Hyster S70XL, S80XL, S120XL D004, S135XL, S155XL Operating Manual

...

OPERATING MANUAL

SPACESAVER

S70XL, S80XL, S80XL BCS, S100XL,

S120XLS, S120XL (D004)

S135XL, S155XL, S155XLS, S135XL

(B024, C024)

DO NOT REMOVE THIS MANUAL FROM THIS UNIT

, S155XL

2

2

Property of American Airlines

HYSTER COMPANY P ART NO. 897366

LIFT TRUCK MODEL SERIAL NUMBER

ENGINE MODEL SERIAL NUMBER

TRANSMISSION TYPE SERIAL NUMBER

MAST LIFT HEIGHT GROUP NUMBER

CARRIAGE TYPE GROUP NUMBER

DRIVE TIRE SIZE STEERING TIRE SIZE

SPECIAL EQUIPMENT OR ATTACHMENTS

Hyster,

countries.

EZXchanget,HSMt, ReachStackert, SitDrivet, StanDrivet, Multiquipt, and Unisourcet are trademarks of Hyster

Company in the united States and/or in certain countries where rights in unregistered trademarks are recognized. Hyster

Company products included in this document may be covered by U.S. Patenet No. 6,684,148 and other U.S. and foreign

patents pending. EHyster Company 2005. All rights reserved.

,Fortist, Fortenst, Pacesetter VSMt, DuraMatcht, Spectrumt, TouchPointt, TouchControlt,

,Vista, MONOTROL and Yardmaster are registered trademarks of Hyster Company in certain

Property of American Airlines

FOREWORD

FOREWORD

To OWNERS, USERS, and OPERATORS:

The safe and efficient operation of a lift truck requires

skill and alertness on the part of the operator. To develop

the skill required the operator must:

• receive training in the proper operation of THIS lift

truck.

• understand the capabilities and limitations of the lift

truck.

• become familiar with the construction of the lift truck

and see that it is maintained in good condition.

• read and understand the warnings and operating

procedures in this manual.

In additionaqualified person,experienced in lift truck operation, must guide a new operator through several driving and

load handling operations before the new operator attempts

to operate the lift truck alone.

It is the responsibility of the employer to make sure that

the operator can see, hear, and has the physical and mental ability to operate the equipment safely.

Various laws and regulations require the employer to train

lift truck operators. These laws and regulations include:

Occupational Safety and Health Act (USA)

Canada Material Handling Regulations

NOTE: A comprehensive operator training program is

available from HYSTER COMPANY. For further details,

contact your dealer for Hyster lift trucks.

This OPERATING MANUAL contains information necessary for the operation and maintenance of a basic fork lift

truck. Optional equipment is sometimes installed that can

change some operating characteristics described in this

manual. Make sure the necessary instructions are available and understood before operating the lift truck.

Some of the components and systems described in this

OPERATINGMANUALwillNOTbeinstalledonyourunit.

If you have a question about any item described, contact

your dealer for Hyster lift trucks.

HYSTER COMPANY 2005 897366 -- ENGLISH

1

Property of American Airlines

FOREWORD

Additional information that describes the safe operation

and use of lift trucks is available from the following

sources:

• employment safety and health standards or regulations

(Examples: “Occupational Safety and Health Standards

(USA)”, “Canada Material Handling Regulations”.

• safety codes and standards (Example: Industrial Truck

Standards Development Foundation, ITSDF B56.1,

Safety Standard For Low Lift And High Lift Trucks.

• publications from government safety agencies,

government insurers, private insurers and private

organizations (Example: Accident Prevention Manual

For Industrial Operations, from the National Safety

Council).

NOTE: Hyster lift trucks are not intended for use on public

roads.

NOTE: The following symbols and words indicate safety

information in this manual:

W ARNING

Indicates a condition that can cause injury!

CAUTION

Indicates a condition that can cause property damage!

2

Property of American Airlines

CONTENTS

CONTENTS

FOREWORD 1..................................

CONTENTS 3...................................

MODEL DESCRIPTION 7.........................

GENERAL 7..................................

OPERATOR PROTECTION EQUIPMENT 8......

NAMEPLATE 8...............................

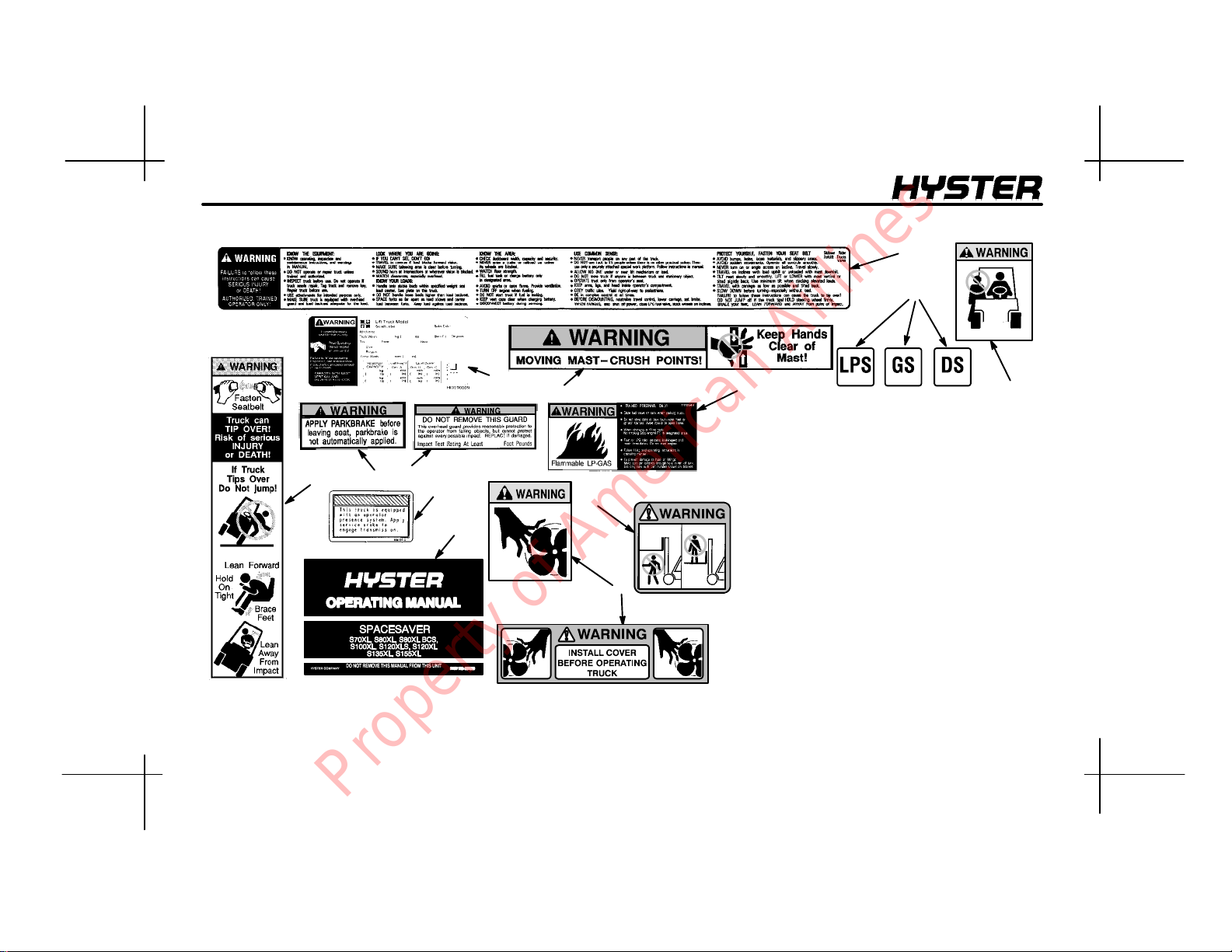

SAFETY LABELS 9............................

INSTRUMENTS AND CONTROLS 13.............

OPERATING PROCEDURES 23....................

GENERAL 23..................................

Know Your Lift Truck 23......................

Stability and Center Of Gravity 23..............

Capacity

(Weight and Load Center) 25..................

INSPECTION BEFORE OPERATION 25..........

Checks With the Engine Stopped 25...........

Starting Procedures 26.......................

Gasoline Or LPG Engine 26...................

Diesel Engine 27............................

Checks With the Engine Running 28...........

OPERATING TECHNIQUES 29..................

Basic Operating Procedures 29................

Driving And Direction Changes 32.............

Operator Presence System 33................

Inching 33..................................

Steering (Turning) 34........................

Load Handling, General 36...................

Load Handling, Lifting,

Lowering, And Tilting 38......................

Load Handling, How To Engage And Disengage A

Load 40....................................

Load Handling, Traveling 43..................

HIGHWAY TRUCKS, RAILROAD CARS AND

DOCKS 47....................................

ATTACHMENTS 49.............................

STOPPING 49.................................

PARKING 49..................................

MAINTENANCE 51...............................

GENERAL 51..................................

HOW TO MOVE A DISABLED LIFT TRUCK 52.....

HowToTowTheLiftTruck 52.................

How To Put A Lift Truck On Blocks 53..........

HowToRaiseTheDriveTires 53..............

How To Raise The Steering Tires 53...........

3

Property of American Airlines

CONTENTS

MAINTENANCE SCHEDULE 55....................

HOW TO MAKE THE CHECKS WITH THE

ENGINE STOPPED 69..........................

Hydraulic System Oil 69......................

Engine Oil 72...............................

Drive Belts 72...............................

Cooling System 72..........................

Air Filter 74.................................

Fuel System 74.............................

Primary Fuel Filter, Diesel Engine 74...........

Battery 75.................................

Tires And Wheels 76.........................

Forks 77...................................

Forks, Adjustment 77........................

Forks, Removal And Installation 77............

Inspection Of Forks, Mast, and Lift Chains 80....

Safety Labels 82............................

Operator Restraint System 83................

Automatic Locking Retractor (ALR) 83..........

Emergency Locking Retractor (ELR) 83.........

Hood And Seat Latches 84...................

HOW TO MAKE THE CHECKS WITH THE

ENGINE RUNNING 86..........................

Gauges, Lights, Horn And Fuses 87............

Oil Level, Powershift Transmission 90..........

Oil Level, Oil Clutch System 90................

Control Levers and Pedals 91.................

Lift System Operation 92.....................

Inching/Brake Pedal 92.......................

Service Brakes 93...........................

Parking Brake 93............................

Steering System 93..........................

HOW TO ADD FUEL TO THE LIFT TRUCK 94.....

Liquified Petroleum Gas (LPG) 94.............

Gasoline Or Diesel Fuel 97...................

WHEELS AND TIRES 98..........................

HOW TO CHANGE A SOLID RUBBER TIRE 98....

INSTALLTHE WHEELS 99......................

Steering Wheels 99..........................

Drive Wheels 99.............................

OPERATING PROCEDURES FOR A NEW OR

REBUILT ENGINE 99...........................

4

Property of American Airlines

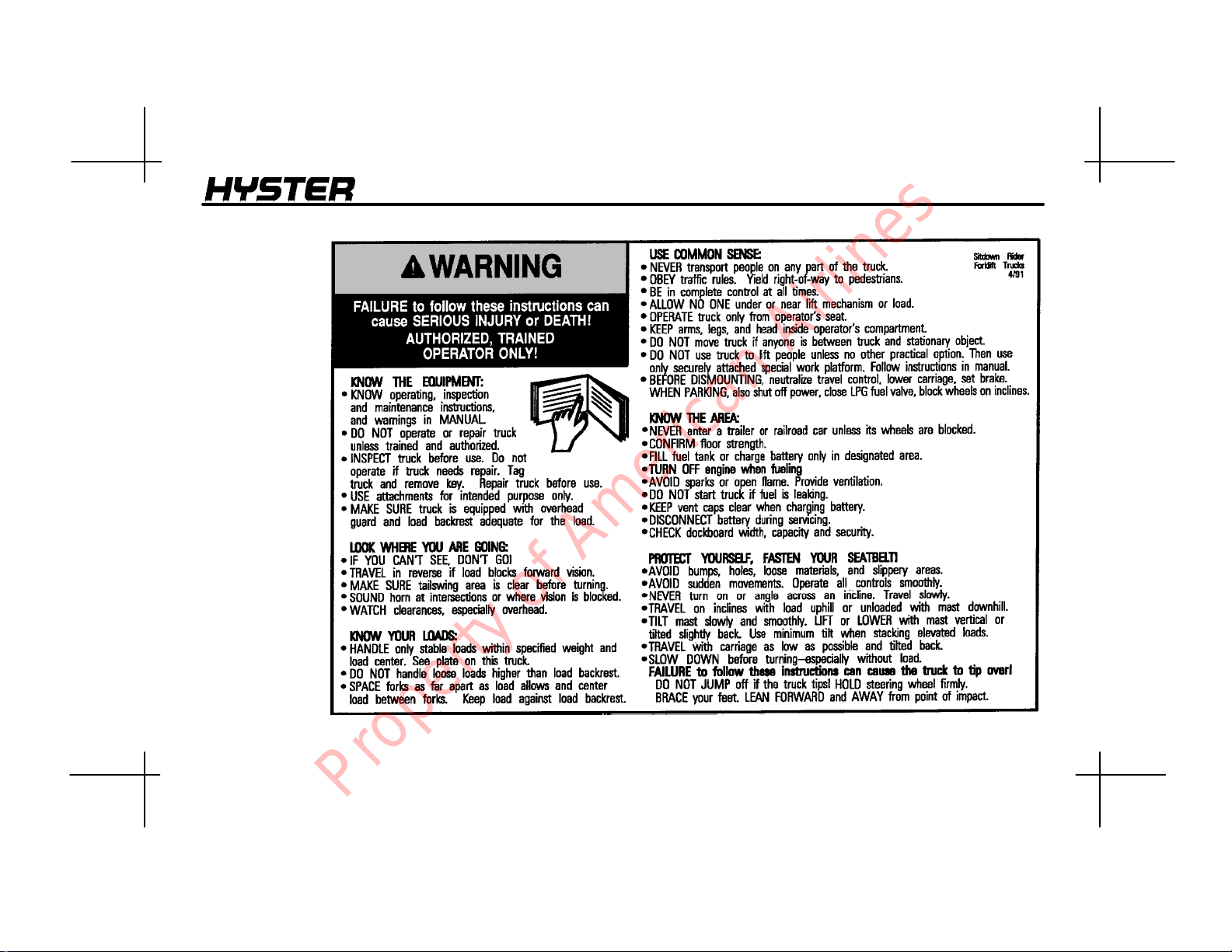

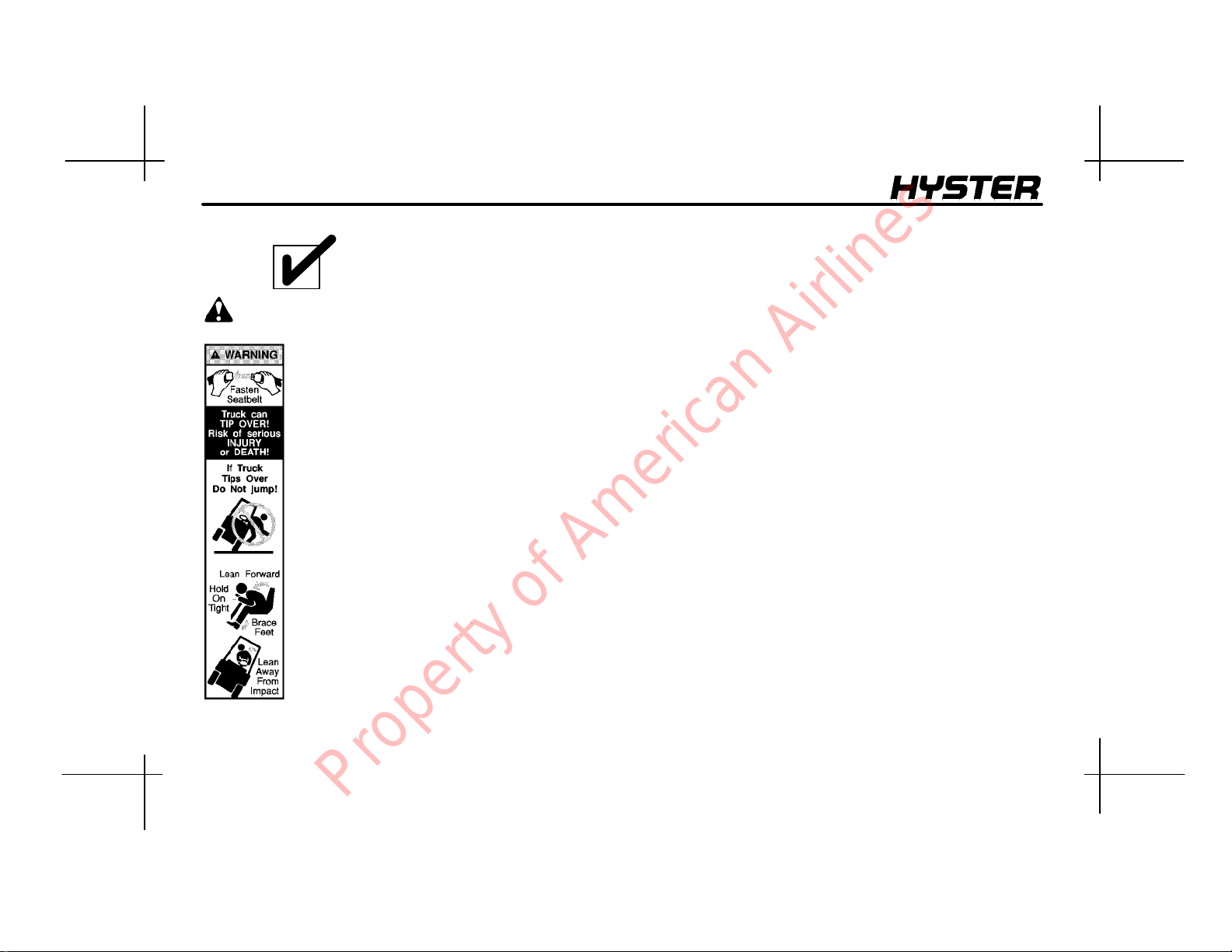

A WARNING

label with this

information

must be on

the lift truck.

W ARNING

5

Property of American Airlines

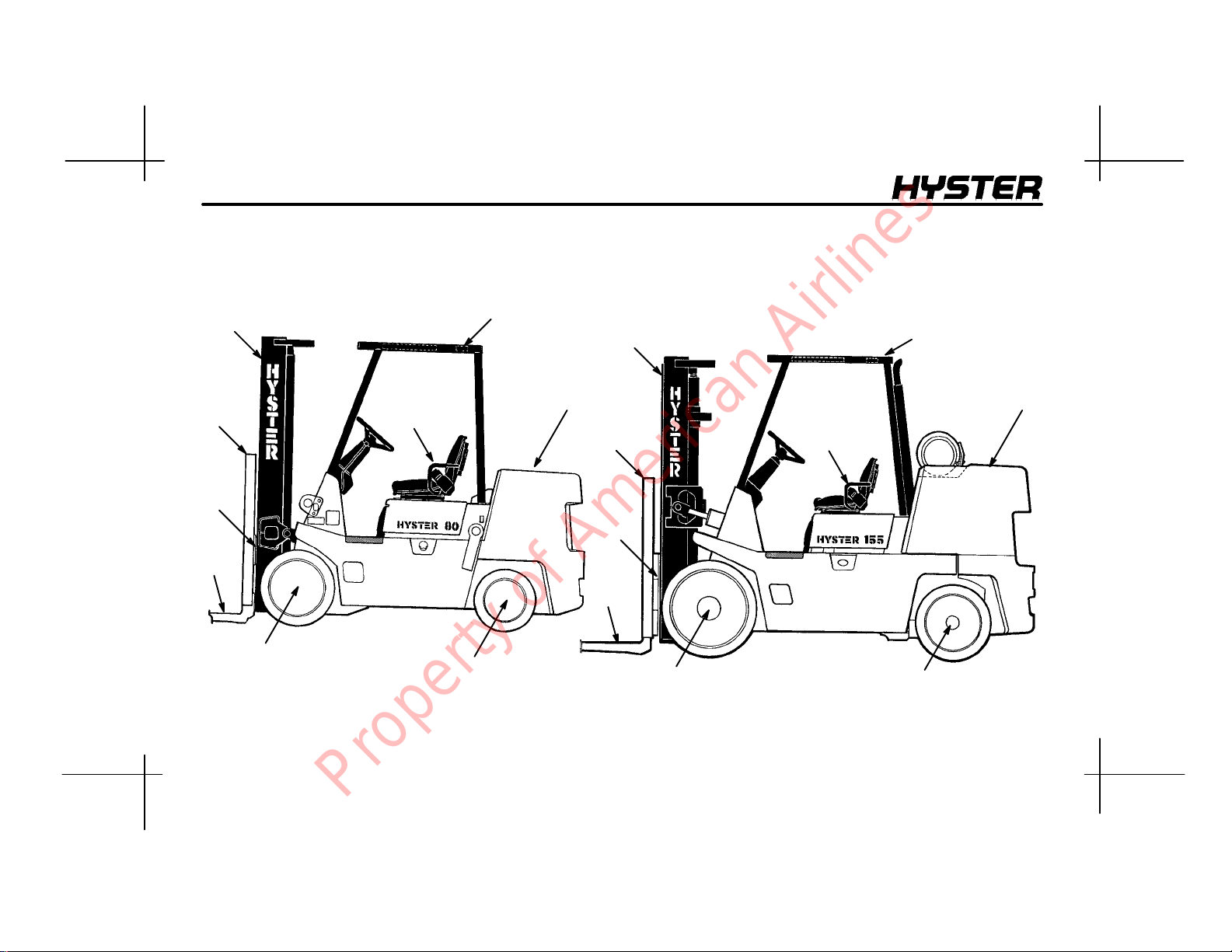

MODEL DESCRIPTION

1. OVERHEAD GUARD

2. COUNTERWEIGHT

3. STEERING AXLE

4. DRIVE AXLE

5

8

7

6

S70 --120XL

4

9

1

3

5. MAST

6. FORKS

7. CARRIAGE

8. LOAD BACKREST EXTENSION

9. SEAT BELT AND HIP RESTRAINT BRACKET

5

22

8

7

6

4

9

S135--155XL

1

3

1244312177

FIGURE 1. MODEL VIEW SHOWING MAJOR COMPONENTS

6

Property of American Airlines

MODEL DESCRIPTION

MODEL DESCRIPTION

GENERAL

This Operating Manual is for the following models of lift

trucks:

• the S70--120XL (D004) series includes the S70XL,

S80XL, S80XL BCS, S100XL, S120XLS, and S120XL

• the S135--155XL (B024, C024) series includes the

S135XL, S135XL

The S70--120XL and the S135--155XL series of lift trucks

are available with a gasoline engine, an LPG fuel engine,

or a diesel engine.

The S70--120XL series of lift trucks has a single--speed

powershift transmission. The lift trucks can be equipped

with two kinds of controls:

• a MONOTROL pedal that controls both the forward

and reverse operation of the powershift transmission

and the speed of the engine.

• a direction control lever near the left side of the steering wheel that controls the forward and reverse operation of the powershift transmission. A separate accelerator pedal controls the engine speed.

, S155XL, S155XL2, and S155XLS.

2

The S135--155XL series of lift trucks can have either a

three--speed manual transmission with an oil clutch (B024

models only) or a two--speed powershift transmission.

Lift trucks with a three--speed manual transmission have

two control levers on the left side of the steering wheel.

One lever controls the forward and reverse direction of the

lift truck and the other lever is used to select the speed

range. These lift trucks have a clutch pedal and an accelerator pedal.

The two--speed powershift transmission has a range lever

on the left side of the steering column to control the two

speed ranges. The two--speed powershift transmission

can be equipped with two kinds of controls for forward and

reverse and engine speed control:

• a MONOTROL pedal that controls both the forward

and reverse operation of the powershift transmission

and the speed of the engine.

• a direction control lever near the left side of the steering wheel that controls the forward and reverse operation of the powershift transmission. A separate accelerator pedal controls the engine speed.

7

Property of American Airlines

MODEL DESCRIPTION

OPERATOR PROTECTION EQUIPMENT

The LOAD BACKREST EXTENSION is installed to keep

loose parts of the load from falling back toward the operator. It must be high enough, with openings small enough to

prevent the parts of the load from falling backwards. If a

load backrest extension that is different from the one installed on your lift truck is required, contact your Hyster lift

truck dealer.

The OVERHEAD GUARD is intended to offer reasonable

protection to the operator from falling objects, but can not

protect against every possible impact. Therefore, it must

not be considered a substitute for good judgment and care

when handling loads. Do not remove the overhead guard.

The SEAT BELT AND HIP RESTRAINT BRACKET provide additional means to help the operator keep the head

and torso substantially within the confines of the lift truck

frame and overhead guard if a tipover occurs. This restraint system is intended to reduce the risk of the head

and torso being trapped between the lift truck and the

ground, but it can not protect the operator against all possible injury in a tipover. The hip restraint bracket will help

the operator resist side movement if the seat belt is not

fastened. It is not a substitute for the seat belt. Always fasten the seat belt.

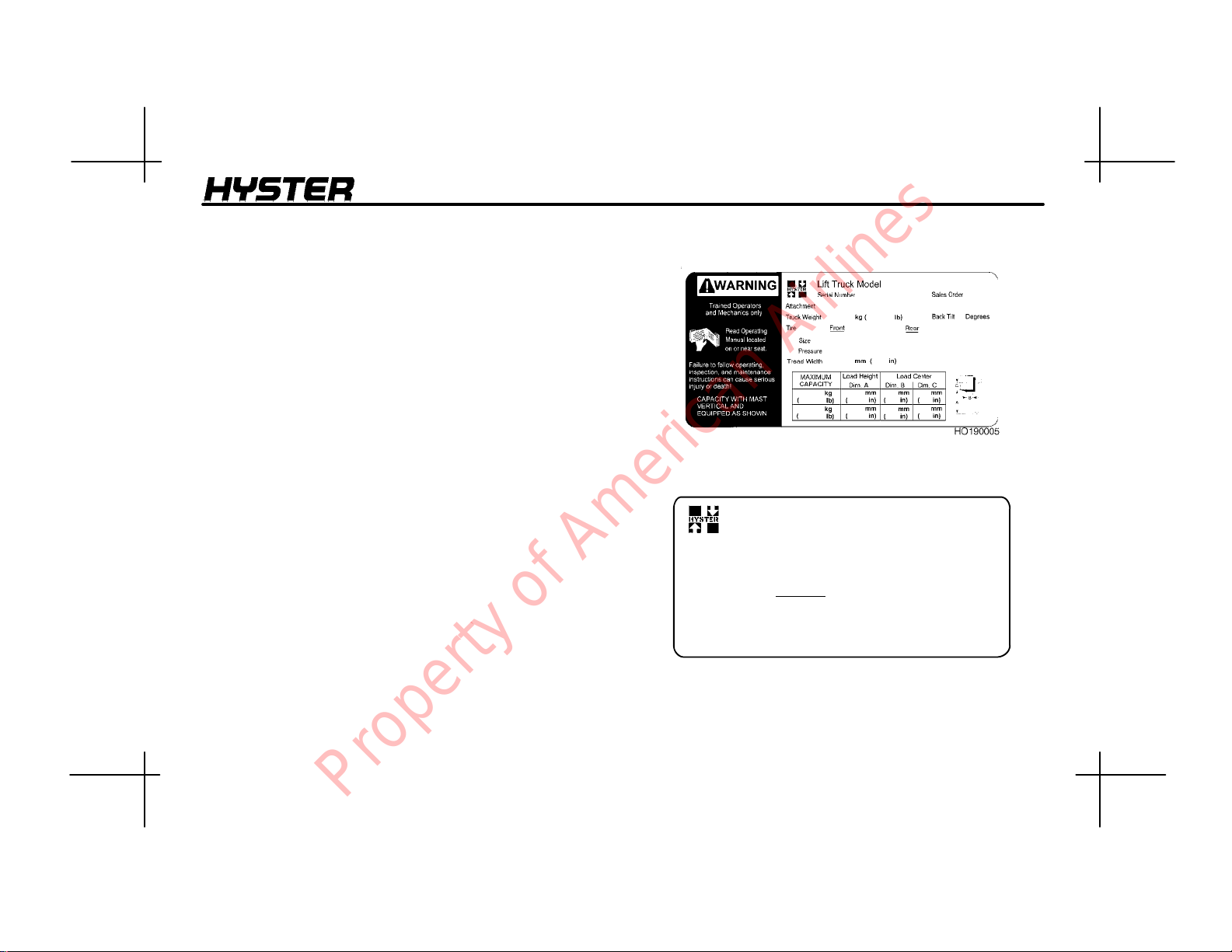

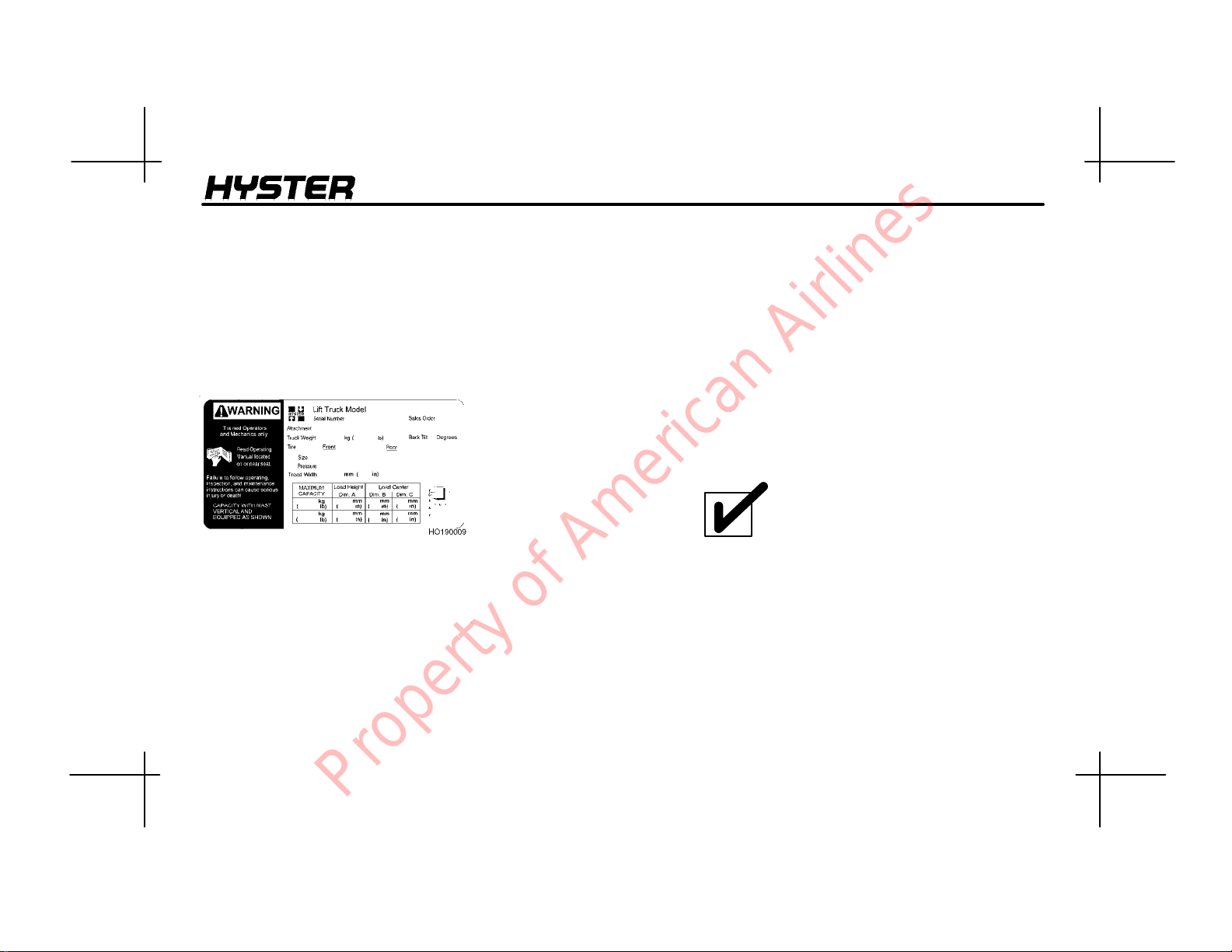

NAMEPLA TE

W ARNING

Any change to the lift truck, the tires or its equipment

can change the lifting capacity. If the Nameplate does

not show the maximum capacity, or if the lift truck

equipment, including the battery for electric trucks,

does not match that shown on the Nameplate, the lift

truck must not be operated.

The capacity is specified in kilograms (kg) and pounds

(lb). The capacity is the maximum load that the lift truck

can handle for the load condition shown on the Nameplate.

The maximum capacity for the lift truck, at full load height,

must be shown on the Nameplate. Special capacities with

the load height reduced or with optional load centers, may

also be shown on the Nameplate.

The lift truck serial number code is on the Nameplate. The

serial number code is also stamped on the lift truck frame.

8

Property of American Airlines

When a lift truck is shipped incomplete from the factory,

the nameplate is covered by a label as shown in

FIGURE 2. If your lift truck has this type of label, do not

operate the lift truck. Contact your dealer for HYSTER lift

trucks to obtain a complete nameplate.

SAFETY LABELS

Safety labels are installed on the lift truck to give information about possible hazards. It is important that all safety

labels are installed on the lift truck and can be read. See

FIGURE 3.

MODEL DESCRIPTION

NAME PLATE

TRUCK MODEL

Serial no.

Approx. weight

NOTICE TO USER

This unit was shipped incomplete from factory/

The U.S.A. Occupational Safety and Health Act of 1970 and other national

safety codes require the installation of a completed Nameplate showing unit

configuration and rated capacity. Completed Nameplates may be obtained

through your HYSTER dealer.

LABEL

FIGURE 2. NAMEPLATE AND LABEL

9

Property of American Airlines

MODEL DESCRIPTION

1

7

10

3

4

6

11

13

2

FIGURE 3. WARNING AND SAFETY LABELS

12

5

8

10

1. WARNING, OPERATION

2. OPERA TING MANUAL

3. NAMEPLATE

4. IMPACT TEST

5. NO ONE ON OR UNDER FORKS

6. TIPOVER WARNING

7. FIRE SAFETY

8. FAN WARNING

9. NO RIDERS

10. FLAMMABLE LP--GAS

11. WARNING FOR PARKING BRAKE

12. MAST WARNING

13. OPERATOR PRESENCE SYSTEM

SEE THE PARTS MANUAL FOR THE

PART NUMBER AND LOCATION

9

Property of American Airlines

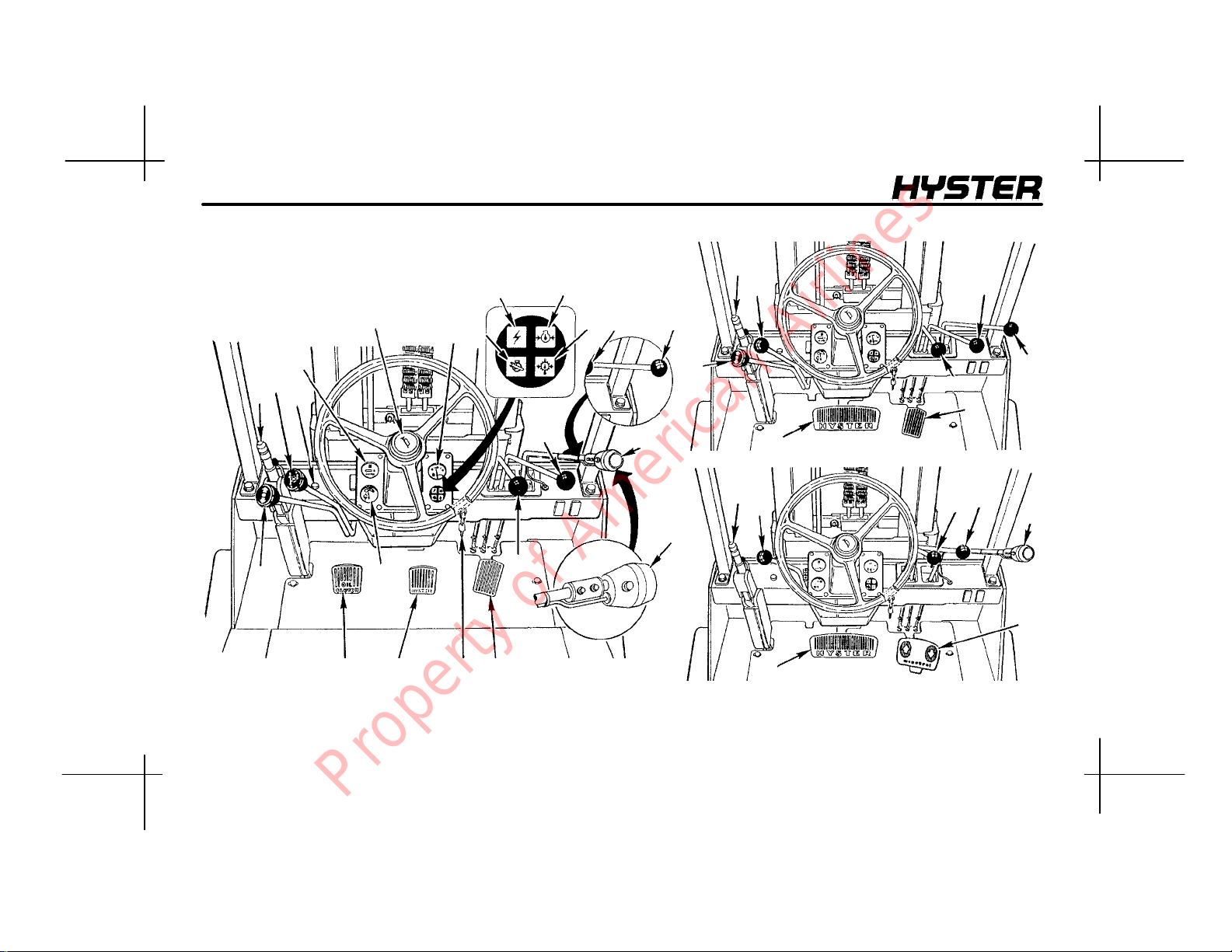

NOTE: THIRD--FUNCTION CONTROL LEVER (17a)

IS AVAILABLE ON ALL UNITS

10

1

4

6

3

16

15

MODEL DESCRIPTION

5

7

1

12

10

3

16

15

16

17

17a

11

17

2

8

9

POWERSHIFT TRANSMISSION WITH MONOTROL PEDAL

FIGURE 4. CONTROLS AND INSTRUMENTS, S70--120XL

1920

Property of American Airlines

11

2

8

20

POWERSHIFT TRANSMISSION WITH

DIRECTION CONTROL LEVER

18

9

17a

12189

11

MODEL DESCRIPTION

NOTE: THIRD--FUNCTION CONTROL LEVER (17a)

IS AVAILABLE ON ALL UNITS

4

11

5

14

16

12

11

12

10

1

13

8

2

2122

MANUAL TRANSMISSION

17a

17

12

20

POWERSHIFT WITHOUT MONOTROL PEDAL

11

14

17a

20

POWERSHIFT WITH MONOTROL PEDAL

16

6

3

16

15

9

18

FIGURE 5. CONTROLS AND INSTRUMENTS, S135--155XL

7

12189

15

15

17

12402

18

16

17a

19

12189

Property of American Airlines

MODEL DESCRIPTION

INSTRUMENTS AND CONTROLS

(See TABLE 1., TABLE 2., TABLE 3., FIGURE 4., and FIGURE 5.)

W ARNING

If any of the instruments, levers, or pedals do not operate as described in the following tables, report the problem

immediately. DO NOT operate the lift truck until the problem is corrected.

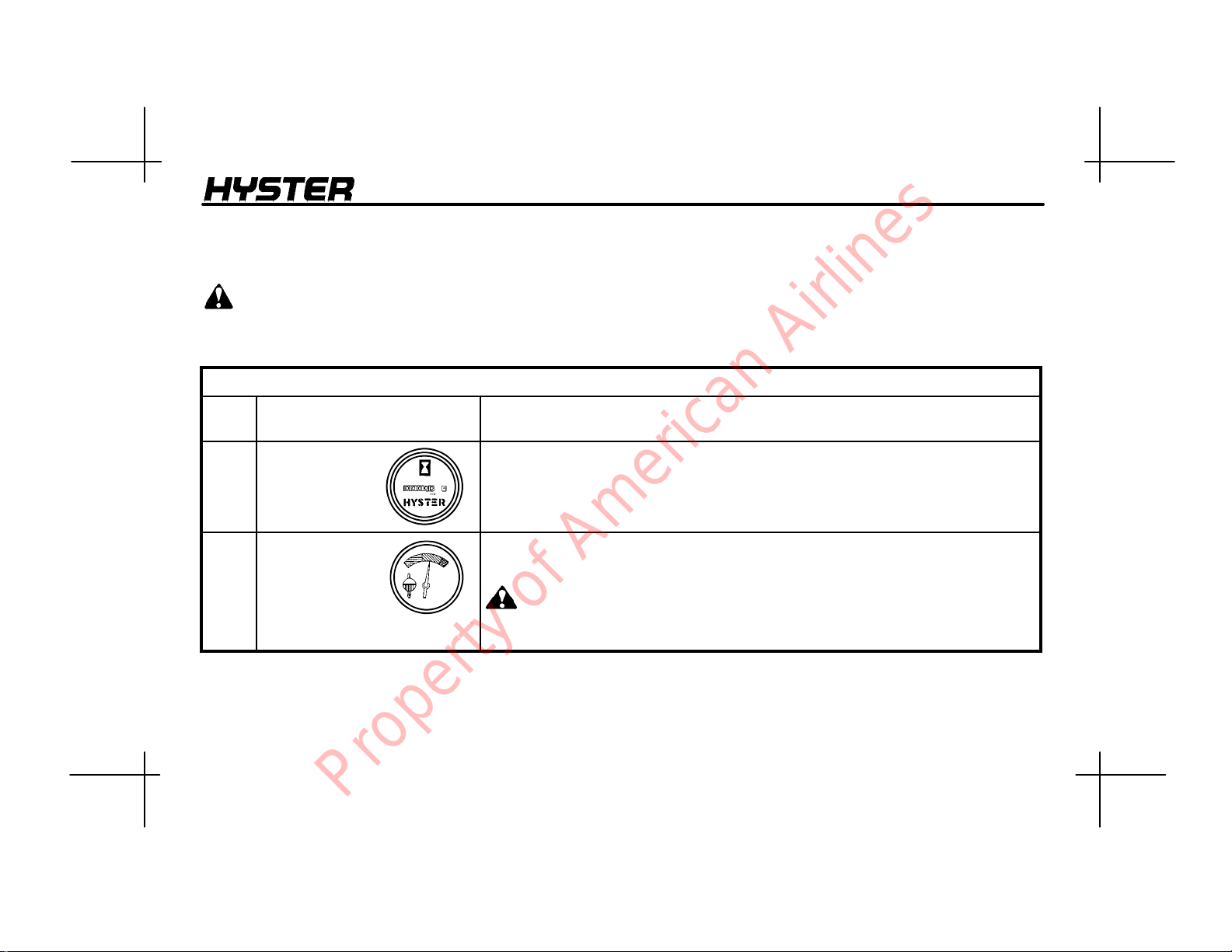

TABLE 1. INSTRUMENTS

ITEM

NO.

1 Hour Meter The hour meter operates when the key switch is in the ON position. Periodic

2 Coolant

Temperature

Gauge

ITEM FUNCTION

Maintenance recommendations are based on these hours.

Indicates engine coolant temperature when the key switch is in the ON

position. During normal operation, the needle will indicate in the green zone of

the gauge.

CAUTION

Do not continue to operate the lift truck when the gauge indicates that

the engine is too hot (needle in the red zone).

Property of American Airlines

13

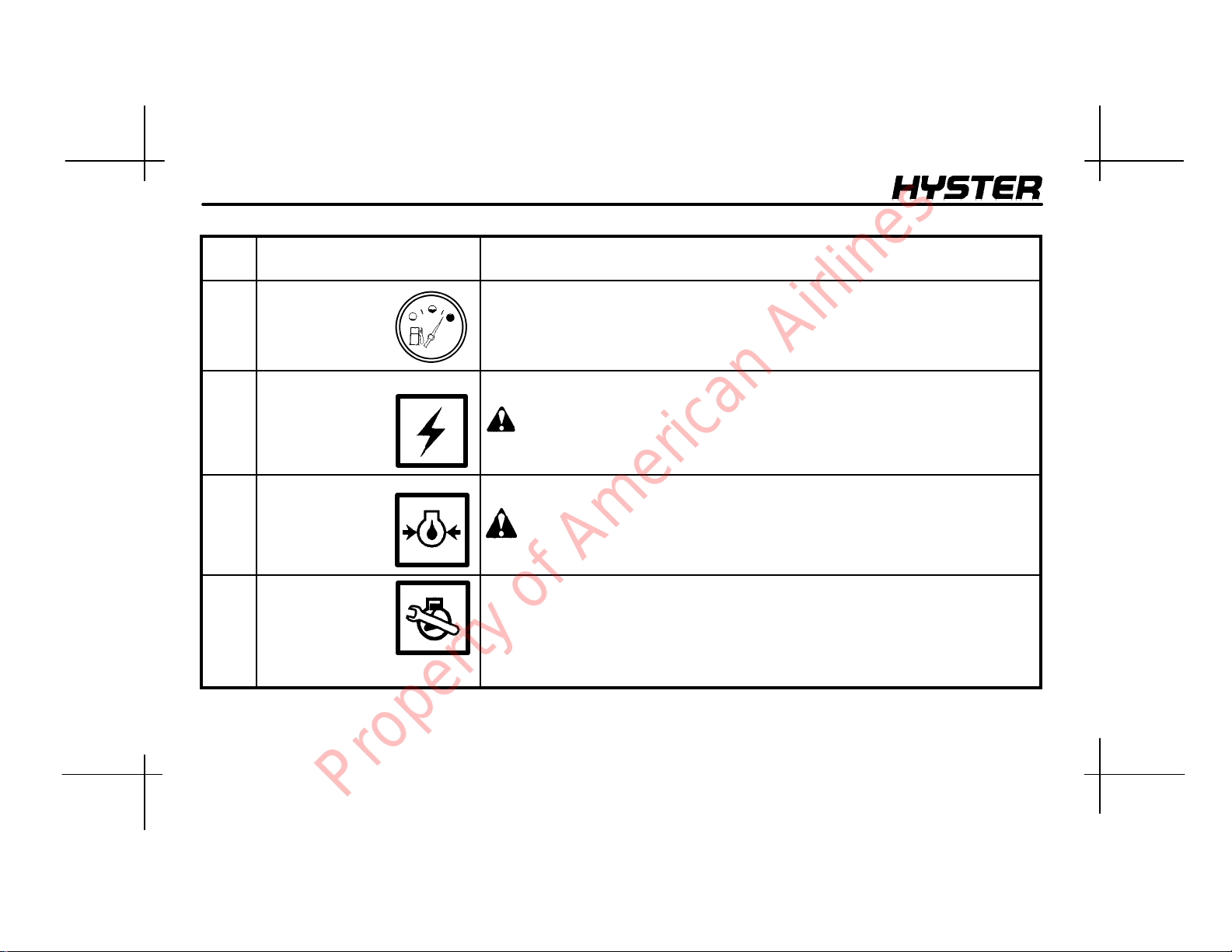

MODEL DESCRIPTION

ITEM

NO.

3 Fuel Gauge Indicates the amount of fuel in the gasoline or diesel fuel tank.

4 Warning Light,

Alternator

ITEM FUNCTION

The red light will be ON when the key switch is ON and the engine is not

running.

CAUTION

Do not continue to operate the lift truck if the red light is ON at engine

speeds above idle.

5 Warning Light,

Engine Oil

Pressure

The red light is ON when the key switch is in the START position.

CAUTION

Stop the engine immediately if the light is ON when the engine is running.

6

Warning Light,

“Check Engine”

Lift trucks with electronic engine control (electronic spark timing and fuel

injection). This light will be ON when the key switch is ON and the engine is not

running. This light will illuminate when the ECM computer senses a fault in the

operation of the engine. If the engine will start, the operation of the engine will

not be correct until the fault is corrected. A trained service person must make

repairs and adjustments if this light is ON when the engine is running.

14

Property of American Airlines

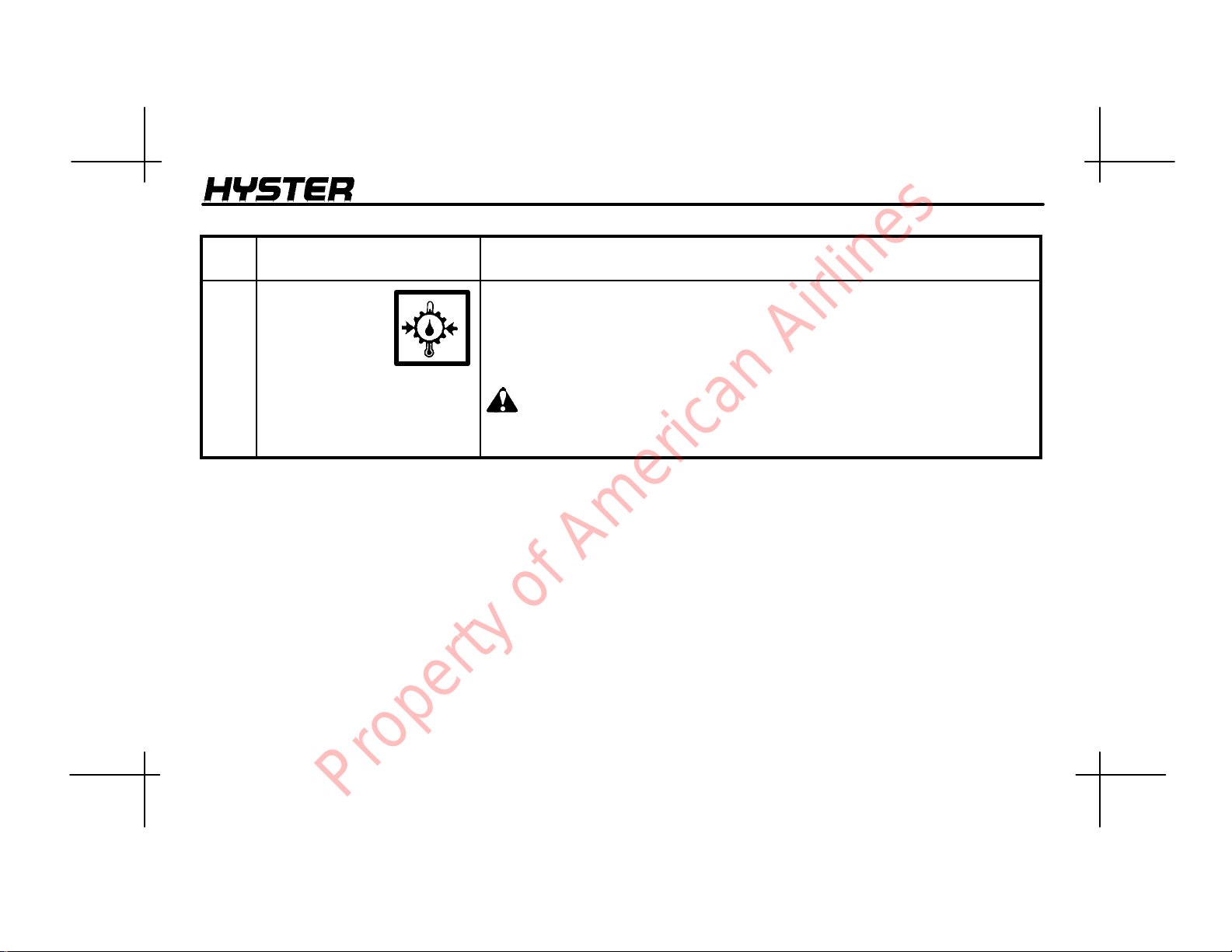

MODEL DESCRIPTION

ITEM

NO.

7 Warning light,

Powershift

Transmission

Oil Temperature

or

Oil Pressure for

Clutch, Manual

Transmission

(S135--155XL)

ITEM FUNCTION

Powershift Transmission: The red light is ON when the key switch is in the

ST ART position.

Manual Transmission: The red light is ON when the oil pressure in the clutch

system is too low for continued operation. The red light is ON when the key

switch is ON and the engine is not running.

CAUTION

Do not continue to operate the lift truck if the light is ON during

operation.

15

Property of American Airlines

MODEL DESCRIPTION

K

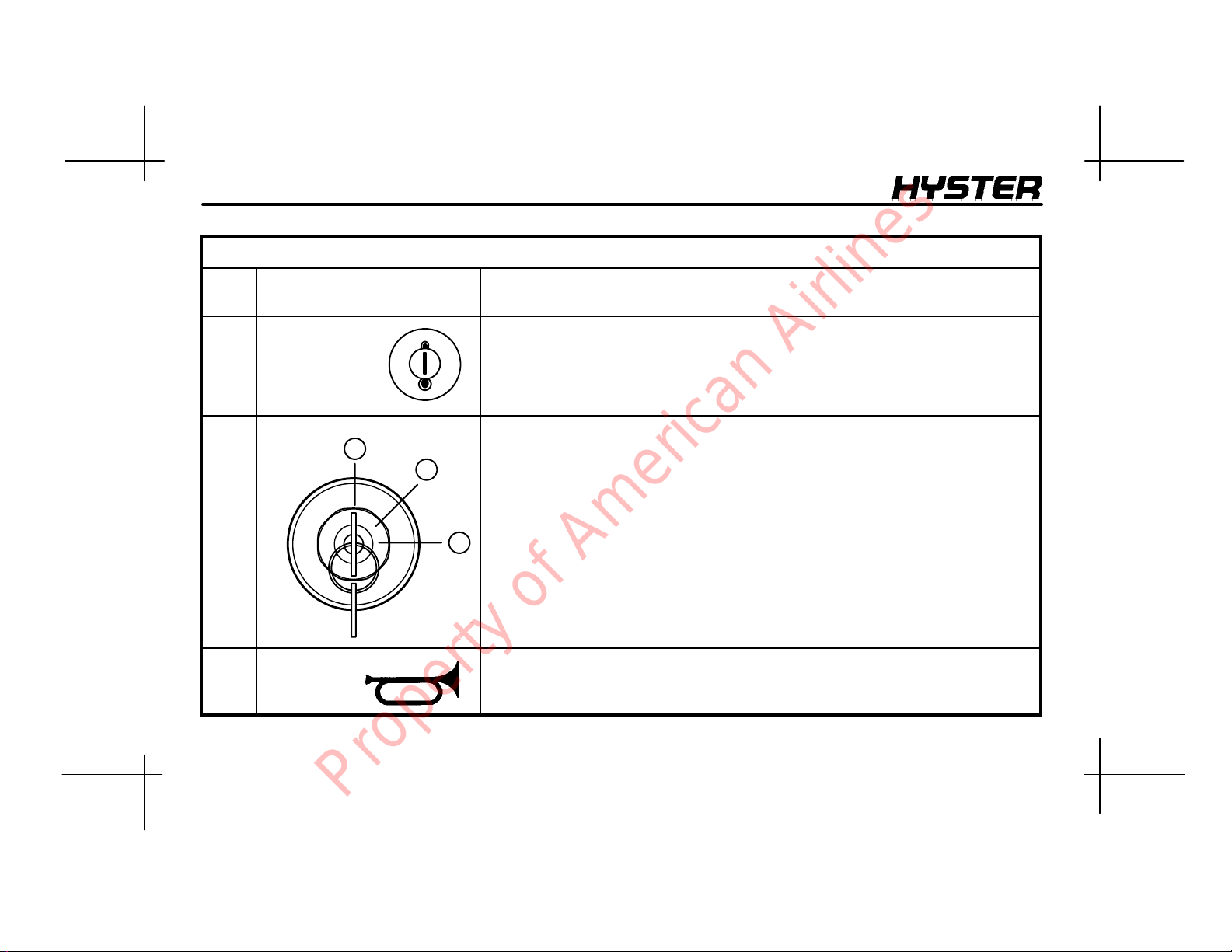

TABLE 2. CONTROLS

ITEM

NO.

8 Cold Start Aid The cold start aid is used on lift trucks with a diesel engine. For S70--120XL lift

9

10

ey

Switch

Horn

ITEM FUNCTION

trucks, the control button is to the left of the steering column. On S135XL,

S155XL lift trucks, the control button is on the top of the instrument panel. The

keyswitchmustbeintheON position before the cold start aid can be

energized.

The key switch has three positions:

1

2

No. 1 Position: OFF position. Deenergizes all electric circuits except for the

horn and headlights.

No. 2 Position: ON position. Energizes all electric circuits except the starter

circuit. The key switch will be in this position during normal operation.

No. 3 Position: START position. Energizes the starter motor for starting the

3

engine. A spring returns the key to position No. 2 (ON position) when the key is

released.

NOTE: There is a mechanical lockout that prevents the key switch from being

returned to the START position without first being returned to the OFF position.

The horn button controls the operation of the horn.

16

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

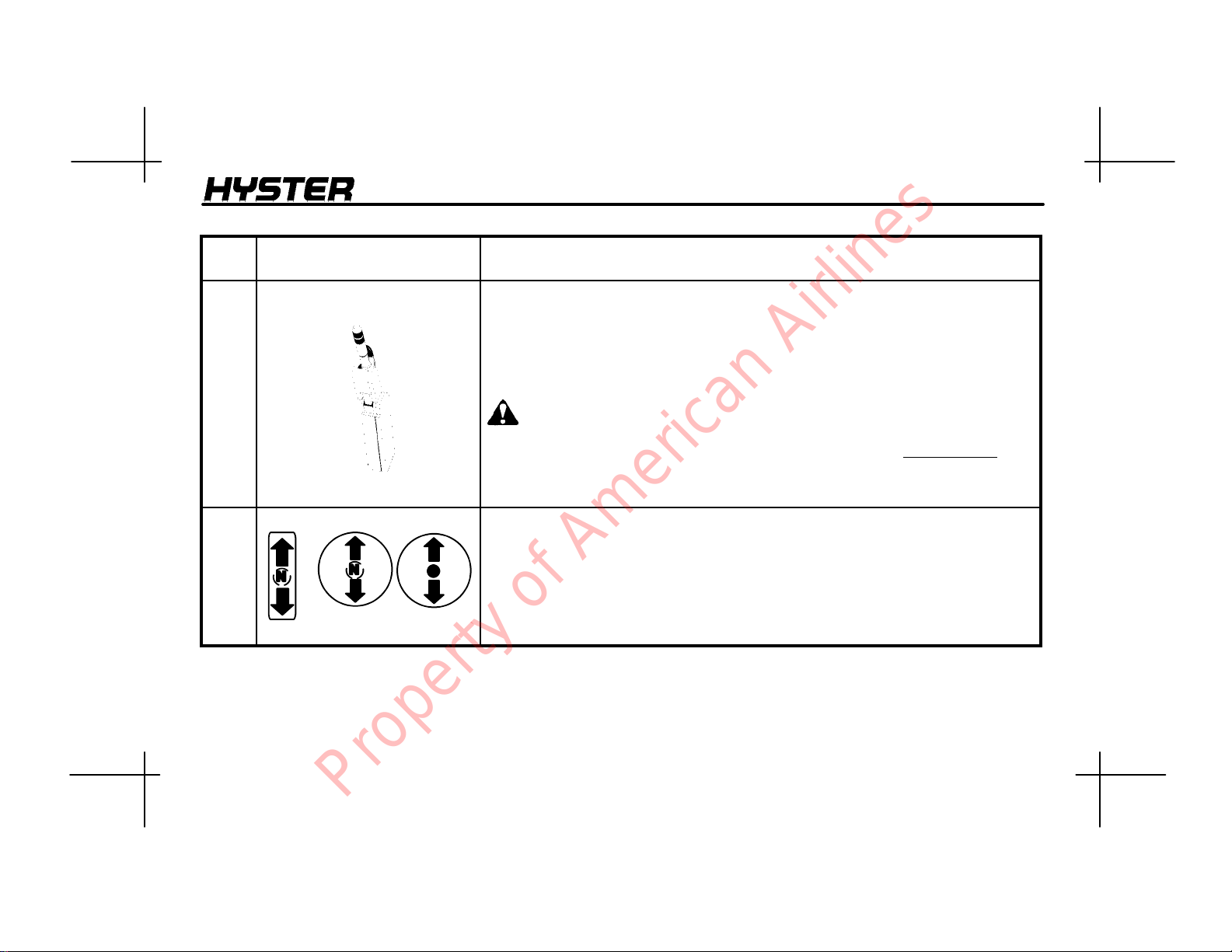

11 Parking Brake Lever The lift truck is equipped with a lever to apply the parking brake. Pull the lever

ITEM FUNCTION

to the vertical position to apply the parking brake.

Lift trucks with a MONOTROL pedal: when the parking brake is applied, a

switch in the starting circuit is closed so that the engine can be started. The

switch also puts the transmission in NEUTRAL. Use your finger to release the

lock on the lever when the lever is moved to release the parking brake.

WARNING

Correct adjustment is necessary to provide adequate braking and to keep

the parking brake lever in the engaged position. See the Maintenance

section for adjustment procedures.

Always apply the parking brake when leaving the lift truck.

12 Direction Control Lever

S135--155XL

S70--120XL

The direction control for the transmission is to the left of the steering column.

The direction control lever is used on lift trucks with a manual transmission and

those lift trucks with a powershift transmission without a MONOTROL pedal.

The direction control lever has three positions: FORWARD, NEUTRAL (N), and

REVERSE. Move the lever to one of the direction positions for travel.

NOTE: The direction control lever must be in the NEUTRAL (N) position before

the engine can be started.

17

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

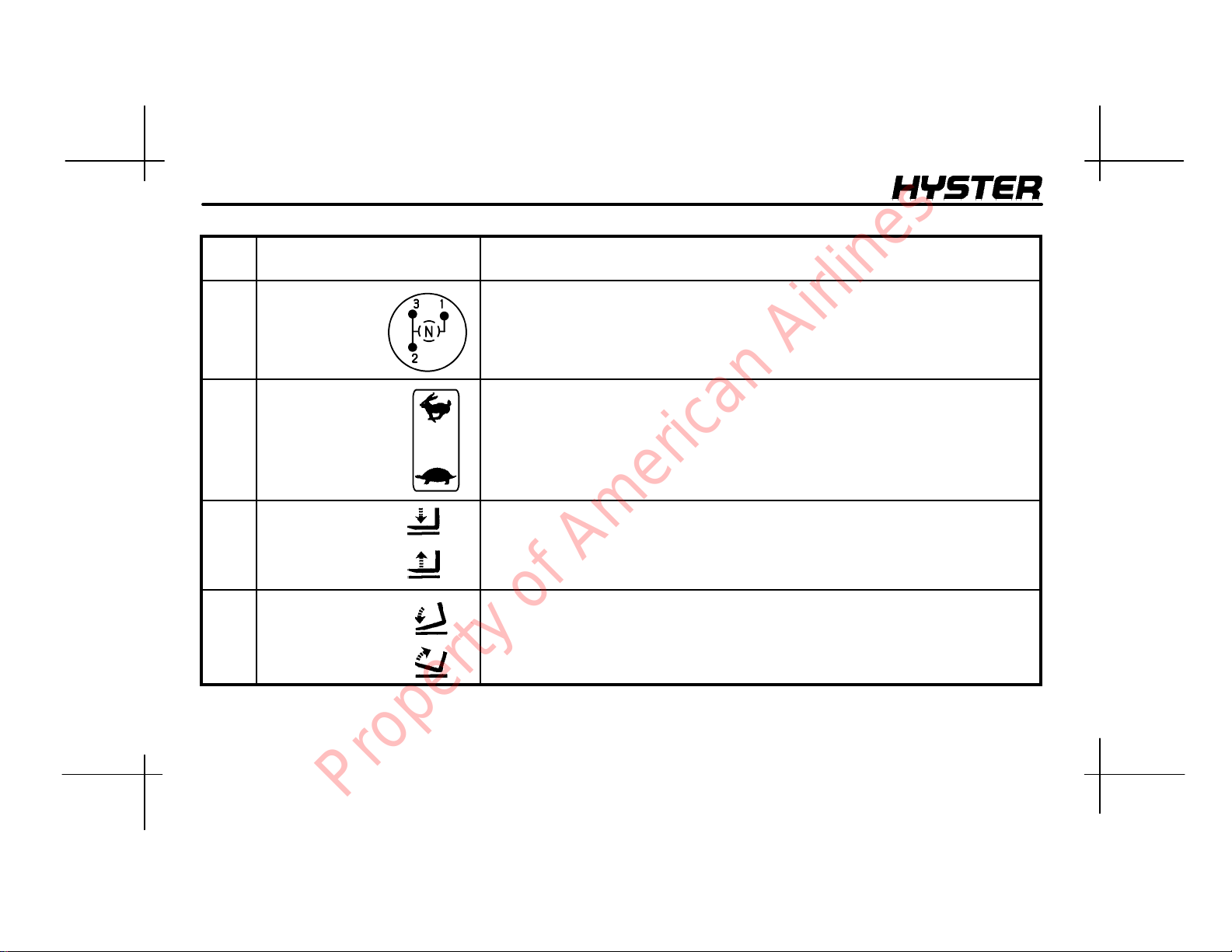

13 Range Lever

(Manual

Transmission)

(S135--155XL)

14 Range Lever

(Powershift

Transmission)

(S135--155XL

Only)

15 Lift/Lower

Control

Lever

16 Tilt

Control

Lever

ITEM FUNCTION

The range lever is located to the left of the steering column. This lever controls

the three speed ranges of the S135--155XL manual transmission.

The range lever for the transmission is to the left of the steering column. The

range lever controls the two speed ranges of the powershift transmission.

The lift/lower control lever is the first lever to the right of the steering wheel. Pull

backward on the control lever to raise the carriage and forks. Push the control

lever forward to lower the carriage and forks.

The tilt control lever is on the right of the lift/lower control lever. Push the control

lever forward to tilt the upright and forks forward. Pull backward on the control

lever to tilt the upright and forks backward.

18

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

17 Control Leverfor Auxiliary

Hydraulic Functions

See TABLE 3.

ITEM FUNCTION

The control lever for auxiliary hydraulic functions is installed to the right of the

tilt control lever. This control lever actuates a control spool in the control valve

for a single function attachment and two control spools for a two--function

attachment.

Single Function Operation: The lever is spring--loaded to the left and must be

pushed to the right before operating the auxiliary function.

Two Function Operation: The lever is spring--loaded to the left and will

operate one auxiliary function in this position. The lever must be pushed to the

right before operating the other auxiliary function.

19

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

17a Control Lever and Switchfor

Optional Auxiliary Hydraulic

Functions

See TABLE 3.

18

Accelerator Pedal

ITEM FUNCTION

Three-- Function Operation:

The control lever will have a special knob with a button. The button permits the

lever to control three functions of an attachment. The button operates a function

only when the control lever is in the left position. When the button is pushed,

the third auxiliary function will operate when the control lever is moved forward

or backward.

This option is often used with an attachment for moving paper rolls as

described in the following example:

Button not depressed: Push the control lever forward to rotate the attachment

to the left. Pull the control lever backward to rotate the attachment to the right.

Button depressed: Push the control lever forward to swing the attachment to

the left. Pull the control lever backward to swing the attachment to the right.

Push the control lever to the right and forward to open the clamp. Push the

control lever to the right and pull backward to close the clamp.

This pedal controls the engine speed and is operated by the operator’s right

foot. It is used on units that have a direction control lever.

20

Property of American Airlines

MODEL DESCRIPTION

ITEM

NO.

19 MONOTROL

Pedal

(Powershift

Transmission

Only)

20

Inching/Brake Pedal

(Powershift Transmission)

21

Brake Pedal

(Manual

Transmission)

(S135--155XL

Only)

22

Clutch Pedal

(Manual

Transmission)

(S135--155XL

Only)

ITEM FUNCTION

The MONOTROL pedal controls the speed and direction of the lift truck.

Pushing on the right side of the pedal causes the lift truck to move in

REVERSE. Pushing on the left side of the pedal causes the lift truck to move in

FORWARD. The speed of the engine increases as the pedal is depressed.

By varying the position of the inching/brake pedal, the operator can move the

lift truck slowly while a high engine speed is used for lifting loads. Completely

depressing the pedal disengages the transmission and applies the service

brakes. The engine can be started when the inching/brake pedal is fully

depressed.

This pedal, controlled by the operator’s right foot, controls the application of the

service brakes.

The clutch pedal is located to the left of the brake pedal. This pedal, controlled

by the operator’s left foot, controls clutch engagement for the transmission and

inching operations.

21

Property of American Airlines

MODEL DESCRIPTION

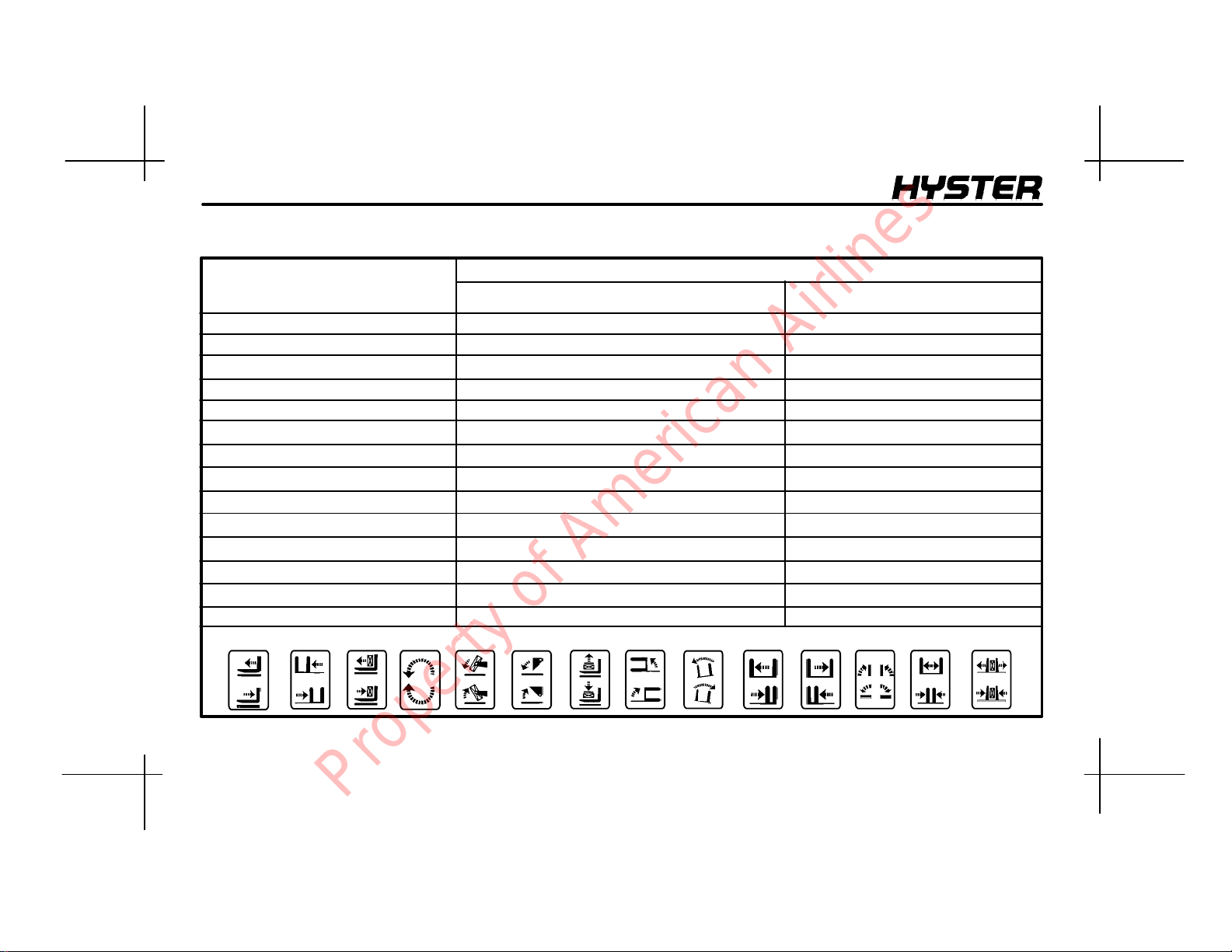

TABLE 3. AUXILIARY CONTROL LEVERS

FUNCTION

The control levers will be arranged in the

following order from left to right.

REACH Backward/Forward

1

2

SIDE SHIFT

3

PUSH -- PULL

ROTATE

4

UPENDER

5

6

SCOOP

LOAD STABILIZER

7

SWING (FORKS)

8

SWING (CLAMP)

9

L.H. FORK POSITIONER

10

R.H. FORK POSITIONER

11

TURN FORK

12

FORK SPREAD

13

14 CLAMP

LOAD OR EQUIPMENT CONTROL LEVER

Retract / Extend

Backward / Forward

Clockwise / Counterclockwise

Down (Clamp) / Up (Release)

Together / Apart

Together / Apart

Horizontal / Vertical

Together / Apart

Clamp / Release

DIRECTION OF MOVEMENT

Right / Left

Up / Down

Up / Down

Right / Left

Right / Left

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

Backward/Forward

1234567891011121314

12384

22

Property of American Airlines

OPERATING PROCEDURES

OPERATINGPROCEDURES

GENERAL

Know Your Lift Truck

The fork lift truck is designed to pick up and move materials.

The basic lift truck has a lift mechanism and forks on the

front to engage the load. The lift mechanism lifts the load so

that it can be moved and stacked.

In order to understand how the fork lift truck can pick up a

load, you must first know some basic things about the lift

truck.

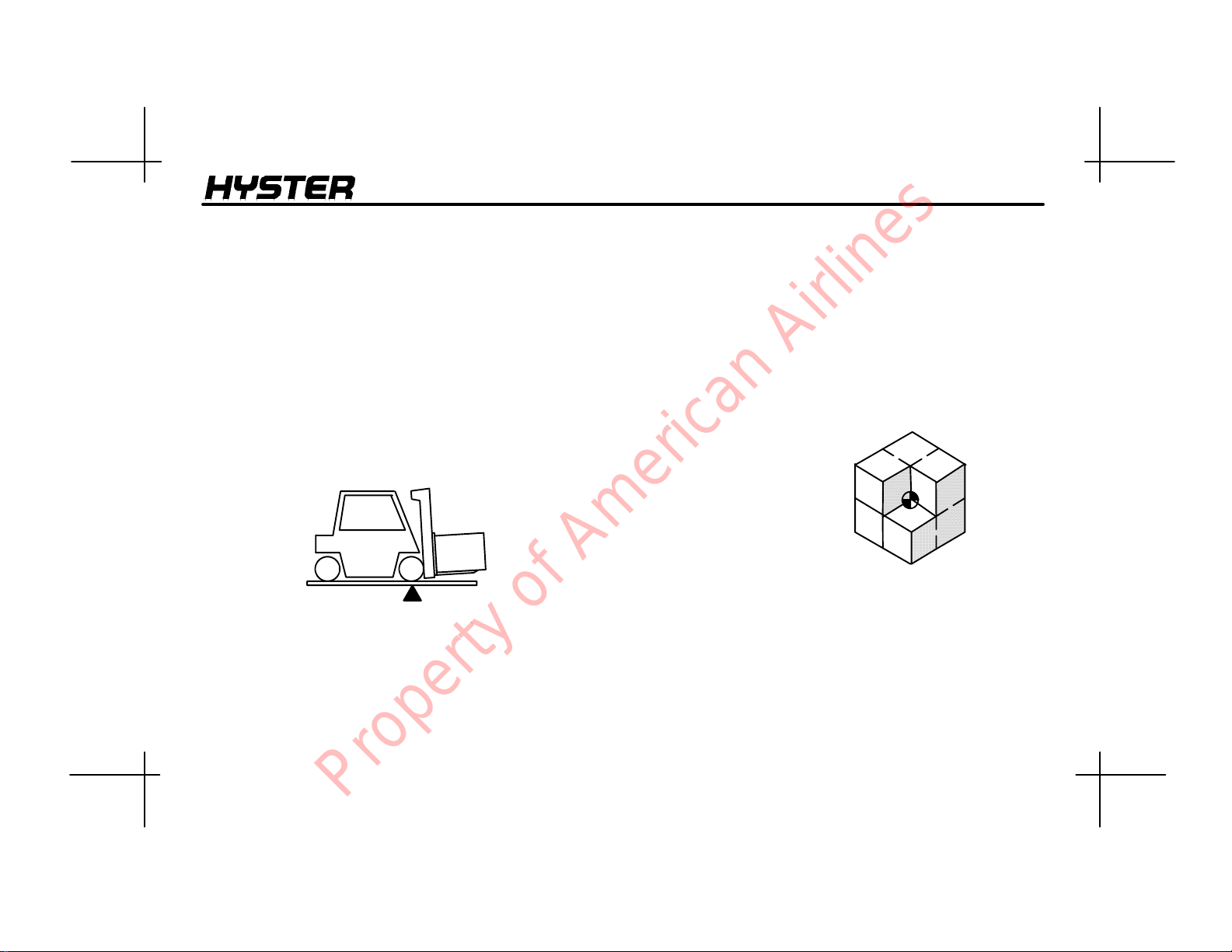

The lift truck is based on the principle of two weights balanced on opposite sides of a pivot (fulcrum). This is the

same principle used for a see--saw. In order for this princi-

ple to work for a lift truck, the load on the forks must be balanced by the weight of the lift truck. The location of the center of gravity of both the truck and the load is also a factor.

This basic principle is used for picking up a load. The ability

of the lift truck to handle a load is discussed in terms of center of gravity and both forward and side stability.

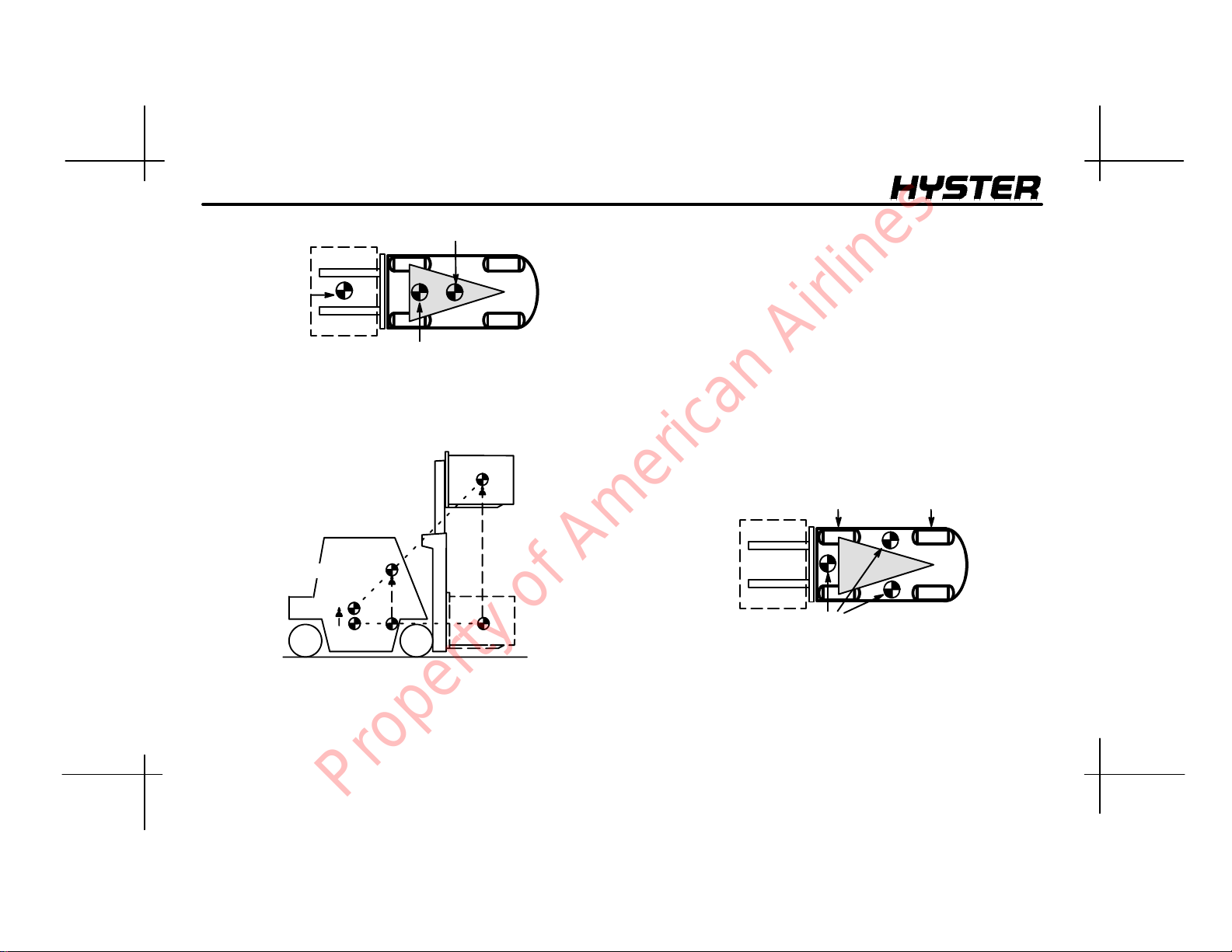

Stability and Center Of Gravity

The center of gravity (CG) of any object is the single

point about which

the object is balanced in all directions.

Every object has a CG. When the lift truck picks up a load,

the truck and load have a new combined CG.

The stability of the lift truck is determined by the location of

its CG, or if the truck is loaded, the combined CG.

23

Property of American Airlines

OPERATING PROCEDURES

CG Truck

CG Load

Combined CG

The lift truck has moving parts and therefore has a CG that

moves. The CG moves forward and back as the mast is

tilted forward and back. The CG moves up and down as the

mast moves up and down.

CG Load

Combined CG

CG Truck

The center of gravity, and therefore the stability, of the

loaded lift truck is affected by a number of factors, such as

size, weight, shape, and position of the load; the height to

which the load is raised; the amount of forward and backward tilt; tire pressure; and the dynamic forces created

when the truck is moving. These dynamic forces are caused

by things like acceleration, braking, turning, and operating

on uneven surfaces or on an incline. These factors must be

considered when traveling with an unloaded truck, as well,

because an unloaded truck will tip over to the side eas-

ier than a loaded truck with its load in the lowered position.

In order for the lift truck to be stable (not tip over forward or

to the side) the CG must stay within the area of the lift the

truck represented by a triangle drawn between the drive

wheels and the pivot of the steering axle.

Drive Axle

CG - - Truck Will Tip Over

If the CG moves forward of the drive axle, the lift truck will

tip forward. If the CG moves outside of the line represented

by the lines drawn between the drive wheels and the steering axle pivot, the lift truck will tip to that side.

Steering Axle

24

Property of American Airlines

OPERATINGPROCEDURES

Capacity

(Weight and Load Center)

The capacity of the lift truck is shown on the Nameplate.

The capacity is listed in terms of weight and load center.

The weight is specified in kilograms and pounds. The load

center is specified in millimeters and inches. The capacity is

the maximum load that the lift truck can handle for the load

condition shown on the Nameplate.

The load center of a load is determined by the location of its

center of gravity . The load center is measured from the front

face of the forks, or the load face of an attachment, to the

center of gravity of the load. Both the vertical and horizontal

load centers are specified on the Nameplate.

For carriages or attachments that can be sideshifted, the

Nameplate specifies capacities in the “Centered” and “Sideshifted” conditions. Capacities listed under “Centered” on

the Nameplate apply when transporting loads that are centered on the centerline of the lift truck. Capacities listed under “Sideshifted” on the Nameplate apply if loads are transported that are not centered on the centerline of the lift

truck. Loads should be transported while centered on the

centerline of the lift truck.

The operator must know whether or not a load is within the

maximum capacity of the lift truck before the load is handled.

INSPECTION BEFORE

OPERATION

Checks With the

Engine Stopped

Inspect the lift truck before use and every eight hours or

daily as described in the MAINTENANCE section of this

OPERATING MANUAL.

Before using the lift truck, make the following checks:

• Fuel level (if the lift truck has a diesel engine, drain

water from the primary filter).

• Electrolyte level of the battery (unless maintenance

free).

25

Property of American Airlines

OPERATING PROCEDURES

• Oil level in the engine and hydraulic tank.

• Coolant level in the cooling system and condition of the

drive belts.

• Condition of the radiator. Clean if necessary.

• Condition of forks, carriage, chains, mast, attachment

and overhead guard.

• Leaks from the engine, transmission, hydraulic system

and fuel system.

• Condition of wheels and tires.

• Seat belt latches properly.

• Seat is correctly fastened to its mounts. Hood is securely

latched.

W ARNING

Report damage or faulty operation immediately. Do not

operate a damaged or defective lift truck. A lift truck

will only do its job when it is in proper working order. If

repairs are required, install a tag in the operator’s area

stating “DO NOT OPERATE” and remove the key from

the key switch.

Starting Procedures

Do not start nor

operate the lift

truck, including

any of its functions or attachments, from any

place other than

the designated

operator’s position.

Gasoline Or LPG Engine

W ARNING

LPG is very flammable. An odor of LPG fuel can indicate a leak in the fuel system. DO NOT start the engine

until the fuel leak is repaired.

1. If the lift truck uses LPG fuel, open the fuel valve on the

LPG tank.

2. Make sure the parking brake is applied or push on the

inching/brake pedal.

26

Property of American Airlines

OPERATINGPROCEDURES

3. If equipped, put the direction control lever for the trans-

mission in the NEUTRAL (N) position.

CAUTION

Do not engage the starter for more than 30 seconds at a

time. If the engine does not start, turn the key switch to

OFF. Wait 60 seconds before engaging the starter

again.

4. Turn the key to the START position to engage the starter.

5. If the engine does not start after four attempts, get help

from authorized service personnel.

6. When the engine is running, check the gauges and indi-

cator lights for the correct operation. See the Instruments

AndControlssectioninthisOPERATING MANUAL for a

description of the correct operation.

Diesel Engine

1. Make sure the parking brake is applied or push on the

inching/brake pedal.

2. If equipped, put the direction control lever for the trans-

mission in the NEUTRAL (N) position.

3. Turn the key to START to engage the starter. If the out-

side temperature is 7°C(45°F) or below, crank the engine

two revolutions to prime the fuel system. Turn the key to the

OFF position. Push the HEAT button and hold it for 20 to 25

seconds, then engage the starter again for 10 seconds.

CAUTION

Use only approved starting aids. Use of non--approved

starting aids can result in engine damage and void engine warranty.

4. If the engine does not start after four attempts, get help

from authorized service personnel.

5. When the engine is running, check the gauges and indicator lights for the correct operation. See the INSTRUMENTS AND CONTROLS section for a description of the

correct operation.

27

Property of American Airlines

OPERATING PROCEDURES

W ARNING

FASTEN YOUR

SEA T BELT!

The seat belt is installed to help the

operatorstay on the

truck if the lift truck

tips over. IT CAN

ONLY HELP IF IT IS

FASTENED.

Checks With the

Engine Running

The operator must be aware that the lift truck can tip over.

There is a great risk that the operator or someone else can

be killed or injured if trapped or hit by the truck as it tips

over. The risk of injury can be reduced if the operator stays

on the truck. If the truck tips over do not jump off.

The SEAT BELT AND HIP RESTRAINT BRACKET provide

a means to help the operator keep the head and torso substantially within the confines of the truck frame and overhead guard if a tipover occurs. This protection system is

intended to reduce the risk of the head and torso being

trapped between the truck and the ground, but it can not

protect the operator against all possible injury in a tipover.

Make sure that the area around the lift truck is clear before

starting the engine or making any operational checks. Be

careful when making the checks. If the lift truck is stationary

during a check, apply the parking brake and put the transmission in NEUTRAL. Proceed carefully.

Check the operation of the following functions as described

in the MAINTENANCE section.

• Check the operation of the horn, gauges and indicator

lights.

28

• Check the oil level in the transmission:

Property of American Airlines

Loading...

Loading...