Page 1

45

Plasma arc cutting system

Service Manual – 806110

Revision 2

Page 2

Register your new Hypertherm system

Register your product online at www.hypertherm.com/registration for easier technical

and warranty support. You can also receive updates on new Hypertherm products and a free

gift as a token of our appreciation.

For your records

Serial number:________________________________________________________________

Purchase date: _______________________________________________________________

Distributor: __________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

Maintenance notes:

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

Page 3

Service Manual

45

(P/N 806110)

Revision 2 – April, 2013

Hypertherm, Inc.

Hanover, NH USA

www.hypertherm.com

© Copyright 2013 Hypertherm, Inc.

All Rights Reserved

Hypertherm and powermax are trademarks of Hypertherm, Inc.

and may be registered in the United States and/or other countries.

Page 4

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

65 6841 2489 (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

Unit 301, South Building

495 ShangZhong Road

Shanghai, 200231

PR China

86-21-60740003 Tel

86-21-60740393 Fax

Hypertherm Europe B.V.

Vaartveld 9

4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP - Brasil

CEP 07115-030

55 11 2409 2636 Tel

55 11 2408 0462 Fax

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Hypertherm Korea Branch

#3904 Centum Leaders Mark B/D,

1514 Woo-dong, Haeundae-gu, Busan

Korea, 612-889

82 51 747 0358 Tel

82 51 701 0358 Fax

07/18/12

Page 5

Safety information

Before operating any Hypertherm equipment, read the separate Safety and Compliance Manual (80669C) included

with your product for important safety information.

Page 6

Page 7

TABLE OF CONTENTS

ELECTROMAGNETIC COMPATIBILITY EMC .......................................................................................................EMC1

WARRANTY ............................................................................................................................................................................ W1

SECTION 1

SPECIFICATIONS

System description ....................................................................................................................................................................................1-2

Where to find information ........................................................................................................................................................................1-2

Power supply dimensions and weights ................................................................................................................................................1-3

Dimensions .......................................................................................................................................................................................1-3

Weights .............................................................................................................................................................................................1-3

Power supply ratings .................................................................................................................................................................................1-4

T45v torch dimensions .............................................................................................................................................................................1-5

T45m torch dimensions ............................................................................................................................................................................1-5

T45v and T45m torch specifications .....................................................................................................................................................1-6

Symbols and marks ...................................................................................................................................................................................1-7

IEC symbols ................................................................................................................................................................................................1-8

SECTION 2

POWER SUPPLY SETUP

Unpack the Powermax45 .........................................................................................................................................................................2-2

Claims ................................................................................................................................................................................................2-2

Contents ............................................................................................................................................................................................2-2

Position the power supply........................................................................................................................................................................2-3

Prepare the electrical power ...................................................................................................................................................................2-3

Voltage configurations ....................................................................................................................................................................2-3

Install a line-disconnect switch ....................................................................................................................................................2-4

Requirements for grounding .........................................................................................................................................................2-4

powermax

45

Service Manual

i

Page 8

Table of ConTenTs

Power cord considerations ......................................................................................................................................................................2-4

Extension cord recommendations ...............................................................................................................................................2-5

Generator recommendations ........................................................................................................................................................2-6

Prepare the gas supply .............................................................................................................................................................................2-6

Connect the gas supply .................................................................................................................................................................2-7

Additional gas filtration ...................................................................................................................................................................2-7

SECTION 3

TORCH SETUP

Introduction .................................................................................................................................................................................................3-2

Consumable life ..........................................................................................................................................................................................3-2

Hand torch setup .......................................................................................................................................................................................3-2

Choose the consumables ..............................................................................................................................................................3-3

Install the consumables ..................................................................................................................................................................3-5

Machine torch setup..................................................................................................................................................................................3-6

Mount the torch ................................................................................................................................................................................3-6

Choose the consumables (cut charts) .......................................................................................................................................3-8

Using the cut charts ........................................................................................................................................................................3-8

T45m shielded consumables ........................................................................................................................................................3-8

Align the torch ............................................................................................................................................................................... 3-24

Connect the remote-start pendant ...........................................................................................................................................3-25

Connect a machine interface cable .........................................................................................................................................3-25

Accessing raw arc voltage ......................................................................................................................................................... 3-27

Connect the torch lead .......................................................................................................................................................................... 3-30

SECTION 4

OPERATION

Controls and indicators ............................................................................................................................................................................4-2

Front controls and LEDs ................................................................................................................................................................4-2

Rear controls ....................................................................................................................................................................................4-3

Operate the Powermax45 ........................................................................................................................................................................4-3

Connect the electrical power and gas supply ..........................................................................................................................4-3

Power ON the system ....................................................................................................................................................................4-4

Set the mode switch .......................................................................................................................................................................4-4

Adjust the gas pressure .................................................................................................................................................................4-4

Check the indicator LEDs .............................................................................................................................................................4-6

Attach the work clamp ...................................................................................................................................................................4-6

Understand duty-cycle limitations ..........................................................................................................................................................4-6

How to use the hand torch ......................................................................................................................................................................4-7

Operate the safety trigger .............................................................................................................................................................4-7

Hand torch cutting hints ................................................................................................................................................................4-7

Start a cut from the edge of the workpiece...............................................................................................................................4-8

ii powermax

45

Service Manual

Page 9

Table of ConTenTs

Pierce a workpiece ..........................................................................................................................................................................4-9

Gouge a workpiece .....................................................................................................................................................................4-10

Common hand-cutting faults ..................................................................................................................................................... 4-12

How to use the machine torch .............................................................................................................................................................4-12

Ensure the torch and table are set up correctly .................................................................................................................... 4-12

Understand and optimize cut quality ........................................................................................................................................4-13

To pierce a workpiece using the machine torch ................................................................................................................... 4-14

Common machine-cutting faults ............................................................................................................................................... 4-15

SECTION 5

TROUBLESHOOTING AND SYSTEM TESTS

Theory of operation ....................................................................................................................................................................................5-2

General ..............................................................................................................................................................................................5-2

200–240V CSA and 230V CE 1-phase power supply functional description..............................................................5-2

400V CE 3-phase power supply functional description .......................................................................................................5-2

480V CSA 3-phase power supply functional description ....................................................................................................5-3

Sequence of operation ...................................................................................................................................................................5-4

Troubleshooting preparation ...................................................................................................................................................................5-5

Test equipment ................................................................................................................................................................................5-5

Troubleshooting procedures and sequence .............................................................................................................................5-5

External inspection ..........................................................................................................................................................................5-6

Internal inspection ...........................................................................................................................................................................5-6

Initial resistance check ..............................................................................................................................................................................5-7

200–240V CSA and 230V CE power supply overview ................................................................................................................5-8

400V CE power supply overview .........................................................................................................................................................5-9

480V CSA power supply overview ...................................................................................................................................................5-10

Troubleshooting guide ........................................................................................................................................................................... 5-11

Control Board LEDs ............................................................................................................................................................................... 5-16

Use the control board Error and Reset LEDs to troubleshoot ...........................................................................................5-17

System tests.............................................................................................................................................................................................5-18

Test 1 – voltage input ..................................................................................................................................................................5-18

Test 2 – power board voltage checks ..................................................................................................................................... 5-19

Test 3 – VBUS and voltage balance .......................................................................................................................................5-20

Test 4 – solenoid valve ...............................................................................................................................................................5-24

Test 5 – torch stuck open (TSO) or torch stuck closed (TSC) ........................................................................................5-25

Test 6 – plasma start ................................................................................................................................................................... 5-26

Test 7 – torch cap sensor .......................................................................................................................................................... 5-27

Test 8 – fan ....................................................................................................................................................................................5-27

Test 9 – pressure transducer .................................................................................................................................................... 5-28

Test 10 – power switch trip coil ............................................................................................................................................... 5-28

powermax

45

Service Manual

iii

Page 10

Table of ConTenTs

SECTION 6

COMPONENT REPLACEMENT

Remove and replace the cover and Mylar® barrier .............................................................................................................................6-2

Removal .............................................................................................................................................................................................6-2

Replacement .....................................................................................................................................................................................6-3

Replace the work lead (CSA and CE) ..................................................................................................................................................6-3

Replace the power cord (200–240V CSA) .......................................................................................................................................6-5

Replace the power cord (230V CE) ....................................................................................................................................................6-6

Replace the power cord (400V CE) ....................................................................................................................................................6-8

Replace the power cord (480V CSA) .............................................................................................................................................. 6-10

Replace the fan .......................................................................................................................................................................................6-12

Replace the gas filter element .............................................................................................................................................................6-13

Replace the air filter and regulator ...................................................................................................................................................... 6-15

Replace the control board .................................................................................................................................................................... 6-16

Replace the power board (200–240V CSA and 230V CE) ......................................................................................................6-17

Replace the power board (400V CE and 480V CSA) ................................................................................................................ 6-21

SECTION 7

PARTS

Power supply parts ....................................................................................................................................................................................7-2

Exterior ...............................................................................................................................................................................................7-2

Interior, power board side .............................................................................................................................................................7-4

Interior, fan side ...............................................................................................................................................................................7-5

Interior, heat sink side .....................................................................................................................................................................7-6

T45v hand torch parts...............................................................................................................................................................................7-7

T45v hand torch consumables .....................................................................................................................................................7-8

T30v (Powermax30) 30A consumables ...................................................................................................................................7-8

T45m machine torch parts .......................................................................................................................................................................7-9

T45m machine torch consumables .......................................................................................................................................... 7-10

Accessory parts.......................................................................................................................................................................................7-10

Safety-critical parts.................................................................................................................................................................................7-11

Recommended spare parts .................................................................................................................................................................. 7-12

Powermax45 labels ................................................................................................................................................................................ 7-13

SECTION 8

WIRING DIAGRAMS

Control board diagram: 200–240V CSA and 230V CE ...............................................................................................................8-2

Control board diagram: 400V CE and 480V CSA ..........................................................................................................................8-3

Power board wiring diagram: 200–240VCSA and 230VCE .....................................................................................................8-5

Power board wiring diagram: 400VCE ..............................................................................................................................................8-6

Power board wiring diagram: 480VCSA ...........................................................................................................................................8-7

iv powermax

45

Service Manual

Page 11

ELECTROMAGNETIC COMPATIBILITY EMC

Introduction

Hypertherm’s CE-marked equipment is built in compliance

with standard EN60974-10. The equipment should be

installed and used in accordance with the information

below to achieve electromagnetic compatibility.

The limits required by EN60974-10 may not be adequate

to completely eliminate interference when the affected

equipment is in close proximity or has a high degree of

sensitivity. In such cases it may be necessary to use other

measures to further reduce interference.

This cutting equipment is designed for use only in an

industrial environment.

Installation and use

The user is responsible for installing and using the plasma

equipment according to the manufacturer’s instructions.

If electromagnetic disturbances are detected then it shall

be the responsibility of the user to resolve the situation

with the technical assistance of the manufacturer. In some

cases this remedial action may be as simple as earthing

the cutting circuit, see Earthing of the workpiece. In other

cases, it could involve constructing an electromagnetic

screen enclosing the power source and the work

complete with associated input filters. In all cases,

electromagnetic disturbances must be reduced to the

point where they are no longer troublesome.

Assessment of area

Before installing the equipment, the user shall make an

assessment of potential electromagnetic problems in

the surrounding area. The following shall be taken into

account:

a. Other supply cables, control cables, signaling and

telephone cables; above, below and adjacent to the

cutting equipment.

b. Radio and television transmitters and receivers.

c. Computer and other control equipment.

d. Safety critical equipment, for example guarding

ofindustrial equipment.

e. Health of the people around, for example the use

ofpacemakers and hearing aids.

f. Equipment used for calibration or measurement.

g. Immunity of other equipment in the environment. User

shall ensure that other equipment being used in the

environment is compatible. This may require additional

protection measures.

h. Time of day that cutting or other activities are to be

carried out.

The size of the surrounding area to be considered

will depend on the structure of the building and other

activities that are taking place. The surrounding area may

extend beyond the boundaries of the premises.

Methods of reducing emissions

Mains supply

Cutting equipment must be connected to the mains

supply according to the manufacturer’s recommendations.

If interference occurs, it may be necessary to take

additional precautions such as filtering of the mains

supply.

Compliance Information EMC-1

7/ 10

Page 12

ELECTROMAGNETIC COMPATIBILITY

Consideration should be given to shielding the supply

cable of permanently installed cutting equipment,

in metallic conduit or equivalent. Shielding should

be electrically continuous throughout its length. The

shielding should be connected to the cutting mains

supply so that good electrical contact is maintained

between the conduit and the cutting power source

enclosure.

Maintenance of cutting equipment

The cutting equipment must be routinely maintained

according to the manufacturer’s recommendations. All

access and service doors and covers should be closed

and properly fastened when the cutting equipment is in

operation. The cutting equipment should not be modified

in any way, except as set forth in and in accordance with

the manufacturer’s written instructions. For example,

the spark gaps of arc striking and stabilizing devices

should be adjusted and maintained according to the

manufacturer’s recommendations.

Cutting cables

The cutting cables should be kept as short as possible

and should be positioned close together, running at or

close to the floor level.

Earthing of the workpiece

Where the workpiece is not bonded to earth for

electrical safety, nor connected to earth because of its

size and position, for example, ship’s hull or building

steel work, a connection bonding the workpiece to earth

may reduce emissions in some, but not all instances.

Care should be taken to prevent the earthing of the

workpiece increasing the risk of injury to users, or

damage to other electrical equipment. Where necessary,

the connection of the workpiece to earth should be

made by a direct connection to the workpiece, but

in some countries where direct connection is not

permitted, the bonding should be achieved by suitable

capacitances selected according to national regulations.

Note: The cutting circuit may or may not be earthed for

safety reasons. Changing the earthing arrangements

should only be authorized by a person who is competent

to assess whether the changes will in crease the risk of

injury, for example, by allowing parallel cutting current

return paths which may damage the earth circuits

of other equipment. Further guidance is provided

in IEC60974-9, Arc Welding Equip ment, Part 9:

Installation and Use.

Screening and shielding

Equipotential bonding

Bonding of all metallic components in the cutting

installation and adjacent to it should be considered.

However, metallic components bonded to the workpiece

will increase the risk that the operator could receive a

shock by touching these metallic components and the

electrode (nozzle for laser heads) at the same time.

The operator should be insulated from all such bonded

metallic components.

Selective screening and shielding of other cables

and equipment in the surrounding area may alleviate

problems of interference. Screening of the entire plasma

cutting installation may be considered for special

applications.

EMC-2 Compliance Information

7/ 10

Page 13

WARRANTY

Attention

Genuine Hypertherm parts are the factoryrecommended replacement parts for your Hypertherm

system. Any damage or injury caused by the use of other

than genuine Hypertherm parts may not be covered by

the Hypertherm warranty, and will constitute misuse of

the Hypertherm Product.

You are solely responsible for the safe use of the

Product. Hypertherm does not and cannot make any

guarantee or warranty regarding the safe use of the

product in your environment.

General

Hypertherm, Inc. warrants that its Products shall be

free from defects in materials and workmanship for the

specific periods of time set forth herein and as follows: if

Hypertherm is notified of a defect (i)with respect to the

plasma power supply within a period of two (2) years

from the date of its delivery to you, with the exception of

Powermax brand power supplies, which shall be within

a period of three (3) years from the date of delivery to

you, and (ii)with respect to the torch and leads within

a period of one (1) year from its date of delivery to you,

and with respect to torch lifter assemblies within a

period of one (1) year from its date of delivery to you,

and with respect to Automation products one (1) year

from its date of delivery to you, with the exception of

the EDGE Pro CNC and ArcGlide THC, which shall be

within a period of two (2) years from the date of delivery

to you, and (iii)with respect to HyIntensity fiber laser

components within a period of two (2) years from the

date of its delivery to you, with the exception of laser

heads and beam delivery cables, which shall be within a

period of one (1) year from its date of delivery to you.

Hypertherm provides repair, replacement or adjustment

of the Product as the sole and exclusive remedy, if

and only if the warranty set forth herein properly is

invoked and applies. Hypertherm, at its sole option,

shall repair, replace, or adjust, free of charge, any

defective Products covered by this warranty which

shall be returned with Hypertherm’s prior authorization

(which shall not be unreasonably withheld), properly

packed, to Hypertherm’s place of business in Hanover,

New Hampshire, or to an authorized Hypertherm repair

facility, all costs, insurance and freight pre paid by the

customer. Hypertherm shall not be liable for any repairs,

replacement, or adjustments of Products covered by this

warranty, except those made pursuant to this paragraph

and with Hypertherm’s prior written consent.

The warranty set forth above is exclusive and is in

lieu of all other warranties, express, implied, statutory,

or otherwise with respect to the Products or as to

the results which may be obtained therefrom, and

all implied warranties or conditions of quality or of

merchantability or fitness for a particular purpose or

against infringement. The foregoing shall constitute the

sole and exclusive remedy for any breach by Hypertherm

of its warranty.

Distributors/OEMs may offer different or additional

warranties, but Distributors/OEMs are not authorized

togive any additional warranty protection to you or make

any representation to you purporting to be binding upon

Hypertherm.

This warranty shall not apply to any Powermax brand

power supplies that have been used with phase

converters. In addition, Hypertherm does not warranty

systems that have been damaged as a result of poor

power quality, whether from phase converters or

incoming line power. This warranty shall not apply to any

product which has been incorrectly installed, modified,

or otherwise damaged.

Compliance Information W-1

9/10

Page 14

WARRANTY

Patent indemnity

Except only in cases of products not manufactured by

Hypertherm or manufactured by a person other than

Hypertherm not in strict conformity with Hypertherm’s

specifications and in cases of designs, processes,

formulae, or combinations not developed or purported

to be developed by Hypertherm, Hypertherm will have

the right to defend or settle, at its own expense, any

suit or proceeding brought against you alleging that

the use of the Hypertherm product, alone and not in

combination with any other product not supplied by

Hypertherm, infringes any patent of any third party. You

shall notify Hypertherm promptly upon learning of any

action or threatened action in connection with any such

alleged infringement (and in any event no longer than

fourteen (14) days after learning of any action or threat

of action), and Hypertherm’s obligation to defend shall

be conditioned upon Hypertherm’s sole control of, and

the indemnified party’s cooperation and assistance in,

the defense of the claim.

Limitation of liability

In no event shall Hypertherm be liable to any

person or entity for any incidental, consequential

direct, indirect, punitive or exemplary damages

(including but not limited to lost profits)

regardless of whether such liability is based on

breach of contract, tort, strict liability, breach

of warranty, failure of essential purpose, or

otherwise, and even if advised of the possibility

of such damages.

Liability cap

In no event shall Hypertherm’s liability, if any,

whether such liability is based on breach of

contract, tort, strict liability, breach of warranties,

failure of essential purpose or otherwise, for

any claim, action, suit or proceeding (whether

in court, arbitration, regulatory proceeding or

otherwise) arising out of or relating to the use of

the Products exceed in the aggregate the amount

paid for the Products that gave rise to such claim.

Insurance

At all times you will have and maintain insurance in such

quantities and types, and with coverage sufficient and

appropriate to defend and to hold Hypertherm harmless

in the event of any cause of action arising from the use

of the products.

Transfer of rights

You may transfer any remaining rights you may have

hereunder only in connection with the sale of all or

substantially all of your assets or capital stock to a

successor in interest who agrees to be bound by all of

the terms and conditions of this Warranty. Within thirty

(30) days before any such transfer occurs, you agree to

notify in writing Hypertherm, which reserves the right of

approval. Should you fail timely to notify Hypertherm and

seek its approval as set forth herein, the Warranty set

forth herein shall be null and void and you will have no

further recourse against Hypertherm under the Warranty

or otherwise.

National and local codes

National and local codes governing plumbing and

electrical installation shall take precedence over any

instructions contained in this manual. In no event shall

Hypertherm be liable for injury to persons or property

damage by reason of any code violation or poor work

practices.

W-2 Compliance Information

9/10

Page 15

Section 1

SPECIFICATIONS

In this section:

System description ....................................................................................................................................................................................1-2

Where to find information ........................................................................................................................................................................1-2

Power supply dimensions and weights ................................................................................................................................................1-3

Dimensions .......................................................................................................................................................................................1-3

Weights .............................................................................................................................................................................................1-3

Power supply ratings .................................................................................................................................................................................1-4

T45v torch dimensions .............................................................................................................................................................................1-5

T45m torch dimensions ............................................................................................................................................................................1-5

T45v and T45m torch specifications .....................................................................................................................................................1-6

Symbols and marks ...................................................................................................................................................................................1-7

IEC symbols ................................................................................................................................................................................................1-8

powermax

45

Service Manual 1-1

Page 16

SpecificationS

System description

The Powermax45 is a highly portable, 45-amp, handheld and mechanized plasma cutting system appropriate for a

wide range of applications. The Powermax45 uses air or nitrogen to cut electrically conductive metals, such as mild

or stainless steel or aluminum. With it, you can cut thicknesses up to 25.4mm (1inch) and pierce thicknesses up to

9.5mm (3/8inch).

The standard Powermax45 includes one complete set of the consumables needed for cutting (shield, retaining cap,

swirl ring, nozzle, electrode), 2spare electrodes, 2spare nozzles, gouging consumables (handheld configurations only),

a quick-disconnect air fitting (1/4NPT on CSA units and 1/4NPT x G-1/4BSPP on CE units), a consumables box,

a shoulder strap, an Operator Manual, a Quick Setup Card, and a Setup DVD. Mechanized configurations include a

remote-start pendant as well.

You can order additional consumables and accessories – such as the plasma cutting guide – from any Hypertherm

distributor. See the Parts section for a list of spare and optional parts.

The power cords on the 200–240V CSA power supplies are shipped with a 50A, 250V plug (NEMA6-50P) on the

power cord. The CE units and the 480V CSA units are shipped without a plug on the power cord. See Prepare the

electrical power in the Power Supply Setup section for more information.

Where to find information

System specifications, such as size, weight, detailed electrical specifications, and cut speeds can be found in this

section. For information on:

• Safety information – see the Safety and Compliance Manual for detailed safety information.

• Setup requirements, including power requirements, grounding, power cord configurations, extension cord

requirements, and generator recommendations – see the Power Supply Setup section.

• Handheld and machine torch consumables, cut charts, and torch setup information – see the Torch Setup section.

• Information about the controls and LEDs, steps for system operation, and hints for improving cut quality – see the

Operation section.

• Troubleshooting – see the Troubleshooting and System Tests section.

• Maintenance and repair instructions – see the Component Replacement section.

• Part numbers and ordering information for accessories, consumables, and replacement parts – see the Parts

section.

• Wiring and timing diagrams – see the Wiring Diagrams section.

1-2 powermax

45

Service Manual

Page 17

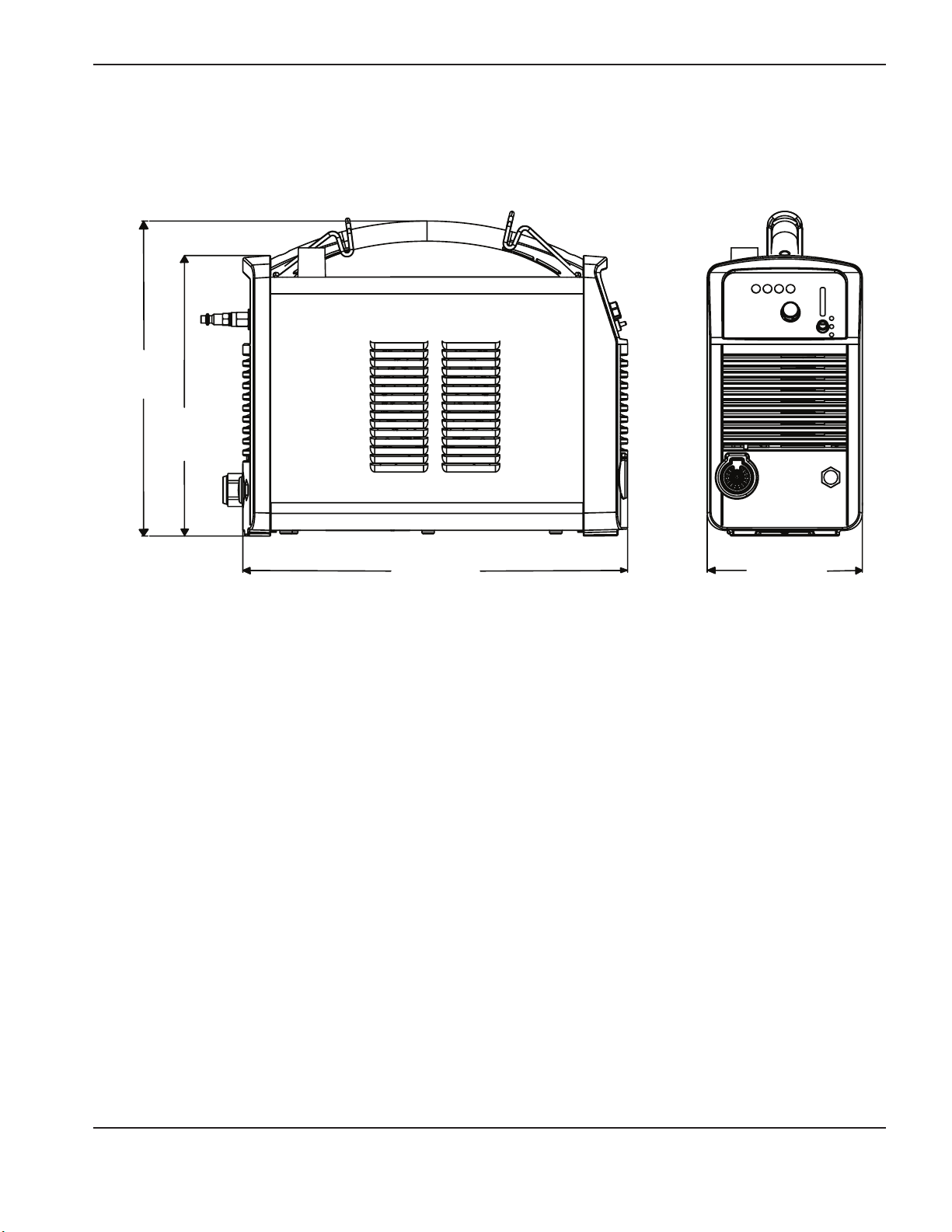

Power supply dimensions and weights

Dimensions

34.8 cm

(13.7 in)

31 cm

(12.19 in)

SpecificationS

42.6 cm

(16.75 in)

17.2 cm

(6.75 in)

Weights

Power supply weights given below include the hand torch with 6.1m (20foot) lead, a 6.1m (20foot) work lead, and a

3m (10foot) power cord.

• CSA 200–240V power supply: 16.8 kg (37 pounds)

• CSA 480V power supply: 15.9 kg (35 pounds)

• CE 230V power supply: 16.6 kg (36.5 pounds)

• CE 400V power supply: 15.9 kg (35 pounds)

powermax

45

Service Manual 1-3

Page 18

SpecificationS

Power supply ratings

Rated open-circuit voltage (U0)

CSA/CE, single-phase

CE, 3-phase

CSA, 3-phase

275VDC (CSA/CE single-phase)

275VDC (CE 3-phase)

278VDC (CSA 3-phase)

Rated output current (I2) 20 A to 45 A

Rated output voltage (U

Duty cycle at 40° C

(See data plate on power supply for moreinformation on

dutycycle.)

) 132VDC

2

50% (I

=45 A, U2=132V)

2

60% (I2=41 A, U2=132V)

100% (I2=32 A, U2=132V)

Operating temperature -10° to 40° C (14° to 104° F)

Storage temperature -25° to 55° C (-13° to 131° F)

Power factor

200–240V CSA, 230V CE, 1-phase

400V CE, 3-phase

480V CSA, 3-phase

Input voltage (U

ratedoutput(U

) / Input current (I1) at

1

,I

2MAX

)

2MAX

(See Voltage configurations in the Power Supply Setup

section for more information.)

200–240VAC / 34–28 A (200–240V CSA)

230VAC / 30 A (230V CE)*

400VAC / 10 A (400V CE)**

480VAC / 8.5A (480V CSA)

0.99

0.94

0.93

Gas type Air Nitrogen

Gas quality Clean, dry, oil-free per ISO

99.995% pure

8573-1 Class 1.2.2

Recommended gas inlet flow and pressure 170 l/min at 6.2 bar (360 scfh at 90 psi)

* Equipment complies with IEC 61000-3-12.

** Equipment complies with IEC 61000-3-12 provided that the short-circuit power S

is greater than or equal to

sc

692KVA at the interface point between the user’s supply and the public system. It is the responsibility of the installer

or user of the equipment to ensure, by consultation with the distribution network operator if necessary, that the

equipment is connected only to a supply with a short-circuit power Ssc greater than or equal to 692 KVA.

1-4 powermax

45

Service Manual

Page 19

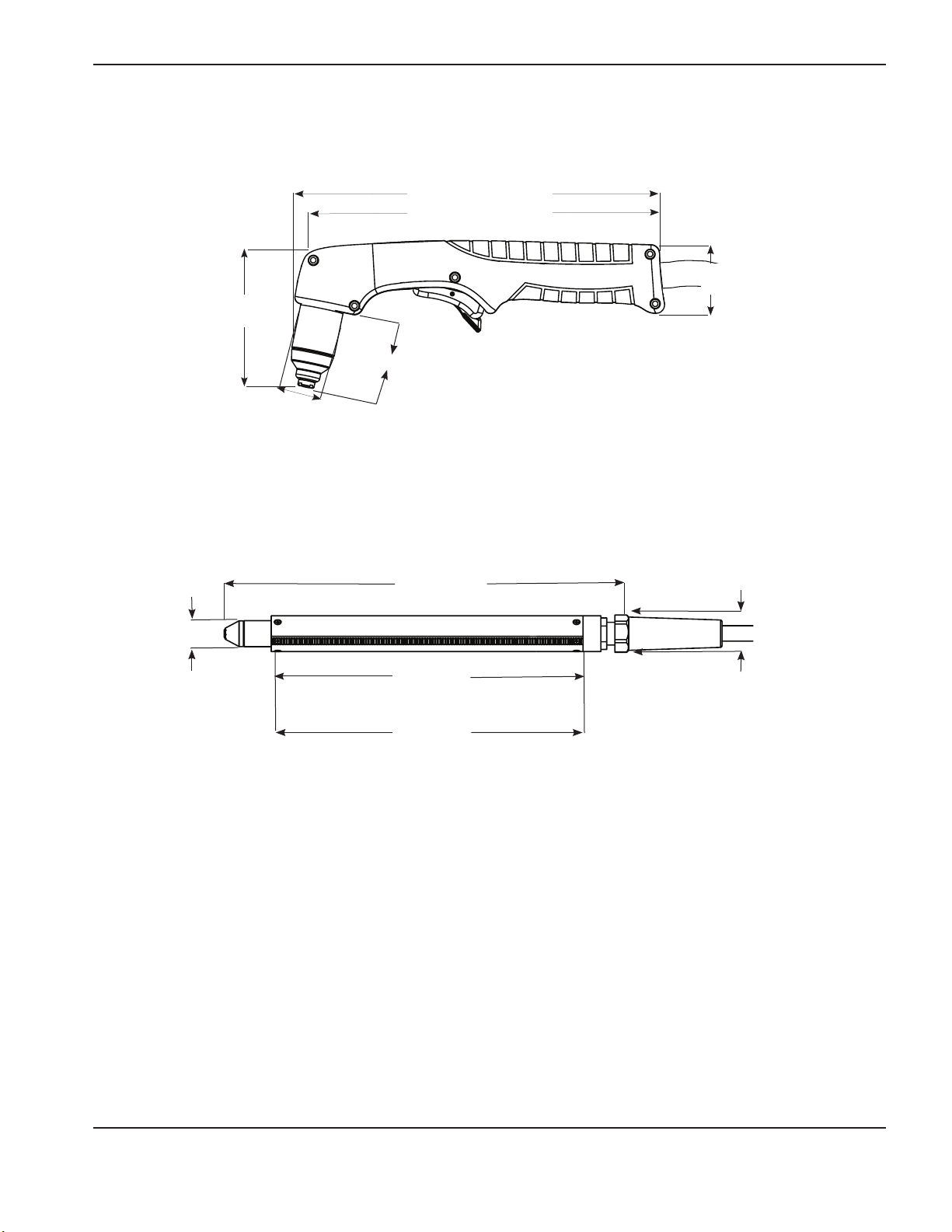

T45v torch dimensions

8.3 cm

(3.28 in)

2.5 cm

(1 in)

SpecificationS

22.1 cm (8.72 in)

21.6 cm (8.5 in)

4.0 cm

(1.58 in)

4.9 cm (1.91 in)

T45m torch dimensions

2.5 cm

(1 in)

36.5 cm

(14.36 in)

(30.5 cm)

12 in

33.0 cm

(13 in)

3.6 cm (1.43 in) outer dimension,

3.3 cm (1.3 in) flat sides

powermax

45

Service Manual 1-5

Page 20

SpecificationS

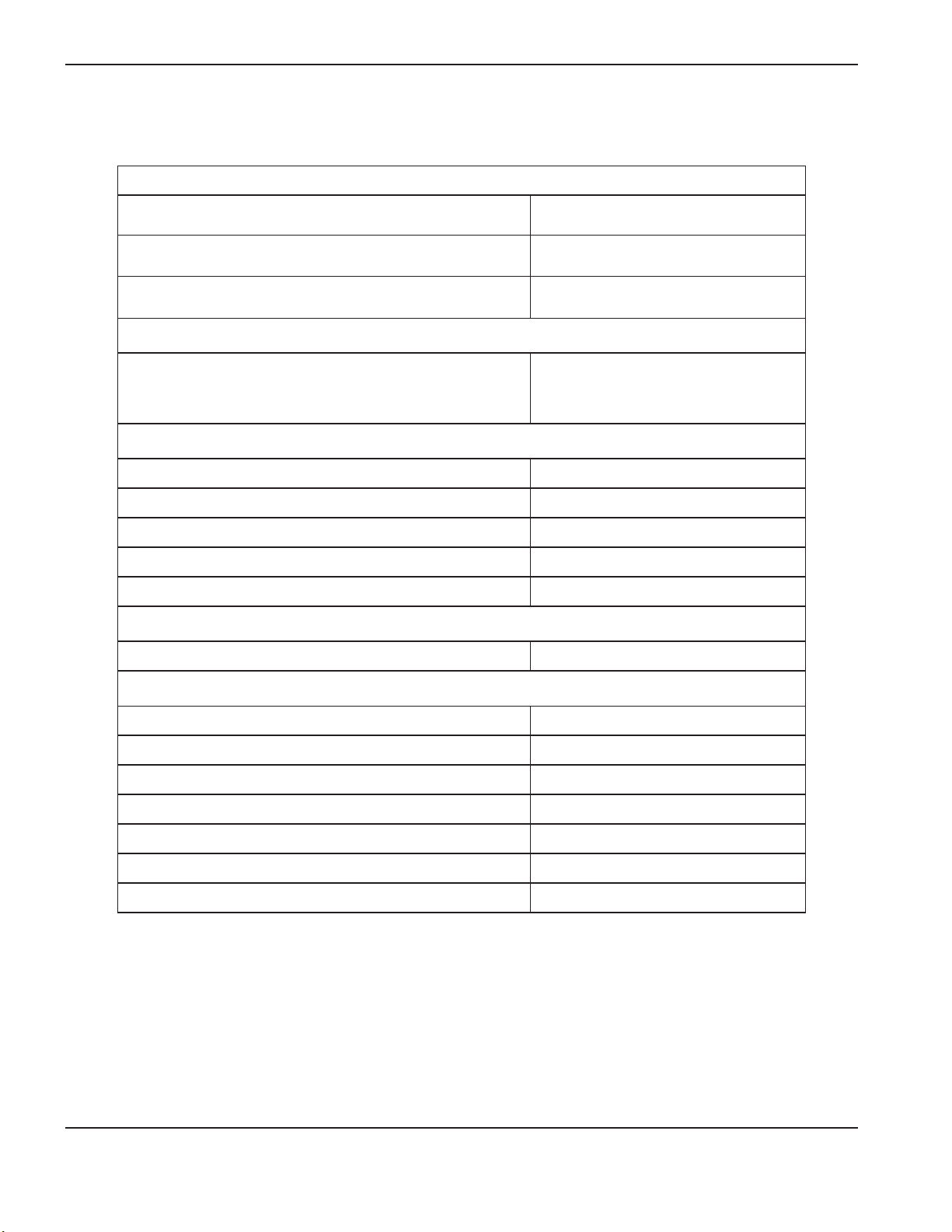

T45v and T45m torch specifications

Handheld cut capacity (material thickness)

Recommended cut capacity (hand cutting) 12.7 mm (1/2 inch)

Maximum cut capacity (hand cutting or mechanized

edgestart)

Severance capacity (hand cutting or mechanized edgestart) 25.4 mm (1 inch)

Mechanized pierce capacity (material thickness)

Pierce capacity

(for edge starts, the capacities are the same as the handheld

capacities)

Recommended cut speed (on mild steel)

6.35 mm (1/4 inch) 1524 mm/min (60 ipm)

9.53 mm (3/8 inch) 813 mm/min (32 ipm)

12.7 mm (1/2 inch) 508 mm/min (20 ipm)

19.1 mm (3/4 inch) 203 mm/min (8 ipm)

25.4 mm (1 inch) 102 mm/min (4 ipm)

Gouging capacity

Metal removal rate on mild steel 2.8 kg/hr (6.2 lbs/hr)

Weight

T45v torch only 0.27 kg (0.6 lb)

19.1 mm (3/4 inch)

9.5 mm (3/8 inch)

T45v with 6.1 m (20 foot) lead 1.55 kg (3.4 lb)

T45v with 15.24 m (50 foot) lead 3.54 kg (7.8 lb)

T45m torch only 0.45 kg (1.0 lb)

T45m with 7.62 m (25 foot) lead 2.27 kg (5.0 lb)

T45m with 10.7 m (35 foot) lead 2.90 kg (6.4 lb)

T45m with 15.24 m (50 foot) lead 3.85 kg (8.5 lb)

1-6 powermax

45

Service Manual

Page 21

SpecificationS

Symbols and marks

Your Hypertherm product may have one or more of the following markings on or near the data plate. Due to differences

and conflicts in national regulations, not all marks are applied to every version of a product.

S mark symbol

The S mark symbol indicates that the power supply and torch are suit able for operations carried out in

environments with in creased hazard of elec tri cal shock per IEC 60974-1.

CSA mark

Hypertherm products with a CSA mark meet the United States and Canadian regulations for product safety.

The products were evaluated, tested, and certified by CSA-International. Alternatively the product may have

amark by one of the other Nationally Recognized Testing Laboratories (NRTL) accredited in both the United

States and Canada, such as Underwriters Laboratories, Incorporated (UL) or TÜV.

CE marking

The CE marking signifies the manufacturer’s declaration of conformity to applicable European directives

andstandards. Only those versions of Hypertherm products with a CE marking located on or near the

dataplate have been tested for compliance with the European Low Voltage Directive and the European

Electromagnetic Compatibility (EMC) Directive. EMC filters needed to comply with the European EMC

Directive are incorporated within versions of the product with a CE marking.

GOST-TR mark

CE versions of Hypertherm products that include a GOST-TR mark of conformity meet the product safety

andEMC requirements for export to the Russian Federation.

C-Tick mark

CE versions of Hypertherm products with a C-Tick mark comply with the EMC regulations required for sale

inAustralia and New Zealand.

CCC mark

The China Compulsory Certification (CCC) mark indicates that the product has been tested and found

compliant with product safety regulations required for sale in China.

UkrSEPRO mark

CE versions of Hypertherm products that include a UkrSEPRO mark of conformity meet the product safety and

EMC requirements for export to the Ukraine.

powermax

45

Service Manual 1-7

Page 22

SpecificationS

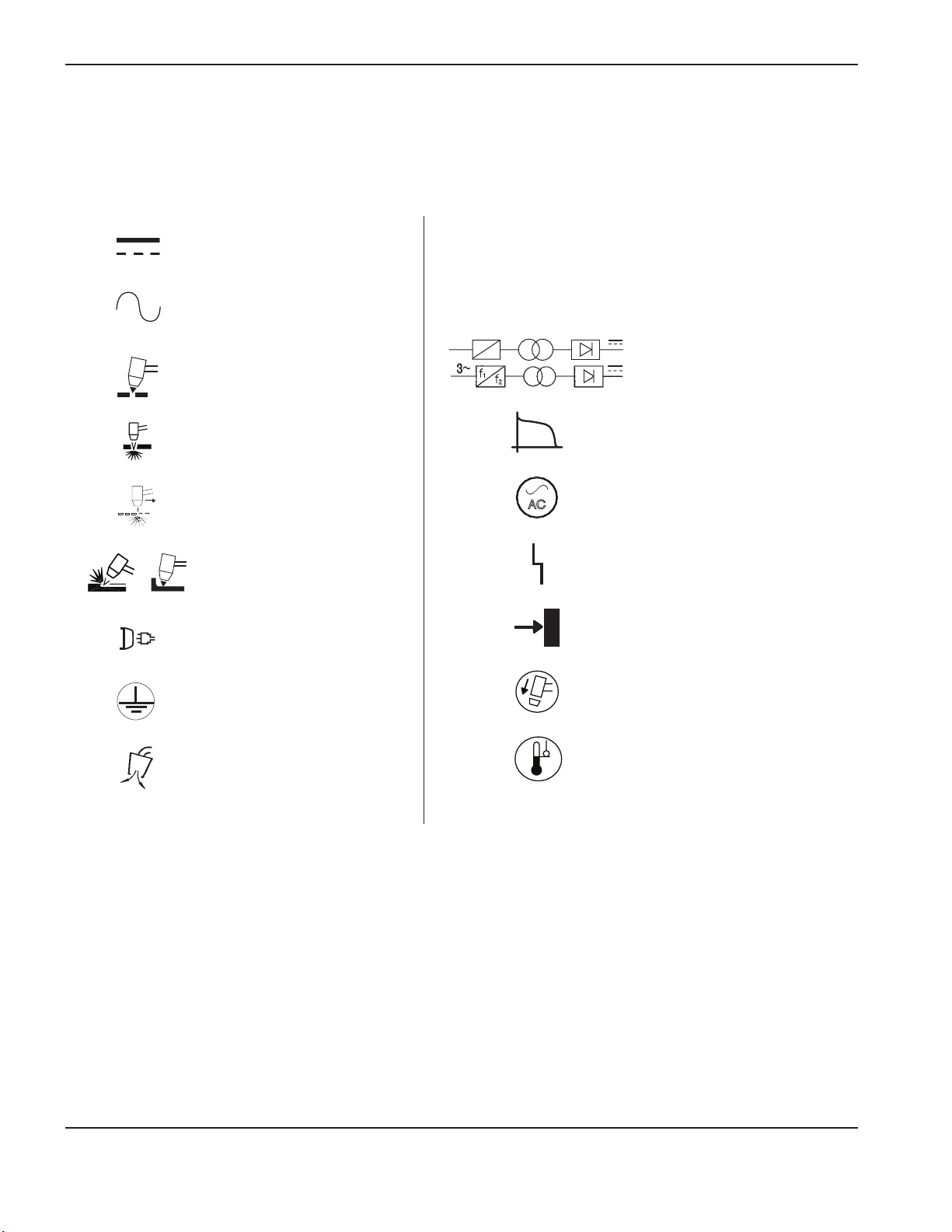

IEC symbols

The following symbols may appear on the power supply data plate, control labels, switches, and LEDs.

Direct current (DC)

Alternating current (AC)

Plasma torch cutting

Plate metal cutting

Expanded metal cutting

Gouging

AC input power connection

The terminal for the external

protective (earth) conductor

l

O

1~

f

1

f

2

AC

Power is ON

Power is OFF

An inverter-based power

source, either 1-phase or

3-phase

Volt/amp curve, “drooping”

characteristic

Power is ON (LED)

System fault (LED)

Inlet gas pressure fault (LED)

Missing or loose consumables

(LED)

Power supply is out of

Gas test mode

temperature range (LED)

1-8 powermax

45

Service Manual

Page 23

Section 2

POWER SUPPLY SETUP

In this section:

Unpack the Powermax45 .........................................................................................................................................................................2-2

Claims ................................................................................................................................................................................................2-2

Contents ............................................................................................................................................................................................2-2

Position the power supply........................................................................................................................................................................2-3

Prepare the electrical power ...................................................................................................................................................................2-3

Voltage configurations ....................................................................................................................................................................2-3

Install a line-disconnect switch ....................................................................................................................................................2-4

Requirements for grounding .........................................................................................................................................................2-4

Power cord considerations ......................................................................................................................................................................2-4

Extension cord recommendations ...............................................................................................................................................2-5

Generator recommendations ........................................................................................................................................................2-6

Prepare the gas supply .............................................................................................................................................................................2-6

Connect the gas supply .................................................................................................................................................................2-7

Additional gas filtration ...................................................................................................................................................................2-7

powermax

45

Service Manual 2-1

Page 24

Power suPPly setuP

Unpack the Powermax45

1. Verify that all items on your order have been received in good condition. Contact your distributor if any parts are

damaged or missing.

2. Inspect the power supply for damage that may have occurred during shipping. If there is evidence of damage,

refer to Claims, below. All communications regarding this equipment must include the model number and the serial

number located on the bottom of the power supply.

3. Before you set up and operate this Hypertherm system, read the Safety and Compliance Manual.

Claims

• Claims for damage during shipment – If your unit was damaged during shipment, youmust file a claim

with the carrier. Hypertherm will furnish you with a copy of the bill oflading upon request. If you need additional

assistance, call the nearest Hypertherm office listed in the front of this manual.

• Claims for defective or missing merchandise – If any component is missing or defective, contact your

Hypertherm distributor. If you need additional assistance, call thenearest Hypertherm office listed in the front of

this manual.

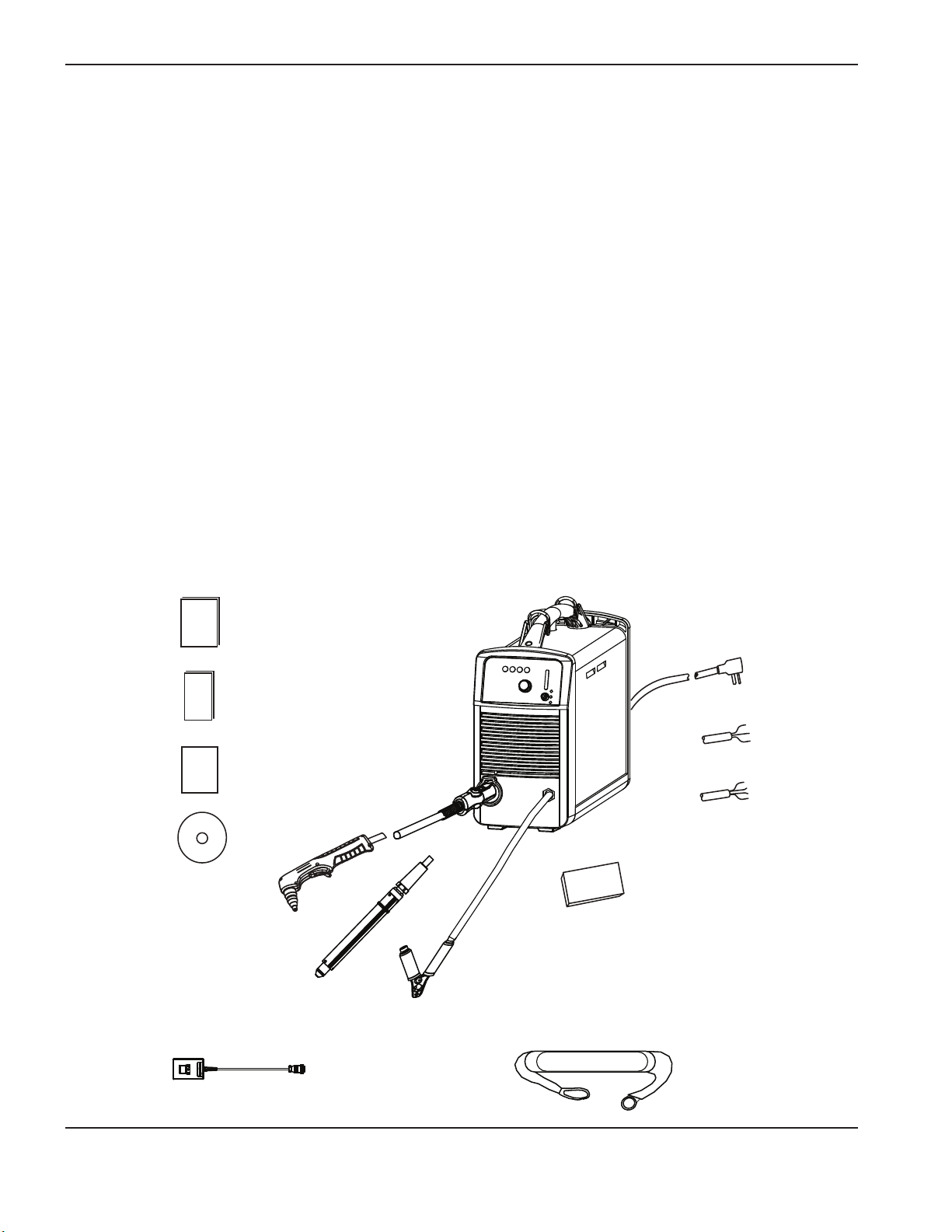

Contents

Verify the items in the box against the illustration.

Operator Manual

Quick Setup Card

Registration Card

Setup DVD

or

200–240V (CSA)

(plug included)

230V (CE)

(plug not included)

400V (CE)

480V (CSA)

(plug not included)

Box with extra

consumables

Remote-start pendant (optional) Shoulder strap

2-2 powermax

45

Service Manual

Page 25

power supply setup

Position the power supply

Locate the Powermax45 near an appropriate 200–240volt power receptacle for CSA or CE 1-phase power supplies,

a 400volt receptacle for 3-phase CE power supplies, or a 480volt receptacle for 3-phase CSA power supplies. The

Powermax45 has a 3m (10-foot) power cord. Allow at least 0.25m (10inches) of space around the power supply for

proper ventilation.

Prepare the electrical power

The maximum output voltage will vary based on your input voltage and the circuit’s amperage. Because the current

draw varies during startup, slow-blow fuses are recommended as shown in the following chart. Slow-blow fuses can

withstand currents up to 10times the rated value for short periods of time.

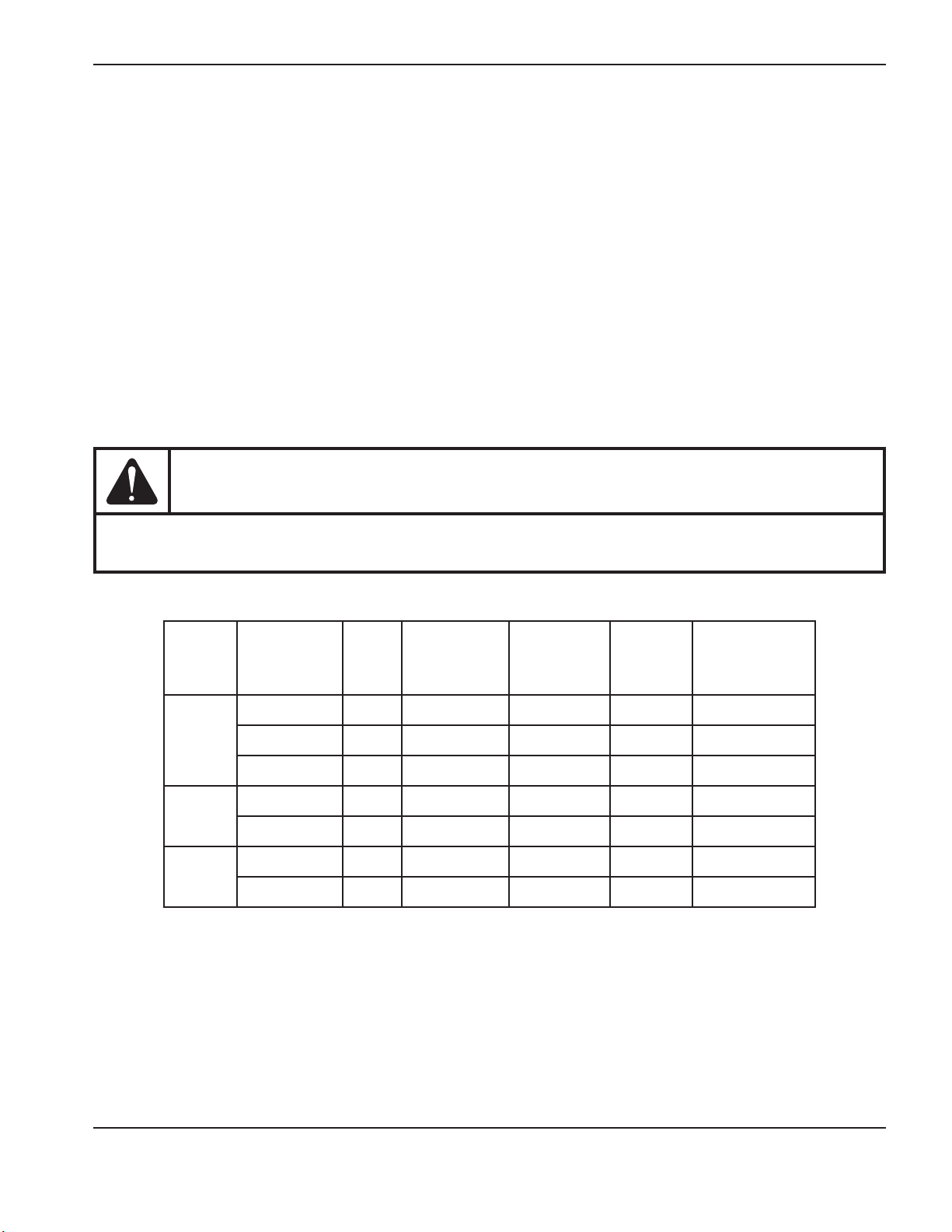

Voltage configurations

The following chart shows the maximum rated output for typical combinations of input voltage and amperage.

Acceptable input voltages can be ±10% of the values given below.

CAUTION

Protect the circuit with appropriately sized time-delay (slow-blow) fuses and a line-disconnect

switch.

Input

Model Input voltage Phase Rated output

200–240 VAC 1 45 A, 132V 34–28A 55–45A 50 A

CSA

CE

CE/CCC

* Use the higher amperage fuse for applications that require a long arc stretch.

208VAC 1 45 A, 132V 33 A 54.5 A 50 A

480VAC 3 45 A, 132V 8.5A 12A 15 or 20*A

200–240 VAC 1 45 A, 132V 34–28A 55–45A 35 or 50*A

400VAC 3 45 A, 132V 10 A 15.5 A 15 or 20*A

220VAC 1 45 A, 132V 31 A 53 A 35 or 50*A

380VAC 3 45 A, 132V 11 A 14 A 15 A

current at

6kw output

Input

current

during arc

stretch

Recommended

slow-blow fuse

size

powermax

45

Service Manual 2-3

Page 26

Power suPPly setuP

Install a line-disconnect switch

Use a line-disconnect switch for each power supply so that the operator can turn off the incoming power quickly in an

emergency. Locate the switch so that it is easily accessible to the operator. Installation must be performed by a licensed

electrician according to national and local codes. The interrupt level of the switch must be equal to or exceed the

continuous rating of the fuses. In addition, the switch should:

• Isolate the electrical equipment and disconnect all live conductors from the incoming supply voltage when in the

OFF position.

• Have one OFF and one ON position that are clearly marked with O (OFF) and I (ON).

• Have an external operating handle that can be locked in the OFF position.

• Contain a power-operated mechanism that serves as an emergency stop.

• Have slow-blow fuses installed as recommended in the table on the previous page.

Requirements for grounding

To ensure personal safety, proper operation, and to reduce electromagnetic interference (EMI), the Powermax45 must

be properly grounded:

• The power supply must be grounded through the power cord according to national and local electrical codes.

• Single-phase service must be of the 3-wire type with a green or green/yellow wire for the protective earth ground

and must comply with national and local requirements. Do not use a 2-wire service.

• Three-phase service must be of the 4-wire type with a green or green/yellow wire for the protective earth ground

and must comply with national and local requirements.

• Refer to the Safety and Compliance Manual for more information.

Power cord considerations

Powermax45 power supplies are shipped with CSA and CE power cord configurations.

The power cords on the 200–240V CSA power supplies are shipped with a 50 amp, 250V plug (NEMA 6-50P) on the

power cord.

The CE power supplies and the 480V CSA power supplies are shipped without a plug on the power cord. Obtain

the correct plug for your unit (230V CE, 400V CE, or 480V CSA) and location and have it installed by a licensed

electrician.

2-4 powermax

45

Service Manual

Page 27

power supply setup

Extension cord recommendations

Use an extension cord of an appropriate wire size for the cord length and system voltage. Usea cord that meets national

and local codes.

The following tables provide the recommended gauge size for various lengths and input voltages. The lengths in the

tables are the length of the extension cord only; they do not include the power supply’s power cord.

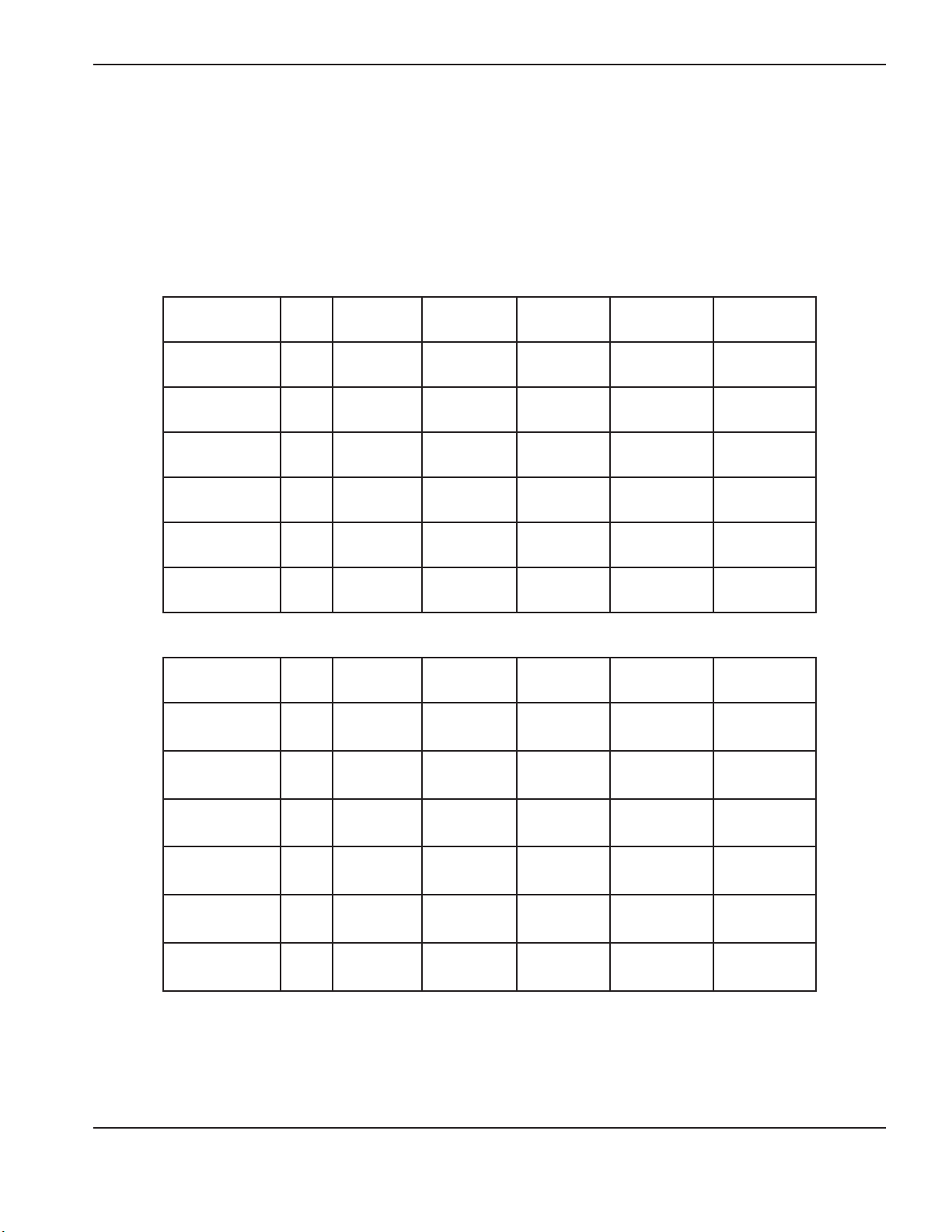

Metric

Input voltage Phase < 3 m 3–7.5 m 7.5–15 m 15–30 m 30 –45 m

208VAC 1 10 mm

220VAC

200–240VAC

380VAC

400VAC

480VAC

1

1

3

3

3

10 mm

10 mm

4 mm

4 mm

4 mm

2

10 mm

2

10 mm

2

10 mm

2

2

2

4 mm

4 mm

4 mm

2

2

2

2

2

2

10 mm

10 mm

10 mm

4 mm

4 mm

4 mm

2

2

2

2

2

2

16 mm

16 mm

16 mm

6 mm

6 mm

6 mm

2

2

2

2

2

2

25 mm

25 mm

25 mm

6 mm

6 mm

6 mm

2

2

2

2

2

2

English

Input voltage Phase < 10 feet 10–25 feet 25–50 feet 50–100 feet 100–150 feet

208VAC 1 8 AWG 8 AWG 8 AWG 6 AWG 4 AWG

220VAC 1 8 AWG 8 AWG 8 AWG 6 AWG 4 AWG

200–240VAC 1 8 AWG 8 AWG 8 AWG 6 AWG 4 AWG

380VAC 3 12 AWG 12 AWG 12 AWG 10 AWG 10 AWG

400VAC 3 12 AWG 12 AWG 12 AWG 10 AWG 10 AWG

480VAC 3 12 AWG 12 AWG 12 AWG 10 AWG 10 AWG

powermax

45

Service Manual 2-5

Page 28

Power suPPly setuP

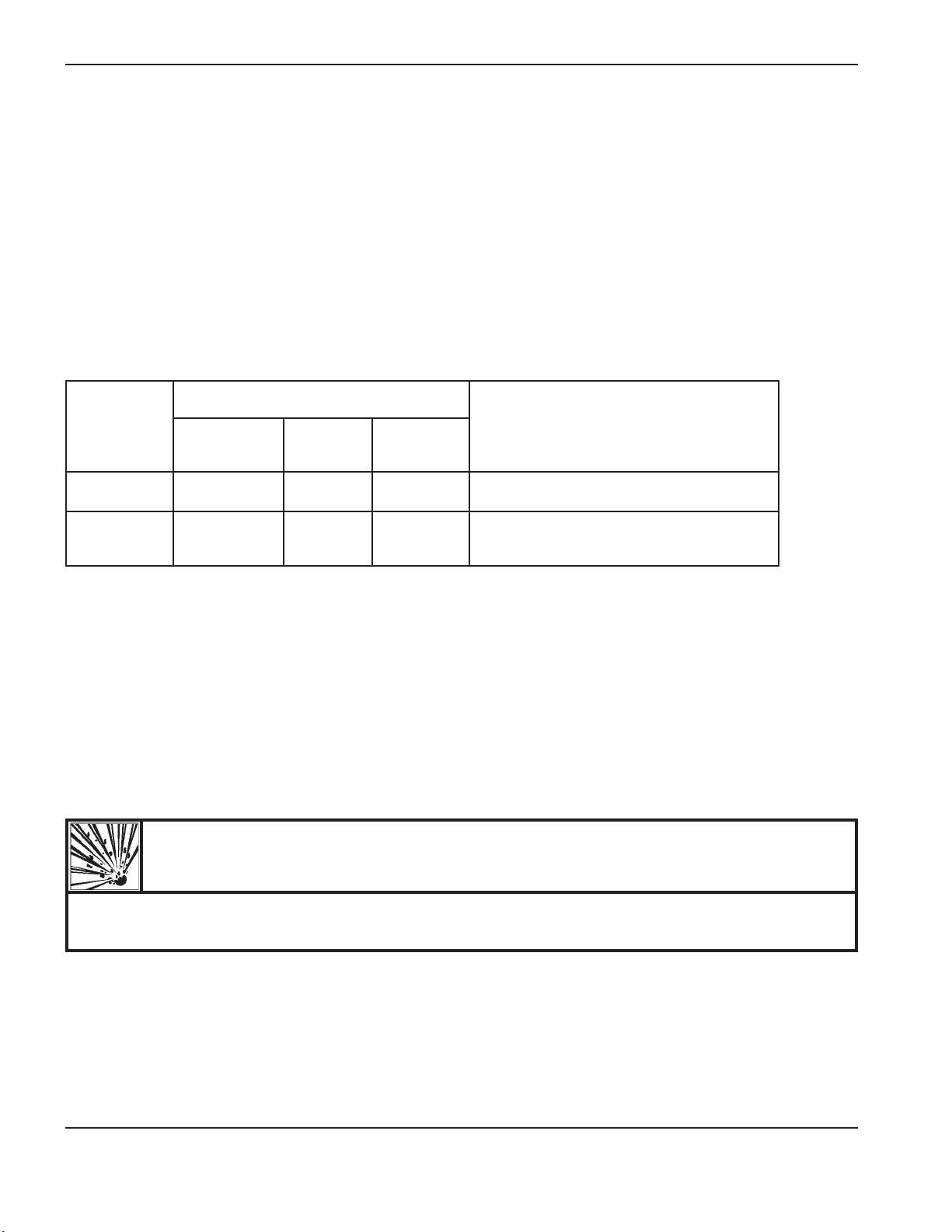

Generator recommendations

Generators used with the Powermax45 should satisfy the following requirements:

CSA

• 1-phase, 50/60Hz, 230/240VAC

• 3-phase, 50/60Hz, 480VAC

CE

• 1-phase, 50/60Hz, 230VAC

• 3-phase, 50/60Hz, 380/400VAC (400VAC recommended for best performance)

Engine drive outputcurrent

Engine

driverating

8 KW 33 A 11.5A 10A Good arc stretch at 45A cutting current

1-phase

(CSA/CE)

3-phase

(CE)

3-phase

(CSA)

Performance

(arc stretch)

6 KW 25 A 9A 7A

Notes: Based on the generator rating, age, and condition, adjust the cutting current as needed.

If a fault occurs while using a generator, turning the power switch quickly to OFF and then to ON again

(sometimes called a “quick reset”) may not clear the fault. Instead, turn the power supply off and wait 30 to

45seconds before turning it on again.

Limited arc stretch at 45A cutting current

Good arc stretch at 30A cutting current

Prepare the gas supply

The gas supply for the Powermax45 can be shop-compressed or cylinder-compressed.A high-pressure regulator must

be used on either type of supply and must be capable of delivering gas to the filter on the power supply at 170l/min at

6.2bar (360scfhat90psi).

WARNING

Do not allow the gas supply pressure to exceed 9.3 bar (135 psi). The filter bowl may explode if this

pressure is exceeded.

If gas supply quality is poor, cut speeds decrease, cut quality deteriorates, cutting thickness capability decreases, and

the life for consumables shortens. For optimum performance, the gas should have a maximum particle size of 0.1micron

at a maximum concentration of 0.1mg/m3, a maximum dew point of -40°C (-40°F), and a maximum oil concentration of

0.1mg/m3 (per ISO8573-1 Class1.2.2).

2-6 powermax

45

Service Manual

Page 29

power supply setup

Connect the gas supply

Connect the gas supply to the power supply using an inert gas hose with a 9.5mm (3/8 inch) internal diameter and a

1/4NPT quick-disconnect coupler or a 1/4NPTxG-1/4 BSPP (CE units) quick-disconnect coupler.

CAUTION

Synthetic lubricants containing esters that are used in some air compressors will damage

polycarbonates used in the air regulator bowl.

5.5 – 6.9 bar (80 – 100 psi) gas supply

(maximum 9.3 bar or 135 psi) with a flow

rate of at least 165.2 l/min (350 scfh). The

recommended flow rate and pressure is 170 l/min

at 6.2 bar (360scfh at 90 psi).

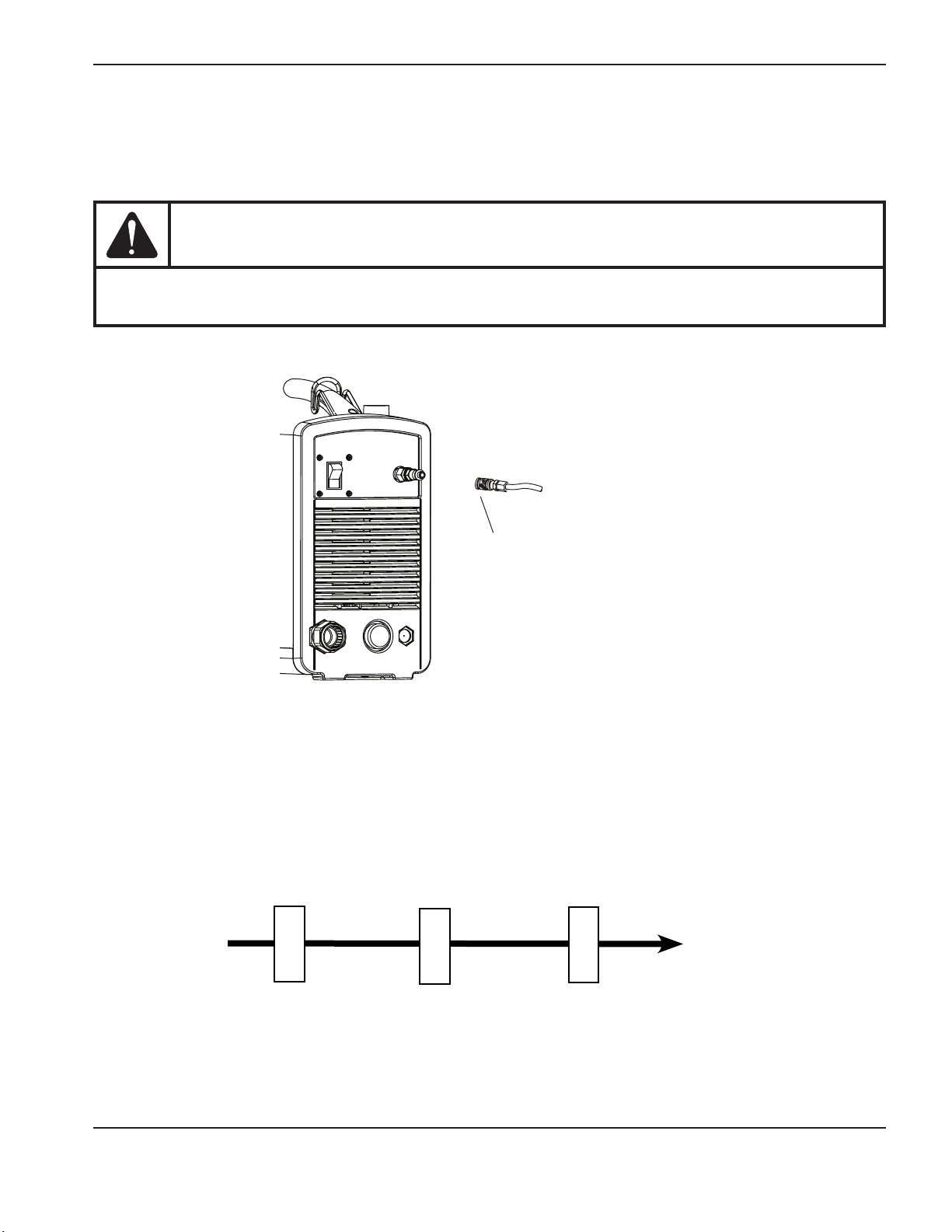

Additional gas filtration

When site conditions introduce moisture, oil, or other contaminants into the gas line, use a three-stage coalescing

filtration system, such as the Eliminizer filter kit (128647) available from Hypertherm distributors. A three-stage filtering

system works as shown below toclean contaminants from the gas supply.

Oil vapor filter

Powermax45

Gas supply

Water and particle filter

Oil filter

The filtering system should be installed between the quick-disconnect coupler and the power supply.

powermax

45

Service Manual 2-7

Page 30

Power suPPly setuP

2-8 powermax

45

Service Manual

Page 31

Section 3

TORCH SETUP

In this section:

Introduction .................................................................................................................................................................................................3-2

Consumable life ..........................................................................................................................................................................................3-2

Hand torch setup .......................................................................................................................................................................................3-2

Choose the consumables ..............................................................................................................................................................3-3

Install the consumables ..................................................................................................................................................................3-5

Machine torch setup..................................................................................................................................................................................3-6

Mount the torch ................................................................................................................................................................................3-6

Choose the consumables (cut charts) .......................................................................................................................................3-8

Using the cut charts ........................................................................................................................................................................3-8

T45m shielded consumables ........................................................................................................................................................3-8

Align the torch ............................................................................................................................................................................... 3-24

Connect the remote-start pendant ...........................................................................................................................................3-25

Connect a machine interface cable .........................................................................................................................................3-25

Accessing raw arc voltage ......................................................................................................................................................... 3-27

Connect the torch lead .......................................................................................................................................................................... 3-30

powermax

45

Service Manual 3-1

Page 32

torch setup

Introduction

Both the T45v hand torch and the T45m machine torch are available for the Powermax45. The torch FastConnect™

system makes it easy to remove the torch for transport or to switch from one torch to the other if your applications

require the use of both torches.

This section explains how to set up your torch and choose the appropriate consumables for the job.

Consumable life

How often you will need to change the consumables on your Powermax45 will depend on a number of factors:

• The thickness of the metal being cut.

• The length of the average cut.

• Whether you are doing machine or hand cutting.

• The air quality (presence of oil, moisture, or other contaminants).

• Whether you are piercing the metal or starting cuts from the edge.

• Proper torch-to-work distance when gouging or cutting with unshielded consumables.

• Proper pierce height.

• Which consumables you are using. The T30v (Powermax30) 30 amp consumables will have a shorter life when

used on the T45v. However, they provide optimum cut quality for certain applications.

Under normal conditions, the electrode will wear out first during machine cutting, and the nozzle will wear out first when

hand cutting.

A good rule of thumb is that a set of consumables will last approximately 1to2hours of actual “arc on” time for hand

cutting, depending on these factors. For cutting with a machine torch, consumables may last up to 3to5hours.

You will find more information about proper cutting techniques in the Operation section.

Hand torch setup

Consumables

Safety trigger

3-2 powermax

45

Service Manual

Page 33

torch setup

Choose the consumables

The Powermax45 with the T45v handheld torch comes with a full set of consumables for cutting installed on the torch,

spare electrodes and nozzles in the consumables box, and consumables for gouging in the consumables box. In nonCE-regulated countries, you can also purchase unshielded consumables that are useful for certain applications.

With shielded consumables, you drag the torch tip along the metal to cut. With unshielded consumables, you must

keep the torch a small distance, about 2mm (0.08inch), away from the metal. Unshielded consumables generally have

a shorter life than shielded consumables; however, you may find that visibility and accessibility are better for some

applications.

Consumables for hand cutting are shown below. Notice that the retaining cap, swirl ring, and electrode are the same for

shielded, unshielded, and gouging applications. Only the shield (deflector for unshielded consumables) and the nozzle

are different.

For the best cut quality on thin gauge stainless steel, you may prefer to reduce the amperage setting to 30amps and

use the T30v (Powermax30) 30A consumables available from Hypertherm.

T45v shielded consumables

220674

Shield

220713

Retaining cap

T45v gouging consumables

220675

Shield

220713

Retaining cap

220671

Nozzle

220672

Nozzle

220670

Swirl ring

220670

Swirl ring

220669

Electrode

220669

Electrode

powermax

45

Service Manual 3-3

Page 34

torch setup

T45v unshielded consumables*

220717

Deflector

220713

Retaining cap

220718

Nozzle

220670

Swirl ring

* Unshielded consumables are not available for use in CE-regulated countries.

T30v (Powermax30) 30 A consumables

220569

Optional deflector

220483

Retaining cap

220480

Nozzle

220479

Swirl ring

220669

Electrode

220478

Electrode

3-4 powermax

45

Service Manual

Page 35

Install the consumables

torch setup

WARNING

INSTANTON TORCHES

PLASMA ARC CAN CAUSE INJURY AND BURNS

I

O

The plasma arc comes on im me di ate ly when the torch trigger is activated. Makesure

the power is OFF before changing consumables.

To operate the T45v torch, it must have a complete set of consumable parts installed: a shield or deflector, retaining

cap, nozzle, swirl ring and electrode.

With the power switch in the OFF (O) position, verify that the torch consumables are installed as shown.

Electrode

Swirl ring

Nozzle

Retaining cap

Shield or deflector

Note: Tighten only to finger-tight. Overtightening

will cause the torch to misfire.

powermax

45

Service Manual 3-5

There should be a small gap

between the consumables and the

torch handle. Air will blow out from

this gap during normal operation.

Page 36

torch setup

Machine torch setup

Consumables

Before using the T45m, you must:

• Mount the torch on your cutting table or other equipment.

• Choose and install the consumables.

• Align the torch.

• Attach the torch lead to the power supply.

• Set up the power supply for remote starting with either the remote-start pendant or a machine interface cable.

Positioning sleeve

Gear rack

Brass strain relief

Strain relief

Mount the torch

Depending on the type of cutting table you have, you may or may not need to disassemble the torch to route it through

the track and mount it. If your cutting table’s track is large enough for you to thread the torch through it without removing

the torch body from the lead, do so and then attach the torch to the lifter per the manufacturer’s instructions.

Note: The T45m can be mounted on a wide variety of X-Y tables, track burners, pipe bevelers, and other equipment.

Install the torch per the manufacturer’s instructions and following the instructions below for disassembly if

necessary.

If you need to disassemble the torch, follow these steps:

1. Disconnect the torch lead from the power supply and remove the consumables from the torch.

2. Remove the gear rack from the positioning sleeve by removing the 2black screws that secure it to the positioning

sleeve. Remove the 6screws (3 at each end) that secure the positioning sleeve to the brass strain relief ring and to

the torch body. Slide the positioning sleeve off the torch.

3-6 powermax

45

Service Manual

Page 37

3. Disconnect the wires for the cap-sensor switch at the connector in the middle.

Gas supply line connection

torch setup

Screw to connect the power cable

to the plunger

4. Use a #2Phillips screwdriver and a 6mm (1/4inch) nut driver (or adjustable wrench) to remove the screw and nut