Page 1

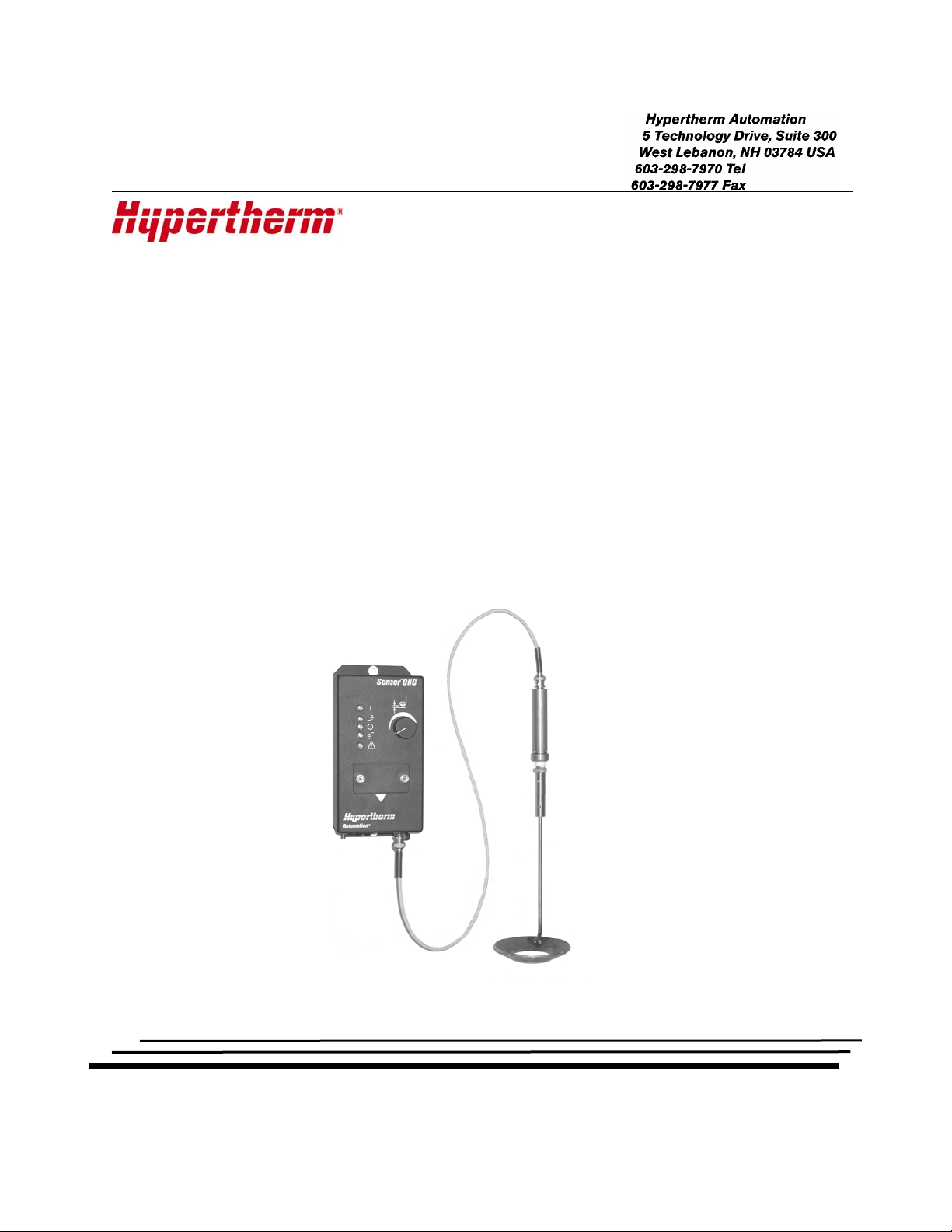

HYPERTHERM SENSOR™ OHC

A

UTOMATED OXY HEIGHT CONTROL

PERATION & SET UP GUIDE

O

Making people and machines more productive through process Automation

Page 2

D

ISCLAIMER The information in this document is subject to change without notice and should not

be construed as a commitment by Hypertherm Automation

Automation

®

assumes no responsibility for any errors that may appear.

T

RADEMARKS Hypertherm Automation is a wholly owned subsidiary of Hypertherm

®

. Hypertherm

®

, Inc.

Sensor™ is a trademark of Hypertherm Automation.

AR-300/100W Levilator Clearance Control is a trademark of CMC Burny.

C

OPYRIGHT ©2004 by Hypertherm Automation. All rights Reserved

Printed in USA

Page 3

Table of Contents

SAFETY ................................................................................................................................................ 1

Read This Manual ............................................................................................................................. 1

Dangerous Machinery ....................................................................................................................... 1

High Voltages.....................................................................................................................................1

SECTION 1: OVERVIEW .................................................................................................................. 3

Introduction ....................................................................................................................................... 3

Description and Features.................................................................................................................. 4

Hardware Specifications................................................................................................................5

Control Unit Front ............................................................................................................................6

Control Unit Bottom.......................................................................................................................... 7

Sensor and Mounting Isolator .......................................................................................................... 8

SECTION 2: OPERATION ................................................................................................................ 9

Operation Modes................................................................................................................................ 9

Automatic Operation .....................................................................................................................9

Manual Operation.......................................................................................................................... 9

Errors.............................................................................................................................................. 9

Error Conditions..............................................................................................................................10

SECTION 3: INSTALLATION AND SET UP ..............................................................................11

Installation....................................................................................................................................... 11

Sensor Mounting .......................................................................................................................... 11

Sensor Position to Torch..............................................................................................................11

Connectors....................................................................................................................................12

Power Connections....................................................................................................................... 12

Limit Switch.................................................................................................................................13

Digital I/O..................................................................................................................................... 13

Optional External Height Set Pot............................................................................................... 13

Optional External Second Height Set Pot.................................................................................. 13

Standard Wiring Installation...................................................................................................... 15

IO Interfacing ..................................................................................................................................16

IO Interfacing Examples ............................................................................................................. 16

DIP Switch Setup ............................................................................................................................17

Calibration Procedure .....................................................................................................................18

Component List ...............................................................................................................................19

Optional Sensor Cables ...............................................................................................................19

Page 4

Page 5

Safety 1

Safety

Read This Manual

Read and understand this instructional manual, the cutting machine manuals, and your

employer’s safety practices. Note: This product is not designed to be field serviceable. Please

return to an authorized repair center for any required service.

Dangerous Machinery

Operation and maintenance of automated equipment involves potential hazards. Personnel

should take precautions to avoid injury.

Injury and entanglement may occur if hands and limbs come in contact with moving machinery.

KEEP HANDS CLEAR of dangerous moving machinery. All control, including manual, can be

affected using the remote interface.

Loose fitting clothing or ties may become entangled in the machinery. These items should not be

worn while operating or servicing the machine.

High Voltages

Electric shock can kill. Be sure this equipment is safely installed in accordance with the enclosed

procedures and specifications.

Avoid contact with electrical wires and cabling while power is on.

This equipment should only be opened by trained service personnel.

Please refer to the appropriate appendix in the Installation Guide provided with your control for

details on safety certification for that product.

Page 6

2 Sensor OHC Operation and Set Up Guide

Page 7

Section 1: Overview 3

Section 1: Overview

Introduction

One of the most important parameters in Oxy Torch cutting is consistent torch tip to plate standoff

distance. The Hypertherm Sensor OHC uses a capacitive sensor to measure the torch to plate

distance. The unit will drive a DC motor on the torch lifter to automatically maintain a user

selected torch to plate distance. This automatic closed loop control of the torch height will

dramatically improve the cutting speed, quality and consistency.

The Sensor OHC includes the control unit, the capacitive sensor, sensor mounting isolator,

sensor spring style breakaway, and standard 1 meter coax cable. A connector kit is available for

the standard mating connectors. For demonstration purposes, a connector conversion kit is

available that will make the unit plug compatible with the Burny AR 300/100 “Levitator Clearance

Controller”.

It is the installer’s responsibility to provide a compatible lifter mechanism. A compatible lifter will

utilize a 24Vdc motor between 2 Amps, 50 Watts and 6 Amps 150 Watts. The full speed

operation must be geared to produce a linear full speed of between 20 in/ min (500 mm/min) and

140 in/min (3500 mm/min). The tradeoff being between a low speed extremely high accuracy lifter

and a high speed lower accuracy lifter. The lifter should have adequate rigidity and very little

backlash and moving inertia. The lifter should also have normally closed upper and lower limit

switches mounted at the extremes of travel.

The installer must also provide an appropriate mounting clamp that will attach the 20 mm

diameter sensor mounting isolator to the torch. The mounting clamp should be designed for a

center of torch to center of isolator distance of 2 inches or 50mm so that that the sensor ring will

be properly centered and positioned around the torch tip. Additionally, the mounting clamp

should provide a good electrical ground connection to the overall machine frame and to the metal

plate being sensed. Failure to provide an adequate ground connection to the plate will have a

negative effect on the height measurement and control accuracy.

Main Power Supply: 24Vac +/- 10%, 50, 60 Hz

Compatible Lifter Motors DC shunt, 24Vdc, 2 Amps to 6 Amps

Max Power Output 150 Watts

Page 8

4 Sensor OHC Operation and Set Up Guide

Description and Features

SENSOR™ OHC - Oxy Height Control is an advanced automated height control system for

oxy fuel shape cutting applications. This product utilizes advanced capacitive sensing and

microprocessor technology to automatically detect the plate and adjust torch position to a

desired set point during oxy fuel cutting operations. This reduces operator input, improves

accuracy and increases productivity.

Features

¾ Sensor OHC can be used with any CNC

¾ Easy setup & operation

¾ Both manual & automatic operation modes

¾ Microprocessor control for increased sensitivity and control

¾ High positioning speeds possible with up to 6 amps continuous current and linear

adjustment over full range

¾ Built-in diagnostic and fault detection features

¾ Auto retract on plate contact

¾ Optional second height set point input for preheat or pierce

¾ Indicator lights for operation including:

⇒ Power On

⇒ Upper Limit Switch

⇒ Lower Limit Switch

Options

¾ Five Cable Lengths from 19.7” (500mm) to 59” (1500mm)

¾ Adapter cables allowing direct replacement for existing AR-300/100W Levilator Clearance

Controls

⇒ In Position Indicator

⇒ Attention / Error indicator

System Features*

Compatible Motors DC shunt 24VDC, 2 Amps to 6 Amps ( customer supplied )

Max Power Output 150W

Control Range Linear 0.1” (2.5mm ) to 1.0” (25mm)

Motor Output Full “H” bridge PWM with current sensing

Accuracy .01” (.25mm )**

Operator controls Easy to use control set point knob and easy read indicators

Calibration Easy access calibration pot on front Panel

Measuring Technology Capacitive Ring with Coax Cable

Dimensions 8.50” (216mm ) W x 4.21” (107mm) D x 4.02” (102mm) H

Inputs/ Outputs 3 outputs and 6 inputs optically isolated on “D” connectors

Weight 2.4 lbs

Operating Environment 0 to 50C; 95% relative humidity (non-condensing)

Power 24VAC +/- 10% 50/60 Hz

*Information subject to change without notice.

** Dependent on customer supplied lifter mechanics

Page 9

Section 1: Overview 5

Hardware Specifications

Main Power Supply: 24 Vdc +/- 10%, 50/60 Hz

Compatible Lifter Motors: DC shunt motor 24Vdc, 2 Amps to 6 Amps

Operating Temperature: 0 to +50 deg C

Control Range: Linear 0.1 inch to 1.0 inch (2.5 to 25 mm)

(standard sensor & cable)

Height Measuring Technology: Capacitive Ring with Coax Cable

Accuracy: 0.01 inch (0.25 mm) w/ representative Lifter

(dependent on lifter mechanics)

HF Coax Cable: 500 mm to 1500 mm (1000 mm standard)

Standard Sensor: Stainless Steel Ring 100 mm outer & 50 mm inner

diameters. Can be calibrated for others

Dimensions:

Control Type: Digital Micro Processor based

Motor Output: Full “H” Bridge PWM with current sensing

Control Interface: Optically Isolated I/O on “D” connectors

Outputs: Digital In-Position Output

Digital Error Output

Digital Plate Contact Output

Inputs: Digital Manual/Auto Select

Digital Manual Up

Digital Manual Down

Digital Upper Limit Switch

Digital Lower Limit Switch

Digital Second Height Select

Remote Height Set-point Pot

Second Height Set-point Pot

Front Panel Indicators green Power

yellow Upper Limit Switch

green In Position

yellow Lower Limit Switch

red Attention/Error Code

8.50” (216mm) W x 4.21” (107mm) D x 4.02” (102mm) H

Page 10

6 Sensor OHC Operation and Set Up Guide

g

Control Unit Front

Power Indicator

Upper Limit Indicator

In Position Indicator

Lower Limit Indicator

Error Code Indicator

ht Set Point Adjust

Hei

Set Up & Calibration

Access Panel

Page 11

Section 1: Overview 7

Control Unit Bottom

Capacitive Sensor

Ground

Limit Switches

Power & Motor

Control Interface

6 Amp Fuse

Page 12

8 Sensor OHC Operation and Set Up Guide

Sensor and Mounting Isolator

Mounting Isolator

Spring Breakaway

Capacitive Sensor Ring

Page 13

Section 2: Operation 9

Section 2: Operation

Operation Modes

The two basic modes of operation are “Automatic” and “Manual”.

Note: The control unit must be calibrated prior to use. See calibration instructions in this guide.

Automatic Operation

“Automatic” mode is active whenever the “Manual” input on pin-3 of the 15 pin I/O connector is

open. During “Automatic” operation, the height of the torch is constantly maintained at the set

height. When the unit is operating, the green “In-Position” front panel light and corresponding I/O

output will indicate that the unit is maintaining the set height. At any time during “Automatic”

operation the set height can be changed and the unit will quickly respond and position to the new

desired height. The ‘Up/Down” switch can be used at any time to temporarily override automatic

operation and force the lifter to move in the desired direction. As soon as the Up/Down switch is

released, the unit will return to automatic operation. Activation of either limit switch will prohibit

further motion in that direction.

Manual Operation

“Manual” mode is activated by connecting the input on pin-3 of the 15 pin I/O connector to the

signal Ground on pin-2. In manual mode, the unit is controlled by using the Up/Down switch only.

The control will not respond to the “Set Height” and will stay fixed in the position that it was last

driven to using the Up/Down switch. The Up/Down switch has two speeds depending on how long

it is held active. During the first second, the control will move at low speed to allow the operator to

finely position the torch. The low speed can be maintained by pulsing the Up/Down switch. If the

Up/Down switch is maintained for more than one second, then the control will shift to full speed to

drive the lifter in the desired direction. Activation of either limit switch will prohibit further motion in

that direction.

Errors

During “Automatic” operation mode, if the sensor should come too close to the plate (less than

1/10 inch or 2.5 mm), the unit will automatically force a retract in an attempt to avoid a crash. This

error condition and others listed in the following figure will be indicated by a code number that

flashes on the red “Error” front panel light. Any error will also cause the “Error” output on the I/O

connector to become active until the error is corrected.

Page 14

10 Sensor OHC Operation and Set Up Guide

Error Conditions

Red Error LED

Error Indications

The red ERROR LED indicates abnormal conditions by flashing an error code. The error code

meanings are listed below.

1 Flash - Sensor Shorted Error

Indicates that the sensor is in contact with the plate. In Auto Height mode, this will cause a rapid

retract until the sensor no longer is in contact with the plate. This may also indicate that recalibration is required

2 Flashes - Sensor Open Error

Indicates that the sensor is not plugged in or the sensor cable has opened. In Auto Height

mode, this error will disable all motion. This may also indicate that re-calibration is required

3 Flashes - Input Voltage Low

Indicates that the 24Vac power source has dropped more than 25% below nominal. Check the

power source and all connections.

4 Flashes - Input Voltage High

Indicates that the 24Vac power source is more than 20% high and may cause damage to the

unit.

5 Flashes - Motor Drive Over Temp Warning

Suspend operation and allow unit to cool down.

6 Flashes - Invalid data in the selected cable length data table.

Set DIP switches 1 thru 3 to a valid cable length setting.

Page 15

Section 3: Installation and Set Up 11

Section 3: Installation and Set Up

Installation

Sensor Mounting

The sensor connection is thru the coax cable to the sensor mounting isolator. It is the

responsibility of the installer to provide a mounting clamp that will correctly position the sensor

ring with respect to the torch tip. The mounting clamp should be designed for a center of torch to

center of isolator distance of 2 inches or 50mm so that that the sensor ring will be properly

centered and positioned around the torch tip. Additionally, the mounting clamp should provide a

good ground electrical connection between the sensor mounting isolator and the machine frame.

Sensor Position to Torch

Page 16

12 Sensor OHC Operation and Set Up Guide

Connectors

Wire the unit as shown with reference to the following figures. A standard mating connector kit is

available which provides the mating 9 pin & 15 pin “D” type connectors and the 7 pin circular

power connector (CONN-0141). Also available for drop-in demonstration purposes is a connector

conversion kit that will adapt the unit to AR300/100 style connectors (CABL-0163). It is

recommended that you use the AR300/100 conversion kit for demonstration purposes only. Use

of the plastic housings on the AR300/100 style connectors does not allow for proper cable

shielding. Improper cable shielding can result in severe electrical interference problems.

Control Interface

Limit Switches

Power & Motor

Power Connections

All power connections are made to the 7 pin circular connector. When connecting to the motor,

ensure that the motor polarity is such that if pin 2 is positive with respect to pin 5 the slide will

move in the UP direction. The 24 Vac power source is connected between pins 3 and 6. Pin 4 is

connected internally to the grounding stud on the enclosure and the ground stud should be

connected to the machine chassis.

24VAC Input / Motor Pinout

7 Pin Amp Connector

Pin Description

3 24VAC

6 24VAC Return

4 Ground

2 Motor

5 Motor

Page 17

Section 3: Installation and Set Up 13

Limit Switch

The lifter upper and lower limit switches are connected to the 9 pin “D” connector. These switches

are normally closed switches that open when the limit is reached. The upper limit switch connects

between pins 5 & 6 and the lower limit switch connects between pins 2 & 3. This connector also

provides limited +12 Vdc on pins 1 & 4 that can be used to power either optical or hall-effect limit

switches.

Limit Switch Pinout

9 Pin D-Sub

Pin Description

2 Lower Limit ( contact closure )

3 Lower Limit ( contact closure )

5 Upper Limit ( contact closure )

6 Upper Limit ( contact closure )

Digital I/O

The digital I/O interface on the 15 pin “D” connector should include a switch to select between

manual and automatic operation. This switch connects from the input on pin 3 to the signal return

on pin 2. When this switch is closed, the unit will operate in manual mode. The digital I/O

interface also needs a three position center off momentary Up/Down switch to operate in manual

mode or manual override in automatic mode. When the input on pin 4 is connected to the signal

return, the slide will be driven up; and when the input on pin 5 is connected to signal return, the

slide will be drive down. The “Second height Select” input on pin 6 is used to select a second

height set-point from an optional external pot. The optional status output signals “In-Position”,

“Error” and “plate Contact” are available on pins 7 , 8 7 9 respectively. The outputs are transistors

connected to signal return and are capable of switching up to 30V at 100 mA each. A source of

+12V dc is available on pin 1, for use in interfacing to the output signals. Care should be taken

that the total +12 Vdc current drawn from pin 1 plus the current drawn from pins 1 & 4 of the 9 pin

“D” connector, does not exceed 50 mA.

Optional External Height Set Pot

An optional 10K pot can be connected between pins 10 & 11 to allow external setting of the

automatic height set-point. This pot will work in conjunction with the unit’s front panel height

setting pot and both will affect the height set-point. The control unit front panel set pot and the

external set pot are electrically in parallel. This will cause some non-linearity in the height set

point. Usually the front panel control is used as the coarse adjustment and the external pot will

provide a fine tuning of the set point.

Optional External Second Height Set Pot

An optional 10K pot can be connected between pins 12, 13, & 14. This pot will provide an active

height set-point whenever the digital “Second Height Select” input is switched active by

connecting the input on pin 6 to the signal return on pin 2. Unlike the external pot for normal

height set point, this pot will completely override the control front panel height set point. This

external point will provide a linear adjustment of height vs. set point

Page 18

14 Sensor OHC Operation and Set Up Guide

This second external height set point could be useful to provide an independent pierce or preheat

height. By using the digital input “Second Height Select”, it is possible to rapidly switch between

normal height and second height while in motion. Another use for the second set height would be

to effectively disable the control unit front panel height set point pot. This would allow for central

control of cutting height and eliminate the possibility of accidental errors due to the unintentional

changing of the control front panel height set point pot.

I/O and Control Pot Pin out

15 Pin D-Sub

Pin Description

1 I/O Power 12VDC at 50Ma Max

2 I/O Ground

3 Manual Select Input

4 Up Input

5 Down Input

6 Second Height Select Input

7 In Position Output

8 Error Output

9 Plate Contact Output

10 Remote Height Adjust Pot

11 Remote Height Adjust Return

12 Second Height Pot High

13 Second Height Pot Wiper

14 Second Height Pot low

15 I/O Ground

Page 19

Section 3: Installation and Set Up 15

Standard Wiring Installation

+ UP

3

67

1

45

LOWER LIMIT SW

2

J1

24V AC

Normally

Closed

BNC

Power

7 pin circ conn

24V RET

Source

POWER

HEIGHT

UPPER

LIMIT

IN

POSITION

MAX

MIN

LOWER

LIMIT

ERROR

LIFTER

MOTOR

PIN2

PIN5

PIN4

7 PIN CIRC

PIN6

PIN3

PIN3

PIN2

PIN6

9 PIN D SUB

PIN5

CALIBRATION

PANEL

BNC

PIN15

PIN14

PIN13

PIN12

PIN11

PIN10

PIN9

PIN8

PIN7

15 PIN D SUB

PIN6

PIN5

PIN4

PIN3

PIN2

PIN1

+ DWN

UPPER LIMIT SW

Normally

Closed

COAX

CAPACITIVE SENSOR

PIN15

PIN5

PIN4

PIN1

V I/O+ = 12Vdc at 50mA MAX

PIN3

PIN2

MANUAL

I/O GND

Closed = Manual

PIN6

DOWN

UP

SECOND HEIGHT SELECT

SW SPDT - moment ary - center of f

PIN9

PIN7

IN POS OUTPUT

PIN10

PIN8

ERROR OUTPUT

PLATE CONTACT OUTPUT

REMOTE HEIGHT ADJ

PIN13

PIN11

REMOTE HEIGHT RET

PIN14

PIN12

I/O GND

SECOND HEIGHT POT - LOW

SECOND HEIGHT POT - HIGH

SECOND HEIGHT POT - WIPER

REMOTE INTERFACE using "D"

type connectors for

permanent installations.

Outputs are transistors to I/O

Gnd.

If using the internal V I/O +12V

supply do not exceed 50mA of total

current load.

If using an external supply with

the outputs do not exceed max

ratings of 30V and 100mA per

output.

Page 20

16 Sensor OHC Operation and Set Up Guide

IO Interfacing

The attached figure shows the details of connecting the IO to external switches, relays,

transistors, and other circuitry. The figure shows examples using the available isolated +12V

source and using an external voltage source.

IO Interfacing Examples

Sensor OHC

Example

Outputs

External

C59

ISOLATED +12V

Circuitry

0.1

DSUB 15 Female

DSUB 15 Male

Max total +12V current draw

+5V

5

6

12

Internal Output Details

IN POS OUTPUT

SPARE OUTPUT

ERROR OUTPUT

123456789101112131415

123456789

1011121314

LED

Isolated +12V

RESISTOR

50 mA

16

15

1

2

0.1

1K

475

11

0.01

LED using Internal

15

+12V

Internal Output Details

C59

0.1

123456789101112131415

DSUB 15 Female

123456789

DSUB 15 Male

RELAY SPST

RL1

2

1

3

4

16

15

1

2

0.1

1K

+5V

475

5

6

12

11

0.01

IN POS OUTPUT

SPARE OUTPUT

ERROR OUTPUT

1011121314

DIODE

+

External +24V

15

IO Gnd

ISOLATED +12V

16

16

Transistor using

External +24V

Max output voltage 30V

Max output sink current 100 mA

16

1

1K

Internal Output Details

C59

0.1

123456789101112131415

DSUB 15 Female

123456789

DSUB 15 Male

RESISTOR

15

2

0.1

+5V

475

5

6

12

11

0.01

IN POS OUTPUT

SPARE OUTPUT

ERROR OUTPUT

16

16

1011121314

15

RESISTOR

IO Gnd

2N2907

+

External +24V

1

2

LAMP

+5V

475

5

6

12

11

0.01

Internal Output Details

IN POS OUTPUT

C59

0.1

ISOLATED +12V

16

16

DSUB 15 Female

DSUB 15 Male

SPARE OUTPUT

ERROR OUTPUT

123456789101112131415

123456789

1011121314

LED

RESISTOR

+

LED using External

+5V

16

15

1

2

0.1

1K

ISOLATED +12V

16

16

15

IO Gnd

Relay using

External +24V

External +5V

Sensor OHC

Example

Inputs

External

ISOLATED +12V

MANUAL INPUT

Internal Input Details

C59

0.1

DOWN INPUT

UP INPUT

ISOLATED +12V

Circuitry

SPARE INPUT

123456789101112131415

DSUB 15 Female

123456789

DSUB 15 Male

IO Gnd

Switch

1011121314

External switc h Manual Input

ISOLATED +12V

MANUAL INPUT

Internal Input Details

C59

0.1

DOWN INPUT

SPARE INPUT

UP INPUT

ISOLATED +12V

16

16

15

123456789101112131415

DSUB 15 Female

123456789

DSUB 15 Male

IO Gnd

RL1

1011121314

431

2

Relay

ISOLATED +12V

MANUAL INPUT

Internal Input Details

C59

0.1

DOWN INPUT

UP INPUT

ISOLATED +12V

16

16

15

RELAY SPST

SPARE INPUT

123456789101112131415

DSUB 15 Female

123456789

DSUB 15 Male

RESISTOR

1011121314

NPN

RESISTOR

Transistor

+

ISOLATED +12V

MANUAL INPUT

Internal Input Details

C59

0.1

SPARE INPUT

UP INPUT

ISOLATED +12V

16

16

15

IO Gnd

DOWN INPUT

123456789101112131415

DSUB 15 Female

123456789

DSUB 15 Male

RESISTOR

Opto

Isolator

34

12

1011121314

OPTO ISOLATOR

16

16

15

IO Gnd

Page 21

Section 3: Installation and Set Up 17

DIP Switch Setup

DIP Switches

SW1 SW2 SW3 Sensor Cable Length

on on on cable length = 500 mm

off on on cable length = 800 mm

on off on cable length = 900 mm

off off on cable length = 1000 mm *

on on off cable length = 1200 mm

off on off cable length = 1500 mm

SW4

In Position 0utput in Manual Mode

off Normal - active output near height set point*

on Forced active - always active in Manual Mode

SW5

SW6 Sensitivity & Loop Gain

off off Sensitivity lowest - Lowest Gain Most Stable / use for high speed lifters ( > 3000 mm/min )*

on off Sensitivity medium low

off on Sensitivity medium high

on on Sensitivity highest - Highest Gain Least Stable / use for low speed lifters ( < 750 mm/min )

SW7

SW8 Max Motor Current

off off Current lowest = 2.0 Amp 50W

on off Current medium low = 3.0 Amps 75W

off on Current medium high = 4.0 Amps 100W

on on Current highest = 6.0 Amps 150W*

* Indicates setting as shipped.

NOTE: The RJ45 connector under the calibration panel is not a network connection. It is a proprietary

connector and is for the use of authorized service personnel only.

Page 22

18 Sensor OHC Operation and Set Up Guide

Calibration Procedure

Calibration LED

Height Set Point

Calibration Pot

Calibration Instructions

1) Install the torch and sensor ring with torch tip aligned with the bottom edge of the sensor. Ensure that

all DIP switches are correctly set for cable length, lifter speed, and sensitivity, and max motor current

(see DIP Switch Set Up).

2) Set the unit for Manual operation and then apply power to unit.

3) Position the sensor ring above the plate. Use the UP/DOWN switch to raise the sensor ring at least

100 mm or 4 inches above the plate.

4) Remove the Calibration Panel and adjust the CALIBRATION POT. When adjusting the calibration,

check that nothing abnormal is in the vicinity of the sensor ring. This includes the person who is

performing the calibration. The CALIBRATION LED should remain flashing even when the screwdriver

is removed from the CALIBRATION POT.

If the CALIBRATION LED is OFF, then rotate the pot clockwise (CW) until the LED is flashing.

If the CALIBRATION LED is ON, then rotate the pot counter clockwise (CCW) until the LED is flashing.

5) Check the Calibration - Set the Height Set Point to MAX and place the unit into the AUTO mode. The

sensor should be stable about 1 inch or 25mm above the plate. Adjust the Height Set Point to MIN.

The sensor should now be about 1/10 inch or 2.5 mm above the plate.

NOTE: The RJ45 connector under the calibration panel is not a network connection. It is a proprietary

connector and is for the use of authorized service personnel only.

Page 23

Section 3: Installation and Set Up 19

Component List

Optional Sensor Cables

Part Number

CONN-0141 MATING CONNECTOR KIT

CABL-0163 AR-300/100 CONVERSION ADAPTER CABLE

CABL-0157 COAX CABLE, 0.5M

CABL-0158 COAX CABLE, 0.8M

CABL-0159 COAX CABLE, 1.0M

CABL-0160 COAX CABLE, 1.2M

CABL-0161 COAX CABLE, 1.5M

Description

Page 24

20 Sensor OHC Operation and Set Up Guide

Connector Kit (CONN-141) Components

Page 25

Page 26

Printed in the USA

MANU-0044

Loading...

Loading...