Page 1

Phoenix™ Software Version 9 Series

Installation and Setup Manual

806410 | Revision 11 | English

Page 2

© 2014 Hypertherm, Inc.

ArcGlide, COMMAND, EDGE Pro, EDGE Pro Ti, HPR, HSD, HyIntensity Fiber Laser, Hypernest, Hypernet, Hypertherm,

HyPrecision, MAXPRO, MicroEDGE Pro, Phoenix, Powermax, and Sensor are trademarks of Hypertherm, Inc. and may be registered

in the United States and other countries.

Microsoft, the Microsoft logo, and Windows are registered trademarks of Microsoft Corporation.

Other trademarks are the property of their respective owners.

Page 3

Phoenix Software® Version 9 Series

Installation and Setup Manual

806410

Revision 11

English

December 2014

Hypertherm Inc.

Hanover, NH 03755 USA

Page 4

Hypertherm Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

65 6841 2489 (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

Unit 301, South Building

495 ShangZhong Road

Shanghai, 200231

PR China

86-21-60740003 Tel

86-21-60740393 Fax

Hypertherm Europe B.V.

Vaartveld 9

4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP - Brasil

CEP 07115-030

55 11 2409 2636 Tel

55 11 2408 0462 Fax

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Hypertherm Korea Branch

#3904 Centum Leaders Mark B/D,

1514 Woo-dong, Haeundae-gu, Busan

Korea, 612-889

82 51 747 0358 Tel

82 51 701 0358 Fax

Page 5

Contents

Safety ....................................................................................................................................... SC-15

Recognize safety information ...............................................................................................................................................SC-15

Follow safety instructions ......................................................................................................................................................SC-15

Electrical hazards ....................................................................................................................................................................SC-15

Electric shock can kill ............................................................................................................................................................SC-16

Cutting can cause fire or explosion ....................................................................................................................................SC-17

Fire prevention .................................................................................................................................................................SC-17

Explosion prevention ......................................................................................................................................................SC-17

Toxic fumes can cause injury or death ...............................................................................................................................SC-18

Grounding safety ....................................................................................................................................................................SC-19

Static electricity can damage circuit boards ....................................................................................................................SC-19

A plasma arc can cause injury and burns .........................................................................................................................SC-20

Compressed gas equipment safety ...................................................................................................................................SC-20

Gas cylinders can explode if damaged .............................................................................................................................SC-20

Arc rays can burn eyes and skin .........................................................................................................................................SC-21

Pacemaker and hearing aid operation ...............................................................................................................................SC-22

Noise can damage hearing ...................................................................................................................................................SC-22

A plasma arc can damage frozen pipes ............................................................................................................................SC-22

Dry dust collection information ............................................................................................................................................SC-23

Laser radiation .........................................................................................................................................................................SC-24

Additional safety information ................................................................................................................................................SC-24

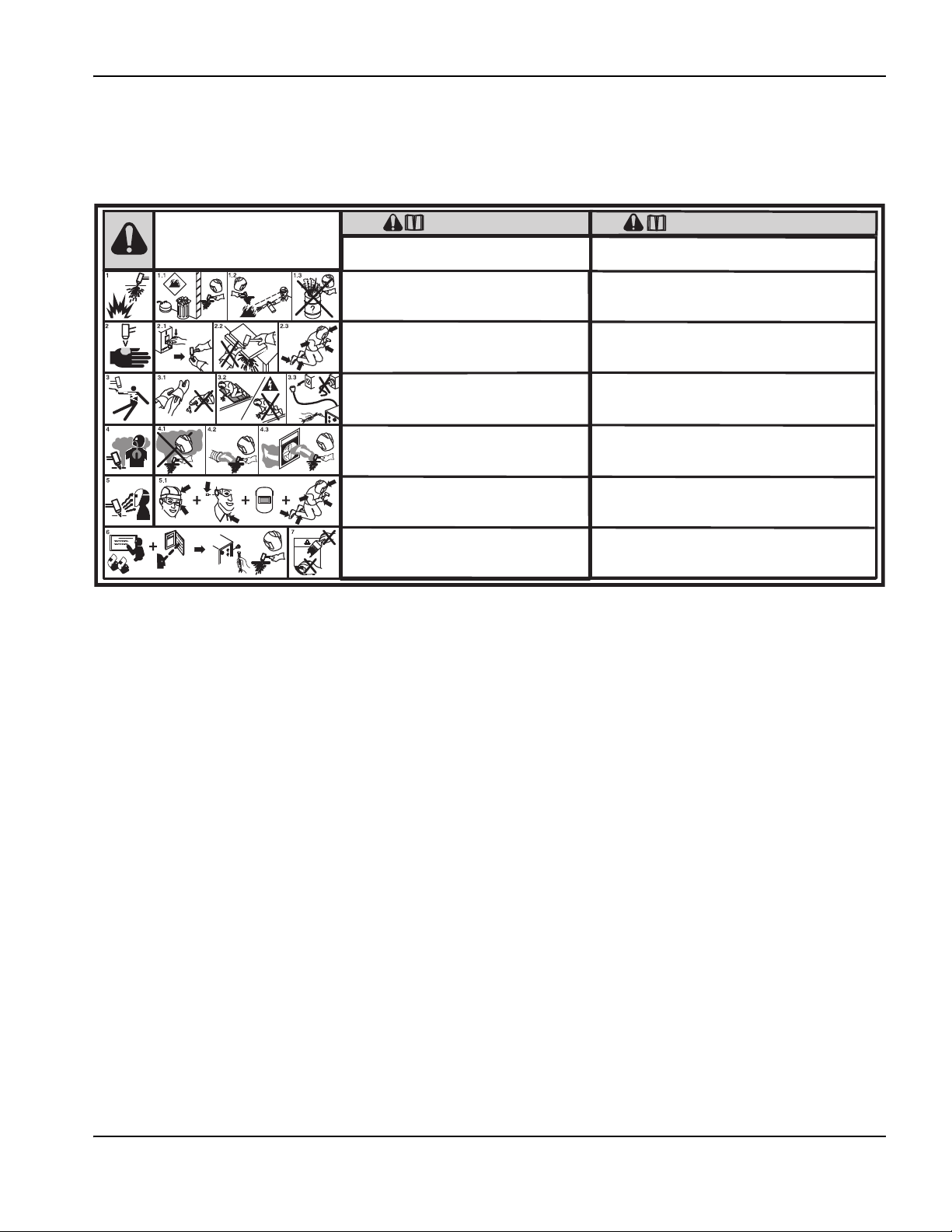

Warning labels ........................................................................................................................................................................SC-25

Symbols and marks ................................................................................................................................................................SC-27

Product Stewardship ...........................................................................................................SC-29

Introduction ..............................................................................................................................................................................SC-29

National and local safety regulations ..................................................................................................................................SC-29

Certification test marks .........................................................................................................................................................SC-29

Phoenix 9.76.0 Installation and Setup Manual 806410 5

Page 6

Contents

Differences in national standards .......................................................................................................................................SC-29

Safe installation and use of shape cutting equipment ...................................................................................................SC-30

Procedures for periodic inspection and testing ..............................................................................................................SC-30

Qualification of test personnel .............................................................................................................................................SC-30

Residual current devices (RCDs) .......................................................................................................................................SC-30

Higher-level systems ..............................................................................................................................................................SC-31

Environmental Stewardship .............................................................................................. SC-33

Introduction ..............................................................................................................................................................................SC-33

National and local environmental regulations ...................................................................................................................SC-33

The RoHS directive ................................................................................................................................................................SC-33

Proper disposal of Hypertherm products ..........................................................................................................................SC-33

The WEEE directive ...............................................................................................................................................................SC-33

The REACH regulation ..........................................................................................................................................................SC-34

Proper handling and safe use of chemicals .....................................................................................................................SC-34

Fumes emission and air quality ...........................................................................................................................................SC-34

Shrink-wrap License Agreement ...................................................................................... SC-35

1 System Tools ............................................................................................................................... 37

Introduction .................................................................................................................................................................................... 37

CNC performance information .................................................................................................................................................. 39

Back up the hard drive ................................................................................................................................................................ 40

Scan Hard Disk ............................................................................................................................................................................. 41

Antivirus .......................................................................................................................................................................................... 42

Defragment hard disk .................................................................................................................................................................. 43

Launch an External Program ...................................................................................................................................................... 43

Software installed on the CNC ................................................................................................................................................. 45

Phoenix software version number ..................................................................................................................................... 45

Phoenix setup files ........................................................................................................................................................................ 46

About setup files ................................................................................................................................................................... 46

Setup files from previous versions of Phoenix ............................................................................................................... 47

Save and load the setup file ............................................................................................................................................... 47

Save a setup file without using a password ........................................................................................................... 47

Save a setup file with a different name .................................................................................................................... 47

Load a setup file ............................................................................................................................................................ 48

Save and load default settings .......................................................................................................................................... 48

Save Default.ini .............................................................................................................................................................. 48

Load Default.ini .............................................................................................................................................................. 48

Reload factory settings ........................................................................................................................................................ 49

6 Phoenix 9.76.0 Installation and Setup Manual 806410

Page 7

Contents

2 Machine Setup ............................................................................................................................ 51

Axis orientation and positive motion ......................................................................................................................................... 51

About axis assignments ............................................................................................................................................................... 55

Change the axis assignments with passwords ...................................................................................................................... 55

System axis screens ..................................................................................................................................................................... 58

Machine Setups screen ...................................................................................................................................................... 58

Transverse or Rail Axis ........................................................................................................................................................ 60

Using software travel limits ................................................................................................................................................. 63

Dual Gantry Axis .................................................................................................................................................................... 64

CBH Axis ................................................................................................................................................................................ 67

Rotate Axis ............................................................................................................................................................................. 69

Tilt Axis .................................................................................................................................................................................... 71

Transverse 2 Axis .................................................................................................................................................................. 74

Laser Mapping ............................................................................................................................................................................... 78

Setting Speeds ............................................................................................................................................................................. 79

CBH Speeds ......................................................................................................................................................................... 81

THC Speeds .......................................................................................................................................................................... 81

Tilt/Rotator Speeds .............................................................................................................................................................. 82

S-curve acceleration .................................................................................................................................................................... 82

S-curve setup ........................................................................................................................................................................ 84

Torch Height Disable ................................................................................................................................................................... 85

Configuring Ports ......................................................................................................................................................................... 87

Basic Configuration .............................................................................................................................................................. 87

Phoenix Link Configuration ................................................................................................................................................. 90

Command THC Port Designation ..................................................................................................................................... 91

RS-422 Connections to Command THC with 25-pin D-type Connector ...................................................... 91

Configuring I/O ............................................................................................................................................................................. 92

Digital Input Definitions ........................................................................................................................................................ 93

Digital Output Definitions .................................................................................................................................................... 97

THC I/O ................................................................................................................................................................................ 100

Speed Pot and Joystick Setup ................................................................................................................................................ 101

3 Torch Height Control Axis Setup ......................................................................................... 103

Sensor THC axis ......................................................................................................................................................................... 103

Initial height sense .............................................................................................................................................................. 103

Entering the slide length ................................................................................................................................................... 104

Assigning the Sensor THC to an axis and selecting an analog input .................................................................... 104

Setting speeds and acceleration .................................................................................................................................... 105

Assigning the Sensor THC as a lifter ............................................................................................................................. 106

Setting servo error tolerance and stall force tolerance .............................................................................................. 106

Phoenix 9.76.0 Installation and Setup Manual 806410 7

Page 8

Contents

Sensor THC axis screen ........................................................................................................................................................... 108

Tuning the axis with gains ................................................................................................................................................. 109

Home settings for current-type drives ........................................................................................................................... 113

Tracking Mode ..................................................................................................................................................................... 113

Sensor THC I/O points ............................................................................................................................................................. 114

Watch Window setup ............................................................................................................................................................... 115

Sensor Ti axis setup ................................................................................................................................................................... 116

Machine Setups screen .................................................................................................................................................... 116

Speeds screen .................................................................................................................................................................... 116

Sensor THC Axis screen .................................................................................................................................................. 117

Station Configuration screen ........................................................................................................................................... 117

ArcGlide THC axis ..................................................................................................................................................................... 118

Gains ..................................................................................................................................................................................... 118

Speeds .................................................................................................................................................................................. 120

Mechanical ........................................................................................................................................................................... 121

Miscellaneous ...................................................................................................................................................................... 121

4 SERCOS setup ........................................................................................................................... 123

SERCOS III support .................................................................................................................................................................. 123

Drives ..................................................................................................................................................................................... 123

Bus couplers ........................................................................................................................................................................ 123

Cabling .................................................................................................................................................................................. 124

General recommendations ............................................................................................................................................... 124

Drive I/O ................................................................................................................................................................................ 124

Inline I/O bus coupler ........................................................................................................................................................ 125

Troubleshooting tips .......................................................................................................................................................... 125

SERCOS setup screen ..................................................................................................................................................... 126

SERCOS II support ................................................................................................................................................................... 127

Drives ..................................................................................................................................................................................... 127

I/O bus couplers and I/O modules ................................................................................................................................. 127

I/O bus couplers ................................................................................................................................................................. 127

I/O modules ......................................................................................................................................................................... 128

SERCSO II setup screen .................................................................................................................................................. 129

5 Station Setup ............................................................................................................................. 131

Overview ....................................................................................................................................................................................... 131

Generic and numbered I/O ...................................................................................................................................................... 131

Generic I/O .......................................................................................................................................................................... 131

Numbered I/O ...................................................................................................................................................................... 132

8 Phoenix 9.76.0 Installation and Setup Manual 806410

Page 9

Contents

Enabling station I/O ................................................................................................................................................................... 132

Auto Select and Manual Select inputs and Station Enable LED output ................................................................ 132

Basic operating sequence ................................................................................................................................................ 133

Using manual mode as an override ................................................................................................................................ 133

Summary ............................................................................................................................................................................... 133

Station configuration screen .................................................................................................................................................... 136

Guidelines for using the Station Configuration screen ...................................................................................................... 136

Conflicting process .................................................................................................................................................................... 137

Example of a conflicting process .................................................................................................................................... 138

How a tool is associated with a station ......................................................................................................................... 140

Troubleshooting a conflicting process error ......................................................................................................................... 142

The settings look correct on the screen below .................................................................................................... 142

The cause of the error ................................................................................................................................................ 143

Troubleshooting steps ............................................................................................................................................................... 144

6 Special Setups .......................................................................................................................... 145

Status/Feature List ..................................................................................................................................................................... 147

Status/Message or Wizard List ............................................................................................................................................... 148

Soft Keys ...................................................................................................................................................................................... 149

7 Plasma Setup ............................................................................................................................. 151

Plasma 1 and Plasma 2 ............................................................................................................................................................. 151

Examples using Plasma 1 and Plasma 2 ....................................................................................................................... 152

Sample settings for a multiple-torch cutting system .................................................................................................. 153

Sample settings for two-torch cutting system ............................................................................................................. 154

Plasma cut sequence ................................................................................................................................................................ 155

Setting up inputs and outputs for plasma ............................................................................................................................. 157

Summary: setting up the plasma routine ............................................................................................................................... 158

I/O and diagnostics .................................................................................................................................................................... 159

HPR diagnostics ......................................................................................................................................................................... 159

Power Supply Inputs .......................................................................................................................................................... 160

Gas Console Inputs ........................................................................................................................................................... 161

Power Supply Outputs ...................................................................................................................................................... 162

Gas Console Outputs ....................................................................................................................................................... 163

Serial communication interface ............................................................................................................................................... 164

RS-422C connections to HPR CNC interface ........................................................................................................... 164

Phoenix 9.76.0 Installation and Setup Manual 806410 9

Page 10

Contents

Powermax plasma supply ......................................................................................................................................................... 164

Selecting the Powermax in the Station Configuration screen ................................................................................. 164

Assigning the Powermax to a serial port ....................................................................................................................... 165

I/O selection for the Powermax ....................................................................................................................................... 166

Setting cut mode, gas pressure, and current from the CNC ................................................................................... 167

Powermax Diagnostic screen .......................................................................................................................................... 168

MAXPRO200 plasma supply ................................................................................................................................................... 169

Selecting the MAXPRO200 in the Station Configuration screen ........................................................................... 169

Assigning the MAXPRO200 to a serial port ................................................................................................................ 169

I/O selection for the MAXPRO200 ................................................................................................................................ 170

System error output ........................................................................................................................................................... 171

Watch Window setup for the MAXPRO200 ............................................................................................................... 172

Adjusting default cut chart settings from the CNC .................................................................................................... 173

MAXPRO200 Diagnostic screen .................................................................................................................................... 174

8 Diagnostics ................................................................................................................................. 177

Remote Help ................................................................................................................................................................................ 177

Load Additional Manuals ........................................................................................................................................................... 177

EDGE Pro Machine Interface Tests ....................................................................................................................................... 179

Serial Test ............................................................................................................................................................................. 180

USB Test .............................................................................................................................................................................. 181

I/O Test ................................................................................................................................................................................. 182

Axis Test ................................................................................................................................................................................ 184

THC Test .............................................................................................................................................................................. 186

LAN and Hypernet Tests ................................................................................................................................................... 187

Operator Interface Test ..................................................................................................................................................... 187

MicroEDGE Pro Machine Interface Tests ............................................................................................................................. 189

Serial Test ............................................................................................................................................................................. 190

USB Test .............................................................................................................................................................................. 191

I/O Test ................................................................................................................................................................................. 192

Axis Test ................................................................................................................................................................................ 194

THC Test .............................................................................................................................................................................. 195

LAN and Hypernet Tests ................................................................................................................................................... 197

Joystick and Speedpot Test ............................................................................................................................................. 197

I/O .................................................................................................................................................................................................. 199

Inputs ..................................................................................................................................................................................... 199

Outputs ................................................................................................................................................................................. 200

Expanded I/O ....................................................................................................................................................................... 201

10 Phoenix 9.76.0 Installation and Setup Manual 806410

Page 11

Contents

Analog Input Diagnostics .......................................................................................................................................................... 202

Inputs ..................................................................................................................................................................................... 202

Analog Inputs ....................................................................................................................................................................... 202

Drives and Motors ...................................................................................................................................................................... 203

SERCOS Drives and Motors Test .......................................................................................................................................... 204

Using Norton Ghost Utility ........................................................................................................................................................ 204

Creating a Ghost Recovery File ...................................................................................................................................... 205

Retrieving an Image File .................................................................................................................................................... 206

9 Motion Control .......................................................................................................................... 207

Closed Loop Servo Control ..................................................................................................................................................... 207

Typical Velocity and Position Loop System .................................................................................................................. 208

Encoders ....................................................................................................................................................................................... 209

Following Error .................................................................................................................................................................... 210

Position and Servo Error ................................................................................................................................................... 210

Encoder Counts and Maximum Machine Speed ................................................................................................................. 210

Determining Maximum Machine Speed ......................................................................................................................... 210

Gain ............................................................................................................................................................................................... 211

Proportional Gain ................................................................................................................................................................ 211

Integral Gain ......................................................................................................................................................................... 211

Derivative Gain .................................................................................................................................................................... 211

Feedforward ......................................................................................................................................................................... 211

Velocity Gain ........................................................................................................................................................................ 212

Tuning Procedures ..................................................................................................................................................................... 212

Tuning for Velocity Drives ................................................................................................................................................. 212

Tuning for Current Drives .................................................................................................................................................. 213

Motion Tuning Watch Windows ............................................................................................................................................. 214

10 Motion Compensation ............................................................................................................. 217

Hardware and Software Requirements ................................................................................................................................. 217

Overview ....................................................................................................................................................................................... 217

Calculating Compensation Data ............................................................................................................................................. 218

Calculating Backlash Compensation ............................................................................................................................. 221

Capturing and Using Motion Data in Phoenix ...................................................................................................................... 222

Map Axes ...................................................................................................................................................................................... 225

Create the Motion Compensation Data File ......................................................................................................... 228

Load the Data File ...................................................................................................................................................................... 229

Turn on Motion Compensation ................................................................................................................................................ 229

Save the Setup File .................................................................................................................................................................... 230

Phoenix 9.76.0 Installation and Setup Manual 806410 11

Page 12

Contents

11 Networking ................................................................................................................................. 231

Before You Begin ....................................................................................................................................................................... 231

Dynamic Host Configuration Protocol ........................................................................................................................... 231

Using the CNC in a Domain-based Network ............................................................................................................... 231

Administrator and User Accounts on the CNC ........................................................................................................... 232

About Network Connections ................................................................................................................................................... 232

Connecting the CNC to a Network (DHCP) ....................................................................................................................... 233

Connecting the CNC to a Network (non-DHCP) ............................................................................................................... 234

Connecting the CNC to a Workgroup .................................................................................................................................. 236

Mapping a Network Drive ......................................................................................................................................................... 238

Adding a Folder in Phoenix ...................................................................................................................................................... 240

12 Serial Ports ................................................................................................................................. 241

Control RS-232C DB-9 Pinout .............................................................................................................................................. 242

RS-232C Connections to Host PC with 9-pin D-type Connector ................................................................................ 242

RS-232C Connections to Host PC with 25-pin D-type Connector .............................................................................. 242

Control RS-422 DB-9 Pinout .................................................................................................................................................. 243

RS-422 Connections to Host PC with 9-pin D-type Connector ................................................................................... 243

RS-422 Connections to Host PC with 25-pin D-type Connector ................................................................................. 243

13 Phoenix Link .............................................................................................................................. 245

Files Menu .................................................................................................................................................................................... 246

Settings Menu ............................................................................................................................................................................. 247

Installation ..................................................................................................................................................................................... 248

Minimum System Requirements ...................................................................................................................................... 248

Software ................................................................................................................................................................................ 248

Change Master Folder ....................................................................................................................................................... 249

Operating Multiple Links ................................................................................................................................................... 251

Hardware ...................................................................................................................................................................................... 252

Operating Phoenix Link ............................................................................................................................................................. 252

Common Errors ........................................................................................................................................................................... 253

Error Messages ................................................................................................................................................................... 253

14 Aligning Plates .......................................................................................................................... 255

Notes about APA ........................................................................................................................................................................ 255

Sensing Sequence ..................................................................................................................................................................... 256

Five-Point Alignment .................................................................................................................................................................. 256

Three Point Alignment ............................................................................................................................................................... 257

Program Code ..................................................................................................................................................................... 257

Motion Path .......................................................................................................................................................................... 257

12 Phoenix 9.76.0 Installation and Setup Manual 806410

Page 13

Contents

15 Oxyfuel Application .................................................................................................................. 259

Oxyfuel overview ......................................................................................................................................................................... 260

Two-torch oxyfuel system diagram ......................................................................................................................................... 261

Low preheat fuel gas options ................................................................................................................................................... 262

Oxyfuel cut sequence ................................................................................................................................................................ 262

Oxyfuel inputs .............................................................................................................................................................................. 266

Oxyfuel outputs ........................................................................................................................................................................... 267

Setting up oxyfuel ....................................................................................................................................................................... 269

Oxyfuel cut chart ......................................................................................................................................................................... 271

Controlling proportional gas regulators with analog outputs ........................................................................................... 272

Setting up analog outputs ........................................................................................................................................................ 273

Setting gas pressures from the CNC ............................................................................................................................ 274

Staged pierce for oxyfuel cutting ............................................................................................................................................ 276

16 Waterjet Application ................................................................................................................ 279

Waterjet system overview ......................................................................................................................................................... 280

Enabling the waterjet process on the CNC .................................................................................................................. 281

Selecting the waterjet pump model ................................................................................................................................ 282

Serial communications .............................................................................................................................................................. 282

Assigning a serial port ....................................................................................................................................................... 283

Sequence of operations ............................................................................................................................................................ 283

Waterjet I/O ................................................................................................................................................................................. 286

Automatically setting abrasive delays .................................................................................................................................... 287

Waterjet height control .............................................................................................................................................................. 287

Speeds for waterjet height control ................................................................................................................................. 288

Calibration ............................................................................................................................................................................ 289

Foot Sensor Up input ......................................................................................................................................................... 289

Initial height sense (IHS) ................................................................................................................................................... 289

Performing a first IHS ........................................................................................................................................................ 290

Skip IHS ................................................................................................................................................................................ 290

Low pressure piercing ............................................................................................................................................................... 290

Cutting a part ............................................................................................................................................................................... 291

Enabling a station ............................................................................................................................................................... 291

Setting the cut height without height control ............................................................................................................... 291

Cut speed calculator ................................................................................................................................................................. 292

Waterjet system messages ...................................................................................................................................................... 292

Phoenix 9.76.0 Installation and Setup Manual 806410 13

Page 14

Contents

14 Phoenix 9.76.0 Installation and Setup Manual 806410

Page 15

Safety

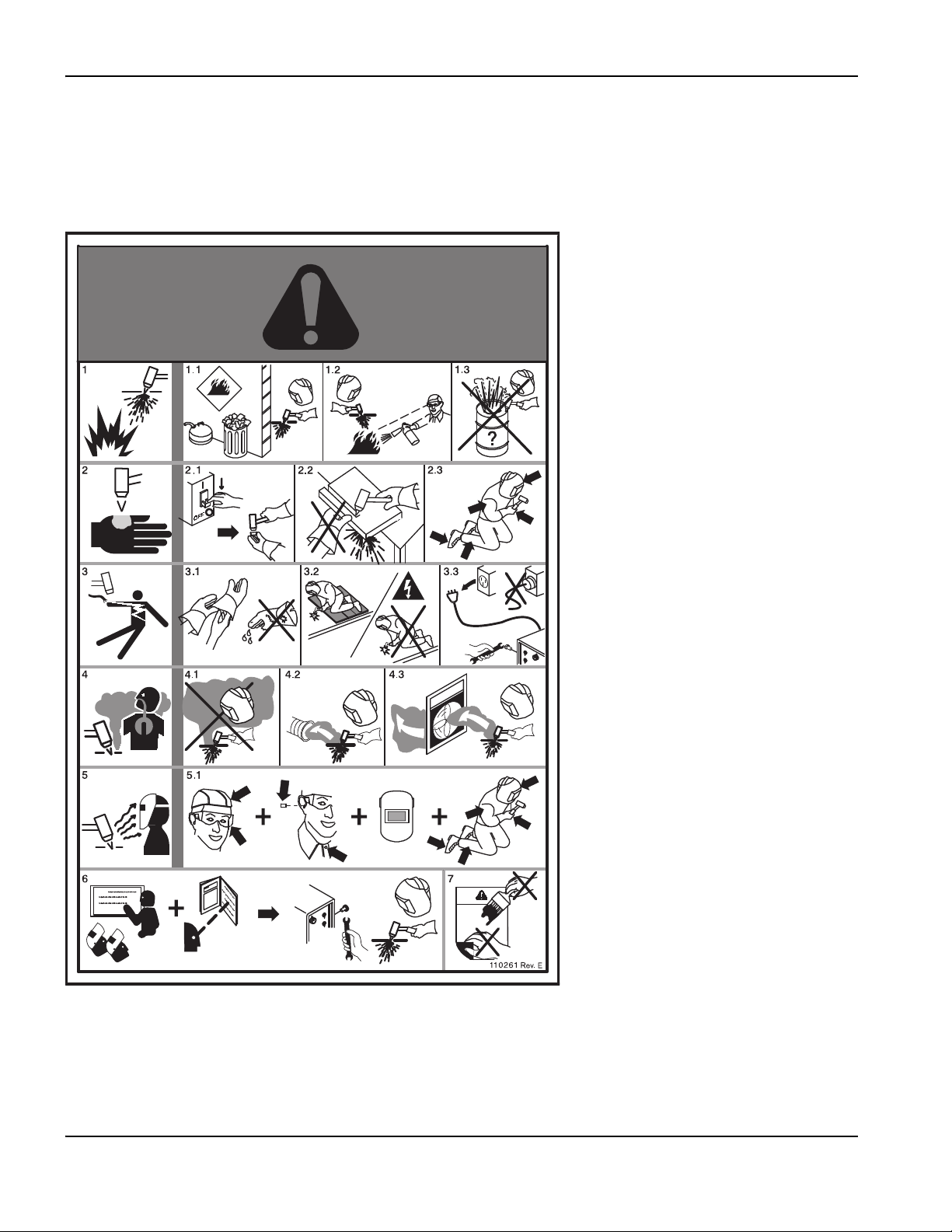

RECOGNIZE SAFETY INFORMATION

The symbols shown in this section are used to identify

potential hazards. When you see a safety symbol in this

manual or on your machine, understand the potential

for personal injury, and follow the related instructions to

avoid the hazard.

FOLLOW SAFETY INSTRUCTIONS

Read carefully all safety messages in this manual and

safety labels on your machine.

• Keep the safety labels on your machine in good

condition. Replace missing or damaged labels

immediately.

• Learn how to operate the machine and how to use

the controls properly. Do not let anyone operate it

without instruction.

• Keep your machine in proper working condition.

Unauthorized modifications to the machine may

affect safety and machine service life.

DANGER WARNING CAUTION

Hypertherm uses American National Standards Institute

guidelines for safety signal words and symbols. A signal

word DANGER or WARNING is used with a safety

symbol. DANGER identifies the most serious hazards.

• DANGER and WARNING safety labels are located on

your machine near specific hazards.

• DANGER safety messages precede related

instructions in the manual that will result in serious

injury or death if not followed correctly.

• WARNING safety messages precede related

instructions in this manual that may result in injury or

death if not followed correctly.

• CAUTION safety messages precede related

instructions in this manual that may result in minor

injury or damage to equipment if not followed correctly.

ELECTRICAL HAZARDS

• Only trained and authorized personnel may open this

equipment.

• If the equipment is permanently connected, turn it off,

and lock out/tag out power before the enclosure is

opened.

• If power is supplied to the equipment with a cord,

unplug the unit before the enclosure is opened.

• Lockable disconnects or lockable plug covers must be

provided by others.

• Wait 5 minutes after removal of power before entering

the enclosure to allow stored energy to discharge.

Safety and Compliance SC-15

• If the equipment must have power when the enclosure

is open for servicing, arc flash explosion hazards may

exist. Follow ALL local requirements (NFPA 70E in the

USA) for safe work practices and for Personal

Protective Equipment when servicing energized

equipment.

• The enclosure shall be closed and the proper earth

ground continuity to the enclosure verified prior to

operating the equipment after moving, opening, or

servicing.

• Always follow these instructions for disconnecting

power before inspecting or changing torch

consumable parts.

Page 16

Safety

Touching live electrical parts can cause a fatal shock or

severe burn.

• Operating the plasma system completes an electrical

circuit between the torch and the workpiece. The

workpiece and anything touching the workpiece are

part of the electrical circuit.

• Never touch the torch body, workpiece or the water in

a water table when the plasma system is operating.

Electric shock prevention

All Hypertherm plasma systems use high voltage

in the cutting process (200 to 400 VDC are

common). Take the following precautions when

operating this system:

• Wear insulated gloves and boots, and keep your body

and clothing dry.

• Do not stand, sit or lie on – or touch – any wet surface

when using the plasma system.

• Insulate yourself from work and ground using dry

insulating mats or covers big enough to prevent any

physical contact with the work or ground. If you must

work in or near a damp area, use extreme caution.

• Provide a disconnect switch close to the power supply

with properly sized fuses. This switch allows the

operator to turn off the power supply quickly in an

emergency situation.

• When using a water table, be sure that it is correctly

connected to earth ground.

• Install and ground this equipment according to the

instruction manual and in accordance with national

and local codes.

• Inspect the input power cord frequently for damage or

cracking of the cover. Replace a damaged power cord

immediately. Bare wiring can kill.

• Inspect and replace any worn or damaged torch leads.

• Do not pick up the workpiece, including the waste

cutoff, while you cut. Leave the workpiece in place or

on the workbench with the work cable attached during

the cutting process.

• Before checking, cleaning or changing torch parts,

disconnect the main power or unplug the power

supply.

• Never bypass or shortcut the safety interlocks.

• Before removing any power supply or system

enclosure cover, disconnect electrical input power.

Wait 5 minutes after disconnecting the main power to

allow capacitors to discharge.

• Never operate the plasma system unless the power

supply covers are in place. Exposed power supply

connections present a severe electrical hazard.

• When making input connections, attach proper

grounding conductor first.

• Each Hypertherm plasma system is designed to be

used only with specific Hypertherm torches. Do not

substitute other torches which could overheat and

present a safety hazard.

ELECTRIC SHOCK CAN KILL

SC-16 Safety and Compliance

Page 17

CUTTING CAN CAUSE FIRE OR EXPLOSION

Safety

Fire prevention

• Be sure the area is safe before doing any cutting.

Keep a fire extinguisher nearby.

• Remove all flammables within 35 feet (10 m) of the

cutting area.

• Quench hot metal or allow it to cool before handling

or before letting it touch combustible materials.

• Never cut containers with potentially flammable

materials inside – they must be emptied and properly

cleaned first.

• Ventilate potentially flammable atmospheres before

cutting.

• When cutting with oxygen as the plasma gas, an

exhaust ventilation system is required.

Explosion prevention

• Do not use the plasma system if explosive dust or

vapors may be present.

• Do not cut pressurized cylinders, pipes, or any

closed container.

• Do not cut containers that have held combustible

materials.

WAR N I NG

Explosion Hazard

Argon-Hydrogen and Methane

Hydrogen and methane are flammable gases that

present an explosion hazard. Keep flames away from

cylinders and hoses that contain methane or hydrogen

mixtures. Keep flames and sparks away from the torch

when using methane or argon-hydrogen plasma.

WAR N I NG

Hydrogen Detonation with

Aluminum Cutting

• Do not cut aluminum underwater or with water

touching the underside of the aluminum.

• Cutting aluminum underwater or with the water

touching the underside of the aluminum can result in

an explosive condition that can detonate during

plasma cutting operations.

WAR N I NG

Explosion Hazard

Underwater Cutting with Fuel Gases

• Do not cut under water with fuel gases containing

hydrogen.

• Cutting under water with fuel gases containing

hydrogen can result in an explosive condition that

can detonate during plasma cutting operations.

Safety and Compliance SC-17

Page 18

Safety

TOXIC FUMES CAN CAUSE INJURY OR DEATH

The plasma arc by itself is the heat source used for

cutting. Accordingly, although the plasma arc has not

been identified as a source of toxic fumes, the material

being cut can be a source of toxic fumes or gases that

deplete oxygen.

Fumes produced vary depending on the metal that is

cut. Metals that may release toxic fumes include, but are

not limited to, stainless steel, carbon steel, zinc

(galvanized), and copper.

In some cases, the metal may be coated with a

substance that could release toxic fumes. Toxic coatings

include, but are not limited to, lead (in some paints),

cadmium (in some paints and fillers), and beryllium.

Gases produced by plasma cutting vary based on the

material to be cut and the method of cutting, but may

include ozone, oxides of nitrogen, hexavalent chromium,

hydrogen, and other substances if such are contained in

or released by the material being cut.

Caution should be taken to minimize exposure to fumes

produced by any industrial process. Depending upon

the chemical composition and concentration of the

fumes (as well as other factors, such as ventilation),

there may be a risk of physical illness, such as birth

defects or cancer.

It is the responsibility of the equipment and site owner

to test the air quality in the area where the equipment is

used and to ensure that the air quality in the workplace

meets all local and national standards and regulations.

The air quality level in any relevant workplace depends

on site-specific variables such as:

• Table design (wet, dry, underwater).

• Material composition, surface finish, and composition

of coatings.

• Volume of material removed.

• Duration of cutting or gouging.

• Size, air volume, ventilation and filtration of the work

area.

• Personal protective equipment.

• Number of welding and cutting systems in operation.

• Other site processes that may produce fumes.

If the workplace must conform to national or local

regulations, only monitoring or testing done at the site

can determine whether the site is above or below

allowable levels.

To reduce the risk of exposure to fumes:

• Remove all coatings and solvents from the metal

before cutting.

• Use local exhaust ventilation to remove fumes from

the air.

• Do not inhale fumes. Wear an air-supplied respirator

when cutting any metal coated with, containing, or

suspected to contain toxic elements.

• Assure that those using welding or cutting

equipment, as well as air-supplied respiration

devices, are qualified and trained in the proper use of

such equipment.

• Never cut containers with potentially toxic materials

inside. Empty and properly clean the container first.

• Monitor or test the air quality at the site as needed.

• Consult with a local expert to implement a site plan

to ensure safe air quality.

SC-18 Safety and Compliance

Page 19

GROUNDING SAFETY

Safety

Work cable Attach the work cable securely to the

workpiece or the work table with good metal-to-metal

contact. Do not connect it to the piece that will fall away

when the cut is complete.

Work table Connect the work table to an earth

ground, in accordance with appropriate national and

local electrical codes.

STATIC ELECTRICITY CAN DAMAGE CIRCUIT BOARDS

Use proper precautions when handling printed circuit boards:

• Store PC boards in anti-static containers.

• Wear a grounded wrist strap when handling PC boards.

Input power

• Be sure to connect the power cord ground wire to

the ground in the disconnect box.

• If installation of the plasma system involves

connecting the power cord to the power supply, be

sure to connect the power cord ground wire properly.

• Place the power cord’s ground wire on the stud first,

then place any other ground wires on top of the

power cord ground. Fasten the retaining nut tightly.

• Tighten all electrical connections to avoid excessive

heating.

Safety and Compliance SC-19

Page 20

Safety

COMPRESSED GAS EQUIPMENT SAFETY

• Never lubricate cylinder valves or regulators with oil

or grease.

• Use only correct gas cylinders, regulators, hoses and

fittings designed for the specific application.

• Maintain all compressed gas equipment and

associated parts in good condition.

• Label and color-code all gas hoses to identify the

type of gas in each hose. Consult applicable national

and local codes.

GAS CYLINDERS CAN EXPLODE IF DAMAGED

Gas cylinders contain gas under high pressure.

If damaged, a cylinder can explode.

• Handle and use compressed gas cylinders in

accordance with applicable national and local codes.

• Never use a cylinder that is not upright and secured

in place.

• Keep the protective cap in place over valve except

when the cylinder is in use or connected for use.

• Never allow electrical contact between the plasma

arc and a cylinder.

• Never expose cylinders to excessive heat, sparks,

slag or open flame.

• Never use a hammer, wrench or other tool to open a

stuck cylinder valve.

A PLASMA ARC CAN CAUSE INJURY AND BURNS

Instant-on torches

Plasma arc comes on immediately when the torch

switch is activated.

The plasma arc will cut quickly through gloves and skin.

• Keep away from the torch tip.

• Do not hold metal near the cutting path.

• Never point the torch toward yourself or others.

SC-20 Safety and Compliance

Page 21

ARC RAYS CAN BURN EYES AND SKIN

Eye protection Plasma arc rays produce intense

visible and invisible (ultraviolet and infrared) rays that

can burn eyes and skin.

• Use eye protection in accordance with applicable

national and local codes.

• Wear eye protection (safety glasses or goggles with

side shields, and a welding helmet) with appropriate

lens shading to protect your eyes from the arc’s

ultraviolet and infrared rays.

Skin protection Wear protective clothing to protect

against burns caused by ultraviolet light, sparks, and hot

metal.

• Gauntlet gloves, safety shoes and hat.

• Flame-retardant clothing to cover all exposed areas.

• Cuffless trousers to prevent entry of sparks and slag.

• Remove any combustibles, such as a butane lighter

or matches, from your pockets before cutting.

Cutting area Prepare the cutting area to reduce

reflection and transmission of ultraviolet light:

• Paint walls and other surfaces with dark colors to

reduce reflection.

• Use protective screens or barriers to protect others

from flash and glare.

• Warn others not to watch the arc. Use placards or

signs.

Safety

Minimum

Arc current

(amps)

protective shade

number

(ANSIZ49.1:2005)

Less than 40 A

41 to 60 A

61 to 80 A

81 to 125 A

126 to 150 A

151 to 175 A

176 to 250 A

251 to 300 A

301 to 400 A

401 to 800 A

5589

6689

8889

8989

89810

89811

89812

89813

912913

10 14 10 N /A

Safety and Compliance SC-21

Suggested shade

number for

comfort

OSHA 29CFR

1910.133(a)(5)

EN168:2002

(ANSI Z49.1:2005)

Europe

Page 22

Safety

PACEMAKER AND HEARING AID OPERATION

Pacemaker and hearing aid operation can be affected

by magnetic fields from high currents.

Pacemaker and hearing aid wearers should consult a

doctor before going near any plasma arc cutting and

gouging operations.

NOISE CAN DAMAGE HEARING

Cutting with a plasma arc can exceed acceptable noise

levels as defined by local codes in many applications.

Prolonged exposure to excessive noise can damage

hearing. Always wear proper ear protection when

cutting or gouging, unless sound pressure level

measurements taken at the installed site have verified

personal hearing protection is not necessary per

relevant international, regional, and local codes.

Significant noise reduction can be obtained by adding

simple engineering controls to cutting tables such as

barriers or curtains positioned between the plasma arc

and the workstation; and/or locating the workstation

away from the plasma arc. Implement administrative

controls in the workplace to restrict access, limit

operator exposure time, screen off noisy working areas

and/or take measures to reduce reverberation in

working areas by putting up noise absorbers.

To reduce magnetic field hazards:

• Keep both the work cable and the torch lead to one

side, away from your body.

• Route the torch leads as close as possible to the

work cable.

• Do not wrap or drape the torch lead or work cable

around your body.

• Keep as far away from the power supply as possible.

Use ear protectors if the noise is disruptive or if there is

a risk of hearing damage after all other engineering and

administrative controls have been implemented. If

hearing protection is required, wear only approved

personal protective devices such as ear muffs or ear

plugs with a noise reduction rating appropriate for the

situation. Warn others in the area of possible noise