HySecurity SlideDriver 15, SlideDriver 50VF 2/3, SlideDriver 30F, SlideDriver 200, SlideDriver 40 Programming & Operation Manual

...Page 1

Programming & Operations Manual

with

HySecurity Smart Touch Controller

SlideDriver 15, 30F, 40, 50VF 2/3, 80, 200

This document provides Important Safety Information, specications, and references along with

an overview of programming user and installer menu options, designing vehicle loop layouts,

troubleshooting, and maintaining the gate operator.

Page 2

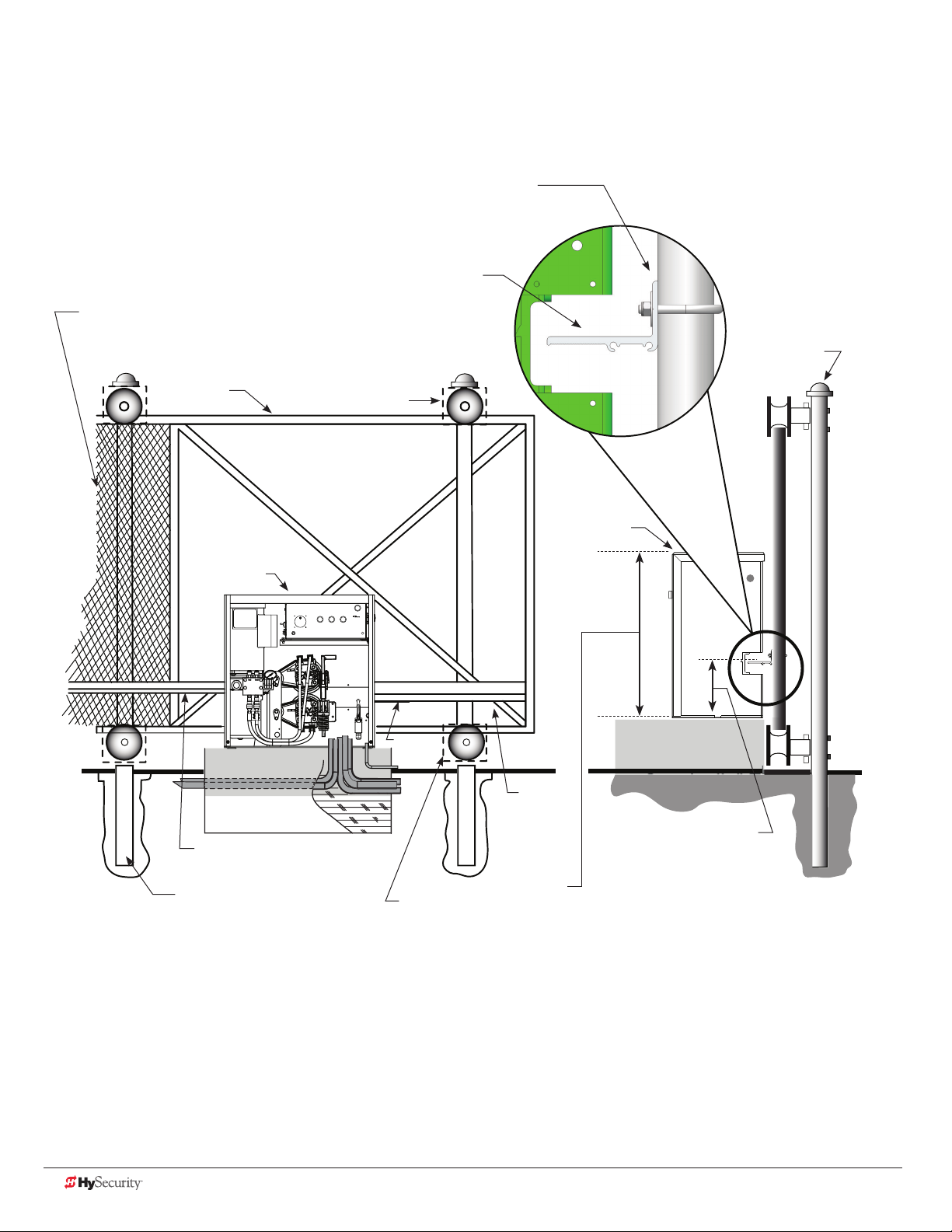

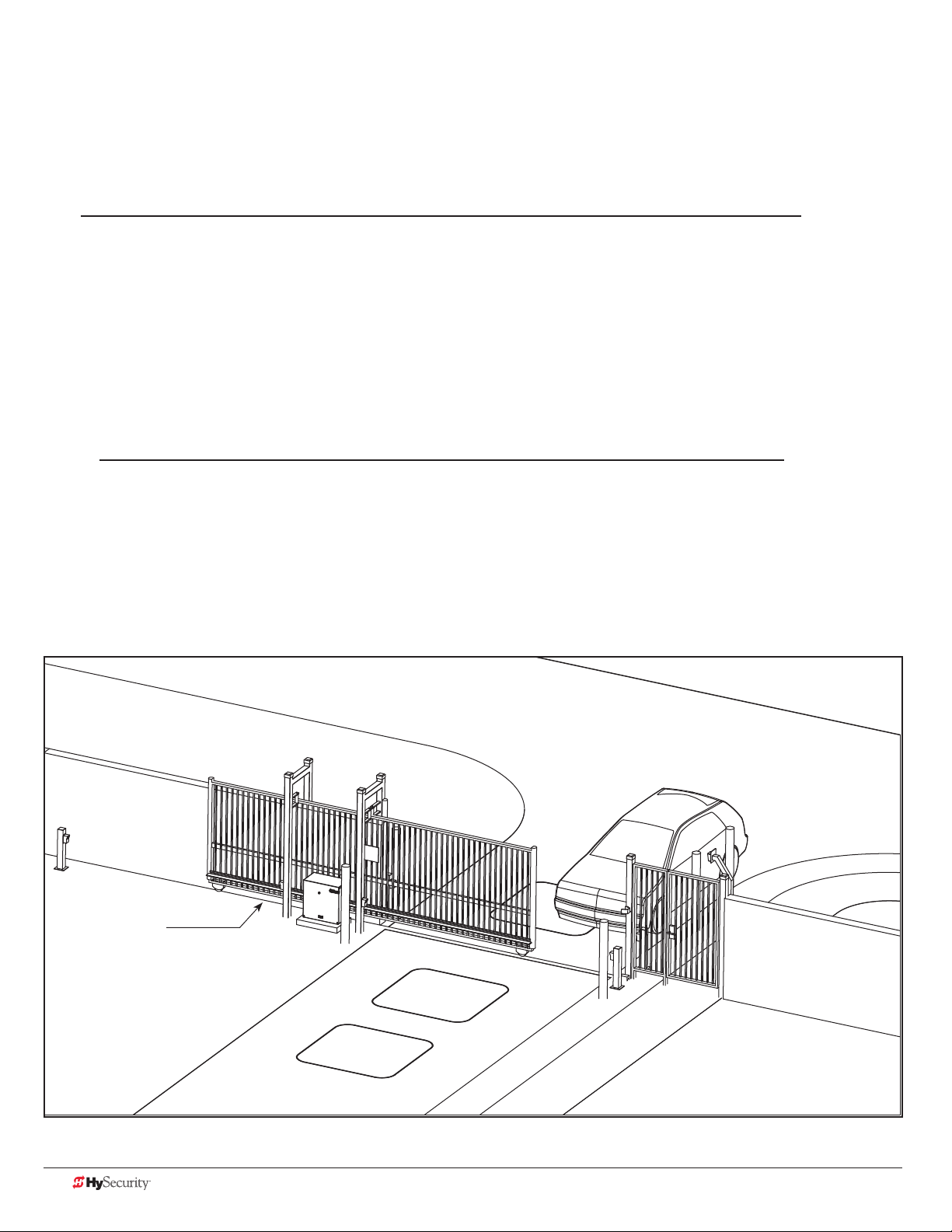

SlideDriver/SlideDriver 50VF

Site Installation Overview

Gate Face*

Use shims as needed

Grooved Drive Rail

Screen Safety Mesh on Gate Height: Per UL 325 and ASTM

F2200, all openings in a sliding gate up to a 72-inch (6 foot or

183 cm) height must be guarded or screened.

Support Post

Gate

SlideDriver

Concrete Pad

Drive Rail

Support Post

Wheel Cover

For clarity, safety mesh

is not shown

Limit

Ramp

Wheel Cover

SlideDriver

Drive

Rail

All models:

(except SD 200)

26" (66cm)

SlideDriver 200:

43¼" (109.5cm)

Height from top of

Drive Rail* to bottom

of gate operator.

All models:

9¼" (23.5cm) using standard AdvanceDrive™

wheels, 6 or 8 inch.

*NOTE: using XtremeDrive™ wheels, adjust

height along the length of the Drive Rail by

¼ to ½ inch which increases overall height

between 9¾ and 10 inches (24 to 25 cm).

ii D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 3

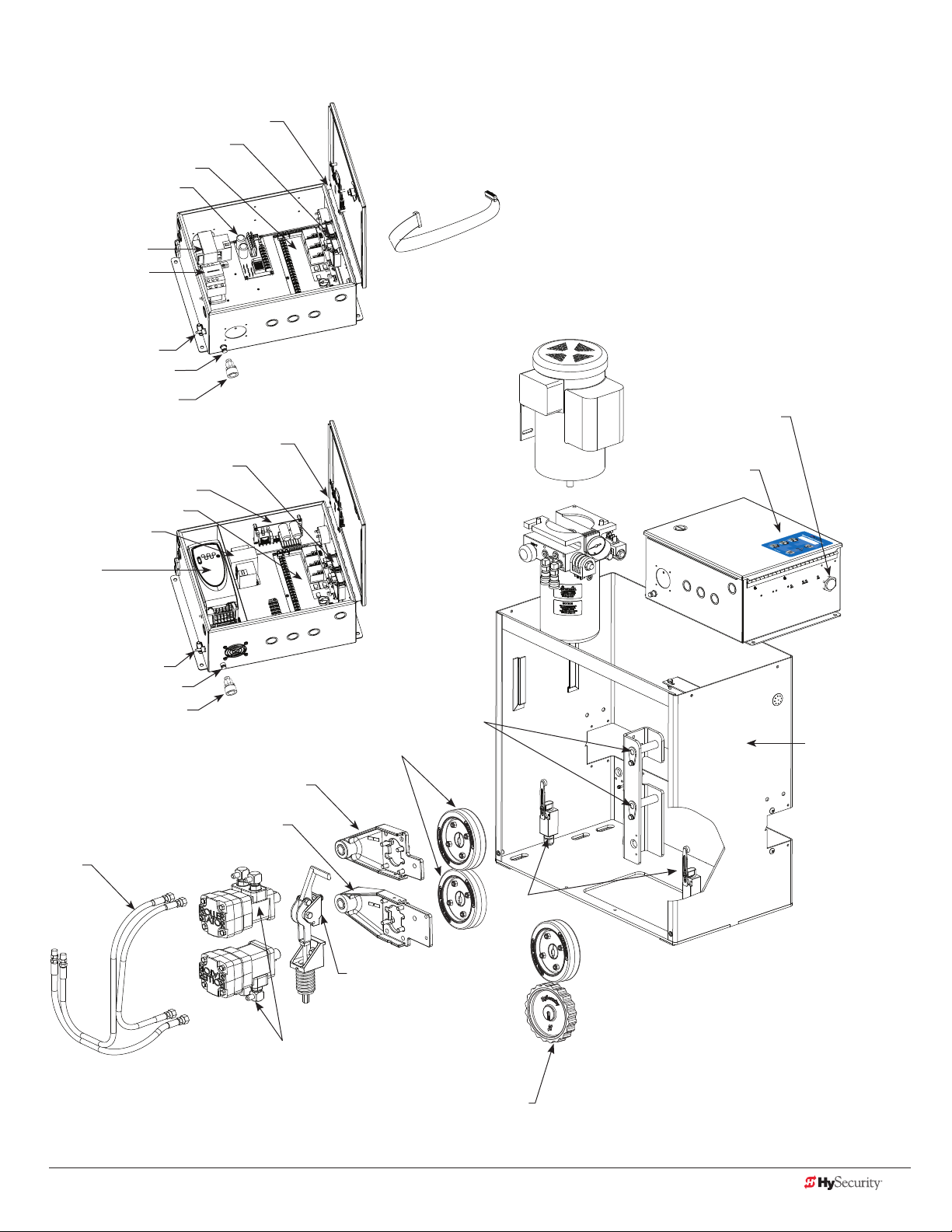

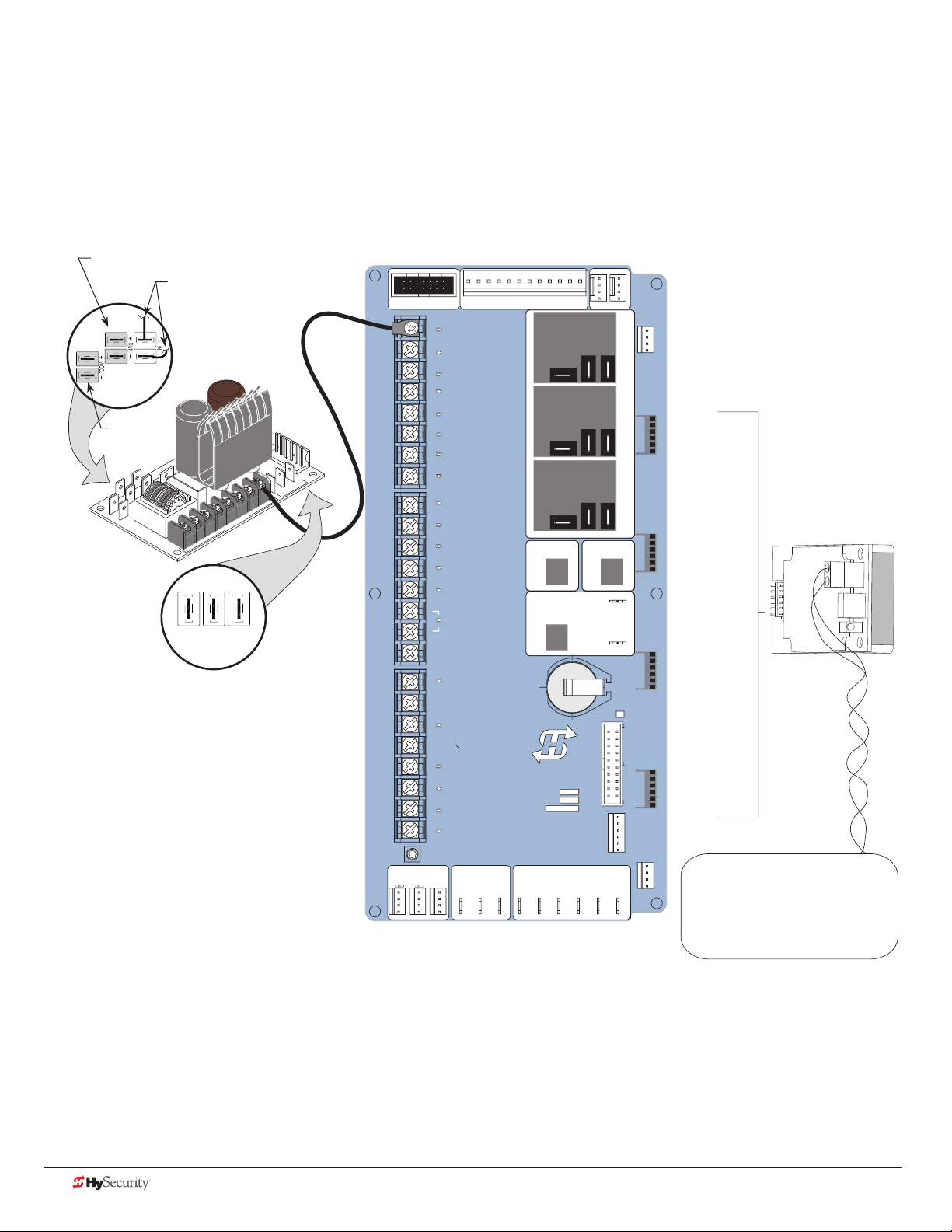

SlideDriver/SlideDriver 50VF Components

UC 2

USAGE CLASS

Board, Display

Detector, Vehicle

Board, Smart Touch

Board, Power Supply

Transformer

Contactor, Motor

Switch, Disconnect

Reset Switch, Internal

Reset Button, External

HY-5A Detector, Vehicle

Board, Power Supply

Board, Smart Touch

Transformer

Variable

Frequency Drive

(VFD) Power Unit

Switch, Disconnect

Reset Switch, Internal

Reset Button, External

Drive Arm, Motor Mount, Top

SlideDriver Control Box

Board, Display

SlideDriver 50VF Control Box

AdvanceDrive™ Wheel Kit

[Motor, Electric]

[Pump Pack]

Drive Arm, Pivot Kit

Cable, Ribbon

Buzzer, Piezo

Keypad

Chassis

Cover not shown

Drive Arm, Motor Mount, Bottom

Hose

Limit

Switches

Release,

Manual

Motor, Hydraulic

Combination AdvanceDrive

and XtremeDrive Wheels

www.hysecurity.com Introduction D0559 Rev. A iii

Page 4

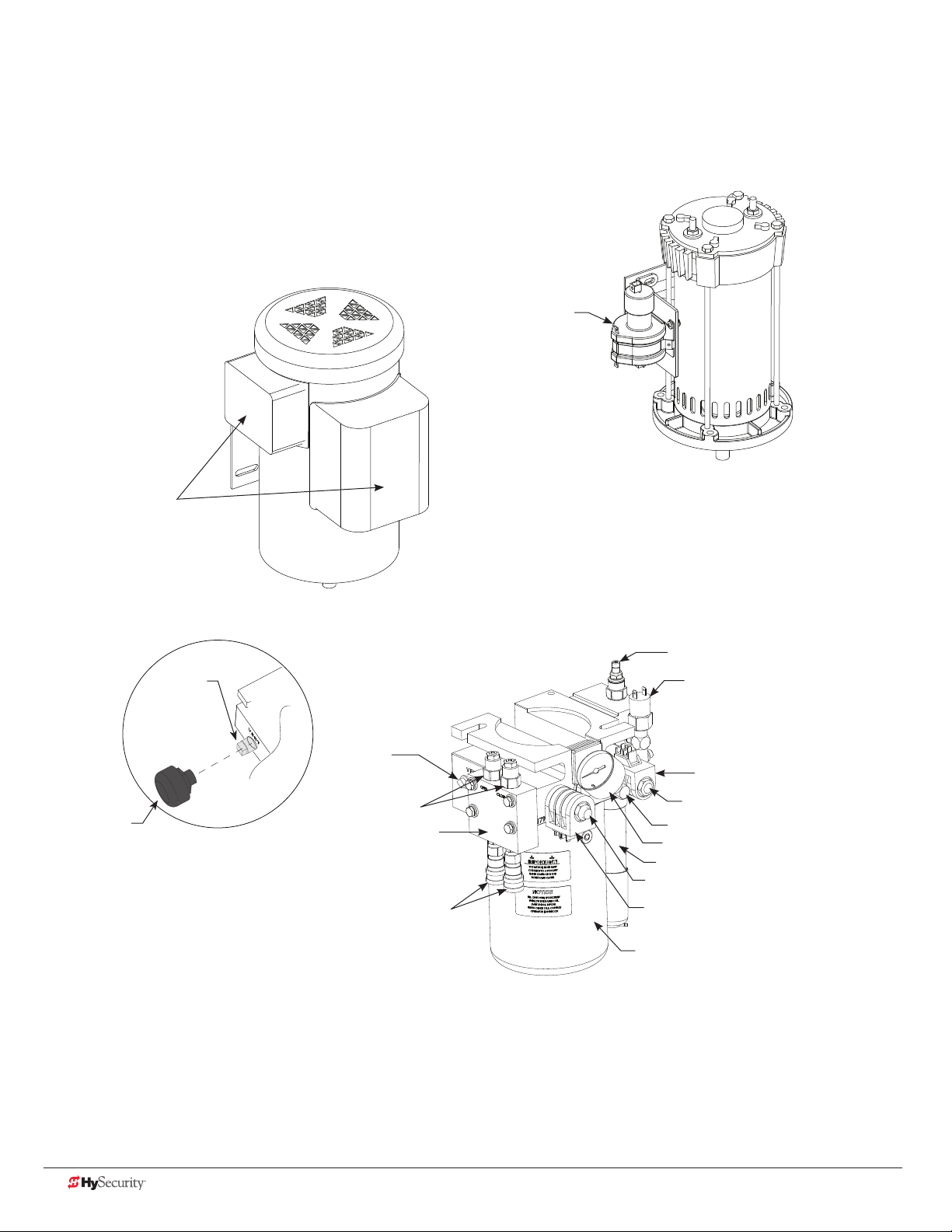

SlideDriver/SlideDriver 50VF Components

Motor, Electric, DC

Motor, Electric, AC

Contactor, Mercury

Motor Starting Kit

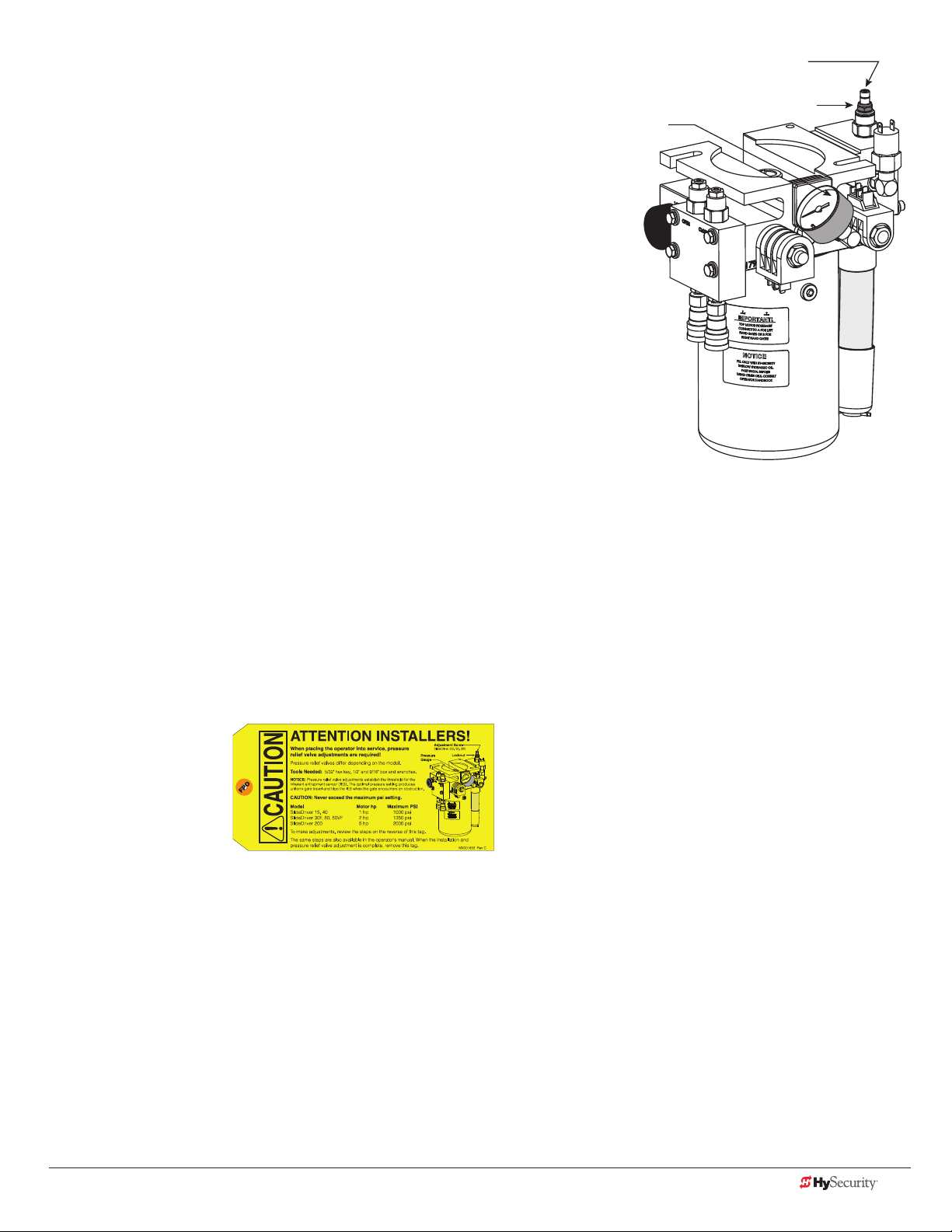

Breather cap

Vent plug

Vent plug

Valve, Braking

Braking Kit

Quick Disconnect, Socket

Valve, Relief

Sensor Kit, Inherent Entrapment

Valve Coil, Quick Stop

Valve, Quick Stop

Valve, Check, Endhead

Gauge, Pressure

AWOG

Valve, 2 Position Directional

Valve Coil, Directional

Reservoir

iv D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 5

Contents

SlideDriver Site Installation Overview ..............................................................................................................................ii

SlideDriver and SlideDriver 50VF Components ........................................................................................................ iii - iv

Welcome to HySecurity ...........................................................................................1

Contact Information .........................................................................................................................................................2

Notices and Bulletins .......................................................................................................................................................2

Supplemental Documents ................................................................................................................................................2

IMPORTANT SAFETY INFORMATION .............................................................................................................................3

Safety - Additional Installer Responsibility ....................................................................................................................4

Safety - Owner/User Responsibility ...............................................................................................................................6

Hazardous Materials and Proper Disposal .......................................................................................................................6

Identifying Gate Operator Category and Usage Class ....................................................................................................7

Choosing Secondary Entrapment Protection ...................................................................................................................8

Grounding, Breather Cap Installation & Handing ...........................................................................................................9

Emergency Stop Button ................................................................................................................................................10

Emergency Release .......................................................................................................................................................10

SlideDriver Slow Down Limit Ramps ...........................................................................................................................11

Safety Notices ................................................................................................................................................................12

Common Industrial Symbols ..........................................................................................................................................12

PoWer ..................................................................................................................13

Installing the Earth Ground ...........................................................................................................................................13

Site Considerations .....................................................................................................................................................14

Wiring AC Power ............................................................................................................................................................14

Turning the Power Switch ON .....................................................................................................................................15

Wire Sizing and Runs ......................................................................................................................................................16

Low Voltage Control Wiring ........................................................................................................................................16

SlideDriver Wiring Charts (Incoming Power) ...............................................................................................................17

SlideDriver 50VF-series Wiring Chart (Incoming Power) .............................................................................................19

Performance of 50VF-series Operators on 1 and 3 Phase, 50 or 60Hz.......................................................................19

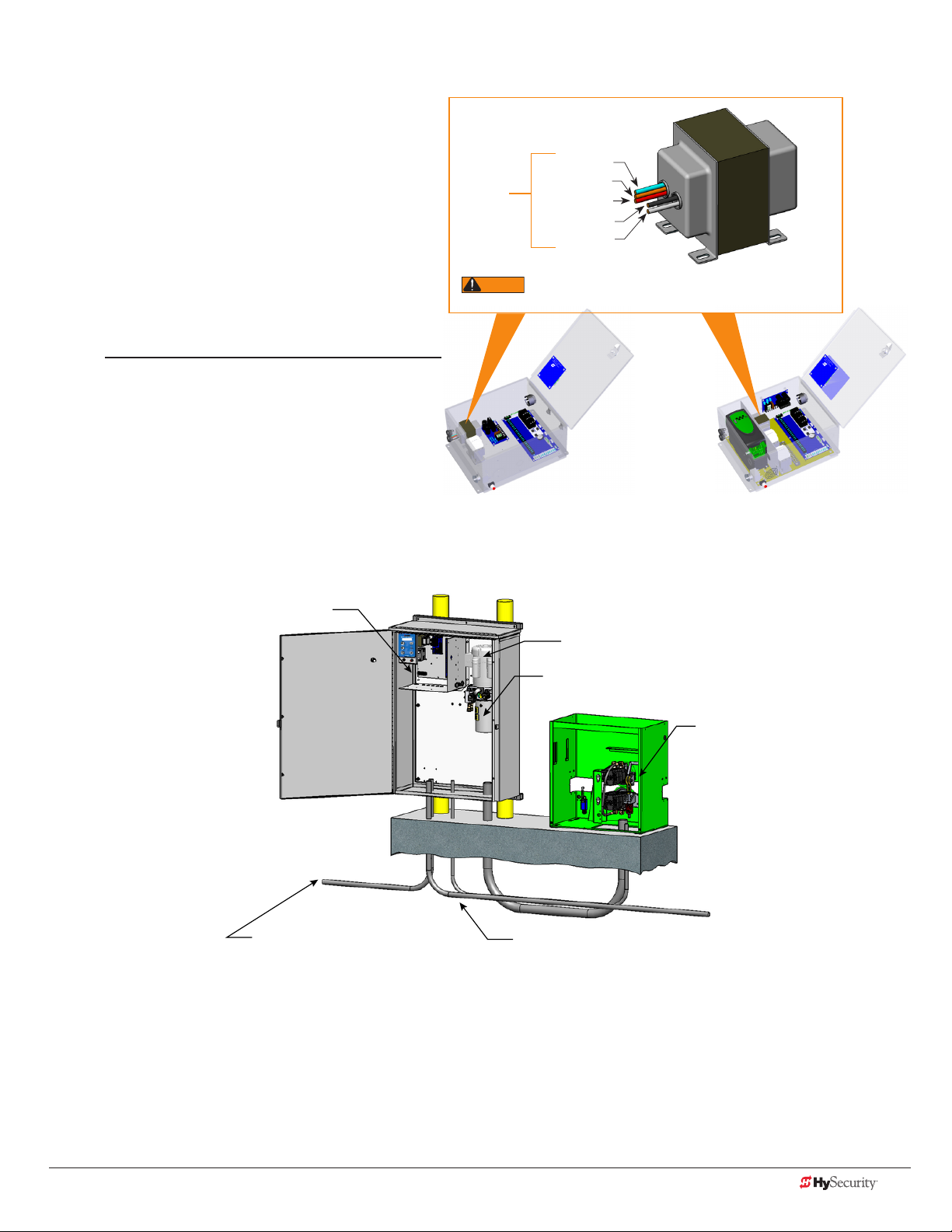

Control Transformer Connections (Non-UPS) ...............................................................................................................21

Gate Operator Connections (Modular Unit) ..................................................................................................................21

DC Power Supply (UPS) Connections .............................................................................................................................22

www.hysecurity.com Table of Contents D0559 Rev. A v

Page 6

configure tHe oPerator ........................................................................................23

Gate Handing .................................................................................................................................................................23

Hydraulic Hose Swap .....................................................................................................................................................24

Adjusting the Pressure Relief Valve ................................................................................................................................24

The Inherent Entrapment Sensor (IES) ..........................................................................................................................26

Manufacturer’s responsibility .......................................................................................................................................26

Pressure Relief Valve – All Hydraulic Operators: ........................................................................................................26

Inherent Entrapment Sensor – (IES) ...........................................................................................................................27

ModBus RTU in SlideDriver 50VF-series ........................................................................................................................27

Emergency Fast Operate (EFO) in SlideDriver 50VF-series ...........................................................................................28

Setting the Emergency Fast Close ..............................................................................................................................28

Installing a Push-Button Device for EFC ....................................................................................................................28

Emergency Fast Close Speeds ...................................................................................................................................28

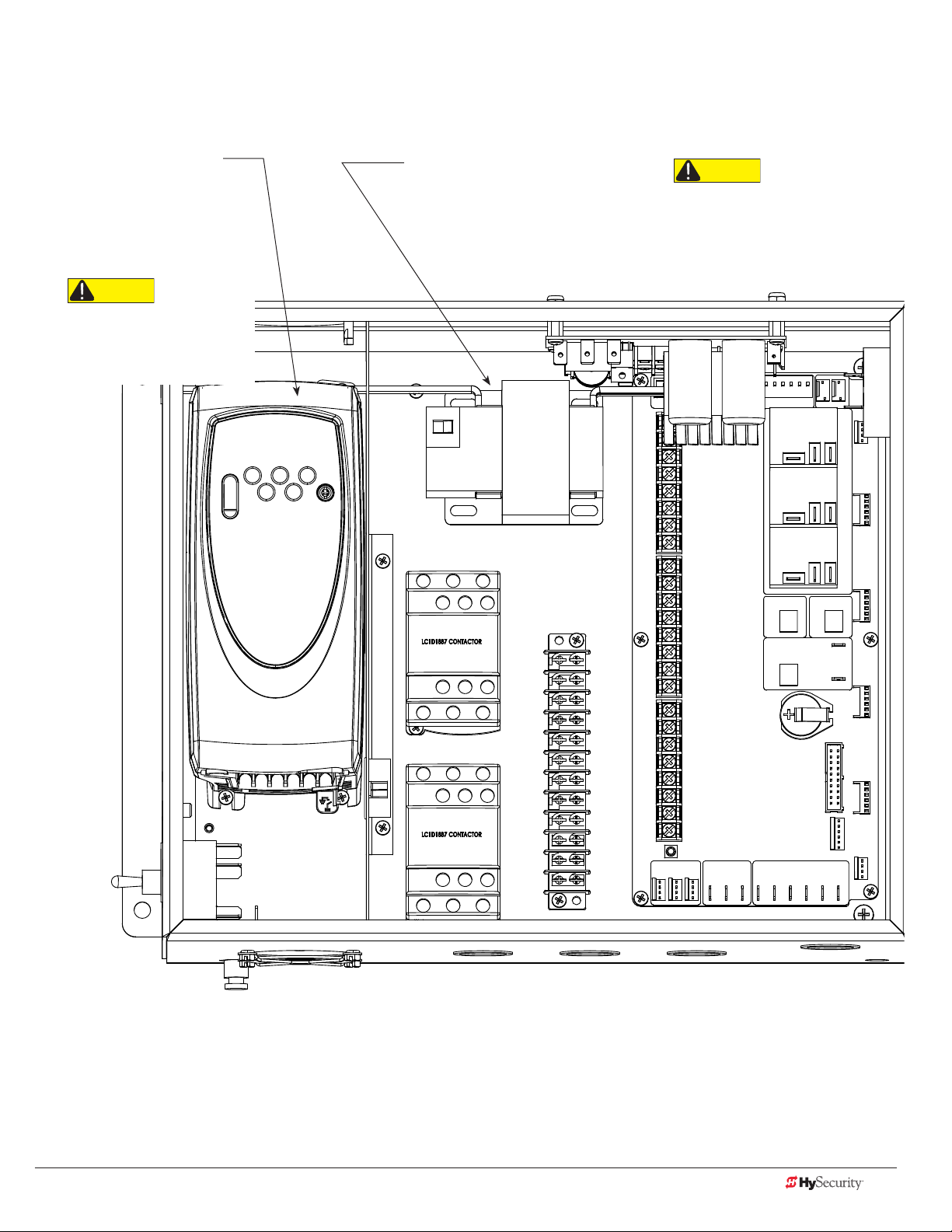

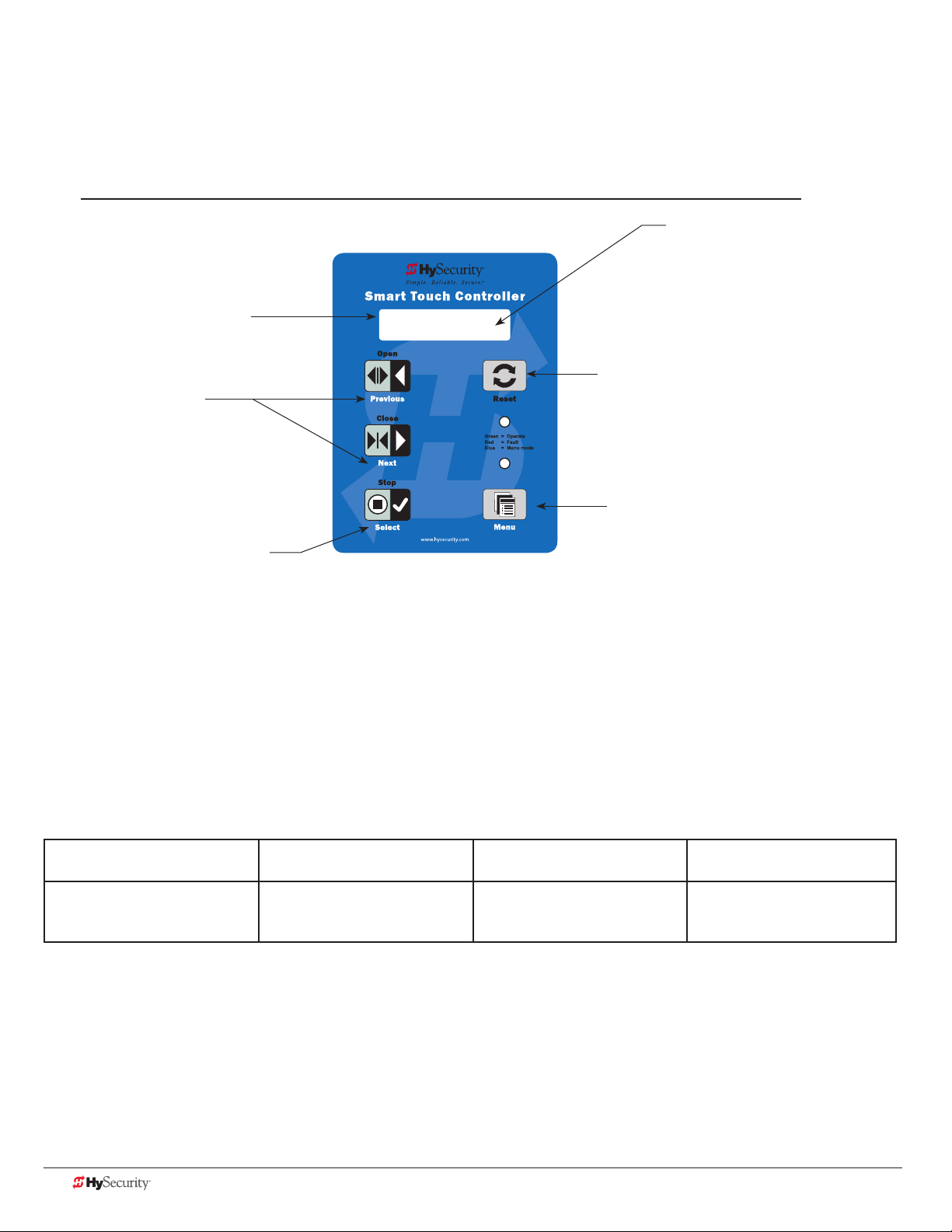

control Panel overvieW .......................................................................................29

SlideDriver Wiring Diagram, D0266 REV B ....................................................................................................................30

Variable Speed Drive (VFD) Control Box .......................................................................................................................31

Variable Speed Drive Wiring Diagram ...........................................................................................................................32

STC Board, Power Module and Display .........................................................................................................................33

DiSPlay & menu oPtionS ........................................................................................35

Initial Setup ....................................................................................................................................................................35

Understanding the Display and Keypad .......................................................................................................................35

Menu Mode and the STC Keypad ................................................................................................................................36

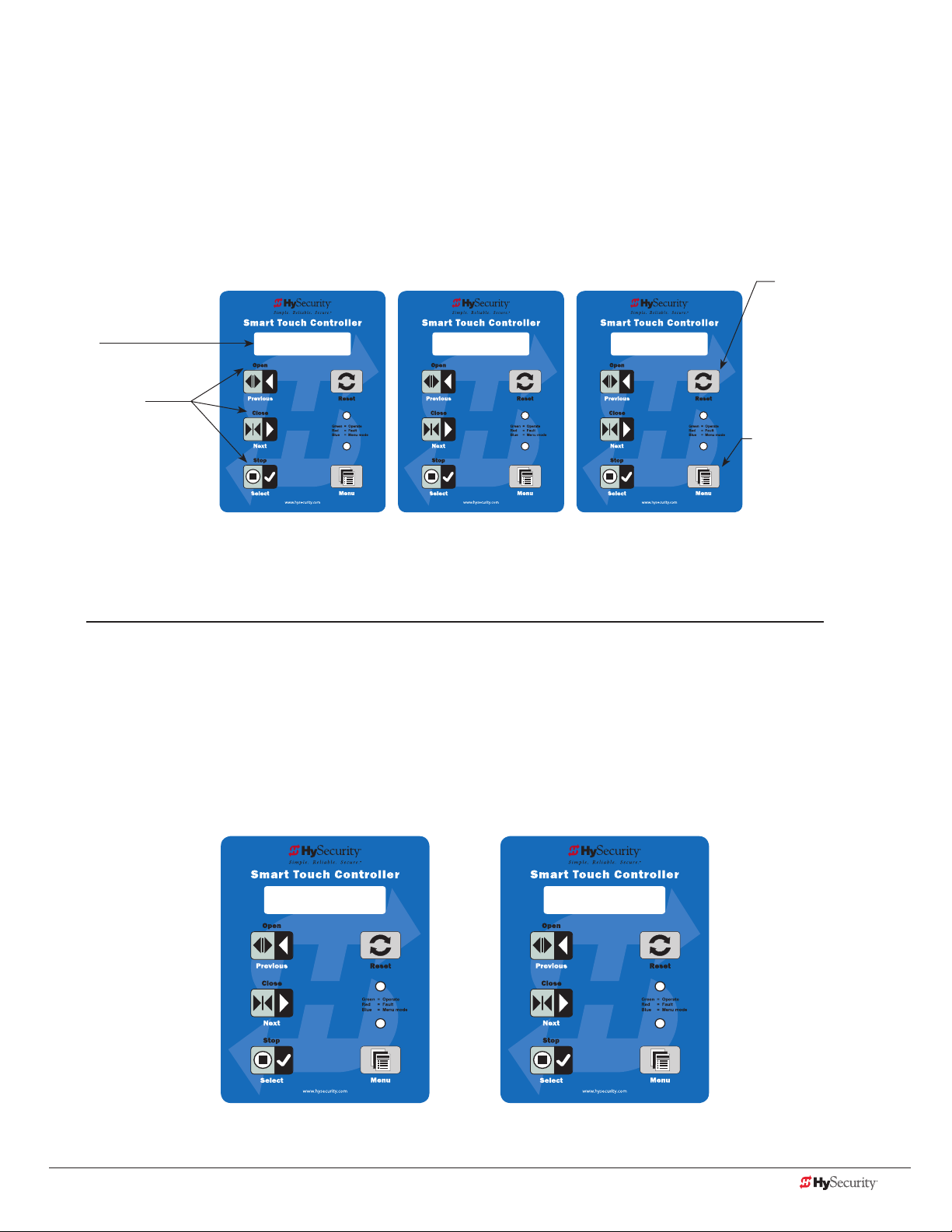

Menu Mode Navigation .................................................................................................................................................36

Run Mode and the STC Keypad ...................................................................................................................................37

Viewing Operator Status Displays ..................................................................................................................................37

Stop the Status Display Scrolling ................................................................................................................................38

Change the Display Contrast ......................................................................................................................................38

Check Time and Date .................................................................................................................................................38

User Menu ......................................................................................................................................................................39

User Menu: Table 1 ........................................................................................................................................................39

Installer Menu ................................................................................................................................................................41

Installer Menu: Table 2 ...................................................................................................................................................42

Setting the Close Timer .................................................................................................................................................47

Test the Operator ...........................................................................................................................................................48

vi D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 7

Stc inPutS & Wiring .............................................................................................49

Overview of the STC and Power Module .......................................................................................................................50

Integrating with Security Systems ..................................................................................................................................51

Smart Touch Controller Inputs........................................................................................................................................52

STC Terminal Inputs .......................................................................................................................................................52

Connecting Accessory Devices ......................................................................................................................................54

User Relays – Programming Procedure ..........................................................................................................................55

Hy8Relay Module Option ...............................................................................................................................................57

Vehicle Detector Logic ...................................................................................................................................................58

TailGate Alert .............................................................................................................................................................58

Anti-TailGate Mode Selection .....................................................................................................................................58

Vehicle Detector Installation: HY-5A ..............................................................................................................................59

Connecting HY-5A Vehicle Detectors .............................................................................................................................60

Photo Eyes (Non-Contact) Installation ...........................................................................................................................61

Compatibility ..............................................................................................................................................................62

Installation ...................................................................................................................................................................62

Conguration .............................................................................................................................................................62

Photo Eye Connections ..............................................................................................................................................63

Photo Eye Alignment ..................................................................................................................................................64

Monitored Connection ................................................................................................................................................64

Photo Eye Function .....................................................................................................................................................64

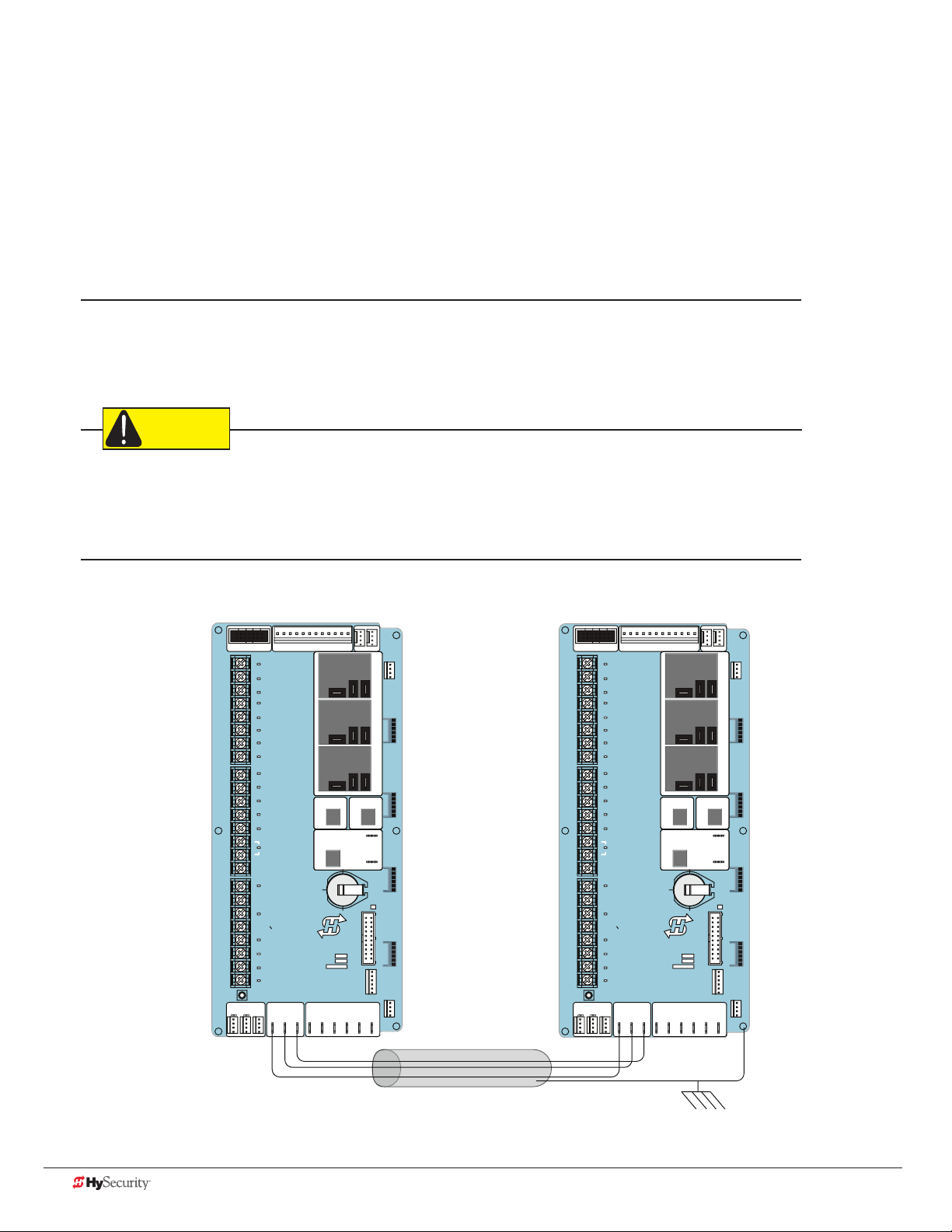

Dual gate SyStemS ................................................................................................65

Connecting an Interlocked Pair (Dual Gate) ...................................................................................................................65

Dual Gate Wiring Connections ...................................................................................................................................66

Dual or Sequenced Gates: Power, Software & Accessory Requirements ..................................................................67

Programming a Dual Gate (Interlocked Pair) .............................................................................................................67

Connecting Sequenced Gates .......................................................................................................................................68

Sequenced Gate: Conguration #1 ...............................................................................................................................70

Sequenced Gate: Conguration #2 ...............................................................................................................................71

troubleSHooting ...................................................................................................73

System Diagnostic Messages .........................................................................................................................................73

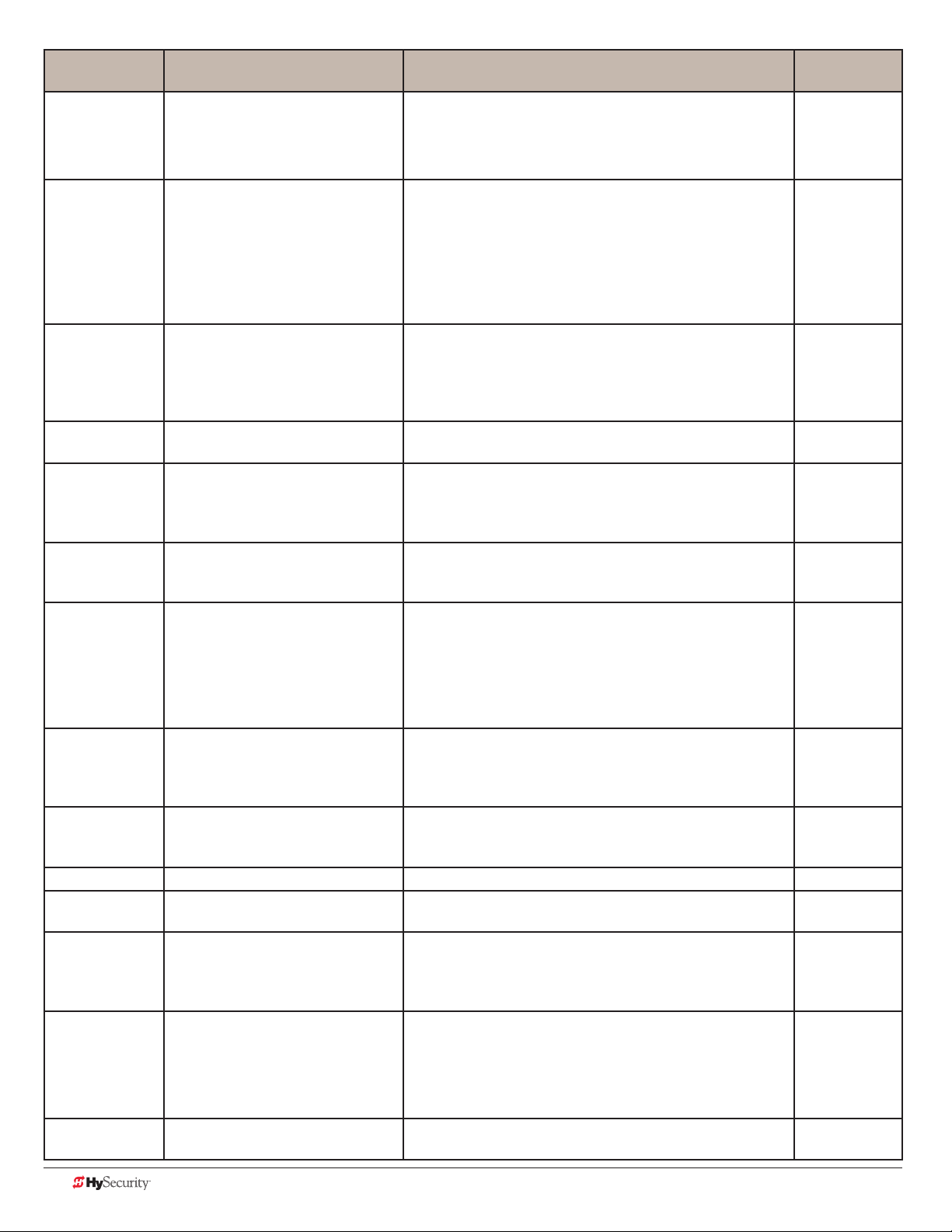

Troubleshooting Codes: Table 3 .................................................................................................................................74

Electrical Issues ..............................................................................................................................................................79

AC-Powered Gate Operators ......................................................................................................................................79

Mechanical Issues ...........................................................................................................................................................80

Hydraulic Issues ..............................................................................................................................................................80

Typical Problems and Troubleshooting Procedures .......................................................................................................81

www.hysecurity.com Table of Contents D0559 Rev. A vii

Page 8

general maintenance ...........................................................................................83

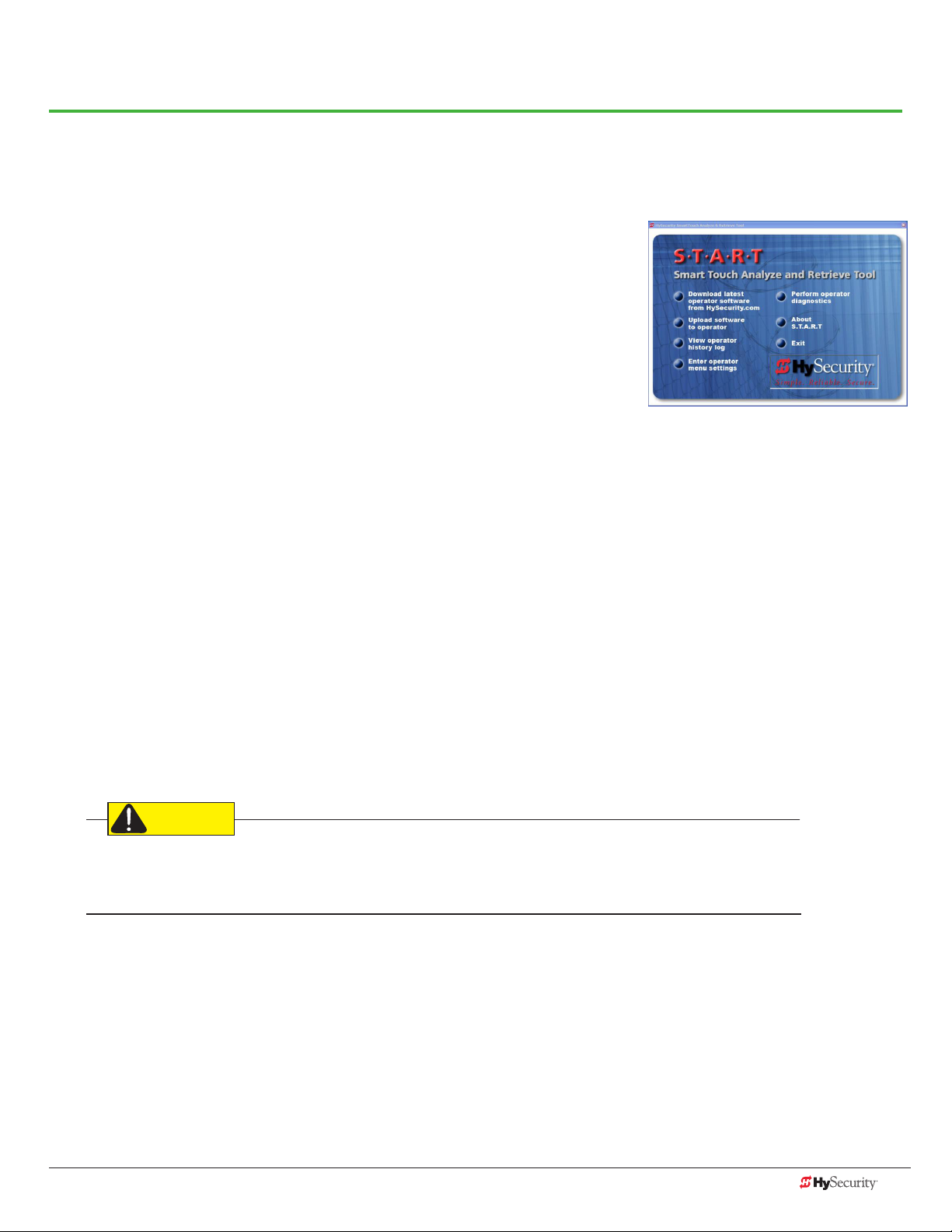

Smart Touch Analyze and Retrieve Tool (S.T.A.R.T.) .......................................................................................................83

What You Need ...........................................................................................................................................................83

Installing S.T.A.R.T. Software .......................................................................................................................................83

Software Maintenance ....................................................................................................................................................84

Electrical Controls ..........................................................................................................................................................85

Clock Battery Replacement ........................................................................................................................................85

Mechnical Controls.........................................................................................................................................................85

Stopping the Gate .....................................................................................................................................................85

Starting the Gate .......................................................................................................................................................85

Mechanical Maintenance ...............................................................................................................................................86

Drive Rail .....................................................................................................................................................................86

Drive Wheel Spring Tension (Adjustment of Manual Release) ....................................................................................87

Grooved Drive Rail .....................................................................................................................................................88

Drive Wheel Assembly ................................................................................................................................................89

Hydraulic System Maintenance ......................................................................................................................................90

Brake Valve Adjustments ............................................................................................................................................91

Pressure Relief Valve Adjustments ..............................................................................................................................91

Open Valve .................................................................................................................................................................91

SlideDriver Operator Maintenance Schedule ................................................................................................................92

SlideDriver Installer Checklist .........................................................................................................................................93

Specications .................................................................................................................................................................96

viii D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 9

Welcome to HySecurity

Thank you for purchasing our premium SlideDriver™ gate operator. HySecurity Gate, Inc. has manufactured some

of the nest, sturdiest, most innovative, and reliable hydraulic gate operators since the 1970s. We use the same

hydraulic technology common in the aircraft industry while incorporating software capabilities that far exceed the

competition.

All operator designs are tested for hundreds of thousands of cycles before being released to the market. Slide,

swing, trafc barrier, fortied crash barrier gate and vertical lift operators have all received rigorous testing and

certication. Security, low maintenance, exible conguration, and overall toughness are the foremost criteria for

all HySecurity products.

Our commitment to quality and innovation will become evident as the features and performance of the expertly

engineered and manufactured SlideDriver become familiar to you. Thank you again for the condence you’ve

shown in becoming part of the HySecurity family and in choosing a premium, industry-leading product.

HySecurity Gate, Inc. Headquarters in Kent, WA

www.hysecurity.com Safety D0559 Rev. A 1

Page 10

ContaCt InformatIon

Qualied HySecurity distributors are experienced and trained to assist in resolving any problems. For the name of

a qualied distributor near you, call HySecurity at 800-321-9947.

Before contacting your distributor or HySecurity Technical Support, obtain the serial number of your operator.

For information about HySecurity training for installers, maintenance personnel, and end users, refer to the

company website at www.hysecurity.com.

notICes and BulletIns

Installers should visit HySecurity’s online Technical Support page at www.hysecurity.com or contact HySecurity

prior to installing product to make sure they have received the most up-to-date information.

supplemental doCuments

The product literature is comprehensive and contains information needed to plan, install, operate and maintain

your gate operator. Additional general information concerning HySecurity gate operators can be obtained from

the following:

• HySecurity website www.hysecurity.com - Contains links to the product catalog, product order form,

operator manuals, operator software downloads, technical support bulletins and other useful information.

• S.T.A.R.T. - Smart Touch Analyze and Retrieve Tool - User’s Guide (D0049) detailing the extensive software,

diagnostic and troubleshooting capabilities of the Smart Touch Controller board.

• Technical Bulletins (as applicable).

NOTE: Technical Bulletins are automatically issued to registered users of HySecurity products. The

product warranty registration card can be lled out online at www.hysecurity.com.

2 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 11

Important safetY InformatIon

WARNING

Read all the product safety information prior to installation. Automatic gate operators move the gate with high

force and can cause serious injury and death! Make sure the automatic gate operator is installed to reduce the

risks of entrapment. Verify the gate operator is installed to comply with all safety standards and local and federal

regulations.

Understand that you as the site designer, installer, maintenance crew, or owner/user must consider the risks

associated with gate operators. Be sure to take responsibility, read, and follow the Important Safety Information

in this manual and review all the literature that accompanies the product.

Hazards, associated with automatic gates, can be reduced with proper site design, installation, and use. Installers,

maintenance crews, and owners/users must read and follow the safety requirements found in the HySecurity

product manuals.

It is important that only qualied installers handle the installation of the HySecurity equipment and gate operator.

A “qualied” installer has one of the following:

• A minimum of three years experience installing similar equipment

• Proof of attending a HySecurity Technical Training seminar within the past three years

• Signicant manufacturer endorsements of technical aptitude in gate operator installation and operation

Underwriter Laboratories (UL) and the American Society for Testing and Materials (ASTM) are responsible for

current safety standards and regulations regarding automatic vehicular gate operators. To pass certication, all

aspects of gate operator and gate installation must comply with the appropriate safety standards.

For the most up-to-date ASTM F2200 Gate and Fence Standards, refer to www.astm.org.

For UL 325 Safety Standards, refer to www.ul.com.

www.hysecurity.com Safety D0559 Rev. A 3

Page 12

WARNING

A moving gate or barrier arm, bollard, or wedge can cause serious injury or death.

To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS. Read the gate operator’s product manual and review all the

product labels and literature prior to installing, operating, or maintaining the automatic gate operator.

2. Never let children operate or play with gate controls. Keep all remote controls, especially radio

transmitters, away from children. Do not allow children to play on or around the gate or gate operators.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE

MOVING GATE. Start the gate operator only when a gate’s travel path is clear.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an

object activates the non-contact sensors. After adjusting the force or the limit of travel, retest the gate

operator. Perform routine tests of the entrapment protection sensors, such as photo eyes and gate edges.

Failure to adjust and retest the gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the product manuals. Have a qualied service person make

repairs to gate hardware and replace batteries in accessory or entrapment sensory devices on a regular

basis.

7. The automated gate entry is for vehicle use only. Pedestrians must use a separate entrance. Make sure a

separate walk-through entrance is nearby. Make certain a clear pedestrian path is designated and signs

direct pedestrians to the walk-through gate.

8. Install the supplied WARNING signs on the inside and outside of the gate or barrier gate/operator so they

are clearly visible from both the secure and public sides. Installing the signs is a requirement for UL 325

compliance.

Safety - Additional Installer Responsibility

• Verify the gate operator usage class for the site. For all gate operators other than Crash-rated, refer to

Identifying Gate Operator Category and Usage Class in this product manual. Install the operator only

when the gate operator class is correct for the site, size, and type of gate.

• The gate operator must be properly grounded and the incoming power voltage must match the voltage

label on the junction box.

• Install an automatic operator only on gates that comply with ASTM F2200 Gate and Fence Standards.

Screen or enclose openings in the gate per UL 325 Safety Standards which include:

All horizontal slide gates must guard or screen openings from the gate’s base support to a minimum

height of 6 feet (183 cm) above the ground. This must prevent a sphere of 2¼-inches (57 mm) in

diameter from passing through an opening in the gate or the adjacent fence that is covered in the

gate’s open position.

Physical stops must exist in the gate construction to prevent over-travel in both directions and, for

slide gates, guard posts must be installed to prevent the gate from falling in the event of a roller

failure.

4 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 13

Safety - Installer’s Responsibility, continued

• Before attaching the operator to the gate, move the gate or barrier gate in both directions. Make sure it

is level and moves freely. A gate or barrier gate that moves easily reduces strain on operator components.

Gravity should play no part in the opening or closing of a slide gate.

• Never over-tighten a clutch or pressure relief valve to compensate for a stiff or damaged gate.

• Make sure all exposed pinch points, rollers and wheels are guarded.

• Reduce the risk of entrapment throughout the entire travel path by making sure the gate is installed in a

location which ensures the required clearance between the gate and adjacent structures when opening

or closing. On slide gates, minimize the parallel gap between the gate and the fence.

• Install the gate operator on the secure (non-public) side of the gate. Note that swing gates cannot open

into public areas.

• Install external entrapment protection sensors so pedestrians are protected from entrapment in both

directions of gate travel and all hazard areas are fully protected. On hydraulic gates, set the pressure

relief valve at the lowest allowable setting that will reliably operate the gate. The pressure relief valve

controls the applied force of the operator and the sensitivity of the inherent entrapment sensor (IES).

Note that no IES exists in the StrongArm operator.

• Never disable the Warn Before Operate buzzer. This buzzer provides an alert that the gate is about to

move.

• Mount access control devices beyond reach of the gate. The control devices that operate the gate must:

Be located in a clear line of sight to the gate. Locate controls (Open, Close, Stop/Reset) where a user

will have a clear view of the gate.

Be mounted beyond 6 feet (183 cm) of the gate, to prevent users from touching or accessing the gate

while operating the controls. People attempting to access the controls by reaching through or around

the gate can be seriously injured or killed by the moving gate.

Incorporate a security feature to prevent unauthorized use.

Connect radio and other remote access (non-resetting controls) to the RADIO OPTIONS terminal.

• Open and close the gate to conrm that it was properly installed and to ensure reduced risk of

entrapment. Verify the clearance between the gate and adjacent structures per UL 325 Safety Standards.

Have a qualied technician test the gate monthly.

• When you complete the installation, demonstrate the safety features and operation of the gate operator

to the end user:

Clearly explain and demonstrate the consequences of removing or defeating any of the safety

features.

Remove the operator cover(s), and then turn the power on and off.

Manually release the gate. (Use the manual release only when the gate is NOT moving.)

Use the Emergency Stop Button. (If an emergency stop button is not available, show the user where

the Stop button is located on the gate operator.)

NOTE: Gate operator instructions must be given to the owner per UL 325 Safety Standards.

Take photographs of the completed installation site and save it in your business les.

www.hysecurity.com Safety D0559 Rev. A 5

Page 14

Safety - Owner/User Responsibility

CAUTION

As the owner/user, you are responsible for the correct and safe installation, operation and maintenance of the

SlideDriver gate operator. It is of the utmost importance that you read and follow the specic instructions and

precautions found in the IMPORTANT SAFETY INFORMATION addressed in this manual. In addition, you must

adhere to the safety standards of applicable federal, state, and local safety regulations, industry standards, and/

or procedures.

NOTICE: For installations outside the United States, make sure that you follow the applicable international,

regional, and local safety standards.

• Automatic gates are for vehicular use only; provide and maintain walkways and signs to direct pedestrians

to a separate walk-through entrance.

• An automatic gate can start at any time without warning; always keep people away from the gate area.

• Never let children operate or play with gate controls. Keep all remote controls, especially radio

transmitters, away from children. Do not allow children to play on or around the gate, gate area, or

gate operators.

• Learn how to turn the power on and off. Learn how to manually operate the gate.

• WARNING signs supplied with the gate operator must remain installed and clearly visible on both sides

of the gate. The signs are required to maintain UL 325 compliance.

• Do not physically disable the warning buzzer and NEVER disconnect or cut its wires. The buzzer provides

compliance with the Manual on Uniform Trafc Control Devices (MUTCD) standards. Disabling the

warning buzzer may increase the risk of death or serious injury.

• Do not remove entrapment devices or any other safety features.

• Have a professional gate installer routinely inspect the gate hardware and test the entrapment protection

sensors and overall gate operation. Have a qualied service person make repairs to gate hardware and

equipment to keep the gate running smoothly.

Hazardous materIals and proper dIsposal

Be aware of the international, federal, and local codes in your area and how best to handle hazardous waste

materials.

The pump pack uid, found in all hydraulic HySecurity operators, can be recycled. Gear oil, found in HySecurity

electromechanical gate operators, can also be recycled. If the uids are mixed or contaminated with any solvents

or other chemicals, they become hazardous waste. Hazardous waste requirements for storage and disposal must

be followed.

If the gate operator has a battery backup system, the batteries contain materials that are considered hazardous

to the environment. Proper disposal of the battery is required by federal law. In the U.S.A., refer to federal EPA

guidelines for proper hazardous waste disposal.

6 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 15

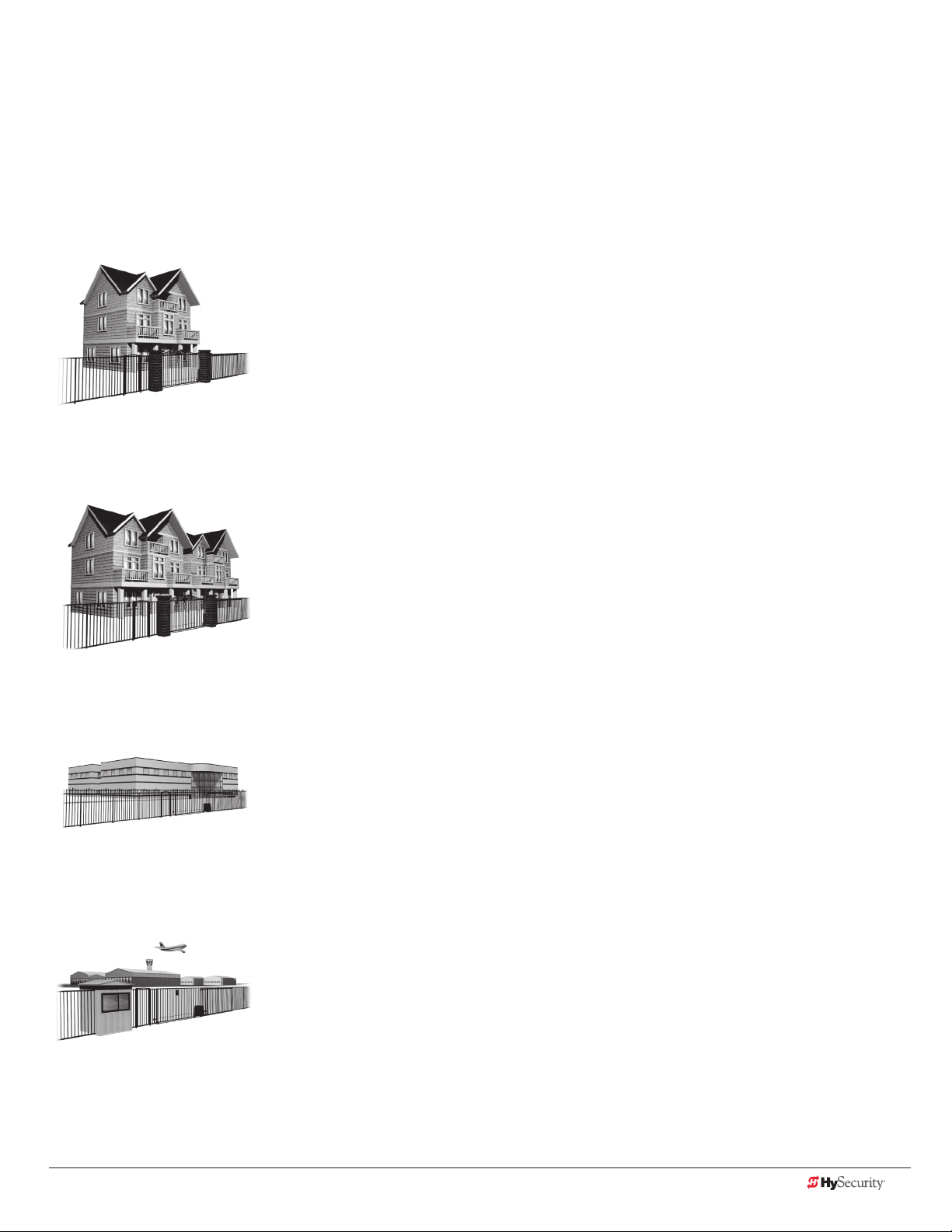

IdentIfYIng gate operator CategorY and usage Class

The SlideDriver operator, according to UL 325 Safety Standards, falls in the horizontal slide, vertical lift and

vertical pivot category for gate operators. Its usage class is determined by the area that the vehicular gate

services.

Four different vehicular usage classes are dened by UL 325:

Class I

Class I: Intended for use in garages or parking areas associated with a residence

of one to four single families.

Class II

Class II: Intended for use in a commercial location or building such as a multifamily housing units (ve or more single family units) hotels, garages, retail stores

or other buildings accessible by or intended to service the general public.

Class III

Class IV

Class III: Intended for use in an industrial location or building such as a factory

or loading dock or other locations NOT accessible by or intended to service the

general public.

Class IV: Intended for use in a guarded industrial location or building such as an

airport security area or other restricted access locations, not servicing the general

public, in which unauthorized access is prevented via supervision by security

personnel.

www.hysecurity.com Safety D0559 Rev. A 7

Page 16

CHoosIng seCondarY entrapment proteCtIon

CAUTION

The site designer or installer must determine which secondary entrapment sensor devices will be installed with

the SlideDriver operator to meet UL compliance. The type of entrapment sensor device systems are described

below. For a complete listing of the requirements, refer to UL 325 Safety Standards.

NOTICE: SlideDriver is equipped with a primary, Type A, inherent entrapment sensor (IES) that complies with

UL 325. Any impediment to gate travel causes the gate to stop and reverse.

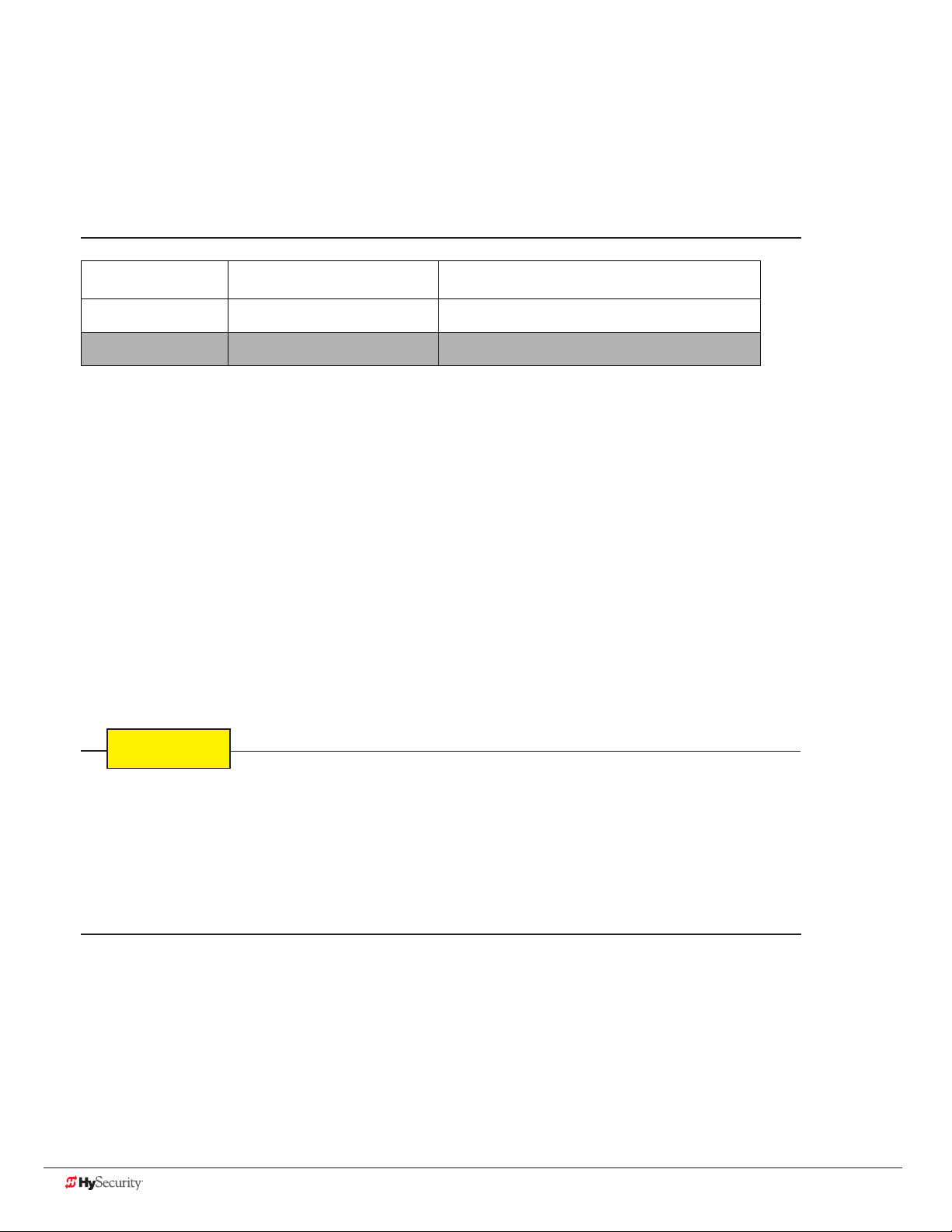

Usage Class Primary Type Device Secondary Type Device

Class I, II, III A B1, B2, C, or D

Class IV A B1, B2, C, D, or E

To comply with UL 325, refer to the chart and take the following steps:

1. Select the Usage Class according to the gate’s locale and purpose.

2. The required UL 325 primary Type A sensor is an integral part of the SlideDriver system.

3. Based on the gate’s usage class, choose Secondary Type Devices: B1, B2, C, D, or E.

• To comply using B1 - install non-contact sensors (photoelectric sensor or the equivalent).

• To comply using B2 - install contact sensors (edge sensor device or the equivalent).

• To comply using a Type D device requires a CONSTANT HOLD push-button station. This CONSTANT

HOLD push-button station must be the only device that opens and closes the gate. It can only be used

where the gate and push button station will be monitored by personnel 24 hours a day in full view of

the gate area. An automatic closing device (such as a timer, loop sensor, or similar device) must not

be employed. A Warning placard stating, “WARNING - Moving Gate has the Potential of Inicting

Injury or Death - Do Not Start the Gate Unless the Path is Clear” must be placed adjacent to the gate

operator controls.

While compliance is possible with Type C, which is a low force limiting clutch, the SlideDriver operator does not

utilize a clutch, therefore this option is not available.

Similar compliance issues exist with a Type E device (audio warn before operate alarm). A Type E device is

permitted as a means of secondary entrapment protection by UL 325 in Class IV applications, but it is not

recommended by HySecurity because a buzzer warns, but cannot protect against possible entrapment.

HySecurity highly recommends, even for Class IV use, that secondary entrapment protection (edge or photoeye sensor) devices be installed to detect possible entrapment.

8 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 17

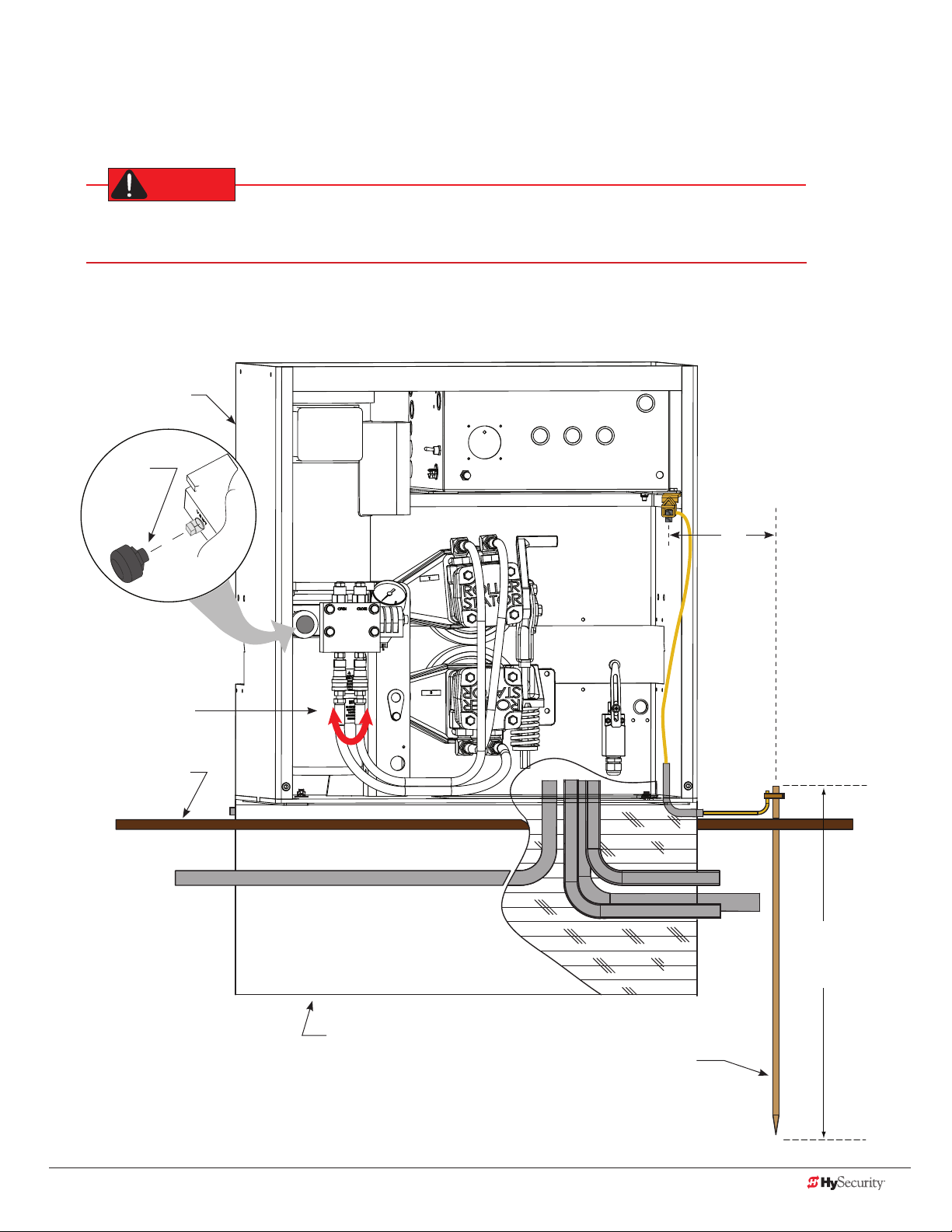

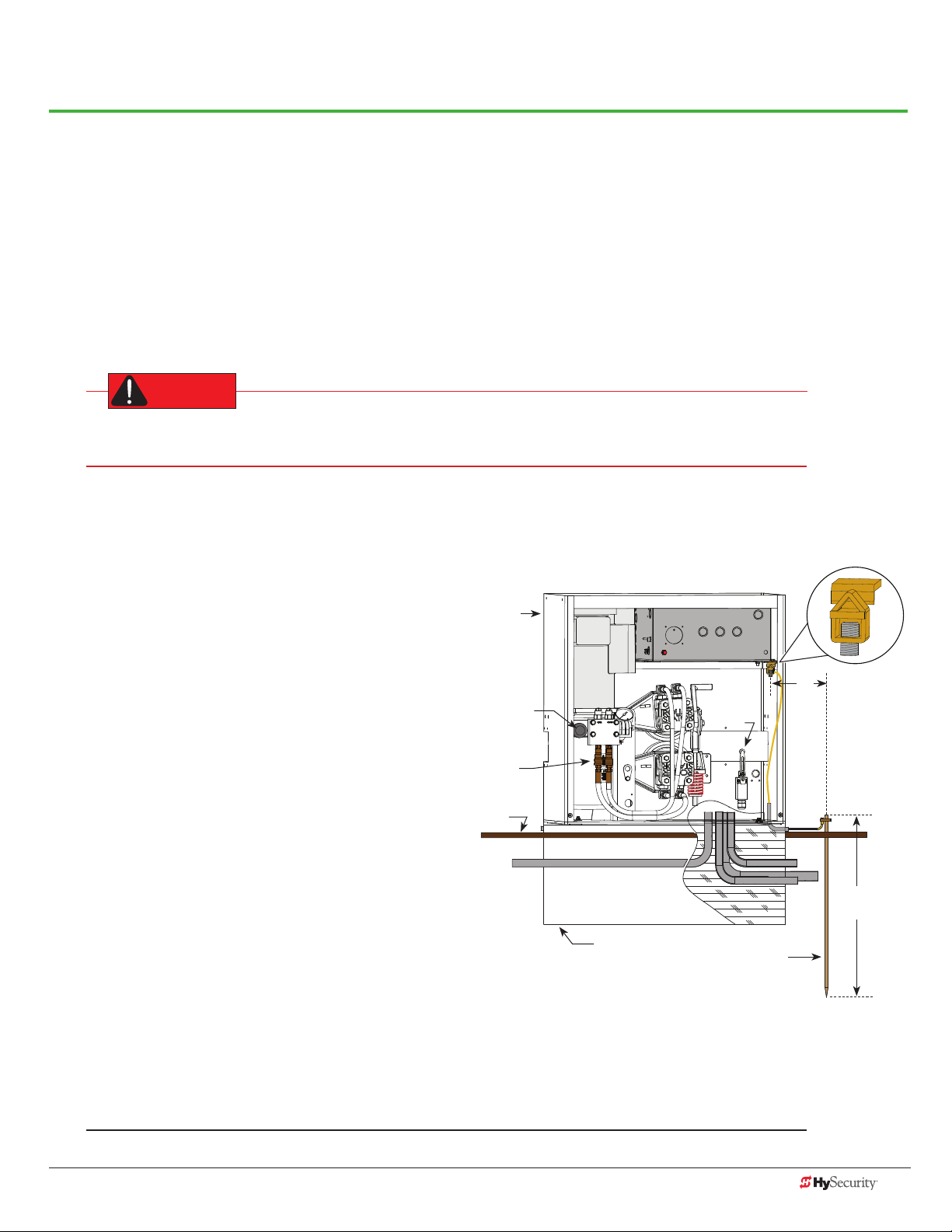

groundIng, BreatHer Cap InstallatIon & HandIng

DANGER

The gate operator has a vent plug that keeps the hydraulic uid from spilling during shipment. The vent plug

must be replaced by the breather cap before operating the slide gate.

Failure to perform the following procedure will cause premature pump shaft failure and void the

Limited Warranty.

1. Remove the vent plug and discard it.

2. Replace the vent plug with the breather cap.

SlideDriver

Replace red vent plug

with breather cap

Operator is shipped

hydraulically congured

for “right hand” operation.

Refer to “Gate Handing”

on page 23.

Swap hydraulic hoses for

left handling.

Grade level

Cut-away view

3 ft

(91.4 cm)

Maximum

distance

Consult local

codes for

proper depth

Concrete foundation

Ground rod

www.hysecurity.com Safety D0559 Rev. A 9

Page 18

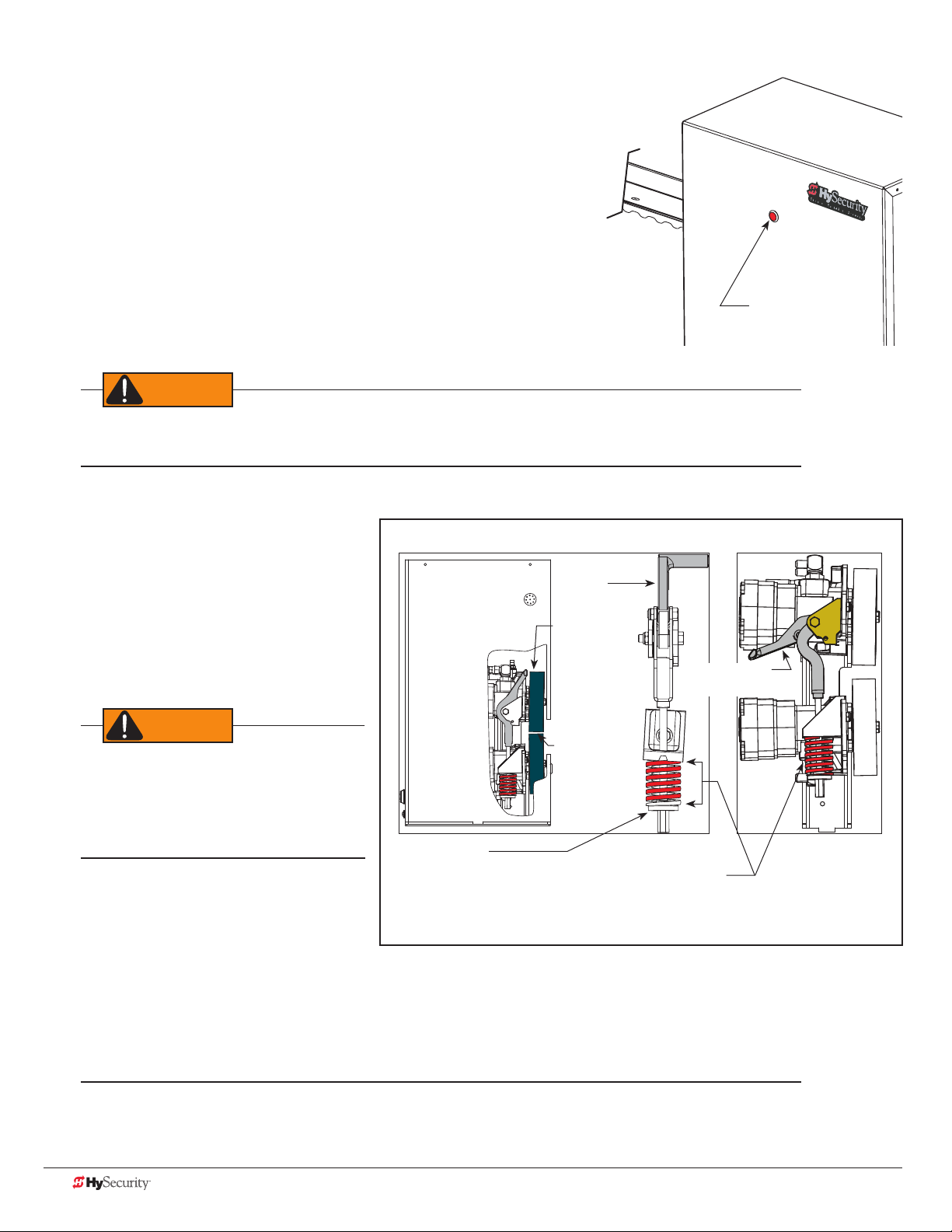

emergenCY stop Button

WARNING

WARNING

Make sure all users of the gate know where the emergency stop button

is located (see illustration). It complies with UL 325 Safety Standards

requirements.

Pressing the emergency stop button while the gate is opening or

closing disables the automatic close timer and stops gate travel. Gate

travel remains stopped until the operator receives another open or

close signal.

Emergency Stop button

emergenCY release

Before attempting a manual release, make sure the gate is not in motion and power is disconnected

(turned OFF).

Make sure and teach all users how to turn off electric power and how to move the gate manually. To prepare for

manual operation, power must turned off

and the drive wheels must be released

Note: Drive Rail must be aligned and secured before adjusting wheel loading

Know the weight of the gate you are

Toggle Handle

clamped

moving. Excessively heavy gates can be

difcult to move and may cause serious

Drive Wheels

injury to those involved in moving the

gate. Take the necessary precautions when

manually moving any gate.

When releasing the handle inside the

chassis, be careful as the mechanism is

spring-loaded and drops rapidly. Hold the

handle appropriately so your ngers do not

get injured or pinched.

To disengage the drive wheels from the

drive rail and manually move the gate, take

the following steps:

Coupling Nut:

Adjusts compression spring.

Drive Rail

slides between

drive wheels

Compression Spring:

Controls drive wheel gripping force. Set at 2 in.

(5cm) when Drive Wheels are clamped on the

Drive Rail. Toggle handle is in the clamped (load)

position.

Toggle Handle

unclamped

1. Remove the front chassis cover and set it aside.

2. Pull the toggle handle down. The manual release is located under the electric control panel and to the

right of the hydraulic motors.

NOTE: For more information, refer to “Drive Wheel Spring Tension (Adjustment of Manual Release)” on page 87.

Other types of release mechanisms exist. For example, the Fire and Emergency Access Lock Box is available

through HySecurity distributors. Contact your distributor for more information.

10 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 19

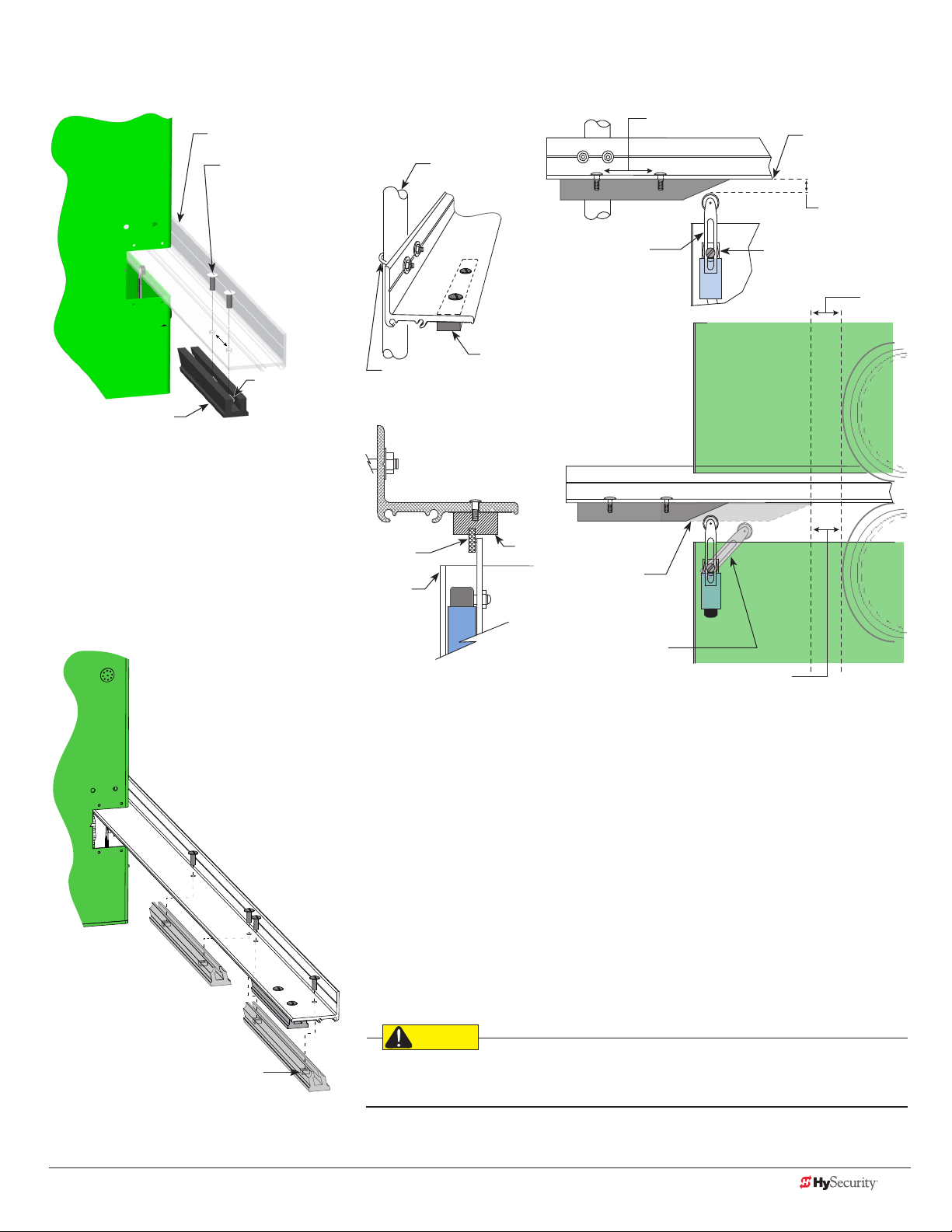

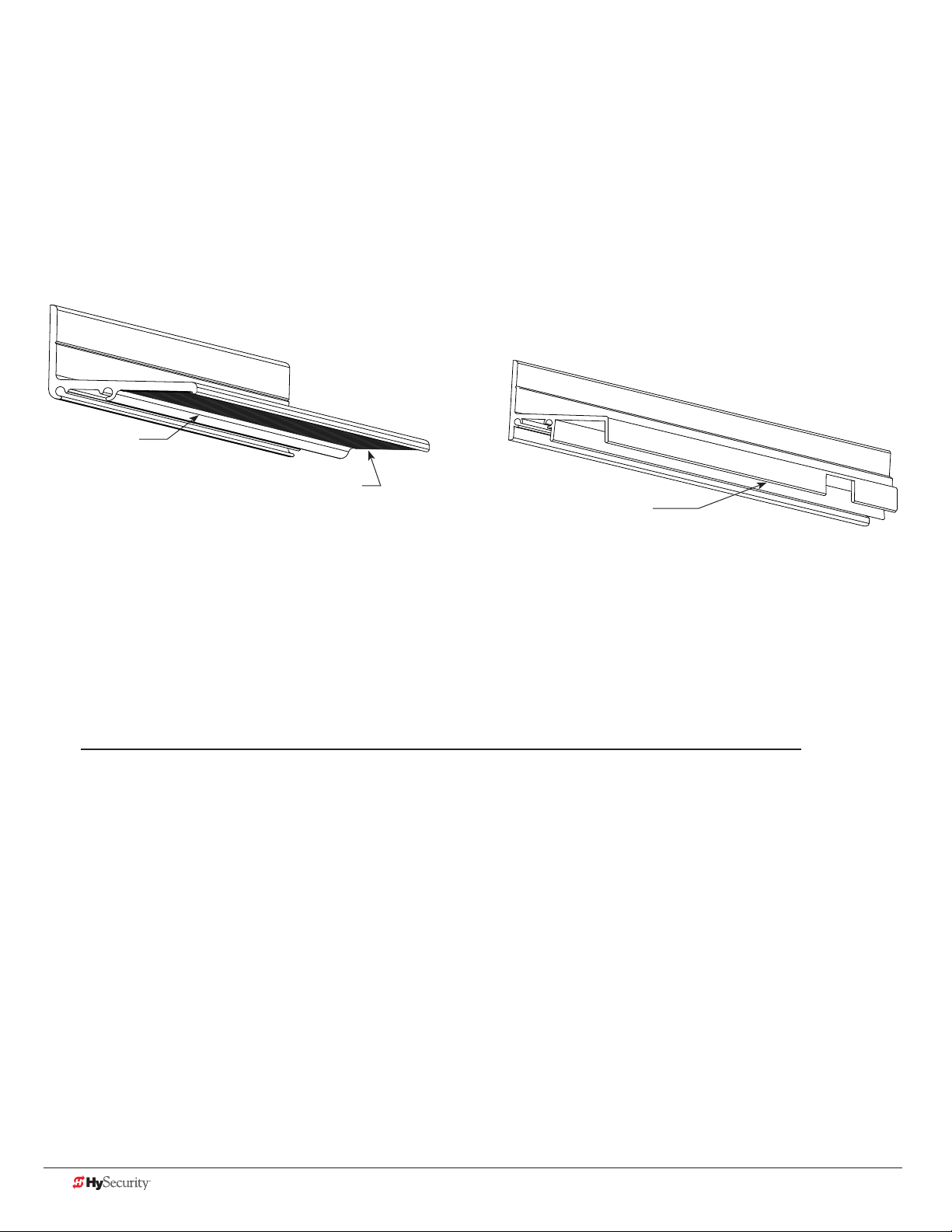

slIdedrIver slow down lImIt ramps

CAUTION

Drive rail

Round-head bolts:

3/8 " (9 mm)

Must be fully

tightened and ush

before adjusting

limit switch.

4"

10 cm)

Nut

Standard Limit Ramp

The standard limit ramp is positioned

on the drive rail so it will make

contact with the limit switch and stop

approximately 2 inches (5 cm) from the

drive wheel.

Limit ramps are attached to the

underside of the drive rail when the

gate is fully open and fully closed.

Chassis

cutout

U-bolt

Roller

Support

Post

Limit Ramp

Limit Ramp

4" (10 cm)

Spacing approximate

Limit

Switch

Limit Ramp

enters chassis

cutout

Actuating Arm

(Tripped position)

Base of Drive Rail

3/8 " (9 mm)

Height

Adjusting

Screw

2"

(5 cm)

Drive

Wheel

2" (5 cm)

Nut

SlideDriver 50VF

Slow Down Limit Ramp Kit

Two truss head screws secure each limit ramp to the drive rail. The bolts

are spaced about 4 inches (10 cm) apart.

The limit switch must be set ⅜-inch (9 mm) from the base of the drive

rail. A screw on the limit switch allows for slight adjustments in height. If

XtremeDrive wheels are used, you will need to raise the drive rail

¼ to ½ inch (3 to 13 mm) along the gate uprights and the entire

drive rail path. The limit switch placement will need to be adjusted

accordingly.

All the limit ramps are the same length.

NOTE: For a 50VF-series SlideDriver, you will need to order four (4)

Slow Down Limit Ramp Kits.

Be sure to securely fasten all limit ramps to the underside of the

drive rail when installing a 50VF-series operator.

www.hysecurity.com Safety D0559 Rev. A 11

Page 20

safetY notICes

DANGER

WARNING

CAUTION

- Take Note -

Keep Away

Zone

Pinch Point

The following four levels of safety notices are used where applicable within this manual; each notice contains

information specic to the situation.

Indicates death or serious injury will occur if the hazardous situation is not avoided.

Indicates death or serious injury could occur if the hazardous situation is not avoided.

Indicates mild or moderate injury could occur if the hazardous situation is not avoided.

NOTICE: Indicates damage to equipment is probable if the hazardous situation in not avoided.

Common IndustrIal sYmBols

The following international safety symbols may appear on the product or in its literature. The symbols are used

to alert you to potential personal injury hazards. Obey all safety messages that follow these symbols to avoid

possible injury or death.

Attention

- Danger -

Entrapment

Possible

12 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 21

Power

DANGER

How to wire the operator is presented in the Installation Instructions, but detailed information about the earth

and equipment ground, wiring to AC power and the availability of UPS systems are described in this section.

Supplemental documents to this section include:

• DC Power Supply supplemental manual

InstallIng tHe eartH ground

An earth ground refers to the grounding rod and accompanying equipment ground which need to be installed to

safeguard against potential electrical shock and damage to personnel and equipment.

The potential for lightning discharge exists with all gates, fences and gate operators. National Electric

Code (NEC) - Article 250 requires a separate earth ground in addition to the required equipment ground.

HySecurity recommends grounding the operator with a separate earth ground rod (or a similar device

in the case of crash products) to shield the operator against electromagnetism and other electrical signals that

may cause, erratic operation with, or damage to, the Smart Touch Controller and other electrical parts.

For earth grounding requirements in the U.S.A.,

refer to the National Fire Protection Association

(NFPA) 780 - Standard for the Installation of

Lightning Protection Systems. Highlights of the

standard include:

• The ground rod must be UL listed copperclad steel, solid copper, hot-dipped

galvanized steel, or stainless steel. Minimum

requirements: ½ inch (13 mm) diameter and

8 feet (244 cm) in length.

• The ground rod is driven into the earth

(refer to local codes for proper depth

requirements).

• The ground rod is electrically bonded to the

chassis with a single length of un-spliced

6AWG copper wire less than 3 feet (91 cm)

long. Due to the large concrete foundation

on crash products, make the necessary

adjustments to accommodate for earth

ground requirements.

• Local jurisdictions may impose other

requirements above the NEC, Article 250 and NFPA 780. Consult

the local codes and regulations regarding requirements in your area.

SlideDriver

Chassis

Breather Cap

Quick

Disconnects

Grade

level

Cut-away view

Concrete foundation

Control Box

Toggle Handle

Limit

Switch

Earth ground

3 ft

(91.4cm)

Maximum

distance

Ground lug

Consult local

codes for

proper depth

NOTICE: Properly grounding the gate operator is critical to gate operator performance and the life of its

electrical components. Use sufcient wire size during installation. If you do not ground the operator with a

separate earth ground, you risk voiding the HySecurity Limited Warranty.

www.hysecurity.com Power D0559 Rev. A 13

Page 22

Site Considerations

WARNING

HySecurity gate operators are intended for permanent installation. Make sure you prepare the site with the

following considerations:

• Make sure all electrical wiring is properly routed via conduits.

• Check the distance of the wiring run from the main panel to the gate operator. Make sure the wire size

of the branch circuit supplying power to the gate operator is large enough to avoid excess voltage drop.

Refer to “Wire Sizing and Runs” on page 16.

• Make sure the available power source matches the electrical requirements specied on the voltage

nameplate.

Each gate operator is built to run on a specic line power voltage and phase. Failure to ensure the source

voltage, phase and frequency match what is specied for the equipment, may result is severe damage to the

equipment.

• Make sure a 20-amp circuit (minimum) protected with a 20-amp Inverse Time Breaker is provided for all

AC power connections.

• Verify that the operator is electrically grounded per NFPA 780 and NEC Article 250, and local codes.

wIrIng aC power

The SlideDriver has separate Installation Instructions that explain how to connect to AC power. For reference

purposes, the same information is provided below.

In-rush Current: The current needed to start the electric motor spinning in the proper direction (CCW). It may

take as much as 6 to 9 times the run current to start one of the heavy duty operators.

NOTE: Use a 20A (minimum) slow kick (thermal) circuit breaker for all AC motors.

Size the primary wires. Consider the voltage, horsepower, and length of the wire run from the main power panel.

Make sure you have the proper voltage and conversion of voltage taps at the motor and transformer.

DANGER

Turn OFF AC power at the source (circuit breaker panel) before accessing the wires in the SlideDriver.

Follow facility Lock Out/Tag Out procedures. Make sure all power switches are in the OFF position. Follow

all electrical code standards and regulations.

14 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 23

1. Connect to Power: Three wires and a ground are available for connection to a 3 Phase power source

WARNING

(3Ø). Loosen the screws on the power module to open the wire slots at the top and bottom.

2. Connect AC Power: Place the incoming power wires into their appropriate slots. Attach the ground wires

to the chassis. A wiring diagram is provided in the appendix.

Blue - 480 VAC

Orange - 240 VAC

Input taps

connection wires match the voltage found on the operator’s nameplate.

Red - 208 VAC

Black - Common

White - 120 VAC*

Control Transformer

* Variable Frequency (VF) or 2 hp gate operators:

Never connect to the white 120V wire. Make sure the

All (Excluding SD50VF) SD50VF - series

CAUTION

Wiring of gate operators must conform to NFPA and NEC standards and

comply with all local codes. When the installation is compliant and complete,

turn on AC power at the source and at the control box.

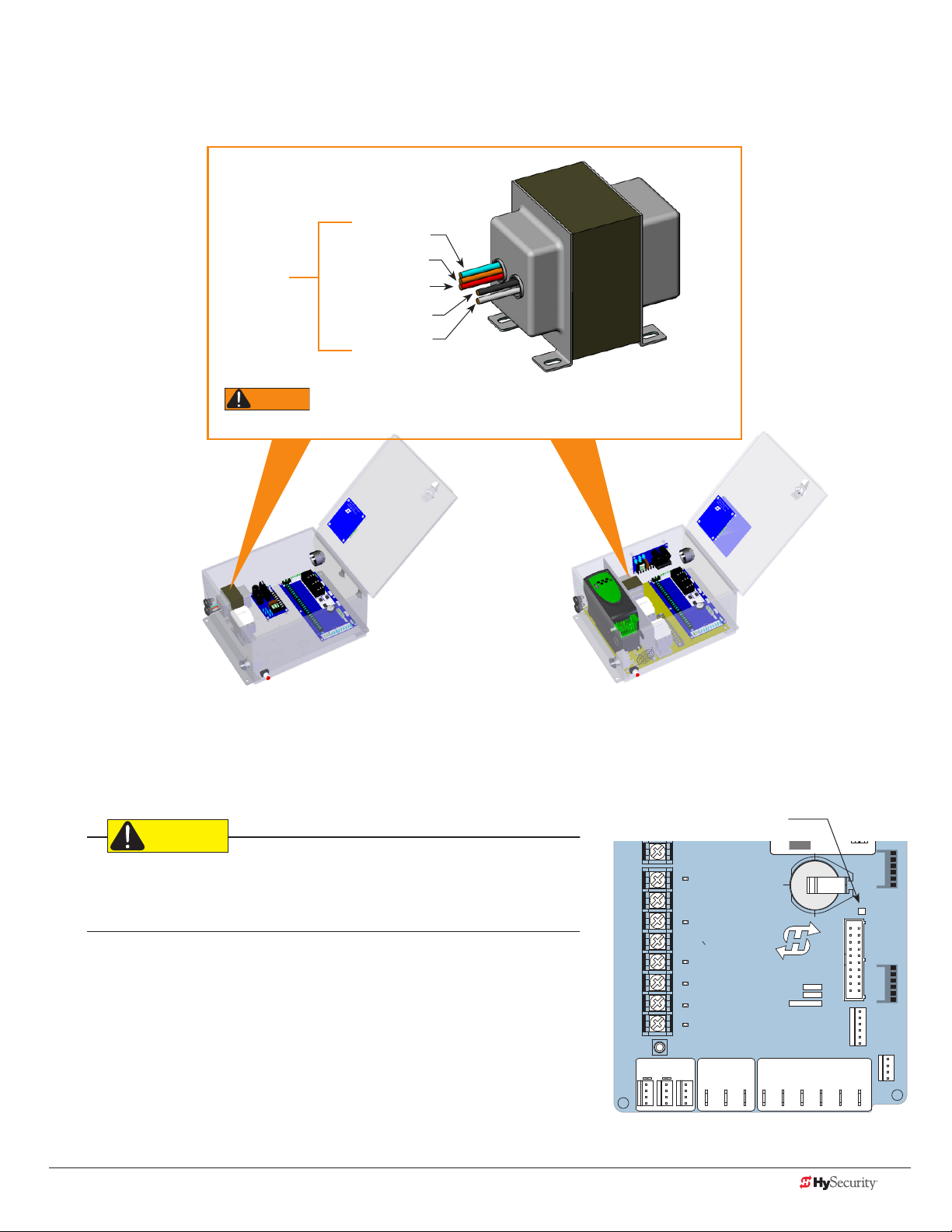

Turning the Power Switch ON

The AC power disconnect switch is located on the same enclosure

(control box) where the electrical components, Smart Touch

Controller, transformer, power module, etc., are found.

When power is turned ON, a green status light on the Smart Touch

Controller blinks. The status light appears below the coin battery and

indicates that the processor is receiving power. For more information,

refer to “Smart Touch Controller Inputs” on page 52.

Green LED ashes indicating

processor is receiving power.

LED

RPM

DO NOT USE

PHOTO EYE

OPEN DIRECTION

DO NOT USE

PHOTO EYE

CLOSE DIRECTION

DO NOT USE

CHARGER

AC LOSS

LOCK INTERLOCK

EMERG CLOSE

FIRE DEPT OPEN

16

17

18

19

20

21

22

23

24

LIMIT DUAL GATE

HySecurity

MX000585

VERSION

S/N

Smart Touch Controller

RADIO OPTIONS

COM COMA B

VEHICLE DETECTOR

STATU S

SHADOW

RESET

DISPLAY

RS232

VEHICLE DETECTOR

WIEGAND

COMOPEN EDGE+24V +24V

www.hysecurity.com Power D0559 Rev. A 15

Page 24

wIre sIzIng and runs

Supplying a gate operator with the correct electrical service is crucial to the performance of the operator and

the life of its electrical components. If the wire size used is too small, the voltage loss, especially during motor

startup, will prevent the motor from attaining its rated horsepower. The percentage of horsepower lost is far

greater than the percentage of voltage loss.

A voltage loss can also cause the control components to chatter while the motor is starting, substantially reducing

their life due to the resultant arcing. There is no way to restore lost performance resulting from undersized wires,

except to replace them. Be sure to choose a sufcient wire size at initial installation to avoid costly rewiring. Refer

to “Wire Sizing and Runs” on page 16.

The tables on the following page are based on copper wire and allow for a 5% voltage drop. The ampere values

shown are the service factor ampere rating (maximum full load at continuous duty) of the motor. A 20A circuit

(protected with a 20A Inverse Time Breaker) should be provided, at minimum.

Always connect electrical power and ground the operator in accordance with the NFPA 780 & NEC, Article 430

and Article 250. Research and adhere to other local codes that may apply.

Low Voltage Control Wiring

The Smart Touch Controller has very sensitive control inputs. The following is a chart of maximum distances for

wire size:

Wire Size Maximum Distance

18 ga 7.0 miles (11 km)

20 ga 3.5 miles (5.6 km)

22 ga 2.7 miles (4.3 km)

24 ga 2.0 miles (3.2 km)

26 ga 1.0 mile (1.6 km)

28 ga 3700 feet (1.1 km)

16 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 25

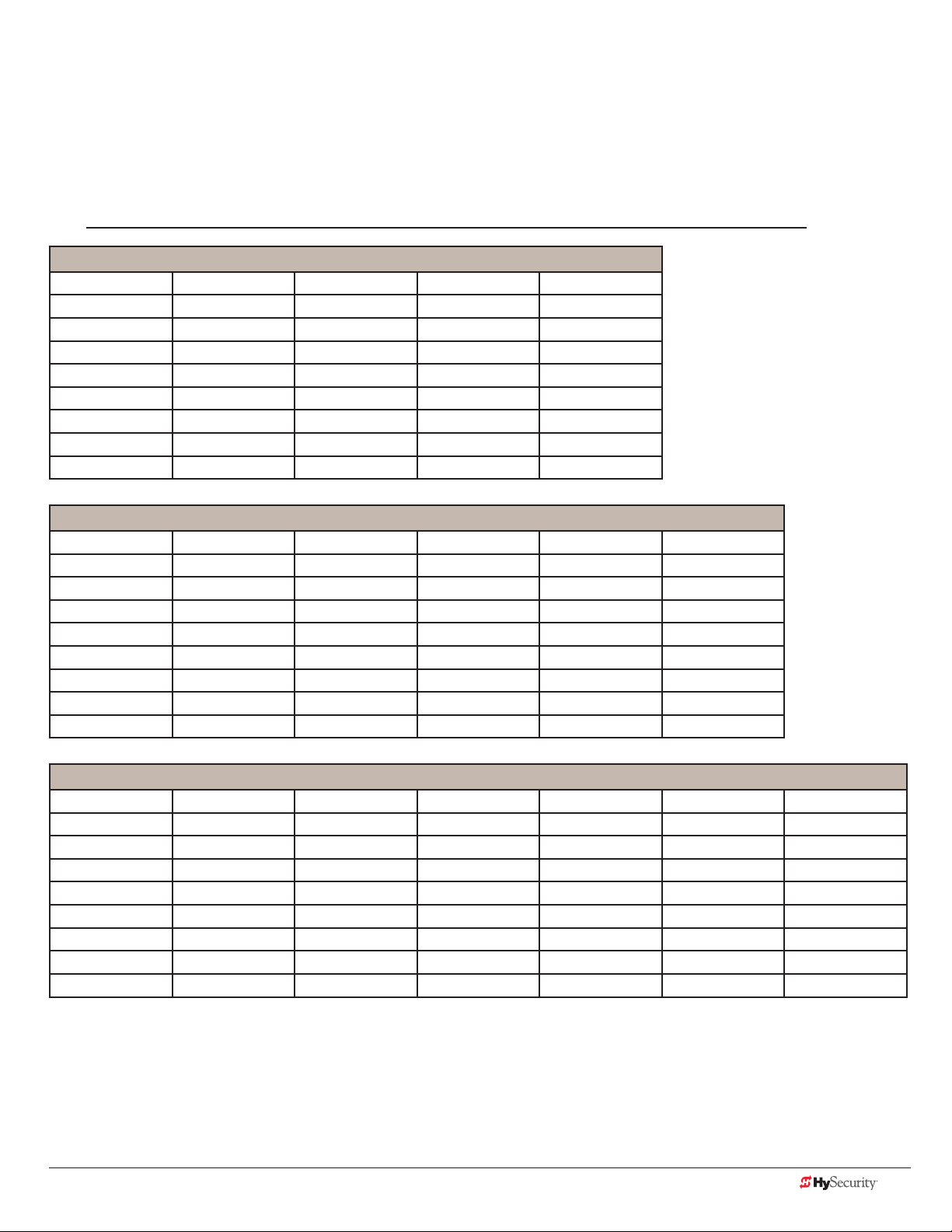

SlideDriver Wiring Charts (Incoming Power)

The maximum distance shown is from the operator to the power source, assuming that source power is from a

panel box with adequate capacity to support the addition of this motor load. The values are for one operator,

with no other loads applied to the branch circuit. Avoid placing more than one operator to a circuit, but if you

must, be certain to reduce the maximum allowed wire distance by half.

NOTE: Distance shown in U.S. Standard “feet.” Metric equivalent shown in parentheses.

SlideDriver Wire Size Chart – 115V Single Phase

Horsepower ½ ¾ 1 2

Amps 10 11.6 14.4 27.2

Wire Gauge Distance Distance Distance Distance

12 90 (27m) 75 (23m) 60 (18m) 30 (9m)

10 140 (43m) 120 (37m) 100 (30m) 50 (15m)

8 220 (67m) 190 (58m) 155 (47m) 80 (24m)

6 350 (107m) 300 (91m) 245 (75m) 130 (40m)

4 555 (169m) 480 (146m) 385 (117m) 205 (62m)

2 890 (271m) 765 (233m) 620 (189m) 330 (101m)

SlideDriver Wire Size Chart – 208V Single Phase

Horsepower ½ ¾ 1 2 3

Amps 5.5 6.1 7.6 14.2 16.2

Wire Gauge Distance Distance Distance Distance Distance

12 290 (88m) 260 (79m) 205 (62m) 110 (33m) 100 (30m)

10 460 (140m) 415 (126m) 330 (101m) 175 (53m) 155 (47m)

8 725 (221m) 650 (198m) 525 (160m) 280 (85m) 245 (74m)

6 1150 (350m) 1040 (317m) 835 (254m) 445 (135m) 390 (119m)

4 1825 (556m) 1645 (501m) 1320 (402m) 710 (216m) 620 (189m)

2 2920 (890m) 2630 (801m) 2110 (643m) 1130 (344m) 1000 (305m)

SlideDriver Wire Size Chart – 230V Single Phase

Horsepower ½ ¾ 1 2 3 5

Amps 5.0 5.8 7.2 13.6 14.8 27.0

Wire Gauge Distance Distance Distance Distance Distance Distance

12 350 (107m) 300 (91m) 245 (75m) 130 (40m) 120 (37m) 65 (20m)

10 560 (171m) 480 (146m) 385 (117m) 205 (62m) 190 (58m) 105 (32m)

8 880 (268m) 760 (232m) 610 (186m) 325 (99m) 300 (91m) 165 (50m)

6 1400 (427m) 1120 (341m) 975 (297m) 515 (157m) 475 (145m) 260 (79m)

4 2220 (670m) 1915 (584m) 1550 (472m) 815 (248m) 750 (229m) 410 (125m)

2 3550 (1082m) 3080 (939m) 2465 (751m) 1305 (398m) 1200 (366m) 650 (198m)

www.hysecurity.com Power D0559 Rev. A 17

Page 26

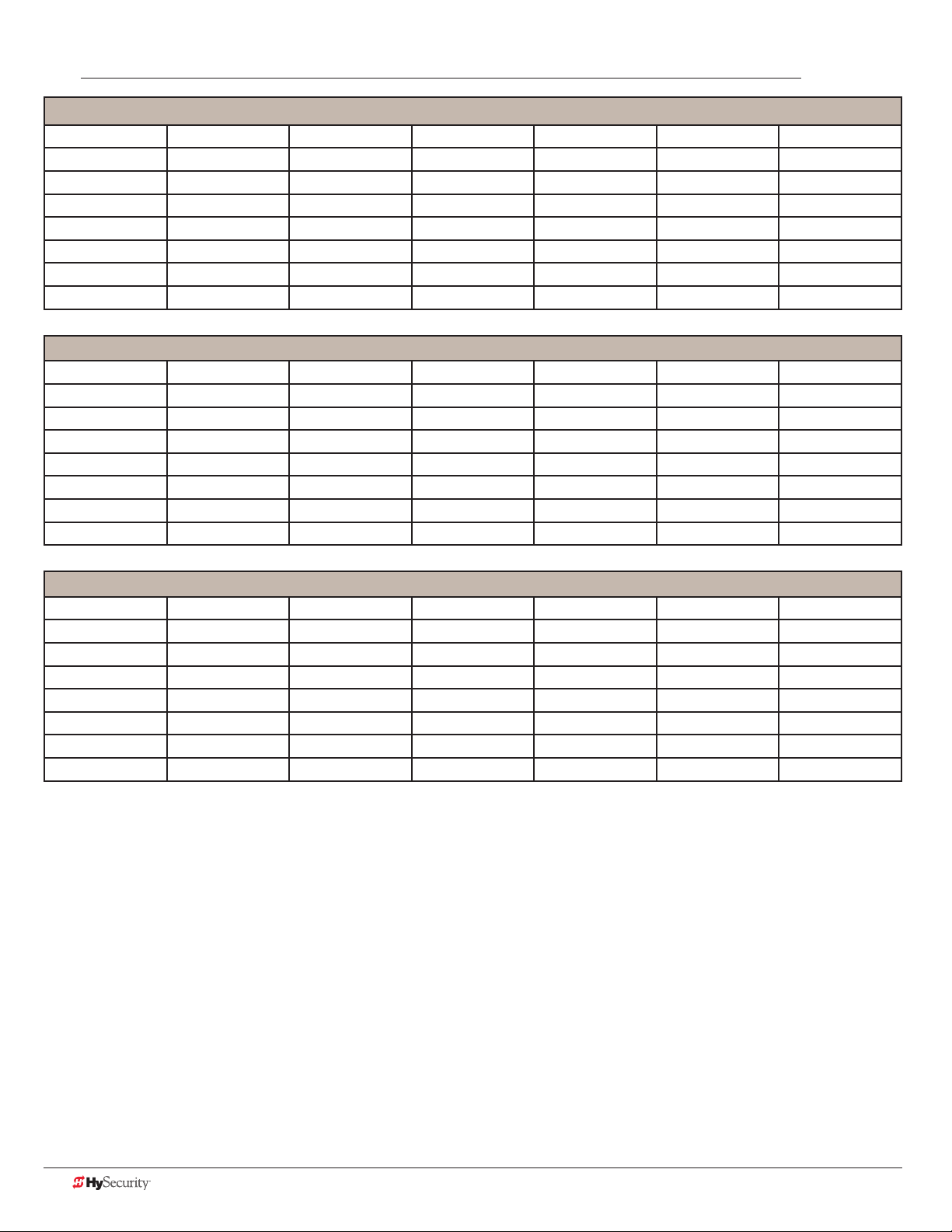

NOTE: Distance shown in U.S. Standard “feet.” Metric equivalent shown in parentheses.

SlideDriver Wire Size Chart – 208V Three Phase

Horsepower ½ ¾ 1 2 3 5

Amps 2.7 3.1 4.2 6.5 6.7 16

Wire Gauge Distance Distance Distance Distance Distance Distance

12 590 (180m) 510 (155m) 375 (114m) 245 (75m) 235 (72m) 100 (30m)

10 930 (283m) 810 (247m) 600 (183m) 390 (119m) 575 (175m) 160 (49m)

8 1475 (449m) 1285 (392m) 950 (289m) 615 (187m) 595 (181m) 250 (76m)

6 2350 (716m) 2045 (623m) 1510 (460m) 975 (297m) 945 (288m) 400 (122m)

4 3720 (1134m) 3240 (987m) 2390 (728m) 1545 (471m) 1500 (457m) 630 (192m)

SlideDriver Wire Size Chart – 230V Three Phase

Horsepower ½ ¾ 1 2 3 5

Amps 2.4 3.0 3.8 6.2 6.4 15.4

Wire Gauge Distance Distance Distance Distance Distance Distance

12 730 (222m) 585 (178m) 460 (140m) 280 (85m) 270 (82m) 115 (35m)

10 1160 (353m) 930 (283m) 730 (222m) 450 (137m) 435 (133m) 180 (55m)

8 1835 (559m) 1470 (448m) 1160 (353m) 710 (216m) 690 (210m) 285 (87m)

6 2925 (891m) 2340 (713m) 1845 (562m) 1130 (344m) 1095 (334m) 455 (139m)

4 4625 (1410m) 3700 (1128m) 2920 (890m) 1790 (546m) 1735 (529m) 720 (219m)

SlideDriver Wire Size Chart – 460V Three Phase

Horsepower ½ ¾ 1 2 3 5

Amps 1.2 1.5 1.9 3.1 3.2 7.7

Wire Gauge Distance Distance Distance Distance Distance Distance

12 2915 (888m) 2350 (716m) 1850 (564m) 1130 (344m) 1100 (335m) 455 (139m)

10 4640 (1414m) 3710 (1131m) 2930 (893m) 1800 (549m) 1740 (530m) 725 (221m)

8 7340 (2237m) 5870 (1789m) 4650 (1417m) 2840 (866m) 2750 (838m) 1150 (350m)

6 11700 (3566m) 9350 (2850m) 7400 (2255m) 4550 (1387m) 4400 (1341m) 1800 (549m)

4 18500 (5639m) 14800 (4511m) 11700 (3566m) 7200 (2194m) 7000 (2134m) 2900 (884m)

18 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 27

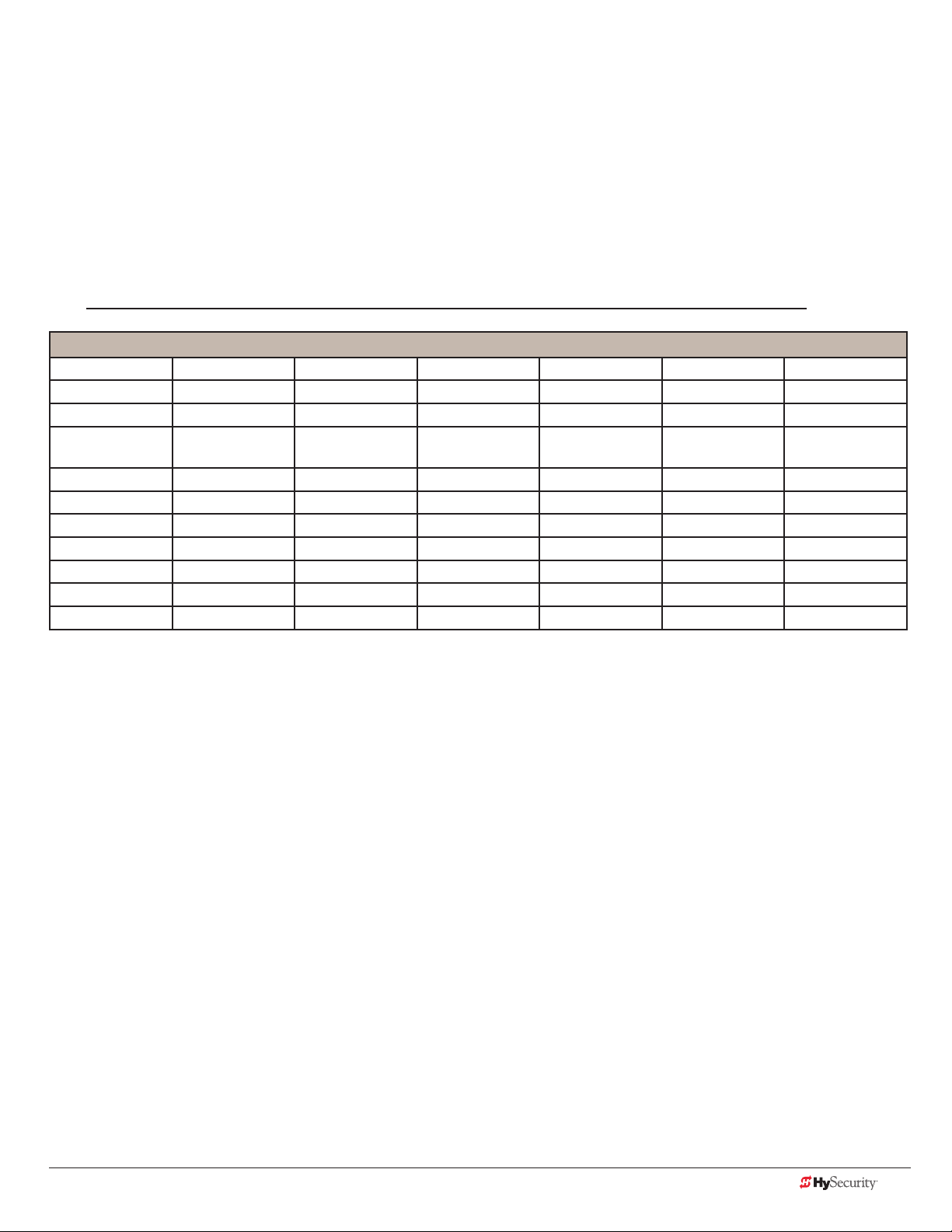

SlideDriver 50VF-series Wiring Chart (Incoming Power)

The maximum distance shown is from the operator to the power source, assuming that source power is from a

panel box with adequate capacity to support the addition of this motor load. The values are for one operator,

with no other loads applied to the branch circuit. Avoid placing more than one operator to a circuit, but if you

must, be certain to reduce the maximum allowed wire distance by half.

Make sure proper wiring is being used. The following table shows the maximum allowable wire run from the

power source to the operator for various wire sizes. Performance of 50VF-series operators on 1Ø and 3Ø

50 or 60 Hz Power.

NOTE: Distance shown in U.S. Standard “feet.” Metric equivalent shown in parentheses.

SlideDriver 50VF-series Wire Size Chart

Phase Ø 1 1 3 3 3 3

Voltage 208 230 208 230 380 460

Horsepower 2 2 2 2 2 2

VFD Rating

Amps

Wire Gauge Distance Distance Distance Distance Distance Distance

12 90 (27m) 100 (30m) 220 (67m) 240 (73m) 680 (207m) 830 (253m)

10 150 (46m) 170 (52m) 350 (107m) 390 (119m) 1090 (332m) 1310 (399m)

8 240 (73m) 270 (82m) 560 (171m) 620 (189m) 1730 (527m) 2100 (640m)

6 390 (119m) 430 (131m) 900 (274m) 990 (302m) 2750 (838m) 3330 (1015m)

4 620 (189m) 680 (207m) 1430 (436m) 1580 (482m) 4380 (1335m) 5300 (1615m)

2 990 (302m) 1090 (332m) 2280 (695m) 2530 (771m) 6990 (2130m) 8470 (2582m)

17.4 17.4 8.7 8.7 5.2 5.2

Performance of 50VF-series Operators on 1 and 3 Phase, 50 or 60Hz

A HySecurity 50VF2, 50VF-EFO, or 50VF3 operator can operate on a wide variety of incoming power.

• 50Hz/60Hz operation with no changes or reconnection

• 1Ø or 3Ø operation by eld rewiring and reconnection

• The incoming voltage must match the operator nameplate. Although the electric motor can be

reconnected, a different VFD (motor controller inside the grey control box) is required between 460V and

208V/230V.

• Any AC powered peripherals such as locks, card readers and other devices need to be checked for

compatibility.

• The electric motors in all VF2 and VF3 operators are 3Ø/60Hz motors and are connected for the voltage

shown on the operator’s nameplate. (208V/230V or 460V)

www.hysecurity.com Power D0559 Rev. A 19

Page 28

How is this done?

WARNING

WARNING

• The VF controller in the operator is rated to operate on input frequencies ranging from 48Hz through

62Hz on 1Ø or 3Ø power (a jumper connection is required for phase change) but only on either 460VAC

or 208V/230V. (A change between 460V and 230V, either direction, requires replacing the VF controller).

• The control transformer in the operator is tapped for multiple voltages and rated for 50/60Hz operation.

• The VF controller rst recties and lters the incoming power to DC, which has no frequency or phase. It

then creates 3Ø variable voltage/variable frequency AC for the motor from the DC.

• Depending on the model, the VF controller ramps the motor voltage and frequency from 0V@0Hz at

start, to either 208/230 or 480 VAC @ 60Hz for full speed. This allows use of 60Hz motors regardless of the

incoming frequency.

• Since the input voltage/frequency is converted to DC to begin with, there is absolutely no relationship

between the input frequency/phase and frequency/phase of the power supplied to the motor. The input

could be 1Ø or 3Ø, 48Hz or 62Hz and the controller/motor combination wouldn’t care. It will create the

ramped 3Ø voltage and frequency for which it is programmed.

NOTE: SlideDriver 50VF operators connected for 1Ø operation will draw more current because the utility power

to run the machine will be carried to the operator on two wires instead of the three used for 3Ø operators. Be

sure to allow for this difference when specifying wire size.

In-Field Connections

SlideDriver 50VF-series operators are eld re-connectable for 1Ø or 3Ø, 208/230VAC input power without

changing the VFD.

SlideDriver 50VF-series operators CANNOT be connected to 120V, 1Ø power or 575V, 3Ø power. If any attempts

are made to do so, serious injury, electrical shock, or death may result. Any electrical damage occurring to the

operator will not be covered by the Limited Warranty.

SlideDriver 50VF-series operators are NOT eld recongurable between 208/230VAC and 480VAC power. The

VFD Motor Controller in a 208/230VAC unit must be replaced with a VFD Motor Controller manufactured for the

higher (480VAC) voltage input.

20 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 29

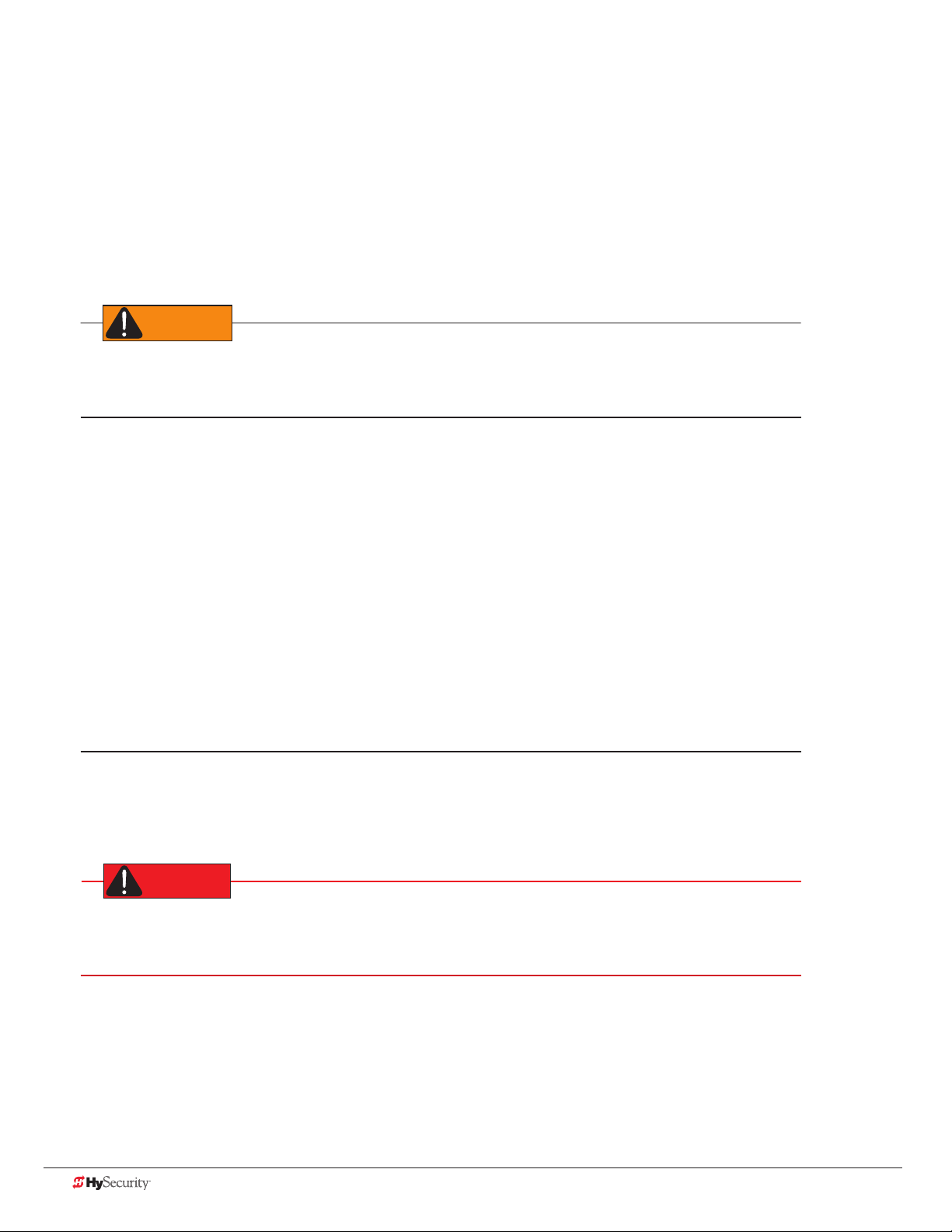

Control transformer ConneCtIons (non-ups)

WARNING

Connect the AC input power to the control

transformer according to the following procedure.

1. Ensure that the primary tap on the control

transformer matches the line voltage and

frequency connected to the gate operator.

2. Measure the line voltage carefully to

distinguish between 208V and 230V branch

circuits.

NOTE: A label on the transformer top identies the

various voltage taps available.

3. Use wire nuts or crimp-connectors to

connect the power input conductors to the

applicable taps on the Control Transformer.

Input taps

connection wires match the voltage found on the operator’s nameplate.

Blue - 480 VAC

Orange - 240 VAC

Red - 208 VAC

Black - Common

White - 120 VAC*

* Variable Frequency (VF) or 2 hp gate operators:

Never connect to the white 120V wire. Make sure the

All (Excluding SD50VF) SD50VF - series

Control Transformer

gate operator ConneCtIons (modular unIt)

Control box with display

Electric motor

Hydraulic pump pack

Hydraulic motors,

Drive dheels,

Limit switches,

Toggle handle release

High voltage electrical power

input wiring

Vehicle detector & control

signal input wiring

If you have the modular unit, additional conduit is needed to house the hydraulic hoses and electrical wiring.

You need a 2-inch (5 cm) diameter conduit for hydraulic hoses and a ¾-inch (19 mm) conduit for electrical wiring.

AC input power is connected to the hydraulic pump and electrical components enclosure (HydraSupply).

A supplemental manual, provided with the product, describes the installation overview, wiring and conduit

considerations.

www.hysecurity.com Power D0559 Rev. A 21

Page 30

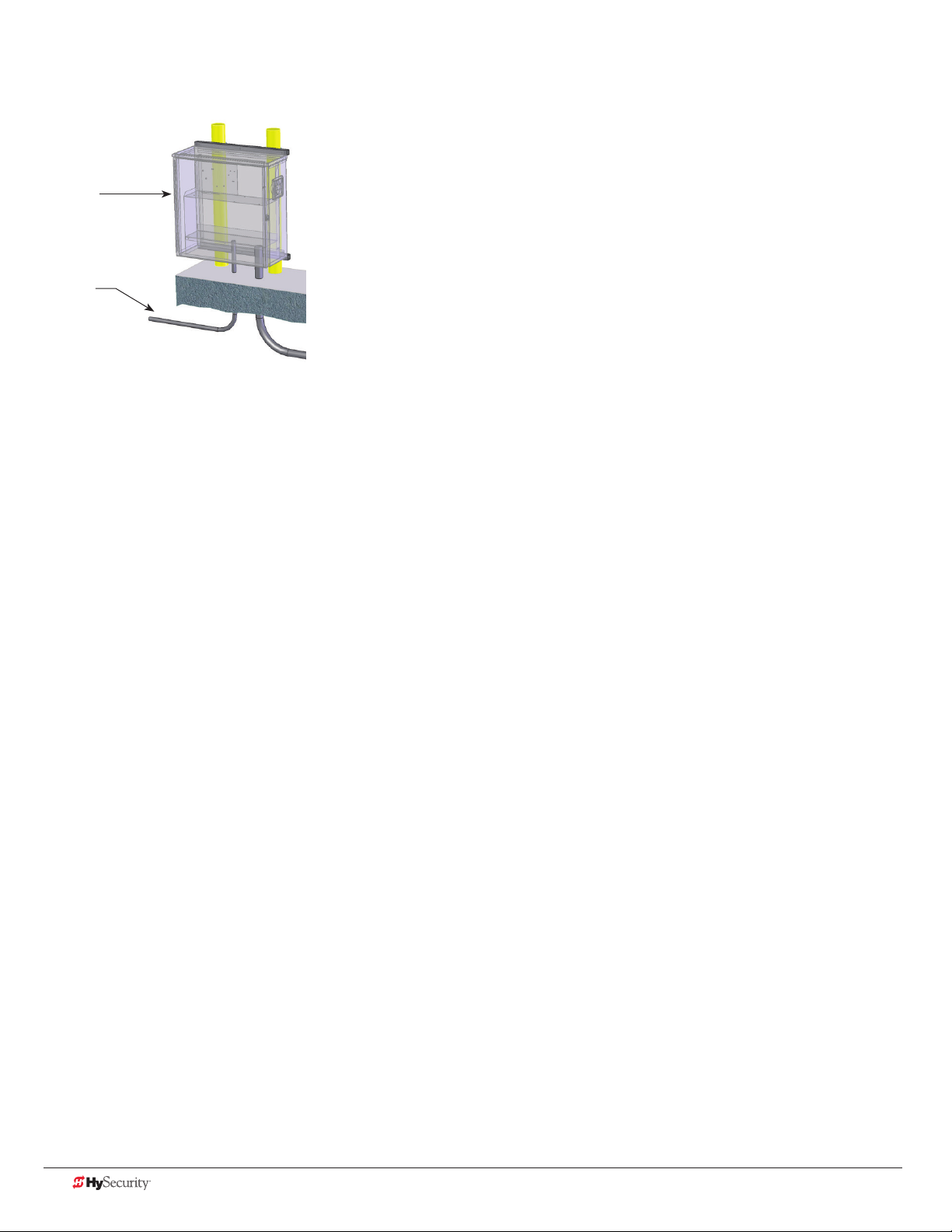

dC power supplY (ups) ConneCtIons

If you have a gate operator with a DC Power Supply unit, you will need to

connect the primary AC input power to the DC Power Supply.

DC Power

Supply

Cabinet

Additional ¾-inch (19 mm) conduit is needed for electrical wiring

interconnections between the gate operator and DC Power Supply

Cabinet. AC input power is connected to the electrical components in

the chassis, and additional wiring is run through conduit to the DC Power

Supply Cabinet.

Conduit

A supplemental manual (D0598), provided with the DC Power Supply

Cabinet, describes the installation overview, wiring and conduit

considerations.

22 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 31

Configure the Operator

When you rst apply power to the operator, it is locked in Menu mode

and prompts appear on the display. The gate will not move and the

controls will not function until the prompts have been answered. The

prompts include:

• Usage Class setting

• Gate handing

NOTICE: Before turning the power switch to ON, make sure all site requirements

concerning proper wiring, safety, foundation installation, and electrical power

have been met.

Five buttons on the display keypad provide operational controls. Refer

to Initial Setup on page 35 for more information. To answer the initial

prompts, use the Previous, Next, and Select buttons as described in the

chart below:

Smart Touch Controller: Menu Mode Navigation Buttons

UC 2

USAGE CLASS

To change that data appearing

in the display

Press Select.

Two left characters blink.

To navigate through the

Selections

Press Next.

Continue pressing Next to view

all selections. (Press Previous to

reverse direction.)

To choose what appears on

the display

Press Select.

Blinking characters

become static.

To navigate between menu

items

Press Next or Previous.

Advance - press Next

Previous - press Previous

If you are unsure of the usage classication, refer to Identifying Gate Operator Category and Usage Class on

page 7. It explains the different usage site classications for UL 325.

gate HandIng

The handing is determined by the position of the operator and which way the gate opens.

To determine handing, face the front cover panel on the operator. Refer to the illustration below.

OPEN OPEN

Left-Hand

Gate

www.hysecurity.com Congure the Operator D0559 Rev. A 23

Right-Hand

Gate

Page 32

HYdraulIC Hose swap

CAUTION

SH L

GATE HANDING

Gate Handing is determined by viewing the gate opening from the secure side. If the gate opens to the left, the

gate must be set for left handing.

All SlideDrivers are set at the factory for right handing. If the gate has left handing, you must

• select SH L when prompted (or access the

• swap position of the hydraulic hoses.

Installer Menu)

adjustIng tHe pressure relIef valve

Factory set for right-handing.

Swap hose connections for

left-handing gate.

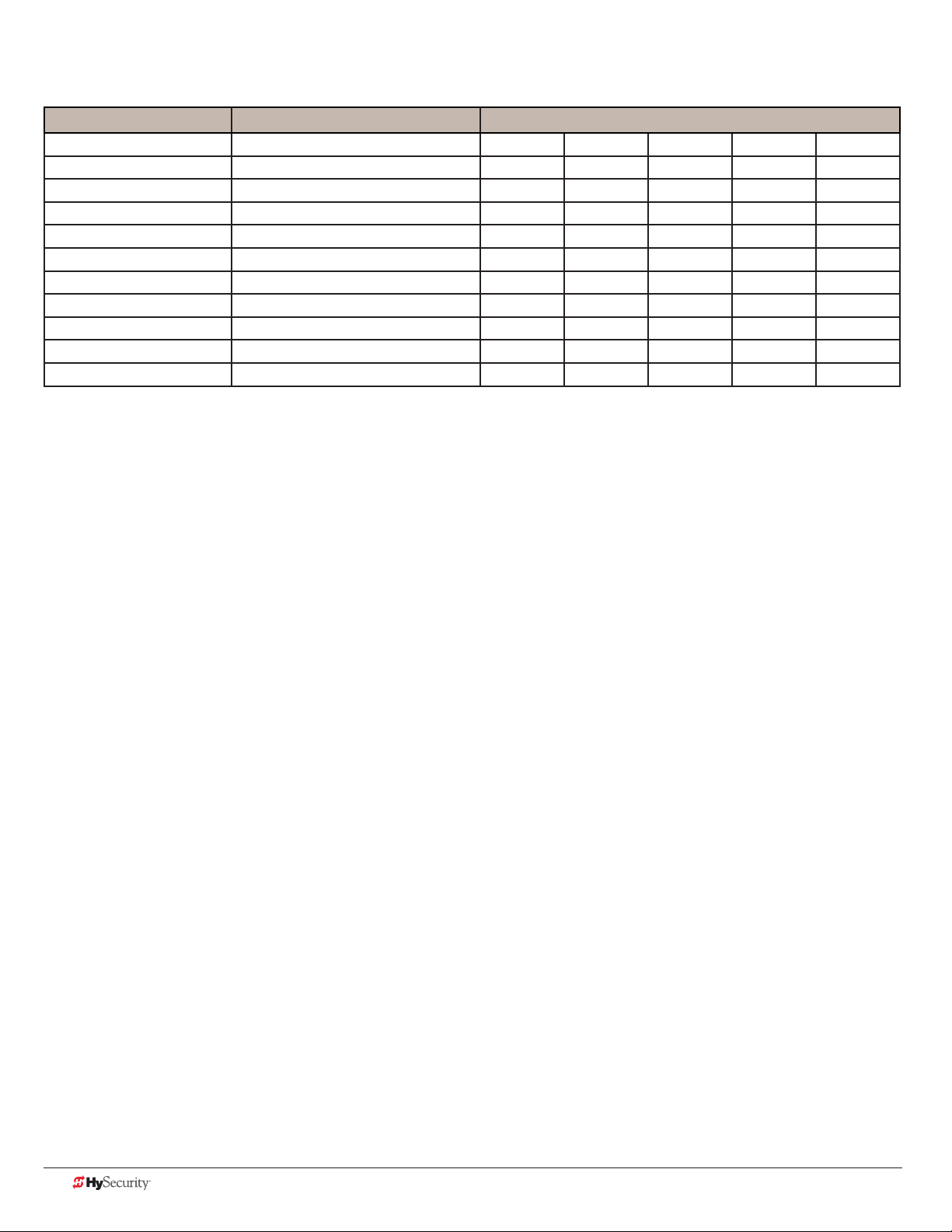

When placing the operator into service, pressure relief valve

adjustments are required! To provide instruction during

installation, a cautionary yellow tag is wire tied to every pump

pack. The same instructions are provided in this section.

Pressure relief valves differ depending on the model.

Tools Needed: 5/32 " hex key, ½" and 9/16 " box end wrenches.

NOTICE: Pressure relief valve adjustments establish the threshold for the inherent entrapment sensor (IES). The

optimal pressure setting produces uniform gate travel and trips the IES when the gate encounters an obstruction.

Model Motor hp Maximum PSI

SlideDriver 15, 40 1 hp 1000 psi

SlideDriver 30F, 80, 50VF 2 hp 1350 psi

SlideDriver 200 5 hp 2000 psi

Never exceed the maximum psi setting.

24 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 33

Adjustment Screw

DANGER

SlideDriver 30F, 80, 200

Pressure

Gauge

The Pressure Relief

Valve is located

behind the motor

on the pump rack or

soft start manifold.

Motor

Pump

pack

Adjustment Screw

SlideDriver 15, 40, 50VF

Make sure the gate is properly installed and aligned before performing the following steps. Take precautionary

measures to keep the gate’s travel path clear. The gate will be moving while you adjust the pressure relief valve.

DO NOT attempt to adjust the pressure relief valve unless you are an experienced hydraulic gate

operator installer. Incorrect pressure settings can cause injury and even death!

1. Expose several threads on the Pressure Relief Valve by loosening the locknut with a 9/1 6" box end wrench.

2. Depending on the model, insert a 5/3 2" hex key or use a ½" box end wrench to turn the Adjustment Screw.

3. Use the keypad to cycle the gate open or close and, while the motor is running, turn the Adjustment

Screw clockwise (CW) to raise the pressure. The motor runs for a few seconds, stops, and then enters safe

mode. SAFE appears on the display.

4. Press RESET and repeat step 3 until gate travel is reliably consistent without entering SAFE mode.

5. To lock in the pressure setting, hold the Adjustment Screw with a hex key or wrench and tighten the

locknut.

www.hysecurity.com Congure the Operator D0559 Rev. A 25

Page 34

tHe InHerent entrapment sensor (Ies)

The IES on HySecurity hydraulic operators is a primary entrapment device that is required by UL 325 as a type “A”

detection device. It is tripped through software programming OR hydraulic pressure settings. It does not function

solely on its own accord and must be connected to the Smart Touch Controller. The sensitivity and response of

the IES when tripped is factory set, but can be adjusted through the Installer Menu items:

• SE (Inherent Sensor sensitivity)

• SS (Inherent Sensor function)

• SR (IES reverse to open)

Smart Touch Controller™ – Installer Menu Functions for IES

Installer Menu

Display Code

SE 2

IES SENSITIVITY

1 = max. sensitivity

2 = Default setting

9 = least sensitivity

Setting Options

(Bold – Factory Settings)

Description

Adjusts the sensitivity of the internal inherent entrapment sensor (IES).

Available settings are 1 to 9 with 9 being the least sensitive. HySecurity

strongly recommends that you avoid setting the IES sensitivity higher

than 6.

Note: Adjust pressure relief valve on hydraulic operators for security

and gate impact purposes prior to changing IES sensitivity. Refer to

the operator’s manual for steps involved in adjusting the pressure relief

valve setting.

SS 0 (OFF)

IES STOP ONLY

SR 0 (FULL OPEN)

REVERSAL LOGIC

0 = stop, reverse for 2s

1 = stop only

0 = IES reverses full open

1 = 2 second reversal only

In a Usage Class IV environment, the operator can be set to stop the

gate and not reverse gate travel after and IES trip.

The default setting is a 2-second duration reversal if the inherent sensor

is triggered. The optional setting of 0 will cause the gate to reopen fully

if triggered while closing.

Manufacturer’s responsibility

• Build into the gate operator a means of detecting an obstruction or an inherent entrapment detection

device (UL 325 30A.1.1)

• Accept input from external entrapment detection devices

• Provide warning signs and an installation manual which, if followed, will result in a UL 325 compliant

installation

Pressure Relief Valve – All Hydraulic Operators:

• Limits hydraulic system pressure

• By-passes uid to tank when set-point exceeded

• By-passed uid triggers the IES

NOTICE: Pressure relief valve adjustments establish the threshold for the Inherent Entrapment Sensor (IES). The

optimal pressure setting produces uniform gate travel and trips the IES when the gate encounters an obstruction.

26 D0559 Rev. A SlideDriver/SlideDriver 50VF Series www.hysecurity.com

Page 35

Inherent Entrapment Sensor – (IES)

SP 2

SPEED

• Normally closed pressure switch on pump manifold

• Senses uid ow “above” pressure relief valve indicating high pressure and possible gate obstruction

• An open contact during gate movement signals the Smart Touch Controller to put operator into “SAFE”

mode

• Ignored for the rst second of operation to get past starting pressure spike

• An open contact while the gate is not operating will generate Err2 – disconnected IES

• A second open contact, in either direction of travel, will lock the machine out and the “ENTR”, or

entrapment mode, appears on the display

modBus rtu In slIdedrIver 50vf-serIes

In the 50VF series SlideDriver™, a communication protocol allows the Smart Touch

Controller to constantly monitor the Variable Frequency Drive (VFD) and record

events in the STC history log. The history log is easily accessible using the HySecurity