HySecurity HydraSwing 40F, HydraSwing 40F Twin, HydraSwing 40, HydraSwing 40 Twin, HydraSwing 80F Installation Instructions Manual

...Page 1

MX3635-01

800-321-9947 www.hysecurity.com

Installation Instructions

MX3635-01 Rev. D

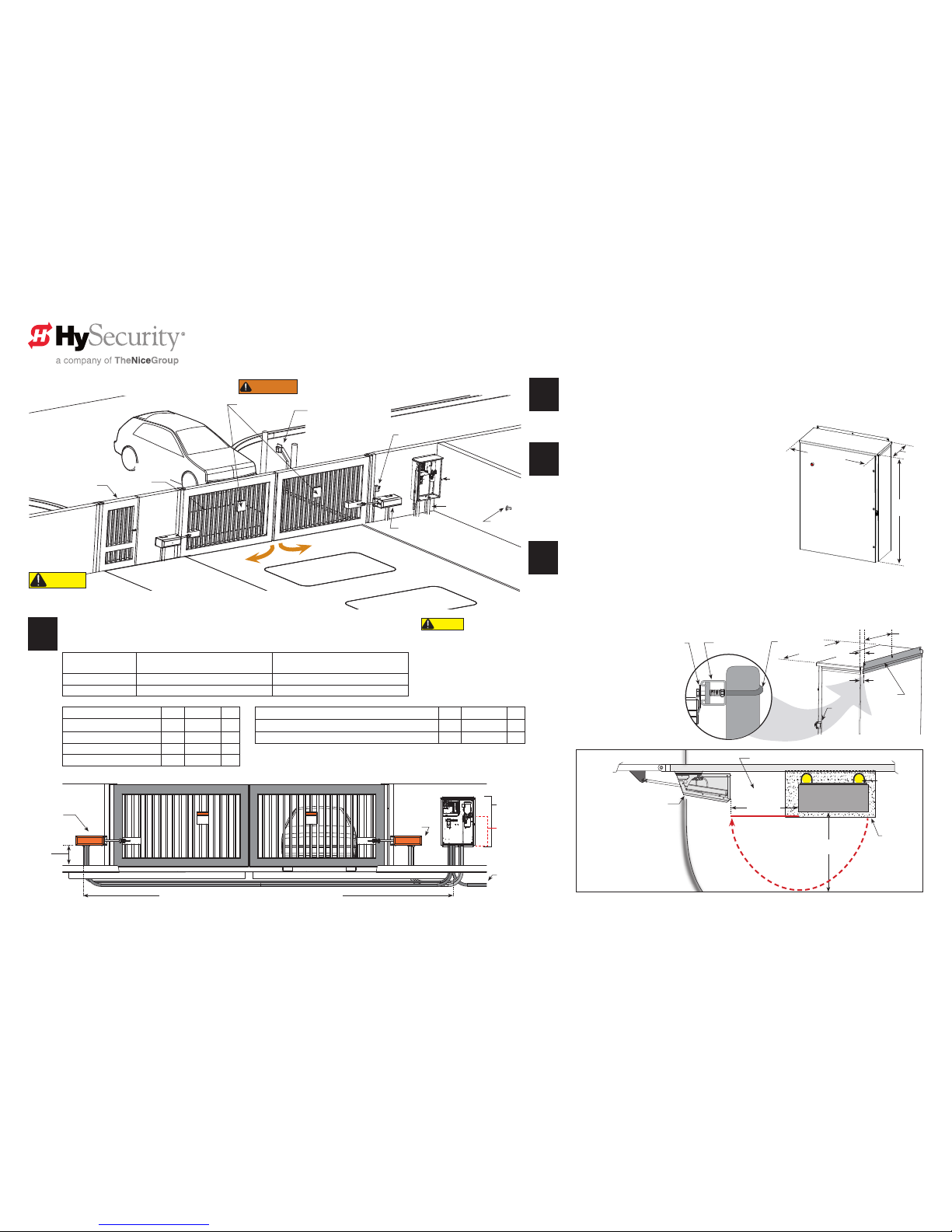

Linear actuators for large, heavy swing gates and swing gates subject to extreme peak winds

HydraSwing 80 & 150

HydraSwing 40s

Models

HydraSwing 40F

4,000 lb (1,814 kg) 10-15 seconds

HydraSwing 40 4,000 lb (1,814 kg) 15-20 seconds

HydraSwing 40 Twin 4,000 lb (1,814 kg)/leaf 15-20 seconds

HydraSwing 40F Twin 4,000 lb (1,814 kg)/leaf 10-15 seconds

HydraSwing 80F 8,000 lb (3,629 kg) 15-25 seconds

HydraSwing 150 15,000 lb (6.804 kg) 20-30 seconds

Page 2

© 2017 www.hysecurity.com HydraSwing Installation and Assembly MX3635-01 Rev. D Page 2

Read & Plan

Read and follow the Important Safety Information provided in the Programming and

Operations Manual prior to installing the HydraSwing. Read and follow these installation

instructions and make sure to conform to site specications and all local and federal

regulations and codes.

30⅝” (78 cm)

HydraSwing: Plan Site Design

1

2

Measure and Calculate

Pay attention to gate swing (retracted or extended

cylinder) and clearance around the mounting location.

Consider right handing and left handing. Allow for

access to brake valves.

Use the charts, provided on pages 3 and 4, to

determine gate geometry and placement of the chassis

and gate mount.

HydraSupply

Reector

Key or card reader

Mount access control

devices at least 6 ft (183 cm)

beyond gate.

Pedestrian gate

HydraSwing

Warning Signs

Shadow Loop

Inside Obstruction Loop

or Free Exit

Outside

Obstruction

Loop

3

Design Vehicle Loops

If automatic close is desired for a uni- or bi-directional

gate, a SHADOW and one other loop (IOLD or OOLD) is required.

Three loops are preferred: SHADOW, IOLD, OOLD (Free Exit, optional)

NOTE: Loop layout is dependent on uni- or bi-directional trafc and length of gate and width

of roadway. Vehicle must move from one loop to the next without loss of detection. The site

design shown on this page is for illustrative purposes only.

NOTE: Pay attention to

and plan for clearance

and access.

4

Install conduit for communication and power

Locate and install the HydraSupply within 50 feet (6.1 m) of the HydraSwing gate operator.

NOTE: Order hose through HySecurity. See CAUTION.

Hose length in feet

(Total Run)

Hose Diameter: Model 40 & 40F, Twin Hose Diameter: Model 80F & Model 150

0 to 50 ft 1/4 inch 3/8 inch

50 to 100 ft 3/8 inch 1/2 inch*

Minimum conduit required No. Min. Size cm

3/8 inch Hydraulic hoses* 1 2 inch 5

1/2 inch Hydraulic hoses* 1 3 inch 7.6

Sensor wire to operator 1 3/4 inch 2

AC Main power 1 1 inch 2.5

Conduit

Addt’l conduit may be ordered and used for: No. Min. Size cm

Bi-parting gate connection for low voltage wiring 1 1 inch 2.5

Heater or Emergency Release options 2 3/4 inch 2

HydraSupply Cabinet

Concrete pad

Shown

Post-mounted.

Roadway

Gate

Secure base plate with anchor

bolts. See NOTE regarding

bolt sizes on page 3.

HydraSwing 80F & 150 chassis

dimensions: 41”L x 20½” W

(104 x 52 cm) optional base

extension adds an additional

4” to the width

HydraSwing 40 & 40F chassis

dimensions: 27” L x 13” W

(69 x 33 cm)

Conduit runs between HydraSwing and cabinet.

NOTE: Design shown for illustrative purposes only.

Drawings are NOT TO SCALE.

WARNING

Be sure to place the WARNING signs on the gate. For your

records, take a photograph of the completed installation site.

Wall

36” (91 cm)

minimum

36” (91 cm)

Door swing

Photo eye

Left handing

Right handing

12⅝”

(32 cm)

42⅜”

(107 cm)

HydraSupply

Cabinet

*NOTE: HydraSwing orders include two (2) uid-charged hoses and attached ttings totaling up to 50 ft (15 m).

Additional hose is billed by the foot. For HydraSwing 80F and 150, use 1/2-inch hose and ttings where the

HydraSupply cabinet is installed more than 50 ft from the actuator AND temperatures routinely fall below 0°F.

For distances between the HydraSupply and actuator longer than 100 ft (30 m), contact Tech Support.

HydraSwing

Left

handing

Incoming power

HydraSupply Cabinet

Inches: 30⅝W x 42⅜H x 12⅝D

Centimeters: 78W x 107H x 32D

Additional Hose

estimate

HydraSwing

Right

handing

HydraSupply

HydraSwing Bi-parting Gate

Maximum 50 foot run (15 m). See Hose Diameter chart above.

12 inches

(30 cm)

minimum

clearance from

grade

HydraSupply Cabinet

Wall or post-mount the

HydraSupply cabinet.

If planning a post mount, mounting

holes need to be drilled (U-bolts,

fasteners, and unistrut are not

provided). Cabinet may also be wallmounted with anchor bolts.

NOTE: The mounting holes on the

top and bottom anges are 5/16-

inch diameter.

13½”

(34 cm)

1⅞”

(5 cm)

1¼”

(3 cm)

Door clip

C

/

L

C

/

L

Flange

Flange Unistrut

U-bolt

30¾” (78 cm)

CAUTION

Remember to order hose through HySecurity!

In addition to conduit length, make sure

to measure hose requirements inside the

HydraSwing and HydraSupply. For example,

HydraSwing 80F requires about 1 ft of

additional hose length inside the operator

and another 2 or 3 ft inside the HydraSupply.

For proper sequencing of bi-parting (dual) gate systems, it is critical that the hydraulic

cylinder be fully extended. See “Determine Arm Geometry: 40 & 40F” on page 4.

CAUTION

Page 3

© 2017 www.hysecurity.com HydraSwing Installation and Assembly MX3635-01 Rev. D Page 3

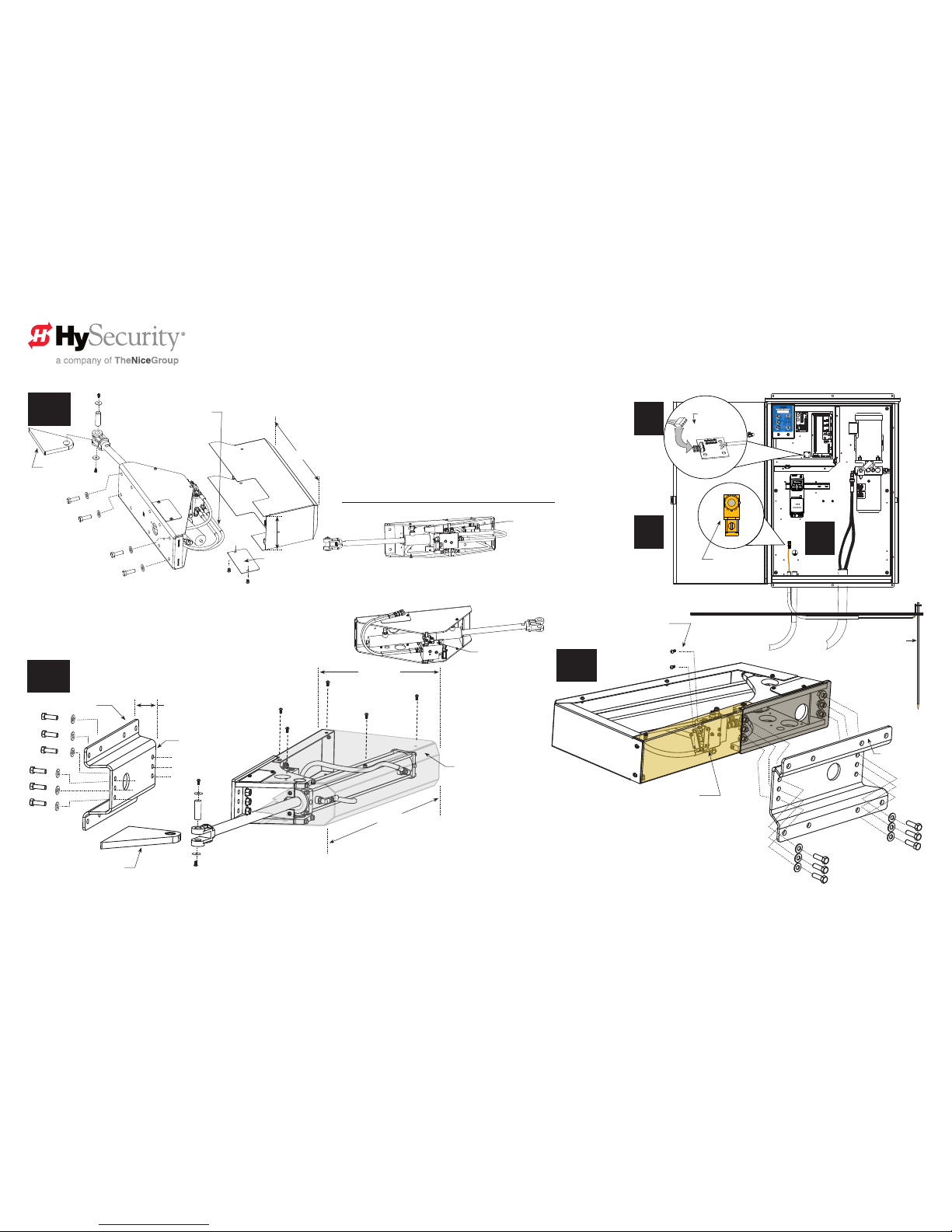

Assembly: Exploded Views

Optional base extension

provides 4” offset for 80F

or 150 models.

HydraSwing: Model 40 and 40F

HydraSwing: Model 80F and 150

Nuts and washers (6x)

secure optional base

extension.

Remove 2 phillips-head screws to move

brake manifold and provide access to

mounting holes on the HydraSwing chassis.

Remove 5 fasteners on the

top panel to access interior

of HydraSwing. Tamper

proof screws require TX40

drive bit (included).

1a

1c

2

1b

1. Assemble and secure chassis to mounting surface.*

2. Feed hoses through conduit and connect them to the QD ttings

(quick disconnects).

3. Ground the gate operator.

4. Feed sensor wire through conduit to HydraSupply and connect it

to the 4-pin receiver board.

*NOTE: Refer to Arm Geometry, on pages 3 and 4, for mounting

dimensions and requirements.

Gate

mount**

Access cover

plate (for conduit

and hoses)

3

4

Conduit

HydraSwing: Model 80F and 150

Move the brake manifold to mount the

HydraSwing chassis whether you use the

optional base extension or not.

Two hoses connect to QDs (quick

disconnects) on the hoses fed through

conduit from the HydraSupply

Drawings NOT to Scale

HydraSwing 40 & 40F

Right handing

HydraSwing 40 & 40F

Left handing

Brake valve

location

Brake valve

location

**NOTE: Depending on whether the chassis is mounted

recessed or elevated, you will need to modify the gate mount

to accommodate the gate geometry.

20½” (52 cm)

Additional 4” for

the optional base

extension

4” (10 cm)

41” (104 cm)

HydraSwing 80F & 150 chassis dimensions:

41”L x 20½” W (104 x 52 cm) optional base extension adds an additional 4 inches to the width

HydraSwing 40 & 40F chassis dimensions:

27” L x 13” W (69 x 33 cm)

27” (69 cm)

13”

(33 cm)

Base extension

(option)

Base extension

(option)

NOTE: Anchor bolts for 80F and 150.

5/8-inch, Grade 8.

Minimum 4 bolts required for steel to steel mount.

Anchoring to concrete is dependent on concrete

strength. Before installing, consult a structural engineer.

NOTE: Anchor bolts for 40 and 40F.

1/2-inch, Grade 8. Minimum 4 bolts

required for steel to steel mount.

Anchoring to concrete is

dependent on concrete

strength. Before installing,

consult a structural engineer.

.....

4-pin sensor

wire connector

Earth ground

Ground rod

NOTE: Outswing gate mount

requires customer fabrication.

See pages 4 and 5.

Page 4

© 2017 www.hysecurity.com HydraSwing Installation and Assembly MX3635-01 Rev. D Page 4

Determine Arm Geometry: 40 & 40F

90° Opening

95° Opening

100° Opening

Inswing Closed Position:

Center hinge

Gate Opening and Gate Geometry: Outswing

Degree of Swing Xf Xg Yg

90 8” (20 cm) 5¼” (13.3 cm) 8½” (21.6 cm)

95 8¼” (21 cm) 5⅝” (14.3 cm) 7½” (19 cm)

100 8⅝” (22 cm) 6” (15.2 cm) 6¾” (17.1 cm)

Gate Opening and Gate Geometry:

Inswing

Degree

of Swing

Xf Xg Yg

90

8”

(20 cm)

8¼”

(21 cm)

5¼”

(13.3 cm)

95

8¼”

(21 cm)

8”

(20 cm)

5”

(12.7 cm)

100

8⅝”

(22 cm)

7¾”

(19.7 cm)

4¾”

(12 cm)

Open Position = R

“Retracted”

in the Installer Menu

Gate

Gate mount

Cylinder rod

Gate swing OPEN

Drawings NOT to Scale

Open Position = E

“Extended”

in the Installer Menu

Outswing Open Position: Center hinge

Cylinder rod

NOTE: Outswing gate

mount requires customer

fabrication.

90° Opening

95° Opening

100° Opening

Shadow Loop

Entering vehicle

Access control

HydraSupply

Photo eye

Gate swing

OPEN

34½” (88 cm)

minimum

Hinge centerline

Xg

Mounting Surface: Shimmed, Flush, or Inset

If Yf dimension is between Then use Cylinder Position

2¾” to 3¾” (7 to 9.5 cm) 1

1 to 2” (2.5 to 5 cm) 2

0 ± ½” (0 ± 1.3 cm) 3

13”

(33 cm)

2

1

Photo eye

Roadway edge

C

/

L

Xg Xf

5”

(13cm)

14”

(35cm)

24”

(61cm)

5”

(13cm)

Yg

C

/

L

C

/

L

C

/

L

Yf

Hinge

centerline

Mounting Surface

Dashed lines:

Indicate mounting

hole centerlines

Gate

Overhead View: Model 40 and 40F

Gate hinge

centerline

NOTE: Use the Mounting

Surface chart to determine

the best position for the

cylinder. Round up and

shim to meet Yf dimension

requirements.

Inswing mount shown: Center hinge

C

/

L

Yg

C

/

L

Inline hinge example

Xg Xf

Cylinder Position 3

Flush mount or slightly inset

C

/

L

C

/

L

Mounting surface

Gate

Cylinder Position 1

Cylinder Position 2

Cylinder Position 3

Mounting holes shared with

brake cylinder bracket

Position 3

Cut out view

Conduit

cover (2x)

Brake manifold

CAUTION

Use the measurements for your gate type:

Inswing or Outswing.

Measure and cut (or shim) gate mount to meet

the Yg requirement. Fasten the gate mount to the

cylinder to meet the Xg requirement. Tack weld until

hoses available or the accuracy of the dimensions

are conrmed. The gate mount and cylinder need to

remain in a horizontal plane throughout gate travel.

If any vertical movement occurs, the load on the

cylinder is strained and will lessen its life and void the

Warranty.

Torque fasteners to

70 ft-lbs

Discard washers and

lock nuts if using

Cylinder Position 3

Cut or shim along mounting edge

depending on your gate arm

geometry. Refer to tables for Yg

and Xg measurements.

Gate mount:

6½ inch dimension

Cylinder end head with swivel

Three cylinder positions adjust for the differences in

surface mounting requirements: shimmed, ush, or

inset (notched). For example, inset type mounts use

Cylinder Position 3.

Xg

Outswing Gate

See NOTE’s.

Xf

Yf

NOTE: Outswing gate mount requires customer

fabrication.

Close the gate. Measurements are based on a closed gate. Use the hand

pump, if necessary. For bi-parting (dual) gates and proper sequencing on

HydraSwing 40 Twin or 40F Twin models, the hydraulic cylinder must be

fully extended. Abiding by arm geometry on this page is critical.

CAUTION

Yg

Hinge

centerline

Page 5

© 2017 www.hysecurity.com HydraSwing Installation and Assembly MX3635-01 Rev. D Page 5

Determine Arm Geometry: 80F & 150

HydraSwing: Model 80F and 150

Gate Opening and Gate Geometry: 80F & 150

Degree of Swing Xf Xg Yf ± ¼” Yg

90 11” (28 cm) 13½” (34.3 cm) 5” (12.7 cm) 9½” (24.1 cm)

100 11¼” (28.6 cm) 13¼” (33.6 cm) 3½” (8.9 cm) 8” (20.3 cm)

HydraSwing: Model 80F and 150

Overhead View

HydraSwing: Model 80F and 150

Mounting Dimension 90° Opening

with Optional Base Extension: Provides 4-inch offset

C

/

L

Yg

C

/

L

C

/

L

Gate

Yf

C

/

L

Mounting bolts

Centerlines

Xg Xf

Gate hinge

Optional base extension: Provides

4-inch offset from mounting surface.

Anchor bolts: 5/8-inch, Grade 8

See NOTE on page 3.

Suggested minimum

height from grade:

12” (30.5 cm)

Mounting tab included:

1” (2.5 cm) thick

Must be cut and welded by installer

to meet Yg measurement

requirements.

C

/

L

Gate hinge

Xf

16 inches (40.6 cm)

5”

(12.7 cm)

10”

(25.4 cm)

20” (50.8 cm)

CAUTION

The gate mount and cylinder need to remain in a horizontal plane

throughout gate travel. If any vertical movement occurs, the load on the

cylinder is strained and will lessen its life and void the Warranty.

3”

(7.6 cm)

1½”

(3.8 cm)

Optional base extension: Provides

4-inch offset from mounting surface

2”

(5 cm)

Drawings NOT to Scale

7½ inch (19 cm)

Models: 80F and 150

Minimum 41 inches (104 cm)

Minimum space required: 49 inches (125 cm)

(Cylinder housing plus Xf dimension)

Fully extended cylinder: 62½ inches (159 cm)

Optional base

extension shown

22¼” (57 cm)

13”

(33 cm)

10”

(25 cm)

1

2

C

/

L

Gate Geometry: View B Outswing: 80F & 150

Degree of Swing Xf Xg Yf ± ¼” Yg

90 12” (30.5 cm) 11” (28 cm) 5” (12.7 cm) 13½” (34.3 cm)

Hinge centerline

Mounting

Surface

Gate hinge

centerline

NOTE: Use the chart

below to determine

Yf dimension requirements. If needed, notch

or shim the mounting

surface to remain

within ± ¼ inch of the

dimension given.

Xg

View B

Xf

Yf

Yg

Outswing gate mount requires

customer fabrication

Gate mount

To assemble the HydraSwing 80F or 150, close the gate. Take

measurements based on a closed gate position.

Determine the best geometry for your site. An optional 4-inch

base extension may be ordered to help create the appropriate Yf

mounting surface dimension.

Page 6

© 2017 www.hysecurity.com HydraSwing Installation and Assembly MX3635-01 Rev. D Page 6

STOP BUTTON

OPEN BUTTON

CLOSE BUTTON

REMOTE OPEN AND

RADIO CONTROL

OPEN/CLOSE

1

OPEN PARTIAL

INTERLOCK OPEN

TIME CLOCK OPEN

FREE EXIT DETECTOR

DISABLE EXIT DETECTOR

DISABLE CLOSE TIMER

INSIDE OBSTRUCTION

VEHICLE DETECTOR

OUTSIDE OBSTRUCTION

VEHICLE DETECTOR

SHADOW/RESET

VEHICLE DETECTOR

EDGE SENSOR

PHOTO EYE POWER

24 VOLTS COMMON

PHOTO EYE POWER

DO NOT USE

PHOTO EYE

OPEN DIRECTION

DO NOT USE

PHOTO EYE

CLOSE DIRECTION

DO NOT USE

CHARGER

AC LOSS

LOCK INTERLOCK

EMERG CLOSE

FIRE DEPT OPEN

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

21

22

23

24

Smart Touch Controller

LIMITDUAL GATE

RADIO OPTIONS

DRIVE

POWER

RS485

MOTORUSER 1

USER 2

USER 3

VEHICLE DETECTORVEHICLE DETECTORVEHICLE DETECTOR

STOP/BUZZER

FREE

EXIT

INSIDE

OBSTR

OUTSIDE

OBSTR

SHADOW

RESET

WIEGAND

HySecurity

COM

NO

MX000585

VERSION

S/N

RS232

DISPLAY

VEHICLE DETECTOR

COMCOMAB

RPM

COMOPEN EDGE+24V +24V

STATUS

LED

Wiring AC Power

Power connection

Size the primary wires, appropriately.

Consider the voltage, horsepower,

and length of the wire run from the

main power panel.

Verify you have the proper input

voltage and make sure the motor

and transformer are wired correctly.

NOTE: Use a 20A (minimum) protected with

a 20A Inverse Time Breaker for all AC motor

connections.

1. Connect to Power: Three

pig tails and a ground are

available for connection to a

3 Phase power source (3Ø)

on the back of the keypad

display enclosure.

2. Connect AC Power: Wire nut

the incoming power wires to their appropriate pig tails. Attach the ground wire to the chassis. A wiring diagram is provided in the

appendix. Note that for 1Ø wiring, only the two outside connections/pig tails are used.

DANGER

Turn OFF AC power at the source (circuit breaker panel) before accessing the wires in the HydraSwing.

Follow facility Lock Out/Tag Out procedures. Make sure all power switches are in the OFF position. Follow

all electrical code standards and regulations.

Turning the Power Switch ON

The AC power disconnect switch (ON/OFF switch) is located on the same enclosure as

the STC keypad and display.

When power is turned ON, a green status

light on the Smart Touch Controller blinks.

The status light appears below the disc

battery and indicates that the processor is

receiving power.

Site Considerations

HySecurity gate operators are intended

for permanent installation. Make sure

you prepare the site with the following

considerations:

• Make sure all electrical wiring is

properly routed via conduits.

• Check the distance of the wire run

from the main panel to the gate operator. Make sure the wire size of the branch

circuit supplying power to the gate operator is large enough to avoid excess

voltage drop. Refer to Wire Sizing and Runs in the HydraSwing Programming

and Operations Manual.

• Make sure the available power source matches the electrical requirements

specied on the voltage nameplate.

CAUTION

Each gate operator is built to run on a specic line power voltage and phase. Failure to ensure

the source voltage, phase and frequency match, what is specied for the equipment, may result is

severe damage to the equipment.

• Make sure a 20A circuit (minimum) protected with a 20A Inverse Time Breaker is

provided.

• Verify that the operator is electrically grounded per NFPA 780 and NEC Article

250, and local codes.

NOTE: Refer to the HydraSwing Programming and Operations manual for Important Safety Instructions,

programming, troubleshooting, maintenance and general information

Green LED ashes indicating

processor is receiving power.

DO NOT USE

PHOTO EYE

OPEN DIRECTION

DO NOT USE

PHOTO EYE

CLOSE DIRECTION

DO NOT USE

CHARGER

AC LOSS

LOCK INTERLOCK

EMERG CLOSE

FIRE DEPT OPEN

16

17

18

19

20

21

22

23

24

Smart Touch Controller

LIMIT DUAL GATE

RADIO OPTIONS

VEHICLE DETECTOR

SHADOW

RESET

WIEGAND

HySecurity

MX000585

VERSION

S/N

RS232

DISPLAY

VEHICLE DETECTOR

COM COMA B

RPM

COMOPEN EDGE+24V +24V

STATUS

LED

CAUTION

Wiring of gate operators must conform to NFPA and NEC standards and comply with all local codes.

When the installation is compliant and complete, turn on AC power at the source and at the control box.

For Variable Frequency (VF) operators, make sure the connection wires match the voltage found on the

operator’s nameplate.

WARNING

In-Field Connections: HydraSwing operators are eld re-congurable for 1Ø or 3Ø, 208/230VAC input power

without changing the VFD. However, if reconguring from 208/230VAC to 460/480VAC the VFD Motor

Controller in a 208/230VAC unit must be replaced with a VFD Motor Controller manufactured for the higher

(460/480VAC) voltage input. Any electrical damage occurring to the operator will not be covered by the Warranty.

WARNING

HydraSwing operators CANNOT be connected to 115/120VAC, 1Ø power or 575V, 3Ø power. If any attempts

are made to do so, serious injury and possible electrical shock may result. Any electrical damage occurring to the

operator will not be covered by the Warranty.

Drawings NOT to Scale

VFD not shown

Page 7

© 2017 www.hysecurity.com HydraSwing Installation and Assembly MX3635-01 Rev. D Page 7

Complete the Installation

Replace Vent Plug with Breather Cap

Manual Hand Pump: 80F and 150 Models

.....

DANGER

Failure to perform the following procedure will

cause premature pump shaft failure and void the

Warranty.

The gate operator has a vent plug that

keeps the hydraulic uid from spilling

during shipment. The vent plug must

be replaced by the breather cap before

operating the swing gate.

• Remove the vent plug and discard

it.

• Replace the vent plug with the

breather cap.

Breather cap

Vent plug

Manual Hand Pump: 40 and 40F Models

WARNING

Before attempting a manual release, make sure the gate is not in motion and power is

disconnected (turned OFF).

CAUTION

Pushing the gate closed when the lever is in the released position may cause

an air pocket to form in the hydraulic cylinder and cause overow from the

reservoir. If you notice uid leakage, stop gate travel immediately and use

the hand pump.

Integrated manual release

Run mode

Brake manifold

Released position

When the hoses are installed, the gate may be opened

(cylinder retracted) manually by moving the release

lever as shown in the illustration.

NOTE: For models 80F and 150, DO NOT extend the cylinder

using the manual release lever. Refer to CAUTION below.

Outswing installation sites must pull the cylinder pin (disengages

the gate from the operator) or use the hand pump.

When the hoses are installed, a hand pump option kit can be used to manually operate the hydraulic mechanism that secures the

gate. In the event of a power failure, manual operation is achieved by accessing the hydraulics cabinet.

Follow the steps below to open or close the gate:

NOTE: An integrated manual release mechanism exists on the brake manifold assembly.

Open the Gate using the Hand Pump

1. Open the HydraSupply cabinet.

2. Turn the power switch OFF.

3. Locate the hand pump and the Knurled Knob on the Open Valve.

4. Firmly, pull and twist the knurled knob counterclockwise. Release the knob so that it

remains in the open position.

NOTE: If the valve re-seats itself, repeat the pull and twist in the opposite direction until the valve remains open.

5. Begin pumping the handle up and down. As hydraulic uid is pumped into the cylinder, it begins to move the gate.

6. Continue pumping until the gate reaches full open position.

7. Turn the knurled knob so it springs back to the closed position.

Close the Gate using the Hand Pump

1. Check that the knurled knob is in the closed position. Begin pumping the handle up and down. The gate slowly closes with

the pumping motion.

2. The gate will maintain its position whenever you stop pumping.

3. Continue pumping until the gate reaches the full closed position.

Hand pump: 40 & 40F models

.

.

.

.

.

High capacity hand pump: 80F & 150 models

Released

Run mode

Drawings NOT to Scale

Knurled knob

.

.

.

.

.

Cylinder pin

Page 8

800-321-9947 www.hysecurity.com

MX3635-01

Loading...

Loading...