Page 1

Hy-Security

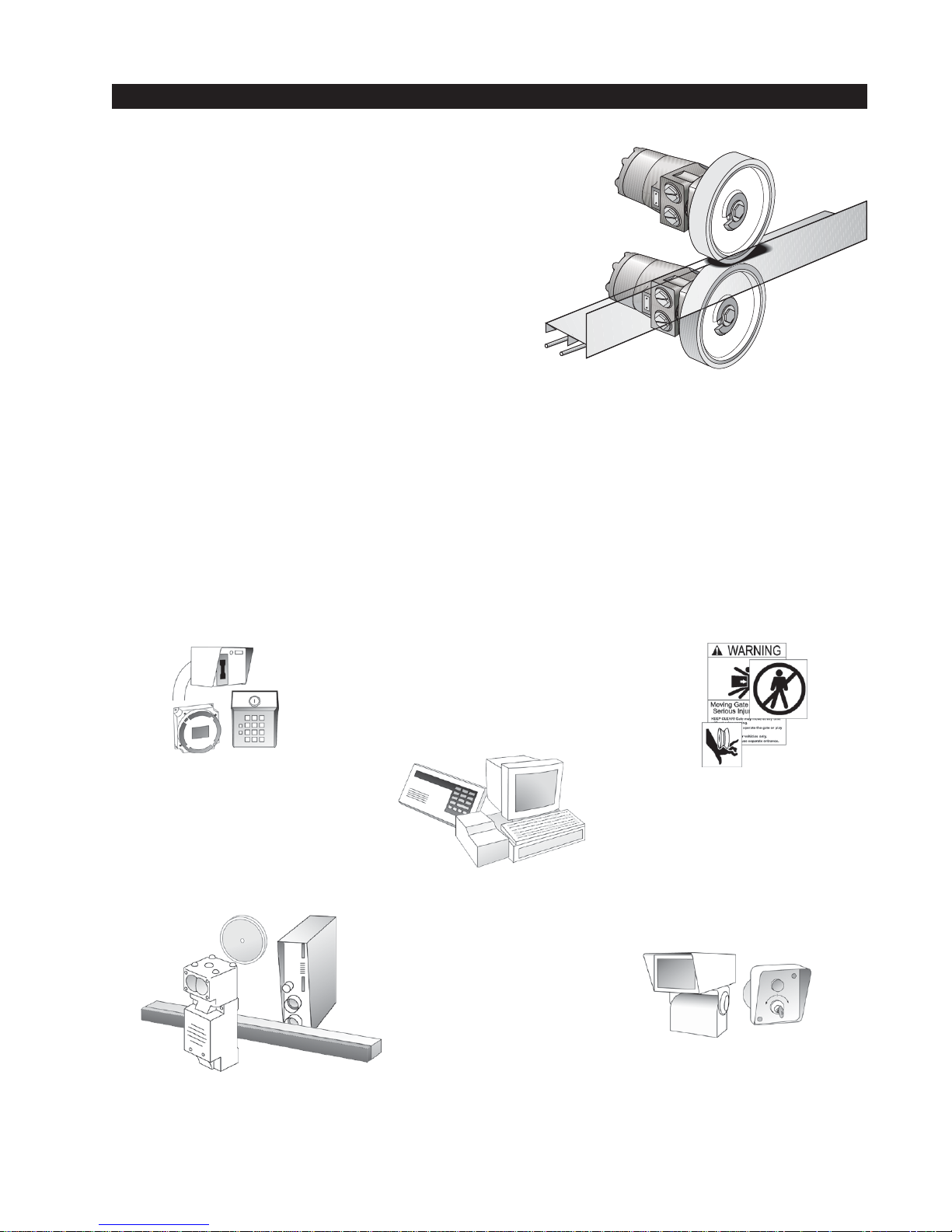

Gate Operators

HYDRAULIC

SLIDE GATE

Operators

With Smart Touch Controller

Installation and Maintenance Manual

Models 222 SS, E, EX, XI

333 MS, E, EX

222 CF, CE, CX

444 XS

and

DC Battery Operated Models

222 DS, DE, DX

444 DX

Revision: ___

Hy-Security Gate Operators

Phone: 1-800-321-9947

F AX: (206) 286-0614 INSTR# 103

Internet: www.hy-security .com

Email: Info@hy-security .com Date 04/01/02

Page 2

Installation and Maintenance Manual

Heavy Duty Industrial Slide Gate Operator

(c)Copyright 2001 Hy-Security Gate Inc.

All rights reserved. No part of this manual may be reproduced by any means: photocopier, electronic or

mechanical, without the express written permission of Hy-Security Gate Inc. Additionally, Hy-Security Inc.

makes no representations or warranty with respect to this manual. We also reserve the right to make

changes in the products described without notice and without any obligation to notify any persons of any

such revision or change.

ii

Page 3

Installation and Maintenance Manual

Table of Contents

Introduction .................................................................................................................v

Warranty Registration................................................................................................vi

Available Models and Features.............................................................................. 1-2

I. Safe Gate Design

Important Information.................................................................................................3

Entrapment Protection Schematic ............................................................................4

Install an Automatic Operator only When: ................................................................5

Important Information for Gate System Owners & Users........................................6

II. Installation

Tools Required – Getting Started with an Automated Gate System ................... 7-8

Installation Preparations and Installation ........................................................... 9-12

Mechanical & Hydraulic Adjustment s......................................................................13

Technical Drawings............................................................................................. 14-16

III. Smart Touch Set up

Basics of Using the Smart Touch Controller ..........................................................17

Installation Configuration for Smart Touch Controller ..........................................18

Wiring Control Inputs to the Smart Touch Controller ...................................... 19-20

Connecting a Master/Slave Pair...............................................................................21

Table of User and Installer Menu Functions ..................................................... 22-23

User Menu: Description Functions Available .........................................................24

Installer Menu: Description Functions Available.............................................. 25-26

Correctional Facility / Interlocked Pair / User Optional Wiring .............................27

Options for User Programmable Output Relays ....................................................28

Clock Functions ........................................................................................................29

IV. Entrapment Protection

Entrapment Protection Schematic ..........................................................................30

UL 325 Standard Requirements for Entrapment Protection Devices ...................31

Placement and Use of Secondary Pedestrian Entrapment Sensors ....................32

Installing Gate Edge (Cont act Type) Reversing Sensor.........................................33

Installing Photoelectric (Non-Cont act) Sensor................................................. 34-35

iii

Page 4

Installation and Maintenance Manual

Table of Contents, continued

V. Detectors and Loops

Loop and Detector Installation Guide ............................................................... 36-38

Vehicle Detector Options..........................................................................................39

Hy-Security Hy-5A Vehicle Detector Installation.....................................................40

Standard 11 Pin Vehicle Detector Installation.........................................................41

Vehicle Detector & Loop Fault Diagnostics ............................................................42

V ehicle Detector Configuration and Anti-Tailgate Modes......................................43

VI. Accessories

24 Hr / 7 Day Time Clock Option ..............................................................................44

Connecting a Radio Receiver...................................................................................45

Remote Release Mechanism....................................................................................46

Internal Solenoid Lock Options ......................................................................... 47-49

VII.Troubleshooting and Maintenance

Troubleshooting .................................................................................................. 50-51

Maintenance ........................................................................................................ 52-53

Manual Release Mechanism.....................................................................................54

VIII.Two part Operators (Battery types & 333)

Battery DC Systems (DS, DE, DX)

Important Notes about DC Powered Gates.............................................................55

Wiring & Control of DC Operators ...........................................................................56

Plan and Elevation for DC Power Supply................................................................57

Battery Connection diagrams ............................................................................ 58-59

Modular Systems (333 MS Series) ..................................................................... 60-61

IX. Appendix

Wiring Size Schedules........................................................................................ 62-63

444 Operator Components & Footprint...................................................................64

Components & Replacement Parts.................................................................... 65-71

Limited Warranty.......................................................................................................72

iv

Page 5

Installation and Maintenance Manual

Introduction

Welcome – We would like to take this opportunity to thank you for this

purchase. Hy-Security has manufactured the finest hydraulic gate

operators available since the 1970s. Our commitment to quality and

innovation will become evident as you become familiar with the features

and performance of this expertly engineered machine. All Hy-Security

operators are equipped with the Smart Touch Controller, a digital electronic brain that offers unparalleled features.

Please take a few minutes to study the contents of this instruction

manual. The benefits of taking a little extra time to align the gate operator properly and to verify a fully functional installation will ensure customer satisfaction and a longer life with minimal maintenance costs.

Installers and owners must be certain to thoroughly review and

understand the Import ant Information regarding pedestrian entrapment protection contained within this manual. There are hazards

associated with automatic gates that can be greatly reduced with

proper design, installation use. When an automatic gate is first

made functional, the installer must teach the owners and users how

to operate this system correctly. When the installation is complete,

leave this manual for the owner’s use and reference.

Please do not hesitate to give your Hy-Security distributor a call if you

experience any difficulties during the installation. They are experienced

and trained to assist in resolving any problems.

v

Page 6

Installation and Maintenance Manual

For warranty registration, please fill in this information, fax or mail a

copy to Hy-Security, then give this manual to the owner of the gate.

Owner Name: _______________________________

Telephone number: ___________________________

Hy-Security Distributor: ________________________

Telephone number: ___________________________

Installer name: ______________________________

Telephone number: ___________________________

Serial number of operator: _____________________

Date installed: _______________________________

Model of Operator____________________________

Warranty Registration

Hy-Security Address:

1200 W Nickerson

Seattle, WA 98119

FAX: (206) 286-0614

Date: ________

vi

Page 7

Installation and Maintenance Manual

Available Models and Features

Hy-Security manufacturers eighteen different models of hydraulic slide gate operators to suit the

size, weight and desired speed of the gate panel. All of the operator models are derived from the

standard 222 SS, upon which this manual is designed. Take a moment to identify the operator

model you have and note there are some changes in the instructions, especially in regards to final

adjustments. The following chart shows the differences at a glance:

Std. Models 222 SS 222 E 222 EX* 444 XS

Modular Models 333 MS 333 E 333 EX*

Prison Models 222 CF 222 CE 222 CX*

24V UPS Models 222 DS 222 DE 222 DX* 444 DX

Features:

Horsepower 1HP 1HP 2HP 5HP

Rate of Travel 1.0 ft/sec 1.0 ft/sec 2.0 ft/sec 1.0 ft/sec

UL Usage Class 1 - 4 1 - 4 3 - 4 3 - 4

Warranty 5 years 5 years 5 years 5 years

Soft Stop yes yes yes yes

Brake Valves no yes yes yes

Soft Start no no yes yes

Drawbar Pull 300 lbs 300 lbs 300 lbs 1200 lbs

*X1 Option (1'/sec) 600 lbs

Weight Capacity 1000 lbs 4000 lbs 4000 lbs contact factory

*X1 Option 8000 lbs

Notes: Std. unit brake valve heavier 4 drive wheels

2 drive for heavy gates for very heavy

wheels gates 2 foot/sec gates

Stopping the Gate

All models employ a time delay Soft Stop system. Additionally,

optional brake valves (shown at right) are used to control the

stopping of heavy or fast moving gates. These valves are exclusive to Hy-Security operators. They are independently adjustable

to allow the gate to stop predictably and without banging.

Starting the Gate

When starting very heavy gates to accelerate faster than one foot

per second, it is necessary to Soft Start the load gently, in addition

to stopping it smoothly. Hy-Security accomplishes Soft Start with

another exclusive feature we call an AWOG, which diverts some of

the start-up hydraulic flow and thereby allows the gate to accelerate over a period of about 2 seconds. This is much like letting your

foot slowly off a car clutch - no lurching when the gate starts. The

AWOG definitely improves the life and performance of a gate

system and never needs adjustment.

1

Page 8

Installation and Maintenance Manual

Available Models and Features

Operators for Heavy Gates: E Models

Models 222 E, 333 E, 222 CE and 222 DE differ from the base model only by the addition of a

hydraulic manifold with two adjustable brake valves, shown on the previous page. The brake valves

extend the maximum weight capacity from 1,000 pounds to up to a 4,000-pound gate. Brake valves

are highly recommended for heavy-duty applications.

High Speed Operators: EX Modes (UL class III and IV only)

The AWOG soft starting system and the brake valves are keys to smoothly moving gates faster than

one foot per second. These devices, together with our hydraulic drive, create smooth and predictable handling for both small lightweight or large heavy gates. The 222 EX, CX, and DX models also

employ larger drive wheels and a higher flow rate pump to achieve a speed of 2.0 feet per second.

DC 24-Volt UPS (Un-interruptible Power Supply) Operators

These gate operators function from 24 Volts DC Batteries all of the time to achieve a true UPS

system. Our Un-interruptible Power Supply is the most certain way to know that your gate will work

when the local AC power fails. This system features fully sealed maintenance free batteries in a

separate insulated and ventilated enclosure. A two-battery version provides at least 3,000 feet of

backup gate travel. A four-battery version provides at least 8,000 feet of backup travel during local

power loss.

“CF” Correctional Facility Operators

The CF models offer an extra heavy 10-gage cover with three different locking options. Type CF

operators are shipped ready to interface to the many options and interlocks commonly used at

correctional facilities, such as gate position outputs, interlock capability for sally ports and an interface relay to control an external solenoid lock.

333 Modular Operators

The family of 333 type operators is a two part modular version of the standard 222 operator. The

motor, hydraulic pump and electric controls are located in a separate enclosure from the drive unit.

This version allows for a more flexible placement of the operator, which may be required or desirable

in some situations involving unique mounting, special security or those wanting a very quiet operator. (When the hydraulic controller is mounted at a distance)

444 Super Powerful Operators

The 444 type operators are for heavier gates, weighing up to 20,000 lbs. They employ a much

larger chassis with four drive wheels and hydraulic motors, and a five horsepower electric motor to

generate up to 1200 pounds of draw bar pull.

The Smart Touch Controller

This is the brain of Hy-Security’s automatic operators. Truly high technology, but also very rugged to

reliably serve in the harshest environments. The Smart Touch Controller can quickly be configured

by an installer or user to adapt to about any functional requirement for a specific site. All system

settings are performed with the use of just four programming buttons and an LCD display. The

Smart Touch Controller has no switches of any type to set. An RS232 port for external communication is standard. A real time clock and an EEPROM record system events. With optional software, a

log of events can be downloaded from the RS232 port. Vehicle detector modules will set a new

industry standard by communicating a host of valuable performance data to the main Smart Touch

controller via a serial data stream, allowing user-friendly diagnostics.

2

Page 9

Installation and Maintenance Manual

READ THIS FIRST!

Important Information - Review Before Installation

Automatic gate operators provide convenience and security to users. However, because these

machines can produce high levels of force it is important that all gate operator system designers,

installers and end users be aware of the potential hazards associated with improperly designed,

installed or maintained systems. Keep in mind that the gate operator is only one component of the

total gate operating system. It is the joint responsibility of the specifier, designer, purchaser, installer and end user to verify that the total system is appropriately configured for its intended use.

All parties should be informed that entrapment in a moving gate could cause serious injury or death.

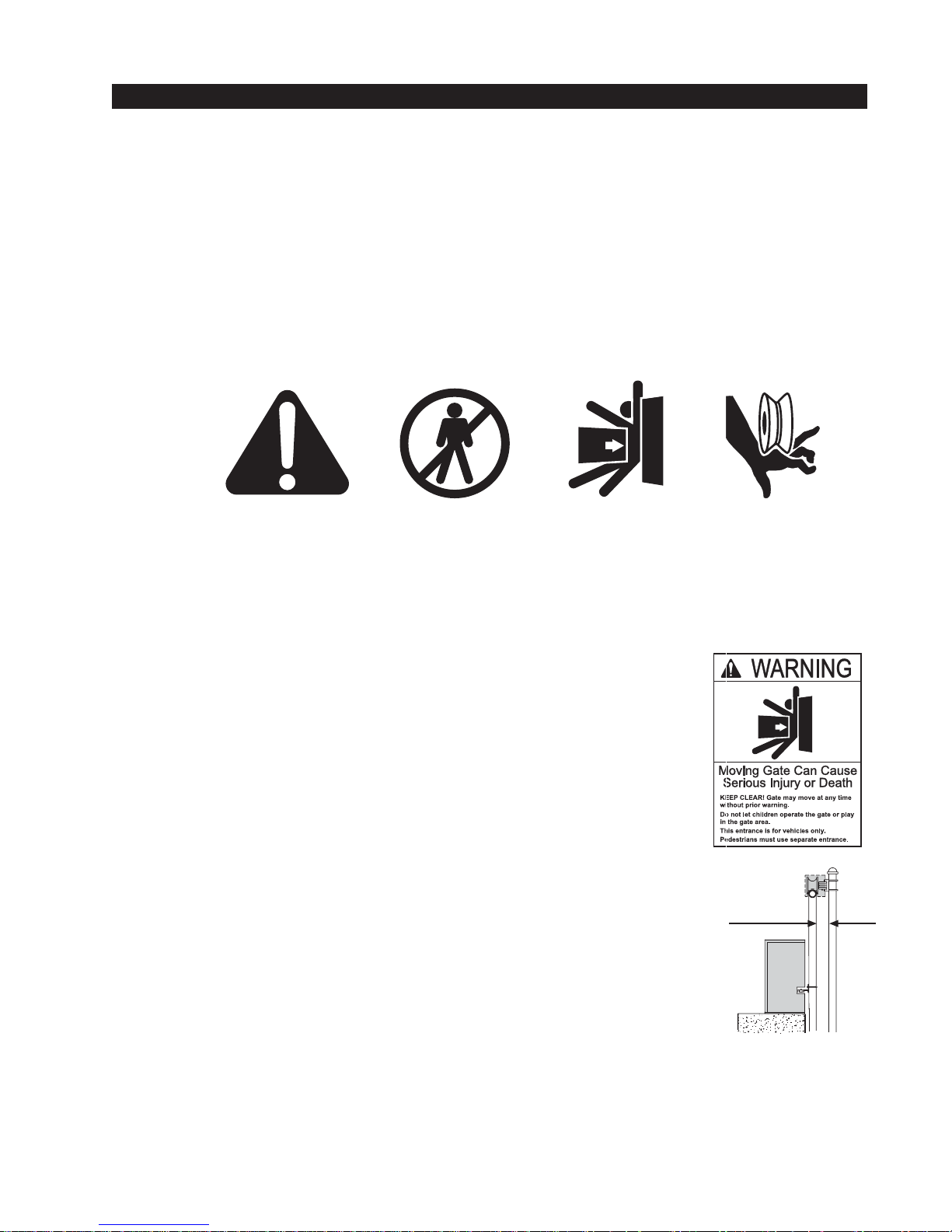

Common

Industry

Symbols

Important Instructions for Gate System Designers & Installers:

WARNING: To reduce the risk of serious injury or death, read and

follow all instructions in the gate operator handbook and on the

warning labels.

Install an Automatic Gate Operator only When:

• The entry is configured for vehicular use only. Pedestrians must be directed to a separate walk-through entrance. The Warning signs that have

been supplied with this operator must be installed, in manner clearly

visible, in the area of both sides of the gate.

• All openings of a horizontal slide gate are guarded or screened, from the

bottom of the gate to a minimum of 4 feet (1.2 m) height above the

ground, to prevent a sphere 2 1/4 inches (57 mm) in diameter from passing through an opening anywhere in the gate or the portion of the adjacent

fence that is covered in the open position.

• All exposed pinch points, rollers and wheels are guarded. To reduce the

risk of entrapment, the gate must also be installed so that enough clearance is provided between the gate and adjacent structures both when

opening and closing. Minimize the parallel gap between the gate and the

fence.

minimize

gap

• The gate has been constructed with physical stops to prevent over-travel

in both directions and has guard posts that prevent the gate from falling in

the event of a roller failure.

3

Page 10

Installation and Maintenance Manual

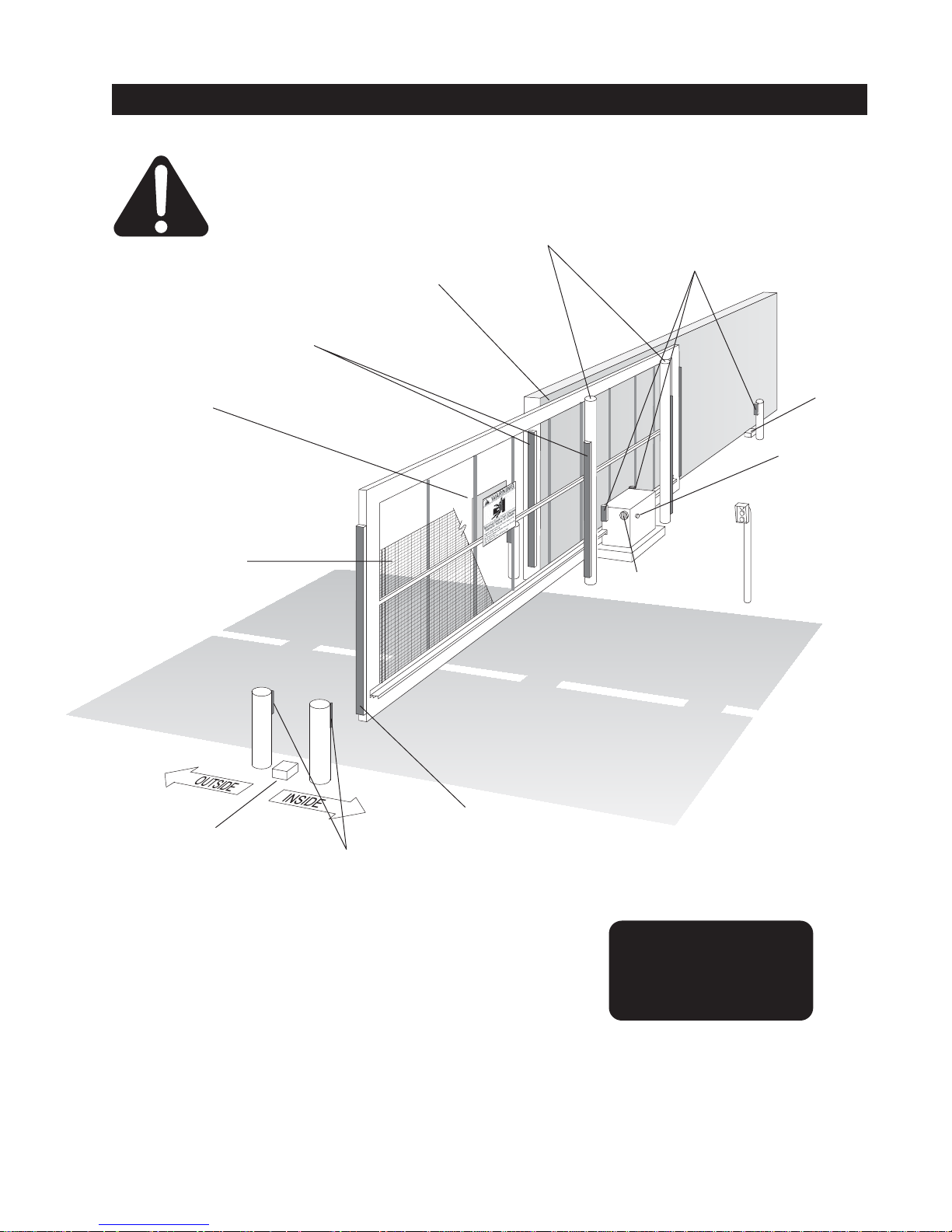

Entrapment Protection Device Schematic for Sliding Gates

Attention

Warning signs must be

on both sides

2" safety mesh

prevents reachthrough: height not

less than 48 inches

Gate edge

sensors

Keep this gap as

small as possible

Guard posts

Photo Eyes for

both directions

Physical travel

stop, both ends

Stop and reset

button

Access controls at

least six feetaway

from gateand

operator

Audio alarm

Physical travel

stop, both ends

Photo Eyes for

both directions

each side of gate

This schematic view is not meant to recommend the only way to set up your configuration, but to

point out the various elements of a proper automatic vehicular gate installation. The gate operator

itself is only one component in the total system. Always install a separate pedestrian gate.

Gate edge sensor, on

leading edge and

trailing edge

Note: All wheels must

be covered. (Wheels

and covers not shown

for clarity)

4

Page 11

Installation and Maintenance Manual

Install An Automatic Sliding Gate Operator Only When:

• The gate moves freely in both directions. Never over-tighten a clutch or pressure relief valve to

compensate for a stiff gate.

• The operator will be installed on the secured (non-public) side of the gate.

• The operator will be properly electrically grounded and the intended supply voltage matches the

voltage label on the operator.

• The controls that operate the gate have been mounted far enough away from the moving gate

such that users cannot touch the gate while operating the controls. All easily accessible controls

must have a security feature to prevent unauthorized use.

• The operator controls will be located in a clear line-of-sight to the gate. Radio controls and other

remote access controls must be connected only to the Remote Open input.

• The required external entrapment sensors will be installed. Be certain to carefully review the

instructions for placement, installation and adjustment of these external entrapment sensors.

External entrapment sensors must function to reverse the movement of the gate in both the

opening and closing directions. If edge (contact) sensors are used, they are to be mounted on

the leading edge, trailing edge of the gate, as well as post mounted on the inside and outside of

the gate (See figure on page 4). If photo eyes or other non-contact sensors are used, they are to

be mounted in locations most likely to guard against entrapment. A combination of contact and

non-contact sensors may be used, but all must be recognized components under the UL 325

standard. See pages 31 and 32 for details on the requirements.

• If the Entrapment protection is provided by a continuous pressure actuation control, a placard

stating “WARNING” - “Moving Gate has the Potential of Inflicting Injury or Death - Do Not Start

Gate Unless Path is Clear.” Additionally, no other activation device shall be connected and an

automatic closing device of any kind shall not be used.

• The automatic operator is labeled as appropriate for both the type and UL usage class of the

gate. Note: Sliding gate operators installed in Class I & II applications must not move the gate

faster than one foot per second.

Class I: Intended to serve single to four family residential uses

Class II: Multi-family use, or any application intended to serve the general public

Class III: Commercial applications not intended to serve the general public

Class IV: Highest security. Security personnel prevent unauthorized access

• Sliding gate operators installed in Class III & IV applications do not have a speed restriction and

the secondary entrapment sensor requirement is met if the system is configured as described for

Class I & II use, or by the following alternate means: Employ the use of a 100dB buzzer, which

sounds at least 3 seconds before the gate moves, and/or functions only by use of a constant

hold type push button control

5

Page 12

Installation and Maintenance Manual

Important Information For Gate System Owners & Users

WARNING: To reduce the risk of serious injury or death, read and follow all instructions in

the gate operator handbook and on the warning labels.

Save These Important Owner and User Instructions:

(Installers - be certain to instruct the owners and users about the following items)

• Automatic gates are for vehicular use only! Provide walkways and signs to direct pedestrians to

a separate walk-through entrance. Because an automatic gate can start at any time without

warning, always keep people away from the area of the gate. The Warning signs that have been

supplied with this operator must remain installed, in manner clearly visible, in the area of both

sides of the gate.

• Never allow children to use or play with controls that operate the gate. Keep all remote controls,

especially radio transmitters, away from children.

• Teach all users how to turn off the electric power and how to release and move the gate manually. Use the manual release only when the gate is not moving.

• Test the function of the gate operator monthly. The gate MUST reverse its direction of travel

upon contact with a rigid object, and/or stop upon a sensing a 2nd sequential activation prior to

reaching a full travel limit. Also test for the normal function of any non-contact sensors. If the

gate system employs the use of a transmitting edge sensor, be especially certain to test and

replace its battery on a routine basis.

• KEEP AUTOMATIC GATES PROPERLY MAINTAINED. Have a professional gate installer

perform routine tests of the entrapment protection sensors, such as photo eyes and gate edges.

Also, make all necessary repairs to the gate hardware to keep the gate running smoothly. Failure to adjust and test a gate operator properly can increase the risk of injury or death.

• In addition to appropriately placed external entrapment sensors, ask your installer to reduce the

setting of the pressure relief valve to the lowest setting allowable that reliably operates the gate.

This valve controls the force of the operator, and the sensitivity of the inherent reversing sensor.

• Do not attempt disable or muffle the Warn Before Operate buzzer, except in class IV

restricted access locations. This buzzer provides an alert that the gate is about to move.

6

Page 13

Installation and Maintenance Manual

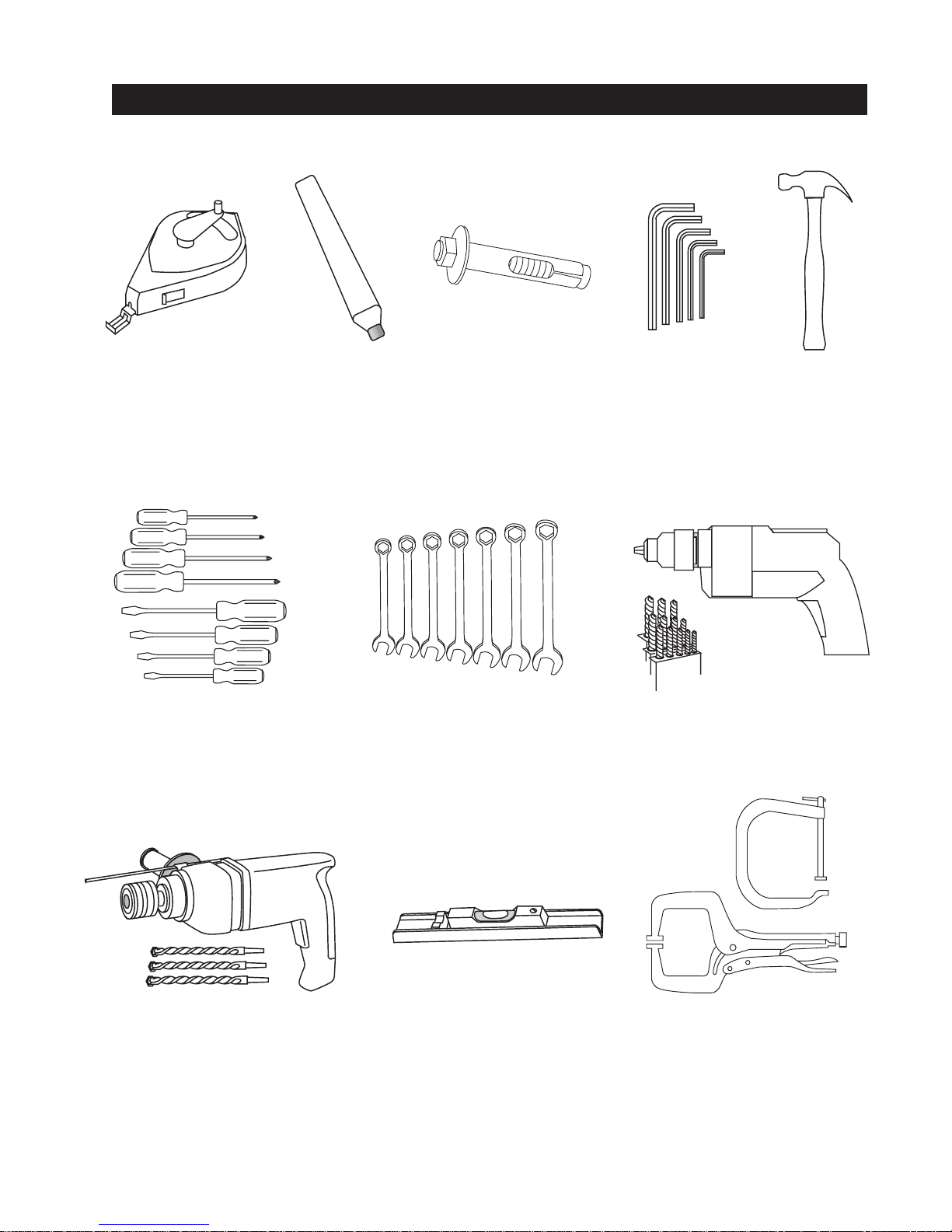

Tools Required for an Efficient Installation

1. chalkline or other

builders string

6. screwdriver sets,

Straight and Phillips

2. carpenters

pencil or crayon

7. wrench set, open

end,

3. concrete anchor

bolts - four

1

/4" through 1"

1

/2" x 4

4. allen wrench set 5. hammer

8. electric drill and

bits 1/8" through 3/8"

9. roto-hammer and

3

/8" through 1/2"

bits,

10. level - it doesn't

have to look like this

one, but the installation

needs to be level!

7

11. Two pair wide

jaw vice grip pliers,

or two C clamps,

4" capacity

Page 14

Installation and Maintenance Manual

Getting Started with an Automated Gate System

• How our hydraulic operator works

Hy-Security industrial slide gate operators rotate

polyurethane treaded drive wheels which grip a rigid

metal drive rail and feed it right or left during the gate

travel. The drive wheels are clamped above and below

the drive rail and are directly coupled to powerful

hydraulic motors, which can easily move huge gates.

This simple yet durable drive system is one of the

unique features giving our hydraulic operators their

reputation for reliability.

• Accessory Compatibility

Hy-Security’s Hydraulic Slide Operators are fully compatible with all standard access control devices and entrapment protection devices, some of which are listed below.

• Pedestrian Entrapment Protection

Read and understand all the Important Information in Section 1, the Entrapment Protection Schematic on page 4 and the UL requirements on page 31 before beginning the installation. Be absolutely certain that the required type and quantity of Entrapment Protection devices have been

supplied and that you understand how to install them correctly. Contact your local distributor with

questions about Entrapment Protection.

Basic Access Control

Radio Transmitter

Long Distance Control

Pushbutton Control Station

Programmable Time Clock

Card Reader

Obstruction Sensing Devices

Inherent Sensing Device

Gate Edges

Photo Eyes

Vehicle Detectors

Information

Signs

Labels

Warnings

Advanced Access Control

Access Control Interface

Card Reader

Keypad

Telephone Entry

Input/Output

Computer Interface RS232/485

Security

Key Locks

Closed Circuit Television

Gate Position Indicator

Interlock/Sally Port

Gate Status Indicator

8

Page 15

Installation and Maintenance Manual

Remember to

cover all four of

the cantilever

gate wheels

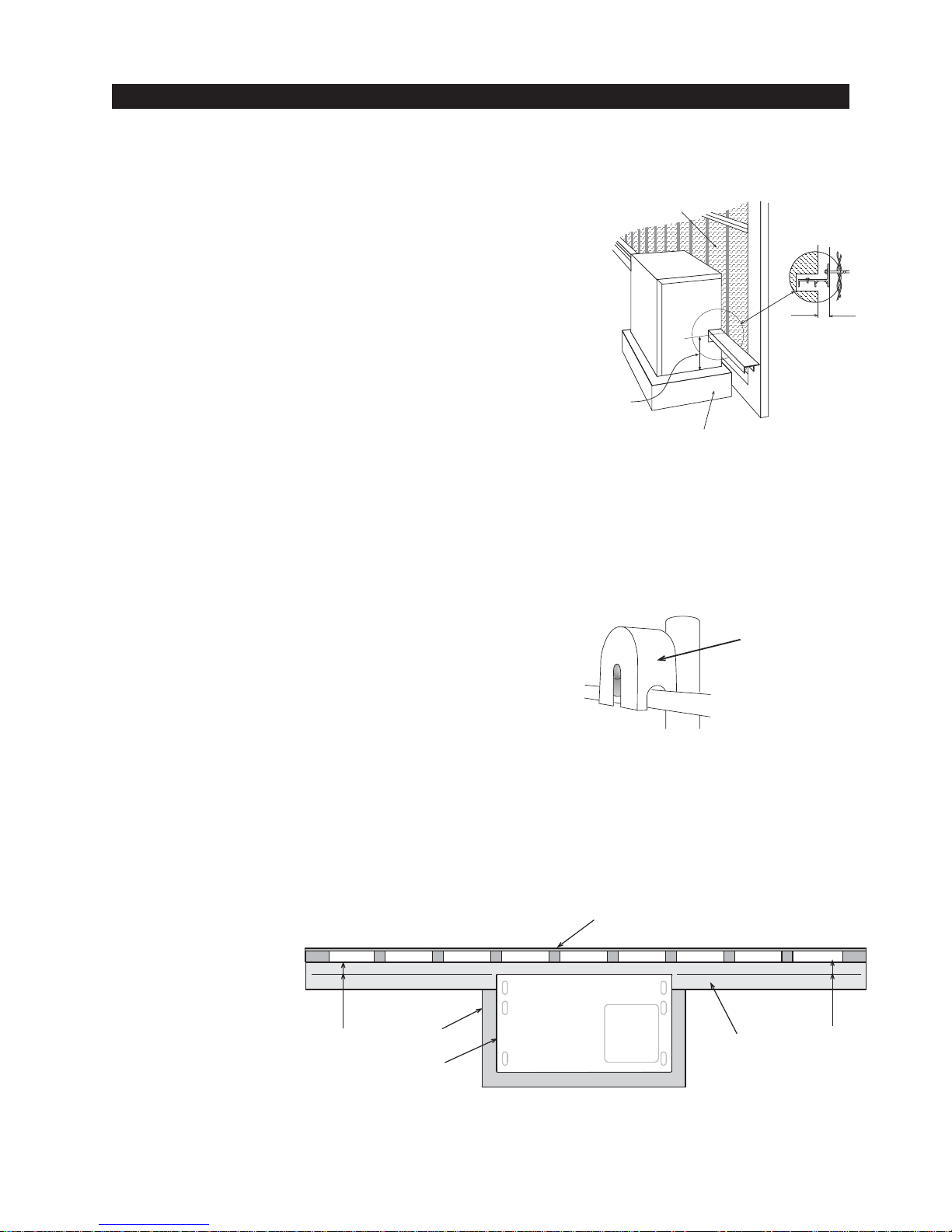

Installation Preparation Checklist

1. Read all of the instructions, especially the Important

Information in Section 1 at the beginning of this

manual, before you attempt installation. This section is

focused upon mechanical installation. For electrical

setup, refer to Section 3, on system configuration and

safety mesh to prevent

reach-through

use of the Smart Touch Controller.

2. Check to see that the mounting slab is the recommended size and ready to have an operator attached.

Also check that electrical conduits are correctly located

to enter the chassis. Hy-Security recommends a slab

reaches below the local frost line and extends somewhat above grade. See the footprint plan and elevation

view on pages 14 & 15.

Drive rail

location:

3

9

/4" from top

of slab to top of

drive rail

concrete slab

3. Make sure the gate rolls smoothly in both directions, without any binding of the gate hardware. If the

gate is warped or hard to move, stop and fix the gate before attempting to automate.

Figure A

Gate distance

from operator:

3

/4" back of

1

drive rail to edge

of operator

4. Verify that you have covers for all exposed gate support

wheels. These must be installed. Also, look around to

identify all of the potential pinch points and hazardous areas,

Figure B

and plan the best location for the entrapment protection

devices and warning signs. Remember that you are required to advise the owner regarding the potential hazards

of an automatic gate and about the function of the entrapment protection sensors that you have selected and installed.

5. There are 3 steps to a perfect inst all: location, location, location. One of the most critical adjustments in installation will be to make sure the operator is located the proper distance from the gate,

and that the gate and operator are as parallel as possible. See Figure C below . Prepare some

shims for aligning the drive rail.

fence

Figure C

Note: If necessary, shim the drive rail so that it is straight 1/4" throughout the travel distance of

the gate.

3

1

/4"

slab

drive rail

operator

3

1

/4"

9

Page 16

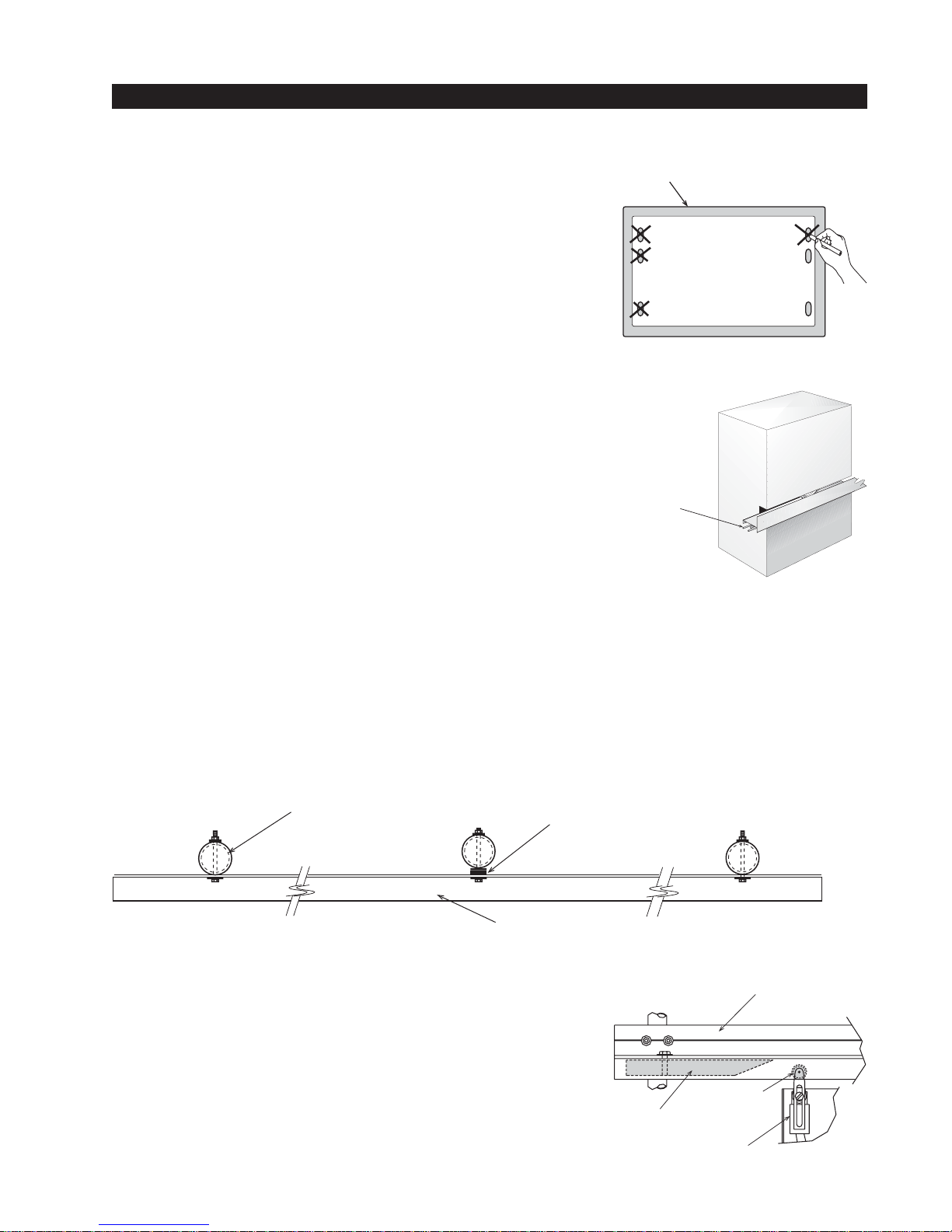

Installation

1. Drill four holes for concrete anchors

Each operator comes with a paper template with the anchor

slots. Place the template on the slab; making sure that it is

parallel to and 1 3/4" from the gate. Trace the slots, remove the

template, and then scribe the locations for your anchor bolts.

Drill holes for the anchor bolts in the center of the slots you

marked, so that you will have some room for adjustment. There

are six mounting slots in the chassis, install at least four 1/2 “ x

4” concrete anchor bolts, using two per side.

2. Line up the operator

Put the operator in position onto the anchor bolts. Verify that the

operator is parallel and 1 3/4" away from the gate on both the left

and right sides, and then tighten the anchors securely.

Installation and Maintenance Manual

slab

3. Two part Operators (battery models and 333 modular

models)

These two part operators come with a separate enclosure, which

Roll pins line

up drive rail

segments to

assure perfect

splicing

should be mounted within 10 feet of the operator, but not more

than 100 feet. We recommend wall mounting or using two 4"

posts, with horizontal mounting strut to create a support for this

enclosure.

4. Bolt the Drive Rail to the Gate Panel

Connect multiple sections of drive rail together with 1/4" roll pins for a perfect splice. The drive rail

must be bolted to each vertical member of the gate panel. This may be done with U-bolt clamps or

through bolts, however U-bolt clamps allow for easy up down adjustment. If the gate is bent or

warped, shim the drive rail so that it is straight ± 1/4" throughout the travel of the gate. When the

drive rail has been installed at the correct height, the top surface is 9 3/4" above the operator base.

A label on each side of the operator indicates the correct height.

fencepost shim as necessary

5. Install Limit Ramps on Underside of Drive Rail

Push the gate to the fully closed position and drill a 3/8" hole in

through the drive rail to mount a 12" plastic limit ramp under the

drive rail, in the wheel channel, at a location that will trip the

limit switch approx. 6" before the exact spot you want the gate

to stop. Adjust the lever arms on the limit switch so that the

roller clears the underside of the drive rail by at least 1/4 inch.

Push the gate fully open and repeat this procedure with the

other limit ramp. See the Drive Rail drawing S22 on page 16.

drive rail

drive rail

limit roller

limit ramp

limit switch

10

Page 17

Installation and Maintenance Manual

OFF

POWER

ON

manual

release

verify 2" when

engaged

Installation

6. Install Grip Tape to Underside of Drive Rail

Two pieces of grip tape have been provided that should be installed on the underside of the drive

rail. Place the tape on the first and last 2 ft. of travel, just in front of each limit ramp. Be certain the

drive rail is clean and dry, and then peel off just a bit of the backing to expose only about 2" of the

adhesive. Attach the tape to the underside of the drive rail, within 1" of the front of the limit ramp.

Now that the tape is lined up, peel the remainder of the backing away and attach the full length of

the tape. Repeat this procedure for the other end of the drive rail.

7. Clamp the Drive Wheels to the Drive Rail

When the wheels are fully clamped on the drive rail, the

red spring should be compressed to 2" in height. If

adjustment is necessary, turn the nut at the bottom of the

threaded rod assembly. Slightly less compression is okay

for lighter gates. See Use of Manual Release on page 54

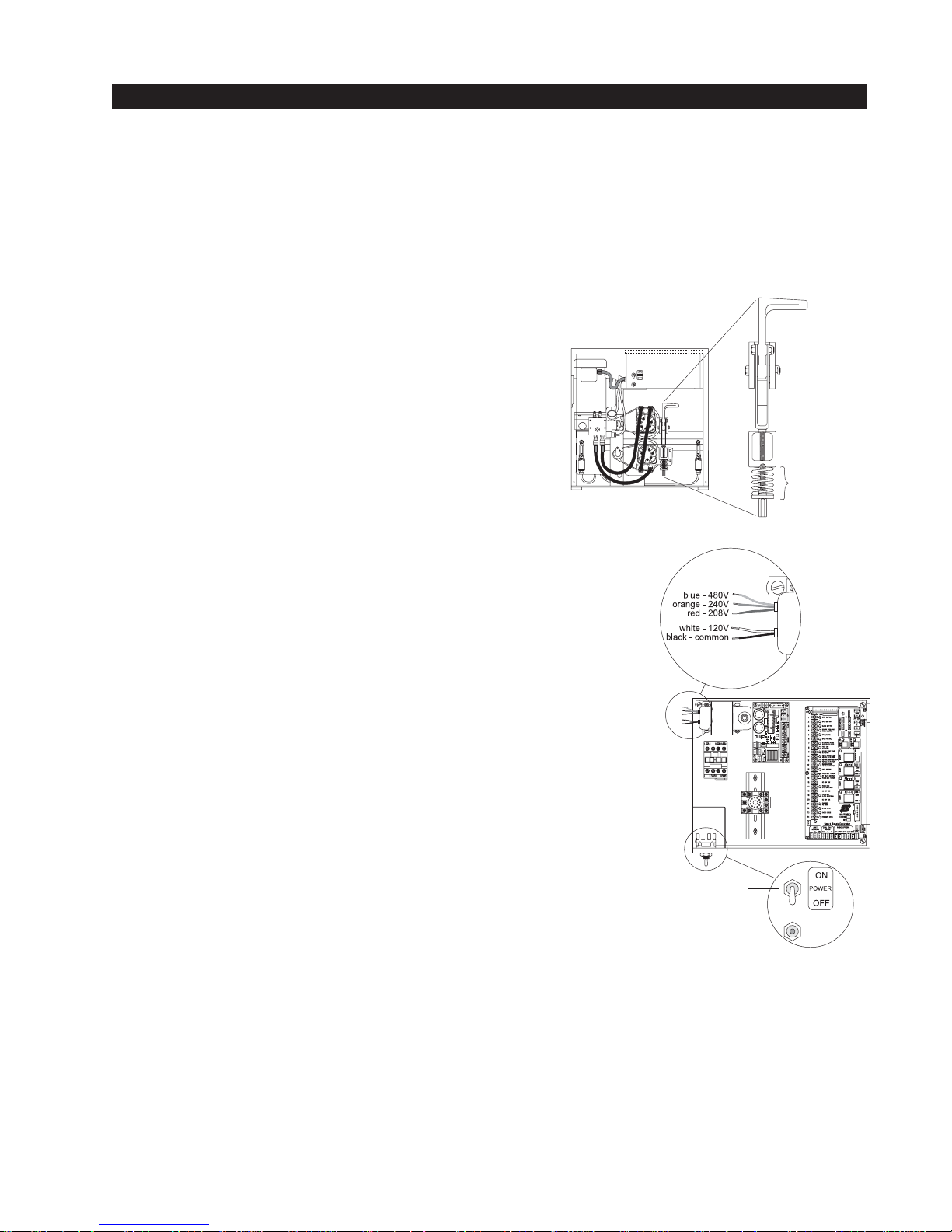

8. Electrical Power Connection

This operator is intended for permanent installation, so all

electrical conduits must be properly connected to the

control box. The entry for the primary power is a 1/2 - 3/4"

knockout on the left side of our control box next to the on-off

switch. When this operator was manufactured, it was built to

run on a specific voltage and phase for line power. Make sure

you have compared the line voltage and phase available with

the nameplate on this machine. They must match! Be certain

that the wire size of the branch circuit that will supply the operator vs. the distance of the run from the main panel is large

enough to avoid excess voltage drop. Also be sure the operator

is electrically well grounded. See the Appendix, page 63 for

correct wire sizes and detailed electrical wiring information.

9. Primary Tap of Control Transformer

(not on battery operators)

Check to make sure that the primary tap on the control transformer matches the line voltage you have connected to the

operator. Measure the line voltage carefully to distinguish between 208V and 230V branch circuits. A label on top of the

transformer identifies the various voltage taps.

power

connection

on/off switch

stop/reset

P

R

R

E

E

K

S

A

S

E

T

R

O

B

R

T

I

E

U

S

C

E

R

I

T

C

control

transformer

primary taps

RUN

RELAY

15 AMP

PROGRAMMABLE

USER RELAY

15 AMP

PROGRAMMABLE

USER RELAY

15 AMP

PROGRAMMABLE

USER RELAY

10. Electrical Power for Two Part 333 type operators

The primary AC power must be routed to the controller enclosure with the pump, but there must

also be conduits between the gate operator and the controller enclosure.

Note: AC power is not needed in the gate operator, unless there is an optional heater. A minimum

of two separate conduits must be provided, 2" for the hydraulic hoses and 3/4" for the electrical

interconnections. Unless there are accessories in the gate operator, the only electrical interconnection between the two enclosures will be three wires between the two terminal strips for the limit

switches. Join the hydraulic hoses by plugging the quick coupling together according to the hand of

the gate. See the drawing in Section 8, page 60.

11

Page 18

Installation and Maintenance Manual

Installation

11. Connections for Two Part Battery Operators

The primary AC power must be routed to the DC power supply enclosure, but there must also be at

least a 1" conduit between the gate operator and the DC supply enclosure. Note: AC power is not

needed in the gate operator enclosure, unless there is an optional heater. Three separate DC

circuits are required between the battery supply and the gate operator. Heavy gage wires to supply

the motor and two 14-gage circuits for the controls. The heavy gage wire must be at least 6-gage if

the DC supply is within 20 feet of the operator, but must be increased to 2-gage if the DC supply is

located farther from the operator, or the this is an EX - 2'/sec model. Also see page 56 titled “Wiring and Control Configuration for DC Operators” and Drawing E125 in Section 8, page 58.

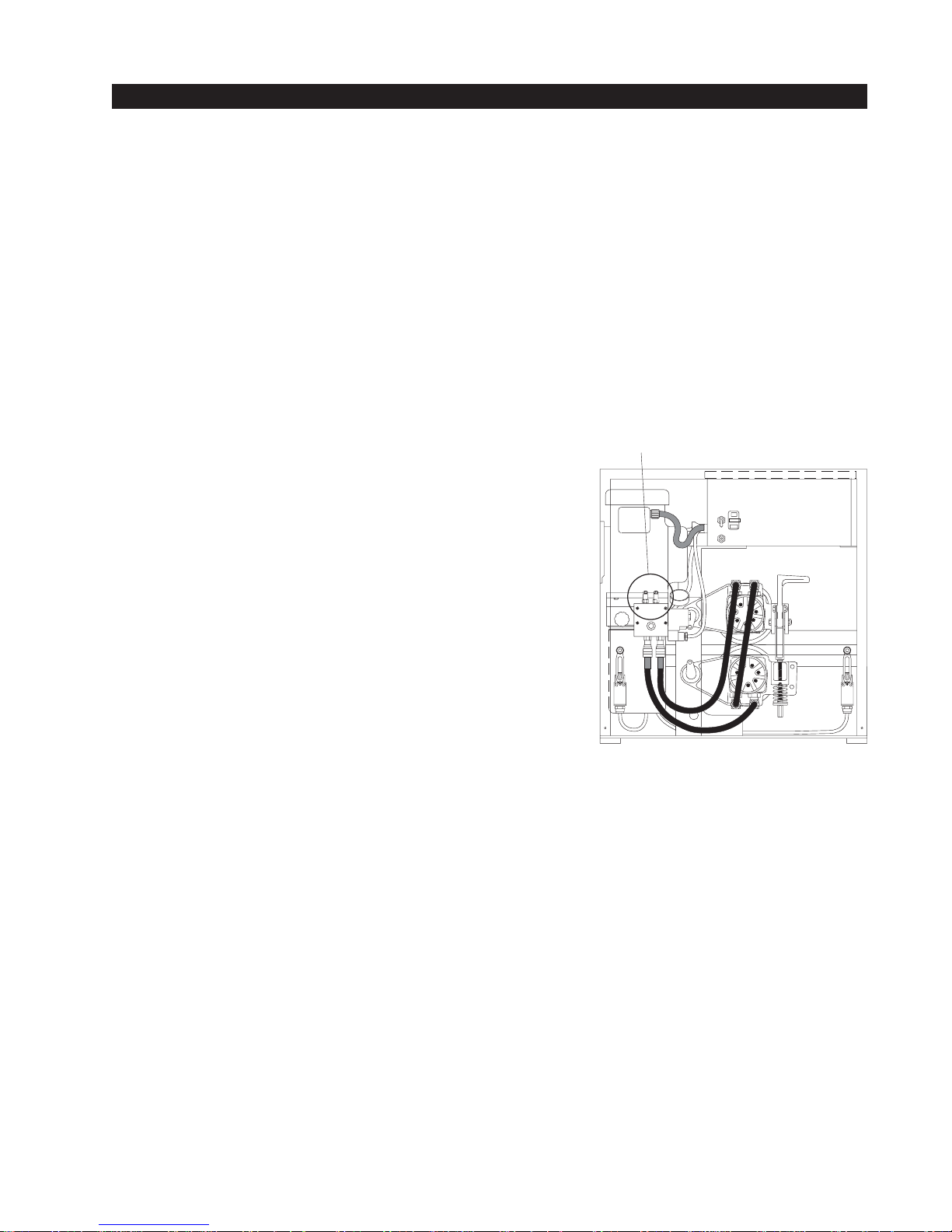

12. Check the “Hand” of the Operator

All slide operators must have their “hand” set

before they can function. The “handing” must

be set both by the proper hydraulic hose

connection and electrically. The hose connection for proper handing is described on a label

near the hose connection point. Also, see the

instructions to set handing on page 18 “Installation Configuration for Smart Touch Controller.” Handing is viewed by standing in the

middle of the road on the inside looking out.

Remove the blue plastic

shipping plug and replace

with black breather cap.

To change hand connect

hoses according to label

on tank.

ON

POWER

OFF

13. Replace the Blue Plug!

Replace the blue plastic shipping plug on the front side of the pump with the black breather cap.

14. Setup Smart Touch Controller

The operator controls will not allow the gate to function until the Smart Touch Controller has been

configured. Wait to connect the external controls until you have reviewed the Smart Touch Controller instructions and tested the basic functions.

Note: Hy-Security has an installation CD available free of charge to installers. Call a Hy-Security

distributor for a copy.

12

Page 19

Installation and Maintenance Manual

OFF

POWER

ON

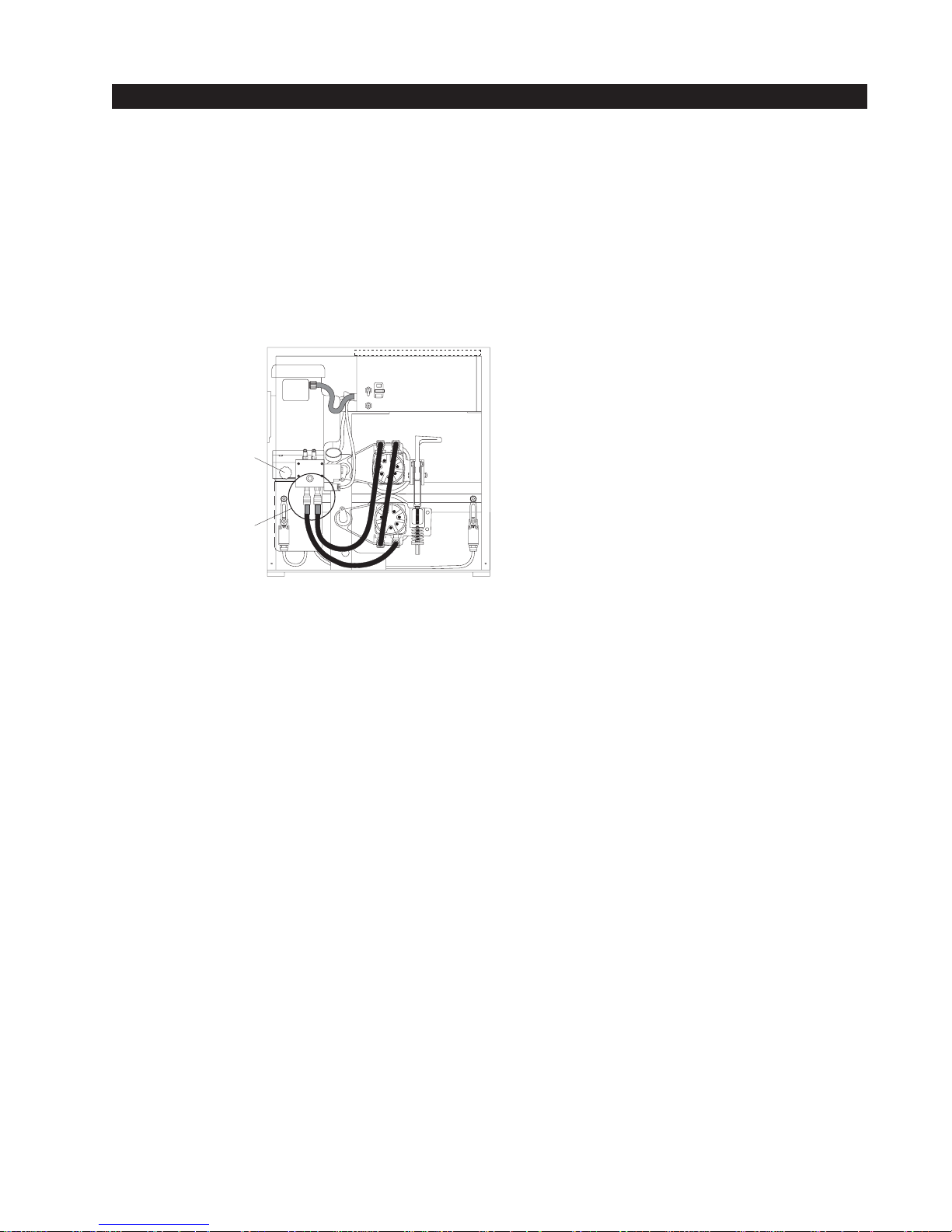

Optional brake valves CCW = quicker stop.

Left valve controls open

Right valve controls close

Mechanical and Hydraulic Adjustments

1. Drive Wheel Spring Tension

When the drive wheels are fully clamped on the rail, the red spring should be compressed to 2" in

height. If adjustment is necessary, turn the nut at the bottom of the threaded rod assembly. Slightly

less compression is okay for lighter gates. (See Figure on page 11, and full details on page 54).

2. Drive Rail

Verify that the drive rail does not vary more than 1" up and down, or 1/4" in and out throughout the

entire horizontal travel of the gate. Re-alignment is simple if the rail is mounted with U bolts. To

adjust in and out, loosen the U bolts and add or remove shim stock. To adjust up or down, loosen

the U bolts and simply tap the rail with a hammer until the correct height is reached. Adjusting the

rail in or out requires inserting shims between the rail and the gate where necessary.

3. Brake Valves (suffix E, EX models only)

If your operator is equipped with brake valves, their proper

adjustment is important for smooth operation of the gate. In

order for the brake valves to have time to function, the limit

ramp must trigger the limit switch at least six inches before

the point at when you want the gate to stop. Adjustment of

the brake valves, one for each direction of travel, will determine how quickly the gate actually stops. If adjustment is

needed, loosen the 9/16" lock nut on the top of the brake

valve and turn the adjustment stem, in about 1/4 turn increments, with an Allen wrench. The adjustment works opposite

of typical, such that a counter-clockwise adjustment will stop

the gate more rapidly. If the adjustment is set too loose, the

limit ramps will bang into the drive wheels. If the adjustment

is set too tight, the system pressure will increase, the gate

speed may decrease and the gate will jerk to a stop. Set the

brake valve to achieve a controlled smooth stop, and then

retighten the locking nut to hold the setting.

4. Pressure Relief Valve

This valve, which governs the maximum system hydraulic pressure available, is located on the

backside of the pump, just above the limit switch. Installers are encouraged to reduce the relief

valve setting to the lowest pressure that will reliably operate the gate. A lower setting reduces the

maximum force that the gate operator can exert. If adjustment is needed, loosen the 9/16" lock nut

and turn the adjustment stem with a wrench. Lower pressure (force) is achieved by turning the

adjuster stem counter-clockwise. The only way to display the actual relief valve setting is to unplug

the hydraulic hoses from the quick disconnect fittings. Be certain to retighten the locking nut to

hold the desired setting and reconnect the hoses correctly. Also see the drawing in Section 7, page

52 for the location and a schedule of factory pressure relief settings.

5. Directional and Quick Stop Valves

These two valves are solenoid operated. The directional valve is below the motor near the front of

the pump and energizes in order to direct the hydraulic flow to open the gate. The quick stop valve,

which is near the back of the pump energizes at the beginning of a cycle to allow no load motor

starts and at the end of each cycle to aid in decelerating the gate. No adjustment of these valves is

possible or ever needed.

13

Page 20

Installation and Maintenance Manual

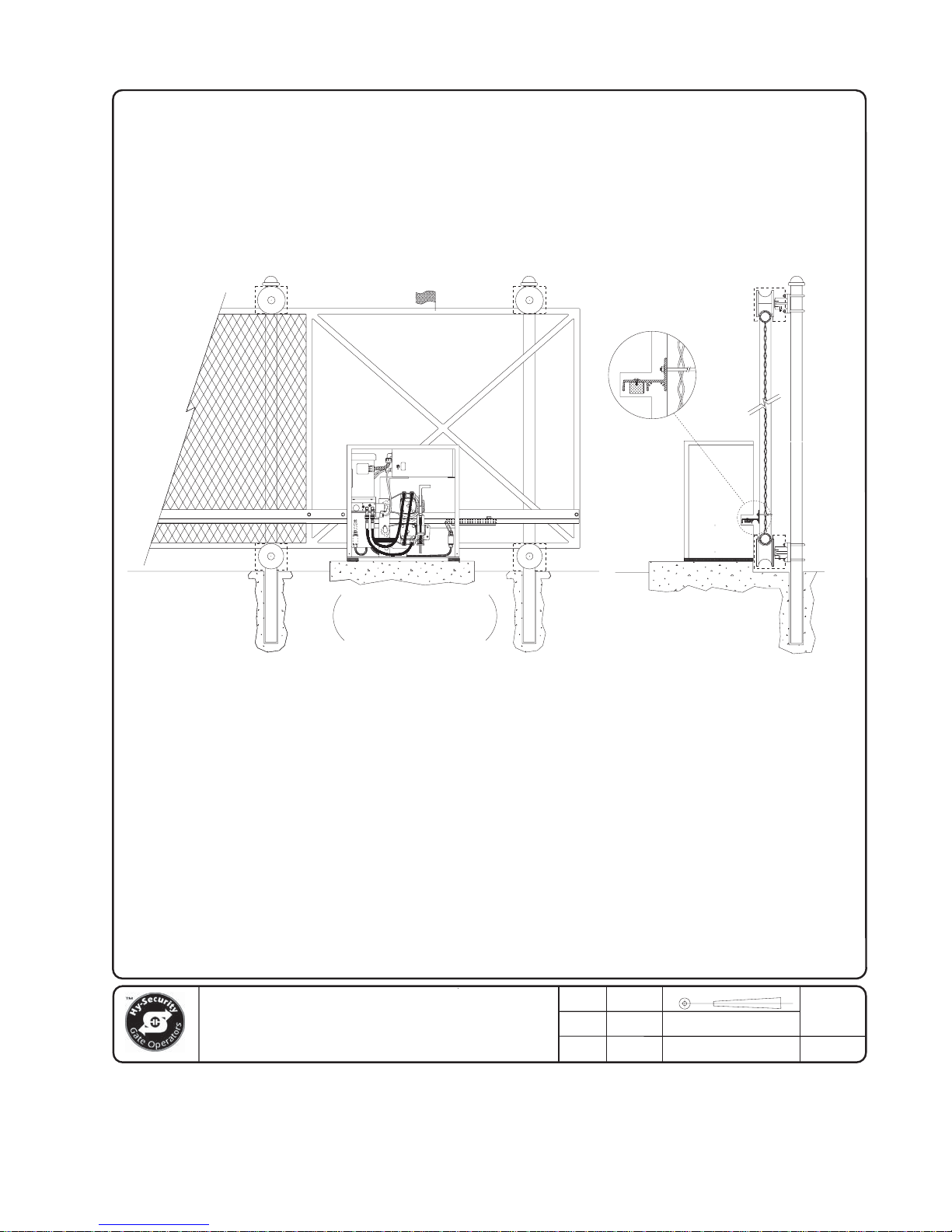

NOTE: COVERS MUST BE USED FOR

PROTECTION ON ALL EXPOSED WHEELS

AND/OR HARDWARE. COVERS ARE SHOWN

HERE AS DOTTED LINES.

ON

POWER

OFF

NOTE: SEE DWG# S13B

FOR RECOMMENDED SLAB

DIMENSIONS.

NOTE: DRIVE RAIL HEIGHT

IS MARKED ON THE SIDE

OF EACH CHASSIS.

seattle, washington

RIGHT HAND CANTILEVER GATE IS

SHOWN IN THE FULLY CLOSED POSITION.

OPERATOR COVER OMITTED FOR DETAIL.

( DO NOT SCALE )

NOTE: CONSULT FENCE CONTRACTOR

FOR RECOMMENDED CANTILEVER POST

SPACING. 50% OF GATE OPENING

GENERALLY PROVIDES SMOOTH OPERATION.

TITLE

Typical Slide Gate Operator with

R.H. Cantilever Gate Panel

SECTIONELEVATION

NOTE: IT MAY BE NECESSARY TO

SHIM DRIVE RAIL IF GATE PANEL

IS "BOWED". RAIL MUST BE INSTALLED

IN A STRAIGHT LINE.

KERI

CHECKED

SHOP

APPROVED

ENGRNG

DATE

4/20/00

DATE

MM/YY/DD

DATE

MM/YY/DD

THIRD ANGLE PROJECTION REVDRAWN

PART NUMBER

N/A

DRAWING NUMBER:

S13A

--

SHT OF

1 1

14

Page 21

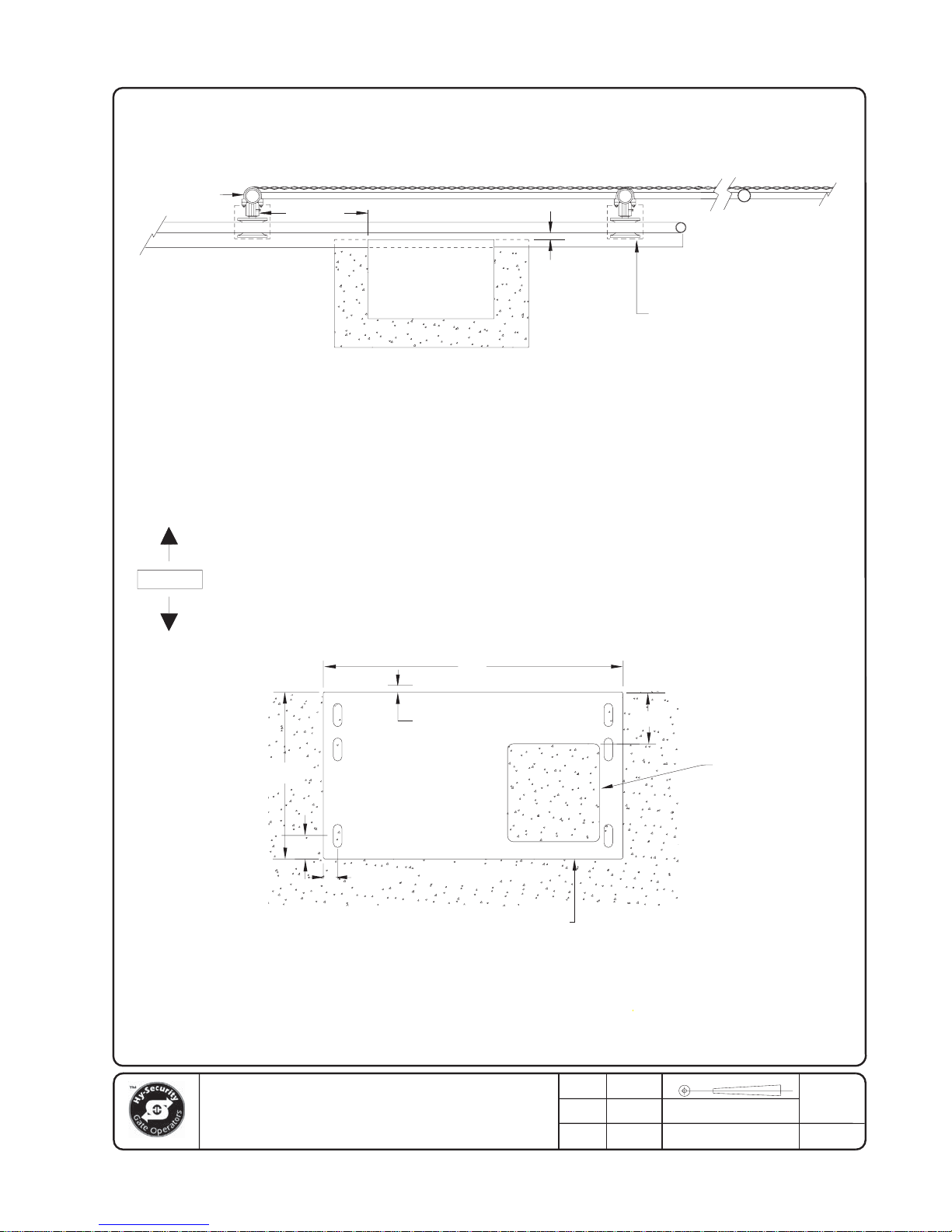

FENCE LINE

Installation and Maintenance Manual

GATE POST

GATE PANEL WITH

DRIVE RAIL ATTACHED

ROADWAY

ALLOW

12" TO 16"

GATE

OPERATOR

1-3/4"

NOTE: CANTILEVER WHEELS MUST

BE COVERED TO HELP PREVENT

INJURIES. COVERS SHOWN HERE

IN DOTTED LINES.

NOTE:

MINIMUM CONCRETE SLAB DIMENSIONS RECOMMENDED ARE:

30"WIDE, 20" FROM FRONT TO BACK AND 16" DEEP.

CHECK LOCAL FROST CONDITIONS AND SOIL CHARACTERISTICS

FOR EXACT REQUIREMENTS IN YOUR AREA.

OPERATOR IS INSTALLED ON A CONCRETE PAD AND CONNECTED

TO THE RIGHT HAND CANTILEVER GATE PANEL. 4" POSTS ARE

SHOWN FOR GATE SUPPORT AND FENCE TERMINATION.

DIMENSIONS OF OPERATOR AND BASE

( FENCE/GATE SIDE)

26"

seattle, washington

14½"

MINIMUM OF FOUR

ANCHOR BOLTS REQD.

½" X 4" OR

THIS TEMPLATE IS FOR

BOTH RIGHT AND LEFT

OPERATOR.

2"C/L

1-¼"C/L

OPERATOR BASE ¼" PLATE, PLAN VIEW

NOTE:

CONTACT A FENCE CONTRACTOR FOR EXACT SPACING ON CANTILEVER POSTS.

50% OF OPENING WIDTH GENERALLY PROVIDES A SMOOTH OPERATION.

TITLE

Slide Gate Operator (typ) R.H.

Cantilever Gate Panel

1-3/4" TO FACE

OF GATE

½" X 6"

( SECURE OR INSIDE )

KERI

CHECKED

SHOP

APPROVED

ENGRNG

5"

DATE

6/12/00

DATE

MM/YY/DD

DATE

MM/YY/DD

ELECTRICAL

ACCESS

8½" X 8"

THIRD ANGLE PROJECTION REVDRAWN

PART NUMBER

N/A

DRAWING NUMBER:

S13B

B

SHT OF

1 1

15

Page 22

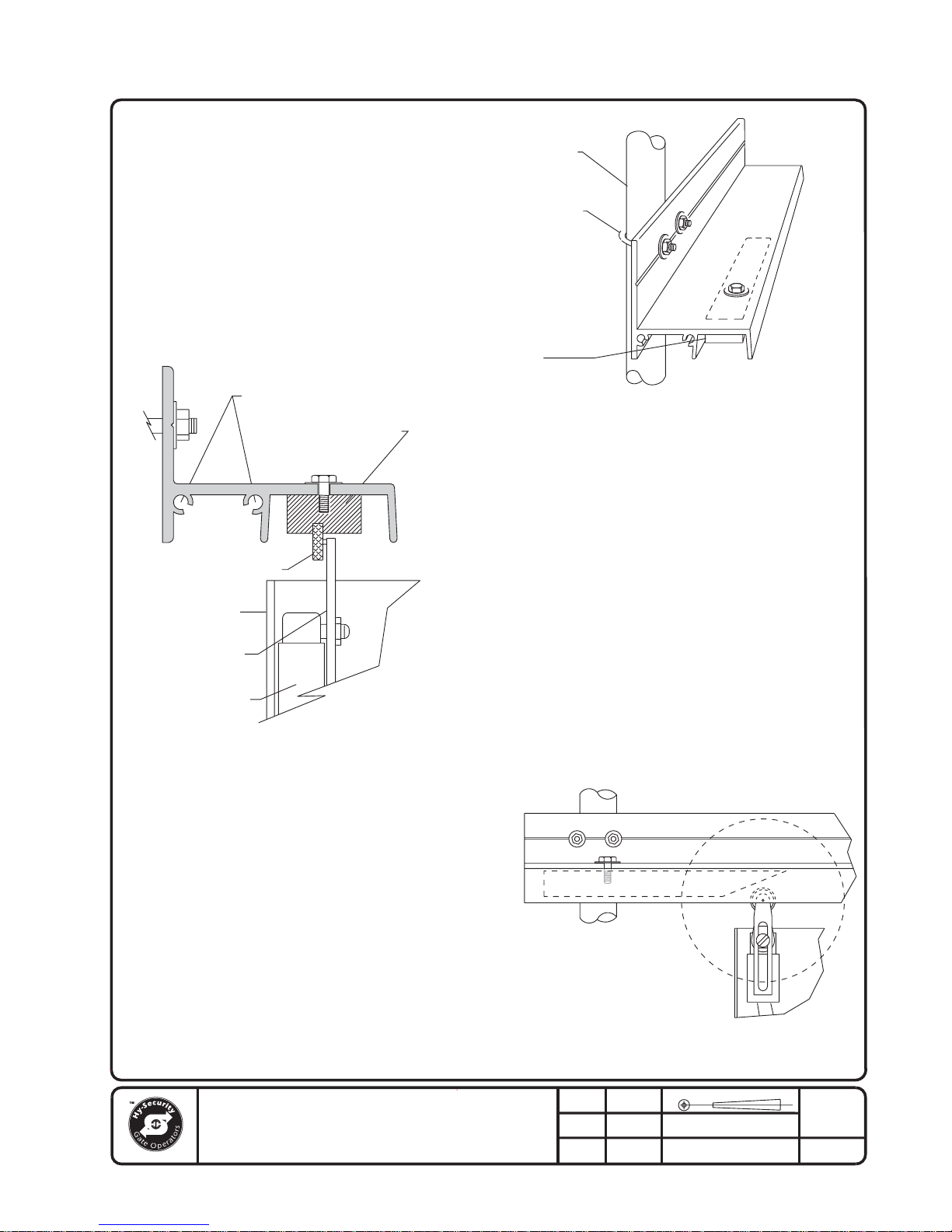

Installation and Maintenance Manual

KEYWAYS FOR SPLICE PINS

LIMIT SWITCH RAMP

LIMIT SWITCH WHEEL

OPERATOR

VERTICAL GATE

MEMBER

"U" BOLTS

LIMIT

SWITCH

RAMP

SECTION THROUGH DRIVE RAIL AND

LIMIT SWITCH SHOWING RELATIONSHIP

OF SWITCH, LIMIT RAMP AND DRIVE RAIL.

LIMIT SWITCH

ARM

LIMIT SWITCH

BODY

SIDE VIEW OF LIMIT RAMP AND LIMIT SWITCH

IN OPERATION. TAPERED ENDS, ALWAYS POINT

TOWARD THE OPERATOR DRIVE WHEELS.

NOTE: ALUMINUM RAIL SHOWN, STEEL RAIL SIMILAR.

TITLE

Drive Rail Slide Gate Operation

seattle, washington

KERI

CHECKED

SHOP

APPROVED

ENGRNG

DRIVE RAIL

LIMIT RAMP

DATE

6/12/00

DATE

MM/YY/DD

DATE

MM/YY/DD

THIRD ANGLE PROJECTION REVDRAWN

PART NUMBER

N/A

DRAWING NUMBER:

S22

SHT OF

1 1

16

Page 23

Installation and Maintenance Manual

Basics of Using the Smart Touch Controller System

Read this page if you are unfamiliar with using the Smart Touch Controller.

You must learn to navigate and change menu settings within the Smart Touch Controller before an

installation can be completed or any control settings or function changes can be made.

Until a new operator has been configured, the controls are not functional and the display is

locked in the menu mode until the User Class 1-4, and Left or Right hand use have been

selected. See the next page for instructions on how make these settings.

1. There are five buttons on the membrane switch pad that provide

control of everything. The Open, Close and S top buttons serve as a

three-button control station, but in the Menu Mode, they become Previous, Next and Select buttons. The Program Menu button is used to

both enter and exit the Menu Mode. The Reset button clears all Errors

and Faults that may occur and returns the control to its normal functioning state.

2. When in a Menu Mode, changes to be made to a Menu setting are

accomplished by pressing the Previous, Next and Select buttons in the

following sequence:

a. Press the Next button to move forward through the list of menu

items that are available, as shown on pages 22 and 23, or press

the Previous button to move back to an item that you recently passed.

b. Press the Select button if you wish to make a setting change to a menu item. The menu item will

flash to indicate that its setting is ready to be changed.

c. Press Next to move forward or Previous to go back to an earlier setting choice.

d. When you have located the setting that you want to use, press the Select button and the pro-

gram will accept the change and stop blinking.

e. The Program Menu button does not allow an exit to Run Mode while a selection is still blinking.

Press the Select button to stop the blinking, then you may exit to Run Mode.

f. Pressing the Next or Previous buttons when the menu item is not blinking will move to the next or

previous menu item.

g. When done, press Program Menu to exit to the Run Mode.

3. Once configured, the operator will be in the Run Mode. From the Run Mode, to gain access the

User Menu or the Installer Menu, follow these steps:

a. Note that the Program Menu button will not function unless the gate is at rest and no open or

close inputs are active. V erify system status by pressing the LED button to disclose any active

inputs. There also must not be any Alert s, Fault s or Errors. Press the Reset button to clear the

system if necessary .

17

Page 24

Installation and Maintenance Manual

b. Press the Program Menu button and watch the LCD scroll the system data, or press the Pro-

gram Menu key a 2nd time to skip the scroll. The scrolled data displays the information in the

table on page 22.

c. The LCD display scroll will stop at the menu item for the automatic close timer setting [Ct __].

This is the first item in the User Menu.

d. To access the more detailed Installer Menu, the system must first be in the User Menu, and then

simultaneously press the Reset button and the Open button. The LCD will change to display the

UL usage class menu item [uC __] This is the first item in the Inst aller Menu.

4. Pressing the Program Menu button when the User or Installer Menu is not blinking will return the

system to the Run Mode.

Installation Configuration for Smart Touch Controller

Setting Operator Handing and Usage Class

1. Connect the hydraulic hoses to the quick couplers on the pump in order to configure left or right hand

opening function (as viewed from the secured side of the gate). There is a label near the connection

point describing this procedure. Also see the illustration on p age 12. If the hoses are connected

incorrectly , the gate will run backwards (close when open button is activated) and this may trigger an

error [Err 1] on the LCD display. (The Reset button must be pushed if this happens).

2. Turn on the power switch and observe that the LCD will first show the sof tware version, and then stop

at a steady display within two seconds. If the display reads [uC 0] go to step 3. If the operator has

previously been configured, the Installer Menu must be accessed in order to reach the system configuration menu items: see step #3d at the top of this page.

3. When turning on the power for a new machine, the LCD display directly enters the Installer Menu at the

[uC __] menu item, which is for selecting the user class as defined by UL. Select [uC 1] - [uC 2] [uC 3] or [uC 4] depending upon the use application. See Section 4, page on page 31, for UL usage

class definitions.

4. To set the operator handing, use the “Next” button and move one click down the menu to item [Sh __]

Enter r for right hand or L for a gate that opens to the left. Never alter the limit switch mounting or

change the order of their connection to the controller board. At this point you should exit the Installer

Menu, by pressing the Program Menu button. The LCD display jumps to the close timer [Ct__] setting

in the User menu, which may now be set. Either press the Program Menu button again to exit to

normal run mode or set the close timer by the same programming sequence described at the previous

page.

5. Note that the Installer menu cannot be exited by any means until the selection for UL usage

class [uC __] and the selection for gate handing [Sh __] have been entered.

6. Test for normal function of the gate operator, with the wheels unclamped, by running it both open and

closed from the pushbuttons on the membrane switch pad. Neither limit switch should be triggered at

the start of this test or an alert [ALE6] may trigger because the control did not sense gate motion. If

this occurs a new input will restart the motor .

18

Page 25

Installation and Maintenance Manual

Wiring Control Inputs to the Smart Touch Controller

1. Test the basic open and close operator function before wiring the external control inputs. This makes it

easier to troubleshoot if an unexpected function issue arises.

2. Each input has an LED to indicate when that input is active. To disclose the input status, the LED tact

button must be pushed. This button is in corner near the S top input.

3. All the control device input s listed below are shown as a single input because the other wire is connected the Common Terminal Buss on the Power Supply board. The Emergency Close and Fire Dept.

Open inputs are an exception and require a +24 V olt input in order to be activated. The +24 is available at the spade terminals next to the Common Buss.

Smart Touch Controller Inputs

1) *Stop Push button (N.C. input, jumper to Common if unused)

2) *Open Push Button (not for radio or remote access controls)

3) *Close Push button (not for radio or remote access controls)

4) Remote Open & Radio Control (For radio / remote open device -

menu opt. to also close)

5) Open/Close button (pushbutton or radio controls)

6) Partial Open (installer adjustable from 7- 99 seconds)

7) Open interlock input or Time clock Open (menu configurable)

8) Free Exit vehicle detector

9) Disable Free Exit vehicle detector

10) Inside Obstruction vehicle detector (Inside reversing loop)

11) Outside Obstruction vehicle detector (Outside reversing loop)

12) Shadow/Reset vehicle detector (Shadow is for Swing gates only)

(Reset function is for Arm gates)

13) Edge Sensor (one input works for both directions of travel)

(14-15) Photo eye Common Power (supply for PE power & PE Com)

(17) Photo eye Open direction (spans the gate storage area)

(19) Photo eye Close direction (spans the roadway)

(21) Charger AC power loss (only used in battery type operators)

(22) Spare Input (unused - may have function in custom applications)

(23) *Emergency Close (must menu enable and input +24 Volts to

trigger) Overrides photo eyes, gate edge & vehicle detectors.

(24) *Fire Dept. Open (must menu enable and input +24 Volts to

trigger) Overrides photo eyes & gate edge.

* Do not connect an external control to terminals #1, 2 or 3,

unless the controls are located such that there is a clear

view of the entire gate area. For controls not within sight,

Attention

use input terminals #4, 5, 6 or 7.

*The Emergency Close and Fire Dept. Open inputs are to be used only

if access to these controls are guarded in sufficient manner such that

there is always supervision when activated.

19

Page 26

Press to

disclose

active LEDs

ACCESSORY

POWER

(+)

POWER STATUS

+24 INPUT

GND

MOTOR OVERLOAD

INHERENT SENSER

UNLOAD VALVE

+24V

GND

+24V

OPEN VALVE

RUN N.O.

Installation and Maintenance Manual

RUN COM

Hydraulic Directional

Valve - activates

to OPEN.

Hydraulic Unloading

or Quick Stop Valve

- activates when

starting or stopping.

ACCESSORY DETECTOR ACCESSORY DETECTOR ACCESSORY DETECTOR ACCESSORY DETECTOR

POWER

SUPPLY

BOARD

COMMON

BUSS

(-)

Processor

heartbeat

LED. Blinks at

a regular beat

when normal

RUN

RELAY

15 AMP

PROGRAMMABLE

USER RELAY

15 AMP

PROGRAMMABLE

USER RELAY

15 AMP

PROGRAMMABLE

USER RELAY

8

Clock

Battery

Optional

Hy-Security

HY-5A

Vehicle

Detector

Modules

Limit

Switch

Inputs

Master

Slave

Connection

20

Open

Radio

External

Communication

Port

Gate Edge

Radio

S ICB01Smart Touch Controller - Integrated Circuit Board

Page 27

Installation and Maintenance Manual

Connecting a Master / Slave Pair

Configuring two operators to be a Master & Slave pair is easy with the Smart Touch Controller.

There is no need to order a special model or any adapters. The area of the board marked Dual

Gate employs a 3-wire RS485 serial port for communication between Master & Slave operators.

1. An electrical conduit for the interconnecting wires must sp an between the two operators.

2. Complete the installation of both of the operators as separate machines and verify that their basic

functions are correct as solo operators before interconnecting them.

3. The two gate operators should be supplied by home runs from separate 20 Ampere circuit breakers in

the main panel, but if there is only one circuit, be absolutely certain that the breaker and wire size is

sufficient for the load of two motors. See the Appendix, p age 63.

4. External control inputs, vehicle detectors and entrapment protection sensors may be connected to

either gate operator without regard to preference.

5. To interconnect the two operators, route a shielded twisted pair with an internal ground wire between

the electric control boxes and connect to the RS485 Dual Gate terminals, in matching order on both

machines: In the RS485 shaded area connect the terminals for Master Com to Slave Com with the

ground shield trace wire, and connect the Master A to Slave A and the Master B to Slave B using the

insulated twisted pair of wires.

6. The Installer Menu in each machine must be set as a Master or a Slave under menu item [dg__]. Set

one operator as a Slave [dg_1] and the other as a Master [dg_2]. If the function of any external input is

to be different than the factory default, configure for the desired function on the operator where that

input is connected. Internal functions, such as the close timer or reversal distance, are controlled by

the Master operator regardless of the settings in the Slave.

7. Once set as a Master or a Slave the operators will be in constant communication with each other . If

that communication stops because the wires become severed or one operator is turned off, both

machines will cease functioning and the LCD will display Err4, which is a Master/Slave communication

error. This error cannot be reset until both machines are functional and communicating properly again.

21

Page 28

Installation and Maintenance Manual

Smart Touch Controller User Menu Functions

Initial Power Up - When power is turned on, the display will disclose the software revision:

Display Revision Number 2s delay Displays software version Number , ex. [h3.02]

System Data and accessing the User Menu Settings:

If the gate is stopped in the Run Mode, pressing of the Menu button accesses the User Menu. After

the menu button is pressed, the LCD will scroll the system data in the table below. The scrolling

display stops at the close timer setting, which is the beginning of the User Menu. To exit the Menu

Mode, the display must not be blinking, then simply pressing the Menu button will return the display

to the Run Mode and re-enable the controls. The menu mode will also automatically return to the

Run Mode if there is no activity for two minutes.

Data Displayed in Scroll Time Description

S1 [SLAu] or [LEAd] 2s SLAVE Operator or LEAd Operator (master)

S2 [ot 1] Gate type (1-5) 2s Operator type: 1 =HSG, 2 =HRG , 3 HVG, 4 =HTG

S3 [_rh_] or [_Lh_] Hand setting 2s Displays hand configuration [_rh_] or [_Lh_]

S4 [uC _] UL usage class (1-4) 2s Installer setting of usage class: type 1-4

S5 [d___] 24VDC Buss Volt age 2s Actual VDC buss voltage

S6 [CC__] Life cycle counter 2s High digits of 6 digit life cycle counter

S7 [____] Life cycle counter 2s Last 4 digits of 6 digit life cycle counter

Read through the options available in the User Menu and the Installer Menu on the next page and

you can see that the functions of this gate operator can be configured to suit most any specific

need. Once you have learned to navigate the menus, as described in #2 on page 17, and how to

change a setting, the full range of features and choices of the Smart Touch Controller are available

to use. The User Menu contains the basic configuration items and the Installer Menu contains the

more advanced menu items.

User Menu Options Default Description

U1 [Ct 0] Close timer setting 0 0 = Close timer off or 1 - 99 seconds

U2 [hC 0] Moment ary Close 0 0 = momentary, 1 = Constant hold Close PB required

U3 [ho 0] Moment ary Open 0 0 = momentary, 1= Constant hold Open PB required

U4 [AP 0] Power loss function 0 0 - 3 (0=Type A, 1 = B, 2 = C, 3 = D) See page 56

U5 [ro 0] Radio control option 0 0 = Open only, 1 = Adds close ability when full open

U6 [bF 2] Warn before operate 2 0 =off, 1 = Buzzer alerts 3 seconds before + in motion,

2 =Buzzer alerts 3 secs before + 2 seconds in motion

U7 [FA 0] Forced open Alert and 0 0 = OFF, 1 = sound buzzer (2 pulses/sec) if forced

automatic gate reposition open for more than four seconds, time out in 30 Sec

U8 [dA 0] Drift Closed Alert and 0 0 = OFF, 1 = sound buzzer (2 pulses/sec) if drift

automatic gate reposition closed and cannot reopen within four seconds.

U9 [PE 0] Photo Eye Align Mode 0 0= off, 1 = on (auto off when close limit triggered)

U10 [CL 0] Clock set (24 hour type) 0 0= display, 1= set mins, 2= set hours, 3= day, 4= month

U11 [Ld 5] LCD Contrast set 5 1 - 9 = Adjusts contrast of the display

S1 Appears only if the operator is configured as a master or a slave unit

U1 Close timer setting does not appear when set for constant contact close function

U4 Power loss function only appears if factory has provided DC battery type operator

U6 We strongly advise never disabling the Warn Before Operate buzzer.

These Notes Refer to the Menu Above:

22

Page 29

Installation and Maintenance Manual

Smart Touch Controller Installer Menu Functions

The Installer Menu can be accessed only by entering the User Menu first, and then by pressing the

Reset button and the Open button simultaneously.

To restore the factory default settings, go to menu item [Fd_0] and change the setting to 1,

then press the Program Menu button. The entire menu will reset to the factory defaults.

Installer Menu Options Default Description

I

1 [uC 0] Set UL Usage Class 0 0 = gate disabled, Set Class 1 through 4 use

I

2 [Sh 0] Set Handing of gate 0 0 = gate disabled, r = Right Hand, L = Left Hand

I3 [Fd 0] Load Factory Defaults 0 0 = User settings, 1 = Load defaults (resets full menu)

I4 [dg 0] Set Master/Slave type 0 0 = solo operator, 1 = Slave unit, 2 = Master unit

I

5 [Ch 0] Set AC Charger or Solar 0 0 = DC + AC charger 1 = DC + Solar charger

I6 [Fo 0] Enable Fire Dept. Open 0 0 = disabled, 1 = enabled

I7 [oC 0] Enable Emergency close 0 0 = disabled, 1 = enabled

I8 [SE 3] Inherent Sensor sens. 3 1 = maximum sensitivity, 9 = Lowest sensitivity

I

9 [SS 0] Inherent Sensor function 0 1 = stop only (note, functions in usage class 4 only)

I

10 [LC 0] Leaf delay Close 0 0 = none (1-7) 1/2 second steps (Master/Slave only)

I

11 [Lo 0] Leaf delay Open 0 0 = none (1-7) 1/2 second steps (Master/Slave only)

I12 [rt 0] Maximum run timer 0 0 = 60 Seconds max run, 1 = 300 Seconds max run

I13 [Po 0] Partial Open distance 0 0 = none, or 7 - 99 seconds

I14 [EC 0] PEC reverse to open 0 0 = Close eye stops only, 1 = 2 sec reverse to open

I15 [EO 0] PEO reverse to close 0 0 = Open eye stops only, 1 = 2 sec reverse to close

I16 [gr 0] Edge reverse to open 0 0 = Edge reverses fully open, 1 = 2 sec reversal only

I17 [Sr 1] IES reverse to open 1 0 = IES reverses fully open, 1 = 2 sec reversal only

I18 [PC 0] Set PEO/ PEC - NO/NC 0 0 = Normally Open PE output, 1 = N.C. (supervised)

I19 [gC 0] Set Edge input - NO/NC 0 0 = Normally Open Edge output, 1 = Normally Closed

I20 [tC 1] Time clock/ Interlock input 1 0 = select Time Clock, 1 = select Open Interlock

I21 [or 1] OOLD detector function 1 0 = pause closing only, 1 = enable reversing to open

I22 [ir 1] IOLD detector function 1 0 = pause closing only, 1 = enable reversing to open

I23 [dL 1] Vehicle detector logic 1 1 = std, 2 & 3 = quick close, 4 = full anti-tailgate*

I24 [r1 0] User relay 1 option 1 0 = disabled, 1 - 19 = see output options page 28

I25 [r2 0] User relay 2 option 6 0 = disabled, 1 - 19 = see output options page 28

I26 [r3 0] User relay 3 option 1 0 = disabled, 1 - 19 = see output options page 28

I

27 [t L 0] Gate Open alert 2 0 = 0 sec, 1=15s, 2=45s, 3=75s, 4=105s, 5=135s

I

28 [Lt 0] Loitering alert 3 0 = 0 sec, 1=15s, 2=45s, 3=75s, 4=105s, 5=135s

I29 [ELd0] Test factory ELD* 0 0=Run, 1=show freq, 2=show call level 0-7, 3= set Freq 1-4

I30 [iLd0] Test factory IOLD* 0 0=Run, 1=show freq, 2=show call level 0-7, 3= set Freq 1-4

I31 [oLd0] Test factory OOLD* 0 0=Run, 1=show freq, 2=show call level 0-7, 3= set Freq 1-4

I32 [SLd0] Test factory SLD* 0 0=Run, 1=show freq, 2=show call level 0-7, 3= set Freq 1-4

*See page 43 for description of vehicle detector & Loop Fault diagnostics

These Notes Refer to the Menu Above:

I1,I

2 These settings must be configured or the gate cannot function and menu will not exit.

I

5 These settings appear only if the factory has provided a DC powered gate operator

I9

IES stop only setting [SS __] does not appear unless set as a class 4 operator

I

10,I11 These settings appear only if the Installer Menu is set for Master / Slave function

I

27,I28 These settings appear only if the Installer Menu has set relays r1-r3 for these alerts

23

Page 30

Installation and Maintenance Manual

Description of Functions Available in the User Menu

User 1 [Ct _] Close timer setting: This menu item is the automatic close timer for the gate. The

factory setting is zero, which is off. It may be configured up to 99 seconds.

User 2 [hC 0] Momentary Close: This menu item is to configure for the system for constant hold

push button Close function. The factory setting is zero, which is momentary contact input.

User 3 [ho 0] Momentary Open: This menu item is to configure for the system for constant hold

push button Open function. The factory setting is zero, which is momentary contact input.

User 4 [AP 0] Power loss function: This menu item only appears if the operator is a DC battery

powered version. This item is to configure what gate function will occur when the AC power fails.

See page 56 for more detailed information on DC operators.

User 5 [ro 0] Radio control option: This menu item is to configure whether a radio input can

open only (default) or if set to 1, also has the ability to close the gate when it is fully open.

User 6 [bF 2] Warn before operate: This menu item controls the warn before operate buzzer

and can be configured three ways. Setting the menu item to zero turns the buzzer off, but we

strongly advise leaving this valuable warning feature active to alert prior to gate motion. Never cut

the wires to the buzzer or unplug it. Set to 1 and the buzzer will sound three seconds before

motion and the entire time during gate motion. Set to 2 (default) and the buzzer will sound three

seconds before motion and for the first two seconds of motion.

User 7 [FA 0] Forced open Alert and automatic gate reposition: This function is intended for

highly secure facilities. If it is enabled, by setting the selection to 1, it will reinitiate a closure if a

gate is somehow forced to open far enough that the close limit switch releases. The Alert buzzer

will sound immediately, even if it had been turned off, and the motor will restart to secure the gate

fully closed. If the gate is not fully closed within four seconds the motor turns off and the alert

buzzer sounds an intruder alert for thirty seconds. The LCD display reads ALE1.

User 8 [dA 0] Drift Closed Alert and automatic gate reposition: If it is enabled, by setting the

selection to 1, it will restore a gate to back its fully open position if it drifts closed for any reason.

The buzzer will sound a warn before operate alert, even if it had been turned off, and the motor will

restart to reopen the gate. The motor will run for a maximum of four seconds and if the gate is not

fully open in this period, the buzzer sounds for ten seconds and the LCD display reads ALE2.

User 9 [PE 0] PE Alignment Mode: This feature may be activated as an aide to photo-eye

emitter / receiver alignment. The buzzer chirps once as the photo eye is triggered or twice when

the photo eye is released. The Alignment Mode is cancelled with any close limit input or reset input.

User 10 [CL 0] Clock and date set: The Smart Touch Controller is equipped with a 24 hour 365

day clock, so that events of significance can be logged and stamped with the time and date. This

feature is useful to record historical operation data, which can be accessed via the RS232 port. To

set or adjust the hour, minute, day or month, see page 29.

User 11 [Ld 5] LCD Contrast set: Under some extreme high or low temperature conditions, it

may be necessary to adjust the contrast of the LCD display. The display is adjustable from 0-9 with

a factory default setting of 5.

24

Page 31

Installation and Maintenance Manual

Description of Functions Available in the Installer Menu

Installer 1 [uC 0] Set UL Usage Class: This menu item is used to set the UL usage class, which must be

set by the installer before the operator will function. See page 18, step 3.

Installer 2 [Sh 0] Set Handing of gate: This menu item is used to set the gate handing, which must be set

by the installer before the operator will function. See page 18, step 4.

Installer 3 [Fd 0] Load Factory Defaults: This menu item is used to globally restore all menu settings

back to new machine status. To activate, change the setting from 0 to 1 and push the Menu button. The UL

usage class and the hand configuration will need to be set again.

Installer 4 [dg 0] Set Solo, Master or Slave type: This menu item is used to configure an operator as a

Master or a Slave operator in Master/Slave paired gate installations.

Installer 5 [Ch 0] Set AC Charger or Solar: This menu item appears on 24 VDC battery machines only

and is set to solar only when there is no AC battery charger.

Installer 6 [Fo 0] Enable Fire Dept. Open: This menu item is used to enable the Fire Dept. Open input.

When set to [Fo_1] this input will override vehicle detectors, photo eyes and gate edges to open a gate. A

reset is required before the gate can be closed. The LCD display reads ENTR.

Installer 7 [oC 0] Enable Emergency Close: This menu item is used to enable the Emergency Close

input. When set to [oC_1] this input will override vehicle detectors, photo eyes and gate edges to close a gate.

A reset is required before the gate can be opened.

Installer 8 [SE 6] Inherent Sensor sensitivity:. This menu item is to adjust the sensitivity of the internal

inherent sensor. Available settings are 1-9, with 9 being the least sensitive.

Installer 9 [SS 0] Inherent Sensor function: This menu item is only available in UL class 4 operators and

allows an option whereby the inherent sensor will only stop the gate.

Installer 10 [LC 0] Leaf delay Close: This menu item only appears if the operator is set up as a Master or a

Slave. A vailable settings are 1-7. Each increment adds 1/2 second, to a maximum of

3 1/2 seconds time delay , before the operator activates when commanded to close.

Installer 1 1 [Lo 0] Leaf delay Open: This menu item only appears if the operator is set up as a Master or a

Slave. A vailable settings are 1-7. Each increment adds 1/2 second, to a maximum of 3 1/2 seconds time

delay , before the operator activates when commanded to open.

Installer 12 [rt 0] Maximum run timer: The maximum run timer has a default setting of 60 seconds. This

menu item allows an optional setting of 300 seconds, if changed to [rt_1].

Installer 13 [Po 0] Partial Open distance: This menu item both activates the p artial open input and allows

an adjustable distance by setting the open duration. The available time settings are 7-99 seconds. The

default setting of [Po_0] leaves this input inactive.

Installer 14 [EC 0] PEC (photo eye close) reverse to open: The default for this menu item is for nonreversal if the close photo eye is triggered. The optional setting of [EC_1] will cause the gate to reverse to

open for two seconds if triggered while closing.

Installer 15 [EO 0] PEO (photo eye open) reverse to close: The default for this menu item is for nonreversal if the open photo eye is triggered. The optional setting of [EO_1] will cause the gate to reverse to

close for two seconds if triggered while opening.

25

Page 32

Installation and Maintenance Manual

Description of Functions Available in the Installer Menu

Installer 16 [gr 0] Edge reverse to open: The default for this menu item is for a 2 second

reversal if the gate edge is triggered. The optional setting of [gr_1] will cause the gate to reopen

fully if triggered while closing.

Installer 17 [Sr 1] IES (inherent sensor) reverse to open: The default for this menu item is for

a 2 second reversal if the inherent sensor is triggered. The optional setting of [Sr_1] will cause the

gate to reopen fully if triggered while closing.

Installer 18 [PC 0] Set PEO/ PEC - NO/NC: The default for this menu item is for photo eyes with

Normally Open outputs. The optional setting of [PC_1] will require a Normally Closed output. If set

for N.C. the connection is also supervised and any open or short circuit fault will generate a FAL2

alert, which requires a Stop button reset to re-enable any function if triggered.

Installer 19 [gC 0] Set Edge input - NO/NC: The default for this menu item is for edge sensor

with Normally Open outputs. The optional setting of [gC_1] will require a N.C. output.

Installer 20 [tC 1] Time clock / Interlock input: This menu item configures the input at terminal

#7 to be either for the gate interlock function, as described on page 27, or for an external time clock

to open input, as described on page 44. The default setting is [tC_1] for the interlock function.

Installer 21 [or 1] OOLD (Outside Obstruction loop detector) function: The default for this

menu item is for full reversal when the OOLD is triggered. The optional setting [or_0] causes the

gate to only pause when triggered. Closure begins as soon as the loop is clear again.

Installer 22 [ir 1] IOLD (Inside Obstruction loop detector) function: The default for this menu

item is for full reversal when the IOLD is triggered. The optional setting [ir_0] causes the gate to

only pause when triggered. Closure begins as soon as the loop is clear again.

Installer 23 [dL 1] Vehicle detector logic: This menu item is used to configure quick close and

anti-tailgate logic. There are four modes. See the full description on page 43.

Installer 24, 25, 26 [r1 0], [r2 0], [r3 0] User output relay 1 - 3 programming options: These

three menu items are used to configure the function of the three user output relays. There are 19

optional choices, which are described in detail on page 28.

Installer 27 [t L 0] Gate Open alert: This menu item is to adjust the time delay before activating

the user relay function #8, described on page 28. Time settings up to 135 seconds.

Installer 28 [Lt 0] Loitering alert: This menu item is to adjust the time delay before activating the

user relay function #13, described on page 28. Time settings up to 135 seconds.

Installer 29 [ELd0] Factory ELD: Controls the HY-5A Free Exit detector, see page 42.

Installer 30 [iLd0] Factory IOLD: Controls the HY-5A IOLD detector, see page 42.

Installer 31 [oLd0] Factory OOLD: Controls the HY-5A OOLD detector, see page 42.

Installer 32 [SLd]. Factory SLD: Controls the HY-5A Shadow detector, see page 42.

26

Page 33

Installation and Maintenance Manual

Correctional Facility - User Optional Wiring

A special terminal strip has been pre-wired in Correctional facilities models to the three user relay

outputs for easy field wiring of the common interconnect options. If alternate output functions are

required, see page 28 titled Options for User Programmable Output Relays 1-3.

Connecting an Interlocked Pair:

An interlocked pair of operators is not a Master/Slave system, but is simply two gate operators

interlocked such that the one cannot open unless the other is fully closed. This connection is used

frequently at correctional facilities for Sally Port gates. The Smart Touch Controller provides both an

interlock input (#7) and the interlock output contact that is required.

1. User relay 1 on the Smart Touch Board has been set by the factory to provide the necessary interlock function. Connect a total of four wires between operator #1 and operator #2 as follows: One wire

to the Common buss of each operator to the User 1 relay COM terminal of the other operator. Then,

connect wires from the User 1 relay NC terminal to the Interlock input (#7) of the other operator.

2. If User relay 1 has already been used for a different function, then one of the other relays User 2 or