Page 1

THC-2

Torch Height Control

Instruction Manual

800200 Rev. 6

Page 2

THC-2

Torch Height Control

Instruction Manual

P/N 800200

Revision 6 September, 2002

Hypertherm, Inc.

Hanover, NH USA

www.hypertherm.com

© Hypertherm, Inc., 2002

All Rights Reserved

HYPERTHERM is a trademark of Hypertherm, Inc. and is

registered in the United States; International registration is pending.

Page 3

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

800-643-9878 Tel (Technical Service)

800-737-2978 Tel (Customer Service)

Hypertherm Automation

5 Technology Drive

West Lebanon, NH 03755 USA

603-298-7970 Tel

603-298-7977 Fax

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm Singapore Pte Ltd

No. 19 Kaki Bukit Road 2

K.B. Warehouse Complex

Singapore 417847, Republic of Singapore

65 841 2489 Tel

65 841 2490 Fax

65 841 2489 (Technical Service)

Japan

1952-14 Yata-Natsumegi

Mishima City, Shizuoka Pref.

411-0801 Japan

81 0 559 75 7387 Tel

81 0 559 75 7376 Fax

Hypertherm UK Ltd

9 Berkeley Court, Manor Park

Runcorn, Cheshire, England WA7 1TQ

44 1928 579 074 Tel

44 1928 579 604 Fax

France

15 Impasse des Rosiers

95610 Eragny, France

0805 050 111 Tel

0805 050 222 Fax

Hypertherm S.r.L.

Via Torino 2

20123 Milano, Italia

39 02 725 46 312 Tel

39 02 725 46 400 Fax

39 02 725 46 314 (Technical Service)

Hypertherm B.V.

Burg. Haverkampstraat 13

7091 CN Dinxperlo, Nederland

31 315 655866 Tel

31 315 655886 Fax

Hypertherm B.V. (ETSO)

Vaartveld 9

4704 SE Roosendaal, Nederland

00 800 49 73 7843 – toll-free in Europa

31 165 596900 Tel

31 165 596901 Fax

Hypertherm Brasil Ltda.

Rua Visconde de Santa Isabel, 20 – Sala 611

Vila Isabel, RJ

Brasil CEP 20560-120

55 21 2278 6162 Tel

55 21 2578 0947 Fax

10/30/01

Page 4

ELECTROMAGNETIC COMPATIBILITY (EMC)

EMC INTRODUCTION

Hypertherm's CE-marked equipment is built

in compliance with standard EN50199. The

equipment should be installed and used in

accordance with the information below to

achieve electromagnetic compatibility.

The limits required by EN50199 may not be

adequate to completely eliminate interference when the affected equipment is in

close proximity or has a high degree of

sensitivity. In such cases it may be necessary to use other measures to further

reduce interference.

This plasma equipment is designed for use

only in an industrial environment.

INSTALLATION AND USE

The user is responsible for installing and

using the plasma equipment according to

the manufacturer's instructions. If electromagnetic disturbances are detected then it

shall be the responsibility of the user to resolve the situation with the technical assistance of the manufacturer. In some cases

this remedial action may be as simple as

earthing the cutting circuit, see Earthing of

Workpiece. In other cases it could involve

constructing an electromagnetic screen

enclosing the power source and the work

complete with associated input filters. In all

cases electromagnetic disturbances must

be reduced to the point where they are no

longer troublesome.

ASSESSMENT OF AREA

Before installing the equipment the user

shall make an assessment of potential electromagnetic problems in the surrounding

area. The following shall be taken into

account:

a. Other supply cables, control cables,

signalling and telephone cables; above,

below and adjacent to the cutting equipment.

b. Radio and television transmitters and

receivers.

c. Computer and other control equipment.

d. Safety critical equipment, for example

guarding of industrial equipment.

e. Health of the people around, for

example the use of pacemakers and hearing aids.

f. Equipment used for calibration or measurement.

g. Immunity of other equipment in the environment. User shall ensure that other

equipment being used in the environment is

compatible. This may require additional

protection measures.

h. Time of day that cutting or other activities

are to be carried out.

Earthing of Workpiece

Where the workpiece is not bonded to earth

for electrical safety, nor connected to earth

because of its size and position, for example,

ship's hull or building steelwork, a connection

bonding the workpiece to earth may reduce

emissions in some, but not all instances.

Care should be taken to prevent the earthing

of the workpiece increasing the risk of injury

to users, or damage to other electrical equipment. Where necessary, the connection of

the workpiece to earth should be made by a

direct connection to the workpiece, but in

some countries where direct connection is

not permitted, the bonding should be

achieved by suitable capacitances selected

according to national regulations.

Note. The cutting circuit may or may not be

earthed for safety reasons. Changing the

earthing arrangements should only be authorized by a person who is competent to

assess whether the changes will increase

the risk of injury, for example, by allowing

parallel cutting current return paths which

may damage the earth circuits of other

equipment. Further guidance is given in IEC

TC26 (sec)94 and IEC TC26/108A/CD Arc

Welding Equipment Installation and Use.

Screening and Shielding

Selective screening and shielding of other

cables and equipment in the surrounding

area may alleviate problems of interference.

Screening of the entire plasma cutting

installation may be considered for special

applications

The size of the surrounding area to be

considered will depend on the structure of

the building and other activities that are taking place. The surrounding area may extend

beyond the boundaries of the premises.

METHODS OF REDUCING EMISSIONS

Mains Supply

Cutting equipment must be connected to the

mains supply according to the manufacturer's recommendations. If interference

occurs, it may be necessary to take

additional precautions such as filtering of

the mains supply. Consideration should be

given to shielding the supply cable of permanently installed cutting equipment, in

metallic conduit or equivalent. Shielding

should be electrically continuous throughout

its length. The shielding should be connected to the cutting mains supply so that good

electrical contact is maintained between the

conduit and the cutting power source

enclosure

Maintenance of Cutting Equipment

The cutting equipment must be routinely

maintained according to the manufacturer's

recommendations. All access and service

doors and covers should be closed and

properly fastened when the cutting

equipment is in operation. The cutting

equipment should not be modified in any

way except for those changes and adjustments covered in the manufacturer's

instructions. In particular, the spark gaps of

arc striking and stabilizing devices should

be adjusted and maintained according to

the manufacturer's recommendations.

Cutting Cables

The cutting cables should be kept as short

as possible and should be positioned close

together, running at or close to the floor

level.

Equipotential Bonding

Bonding of all metallic components in the

cutting installation and adjacent to it should

be considered. However, metallic components bonded to the workpiece will increase

the risk that the operator could receive a

shock by touching these metallic

components and the electrode at the same

time. The operator should be insulated from

all such bonded metallic components.

Hypertherm Plasma Systems i

Page 5

WARRANTY

ii Hypertherm Plasma Systems

9-01

WARNING

Genuine Hypertherm parts are the factory-recommended

replacement parts for your Hypertherm system. Any damage

caused by the use of other than genuine Hypertherm parts may

not be covered by the Hypertherm warranty.

WARNING

You are responsible for the safe use of the Product.

Hypertherm does not and cannot make any guarantee or

warranty regarding the safe use of the Product in your

environment.

GENERAL

Hypertherm, Inc. warrants that its Products shall be free from

defects in materials and workmanship, if Hypertherm is notified

of a defect (i) with respect to the power supply within a period

of two (2) years from the date of its delivery to you, with the

exception of G3 Series power supplies, which shall be within a

period of three (3) years from the date of delivery to you, and

(ii) with respect to the torch and leads within a period of one (1)

year from its date of delivery to you. This warranty shall not

apply to any Product which has been incorrectly installed,

modified, or otherwise damaged. Hypertherm, at its sole

option, shall repair, replace, or adjust, free of charge, any

defective Products covered by this warranty which shall be

returned with Hypertherm’s prior authorization (which shall not

be unreasonably withheld), properly packed, to Hypertherm’s

place of business in Hanover, New Hampshire, or to an

authorized Hypertherm repair facility, all costs, insurance and

freight prepaid. Hypertherm shall not be liable for any repairs,

replacement, or adjustments of Products covered by this

warranty, except those made pursuant to this paragraph or with

Hypertherm’s prior written consent. The warranty above is

exclusive and is in lieu of all other warranties, express,

implied, statutory, or otherwise with respect to the

Products or as to the results which may be obtained

therefrom, and all implied warranties or conditions of

quality or of merchantability or fitness for a particular

purpose or against infringement. The foregoing shall

constitute the sole and exclusive remedy for any breach

by Hypertherm of its warranty. Distributors/OEMs may offer

different or additional warranties, but Distributors/OEMs are

not authorized to give any additional warranty protection to you

or make any representation to you purporting to be binding

upon Hypertherm.

PATENT INDEMNITY

Except only in cases of products not manufactured by

Hypertherm or manufactured by a person other than

Hypertherm not in strict conformity with Hypertherm’s

specifications and in cases of designs, processes, formulae, or

combinations not developed or purported to be developed by

Hypertherm, Hypertherm will defend or settle, at its own

expense, any suit or proceeding brought against you alleging

that the use of the Hypertherm product, alone and not in

combination with any other product not supplied by

Hypertherm, infringes any patent of any third party. You shall

notify Hypertherm promptly upon learning of any action or

threatened action in connection with any such alleged

infringement, and Hypertherm’s obligation to indemnify shall be

conditioned upon Hypertherm’s sole control of, and the

indemnified party’s cooperation and assistance in, the defense

of the claim.

LIMITATION OF LIABILITY

In no event shall Hypertherm be liable to any person or

entity for any incidental, consequential, indirect, or

punitive damages (including but not limited to lost profits)

regardless of whether such liability is based on breach of

contract, tort, strict liability, breach of warranties, failure of

essential purpose or otherwise and even if advised of the

possibility of such damages.

LIABILITY CAP

In no event shall Hypertherm’s liability, whether such

liability is based on breach of contract, tort, strict liability,

breach of warranties, failure of essential purpose or

otherwise, for any claim action suit or proceeding arising

out of or relating to the use of the Products exceed in the

aggregate the amount paid for the Products that gave rise

to such claim.

INSURANCE

At all times you will have and maintain insurance in such

quantities and types, and with coverage sufficient and

appropriate to defend and to hold Hypertherm harmless in

the event of any cause of action arising from the use of the

Products.

NATIONAL AND LOCAL CODES

National and Local codes governing plumbing and electrical

installation shall take precedent over any instructions

contained in this manual. In no event shall Hypertherm be

liable for injury to persons or property damage by reason of any

code violation or poor work practices.

TRANSFER OF RIGHTS

You may transfer any remaining rights you may have

hereunder only in connection with the sale of all or substantially

all of your assets or capital stock to a successor in interest who

agrees to be bound by all of the terms and conditions of this

Warranty.

Page 6

TABLE OF CONTENTS

DESCRIPTION AND SPECIFICATIONS .................................................................. v

SECTION 1 INSTALLATION - To Cutting Machine and Torch Lifter ..................1-1

Install the THC-2 Control Module ...........................................................................1-2

Mount the THC-2 Control Module .....................................................................1-2

Connect the THC-2 Control Module to the Cutting Machine

Computer Interface and Torch Lifter Motor .......................................................1-3

SECTION 1a INSTALLATION - MAX100 or MAX100D ...................................... 1a-1

Mount the Voltage Divider to MAX100 or MAX100D ............................................ 1a-2

Install Interconnect Cable to MAX100 or MAX100D .............................................1a-2

SECTION 1b INSTALLATION - MAX200 ...........................................................1b-1

Mount the Voltage Divider to MAX200 .................................................................1b-2

Install Interconnect Cable to MAX200 ..................................................................1b-4

SECTION 1c INSTALLATION - PAC-500 .......................................................... 1c-1

Mount the Voltage Divider to PAC-500................................................................. 1c-2

Install Interconnect Cable to PAC-500 .................................................................1c-3

SECTION 2 OPERATION ..................................................................................2-1

Description of Controls and Indicators ...................................................................2-2

Operating Instructions ............................................................................................2-3

Notes on Operation...........................................................................................2-3

SECTION 3 PARTS LIST...................................................................................3-1

THC-2 Torch Height Control Systems ....................................................................3-2

Torch Height Control System for MAX100, MAX100D, MAX200....................... 3-2

Torch Height Control System for PAC-500 .......................................................3-2

THC-2 Interconnect Cable - #023264 ....................................................................3-3

THC-2 Control Module - #053005 ..........................................................................3-5

THC-2 Torch Height Control

Page iii

Page 7

TABLE OF CONTENTS

List of Figures

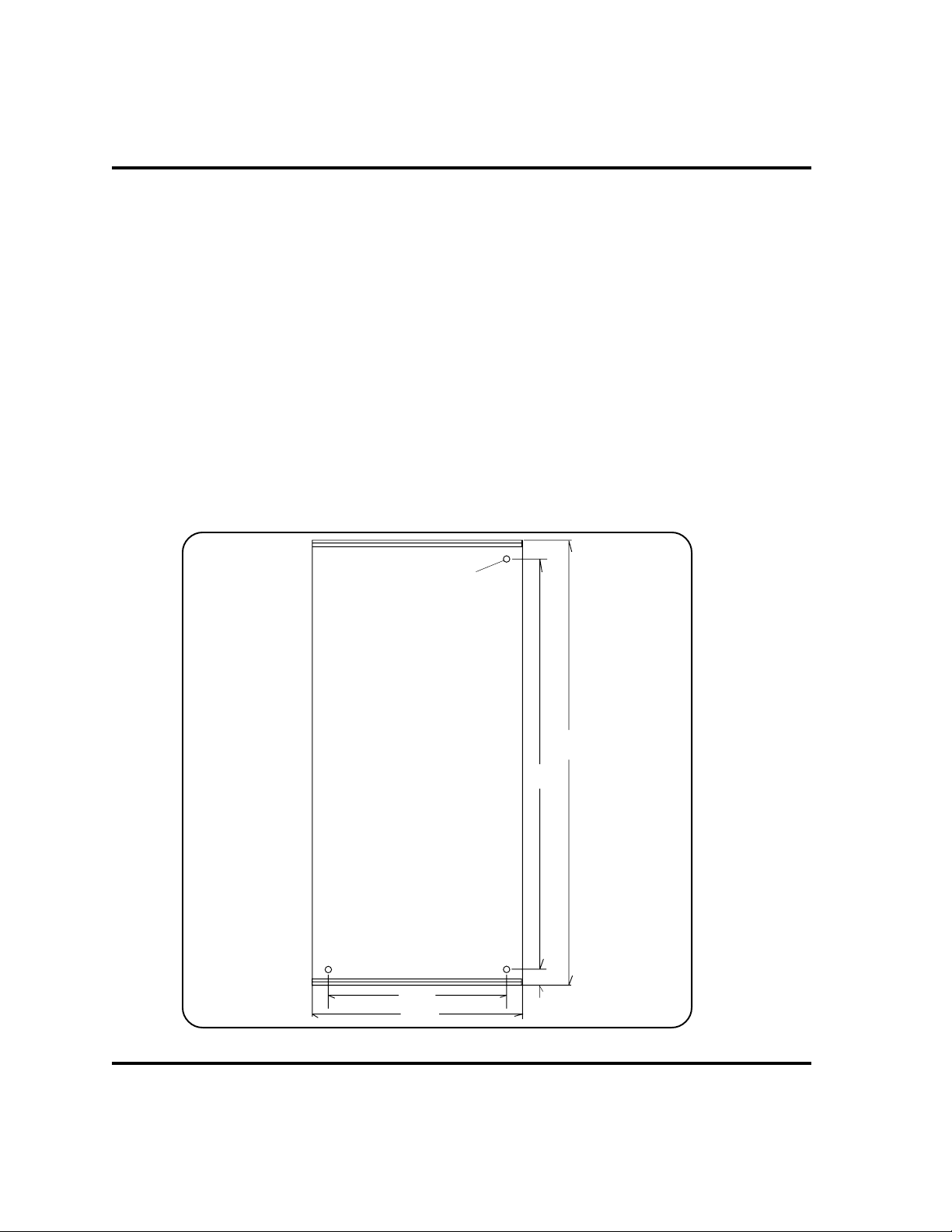

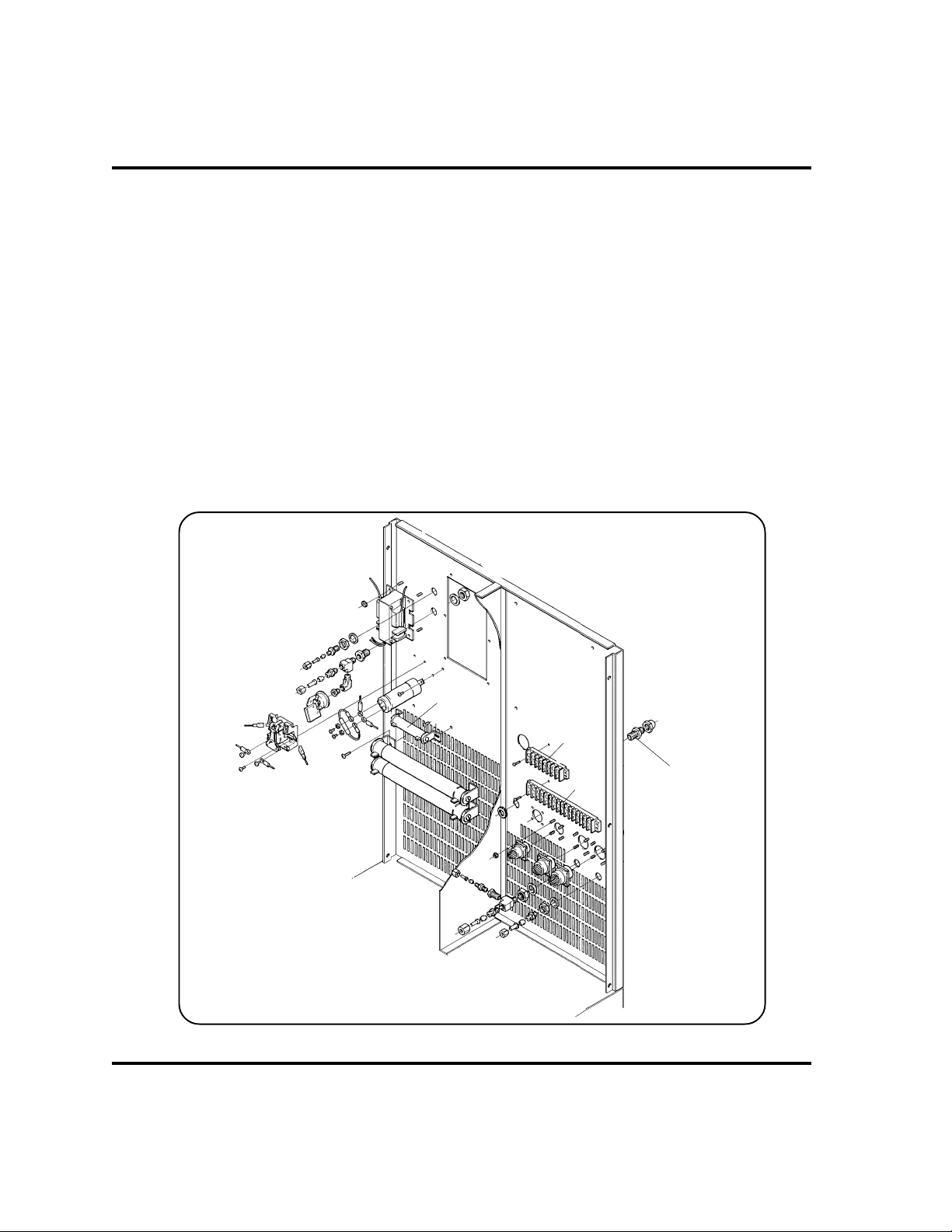

Figure 1-1 THC-2 Control Module Mounting Dimensions....................................................... 1-2

Figure 1-2 THC-2 Control Module Front and Rear Views ...................................................... 1-3

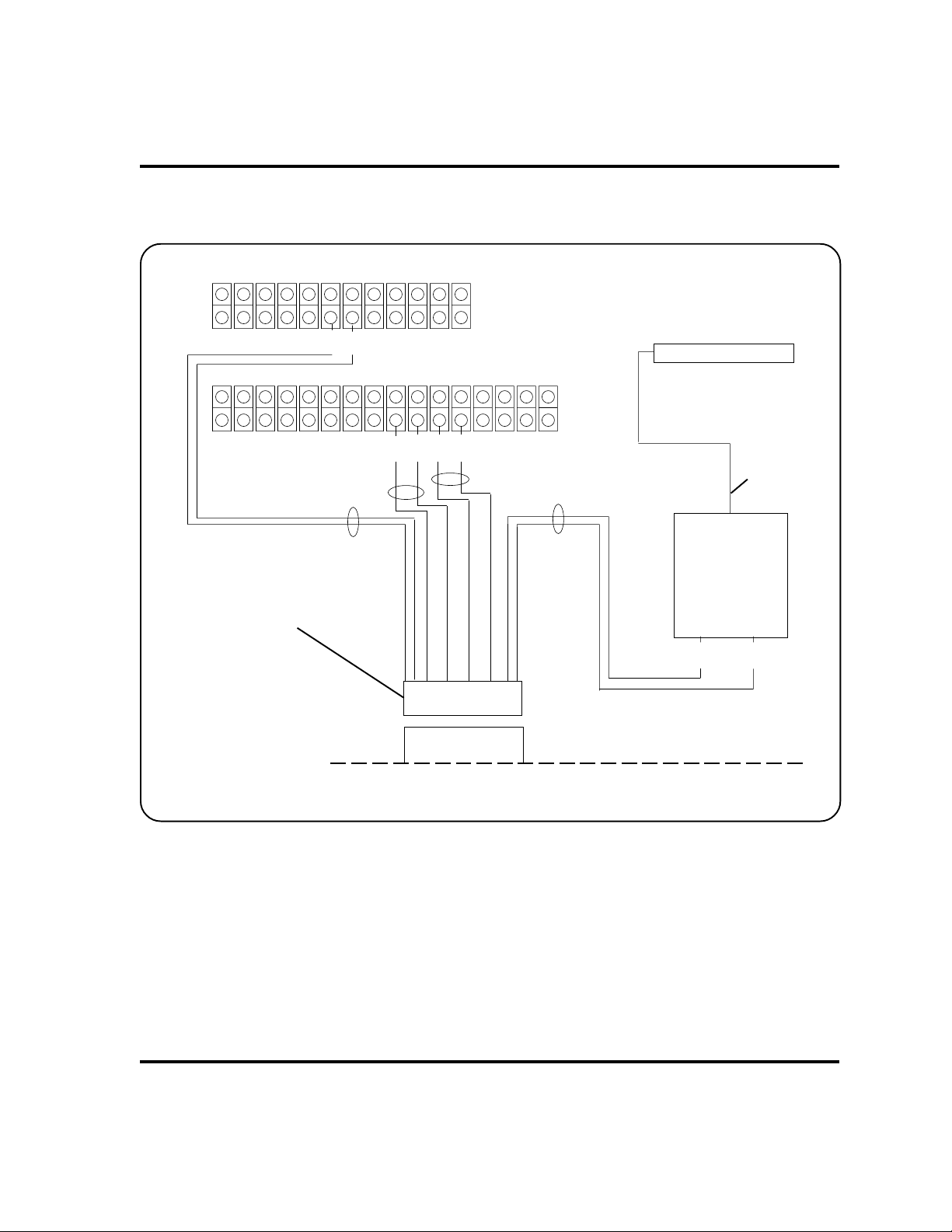

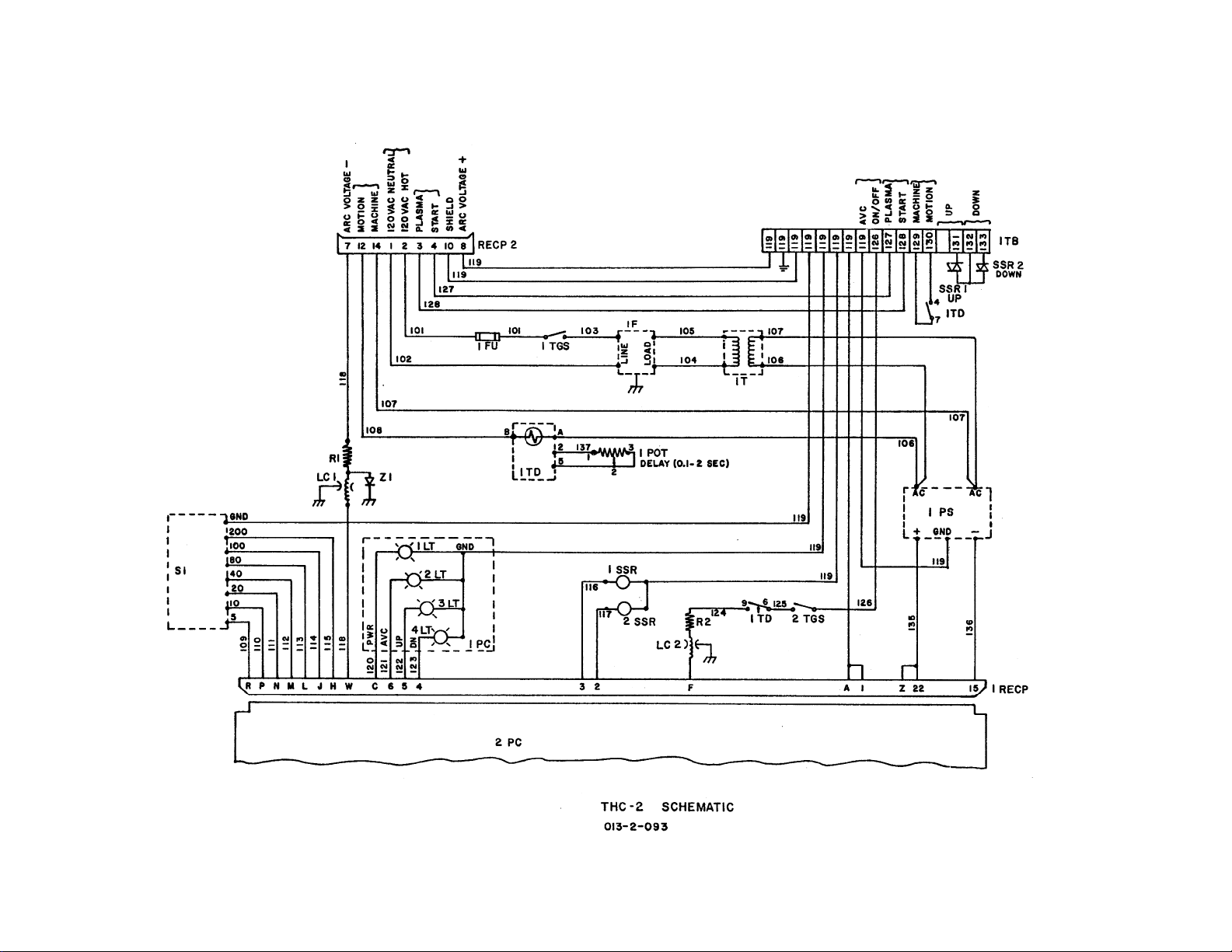

Figure 1-3 Wiring Diagram -

THC-2 to Cutting Machine Interface and Lifter Motor ........................................... 1-4

Figure 1-4 Typical DC Lifter Wiring ........................................................................................ 1-5

Figure 1a-1 Connections to MAX100 or MAX100D ................................................................. 1a-3

Figure 1b-1 Voltage Divider Template Location -

MAX200 Center Wall Right Rear ........................................................................ 1b-3

Figure 1b-2 Voltage Divider Mounting Location -

MAX200 Center Wall Left Rear ........................................................................... 1b-3

Figure 1b-3 Inside Rear of MAX200 Power Supply ................................................................ 1b-4

Figure 1b-4 Wiring Diagram - THC-2 to MAX200 ................................................................... 1b-5

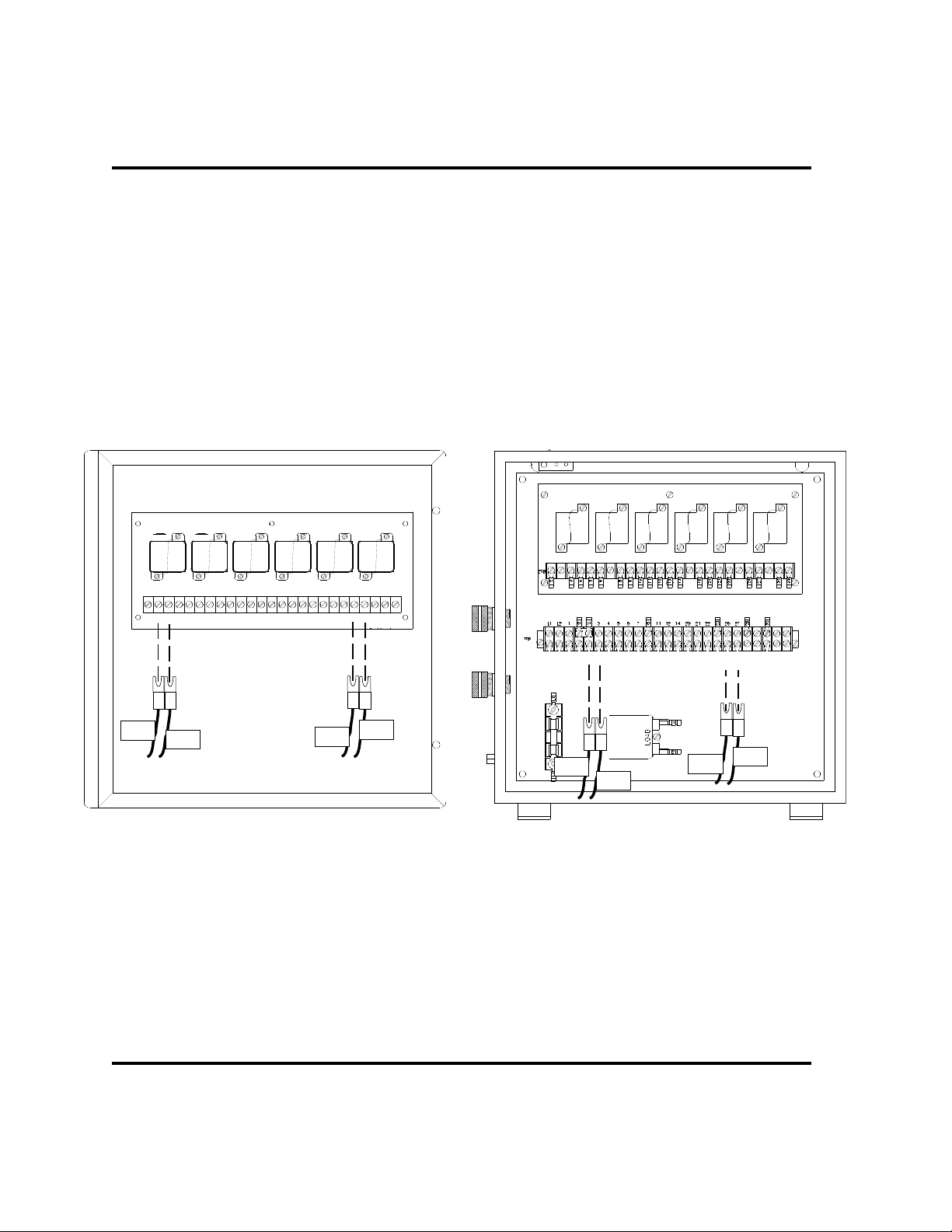

Figure 1c-1 PAC-500 Plasma Control Console Plumbing Compartment ................................ 1c-2

Figure 1c-2 PAC-500/500L Plasma Control Consoles ............................................................ 1c-3

Figure 1c-3 PAC-500/500L Plasma Control Consoles - 1TB Location .................................... 1c-4

Figure 1c-4 HF Compartment - PAC-500 Console .................................................................. 1c-5

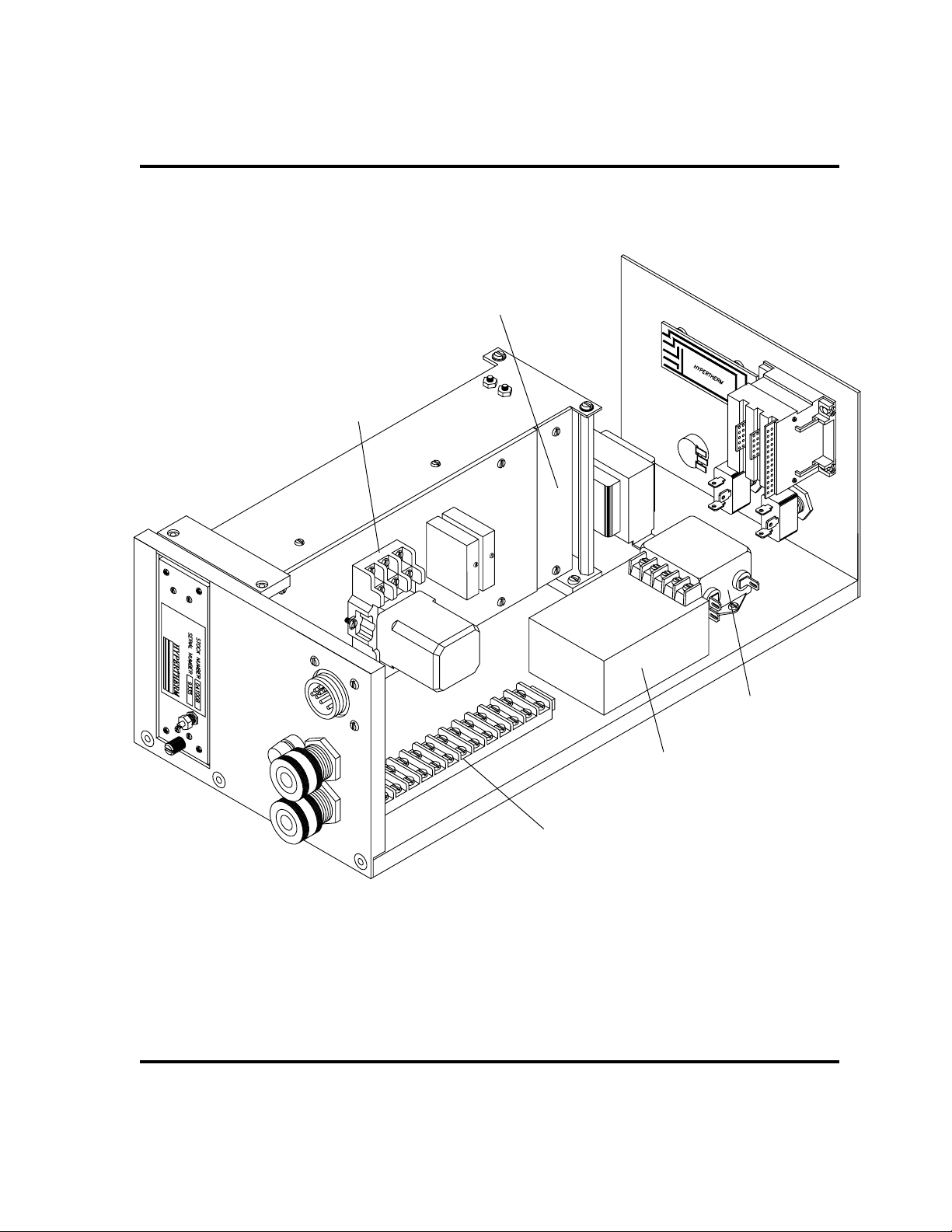

Figure 1c-5 Top Rear View of THC-2 ......................................................................................1c-6

Figure 1c-6 Inside View of THC-2 ........................................................................................... 1c-7

Figure 2-1 THC-2 Front Panel ................................................................................................ 2-2

Figure 3-1 THC-2 Control Cable - MAX100/100D/200 ............................................................ 3-3

Figure 3-2 THC-2 Front and Rear Panels .............................................................................. 3-4

Figure 3-3 THC-2 Interior ....................................................................................................... 3-6

FIgure 3-4 Voltage Divider - 041007 - .................................................................................... 3-8

Page iv

THC-2 Torch Height Control

Page 8

DESCRIPTION AND SPECIFICATIONS

DESCRIPTION

he THC-2 Torch Height Control automatically controls torch height while plasma cutting. After

setting the arc voltage with the thumbwheel on the front panel, the THC-2 controls the torch

T

the workpiece. If the torch is too high from the workpiece, the actual arc voltage will be greater than

the reference voltage. The Arc Voltage Control will then activate the torch suspension motor to move

the torch downward. If the torch is too close to the workpiece, the arc voltage will be less than the

reference voltage. In this case, the Arc Voltage Control will activate the torch suspension motor to

move the torch upward.

The THC-2 comes with a voltage divider that mounts in the MAX100 , MAX100D and MAX200 power

supplies, or in the PAC-500/500L Plasma Control Console. The voltage divider reduces the arc

voltage by a ratio of 25:1.

Section 1 of this manual - Installation - describes mounting the THC-2 module and connecting it to

the cutting machine computer and the torch lifter. Sub-sections 1a, 1b etc. describe hooking the

THC-2 to Hypertherm products that utilize this type of torch-height control. Section 2 is a brief

operation section, and Section 3 is a parts list. A wiring diagram follows the parts list.

suspension motor by comparing this reference voltage with the voltage between the torch and

SPECIFICATIONS

THC-2 Control Module - #053005*

Power Input .........................................................115 VAC, 50/60 Hz

Operating Environment ....................................... 32°F (0°C) to 122°F (50°C)

Height .................................................................. 6 inches (152 mm)

Width ...................................................................8 inches (203 mm)

Depth................................................................... 17 inches (432 mm)

Weight .................................................................15 pounds (6.8 kg)

Arc Voltage Setting Range .................................. 100-250 V

Control Accuracy ................................................. +/- 2 V

* For a parts list breakdown of the THC-2 systems see Section 3 - Parts List

THC-2 Torch Height Control

Page v

Page 9

Section 1 INSTALLATION - To Cutting Machine and

Torch Lifter

In this section:

Install the THC-2 Control Module........................................................1-2

Mount the THC-2 Control Module...................................................1-2

Connect the THC-2 Control Module to the Cutting Machine

Computer Interface and Torch Lifter Motor.....................................1-3

THC-2 Torch Height Control

Page 1-1

Page 10

INSTALLATION - To Cutting Machine & Torch Lifter

INSTALL THE THC-2 CONTROL MODULE

Before installing the THC-2 system, verify the following components after unpacking:

• Voltage Divider

• THC-2 Control Module

• Interconnecting cable #023264 (Cable not available for PAC-500 systems)

Mount the THC-2 Control Module

1. Mount the THC-2 Control Module in a convenient location for the operator. See Fig.1-1

for mounting dimensions. Note the length of the control cable (5 feet) that will connect

from the THC-2 to the inside of the MAX100, MAX100D, or MAX200 and make certain

that the cable will reach before mounting. Customers must supply and fabricate cables

for the PAC-500 systems.

8-32

Tapped

Hole (3)

Page 1-2

Bottom

View

FRONT

6-3/4"

8"

Figure 1-1 THC-2 Control Module Mounting Dimensions

17-3/32"

15-5/8"

5/8"

THC-2 Torch Height Control

Page 11

INSTALLATION - To Cutting Machine & Torch Lifter

2. To ensure proper grounding at the THC-2, run a #10 gauge copper cable from the ground

stud on the rear of the THC-2 (Fig. 1-2) to a common earth ground. To correctly operate

the THC-2 system, it must be grounded properly.

Connect the THC-2 Control Module to the Cutting Machine Computer Interface

and Torch Lifter Motor

A cable running from the THC-2 control module to the cutting machine interface and torch

lifter must be fabricated. Hypertherm recommends a 7-conductor 24-gauge shielded cable.

3. Remove the eight screws on the THC-2 Control Module and take off the top

panel - Fig. 1-2.

Remove Screws

Figure 1-2 THC-2 Control Module Front and Rear Views

THC-2 Torch Height Control

Remove Screws

RECP2

Ground

Stud

Strain

Reliefs

Page 1-3

Page 12

INSTALLATION - To Cutting Machine & Torch Lifter

4. Feed the cable through one of the strain reliefs located on the THC-2 rear panel (Fig.

1-2). See Figure 1-3 for cable connections. Consult your cutting machine schematics, or

call the cutting machine manufacturer for actual connections on the cutting machine

interface.

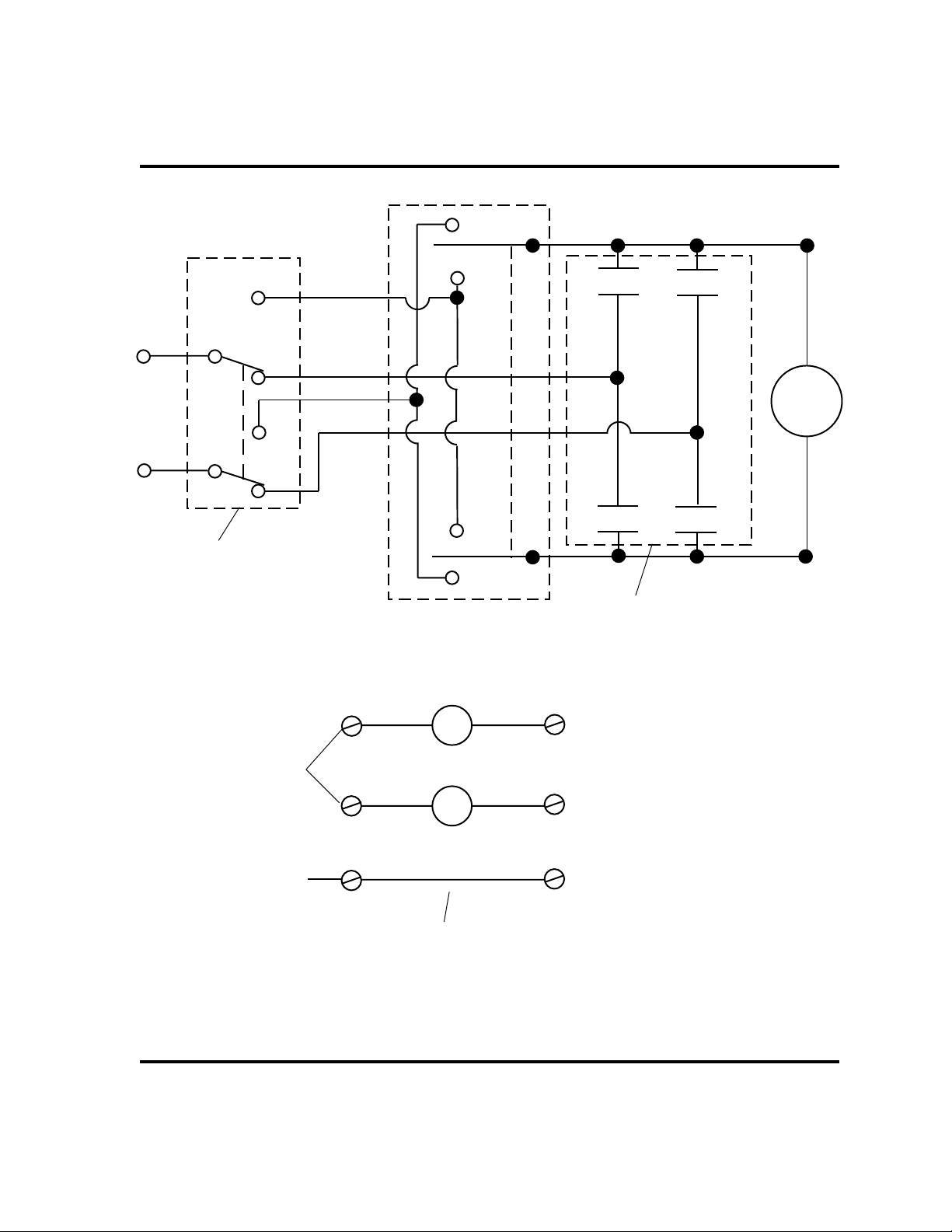

Note: The THC-2 normally operates AC lifter motors. See Figure 1-4 and refer to THC-2

schematic for DC lifter connections.

This completes installation of THC-2 to the cutting machine interface and torch lifter. For

installation of voltage divider and cable to: MAX100 or MAX100D - go to Section 1a;

MAX200 - go to Section 1b; PAC-500 - go to Section 1c.

1TB

Cutting Machine

Interface

Start*

Machine Motion**

AVC***

AC Lift Motor

UP

120

Common

DOWN

120 VAC Hot for

AC Lift Motor

Notes: * Not used for the PAC-500 system

** Dry contacts to CNC control. Closed = Motion; Open = No Motion

*** Dry contacts to CNC control. Closed = AVC allowed; Open = No AVC

127

128

129

130

131

132

133

126

119

THC-2

Figure 1-3 Wiring Diagram - THC-2 to Cutting Machine Interface and Lift Motor

Page 1-4

THC-2 Torch Height Control

Page 13

INSTALLATION - To Cutting Machine & Torch Lifter

UP

DOWN

DN

MAN

+

UP

DC

Power

_

AUTO

MAN

AUTO

Double pole, single throw

toggle switch - Mount in

operator station

Jump to wire 106

on DC Power Supply

1PS in THC-2

UP

115VAC

DN

115VAC

UP

DOWN

UP

Quantity (2), 2 pole, N/O relays,

115 VAC coils - Mount in the THC-2

1TB-131

1TB-133

DN

Lifter

Motor

Jump to wire 107

on DC Power Supply

1PS in THC-2

Add jumper and relays to THC-2

Figure 1-4 Typical DC Lifter Wiring

THC-2 Torch Height Control

JUMPER

1TB-132

Page 1-5

Page 14

Section 1a INSTALLATION - MAX100 or MAX100D

In this section:

Mount the Voltage Divider to MAX100 or MAX100D ........................1a-2

Install Interconnect Cable to MAX100 or MAX100D .........................1a-2

THC-2 Torch Height Control

Page 1a-1

Page 15

INSTALLATION - MAX100 or MAX100D

MOUNT THE VOLTAGE DIVIDER TO MAX100 OR MAX100D

Be sure to complete all steps in Section 1: Installation - To Cutting Machine & Torch Lifter in addition to the following procedure for hooking the THC-2 to the MAX100 or MAX100

WARNING!

The line disconnect switch for the MAX100 / MAX100D must be in the OFF

position before proceeding with the installation of the voltage divider and

interconnect cable.

1. Remove the four screws on the rear of the voltage divider, but do not remove the cover.

2. Remove the left cover on the MAX100 or MAX100D power supply.

3. Place the voltage divider on the upper inside of the rear wall, lining up the screw holes of

the voltage divider with slots in the rear panel. (Be certain that the white wire from the

voltage divider reaches the terminal strip TB1.) Secure with the four screws.

D.

4. Connect the white wire on the voltage divider labeled "39" to wire labeled 39 on

TB1 - Fig. 1a-1.

INSTALL INTERCONNECT CABLE TO MAX100 OR MAX100D

1. Attach the connector end of the interconnect cable to the receptacle on the rear of the

THC-2 module (RECP2).

2. Feed the other end of the cable through the strain relief at the lower rear of the

MAX100 or MAX100D power supply and make connections to TB1 as in Figure 1a-1.

3. Connect a 24-gauge wire from TB1 - 70 to SIGNAL on the voltage divider - Fig. 1a-1.

Note: The 24-gauge wire is not supplied by Hypertherm.

4. Connect a 24-gauge wire from TB1 - 42 to GROUND on the voltage divider - Fig. 1a-1.

Note: The 24-gauge wire is not supplied by Hypertherm.

This completes installation of the THC-2 to the MAX100 or MAX100D. See Section 2 for

operation instructions.

Page 1a-2

THC-2 Torch Height Control

Page 16

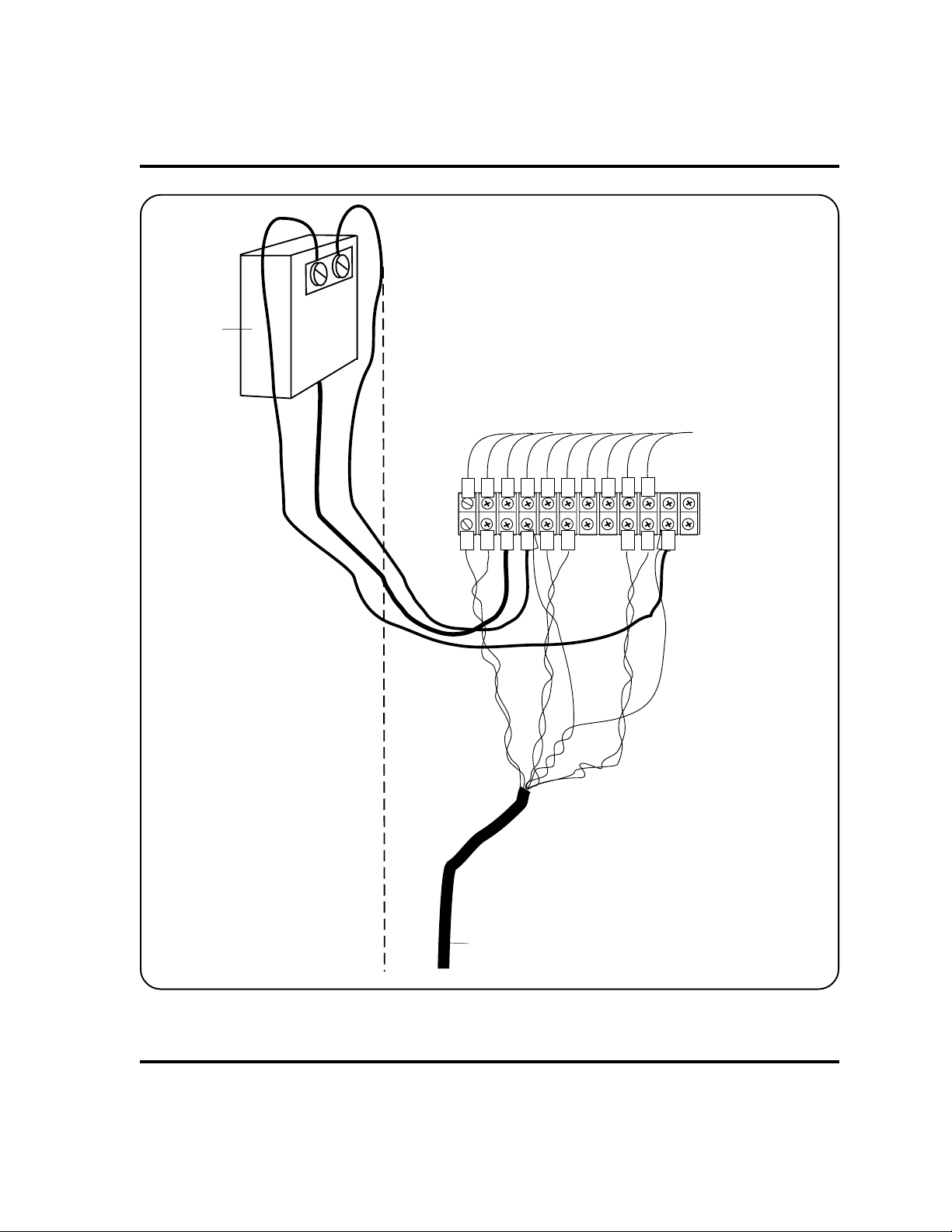

Voltage

Divider

INSTALLATION - MAX100 or MAX100D

GROUND

SIGNAL

MAX100 or MAX100D Harness

1

2

4239

33 37 38

34

35 36

TB1

391234

42

33

Interconnect Cable

35 36 70

Figure 1a-1 Connections to MAX100 or MAX100D

THC-2 Torch Height Control

Page 1a-3

Page 17

Section 1b INSTALLATION - MAX200

In this section:

Mount the Voltage Divider to MAX200 .............................................1b-2

Install Interconnect Cable to MAX200 .............................................. 1b-4

THC-2 Torch Height Control

Page 1b-1

Page 18

INSTALLATION - MAX200

MOUNT THE VOLTAGE DIVIDER TO MAX200

Be sure to complete all steps in Section 1: Installation - To Cutting Machine & Torch Lifter in addition to the following procedure for hooking the THC-2 to the MAX200.

WARNING!

The line disconnect switch for the MAX200 must be in the OFF position

before proceeding with the installation of the voltage divider and interconnect

cable.

1. Remove top panel and both left and right side panels of the MAX200.

2. Remove voltage divider template from the last page of this manual and punch out the

four mounting holes. Check dimensions as provided on template.

3. Place template approximately as shown in Figure 1b-1.

4. Mark the hole locations with a pencil and remove template.

5. Protect the base of the MAX200 (especially the transformer) with a cloth, and drill the

four holes using a #29 drill bit.

6. Unscrew the 4 screws from the voltage divider.

7. Mount the voltage divider as shown in Figure 1b-2 with the white wire facing down.

Screw the voltage divider in place from the center wall right rear side (see Figure 1b-1).

8. Carefully remove protective cloth and blow out any metal shavings inside of MAX200

power supply with shop or compressed air.

Page 1b-2

THC-2 Torch Height Control

Page 19

Top of MAX200

power supply

Figure 1b-1 Voltage Divider Template Location - MAX200 Center Wall Right Rear

INSTALLATION - MAX200

Lifting eye

Voltage divider template and

screw hole locations

Cable assembly

Feed-thru

Lifting eye

Top of MAX200

Voltage divider

mounting

location

Feed-thru

White wire

Figure 1b-2 Voltage Divider Mounting Location - MAX200 Center Wall Left Rear

power supply

THC-2 Torch Height Control

Page 1b-3

Page 20

INSTALLATION - MAX200

INSTALL INTERCONNECT CABLE TO MAX200

1. Connect the interface cable to RECP2 on the THC-2 module.

2. Loosen the adjustable strain relief on the rear of the MAX200 power supply - Fig. 1b-3.

3. Thread the other end of the interface cable through this strain relief and make

connections to TB4, TB3 (Fig. 1b-3) and voltage divider as shown in the Figure 1b-4

wiring diagram. Note: Push wires labeled 42 and 70 through the center wall feed-thru to

get to voltage divider.

4. Connect the white wire from the voltage divider to location #45 on R4 which is located on

the left rear wall of the MAX200 power supply - Fig. 1b-4.

This completes installation of the THC-2 to the MAX200. See Section 2 for operation

instructions.

Page 1b-4

R4

TB4

Strain Relief

TB3

Figure 1b-3 Inside Rear of MAX200 Power Supply

THC-2 Torch Height Control

Page 21

88 89

INSTALLATION - MAX200

TB4

Interconnect Cable

1 2

45

R4

82 83 84 85

TB3

33 34 35 36

White Wire

Voltage

Divider

GND SIGNAL

42 70

RECP2

THC-2

Figure 1b-4 Wiring Diagram - THC-2 to MAX200

THC-2 Torch Height Control

Page 1b-5

Page 22

Section 1c INSTALLATION - PAC-500

In this section:

Mount the Voltage Divider to PAC-500.............................................. 1c-2

Install Interconnect Cable to PAC-500 .............................................. 1c-3

THC-2 Torch Height Control

Page 1c-1

Page 23

INSTALLATION - PAC-500

MOUNT THE VOLTAGE DIVIDER TO PAC-500

Be sure to complete all steps in Section 1: Installation - To Cutting Machine & Torch Lifter in addition to the following procedure for hooking the THC-2 to the PAC-500.

WARNING!

The line disconnect switch for the PAC-500 must be in the OFF position

before proceeding with the installation of the voltage divider and interconnect

cable.

1. Open the left door of the PAC-500 plasma control console (plumbing compartment) and

place the voltage divider on the floor of the console - Fig. 1c-1.

2. Attach the white wire from the voltage divider to terminal 34 located on the cathode block

- Fig. 1c-1.

Page 1c-2

34

Approximate location

of Voltage Divider

Figure 1c-1 PAC-500 Plasma Control Console Plumbing Compartment

THC-2 Torch Height Control

Page 24

INSTALLATION - PAC-500

INSTALL THE INTERCONNECT CABLE TO PAC-500

1. The cable from the THC-2 to the PAC-500 console must be fabricated. Hypertherm

recommends using 3-pair 22-gauge shielded cable. The cable will run between the

plasma control console and the THC-2 module. Be certain to supply a cable that will

reach between these two components.

2. Strip the outer shielding away on both ends of the cable and tag individual wire ends 1

through 6. Tag both ends so that wire "1" on one end is the same wire that is marked "1"

on the other end, etc.

3. Crimp #6 terminals on all wires on one end of the cable. On the other end of the cable,

crimp #6 terminals on wires 4 and 6 and strip and tin the remaining wires.

4. Feed the cable end with all terminals attached through one of the strain reliefs of the

plasma control console - Fig. 1c-2.

Strain Reliefs

GAS OUT

WATER OUT

PAC-500

Figure 1c-2 PAC-500/500L Plasma Control Consoles

Strain Reliefs

Strain Reliefs

PAC-500L

THC-2 Torch Height Control

Page 1c-3

Page 25

INSTALLATION - PAC-500

5. Make the following connections to 1TB located on the console door of the PAC-500, or

on the inside of the PAC-500L - Fig. 1c-3:

Cable wire labeled 1 to 1TB terminal labeled 3

Cable wire labeled 2 to 1TB terminal labeled 2

Cable wire labeled 3 to 1TB terminal labeled 26

Cable wire labeled 4 to 1TB terminal labeled 27

1TB

2

2 2 3

26 27

4

1

3

1TB

2

2 2 3

2 2 3

1

PAC-500

Figure 1c-3 PAC-500/500L Plasma Control Consoles - 1TB Location

PAC-500L

26 27

26 27

4

3

Page 1c-4

THC-2 Torch Height Control

Page 26

INSTALLATION - PAC-500

6. Run cable wires 5 and 6 through the feed hole in center wall of plasma control console

(Fig. 1c-4) and attach wire 5 to voltage divider terminal labeled

voltage divider terminal labeled GROUND.

Feed wires 5 and 6 through

to other side

SIGNAL and cable 6 to

Figure 1c-4 HF Compartment - PAC-500 Console

THC-2 Torch Height Control

Note: Internal components shown in HF

Compartment may vary from your unit

Page 1c-5

Page 27

INSTALLATION - PAC-500

7. Pass the remaining end of the interconnect cable through the strain relief on the rear of

the THC-2 module.

8. Facing the rear of the THC-2 module with the cover removed, look down inside the

module and observe where one of the wires from the THC-2 receptacle RECP2

connects to the rear-panel fuse (1FU) - Fig. 1c-5. Cut this wire and solder interconnect

cable wire labeled "1" to the end of the wire that goes to the fuse.

Figure 1c-5 Top Rear View of THC-2

Cut and solder wire "1" here

1FU

RECP2

9. Find the line filter (1F) on the inside of the THC-2 module - Fig. 1c-6. Solder interconnect

10. Find the timer relay device (1TD) in the THC-2 - Fig. 1c-6. Attach interconnect cable wire

11. Find the power supply (1PS) in the THC-2 - Fig. 1c-6. Attach interconnect cable wire

12. Find the 390Ω 1/8 W resistor (R1) that THC-2 wire labeled 118 connects to - Fig. 1c-6.

13. Find the big terminal strip (1TB) in the THC-2 module - Fig. 1c-6. Attach interconnect

This completes installation of the THC-2 to the PAC-500. See Section 2 for operation

instructions.

Page 1c-6

cable wire labeled "2" to terminal that has THC-2 wire labeled 102 connected to it.

labeled "3" to timer relay terminal that has THC-2 wire labeled 108 connected to it.

labeled "4" to power supply terminal that has THC-2 wire labeled 107 connected to it.

Solder interconnect cable wire labeled "5" to the wire end of that resistor.

cable wire labeled "6" to terminal 119 (ground).

THC-2 Torch Height Control

Page 28

INSTALLATION - PAC-500

1TD

Attach wire labeled #3

to terminal labeled #108

R1 - 390

location)

Solder wire labeled #5 to

the wire end of this

resistor

Ω (approximate

Figure 1c-6 Inside View of THC-2

THC-2 Torch Height Control

1F

Solder wire labeled #2

to terminal labeled #102

1PS

Attach wire labeled #4

to terminal labeled #107

1TB

Attach wire labeled #6

to terminal labeled #119

(ground).

Page 1c-7

5

Page 29

Section 2 OPERATION

In this section:

Description of Controls and Indicators ................................................2-2

Operating Instructions .........................................................................2-3

Notes on Operation ........................................................................2-3

THC-2 Torch Height Control

Page 2-1

Page 30

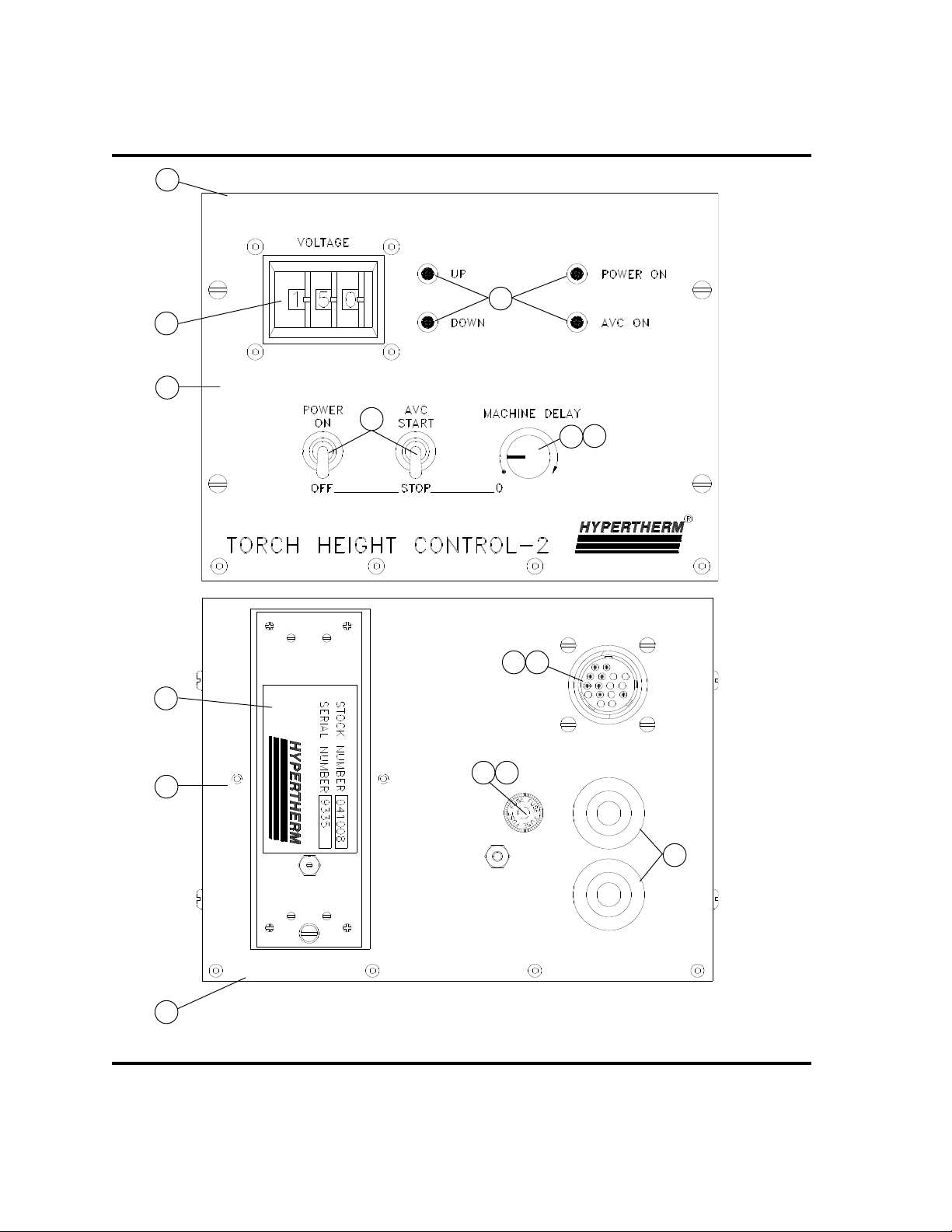

OPERATION

DESCRIPTION OF CONTROLS AND INDICATORS

• VOLTAGE thumbwheel

Sets the plasma arc voltage for the AVC (Automatic Voltage Control).

• POWER ON/OFF switch

Turns power to the THC-2 on or off.

• AVC START/STOP switch

Activates or deactivates the Automatic Voltage Control.

• MACHINE DELAY knob

Sets the delay time for the motion of the cutting machine after arc transfer.

• UP/DOWN LEDs

Indicates when the THC-2 gives the cutting machine a signal to move up or down.

• POWER ON LED

Indicates that the POWER switch to the THC-2 is on.

• AVC ON LED

Indicates that the AVC START switch is on.

Page 2-2

Figure 2-1 THC-2 Front Panel

THC-2 Torch Height Control

Page 31

OPERATING INSTRUCTIONS

1. Turn POWER to the THC-2 ON.

2. Turn the AVC switch to START.

3. Find the Arc Voltage setting for the type of metal and thickness of metal you are

cutting in the

manual. Adjust the VOLTAGE thumbwheel to the recommended arc voltage setting.

4. Find the Pierce Time or Approx. Motion Delay Time for the type of metal and

thickness of metal you are cutting in the

section of your instruction manual. Adjust the MACHINE DELAY knob to the

recommended setting for Pierce Time or Approx. Motion Delay Time. (The range of

machine delay is from .1 sec to 2 sec.)

5. Find the Torch-to-Work Distance for the type and thickness of metal you are cutting

in the

Operating Data

Adjust the torch height to the proper torch-to-work distance before starting cut.

The THC-2 is now ready for operation and will be activated after the plasma START

command is given.

Operating Data

or

Cut / Gouging Chart

or

Cut / Gouging Chart

Operating Data

OPERATION

section of your instruction

or

Cut / Gouging Chart

section of your instruction manual.

Notes on Operation

• Placing the AVC switch to STOP during the cut will halt AVC control.

• In order to increase the torch height, adjust the voltage on the thumbwheel to a

higher value. In order to decrease the torch height, adjust the voltage on the

thumbwheel to a lower value.

– Each 5 volt change on the thumbwheel is approximately equal to a .050 inch

change in torch-to-work distance.

THC-2 Torch Height Control

Page 2-3

Page 32

Section 3 PARTS LIST

In this section:

THC-2 Torch Height Control Systems .................................................3-2

Torch Height Control System for MAX100, MAX100D, MAX200 ....3-2

Torch Height Control System for PAC-500 .....................................3-2

THC-2 Interconnect Cable - #023264 .................................................3-3

THC-2 Control Module - #053005 .......................................................3-5

THC-2 Torch Height Control

Page 3-1

Page 33

PARTS LIST

THC-2 TORCH HEIGHT CONTROL SYSTEMS

Torch Height Control System for MAX100, MAX100D, MAX200

Part

Number Description Qty.

052002 THC-2 Torch Height Control MAX100/200

023264* Cable:MAX100/THC2 5' 1

041007** Volt Divider THC1/THC-2 1

053005*** Control Module, THC-2 1

800200 IM20:THC-2 Torch Height Control 1

Torch Height Control System for PAC-500

Part

Number Description Qty.

052001 THC-2 Torch Height Control PAC-500

041007** Volt Divider THC1/THC-2 1

053005*** Control Module, THC-2 1

800200 IM20:THC-2 Torch Height Control 1

* See page 3-3 for detail

** See page 3-8 for picture

*** See pages 3-4 through 3-7 for detailed parts breakdown.

Page 3-2

THC-2 Torch Height Control

Page 34

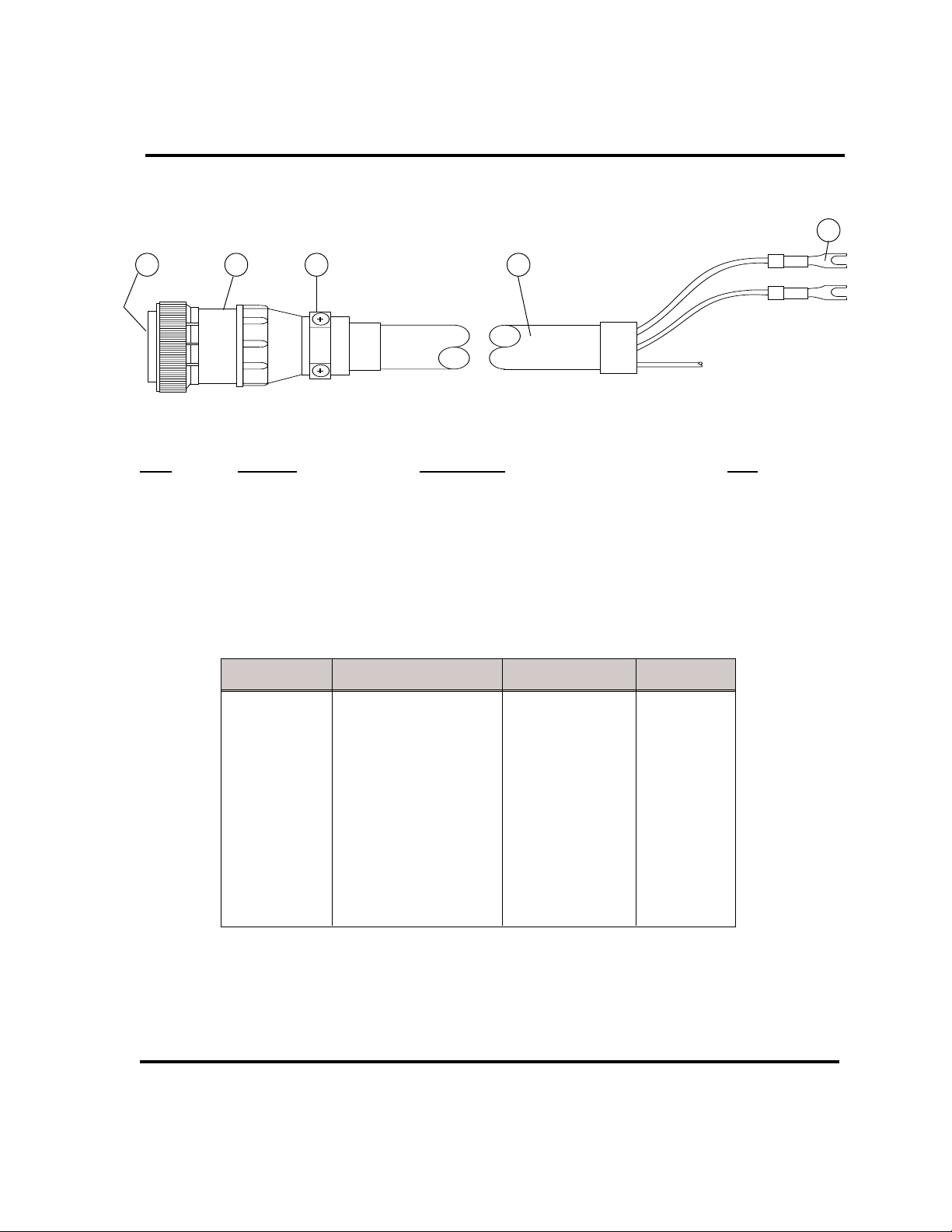

THC-2 INTERCONNECT CABLE - #023264

PARTS LIST

5

21 3 4

Part

Item Number Description Qty.

023264 Cable: MAX100 THC-2 5'

1 008186 Skt:24-20 AWG Type III 9

2 008191 Plug Shell:CPC 17-16 Std Sex 1

3 008192 Caclp:CPC Size 17 1

4 047027 Cable, 22-6 TW Pr, OA Shielded 5 ft

5 074027 Term, 22-16 #6 Lck Fork Insul 8

Terminal# Wire Function Color Code Socket#

1 120VAC neutral Black 2

2 120VAC hot White 1

1

2

etc.

33 Plasma Start White 3

34 Plasma Start Brown 4

35 Machine Motion Orange 14

36 Machine Motion White 12

42 Arc Voltage + White 8

70 Arc Voltage - Red 7

Figure 3-1 THC-2 Control Cable - MAX100/100D/200

THC-2 Torch Height Control

Page 3-3

Page 35

PARTS LIST

3

9

1

12

8

13

14

15

2

4

Page 3-4

1110

5 6

7

Figure 3-2 THC-2 Front and Rear Panels

THC-2 Torch Height Control

Page 36

THC-2 CONTROL MODULE - #053005

Part

Item Number Description Designator Qty.

001037 Cov:THC-2 Rear Acs 1

029019 Card Cage SA:THC2 PC 1

1 001034 Pnl:THC-2 Fr 1

2 001035 Pnl:THC-2 Rear 1

3 001057 Pnl:THC-2 Top 1

4 001058 Pnl:THC-2 Bot 1

5 008068 Fuseholder:Pnl Mt 1P 1/4 X 1-1/4 1

6 008069 Fuse:3/8A 250V 1/4 X 1-1/4 Slo 1FU 1

029024 Harn:THC-2 053005 1

7 008070 Strainrlf:1/2NPT X .312-.375 2

8 005044 Tgl Sw:SPDT Maint ON 1,2 TGS 2

9 005052 Thmbwhl Sw:Rear Mtg S1 1

10 008193 Rcpt Shell:CPC 17-16 RECP2 1

11 008176 Pin: 24-20 AWG Type III 8

12 009306 Plt Lt:Red LED T-1 3 1,2,3,4 LT 4

13 008164 Knob: .735 Dia. 1/4 Sft Blck 1

14 009442 Pot:50K-Ohm 10% 1W 1T Cerm 1 POT 1

15 041008 PC BD Assy Digital/Analog THC2 2PC 1

PARTS LIST

THC-2 Torch Height Control

Page 3-5

Page 37

PARTS LIST

10

5

6

2

13

4

3

Page 3-6

5

11

12

14

8

7

9

1

Figure 3-3 THC-2 Interior

THC-2 Torch Height Control

Page 38

THC-2 CONTROL MODULE - #053005 (cont.)

Part

Item Number Description Designator Qty.

1 009040 Filter:3A 3WT AC Elek 1F 1

2 014003 Xfmr:15VA 115V In/Out ISln 1T 1

029019 Card Cage SA:THC2 PCB 1

** 041737 Relay PCB Assembly 1

3 003040 Rly:120VAC TD IceCube 1TD 1

4 003097 Rly:250VAC Sol State I/O Conv SSR1,2 2

5* 009034 Diode:12V 210ma 10W 10% Zener Z1 1

6* 009484 Res:390-Ohm 1/4W 5% CBN CMPSN R1 1

029024 Harn:THC2 053005 1

7 008073 Terminal Board: 16-Term 1TB 1

8 008070 Strainrlf:1/2NPT X .312-.375 2

9 005044 Tgl Sw:SPDT Maint ON 1,2 TGS 2

10 005052 Thmbwhl Sw:Rear Mtg S1 1

11 008193 Rcpt Shell:CPC 17-16 RECP2 1

12 008176 Pin: 24-20 AWG Type III 8

13 009442 Pot:50K-Ohm 10% 1W 1T Cerm 1 POT 1

14 041011 Power Source, THC-1/THC-2 1PS 1

PARTS LIST

* Approximate location pointed to.

** This PCB assembly and it's associated parts can not be used in units produced before 5/2001.

THC-2 Torch Height Control

Page 3-7

6

Page 39

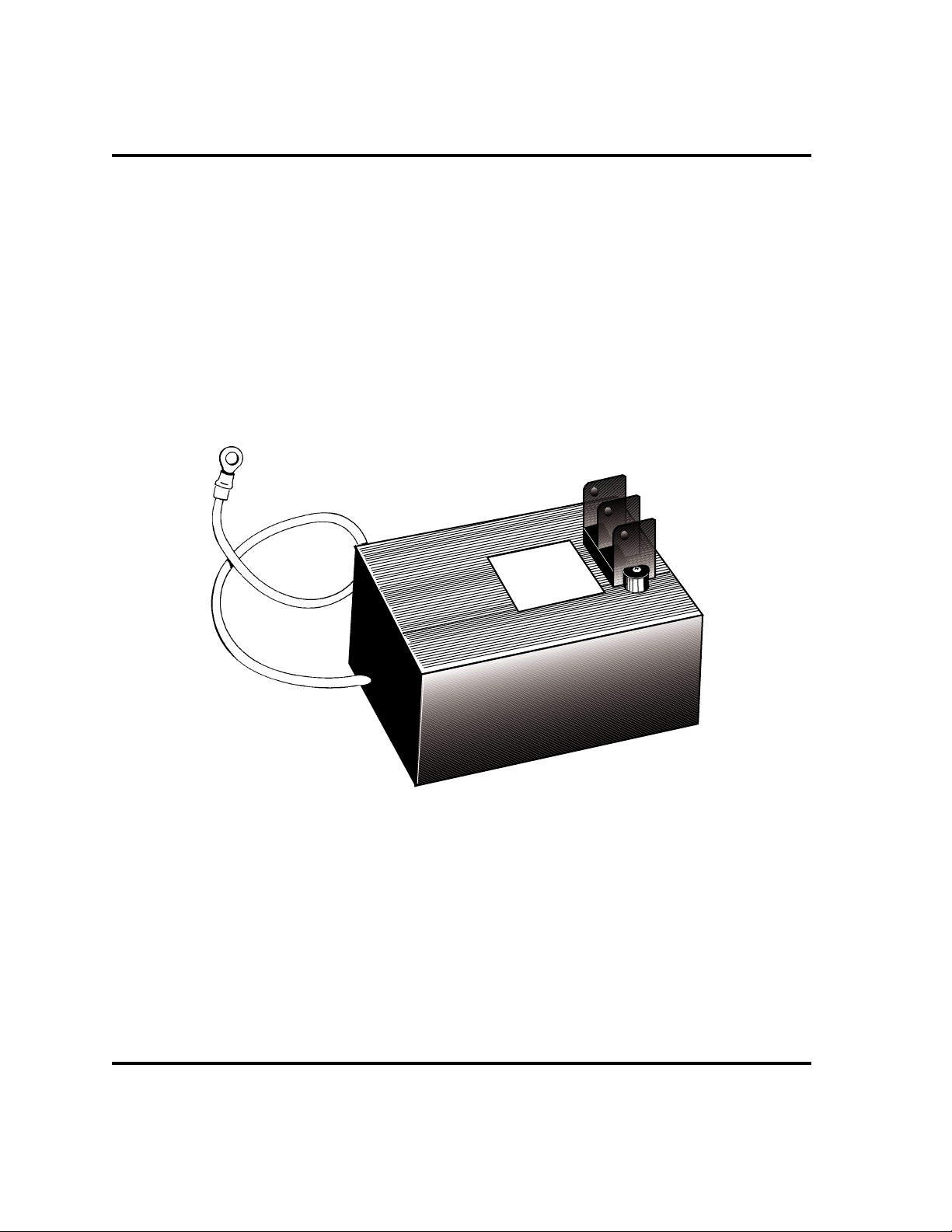

PARTS LIST

SIGNAL

GROUND

Page 3-8

Figure 3-4 Voltage Divider -041007

THC-2 Torch Height Control

Page 40

Page 41

3-7/16" (87mm)

center to center

2-5/16" (59mm)

center to center

Voltage Divider Mounting Template for MAX200

Loading...

Loading...