Page 1

®

THC.14

command THC

Control PC Board

Replacement and Calibration

Kit 128407

Kit Instructions

803600 - Revision 2

Page 2

command THC

Control PC Board Replacement

and

Calibration

Kit 128407

Kit Instructions

IM-360

(P/N 803600)

Revision 2 - April 2000

Hypertherm, Inc.

Hanover, NH USA

http://www.hypertherm.com

email: info@hypertherm.com

© Copyright 2000 Hypertherm, Inc.

All Rights Reserved

Hypertherm and Command THC are trademarks of Hypertherm, Inc. and may be

registered in the United States and/or other countries.

Page 3

Hypertherm Offices Worldwide

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

Tel.: (603) 643-3441 (Main Office)

Fax: (603) 643-5352 (All Departments)

Tel.: (800) 643-9878 (Technical Service – toll-free in USA and Canada)

Tel.: (800) 737-2978 (Customer Service – toll-free in USA and Canada)

email: info@hypertherm.com (General Information)

email: service@hypertherm.com (Technical/Customer Services)

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D–63457 Hanau-Wolfgang, Germany

Tel.: 49 6181 58 2100

Fax: 49 6181 58 2134

Hypertherm (S) Pte Ltd

No. 19 Kaki Bukit Road 2

K.B. Warehouse Complex

Singapore 417847

Tel.: 65 841 2489

Fax: 65 841 2490

Hypertherm UK Ltd

9 Berkeley Court, Manor Park

Runcorn, Cheshire, England WA7 1TQ

Tel.: 44 1928 579 074

Fax: 44 1928 579 604

:

France

15 Impasse des Rosiers

95610 Eragny, France

Tel.: 33 1 30 37 15 28

Fax: 33 1 30 37 15 79

Hypertherm S.r.L.

Via Torino 2

20123 Milan, Italy

Tel.: 39 02 725 46 312 (Customer Service)

Tel.: 39 02 725 46 314 (Technical Service)

Fax: 39 02 725 46 400 (All Departments)

Hypertherm B.V.

Burg, Haverkampstraat 13

7091 CN Dinxperlo, The Netherlands

Tel.: 31 315 655 866 (Customer Service)

Fax: 31 315 655 886

European Technical Support Organization (ETSO)

Edisonstraat 12

3281 NC Numansdorp, The Netherlands

Tel.: +800 4973 7843 (+800 Hypertherm) – (toll-free Technical Service)

Tel.: 31 186 659494

Fax: 31 186 659495

Japan

Shinjuku Park Tower

30th Floor

3-7-1 Nishi-Shinjuku

Shinjuku-ku, Tokyo

163-1030, Japan

Tel.: 81 03 5326 3142

Fax: 81 03 5326 3001

3/00

Page 4

Command THC Control PC Board Calibration

In This Bulletin:

128407 KIT CONTENTS ........................................................................................................... Page 2

PURPOSE................................................................................................................................. Page 2

REQUIREMENTS ..................................................................................................................... Page 3

Tools Needed .........................................................................................................................Page 3

HD4070 PROCEDURE .............................................................................................................Page 4

HT4400 PROCEDURE ............................................................................................................. Page 6

POWERMAX, MAX100, MAX200, HD3070, HT2000,

HT2000LHF, AND HT4001 PROCEDURE............................................................................. Page 8

128407 Kit Instructions

Page 1

Page 5

Command THC Control PC Board Calibration

128407 KIT CONTENTS

041507 Control Module PC Board

803600 Instructions

PURPOSE

After installing the replacement PC board included with this kit, calibration of the THC system is required.

These instructions provide calibration procedures.

Page 2

128407 Kit Instructions

Page 6

Command THC Control PC Board Calibration

REQUIREMENTS

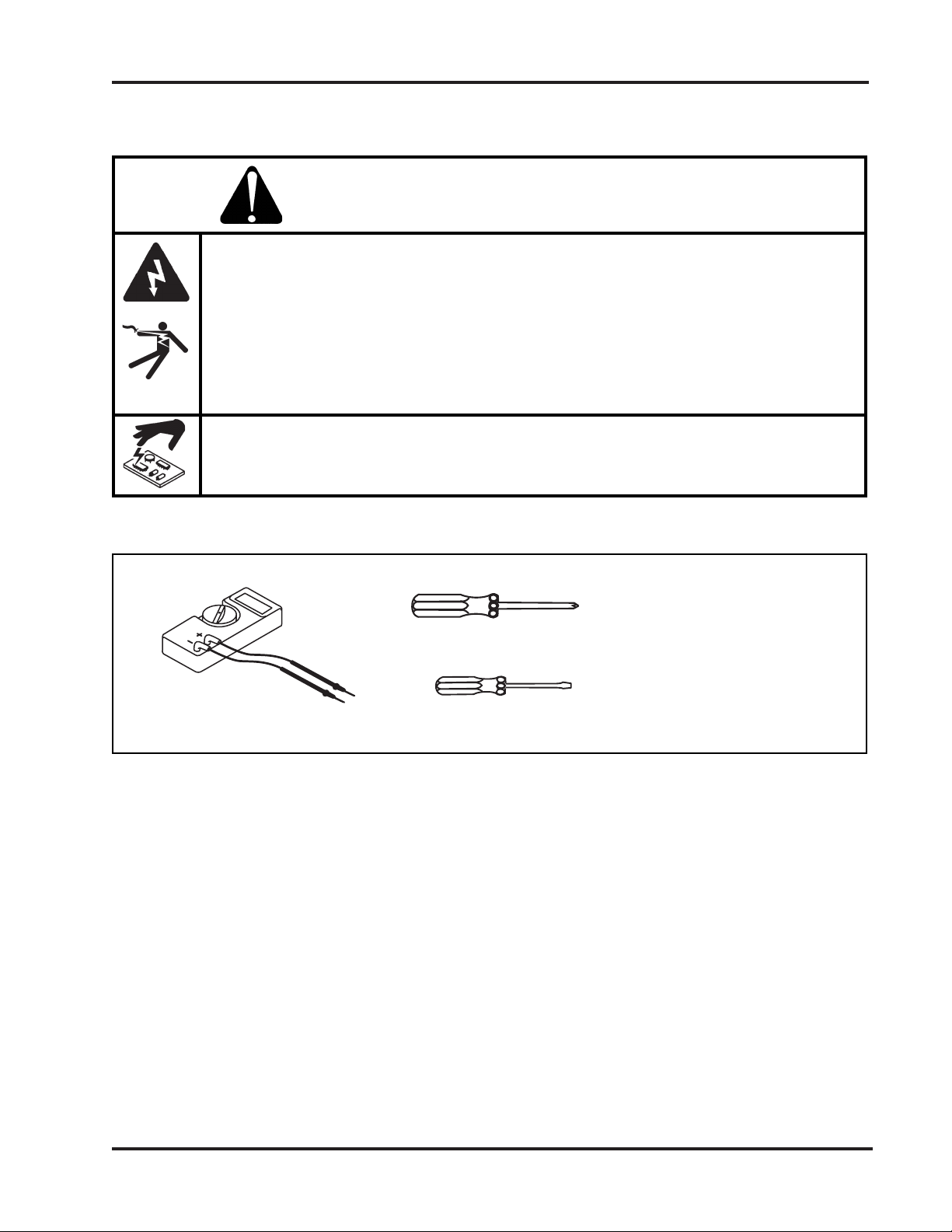

ELECTRIC SHOCK CAN KILL

• Turn off the power and remove the input power plug from its receptacle before

removing any access cover. If the power supply is directly connected to a line

disconnect box, switch the line disconnect to OFF (O). In the U.S., use a "lock-out

/ tag-out" procedure until the service or maintenance work is complete. In other

countries, follow appropriate national or local safety procedures.

• Do not touch live electrical parts! If power is required for servicing, use extreme

caution when working near live electrical circuits. Dangerous voltages exist inside

the THC control module that can cause serious injury or death.

STATIC ELECTRICITY CAN DAMAGE CIRCUIT BOARDS

• Put on a grounded wrist strap BEFORE handling PC boards.

WARNING

Tools Needed

Digital Volt Meter

#2 Phillips Screw Driver

Small, Flat Screw Driver

128407 Kit Instructions

Page 3

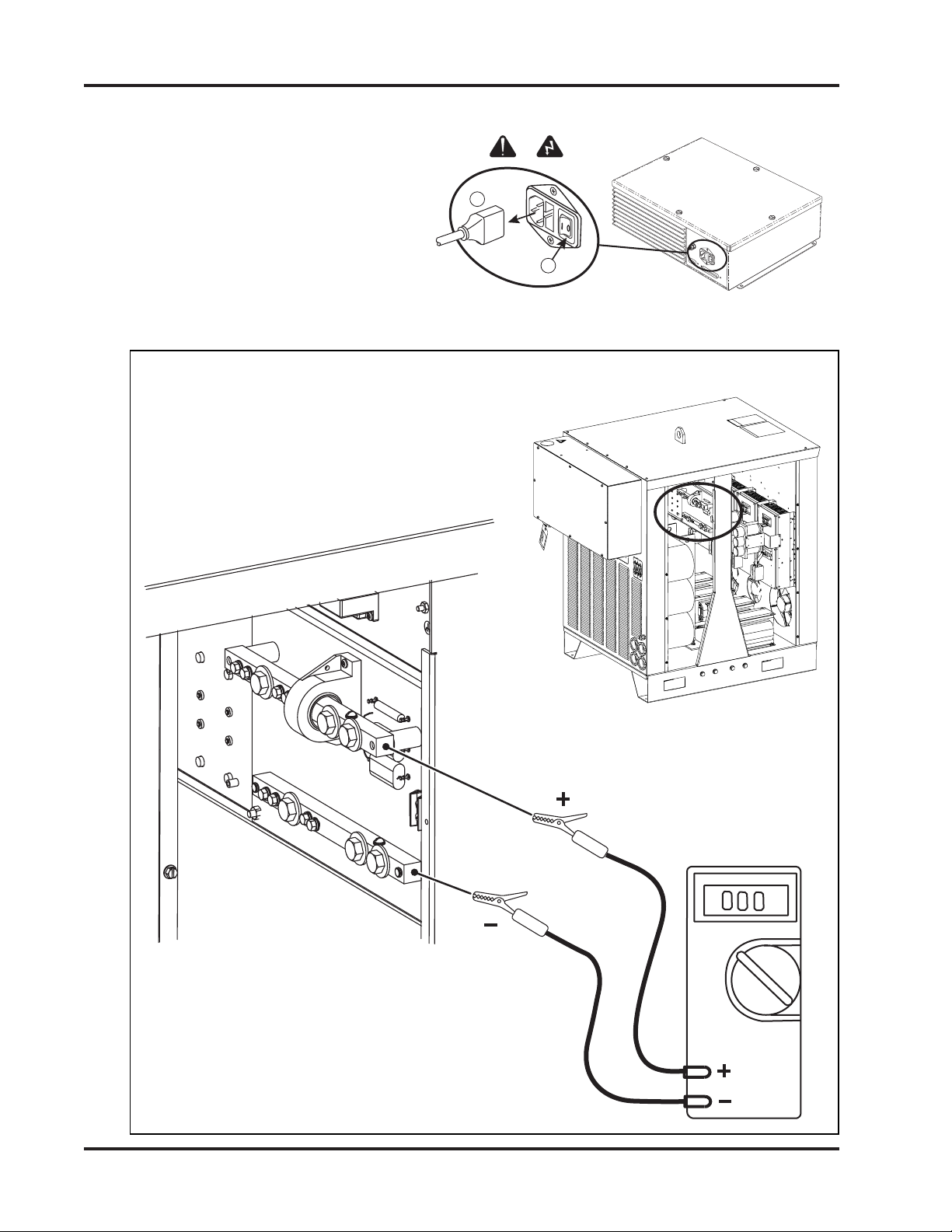

Page 7

THC.108

HD4070 THC Control PC Board Calibration

HD4070 PROCEDURE

1. Turn off the power to the power supply.

2. Install the replacement PC board in to the power supply and attach all electrical connections.

3 Attach the volt meter to measure the arc voltage between power supply I/O board bus bars as shown

below.

Page 4

Set volt meter to

measure 100-500 VDC.

128407 Kit Instructions

Page 8

HD4070 THC Control PC Board Calibration

THC.107

Torch #1

THC Control

PC Board

Torch #2

THC Control

PC Board

4. Turn on power to the power supply.

5. Put the Command THC in MANUAL MODE.

6. For 2-torch systems, select the applicable torch.

7. Begin a cutting process and compare the voltage displayed on the volt meter to the arc voltage

displayed on the CNC or power supply display.

8 Adjust the potentiometer on the control board so that the voltage displayed on the volt meter is the

same as the arc voltage displayed on the CNC or power supply display.

9. Turn off the power to the power supply.

10. Remove the volt meter from the power supply.

11. Replace the access covers to the power supply.

128407 Kit Instructions

Page 5

Page 9

HT4400 THC Control PC Board Calibration

THC.109

IM379.01

1

2

HT4400 PROCEDURE

1. Turn off the power to the THC control

module and to the power supply.

2. Install the replacement PC board in to the THC control module and attach the electrical connections.

3 Attach the volt meter to measure the arc voltage between power supply I/O board bus bars as shown

below.

Page 6

Set volt meter to

measure 100-500 VDC.

128407 Kit Instructions

Page 10

IM360.02

HT4400 THC Control PC Board Calibration

4. Turn on the power to the THC control module and to the power supply.

5. Put the Command THC in MANUAL MODE.

6. Begin a cutting process and compare the voltage displayed on the volt meter to the arc voltage

displayed on the CNC or THC pendant.

7 Adjust the potentiometer on the control board so that the voltage displayed on the volt meter is the

same as the arc voltage displayed on the CNC or THC pendant.

8. Turn off the power to the THC control module and to the power supply.

9. Remove the volt meter from the power supply.

10. Replace the access covers to the THC control module and to the power supply.

128407 Kit Instructions

Page 7

Page 11

THC.91

GND

ELECTRODE

WORK

J5

12345

IM360.01

IM379.01

1

2

Powermax, MAX100, MAX200, HD3070, HT2000,

HT2000LHF, and HT4001 THC Control PCB Calibration

POWERMAX, MAX100, MAX200,

HD3070, HT2000, HT2000LHF, AND

HT4001 PROCEDURE

1. Turn off the power to the power supply.

2. Turn off power to THC system

and remove power cord.

3 Remove access covers from the THC control

module and the THC plasma interface assembly.

4. Install the replacement PC board in to the THC control module and attach electrical connections.

5 Attach the volt meter to measure the arc voltage between J5-2 and J5-3 in the plasma interface

assembly.

Set volt meter to

measure 100-500 VDC.

Page 8

128407 Kit Instructions

Page 12

IM360.02

Powermax, MAX100, MAX200, HD3070, HT2000,

HT2000LHF, and HT4001 THC

6. Replace power cord to the THC control module.

7. Turn on power to the THC and to the power supply.

8. Put the Command THC in MANUAL MODE.

9. Begin a cutting process and compare the voltage displayed on the volt meter to the arc voltage

displayed on the CNC or THC pendant.

10 Adjust the potentiometer on the control board so that the voltage displayed on the volt meter is the

same as the arc voltage displayed on the CNC or THC pendant.

Control PCB Calibration

11. Turn off power to power supply and to THC system.

12. Remove volt meter from the plasma interface assembly.

13. Replace access covers to the THC control module and the THC plasma interface assembly.

128407 Kit Instructions

Page 9

Page 13

Blank

Page 10

128407 Kit Instructions

Loading...

Loading...