Page 1

Automation

Hypertherm Automation

5 Technology Drive, Suite 300

W. Lebanon, NH 03784 USA

Phone: 603-298-7970

Fax: 603-298-7977

YPERTHERM SHAPE CUTTING CONTROL

H

MACHINE INTERFACE MANUAL

February 2009

Page 2

D

ISCLAIMER The information in this document is subject to change without notice and should not be

construed as a commitment by Hypertherm Automation. Hypertherm Automation

assumes no responsibility for any errors that appear.

T

RADEMARKS Hypertherm Automation is a wholly owned subsidiary of Hypertherm, Inc.

Command, HT 4400, HD3070 HyDefinition Plasma and HD4070 HyDefinition Plasma

are registered trademarks of Hypertherm, Inc.

FASTLaser is a trademark of Hypertherm, Inc.

EDGE, HyperCAD, HyperNet, HyperNest, Phoenix, and ShapeWizard are registered

trademarks of Hypertherm Automation.

Align, APC, CutPro, Gemini, HPR130, HPR260 HyPerformance Plasma, Mariner,

Nester, Remote Help, Sensor, and Voyager are trademarks of Hypertherm Automation.

HASP is a registered trademark of Aladdin Knowledge Systems Ltd.

Indramat is a trademark of Bosch Rexroth.

Pacific Scientific is a trademark of Danaher Motion.

Pentium and Celeron are registered trademarks of Intel Corporation.

Virus Scan is a registered trademark of McAfee Associates, Inc.

Microsoft, the Microsoft logo, and Windows are registered trademarks of Microsoft

Corporation.

NJWIN is a registered trademark of NJStar Software Corporation.

SERCOS Interface is a trademark of SERCOS North America.

Norton AntiVirus and Norton Ghost are trademarks of Symantec Corporation.

Other trademarks are the property of their respective holders.

C

OPYRIGHT 2009 by Hypertherm Automation. All rights Reserved

Printed in USA

ii

Page 3

Contents

Safety ....................................................................................................................... 1

MicroEdge .................................................................................................................... 9

Overview ............................................................................................................. 9

Keyboard Layout ............................................................................................... 10

System Requirements ....................................................................................... 10

Monitor Requirements (CRT or LCD) ................................................................ 10

Keyboard Requirements ................................................................................... 10

Optional Mouse Requirements .......................................................................... 10

THC, Joystick & Speedpots ............................................................................... 11

Machine Interface .............................................................................................. 11

Serial Port ......................................................................................................... 12

I/O Configuration ............................................................................................... 12

I/O Connector .................................................................................................... 12

I/O Interface ...................................................................................................... 13

Single Ended I/O Pinout .................................................................................... 15

Drive/Encoder Connector .................................................................................. 16

Axes Assignments ............................................................................................. 16

Drive/Encoder Pinout ........................................................................................ 17

Drive/Encoder Pinout (For 3 and 4 Axes units) ................................................. 17

THC and Joystick Interface ............................................................................... 18

Series 1 PCI Analog Card ................................................................................. 18

THC 1 ................................................................................................................ 18

THC 2 ................................................................................................................ 18

Joystick ............................................................................................................. 19

THC and Joystick Cable Grounding .................................................................. 19

Sensor THC ...................................................................................................... 20

Voltage Divider Card Pinout (Series 3) ............................................................. 20

Control & Cable Pinout for Sensor THC ............................................................ 21

I/O Configuration Type “P” ................................................................................ 21

Calibration ......................................................................................................... 22

Series 1 Analog Card ........................................................................................ 22

Edge Ti ..................................................................................................................... 23

Overview ........................................................................................................... 23

Touch Screen .................................................................................................... 23

THC, Joystick & Speedpots ............................................................................... 23

Machine Interface .............................................................................................. 24

AC Input ............................................................................................................ 24

Serial Port ......................................................................................................... 25

I/O Configuration ............................................................................................... 25

Input Mode ........................................................................................................ 26

I/O Interface ...................................................................................................... 26

I/O Pinout .......................................................................................................... 27

I/O Setup Screen ............................................................................................... 28

Lifter Interface ................................................................................................... 29

iii

Page 4

Lifter Pinout (9 Pin Dsub) .................................................................................. 29

Plasma Interface ............................................................................................... 30

External Interlock .............................................................................................. 31

Motor Encoder Connections .............................................................................. 31

Axes Assignments ............................................................................................. 32

Optional Motor Information ................................................................................ 35

Optional Lifter Assembly Information ................................................................ 36

Plasma Interface Assembly Mountings ............................................................. 37

Optional Lifter Assembly ................................................................................... 38

Lifter Assembly Mounting .................................................................................. 38

Torch Breakaway Assembly .............................................................................. 40

Torch Mounting Block Kit .................................................................................. 41

Grounding Requirements .................................................................................. 42

Voyager III ................................................................................................................... 43

Overview ........................................................................................................... 43

Touch Screen .................................................................................................... 43

THC, Joystick & Speedpots ............................................................................... 43

Setups ............................................................................................................... 45

Drive Type ......................................................................................................... 45

Update Rate ...................................................................................................... 45

Baud Rate ......................................................................................................... 45

Light Level ......................................................................................................... 45

Drive I/O ............................................................................................................ 46

RECO I/O at Address 50 ................................................................................... 46

HTA I/O at Address 70 ...................................................................................... 46

Common Status Messages ............................................................................... 46

Machine Interface .............................................................................................. 47

I/O Configuration Type “V” ( Positive Logic Single Ended I/O ) ......................... 47

Single Ended I/O Pinout .................................................................................... 48

I/O Connector .................................................................................................... 48

Mating Connector .............................................................................................. 49

Drive/ Encoder Pinout ....................................................................................... 49

Drive/ Encoder Input Mating Connector ............................................................ 50

Analog Connection Pinout ................................................................................. 50

Analog 1 ............................................................................................................ 50

Mating Connector .............................................................................................. 51

Sensor THC Interface ....................................................................................... 51

Mating Connector .............................................................................................. 51

Voltage Divider Card Pinout ( Series 3 ) ........................................................... 51

Mating Connector .............................................................................................. 51

Mating Connector .............................................................................................. 52

SERCOS to Analog Conversion Card ............................................................... 52

Decimal Read Out ............................................................................................. 52

Address Rotary Hex Switches ( for I/O only ) .................................................... 53

Programming Port ............................................................................................. 53

Dip Switch Settings ........................................................................................... 53

iv

Page 5

Fiber Optic Light Level: ..................................................................................... 53

Baud Rate: ........................................................................................................ 53

Error Codes: ...................................................................................................... 54

Mariner ..................................................................................................................... 55

Overview ........................................................................................................... 55

Touch Screen .................................................................................................... 55

THC, Joystick and Speedpots ........................................................................... 55

AC Input Pinout ................................................................................................. 56

E-Stop ............................................................................................................... 56

Diagram Location Din-02 .................................................................................. 56

SERCOS Motion and I/O................................................................................... 57

v

Page 6

vi

Page 7

Safety

Read This Manual

Read and understand this instructional manual, the cutting machine manuals, and your

employer’s safety practices.

Note: This product is not designed to be field serviceable. Please return to an authorized repair

center for any required service.

Product Listings

MicroEdge and Voyager III

Note: This product has been designed and manufactured in accordance with CE and UL Safety

Standards.

Edge TI

Note: This product has been designed and manufactured in accordance with CE and UL Safety

Standards.

Please contact Hypertherm Automation for further safety listing information.

1

Page 8

2 Safety

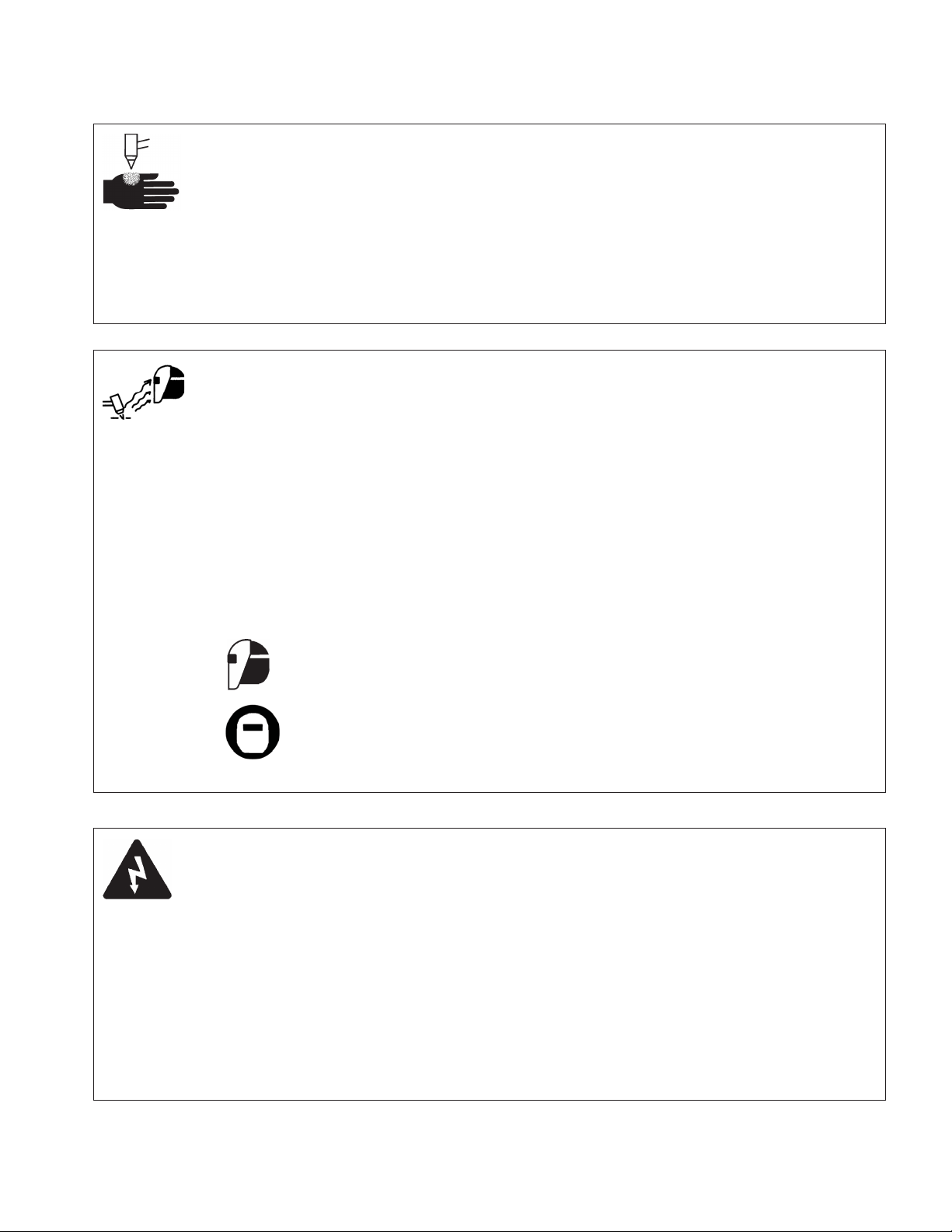

RECOGNIZE SAFETY INFORMATION

The symbols shown in this section are used to

identify potential hazards. When you see a safety

symbol in this manual or on your machine, understand

the potential for personal injury, and follow the related

instructions to avoid the hazard.

FOLLOW SAFETY INSTRUCTIONS

Read carefully all safety messages in this manual and

safety labels on your machine.

• Keep the safety labels on your machine in good

condition. Replace missing or damaged labels

immediately.

• Learn how to operate the machine and how to use

the controls properly. Do not let anyone operate it

without instruction.

• Keep your machine in proper working condition.

Unauthorized modifications to the machine may

affect safety and machine service life.

DANGER WARNING CAUTION

A signal word DANGER or WARNING is used with a

safety symbol. DANGER identifies the most serious

hazards.

• DANGER and WARNING safety labels are located

on your machine near specific hazards.

• WARNING safety messages precede related

instruc tions in this manual that may result in injury

or death if not followed correctly.

• CAUTION safety messages precede related

instructions in this manual that may result in

damage to equipment if not followed correctly.

Fire Prevention

• Be sure the area is safe before doing any cutting.

Keep a fire extinguisher nearby.

• Remove all flammables within 35 feet (10 m) of the

cutting area.

• Quench hot metal or allow it to cool before handling

or before letting it touch combustible materials.

• Never cut containers with potentially flammable

materials inside – they must be emptied and

properly cleaned first.

• Ventilate potentially flammable atmospheres before

cutting.

• When cutting with oxygen as the plasma gas, an

exhaust ventilation system is required.

Explosion Prevention

• Do not use the plasma system if explosive dust or

vapors may be present.

• Do not cut pressurized cylinders, pipes, or any

closed container.

• Do not cut containers that have held combustible

materials.

CUTTING CAN CAUSE FIRE OR EXPLOSION

WARNING

Explosion Hazard

Argon-Hydrogen and Methane

Hydrogen and methane are flammable gases that

present an explosion hazard. Keep flames away from

cylinders and hoses that contain methane or hydrogen

mixtures. Keep flames and sparks away from the torch

when using methane or argon-hydrogen plasma.

WARNING

Hydrogen Detonation with Aluminum Cutting

• When cutting aluminum underwater, or with the

water touching the underside of the aluminum, free

hydrogen gas may collect under the workpiece and

detonate during plasma cutting operations.

• Install an aeration manifold on the floor of the water

table to eliminate the possibility of hydrogen

detonation. Refer to the Appendix section of this

manual for aeration manifold details.

Page 9

Safety 3

Touching live electrical parts can cause a fatal shock

or severe burn.

• Operating the plasma system completes an

electrical circuit between the torch and the

workpiece. The workpiece and anything touching

the workpiece are part of the electrical circuit.

• Never touch the torch body, workpiece or the water

in a water table when the plasma system is

operating.

Electric Shock Prevention

All Hypertherm plasma systems use high voltage

in the cutting process (200 to 400 VDC are

common). Take the following precautions when

operating this system:

• Wear insulated gloves and boots, and keep your

body and clothing dry.

• Do not stand, sit or lie on – or touch – any wet

surface when using the plasma system.

• Insulate yourself from work and ground using dry

insulating mats or covers big enough to prevent any

physical contact with the work or ground. If you must

work in or near a damp area, use extreme caution.

• Provide a disconnect switch close to the power

supply with properly sized fuses. This switch allows

the operator to turn off the power supply quickly in

an emergency situation.

• When using a water table, be sure that it is correctly

connected to earth ground.

ELECTRIC SHOCK CAN KILL

• Install and ground this equipment according to the

instruction manual and in accordance with national

and local codes.

• Inspect the input power cord frequently for damage

or cracking of the cover. Replace a damaged power

cord immediately. Bare wiring can kill.

• Inspect and replace any worn or damaged torch

leads.

• Do not pick up the workpiece, including the waste

cutoff, while you cut. Leave the workpiece in place

or on the workbench with the work cable attached

during the cutting process.

• Before checking, cleaning or changing torch parts,

disconnect the main power or unplug the power

supply.

• Never bypass or shortcut the safety interlocks.

• Before removing any power supply or system

enclosure cover, disconnect electrical input power.

Wait 5 minutes after disconnecting the main power

to allow capacitors to discharge.

• Never operate the plasma system unless the power

supply covers are in place. Exposed power supply

connections present a severe electrical hazard.

• When making input connections, attach proper

grounding conductor first.

• Each Hypertherm plasma system is designed to be

used only with specific Hypertherm torches. Do not

substitute other torches which could overheat and

present a safety hazard.

Use proper precautions when handling printed

circuit boards.

STATIC ELECTRICITY CAN DAMAGE CIRCUIT BOARDS

• Store PC boards in anti-static containers.

• Wear a grounded wrist strap when handling

PC boards.

Page 10

4 Safety

The plasma arc by itself is the heat source used for

cutting. Accordingly, although the plasma arc has not

been identified as a source of toxic fumes, the

material being cut can be a source of toxic fumes or

gases that deplete oxygen.

Fumes produced vary depending on the metal that is

cut. Metals that may release toxic fumes include, but

are not limited to, stainless steel, carbon steel, zinc

(galvanized), and copper.

In some cases, the metal may be coated with a

substance that could release toxic fumes. Toxic

coatings include, but are not limited to, lead (in some

paints), cadmium (in some paints and fillers), and

beryllium.

Gases produced by plasma cutting vary based on the

material to be cut and the method of cutting, but may

include ozone, oxides of nitrogen, hexavalent

chromium, hydrogen, and other substances if such

are contained in or released by the material being cut.

Caution should be taken to minimize exposure to

fumes produced by any industrial process. Depending

upon the chemical composition and concentration of

the fumes (as well as other factors, such as

ventilation), there may be a risk of physical illness,

such as birth defects or cancer.

It is the responsibility of the equipment and site owner

to test the air quality in the area where the equipment

is used and to ensure that the air quality in the

workplace meets all local and national standards

and regulations.

TOXIC FUMES CAN CAUSE INJURY OR DEATH

The air quality level in any relevant workplace

depends on site-specific variables such as:

• Table design (wet, dry, underwater).

• Material composition, surface finish, and

composition of coatings.

• Volume of material removed.

• Duration of cutting or gouging.

• Size, air volume, ventilation and filtration of the

work area.

• Personal protective equipment.

• Number of welding and cutting systems in

operation.

• Other site processes that may produce fumes.

If the workplace must conform to national or local

regulations, only monitoring or testing done at the site

can determine whether the site is above or below

allowable levels.

To reduce the risk of exposure to fumes:

• Remove all coatings and solvents from the metal

before cutting.

• Use local exhaust ventilation to remove fumes from

the air.

• Do not inhale fumes. Wear an air-supplied

respirator when cutting any metal coated with,

containing, or suspected to contain toxic elements.

• Assure that those using welding or cutting

equipment, as well as air-supplied respiration

devices, are qualified and trained in the proper use

of such equipment.

• Never cut containers with potentially toxic materials

inside. Empty and properly clean the container first.

• Monitor or test the air quality at the site as needed.

• Consult with a local expert to implement a site plan

to ensure safe air quality.

Page 11

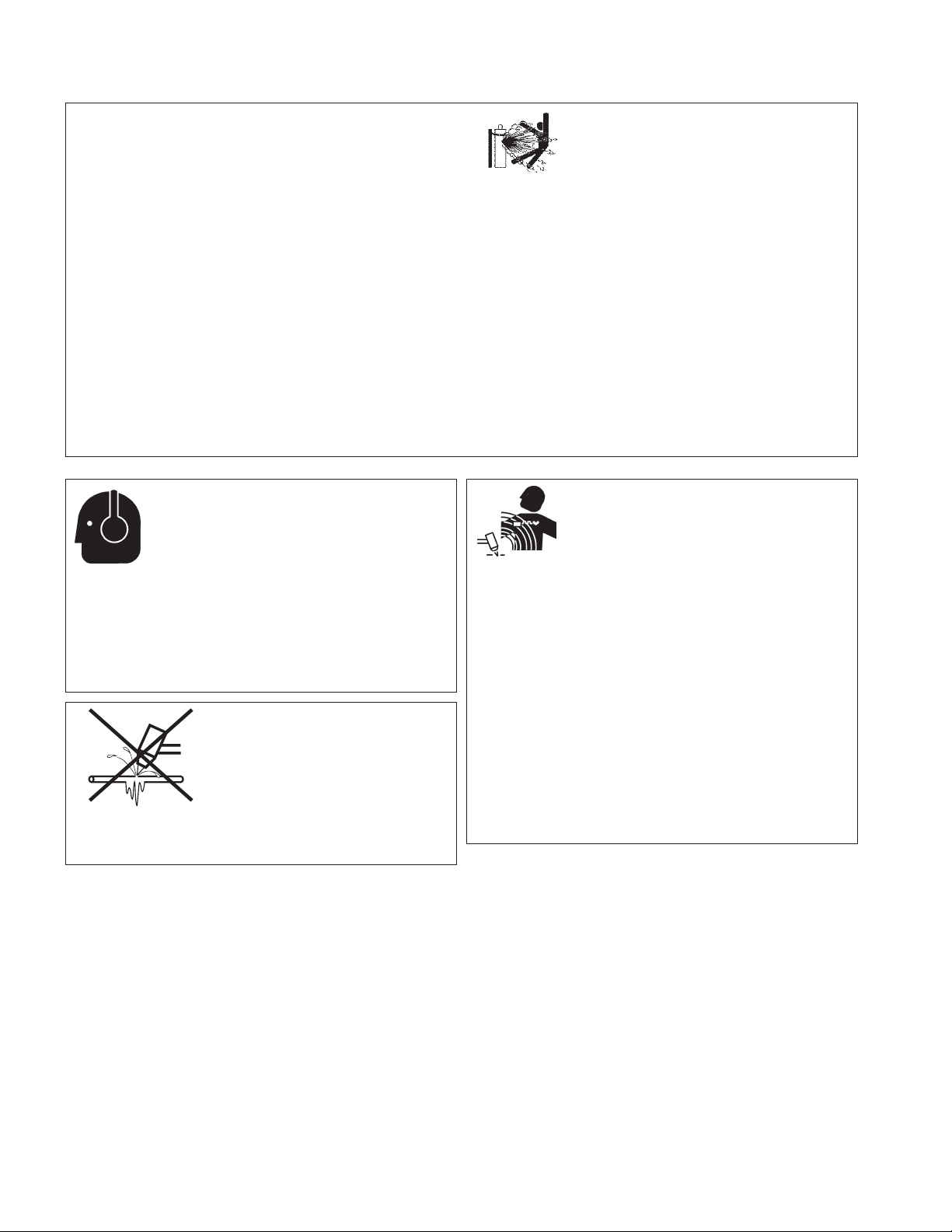

Safety 5

Instant-On Torches

Plasma arc comes on immediately when the torch

switch is activated.

A PLASMA ARC CAN CAUSE INJURY AND BURNS

The plasma arc will cut quickly through gloves and

skin.

• Keep away from the torch tip.

• Do not hold metal near the cutting path.

• Never point the torch toward yourself or others.

Eye Protection Plasma arc rays produce intense

visible and invisible (ultraviolet and infrared) rays that

can burn eyes and skin.

• Use eye protection in accordance with applicable

national or local codes.

• Wear eye protection (safety glasses or goggles with

side shields, and a welding helmet) with appropriate

lens shading to protect your eyes from the arcʼs

ultraviolet and infrared rays.

Lens Shade

Arc Current AWS (USA) ISO 4850

Up to 100 A No. 8 No. 11

100-200 A No. 10 No. 11-12

200-400 A No. 12 No. 13

Over 400 A No. 14 No. 14

ARC RAYS CAN BURN EYES AND SKIN

Skin Protection Wear protective clothing to protect

against burns caused by ultraviolet light, sparks and

hot metal.

• Gauntlet gloves, safety shoes and hat.

• Flame-retardant clothing to cover all exposed areas.

• Cuffless trousers to prevent entry of sparks and

slag.

• Remove any combustibles, such as a butane lighter

or matches, from your pockets before cutting.

Cutting Area Prepare the cutting area to reduce

reflection and transmission of ultraviolet light:

• Paint walls and other surfaces with dark colors to

reduce reflection.

• Use protective screens or barriers to protect others

from flash and glare.

• Warn others not to watch the arc. Use placards or

signs.

Work Cable Attach the work cable securely to the

workpiece or the work table with good metal-to-metal

contact. Do not connect it to the piece that will fall

away when the cut is complete.

Work Table Connect the work table to an earth

ground, in accordance with appropriate national or

local electrical codes.

GROUNDING SAFETY

Input Power

• Be sure to connect the power cord ground wire to

the ground in the disconnect box.

• If installation of the plasma system involves

connecting the power cord to the power supply, be

sure to connect the power cord ground wire

properly.

• Place the power cord's ground wire on the stud first,

then place any other ground wires on top of the

power cord ground. Fasten the retaining nut tightly.

• Tighten all electrical connections to avoid excessive

heating.

Page 12

6 Safety

ADDITIONAL SAFETY INFORMATION

1. ANSI Standard Z49.1,

Safety in Welding and Cutting,

American

Welding Society, 550 LeJeune Road

P.O. Box 351020, Miami, FL 33135

2. ANSI Standard Z49.2,

Fire Prevention in the Use of Cutting and

Welding Processes,

American National Standards Institute

1430 Broadway, New York, NY 10018

3. ANSI Standard Z87.1,

Safe Practices for Occupation and

Educational Eye and Face Protection,

American National

Standards Institute, 1430 Broadway, New York, NY 10018

4. AWS F4.1,

Recommended Safe Practices for the Preparation for

Welding and Cutting of Containers and Piping That Have Held

Hazardous Substances,

American Welding Society

550 LeJeune Road, P.O. Box 351040, Miami, FL 33135

5. AWS F5.2,

Recommended Safe Practices for Plasma Arc

Cutting,

American Welding Society

550 LeJeune Road, P.O. Box 351040, Miami, FL 33135

6. CGA Pamphlet P-1,

Safe Handling of Compressed Gases in

Cylinders,

Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202

7. CSA Standard W117.2,

Code for Safety in Welding and Cutting,

Canadian Standards Association Standard Sales

178 Rexdale Boulevard, Rexdale, Ontario M9W 1R3, Canada

8. NFPA Standard 51B,

Cutting and Welding Processes,

National

Fire Protection Association

470 Atlantic Avenue, Boston, MA 02210

9. NFPA Standard 70–1978,

National Electrical Code,

National Fire

Protection Association, 470 Atlantic Avenue, Boston, MA 02210

10. OSHA,

Safety and Health Standards,

29FR 1910

U.S. Government Printing Office, Washington, D.C. 20402

• Never lubricate cylinder valves or regulators with oil

or grease.

• Use only correct gas cylinders, regulators, hoses

and fittings designed for the specific application.

• Maintain all compressed gas equipment and

associated parts in good condition.

• Label and color-code all gas hoses to identify the

type of gas in each hose. Consult applicable

national or local codes.

GAS CYLINDERS CAN

EXPLODE IF DAMAGED

COMPRESSED GAS EQUIPMENT SAFETY

Gas cylinders contain gas under high pressure. If

damaged, a cylinder can explode.

• Handle and use compressed gas cylinders in

accordance with applicable national or local codes.

• Never use a cylinder that is not upright and secured

in place.

• Keep the protective cap in place over valve except

when the cylinder is in use or connected for use.

• Never allow electrical contact between the plasma

arc and a cylinder.

• Never expose cylinders to excessive heat, sparks,

slag or open flame.

• Never use a hammer, wrench or other tool to open

a stuck cylinder valve.

Prolonged exposure to noise from cutting or gouging

can damage hearing.

• Use approved ear protection when using plasma

system.

• Warn others nearby about the noise hazard.

NOISE CAN DAMAGE HEARING

Pacemaker and hearing aid operation can be affected

by magnetic fields from high currents.

Pacemaker and hearing aid wearers should consult a

doctor before going near any plasma arc cutting and

gouging operations.

To reduce magnetic field hazards:

• Keep both the work cable and the torch lead to one

side, away from your body.

• Route the torch leads as close as possible to the

work cable.

• Do not wrap or drape the torch lead or work cable

around your body.

• Keep as far away from the power supply as

possible.

PACEMAKER AND HEARING

AID OPERATION

A PLASMA ARC CAN

DAMAGE FROZEN PIPES

Frozen pipes may be damaged or can burst if you

attempt to thaw them with a plasma torch.

Page 13

Safety 7

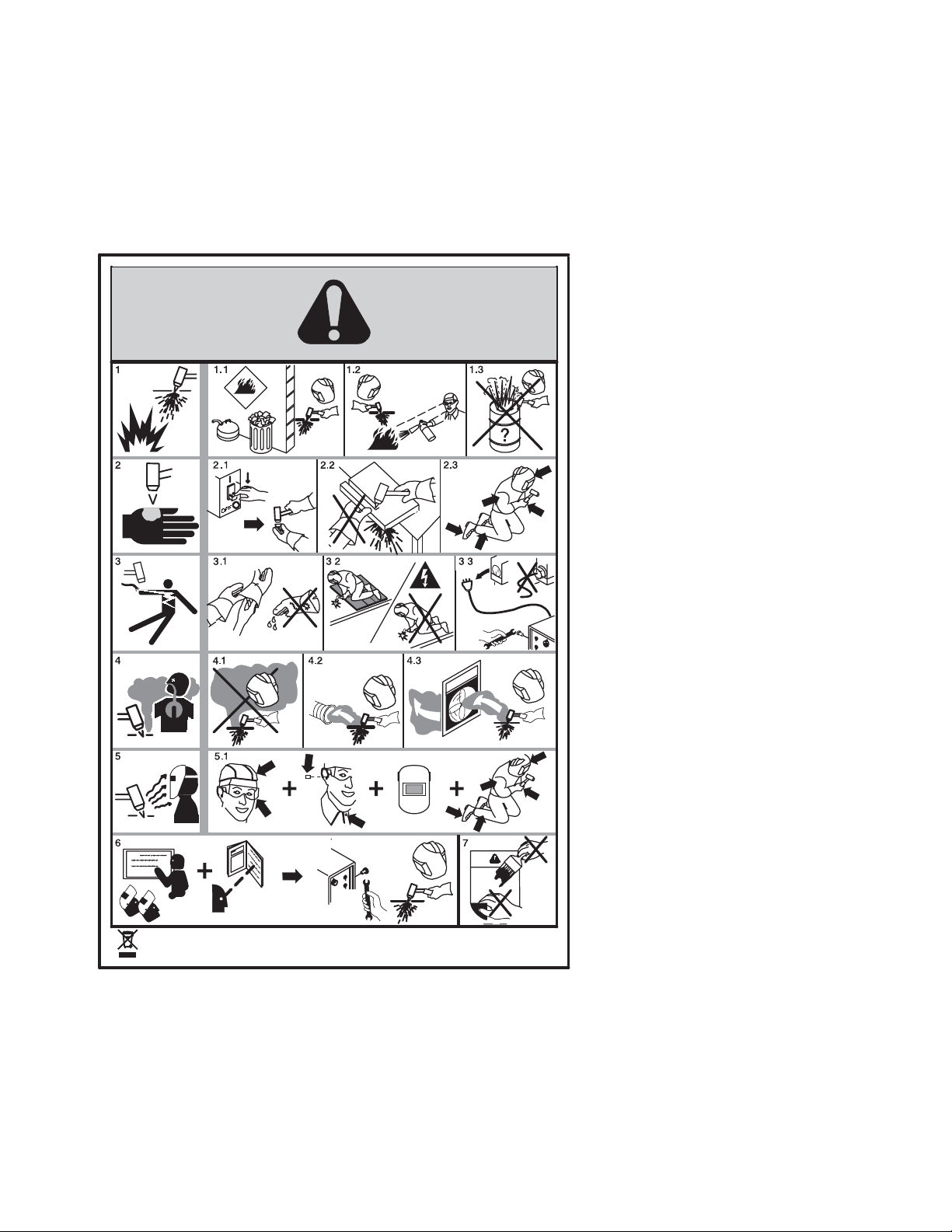

WARNING LABEL

This warning label is affixed to some power supplies. It is

important that the operator and maintenance technician

understand the intent of these warning symbols as described.

The numbered text corresponds to the numbered boxes on

the label.

1. Cutting sparks can cause explosion or fire.

1.1 Keep flammables away from cutting.

1.2 Keep a fire extinguisher nearby, and have

a watchperson ready to use it.

1.3 Do not cut on any closed containers.

2. The plasma arc can cause injury and

burns.

2.1 Turn off power before disassembling torch.

2.2 Do not hold the material near cutting path.

2.3 Wear complete body protection.

3. Electric shock from torch or wiring can kill.

Protect yourself from electric shock.

3.1 Wear insulating gloves. Do not wear wet or

damaged gloves.

3.2 Insulate yourself from work and ground.

3.3 Disconnect input plug or power before

working on machine.

4. Breathing cutting fumes can be hazardous

to your health.

4.1 Keep your head out of the fumes.

4.2 Use forced ventilation or local exhaust to

remove the fumes.

4.3 Use ventilating fan to remove the fumes.

5. Arc rays can burn eyes and injure skin.

5.1 Wear hat and safety glasses. Use ear

protection and button shirt collar. Use

welding helmet with correct shade of filter.

Wear complete body protection.

6. Become trained and read the instructions

before working on the machine or cutting.

7. Do not remove or paint over (cover)

warning labels.

www.hypertherm.com/weee

110647 Rev. A

Page 14

8 Safety

Page 15

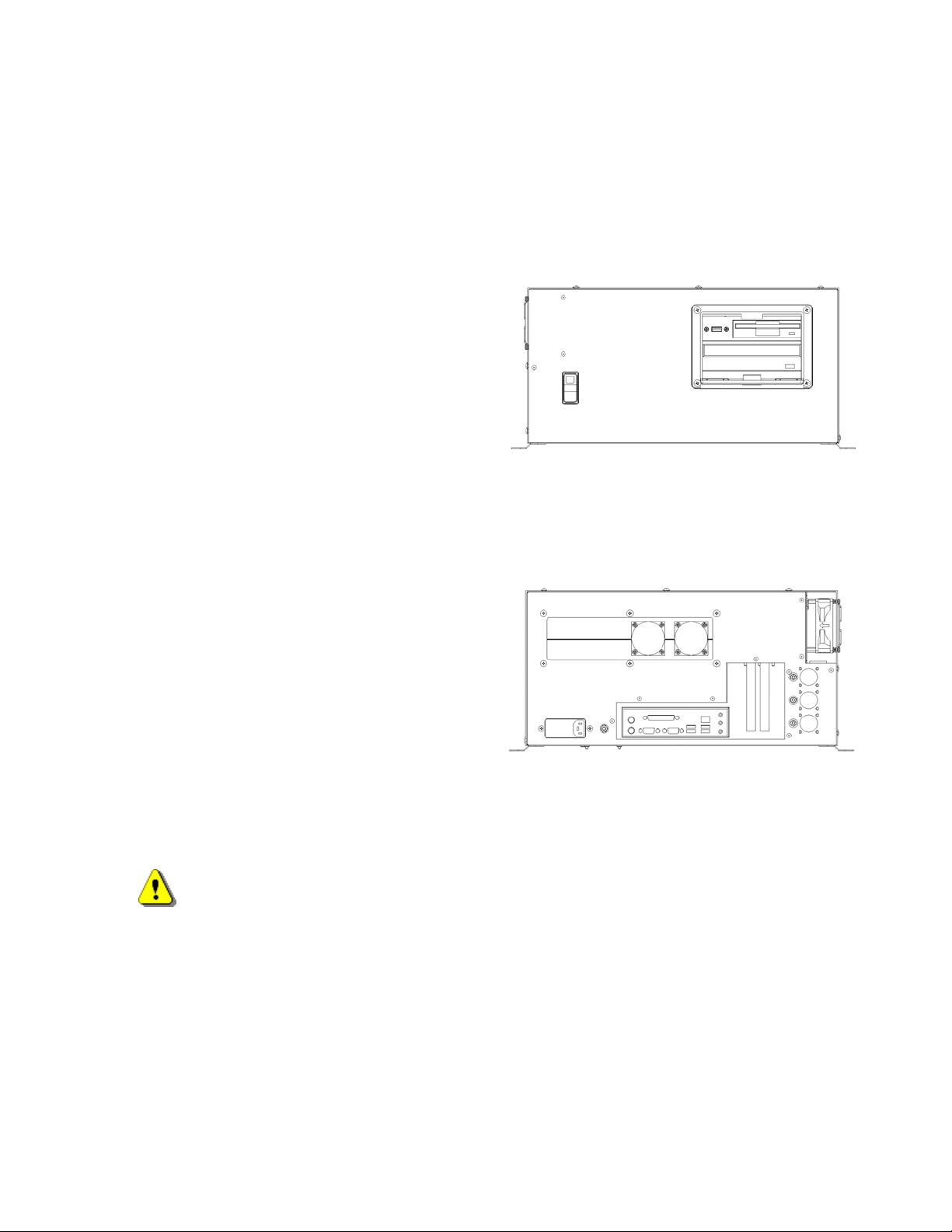

MicroEdge

Overview

The MicroEDGE™ PC based motion

control from Hypertherm Automation

is specifically for the metal cutting

industry. This control package

provides a unique combination of

flexible table configurations,

expandable features and an

unparalleled ease of use.

MicroEDGE utilizes our proprietary

Graphical User Interface (GUI) and

SoftMotion Technology with motion

control operation of up to four axes

with 24 I/O signals.

This product offers a unique

approach to the motion control

market by allowing custom

configuration the final package by

adding a PC style Monitor, Keyboard

and Mouse.

Additional features such as Joystick,

Speed Pots, Integrated Sensor THC,

networking, CAD/CAM Software,

Nesting Software provide unlimited

combinations of options for

increased productivity.

MicroEDGE™

Rear View

Operation and maintenance of

automated equipment involves

potential hazards. Personnel should

take precautions to avoid injury. This

equipment should only be opened by

trained service personnel.

9

Page 16

MicroEdge

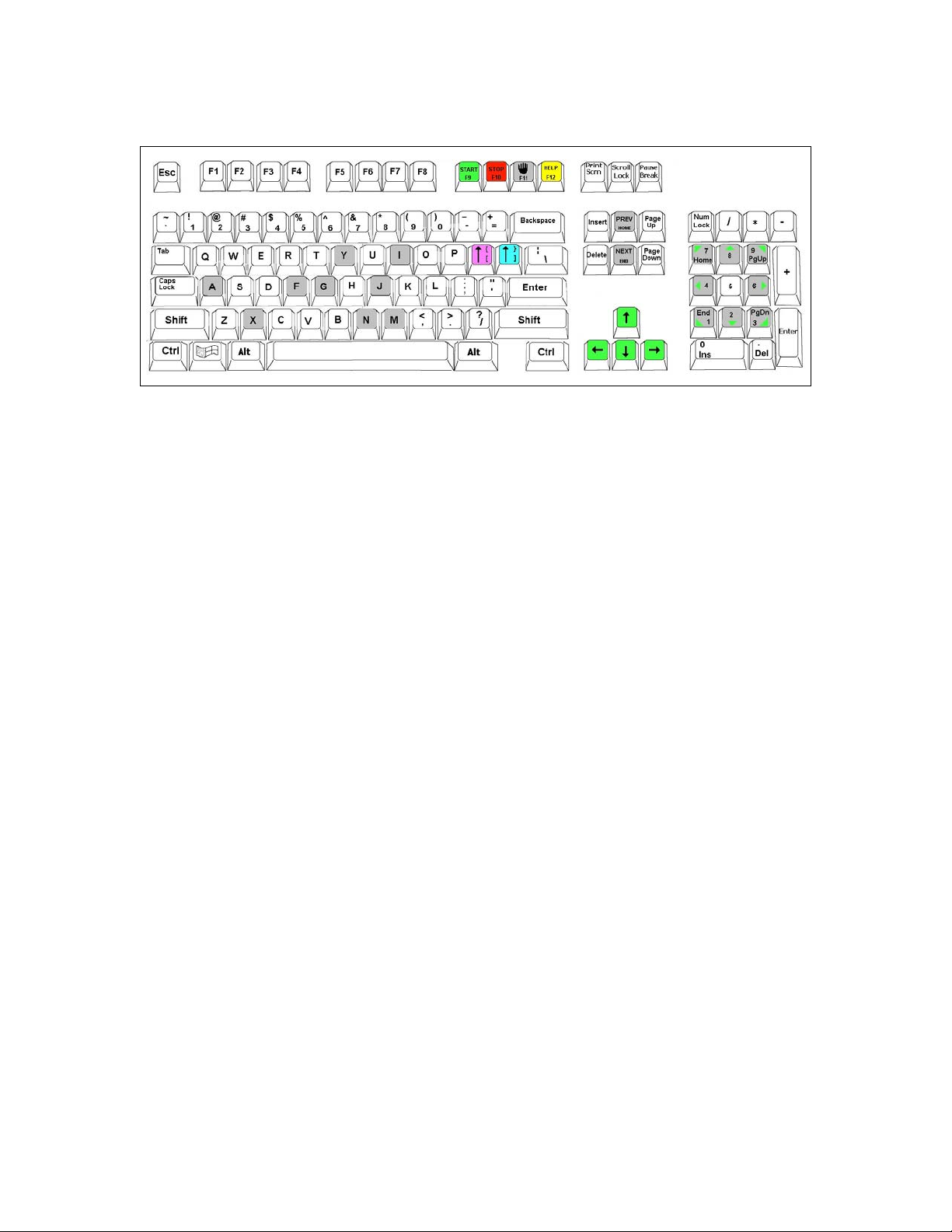

Keyboard Layout

Typical Keyboard Layout

Keyboard Functions

Function Keys F1-F8 are equivalent to the soft keys on the display screen.

Function Key F9 is equivalent to the START key.

Function Key F10 and Pause Key are equivalent to the STOP key.

Function Key F11 is equivalent to the MANUAL MODE key.

Function Key F12 is equivalent to the HELP key.

Arrow direction keys are used for manual motion.

The HOME key is equivalent to the PREV field key.

The END key is equivalent to the NEXT field key.

The [ key is equivalent to the purple arrow shift key.

The ] key is equivalent to the blue arrow shift key.

The Esc key is equivalent to the CANCEL key.

To exit the control software press Alt F4.

To switch between applications press Alt Tab.

A color coded key cap sticker set is provided to allow easy reference to the keys

used by the control software.

System Requirements

Monitor Requirements (CRT or LCD)

Standard VGA capable 1240 x780 analog monitors or better with 15 pin High

Density D-sub connector. Touch screen displays are also supported.

Keyboard Requirements

Standard 101/ 104 Key PS/2 or USB Compatible Keyboard

Optional Mouse Requirements

PS/2 or USB Compatible Mouse

10

Page 17

MicroEdge

THC, Joystick & Speedpots

Optional features for two Sensor THC, one Joystick and two Speedpots are

offered.

Note: Use of some monitors and other devices may require loading of a device

driver for operation. Many standard device drivers are located in the C:\CABS or

C:\CABS\I386 folders.

Machine Interface

The MicroEDGE shape cutting control is an extremely versatile product offering

up to four configurable axes of motion, configurable I/O locations and a

convenient table interface for ease of installation. The control features may also

be expanded through use of optional analog and network interface cards.

The rear panel of the control has several cable connectors to connect the control

to power, I/O and communication ports. These connectors are clearly labeled as

to their function.

11

Page 18

MicroEdge

AC Input

The AC power cable is inserted into the AC power connector and plugged into a

standard 3-way 110 or 220 volt outlet. The control has a universal AC input

power module that allows the user to plug into either voltage without changing

additional jumpers. In addition, the AC Power connector contains an integral

fuse receptacle and line filter.

A remote communications link can be connected to one of the two serial ports

and an external ground (PE) lug for earth grounding of the unit is also provided.

Serial Port

Please refer to the Ports Information section of the Installation Guide for

additional information on configuration of Serial ports for communication. Note:

Serial ports for the MicroEDGE are not optically isolated. Appropriate grounding

or after market port isolator or protocol converter to add optical isolation is

recommended.

I/O Configuration

The cables that connect the control to the cutting machine are attached to the I/O

(Input/Output), and the DRIVE/ENCODER connectors. For the purposes of this

guide Single Ended I/O is referred to as Type “P” configuration.

The information provided here is the basic information for connection of the

shape cutting control to the cutting table. Each machine interface will vary

slightly based on the cutting table configuration and features. Additionally, I/O

pinout information may vary slightly based on the configuration of the selected

I/O and their locations. Changes to the I/O configuration may be made in the

password protected I/O screen. All controls are shipped with the default

selection of Inputs and interface locations for the selected control Interface (I/O)

configuration. Installation and service should only be performed by a qualified

service technician.

I/O Connector

The I/O connector is a standard sex circular CPC connector from AMP. This

connector was specifically chosen for its rugged industrial design and its metal

insulation characteristics for EMI/RFI noise immunity.

In the single ended I/O scheme, a ground is provided on the I/O pin. The

advantage to single ended I/O is that it takes one pin for each point versus two

for the double-ended I/O scheme, thus increasing the total number of I/O points

available to the user.

12

Page 19

I/O Mating Connector

Connector AMP #208470-1

Backshell AMP #208945-8

Sockets (16-18 ga) AMP #66101-3

Sockets (20-24 ga) AMP #66105-3

MicroEdge

I/O Interface

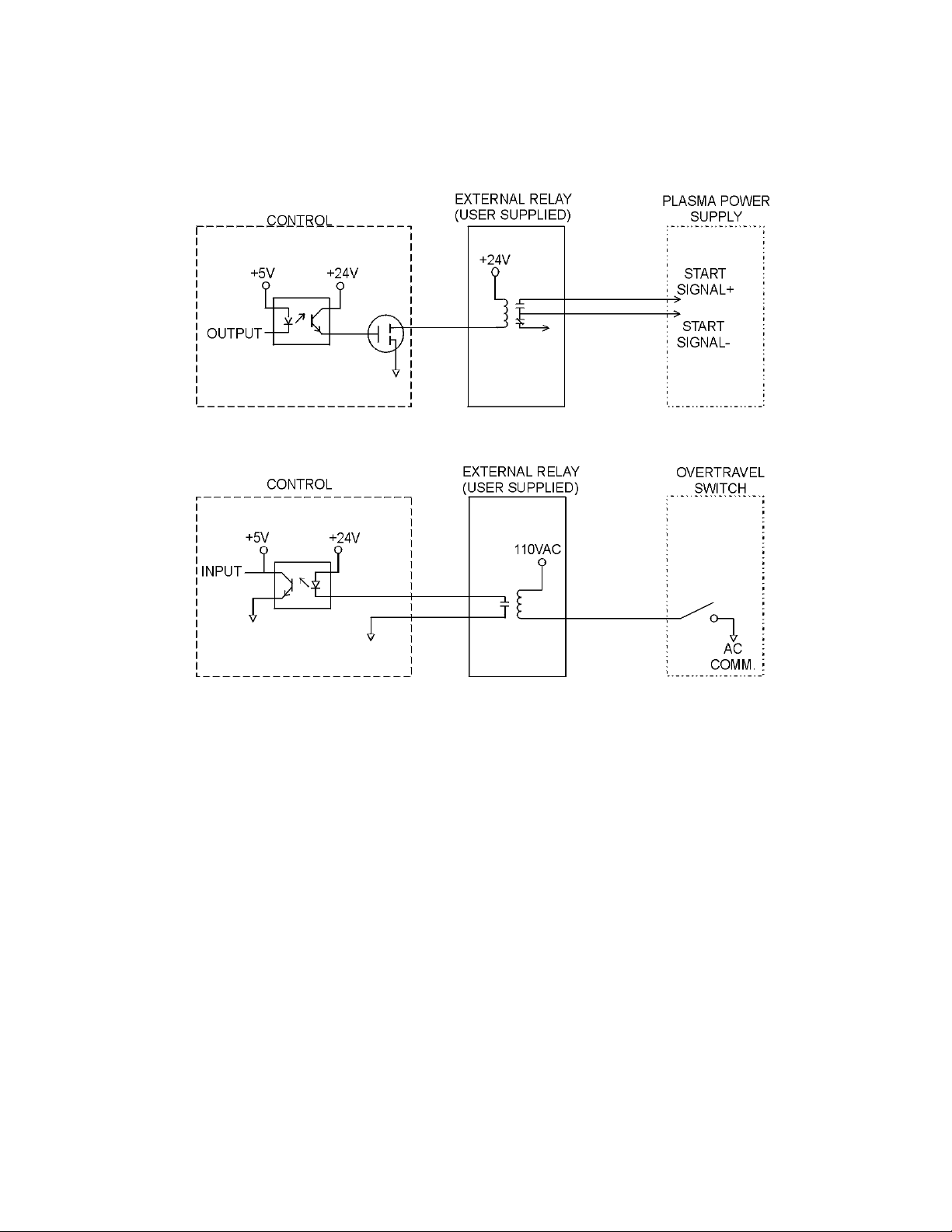

Connecting single ended I/O to the control. These examples assume a +24V

power supply has been connected across pins 34 and 36 of the control, or that

the optional internal +24V power supply has been installed.

Output tied to external Cut On Input tied to Cut Sense Relay

13

Page 20

MicroEdge

Examples of possible circuits

Output

Input

14

Page 21

MicroEdge

Single Ended I/O Pinout

The Single Ended I/O offers 12 outputs which are rated at 24VDC for up to 1amp loads and 12 inputs rated for 24VDC.

Pin I/O Description

1 Input 1 Torch Up Sense

2 Input 2 Torch Down Sense

3 Input 3 Preheat Sense or X -Overtravel Switch

4 Input 4 Cut Sense

5 Input 5 Tracer on Path or Z Home Switch

6 Input 6 Spare or Y -Overtravel Switch

7 Input 7 Spare

8 Input 8 Spare or Remote Pause

9 Input 9 X Home Switch

10 Input 10 X Overtravel Switch or X +Overtravel Switch

11 Input 11 Y Home Switch

12 Input 12 Y Overtravel Switch or Y +Overtravel Switch

13 N/C No Connection

14 +24 VDC + I/O Power Supply

15 +24 VDC + I/O Power Supply

16 N/C No Connection

17 24V Common I/O Power Supply Common

18 24V Common I/O Power Supply Common

19 N/C No Connection

20 N/C No Connection

21 Output 1 Torch Up

22 Output 2 Torch Down

23 Output 3 Ignition Control

24 Output 4 Torch Height Disable/Dual Grid Control

25 Output 5 CNC/Tracer

26 Output 6 Marker Enable

27 Output 7 Cut Control

28 Output 8 Spare

29 Output 9 Spare or Low Preheat

30 Output 10 Preheat Control

31 Output 11 Key Press Indicator or Motion Indicator

32 Output 12 Spare or Plasma Select

33 I/O Shield Chassis Ground

34 +24 VDC +I/O Power Supply

35 +24 VDC +I/O Power Supply

36 24 V Common I/O Power Supply Common

37 24 V Common I/O Power Supply Common

15

Page 22

MicroEdge

Drive/Encoder Connector

The Drive/Encoder connector is a reverse sex circular CPC connector from AMP.

This connector was specifically chosen for its rugged industrial design and its

metal insulation characteristics for EMI/RFI noise immunity.

NOTE: For optimum noise immunity, cable shields may be tied externally to the

control enclosure or to the metal AMP connectors.

Drive/Encoder Mating Connector and Cable

Connector AMP #208472-1

Backshell AMP #208945-8

Pins (16-18 ga) AMP #66099-3

Pins (20-24 ga) AMP #66103-3

Cabling: Use Belden # 9504 or equivalent for encoder signals

Cabling: Use Belden # 9501 or equivalent for drive signals

Axes Assignments

Axes Axes Assignment

1 (X) Transverse or Rail

2 (Y) Transverse or Rail

3 (Z) Dual Gantry, CBH, Rotate or THC

4 (W) CBH, Tilt or THC

16

Page 23

Drive/Encoder Pinout

Pin Description

2 Encoder Power Supply Input (+5V)

3 Encoder Power Supply Common

4 Encoder Power Supply Shield

8

X Axis Y Axis Description

4 1 Encoder Power Output

8 6 Encoder Power Common

9 5 Encoder Channel A input

14 11 Encoder Channel /A Input

15 10 Encoder Channel B Input

21 17 Encoder Channel /B Input

22 16 Encoder Channel Z Input

28 23 Encoder Channel /Z Input

13 12 Encoder Shields

24 26 Drive Enable In (relay contact)

25 27 Drive Enable Out (relay contact)

37 34 Drive Power Input (+12 or +15)

33 29 Servo Output (± 10V)

32 30 Drive Power Common

36 35 Drive Power Input (-12 or –15)

20 18 Servo Output Common

19 31 Drive/Servo Shield

Drive/Encoder Pinout (For 3 and 4 Axes units)

Pin Description

2 Encoder Power Supply Input (+5V or +12V)

3 Encoder Power Supply Common

7 Encoder Power Supply Shield

Z Axis W Axis Description

4 1 Encoder Power Output

8 6 Encoder Power Common

9 5 Encoder Channel A input

14 11 Encoder Channel /A Input

15 10 Encoder Channel B Input

21 17 Encoder Channel /B Input

22 16 Encoder Channel Z Input

28 23 Encoder Channel /Z Input

13 12 Encoder Shields

24 26 Drive Enable In (relay contact)

MicroEdge

17

Page 24

MicroEdge

25 27 Drive Enable Out (relay contact)

37 34 Drive Power Input (+12 or +15)

33 29 Servo Output (± 10V)

32 30 Drive Power Common

36 35 Drive Power Input (-12 or –15)

20 18 Servo Output Common

19 31 Drive/Servo Shield

THC and Joystick Interface

MicroEdge has dedicated connectors for THC 1, THC and Joystick / Speedpots.

Series 1 PCI Analog Card

Note: The Analog Card will be designated as PCI-AIC Rev A in the Control

Information Diagnostic screen.

Board Marking PCI Analog 1 Part # PCBS-0074

THC 1

Pin # Designation Description

1 Common Common

2 Input 5 Nozzle Contact Sense – ( Relay Contact

3 Input 5 – Nozzle Contact Sense - ( Relay Contact )

4 Output 1 + Nozzle Contact Enable + ( Relay Contact )

5 Output 1 – Nozzle Contact Enable - ( Relay Contact )

6 Analog Input 1 + THC +

7 Analog Input 1 – THC –

8 Output 2 + Hold Ignition ( Relay Contact )

9 Output 2 – Hold Ignition ( Relay Contact )

Ground Stud Shield

Mating Connector

Connector AMP #206708-1

Backshell AMP #206966-1

Sockets (20-24 ga) AMP #66105-3

Cabling: Use Belden # 9504 or equivalent

THC 2

Pin # Designation Description

1 Common Common

2 Input 6 + Nozzle Contact Sense + ( Relay Contact )

3 Input 6 – Nozzle Contact Sense – ( Relay Contact )

4 Output 3 + Nozzle Contact Enable + ( Relay Contact )

5 Output 3 – Nozzle Contact Enable – ( Relay Contact )

6 Analog Input 2 + THC +

7 Analog Input 2 – THC –

18

Page 25

MicroEdge

8 Output 4 + Hold Ignition ( Relay Contact )

9 Output 4 – Hold Ignition ( Relay Contact )

Ground Stud Shield

Mating Connector

Connector AMP #206708-1

Backshell AMP #206966-1

Sockets (20-24 ga) AMP #66105-3

Cabling: Use Belden # 9504 or equivalent

Joystick

Pin # Designation Description

1 Input 1 Joystick UP

2 Input 2 Joystick DWN

3 Input 3 Joystick LT

4 Input 4 Joystick RT

5 Common Common

6 Analog Input 3 + Speed Pot 1

7 Analog Input 3 – Speed Pot 1

8 Analog Input 4 + Speed Pot 2

9 Analog Input 4 – Speed Pot 2

Ground Stud Shield

Note: Joystick inputs are activated by passing the Common signal ( pin 5 ) to the

desired input.

Analog inputs for the speedpots are rated at 0 - +10VDC

Mating Connector

Connector AMP #206708-1

Backshell AMP #206966-1

Sockets (20-24 ga) AMP #66105-3

Cabling: Use Belden # 9504 or equivalent

THC and Joystick Cable Grounding

Cable shields should be tied to the external PE studs for optimum noise

immunity.

19

Page 26

MicroEdge

Sensor THC

This section refers to following hardware configuration. Note: The Analog Card

will be designated as Rev 0 in the Control Information Diagnostic screen.

Series 1 PCI Analog Card Part # PCBS-0074

(Board Marking PCBS-0073)

Series 3 Voltage Divider Card Part # PCBS-0061

Instructions

If the voltage divider card has not been installed in the plasma power supply,

mount the card in an accessible location away from high electrical noise areas.

Wire the VDC to the appropriate signal inside the power supply as outlined in the

following pinout information

Voltage Divider Card Pinout (Series 3)

Divider PCB - 2C Connector J1

Pin # Description

1 85 -265 VAC Power Input (47-63Hz)

2 285 -265 VAC Neutral Input

Mating Connector

2C Phoenix Connector – Phoenix Part # 1840366

Divider PCB - 8C Connector J2 To Control

Pin # Description

1 +24 VDC Common

2 +24 VDC

3 Nozzle Contact Sense

4 Nozzle Contact Enable

5 +24 VDC Common

6 Analog Out +

7 Analog Out –

8 E Ground

Mating Connector

8C Phoenix Connector – Phoenix Part # 1803633

Divider PCB - 5C Connector J3 to Power Supply / Table

Pin # Description

1 Ground (Chassis Ground)

2 Electrode (Plasma DC –)

3 Work (Plasma DC +)

4 NC

5 Shield (Nozzle Contact)

20

Page 27

MicroEdge

Mating Connector

Terminal Connections

Control & Cable Pinout for Sensor THC

I/O Configuration Type “P”

Note: A 9C Amp connector is provided on the back of the control (I/O Type “P”)

for interfacing.

Control 9C Divider J2

Analog Pin # Description Pin #

1 24V Common 1

2 Nozzle Contact Sense + 2

3 Nozzle Contact Sense – 3

4 Nozzle Contact Enable + 4

5 Nozzle Contact Enable – 5

6 Analog + 6

7 Analog – 7

8 Hold Ignition + N/A (direct to power supply)*

9 Hold Ignition – N/A (direct to power supply)*

Ground Stud Shield No Connection

Analog Mating Connector

Connector AMP # 206708-1

Backshell AMP #206966-1

Sockets #66105-3 (20-24 ga)

VDC Mating Connector

8C Phoenix Connector – Phoenix Part # 1803633

Cable

Belden #9505 or equivalent

* Note: It is recommended that the Hold Ignition input be wired to the Power

Supply through an external relay for noise immunity. Please refer to Instructions

from the supply manufacturer for details on connection to the Hold Ignition Input.

21

Page 28

MicroEdge

Calibration

Series 1 Analog Card

Note: The Series 1 Analog Card will be designated as Rev 0 in the Control

Information Diagnostic screen.

Board Marking PC-012-1098 Rev. B Part # PCBS-0010-B

After the voltage divider card and control cabling have been connected, the

system is ready to be calibrated for use.

Analog Offset: To adjust the Analog Offset, place a jumper on the Analog In

signals on the Analog input card or at the 9C connection for the Analog Input

Card located at the back of the control. The analog input voltage would then be

viewed at the I/O Diagnostics screen to read any incoming voltage for the THC. If

any voltage is displayed at the diagnostic screen, an Offset Voltage equal to the

incoming voltage being read can be entered at the Password protected Analog

I/O screen to correct for any imbalance and “zero” the incoming voltage

Example: If an incoming Analog Input Voltage is reading .1 volts, simply enter .1

at the Analog Offset and correct the imbalance.

22

Page 29

Edge Ti

Overview

The Edge Ti shape cutting control is an

extremely versatile product offering up to four

configurable axes of motion, built-in Servo

Amplifiers and configurable I/O. Use of built in

relay contacts for I/O increases interface

options and minimizes external interface

components.

Hypertherm Automation PC based CNC

controls for the shape cutting industry utilize our

proprietary Graphical User Interface (GUI), and

SoftMotion Technology to increase productivity,

reduce operational costs while providing

unsurpassed operational flexibility. The control

features may be further expanded through use

of integrated Sensor™ THC interface and

networking

Touch Screen

The 15” display used in the Edge Ti is a

patented IntelliTouch Surface Wave technology

which provides precise drift free touch accuracy

and unsurpassed clarity. Pure glass

construction with tiny transducers on the back

of the touch screen preserves color purity and

works even if scratched. There is no known

wear out mechanism as there are no layers,

coatings or moving parts. IntelliTouch

technology has been tested by the supplier for

more than 50 million touches in one location

without failure.

THC, Joystick & Speedpots

Features for Joystick and Speedpots are

offered as standard. Optional features for

integrated Sensor THC are available.

Note: Use of some devices such as USB

memory devices may require loading of a

device driver for operation. Many standard

device drivers are located in the C:\CABS or

D:\CABS\I386 folders.

Edge Ti™

Rear View

23

Page 30

Edge Ti

Operation and maintenance of automated equipment involves potential hazards.

Personnel should take precautions to avoid injury. This equipment should only be

opened by trained service personnel.

Machine Interface

The information provided here is the basic information for connection of the

shape cutting control to the cutting table. Each machine interface will vary slightly

based on the cutting table configuration and features. Additionally, I/O pinout

information may vary slightly based on the configuration of the selected I/O and

their locations. Changes to the I/O configuration may be made in the password

protected I/O screen. All controls are shipped with a default selection of Inputs

and interface locations for the selected control Interface (I/O) configuration.

Installation and service should only be performed by a qualified service

technician.

The rear panel of the control has several cable connectors to connect the control

to power, I/O and communication ports. These connectors are clearly labeled as

to their function.

AC Input

The AC power cable is inserted into the AC power connector and plugged into a

standard 3-way 115 or 230 volt outlet. The AC Power connector contains an

integral fuse module and line filter. AC input power can be selected by the user

by changing position of the fuse module so that the selected voltage is displayed.

WARNING! Ensure proper orientation of fuse module for input power

before applying power to the CNC. Component damage could occur with

incorrect voltage setting.

24

Page 31

Edge Ti

Recommended AC Fuses

Different fuse ratings are recommended based on incoming voltage selected.

Voltage Input: 120Vac uses 8 amp (slow blow) Littlefuse part #313008

Voltage Input: 220Vac uses 5 amp (slow blow) Littlefuse part #313005

Size: ¼” x 1¼” or 5mm x 20MM fuse can be used

Serial Port

Please refer to the Ports Information section of the Installation Guide for

additional information on configuration of Serial ports for communication.

A remote communications link can be connected to one of the two serial ports

and an external ground (PE) lug for earth grounding of the unit is also provided.

I/O Configuration

The Edge – Ti provides several options for I/O interfacing with built in circuitry

providing interface flexibility and reducing the need for external components.

Inputs are through optoisolators and outputs are through relays. Contacts for

both normally closed and normally open outputs are available for use.

25

Page 32

Edge Ti

Input Mode

Note that the inputs have two different modes that are selectable using DIP

switch SW1-3. When this switch is OFF the inputs are in the sourced input mode

and an external voltage source of between 12V and 24V is required to activate

each input.

When DIP switch SW1-3 is ON, the inputs are all in the dry contact mode and

require an external switch to common to activate the inputs. The logic states

sensed by the CNC are reversed between the two input modes.

In a sourced input circuit, an inactive input will produce a logic low and an active

input will produce logic high. In dry contact mode these logic levels are reversed

with an inactive input producing logic high and an active input producing a logic

low.

Switch SW1-3

I/O Interface

The following illustration shows the details of connecting the I/O to common

circuitry. All outputs are relay contacts rated at 1 AMP 250VAC maximum

Example Inputs

External Circuitry

Dry Contact Inputs

Note: Logic Level Reversal

SWITCH

Normal Sourced Inputs

Use External +12V Supply

OPTO ISOLATOR

Normal Sourced Inputs

Use External +24V Supply

+

24V

GND_External

+

RELAY

12V

GND_Extern al

Edge-Ti Internal Circuitry

Inputs

Dry Contact Inputs

DIP Sw 1-C Closed

3900

GND

Normal Sourced Inputs

DIP Sw 1-C Open

3900

GND

Normal Sourced Inputs

DIP Sw 1-C Open

3900

GND

+24V Field

3900

Open

3900

Open

3900

Outputs

COM

NC

NO

RELAY SPD T

COM

NC

NO

RELAY SPD T

COM

NC

NO

RELAY SPD T

Example Outputs

External Circuitry

Use External +12V Supply

& normally Closed Contact

RESISTOR

Use External +5V Supply

& normally Open Contact

RESISTOR

Use External 120 Vac

& normally open contact

RELAY

LED

GND_External

OPTO ISOLATOR

+

GND_External

GND_External

120 Vac

12V

+

5V

26

Page 33

Edge Ti

WARNING! Do not exceed 24Vdc or 10mA into any optoisolator input. Use

care to observe the correct signal polarities or damage may occur! Do not

exceed 250 Vac or 1 Amp through any relay output.

I/O Pinout

Three inputs and three outputs are provided per connector

Connector I/O 1-3 Connector I/O 4-6

Pin# Signal Pin# Signal

1 OUT1 Common 1 OUT4 Common

2 OUT1 Normally Closed 2 OUT4 Normally Closed

3 OUT1 Normally Open 3 OUT4 Normally Open

4 OUT2 Common 4 OUT5 Common

5 OUT2 Normally Closed 5 OUT5 Normally Closed

6 OUT2 Normally Open 6 OUT5 Normally Open

7 OUT3 Common 7 OUT6 Common

8 OUT3 Normally Closed 8 OUT6 Normally Closed

9 OUT3 Normally Open 9 OUT6 Normally Open

10 IN1 10 IN4

11 IN1 Common 11 IN4 Common

12 IN2 12 IN5

13 IN2 Common 13 IN5 Common

14 IN3 14 IN6

15 IN3 Common 15 IN6 Common

16 Cable Shield 16 Cable Shield

Connector I/O 7-9 Connector I/O 10-12

Pin# Signal Pin# Signal

1 OUT7 Common 1 OUT10 Common

2 OUT7 Normally Closed 2 OUT10 Normally Closed

3 OUT7 Normally Open 3 OUT10 Normally Open

4 OUT8 Common 4 OUT11 Common

5 OUT8 Normally Closed 5 OUT11 Normally Closed

6 OUT8 Normally Open 6 OUT11 Normally Open

7 OUT9 Common 7 OUT12 Common

8 OUT9 Normally Closed 8 OUT12 Normally Closed

9 OUT9 Normally Open 9 OUT12 Normally Open

10 IN7 10 IN10

11 IN7 Common 11 IN10 Common

12 IN8 12 IN11 (shared w/ lifter Lower

limit input)

13 IN8 Common 13 IN11 Common

14 IN9 14 IN12 (shared w/ lifter Upper

limit input)

15 IN9 Common 15 IN12 Common

16 Cable Shield 16 Cable Shield

27

Page 34

Edge Ti

Shared Inputs

Note that general inputs #11 and #12 are shared with the Lifter Interface Limit

Switch inputs. These inputs can only be used as general purpose inputs if they

are NOT used by the Lifter limit switches.

If you are using the Lifter Interface and limit switches are connected to these

inputs you must set DIP switches SW1-1 and SW1-2 to ON and you should not

connect to inputs #11 and #12. Note that the standard Hypertherm Lifter does not

use limit switches and the DIP switches SW1-1 & SW1-2 should be OFF so that

inputs #11 and #12 can be used.

Switch SW1-1 and SW1-2

I/O Mating Connector

The I/O connector is a standard sex circular CPC connector from AMP

Connector AMP 16C #206037-1

Backshell AMP #206070-1

Sockets 20-24AWG AMP #66105-3

I/O Setup Screen

The I/O setup screen is used to define inputs, outputs and their logic state.

28

Page 35

Edge Ti

Note: The input logic for the first twelve I/O would need to be inverted for Dry

Contact Mode Inputs so that logic state is shown correctly for operational mode.

An Inputs Inverted parameter has been provided for this purpose.

Front Panel I/O

Edge TI has dedicated I/O for operation of front panel switches. NOTE: For

proper operation, these inputs should not be reassigned.

Input # Description

24 Front Panel Start

25 Front Panel Stop

26 Front Panel Forward on Path

27 Front Panel Forward on Path

28 Raise Torch 1

29 Lower Torch 1

30 Front Panel Manual

31 Front Panel E-Stop

Lifter Interface

Edge Ti offers the option of an integrated Torch Height Control. The lifter

interface connector is provided for this use. Lower Limit, Upper Limit and

Breakaway inputs are sinking inputs to Field Common. Please refer to Sensor™

PHC manual for additional information.

Lifter Pinout (9 Pin Dsub)

Pin# Description

1 Field +12VDC

2 Lower Limit (shared w/ general input 11)

3 Upper Limit (shared w/ general input 12)

4 Breakaway (Torch Collision)

5 Field Common

6 Field Common

7 Plate Contact -12Vdc

8 Plate Contact Sense

9 Plate Contact Common

Shared Inputs

Note that general inputs #11 and #12 are shared with the Lifter Interface Limit

Switch inputs. These inputs can only be used as general purpose inputs if they

are NOT used by the Lifter limit switches.

If you are using the Lifter Interface and limit switches are connected to these

inputs you must, close DIP switches SW1-1 and SW1-2 and you should not

connect to inputs #11 and #12. Note that the standard Hypertherm Lifter does not

29

Page 36

Edge Ti

use limit switches and that the DIP switches SW1-1 & SW1-2 should be left open

so that inputs #11 and #12 can be used.

Switch SW1-1 and SW1-2

Mating Connector

Use Hypertherm cable CABL-0207 or recommended 9 Pin Dsub (or equivalent)

Connector AMP #205204-3

Backshell Northern Technology #C88000209

Pins AMP #1-66506-0

Cabling: Use Belden # 9540 or equivalent

Plasma Interface

A plasma interface is provided as standard for Edge TI. This feature is used in

conjunction with a Plasma Interface Module to provide connections at the Plasma

Supply. Inputs and outputs are dry contact mode. Arc voltage is assigned to

Analog Input 5. Please refer to Sensor™ PHC manual for additional information.

Plasma Interface Pinout (15 Pin Dsub)

Pin# Description

1 Field +12VDC

9 Field +12VDC

2 Plasma Start Output (Cut Control)

10 Plasma Start Output (Cut Control)

3 Hold Ignition Output +

11 Hold Ignition Output 4 Transfer Input + (Cut Sense)

12 Transfer Input - (Cut Sense)

5 Field Common

6 Field Common

7 Field Common

13 Field Common

14 Field Common

15 Electrode Arc Voltage (–)

8 Work Arc Voltage (+)

30

Page 37

Edge Ti

Mating Connector

Use Hypertherm cable CABL-0208 or recommended 15 Pin Dsub (or equivalent).

Connector AMP #205206-1

Backshell Northern Technology #C88000207

Pins AMP #1-66506-0

Cabling: Use Belden # 9541

External Interlock

An external interlock is provided to remotely disable servo power.

Interlock Pinout

Pin# Description

1 Interlock Relay Coil (24VDC)

2 GND

3 GND

4 +24VDC (50 milliamps maximum)

Additional Notes:

1. For Servo Drive Amplifiers to operate, Pin 1 must be connected to GND

Pin 2, typically through a remote mushroom type switch. If no remote

switch is to be used, connect pin 1 to pin 2 with a jumper or the servo

drives will not power on.

2. 24VDC is provided for use to activate the digital inputs only in the case

where sourced inputs are selected, it must not be used for any other

auxiliary purpose.

Mating Connector

Connector AMP #206060-1

Backshell AMP #206062-3

Sockets 20-24AWG AMP #66105-3

Motor Encoder Connections

Edge Ti supports DC brush and brushless motors. Switch SW1 on the drive

interface can be used to select motor type being used. Please note the location

and setting in the following illustration.

Drive Type selection on Axes Setup screen must be set to CURRENT mode.

31

Page 38

Edge Ti

Motor Requirements

250 Watts (each amplifier, 1,000 watts total)

70 VDC Bus

4 Amps Continuous, 6 Amps Peak (for 2 seconds)

+5VDC differential encoders

Brushless motors also require Hall Effect sensors phased at 120 degrees

Axes Assignments

Axes Axes Assignment

1 (X) Transverse or Rail

2 (Y) Transverse or Rail

3 (Z) Dual Gantry, CBH, or THC

4 (W) CBH, or THC

32

Page 39

Edge Ti

Motor Power Pinout

Pin# Description

1 Brushless Motor-A or Brush +

2 Brushless Motor-B or Brush 3 Brushless Motor-C

4 Brake + (24VDC, 250ma max)

5 Brake 6 Cable Shield

7 No Connect

Additional Notes:

1. Brake output is limited to 250ma total. This output is only used on the THC

vertical axis.

Drive Motor Mating Connector

Connector AMP #211399-1

Backshell AMP #206966-1

Sockets 16-18AWG AMP #66101-3

Cabling: Use Belden # 9552 or equivalent for brushed motor signals

Cabling: Use Belden # 9553 or equivalent for brushless motor signals

Encoder Pinout:

1 Encoder +5V

2 Encoder GND

3 Encoder Channel A

4 Encoder Channel A/

5 Encoder Channel B

6 Encoder Channel B/

7 Encoder Channel Z

8 Encoder Channel Z/

9 +V Hall Out (6V @ 30MA max)

10 Hall GND

11 Hall - A

12 Hall - B

13 Hall - C

14 Cable Shield

33

Page 40

Edge Ti

Additional Notes:

1. Only 5 Volt encoders are supported.

2. Hall Sensors are used with Brushless motors only.

3. Inside the Edge Ti, dipswitches are used to select Brush or Brushless

mode, 2 switches per axis. Can mix Brushed and Brushless if switches are

set properly.

4. For optimum noise immunity, cable shields may be tied externally to the

control enclosure.

Encoder Mating Connector

Connector AMP #206044-1

Backshell AMP #206070-1

Pins (20-14AWG) AMP #66103-3

Cabling: Use Belden # 9504 or equivalent for brushed motor signals

Cabling: Use Belden # 9507 or equivalent for brushless motor signals

Reminder: Drive Type selection on Axes Setup screen must be set to

CURRENT mode.

34

Page 41

Optional Motor Information

Edge Ti

35

Page 42

Edge Ti

Optional Lifter Assembly Information

Plasma Interface

Start Output

(contact

closure)

+12V

Output

Hold Output +

Hold Output -

Common for

12V Output

Signals

Enter Here

High

Voltage

Enter Here

-Transfer Input

+Transfer Input

Work

Connection

(positive

ground)

Connect

Negative

Electrode

Voltage Here

36

Page 43

Edge Ti

Plasma Interface Assembly Mounting

Mount the plasma interface assembly close to the plasma power supply for easy

connection of arc voltage and signal wires between the units. The unit can be

mounted in any position and can be mounted directly to the back or inside of the

power supply. The mounting holes are sized for #6 or M3 fasteners. See Below

NOTE: For reliable operation the ground terminal must be connected to the

plasma power supply positive ground. This connection provides the grounded

positive arc voltage sense point.

WARNING!

Connect to WORK

(positive) ground.

37

Page 44

Edge Ti

Optional Lifter Assembly

All Cable

Connections exit top

Torch Magnetic

Breakaway

All Lifter components,

including Motor and

Brake, are fully enclosed

Lifter Assembly Mounting

Mount the lifter assembly on the cutting table. The lifter should be mounted to

take the maximum advantage of the vertical travel range. Typically the bottom of

the lifter should be between 6 and 8 inches above the cutting table. If required

the torch breakaway gap set-screw can be adjusted to change the clamping

force. For normal operation this adjustment is preset at the factory.

NOTE: For reliable operation the ground must be connected.

38

Page 45

Edge Ti

WARNING!

Connect Ground

Here

39

Page 46

Edge Ti

Torch Breakaway Assembly

The torch breakaway (MECO-0234) should be mounted to the lifter as shown in

figure below.

CAUTION: The breakaway uses extremely strong magnets to clamp the

two halves of the breakaway unit together. Extra care should be used when

mating the two halves of the breakaway.

Hold the breakaway at a 45 degree angle to the mounting plate and carefully

place the lower alignment pin into the mating depression on the breakaway back

plate. Slowly angle the breakaway toward the back plate, being careful not to get

your fingers pinched between the two halves. Once installed, it will be nearly

impossible to separate the two halves without the leverage provided by the

mounting block and torch.

40

WARNING!

Pinch Point: Use

Caution when

mating two halves

of Torch

Breakaway

Assembly.

Page 47

Edge Ti

Torch Mounting Block Kit

Mount the torch mounting block kit to the lifter torch breakaway assembly. See

below.

The mounting blocks are available in three sizes as listed.

• PN = MECO-0108 Torch Mounting Block 1 3/4” diameter

• PN = MECO-0109 Torch Mounting Block 2” diameter

• PN = MECO-0130 Torch Mounting Block 1 3/8” diameter

Breakaway

Mounting Plate

Torch Breakaway

Torch Mounting

Clamp

41

Page 48

Edge Ti

Grounding Requirements

WARNING! To ensure personal safety, proper operation and to reduce

electromagnetic interference (EMI), the PHC system must be properly grounded.

Power cord grounding

The PHC control module must be properly grounded through the power cord

according to national or local electrical codes.

Protective earth ground

Install protective earth (PE) grounding cables to the PHC components as shown

below. Grounding must comply with national or local electrical requirements.

Note: The PE (Ground) cables must be supplied by the customer.

Ground Lifter

Assembly

WORK

Connection

42

Page 49

Voyager III

Overview

The Voyager III™ PC based CNC

control for the metal cutting industry

utilizes our proprietary Graphical User

Interface (GUI) and SoftMotion

Technology. Voyager III provides the

user with increased performance and

greater operational flexibility utilizing a

15” touch screen display, 2.4Ghz Intel

processor, proprietary operational

software and a unique SERCOS/Analog

machine interface. Common

applications for Voyager class controls

include: bevel head systems, multiple

Sensor Torch Height Controls and other

advanced systems requiring more than

four axes for machine interfacing.

Touch Screen

The 15” display used in the Voyager III

is a patented IntelliTouch Surface Wave

technology which provides precise drift

free touch accuracy and unsurpassed

clarity. Pure glass construction with tiny

transducers on the back of the touch

screen preserves color purity and works

even if scratched. There is no known

wear out mechanism as there are no

layers, coatings or moving parts.

IntelliTouch technology has been tested

by the supplier for more than 50 million

touches in one location without failure.

THC, Joystick & Speedpots

Optional features for Sensor THC,

Joystick and Speedpots are offered.

Note: Use of some devices such as

USB memory devices may require

loading of a device driver for operation.

Voyager III™

Rear View

43

Page 50

Voyager III

Voyager III incorporates a unique machine interface designed by Hypertherm

Automation to convert SERCOS (Serial Real Time Communication) to a

traditional analog interface. For those not familiar with SERCOS, it is a fiber

optic communication ring for commanding motion and controlling I/O that is

available from many drive suppliers.

This new interface approach allows Voyager III to offer three styles of machine

interface, increasing system flexibility for wiring and features.

Interface options:

1) The standard configuration of Voyager III uses SERCOS internally but

provides a traditional and familiar analog machine interface on the back of the

CNC.

2) Standard SERCOS interface with a fiber optic cable connected to SERCOS

amplifiers and I/O.

3) The new SERCOS to Analog conversion card (part # ASSY-0191) is mounted

externally using fiber optic communications to the card. The card then

provides a traditional analog interface output to motion amplifiers and I/O.

Each interface card offers two axes of motion, thirty-two (16/16) 24VDC positive

logic inputs and outputs, plus two analog inputs for Speedpot and Sensor THCs.

The information contained in this section is intended to provide the basic

information for connection of the Voyager III™ Shape Cutting Control to the

cutting table. Each machine interface will vary slightly based on the cutting table

configuration and features. Additionally, I/O pinout information may vary slightly

based on the configuration of the selected I/O and their locations. Changes to

the I/O configuration may be made in the password protected I/O screen. All

controls are shipped with the default selection of Inputs and interface locations

for the selected control Interface (I/O) configuration. Installation and service

should only be performed by a qualified service technician. For more information

regarding the I/O process definitions, please refer to the Setups section of this

guide.

44

Page 51

Setups

Voyager III

Drive Type

The manufacturer of the SERCOS style drive being used would be selected.

This allows proper operation and tuning parameters to be available. SMCC is

the default setting for Voyager III.

Update Rate

The update rate for the ring may be selected for motion and I/O. One millisecond

is the default setting for Voyager III.

Baud Rate

Communication rate for the ring may be selected. 16 Mbaud is the default

setting for Voyager III.

Light Level

The user has the ability to adjust the intensity of the light pulses used on the fiber

optic ring. This feature is used to compensate for diminished signal due to

issues such as ring distance. Low is the default setting for Voyager III

45

Page 52

Voyager III

Drive I/O

The user may select to use I/O options directly supported on the Drive Amplifier.

Options are None, Overtravel and Home Switches only or All I/O. Note: The

Drive I/O will populate the general purpose I/O (both analog and digital) in order

from the lowest SERCOS drive axis to the highest SERCOS drive axis. All I/O is

the default setting for SMCC / Voyager III interface.

RECO I/O at Address 50

This parameter is set to Yes if the Indramat RECO I/O module is being used to

expand the total number of I/O being used on the standard fiber optic ring. Note:

The RECO I/O will populate the general purpose I/O (both analog and digital)

following all drive I/O. The default setting for Voyager III is NO.

HTA I/O at Address 70

This parameter is set to Yes if one of the SERCOS to Analog cards is set to be

used for I/O expansion.

Common Status Messages

Starting Up Drives on SERCOS Ring. Phase 1 -4

This is a status message to indicate the SERCOS ring power up and will

advance through phases 1-4. Failure to reach phase 4 indicates a problem with

power up. Cycle power to initiate SERCOS phase up again. If the system

repeatedly fails to enable the SERCOS ring, contact your vendor for assistance.

SERCOS Ring not Running. Restart Ring?

This status message indicates the SERCOS ring is currently not running. You

may see this when a command such as a motion command is requested but the

RING was not enabled. Restart of the ring is recommended.

Updating SMCC software.....

After a control software update, the SERCOS to Analog card software may also

be updated at restart of SERCOS ring. It is important not to interrupt this update

sequence.

SERCOS Ring Not Running. Please Check Power, Status of LEDs on

Drives and I/O Modules, Fiber Optic Ring Connections and SERCOS Baud

Rate.

This status message indicates the SERCOS ring is not running after power up. It

is recommended to check hardware and parameters then restart the ring by

power cycle.

46

Page 53

Voyager III

New Setups May Require Restarting SERCOS Ring to Take Effect. Restart

SERCOS Ring?

When changes are made to system configuration that affect the SERCOS ring

operation, you may be prompted to restart the ring. Restart of the ring is

recommended.

SERCOS Drives Not Enabled and Ready. Please Check Drive are Enabled

and Ready with No Errors.

This status message indicates the SERCOS ring is not running due to a missing

enable signal. First check that the Control Enable Disabled softkey is correct.

The softkey should read DISABLE CONTROL. Then check status of ring

hardware or external drives to ensure there are no errors displayed.

Machine Interface

I/O Configuration Type “V” ( Positive Logic Single Ended I/O )

Connecting single ended I/O to the control. The control provides +24V power on

pins 22, 23 & 24 (+24 VDC) and pins 9, 10, 11 &12 (24 VDC Common) on the I/O

connector.

Output tied to external Cut On Input tied to Cut Sense Relay

47

Page 54

Voyager III

Examples of possible circuits

Output

24 VDC

Com

Input

Single Ended I/O Pinout

The Single Ended I/O offers up to 48 outputs which are rated at 24VDC for up to

1-amp loads and 32 inputs rated for 24VDC as standard

I/O Connector

Pin Description

1 Output 1

2 Output 2

3 Output 3

4 Output 4

5 Output 5

6 Output 6

7 Output 7

8 Output 8

9 +24 VDC Common

10 +24 VDC Common

48

Page 55

Voyager III

11 +24 VDC Common

12 +24 VDC Common

13 Watchdog Contact

14 Input 1

15 Input 2

16 Input 3