Page 1

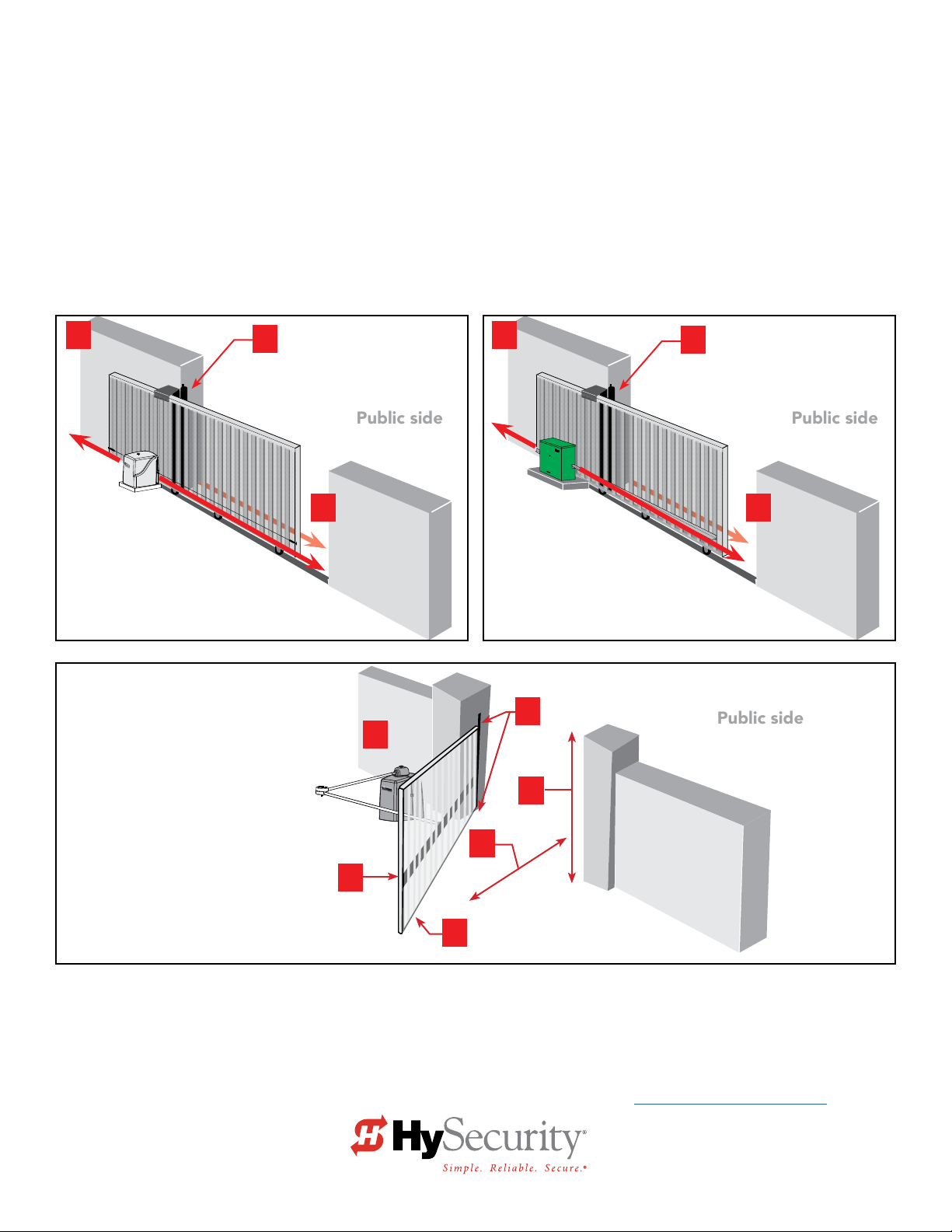

UL 325 Standard For Safety

1

3

2

Public side

3

Public side

Public side

2

4

Protection Against Entrapment

HySecurity Gate Operators

UL 325 – 2016

Quick Start - Supplement

Revision J

Trailing End

Slide Gates:

Potential Zones for

Entrapment Protection

1. Draw-in zones

2. Leading end

3. Trailing end

Swing Gates:

Potential Zones requiring

Entrapment Protection

1. Leading Edge

2. Bottom Edge

3. Entry / Exit

4. Posts

5. Post Pivot / Pinch Points

6. Arm Movement

Draw-in Zones

Wired edge sensors can protect

areas of entrapment along

posts or walls

Leading End

Secure side

6

1

1

Trailing End

Slide Gates:

Potential Zones for

Entrapment Protection

1. Draw-in zones

2. Leading end

3. Trailing end

5

5

4

3

3

2

Secure side

Draw-in Zones

1

Wired edge sensors can protect

areas of entrapment along

posts or walls

Leading End

2

Secure side

Drawings NOT TO SCALE

This document supplies site planning scenarios and reference tables that help explain the UL 325-2016 requirements for

monitoring of external entrapment protection sensors. HySecurity is monitoring Normally Closed (NC) sensors to conform to

UL 325 monitored entrapment protection requirements.

Approved sensors recommended for use with HySecurity gate operators are specied in this document.

For more information regarding UL 325-2016, refer to the HySecurity website section: www.hysecurity.com/gatesafety

Page 2

Important Safety Information

WARNING

A moving gate or barrier arm, bollard, or wedge can cause serious injury or death. It is therefore incumbent on the site designer, installer, and

property owner to ensure that these hazards are mitigated and the public is warned of the existence of a potential hazard. Read all the product

safety information prior to installation. Verify the gate operator is installed to comply with all safety standards and local and federal regulations

and is designated for its proper usage class. For more information, refer to your gate operator's product manual.

To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS. Read the gate operator’s product manual and review all the product labels and literature prior to

installing, operating, or maintaining the automatic gate operator.

2. Never let children operate or play with gate controls. Keep all remote controls, especially radio transmitters, away from children. Do not allow

children to play on or around the gate or gate operators.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE. Start the gate operator

only when a gate’s travel path is clear.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object activates the non-contact

sensors. After adjusting the force or the limit of travel, retest the gate operator. Perform routine tests of the entrapment protection sensors,

such as photo eyes and edge sensors. Failure to adjust and retest the gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the product manuals. Have a qualied service person make repairs to gate hardware and replace

batteries in accessory or entrapment protection sensory devices on a regular basis.

7. The automated gate entry is for vehicle use only. Pedestrians must use a separate entrance. Make sure a separate walk-through entrance is

nearby. Make certain a clear pedestrian path is designated and signs direct pedestrians to the walk-through gate.

8. Install the supplied WARNING signs on the inside and outside of the gate or barrier gate/operator so they are clearly visible from both the

secure and public sides. Installing the signs is a requirement for UL 325 compliance.

9. Use monitored sensors for protection against entrapment as specied in the current UL 325 Standard for Safety. Refer to General Entrapment

Protection Provisions per UL 325, Table 31.1 on page 18.

NOTICE: Extensive safety information exists in the gate operator product manuals. Be aware and read all safety information, labels and signage

that is shipped with your gate operator

document is a supplement, and as such, focuses on the differences in monitoring external entrapment protection sensors and the application of

external sensors.

Be sure to read all the information provided with your product manuals.

to ensure quality site design, proper set up for functional gate operation and pedestrian safety

. This

Safety InformatIon SpecIfIc to monItored entrapment

The following is found in HySecurity Programming and Operations Manuals, but re-iterated here. Before

installing the gate operator:

Mount access control devices beyond reach of the gate. The control devices that operate the gate must:

• Be located in a clear line of sight to the gate. Locate controls (Open, Close, Stop/Reset) where a user will have a clear view of the gate.

NOTE: An exception for Emergency Access Control devices exists. An EAC device accessible by authorized

personnel only (e.g. re, police, EMS), may be placed at any location within the line-of-sight.

• Be mounted beyond 6 feet (183 cm) of the gate to prevent users from touching or accessing the gate while operating the controls. People

attempting to access the controls by reaching through or around the gate can be seriously injured or killed by the moving gate.

• Connect radio and other remote access (non-resetting controls) to the RADIO OPTIONS terminal.

Install an automatic operator only on gates that comply with ASTM F2200 Gate and Fence Standards and the usage class of the gate. Screen or

enclose openings in the gate per UL 325 Standards for Safety which include:

• All horizontal slide gates must guard or screen openings from the gate’s base support to a minimum height of 6 feet (183 cm) above the

ground. This must prevent a sphere of 2¼-inches (57 mm) in diameter from passing through an opening in the gate or the adjacent fence that

is covered in the gate’s open position.

• All exposed pinch points are eliminated or guarded.

• Physical stops must exist in the gate construction to prevent over-travel in both directions and, for slide gates, guide posts must be installed

to prevent the gate from falling in the event of a roller failure. Guarding must be supplied for exposed rollers.

• External entrapment protection sensors must be used wherever the risk of entrapment exists. Refer to 6

SAVE THESE INSTRUCTIONS

2 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

.

Page 3

Contents

Important Safety InformatIon ..................................................................................2

Safety Information Specic to Monitored Entrapment ....................................................................................................2

HySecurity Gate Operators ..............................................................................................................................................5

Table 1: HySecurity Gate Operators requiring External Monitored Entrapment Protection Sensors ...........................5

Table 2: HySecurity Gate Operators maintaining Object Detection .............................................................................5

Table 3: External Entrapment Protection Sensors Approved for Use with HySecurity Gate Operators .......................6

Label Changes to Controller Inputs .................................................................................................................................7

How Software Handles Monitored Entrapment ...............................................................................................................8

Table 4: Changes to Sensor Inputs on the Controller ...................................................................................................8

What the Installer Needs to Do .......................................................................................................................................9

Table 5: Installer Menu Settings for SENSOR Inputs ..................................................................................................10

Table 6: Setting the Sensor Logic ...............................................................................................................................11

Temporarily Power the Sensors ......................................................................................................................................12

Photo Eye Alignment ....................................................................................................................................................12

Troubleshooting .............................................................................................................................................................13

Table 7: Troubleshooting Codes ................................................................................................................................14

Site Assessment & Gate Design for Monitored Entrapment ..........................................................................................16

Site Assessment & Gate Design for Monitored Entrapment ..........................................................................................17

Usage Class 4 Designated Gate Operator Provisions ................................................................................................18

General Entrapment Protection Provisions per UL 325, Table 31.1 ............................................................................18

Diagram 1: Typical Slide Gate Site Assessment .............................................................................................................19

Diagram 2: Typical Swing Gate Site Assessment ...........................................................................................................20

Diagram 3: Typical Barrier Arm Site Assessment ...........................................................................................................21

Diagram 4: Typical Vertical Lift Site Overview ................................................................................................................22

Diagram 5: Typical SlideSmart DC Site Assessment ......................................................................................................23

Diagram 6: SwingSmart DC Site Overview (Dual Gate) .................................................................................................24

WIrIng HySecurIty SenSorS: Smart toucH ...............................................................25

Smart Touch: Wired Edge Sensor with GEM (-104)........................................................................................................26

Smart Touch: Photo Eye Thru Beam (EMX IRB MON) ....................................................................................................27

Smart Touch: Photo Eye / Reective (E3K R10K4) .........................................................................................................28

Smart Touch: The Solution, MIM-62 (Multi-input Module) .............................................................................................29

Smart Touch: Photo Eye / Reecti-Guard (RG-R) ............................................................................................................30

Smart Touch: Wireless Edge, Wireless Gate Link ...........................................................................................................31

Smart Touch: Wired Edge with GEM-104 & Photo Eye .................................................................................................32

Smart Touch: WireLess Edge Gate Link & Photo Eye ....................................................................................................33

Smart Touch: 2 CH Wired Edge with GEM-204 .............................................................................................................34

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 3

Page 4

WIrIng HySecurIty SenSorS: Smart Dc ..................................................................35

Wiring Tips for SENSOR COM Terminal: Smart DC .......................................................................................................36

Menu Mode Navigational Tips .......................................................................................................................................36

Smart DC: Wired Edge Sensor with GEM-104 ...............................................................................................................37

Smart DC: Photo Eye Thru Beam (EMX IRB MON) ........................................................................................................38

Smart DC: Photo Eye / Reective (E3K R10K4) ..............................................................................................................39

Smart DC: Multi-input Module (The Solution, MIM-62) .................................................................................................40

Smart DC: Photo Eye / Reecti-Guard (RG-R) ................................................................................................................41

Smart DC: MGL-RX20 Wireless Gate Link .....................................................................................................................42

Smart DC: Wired Edge with GEM-104 and Photo Eye ..................................................................................................43

Smart DC: WireLess Edge Gate Link and Photo Eye .....................................................................................................44

Smart DC: 2 CH Wired Edge with GEM-204 .................................................................................................................45

Smart DC Bi-Parting Gates: Dual Gate Wiring ............................................................................................................46

Smart DC Bi-Parting Gates: Photo Eye (EMX IRB MON) ...............................................................................................46

HySecurity Contact Information .................................................................................................................................48

4 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Page 5

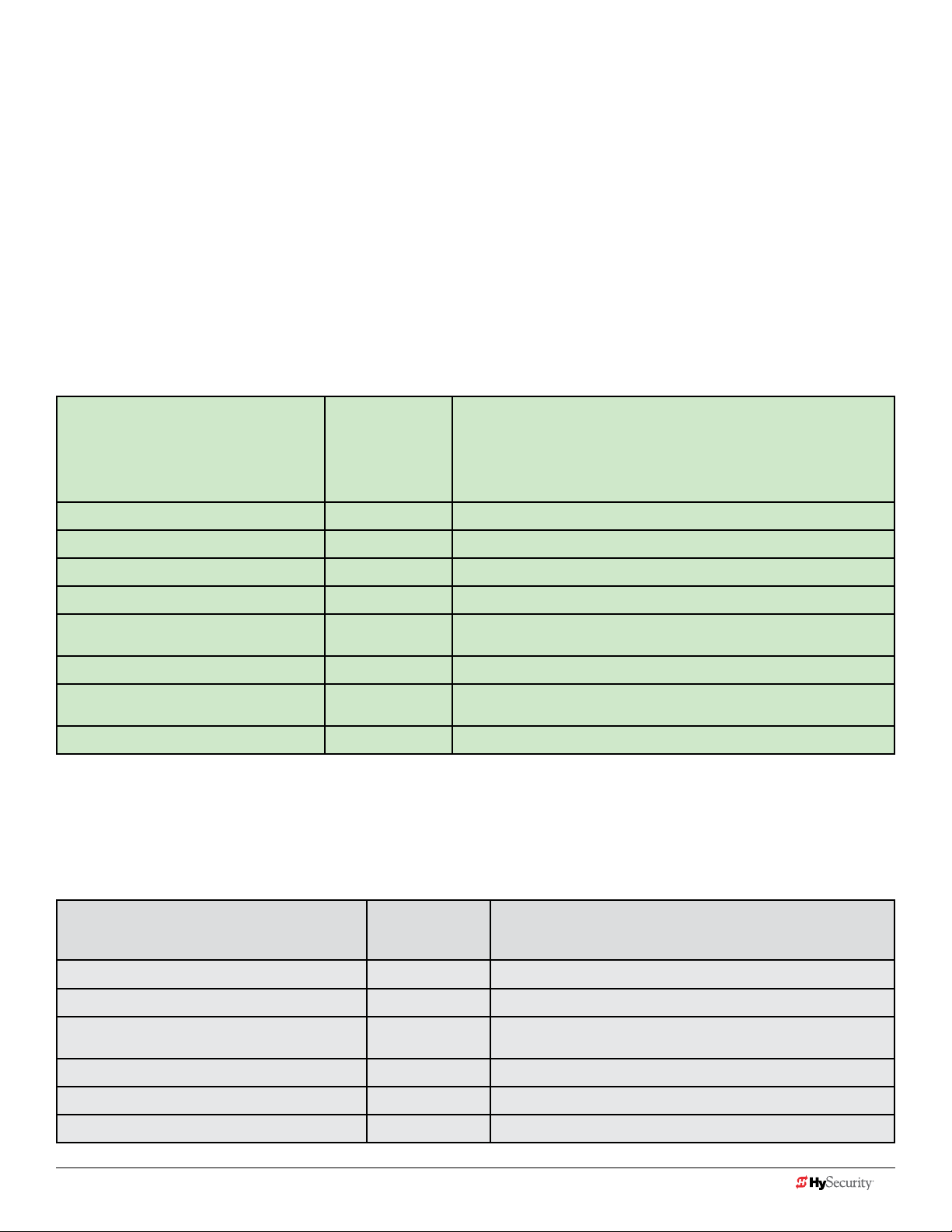

HySecurIty Gate operatorS

The following bullet points highlight how your automated gate system sites can monitor external entrapment protection

using HySecurity gate operators:

• Normally Closed (NC) sensors - Before gate movement occurs, the gate operator veries that the external entrapment protection

sensor is connected and fully functional.

• Build Year (BY) - An added menu item distinguishes between pre-2016 manufacturing dates and post-2016 manufacturing dates.

Build Year (BY) is a factory-setting. Build Year 2 (BY 2) is the default for all HySecurity gate operators indicating a manufacturing date

of 2016 in the serial number. Replacement controller boards for existing sites allow for a Build Year setting of 1 (BY 1) (pre-2016).

• Independent Sensor Inputs - The edge, photo eye and photo eye COM inputs on the Smart Touch and Smart DC Controllers (STC

and SDC) have been re-labeled. The same wiring connections become three independent methods for easy entrapment sensor

conguration and normally closed outputs. Refer to page 7.

Table 1: HySecurity Gate Operators requiring External Monitored Entrapment Protection Sensors

UL 325 Entrapment Protection Device Monitoring Required

HySecurity Gate Operators

(includes Modular, Correctional, and UPS

models)

Build Year

post-2016

(set at the factory)

Normally Closed (NC) sensors tested & approved.*

Three SENSOR Inputs on Controller.

Installer Menu congurable.*

Build Year (BY) factory-set to post-2016.

SlideDriver 15, 40, 30F, 50VF 2/3, 80, 200 2

SlideDriver 50VF series 2

SlideSmart DC 15 & DCS 15 2

SlideSmart DC 10F & DCS 10F 2

SwingRiser 14, 14-Twin, 19,

19-Twin, 30, 30-Twin

SwingSmart DC 20 & DCS 20 2

HydraSwing 40, 40F, 40-Twin, 40F-Twin,

80F, 150

HydraLift 10, 10F, 20, 20F 2

*NOTE: Refer to tables on 6 and 10.

2

2

●

●

●

●

●

●

●

●

Table 2: HySecurity Gate Operators maintaining Object Detection

Table 2 indicates those HySecurity gate operators that may be within the exception parameters of UL 325 or comply with

standards other than UL 325, but continue to maintain object detection capabilities. HySecurity strongly recommends that

you assess every site for entrapment zones and provide the necessary protection to guard against entrapment.

HySecurity Gate Operators

with

Obstruction Protection (Object Detection)

StrongArm (HTG) 14, 20, 28, 36 2

Build Year

post-2016

Sensor Inputs automatically set to "NOT USED"

Installer has option to change settings as site design dictates.

●

StrongArmCRASH (M30/M50) 2

StrongArmPark DC 10 & DCS 10

StrongArmPark DC 14 & DCS 14

WedgeSmart DC 10 & 10 DCS 2

WedgeSmart DC 14 & 14 DCS 2

HydraWedge SM50 with HydraSupply XL 2

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 5

2

●

●

●

●

●

Page 6

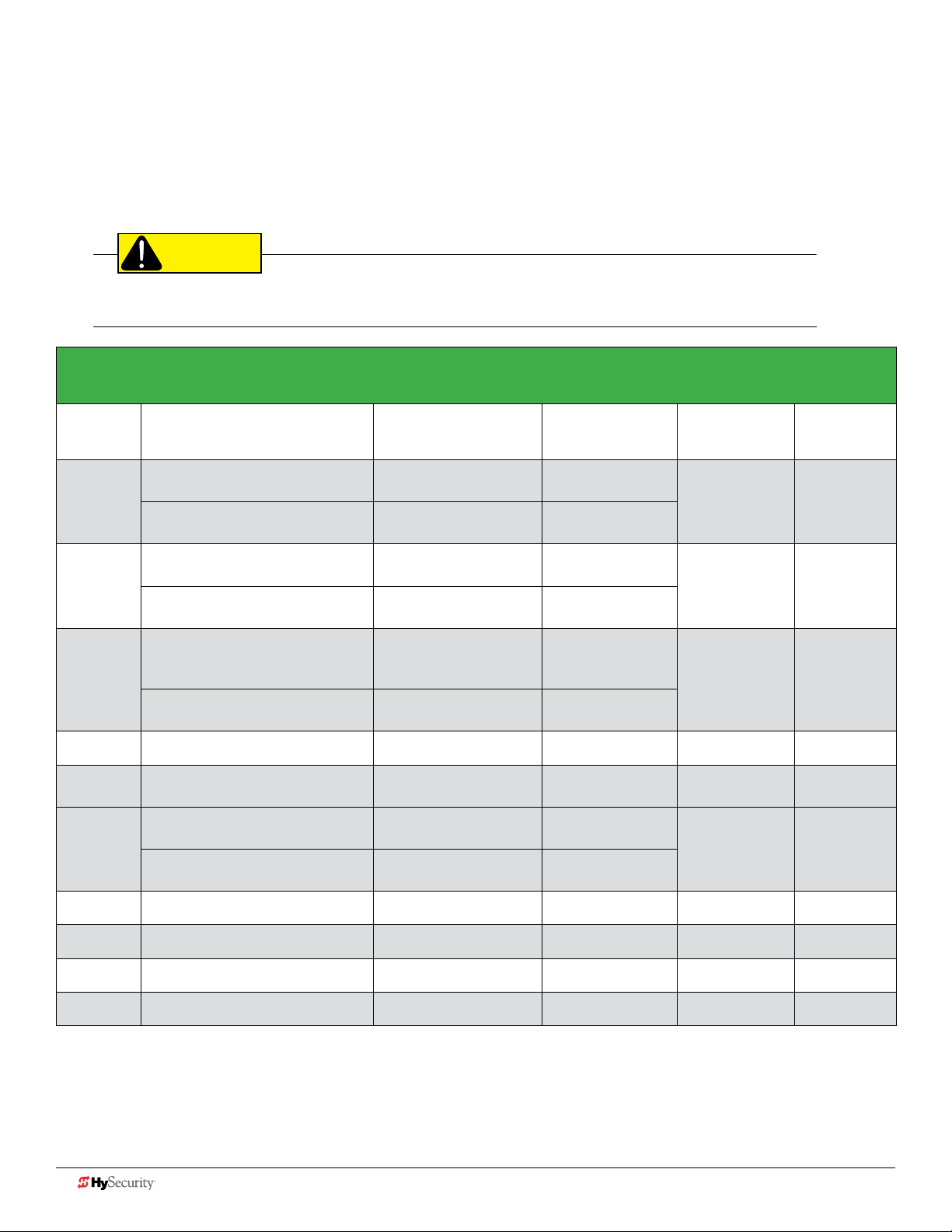

Table 3: External Entrapment Protection Sensors Approved for Use with HySecurity Gate Operators

The site designer or installer must determine which external entrapment protection sensors will be installed

with the gate operator to create a UL 325 compliant installation site.

NOTE: Table 3 provides the list of sensors that are approved for use with HySecurity gate operators using the monitoring

capabilities found in software versions h4.50 or h5.50 (or higher).

CAUTION

Temperatures and environmental conditions affect proper operation of external entrapment protection sensors.

Always check the manufacturer's specications shipped with the sensors.

External Entrapment Protection Sensors: Normally Closed Contact, Compatible with

HySecurity Gate Operators

P/N 2016 Monitored Sensors Sensor Type Output Manufacturer

MX3981

MX4161

MX3982

MX4161

MX4037

MX4161

MX3985

MX4015

MX3986

MX4013

Wired Gate Edge Sensor

MGR20-2U-05-T2, Round

2 CH Gate Edge Module

(GEM-204)

Wired Gate Edge Sensor

MGS20-2U-05-T2, Square

2 CH Gate Edge Module

(GEM-204)

KIT: Wired Gate Edge Sensor

MGO20-2E-05-T2, Square

and Channel mount

2 CH Gate Edge Module

(GEM-204)

Reecti-Guard (RG-R) Photo eye, reective Normally Closed

KIT: MGL-K20

(includes MX3986 and MX4013)

Wireless Gate Link

MGL-TX20

Wireless Gate Link

MGL-RX20

Wraparound edge

(5 ft for 2" round post)

Edge Interface Module Normally Closed

Wraparound edge

(5 ft for 2" square post)

Edge Interface Module Normally Closed

Edge (3-sided activation

Slide In Style)

(5 ft, 1½" width)

Edge Interface Module Normally Closed

Wireless Gate Link Normally Closed

Transmitter (battery-

operated, radio control)

Receiver (24VDC, radio

control)

10K Resistor

10K Resistor

10K Resistor

N/A

Normally Closed

Miller Edge Type B2

Miller Edge Type B2

Miller Edge Type B2

Miller Edge Type B1

Miller Edge Yes

Miller Edge Yes

UL 325

Recognized

MX3987

MX3990

MX000846

MX000999

NOTE: Bold type indicate sensors or accessories that must be installed together for external entrapment protection to be properly

monitored.

6 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

The Solution, MIM-62 Multi-Input Module Normally Closed

IRB-MON (Dist.~ 65 ft) Thru-beam photo eye Normally Closed

KIT: IRB-325 (Dist.~ 50 ft) Thru-beam photo eye Normally Closed

KIT: E3K-R10K4-NR (Dist. ~ 40 ft) Photo eye, reective Normally Closed

Miller Edge Yes

EMX Industries Type B1

EMX Industries Type B1

Omron Type B1

Page 7

24VDC

24VDC

24VAC

24VAC

12VDC

12VDC

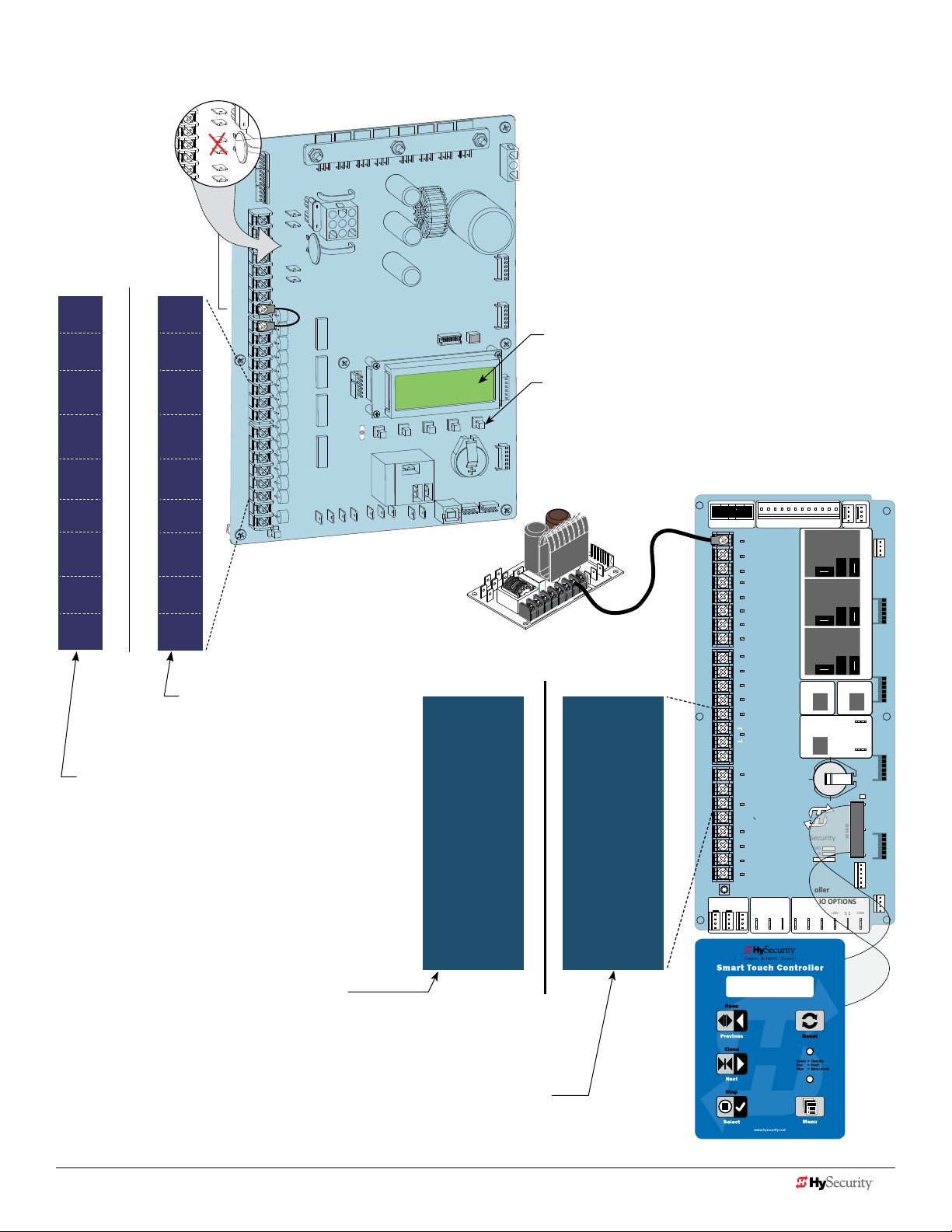

LabeL cHanGeS to controLLer InputS

Labels are available and may be overlaid to cover

the silk screened text on the controller inputs.

24VDC

COM

24VDC

COM

COM

COM

COMMON

COM

TERMINALS

EYE

OPEN

EYE

CLOSE

EXIT

LOOP

BLOCK

EXIT

IN OBS

LOOP

OUT OBS

LOOP

CENTER

LOOP

EDGE

EYE

COM

SENSOR 2

SENSOR 3

EXIT

LOOP

BLOCK

EXIT

IN OBS

LOOP

OUT OBS

LOOP

CENTER

LOOP

SENSOR 1

SENSOR

COM

Post 2016 Label

Build Year (BY 2)

MX3978-01

Temporary use on existing inventory.

Pre-2016

Build Year (BY 1)

MX3978-02

Used on replacement boards for gate

operators manufactured prior to 2016.

12VDC

12VDC

COM

COM

COM

STOP

OPEN

CLOSE

RADIO

OPEN

OPEN

PARTIAL

SENSOR 2

SENSOR 3

EXIT

LOOP

BLOCK

EXIT

IN OBS

LOOP

OUT OBS

LOOP

CENTER

LOOP

SENSOR 1

SENSOR

COM

+ 24 V

EMERG

OPEN

SHOW

LEDs

B

M

O

C

AL

U

D

USER RELAY 1

Electro-mechanical

1

S

24V

+

EN

OP

M

O

C

A

E

T

A

G

N

IO

OPT

O

I

D

A

R

Smart DC Controller

Pre-2016

Build Year (BY 1)

MX3979-02

Used on replacement boards for gate

operators manufactured prior to 2016.

R

B

S

U

C

D

R2

E

S

U

O

N

M

O

C

S

EDGE SENSOR

EDGE SENSOR

PHOTO EYE POWER

PHOTO EYE POWER

24 VOLTS COMMO

24 VOLTS COMMON

PHOTO EYE POWER

PHOTO EYE POWER

DO NOT USE

PHOTO EYE

PHOTO EYE

OPEN DIRECTION

OPEN DIRECTION

DO NOT USE

PHOTO EYE

PHOTO EYE

CLOSE DIRECTION

CLOSE DIRECTION

Smart DC Display

Keypad (buttons)

5

8

4

-

S

2

4

V

A

C

A

c

ce

ss

o

ry

p

ower

ON

COMM

Power Supply Board

SENSOR 1

SENSOR 1

SENSOR

SENSOR

COM

COM

DO NOT USE

SENSOR 2

SENSOR 2

DO NOT USE

SENSOR 3

SENSOR 3

Smart Touch Controller

USER 3

HySecurity

MX000585

VERSION

S/N

RADIO OPTIONS

+24V +24V

DISPLAY

S 1

RS485

STATUS

RS232

COM

NO

COMOPEN

MOTOR USER 1

EXIT

USER 2

OBSTR

OBSTR

RESET

STOP/BUZZER

FREE

INSIDE

OUTSIDE

VEHICLE DETECTORVEHICLE DETECTORVEHICLE DETECTOR

SHADOW

VEHICLE DETECTOR

WIEGAND

DRIVE

1

2

C

D

V

4

2

+

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

21

22

23

24

LED

LIMIT DUAL GATE

RPM

S2 7 (EYE BOTH)

SENSOR #2 TYPE

POWER

STOP BUTTON

OPEN BUTTON

CLOSE BUTTON

REMOTE OPEN AND

RADIO CONTROL

OPEN/CLOSE

OPEN PARTIAL

INTERLOCK OPEN

TIME CLOCK OPEN

FREE EXIT DETECTOR

DISABLE EXIT DETECTOR

DISABLE CLOSE TIMER

INSIDE OBSTRUCTION

VEHICLE DETECTOR

OUTSIDE OBSTRUCTION

VEHICLE DETECTOR

SHADOW/RESET

VEHICLE DETECTOR

EDGE SENSOR

PHOTO EYE POWER

24 VOLTS COMMON

PHOTO EYE POWER

DO NOT USE

PHOTO EYE

OPEN DIRECTION

DO NOT USE

PHOTO EYE

CLOSE DIRECTION

DO NOT USE

CHARGER

AC LOSS

LOCK INTERLOCK

EMERG CLOSE

FIRE DEPT OPEN

Smart Touch Controller

COM COMA B

Post 2016 Label

Build Year (BY 2)

MX3978-01

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 7

Temporary use on existing inventory.

Keypad and Display

Page 8

How Software HandLeS monItored entrapment

Since HySecurity gate operators use software to control gate movement, contacts, and accessories, the changeover to

monitored sensors is simple. In fact, the ability to monitor sensors has always been an available Installer Menu item. (Refer

to Table 6: Setting the Sensor Logic on page 11) Instead of an option, it now becomes the default standard.

• Build Year is a new Installer Menu item in Smart DC and Smart Touch Controllers versions h5.50 and h4.50 (and

higher).

• New labels show where Edge, Photo Eye Open and Photo Eye Closed have changed to "SENSOR" inputs. You

can program the type of sensor wired to one of those inputs. Refer to illustrations on page 7 and Table 4

below.

• Installer Menu items, PC and GC (Photo eye output and edge sensor output) which used to default to Normally

Open (NO) have been converted to Normally Closed (NC) contacts so the software can detect the presence and

proper operation of entrapment protection sensors.

Table 4: Changes to Sensor Inputs on the Controller

Location of Sensor Inputs on Controller Installer Menu Item Codes

Smart Touch Controller (STC): Hydraulic gate operators Smart Touch Display:

Input # Current Silk Screen Label 2016 Silk Screen

Label

13 EDGE SENSOR SENSOR 1 S1 SENSOR 1

17 PHOTO EYE OPEN DIRECTION SENSOR 2 S2 SENSOR 2

19 PHOTO EYE CLOSE DIRECTION SENSOR 3 S3 SENSOR 3

Smart DC Controller (SDC):

Electromechanical gate operators

No numerical input

number appears on

Smart DC

EYE OPEN SENSOR 2 S2 SENSOR 2

EYE CLOSE SENSOR 3 S3 SENSOR 3

EDGE SENSOR 1 S1 SENSOR 1

OLED - two line,

32 character

Smart DC Display:

32 character LCD

LCD - 7

segment text

S1

S2

S3

NOTE: Three inputs for external entrapment protection sensors are available on the HySecurity gate operator controller. New silk

screen controller boards are on order, but until they are ready for shipment, labels will be overlaid on the board to indicate

terminology adaptations.

Table 4 indicates how the edge and photo eye inputs have been renamed to generic "sensor" inputs. They are

interchangeable and congurable. The software must know what type of sensor is wired to SENSOR 1, 2, and 3 BEFORE it

will allow gate travel. Refer to page 10.

8 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Page 9

wHat tHe InStaLLer needS to do

1

2

All HySecurity gate operators indicating a manufacturing date of 2016 (or later) in the serial number, will have the Build Year set to 2.

A Build Year of 2 (BY 2) indicates that your gate operator is prepared to monitor for external entrapment protection sensors. The Build

Year setting appears in the system scroll on the gate operator display. The gate operator will not automatically cycle the gate unless

an indication that the appropriate number of external entrapment protection sensors are connected and operational.

The normally closed (NC) entrapment protection sensors wired to the Controller's SENSOR inputs are monitored using

HySecurity software. Prompts appear in the display requesting specic congurations based on the gate operator type.

Table 5 illustrates what options are available for the HySecurity Controller's congurable inputs.

SENSOR 1 SENSOR 2 SENSOR 3 SENSOR COM

CAUTION

All external entrapment protection sensors must be NC sensor outputs and wired to

the SENSOR COM terminal for monitoring and powering purposes. The sensor becomes

actively powered when the gate operator receives a run command.

Assess Your Gate Site.

Design your gate installation so entrapment zones are kept to

a minimum, and then install your HySecurity gate operator.

Draw-in zone

Edge sensor (protecting open direction)

(EDGE OPEN)

Photo eye thru beam protecting

Leading End

(EYE CLOSE)

Photo eye thru-beam

protecting Trailing End (EYE

OPEN)

Install NC sensors.

Install NC contact and non-contact

eyes) for all potential entrapment zones. HySecurity gates monitor normally

closed (NC) sensors. Wire your NC sensors to SENSOR input terminals (SENSOR 1,

SENSOR 2, or SENSOR 3) on the Smart Touch or Smart DC Controllers. The SENSOR

inputs are interchangeable and congurable. For example, it doesn't matter whether you

wire a normally closed photo eye sensor or edge sensor to the SENSOR 1, 2, or 3 input.

NOTE: When installing wired edge sensors, the WIRED EDGE edge must be connected to an interface module

that produces an NC output. Refer to Table on page 6. Wireless edge sensors require no interface module.

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 9

sensors (edge sensors and photo

Page 10

3

Turn Power ON.

4

Electromechanical

Hydraulic

I/0 Switch

DC Power

I/0 Switch

2

4

V

A

C

A

c

ce

ss

o

ry

p

ower

I/0 Switch

AC Power

S1 2 (EYE CLOSE)

SENSOR #1 TYPE

SlideSmart DC

Control Box

SlideDriver Control Box

NOTE: Use PE, Photo Eye Alignment mode to temporarily

power the sensors. Refer to Photo Eye Alignment on page 12.

Answer Initial Setup Prompts.

For slide gates you will be prompted for USAGE CLASS,

GATE HANDING, and SENSOR 1, SENSOR 2, and

SENSOR 3. Each SENSOR input, whether or not it has a contact or non-contact sensor

wired to it, must be programmed to a non-zero setting before the gate will move.

NOTE: The gate operator will not automatically cycle unless an indication is received that the

appropriate number of external entrapment protection sensors are connected and

operational.

STOP BUTTON

OPEN BUTTON

CLOSE BUTTON

REMOTE OPEN AND

RADIO CONTROL

OPEN/CLOSE

OPEN PARTIAL

INTERLOCK OPEN

TIME CLOCK OPEN

FREE EXIT DETECTOR

DISABLE EXIT DETECTOR

DISABLE CLOSE TIMER

INSIDE OBSTRUCTION

VEHICLE DETECTOR

OUTSIDE OBSTRUCTION

VEHICLE DETECTOR

SHADOW/RESET

VEHICLE DETECTOR

SENSOR 1

SENSOR COM

DO NOT USE

SENSOR 2

DO NOT USE

SENSOR 3

DO NOT USE

CHARGER

AC LOSS

LOCK INTERLOCK

EMERG CLOSE

FIRE DEPT OPEN

LED

Smart Touch Controller

RPM

COM COMA B

POWER

USER 3

HySecurity

MX000585

VERSION

S/N

RADIO OPTIONS

+24V +24V

STOP/BUZZER

MOTOR USER 1

FREE

EXIT

USER 2

INSIDE

OBSTR

OUTSIDE

OBSTR

COM

NO

VEHICLE DETECTORVEHICLE DETECTORVEHICLE DETECTOR

STATUS

SHADOW

RESET

DISPLAY

VEHICLE DETECTOR

RS232

WIEGAND

COMOPEN

S 1

DRIVE

1

2

3

4

5

6

7

8

C

D

V

4

2

+

ON

COMM

9

10

11

12

14

15

16

17

18

19

20

21

22

23

24

LIMIT DUAL GATE

RS485

S1 2 (EYE CLOSE)

SENSOR #1 TYPE

OPEN

PREV

CLOSE

NEXT

STOP

SELECT

MENU

RESET

Smart Touch and Smart DC Controller: Menu Mode Navigation Buttons

To change data

appearing in the display

Press Select.

Two left characters blink.

To navigate through

the Selections

Press Next or Previous.

Continue pressing Next to view

all selections.

To choose what appears

on the display

Press Select.

Blinking characters

become static.

Table 5: Installer Menu Settings for SENSOR Inputs

UL 325

HySecurity Gate

Operator

Build

Year

2016

(BY set)

SlideDriver

(xed speed)

SlideDriver VFD 2

SlideSmart DC 15 2

SlideSmart DC 10 2

SwingRiser * 2

SwingSmart DC * 2

HydraSwing * 2

HydraLift 2

DISABLED

2

Installer Menu Settings for STC & SDC Sensors 1, 2, or 3 (solo operators)

#0

#1

NOT USED

#2

EYE CLOSE

#3

EDGE

CLOSE

● ● ● ● ● ● ●

● ● ● ● ● ● ●

● ● ● ● ● ● ●

● ● ● ● ● ● ●

● ● ● ● ● ● ●

● ● ● ● ● ● ●

● ● ● ● ● ● ●

● ● ● ●

#4

EYE OPEN

To navigate between

menu items

Press Next or Previous.

Advance - press Next

Previous - press Previous

#5

EDGE

OPEN

#6

EDGE BOTH

DIRECTIONS

#7

EYE BOTH

DIRECTIONS

NOTE: HySecurity does not update software for SlideWinder models. Refer to Table 2: HySecurity Gate Operators maintaining

Object Detection on page 5 for an overview of HySecurity gate operators not requiring monitoring of external entrapment

protection sensors to meet the 2016 UL 325 Standard of Safety regulations. * For notes on swing gates, refer to page 20.

10 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Page 11

Table 6: Setting the Sensor Logic

External entrapment protection sensors can be wired to any one of the three sensor inputs on the HySecurity Controller.

The sensor logic, such as Eye Close Logic (EC), Eye Open Logic (EO) and Gate Edge Logic (GR) remain accessible in

the Installer Menu, if the corresponding sensor type is installed, and determine how the gate operator will react when a

monitored sensor is activated.

NOTE: Default settings shown in Bold.

Installer Menu Setting Options Menu Tasks & Explanations

EC 0 STOP ONLY

EYE CLOSE LOGIC

EO 0 STOP ONLY

EYE OPEN LOGIC

GR 0 FULL OPEN

GATE EDGE LOGIC

SR 1 REVERSE 25

REVERSAL LOGIC

0 = Close eye stops only

1 = Two second reversal to open

on swing, slide, or vertical gates.

Reverse to full open with barrier

gates, StrongArm M30 and

StrongArm M50.

2 = Reverse to full open.

0 = Open eye stops only

1 = Two second reverse to close

0 = Edge reverses fully open

1 = Two second reversal only

0 = IES reverses fully open

1 = Two second reversal only

If the close photo eye is triggered, the default

setting is non-reversal while the gate is traveling

in the close direction. When triggered, with the

optional setting of EC 1, the gate pauses and

reverses it's direction for a 2-second interval,

and then resumes moving in the close direction

if the photo eye clears within 5 seconds. (See

exception for barrier arms.) A setting of EC 2

causes the gate to reverse and travel full open

when triggered.

If the open photo eye is triggered, the default

setting is non-reversal while the gate is traveling

in the open direction. When triggered, with the

optional setting of EO 1, the gate pauses and

reverses it's direction for a 2-second interval, and

then resumes moving in the open direction if the

photo eye clears within 5 seconds.

The default setting is to reopen fully if the edge

sensor is triggered while closing. The optional

setting of GR 1 sets the gate to a 2-second

reversal if triggered while closing.

If the inherent sensor is triggered, the default

setting reverses the gate travel for a 2-second

duration. The optional setting of SR 0 will cause

the gate to reopen fully if triggered while closing.

STC Wire

Connections

Sensor 1, 2, or 3

Sensor COM

COM

+24V

Sensor 1, 2, or 3

Sensor COM

COM

+24V

Sensor 1, 2, or 3

Sensor COM

+24V

10K resistor

(Edge)

N/A

PC 0 NO INPUT

PHOTO EYE OUTPUT

GC 0 NO INPUT

GATE EDGE OUTPUT

NOTE: The shaded Installer Menu items do not appear when Build Year is set to 2 (BY 2), post-2016. Exceptions exist for barrier

arms, CRASH products, operators set to pre-2016 and Usage Class 4 provisions.

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 11

0 = Normally Open NO input

1 = Normally Closed NC input

(monitored)

0 = Normally Open NO input

1 = Normally Closed NC input

(monitored)

Changes occurring in 2016.

The default setting is for photo eyes with

Normally Close outputs. When set for NC, the

connection is monitored and any short circuit

fault will generate a FAULT 2 (FAL2) alert. Press

the Stop or Reset button to clear.

See NOTE.

Changes occurring in 2016.

The default setting is edge sensor with Normally

Closed (NC) output. The optional setting of 0

requires an (NO) output.

See NOTE.

EYE Close

EYE COM

4 wires total:

COM

+24V

COM

PHOTO EYE

CLOSE

EDGE SENSOR

COM

4 wires total:

COM

+24V

COM

EDGE

Page 12

temporarILy power tHe SenSorS

The sensors are not receiving power until the gate operator receives a command to run (open or close command). To

temporarily power sensors and check that the gate operator is monitoring the sensors properly, turn on Photo Eye Align

by taking the following steps:

1. Access the User Menu and select PE.

To access the User Menu, press the Menu button twice. For a refresher on

using the Menu Mode navigational buttons, refer to the chart below.

2. Press NEXT and continue to press NEXT until PE 0 (OFF) appears.

3. Press SELECT.

PE characters begin blinking.

4. To turn ON photo eye alignment and temporarily power the sensors, press

NEXT so PE 1 (ON) appears.

5. Press SELECT.

PE stops blinking.

6. Press MENU to exit Menu Mode and return to Run Mode.

NOTE: NOTE: The Photo Eye Align mode turns OFF with the next limit contact.

Controller Temporarily apply Power to Sensors LED Status

Smart DC PE 1 (ON)

PHOTO EYE ALIGN

Smart Touch PE 1 (ON)

PHOTO EYE ALIGN

When PE is ON, the LEDs associated with the sensor devices will be lit

if the sensors are properly connected and sensors are grounded. The

LEDs turn off when the ground circuit is removed.

LEDs next to the sensor connections will be lit when no power is being

applied. When PE is turned ON, the LEDs turn off. If they do not turn

off, check for wiring issues such as a short or misapplied relay COM

connections. See CAUTION. If error messages appear on the display,

refer to Table 7: Troubleshooting Codes on page 14.

PE 0 (OFF)

PHOTO EYE ALIGN

OPEN

PREV

CLOSE

NEXT

SELECT

STOP

MENU

Smart DC display and keypad

RESET

pHoto eye aLIGnment

PE 1 (ON)

Most photo eyes require careful optical alignment in order to aim the emitter

beam to the center of the receiver or reector. In order to avoid false triggering, it is

important to carefully align the system.

Align the photo eyes using this feature by taking the following steps:

1. Follow steps 1 through 6 in Temporarily Power the Sensors.

2. Move the photo eyes (up/down, side to side) to align the emitter beam.

Audible Chirp Beam Aligned ??

One No

Two Yes

3. When the buzzer chirps twice, indicating the photo eyes are aligned, set the next

photo eye (if the site has one) and continue the process until all photo eyes are

aligned.

4. Run the gate with an open or close command. When any limit is triggered, the

User Menu item PE resets to zero (OFF).

NOTE: To cover the potential entrapment areas, mount photo eyes preferably within 5 inches

(13 cm) of the gate face. For more information, refer to ASTM F2200 Gate and Fence Standards.

12 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

PHOTO EYE ALIGN

CLOSE

OPEN

NEXT

PREV

PE 1 (ON)

PHOTO EYE ALIGN

STOP

SELECT

MENU

RESET

Page 13

troubLeSHootInG

The Smart Touch Controller reports system malfunctions using three simultaneously occurring methods:

• Codes presented on its display (alert, fault or error)

• Activation of a buzzer which emits a series of chirps at dened intervals

• Stop gate travel (and/or reverse direction of travel)

Overriding a tripped sensor or fault condition on a HySecurity gate operator

with monitored entrapment sensors requires a 2-step process:

• Press Open or Close momentarily. Audible beeps in quick succession

indicate tripped sensors or fault conditions.

• Within 5 seconds of hearing the beeps, apply constant hold pressure

to override the tripped sensor or fault. The gate operator runs while

pressure is maintained to actuating device (examples include, Push

button Open, Push button Close, Open Partial or Keypad Open/

Close), or a limit is reached, or another sensor trips.

A short list of codes appears in Table 7: Troubleshooting Codes and provides

additional troubleshooting solutions. For a complete list of troubleshooting

codes, refer your gate operator’s Programming and Operations manual.

NOTE: A qualied technician may troubleshoot the operator with the aid of the

information and procedures that follow. If it is necessary to call a distributor for

assistance, be sure to have the model and serial numbers available. Other helpful

information is the job name, approximate installation date, and service records of any

recently-performed maintenance work.

FAULT 2

SENSOR #1

HYSECURITY

GATE STOPPED

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 13

Page 14

Table 7: Troubleshooting Codes

Type Display Buzzer Chirp Sequence Possible Cause & Suggested Corrective Action

ALERT HYSECURITY

ENTRAPMENT MODE

ENTR

ALERT HYSECURITY

SAFE MODE

SAFE

ALERT !ACTION BLOCKED

PHOTO EYE CLOSE

PEC

ALERT !ACTION BLOCKED

PHOTO EYE OPEN

PEO

ALERT !ACTION BLOCKED

GATE EDGE

(Open or Close)

GEO

FAULT FAULT 2

FAL2

2 chirps per second every

2s while control input is

active

2 chirps once when in Safe

Mode

5 chirps indicating that

the command cannot be

initiated

5 chirps indicating that

the command cannot be

initiated

5 chirps indicating that

the command cannot be

initiated

2 chirps per second once

per minute

An IES has been tripped twice within a specic period of time.

Check the gate site for obstructions and clear the gate area. To

return to run mode operation, press the Reset button.

A gate “edge” or IES has been tripped or the operator has exited

entrapment mode. Refer to the description above.

NOTE: Gate will operate, if it receives a RUN command.

Operator received command to run, but movement is prevented.

Photo eye is not recognized as active.

• Clear photo eye path

• Realign photo eye. Refer to Photo Eye Alignment on page 12.

• Replace photo eye battery

• Check N.C. wiring (verify wires are not disconnected or shorted)

• Review wiring diagrams. Especially path to SENSOR COM

• Make sure SENSOR settings S1, S2, and S3 are correctly

assigned. Refer to What the Installer Needs to Do on page 9.

Operator received command to run open, but movement is

prevented. Photo eye is not recognized as active.

• Clear photo eye path

• Realign photo eye. Refer to Photo Eye Alignment on page 12.

• Replace photo eye battery

• Check N.C. wiring (verify wires are not disconnected or shorted)

• Review wiring diagrams. Especially path to SENSOR COM

• Make sure SENSOR settings S1, S2, and S3 are correctly

assigned. Refer to What the Installer Needs to Do on page 9.

Operator received command to run open, but movement is

prevented. Gate edge blocked or disconnected and causes

operator to enter SAFE mode.

Gate edge is not recognized as active.

• Replace sensor batteries

• If using Miller Monitored Edge Link, be aware. Issues with radio

interference cause false trips. Placing the antenna high and

reducing environmental “noise” is critical to proper wireless

transmission. Avoid placing the receiver sets within 100 feet of

each other as crosstalk may occur. Use receivers & transmitters

Version 1.02 or higher.

• Verify wired edges are using a gate edge converter-type module.

Miller Edges must have a wire with blue tape. The blue tape

indicates that a resistor is built in.

• Check N.C. wiring (verify wires are not disconnected or shorted)

• Review wiring diagrams. Especially path to SENSOR COM

• Make sure SENSOR settings S1, S2, and S3 are correctly

assigned. Refer to What the Installer Needs to Do on page 9.

“Monitored” means the Controller must see the photo eye N.C.

contact change from open to close after receiving the command to

run, but before starting the motor. FAULT 2 indicates the controller

did not see this sequence when the gate received a run command.

• Check the wiring. Refer to the wiring diagram associated with the

attached sensor.

• Be sure the eye “common” wire is wired properly to the SENSOR

COM terminal.

14 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Page 15

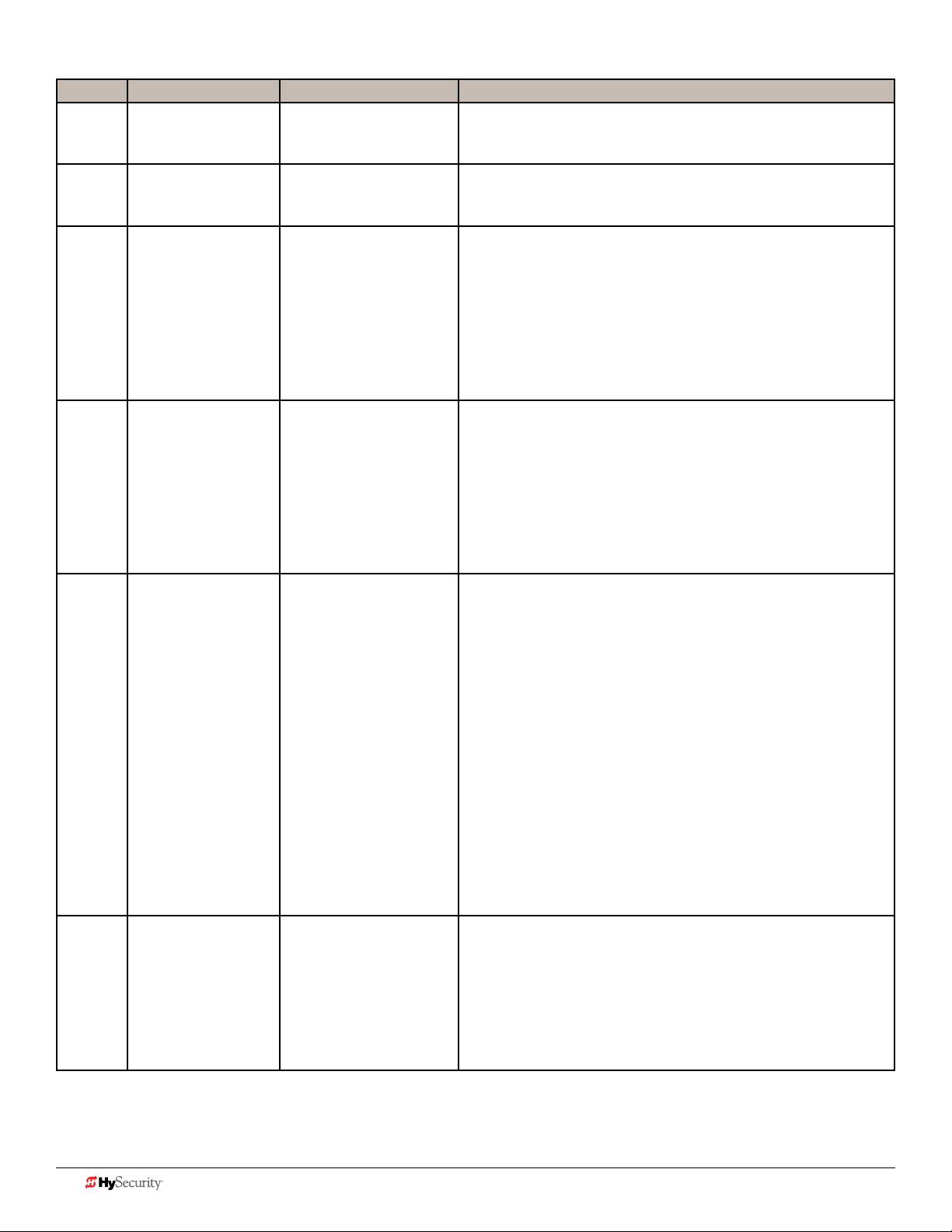

Type Display Buzzer Chirp Sequence Possible Cause & Suggested Corrective Action

ERROR

ERROR ERROR 2

ERROR ERROR 7

FAIL FAIL

ERROR 4

DUAL GATE

IES DISCONNECT

MENU CHECKSUM

ERR7

PROGRAM DATA ERR

FAIL

3 chirps per second once

per minute

3 chirps per second once

per minute

3 chirps per second once

per minute

3 chirps per second once

per minute

Indicates a problem with the communication between the two gate

operators in a bi-parting gate system.

• Check the version of software by pressing Reset. The version

number ashes on the display (examples, h4.54 or h5.56).

• The software versions on the Primary and Secondary gate should

be the same. If not, upload current software version using

S.T.A.R.T. and a PC laptop computer.

• Verify the Installer Menu item DG (DUAL GATE) is set to DG2 in

Primary and set to DG1 in Secondary gate operator.

• Make sure the wires are twisted and shielded. See illustration on

page 46.

• Be sure the low voltage wire runs, which include the bi-parting

gate communication wires, are separate from any high voltage

wires runs. Interference occurs if wire runs are mixed or too close

to each other.

The error automatically clears when the communication fault is

resolved.

• The IES sensor could be bad, check to see that the NC contact is

intact.

• Check that you have the most current sensor; visit our website

and view the technical bulletins in the Tech Support area. The

sensor wire could be loose; you may want to tighten the female

connectors with some pliers.

• Verify the version of the software by pressing the Reset button.

The software version appears on the display. Make a note of it.

The software version should be h4.50 or h5.50 (or higher).

• If necessary, update the software using a PC laptop and

S.T.A.R.T. Register and login in at www.hysecurity.com

Contact HySecurity.

1. Try turning off the power to the operator and having the

customer re-seat all of the various connectors and cables.

2. Upload the latest software release. If the fail does not go away,

contact Technical Support.

NOTE: For a more extensive list of error codes, refer to your gate operator’s product manual.

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 15

Page 16

SIte aSSeSSment & Gate deSIGn for monItored entrapment

Edge Open

Eye Close

Eye Open

Check gap & protect

potential draw-in zones

SECURE

NOTE: Any gap larger than 2¼" (57 mm) between gate and xed objects must be

protected. Install edge sensors where gap between post and gate creates a draw-in zone.

Slide Gate: Monitored Entrapment Site Scenario (Viewing from SECURE side)

PUBLIC

Eye Close

SECURE

PUBLIC

Slide Gate: Monitored Entrapment Site Scenario (Viewing from PUBLIC side)

NOTICE: UL 325 Standard of Safety provides the MINIMUM safety standards. Site, gate hardware usage,

and other conditions may dictate the use of additional safety designs/components. It is up to the gate system

designer and installer to assess appropriate safety design and components above and beyond minimum

UL 325 and ASTM F2200 standards. Always check your local area codes and comply with all regulations.

16 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Page 17

SIte aSSeSSment & Gate deSIGn for monItored entrapment

continued...

Edge Open

Check gap & protect

potential draw-in zones

Eye Close

Eye Open

SECURE

NOTE: Any gap larger than 2¼" (57 mm) between gate and

xed objects must be protected. Install edge sensors where

gap between post and gate creates a draw-in zone.

PUBLIC

Eye Open

Retro-reective

photo eye shown

Edge Both

SECURE

Slide Gate: Monitored Entrapment Site Scenario (Viewing from SECURE side)

Eye Close

PUBLIC

Edge Both

Wrap around edge

sensor example

Swing Gate: Monitored Entrapment Site Scenario (Viewing from SECURE side)

NOTICE: UL 325 Standard of Safety provides the MINIMUM safety standards. Site, gate hardware usage, and

other conditions may dictate the use of additional safety designs/components. It is up to the gate system

designer and installer to assess appropriate safety design and components above and beyond minimum UL 325

and ASTM F2200 standards. Always check your local area codes and comply with all regulations.

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 17

Page 18

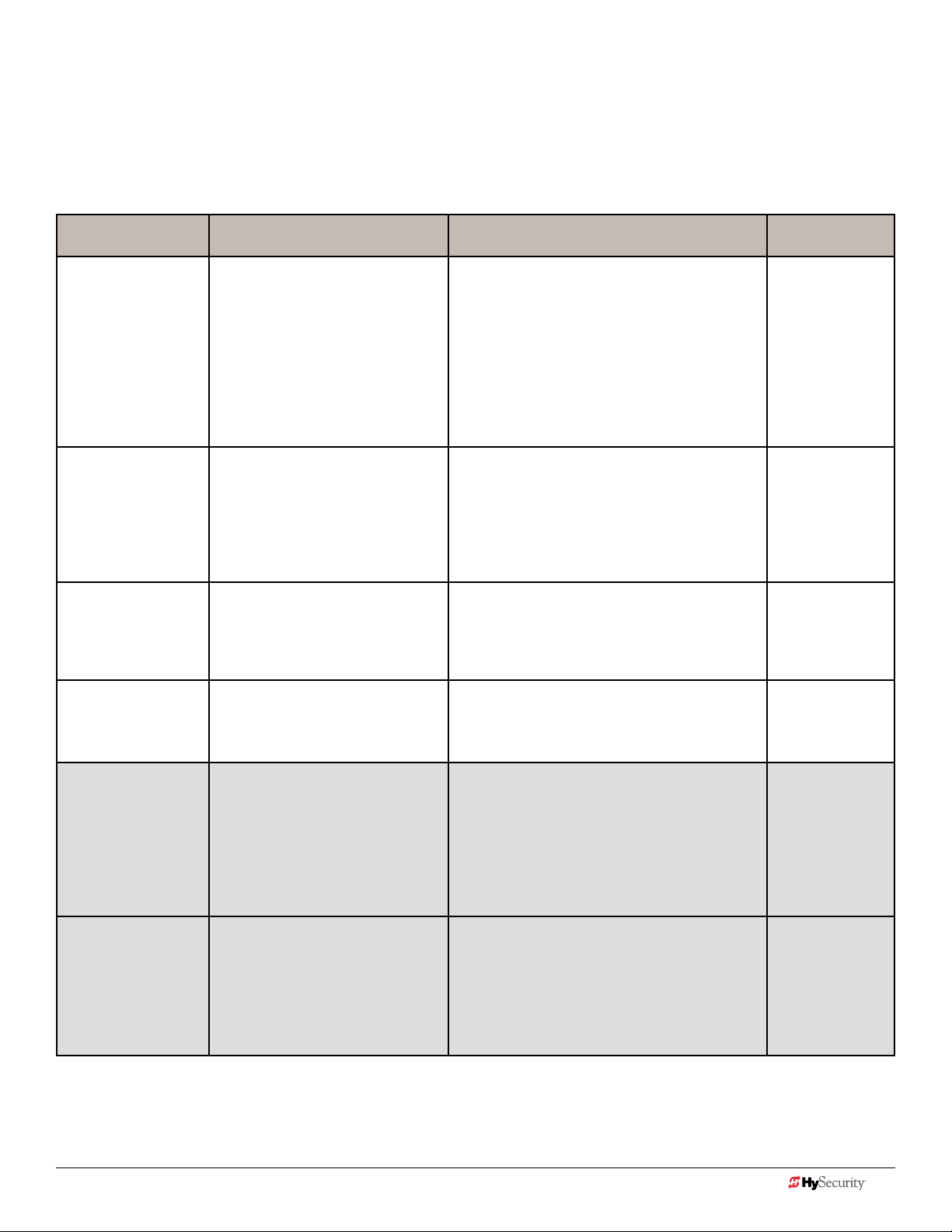

General Entrapment Protection Provisions per UL 325, Table 31.1

Effective January 12, 2016, Table 31.1 General Entrapment Protection Provisions for gate operator categories.

The following chart is a copy of UL 325 Standard of Safety, Table 31.1

Gate Operator Category

Horizontal Slide, Vertical Lift and Vertical Pivot Swing and Vertical barrier (arm)

Entrapment protection types: A, B1, B2, D Entrapment protection types: A, B1, B2, C or D

NOTE: The same type of device shall not be utilized for both entrapment protection means. Use of a single device to cover both

the opening and closing directions is in accordance with the requirement; however, a single device is not required to cover both

directions. A combination of one Type B1 for one direction and one Type B2 for the other direction is the equivalent of one

device for the purpose of complying with the requirements of either entrapment protection means.

Type A – Inherent entrapment protection system.

Type B1 – Non-contact sensor (photoelectric sensor or the equivalent).

Type B2 – Contact sensor (edge device or the equivalent).

Type C – Inherent force limiting, inherent adjustable clutch or inherent pressure relief device.

Type D – Actuating device requiring continuous pressure to maintain opening or closing motion of the gate.

The changes that occurred to HySecurity software and discussed on the previous pages are based on compliance with the

UL 325 -2016 Standard of Safety.

An exception for vehicular barrier arms exists. As stated in UL 325 Standard of Safety:

An operator for a vehicular barrier (arm) that is not intended to move toward a rigid object closer than 16 inches

(406 mm), and does not have a pinch point between moving parts by virtue of the operator’s design or as a result of

installation in accordance with instructions supplied with the operator as specied in UL 325 Standard of Safety is not

required to be provided with means to protect against entrapment.

A provision also exists for Usage Class 4 and is described below.

Usage Class 4 Designated Gate Operator Provisions

Usage Class 4 sites must have a guard house or CCTV gate monitoring to verify credentials of vehicles entering or exiting

the facility and to ensure safe gate operation in the rare occurrence where pedestrians may be present. HySecurity

handles the UL 325 - 2016 gate operator provisions for Usage Class 4 in the following manner:

• SENSOR inputs default to 0 and must be set to a non-zero number before automatic gate operation is allowed.

Normally Closed (NC) sensors become the default for monitoring if external entrapment protection sensors are

connected. However, the gate operator can be congured through the Installer Menu to accept either Normally

Closed (NC) or Normally Open (NO) outputs from sensors.

• When SENSOR 1, 2, and 3 are set to 1 (NOT USED) or when the software detects a programmed monitored

sensor fault, a Warn-Before-Operate buzzer automatically sounds 3 seconds before movement and throughout

gate travel.

• If a sensor input is held tripped, the gate operator can move the gate in the same manner as other usage classes

with a simple constant hold input (Push button Open, Push button Close, Open Partial or Keypad Open/Close

activation). Refer to Troubleshooting on page 13.

• Note that Alerts, Faults, and Errors used for troubleshooting are handled in the same manner as other HySecurity

gate operator usage classes.

18 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Page 19

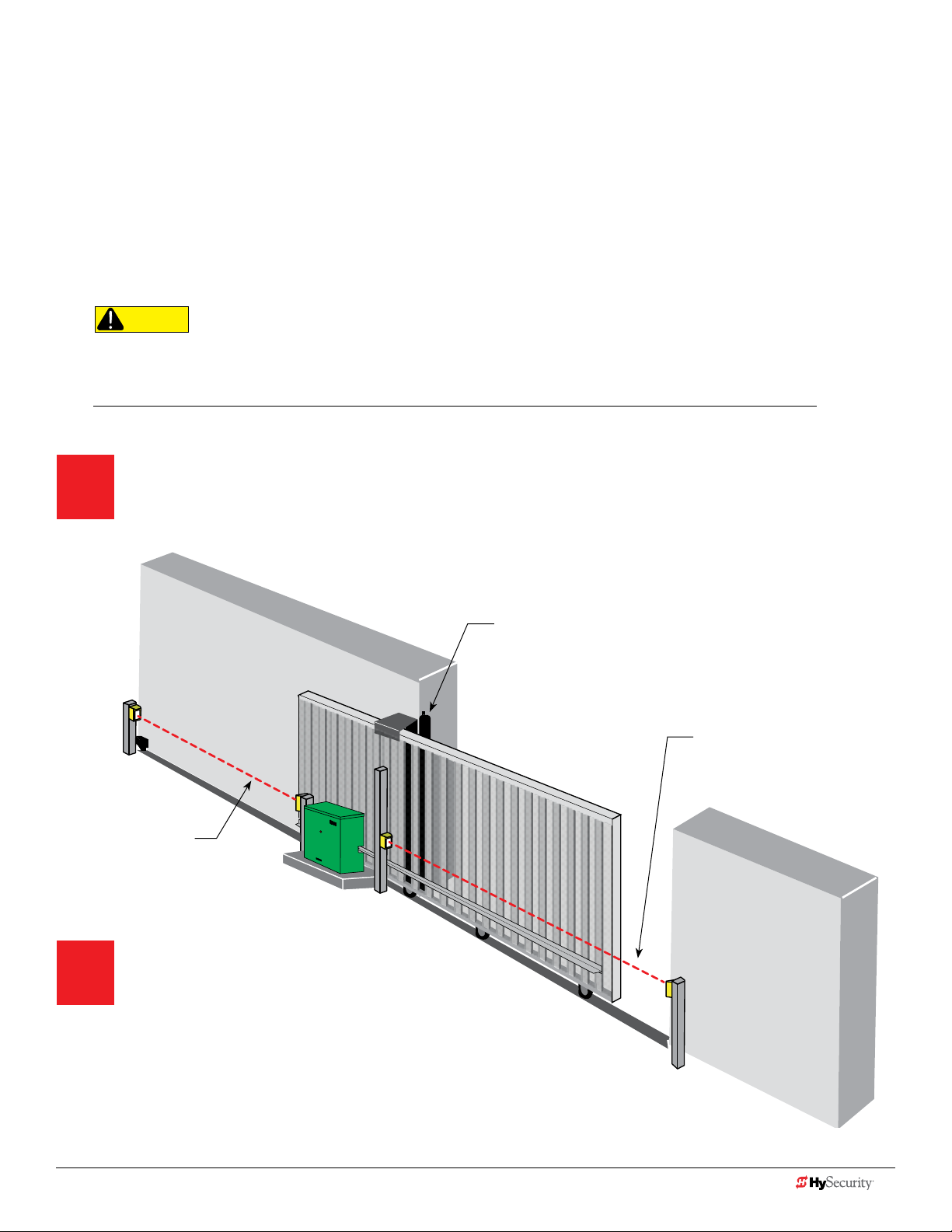

dIaGram 1: typIcaL SLIde Gate SIte aSSeSSment

NOTE: This scenario shows a possible conguration with the minimum recommended external entrapment protection sensors.

Other sensor congurations are valid. Each gate site is different. It is the installer's responsibility to assess and protect all

entrapment zones.

Edge sensor

(protecting open

direction) Draw-in

zones

Photo eye thru-beam

protecting Trailing End of

gate (Open direction of

travel)

Photo eye thru beam

protecting Leading End of

gate (Close direction of travel)

Drawing is not to scale

NOTICE: HySecurity slide gates are equipped with a Type A inherent entrapment sensor (IES) that complies with

UL 325. Any impediment to gate travel causes the gate to stop and reverse.

Monitored external entrapment protection sensors, which can be used in this site scenario and are compatible with

HySecurity slide gates, appear in the following chart. For a full list, refer to page 6.

EXAMPLE: External Entrapment Protection Sensors: Normally Close Contact, Compatible with HySecurity Gate Operators

P/N 2016 Monitored Sensors Sensor Type Output Manufacturer

MX3981

MX3983

MX3990 IRB-MON (Dist.~ 65 ft)t Thru-beam photo eye

MX3990 IRB-MON (Dist.~ 65 ft) Thru-beam photo eye

Wired Gate Edge Sensor

MGR20-2U-05-T2, Round

Gate Edge Module (GEM -104) Edge Interface Module

Wraparound edge

(5 ft for 2" round post)

10K

Resistor

Normally

Closed

Normally

Closed

Normally

Closed

Miller Edge Type B2

EMX Industries Type B1

EMX Industries Type B1

UL 325

Recognized

A minimum of one monitored external entrapment protection sensor, in addition to the slide gate operator’s inherent

sensor, is required before enabling momentary control activation. However, if there is a risk of entrapment in both

directions of gate travel, then both directions of travel must be protected by an external sensor.

NOTE: At minimum, external entrapment protection sensors must be installed wherever potential for entrapment exists during gate

movement. Note that every site is different. All potential entrapment zones should be protected with contact or non-contact

sensors. HySecurity gate operators detect NC output sensors and monitor them to comply with UL 325 Standard of Safety.

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 19

Page 20

dIaGram 2: typIcaL SwInG Gate SIte aSSeSSment

Pedestrian

gate

WARNING

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any me without

prior warning.

Do not let children operate the gate or play in

the gate area.

This entrance is for vehicles only. All pedestrians

must use a separate entrance.

Read the owner’s manual and safety instrucons.

Wraparound edge sensor

for potential Entrapment

Zone along base of gate.

Wraparound *

edge sensor on the

Leading End.

* If gate does not accommodate 2" wraparound edge

sensor, two standard channel mount edge sensors may

need to be used.

NOTE: If the bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at

any point in its arc of travel, one or more contact sensors shall be located on the bottom edge.

Reective Photo Eye to

protect potential

Entrapment Zone

which exists if gate

comes within 16 inches

of a rigid object.

Drawing is not to scale.

NOTICE: HySecurity swing gates are equipped with a Type A inherent entrapment sensor (IES) that complies with

UL 325. Any impediment to gate travel causes the gate to stop and reverse.

Monitored external entrapment protection sensors, which can be used in this site scenario and are compatible with

HySecurity swing gates, appear in the following chart. *For a full list, refer to page 6.

Example: External Entrapment Protection Sensors: Normally Close Contact, Compatible with HySecurity Gate Operators*

P/N 2016 Monitored Sensors Sensor Type Output Manufacturer

MX3981

Wired Gate Edge Sensor

MGR20-2U-05-T2, Round

MX3983

Gate Edge Module (GEM -104) Edge Interface Module

MX3985 Reecti-Guard (RG-R) Photo eye, reective

Wraparound edge

(5 ft for 2" round post)

10K

Resistor

Normally

Closed

Normally

Closed

Miller Edge Type B2

Miller Edge Type B1

UL 325

Recognized

A minimum of one monitored external entrapment protection sensor, in addition to the swing gate operator’s inherent

sensor, is required before enabling momentary control activation. Installers may decide both the type and location of the

one required entrapment protection sensor to protect either the open direction, the close direction or both directions of

swing gate travel. However, if there is a risk of entrapment in both directions of gate travel, then both directions of travel

must be protected by an external sensor.

NOTE: If a photo eye open is the only external entrapment protection sensor connected to a swing gate, it's application will require

a constant push button hold close for the swing gate to operate. HySecurity gate operators detect NC output sensors and monitor

them to comply with UL 325 Standard of Safety. Understand that UL 325 conveys the minimum standard of safety. Installers must

assess each specic gate design and site and install external entrapment protection sensors to guard all potential entrapment zones.

20 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Page 21

dIaGram 3: typIcaL barrIer arm SIte aSSeSSment

M

X

31

86-

0

1,

-02,

-

0

3

Access control device

WARNING Signs

Photo eye

Photo eye receiver (not

shown in illustration)

emitter

NOTICE: Site design considerations: Any rigid object such as, bollards, photo eye mounting

posts, fencing and walls cannot be within 16 inches of barrier arm travel. If a potential exists for a

barrier arm to travel within 16 inches of a solid, rigid object, the potential entrapment zone must

be protected with a monitored external entrapment protection sensor.

UL 325 Exception: An operator for a vehicular barrier (arm) that is not intended to move toward a rigid object closer

than 16 inches (406 mm), and does not have a pinch point between moving parts by virtue of the operator’s design or

as a result of installation in accordance with instructions supplied with the operator as specied in UL 325 Standard of

Safety is not required to be provided with means to protect against entrapment.

HySecurity barrier arms provide features for object detection. For more information, refer to the gate operator’s product

manual. Since the StrongArm falls in the exception classication for monitored entrapment, your options for accessory

connections and programming vary depending on your site requirements.

If your StrongArm uses version h4.50 software or higher:

• Build Year (BY) is set to 2

• SENSOR inputs default to normally closed contacts

• SENSOR input conguration defaults to “NOT USED”

• Gate will run with all SENSOR inputs set to “NOT USED”

All three sensor inputs can be re-congured.

NOTE: Even though no wires are attached to a SENSOR input, it must be “set” to 1 (NOT USED). The software requires

conrmation of all 3 monitored input designations before allowing the gate to move.

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 21

Page 22

dIaGram 4: typIcaL VertIcaL LIft SIte oVerVIew

WARNING

Minimum

8 ft (2.4 m)

Clearance

KEEP CLEAR!

Moving Gate Can Cause Serious

Injury, Death, or Vehicle Damage

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use a separate entrance.

Thru-beam Photo Eye

NOTICE: HySecurity vertical lift gates are equipped with a Type A inherent entrapment sensor (IES) that complies

with UL 325. Any impediment to gate travel causes the gate to stop and reverse.

Monitored external entrapment protection sensors, which can be used in this site scenario and are compatible with

HySecurity vertical lift gates, appear in the following chart. For a full list, refer to page 6.

EXAMPLE: External Entrapment Protection Sensors: Normally Close Contact, Compatible with HySecurity Gate Operators

P/N 2016 Monitored Sensors Sensor Type Output Manufacturer

MX3990 IRB-MON (Dist.~ 65 ft) Thru-beam photo eye Normally Closed EMX Industries Type B1

NOTE: A Thru-beam Photo Eye is recommended in this site scenario. A monitored wireless edge sensor is a viable option, though it

is not called out in the site scenario, chart above, or wiring diagram. Every site is different. On vertical lift gates, one monitored

sensor must be installed to protect the close direction of travel. However, all potential entrapment zones should be protected with

contact or non-contact sensors. HySecurity gate operators detect NC output sensors and monitor them to comply with UL 325

Standard of Safety.

UL 325

Recognized

22 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Page 23

dIaGram 5: typIcaL SLIdeSmart dc SIte aSSeSSment

Left Hand Gate

opening

ENTRAPMENT

6 ft (1.8 m) minimum

ZONE

Public Side

WARNING

sides of the gate in clear view.

For your records, take a photograph of

the completed installation site.

Gap between vertical bars

must be less than 2¼” (57 mm)

If gap is larger, a screened wire

mesh must extend to top of gate

or, to a minimum height

of 6 ft (1.8 m).

Be sure to place the

WARNING signs on both

Photo eye (Emitter or Reector in the Open direction)

Physical stop - at both ends of gate rail.

Interior posts,

Non-pinch

rollers (2x)

Mount access control

devices at least 6 ft

(1.8 m) beyond the gate.

Earth ground

Photo eye (Receiver)

Pedestrian gate located

near the slide gate.

Make sure a separate walk-

through entrance is available

and its pedestrian path is

clearly designated.

Physical

V track

stop

(gate rail)

Edge sensors (Public and Secure sides)

(Draw-in zone)

Photo eye (Receiver)

Secure Side

NOTE: Any gap larger than 2¼” (57 mm)

between gate and xed objects must be

protected. Install wrap around edge sensors

where gap between post and gate creates a

draw-in zone.

Photo eye

Emitter or Reector

(Close direction)

NOTE: To use monitored entrapment protection sensors for all four areas called out in this site scenario, The Solution multi-

input device would be required. Refer to page 6. Note that every site is different. All potential entrapment zones should be

protected with contact or non-contact sensors.

After wiring your external entrapment protection sensors to the Controller’s sensor inputs, access the Installer Menu. Set

sensors S1, S2, and S3 for this example of a site scenario, as follows:

GATE OPERATOR: SlideSmart DC and SlideSmart DCS using multi-input device.

S1 0

SENSOR #1 TYPE

CLOSE

OPEN

NEXT

PREV

OPEN

PREV

OPEN

PREV

S1 5 (EDGE OPEN)

STOP

MENU

RESET

SENSOR #1 TYPE

SELECT

CLOSE

STOP

MENU

S2 5 (EDGE OPEN)

SENSOR #2 TYPE

SELECT

NEXT

CLOSE

S3 7 (EYE BOTH)

STOP

MENU

SENSOR #3 TYPE

SELECT

NEXT

CLOSE

OPEN

STOP

SELECT

NEXT

PREV

Initial SENSOR setting = 0

Set SENSOR 1 = #5

EDGE OPEN (public side)

RESET

Set SENSOR 2 = #5

EDGE OPEN (secure side)

RESET

MENU

RESET

Set SENSOR 3 = #7

EYE BOTH **

**Since in the site scenario there are two monitored photo eye sensors protecting open and close

directions of travel and only one input remaining, you could use a Multi-input device (The Solution).

Connect sensors to two separate inputs on The Solution, set to NC contact (not Pulse) and wire The

Solution output to SENSOR 3 on the Controller. In the Installer Menu, set SENSOR #3 TYPE to EYE

BOTH. Another option? Use a long range photo eye and wire as a singular SENSOR input 1.

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 23

Page 24

dIaGram 6: SwInGSmart dc SIte oVerVIew (duaL Gate)

Public Side

WARNING

sides of the access point in clear view of vehicles.

For your records, take a photograph of the

completed installation site.

Be sure to place the

WARNING signs on both

Mount access control

devices at least 6 ft

(1.8 m) beyond the gate.

Photo eye

(transmitter)

Gate Operator 1

Set SENSOR 1 input to #2

Photo eye Close

(Receiver)

Gate Operator 2

Photo

Set SENSOR 3 input to

eye

#4 (EYE OPEN)

Gate

Operator 2

ZONE

Reector

for Photo

Eye

Gate

Operator 1

Earth ground

Curb

ENTRAPMENT

Wrap around

Edge sensor (2x)

Wrap around

Edge sensor (2x)

ENTRAPMENT

Curb

A

ENTRAPMENT

ZONE

Pedestrian gate located

near the swing gate.

Make sure a separate walk- through entrance is

available and its pedestrian path is clearly designated.

View A

Cross Section

NOTE: If the bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of travel,

one or more contact sensors shall be located on the bottom edge. In this gate site scenario, two wraparound edge sensors are

used on both gates which requires 2 inputs and 2 Installer Menu settings. See displays below for Gate operator 1 and 2.

Secure Side

After wiring your external entrapment protection sensors to the Controller’s sensor inputs, access the Installer Menu, Set

sensors S1, S2, and S3. (Refer to Table 5: Installer Menu Settings for SENSOR Inputs on page 10.)

GATE OPERATOR 1: SwingSmart DC or DCS GATE OPERATOR 2: SwingSmart DC or DCS

S1 0

SENSOR #1 TYPE

S1 0

SENSOR #1 TYPE

Set Sensor 1 = #2

Initial Sensor setting = 0

OPEN

PREV

S1 2 (EYE CLOSE)

CLOSE

STOP

SENSOR #1 TYPE

SELECT

NEXT

CLOSE

OPEN

S2 6 (EDGE BOTH)

SENSOR #2 TYPE

NEXT

PREV

STOP

SELECT

MENU

MENU

RESET

RESET

Photo EYE CLOSE

Set Sensor 2 = #6

EDGE BOTH

OPEN

PREV

S1 6 (EDGE BOTH)

CLOSE

STOP

SENSOR #1 TYPE

SELECT

NEXT

CLOSE

OPEN

S2 6 (EDGE BOTH)

SENSOR #2 TYPE

SELECT

NEXT

PREV

STOP

MENU

RESET

MENU

Set Sensor 3 = #6

OPEN

PREV

CLOSE

S3 6 (EDGE BOTH)

SENSOR #3 TYPE

NEXT

CLOSE

OPEN

NEXT

PREV

STOP

SELECT

STOP

SELECT

MENU

MENU

RESET

RESET

EDGE BOTH

OPEN

PREV

CLOSE

STOP

S3 4 (EYE OPEN)

SENSOR #3 TYPE

SELECT

NEXT

CLOSE

OPEN

NEXT

PREV

MENU

STOP

SELECT

24 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

Initial Sensor setting = 0

Set Sensor 1 = #6

EDGE BOTH

RESET

Set Sensor 2 = #6

EDGE BOTH

RESET

MENU

RESET

Set Sensor 3 = #4

EYE OPEN

Page 25

Wiring HySecurity Sensors: Smart Touch

Wiring diagrams are provided on the following pages. The diagrams illustrate how to connect sensors and program the

gate operator. HySecurity Smart Touch gate operators can monitor entrapment protection sensors per UL 325 - 2015

Standard of Safety using software version h4.50 (or higher).

The site designer or installer must determine which external entrapment protection sensors will be installed with the

gate operator to create a UL 325 compliant installation site. For additional information, review For additional information,

review Gate Safety on the HySecurity website.

Power Supply Board

2

4

V

A

C

A

c

ce

ss

Label: pre-2016

EDGE SENSOR

EDGE SENSOR

PHOTO EYE POWER

PHOTO EYE POWER

24 VOLTS COMMO

24 VOLTS COMMON

PHOTO EYE POWER

PHOTO EYE POWER

DO NOT USE

PHOTO EYE

PHOTO EYE

OPEN DIRECTION

OPEN DIRECTION

DO NOT USE

+24V +24V

RS485

STATU S

DISPLAY

S 1

RS232

COM

NO

COMOPEN

MOTOR USER 1

EXIT

USER 2

OBSTR

OBSTR

RESET

STOP/BUZZER

FREE

INSIDE

OUTSIDE

VEHICLE DETECTORVEHICLE DETECTORVEHICLE DETECTOR

SHADOW

VEHICLE DETECTOR

WIEGAND

DRIVE

1

2

C

D

V

4

2

+

ON

o

ry

p

ower

COMM

Label: 2016

SENSOR 1

SENSOR 1

SENSOR

SENSOR

COM

COM

DO NOT USE

SENSOR 2

SENSOR 2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

21

22

23

24

STOP BUTTON

OPEN BUTTON

CLOSE BUTTON

REMOTE OPEN AND

RADIO CONTROL

OPEN/CLOSE

OPEN PARTIAL

INTERLOCK OPEN

TIME CLOCK OPEN

FREE EXIT DETECTOR

DISABLE EXIT DETECTOR

DISABLE CLOSE TIMER

INSIDE OBSTRUCTION

VEHICLE DETECTOR

OUTSIDE OBSTRUCTION

VEHICLE DETECTOR

SHADOW/RESET

VEHICLE DETECTOR

EDGE SENSOR

PHOTO EYE POWER

24 VOLTS COMMON

PHOTO EYE POWER

DO NOT USE

PHOTO EYE

OPEN DIRECTION

DO NOT USE

PHOTO EYE

CLOSE DIRECTION

DO NOT USE

CHARGER

AC LOSS

LOCK INTERLOCK

EMERG CLOSE

FIRE DEPT OPEN

LED

Smart Touch Controller

LIMIT DUAL GATE

RPM

COM COMA B

POWER

USER 3

HySecurity

MX000585

VERSION

S/N

RADIO OPTIONS

DO NOT USE

PHOTO EYE

PHOTO EYE

SENSOR 3

Label:

Pre-2016

Build Year (BY 1)

CLOSE DIRECTION

CLOSE DIRECTION

SENSOR 3

S2 6 (EDGE BOTH)

SENSOR #2 TYPE

MX3979-02

Used on replacement boards for gate

operators manufactured prior to 2016.

Label:

Post 2016 Label

Build Year (BY 2)

MX3978-01

Change effective January 12th 2016

per UL 325 - 2016 Standard of Safety

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 25

Page 26

Smart toucH: wIred edGe SenSor wItH Gem (-104)

1. Turn OFF power.

2. Connect the Green NC relay wire from GEM to Sensor 1, 2, or 3.

3. Connect Red & Green wires from GEM to SENSOR COM on Controller (or Power Supply Board, STC).

4. Connect Red wire from GEM to +24V on Controller (or Power Supply Board, STC).

5. Connect Black & White wire from GEM to 10K resistor in edge

sensor.

6. Turn ON power and access the Installer Menu.

Congure SENSOR setting accordingly (i.e. Edge Open, Edge

S2 0

SENSOR #2 TYPE

Installer Menu

showing Sensor 2

set to Edge Open

(Option #5)*

Close, or Edge Both). See Table 5: Installer Menu Settings for

SENSOR Inputs on page 10.

S2 5 (EDGE OPEN)

SENSOR #2 TYPE

CAUTION

All external entrapment protection sensors

must be NC sensor outputs and wired to the

SENSOR COM terminal for monitoring and

powering purposes. The sensor becomes

actively powered when the gate operator's

motor runs.

*NOTE: For 2 channel

capabilities, refer to Smart

Touch: 2 CH Wired Edge with

GEM-204 on page 34

Power Supply

Board

24V

A

C A

cce

s

s

or

y powe

r

ON

MM

O

C

C

D

V

24

+

GEM: Red Wire

CONNECT TO GATE EDGE

WITH 10K OHM RESISTOR

Black & White

GEM:

Red Wire

Wires

GEM:

Green Wire

B W

MILLER EDGE

GEM

GEM:

Green Wire

Green output wire can attach

to any SENSOR input.

*NOTE: Make sure whichever wired input used (SENSOR 1, 2, or 3) is the

same Sensor # congured through the Installer Menu.

DRIVE

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

21

22

23

24

LIMIT DUAL GATE

STOP BUTTON

OPEN BUTTON

CLOSE BUTTON

REMOTE OPEN AND

RADIO CONTROL

OPEN/CLOSE

OPEN PARTIAL

INTERLOCK OPEN