Page 1

RoboTester

Troubleshooting Kit

Instruction Manual

804010 - Revision 0

Page 2

Instruction Manual

P/N 804010

Revision 0 - December 2001

© Copyright 2001 Hypertherm, Inc.

All Rights Reserved

Hypertherm and Command are trademarks of Hypertherm, Inc., and

may be registered in the United States and/or other countries

RoboTester

Hypertherm, Inc.

P.O. Box 5010

Hanover, NH USA

www.hypertherm.com

Page 3

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

800-643-9878 Tel (Technical Service)

800-737-2978 Tel (Customer Service)

Hypertherm Automation

5 Technology Drive

West Lebanon, NH 03755 USA

603-298-7970 Tel

603-298-7977 Fax

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm Singapore Pte Ltd

No. 19 Kaki Bukit Road 2

K.B. Warehouse Complex

Singapore 417847, Republic of Singapore

65 841 2489 Tel

65 841 2490 Fax

65 841 2489 (Technical Service)

Japan

1952-14 Yata-Natsumegi

Mishima City, Shizuoka Pref.

411-0801 Japan

81 0 559 75 7387 Tel

81 0 559 75 7376 Fax

Hypertherm UK Ltd

9 Berkeley Court, Manor Park

Runcorn, Cheshire, England WA7 1TQ

44 1928 579 074 Tel

44 1928 579 604 Fax

France

15 Impasse des Rosiers

95610 Eragny, France

0805 050 111 Tel

0805 050 222 Fax

Hypertherm S.r.L.

Via Torino 2

20123 Milano, Italia

39 02 725 46 312 Tel

39 02 725 46 400 Fax

39 02 725 46 314 (Technical Service)

Hypertherm B.V.

Burg. Haverkampstraat 13

7091 CN Dinxperlo, Nederland

31 315 655866 Tel

31 315 655886 Fax

Hypertherm B.V. (ETSO)

Vaartveld 9

4704 SE Roosendaal, Nederland

00 800 49 73 7843 – toll-free in Europa

31 165 596900 Tel

31 165 596901 Fax

Hypertherm Brasil Ltda.

Rua Visconde de Santa Isabel, 20 – Sala 611

Vila Isabel, RJ

Brasil CEP 20560-120

55 21 2278 6162 Tel

55 21 2578 0947 Fax

10/30/01

Page 4

Section 1 - Safety ....................................................................................................................................................1

Section 2 - Software Installation and overview ................................................................................................2-1

Introduction ......................................................................................................................................................2-2

Software installation ........................................................................................................................................2-3

RoboTester overview........................................................................................................................................2-4

Manipulating machines and devices................................................................................................................2-5

Executing test scripts ......................................................................................................................................2-6

Viewing script results ......................................................................................................................................2-7

Section 3 - Setup and Operation ........................................................................................................................3-1

Figure list..........................................................................................................................................................3-2

Full system set-up ............................................................................................................. ...............................3-3

Robotester startup............................................................................................................................................3-7

Stand alone gas console test ................................................................................................... .......................3-8

Stand alone torch height control (THC) test..................................................................................................3-10

Gas flow test ..................................................................................................................................................3-11

Chopper current test......................................................................................................................................3-15

Chopper voltage test ........................................................................................................... ...........................3-16

Coolant flow test ............................................................................................................................................3-20

Flow switch test..............................................................................................................................................3-21

Missing phase detect test ..............................................................................................................................3-22

Gas leak test..................................................................................................................................................3-23

Section 4 - Parts lists ..........................................................................................................................................4-1

Parts list - Items 1-16 ......................................................................................................................................4-2

Parts list - Items 17-21 ....................................................................................................................................4-3

Parts list - Items 22-33 ....................................................................................................................................4-4

Parts list - Items 34-40 ....................................................................................................................................4-5

RoboTester Instruction Manual i

TABLE OF CONTENTS

Page 5

RoboTester Instruction Manual 1-1

0

WARNING

ELECTRIC SHOCK CAN KILL

Turn off all electrical power before removing the power supply cover. Put the power

supply circuit breaker in the OFF (0) position and set the line disconnect switch to

OFF. In the U.S., use a "lock-out and tag-out" procedure until the service or

maintenance is complete. In other countries, follow appropriate local or national

safety procedures.

The RoboTester Troubleshooting Software is to be used only by qualified service personnel. It is an inherently

“expert-only” system because it provides full manual control over the plasma system, so the technician can run all

devices. This means you can create hazardous situations if you don’t know what you are doing!

Some simple rules can help prevent accidents:

– Always follow safety precautions in the instruction manual (803760) for the HD4070 system.

– Always disconnect power before touching any machine or device.

– Never let anybody near the system while you are troubleshooting it.

– Never leave a system unattended.

Section 1

SAFETY

2WRENCHES

Page 6

RoboTester Instruction Manual 2-1

0

In this section:

Introduction ............................................................................................................................................................2-2

Software installation................................................................................................................................................2-3

RoboTester overview..............................................................................................................................................2-4

Manipulating machines and devices ......................................................................................................................2-5

Executing test scripts..............................................................................................................................................2-6

Viewing script results..............................................................................................................................................2-7

Section 2

SOFTWARE INSTALLATION AND OVERVIEW

Page 7

2-2 RoboTester Instruction Manual

SOFTWARE INSTALLATION AND OVERVIEW

0

Introduction

Note: The RoboTester software is only compatible with Windows ’95, ’98 and NT.

The laptop computer being used must have a serial communication port.

The RoboTester is an effort to compensate for the trend toward more complex machines, by creating an

automated troubleshooting tool. The HD4070 is the only product supported at this time, but the RoboTester is a

testing framework that is flexible enough to accommodate other Hypertherm products. Current and future systems

may be incorporated at a later date.

Core features:

– The ability to view and modify the internal state of all machines, down to individual devices. This gives the

troubleshooter full manual control of the plasma cutting system.

– Automated tests. The troubleshooter can execute various testing scripts, see which areas are in good condition,

which ones need attention and save the results to file.

– Troubleshooting database. As more information about each specific product is gathered over its lifetime, we can

make the troubleshooting information increasingly specific, and the suggested remedies more accurate. The

RoboTester is therefore a repository of troubleshooting experience.

Additional features:

– The "Demo mode" lets you learn how to use the RoboTester, without having to connect to real machines.

– Python is the Scripting language: Python is simpler than Visual Basic, and more powerful than Java.

Experienced troubleshooters can create their own scripts.

– There is no installation program for the RoboTester, meaning it doesn't touch your Registry, and is very easy to

upgrade. Also, the scripts and troubleshooting database are all contained in plain text files, which means no

information is “locked” into a proprietary format.

Caution: Failure to use the Optical Isolator when connecting to

the laptop can cause the communication port to be

destroyed.

Page 8

RoboTester Instruction Manual 2-3

SOFTWARE INSTALLATION AND OVERVIEW

0

Note: The RoboTester software is only compatible with Windows ’95, ’98 and NT.

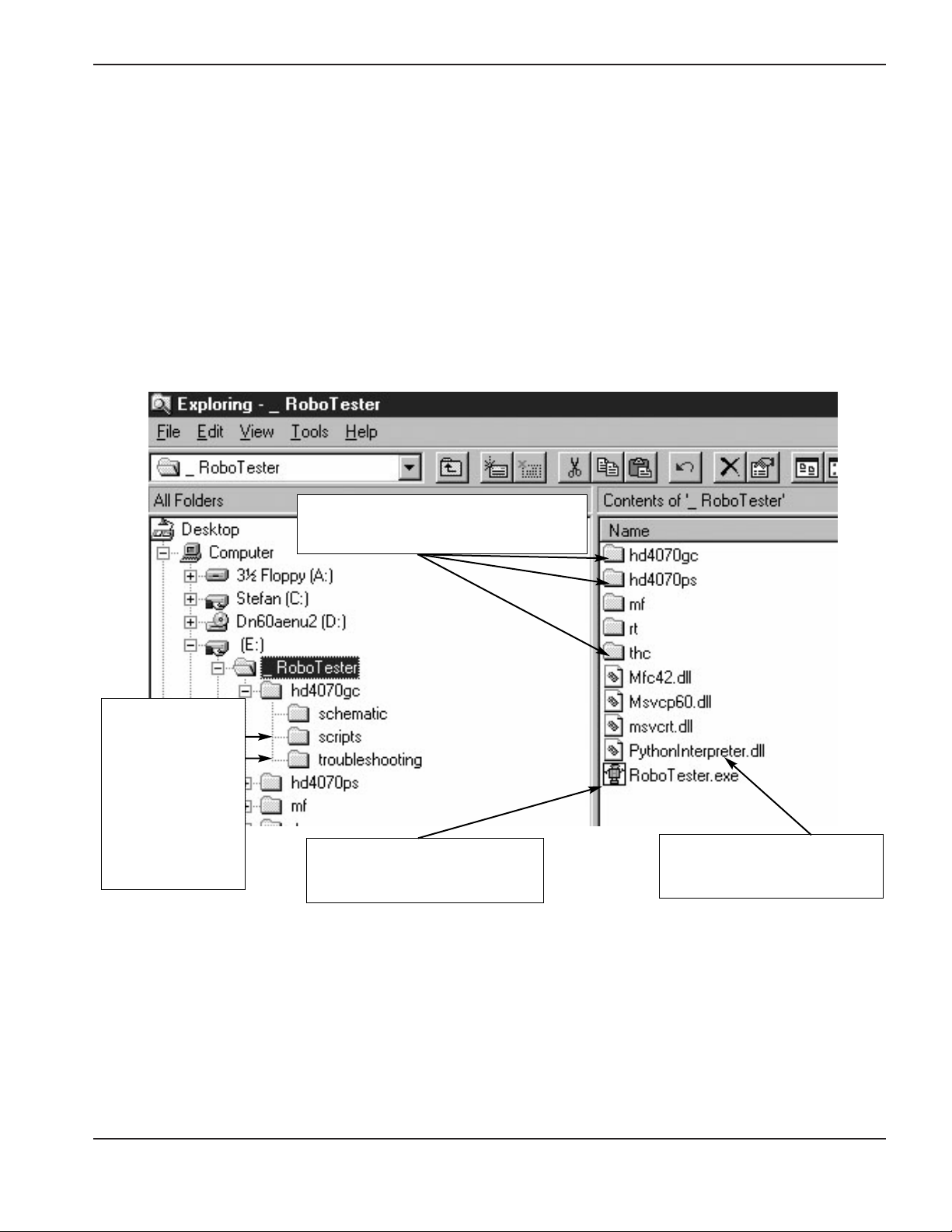

– Obtain the latest copy of the RoboTester software diskette (available in the RoboTester toolbox). Insert disk into

your laptop.

– The “RoboTester.zip” is just a WinZip file, so you can extract it to any location you want on your hard drive. This

also means that uninstallation and upgrades are just a matter of deleting the RoboTester folder, and unzipping a

newer version.

– After unzipping, you should see something like this in the Windows Explorer

Every testable machine has it’s own

folder

This is the python scripting

language engine used for test

scripts.

The actual RoboTester software.

Double click to start.

There are three

sub-folders inside

every machine

folder. The most

important ones for

the user are the

scripts and

troubleshooting

database files.

Software installation

Page 9

2-4 RoboTester Instruction Manual

SOFTWARE INSTALLATION AND OVERVIEW

0

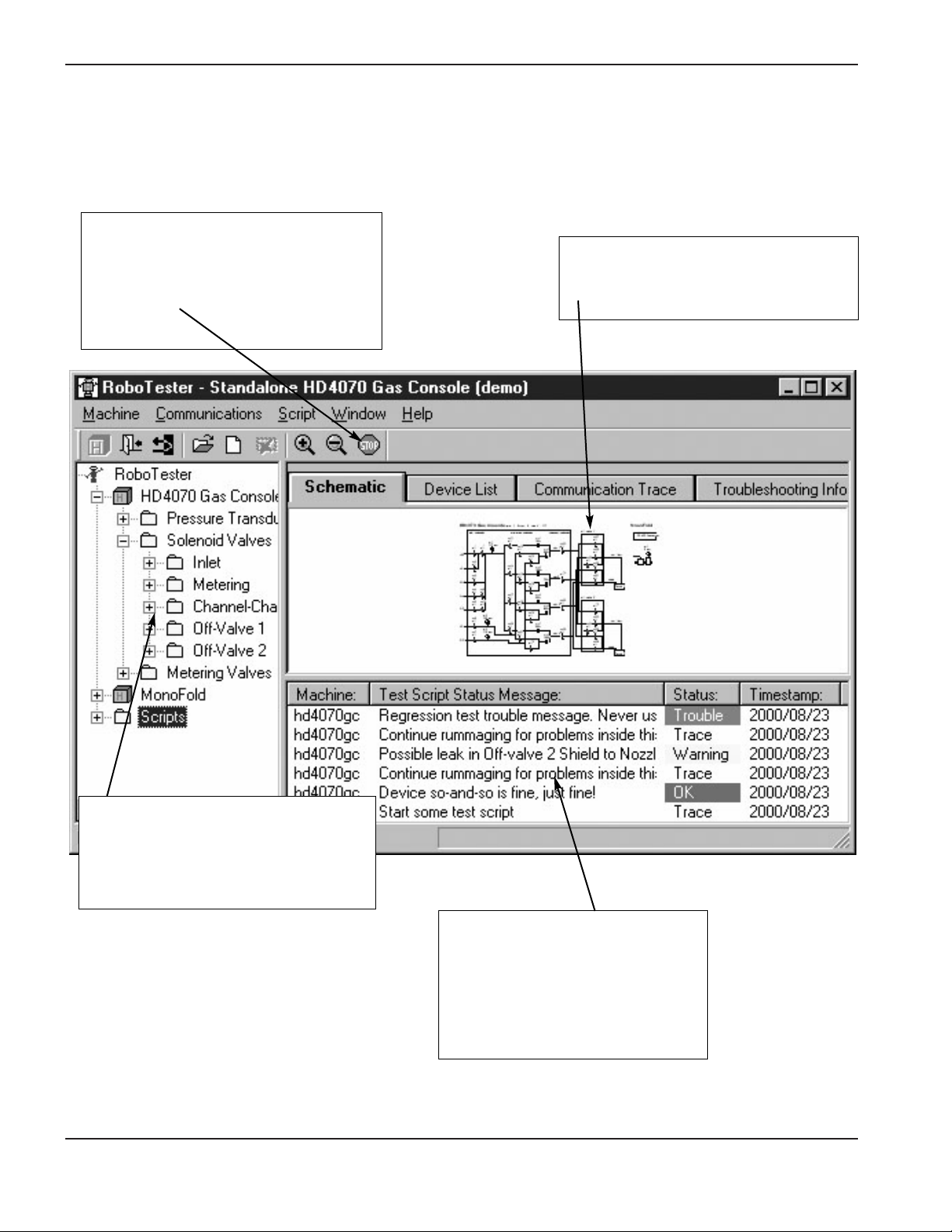

RoboTester Overview

E-Stop button

– Puts all machines in a fail-safe mode

– The “break” key (on the laptop) has the

same function

Hierarchical View

– Shows everything that is in the system:

Machines, devices, and scripts in a

“whole part” view

Trouble message view

– Shows the results of test scripts

– Lets you display troubleshooting

information, by right clicking on the

trouble message

Schematic view

– Graphically displays the most important

devices

Page 10

RoboTester Instruction Manual 2-5

SOFTWARE INSTALLATION AND OVERVIEW

0

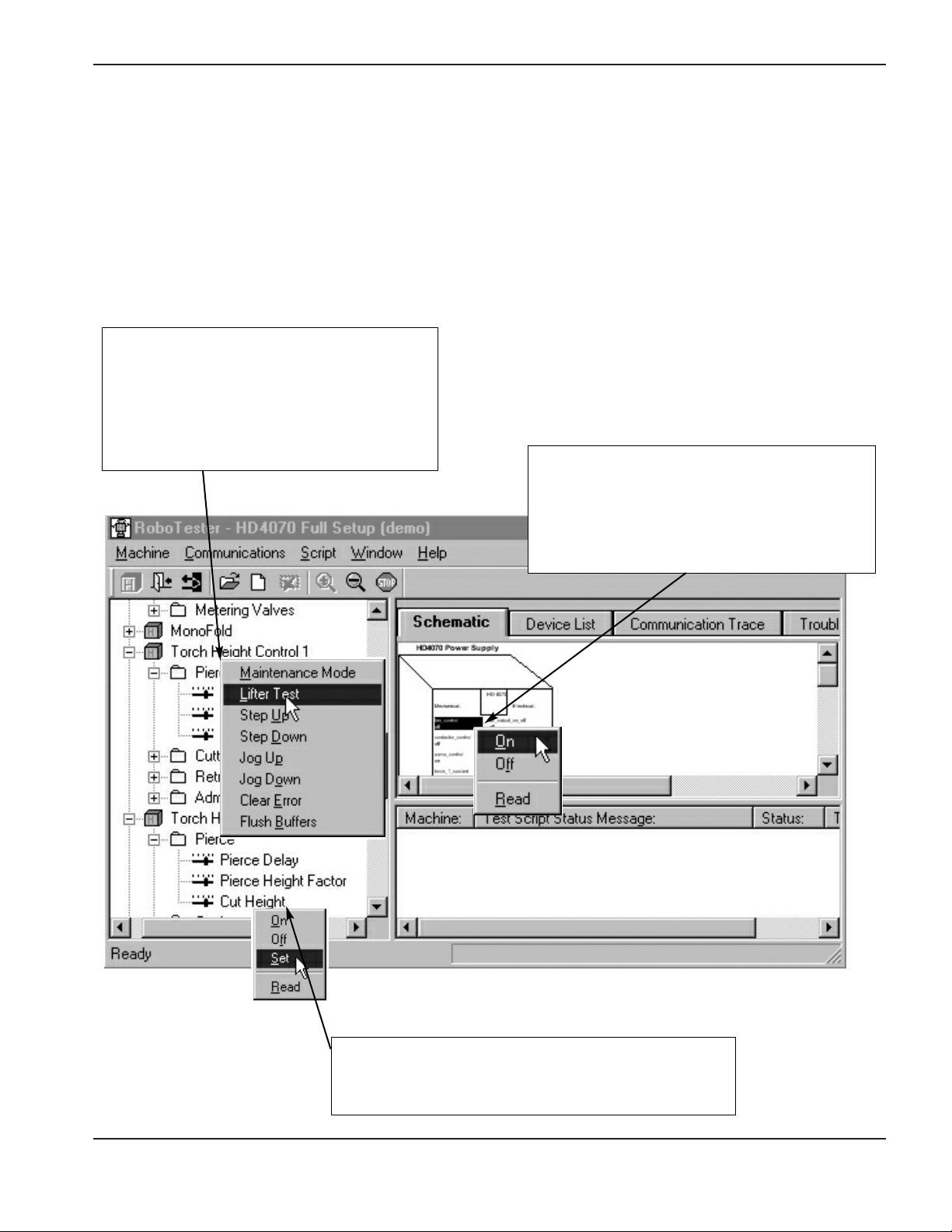

Manipulating machines and devices

In general, double-clicking or right-clicking any machine or device in the hierarchical view, the schematic view or

the device list view will let you manipulate it.

Double-clicking usually causes some “default” behavior. For an “on-off” type of device, Double-clicking will toggle it

between the on and off states.

Right click on machine in hierarchical view

– This allows you to manipulate both machines

and devices

– This can also be accomplished by right-

clicking the machine name in the schematic

view

Right-click on device in schematic view

– The fan for the power supply is shown being

turned on by the user

– The user can zoom in more to make the

devices easier to see

Right-click on device in hierarchical view

The user is setting the Cut Height. The same action can

be taken from the “device list” view

Page 11

2-6 RoboTester Instruction Manual

SOFTWARE INSTALLATION AND OVERVIEW

0

Executing test scripts

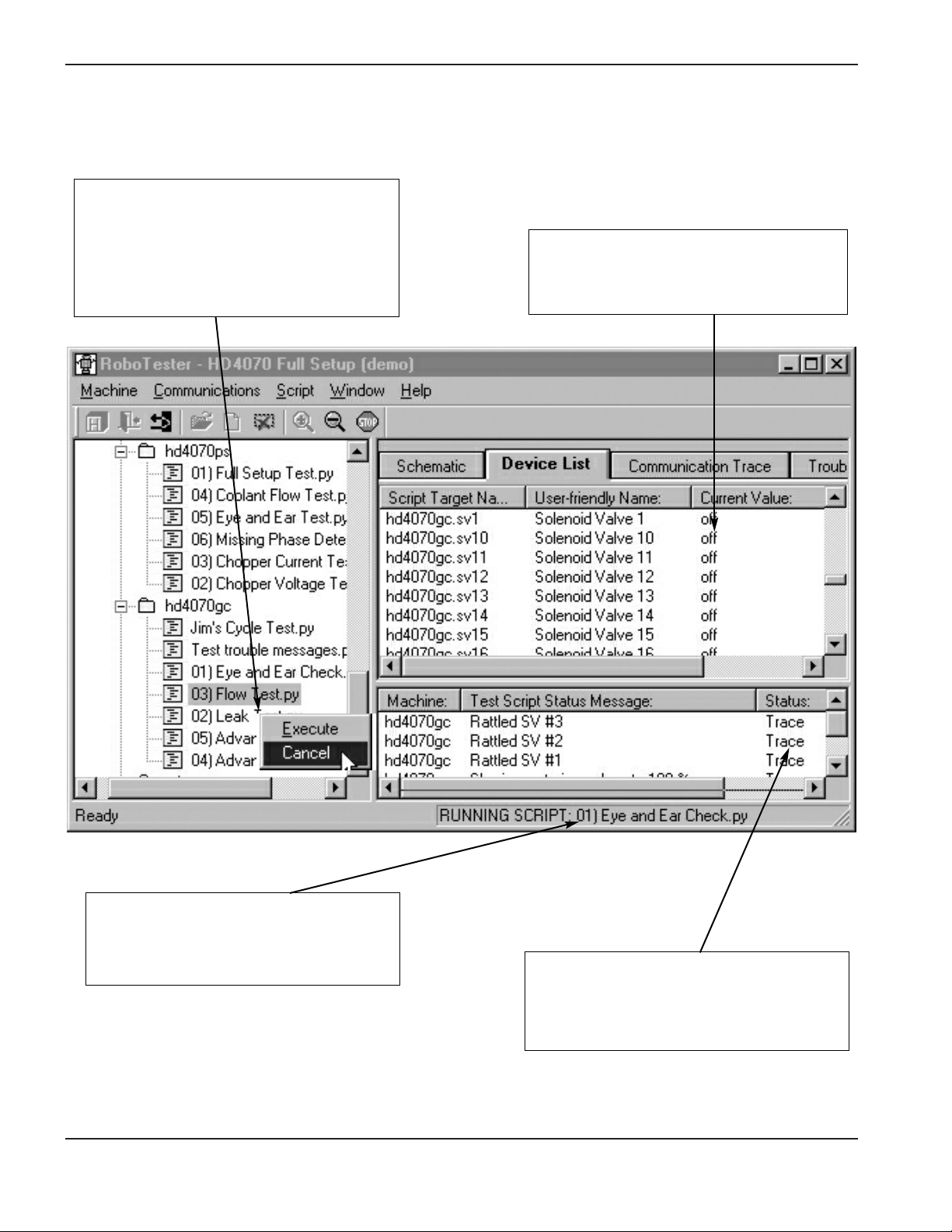

Starting and stopping a script

– Right-clicking will allow the user to turn a

script on and off. The menus or toolbar

buttons can also be used

– In the example shown: the user is stopping

the script

Viewing status changes

– The “device list” and “schematic” views will

show updated device and machine

statuses

Knowing if a script is running

– When a script is running, the status bar at

the bottom of the main window displays

it’s name

Understanding what the script is doing

– Awell written script will regularly send trace

messages to the “trouble message” view to

let the user see what it is currently doing

Page 12

RoboTester Instruction Manual 2-7

SOFTWARE INSTALLATION AND OVERVIEW

0

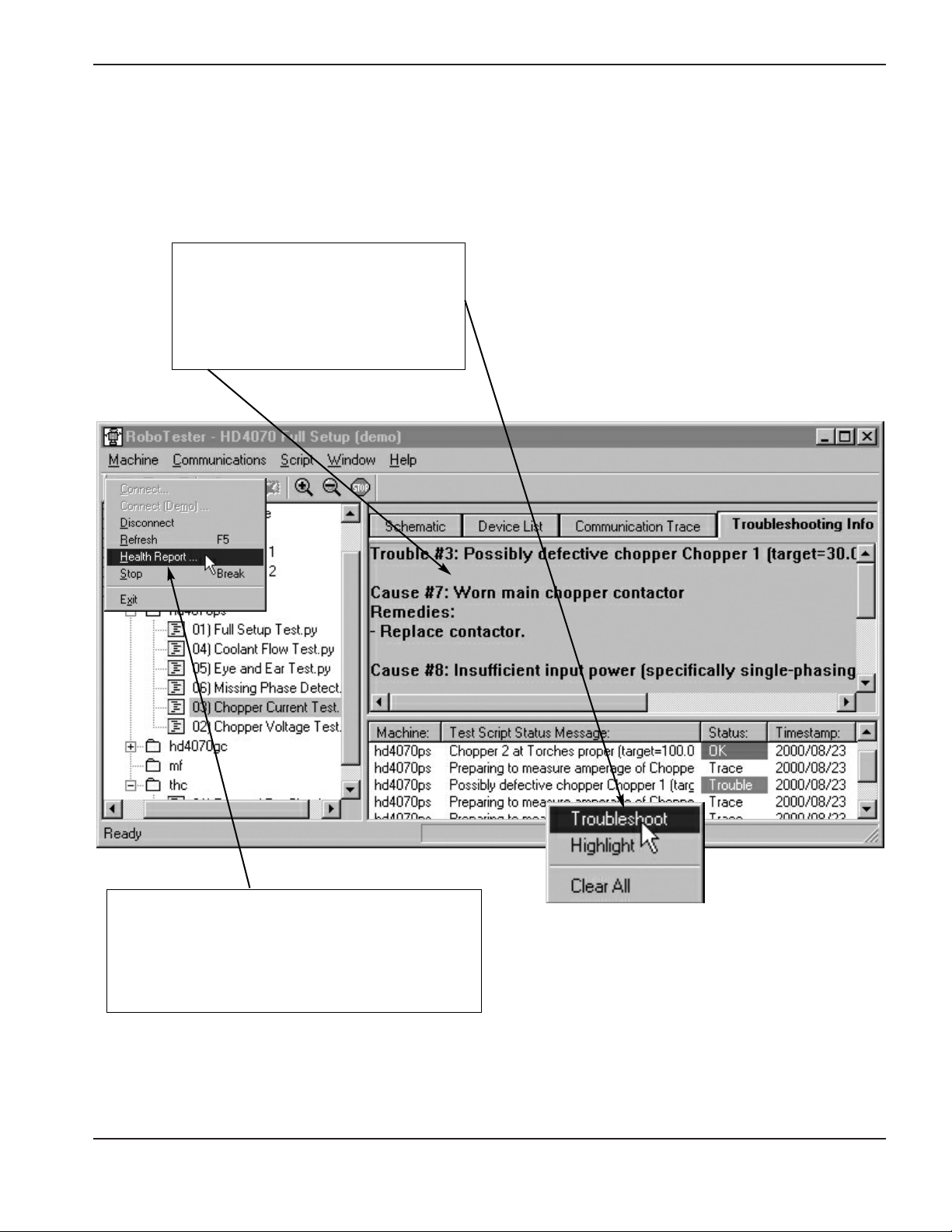

Showing troubleshooting information

– The user has right-clicked on a trouble

message, and chosen “Troubleshoot”.

The troubleshooting information is

displayed in the “troubleshooting Info”

view

Saving a “Health Report” after a script

– Choose “Health report” from the machine menu to

save the results of a script to file

– The menu item is only available if there are red,

yellow or green trouble messages available

Viewing script results

Page 13

RoboTester Instruction Manual 3-1

0

In this section:

Figure list................................................................................................................................................................3-2

System set-up ........................................................................................................................................................3-3

Robotester startup..................................................................................................................................................3-7

Stand alone gas console test ................................................................................................................................3-8

Stand alone torch height control(THC) test ..........................................................................................................3-10

Gas flow test ........................................................................................................................................................3-11

Chopper current test ............................................................................................................................................3-15

Chopper voltage test ............................................................................................................................................3-16

Coolant flow test ..................................................................................................................................................3-20

Flow switch test ....................................................................................................................................................3-21

Missing phase detect test ....................................................................................................................................3-22

Gas leak test ........................................................................................................................................................3-23

Section 3

SETUP AND OPERATION

Page 14

3-2 RoboTester Instruction Manual

SETUP AND OPERATION

0

HD4070 – Figure list

Figure 1 Satisfying interlock switches.

Figure 2 CNC dongle connection.

Figure 3 Null modem to J7 connection and disk drive location.

Figure 4 Connection of the laptop serial port to the null-modem dongle.

Figure 5 Robotester startup 1.

Figure 6 Robotester startup 2.

Figure 7 Connection of the laptop serial port to the RS-422 converter.

Figure 8 Connection of the RS-422 converter to the stand-alone gas console.

Figure 9 Connection of gas console power (VAC input).

Figure 10 Connection of the laptop serial port to the RS-422 converter.

Figure 11 Connection of the RS-422 converter to the stand-alone THC connector (J4).

Figure 12 Gas console inlet manifold connection with regulator.

Figure 13 Gas console spare I/O port for pressure transducer manifold assembly.

Figure 14 Torch slip-on cap, pressure transducer manifold assembly and calibrated orifice.

Figure 15 Torch and consumables reference for flow test.

Figure 16 Gas console with outlet manifold, pressure transducer manifold assembly and calibrated orifice.

Figure 17 I/O Board shorted out with DC short wire.

Figure 18 Chopper output (wires 39 and 48) with digital volt meter (DVM).

Figure 19 Pilot arc controller leads with DVM.

Figure 20 I/O Board with DVM.

Figure 21 Torch leads (RHF box) with DVM.

Figure 22 Torch head (electrode) with DVM.

Figure 23 Power supply with chopper fuse 1 removed.

Figure 24 Power supply with chopper fuse 2 removed.

Figure 25 Coolant return hose disconnected and placed in container for coolant flow test.

Figure 26 Connection of normal torch coolant hoses.

Figure 27 Connection of torch coolant loop-back hoses.

Figure 28 Phase loss detection board.

Figure 29 Gas console outlets for torch 1 plugged and torch 2 open.

Figure 30 Torch and torch plug for leak test.

Page 15

RoboTester Instruction Manual 3-3

SETUP AND OPERATION

0

System Set-Up: Full system or power supply only

Enables testing of the entire plasma system

Items needed: See parts list for details

#16 I/O Shunter Diskette

#25 Null Modem Dongle

#26 CNC Dongle

#29 Extension Cable

#29a optical Isolator

Set-Up

1 – Remove top and side panels from power supply.

2 – Connect the Optical Isolator to the communication port on the laptop computer.

3 – Connect Extension Cable to the Optical Isolator..

4 – Connect opposite end of Extension Cable to Null Modem Dongle.

5 – Connect Null Modem Dongle to J7 on Breakout board (PCB6).

6 – Install CNC Dongle,If no CNC cable is connected to power supply.

7 – Make sure all door switches (3) are satisfied.

8 – Insert the I/O Shunter Diskette into floppy disk drive.

9 – Turn power on HD4070 and wait until floppy disk is loaded into the HD4070 system.

WARNING

ELECTRIC SHOCK CAN KILL

Disconnect electrical power before performing any maintenance.

All work requiring removal of the power supply cover must be performed by a

qualified technician.

See Section 1 of the Operator Manual for more safety precautions.

Note: The RoboTester software is only compatible with Windows ’95, ’98 and NT.

The laptop computer being used must have a serial communication port.

Caution: Failure to use the Optical Isolator when connecting to

the laptop can cause the communication port to be

destroyed.

Page 16

3-4 RoboTester Instruction Manual

SETUP AND OPERATION

0

Satisfy the top door switch. The switch

needs to be held down flush with frame.

Satisfy the two side door switches, by

pulling them all the way out. (The second

switch is on the opposite side, not visible

in this picture)

System setup: Full system or power supply only

Figure 1 Satisfying interlock switches

Page 17

Figure 2 CNC dongle connection

RoboTester Instruction Manual 3-5

SETUP AND OPERATION

0

CNC dongle

Insert the I/O-Shunter boot diskette.

Connect null-modem cable to the J7 serial

connector, and the other end to your laptop.

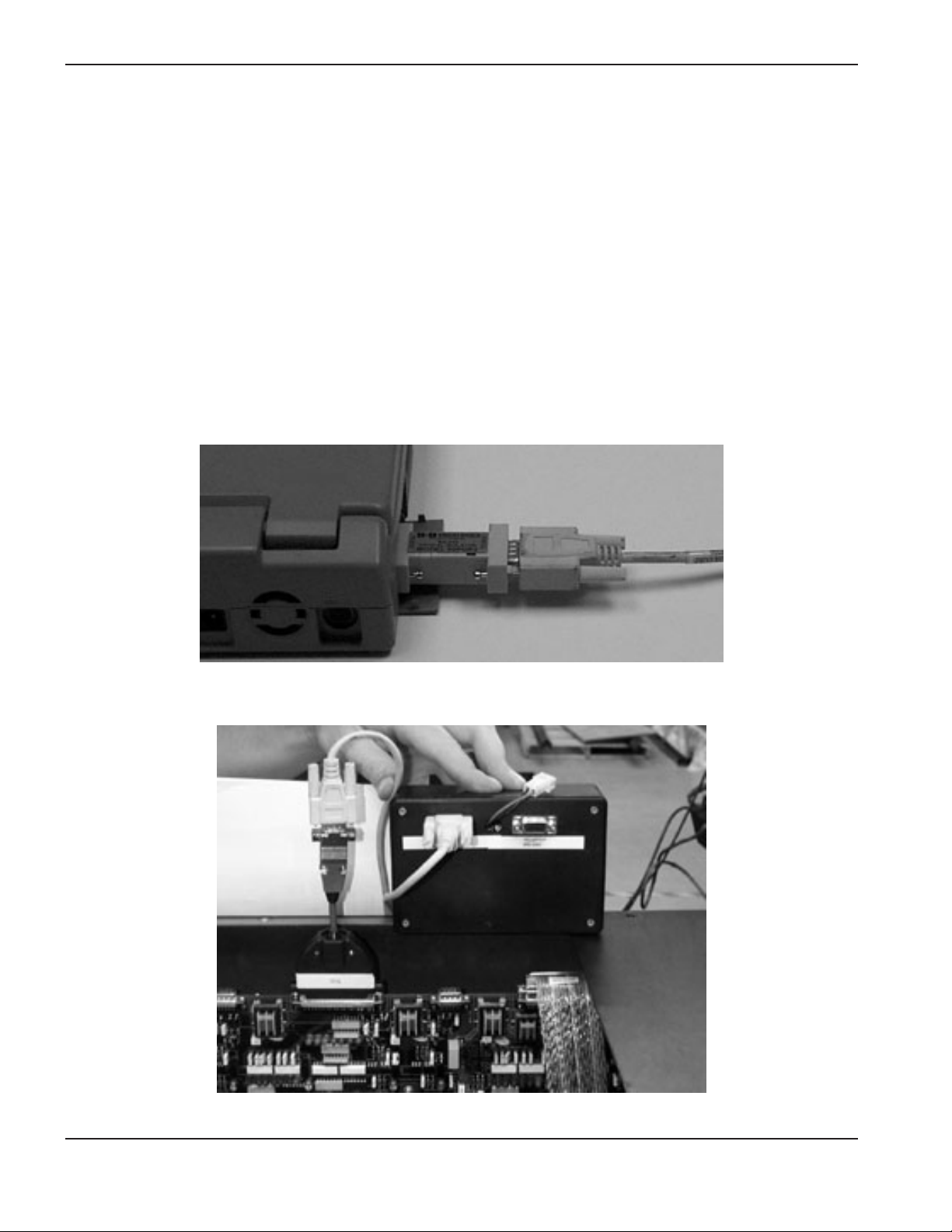

System setup – continued

Figure 3 Null modem to J7 connection and disk drive location

Page 18

3-6 RoboTester Instruction Manual

SETUP AND OPERATION

0

System setup – continued

Figure 4 Connection of the laptop serial port to the null-modem dongle

Page 19

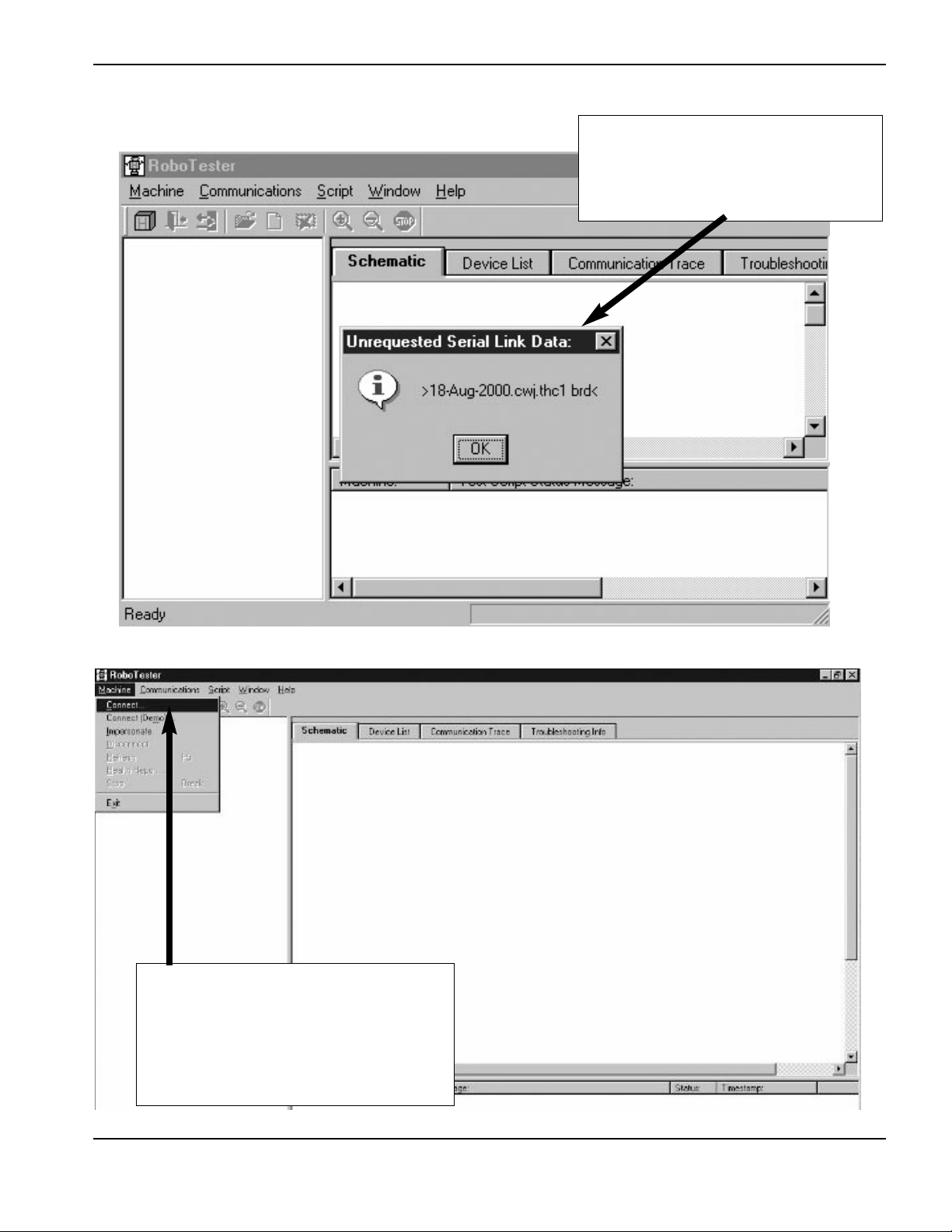

After turning the power supply ON, Wait

for the I/O-shunter to load (About 30

seconds). This message box will appear

when loading is complete.

Robotester startup

RoboTester Instruction Manual 3-7

SETUP AND OPERATION

0

Connect to “HD4070 Full Setup”. You can

now view and manipulate machines and

devices. Normally, any connection problems

will give you a red troubleshooting message.

Right click on the message for more

information.

Figure 5 Robotester startup 1

Figure 6 Robotester startup 2

Page 20

3-8 RoboTester Instruction Manual

SETUP AND OPERATION

0

Stand Alone Gas Console test

Enables testing of gas console as a stand alone unit.

Items needed: See parts list for details

#22 RS-422 Converter

#23 Gas Console Dongle

#29 Extension Cable (2)

#29a Optical Isolator

#30 Gas Console Power Cable

Set-Up

1 – Connect the Optical Isolator to the communication port on the laptop computer.

2 – Connect Extension Cable to the Optical Isolator.

3 – Connect opposite end of Extension Cable to the RS-232 port on the RS-422 Converter.

4 – Connect one end of the second Extension Cable to the RS-422 port on the RS-422 Converter.

5 – Connect opposite end of Extension Cable to Gas Console Dongle.

6 – Connect opposite end of Gas Console Dongle to 3X2 on back of Gas Console.

7 – Connect the Gas Console Power Cord to 3X1 on back of Gas Console.

Figure 7 Connection of the laptop serial port to the RS-422 converter

Page 21

RoboTester Instruction Manual 3-9

SETUP AND OPERATION

0

Figure 8 Connection of the RS-422 converter to the stand-alone gas console

Figure 9 Connection of gas console power (VAC input)

Stand alone gas console test – continued

Page 22

3-10 RoboTester Instruction Manual

SETUP AND OPERATION

0

Figure 11 Connection of the RS-422 converter to the stand-alone THC connector (J4)

Figure 10 Connection of the laptop serial port to the RS-422 converter

Stand alone THC test

Enables testing of Command THC as a stand alone unit.

Items needed: See parts list for details

#22 RS-422 Gas Console Dongle

#24 THC Dongle

#29 Extension Cable (2)

#29a Optical Isolator

Set-Up

1 – Connect the Optical Isolator to the communication port on the laptop computer.

2 – Connect Extension Cable to the Optical Isolator.

3 – Connect the other end of the extension cable to the RS-232 port on the RS-422 converter.

4 – Connect one end of the second extension cable to the RS-422 port on the RS-422 converter.

5 – Connect the other end of the second extension Cable to the THC Dongle.

6 – Connect THC Dongle to J4 on the THC Control board you want to test.

Page 23

RoboTester Instruction Manual 3-11

SETUP AND OPERATION

0

Gas flow test

Checks the gas flow from the Gas Console through the torch. Will isolate flow errors in the torch leads,

consumables, gas leads, and/or gas console.

Items Needed: See parts list for details

#3 Inert to Right Hand ‘A’ Adapter (N2)

#8 Small Orifice Assembly

#9 Large Orifice Assembly

#10 100A Mild Steel Nozzle/Shield Assembly

#1 1 100A Swirl-ring Assembly

#11a 100A Electrode

#17 Inlet Manifold Assembly

#18 Slip-on Torch Cap Assembly

#19 Regulator Assembly

#21 Pressure Transducer Manifold Assembly

#32 Right Hand ‘A’ Hose Assembly (2)

Set-Up

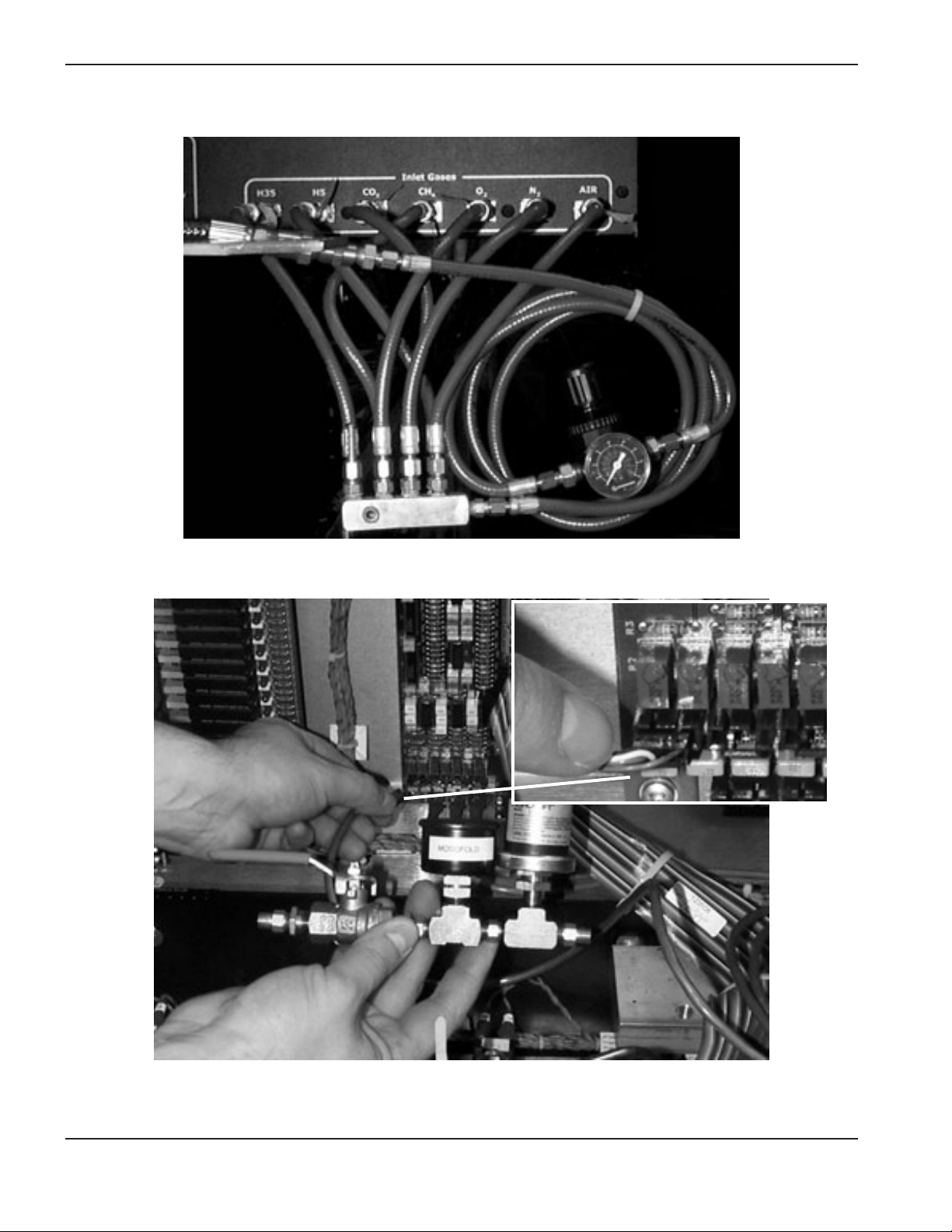

1 – Install Inlet manifold assembly to Inlet manifold of gas console.

2 – Connect input hose of the inlet manifold to the outlet side of the regulator assembly.

3 – Connect one of the hose assemblies to the inlet side of the regulator assembly.

4 – Connect the other end of the hose assembly to the Inert Adapter.

5 – Connect the nitrogen supply line into the inert adapter.

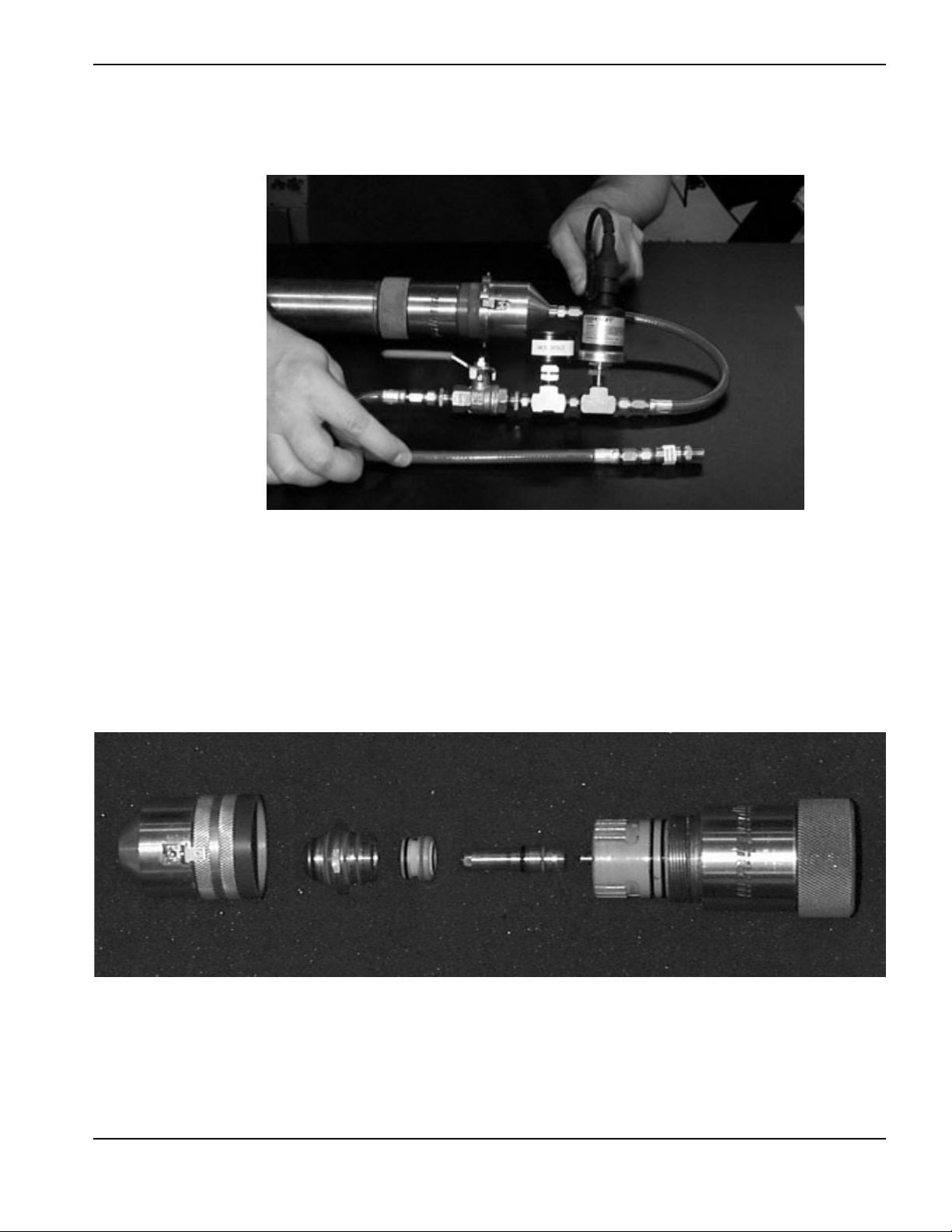

6 – Install the 100A consumable parts into the torch.

7 – Install the slip-on torch cap assembly to the end of the torch. Make sure thumb screws tighten into the groove

on the retaining cap.

8 – Connect hose end of the torch cap assembly to the pressure transducer manifold assembly. Make sure the

shut-off lever is in the ON position.

9 – Connect the second hose assembly to the pressure transducer manifold.

10 – Connect opposite end of the Hose Assembly to the large orifice assembly.

11 – Connect Pressure Transducer Manifold Assembly cable to J2 on the gas console board (PCB2).

12 – Set pressure at regulator assembly to 100 psi (6.9 bar). Set gas pressure at source (N2) to 120 psi (7.3 bar).

Before running the gas flow test, check the calibration of the 4 pressure transducers.

To check the calibration perform the following functions:

1 – Turn the gas shut-off lever on the pressure transducer manifold to the OFF position.

2 – Manually turn SV5, SV10, SV11, SV12, SV13, and SV23 ON.

3 – Read the pressure for PT1, PT2, PT3 and PT4.

4 – Values should be within +/- 2psi of each other.

If values are not within specification, call Hypertherm technical service for PCB2 calibration procedure.

Page 24

3-12 RoboTester Instruction Manual

SETUP AND OPERATION

0

Gas flow test – continued

Figure 12 Gas console inlet manifold connection with regulator

Figure 13 Gas console spare I/O port for pressure transducer manifold assembly

Page 25

RoboTester Instruction Manual 3-13

SETUP AND OPERATION

0

Figure 14 Torch slip-on cap, pressure transducer manifold and calibrated orifice

Figure 15 Torch and consumables reference for flow test

Gas flow test – continued

Page 26

3-14 RoboTester Instruction Manual

SETUP AND OPERATION

0

Figure 16 Gas console with outlet manifold, pressure transducer manifold assembly, and calibrated orifice

Gas flow test – continued

Page 27

RoboTester Instruction Manual 3-15

SETUP AND OPERATION

0

Figure 17 I/O Board shorted out with DC short wire

Chopper current test

Checks the current output of each chopper. Chopper 1 is tested a 30-amps and Chopper 2 is tested at 100-amps.

If proper current is detected the choppers are functioning properly.

Items Needed: See parts list for details

#1 4/O Jumper Cable

Set-Up

1 – Remove Negative and Work Lead 4/O cables from large brass bus bars inside HD4070

2 – Install 4/O Jumper Cable across buss bars in place of Negative and Work Leads

Page 28

3-16 RoboTester Instruction Manual

SETUP AND OPERATION

0

Chopper voltage test

Checks the open circuit voltage at various points in the plasma system.

Items Needed:

Digital Volt Meter – Not included in kit

Figure 18 output (wires 39 and 48) with digital volt meter (DVM)

Figure 19 Pilot arc controller leads with DVM

Page 29

RoboTester Instruction Manual 3-17

SETUP AND OPERATION

0

Figure 20 I/O Board with DVM

Figure 21 Torch leads (RHF box) with DVM

Chopper voltage test – continued

Page 30

3-18 RoboTester Instruction Manual

SETUP AND OPERATION

0

Figure 22 Torch head (electrode) with DVM

Figure 23 Power supply with chopper fuse 1 removed

Chopper voltage test – continued

Page 31

RoboTester Instruction Manual 3-19

SETUP AND OPERATION

0

Figure 24 Power supply with chopper fuse 2 removed

Chopper voltage test – continued

Page 32

3-20 RoboTester Instruction Manual

SETUP AND OPERATION

0

Figure 25 Coolant return hose disconnected and placed in container for coolant flow test

Coolant flow test

Tests total coolant flow through each torch.

Items Needed:

1 Gallon Container – Not included in kit

Figure 26 Connection of normal torch coolant hoses

Page 33

RoboTester Instruction Manual 3-21

SETUP AND OPERATION

0

Figure 27 Connection of torch coolant loop-back hoses

Flow switch test

Tests the flow-switch by bypassing the torch and .

Items Needed: See parts list for details

#33 Coolant loop-back hose

Set-Up

1 – Install coolant loop-back hose in place of the torch coolant hoses for the torch that is being tested.

Page 34

3-22 RoboTester Instruction Manual

SETUP AND OPERATION

0

Missing phase detect test

Tests the three phases on the secondary side of the main transformer.

Items Needed:

None

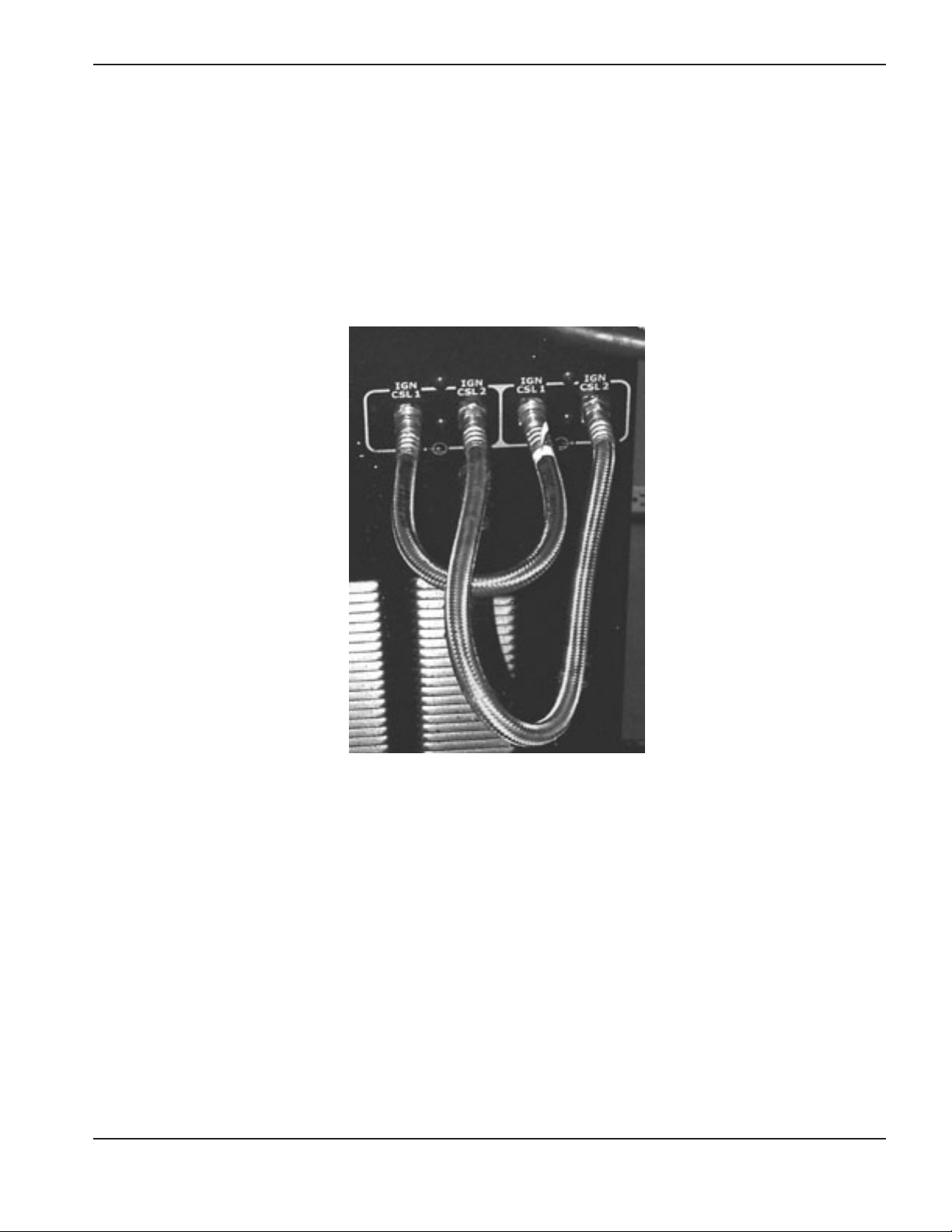

Figure 28 Phase loss detection board

Page 35

RoboTester Instruction Manual 3-23

SETUP AND OPERATION

0

Gas leak test

Checks for leaks from the torch to the gas console. Test is designed to locate leaks inside the gas console, or at

the torch.

Items Needed: See parts list for details

#3 Inert to right hand ‘A’ adapter (N2)

#12 Right hand ‘A’ plug (2)

#13 Left hand ‘A’ plug (2)

#14 Torch receptacle plug

#17 Inlet manifold assembly

#19 Regulator assembly

#32 Right hand ‘A’ hose assembly

Set-Up

1 – Remove all gas supply lines from the back of the gas console.

2 – Install inlet manifold to the gas console.

3 – Install outlet of regulator assembly to inlet manifold assembly.

4 – Install one end of the hose assembly to inlet side of the pressure regulator assembly.

5 – Install the other end of the hose to the inert adapter (N2).

6 – Connect the N2supply line to the inert adapter.

7 – Set pressure at regulator assembly to 100 psi (6.9 bar). Set gas pressure at source (N2) to 120 psi (7.3 bar).

Page 36

3-24 RoboTester Instruction Manual

SETUP AND OPERATION

0

Figure 29 Gas console outlets for torch 1 plugged and torch 2 open

Figure 30 Torch and torch plug for leak test

Gas leak test – continued

Page 37

RoboTester Instruction Manual 4-1

0

In this section:

Parts list – Items 1-16...............................................................................................................................................4-2

Parts list – Items 17-21.............................................................................................................................................4-3

Parts list – Items 22-33.............................................................................................................................................4-4

Parts list – Items 34-40.............................................................................................................................................4-5

Section 4

PARTS LIST

Page 38

4-2 RoboTester Instruction Manual

PARTS LIST

0

Parts list – Items 1-16

This list of hardware is not final, but gives a good idea of what the kit should contain

10

987654321

3

Part

Item Number Description Qty

1 123624 Cable to short circuit I/O board 1

2 128584 Adapter: Left hand ‘B’ to right hand ‘A’ 3

3 128585 Adapter: Inert to right hand ’A’ 2

4 128587 Adapter: Right hand ‘B’ to right hand ‘A’ 1

5 128586 Adapter: #6 to right hand ‘A’ 1

6 128593 Adapter: Right hand ‘A’ to quick disconnect 1

7 128590 Medium (.024") orifice assembly 1

8 128591 Small (.014") orifice assembly 1

9 128592 Large (.030”) orifice assembly 1

10 120660 100A mild steel nozzle/shield assembly 1

11 120783 100A Swirl ring 1

11a 120654 100A Electrode 1

12 004918 Right hand ‘A’ plug 8

13 004917 Left hand ‘A’ plug 4

14 129671 Torch receptacle plug 1

15 081069 RoboTester software 1

16 081070 I/O shunter diskette (2 copies provided) 2

12

131416

15

11

11

a

Page 39

RoboTester Instruction Manual 4-3

PARTS LIST

0

Parts list – Items 17-21

17

21

18

19

20

Part

Item Number Description Qty

17 128597 Inlet manifold assembly 1

18 128581 Slip-on torch cap assembly 1

19 128594 Regulator assembly 1

20 128617 Outlet manifold assembly 1

21 128582 Pressure transducer manifold assembly 1

Page 40

4-4 RoboTester Instruction Manual

PARTS LIST

0

Parts list – Items 22-33

30

29

28272625232224

Part

Item Number Description Qty

22 128614 RS-422 converter 1

23 123626 Gas console dongle 1

24 123625 THC dongle 1

25 123628 Null modem dongle 1

26 123629 CNC dongle 1

27 004944 1/4" compression plugs 4

28 044548 Replacement o-rings for slip-on cap 2

29 123632 9 pin extension cable 2

29a 108258 Optical Isolator 1

30 129698 Gas console power cord 1

31 024710 Hose assembly: 3/16 inch right hand to 3/16 inch left hand 2

32 024711 Hose assembly: 3/16 inch right hand ‘A’ 6

33 024162 Coolant loop-back hose: 1/2 inch #8 2

29

a

33

31

32

Page 41

RoboTester Instruction Manual 4-5

PARTS LIST

0

Parts list – Items 34-40

Part

Item Number Description Qty

34 128588 Adapter: Left hand ‘A’ male to right hand ‘A’female 4

35 220002 Ignition testing: Cap 1

36 220003 Ignition testing: Nozzle 1

37 220004 Ignition testing: Electrode 1

38 128604 Ignition testing: Torch receptacle 1

39 804010 RoboTester instruction manual 1

40 001782 RoboTester tool box (not shown) 1

34

35

38

36

39

37

Loading...

Loading...