Page 1

MX3037, MX3037R, MX001457

EXAMPLE

Smart DC Controller Installation Instructions

The following instructions are intended to assist the user in replacing the Smart DC Controller (SDC) in HySecurity

electromechanical gate operators. Please read all assembly instructions before installing the kit.

REQUIRED TOOLS

Phillips head screwdriver

Needle nose pliers

Always ensure operator rmware is updated to

latest available version. The latest available version

is at www.hysecurity.com/contact-us/technical-

support/operator-software/ or by naviagting the

HySecurity website by clicking:

TechSupport Resources Operator Software

Current Operator Software Versions

UL 325 - 2018 requires that gate operators monitor

external entrapment protection sensors. Affects

all HySecurity gate operators manufactured

beginning in 2016.

CAUTION

Remember the operator may have unique user

& installer menu settings on the existing board.

Prior to replacing the SDC board, compare

the programmed settings that appear in the

existing board’s display to the default settings

shown in the "Smart DC Controller Worksheet"

on page 2 and note any changes. If you have

a bi-parting gate system, be sure the software

version in both operators is identical.

COPY USER & INSTALLER MENU SETTINGS

Examples of the settings that need to be

reprogrammed when you replace an SDC board

include: Build Year, Operator Type, Usage Class,

Gate Handing and Learn Limits. Other settings

may include Gate Weight, Close Timer, and

accessory congurations. The operator can be

reprogrammed on site by entering the User or

Installer Menu via the Menu buttons or using

S.T.A.R.T. software and a laptop PC to save/load

existing settings. If you need more information,

see "Technical Support" on page 1.

Create a backup copy of the gate operator

congurations, using one of two methods:

z Use a PC laptop and S.T.A.R.T. with a USB cable

(Type A to Type B).

z Use the "Smart DC Controller Worksheet" on

page 2. Go through each menu item and

write the number that appears in the display

into the chart’s column titled, “Display Setting.”

TWO METHODS TO RECORD USER &

INSTALLER MENU SETTINGS

TECHNICAL SUPPORT

For technical support, call your installer or

authorized HySecurity distributor. Obtain the serial

number of your operator before calling. For the

name of a distributor near you, contact HySecurity

at 800-321-9947.

For more information regarding how HySecurity

is handling monitoring of external entrapment

protection sensors, go online to:

www.hysecurity.com/gatesafety

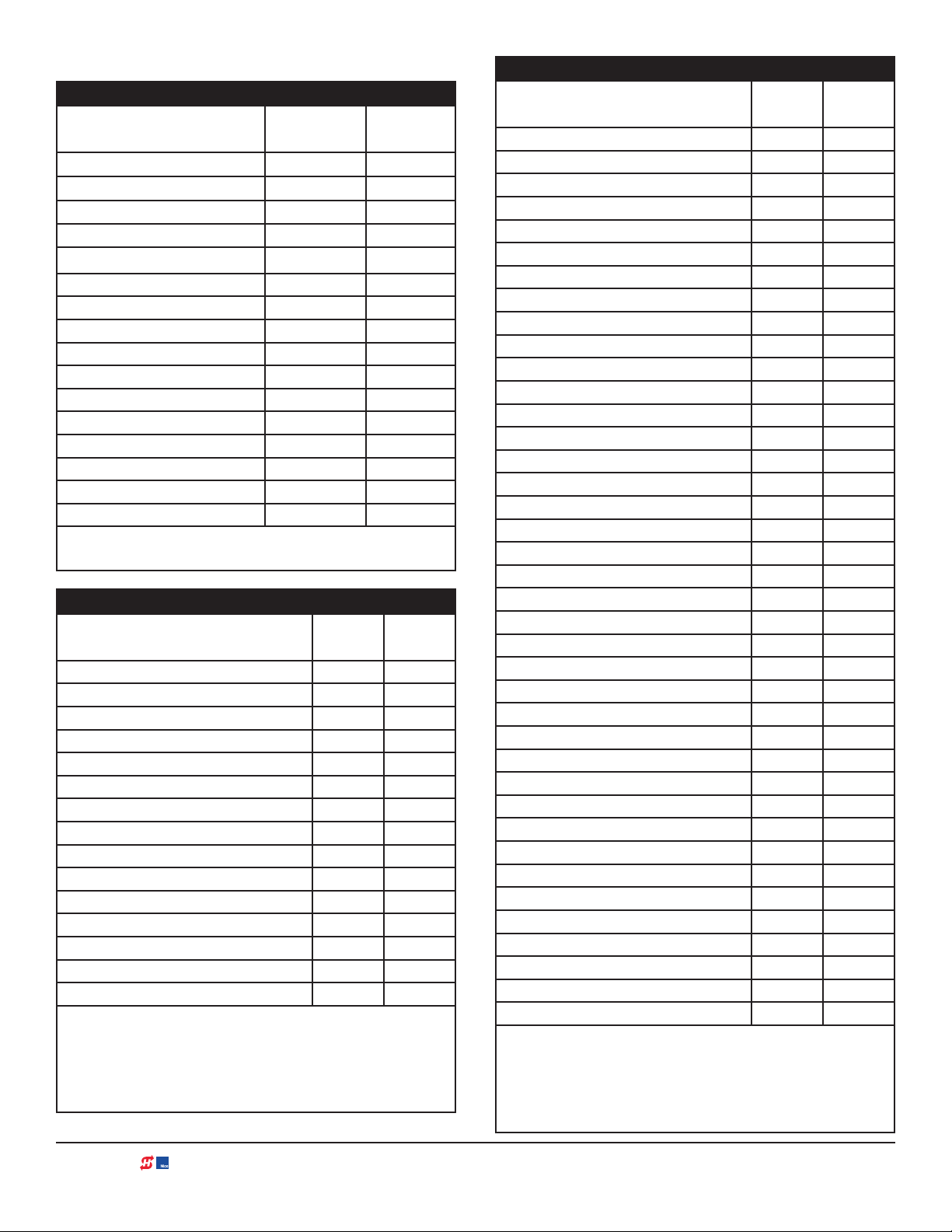

Figure 2. SDC Programmable Menu Items Settings

D0360 REV. I ©2018 SMART DC INSTALLATION INSTRUCTIONS www.hysecurity.com | 1

Figure 1. S.T.A.R.T. Display

User Menu Item* Default Setting Display Setting

CT _ Close Timer 0

HC _ Hold to Close 0

HO _ Hold to Open 0

AP _ AC Loss function 0

RO_ Radio Open/Close 0

BF _ Warn Before Operate 2

FA _ Forced Open Alert 0

DA _ Drift Close Alert 0

PE _ Photo Eye Alignment 0

CL_ Set Clock (24 hour) 0

LD_ LCD Contrast setting 5

CA_ Close Limit Adjustment 0

AL_ Flash on Close Limit 1

DS_ Diagnostic Log 0

*NOTE: The items shown in the user & installer menu charts may or may not appear on

your operator’s display. The menu items that appear are dependent on the operator type

Installer Menu Item* Default Setting Display Setting

OT _ Select Operator Type 0

MN _ Model Number 0

LL _ Learn Limits 0

UC _ Usage Class 0

SH _ Gate Handing 0

WT _ Gate Weight (lbs) 0

LN _ Gate Length (Feet) 0

OS _ Open Speed 5

CS _ Close Speed 5

FD _ Load Factory Defaults 0

DG _ Dual Gate 0

SG _ Sequenced Gate 0

CH _ Charger Type 0

FO _ Fire Dept. Open 0

Smart DC Controller Worksheet

(write it down here)

(write it down here)

Notes:

SE _ IES Sensitivity 2

SS _ Inherent sensor Stop 0

LC _ Leaf Delay Close 0.0 Secs

LO_ Leaf Delay Open 0.0 Secs

RT _ Maximum Run Timer 30 Secs

PO _ Partial Open distance 0

EC _ Eye Close Logic 0

EO _ Eye Open Logic 0

GR _ Gate Edge Logic 0

SR _ IES Sensor Logic 1

PC _ Photo Eye Contact NC 0

GC _ Gate Edge Output NC 0

DT _ Disable Free Exit 0

OR _ Outside Obstr Loop 1

IR _ Inside Obstr Loop 1

HD _ Center Loop Hold 1

DL _ Detector Logic 1

CR _ RLD Reverse Open 0

CB _ RLD Disables ELD 0

CP _ Counts PBO 0

EB _ ELD Back off - Detector 0

R1 _ Relay 1 Logic - disabled 0

R2 _ Relay 2 Logic - Close Limit 1

TL _ Gate Open alert 2

LT _ Loitering alert 3

SA _ STC Address 0

ELD _ Exit Loop Set 0

ILD _ Inside Obstr. Loop Set 0

OLD _ Outside Obstr. Loop Set 0

CLD _ Center Loop Set 0

Installer Menu Item* Default Setting Display Setting

(write it down here)

Notes:

Page 2

SMART DC CONTROLLER WORKSHEET

Table 1. User Menu

User Menu Item*

Default

Setting

CT _ Close Timer 0

HC _ Hold to Close 0

HO _ Hold to Open 0

AP _ AC Loss function 0

RO_ Radio Open/Close 0

BF _ Warn Before Operate 2

FA _ Forced Open Alert 0

DA _ Drift Close Alert 0

PE _ Photo Eye Alignment 0

CL_ Set Clock (24 hour) 0

LD_ LCD Contrast setting 5

US_ Clear count 0

CA_ Close Limit Adjustment 0

AL_ Flash on Close Limit 1

DS_ Diagnostic Log 0

PD_ Set password 0

NOTE: Available menu items are dependent on operator type

and programming congurations or options.

Table 2. Installer Menu

Installer Menu Item*

BY _ Build Year

OT _ Select Operator Type 0

MN _ Model Number 0

S1_ Sensor 1 Type

S2_ Sensor 2 Type

S3_ Sensor 3 Type

LL _ Learn Limits 0

UC _ Usage Class 0

SH _ Gate Handing 0

WT _ Gate Weight (lbs) 0

LN _ Gate Length (Feet) 0

OS _ Open Speed 5

CS _ Close Speed 5

FD _ Load Factory Defaults 0

DG _ Dual Gate 0

1

See "Setting the Build Year" and Table 3 on page 5

2

Setting dependent on BY. S1, S2, S3 appear if BY is set to 2 or

higher.

NOTE: Available menu items are dependent on operator type

and programming congurations or options.

1

1

1

1

Default

Setting

Display

Setting

Display

Setting

0

0

0

0

Table 2. Installer Menu

Installer Menu Item*

Default

Setting

SG _ Sequenced Gate 0

CH _ Charger Type 0

OC_Emergency Close 0

BT_ Battery type 0

FO _ Fire Dept. Open 0

DR_ Reversing Sensor 0

SE _ IES Sensitivity 2

SS _ Inherent sensor Stop 0

LC _ Leaf Delay Close 0.0 Secs

LO_ Leaf Delay Open 0.0 Secs

RT _ Maximum Run Timer 30 Secs

PO _ Partial Open distance 0

EC _ Eye Close Logic 0

EO _ Eye Open Logic 0

GR _ Gate Edge Logic 0

SR _ IES Sensor Logic 1

PC _ Photo Eye Contact NC

GC _ Gate Edge Output NC

2

2

0

0

DT _ Disable Free Exit 0

OR _ Outside Obstr Loop 1

IR _ Inside Obstr Loop 1

HD _ Center Loop Hold 1

DL _ Detector Logic 1

CR _ RLD Reverse Open 0

CB _ RLD Disables ELD 0

CP _ Counts PBO 0

EB _ ELD Back off - Detector 0

R1 _ Relay 1 Logic - disabled 0

R2 _ Relay 2 Logic - Close Limit 1

R3 -R10 Multiple Relay Logic 0

TL _ Gate Open alert 2

LT _ Loitering alert 3

BA_ Break Away (Arm only) 0

SA _ SDC Address 0

NE_ Network Address 0

ELD _ Exit Loop Set 0

ILD _ Inside Obstr. Loop Set 0

OLD _ Outside Obstr. Loop Set 0

CLD _ Center Loop Set 0

1

See "Setting the Build Year" and Table 3 on page 5

2

Setting dependent on BY. S1, S2, S3 appear if BY is set to 2 or

higher.

NOTE: Available menu items are dependent on operator type

and programming congurations or options.

Display

Setting

2 | www.hysecurity.com SMART DC BOARD INSTALLATION INSTRUCTIONS D0360 REV. I ©2018

Page 3

TO

SCREWS

ANDOFF

REPLACING THE SMART DC CONTROLLER

To replace a SDC board, take the following steps:

1. Back up (make a copy) of the existing board’s menu

settings. See "www.hysecurity.com/gatesafety" on

page 1 and "Smart DC Controller Worksheet"

on page 2.

2. Turn OFF power to the Control Box (both AC & DC

switches).See Figure 3.

3. Use tape to identify the various accessory

connections and then disconnect all accessory

cables attached to the board. See Figure 4.

4. Disconnect all harness connectors and any

HY-5A or HY-5B vehicle loop detectors. Use

needle nose pliers to crimp the HY-5A or HY-5B

standoffs and then push the standoff through

the mounting hole. See Figure 4.

5. Use a Phillips-head screwdriver to remove the

seven screws from the board and three screws

at the top of the control box. Set the Smart

DC Controller board and the ten screws aside.

See Figure 4.

6. Note the orientation of the replacement

board and align the holes with the mounting

standoffs. Secure the board using the screws

removed in Step 5.

NOTICE

Tighten the three screws on top of the control

box rst, then tighten the remaining screws

that secure the board.

7. Reattach all accessories, harness connectors,

and HY-5A or HY-5B vehicle detectors to their

proper locations on the replacement Smart

DC Controller board. Make sure all jumpers

are wired correctly. See Figure 4.

DC POWER

I/O

AC POWER

I/O

Figure 3. Turn AC and DC Power On

P THREE

CONTROL BOX

Phillips Head

Screws (7x)

CUT-AWAY

VIEW

MOUNTING STANDOFF

SDC BOARD

HY-5A or HY-5B

HY-5A or HY-5B

MOUNTING ST

HY-5A or HY-5B

HY-5A or HY-5B

MOUNTING

STANDOFF

8. Turn ON the Control Box AC & DC power switches

(Figure 3), and then set the operator type and other

parameters by following "Setting the Operator

Type" on page 4.

Figure 4. Control Box - Cut-away view of the SDC

Board in a SwingSmart DC Operator

DANGER

Failure to select the correct operator type

(OT) can result in gate operator malfunction

which has the potential to cause serious injury

or death due to the improper operation of

the gate.

D0360 REV. I ©2018 SMART DC INSTALLATION INSTRUCTIONS www.hysecurity.com | 3

Page 4

SETTING THE OPERATOR TYPE

After replacing an SDC board and supplying

power, the display prompts you to address the

operator type. Depending on what operator

type you have, several other prompts need to

be addressed before the operator will enter Run

Mode.

1. Press SELECT. Display characters blink which

indicates that the menu item can be addressed.

2. Use the NEXT and PREV buttons to scroll

through the options and display the appropriate

data for entry before pressing Select again to

lock-in the selection.

NOTICE

Make sure you designate the correct operator

type! Refer to Table 3.

3. The display prompts you to complete the

standard setup. A sequence of menus, such

as build year, usage class, gate handing, or

model number need to be addressed before

the operator will work properly. Pressing

NEXT allows you to ow through the set up.

If necessary, review the operator’s product

manual.

4. When the last menu item in the series is

addressed, the operator enters Run Mode and

a gate status appears on the display.

NOTICE

If you make a mistake and need to redene the

operator type, use a PC and S.T.A.R.T. software

version 3.00 or higher to reset the operator

type. If necessary, contact HySecurity Technical

Support at 800-321-9947.

Load operator’s custom settings that you saved

in the S.T.A.R.T. backup copy or wrote on the

worksheet on "Smart DC Controller Worksheet"

on page 2. This reprograms the replacement

SDC board with the same settings and operator

functionality as the old board.

4 | www.hysecurity.com SMART DC BOARD INSTALLATION INSTRUCTIONS D0360 REV. I ©2018

Page 5

ASSESS YOUR GATE SITE. UL 325-

Left Hand Gate

24VDC

24VDC

24VAC

24VAC

12VDC

12VDC

(BUTTONS)

1

Three inputs are available on the Controller

for monitoring external entrapment protection

sensors. Set Build Year according to your gate

manufacturing date. See "Setting the Build Year"

on page 6.

opening

2016 COMPLIANCE

Review your gate installation. Entrapment

zones should be kept to a minimum.

6 ft (1.8 m) minimum

WARNING

ENTRAPMENT

Photo eye thru-beam

protecting Trailing End

(EYE OPEN)

Figure 5. Site Overview

ZONE

Photo eye

thru-beam

protecting

Leading End

(EYE CLOSE)

WHEN BY ≥ 2, INSTALL NC

2

for all entrapment zones. HySecurity gates monitor

normally closed (NC) sensors. Wire your NC

sensors to SENSOR input terminals (SENSOR 1,

SENSOR 2, or SENSOR 3) on Smart DC Controllers.

SENSORS.

Install contact and/or non-contact

sensors (edge sensors and photo eyes)

CAUTION

Table 3. Menu Mode Navigation

Change

Displayed

Data

Press

Select.

Two left

characters

blink.

Labels are

available and

may be overlaid

to cover the silk

screened text

on the controller

inputs.

EYE

OPEN

EYE

CLOSE

EXIT

LOOP

BLOCK

EXIT

IN OBS

LOOP

OUT OBS

LOOP

CENTER

LOOP

EDGE

EYE

COM

Pre-2016

Build Year (BY 1)

MX3978-02

Figure 6. SDC Board BY-Lable Changes

3

Navigate

Selections

Press Next

or Previous.

Continue

pressing

Next to

view all

selections.

COMMON

TERMINALS

SENSOR 2

SENSOR 3

EXIT

LOOP

BLOCK

EXIT

IN OBS

LOOP

OUT OBS

LOOP

CENTER

LOOP

SENSOR 1

SENSOR

COM

Post 2016 Label

Build Year (BY 2)

MX3978-01

COM

COM

COM

COM

COM

COM

COM

COM

STOP

OPEN

CLOSE

OPEN

PARTIAL

SENSOR 2

SENSOR 3

EXIT

LOOP

BLOCK

EXIT

IN OBS

LOOP

OUT OBS

LOOP

CENTER

LOOP

SENSOR 1

SENSOR

COM

+ 24 V

EMERG

OPEN

24VDC

24VDC

12VDC

12VDC

RADIO

OPEN

SHOW

LEDs

Choose

Displayed

Data

Press

Select.

Blinking

characters

become

static.

USER RELAY 1

Electro-mechanical

2

+

N

E

P

O

M

O

C

A

B

M

OP

O

C

O

I

AD

R

E

T

A

G

L

A

U

D

TURN POWER ON.

See Figure 3.

Navigate

Menu Items

Press Next

to Advance

Press

Previous to

Previous.

SMART DC

DISPLAY

KEYPAD

5

-48

S

R

B

S

U

C

2

D

R

E

S

U

1

O

S

N

V

4

M

O

C

S

ON

I

T

All external entrapment protection sensors

must be wired to the SENSOR COM terminal

for power and monitoring purposes. The

three SENSOR inputs are interchangeable and

congurable. For example, it doesn’t matter

whether you wire a normally closed photo

eye sensor or edge sensor to the SENSOR

1, 2, or 3 input. However, due to monitoring

requirements, each SENSOR input (1, 2, and

3) can only accept one NC sensor output

4

based on the date the gate was manufactured.

Each SENSOR input whether or not it has

a sensor wired to it, must be programmed

before the gate will move.

ANSWER INITIAL SETUP PROMPTS.

Answer the prompts. When you enter

Operator Type, access the next prompt

by pressing Next. Enter the Build Year

connection.

D0360 REV. I ©2018 SMART DC INSTALLATION INSTRUCTIONS www.hysecurity.com | 5

Page 6

SETTING THE BUILD YEAR

Set the Build Year to 1 for HySecurity gate operator’s manufactured prior to 2016. Set the Build Year to

2 for gate operators manufacutured between 1/1/2016 and 7/31/2018. Set the Build Year to for gate

operators manufactured after 7/31/2018.

`

CAUTION

When Build Year is set to 2 or 3, the gate operator will not automatically cycle unless an indication

is received that the appropriate number of external entrapment protection sensors are connected

and operational. See Table 4 for SENSOR settings. At minimum, external entrapment protection

sensors must be used to protect both open and close directions of gate travel. If you choose not

to use the monitoring capabilities of the gate operator, your site may not be in compliance with

UL 325-2016 Standard of Safety.

Table 4. Installer Menu Settings for SENSOR Inputs

Build

UL 325 HySecurity

Gate Operator

SlideDriver

(xed speed)

SlideDriver VFD 2 or 3

SlideSmart DC 15 2 or 3

SlideSmart DC 10 2 or 3

SlideSmartDC HD

25

SlideSmartDC HD

30

SwingRiser 2 or 3

SwingSmart DC 2 or 3

HydraSwing 2 or 3

HydraLift 2 or 3

NOTE: HySecurity does not update software for SlideWinder models.

Year

2018

(BY set)

2 or 3

2 or 3

2 or 3

#0

DISABLED

USED

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • •

Installer Menu Options for Sensors 1, 2, or 3

#1

NOT

#2

EYE

CLOSE

#3

EDGE

CLOSE

#4

EYE

OPEN

#5

EDGE

OPEN

#6

EDGE BOTH

DIRECTIONS

#7

EYE BOTH

DIRECTIONS

6 | www.hysecurity.com SMART DC BOARD INSTALLATION INSTRUCTIONS D0360 REV. I ©2018

Page 7

Table 5. HySecurity Gate Operators requiring External Monitored Entrapment Protection Sensors

UL 325 Entrapment Protection Device Monitoring Required

Normally Closed (NC) sensors tested & approved.*

Three SENSOR Inputs On Controller.

Installer Menu congurable.*

Build Year (BY) factory-set to post-2018.

•

•

•

•

•

•

•

•

•

HySecurity Gate Operator

(includes Modular, Correctional, and UPS

models)

SlideDriver 15, 40, 30F, 80, 200 2 or 3

SlideDriver 50VF series 2 or 3

SlideSmart DC 15 & DCS 15 2 or 3

SlideSmart DC 10F & DCS 10F 2 or 3

SlideSmartDC HD 25 & HD 30 2 or 3

SwingRiser 14, 14-Twin, 19, 19-Twin, 30,

30-Twin

SwingSmart DC 20 & DCS 20 2 or 3

HydraSwing 2 or 3

HydraLift 10, 10F, 20, 20F 2 or 3

Build Year

post-2016

(set at the

factory)

2 or 3

Table 6 indicates those HySecurity gate operators that may be within the exception parameters of UL

325 or comply with standards other than UL 325, but continue to maintain object detection capabilities.

HySecurity strongly recommends that you assess every site for entrapment zones and provide the

necessary protection to guard against entrapment.

Table 6. HySecurity Gate Operators maintaining Object Detection

HySecurity Gate Operator with

Obstruction Protection (Object

Detection)

StrongArm (HTG) 2 or 3

StrongArmCRASH (M30/M50) 2 or 3

StrongArmPark DC 10 & DCS 10

StrongArmPark DC 14 & DCS 14

WedgeSmart DC 10 & 10 DCS

WedgeSmart DC 14 & 14 DCS

HydraWedge SM50 2 or 3

NOTE: For more information, refer to the Quick Start Supplement describing changes to HySecurity software due to UL

325 - 2016 Standard of Safety updates. Review the information regarding monitoring of external entrapment protection

sensors online at www.hysecurity.com/gatesafety

Build Year

2018

2 or 3

2 or 3

Sensor Inputs automatically set to "NOT USED"

Installer has option to change settings as site design dictates.

•

•

•

•

•

D0360 REV. I ©2018 SMART DC INSTALLATION INSTRUCTIONS www.hysecurity.com | 7

Page 8

Table 7. Reprogramming the SDC Replacement Board (OT_12 - OT_17)

Operator

Model

Operator Type

(OT)

Build Year (BY)**

SwingSmart

DC20 & DCS

20 Solar

WedgeSmart

DC

OT_12 OT_13 OT_13 OT_14 OT_15 OT_16 OT_17

BY_3 (post-2018

monitored)

BY_3 BY_3 BY_3 BY_3 BY_3 BY_3

1 = family

dwelling

User Class

(UC)

2 = multi-family

3 = industrial*

4 = guarded

location

Model Number

(MN)

1

1 =

Arm

2 =

Wedge

SH_R = Face

Gate Handing

(SH)

SH_R = Face

Smart DC

Controller display.

Gate swings right

to open

SH_L = Face

Smart DC

Controller display.

Gate swings left

to open

Smart DC

Controller

display. Arm

raises right to

open.

SH_L = Face

Smart DC

Controller

display. Arm

raises left to

open.

Gate Weight

(WT)

(Enter weight in

pounds (lbs.))

Gate Length

(LN)

Enter length in

feet (ft.))

SENSOR Type

1

Not servicing general public.

2

Only appears when BY is set to 2 or higher.

0 = Gate Disabled

1 = 0 to 300

2 = 301 to 600

3 = 601 to 800

4 = 800 to 1300

0 = Gate Disabled

1 = 0 to 8

2 = 8 to 12

3 = 12 to 16

4 = 16 to 20

2

S1, S2, S3 S1, S2, S3 S1, S2, S3 S1, S2, S3 S1, S2, S3 S1, S2, S3

NOTE: Build Year is an Installer Menu item added in 2016 and denes HySecurity gate operators as having monitoring capabilities

for external entrapment protection sensors per UL 325 Standard of Safety. See page 6

StrongArmPark

DC10 & DC14

DCS 10 Solar &

DSC 14 Solar

0 = Gate Disabled

1 = DC10 model

or DCS 10 solar

2 = DC 14 model

or DCS 14 solar

SH_R = Face

Smart DC

Controller display.

Arm raises right to

open

SH_L = Face

Smart DC

Controller display.

Arm raises left to

open.

SlideSmart

DC 15 & DCS

15 Solar

1 = family

dwelling

2 = multi-family

3 = industrial*

4 = guarded

location

SH_R = Face

Smart DC

Controller

display. Gate

slides right to

open.

SH_L = Face

Smart DC

Controller

display. Gate

slides left to

open.

0 = Gate

Disabled

1 = 0 to 400

2 = 401 to 800

3 = 801 to 1100

4 = 1101 to 1500

1

SlideSmart DC

10F & DCS 10F

Solar

1 = family

dwelling

2 = multi-family

3 = industrial*

4 = guarded

location

SH_R = Face

Smart DC

Controller display.

Gate slides right

to open.

SH_L = Face

Smart DC

Controller display.

Gate slides left to

open.

0 = Gate Disabled

1 = 0 to 250

2 = 251 to 500

3 = 501 to 750

4 = 751 to 1000

1

SlideSmart

DC HD 25 &

30

1 = family

dwelling

2 = multi-family

3 = industrial*

4 = guarded

location

SH_R = Face

Smart DC

Controller

display. Gate

slides right to

open.

SH_L = Face

Smart DC

Controller

display. Gate

slides left to

open.

0 = Gate

Disabled

1 = 0 to 700

2 = 701 to 1400

3 = 1401 to

2100

4 = >2100

1

8 | www.hysecurity.com SMART DC BOARD INSTALLATION INSTRUCTIONS D0360 REV. I ©2018

Loading...

Loading...