Page 1

MX3762-01

Installation Instructions

Surface mount parking wedge with electromechanical barrier arm operator and Smart DC Controller

Models

WedgeSmart DC

WedgeSmart DCS (Solar)

WedgeSmart

TM

DC

Page 2

WedgeSmart DC Installation & Assembly - Plan Site Design MX3672-01 Rev. A Page 1

SECURE

PUBLIC

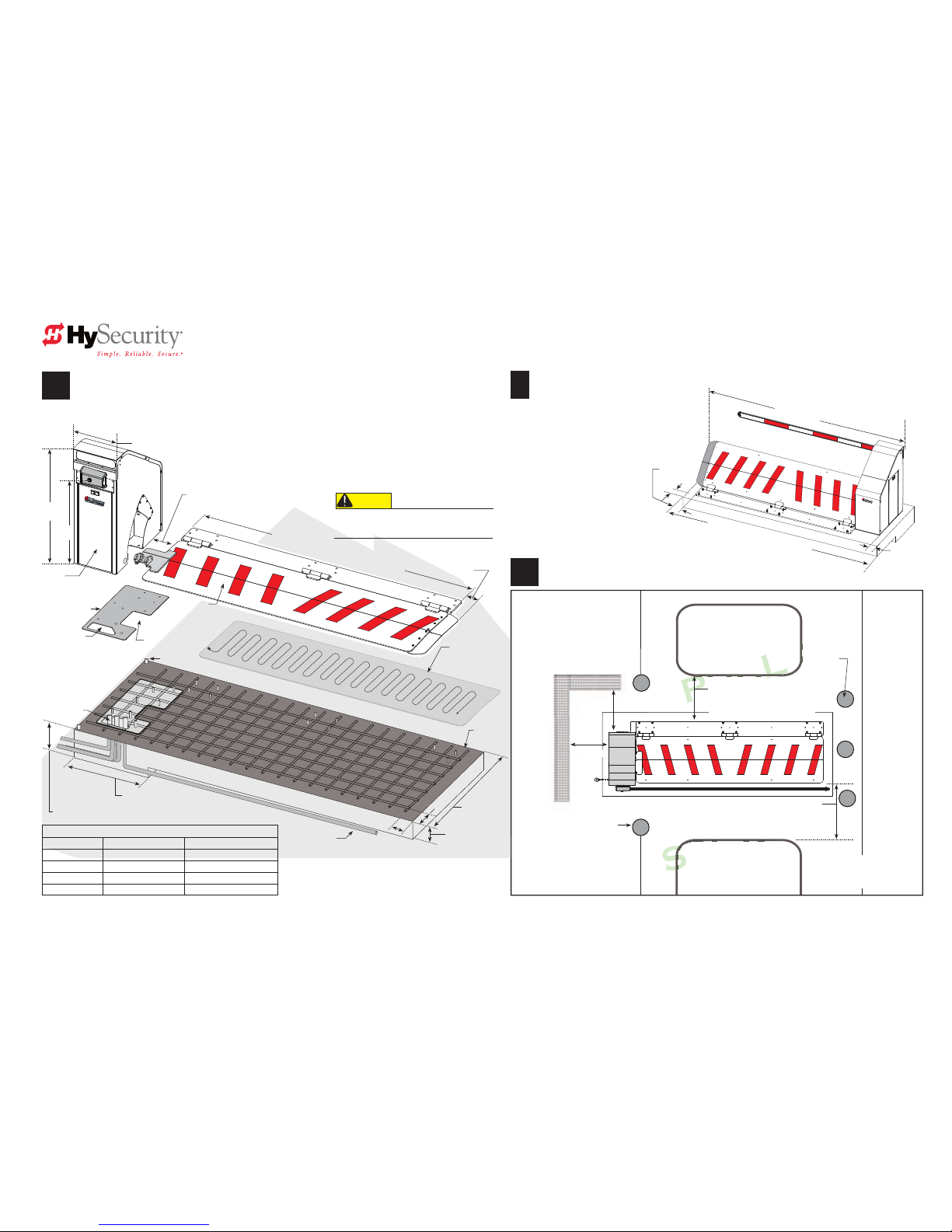

WedgeSmart DC: Plan Site Design

1

2

3

Read & Plan

Read and follow the Important Safety Information provided in the Programming and Operations

Manual prior to installing the WedgeSmart DC. Review the following installation instructions and

make sure to conform to UL 508A site specications and all local and federal regulations and codes.

Consider

accessibility &

clearance

Determine Wedge Plate Location

For alignment purposes, use the chassis

template provided. Consider recessing

the wedge plate if vehicle clearance issues

exist. For example, car haulers have minimal

clearance between the pavement and the

trailer. For additional foundation information,

see page 2.

Typical Single Lane Parking Garage Vehicle Loop Layout

For additional Loop Layout information, see page 7 and page 8.

3 feet (91 cm)**

**NOTICE: Deviating from the 3 ft mark will:

• Increase interference from the moving wedge plate

• Reduce the ability to activate automatic closure.

44½"

(113 cm)

36½"

(93 cm)

C

/

L

16⅛" (41 cm)

½ inch gap (14 mm)

when fully assembled

End guard

4½ inches

(11 cm)

Concrete Pad Dimensions

Lane Width (Ft) Pad Length (Inch) Pad Width/Length (cm)

9 128 274 x 325

10 140 304 x 355

12 164 365 x 416

14 188 426 x 477

51"

(129 cm)

Chassis template

* NOTICE: Eleven inch minimum depth required to accommodate

¾-inch anchor bolts used to secure wedge plate strap.

28" (113 cm)

Conduit cutout

Consider a

concrete heating

pad for sites

prone to freezing

temperatures.

Chassis

Total weight:

501 lb (227 kg)

Vehicle loop conduit

Wedge plate cutout

7” minimum

(18 cm)

11” (28 cm) See *NOTICE.

Conduit for

Dual Gate (DG)

Conduit:

• High voltage AC

• Low voltage / Comm

• Ground

• Vehicle Loops

• Dual gates

See pg 2.

Concrete pad

Rebar mat

See pg 2.

3"minimum (76 mm) all sides

NOTICE: To achieve CRASH ENGINEERED RATING:

• Excavate hole for the foundation. Soil density to 95% of standard proctor (ASTM-698).

• Reinforced concrete pad. One layer rebar #5 (⅝ inch) Grade 40 or better, spaced approx. 8"apart.

• Cure concrete properties, at minimum, 3000 psi with a smooth nish and proper drainage.

• Use Anchor Kit MX3460 (Grade B7 threaded steel rod and HIT-RE500 Epoxy adhesive).

Minimum 4 anchor bolts secure each hinge (6 mounting holes available at each hinge).

4" or

greater

(10 cm)

5½"

(14 cm)

9 ft lane = 123" (312 cm)

10 ft lane = 135” (343 cm)

12 ft lane = 159“ (404 cm)

14 ft lane = 183“ (465 cm)

See Wedge Plate Dimensions Chart on page 2.

Overall Width

Recommend

2 feet

(61 cm)

Use xed bollards to protect

front and back of chassis.

LOOP

See page 7 and page 8

B LOOP

See page 7 and page 8

Site Considerations

• Types of vehicles using the facility

• Clearance considerations

• Grade of ingress and egress

• Pad mount: Grade level or Recessed

• Grounding requirements

• Use of auto close feature

• Loops: A, B, C, D

• Access control

The B loop must be

located on the barrier arm

side.

Bollard

Wedge plate

and anchor plate.

Total weight, see page 3.

2 feet (61 cm)

Installing Loop C, 2 ft from the edge of

hinge plate allows a standard vehicle to

bridge and trigger both loops which, when

cleared, activates automatic closure.

See “WedgeSmart DC: Loop

Layouts” for more information.

Epoxy is used to secure anchor bolts.

It requires 12 hours to cure. WedgeSmart DC

cannot be operated during the curing time.

CAUTION

See Concrete Pad Dimensions Chart

Page 3

WedgeSmart DC Installation & Assembly - Foundation, Conduit, Anchor Cage MX3672-01 Rev. A Page 2

4⅜" (12 cm)

minimum

WedgeSmart DC: Install Foundation

1

2

4

Set the Foundation

To ensure the stability of the WedgeSmart DC, the foundation must be constructed

in accordance with the following guidelines:

Measure and Lay Conduit for Communication & Power

Assemble Rebar Mat

1. Place one layer rebar mat at 8-inch on center (OC)

2. Stagger rebar mat between anchor bolts.

3. Use rebar #5 (⅝ inch), Grade 40 or better.

Soil Density compacted to 95%

per ASTM-698

Excavate for Concrete Pad and Rebar Mat

Conduit Description Min. Size cm

AC Main power 1 inch 2.5

Low voltage power (accessories) and controls 1 inch 2.5

Earth Ground 3/4 inch 2

Vehicle Loop wires (IALD, Center, OALD, and/or Free Exit) 1 inch 2.5

Dual Gate systems conduit required for: No. Min. Size cm

AC power in 1 1 inch 2.5

Low voltage systems/communications 1 1 inch 2.5

Dimensions: Wedge Plate & Arm

Lane

Width

Wedge Plate

Length

Wedge Plate

Width

Arm

Length

Plate

Height

9 ft 102” 29½” 9 ft 21⅝”

10 ft 114” 29½” 10 ft 21⅝”

12 ft 138” 24½” 10 ft 18”

14 ft 162” 24½” 10 ft 18”

Tools Required

Forklift, crane or other heavy lifting equipment

Lifting straps rated to minimum of 4000 lbs

Lifting hooks or D connectors

Hammer drill with 9/16-inch and 7/8-inch bits.

(1/4-inch optional)

Reciprocating saw or grinder

Standard set of box end wrenches and sockets

(using ¾-inch and 1¼-inch)

Phillips head and at head screwdrivers

Standard set of hex keys

Wire cutters

Wire strippers

Protective material (cardboard) to prevent scufng

3" minimum

(76 mm)

8½"

(22 cm)

minimum

5¾"

(22 cm) minimum

10" (25 cm)

11” (28 cm)

See *NOTICE

on page 1.

Road surface level

Consider vehicle

clearance (semi truck

and car hauler rigs)

and road surface grade

changes. The need for

recessed mounts may be

a site requirement.

28” (113 cm) Length and depth minimums required to handle ¾-inch anchor bolts.

25½"

(65 cm)

45º

32¼”

(82 cm)

42½”

(108 cm)

4” (10 cm)

Wedge Plate Closed

21⅝"(55 cm) 9 & 10 ft

18”(46 cm) 12 & 14 ft

Wedge Plate Open

Hinge Plate

8" (20 cm)

1⅞”

(48 mm)

NOTICE: Six bolt hole mounts exist at 3 hinge locations.

CAUTION

Use the template to make sure rebar

#5 (⅝ inch), Grade 40 or better,

does not interfere with anchor bolts.

Also, note that the anchor holes cannot

be drilled with the chassis in place.

Example

Concrete Template

Chassis base & conduit

Min. Requirement: Use of 4 anchor bolts at each hinge location.

1" (25 mm)

Two ¾" anchor mounts for strap bracket. AVOID REBAR interference in this area.

• Excavate a hole for the foundation to house the rebar mat and anchor bolt

assemblies. Soil compression under and around the foundation shall be compacted

to a soil density of 95% of standard proctor (ASTM-698).

• Add gravel where necessary to ensure a solid soil base. Soil must be stable and adequate to support the

weight of the foundation.

NOTICE: Softer soils require a larger footing. Employ the services of a structural or civil engineer for site

specic considerations. In Northern latitudes, consider the frost line.

• The WedgeSmart DC must be installed on a level surface. The chassis and wedge plate must be

plumb, level and on grade with the roadway surface.

NOTICE: Be aware of low clearance vehicles, such as car haulers. Recess the concrete pad accordingly.

• Cure concrete properties, at minimum, 3000 psi with a smooth nish and proper drainage. Slope

drainage ¼-inch per foot within 2 feet of the operator (2 cm per meter).

• Use Anchor Kit MX3460 (Grade B7 threaded steel rod and HIT-RE500 Epoxy adhesive.

A minimum of 4 anchor bolts required to secure each hinge

(6 mounting holes available at each hinge).

3

Page 4

WedgeSmart DC Installation & Assembly - Foundation, Conduit, Anchor Cage MX3672-01 Rev. A Page 3

WedgeSmart DC: Drill & Set Anchors

1

When the concrete has sufciently hardened, move the wedge plate into the designated clear

opening on it’s concrete pad. To prevent scufng, use cardboard underlayment. Align the wedge

plate with the plastic chassis template. Lifting straps and eye bolts kit is available for purchase.

2

IMPORTANT: Vacuum all concrete dust from the anchor holes.

Position the wedge plate. Use heavylifting equipment and straps rated to

4000 lbs minimum. Kit MX3700.

Align wedge plate with chassis template.

Note conduit and loop wires. Temporarily,

stabilize template with concrete screws.

Use wedge base holes as drill template (9/16"

drill bit for ½" all thread). Use tape to mark drill

bit depth. See chart for depth requirements

Cutaway View Concrete Pad

Conduit

(See chart on page 2, step 2.)

Anchor fasteners shown for reference only.

Require minimum 5½" engagement in concrete.

b ca

To prevent scufng, place

cardboard under wedge plate.

To alleviate issues in colder climates,

consider installing heating elements

within concrete pad. See page 1.

Drill mounting holes straight and plumb. Wedge base

Wedge plate

Chassis

template

Ground rod

Conduit

window

Lifting tab

Verify conduit aligns with chassis template window. If not, shift both wedge plate and

template positions to t.

Anchor bracket holes

7/8-inch

Strap anchors minimum 6¼” depth engagement.

Where

used

Hammer Drill

Bit Size

Depth

minimum

Size of

Anchor

Epoxy & insert

anchor rods*

Torque

nuts**

Auxiliary Hole Usage

Chassis, strap

anchor bracket

7/8“

6¼”

¾“ (2X)

Fill hole ~ 1/2 full &

twirl in anchor rods

150 ft-lbs None

Chassis 9/16“

5½” ½” (5X)

Fill hole ~ 1/2 full &

twirl in anchor rods

30 ft-lbs

Use 4 of 6 holes provided at each

hinge.

Wedge base

plate

9/16“

5½”

½” (

min. 4X

per hinge)

Fill hole ~ 1/2 full &

twirl in anchor rods

30 ft-lbs

Use 4 of 6 holes provided at each

hinge.

* Allow a minimum of 12 hours for the epoxy to cure.

** After the required epoxy curing time has elapsed, install lock washers and nuts onto the anchor rods. Torque to specs found in chart.

To protect vehicle tires from damage, cut or grind any threaded rod extending past the nuts.

Anchoring the WedgeSmart DC

Review CAUTION

Vacuum concrete dust

Hinge

Chassis template

Position equipment on the anchor holes. Add epoxy and anchors. Allow 12 hours for epoxy to cure.

Remove covers and door panels

including the interior covers from the

chassis.

Lift the chassis into position with heavylifting equipment and straps. Large slots at

the top of the chassis are used for lifting.

Set the chassis on the plastic template; it

serves as a corrosion barrier. Align the chassis

with its anchor holes. Add epoxy & anchors.

b ca

3

Attach the anchor strap and wedge lifting chain. When the epoxy has cured (minimum 12 hours), place

the anchor strap pivot bracket over the two 7/8“ anchors protruding from the concrete pad.

NOTE: The anchor strap folds easier in one direction compared to

the other. Orient the strap so it bends in the easier direction while

connecting it to the anchor bracket.

Remove the spring clips and slide the pins into the anchor

and through the bushing end of the anchor strap.

Pins slide in from the plate side of the operator allowing the

spring clips to be on the secure inside of the operator.

b

a

For security,

place spring

clips on the

interior-side of

the chassis.

Pins

Anchor strap

Install cover guard

before securing

the wedge plate to

the concrete pad.

Tools: Flat head

screwdriver and

6 screws (provided)

Install cover guard.

c

CAUTION

• Use the chassis template as a guide to drill anchor holes. Mounting holes cannot be drilled through chassis.

• Secure chassis template with temporary concrete screws while drilling holes for wedge base.

• DRILL 7/8” anchor bracket holes (chassis template) first BEFORE the remaining 9/16” anchor holes.

Use a ¼” bit to hammer drill a pilot hole, centered in each of the two 7/8" chassis template’s anchor bracket holes

(used for ¾" anchors). If the drill bit hits rebar before reaching the required 6¼” minimum depth, shift both the

wedge plate and chassis template positions to find obstruction free concrete.

• If the drill hits rebar, use one of the other 9/16" chassis template anchor holes provided.

• Use epoxy and anchor bolts on all mounting locations AFTER setting chassis and properly aligning holes.

Page 5

WedgeSmart DC Installation & Assembly - Attach Chain and Assemble Barrier Arms MX3672-01 Rev. A Page 4

1. Make sure both AC and DC power switches are turned OFF.

2. Insert leads of wire harness through the hole in chassis. Feed the cable through the interior of

the chassis. Pull enough cable to reach the Smart DC Controller terminals.

NOTE: Connect wire lead to 24VDC!

Lights are dim when connected to 12VDC.

3. Attach the end of the wire harness (on outside of chassis) to the LED light connector on the arm.

4. Secure the harness to the chassis with the strain relief bushing.

5. Connect the one wire lead to the 24VDC power

supply terminal.

6. Connect the other wire lead to the NO terminal

on User 2 Relay.

WedgeSmart DC: Attach Chain & Arm

1

Attach the Wedge Plate Chain

A counter balance spring is used to assist the motor when lifting the wedge plate from the

Open (down) position. The spring is shipped extended (unloaded). To lower and attach

the plate side chain you must use the manual hand wheel to compress the spring.

• Verify both the AC & DC power is OFF

• Pull the manual override pin allowing the hand crank to

drop down and engage the square output shaft on the

gearbox.

NOTE: Removing the pin opens the stop switch which sends a

stop command to the ST Controller to prevent the operator

from running.

• Turn the hand wheel to lower the chain. Continue turning

until ball swivel reaches the wedge plate connection

point.

NOTE: Turning the hand wheel will grow more difcult as the

chain wraps the sprocket and compresses the spring.

• Attach chain with aluminum bolt. Use washers to align

chain with the gear box pulley. Tighten securely. (Snug

with additional 1/4 turn.)

NOTE: This aluminum bolt serves as a shearing connection if the

wedge plate is ever struck from the opposite direction. Using a

steel bolt at this connection may damage the gearbox and chassis

and void the HySecurity warranty.

• Turn the manual override hand wheel in the opposite

direction to lift the wedge plate. The anchor strap will limit

travel of the plate at 45 degrees.

• Turn the manual override to lower the plate. Verify the

anchor strap folds in the correct direction.

• Attach the two inside covers and the anchor strap cover.

• Lift the manual override hand wheel to align the holes and insert the manual override pin.

• Verify the end of the pull pin trips the STOP switch.

2

Install the Barrier Arm

The barrier arm bracket, attachment plate and end cap are

assembled on the gate operator chassis.

1. Loosen the knob to remove the end cap.

2. Loosen the nuts (do not remove them) on the attachment plate

and slide the arm into place.

3. Re-tighten the nuts, securely.

Manual override pin

Stop

switch

Hand

wheel

3

Connect Arm Lights to Smart DC Controller

NOTE: The top Smart DC Controller affects the arm while the bottom Controller affects the wedge. Arm and signal

lights are handled through wired connections on the bottom wedge Controller. Only the Arm Controller has relays

available for accessories.

Strain relief

Aluminum bolt

Chain

DC breaker

switch

Connect to 24VDC

Arm

Controller

AC 3A Fused

switch

Wedge

Controller

Strap cover

Inside covers

Attachment plate

End cap

Knob

Barrier arm

Arm bracket

USER Relay 2, N.O.

Page 6

WedgeSmart DC Installation & Assembly - Connect Power, Battery and Set Targets MX3672-01 Rev. A Page 5

Connect Power, Battery & Set Targets

1

DANGER

Turn OFF AC power at the source (circuit breaker panel) before accessing

the wires in the WedgeSmart DC. Follow facility Lock Out/Tag Out

procedures. Make sure all power switches are in the OFF position. Follow all

electrical code standards and regulations.

Connect DC Wire Harnesses on both Controllers.

9-pin Harness plug

Ships disconnected

9-pin Harness plug

Ships disconnected

AC 3A Fused

switch

DC breaker disconnect

switch

Establish Limits (Home Target)

1. When the installation is compliant and complete, turn AC

power ON at the source (circuit breaker panel).

2. Turn ON the AC and DC disconnect switches and toggle the

motor switch to “Enabled.” A prompt on the arm controller

display requests that the installer initiates a target search.

NOTE: An Error 12 “ARM-WEDGE COMM” will appear on the display

that is waiting to learn its home target. The error message disappears

when a target is set for both controllers.

3

Wedge and Arm

motor switch.

Turn OFF to

disconnect motors.

Used for

Troubleshooting.

Hold operator

OPEN or CLOSE.

Wedge plate is

down, barrier arm

up when “open.”

Smart DC Controller

Arm Controller

Wedge Controller

3. Press OPEN on the Arm Controller. The

barrier arm moves and establishes the

OPEN/CLOSE limits.

4. After anchors are set, the wedge plate

may be lying at on grade, in the open

position. When prompted, establish

the OPEN limits for the wedge plate by

pressing and holding the OPEN button

on the Wedge Controller. If you go too

far past the desired open position, you

can press CLOSE to reverse direction.

NOTE: Some amount of slack needs to be in the

chain when the wedge plate is open. The same

is true for the yellow strap when the wedge

plate is closed. Be sure to check these items.

Too taut and binding may occur. Too much

tension causes a greater load on either chain or

strap and can reduce its life span.

5. Check for slack in the chain. Use the

OPEN or CLOSE buttons to make

appropriate adjustments and press

SELECT twice on the Wedge Controller

(lower board) . An audible beep

indicates that the open limit has been

established and stored in memory.

6. When prompted, press and hold the

CLOSE button while the degrees

increase toward 45 and the wedge plate

reaches the desired full closed position.

7. Release the CLOSE button as the

wedge plate nears full closed. The

WAIT - SEARCHING

FOR HOME TARGET

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

ALERT 15

NO TARGET

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

motor slows as do the numbered increments on the display. To

preserve the CLOSE limit position, press SELECT twice. A buzzer chirps

twice and the full CLOSE position is retained in memory.

8. An ALERT - 15 appears in the Arm’s Smart DC display.

9. Using the Arm Controller, cycle the operator, by pressing OPEN and then

CLOSE. When the open/close cycle is complete, ALERT - 15 disappears from

the display and a HySecurity gate status appears.

At this point, the limits (target home positions) are established.

LEARN OP EN

DEGS: + XXX.X

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

LEARN CLOSE

DEGS: - XXX.X

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

With the motor switch toggled to “Disabled” and the AC and DC

disconnect switches OFF, connect the 9 pin harness blocks at the

center of each Controller.

PREV

OPEN

NEXT

SELECT

CLOSE

STOP

MENU

RESET

LED indicator changes color:

GREEN = AC power present and operator is stopped awaiting

Run commands.

Flashing YELLOW = operator is running, barrier/gate moving

Solid YELLOW = Menu mode

RED = operator experiencing an Alert, Fault, or Error

Not lit = AC power lost. Pressing SHOW LED’s button indicates

which inputs, if any are active

RED “Heart Beat” indicates Controller is receiving power.

Flashing indicates AC or DC present.

When AC power is lost, rate of RED blinking LED slows down.

2

Connect to AC Power

1. Turn off the AC and DC disconnect switches and connect two

wires and a ground to the terminals on the power module.

2. Place the incoming power wires into their appropriate slots.

Attach the ground wire to the chassis. Tighten the terminals

securely with a screwdriver.

NOTE: Wiring of gate operators must conform to NEC standards

and comply with all local codes.

AC Wires

White

Black

Green

Ground

Wire

Be sure AC and DC disconnect switches are in the OFF position

before connecting the 9-pin wire harnesses. An electrical spark

will occur if power is present.

CAUTION

Power

Module

Power Module

Secure wires by

tightening the screws

Page 7

WedgeSmart DC Installation & Assembly - Ground Equipment and Complete Installation MX3572-01 Rev. A Page 6

WedgeSmart DC: Complete the Install

2

For earth grounding requirements in the U.S.A., refer to the National Fire

Protection Association (NFPA) 780 - Standard for the Installation of Lightning

Protection Systems.

Highlights of the standard include:

• The ground rod must be UL listed copper-clad steel, solid copper, hot-dipped

galvanized steel, or stainless steel. Minimum requirements: ½ inch (13 mm)

diameter and 8 feet (244 cm) in length.

• The ground rod is driven into the earth (refer to local codes for proper depth

requirements).

• The ground rod is electrically bonded to the chassis with a single length of unspliced 6AWG copper wire less than 3 feet (91cm) long. Due to the large concrete

foundation, make the necessary adjustments to accommodate for earth ground

requirements.

• Local jurisdictions may impose additional or different requirements above

the NEC and NFPA 780. Consult the local codes and regulations regarding

requirements in your area.

NOTICE: Properly grounding the gate operator is critical to gate operator

performance and personnel safety. Equipment containing electronics may

benet when the earth ground discharges excessive voltage. Use sufcient

wire size during installation. If you do not ground the operator with a separate

earth ground rod, you risk voiding the Warranty.

1. Install the grounding rod per local building codes.

2. Attach a large earth ground wire (6AWG) from the grounding rod to the

lug nut on the chassis. Feed the 6AWG wire from the chassis to the earth

ground rod.

DANGER

The potential for lightning discharge exists with all gates, barrier arms,

fences, and gate operators. National Electric Code (NEC) requires a

separate earth ground in addition to the required equipment ground.

NOT TO SCALE

TRAFFIC LIGHT OPTION

An additional trafc light can be mounted on the chassis and is

useful in bi-directional trafc situations. The packaged option kit

(MX3805) comes equipped with mounting hardware and cable

harness.

Trafc light

Trafc light

Drill mounting

holes for fasteners

and cable harness.

Be sure to Ground the Operator

Ground rod

Ground lug

6AWG copper wire

less than 3 ft (91 cm)

in length

Consult local

codes for

required depth

REAR BRACKET BATTERY SHELF

If the operator is mounted close to a wall, the side door access

may be blocked. A rear bracket battery shelf option is available.

The packaged option kit (MX3900) comes equipped with

mounting hardware and battery extension wires and ttings.

Assemble rear bracket with

shelves and install inside the

chassis. Rework battery cables

and feed through chassis to

connect to Controller wires.

1

Configure the AL (Arm Lights) settings.

Check that the arm lights blink while the arm cycles and

searches for the target home position. See page 5.

When the arm has stopped moving, the arm lights continue to blink.

(If you want lights to remain lit without blinking, access the User Menu.)

The default (0) setting assures the arm

lights ash constantly while closing and

opening and when fully closed (barrier arm

down, wedge plate up).

If you prefer lights to remain lit without

blinking when operator is fully closed, access

the User Menu and change the AL setting.

Use the Arm Controller display menu buttons.

1. Press MENU twice and press NEXT

until AL appears in the display.

2. Press SELECT. “AL” blinks indicating it can accept changes. Press

NEXT to display 1.

3. Press SELECT and “AL” stops blinking.

4. Press MENU to exit Menu Mode.

Configure the User Menu: AL

AL 0 (OFF)

ARM LIGHTS BLINK

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

3

To congure User and Installer Menu options such as arm speed, Close Timer,

etc..., refer to the Programming and Operations Manual

• Make sure the operator is grounded.

• Review, with the end user, the Important Safety Instructions and the proper use of

WedgeSmart DC operator. Include how to manually operate the wedge plate.

• Replace operator’s covers and side panels. Secure with a key latch.

• Take photos of the installation site.

Complete the Installation

Page 8

WedgeSmart DC Installation & Assembly - Loop Layouts MX3572-01 Rev. A Page 7

Threat Protection: Prevent Unauthorized Entry

SECURE

WedgeSmart DC: Loop Layouts

2 to 4 foot between loop and

edge of roadway (61 to 122 cm)

6 ft minimum (183 cm)

4 ft min.

(121 cm)

Consider

accessibility and

clearance.

Loop C

Loop B

Loop D

Attack

Direction

2 feet (61 cm)

Installing Loop C, 2 ft from the edge of

hinge plate allows a standard vehicle to

bridge and trigger both loops which,

when cleared, activates automatic closure.

NOTICE: Deviating

from the 3 ft mark will:

• Increase interference

from the moving

wedge plate

• Reduce the ability to

activate automatic

closure.

3 ft (91 cm)

The B loop (CLD) must be

located on the barrier arm side.

Use xed bollards

to direct ow of

trafc and protect

front and back of

chassis.

2 to 4 foot

between loop and

edge of roadway

(61 to 122 cm)

To help mitigate

automobiles from

tailgating, maintain 4

foot distance between

loops. If frequented by

high bed vehicles, move

loops closer together.

Recommend

2 feet (61 cm)

Site Considerations

• Types of vehicles using the facility

• Clearance considerations

• Grade of ingress and egress

• Pad mount: Grade level or Recessed

• Grounding requirements

• Use of auto close feature

• Loops: A, B, C, D

• Access control

For threat protection applications, use site scenarios similar to the illustrations shown on this page.

TRAFFIC FLOW: PUBLIC ---> SECURE

TRAFFIC FLOW: SECURE ---> PUBLIC

Loop IDHY-5A

Connection

SDC Input

Connection:

Installer Menu

Settings

A*

OUTSIDE (Arming)

OBSTRUCTION

OUT OBS LOOP OALD, OOLD, OR

B

CENTER LOOP CENTER CLD, CR, CP

C

INSIDE (Arming)

OBSTRUCTION

IN OBS LOOP IALD, OALD, IR

D

EXIT LOOP

(optional)

EXIT LOOP ELD, DT, EB, CB

SECURE

Loop CLoop B

Attack

Direction

Loop A

Traffic Flow

SECURE

Attack

Direction

Loop CLoop BLoop A Loop D

Traffic Flow

Traffic Flow

TRAFFIC FLOW: BI-DIRECTIONAL

*NOTE: Arming loop does not affect operation.

Page 9

WedgeSmart DC Installation & Assembly - Loop Layouts MX3572-01 Rev. A Page 8

SECURE

WedgeSmart DC: Loop Layouts

Theft Prevention: Prevent Unauthorized Exit

For theft prevention applications, use site scenarios similar to the illustrations shown on this page.

Site Considerations

• Types of vehicles using the facility

• Clearance considerations

• Grade of ingress and egress

• Pad mount: Grade level or Recessed

• Grounding requirements

• Use of auto close feature

• Loops: A, B, C, D

• Access control

Attack

Direction

Loop B Loop DLoop CLoop A

TRAFFIC FLOW: BI-DIRECTIONAL

Traffic Flow

Traffic Flow

SECURE

TRAFFIC FLOW: PUBLIC ---> SECURE WITH EMERGENCY CLOSE

Attack

Direction

Loop B Loop

E1

Loop CLoop A Loop

E2

OC 1 (ENABLED)

EMERGENCY CLOSE

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

To connect and congure

Emergency Close, refer

to chart below.

Emergency Close when E2 to E1

Traffic Flow

Loop IDHY-5A

Connection

SDC Input

Connection:

Installer Menu

Settings

A *

OUTSIDE (Arming)

OBSTRUCTION

OUT OBS

LOOP

OALD, OOLD, OR

B

CENTER LOOP CENTER CLD, CR, CP

C

INSIDE (Arming)

OBSTRUCTION

IN OBS LOOP IALD, OALD, IR

D

EXIT LOOP

(optional)

EXIT LOOP ELD, DT, EB, CB

E1

Requires 2 channel box detector. Connect to Emer Open and

+24V on the Wedge Smart DC Controller (SDC). Congure

Installer Menu on the Wedge SDC: Set OC to 1. Emergency Close

triggers when vehicles detected crossing from E2 to E1 loop.

E2

Attack

Direction

Loop C

Loop B

Loop D

To congure loops, refer to chart below and to the Programming and

Operations Manual.

TRAFFIC FLOW: SECURE ---> PUBLIC

Traffic Flow

Traffic Flow

*NOTE: Arming loop does not affect operation.

2 to 4 foot between loop and

edge of roadway (61 to 122 cm)

To help mitigate

automobiles from

tailgating, maintain

4 foot distance

between loops.

If frequented by

high bed vehicles,

move loops closer

together.

6 ft minimum (183 cm)

The B loop (CLD) must be

located on the barrier arm side.

Use xed bollards to direct

ow of trafc and protect front

and back of chassis.

3 ft (91 cm)

Installing Loop C, 2 ft from the edge of hinge

plate allows a standard vehicle to bridge and

trigger both loops which, when cleared,

activates automatic closure.

2 feet (61 cm)

NOTICE: Deviating from

the 3 ft mark will:

• Increase interference from

the moving wedge plate

• Reduce the ability to

activate automatic closure.

4 ft min.

(121 cm)

SECURE

Page 10

1- 80 0-2 36 -0 112

www.tapconet.com

5100 West Brown Deer Road

Brown Deer, WI 53223

Distributed by

MX3672-01

Loading...

Loading...