Hyster S40XM, S45XM, S50XM, S60XM, S65XM Operating Manual

...

OPERATING MANUAL

CHALLENGER

H45XM,H50XM,H55XM,H60XM,H65XM

SPACESAVER

S40XM, S45XM, S50XM, S55XM, S55XMS, S60XM,

S65XM

DO NOT REMOVE THIS MANUAL FROM THIS UNIT

Property of American Airlines

HYSTER COMP ANY

P ART NO. 1458874

LIFT TRUCK MODEL SERIAL NUMBER

ENGINE MODEL SERIAL NUMBER

TRANSMISSION TYPE SERIAL NUMBER

MAST LIFT HEIGHT GROUP NUMBER

CARRIAGE TYPE GROUP NUMBER

DRIVE TIRE SIZE STEERING TIRE SIZE

SPECIAL EQUIPMENT OR ATTACHMENTS

REGISTERED TRADEMARKS

Hyster,

Hyster Company.

, Challenger, SpaceSaver, Monotrol, RACKLOADER, SitDrive and StanDrive are trademarks of

Property of American Airlines

FOREWORD

FOREWORD

To OWNERS, USERS, and OPERATORS:

The safe and efficient operation of a lift truck requires

skill and alertness on the part of the operator. To develop

the skill required the operator must:

• Receive training in the proper operation of THIS lift

truck.

• Understand the capabilities and limitations of the lift

truck.

• Become familiar with the construction of the lift truck

and see that it is maintained in good condition.

• Read and understand the warnings and operating

procedures in this manual.

In addition, a qualified person, experienced inlift truck operation,mustguidea newoperatorthroughseveral drivingand

load handling operations before the new operator attempts

to operate the lift truck alone.

HYSTER COMPANY 2003

It is the responsibility of the employer to make sure that

the operator can see, hear, and has the physical and

mental ability to operate the equipment safely.

Various laws and regulations require the employer to train

lift truck operators. These laws and regulations include:

• Occupational Safety and Health Act (USA)

• Canada Material Handling Regulations

NOTE: A comprehensive operator trainingprogram isavailable from HYSTER COMPANY. For further details, contact

your dealer for Hyster lift trucks.

This OPERATING MANUAL contains information necessary for the operation and maintenance of a basic fork lift

truck. Optional equipment is sometimes installed that can

change some operating characteristics described in this

manual. Make sure the necessary instructions are available and understood before operating the lift truck.

1

Property of American Airlines

FOREWORD

Some of the components and systems described in this

OPERATING MANUAL will NOT be installed on your unit.

If you have a question about any item described, contact

your dealer for Hyster lift trucks.

Additional information that describes the safe operation

and use of lift trucks is available from the following

sources:

• Employment safety and health standards or

regulations (Examples: “Occupational Safety and

Health Standards (USA)”, “Canada Material Handling

Regulations”.

• Safety codes and standards (Example: American

National Standard, ANSI B56.1, Safety Standard For

Low Lift And High Lift Trucks.

• Publications from government safety agencies,

government insurers, private insurers and private

organizations (Example: Accident Prevention Manual

For Industrial Operations, from the National Safety

Council).

• Guide for Users of Industrial Lift Trucks (Hyster Part

No. 852930) describes lift truck safety, good

maintenance practices, and training programs and is

available from your dealer for Hyster lift trucks.

NOTE: Hyster lift trucks are not intended for use on public

roads.

NOTE: The following symbols and words indicate safety information in this manual:

WARNING

Indicates a condition that can cause death or injury!

CAUTION

Indicatesa condition that can causeinjury or property

damage!

2

Property of American Airlines

CONTENTS

CONTENTS

FOREWORD 1..................................

To OWNERS, USERS, and OPERATORS 1......

CONTENTS 3...................................

MODEL DESCRIPTION 11.........................

GENERAL 1 1..................................

OPERATOR PROTECTION EQUIPMENT 11......

NAMEPLATE 12...............................

SAFETY LABELS 13...........................

INSTRUMENTS AND CONTROLS 17............

OPERATING PROCEDURES 33....................

GENERAL 33..................................

Know Your Lift Truck 33......................

Stability And Center Of Gravity 35.............

Capacity (Weight And Load Center) 36.........

INSPECTION BEFORE OPERATION 37..........

Checks With The Engine Stopped 37..........

Starting Procedures 38.......................

Starting Procedures, Gasoline Or LPG

Engine 38..................................

Starting Procedures, Diesel Engine 38.........

Checks With The Engine Running 39..........

OPERATING TECHNIQUES 40..................

Basic Operating Procedures 41...............

Driving And Direction Changes 42.............

Inching 43..................................

Steering (Turning) 44........................

Load Handling, General 46...................

Load Handling, Lifting, Lowering And

Tilting 47...................................

Load Handling, How To Engage And Disengage

A Load 49..................................

Load Handling, Travelling 52..................

HIGHWAY TRUCKS, RAIL CARS AND

DOCKS 56....................................

ATTACHMENTS 58............................

STOPPING 58.................................

PARKING 58..................................

MAINTENANCE 61...............................

GENERAL 61..................................

Serial Number Data 62.......................

HOW TO MOVE A DISABLED LIFT TRUCK 62....

HowToTowtheLiftTruck 62..................

HOW TO PUT A LIFT TRUCK ON BLOCKS 63....

How To Raise the Drive Tires 63..............

3

Property of American Airlines

CONTENTS

How To Raise the Steering Tires 64...........

MAINTENANCE SCHEDULE 67...................

MAINTENANCE PROCEDURES EVERY 8 HOURS

OR DAILY 81.....................................

HOW TO MAKE CHECKS WITH THE ENGINE

STOPPED 81..................................

Tires and Wheels 81........................

Forks 83...................................

Forks, Adjustment 83........................

Forks, Removal 83..........................

Forks, Installation 85.........................

Inspection Of Forks, Mast, and Lift Chains 85...

Safety Labels 87............................

Operator Restraint System 87................

Steering Column Latch 89....................

Check For Fuel, Oil Or Coolant Leaks 89.......

Drive Belt 89...............................

Engine Oil 89...............................

Transmission Oil Temperature 92.............

Hydraulic System Oil 93.....................

Battery 94.................................

Air Filter 94................................

HOW TO MAKE CHECKS WITH THE ENGINE

RUNNING 95..................................

Gauges, Lights, Horn, Fuses and Relays 98....

“Check Engine” Light(Mazda and GM3.0L LPG

Closed--Loop With Emission System) 98........

“Check Engine” Light

(GM 3.0 Liter Gasoline) 98....................

Engine Oil Pressure 98.......................

Cooling System 99..........................

Steering System 99..........................

Service Brakes 99...........................

Parking Brake 100............................

Fuel System 101.............................

Water Separator, Diesel Engine 101.............

Fuel Filter, Diesel Engine 102..................

Remove Air From The Diesel Fuel System 102...

Control Levers and Pedals 102.................

Lift System Operation 102.....................

Cooling System 103..........................

HOW TO ADD FUEL TO THE LIFT TRUCK 104....

Liquefied Petroleum Gas (LPG) 105.............

Gasoline or Diesel Fuel 108....................

4

Property of American Airlines

CONTENTS

WHEELS AND TIRES 108.......................

General 108.................................

How To Change A Solid Rubber Tire

S40--65XM Models 109.......................

RemoveAndInstallTheTireOnThe

Wheel 109...................................

How To Repair A Pneumatic Tire H45--65XM

Models 1 11..................................

Remove The Wheels From The Lift Truck 111....

Remove The Wheel From The Tire 112..........

Install The Wheel in the Tire 1 15................

AddAirToTheTires 117......................

Install the Wheels 118.........................

INSTALLATION PROCEDURES, DUAL DRIVE

WHEELS 119...................................

SOLID RUBBER TIRES 119......................

Remove The Tire From The Wheel 120..........

Install The Tire On The Wheel 120..............

OPERATING PROCEDURES FOR A NEW OR

REBUILT ENGINE 123...........................

CHANGES TO THE OVERHEAD GUARD 123......

HOW TO PUT INTERNAL COMBUSTION

ENGINE (I.C.E.) TRUCKS IN STORAGE 123.......

HOW TO PUT BATTERIES IN STORAGE 124......

HOW TO STORE A LIFT TRUCK 125.............

HOW TO MOVE A LIFT TRUCK ON A

TRANSPORT 127...............................

Loading 127.................................

Unloading 128...............................

PREPARATION FOR USE 129....................

Preparation After Transport 129................

Preparation After Storage 129..................

5

Property of American Airlines

CONTENTS

NOTES

6

Property of American Airlines

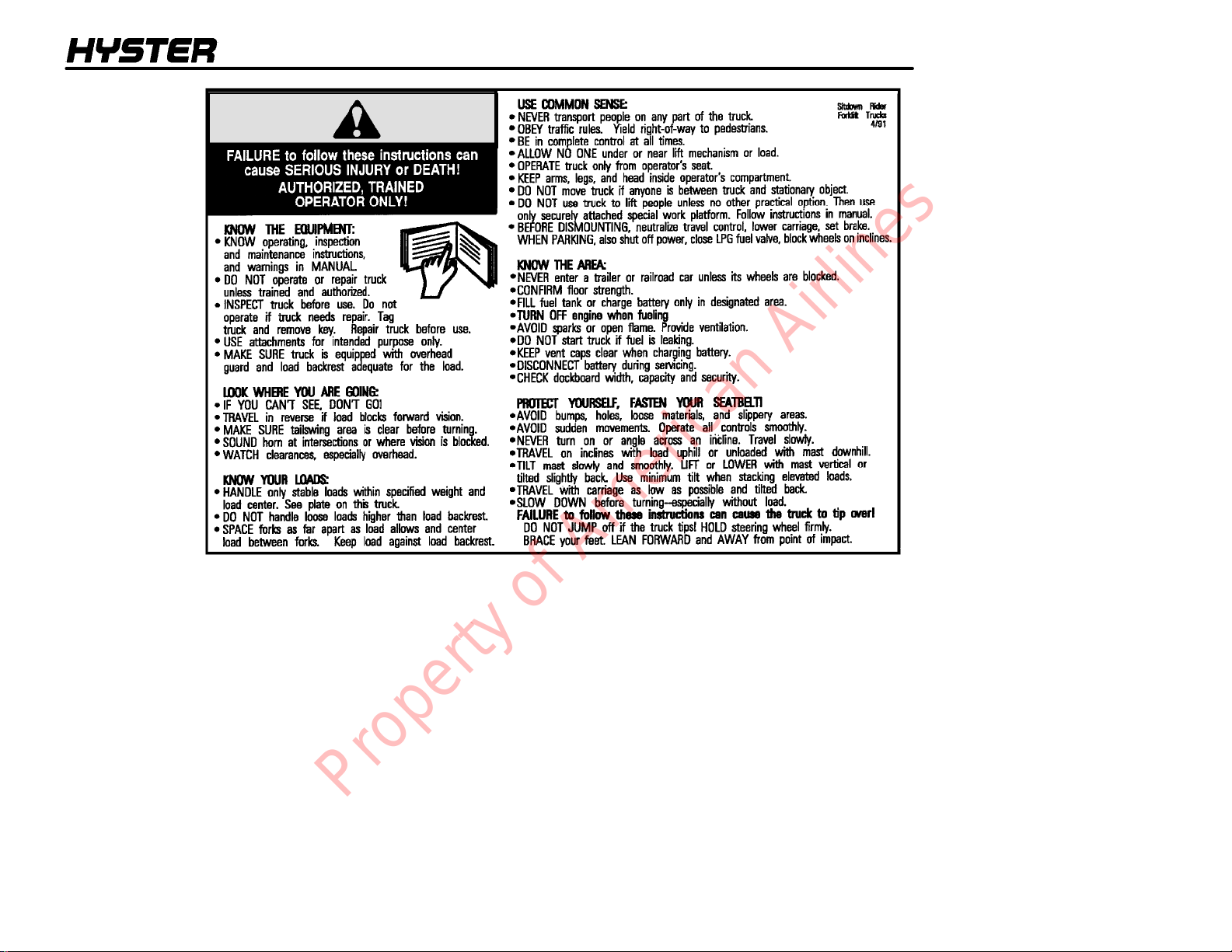

A WARNING

label with this

information

must be on the

lift truck.

WARNING

7

Property of American Airlines

WARNING

NOTES

8

Property of American Airlines

MODEL DESCRIPTION

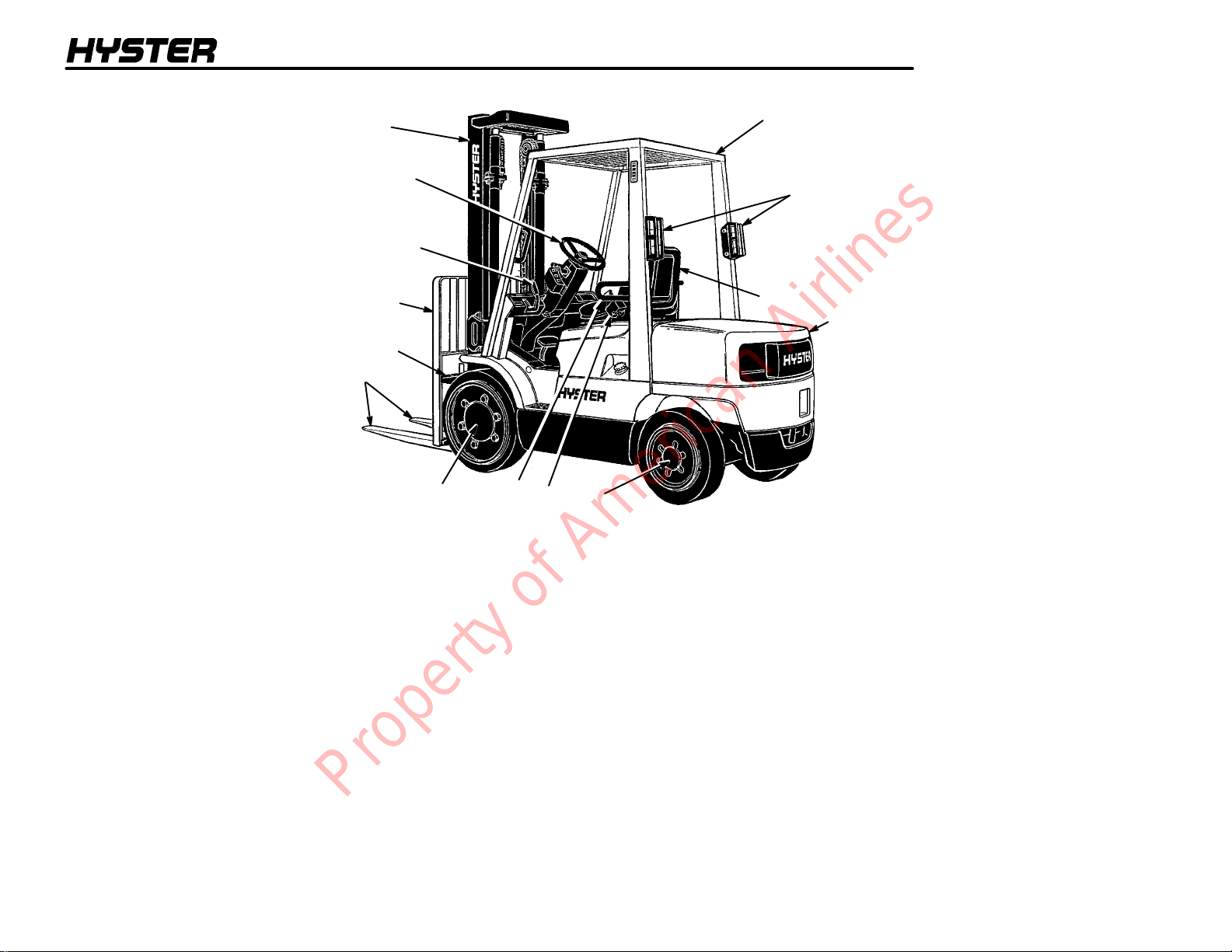

1. OVERHEAD GUARD

2. TAIL LIGHT, BRAKE

LIGHT, REVERSE LIGHT

3. SEAT

4. COUNTERWEIGHT

5. STEERING AXLE

6. SEAT BELT AND

HIP RESTRAINT

7. DRIVE AXLE

8. FORKS

9. CARRIAGE

10. LOAD BACKREST

EXTENSION

11. PARKING BRAKE

12. STEERING WHEEL

13. MAST

FIGURE 1. MODEL VIEW SHOWING MAJOR COMPONENTS OF S40--65XM SERIES

13

12

11

10

9

8

7

6

6

5

1

2

3

4

12779

9

Property of American Airlines

MODEL DESCRIPTION

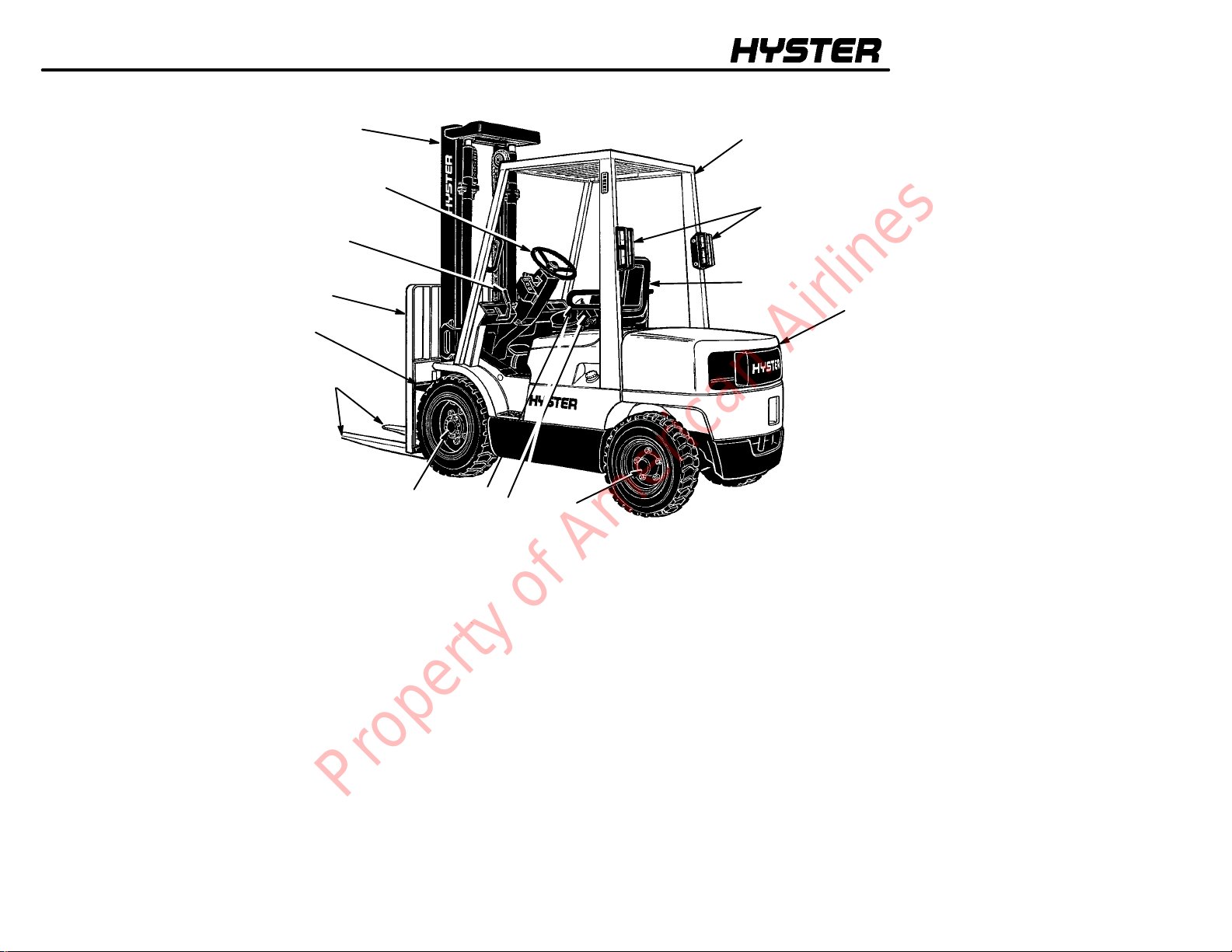

1. OVERHEAD GUARD

2. TAIL LIGHT, BRAKE

LIGHT, REVERSE LIGHT

3. SEAT

4. COUNTERWEIGHT

5. STEERING AXLE

6. SEAT BELT AND

HIP RESTRAINT

7. DRIVE AXLE

8. FORKS

9. CARRIAGE

10. LOAD BACKREST

EXTENSION

11. PARKING BRAKE

12. STEERING WHEEL

13. MAST

FIGURE 2. MODEL VIEW SHOWING MAJOR COMPONENTS OF H45--65XM SERIES

13

12

11

10

9

8

7

6

6

5

1

2

3

4

12626

10

Property of American Airlines

MODEL DESCRIPTION

MODEL DESCRIPTION

GENERAL

This OPERATING MANUAL is for the following models of

lift trucks:

S45XM, S45XM, S50XM, S55XM, S55XMS,

S60XM, S65XMS

H40XM, H50XM, H55XM, H60XM, H65XM

These lift trucks are available with the following engines:

• Mazda M4--2.0G or M4--2.2G engine which use

gasoline or LPG fuel

• GM 3.0L engine that uses gasoline or LPG fuel

• Perkins 704--26 (UB) diesel engine

H45--65XM only

The single--speed powershift transmission can be

equipped with two types of controls:

• A MONOTROLR pedal that controls both the for-

ward and reverse operation of the powershift transmission and the speed of the engine.

• A direction control lever on the left side of the

steering column that controls the forward, neutral

and reverse operation of the powershift transmission. A separate accelerator pedal controls the engine speed.

The S40--65XM lift trucks are equipped with solid rubber

tires. The H45--65XM lift trucks are equipped with pneumatic tires or solid rubber tires that look like pneumatic

tires. See Wheels And Tires in the MAINTENANCE

SECTION for a description of these tires.

OPERATOR PROTECTION EQUIPMENT

The LOAD BACKREST EXTENSION is installed to keep

loose parts of the load from falling back toward the operator. It must be high enough, with openings small enough

to prevent the parts of the load from falling backwards. If

a load backrest extension that is different from the one

installed on your lift truck is required, contact your Hyster

lift truck dealer.

The OVERHEAD GUARD is intended to offer reasonable

protection to the operator from falling objects, but can not

protect against every possible impact. Therefore, it must

11

Property of American Airlines

MODEL DESCRIPTION

not be considered a substitute for good judgment and

care when handling loads. Do not remove the overhead

guard.

The SEAT BELT AND HIP RESTRAINT provide additional

means to help the operator keep the head and torso substantially within the confines of the lift truck frame and

overhead guard if a tipover occurs. This restraint system

is intended to reduce the risk of the head and torso being

trapped between the lift truck and the ground, but it can

not protect the operator against all possible injury in a

tipover. The hip restraint will help the operator resist side

movement. It is not a substitute for the seat belt. Always

fasten the seat belt.

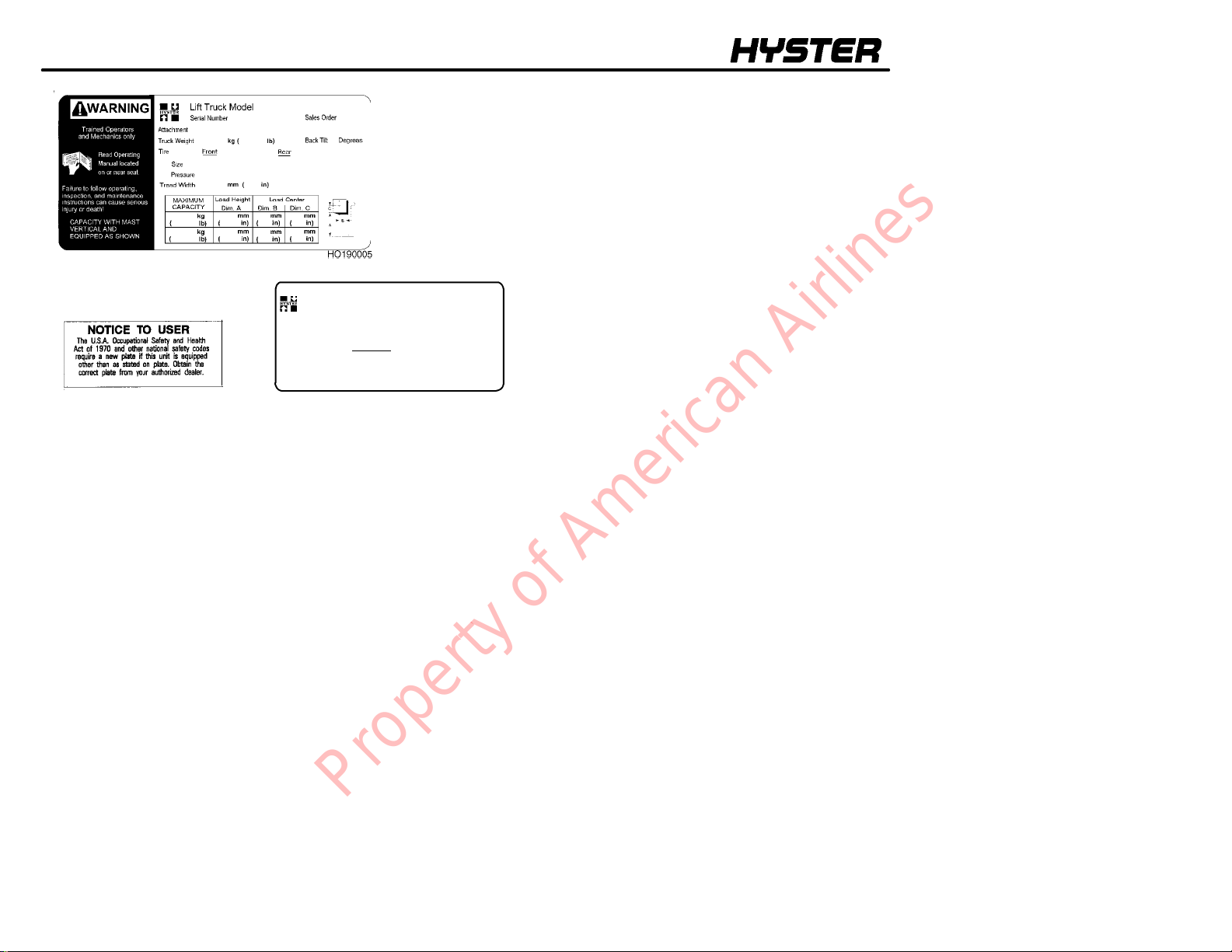

NAMEPLATE

WARNING

Any change to the lift truck, the tires or its equipment

can change the lifting capacity. If the Nameplate does

not show the maximum capacity , or if the lift truck

equipment, including the battery for electric trucks,

does not match that shown on the Nameplate, the lift

truck must not be operated.

The capacity is specified in kilograms (kg) and pounds

(lb). The capacity is the maximum load that the lift truck

can handle for the load condition shown on the Nameplate.

The maximum capacity for the lift truck, at full load height,

must be shown on the Nameplate. Special capacities

with the load height reduced or with optional load centers,

may also be shown on the Nameplate.

The lift truck serial number code is on the Nameplate. The

serial number code is also stamped on the lift truck frame

When a lift truck is shipped incomplete from the factory,

the Nameplate is covered by an INCOMPLETE label as

shown in FIGURE 3. If the equipment on the truck is

changed, the Nameplate is covered by a NOTICE label as

shown in FIGURE 3. If your lift truck has either of these

labels, do not operate the lift truck. Contact your dealer

for HYSTER lift trucks to obtain a complete correct Nameplate.

.

12

Property of American Airlines

MODEL DESCRIPTION

WARNING

DO NOT add to or modify the lift truck. Any change to

the lift truck, the tires or its equipment can change

the lifting capacity. The lift truck must be rated as

equipped and the nameplate must show the new capacity rating.

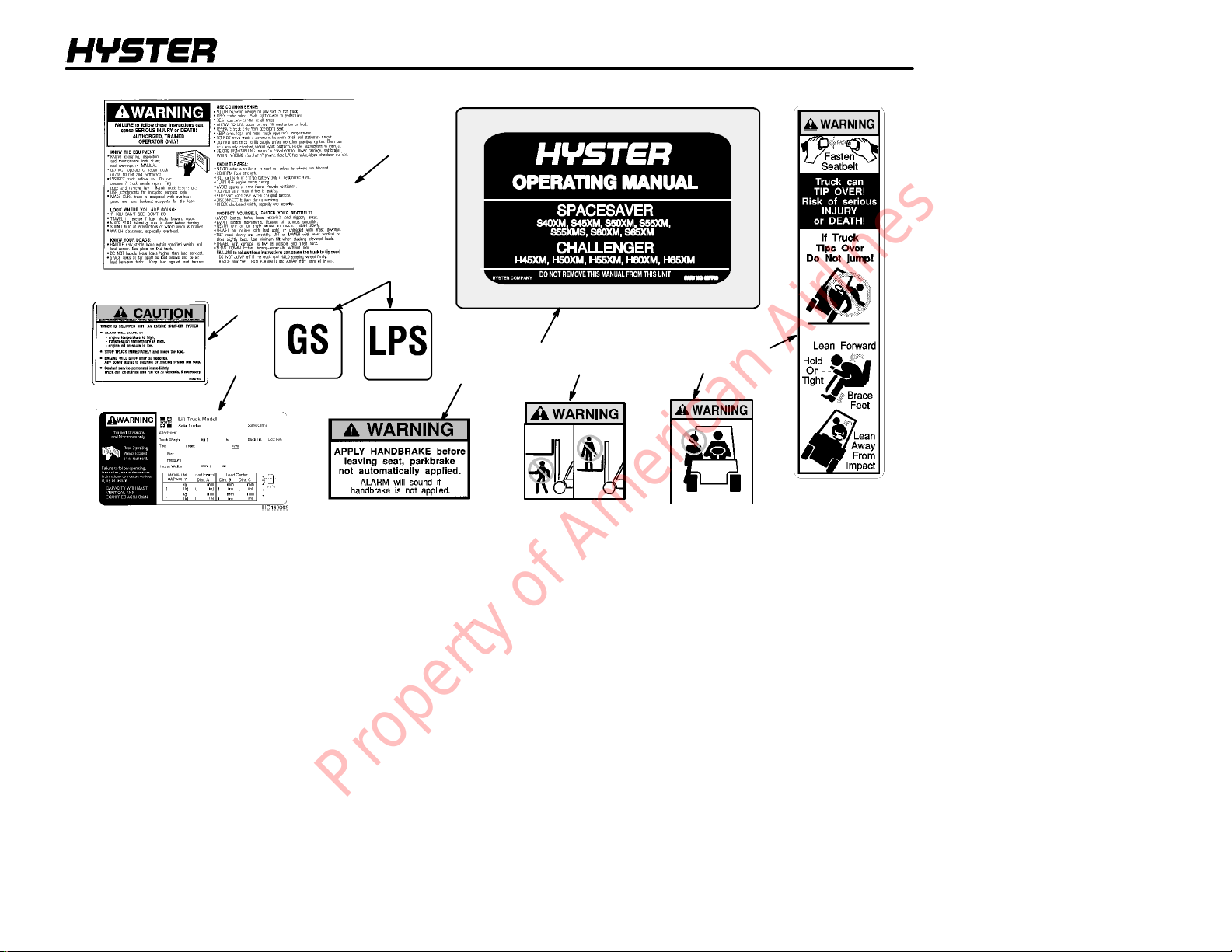

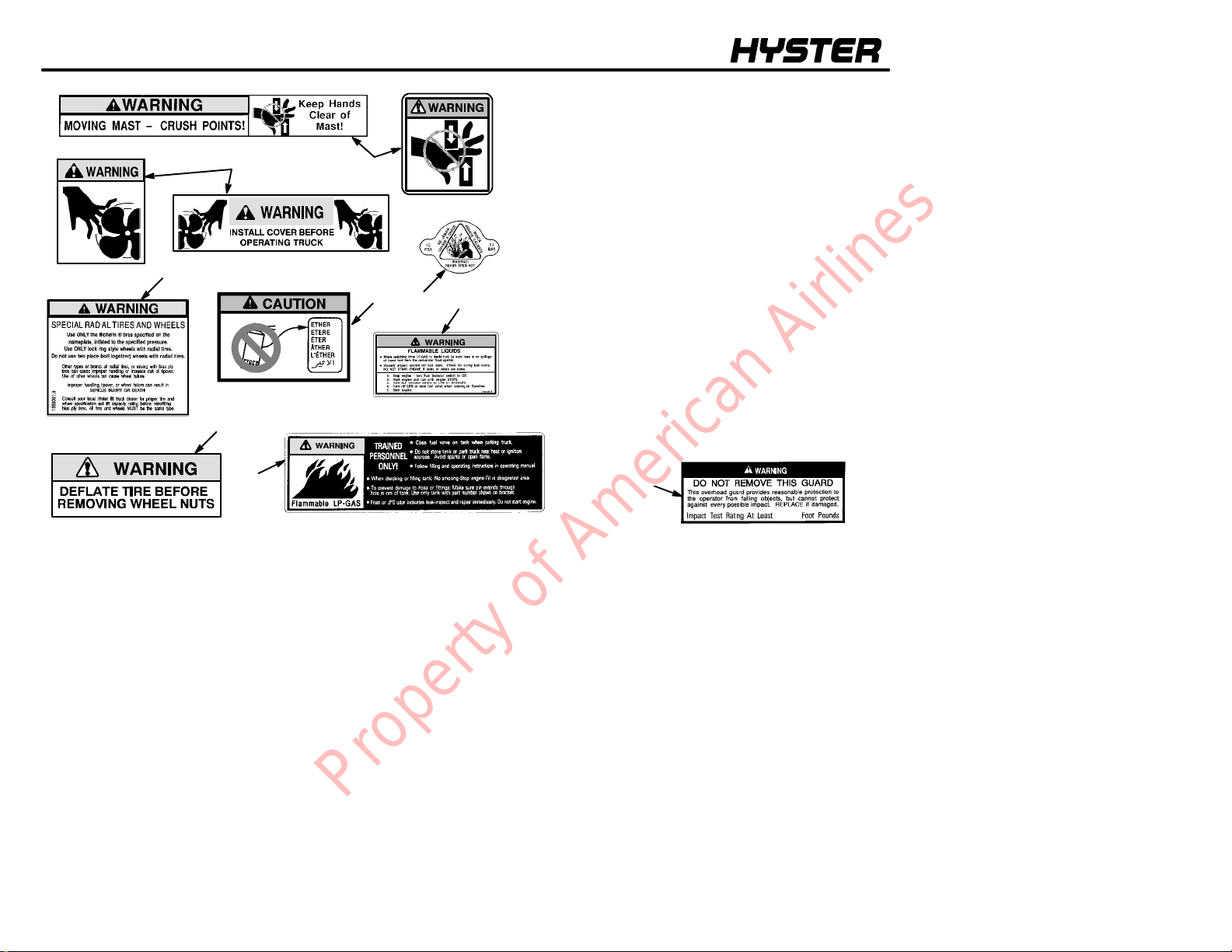

SAFETY LABELS

Safety labels are installed on the lift truck to give information about possible hazards. It is important that all safety

labels are installed on the lift truck and can be read. See

FIGURE 4.

13

Property of American Airlines

MODEL DESCRIPTION

NAMEPLATE

NOTICE LABEL

FIGURE 3. NAMEPLATE AND LABELS

TRUCK MODEL

Serial no.

Approx.weight

This unit was shipped incomplete from factory/

The U.S.A. Occupational Safety and Health Act of 1970 and other

national safety codes require the installation of a c ompleted Nameplate

showing unit configurationand ratedcapacity.Completed Nameplates

may be obtained through your HYSTER dealer.

NOTICE TO USER

1304058R

INCOMPLETE LABEL

14

Property of American Airlines

MODEL DESCRIPTION

1

3

2

5

SEE THE PARTS MANUAL FOR THE PART NUMBER AND LOCATION OF LABELS

FIGURE 4. WARNING AND SAFETY LABELS (1 of 2)

6

4

7

8

9

Property of American Airlines

15

MODEL DESCRIPTION

Y

)

11

12

16

10

13

14

15

1. WARNING, OPERATION

2. DRIVE TRAIN PROTECTION CAUTION

3. OPTIONAL FIRE SAFETY RATING

4. CASE WITH OPERATING MANUAL

5. NAMEPLATE

6. WARNING FOR PARKING BRAKE

7. NO ONE ON OR UNDER FORKS

8. NO RIDERS

9. TIPOVER WARNING

10. MAST WARNING

1 1. FAN WARNING

12. RADIAL TIRE WARNING--H45--65XM Only

13. ETHER WARNING--H45--65XM Only

14. RADIATOR CAP WARNING -- H45--65XM

Only

15. DUAL FUEL WARNING

16. TWO--PIECE WHEEL WARNING

H45--65XM Only

17. FLAMMABLE LP--GAS

18. GUARD LABEL

16

17

SEE THE PARTS MANUAL FOR THE PART NUMBER AND LOCATION OF LABELS

FIGURE 4. WARNING AND SAFET

LABELS(2of2

18

Property of American Airlines

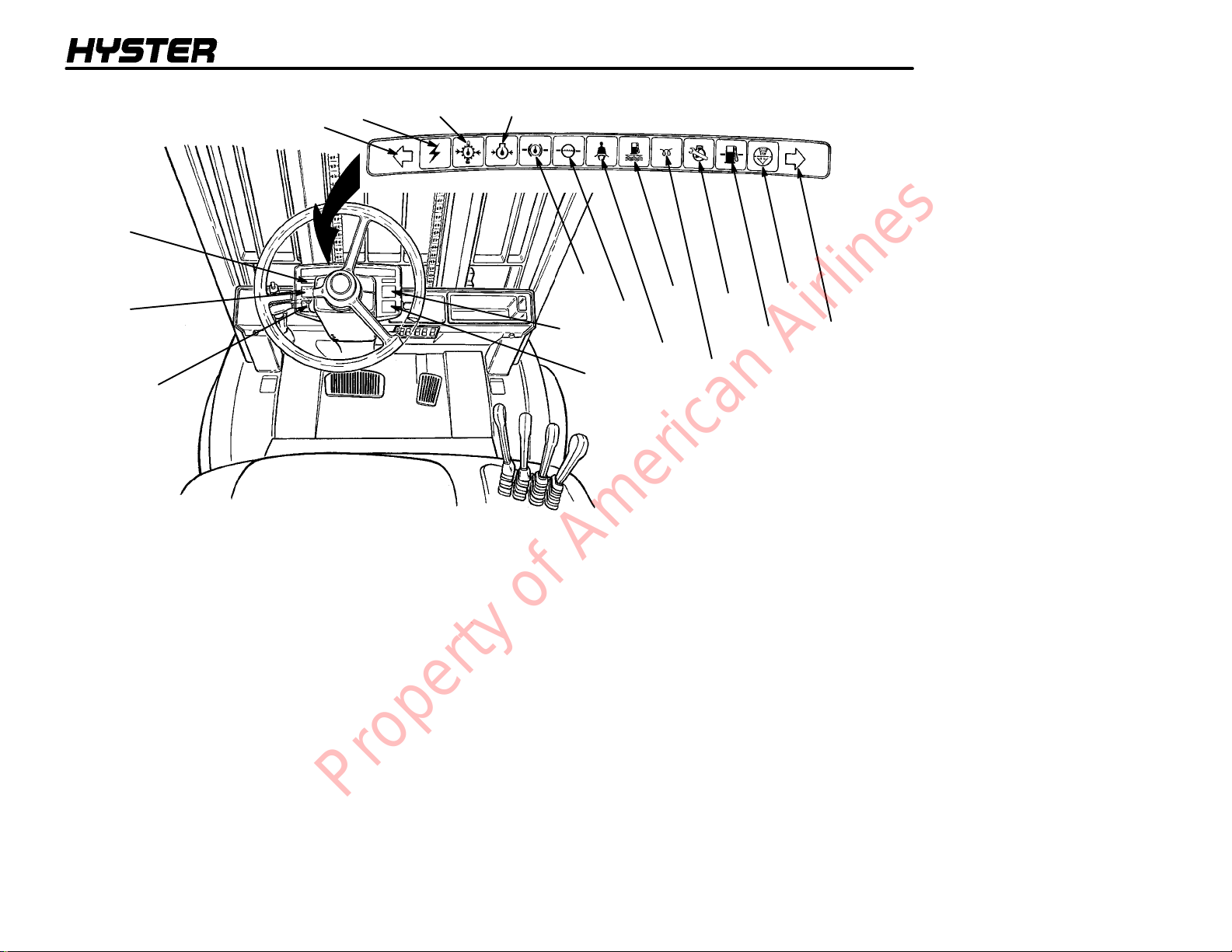

MODEL DESCRIPTION

5

4

3

2

1

6

FIGURE 5. INSTRUMENTS

7

17

8

18

11

9*

10

*

USED ONLY ON S40--65XM

MODEL TRUCKS

13

12

14

15

16

17

Property of American Airlines

MODEL DESCRIPTION

INSTRUMENTS AND CONTROLS

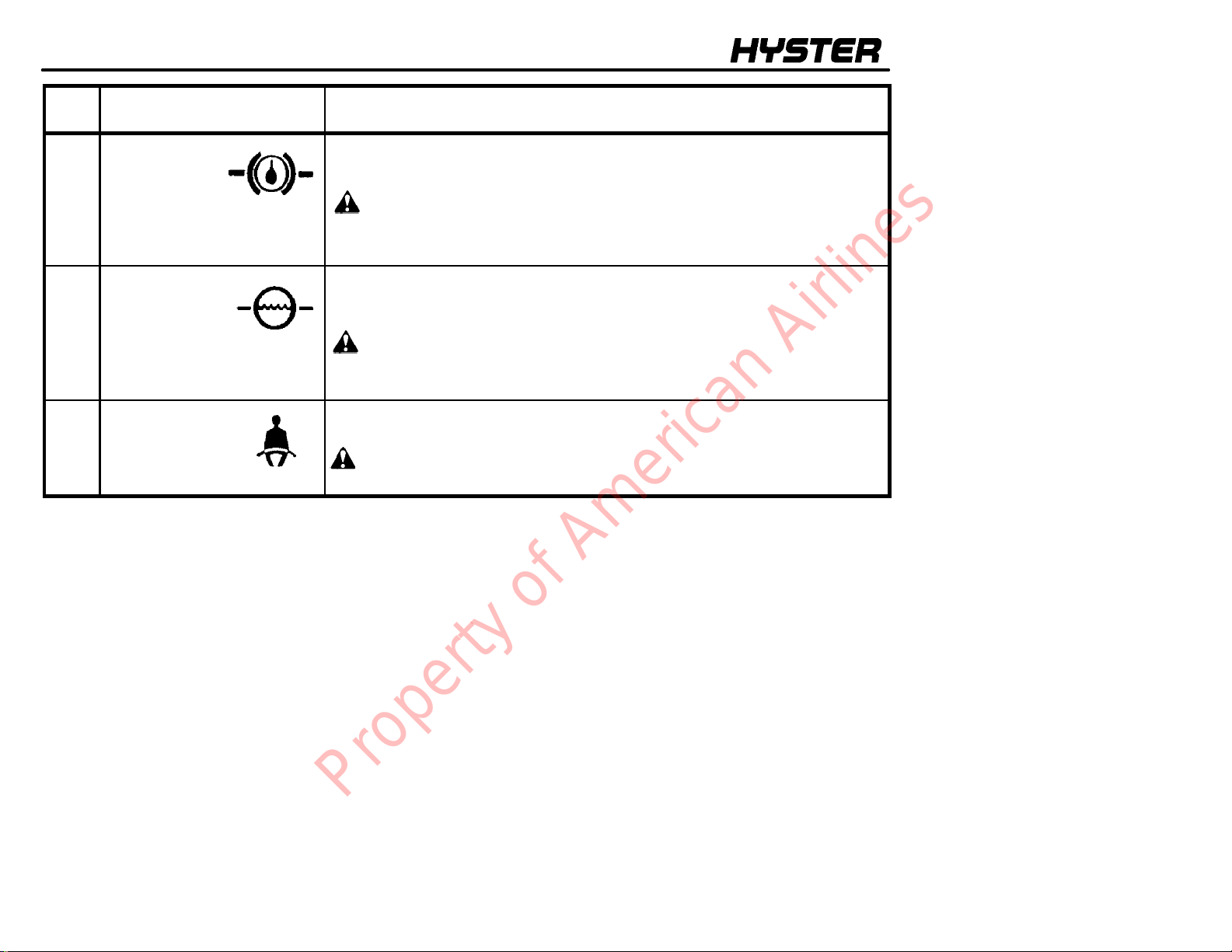

WARNING

If any of the instruments, levers, or pedals do not operate as described in the following tables, report the problem immediately. DO NOT operate the lift truck until the problem is corrected.

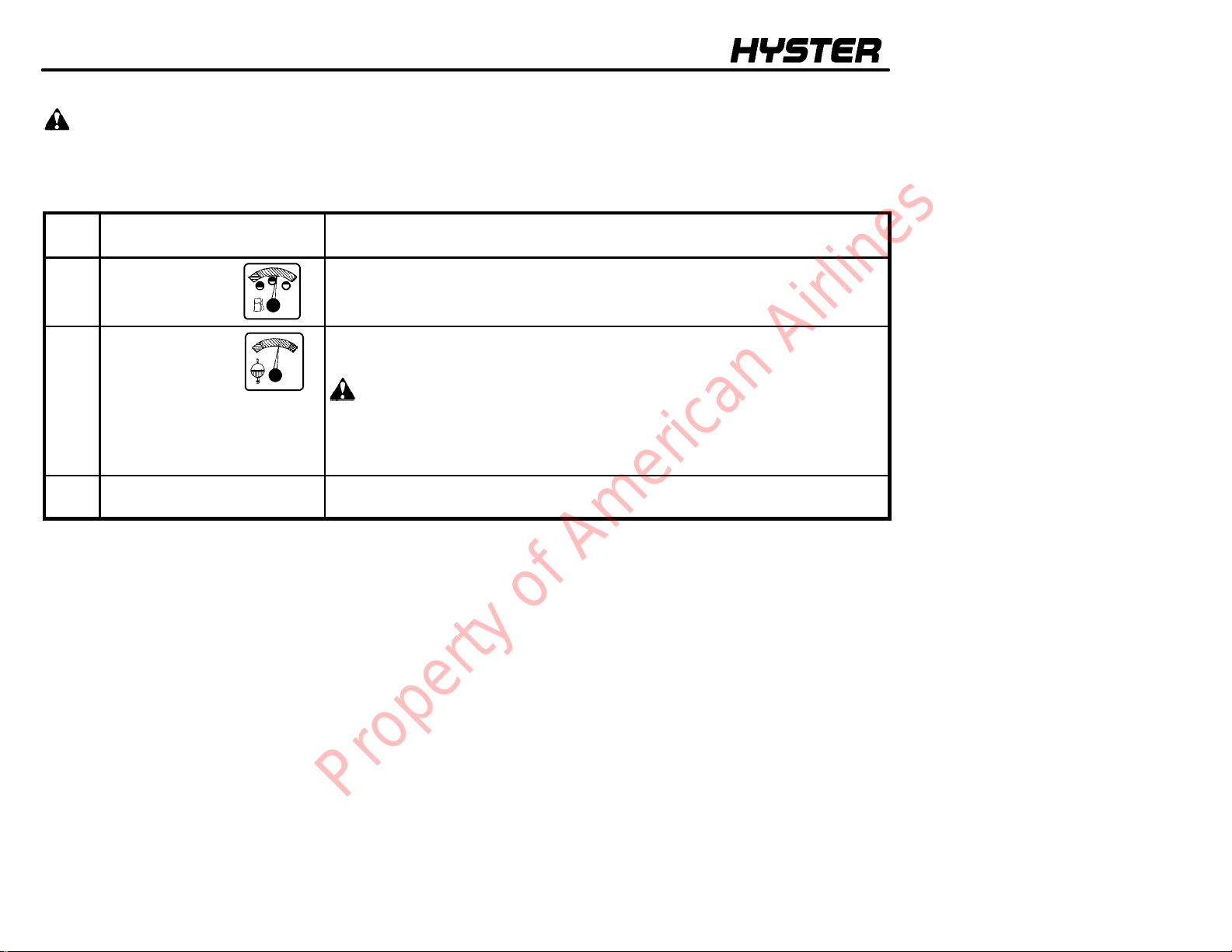

TABLE 1. INSTRUMENTS (See FIGURE 5.)

ITEM

NO.

1

2

Fuel Gauge

Coolant

Temperature

Gauge

ITEM

FUNCTION

This gauge indicates the amount of fuel in the gasoline or diesel fuel tank.

This gauge indicates engine coolant temperature when the key switch is in the

ON position. During normal operation the gauge needle will be in the green

area.

CAUTION

Do not continue to operate the lift truck when the gauge indicates that

the engine is too hot (needle in the red zone).

NOTE: Engine will stop after a 30 second warning buzzer if coolant is over

121°C (250°F) on S40--65XM series with protection system.

3 Hour Meter The hour meter operates when the key switch is in the ON position. Periodic

Maintenance recommendations are based on these hours.

18

Property of American Airlines

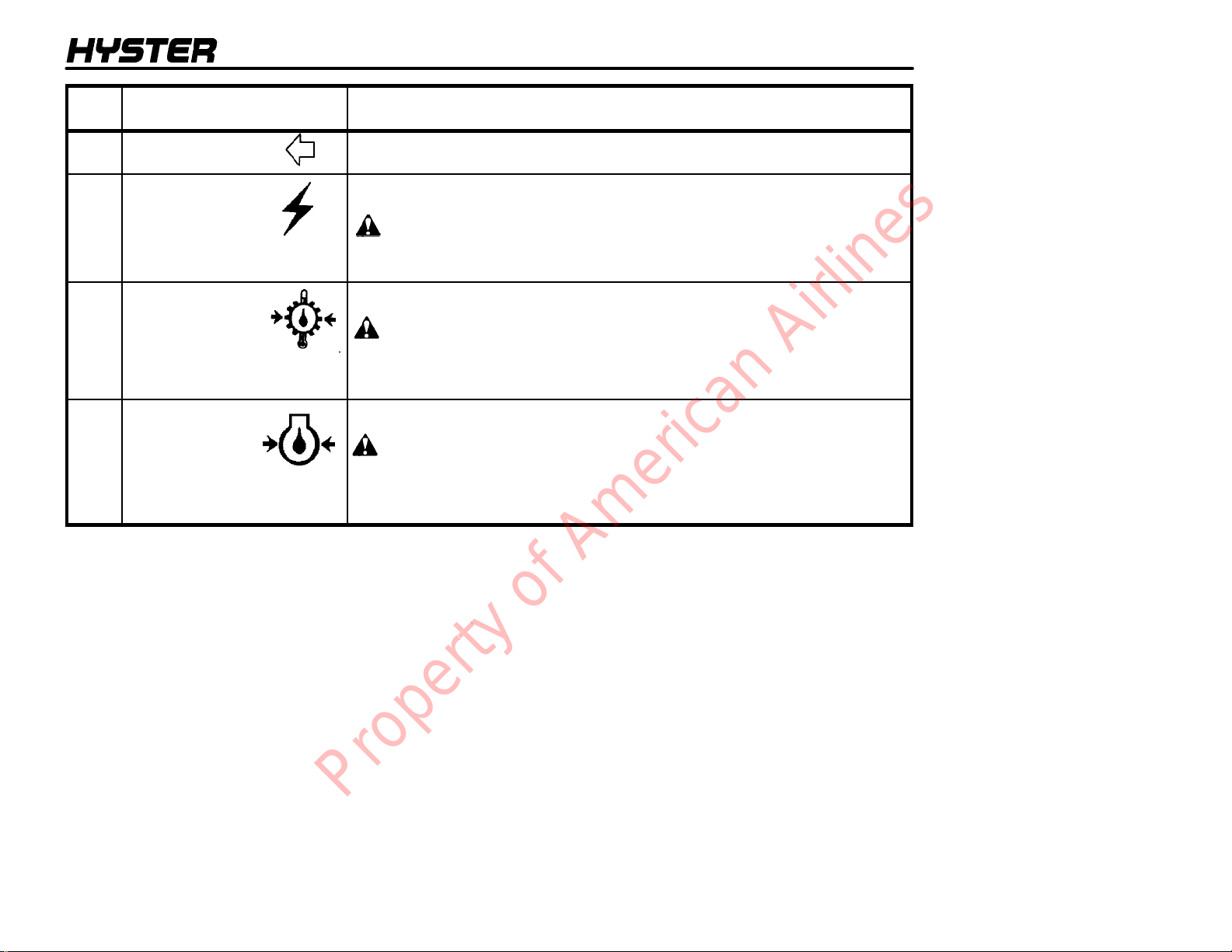

MODEL DESCRIPTION

ITEM

NO.

4

Left--Hand

Turn Indicator

5 Warning Light,

Alternator

6

Warning light,

Transmission

Oil Temperature

7 Warning Light,

Engine Oil

Pressure

ITEM FUNCTION

The light is on when the turn indicator lever is in the left turn position.

The light will be ON when the key switch is ON and the engine is not running.

The light must go OFF when the engine is running.

CAUTION

Do not continue to operate the lift truck if the red light is ON at engine

speeds above idle.

The red light is ON when the key switch is in the START position and must go

OFF when the engine is running.

CAUTION

Do not continue to operate the lift truck if the red light is ON.

NOTE: Engine will stop after a 30 second warning buzzer if transmission oil is

over 121°C (250°F) on S45--65XM series with protection system.

The red light is ON when the key switch is in the ON position and must go OFF

when the engine is running.

CAUTION

Stop the engine immediately if the red light is ON while the engine is

running.

NOTE: Engine will stop after a 30 second warning buzzer if engine oil pressure

is less than 13.8 kPa (2 psi) on S40--65XM series with protection system.

19

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

8 Warning Light,

Brake Fluid

Level

9 Warning Light,

Coolant Level in

the Radiator

(Used only on

S40--65XM model trucks.)

10 Warning Light,

Fasten Seat Belt

ITEM FUNCTION

The red light is ON when the key switch is in the START position and must go

OFF when the engine is running. If the light is ON when the engine is running,

the brake fluid level in the reservoir is too low.

CAUTION

Do not continue to operate the lift truck if the light is ON during

operation.

The red light is ON when the key switch is in the START position and must go

OFF when the engine is running. If the light is ON when the engine is running,

the level of the coolant in the radiator is too low.

CAUTION

Do not continue to operate the lift truck if the light is ON during

operation.

The red light is ON for ten seconds anytime the key switch is turned to the ON

position.

WARNING

Always fasten the seat belt when operating the lift truck.

20

Property of American Airlines

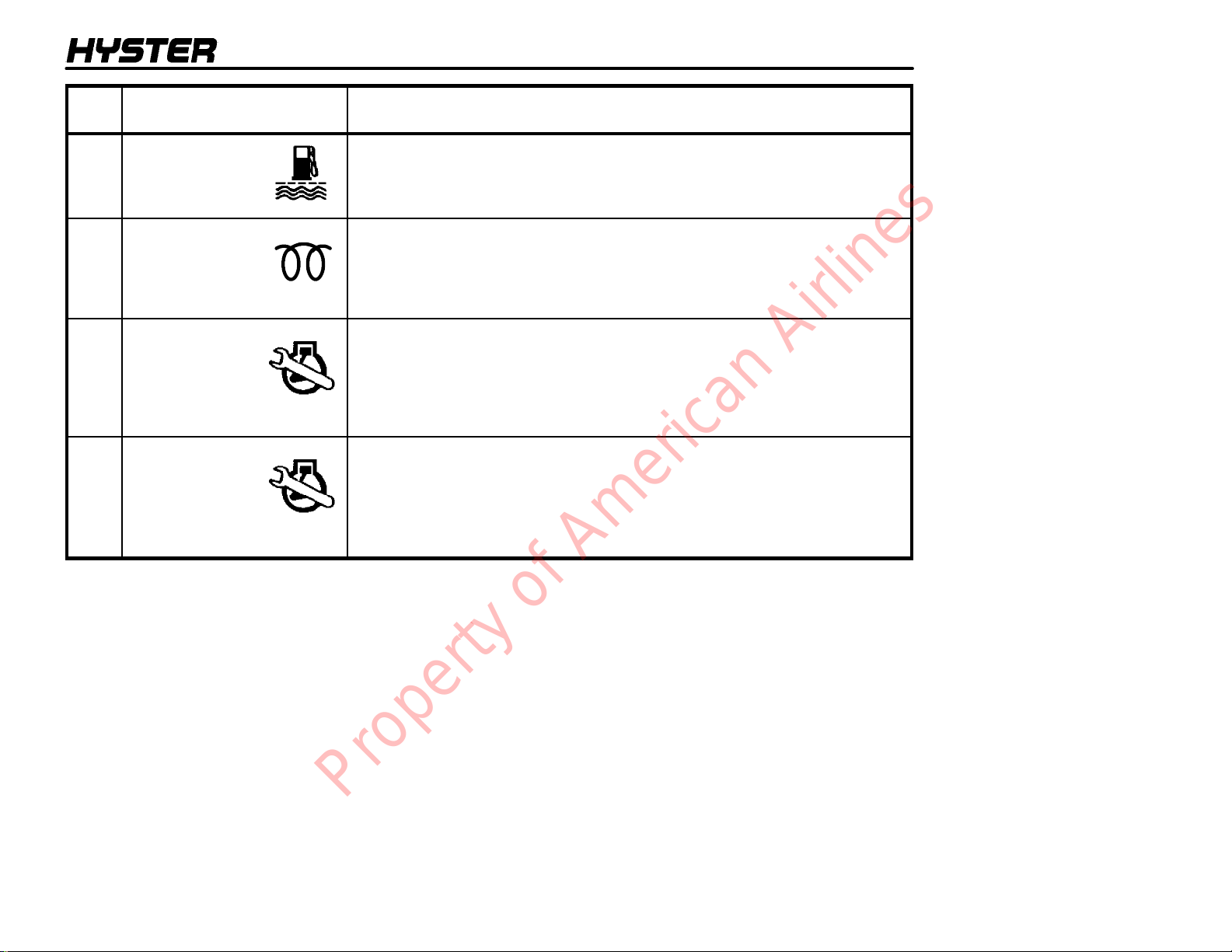

MODEL DESCRIPTION

ITEM

NO.

11

Water separator

Warning Light,

(Diesel Only)

12 Indicator Light,

Cold Start

(Diesel Only)

13 Malfunction

Indicator Lamp

(Lift trucks with

GM 3.0L engine, gas

fuel system)

13 Malfunction

Indicator Lamp

(Lift trucks with Gas-

oline or LPG closed

loop low emission

system)

ITEM FUNCTION

The red light is ON when the key switch is in the START position and must go

OFF when the engine is running. If the light is ON when the engine is running,

the water separator must be drained.

The red light is ON when the key switch is ON and the glow plugs are

activated. The length of time that the light is ON (glow plugs activated) is

determined by the temperature of the engine. When the light goes out, the

engine can be started. When the starter is cranking, the light will come ON

again until the starter is off and the engine is running.

This light will be ON when the key switch is ON and the engine is not running.

This light will illuminate when the Electronic Control Module computer senses a

fault in the operation of the engine. If the engine will start, the operation of the

engine will not be correct until the fault is corrected. A trained service person

must make repairs and adjustments if this light is ON when the engine is

running.

This light will be ON when the key switch is ON and the engine is not running.

This light will illuminate when the Electronic Control Module computer senses a

fault in the operation of the closed loop low emission system and the engine is

running. A trained service person must make repairs and adjustments if this

light is ON when the engine is running.

21

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

14 Indicator Light,

Low LPG Fuel

Level

15 Indicator Light,

Air Filter Restriction

16 Right--Hand

Turn Indicator

17

Engine Oil

Pressure Gauge

ITEM FUNCTION

The red light is ON when the key switch is in the START position and must go

OFF when the engine is running. If the light is ON when the engine is running,

the fuel level in the tank is low.

The red light is ON when the when the key switch is in the START position and

must go OFF when the engine is running. If the light is ON when the engine is

running, the air cleaner has a restriction and needs cleaning.

The light is on when the turn indicator lever is in the right turn position.

This gauge indicates the pressure of the oil in the engine. During normal

operation the gauge needle will be in the green area.

CAUTION

Do not continue to operate the lift truck when the gauge indicates low

oil pressure (needle in the red area).

NOTE: Engine will stop after a 30 second warning buzzer if engine oil pressure

is less than 13.8 kPa (2 psi) on S40--65XM series with protection system.

22

Property of American Airlines

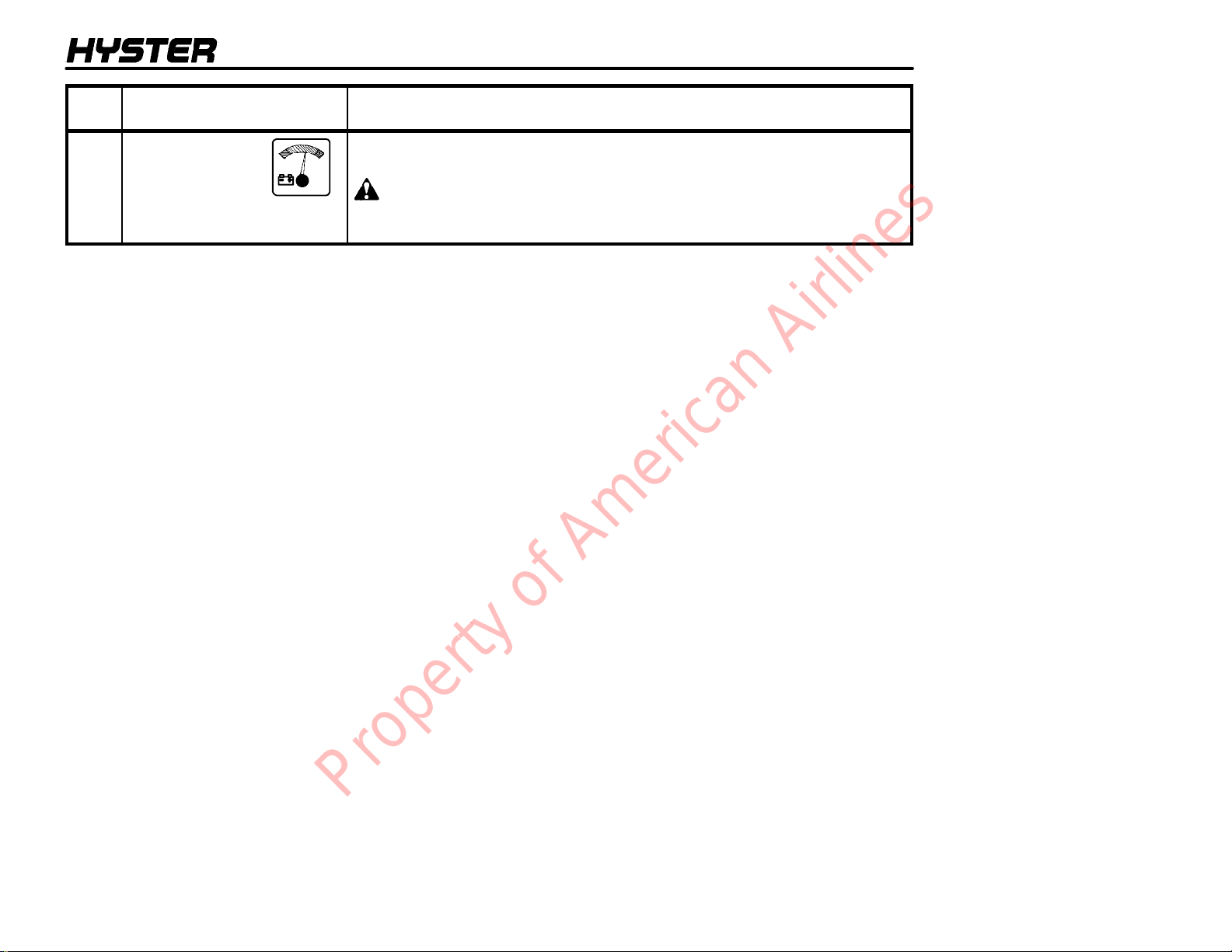

MODEL DESCRIPTION

ITEM

NO.

18 Voltmeter This gauge indicates the output of the alternator. During normal operation the

ITEM FUNCTION

gauge needle will be in the green area.

CAUTION

Do not continue to operate the lift truck when the gauge indicates in the

yellow or red areas of the gauge.

23

Property of American Airlines

MODEL DESCRIPTION

11

12

10

9

13

14

5

4

2

1

19

17

18

16

5

6

4

3

2

1

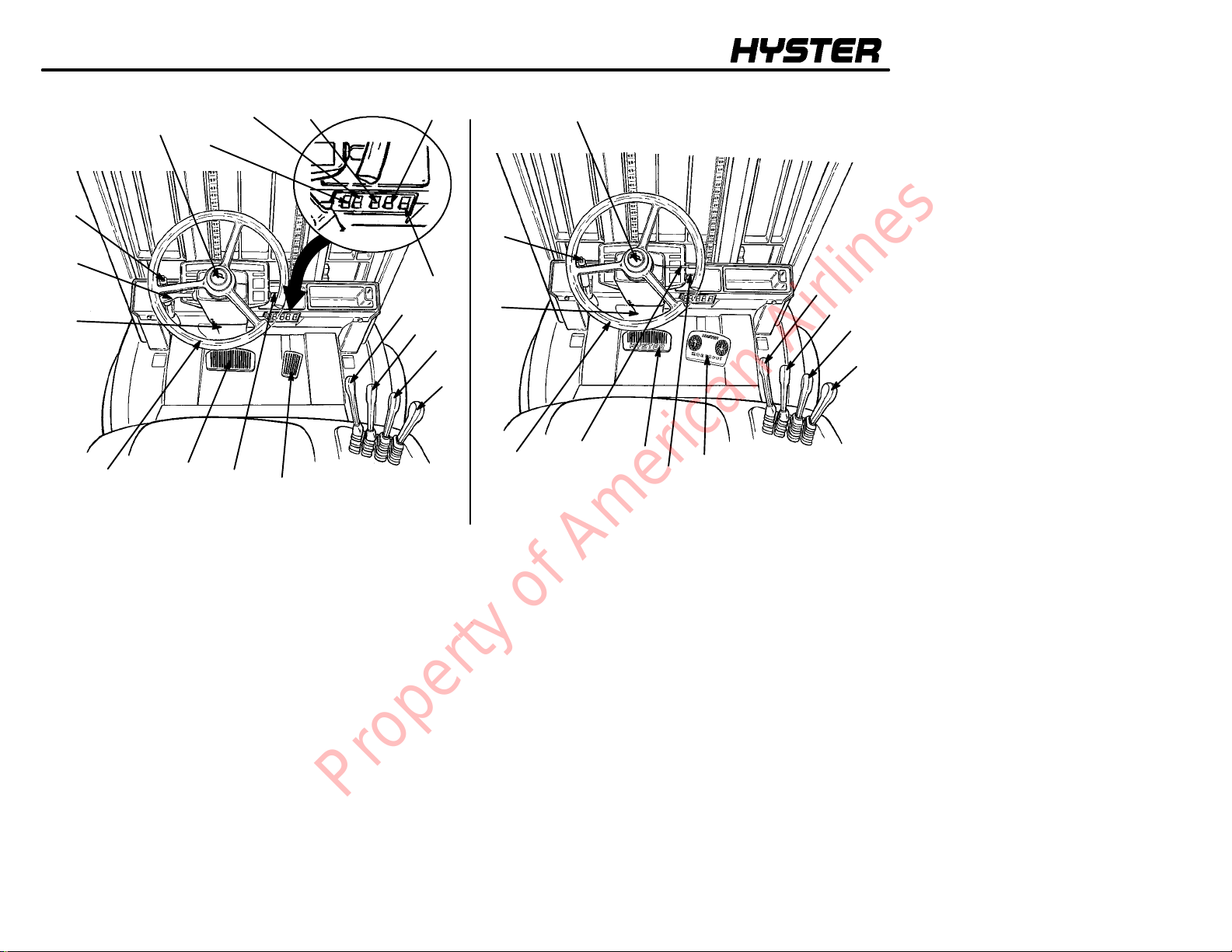

UNITS WITH DIRECTION CONTROL LEVER UNITS WITH MONOTROLR PEDAL

17

7

16

8

15

FIGURE 6. CONTROLS

11

12

13

14

24

Property of American Airlines

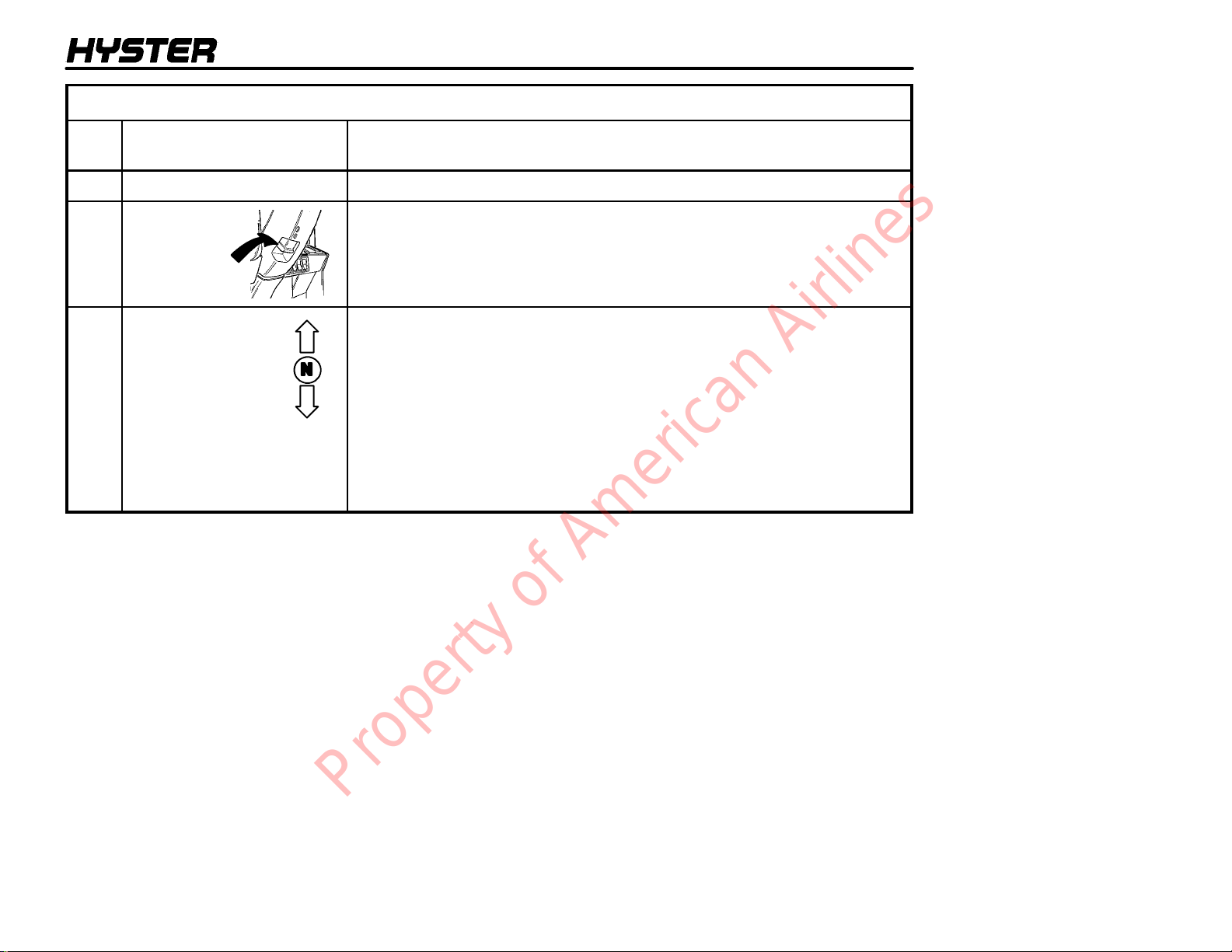

TABLE 2. CONTROLS (See FIGURE 6.)

MODEL DESCRIPTION

ITEM

NO.

1

Steering Wheel

2 Latch for Tilt

Steering Column

3 Direction Control

Lever

ITEM FUNCTION

The steering wheel controls the position of the steer tires.

A latch located on the lower left side of the steering column allows the operator

to select different positions for the steering wheel. Raise the latch to release the

steering column. Move the steering column to the selected position. Release

the latch to lock the steering column in position.

The direction control lever for the transmission is on the left side of the steering

column. The direction control lever is used on lift trucks without a

MONOTROLR pedal. This direction control lever has three positions:

FORWARD, NEUTRAL (N) and REVERSE. Move the lever to one of the

direction positions for travel. The direction control lever must be in the

NEUTRAL (N) position before the engine can be started. The reverse lights

and the optional reverse alarm will be on in the REVERSE position during

normal operation.

NOTE: There is a switch in the seat that actuates an audible buzzer. If the

operator leaves the seat with the key switch ON and the lever is not in

NEUTRAL, the buzzer will pulse ON and OFF for 10 seconds.

25

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

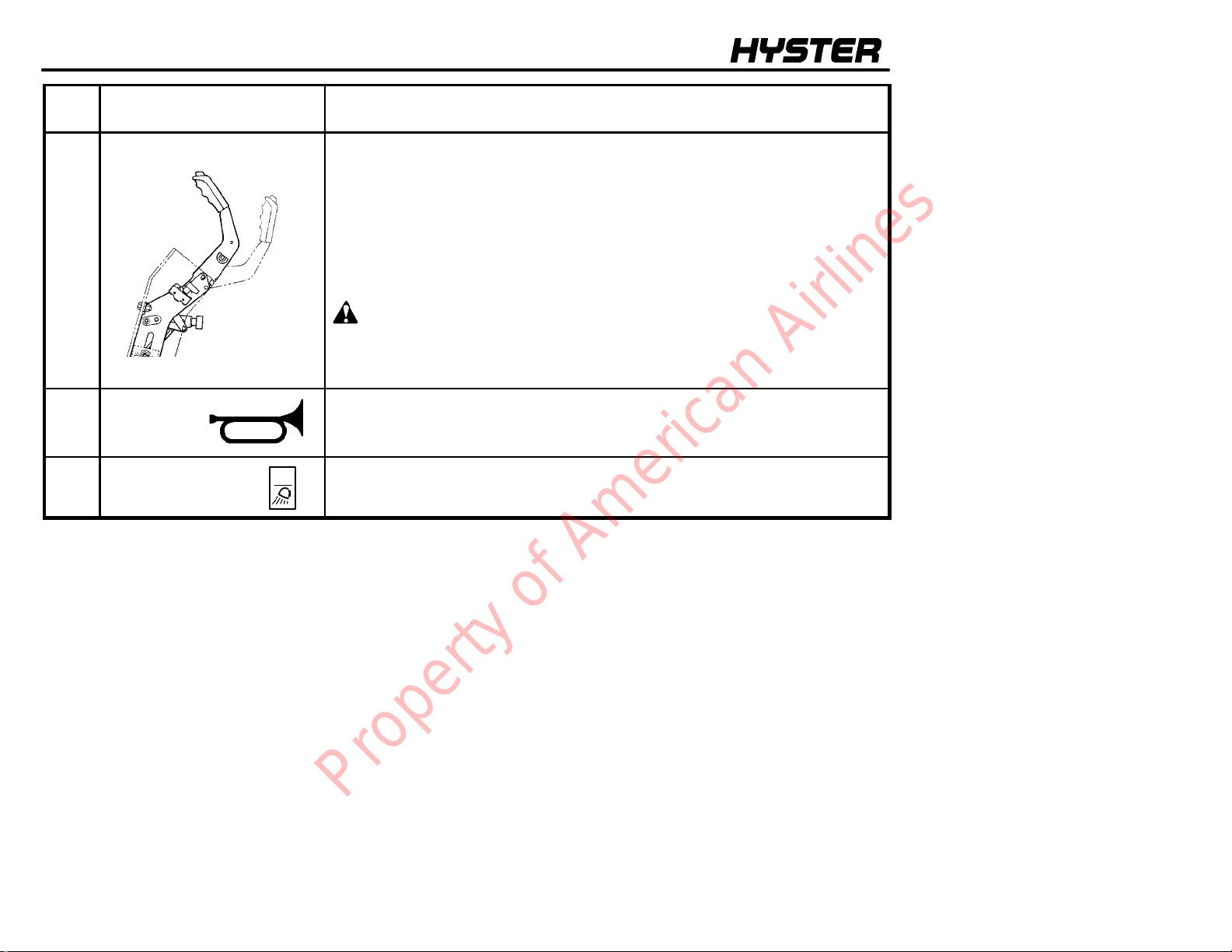

4 Parking Brake Lever The lift truck is equipped with a lever to apply the parking brake. Pull the lever

ITEM FUNCTION

to apply the parking brake. Use your thumb to release the button on the lever

when the lever is moved to release the parking brake.

On lift trucks with a MONOTROLR pedal, applying the parking brake puts the

transmission in NEUTRAL. The parking brake must be applied when leaving

the lift truck or when starting the engine.

NOTE: There is a switch in the seat that actuates an audible buzzer. If the

operator leaves the seat or turns the key to the OFF position without applying

the parking brake, the buzzer will be ON for 10 seconds.

WARNING

Correct adjustment is necessary to provide adequate braking. See the

MAINTENANCE section for adjustment procedures.

Always apply the parking brake when leaving the lift truck.

5

Horn

6 Switch The switch controls the operation of front drive lights. Push on the top of the

The horn button controls the operation of the horn.

switch to turn the lights ON.

26

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

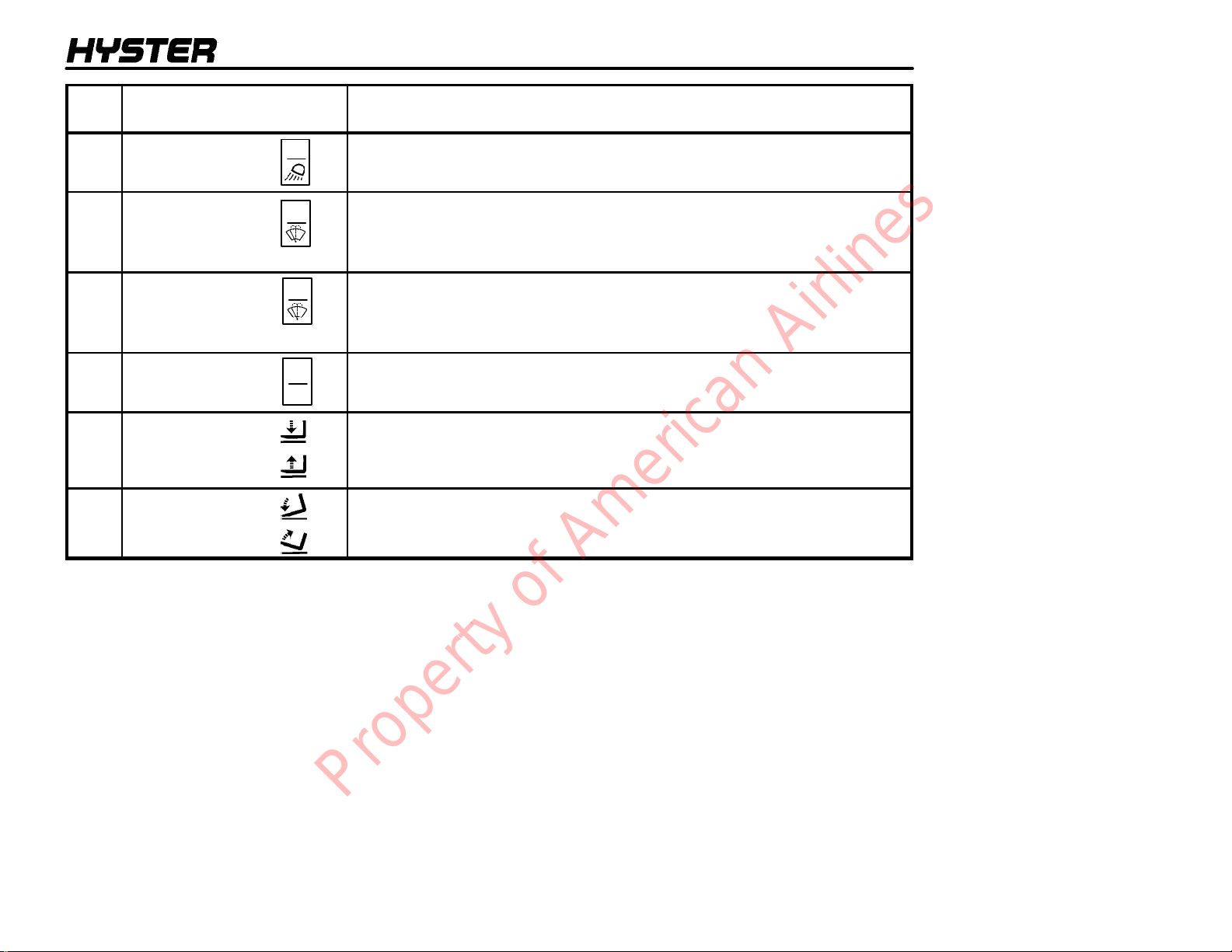

7 Switch The switch controls the operation of the rear drive lights. Push on the top of the

8 Switch The switch controls the operation of the front windshield wiper and windshield

9 Switch The switch controls the operation of rear windshield wiper and windshield

10 Switch The switch controls the operation of the heater. Push on the top of the switch to

11

Lift/Lower

Control

Lever

12 Tilt

Control

Lever

ITEM FUNCTION

switch to turn the lights ON.

washer. Push the front of the switch to the first position to turn ON the

windshield wiper. Push the front of the switch past the ON position to activate

the windshield washer.

washer. Push the front of the switch to the first position to turn ON the

windshield wiper. Push the front of the switch past the ON position to activate

the windshield washer.

turn the heater ON.

The lift/lower control lever is the first lever to the right of the operator’s seat.

Pull backward on the control lever to raise the carriage and forks. Push the

control lever forward to lower the carriage and forks.

The tilt control lever is on the right of the lift/lower control lever. Push the

control lever forward to tilt the mast and forks forward. Pull backward on the

control lever to tilt the mast and forks backward.

27

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

13 Control Leverfor Auxiliary

Hydraulic Functions (3

lever). See FIGURE 6.

14 Control Leverfor Auxiliary

Hydraulic Functions (4

lever).

See FIGURE 6.

15

Accelerator Pedal

ITEM FUNCTION

rd

The third control lever is installed to the right of the tilt control lever. This control

lever can have two methods of operation, depending on the attachment.

WARNING

The control lever with a detent must be installed when an attachment

with a clamp is installed. See your dealer for Hyster lift trucks to get the

correct control lever.

Control Lever with a Detent -- Attachments with a clamp action: The lever

is spring--loaded toward the operator. The lever is operated by moving it to the

right, then forward and backward.

Control Lever without a Detent -- Attachments without a clamp action:

The lever is operated by moving it forward and backward.

th

The fourth control lever is installed to the right of the third control lever. The

lever is spring--loaded toward the operator. The lever is operated by moving it

to the right, then forward and backward.

This pedal controls the speed of the engine and is operated by the operator’s

right foot. It is used on units that have a direction control lever.

28

Property of American Airlines

Loading...

Loading...