Hyster Narrow Aisle N30XMR3, Narrow Aisle N45XMR3, Narrow Aisle N25XMDR3, Narrow Aisle N30XMDR3, Narrow Aisle N40XMR3 Operating Manual

...

OPER

A

A

NARROW AISLE

N30--40XMR3, N25XMDR3 (C470)

N45XMR3, N30XMDR3 (G138)

TING MANU

N50XMA3 (C471)

L

DO NOT REMOVE THIS MANUAL

FROM THIS UNIT

1487036

12/05

Property of American Airlines

LIFT TRUCK MODEL SERIAL NUMBER

TRACTION MOTOR SERIAL NUMBER

HYDRAULIC PUMP MOTOR SERIAL NUMBER

STEERING GEAR MOTOR SERIAL NUMBER

LIFT HEIGHT GROUP NUMBER

DRIVE TIRE SIZE COMPOSITION

SPECIAL EQUIPMENT OR ATTACHMENTS

REGISTERED TRADEMARKS

Hyster,

SitDrive and StanDrive are registered trademarks of Hyster Company.

, SpaceSaver, Straddle Truck, Karry Krane, Yardmaster, Monotrol, OrderMaster, SpaceMaster, RACKLOADER,

Property of American Airlines

NARROW AISLE

FOREWORD

TO OWNERS, USERS, AND OPERATORS:

The safe and efficient operation of a lift truck requires

skill and alertness on the part of the operator. To develop

the skill required the operator must:

S receive training in the proper operation of this lift truck.

S understand the capabilities and limitations of the lift

truck.

S becomefamiliar with the constructionof the lift truck and

see that it is maintained in good condition.

S read and understand the warnings and operating

procedures contained in this manual.

Inaddition,aqualifiedperson,experiencedinlift truckoperation, must guide a new operator through several driving

and load handling operations before the new operator attempts to operate the lift truck alone.

It is theresponsibility of the employer tomake sure thatthe

operator can see, hear, and has the physical and mental

ability to operate the equipment safely.

Various laws and regulations require the employer to train

lift truck operators. These laws and regulations include:

Occupational Safety and Health Act (OSHA) (USA)

Canada Material Handling Regulations

NOTE: A comprehensive operator training program is

available from HYSTER COMPANY. For further details

contact your HYSTER lift truck dealer.

This Operating Manual is stored in the container on the

mast screen. Read and understand this manual before operating the lift truck. This is a permanent reference and

must be available for use at all times.

This Operating Manual contains information necessary for

theoperation andmaintenance of abasic fork lift truck. Optional equipment is sometimes installed that can change

some operating characteristics described in this manual.

Makesurethenecessary instructions are available and understood before operating the lift truck.

HYSTER COMPANY 2005 1487036 ENGLISH

1

Property of American Airlines

NARROW AISLE

FOREWORD

TO OWNERS, USERS, AND OPERATORS:

Some of the components and systems described in this

OPERATING MANUAL will NOT be installed on your unit.

If you have a question about any item described, contact

your dealer for HYSTER lift trucks.

Additional informationthat describes the safe operation

anduseoflifttrucks is available from the followingsources:

S Employment safety and health standards or regulations

(Examples: “Occupational Safety and Health Standards

(USA)”, “Canada Material Handling Regulations”.

S Safety codes and standards (Example: American

NationalStandard,ANSIB56.1,SafetyStandard forLow

Lift and High Lift Trucks).

S Publications from government safety agencies,

government insurers, private insurers and private

organizations (Example: Accident Prevention for

Industrial Operations from the National Safety Council).

S “Guide for Users of Industrial Lift Trucks” describes lift

truck safety, good maintenance practices, and training

2

programs. Available from your dealer for HYSTER lift

trucks. HYSTER part number 852930.

NOTE: HYSTER lift trucks are not intended for use on

public roads.

NOTE: Throughout this manual, the terms right, left,front

and rear relate to the viewpoint of an operator standing in

the operator’s compartment facing the forks.

NOTE: The following symbols and words indicate safety

information in this manual:

DANGER

Indicatesa condition which willcauseimmediateinjury or death.

WARNING

Indicates a condition that can cause injury

CAUTION

Indicates a condition that can cause property damage!

Property of American Airlines

TABLE OF CONTENTS

CONTENTS

FOREWORD 1..................................

MODEL DESCRIPTION 7.........................

NAMEPLATE 8...............................

OPERATING PROCEDURES 21....................

GENERAL 21..................................

Stability and Center of Gravity 21..............

CHECKS WITH THE KEY SWITCH OFF 24.......

CHECKS WITH THE KEY SWITCH ON 25........

OPERATING TECHNIQUES 25..................

Starting Sequence 27........................

Driving and Direction Changes 28.............

Steering (Turning) 28........................

Load Handling -- General 30..................

Lifting, Lowering and Tilting 30................

How to Engage and Disengage a Load 32......

Traveling 35................................

Highway Trucks, Railroad Cars and Docks 37...

MAINTENANCE 41...............................

GENERAL 41..................................

HOW TO MOVE A DISABLED LIFT TRUCK 42....

HowtoTowtheLiftTruck 42..................

How to put a Lift Truck on Blocks 43...........

MAINTENANCE PROCEDURES 50.................

CHECKS WITH THE KEY SWITCH OFF 50.......

Hydraulic System 50.........................

Forks 51...................................

Reach, Tilt and Sideshift 54...................

Articulation Stop Adjustment 54...............

Battery 55..................................

CHECKS WITH THE KEY SWITCH ON 56........

Gauges, Horn and Fuses 56..................

Control Levers and Pedals 56.................

Lift System Operation 56.....................

Brake 57...................................

HOW TO CHARGE THE BATTERY 58............

HOW TO CHANGE THE BATTERY 60............

Battery Removal 60..........................

Battery Installation 61........................

BATTERY SPECIFICATIONS 63.................

TIRES AND WHEELS 64.......................

Drive/steer tire 64...........................

Load Wheels 65.............................

Caster Wheels 66...........................

Tire and Wheel Sizes 66.....................

CHANGES TO THE OVERHEAD GUARD 67......

3

Property of American Airlines

CONTENTS

NOTES

4

Property of American Airlines

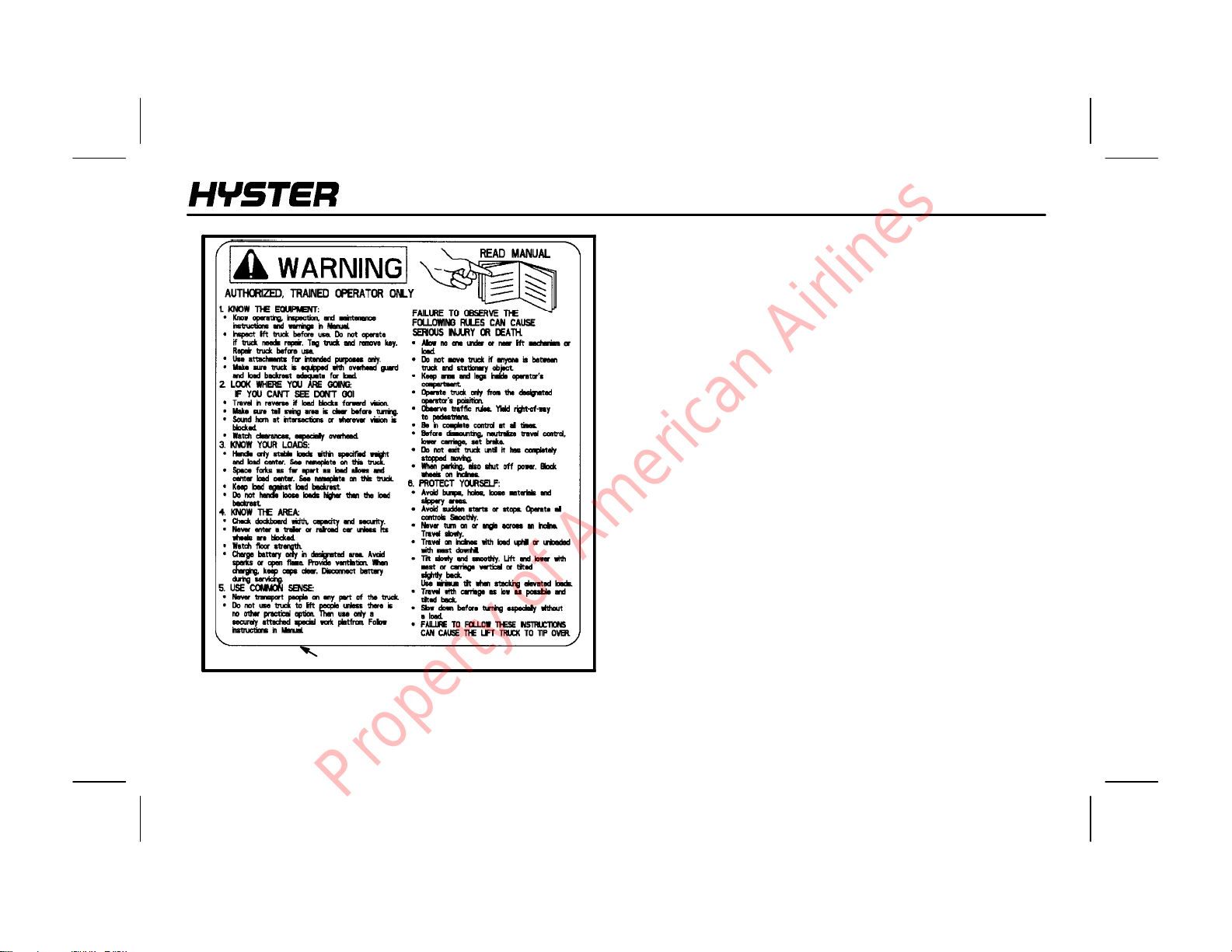

FAILURE TO OBSERVE THE FOLLOWING RULES CAN CAUSE SERIOUS INJURY OR DEATH!

KNOW THE EQUIPMENT:

NARROW AISLE

WARNING

WARNING

AUTHORIZED, TRAINED OPERAT OR ONLY!

KNOW YOUR LOADS:

S Know operating, inspection and maintenance instruc-

tions and warnings in Manual.

S Inspect truck before use. Do not operate if truck needs

repair. Tag truck and remove key. Repair truck before

use.

S Use attachments for intended purpose only.

S Make sure truck is equipped with overhead guard and

load backrest adequate for the load.

LOOKWHERE YOUARE GOING: IFYOUCAN’TSEE,

DON’T GO!

S Travel in reverse if load blocks forward vision.

S Make sure tailswing area is clear before turning.

S Sound horn at intersections or wherever vision is

blocked.

S Watch clearances, especially overhead.

Property of American Airlines

S Handle only stable loads within specifiedweight andload

center. See nameplate on this truck.

S Space forks as far apart as load allows and center load

between forks.

S Keep load against load backrest.

S Do not handle loose loads higher than load backrest.

KNOW THE AREA:

S Check dockboard width, capacity and security.

S Never enter a trailer or railroad car unless its wheels are

blocked.

S Watch floor strength.

S Charge battery only in designated area. Avoid sparks or

open flame. Provide ventilation. When charging, keep

vent caps clear. Disconnect battery during servicing.

5

WARNING

NARROW AISLE

USE COMMON SENSE:

S Never transport people on any part of the truck.

S Do not use truck to lift people unless there is no other

practical option. Then use only a securely attached

special work platform. Follow instructions in manual.

S Allow no one under or near lift mechanism or load.

S Do not move truck if anyone is between truck and

stationary object.

S Keep arms, legs, and head inside operator’s compart-

ment.

S Operate truck only from the designated operator’s

position.

S Obey traffic rules. Yield right-of-way to pedestrians.

S Be in complete control at all times.

S Before dismounting, neutralize travel control, lower

carriage, set brake. Do not exit truck until it has

completely stopped moving.

S When parking, also shut off power. Block wheels on

inclines.

PROTECT YOURSELF:

S Avoid bumps, holes, loosematerials, andslippery areas.

S Avoid sudden starts or stops. Operate all controls

smoothly.

S Never turn on or angle across an incline. Travel slowly.

S Travel on inclines with load uphill or unloaded with mast

downhill.

S Tilt slowly and smoothly. Lift and lower with mast or

carriage vertical or tilted slightly back. Use minimum tilt

when stacking elevated loads.

S Travel with carriage as low as possible and tilted back.

S Slow down before turning - especially without load.

S FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

CAUSE THE LIFT TRUCK TO TIP OVER!

Although there is no sure way in all circumstances to avoid

injury, where possible, in the event of an imminent tipover

or off--the--dock accident, the operator should STEP OFF

AND AWAY FROM THE TRUCK. These actions are

intended to reduce the risk of serious injury or death.

6

Property of American Airlines

NARROW AISLE

MODEL DESCRIPTION

MODEL DESCRIPTION

This Operating Manual describes the operation and basic

maintenance of the HYSTER Narrow Aisle N30XMR3,

N40XMR3, N45XMR3 (reach), N25XMDR3, N30XMDR3

(double reach) and N50XMA3 (straddle) lift trucks. The lift

trucks are available with 24 volt or 36 volt systems,

depending upon the model selected. These battery

powered lift trucks have lifting capacities of1,134 to 2,268

kg(2,500to5,000lb)ata610mm(24inch)loadcenterand

are available with two or three stage masts.

These trucks feature a SEM (Separately Excited Motor)

traction control system as well as neutral braking. The

controller has diagnostic capabilities and thermal

protection. Travel acceleration, top speed and operator

drive modes are set through the traction controller.

Proportional plugging is standard.

Amulti-functioncontrolhandleprovidescontrolof direction,

lift/lower,extend/retract, tilt and optionalsideshift. The horn

button is also on the side of the control handle.

The instrument display includes a battery discharge

indicator with lift interrupt, hourmeters, LED function

selection lights, operator selectable drive modes for speed

of tractionand an LCD display which provides the status of

systems and fault messages in English, not in numerical

codes.

All lift trucks have operator protection equipment. The

overhead guard is intended to offer reasonable protection

to the operator from falling objects, but cannot protect

against every possible impact. Therefore, it must not be

considered a substitute for good judgement and care when

handling loads. A rear overhead guard leg provides

protection for the operator and unobstructed operation of

the lift truck. A fullheight wire mast guardismounted to the

rearofthemast.Donot remove anyequipmentprovidedfor

the protection of the operator.

The battery compartment must have spacers to prevent

horizontal movement of more than 13 mm (0.5 in). The

battery restraintpanelsmustbeinplacebeforethe lift truck

is operated. The battery can be removed from either side

of the lift truck, although right side removal is preferred to

avoid damage to the battery cables. A roller rack under the

battery permitseasybatterymovement. For correct battery

sizes, see the Battery Specifications in the Maintenance

Section.

7

Property of American Airlines

NARROW AISLE

MODEL DESCRIPTION

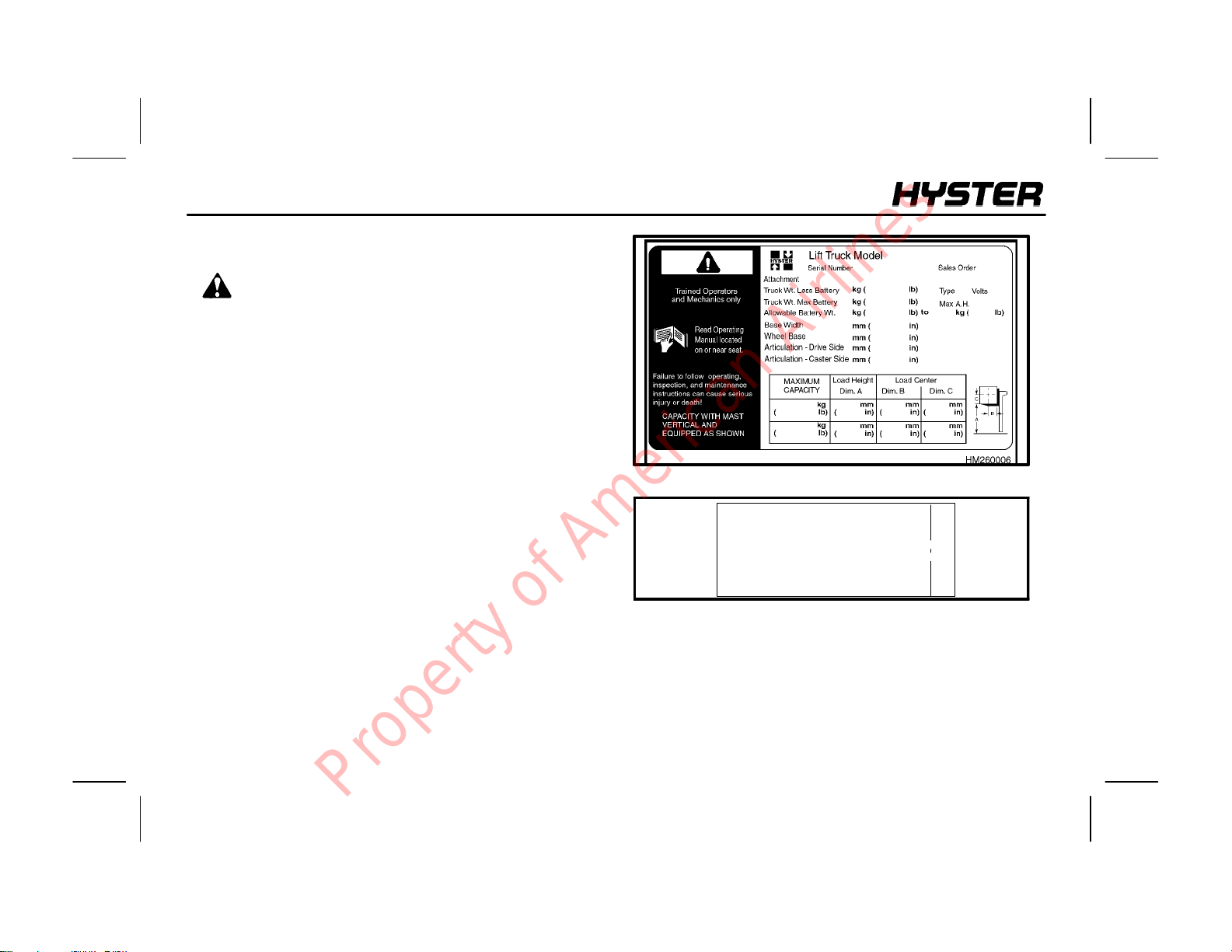

NAMEPLATE

WARNING

Any change to the lift truck, the tires or its equipment

can change the lifting capacity. If the nameplate does

not show the maximum capacity , or if the lift truck

equipment,includingthe battery,doesnot match that

shown on the nameplate, then the lift truck must not

be operated.

The lift truck nameplate is located inside the operator’s

compartment. The shown is for a lift truck equipped as

shown on the nameplate. The capacity is specified in

kilograms (kg), and pounds (lb). The capacity is the

maximumloadthelifttruckcanhandle fortheloadcondition

shown on the nameplate.

The maximum capacity for the lift truck must be shown on

the nameplate. If the lift truck nameplate already has a

capacity for special load handling equipment, it will be

listed. Make sure the nameplate data is complete and fully

understood before operating the lift truck.

The lift truck serial code number is on the nameplate. The

serial code number is also stamped on the lift truck frame.

FIGURE 1. NAMEPLATE

NOTICE TO USER

The U.S.A. Occupational Safety and Health

Act of 1970 and other national safety codes

require anew plate if this unit is equipped

other thanas stated on plate. Obtain the

correct plate from your authorized dealer.

FIGURE 2. DECAL

When a unit is shipped incomplete from the factory to the

dealer, the nameplate is covered by a label as shown in

FIGURE 2. If your lift truck has this type of label, do not

operate the lift truck. Contact your dealer for HYSTER lift

trucks to obtain a complete nameplate.

To remove pull here

8

Property of American Airlines

NARROW AISLE

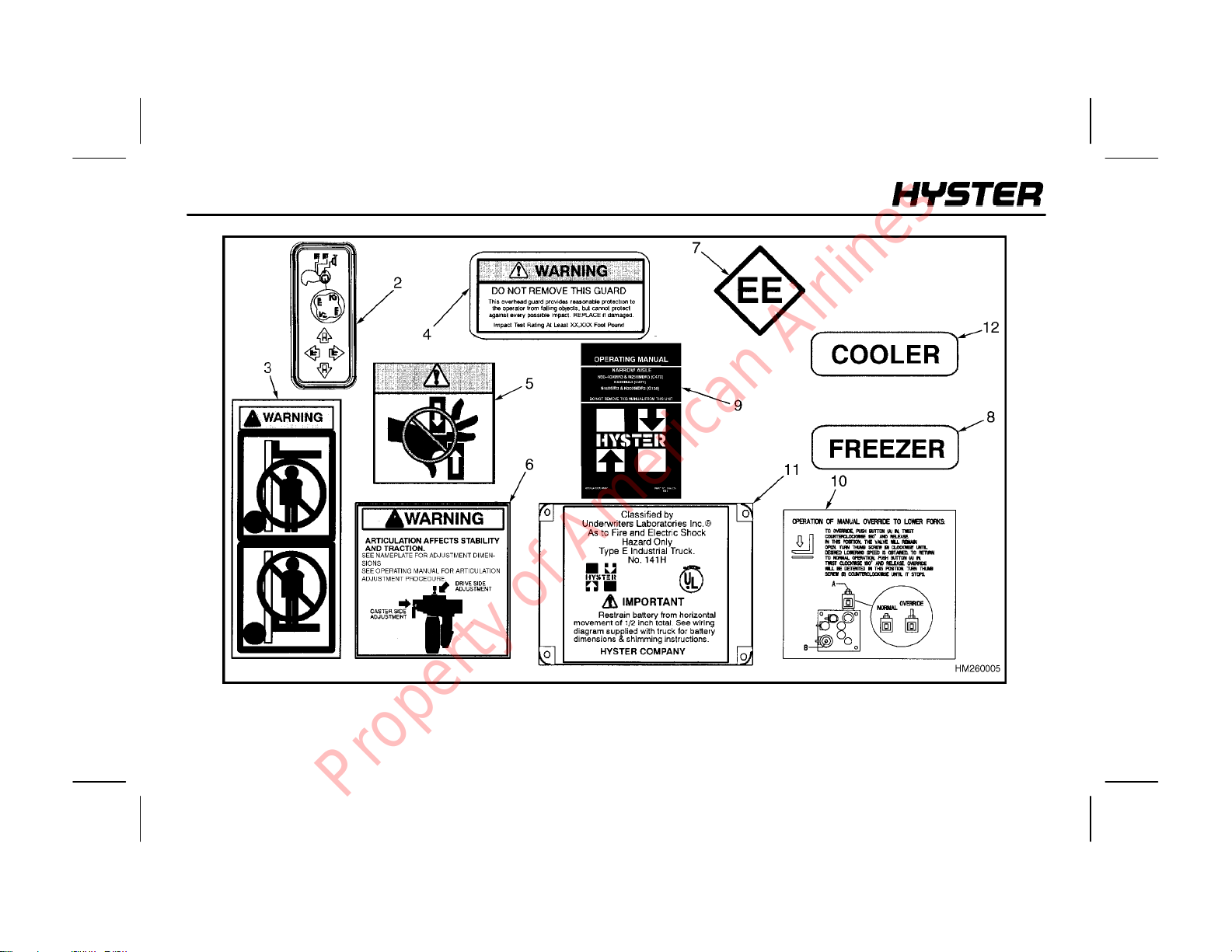

WARNING LABELS (FIGURE 3. & FIGURE 4.)

11. Label, Operator Warning

12. Label, Multi--Function Handle

13. Label, Fork Warning

14. Label, Overhead Guard

15. Label, Pinch Points

16. Label, Articulation

17. Label, Identification EE

MODEL DESCRIPTION

1

FIGURE 3. WARNING LABELS

NA02230

Property of American Airlines

18. Label, Freezer Identification

19. Operating Manual

10. Label, Manual Lowering

1 1. Label, Underwriters Laboratory

12. Label, Cooler Identification

9

MODEL DESCRIPTION

NARROW AISLE

10

FIGURE 4. WARNING LABELS

Property of American Airlines

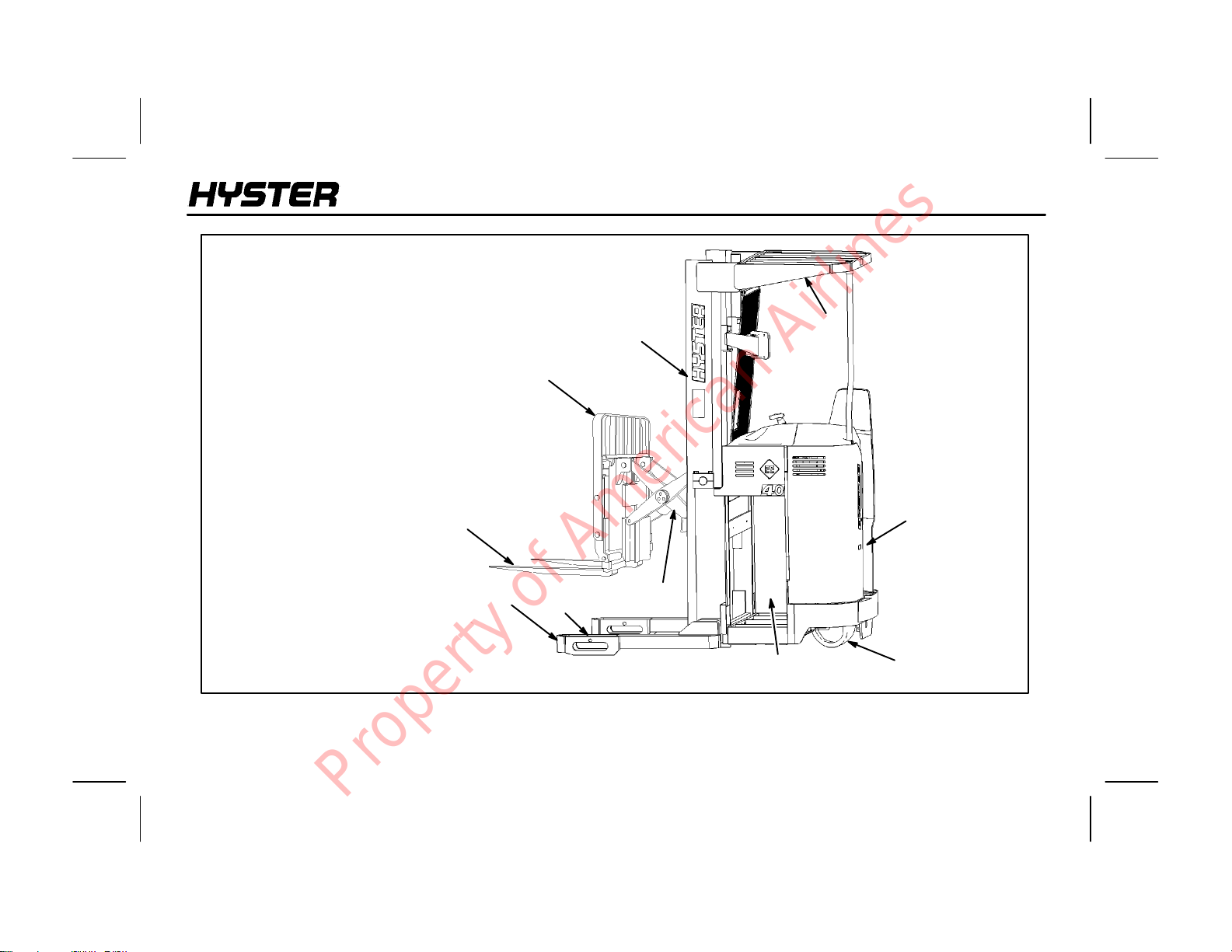

Major Components of the Lift Truck

1. Overhead Guard

2. Mast

3. Load Backrest

4. Forks

5. Basearms

6. Battery Compartment

7. Drive/Steer Wheel

8. Load Wheels

9. Operator’s Compartment

10. Carriage

NARROW AISLE

MODEL DESCRIPTION

1

2

3

4

5

FIGURE 5. MAJOR COMPONENTS OF THE LIFT TRUCK

8

10

6

9

7

11

Property of American Airlines

MODEL DESCRIPTION

NARROW AISLE

12

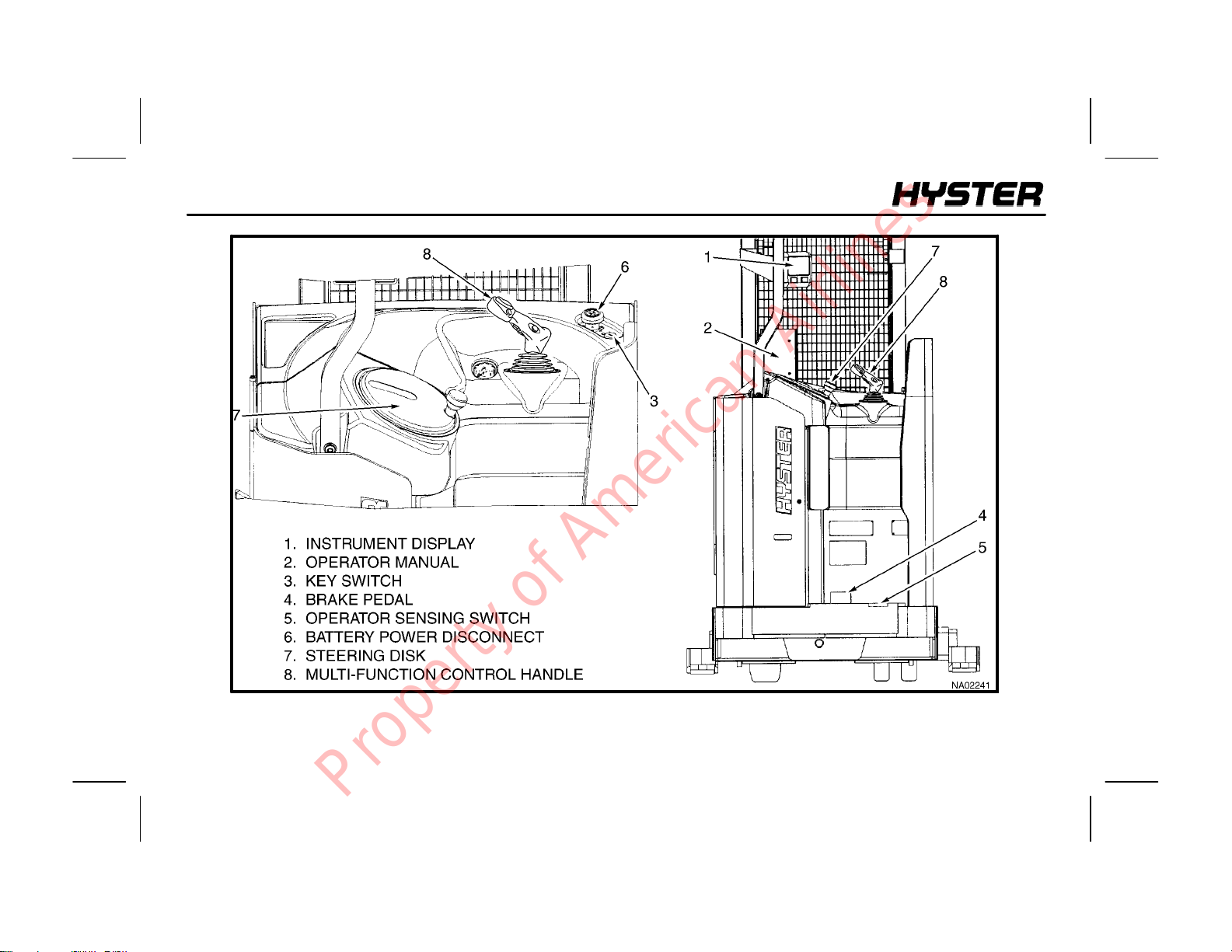

FIGURE 6. INSTRUMENTS AND CONTROLS

Property of American Airlines

NARROW AISLE

MODEL DESCRIPTION

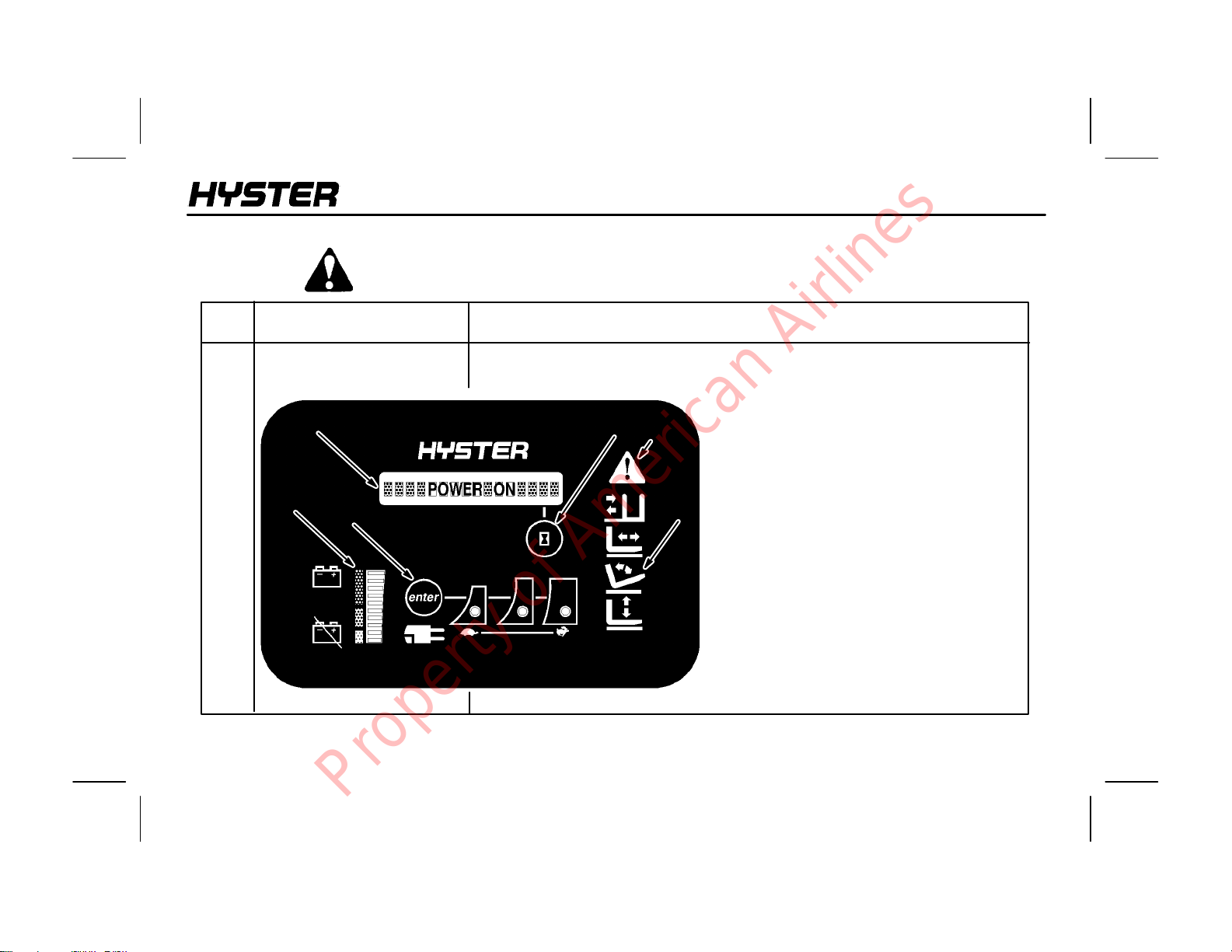

TABLE 1. INSTRUMENTS AND CONTROLS

WARNING: If any of the instruments or controls do not operate as described in this table,

report the problem immediately. DO NOT operate the lift truck until the problem is corrected.

ITEM

NO.

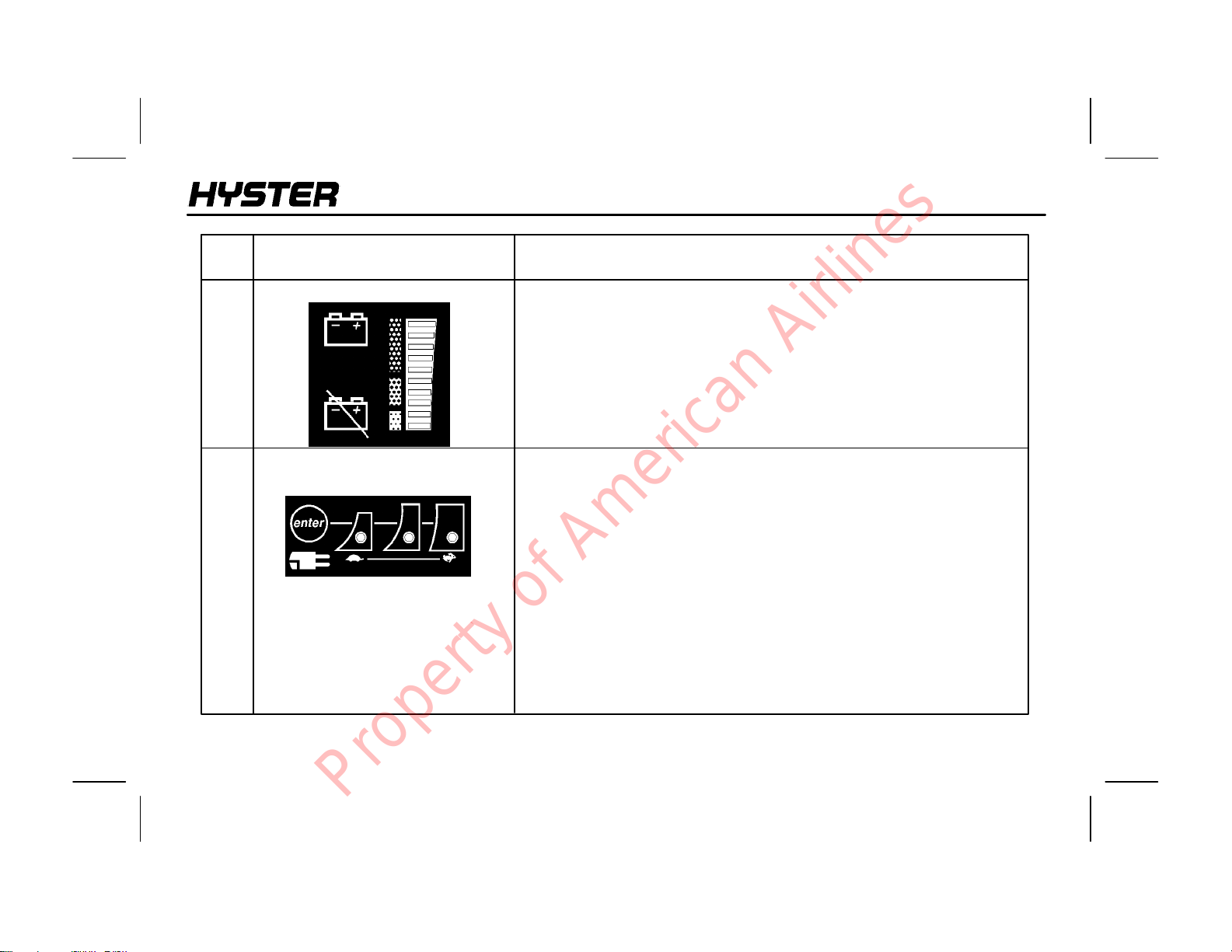

1

ITEM

Instrument Display

a

c

d

FUNCTION

The instrument display is mounted on a bracket at eye level in the

operator’s compartment and has the following features:

a. Message Center

e

f

b. Function Selection Lights

c. Battery Indicator

d. Drive Mode Feature

e. Hourmeter

f. Warning Lights

b

The instrument display is powered even

when the vehicle is not being operated.

When the battery is disconnected, the

dashboard contains an internal back-up

battery, capable of memory retention of

the battery indicator and hourmeter.

13

Property of American Airlines

MODEL DESCRIPTION

NARROW AISLE

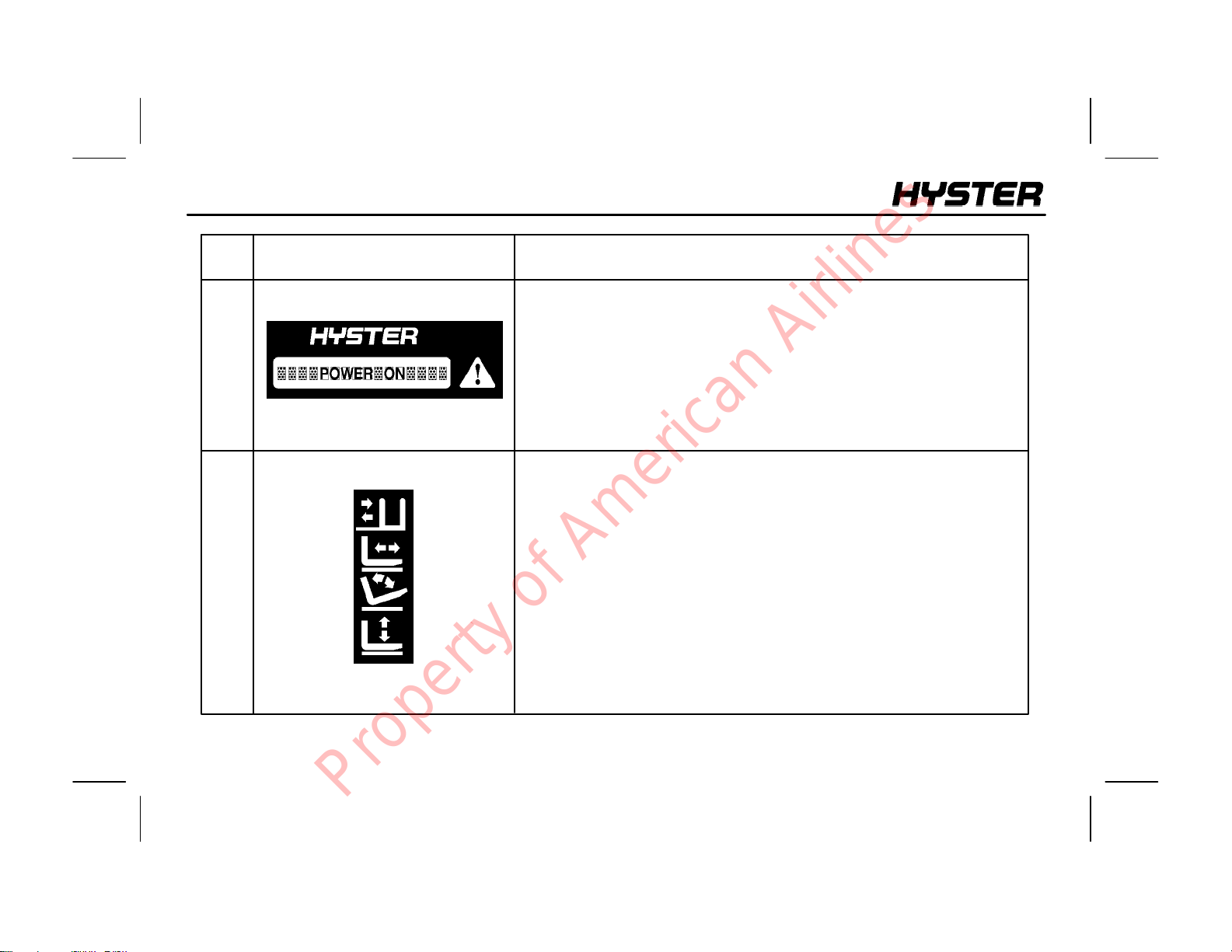

ITEM

NO.

a

b

ITEM FUNCTION

Message Center

LCD indicators

Function Selection Lights

LEDindicators

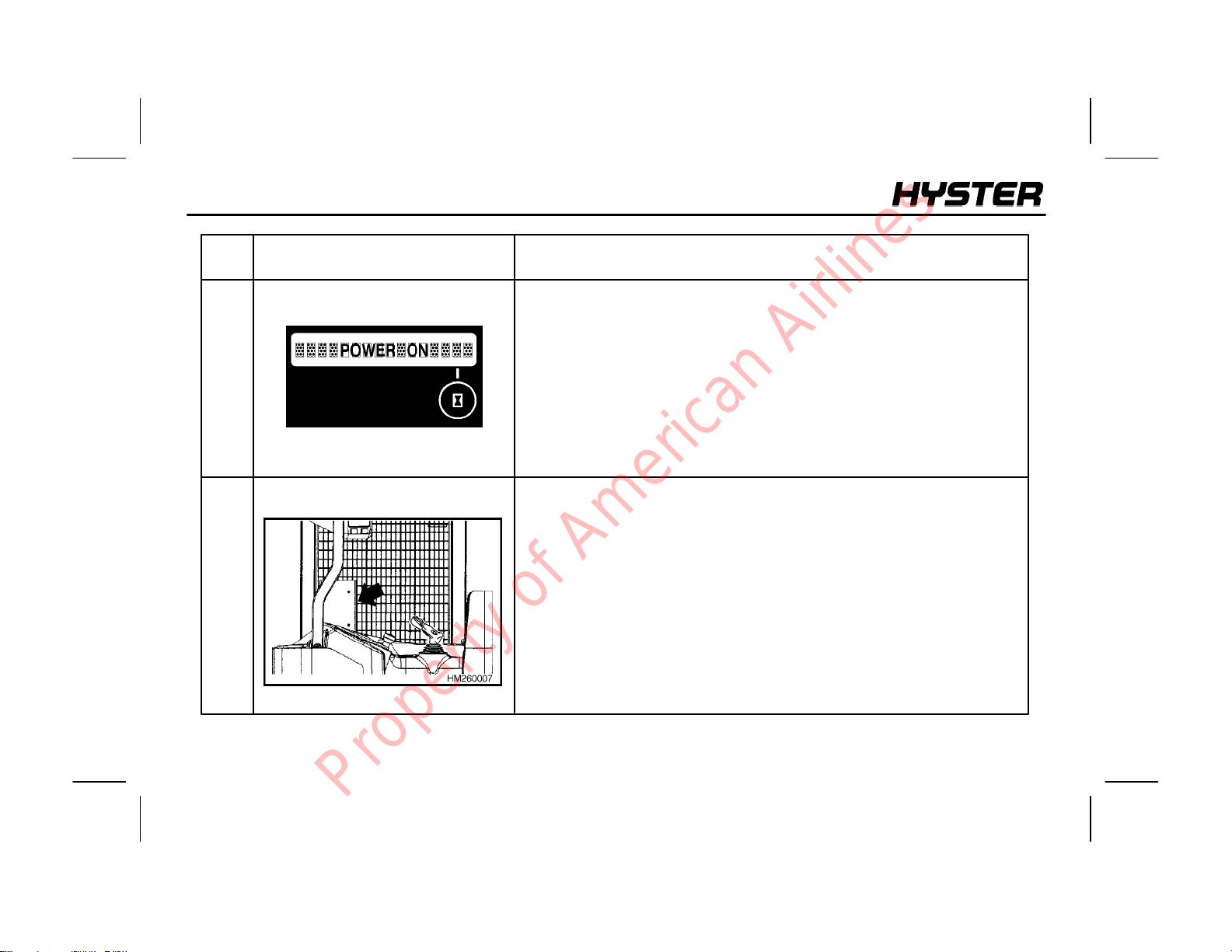

The Message Center is a 16 character, dot matrix LCD (Liquid Crystal

Display)withgreenbacklighting.The16character,alpha-numericdisplay

showsthehourmeter readings, lift truckperformancestatus, andwarning

or fault conditions in English. When a warning message is received, the

warning/fault indicator will blink as a yellow light. When a fault message

is received, the warning/fault indicator will blink as a red light.

TheFunction SelectionLightsdisplay the selected hydraulic function.

Status messages will be displayed for LIFT, REACH, TILT AND

SIDESHIFT.Thefunctionselectionlightswill display the current hydraulic

function, independent of the present LCD display.

14

Property of American Airlines

NARROW AISLE

MODEL DESCRIPTION

ITEM

NO.

c

d

ITEM FUNCTION

Battery Indicator

Drive Mode Display

TheBattery Indicatorhasa10barmulticolor LED (Light Emitting Diode)

to indicate battery charge status. The bars are green, yellow and red. As

battery power is used, the LED lightbarsturnOFF,firstgreen,thenyellow,

then red. The next to bottom red bar will flash indicating a nearly

discharged battery.At empty, the bottom red bar will alternately flashwith

the LO-BA TT indicator LED (a crossed battery symbol). The lift function

will be locked out at this point. Continued operation with a discharged

battery can damage the battery, motors or the contactors.

The Drive Mode Display allows the operator to select the traction motor

controller speed most suited to the application. Operation of the drive

mode switch will cause the green indicators and corresponding drive

modes to increase from Turtle to Mid to Rabbit. Turtle mode provides

slower acceleration and reduced top speed. It is also a valuable setting

when training new operators or on wet floorsfor better traction. Mid mode

reduces acceleration with full travel speed. Rabbit mode provides

maximum acceleration and travel speed. When the key switch is turned

to OFF, the selected drive mode is retained. When the battery is

disconnected the drive mode returns to the Rabbit mode. The rates of

acceleration and travelspeedsare programmable and can be adjusted by

a qualified service technician. The drive mode can only be selected while

in neutral.

15

Property of American Airlines

MODEL DESCRIPTION

NARROW AISLE

ITEM

NO.

e

2

ITEM FUNCTION

Hourmeter

Operating Manual

The Hourmeter switch is controlled by the operator and is used for

on-demanddisplayofhourmeterinformation. The hourmeter data canbe

displayed at any time by pressing the hourmeter switch. The switch is

marked with anhourglasssymbol. Press the switch once to display truck

hours to 1/10 of an hour. Presstwice todisplay drive motor hours. Press

three times to display the lift motor hours. Press four times to return to

the normal display mode. If the hourmeter is left in any of the first three

positions, the display will return to the normal display mode, which

indicates the current operational status of the lift truck after 30 seconds.

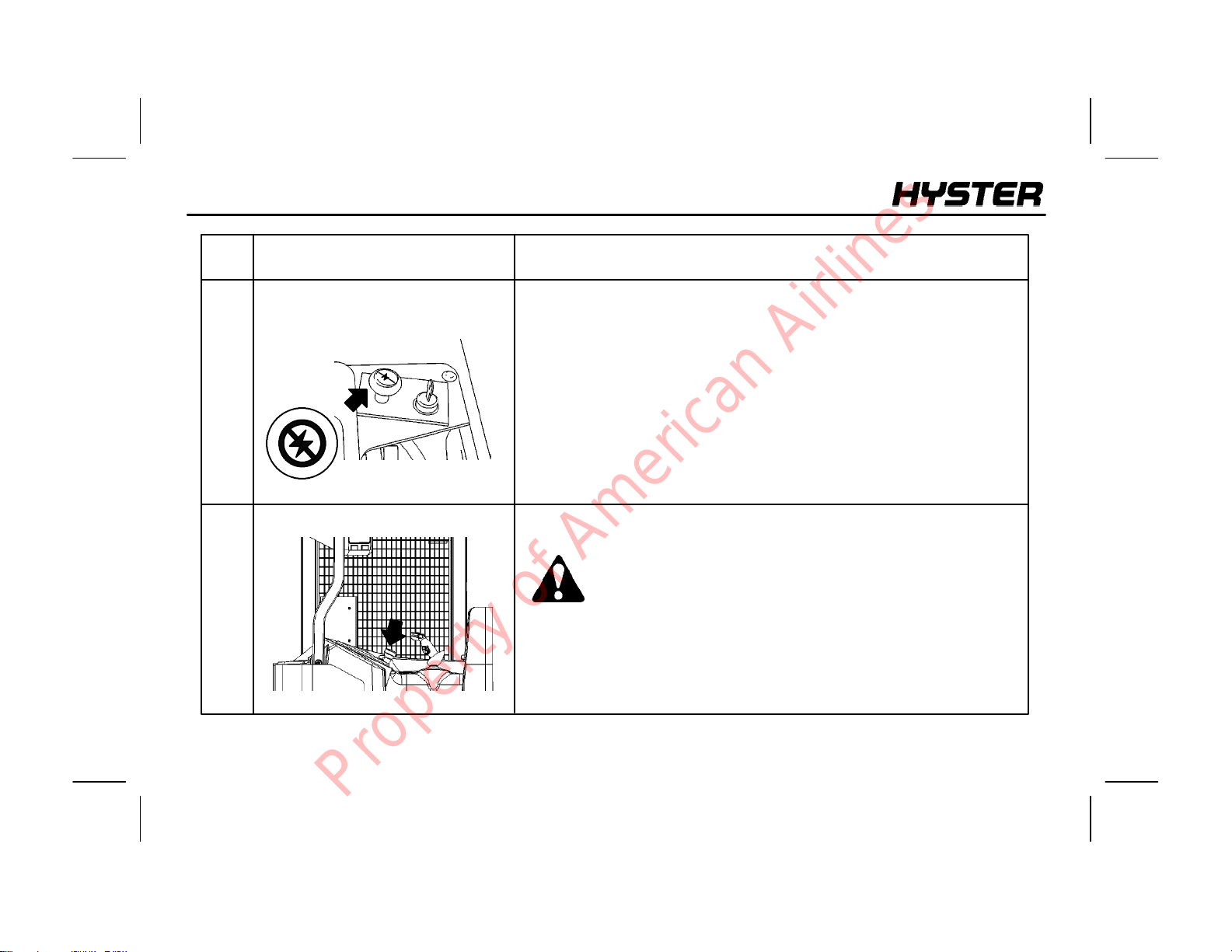

The Operating Manual is sent with the lift truck and is located in the

container on the wire mast guard mounted behind the mast. The

OperatingManualisapermanentreference andmustbeavailableforthe

operator’s use at all times. Read and understand this manual before

operating the lift truck.

16

Property of American Airlines

NARROW AISLE

MODEL DESCRIPTION

ITEM

NO.

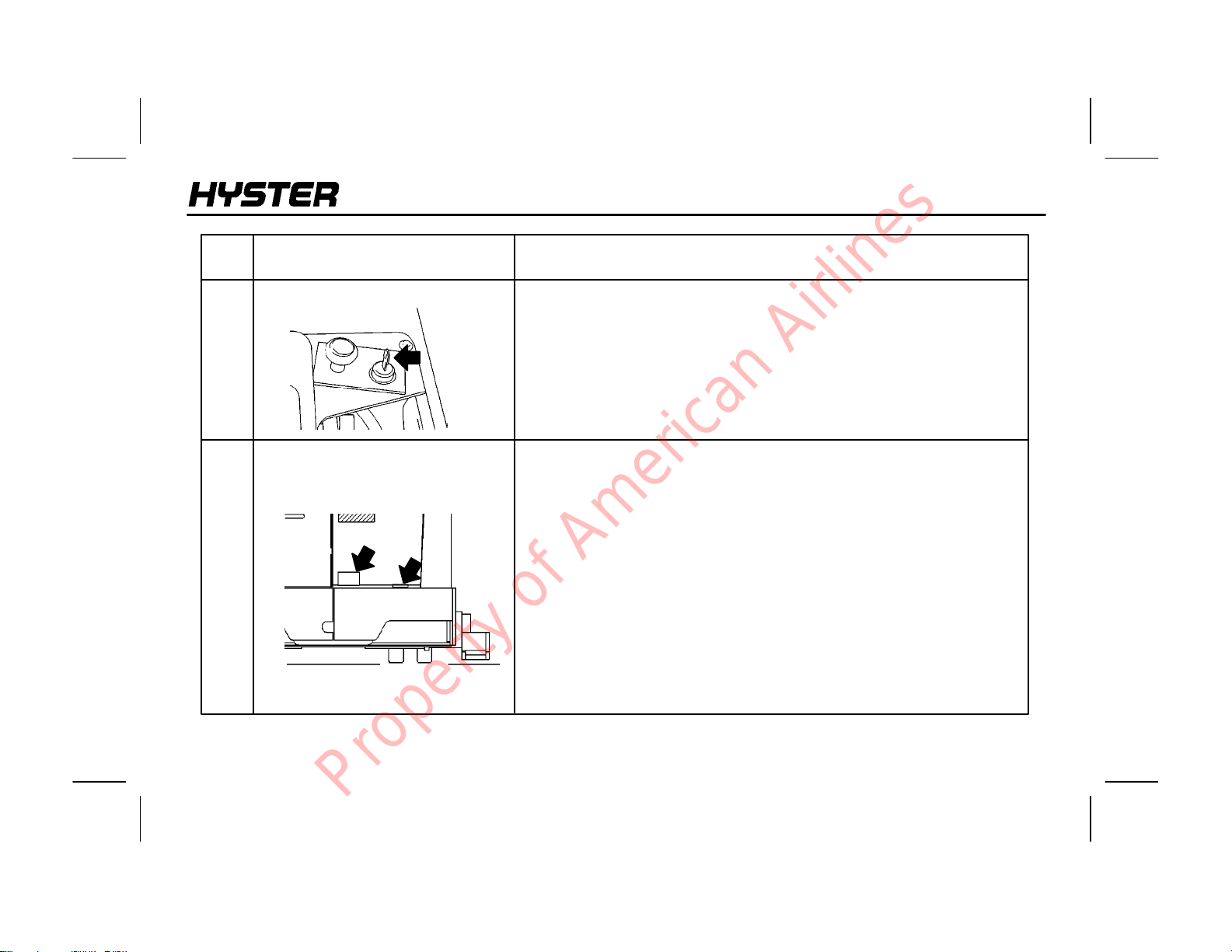

3

4, 5

ITEM FUNCTION

Key Switch

Brake Pedal and

Operator Sensing Switch

The key switchis a three position switch. The first positionis OFF(marked

O). The second position is RUN (marked I). The thirdposition is unmarked

and not used. It is spring loaded and automatically returns the key to the

RUNpositionafter thekeyisreleased.Thekeyswitchislocatedtotheright

side of the battery power disconnect knob.

The brake is designed for both service and parking brake use. The brake

is spring applied and hydraulically released. The push down brake pedal

is on the floor in the rear of the operator’s compartment. The brake is

automatically applied when the brake pedal is released.

An operator sensing switch is on the floor to the right of the brake pedal

and must be closed with the brake pedal switch before lift truck operation

ispermitted. The operator must stepinto the operator’scompartment and

close both switches before driving or operating any hydraulics. When the

operator leaves the lift truck the parking brake is automatically applied.

17

Property of American Airlines

MODEL DESCRIPTION

NARROW AISLE

ITEM

NO.

6

7

ITEM FUNCTION

Battery Power Disconnect

Steering Disk

Theredbattery power disconnect switchislocatednexttothe key switch.

When pressed, power is shut off to all circuits in the lift truck. Power is

restored to the lift truck by pulling the switch upward.

The steering disk controls lift truck direction with 4 turns lock to lock.

WARNING: Reversesteeringisavailableforthis lift truck.

The operator should check the steering direction before

operating the lift truck.

18

Property of American Airlines

NARROW AISLE

MODEL DESCRIPTION

ITEM

NO.

8

ITEM FUNCTION

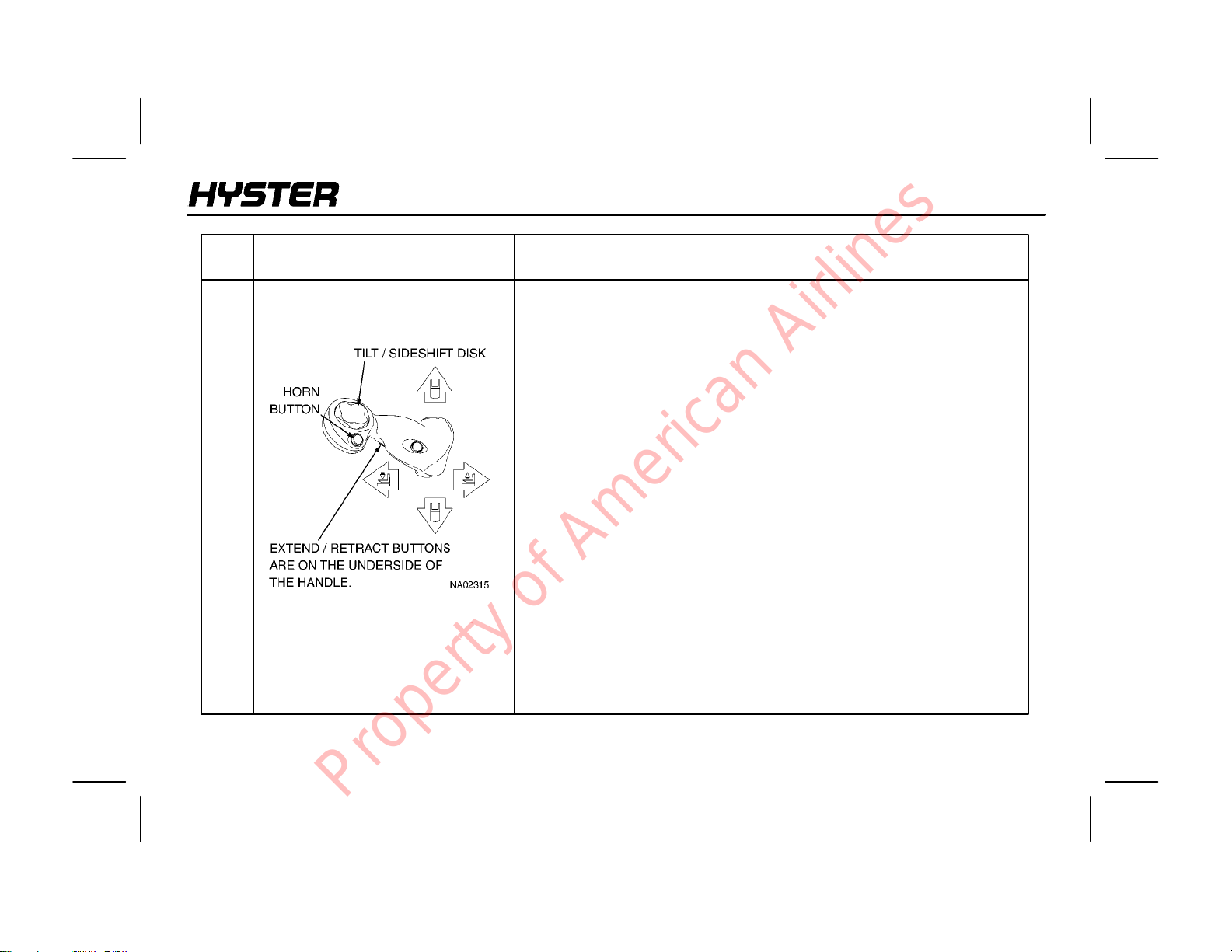

Multi-function Control Handle

The multi-function control handle allows the operator tocontrol travel, lift,

lower,tilt, sideshift, horn, and extend and retract functions. Eachfunction

has an independent control device.

Travel is activated by tilting the entire control handle in the direction of

travel. Pushing the control handle toward the forks makes the lift truck

travel forward. To change direction, move themulti-functionhandleinthe

oppositedirectionthelifttruckistraveling,regardless oftravelspeed.The

lift truck will come to a stop, then accelerateintheoppositedirection.This

control is proportional; therefore, the fartherthe control handle is pushed,

the faster the lift truck will accelerate or decelerate. If the multi-function

handle is released, it will return to neutral, and the truck will decelerate at

aprogrammedratetoastop.

The multi-function handle controls the direction and speed at which the

carriage moves vertically on the mast. Lift/Lower is activated by tilting

the entire control handle toward the left or right side of the lift truck. If the

control handle is tilted toward the right, the carriage lifts; if the control

handle is tilted toward the left, the carriage lowers. The farther the lever

is tilted, the faster the carriage lifts or lowers.

TheHorn button is located on the side of the multi-function handle facing

the operator, just to the left of the tilt/sideshift disk. The horn is activated

by pressing the button with the thumb.

19

Property of American Airlines

MODEL DESCRIPTION

NARROW AISLE

ITEM

NO.

8

ITEM FUNCTION

Tilt/Sideshift Disk

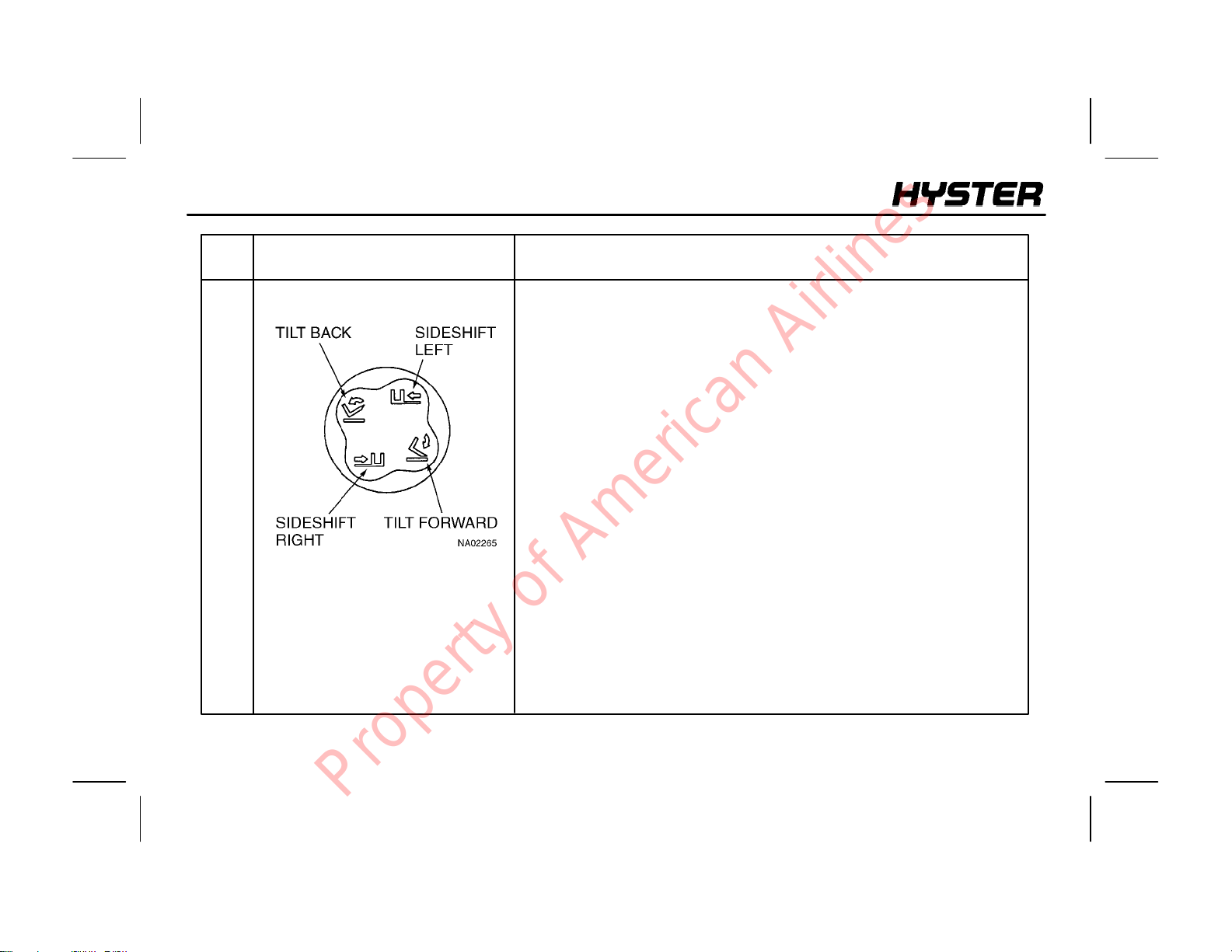

The Tilt/Sideshift Disk, located at the top of the multi-function handle

lever, controls the tilting and side--shifting of the carriage. The disk is

operated with the thumb of the right hand. To tilt the carriage forward,

press the top of the disk. To tilt the carriage back, press the bottom of the

disk. On lift trucksequippedwithasideshifting carriage, press the left side

of the disk to move the carriage to the left, and press the right side of the

disk to move the carriage to the right. Tilt and sideshift are single speed

functions.

The Extend and Retract buttons are located on the shaft of the

multi-function handle. Press the top button to provide low speed extend.

While the top button is still actuated, press the bottom button to provide

high speed extend. Press the bottom button to provide low speed retract.

While the bottom button is still actuated, press the top button to provide

high speed retract.

Themulti-function handleiscapableofprovidingvariabletraction,variable

lift or lower, a single auxiliary function and the horn simultaneously for

improved productivity.

20

Property of American Airlines

Loading...

Loading...