Hytera PT580 Service Manual

Service Manual

i

Contents

Revision History .............................................................................................................................................. 1

Copyright Information..................................................................................................................................... 1

Disclaimer......................................................................................................................................................... 1

Introduction...................................................................................................................................................... 2

Product Controls ............................................................................................................................................. 3

Circuit Description........................................................................................................................................... 4

T uning Description........................................................................................................................................ 17

Interface Definition........................................................................................................................................ 18

Troubleshooting Flow Chart......................................................................................................................... 23

Disassembly and Assembly......................................................................................................................... 43

Exploded View ............................................................................................................................................... 48

Parts List 1...................................................................................................................................................... 50

Packing Guide................................................................................................................................................ 52

PCB View........................................................................................................................................................ 53

Schematic Diagram ....................................................................................................................................... 57

Parts List 2...................................................................................................................................................... 76

Specifications .............................................................................................................................................. 100

Service Manual

1

Revision History

Version Date Description

V00 08-2011 Initial Release

Copyright Information

Hytera is the trademark or registered trademark of Hytera Communications Co., Ltd. (the Company) in

PRC and/or other countries or areas. The Company retains the ownership of its trademarks and product

names. All other trademarks and/or product names that may be used in this manual are properties of

their respective owners.

The product described in this manual may include the Company’s computer programs stored in memory

or other media. Laws in PRC and/or other countries or areas protect the exclusive rights of the Company

with respect to its computer programs. The purchase of this product shall not be deemed to grant, either

directly or by implication, any rights to the purchaser regarding the Company’s computer programs. Any

of the Company’s computer programs may not be copied, modified, distributed, decompiled, or

reverse-engineered in any manner without the prior written consent of the Company.

Disclaimer

The Company endeavors to achieve the accuracy and completeness of this manual, but no warranty of

accuracy or reliability is given. All the specifications and designs are subject to change without notice

due to continuous technology development. No part of this manual may be copied, modified, translated,

or distributed in any manner without the express written permission of us.

If you have any suggestions or would like to learn more details, please visit our website at:

http://www.hytera.com.

Service Manual

2

Introduction

Intended User

This manual is intended for use by qualified technicians only.

Service Manual

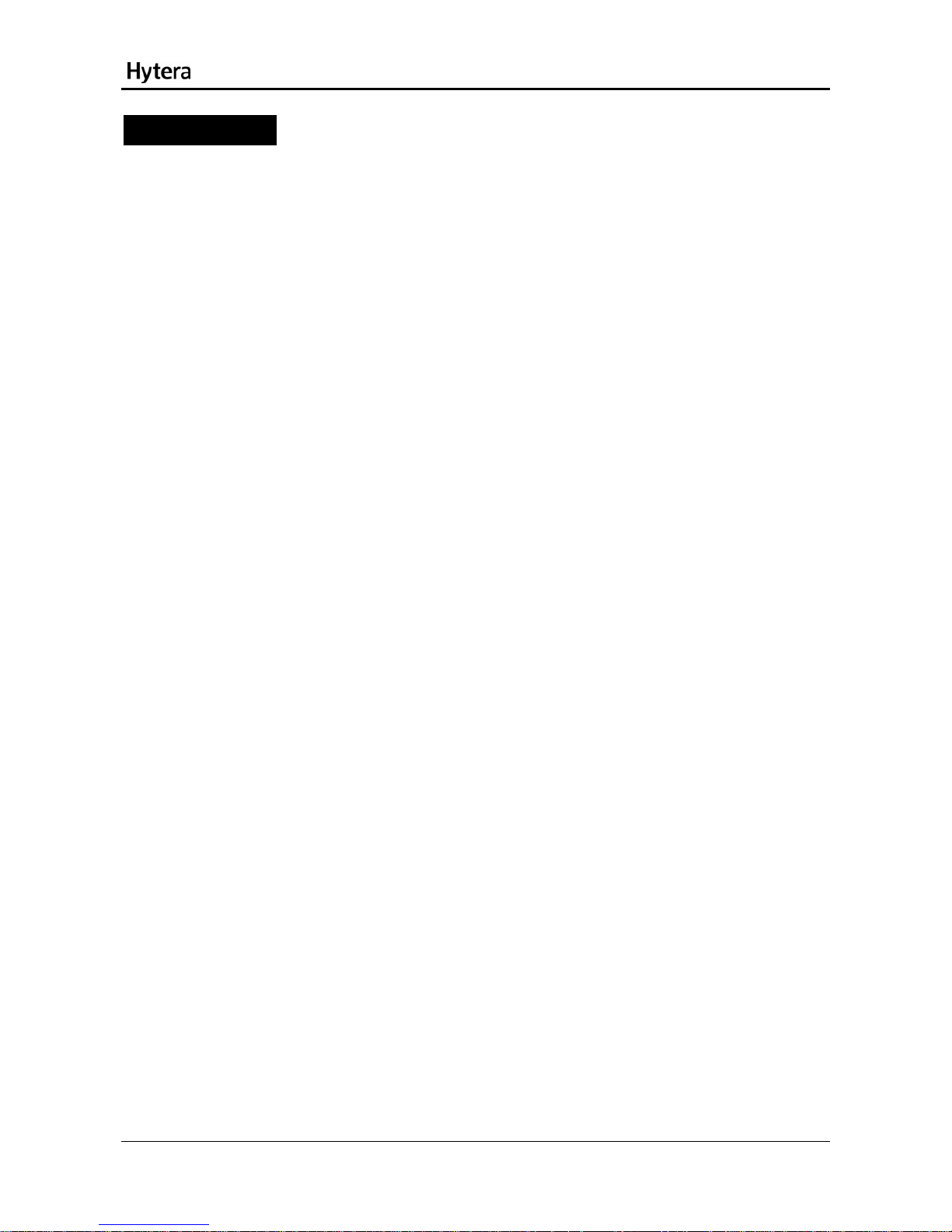

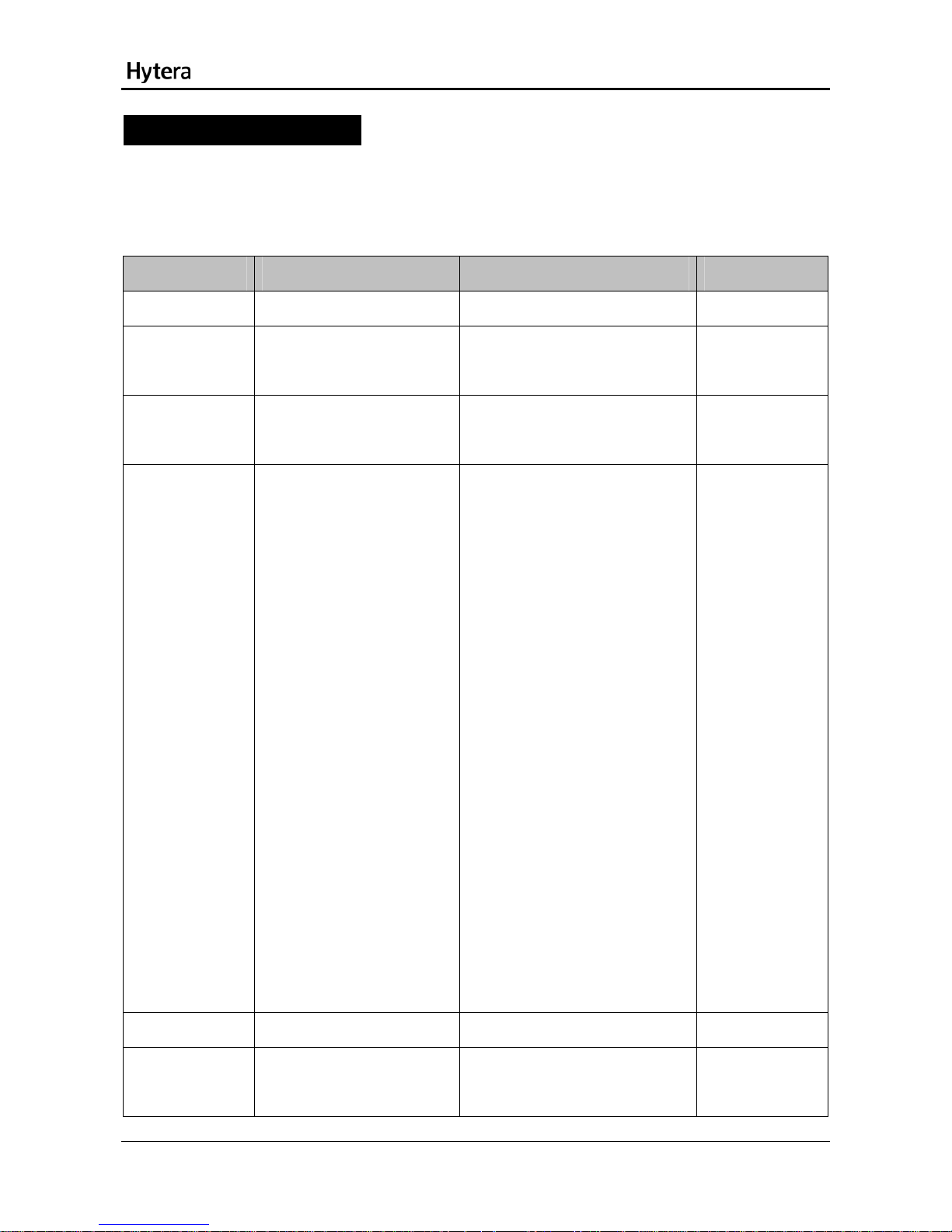

Product Controls

No. Part Name No. Part Name

○

1

SK1 (programmable)

○

2

PTT Key

○

3

SK2 (programmable)

○

4

Emergency Key

○

5

LED Indicator

○

6

Antenna

○

7

Multi-function Control Knob

○

8

Receiver

○

9

Display

○

10

Function Keypad

○

11

Speaker

○

12

Numeric Keypad

○

13

Light Sensor

○

14

Battery Latch

○

15

Duplex Microphone

○

16

Simplex Microphone

○

17

Accessory Jack Cover

○

18

Accessory Jack

○

19

Strap Hole

○

20

Belt Clip

○

21

Battery

○

22

Charging Piece

3

Service Manual

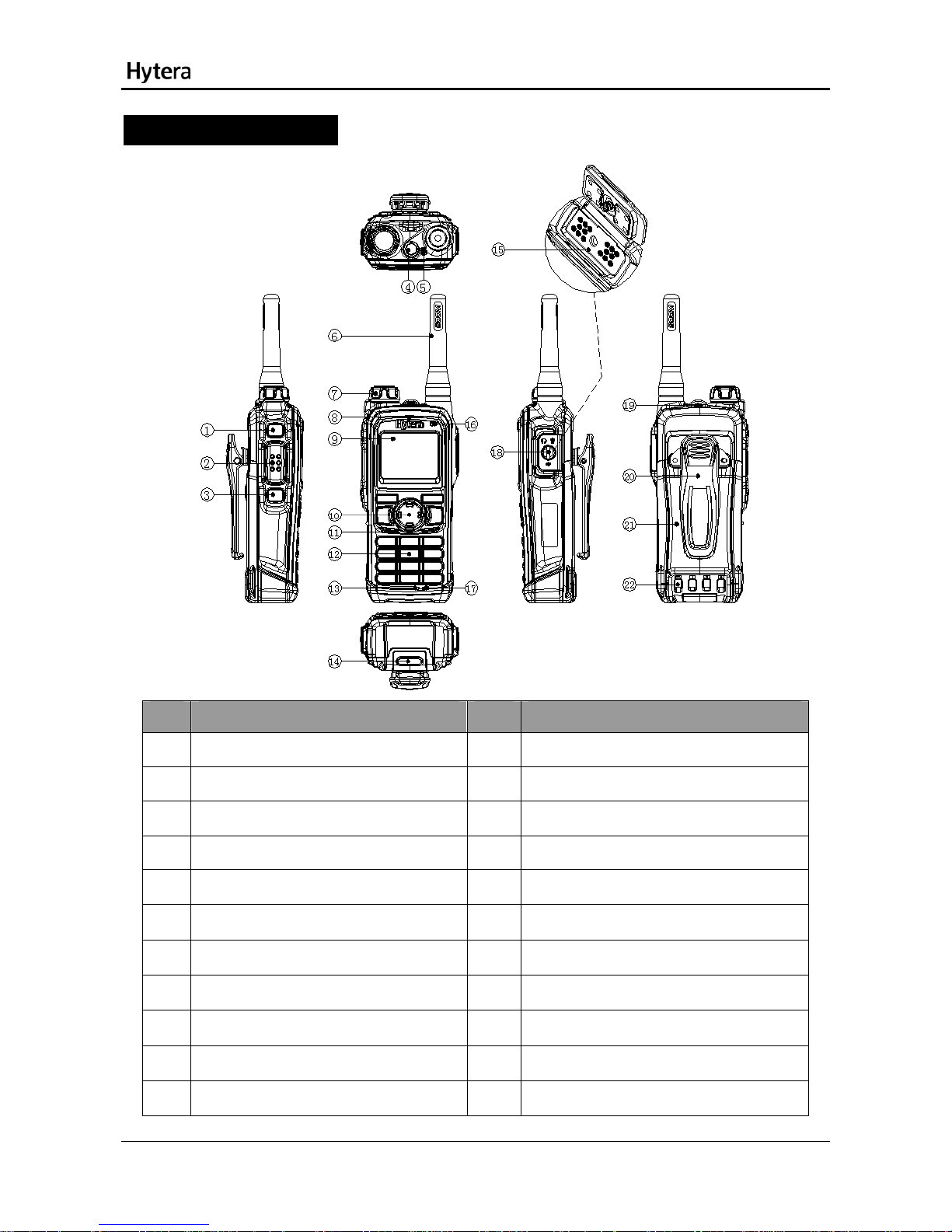

Circuit Description

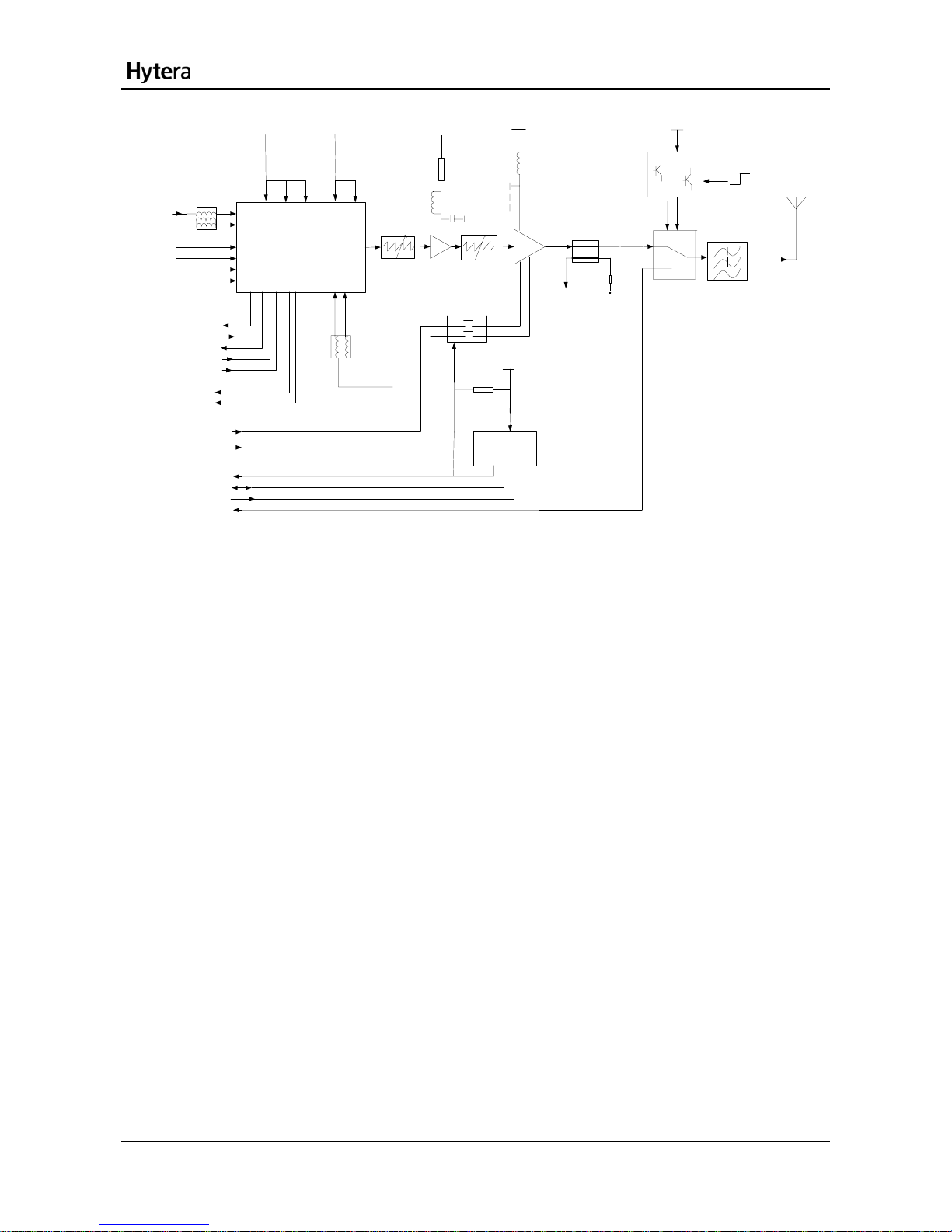

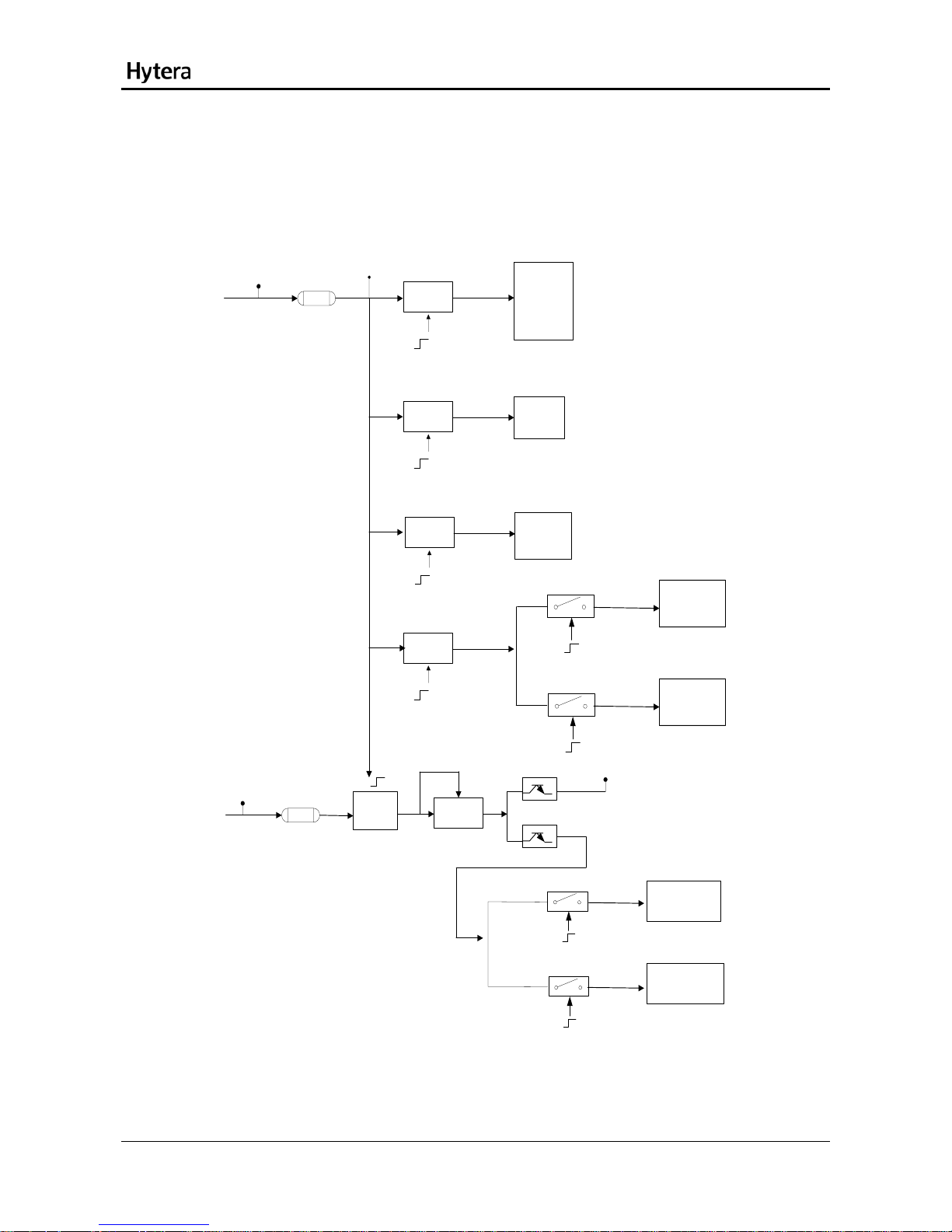

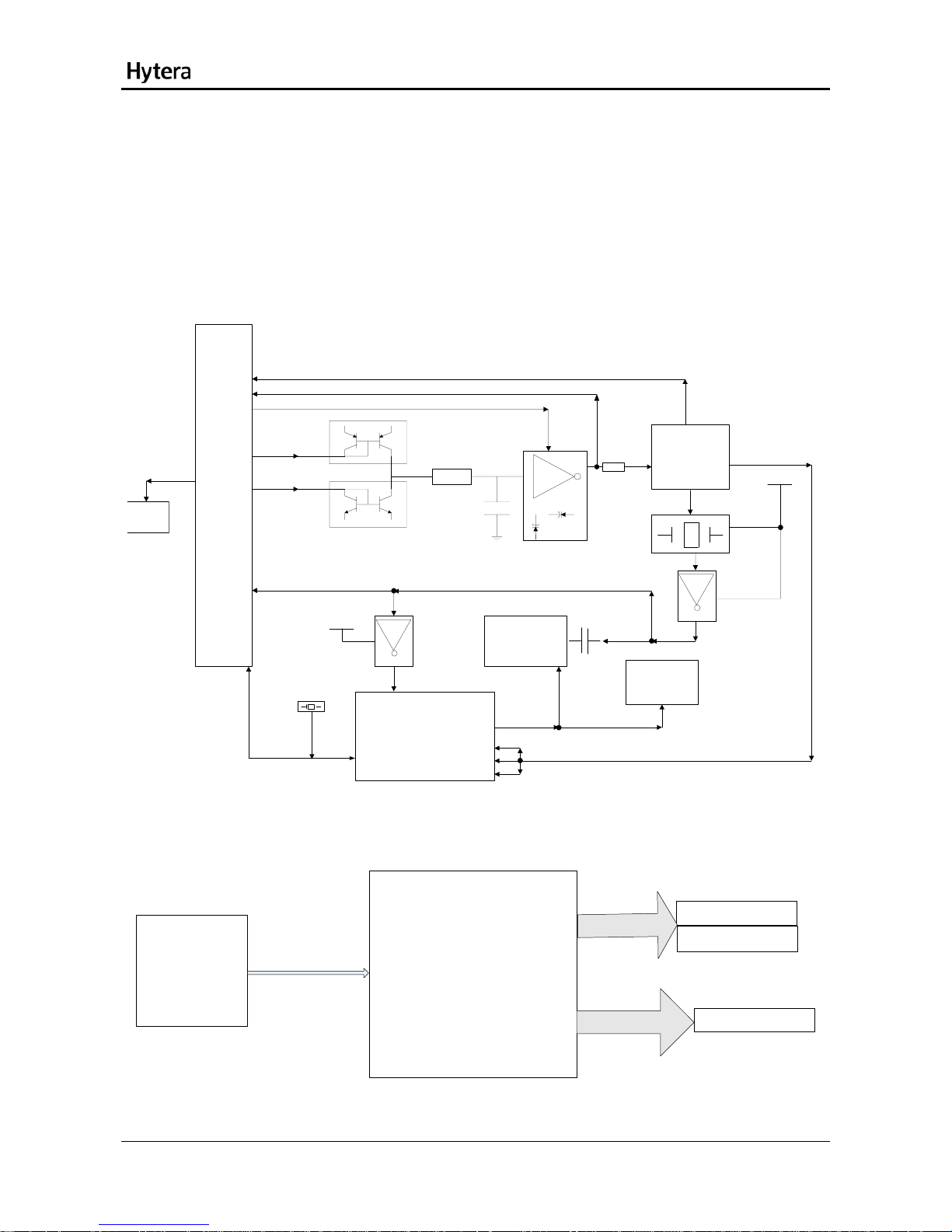

1. RF Section

The frequency range for PT580 F5 is 806~870MHz (in TMO mode, the frequency range for TX is

806~825MHz, while the frequency range for RX is 851~870MHz; in DMO mode, the frequency range for

both TX and RX is 851~870MHz). The block diagram for the RF section is shown below.

PA

Cartesian

Loop ASIC

RX FGU

POWER_RF

BB TOP

Figure 1 Diagram of RF Section

The RF section consists of PA module, Cartesian Loop ASIC module, RX module, FGU and power

supply module (POWER_RF).

1.1 TX Circuit

4

Service Manual

Ca rtesia n IC

DCMEAS

RF_SCLK

RF_DIN

RF_DOUT

TxI+

TxITxQ+

TxQ-

Tx_LO

3V_Tx

RF_SW

7V5

Antenna

PA

3V6_RF

3V_A

Temp erature

Sensor

RF_ F B

TMP_ALERT

SDA

SCL

RX

PA_BIAS1

PA_BIAS2

3V_TxA

3V_TxD

attenu at o r

CSN

DOI

DOQ

RF_ F B

Figure 2 Diagram of TX Circuit

The TX circuit consists of PA, harmonic filter, pre-amplifier, duplexer, coupler, temperature sensor,

TX/RX switch, antenna and etc. The working principle of the TX circuit is described below:

The TX circuit sends the I/Q signal from the baseband section to the Cartesian IC, which outputs

800MHz TX signal after appropriate processing. The TX signal goes to the filter and then to the PA circuit

for amplification after it is converted by BALUN.

The PA circuit is to amplify the RF signal output by the Cartesian IC to obtain an appropriate power level.

Then the signal passes through the TX/RX switch and is sent out from the antenna.

The feedback channel is to couple the power output by the main PA to the Cartesian IC, to form a

complete Cartesian loop. In this way, the output power can be controlled via the attenuation of the

feedback loop.

The temperature sensor will give protection signal if the PA temperature is too high. In such case, the

output power of the PA will be decreased appropriately to prevent damage to the parts.

The signal output by the main PA passes through the TX/RX switch and then goes to the antenna. The

TX/RX switch controls the TX/RX status according to the control signal output by the baseband.

The interfaces between the TX circuit and the baseband or other circuits are described below.

(1) TMP_ALERT

This is the alarm output interface of the temperature sensor, and is connected with the baseband. It

5

Service Manual

6

outputs low level during normal operation, and outputs high level to notify the baseband to reduce the PA

power if the temperature exceeds the preset level.

(2) PA_BIAS1 (same as PA_BIAS2)

This interface is used by the baseband to set the bias status of the PA. In TX status, the level is 2.47V.

(3) RF_SW

This interface is used to transfer the TX/RX switch signal output by the baseband. In the case of high

level, the antenna switch is connected to the output end of the PA, and the RF signal output by the PA is

sent to the antenna via the antenna switch. In the case of low level, the receiver is on, while the

transmitter is off. The antenna switch is connected to the RX interface.

(4) RX

This interface sends the signal to the RX module when the RF_SW switches to the RX end.

(5) RF_FB

This interface feeds the coupled signal back to the Cartesian IC to control the output power.

(6) Tx I+/- and Tx Q+/-

These interfaces are used to transfer the I/Q differential signals from the modulator. The DC level of the

signals is 1.6V, and Vp-p is 1.3 V.

(7) RF_SCLK/RF_DIN/RF_DOUT/CSN

These interfaces are used to transfer the clock signal, data signal and enable signal from the baseband,

and used by the baseband to program the register.

(8) DCMEAS

This interface is used to transfer the signal sent to the baseband for determining whether the DC

calibration is successful.

(9) TX_LO

The signals generated by the TX 1st LO are sent by the VCO to the Cartesian IC, where they are divided

to TX carrier signals. This interface is used to transfer such TX carrier signals.

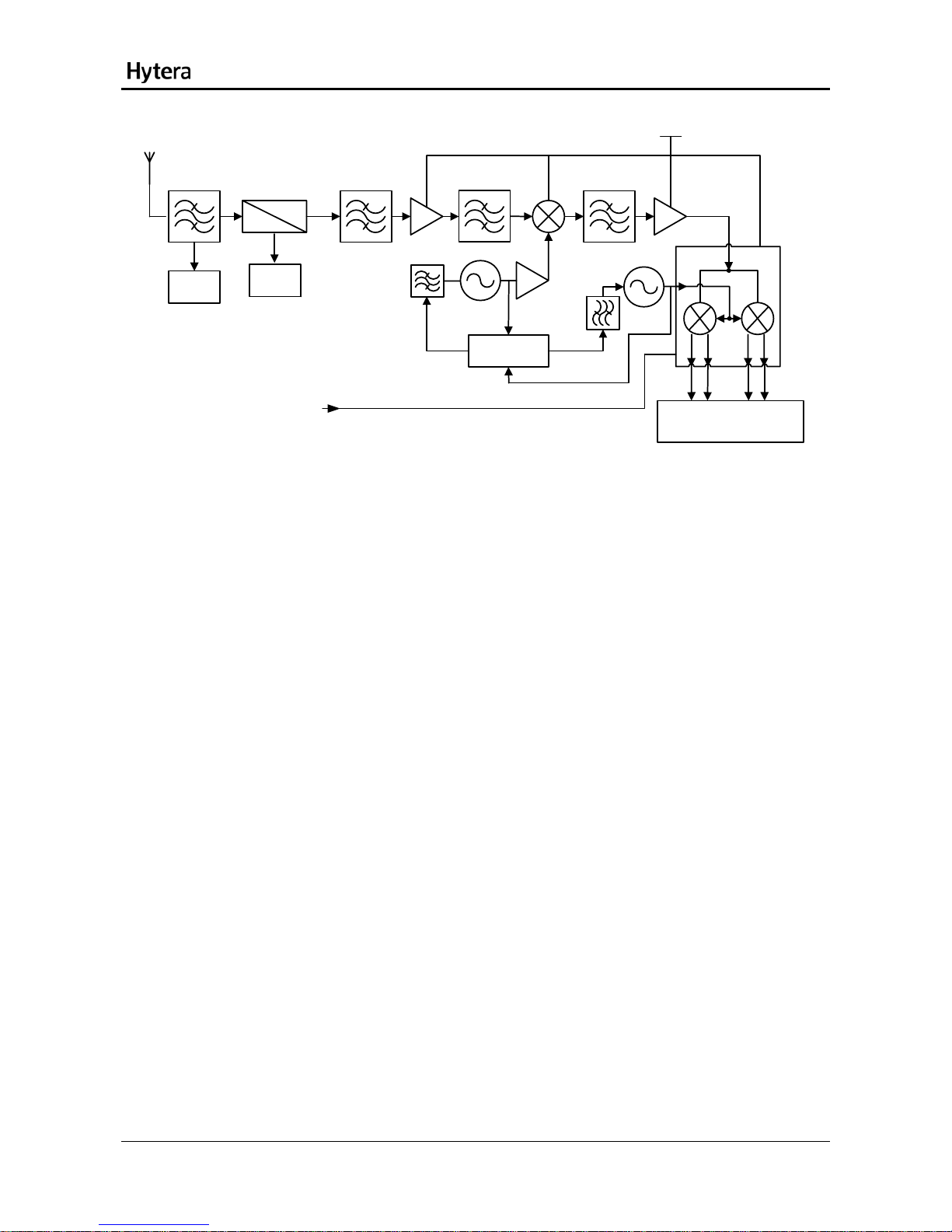

1.2 RX Circuit

Service Manual

T

R

LNA

IF Amplifier

IF BPF

Mixer

Diplexer

ANT

BPF BPF

Buffer

Demodulator

LPF

LPF

Rx_LO1

Rx_LO2

Rx PLL

IQ Processor

ANT Switch

GPS

TX

3V_Rx

RX I+

RX I-

RX Q+

RX Q-

AGC

RX

Figure 3 Diagram of RX Circuit

The working principle of the RX circuit is described below:

The RX signals pass through the RF switch. First, they are filtered to remove out-of-band signals. Then

they are amplified by the LNA and filtered again. After that, the signals are sent to the mixer for

appropriate processing. The signals output from the mixer are processed by the IF low-noise amplifier

and then by the IF filter to select desired IF signals for demodulation. The obtained I/Q signals are

filtered and finally sent to the baseband for processing.

The interfaces between the RX circuit and the baseband or other circuits are described below.

(1) 3V_RX

This interface is used to transfer the receiver on/off signal from the baseband. If the signal is at high level,

the receiver is on and the RX channel works.

(2) RX

This interface is used to transfer the RX signal output by the antenna switch of the PA.

(3) RX_LO1

This interface is used to transfer the first RX LO signal output by the VCO.

(4) RX_LO2

This interface is used to transfer the second RX LO signal (level: -10dBm) output by the VCO. The signal

enters the IF demodulator, where it is divided and then demodulated together with the first RX IF signal.

(5) AGC

The AGC control voltage from the baseband enters via this interface, to stabilize output of the I/Q

7

Service Manual

demodulator. The AGC voltage varies within 0.2V~1.2V. When the AGC control voltage is 0.2V, the gain

gets to its maximum value.

(6) Rx I+/ - and Rx Q+/-

These interface are used to transfer the differential I/Q signals output by the I/Q demodulator.

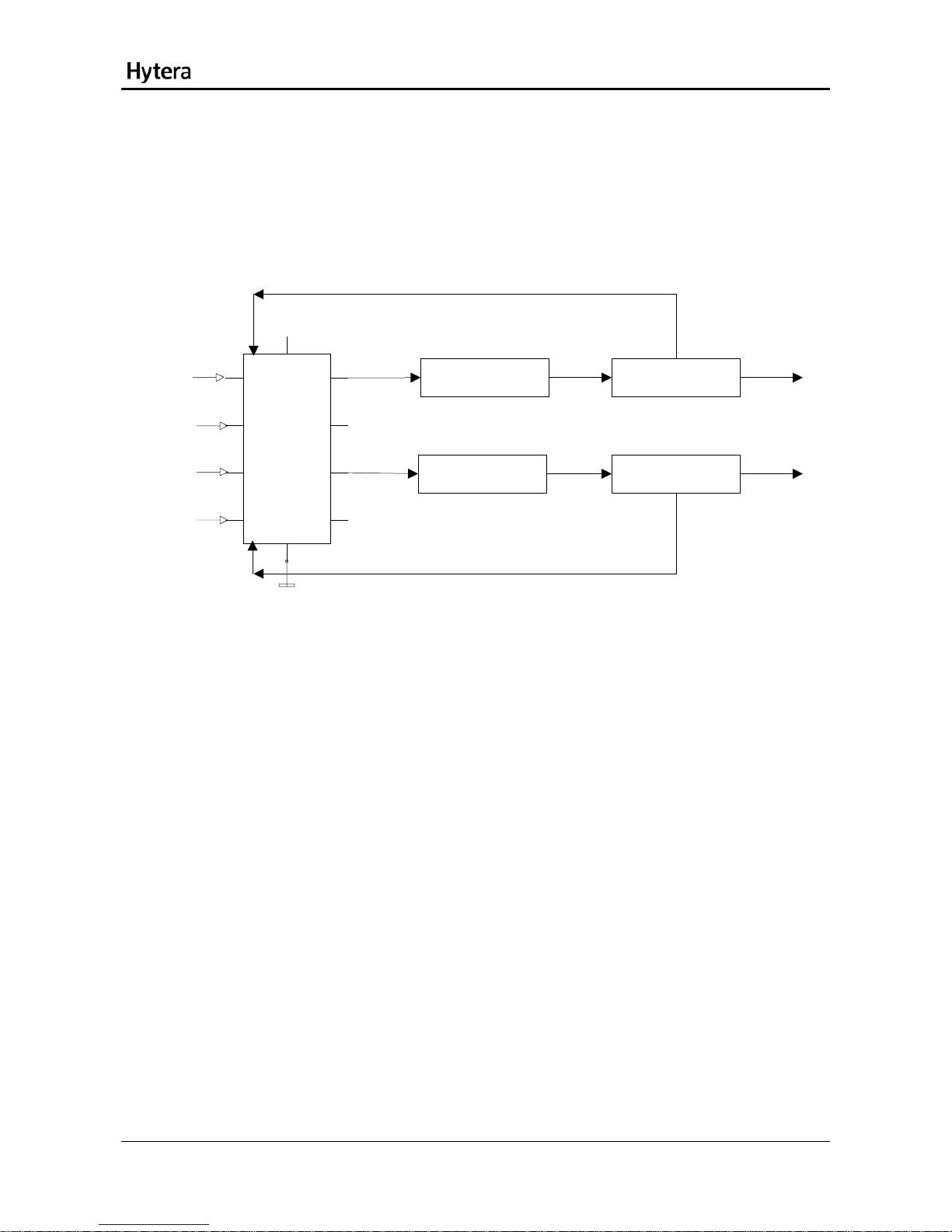

1.3 FGU

a1

1

a2

2

3

a3

4

a4

b1

b2

b3

b4

5

6

7

8

Vcc 1

0

GND

0

PLL IC

12MHz _REF

SYN_ON

SYN_CS

SYNTH _LOCK

Loop Filter RxVCO 2

CPout IF

LOOP Filter TXVCO & RXVCO1

CPout RF

5V_SYN

FLout IF

FLout RF

FinIF

FinRF

Figure 4 Diagram of FGU

The working principle of the FGU is described below:

The reference frequency output by the baseband enters the PLL for frequency division. Meanwhile, the

frequency generated by the VCO goes to the divider for frequency division. Then the signals resulted

from both frequency divisions are sent to the phase detector for phase detection. If the signals have

different frequencies or phases, the phase detector will output a signal corresponding to the phase

difference. The signal goes to the low-pass filter to remove high-order harmonics, so as to control the

oscillation frequency of the VCO.

The interfaces between the FGU and the baseband are described below:

(1) FinRF

This interface is used to transfer the feedback signal from the TX/RX VCO to the PLL.

(2) FinIF

This interface is used to transfer the feedback signal from the RX IF VCO to the PLL.

(3) CPout RF

This interface is used to transfer the charging voltage signal from the PLL to the TX/RX VCO.

(4) CPout IF

8

Service Manual

This interface is used to transfer the charging voltage signal from the PLL to the RX IF VCO.

(5) FLout IF

This interface is used to transfer the charging voltage lock signal from the PLL to the RX IF VCO.

(6) FLout RF

This interface is used to transfer the charging voltage lock signal from the PLL to the TX/RX VCO.

(7) SYNTH_LOCK

This interface is used to transfer the PLL lock indication signal to the baseband. When this pin outputs

high level signal, it indicates the PLL is locked.

(8) SYN_ON

This interface is used to transfer the PLL enable signal from the baseband. It outputs 3.3V voltage, and

is open in normal status.

(9) 12MHz_REF

This interface is used to transfer the reference frequency for the PLL.

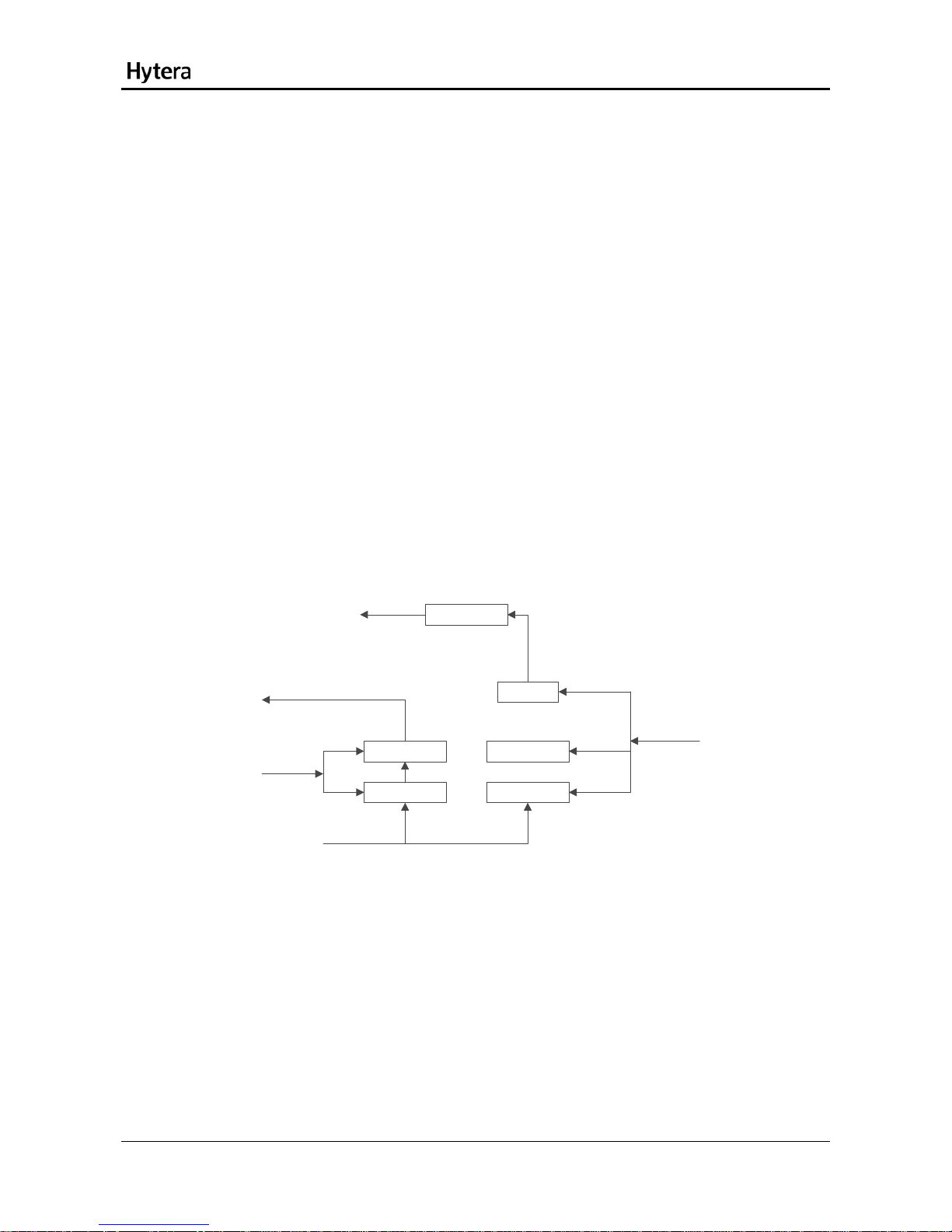

1.4 VCO

VCO VCO

BP filter

BUFFERBUFFER

TRIPLE

5V SYN _ON

TX LO

RX LO

RVO SWITCH

TVO SWITCH

RX LO OUTPUT

TX LO OUTPUT

Figure 5 Diagram of VCO

The working principle of the VCO is described below:

The PLL outputs the control voltage CV. When the RX VCO is locked, it will be output to the receiver via

the BUFFER. When the TX VCO is locked, it will be output to the receiver via the BUFFER, TRIPLE and

filter. The VCO that is powered up will be locked.

The interfaces between the VCO and the baseband or other circuits are described below.

(1) CV: This interface is used by the PLL to output control voltage.

(2) RVO SWITCH: This interface is used to supply power to the RX VCO.

9

Service Manual

(3) TVO SWITCH: This interface is used to supply power to the TX VCO.

(4) RX LO OUTPUT: This interface is used by the RX LO to output signal to the RX mixer.

(5) TX LO OUTPUT: This interface is used by the TX LO to output signal to the Cartesian IC.

1.5 Power Supply Module

3V3D

60R

3V3_RF

LDO

Rx_ON

RF LNA

MIXER

IF LN A

Demodulator

3V_RX

80mA

LDO

Tx_ON

Modulator

3V_TX

140mA

LDO

Modulator

PLL IC

LT5509

3V_A

9mA

SYN_ON

LDO

3V_B

100uA

SYN_ON

Tx_ON

Rx_VCO _ON

TX_ L O _B uffe r

TX_Drive

3V_TX DR V

LO1_Drive

RX LO2_VCO

3V_RVC O

V_PA

60R

DC/DC

LDO

5V_SYN

RX_VCO_ON

Tx_VCO _ON

RX LO1 VCO

5V_RVC O

TX LO VCO

5V_TVC O

Figure 6 Diagram of Power Supply Module

This module is to supply appropriate voltages to the RF circuits. The 3V3D voltage is supplied by the

power management IC of the baseband section, and passes through different LDOs to supply the

10

Service Manual

Cartesian IC, TX VCO, RX VCO, pre-amplifier and other RX parts respectively. The V_PA is supplied by

the battery directly. The SYN control signal is open while the portable terminal is operating.

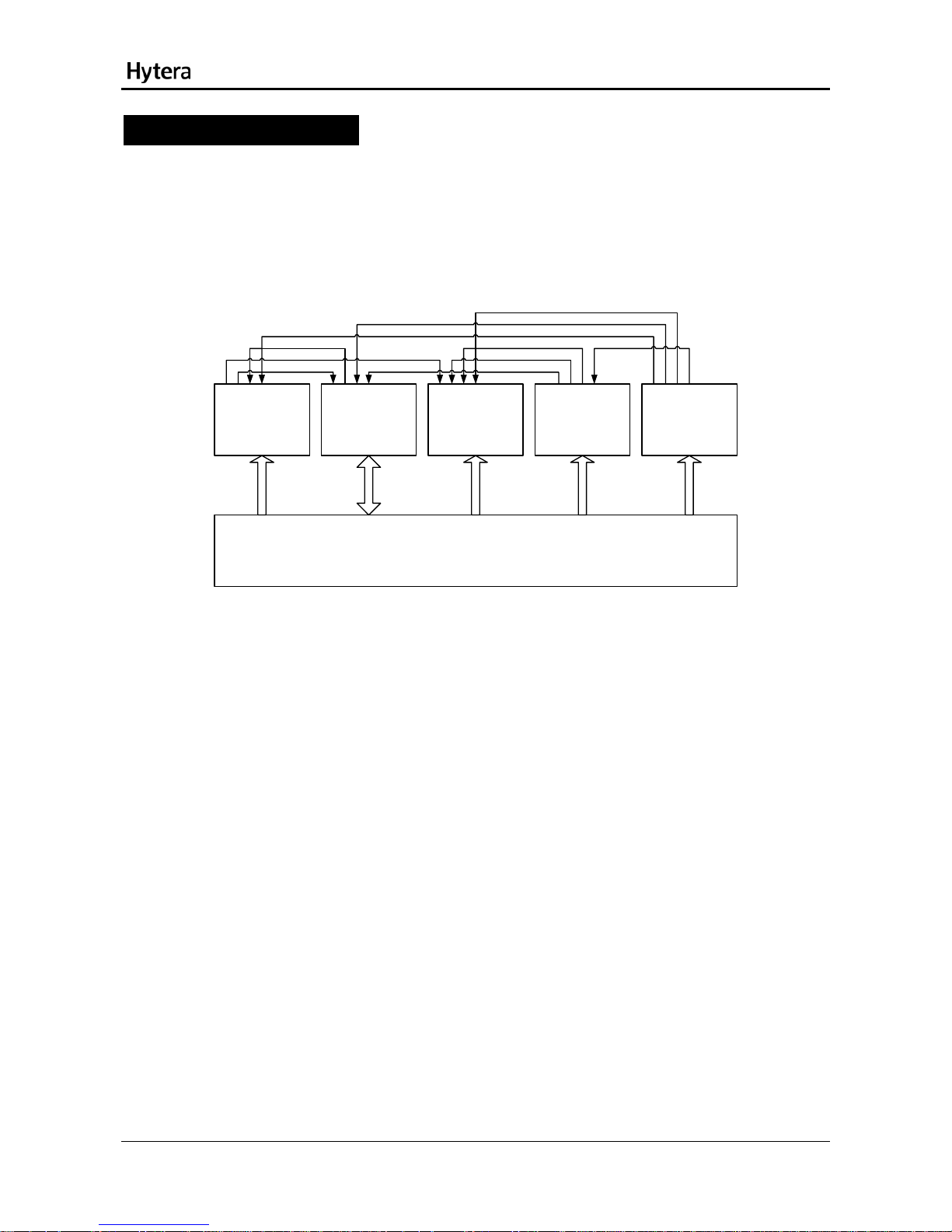

2. Baseband Section

2.1 Power Section

BATTERY

Farad Battery

Z

Z

ON/OFF

V_PA

VBAT

1V8D

1V6D

2V5D

3V_TXCO

3V3D

3.3V_RF

LDO

1V2D

TO RF PART

TO RF PART

PMU

U6001

Figure 7 Diagram of Power Section

The 3V3D, 1V6D, 1V8D and 3V_TXCO are the necessary voltages for the MCU to start up. The MCU

may not start if any of the four voltages becomes invalid.

The 3V3D, 2V5D, 1V2D and 3V_TXCO are the necessary voltages for the FPGA to start up. The FPGA

may not start if any of the four voltages becomes invalid.

No. Network Test Point

Reference Voltage during Start-up (V)

(while running Bootloader)

Reference Voltage

after Start-up (V)

1 VBAT L6004_2

3.6~4.2 3.6~4.2

2 3V3D TP6001 3.3 3.15

3 1V8D TP6002 1.8 1.8

4 1V6D TP6003 1.6 1.35

5 2V5D TP6004 2.5 2.5

6 3V_TXCO TP6005 3 3

7 1V2D TP6006 1.2 1.2

11

Service Manual

2.2 Control Section

2.2.1 MCU

CAMERA

LCD(WITH

CONTROL

)

GPIO

16 bit EMIFS

16 bit EMIFF

JTAG

32.768 KHz and

12 MHz CLOCK

MCU(ARM+DSP

)

UART 1

UART 3

UART 2

MCBSP3

MCBSP2

MCBSP1

I2C

MMC/ SD CARD

MPUIO

5* 5 KEY

PWL

SPI

8 bit

Reserve

5*5

25 KEY

EMLUATOR

CLOCK

CONTROL

LED and GPIO

LCD and KEY

BACKLED CONTROL

LED

128 Mbit SDRAM

16 bit

128Mbit FLASH

16 bit

16 bit

PIXEL≤160 * 128

,

COLOR=262K

RF and LCD etc.

RF etc.

CMD1

CMD2

TX/RX

CHANNEL

CODEC

CONTROL

FPGA

FLASH.CS and

GPIO

Reserve

Baseband

Processor

PC

Reserve

Reserve

LCD

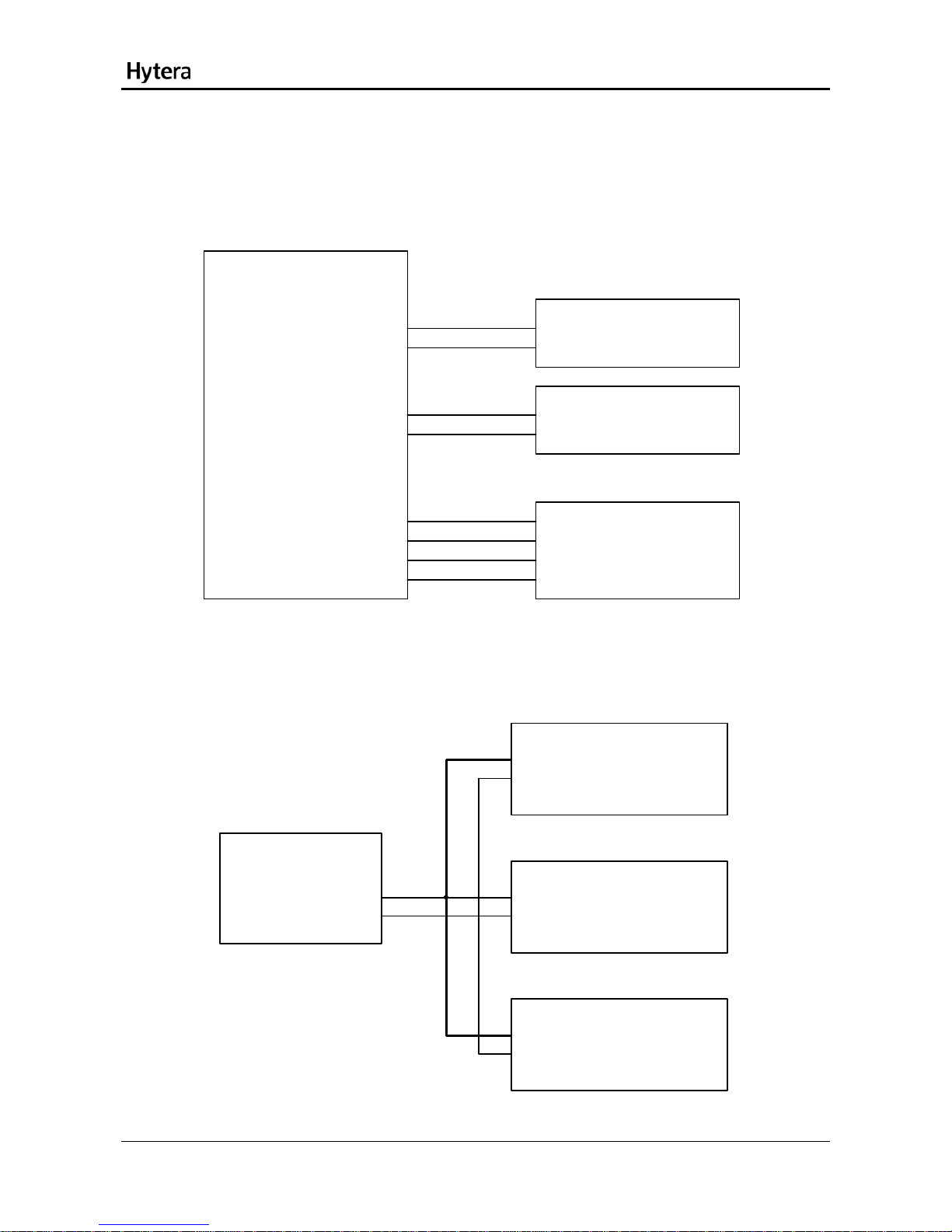

Figure 8 Diagram of MCU

The dual-core (ARM+DSP) MCU (main frequency speed of 144MHz) accommodates multiple peripheral

interfaces to directly control the LED, LCD, keys and etc. The serial interfaces contain I

2

C, SPI, MCBSP

and MCSI.

12

Service Manual

2.2.2 FPGA

FPGA

MCU

CODER SWITCH

LCD

SIM CARD

SIM _RST

SIM_CLK

SIM_DATA

SIM_SUPPLY

9. 2 16 M _ F PG A

9.216MHz

9.216M_VCO_ON

/VCO_UP

VCO_D OW N

12MHz

BB

.

PROCESSOR

/RST_OUT

/RS T.OUT

RF

MANOUTX

MANOUTY

Acceleration

Sensor

MEMORY

MCBSP2. FSX

CMX_ IRQ2

CMX_ BITCLK

SYMCLOCK

SPI

CONTRAL

I/O

CLK

EMIFS

Figure 9 Diagram of FPGA

The FPGA is mainly for channel control, volume control, sequence control, clock management, IO

expansion control, encryption algorithm and etc.

2.2.3 Memory

The MCU provides two types of external memory interfaces: external memory interface slow (EMIFS)

and external memory interface fast (EMIFF).

MCU U2001

EMIFF EMIFS

SDRAM.A[0:12]

FLASH.A[24:1]

SDRAM.D[0:15] FLASH.A[15:0]

SDR AM.BA0

SDR AM.BA1

SDRAM.CAS#

FLASH.CS3#

SDR AM.RAS#

RST_OUT#

SDRAM.CKE#

SDRAM.CLK#

SDRAM.CS#

SDRAM.WE#

SDRAM.DQML

SDRAM.DQMU

A[0:12]

D[0:15]

BA0

BA1

CAS#

RAS#

CKE

CLK

CS#

WE#

LDQM

ULQM

FLASH U2003

A[23:0]

DQ[15:0]

OE#

WE#

Cef#

RESET#

WP#/ACC

RY/Byf#

FLAS H.WP #

FLAS H.RD Y

FLASH.OE#

FLASH.WE#

SDRAM U2004

Figure 10 Diagram of Memory

13

Service Manual

The MCU is connected with a 128Mbits NOR FLASH (for program or data storage) and a 128Mbits

SDRAM (for temporary data storage).

2.2.4 CLOCK

The 32K clock, also called real-time clock (RTC), is used for system starting, timing, sleeping and etc.

The generation of the 9.216MHz clock is controlled by the FPGA. This clock is provided to the baseband

processor.

FPGA

R

9.216_VCO_ON

/VCO_UP

VCO_DOWN

MCLK

DA

+3V_TCXO

12MHz_REF

PLL

OSCINIF

RF

12MHz

AFC

Synthesizer

12MHz_CLK

CPU

OSC1_IN

OSC1.IN

1V6D

32.768K

12MHz_CLK

9.216M_FPGA

SIM

SIM_CLK

Cartesian

Loop IC

SCLK

BITCLK

SPI.SCK

MCBSP1_CLKX

MCBSP2_CLKX

MCBSP3 _CLKX

9.216M_CLK

CLK32_K

IN

CLK

32K

_

SYMCLOCK

CMX_SCLK

SPI.SCK

SCK

CLK

RF

Baseband

Processor

IO

_L02P

_1/A14

R

Figure 11 Diagram of CLOCK

2.2.5 Reset signal

NOR Flash

PMU

/RESET

/RST-OUT

LCD

CODEC

MCU

RESET-CODEC

/RST-OUT

Figure 12 Diagram of Reset Signal

14

Service Manual

2.2.6 UART

The MCU has 3 UART interfaces: UART1, UART2 and UART 3. The communication rate can be up to

1.5Mbps. The UART connection is shown in Figure 13. The UART2 interface is connected to the

accessory jack for upgrading and programming, while the UART1 and UART3 interfaces are reserved.

UART_RXD

UART_TXD

UART_RTS

UART_CTS

U2501

PC

Reserve

U2001

UART3.RX

UART3.TX

UART2.RX

UART2.TX

UART1.RX

UART1.TX

MCU

UART3.CTS

UART3.RTS

RXA

TXA

J2502

TXA

RXA

J2501

Reserve

Figure 13 Diagram of UART Connection

2.2.7 I2C

The MCU provides one I

2

C interface for the MCU to control the PMU and RTC.

I2C.SCL

SCL

SDA

PMU

SDA

SCL

RTC

SDA

SCL

Reserve

U2001

I2C.SDA

MCU

Figure 14 Diagram of I

2

C Connection

15

Service Manual

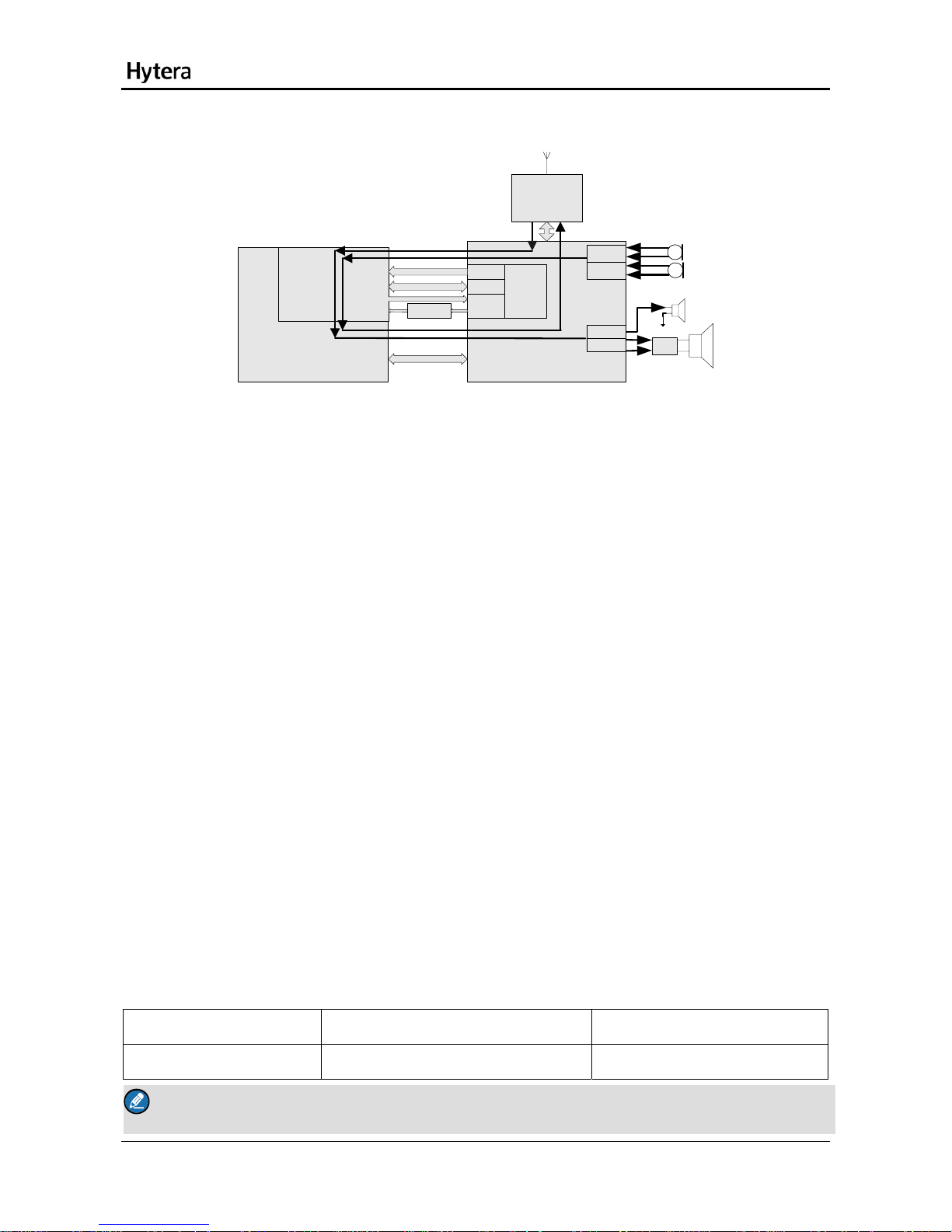

2.3 Audio Section

MCBSP 1

MCBSP 3

MCBSP 2

FSB3

FSB1

FSB2

RF

CLOCK

IRQ

RESET

IRQ

RESET

CLOCK

MIC 1

MIC 2

AUD

EAR

PA

CODEC

MCU

DSP

I/Q

FPGA

b

Baseband

Processor

Figure 15 Diagram of Audio Processing Circuit

2.3.1 Audio input

The audio signal from the MIC goes to the baseband processor for amplification, A/D conversion,

encoding and filtering. After such processing, the PCM code is generated, and is then sent to the MCU

for voice encoding and channel encoding by the DSP. After that, it is converted to I/Q signal by the

baseband processor via π/4 DQPSK modulation, filtering and D/A conversion. Finally, the I/Q signal is

sent via the antenna after modulation, amplification and filtering.

2.3.2 Audio output

The RF signal passes through the antenna, LNA, mixer, filter, IF amplifier and demodulator. After

demodulation, the I/Q signal is sent to the baseband processor for A/D conversion and filtering, and then

enters the MCU via the serial port. After π/4 DQPSK demodulation, channel decoding, voice decoding

by the MCU, the signal is converted to audio signal by the baseband processor via filtering and D/A

conversion. Then the audio signal goes to the audio amplifier. After amplification, the audio can drive the

speaker (the audio can be heard from an earpiece if the analog switch is connected with the accessory

jack). The signal from the receiver (duplex) is output by the baseband processor directly (not passing

through the audio amplifier).

2.3.3 Audio Amplifier Output

Main parameters are listed in the table below:

Rated Power (P

o

) 1W

R L = 4Ω

Maximum Power (P

max

) 1.5W

R

L

= 4Ω

Note: The terminal adopts the class D amplifiers.

16

Service Manual

17

Tuning Description

For details about tuning, please refer to the help file for appropriate tuner software supplied by us.

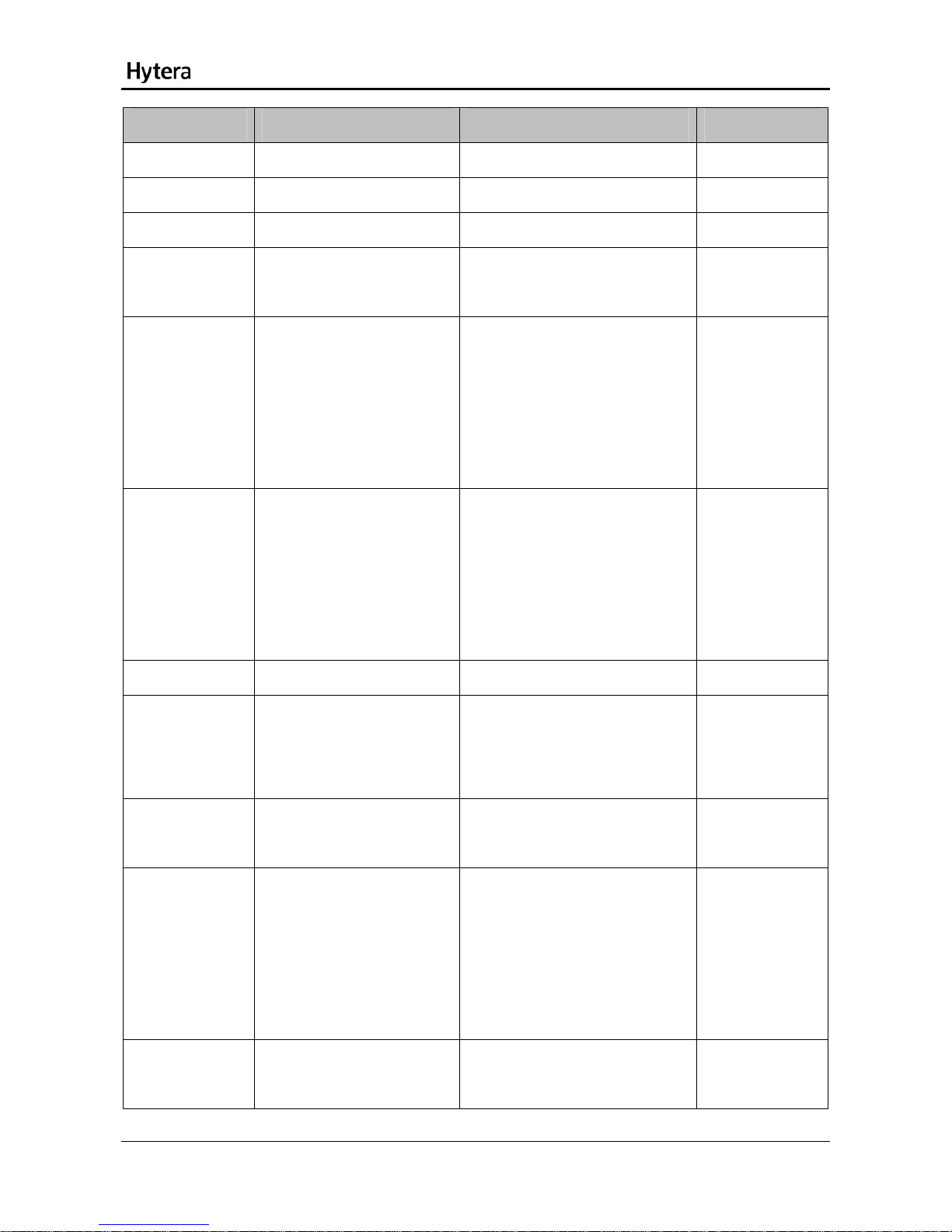

The test standard for current is described in the table below:

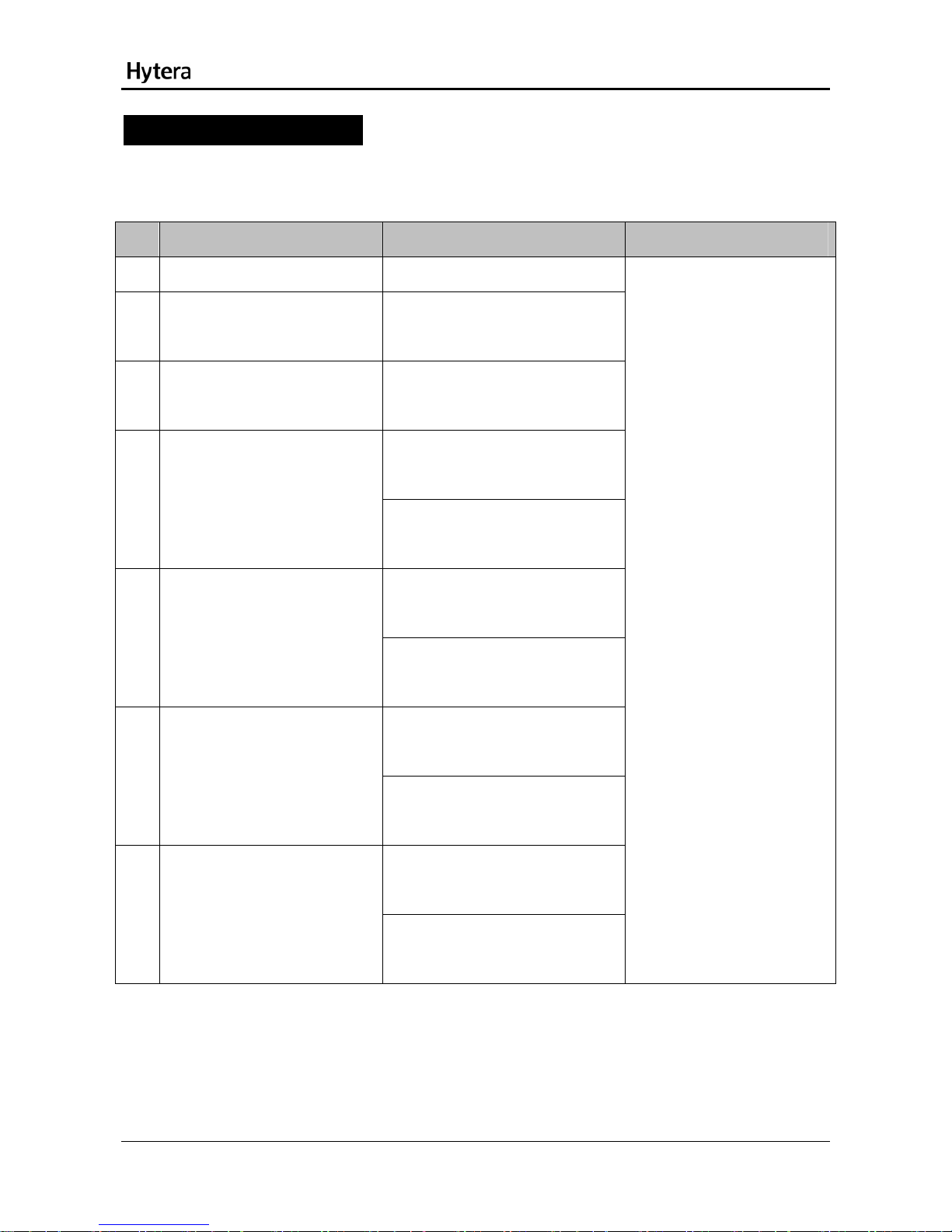

No. Test Item Test Value Test Condition

1 Power-off current Test value≤2mA

2 Mean stand-by current in TMO

(screen off)

140mA≤test value≤170mA

3

Mean stand-by current in DMO

(screen off)

210mA≤test value≤250mA

300mA≤test value≤650mA (the

antenna is connected.)

4

Mean TX current in DMO

(screen off)

300mA≤test value≤650mA (the

50Ω load is connected.)

Test v a l u e ≤1900mA (the antenna

is connected.)

5

Max. TX current in DMO

(screen off)

Test v a l u e ≤1800mA (the 50Ω

load is connected.)

300mA≤test value≤650mA (the

antenna is connected.)

6

Mean TX current in TMO

(screen off)

300mA≤test value≤650mA (the

50Ω load is connected.)

Test v a l u e ≤1900mA (the antenna

is connected.)

7

Max. TX current in TMO

(screen off)

Test v a l u e ≤1800mA (the 50Ω

load is connected.)

The voltage is 3.7V. Test

instrument and software:

Agilent power supply, GPIB

card, computer and current

test software.

Service Manual

18

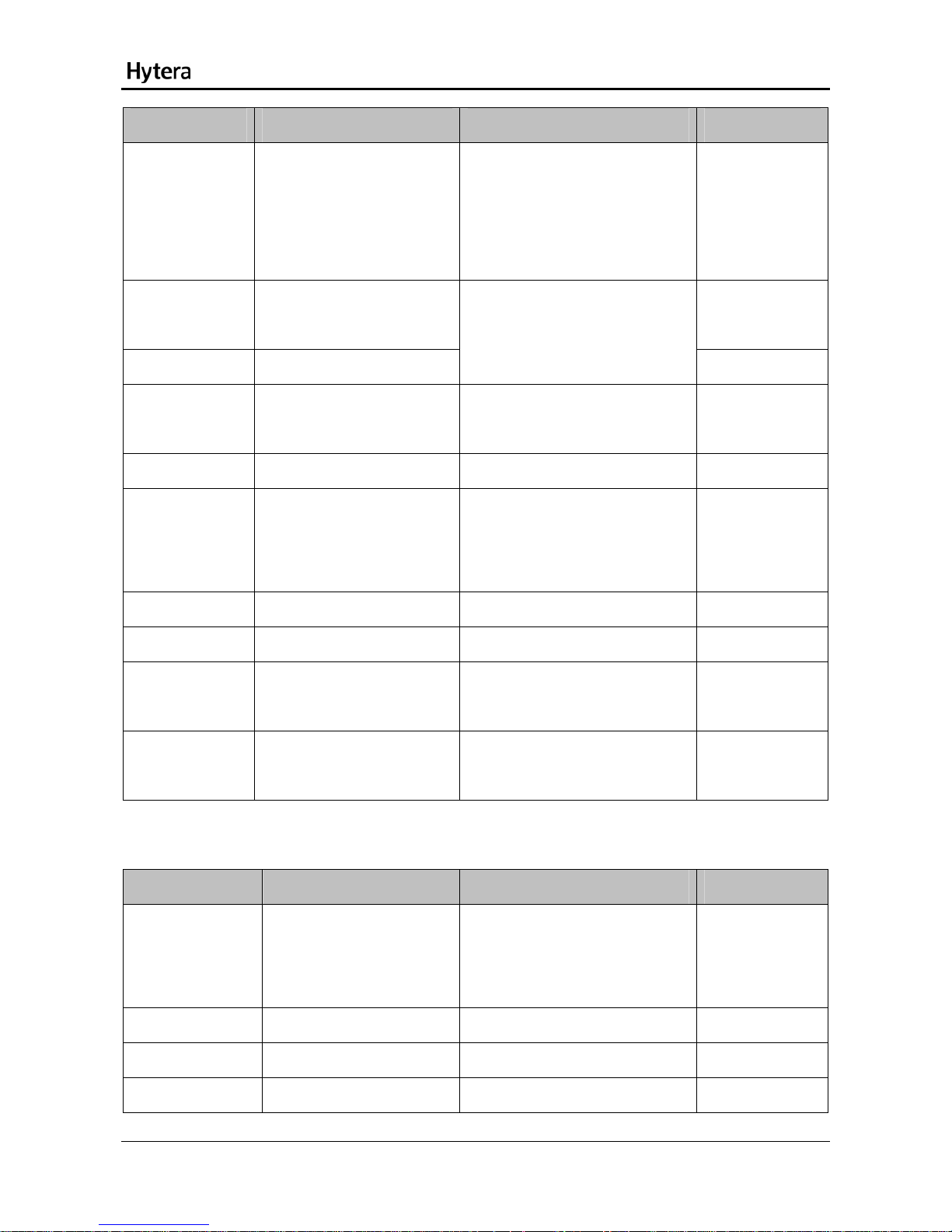

Interface Definition

The interfaces on the main board contain those for data, keyboard, side key, LED, receiver, MIC,

speaker motor, encoder switch and etc.

J7001: 70-Pin Interface

Pin No. Name Function Valid Level

69, 70 GND Power supply: ground (analog) L

4

5

UP_MIC+

UP_MIC-

Upper MIC interface -

6

7

LOW-MIC-

LOW-MIC+

Lower MIC interface -

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

LCD data cable -

34, 35 3V3D Power supply: 3.3V H

9

11

USB-D+

USB-D-

Reserved -

Service Manual

19

Pin No. Name Function Valid Level

47 ALARM Alarm signal L

32, 33 VBAT Battery voltage H

1 RECEIVER Receiver signal -

53

54

LED1

LED2

LED control signal H

65

64

63

62

61

KB-R0

KB-R1

KB-R2

KB-R3

KB-R4

Keyboard row L

60

59

58

57

56

KB-C0

KB-C1

KB-C2

KB-C3

KB-C4

Keyboard column -

46 PTT PTT key detection L

43

42

30

OPT_SEL1

OPT_SEL2

OPT_SEL3

Accessory identification -

29

28

UART2.TX

UART2.RX

PC serial port connection -

31

51

52

36

48

USB.PUEN

USB.DP

USB.DM

RTS

CTS

Reserved -

8

9

/OE

/WE

LCD control interface -

Service Manual

20

Pin No. Name Function Valid Level

10

11

50

55

/LCD_CS

A1

LCD_RST

LCD_BACKLIGHT

67

66

I2C-SCL

I2C-SDA

-

49 L_INT

Reserved

-

44

45

AUDIO_PA_ON

INT/EXT AUDIO

Audio control -

37 ON/OFF Power-on/off control H

39

40

41

ENC_S

ENC_A

ENC_B

Encoder switch signal -

68 ACC_DET Reserved -

38 KEY_LIGHT Key light control H

48

50

IN-SPK-

IN-SPK+

Internal speaker -

2

3

SPK-

SPK+

Speaker audio -

J7004: 30-Pin LCD Interface

Pin No. Name Function Valid Level

1

23

26

VSS Ground (digital) -

2-17 LCD-D0----LCD-D15 LCD data -

18 CS LCD chip select L

19 RESET Reset signal -

Service Manual

21

Pin No. Name Function Valid Level

20 RS Data and command -

21 WR Write signal L

22 /OE Read signal L

24

25

3V3D Power supply: 3.3V -

27 LEDA Power supply for backlight -

28

29

30

LEDK1

LEDK2

LEDK3

Backlight control L

J7007: 21-Pin Keyboard Interface

Pin No. Name Function Valid Level

1

4

21

GND Ground (analog & digital) L

2

3

LOW-MIC+

LOW-MIC-

Lower MIC interface -

5

6

16

I2C-SCL

I2C-SDA

L_INT

Reserved -

7

8

9

10

11

KB-C3

KB-C4

KB-C0

KB-C1

KB-C2

Keyboard column -

12

13

14

KB-R1

KB-R2

KB-R3

Keyboard row L

Service Manual

22

Pin No. Name Function Valid Level

15 KB-R4

17 KEY_LED LED control -

18 3V3D 3.3V power supply -

19 VBAT Battery voltage -

20 ON/OFF Power-on/off control H

Service Manual

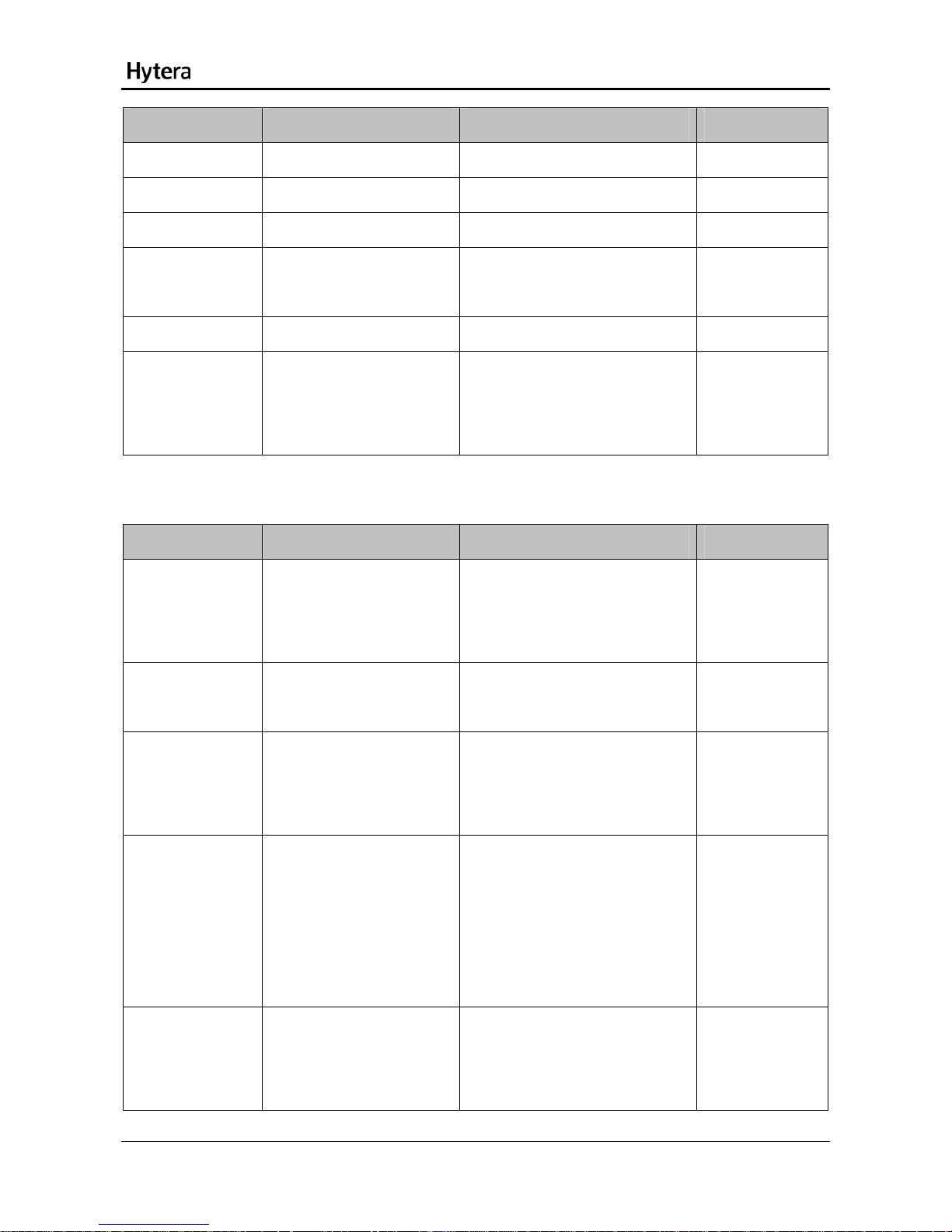

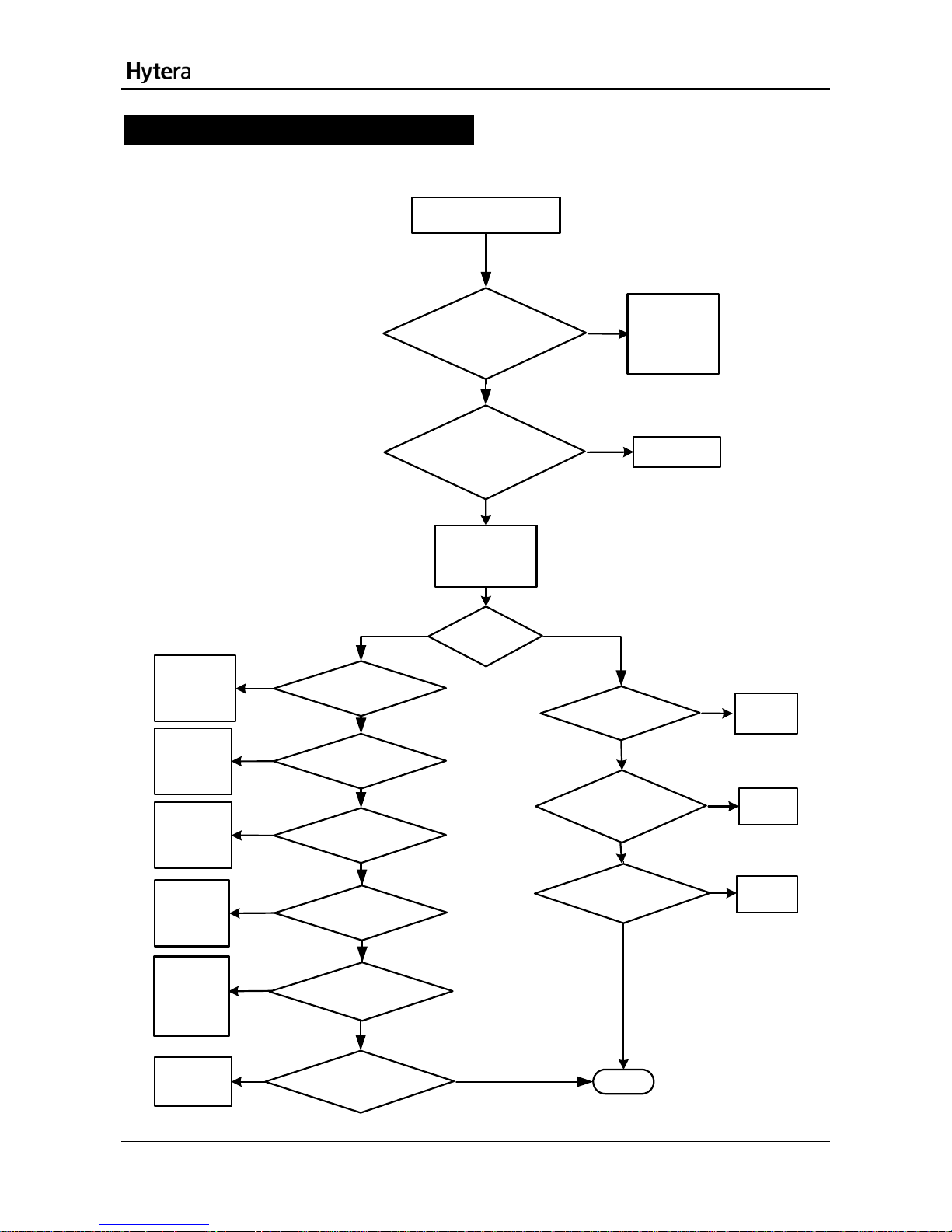

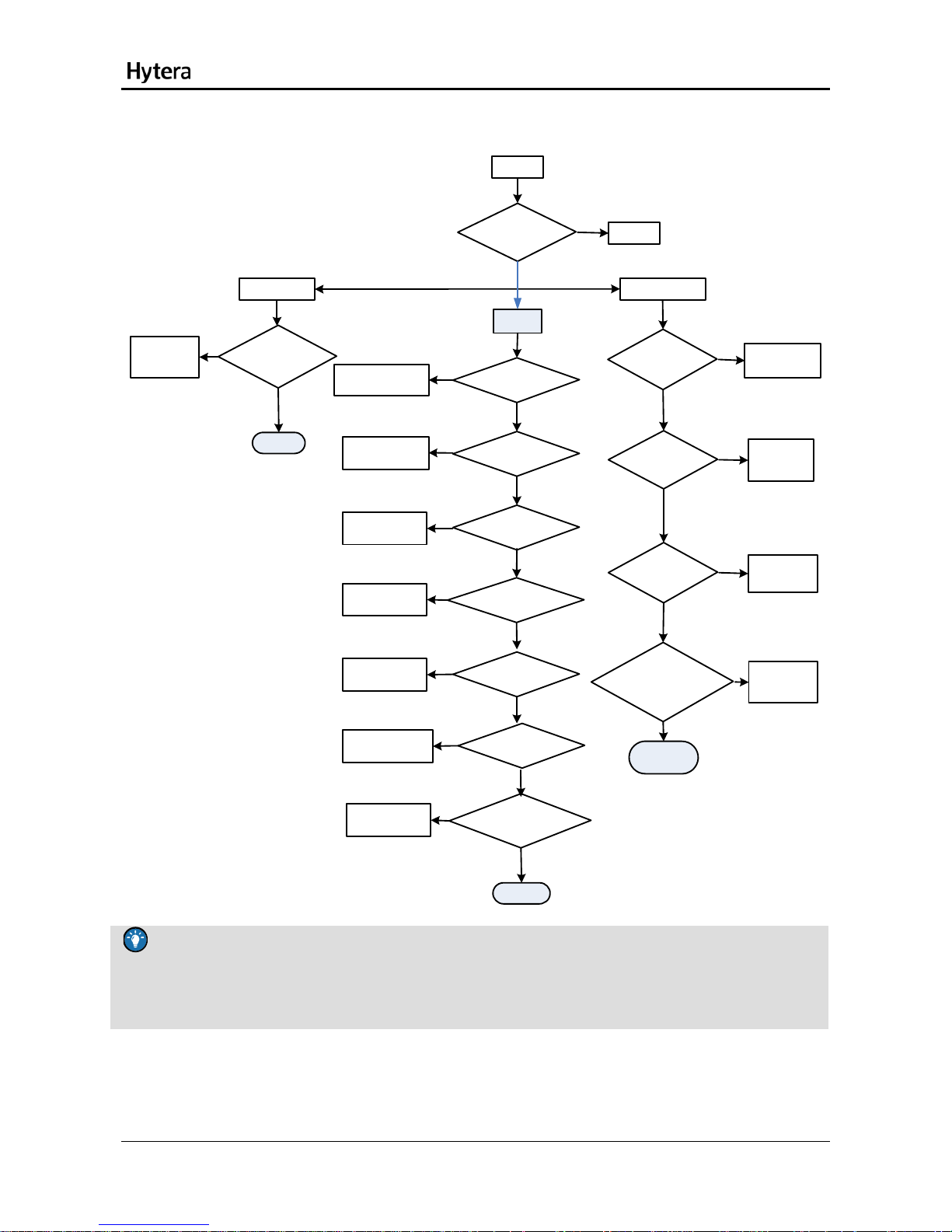

Troubleshooting Flow Chart

TX Circuit

Yes

Abnormal powe r output

If the current is over

500mA, it indicates

the PA is damaged.

Please replace the

PA (U4102).

Select the test mode and supply 3.7V

voltage. Then check whether the standby

current (240mA) is normal.

No

Yes

Check the TX VCO.

Make the TX VCO locked. Then check

whether the TX VCO outputs stably

[1]

No

Make the TX link in

open-loop working

status.

Check whether the

open-loop transmission

is normal. [2}

Yes

No

Replace

C4139.

Check whether C4139

is soldered inappropriately or

damaged.

Yes

No

Replace the

damaged

parts.

Check whether R4010\

R4011\R4015\C3013\C4014

is soldered inappropriately or

damaged.

Yes

No

Replace the

feedback

balun.

Check whether T4002 is soldered

inappropriately or damaged.

No

Yes

Check whether U4002 outputs

normally. [ 6]

No

Yes

Replace U4002.

Check whether

U4001 outputs normally. [7]

No

Yes

Check whether

T4001 and the

filter are

soldered

inappropriately

or damaged.

Check whether the input I/Q signal for

U4001 is normal. [8]

Yes

Check the

baseband.

Completed

Check whether the s pring

plate for the antenna is assembled

properly. [3]

Check whether U4103 is normal. [4]

Check whether U4102 is supplied

normally. [ 5]

Re-assemble the

spring plate or

replace it.

Replace U4103.

Replace U4102.

Yes

No

No

No

No

Yes

Yes

Yes

23

Service Manual

24

Description:

[1] The lock range for the TX VCO is 1612~1740MHz, and the output amplitude is over -15dBm.

[2] The output power is 27~30dBm during normal open-loop transmission.

[3] The spring plate is flexible and is securely connected with the antenna connector.

[4] When U4103 is normal, Pin4=6.5V, Pin6=0V

[5] When U4102 is supplied normally, Pin15/Pin16=2.8V, Pin9/Pin10/Pin11/Pin12=3.7V, Pout=28~

31dBm.

[6] When U4002 outputs normally, Pin6=3.0V, Pout=about 0dBm.

[7] U4001 outputs 806~870MHz Tetra signal and the amplitude is about -15~-5dBm.

[8] I/Q signal input at Pin20/Pin61: Detect the I/Q signal via an oscilloscope. In normal situation, it is the

modulation signal loaded on the 1.6V DC voltage, and its Vp-p is above 50mV.

Service Manual

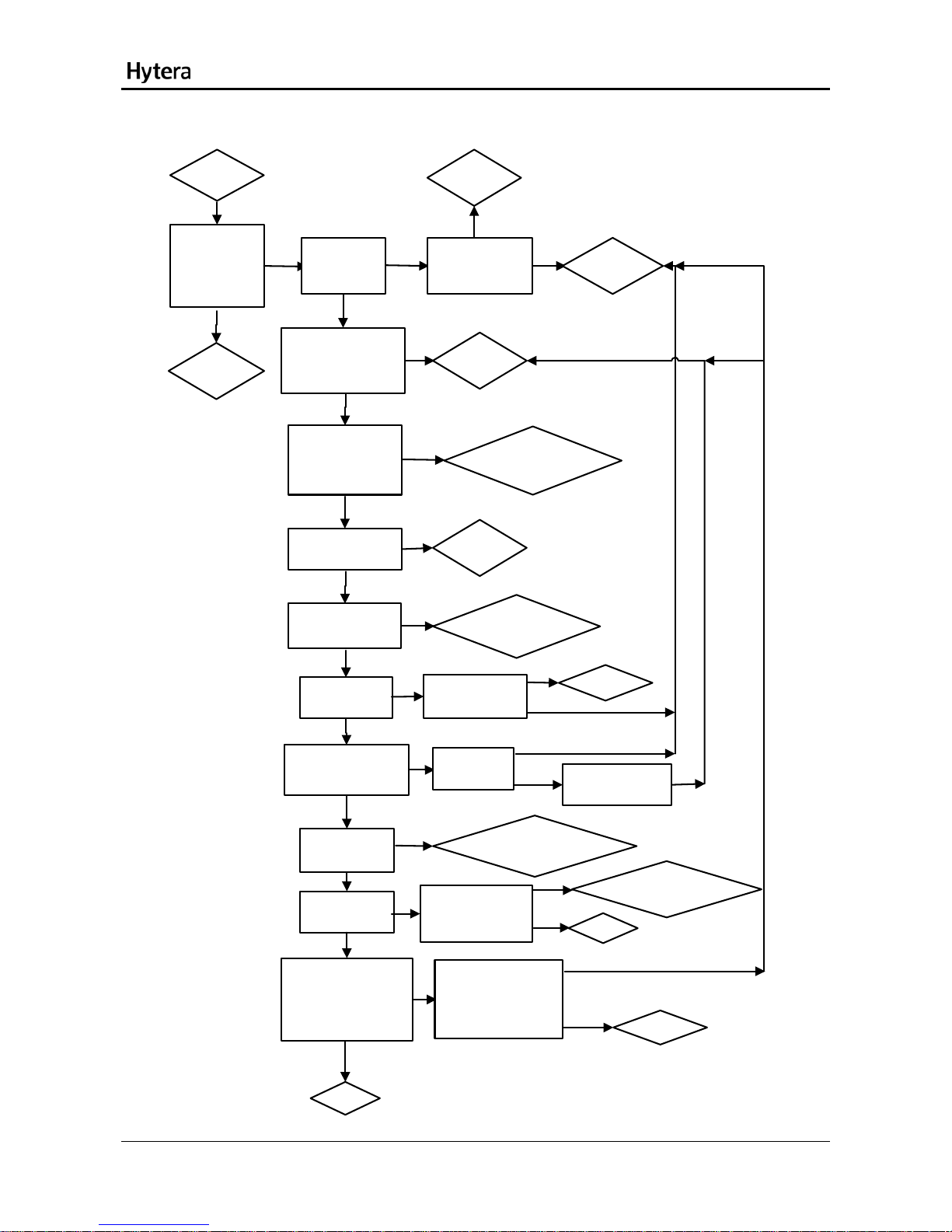

RX Circuit

Abnormal reception

Test TP5001 and

TP5002 to check

whether the I/Q signal is

normal. [12]

Yes

Check whether

I/Q signal is output

via the baseband.

No

Check the power

supply for the receiver

and whether U6501

outputs 3V voltage.

No

Check whether 3.3V input

voltage is available at Pin1

of U6501 and 3.3V enable

signal is available at Pin3.

No

Yes

Check the

enable signal and

power supply via the

baseband.

Replace U6501.

Yes

Check whether the RF LO and IF

LO of the receiver work normally

and whether normal stable

voltage is available at L1001 and

L1004. [1]

No

Check the FGU.

Yes

Check whether the amplitude

of the signal at Pin5 of U4103

is normal. [2]

No

Check whether the antenna

connector or duplexer is inappropriately

soldered or damaged.

Yes

Check whether the amplitude

of the signal at Pin1 of U410 is

normal. [3]

No

Replace U4103.

Yes

Check whether the amplitude

of the input signal at Pin1 of

U5001 is normal. [4]

No

Check whether Z5001/D5001

/C5001 is inappropriately soldered or

damaged.

Yes

Check whether the

amplitude of the output

signal at U5001 is

normal. [5]

No

No

Check whether Pin3/Pin4

of U5001 is supplied

normally. [6]

Replace U5001.

Yes

Yes

Check whether U5002 outputs

73.35MHz IF signal. [7]

No

Check whether Pin4

of U5002 is supplied

normally. [8]

No

Yes

Check whether normal RF

LO signal is available at Pin3

of U5002. [13]

Yes

Check whether the

amplitude of the output

signal at Z5003 is

normal. [9 ]

No

Check the Z5003 match circuit to see

whether Z5003 is soldered inappropriately. If

not, please replace Z5003.

Yes

Check whether the

amplitude of the output

signal at Q5001 is

normal. [10 ]

No

Check whether the voltage for

Pin2/Pin3 of Q5001 is normal.

[11]

No

Yes

Check whether the 3.3V RX voltage is

normal. If yes, please replace U5003.

Replace

Q5001.

Yes

Test TP5001 and TP5002 to check

whether normal I/Q signal is

availablel. [12]

No

Check whether 3V voltage is

supplied to Pin2/Pin20 of U5005,

and whether 146.7MHz IF LO

signal is available at Pin1/Pin28.

No

Yes

Replace U5005.

Yes

Completed

25

Service Manual

26

Description:

[1] The I/Q signals detected by the oscilloscope are modulation signals above 100mV.

[2] Apply -40dBm dot-frequency signal at the RF antenna connector (the -40dBm dot-frequency signal

will be applied at the antenna connector for the following signal amplitude detections unless

otherwise specified), and the amplitude of the signal at Pin5 of U4103 is -40~-50dBm when the

receiver is working.

[3] If the signal amplitude is normal, Pin4=0.3V, Pin6=3.3V.

[4] The normal amplitude range is -40~-55dBm.

[5] The amplitude of the output signal at U5001 should be larger than that of the input signal. The

normal range is -30~-40dBm.

[6] The normal voltage for U5001 is 3V.

[7] U5002 outputs 73.35MHz signal. The normal amplitude range is -50~-65dBm.

[8] The normal voltage for U5002 is 3V.

[9] Z5003 is the IF filter. The insertion loss should be less than 4dB, and the amplitude of the output

signal is -50~-70dBm.

[10] The amplitude of the output signal at Q5001 (IF amplifier) is -40~-55dBm, and should be larger than

that at Z5003.

[11] The normal voltage for Q5001 is 3V.

[12] Apply -40dBm Tetra signal at the antenna connector, and check whether I/Q signal is available at

TP5001 and TP5002 via an oscilloscope.

[13] The normal amplitude range is -10~0dBm.

Service Manual

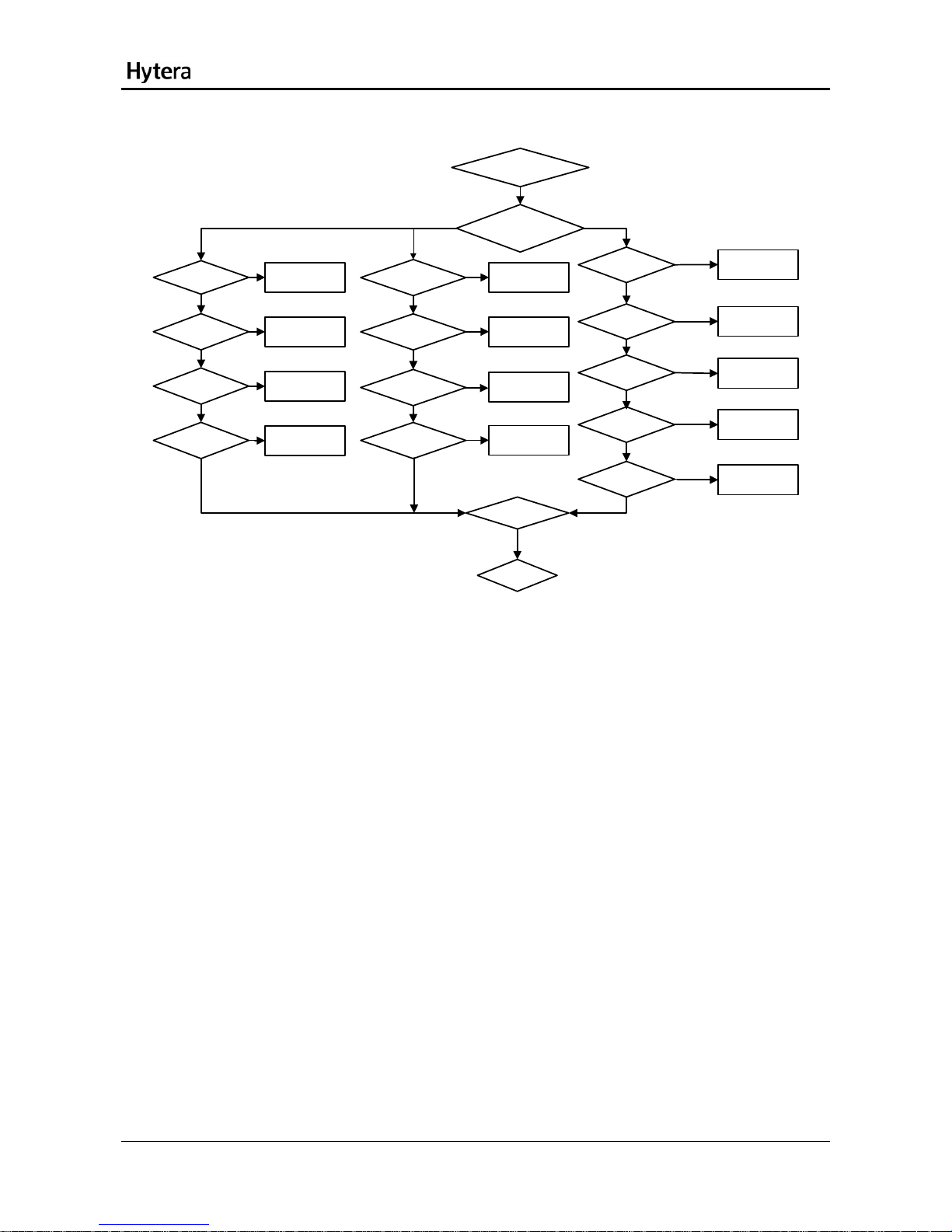

FGU Circuit

CP voltage for TX/RX LO [1]

Check whether

Q6503 is normal . [2]

Check whether

Q6504 is normal . [8]

Check Q6502 and

Q6504.

Check whether

Q1004 is normal.

[4]

Check whether

Q1003 is normal . [4]

Check the varactor. [3]

Check whether

Q1002 is normal. [7]

Check whether

Q1001 is normal. [7]

Check the varactor. [6]

Abnormal FGU

Check whether

Q6502 is normal. [5]

Check U1001. [ 12]

Check whether

Q1007 is normal. [11]

Check whether

Q1006 is normal. [11]

Check whether

Q1005 is normal. [10]

Check the varactor. [9]

Replace the varactor .

Replace Q1005.

Replace Q1006.

Replace Q1007.

Replace Q1004.

Replace Q1003.

Replace the varactor .

Replace Q6503 and

Q6506.

Replace Q1002.

Replace Q1001.

Replace the varactor .

Replace Q6504 and

Q6506.

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

No

Yes

Replace U1001.

No

Description:

[1] The CP voltage is 0.5~4.5V.

[2] The voltage at Pin4 of Q6503/Q6506 is 5V.

[3] The varactor is not damaged.

[4] The output voltage by Q1003/Q1004 is 4.8V.

[5] The voltage at Pin4 of Q6502/Q6504 is 5V.

[6] The varactor is not damaged.

[7] The output voltage by Q1001/Q1002 is 4.8V.

[8] The voltage at Pin4 of Q6504/Q6506 is 5V.

[9] The varactor is not damaged.

[10] For Q1005/Q1006, the voltage at the collector is 4.8V; the voltage at the grid is 1.8V; and the

voltage at the emitter is 1.2V.

[11] For Q1007, the voltage at the collector is 4.5V; the voltage at the grid is 0.3V; and the voltage at the

emitter is 0V.

[12] For U1001, the voltage at Pin1 is 3V (i.e. voltage at the R1002 end); the voltage at Pin2 is 5V (i.e.

voltage at the R1004 end); Pin9 provides 12MHz sine signal (amplitude: 0.8V).

27

Service Manual

RF POWER Circuit

Abnormal

power

supply

Yes

Check whether

3V3D(TP6001) ou tputs 3.3V

voltage.

No

Check the

baseband.

Yes

Power supply for TX

Power supply for

RX

Check whether

3V_TX is normal. [9]

No

If soldered properl y,

replace U6502.

是

Check whether

3V_A is normal . [10]

No

If soldered

properly, replace

U6503.

Yes

Check whether

3V_RX is normal. [1]

No

Power

supply for

FGU

Yes

Completed

Check whether

3V_B is normal . [11]

No

If soldered

properly, repl ace

U6504.

Yes

Check whether

3V_TXDRV and Q 6501 are normal.

[12]

No

If soldered

properly, replac e

Q6501.

Yes

If soldered

properly, replac e

U6501.

Completed

Check whether U6505 is

normal. [2]

No

If soldered properl y,

replace U6505.

Check whether U6506 is

normal. [3]

If soldered properl y,

replace U6506.

No

Yes

Yes

Check whether Q6505 is

normal. [4]

If soldered properl y,

replace Q6505.

Yes

No

Check whether Q6506 is normal.

[5]

If soldered properl y,

replace Q6506.

No

Yes

Check whether Q6503 is

normal. [7]

If soldered properl y,

replace Q6503.

No

Yes

Check whether Q 6504 is normal.

[8]

If soldered properly,

replace Q6504.

No

Completed

Check whether Q6502 is

normal. [6]

If soldered properl y,

replace Q6502.

No

Yes

Yes

Tip: To check output voltage of U6501/U6502/U6503/U6504/Q6501/Q6502/Q6503/Q6504, the 3.3V

voltage (from the 3.3V control signal of the baseband) is needed at the their enable ends.

28

Loading...

Loading...