Page 1

Installation and Reference Manual

™

SwingSmart DC

SwingSmart DC 20

SwingSmart DCS 20 (solar)

Pad-mounted, electromechanical swing gate operator with Smart DC Controller

Sales: 1-800-321-9947 Fax: 1-888-321-9946

www.hysecurity.com Email: info@hysecurity.com

Tech Support: Call your dealer or distributor

6623 South 228th Street, Kent, WA 98032

Sold by

Dealer/Installer: __________________________

Phone: ________________________________

Distributor: ______________________________

Phone: ________________________________

D0149

Page 2

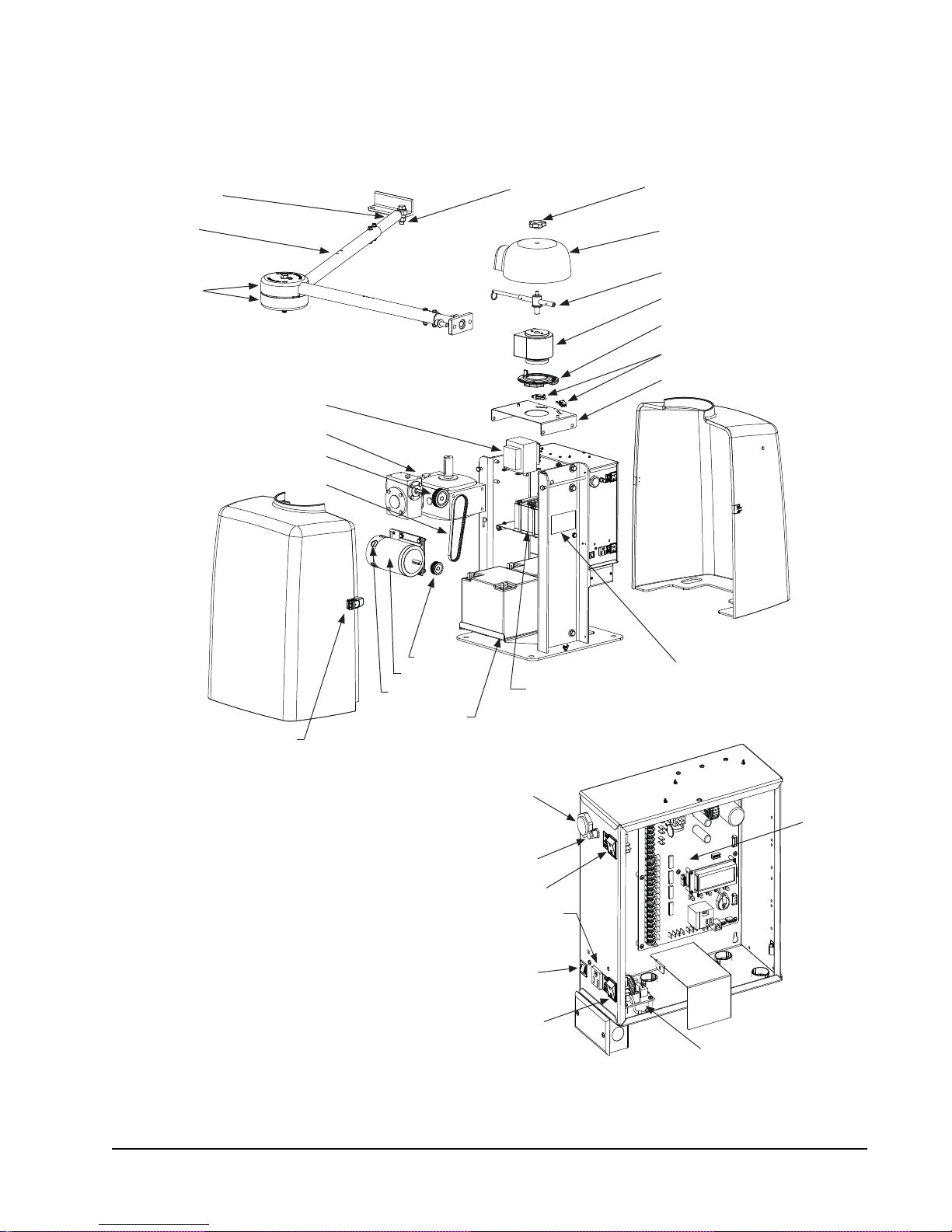

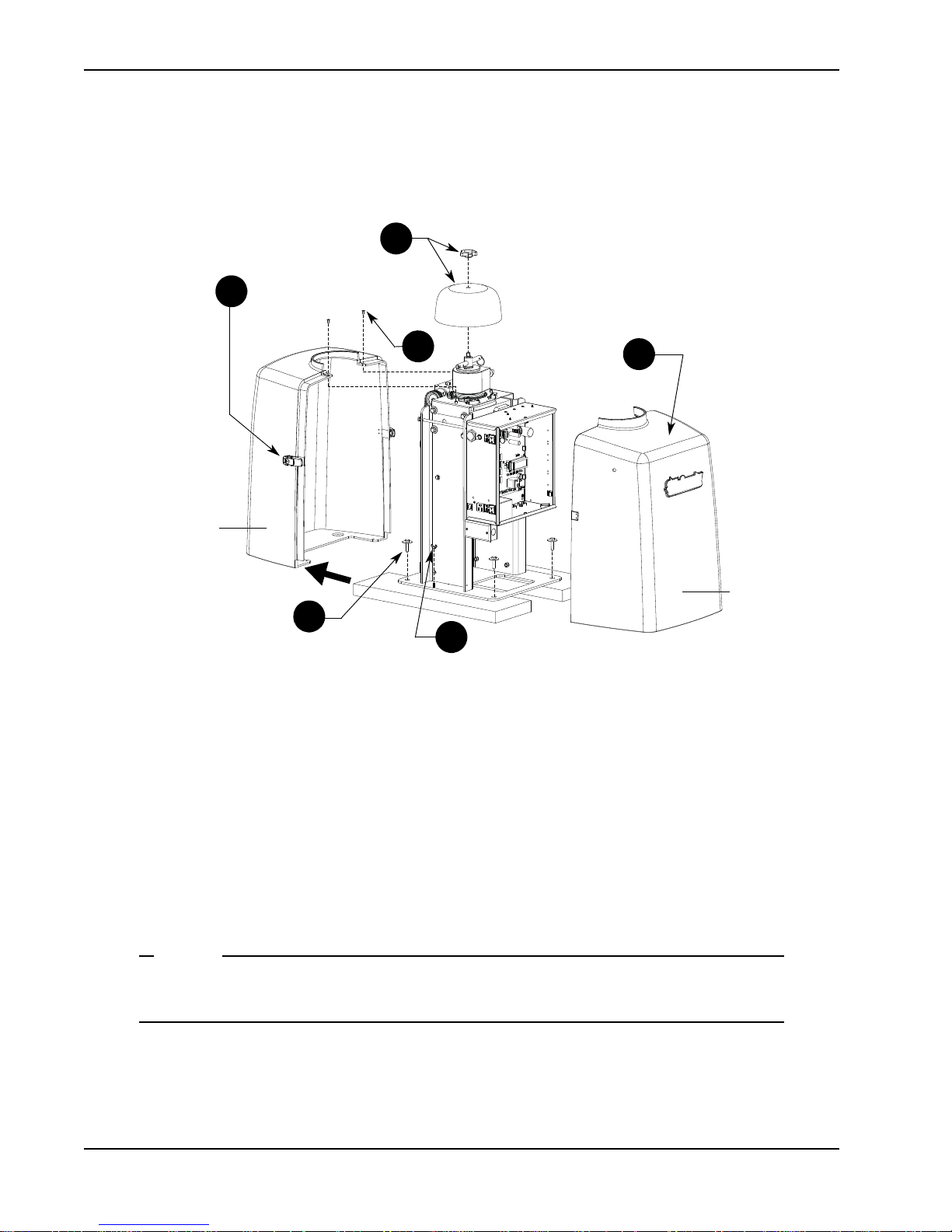

SWINGSMART COMPONENTS

A

Buzzer

Switch, Reset

DC Switch, On/Off

Circuit Breaker

Board, Power Supply

Board,

Smart DC

Controller

AC Switch, On/Off

115VAC Convenience Outlet

Stub Arm

rm Assembly

Cover, Pinch

Rear Cover

Transformer

Gearbox

Pulley, Gearbox

Belt

Swivel Eye Bolt

Knob,

Top Cap

Cover,

Top Cap

Handle, Clamp

Taper Clamp Assembly

Limit Plate with Limit Cams

Limit Switch

Bracket, Limit Switch

Front Cover

Cover Latch (2)

Pulley, Motor

DC Motor

Brush

Battery Kit, 50AH

(optional)

Label, Serial/Model #

Battery Kit, 8AH

Note: Refer to Parts & Limited Warranty for the SwingSmart parts list.

Revision A Intro-1

Page 3

PRODUCT & WARRANTY REGISTRATION

Enter the following information to register your HySecurity product. Please write legibly. Today’s Date:_____________________

NOTE: To extend the operator warranty beyond 1 year, be sure to return this registration within 60 days of purchase. Refer to the Limited Warranty.

Installer Information

First/Last Name: _________________________________________

Company Name: _________________________________________

Address: _______________________________________________

City: ____________________________ State/Province: __________

Country: _______________________ Postal Code: ____________

Daytime Phone: ___________________ Fax: __________________

E-mail: _________________________________________________

End-user Information

First/Last Name: _________________________________________

Company/Association: ____________________________________

Address: _______________________________________________

City: ____________________________ State/Province: __________

Country: _______________________ Postal Code: ____________

Daytime Phone: ___________________ Fax: __________________

Product Information

Model name/number: ______________________________________

Serial number: ___________________________________________

Purchase Date: __________________________________________

Purchase Price: __________________________________________

Distributor’s name: _______________________________________

Distributor’s City: ________________________________________

Country: ________________________________________________

Installation Date: _________________________________________

Who is completing this form?

Installer End User Distributor

Maintenance Personnel Other ___________________

Additional Comments

_______________________________________________________

E-mail: _________________________________________________

Did you visit the HySecurity website bef ore purchasing your product?

Yes No

How did you hea r about HySecurity gate operators? (Check all that apply.)

Advertisement Exhibition Distributor

Business associate Other (please specify): ____________________________________

What factor(s) most influenced your purchase? (Check all that apply.)

Performance Price Power

Reliability Brand Prior Experience

Recommendation Warranty Product Weight

Fax or Mail this completed form to:

HySecurity, Inc Fax: 888-321-9946

6623 South 228

Kent, WA 98032

HySecurity provides product installation, maintenance and troubleshooting t rai ni ng. View opportuniti es online at the HySecurity website:

www.hysecurity.com/support. For Technical Support, call 800-321-9947.

HySecurity does not share this warranty registration information with third parties unless the requested services, transactions, or legal requirements necessitate it.

© 2009 D0119 Rev. G

th

Street Email: info@hysecurity.com

_______________________________________________________

Page 4

Page 5

Contents

SwingSmart Components

Introducing SwingSmart

INTELLIGENT FEATURES: SMART DC CONTROLLERTM ......................................................................... INTRO-2

T

ECHNICAL SUPPORT .............................................................................................................................. INTRO-3

Safety Requirements

IMPORTANT SAFETY INSTRUCTIONS ............................................................................................................... S-1

Safety Standards - Installer's Responsibility ............................................................................................... S-1

Safety Standards - Owner/User Responsibility ........................................................................................... S-2

Hazardous Materials and Proper Disposal ................................................................................................. S-3

ECONDARY ENTRAPMENT PROTECTION SENSORS ........................................................................................ S-4

S

Identifying Gate Operator Category and Usage Class ................................................................................ S-5

Choosing Secondary Entrapment Protection ............................................................................................. S-6

E

MERGENCY STOP BUTTON ............................................................................................................................ S-7

C

OMMON INDUSTRIAL SYMBOLS .................................................................................................................... S-7

Chapter 1: Installation

STEP-BY-STEP ................................................................................................................................................... 1-1

P

AD CONDITION ............................................................................................................................................. 1-1

Pouring the Concrete ................................................................................................................................ 1-1

Using an Existing Pad ............................................................................................................................... 1-3

U

NPACKING THE OPERATOR ........................................................................................................................... 1-4

M

OUNTING THE OPERATOR ........................................................................................................................... 1-5

G

ATE BRACKET AND LINKAGE ARMS .............................................................................................................. 1-6

Installing the Gate Bracket ........................................................................................................................ 1-6

Attaching the Stub Arms ........................................................................................................................... 1-7

Installing the Linkage Arms ....................................................................................................................... 1-8

Adjusting the Limit Switches ................................................................................................................... 1-10

Completing Gate Arm Installation .......................................................................................................... 1-11

Setting the Taper Clamp ......................................................................................................................... 1-13

Revision A Contents - 1

Page 6

Contents

Chapter 2: Power

STEP-BY-STEP ................................................................................................................................................... 2-1

I

NSTALLING THE EARTH GROUND .................................................................................................................. 2-1

W

IRING AC POWER ......................................................................................................................................... 2-2

Wiring 115VAC Power .............................................................................................................................. 2-3

Wiring 208/230VAC Power ...................................................................................................................... 2-4

C

ONNECTING DC POWER ............................................................................................................................... 2-5

Important Considerations for DC-powered Operators ............................................................................... 2-5

Installing the Extended Battery Backup Kit ................................................................................................ 2-7

Chapter 3: Display and Menu Options

STEP-BY-STEP ................................................................................................................................................... 3-1

I

NITIAL SETUP .................................................................................................................................................. 3-1

Turning Both Power Switches On ............................................................................................................. 3-2

Using the Smart DC Controller Buttons In Menu Mode ........................................................................... 3-3

Configuring the Setup Menu ..................................................................................................................... 3-4

UN MODE ...................................................................................................................................................... 3-5

R

Understanding Gate Status Displays .......................................................................................................... 3-5

Using the Smart DC Controller Buttons In RUN Mode ........................................................................... 3-6

Viewing Operator Status Displays .............................................................................................................. 3-7

U

SER MENU ..................................................................................................................................................... 3-8

Adjusting the Close Timer ......................................................................................................................... 3-9

Setting the Time and Date ....................................................................................................................... 3-10

Setting AC Power Loss Gate Function ..................................................................................................... 3-11

Adjusting the Display Contrast ................................................................................................................ 3-12

I

NSTALLER MENU .......................................................................................................................................... 3-16

Adjusting the Gate Speed ......................................................................................................................... 3-17

Adjusting the IES Sensitivity .................................................................................................................... 3-18

Enabling the Fire Department Override ................................................................................................... 3-19

Reinstating Factory Defaults .................................................................................................................... 3-20

Chapter 4: Smart DC Controller

STEP-BY-STEP ................................................................................................................................................... 4-1

O

VERVIEW OF THE SMART DC CONTROLLER ................................................................................................. 4-2

Preliminary Testing .................................................................................................................................... 4-3

Vehicle Detector Installation Options ........................................................................................................ 4-4

Connecting HY-5A Vehicle Detectors ................................................................................................. 4-5

Installing Standard 11-Pin Box Type Vehicle Detectors ...................................................................... 4-7

Vehicle Detector Configuration and Quick Close Mode Selection ...................................................... 4-8

Contents - 2 SwingSmart - Installation, Operation and Maintenence Manual Revision A

Page 7

Contents

C

ONNECTING ACCESSORY DEVICES ............................................................................................................... 4-9

Entrapment Sensor Connections ............................................................................................................... 4-9

Access Controls ....................................................................................................................................... 4-10

Manual Push-button Station ................................................................................................................... 4-11

User Relays - Programming Procedure .................................................................................................... 4-12

Chapter 5: Bi-parting Gate Systems

STEP-BY-STEP ................................................................................................................................................... 5-1

P

OWER REQUIREMENTS .................................................................................................................................. 5-2

M

ASTER AND SLAVE WIRING CONNECTIONS ................................................................................................. 5-3

M

ASTER AND SLAVE MENU SETUP .................................................................................................................. 5-4

Chapter 6: Reference

CONNECTING A RADIO RECEIVER FOR REMOTE OPEN .................................................................................. 6-1

I

NSTALLING A MAGLOCK OR SOLENOID LOCK ............................................................................................... 6-3

Installing a Lock for 12VDC or 24VDC Systems ...................................................................................... 6-3

Installing a Lock on 24VAC Systems ......................................................................................................... 6-4

Installing a Lock for High Voltage Systems ............................................................................................... 6-4

Setting the User Relay Function in the

Installer Menu ........................................................................................................................................... 6-5

I

NSTALLING A SOLAR-POWERED OPERATOR .................................................................................................. 6-6

I

NSTALLING VEHICLE DETECTORS AND LOOPS .............................................................................................. 6-6

I

NSTALLING PHOTOELECTRIC SENSORS ........................................................................................................ 6-11

I

NSTALLING GATE EDGE SENSORS ................................................................................................................ 6-14

S

MART DC CONTROLLER TROUBLESHOOTING ............................................................................................ 6-16

Vehicle Detector and Loop Fault Diagnostics .......................................................................................... 6-23

SwingSmart Schematics ........................................................................................................................... 6-25

G

ENERAL MAINTENANCE .............................................................................................................................. 6-27

Smart Touch Analyze and Retrieve Tool ................................................................................................. 6-27

What You Need ................................................................................................................................ 6-27

Installing START Software ............................................................................................................... 6-27

Electrical Controls ................................................................................................................................... 6-28

Mechanical Maintenance ......................................................................................................................... 6-28

Drive Belt Tension and Alignment ................................................................................................... 6-29

DC Battery Replacement .................................................................................................................. 6-30

Clock Battery Replacement ............................................................................................................... 6-31

Chapter 7: Parts & Limited Warranty

SWINGSMART PARTS ...................................................................................................................................... G-1

S

WINGSMART PARTS LIST .............................................................................................................................. G-2

L

IMITED WARRANTY ...................................................................................................................................... G-3

S

WINGSMART DC SPECIFICATIONS ................................................................................................................ G-4

Revision A Contents Contents - 3

Page 8

Contents

This page intentionally blank.

Contents - 4 SwingSmart - Installation, Operation and Maintenence Manual Revision A

Page 9

Introducing SwingSmart

Thank you for purchasing our premium SwingSmart DC™ 20 swing gate operator. At HySecurity® Gate, Inc.,

we pride ourselves on quality. Our new line of electromechanical gate operators include a number of

unparalleled user benefits:

Robust - An especially strong twin channel steel chassis and adjustable taper clutch greatly improves the ability

for SwingSmart to resist damage from vehicle hits on the gate. The components on the Smart DC Controller

are protected by opto-isolators which shield them from power surges and lightning strikes.

Power - A variable speed control board supplies a powerful, continuous 24V DC motor which drives a 600:1

gearbox providing variable speeds. The electronics, motor and gear box are rated to operate in very broad

temperatures that range from -13°F to 158°F (-25°C to 70°C). SwingSmart DC is rated for gates up to 20 feet

long and 1,300 pounds.

Finesse - A variable rate of gate acceleration and deceleration, dependent upon gate weight and length, assures

very smooth handling.

UPS backup and Solar ready - Two 12V, 8 amp hour (AH) batteries will provide a fully functional gate

operator (up to 300 gate cycles) when AC power is unavailable. Four user-selectable UPS modes are available.

12VDC and 24VDC are available to power access controls. The unit’s design also incorporates space for

optional 50AH batteries to support solar applications or usage during extended power outages.

I

NTELLIGENT

Automatic adjustment and synchronization of bi-parting gates - The Smart DC Controller automatically

adjusts the gate speed to synchronize the left and right gates so that they reach the open and close positions at

the same time. Independent leaf delay adjustment for bi-parting gates is selectable in ½ second increments.

Menus and User relays - The Smart DC Controller has 48 menu items to allow installer configuration of gate

function and two user relays, which can be configured for 22 different functions.

Independent adjustment for open and close gate speeds - An easy-to-use menu on the Smart DC Controller

allows the installer to vary the open and close speed settings in a range between 10 and 15 seconds.

Intelligent Inherent Entrapment Sensor (IES) - Any impediment to gate travel is sensed by the system, stopping

gate movement per UL 325 Safety Standards. The intelligent system monitors gate power then adapts the IES

to trip at an adjustable threshold above normal power.

Improved Liquid Crystal Display (LCD) - A 32-character LCD provides increased readability for programming

and troubleshooting.

USB communications port - A direct connect provides accessibility to download system diagnostics and upload

system configurations using the Smart Touch Analyze and Retrieve Tool (START) software.

START software and diagnostics - With START software loaded on a laptop computer, you have an invaluable

management tool for all HySecurity operators. To download this free software, visit the HySecurity website at

www.hysecurity.com.

F

EATURES

: S

MART

DC C

ONTROLLER

TM

Revision A Intro-2

Page 10

Technical Support

TECHNICAL SUPPORT

For technical support, call your installer or authorized HySecurity distributor. Obtain the serial number of your

operator before calling. Refer to SwingSmart Components on the front page. For the name of a distributor near

to your locale, call HySecurity at 800-321-9947.

For information about HySecurity training for installers, maintenance personnel and end-users, refer to the

company website at www.hysecurity.com or call 800-321-9947.

Intro-3 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 11

Safety Requirements

WARNING

!

Automatic gate operators provide user convenience and security. However, because these machines can produce

high levels of force, it is imperative that gate operator system designers, installers and end users be aware of

potential hazards associated with improperly designed, installed, or maintained systems. The gate operator is

only one component of the total gate operating system. It is the joint responsibility of the architect, site

designer, purchaser, installer and end user to verify that the total system is appropriately configured for its

intended use. Additionally, certain municipalities have established licensing, codes or regulations that regulate

automated gate system design and installation. Consult local government agencies for up-to-date rules and

regulations prior to gate system design or installation.

IMPORTANT SAFETY I NSTRUCTIONS

A moving gate can cause serious injury or death. Start the gate operator only when the gate’s

travel path is clear.

Hazards, associated with automatic gates, can be reduced with proper site design, installation, and use.

Installers, maintenance crew, and owners/users must read and follow the Important Safety Instructions in this

manual and review all the literature that accompanies the product. It is important that only qualified installer’s

handle the installation of the SwingSmart gate operator.

• A minimum of three years experience installing similar equipment.

• Proof of attending a HySecurity Technical Training seminar within the past three years.

• Significant manufacturer endorsements of technical aptitude in gate operator installati

A “qualified” installer has one of the following:

on and operation.

Underwriter Laboratories (UL) and the American Society for Testing and Materials (ASTM) are

current safety standards and regulations regarding gate operators and automated gates. To pass UL certification,

all aspects of gate installation must comply with the UL 325 Safety Standard. For the most up-to-date UL 325

Safety Standard, refer to the UL website www.ul.com. For ASTM F2200 Gate and Fence Standards, refer to

www.astm.org.

responsible for

Safety Standards - Installer's Responsibility

• Study the entire contents of this manual prior to installing, operating, or maintaining the SwingSmart gate

operator. Taking extra time to align the gate operator and verify a fully functional installation will reduce

maintenance, guarantee longest system life, and ensure customer satisfaction.

• Verify the gate operator usage class for the site. Refer to Identifying Gate Operator Category and Usage Class

for gate classifications. Install SwingSmart only when the gate operator class is correct for the site and type

of gate.

• Install an automatic operator only on gates that comply with ASTM F2200 Gate and Fence Standards.

Screen or

Revision A S-1

enclose openings in the gate per UL 325 Safety Standards.

Page 12

Important Safety Instructions

NOTE

WARNING

!

• Before attaching the operator’s arm, swing the gate in both directions. Make sure it is level and moves

freely. A gate that swings easily reduces strain on operator components. Gravity should play no part in the

opening or closing of the gate.

• Make sure there is a separate walk-through entrance nearby. Make cer

designated and signs direct pedestrians to the walk-through gate. The automated gate entry is for vehicle

use only.

• Install the gate operator on the secure (non-public) side of the gate. Swin

public areas.

• Mount access control devices beyond reach of the gate. The

→ Located in a clear line of sight to the gate.

→ Mounted

operating the controls. People attempting to access the controls by reaching through or around the

gate can be seriously injured or killed by the moving gate.

→ Incorporate a security feature to prevent unauthorized use.

• The gate operator must be properly grounded and the incoming powe

label on the junction box.

• Install enough external entrapment protection sensors so that pedestrians are protected from entrapment in

both dire

Secondary Entrapment Protection Sensors.

• Install the supplied WARNING signs on the inside and outside of the gate so they are clearly visible from

both sides of t

• Locate controls (Open, Close, Stop/Reset) where a user will have a clear view of the gate. Refer to the

Emergency Stop Button. Connect radio and other remote access (non-resetting controls) to the REMOTE

OPEN terminal.

• Open and close the gate to confirm that it was properly installed and to ensure reduced risk of entrapment.

erify the clearance between the gate and adjacent

V

• When you complete the installation, show the end-user how to:

→ Remove the operator cover.

→ Turn the power on and off.

→ Manually release the gate.

beyond 6 feet of the gate, to prevent users from touching or accessing the gate while

ctions of the gate travel and all hazard areas are fully protected. Review the information found in

he gate. Installing the signs is a requirement for UL 325 compliance.

structures per UL 325 Safety Standards.

control device

tain a clear pedestrian path is

g-type gates cannot open into

s that operate the gate must be:

r voltage must match the voltage

Gate operator instructions must be given to the owner per UL 325 Safety Standards.

Safety Standards - Owner/User Responsibility

A moving gate can cause serious injury or death. Automatic gate operators move gates with high

force. Make sure gates and gate operators are installed to reduce the risks of entrapment. Verify

your gate and gate operator comply with UL 325 Safety Standards and ASTM F2200 Gate and

Fence Standards. Ask for a copy of the gate operator’s product literature and review it. You are

responsible for educating all gate system users about proper use of the automated gate system.

S-2 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 13

Important Safety Instructions

CAUTION

CAUTION

!

• Automatic gates are for vehicular use only; provide and maintain walkways and signs to direct pedestrians

to a separate walk-through entrance.

• An automatic gate can start at any time without warning; always keep people away from the gate area.

• Never allow children to use or play with gate controls. K

transmitters, away from children. Do not allow children to play on or around the gate or gate operator.

• Learn how to turn the power on and off. Learn how to manually release the gate.

Before attempting a manual release, make sure the gate is not moving.

• WARNING signs supplied with the gate operator must remain installed and clearly visible on both sides of

the gate. The signs are required to maintain UL 325 compliance.

• Do not physically disable the warning buzzer and NEVER disconnect or cut its wires. The buzzer is

equired to function in the event of entrapment, regardless of UL 325 gate usage class. It provides an alert

r

that the gate is about to move. Disabling the warning buzzer may increase the risk or extent of injury if

entrapment occurs.

• Test the primary Inherent Entrapment Sensor (IES) and secondar

monthly. The gate must r

senses a second activation signal in a row, before it reaches its full travel limit.

• Have a professional gate installer routinely test the entir

Repair gate hard

operator on a regularly maintained schedule can increase the risk of injury or death.

ware as necessary to keep the gate running smoothly. Failure to adjust and test the gate

everse its direction of travel upon contact with a rigid object and/or stop, when it

eep all re

e gate operator and entrapment protection sensors.

mote controls, especially radio

y entrapment protection sensors

Hazardous Materials and Proper Disposal

SwingSmart uses sealed, state-of-the-art Absorbed Glass Mat (AGM) batteries and highly recommends

replacing used batteries with new AGM-type batteries.

The batteries used with the SwingSmart gate operator contain materials that are considered hazardous to the environment. Proper disposal of the battery is required by federal law. Refer to

federal guidelines found in Hazardous Waste Regulations.

To reduce the risk of fire or injury to persons:

• Observe the polarity between the batteries and charging circuit.

Never mix battery sizes, types, or brands. HySecurity strongly recommends that only sealed AGM style

•

batteries be used.

• Exercise care in handling batteries. Be aware that the metal found in rings, bracelets, and keys can conduct

electricity, short the batteries, and cause potential injury.

• Do not open or mutilate the batteries. Battery cells contain corrosive materials which may

other injuries. The material within batteries is toxic.

• Always dispose of batteries properly. Do

federal guidelines for proper disposal of hazardous waste.

• R

eplace batteries according to the instructions found in General Maintenance.

NOT place batteries in fire. The battery cells may explode. Follow

cause burns and

S-3 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 14

Secondary Entrapment Protection Sensors

CAUTION

!

S

ECONDARY

SwingSmart is equipped with a primary, Type A, inherent entrapment sensor (IES). UL 325 Safety Standard

compliance requires installation of secondary entrapment protection sensors, the number of which, depends on

the entrapment hazards that exist at each particular installation.

To comply with UL 325, the following external sensors may be used:

• Contact sensors, such as edge sensors

• Non-contact sensors, such as photoelectric eyes

The site designer or installer can choose either photoelectric eyes or edge sensors or use these devices in

combination. Whatever devices are used, protection in both the opening and closing directions of gate travel

must be provided.

The UL 325 Safety Standard for automatic swinging gates specifically requires that edge sensors or

photoelectric eyes or a combination of both devices be installed to protect against pedestrian entrapment in

BOTH directions of the gate travel and where an entrapment hazard exists.

PHOTOELECTRIC EYES: One or more photoelectric eyes shall be located where the risk of entrapment or

obstruction exists, such as the perimeter reachable by a moving gate.

E

NTRAPMENT

P

ROTECTION

S

ENSORS

A photoelectric eye or contact sensor is also required to protect against possible entrapment if

the gate opens to a position less than 16 inches from any object, such as a post or wall.

EDGE SENSORS: One or more edge sensors shall be located on the inner and outer leading edge of a swing

gate where the risk of entrapment or obstruction exists. If the bottom edge of the swing gate is situated more

than 6-inches (152 mm) above ground level at any point in its arc of travel, one or more contact sensors must

be located on the bottom edge, as well.

SENSOR SECURITY: A hard-wired sensor shall be located and its wiring arranged so that communication

between the sensor and gate is not subjected to mechanical damage.

SENSOR FUNCTION and COMMUNICATION: A sensor that transmits its signal to the gate operator

must be located so its signal is not impeded by building structures or other obstructions. All sensors must be

installed so that they function as intended for the end-use conditions.

UL 325 LISTING: The edge sensors and photo electric eyes must be tested and labeled as “Recognized

Components” under UL 325 in order to be deemed acceptable for use in a gate operator. Study the Important

Safety Instructions and consider your specific installation to determine where the greatest entrapment risks exist.

Locate edge sensors and/or photoelectric sensors accordingly.

Be certain that a sufficient number of sensors are used so that pedestrians are protected from entrapment in

both directions of the gate travel and all hazard areas are fully protected. Refer to the UL website at

www.ul.com for the most up-to-date list of gate operator safety standards (UL 325). Refer to www.astm.org for

a complete list of ASTM F2200 Gate and Fence Standards.

S-4 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 15

Secondary Entrapment Protection Sensors

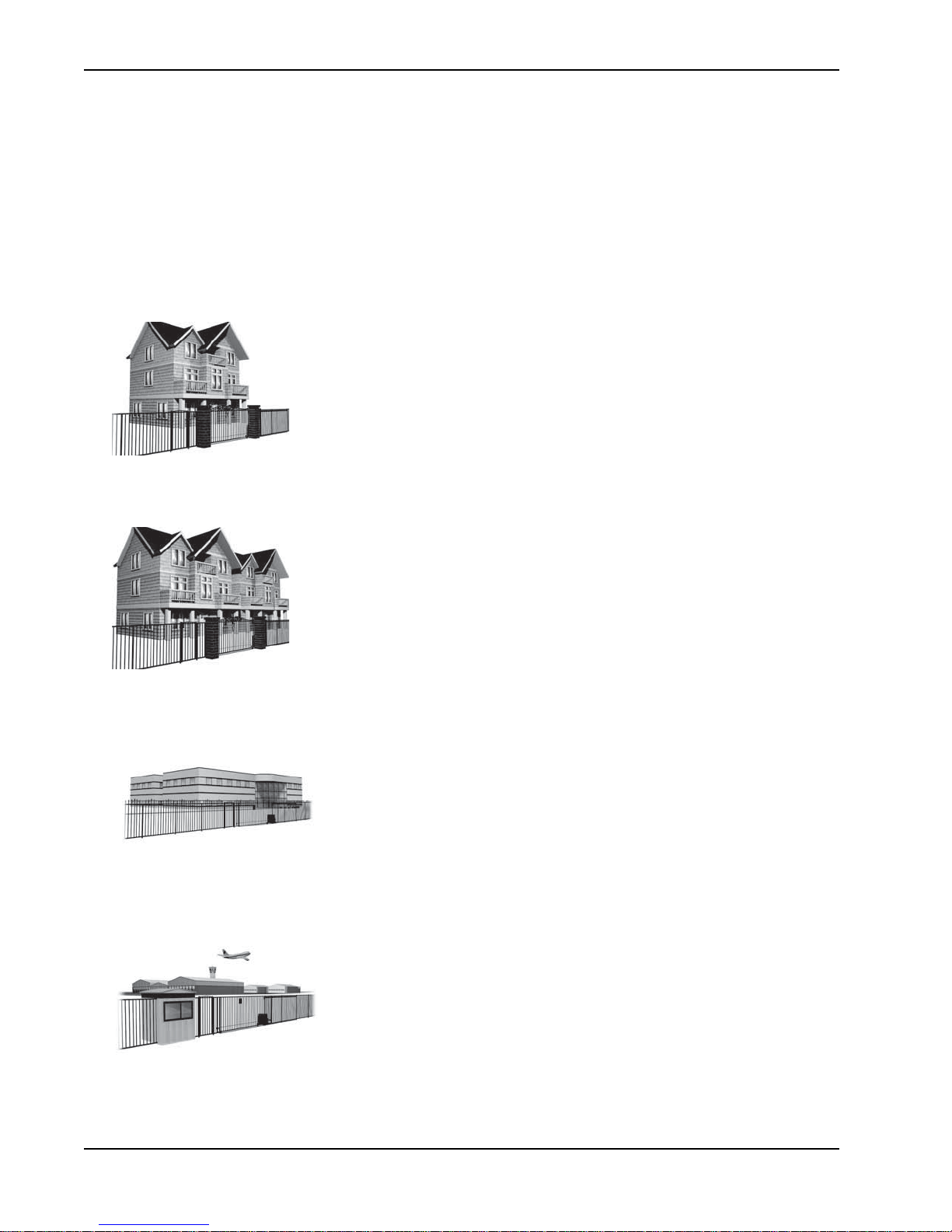

Identifying Gate Operator Category and Usage Class

The SwingSmart operator, according to UL 325 Safety Standards, falls in the Swing Gate and Vertical Barrier

Arm category for gate operators. It’s usage class is determined by the area that the vehicular gate services.

Four different vehicular usage classes are defined by UL 325:

Class I

Class I: Intended for use in a location of one to four single family dwellings or a

parking area associated with one to four single family dwellings.

Class II

Class III

Class IV

Class II: Intended for use in a commercial location or building such as a multifamily housing units (five or more single family units) hotels, garages, retail stores

or other buildings servicing the general public.

Class III: Intended for use in an industrial location or building such as

factories or loading docks or other locations not intended to service the

general public.

Class IV: Intended for use in guarded industrial locations or buildings such

as an airport security area or other restricted access location, not servicing

the general public, in which access is monitored by security personnel or via

closed circuitry.

S-5 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 16

Secondary Entrapment Protection Sensors

NOTE

CAUTION

Choosing Secondary Entrapment Protection

The site designer or installer must determine which secondary entrapment sensor devices will be installed with

the SwingSmart operator to meet UL compliance. The type of entrapment sensor device systems are described

below. For a complete listing of the requirements, see UL 325 Safety Standards.

SwingSmart is equipped with a primary, Type A, inherent entrapment sensor (IES) that complies with UL 325. Any impediment to gate travel causes the gate to stop.

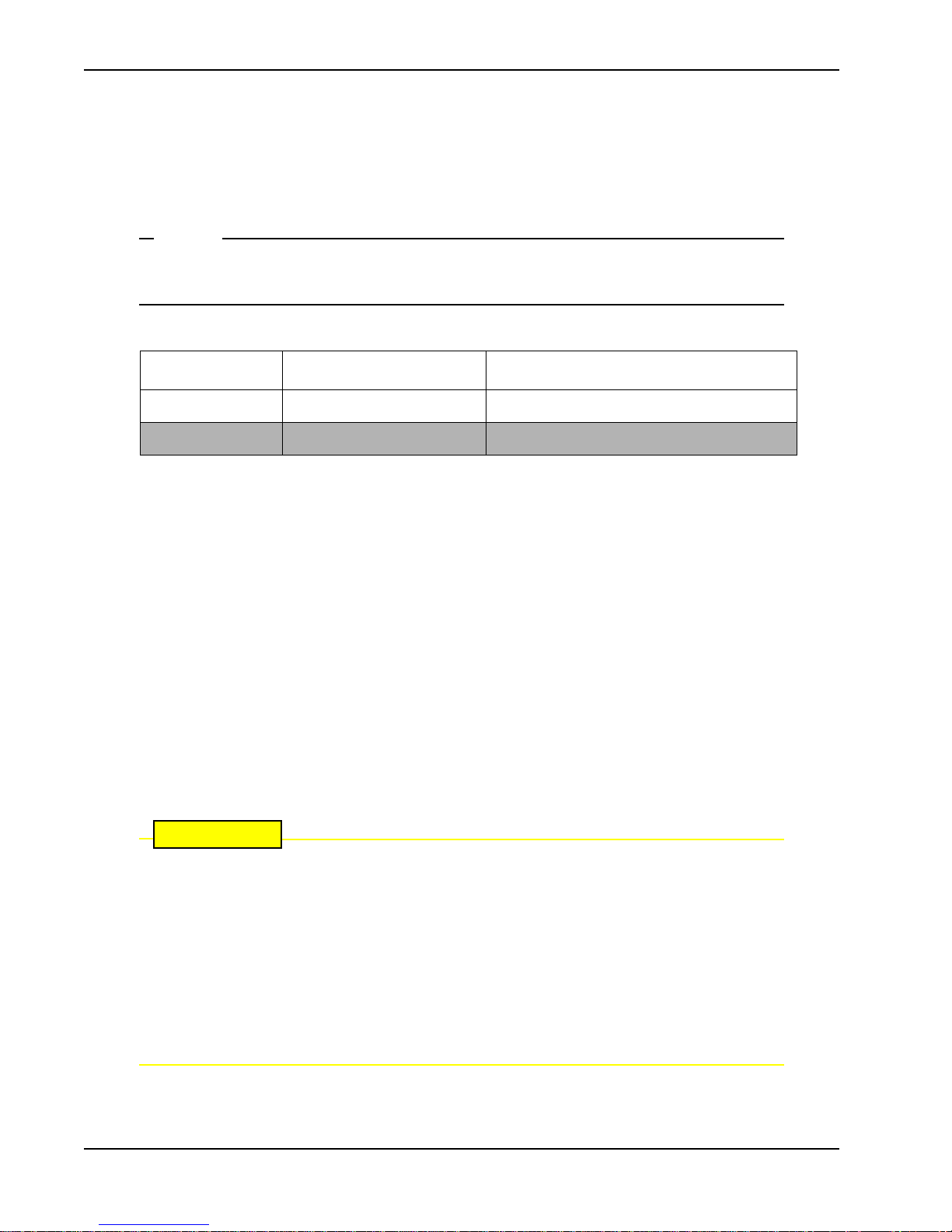

Usage Class Primary Type Device Secondary Type Device

Class I, II, III A B1, B2, C, or D

Class IV A B1, B2, C, D, or E

To comply with UL 325, refer to the chart and take the following steps:

1. Select the Usage Class according to the gate’s locale and purpose.

2. The required UL 325 primary Type A sensor is an integral part of the

3. Based on the gate’s usage class, choose Secondary Type

• To comply using B1 - install non-contact sensors (photoelectric sensor or the equivalent).

• To comply using B2 - install contact sensors (edge sensor device or the equivalent).

• To comply using a Type D device requires a CONSTANT HOLD push-button station. This CONSTANT

HOLD push-button station must be the only device that opens and closes the gate. It can only be used where

the gate and push button station will be monitored by personnel 24 hours a day in full view of the gate area.

An automatic closing device (such as a timer, loop sensor, or similar device) must not be employed. A Warning

placard stating, “WARNING - Moving Gate has the Potential of Inflicting Injury or Death - Do Not Start the

Gate Unless the Path is Clear” must be placed adjacent to the gate operator controls.

While compliance is possible with Type C, which is a low force limiting clutch, the SwingSmart

operator develops more gate actuation force than is permitted under the UL 325 Safety Standards and, therefore, its clutch cannot be considered an entrapment protection device.

Similar compliance issues exist with a Type E device (audio warn before operate alarm). A Type

E device is permitted as a means of secondary entrapment protection by UL 325 in Class IV

applications, but it is not recommended by HySecurity because a buzzer warns, but cannot

protect against possible entrapment. HySecurity highly recommends, even for Class IV use, that

secondary entrapment protection (edge or photo-eye sensor) devices be installed to detect

possible entrapment.

Devices: B1, B2, C, D, or E.

SwingSmart system.

S-6 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 17

Emergency Stop Button

Emergency

Stop button

Attention

- Take Note -

- Danger -

Keep Away

Entrapment

Zone

Possible

Pinch Point

EMERGENCY STOP BUTTON

An emergency stop button that is accessible from the

outside of the operator is a requirement for compliance

with UL325 Safety Standards. The red emergency stop

button on the SwingSmart operator is located inside a hole

cutout on the cover.

Pressing the emergency stop button while the gate is

opening or closing disables the automatic close timer and

stops gate travel. The gate travel remains stopped until the

operator receives any open or close signal.

Make sure all users of the gate know where the emergency

stop button is located.

A screwdriver or hex key can be used to press lightly on the

switch to activate it.

COMMON INDUSTRIAL SYMBOLS

The following international safety symbols may appear on the product or in its literature. The symbols are used

to alert you to potential personal injury hazards. Obey all safety messages that follow these symbols to avoid

possible injury or death.

S-7 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 18

Common Industrial Symbols

This page intentionally blank.

S-8 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 19

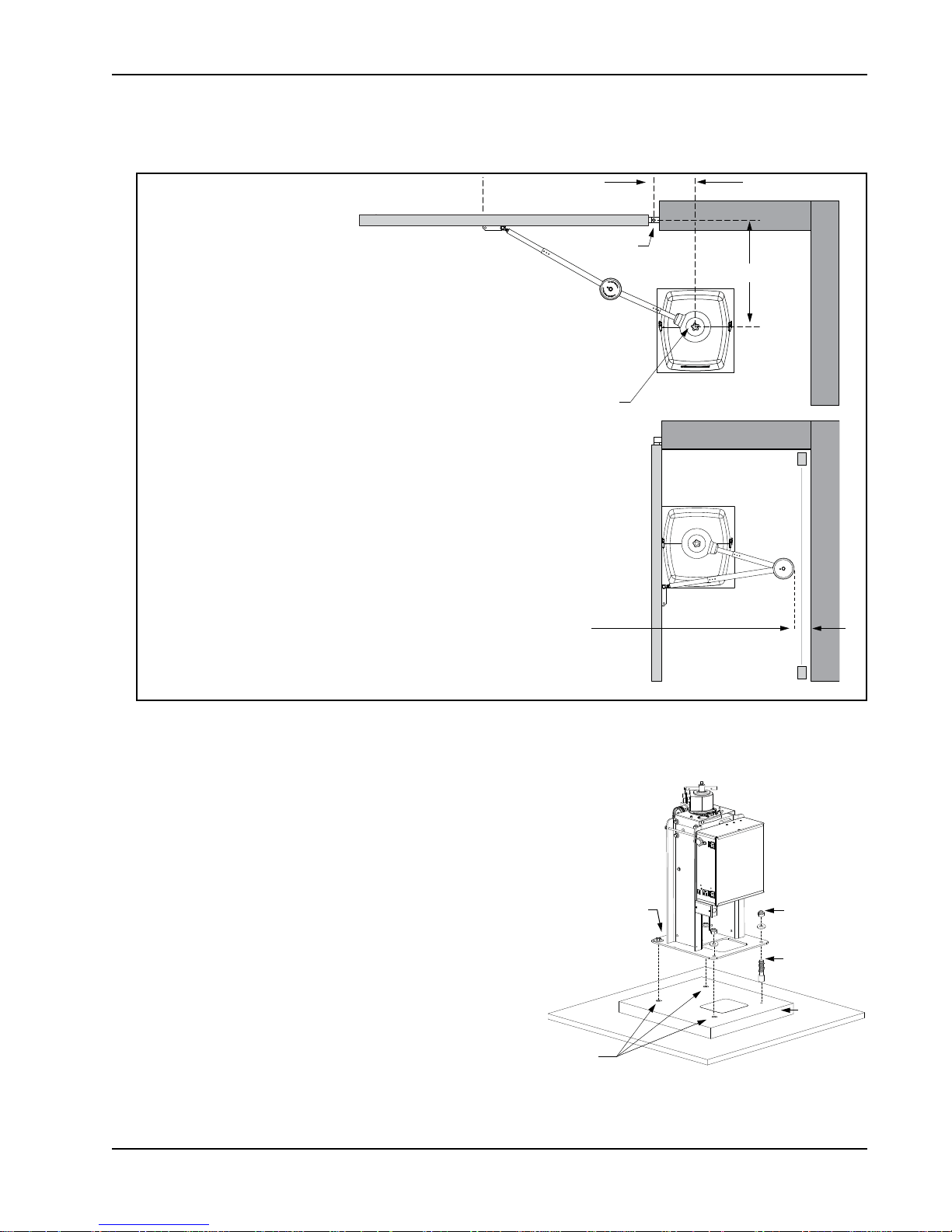

Installation

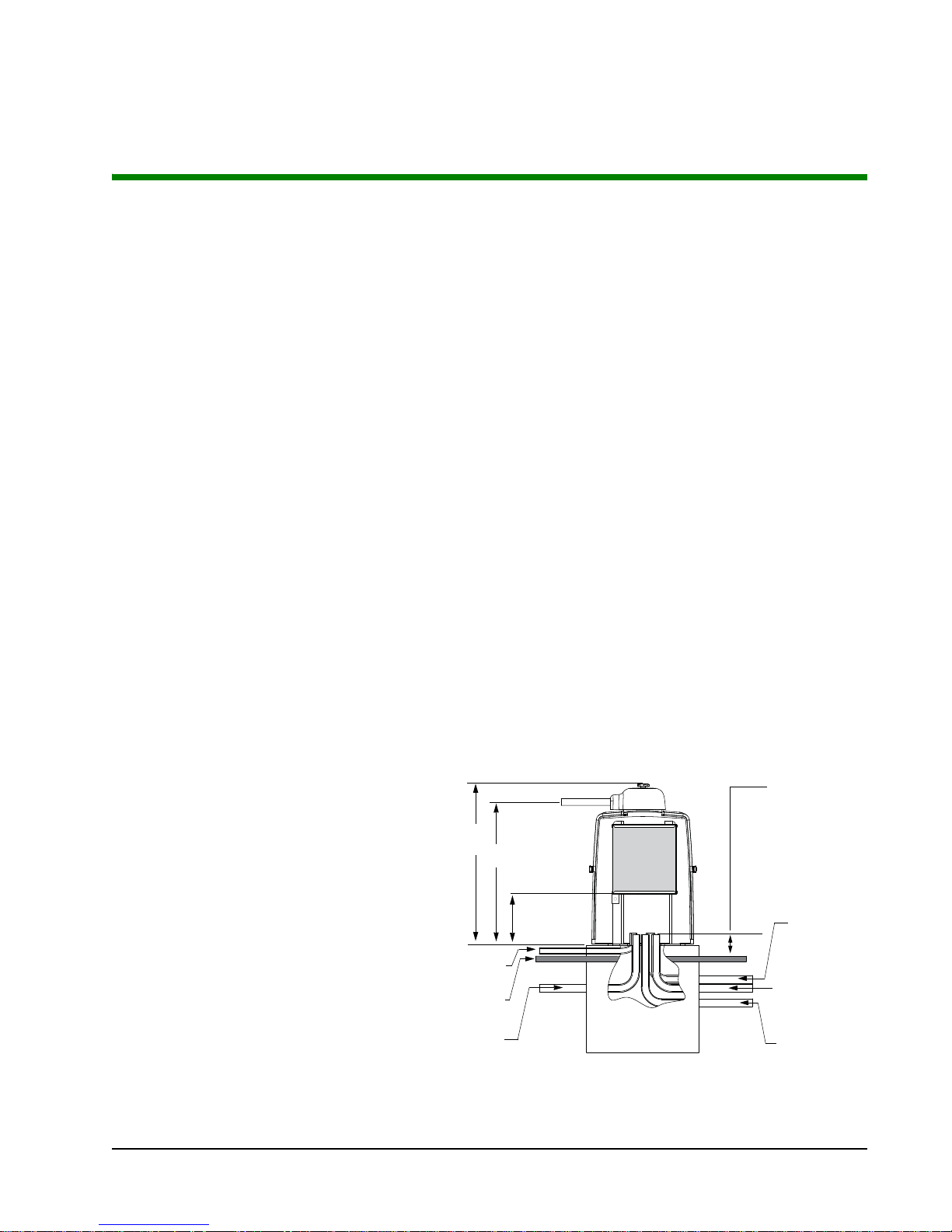

Figure 1-1.

Low voltage/

Communication

wires

Master/slave

wires - optional

High voltage

30.2”

26.8”

Vehicle Loop

control wires

Earth ground

Ground level

9.6-inch

control box

height

Stub out conduit

4-inches above

ground level

(2-inch height

above pad.

TEP-BY-STEP

S

1. Pour pad and mount SwingSmart - Chapter 1.

2. Install gate bracket & linkage arms - Chapter 1.

3. Adjust open and close limit switches - Chapter 1.

4. Connect power - Chapter 2.

5. Program the Initial Setup Menu on the Smart DC Controller - Chapter 3.

6. Configure the User and Installer Menu options - Chapter 3.

7. Review the connections on the Smart DC Controller - Chapter 4.

8. Install Master/Slave connections - Chapter 5.

9. Attach accessory devices - Chapter 6.

Chapter 1

PAD CONDITION

Pouring the Concrete

1. Follow the local building codes to

identify the frost line and determine

the required depth of the concrete pad.

HySecurity recommends a minimum

16-inch depth with a minimum 2-inch

extension above ground level. Refer to

and Figure 1-2.

supply po

equipment ground

accessory power)

• veh

• master/slave connections

wer) including

icle loop control wiring

Figure 1-1

2. Before pouring the pad, consider

conduit placement so it fits within the

confines of the cutout in the

Sw

ingSmart base plate as shown in

Figure 1-2. Run separate conduits for:

•high voltage wiring (115-230V

• low voltage wiring (12V and 24V

•earth ground (NEC/NFPA)

Revision A 1-1

Page 20

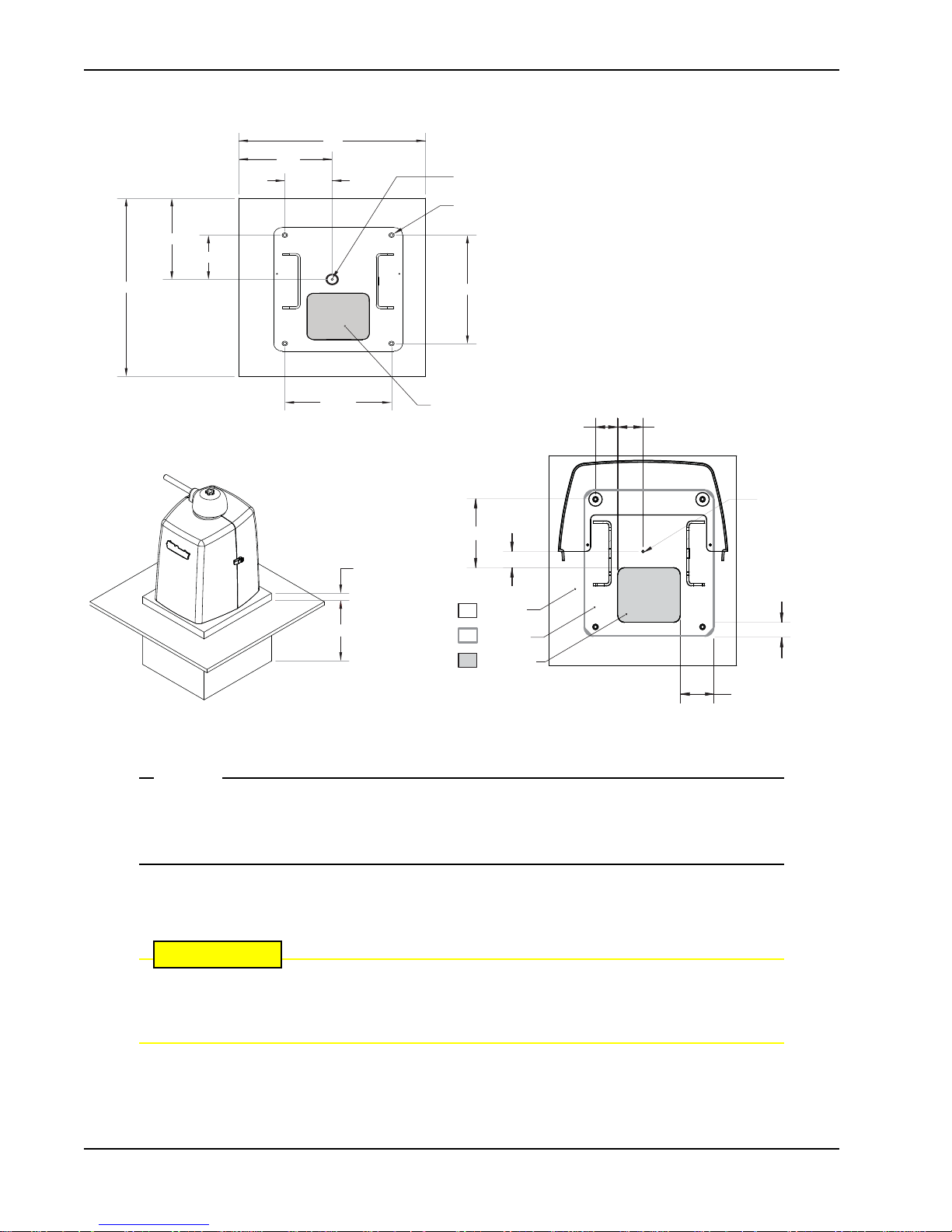

10.5"

10.5"

23"

21"

12"

14"

5.3"

5.7"

Output Shaft Center

Drill 4 holes for ½" x 3 ½" concrete anchors

6" x 7" conduit area

Pad Condition

NOTE

CAUTION

2.5 "

2.8"

7.6"

2

-inch m

inimum

1.8"

COVER AREA

Pad Depth: 16-inch minimum

CHASSIS BASE

CONDUIT AREA

6 " x 7 "

Figure 1-2.

3.5"

SwingSmart provides a 6-inch by 7-inch cutout in its chassis base for conduit.

Refer to Figure 1-2. The design also provides a 9.6-inch height between the control box and

chassis base for pulling and placement of wires.

Output Sha Center

1.5"

3. Extend conduit height 2-inches above the pad (4-inches above ground level). Make sure the concrete forms

are square with the gate and the pad is level. Refer to Figure 1-2 for minimum pad dimensions.

Be sure to restrict conduit to the 6-inch by 7-inch cutout in the chassis base if you plan to use

the extended battery backup kit. The area designed for the optional dual 50AH batteries may be

obstructed if conduit is routed elsewhere. Refer to Installing the Extended Battery Backup Kit.

1-2 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 21

Pad Condition

CAUTION

Using an Existing Pad

In many applications, SwingSmart may be a replacement operator for an existing gate system. Make sure the

pad is level and inspect the pad for:

• Compliance with local building codes.

• Appropriate distance from the gate. Refer to Figure 1-2.

• Appropriate dimensions for SwingSmart installation.

• Durability.

To use an existing pad, take the following steps:

1. Remove any existing equipment from the pad.

2. Measure the pad to ensure it is sized properly for SwingSmart.

3. Mark the center shaft location.

4. Follow the steps in Mounting the Operator.

Consider positioning the operator so existing conduit exits through the cutout in the SwingSmart base plate. Cutting small holes in the base plate for pre-existing conduit is permissible,

but not recommended because it can impair the strength of the chassis and void the Limited

Warranty.

Revision A Installation 1-3

Page 22

Unpacking the Operator

1

2

3

5

6

4

Front cover

Rear cover

NOTE

UNPACKING THE OPERATOR

1-4 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Figure 1-3.

Prepare the gate operator for installation. See Fig

1. Remove the top cap by unscrewing the knob.

2. Unfasten the side cover latches.

3. Remove the front cover.

4. Use a Phillips-head screwdriver to remove the two screws that secure the top of the rear cover. Set the

screws aside.

5. Remo

6. Remove the four wood screws and separate the operator from the shipping boards.

ve the two wing nuts that secure the rear cover to the base plat

wing nuts aside.

Do not lose the Phillips-head screws or wing nuts as they are used to secure the rear cover when

the installation is complete.

ure 1-3.

e and set the rear cover aside. Set the

Page 23

MOUNTING THE OPERATOR

Photo Eye

Photo Eye

For short gates up to 10 feet:

If X = 10.5 inches then set the Y

dimension at 14, 18, or 20 inches.

For medium gates up to 13 feet:

If X = 12 inches, then set the Y

dimension at 22, 24, or 28 inches.

For long gates up to 20 feet:

If X = 15 inches, then set the Y

dimension at 30, 35, or 40 inches.

Hinge Center

Output Shaft Center

X

Y

Potential entrapment area.

Minimum 16-inch clearance required.

If less than 16-inches, install a photoeye or edge sensor.

Figure 1-5.

Concrete

anchor

Fasteners

Concrete

anchors

Base plate

Concrete

pad

Mounting the Operator

Install the operator, by taking the following steps:

1. Assess any limitations in the surrounding area such as

curbs, walls, or bushes.

2. Before placing the operator on the pad, measure and

mark the output shaft center on the concrete pad by

selecting the X and Y dimensions. Refer to Figure 1-2

and Figure 1-4.

3. Set the operator base on the concrete pad and use it as a

ate. Position the operator base so the ce

templ

on the pad aligns with the small hole in the base plate.

Mark the fastener and conduit cutouts. Remove the

operator from the concrete pad and drill the holes for

the concrete anchors.

4. Mount the operator with four ½ x 3½-inch concrete

anchors as sho

Revision A Installation 1-5

wn in Figure 1-5

Figure 1-4.

.

nter mark

Page 24

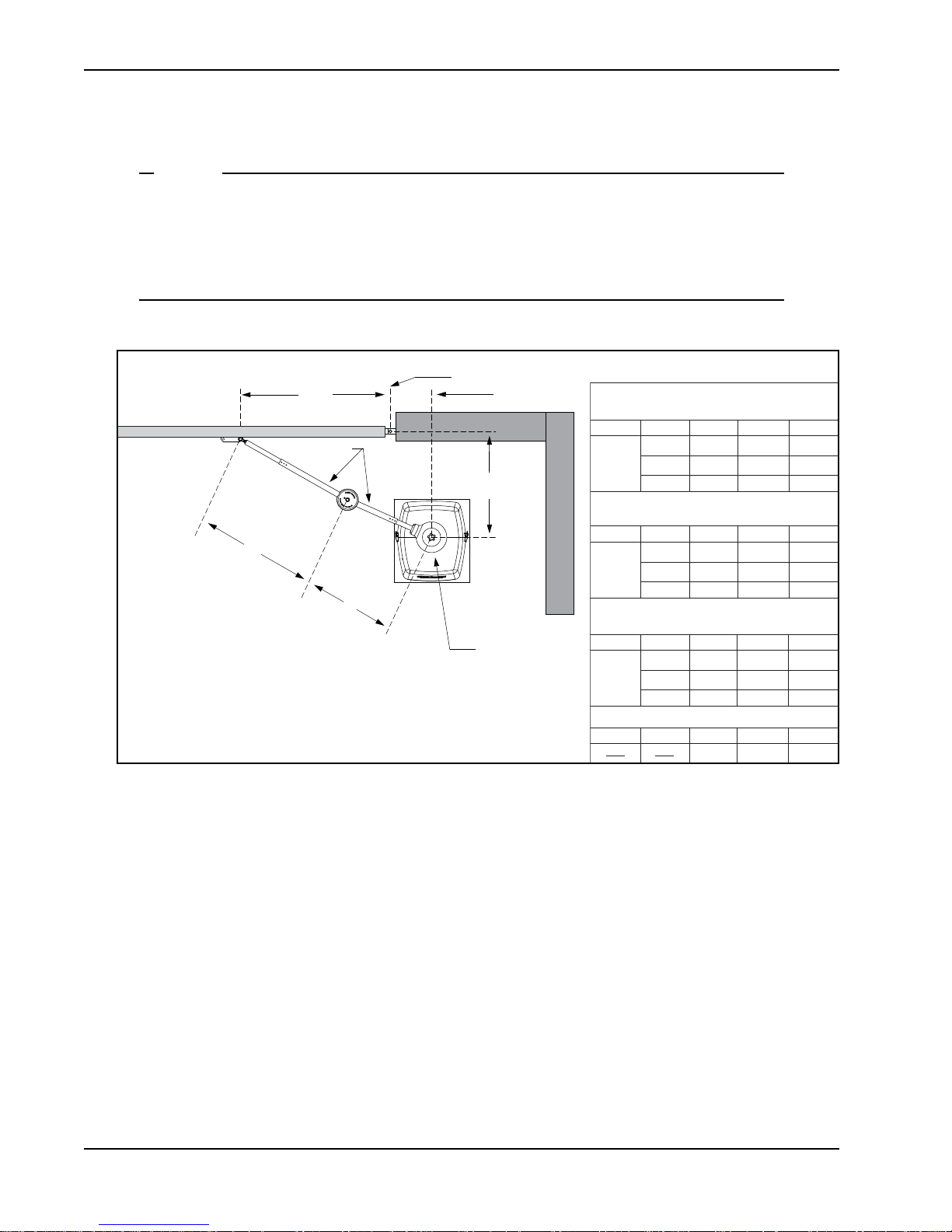

Gate Bracket and Linkage Arms

Short Gate Installation:

For gates up to 10 feet

X

Y

Xg

14 23.5

10.5

18 27.5

20 29.5

X

Y

Xg

22 33.0

12

24 35.0

28 39.0

Medium Gate Installation:

For gates up to 13 feet

X

Y

Xg

30 44.0

15

35 49.0

40 54.0

Long Gate Installation:

For gates up to 20 feet

Custom Gate Installation:

X

Y

Xg

X + Y - 1

Operator Center

Photo eye

Horizontal

cross member

Hinge Center

X

Y

Xg

Gate operator - shows left arm

mounted on right-hand gate.

CAUTION

!

GATE BRACKET AND LINKAGE ARMS

Installing the Gate Bracket

1. Secure the gate to prevent movement.

If vertical bars make up the gate design, be sure to install a horizontal cross member to provide

the necessary support to the gate arm. Do not mount the bracket to a small number of vertical

pickets. Pickets will bend in the event of a gate strike.

1-6 SwingSmart - Installation, Operation and Maintenance Manual Revision A

2. Determine the proper position of the gate bracket. Use the chart for reference.

Hint: Determine if you have a short, medium, or long gate. If the X and Y dimensions in

same as your install, set the gate bracket at the Xg dimension. If your install does not fit to the chart specs,

use the Custom Gate Installation formula to determine the proper gate bracket placement.

3. Measure and position the gate bracket so it is level with the arm on the operator. Clamp the gate bracket to

the horiz

ontal cross member.

Figure 1-6.

the chart are the

Page 25

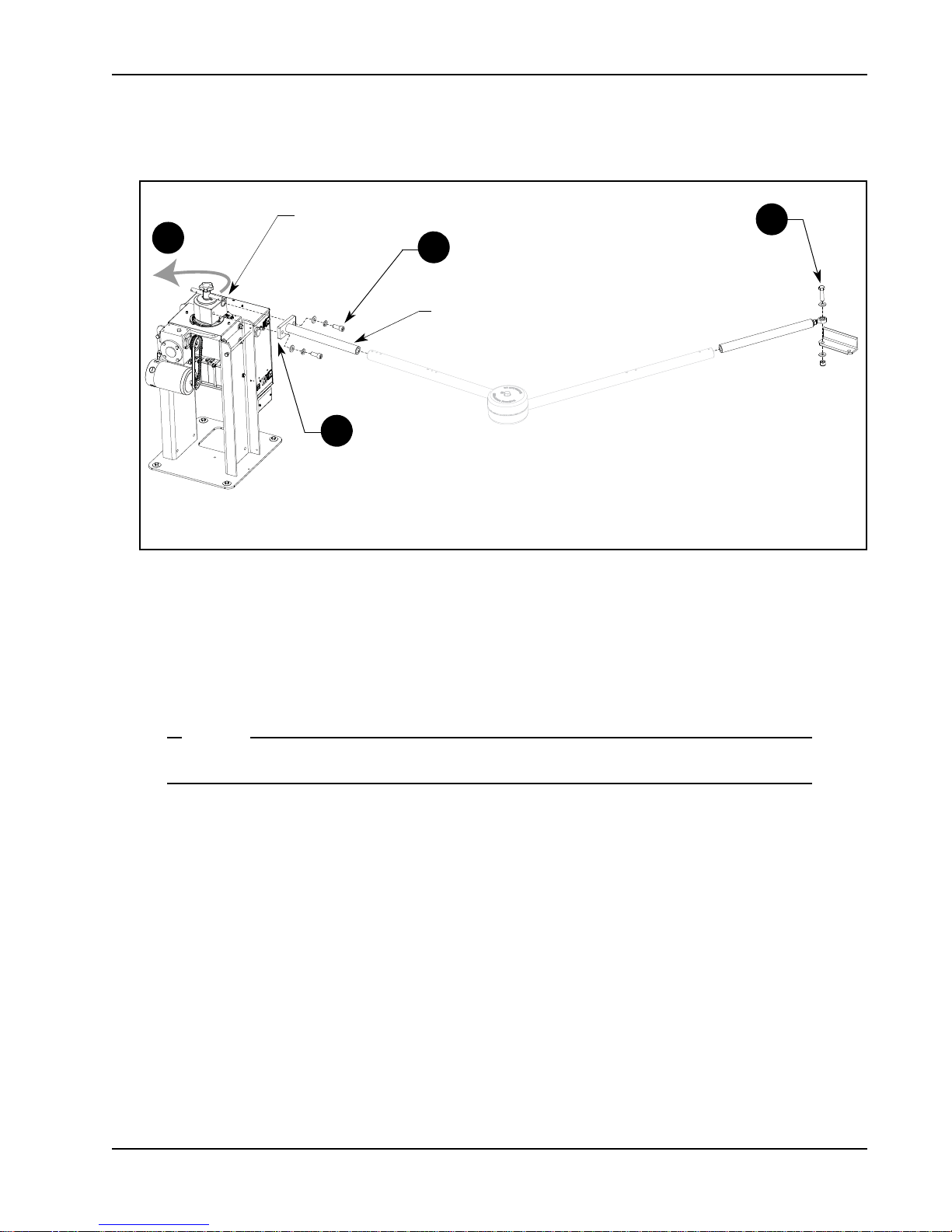

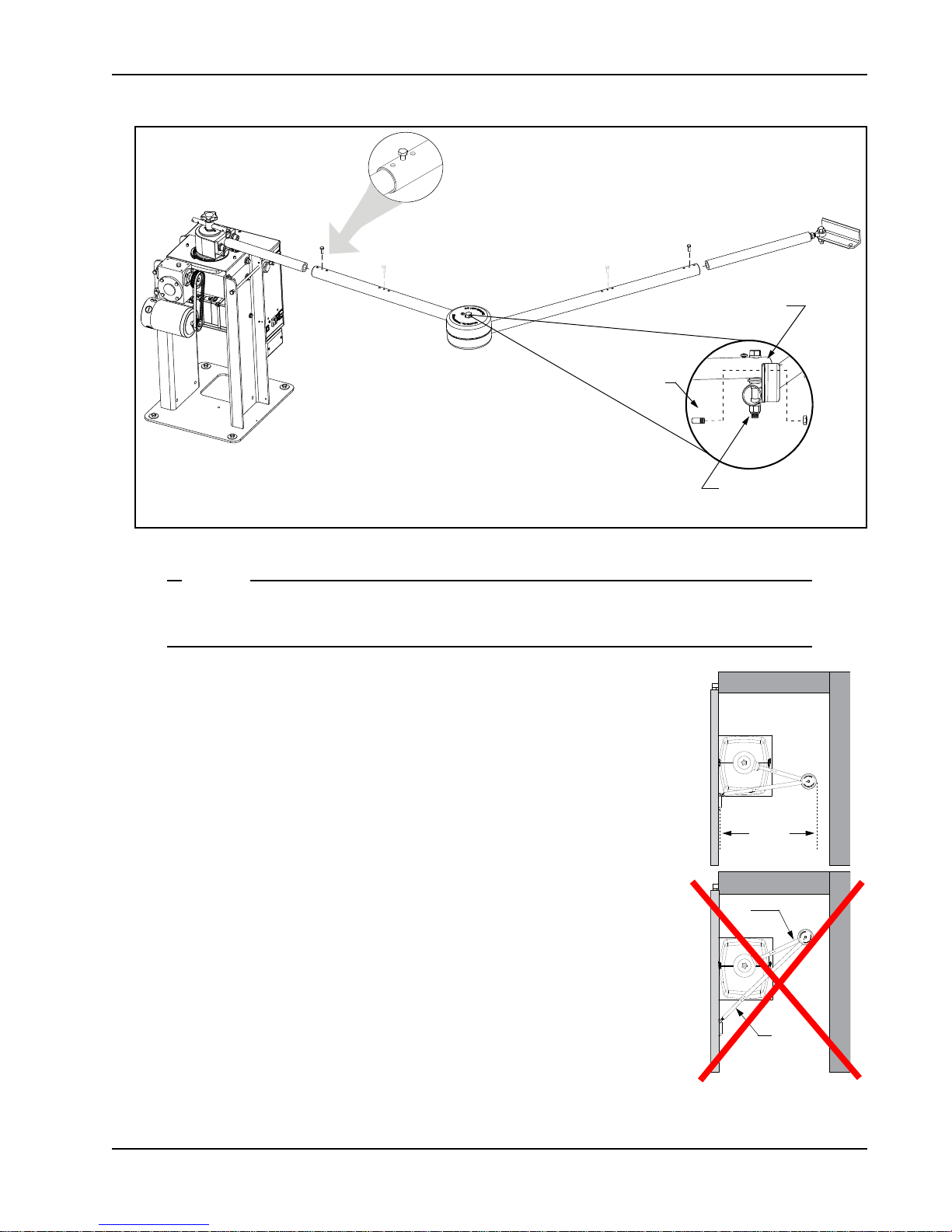

Attaching the Stub Arms

2

1

4

3

Taper handle

Stub arm

NOTE

Gate Bracket and Linkage Arms

Figure 1-7.

1. Attach the swivel eye bolt to the gate bracket using the fasteners provided.

2. Remove the fasteners from the taper clamp assembly.

3. Align the stub arm and secure it to the taper clamp assembly

4. Pull the taper handle to lengthen it. Adjust the handle so the ball detent fits into its cutout and secures the

handle length. Turn the hand

Do not retighten the taper clamp. It needs to remain loose for manual gate adjustments.

le counter clockwise to loosen the taper clamp. Figure 1-7.

using the fasteners remov

ed in step 2.

Revision A Installation 1-7

Page 26

Gate Bracket and Linkage Arms

Short Gate Installation:

For gates up to 10 feet

X

Y

Xg

14 23.5

10.5

18 27.5

20 29.5

X

Y

Xg

22 33.0

12

24 35.0

28 39.0

Medium Gate Installation:

For gates up to 13 feet

X

Y

Xg

30 44.0

15

35 49.0

40 54.0

Long Gate Installation:

For gates up to 20 feet

Custom Gate Installation:

X

Y

Xg

X + Y - 1

A

B

15.5 21.5

17.5 24.5

19.0 26.0

A

B

21.0 29.0

22.0 30.5

24.5 33.5

A

B

28.0 38.5

30.5 42.5

33.5 46.5

A

B

0.87 * Xg

0.63 * Xg

X

Xg

Hinge Center

Y

Operator Center

A

B

Linkage arms

NOTE

Installing the Linkage Arms

SwingSmart operators ship with a standard left-hand linkage arm. The left-hand linkage arm

can be used on a right-hand operator (and vice versa) by flipping the arm. This causes the gate

attachment point to be approximately 2-inches higher which means the gate bracket needs to be

positioned accordingly. For aesthetics and ease of installation, order a left-hand and right-hand

arm for bi-parting gate systems.

1. Slide the linkage tubes on the appropriate stub arms and use the tapped holes for adjust

Tighten the hex-head bolts to hold the arms in place. Refer to Figure 1-9.

2. Verify the A and B dimensions on the arm linkage tubes. For short gate applications, the linkage arms must

1-8 SwingSmart - Installation, Operation and Maintenance Manual Revision A

be cut

use the Custom Gate Installation formula to determine the proper length.

to achieve the required lengths. See Figure 1-8. If your operator position does not fit the chart specs,

Figure 1-8.

ment purposes.

Page 27

Note: Elbow pivot bolts must be parallel with the vertical axis of the operator . If the pivot bolt is

not vertical, binding of the arm assembly may occur during operation.

Elbow

Pivot bolt runs parallel

with the vertical axis of

the operator.

Tapped hole used for

linkage arm adjustments.

Set screw

Gate Bracket and Linkage Arms

NOTE

Figure 1-10.

CORRECT

alignment with

gate in the open

position.

INCORRECT

alignment.

Linkage arm (B)

needs to be

shortened.

B

A

B + 3

Figure 1-9.

The linkage tubes used for the arm can be drilled and bolted or welded together. Do the finishing

work AFTER the arm and gate adjustments are complete. See

Completing Gate Arm Installation

3. To verify appropriate arm length, manually push the gate to the

full open and close positions. Maximum security is obtained

when the elbow on the linkage arms is slightly bent with the gate

closed and at an approximate 90° angle with the gate in the open

position. See Figure 1-10

. Refer to NOTE on page 1-11.

4. During the open and close process:

• Verify all pivot joints rotate smoothly without binding. At

the full open position, linkage arms must

bind.

not scissor or

• Make sure the longer arm (B) does not collide with the top

cap cover.

•See

Figure 1-9 and make adjustments to arm lengths by:

• loosening the set screws

• telescoping the arms

• retightening the set screws

.

Revision A Installation 1-9

Page 28

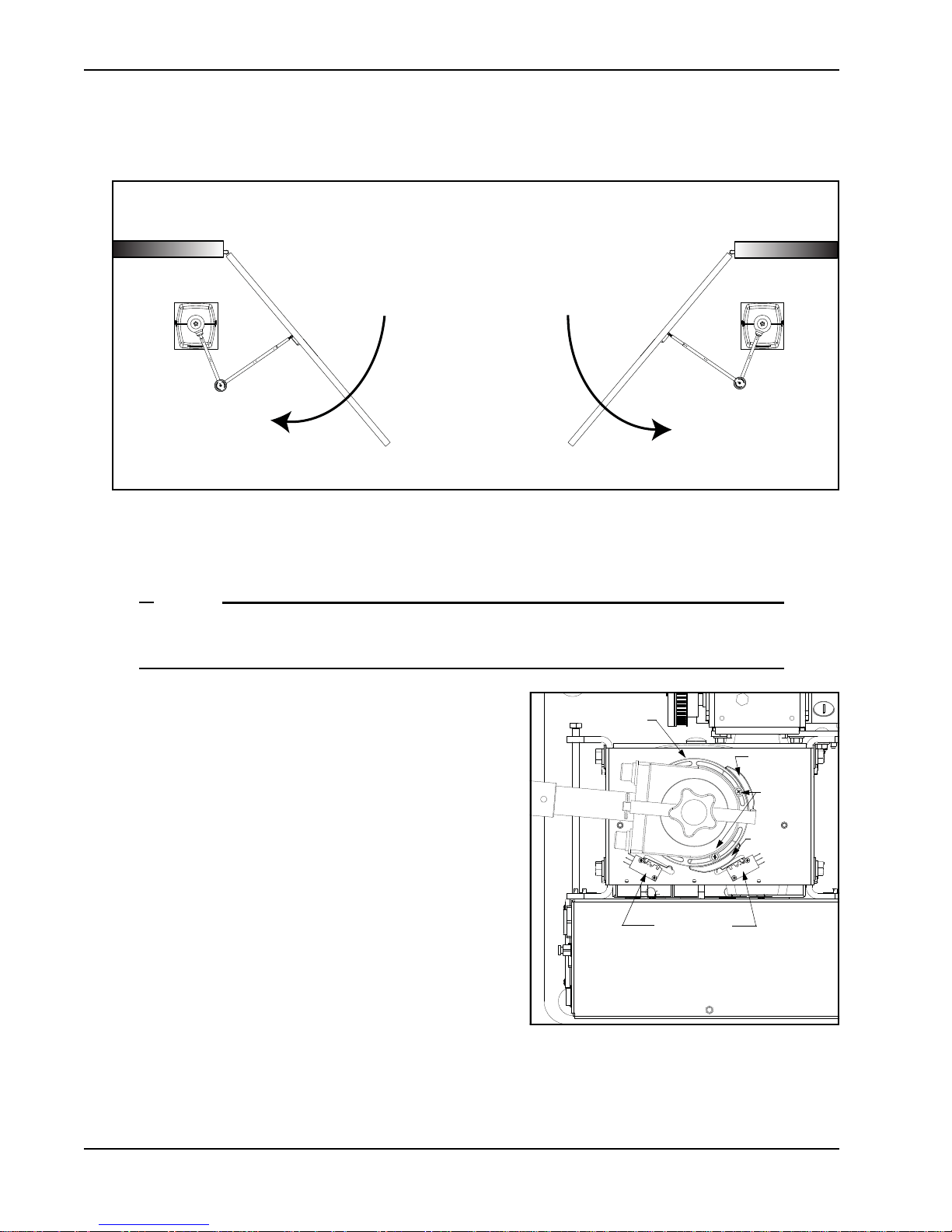

Gate Bracket and Linkage Arms

Left hand OPEN

Right hand OPEN

PUBLIC SIDE

SECURE SIDE

NOTE

Limit switches

Figure 1-12.

Loosen

screws

Limit plate

Limit cam

Limit cam

Adjusting the Limit Switches

Figure 1-11.

1. Determine whether the gate operator is a right-hand operator or left-hand operator. See Figu

on the secure side of the gate. If the gate opens to the right, it is a right-hand operator.

For a right-hand operator, the OPEN switch is the left limit switch as shown in Figure 1-12

The opposite occurs in a left-hand operator; the OPEN switch becomes the right limit switch.

2. To adjust the limit cams, use a Phillips-head screwdriver

and loosen the fastener that secures each limit cam to the

limit plate.

3. Manually, open and close the gate. Move the limit cams

so they trip the appropriate limit switch at the full OPEN

and full CLOSE positions.

4. Secure the limit cams by retightening the two Phillipshead scr

A fin on the limit plate

ensures the limits always

the gate is struck and the taper clamp slips.

Note:When reassembling the taper clamp, make sur

plate fin is seated into the slot on the taper clamp.

ews.

fits into the taper clamp. This feature

track the gate arm position even if

e the limit

re 1-11. Stand

1-10 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 29

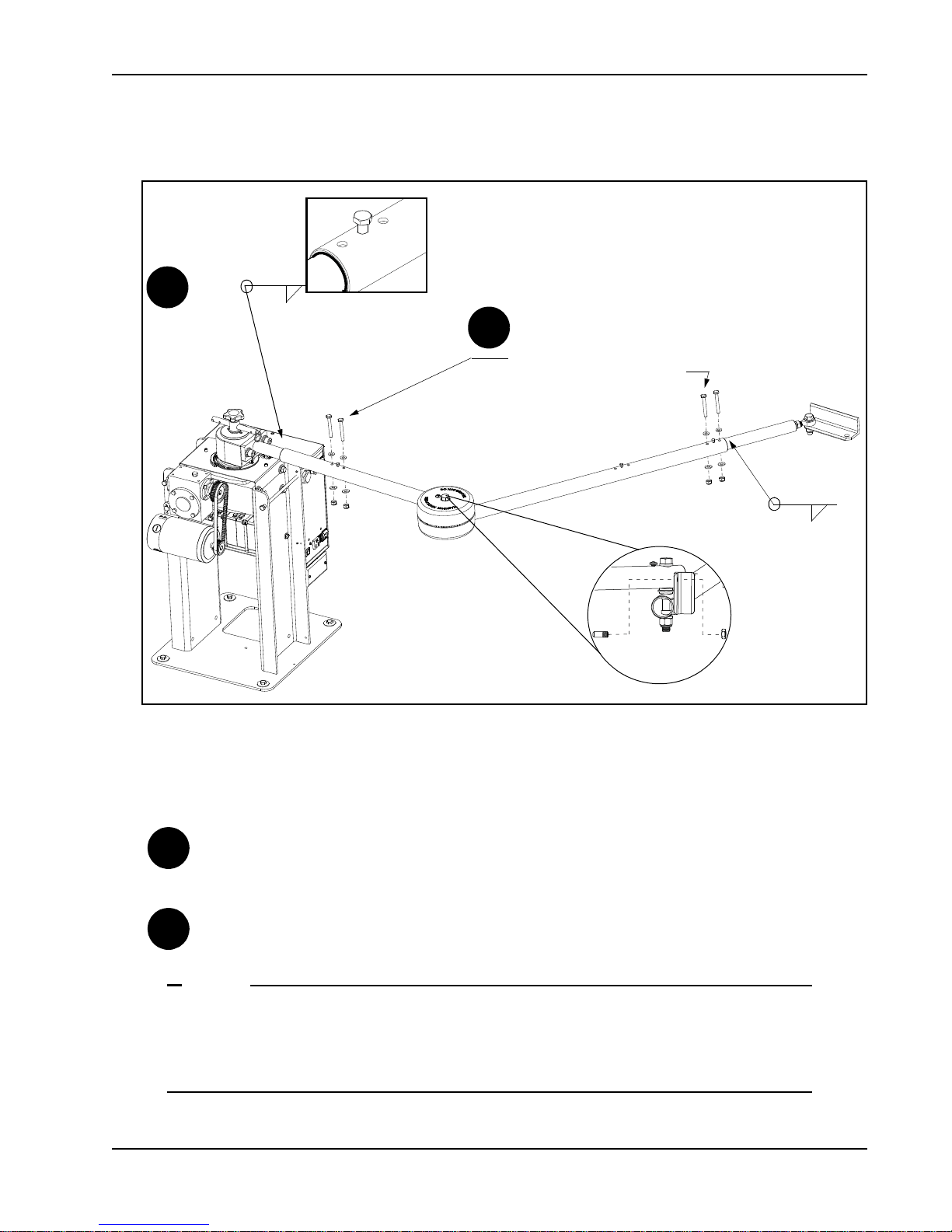

Completing Gate Arm Installation

To weld the linkage arms:

Weld a 1/8-inch fillet

around the tubing joint.

To use fasteners: Drill holes with a 17/64-inch drill bit and connect

arms with 1/4 - 20 UNC fasteners.

1/8”

1/8”

DRILL & BOLT (2x)

WELD

1A

1B

Set screw

Elbow joint

1A

1B

NOTE

Gate Bracket and Linkage Arms

Revision A Installation 1-11

Figure 1-13.

1. Drill & bolt (or weld the arms) to complete arm installation. See Figure 1-13. Paint welded areas to prevent

rusting. Consider the following when determining whether to

drill and bolt or weld the linkage arms:

DRILL & BOLT: Use at sites where fire bans do not permit outdoor welding and where the security

level is not high. In the event of a gate strike, bolts will shear and prevent full force impact to the gear

box. Damage is usually sustained to the less costly equipment such as th

WELD: Use at sites where the security level is high and the likelihood of gate strikes negligible. Be

e gate linkage arms.

aware, if you weld the arms and a gate strike occurs, damage may occur to the gearbox and linkage

arm assembly

.

For sites where incident of gate strikes are high, HySecurity recommends setting the elbow with

a slight offset at the full close position. Use the supplied set screw to prevent the arm from locking. The intent of the offset is that, upon gate strike, the elbow will bend and the taper clamp

will slip, minimizing damage to the gearbox and operator.

Page 30

Top and bottom covers need to be

evenly aligned. Gap should be less

than ¼-inch.

Cover

fastener

Cover

fastener

Bottom cover

Top cover

Elbow joint

2

Gate Bracket and Linkage Arms

NOTE

CAUTION

!

The two elbow joint cover fasteners are shipped with the covers.

2. Place the covers over the elbow joint.

3. Align the mounting holes and cutouts in the covers with the gate arms.

4. Make sure the gap between the top and bottom covers is evenly aligned. See Figure 1-14.

5. Insert the two fasteners and secure the covers.

It is critical that you install the elbow joint covers to comply with UL325 Safety Standards. The

elbow joint is considered a pinch point and serious injury may occur if the elbow joint covers

are not secured properly to the gate arms.

1-12 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Figure 1-14.

Page 31

Setting the Taper Clamp

Loosen

Tighten

Retract

45° angle

Simulate a gate strike

with ~ 100 lbs. of

force.

NOTE

Gate Bracket and Linkage Arms

Figure 1-15.

Setting the taper clamp with the gate closed impedes traffic flow. If vehicles need to pass

through the gate area, delay setting the taper clamp until after the operator has been configured

to run. Refer to Chapter 3, Configuring the Setup Menu.

1. Manually, swing the gate half way between the open and closed position (approximate 45° angle).

2. Turn the taper clamp handle clockwise to hand-tighten the assembly. A large am

ount of torque is not

required in order to obtain a tight clutch setting.

3. Push the gate end with approximately 100 pounds of force to simulate a gate strike. If the clamp taper

slips, use the taper handle to furthe

r tighten the assembly.

4. Continue to adjust the taper clamp until no slippage occurs.

5. Retract and center the taper clamp handle.

Revision A Installation 1-13

Page 32

Gate Bracket and Linkage Arms

This page intentionally blank.

1-14 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 33

Power

DANGER

!

NOTE

Chapter 2

TEP-BY-STEP

S

1. Install the earth ground.

2. Wire AC Power.

3. Connect DC Power.

INSTALLING THE EARTH GROUND

An earth ground refers to the grounding rod and accompanying equipment ground which need to be installed

to safeguard against potential electrical shock and damage to personnel and equipment.

The potential for lightning discharge exists with all gates, fences and gate operators. National Electric Code (NEC) requires a separate earth ground in addition to the required equipment ground.

HySecurity recommends grounding the operator with a separate earth ground connected to a ground rod to

assure proper operation and shield it against electromagnetism and other electrical signals that may cause

erratic operation with or damage to the Smart DC Controller.

If you do not ground the operator with a separate earth ground rod, you risk voiding the

Limited Warranty.

For earth grounding requirements, refer to the National Fire Protection Association (NFPA) 780 - Standard for

the Installation of Lightning Protection Systems. Highlights of the standard include.

• The ground rod is a solid copper ground rod: minimum requirements: ⅝" (16mm) diameter and 10 feet

(3m) in length.

• The ground rod is driven into the earth (refer to local codes for proper depth requirements).

• The ground rod is electrically bonded to the chassis with a single length of un-spliced 6AW

less than 3 feet (91cm) long.

• Local jurisdictions may impose additional requirements above the NEC and NFPA 780. Consult the local

codes

and regulations regarding requirements in your area.

G copper wire

Revision A 2-1

Page 34

Wiring AC Power

Buzzer/Alarm

Emergency Stop Button

DC Power Switch

Up is ON, Down is OFF

AC Circuit Breaker

115VAC Convenience Outlet

High Voltage Junction Box Cover

AC Input Wiri ng

AC Power Switch

Up is ON, Down is OFF

High Voltage Protection Cover

Smart DC Controller Display

DANGER

!

WARNING

!

Lug nut

Consult local

codes for

proper depth.

3 ft

Run ground wire

through concrete

base.

Figure 2-1.

Take the following steps to comply with NEC and NFPA 780 standards:

1. Install a grounding rod per local building codes. See Figure 2-1.

2. Attach a large earth ground wire (6AWG) from the grounding rod to

the lug nut on the base of the

chassis. Depending on whether you’ve

installed the operator at a new or existing site,

• Ne

w site: Run the 6AW

G wire through the concrete base and into

the cutout on the chassis base.

• Existing site: Run the 6AW

G wire beneath the rear cover. Make

sure the covers align and side latches lock properly.

Properly grounding the gate operator is critical to gate operator

performanc

e and the life of its electrical components. Use sufficient wire

size during installation. Refer toWiring 115VAC Power or Wiring 208/

230VAC Power.

WIRING AC POWER

Turn off AC power at the source (circuit breaker panel) before accessing the wires in the SwingSmart junction box. Follow facility Lock Out/Tag Out procedures. Make sure both the DC and AC

power switches, on the side of the SwingSmart control box are in the off position. See Figure 2-2.

Wiring of gate operators must conform to the NEC standards and comply with all local codes.

2-2 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Figure 2-2.

Page 35

Wiring AC Power

NOTE

NOTE

Wiring 115VAC Power

For standard 115VAC power connection:

• Verify AC power supply wires and low voltage (12V & 24V accessory power wir

separate conduits.

The higher voltage from the AC power supply may cause interference and anomalies in SwingSmart operation if the high and low voltage wires are routed through the same conduit.

• Make sure proper wiring is being used. The following table shows the maximum allowable wire run from

the power source to the operator for various wire sizes:

AC Power 14 gauge wire 12 gauge wire 10 gauge wire 8 gauge wire

One operator 115V 610 ft (185 m) 1000 ft (300 m) 1550 ft (475 m) 2500 ft (755 m)

Two operators 115V 305 ft (95 m) 500 ft (150 m) 775 ft (240 m) 1250 ft (380 m)

es) run through two

Figure 2-3.

To connect to 115VAC power, take the following steps:

1. Make sure the AC power is turned off at its source and the DC and AC power switches on the operator are

in the off position.

2. Access the input pow

er wires and convenience outlet wire

s by remo

ving the two Phillips-head screws that

secure the high voltage junction box cover.

The convenience outlet wires are solid copper and are labeled and bound together to keep them

separate from the AC power switch wires.

3. Wire nut or crimp bond the power supply wires to the black and white lead wires coming from the AC

power switch (no label). See Figure 2-3.

4. Wire nut or crimp bond the equipment ground wire to the green ground wire in the junction box.

5. To activate the 115VAC convenience outlet, include the black and white outlet lead wires and the green

ground wire in the connections made ab

6. Neatly organize all wire connections and replace the high voltage junction box cover. S

ove.

ecure it with the two

Phillips-head screws.

Revision A Power 2-3

Page 36

Wiring AC Power

CAUTION

!

30V

Figure 2-4.

Voltage selector switch

set to 230V.

Wiring 208/230VAC Power

All SwingSmart operators are shipped from the factory as 115VAC units. When connecting to

208/230VAC power, the voltage selector switch on the AC power board must be moved to the

230V position or damage to the operator will occur and void the Limited Warranty.

For the 208/230VAC power connection:

• Verify AC power supply wires and low voltage (12V & 24V accessory power wires) run through two

separate conduits as discussed in Wiring 115VAC Power.

• Make sure proper wiring is being used. The following table provides the size wire for dis

the power source to the operator:

AC Power 14 gauge wire 12 gauge wire 10 gauge wire 8 gauge wire

One operator 208/230V 2440 ft (745 meters) 3900 ft (1180 meters) 6200 ft (1885 meters) 9900 ft (4950 meters)

tance (in feet) from

Two operators 208/230V 1220 ft (370 meters) 1950 ft (590 meters) 3100 ft (940 meters) 3005 ft (1500 meters)

To connect to 208/230VAC power, take the

following steps:

1. Make sure the AC power is turned off at its

source and the DC and AC powe

r switches

on the operator are in the off position.

2. Remove the High Voltage Protection cover

by unscrewing the tw

o Phillips-head screws

that secure it.

3. Toggle the voltage selector switch from 115V

to 230V. R

eplace the High Voltage cover and

secure it. See Figure 2-4.

4. Access the input power wires by removing the

two Phillips-head screws that secure the High

Voltage Junction Box Cover. See Figure 2-2.

5. Wire nut or crimp bond the power supply

wires to the black and white lead wires

coming from the AC power switch (no label).

6. Wire nut or crimp bond the equipment

ground wire to the green ground wire in the

junction box.

2-4 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 37

Connecting DC Power

DANGER

!

Figure 2-5.

Do not connect the 115VAC convenience outlet to 230VAC power supply wires. To use the 115VAC

convenience outlet with 230VAC supply power, a separate neutral wire (white) must be run from the

power source. Follow guidelines according to the National Electrical Code Article 250.

7. Neatly organize all wire connections and secure the High Voltage Junction Box Cover with the two

Phillips-head screws.

8. Place the 230V 1Ø label on the High Voltage Junction Box Cover over the 115V 1Ø label.

CONNECTING DC POWER

To connect the DC power:

1. Turn off the DC and AC power switches.

2. Slide the plastic cover off the control box.

3. Attach the red spade connector to the battery terminal on

the DC powe

r switch. See Figure 2-5.

Note: For extended battery backup installation, refer to the

Installing the Extended B

attery Backup Kit instructions.

Important Considerations for DC-powered Operators

• Since the operator is intended to run on batteries, control of the load is important. Gates that move easily

and do not bind will drain less energy from the battery, preserving capacity for more cycles during a power

failure.

• Be certain to observe polarity when connecting the batteries or adding accessories. Reversed polarity may

result in a non-functional operator or damage to a co

If shorted, the batteries will generate a very high current. The batteries are connected in a series circuit:

Join the positive (+) terminal from one battery to the negative (-) terminal of the next battery.

• When the operator is not in use, and no AC power is connected, be sure to shut

unplug the red battery wire from it. This will prevent the batteries from slowly discharging over time.

Batteries have a finite life. As the batteries age, they will lose some of their capacity to store energy. If the

total amount of back-up capacity is critical, plan to replace the batteries after two years of use. Properly

dispose of or recycle used batteries. Refer to Hazardous Materials and Proper Disposal.

mponent. Red (+) is positive and black (-) is negative.

off the DC switch, and

Revision A Power 2-5

Page 38

Connecting DC Power

WARNING

!

NOTE

Batteries contain sulfuric acid. Acid in your eyes, on your skin, or on your clothing can cause

injury and severe burns. If batteries are dropped or damaged dispose of them properly.

• Batteries are rated to perform to capacity at certain temperatures. Variations in temperature affect

performance of the batteries. An example of amp hour performance is shown in Table 2-1. HySecurity

mounts the battery pack near the transformer to provide residual heat around the batteries which guards

against amp hour loss.

able 2-1.

T

Amp Hour - Example of Battery Performanc

e

Temperature Capacity

77°F (25°C) 100

32°F (0°C) 75

10°F (-12°C) 50

• HySecurity uses a permanently sealed AGM-type battery which needs no maintenance over its life span.

Batteries are protected from over discharge by a low voltage sensing circuit. The charger circuit regulates to

only allow high charger output when the battery is partially discharged. The charger circuit automatically

reduces the output to near zero as the batteries become fully charged.

The SwingSmart operator stores all User and Installer Menu settings in non-volatile memory

(EEPROM). Whatever configurations exist, if power loss occurs, are saved and reinstated once

power is restored.

2-6 SwingSmart - Installation, Operation and Maintenance Manual Revision A

Page 39

Connecting DC Power

50 AH

50 AH

Battery

Battery

DC power switch in

the off position

AC power switch in

the off position

DANGER

!

Figure 2-7.

Loosen tray

screws (2x)

Remove tray

screws (2x) and

rotate the tray

down to

remove the

batteries.

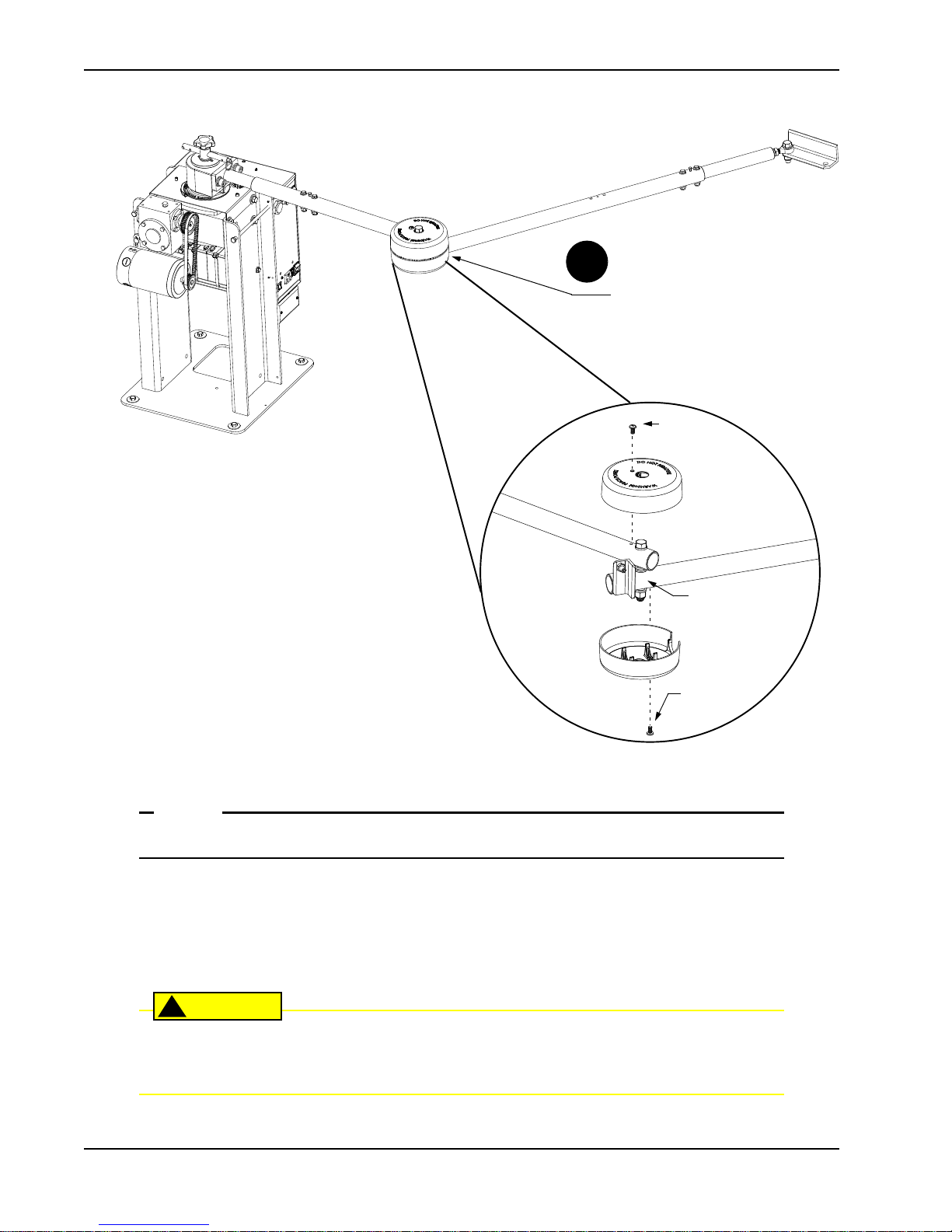

Installing the Extended Battery Backup Kit

Figure 2-6.

HySecurity offers extended DC power back up via two 50AH batteries. Contact HySecurity parts department

to order extended battery backup

kit (P/N MX001810).

To install the extended battery backup kit:

1. Turn off the DC and AC power switches.

2. Unlock side latches to remove the SwingSmart front cover.

Remove the two Phillips-h

ead screws and the two wing nuts

that secure the rear cover. Set the covers aside.

3. Cut the two black zip ties which secure the 8AH batteries to

the tray.

4. To

access the 8AH batteries and disconnect its wires, remove

the two screws closest to the motor and loosen the other

two

screws that secure the support tray as shown in Figure 2-7.

5. Carefully rotate the support tray to access the battery wir

es.

Lift the 8AH batteries from the support tray. Disconnect the black and blue wires and set the 8AH

batteries aside.

6. Return the support tray to it’s original position and secure it properly.

Make sure both the left and right 8AH DC battery wires are disconnected. Remove the batteries

from the unit and properly store or discard them. Refer to

. Never mix battery sizes, types, or brands. HySecurity strongly recommends that only sealed

posal

AGM style batteries be used.

Revision A Power 2-7

Hazardous Materials and Proper Dis-

Page 40

Connecting DC Power

Black

Blue

Red

Figure 2-8.

CT 0 (OFF)

CLOSE TIMER

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

1. Start at a gate status

display.

2. Access the User

Menu, by pressing

MENU twice.

3. Access the Installer

Menu, by

simultaneously

pressing OPEN and

RESET. Release the

buttons.

4. Use NEXT to

navigate to the menu

display. Change the

setting using the

SELECT and NEXT

buttons.

7. Place the 50AH battery tray

between the chassis posts and

secure it using the four fasteners

provided in the kit. See

Figure 2-8.

8. Situate the two 50AH batteries

on the tray.

9. Attach the blue wire from the

red terminal on one 50AH

y to the black terminal on

batter

other 50AH battery.

10. Run the 8AH wire harness

throu

gh hole in

the 8AH

battery support tray.

11. Using the wires attached in the

50AH bat

tery kit, attach

wire to the red positive terminal

on the 50AH battery. Connect

its opposite end to the red lead

exiting the support tray.

Connect the black wire to the

black negative terminal on the

50AH battery. Connect its

opposite end to the black lead

exiting the support tray.

12. Access the Installer Menu on the

Smart DC Controller.

13. Change the Battery Setting (BT)

in the I

nstaller M

number 1 (Extended). Follow

the steps in the menu tree

shown here.

enu to a

the red

HYSECURITY

GATE CLOSED

CLOSE

OPEN

NEXT

PREV

STOP

SELECT

MENU

RESET

2-8 SwingSmart - Installation, Operation and Maintenance Manual Revision A

UC 2

USAGE CLASS

CLOSE

OPEN

NEXT

PREV

BT 1 (EXTENDED)

BATTERY TYPE

CLOSE

OPEN

NEXT

PREV

STOP

SELECT

STOP

SELECT

MENU

MENU

RESET

RESET

Page 41

Display and Menu Options

NOTE

Chapter 3

TEP-BY-STEP

S

1. Turn both AC and DC power switches on.

2. Configure the Setup Menu

3. Review how to use the Smart DC Controller Buttons in Menu Mode

4. Review Run Mode and Gate Status Displays

5. Access and Configure User Menu Options

• Adjust the Close Timer

• Set the Time and Date

• Set the AC Power Loss Gate Function

• Adjust the Display Contrast

6. Access and Configure Installer Menu Options

• Set the Open and Close Gate Speed

• Adjust IES Sensitivity

• Enable Fire Department Access

• Reinstate Factory Defaults

INITIAL SETUP

Once you’ve completed the installation of the SwingSmart operator and attached the wired accessories, you’re

ready to program the operator. Two different approaches exist:

• Connect a laptop computer to the USB or serial (RS-232) por

operator menu configurations via the START software.

Use a laptop computer at your place of business to conveniently download the free START software from www.hysecurity.com before heading out into the field. A START User Guide is also

available online.

• Manually navigate through the User and Installer Menus using the buttons located on the Smart DC

Controller. The instructions for performing this second option are provided in this section.

t and upload the

gate settings and set the

Revision A 3-1

Page 42

Initial setup

Figure 3-1.

DC Power

Switch

AC Power

Switch

NOTE

NOTE

Turning Both Power Switches On

One AC and one DC rocker power switch are located on the outside edge of the control box.

Refer to Figure 3-1.

1. Turn both power switches ON. An audible beep occurs and a red light

sates next to

pul

indicates the system is functioning.

Note:If AC power is lost, the rate of flashing slows down. Other indicator

lights are described below.

2. The software version briefly appears on the LCD display and the

display settles on one of the following modes:

the OPEN button on the Smart DC Controller which