Hyster J30XNT, K160, J35XNT, J40XNT Operating Manual

OPERATING MANUAL

J30-40XNT (K160)

Property of American Airlines

DO NOT REMOVE THIS MANUAL FROM THIS UNIT

PART NO. 1676236 2/17

Spacer

LIFT TRUCK MODEL

TRACTION MOTOR

HYDRAULIC PUMP MOTOR

STEERING PUMP MOTOR

MAST LIFT HEIGHT

CARRIAGE TYPE

DRIVE TIRE SIZE

SPECIAL EQUIPMENT OR ATTACHMENTS

© Hyster Company 2017. All Rights Reserved.

HYSTER,

are Trademarks in the United States and certain other jurisdictions.

, FORTIS, MONOTROL, and YARDMASTER are Registered Trademarks of Hyster-Yale Group, Inc. HSS, DURAMATCH, UNISOURCE, and

SERIAL NUMBER

SERIAL NUMBER

SERIAL NUMBER

SERIAL NUMBER

GROUP NUMBER

GROUP NUMBER

STEERING TIRE SIZE

Foreword

Foreword

To OWNERS, USERS, and OPERATORS:

The safe and efficient operation of a lift truck requires

skill and alertness on the part of the operator. To develop

the skill required, the operator must:

• Receive training, pursuant to OSHA 1910.178(l) dated

12/98, in the proper operation of THIS lift truck.

• Understand the capabilities and limitations of the lift

truck.

• Become familiar with the construction of the lift truck and

see that it is maintained in good condition.

• Read and properly understand the warnings, instructions, and operating procedures in this manual.

In addition, a qualified person, experienced in lift truck

operation, must guide a new operator through several driving and load handling operations before the new operator

attempts to operate the lift truck alone.

It is the responsibility of the employer to make sure that the

operator can see, hear, and has the physical and mental

ability to operate the equipment safely.

©HYSTER COMPANY 2017 1676236 - ENGLISH-US 1

Various laws and regulations require the employer to train

lift truck operators. These laws and regulations include:

• Occupational Safety and Health Act (OSHA) (USA)

• Canada Material Handling Regulations

NOTE: A comprehensive operator training program is avail-

able from Hyster Company. For further details, contact

your dealer for Hyster lift trucks.

This Operating Manual is the original instruction and contains information necessary for the operation and maintenance of a basic fork lift truck. Optional equipment is

sometimes installed that can change some operating characteristics described in this manual. Make sure the necessary instructions are available and understood before

operating the lift truck.

Some of the components and systems described in this

Operating Manual will NOT be installed on your unit. If you

have a question about any item described, contact your

dealer for Hyster lift trucks.

Foreword

Additional information that describes the safe operation

and use of lift trucks is available from the following sources:

• Employment safety and health standards or regulations

(Examples: "Occupational Safety and Health Standards

(USA)," "Canada Material Handling Regulations."

• Safety codes and standards (Example: Industrial Truck

Standards Development Foundation, ANSI/ITSDF

B56.1, Safety Standard for Low Lift and High Lift

Trucks).

• Publications from government safety agencies, government insurers, private insurers, and private organizations

(Example: Accident Prevention Manual For Industrial

Operations, from the National Safety Council).

• Guide for Users of Industrial Lift Trucks (Hyster Part No.

852930) describes lift truck safety, good maintenance

practices, and training programs and is available from

your dealer for Hyster lift trucks.

NOTE: Hyster lift trucks are not intended for use on public

roads.

NOTE: The following symbols and words indicate safety

information in this manual:

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury and property

damage.

On the lift truck, the WARNING symbol and word are on

orange background. The CAUTION symbol and word

are on yellow background.

2

Contents

Foreword ...................................................................... 1

TO OWNERS, USERS, AND OPERATORS: ............. 1

Warning ........................................................................ 7

Model Description ....................................................... 10

GENERAL ................................................................... 11

OPERATOR PROTECTION EQUIPMENT ................. 18

NAMEPLATE .............................................................. 19

SAFETY LABELS ....................................................... 20

OPERATOR CONTROLS ........................................... 24

Display Panel Features ............................................... 55

DISPLAY PANEL ........................................................ 55

DISPLAY PANEL KEYS ............................................. 56

DISPLAY PANEL - LCD SCREEN AND WARNING

AND INDICATOR LIGHTS ....................................... 64

NORMAL SEQUENCE OF OPERATION - DISPLAY

PANEL ...................................................................... 76

NORMAL SEQUENCE OF OPERATION - DISPLAY

PANEL WITH OPTIONS ........................................... 77

Operating Procedures ................................................ 79

GENERAL ................................................................... 79

Know Your Lift Truck ................................................ 79

Stability and Center of Gravity .................................. 80

Capacity (Weight and Load Center) ......................... 81

Contents

Impact Sensor ........................................................... 82

INSPECTION BEFORE OPERATION ........................ 83

Checks With the Key or Keyless Switch OFF ........... 83

Operator Passwords ................................................. 84

Operator Checklist .................................................... 86

Mounting and Dismounting ....................................... 89

Start-Up Procedure - SRO Circuit ............................. 89

Lift Trucks with Software Versions Less than 4.32 . 89

Lift Trucks with Software Versions 4.32 and

Greater ............................................................. 90

Lift Truck Interlocks ................................................... 92

Checks With the Key or Keyless Switch ON ............. 100

Load Weighing Sensor ............................................. 101

Set Load Weight to Zero ........................................... 103

OPERATING TECHNIQUES ...................................... 104

Basic Operating Procedures ..................................... 105

Driving and Direction Changes ................................. 109

Steering (Turning) ..................................................... 110

Synchronized Steering Control ................................. 112

Auto Power Off ......................................................... 112

Standard Operator Presence System ....................... 113

Lift Trucks with Software Versions Less than 4.32 . 113

3

Contents

Lift Trucks with Software Versions 4.32 and

Greater ............................................................. 113

Optional Operator Presence System ........................ 114

Lift Trucks with Software Versions 4.32 and

Greater ............................................................. 114

Automatic Parking Brake .......................................... 115

Load Handling - General ........................................... 117

Lifting, Lowering, and Tilting ..................................... 118

How to Engage and Disengage a Load .................... 121

Load Handling, Traveling .......................................... 124

Load Handling, Emergency Load Lowering .............. 127

Manual Main Control Valve ..................................... 127

E-Hydraulic Main Control Valve .............................. 129

HIGHWAY TRUCK, RAILROAD CARS, AND

DOCKS ..................................................................... 131

ATTACHMENTS ......................................................... 132

STOPPING ................................................................. 133

PARKING .................................................................... 133

Maintenance ................................................................ 134

GENERAL ................................................................... 134

SERIAL NUMBER DATA ............................................ 135

HOW TO MOVE A DISABLED LIFT TRUCK .............. 136

How to Tow the Lift Truck ......................................... 137

HOW TO PUT A LIFT TRUCK ON BLOCKS .............. 139

How to Raise the Drive Tires .................................... 139

How to Raise the Steer Tire ...................................... 140

HOW TO CLEAN A LIFT TRUCK ............................... 142

Maintenance Schedule ............................................... 142

Maintenance Procedures Every 8 Hours or Daily .... 156

HOW TO MAKE CHECKS WITH THE KEY OR

KEYLESS SWITCH OFF .......................................... 156

Wheels and Tires ...................................................... 156

Safety Labels ............................................................ 157

Frame and Covers .................................................... 158

Forks, General .......................................................... 160

Forks, Remove ......................................................... 160

Forks, Inspect ........................................................... 165

Forks, Install ............................................................. 166

Forks, Adjust ............................................................. 167

Inspection of Mast, Carriage, Header Hoses, Lift

Chains, and Attachments ...................................... 167

Hydraulic Oil Level and Leaks .................................. 170

Operator Restraint System ....................................... 170

Emergency Locking Retractor (ELR) ........................ 174

Battery Restraint System .......................................... 175

Lift Trucks Manufactured Before November, 2014 . 178

Lift Trucks Manufactured After November, 2014 .... 178

Steering Column Adjustments .................................. 182

Tilt Adjust Feature ................................................... 183

Tilt Memory Feature ................................................ 183

4

Contents

Telescopic Feature ................................................. 183

Battery Check ........................................................... 184

HOW TO MAKE CHECKS WITH THE KEY OR

KEYLESS SWITCH ON ............................................ 185

Control Levers and Pedals ....................................... 185

Direction and Speed Control Pedals ......................... 185

Electrical Components .............................................. 185

Steering System ....................................................... 187

Hydraulic System ...................................................... 188

Service Brakes .......................................................... 189

Automatic Parking Brake .......................................... 189

Operator Presence System ...................................... 189

Oil Leaks ................................................................... 190

HOW TO CHARGE THE BATTERY ........................... 190

HOW TO CHANGE THE BATTERIES ........................ 193

General ..................................................................... 193

Remove the Battery .................................................. 193

Install the Battery ...................................................... 195

Optional Side Removal of Battery ............................. 197

BATTERY SPECIFICATIONS .................................... 200

WHEELS AND TIRES ................................................. 202

General ..................................................................... 202

PNEUMATIC TIRE REPAIR ....................................... 204

Remove Wheels From Lift Truck .............................. 204

Remove Tire From Wheel ......................................... 204

Tire Removal, Two-Piece Wheel ............................ 205

Tire Removal, Three- and Four-Piece Wheels ....... 206

Install the Wheel in the Tire ...................................... 207

Install Wheel in Tire, Three- or Four-Piece Wheel .. 208

Install Wheel in Tire, Two-Piece Wheel .................. 209

Add Air to the Tires ................................................... 210

Install the Wheels ..................................................... 211

SOLID RUBBER TIRES REPAIR ............................... 211

Change Solid Rubber Tires on Pneumatic Wheels .. 211

Remove Wheels From Lift Truck .............................. 211

Remove Tire From Wheel ......................................... 211

Install Tire on Wheel ................................................. 213

Install the Wheels ..................................................... 214

SOLID RUBBER (CUSHIONED) TIRES REPAIR ...... 215

Remove Wheels From Lift Truck .............................. 215

Remove and Install Tire on Wheel ............................ 215

HOW TO PUT AN ELECTRIC SIT DOWN RIDER

TRUCK IN STORAGE .............................................. 217

HOW TO PUT BATTERIES IN STORAGE ................. 218

HOW TO PUT A LIFT TRUCK BACK INTO

SERVICE .................................................................. 219

HOW TO MOVE A LIFT TRUCK ON A

TRANSPORT ............................................................ 219

Loading ..................................................................... 220

Unloading .................................................................. 220

5

Contents

PREPARATION FOR USE ......................................... 221

Preparation After Transport ...................................... 221

CHANGES TO THE OVERHEAD GUARD ................. 221

6

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN CAUSE SERIOUS INJURY OR DEATH!

AUTHORIZED, TRAINED OPERATOR ONLY!

The following WARNING is a label and must be on the

lift truck.

KNOW THE EQUIPMENT:

• KNOW operating, inspection, and maintenance instruc-

tions in Operating Manual.

• DO NOT operate or repair truck unless trained and

authorized.

• INSPECT truck before use.

• DO NOT operate if truck needs repair. Tag truck and

remove key. Repair truck before use. Always use Hyster

Approved parts when making repairs. Replacement

parts must meet or exceed the specifications of the original equipment manufacturer.

• USE attachments for intended purpose only.

• MAKE SURE truck is equipped with overhead guard and

load backrest adequate for the load.

Warning

LOOK WHERE YOU ARE GOING:

• IF YOU CAN'T SEE, DON'T GO.

• TRAVEL in reverse if load blocks forward vision.

• MAKE SURE tail swing area is clear before turning.

• SOUND horn at intersections or whenever vision is

blocked.

• WATCH clearances, especially overhead.

KNOW YOUR LOADS:

• HANDLE only stable loads within specified weight and

load center. See Nameplate on this truck.

• DO NOT handle loose loads higher than load backrest.

• SPACE forks as far apart as load allows and center load

between forks. Keep load against load backrest.

7

Warning

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN CAUSE SERIOUS INJURY OR DEATH!

AUTHORIZED, TRAINED OPERATOR ONLY!

KNOW THE AREA:

• CHECK dockboard width, capacity, and security.

• NEVER enter a trailer or railroad car unless the wheels

are blocked.

• WATCH floor strength.

• FILL fuel tank or charge battery only in designated area.

• AVOID sparks or open flame.

• Provide ventilation.

• DO NOT use truck to lift people unless there is no other

practical option. Then, use only a securely attached special work platform.

• ALLOW NO ONE under or near lift mechanism or load.

• DO NOT move truck if anyone is between truck and sta-

tionary object.

• OPERATE truck only from operator's seat.

• KEEP arms, legs, and head inside operator's compart-

ment.

• TURN OFF engine when fueling.

• DO NOT start truck if fuel is leaking.

• KEEP vent caps clear when charging battery.

• DISCONNECT battery during servicing.

USE COMMON SENSE:

• NEVER transport people on any part of the truck.

8

• OBEY traffic rules. Yield right-of-way to pedestrians.

• BE in complete control at all times.

• BEFORE DISMOUNTING, neutralize travel control,

lower carriage, and set brake.

• WHEN PARKING, also shut off power, close LPG fuel

valve, block wheels on inclines.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN CAUSE SERIOUS INJURY OR DEATH!

AUTHORIZED, TRAINED OPERATOR ONLY!

PROTECT YOURSELF, FASTEN YOUR SEAT BELT!

• AVOID bumps, holes, loose materials, and slippery

areas.

• AVOID sudden movements. Operate all controls

smoothly.

Warning

WARNING

• LIFT or LOWER with mast vertical or tilted slightly back.

Use minimum tilt when stacking elevated loads.

• TRAVEL with carriage as low as possible and tilted

back.

• SLOW DOWN before turning, especially without load.

• NEVER turn on, or angle across an incline. Travel

slowly.

• TRAVEL on inclines with load uphill or unloaded with

mast downhill.

• TILT mast slowly and smoothly.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

CAUSE THE LIFT TRUCK TO TIP OVER!

DO NOT JUMP off if the truck tips! HOLD steering

wheel firmly. BRACE your feet. LEAN FORWARD and

AWAY from point of impact.

9

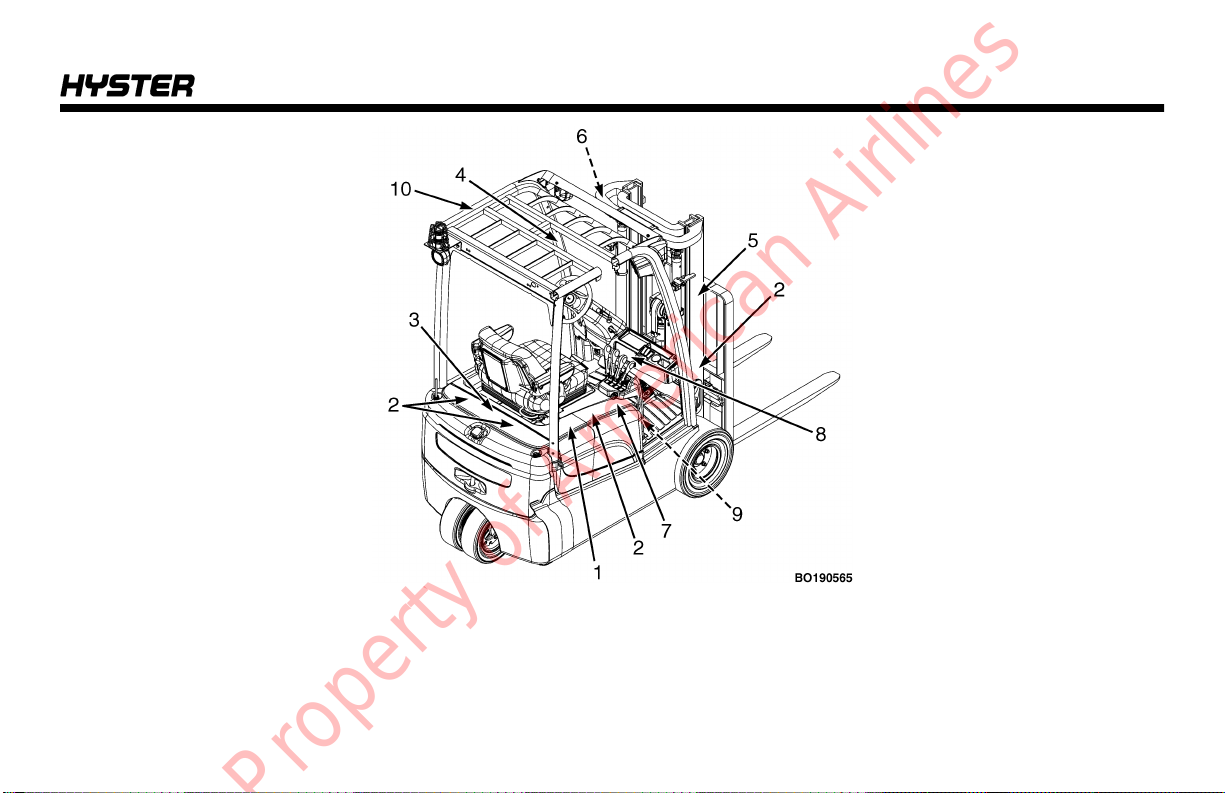

Model Description

Model Description

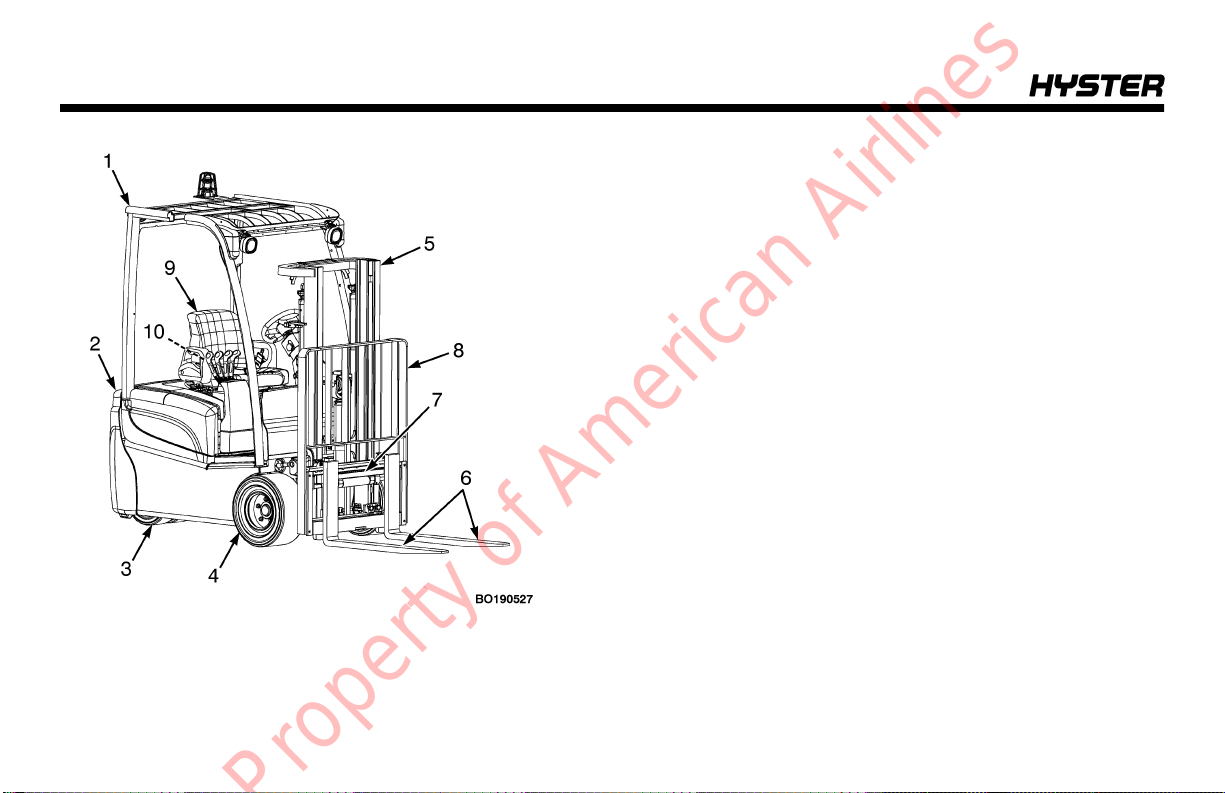

1. OVERHEAD GUARD

2. COUNTERWEIGHT

3. STEER WHEELS

4. DRIVE WHEELS

5. MAST

6. FORKS

7. CARRIAGE

8. LOAD BACKREST EXTENSION

9. OPERATOR SEAT

10. SEAT BELT AND HIP RESTRAINT

Figure 1. Major Components of the Lift Truck

10

Model Description

Model Description

General

This series of electric lift trucks is available in the following

models: (see Figure 1).

J30XNT, J35XNT, and J40XNT (K160)

The lift trucks covered in this Operating Manual are equipped with solid rubber tires that look like pneumatic tires.

See Wheels and Tires in the Maintenance Section for a

description of these tires.

The operation of the lift truck is the same for all models. A

battery supplies power for the traction motors, hydraulic

pump motor, control panel, and display panel.

The lift trucks covered in this Operating Manual are manufactured with three motors: two traction motors and a

hydraulic pump motor. See Figure 2 and Figure 3.

The motors use AC motor and control technology. The traction motors are mounted between the left and right trans-

missions on the drive axle. The hydraulic pump motor is

mounted behind the driver and in front of the counterweight. See Figure 2 and Figure 3.

In addition to dual, hydraulically-operated, wet disc service

brakes and electrically-operated disc parking brake, the lift

trucks covered in this Operating Manual are equipped with

electric braking (plugging) and an auto brake feature. When

the lift truck is traveling in one direction and the direction

control switch or MONOTROL® pedal is changed to the

opposite direction, the plugging function is energized.

Auto regenerative braking allows the user to set the distance the truck will coast when the direction control switch

is returned to the NEUTRAL position or when the MONOTROL® or accelerator pedal is released.

11

Model Description

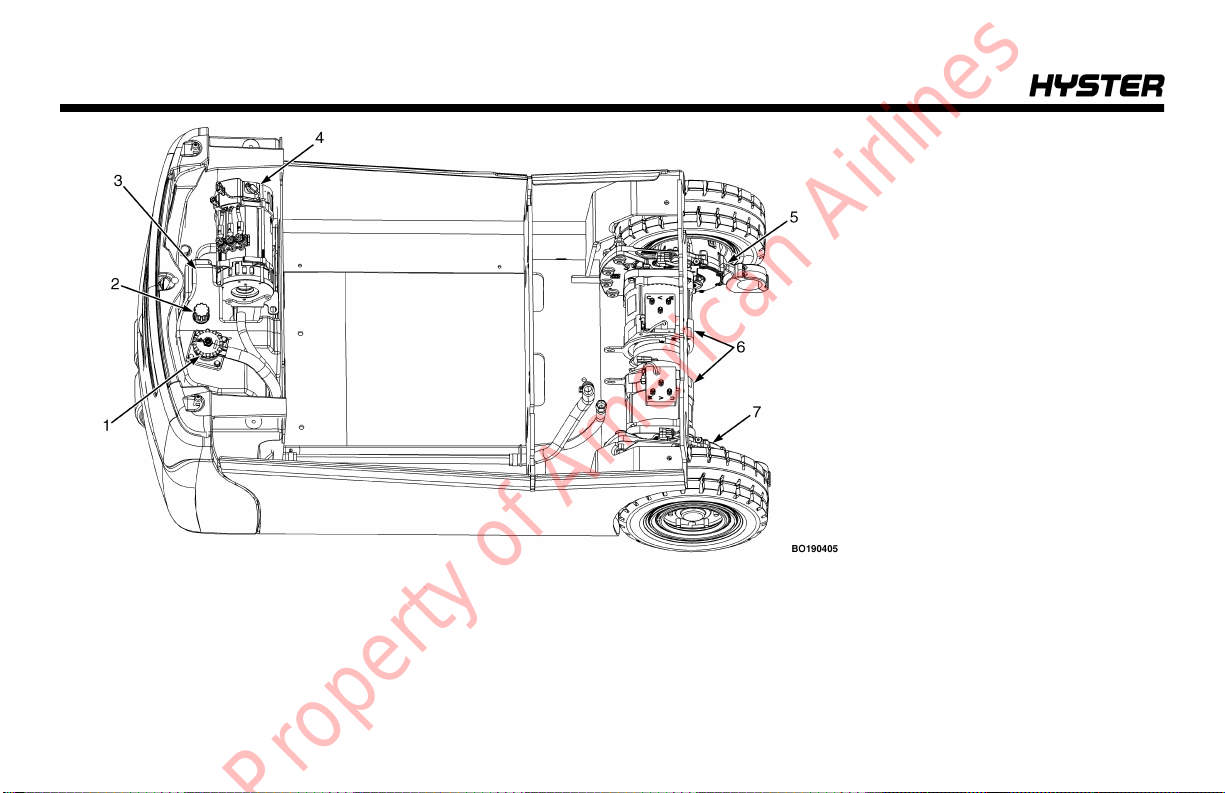

Figure 2. Motor Locations, Lift Trucks Manufactured Before November, 2014

1. HYDRAULIC FILTER

2. HYDRAULIC BREATHER CAP/

DIPSTICK

3. HYDRAULIC TANK

4. HYDRAULIC PUMP MOTOR

5. LEFT TRANSMISSION

6. TRACTION MOTORS

7. RIGHT TRANSMISSION

12

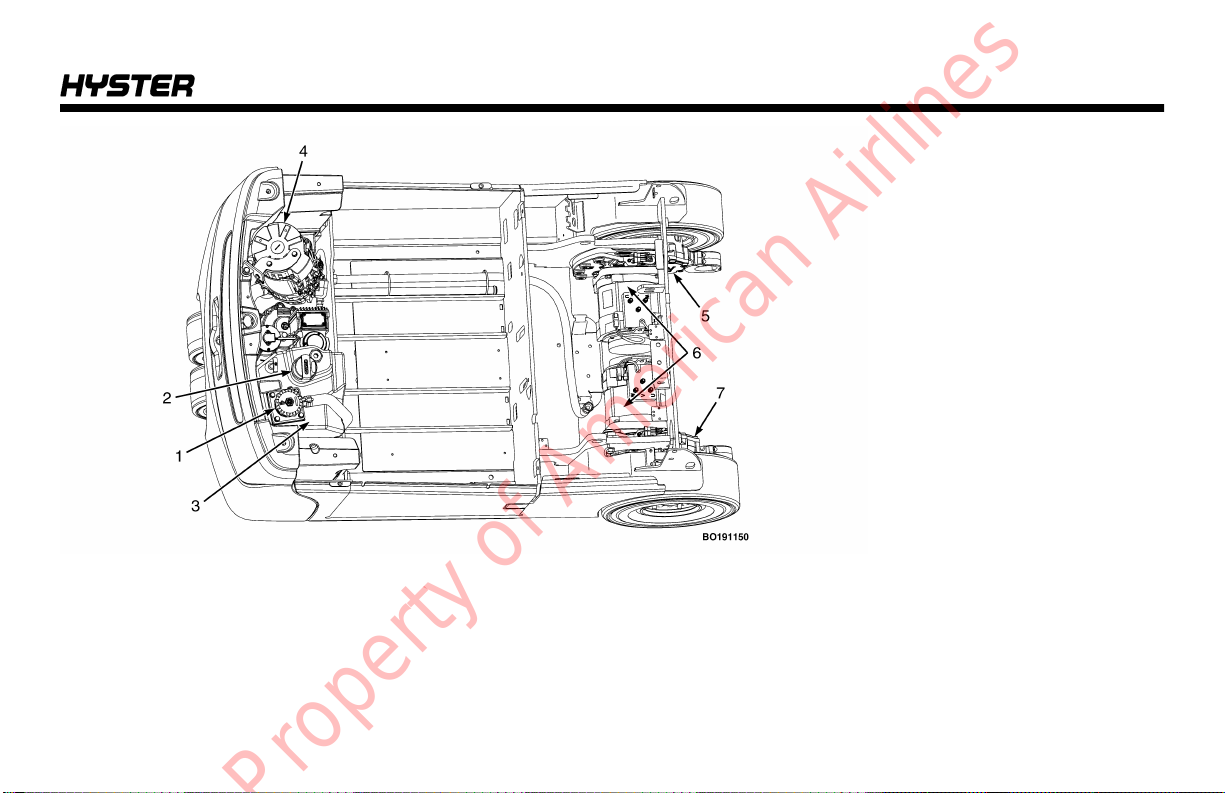

1. HYDRAULIC FILTER

2. HYDRAULIC BREATHER CAP/

DIPSTICK

3. HYDRAULIC TANK

4. HYDRAULIC PUMP MOTOR

5. LEFT TRANSMISSION

6. TRACTION MOTORS

7. RIGHT TRANSMISSION

Figure 3. Motor Locations, Lift Trucks Manufactured After November, 2014

Model Description

13

Model Description

A brake pedal actuates the hydraulic service brakes at the

drive wheels.

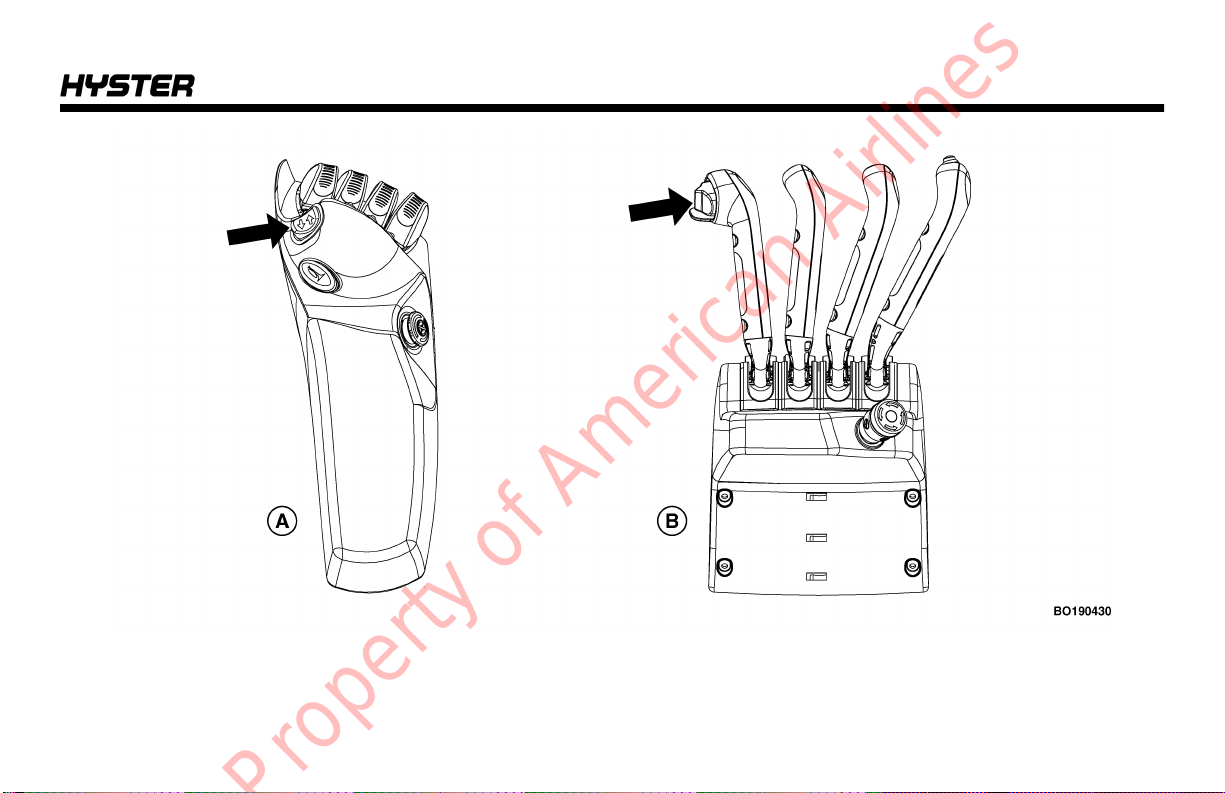

The lift trucks covered in this Operating Manual can be

equipped with either standard manual hydraulic levers, or

Electro-Hydraulic (E-Hydraulic) mini-levers.

Forward or reverse movements can be controlled by either

a MONOTROL® pedal or a direction control switch. If the

lift truck is equipped with E-Hydraulic mini-levers, the direction control switch is located on the left side of the armrest,

in front of the horn button. If the lift truck is equipped with

manual hydraulic levers, the direction control switch is located on the left side of the first lever. See Figure 4.

All lift trucks are equipped with a Battery Discharge Indicator (BDI) and an hourmeter. The bar graph type of BDI

shows the state of charge of the battery. These lift trucks

have Liquid Crystal Display (LCD) screen. The LCD screen

shows the battery bar graph and provides other service

information. Hourmeter operating time(s) are also shown

on the LCD screen.

See Display Panel Features in this section for a more

detailed description of how these display panels operate.

14

A. E-HYDRAULIC CONTROL MINI-LEVERS B. MANUAL HYDRAULIC CONTROL LEVERS

Model Description

Figure 4. Direction Control Switch

15

Model Description

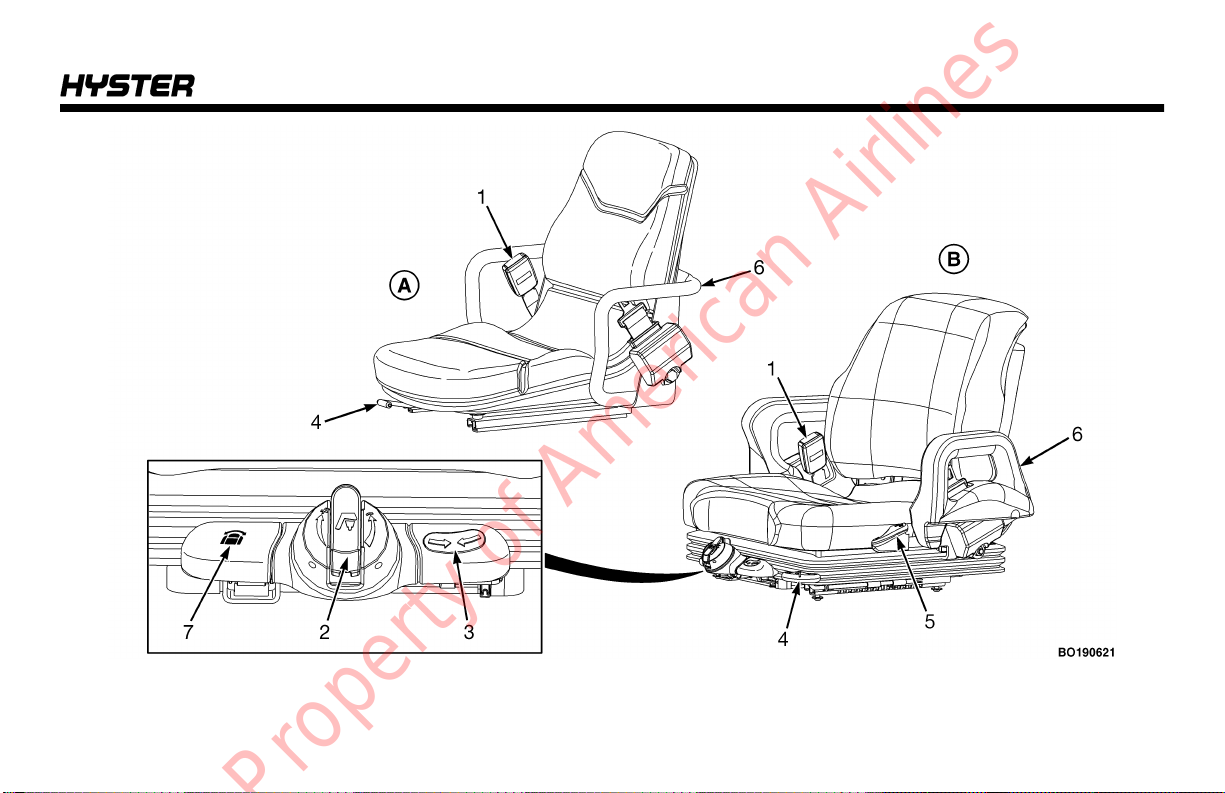

The electric lift trucks described in this manual are equipped with a standard, non-swivel seat or a full suspension

swivel seat. See Figure 5.

The full suspension swivel seat allows the operator to move

the seat to the left and to the right. The seat can be moved

5 degrees to the left and 12 degrees to the right.

The full suspension swivel seat option allows the operator

to better see where he is going when driving the lift truck in

reverse.

16

Model Description

Figure 5. Seat Components

17

Model Description

Legend for Figure 5

A. STANDARD, NON-SWIVEL SEAT B. FULL SUSPENSION SWIVEL SEAT

1. SEAT BELT

2. WEIGHT ADJUSTMENT KNOB

3. RIDE POSITION INDICATOR

4. FORWARD/BACKWARD ADJUSTMENT LEVER

5. BACKREST ANGLE ADJUSTMENT LEVER

6. HIP RESTRAINT BRACKET

7. SWIVEL LATCH RELEASE LEVER

Operator Protection Equipment

The OVERHEAD GUARD is intended to offer reasonable

protection to the operator from falling objects, but cannot

protect against every possible impact. Therefore, it must

not be considered a substitute for good judgment and care

when handling loads. Do not remove the overhead guard.

See Figure 1.

The BATTERY RESTRAINT SYSTEM is designed to hold

the battery within the battery compartment if a tipover

occurs. The battery restraint system contains a front spacer

plate, a battery plate, front and rear bulkheads, and the left

and right frame plates. The lift truck can be equipped with

optional side rollers or fork pockets on the battery plate to

help in removing the battery from the truck.

The hood and hood latch mechanism also help keep the

battery within the battery compartment if a tipover occurs.

18

The hood can be raised for access to the battery. A gas

spring helps raise and hold the hood in the up position.

The battery restraint system must function so that the operator restraint system can operate correctly. Operation of

the battery restraint system requires that the maximum

movement allowed for the battery is 13 mm (0.5 in.) in any

horizontal direction. This will reduce the risk of operator

injury in a truck tipover. An adjustable front battery spacer

plate prevents the front-to-back movement of the battery.

Batteries for this series of lift trucks must all have the same

length dimension to just fit the battery compartment width.

For correct battery sizes, see the Battery Specifications in

the back of this manual.

NOTE: The seat belt can be either black or red.

This lift truck is equipped with one of the three seat belt

configurations.

Model Description

• Seat belt with no operation interlock.

• Seat belt with operation interlock. Seat belt must be fas-

tened for lift truck to start or to travel.

• Seat belt with sequencing interlock. Operator must be in

the seat, then the seat belt fastened before lift truck will

operate. This seat belt is used with the Optional Operator Presence System.

The SEAT BELT and HIP RESTRAINTS provide additional

means to help the operator keep the head and torso substantially within the confines of the truck frame and operator compartment if a tipover occurs. This restraint system is

intended to reduce the risk of the head and torso being

trapped between the lift truck and the ground, but it cannot

protect the operator against all possible injury in a tipover.

The hip restraint will help the operator resist side movement if the seat belt is not fastened. It is not a substitute for

the seat belt. Always fasten the seat belt.

This lift truck may be equipped with an optional operator

presence system which will not allow the truck to travel

unless the seat belt is fastened. When equipped, a seat

belt interlock includes sequencing/logic for the seat pressure switch and seat belt switch. The weight of the operator

must be detected prior to the seat belt switch being

engaged to enable operations.

The LOAD BACKREST EXTENSION is installed to keep

loose parts of the load from falling back toward the operator. It must be high enough, with openings small enough to

prevent the parts of the load from falling backward. If a load

backrest extension that is different from the one installed

on your truck is required, contact your dealer for Hyster lift

trucks.

Nameplate

WARNING

Any change to the lift truck, the tires, or its equipment

can change the lifting capacity. If the Nameplate does

not show the maximum capacity, or if the lift truck

equipment, including the battery for electric trucks,

does not match that shown on the Nameplate, the lift

truck must not be operated.

The capacity is the maximum load that the lift truck can

handle for the load condition shown on the Nameplate. The

capacity is specified in kilograms (kg) and pounds (lb).

19

Model Description

The maximum capacity for the lift truck, at full load height,

must be shown on the Nameplate. Special capacities with

the load height reduced or with optional load centers, may

also be shown on the Nameplate.

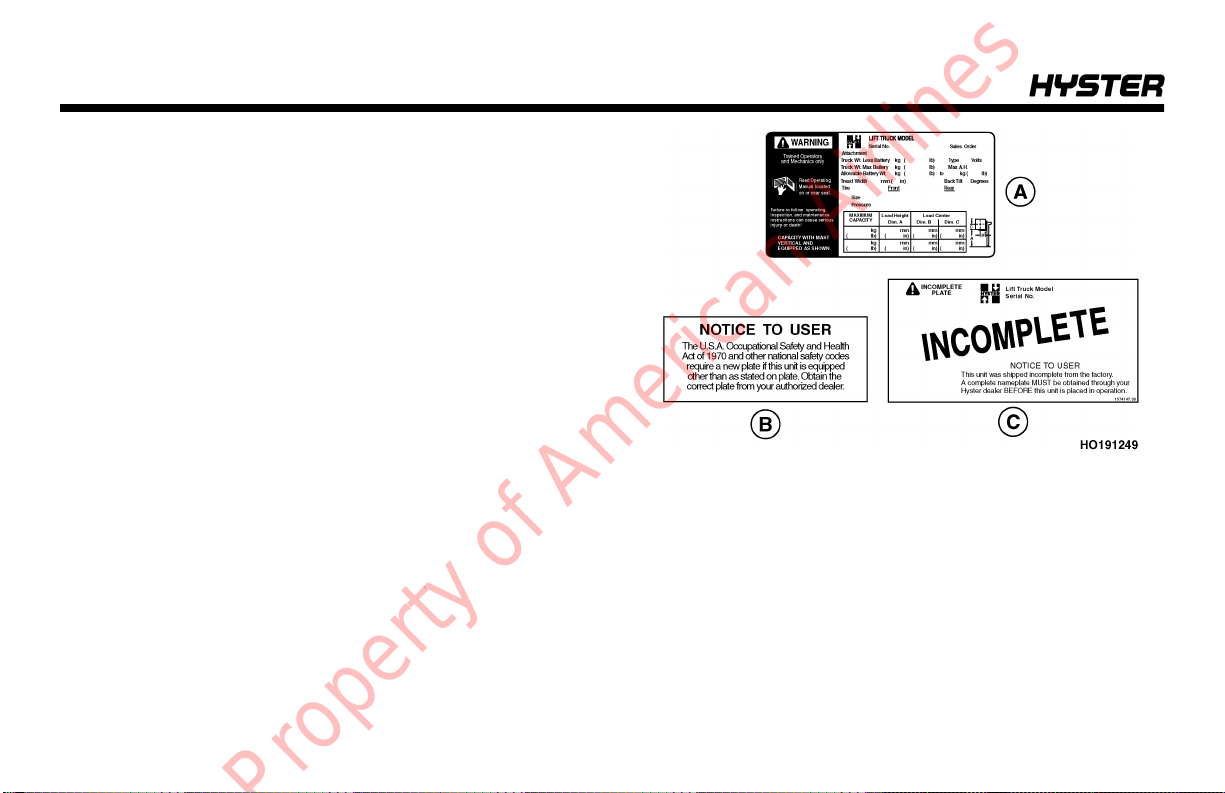

NOTE: The image in Figure 6 is a sample only. Reference

the actual nameplate installed on the truck for actual truck

specifications.

The lift truck serial number code is on the Nameplate. The

serial number code is also stamped on the left side of the

front face of the cowl.

When a lift truck is shipped incomplete from the factory, the

Nameplate is covered by the labels shown in Figure 6. If

your lift truck has this type of label, do not operate the lift

truck. Contact your dealer for Hyster lift trucks to obtain a

complete Nameplate.

A. NAMEPLATE

B. NOTICE LABEL

C. INCOMPLETE LABEL

Figure 6. Nameplate and Label

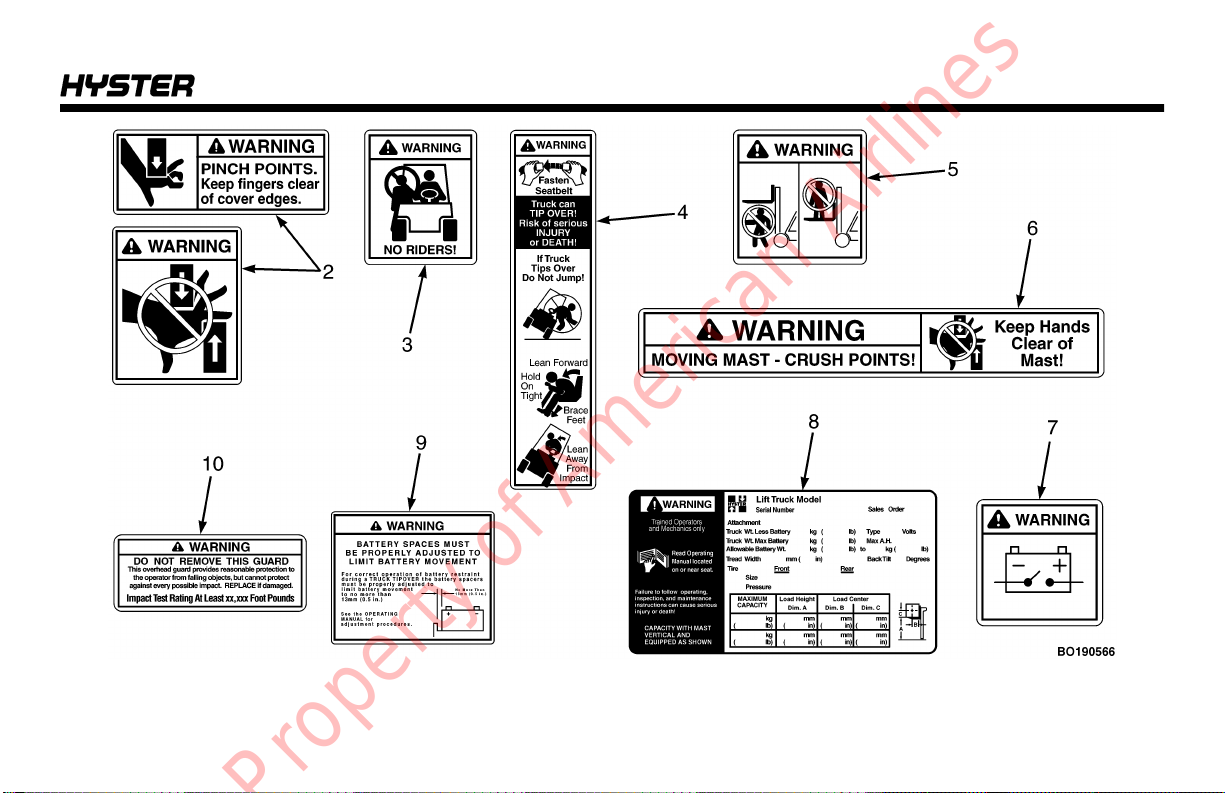

Safety Labels

Safety labels are installed on the lift truck to provide information about possible hazards. It is important that all safety

labels are installed on the lift truck and can be read. See

Figure 7. See the Parts Manual for a list of all the labels

installed on the lift truck and for the location of the labels.

20

Figure 7. Warning Labels (Sheet 1 of 3)

Model Description

21

Model Description

22

Figure 7. Warning Labels (Sheet 2 of 3)

Model Description

Figure 7. Warning Labels (Sheet 3 of 3)

23

Model Description

1. OPERATOR WARNING

2. PINCH POINTS

3. NO RIDERS

4. TIPOVER WARNING UNITS WITH SEAT BELTS

5. MAST WARNING

Legend for Figure 7

6. MAST WARNING

7. BATTERY DISCONNECT

8. NAMEPLATE

9. BATTERY SPACER

10. OVERHEAD GUARD IMPACT RATING

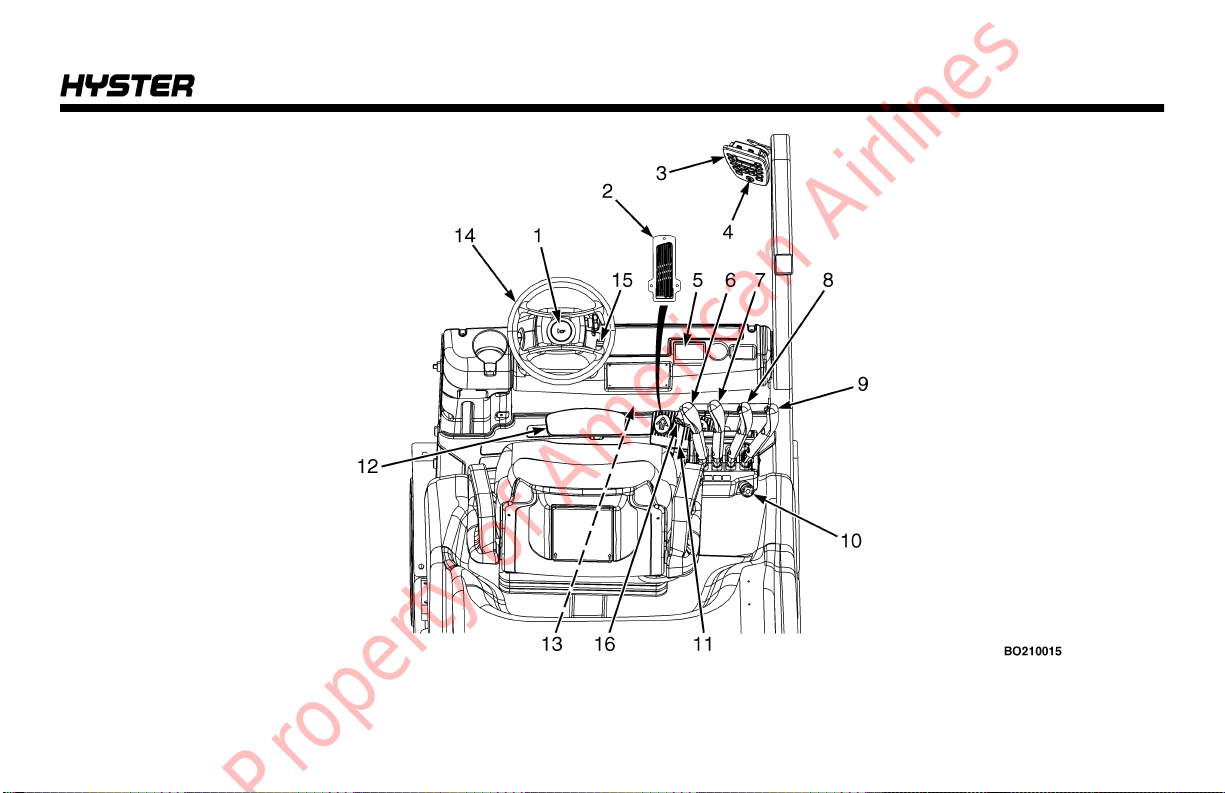

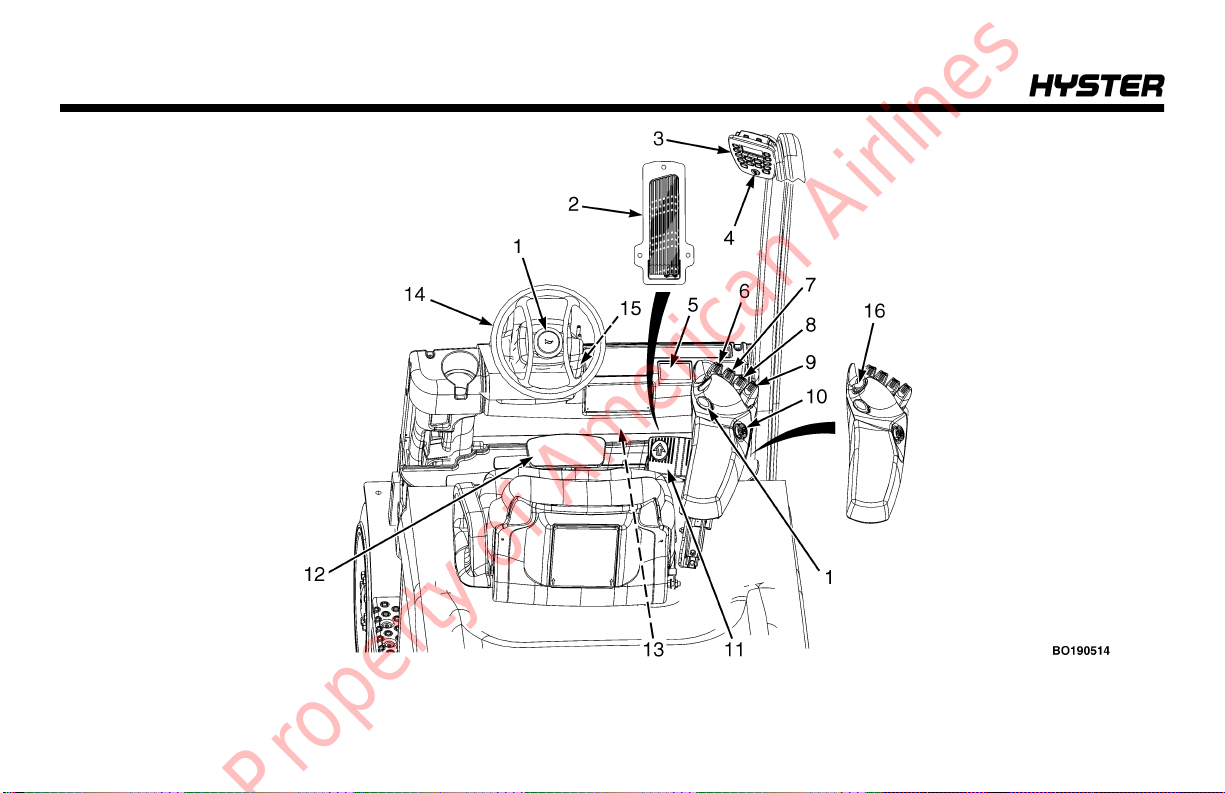

Operator Controls

(See Figure 8, Figure 9, and Table 1)

WARNING

If any of the levers or pedals do not operate as described in the following tables, report the problem immedi-

24

ately. Injury to personnel can occur if the levers or

pedals do not operate as described in the following

table. DO NOT operate the lift truck until the problem is

corrected.

Model Description

Figure 8. Operator Controls - Manual Hydraulic Controls

25

Model Description

26

Figure 9. Operator Controls - Electro-Hydraulic Controls

Model Description

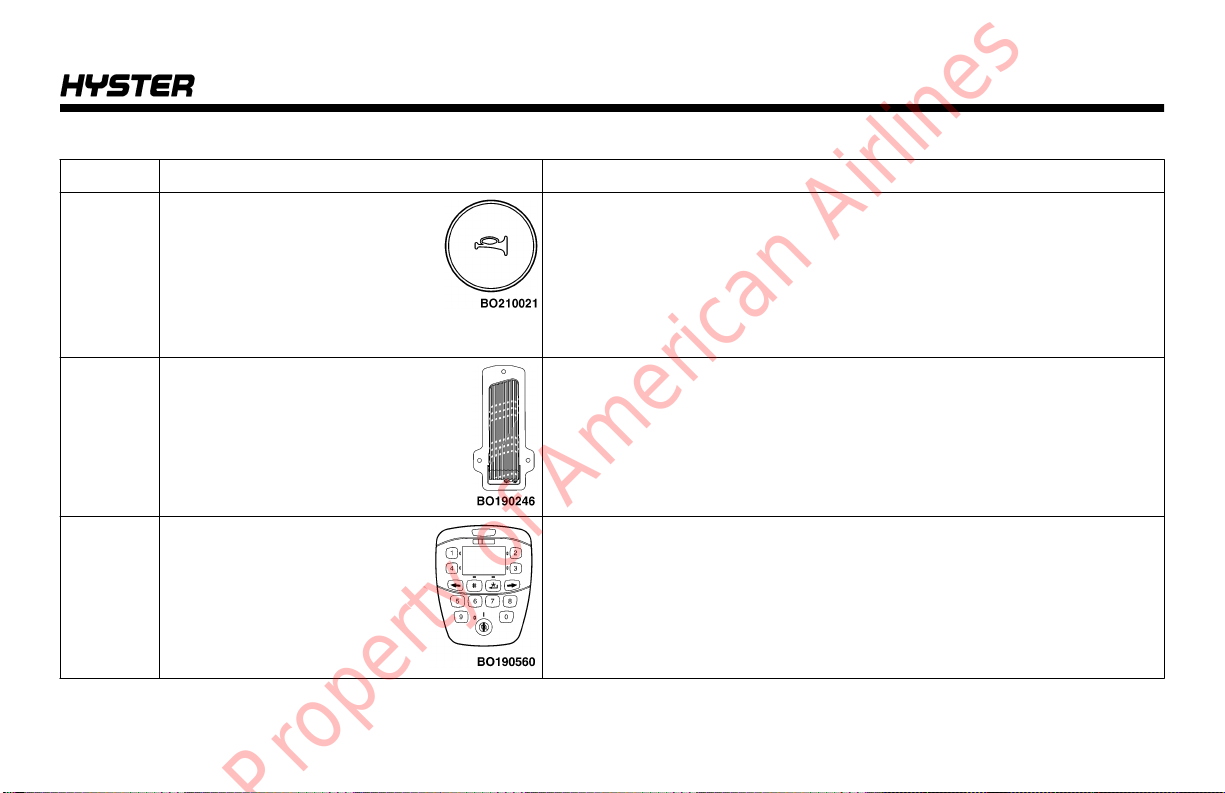

Table 1. Operator Controls (See Figure 8 and Figure 9)

Item No. Item Function

1 Horn Button Push the horn button to warn pedestrians and others when

approaching intersections and other blind areas.

If lift truck is equipped with E-Hydraulic controls, there is another

horn button located on the armrest. There may also be a handle on

the rear right side overhead guard leg that has a horn button on it.

See the end of Table 1 for more information.

2 Accelerator Pedal The accelerator pedal is used with the direction control switch descri-

bed in this table and when the lift truck is not equipped with a MONOTROL® pedal. Push down on the accelerator pedal to increase the

speed of the lift truck

3 Display Panel See Display Panel Features in this section, and Figure 10, Fig-

ure 11, Table 2, and Table 3 for a detailed description.

27

Model Description

Table 1. Operator Controls (See Figure 8 and Figure 9) (Continued)

Item No. Item Function

4 Key Switch and

Keyless Switch

WARNING

The ignition switch is a reed switch which uses an applied magnetic field. If a strong magnet is placed near the ignition switch,

it may not function properly (such as not shutting off power). To

ensure ignition switch functions properly, DO NOT place a magnet near the ignition switch.

The lift trucks covered in this Operating Manual can be equipped

with either a key switch or keyless switch. Both options will have two

positions:

No. 1 Position: OFF position. De-energizes all electric circuits except

for the horn.

No. 2 Position: ON position. Energizes all electric circuits. The key or

keyless switch will be in this position during normal operation.

28

Loading...

Loading...