HySecurity HydraSwing 40, HydraSwing 40F, HydraSwing 40 Twin, HydraSwing 150, HydraSwing 40F Twin Programming And Operations Manual

...Page 1

™

HydraSwing

HydraSwing 40, 40F, 40 Twin, 40F Twin, 80F and 150

Programming & Operations Manual

with

HySecurity Smart Touch Controller

MX3636-01 Revision C

This document provides Important Safety Information, specications, and references along with

an overview of programming user and installer menu options, designing vehicle loop layouts,

troubleshooting, and maintaining the gate operator.

Page 2

HySecurity Gate OperatOrS: uL 325 – 2016

The following bullet points highlight how your automated gate system sites can monitor external entrapment

protection using HySecurity gate operators:

• Normally Closed (NC) sensors – Before gate movement occurs, the gate operator veries that the

external entrapment protection sensor is connected and fully functional.

• Build Year (BY) – An added menu item distinguishes between pre-2016 manufacturing dates and

UL 325 - 2016 manufacturing dates. Build Year (BY) is a factory-setting. Build Year 2 (BY 2) is the default for

all HySecurity gate operators indicating a manufacturing date of 2016 in the serial number. Replacement

controller boards for existing sites allow for a Build Year setting of 1 (BY 1) (pre-2016).

• Independent Sensor Inputs – The edge, photo eye and photo eye COM inputs on the Smart Touch and

Smart DC Controllers (STC and SDC) have been re-labeled. The same wiring connections become three

independent methods for easy entrapment protection sensor conguration and normally closed outputs.

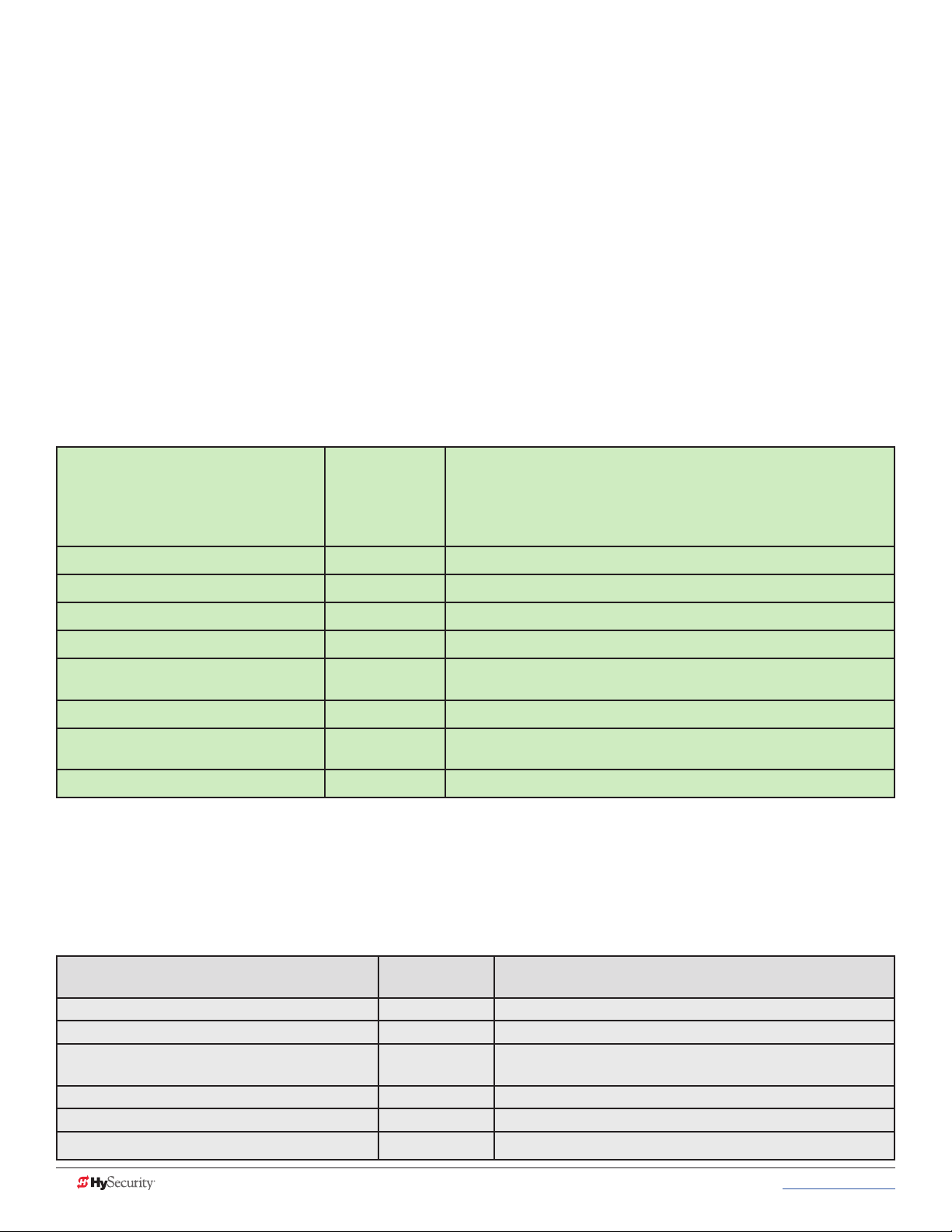

Table 1: HySecurity Gate Operators requiring External Monitored Entrapment

Protection Sensors

UL 325 Entrapment Protection Sensor Monitoring Required

HySecurity Gate Operators

(includes Modular, Correctional, and

UPS models)

Build Year

UL 325 - 2016

(set at the factory)

Normally Closed (NC) sensors tested & approved.

Three SENSOR Inputs on Controller.

Installer Menu congurable.

Build Year (BY) factory-set to UL 325 - 2016.

SlideDriver 15, 40, 30F, 50VF 2/3, 80, 200 2

SlideDriver 50VF series 2

SlideSmart DC 15 & DCS 15 2

SlideSmart DC 10F & DCS 10F 2

SwingRiser 14, 14-Twin, 19,

19-Twin, 30, 30-Twin

SwingSmart DC 20 & DCS 20 2

HydraSwing 40, 40F, 40-Twin, 40F-Twin,

80F, 150

HydraLift 10, 10F, 20, 20F 2

2

2

●

●

●

●

●

●

●

●

Table 2: HySecurity Gate Operators maintaining Object Detection

Table 2 indicates those HySecurity gate operators that may be within the exception parameters of UL 325 or

comply with standards other than UL 325, but continue to maintain object detection capabilities. HySecurity

strongly recommends that you assess every site for entrapment zones and provide the necessary protection to

guard against entrapment.

HySecurity Gate Operator's with

Obstruction Protection (Object Detection)

StrongArm (HTG) 14, 20, 28, 36 2

StrongArmCRASH (M30/M50) 2

StrongArmPark DC 10 & DCS 10

StrongArmPark DC 14 & DCS 14

WedgeSmart DC 10 & 10 DCS 2

WedgeSmart DC 14 & 14 DCS 2

HydraWedge SM50 2

Build Year

UL 325 - 2016

2

Sensor Inputs automatically set to "NOT USED"

Installer has option to change settings as site design dictates.

●

●

●

●

●

●

ii MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 3

External Entrapment Protection Sensors monitored by HySecurity Gate Operators

Any external entrapment protection sensor may be monitored by HySecurity gate operators, provided the

following requirements are met:

• Sensor is marked as certied to UL 325 Standard of Safety by a Nationally Recognized Test laboratory,

such as UL or ETL.

• If the sensor only has a normally open (NO) output with a 8.2KΩ or 10KΩ resistor, such as an edge

sensor, then a conversion device must be used to convert the NO resistor output to an NC output.

Example of two different installation methods:

• Method A - Wired

Connect the edge sensor to a NC conversion module (GEM-104 or GEM-204) and connect the

module to the operator controls according to the manufacturer's instructions.

• Method B - Wireless

Connect the edge sensor to a UL 325 certied wireless edge transmitter and connect a matching

receiver to the operator controls according to the manufacturer's instructions.

A resource list is available from the drop down Gate Safety menu on the HySecurity website. The HySecurity

recommended list shows examples of external entrapment protection sensors available for NC monitoring of

automatic gate operators. All HySecurity gate operators manufactured after January 1, 2016 using software

versions h4.50 or h5.50 (or later) comply with UL 325 Standard of Safety for monitoring entrapment protection

sensors using normally closed contacts.

The site designer or installer must determine which external entrapment protection sensors will be installed

with the gate operator to create a UL 325 compliant automatic gate operator site.

The UL 325 Standard of Safety and ASTM F2200 dene the MINIMUM gate site requirements. Gate site,

gate hardware, gate usage and other conditions may dictate the use of additional entrapment protection

sensors. It is up to the gate system designer and installer to assess appropriate gate safety design and install

the components required to protect all potential entrapment zones. Always check your local area codes and

comply with all standards and regulations.

CAUTION

Temperatures and environmental conditions affect proper operation of external entrapment protection sensors.

Always check the manufacturer's specications shipped with the sensors. Consult the manufacturer’s instructions

for correct wiring connections, hardware installation and proper operation.

www.hysecurity.com © 2017 Introduction MX3636-01 Rev. C iii

Page 4

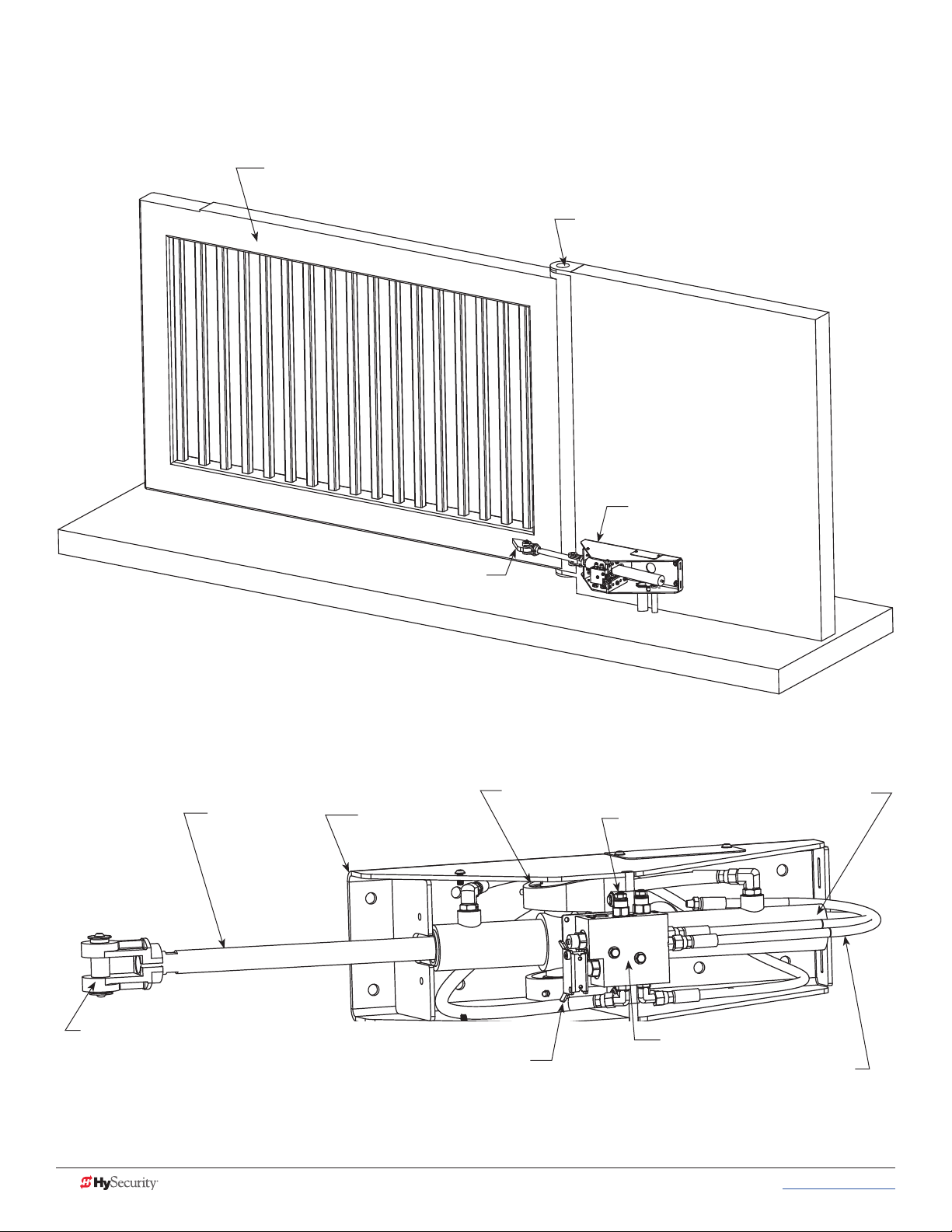

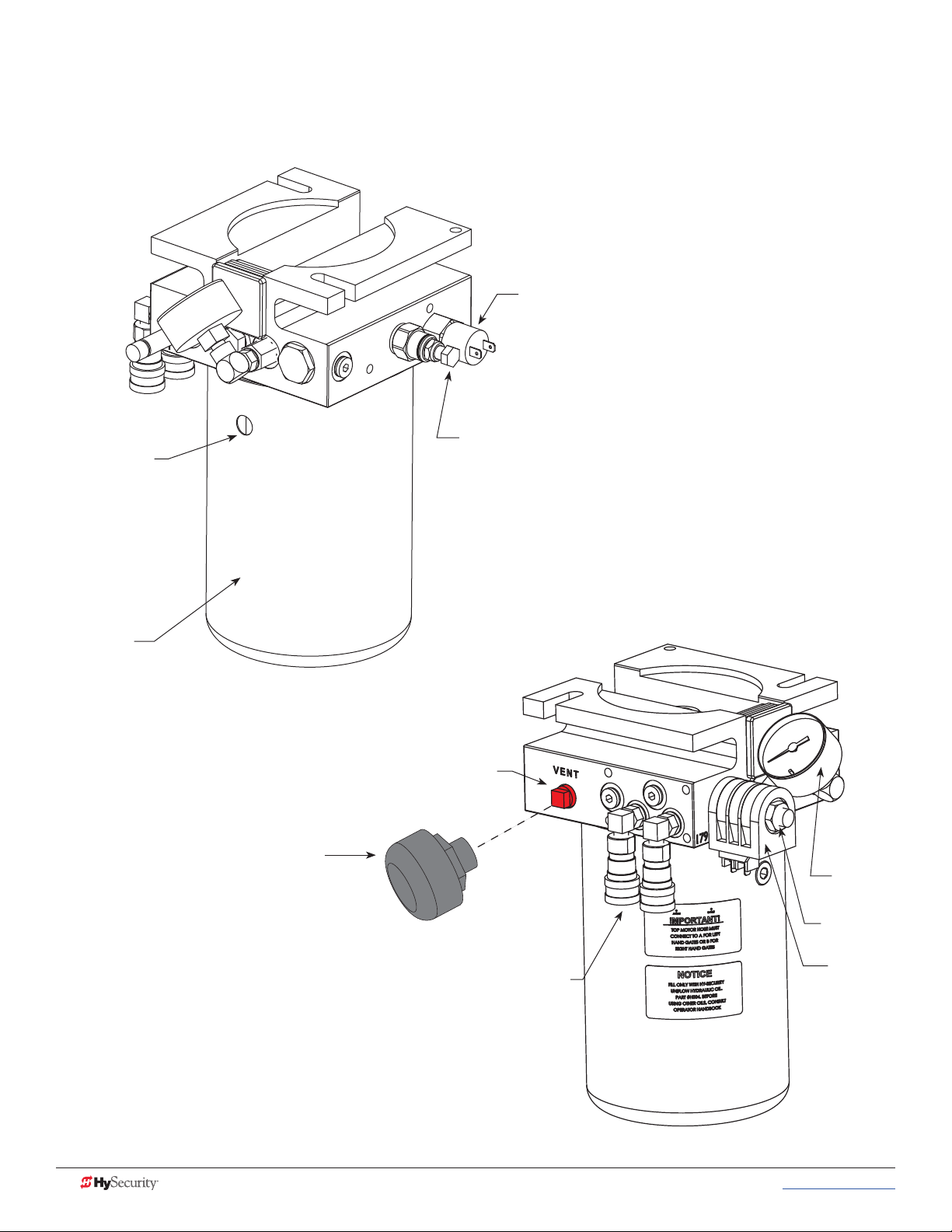

HydraSwinG cOmpOnentS

Swing gate

Gate hinge pin

HydraSwing 40

(cover off)

Cylinder

Gate mount

welded to gate

Chassis with

mounting holes

Bearing (2x)

Base of cylinder

Brake valves

Rod end

(clevis end)

Manual release

Brake manifold

assembly

Hoses with

Quick Disconnects

HydraSwing 40, 40F and 40 Twin

iv MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 5

HydraSuppLy cOmpOnentS

Smart Touch Controller

display and keypad

Reset button

(external)

Earth ground

location in cabinet

Power board

Smart Touch Controller

Motor

Control box

.....

Pump pack

assembly

Variable Speed

Drive

Hand pump

location

(Hand pump

not shown)

Grade level

Conduit

Ground rod

www.hysecurity.com © 2017 Introduction MX3636-01 Rev. C v

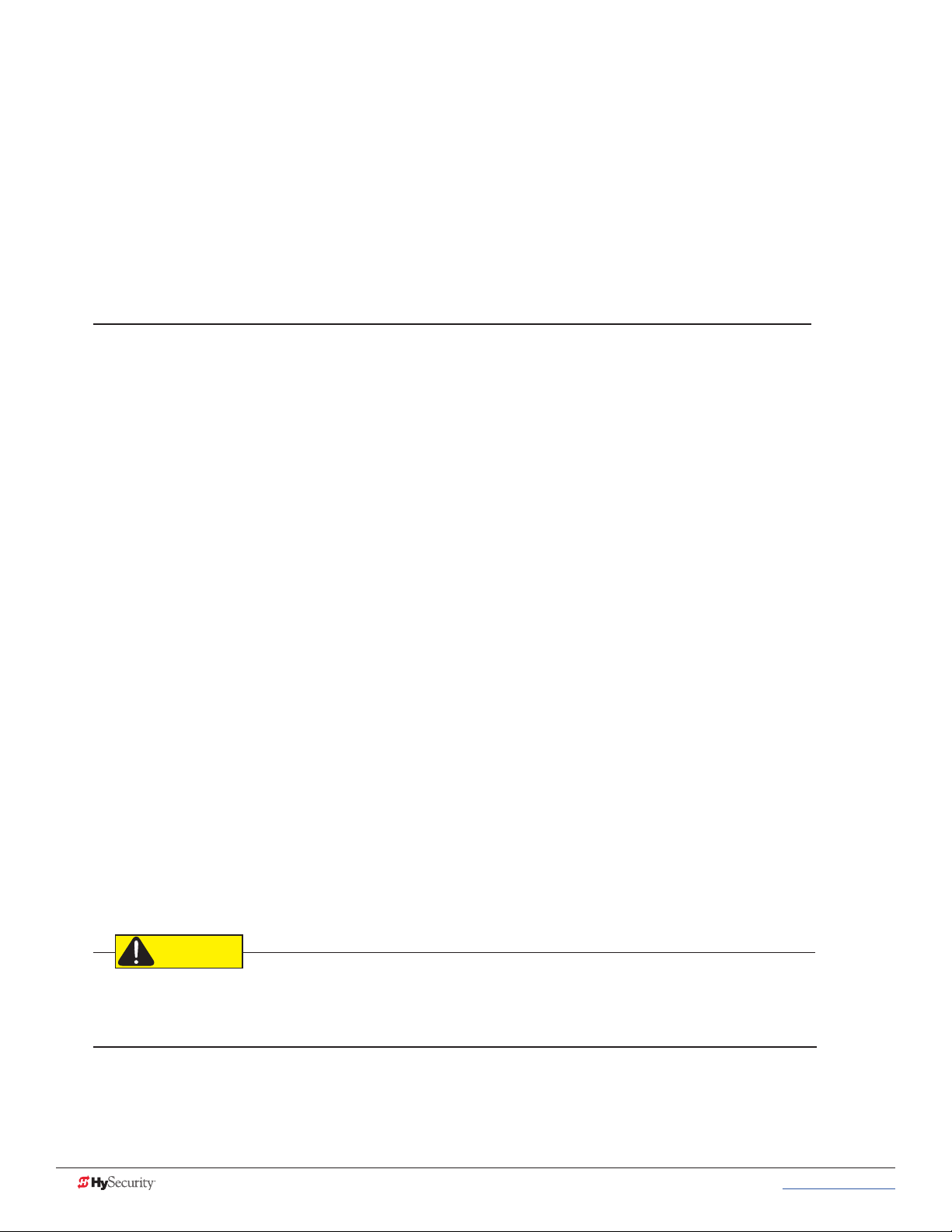

Page 6

HydraSwinG pump pack cOmpOnentS

Inherent Entrapment Sensor (IES)

Pressure relief valve

Filler plug

Reservoir

Breather cap

Vent plug

Quick Disconnects

Pressure

gauge

Open valve

Solenoid

vi MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 7

Contents

HySecurity Gate Operators: UL 325 – 2016 ..................................................................................................................... ii

Table 1: HySecurity Gate Operators requiring External Monitored Entrapment Protection Sensors ...........................ii

Table 2: HySecurity Gate Operators maintaining Object Detection .............................................................................ii

External Entrapment Protection Sensors monitored by HySecurity Gate Operators ..................................................iii

HydraSwing Components ..............................................................................................................................................iv

HydraSupply Components ............................................................................................................................................... v

HydraSwing Pump Pack Components ............................................................................................................................vi

Welcome to HySecurity ...........................................................................................1

Contact Information .........................................................................................................................................................2

Notices and Bulletins .......................................................................................................................................................2

Supplemental Documents ................................................................................................................................................2

IMPORTANT SAFETY INFORMATION .............................................................................................................................3

Safety - Additional Installer Responsibility ....................................................................................................................4

Safety - Additional Installer’s Responsibility, continued ................................................................................................5

Safety - Owner/User Responsibility ...............................................................................................................................6

Hazardous Materials and Proper Disposal .......................................................................................................................6

Identifying Gate Operator Category and Usage Class ....................................................................................................7

Breather Cap Installation and Grounding ........................................................................................................................8

Emergency Stop Button ..................................................................................................................................................9

Manual Release Option ....................................................................................................................................................9

Hand Pump: Manual Release ........................................................................................................................................10

Wind Load Considerations .............................................................................................................................................11

Safety Notices ................................................................................................................................................................12

Common Industrial Symbols ..........................................................................................................................................12

PoWer ..................................................................................................................13

Installing the Earth Ground ...........................................................................................................................................13

Gate Site Considerations ...............................................................................................................................................14

Wiring AC Power ............................................................................................................................................................14

Turning the Power Switch ON .....................................................................................................................................15

Wiring Diagram: HydraSwing/HydraSupply ..................................................................................................................16

Wire Sizing and Runs ......................................................................................................................................................17

Low Voltage Control Wiring ........................................................................................................................................17

Performance of Operators on 1 and 3 Phase 50/60Hz ...............................................................................................18

UPS Backup Power Options ..........................................................................................................................................20

DC Power Supply (UPS) Connections ........................................................................................................................20

AC Power Supply with HyInverter AC .........................................................................................................................21

www.hysecurity.com © 2017 Introduction MX3636-01 Rev. C vii

Page 8

initial SetuP ..........................................................................................................23

Open Position and Hydraulic Hose Swap ......................................................................................................................23

Setting the Close & Open Limits ....................................................................................................................................24

Adjusting the Pressure Relief Valve ................................................................................................................................25

The Inherent Entrapment Sensor (IES) ..........................................................................................................................26

Manufacturer’s responsibility .......................................................................................................................................26

Pressure Relief Valve – All Hydraulic Operators: ........................................................................................................26

Inherent Entrapment Sensor – (IES) ...........................................................................................................................27

ModBus RTU in HydraSwing .........................................................................................................................................27

Emergency Fast Operate (EFO) ....................................................................................................................................28

Setting the Emergency Fast Close ..............................................................................................................................28

Installing a Push-Button Device for EFC ....................................................................................................................28

entraPment Protection .........................................................................................29

Manufacturer’s responsibility ..........................................................................................................................................29

Pressure Relief Valve – All Hydraulic Operators: ........................................................................................................29

Inherent Entrapment Sensor System – Hydraulic Operators (IES) ..............................................................................30

The Inherent Entrapment Sensor (IES) ..........................................................................................................................30

How Software Handles Monitoring External Entrapment Protection Sensors ...............................................................31

Table 3: Changes to Sensor Inputs on the Controller .................................................................................................31

External Entrapment Protection Sensors: What the Installer Needs to Do ....................................................................31

Table 4: Installer Menu Settings for SENSOR Inputs ..................................................................................................33

Supply Power to the Sensors .........................................................................................................................................34

control Panel overvieW .......................................................................................35

STC Board, Power Supply Board and Display ................................................................................................................36

DiSPlay & menu oPtionS ........................................................................................37

Understanding the Display and Keypad .......................................................................................................................37

Initial Setup ....................................................................................................................................................................38

Initial Setup Using S.T.A.R.T. ......................................................................................................................................39

Menu Mode and the STC Keypad ................................................................................................................................40

Menu Mode Navigation .................................................................................................................................................40

Run Mode and the STC Keypad ...................................................................................................................................41

Viewing Gate Operator Scrolling Status ........................................................................................................................41

Stop the Status Display Scrolling ................................................................................................................................42

Change the Contrast on 7 Segment Displays .............................................................................................................43

Display Power Saving Mode .......................................................................................................................................43

Check the Software Version ........................................................................................................................................43

Check Time and Date .................................................................................................................................................43

viii MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 9

User Menu ......................................................................................................................................................................43

Table 5: User Menu ........................................................................................................................................................44

Installer Menu ................................................................................................................................................................46

Table 6: Installer Menu ...................................................................................................................................................46

Adjusting the Gate Speed..............................................................................................................................................53

Resetting Open and Close Limits ..................................................................................................................................54

Learn Close Limits .......................................................................................................................................................54

Learn Open Limits .......................................................................................................................................................54

Setting the Close Timer .................................................................................................................................................55

Test the Operator ...........................................................................................................................................................56

Stc inPutS & Wiring .............................................................................................57

Overview of the STC and Power Supply Board ..............................................................................................................58

Integrating with Security Systems and HyNet™ Gateway .............................................................................................59

Smart Touch Controller Inputs........................................................................................................................................60

STC Terminal Inputs .......................................................................................................................................................60

User Relays – Programming Procedure ..........................................................................................................................63

Table 7: Programmable User Relays............................................................................................................................63

Hy8Relay Module Option ...............................................................................................................................................66

Bi-Parting & Dual gate SyStemS ............................................................................67

Connecting an Interlocked Pair (Dual Gate) ...................................................................................................................67

Dual Gate Wiring Connections ...................................................................................................................................68

Dual or Sequenced Gates: Power, Software & Accessory Requirements ..................................................................69

Programming a Dual Gate (Interlocked Pair) .............................................................................................................69

Connecting Sequenced Gates .......................................................................................................................................70

Twin HydraSwings ..........................................................................................................................................................72

Sequenced Gate: Conguration #1 ...............................................................................................................................73

Sequenced Gate: Conguration #2 ...............................................................................................................................74

veHicle Detector inStallation anD looP layoutS .....................................................75

Anti-TailGate Mode (Closing Logic) ............................................................................................................................75

TailGate Alert .............................................................................................................................................................75

Vehicle Detectors and the Smart Touch Controller ........................................................................................................76

Hy5B Installation ........................................................................................................................................................76

Test the Vehicle Loop ..................................................................................................................................................77

Check the Version of Software ....................................................................................................................................77

Install Hy5B Vehicle Detectors ....................................................................................................................................78

Installing Standard 11-Pin Box Type Vehicle Detectors ..................................................................................................80

Loop Layouts: Single Lane, Bi- or Single-Directional .....................................................................................................81

Loop Layouts: Two Lane, Bi-Directional .........................................................................................................................82

www.hysecurity.com © 2017 Introduction MX3636-01 Rev. C ix

Page 10

PHoto eye inStallation ..........................................................................................83

Photo Eyes (Non-Contact) Installation ...........................................................................................................................84

Compatibility ..............................................................................................................................................................84

Installation ...................................................................................................................................................................84

Conguration ..............................................................................................................................................................85

Photo Eye Connections: Smart Touch & Smart DC Controllers ..................................................................................85

Photo Eye Function .....................................................................................................................................................85

Retro-Reective Photo Eye Systems ..............................................................................................................................86

Using Photo Eye Sensors

instead of Vehicle Loops ...............................................................................................................................................87

Photo Eye Alignment Feature .......................................................................................................................................88

inStalling gate eDge SenSorS.................................................................................89

Compatibility ..............................................................................................................................................................90

Installation ...................................................................................................................................................................90

Gate Edge Function ....................................................................................................................................................90

trouBleSHooting ...................................................................................................91

System Diagnostic Messages .........................................................................................................................................91

Table 8: Troubleshooting Codes .................................................................................................................................92

Access the Event Log through the User Menu ..............................................................................................................97

Electrical Issues ..............................................................................................................................................................98

AC-Powered Gate Operators ......................................................................................................................................98

HydraSwing Wiring Diagram: Pre-May 2017 ..............................................................................................................99

Mechanical Issues .........................................................................................................................................................100

Hydraulic Issues ............................................................................................................................................................100

Typical Problems and Troubleshooting Procedures .....................................................................................................101

general maintenance .........................................................................................103

Smart Touch Analyze and Retrieve Tool (S.T.A.R.T.) .....................................................................................................103

What You Need .........................................................................................................................................................103

Installing S.T.A.R.T. Software .....................................................................................................................................103

Software Maintenance ..................................................................................................................................................104

Electrical Controls ........................................................................................................................................................104

Clock Battery Replacement .....................................................................................................................................104

Mechanical Maintenance .............................................................................................................................................105

Hydraulic System Maintenance ....................................................................................................................................105

Brake Valve Adjustments ..........................................................................................................................................106

Pressure Relief Valve Adjustments ...........................................................................................................................107

Open Valve ...............................................................................................................................................................107

HydraSwing Hydraulic Cylinder Maintenance ..........................................................................................................107

HydraSwing Operator Maintenance Schedule .............................................................................................................108

HydraSupply Maintenance Schedule ...........................................................................................................................109

x MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 11

Wiring HySecurity SenSorS: Smart toucH .............................................................111

Wiring Tips for SENSOR COM Terminal: Smart Touch ................................................................................................112

Menu Mode Navigational Tips .....................................................................................................................................112

Smart Touch: 2 CH Wired Edge with Hy2NC ...............................................................................................................113

Smart Touch: Wired Edge Sensor with GEM (-104)......................................................................................................114

Smart Touch: Photo Eye Thru Beam (EMX IRB MON) ..................................................................................................115

Smart Touch: Photo Eye / Reective (E3K R10K4) .......................................................................................................116

Smart Touch: The Solution, MIM-62 (Multi-input Module) ...........................................................................................117

Smart Touch: Photo Eye / Reecti-Guard (RG-R) ..........................................................................................................118

Smart Touch: Wireless Edge, Wireless Gate Link .........................................................................................................119

Smart Touch: Wired Edge with GEM-104 & Photo Eye ...............................................................................................120

Smart Touch: WireLess Edge Gate Link & Photo Eye ..................................................................................................121

WARRANTY ..................................................................................................................................................................123

Specications ...............................................................................................................................................................124

www.hysecurity.com © 2017 Introduction MX3636-01 Rev. C xi

Page 12

Page intentionally left blank

xii MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 13

Welcome to HySecurity

Thank you for purchasing our premium HydraSwing™ gate operator. HySecurity Gate, Inc. has manufactured

some of the nest, sturdiest, most innovative, and reliable hydraulic gate operators since the 1970s. We use the

same hydraulic technology common in the aircraft industry while incorporating software capabilities that far

exceed the competition.

All operator designs are tested for hundreds of thousands of cycles before being released to the market. Slide,

swing, trafc barrier, fortied crash barrier gate, wedge, and vertical lift operators have all received rigorous

testing and certication. Security, low maintenance, exible conguration, and overall toughness are the

foremost criteria for all HySecurity products.

Our commitment to quality and innovation will become evident as the features and performance of the

expertly engineered and manufactured HydraSwing gate operator become familiar to you. Thank you for the

condence you’ve shown in becoming part of the HySecurity family and in choosing a premium, industryleading product.

HySecurity Gate, Inc. Headquarters in Kent, WA

www.hysecurity.com © 2017 Safety MX3636-01 Rev. C 1

Page 14

cOntact infOrmatiOn

Qualied HySecurity distributors are experienced and trained to assist in resolving any problems. For the name

of a qualied distributor near you, call HySecurity at 800-321-9947.

Before contacting your distributor or HySecurity Technical Support, obtain the serial number of your operator.

For information about HySecurity training for installers, maintenance personnel, and end users, refer to the

company website at www.hysecurity.com.

nOticeS and BuLLetinS

Installers should visit HySecurity’s online Technical Support page at www.hysecurity.com or contact HySecurity

prior to installing product to make sure they have received the most up-to-date information.

SuppLementaL dOcumentS

The product literature is comprehensive and contains information needed to plan, install, operate and maintain

your gate operator. Additional general information concerning HySecurity gate operators can be obtained

from the following:

• The gate safety section of the HySecurity website contains published materials regarding industry

changes due to UL 325 - 2016 requirements involving external entrapment protection sensors.

• Links to the product catalogs, product order form, operator manuals, operator software downloads,

technical support bulletins and other useful information.

• S.T.A.R.T. User’s Guide (D0049) - Smart Touch Analyze and Retrieve Tool - details the extensive

software, diagnostic and troubleshooting capabilities of the Smart Touch Controller board.

• DC Power Supply with HyCharger DC, supplement

• AC Power Supply with HyInverter AC, Installation and Reference Manual

• Technical Bulletins (as applicable).

NOTE: Technical Bulletins are automatically issued to registered users of HySecurity products. The product

warranty registration card can be lled out online at www.hysecurity.com.

2 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 15

impOrtant Safety infOrmatiOn

WARNING

Read all the product safety information prior to installation. Automatic gate operators move the gate with high

force and can cause serious injury and death! Make sure the automatic gate operator is installed to reduce the

risks of entrapment. Verify the gate operator is installed to comply with all safety standards and local and federal

regulations.

Understand that you as the site designer, installer, maintenance crew, or owner/user must consider the risks

associated with automatic gate operators. Hazards exist with automatic gate operators and can be reduced

with proper gate site design, installation and use. Installers, maintenance crews, and owners/users must

take responsibility to read and follow the safety requirements and Important Safety Information found in the

HySecurity product manuals and review all the literature that accompanies the product.

It is important that only qualied installers handle the installation of the HySecurity equipment and gate

operator. A “qualied” installer has one of the following:

• A minimum of three years experience installing similar equipment

• Proof of attending a HySecurity Technical Training seminar within the past three years

• Signicant manufacturer endorsements of technical aptitude in automatic gate operator installation

and operation

Underwriter Laboratories (UL) and the American Society for Testing and Materials (ASTM) are responsible for

current safety standards and regulations regarding automatic vehicular gate operators. To pass certication, all

aspects of gate operator and gate installation must comply with the appropriate safety standards.

For the most up-to-date ASTM F2200 Gate and Fence Standards, refer to www.astm.org.

For UL 325 Standard of Safety, refer to www.ul.com.

SAVE THESE INSTRUCTIONS

www.hysecurity.com © 2017 Safety MX3636-01 Rev. C 3

Page 16

impOrtant Safety infOrmatiOn

WARNING

A moving gate or barrier arm, bollard, or wedge can cause serious injury or death.

To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS. Read the gate operator’s product manual and review all the product

labels and literature prior to installing, operating, or maintaining the automatic gate operator.

2. Never let children operate or play with gate controls. Keep all remote controls, especially radio transmitters, away

from children. Do not allow children to play on or around the gate or gate operators.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING

GATE. Start the gate operator only when a gate’s travel path is clear.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object

activates the non-contact sensors. After adjusting the force or the limit of travel, retest the gate operator. Perform

routine tests of the entrapment protection sensors, such as photo eyes and gate edges. Failure to adjust and

retest the gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the product manuals. Have a qualied service person make repairs

to gate hardware and replace batteries in accessory or entrapment sensory devices on a regular basis.

7. The automated gate entry is for vehicle use only. Pedestrians must use a separate entrance. Make sure a separate

walk-through entrance is nearby. Make certain a clear pedestrian path is designated and signs direct pedestrians

to the walk-through gate.

8. Install the supplied WARNING signs on the inside and outside of the gate or barrier gate/operator so they are

clearly visible from both the secure and public sides. Installing the signs is a requirement for UL 325 compliance.

9. Use monitored sensors for protection against entrapment as specied in the current UL 325 Standard of Safety.

Safety - Additional Installer Responsibility

• The gate operator must be properly grounded and the incoming power voltage must match the voltage label on

the junction box.

• Verify and install an automatic gate operator per its usage class and only on gate sites that comply with ASTM

F2200 Gate and Fence Standards. See Identifying Gate Operator Category and Usage Class on page 5.

Screen or enclose openings in the gate and install sensors to monitor potential entrapment areas per UL 325

Standard of Safety, which includes:

• All horizontal slide gates must guard or screen openings from the gate’s base support to a minimum height of

6 feet (183 cm) above the ground. This must prevent a sphere of 2¼ inches (57 mm) in diameter from passing

through an opening in the gate or the adjacent fence that is covered in the gate’s open position.

• Physical stops must exist in the gate construction to prevent over-travel in both directions and, for slide gates,

guard posts must be installed to prevent the gate from falling in the event of a roller failure. Exposed rollers

must be capped to avoid potential entrapment.

• Make sure all exposed pinch points are eliminated or any exposed pinch points, rollers and wheels are

guarded.

• External entrapment protection sensors must be used wherever the risk of entrapment exists.

SAVE THESE INSTRUCTIONS

4 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 17

impOrtant Safety infOrmatiOn

Safety - Additional Installer’s Responsibility, continued

• Before attaching the operator to the gate, move the gate or barrier gate in both directions. Make sure it is level

and moves freely. A gate or barrier gate that moves easily reduces strain on operator components. Gravity should

play no part in the opening or closing of a slide gate.

• Never over-tighten a clutch or pressure relief valve to compensate for a stiff or damaged gate.

• Reduce the risk of entrapment throughout the entire travel path by making sure the gate is installed in a location

which ensures the required clearance between the gate and adjacent structures when opening or closing. On

slide gates, minimize the parallel gap between the gate and the fence.

• Install the gate operator on the secure (non-public) side of the gate. Note that swing gates cannot open into

public areas.

• Install external entrapment protection sensors so pedestrians are protected from entrapment in both directions

of gate travel and all hazard areas are fully protected. On hydraulic gates, set the pressure relief valve at the

lowest allowable setting that will reliably operate the gate. The pressure relief valve controls the applied force of

the operator and the sensitivity of the inherent entrapment sensor (IES). Note that no IES exists in the StrongArm.

• Never disable the Warn Before Operate buzzer. This buzzer provides an alert that the gate is about to move.

• Mount access control devices beyond reach of the gate. The control devices that operate the gate must:

• Be mounted beyond 6 feet (183 cm) of the gate to prevent users from touching or accessing the gate while

operating the controls. People attempting to access the controls by reaching through or around the gate can

be seriously injured or killed by the moving gate.

• Incorporate a security feature to prevent unauthorized use.

• Connect radio and other remote access (non-resetting controls) to the RADIO OPTIONS terminal.

• Be located in a clear line of sight to the gate. Locate access controls (Open, Close, Stop/Reset) where a user

will have a clear view of the gate.

NOTE: An exception for Emergency Access Control devices exists. An EAC device accessible by

authorized personnel only (e.g. re, police, EMS) may be placed at any location within the line-of-sight.

• Open and close the gate to conrm that it was properly installed and to ensure monitoring sensors are working

correctly. Verify the clearance between the gate and adjacent structures per UL 325 Standard of Safety. Have a

qualied technician test the gate monthly.

• When you complete the installation, demonstrate the safety features and operation of the gate operator to the

end user:

• Clearly explain and demonstrate the consequences of removing or defeating any of the safety features.

• Remove the operator cover(s), and then turn the power on and off.

• Manually release the gate. (Use the manual release only when the gate is NOT moving.)

• Use the Emergency Stop Button. (If an emergency stop button is not available, show the user where the Stop

button is located on the gate operator.)

NOTE: Gate operator instructions must be given to the owner per UL 325 Standard of Safety.

• Take photographs of the completed installation site and save it in your business les.

SAVE THESE INSTRUCTIONS

www.hysecurity.com © 2017 Safety MX3636-01 Rev. C 5

Page 18

impOrtant Safety infOrmatiOn

CAUTION

Safety - Owner/User Responsibility

As the owner/user, you are responsible for the correct and safe installation, operation and maintenance of the

HydraSwing gate operator. It is of the utmost importance that you read and follow the specic instructions and

precautions found in the IMPORTANT SAFETY INFORMATION addressed in this manual. In addition, you must

adhere to the safety standards of applicable federal, state, and local safety regulations, industry standards,

and/or procedures.

NOTICE: For installations outside the United States, make sure that you follow the applicable international,

regional, and local safety standards.

• Automatic gates are for vehicular use only; provide and maintain walkways and signs to direct pedestrians to a

separate walk-through entrance.

• An automatic gate can start at any time without warning; always keep people away from the gate area.

• Never let children operate or play with gate controls. Keep all remote controls, especially radio transmitters, away

from children. Do not allow children to play on or around the gate, gate area, or gate operators.

• Learn how to turn the power on and off. Learn how to manually operate the gate.

• WARNING signs supplied with the gate operator must remain installed and clearly visible on both sides of the

gate. The signs are required to maintain UL 325 compliance.

• Do not physically disable the warning buzzer and NEVER disconnect or cut its wires. The buzzer provides

compliance with the Manual on Uniform Trafc Control Devices (MUTCD) standards. Disabling the warning

buzzer may increase the risk of death or serious injury.

• Do not remove external entrapment protection sensors or any other safety features.

• Have a professional gate installer routinely inspect the gate hardware and test the entrapment protection sensors

and overall gate operation. Have a qualied service person make repairs to gate hardware and equipment to

keep the gate running smoothly.

HazardOuS materiaLS and prOper diSpOSaL

Be aware of the international, federal, and local codes in your area and how best to handle hazardous waste

materials.

The pump pack uid, found in all hydraulic HySecurity operators, can be recycled. Gear oil, found in HySecurity

electromechanical gate operators, can also be recycled. If the uids are mixed or contaminated with any

solvents or other chemicals, they become hazardous waste. Hazardous waste requirements for storage and

disposal must be followed.

If the gate operator has a battery backup system, the batteries contain materials that are considered hazardous

to the environment. Proper disposal of the battery is required by federal law. In the U.S.A., refer to federal EPA

guidelines for proper hazardous waste disposal.

SAVE THESE INSTRUCTIONS

6 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 19

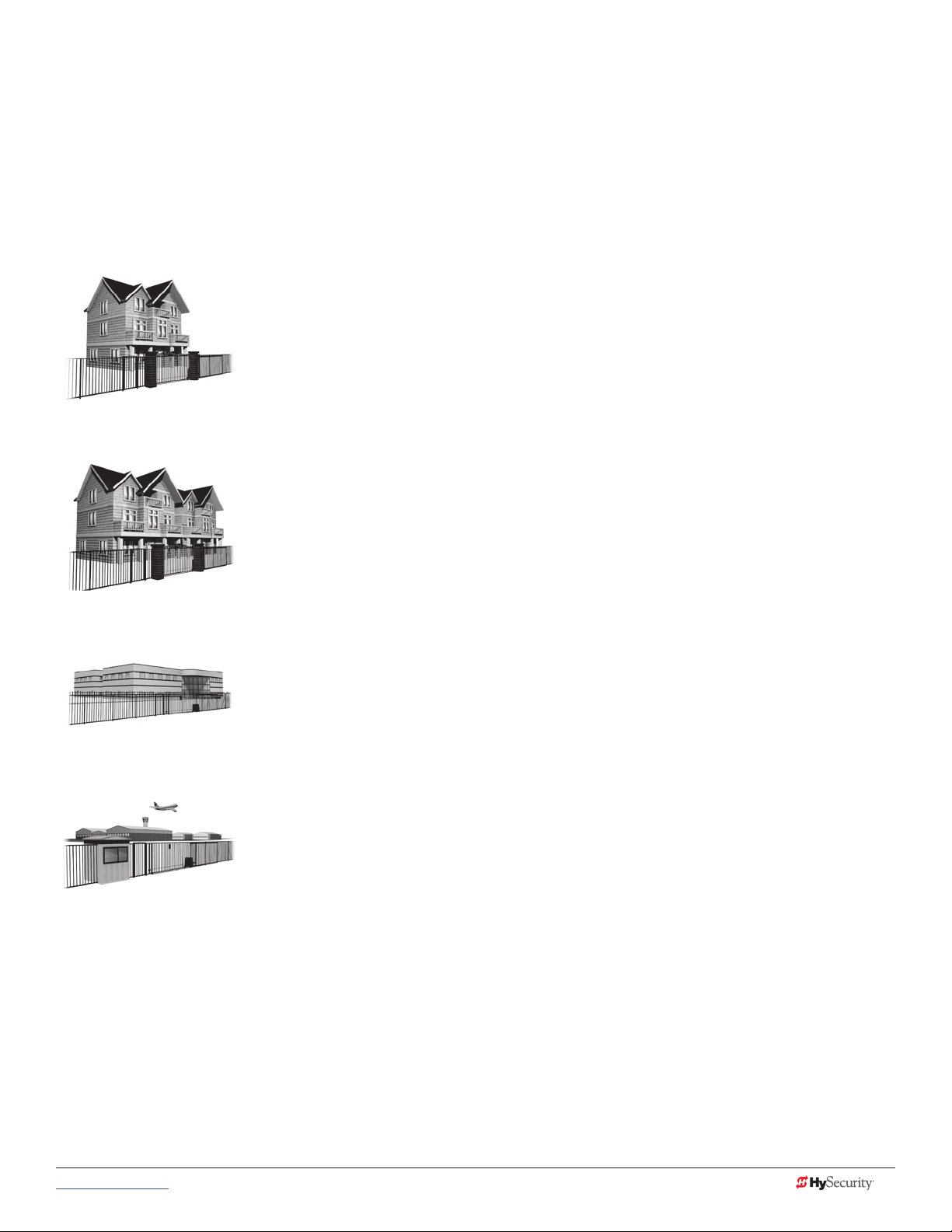

identifyinG Gate OperatOr cateGOry and uSaGe cLaSS

Gate operators are given a usage class according to UL 325 Standard of Safety. The usage class is determined

by the area that the vehicular gate operator services.

Four different vehicular usage classes are dened by UL 325:

Class I

Class I: Intended for use in garages or parking areas associated with a residence

of one to four single families.

Class II

Class II: Intended for use in a commercial location or building such as a multifamily housing unit (ve or more single family units) hotels, garages, retail stores

or other buildings accessible by or servicing the general public.

Class III

Class IV

Class III: Intended for use in an industrial location or building such as a factory

or loading dock area or other locations NOT accessible by or intended to

service the general public.

Class IV: Intended for use in a guarded industrial location or building such as

an airport security area or other restricted access locations, NOT servicing the

general public, in which unauthorized access is prevented via supervision by

security personnel.

SAVE THESE INSTRUCTIONS

www.hysecurity.com © 2017 Safety MX3636-01 Rev. C 7

Page 20

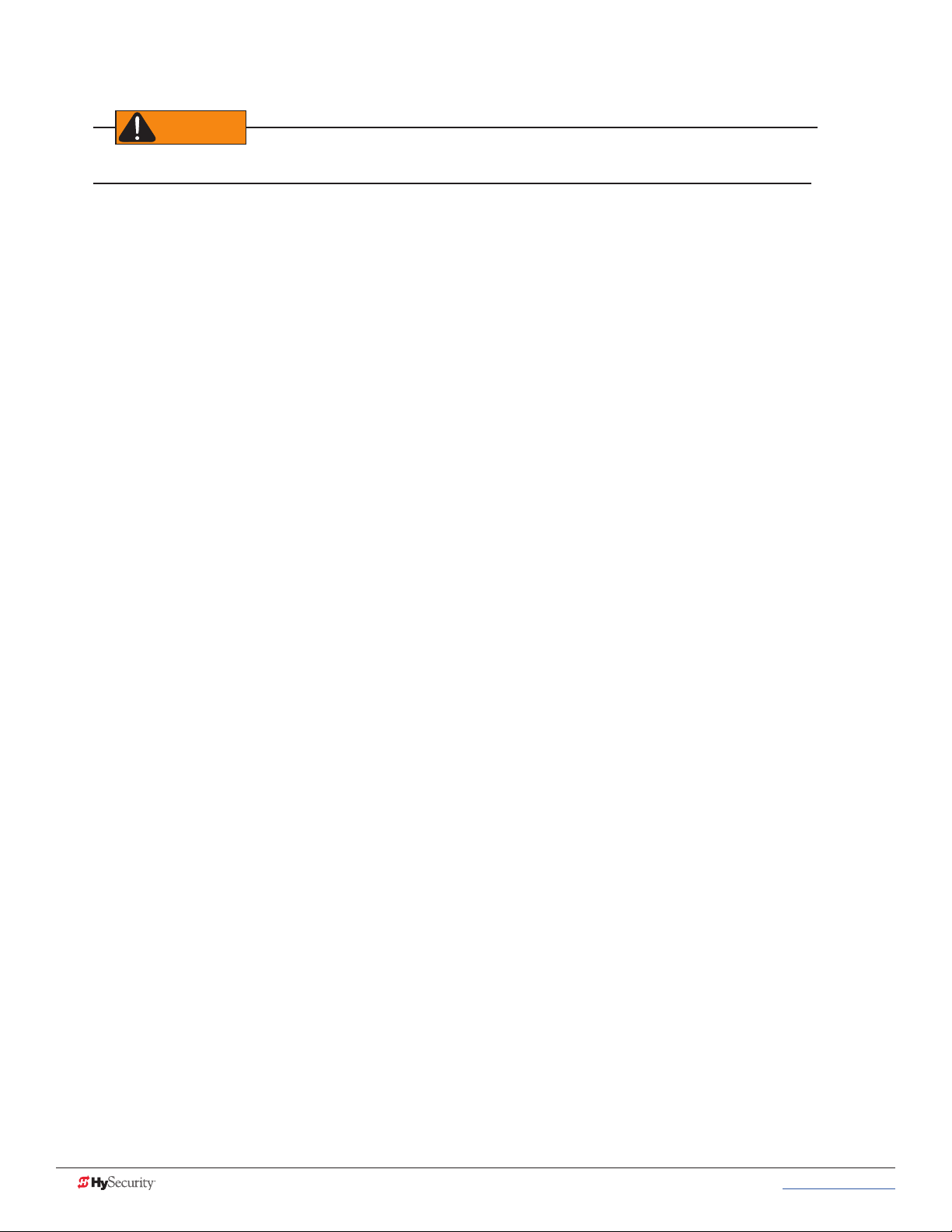

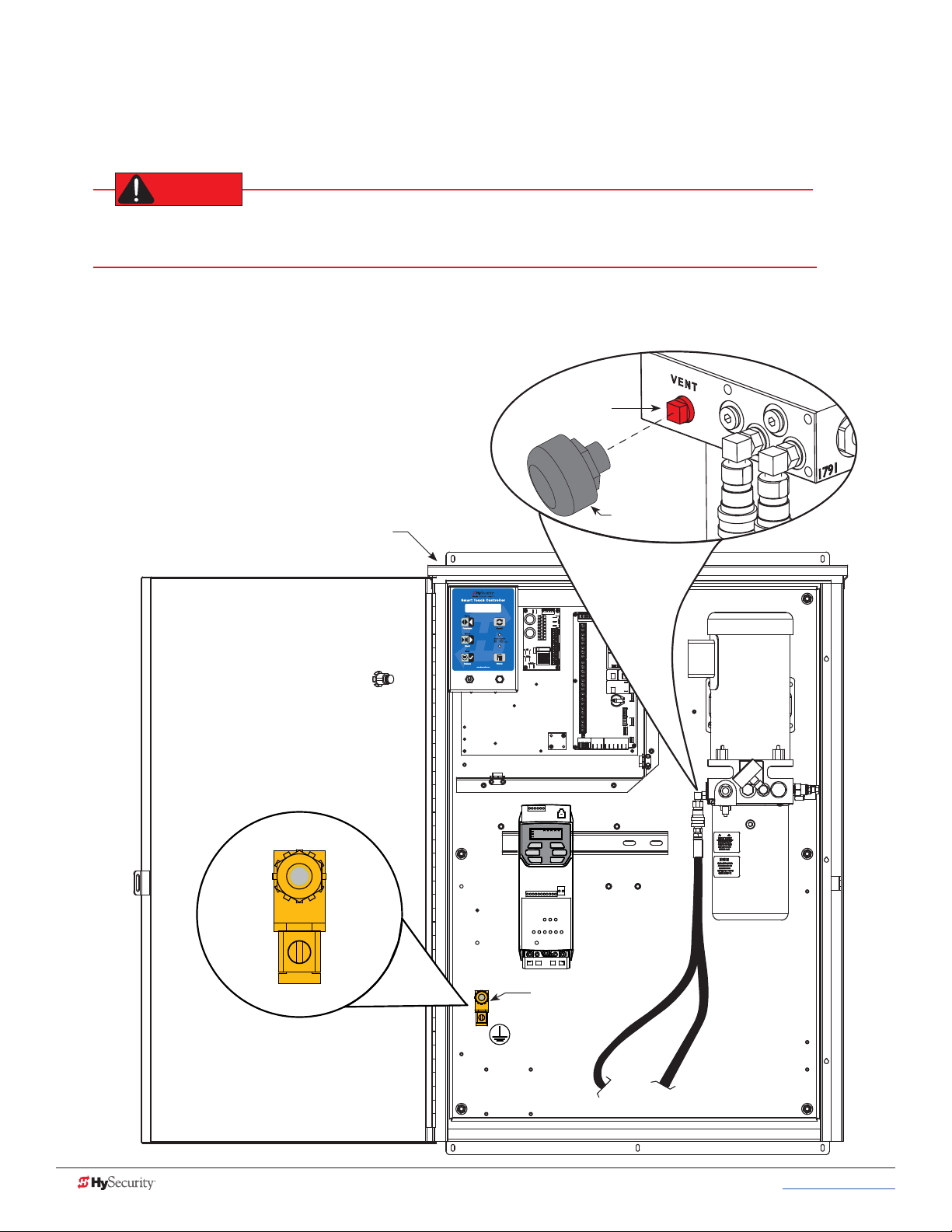

BreatHer cap inStaLLatiOn and GrOundinG

DANGER

The gate operator has a vent plug that keeps the hydraulic uid from spilling during shipment. The vent plug

must be replaced by the breather cap before operating the swing gate.

Failure to perform the following procedure will cause premature pump shaft failure and void the

Limited Warranty.

1. Remove the vent plug and discard it.

2. Replace the vent plug with the breather cap.

Vent plug

Breather cap

HydraSupply

.....

Ground lug

Refer to the Power section for more

information about the earth ground.

Consult local codes for proper

connection and depth of ground rod.

8 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 21

emerGency StOp ButtOn

WARNING

Make sure all users of the gate know where the emergency stop

button is located (see illustration). It complies with UL 325 Safety

Standards requirements.

Pressing the emergency stop button while the gate is opening or

closing disables the automatic close timer and stops gate travel.

Gate travel remains stopped until the operator receives another

Emergency Stop

button

open or close signal.

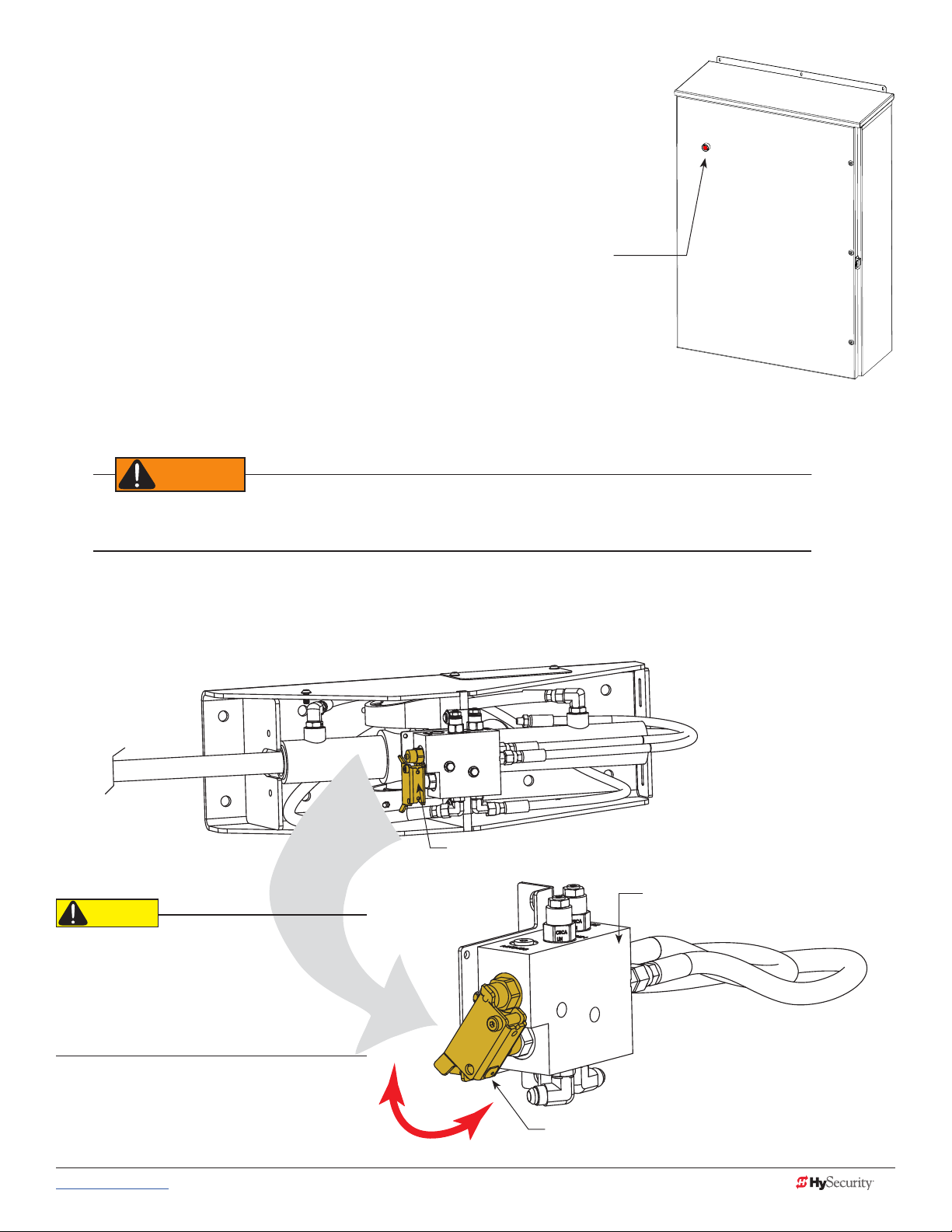

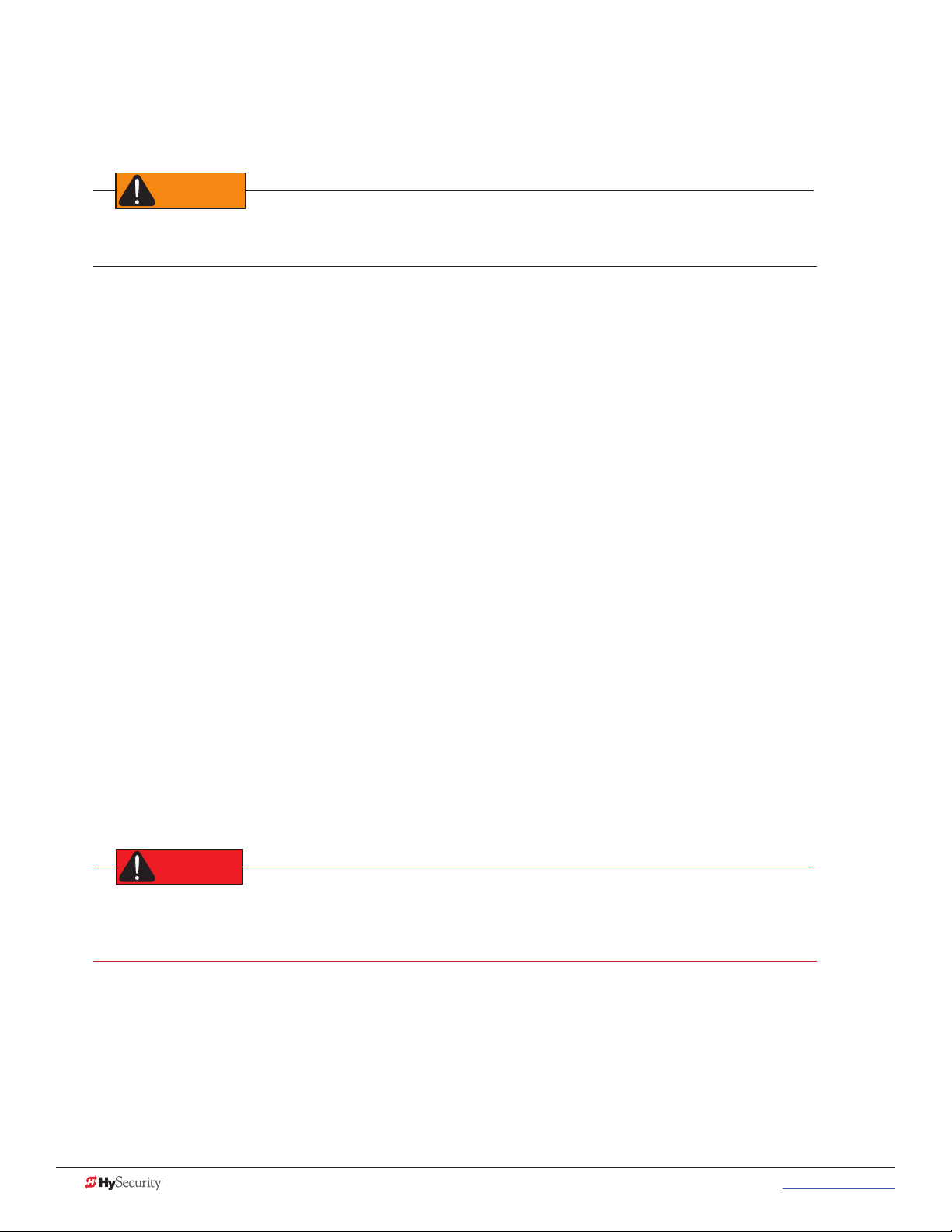

manuaL reLeaSe OptiOn

Before attempting a manual release, make sure the gate is not in motion and power is disconnected

(turned OFF).

HydraSupply

The manual release option can be found on the brake manifold.

To move the gate manually, turn OFF the power switch on the control box in the HydraSupply cabinet, and

then simply push the release lever, as shown in the illustration.

CAUTION

For the HydraSwing 80F or 150 models, pushing

close while using the manual release option may

cause an air pocket to form in the hydraulic

cylinder and cause overow from the reservoir.

If you notice uid leakage, stop gate travel

immediately and use the hand pump.

Manual Release

Open position

HydraSwing 40, 40F, and 40 & 40F Twin

Brake manifold

Closed position

www.hysecurity.com © 2017 Safety MX3636-01 Rev. C 9

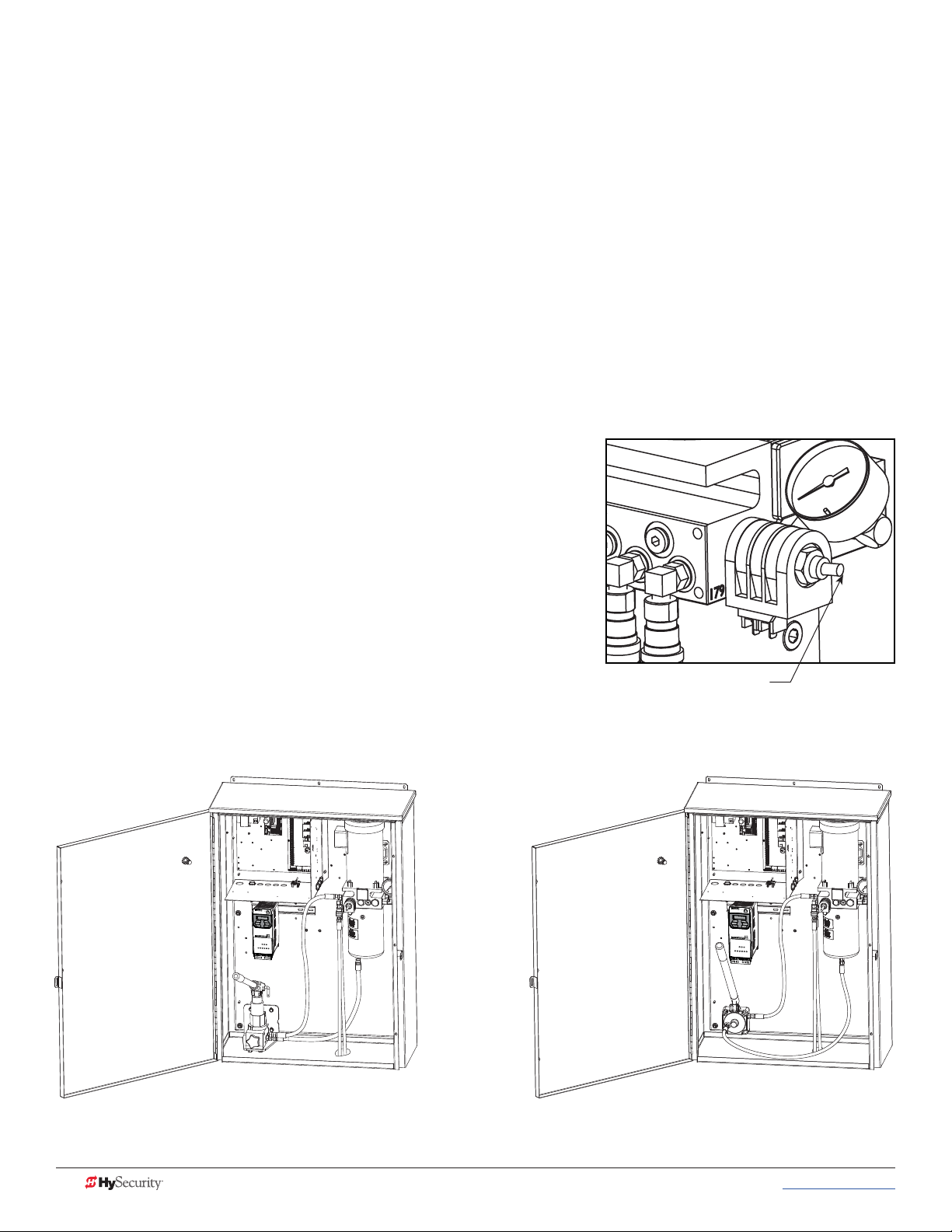

Page 22

Hand pump: manuaL reLeaSe

A hand pump kit is used to manually operate the hydraulic mechanism that secures the gate. In the event of a

power failure, manual operation can be achieved by accessing the hydraulics cabinet. Follow the steps below

to open or close the gate:

NOTE: A manual release mechanism exists on the brake manifold assembly. Refer to Manual Release Option on page 9.

Open the Gate using the Hand Pump

1. Open the HydraSupply cabinet.

2. Turn the power switch OFF.

3. Locate the hand pump and the Knurled Knob on the Open Valve.

4. Firmly, pull and twist the knurled knob counterclockwise. With a few threads showing, release the knob

so that it remains in the open position.

NOTE: If the valve re-seats itself, repeat the pull and twist in the opposite direction until the valve remains open.

5. Begin pumping the handle up and down. As hydraulic uid is

pumped into the cylinder, it begins to move the gate. It is a slow

process.

6. Continue pumping until the gate reaches full open position.

7. Turn the knurled knob so it springs back to the closed position.

Close the Gate using the Hand Pump

1. Check that the knurled knob is in the closed position. Begin

pumping the handle up and down. The gate slowly closes with

the pumping motion.

2. The gate will maintain its position whenever you stop pumping.

3. Continue pumping until the gate reaches the full closed position.

.

.

.

.

.

Knurled knob

.

.

.

.

.

HydraSwing 80F and 150 HydraSwing 40, 40F and Twin 40 & 40F

10 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 23

wind LOad cOnSideratiOnS

Wind load is always a factor when considering the appropriate gate for a particular site. The HydraSwing

incorporates a primary Type-A inherent entrapment sensor (IES) into its design per UL 325 Safety Standards.

When the IES trips, it sends a signal to the gate operator to stop and reverse direction. This feature may be

falsely triggered in excessively windy conditions because the wind itself, acting over the surface area of the

gate panel, can provide the necessary force to trigger the IES.

• Check gate operator specications. If the gate is heavy and near the weight capacity of what the gate

operator can handle, make sure the gate has an open design that allows wind to ow through it. A

solid gate, under certain wind load conditions, may cause damage to the gate operator and is not

covered by the HySecurity Warranty.

• Do NOT adjust the IES sensitivity to accommodate for inappropriately designed gate panels. Loss of

IES sensitivity increases mechanical wear on the gate hardware and the gate operator. It may also pose

a safety hazard.

NOTICE: Under certain wind load conditions, damage to the gate or gate operator may occur and is not covered

by the HySecurity Warranty.

www.hysecurity.com © 2017 Safety MX3636-01 Rev. C 11

Page 24

Safety nOticeS

DANGER

WARNING

CAUTION

The following four levels of safety notices are used where applicable within this manual; each notice contains

information specic to the situation.

Indicates death or serious injury will occur if the hazardous situation is not avoided.

Indicates death or serious injury could occur if the hazardous situation is not avoided.

Indicates mild or moderate injury could occur if the hazardous situation is not avoided.

NOTICE: Indicates damage to equipment is probable if the hazardous situation in not avoided.

cOmmOn induStriaL SymBOLS

The following international safety symbols may appear on the product or in its literature. The symbols are used

to alert you to potential personal injury hazards. Obey all safety messages that follow these symbols to avoid

possible injury or death.

O

Electrical Phase

Symbol

Ground

Symbol

- Danger -

Keep Away

Entrapment

Zone

Possible

Pinch Point

Attention

- Take Note -

12 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 25

Power

DANGER

How to wire the operator is presented in the Installation Instructions, but detailed information about the earth

and equipment ground, wiring to AC power and the availability of UPS systems are described in this section.

Supplemental documents to this section include:

• DC Power Supply with HyCharger DC • AC Power Supply with HyInverter AC

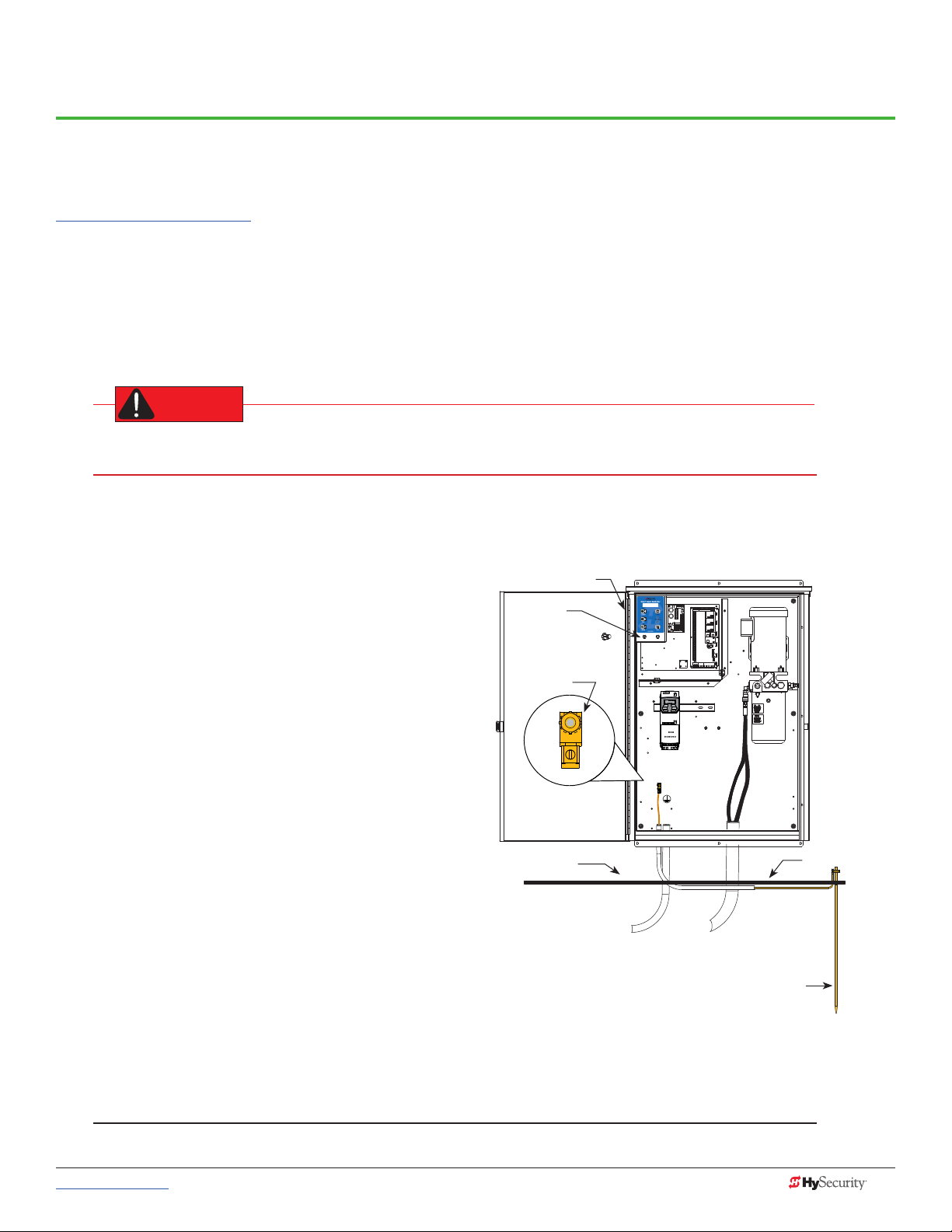

inStaLLinG tHe eartH GrOund

An earth ground refers to the grounding rod and accompanying equipment ground which need to be installed

to safeguard against potential electrical shock and damage to personnel and equipment.

The potential for lightning discharge exists with all gates, fences and gate operators. National Electric

Code (NEC) - Article 250 requires a separate earth ground in addition to the required equipment ground.

HySecurity recommends grounding the operator with a separate earth ground rod (or a similar device

in the case of crash products) to shield the operator against electromagnetism and other electrical signals

that may cause, erratic operation with, or damage to, the Smart Touch Controller and other electrical parts.

For earth grounding requirements in the U.S.A., refer

to the National Fire Protection Association (NFPA) 780

- Standard for the Installation of Lightning Protection

Systems. Highlights of the standard include:

• The ground rod must be UL listed copperclad steel, solid copper, hot-dipped

galvanized steel, or stainless steel. Minimum

requirements: ⅝ inch (16 mm) diameter and 8

feet (244 cm) in length.

• The ground rod is driven into the earth (refer

to local codes for proper depth requirements).

• The ground rod is electrically bonded to the

chassis with a single length of un-spliced 6

AWG copper wire less than 3 feet (91 cm) long.

Due to the large concrete foundation on crash

products, make the necessary adjustments to

accommodate for earth ground requirements.

• Local jurisdictions may impose other

requirements above the NEC, Article 250

and NFPA 780 Consult the local codes and

regulations regarding requirements in your

area.

HydraSupply cabinet

Power switch

Ground lug

Grade level

Control Box

.....

Variable speed

Drive (VFD)

Consult local

codes for

proper depth

Ground rod

3 ft (91.4cm)

Maximum distance

NOTICE: Properly grounding the gate operator is critical to gate operator performance and the life of its

electrical components. Use sufcient wire size during installation. If you do not ground the operator with a

separate earth ground, you risk voiding the HySecurity Warranty.

www.hysecurity.com © 2017 Power MX3636-01 Rev. C 13

Page 26

Gate Site cOnSideratiOnS

WARNING

HySecurity gate operators are intended for permanent installation. Make sure you prepare the site with the

following considerations:

Each gate operator is built to run on a specic line power voltage and phase. Failure to ensure the source voltage

(phase and frequency match what is specied for the equipment), may result is severe damage to the equipment.

• Make sure all electrical wiring is properly routed via conduits.

• Check the distance of the wiring run from the main panel to the gate operator. Make sure the wire size

of the branch circuit supplying power to the gate operator is large enough to avoid excess voltage

drop. Refer to Wire Sizing and Runs on page 17.

• Make sure the available power source matches the electrical requirements specied on the voltage

nameplate.

• Make sure a 20-amp circuit (minimum) protected with a 20-amp Inverse Time Breaker is provided for all

AC power connections.

• Verify that the operator is electrically grounded per NFPA 780 and NEC Article 250 and local codes.

wirinG ac pOwer

The HydraSwing has separate Installation Instructions that explain how to connect to AC power. For reference

purposes, the same information is provided below.

In-rush Current is the current needed to start the electric motor spinning in the proper direction (CCW). It may

take as much as 6 to 9 times the in-rush current to start one of the heavy duty operators.

NOTE: Use a 20A (minimum) slow kick (thermal) circuit breaker for all AC motors.

Size the primary wires. Consider the voltage, horsepower, and length of the wire run from the main power

panel.

Make sure you have the proper voltage and conversion of voltage taps at the motor and transformer.

DANGER

Turn OFF AC power at the source (circuit breaker panel) before accessing the wires in the HydraSwing.

Follow facility Lock Out/Tag Out procedures. Make sure all power switches are in the OFF position. Follow

all electrical code standards and regulations.

14 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 27

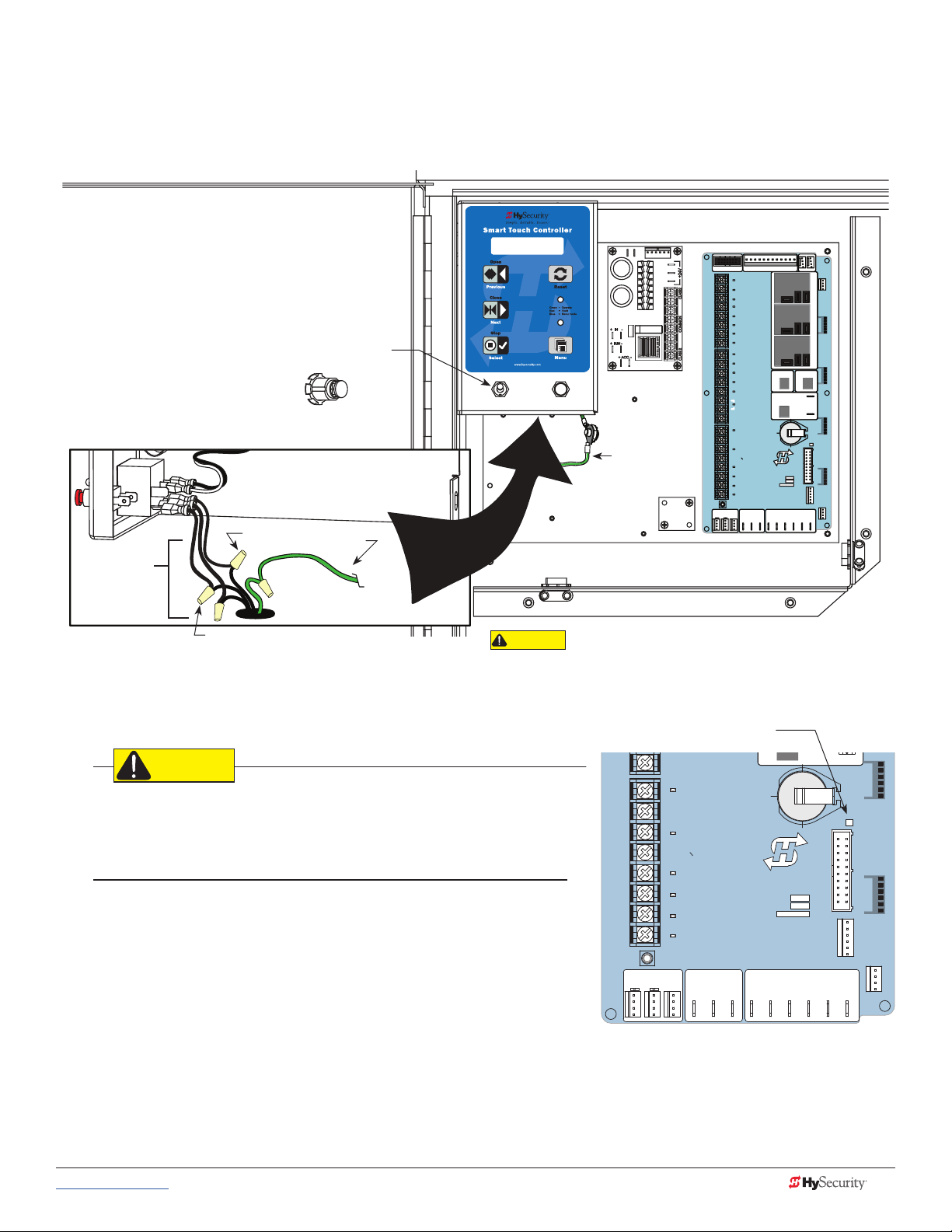

1. Connect to Power: Three pig tails and a ground are available for connection to a 3 Phase power

STOP BUTTON

OPEN BUTTON

CLOSE BUTTON

REMOTE OPEN AND

RADIO CONTROL

OPEN/CLOSE

1

OPEN PARTIAL

INTERLOCK OPEN

TIME CLOCK OPEN

FREE EXIT DETECTOR

DISABLE EXIT DETECTOR

DISABLE CLOSE TIMER

INSIDE OBSTRUCTION

VEHICLE DETECTOR

OUTSIDE OBSTRUCTION

VEHICLE DETECTOR

SHADOW/RESET

VEHICLE DETECTOR

EDGE SENSOR

PHOTO EYE POWER

24 VOLTS COMMON

PHOTO EYE POWER

DO NOT USE

PHOTO EYE

OPEN DIRECTION

DO NOT USE

PHOTO EYE

CLOSE DIRECTION

DO NOT USE

CHARGER

AC LOSS

LOCK INTERLOCK

EMERG CLOSE

FIRE DEPT OPEN

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

21

22

23

24

Smart Touch Controller

LIMITDUAL GATE

RADIO OPTIONS

DRIVE

POWER

RS485

MOTORUSER 1

USER 2

USER 3

VEHICLE DETECTORVEHICLE DETECTORVEHICLE DETECTOR

STOP/BUZZER

FREE

EXIT

INSIDE

OBSTR

OUTSIDE

OBSTR

SHADOW

RESET

WIEGAND

HySecurity

COM

NO

MX000585

VERSION

S/N

RS232

DISPLAY

VEHICLE DETECTOR

COMCOMAB

RPM

COMOPEN EDGE+24V +24V

STATUS

LED

CAUTION

VEHICLE DETECTOR

VEHICLE DETECTOR

source (3Ø) on the back of the keypad display enclosure.

2. Connect AC Power: Wire nut the incoming power wires to their appropriate pig tails. Attach the

ground wire to the chassis. A wiring diagram is provided in the appendix. Note that for 1Ø wiring, only

the two outside connections/pig tails are used.

ON/OFF power

disconnect switch

Ground

1Ø

3Ø

Wire nut all

three pigtails

1Ø

Ground wire

VFD (Variable Frequency Drive) module

not shown

* Variable Frequency (VF) operators:

Make sure the connection wires match

the voltage found on the operator’s nameplate.

Green LED ashes indicating

processor is receiving power.

CAUTION

Wiring of gate operators must conform to NFPA and NEC standards and

comply with all local codes. When the installation is compliant and

complete,

turn on AC power at the source and at the control box.

16

17

18

19

20

21

22

Turning the Power Switch ON

23

24

The AC power disconnect switch (ON/OFF switch) is located on the

enclosure with keypad display. See the illustration on the previous

LIMIT DUAL GATE

page.

When power is turned ON, a green status light on the Smart Touch

Controller blinks. The status light appears below the disc battery and indicates that the processor is receiving

power. For more information, refer to STC Board, Power Supply Board and Display on page 36.

DO NOT USE

PHOTO EYE

OPEN DIRECTION

DO NOT USE

PHOTO EYE

CLOSE DIRECTION

DO NOT USE

CHARGER

AC LOSS

LOCK INTERLOCK

EMERG CLOSE

FIRE DEPT OPEN

LED

Smart Touch Controller

RPM

COM COMA B

HySecurity

MX000585

VERSION

S/N

RADIO OPTIONS

STATU S

RESET

DISPLAY

RS232

COMOPEN EDGE+24V +24V

SHADOW

WIEGAND

www.hysecurity.com © 2017 Power MX3636-01 Rev. C 15

Page 28

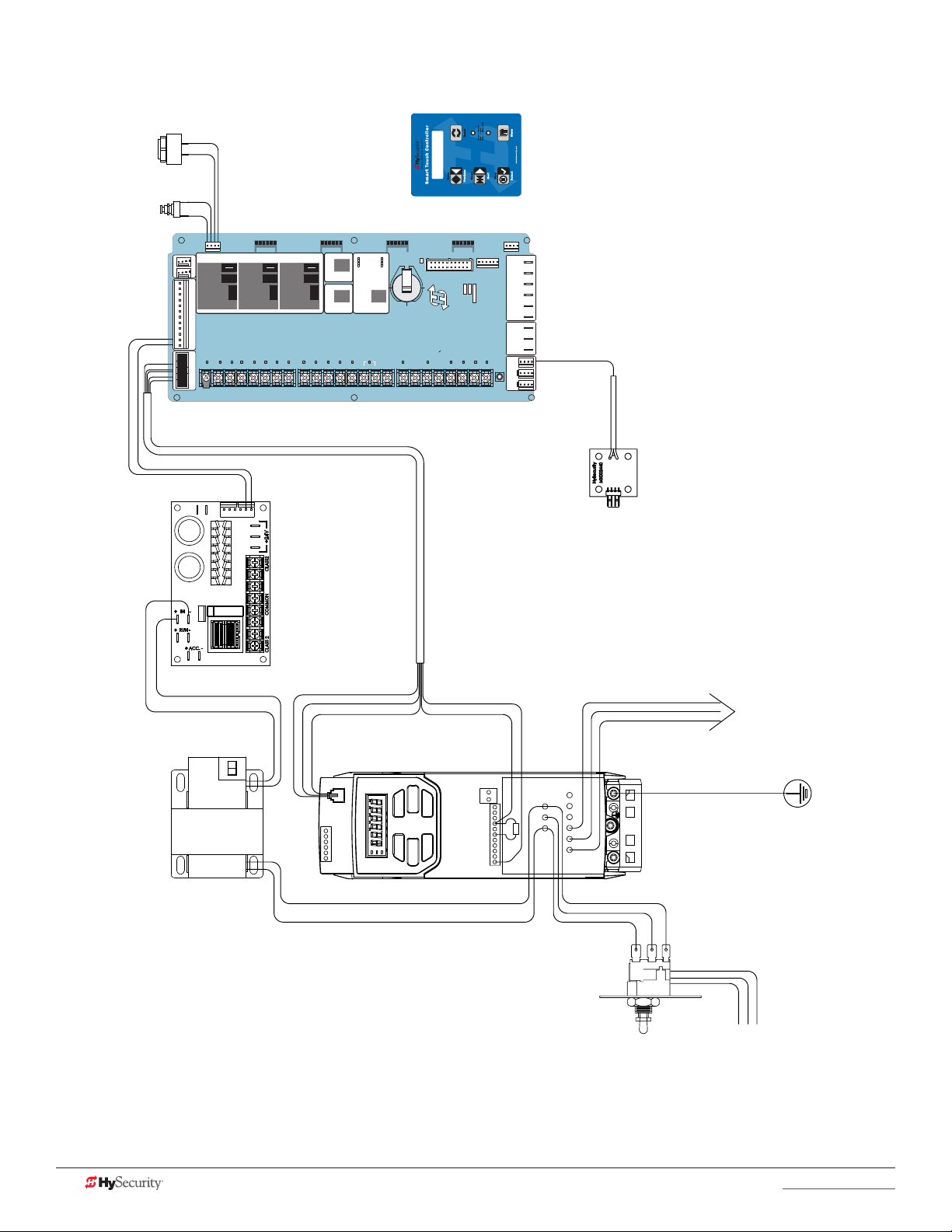

wirinG diaGram: HydraSwinG/HydraSuppLy

AC POWER IN

FOR SINGLE PHASE (1Ø)

CONNECT TO L1 & L3

FOR 3Ø

CONNECT TO L1,L2 & L3

BE PROVIDED IN THE FIELD BY

THE INSTALLER

STOP

24V DC

COMMON

BUZZER

BUTTON

POWER MODULE

STOP/BUZZER

MOTOR USER 1

RS485

POWER

STOP BUTTON

OPEN BUTTON

DRIVE

2

1

3

CLOSE BUTTON

FREE

EXIT

REMOTE OPEN AND

RADIO CONTROL

4

USER 2

OPEN/CLOSE

FREE EXIT DETECTOR

INTERLOCK OPEN

TIME CLOCK OPEN

OPEN PARTIAL

56789

INSIDE

OBSTR

DISABLE EXIT DETECTOR

DISABLE CLOSE TIMER

INSIDE OBSTRUCTION

VEHICLE DETECTOR

OUTSIDE OBSTRUCTION

VEHICLE DETECTOR

10111214151617181920212223

VEHICLE DETECTORVEHICLE DETECTORVEHICLE DETECTOR

OUTSIDE

OBSTR

NO

COM

USER 3

SHADOW/RESET

VEHICLE DETECTOR

SENSOR 1

SENSOR

COMMON

SHADOW

RESET

STATUS

SENSOR 2

DO NOT USE

SENSOR 3

DO NOT USE

(MX002413)

VEHICLE DETECTOR

DISPLAY

CHARGER

DO NOT USE

HySecurity

AC LOSS

MX000585

LOCK INTERLOCK

NOT SHOWN

DISPLAY AND

KEYPAD WIRING

WIEGAND

COMOPEN EDGE+24V +24V

RS232

D0810 Rev. A

S/N

VERSION

RADIO OPTIONS

Smart Touch Controller

COM COMA B

FIRE DEPT OPEN

EMERG CLOSE

RPM

LED

LIMIT DUAL GATE

24

BOARD, 5V-12V

ENCODER

TO CYLINDER -

SENSOR

GREEN -

RED +

TRANSFORMER

75VA

24VAC

SECONDARY

VARIABLE

FREQUENCY

DRIVE

(VFD)

RS-485

CONNECTION

BLACK XFMR TO L3

11

9

1

COLOR CODED XFMR TO L1

BLUE

2.2K

WHITE/BLUE

L3L2L1

W

V

U

L2

L1

L1 & L3

1 PH. USE ONLY

OR

2 HP @ 230V

2 HP @ 460V

3Ø TO THE ELECTRIC MOTOR

CHASSIS GROUND

L3

A 20A CIRCUIT BREAKER MUST

16 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 29

wire SizinG and runS

Supplying a gate operator with the correct electrical service is crucial to the performance of the operator and

the life of its electrical components. If the wire size used is too small, the voltage loss, especially during motor

startup, will prevent the motor from attaining its rated horsepower. The percentage of horsepower lost is far

greater than the percentage of voltage loss.

A voltage loss can also cause the control components to chatter while the motor is starting, substantially

reducing their life due to the resultant arcing. There is no way to restore lost performance resulting from

undersized wires, except to replace them. To avoid costly rewiring, be sure to choose a sufcient wire size

during site planning phases and at initial installation.

The tables on the following page are based on copper wire and allow for a 5% voltage drop. The ampere

values shown are the service factor ampere rating of the motor (maximum full load at continuous duty). At

minimum, a 20A circuit (protected with a 20A Inverse Time Breaker) should be provided.

Always connect electrical power and ground the operator in accordance with the NFPA 780 & NEC, Article 430

and Article 250. Research and adhere to other local codes that may apply.

Low Voltage Control Wiring

The Smart Touch Controller has very sensitive control inputs. The following is a chart of maximum distances for

wire size:

Wire Size Maximum Distance

18 ga 7.0 miles (11 km)

20 ga 3.5 miles (5.6 km)

22 ga 2.7 miles (4.3 km)

24 ga 2.0 miles (3.2 km)

26 ga 1.0 mile (1.6 km)

28 ga 3700 feet (1.1 km)

www.hysecurity.com © 2017 Power MX3636-01 Rev. C 17

Page 30

HydraSwing Wiring Chart (Incoming Power)

The maximum distance shown is from the operator to the power source, assuming that source power is from a

panel box with adequate capacity to support the addition of this motor load. The values are for one operator,

with no other loads applied to the branch circuit. Avoid placing more than one operator to a circuit, but if you

must, be certain to reduce the maximum allowed wire distance by half.

NOTE: HydraSwing gate operators connected for 1Ø operation will draw more current because the utility power to run the

machine will be carried to the operator on two wires instead of the three used for 3Ø operators. Be sure to allow for this difference

when specifying wire size.

Make sure proper wiring is being used. The following table shows the maximum allowable wire run from the

power source to the operator for various wire sizes. Performance of VFD operators on 1Ø and 3Ø 50\60 Hz

Power.

NOTE: Distance shown in U.S. Standard “feet.” Metric equivalent shown in parentheses.

HydraSwing VFD Wire Size Chart

Phase Ø 1 1 3 3 3 3

Voltage 208 230 208 230 380 460

Horsepower 2 2 2 2 2 2

VFD Rating

Amps

Wire Gauge Distance Distance Distance Distance Distance Distance

12 90 (27m) 100 (30m) 220 (67m) 240 (73m) 680 (207m) 830 (253m)

10 150 (46m) 170 (52m) 350 (107m) 390 (119m) 1090 (332m) 1310 (399m)

8 240 (73m) 270 (82m) 560 (171m) 620 (189m) 1730 (527m) 2100 (640m)

6 390 (119m) 430 (131m) 900 (274m) 990 (302m) 2750 (838m) 3330 (1015m)

4 620 (189m) 680 (207m) 1430 (436m) 1580 (482m) 4380 (1335m) 5300 (1615m)

2 990 (302m) 1090 (332m) 2280 (695m) 2530 (771m) 6990 (2130m) 8470 (2582m)

17.4 17.4 8.7 8.7 5.2 5.2

Performance of Operators on 1 and 3 Phase 50/60Hz

A HySecurity Variable Speed Drive (VFD) operators can operate on a wide variety of incoming power.

• 50Hz/60Hz operation with no changes or reconnection

• 1Ø or 3Ø operation by eld rewiring and reconnection. The incoming voltage must match the operator

nameplate. Although the electric motor can be reconnected, a different VFD (motor controller inside

the grey control box) is required between 460V and 208V/230V.

• Any AC powered peripherals such as locks, card readers and other devices need to be checked for

compatibility.

• The electric motors in all variable frequency drive operators are 3Ø/60Hz motors and are connected

for the voltage on the operator nameplate. (208V/230V or 460V)

18 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 31

How is this done?

WARNING

WARNING

• The VFD controller in the operator is rated to operate on input frequencies ranging from 48Hz through

62Hz on 1Ø or 3Ø power, but only on either 460VAC or 208V/230V. (A change between 460V and 230V,

either direction, requires replacement of the VFD controller).

• The control transformer in the operator has multiple voltage taps and rated for 50/60Hz operation.

• The VFD controller rst recties and lters the incoming power to DC, which has no frequency or

phase. It then creates 3Ø variable voltage/variable frequency AC for the motor from the DC.

• Depending on the model, the VFD controller ramps the motor voltage and frequency from 0V@0Hz at

start, to either 208/230 or 460 VAC at various frequencies for full speed. This allows use of 60Hz motors

regardless of the incoming frequency.

• Since the input voltage/frequency is converted to DC to begin with, there is absolutely no relationship

between the input frequency/phase and frequency/phase of the power supplied to the motor. The

input could be 1Ø or 3Ø, 48Hz or 62Hz and the controller/motor combination wouldn’t care. It will

create the ramped 3Ø voltage and frequency for which it is programmed

In-Field Connections

HydraSwing operators are eld re-connectable for 1Ø or 3Ø, 208/230VAC input power without changing

the VFD.

HydraSwing operators CANNOT be connected to 115/120VAC, 1Ø power or 575V, 3Ø power. If any attempts

are made to do so, serious injury, electrical shock, or death may result. Any electrical damage occurring to the

operator will not be covered by the Limited Warranty.

HydraSwing operators are NOT eld re-congurable between 208/230VAC and 460VAC power. The VFD Motor

Controller in a 208/230VAC unit must be replaced with a VFD Motor Controller manufactured for the higher

(460VAC) voltage input.

www.hysecurity.com © 2017 Power MX3636-01 Rev. C 19

Page 32

upS Backup pOwer OptiOnS

If you plan to use back up power options, additional site considerations are needed including conduit to house

the hydraulic hoses and electrical wiring. You need a 2-inch (5 cm) diameter conduit for hydraulic hoses and a

¾-inch (19 mm) conduit for electrical wiring. Mounting locations such as pad mount or wall mount also need to

be determined. See site planning overview in the installation instructions.

Supplemental manuals, available online, describe the installation overview, wiring and conduit considerations.

DC Power Supply (UPS) Connections

If you have a gate operator with a DC Power Supply unit, you will need

to connect the primary AC input power to the DC Power Supply.

Additional ¾-inch (19 mm) conduit is needed for electrical wiring

interconnections between the gate operator and DC Power Supply

Cabinet. AC input power is connected to the electrical components

in the chassis, and additional wiring is run through conduit to the DC

Power Supply Cabinet.

System features are covered in the DC Power Supply with HyCharger

Posts

Conduit

DC supplement shipped with the product and available online at

www.hysecurity.com.

20 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 33

AC Power Supply with HyInverter AC

Gate operators equipped with the AC Power Supply with HyInverter AC option are powered by four 12-Volt,

110Ah DC batteries which, when AC power loss occurs, maintain a true Uninterrupted Power Supply (UPS)

system. When the local AC power fails, the UPS back up system continues to move the gate. System features

are covered in the HyInverterAC Installation and Reference Manual shipped with the product and available

online at www.hysecurity.com.

NOTICE: The AC Power Supply with HyInverter AC option is intended for single phase (1 hp) gate operators and

single phase (2 hp) gate operators that use Variable Speed Drives (VFD).

Straps

Footman

Loops (2x)

HyInverter AC

Four 12V, 110Ah AGM batteries

Internal & external wiring not shown.

Drawing is not to scale

www.hysecurity.com © 2017 Power MX3636-01 Rev. C 21

Page 34

Page intentionally left blank

22 MX3636-01 Rev. C HydraSwing Programming & Operations © 2017 www.hysecurity.com

Page 35

Initial Setup

CAUTION

When you rst apply power to the operator, it is locked in Menu mode

and prompts appear on the display. The gate will not move and the

controls will not function until the prompts have been answered. The

prompts include:

• Usage Class setting

• Open Position setting (refers to the cylinder’s position when the

gate is open: Retracted or Extended)

• Three external entrapment protection SENSOR requirements.