Hyster Fortis S40FT, Fortis S50FT, Fortis S55FTS, Fortis S70FT, Fortis H40FT Operating Manual

...

OPERATING MANUAL

FORTIS®

S40FT, S50FT, S55FTS, S60FT, S70FT (F187)

H40FT, H50FT, H60FT, H70FT (L177)

Property of American Airlines

DO NOT REMOVE THIS MANUAL FROM THIS UNIT

PART NO. 1580499 10/16

Spacer

LIFT TRUCK MODEL

ENGINE MODEL

TRANSMISSION TYPE

MAST LIFT HEIGHT

CARRIAGE TYPE

DRIVE TIRE SIZE

SERIAL NUMBER

SERIAL NUMBER

SERIAL NUMBER

GROUP NUMBER

GROUP NUMBER

STEERING TIRE SIZE

SPECIAL EQUIPMENT OR ATTACHMENTS

© Hyster Company 2016. All rights reserved.

HYSTER, , FORTENS, and MONOTROL are Registered Trademarks of Hyster-Yale Group, Inc. DURAMATCH, UNISOURCE, and are Trademarks

in the United States and certain other jurisdictions.

Foreword

Foreword

To OWNERS, USERS, and OPERATORS:

The safe and efficient operation of a lift truck requires

skill and alertness on the part of the operator. To develop

the skill required the operator must:

• Receive training in the proper operation of THIS lift truck.

• Understand any potential hazards that may exist in the

work place where the lift truck is intended to be used.

• Understand the capabilities and limitations of the lift

truck.

• Become familiar with the construction of the lift truck and

see that it is maintained in good condition.

• Read and properly understand the warnings, instruc-

tions, and operating procedures in this manual.

In addition, a qualified person, experienced in lift truck

operation, must guide a new operator through several driving and load handling operations before the new operator

attempts to operate the lift truck alone.

©HYSTER COMPANY 2016 1580499 - ENGLISH-US 1

It is the responsibility of the employer to make sure that the

operator can see, hear, and has the physical and mental

ability to operate the equipment safely.

Various laws and regulations require the employer to train

lift truck operators. These laws and regulations include:

• Occupational Safety and Health Act (USA)

• Canada Material Handling Regulations

NOTE: A comprehensive operator training program is avail-

able from Hyster Company. For further details, contact

your dealer for Hyster lift trucks.

This Operating Manual is the original instruction and contains information necessary for the operation and maintenance of a basic lift truck. Optional equipment is sometimes

installed that can change some operating characteristics

described in this manual. Make sure the necessary instructions are available and understood before operating the lift

truck.

Foreword

Some of the components and systems described in this

Operating Manual will NOT be installed on your unit. If you

have a question about any item described, contact your

dealer for Hyster lift trucks.

Additional information that describes safe operation and

use of lift trucks is available from the following sources:

• Employment safety and health standards or regulations

(Examples: "Occupational Safety and Health Standards

(USA)", "Canada Material Handling Regulations".

• Safety codes and standards (Example: Industrial Truck

Standards Development Foundation, ANSI/ITSDF

B56.1, Safety Standard for Low Lift and High Lift

Trucks).

• Publications from government safety agencies, govern-

ment insurers, private insurers and private organizations

(Example: Accident Prevention Manual for Industrial

Operations, from the National Safety Council).

• Guide for Users of Industrial Lift Trucks (Hyster Part No.

852930) describes lift truck safety, good maintenance

practices, and training programs and is available from

your dealer for Hyster lift trucks.

• Lift Truck/Pedestrian Accidents, Causes and Prevention.

Hyster Company (LIFTPED/B 12/2003).

NOTE: Hyster lift trucks are not intended for use on public

roads.

NOTE: The following symbols and words indicate safety

information in this manual:

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury and property

damage.

On the lift truck, the WARNING symbol and word are on

orange background. The CAUTION symbol and word

are on yellow background.

2

Contents

Foreword ...................................................................... 1

TO OWNERS, USERS, AND OPERATORS: ............. 1

Warning ........................................................................ 7

Model Description ....................................................... 10

GENERAL ................................................................... 11

OPERATOR PROTECTION EQUIPMENT ................. 14

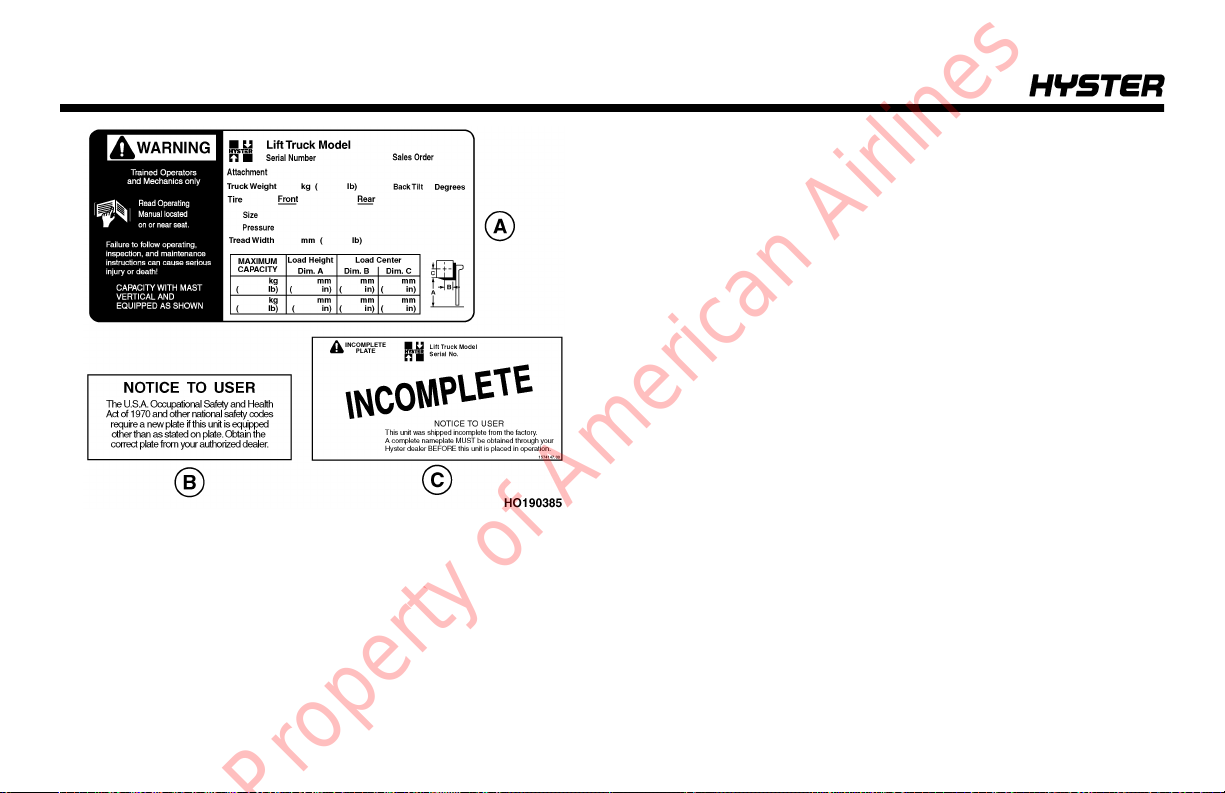

NAMEPLATE .............................................................. 15

SAFETY LABELS ....................................................... 16

DISPLAY SWITCH CLUSTER .................................... 21

Display Switch Cluster – Right-Side Display Inputs .. 21

Display Switch Cluster – LCD Screen and Warning

and Indicator Lights .............................................. 28

OPERATOR CONTROLS ........................................... 37

OPERATOR CONTROLS – JOYSTICK FEATURES . 57

Operating Procedures ................................................ 63

GENERAL ................................................................... 63

Know Your Lift Truck ................................................ 63

Stability and Center of Gravity .................................. 65

Capacity (Weight and Load Center) ......................... 66

Impact Sensor ........................................................... 67

INSPECTION BEFORE OPERATION ........................ 68

Checks With the Engine Stopped ............................. 68

Mounting and Dismounting ....................................... 69

Contents

Operator Passwords ................................................. 69

Starting Procedures .................................................. 71

Starting Procedures, Trucks With Key Switch .......... 71

Starting Procedures, Trucks With Keyless Start

Option ................................................................... 73

Checks With the Engine Running ............................. 74

Load Weighing Sensor ............................................. 75

Set Load Weight to Zero ........................................... 76

Engine Shutdown ...................................................... 76

OPERATING TECHNIQUES ...................................... 77

Basic Operating Procedures ..................................... 78

Driving and Direction Changes ................................. 83

General ................................................................... 85

Normal Operations .................................................. 85

Standard Operator Presence System ..................... 86

Optional Operator Presence System ...................... 87

Basic Powershift and Powershift 1 Speed

Transmissions .................................................. 87

DuraMatch .............................................................. 88

Inching ...................................................................... 90

Steering (Turning) ..................................................... 91

Load Handling, General ............................................ 92

Load Handling, Lifting, Lowering, and Tilting ............ 93

3

Contents

Load Handling, How to Engage and Disengage a

Load ...................................................................... 96

Load Handling, Traveling .......................................... 99

Load Handling, Emergency Load Lowering .............. 103

HIGHWAY TRUCKS, RAIL CARS, AND DOCKS ....... 105

ATTACHMENTS ......................................................... 106

Disconnecting Attachment Hydraulic Quick-

Disconnect Hoses ................................................. 107

Connecting Attachment Hydraulic Quick-Disconnect

Hoses .................................................................... 108

STOPPING ................................................................. 108

PARKING .................................................................... 109

Maintenance ................................................................ 110

GENERAL ................................................................... 110

Serial Number Data .................................................. 111

HOW TO MOVE A DISABLED LIFT TRUCK .............. 111

How to Tow the Lift Truck ......................................... 111

HOW TO PUT A LIFT TRUCK ON BLOCKS .............. 112

How to Raise the Drive Tires .................................... 112

How to Raise the Steering Tires ............................... 113

HOW TO CLEAN A LIFT TRUCK ............................... 113

Maintenance Schedule ............................................... 114

Maintenance Procedures Every 8 Hours or Daily .... 150

HOW TO MAKE CHECKS WITH THE ENGINE

STOPPED ................................................................. 150

Tires and Wheels ...................................................... 150

Safety Labels ............................................................ 152

Mast, Carriage, Header Hoses, Lift Chains, and

Attachment ............................................................ 152

Operator Restraint System ....................................... 154

Automatic Locking Retractor (ALR) ........................ 157

Emergency Locking Retractor (ELR) ...................... 158

Hood and Seat Latches ............................................ 158

Engine Compartment ................................................ 160

Paper Application ...................................................... 160

Fuel, Oil, and Coolant Leaks, Check ........................ 162

Hydraulic Hoses ........................................................ 162

Coolant Hoses .......................................................... 162

Steering Column Gas Cylinder ................................. 163

Transmission ............................................................ 163

Hydraulic System Oil ................................................ 164

Engine Oil ................................................................. 164

Air Filter .................................................................... 169

Forks ......................................................................... 169

Forks, Remove ......................................................... 169

Forks, Inspect ........................................................... 172

Forks, Install ............................................................. 172

Forks, Adjust ............................................................. 173

HOW TO MAKE CHECKS WITH THE ENGINE

RUNNING ................................................................. 175

4

Contents

Indicator Lights, Horn, Fuses, and Relays ................ 175

Service Brakes .......................................................... 177

Brake Fluid Level .................................................... 177

Operation, Check .................................................... 177

Parking Brake ........................................................... 178

Engine Oil Pressure .................................................. 179

Cooling System ......................................................... 179

Steering System ....................................................... 181

Control Levers and Pedals ....................................... 181

Lift System Operation ............................................... 181

HOW TO ADD FUEL TO THE LIFT TRUCK .............. 182

Liquefied Petroleum Gas (LPG) ................................ 183

LPG Tank, Remove ................................................ 184

LPG Tank, Fill ......................................................... 186

LPG Tank, Install .................................................... 187

Gasoline or Diesel Fuel ............................................ 188

WHEELS AND TIRES ................................................. 188

General ..................................................................... 188

How to Change a Solid Rubber Tire (S Series) ........ 188

Remove and Install the Tire on the Wheel ................ 189

PNEUMATIC TIRE WITH TUBE, REPAIR ................. 191

Remove Wheels From Lift Truck .............................. 191

Remove Tire From Wheel ......................................... 191

Tire Removal, Two-Piece Wheel ............................ 193

Tire Removal, Three- and Four-Piece Wheels ....... 194

Install Wheel in Tire .................................................. 195

Tire Installation, Three- or Four-Piece Wheel ......... 196

Tire Installation, Two-Piece Wheel ......................... 197

Add Air to Pneumatic Tires With Tube ...................... 198

Install the Wheels ..................................................... 199

PNEUMATIC TUBELESS TIRE, REPAIR .................. 199

Remove Tire From Lift Truck .................................... 199

Remove Tire From Wheel ......................................... 200

Install Tire on Wheel ................................................. 202

Add Air to Pneumatic Tubeless Tire ......................... 205

Install the Wheels ..................................................... 206

SOLID RUBBER TIRES ON PNEUMATIC WHEELS,

CHANGE .................................................................. 206

Remove Tire From Wheel ......................................... 206

Install Tire on Wheel ................................................. 208

DUAL DRIVE WHEELS, INSTALL ............................. 210

JUMP-STARTING THE LIFT TRUCK ......................... 211

Jump-Starting Using a Battery Charger .................... 211

Jump-Starting Using Another Lift Truck .................... 211

JUMP-STARTING THE LIFT TRUCK ......................... 212

Jump-Starting Using a Battery Charger .................... 212

Jump-Starting Using Another Lift Truck .................... 212

OPERATING PROCEDURES FOR A NEW OR

REBUILT ENGINE .................................................... 213

CHANGES TO THE OVERHEAD GUARD ................. 213

5

Contents

HOW TO PUT INTERNAL COMBUSTION ENGINE

(ICE) TRUCKS IN STORAGE .................................. 213

Short-Term Storage .................................................. 214

Long-Term Storage ................................................... 215

While the Lift Truck is in Storage .............................. 215

How to Put Batteries in Storage ................................ 215

Putting a Stored Lift Truck Back Into Service ........... 216

HOW TO MOVE A LIFT TRUCK ON A

TRANSPORT ............................................................ 217

Loading ..................................................................... 218

Unloading .................................................................. 219

PREPARATION FOR USE ......................................... 219

Preparation After Transport ...................................... 219

6

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN CAUSE SERIOUS INJURY OR DEATH!

AUTHORIZED, TRAINED OPERATOR ONLY!

KNOW THE EQUIPMENT:

• ALWAYS use 3 points of contact when getting on and off

the truck.

Warning

• VERIFY truck is equipped with overhead guard and load

backrest adequate for the load.

LOOK WHERE YOU ARE GOING:

• KNOW operating, inspection, and maintenance instruc-

tions in Operating Manual.

• DO NOT operate or repair truck unless trained and

authorized.

• INSPECT truck before use.

• DO NOT operate if truck needs repair. Tag truck and

remove key. Repair truck before use. Always use Hyster

Approved parts when making repairs. Replacement

parts must meet or exceed the specifications of the original equipment manufacturer.

• USE auxiliary equipment (attachments) for intended purpose only.

• IF YOU CAN'T SEE, DON'T GO.

• TRAVEL in reverse if load blocks forward vision.

• MAKE SURE tail swing area is clear.

• SOUND horn at intersections or where vision is blocked.

• WATCH clearances, especially overhead.

KNOW YOUR LOADS:

• HANDLE only stable loads within specified weight and

load center. See Nameplate on truck.

• DO NOT handle loose loads higher than load backrest.

• SPACE forks as far apart as load allows and center load

between forks. Keep load against load backrest.

7

Warning

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN CAUSE SERIOUS INJURY OR DEATH!

AUTHORIZED, TRAINED OPERATOR ONLY!

USE COMMON SENSE:

• DO NOT use truck to lift people unless there is no other

practical option. Then, use only a securely attached special work platform. Follow instructions in this Operating

Manual.

• OBEY traffic rules. Yield right-of-way to pedestrians.

• BE in complete control at all times.

• ALLOW NO ONE under or near lift mechanism or load.

• OPERATE truck only from operator's seat.

• KEEP arms, legs, and head inside operator's compart-

ment.

• DO NOT move truck if anyone is between truck and stationary object.

• WHEN PARKING, also shut off power, close LPG fuel

valve, block wheels on inclines.

KNOW THE AREA:

• NEVER enter a trailer or railroad car unless its wheels

are blocked.

• CONFIRM floor strength.

• FILL fuel tank or charge battery only in designated area.

• TURN OFF engine when fueling.

• AVOID sparks or open flame. Provide ventilation.

• DO NOT start if fuel is leaking.

• KEEP vent caps clear when charging battery.

• DISCONNECT battery during servicing.

• BEFORE DISMOUNTING, neutralize travel control,

lower carriage, and set brake.

8

• CHECK dockboard width, capacity, and security.

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN CAUSE SERIOUS INJURY OR DEATH!

AUTHORIZED, TRAINED OPERATOR ONLY!

PROTECT YOURSELF FASTEN YOUR SEAT BELT!

• AVOID bumps, holes, and loose materials.

• AVOID sudden starts or stops.

• NEVER turn on or angle across an incline.

• TRAVEL on inclines with load uphill or when unloaded

with lift mechanism downhill.

• TILT mast slowly and smoothly. LIFT or LOWER with

upright vertical or tilted slightly back. Use minimum tilt

when stacking elevated loads.

Warning

• TRAVEL with carriage as low as possible and tilted

back.

• SLOW DOWN before turning, especially without load.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

CAUSE THE LIFT TRUCK TO TIP.

DO NOT JUMP off if the truck tips over. HOLD steering

wheel firmly. BRACE your feet. LEAN FORWARD and

AWAY from point of impact.

9

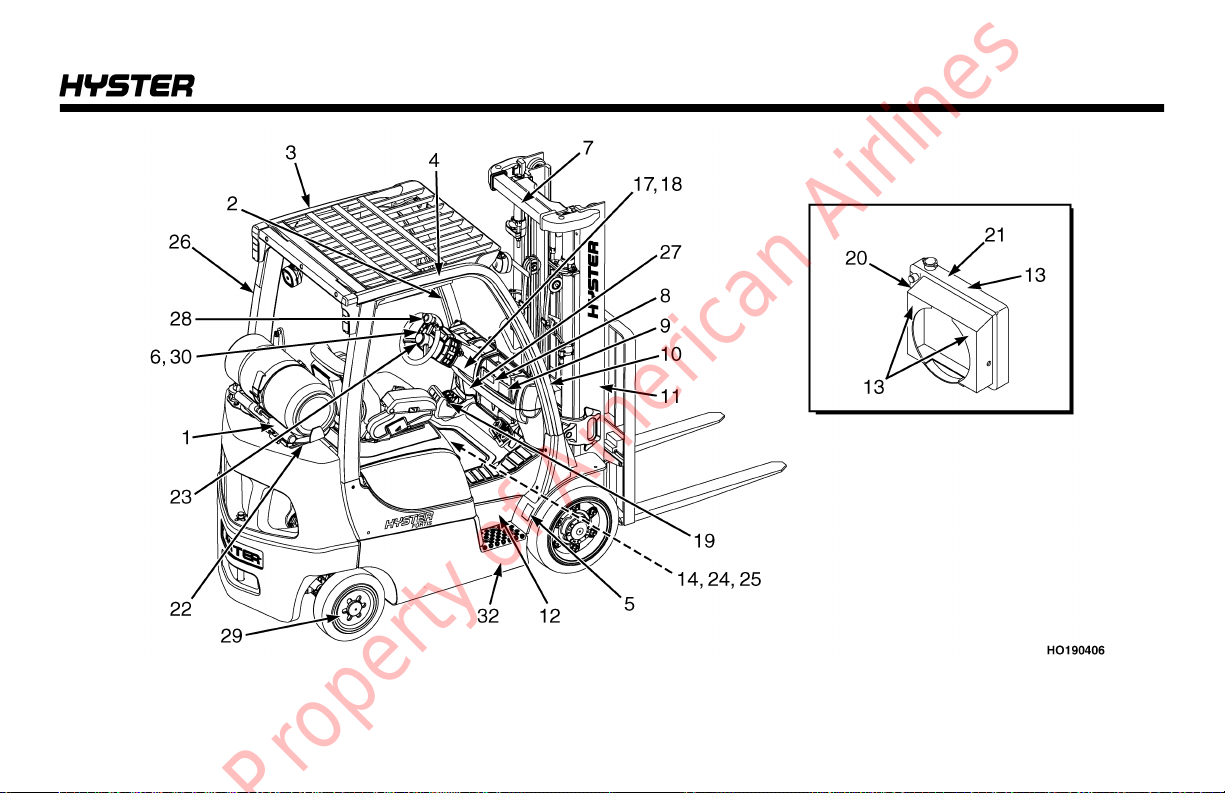

Model Description

Model Description

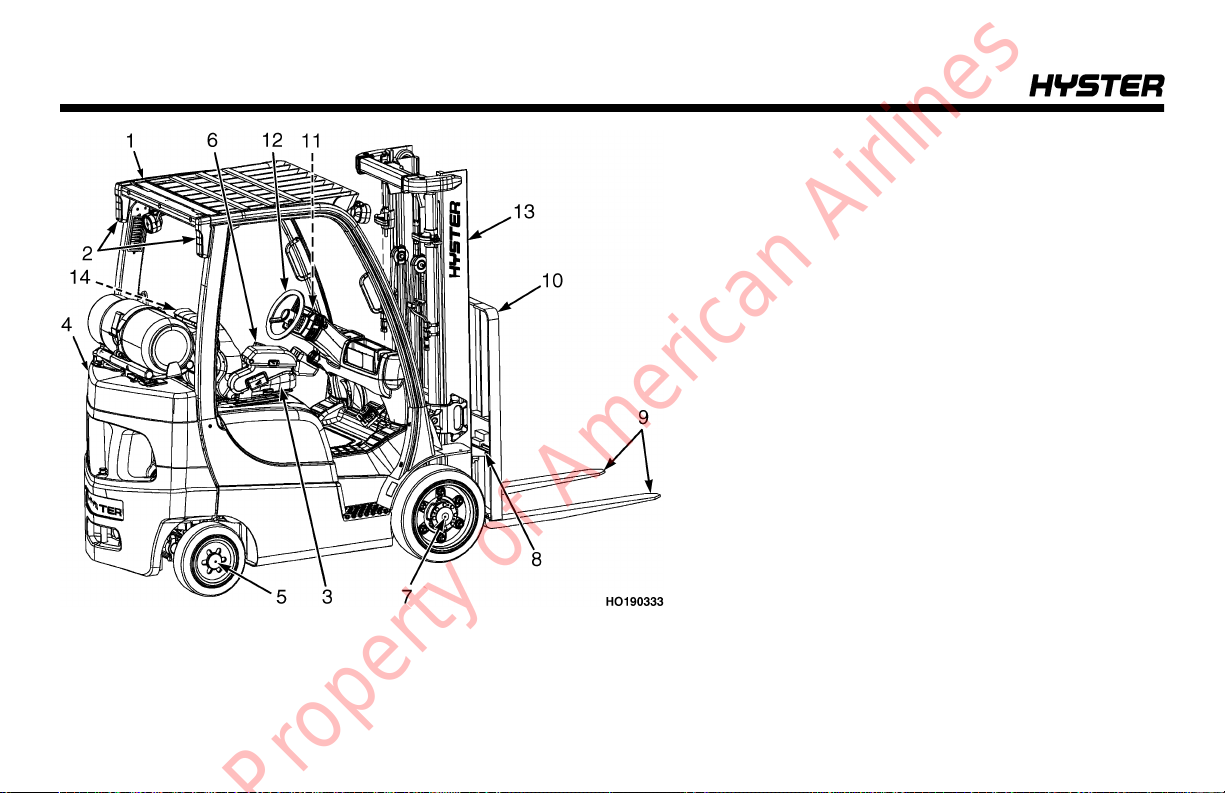

Figure 1. Model View Showing Major Components of S40-70FT, S55FTS Series

COMPONENTS FOR H40-70FT TRUCKS ARE IN SAME

LOCATIONS.

1. OVERHEAD GUARD

2. TAIL, BRAKE, AND REVERSE LIGHTS

3. SEAT

4. COUNTERWEIGHT

5. STEERING AXLE

6. SEAT BELT AND HIP RESTRAINT

7. DRIVE AXLE

8. CARRIAGE

9. FORKS

10. LOAD BACKREST EXTENSION

11. PARKING BRAKE

12. STEERING WHEEL

13. MAST

14. OPERATING MANUAL (BEHIND SEAT)

10

Model Description

Model Description

General

This Operating Manual is for the following models of lift

trucks:

S40FT, S50FT, S55FTS, S60FT, and S70FT (F187)

H40FT, H50FT, H60FT, and H70FT (L177)

These lift trucks are available with the following engines:

• Mazda 2.0L engine which uses gasoline or LPG fuel

• Mazda 2.2L engine which uses gasoline or LPG fuel

• GM 2.4L engine which uses gasoline or LPG fuel

• Yanmar 2.6L engine which uses diesel fuel

• Yanmar 3.3L engine which uses diesel fuel

Prior to January, 2011, these lift truck models can be

equipped with a Basic Powershift (iron case), Powershift 1

Speed (aluminum case gear drive) or DuraMatch transmission (see Table 1). After January 2011, these truck models

will be equipped with a Powershift 1 Speed (aluminum case

chain drive) or DuraMatch transmission (see Table 1) and

can be equipped with three types of controls:

• A MONOTROL® pedal that controls both the forward

and reverse operation of the powershift transmission and

the speed of the engine.

• A Direction Control Lever on the left side of the Display

Switch Cluster that controls the forward, neutral, and

reverse operation of the powershift transmission. A separate accelerator pedal controls the engine speed.

• A directional control switch integrated into the armrest on

units equipped with E-hydraulics controls both forward

and reverse operation of the transmission. A separate

accelerator pedal controls engine speed.

The S40-70FT lift trucks are equipped with solid rubber

tires. The H40-70FT lift trucks are equipped with pneumatic

tires or solid pneumatic-shaped tires. See Wheels and

Tires in the Maintenance Section for a description of

these tires.

If your lift truck is an S40-70FT, S55FTS (F187) with manual hydraulics and manufactured prior to March, 2009, it is

not equipped an emergency lowering valve. If manufactured after March, 2009, it is equipped with an emergency

lowering valve.

11

Model Description

If your lift truck is an H40-70FT (L177) with manual hydraulics and manufactured prior to March, 2009, is it not equipped with an emergency lowering valve. If manufactured

after March, 2009, it is equipped with an emergency lowering valve.

If your lift truck is equipped with electronic hydraulics, it has

an emergency lowering valve.

This emergency lowering valve (see Figure 15) allows the

operator or service technician to lower the lift truck's mast

assembly if the electrical signal to the main control valve is

disrupted. See the section Load Handling, Emergency

Load Lowering in the Operating Procedures section.

12

Table 1. Transmissions

Model Description

Operational

Feature

Electronic Inching Yes Yes

Electronic Control of

Direction Changes

Auto Deceleration – Yes

Controlled Power Reversal – Yes

Roll Reduction Feature – Yes

Roll Back Feature – Yes

Reduced Drive Tire Slippage – Yes

Powershift 1 Speed Transmission

Basic Powershift or

Yes Yes

DuraMatch Transmission

13

Model Description

1. BASIC POWERSHIFT TRANSMISSION

2. DURAMATCH TRANSMISSION

3. POWERSHIFT 1 SPEED TRANSMISSION

Figure 2. Transmission Labels

Operator Protection Equipment

The LOAD BACKREST EXTENSION is installed to keep

loose parts of the load from falling back toward the operator. It must be high enough, with vertical openings small

enough, to prevent the parts of the load from falling backwards. If a load backrest extension that is different from the

one installed on your lift truck is required, contact your Hys-

ter lift truck dealer.

The OVERHEAD GUARD is intended to offer reasonable

protection to the operator from falling objects, but cannot

protect against every possible impact. Therefore, it must

not be considered a substitute for good judgment and care

when handling loads. Do not remove the overhead guard.

NOTE: The seat belt can be either black or red.

The SEAT BELT AND HIP RESTRAINT provide additional

means to help the operator keep the head and torso substantially within the confines of the lift truck frame and overhead guard if a tipover occurs. This restraint system is

intended to reduce the risk of the head and torso being

trapped between the lift truck and the ground, but it cannot

protect the operator against all possible injury in a tipover.

The hip restraint will help the operator resist side movement. It is not a substitute for the seat belt. Always fasten

the seat belt.

This lift truck may be equipped with an optional operator

presence system which will not allow the truck to travel

unless the seat belt is fastened. When equipped, the seat

belt interlock includes sequencing/logic for the seat pressure switch and seat belt switch. The weight of the operator

must be detected prior to the seat belt switch being

engaged to enable operations.

14

Model Description

Nameplate

WARNING

DO NOT add to or modify the lift truck. Any modification that affects the safe operation of the truck cannot

be undertaken without the written authorization of Hyster Company.

Any change to the lift truck, the tires, or its equipment

can change the lifting capacity. The lift truck must be

rated as equipped and the Nameplate must show the

new capacity rating.

The capacity is specified in kilograms (kg) and pounds (lb).

The capacity is the maximum load that the lift truck can

handle for the load condition shown on the Nameplate.

The maximum capacity for the lift truck, at full load height,

must be shown on the Nameplate. Special capacities with

the load height reduced or with optional load centers, may

also be shown on the Nameplate.

The lift truck serial number code is on the Nameplate. The

serial number code is also stamped on the right-hand side

of the lift truck frame, under the floorplate.

When a lift truck is shipped incomplete from the factory, the

Nameplate is covered by an INCOMPLETE label as shown

in Figure 3. If the equipment on the truck is changed, the

Nameplate is covered by a NOTICE label as shown in Fig-

ure 3. If your lift truck has either of these labels, do not

operate the lift truck. Contact your dealer for lift trucks to

obtain a complete and correct Nameplate.

15

Model Description

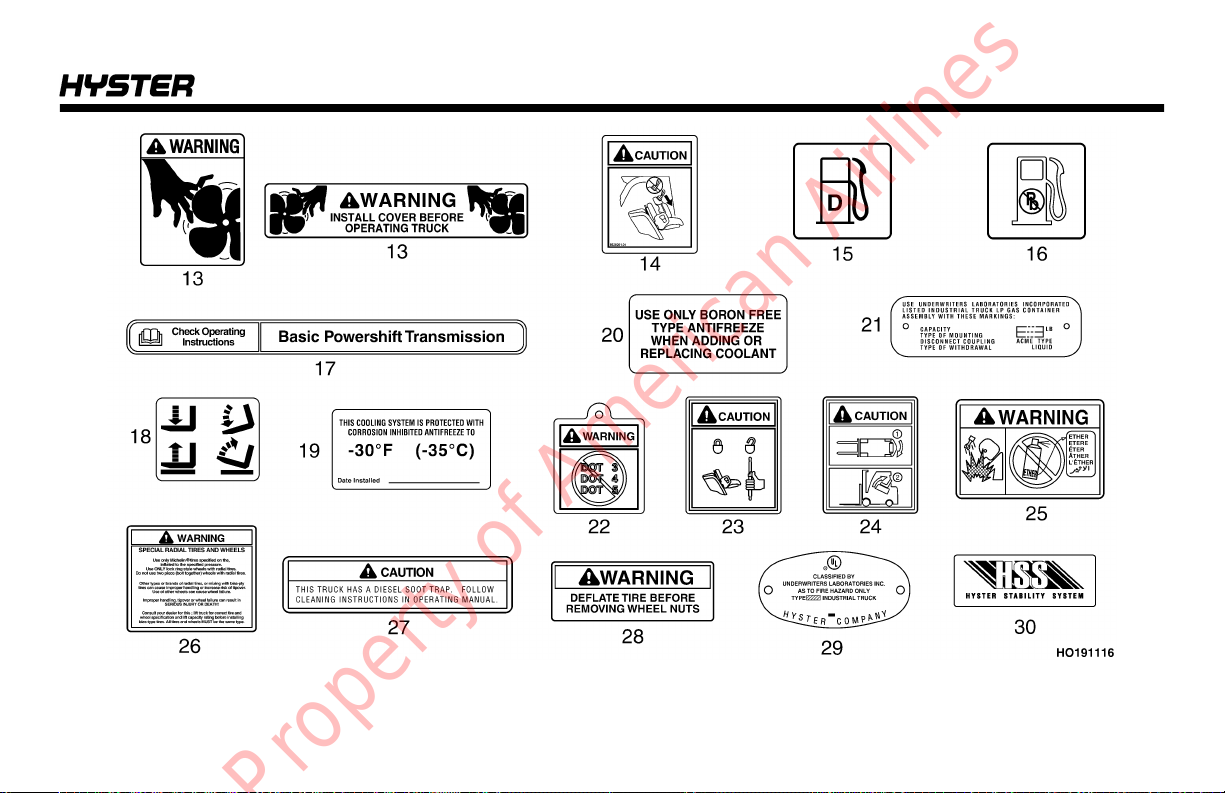

Safety Labels

Safety labels are installed on the lift truck to provide information about possible hazards. It is important that all safety

labels are installed on the lift truck and can be read. See

Figure 4.

All possible label configurations that can be on the lift

trucks covered in this Operating Manual are not shown in

Figure 4. See the Parts Manual for label part numbers and

a complete listing of all labels that are available for the lift

trucks covered in this Operating Manual.

A. NAMEPLATE

B. NOTICE LABEL

Figure 3. Nameplate and Labels

16

C. INCOMPLETE LABEL

Model Description

LABELS FOR H40-70FT TRUCKS ARE IN SAME LOCATIONS.

Figure 4. Warning and Safety Labels (Sheet 1 of 3)

17

Model Description

SEE THE PARTS MANUAL FOR THE PART NUMBER.

18

Figure 4. Warning and Safety Labels (Sheet 2 of 3)

Model Description

SEE THE PARTS MANUAL FOR THE PART NUMBER.

Figure 4. Warning and Safety Labels (Sheet 3 of 3)

19

Model Description

Legend for Figure 4

1. FLAMMABLE LP-GAS

2. TIPOVER WARNING

3. OVERHEAD GUARD LABEL

4. WARNING, OPERATION

5. NO RIDERS

6. WARNING FOR PARKING BRAKE

7. MAST WARNING

8. NAMEPLATE

9. DRIVE TRAIN PROTECTION CAUTION

10. NO ONE ON OR UNDER FORKS

*THIS PARKING BRAKE LABEL (SEE SHEET 2) USED ON LIFT TRUCKS MANUFACTURED AFTER JANUARY, 2012.

**THIS LABEL USED ON LIFT TRUCKS MANUFACTURED AFTER JANUARY, 2012.

11. MAST WARNING

12. OPTIONAL FIRE SAFETY RATING

13. FAN WARNING

14. JOYSTICK LABEL

15. DIESEL FUEL LABEL (NOT SHOWN)

16. UNLEADED FUEL LABEL (NOT

SHOWN)

17. TRANSMISSION LABEL (EXAMPLE

ONLY)

18. LIFT AND TILT LABEL

19. ANTIFREEZE WARNING

20. BORON-FREE LABEL

21. LPG TANK WARNING

22. BRAKE FLUID WARNING (PNEUMATIC

TRUCKS ONLY)

23. LOCKING GAS SPRING

24. HOOD OPENING CAUTION

25. EITHER WARNING (DIESEL ONLY)

26. RADIAL TIRES AND WHEELS

(PNEUMATIC TIRES ONLY)

27. SOOT TRAP WARNING (DIESEL ONLY)

28. SPLIT WHEEL WARNING (PNEUMATIC

TIRES ONLY)

29. UL LABEL

30. STABILITY SYSTEM LABEL (ON BOTH

SIDES OF TRUCK)**

20

Model Description

Display Switch Cluster

WARNING

If any of the instruments, levers, or pedals do not operate as described in the following tables, report the

problem immediately. DO NOT operate the lift truck

until the problem is corrected.

NOTE: On the lift truck models covered in this manual, the

left side (see Figure 5) of the Display Switch Cluster does

not perform any functions.

Display Switch Cluster – Right-Side Display Inputs

The lift trucks covered in this manual can have several different options and configurations. Depending on the equipment on the lift truck, warning and indicator lights on the

right side of the Display Switch Cluster will vary and the

truck may not contain all the warning and indicator lights

shown in Figure 6 and Table 2.

21

Model Description

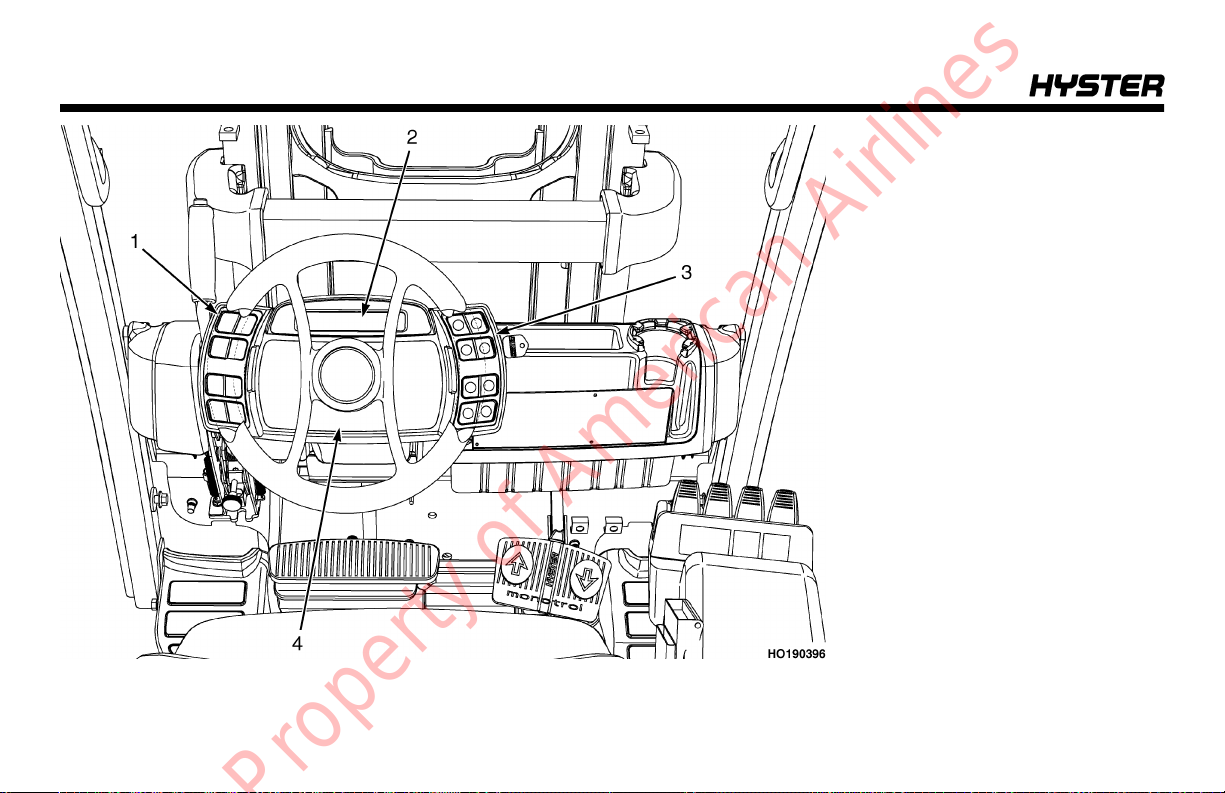

1. LEFT SIDE DISPLAY INPUTS

2. LCD SCREEN

3. RIGHT SIDE DISPLAY INPUTS

4. WARNING AND INDICATOR LIGHTS

22

Figure 5. Display Switch Cluster

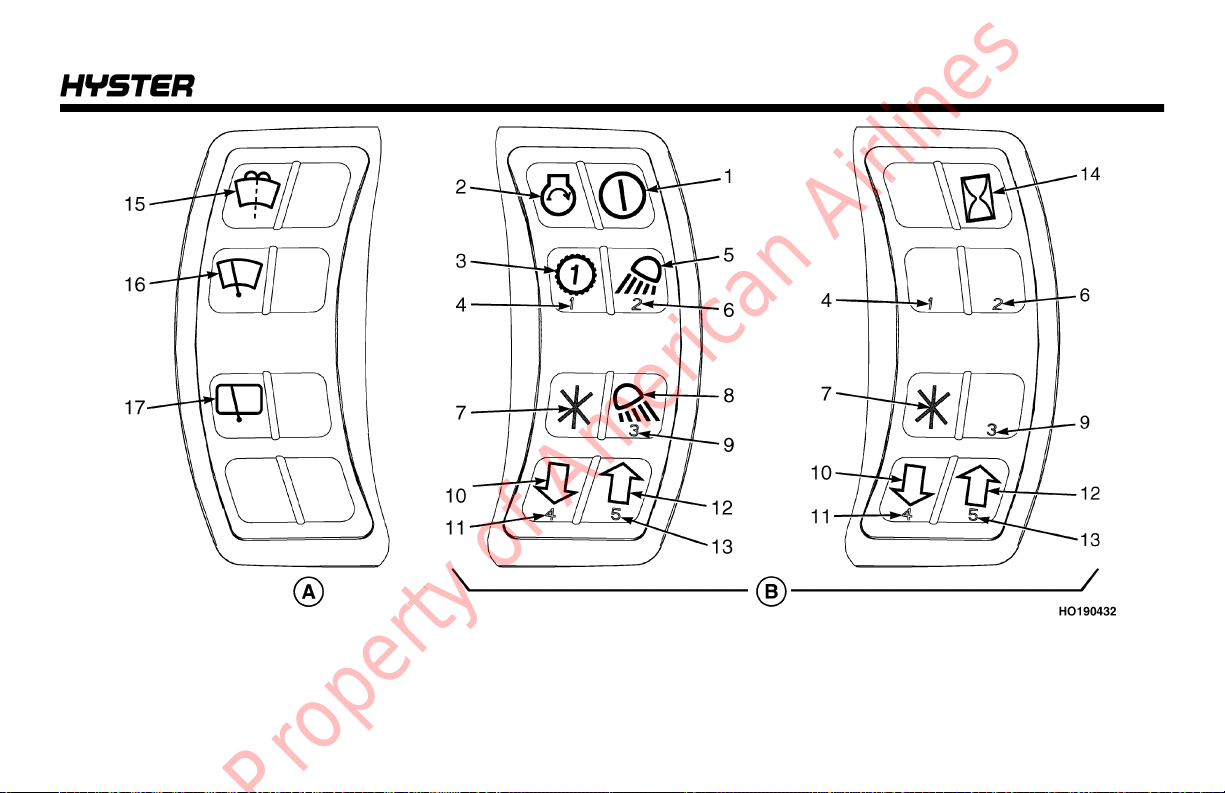

A. LEFT SIDE DISPLAY – CAB OPTION H40-70FT ONLY B. RIGHT SIDE DISPLAY

Model Description

Figure 6. Display Switch Cluster

23

Model Description

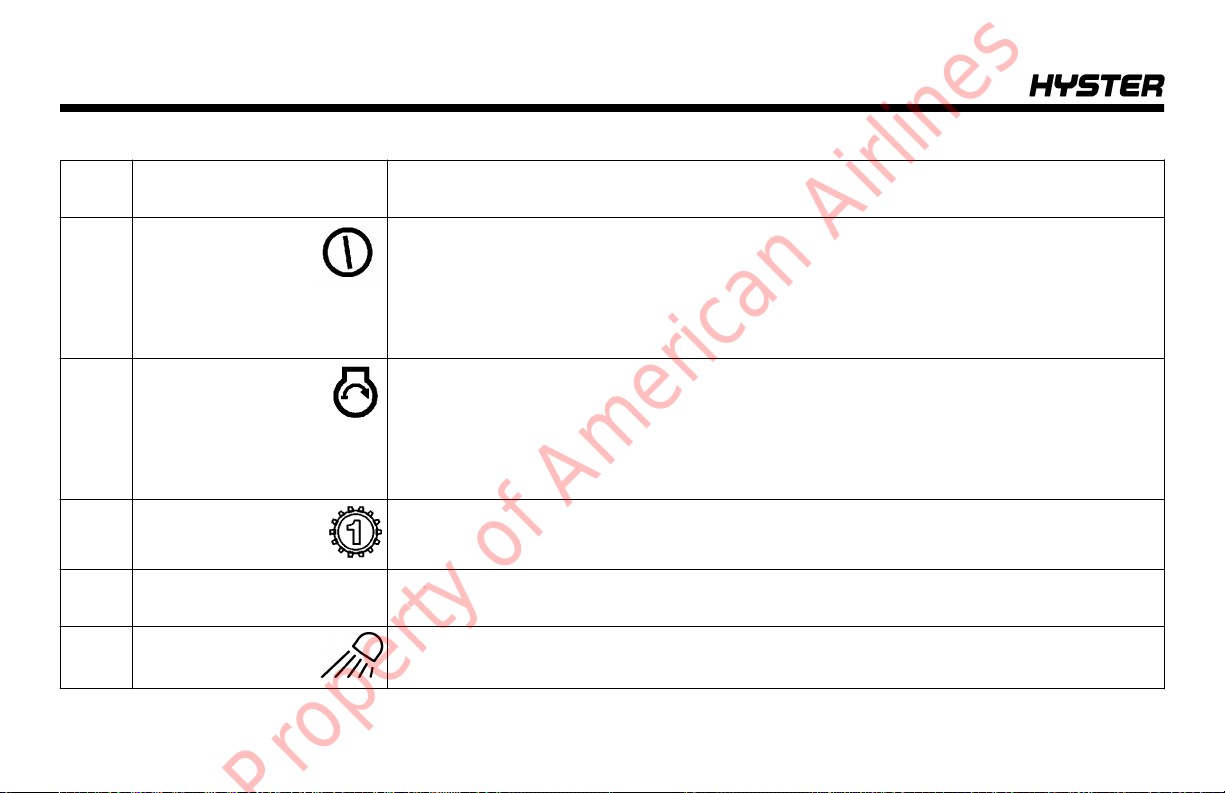

Table 2. Display Switch Cluster – Right-Side Display Inputs (See Figure 6)

Item

No.

1 Power ON/OFF If the lift truck is equipped with the keyless start option, lift truck system power is

2 Engine Start This button is used when the lift truck is equipped with the keyless start option. The

1st Gear Locking

Button

4 #1 Button When an operator or supervisor is in the main menu for entering and administering

5 Front Work Lights This button controls the front work lights and the marker lights on lift trucks equipped

24

Item Function

turned ON by pressing this button. To turn the lift truck system power and engine OFF,

press the Power ON/OFF button again.

If lift truck has a key switch, the Power ON/OFF symbol is replaced with the Hourmeter

symbol.

engine is started by pressing and holding this button. Lift truck power must be turned

ON (pressing Power ON/OFF button) before starting engine.

If the lift truck contains a key switch, the Engine Start graphic is covered and the function disabled.

This button engages and disengages the 1st Gear Locking function on trucks equipped with a the DuraMatch plus 2 transmission.

passwords, this button is used to enter the number 1 for password purposes.

with this option.

Model Description

Table 2. Display Switch Cluster – Right-Side Display Inputs (See Figure 6) (Continued)

Item

No.

6 #2 Button If the lift truck is equipped with front work lights, the #2 Button and the Front Work

7 Enter Button This button is used for menu entry, navigation, and data entry.

8 Rear Work Lights This button controls the rear work lights on lift trucks equipped with this option.

9 #3 Button If the lift truck is equipped with rear work lights, the #3 Button and the Rear Work Light

Item Function

Light button will share space on the Display Switch Cluster.

When an operator or supervisor are in the main menu for entering and administering

passwords, the Front Work Lights function is disabled and the button is enabled to

enter the number 2 for password purposes. If the lift truck is not equipped with Front

Work Lights, then this button functions only as Password entry #2.

button will share space on the Display Switch Cluster.

When an operator or supervisor is in the main menu for entering and administering

passwords, the Rear Work Lights function is disabled and the button is enabled to

enter the number 3 for password purposes. If the lift truck is not equipped with rear

work lights, then this button functions only as Password entry #3.

25

Model Description

Table 2. Display Switch Cluster – Right-Side Display Inputs (See Figure 6) (Continued)

Item

No.

10 Scroll Down This button is used for the following functions:

11 #4 Button The Scroll Down and #4 Button share the same space on the Display Switch Cluster.

12 Scroll Up This button is used for the following functions:

13 #5 Button The Scroll Up and #5 Button share the same space on the Display Switch Cluster.

26

Item Function

• Decreasing the value of a selected operating function

• Scrolling downward through a list of possible menu selections

When an operator or supervisor is in the main menu for entering and administering

passwords, the Scroll Down function is disabled and the button is enabled to enter the

number 4 for password purposes.

• Increasing the value of a selected operating function

• Scrolling upward through a list of possible menu selections

When an operator or supervisor is in the main menu for entering and administering

passwords, the Scroll Up function is disabled and the button is enabled to enter the

number 5 for password purposes.

Model Description

Table 2. Display Switch Cluster – Right-Side Display Inputs (See Figure 6) (Continued)

Item

No.

14 Hourmeter On trucks with key switch start, when truck is ON, engine hours will be displayed on

15 Windshield Washer On lift trucks with the cab option, press this button to wash the front windshield. Wind-

16 Front Windshield

Wiper

17 Rear Windshield

Wiper

Item Function

LCD screen on right side of second line. When truck is OFF, press hourmeter button to

display engine hours.

On trucks with keyless start option, when truck is ON, engine hours will be displayed

on LCD screen on right side of second line. When truck is OFF, engine hours can be

displayed when accessing menu to enter password. Password not required to view

engine hours.

Periodic Maintenance recommendations are based on these hours.

shield wipers will turn on and off automatically.

On lift trucks with cab option, press this switch to turn the front windshield wiper ON.

Press the switch again to turn the front windshield wiper OFF.

On lift trucks with cab option, press this switch to turn the rear windshield wiper ON.

Press the switch again to turn the rear windshield wiper OFF.

27

Model Description

Display Switch Cluster – LCD Screen and Warning and Indicator Lights

The LCD screen (see Figure 7) shows operator messages

for the different functions. The LCD screen can display

messages on two lines with up to 20 characters per line.

Bar graphs are also shown on the display using solid block

characters of varying heights.

The following information is displayed on the LCD screen

when the truck is running:

• Engine coolant temperature (standard)

• Fuel level, diesel and gasoline engines (standard)

The engine coolant temperature is displayed on the top line

and the fuel level is shown on the bottom line. If load

weight and travel speed options are available, press the

scroll down button to display the information for these features. Press the scroll up button to return to the engine

coolant temperature and fuel level displays. If a fault

occurs, the fault number will be displayed on the top line.

The time of day is displayed on the right side of the top line

at all times during the selection of displayed text. "HYD

TEMP/FUNCTION REDUCED" is displayed when the

hydraulic oil temperature is higher or lower than specified

limits.

The warning lights and indicator symbols shown in Fig-

ure 7 are on all lift truck models. Depending on the equipment on the lift truck, the warning and indicator lights on

the Display Switch Cluster will vary and not all the warning

and indicator lights shown in Figure 7 will illuminate. When

the warning lights and indicators are on, the operator will

see the appropriate symbol. When the warning lights and

indicators are off, the operator will see a black panel.

Unless noted in Table 3, all programmed warning and indicator lights will light up for two seconds (Start Check) when

System Power is turned ON.

28

Loading...

Loading...