Page 1

QUick Start StepS

Keyed latch

Cover

Operator

Service Outlet

115VAC, 15A

Plastic base

Unpack

the OperatOr

Page 2

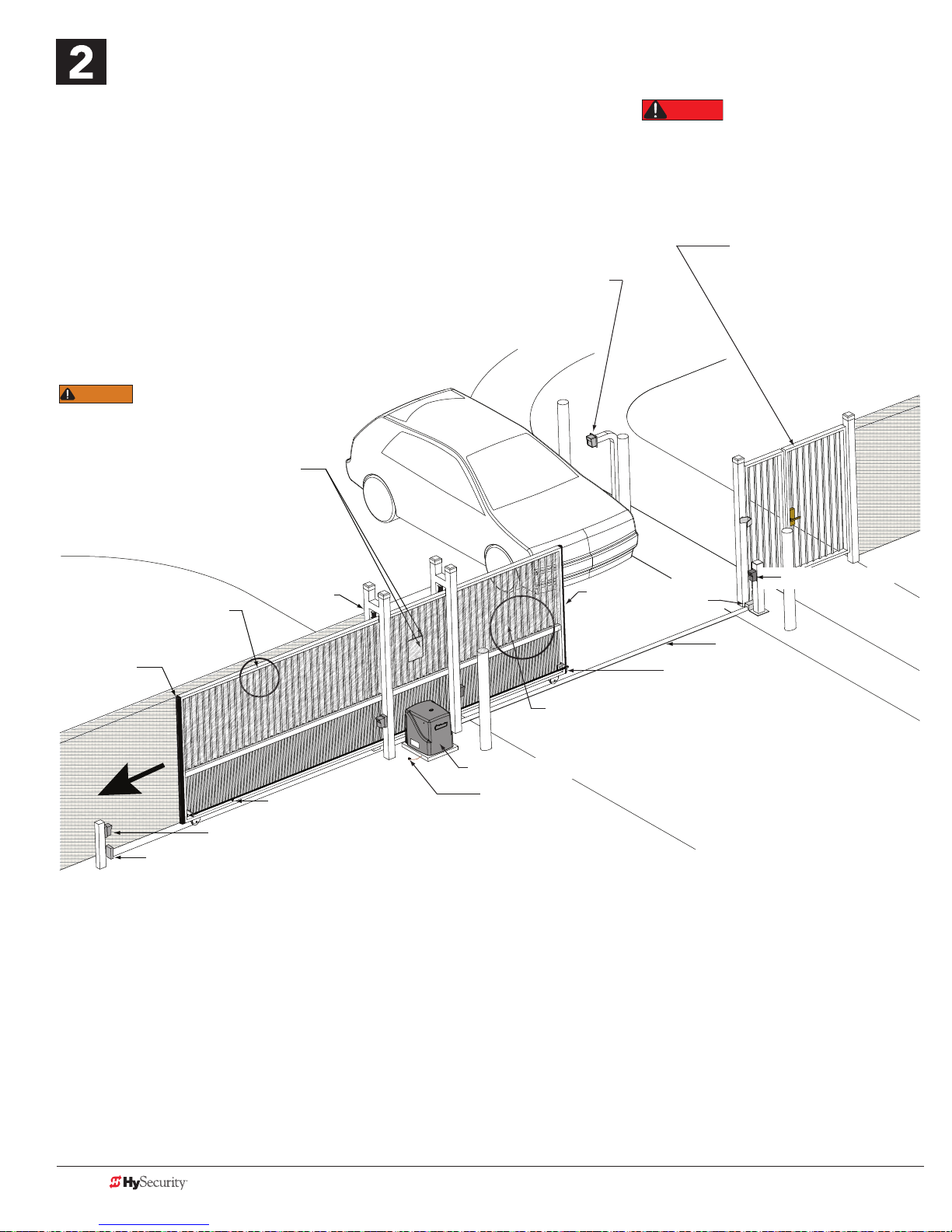

Site Planning and OPeratOr inStallatiOn

WARNING

DANGER

The illustrations and instructions presented in this guide provide a quick

overview of the SlideSmart installation process. For more detailed steps,

refer to the SlideSmart DC Installation and Reference Manual.

IMPORTANT: When installing the operator, be sure to comply

with all local government regulations and codes, and read the

Important Safety Instructions found in the manual.

Key or Card reader

Mount access control

devices at least 6ft

(183cm) beyond gate.

Public Side

Be sure to place the

WARNING signs on both

sides of the gate. For your records, take a

photograph of the completed installation site.

attach Warning

SignS

Turn OFF AC power at the source

(circuit breaker panel) before

installing the operator. Follow facility Lock Out /

Tag Out procedures. Make sure both the

DC and AC power switches on the Control Box

are in the OFF position. Refer to step 8.

Pedestrian gate located

near the slide gate

Make sure a separate walkthrough entrance is available

and its pedestrian path is

clearly designated.

Maximum 2¼" (57mm)

width between vertical bars

Edge sensor

on trailing edge

Left Hand Gate

opening

Photo eye (entrapment protection shown in four locations

Physical stop – weld stops at both ends of V track

Non-pinch

rollers (4x)

SlideSmart DC operator

Target magnet on chain

SlideSmart OPeratOrS

SlideSmart dc 15

Duty cycle: continuous

Power, Single phase: Switch selectable

115 volts, 3 amps, 50/60 Hertz

230 volts, 1.5 amps, 50/60 Hertz

Motor: ½ hp

Maximum gate weight: 1500lbs (680kg)

Gate Speed: 1ft/s

Solar Model: SlideSmart DCS 15

NOTE: for SlideSmart DC Solar operates, refer to www.hysecurity.com

SlideSmart dc 10F

Duty cycle: continuous

Power, Single phase: Switch selectable

115 volts, 3 amps, 50/60 Hertz

230 volts, 1.5 amps, 50/60 Hertz

Motor: ½ hp

Maximum gate weight: 1000lbs (454kg)

Gate Speed: 2ft/s

Solar Model: SlideSmart DCS 10F

Earth ground

Edge

sensor

To comply with ASTM F2200, a screened wire mesh extends

to the top of the gate or to a minimum height of 6 ft. (183 cm)

if a 2¼" (57mm) or larger gap exists between the vertical bars.

Physical

stop

V track

Front edge of gate

Photo eye (4x)

Secure Side

Site OvervieW

Recommended Entrapment Protection shown

Page 2 D0349 Rev D SlideSmart DC Quick Start Steps www.hysecurity.com

Page 3

OPeratOr & earth grOund inStallatiOn

DANGER

cOncrete Pad dimenSiOnS

Gate to base mounts

Ideal distance = 5½" (14cm)

5½"

(14cm)

10.5"

(26.7cm)

1.6"

(4.1cm)

Concrete

pad

Area

cut out

for

conduit

6¼" x 12"

(17cm x 30.5cm)

10.4"

(26.4cm)

19" minimum

(48.3cm)

#40 Roller

(53.3cm)

GateChain,

21"

Grade

level

Slotted holes (4x) for

concrete anchors:

½ - 13 x 13½"

mOunt the OPeratOr

Chain to Gate

Ideal distance = 3¼" (8.25cm)

Min. distance = 2½" (5.7cm)

Chain

height

7¾"

(19.7cm)

Concrete pad

Side vieW

NOTE: Operator footprint with covers is

approximately 18" square (45.7cm).

Gate

SlideSmart DC

operator

Consult local

codes for

proper depth

Chain

3

(91.4cm)

Ground

wire

Concrete pad

(depth set per

local codes)

High voltage wires

Main AC power

Grounding rod depth at

10ft (3m) or per local code

Ground

lug

Cut-away

view

Conduit runs

2" (5cm) above

concrete pad

Minimum pad

height is 2" (5cm)

above grade level.

20.7"

(52.6cm)

Side cut-aWay vieW

ShOWS cOnduit

Placement &

grOunding

Grade level

Vehicle loop

control wires

Extra conduit

(Dual/Sequenced gate)

(Conduit may be shared with low voltage wires)

Low

voltage/Communication wires

NOTE: To reduce electrical interference, keep as much distance as possible

between the high voltage and low voltage conduits.

The potential for lightning discharge exists

National Electric Code (NEC) requires a separate earth ground

in addition to the required equipment ground. A local earth

ground also serves to protect the electronic controls.

with all gates, fences and gate operators.

www.hysecurity.com SlideSmart DC Quick Start Steps D0349 Rev D Page 3

Page 4

inStall the chain

Pedestrian gate

Public Side

Trailing edge

of gate

inStall the

chain bracketS

1. Measure for proper chain

alignment BEFORE welding

the brackets to the gate.

Make sure the chain will run

horizontal to the ground

and parallel with the gate.

2. Weld the chain brackets

to gate. Two locations:

front edge and trailing edge.

3. Attach the eye bolts to the

brackets as shown.

4. Attach the connector link to the

chain and eye bolt.

5. Feed the chain around the idler

wheels and over the sprocket.

6. Adjust the nuts on the eye bolt to

tighten the chain and minimize sag.

Chain

bracket

⅛"

Front edge

of gate

Secure Side

Eye bolt

Chain bracket

7¾"

(19.7cm)

inStall and align the chain

Feed chain over sprocket. View illustration in step 7, also.

Connector link

Eye bolt

Measure chain height.

Weld bracket to gate so

chain remains horizontal

and level.

Chain to Gate

Ideal distance = 3¼"

(8.3cm)

NOTE: For rear or post mounted installations, see SlideSmart DC Installation and Reference Manual.

CORRECT INSTALLATION

tOP vieW

Page 4 D0349 Rev D SlideSmart DC Quick Start Steps www.hysecurity.com

Side vieW

Too close to gate

INCORRECT

CORRECT

INCORRECT

INCORRECT INSTALLATION

Page 5

initial SetuP menu

PREV

Connect the red battery wire to its spade terminal. Turn ON DC power.

The USAGE CLASS menu display appears the rst time power is

applied. Five sequential displays present information which must be

congured before SlideSmart will function.

To edit

the MENU

Press SELECT.

Two top

characters blink.

UC 0

USAGE CLASS

CLOSE

OPEN

NEXT

PREV

SH 0

GATE HANDING

CLOSE

OPEN

NEXT

PREV

To navigate through

SELECTIONS

Press NEXT.

Continue pressing NEXT

to view all selections.

MENU

STOP

SELECT

STOP

SELECT

MENU

RESET

RESET

To choose what is

on the display

Press SELECT.

Blinking characters

become static.

To navigate

between menus

Press NEXT or PREV.

Advance – press NEXT

Previous – press PREV

SELECTIONS

0 – No Usage Class set.

1 – Single Family residential up to four units.

2 – Multi-family, hotel, etc.

3 – Industrial use, not for general public.

4 – Guarded and monitored facility not for

general public.

SELECTIONS

0 – No handing set. Gate will not move until

handing is set.

Looking at the gate from the secure, operator

side, choose:

R – If the operator is on your right.

L – If the operator is on your left.

cOnnect the battery

Connect the red battery wire.

ON

DC

POW

OF

Emergency

Stop Button

turn On

dc POWer

RESET

OPEN

CLOSE

NEXT

STOP

SELECT

MENU

SELECTIONS

WT 0

GATE WEIGHT (LB)

0 – Not set.

1 – Gate weight: 0 to 400lbs (0 to 181kg)

OPEN

CLOSE

STOP

MENU

RESET

2 – Gate weight: 401 to 800lbs (182 to 363kg)

3 – Gate weight: 801 to 1100lbs (363 to 499kg)

PREV

4 – Gate weight: 1101 to 1500lbs (499 to 60kg)

SELECT

NEXT

learn limitS

LEARN OPEN

INCHES: +XXX.X

CLOSE

OPEN

NEXT

PREV

Hold the OPEN button until the gate

slides to full open. Release the OPEN

button. Note that if you go too far, you

can press CLOSE to reverse direction.

Press STOP twice to preserve the open

stop location in memory.

STOP

SELECT

MENU

RESET

SlideSmart DC 15 SlideSmart DC 10F

1 – Gate weight: 0 to 400lbs (0 to 181kg)

2 – Gate weight: 401 to 800lbs (182 to 363kg)

3 – Gate weight: 801 to 1100lbs (363 to 499kg)

4 – Gate weight: 1101 to1500lbs (499 to 60kg)

LEARN CLOSE

INCHES: - XXX.X

OPEN

PREV

CLOSE

NEXT

STOP

SELECT

MENU

RESET

Hold the CLOSE button until the gate

slides to full close. Release the CLOSE

button and press STOP twice. The full

close stop is retained in memory.

HYSECURITY

GATE CLOSED

CLOSE

OPEN

SELECT

NEXT

PREV

NOTE: GATE CLOSED appears

on the display and ALERT 15 ashes

until the target magnet is installed

and its location stored in memory.

See page 6, Install the Target Magnet.

STOP

MENU

RESET

www.hysecurity.com SlideSmart DC Quick Start Steps D0349 Rev D Page 5

Page 6

inStall the target magnet

CAUTION

With the gate in the FULL

CLOSE position, mark the

chain link directly opposite

the target sensor.

Use the target sensor

closest to the trailing

edge of the gate.

Target sensor

Public Side

Secure Side

To install the target magnet, take the following steps:

1. With the gate closed, mark the chain link as shown in the illustration above.

2. Press the OPEN button to move the gate and chain a few feet and then press STOP.

3. Turn OFF the DC power switch (leave the AC power switch ON). Performing this step

keeps the gate from moving accidentally while you install the target magnet.

4. Find the mark on the chain link and count about four (4) xed links toward the

operator (approximately 3 inches, 76mm).

Pedestrian gate

When the gate is CLOSED, the target

magnet should stop between the

target sensor and the roller chain sprocket. The target

magnet MUST NOT enter the sprocket teeth.

Screw

Roller chain

Mark on Chain

3"

Target sensor

Install 1 Target Magnet

(large white centerpiece faces sensor

sprocket

Target sensor

(RH gate)

Target

sensor

(LH gate)

(76mm)

Position of the target magnet when

5. Remove the screw from the target magnet.

6. Fasten the target magnet to the chain link as shown in the illustration. Insert the screw and tighten it securely. To avoid damage to

the idler wheel, the head of the screw must be ush with the chain rollers.

7. To allow gate movement, turn ON the DC power switch.

8. Test the application of the target magnet by pressing the CLOSE button. An audible beep is heard the rst time the target magnet

passes the target sensor. The limit sensor light on the Smart DC Controller also ashes red.

NOTE: Use one target magnet and make sure the target magnet activates. Toggle both power switches OFF and ON. The gate will

move. When the target magnet passes the target sensor, limits are automatically restored. If LEARN OPEN appears on the display,

the limits need to be re-established. Return to step 6 on page 5.

the gate is fully closed.

Page 6 D0349 Rev D SlideSmart DC Quick Start Steps www.hysecurity.com

Page 7

turn OFF main POWer and cOntrOl bOx

CAUTION

DANGER

CAUTION

WARNING

SWitcheS, then cOnnect ac POWer

turn POWer OFF

Turn OFF AC power at the source

(circuit breaker panel) before

accessing the wires in the SlideSmart junction box.

Follow facility Lock Out / Tag Out procedures.

Make sure both the DC and AC power switches

are in the OFF position.

Place DC power switch

in the OFF position.

Place AC power switch in

the OFF position.

Service Outlet

DO NOT connect the 115VAC

service outlet to 208 or 230VAC

power supply wires! To use the 115VAC service outlet

on a 208/230VAC installation, the electrician needs to

run an extra neutral wire to the operator from the

power source and wire the service outlet per cover.

O

DC

POW

OF

115VAC wires for the

Service Outlet

Junction

box cover

and label

Junction box

cOnnect the POWer WireS

1. Unscrew the two Phillps-head screws.

2. Remove the cover to the junction box.

3. Connect the AC power and ground wires with wire nuts.

Wiring of gate operators must conform to NEC

standards and comply with all local codes.

O

AC

POW

Service Outlet

OF

115VAC, 15A

Voltage selector switch is

factory set to 115V.

If power input

is 208/230V, move

the switch so 230V

appears and change the

label on the junction box.

When connecting to 208/230VAC on

the AC power, the voltage selector

switch on the AC power board must be moved to the

230V position or damage to the operator will occur

and void the Limited Warranty.

www.hysecurity.com SlideSmart DC Quick Start Steps D0349 Rev D Page 7

Page 8

cOnnect acceSSOrieS

All the accessories require a minimum of two connections on the Smart DC Controller:

a device input

a Common Bus Terminal (COM)

Other devices may require more connections or congurations. For example, the Fire Department (EMERG OPEN)

input requires a +24-volt input. The connection must be activated by changing the settings through the Installer

Menu. Refer to the SlideSmart DC Installation and Reference Manual.

COMMON

TERMINALS

Access controls

(Ex. Card reader, keypad)

Photo eye N.O.

connects to either

EYE OPEN

or EYE CLOSE.

Photo eye

4-wire connecon:

Power COM/+24V

EYE COM

Relay COM

EYE OPEN or CLOSE

(depending on funcon)

Edge

sensor

COM

COM

COM

COM

COM

COM

COM

COM

STOP

OPEN

CLOSE

RADIO

OPEN

PARTIAL

EYE

OPEN

EYE

CLOSE

EXIT

LOOP

BLOCK

EXIT

IN OBS

LOOP

OUT OBS

LOOP

CENTER

LOOP

EDGE

EYE

COM

+ 24 V

EMERG

OPEN

24VDC

24VDC

24VAC

24VAC

12VDC

12VDC

OPEN

SHOW

LEDs

2 channel

radio receiver

Red LED

heart beat

indicates

processor

is working.

Press button

to light active

inputs.

N

PE

O

V

4

2

+

EDGE

TI

P

O

O

DI

A

R

C

ON

O

RS232

B

M

D

S

Multi-colored LED

indicates power and

gate status.

RS485

ethernet

USER RELAY 1

Electro-mechanical

D

2

R

E

S

U

A

M

O

C

AL

U

AT

G

O

C

E

USER RELAY 2

Solid state

HY-5A

FREE EXIT

HY-5A

INSIDE LOOP

HY-5A

OUTSIDE LOOP

HY-5A

CENTER LOOP

C

O

N

M

USB PORT

RS-485

COMMUNICATION

HY-5A

VEHICLE LOOP

Connection for a Dual or Sequential gate system.

See Chapters 2 and 5 in the SlideSmart DC

Installation and Reference Manual.

Page 8 D0349 Rev D SlideSmart DC Quick Start Steps www.hysecurity.com

© 2013

Loading...

Loading...