Page 1

Plasma Arc

Cutting System

Service Manual

803150 - Revision 3

®

EN50199

EN50192

Page 2

Plasma Arc Cutting System

Service Manual

IM-315

(P/N 803150)

for systems beginning with serial number

900-010000

Revision 3 June, 2000

Hypertherm, Inc.

Hanover, NH

http://www.hypertherm.com

email:info@hypertherm.com

© Copyright 2000 Hypertherm, Inc.

All Rights Reserved

Hypertherm and Powermax are trademarks of Hypertherm, Inc.,

and may be registered in the United States and/or other countries

Page 3

Hypertherm Offices Worldwide

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

Tel.: (603) 643-3441 (Main Office)

Fax: (603) 643-5352 (All Departments)

Tel.: (800) 643-9878 (Technical Service – toll-free in USA and Canada)

Tel.: (800) 737-2978 (Customer Service – toll-free in USA and Canada)

email: info@hypertherm.com (General Information)

email: service@hypertherm.com (Technical/Customer Services)

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D–63457 Hanau-Wolfgang, Germany

Tel.: 49 6181 58 2100

Fax: 49 6181 58 2134

Hypertherm (S) Pte Ltd

No. 19 Kaki Bukit Road 2

K.B. Warehouse Complex

Singapore 417847

Tel.: 65 841 2489

Fax: 65 841 2490

Hypertherm UK Ltd

9 Berkeley Court, Manor Park

Runcorn, Cheshire, England WA7 1TQ

Tel.: 44 1928 579 074

Fax: 44 1928 579 604

:

France

15 Impasse des Rosiers

95610 Eragny, France

Tel.: 33 1 30 37 15 28

Fax: 33 1 30 37 15 79

Hypertherm S.r.L.

Via Torino 2

20123 Milan, Italy

Tel.: 39 02 725 46 312 (Customer Service)

Tel.: 39 02 725 46 314 (Technical Service)

Fax: 39 02 725 46 400 (All Departments)

Hypertherm B.V.

Burg, Haverkampstraat 13

7091 CN Dinxperlo, The Netherlands

Tel.: 31 315 655 866 (Customer Service)

Fax: 31 315 655 886

European Technical Support Organization (ETSO)

Edisonstraat 12

3281 NC Numansdorp, The Netherlands

Tel.: 00 800 4973 7843 (00 800 Hypertherm) – (toll-free Technical Service)

Tel.: 31 186 659494

Fax: 31 186 659495

Japan

Shinjuku Park Tower

30th Floor

3-7-1 Nishi-Shinjuku

Shinjuku-ku, Tokyo

163-1030, Japan

Tel.: 81 03 5326 3142

Fax: 81 03 5326 3001

5/00

Page 4

ELECTROMAGNETIC COMPATIBILITY

EMC INTRODUCTION

Hypertherm's CE-marked equipment is

built in compliance with standard

EN50199. The equipment should be

installed and used in accordance with the

information below to achieve

electromagnetic compatibility.

The limits required by EN50199 may not

be adequate to completely eliminate

interference when the affected equipment

is in close proximity or has a high degree

of sensitivity. In such cases it may be

necessary to use other measures to

further reduce interference.

This plasma is designed for use only in an

industrial environment.

INSTALLATION AND USE

The user is responsible for installing and

using the plasma equipment according to

the manufacturer's instructions. If

electromagnetic disturbances are

detected then it shall be the responsibility

of the user to resolve the situation with the

technical assistance of the manufacturer.

In some cases this remedial action may be

as simple as earthing the cutting circuit,

see

Earthing of Workpiece

it could involve constructing an

electromagnetic screen enclosing the

power source and the work complete with

associated input filters. In all cases

electromagnetic disturbances must be

reduced to the point where they are no

longer troublesome.

ASSESSMENT OF AREA

Before installing the equipment the user

shall make an assessment of potential

electromagnetic problems in the

surrounding area. The following shall be

taken into account:

a. Other supply cables, control cables,

signalling and telephone cables; above,

below and adjacent to the cutting

equipment.

b. Radio and television transmitters and

receivers.

c. Computer and other control equipment.

d. Safety critical equipment, for example

guarding of industrial equipment.

e. Health of the people around, for

example the use of pacemakers and

hearing aids.

f. Equipment used for calibration or

measurement.

. In other cases

g. Immunity of other equipment in the

environment. User shall ensure that

other equipment being used in the

environment is compatible. This may

require additional protection measures.

h. Time of day that cutting or other

activities are to be carried out.

The size of the surrounding area to be

considered will depend on the structure of

the building and other activities that are

taking place. The surrounding area may

extend beyond the boundaries of the

premises.

METHODS OF REDUCING

EMISSIONS

Mains Supply

Cutting equipment must be connected to

the mains supply according to the

manufacturer's recommendations. If

interference occurs, it may be necessary

to take additional precautions such as

filtering of the mains supply.

Consideration should be given to

shielding the supply cable of permanently

installed cutting equipment, in metallic

conduit or equivalent. Shielding should

be electrically continuous throughout its

length. The shielding should be

connected to the cutting mains supply so

that good electrical contact is maintained

between the conduit and the cutting

power source enclosure.

Maintenance of Cutting Equipment

The cutting equipment must be routinely

maintained according to the

manufacturer's recommendations. All

access and service doors and covers

should be closed and properly fastened

when the cutting equipment is in

operation. The cutting equipment should

not be modified in any way except for

those changes and adjustments covered

in the manufacturer's instructions. In

particular, the spark gaps of arc striking

and stabilizing devices should be

adjusted and maintained according to the

manufacturer's recommendations.

Cutting Cables

The cutting cables should be kept as

short as possible and should be

positioned close together, running at or

close to the floor level.

Equipotential Bonding

Bonding of all metallic components in the

cutting installation and adjacent to it

should be considered. However, metallic

components bonded to the workpiece will

increase the risk that the operator could

receive a shock by touching these

metallic components and the electrode at

the same time. The operator should be

insulated from all such bonded metallic

components.

Earthing of Workpiece

Where the workpiece is not bonded to

earth for electrical safety, nor connected

to earth because of its size and position,

for example, ship's hull or building

steelwork, a connection bonding the

workpiece to earth may reduce

emissions in some, but not all instances.

Care should be taken to prevent the

earthing of the workpiece increasing the

risk of injury to users, or damage to other

electrical equipment. Where necessary,

the connection of the workpiece to earth

should be made by a direct connection to

the workpiece, but in some countries

where direct connection is not permitted,

the bonding should be achieved by

suitable capacitances selected

according to national regulations.

Note: The cutting circuit may or may not

be earthed for safety reasons. Changing

the earthing arrangements should only

be authorized by a person who is

competent to assess whether the

changes will increase the risk of injury, for

example, by allowing parallel cutting

current return paths which may damage

the earth circuits of other equipment.

Further guidance is given in IEC TC26

(sec)94 and IEC TC26/108A/CD Arc

Welding Equipment Installation and Use.

Screening and Shielding

Selective screening and shielding of

other cables and equipment in the

surrounding area may alleviate problems

of interference. Screening of the entire

plasma cutting installation may be

considered for special applications.

Service Manual

i

Page 5

W

ARRANTY

WARNING

Genuine Hypertherm parts are the factory-recommended

replacement parts for your Hypertherm system. Any

damage caused by the use of other than genuine

Hypertherm parts may not be covered by the Hypertherm

warranty.

WARNING

You are responsible for the safe use of the Product.

Hypertherm does not and cannot make any guarantee or

warranty regarding the safe use of the Product in your

environment.

GENERAL

Hypertherm, Inc. warrants that its Products shall be free

from defects in materials and workmanship, if Hypertherm

is notified of a defect (i) with respect to the power supply

within a period of two (2) years from the date of its delivery

to you, and (ii) with respect to the torch and leads within a

period of one (1) year from its date of delivery to you. This

warranty shall not apply to any Product which has been

incorrectly installed, modified, or otherwise damaged.

Hypertherm, at its sole option, shall repair, replace, or

adjust, free of charge, any defective Products covered by

this warranty which shall be returned with Hypertherm’s

prior authorization (which shall not be unreasonably

withheld), properly packed, to Hypertherm’s place of

business in Hanover, New Hampshire, or to an authorized

Hypertherm repair facility, all costs, insurance and freight

prepaid. Hypertherm shall not be liable for any repairs,

replacement, or adjustments of Products covered by this

warranty, except those made pursuant to this paragraph or

with Hypertherm’s prior written consent. The warranty

above is exclusive and is in lieu of all other warranties,

express, implied, statutory, or otherwise with respect

to the Products or as to the results which may be

obtained therefrom, and all implied warranties or

conditions of quality or of merchantability or fitness for

a particular purpose or against infringement. The

foregoing shall constitute the sole and exclusive

remedy for any breach by Hypertherm of its warranty.

Distributors/OEMs may offer different or additional

warranties, but Distributors/OEMs are not authorized to

give any additional warranty protection to you or make any

representation to you purporting to be binding upon

Hypertherm.

formulae, or combinations not developed or purported to be

developed by Hypertherm, Hypertherm will defend or

settle, at its own expense, any suit or proceeding brought

against you alleging that the use of the Hypertherm

product, alone and not in combination with any other

product not supplied by Hypertherm, infringes any patent of

any third party. You shall notify Hypertherm promptly upon

learning of any action or threatened action in connection

with any such alleged infringement, and Hypertherm’s

obligation to indemnify shall be conditioned upon

Hypertherm’s sole control of, and the indemnified party’s

cooperation and assistance in, the defense of the claim.

LIMITATION OF LIABILITY

In no event shall Hypertherm be liable to any person or

entity for any incidental, consequential, indirect, or

punitive damages (including but not limited to lost

profits) regardless of whether such liability is based on

breach of contract, tort, strict liability, breach of

warranties, failure of essential purpose or otherwise

and even if advised of the possibility of such damages.

LIABILITY CAP

In no event shall Hypertherm’s liability, whether such

liability is based on breach of contract, tort, strict

liability, breach of warranties, failure of essential

purpose or otherwise, for any claim action suit or

proceeding arising out of or relating to the use of the

Products exceed in the aggregate the amount paid for

the Products that gave rise to such claim.

INSURANCE

At all times you will have and maintain insurance in such

quantities and types, and with coverage sufficient and

appropriate to defend and to hold Hypertherm harmless in

the event of any cause of action arising from the use of the

Products.

NATIONAL AND LOCAL CODES

National and Local codes governing plumbing and

electrical installation shall take precedent over any

instructions contained in this manual. In no event shall

Hypertherm be liable for injury to persons or property

damage by reason of any code violation or poor work

practices.

PATENT INDEMNITY

Except only in cases of products not manufactured by

Hypertherm or manufactured by a person other than

Hypertherm not in strict conformity with Hypertherm’s

specifications and in cases of designs, processes,

TRANSFER OF RIGHTS

You may transfer any remaining rights you may have

hereunder only in connection with the sale of all or

substantially all of your assets or capital stock to a

successor in interest who agrees to be bound by all of the

terms and conditions of this Warranty.

ii Hypertherm Warranty

5-00

Page 6

TABLE OF CONTENTS

ELECTROMAGNETIC COMPATIBILITY ............................................................................................... i

WARRANTY...........................................................................................................................................ii

Section 1 Safety ................................................................................................ 1-1

RECOGNIZE SAFETY INFORMATION ............................................................................................. 1-2

FOLLOW SAFETY INSTRUCTIONS ................................................................................................. 1-2

CUTTING CAN CAUSE FIRE OR EXPLOSION ................................................................................ 1-2

ELECTRIC SHOCK CAN KILL........................................................................................................... 1-2

CUTTING CAN PRODUCE TOXIC FUMES ......................................................................................1-3

ARC RAYS CAN BURN EYES AND SKIN......................................................................................... 1-4

COMPRESSED GAS EQUIPMENT SAFETY.................................................................................... 1-4

ADDITIONAL SAFETY INFORMATION ............................................................................................. 1-4

NOISE CAN DAMAGE HEARING ..................................................................................................... 1-4

GAS CYLINDERS CAN EXPLODE IF DAMAGED ............................................................................1-4

GROUNDING SAFETY ...................................................................................................................... 1-5

PLASMA ARC CAN CAUSE INJURY AND BURNS .......................................................................... 1-5

PACEMAKER AND HEARING AID OPERATION .............................................................................. 1-5

Section 1a Sécurité .......................................................................................... 1a-1

IDENTIFIER LES CONSIGNES DE SÉCURITÉ.............................................................................. 1a-2

SUIVRE LES INSTRUCTIONS DE SÉCURITÉ ............................................................................... 1a-2

LE COUPAGE PEUT PROVOQUER UN INCENDIE OU UNE EXPLOSION .................................. 1a-2

DANGER AVERTISSEMENT PRÉCAUTION ................................................................................ 1a-2

LE COUPAGE PEUT PRODUIRE DES VAPEURS TOXIQUES...................................................... 1a-3

LES CHOCS ÉLECTRIQUES PEUVENT ÊTRE FATALS................................................................ 1a-3

L’ARC PLASMA PEUT PROVOQUER DES BLESSURES OU DES BRÛLURES .......................... 1a-4

MISE À LA MASSE ET À LA TERRE............................................................................................... 1a-4

LES RAYONS DE L’ARC PEUVENT BRÛLER LES YEUX ET LA PEAU ........................................ 1a-4

SÉCURITÉ DES BOUTEILLES DE GAZ COMPRIMÉ .................................................................... 1a-5

LE BRUIT PEUT PROVOQUER DES PROBLÈMES AUDITIFS ..................................................... 1a-5

PACEMAKERS ET PROTHÈSES AUDITIVES................................................................................ 1a-5

LES BOUTEILLES DE GAZ COMPRIMÉ PEUVENT EXPLOSER EN CAS DE DOMMAGES ....... 1a-5

Section 2 SPECIFICATIONS............................................................................. 2-1

INTRODUCTION................................................................................................................................ 2-2

SPECIFICATIONS ............................................................................................................................. 2-3

Power Supply .............................................................................................................................. 2-3

PAC125 TORCHES ........................................................................................................................... 2-4

PAC125T Hand Torch Assembly.................................................................................................. 2-4

PAC125M Machine Torch Assembly ............................................................................................ 2-4

S MARK ........................................................................................................................................... 2-5

SETUP SPECIFICATIONS ................................................................................................................ 2-5

Power Cord Plugs........................................................................................................................ 2-5

Power Cords ................................................................................................................................ 2-5

208/240/480/600V Power Supplies ............................................................................................. 2-5

200/230/400V Power Supplies .................................................................................................... 2-5

Power Requirements ................................................................................................................... 2-6

Service Manual

iii

Page 7

TABLE OF CONTENTS

Section 3 MAINTENANCE.................................................................................... 3-1

INTRODUCTION................................................................................................................................ 3-2

ROUTINE MAINTENANCE ................................................................................................................ 3-2

Bowl Draining/Filter Element Cleaning ........................................................................................ 3-2

Removal, Cleaning and Replacement of the Cooling Air Filter.................................................... 3-3

CONTROLS AND INDICATORS ........................................................................................................ 3-4

THEORY OF OPERATION ................................................................................................................ 3-5

General ........................................................................................................................................ 3-5

Functional Description ................................................................................................................. 3-6

SEQUENCE OF OPERATION ........................................................................................................... 3-7

TROUBLESHOOTING .......................................................................................................................3-8

Test Equipment ............................................................................................................................ 3-8

Troubleshooting Procedures........................................................................................................ 3-8

Visual Inspection - External ......................................................................................................... 3-8

Visual Inspection - Internal .......................................................................................................... 3-9

Resistance Checks .................................................................................................................... 3-10

POWERMAX900 TROUBLESHOOTING GUIDE ............................................................................ 3-13

Voltage Checks.......................................................................................................................... 3-18

Power Board Test Points ........................................................................................................... 3-22

POWER BOARD .............................................................................................................................. 3-22

CONTROL BOARD .......................................................................................................................... 3-24

Control Board LEDs................................................................................................................... 3-24

PAC125T TORCH PARTS REMOVAL AND REPLACEMENT ......................................................... 3-26

Torch Main Body Removal and Replacement ........................................................................... 3-26

Torch Switch Removal and Replacement .................................................................................. 3-27

PAC125M TORCH PARTS REMOVAL AND REPLACEMENT ........................................................ 3-28

Removal .................................................................................................................................... 3-28

Replacement ............................................................................................................................. 3-28

QUICK DISCONNECT O-RING REMOVAL AND REPLACEMENT ................................................ 3-30

Section 4 PARTS LIST – 208/240/480V ............................................................. 4-1

POWER SUPPLY - 208/240/480V ..................................................................................................... 4-2

Front ............................................................................................................................................ 4-2

Top and Right Side ...................................................................................................................... 4-4

Bottom and Left Side ................................................................................................................... 4-6

Rear ............................................................................................................................................. 4-8

Powermax900 Field Upgrade Kits and Optional Parts .............................................................. 4-10

POWER SUPPLIES - 208/240/480V, 1F/3F, 60 HZ ......................................................................... 4-10

RECOMMENDED SPARE PARTS - POWERMAX900- 208/240/480V ........................................... 4-11

Section 5 PARTS LIST - 200/230/400V .............................................................. 5-1

POWER SUPPLY - 200/230/400V ..................................................................................................... 5-2

Front ............................................................................................................................................ 5-2

Top and Right Side ...................................................................................................................... 5-4

Bottom and Left Side ................................................................................................................... 5-6

Rear ............................................................................................................................................. 5-8

Powermax900 Field Upgrade Kits and Optional Parts .............................................................. 5-10

POWER SUPPLIES - 200/230/400V, 1F/3F, 50/60 HZ .................................................................... 5-10

RECOMMENDED SPARE PARTS - POWERMAX900- 200/230/400V ........................................... 5-11

iv

Service Manual

Page 8

TABLE OF CONTENTS

Section 6 PARTS LIST - 400V CE ...................................................................... 6-1

POWER SUPPLY - 400V CE ............................................................................................................. 6-2

Front ............................................................................................................................................ 6-2

Top and Right Side ...................................................................................................................... 6-4

Bottom and Left Side ................................................................................................................... 6-6

Rear ............................................................................................................................................. 6-8

Powermax900 Field Upgrade Kits and Optional Parts .............................................................. 6-10

POWER SUPPLIES - 400V CE, 3F, 50 HZ...................................................................................... 6-10

RECOMMENDED SPARE PARTS - POWERMAX900 400V CE .................................................... 6-11

Section 7 PARTS LIST - TORCHES AND CONSUMABLES ........................... 7-1

PAC125T Torch Assembly and 25 ft (7.6 m) Lead - 083066........................................................ 7-2

PAC125T Torch Assembly and 50 ft (15.2 m) Lead - 083067...................................................... 7-2

PAC125M Torch Assembly and 14 ft (4.3 m) Lead - 083069 w/pigtail, 083073 no pigtail ........... 7-3

PAC125M Torch Assembly and 25 ft (7.6 m) Lead - 083068 w/pigtail, 083072 no pigtail ........... 7-3

PAC125M Torch Assembly and 35 ft (10.6 m) Lead - 083070 w/pigtail, 083074 no pigtail ......... 7-3

PAC125M Torch Assembly and 50 ft (15.2 m) Lead - 083071 w/pigtail, 083075 no pigtail ......... 7-3

Consumable Parts Kits ................................................................................................................ 7-4

Consumable Spare Parts Kit - CE (128289) ................................................................................ 7-4

Consumable Configurations ........................................................................................................ 7-5

Section 8 Wiring Diagrams................................................................................. 8-1

Appendix a ........................................................................................................... a-1

AERATION MANIFOLD FOR PLASMA CUTTING ALUMINUM ........................................................ a-1

Introduction .................................................................................................................................. a-1

Making an Aeration Manifold - Figure a-1.................................................................................... a-1

Appendix b ...........................................................................................................b-1

STANDARDS INDEX ......................................................................................................................... b-1

Appendix c ........................................................................................................... c-1

MACHINE INTERFACE SPECIFICATIONS....................................................................................... c-1

Service Manual

v

Page 9

TABLE OF CONTENTS

vi

Service Manual

Page 10

S

AFETY

Section 1

SAFETY

In this section:

Recognize Safety Information ................................................................................1-2

Follow Safety Instructions ......................................................................................1-2

Cutting Can Cause Fire or Explosion .....................................................................1-2

Electric Shock Can Kill ...........................................................................................1-3

Cutting Can Produce Toxic Fumes .........................................................................1-3

Plasma Arc Can Cause Injury and Burns ............................................................... 1-4

Arc Rays Can Burn Eyes and Skin ........................................................................ 1-4

Grounding Safety ...................................................................................................1-4

Compressed Gas Equipment Safety ......................................................................1-5

Gas Cylinders Can Explode if Damaged................................................................ 1-5

Noise Can Damage Hearing ..................................................................................1-5

Pacemaker and Hearing Aid Operation.................................................................. 1-5

Additional Safety Information .................................................................................1-5

Hypertherm Plasma Systems

1-1

8-99

Page 11

S

AFETY

RECOGNIZE SAFETY INFORMATION

The symbols shown in this section are used to identify

potential hazards. When you see a safety symbol in

this manual or on your machine, understand the

potential for personal injury, and follow the related

instructions to avoid the hazard.

FOLLOW SAFETY INSTRUCTIONS

Read carefully all safety messages in this manual and

safety labels on your machine.

• Keep the safety labels on your machine in good

condition. Replace missing or damaged labels

immediately.

• Learn how to operate the machine and how to use

the controls properly. Do not let anyone operate it

without instruction.

• Keep your machine in proper working condition.

Unauthorized modifications to the machine may

affect safety and machine service life.

DANGER WARNING CAUTION

A signal word DANGER or WARNING is used with a

safety symbol. DANGER identifies the most serious

hazards.

• DANGER and WARNING safety labels are located

on your machine near specific hazards.

• WARNING safety messages precede related instructions in this manual that may result in injury or death

if not followed correctly.

• CAUTION safety messages precede related instructions in this manual that may result in damage to

equipment if not followed correctly.

CUTTING CAN CAUSE FIRE OR EXPLOSION

Fire Prevention

• Be sure the area is safe before doing any cutting.

Keep a fire extinguisher nearby.

• Remove all flammables within 35 feet (10 m) of the

cutting area.

• Quench hot metal or allow it to cool before handling

or before letting it touch combustible materials.

• Never cut containers with potentially flammable

materials inside – they must be emptied and

properly cleaned first.

• Ventilate potentially flammable atmospheres before

cutting.

• When cutting with oxygen as the plasma gas, an

exhaust ventilation system is required.

Explosion Prevention

• Do not use the plasma system if explosive dust or

vapors may be present.

• Do not cut pressurized cylinders, pipes, or any

closed container.

• Do not cut containers that have held combustible

materials.

WARNING

Explosion Hazard

Argon-Hydrogen and Methane

Hydrogen and methane are flammable gases that

present an explosion hazard. Keep flames away from

cylinders and hoses that contain methane or hydrogen

mixtures. Keep flames and sparks away from the torch

when using methane or argon-hydrogen plasma.

WARNING

Hydrogen Detonation with Aluminum Cutting

• When cutting aluminum underwater, or with the

water touching the underside of the aluminum, free

hydrogen gas may collect under the workpiece and

detonate during plasma cutting operations.

• Install an aeration manifold on the floor of the water

table to eliminate the possibility of hydrogen detonation. Refer to the Appendix section of this manual

for aeration manifold details.

1-2

8-99

Hypertherm Plasma Systems

Page 12

ELECTRIC SHOCK CAN KILL

S

AFETY

Touching live electrical parts can cause a fatal shock or

severe burn.

• Operating the plasma system completes an electrical

circuit between the torch and the workpiece. The

workpiece and anything touching the workpiece are

part of the electrical circuit.

• Never touch the torch body, workpiece or the water in

a water table when the plasma system is operating.

Electric Shock Prevention

All Hypertherm plasma systems use high voltage in

the cutting process (200 to 400 VDC are common).

Take the following precautions when operating this

system:

• Wear insulated gloves and boots, and keep your

body and clothing dry.

• Do not stand, sit or lie on – or touch – any wet

surface when using the plasma system.

• Insulate yourself from work and ground using dry

insulating mats or covers big enough to prevent any

physical contact with the work or ground. If you must

work in or near a damp area, use extreme caution.

• Provide a disconnect switch close to the power

supply with properly sized fuses. This switch allows

the operator to turn off the power supply quickly in an

emergency situation.

• When using a water table, be sure that it is correctly

connected to earth ground.

• Install and ground this equipment according to the

instruction manual and in accordance with national

and local codes.

• Inspect the input power cord frequently for damage

or cracking of the cover. Replace a damaged power

cord immediately. Bare wiring can kill.

• Inspect and replace any worn or damaged torch

leads.

• Do not pick up the workpiece, including the waste

cutoff, while you cut. Leave the workpiece in place or

on the workbench with the work cable attached

during the cutting process.

• Before checking, cleaning or changing torch parts,

disconnect the main power or unplug the power

supply.

• Never bypass or shortcut the safety interlocks.

• Before removing any power supply or system enclosure cover, disconnect electrical input power. Wait 5

minutes after disconnecting the main power to allow

capacitors to discharge.

• Never operate the plasma system unless the power

supply covers are in place. Exposed power supply

connections present a severe electrical hazard.

• When making input connections, attach proper

grounding conductor first.

• Each Hypertherm plasma system is designed to be

used only with specific Hypertherm torches. Do not

substitute other torches which could overheat and

present a safety hazard.

CUTTING CAN PRODUCE TOXIC FUMES

Cutting can produce toxic fumes and gases that

deplete oxygen and cause injury or death.

• Keep the cutting area well ventilated or use an

approved air-supplied respirator.

• Do not cut in locations near degreasing, cleaning or

spraying operations. The vapors from certain

chlorinated solvents decompose to form phosgene

gas when exposed to ultraviolet radiation.

• Do not cut metal coated or containing toxic materials, such as zinc (galvanized), lead, cadmium or

Hypertherm Plasma Systems

beryllium, unless the area is well ventilated and the

operator wears an air-supplied respirator. The

coatings and any metals containing these elements

can produce toxic fumes when cut.

• Never cut containers with potentially toxic materials

inside – they must be emptied and properly cleaned

first.

• This product, when used for welding or cutting,

produces fumes or gases which contain chemicals

known to the State of California to cause birth

defects and, in some cases, cancer.

1-3

8-99

Page 13

S

AFETY

PLASMA ARC CAN CAUSE INJURY AND BURNS

Instant-On Torches

Plasma arc comes on immediately when the torch

switch is activated.

ARC RAYS CAN BURN EYES AND SKIN

Eye Protection Plasma arc rays produce intense

visible and invisible (ultraviolet and infrared) rays that

can burn eyes and skin.

• Use eye protection in accordance with applicable

national or local codes.

• Wear eye protection (safety glasses or goggles with

side shields, or a welding helmet) with appropriate

lens shading to protect your eyes from the arc’s

ultraviolet and infrared rays.

Lens Shade

Arc Current AWS (USA) ISO 4850

Up to 100 A No. 8 No. 11

100-200 A No. 10 No. 11-12

200-400 A No. 12 No. 13

Over 400 A No. 14 No. 14

The plasma arc will cut quickly through gloves and

skin.

• Keep away from the torch tip.

• Do not hold metal near the cutting path.

• Never point the torch toward yourself or others.

Skin Protection Wear protective clothing to protect

against burns caused by ultraviolet light, sparks and

hot metal.

• Gauntlet gloves, safety shoes and hat.

• Flame-retardant clothing to cover all exposed areas.

• Cuffless trousers to prevent entry of sparks and

slag.

• Remove any combustibles, such as a butane lighter

or matches, from your pockets before cutting.

Cutting Area Prepare the cutting area to reduce

reflection and transmission of ultraviolet light:

• Paint walls and other surfaces with dark colors to

reduce reflection.

• Use protective screens or barriers to protect others

from flash and glare.

• Warn others not to watch the arc. Use placards or

signs.

GROUNDING SAFETY

Work Cable Attach the work cable securely to the

workpiece or the work table with good metal-to-metal

contact. Do not connect it to the piece that will fall away

when the cut is complete.

Work Table Connect the work table to an earth

ground, in accordance with appropriate national or local

electrical codes.

1-4

8-99

Input Power

• Be sure to connect the power cord ground wire to

the ground in the disconnect box.

• If installation of the plasma system involves connect-

ing the power cord to the power supply, be sure to

connect the power cord ground wire properly.

• Place the power cord's ground wire on the stud first,

then place any other ground wires on top of the

power cord ground. Fasten the retaining nut tightly.

• Tighten all electrical connections to avoid excessive

heating.

Hypertherm Plasma Systems

Page 14

S

AFETY

COMPRESSED GAS EQUIPMENT SAFETY

• Never lubricate cylinder valves or regulators with oil

or grease.

• Use only correct gas cylinders, regulators, hoses and

fittings designed for the specific application.

• Maintain all compressed gas equipment and associated parts in good condition.

• Label and color-code all gas hoses to identify the

type of gas in each hose. Consult applicable national

or local codes.

NOISE CAN DAMAGE HEARING

GAS CYLINDERS CAN EXPLODE

IF DAMAGED

Gas cylinders contain gas under high pressure. If

damaged, a cylinder can explode.

• Handle and use compressed gas cylinders in accordance with applicable national or local codes.

• Never use a cylinder that is not upright and secured

in place.

• Keep the protective cap in place over valve except

when the cylinder is in use or connected for use.

• Never allow electrical contact between the plasma

arc and a cylinder.

• Never expose cylinders to excessive heat, sparks,

slag or open flame.

• Never use a hammer, wrench or other tool to open a

stuck cylinder valve.

PACEMAKER AND HEARING

AID OPERATION

Prolonged exposure to noise from cutting or gouging

can damage hearing.

• Use approved ear protection when using plasma

system.

• Warn others nearby about the noise hazard.

ADDITIONAL SAFETY INFORMATION

1. ANSI Standard Z49.1,

Welding Society, 550 LeJeune Road

P.O. Box 351020, Miami, FL 33135

2. ANSI Standard Z49.2,

Welding Processes

1430 Broadway, New York, NY 10018

3. ANSI Standard Z87.1,

Educational Eye and Face Protection

Standards Institute, 1430 Broadway, New York, NY 10018

4. AWS F4.1,

Welding and Cutting of Containers and Piping That Have Held

Hazardous Substances

550 LeJeune Road, P.O. Box 351040, Miami, FL 33135

Recommended Safe Practices for the Preparation for

Safety in Welding and Cutting

Fire Prevention in the Use of Cutting and

, American National Standards Institute

Safe Practices for Occupation and

, American National

, American Welding Society

, American

Pacemaker and hearing aid operation can be affected

by magnetic fields from high currents.

Pacemaker and hearing aid wearers should consult a

doctor before going near any plasma arc cutting and

gouging operations.

To reduce magnetic field hazards:

• Keep both the work cable and the torch lead to one

side, away from your body.

• Route the torch leads as close as possible to the

work cable.

• Do not wrap or drape the torch lead or work cable

around your body.

• Keep as far away from the power supply as possible.

5. AWS F5.2,

Cutting

550 LeJeune Road, P.O. Box 351040, Miami, FL 33135

6. CGA Pamphlet P-1,

Cylinders

1235 Jefferson Davis Highway, Arlington, VA 22202

7. CSA Standard W117.2,

Canadian Standards Association Standard Sales

178 Rexdale Boulevard, Rexdale, Ontario M9W 1R3, Canada

8. NFPA Standard 51B,

Fire Protection Association

470 Atlantic Avenue, Boston, MA 02210

9. NFPA Standard 70–1978,

Protection Association, 470 Atlantic Avenue, Boston, MA 02210

10. OSHA,

U.S. Government Printing Office, Washington, D.C. 20402.

Recommended Safe Practices for Plasma Arc

, American Welding Society

, Compressed Gas Association

Safety and Health Standards

Safe Handling of Compressed Gases in

Code for Safety in Welding and Cutting

Cutting and Welding Processes

National Electrical Code

, 29FR 1910

, National

, National Fire

,

Hypertherm Plasma Systems

1-5

8-99

Page 15

S

AFETY

1-6

8-99

Hypertherm Plasma Systems

Page 16

S

ÉCURITÉ

Section 1a

SÉCURITÉ

Cette section comprend:

IDENTIFIER LES CONSIGNES DE SÉCURITÉ..............................................1a-2

SUIVRE LES INSTRUCTIONS DE SÉCURITÉ ...............................................1a-2

LE COUPAGE PEUT PROVOQUER UN INCENDIE OU UNE EXPLOSION ..1a-2

LES CHOCS ÉLECTRIQUES PEUVENT ÊTRE FATALS................................1a-3

LE COUPAGE PEUT PRODUIRE DES VAPEURS TOXIQUES......................1a-3

L’ARC PLASMA PEUT PROVOQUER DES BLESSURES

OU DES BRÛLURES .......................................................................................1a-4

LES RAYONS DE L’ARC PEUVENT BRÛLER LES YEUX ET LA PEAU........1a-4

MISE À LA MASSE ET À LA TERRE ...............................................................1a-4

SÉCURITÉ DES BOUTEILLES DE GAZ COMPRIMÉ ....................................1a-5

LES BOUTEILLES DE GAZ COMPRIMÉ PEUVENT EXPLOSER EN CAS DE

DOMMAGES ...............................................................................................1a-5

LE BRUIT PEUT PROVOQUER DES PROBLÈMES AUDITIFS .....................1a-5

PACEMAKERS ET PROTHÈSES AUDITIVES ................................................1a-5

HYPERTHERM Systèmes plasma 1a-1

08/99

Page 17

S

ÉCURITÉ

IDENTIFIER LES CONSIGNES

DE SÉCURITÉ

Les symboles indiqués dans cette section sont utilisés pour

identifier les risques éventuels. Si vous trouvez un symbole

de sécurité, que ce soit dans ce manuel ou sur

l’équipement, soyez conscient des risques de blessures et

suivez les instructions correspondantes afin d’éviter ces

risques.

SUIVRE LES INSTRUCTIONS

DE SÉCURITÉ

Lire attentivement toutes les consignes de sécurité dans le

présent manuel et sur les étiquettes de sécurité se trouvant

sur la machine.

• Les étiquettes de sécurité doivent rester lisibles.

Remplacer immédiatement les étiquettes manquantes ou

abîmées.

• Apprendre à faire fonctionner la machine et à utiliser

correctement les commandes. Ne laisser personne utiliser

la machine sans connaître son fonctionnement.

• Garder la machine en bon état. Des modifications non

autorisées sur la machine peuvent engendrer des

problèmes de sécurité et raccourcir la durée d’utilisation

de l’équipement.

DANGER AVERTISSEMENT PRÉCAUTION

Les signaux DANGER ou AVERTISSEMENT sont utilisés

avec un symbole de sécurité, DANGER correspondant aux

risques les plus sérieux.

• Les étiquettes de sécurité DANGER et AVERTISSEMENT sont situées sur la machine pour signaler certains

dangers spécifiques.

• Les messages d’AVERTISSEMENT précèdent les

instructions d’utilisation expliquées dans ce manuel et

signalent les risques de blessures ou de mort au cas où

ces instructions ne seraient pas suivies correctement.

• Les messages de PRÉCAUTION précèdent les

instructions d’utilisation contenues dans ce manuel et

signalent que le matériel risque d’être endommagé si les

instructions ne sont pas suivies correctement.

LE COUPAGE PEUT PROVOQUER UN INCENDIE

OU UNE EXPLOSION

Prévention des incendies

• Avant de commencer, s’assurer que la zone de coupage

ne présente aucun danger. Conserver un extincteur à

proximité.

• Éloigner toute matière inflammable à une distance d’au

moins 10 m du poste de coupage.

• Tremper le métal chaud ou le laisser refroidir avant de

le manipuler ou avant de le mettre en contact avec des

matériaux combustibles.

• Ne jamais couper des récipients pouvant contenir des

matières inflammables avant de les avoir vidés et

nettoyés correctement.

• Aérer toute atmosphère potentiellement inflammable

avant d’utiliser un système plasma.

• Lors de l’utilisation d’oxygène comme gaz plasma, un

système de ventilation par aspiration est nécessaire.

Prévention des explosions

• Ne pas couper en présence de poussière ou de vapeurs.

• Ne pas couper de bouteilles, de tuyaux ou autres

récipients fermés et pressurisés.

• Ne pas couper de récipients contenant des matières

combustibles.

AVERTISSEMENT

Risque d’explosion

Argon-hydrogène et méthane

L’hydrogène et le méthane sont des gaz inflammables et

potentiellement explosifs. Conserver à l’écart de toute

flamme les bouteilles et tuyaux contenant des mélanges à

base d’hydrogène ou de méthane. Maintenir toute flamme

et étincelle à l’écart de la torche lors de l’utilisation d’un

plasma d’argon-hydrogène ou de méthane.

AVERTISSEMENT

Détonation de l’hydrogène lors du

coupage de l’aluminium

• Lors du coupage de l’aluminium sous l’eau, ou si l’eau

touche la partie inférieure de la pièce d’aluminium, de

l’hydrogène libre peut s’accumuler sous la pièce à couper

et détonner lors du coupage plasma.

• Installer un collecteur d’aération au fond de la table à eau

afin d’éliminer les risques de détonation de l’hydrogène.

Se référer à l’annexe du manuel pour plus de

renseignements sur les collecteurs d’aération.

1a-2

08/99

HYPERTHERM Systèmes plasma

Page 18

LES CHOCS ÉLECTRIQUES PEUVENT ÊTRE FATALS

S

ÉCURITÉ

Toucher une pièce électrique sous tension peut provoquer

un choc électrique fatal ou des brûlures graves.

• La mise en fonctionnement du système plasma ferme un

circuit électrique entre la torche et la pièce à couper. La

pièce à couper et tout autre élément en contact avec cette

pièce font partie du circuit électrique.

• Ne jamais toucher le corps de la torche, la pièce à couper

ou l’eau de la table à eau pendant le fonctionnement du

système plasma.

Prévention des chocs électriques

Tous les systèmes plasma Hypertherm utilisent des hautes

tensions pour le coupage (souvent de 200 à 400 V).On doit

prendre les précautions suivantes quand on utilise le

système plasma :

• Porter des bottes et des gants isolants et garder le corps

et les vêtements au sec.

• Ne pas se tenir, s’asseoir ou se coucher sur une surface

mouillée, ni la toucher quand on utilise le système

plasma.

• S’isoler de la surface de travail et du sol en utilisant des

tapis isolants secs ou des couvertures assez grandes

pour éviter tout contact physique avec le travail ou le sol.

S’il s’avère nécessaire de travailler dans ou près d’un

endroit humide, procéder avec une extrême prudence.

• Installer un sectionneur avec fusibles appropriés, à

proximité de la source de courant. Ce dispositif permet à

l’opérateur d’arrêter rapidement la source de courant en

cas d’urgence.

• En cas d’utilisation d’une table à eau, s’assurer que cette

dernière est correctement mise à la terre.

• Installer et mettre à la terre l’équipement selon les

instructions du présent manuel et conformément aux

codes électriques locaux et nationaux.

• Inspecter fréquemment le cordon d’alimentation primaire

pour s’assurer qu’il n’est ni endommagé, ni fendu.

Remplacer immédiatement un cordon endommagé. Un

câble dénudé peut tuer.

• Inspecter et remplacer les câbles de la torche qui sont

usés ou endommagés.

• Ne pas saisir la pièce à couper ni les chutes lors du

coupage. Laisser la pièce à couper en place ou sur la

table de travail, le câble de retour connecté lors du

coupage.

• Avant de vérifier, de nettoyer ou de remplacer les pièces

de la torche, couper l’alimentation ou débrancher la prise

de courant.

• Ne jamais contourner ou court-circuiter les verrouillages

de sécurité.

• Avant d’enlever le capot du système ou de la source de

courant, couper l’alimentation électrique. Attendre ensuite

5 minutes pour que les condensateurs se déchargent.

• Ne jamais faire fonctionner le système plasma sans que

les capots de la source de courant ne soient en place.

Les raccords exposés de la source de courant sont

extrêmement dangereux.

• Lors de l’installation des connexions, attacher tout d’abord

la prise de terre appropriée.

• Chaque système plasma Hypertherm est conçu pour être

utilisé uniquement avec des torches Hypertherm

spécifiques. Ne pas utiliser des torches inappropriées qui

pourraient surchauffer et présenter des risques pour la

sécurité.

LE COUPAGE PEUT PRODUIRE DES VAPEURS TOXIQUES

Le coupage peut produire des vapeurs et des gaz toxiques

qui réduisent le niveau d’oxygène dans l’air et peuvent

provoquer des blessures, voire la mort.

• Conserver le poste de coupage bien aéré ou utiliser un

masque respiratoire homologué.

• Ne pas procéder au coupage près d’endroits où

s’effectuent le dégraissage, le nettoyage ou la

vaporisation. Certains solvants chlorés se décomposent

sous l’effet des rayons ultraviolets et forment du

phosgène.

• Ne pas couper des métaux peints ou contenant des

matières toxiques comme le zinc (galvanisé), le plomb, le

cadmium ou le béryllum, à moins que la zone de travail

soit très bien ventilée et que l’opérateur porte un masque

respiratoire. Les revêtements et métaux contenant ces

matières peuvent produire des vapeurs toxiques lors du

coupage.

• Ne jamais couper de récipients pouvant contenir des

matières inflammables avant de les avoir vidés et

nettoyés correctement.

HYPERTHERM Systèmes plasma 1a-3

08/99

Page 19

S

ÉCURITÉ

L’ARC PLASMA PEUT PROVOQUER DES BLESSURES OU DES BRÛLURES

Torches à allumage instantané

L’arc plasma s’allume immédiatement après que la torche

soit mise en marche.

LES RAYONS DE L’ARC PEUVENT BRÛLER LES YEUX ET LA PEAU

Protection des yeux Les rayons de l’arc plasma

produisent de puissants rayons visibles ou invisibles

(ultraviolets et infrarouges) qui peuvent brûler les yeux et la

peau.

• Utiliser des lunettes de sécurité conformément aux codes

locaux ou nationaux en vigueur.

• Porter des lunettes de protection (lunettes ou masque

muni d’écrans latéraux ou encore masque de soudure)

avec des verres teintés appropriés pour protéger les yeux

des rayons ultraviolets et infrarouges de l’arc.

Puissance des verres teintés

Courant de l’arc AWS (É.-U.) ISO 4850

Jusqu’à 100 A No 8N

100-200 A No 10 No 11-12

200-400 A No 12 No 13

Plus de 400 A No 14 No 14

Protection de la peau Porter des vêtements de sécurité

pour se protéger contre les brûlures que peuvent causer les

rayons ultraviolets, les étincelles et le métal brûlant :

o

11

L’arc plasma coupe facilement les gants et la peau.

• Rester éloigné de l’extrémité de la torche.

• Ne pas tenir de métal près de la trajectoire de coupe.

• Ne jamais pointer la torche vers soi ou d’autres

personnes.

• Gants à crispin, chaussures et casque de sécurité.

• Vêtements ignifuges couvrant toutes les parties exposées

du corps.

• Pantalon sans revers pour éviter que des étincelles ou

des scories puissent s’y loger.

• Avant le coupage, retirer de ses poches tout objet

combustible comme les briquets au butane ou les

allumettes.

Zone de coupage Préparer la zone de coupage afin de

réduire la réverbération et la transmission de la lumière

ultraviolette :

• Peindre les murs et autres surfaces de couleur sombre

pour réduire la réflexion de la lumière.

• Utiliser des écrans et autres dispositifs de protection afin

de protéger les autres personnes de la lumière et de la

réverbération.

• Prévenir les autres personnes de ne pas regarder l’arc.

Utiliser des affiches ou des panneaux.

MISE À LA MASSE ET À LA TERRE

Câble de retour Bien fixer le câble de retour (ou de

masse) à la pièce à couper ou à la table de travail de façon

à assurer un bon contact métal-métal. Ne pas fixer le câble

de retour à la partie de la pièce qui doit se détacher.

Table de travail Raccorder la table de travail à la terre,

conformément aux codes de sécurité locaux ou nationaux

appropriés.

1a-4

08/99

Alimentation

• S’assurer que le fil de terre du cordon d’alimentation est

connecté à la terre dans le coffret du sectionneur.

• S’il est nécessaire de brancher le cordon d’alimentation à

la source de courant lors de l’installation du système,

s’assurer que le fil de terre est correctement branché.

• Placer tout d’abord le fil de terre du cordon d’alimentation

sur le plot de mise à la terre puis placer les autres fils de

terre par-dessus. Bien serrer l’écrou de retenue.

• S’assurer que toutes les connexions sont bien serrées

pour éviter la surchauffe.

HYPERTHERM Systèmes plasma

Page 20

S

ÉCURITÉ

SÉCURITÉ DES BOUTEILLES DE GAZ

COMPRIMÉ

• Ne jamais lubrifier les robinets des bouteilles ou les

régulateurs avec de l’huile ou de la graisse.

• Utiliser uniquement les bouteilles, régulateurs, tuyaux et

accessoires appropriés et conçus pour chaque application

spécifique.

• Entretenir l’équipement et les pièces d’équipement à gaz

comprimé afin de les garder en bon état.

• Étiqueter et coder avec des couleurs tous les tuyaux de

gaz afin d’identifier le type de gaz contenu dans chaque

tuyau. Se référer aux codes locaux ou nationaux en

vigueur.

LE BRUIT PEUT PROVOQUER DES

PROBLÈMES AUDITIFS

LES BOUTEILLES DE GAZ

COMPRIMÉ PEUVENT EXPLOSER

EN CAS DE DOMMAGES

Les bouteilles de gaz contiennent du gaz à haute pression.

Si une bouteille est endommagée, elle peut exploser.

• Manipuler et utiliser les bouteilles de gaz comprimé

conformément aux codes locaux ou nationaux.

• Ne jamais utiliser une bouteille qui n’est pas placée à la

verticale et bien assujettie.

• Le capuchon de protection doit être placé sur le robinet

sauf si la bouteille est en cours d’utilisation ou connectée

pour utilisation.

• Éviter à tout prix le contact électrique entre l’arc plasma et

une bouteille.

• Ne jamais exposer des bouteilles à une chaleur

excessive, aux étincelles, aux scories ou aux flammes

nues.

• Ne jamais utiliser des marteaux, des clés ou d’autres

outils pour débloquer le robinet des bouteilles.

PACEMAKERS ET

PROTHÈSES AUDITIVES

Une exposition prolongée au bruit du coupage ou du

gougeage peut provoquer des problèmes auditifs.

• Utiliser un casque de protection homologué lors de

l’utilisation du système plasma.

• Prévenir les personnes aux alentours des risques

encourus en cas d’exposition au bruit.

Les champs magnétiques produits par les courants à haute

tension peuvent affecter le fonctionnement des prothèses

auditives et des pacemakers. Les personnes portant ce

type d’appareil doivent consulter un médecin avant de

s’approcher d’un lieu où s’effectue le coupage ou le

gougeage plasma.

Pour réduire les risques associés aux champs

magnétiques :

• Garder loin de soi et du même côté du corps le câble de

retour et le faisceau de la torche.

• Faire passer le faisceau de la torche le plus près possible

du câble de retour.

• Ne pas s’enrouler le faisceau de la torche ou le câble de

retour autour du corps.

• Se tenir le plus loin possible de la source de courant.

HYPERTHERM Systèmes plasma 1a-5

08/99

Page 21

S

ÉCURITÉ

1a-6

08/99

HYPERTHERM Systèmes plasma

Page 22

Section 2 SPECIFICATIONS

In this section:

SPECIFICATIONS

Introduction ...................................................................................................... 2-2

Specifications ................................................................................................... 2-3

Power Supply .............................................................................................. 2-3

PAC125 Torches............................................................................................... 2-4

PAC125T Hand Torch Assembly.................................................................. 2-4

PAC125M Machine Torch Assembly............................................................2-4

S Mark ........................................................................................................ 2-5

Setup Specifications......................................................................................... 2-5

Power Cord Plugs........................................................................................ 2-5

Power Cords ................................................................................................ 2-5

208/240/480/600V Power Supplies ............................................................. 2-5

200/230/400V Power Supplies .................................................................... 2-5

Power Requirements ................................................................................... 2-6

Service Manual

2-1

Page 23

SPECIFICATIONS

INTRODUCTION

The Powermax900 plasma cutting system uses an inverter power supply to provide a smooth DC output voltage,

producing excellent cut and gouge quality on mild steel, stainless steel, aluminum and other metals. The

Powermax900 power supply provides constant-current output variable from 20 to 55 amps, for optimum

performance on all thicknesses of metal up to 5/8" (16 mm) thick. At 55 amps, the Powermax900 can also cut

metals up to 7/8" (22 mm) thick and will sever metals up to 1-1/8"

(29 mm) thick.

Air is the primary plasma gas, providing low operating cost combined with high-speed performance. Cylinder air or

shop air can be used as long as it is clean, dry and oil-free. When properly set and maintained, the pressure

regulator and gas filter on the power supply ensure that the correct pressure and flow rate is supplied to the

system at the proper quantity and quality. The Powermax900 can also cut with nitrogen when extended electrode

life is a priority.

This service manual provides information for qualified service technicians to troubleshoot and repair the power

supply and torch. Sections 4, 5 and 6 contain in-depth parts lists of the Powermax900 systems. This manual also

provides a detailed list of safety practices, so that the system can be safely tested and maintained. READ THE

SAFETY SECTION (Section 1) FIRST!

The Powermax900 operator manual provides setup and daily operating instructions.

2-2

Figure 2-1 Powermax900 Hand Plasma Cutting System*

* Single-phase 208/240/480V power supply shown.

Service Manual

Page 24

SPECIFICATIONS

Power Supply

Rated Open Circuit Voltage (OCV) (U0) ........................300 VDC

Rated Output Current (I

Rated Output Voltage (U

Duty Cycle (X) @ 40°C ................................................. 50% (I2=55A, U2=120V)

Ambient temperature/duty cycle....................................Power supplies will operate between +14° and

Apparent Input Power (S1) ............................................ 12.5kVA (U1I1)

Input Voltage (U1)/Input Current (I1)

@ 6.6 kw Output ........................................................... 208V/55A; 240V/47A; 480V/28A - 1φ, 50/60 Hz

Dimensions and Weight:

Depth.............................................................................23.1" (590 mm)

Width .............................................................................10.4" (260 mm) without wheels

Height ............................................................................19.6" (500 mm) without wheels

) ..............................................20–55 amps

2

) ............................................ 120 VDC

2

100% (I2=39A, U2=120V for the 208/240/480V power

supplies) See data tag on power

supply for more information on duty cycle.

104° F (-10° and +40° C). Power supplies

operated in an ambient temperature above 86° F

(30° C) may show some decrease in duty cycle.

208V/32A; 240V/28A; 480V/15A - 3φ, 50/60 Hz

200V/57A; 230V/50A; 400V/33A - 1φ, 50/60 Hz

200V/33A; 230V/29A; 400V/18A - 3φ, 50/60 Hz

230V (CE)/29A; 400V (CE)/18A - 3φ, 50/60 Hz

600V/12A - 3φ, 60 Hz

15.3" (390 mm) with wheels

23.7" (620 mm) with wheels

27.7" (700 mm) for 600V power supply

SPECIFICATIONS

10.4"

Figure 2-2 Powermax900 Power Supply with Dimensions

23.1"

Service Manual

19.6"

2-3

10-98

Page 25

SPECIFICATIONS

Weight ...........................................................................65 pounds (30 kg) without wheels

Gas Type.......................................................................Air or Nitrogen

Gas Quality, Air .............................................................Clean, dry, oil-free

Gas Quality, Nitrogen ....................................................99.995% pure

Gas Inlet Pressure ........................................................90 psi (6.2 bar)

Gas Flow .......................................................................360 scfh/6 scfm at 90 psi (170 l/min at

Power Supply pressure regulator setting ......................70 psi (4.8 bar) flowing

PAC125 TORCHES

Maximum 55A Cutting Capacity (PAC125T) .................7/8" (22 mm) @ 50% duty cycle

Maximum 55A Cutting Capacity (PAC125M) ................1/2" (13 mm) @ 50% duty cycle

Maximum 39A Cutting Capacity (PAC125M) ................3/8" (9.5 mm) @ 100% duty cycle

Maximum current at 50% duty cycle .............................55 amps

Gouging Capability (metal removal rate).......................6.3 pounds (2.9 kg)/hr

Weight PAC125T ..........................................................4.5 pounds (2 kg) with 25 ft (7.6 m) lead

Weight PAC125M..........................................................7 pounds (3.2 kg) with 25 ft (7.6 m) lead

72 pounds (33 kg) with wheels

128 pounds (58 kg) for 600V and 230V-CE

power supplies

6.2 bar) supplied to power supply pressure

regulator

7 pounds (3.2 kg) with 50 ft (15 m) lead

9.5 pounds (4.3 kg) with 50 ft (15 m) lead

PAC125T Hand Torch Assembly

3.10"

1.00"

Figure 2-3 PAC125T Torch with Dimensions

PAC125M Machine Torch Assembly

8.72"

8.50"

PAC125T

1.58"

15.06"

1.38"1.00"

2-4

Figure 2-4 PAC125M Torch with Dimensions

Service Manual

Page 26

SPECIFICATIONS

S MARK

The Powermax900 conforms to standard EN50192. The S mark indicates that the power supply and

torch are suitable for use in environments with increased hazard of electrical shock. The hand torches must have

shielded consumable parts to maintain S mark compliance.

SETUP SPECIFICATIONS

Power Cord Plugs

All 208/240/480V power supplies are shipped with a single-phase power cord and plug. To operate as a three-

phase unit, the user must obtain a power cord and plug that is certified by national or local electrical codes. The plug

should be connected to the power cord by a licensed electrician.

All 200/230/400V and 400V CE power supplies are shipped with a three-phase power cord and no plug. The

user must obtain a plug that is certified by national or local electrical codes. The plug should be connected to the

power cord by a licensed electrician.

Power Cords

If the power cord needs to be changed, use the tables below to choose the proper wire size for the appropriate length

cord. Note that the input current used to determine the cord size is I

for single-phase, and a 4-conductor SO type cord for three-phase power supplies. In other countries, use cords that

are certified by national or local codes. Prepare the power cord wires as shown in Fig. 2-5 for non-CE power

supplies, or Fig. 2-6 for CE power supplies. Note that all 4 wires must loop through the toroid in the CE power supply.

Cap or tin the conductor leads and use a #10 terminal on the ground wire. The cord should be installed only by a

licensed electrician.

. In the U.S., use a 3-conductor SO type cord

1eff

208/240/480/600V Power Supplies

Input Phase Input Recommended Power Cord Gauge Size (AWG) Voltage

Current (I

208 VAC 1 39A 8 8 6 4 4

240 VAC 1 33A 8 8 8 6 4

480 VAC 1 19A 12 12 12 10 8

208 VAC 3 23A 8 8 8 6 4

240 VAC 3 20A 10 10 10 8 6

480 VAC 3 10A 12 12 12 12 10

600 VAC 3 8A 12 12 12 12 10

) < 10 ft 10 – 25 ft 25 – 50 ft 50 – 100 ft 100 – 150 ft

1eff

200/230/400V Power Supplies

Input Phase Input Recommended Power Cord Gauge Size (mm2)

Voltage Current (I

200 VAC 1 40A 10 10 16 25 25

230 VAC 1 35A 6 6 10 16 25

400 VAC 1 23A 4 4 4 6 10

200 VAC 3 23A 4 4 6 16 25

230 VAC 3 21A 2.5 4 6 10 16

400 VAC 3 13A 2.5 2.5 2.5 4 6

) < 3 m 3 – 7.5 m 7.5 – 15 m 15 – 30 m 30 – 45 m

1eff

Service Manual

2-5

Page 27

SPECIFICATIONS

4.5" (114 mm)

3.5" (89 mm)

L1

L2

L3

Ground

Figure 2-5 Power Cord Preparation - Non-CE

0.5" (13 mm)

#10

All wires 1 turn

through 109068 toroid.

Figure 2-6 Power Cord Preparation - CE

4.75" (120 mm)

3.75" (95 mm)

L1

L2

L3

#10

Ground

Power Requirements

Line Voltage Disconnect Box

Use a line disconnect box for each power supply. This disconnect box allows the operator to turn the

power supply off quickly in an emergency situation. The switch should be located on a wall near the

power supply, and should be easily accessible to the operator. The interrupt level of the switch must be

equal to or exceed the continuous rating of the fuses. Use slow-blow fuses according to the power

requirements listed below.

Input Input Current Recommended

Voltage Phase @ 6.6 kw Output Slow-Blow Fuse Size

200 VAC 1 57 amps 70 amp

208 VAC 1 55 amps 70 amp

230 VAC 1 50 amps 70 amp

240 VAC 1 47 amps 60 amp

400 VAC 1 33 amps 40 amp

480 VAC 1 28 amps 35 amp

200 VAC 3 33 amps 40 amp

208 VAC 3 32 amps 40 amp

230 VAC 3 29 amps 35 amp

230 VAC (CE) 3 31 amps 40 amp

240 VAC 3 28 amps 35 amp

400 VAC 3 18 amps 25 amp

400 VAC (CE) 3 18 amps 25 amp

480 VAC 3 15 amps 20 amp

600 VAC 3 12 amps 20 amp

2-6

Service Manual

Page 28

MAINTENANCE

Section 3 MAINTENANCE

In this section:

Introduction .......................................................................................... 3-2

Routine Maintenance ...........................................................................3-2

Bowl Draining/Filter Element Cleaning ............................................3-2

Removal, Cleaning and Replacement of Cooling Air Filter.............. 3-3

Controls and Indicators ........................................................................3-4

Theory of Operation .............................................................................3-5

Sequence of Operation ........................................................................3-7

Troubleshooting....................................................................................3-8

Test Equipment ................................................................................ 3-8

Troubleshooting Procedures............................................................3-8

Visual Inspection - External .............................................................3-8

Visual Inspection - Internal ..............................................................3-9

Resistance Checks ........................................................................ 3-10

Powermax900 Troubleshooting Guide ...............................................3-13

Voltage Checks.............................................................................. 3-18

Power Board ...................................................................................... 3-22

Control Board ..................................................................................... 3-24

Control Board LEDs....................................................................... 3-24

PAC125T Torch Parts Removal and Replacement ............................3-26

Torch Main Body Removal and Replacement ............................... 3-26

Torch Switch Removal and Replacement ...................................... 3-27

PAC125M Torch Parts Removal and Replacement............................ 3-28

Removal ........................................................................................ 3-28

Replacement ................................................................................. 3-28

Quick Disconnect O-Ring Removal and Replacement ...................... 3-30

Service Manual

3-1

Page 29

MAINTENANCE

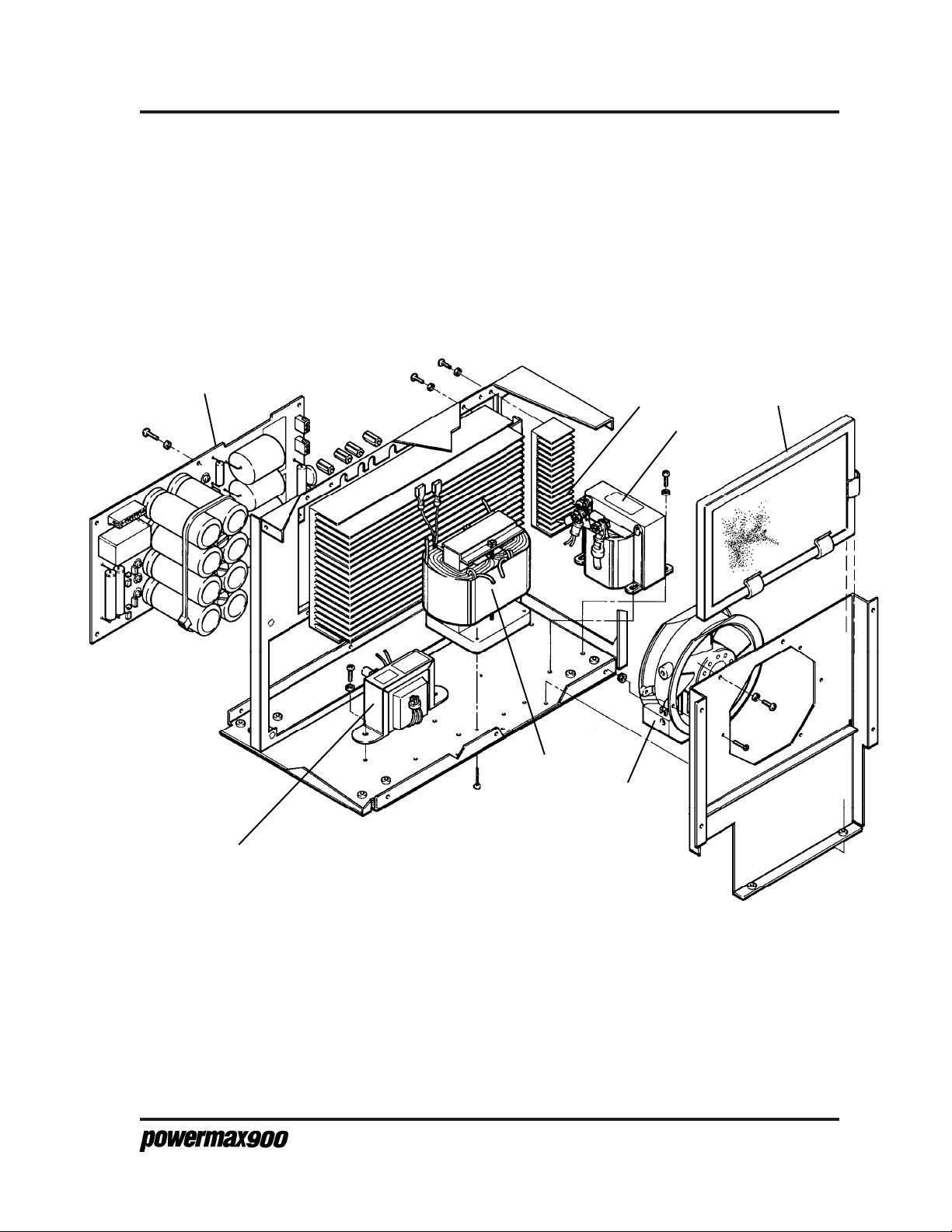

INTRODUCTION

This section provides service technicians with routine maintenance, theory of operation and

troubleshooting of the power supply. Also included in this section is the sequence of operation,

power board and control board test points, and the removal and replacement procedures for the

PAC125T trigger torch and PAC125M machine torch parts.

ROUTINE MAINTENANCE

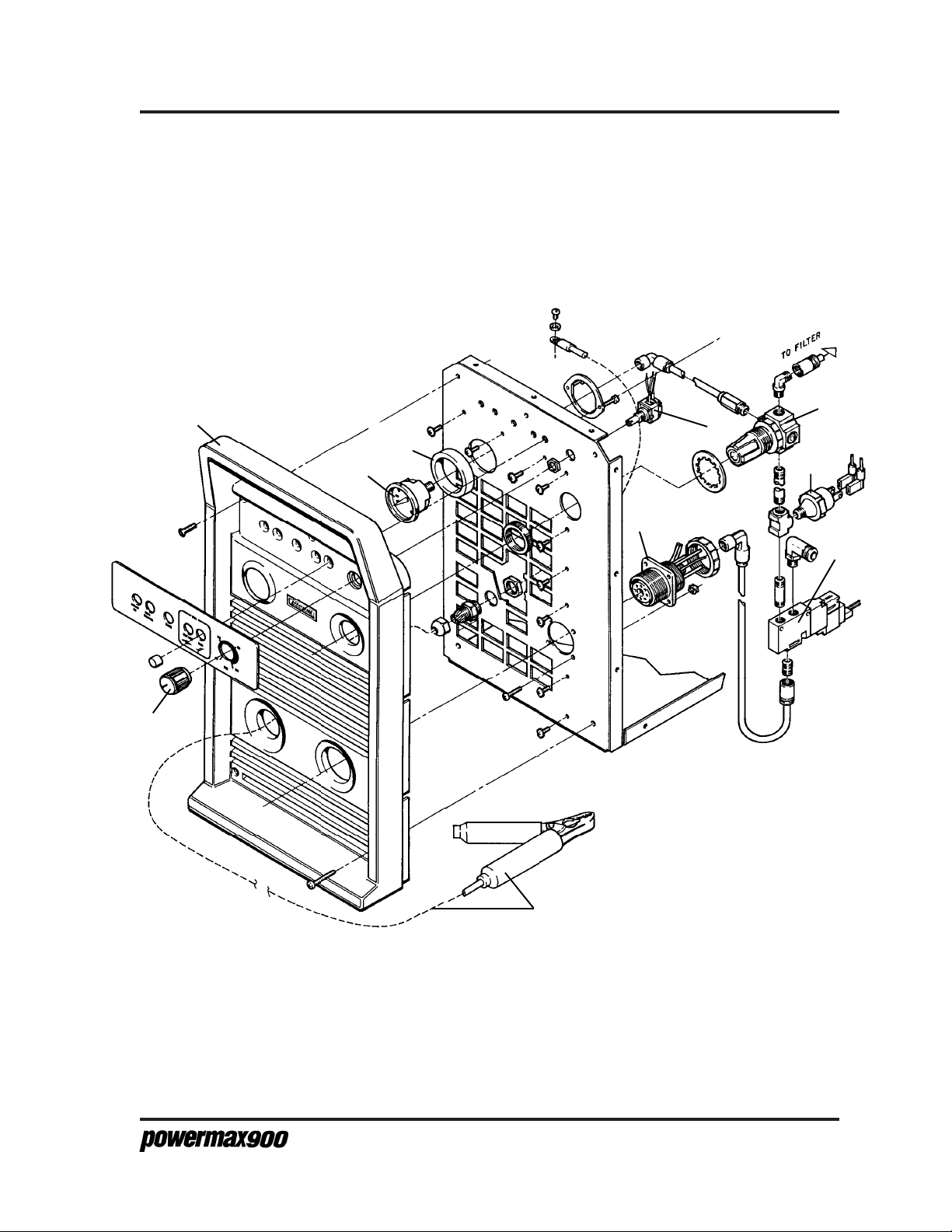

Bowl Draining/Filter Element Cleaning

Moisture coming out of the torch can cause the torch to sputter and hiss. If there is moisture, purge

the lines. If moisture builds up in the bowl of the filter at the rear of the power supply, drain the bowl

and clean the filter element:

1. Shut the gas supply off and disconnect the gas supply hose from the filter assembly

before proceeding.

2. Remove the cap at the bottom of the filter bowl and turn the knurled drain valve to the right to

release water from the bowl.

Gas supply hose

connection

Filter element

Filter Bowl

Cap

Figure 3-1 Filter Assembly

3. Unscrew the filter bowl.

4. Unscrew the filter element. See

Section 4 for part number information.

5. Clean filter element with alcohol, then blow out with air from the inside of the filter element.

Clean the bowl with household soap only.

6. Replace the filter element and filter bowl.

7. Reconnect the gas supply hose.

Powermax900 Field Upgrade Kits and Optional Parts

in

3-2

Service Manual

Page 30

MAINTENANCE

Removal, Cleaning and Replacement of the Cooling Air Filter

Powermax900 systems are normally shipped without air filters. If your Powermax900 has the air filter

option, it will need periodic cleaning. Excessively dirty or dusty environments can block the cooling

air filter (if installed) and cause the power supply to overheat and shut down.

WARNING

SHOCK HAZARD: Always turn off power and unplug cord from wall and wait 5

minutes before removing any power supply cover. If power supply is directly connected to a line disconnect switch, place line disconnect switch to OFF position. In

the U.S., use a "lock-out / tag-out" procedure until the service or maintenance work is

complete. In other countries, follow appropriate local or national safety procedures.

1. Turn the Powermax900 power switch to the OFF (0) position, unplug the power cable

from the wall receptacle and disconnect the gas supply.

2. Remove the screws that secure the power supply cover to the chassis.

3. Remove the cover, and remove the cooling air filter from the clips by sliding the filter to the

left and then up - Fig. 3-2. See

Section 4 for part number information.

Powermax900 Field Upgrade Kits and Optional Parts

in

Cooling Air Filter

Figure 3-2 Air Filter Removal

4. Clean the air filter with either soap and water or with low pressure compressed air.

5. Replace the dry filter in the power unit with the wire mesh facing the fan.