Powermax45 XP® Raw Arc Voltage Kit

Kit de tension d’arc brute Powermax45 XP

Field Service Bulletin

Bulletin de service sur le terrain

809520 | Revision 1 | December 2016

| Révision 1 | Decembre 2016

Hypertherm Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Soporte.Tecnico@hypertherm.com (Technical Service Email)

Hypertherm Plasmatechnik GmbH

Sophie-Scholl-Platz 5

63452 Hanau

Germany

00 800 33 24 97 37 Tel

00 800 49 73 73 29 Fax

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emea@hypertherm.com (Technical Service Email)

Hypertherm (Singapore) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

Marketing.asia@hypertherm.com (Marketing Email)

TechSupportAPAC@hypertherm.com (Technical Service Email)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

HTJapan.info@hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com (Technical Service Email)

Hypertherm Europe B.V.

Vaartveld 9, 4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emea@hypertherm.com

(Technical Service Email)

Hypertherm (Shanghai) Trading Co., Ltd.

B301, 495 ShangZhong Road

Shanghai, 200231

PR China

86-21-80231122 Tel

86-21-80231120 Fax

86-21-80231128 Tel (Technical Service)

techsupport.china@hypertherm.com

(Technical Service Email)

South America & Central America: Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP – Brasil

CEP 07115-030

55 11 2409 2636 Tel

tecnico.sa@hypertherm.com (Technical Service Email)

Hypertherm Korea Branch

#3904. APEC-ro 17. Heaundae-gu. Busan.

Korea 48060

82 (0)51 747 0358 Tel

82 (0)51 701 0358 Fax

Marketing.korea@hypertherm.com (Marketing Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm Pty Limited

GPO Box 4836

Sydney NSW 2001, Australia

61 (0) 437 606 995 Tel

61 7 3219 9010 Fax

au.sales@Hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm (India) Thermal Cutting Pvt. Ltd

A-18 / B-1 Extension,

Mohan Co-Operative Industrial Estate,

Mathura Road, New Delhi 110044, India

91-11-40521201/ 2/ 3 Tel

91-11 40521204 Fax

HTIndia.info@hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

1/28/16

© 2016 Hypertherm Inc. All rights reserved. Tous droits réservés.

Powermax and Hypertherm are trademarks of Hypertherm Inc. and may be registered in the United States and/or other countries. All other trademarks

are the property of their respective holders.

One of Hypertherm’s long-standing core values is a focus on minimizing our impact on the environment. Doing so is critical to our, and our customers’,

success. We are always striving to become better environmental stewards; it is a process we care deeply about.

Powermax et Hypertherm sont des marques d’Hypertherm Inc. qui peuvent être déposées aux États-Unis et/ou dans d’autres pays. Toutes les autres

marques de commerce sont la propriété de leurs détenteurs respectifs.

Une des valeurs fondamentales d’Hypertherm depuis toujours est l’accent mis sur la minimisation de notre impact sur l’environnement. Cet objectif est

essentiel pour notre réussite et celle de nos clients. Nous nous efforçons de devenir de meilleurs gestionnaires environnementaux, c’est une chose qui

nous tient à cœur.

Introduction

Purpose

This field service bulletin explains how to install a customer-supplied machine interface cable that

does not use the internal 50:1 voltage divider on the Powermax45 XP.

Raw Arc Voltage Kit

WARNING

ELECTRIC SHOCK CAN KILL

Disconnect electrical power before performing any maintenance.

All work requiring removal of the power supply cover must be performed

by a qualified technician.

See the safety information provided with your product for more safety

precautions.

Notice: Installation of the system at the installed site is subject to the approval of the Local

Inspection Authorities (LIA). Without approval of the LIA, modification of the factory installed

wiring voids the safety test marks (for example, cCSAus, CCC, CE, GOST-TR, UkrSEPRO,

RCM, EAC) applied to the product in the Hypertherm factory, and the safety certificates

provided by Hypertherm become invalid after modification.

Tools and materials needed

Wire strippers

Wire terminal crimper

Assorted Phillips

Electric drill with a 15 mm or 19/32 inch drill bit

0.75 mm

OLFLEX

M3 (#5) insulated ring terminals, quantity 2

2

or 18 AWG, 2 wire, non-shielded cable similar to

®

190 (manufacturer’s part number 601802)

428689 Kit contents

Part number Description Quantity

®

and TORX® screwdrivers

008279 Strain relief 1

075529 M3 x 10 mm machine screw with lock washer 2

Powermax45 XP Field Service Bulletin 809520 3

Raw Arc Voltage Kit

1

234

3

2

4

1

3

1

2

Install the interface cable

Connecting a cable to the power board to bypass the voltage divider board and access raw arc

voltage must be done by trained service personnel.

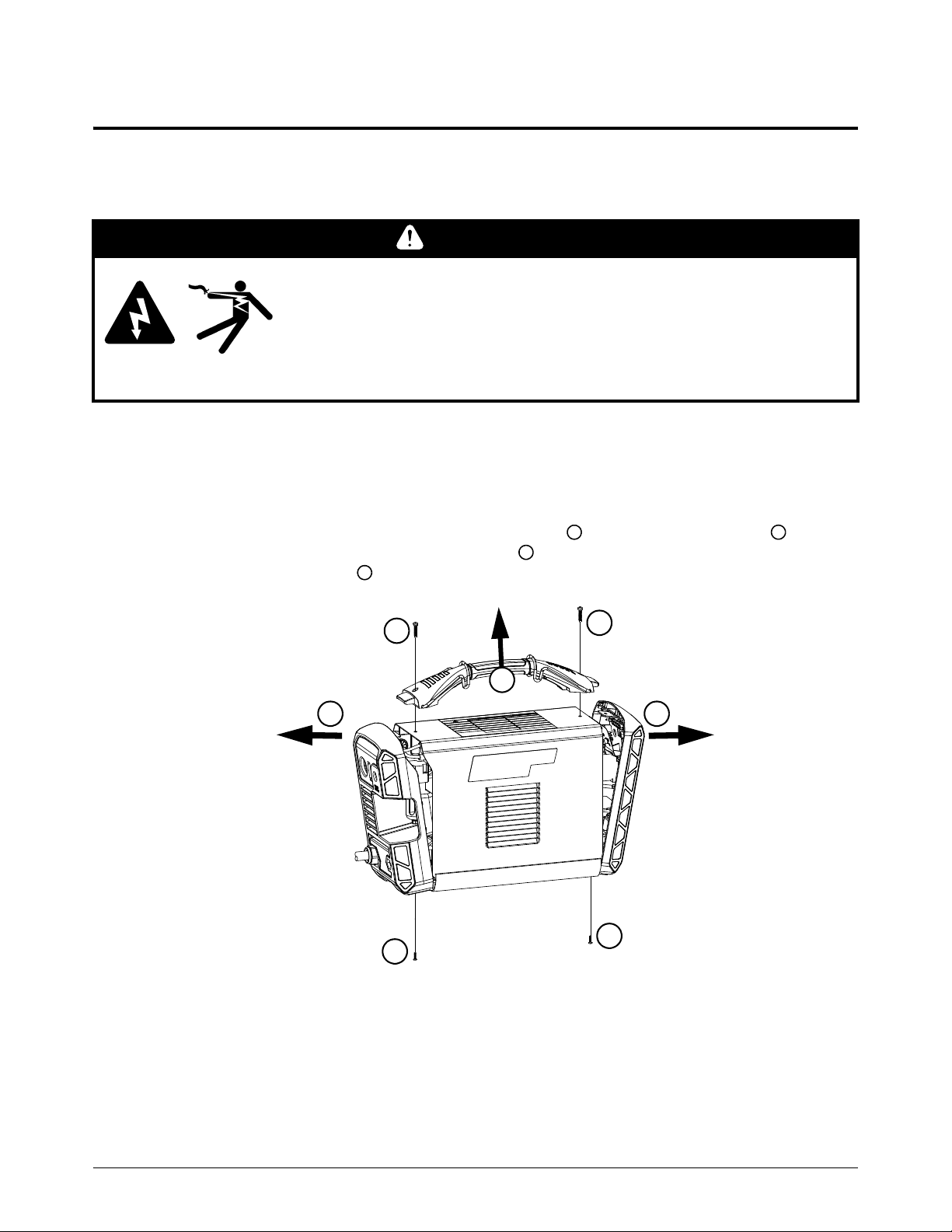

SHOCK HAZARD, ENERGY HAZARD, AND FIRE HAZARD

Connecting directly to the plasma circuit for access to raw arc voltage

increases the risk of shock hazard, energy hazard, and fire hazard in the

event of a single fault. The output voltage and the output current of the

circuit are specified on the data plate.

Remove cover and component barrier

1. Turn OFF the power. Disconnect the power cord and gas supply.

WARNING

2. Remove the two screws from the power supply handle . Remove the two screws from the

bottom of the front and rear panels. Tilt the tops of the front and rear panels away from the

unit to pull the handle out .

4 809520 Field Service Bulletin Powermax45 XP

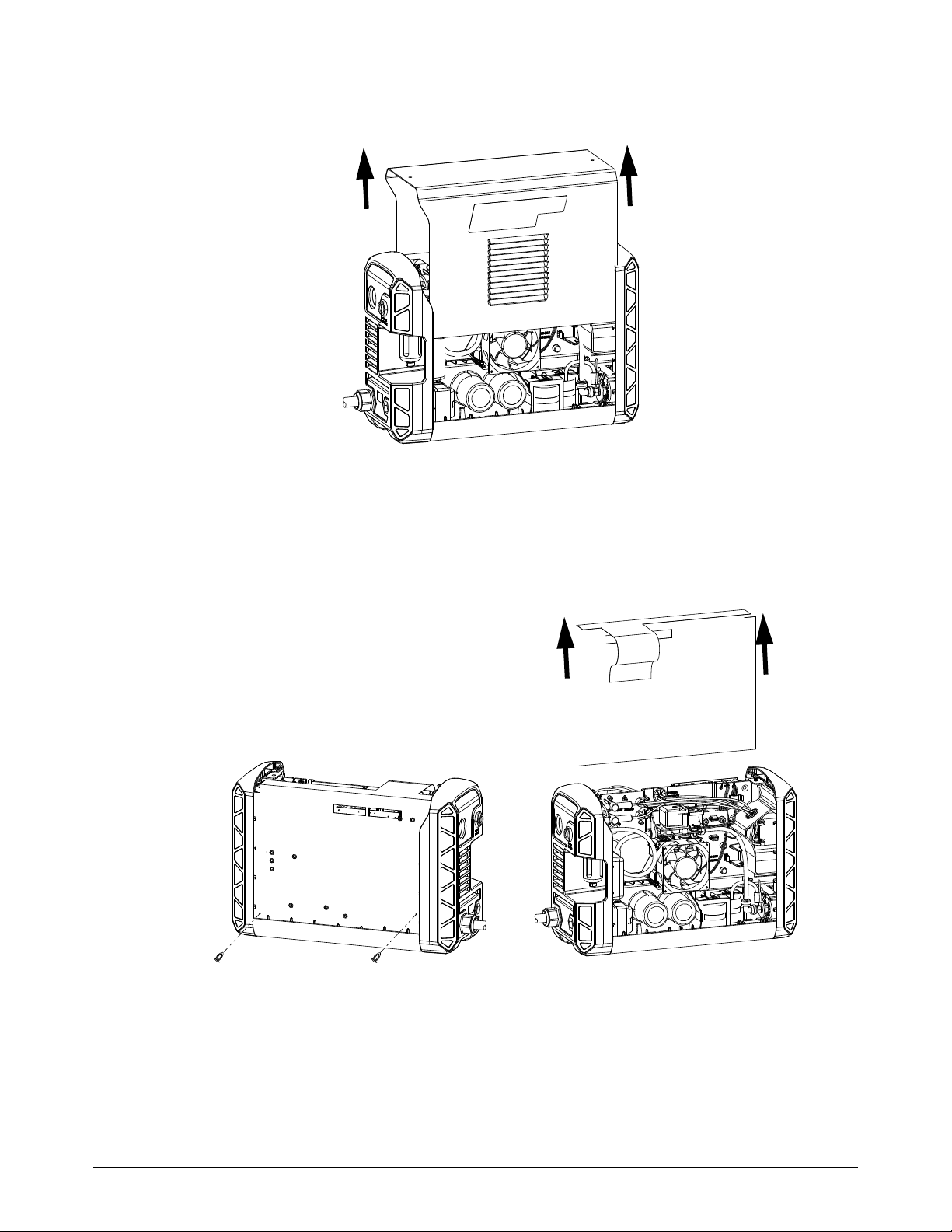

3. Slide the cover off.

Raw Arc Voltage Kit

4. Remove the two plastic pins that secure the component barrier to the main power board. Slide

the component barrier off.

Powermax45 XP Field Service Bulletin 809520 5

Raw Arc Voltage Kit

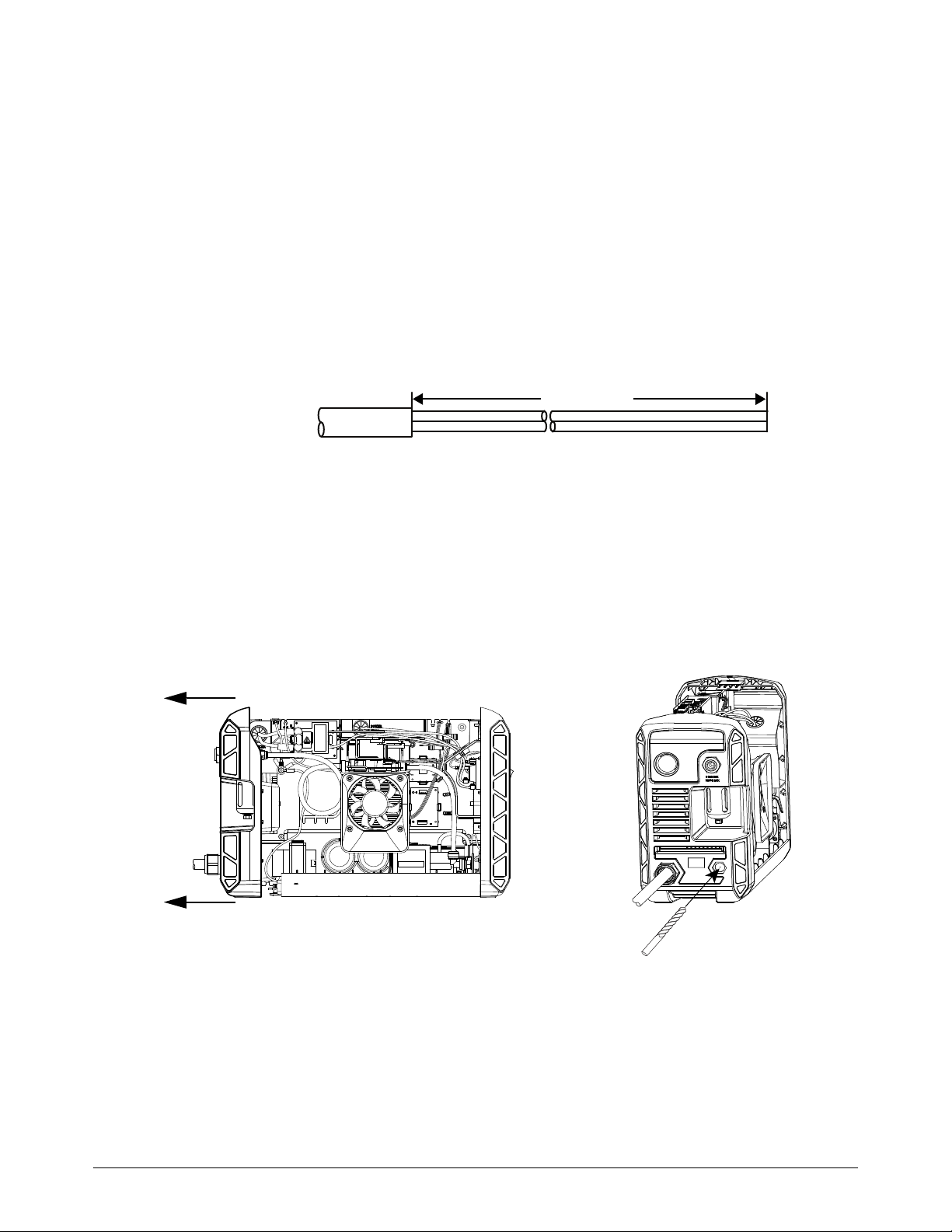

48.3 cm (19 inches)

Prepare the interface cable

1. Use 2 conductor, non-shielded 18 AWG wires to connect to the power supply. Measure the

distance needed to connect from the CNC to the power supply. Add an additional 51.5 cm

(20.25 inches) to make the connection inside the power supply.

2. Cut back the outer jacket 48.3 cm (19 inches) from one end of the cable. Make sure you do not

cut into the insulation on the two 18 AWG wires.

Do not strip the wire ends until after they have been routed through the

power supply.

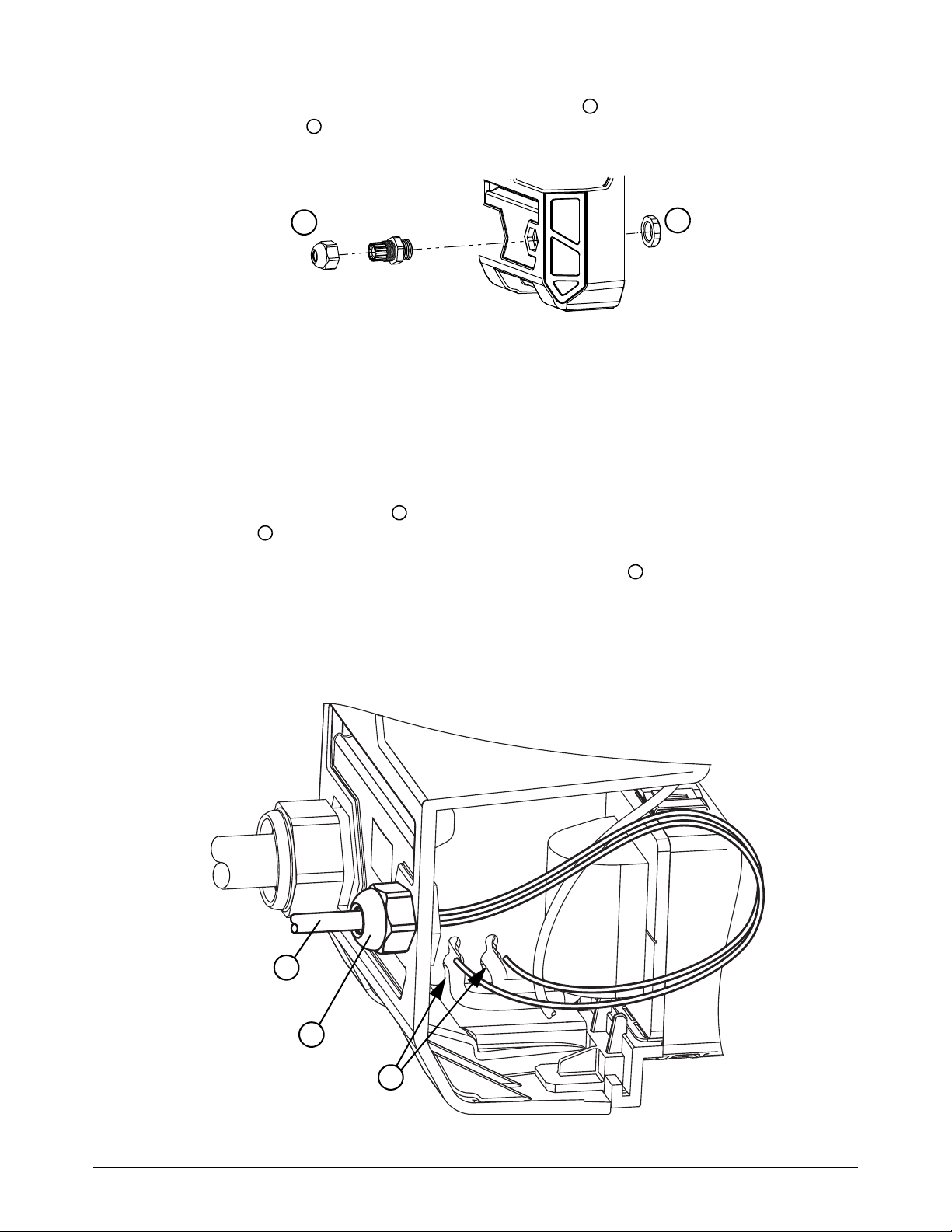

Install the strain relief

1. Pull the rear panel slightly away from the unit leaving enough space to drill a hole while avoiding

any contact with internal components or wires when drilling.

2. Use a 15 mm (19/32 inch) drill to drill out the interface cable entry point on the panel. Clean the

area of any chips from drilling.

6 809520 Field Service Bulletin Powermax45 XP

3. Attach the strain relief (008279) and tighten the inner nut to secure it to the panel. Attach the

1

2

1

2

1

2

3

3

1

2

outer retention nut but do not tighten.

Connect the interface cable

1. Pass the cable through the strain relief. The outer jacket should slightly protrude through the

back of the strain relief. Make sure the wire length is 48.3 cm (19 inches) inside the power

supply.

Raw Arc Voltage Kit

2. Tighten the outer retention nut on the strain relief. Make sure the strain relief closes on the

outer jacket of the cable and holds it securely in place.

3. Insert the interface cable wires through the pass-through holes used by the transformer to

reach the other side of the unit.

Different power supply configurations will have the transformer wires

routed differently. Use the pass-through holes that are not utilized by the

transformer.

Powermax45 XP Field Service Bulletin 809520 7

Raw Arc Voltage Kit

( + )

( - )

(-)

(+)

( + )

( - )

( + )

( - )

( + )

( - )

4. Route the wires to bring the ends to the (-) and (+) threaded inserts on the main circuit board.

5. Strip the insulation 1.27 mm (0.5 inches) from the ends of the wires.

6. Crimp an M3 insulated terminal ring connector on the end of each wire. Make sure there are no

loose wire strands.

7. Connect the positive lead to the (+) threaded insert (J22) on the power supply board. Use one

of the screws included in the kit (075529). Tighten the screw to 23.0 kg∙cm (20 inch·pounds).

Make sure the wire runs downward and the insulated part of the ring terminal is off the board.

8. Connect the negative lead to the (-) threaded insert (J9) on the power supply board. Use one of

the screws included in the kit (075529). Tighten the screw to 23.0 kg∙cm (20 inch-pounds).

Make sure the wire runs downward and the insulated part of the ring terminal is off the board.

9. Make sure to mark on the other end of the cable which wire is positive (+) and which is

negative (-).

10. Replace the component barrier and secure it to the main circuit board with the two plastic pins.

11 . Set the front and rear panels back in place.

8 809520 Field Service Bulletin Powermax45 XP

Raw Arc Voltage Kit

12. Make sure the ground clip is connected to the ground wire. The clip should be set in place to

accept the screw from the handle.

13. Slide the cover back on.

14. Tilt the front and rear panels to reattach the handle.

15. Secure the front and rear panel bottom screws.

16. Secure the front and rear panel top screws.

17. Connect the other end of the cable to the equipment according to the manufacturer’s

instructions. Remember to observe polarity.

Notice: The output of the internal voltage divider board is designed to prevent shock, energy

and fire hazards, and is intended to satisfy most codes and standards for external wiring outside

the electrical enclosure. All external wiring practices for an unprotected raw arc voltage

should be reviewed and approved by the Local Inspection Authorities (LIA) at the

time of installation prior to operation and use.

Raw arc voltage wiring terminals and connections should not be exposed to accidental

contact under normal and single fault conditions.

External wiring from an unprotected (that is, no voltage divider used in the power source)

raw arc voltage routed inside conduit between electrical enclosures will normally satisfy all

electrical codes and standards worldwide. Failure to address the hazards associated

with live contact, accessibility and single fault failures to this unprotected output

can result in death or fire.

Powermax45 XP Field Service Bulletin 809520 9

Raw Arc Voltage Kit

A voltage divider board inside the CNC protects only the CNC and does NOT protect the

external interconnecting wiring between the power source and the CNC. Over-current

protection may be required to protect the user and/or machine in fault conditions.

External wiring outside the electrical enclosure should be suitable for the installation and meet

national and local regulations (for example, NFPA 70 NEC, NFPA 79, Canadian Electrical Code,

CSA/CAN E60974-1, IEC 60204-1, BS 7671) or other codes and/or standards applicable to

the installed site where the equipment will be operated.

10 809520 Field Service Bulletin Powermax45 XP

Introduction

Objet

Kit de tension d’arc brute

AVERTISSEMENT

UN CHOC ÉLECTRIQUE PEUT ÊTRE MORTEL

Avant tout entretien, débrancher l’alimentation électrique.

Tous les travaux nécessitant le retrait du couvercle de la source

de courant doivent être effectués par un technicien qualifié.

Se reporter aux consignes de sécurité incluses avec votre produit pour

d’autres mesures de sécurité.

Le présent bulletin de service sur le terrain décrit comment installer un câble d’interface de machine

fourni par le client n’utilisant pas le diviseur de tension interne 50:1 sur le Powermax45 XP.

Avis : l’installation du système sur le site doit être approuvée par le service d’inspection local (LIA). Sans

l’approbation de la LIA, la modification du câblage fait en usine annule les sigles des essais de sécurité

(comme par exemple cCSAus, CCC, CE, GOST-TR, UkrSEPRO, RCM, EAC) apposés au produit

à l’usine Hypertherm. Les certificats de sécurité fournis par Hypertherm seront également déclarés nuls

et non avenus après ladite modification.

Outils et matériel requis

Pince à dénuder

Pinces à sertir

Tournevis Phillips

Perceuse électrique avec mèche de 15 mm (19/32 po)

0,75 mm

2

(18 AWG), câble non blindé, à 2 fils, similaire au OLFLEX®190

(numéro de référence du fabricant 601802)

Deux cosses rondes isolées M3 (nº 5)

Contenu du kit 428689

®

et TORX® assortis

Numéro de référence Description Quantité

008279 Serre-câble 1

075529 Vis mécanique M3 x 10 mm avec rondelle de blocage 2

Powermax45 XP Bulletin de service sur le terrain 809520 11

Kit de tension d’arc brute

1

2

3

4

3

2

4

1

3

1

2

Installer le câble d’interface

Le branchement d’un câble au panneau d’alimentation afin de contourner le panneau diviseur

de tension et accéder à la tension d’arc brute doit être effectué par un technicien de maintenance

qualifié.

AVERTISSEMENT

DANGER D’ÉLECTROCUTION, D’ÉNERGIE ET D’INCENDIE

Le raccordement direct au circuit plasma pour accéder à la tension

de l’arc brute augmente le danger d’électrocution, de problèmes

d’énergie et d’incendie s’il y a le moindre défaut. La tension de sortie et

le courant de sortie du circuit sont indiqués sur la plaque signalétique.

Retirer le couvercle et la barrière du composant

1. Couper l’alimentation électrique (OFF). Couper l’alimentation en électricité et en gaz.

2. Retirer les deux vis de la poignée de la source de courant . Retirer les deux vis de la partie

inférieure des panneaux avant et arrière. Écarter la partie supérieure des panneaux avant

et arrière de l’unité principale pour retirer la poignée .

12 809520 Bulletin de service sur le terrain Powermax45 XP

3. Retirer le couvercle en le faisant glisser.

Kit de tension d’arc brute

4. Retirer les deux épingles de plastique qui fixent la barrière du composant au circuit imprimé

d’alimentation principal. Retirer la barrière de composant en le faisant glisser.

Powermax45 XP Bulletin de service sur le terrain 809520 13

Kit de tension d’arc brute

48,3 cm (19 po)

Préparation du câble d’interface

1. Utiliser des fils non-blindés 18 AWG à 2 conducteurs pour effectuer le branchement

à la source de courant. Mesurer la distance requise pour effectuer la connexion entre

la commande numérique par ordinateur (CNC) et l’alimentation électrique.

Ajouter 51,5 cm (20.25 po) pour la connexion à l’intérieur de la source de courant.

2. À une extrémité du câble, retirer la gaine extérieure du fil sur une longueur

de 48,3 cm (19 po). S’assurer de ne pas endommager l’isolation des deux câbles 18 AWG.

Il est important de ne pas dégainer les extrémités des fils avant qu’ils

ne soient correctement insérés dans la source de courant.

Installation du protecteur de câble

1. Écarter légèrement le panneau arrière de l’unité afin de dégager suffisamment d’espace pour

pouvoir percer en évitant tout contact avec les composants internes ou les fils.

2. Utiliser une mèche de 15 mm (19/32 po) pour percer le trou d’accès du câble d’interface

dans le panneau arrière. Nettoyer tout débris de perçage.

14 809520 Bulletin de service sur le terrain Powermax45 XP

3. Attacher le protecteur de câble (008279) et serrer l’écrou interne pour le fixer au panneau.

1

2

1

2

1

2

3

3

1

2

Attacher l’écrou de rétention externe mais sans le serrer.

Connexion du câble d’interface

1. Insérer le câble dans le protecteur de câble. La gaine extérieure doit ressortir un peu de l’arrière

du protecteur de câble. S’assurer qu’il y a bien 48,3 cm (19 po) de fil à l’intérieur de la source

de courant.

Kit de tension d’arc brute

2. Serrer l’écrou de rétention externe au protecteur de câble. S’assurer que le protecteur

de câble ferme bien au niveau de la gaine extérieure du câble et le tienne bien en place.

3. Insérer les fils du câble d’interface dans les passe-câbles utilisés par le transformateur pour

atteindre l’autre côté de l’unité.

Les fils du transformateur emprunteront des chemins différents selon

la configuration de la source de courant. Utiliser les passe-câbles qui

ne sont pas déjà occupés par le transformateur.

Powermax45 XP Bulletin de service sur le terrain 809520 15

Kit de tension d’arc brute

( + )

( - )

(-)

(+)

( + )

( - )

( + )

( - )

( + )

( - )

4. Amener les extrémités des fils aux embouts filetés (-) et (+) du circuit imprimé.

5. Dégainer 1,27 cm (1/2 po) des extrémités des fils.

6. Sertir l’extrémité de chaque fil d’une cosse ronde terminale isolée M3. S’assurer qu’aucun

fil n’est pas connecté.

7. Brancher le brin positif à l’embout fileté (+) du circuit imprimé d’alimentation électrique (J22).

Utiliser une des vis comprises dans le kit (075529). Serrer la vis à 23 kg∙cm (20 po-lb).

S’assurer que le fil descende et que la partie isolée de la cosse ronde ne touche pas au circuit

imprimé.

8. Brancher le fil négatif à l’embout fileté (-) du circuit imprimé d’alimentation électrique (J9).

Utiliser une des vis comprises dans le kit (075529). Serrer la vis à 23 kg∙cm (20 po-lb).

S’assurer que le fil descende et que la partie isolée de la cosse ronde ne touche pas au circuit

imprimé.

9. S’assurer de marquer à l’autre extrémité du câble quel fil est positif (+) et lequel est négatif (-).

10. Replacer la barrière du composant et la fixer au circuit imprimé d’alimentation principale avec

les deux épingles en plastique.

11 . Replacer les panneaux avant et arrière.

16 809520 Bulletin de service sur le terrain Powermax45 XP

Kit de tension d’arc brute

12. S’assurer que le collier de mise à la terre est connecté au fil de mise à la terre. Le collier doit

être en place pour pouvoir insérer les vis de la poignée.

13. Glisser le couvercle en place.

14. Incliner les panneaux avant et arrière pour rattacher la poignée.

15. Fixer les vis au bas des panneaux avant et arrière.

16. Fixer les vis en haut des panneaux avant et arrière.

17. Brancher l’autre extrémité du câble à l’équipement selon les instructions du fabricant.

Ne pas oublier de respecter la polarité.

Avis : La sortie du panneau diviseur de tension interne est conçue de sorte à éviter tout risque

de choc électrique, de problème d’énergie et d’incendie et elle est conforme à la plupart des

codes et normes relatives au câblage externe hors du coffret électrique. Tout câblage externe

d’une tension d’arc brute non-protégée doit être revu et approuvé par le service

d’inspection local (LIA) au moment de l’installation et avant toute utilisation.

Les bornes de câblage et les connexions de la tension d’arc brute ne doivent pas être

exposées à un contact accidentel sous des conditions normales ou de défaut unique.

Le câblage externe d’une tension d’arc brute non protégée (aucun diviseur de tension dans

la source de courant) passé à l’intérieur de tuyaux entre les coffrets électriques respectera

généralement tous les codes et normes électriques internationaux. L’incapacité à mettre

en place des mesures préventives concernant le contact direct, l’accessibilité

et les défaillances à défaut unique de ce panneau non-protégé peut entraîner

la mort ou causer un incendie.

Powermax45 XP Bulletin de service sur le terrain 809520 17

Kit de tension d’arc brute

Un diviseur de tension à l’intérieur de la commande numérique par ordinateur (CNC) ne protège

que cette dernière et NE PROTÈGE PAS le câblage connectant l’alimentation électrique

et le CNC. Une protection de surintensité peut être nécessaire afin de protéger l’utilisateur

et/ou la machine en cas de défaillance.

Le câblage externe hors du coffret électrique doit être adapté à l’installation et être conforme

aux codes locaux et nationaux (par exemple NFPA 70 NEC, NFPA 79, le Code canadien

de l’électricité, CSA/CAN E60974-1, IEC 60204-1 et BS 7671) ou autres codes ou normes

s’appliquant au site d’installation où l'équipement est exploité.

18 809520 Bulletin de service sur le terrain Powermax45 XP

Loading...

Loading...