.

• Ergonomic lightweight hand-held design with pistol-grip and trigger activation.

• Portable tool powered by rechargeable extended-life 36V lithium ion battery.

• Standard square-drive with dual-reaction spline.

• Integrated data acquisition and export capability.

10

. SERVICE

FREE SERVICES*

• User safety training upon receipt of merchandise

• Semi-Annual user safety training on request

• Annual safety seminar on appointment

• Loaner tools in event of product failure within 24 hours

• Torque/Tension consultation/seminar

• Half-Day, first-use supervision

• User training for first-time rentals

• Warranty repairs including return-freight

• Annual product inspection on request

• Product demonstrations

• 12-Month no-questions-asked warranty

• Upgrades during the lifetime of the tool to enhance

safety, durability, and function

*Above services are not subject to travel expense charges.

REPAIRS TOOL RENTALS

• All repairs are guaranteed for 6 months.

• All repairs are subject to labor and part cost as outlined

in the oicial HYTORC price list.

• All repairs will be tested and calibrated to ensure the

highest quality repairs.

• 100% of all paid rentals will be applied as a discount

towards any new purchase in that calendar year

• User training for first-time rentals is free of all cost

• Rental tools are guaranteed to perform and are subject

to the free loaner tool policy of HYTORC

• All warranty repairs are free of all charges including

return-freight.

HELP

If you require any further assistance, please call your local HY TORC Representative or 1-800-FOR-HYTORC

(1-800-367-4986). Please visit us at HYTORC.com.

FOLLOW US ONLINE

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

11

. CARE AND HANDLING

INSPECT TOOLS & CALIBRATION

• Inspect all components; if damaged report any sign of

damage to the shipper and do not use the tool.

• Inspect the tool before each use; repair or replace any

obviously worn or damaged parts.

• Maintenance must be performed by a qualified

technician.

• Modifying any of the components invalidates the

warranty.

• Check the calibration date on the tool. HY TORC

recommends tool recalibration annually.

• If more than a year has passed since last calibration,

contact HYTORC for recalibration.

• When not in use store all tool components in the plastic

storage case.

• Save all instructions and calibration reports in the

storage case.

ENVIRONMENTAL CONSIDERATIONS

1 2

The LITHIUM SERIES Tool is a rugged industrial tool with an electric motor and electronic control. The following

environmental considerations will help maintain reliable tool operation. Pictured above, keep cooling vents clear (1), and

secure the tool per local practice (2) to protect from dropping.

• The tool will withstand light splashing but do not submerge or subject to continuous rain or extreme humidity.

• The operating temperature of the tool should be less than 150°F.

• All Cooling Vents should be kept clear of dust, dirt and debris to allow internal fans to maintain airflow to keep the motor

and electronics within temperature limits, do not subject the tool to extreme dust environments that would clog the

vents or do not cover the vents with your hand.

• The tool and electronic components are not certified or approved for explosive environments or areas containing

combustible chemical materials.

12

. CHARGE, TEST & INSTALL BATTERY

1

2

4 5

3

7

6

8 9

1. Charging Cable

2. Battery Pack

3. Charging Cradle

4. Power Supply

5. Power Supply Cord

6. Power Indicator

7. Legend

8. Charging Indicator

9. Fault Indicator

CHARGE THE BATTERY CHARGING INDICATOR

• The LITHIUM SERIES Tool is supplied with two long life

36 volt batteries and a charger.

• Before charging a battery verify the local voltage supply

to ensure capability with the charger; this will typically

be 110 Volts or 220 Volts AC.

• Connect the charging cradle to the power supply.

• Connect the power cord to a grounded outlet.

• If necessary connect the plug adapters for the local

power outlet.

• POWER INDICATOR green when charger is plugged into

AC outlet.

• CHARGING INDICATOR is flashing green while battery

is charging.

• CHARGING INDICATOR solid green when battery is fully

charged.

• FAULT INDICATOR is flashing red for battery fault not

charging.

• Battery is charged in approximately 90 minutes.

• Insert the battery by sliding it into the charger and

locking into place. The power indicator will be

illuminated green when plugged in.

• The charging indicator flashes green while charging and

turns solid green when the battery is fully charged.

• The 36 volt battery is fully charged in approximately 90

minutes.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

13

TEST THE BATTERY

INSTALL THE BATTERY

• The Lithium-Ion battery has a long run life and will

power the tool at full speed until the battery is depleted,

so there is no gradual drop in power during use.

• For continuous use, have one or more spare battery

packs charging while the tool is in use. When need

simply swap batteries from the charger to the tool.

• Batteries can be charged hundreds of times without any

noticeable loss in capacity

• Batteries can be returned at no charge for recycling at

HYTORC locations or local recycling centers.

1. Push the TEST button on the side of the battery and

the LED’s will provide an approximate indicator of

remaining battery life:

1 LED On ≤ 25% Battery Charge Left

2 LEDs On ≤ 50% Battery Charge Left

3 LEDs On ≤ 75% Battery Charge Left

4 LEDs On ≤ 100% Battery Charge Left

The battery easily slides onto the tool

body and snaps into place.

1. Press the release button on the

battery and slide battery pack o

the charger.

2. Align the base of the tool with the

rails in the battery and slide the

battery pack firmly into the handle

until you hear (or see) the lock

snap in place.

3. To remove the battery pack from

the tool, press the release button

on the battery and firmly pull the

battery pack out of the tool.

BATTERY RECYCLING

The RBRC (Rechargeable Battery Recycling Corporation) Seal on the lithium ion battery (or battery pack) indicates that the

costs to recycle the battery (or battery pack) at the end of its useful life have already been paid by HYTORC The RBRC, in

cooperation with HYTORC and other battery users, has established programs in the United States to facilitate the collection

of spent lithium ion batteries. Help protect our environment and conserve natural resources by returning the spent lithium

ion battery to an authorized HYTORC service center for recycling. You may also contact your local recycling center for

information on where to drop o the spent battery. RBRC is a registered trademark of the Rechargeable Battery Recycling

Corporation.

14

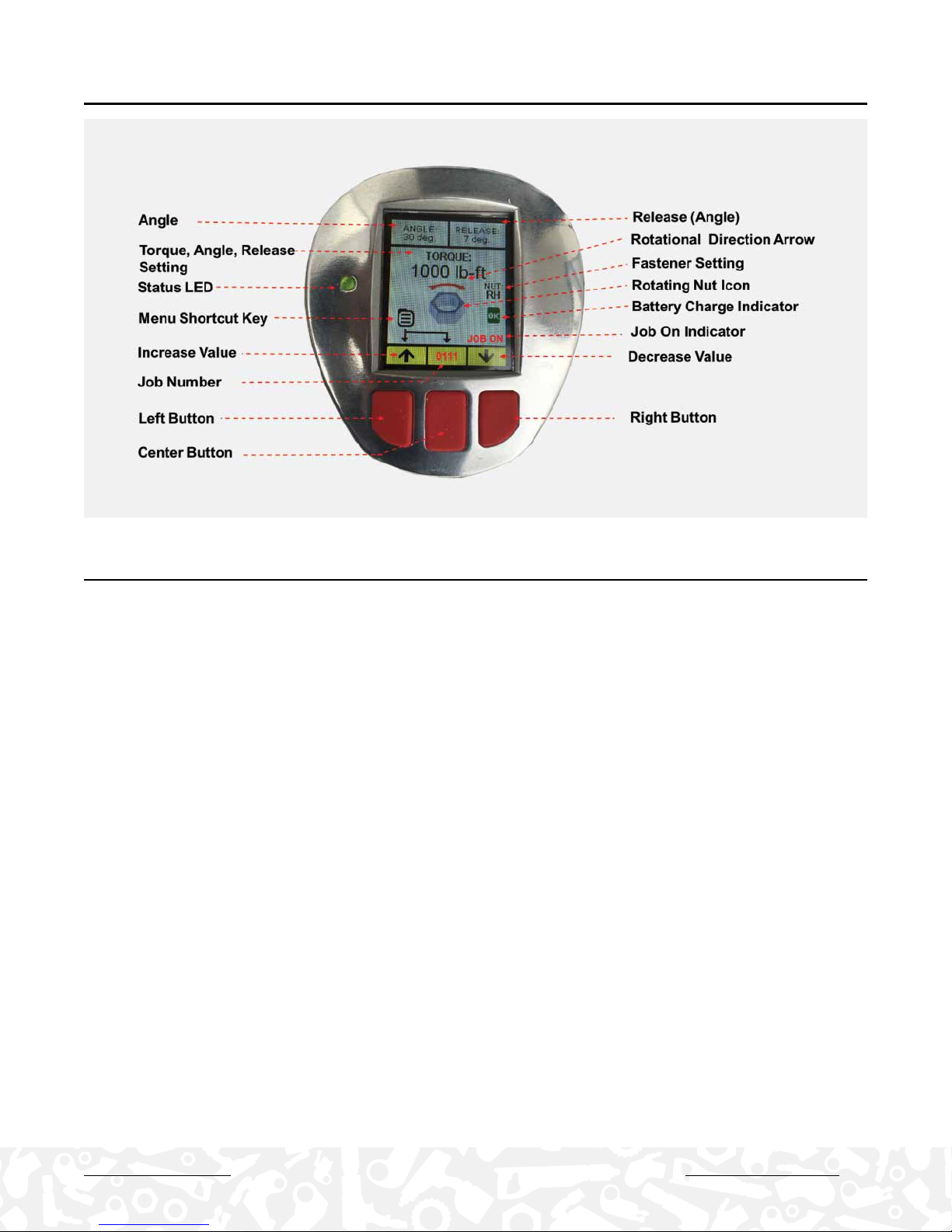

. OPERATING THE CONTROL PANEL

PRIMARY CONTROL FEATURES

• Press Any Button to Power-On Tool (the tool automatically turns o after 5 min)

• A new tool shows the factory default settings

• A tool that has been used before displays the last settings used on the tool before it was powered o .

• Left Button Increases the Torque Value

• Right Button Decreases the Torque Value

• Screen Features; Torque, Angle, Release, Direction, Battery Status, Fastener Type, Data Record Indicator

• Push and hold center button to cycle; TORQUE, ANGLE and RELEASE

• Hold 2 Left Buttons to display main and sub-menu options

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

15

TOGGLE TORQUE, ANGLE & RELEASE

The tool provides simple access to set Torque, Angle and Release by toggling the center button. The torque setup screen is

the home screen for operating the tool.

1. TORQUE: Press and hold the center button for

approximately 3-seconds and release it to access the

Angle screen.

2. ANGLE: Press and hold the center button for

approximately 3-seconds and release it to access the

Release screen.

16

3. RELEASE: Press and hold the center button for

approximately 3-seconds and release it to access the

Torque screen.

SET TORQUE

• Set the Torque Value is set by simply pushing the left button f to increase the torque or by pushing the right button i to

decrease the torque.

• Torque may be set to any value from the minimum to the maximum capability of the tool (or MAX MIN Torque Limits set

in the ADMIN menu).

• Output units may be displayed in lb-ft, N-m, kgf-m or %. (See output unit settings under the ADMIN menu)

• The Torque rotational direction arrow and the rotating nut icon reflect the fastener clockwise or counter clockwise

rotation associate with the specific fastener type. (The fastener type may be set under the Operation – Fastener Type

menu: Right-Hand, Left-Hand, HYTORC NUT and HYTORC Washer).

SET ANGLE

• Certain bolt tightening specifications may require an Angle Value in-addition to or instead of a Torque Value.

• The tool provides the ability to set an Angle value anywhere from 0 degrees to 360 degrees.

• The Angle Value is increased simply by pushing the left button

f to increase the angle or by pushing the right button i

to decrease the angle.

• If an Angle Value is set the gun will add the desired angle of rotation by applying additional torque after the completed

torque operation up to the maximum output of the tool.

• The angle feature is actuated by continuing to hold the trigger after the tool successfully completes the TORQUE.

• The angle force is applied after a time delay set in the Angle Delay menu – typical ½ second to 3 seconds.

SET RELEASE

• When the tool achieves the TORQUE value (and ANGLE if set) the motor automatically stalls and the gear box continues

to exert force (and reaction force) essentially locking the tool onto the nut.

• The gun provides a feature to release the tool from the nut by setting a RELEASE Angle to reverse the motor slightly thus

taking the applied force o the gear box and reaction point and releasing the tool from the nut without loosening the nut.

• The RELEASE Angle Setting may vary depending on the application and may need to be developed iteratively by testing

the value on the application; the objective is to set the minimum RELEASE angle required to release the tool without

applying a force in the opposite direction that would turn or loosen the nut.

• While the tool has a capability to set the RELEASE between 0 and 359 degrees, the RELEASE is typically set on the lower

end and less than 10 degrees (1-to-3 degrees for HYTORC Washer, or 3-to-7 degrees for reaction arms) so that nut is not

loosened. Under certain conditions the operator may need higher RELEASE Angle settings and these should be verified

to make sure that the nut is not being loosened by the higher setting.

• The automatic release feature is actuated by continuing to hold the trigger after the tool successfully completes TORQUE

(and ANGLE if set).

• During the operation the screen will change to show the release angle and direction, the tool motor will reverse by the

desired release angle and then stall again to allow the tool to be removed from the nut.

• The RELEASE Angle is applied following application of TORQE (and ANGLE if set) and after an additional time delay set

in the Angle Delay menu – typical ½ second to 3 seconds.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

17

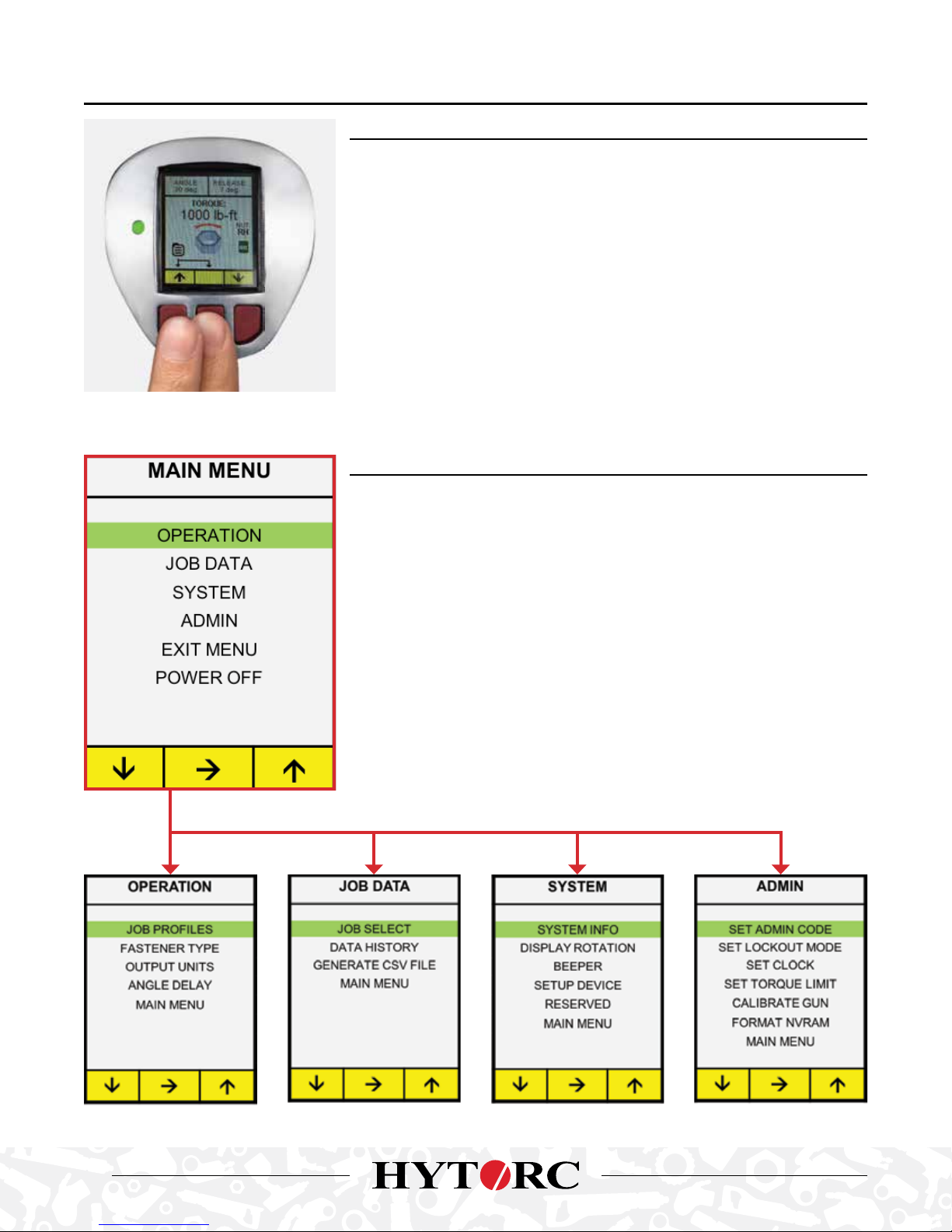

. NAVIGATING THE MENUS

MAIN MENU AND SUBMENUS

The Main Menu provides Operations, Job Data, System, Admin and the Exit and

Power O options.

Press and hold the left and center buttons simultaneously for approximately

three seconds, release buttons when the Main Menu is displayed.

MAIN MENU

• The green bar highlights the current position

• Press left button f to scroll down, right button to scroll up

• Press the center button i to select and display a sub-menu

18

OPERATION MENU

The Operation menu contains most functions for everyday operation.

• The green bar highlights the current position

• Press left button f to scroll down, right button to scroll up

• Press the center button i to select and display a sub-menu

(Continued on following page)

In order to save or load a job profile the

user must first enter the 4-digit code to

unlock the tool. To enter the code press

button to increase the digit or i to

decrease the digit, press to advance

to the next digit until the correct code

is entered (default 0000). When the

4-digit code is entered correctly press

again to JOB PROFILES.

NOTE: Wrong code returns user to

previous screen. There is no limit on

number of attempts. See administrator

for correct code.

Allows the user to save tool parameters

to memory as a Saved Job Profile (SJP),

or to load previously saved parameters

(SJPs) from memory.

The tool can save up to 8 job profiles;

each profile includes saved values for

TORQUE (T), ANGLE (A), RELEASE (R)

and fastener type. Scroll and select the

desired setup values – then select ,

or if saving new setup values select

to access submenu to either SAVE or

LOAD settings.

The user can SAVE the settings

currently on the home display – now

shown in SAVE settings - by pushing

the left button i also adds the profile to

the top of JOB PROFILES.

Alternatively, the user can LOAD the

selected profile – now shown in LOAD

settings - by pushing the right button

. Exit without load or save by hitting

the center button X. Return to the

OPERATION Menu upon completion.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

19

(OPERATION MENU continued from previous page)

Press appropriate button i to scroll

up or down, push to select fastener

type:

RH RIGHT HAND bolts tightened

clockwise.

LH LEFT HAND bolts tightened

counterclockwise.

HN HYTORC NUT tightened

counterclockwise.

HW HYTORC WASHER tightened

clockwise.

Any selection returns users to

OPERATION menu.

NOTE: When using the HYTORC

Washer or HYTORC Nut the safety

feature requiring a push of the button

before operation is disabled. Tool

should never be used with a reaction

arm in this setting.

Allows the operator to select the

preferred units of the torque display.

Press buttons to scroll i or to

highlight the desired units, press to

select desired units and return to the

OPERATION menu.

The user can adjust the time delay for

applying the ANGLE and RELEASE

following the TORQUE operation – the

delay can range from 0ms to 3000ms.

The time delay is applied after the

TORQUE value by continuing to hold

the trigger.

Push up button to increase the delay

or down button i to decrease the delay.

Select to return to the OPERATION

menu.

20

JOB DATA MENU

The Job Data menu contains settings needed to record and download data from

the tool.

• The green bar highlights the current position

• Press left button f to scroll down, right button to scroll up

• Press the center button i to select and display a sub-menu

(Continued on following page)

In order to record data the user must

first enter the 4-digit UNLOCK CODE to

unlock the tool.

To enter the code press button to

increase the digit or i to decrease the

digit, press to advance to the next

digit until the correct code is entered

(default 0000).

When the correct 4-digit code is

entered press again to proceed to

SET RECORDING MODE.

NOTE: Wrong code returns user to

previous screen. There is no limit on

number of attempts. See administrator

for correct code.

User selects JOB NUMBER to turn on

Data Recording for a particular job.

After selecting JOB NUMBER the user

is prompted for a 4-digit job number to

begin recording data.

Alternatively, the user may select END

JOBS to stop recording.

The user is asked to enter a 4-digit JOB

NUMBER (0001 to 9999) for identifying

the data record.

To enter the job number press to

increase the digit or i to decrease the

digit, press to advance to the next

digit until the code is entered.

Press to begin DATA RECORDING

and return to the JOB DATA menu. The

tool is now recording and the JOB ON

and JOB NUMBER are now displayed

on the home screen to indicate the tool

is now recording all job data.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

21

(JOB DATA MENU continued from previous page)

Provides a summary of jobs and events

currently being saved in memory.

Press the buttons i to scroll through

the job numbers to select the data

set you want to download. Press to

select the job number and to generate

the CSV file.

This screen prompts the user to

connect a standard USB cable between

the PC (Type A) to the tool (Micro A).

The tool is discovered by the PC just

as any mass storage device. The PC

will display a folder allowing the user to

click to open the JOB DAT file in Excel

format.

The file serves as an electronic record

of the JOB DATA. When done, press

button to exit the GENERATE CSV

FILE mode and return to the JOB DATA

menu.

22

CONNECT USB CABLE

SAMPLE EXCEL FILE

DATE TIME EVENT TORQUE

18-0 2-31 21:27:40 2 310 — 15 90 7 12 0 G LOOSEN HN F T.- LB S.

18-0 2-31 21: 27:4 8 2 310 — 15 90 7 6 0 G TIGHTEN HN F T.-L BS .

18-0 2-31 22:07:3 5 2 310 — 15 90 7 8 0 G LOOSEN HN F T.- LB S.

18-0 2-31 22 :10:3 8 2 310 — 15 90 7 5 0 G LOOSEN HN FT.-LB S.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

TORQUE

CHECK

ANGLE RELEASE JOB DURATION TEMP VOLTAGE TL FASTENER

TORQUE

UNITS

COMPCODE

PREMATURE

TRIGGER

RELEASE

PREMATURE

TRIGGER

RELEASE

PREMATURE

TRIGGER

RELEASE

PREMATURE

TRIGGER

RELEASE

23

SYSTEM MENU

The SYSTEM menu contains additional settings for tool configuration.

• The green bar highlights the current position

• Press left button f to scroll down, right button to scroll up

• Press the center button i to select and display a sub-menu

NOTE: The SET UP DEVICE and DIAGNOSTIC Menu items are not intended for field use.

These functions are password protected and only accessible by HYTORC in the factory.

Displays Firmware (FW) and Hardware

(HW) versions for MDC (Motor Drive

Control) And UIC (User Interface

Control).

Press any button to return to SYSTEM

menu.

Provides capability to orient the display

in normal or inverted mode:

NORMAL Screen is legible when

battery is down.

INVERT Screen is legible when battery

is up.

INVERT FOR CAL Inverted for

calibration

Scroll down i or scroll up to reach

desired orientation for the display and

push to select the orientation and

return to the SYSTEM SETTINGS menu.

The user can optionally enable or

disable the beeper.

Press buttons to scroll i or to

highlight the desired state for the

beeper, press to select beep OFF or

ON and return to the ADMIN menu.

If turned on, the beeper will sound one

time for each successful operation and

4 times to indicate an error.

24

ADMIN MENU

The ADMIN menu contains less seldom used features or those typically only

configured by an administrator or supervisor.

• The green bar highlights the current position

• Press left button f to scroll down, right button to scroll up

• Press the center button i to select and display a sub-menu

NOTE: The CALIBRATE GUN and FORMAT NVRAM options are not intended for field

use, these are only accessed by HYTORC authorized service personnel.

(Continued on following page)

The user is prompted

to select either

SYSTEM or GENERAL

access level.

The SYSTEM level is

only used by certified

personnel for

calibrating the tool.

The GENERAL level

password is assigned

by an administrator

to provide security for

setting torque limits,

setting the clock and

putting the tool in

lockout mode.

System level user must first enter the old 4 digit

unlock code (default 0000) for access and then

enter a new unlock code for system access.

NOTE: When System password is entered the

General password is cleared to 0000.

General administrator must first enter the old

4-digit unlock code (default 0000) for access

and then enter a new unlock code for system

access.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

25

(ADMIN MENU continued from previous page)

ENTER GENERAL

PASSWORD

The user may enable a

lockout mode that prevents

any user from changing

any parameter except

directional control. This

allows the administrator

to lock the tool at desired

settings for various

users. Press the buttons

i to scroll to ENABLE

or DISABLE lockout

mode, press to select

LOCKOUT MODE and

return to the ADMIN menu

ENTER GENERAL

PASSWORD

Allows user to set time

and date by entering

appropriate numerical

values.

Press up button

increases the value

and down button i

to decrease the value,

select to advance to

the next numerical value,

after setting year push

to return to SYSTEMS

SETTINGS menu.

ENTER GENERAL

PASSWORD

To adjust the minimum

TORQUE limit press button

to increase the value or i

to decrease the value.

Press to save the lower

torque limit – screen

flashes “Saving setting”

and then displays the

upper torque limit screen.

To adjust the maximum

TORQUE limit press button

to increase the value or i

to decrease the value.

Press to save the upper

torque limit – screen

flashes “Saving setting”

and then exits to ADMIN

menu.

26

. DUAL SPEED OPERATION

TWOSPEED OPERATION

Each LITHIUM SERIES Tool is equipped with a dual-speed gearbox. The gearbox has two modes:

1. RUNDOWN MODE: The gearbox is set to run at a higher speed and very

low torque to run nuts down to seated position prior to tightening on an

application. This mode applies a very small amount of torque just to overcome

the resistance of running nuts down onto bolts for a short duration.

2. TORQUE MODE: Used for to apply high torque to fully tighten bolts with

required loads.

The tool is switched between TORQUE and RUNDOWN by setting the dual speed

switch beneath the barrel of the tool. Switch to TORQUE for torque operations,

and RUNDOWN to run down nuts. Always be sure the switch is fully engaged in

either position, never in the middle.

DUAL SPEED JOG

In the event the gear selector does not engage, a JOG FORWARD or JOG REVERSE screen will be displayed. Press the

trigger briefly to synchronize the gears and re-engage the drive mechanism.

JOG FORWARD JOG REVERSE

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

27

. BOLTING WITH CONVENTIONAL REACTION ARM

WARNING!

Failure to make sure the reaction arm is in direct contact with an immovable object before fastening

could result in serious injury. Make sure that no part of your body is in the path of the reaction arm

when the nut is tightened to avoid injury.

INSTALL REACTION ARM

. FLAT ON REACTION SPLINE. . ALLEN SET SCREW TIGHTEN ALLEN SET SCREW

The LITHIUM SERIES Tool is easily configured for conventional torque applications with standard sockets and reaction arms.

• The reaction arm is quickly secured to the tool

• Slide the reaction arm over the drive while aligning the set screw with the flat on the Spline

• Tighten the set screw to firmly attach the reaction arm.

• Challenge the reaction arm to make sure it is firmly secured.

• Never modify a reaction arm as this may lead to personal injury or damage to the tool.

28

INSTALL SOCKET

• Set the Torque Value is set by simply pushing the left button

f to increase the torque or by pushing the right button i

to decrease the torque.

• Torque may be set to any value from the minimum to the maximum capability of the tool (or MAX MIN Torque Limits set

in the ADMIN menu).

• Output units may be displayed in lb-ft, N-m, kgf-m or %. (See output unit settings under the ADMIN menu)

• The Torque rotational direction arrow and the rotating nut icon reflect the fastener clockwise or counter clockwise

rotation associate with the specific fastener type. (The fastener type may be set under the Operation – Fastener Type

menu: Right-Hand, Left-Hand, HYTORC NUT and HYTORC Washer).

CONVENTIONAL TORQUE SETUP

• Power on the tool, adjust the settings and select

fastener. For conventional torque applications the

fastener will be right or left hand.

• If necessary set the speed switch to RUN DOWN to

quickly run down the nuts until they are flush against

the flange.

• Prior to applying torque, position a back wrench to

prevent the back nut from turning during tightening.

• Place the socket on the nut, making sure to fully

engage the nut.

• Make sure the reaction arm is firmly abutted against a

stationary object before applying torque.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

29

CONVENTIONAL TORQUE TIGHTENING

• To begin the TORQUE operation, pull and hold the trigger.

• With Right or Left Fasteners, a message is displayed instructing the user press an additional button on the control panel

to ensure the operator keeps both hands clear of the reaction arm.

• As soon as the user pushes the drive will turn.

• Once the tool starts the reaction arm will move to firmly press against the reaction surface and then the tool will begin

applying torque and tighten the nut.

• Continue holding the trigger until the tool reaches the desired torque and stops.

• If an ANGLE has been specified, continue holding the trigger, the tool will pause and restart after the angle delay.

• If a RELEASE has been specified, continue holding the trigger, the tool will pause and restart after the angle delay.

• Release the trigger after the tool has completed all specified operations.

• The status light turn amber during operation. If the operation is successful, the status light will turn green,

if unsuccessful the status light will turn red.

• If the BEEPER is enabled the tool will provide an audible beep upon completion of the operations.

• Remove the tool socket from the nut.

• Should torque be applied without a release angle the tool may lock onto the nut. If this happens set the tool to loosen to

free the tool and repeat the tighten operation.

30

CONVENTIONAL TORQUE LOOSENING

• The Tool provides the maximum torque capacity in reverse providing a powerful breakout capability.

• Press the center button to toggle to the loosen mode.

• When using conventional torque install a back wrench to keep the back nut from turning.

• Position the tool over the nut.

• Position the reaction arm against a firm surface.

• Pull and hold the trigger and any button on the rear panel to apply torque to loosen the nut.

• Once the tool starts the reaction arm will move and firmly press against the reaction surface. The tool will then begin

applying torque to loosen the nut.

• The status light turn amber during operation. If the operation is successful, the status light will turn green, if

unsuccessful the status light will turn red.

• Remove the tool driver from the nut.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

31

. BOLTING WITH THE HYTORC WASHER

INSTALL THE HYTORC WASHER DRIVER

• The LITHIUM SERIES Tool is easily configured for

tightening bolts where the HYTORC Washer is used.

• Identify the appropriate size HYTORC Washer Driver.

• Slide the washer driver over the square drive and spline

while aligning the thumb screw with the flat on the spline.

• Tighten the thumb screw to secure the Driver.

• Challenge the driver to make sure it is securely attached.

32

TIGHTENING WITH THE HYTORC WASHER DRIVER

• Power on the tool, adjust tool settings and set the

fastener type to HYTORC WASHER.

• If necessary set the speed switch to RUN DOWN to

quickly run down the nuts until they are flush against the

flange. Set the speed switch back to Torque after the

run down is complete.

• Position the tool over the nut and HYTORC Reaction

Washer.

• Pull the trigger to apply torque until the tool reaches the

desired torque and stops.

• If an ANGLE has been specified, continue holding the

trigger, the tool will pause and restart after the angle

delay.

• If a RELEASE has been specified, continue holding the

trigger, the tool will pause and restart after the angle

delay.

• Release the trigger after the tool has completed all

specified operations.

• During the operation the status light turn amber during

operation. If the operation is successful the status light

will turn green, if unsuccessful the status light will turn

red

• If the BEEPER is enabled the tool will provide an audible

beep upon completion of the operations.

• Remove the tool socket from the nut.

• Should torque be applied without a release angle the

tool may lock onto the nut. If this happens set the tool to

loosen to free the tool and repeat the tighten operation.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

33

LOOSENING WITH THE HYTORC WASHER DRIVER

• The Tool provides the maximum torque capacity in reverse providing a powerful breakout capability.

• Press the center button to toggle to the loosen mode.

• Position the driver over the nut and HYTORC reaction washer and hold the trigger and begin applying torque.

• During the operation the status light turn amber during operation. If the operation is successful the status light will turn

green, if unsuccessful the status light will turn red

• Remove the tool driver from the nut.

34

. BOLTING WITH THE HYTORC NUT

INSTALL THE HYTORC NUT DRIVER

• The LITHIUM SERIES Tool is easily configured for tightening HYTORC Nuts.

• Identify the appropriate size HYTORC Nut Driver

• Slide the nut driver over the square drive and spline while aligning the set screw with the flat on the spline.

• Tighten the set screw to secure Nut Driver.

• Challenge the nut driver to make sure it is securely attached.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

35

TIGHTENING THE HYTORC NUT

NOTE: The HYTORC Nut inner sleeve is tightened in the counter clockwise direction (left hand threads).

• Power on the tool, adjust tool settings and set the fastener type to HYTORC Nut.

• Position the tool over the nut.

• Pull the trigger to apply torque until the tool stalls at the specified torque

• If a RELEASE ANGLE has been specified continue holding the trigger and the tool will restart and then stall again after

completing the RELEASE angle. Then the tool can be released from the nut.

• Release the trigger after the tool has completed all specified operations.

• The status light turn amber during operation. If the operation is successful, the status light will turn green, if

unsuccessful the status light will turn red.

• If the BEEPER is enabled the tool will provide an audible beep upon completion of the operations.

• Remove the tool socket from the nut.

• Should torque be applied without a release angle the tool may lock onto the nut. If this happens set the tool to loosen to

free the tool and repeat the tighten operation.

36

LOOSENING THE HYTORC NUT

• The Tool provides the maximum torque capacity in reverse providing a powerful breakout capability.

• Press the center button to toggle to the loosen mode.

• It may necessary to install a back wrench to keep the back nut from turning.

• When loosening HYTORC Nuts position the driver and hold the trigger until the HYTORC Nut is loose.

• The status light turn amber during operation. If the operation is successful, the status light will turn green, if

unsuccessful the status light will turn red.

• Remove the tool driver from the nut.

LITHIUM SERIES® Electric Torque Tool (BTM-DOC Models) Operations Manual

37

. ADDENDUM IMPORTANT

THIS ADDENDUM SUPERSEDES INFORMATION CONTAINED IN THE PRODUCT MANUAL

WHAT HAS CHANGED? HOW HAS IT CHANGED?

This product contains the new and faster HYTORC U85105 120W

36V/18V Battery Charger.

This new battery charger contains a single combined

Charge Status/Fault LED Indicator, circled below in red.

THE CHARGING/FAULT LED INDICATOR OPERATES AS FOLLOWS:

38

OPERATIONAL STATUS LED INDICATOR

Power O O

Power On / Standby O

Charging Flashing Green

Full Charged Solid Green

Fault or Charge Pending Solid Red

HYTORC WORLD HEADQUARTERS

333 Route 17 N., Mahwah, NJ 07430, +1-201-512-9500

WORLDWIDE HYTORC LOCATIONS

ADVANCED BOLTING SOLUTIONS P. LTD

Navi Mumbai, India, +91-22-4171-4444

HYTORC BRAZIL

Rio de Janeiro, BR, +55-21-2621-1911

HYTORC OF CHINA

Shanghai, +86-21-6254-0813

HYTORC MIDDLE EAST

UAE, +44-7436-549468

HYTORC CENTRAL EUROPE & RUSSIA

Perchtoldsdorf, AU, +43-1-86-51-368

HYTORC JAPAN

Suginami-ku, TYO, +81-3-3314-3315

HYTORC UK

Cramlington, NB, +44-1-670-363800

HYTORC OF KOREA

Kyunggi-Do, +82-31-708-0850

HYTORC AUSTRALIA

Adelaide, South Australia, +61-8-8293-8411

Locate your nearest HYTORC representative or location:

hytorc.com/world • info@hytorc.com • +1-201-512-9500

HYTORC SOUTH AFRICA

Mount Edgecombe, DUR, +27-(0)315023119

HYTORC SINGAPORE

Singapore, +65-689-789-95

HYTORC LATIN AMERICA

Coatzaocoalcos, VER, +52-921-21-52760

CATLITHIUM_SERIESMAN

Loading...

Loading...