Page 1

command THC

Plasma Interface

Upgrade

Kit 128503

Kit Instructions

IM-380

(P/N 803800)

Revision 0 - January 2000

Hypertherm, Inc.

Hanover, NH USA

http://www.hypertherm.com

email: info@hypertherm.com

© Copyright 2000 Hypertherm, Inc.

All Rights Reserved

Hypertherm and Command THC are trademarks of Hypertherm, Inc. and may be

registered in the United States and/or other countries.

Page 2

command THC

Command THC

Instruction Manual

Command THC

Instruction Manual

128494 Command THC Plasma Interface Assembly

802780 X-Y Command THC Instruction Manual

8022510 Robotic Command THC Instruction Manual

081029 Real Time Microprocessor

081030 Interface Microprocessor

380.05

Plasma Interface Upgrade

128408 KIT CONTENTS

PURPOSE

To replace the plasma interface assembly or the interface PCB, the command THC must be upgraded with a

new plasma interface assembly. The upgrade requirements include installing the new plasma interface

assembly, installing 2 new control module microprocessors and recalibration of the THC system.

MAX200, HT2000 and HT2000LHF Initial Height Sensing (IHS)

Initial height sensing (IHS) for the MAX200, HT2000 and HT2000LHF systems can now be accomplished

using the new Command THC torch Ohmic Contact Sensing function. To take advantage of this

enhancement, you will need a new torch retaining cap and a THC ohmic contact wire. See the applicable

setup section of the instruction manual (802780) included with this kit for parts and installation requirements.

128503 Kit Instructions

Page 1

Page 3

command THC

INSTRUCTIONS

ELECTRIC SHOCK CAN KILL

• Turn off the power and remove the input power plug from its receptacle before

removing any access cover. If the power supply is directly connected to a line

disconnect box, switch the line disconnect to OFF (O). In the U.S., use a "lock-out

/ tag-out" procedure until the service or maintenance work is complete. In other

countries, follow appropriate national or local safety procedures.

• Do not touch live electrical parts! If power is required for servicing, use extreme

caution when working near live electrical circuits. Dangerous voltages exist inside

the THC control module that can cause serious injury or death.

STATIC ELECTRICITY CAN DAMAGE CIRCUIT BOARDS

• Put on a grounded wrist strap BEFORE handling PC boards.

Plasma Interface Upgrade

WARNING

All work must be performed by a Hypertherm Distributor or a qualified technician.

Tools Needed

Digital Volt Meter

Flat Screw Driver

#2 Phillips Screw Driver

Small, Flat Screw Driver

128503 Kit Instructions

Page 2

Page 4

command THC

Procedure

1. Turn off the power to the power supply.

2 Turn off the power to the THC system and remove power cord.

Plasma Interface Upgrade

2

1

3 Remove the THC control module cover.

3

IM380.02

128503 Kit Instructions

Page 3

Page 5

command THC

Plasma Interface Upgrade

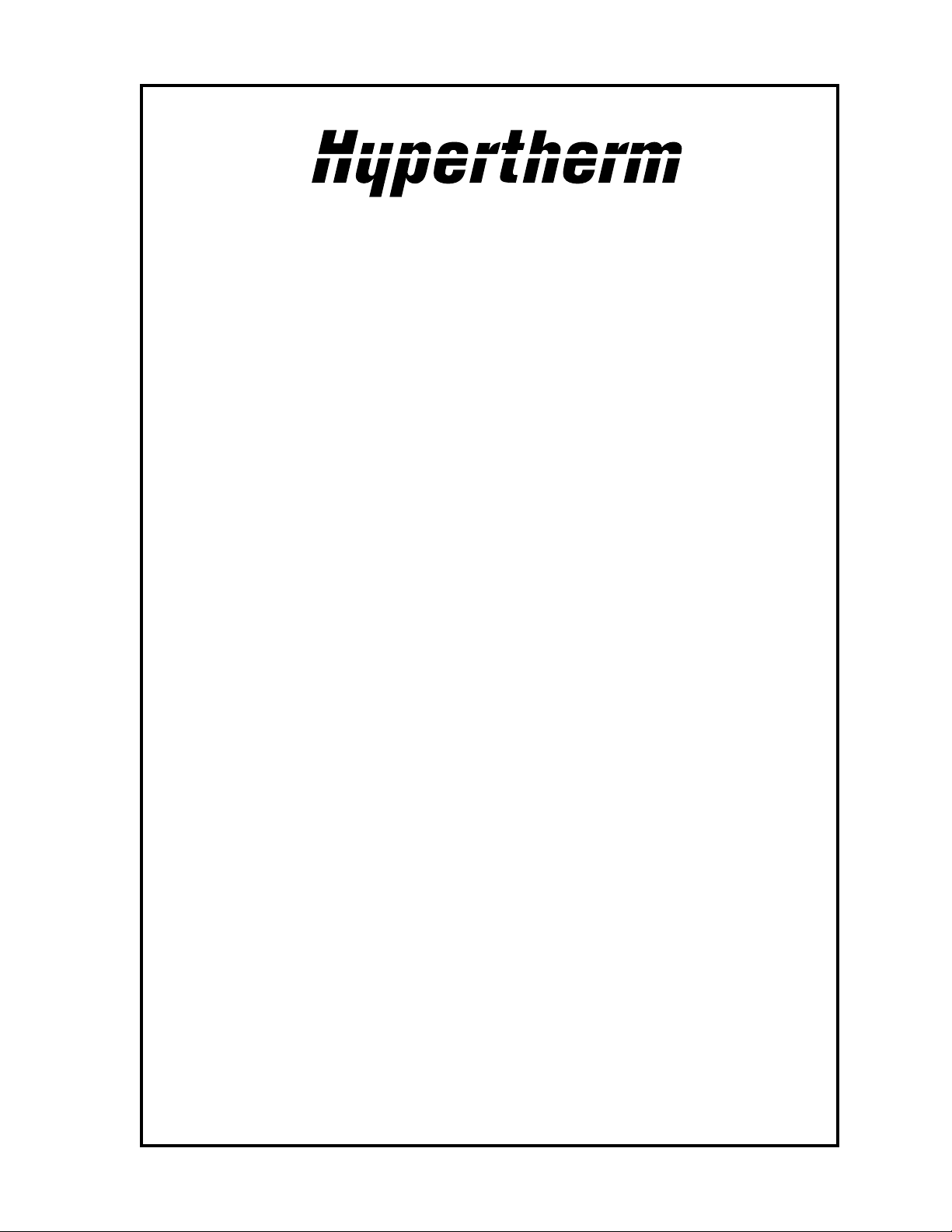

4 Remove and discard the 2 microprocessors from the control PCB.

081030

Rev

INTERFACE MICROPROCESSOR

RS-422 MACHINE INTERFACE PENDANT PLASMA INTERFACE

P1

ARC VOLTAGE

ADJUST

J5

1

J10

J11

D16

G

PLASMA INTERFACE OUTPUTS

34 35 36 37

33

D32 38

PLASMA START OUT

HOLD IGNITION OUT

PIERCE COMPLETE OUT

EXT INTERLOCK OK

PLASMA SPARE OUT 1

J1

1

MACHINE INTERFACE OUTPUTS

27 28 29 30

26D9D25 31

RR RRRRY

MACH SPARE OUT 1

RETRACT COMPLETE

PILOT ARC OUT

THC ERROR OUT

MACH MOTION OUT

MACHINE INTERFACE INPUTS

10 11 12 13 14

CYCLE START IN

AUTO HEIGHT ON/OFF

IHS COMPLETE

ERROR #1

RESERVED 1

RESERVED 2

IHS SYNC IN

15

GGGGGGG

RESERVED 3

MACHINE CABLE

J4

1

YRRRRRR

PLASMA SPARE OUT 3

PLASMA SPARE OUT 2

ERROR #2

1

PLASMA INTERFACE INPUTS

18 19 20 21 22

D17

GG GGGGG

ALT-TORCH-IN-POS

ALT-TORCH-SEL-IN

TRANSFER IN

PILOT ARC IN

NOZZLE CONTACT IN

PLASMA SPARE IN 1

J6

23

PLASMA CABLE

J2

RS-232

DIAGNOSTIC PORT

1

1

U36

INTERFACE

MICROPROCESSOR

J3

EXPANSION PORT

1 1

GGGG

TP3

GND

TP4

+24V

J8 DC POWER IN

CONTROL PCB

D42 D43 D44D41

TP6

TP5

+12V

-12V

TP7

+5V

1

041507

+5V+12V-12V+24V

1

U48

REAL-TIME

MICROPROCESSOR

IM380.04

1

TP2

TP1

ERROR-RESOLUTION

SPEED-RESPONSE

D45 46 47 48 49 50 51 52 53 54 55 56

GGGGGGGGGGGGG

TO MOTOR DRIVE PCB

J7

081029

Rev

REAL TIME MICROPROCESSOR

2

MOTOR CURRENT CHECK

HOME POSITION SWITCH

ASYMETRIC-RESPONSE

LOWER LIMIT SWITCH

CRASH DETECT

MOTOR DRIVE INTERFACE

LIFTER SPARE IN 4

DRIVE ID 4

DRIVE ID 2

DRIVE ID 1

MOTOR DRIVE INSTALLED

LIFTER SPARE IN 5

ENCODER B

ENCODER A

58 5957

GG

128503 Kit Instructions

Page 4

Page 6

command THC

Plasma Interface Upgrade

5 Install the new microprocessors into the control PCB.

081030

Rev H

INTERFACE MICROPROCESSOR

RS-422 MACHINE INTERFACE PENDANT PLASMA INTERFACE

J1

1

MACHINE INTERFACE OUTPUTS

27 28 29 30

26D9D25 31

RR RRRRY

MACH SPARE OUT 1

RETRACT COMPLETE

PILOT ARC OUT

THC ERROR OUT

MACH MOTION OUT

MACHINE INTERFACE INPUTS

10 11 12 13 14

CYCLE START IN

AUTO HEIGHT ON/OFF

IHS COMPLETE

ERROR #1

RESERVED 1

RESERVED 2

IHS SYNC IN

15

GGGGGGG

RESERVED 3

MACHINE CABLE

J4

1

P1

ARC VOLTAGE

ADJUST

J5

1

J10

J11

D16

PLASMA INTERFACE OUTPUTS

33

D32 38

PLASMA START OUT

HOLD IGNITION OUT

EXT INTER-

G

LOCK OK

34 35 36 37

YRRRRRR

PLASMA SPARE OUT 3

PLASMA SPARE OUT 2

PIERCE COMPLETE OUT

PLASMA SPARE OUT 1

ERROR #2

1

PLASMA INTERFACE INPUTS

18 19 20 21 22

D17

GG GGGGG

TRANSFER IN

PILOT ARC IN

NOZZLE CONTACT IN

PLASMA SPARE IN 1

ALT-TORCH-IN-POS

ALT-TORCH-SEL-IN

J6

23

PLASMA CABLE

J2

RS-232

DIAGNOSTIC PORT

1

1

U36

INTERFACE

MICROPROCESSOR

J3

EXPANSION PORT

1 1

GGGG

TP3

GND

TP4

+24V

J8 DC POWER IN

IM380.01

Align the dot on the microprocessor

with the number 1 on the control PCB.

CONTROL PCB

D42 D43 D44D41

TP6

TP5

+12V

-12V

TP7

+5V

1

041507

+5V+12V-12V+24V

1

U48

REAL-TIME

TP2

MICROPROCESSOR

TP1

J7

HOME POSITION SWITCH

ASYMETRIC-RESPONSE

ERROR-RESOLUTION

SPEED-RESPONSE

CRASH DETECT

D45 46 47 48 49 50 51 52 53 54 55 56

GGGGGGGGGGGGG

MOTOR DRIVE INTERFACE

TO MOTOR DRIVE PCB

081029

Rev H

REAL TIME MICROPROCESSOR

MOTOR CURRENT CHECK

LOWER LIMIT SWITCH

LIFTER SPARE IN 4

DRIVE ID 2

DRIVE ID 1

MOTOR DRIVE INSTALLED

LIFTER SPARE IN 5

ENCODER A

DRIVE ID 4

58 5957

ENCODER B

GG

128503 Kit Instructions

Page 5

Page 7

command THC

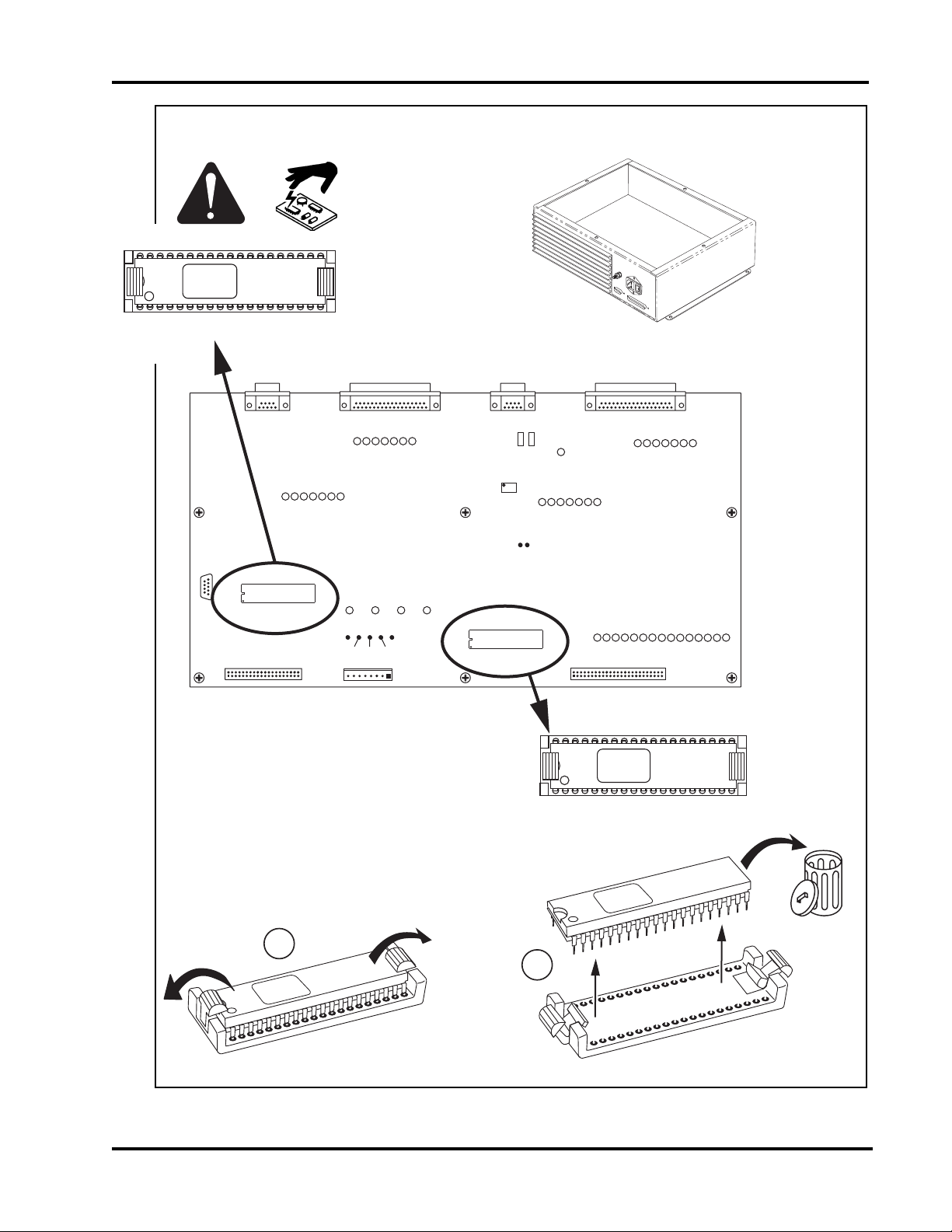

6. Before removing the old plasma interface assembly, mark all of the wire connections so that they can

be reinstalled correctly.

7 Discard your existing Command THC

Instruction Manual.

Plasma Interface Upgrade

802510

OR

802780

Command THC

Instruction Manual

Revisions 1 thru 4

8 Remove the old interface assembly.

9 Install the new interface assembly per the

revised instruction manual included with

this kit.

802780

X-Y

Command THC

Instruction Manual

- OR -

802510

Robotic

Command THC

Instruction Manual

IM308.06

128503 Kit Instructions

Page 6

Page 8

command THC

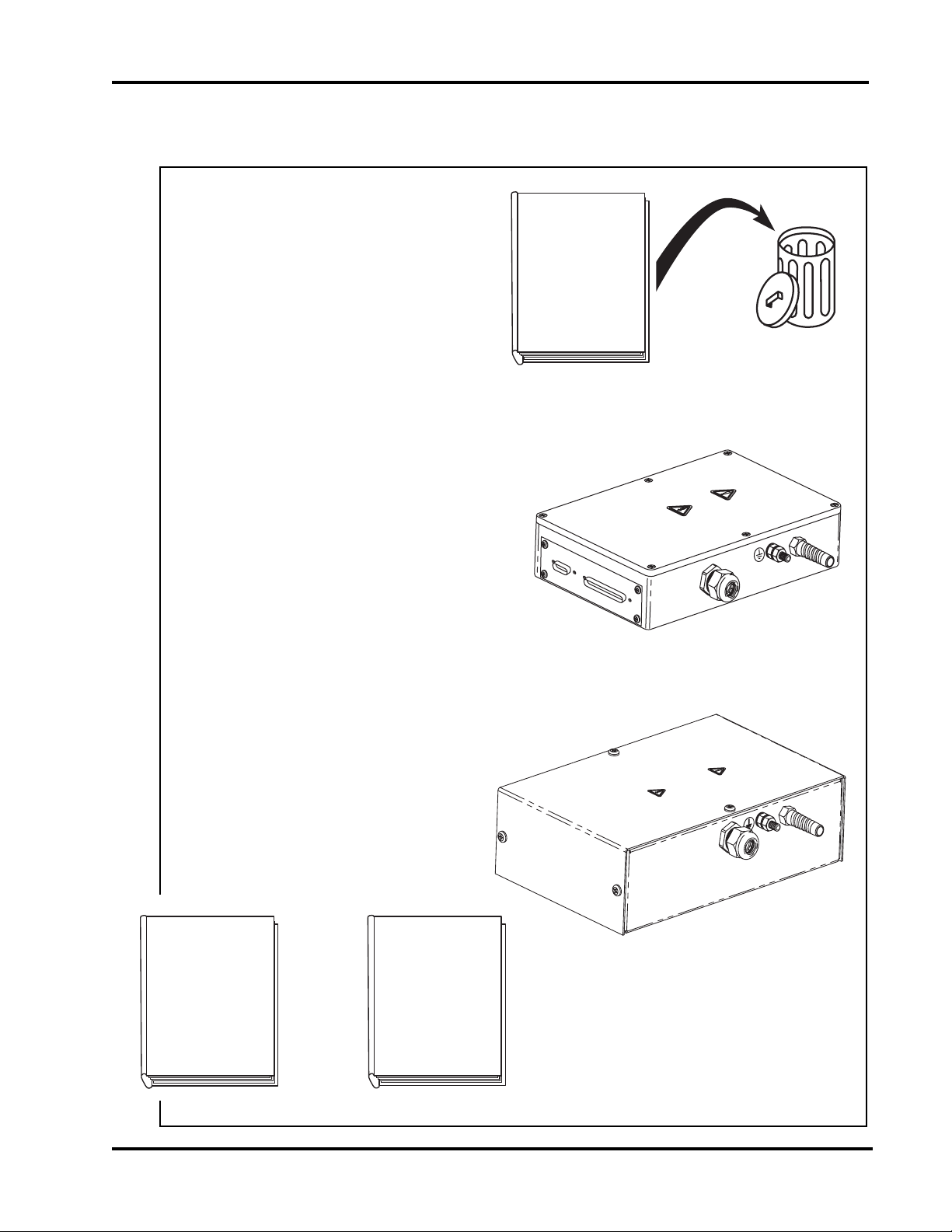

10 Attach the volt meter to measure the arc voltage between J5-2 and J5-3 in the plasma interface

assembly.

Plasma Interface Upgrade

GND

ELECTRODE

WORK

J5

11 Replace the power cord to the THC control module.

12345

THC.91

12 Turn on the power to the THC.

13 Turn on the power to the power supply.

IM380.03

128503 Kit Instructions

Page 7

Page 9

command THC

IM380.08

14. Put the Command THC in MANUAL MODE.

15. Begin a cutting process and compare the voltage displayed on the volt meter to the arc voltage

displayed on the CNC or THC pendant.

16 Adjust the potentiometer on the PC board so that the

voltage displayed on the volt meter is the same as the arc

voltage displayed on the CNC or THC pendant.

Plasma Interface Upgrade

IM380.07

17. Turn off power to power supply and to THC system.

18. Remove volt meter from the plasma interface assembly.

19 Install the access cover to the

THC plasma interface assembly

and the control module.

128503 Kit Instructions

Page 8

Loading...

Loading...