User Manual

Copyright Information

Hytera is the trademark or registered trademark of Hytera Communications Corporation Limited (the

Company) in PRC and/or other countries or areas. The Company retains the ownership of its trademarks

and product names. All other trademarks and/or product names that may be used in this manual are

properties of their respective owners.

The product described in this manual may include the Company’s computer programs stored in memory or

other media. Laws in PRC and/or other countries or areas protect the exclusive rights of the Company with

respect to its computer programs. The purchase of this product shall not be deemed to grant, either directly

or by implication, any rights to the purchaser regarding the Company’s computer programs. Any of the

Company’s computer programs may not be copied, modified, distributed, decompiled, or

reverse-engineered in any manner without the prior written consent of the Company.

Disclaimer

The Company endeavors to achieve the accuracy and completeness of this manual, but no warranty of

accuracy or reliability is given. All the specifications and designs are subject to change without notice due

to continuous technology development. No part of this manual may be copied, modified, translated, or

distributed in any manner without the express written permission of us.

We do not guarantee, for any particular purpose, the accuracy, validity, timeliness, legitimacy or

completeness of the Third Party products and contents involved in this manual.

If you have any suggestions or would like to learn more details, please visit our website at:

http://www.hytera.com.

FCC Statement

This is A 90.219 CLASS A DEVICE.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates and can radiate radio frequency

energy. If not installed and used in accordance with the instructions, it may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. Verification of harmful interference by this equipment to radio or television reception can be

determined by turning it off and then on. The user is encouraged to try to correct the interference by one

or more of the following measures:

Reorient or relocate the receiving antenna. Increase the separation between the equipment and

receiver.

Connect the equipment into an outlet on a different circuit to that of the receiver's outlet.

Consult the dealer or an experienced radio/TV technician for help.

Operation is subject to the following two conditions:

This device may not cause harmful interference.

This device must accept any interference rece

ived, including interference that may cause undesired

operation.

Note: Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

WARNING:

This is NOT a CONSUMER device. It is designed for installation by FCC LICENSEES and QUALIFIED INSTALLERS.

You MUST have an FCC LICENSE or express consent of an FCC Licensee to operate this device.

You MUST register Class B signal boosters (as defined in 47 CFR 90.219) online at

www.fcc.gov/signal-boosters/registration.

Unauthorized use may result in significant forfeiture penalties,

including penalties in excess of $100,000 for each continuing violation.”

Operational Instructions and Training Guidelines

To ensure optimal performance and compliance with

exposure limits in the above standards and guidelines,

Antenna gain must not exceed 2dBi.

The antenna must be installed complying with the requirements of manufacturer or supplier, and it

must be at least 0.65 meters away from human body.

the general/Uncontrolled environment RF energy

users should

always adhere to the following procedures:

Compliance with RF Exposure Standards

Hytera's radio complies with the following RF energy exposure standards and guidelines:

United States Federal Communications Commission, Code of Federal Regulations; 47 CFR §

1.1307, 1.1310 and 2.1091

American National Standards Institute (ANSI) / Institute of Electrical and Electronic Engineers (IEEE)

C95. 1:2005; Canada RSS102 Issue 5 March 2015

Institute of Electrical and Electronic Engineers (IEEE) C95.1:2005 Edition

ISEDC Statement

This device complies with Innovation, Science and Economic Development Canada Compliance

license-exempt RSS standard(s). Operation is subject to the following two conditions:

This device may not cause harmful interference.

This device must accept any interference received, including interference that may cause undesired

operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts

de licence. L'exploitation est autorisée aux deux conditions suivantes: (1) l'appareil ne doit pas produire

de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

ISEDC Radiation Exposure Statement:

This device must be restricted to work relate

d operations in an

General/Uncontrolled RF

exposure Environment.

This equipment should be installed and operated with minimum di

stance 65cm between the

antenna & your body.

ISEDC exposition aux radiations:

Ce dispositif doit être limité aux opérations liées au travail dans un environnement

d'exposition RF

Cet équipement doit être installé et utilisé avec un minimum ance entre le

général/Incontrôlée.

de 65cm de dist

antenne et votre corps.

WARNING:

This is NOT a CONSUMER device. It is designed for installation by an installer approved by an ISED licensee.

You MUST have an ISED LICENCE or the express consent of an ISED licensee to operate this device.

User Manual Contents

Contents

Documentation Information ..................................................................................................................... 1

1. Introduction ........................................................................................................................................... 3

1.1 Product Description ........................................................................................................................... 3

1.2 Highlights ........................................................................................................................................... 3

1.3 System Architecture ........................................................................................................................... 3

1.3.1 Star Topology ........................................................................................................................... 4

1.3.2 Chain Topology ........................................................................................................................ 5

1.3.3 Ring Topology .......................................................................................................................... 5

1.3.4 Hybrid Topology ....................................................................................................................... 6

1.4 Specifications .................................................................................................................................... 6

2. Packing List ......................................................................................................................................... 10

2.1 Cable-access Donor Unit ................................................................................................................. 10

2.2 Wireless-access Donor Unit ............................................................................................................ 10

2.3 Remote Unit ..................................................................................................................................... 10

3. Getting Started .................................................................................................................................... 11

3.1 Appearance ..................................................................................................................................... 11

3.2 Donor Unit Interfaces ....................................................................................................................... 12

3.2.1 Cable-access Donor Unit ....................................................................................................... 12

3.2.2 Wireless-access Donor Unit .................................................................................................. 13

3.3 Remote Unit Interfaces .................................................................................................................... 13

3.4 Interface Description ........................................................................................................................ 14

3.5 Interface Definition ........................................................................................................................... 15

3.6 LED Indicators ............................................................................................................

4. Installation ........................................................................................................................................... 18

4.1 Safety Information ............................................................................................................................ 18

4.2 Installation Flow ............................................................................................................................... 19

4.3 Preparation ...................................................................................................................................... 19

4.3.1 Environment .......................................................................................................................... 20

4.3.2 Instruments and Tools ............................................................................................................ 21

4.3.3 Material Preparation .............................................................................................................. 21

..................... 16

4.4 Installing the Units ........................................................................................................................... 21

4.4.1 Installation Parts .................................................................................................................... 22

4.4.2 Installing the Product ............................................................................................................. 22

4.4.3 Cabling .................................................................................................................................. 27

4.5 Post-installation Check .................................................................................................................... 34

4.5.1 Checking the Installation........................................................................................................ 34

4.5.2 Checking the Device with Power On ..................................................................................... 34

i

Contents User Manual

5. Power On and Power Off .................................................................................................................... 36

5.1 Powering On .................................................................................................................................... 36

5.2 Powering Off .................................................................................................................................... 36

6. Debugging ........................................................................................................................................... 37

6.1 Preparation ...................................................................................................................................... 37

6.2 Procedure ........................................................................................................................................ 37

6.2.1 Querying Parameters ............................................................................................................ 39

6.2.2 Setting Parameters ................................................................................................................ 39

6.2.3 Upgrade ................................................................................................................................. 41

6.2.4 Exporting the Logs ................................................................................................................. 42

7. System Maintenance ........................................................................................................................... 43

7.1 Care and Cleaning ........................................................................................................................... 43

7.2 Routine Maintenance ....................................................................................................................... 43

7.3 Alarm Handling ................................................................................................................................ 44

7.4 Troubleshooting ............................................................................................................................... 45

8. Appendix: Parameters ........................................................................................................................ 46

ii

User Manual Documentation Information

Documentation Information

This section describes the audiences, conventions and revision history of this document.

Intended Audience

This document is intended to be read by:

Sales engineers

Common users

Documentation Conventions

Icon Conventions

Icon Description

Tip Indicates information that can help you make better use of your product.

Note Indicates references that can further describe the related topics.

Caution Indicates situations that could cause data loss or equipment damage.

Warning Indicates situations that could cause minor personal injury.

Danger Indicates situations that could cause major personal injury or even death.

Notation Conventions

Item Description Example

To save the configuration, click Apply.

Boldface

" "

Denotes menus, tabs, parameter names,

window names, dialogue names, and

hardware buttons.

Denotes messages, directories, file names,

1

The Log Level Settings dialogue

appears.

Press the PTT key.

The screen displays "Invalid!"

Documentation Information User Manual

Item Description Example

> Directs you to access a multi-level menu. Go to File > New.

Italic Denotes document titles.

Courier New

folder names, and parameter values.

Denotes commands and their execution

results.

Open "PDT_PSS.exe".

Go to "D:/opt/local".

In the Port text box, enter "22".

For details about using the DWS, refer

to Dispatch Workstation User Guide.

To set the IP address, run the following

command:

vos-cmd - m name IP

Revision History

Document Version Product Version Release Date Description

Added descriptions on digital repeaters

of low configuration.

03 V1.0 August 2018

Added detail steps in “Setting

Parameters”.

Added contents on the wireless-access donor

02 V1.0 May 2018

01 V1.0 March 2018 Modified the names of several devices.

00 V1.0 January 2018 Initial release.

unit and band-selective repeater.

2

User Manual Introduction

1. Introduction

1.1

DS-9300 Digital Repeater ("DS-9300") is the new generation of repeater developed by Hytera. Using

optical fibers to transmit signal, DS-9300 effectively makes up for the signal decline between base stations

(BSs) and radios.

Featuring low transmission loss and easy wiring, DS-9300 delivers long distance transmission of

multicarrier signals and strong and dynamic signal coverage. It is an ideal solution to blind zones such as

populated urban areas, large exhibition halls, stadiums, campuses, tunnels, metro stations and etc.

DS-9300 has two types of configurations, including low configuration and high configuration, which have

the same appearance but different features.

1.2

DS-9300 has the following highlights:

Flexible monitoring

Product Description

Highlights

DS-9300 provides remote monitoring (through IP network) and local monitoring (through RS232 serial

port). Users can manage all devices through the network management system, or remotely query,

configure and upgrade a single device.

Excellent hardware performance

DS-9300 has low intermodulation noise, strong out-of-band rejection, low interference and great

interference resistance.

Software-Defined Radio (SDR) Technology

DS-9300 achieves uplink squelch, delay compensation, carrier rejection, digital multi-carrier and etc

with the SDR Technology. It supports multiple network topologies such as star, chain, ring and hybrid

topologies.

Effective mechanical design

DS-9300 is compact and portable with effective heat dissipation and resistance to water, dust and salt

spray. Various installation methods are available for DS-9300 including wall-mounting, pole-mounting

and etc.

1.3

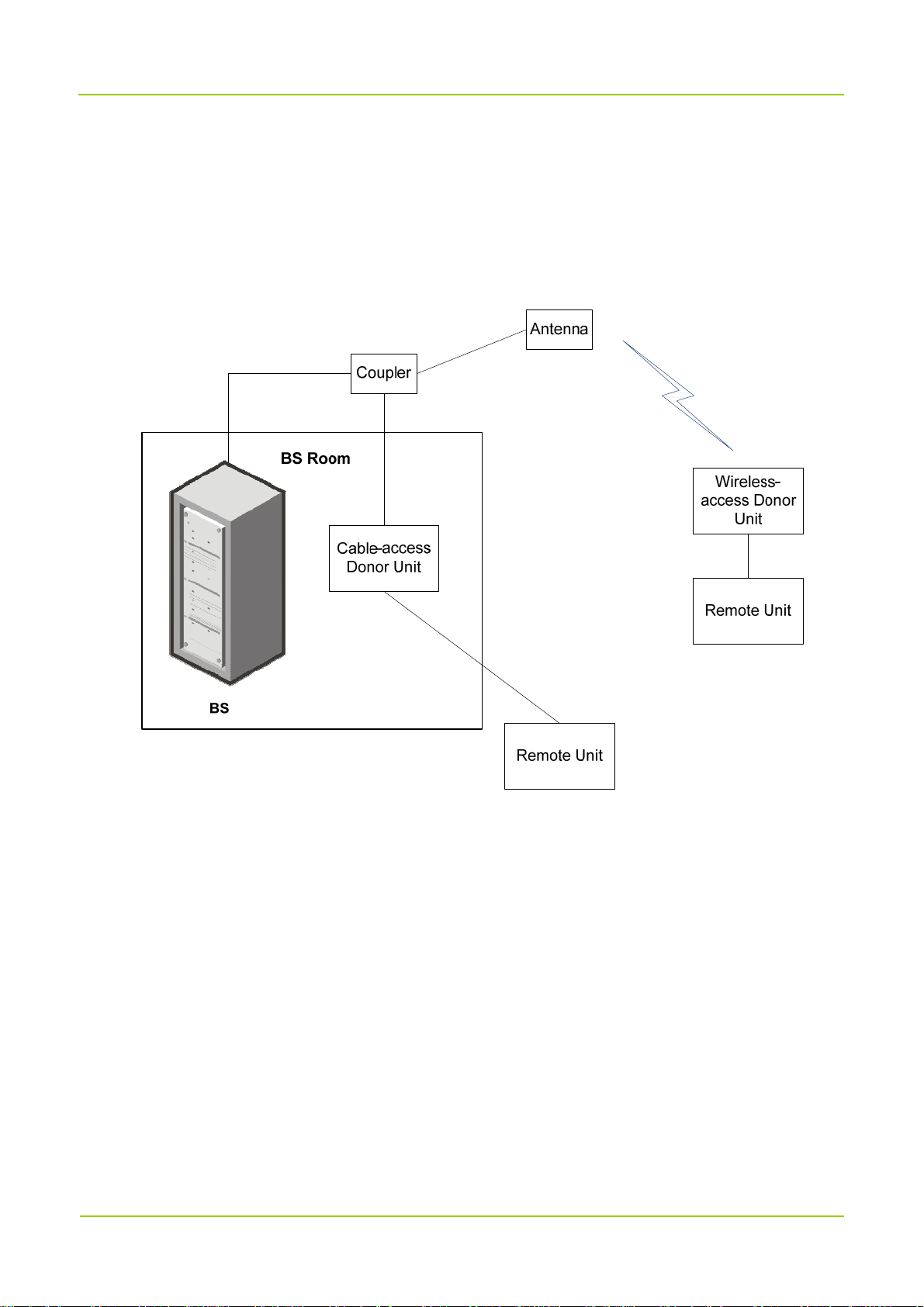

DS-9300 consists of the donor unit and the remote unit. They transparently convey and amplify the

System Architecture

3

Introduction User Manual

wireless signal between the BS and the radios. Donor unit includes the cable-access donor unit and the

wireless-access donor unit. The cable-access donor unit is mounted into a 19-inch rack at the BS location

while the wireless-access donor unit can be installed remotely from the BS. The remote unit is installed

away from the donor unit over a fiber link. The following figure shows the networking of DS-9300 and the

BS.

Various topologies are available for networking between the donor and the remote units, including star,

chain, ring and hybrid topologies.

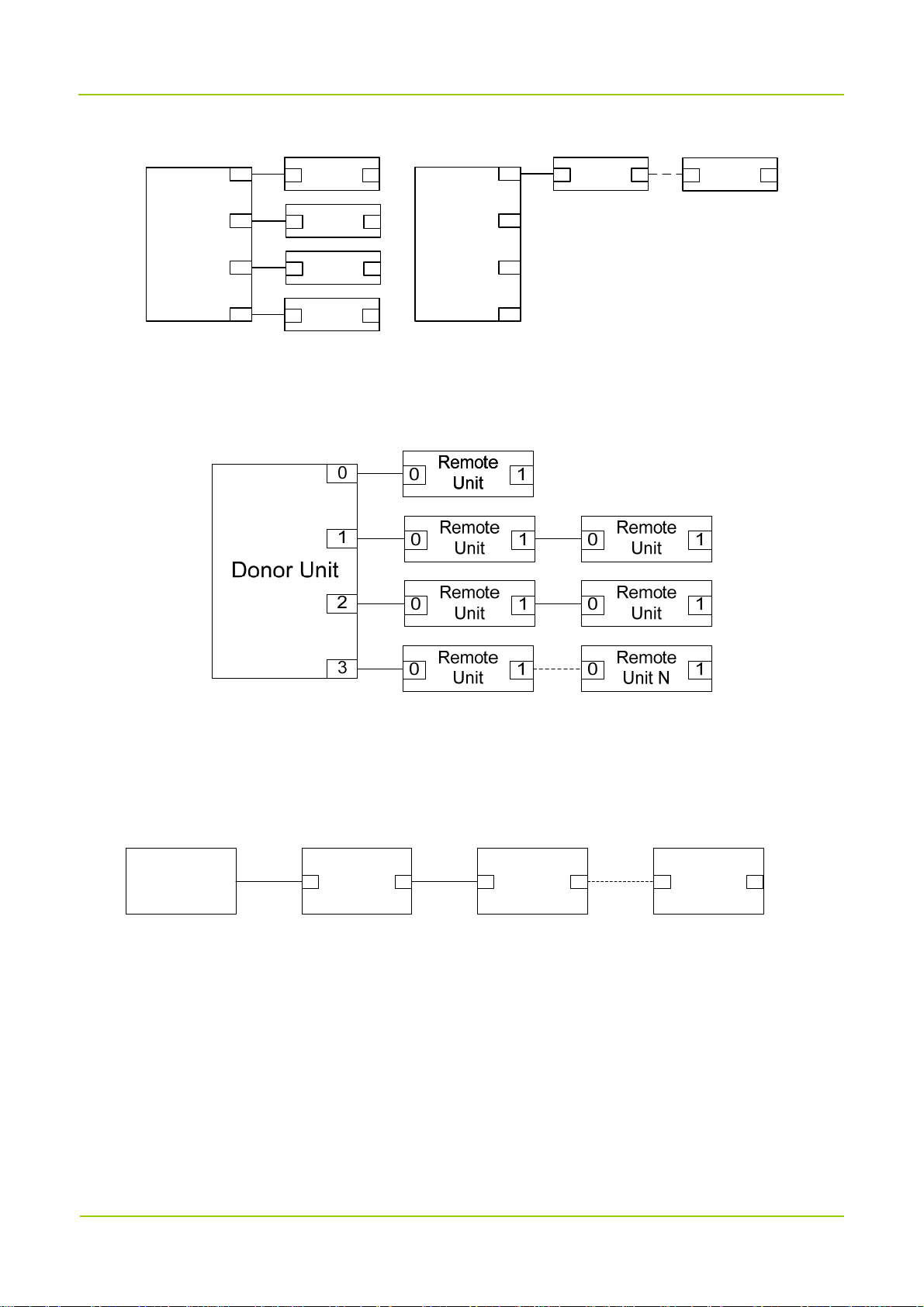

1.3.1

Star Topology

Low Configuration

For low configuration of star topology, each SFP port of the donor unit can connect to up to four remote

units, while one donor unit can connect to at most four remote units (N≤4).

4

User Manual Introduction

Remote

0 1

Unit

Remote

0 1

Unit

Donor Unit

0

1

Remote

0 1

Unit

Remote

0 1

Unit

0

1

Donor Unit

2

3

Remote

0 1

Unit

Remote

0 1

Unit

2

3

High Configuration

For high configuration of star topology, each SFP port of the donor unit can connect to up to eight remote

units, while one donor unit can connect to at most 16 remote units (N≤16).

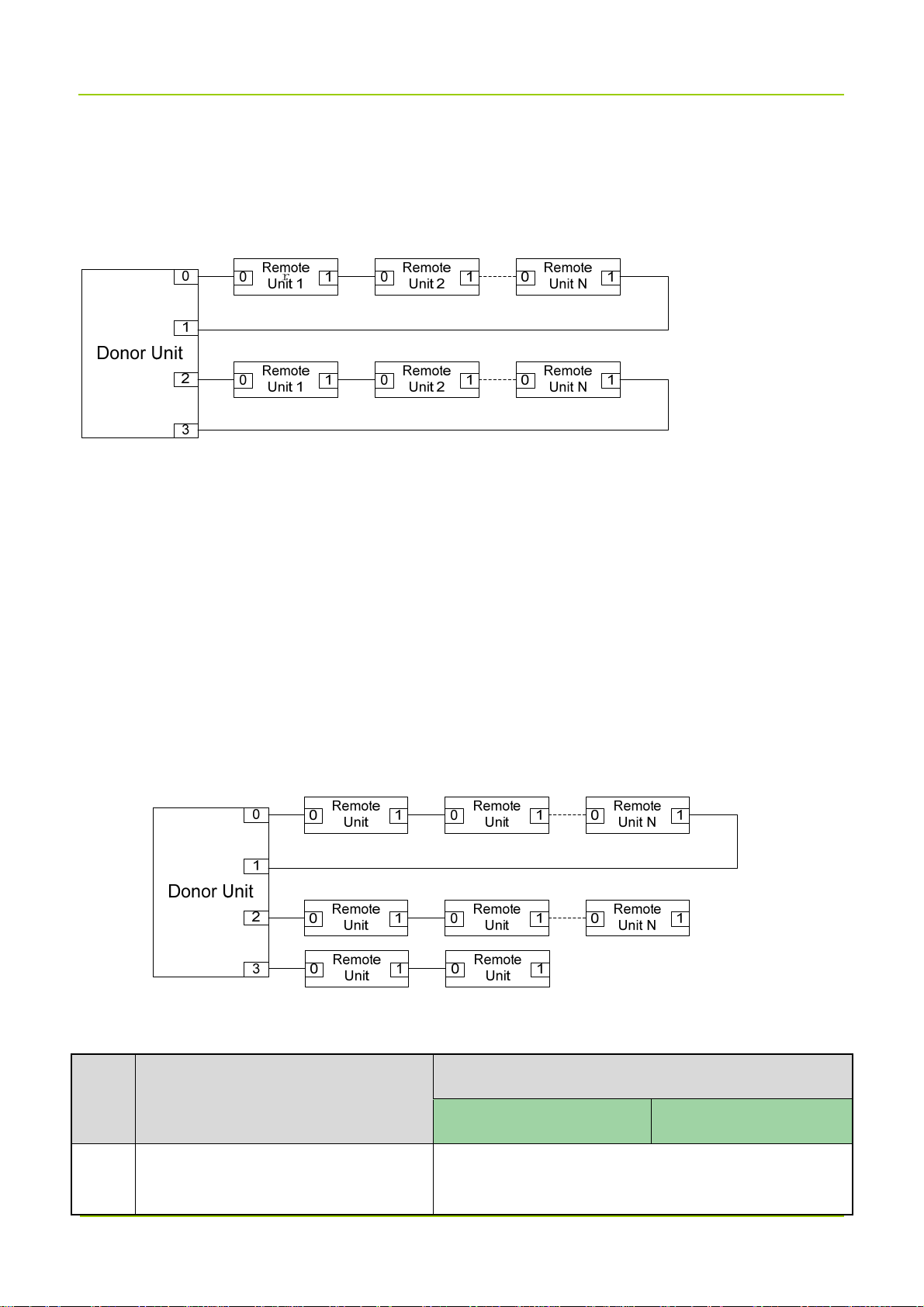

1.3.2

Chain Topology

Low Configuration

For low configuration of chain topology, only one of the SFP ports on the donor unit is used and it can

connect to at most four remote units (N≤4).

Donor Unit

Remote

0 1 0 01 1

Unit 1

Remote

Unit 2

Remote

Unit N

High Configuration

For high configuration of chain topology, the SFP port on the donor unit can connect to at most eight

remote units (N≤8).

1.3.3

Ring Topology

Low Configuration

For low configuration of ring topology, the donor unit can form at most two rings, with each ring can

connect to up to two remote units; or the donor unit forms one ring and connects to four remote units.

5

Introduction User Manual

High Configuration

For high configuration of ring topology, at most two rings can be formed on the donor unit, with each ring

can connect to up to eight remote units (N≤8).

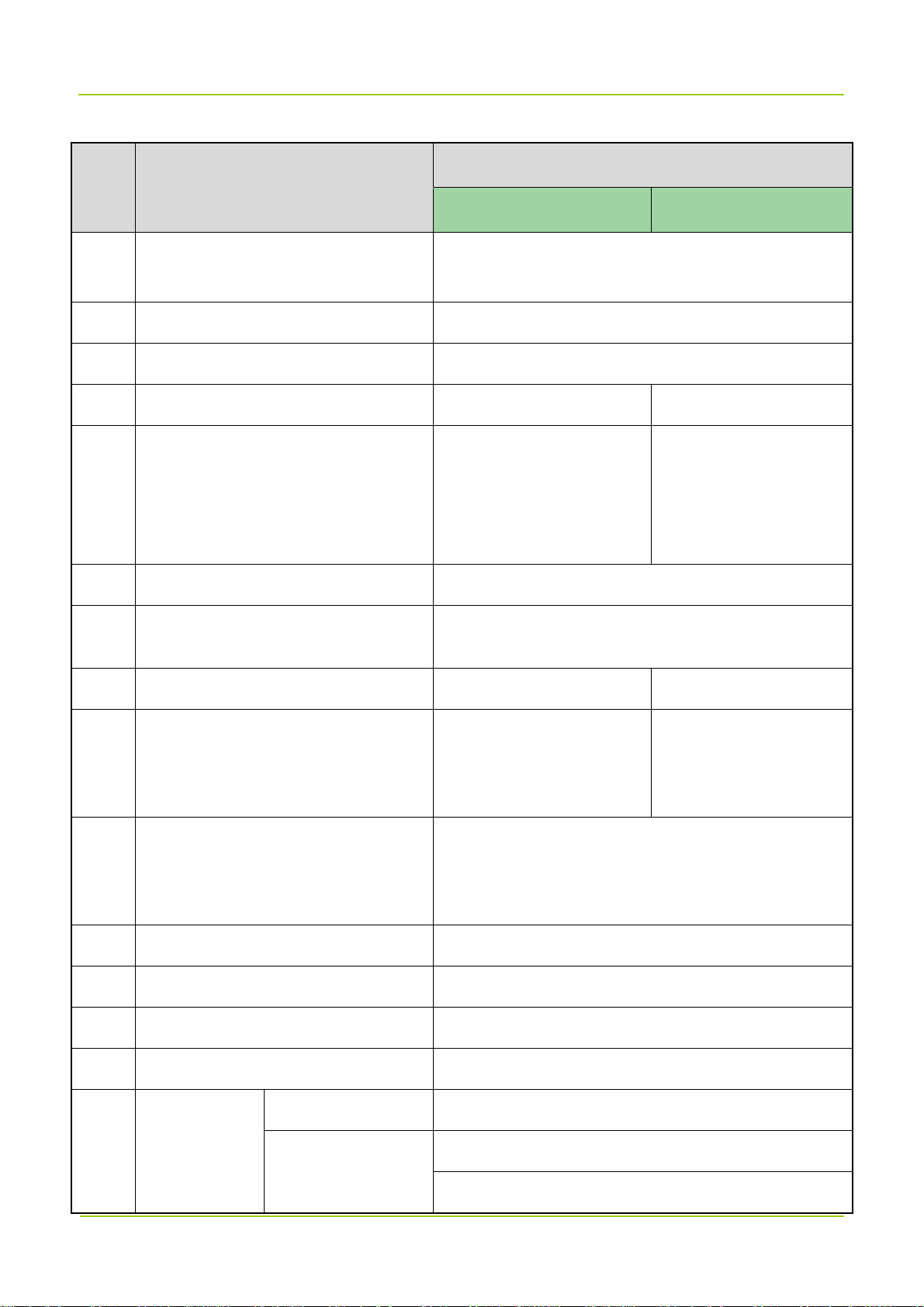

1.3.4

Hybrid Topology

Low Configuration

For low configuration of hybrid topology, each SFP port of the donor unit can connect up to four remote

units, while one donor unit can connect to at most four remote units.

High Configuration

For high configuration of hybrid topology, each SFP port of the donor unit can connect up to eight remote

units, while one donor unit can connect to at most 16 remote units.

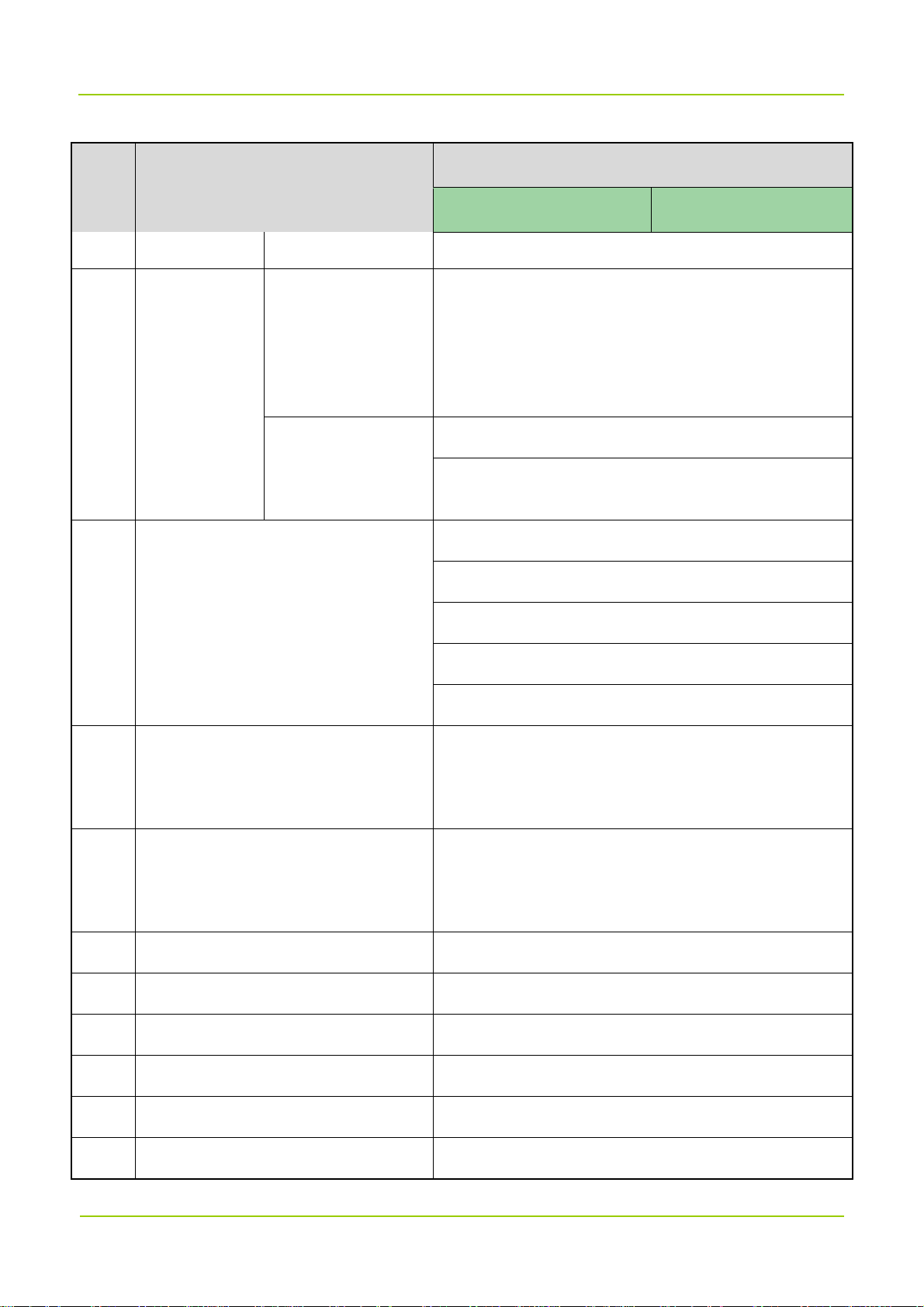

1.4

Specifications

No. Item

1 Frequency Range

Downlink Uplink

460-470MHz(DL)

6

Specifications

450-460MHz(UL)

User Manual Introduction

Specifications

No. Item

Downlink Uplink

5 MHz (operating bandwidth)

2 Channel Bandwidth 25 kHz

3 Channel Capacity 1–8

4 Max. Output Power 5W

Cable-access: 50 dB±3

dB

1W

Cable-access: 45

dB±3 dB

5 Max. Gain

Wireless-access: 95

dB±3 dB

Wireless-access: 90

dB± 3 dB

6 Gain Adjustment Range/Step 30 dB/1 dB

7 Gain Adjustment Error

≤1 dB@ gain of 0–20 dB

≤1.5 dB@ gain of 21–30 dB

8 Noise Figure Wireless-access: ≤5 dB ≤5 dB

Cable-access: 10 dBm

9 Max. Input Level

Wireless-access: –10

–10 dBm

dBm

Output power variation < 2 dB or be off when adding 10

10 Automatic Level Control (ALC)

dB at max output power.

Control range≥20 dB.

11 In-Band Ripple ≤3 dB

12 Input/Output VSWR ≤1.5

13 Delay ≤35 μs

14 Frequency Offset ≤5×10

In-band ≤–15 dBm/30 kHz

Spurious

15

Emission

Out-of-band (2.5

MHz away from the

≤–36 dBm@9 kHz to 1 GHz

≤–30 dBm@1 GHz to 12.75 GHz

7

-8

ppm

Introduction User Manual

Specifications

No. Item

Downlink Uplink

band edge

≤–40 dBc@RBW3 kHz

8 CH 75 kHz Carrier Spacing

In-band

≤–45 dBc@RBW3 kHz

Intermodulation

16

Attenuation

2 CH 75 kHz Carrier Spacing

Out-of-band (2.5

MHz away from the

band edge)

17 Out-of-band Rejection (–6 dB)

18 Optical Bypass (optional)

19 Optical Loop

≤–36 dBm/100 kHz@9 kHz to 1 GHz

≤–30 dBm/1 MHz@1 GHz to 12.75 GHz

≤–20 dBc@±50 kHz

≤–25 dBc@±75 kHz

≤–30 dBc@±125 kHz

≤–63 dBc@±250 kHz

≤–67 dBc@±500 kHz

When the remote unit is powered down or the optical

path is faulty, the optical path is automatically bypassed,

and other cascaded remote units are not affected.

When the remote unit is powered down or the optical

path is interrupted, other cascaded devices can work

normally through the loop.

20 Network Topology Star, Chain, Ring, Hybrid and etc.

21 Optical Transmission Distance ≥20 km

22 Transmission Rate 1.25 GB/s, 2.5 GB/s, 3.02 GB/s, 6.04 GB/s (optional)

23 Optical TX Power –9.5 dBm to –3 dBm

24 Max. Optical RX Sensitivity –20 dBm

25 RF Connector N/F, 50 Ω

8

User Manual Introduction

Specifications

No. Item

Downlink Uplink

Donor Unit: LC/UPC

26 Fiber Connector

Remote Unit: LC/UPC

27 Power Supply Donor Unit /Remote Unit: 90 V to 264 V AC

Cable-access: ≤30 W

28

Power

Consumption

Donor Unit

Wireless-access: ≤100 W

Remote Unit ≤100 W

Cable-access Donor Unit: IP20

29 Ingress Protection Rating

30 Safety IEC 60950 Compliance

31 EMC IEC 61000 class B Compliance

32 Dimensions

33 Monitoring

Wireless-access Donor Unit: IP65

Remote Unit: IP65

Cable-access Donor Unit: 44 mm x 442 mm x 320

mm

Wireless-access Donor Unit: 142 mm x 300 mm x

385 mm

Remote Unit: 142 mm x 300 mm x 385 mm

Supports local monitoring and remote monitoring.

Local monitoring: RS232

Remote monitoring: SNMP

Internal Communication: RS485

34 MTBF ≥100,000 h

Cable-access Donor Unit: –10°C to +45°C

35 Operating Temperature

36 Storage Temperature –40°C to +85°C

Wireless-access Donor Unit: –25°C to +55°C

Remote Unit: –25°C to +55°C

9

Packing List User Manual

2. Packing List

Please unpack carefully and check that all items listed below are received. If any item is missing or

damaged, please contact us or your dealer.

2.1 Cable-access Donor Unit

Item Qty. Item Qty.

Main Unit 1 Cable Kit 1

Packing material for 19-inch Rack 1 Optical Cable Kit 1

Square Nut Kit 4 Power Cord 1

Crown Screw 4 Documentation Kit 1

2.2 Wireless-access Donor Unit

Item Qty. Item Qty.

Main Unit 1 Signal Cable (8-core) 1

Packing material 1 Power Cord 1

Mechanical parts of

1 Cable Kit 1

Die Casting Machine installation

Signal Cable (1-core) 1 Optical Cable Kit 1

Documentation Kit 1 / /

2.3 Remote Unit

Item Qty. Item Qty.

Main Unit 1 Signal Cable (8-core) 1

Packing material 1 Power Cord 1

Mechanical parts of

1 Optical Cable Kit 1

Die Casting Machine installation

Signal Cable (1-core) 1 SFP Optical Module 2

Documentation Kit 1 / /

10

User Manual Getting Started

3. Getting Started

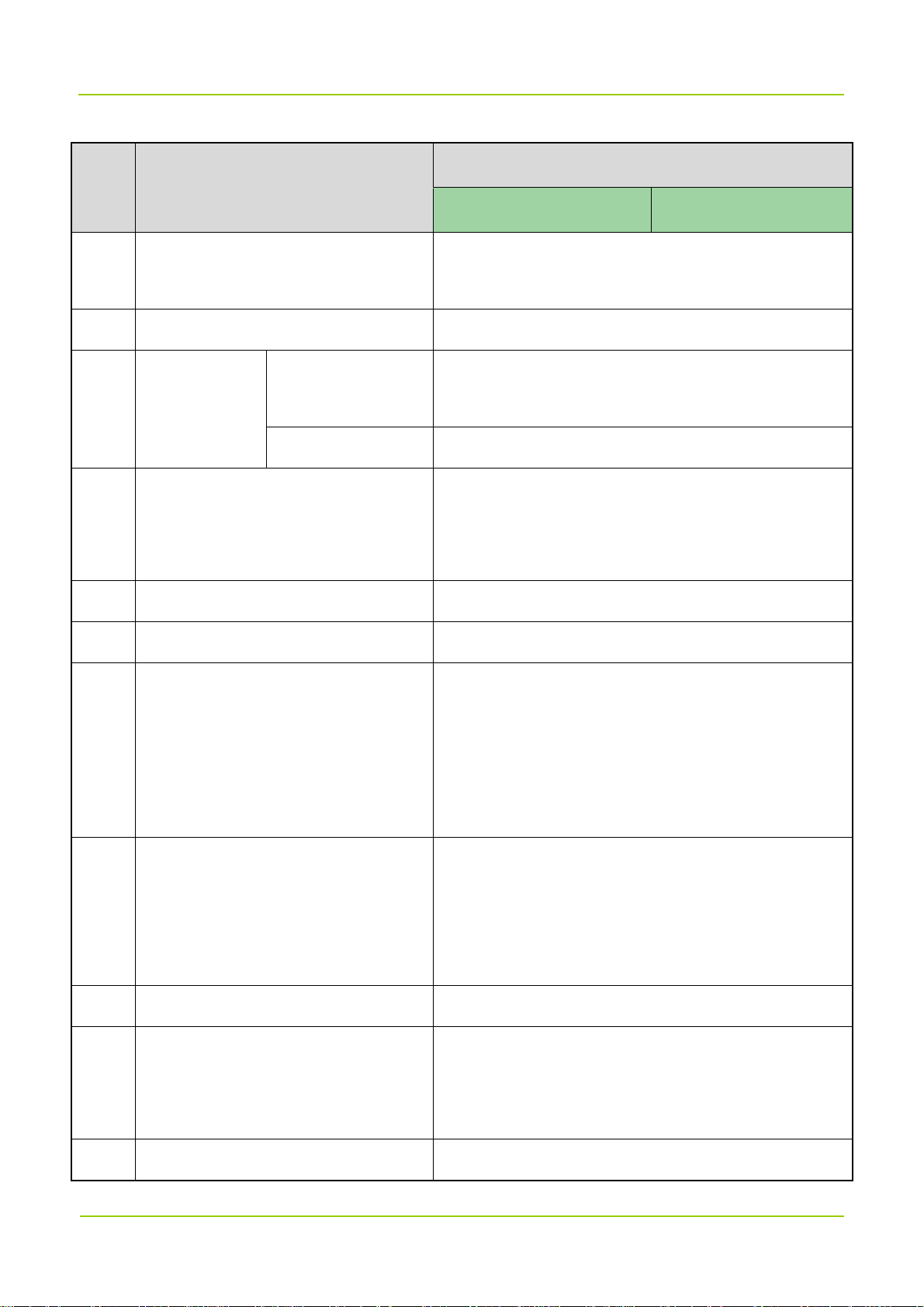

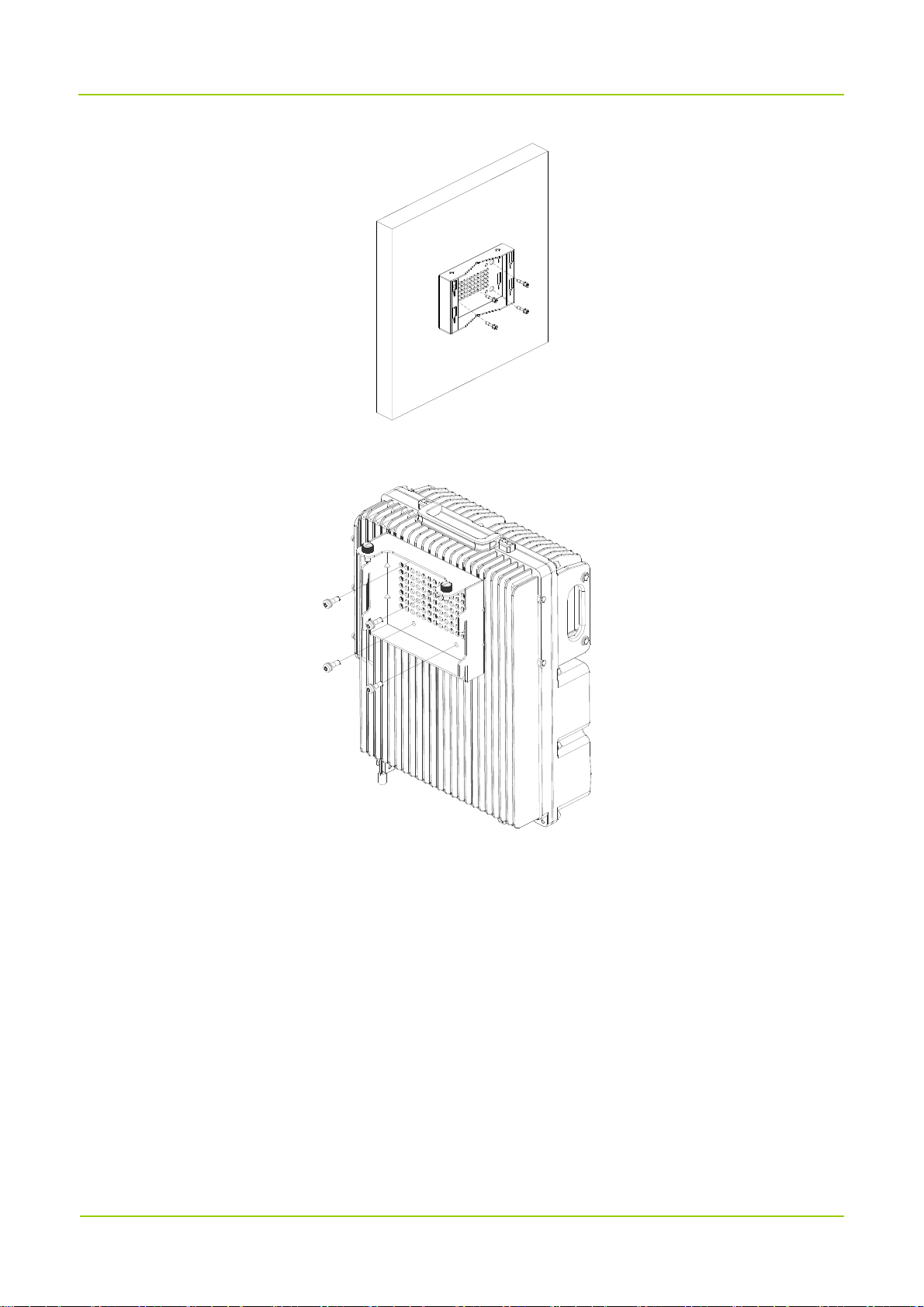

3.1 Appearance

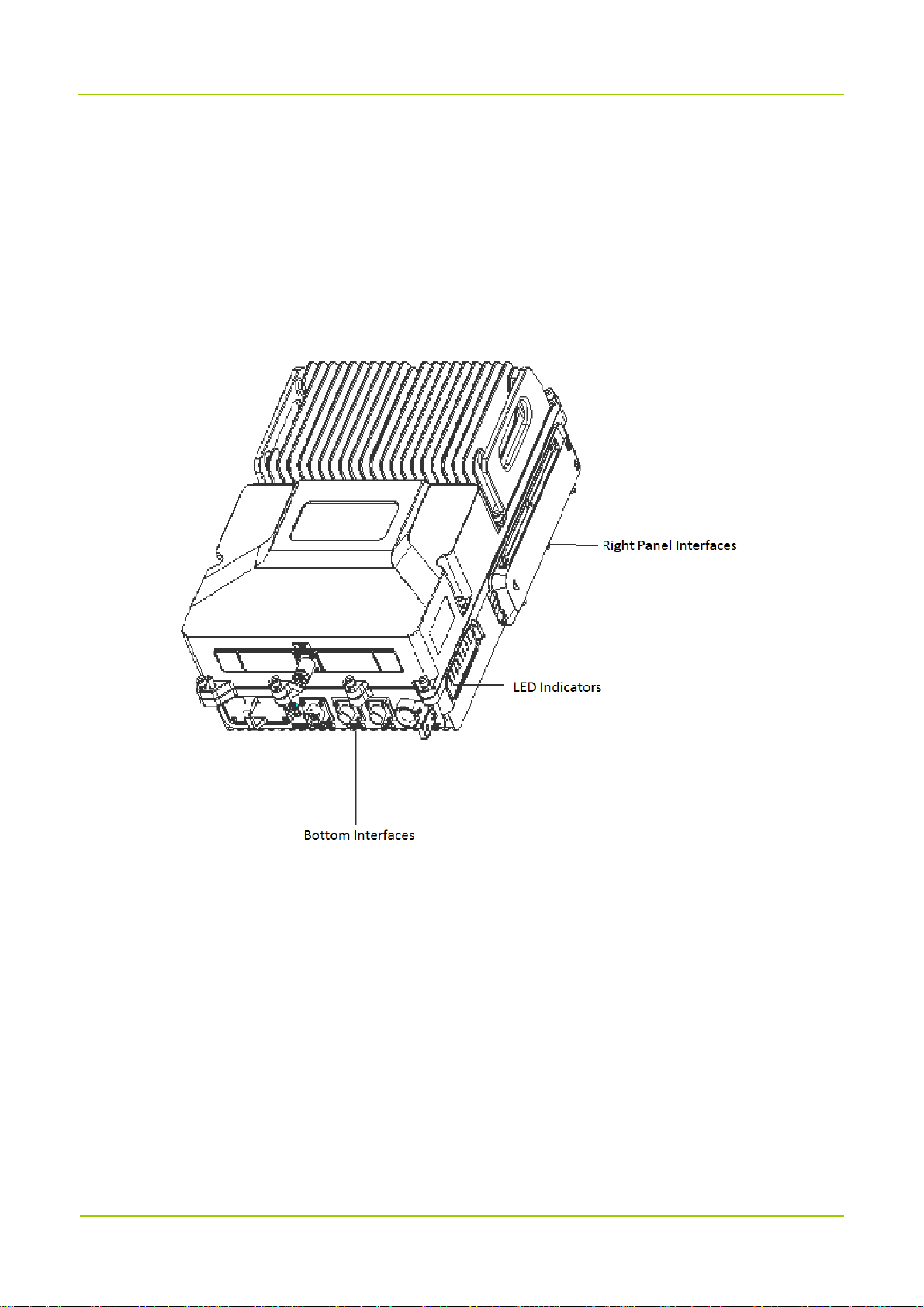

DS-9300 adopts modular design. For the wireless-access donor unit and the remote unit, its LED

indicators and connectors are provided on the front and rear panels of the rack. The following figure shows

the appearance of the remote unit.

For the donor unit, its LED indicators are provided on the right side and connectors are provided on its

bottom and right side. The following figure shows the appearance of the donor unit.

11

Getting Started User Manual

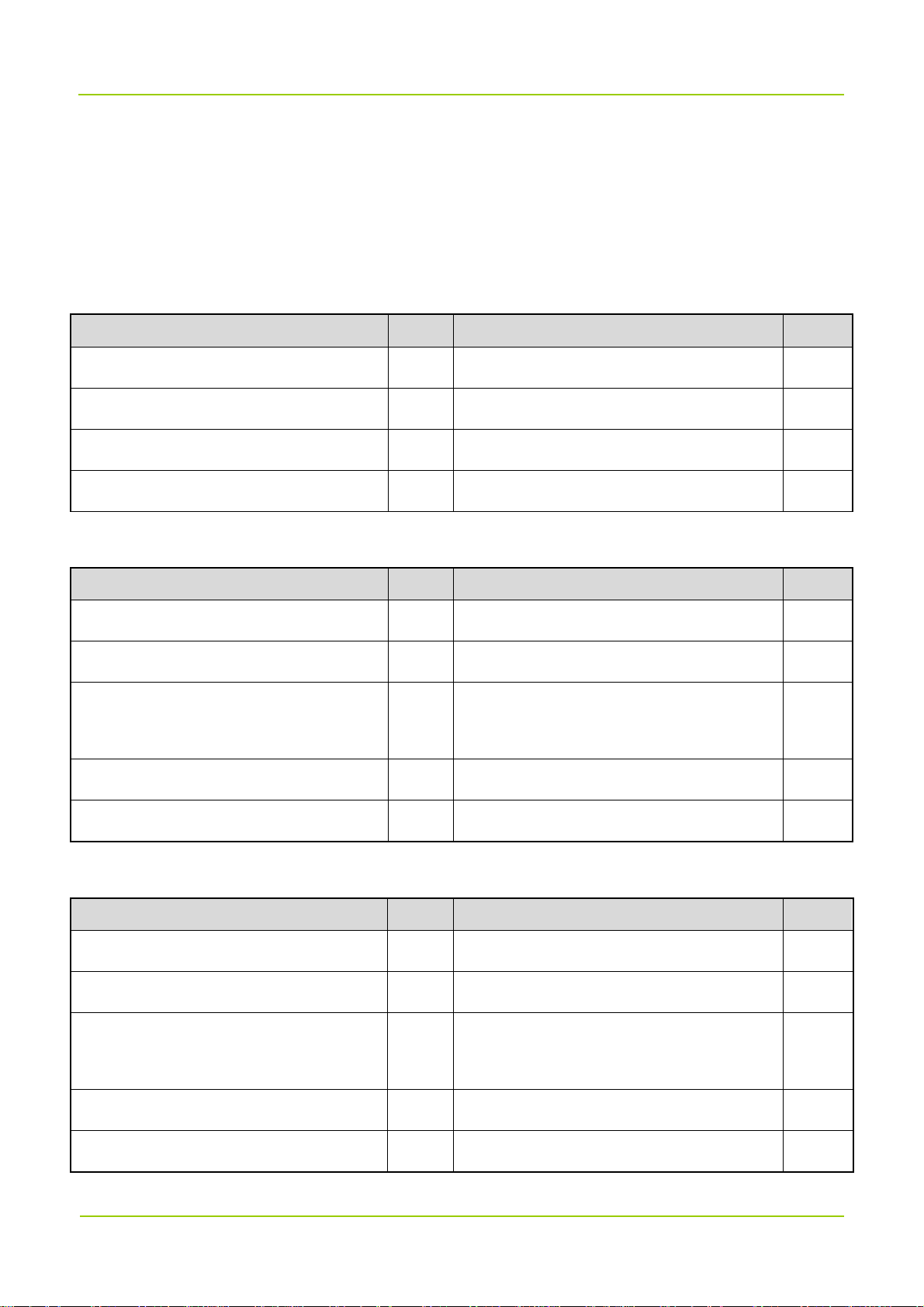

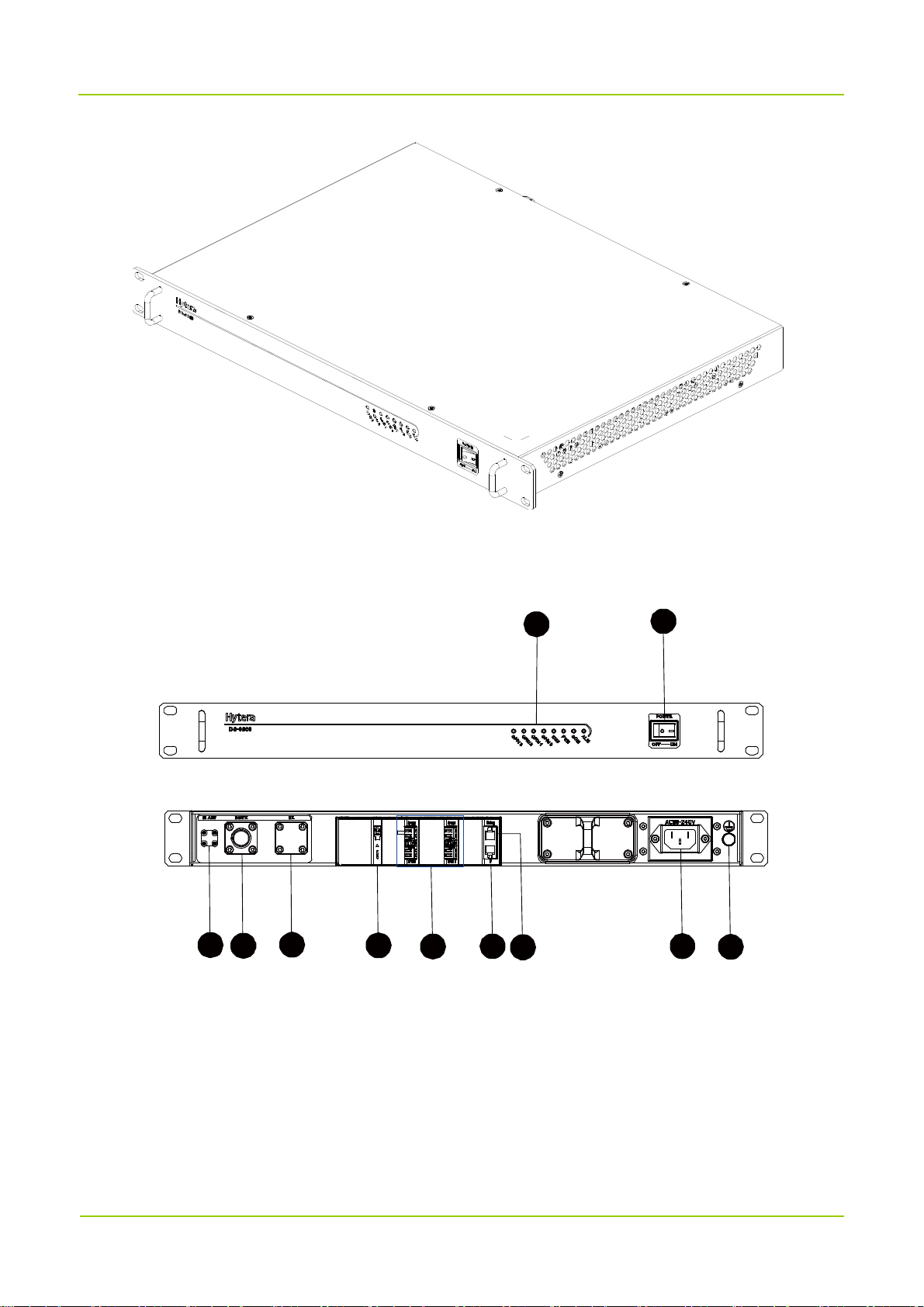

3.2 Donor Unit Interfaces

3.2.1

Cable-access Donor Unit

3

4

5 6

7 8

9

1

2

1010

11

12

User Manual Getting Started

3.2.2 Wireless-access Donor Unit

15

1

3.3 Remote Unit Interfaces

3

12

13

6

16

14

7

11

8

9

13

12

1

13

14

6

11

9

8

7

Getting Started User Manual

3.4 Interface Description

No. Label Meaning Connector Description

1 / LED indicators / See "3.6".

Single-pole-doubl

2 POWER Power switch

Modem antenna

3 MANT

connector

e-throw switch

SMA-F Reserved.

/

ANT port of the

4 BS/TX

5 RX RX port of the BS N/F

6 LOC

7 CPRI 0–3 Optical port

8 IP

9 Debug

duplexer, or TX

port of the BS

Local debug

interface

Remote

monitoring port

Optical module

debug interface

N/F

3-pin connector

SFP connector,

dual-layer

RJ45 port

RJ45 port

Connected to the ANT port of the

duplexer, or connected to the TX port of

the BS if the duplexer does not exist.

Connected to the RX port of the BS if the

duplexer does not exist.

Connected to computer through the serial

cable for debugging and monitoring.

The donor unit connects to remote units

through CPRI interface.

Connected to computer through the

network cable for remote debugging and

monitoring.

Interface for board debugging, used by

R&D engineers.

10

11 GND Ground terminal / /

12 AC Power inlet

13 EXM External alarm port

14 LCT

AC

Power inlet

90-264 V

Alarm port for 6-pin round

3-pin AC

connector

3-pin round

electric connector

8-pin round

electric connector

14

/

AC power inlet.

Connected to external devices that need

alarm monitoring.

Donor Unit: Monitors location change

User Manual Getting Started

No. Label Meaning Connector Description

location change

and door entry

15 BS RF interface N/F Connected to the donor antenna.

16 MS RF interface N/F Connected to the service antenna.

electric connector

(generates an alarm upon illegal

location change).

Remote Unit: Monitors location

change and the optical bypass switch.

3.5 Interface Definition

EXM

Pin No. Signal Name Definition Remarks

1 INT1 External alarm 1 Closed: Alarm; Open: No alarm.

2 INT2 External alarm 2 Closed: Alarm; Open: No alarm.

3 INT3 External alarm 3 Closed: Alarm; Open: No alarm.

4 GND Ground (signal) Common terminal.

Customized Alarm 1

5 OUT1 Reserved

Closed: Alarm; Open: No alarm.

6 GND Reserved Drive current: 10 mA (nominal), and 30 mA (max)

Customized Alarm 2

7 OUT2 Reserved

Closed: Alarm; Open: No alarm.

8 GND Reserved Drive current: 10 mA (nominal), and 30 mA (max)

LCT

Pin No. Signal Name Definition Remarks

Alarm for location

1 LCT

change

2 GND Ground /

Monitors location change of the devices.

3 DOOR Door entry alarm

Subjects to the chassis structure (available for cast

chassis).

15

Getting Started User Manual

Pin No. Signal Name Definition Remarks

4 GND Ground /

LOC

Pin No. Signal Name Definition Remarks

1 TX Data transmission Output.

2 RX Data receiving Input.

5 GND Ground /

3.6 LED Indicators

The LED indicators on the donor and the remote units indicate the running status.

LED

Indicator

ALM/VSWR Red

COM Green

PWR Green

RUN Green

CPRI 0 Green

Color Status Description

Off The device is running well.

Glowing or flashing The device malfunctions.

Glowing Remote communication works well.

Off Remote communication error.

Glowing The device is properly powered.

Flashing or off The device is not properly powered.

Flashing The device runs properly.

Glowing or off The device malfunctions.

Glowing Optical synchronization works well.

Flashing or off Optical synchronization error.

Glowing Optical synchronization works well.

CPRI 1 Green

Flashing or off Optical synchronization error.

Glowing Optical synchronization works well.

CPRI 2 Green

Flashing or off Optical synchronization error.

CPRI 3 Green Glowing Optical synchronization works well.

16

User Manual Getting Started

LED

Indicator

Color Status Description

Flashing or off Optical synchronization error.

17

Installation User Manual

4. Installation

4.1 Safety Information

Before performing any operation, read the following precautions and operation instructions carefully to

ward off potential risks.

Local Laws and Regulations

When installing a device, comply with the local safety laws and regulations.

Power Supply

Danger

Direct contact or indirect contact (through moist objects) with the high voltage or mains

electricity may result in fatal danger.

Non-standard and incorrect operations on the high-voltage power supply may result in fire

and electric shock.

Never wear conductive objects such as watches, bracelets and rings during operation.

Do use special tools when operating at high or AC voltage.

Do keep moisture out of the power system during operation in moist environment.

The equipment should be well earthed to avoid damage as a result of lightning strikes.

Do turn off the power before assembly or disassembly.

Do verify the cable specifications prior to connection.

Ensure that the equipment is well earthed before power-on.

Turn off the power immediately when the cabinet is found to get wet.

Make sure the power switch is toggled to the Off position before installing the equipment.

Working Aloft

Work performed more than 2 m (6.56 ft.) above the ground is regarded as work at heights.

While working at heights, stay alert to the following conditions.

Stop such work in any of the following conditions: adverse weather, wet steel tubes, and other risky

situations.

Set danger signs and prevent unauthorized person from entering the work area.

Avoid stacking scaffolds and other materials, and staying or passing below the aerial work platform.

18

User Manual Installation

Avoid dropping machinery and tools from the heights. Use strong ropes, hanging baskets or cable cars

to deliver tools.

Take sound safety actions such as wearing hamlets and safety belts properly.

Do wear heat-retaining clothes for working in cold areas.

Make sure the ladder is safe for use. Overload is strictly prohibited.

The slant of the ladder is suggested to be 75°. When using a ladder, place it on a stable ground, and

take protective measures on the base part of the ladder for skid resistance.

Handle and use all devices and tools with care to avoid falling.

Do not play or sleep on the aerial work platform.

Personnel

Installation and maintenance personnel must be trained to perform operations correctly and safely.

4.2 Installation Flow

Install DS-9300 device by following the installation flow below.

4.3 Preparation

19

Installation User Manual

4.3.1 Environment

Space Requirements

It is recommended that the space of at least 200 mm be left between the product top and the ceiling,

and 500 mm between the product bottom and the ground.

For product installed at its back, the space of at least 500 mm should be left at the right side, and 200

mm at the left side of product; for product installed at its left side, the space of at least 200 mm should

be left in front of product, and 200 mm in the back of product.

For product installed at its back, the space of at least 800 mm should be left in front of product; for

product installed at its left side, the space of at least 800 mm should be left at its right side.

Install the product upright at a proper position.

Environmental Protection

To ensure device reliability, install the devices in places with stable temperature.

Protection against Sun

If the devices are exposed to the sun, it is necessary to keep them well-ventilated and heat sinking. If

the temperature is more than 40°C, shielding device is required.

Protection against Rain, Water and Snow

The devices are rain proof, waterproof and snow proof. But temporary protective measures are needed

for maintenance.

Protection against Interferences

20

User Manual Installation

The devices should be installed far away from electromagnetic interferences such as large electric

devices.

Outdoor Installation and Maintenance

If the devices are installed outdoor, do not perform maintenance on extreme weathers such as storm,

extreme temperature or high humidity.

Grounding Requirements

The ground wire must be connected before device installation, and be removed after the device is

dismantled. Do not damage the grounding conductors.

Do not operate the devices when the grounding conductor is not installed.

The devices must be permanently grounded. Before any operation, please check the electrical

connection of the devices, making sure they are grounded properly.

4.3.2 Instruments and Tools

The following table lists the required tools:

Torx screwdriver, Philips driver, flat blade screwdriver, adjustable wrench, Allen

Regular Tools

Safety Tools

Cable Making Tools

Measuring Tools

Auxiliary Tools

wrench, cross-type torque screwdriver, combination wrench, rubber hammer,

and torque wrench.

Antistatic wrist strap, safety belt, helmet, safety rope, and slip-proof gloves.

Wire stripper, wire crimper, and wire cutter.

Multi-meter, tape measure, and level.

Fixed pulley, step ladder, marker pen, percussion drill, electrical tape, anti-UV

cable tie, label, screw kit, expansion screw, utility knife, heat gun, and duct tape.

4.3.3 Material Preparation

Before installation, check that all materials are well received according to the packing list.

4.4 Installing the Units

Place and fix the cable-access donor unit inside the cabinet.

The wireless-access donor unit and the remote unit can be mounted on a pole or wall as per needs. Check

latter chapters for more details.

21

Installation User Manual

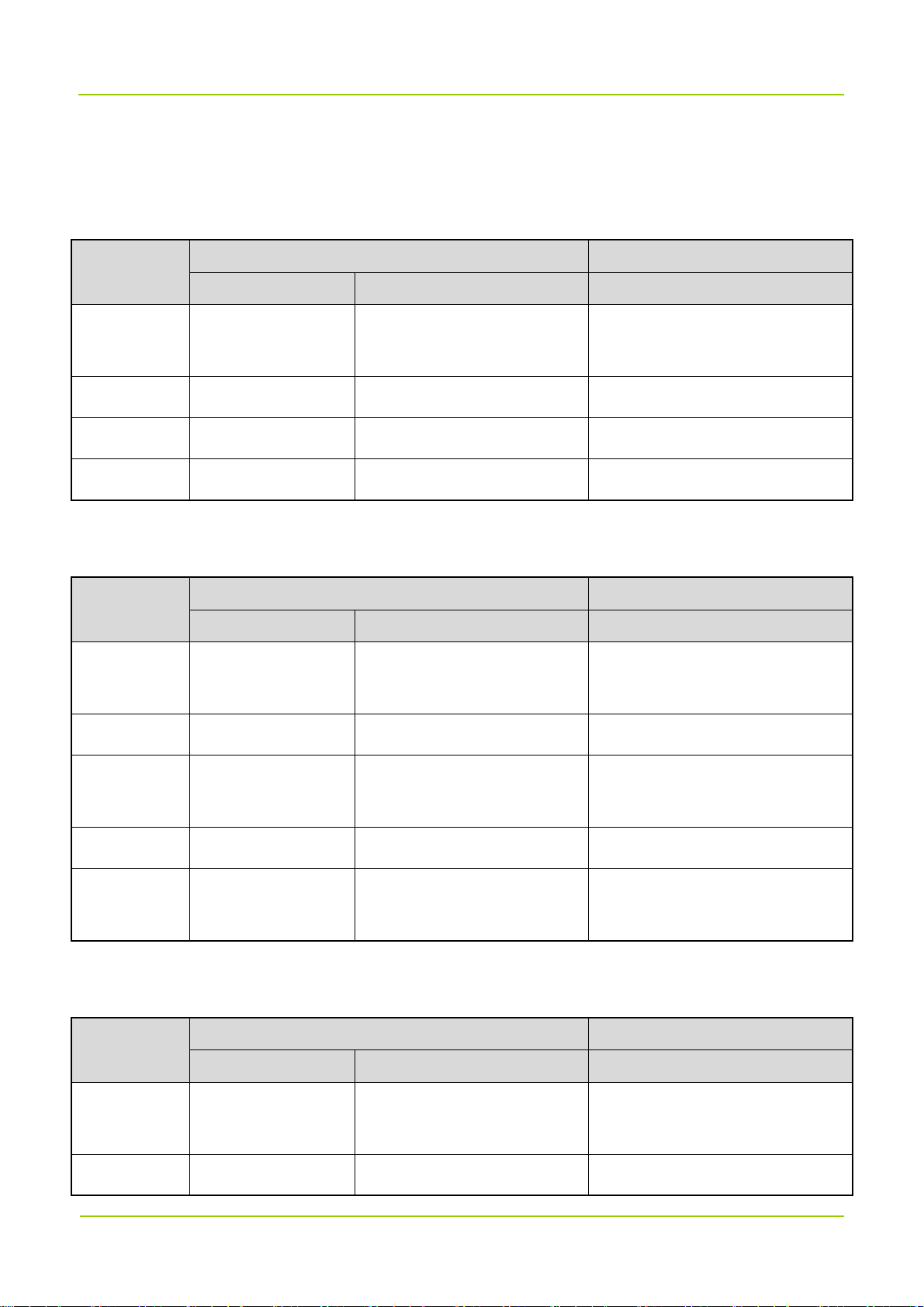

4.4.1 Installation Parts

The following figure shows the parts needed for installation, including the auxiliary fixture, back panel,

latches and M6 screws.

AuxiliaryFixture

CaptiveScrew

BackPanel

M6Screw

Bolt

4.4.2 Installing the Product

Installation on Pole

You can install the product at its back or at its left side. The pole diameter should be between 60 mm to 114

mm.

Installing at Back

1. Mark the installation position of the auxiliary fixture on the pole by using a marking pen.

2. Place the auxiliary fixture onto the pole, insert four bolts into the auxiliary fixture and then tighten four

nuts by using a torque wrench.

3. Secure the back panel onto the back of the product using four M6 screws.

22

User Manual Installation

4. Insert the back panel into the auxiliary fixture and tighten the captive fasteners on the back panel of the

product.

Installing at Left Side

Installing the product at left side and installing the product at back are almost the same. The only difference

is that the back panel is secured to the left side rather than back of the product. The following figure shows

the product installed at its left side.

23

Installation User Manual

Installation on Wall

You can install the product on a wall at the back or left side of the product.

Installing at Back

1. Place the auxiliary fixture on the wall at the installation position and then mark the anchor points by

using a marking pen.

2. Drill holes at the anchor points and then install the expansion bolt assemblies.

3. Fit the auxiliary fixture on the expansion bolts, and then tighten the bolts.

24

User Manual Installation

4. Secure the back panel onto the back of the product using four M6 screws.

5. Insert the back panel into the auxiliary fixture and tighten the captive fasteners on the back panel of the

product.

25

Installation User Manual

Installing at Left Side

Installing the product at left side and installing the product at back are almost the same. The only difference

is that the back panel is secured to the left side rather than back of the product. The following figure shows

the product installed at its left side.

26

User Manual Installation

4.4.3 Cabling

Cabling Requirements

Lay out cables according to requirements to reduce interference between them.

Safety Requirements

Lay out cables away from sharp objects or jagged walls, or protect cables using conduit.

Lay out cables away from heat sources, or add heat-insulation materials between cables and heat

sources.

Requirements for Binding Cables

Bind same cables together.

Bind cables securely and neatly, without damaging the cable jackets.

Ensure that cable ties face the same direction and are aligned in rows horizontally.

After installing cables, attach labels or tags to the two ends of each cable.

Cables of different types cannot be crossed.

Requirements for Laying Out Power Cables

The routing of power cables must meet engineering design drawing requirements.

If the power cable length is insufficient, replace the power cable. The power cable must be complete

and cannot have splices or welding points.

Avoid knotting or twisting the cable.

Requirements for Laying Out Grounding Cables

The grounding cable cannot be led in aerially, but buried in the earth or arranged indoor.

The grounding cables must be separated from signal cables to reduce interference between them.

All metal components in the chassis must be securely connected to the grounding cable.

Requirements for Laying Out Optical Fibers

Do not bind optical fibers where they are bent.

Do not press optical fibers forcibly or crush optical fibers with force. Leave sharp objects away from

optical fibers to prevent damage to optical fibers.

Coil up redundant optical fibers around specialized devices such as the splice tray.

Optical jumpers must be bound with optical fiber tapes. If the fiber is required to be fixed on the cabinet

or device, then use the cable tie to bind the fibers on the optical fiber tape. Attention that the optical fiber

must be flexible in the cable tie, and must not be bent into 90° angle.

Coil optical fibers gently and do not break them.

27

Installation User Manual

Cover idle optical fiber connectors with protective caps.

Cable List

Cable-access Donor Unit Cable List

One end (at DS-9300 device) Other end

Cable

Connector Connected to …… Connected to ……

Grounding

Cable

RF Antenna N-M

Power Cable 3-pin AC Connector AC 90-264 V External Power Supply

Optical Fiber SFP/SFP+ CPRI 0–3 Fiber Optic Network

Ring Terminal Ground Terminal Grounding Bar

RX/TX/BS Interfaces Base Station

Wireless-access Donor Unit Cable List

One end (at DS-9300 device) Other end

Cable

Connector Connected to …… Connected to ……

Grounding

Cable

RF Antenna N-M

Ring Terminal Ground Terminal Grounding Bar

BS Interface Antenna System

Power Cable

Optical Fiber SFP/SFP+ CPRI 0–3 Interfaces Optical Fiber Network

Monitoring

Cable

Round Electric

AC Interfaces External Power Supply

Connector

8-pin/1-pin Aviation

EXM/LCT Interfaces External Monitoring Device

Connector

Remote Unit Cable List

One end (at DS-9300 device) Other end

Cable

Connector Connected to …… Connected to ……

Grounding

Ring Terminal Ground Terminal Grounding Bar

Cable

RF Antenna N-M

MS Interface Antenna System

28

User Manual Installation

One end (at DS-9300 device) Other end

Cable

Connector Connected to …… Connected to ……

Power Cable

Optical Fiber SFP/SFP+ CPRI 0–1 Interfaces Optical Fiber Network

Monitoring

Cable

Round Electric

AC Interfaces External Power Supply

Connector

8-pin/1-pin Aviation

EXM/LCT Interfaces External Monitoring Device

Connector

Cabling Guide

Cable-access Donor Unit

29

Installation User Manual

Wireless-access Donor Unit

Remote Unit

Installing the Grounding Cable

1. According to the route, make a grounding cable with proper length, and install ring terminals at both

ends of the cable.

30

User Manual Installation

The metal wires must be completely sealed, as shown in the figure below.

2. Connect one end of the cable to the ground connector at bottom of DS-9300 and the other end to the

grounding bar.

3. Attach labels or tags to the installed cable.

Installing the RF Antenna

1. Remove protective caps from the antenna connector.

2. Connect the male end of the RF cable to the BS interface of the donor unit or the MS interface of remote

unit and tighten the connector using the torque wrench.

3. Connect the donor unit to the coupler, and connect the other end of the RF antenna from the remote

unit to the service antenna.

If the antenna is installed outdoor, it needs to be connected to a lightning arrestor. In this case, the other

end of the RF antenna connects to the lightning arrestor.

4. Waterproof the cable connectors.

a. Wrap a layer of PVC insulation tape around the cable connector from bottom to top.

b. Wrap three-layer waterproof tape over the PVC insulation tape. Starting from 50 mm from the

bottom of the antenna connector, wrap the three-layer waterproof tape in the following patterns:

31

Installation User Manual

bottom to top, top to bottom, and bottom to top again. Cut off the tape after the three-layer is done.

Tighten the tape at each layer to ensure waterproof.

c. Wrap three-layer PVC insulation tape over the waterproof tape. Starting from 30 mm from the

bottom of the waterproof tape, wrap the three-layer PVC insulation tape in the same method as

introduced in step b.

d. Bundle cable ties at 3–5 mm from both ends of the tape.

5. Check the dustproof cap of the antenna connector, and waterproof it in the same method as introduced

in step 4.

6. Waterproof idle connectors on the bottom of DS-9300 device without removing the protective caps,

according to step 4.

7. Lay out the cable according to design requirements and fix the cable with cable ties.

8. Attach labels or tags to the installed cable.

Installing the Power Cable

Note

Power cable delivered with DS-9300 device is 3*18 AWG cable.

1. Connect one end of the power cable to the PWR connector of DS-9300 device and the other end to the

external power supply. Lay out the cable according to design requirements and fix the cable with cable

ties.

3. Attach labels or tags to the installed cable.

Installing the Monitoring Cable

1. Remove protective cap from the EXM/LCT connector of DS-9300 device. Connect one end of the

monitoring cable to the EXM/LCT connector of DS-9300 device and the other end to the external

monitoring device.

3. Lay out the cable according to design requirements and fix the cable with cable ties.

4. Attach labels or tags to the installed cable.

Installing the Optical Fiber

The remote unit receives signals from the donor unit at CPRI 0 and outputs signals to the connected

remote unit at CPRI 1, as shown in the following figure.

32

User Manual Installation

Procedure of installing the optical fiber is described as follows:

1. Connect the optical module to the SFP connector of DS-9300 device, as shown in the following figure.

Note

DS-9300 device adopts a dual-fiber single mode optical module with a transfer rate of 1.25 Gbps, a

wavelength of 1,310 nm and a communication distance of 20 km.

1

a. Rotate the bail clasp latch down.

b. Insert the optical module into the SFP connector.

c. Rotate the bail clasp latch back.

2

3

2. Connect the fiber pigtail to the optical module and the other end of the fiber to the external transmission

device, as shown in the figure below.

33

Installation User Manual

3. Lay out the cable according to design requirements and fix the cable with cable ties.

4. Attach labels or tags to the installed cable.

4.5 Post-installation Check

4.5.1

Check the cables according to the table below.

No. Item

Checking the Installation

The device is installed by strictly following the design draft. The installing position meets space

1

requirements with maintenance space reserved.

2 The device is securely installed.

3 Waterproof caps are installed on idle connectors and securely fastened.

All power cables or grounding cables are not short-circuited or reversely connected and must be

4

intact with no damage.

5 The power cables and grounding cables are separated from other cables and bundled separately.

Connectors of all cables are complete, intact, and tightly connected. The cables are not damaged

6

or broken.

7 Labels on cables, feeders and jumpers are clear and correct.

4.5.2 Checking the Device with Power On

After the installation is complete, observe indicators on DS-9300 device to determine the system running

status.

34

User Manual Installation

If the RUN indicator flashes green and the ALM indicator is off, the status of DS-9300 device is normal.

35

Power On and Power Off User Manual

5. Power On and Power Off

5.1 Powering On

Toggle the power switch on DS-9300 device to the ON position to power it on. Wait a few minutes and

check the status of LED indicators.

5.2 Powering Off

Toggle the power switch on DS-9300 device to the OFF position to power it off.

36

User Manual Debugging

6. Debugging

Use the Product Support Software (PSS) to configure and upgrade the DS-9300 device.

6.1 Preparation

Before debugging, prepare the PSS tool, and connect the device to the computer. You can debug the

device either locally through the cable or IP connection, or remotely through IP connection. The default IP

address of the device is 192.168.1.100; the IP address of the computer must be set to the same network

segment, 192.168.1. X (X cannot be 100).

The computer for running the PSS must meet requirements specified in the following table:

Item Description

Operating system Windows7 or above

CPU PII300 or above

Memory 128 MB or above

Storage 2 GB or above

Display 14-inch or above, resolution 800x600 or above

6.2 Procedure

The process of local debugging and remote debugging is the same. In this document, local debugging is

taken as example. For remote debugging, please refer to Repeater Management System Operation Guide.

1. Double-click "DS9300_PSS.exe" on the computer. The following main interface appears.

37

Debugging User Manual

2. Click Project, select DS_9300_CUSTOMER and click Lock. A message indicating locking database

succeeded will appear in the message pane.

3. Select Ethernet tab, set the Destination and Port and click Connect.

Note

For debugging through the serial cable, select the Serial tab, set the Serial and Baudrate

(115200) and click Connect.

4. Click Scan and the following window appears.

5. Select devices you want to display on the PSS and click OK.

38

User Manual Debugging

6.2.1

To manually query parameters of the selected device, click Query Parameter.

If you click Auto Query, PSS will query all the parameters of the selected device every two seconds.

In the Scan list, click on the device and check Select All. Click Query Parameter, the parameter values

will be displayed in Status.

Querying Parameters

Note

To query a specific parameter, check the parameter name and click Query Parameter.

To query all parameters on the line, click the blank tab above the checkbox as shown in the figure

below.

6.2.2

1. In the parameter list, click the blank space under Setting tab from the same row the parameter locates

Setting Parameters

(the parameter is thus checked by default), enter or select a value. For the detail description of each

parameter, see chapter Appendix: Parameters.

a. (Optional for channel-selective devices) Select

switch of the current BS, then set the corresponding uplink and downlink working channel frequencies.

Parameter Settings

tab, and turn on the channel

Other spare channel switches need to be turned off.

39

Debugging User Manual

Note

For remote units, set the Downlink Output Under-power Threshold 10 dBm less than the actual

output power in most cases.

b. Select

parameter should be around -13 dBm for a cable-access donor unit, and -58 dBm for a wireless-access

donor unit. In case the differences are large, add attenuators to the power input port of the cable-access

donor unit according to the difference value, or adjust the corresponding donor antenna of the

wireless-access donor unit.

c. Select the

Parameter Value

IP Address

IP Mask

IP Gateway

Real-time Sampling

Device Information

This parameter is subject to actual requirements. The default value is

192.168.1.100.

This parameter is subject to actual requirements. The default value is

255.255.255.0.

This parameter is subject to actual requirements. The default value is

192.168.1.1. The first three numbers must be consistent with that of the

device IP address, the last number must be 1.

tab, and view the

tab, and modify the configuration according to the following table.

Downlink Input Power Level

. The value of this

Device No.

The donor unit is 0; the range for remote unit in low configuration is 1 to 4;

the range for remote unit in high configuration is 1 to 16.

40

User Manual Debugging

d. Select the

configured. When an alarm is generated, it will be alerted in red font and needs handling.

2. Click Setting, the result will be displayed in the message pane.

Alarm Status

tab, and turn on all switches if a repeater management system (RMS) is

Note

To restore the factory settings, click Factory Reset.

6.2.3

PSS allows you to upgrade the main program of the monitor board and the main program and FPGA of the

digital board.

1. In the Upgrade area, click Load.

2. Select the software and click Upgrade. The result will be displayed in the message pane.

Upgrade

41

Debugging User Manual

Note

If the upgrade fails or you want to roll back to the former version, perform the upgrade using the old

upgrade file.

6.2.4 Exporting the Logs

PSS allows you to export the operation logs.

1. In the Log area, click Path.

2. Specify the storage path and click Start.

42

User Manual System Maintenance

7. System Maintenance

7.1 Care and Cleaning

To guarantee optimal performance as well as a long service life of the product, please follow the tips below.

Caution

Be sure to turn off the product before cleaning.

Product Care

Attach the connector cover with waterproof plug when the connector is not in use.

Do not pierce, strike, throw or scrape the product.

Keep the product away from substances that can corrode the circuitry.

Keep the device dry.

Keep this device far away from overheating, which may shorten lifespan of the electronic parts, or even

distort or melt the plastic parts.

Keep this device far away from extreme cold. Otherwise, the circuit board may be damaged by vapor

generated when the device is used at normal temperature.

Product Cleaning

Clean up the dust and fine particles on the product surface and charging piece with a clean and dry

lint-free cloth or a brush regularly.

Use a non-woven cloth with neutral cleanser to clean the device after long-time use. Do not use

chemical preparations such as stain removers, alcohol, sprays or oil preparations, so as to avoid

potential damage on the surface. Make sure the product is completely dry before use.

7.2 Routine Maintenance

To ensure reliable communication, it is recommended to perform the following check tasks on a regular

basis:

Check whether the return loss of the antenna feeder system is normal, whether the position and

direction of the antenna are changed, and whether the RF cable connectors are properly sealed.

Check whether the indoor cables are moved, whether the fixed devices are loosened, and whether the

power connection is in good condition.

Check whether the lightening arrestor and the grounding are in good condition.

Check whether the power voltage of the device is normal.

43

System Maintenance User Manual

Regularly check and record the working status and main parameters such as receiving signal level,

output noise level, and downlink output power.

Check whether the coverage meets the requirements.

Check whether the monitoring system works properly.

Check whether the signs and labels on the devices are complete.

If the device malfunctions, return it for repair.

7.3 Alarm Handling

Alarm Information Solution

Check whether the power supply and signal cable connection of the LNA and

LNA and PA Alarm

PA modules are in good condition. If the alarm still exists, replace the module.

Power Fault and Power

Down Alarm

PA Over-temperature

Alarm

Door Alarm

Location Alarm

Downlink VSWR Alarm

If the power down alarm is generated, check whether the AC power connection

is in good condition, and whether the power supply is normal.

Change the temperature threshold to clear the alarm. It's recommended to set

the maximum temperature threshold to 90°C. If the alarm still exists, cool the

device down.

Check whether the cabinet door is properly closed. If the alarm still exists after

the door is closed, check whether the door and the alarm cable are properly

connected.

Check whether the device is moved illegally. If not, check whether the alarm

cable is properly grounded.

Check whether the SWR threshold of the downlink PA is set correct. It is

recommended to set the threshold as 3.0. If the alarm does not disappear,

check whether the antenna system is connected well, or flooded with water. It

is recommended to use a VSWR tester to test the actual SWR threshold.

Uplink/Downlink

Input/Output

Over-power/Under-power

Alarm

Change the input/output over-power/under-power thresholds to clear the

alarm. It is recommended to set the thresholds as follows:

Uplink Output Over-power Threshold (Donor Unit): 0 dBm (nominal

downlink output power)

Downlink Input Over-power Threshold (Donor Unit): –5 dBm

Downlink Output Under-power Threshold (Remote Unit): +25 dBm (nominal

44

User Manual System Maintenance

Alarm Information Solution

downlink output power)

7.4 Troubleshooting

Phenomena Possible Cause Solution

The device fails to be

powered on.

The RUN indicator glows

green solidly.

The RUN indicator is off.

The ALM indicator glows

red solidly.

The ALM indicator flashes

red.

The power cable is not connected, or the

contact with the socket is loose.

The unit is powered, but a module is

faulty.

The unit is not powered, or a module is

faulty.

A module is faulty. Replace the faulty module.

A connector is faulty. Check the connector.

Connect the power cable

properly and ensure good

contact.

Troubleshoot or replace the

faulty module.

Check whether the power cable

is properly connected, or

troubleshoot the faulty module.

Or replace the faulty module, if

necessary.

The VSWR indicator

flashes red rapidly.

The VSWR indicator

flashes red slowly.

The SFP indicator is off. The optical fiber link is faulty.

If the above solutions cannot fix your problem, please contact us.

One or more ports generate VSWR alarm

during starting of the unit.

One or more channels are abnormal after

the cell is set up.

45

Check whether the connection of

the antenna system is proper.

Check whether the connection of

the antenna system is proper.

Check whether the fiber and the

optical module are properly

connected.

Appendix: Parameters User Manual

8. Appendix: Parameters

Take the donor unit as example.

Device Information

Parameter Configuration Remarks

Electronic Serial Number

(ESN)

Monitor Version Keep the default value unchanged. Version of the monitor board.

FPGA Version Keep the default value unchanged.

Application Version Keep the default value unchanged.

IP Address

Subnet Mask

Enter up to 10 characters, including digits

and letters.

This parameter is subject to actual

requirements. The default value is

192.168.1.100.

This parameter is subject to actual

requirements. The default value is

255.255.255.0.

Serial number of the device.

Version of FPGA in the digital

modules.

Version of applications in the

digital modules.

/

/

Default Gateway

Site ID

This parameter is subject to actual

requirements. The default value is

192.168.1.1. The first three numbers must

be consistent with that of the device IP

address, the last number must be 1.

The range is 0 to 4294967295. The site ID

must end with the ID of its home BS. For

example, if a donor unit has a site ID of

20001, then "2" represents the donor unit

ID and "0001" represents the home BS

ID; if the remote unit has a site ID of

160020001, then “16” represents the

remote unit ID, “002” represents the home

donor unit ID, and “0001” represents the

46

/

The only ID of the device,

consistent with its configuration

in the repeater management

system (RMS).

User Manual Appendix: Parameters

home BS ID.

The donor unit is 0; the range for remote

Device number of

Device No.

unit in low configuration is 1 to 4; the

corresponding donor or remote

range for remote unit in high configuration

units.

is 1 to 16.

The range is 0 to 255.

Manufacturer ID

Device Type

1: Hytera

2: Reserved

The range is 1 to 13.

1: DCCD

2: DCR

3: DICR

4: LA

5: DWCD

6: DCBD

7: DBR

8: DWBD

9: DCCD L

10: DWCD L

/

/

Device Number

Device Description

Device Longitude

11: DCBD L

12: DWBD L

13: Reserved

Enter up to 20 characters, including digits

and letters.

Enter up to 20 characters, including digits

and letters.

This parameter is subject to actual

requirements.

Negative number represents South

47

Material number of the device.

Material description of the

device.

/

Appendix: Parameters User Manual

Latitude or West Longitude.

This parameter is subject to actual

requirements.

Device Latitude

Negative number represents South

Latitude or West Longitude.

The range is 0 to 2.

Communication Method for

1: SNMP

Reporting Alarms

2: Reserved

/

/

This parameter is subject to actual

Monitor Center IP Address

requirements.

The range is 0 to 65535. This parameter

Monitor Center Port No.

is subject to actual requirements.

This parameter is subject to actual

Site Description

requirements.

Real-time Sampling

Parameter Configuration Remarks

Manufacturer ID The range is 0 to 255. /

Location Area ID The range is 0 to 65535. /

Source BS ID The range is 0 to 4294967295. /

BCCH Absolute Carrier No. The range is 0 to 65535. /

IP address of the RMS Monitor

Center.

Port number of the RMS

Monitor Center.

/

BCCH Receiving Level The range is –127 to 127. /

The range is 1 to 4.

1: PDT

Signal Format

Max. Working Channels Keep the default value unchanged.

2: DMR

3: TETRA

4: Others

48

/

Only available on

channel-selective devices.

User Manual Appendix: Parameters

Actual Number of Carriers The range is 0 to 32.

Downlink Input Power Level

(dBm)

Uplink Output Power Level

(dBm)

Remote Unit Online Switch

Remote Unit Connection

Indicator

Donor Unit Connection

Indicator

The range is –110 to 10. /

The range is –110 to 50. /

0: Offline

1: Online

0: Not connected

1: Connected

0: Not connected

1: Connected

Actual number of channels the

device has opened.

Whether the remote unit is

online.

Whether a remote unit is

connected.

Whether a donor unit is

connected.

Setting Parameters

Parameter Configuration Remarks

Downlink Input Over-power

The range is –110 to 10. /

Threshold (dBm)

Uplink Output Over-power

The range is –110 to 50. /

Threshold (dBm)

System Uplink Gain (dB) The range is 0 to 100. /

System Downlink Gain (dB) The range is 0 to 100. /

Uplink Channel Reference

Base Frequency (MHz)

Downlink Channel

Reference Base Frequency

(MHz)

This parameter is subject to actual

requirements.

This parameter is subject to actual

requirements.

/

/

Increment (kHz)

This parameter is subject to actual

/

requirements.

49

Appendix: Parameters User Manual

1: Report

Inspection Report

0: Do not report

1: Report

Troubleshooting Report

0: Do not report

/

/

Configuration Change

Report

Downlink PA Over-current

threshold

Uplink/Downlink Squelch

Threshold (dBm)

Uplink/Downlink Squelch

Switch

Remote Unit Delay

Auto-compensation Switch

Uplink Digital Attenuation

(dB)

Downlink Digital

Attenuation (dB)

1: Report

0: Do not report

The range is 0 to 65535.

The range is –110 to 50. /

0: Enable

1: Disable

0: Enable

1: Disable

The range is 0 to 20. /

The range is 0 to 20. /

/

/

/

/

Monitor Board Software

Version Switch

Digital Board Software

Version Switch

FPGA Software Version

Switch

Uplink Operating Channel

(MHz)

Downlink Operating

Channel (MHz)

0: Do not switch

/

1: Switch

0: Do not switch

/

1: Switch

0: Do not switch

/

1: Switch

This parameter is subject to actual

/

requirements.

This parameter is subject to actual

/

requirements.

50

User Manual Appendix: Parameters

0: Disable

Channel Switch

1: Enable

/

Alarm Status

Parameter Configuration

0: Disable

Master-Slave Monitoring Link Fault Alarm Enable

1: Enable

0: Disable

Power Supply Disconnection Alarm Enable

1: Enable

0: Disable

Power Supply Fault Alarm Enable

1: Enable

Downlink Input Over-power Alarm Enable

Uplink Output Over-power Alarm Enable

Uplink Local Oscillator Unlock Alarm Enable

Downlink Local Oscillator Unlock Alarm Enable

Remote Digital Module Fault Alarm Enable

Downlink LNA Fault Alarm Enable

0: Disable

1: Enable

0: Disable

1: Enable

0: Disable

1: Enable

0: Disable

1: Enable

0: Disable

1: Enable

0: Disable

1: Enable

Optical Receiving Alarm Enable

Optical Transmission Alarm Enable

Downlink PA Over-current Alarm Enable

0: Disable

1: Enable

0: Disable

1: Enable

0: Disable

51

Appendix: Parameters User Manual

Master-Slave Monitoring Link Fault Alarm

Power Supply Disconnection Alarm

Power Supply Fault Alarm

Downlink Input Over-power Alarm

Uplink Input Over-power Alarm

Downlink PA Over-current Alarm

1: Enable

0: Normal

1: Fault

0: Normal

1: Fault

0: Normal

1: Fault

0: Normal

1: Fault

0: Normal

1: Fault

0: Normal

1: Fault

Uplink Local Oscillator Unlock Alarm

Downlink Local Oscillator Unlock Alarm

Remote Digital Module Fault Alarm

Downlink LNA Fault Alarm

Optical Receiving Alarm

Optical Transmission Alarm

0: Normal

1: Fault

0: Normal

1: Fault

0: Normal

1: Fault

0: Normal

1: Fault

0: Normal

1: Fault

0: Normal

1: Fault

52

Loading...

Loading...